Patents

Literature

65results about How to "Increased mesopore volume" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

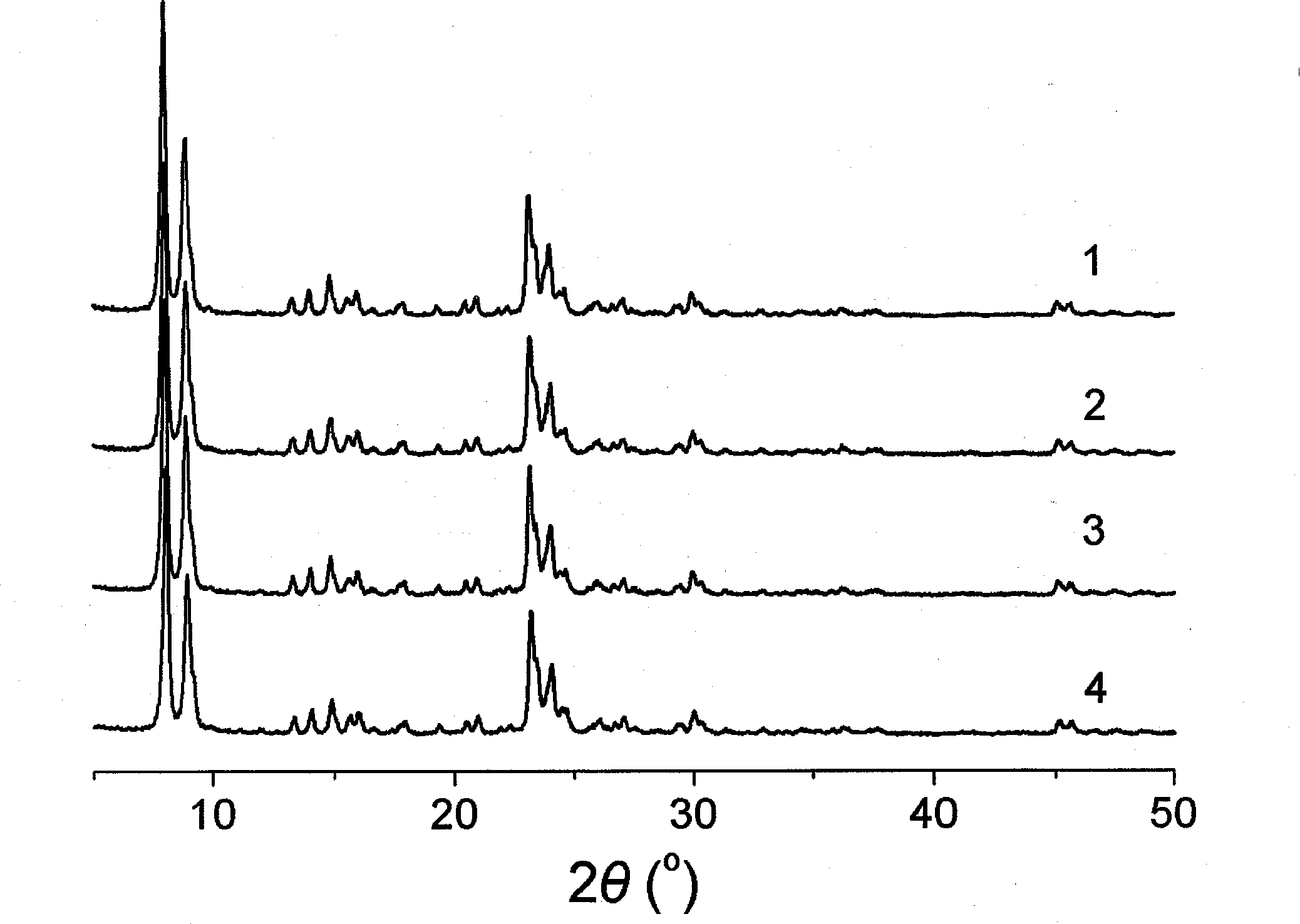

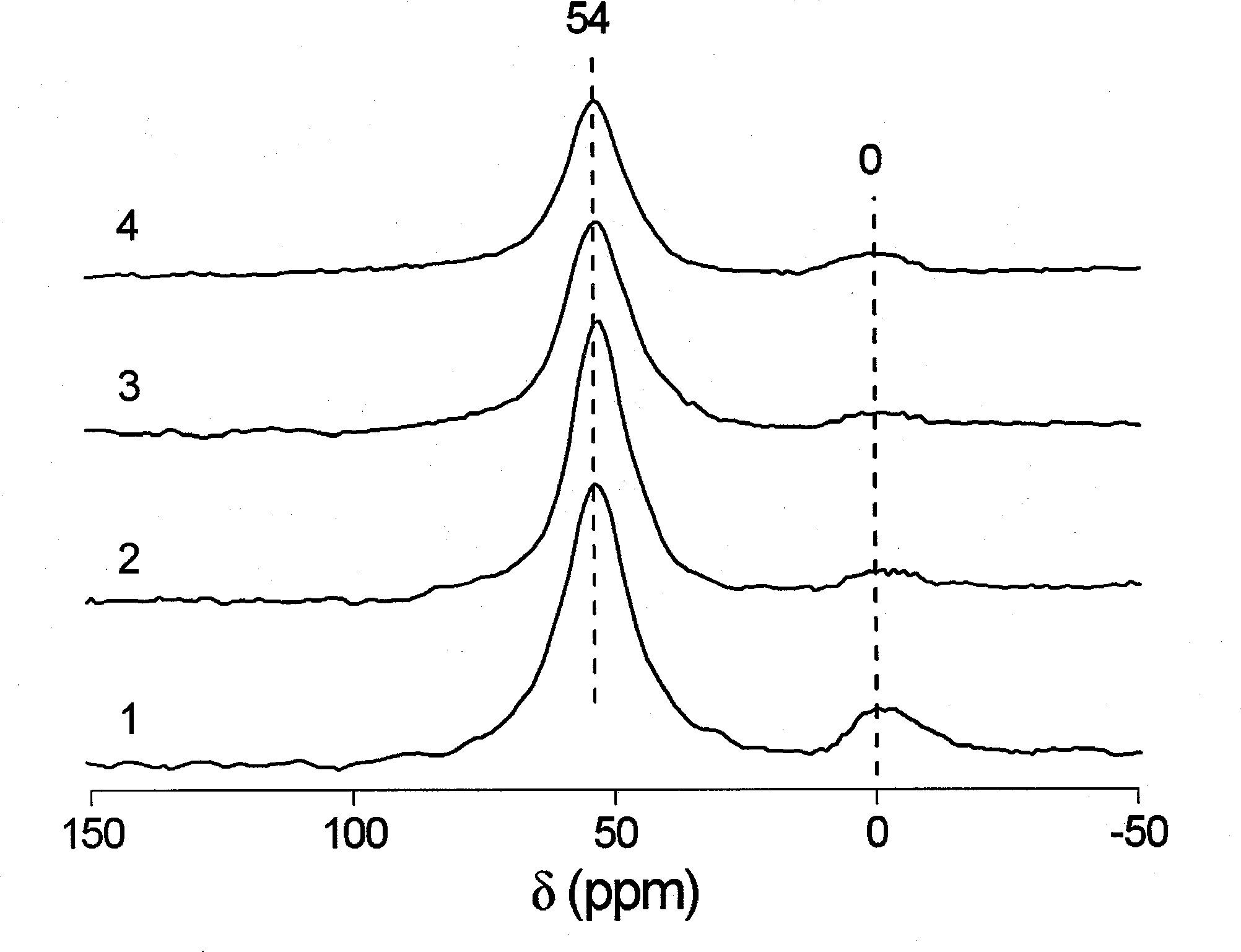

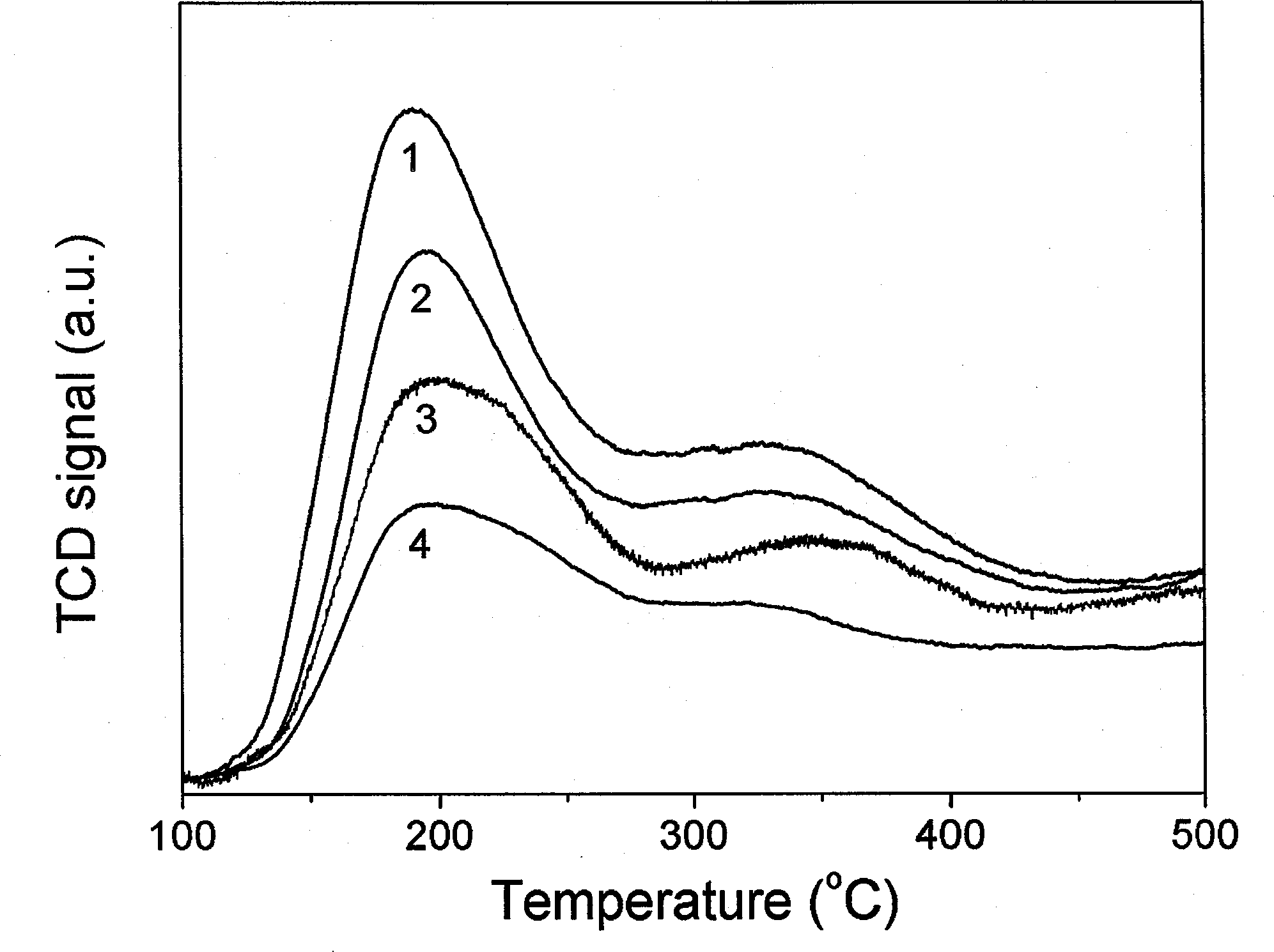

Method for preparing grade porous ZMS (Zeolite Socony Mobil)-5 molecular sieve by acid-base coupling

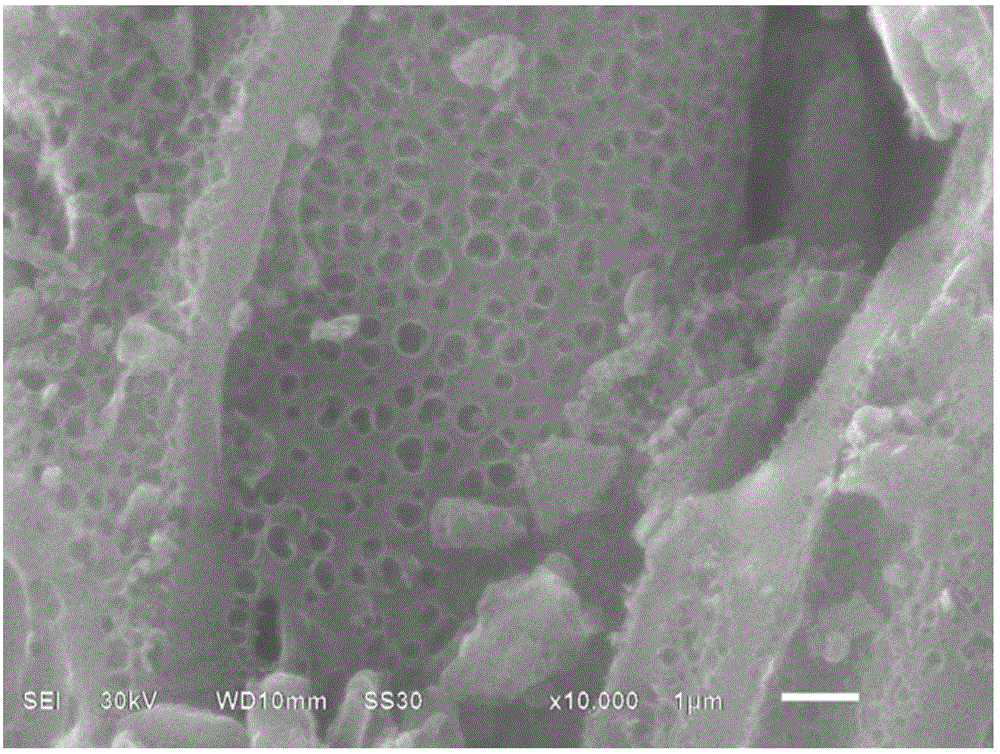

The invention relates to a method for preparing a ZSM (Zeolite Socony Mobil)-5 in a grade structure, and specifically relates to a method for preparing a grade porous ZMS-5 molecular sieve by acid-base coupling. The method comprises the following steps: mixing commercial ZSM-5 and alkali liquor in proportion, and heating and stirring to form a suspension; filtering the suspension; washing the filter cakes by water or acidic liquor; and finally, carrying out ion exchange by using acidic ammonium salt liquor; and then, roasting to obtain the grade porous ZMS-5 molecular sieve. The method provided by the invention aims to prepare the ZSM-molecular sieve rich in secondary mesopores. Firstly, part of aluminum silicon species in the ZSM-5 is removed in an environment-friendly alkali treatment manner to prepare the ZSM-5 molecular sieve with a secondary pore structure. Based on the secondary pore formed, undefined structures on the surface of the ZSM-5 and in the duct are dissolved out by way of acid washing or ion exchange. Meanwhile, the pore volume and the specific surface area of the secondary mesopore-enriching ZSM-5 molecular sieve are improved. Through the acid-base coupling treatment, the distribution state of aluminum outside the framework on the surface of the ZSM-5 is improved, so that the secondary mesopore-enriching ZSM-5 molecular sieve prepared by the method has a huge application potential in catalytic cracking and hydrocracking.

Owner:PETROCHINA CO LTD +1

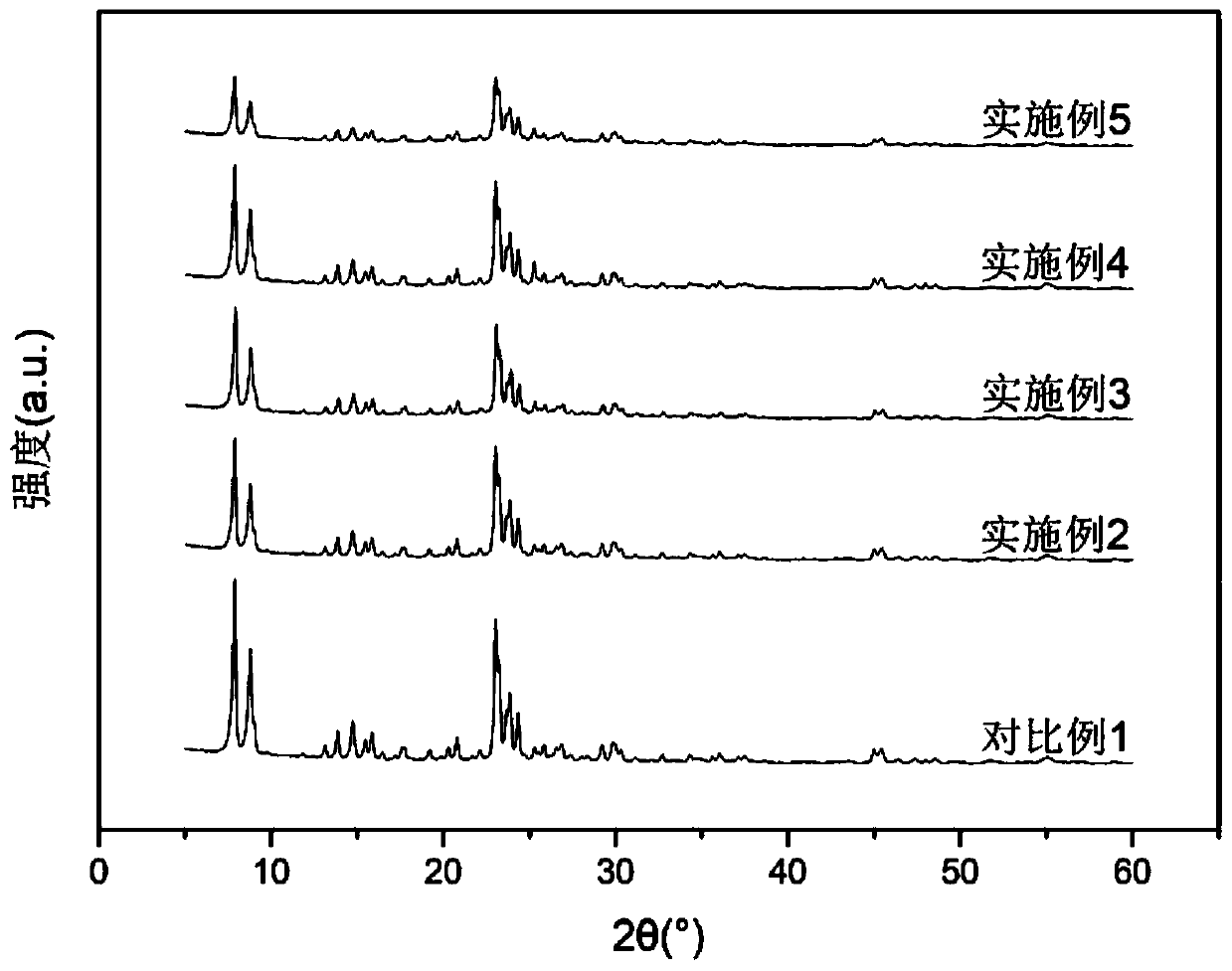

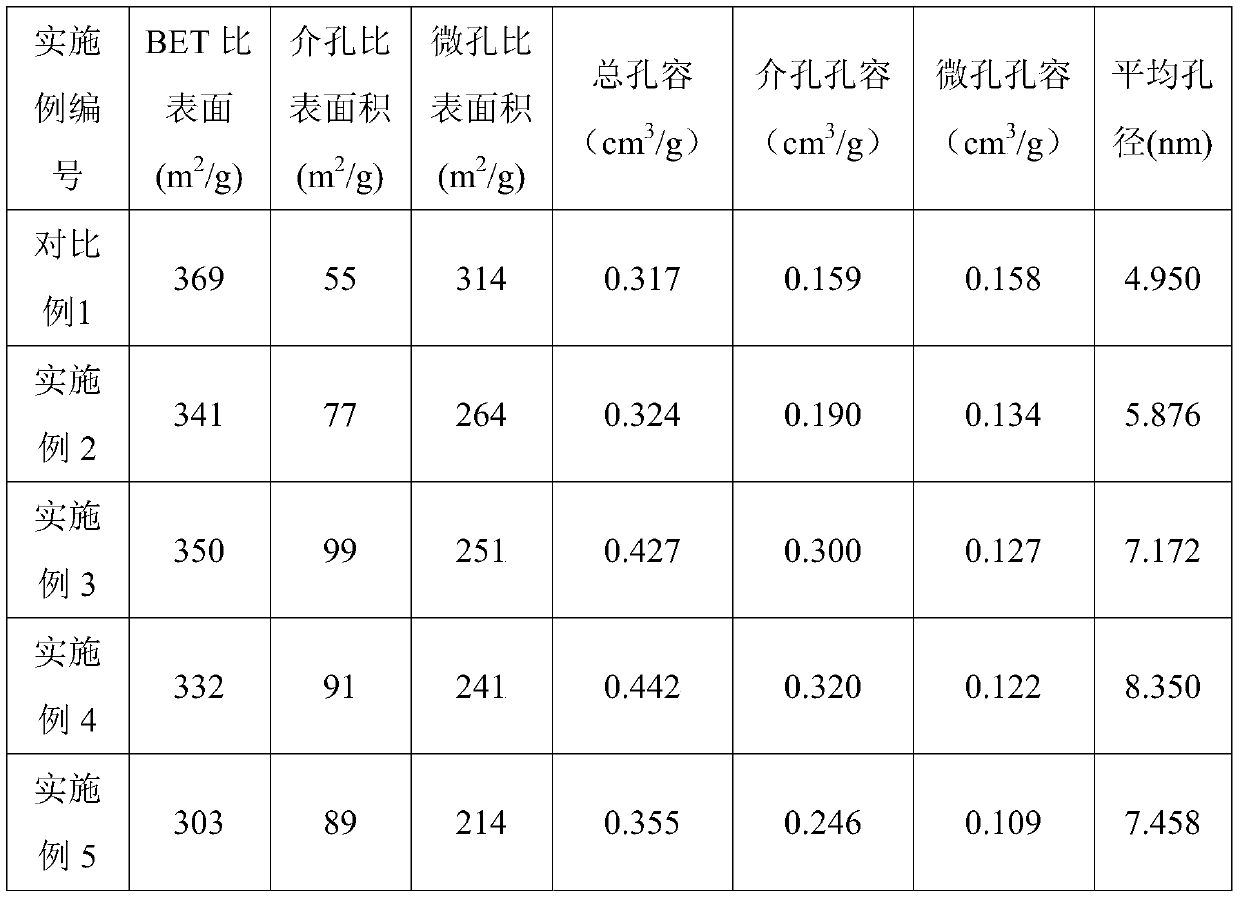

Method for preparing N-doped kudzuvine root-based mesoporous activated carbon and application thereof

