Patents

Literature

728 results about "Deep eutectic solvent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

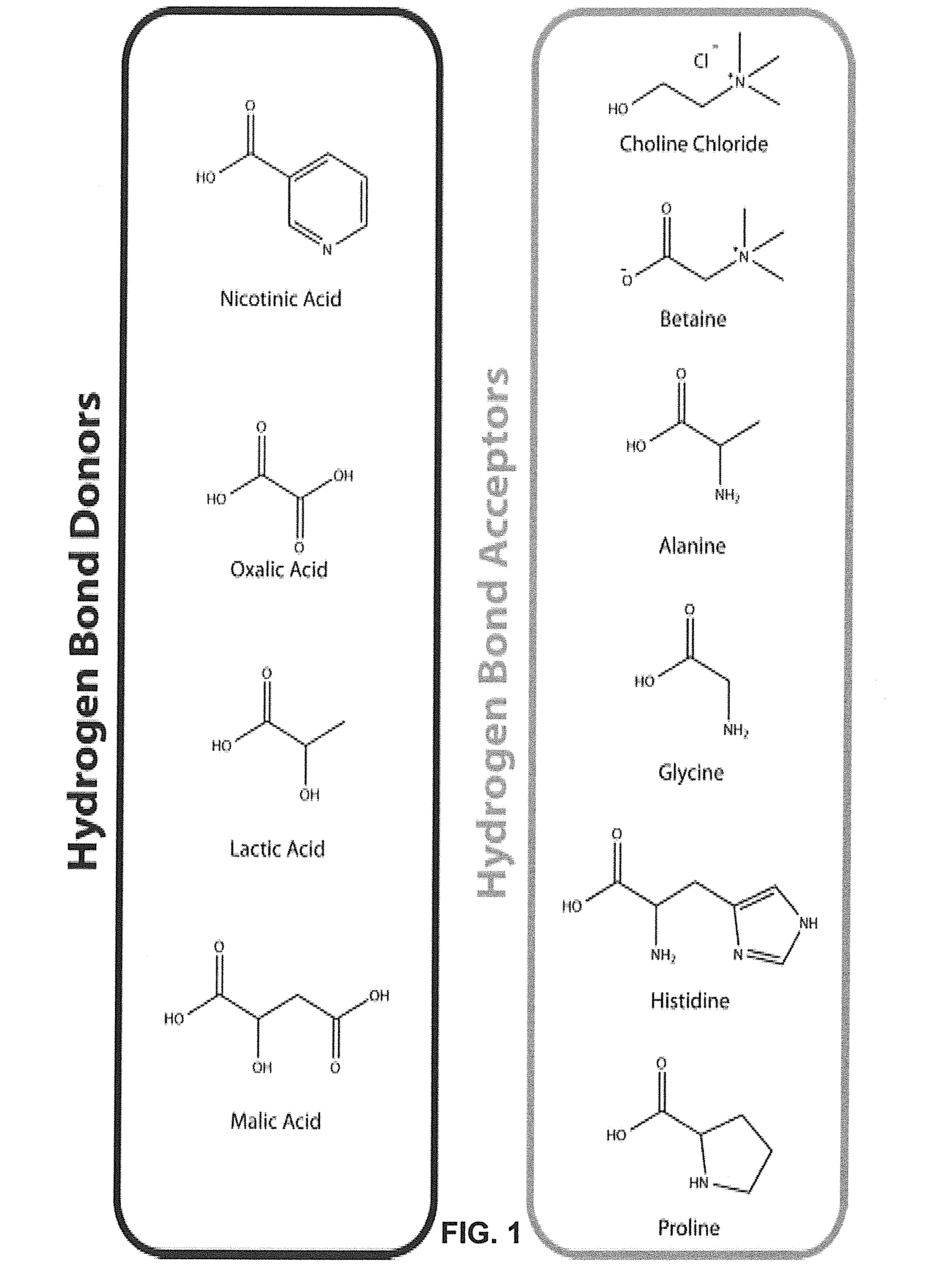

Deep eutectic solvents are systems formed from a eutectic mixture of Lewis or Brønsted acids and bases which can contain a variety of anionic and/or cationic species. They are classified as types of ionic solvents with special properties. They incorporate one or more compound in a mixture form, to give a eutectic with a melting point much lower than either of the individual components. One of the most significant deep eutectic phenomenon was observed for a mixture of choline chloride and urea in a 1:2 mole ratio. The resulting mixture has a melting point of 12 °C (far less than the melting point of choline chloride, 302 °C and urea, 133 °C), which makes it liquid at room temperature.

Deep eutectic solvents and applications

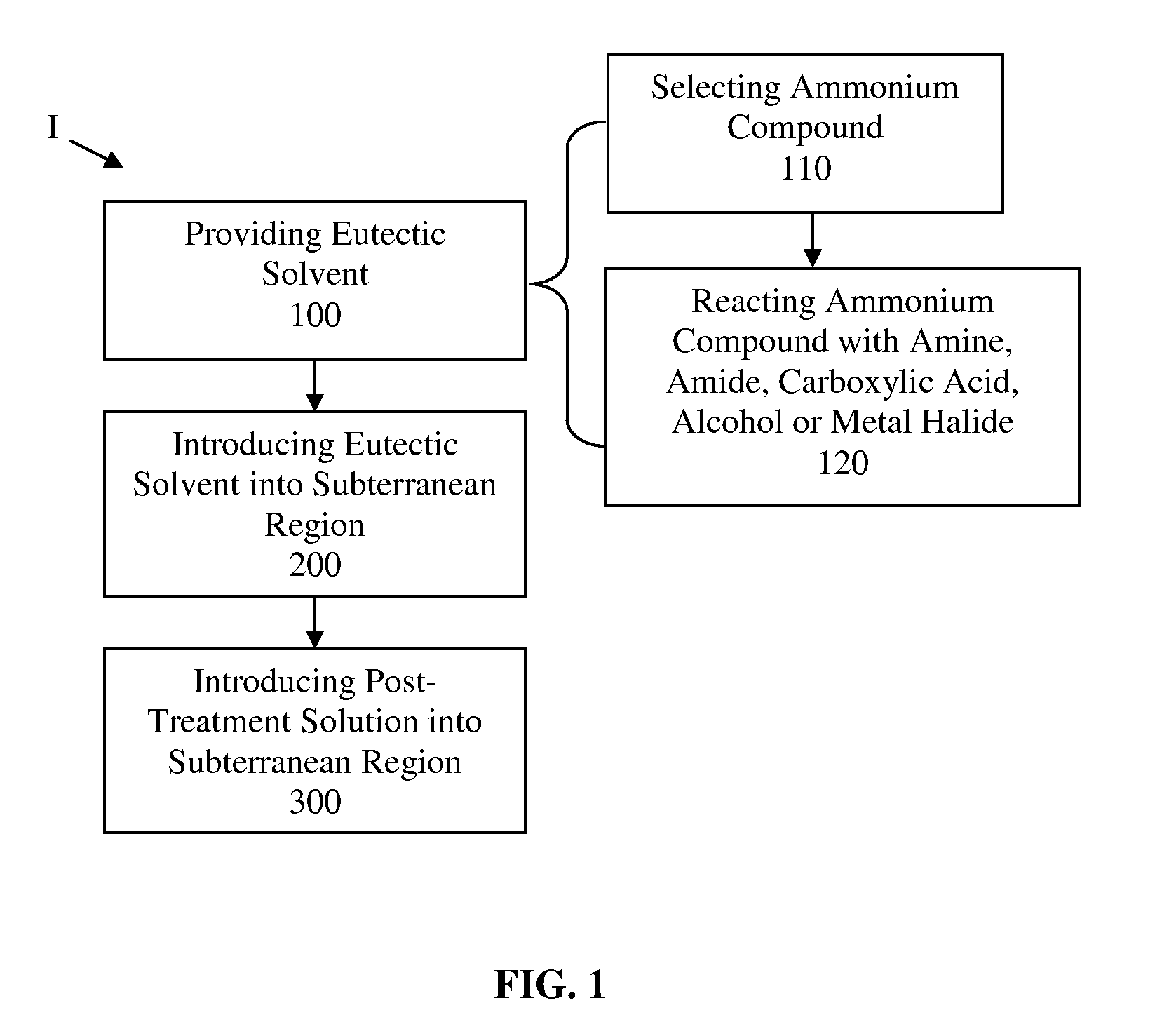

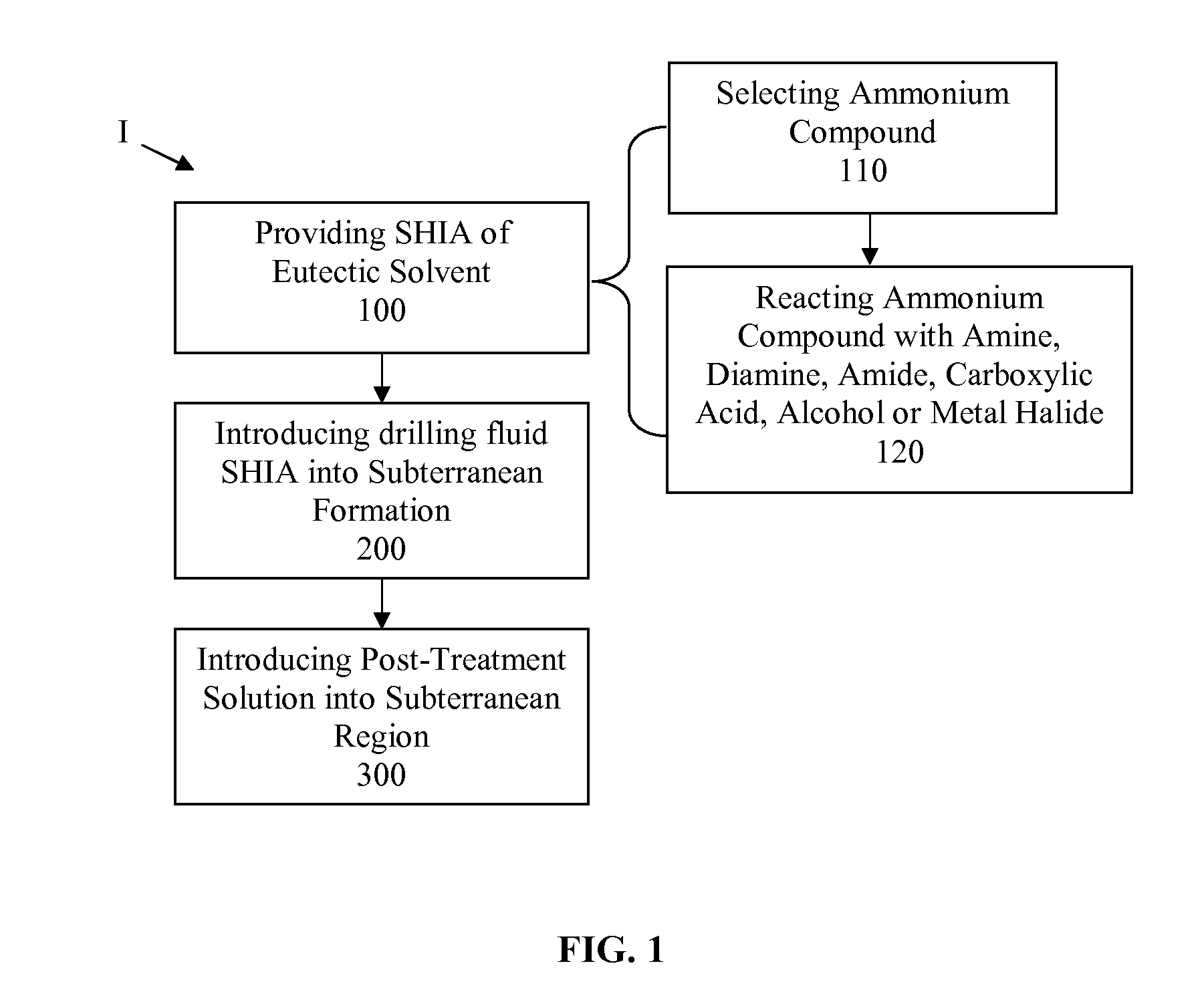

A method of solubilizing / removing cellulose or chemically-modified cellulosic polymers utilized in subterranean drilling operations such as fracturing. The method involves introducing a deep eutectic solvent (DES) into a subterranean region. Deep eutectic solvents useful as cellulose solvents include quaternary ammonium compounds, including choline chloride and chlorcholine chloride, reacted with a compound selected from amides, amines, carboxylic acids alcohols, and metal halides. The DES material can be pumped downhole after fracturing operations to remove cellulosic material used, for example, to thicken fracturing fluid which is left behind in the created fractures, on the face of the formation, along the wellbore, or elsewhere within the subterranean region. The DES can be used alone or in a sequential treatment protocol, whereby the DES is introduced into the subterranean region, followed by post-treatment introduction of water, caustic, acid or anhydride into the subterranean as a flush.

Owner:SHRIEVE CHEM PRODS

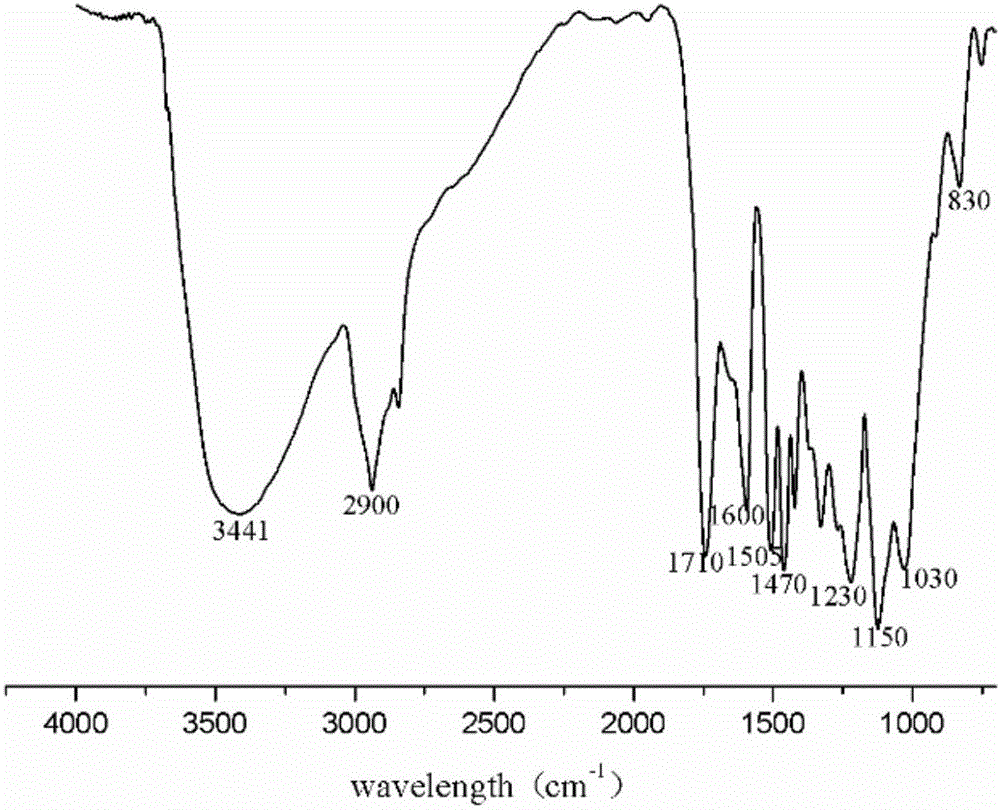

Polymerizable deep eutectic solvent

InactiveCN107417553AOrganic compound preparationGroup 5/15 element organic compoundsMacromolecular SubstancesDeep eutectic solvent

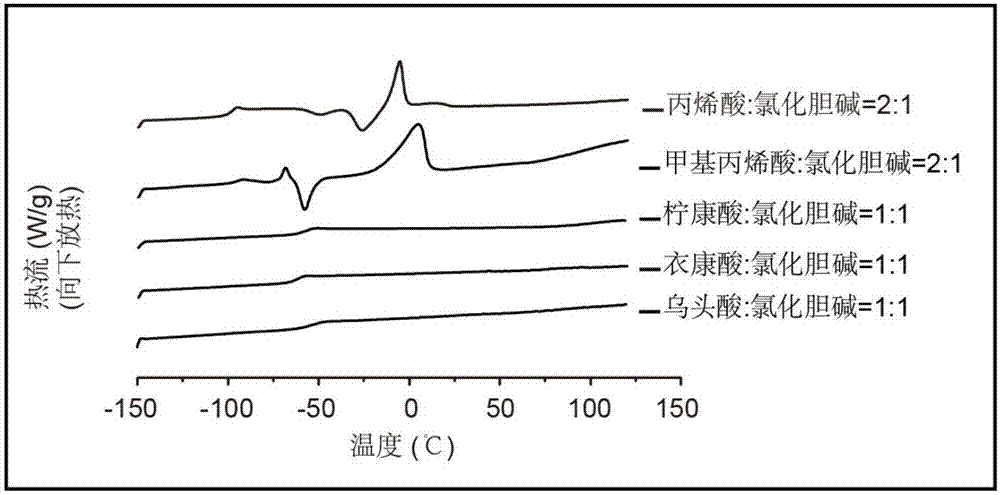

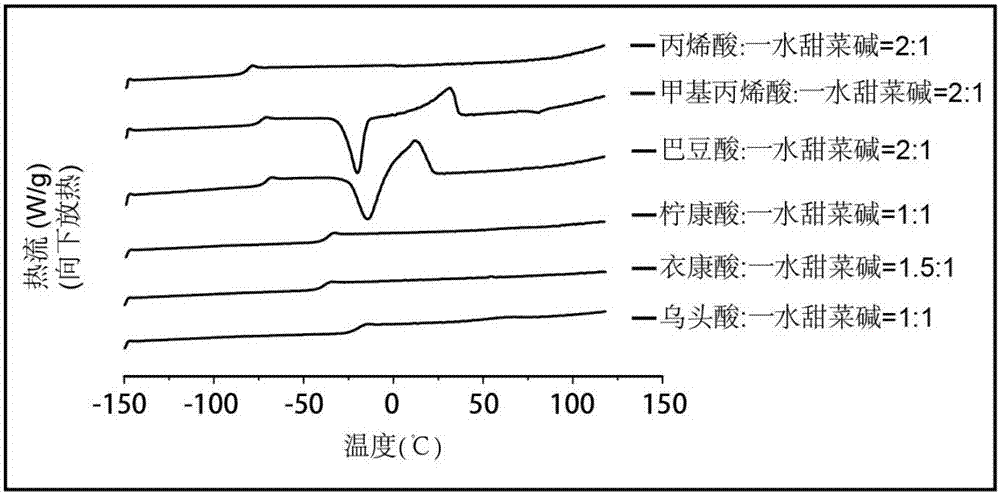

The invention discloses a polymerizable deep eutectic solvent. The polymerizable deep eutectic solvent is obtained by mixing a hydrogen bond acceptor and a hydrogen bond donor at 60 DEG C to 100 DEG C; the mol ratio of the hydrogen bond donor to the hydrogen bond acceptor is not less than 1 to 3. The polymerizable deep eutectic solvent disclosed by the invention can be subjected to polymerization reaction to prepare a macromolecular substance, and a new turn of technical innovation can be brought to the deep eutectic solvent; the knowledge of people that the deep eutectic solvent only has a dissolving effect in processes of preparing and purifying the compound and the like is changed, and an application field of the deep eutectic solvent is greatly expanded.

