TS-1 molecular sieve catalyst with special structure, and application thereof in photocatalytic water hydrogen production

A TS-1, special structure technology, applied in TS-1 molecular sieve catalyst and its application field in photocatalytic water hydrogen production, can solve the problems of insufficient utilization of solar energy, achieve the promotion of semiconductor photocatalytic water hydrogen production reaction, enhance Photocatalytic activity, high activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: Prepare the TS-1 molecular sieve to be regulated by the hole

[0027] The TS-1 molecular sieve to be alkalized was provided by Nanjing Xianfeng Nano Material Technology Co., Ltd. Before alkalization, it is roasted in a tube furnace at a temperature of 540°C for 3 hours to remove impurities and adsorbed water.

Embodiment 2

[0028] Example 2: Carrying out pore regulation on TS-1 molecular sieve

[0029] (1) Take 75 mL of ammonia solution with a concentration of 5.0 mol / L, and at 100° C., use hydrothermal method to carry out alkali treatment on 3 g of TS-1 molecular sieve for 6 hours to obtain alkalized TS-1 molecular sieve.

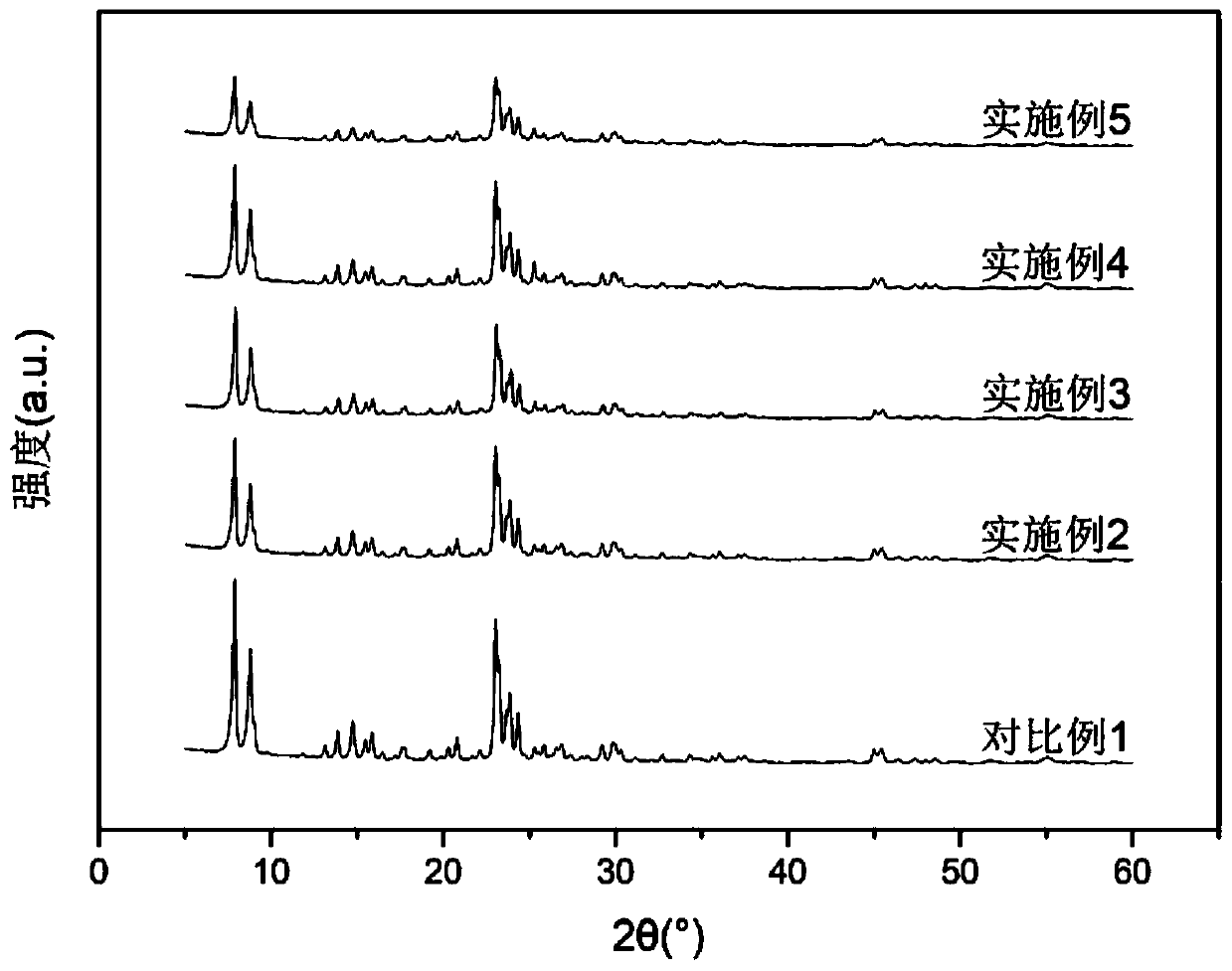

[0030] (2) Wash the alkalized TS-1 molecular sieve with water to neutrality, dry it at 60°C, and then bake it at 580°C for 6 hours to obtain a TS-1 molecular sieve with a hierarchical porous structure. The XRD test is as follows: figure 1 shown.

Embodiment 3

[0031] Example 3: Carrying out pore regulation on TS-1 molecular sieve

[0032] (1) Take 65 mL of Na with a concentration of 0.4 mol / L 2 CO 3 solution, at 80° C., 2.5 g of TS-1 molecular sieves were subjected to alkali treatment by hydrothermal method for 2 hours to obtain alkalized TS-1 molecular sieves.

[0033] (2) Wash the alkalized TS-1 molecular sieve with water to neutrality, dry it at 60°C, and then roast it at 560°C for 4 hours to obtain a TS-1 molecular sieve with a hierarchical porous structure. The XRD test is as follows: figure 1 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com