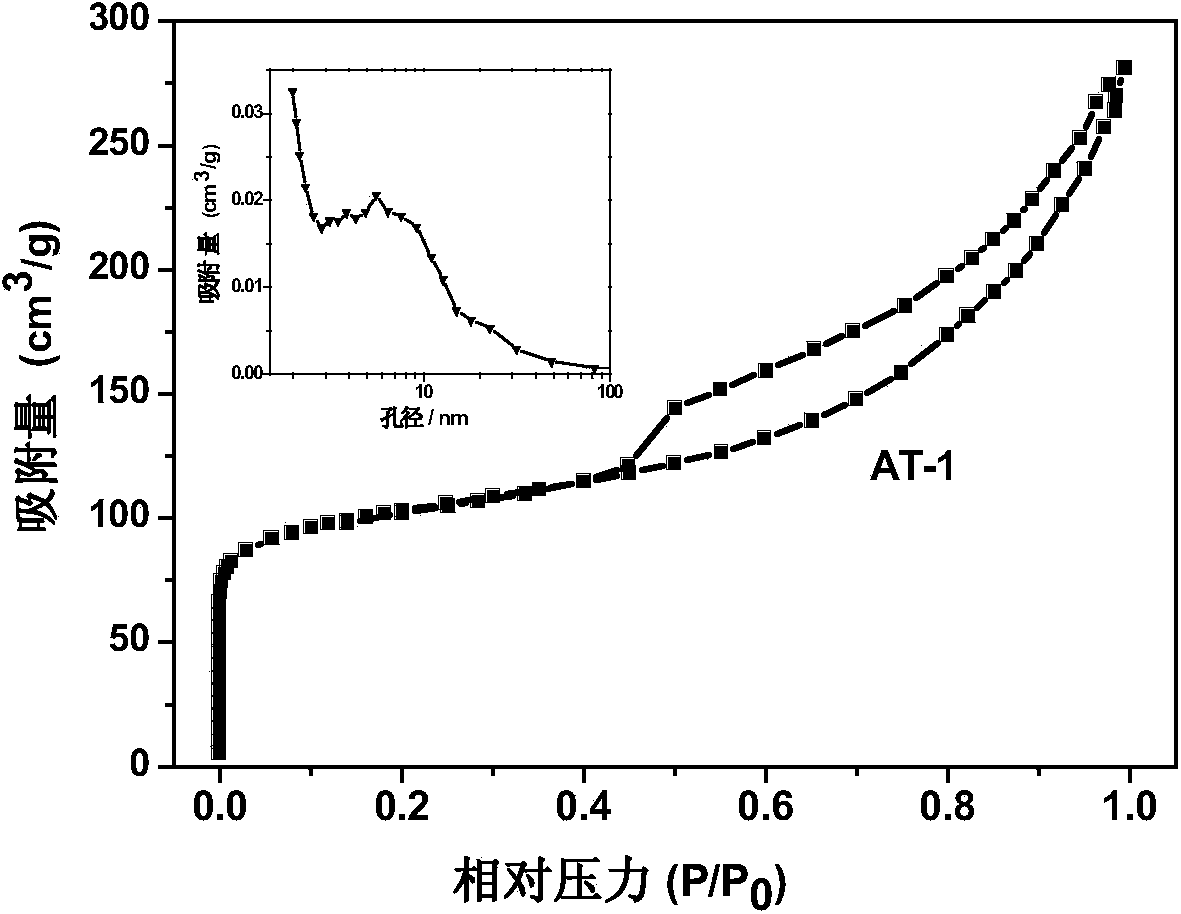

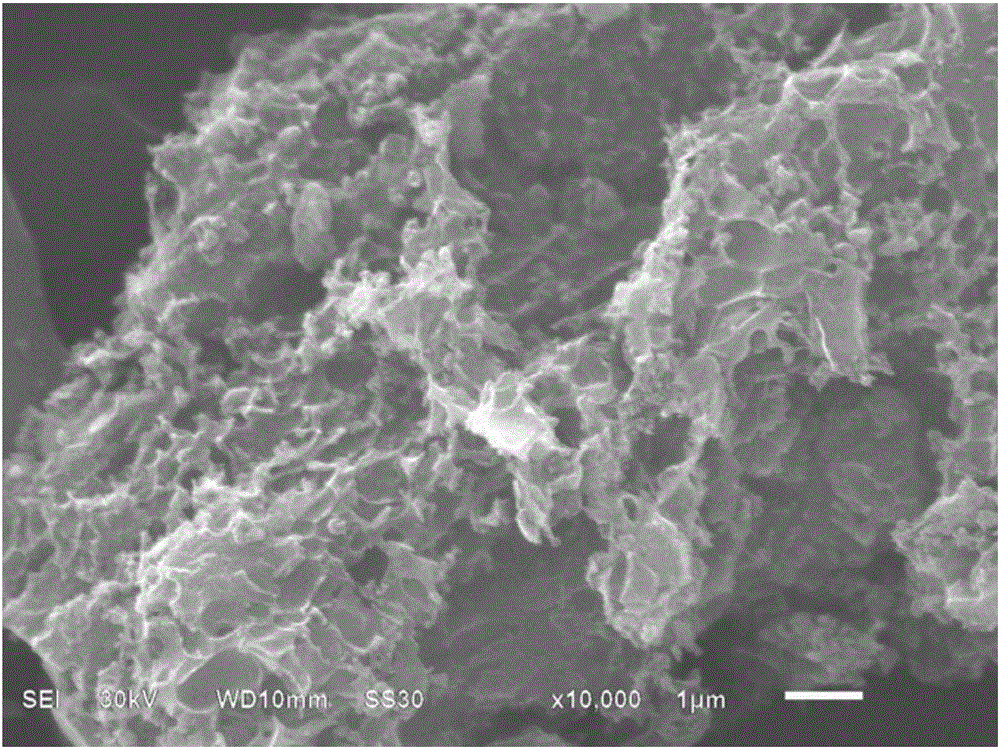

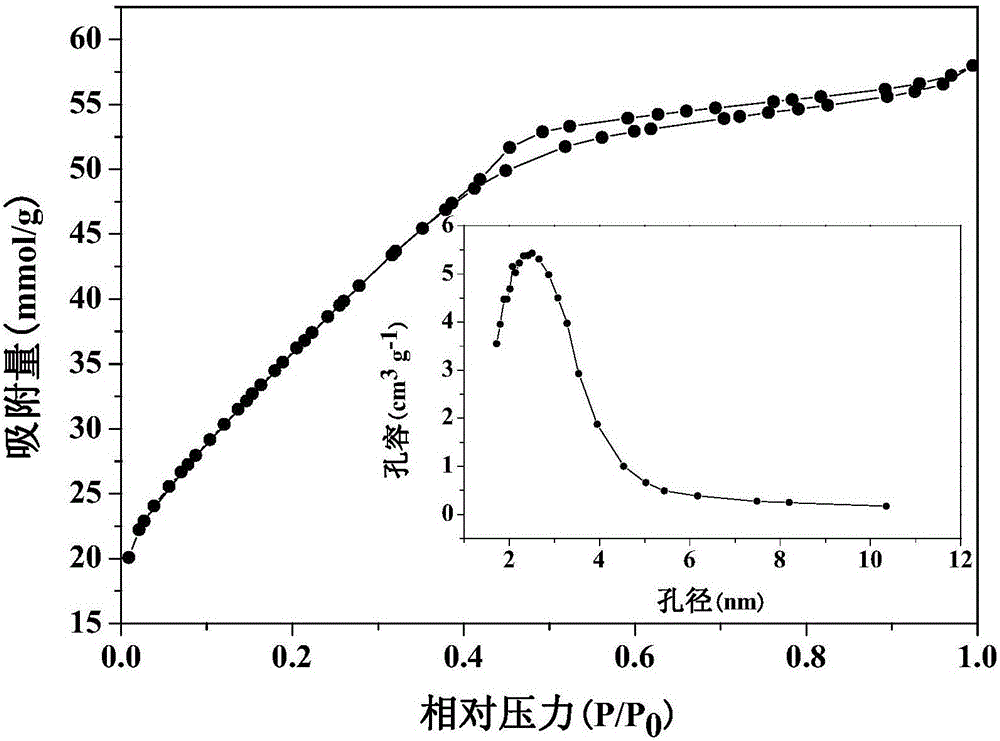

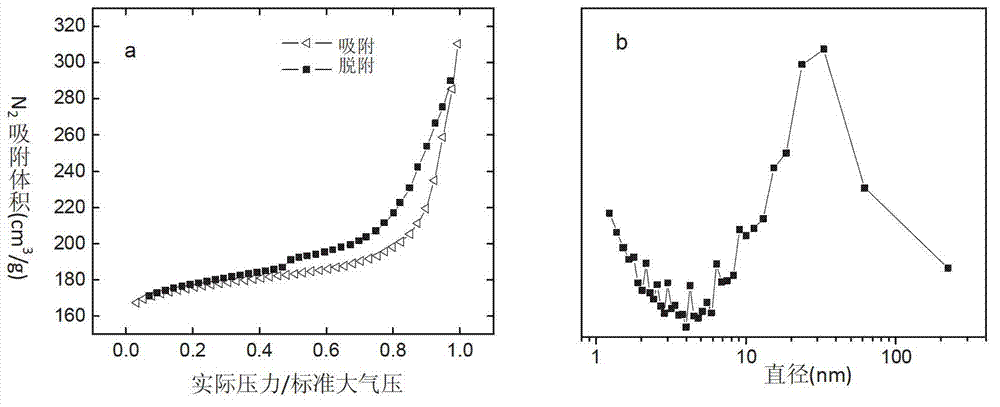

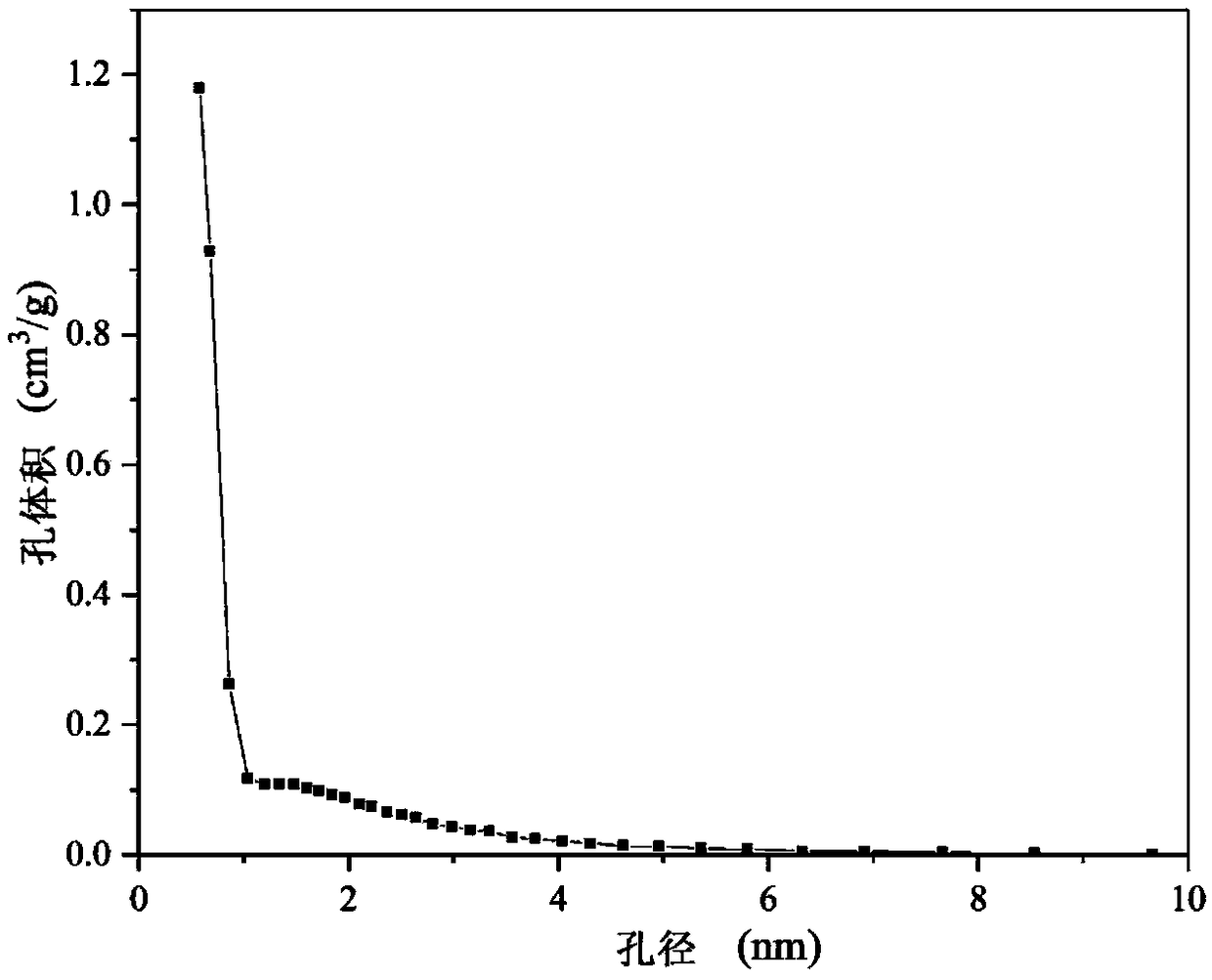

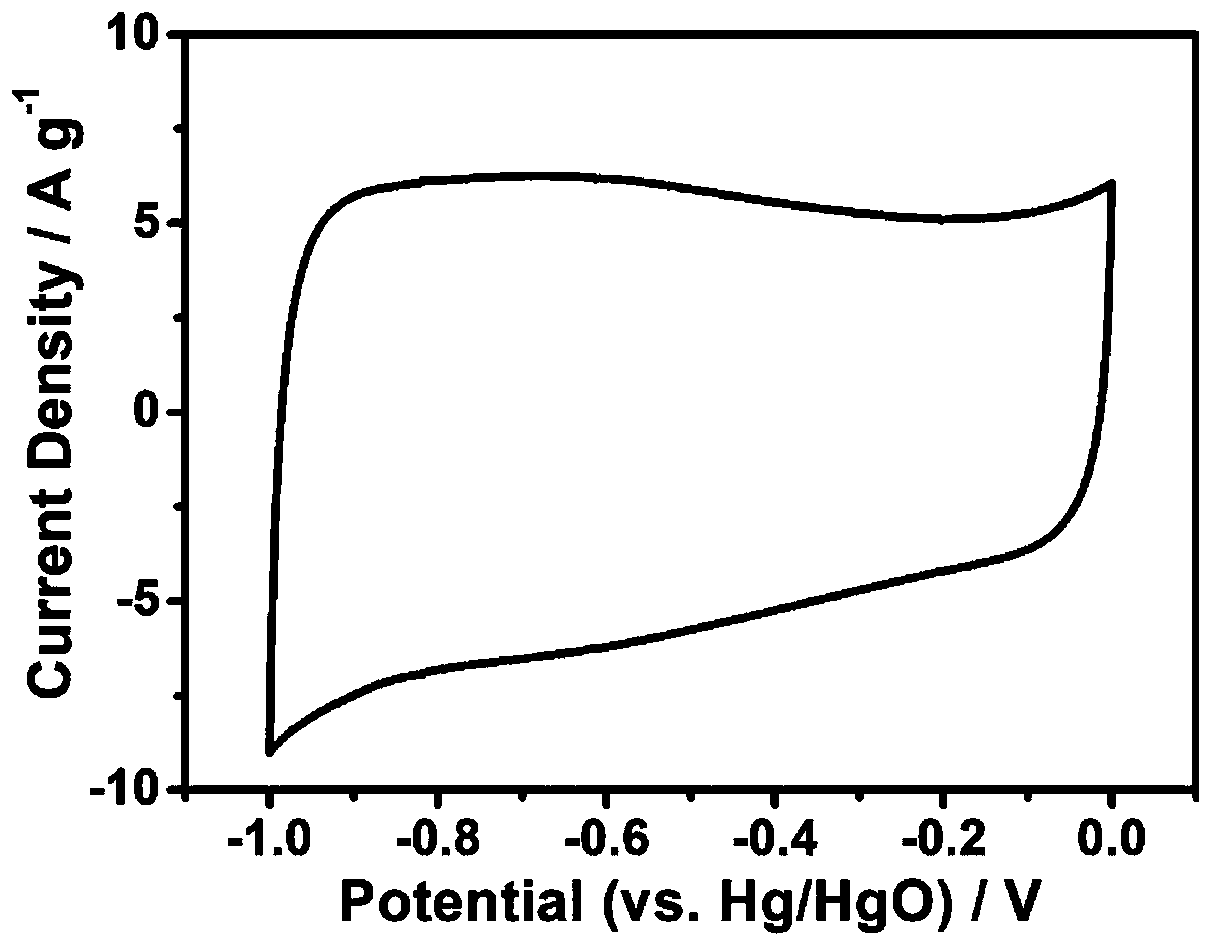

ActiveCN106276893ANitrogen content can be adjustedIncreased mesopore volumeHybrid capacitor electrodesChemistryBiomass

The invention discloses a method for preparing N-doped kudzuvine root-based mesoporous activated carbon and application thereof. The preparation method comprises the steps of pretreatment, nitrogen doping and activating treatment. The nitrogen content of the prepared material is 0.2-16%, the micropore volume is 0.1-0.8 cm3 / g, the mesoporous volume is 0.5-3.4 cm3 / g, the total specific area is 1000-3300 m2 / g, the mesoporous rate is 50-95%, the pore size distribution is 1-5 nm, and the average pore size is 2 to 4 nm. The prepared material involves the fields of electrochemical energy storage, adsorption separation, catalyst carriers and drug carrier and the like and is particularly suitable for electrochemical energy storage. According to the method, green biomass is adopted as a carbon source and is wide in source, low in cost, simple in process, easy to control, environmentally friendly and suitable for large-scale production.

