Patents

Literature

266 results about "Grain quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In agriculture, grain quality depends on the use of the grain. In ethanol production, the chemical composition of grain such as starch contents is important, in food and feed manufacturing, properties such as protein, oil and sugar are significant, in milling industry soundness is the most important factor to consider and for seed producer, the high germination percentage (viability of seed) and seed dormancy is the important feature to consider, for consumers the properties like color and flavor will be important.

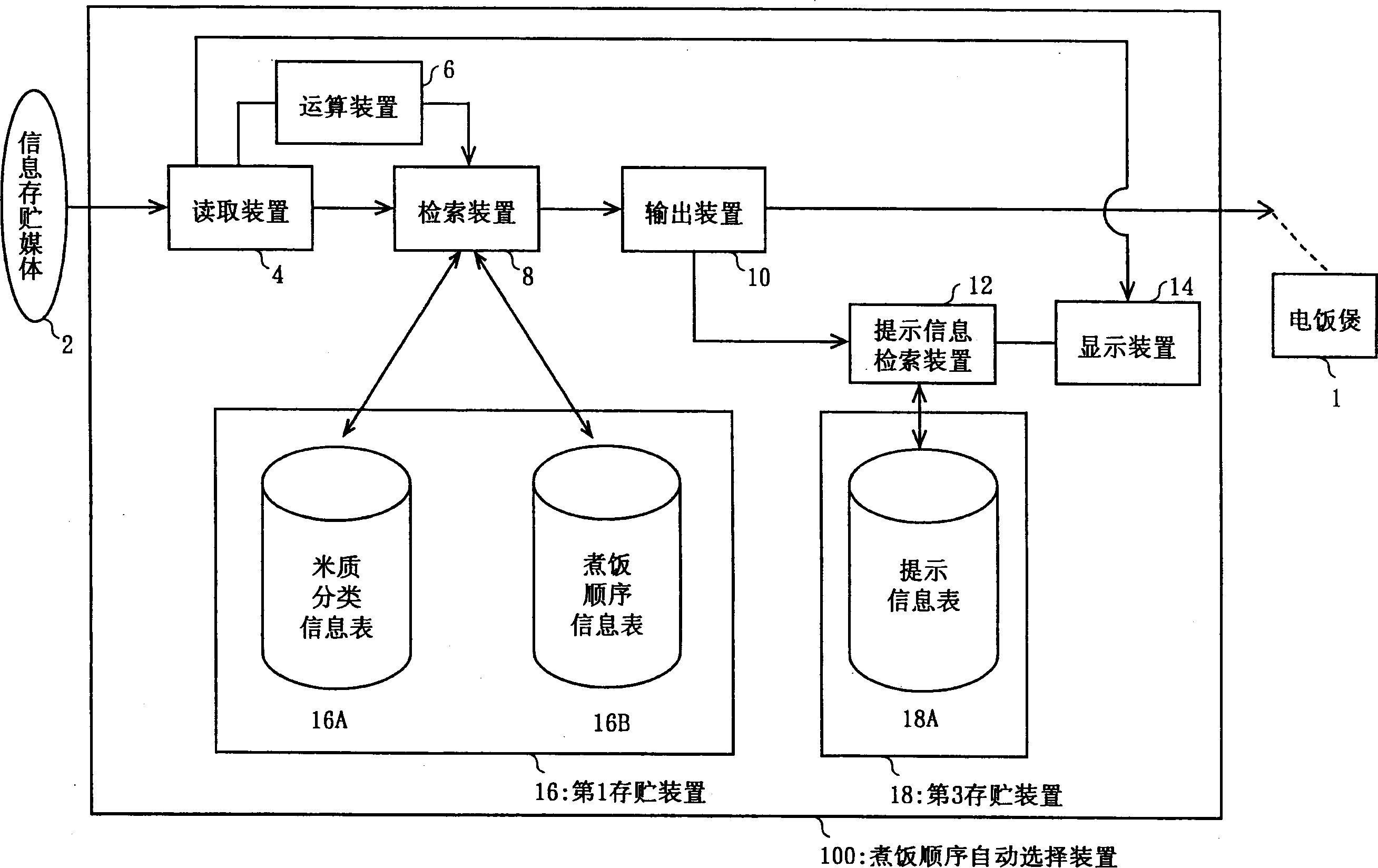

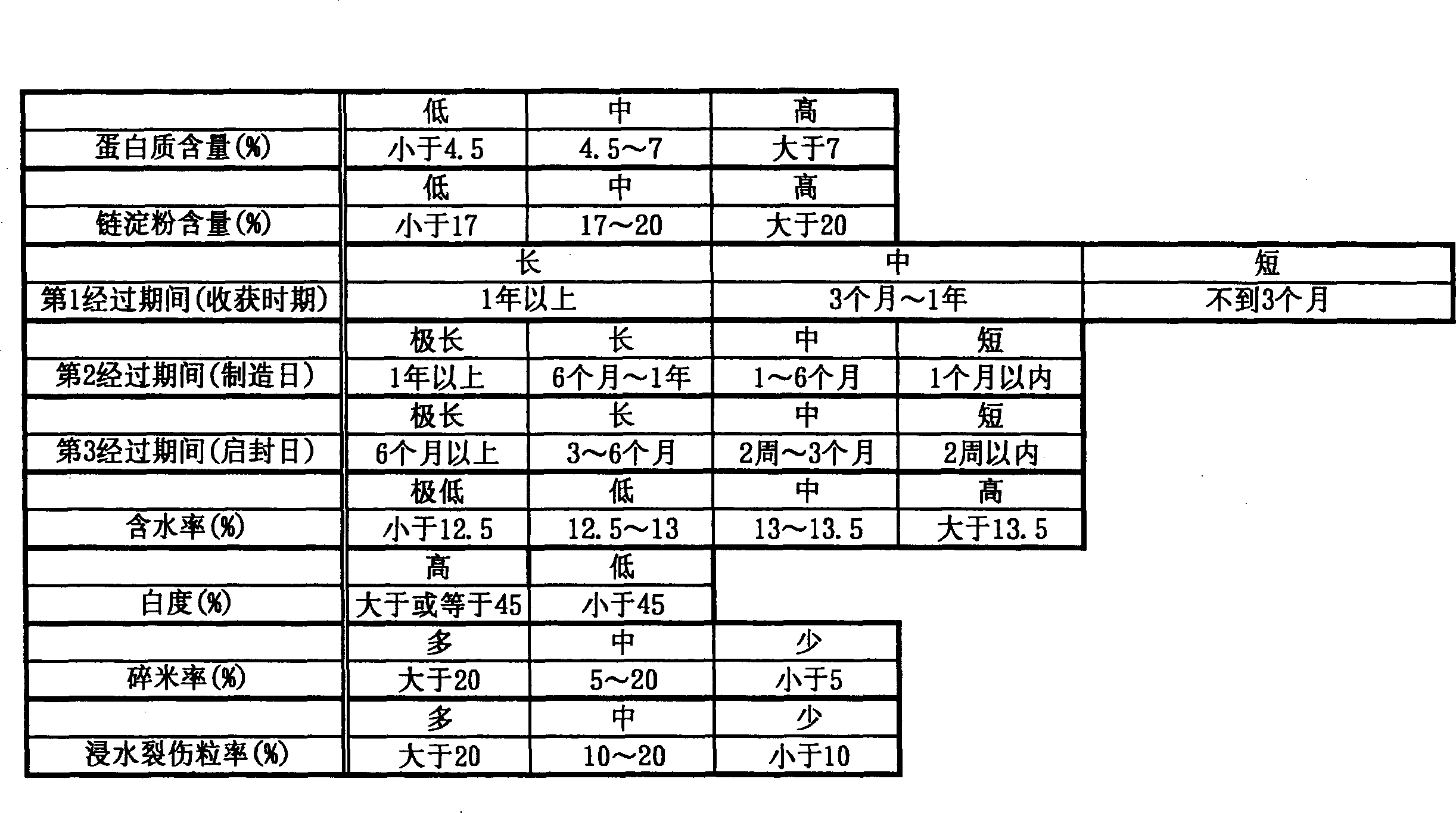

Cooking sequence automatic selection device, method and cooker mounted with the device

ActiveCN1864606AReduce or eliminate misuseEasy to understandCooking vesselsEngineeringSequencing data

The invention provides a device and method for automatically selecting rice cooking sequence and an electric rice cooker equipped with the device. The rice cooking sequence automatic selection device of the present invention includes: a reading device for reading the rice quality information from an information storage medium storing the rice quality information; The storage device of the rice cooking sequence information table corresponding to the data; the retrieval device for retrieving the rice cooking sequence information table according to the rice quality information and taking out the corresponding cooking sequence data; and for outputting the taken out rice cooking sequence data output device.

Owner:PANASONIC CORP

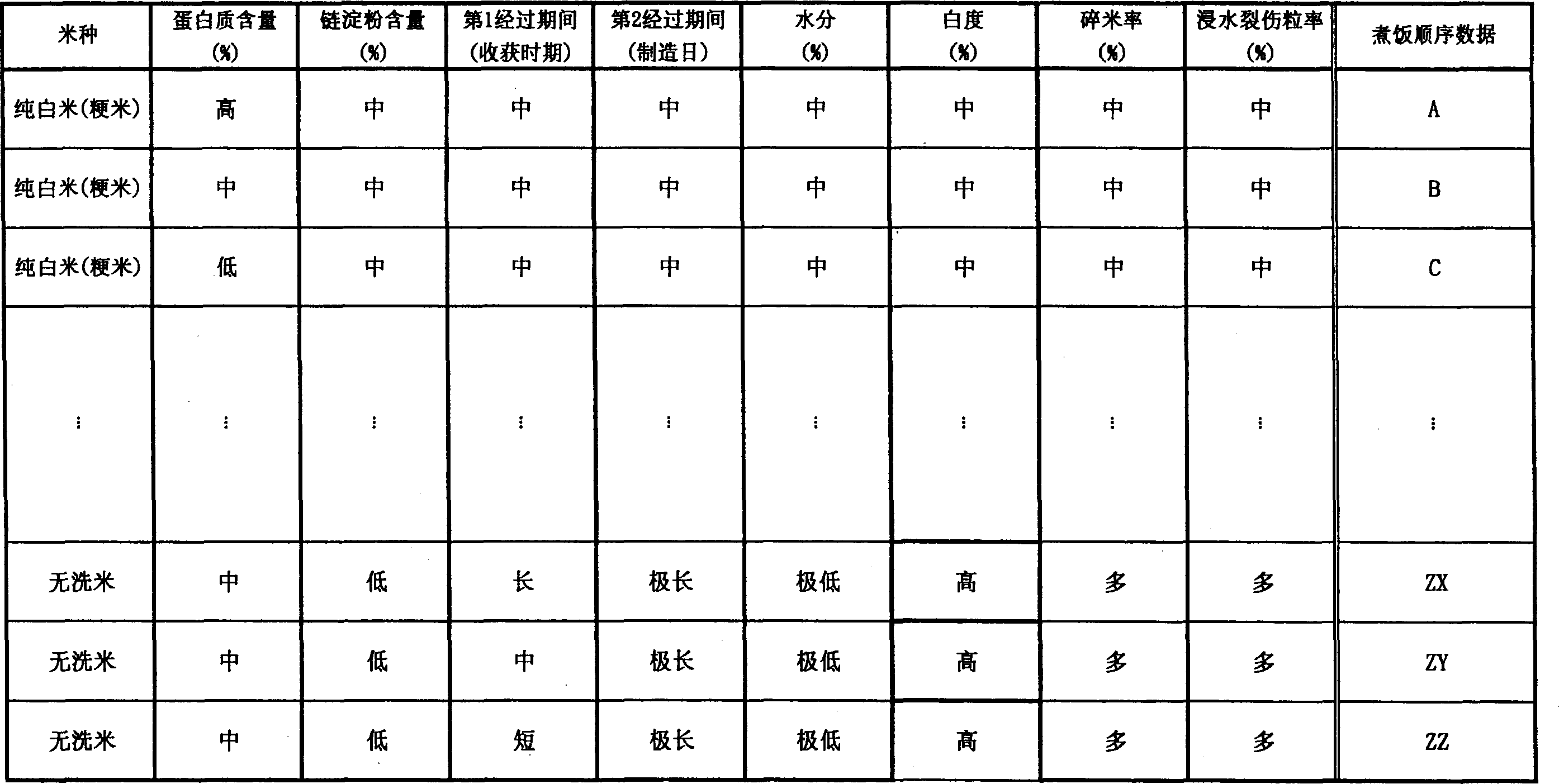

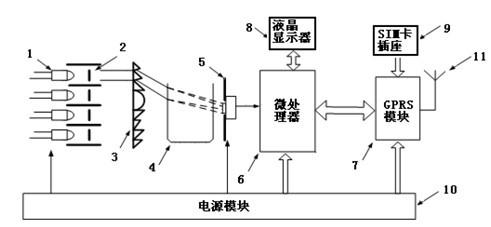

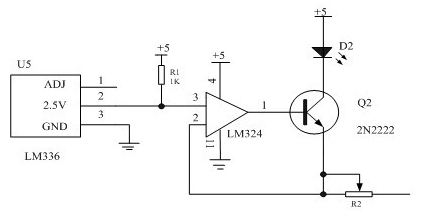

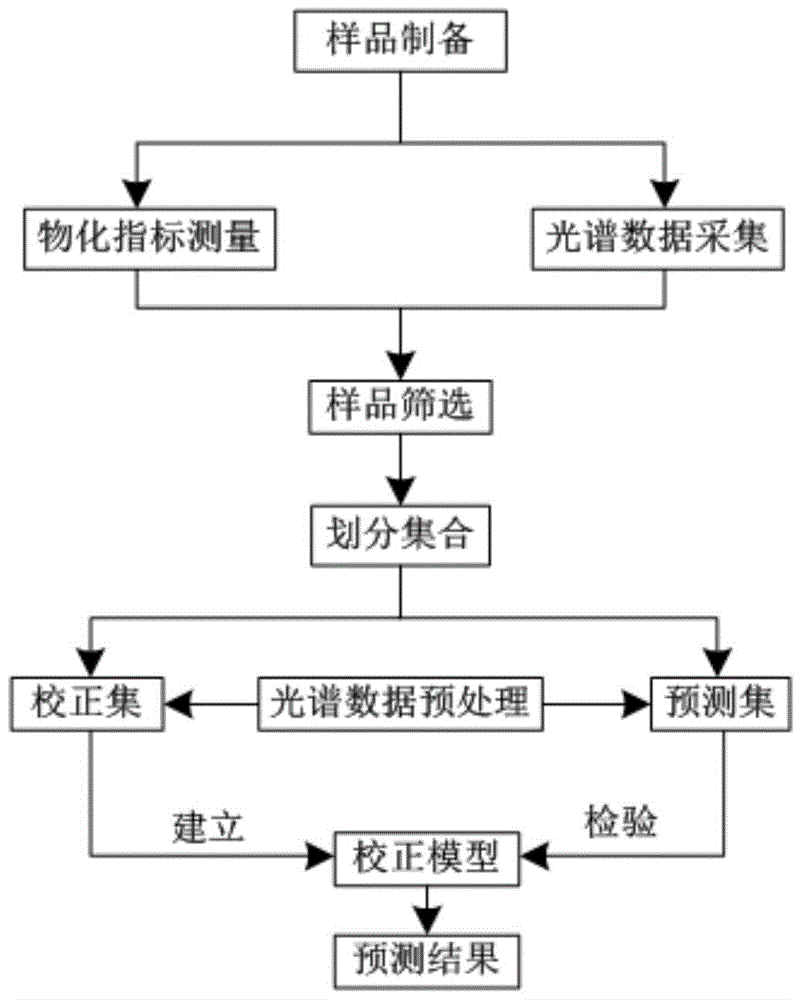

Grain quality near infrared rapid detection wireless system

ActiveCN102042968AReal-time understanding of qualitySave acquisition costsTransmission systemsColor/spectral properties measurementsGeneral Packet Radio ServiceModel selection

The invention discloses a grain quality near infrared rapid detection wireless system, and the system comprises a wireless acquisition device and an information center, wherein the wireless acquisition device is used for acquiring optical absorption signals in a field near infrared spectral region and transmitting the signals to the information center through a GPRS (general packet radio service) network and the Internet; the information center is used for receiving the signals transmitted by the wireless acquisition device and processing the signals; the information center comprises an evaluation model and analysis device, and after the evaluation module and analysis device receives the signals transmitted by the wireless acquisition device, a model is established, and grain samples are analyzed through the established model; the establishment of the model comprises the establishment of a grain database, the pretreatment of data, the trial establishment of the model, the evaluation of the model and the determination of the model; and the analysis of the grain samples comprises the selection of the model, the analysis of components, the post-treatment and the result evaluation of the analysis of the grain samples, and the corresponding fatty acid value is obtained. By utilizing the system, the remote real-time grain quality detection can be realized, and the acquisition cost of grain can be further saved.

