Method and device for treating pollutant and dust in gas

A technology for treating gases and pollutants, applied in chemical instruments and methods, separation methods, use of liquid separation agents, etc., can solve the problems of poor environmental adaptability, easy poisoning of catalysts, high material requirements, and achieve long solution replacement cycle, The effect of promoting the evolution of oxygen and increasing the treatment area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 1. Construction of the device

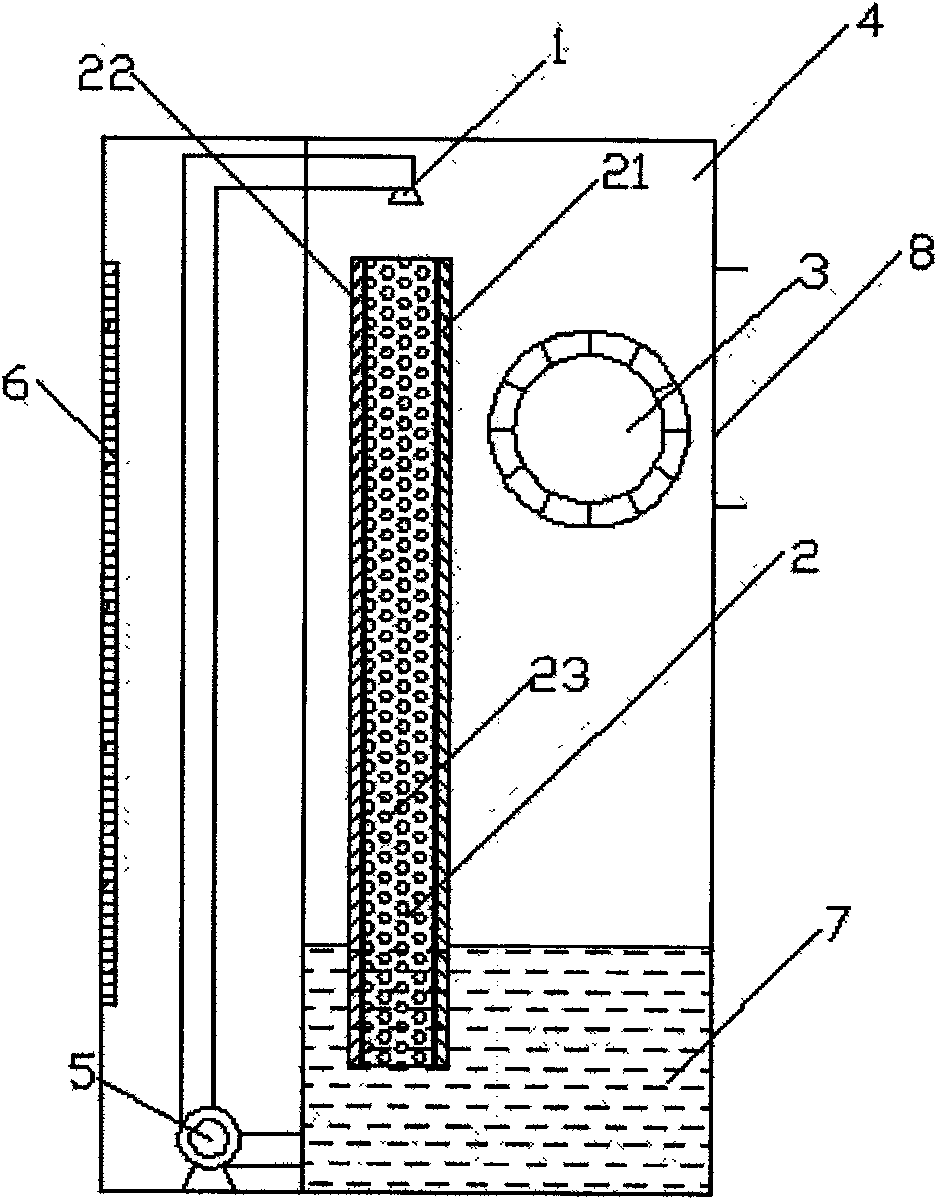

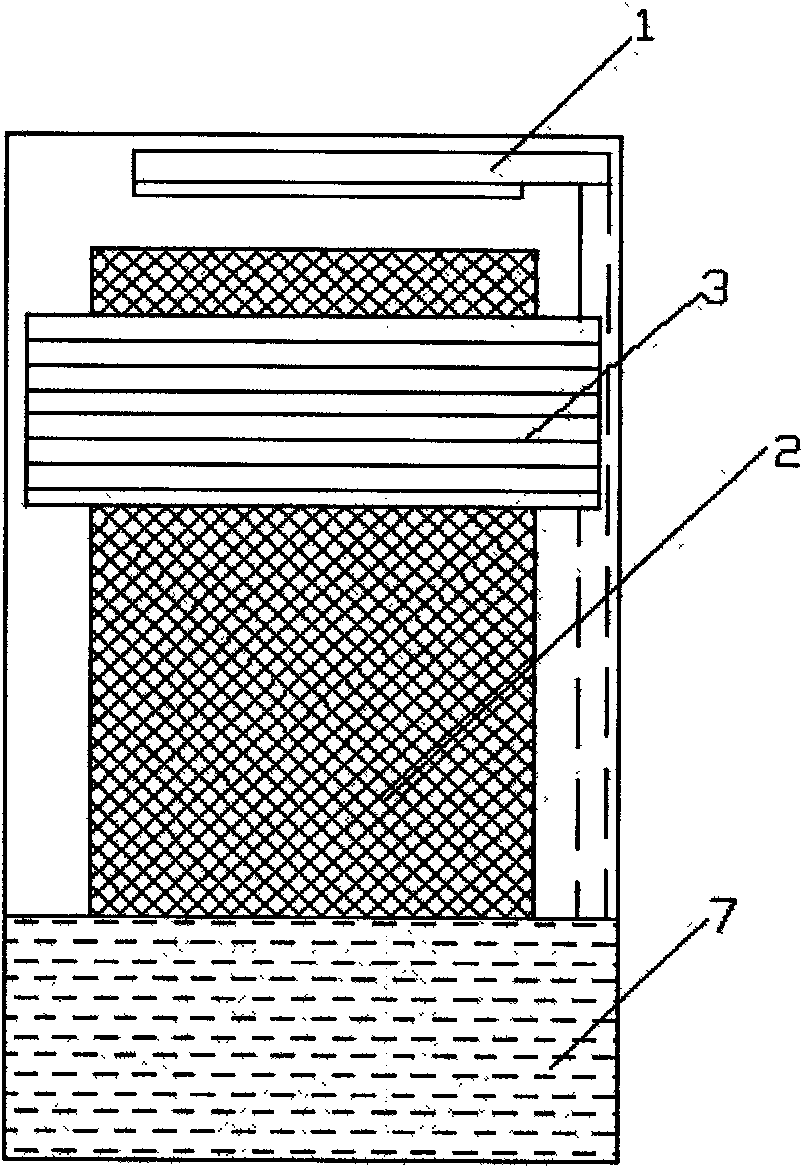

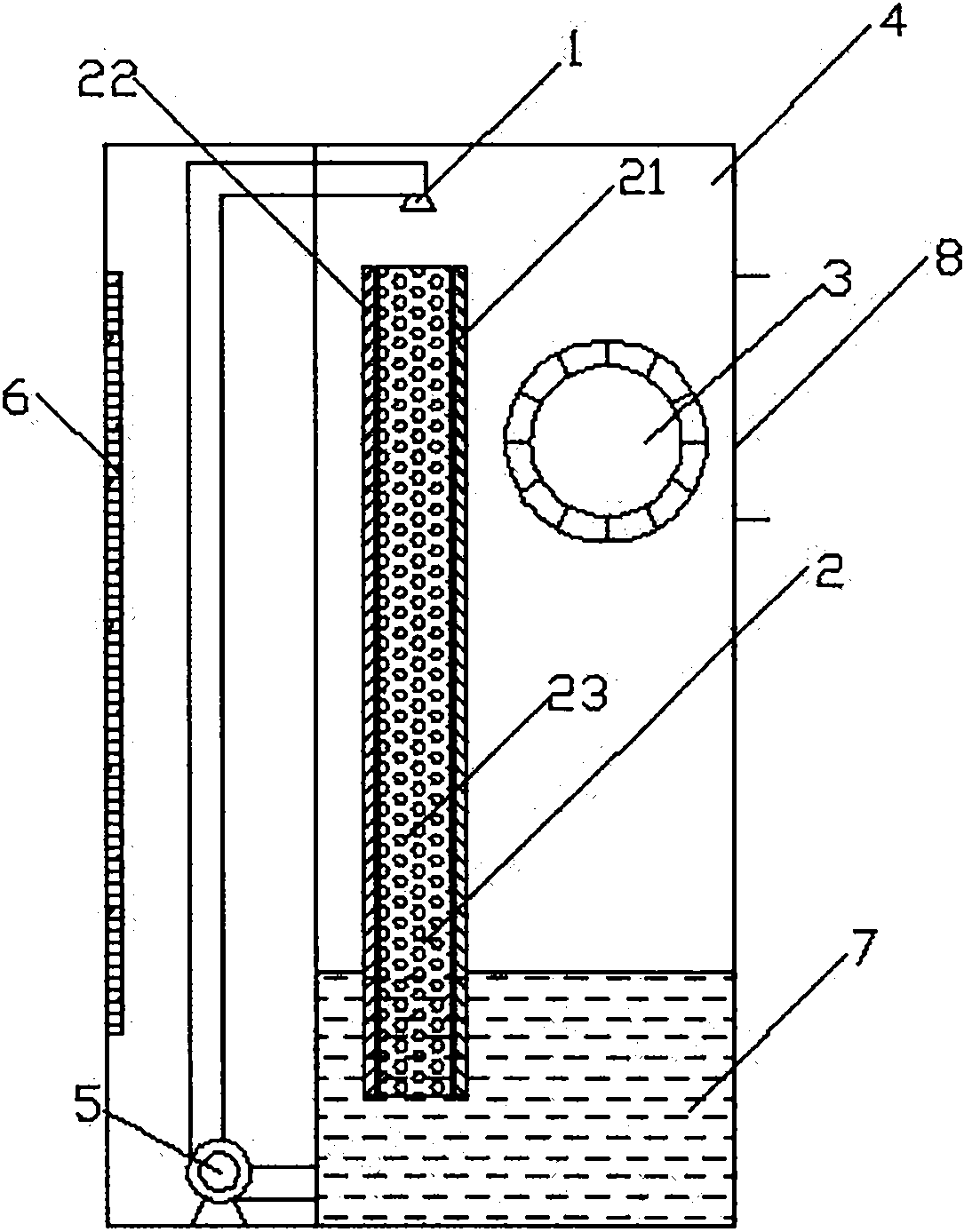

[0040] A cylindrical container is used as a reactor 4, one side of which has a gas inlet 6, and a dust screen is also attached on it; the equipment is divided into two areas by a partition, one of which is close to the gas inlet, and the bottom of the other area is installed. There is liquid, as the liquid storage area 7, the liquid storage area is connected with a circulation pump as the circulation device 5, and its connecting pipeline extends upwards through another area separated by the partition, and its outlet is located above the liquid storage area 7, and the outlet is The liquid distributor is used as the liquid distribution device 1; directly below the liquid distribution device 1, a strip-shaped electrode 2 is arranged, and its lower part is immersed in the liquid storage area 7. The electrode 2 is a three-dimensional nickel foam modified by ruthenium oxide. The three-dimensional filler of polyurethane foam filled between the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com