Owner:XIANGTAN UNIV

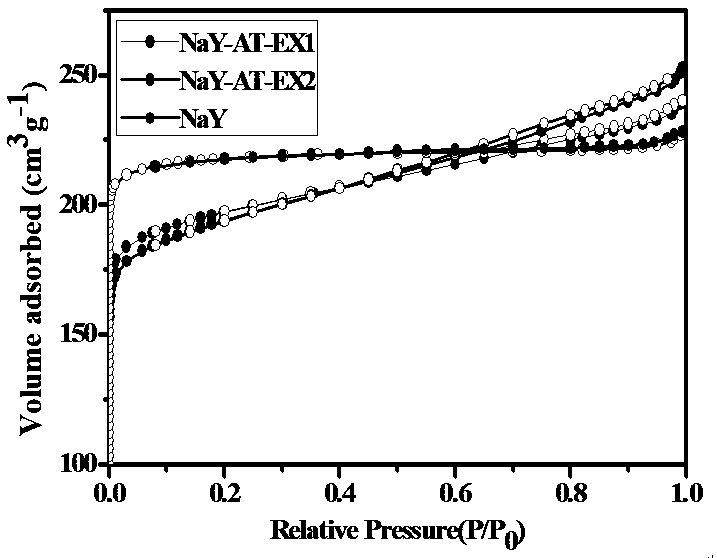

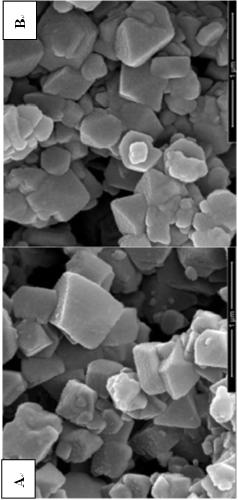

Modified method of Y-type molecular sieve

InactiveCN102951655AIncreased mesopore volumeFaujasite aluminosilicate zeoliteMolecular sieveAluminium sulfate

The invention discloses a modified method of a Y-type molecular sieve. The modified method comprises the following steps of: dissolving the Y-type molecular sieve and aluminum sulfate or aluminum sulfate containing crystal water into water, adding alcohol, reacting for 0-10 days at the temperature of 100-200 DEG C, filtering products after reaction, cleaning and obtaining mixture of an alunite-like phase and the Y-type molecular sieve; and adopting alkali compound to treat the mixture for 0-100 hours at the temperature of 0-100 DEG C and obtaining the modified Y-type molecular sieve. The modified method disclosed by the invention is wide in material source, low in cost and simple in reaction process, and is suitable for industrial production.

Owner:EAST CHINA NORMAL UNIV

Negative electrode active material for charging device

ActiveUS20090023066A1Improve low temperature performanceIncrease energy densityHybrid capacitor electrolytesCarbon compoundsLithiumOrganic solvent

To present a carbon material which provides an electrical storage device not only ensuring a high energy density but also realizing a high output and an excellent low temperature performance.A negative electrode active material for an electrical storage device employing an aprotic organic solvent electrolyte solution containing a lithium salt as an electrolytes characterized in that it is made of a carbon material having a specific surface area of from 0.01 to 50 m2 / g and a total mesopore volume of from 0.005 to 1.0 cc / g, wherein volumes of mesopores having pore diameters of from 100 to 400 Å occupy at least 25% of the total mesopore volume.

Owner:SUBARU CORP

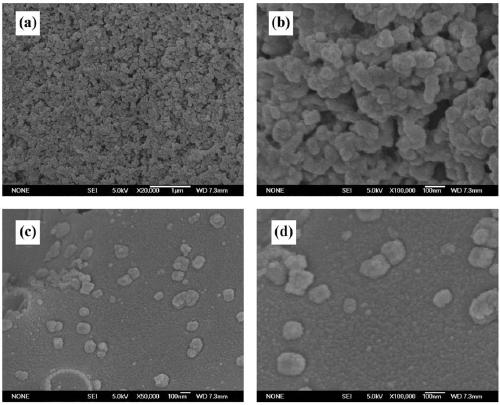

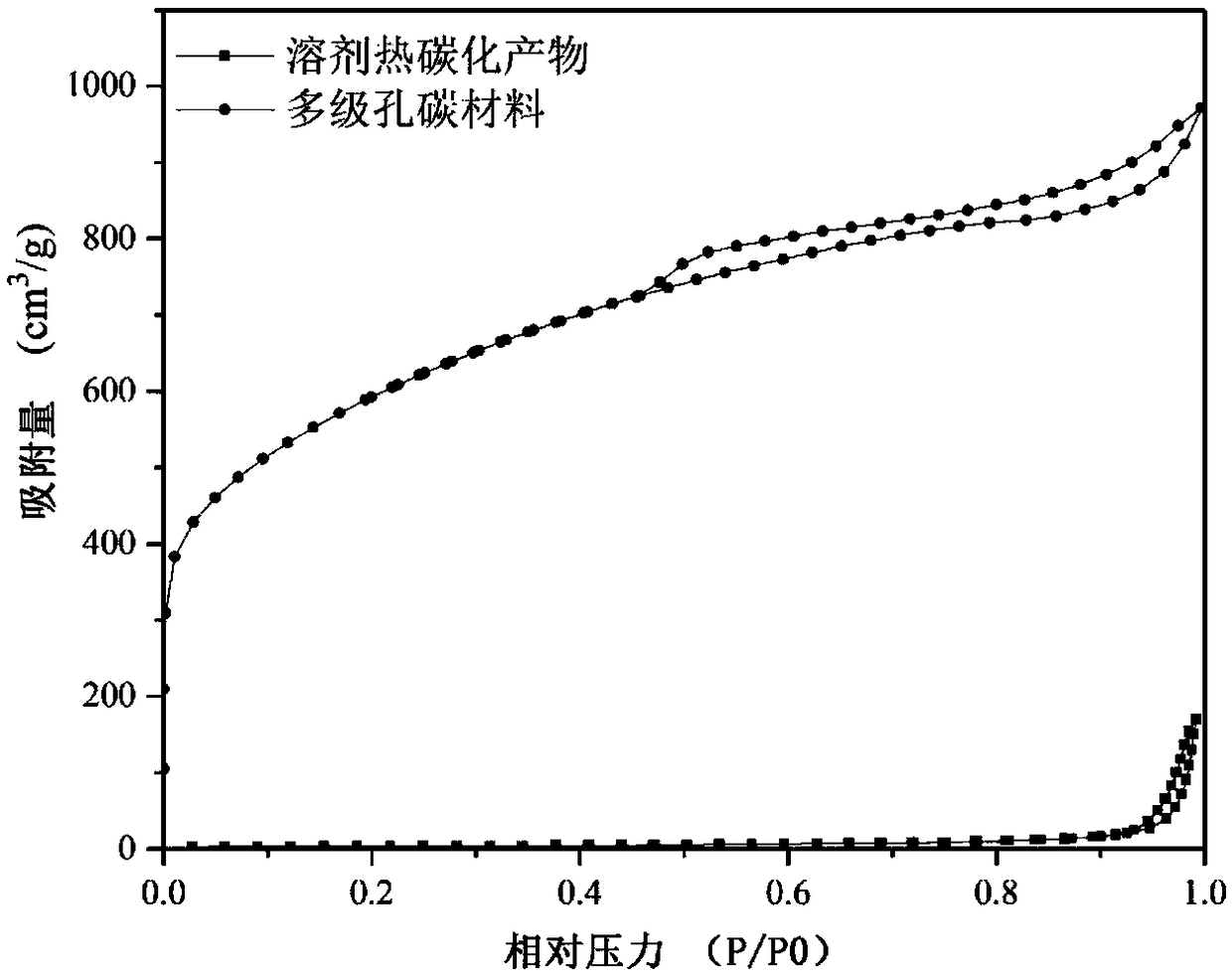

Lignin-based hierarchical porous carbon material and preparation method thereof

The invention relates to a lignin-based hierarchical porous carbon material and a preparation method thereof. The preparation method includes: lignin pretreatment, preparation of a eutectic solvent, eutectic solvent thermal carbonization of lignin, preparation of a solvent thermal carbonization product, activation of the solvent thermal carbonization product, and preparation of the lignin-based hierarchical porous carbon material. The m method provided by the invention adopts the eutectic solvent to dissolve the lignin raw material, is simple in preparation, and is green and non-toxic. The lignin-based hierarchical porous carbon material provided by the invention has abundant macroporous-mesoporous-microporous structures, is uniform and reasonable in distribution, and has good adsorption performance, and can be applied to supercapacitor electrode materials, lithium ion battery negative electrode materials, adsorption materials and other fields.

Owner:BEIJING FORESTRY UNIVERSITY

Preparation method of NaY zeolite

ActiveCN102372281AIncrease contentIncreased zeolite contentFaujasite aluminosilicate zeoliteDimethyldiazeneIn situ crystallization

A preparation method of NaY zeolite. The preparation process comprises the steps of: adding deionized water and an auxiliary agent of polydimethyldiallyl ammonium chloride into a raw material of kaolin; carrying out spray drying on a prepared mixing slurry to obtain kaolin spray microballoons; sintering; mixing the sintered microballoons with a guiding agent; carrying out hydrothermal crystallization; filtering, washing and drying to obtain an in situ crystallization product with a NaY zeolite content of 50-70%, wherein an addition of the polydimethyldiallyl ammonium chloride is 1-10wt% of kaolin.

Owner:PETROCHINA CO LTD

Mesoporous activated carbon and preparation process thereof

The invention relates to mesoporous activated carbon and a preparation method thereof. The technical proposal of the invention comprises the following steps: firstly, high sulfate bituminous coal or high sulfur content petroleum fluid coke are taken as raw materials, KOH is taken as an activating agent, the mass ratio of alkali to coal or the mass ratio of alkali to coke is 1.0-5.0:1, the adjustment of a carbon microcrystalline structure is performed in nitrogen atmosphere at a temperature of between 250 and 400 DEG C, the adjustment time is between 0.5 and 5 hours, and then the preheating treatment is performed for 1 to 5 hours at a temperature of between 400 and 700 DEG C to obtain an amorphous carbon stock; then the prepared amorphous carbon stock is subjected to activating treatment for 0.5 to 5 hours at a temperature of between 800 and 950 DEG C; and carbide after the activating treatment is acid-cleaned, water-scrubbed and dried to obtain the mesoporous activated carbon. The method has the characteristics of simple process, higher yield and productivity, low preparation cost and so on. Mesopores of the mesoporous activated carbon have large specific surface area, the mesopore area exceeds 60 percent of the mesoporous activated carbon, and the mesopore volume is high.

Owner:WUHAN UNIV OF SCI & TECH +1

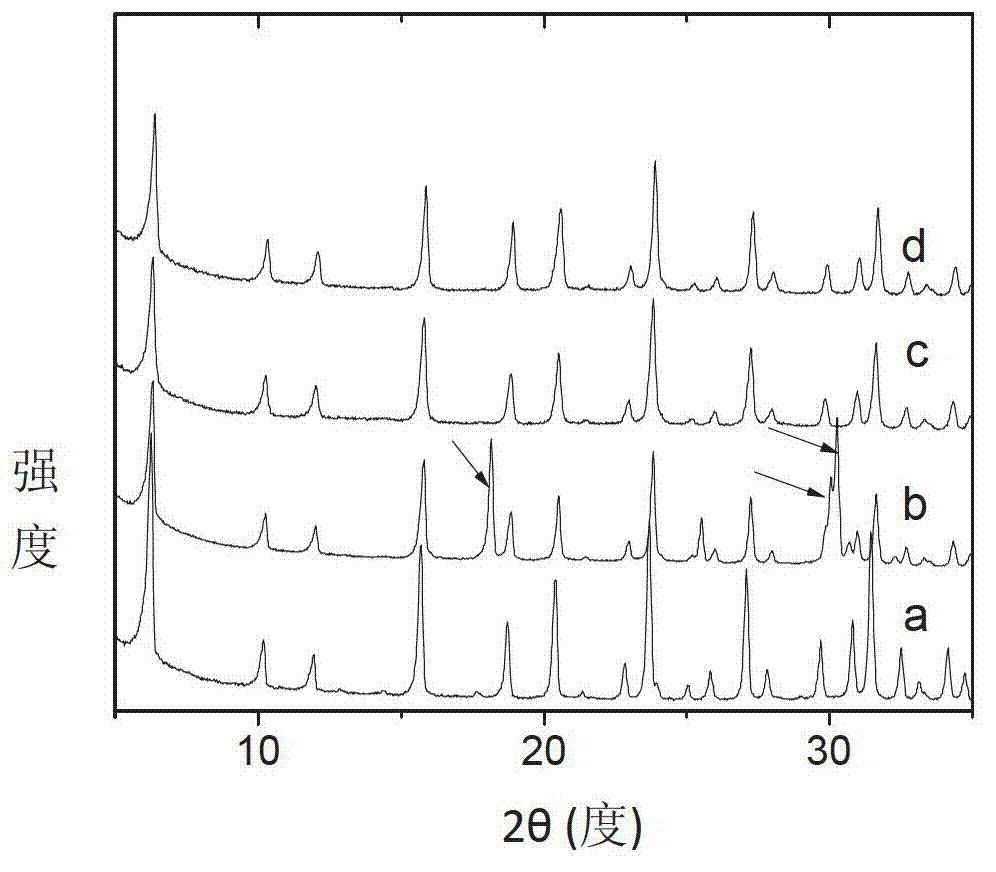

Preparation method and applications of modified ZSM-5 molecular sieve for high-selective preparation of propylene from methanol and dimethyl ether

InactiveCN103418420AEasy to operateStrong controllabilityMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMolecular sieveAmmonium chloride mixture

The invention provides a preparation method and applications of modified ZSM-5 molecular sieve for high-elective preparation of propylene from methanol and dimethyl ether, and mainly solves the problem of bad stability, which is caused by low propylene selectivity and easy carbon deposition, of ZSM-5 molecular sieve in the high-selective preparation of propylene from methanol and dimethyl ether. The preparation method comprises following steps: burning ZSM-5 molecular sieve original powder with a silicon / aluminum ratio in the range of 20 to 1000 and an average particle size in the range of 60 to 5000 nanometers to remove the organic template agent, then exchanging for 3 to 10 hours at the temperature of 20 to 100 DEG C in an ammonium chloride solution or an ammonium nitrate solution with a concentration of 0.1 to 5.0 mol / L, processing the obtained ammonium molecular sieves with different concentration (0.1 to 5.0 mol / L) ammonium fluosilicate solutions at the temperature of 20 to 100 DEG C for 1 to 48 hours, then fully washing with deionized water, filtering, drying for 12 hours at the temperature of 30 to 150 DEG C, and finally burning for 3 to 10 hours at the temperature of 300 to 550 DEG C so as to obtain series modified HZSM-5 molecular sieves. The processing method of ZSM-5 molecular sieve is simple and easy to operate. The modified HZSM-5 molecular sieve catalyst has high propylene selectivity and stability in the selective preparation of propylene from methanol and dimethyl ether.

Owner:巩雁军 +1

Fenton-like oxidation catalyst and application thereof

InactiveCN108654678AReduced Diffusion ResistanceHigh removal rateMolecular sieve catalystsWater treatment compoundsChemical oxygen demandReaction rate

The invention provides a Fenton-like oxidation catalyst and application thereof. A preparation process of the Fenton-like oxidation catalyst comprises the following steps of modifying a microporous ZSM-5 molecular sieve by alkaline so as to prepare a porous ZSM-5 molecular sieve; loading Fe (iron) onto the porous ZSM-5 molecular sieve, so as to obtain the Fenton-like oxidation catalyst. The Fenton-like oxidation catalyst is used for treating the organic amine wastewater, the maximum removal rate of COD (chemical oxygen demand) in water can reach 97%, and the removal rate of ammonia nitrogen can reach 90%. Compared with the conventional organic amine wastewater treatment technique, the Fenton-like oxidation catalyst has the advantages that (1) by performing alkaline modifying, a mesoporousstructure is introduced into the microporous structure of the ZSM-5 molecular sieve, so as to solve the problems of difficulty in molecule diffusion, low catalytic degrading rate of macromolecules andthe like, and accelerate the catalytic reaction rate; (2) the cost is low, the catalyzing activity is high, and the stability is good; (3) the better COD and ammonia-nitrogen removal effect can be realized at the normal pressure and the temperature lower than 100 DEG C, the reaction system is mild, and the treatment effect is good.

Owner:SHANGHAI LVQIANG NEW MATERIALS CO LTD +1

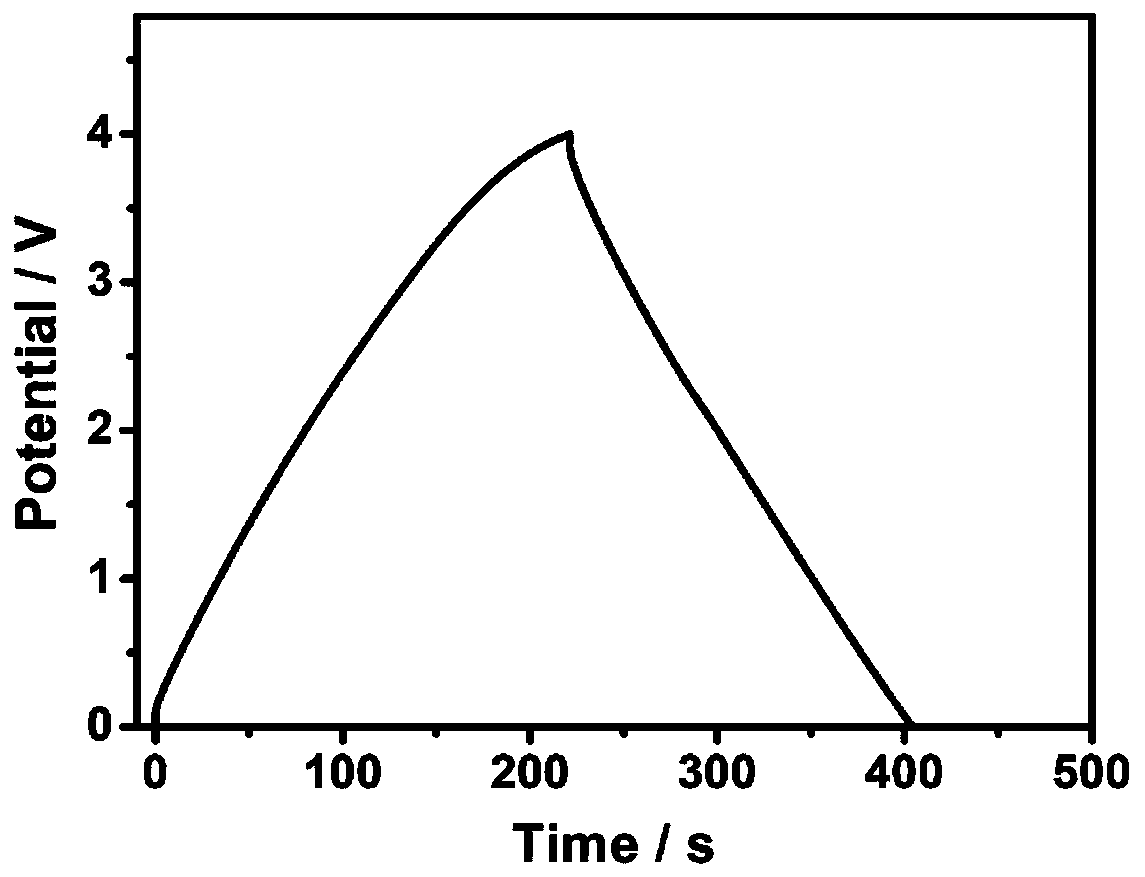

A method of preparing a hierarchical porous carbon material as a supercapacitor electrode material

InactiveCN107098330ASimple processAvoid complicatedHybrid capacitor electrodesCarbon preparation/purificationCapacitancePotassium hydroxide

The invention relates to a method of preparing a hierarchical porous carbon material as a supercapacitor electrode material. Firstly an RF / PAM interpenetrating polymer network is prepared, and then is mixed with an activating agent that is potassium hydroxide, the mixture is put into a tubular furnace and heated and reacted under inert gas protection, and a product is cooled to obtain the target product that is the hierarchical porous carbon material. Compared with the prior art, the method is novel and simple in process, and when the obtained hierarchical porous carbon material is adopted as a supercapacitor electrode material, and under a current intensity of 1 A g<-1>, the highest specific capacitance can reach 261 F g<-1>, the capacity retention ratio after 10000 times of cyclic charging and discharging is 90.8%, and the specific capacitance can still be 216 F g<-1> under a large current intensity of 20 A g<-1>, and therefore the hierarchical porous carbon material shows a high specific capacitance, excellent rate capacity, and good cycle stability.

