Preparation method of color master batch for manufacturing yarn

A technology of color masterbatch and preparation method, which is applied in the manufacture of rayon, textiles and paper, and single-component polyester rayon, etc. It can solve the problem that harmful chemicals cannot absorb, decompose and deodorize, and cannot produce infrared rays. And negative ions, color masterbatch functionality and quality can not be improved and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

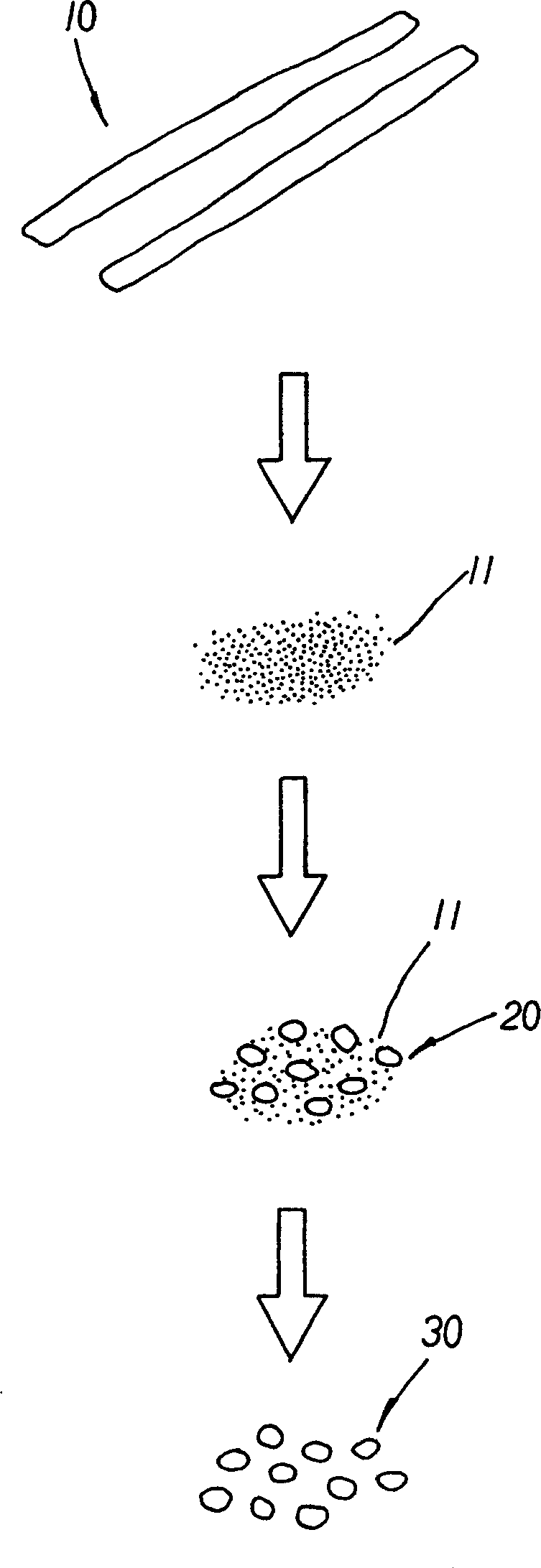

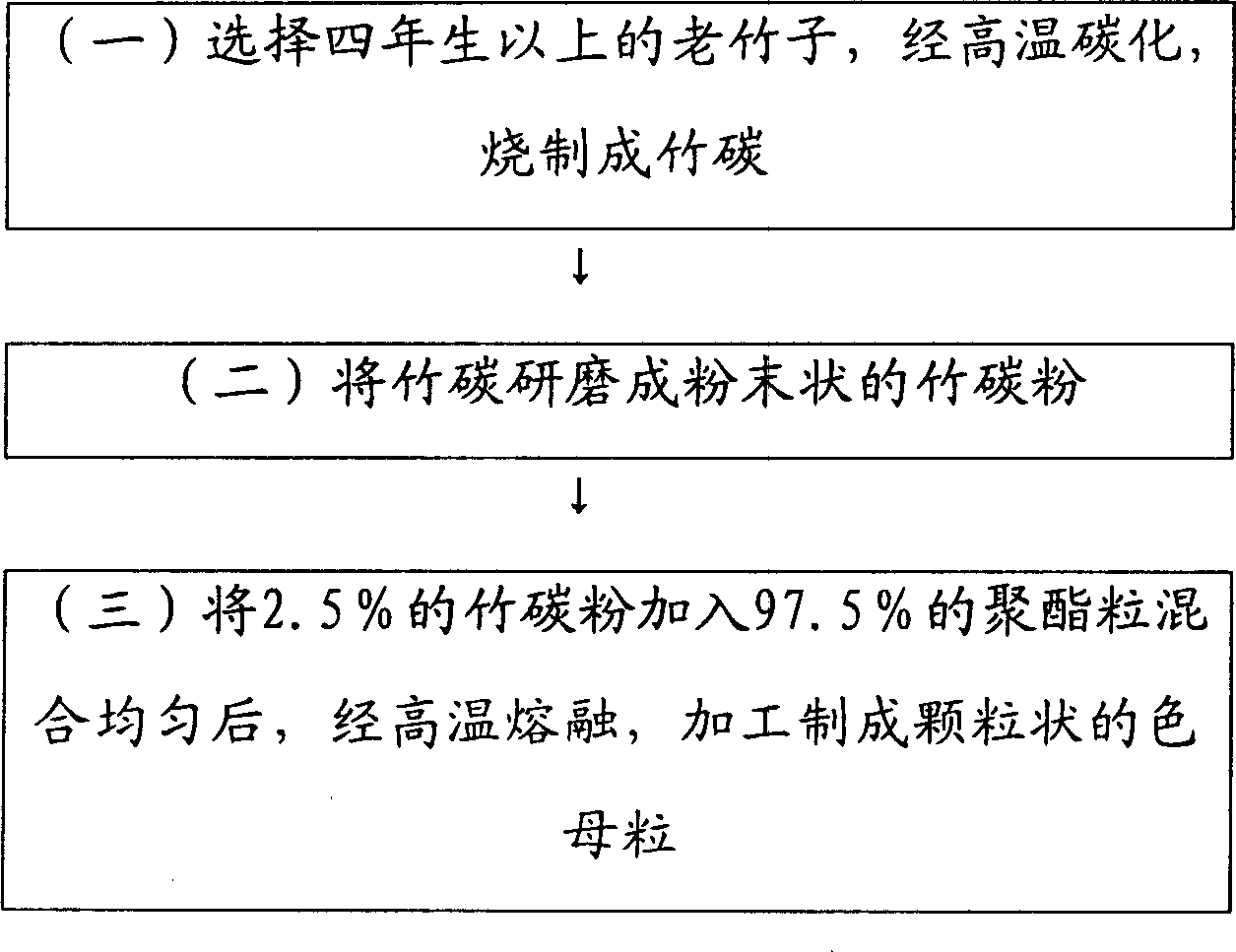

[0013] refer to Figure 1-Figure 3 Shown, the preparation method of the masterbatch of making yarn of the present invention comprises the steps:

[0014] A. First, select old bamboos that are more than four years old and carbonize them at high temperature to produce bamboo charcoal 10 with dense carbonaceous structure, large specific gravity, many pores, and rich mineral content;

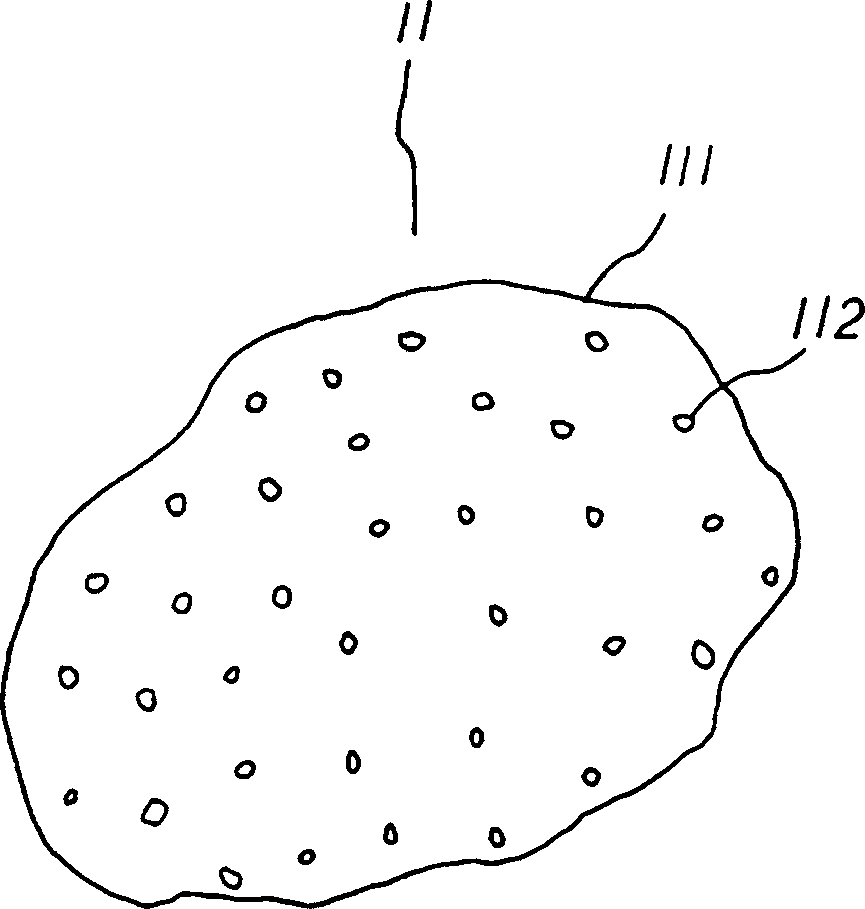

[0015] B, bamboo charcoal 10 is ground into powdery bamboo charcoal powder 11, and in every tiny bamboo charcoal powder particle 111 in bamboo charcoal powder 11, all have some pores 112, as image 3 Shown is the microscope enlarged schematic diagram of single bamboo carbon powder 11 of the present invention, therefore has very strong adsorption and decomposition ability;

[0016] C, after adding 2.5% bamboo carbon powder 11 to 97.5% polyester pellets 20 and mixing evenly, through melting at a high temperature of about 450 degrees, the granular color masterbatch 30 is processed, due to the granulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com