Owner:广州纽楷美新材料科技有限公司

Pretreatment of Lignocellulosic Biomass and Recovery of Substituents using Natural Deep Eutectic Solvents/Compound Mixtures with Low Transition Temperatures

InactiveUS20150094459A1Reduce solubilityPrevent degradationPulping with organic compoundsLignin derivativesCelluloseLignocellulosic biomass

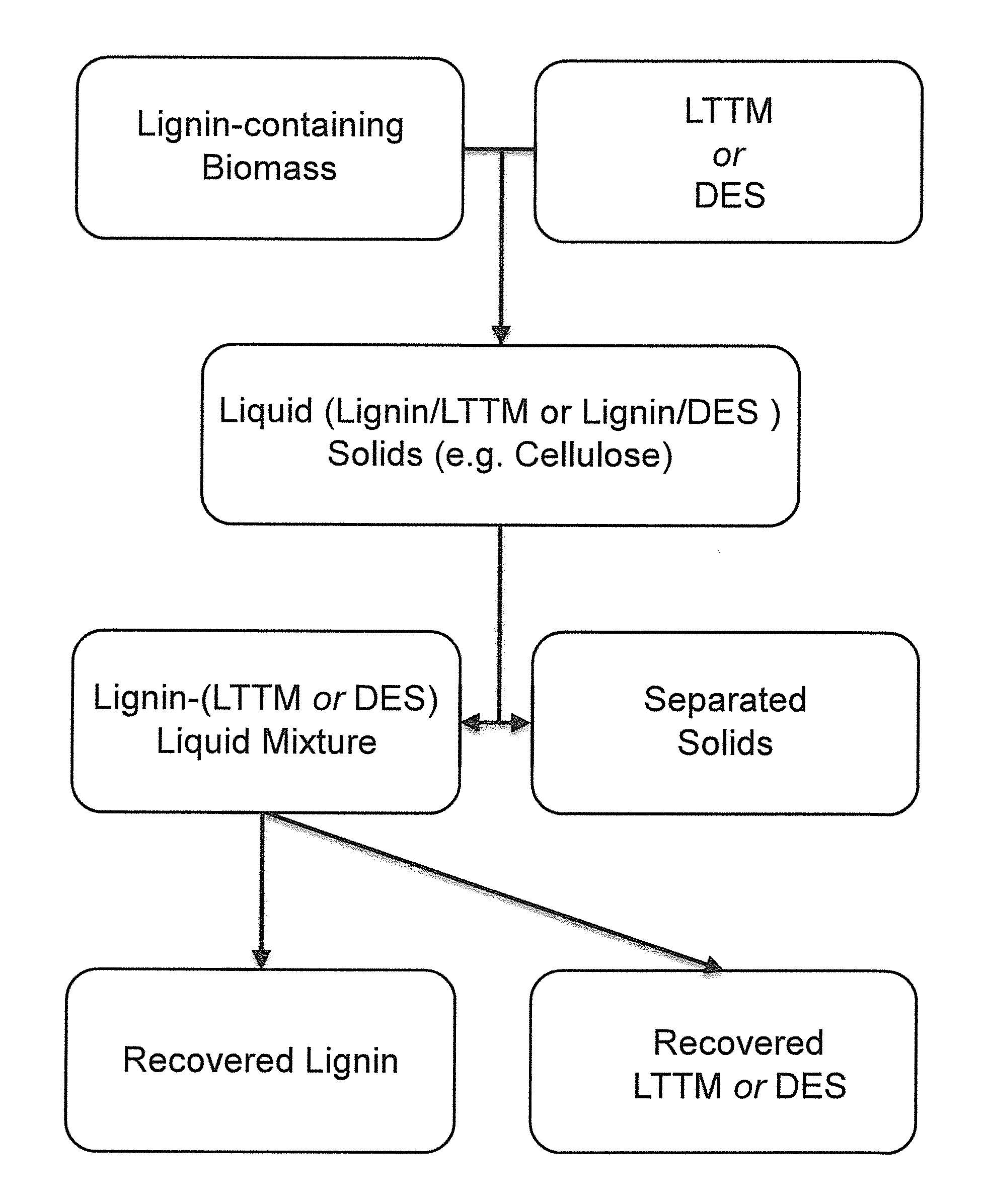

Low transition temperature mixtures (LTTMs) or solvents are provided that can be used in methods and systems to dissolve and bydrolyze certain components from lignin-containing biomass (e.g., lignin) at mild conditions so that further degradation is prevented. The solvents, methods and systems according to the invention have various advantages over prior technology or approaches. For example, LTTMs are cheap solvents, renewable and / or non-toxic food ingredients. LTTMs dissolve lignin selectively from a lignin-containing biomass. A highly efficient (up to 90%) lignin recovery can be achieved. The recovered lignin is of higher quality. The remaining cellulose is also of higher. Much less water is needed, which means a tremendous reduction of the energy requirement in the recovery process, i.e. less energy needed for evaporating large quantities of water.

Owner:TECH UNIV EINDHOVEN

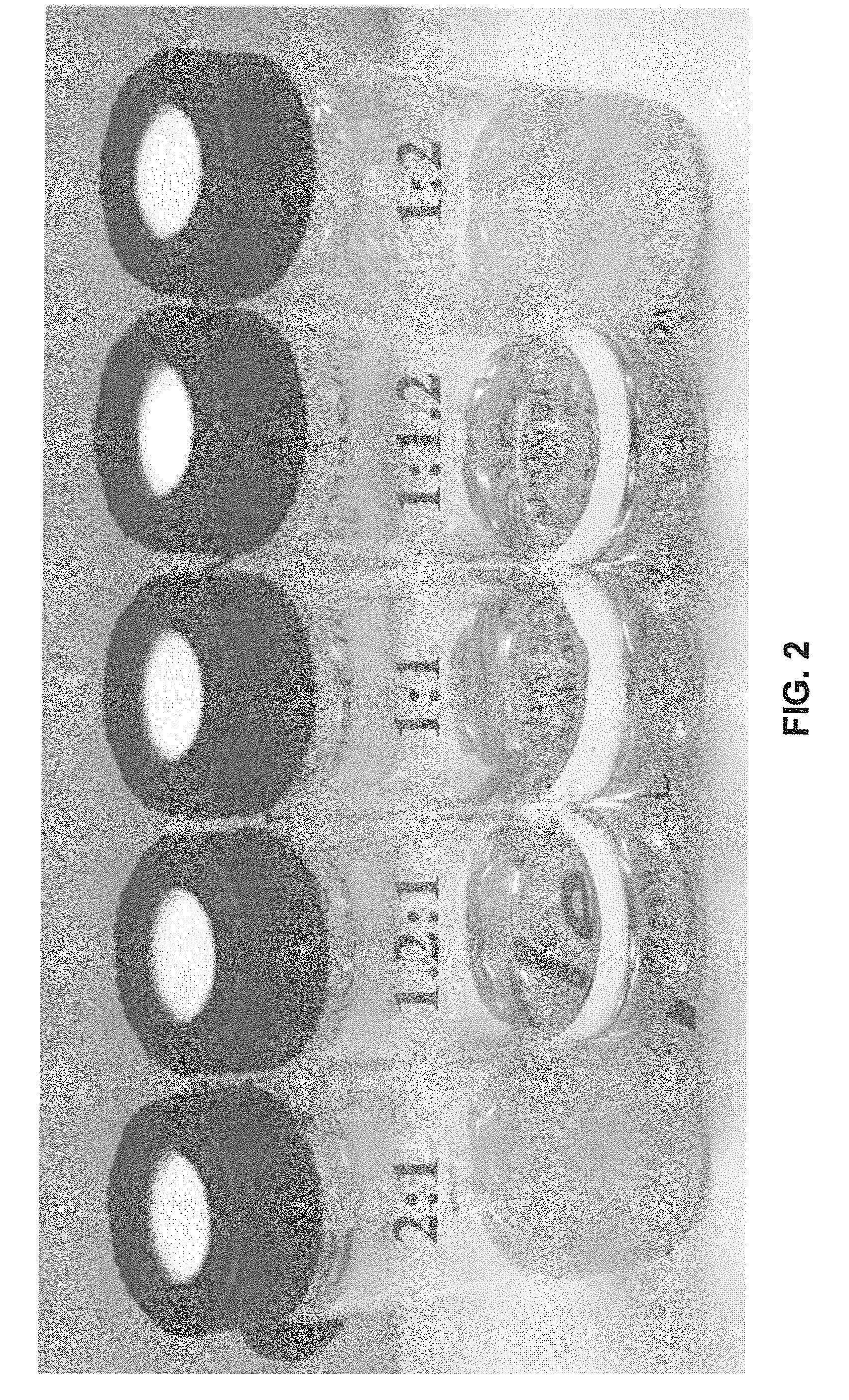

Alcohol-based ternary deep-eutectic solvent and preparation method thereof

InactiveCN105037062AWon't releaseReduce pollutionOrganic chemistry methodsSolid sorbent liquid separationViscous liquidSolvent

An alcohol-based ternary deep-eutectic solvent is composed of a ternary system comprising an alcohol group, a hydrogen-bond donor and quaternary ammonium salt. A preparation method for the alcohol-based ternary deep-eutectic solvent comprises the following steps: uniformly mixing the alcohol group, the hydrogen-bond donor and quaternary ammonium salt, heating the mixture to 60-100 DEG C, and keeping heat for 0.5-2 h until materials are completely dissolved; after completion of reaction, putting the mixture into a drying oven for drying for 12 h at the temperature of 80 DEG C so as to obtain viscous liquid namely the target object; the alcohol-based ternary deep-eutectic solvent is used as a mobile phase additive in high performance liquid chromatography, and used for extraction separation of bioactive components, organic catalytic synthesis and gas absorption. The alcohol-based ternary deep-eutectic solvent has the advantages as follows: the preparation method is simple in process, raw materials are easy to obtain, by-products are not produced in the reaction process, the product can be biodegradable, pollution to the environment is reduced greatly, and the prepared product is high in purity, low in melting point and viscosity, high in stability and suitable for industrial production.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

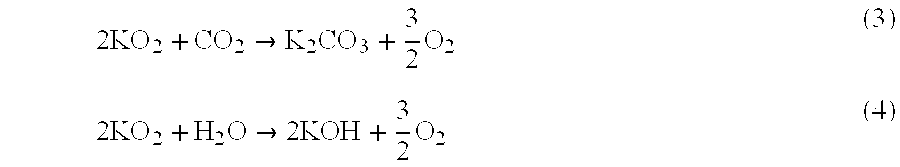

Method for the preparation of reactive compositions containing hydrogen peroxide

The subject invention provides a potentially economically viable method for the preparation of hydrogen peroxide (H2O2) in deep eutectic solvents (DES). H2O2 is then used for the destruction of small to large quantities of sulfur and nitrogen mustards and lewisite, their homologous / analogues, and similar chemical warfare agents at ambient conditions in DES without producing any toxic by-products. Furthermore, H2O2 has been used for the destruction of small to large quantities of halogenated hydrocarbons, their homologous / analogues, and similar hazardous chemicals at ambient conditions. H2O2 can be formed by either the electrochemical reduction of oxygen in DES in the presence of water or by dissolving Group 1 (alkali metals) or Group 2 (alkaline earth metals) superoxides, e.g. potassium superoxide, in DES in the presence of water, with / without chemicals used for the enhancement of the solubility of the metal superoxide in the DES, e.g. crown ethers.

Owner:KING SAUD UNIVERSITY

Firefighting foam compositions containing deep eutectic solvents

The disclosed invention relates to novel biocompatible firefighting foam compositions that include a deep eutectic solvent. Disclosed are methods of making and using firefighting foams containing deep eutectic solvents, which may also be used in existing fire foam compositions as drop in solvent additives. The deep eutectic solvents may also be used in or as a principle component of surrogate firefighting foam compositions.