Owner:NANJING UNIV OF FINANCE & ECONOMICS +1

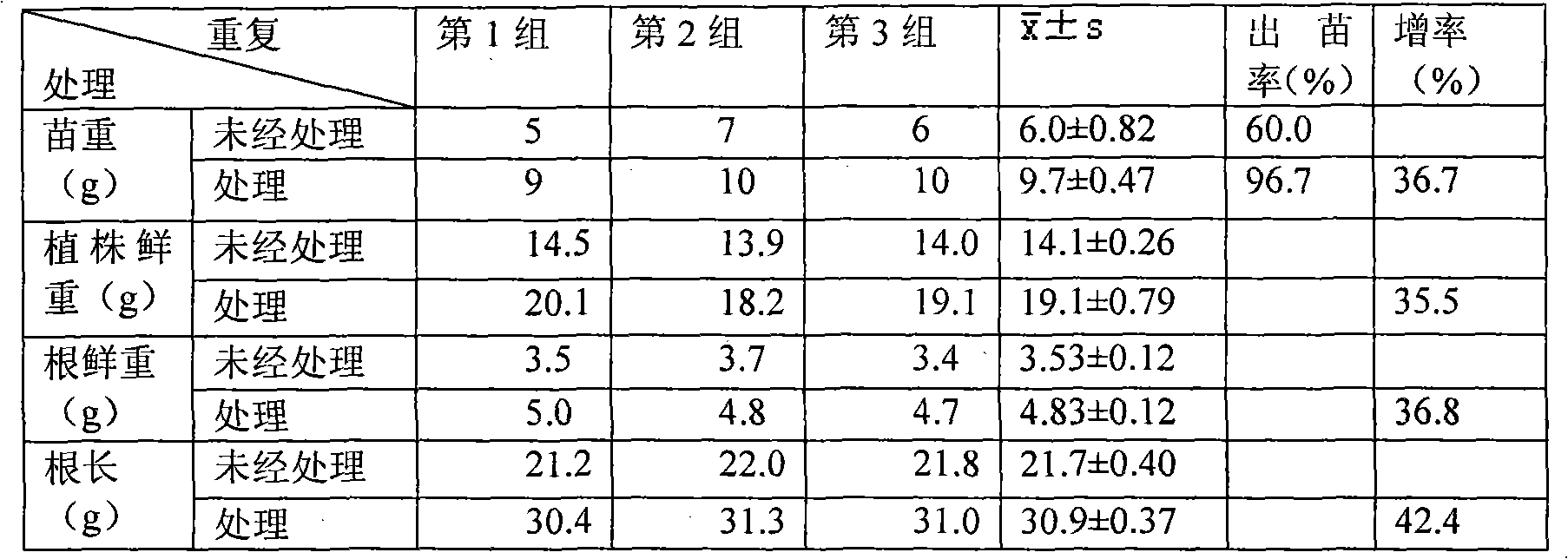

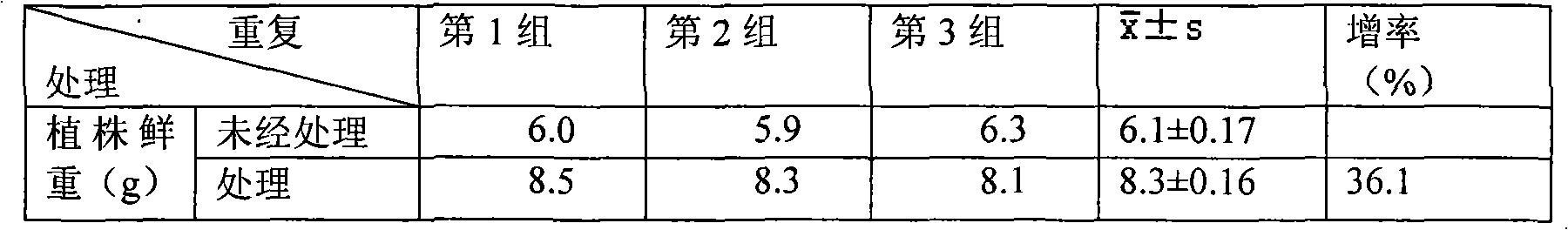

Cold-resistance spraying agent

InactiveCN101253867AImprove cold resistanceReduce mechanical damageBiocidePlant growth regulatorsGrowth plantChilling injury

A cold-resistant sprayer agent relates to a sprayer agent, which solves the problems of maturation period delay, output reduction and grain quality decline resulting from powder seeds under a low temperature condition, chilling injury death, difficult germination and delayed chilling injury in case of encountering the cold current in the seedling stage. The cold resistant sprayer agent is prepared by the weight percent as follows: 30%-80% of cold resistant nutriment, 4%-40% of antifreeze liquid, 0.02%-2.0% of surfactant, 0.001%-1.0% of plant growth regulator and water of the rest. The cold-resistant sprayer improves the cold resistance of the plant at a molecular level and is capable of reducing the mechanical damage formed by the ice crystal in the protoplasm at a low temperature.

Owner:王树禹

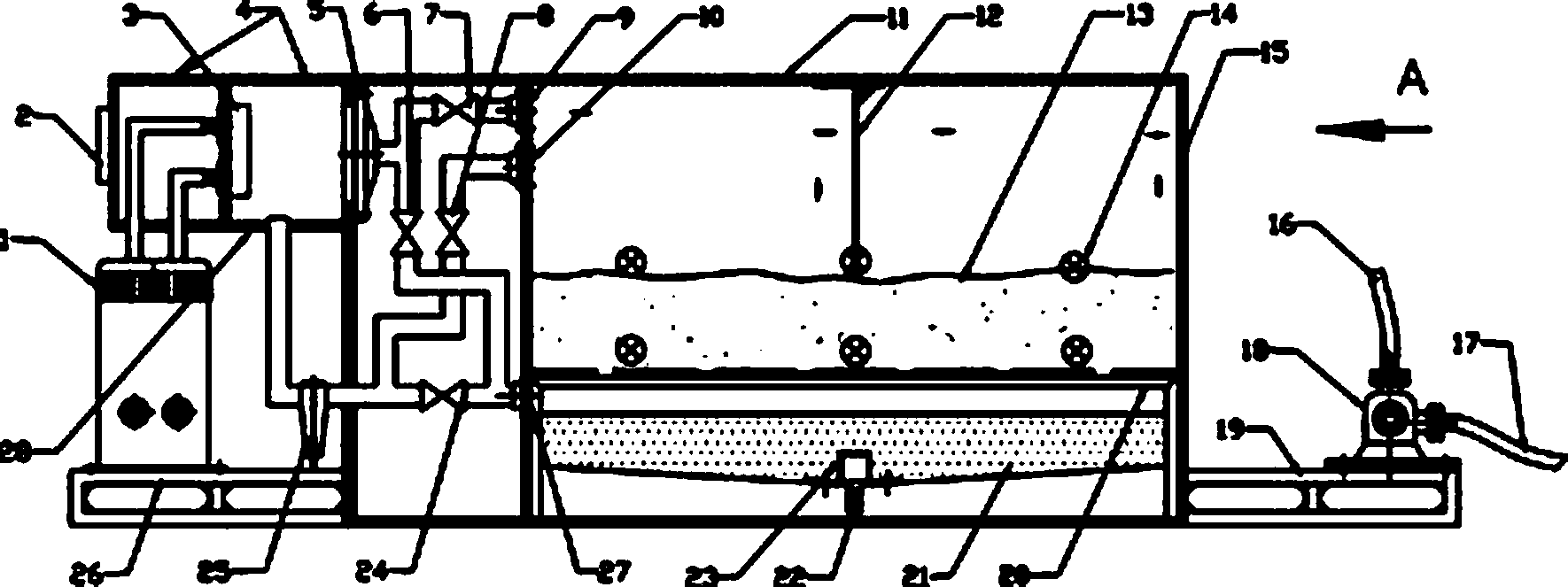

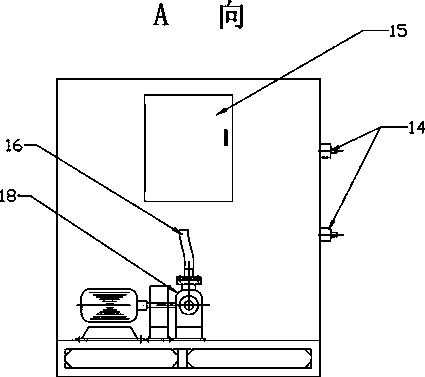

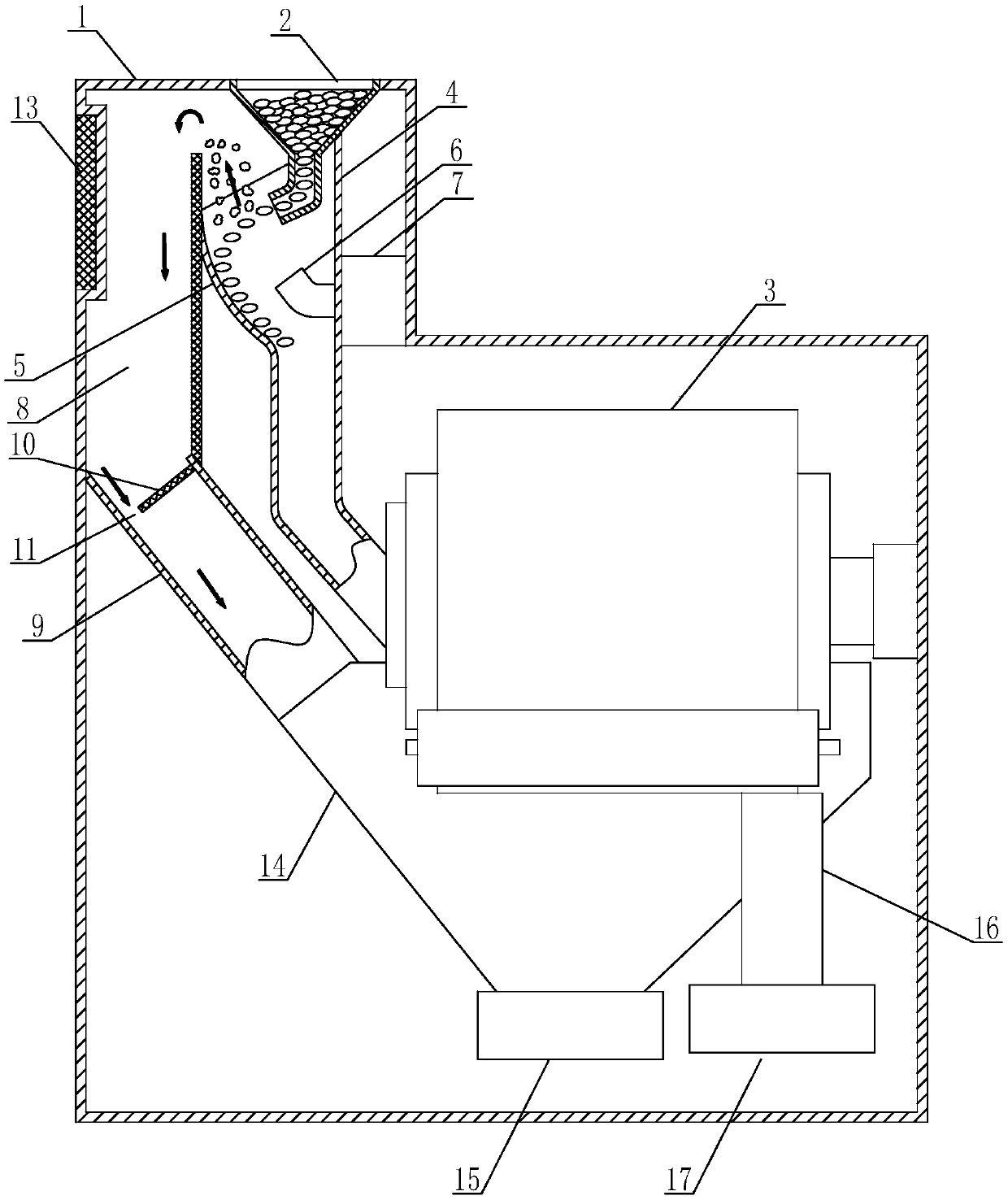

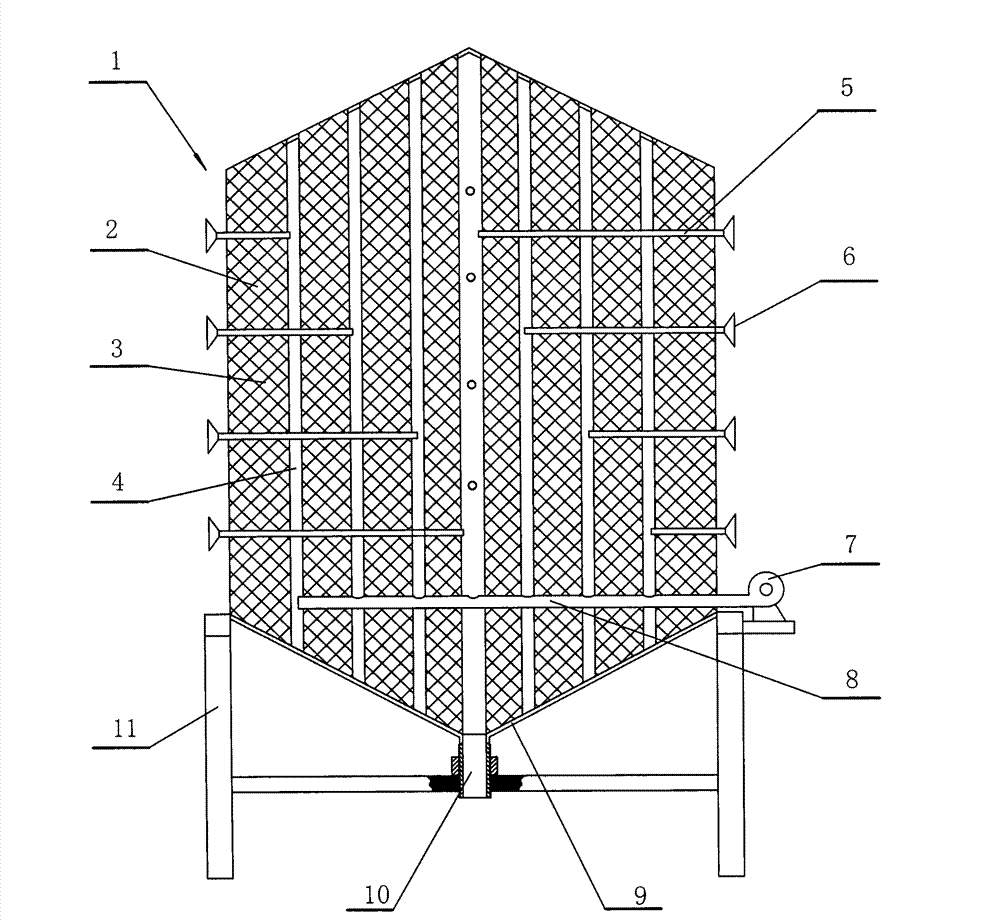

High-efficiency energy-saving grain drying machine and drying method

InactiveCN103749670AReduce drying costsHigh degree of intelligenceFood processingClimate change adaptationProcess engineeringMoisture sensor

The invention discloses a high-efficiency energy-saving grain drying machine and a drying method. The drying machine adopts a brand-new heat source design provided by an air energy heat pump. The high-efficiency energy-saving grain drying machine comprises an air energy dehumidifying pump, a main room body, an auxiliary room body, a heat exchanger, a fan, an intelligent controller, electromagnetic valves, a temperature-humidity sensor, a stacking bed, a dehumidifying mechanism and a cabin door; the intelligent controller is used for transmitting a multi-point average humidity-temperature signal inside a room obtained by the temperature-humidity sensor, and each electromagnetic valve is electrically connected with the intelligent controller so as to realize the intelligent operation of the drying machine. The high-efficiency energy-saving grain drying machine and the drying method are used for drying the grain, so that the characteristics of high efficiency, energy conservation, intelligentization in operation and good grain quality can be realized.