Owner:TONGJI UNIV

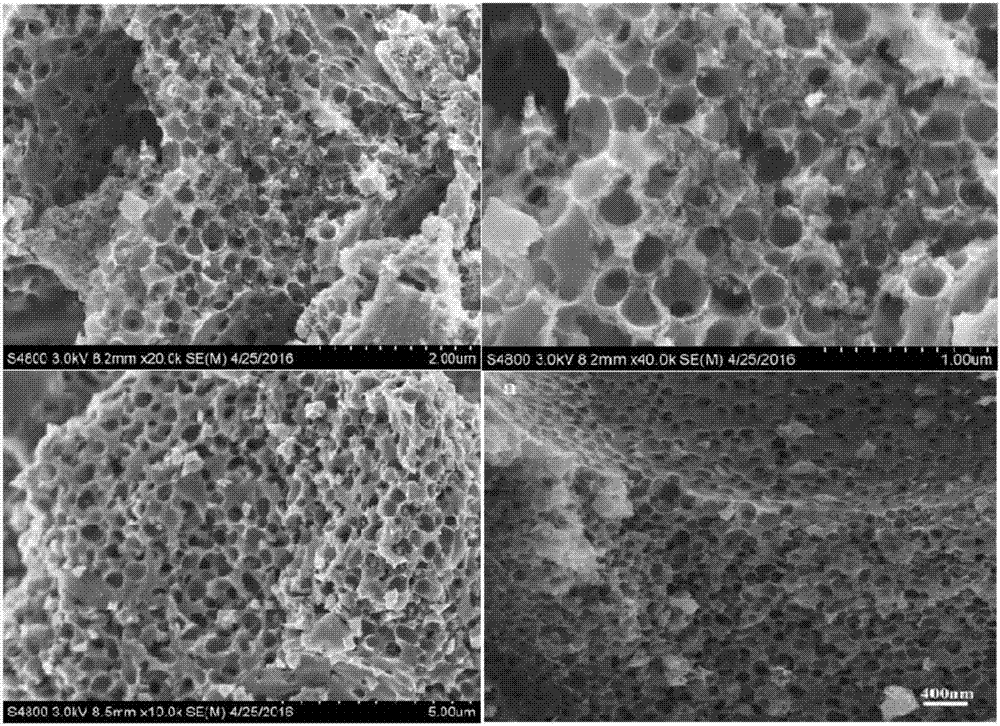

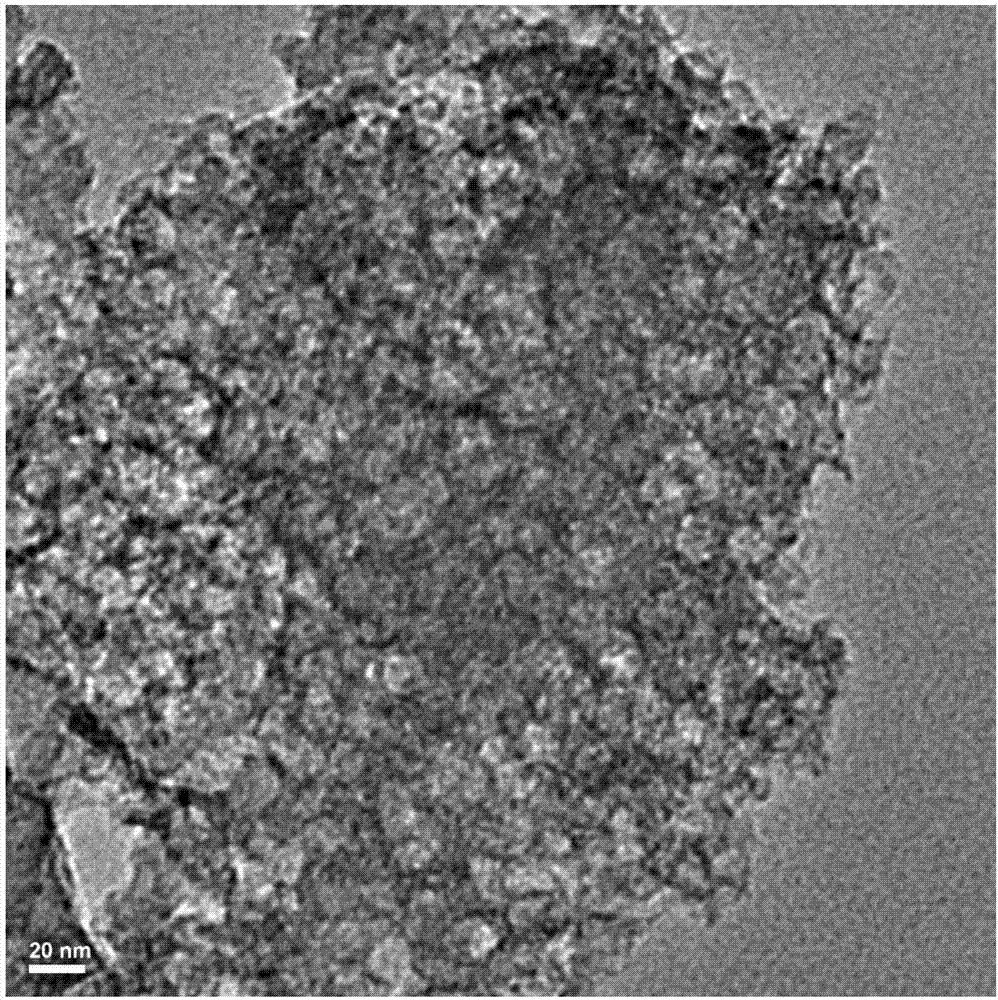

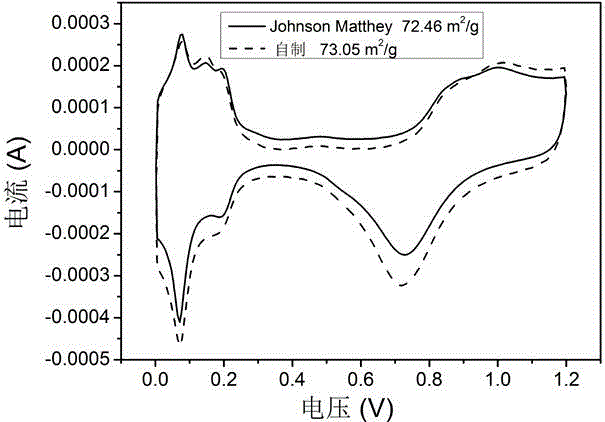

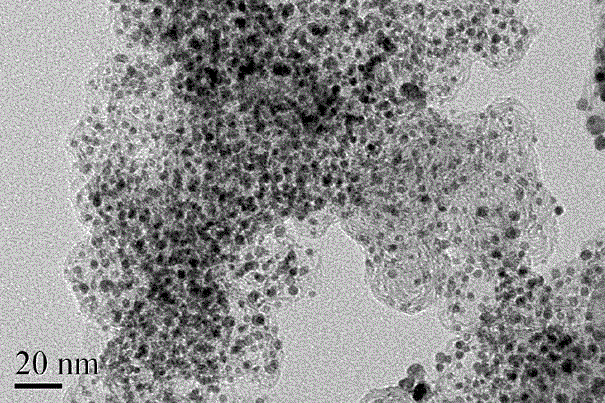

Preparation method for proton exchange membrane fuel cell catalyst

InactiveCN104588001APlay a role in purificationIncreased mesopore volumeCell electrodesMetal/metal-oxides/metal-hydroxide catalystsPlatinumProcess efficiency

The invention discloses a preparation method for a proton exchange membrane fuel cell catalyst. The adoption of a surfactant and a stabilizer is avoided, the preparation method is easy to operate, safe and convenient, and the preparation efficiency is greatly improved; acid is added as a precipitant, so that the precipitation time of the catalyst is greatly shortened, and the process efficiency is improved; a drying process of the catalyst is rapidly finished by a spray drying technology, and materials sprayed in the drying process are instantaneously heated by high temperature only when being sprayed into spray particles, so that the phenomenon of agglomeration of the catalyst is reduced, and the electrochemical activity of the platinum-carbon catalyst is kept high after the catalyst is dried; moreover, by the spray drying technology, the preparation time of the catalyst is further reduced, and the preparation method is easy to realize industrial production, and has broad market prospect.

Owner:KUNSHAN SUNLAITE NEW ENERGY +1

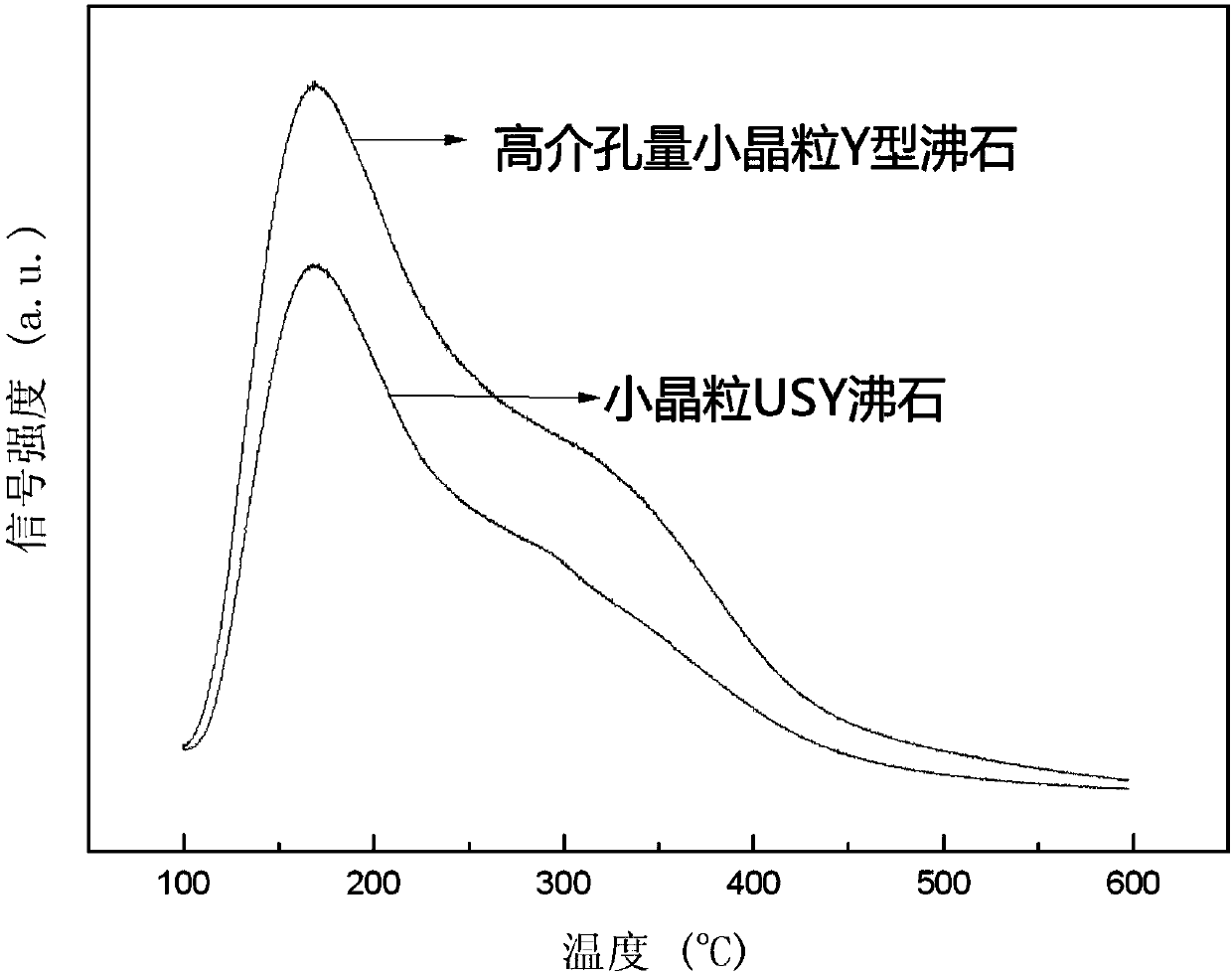

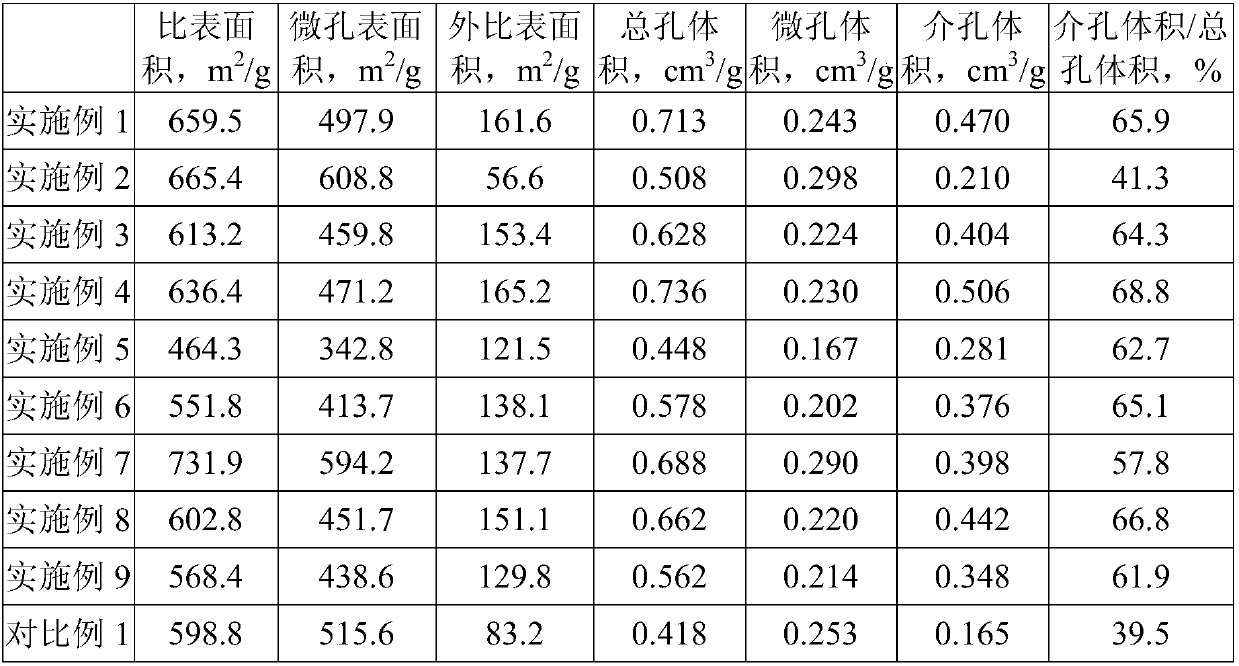

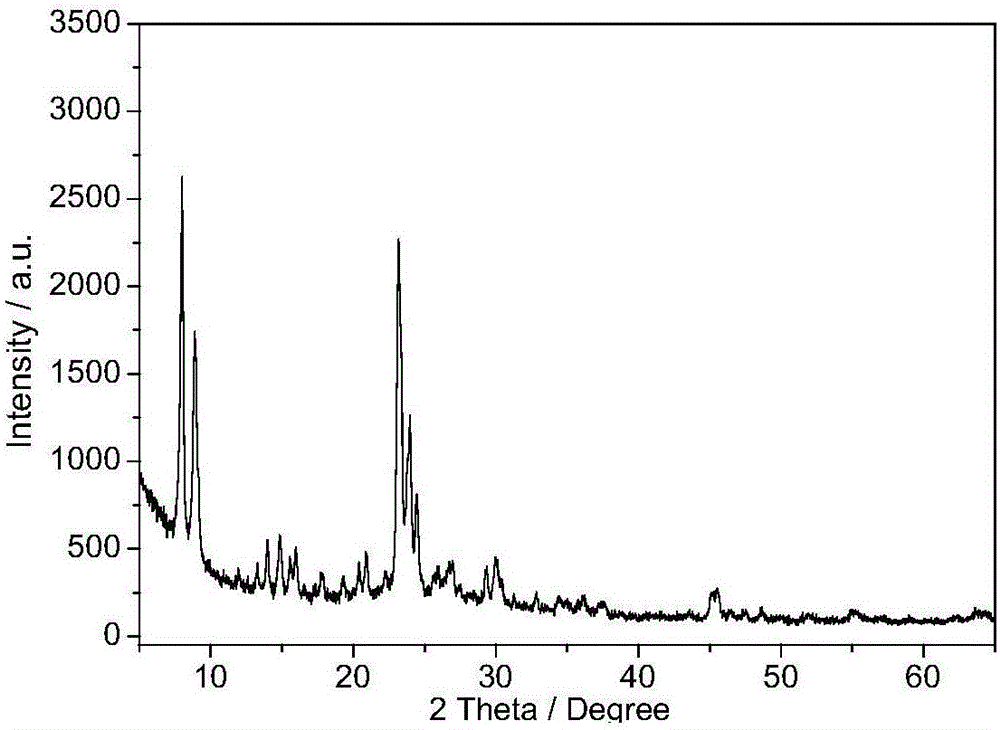

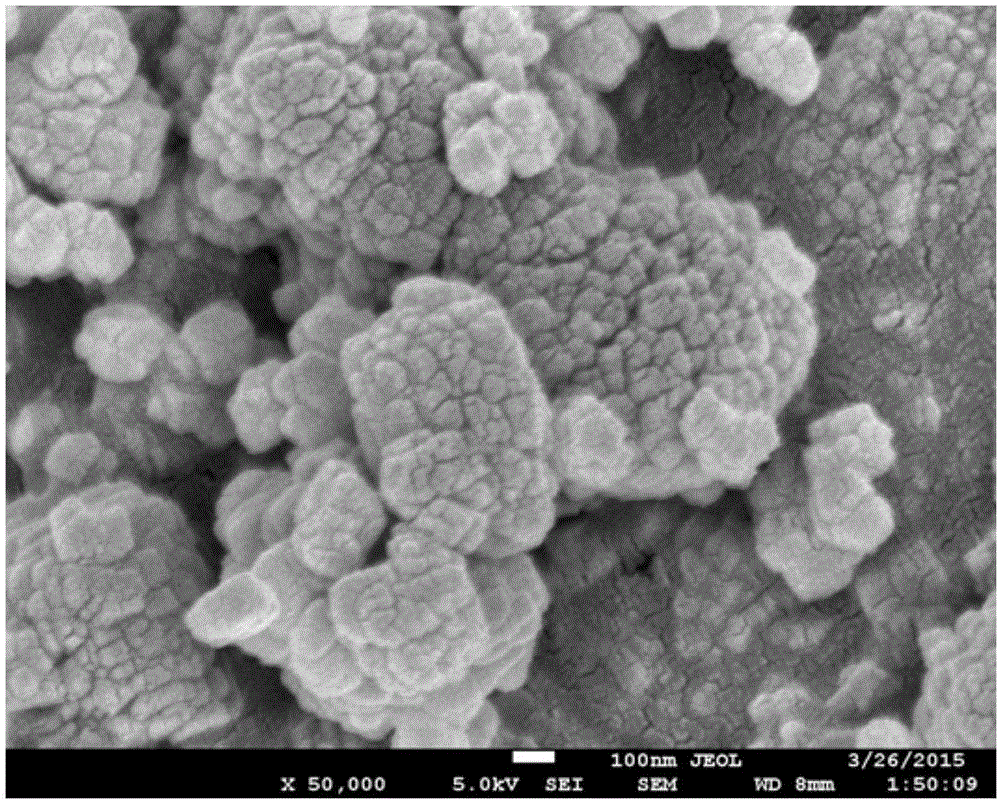

High-mesopore-amount Y type zeolite and preparation method thereof

ActiveCN107758684AEasy to prepareRelaxed experimental conditionsFaujasite aluminosilicate zeoliteIon exchangeChemistry