Owner:TYCO FIRE PRODS LP

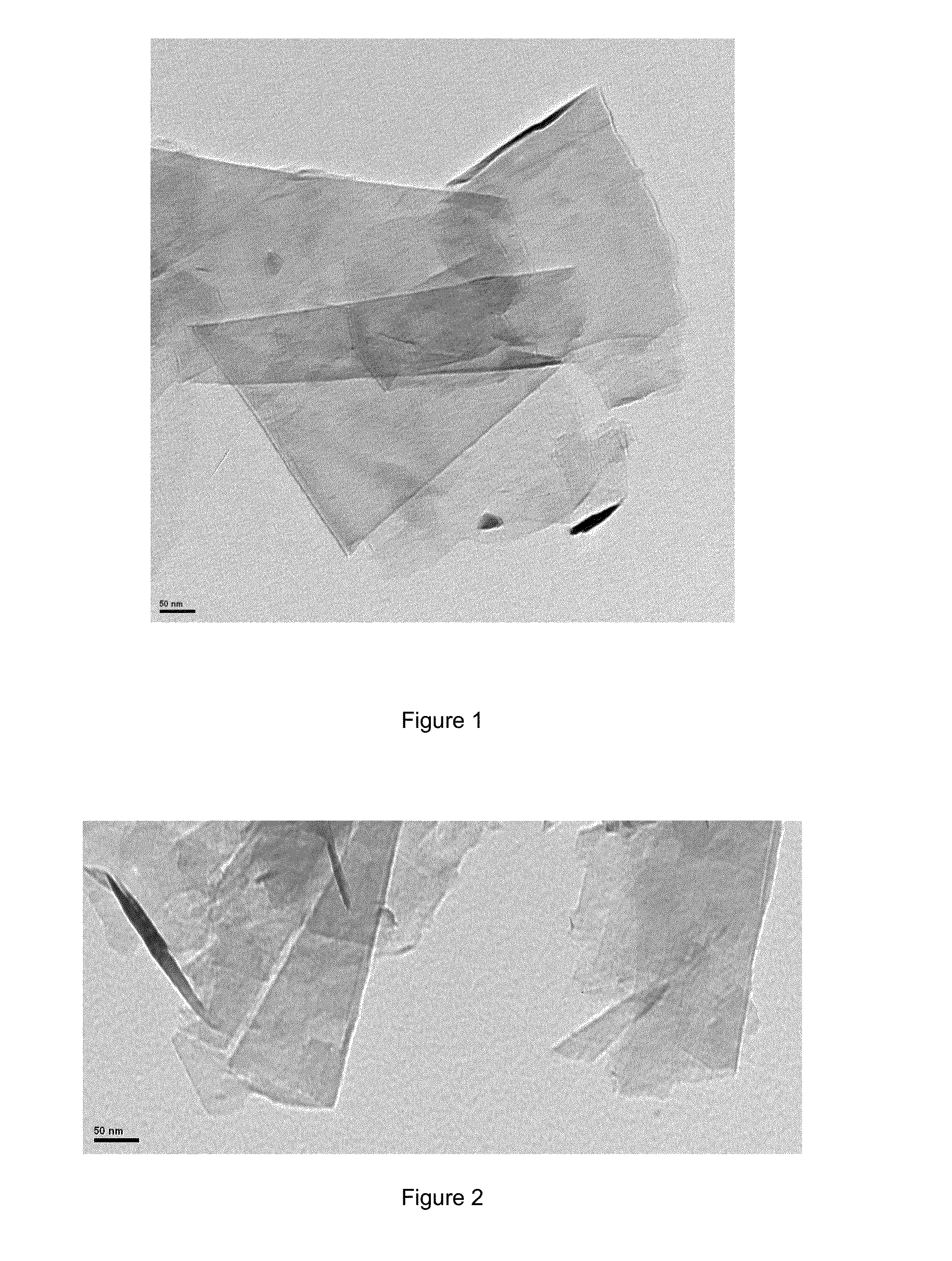

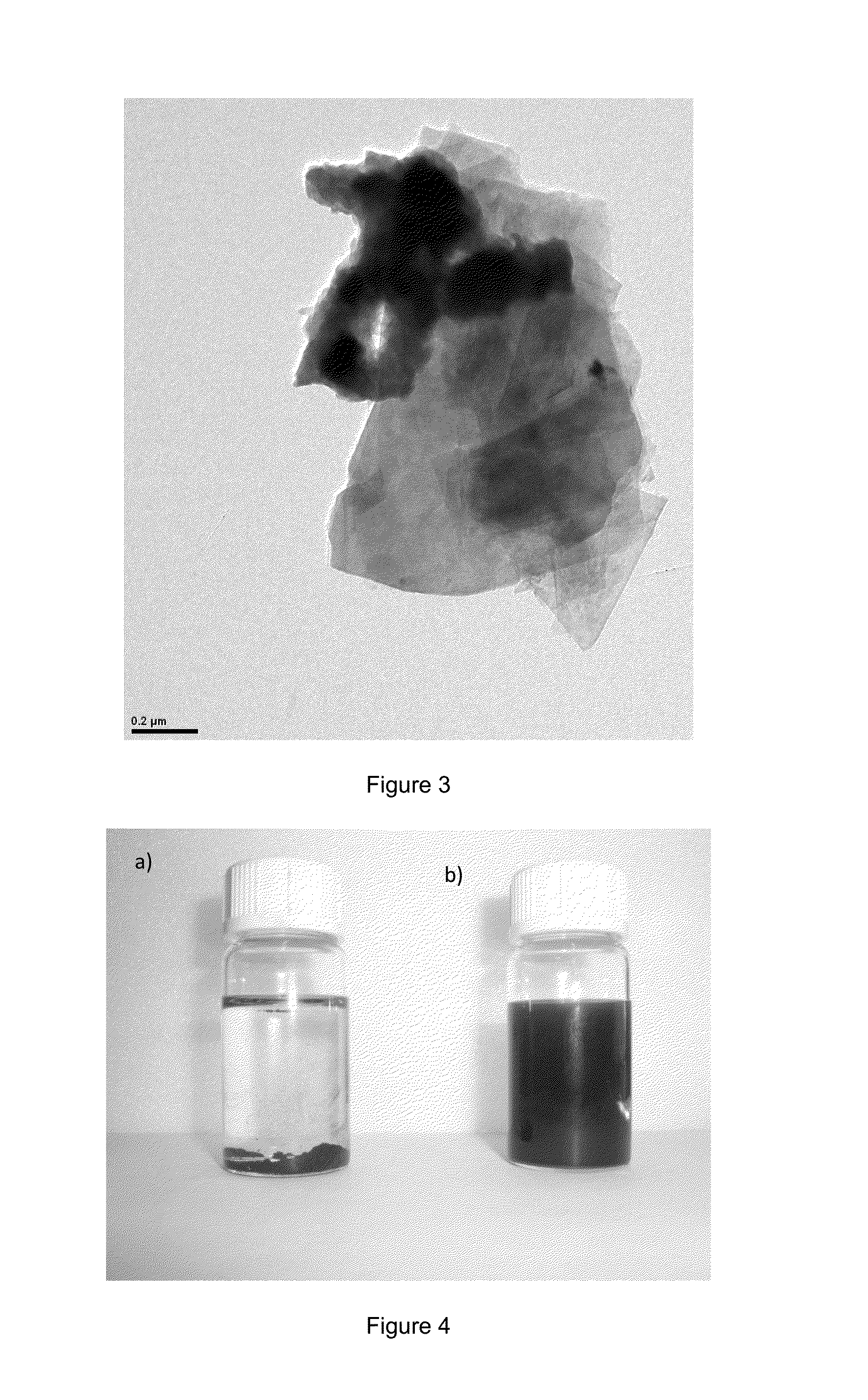

Exfoliation of graphite with deep eutectic solvents

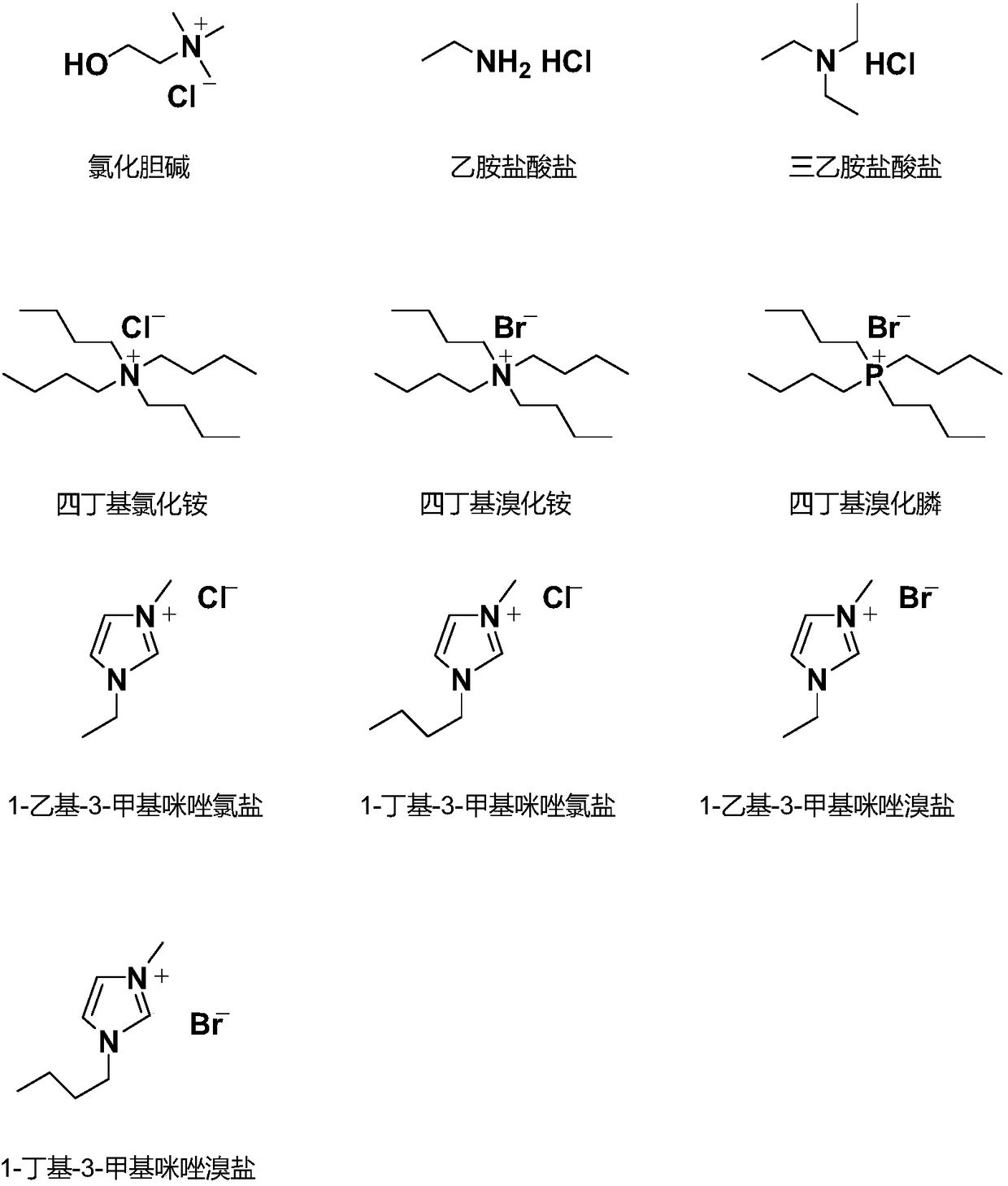

InactiveUS20160236939A1Increased formationMaterial nanotechnologyConductive materialOxide compositeGraphite

The invention relate to graphite materials, and more specifically to the exfoliation of graphite using deep eutectic solvents, to methods related thereto, to polymeric composite materials containing graphene and the methods for the production thereof, and to graphene / metal, exfoliated graphite / metal, graphene / metal oxide and exfoliated graphite / metal oxide composite materials and the methods for the production thereof.

Owner:CONSEJO SUPERIOR DE INVESTIGACIONES CIENTIFICAS (CSIC)

Ternary deep-eutectic solvent

ActiveCN108452640ALarge absorption capacityFastGas treatmentDispersed particle separationAbsorption capacityTrapping

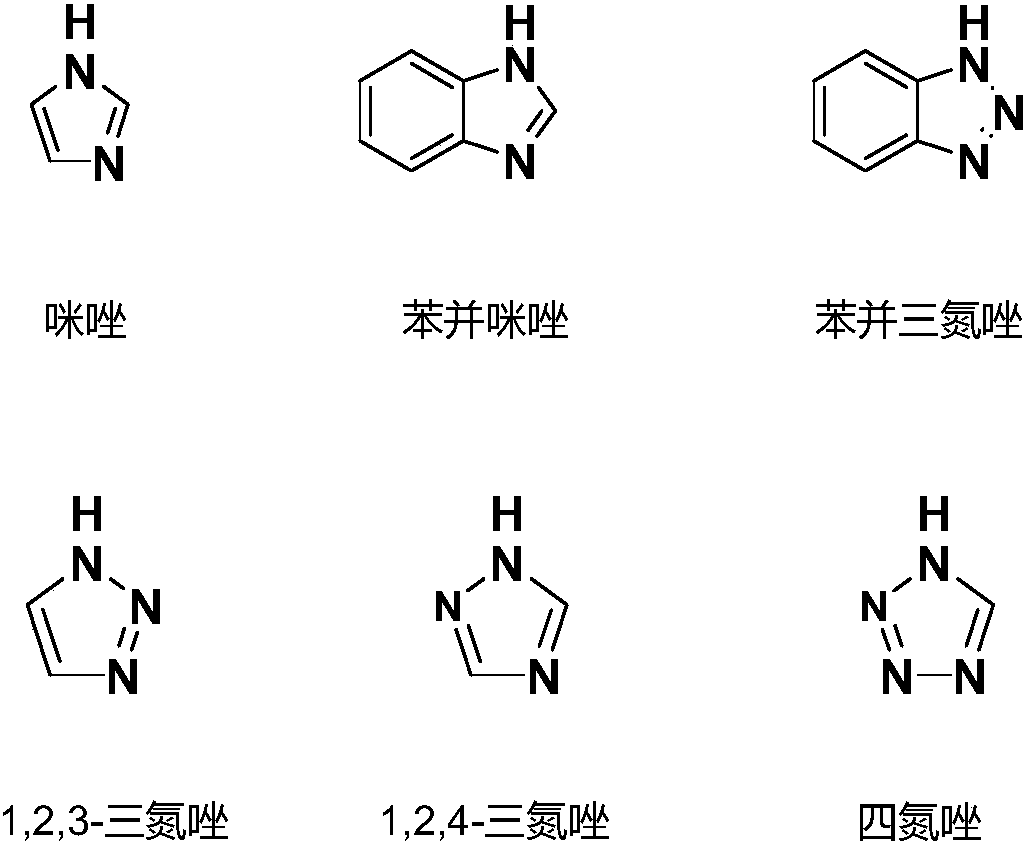

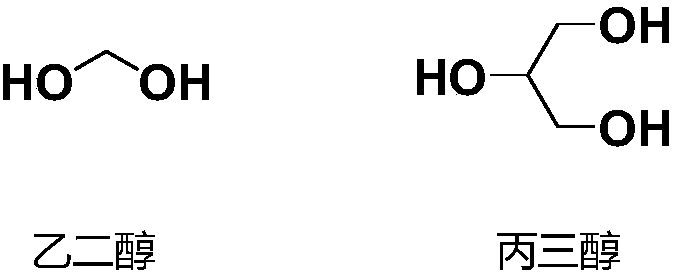

The invention relates to a ternary deep-eutectic solvent and application thereof to NH3 trapping. The deep-eutectic solvent is prepared from a component A, a component B and a component C, wherein thecomponent A is an organic salt type compound containing halogen anions; the component B is a nitrogen-containing heterocyclic compound; the component C is a polyol type compound. In the ternary deep-eutectic solvent provided by the invention, the component A is a hydrogen bond acceptor; the component B and the component C are hydrogen bond donors; the component B is weakly acid, provides an active site for the reversible chemical absorption of the NH3, and serves as a main absorbent; the component C contains abundant hydroxyl functional groups, can form stronger hydrogen bonds with the NH3, and serves as an auxiliary absorbent. The ternary deep-eutectic solvent provided by the invention has the characteristics of high NH3 absorption capacity, easiness in regeneration and high stability, and an efficient, green and environment-friendly absorbent is provided for the separation and recovery of the NH3 from industrial tail gas.

Owner:NANCHANG UNIV

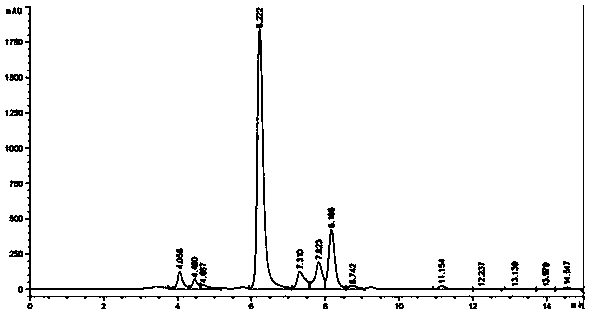

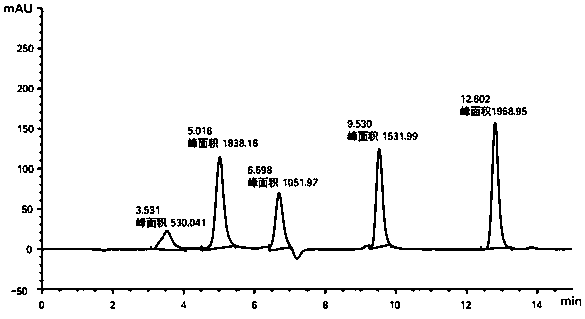

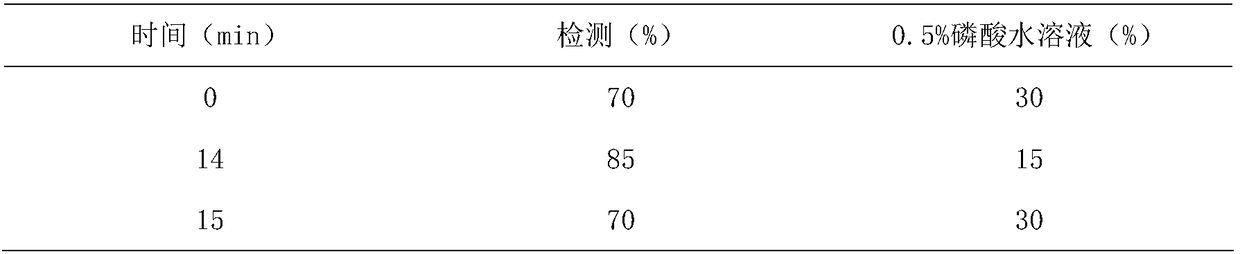

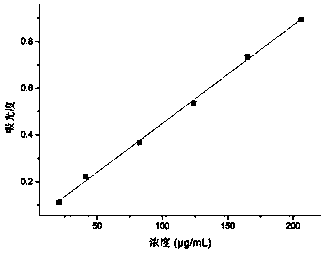

Application of extracting agent and deep-eutectic solvent in determining of effective ingredients in traditional Chinese medicine

InactiveCN108088943AImprove extraction efficiencyReduce lossComponent separationAdditive ingredientRadix Astragali seu Hedysari

The invention relates to the technical field of preparation of extracting agents and deep-eutectic solvents, and relates to application of an extracting agent and a deep-eutectic solvent in determining of effective ingredients in traditional Chinese medicine, in particular to application in determining of flavonoid ingredient in radix scutellariae, and application of an extracting agent and a deep-eutectic solvent in determining of effective ingredients of baicalin, baicalein, wogonoside, wogonin and scutellarin in radix scutellariae. The application is characterized in that the radix scutellariae is used as the raw material, the deep-eutectic solvent, especially choline deep-eutectic solvent, is used as the extracting agent, the water is used as a thinner for reducing the system viscosity, and the flavonoid compound is forcibly extracted under the ultrasonic condition. An extracting method has the advantages that the extracting efficiency of the flavonoid ingredient is higher, the extracting conditions are moderate, and the operation is simple and convenient. The extracting agent has the characteristics of no burning explosion and volatizing, small loss, low energy consumption andthe like. The extracting method is also suitable for extracting the flavonoid-containing traditional Chinese medicines, such as radix astragali seu hedysari, liquorice root, radix puerariae and radixsophorae flavescentis.

Owner:SHENYANG PHARMA UNIVERSITY

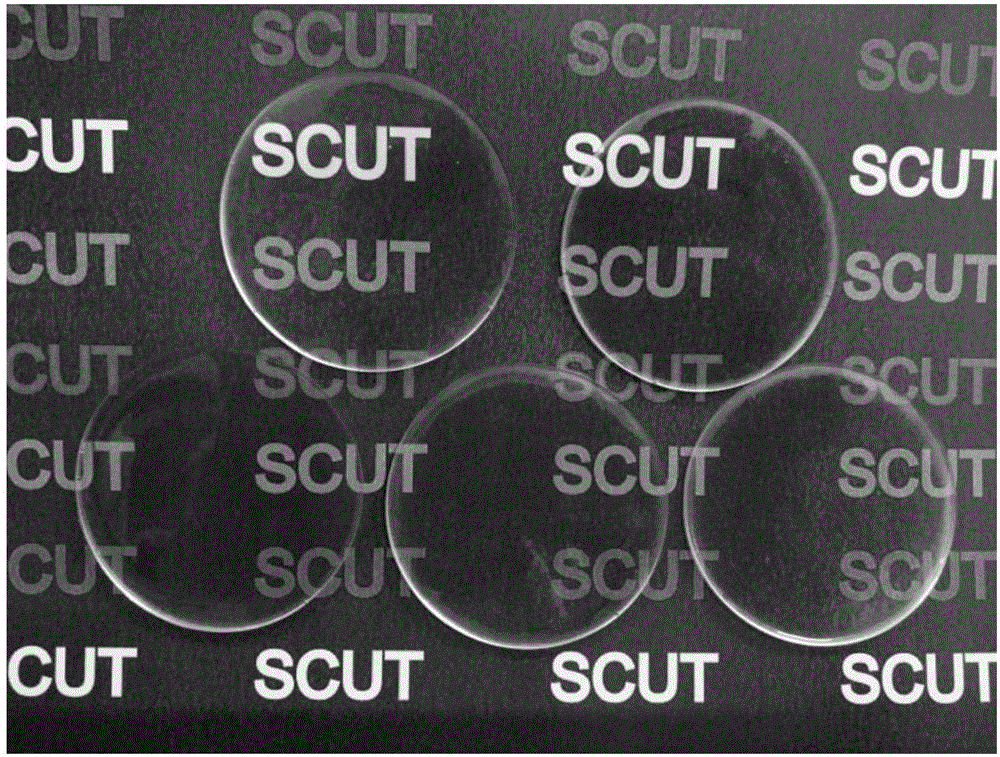

Application of polymerizable deep-eutectic solvents to preparing transparent conductive elastomers

The invention discloses application of polymerizable deep-eutectic solvents to preparing transparent conductive elastomers. Hydrogen bond receptors and hydrogen bond donors are mixed with one another at the temperatures of 60-100 DEG C to obtain the polymerizable deep-eutectic solvents, a molar ratio of the hydrogen bond donors to the hydrogen bond receptors is not smaller than 1:1, and the hydrogen bond donors comprise acrylic acid or methacrylic acid. The polymerizable deep-eutectic solvents, cross-linking agents and photoinitiators are mixed with one another to obtain mixed solution, and the mixed solution can be cured in polytetrafluoroethylene culture dishes under ultraviolet irradiation to obtain the transparent conductive elastomers. The application has the advantage that the transparent conductive elastomers are high in light transmission and conductivity, excellent in tensile property and bendability and good in environmental stability.

