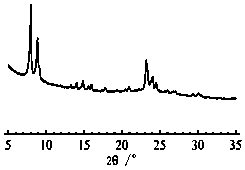

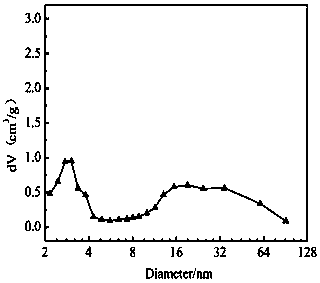

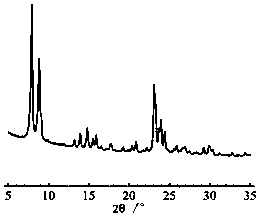

Hierarchical porous titanium-silicon molecular sieve as well as preparation method thereof and olefin epoxidation method

A titanium-silicon molecular sieve and multi-stage pore technology, which is applied in the direction of molecular sieve compounds, molecular sieve catalysts, and molecular sieve characteristic silicates, can solve the problem of large molecular sieve grains with low activity, low distribution of mesopores and macropores, and crystallization of titanium-silicon molecular sieves. The degree is not high enough to achieve the effect of improving selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0088] According to tetraethyl orthosilicate (as SiO 2 Calculated): Tetrabutyl titanate (as TiO 2 Calculated): Tetrapropylammonium hydroxide (in N): The molar ratio of deionized water is 1:0.02:0.4:20. After mixing the above materials, carry out hydrothermal treatment at 80°C for 6 hours under stirring conditions to obtain the first mixture. Then mix N-phenyl-3-aminopropyltrimethoxysilane, cetyltrimethylammonium bromide and deionized water and add polyacrylic acid (purchased from Nantong Puter Chemicals Co., Ltd., CAS No. 9007-20-9, the weight-average molecular weight is 240000) to prepare an emulsion mixture, and the obtained emulsion mixture is added to the first mixture under stirring conditions to obtain the second mixture, wherein the silylating agent, synthetic water-soluble polymer unit Body, surfactant, deionized water and the silicon source tetraethyl orthosilicate in the first mixture (as SiO 2The molar ratio of 0.02:0.15:0.4:5:1. The second mixture was transferr...

Embodiment 2

[0090] According to tetraethyl orthosilicate (as SiO 2 Calculated): Tetrabutyl titanate (as TiO 2 Calculated): Tetrapropylammonium hydroxide (in N): The molar ratio of deionized water is 1:0.04:0.05:150 After mixing the above materials, carry out hydrothermal treatment at 80°C for 10 hours under stirring conditions to obtain the first mixture. Then mix N-(2aminoethyl)-3-aminopropyltrimethoxysilane, hexadecyltrimethylammonium bromide and deionized water and add polyacrylamide (purchased from Shandong Keyu Water Treatment Co., Ltd. Co., Ltd., the CAS number is 9003-05-8, and the weight average molecular weight is 8000000) to prepare the emulsion mixture, and the obtained emulsion mixture is added to the first mixture under stirring conditions to obtain the second mixture, wherein the silylating agent, synthetic Water-soluble macromolecular monomer, surfactant, deionized water and silicon source tetraethyl orthosilicate (as SiO 2 The molar ratio of 0.2:0.05:0.3:8:1. The secon...

Embodiment 3

[0092] According to silica (SiO 2 Calculated): tetrapropyl titanate (as TiO 2 Calculated): Tetrapropylammonium hydroxide (in N): The molar ratio of deionized water is 1:0.06:1:60. After mixing the above materials, carry out hydrothermal treatment at 75°C for 7 hours under stirring conditions to obtain the first mixture. Then mix 3-(2-aminoethylamino)propyltriethoxysilane, tetradecyltrimethylammonium bromide and deionized water and add polyacrylamide (purchased from Shandong Keyu Water Treatment Co., Ltd. company, the CAS number is 9003-05-8, and the weight average molecular weight is 8,000,000) to prepare the emulsion mixture, and the obtained emulsion mixture is added to the first mixture under stirring conditions to obtain the second mixture, wherein the silylating agent, synthetic water-soluble Silicon source silica (using SiO 2 The molar ratio of 0.1:0.005:0.1:10:1. The second mixture was transferred to a pressure-resistant stainless steel reaction kettle, crystallized...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com