Owner:LONGYAN CHENGDE AGRI MACHINERY

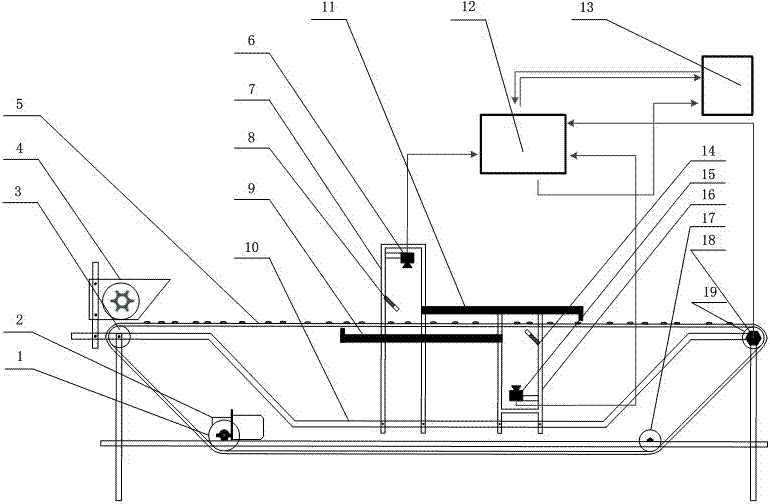

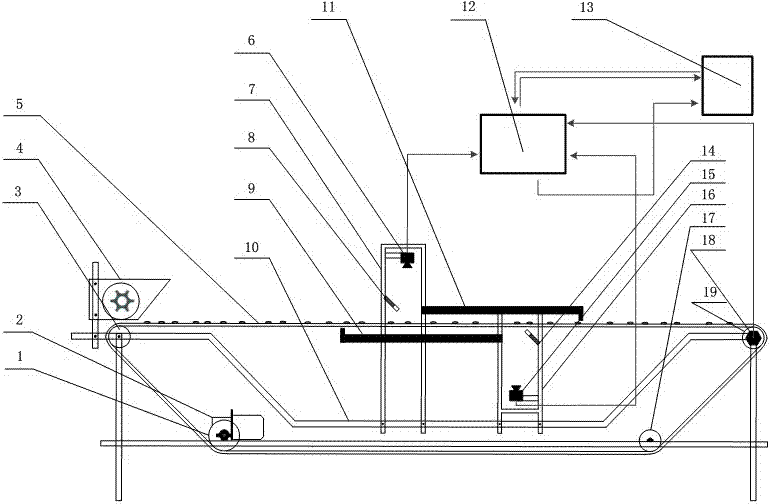

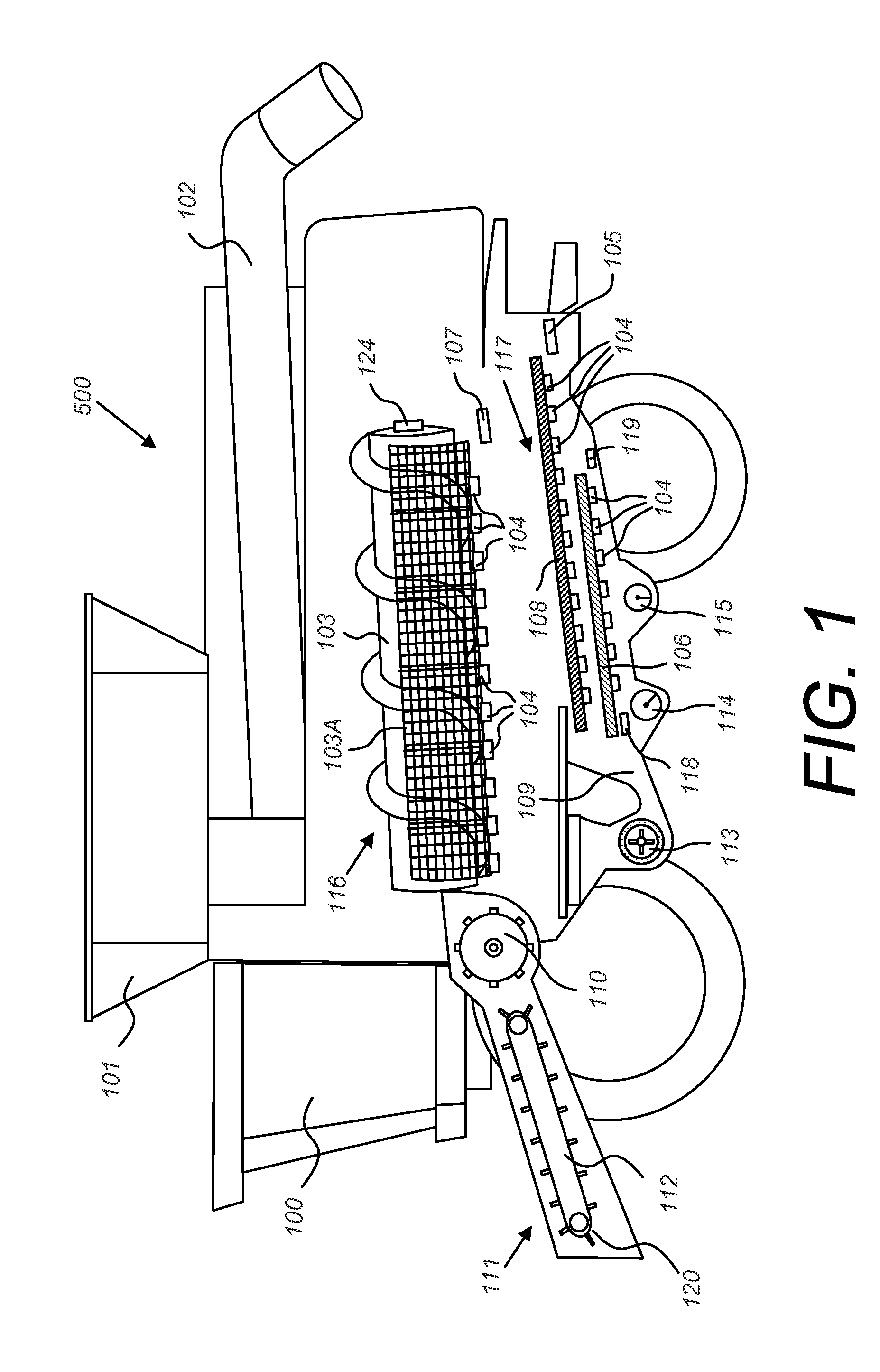

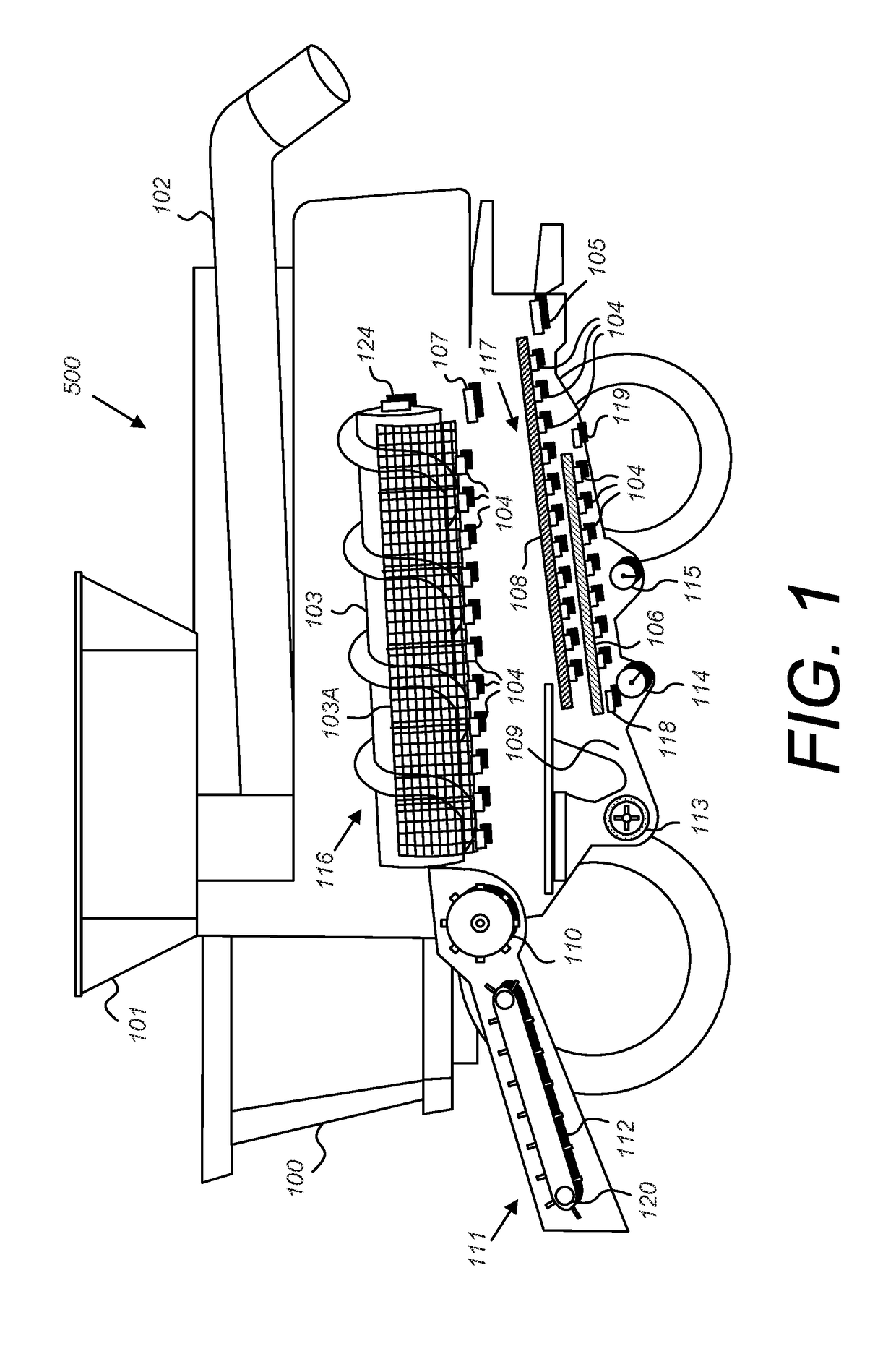

Grain quality on-line detection apparatus based on field programmable gate array (FPGA), and method thereof

ActiveCN102253052AEasy to detectOptically investigating flaws/contaminationField-programmable gate arrayVisual perception

The invention discloses a grain quality on-line detection apparatus based on FPGA, and a method thereof. The apparatus is characterized in that: a multi-line seed metering device is arranged on a left side of a transparent belt; a encoder is arranged on a driven roller, two light boxes are respectively arranged above and below the transparent belt, and are respectively provided with linear light source, a background plate and a line scanning camera, the transparent belt passed between the linear light sources and the background plates; the line scanning cameras are connected with a FPGA imageprocessing plate through CameraLink cables; the power is transmitted to the transparent belt through a speed regulating generator. In the prior art, only the half surface of the grain particle can bedetected during detecting the grain quality through the traditional method. Adoring to the present invention, the disadvantages in the prior art are solved; the amount of the normal grain particles and the amount of the other particles in the sample can be determined rapidly and exactly through detecting the morphological characteristics of the particles and the color characteristics of the wholesurfaces of the particles; the detection performance of the apparatus provided by the present invention is more excellent than the traditional detection apparatus of a machine vision system based on a PC.

Owner:ZHEJIANG UNIV

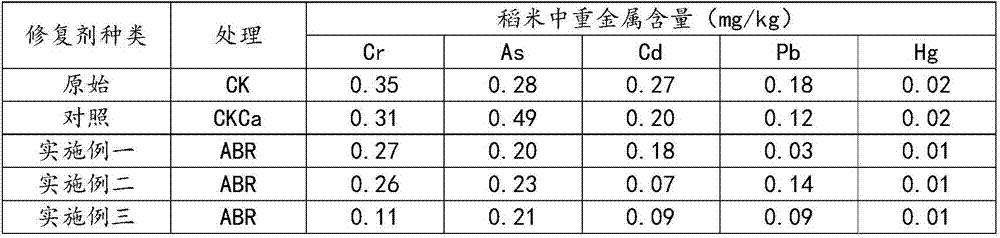

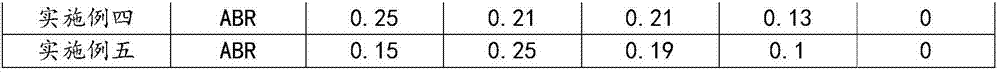

Soil heavy metal remedying biological improver and preparation method thereof

ActiveCN107254320AImprove physical and chemical propertiesImprove microbial environmentAgriculture tools and machinesOrganic fertilisersSoil heavy metalsGrain quality

The invention provides a soil heavy metal remedying biological improver and a preparation method thereof. The soil heavy metal remedying biological improver is obtained by compounding a microbial inoculum, biomass carbon, organosilicone, a nitrogen raw material, quick-acting calcium, a phosphate ore powder and amino acid according to specific proportions. The soil heavy metal remedying biological improver can effectively remedy heavy metal pollution to soil, improve physical and chemical properties of the soil, improve the microbial environment of the soil, balance soil nutrients and improve soil fertility through biological means, and can promote crop growth, so that the grain yield is increased and the grain quality is improved. The preparation method of the soil heavy metal remedying biological improver is simple in process, and is suitable for large-scale production.