Owner:广州纽楷美新材料科技有限公司

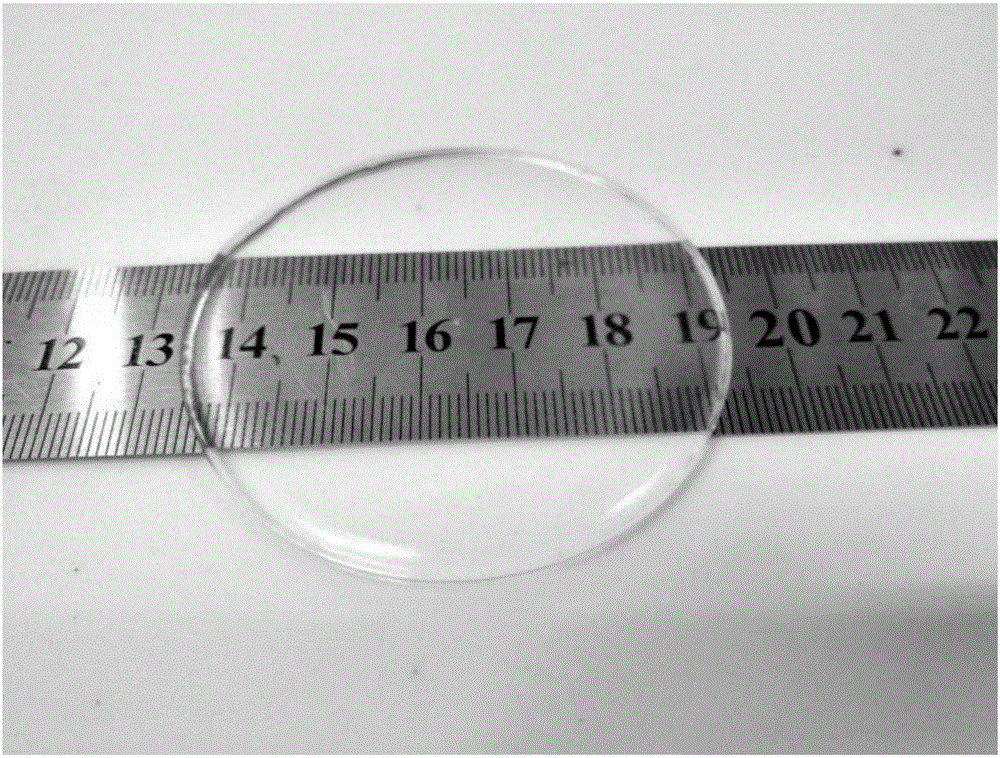

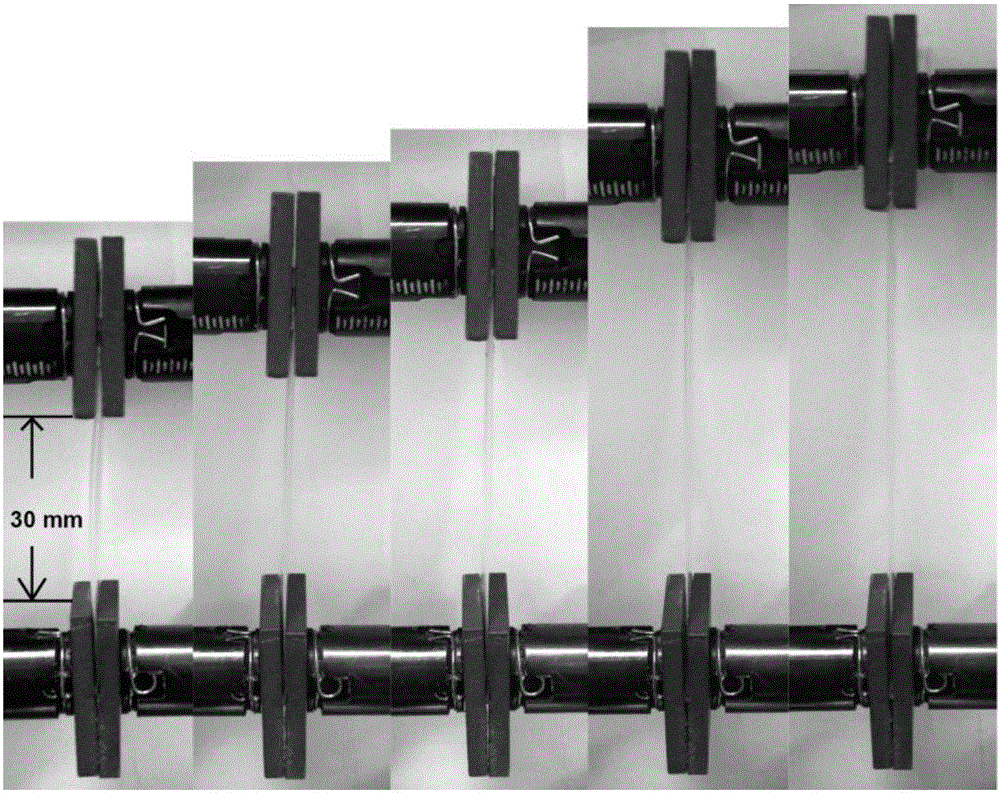

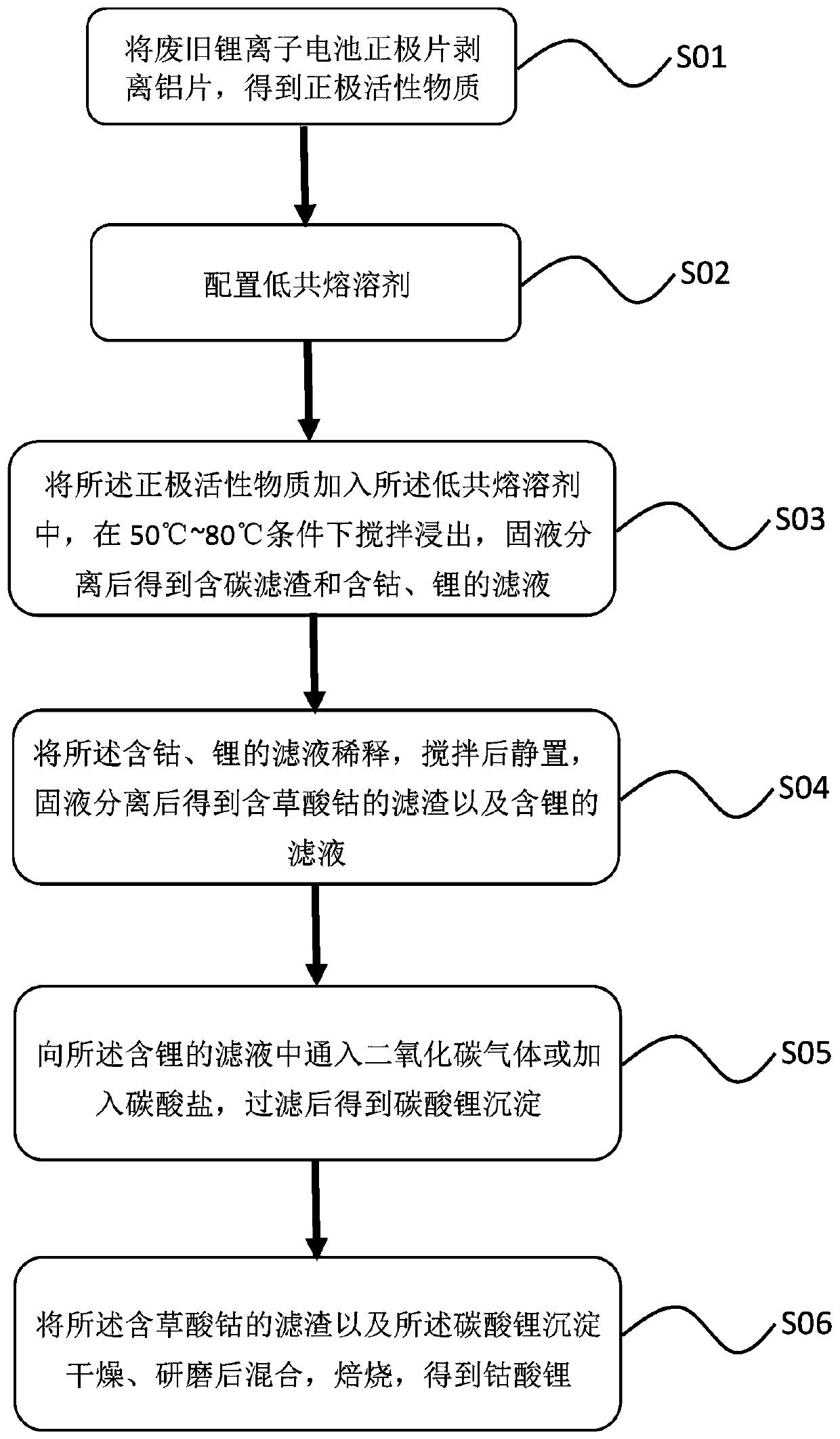

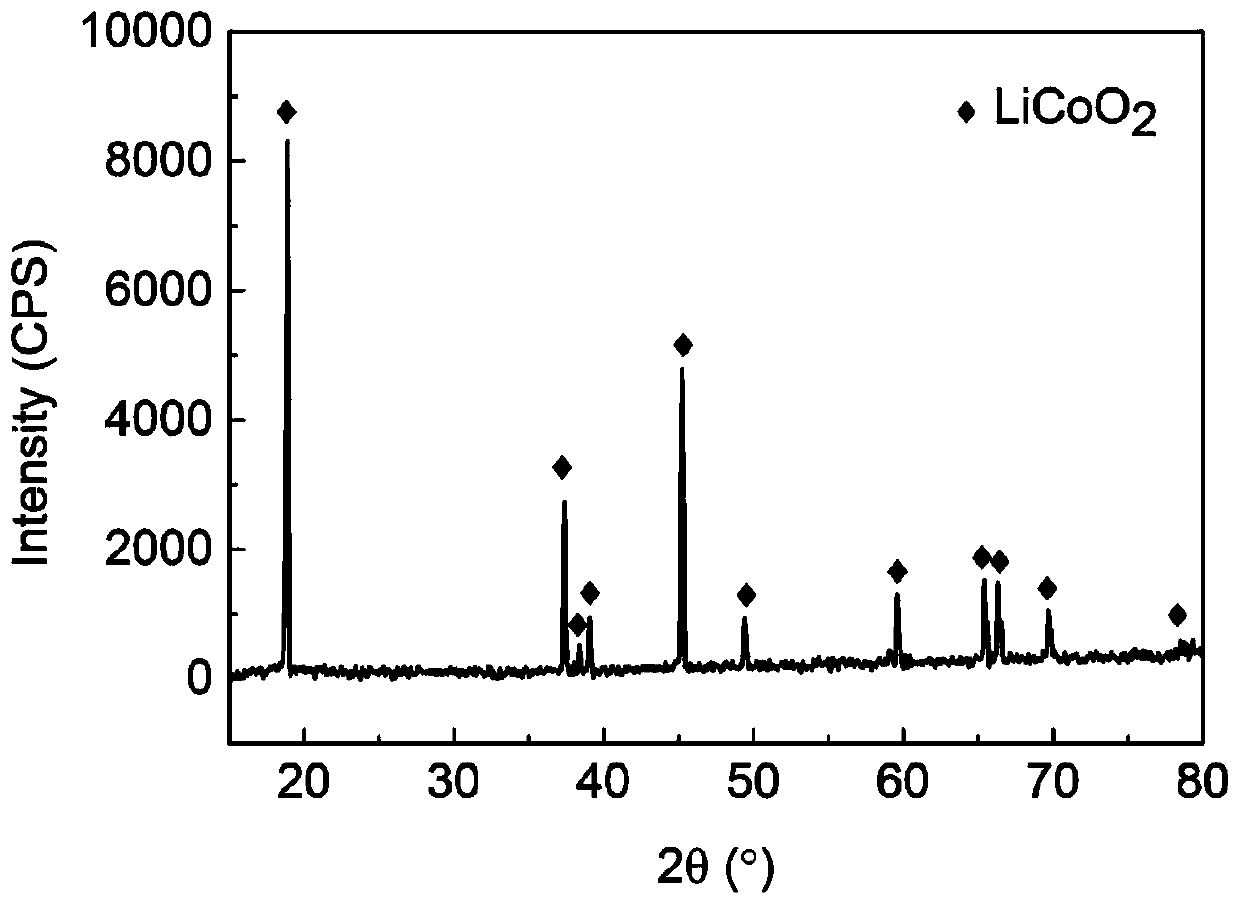

Method for recycling and regenerating lithium cobalt oxide from waste lithium ion batteries

ActiveCN110668506AHigh recovery rateSimple processWaste accumulators reclaimingCobalt compoundsOXALIC ACID DIHYDRATEOxalate

The invention provides a method for recycling and regenerating lithium cobalt oxide from waste lithium ion batteries. The method comprises the following steps: stripping an aluminum sheet from a positive plate of a waste lithium ion battery to obtain a positive active substance; preparing a deep eutectic solvent which is choline chloride-oxalic acid, glycine betaine-oxalic acid or hydroxypropyl trimethyl ammonium chloride-oxalic acid; adding the positive active substance into the deep eutectic solvent, stirring and leaching at 50-80 DEG C, and carrying out solid-liquid separation to obtain carbon-containing filter residue and filtrate containing cobalt and lithium; diluting the filtrate containing cobalt and lithium, stirring, standing, and carrying out solid-liquid separation to obtain afilter residue containing cobalt oxalate and a filtrate containing lithium; introducing carbon dioxide gas or adding carbonic acid into the lithium-containing filtrate, and filtering to obtain a lithium carbonate precipitate; and drying, grinding, mixing and roasting the cobalt oxalate-containing filter residue and the lithium carbonate precipitate to obtain lithium cobalt oxide. The method is simple in process and high in metal recovery rate; and the recovery process is low in condition requirement, low in leaching temperature requirement and environment-friendly.

Owner:KUNMING UNIV OF SCI & TECH

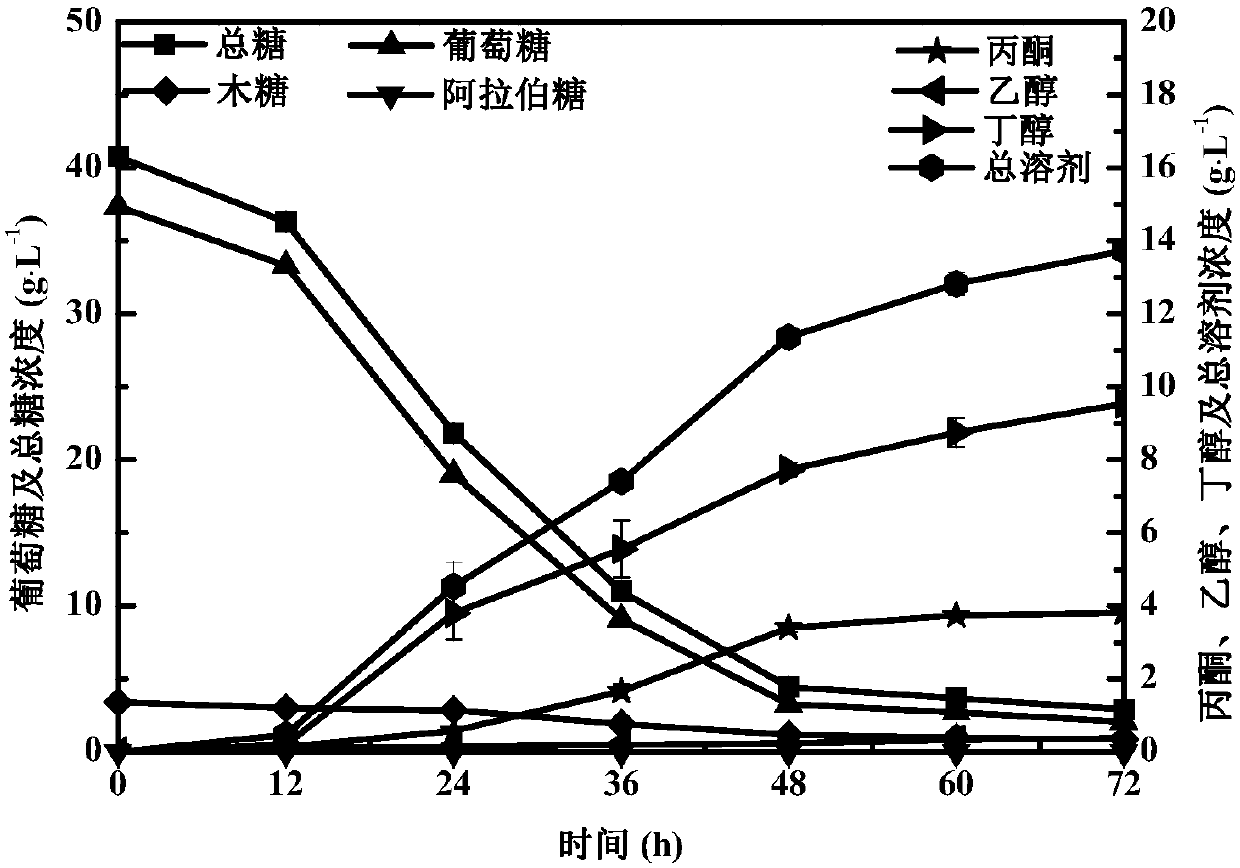

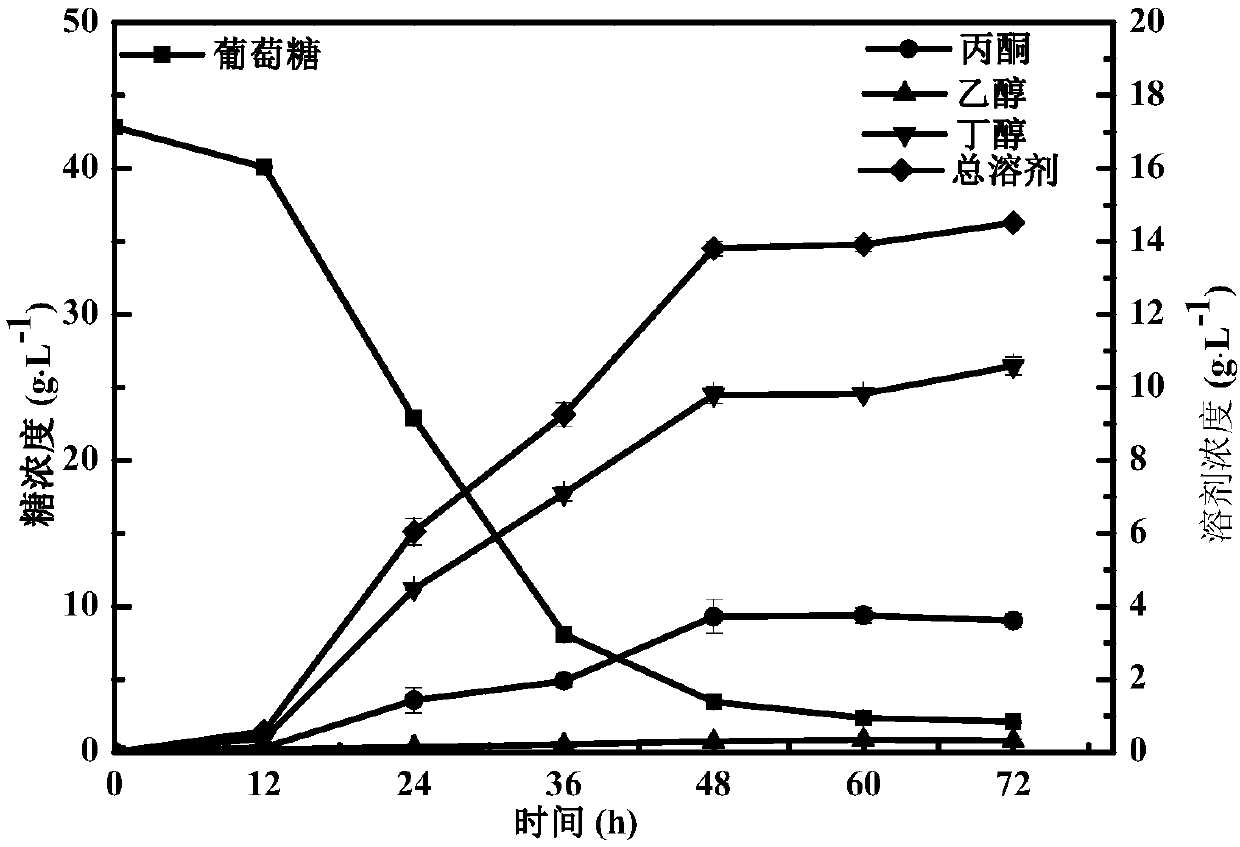

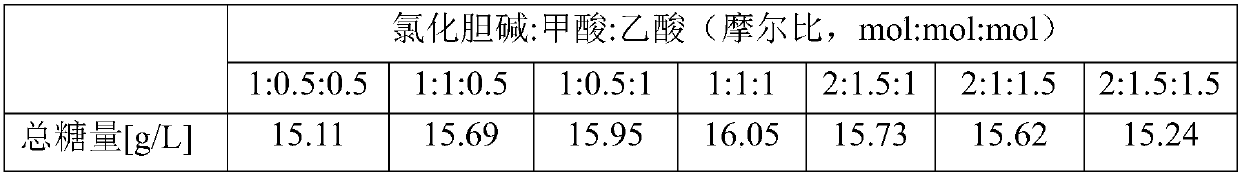

Novel dihydrogen bond deep-eutectic solvent and method for pretreating rice straws through combination of solvent and sodium carbonate

InactiveCN107760739ALow costEasy to synthesizeBiofuelsMicroorganism based processesHydrolysateSolvent

The invention discloses a novel dihydrogen bond deep-eutectic solvent and a method for pretreating rice straws through combination of the solvent and sodium carbonate; straw hydrolysate after enzymolysis can be used for clostridium fermentation to synthesize bio-butanol. The deep-eutectic solvent provided by the invention is the novel dihydrogen bond deep-eutectic solvent which is synthesized by stirring choline chloride, formic acid and acetic acid at a molar ratio of 1:1:1 at the temperature of 30 DEG C; the solvent can be used for reducing the contents of lignin and hemicellulose in a lignocellulose raw material, so that the accessibility of cellulose in the lignocellulose raw material. The solvent and the sodium carbonate are combined to pretreat the rice straws, and enzyme hydrolysisis performed on the pretreated rice straws with cellulose, so as to obtain the hydrolysate containing 4.28g / L of total reducing sugar; the yield of glucose is 80%; in addition, the hydrolysate has noobvious inhibiting effect on the growth of microorganisms such as clostridium and the like, and the yield of butanol is 13.73g.L<-1>. The dihydrogen bond deep-eutectic solvent is an environment-friendly solvent which is simple in synthesis and convenient to use and has good application and development prospects in pretreatment of the lignocellulose raw material.

