Lignin-based hierarchical porous carbon material and preparation method thereof

A lignin-based and lignin technology, which is applied in the field of lignin-based hierarchical porous carbon materials and their preparation, can solve the problems of high price, danger and high cost, and achieves increasing mesopore volume, increasing specific surface area and easy preparation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method comprises the following steps:

[0032] Lignin pretreatment: Air-dry the raw material lignin, put it in an oven after crushing, and dry it at 80-100°C for 1-3 hours, and cool it to room temperature after drying to obtain a lignin sample for later use;

[0033] Preparation of deep eutectic solvent: uniformly mix anhydrous choline chloride and formic acid at a molar ratio of 1:1-5, stir at 50-80°C for 1 hour to obtain a clear and transparent liquid, place it in a closed oven, and heat it at 60-80°C Dry at ℃ for 4-6 hours, remove excess water, seal and cool to room temperature to obtain a deep eutectic solvent, set aside;

[0034] Thermal carbonization of lignin in deep eutectic solvent: mix the deep eutectic solvent and lignin sample evenly, place in a closed oven, and react at 60-190°C for 3-24h to obtain a thermal carbonization mixture;

[0035] Preparation of solvothermal carbonization products: under stirring, drop the thermal carbonization mix...

Embodiment 1

[0041] (1) Dry the prehydrolyzed lignin in an oven at 90°C for 2 hours, take it out and cool it to room temperature, and set it aside.

[0042] (2) Weigh the anhydrous choline chloride and formic acid at a molar ratio of 1:2, stir in a water bath at 80°C for 1 hour to mix, and obtain a clear transparent liquid, place it in an airtight oven at 80°C for 6 hours, Remove excess moisture, take it out, seal and cool to room temperature to obtain a deep eutectic solvent.

[0043] (3) Weigh 0.5g of prehydrolyzed lignin and place it in a polytetrafluoroethylene-lined container, add 5g of deep eutectic solvent, and after the prehydrolyzed lignin is completely dissolved, place it in a closed container and place it in an oven at 160°C React for 6h, take out and cool to room temperature and open.

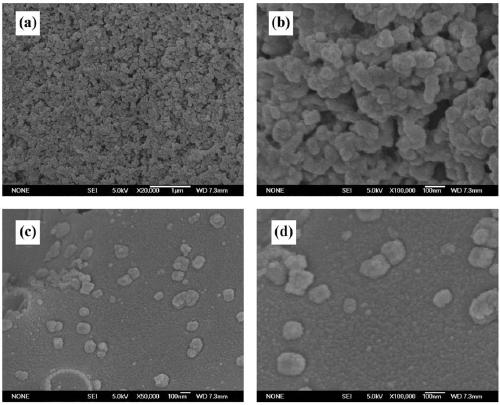

[0044] (4) Under stirring, the mixed solution generated by the reaction in the airtight container was dropped into deionized water at 80°C, centrifuged at 8000rpm for 5min, washed twice with de...

Embodiment 2

[0052] (1) Dry the kraft lignin in an oven at 90°C for 2 hours, take it out and cool it to room temperature, and set it aside.

[0053] (2) Weigh the ratio of anhydrous choline chloride and formic acid at a molar ratio of 1:3 respectively, stir in a water bath at 80°C for 1 hour to mix, and obtain a clear transparent liquid, place it in an airtight oven at 80°C for 1 hour, Remove excess moisture, take it out, seal and cool to room temperature to obtain a deep eutectic solvent.

[0054] (3) Weigh 1g of kraft lignin and place it in a polytetrafluoroethylene-lined container, add 5g of deep eutectic solvent, and after the prehydrolyzed lignin is completely dissolved, place it in a closed container and react in an oven at 175°C 12h, take out and cool to room temperature and open.

[0055] (4) Under stirring, the mixed solution generated by the reaction in the airtight container was dropped into deionized water at 70°C, centrifuged at 8000rpm for 5min, washed twice with deionized w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com