The invention provides a preparation method of high-mesopore-amount Y type zeolite. The preparation method comprises: carrying out ammonium ion exchange treatment on Y type zeolite at a temperature of50-120 DEG C to obtain NH4Y zeolite; adding the NH4Y zeolite to a buffer solution with a concentration of 0.1-1 M, and beating to a slurry; slowly adding an ammonium fluorosilicate solution with a concentration of 0.01-1 M to the slurry in a dropwise manner, and stirring for 0.1-5 h at a temperature of 20-120 DEG C to obtain a crude product; directly carrying out alkali treatment on the crude product or carrying out alkali treatment after washing and drying, wherein the crude product is treated for 0.1-5 h at a temperature of 30-120 DEG C with an alkaline solution with a concentration of 0.01-3.0 M, and a mass ratio of the alkaline solution to the crude product is 1-50:1, preferably 5-40:1; and carrying out ammonium ion exchange on the obtained crude product at a temperature of 50-120 DEGC, calcining for 1-8 h at a temperature of 300-800 DEG C, washing, and drying to obtain the high-mesopore-amount Y type zeolite.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

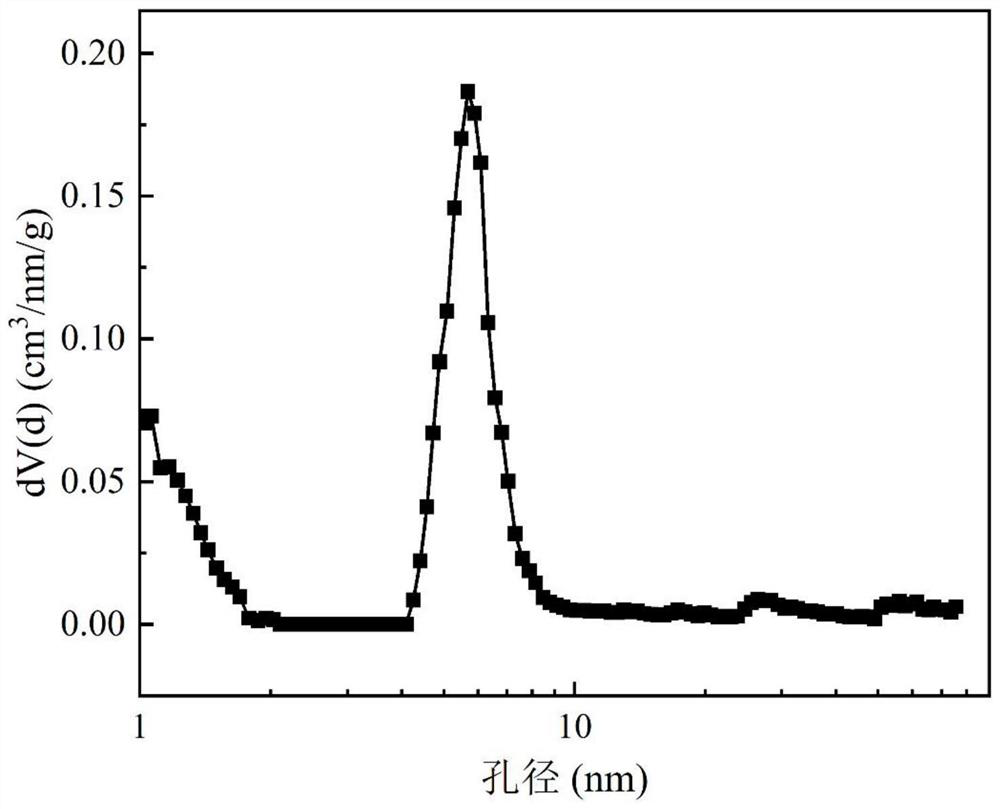

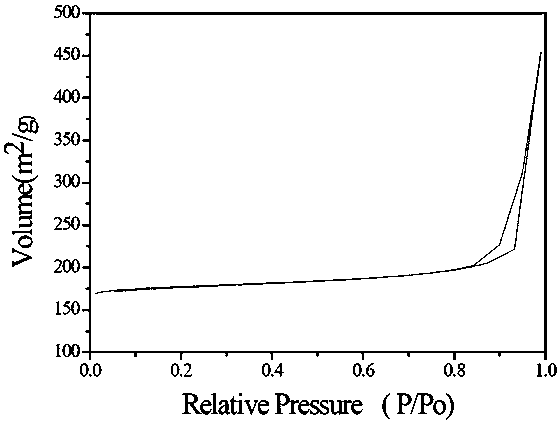

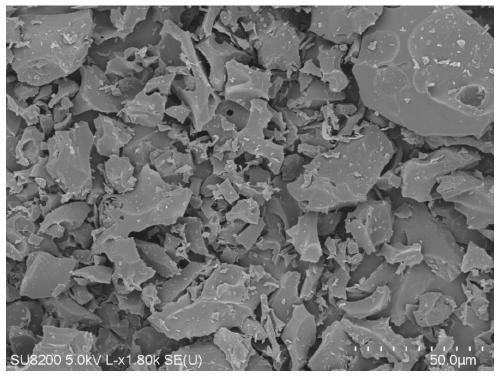

Method for preparing multistage-hole ZSM-5 molecular sieve

The invention discloses a method for preparing a multistage-hole ZSM-5 molecular sieve, and belongs to the technical field of synthesis of molecular sieves. The invention provides the preparation method of the multistage-hole ZSM-5 molecular sieve which is low in cost and low in pollution, can change a silicon aluminum ratio (30-100) to the molecular sieve in a wide range, and has a large mesoporous volume. The method comprises the following steps of I, preparing crystal seeds for the synthesis of the multistage-hole ZSM-5 molecular sieve; II, preparing mixed gel, and performing stirring at room temperature; III, adding the crystal seeds prepared in the step I into the gel obtained in the step II, performing low-temperature crystallization for a short time, and adding a little organic silicon; and IV, continuing crystallization, performing cooling, performing centrifugal filtration, performing washing, performing drying, and performing roasting so as to obtain the multistage-hole ZSM-5 molecular sieve. According to the method provided by the invention, a few organic amine template agents are used only in the crystal seed synthesizing process, an s small, so that d besides, the addition amount of the added organic silicon as a mesoporous hole forming agent i compared with a method for synthesizing other multistage-hole ZSM-5 molecular sieve, the method disclosed by the invention has the advantages that the dosage of the template agents is small, products have a large mesoporous volume, and the problems that the production cost of the molecular sieve is high and environment is polluted caused by the condition that the organic template agent is high in price and large in toxicity can be solved.

Owner:HEILONGJIANG UNIV

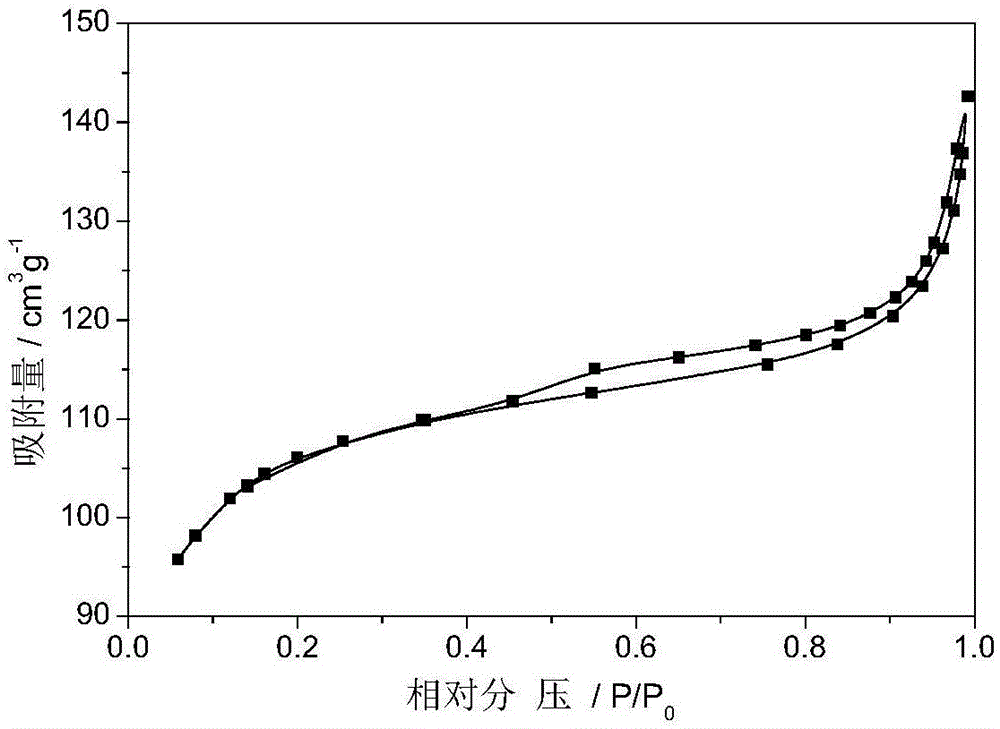

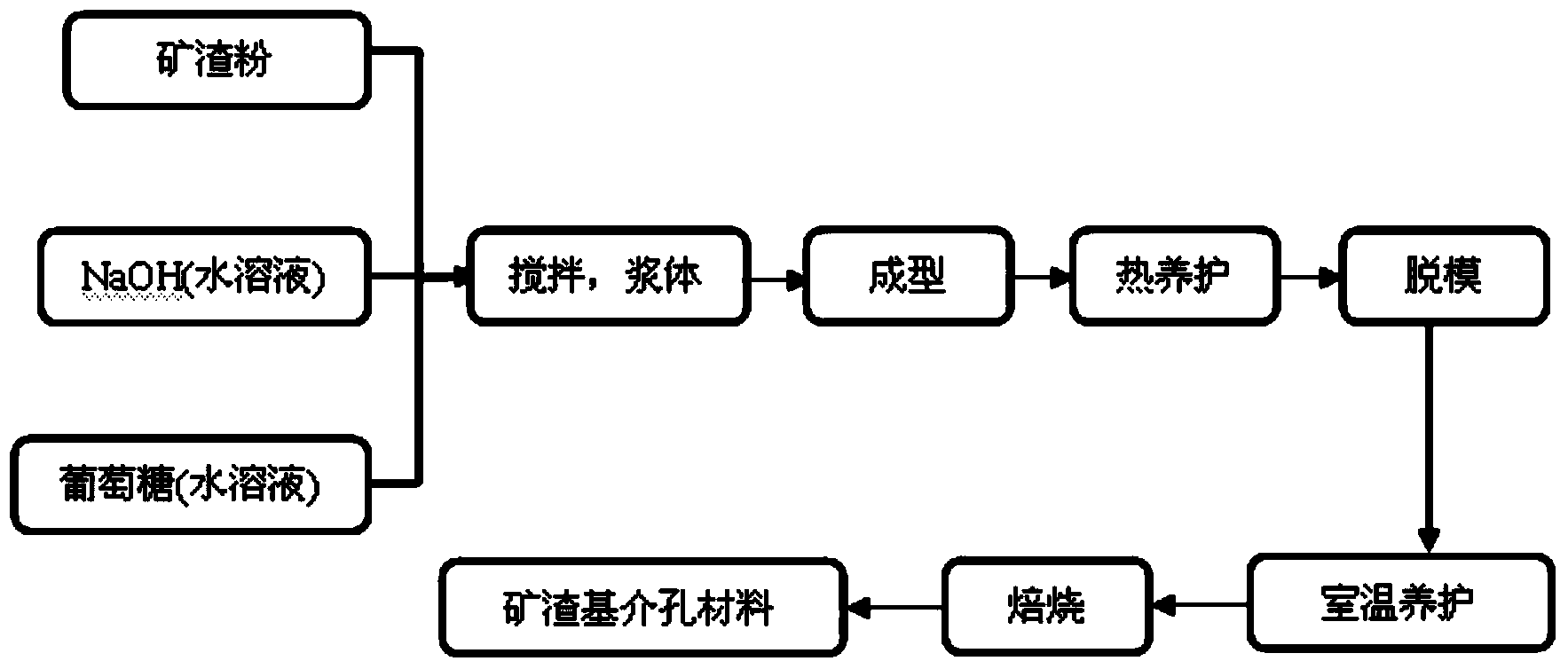

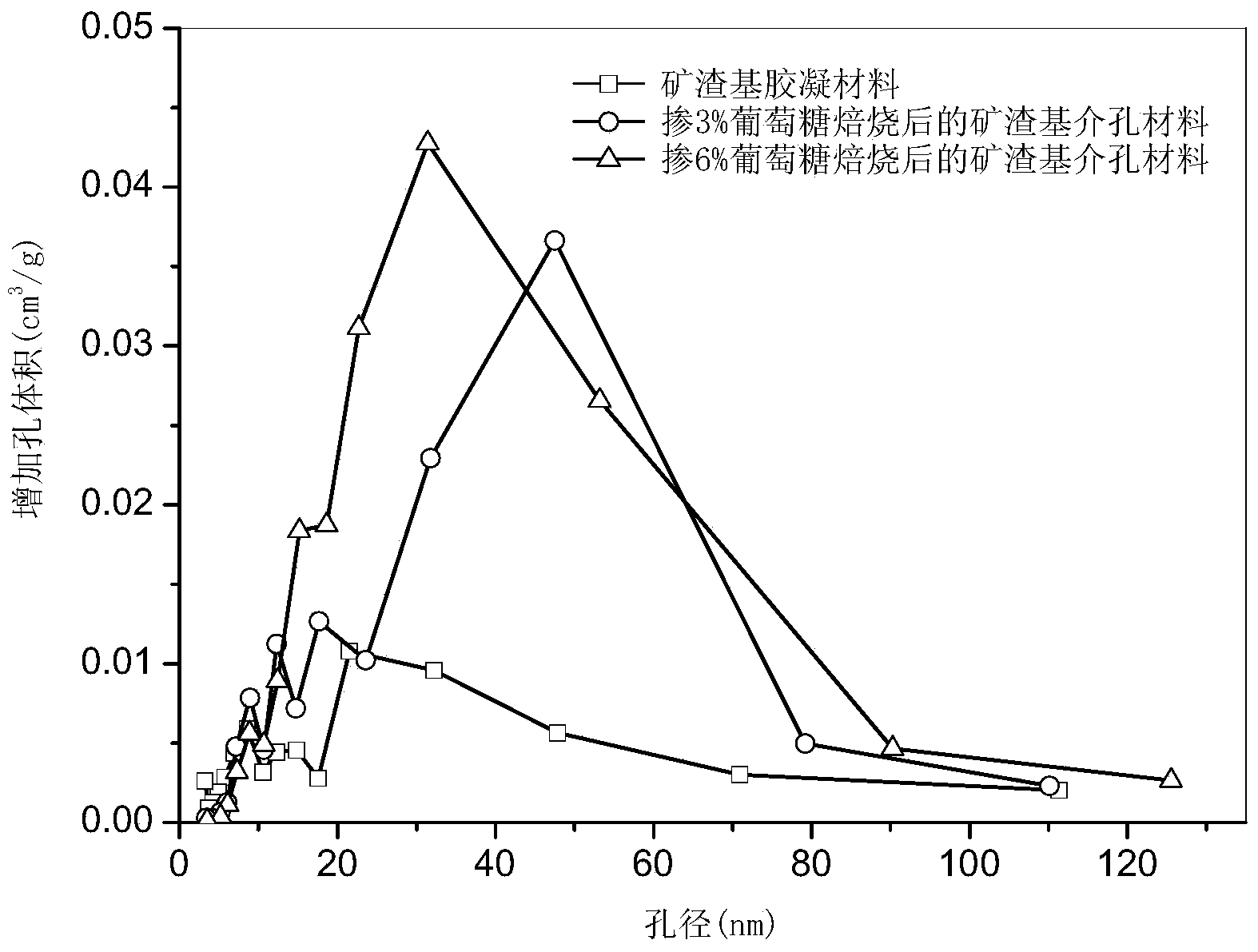

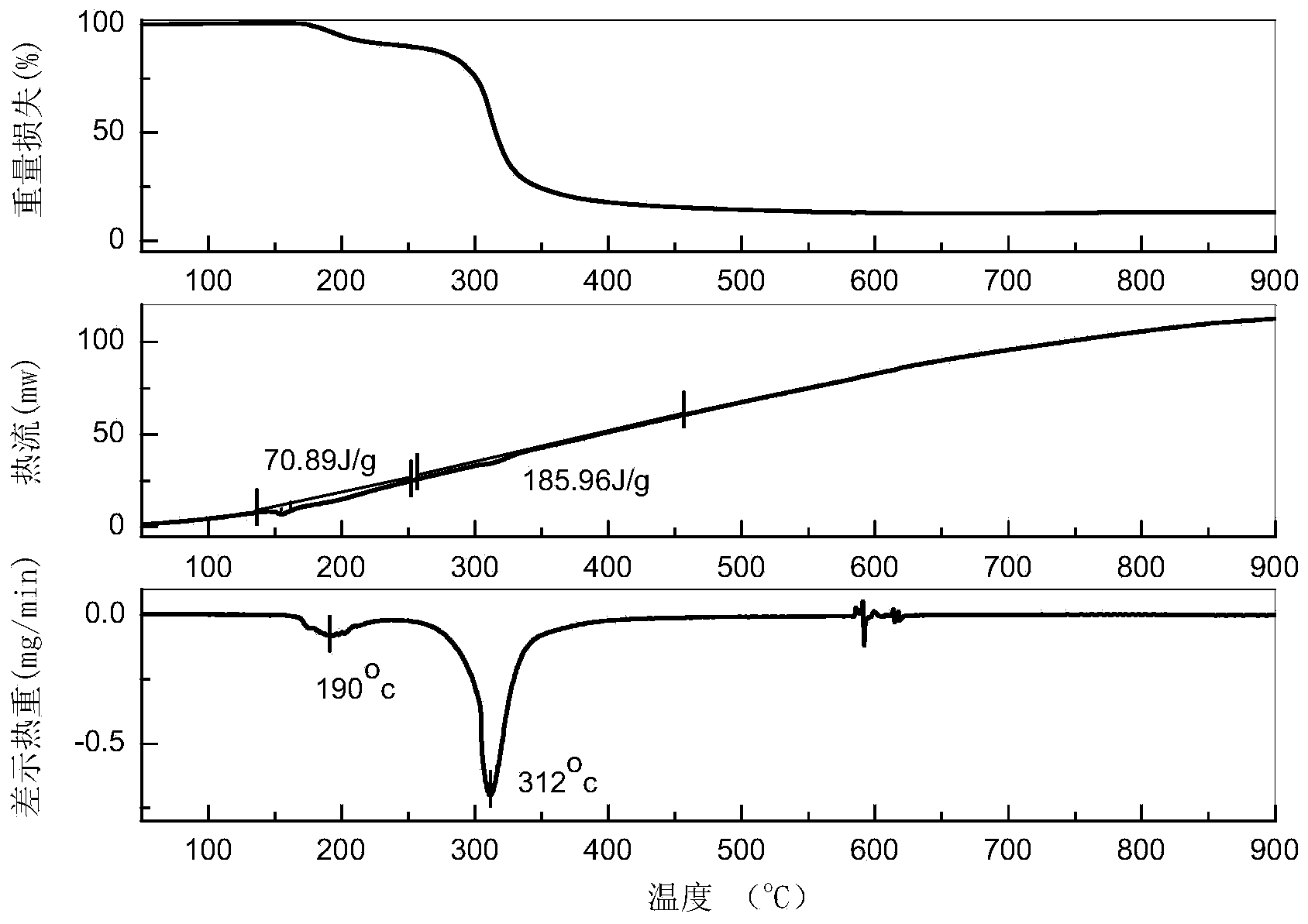

Slag based mesoporous material and preparation method thereof

InactiveCN104163615APromote the development of circular economyIncrease added valueCatalyst carriersSolid waste managementSlagMesoporous material