Owner:北京世纪阿姆斯生物工程有限公司 +1

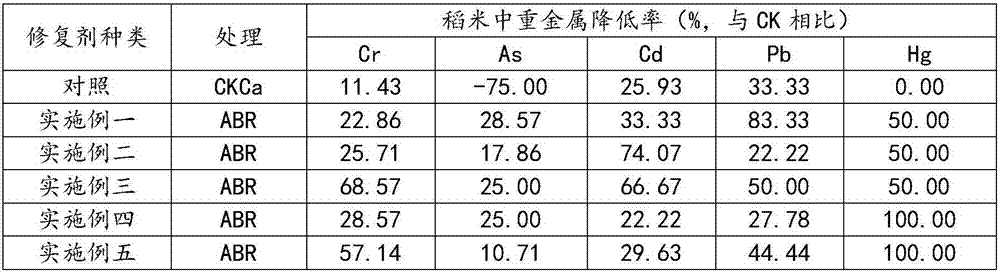

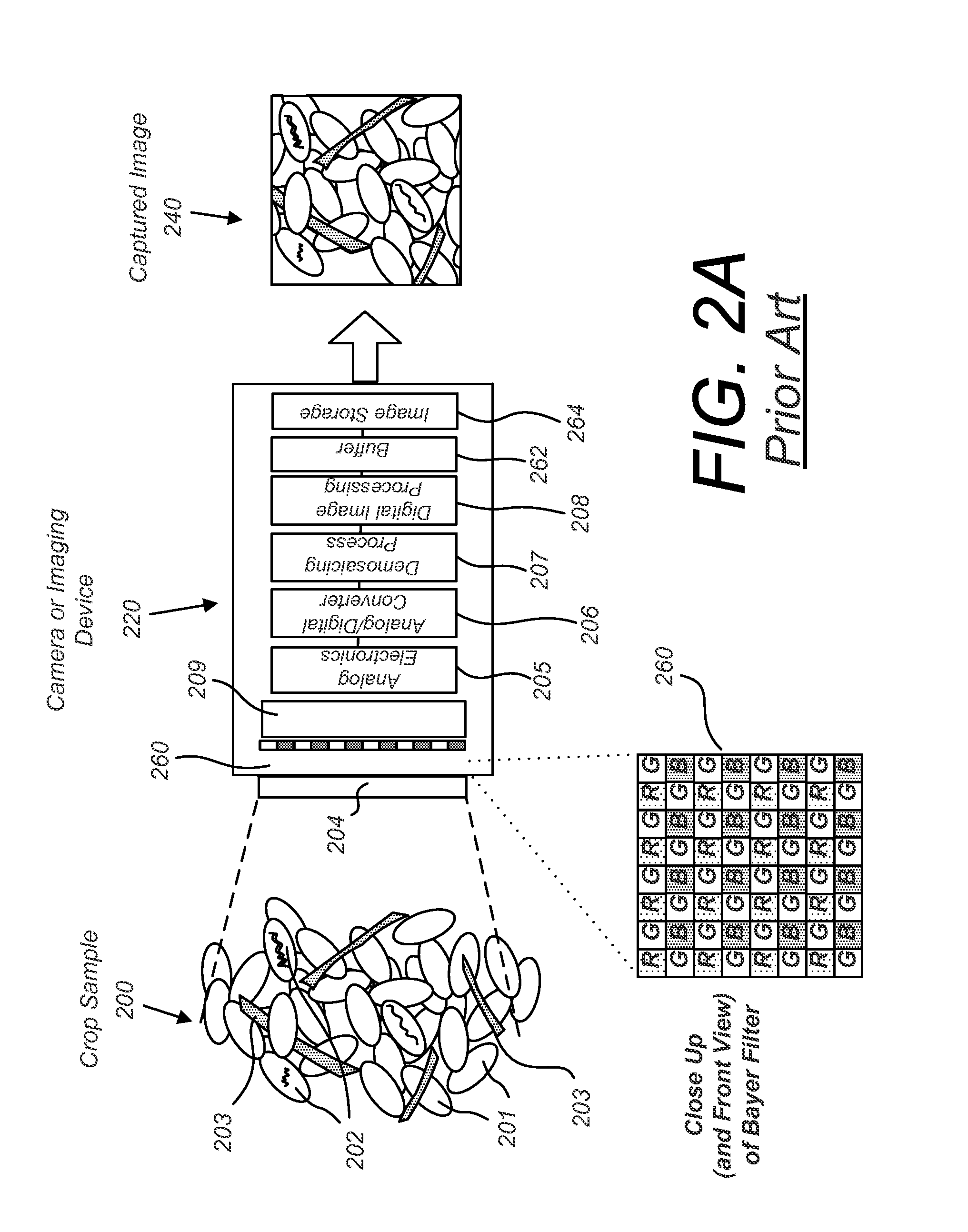

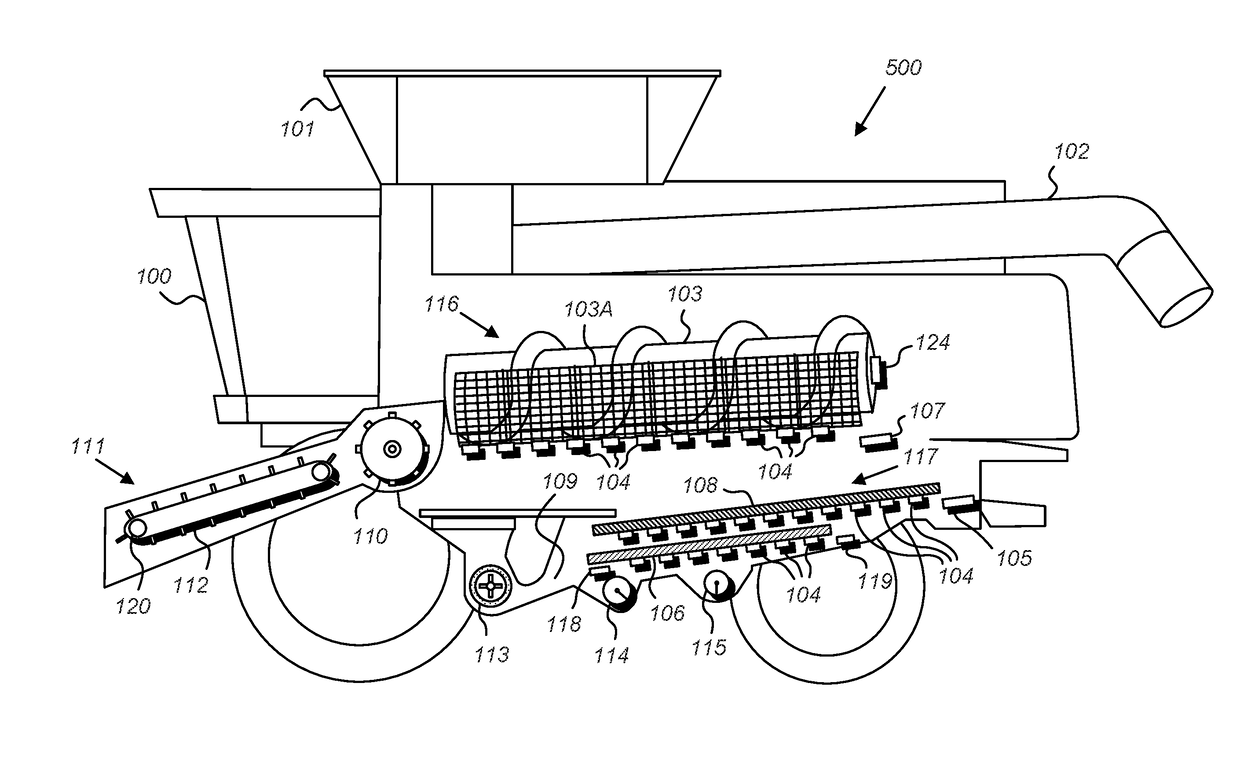

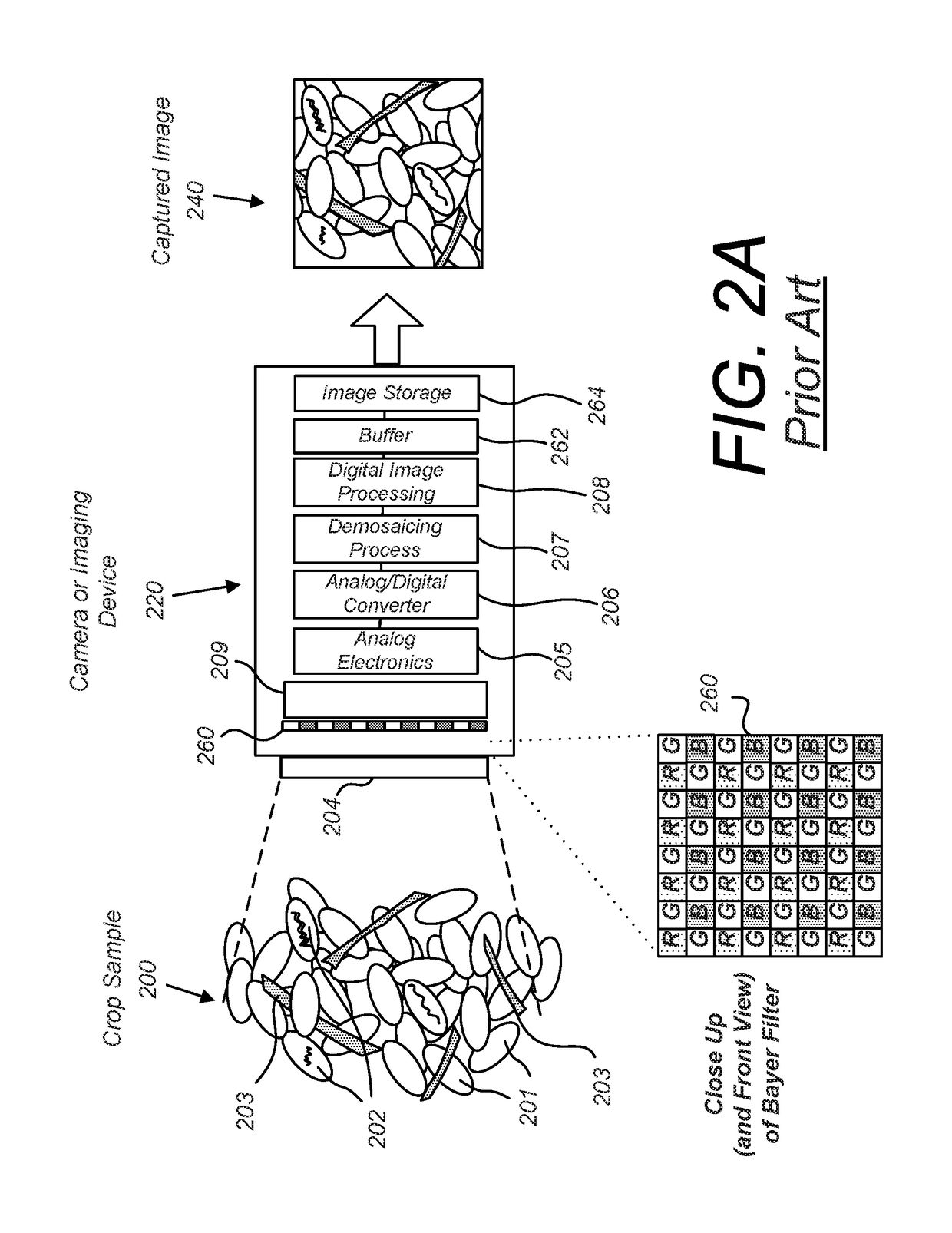

Non-image-based grain quality sensor

A grain quality sensor comprising a lens, a filter, a photosite array, an illumination source, and an electronics module, wherein the illumination source directs light containing a known set of wavelengths onto a crop sample, wherein the lens picks up light reflected by the crop sample and directs it into the filter, which allows light to pass into different parts of the photosite array such that certain locations on the photosite array only get certain frequencies of the reflected light, wherein the electronics module is electrically connected to the photosite array and capable of determining which parts of the photosite array received light and what frequency the light received was, wherein the electronics module can analyze the optical data received by the photosite array, and wherein the analysis of the optical data is used to determine the composition of different parts of the crop sample.