Owner:JIANGNAN UNIV

Method for extracting anthocyanin from plant

ActiveCN107383115ARaw materials are cheap and easy to getReduce extraction timeSugar derivativesOther chemical processesOrganic solventFiltration membrane

The invention relates to the field of edible pigment and discloses a method for extracting anthocyanin from a plant. The method comprises the following steps: pulverizing the plant containing the anthocyani and adding a deep-eutectic solvent; extracting anthocyanin extracting liquid by an electrostatic field ultrasonic extraction method; adding an attapulgite loaded chitosan crosslinked cyclodextrin compound into the anthocyanin extracting liquid to obtain an anthocyanin compound precipitate adsorbed on the attapulgite loaded chitosan crosslinked cyclodextrin compound; dissolving the anthocyanin compound precipitate in an organic solvent to perform desorption and centrifugation to obtain anthocyanin supernatant containing the organic solvent; enabling the anthocyanin supernatant to pass through a microporous filtration membrane to obtain a purified anthocyanin solution containing the organic solvent; and removing the organic solvent from the anthocyanin solution and removing the redundant water to obtain a target product anthocyanin. The deep-eutectic solvent serves as an extracting solvent, so the method is green and environment-friendly, and the extraction rate is high; and the anthocyanin is purified and separated by the attapulgite loaded chitosan crosslinked cyclodextrin compound, so the process is simple and the purification and separation efficiency is high.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

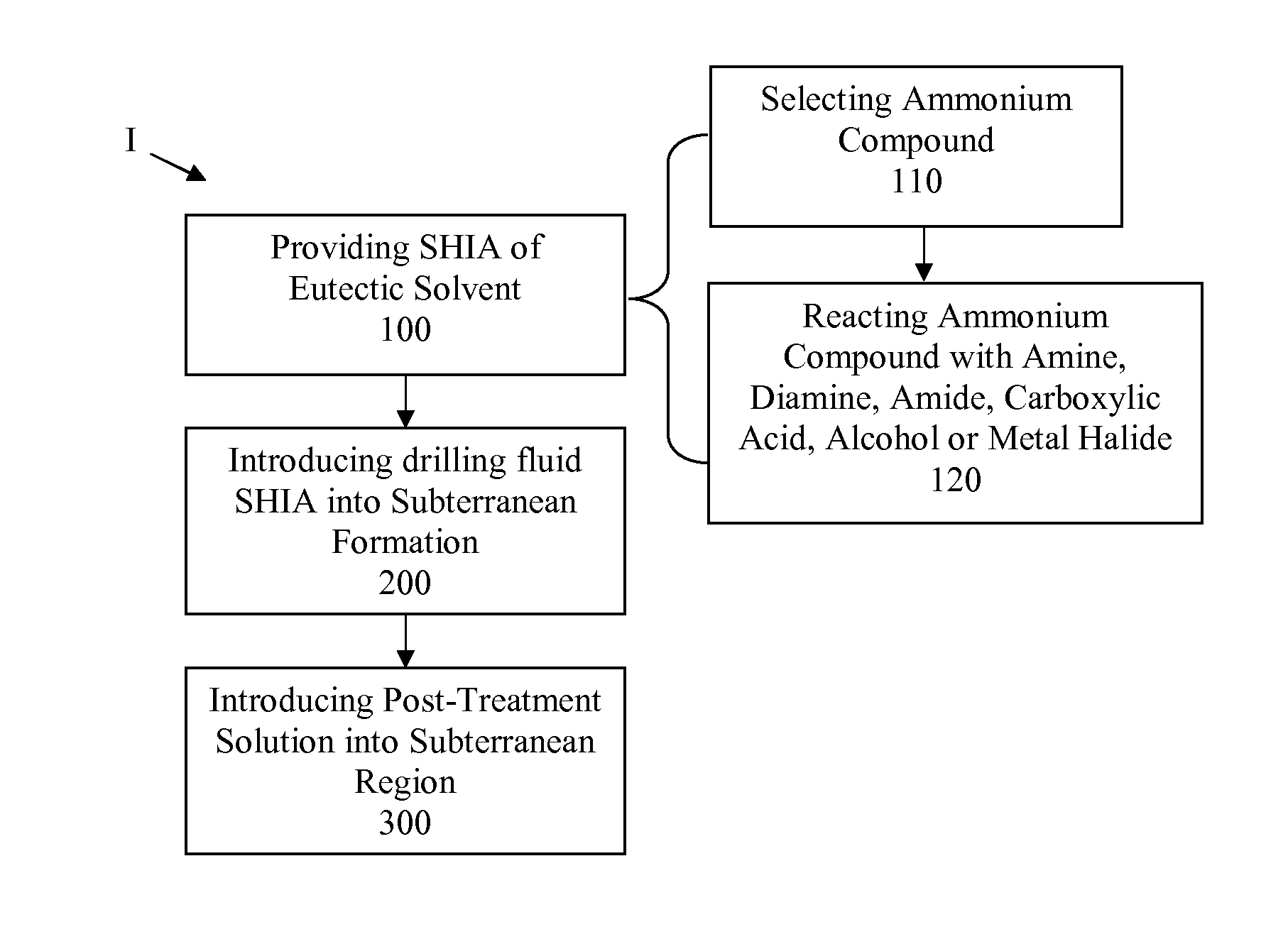

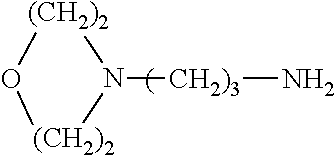

Shale hydration inhibition agent(s) and method of use

InactiveUS20120028855A1Reducing shale swellingReduce shale swellingDrilling compositionWater basedAmmonium compounds

A method of using water-based drilling fluid in a subterranean formation containing shale which swells in the presence of water by circulating a water-based drilling fluid into the formation. The drilling fluid is made of an aqueous based continuous phase, a weighting material, and a shale hydration inhibition agent (SHIA) comprising deep eutectic solvents (DES) formed by the reaction of a first compound comprising an ammonium compound, and a second compound comprising at least one of amides, amines, diamines, cyclic amines, cyclic diamines, and combinations thereof. The SHIA is present in an amount sufficient to reduce shale swelling. A method of reducing shale swelling during wellbore drilling that includes providing a water-based drilling fluid comprising an aqueous based continuous phase, a weighting material, and a SHIA comprising DES formed by the reaction of a quaternary ammonium compound, and a diamine; and circulating the drilling fluid into the subterranean formation.

Owner:SHRIEVE CHEM PRODS

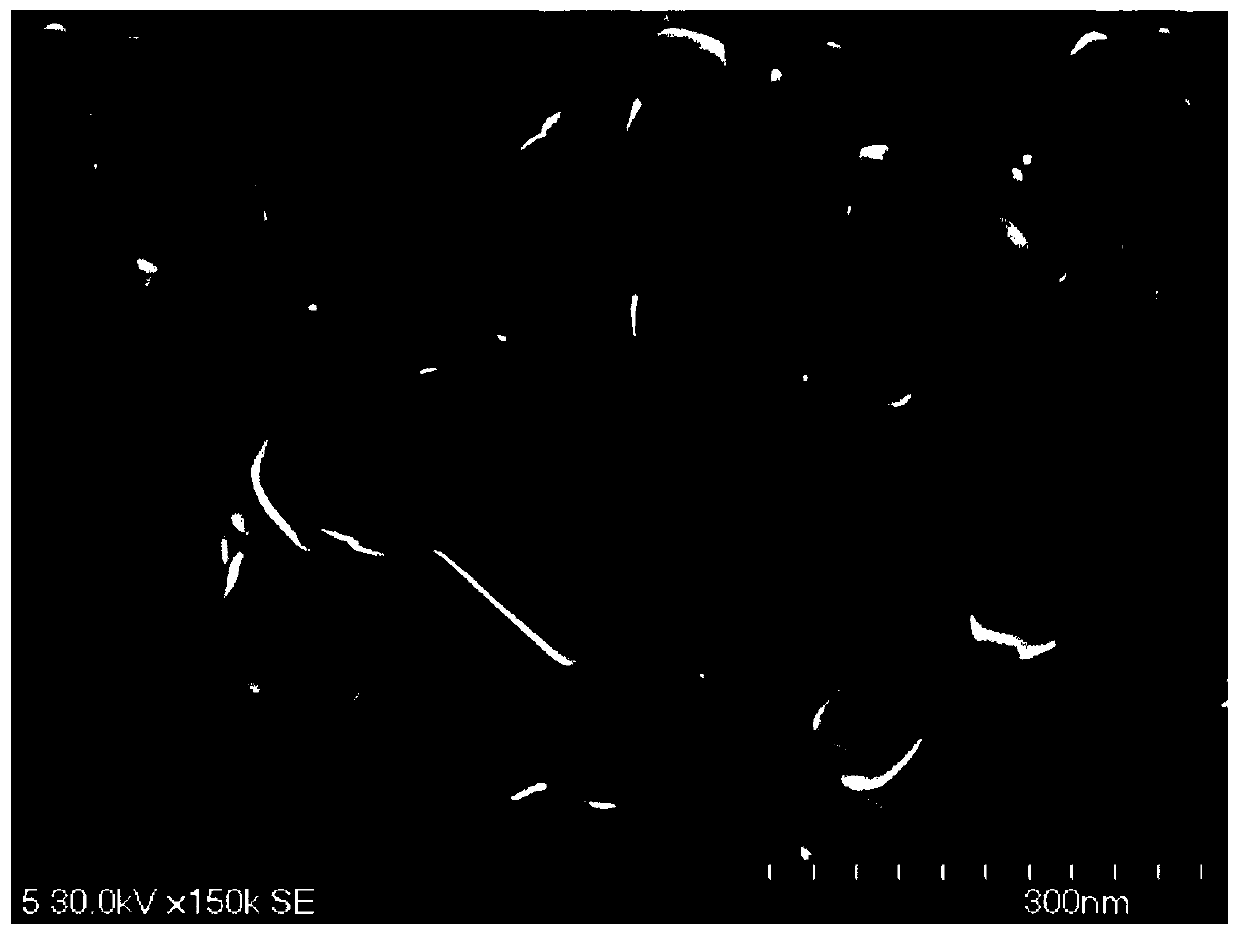

Preparation method of lignocellulose nanofibers

ActiveCN110130136AReduce wasteEfficient recyclingPaper material treatmentDispersion stabilityCellulose

The invention discloses a preparation method of lignocellulose nanofibers. The method comprises the following steps: (1) mixing a hydrogen bond acceptor with a hydrogen bond donor to prepare a deep eutectic solvent; (2) mixing a defibered lignocellulose raw material with the deep eutectic solvent obtained in step (1), and carrying out heat treatment to obtain a swelled, defibered and surface-esterified lignocellulose mixture; (3) mechanically treating the mixture obtained in step (2) to obtain a surface-esterified lignocellulose nanofiber dispersion; and (4) carrying out suction filtration onthe dispersion obtained in step (3), and washing, separating and drying the obtained solid to obtain the lignocellulose nanofibers. The product prepared by the method has the advantages of high length-to-diameter ratio, uniform particle size distribution, obviously improved dispersion stability, obviously improved redispersibility, and good interface compatibility with a polymer matrix. The preparation method has the advantages of mild process conditions, low toxicity, and easiness in operation.

Owner:NANJING FORESTRY UNIV

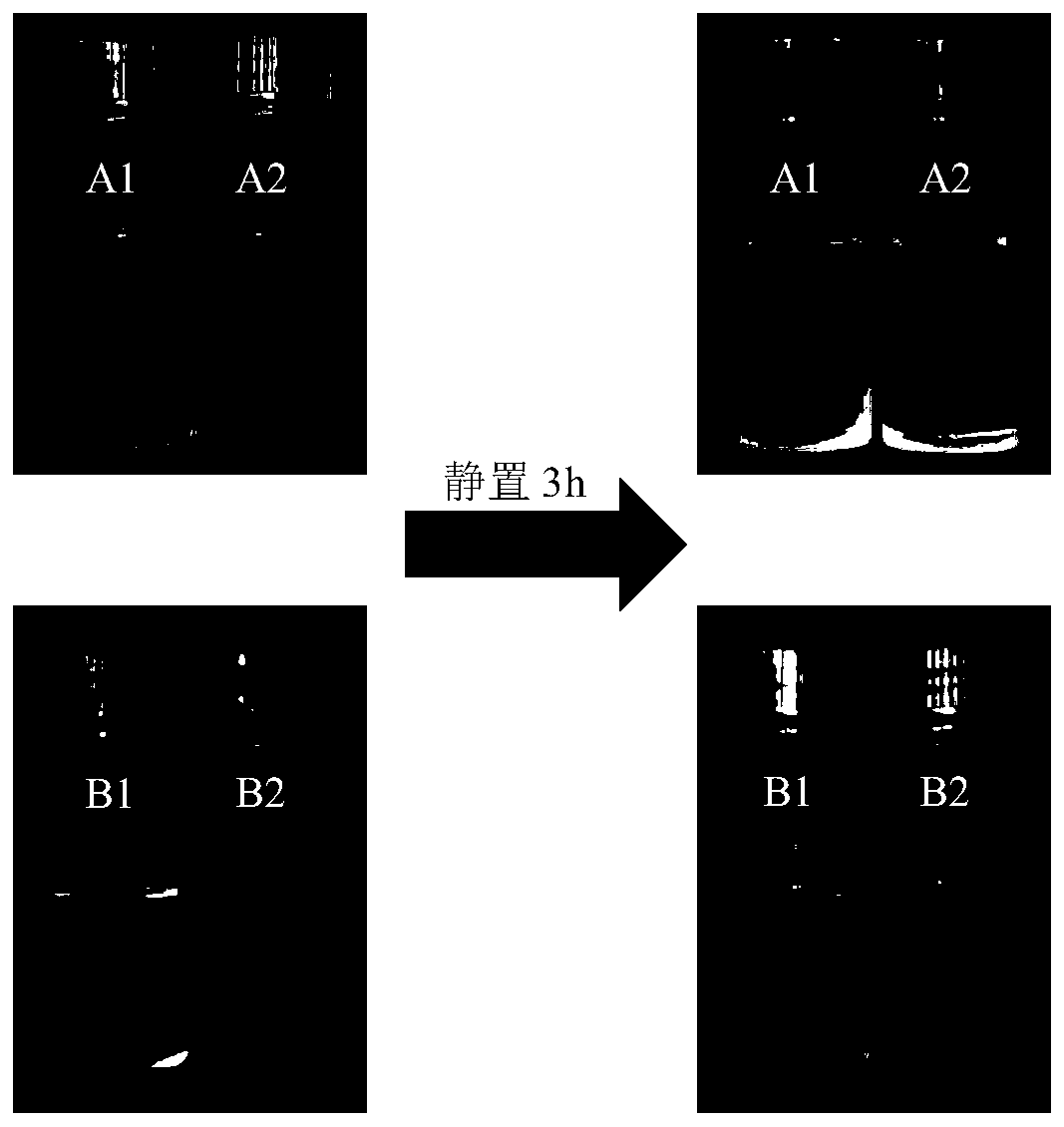

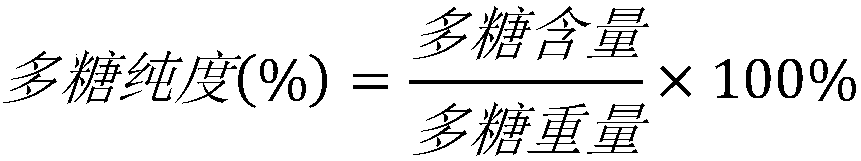

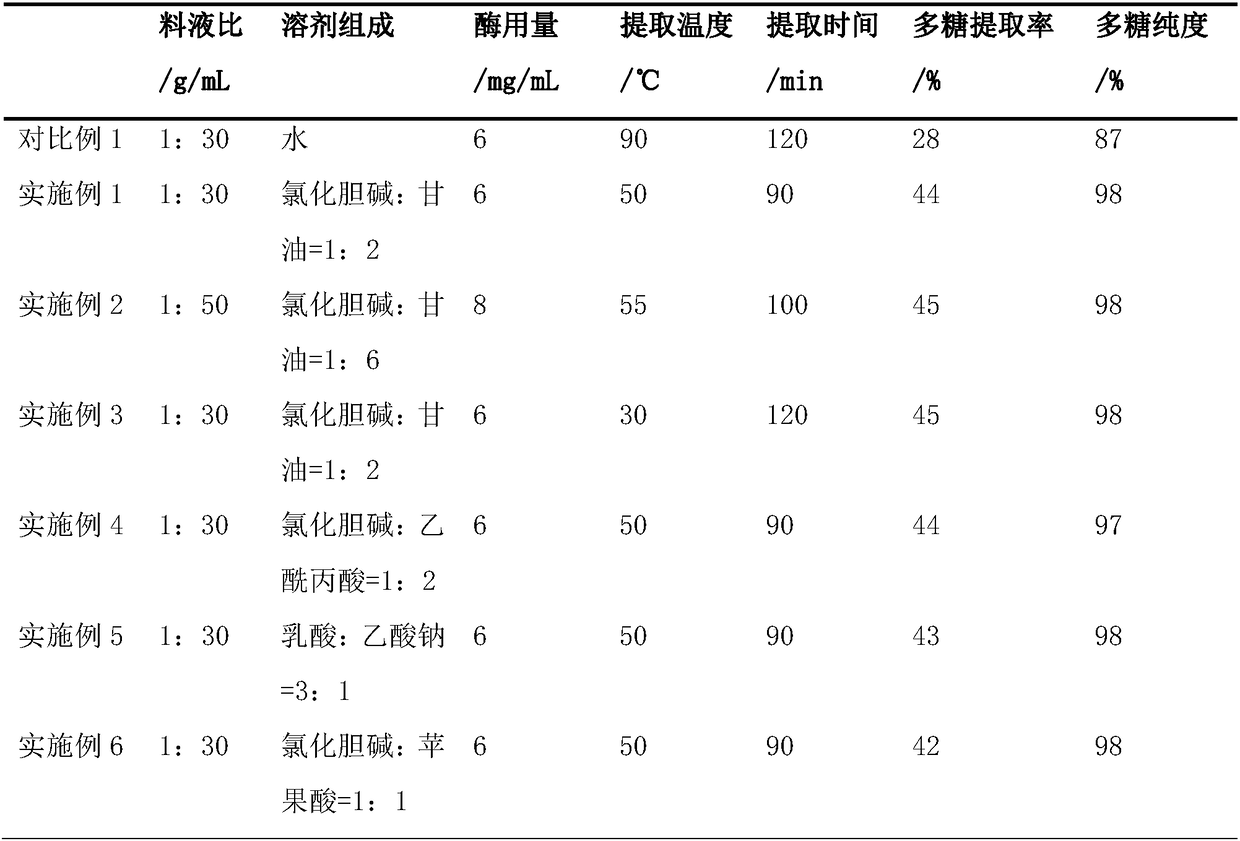

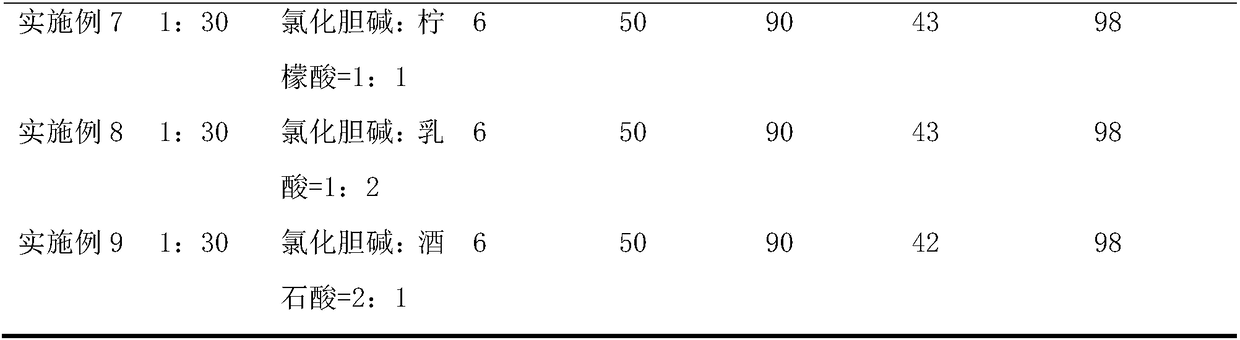

Method for extracting polysaccharide of dendrobium officinale

The invention discloses a method for extracting polysaccharide of dendrobium officinale. The method specifically comprises the following steps of uniformly mixing dendrobium officinale powder and a deep eutectic solvent according to a material and liquid ratio of 1g to (30 to 50)mL, wherein the ratio of hydrogen bond receptor to hydrogen bond donor is 3 to (1 to 18)mol / mol; adding 4 to 8mg / mL of at least one of cellulase and pectinase; extracting for 90 to 120min at the temperature of 30 to 60 DEG C; separating and purifying the extracting solution, so as to obtain the polysaccharide of dendrobium officinale. Compared with the traditional enzyme type water extracting method, the method has the advantages that by using the enzyme-assisted deep eutectic solvent to extract, the volatility islow, the stability is high, and the reaction system is mild; the content of impurities in the extracting solution is reduced, the loss of the solvent is reduced, the purifying burden is decreased, theextracting rate of polysaccharide is increased by 10% or above, and the content of polysaccharide is increased by 10% or above.

