Alcohol amine type ion liquor-containing compound absorbent capable of capturing carbon dioxide

A technology of ionic liquid and carbon dioxide, which is applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of fast deterioration of absorbents, loss of absorbents, equipment corrosion, etc., and achieve greening of the preparation process and increased stability high performance and low regenerative energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

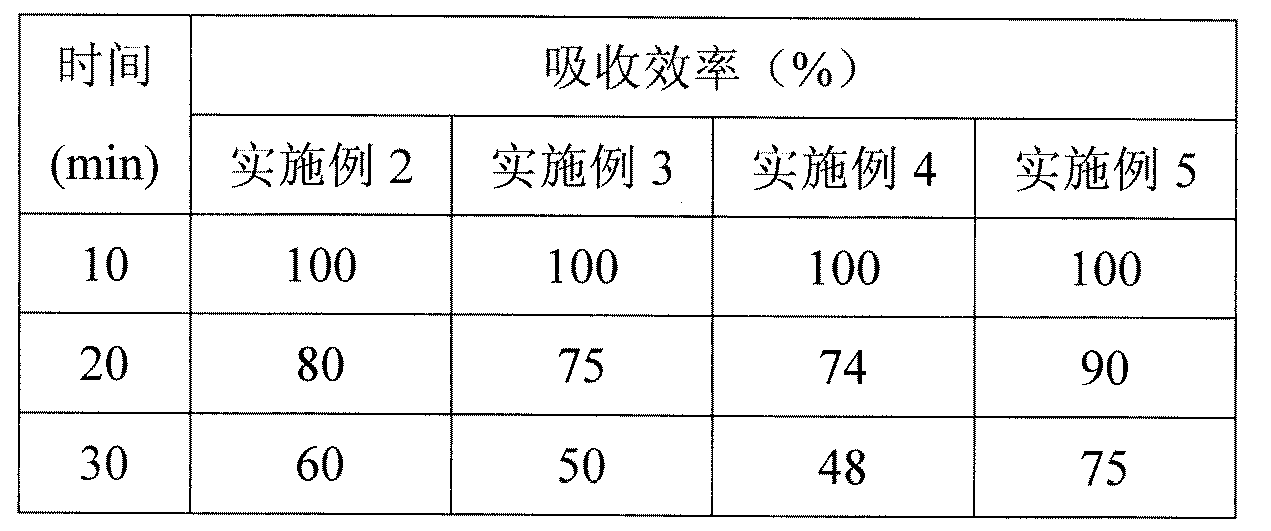

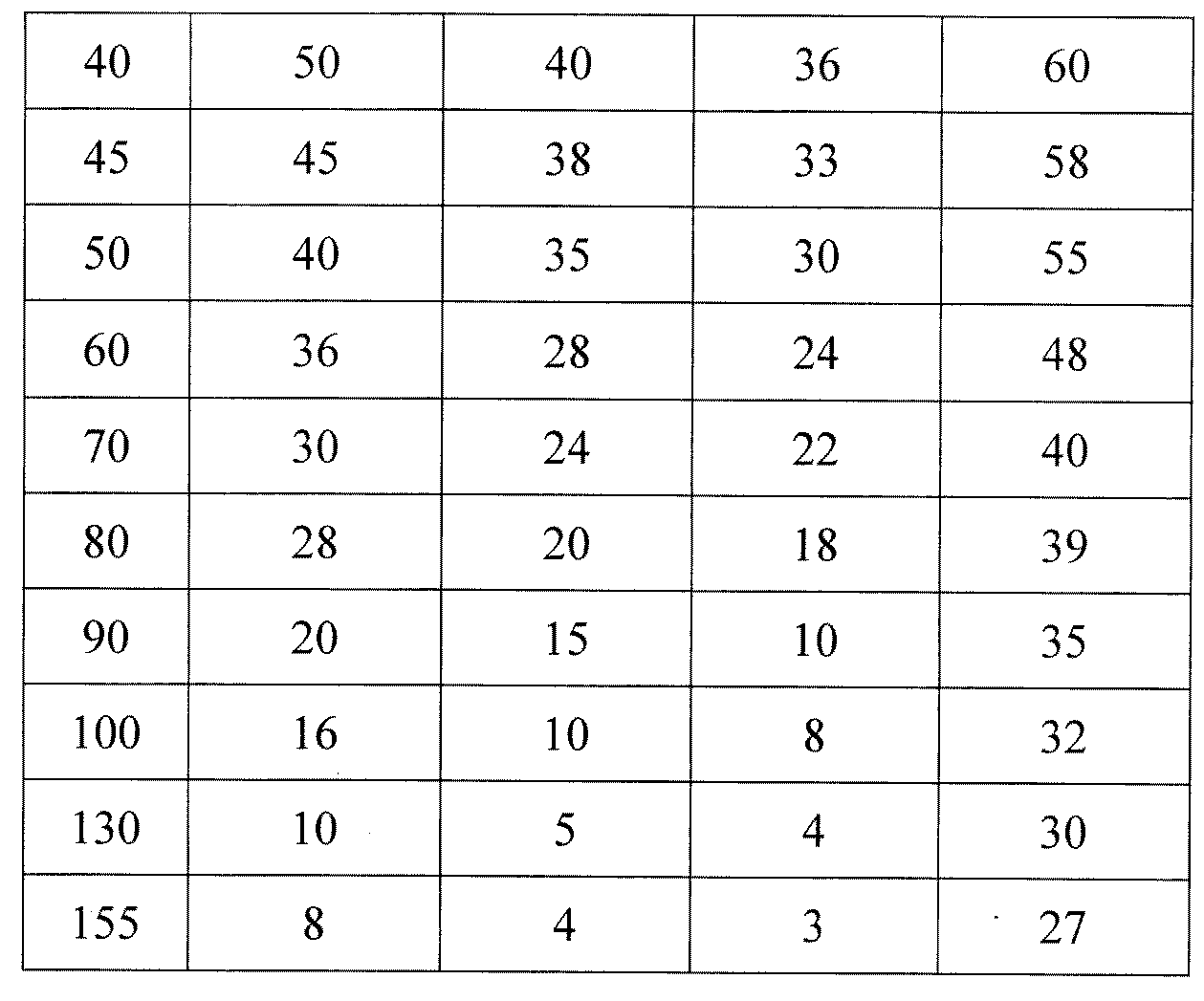

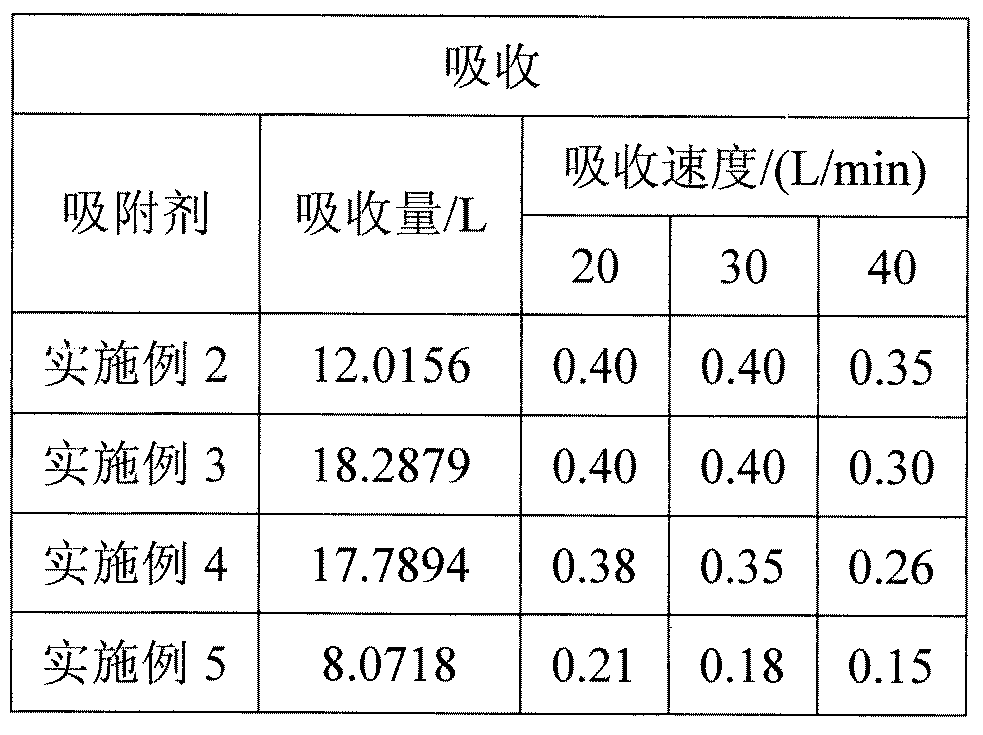

Examples

Embodiment 1

[0031] Example 1: Preparation of ionic liquid

[0032] Example 1: Preparation of ionic liquid

[0033] 1) Device: a three-necked flask; the three-necked flask is equipped with a stirring blade, a dropping funnel and a condensing reflux tube.

[0034] 2) Raw materials: Triethylenetetramine (TETA); Tetrafluoroboric acid (HBF 4 );water.