Owner:INTELLIGENT AGRI SOLUTIONS

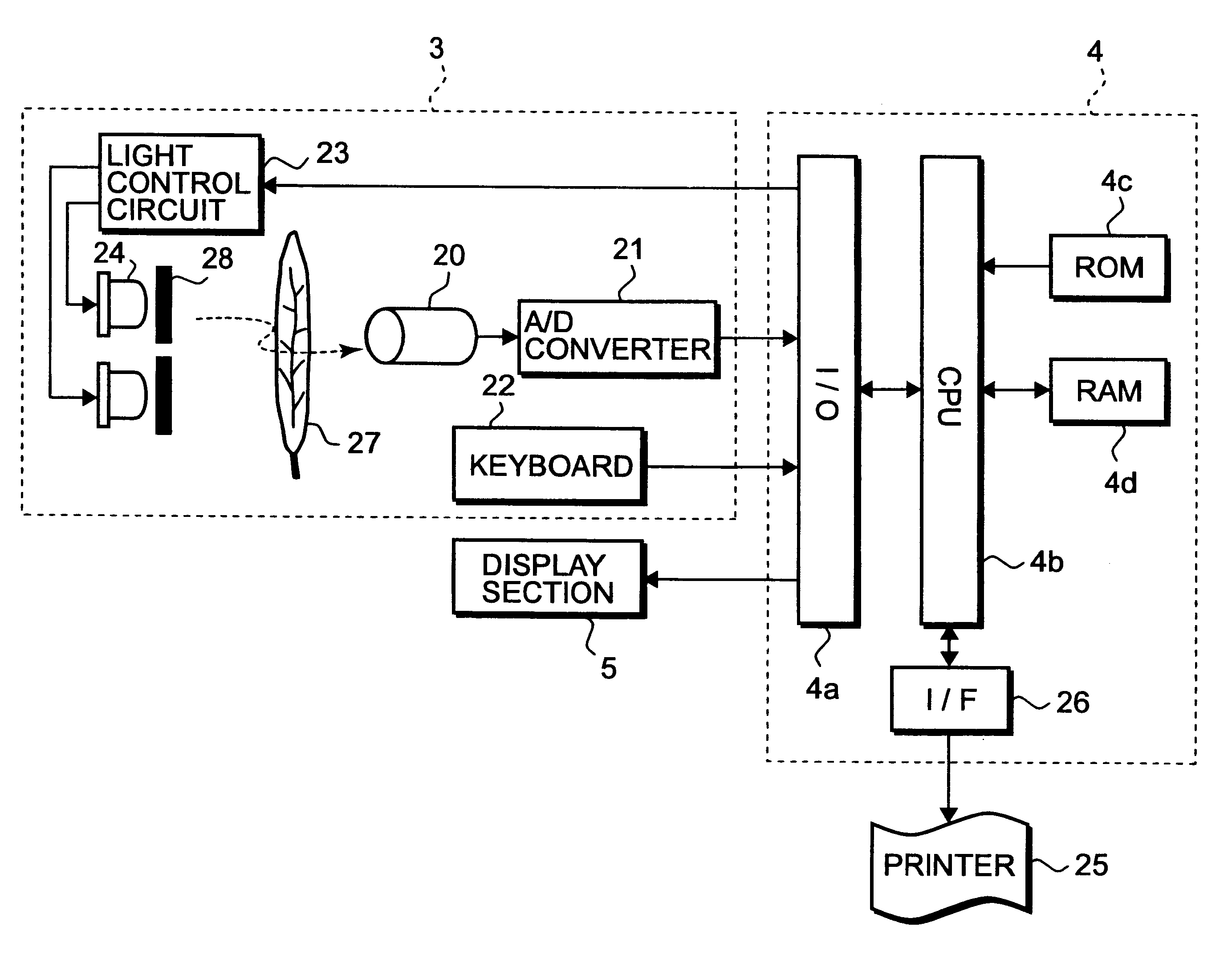

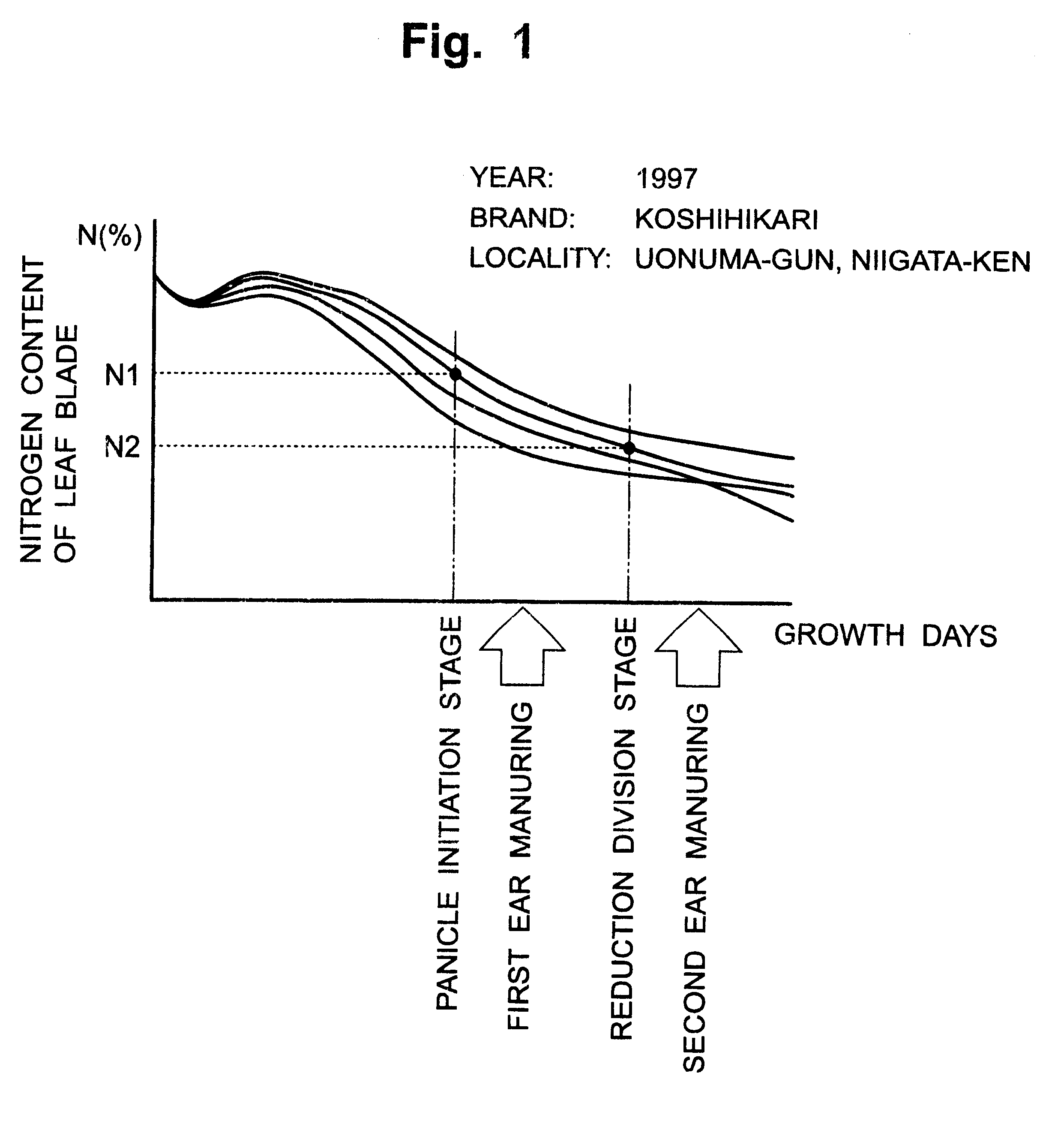

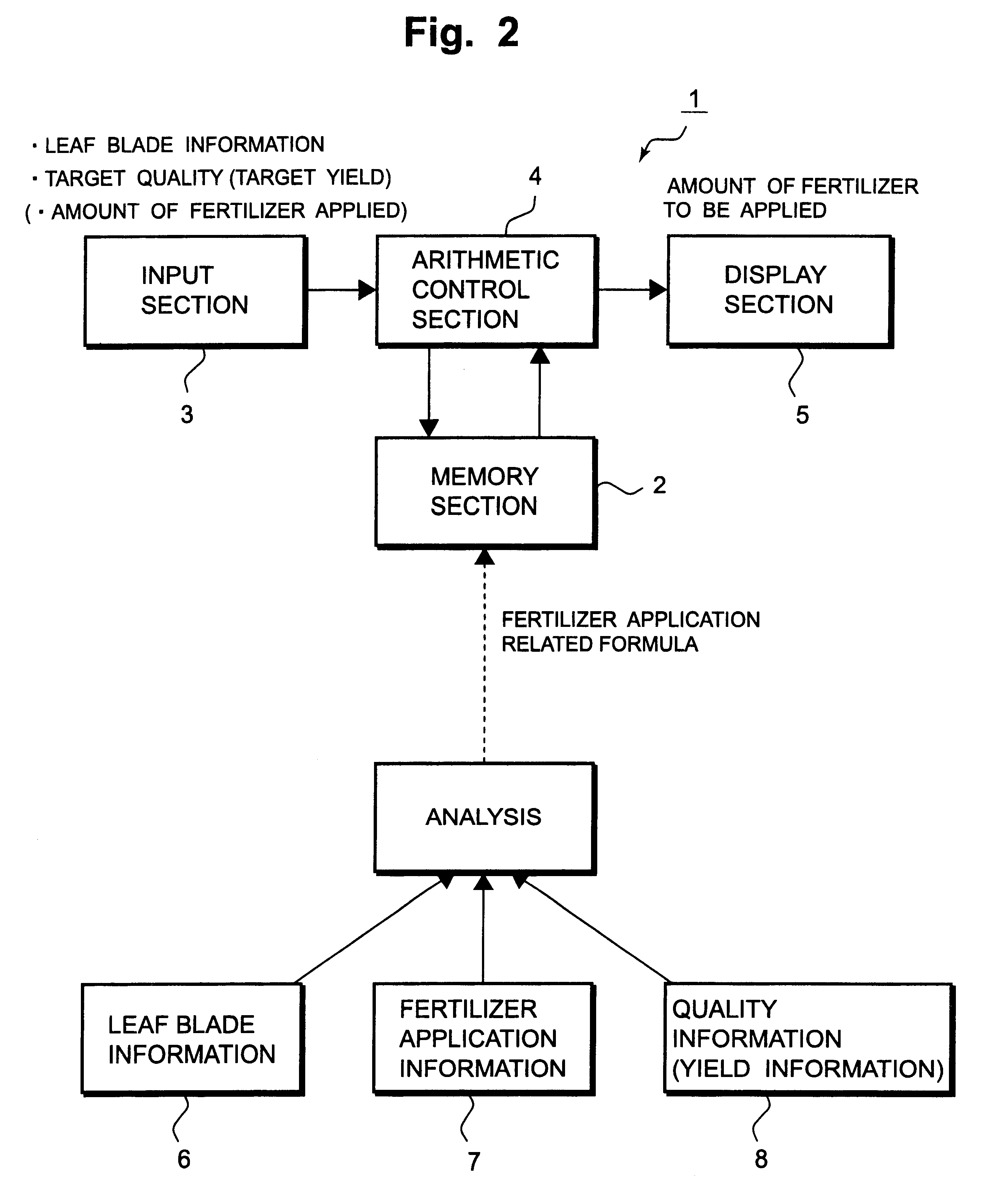

Method for determining amount of fertilizer application for grain crops, method for estimating quality and yield of grains and apparatus for providing grain production information

InactiveUS6442486B1Material analysis by optical meansHorticulture methodsAgricultural scienceEstimation methods

A method and an apparatus for determining an amount of fertilizer to be applied to grain crops are disclosed. A fertilizer application related formula for obtaining the necessary amount of fertilizer to be applied is established by analyzing growth information including leaf blade information, fertilizer application information and quality information, all the above information being obtained in advance from a number of grains or grain crops. The formula thus established is stored in the memory. The necessary amount of fertilizer to be applied for each specific period for grain crops which are presently under growth is calculated by applying to the above formula, growth information of the grain crops presently under growth and target quality information. The growth information includes leaf blade information in relation to a specific period. The results of the calculation are displayed or printed out. A method and an apparatus for estimating a quality or yield of grains prior to the harvesting is also disclosed. In this case, a quality or yield related formula is established in advance and stored in the memory.

Owner:SATAKE CORP

Composite biological agent used for replacing chemical fertilizers and pesticides and preparation method thereof

InactiveCN102417411AIncrease production capacityIncrease vitalityFertilizer mixturesAdditive ingredientGrain quality

For reducing the negative effects of chemical fertilizers and pesticides on grain production and natural environment, the invention provides a composite biological agent used for replacing chemical fertilizers. The use of the composite biological agent can effectively avoid many drawbacks caused by the use of chemical fertilizers and pesticides, and has the effect of increasing both production and income of grains. The composite biological agent comprises the following ingredients: 10-15 wt% of plant enzyme preparation, 0.5-1.5 wt% of composite trace elements, 15-25 wt% of zeolite, and 60-70 wt% of water. The preparation method is characterized by mixing in proportion and fermenting. The composite biological agent can increase the production capacity of grains, improve the grain quality, effectively save resource and protect the environment. The method has the advantages of simple operation, easy control of the parameters, and short period, and is benefit for popularization and application.