Owner:SOUTH CHINA UNIV OF TECH

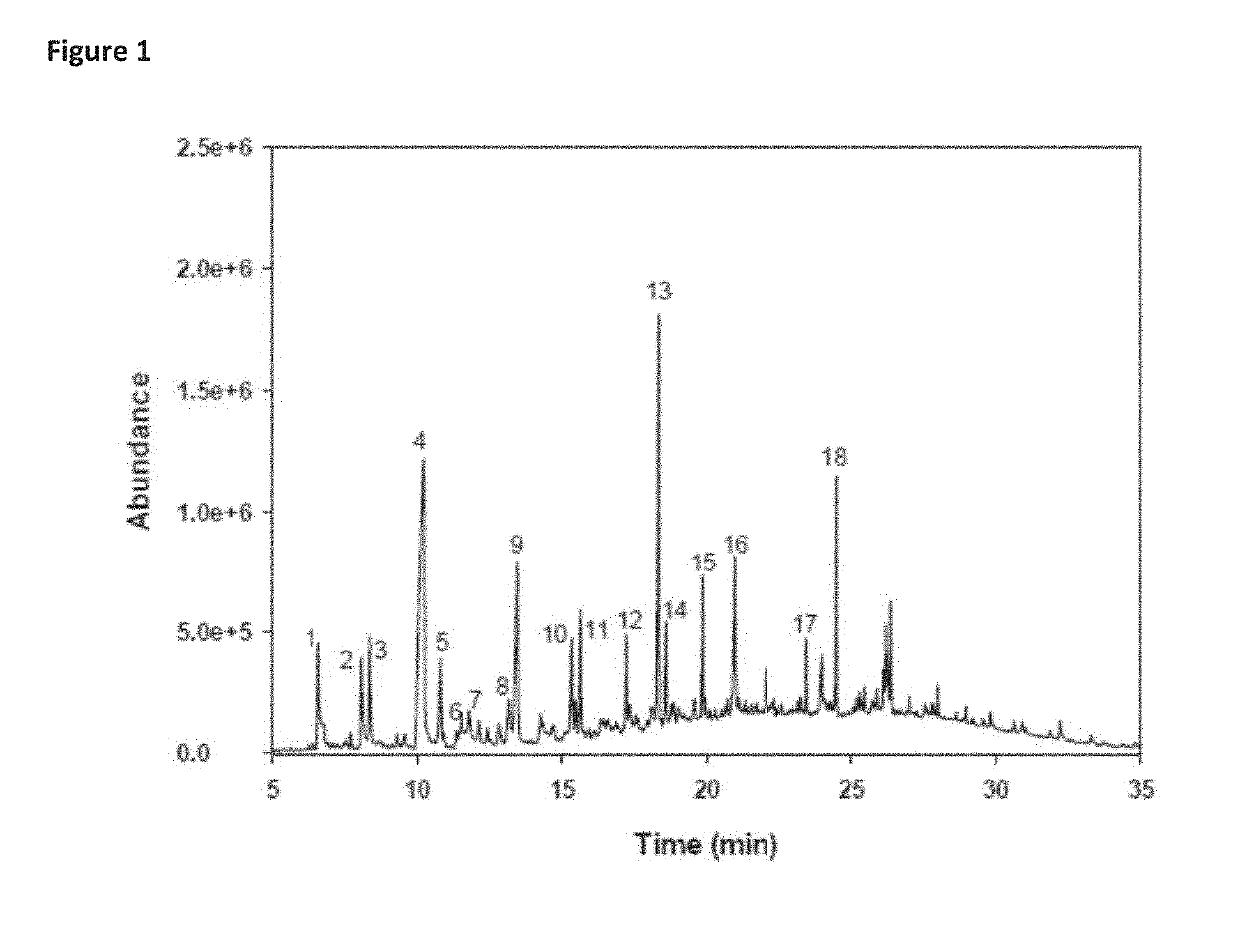

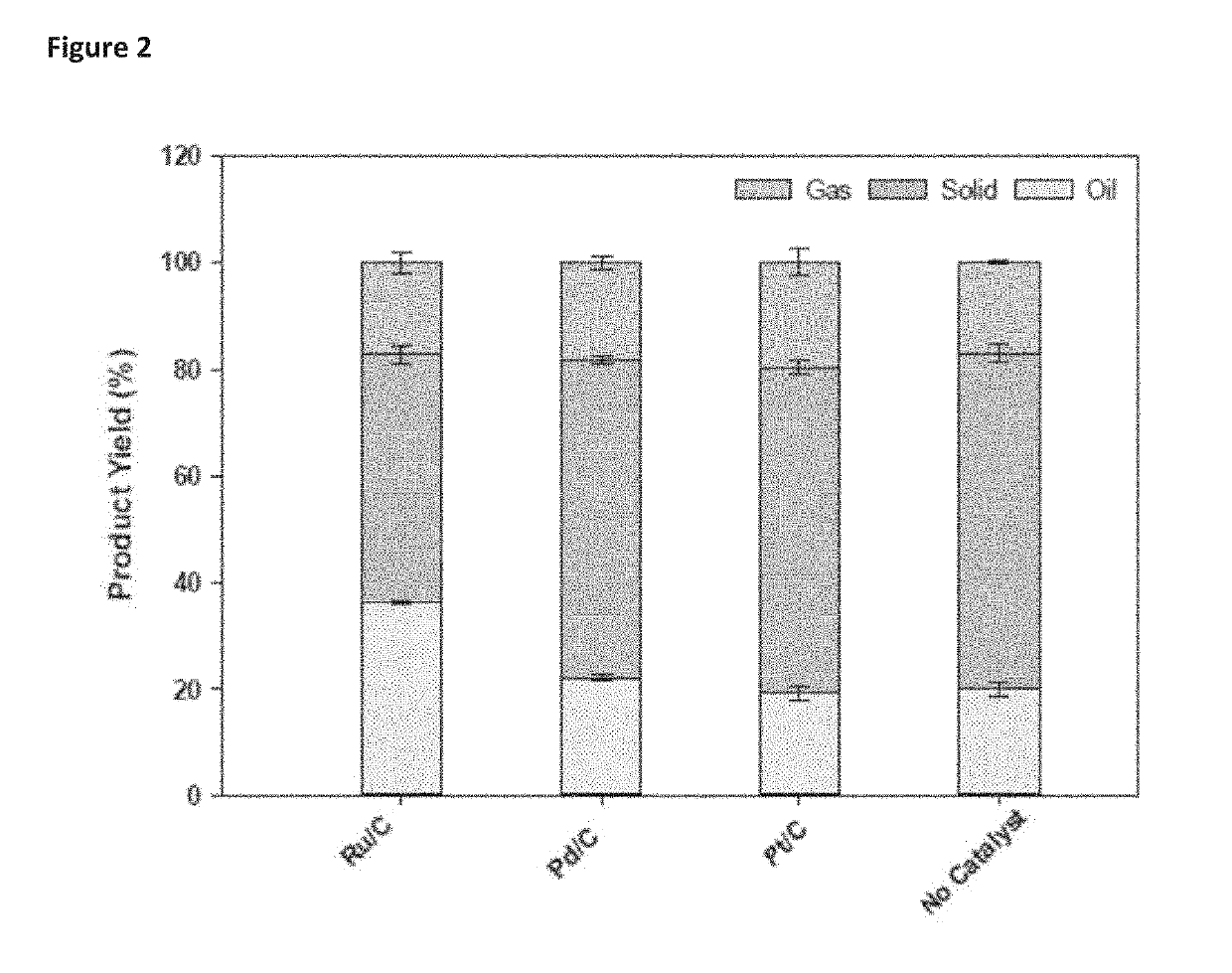

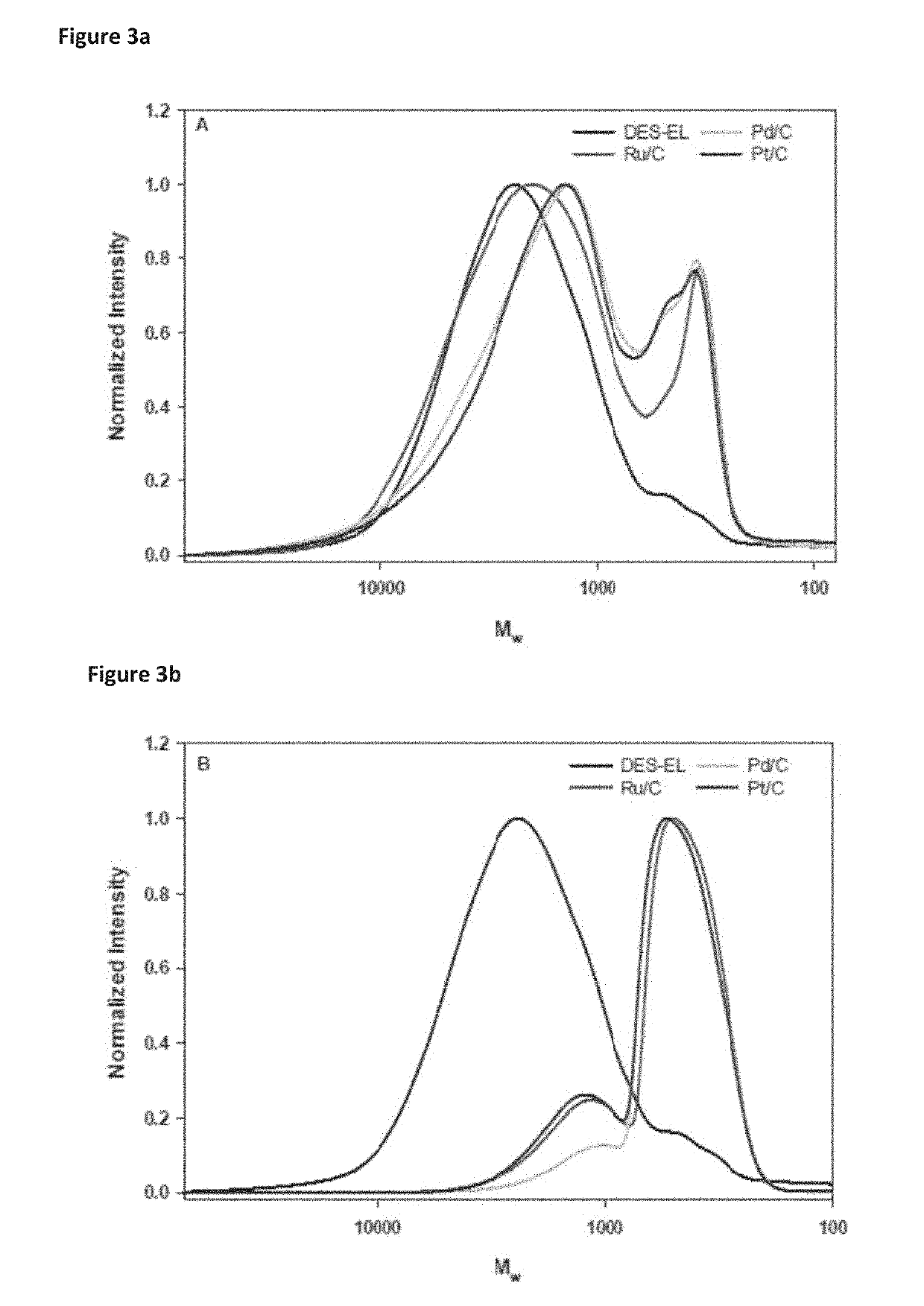

Lignin valorization in ionic liquids and deep eutectic solvent via catalysis and biocatalysis

This invention relates to a method for extracting valorized compounds from lignin by contacting lignins with an ionic liquid and / or a deep eutectic solvent and adding a catalyst and / or a biocatalyst to assist in breaking down the source material. Converting lignin into high value chemicals adds revenues for a bio-refinery and helps to improve the economic viability of biofuel production.

Owner:UNIV OF KENTUCKY RES FOUND

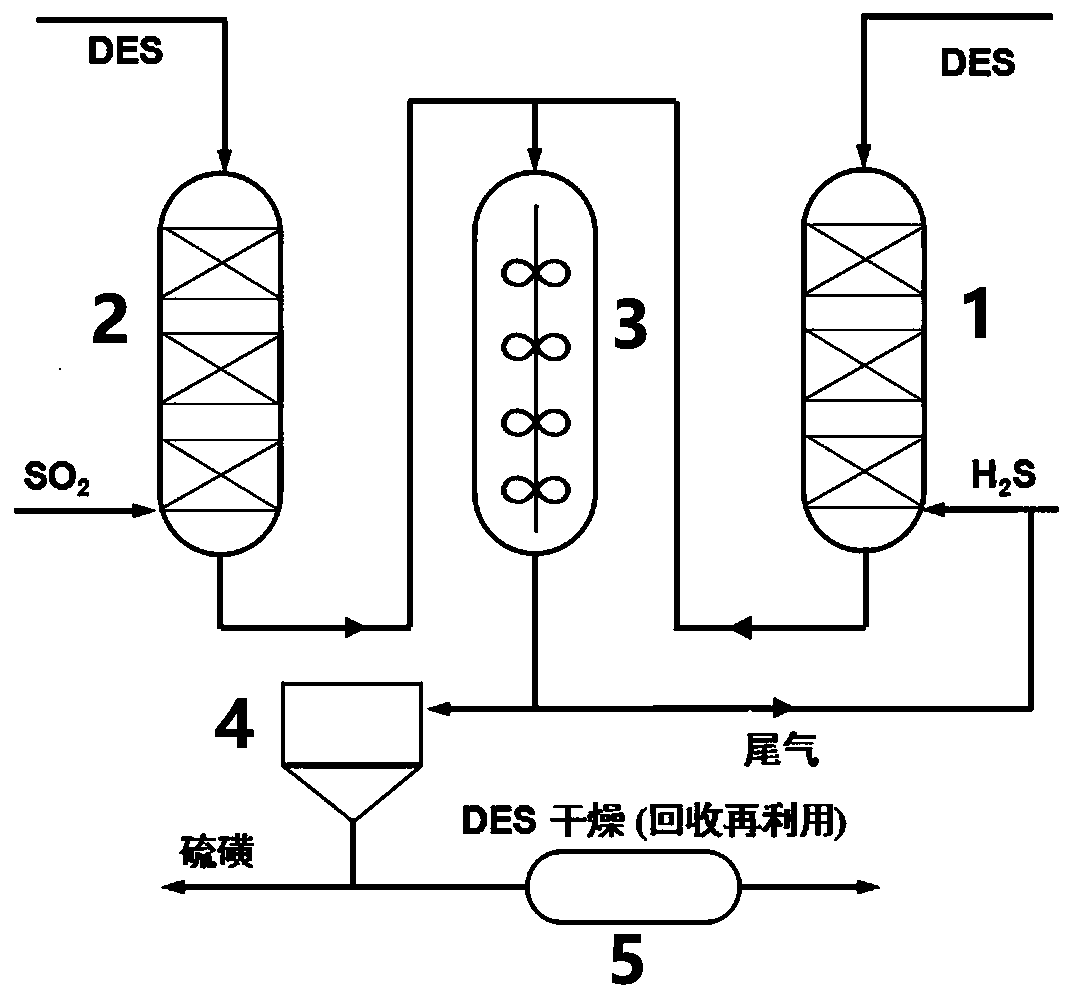

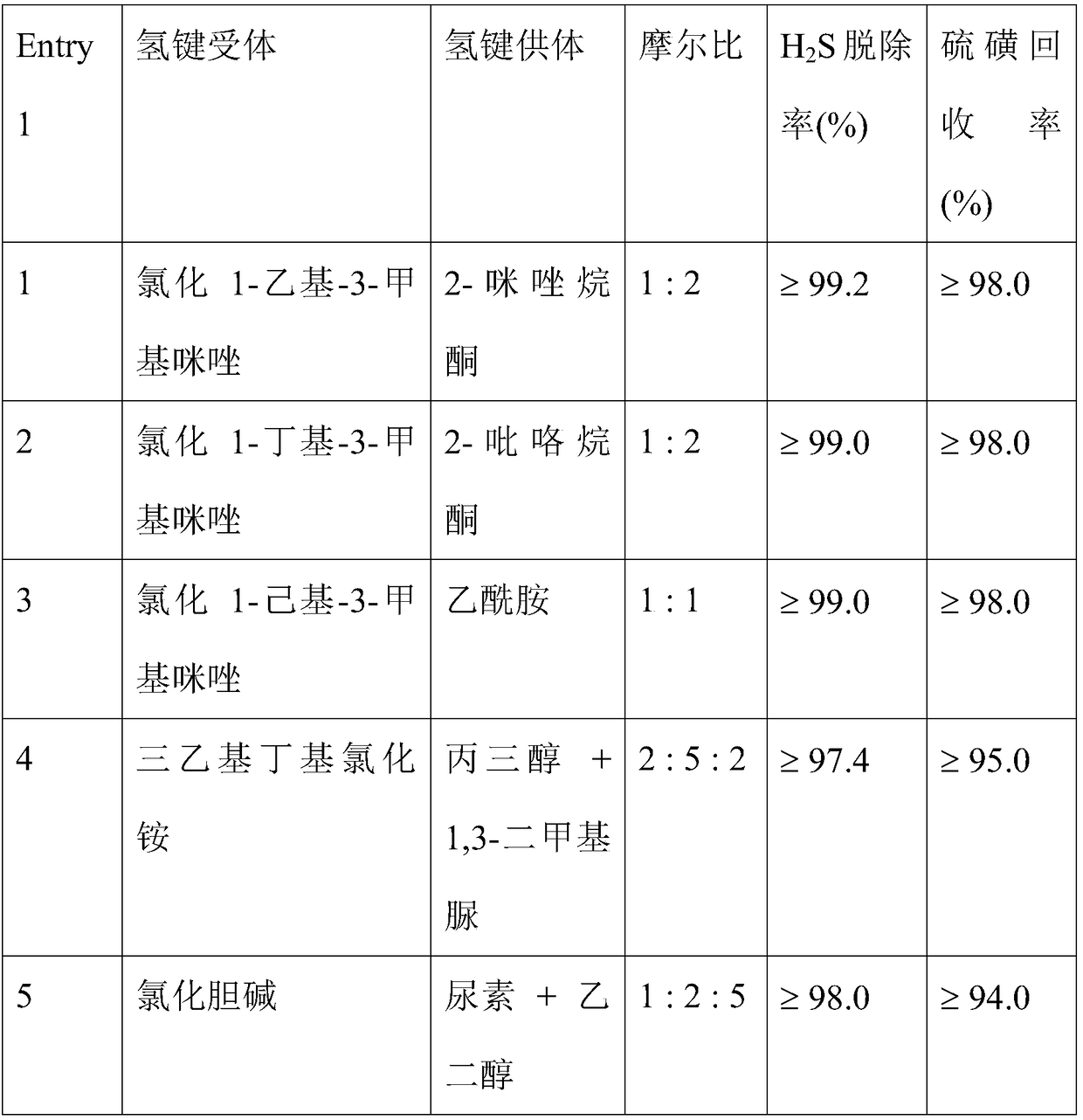

Hydrogen sulfide liquid-phase oxidation removing method taking deep-eutectic solvent as medium

ActiveCN108840311AStable physical and chemical propertiesImprove solubilityDispersed particle separationSulfur preparation/purificationSolubilityTrapping

The invention discloses a hydrogen sulfide liquid-phase oxidation removing method taking a deep-eutectic solvent as a medium, and belongs to the field of chemical separation. Various functionalized deep-eutectic solvents are obtained by mixing one or more of mixture of an amide derivative and a diol derivative serving as a hydrogen bond donor as well as imidazolium salt, quaternary ammonium salt or choline serving as a hydrogen bond receptor according to a certain molar ratio; and the deep-eutectic solvents have the characteristics of stable physical and chemical properties, low price, easiness in preparation, excellent solubility on H2S gas and easiness in recovery. The deep-eutectic solvent designed by the invention can face at the H2S gas in various types of sulfur-containing gas source, efficiently realizes selective trapping of H2S gas and transforms the enriched H2S into high-purity sulfur rapidly by a normal-temperature liquid phase oxidation method; the deep-eutectic solvent can be regenerated and reused after being dried; and the whole process has the advantages of high desulfurization efficiency, mild operation condition, low energy consumption, no discharge of VOCs and the like, and is a novel, green and efficient H2S oxidation removing method.

