Ternary deep-eutectic solvent

A technology of deep eutectic solvent and compound, applied in the field of new ternary deep eutectic solvent, can solve the problem that phenolic compounds are easily oxidized and deteriorated, and achieve the effect of cheap synthetic raw materials, broad application prospects, and large absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

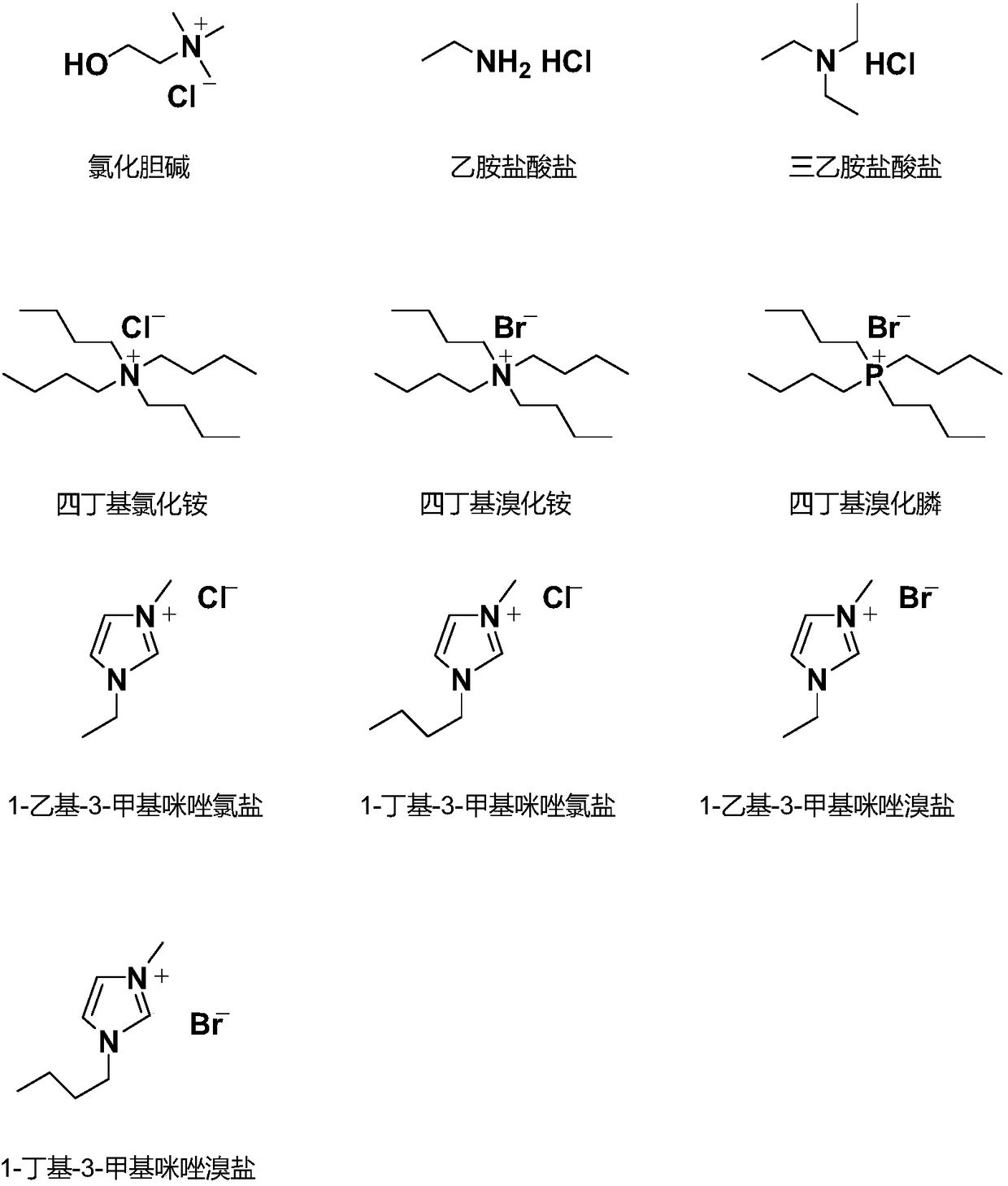

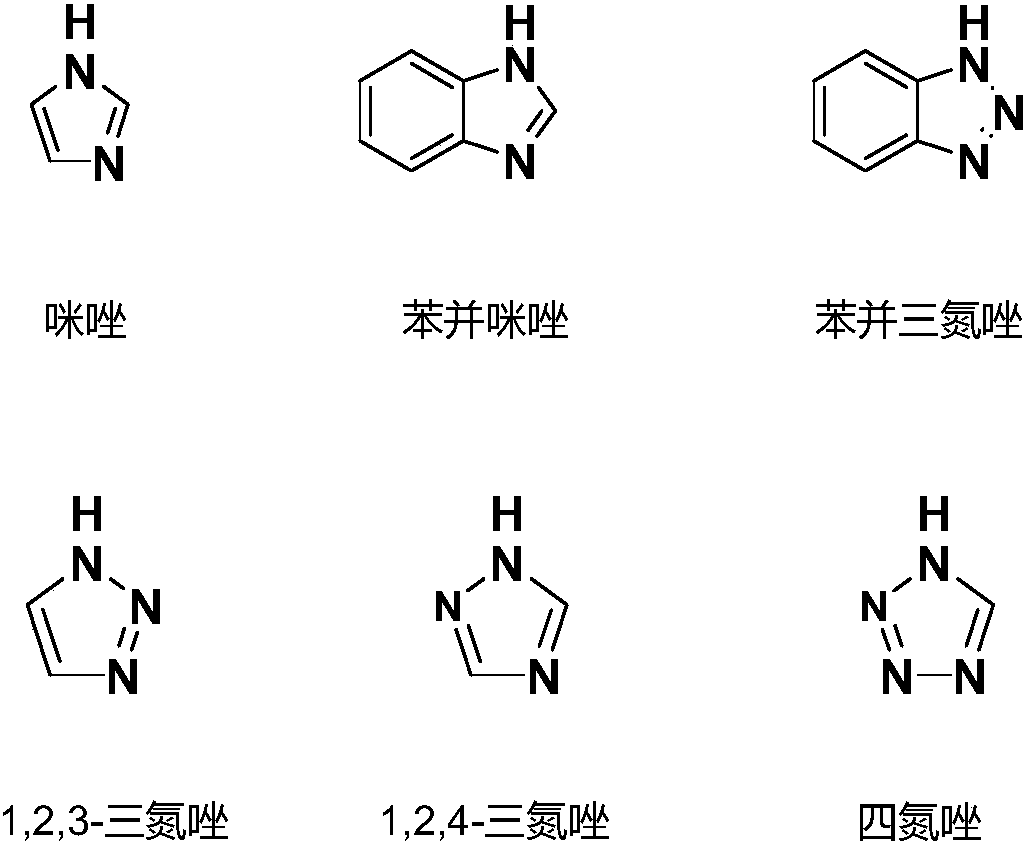

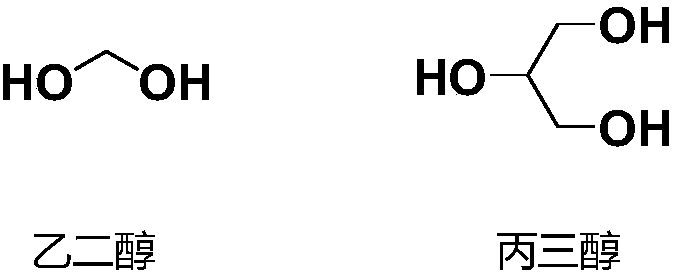

Method used

Image

Examples

Embodiment 1

[0019] Weigh 9.67g (0.03mol) of tetrabutylammonium bromide, 4.76g (0.07mol) of imidazole, and 6.21g (0.10mol) of ethylene glycol in a flask, stir and mix evenly at 80°C to obtain the ternary deep eutectic solvent.

Embodiment 2

[0021] Take by weighing 4.18g (0.03mol) of choline chloride, 4.76g (0.07mol) of imidazole, and 8.68g (0.14mol) of ethylene glycol in a flask, and stir and mix evenly at 80° C. to obtain the three compounds of the present invention. Elemental deep eutectic solvent.

Embodiment 3

[0023] Weigh 9.67g (0.03mol) of tetrabutylammonium bromide, 4.83g (0.07mol) of 1,2,4-triazole, and 6.20g (0.10mol) of glycerol in a flask, stir and mix at 80°C Uniformly, the ternary deep eutectic solvent of the present invention is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com