Owner:JIXI SENQI BIOLOGICAL TECH

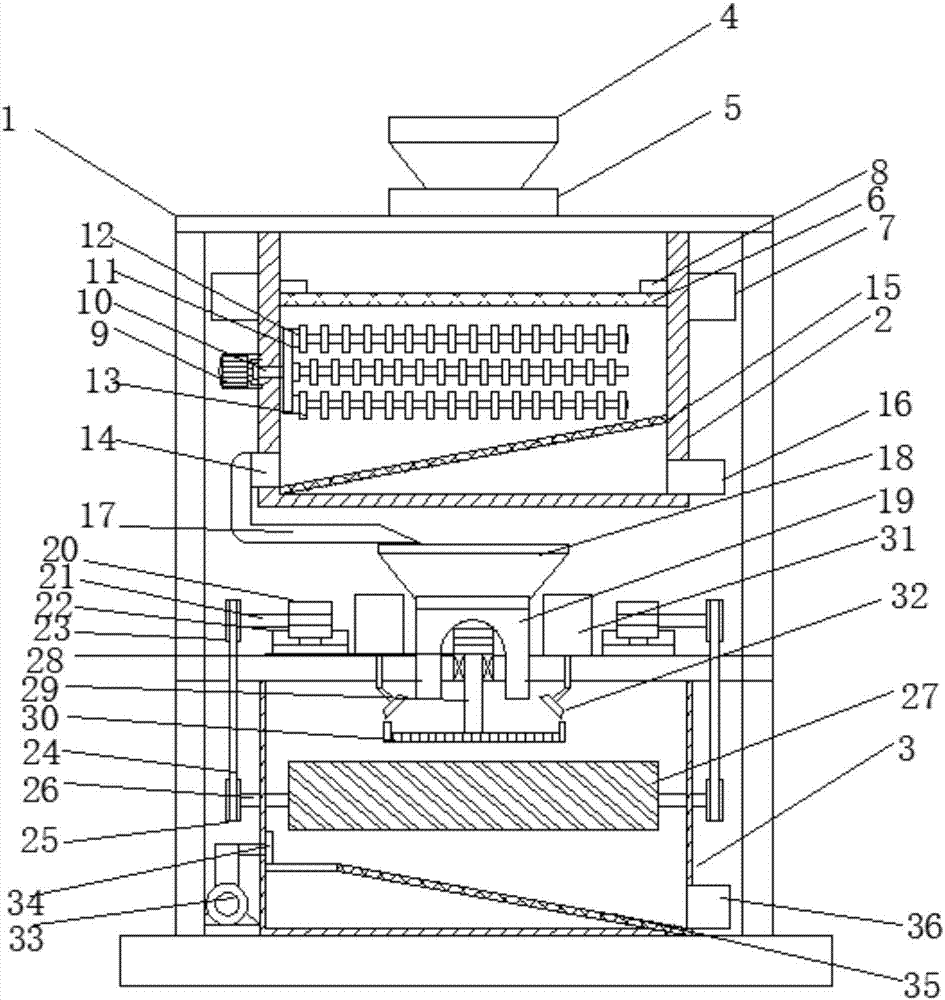

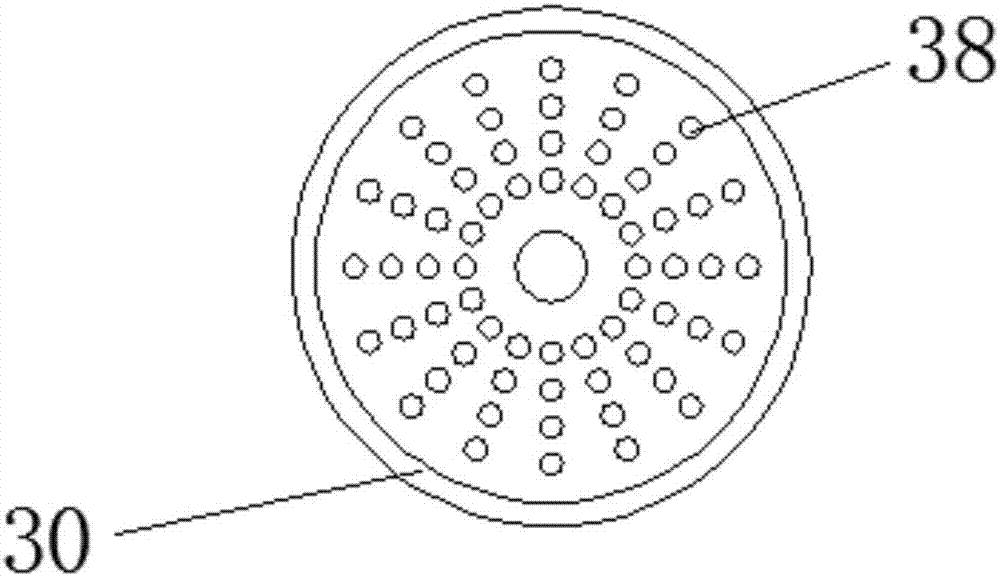

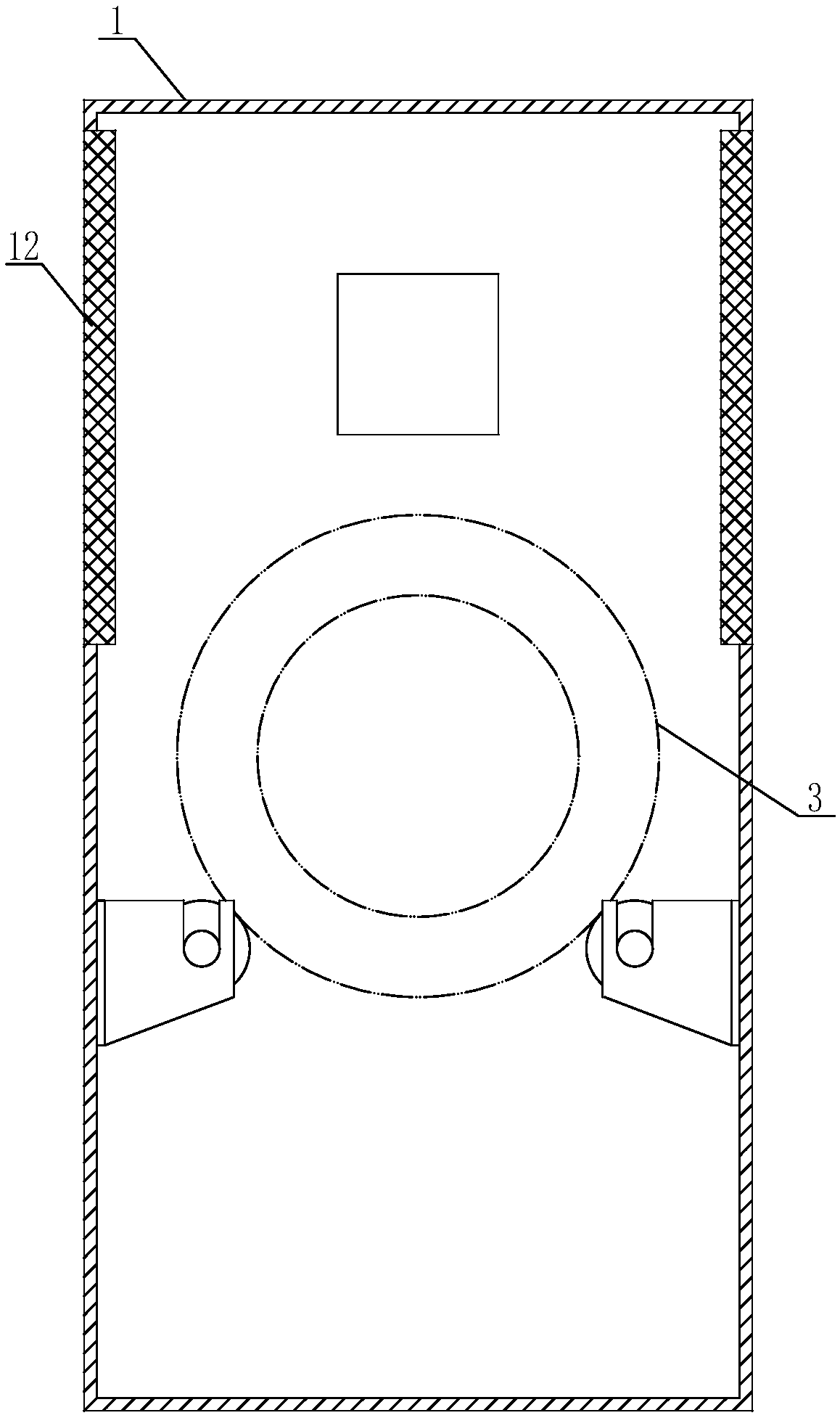

Efficient polishing device capable of keeping rice grain quality

InactiveCN107127000AEfficient removalAvoid loss of nutritional valueGrain huskingGrain polishingDrive wheelAgricultural engineering

The invention discloses a high-efficiency polishing device that maintains the quality of rice grains. It includes a frame. The frame is respectively provided with a pretreatment chamber and a polishing chamber. Fixed brackets are installed on the left and right sides of the upper plane of the polishing chamber. The tops of the fixed brackets are all equipped with polishing motors, and the outer ends of the polishing motors are equipped with polishing rotating shafts, and the outer ends of the polishing rotating shafts are equipped with driving wheels. The middle position is equipped with a throwing roller rotating shaft, and the left and right sides of the throwing roller rotating shaft are equipped with driven wheels, and the left and right driven wheels are connected with the corresponding driving wheels through a transmission belt. A polishing roller is installed on the roller shaft. The invention has the beneficial effects of increasing the polishing effect and polishing efficiency, effectively removing impurities in the polished rice, ensuring the polishing effect, and avoiding the loss of the nutritional value of the rice grains.

Owner:徐立

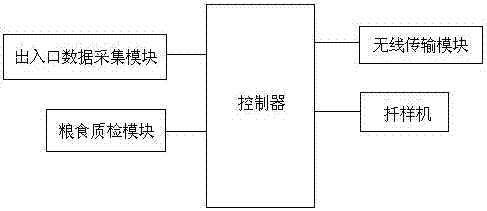

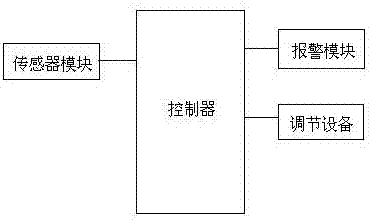

Granary intelligent management device

PendingCN106990744AEasy access to on-site statusFully automatedProgramme controlMeasurement devicesWireless transmissionMultiple sensor

The invention discloses a granary intelligent management device, including a grain storage and retrieval management device, a grain storage management device and a security and protection monitoring device. The grain storage and retrieval management device comprises a controller which is connected with a gateway data collection module, a grain quality inspection module, a wireless transmission module and a grain sampler. The grain storage management device comprises a controller which is connected with a sensor module, an alarm module and an adjusting device. The security and protection monitoring device comprises a video monitor, an electronic fence and a boundary alarm security and protection device, and is used for carrying out real-time monitoring of the granary boundary environment and the in-warehouse grain storage condition to conveniently obtain the granary onsite condition and timely make decisions. The granary intelligent management device is reasonable in structural design, and can guide, control and supervise the process of grain storage and retrieval. The grain sampling, weighing and storage and retrieval can be rapidly identified by the radio frequency technology, and the grain storage, the grain condition, the gas concentration and the granary operation safety of each granary can be timely mastered by integrating multiple sensors and based on the real-time monitoring data.

Owner:JIANGSU ZHONGYUAN INTERNET OF THINGS TECH DEV

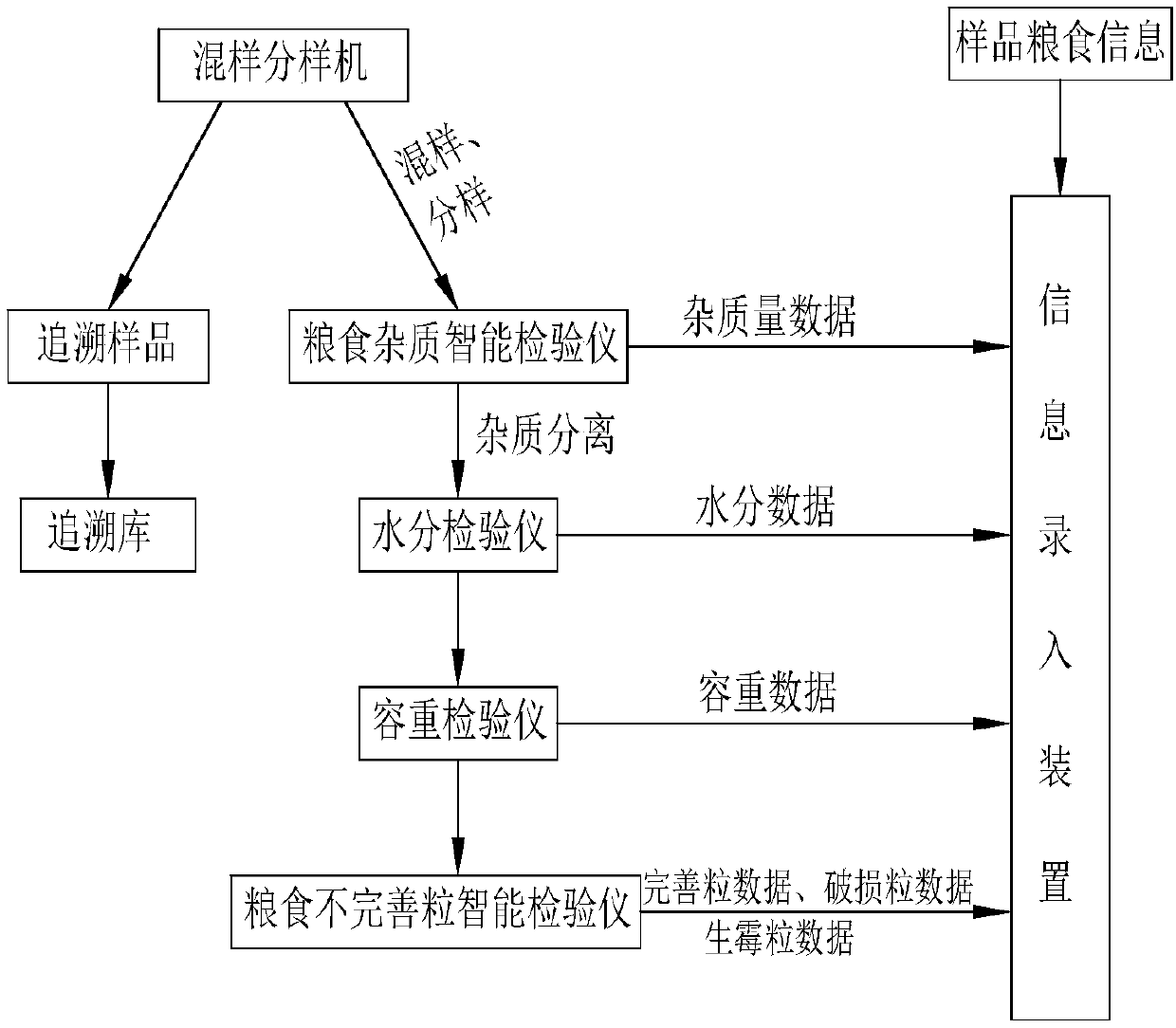

Intelligent grading check system for grain quality and check method thereof

PendingCN109530267AImprove inspection qualityImprove efficiencyInvestigation of vegetal materialGas current separationAgricultural engineeringImpurity

The invention discloses an intelligent grading check system for grain quality. The system comprises a sample mixing and separating machine. A grain impurity intelligent check meter is carried to an output end of the sample mixing and separating machine while the other output end of the sample mixing and separating machine outputs a traceable sample. A water check meter, a volume-weight check meterand a grain unsound grain intelligent check meter are successively connected to the grain impurity intelligent check meter. The system also comprises an information recording device connected to theparts. The invention also discloses a specific check method of the system. The method comprises the following steps: the sample mixing and separating machine separates the traceable sample and the check sample in the grain samples and separates and weighs the impurities and grain for the check sample, separately; a part of separated grain is detected in water and volume-weight while intact particles, damaged particles and mildewed particles of the other part are screened and weighed, separately; and data is transmitted to the information recording device to generate a check result report automatically. The system avoids influence of manual factors, is just and equitable in check result and provides precise reference data for grading and pricing the grain.

Owner:山东泓盛智能科技有限公司

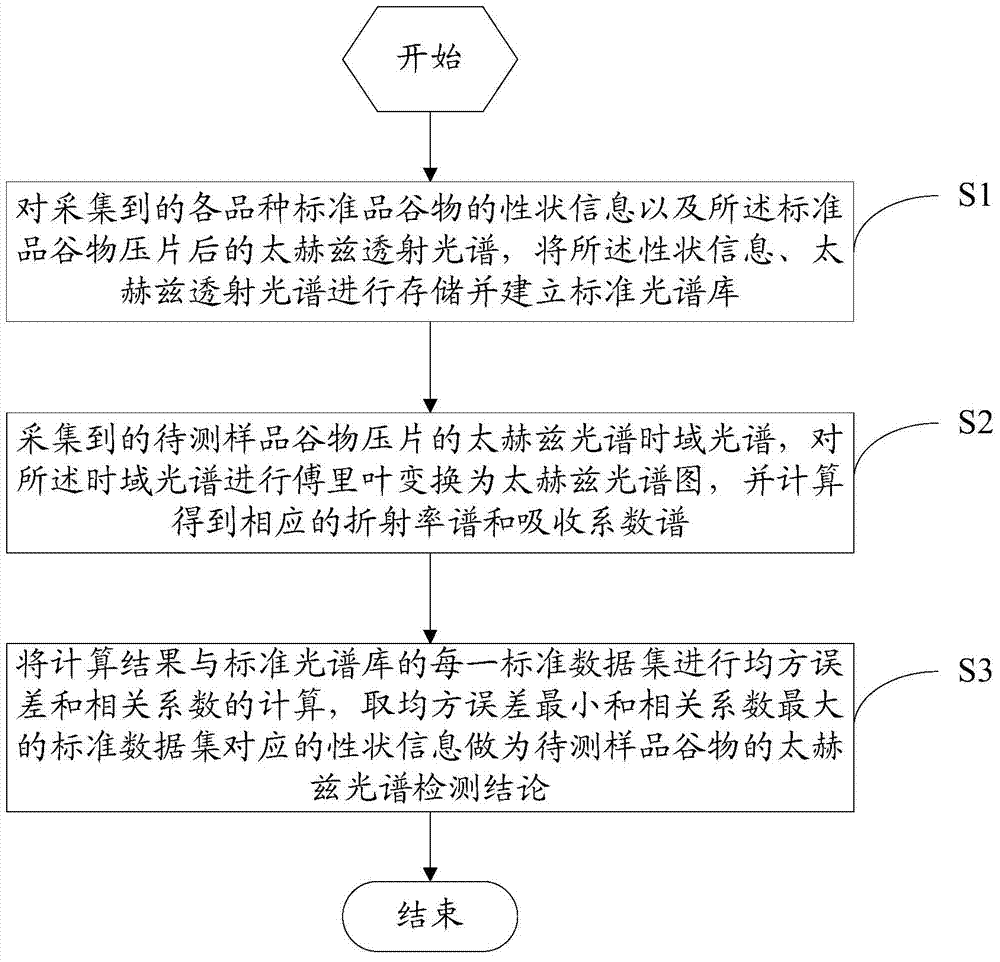

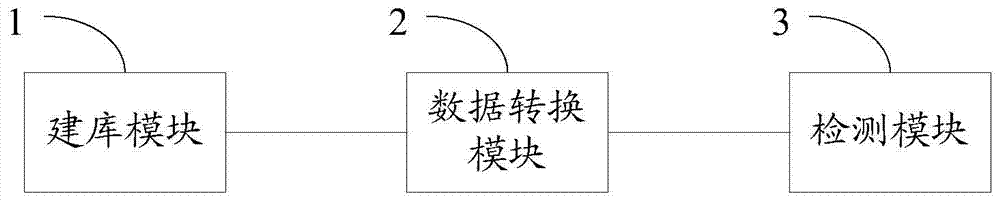

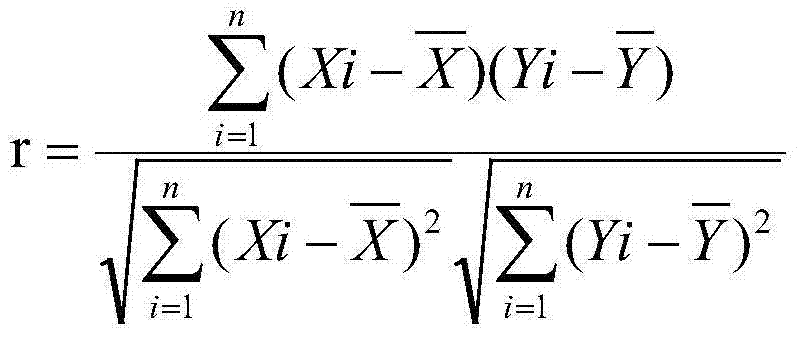

Cereal freshness detecting method and device

The invention provides a cereal freshness detecting method and device. According to the method, acquired character information of standard cereals with different varieties and terahertz transmission spectra obtained after tabletting the standard cereals are stored, and a standard spectrum library is built; performing Fourier transformation on the acquired time-domain spectroscopy of the tabletting terahertz spectrum of one sample cereal to be detected, so as to obtain a terahertz spectrum chart, and calculating to obtain corresponding refractive index spectrum and absorption coefficient spectrum; calculating mean square errors and correlation coefficients for the calculation results and each standard data set of the standard spectrum library, and taking the character information corresponding to the standard data sets with the smallest mean square error and the greatest correlation coefficient as the terahertz spectrum detection conclusion of the sample cereal to be detected. The cereal freshness detecting device corresponds to the cereal freshness detecting method. As terahertz is very safe, is extremely small in photon radiation energy and cannot injure human bodies, the method and the device are suitable for field detection on grain quality, the detection accuracy is high, and the effect is good.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