Owner:NANJING UNIV

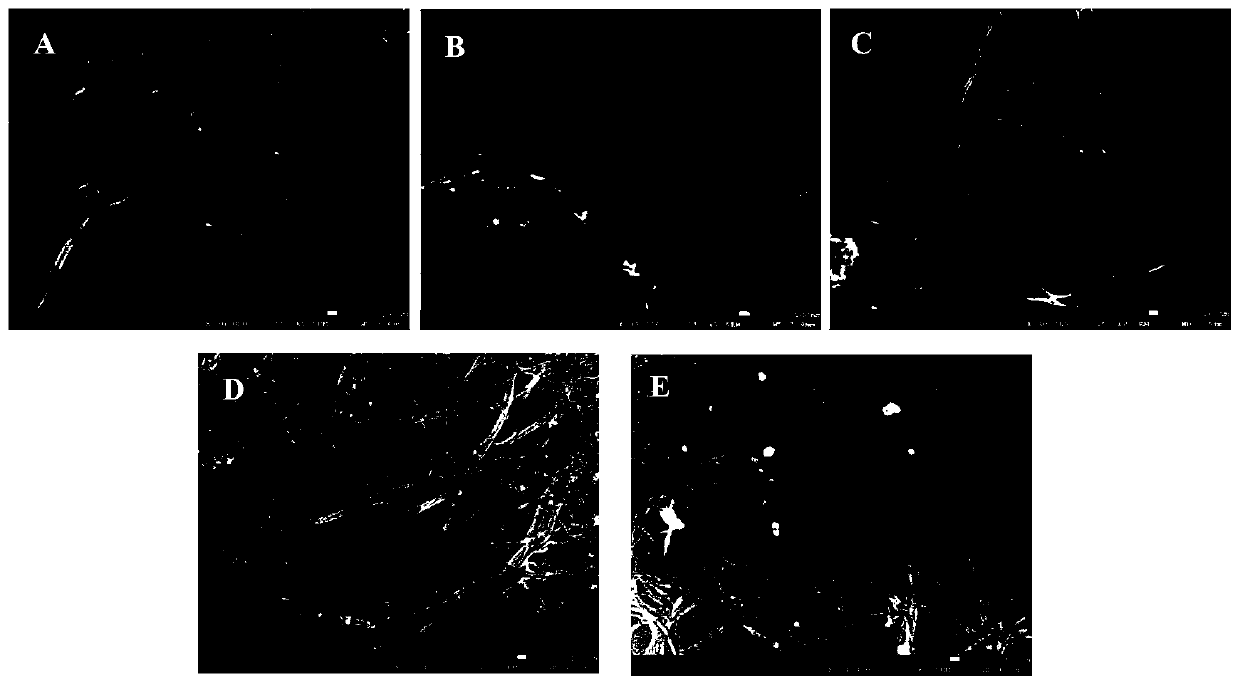

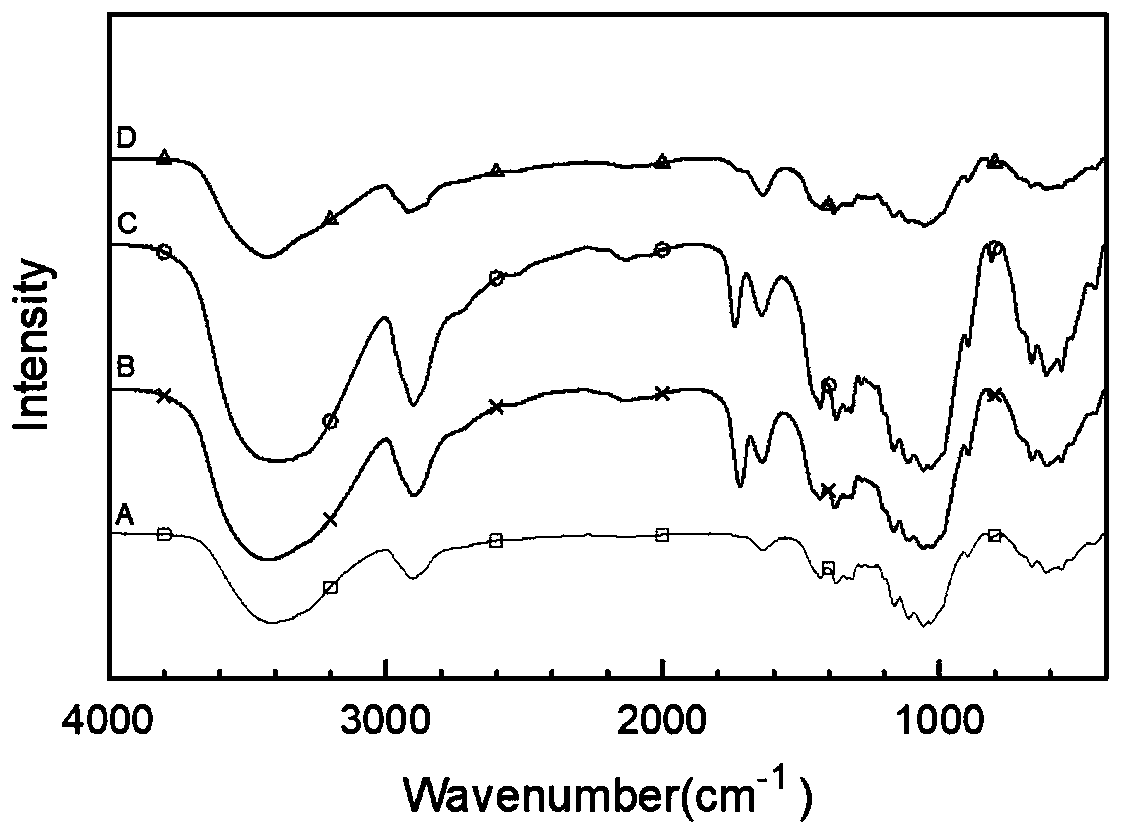

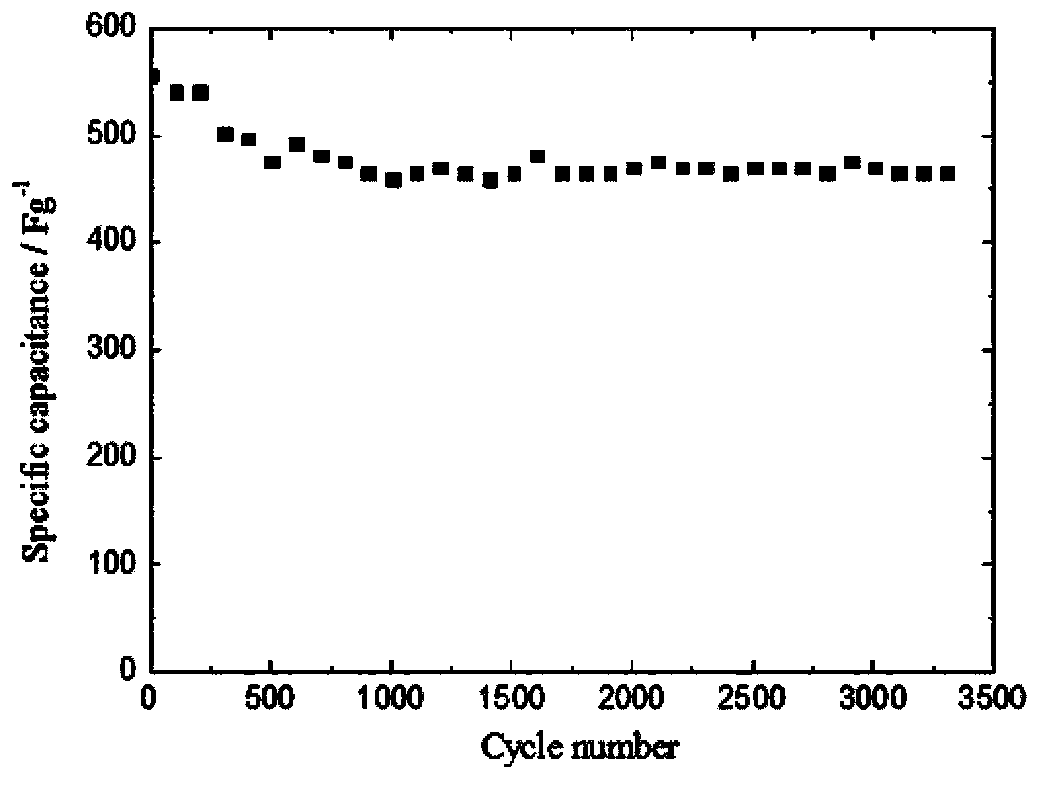

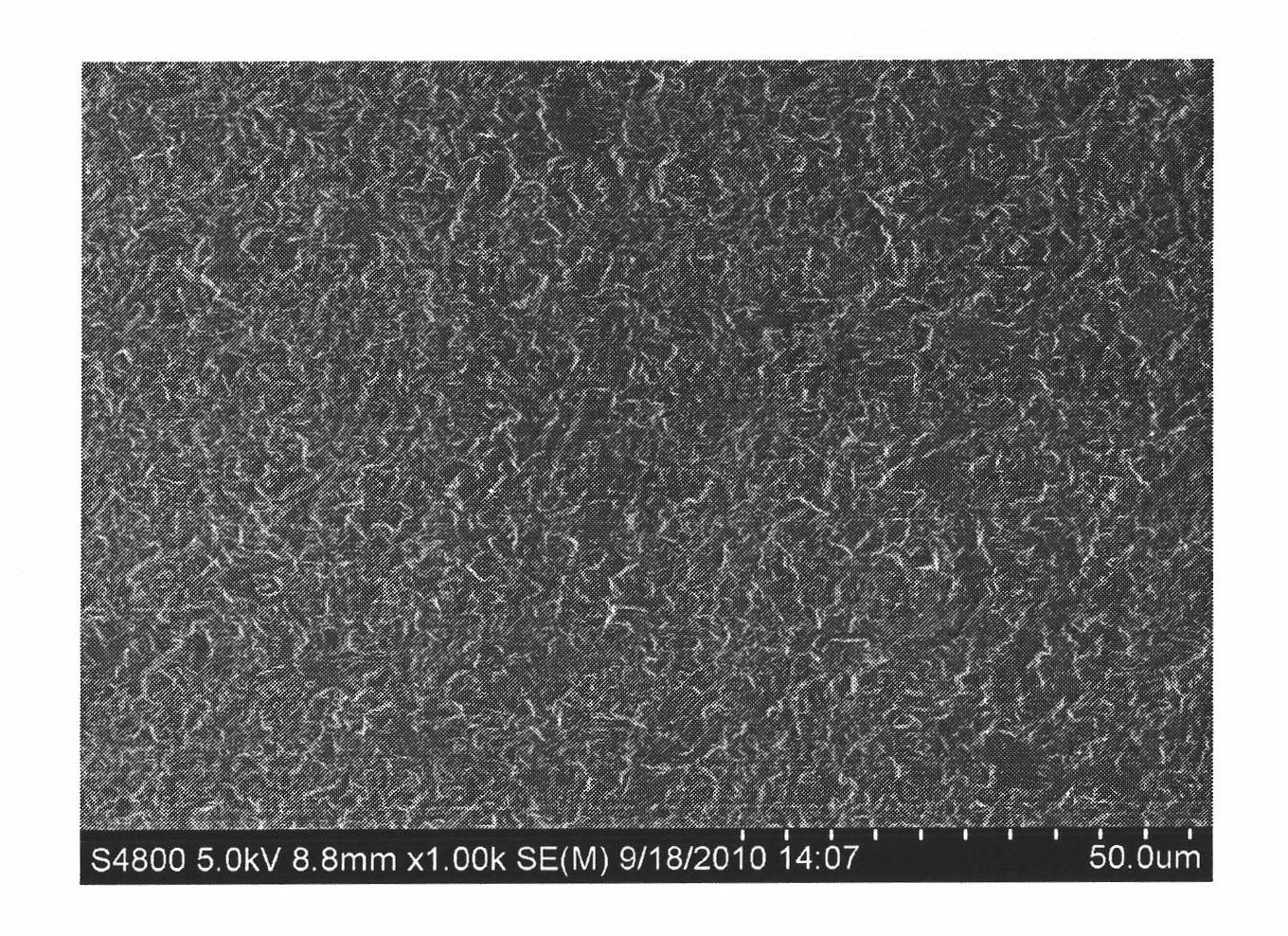

Preparation method of nano-nickel oxide for electrode material of supercapacitor, and nano-nickel oxide prepared by method

ActiveCN103387268ANo pollution in the processReduce manufacturing costMaterial nanotechnologyNickel oxides/hydroxidesDeep eutectic solventChemistry

The invention discloses a preparation method of nano-nickel oxide for an electrode material of a supercapacitor, and the nano-nickel oxide prepared by the method. The preparation method comprises the following steps: mixing NiCl2.6H2O and a choline chloride-based deep eutectic solvent to obtain a solution I with the mass concentration being 10 to 30 g / L; and heating to 120 to 150 DEG C, mixing 100 to 300 parts of deionized water and 1,000 parts of the solution I, reacting for 0.5 to 2 hours, performing centrifugal separation to obtain precipitate, and washing, drying and calcining the precipitate to obtain the nano-nickel oxide. The preparation method is mild in condition, short in consumed time and suitable for large-scale industrialized production. The prepared flower-like nano NiO crystal grains have the grain sizes of being less than 10 nm, are distributed uniformly and are large in specific surface area, so the supercapacitor prepared by taking the nano NiO crystal grins as the electrode material has high reversible capacity and cycling performance, and the specific capacity of the supercapacitor is still stabilized to be close to 460 F / g after 3,000 times of charging / discharging circulation.

Owner:ZHEJIANG UNIV

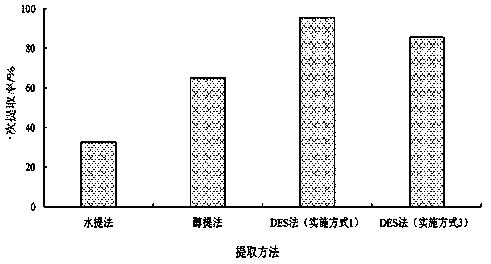

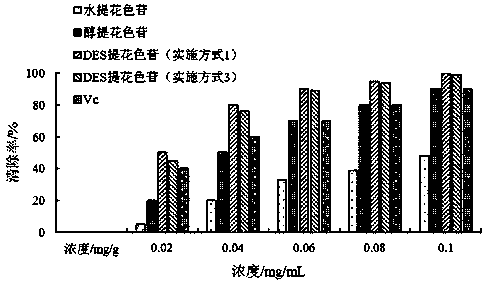

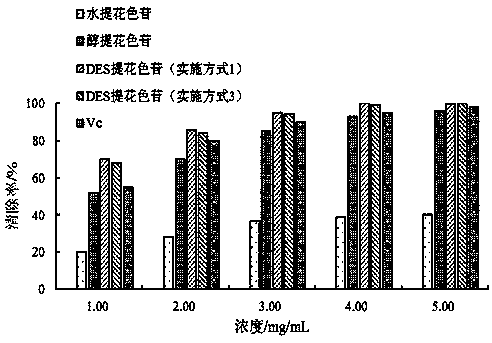

Method for adopting ultrasonic waves for assisting deep-eutectic solvent in extracting smilax china flavonoid compound

InactiveCN109125563AAid in dissolutionAid in diffusioEnergy based chemical/physical/physico-chemical processesSolid solvent extractionUltrasonic cavitationTherapeutic effect

The invention discloses a method for adopting ultrasonic waves for assisting a deep-eutectic solvent in extracting a smilax china flavonoid compound. The method comprises the following steps of preparation of raw materials, ultrasonic treatment and centrifugal extraction. Ultrasonic cavitation is adopted for damaging cell tissue, dissolution and diffusion of active materials in cells are promoted,the ultrasonic waves are combined with the deep-eutectic solvent, and the method is a green method for extraction and separation; moreover, the extraction rate of active components can be effectivelyincreased, thus plant resources are fully utilized, and the drug therapeutic effect is improved; meanwhile, the adopted the adopted preparing method through the deep-eutectic solvent is simple and low in cost, and favorable conditions are provided for industrialized application of extraction of active components of Chinese herbal medicine.

Owner:QIANNAN NORMAL UNIV FOR NATTIES

Process method of absorbing SO2 in smoke by using deep eutectic solvent and regenerating deep eutectic solvent by using H2S

InactiveCN107670464ALow costReduce volatilityGas treatmentDispersed particle separationPresent methodFlue gas

The invention provides a process method for absorbing sulfur dioxide (SO2) in flue gas with a deep eutectic solvent and regenerating it with hydrogen sulfide (H2S). The process method includes using a deep eutectic solvent formed by a hydrogen bond acceptor and a hydrogen bond donor according to a certain ratio as an absorbent, absorbing SO2 in the flue gas at a certain absorption temperature, and then using H2S to regenerate the deep eutectic solvent at a certain temperature. Solvents and recovery of sulfur resources. The method uses cheap, high thermal stability and easy-to-synthesize deep eutectic solvent as an absorbent to absorb SO2 in flue gas. In addition, compared with the traditional regeneration method (steam stripping or flash evaporation), the regeneration temperature of this regeneration method is low, which greatly reduces the regeneration energy consumption, and can quickly and efficiently realize the regeneration of the absorbent and the resource utilization of SO2.

Owner:BEIJING UNIV OF CHEM TECH

New method for the preparation of reactive compositions containing superoxide ion

InactiveUS20090008262A1Photography auxillary processesElectrolysis componentsSolubilityAlkaline earth metal

The subject invention provides a potentially economically viable method for the preparation of reactive superoxide ion in deep eutectic solvents (DES). The superoxide ion can be used for many applications, e.g. the degradation of hazardous chemicals at ambient conditions or in the synthesis of some special chemicals, e.g. carboxylic acids, aldehydes, and ketones from the corresponding alcohols. The superoxide ion can be formed by either the electrochemical reduction of oxygen in DES or by dissolving Group 1 (alkali metals) or Group 2 (alkaline earth metals) superoxides, e.g. potassium superoxide, in DES, with / without chemicals used for the enhancement of the solubility of the metal superoxide in the DES, e.g. crown ethers.

