Olefin epoxidation catalyst, preparation method, and method for epoxidation of olefin

A catalyst and epoxidation technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, molecular sieve catalyst, etc., can solve the problem of low conversion rate of hydrogen peroxide, and achieve the effect of simple and easy method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

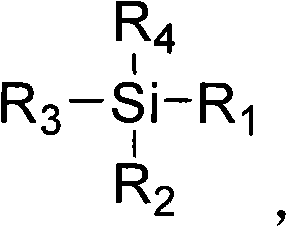

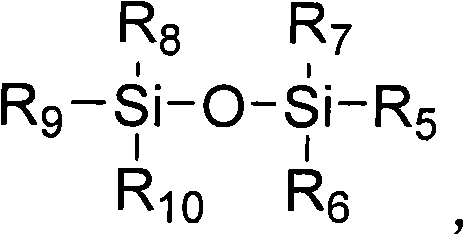

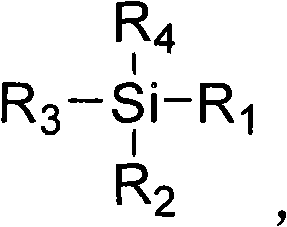

[0026] The present invention also provides a method for preparing a catalyst for olefin epoxidation, wherein the method comprises: preparing a mixture containing titanium-silicon molecular sieve, binder source, alkaline earth metal oxide and water, and forming the mixture A molded body is obtained, and the molded body is dried and calcined; the binder source is selected from silica sol, silane with at least two hydrolyzable groups, and siloxane with at least two hydrolyzable groups At least one of them; in the mixture, titanium silicon molecular sieve, SiO 2 The weight ratio of the binder source, alkaline earth metal oxide and water is (70-98):(1.5-40):(0.05-25):(5-50). In the present invention, the "formed body" refers to a product with a certain shape, such as spherical particles, rod-shaped particles, etc.; the silica sol refers to a colloidal solution of silica with water as the dispersed phase, wherein, The content of silicon may be 20-40% by weight.

[0027] According ...

Embodiment 1

[0060] This example is used to illustrate the olefin epoxidation catalyst and its preparation method and the method for epoxidizing olefin according to the present invention.

[0061] Mix 100g of titanium-silicon molecular sieve powder (Hunan Jianchang Co., Ltd., brand HTS) with 1g of magnesium oxide and 10g of tetramethoxysilane (Qingdao Century Star Chemical Reagent Co., Ltd.), and add 5g of silica sol (silicon dioxide) after mixing. Content 30% by weight), 0.2g Span80, 2g polyvinyl alcohol (Sanming Dinghui Chemical Co., Ltd., trade mark is polyvinyl alcohol 2099), 1g celadon powder (Dongming county Zhuwa tianjing glue factory) and 50g water mix homogeneously , and then extruded and pelletized, followed by drying at 70°C for 4 hours. The resulting shaped body had dimensions of 2×2 mm.

[0062] Take 100 g of the above molded body and put it into a 500 mL three-necked flask, add 200 g of a 10 mol % sodium hydroxide aqueous solution, and heat the above mixture to 90° C. with s...

Embodiment 2

[0071] This example is used to illustrate the olefin epoxidation catalyst and its preparation method and the method for epoxidizing olefin according to the present invention.

[0072] Adopt the same method as Example 1 to prepare the olefin epoxidation catalyst, the difference is that the consumption of titanium silicon molecular sieve powder (Hunan Jianchang Co., Ltd., trade mark is HTS) is 80g, the consumption of magnesium oxide is 3g, tetraethoxy The consumption of silane (Qufu Chenguang Chemical Co., Ltd.) is 64g, the consumption of silica sol (the content of silicon dioxide is 30% by weight) is 30g, the consumption of Span80 is 2g, and the consumption of water is 20g. It was determined that the strength of the catalyst was 180 N / cm; determined by XRF analysis, the content of titanium-silicon molecular sieve in the catalyst was 70% by weight, and the weight ratio of amorphous silicon dioxide to magnesium oxide was 1:0.11.

[0073] The epoxidation reaction was carried out i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com