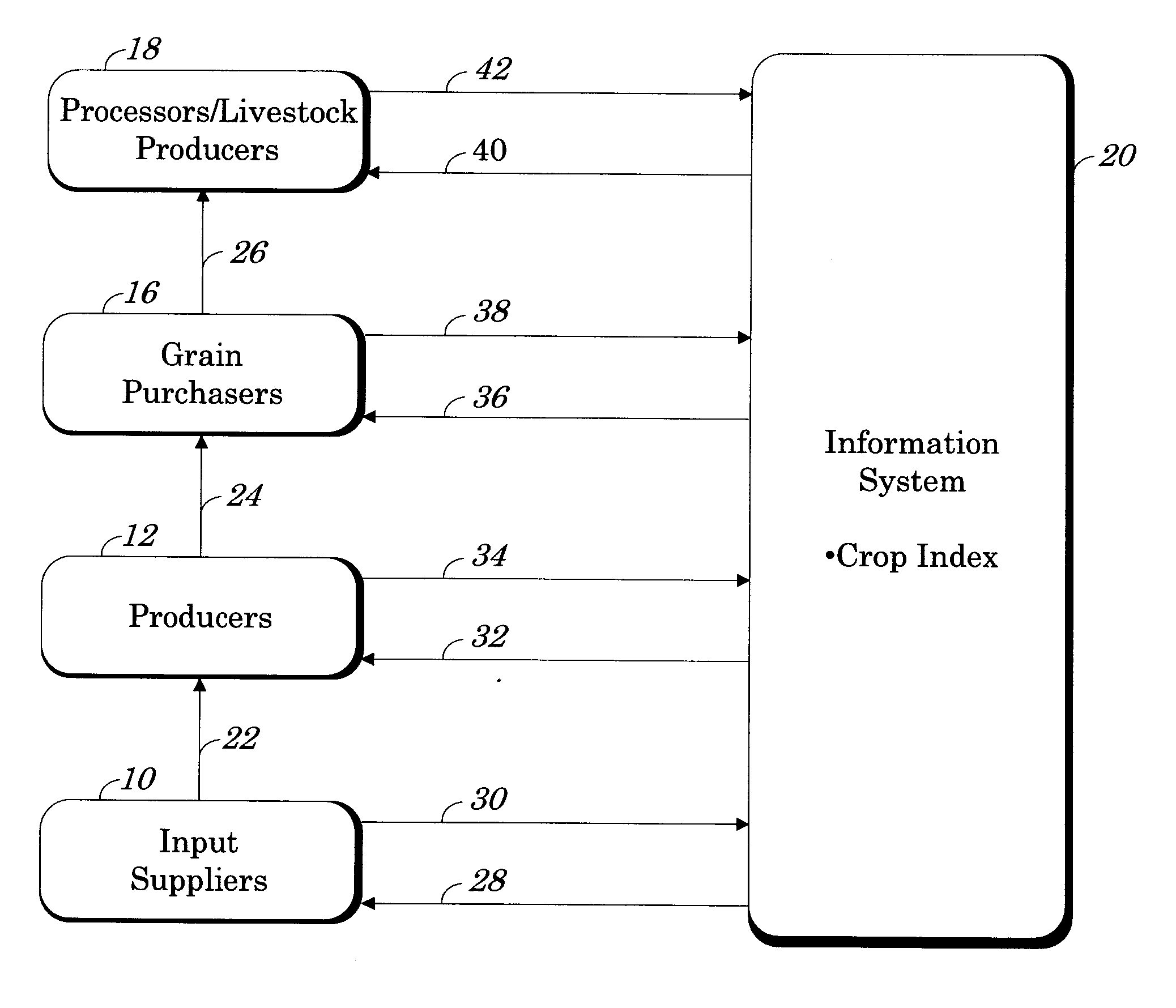

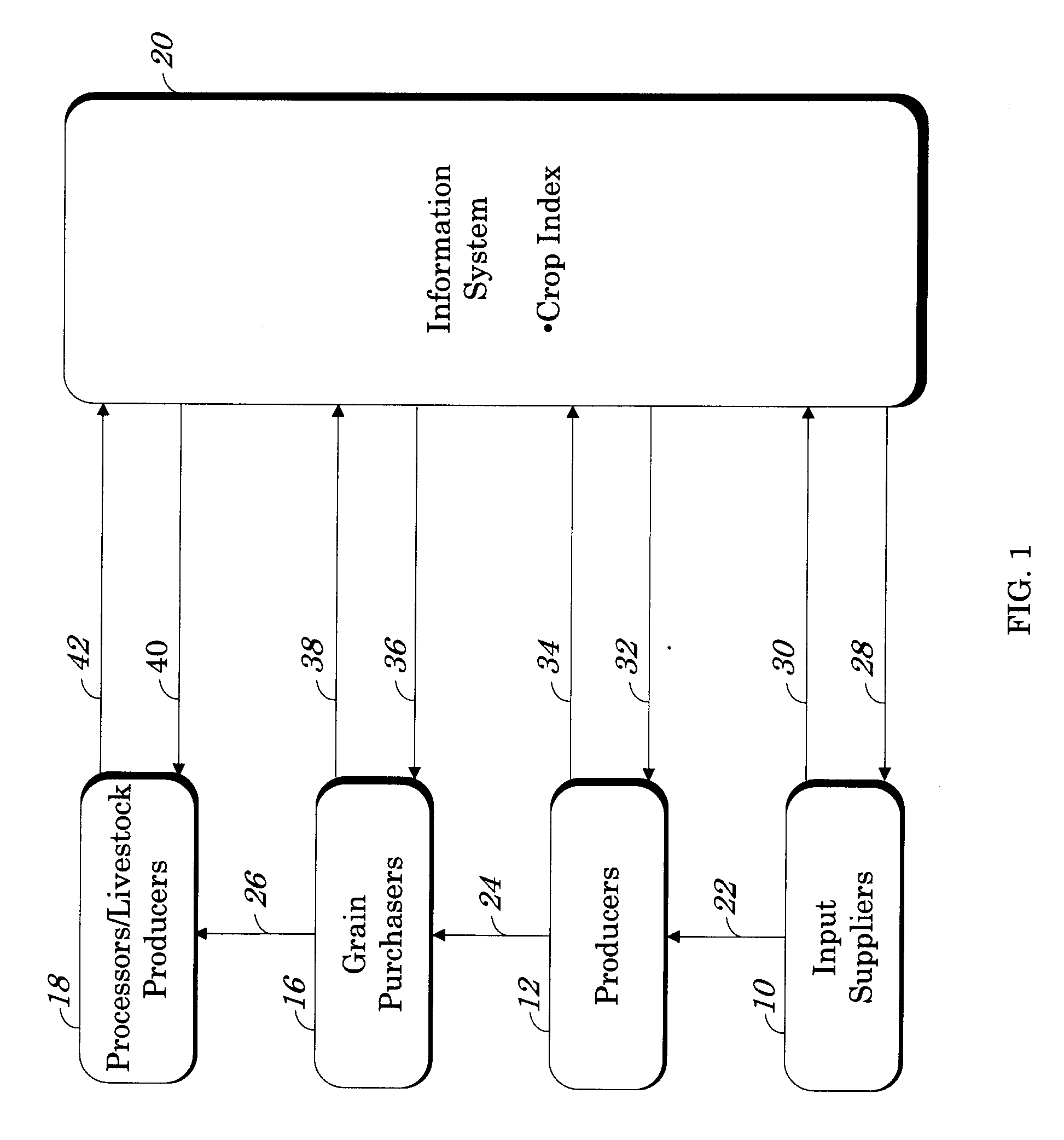

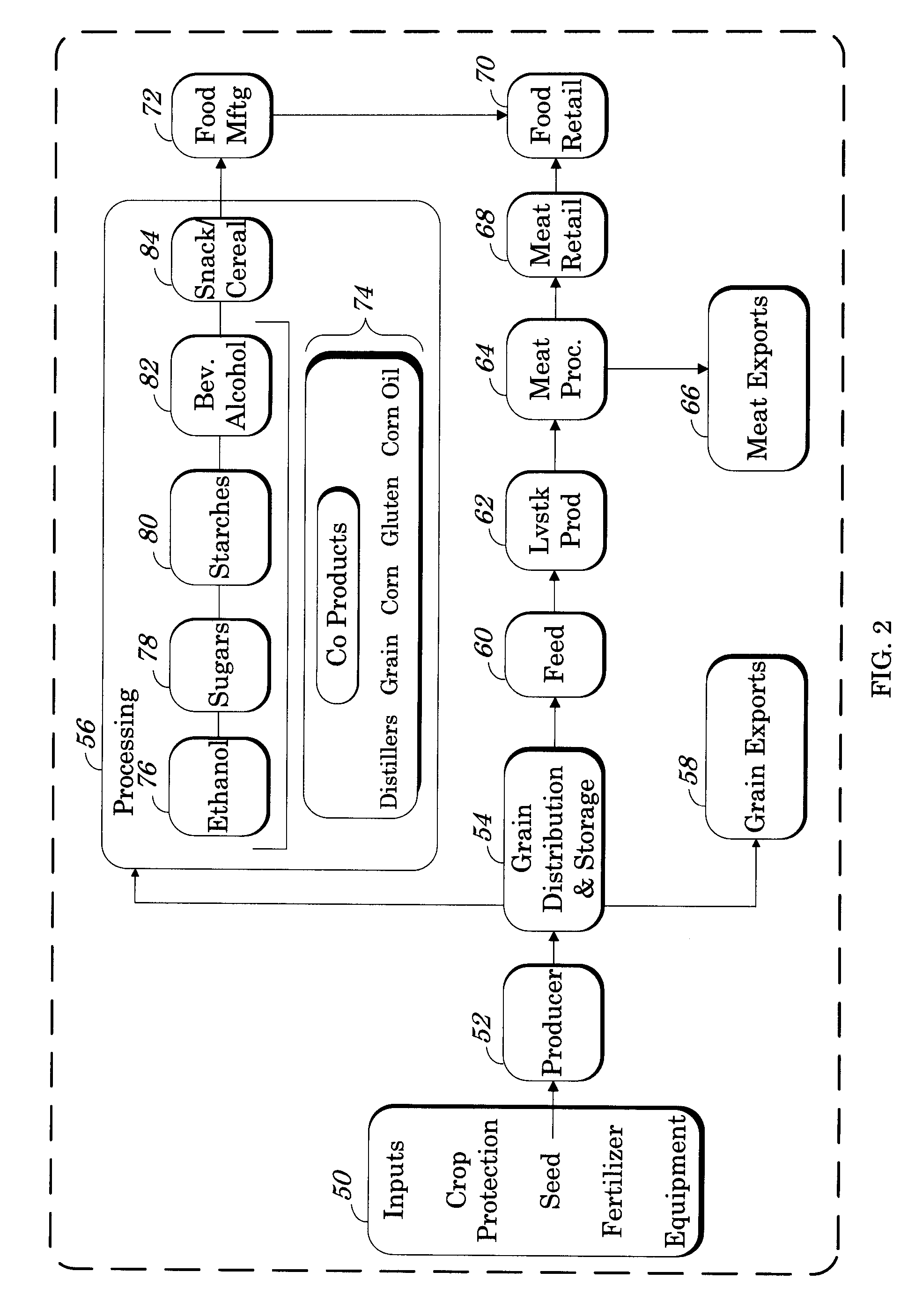

Crop value chain optimization

A method for optimizing a supply chain for grain includes providing an information system adapted to exchange information with at least one input supplier providing seed to the producer, at least one producer providing grain grown from the seed, and at least one processor providing a product produced using the grain. The information system is adapted to provide an output indicative of grain quality and quantity to the at least one processor prior to harvest of the grain to thereby assist the at least one processor in optimizing the supply chain.