The invention discloses a slag based mesoporous material and a preparation method thereof; the slag based mesoporous material is prepared by putting raw material slag, sodium hydroxide water and pore increasing agent glucose into a mixing device for mixing, using a die for molding, curing, and burning; and taking the adding quantity of the slag mass as a basis, the adding quantity of the sodium hydroxide is 6% of the slag mass, the adding quantity of the pore increasing agent glucose is 3%-6% of the slag mass, and the ratio of water adding quantity to slag mass is 0.24-0.28. Compared with a sample free of the pore increasing agent, after addition of the pore increasing agent in an optimum adding amount, the mesopore volume of a sample is increased by 102.63%; slag can be completely used in one time, the slag based mesoporous material with high added value can be obtained, the whole process is simple, no slag treatment is needed, no three wastes is discharged, the slag based mesoporous material is green and environmentally-friendly, and controllable preparation of the slag based mesoporous material can be realized.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

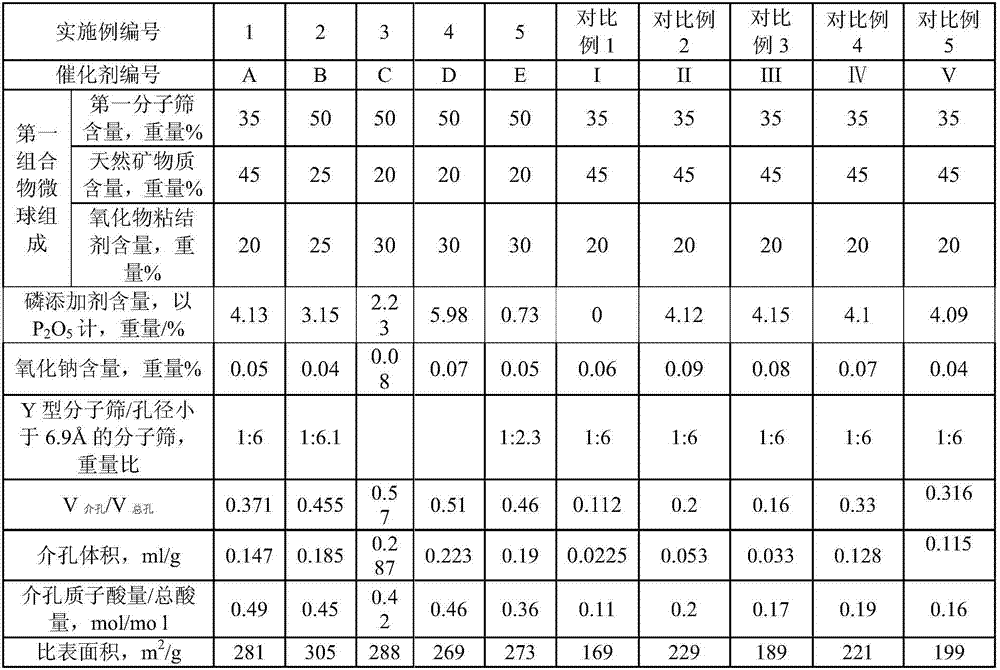

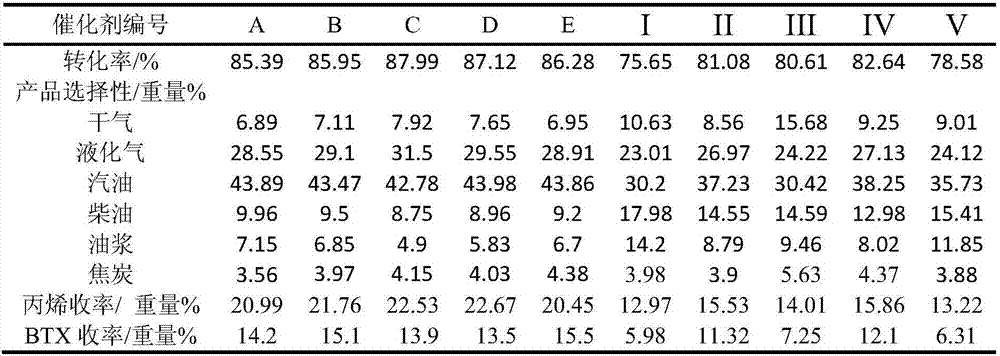

Catalytic cracking catalyst and preparation method thereof

ActiveCN107971013ARich mesostructureImprove stabilityCatalytic crackingMolecular sieve catalystsMolecular sieveSpray dried

The invention provides a catalytic cracking catalyst and a preparation method thereof, wherein the catalyst comprises 5-65% of natural minerals, 10-60% of an oxide binder, 24-75% of a first molecularsieve, and 0.1-15% of a phosphorus additive, the first molecular sieve is a molecular sieve with the pore size of less than 6.9 angstrom, and a Y type molecular sieve, or comprises more than two selected from molecular sieves with the pore size of less than 6.9 angstrom, and the amount of the mesoporous protonic acid of the catalyst accounts for 20-70% of the total acid amount. The preparation method comprises: forming a slurry containing the first molecular sieve, the natural minerals and the inorganic oxide binder, carrying out spray drying, treating with an alkali and a compound acid, and introducing the phosphorus additive. According to the present invention, the catalytic cracking catalyst has high propylene yield and high BTX yield in the catalytic cracking of petroleum hydrocarbons.

Owner:CHINA PETROLEUM & CHEM CORP +1

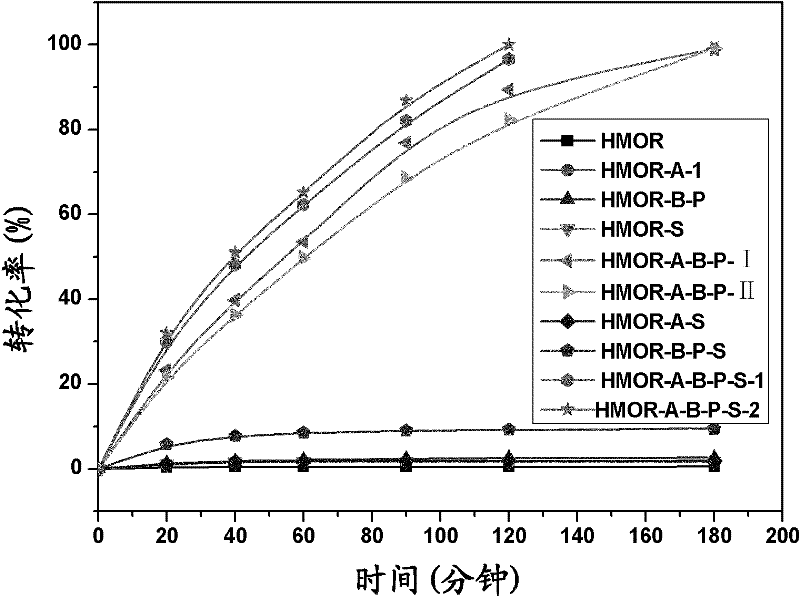

Modified mordenite, preparation method and application thereof

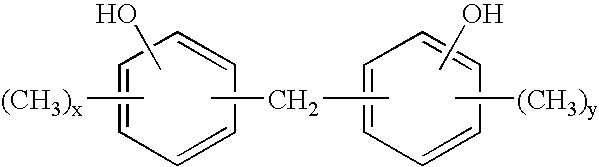

InactiveCN102530984AIncreased mesopore volumeImprove conversion rateMolecular sieve catalystsHydrocarbon from oxygen organic compoundsBenzeneBenzyl alcohol

The invention relates to modified mordenite which has a mesopore increment of 0.170-0.200cm<3>g<-1> relative to the unmodified mordenite. The invention also relates to a preparation method of the modified mordenite, which comprises the steps of: a, treating mordenite with an acid solution; b, treating the mordenite subjected to acid treatment by using an alkaline solution; c, carrying out hydrogen ion exchange on the mordenite subjected to alkaline treatment; and d, carrying out steam treatment on the mordenite obtained in the step c. The invention further relates to a method for enabling benzene and phenylcarbinol to be subjected to a Friedel-Crafts acylation reaction. The method comprises the step of using the modified mordenite as a catalyst or catalyst component. According to the method provided by the invention, the modified mordenite with remarkable mesopore increment is obtained through jointly modifying the mordenite simply and mildly, and the modified mordenite can provide more reaction space for the Friedel-Crafts acylation reaction of the benzene and the phenylcarbinol, thus the conversion rate of the phenylcarbinol is increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic cracking catalyst and preparation method thereof

ActiveCN107971014AImprove open loop rateHigh selectivityCatalytic crackingMolecular sieve catalystsMolecular sieveNatural mineral

The invention provides a catalytic cracking catalyst and a preparation method thereof, wherein the catalyst comprises: (a) 15-65% of natural minerals; (b) 10-60% of an oxide; and (c) 25-75% of a Y type molecular sieve and a mesopore-rich IMF-structure molecular sieve, wherein the total specific surface area of the mesopore-rich IMF-structure molecular sieve is more than 600 m<2> / g, the matrix areais greater than 200 m<2> / g, and the volume of the mesopores is greater than 0.26 ml / g. The preparation method comprises: carrying out mixing beating on the mesopore-rich IMF-structure molecular sieve, the Y type molecular sieve, the natural minerals and an inorganic oxide binder, and carrying out spray drying. According to the present invention, the catalytic cracking catalyst has the high low-carbon olefin yield in the propylene preparation through the catalytic cracking of petroleum hydrocarbons.

Owner:CHINA PETROLEUM & CHEM CORP +1

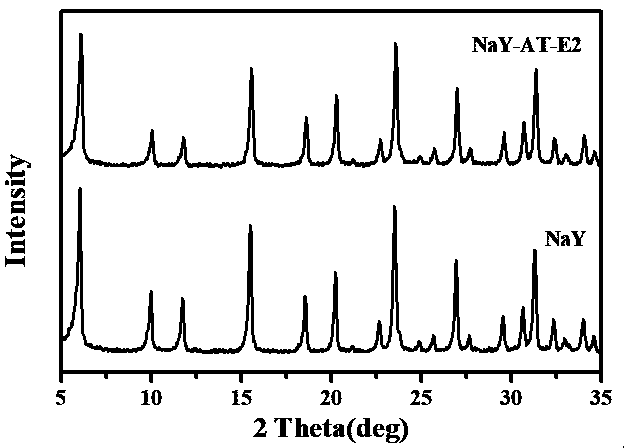

Method for preparing hierarchical pore Y zeolite through oxalic acid-ammonium hydroxide cotreatment

InactiveCN110117017AIncrease the outer surface areaIncreased mesopore volumeFaujasite aluminosilicate zeoliteOxalateCacodylic acid

The invention discloses a method for preparing hierarchical pore Y zeolite through oxalic acid-ammonium hydroxide cotreatment. The method comprises the following steps of 1, acid treatment with an oxalic acid solution, wherein NaY zeolite is obtained to be evenly mixed with the H2C2O4 solution to obtain a mixture, and the mixture is put in an oil bath pan and stirred; the mixed liquid obtained after oil bath treatment is subjected to vacuum suction filtration until filter liquor is close to be neutral, a filter cake is put into a drying oven for overnight drying, and an oxalic acid treated sample is obtained; 2, alkaline treatment with a NH3 H2O solution, wherein the oxalic acid treated sample obtained in the step 1 is evenly mixed with the NH3 H2O solution to obtain a mixture, and the mixture is put into an oil bath pan and treated; the mixed liquid obtained after oil bath treatment is subjected to vacuum suction filtration until filter liquor is close to be neutral, a filter cake istaken out, put into a drying oven for drying and calcined by using a muffle furnace, and then the hierarchical pore Y zeolite is obtained. The hierarchical pore Y zeolite is prepared through the oxalic acid-ammonium hydroxide cotreatment, compared with NaY, the outer surface area of the hierarchical pore Y zeolite is increased by 3 times or above, and the mesoporous volume of the hierarchical poreY zeolite is increased by 4 times or above.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