[0035] 3) Preparation method: place a three-necked flask in an ice water bath; weigh triethylenetetramine (TETA), dilute it with water to a mass concentration of 60wt%, pour it into a three-necked flask and stir; TETA) equimolar tetrafluoroborate (HBF 4 ), dilute it with water to a mass concentration of 60wt%, pour it into a dropping funnel, and slowly drip into a three-necked flask; after the addition is complete, continue to stir in an ice water bath for 3 hours; evaporate the reacted liquid to remove 95 % Moisture, use a vacuum drying oven to dry at 60 ℃ for 24 hours to obtain [TETAH] + [BF 4 ] - Ionic liquid.

Embodiment 2

[0036] Example 2: Configuration of composite absorbent

[0037] 1) Raw material: MDEA; [TETAH] + [BF 4 ] - Ionic liquid (prepared by the method of Example 1); corrosion inhibitor: sodium vanadate; antioxidant: a mixture of sodium sulfite and copper acetate with a weight ratio of 1:1; deionized water.

[0038] 2) Preparation method: Combine 300g MDEA and 100g [TETAH] + [BF 4 ] - The ionic liquid is dissolved in deionized water, 8g of corrosion inhibitor and 8g of antioxidant are added, the volume is made to 1L with deionized water, and the mixture is stirred evenly to obtain a composite absorbent. Place the obtained absorbent in a constant temperature water tank of 30°C for 10 minutes, so that the temperature of the absorbent reaches the set temperature of 30°C, stir evenly, and set aside.

Embodiment 3

[0039] Example 3: Configuration of composite absorbent

[0040] 1) Raw material: MDEA; [TETAH] + [BF 4 ] - Ionic liquid (prepared by the method of Example 1); corrosion inhibitor: sodium vanadate; antioxidant: a mixture of sodium sulfite and copper acetate in a weight ratio of 1:1; deionized water.

[0041] 2) Preparation method: mix 200g MDEA and 200g [TETAH] + [BF 4 ] - The ionic liquid is dissolved in deionized water, 8g of corrosion inhibitor and 8g of antioxidant are added, the volume is made up to 1L with deionized water, and the mixture is stirred evenly to obtain an absorbent. Place the obtained absorbent in a constant temperature water tank of 30°C for 10 minutes, so that the temperature of the absorbent reaches the set temperature of 30°C, stir evenly, and set aside.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com