Activated carbon-loaded cuprous oxide photocatalyst and preparation method thereof

A photocatalyst, cuprous oxide technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc. Inexpensive, easy-to-operate, high-efficiency removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

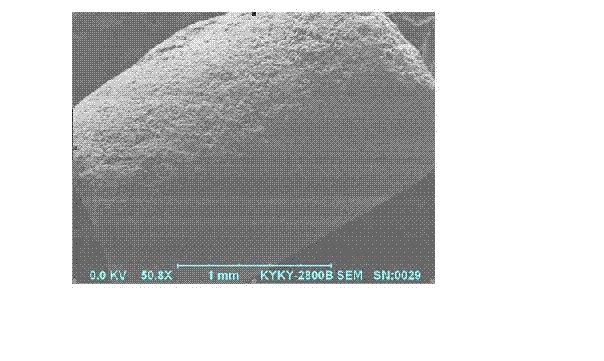

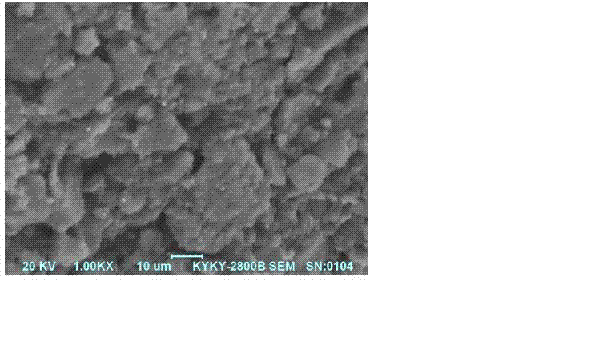

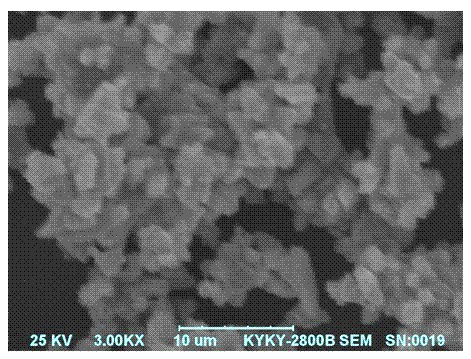

Image

Examples

Embodiment 1

[0026] Activated carbon supported cuprous oxide photocatalyst and preparation method

[0027] (1) Immerse activated carbon with 3mol / L ammonia solution and stir for 24 hours, then filter, wash with distilled water until neutral;

[0028] (2) The activated carbon treated in step (1) was treated with 5mol / L HNO 3 The solution was impregnated and stirred for 24 hours, then filtered, washed with distilled water until neutral, put in an oven, dried at 110°C, and set aside;

[0029] (3) Weigh 5g of pretreated activated carbon and impregnate it in 50mL of 0.04mol / L CuSO 4 In the solution, soak for 24 hours in a constant temperature culture shaker with a rotation speed of 90 rpm and a temperature of 25° C., and then filter.

[0030] (4) The activated carbon that step (3) is obtained is transferred to the carbon dioxide containing 0.2g C 6 h 12 o 6 50mL NaOH (0.05mol / L) solution, and then placed in a constant temperature culture shaker at a temperature of 30°C and a rotation speed...

Embodiment 2

[0033] Steps (1) and (2) are the same as implementation method 1;

[0034] (3) Weigh 5g of pretreated activated carbon and impregnate it in 0.2mol / L CuSO 4 In the solution, soak for 24 hours in a constant temperature culture shaker with a rotation speed of 90 rpm and a temperature of 25° C., and then filter.

[0035] (4) The activated carbon that step (3) is obtained is transferred to the carbon dioxide containing 0.6g C 6 h 12 o 6 50mL NaOH (0.2mol / L) NaOH solution, and then placed in a constant temperature culture shaker at a temperature of 30°C and a rotation speed of 90rpm for 24h, filtered to obtain the product, and washed until neutral.

[0036] (5) The load Cu obtained in step (4) 2 O activated carbon was transferred to a vacuum drying oven at 80 °C for 3 h to obtain a 5% cuprous oxide photocatalyst supported on activated carbon.

Embodiment 3

[0038] Steps (1) and (2) are the same as implementation method 1;

[0039] (3) Take 5g of activated carbon treated in step (2), 50mL of 0.2mol / L CuSO 4 with 50mL 0.05 mol / L Na 2 SO 3 Place in a 500 mL beaker for reaction, add 300 mL pH=5 HAc-NaAc buffer solution and 0.1 g glucose, react at 70°C for 3 hours or microwave for 30 minutes, filter to obtain the product, and wash until neutral.

[0040] (4) The load Cu obtained in step (3) 2 O activated carbon was transferred to a vacuum drying oven at 80 °C for 3 h to obtain a 1% cuprous oxide photocatalyst supported on activated carbon.

[0041] An example of treating wastewater such as phenols with activated carbon-supported cuprous oxide photocatalysts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com