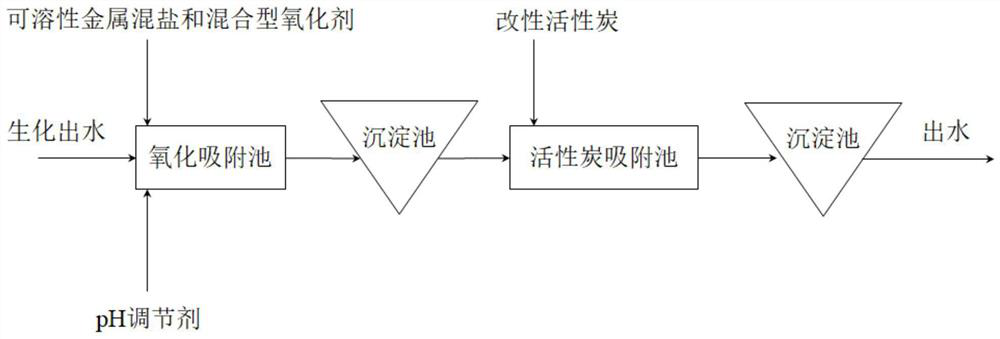

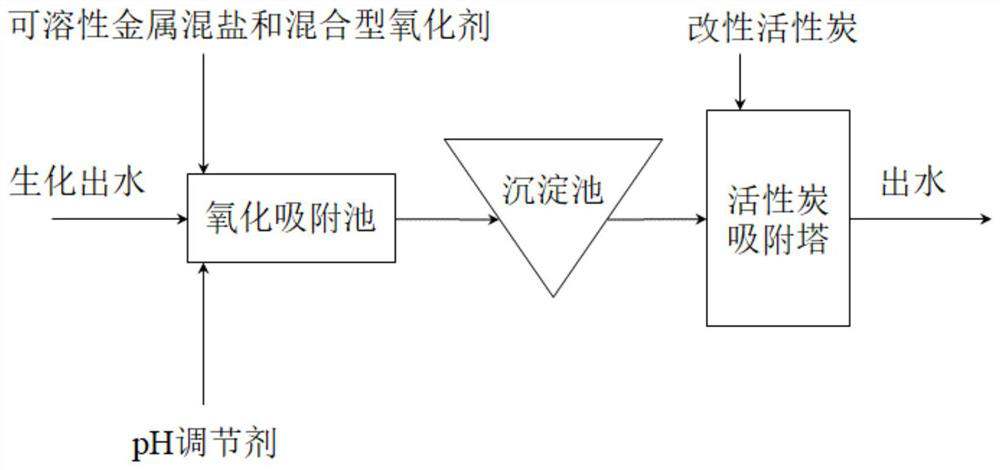

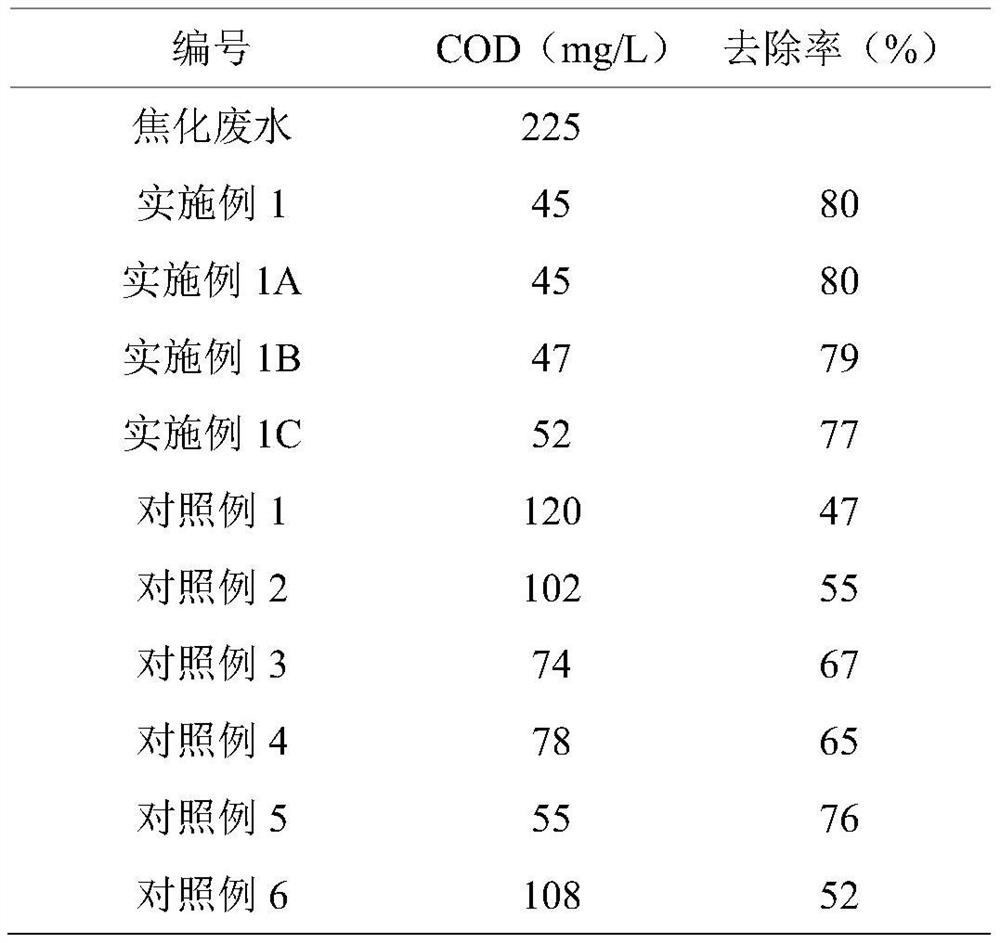

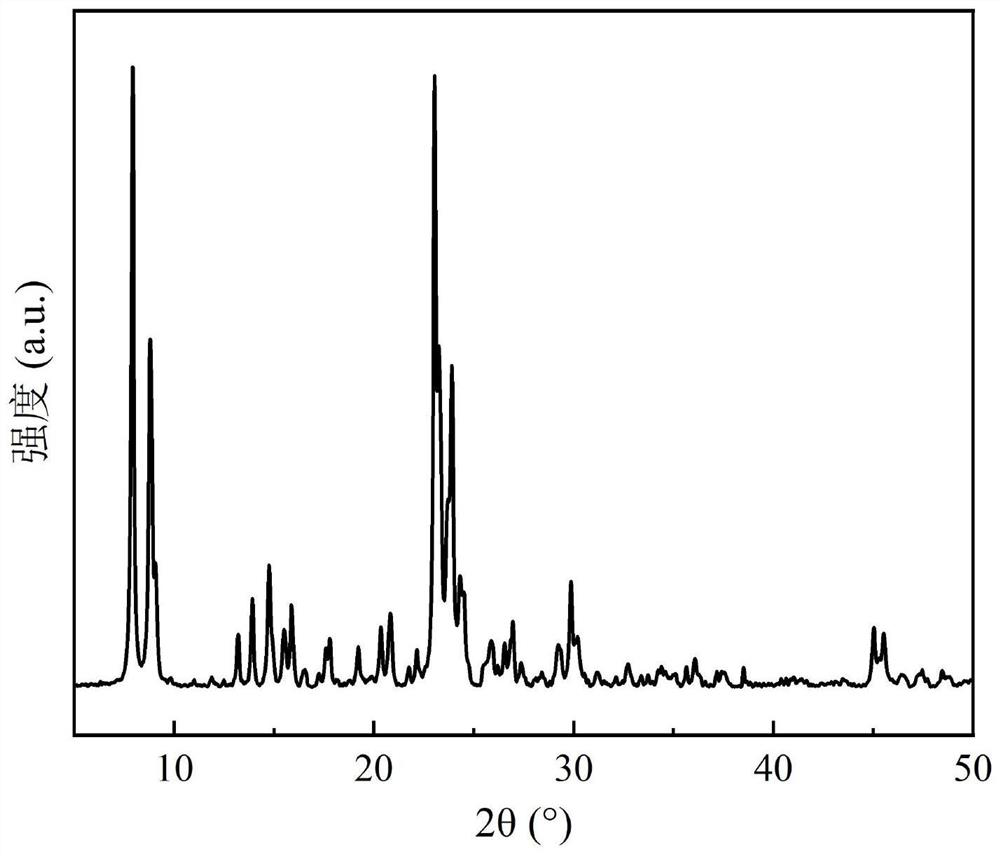

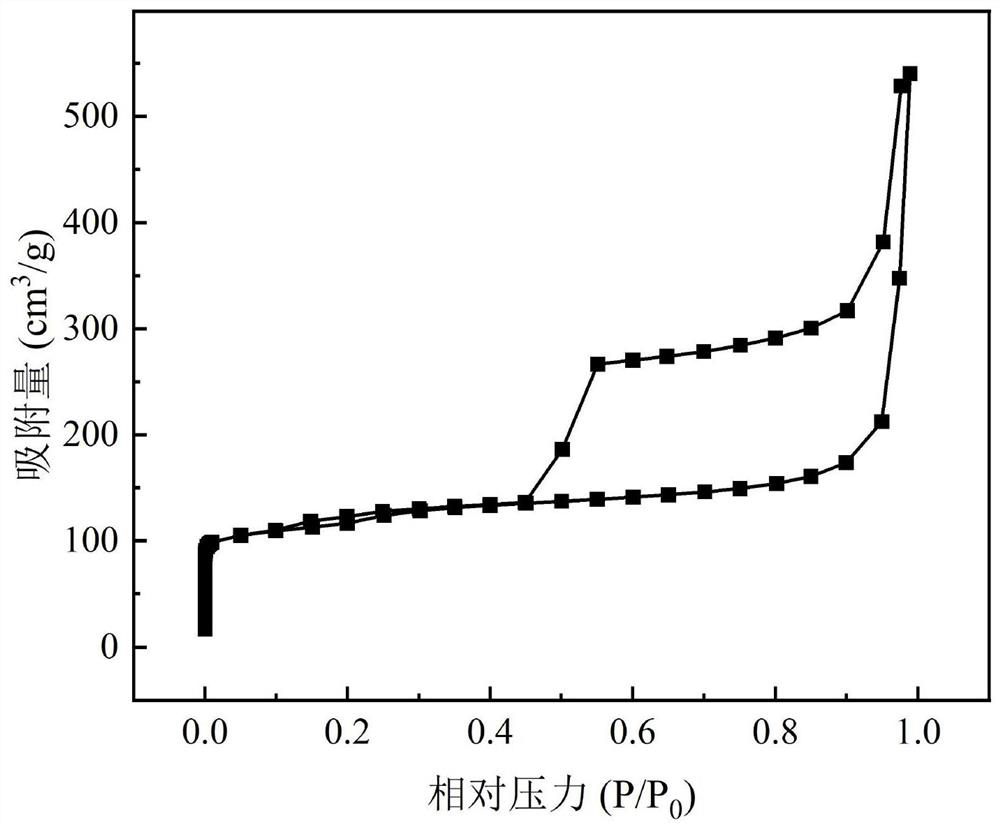

Method for removing refractory organic matters in industrial wastewater

ActiveCN112142231AEfficient removalEffectively remove refractoryWater contaminantsMultistage water/sewage treatmentActivated carbonActive carbon

The invention discloses a method for removing refractory (biodegradable) organic matters in industrial wastewater, which comprises the following steps: adding a composite oxidant, a composite solublemetal salt and modified activated carbon with developed mesopores into wastewater, and regulating the pH value of the wastewater to be greater than or equal to 4; and synchronously carrying out in-situ oxidation adsorption treatment and activated carbon adsorption treatment on refractory organic matters in the industrial wastewater. According to the method, the removal efficiency of refractory organic matters in the wastewater is high; and the problem that the activated carbon is blocked by macromolecular organic matters is remarkably reduced, and the adsorption removal of the activated carbonon refractory organic matters is promoted; in-situ oxidation adsorption and activated carbon adsorption are mutually assisted; and the method has the advantages of mild process conditions, easy reaction control, low consumption of the oxidant and the active carbon, short reaction time, and saving of the occupied area of equipment.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Preparation method of hollow molecular sieve catalyst and application of hollow molecular sieve catalyst in preparation of high-density aviation fuel by hydrogenation of polycyclic aromatic hydrocarbon

ActiveCN113368891AIncrease the areaIncreased mesopore volumeMolecular sieve catalystsRefining by aromatic hydrocarbon hydrogenationPolycyclic aromatic hydrocarbonMolecular sieve

The invention discloses a preparation method of a hollow ZSM-5 molecular sieve catalyst. The preparation method comprises the following steps of: (1) mixing a silicon source and a template agent; (2) crystallizing the mixture; (3) roasting the mixture; (4) mixing the solid powder with an aluminum source and an alkali source; and (5) roasting the obtained solid to obtain a hollow ZSM-5 molecular sieve. (6) loading metal on the hollow ZSM-5 molecular sieve; (7) roasting; and (8) reducing with hydrogen to obtain the hollow ZSM-5 molecular sieve catalyst. The invention also discloses application of the prepared hollow ZSM-5 molecular sieve catalyst in preparation of high-density aviation fuel by hydrogenation of polycyclic aromatic hydrocarbon.

Owner:TIANJIN UNIV

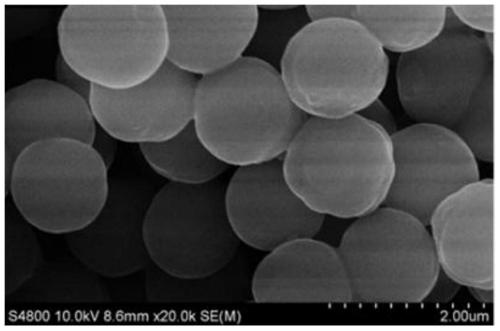

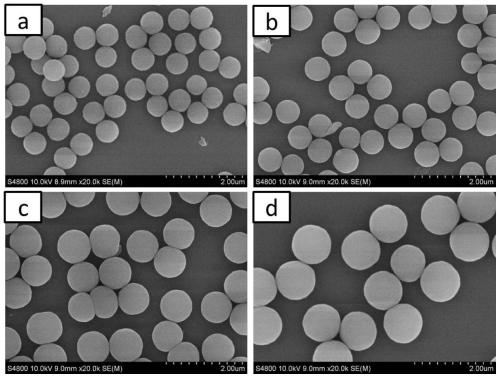

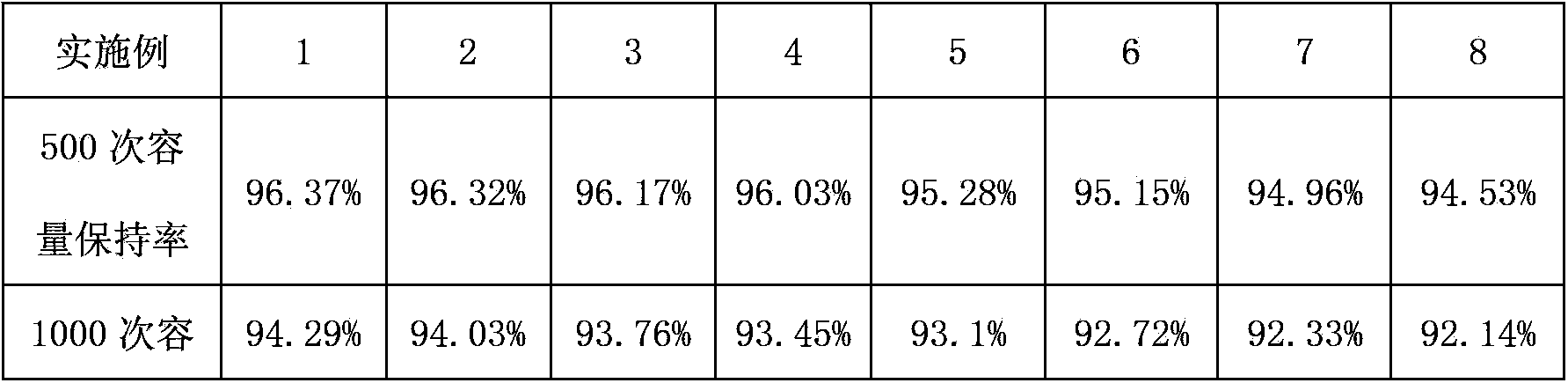

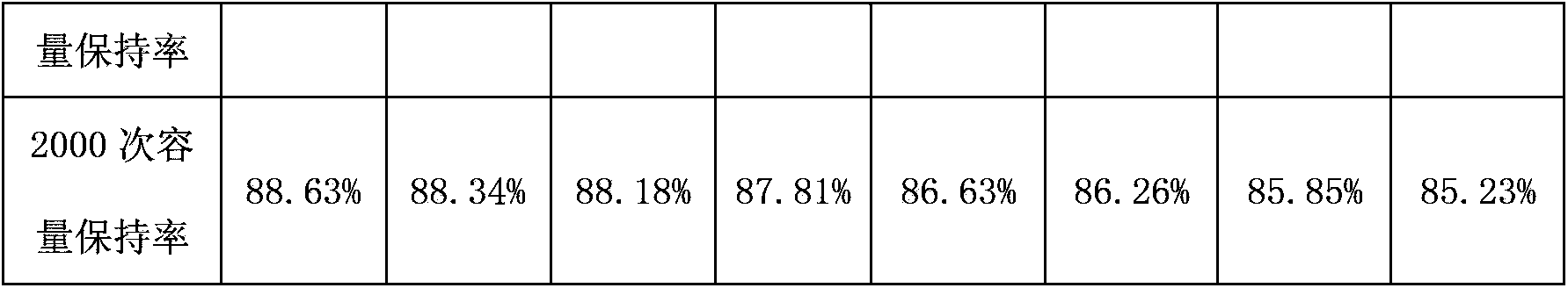

Large-scale prepared particle size-controllable nitrogen and oxygen doped carbon microsphere and preparation method and application thereof

ActiveCN109786118AGood electrochemical performanceIncrease mesopore volumeMaterial nanotechnologyHybrid capacitor electrodesSolventChemistry

The invention discloses a method for large-scale preparation of nitrogen and oxygen doped carbon microspheres. The method comprises the following steps of: stirring 2-8 parts of diallyl phthalate, 5-10 parts of acrylonitrile, 5-30 parts of a polymerizable monomer, 70-80 parts of a solvent and 0.2-1 part of azodiisobutyronitrile by weight under 70-80 DEG C for 3-5 hours, and carrying out centrifugal separation to obtain a solid powder product; heating the solid powder obtained in the step A to 800-900 DEG C at a certain speed under the protection of inert gas so as to obtain constant-temperature carbonization, and washing and drying the obtained black solid powder to obtain the nitrogen and oxygen doped carbon microspheres. The carbon microspheres are high in mesoporous content, high in specific area and favorable in capacitive performance, and can be used as a supercapacitor electrode material.

Owner:ZIBO VOCATIONAL INST

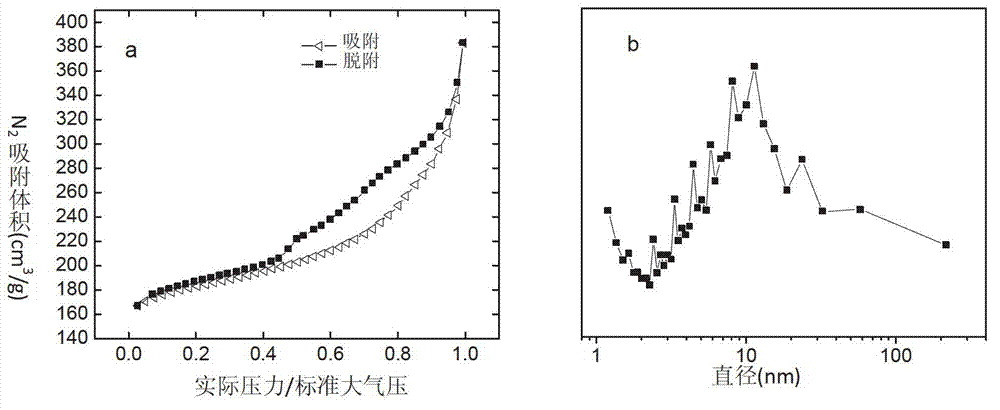

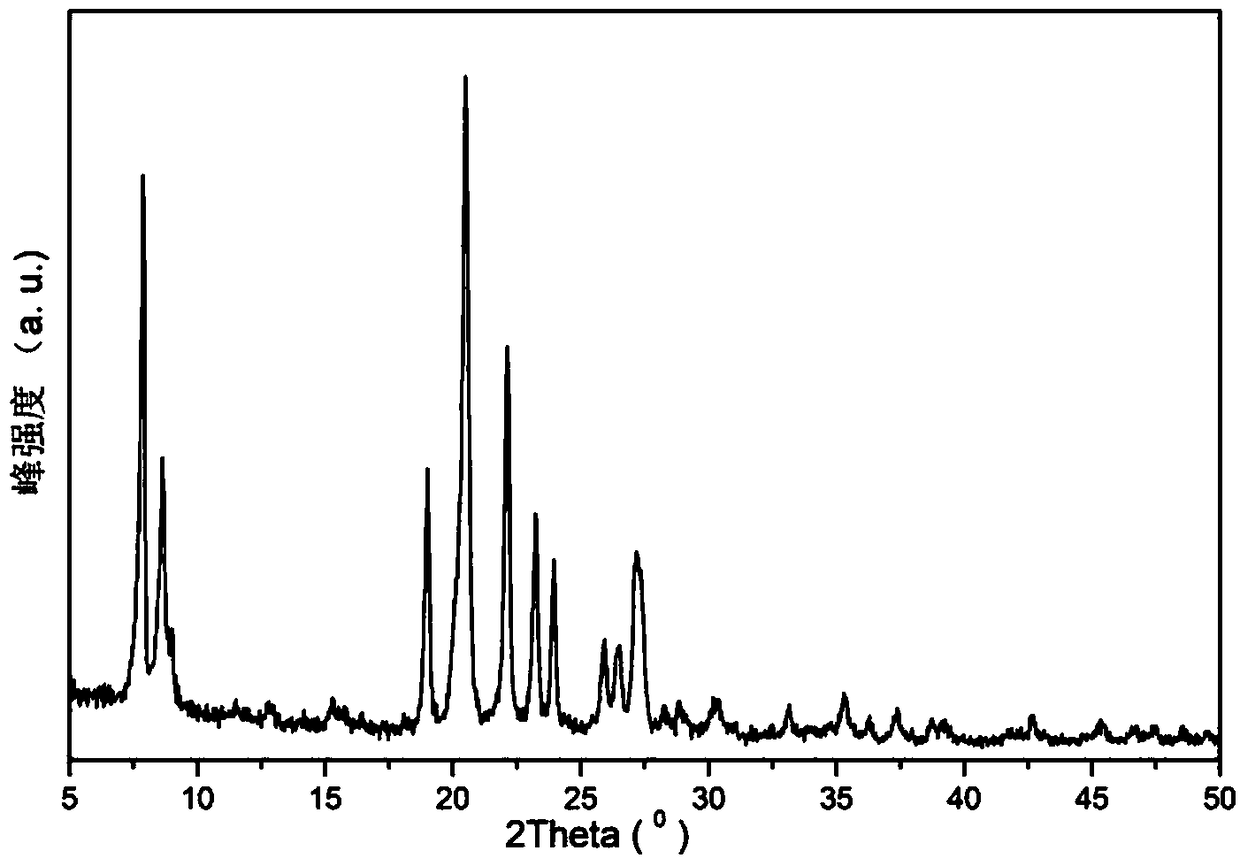

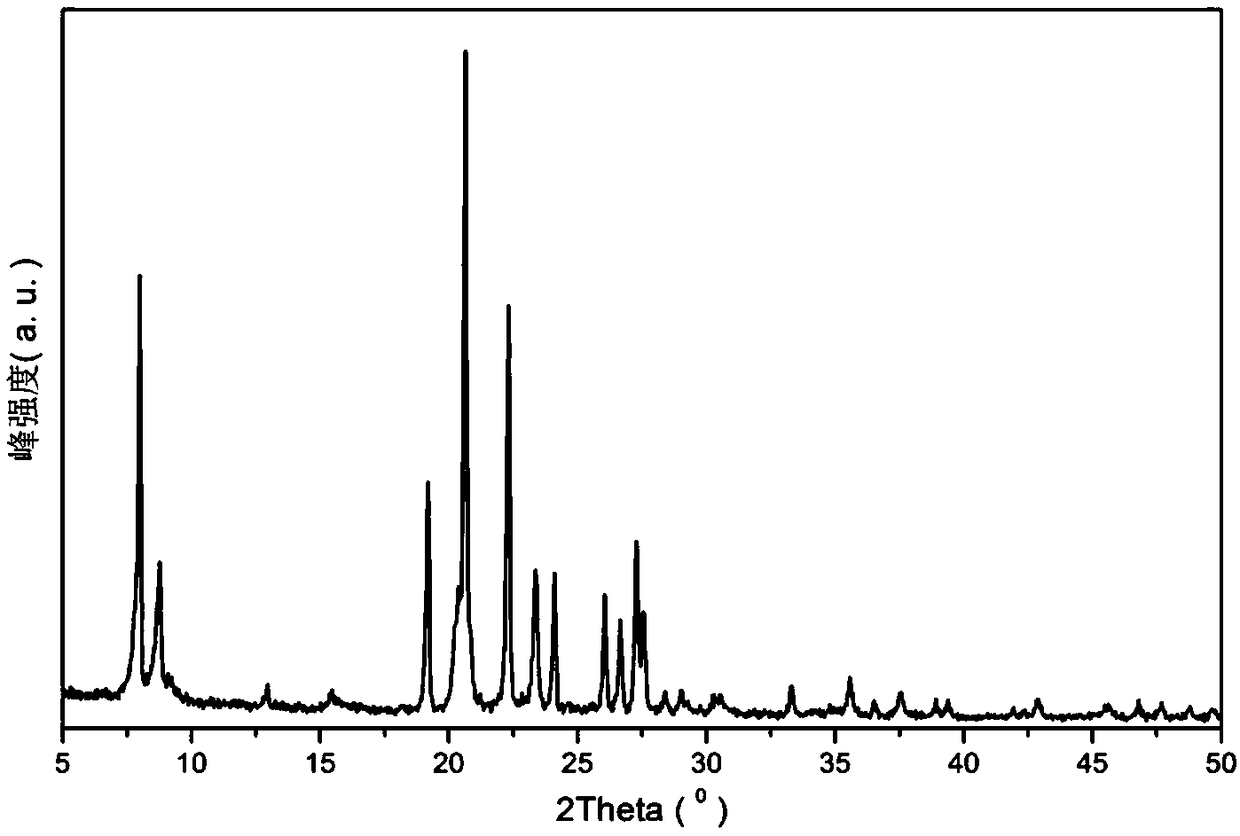

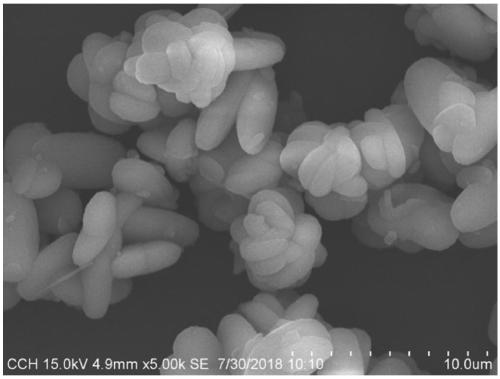

Synthesis method of SAPO-34 molecular sieve with large specific surface area

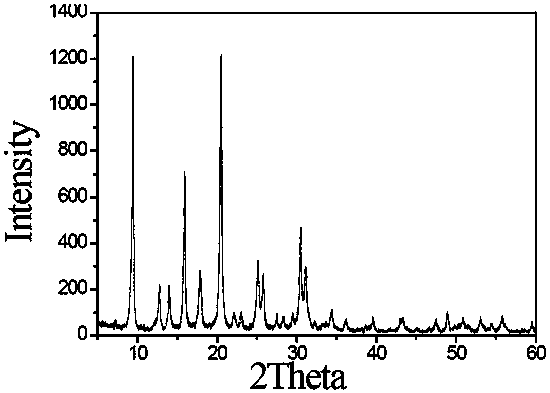

ActiveCN107827121AQuick in and outHigh crystallinityMaterial nanotechnologyMolecular sieve catalystsFiltrationSynthesis methods

The invention discloses a synthesis method of an SAPO-34 molecular sieve with a large specific surface area. The synthesis method comprises the steps as follows: (1) an aluminum source and water are mixed and pulped, tetraethylammonium hydroxide is added, the mixture is stirred, and a solution A is formed; (2) phosphoric acid, acidic silica sol and water are mixed to form a solution B; (3) the solution A and the solution B are subjected to parallel mixing, a mixed solution formed through parallel mixing is stirred in real time, the pH of the system is adjusted to 5.5-7.5, stirring is performed, and gel is obtained; (4) the gel is dewatered and dried, and a precursor is obtained; (5) the precursor is ground, the ground precursor is placed at the upper part of a reaction kettle, water is putin the lower part of the reaction kettle, and crystallization is performed; and (6) filtration is performed, filter residues are dried and calcined, and the SAPO-34 molecular sieve is synthesized. The prepared SAPO-34 molecular sieve is formed by polymerization of crystal grains of 50-200 nm, has the larger specific surface area and higher mesoporous capacity, contributes to quick access of reaction substances into pores and can improve the catalytic activity.