Owner:KING SAUD UNIVERSITY

Environment-friendly electroplate liquid for copper base plating layer and application method thereof

The invention discloses an environment-friendly electroplate liquid for a copper base plating layer, wherein a choline chloride-based deep eutectic solvent is used as a electroplate liquid solvent; every liter of the electroplate liquid contains 0.1-1 mol of CuCl2.2H2O or CuCl2 and 0-10 g of a composite plating layer additive; the composite plating layer additive is one or a mixture of some of nano carbon tube powder, SiC powder, diamond powder and Al2O3 powder; and the choline chloride-based deep eutectic solvent is the mixed liquid of choline chloride and glycol in the molar ratio of 1: 2, or the mixed liquid of the choline chloride and urea in the molar ratio of 1: 2. The electroplate liquid is featured with simple ingredient, convenience in preparation and environment friendliness. The process in which the electroplate liquid is used for electroplating the copper base plating layer is simple and controllable, and the electroplate liquid contains no corrosive material and has no steam discharging in the electroplating process. The surface of the acquired copper base plating layer is even, and especially in the process of electroplating a copper base composite coating, the electroplate liquid is not needed to be mechanically stirred, which simplifies the composite electroplate technology, and is helpful for the large-scale production.

Owner:ZHEJIANG UNIV

Method for separating and extracting lignin from eucalyptus

ActiveCN105908550ALow costReduce pollutionLignin derivativesPaper material treatmentResource utilizationFiltration

The invention discloses a method for separating and extracting lignin from eucalyptus. The method includes the following steps of firstly, adding eucalyptus powder and deep eutectic solvent into a reaction kettle, controlling the reaction temperature to be 60-100 DEG C, and conducting stirring reaction for 4-10 h, wherein the deep eutectic solvent is prepared by evenly mixing lactic acid and benzyl triethyl ammonium chloride according to the molar ratio of 1:3 to 1:9; secondly, taking out a reaction product, conducting decompression and suction filtration, washing away residues through ethyl alcohol, conducting rotary evaporation on filtrate obtained through suction filtration to obtain a concentrated solution, recovering ethyl alcohol, adding deionized water to the concentrated solution, and conducting standing and separating to obtain mixed liquid containing sediment; thirdly, conducting centrifuging on the mixed liquid, conducting solid-liquid separation, and washing a solid phase through deionized water thoroughly to obtain regenerated lignin. Lignin in eucalyptus can be effectively extracted, and the purity of the product is 90% or above. The method is simple in process and mild in condition, biomass resource utilization efficiency is improved, and cost is reduced.

Owner:SOUTH CHINA UNIV OF TECH

Method for the preparation of reactive hydrogen peroxide in deep eutectic solvents

The subject invention provides a potentially economically viable method for the preparation of hydrogen peroxide (H2O2) in deep eutectic solvents (DES). H2O2 is then used for the destruction of small to large quantities of sulfur and nitrogen mustards and lewisite, their homologous / analogues, and similar chemical warfare agents at ambient conditions in DES without producing any toxic by-products. Furthermore, H2O2 has been used for the destruction of small to large quantities of halogenated hydrocarbons, their homologous / analogues, and similar hazardous chemicals at ambient conditions. H2O2 can be formed by either the electrochemical reduction of oxygen in DES in the presence of water or by dissolving Group 1 (alkali metals) or Group 2 (alkaline earth metals) superoxides, e.g. potassium superoxide, in DES in the presence of water, with / without chemicals used for the enhancement of the solubility of the metal superoxide in the DES, e.g. crown ethers.

Owner:KING SAUD UNIVERSITY

Method for deep eutectic solvent electrodeposition of lead powder

The invention relates to a method for deep eutectic solvent electrodeposition of lead powder, belonging to the technical field of non-ferrous metal metallurgy. The method comprises the steps of firstly uniformly mixing quaternary ammonium salt with amide to form a deep eutectic solvent under an inert environment, and then adding lead oxide into the deep eutectic solvent to prepare a deep eutectic solvent electrolyte; by taking graphite as an anode and taking a base body after pretreatment as a cathode, performing electrodeposition in the prepared deep eutectic solvent electrolyte, washing the base body after the electrodeposition with acetone and distilled water, and drying to prepare the lead powder on the base body. By adopting the method provided by the invention, the lead powder with high purity, fine particle size and strong activity can be prepared, and the method has the advantages of simple process, low requirements for equipment materials, relatively low energy consumption, economy and environmental friendliness.

Owner:KUNMING UNIV OF SCI & TECH

Embedding system based on eutectic solvent and using eutectic solvent as solvent

ActiveCN108186575ALow priceEasy to manufactureOrganic active ingredientsPharmaceutical non-active ingredientsControlled releasePolyol

The invention provides an embedding system based on a eutectic solvent and using the eutectic solvent as a solvent. The embedding system comprises an embedding material, a carrier and the eutectic solvent, and the eutectic solvent is formed by a hydrogen bond donor and a hydrogen bond acceptor through hydrogen bond association; the hydrogen bond acceptor includes quaternary ammonium salt, and thehydrogen bond donor includes one or more of urea, polyol, monosaccharide and carboxylic acid. The embedding system uses the eutectic solvent to serve as the solvent, and the eutectic solvent can increase the embedding rate of medicine, is low in toxicity and degradable, can reduce the side effects of the medicine in a controlled release and medicine delivery process and can improve the permeability and controllable release performance of cell membranes.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

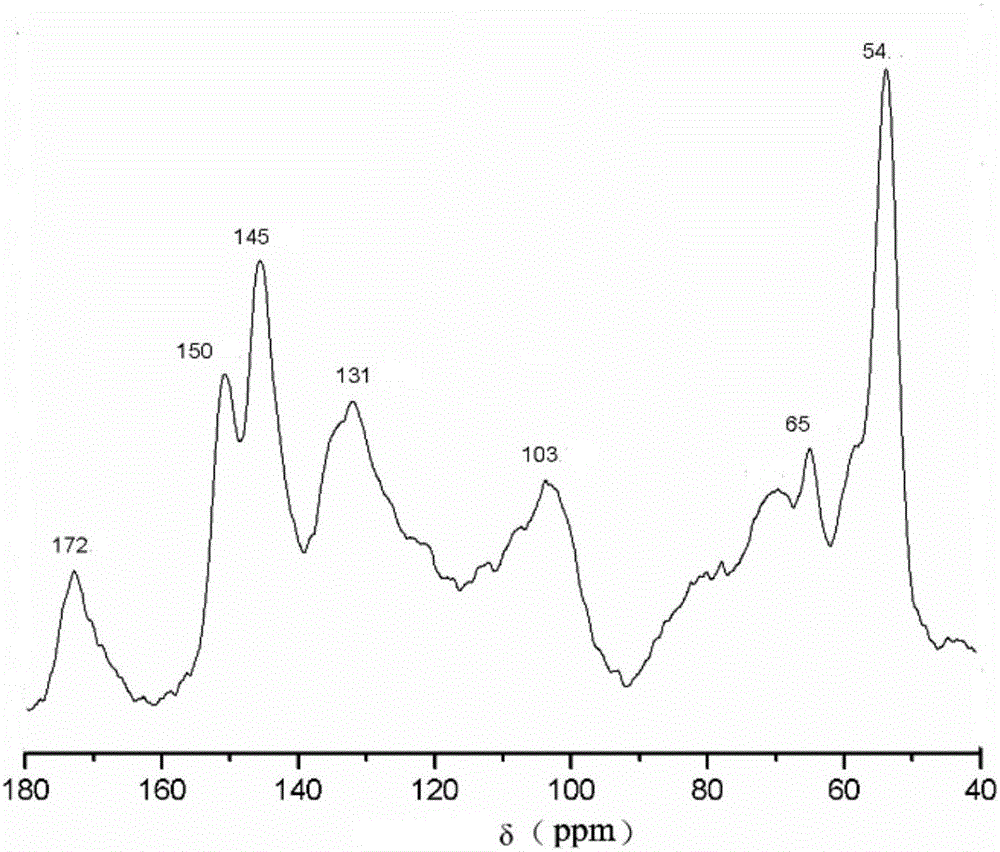

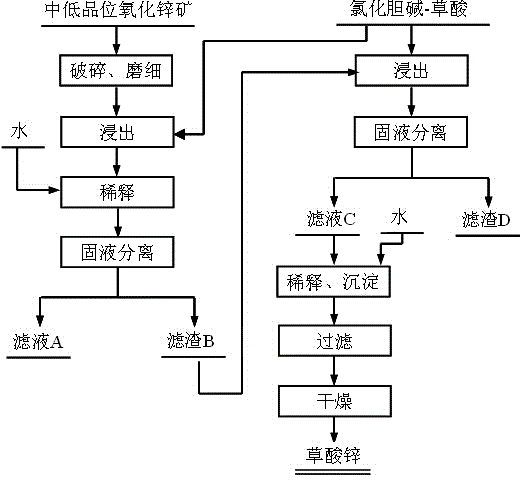

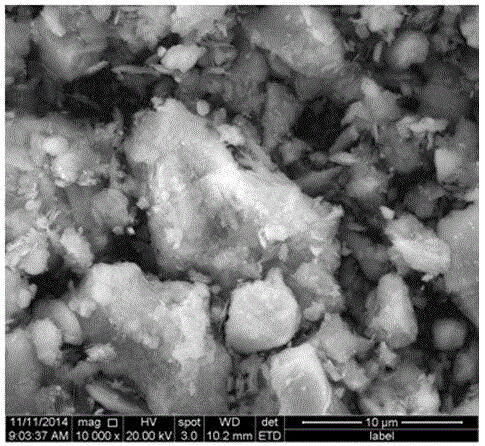

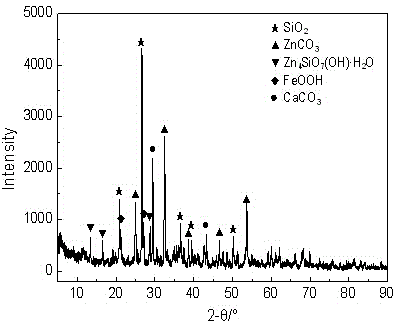

Method for preparing zinc oxalate as zinc oxide powder precursor from middle/low-grade zinc oxide ore

The invention relates to a method for preparing zinc oxalate as a zinc oxide powder precursor from middle / low-grade zinc oxide ore and belongs to the technical field of wet method metallurgy. The method comprises preparing a deep eutectic solvent-type ionic liquid from choline chloride and oxalic acid, fragmenting and fine grinding middle / low-grade zinc oxide ore, adding the middle / low-grade zinc oxide ore powder into the deep eutectic solvent-type ionic liquid, carrying out stirring leaching, adding distilled water into the leached ore pulp, carrying out stirring to obtain a uniform mixture, carrying out standing, carrying out solid-liquid separation to obtain a filtrate A and a zinc oxalate-rich filter residue B, preparing a deep eutectic solvent-type ionic liquid, adding the zinc oxalate-rich filter residue B into the deep eutectic solvent-type ionic liquid, carrying out leaching, carrying out solid-liquid separation to obtain a filtrate C and filter residue D, adding distilled water into the filtrate C, wherein the volume of the distilled water is 2-10 times that of the filtrate C, carrying out filtration after white precipitates are precipitated, washing the filter residue and carrying out drying to obtain zinc oxalate crystals. The method realizes effective utilization of middle / low-grade zinc oxide ore and provides a novel approach for deep eutectic solvent use.

Owner:KUNMING UNIV OF SCI & TECH

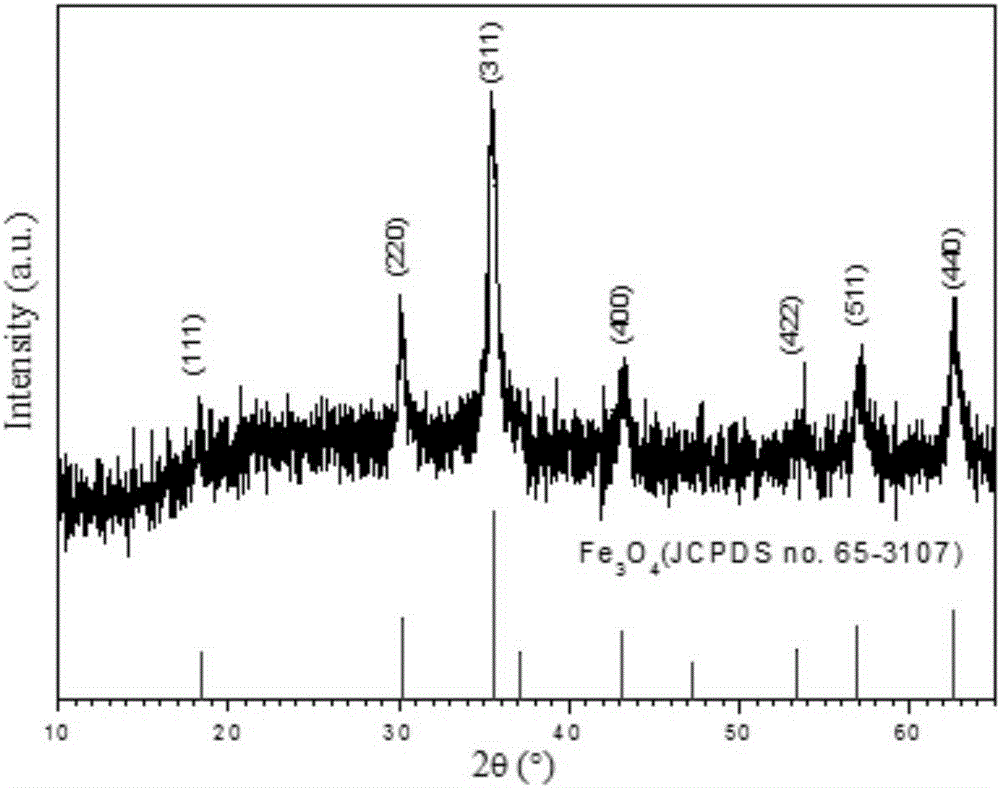

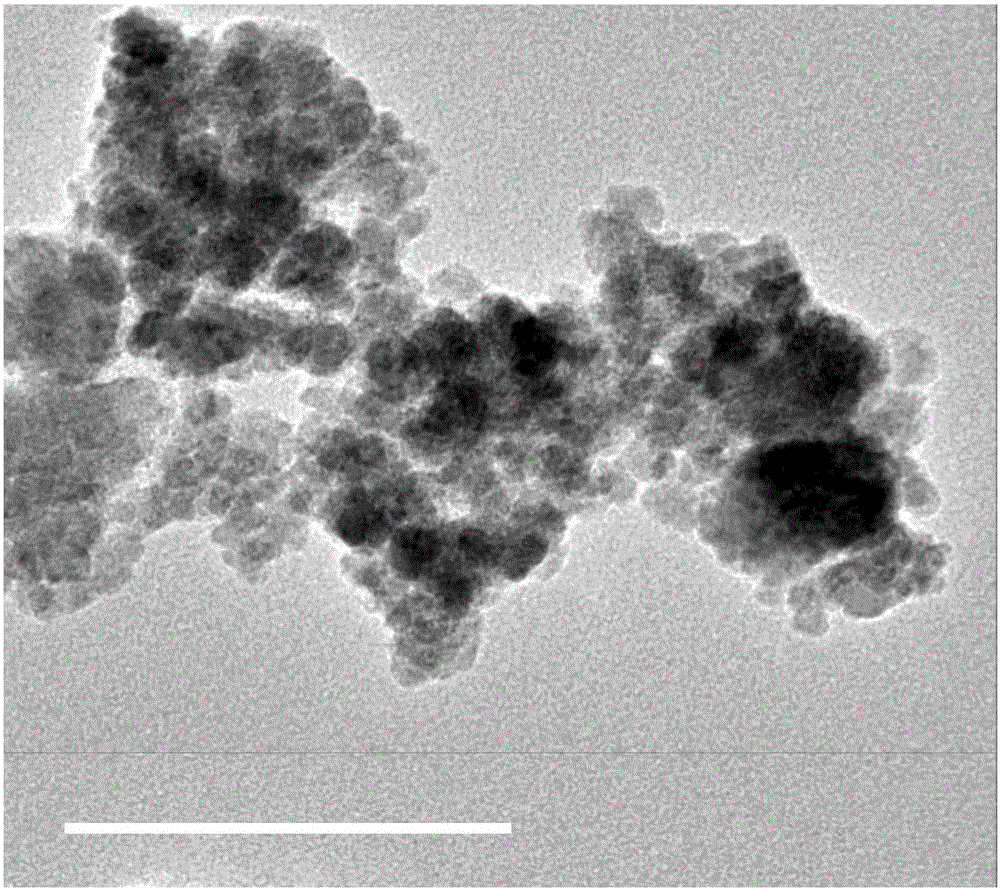

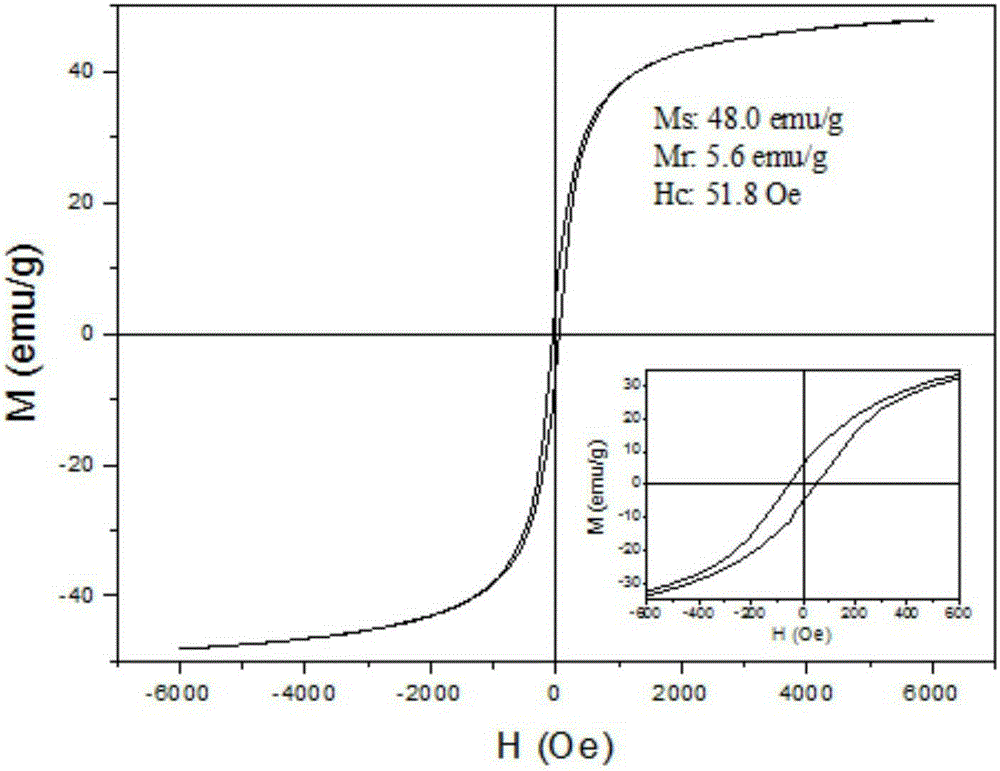

Copper-doped Fe3O4 magnetic composite nanomaterial as well as preparation method and application thereof

InactiveCN105214664ALower requirementSimple ingredientsWater contaminantsMetal/metal-oxides/metal-hydroxide catalystsEnvironmental resistanceMagnetite Nanoparticles

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Preparation method of glycerin-amino acid deep eutectic solvent

InactiveCN105288634AAvoid adverse changes such as degradationPharmaceutical non-active ingredientsFood scienceGlycerolMedicinal chemistry

The invention relates to a preparation method of a glycerin-amino acid deep eutectic solvent. According to the method, glycerin and amino acids are mixed according to a certain molecular ratio and dissolved in a proper amount of water, low-temperature pre-freezing is performed, then freezing and drying are performed, and obtained liquid is the glycerin-amino acid deep eutectic solvent. The technology is simple, cost is low, the obtained deep eutectic solvent can serve as extracting agents, microbial protecting agents and reaction media and is widely used in the industries of food, medicine, biotechnology and the like.

Owner:NANJING AGRICULTURAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com