Owner:SHAANXI YANCHANG PETROLEUM GRP

Preparation method of palladium carbon catalyst

InactiveCN106732558AIncreased payload areaGood dispersionMetal/metal-oxides/metal-hydroxide catalystsActivated carbonOxygen

The invention relates to the technical fields of synthetic resins and plastics, and specifically relates to a preparation method of a palladium carbon catalyst. The preparation method of the palladium carbon catalyst comprises the following steps: (1) pretreating; and (2) preparing the palladium carbon catalyst. After hydrogen peroxide is used for treating an active carbon carrier, the activity of the obtained palladium carbon catalyst is firstly increased and then reduced along the concentration of the hydrogen peroxide; the hydrogen peroxide pretreatment enables the mean pore size and the mesopore volume of the palladium carbon catalyst to be increased; the hydrogen peroxide treatment can introduce an oxygen element to the carrier surface; the hydrogen peroxide pretreatment has no influence to the phase of the palladium carbon catalyst; the hydrogen peroxide pretreatment can increase the effective load area of active carbon and introduces an oxidizing group to promote the dispersion of palladium in the carrier, and the catalytic activity is improved.

Owner:SHAANXI HI-TECH IND CO LTD

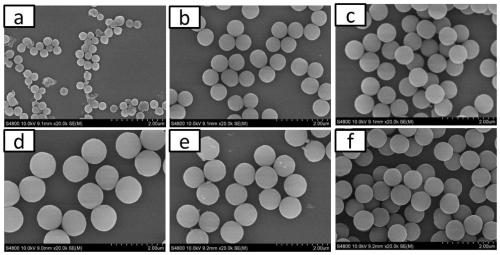

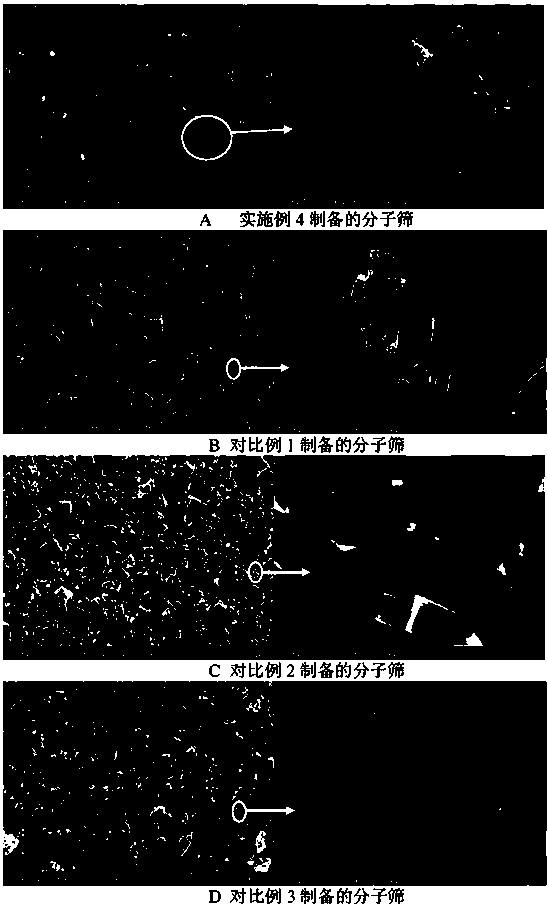

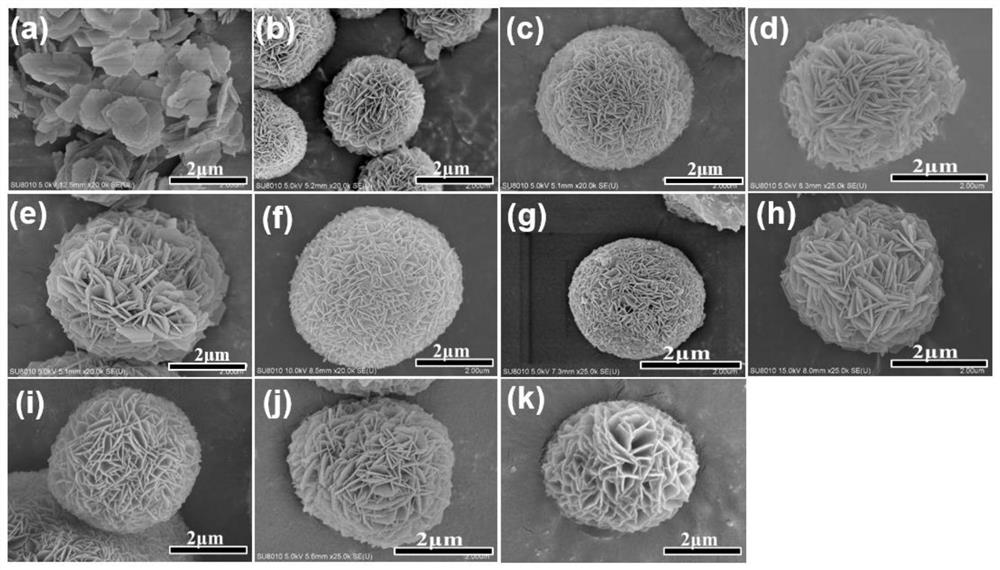

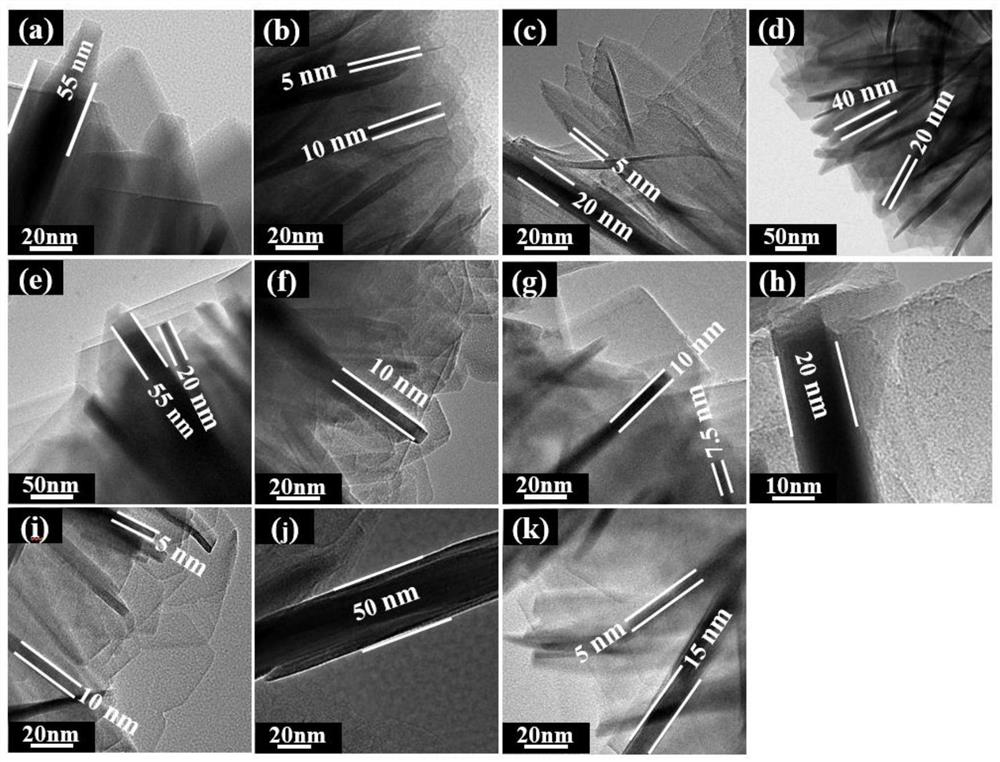

Thin-layer MCM-22 molecular sieve microsphere with microporous/mesoporous structure as well as preparation and application of thin-layer MCM-22 molecular sieve microsphere

ActiveCN114162833AUniform particle sizeImprove responseMolecular sieve catalystsMolecular-sieve and base-exchange compoundsMolecular sieveBenzene

The invention provides a thin-layer MCM-22 molecular sieve microsphere with a microporous / mesoporous structure as well as preparation and application of the thin-layer MCM-22 molecular sieve microsphere. The molecular sieve microspheres have the shape of'desert rose '. The method comprises the following steps: preparing a main template agent, a second template agent and water into a solution A; preparing an aluminum source, NaOH and water into a solution B; mixing and aging the solution A, the solution B and a silicon source to obtain mixed glue; the molar ratio of the components in the mixed glue meets the following conditions: SiO2 / Al2O3 is equal to 5-200, OH <-> / SiO2 is equal to 0.005-1, H2O / SiO2 is equal to 5-100, R1 / SiO2 is equal to 0.01-1, and R2 / SiO2 is equal to 0.005-0.5; and carrying out hydrothermal crystallization on the mixed glue, and then carrying out post-treatment to obtain the MCM-22 molecular sieve microspheres. In a liquid phase alkylation reaction of benzene and ethylene, the molecular sieve prepared by the method shows relatively high benzene conversion rate and ethylene selectivity.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Conductive agent applicable to lithium iron phosphate material and preparation method of conductive agent

The invention relates to a preparation method a lithium ion battery, particularly relates to a conductive agent applicable to a lithium iron phosphate material and a preparation method of the conductive agent, and mainly solves the technical problems in the prior art that the utilization rate of an active material is low, the residual capacity of an electrode is great and the like caused by great inner resistance and not enough discharging depth of the lithium iron phosphate electrode. The method provided by the invention comprises the following steps: under a constant-temperature condition, slowly adding conductive carbon black into a dispersant and a salt solution; heating and agitating to form a rheological phase; putting the rheological phase into a high-temperature furnace and heating; in a heating process, introducing inert gas all the time and cooling the rheological phase to the room temperature along with a furnace; washing with a strong acid and filtering; drying in a vacuum box under a high-temperature condition to prepare the treated conductive carbon black; and mixing a carbon nano tube, the conductive carbon black and conductive graphite according to a mass ratio of (0.1-1) to (0.1-5) to (0.1-1) to prepare the conductive agent.

Owner:杭州金马新能源科技有限公司

Process for preparing an alumina with controlled mesoporosity

ActiveUS8562940B2Increased mesopore volumeImprove catalytic performanceMolecular sieve catalystsAluminium hydroxide preparationOrganic solventSURFACTANT BLEND

A process for preparing a mesoporous alumina is described, comprising the following steps:a) mixing, in aqueous solution, at least one source of aluminum constituted by an aluminum alkoxide, at least one cationic surfactant and at least one organic solvent selected from methanol and ethanol;b) hydrothermally treating the mixture formed in said step a);c) drying the solid formed in said step b);d) calcining the solid formed in said step c).

Owner:INST FR DU PETROLE

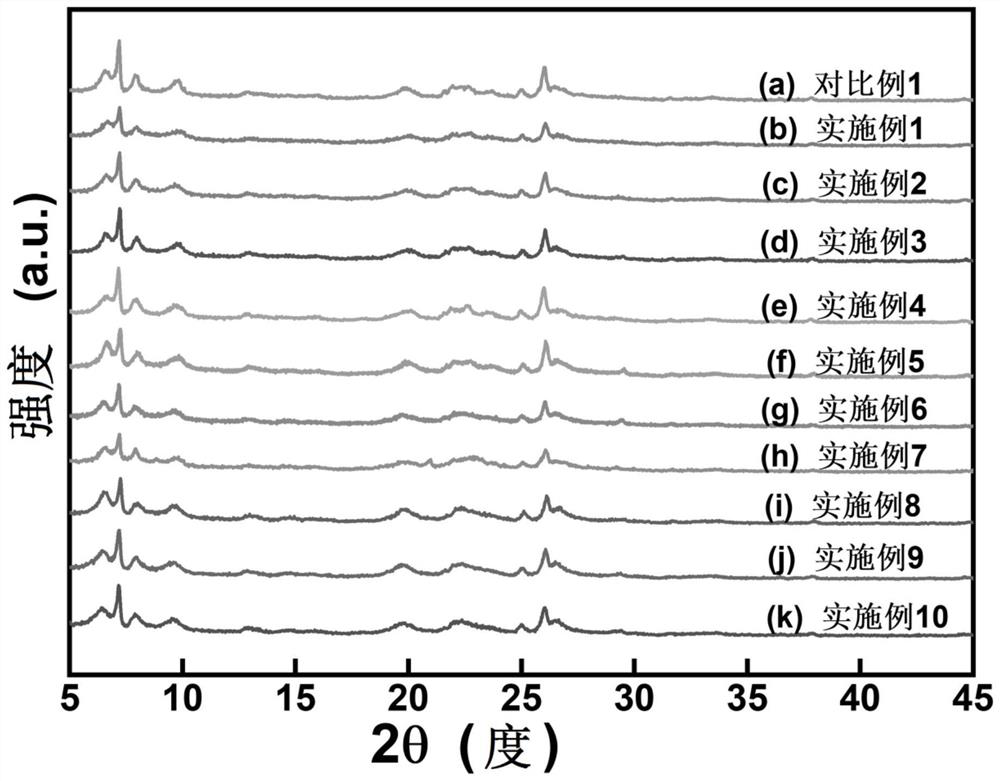

Hierarchical porous EU-1 molecular sieve and preparation method thereof

ActiveCN109081361AImprove diffusion abilityFacilitated DiffusionMolecular sieve catalystsMolecular-sieve and base-exchange compoundsMolecular sieveOrganic base

The invention discloses a hierarchical porous EU-1 molecular sieve and a preparation method thereof. The preparation method includes: putting EU-1 molecular sieve raw powder of 20-200 in silicon oxide / aluminum oxide molar ratio into an inorganic base and piperidine organic base compound mixed basic solution, treating at room temperature for 10-60min according to a solid / liquid mass ratio of 1:(10-50), adding acid to adjust pH value to neutral, filtering, washing, drying, subjecting a sample and an acid solution of 0.01-0.5mol in concentration according to a mass ratio of 1:(10-50) to backflowtreatment at 80-120 DEG C for 0.5-1.2h, filtering, washing, and drying to obtain the hierarchical porous EU-1 molecular sieve. The hierarchical porous EU-1 molecular sieve has good reaction moleculardispersion performance and has great application prospect when serving as a catalyst carrier.

Owner:CHINA CATALYST HLDG CO LTD

Preparation method and application of starch-based mesoporous carbon with high specific surface area

PendingCN110395731AEasy transferFacilitated DiffusionCarbon compoundsHybrid capacitor electrodesNew energyFiltration

The invention relates to the technical field of carbon materials and new energy sources, in particular to a preparation method and application of starch-based mesoporous carbon with high specific surface area. The preparation method comprises the following steps: (1) adding industrial starch and a nitrogen source into deionized water and magnetically stirring, drying the industrial starch and thenitrogen source in a drying box, then taking out and placing the industrial starch and the nitrogen source in a tube furnace, and carrying out pre-carbonization treatment under the protection of inertgas, (2) mixing the pre-carbonization product obtained in the step 1 and potassium hydroxide, adding the mixture into deionized water, uniformly stirring, then drying the mixture in the drying box, taking out and placing the mixture in the tube furnace, and carrying out high-temperature activation treatment under the protection of the inert gas; and (3) adding the activated product obtained in the step 2 into a hydrochloric acid solution, carrying out suction filtration after magnetic stirring, and washing with deionized water until filtrate is neutral, and drying the filtrate in the drying box to obtain a target material. The preparation method is simple in operation process, the equipment cost is low, and a high-performance supercapacitor electrode material can be provided.

Owner:DALIAN UNIV OF TECH

TS-1 molecular sieve catalyst with special structure, and application thereof in photocatalytic water hydrogen production

ActiveCN111054434AImprove photocatalytic activitySave energyMolecular sieve catalystsHydrogen productionMolecular sievePhoto catalytic

The invention discloses a TS-1 molecular sieve catalyst with a special structure, and an application thereof in photocatalytic water hydrogen production. The TS-1 molecular sieve with a hierarchical pore structure is adopted as a carrier to load a noble metal, and a photocatalytic hydrogen production reaction is enhanced in the presence of a sacrificial agent and quantum dots CdS. The TS-1 molecular sieve catalyst with the special structure has the characteristics of being wide in photoresponse range, capable of effectively separating photo-induced electrons from hole pairs, high in photocatalytic activity and good in photocatalytic hydrogen production effect in the field of photocatalytic water hydrogen production.

Owner:ZHEJIANG UNIV

Mesoporous activated carbon and preparation process thereof

The invention relates to mesoporous activated carbon and a preparation method thereof. The technical proposal of the invention comprises the following steps: firstly, high sulfate bituminous coal or high sulfur content petroleum fluid coke are taken as raw materials, KOH is taken as an activating agent, the mass ratio of alkali to coal or the mass ratio of alkali to coke is 1.0-5.0:1, the adjustment of a carbon microcrystalline structure is performed in nitrogen atmosphere at a temperature of between 250 and 400 DEG C, the adjustment time is between 0.5 and 5 hours, and then the preheating treatment is performed for 1 to 5 hours at a temperature of between 400 and 700 DEG C to obtain an amorphous carbon stock; then the prepared amorphous carbon stock is subjected to activating treatment for 0.5 to 5 hours at a temperature of between 800 and 950 DEG C; and carbide after the activating treatment is acid-cleaned, water-scrubbed and dried to obtain the mesoporous activated carbon. The method has the characteristics of simple process, higher yield and productivity, low preparation cost and so on. Mesopores of the mesoporous activated carbon have large specific surface area, the mesopore area exceeds 60 percent of the mesoporous activated carbon, and the mesopore volume is high.

Owner:WUHAN UNIV OF SCI & TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com