Owner:PIONEER HI BRED INT INC +1

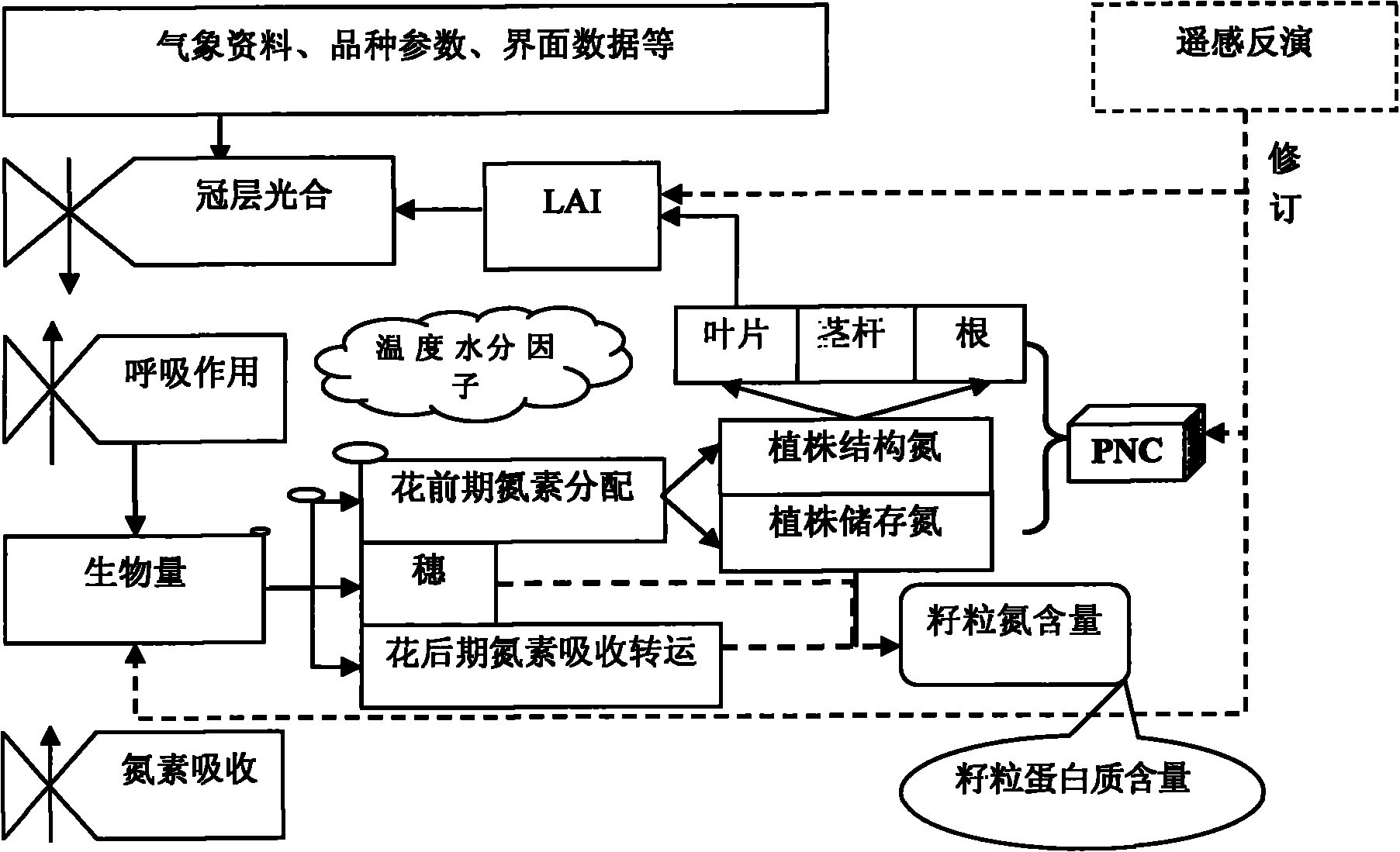

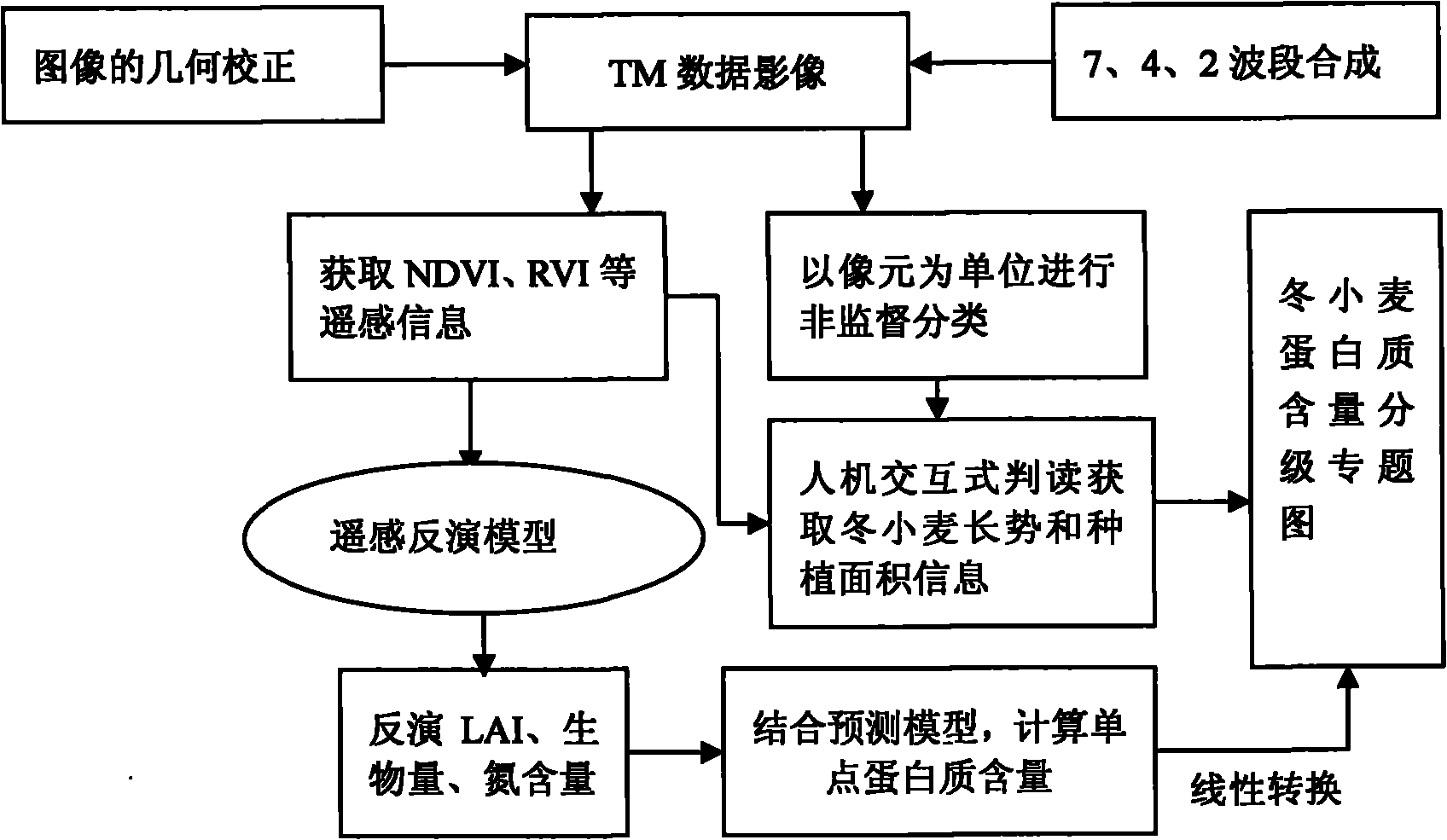

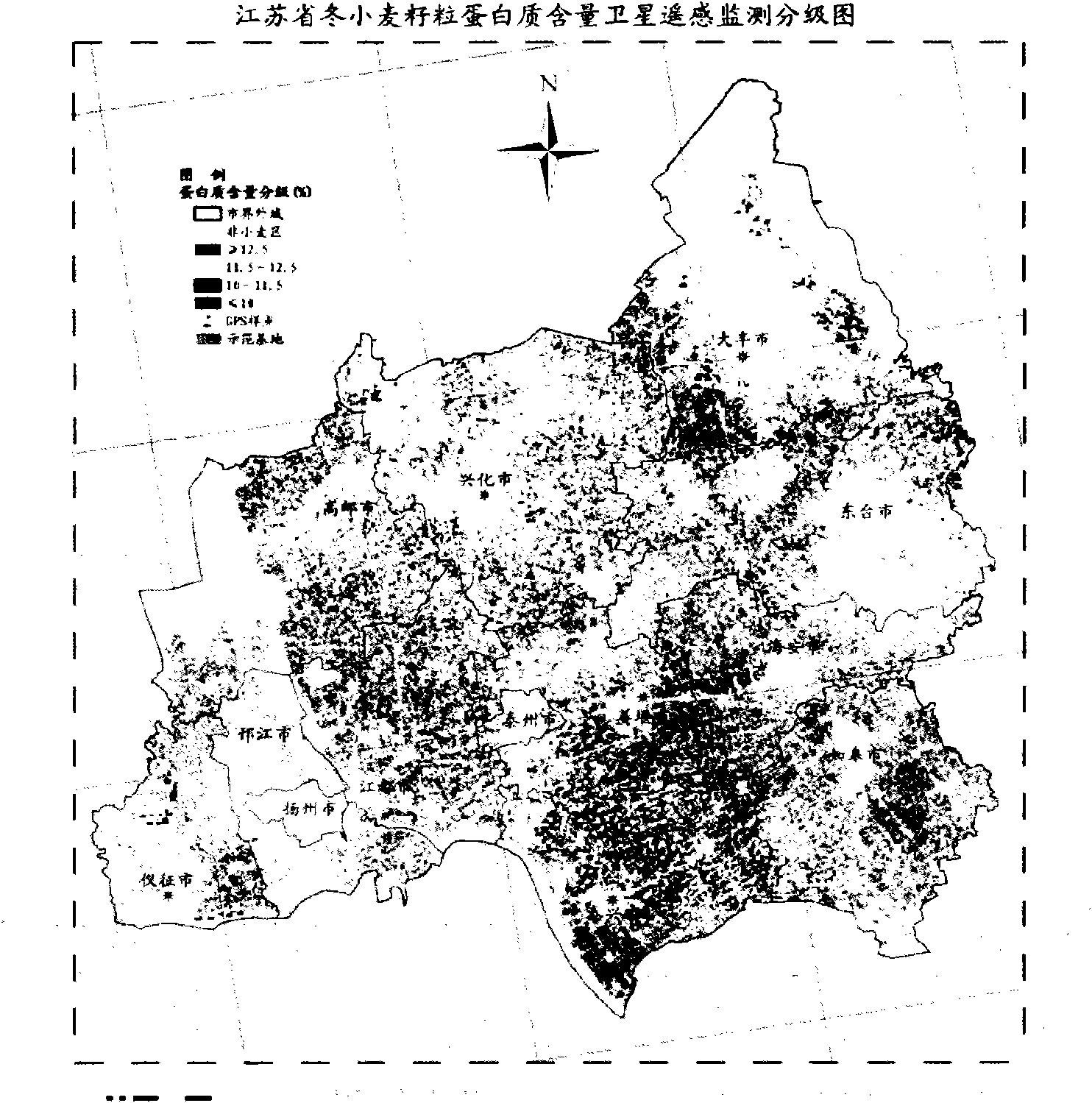

Method for remote sensing monitoring and predicting protein content of winter wheat grains

InactiveCN102156128AEasy to formulateEasy to masterMaterial analysis by optical meansSpecial data processing applicationsNitrogen accumulationSoil science

The invention provides a method, comprising the steps of: based on the instantaneity and wide regional coverage for obtaining remote sensing information, building a grain protein content prediction model based on nitrogen accumulation procedure via combining with the influencing characteristics of climatic environmental conditions in the flowering duration of wheat on the formation of grain quality; realizing the coupling of the remote sensing information and a grain protein content prediction model, namely using LAI (leaf area index), biomass and plant nitrogen content data inverted by flowering duration remote sensing images to displace the corresponding parameter variables of the wheat grain protein content prediction model, so as to realize the prediction for the protein content of single-point wheat grains, wherein the prediction precision is more than 85%; and drawing a graded monitoring and predicting thematic map for protein content of winter wheat grains by a scaling converting method of 'point' (the protein content of sample point grains) and 'face' (remote sensing images). The method has the characteristics of intuitionism and good timeliness, and has relatively good practicability for obtaining regional wheat quality information or guiding grain collection by department of agriculture.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

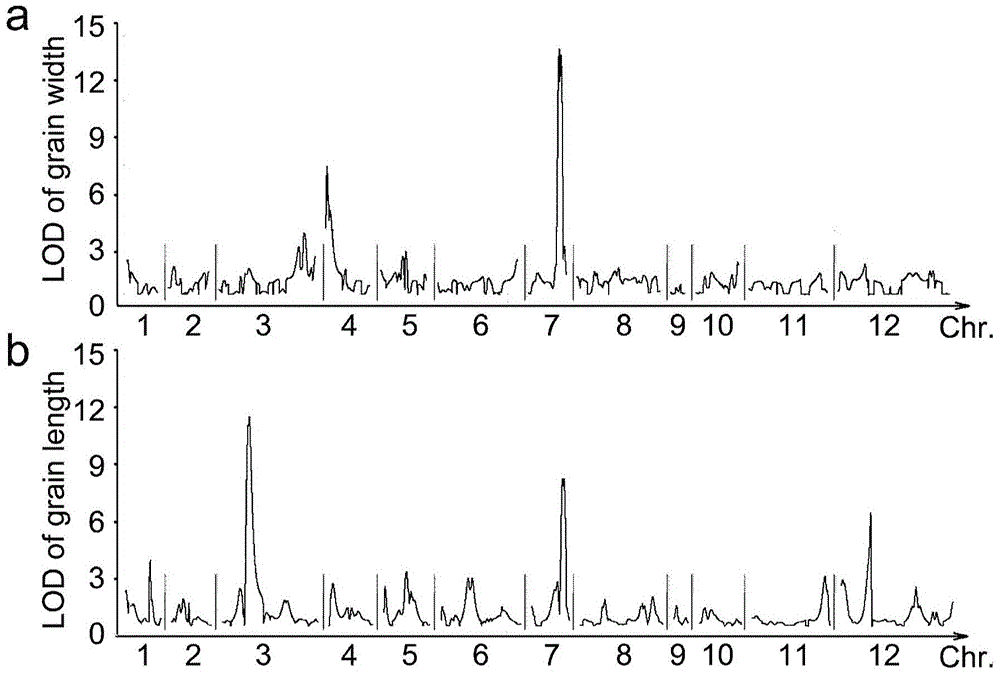

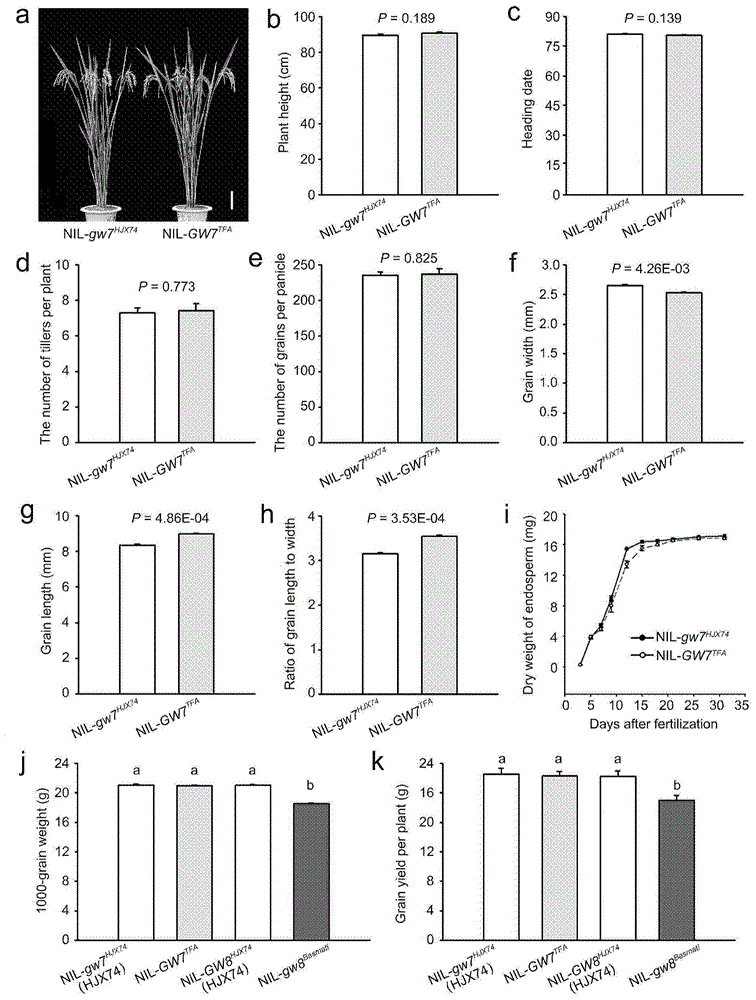

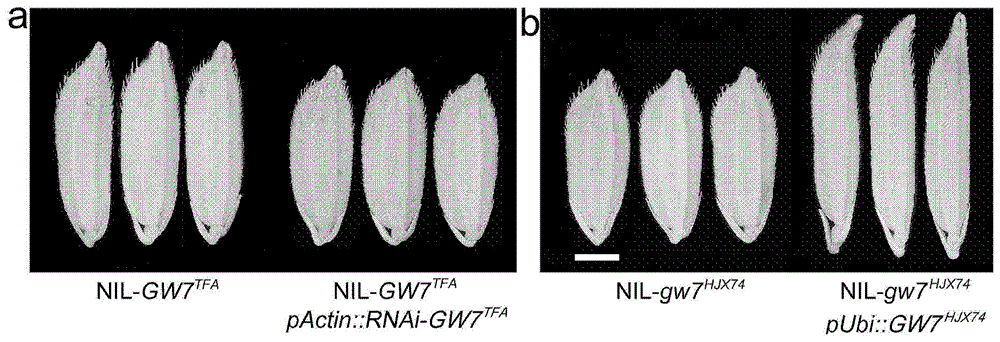

Gene GW7 for controlling grain shape, exterior quality and yield of rice and applications of gene GW7

PendingCN105985965ABacteriaMicrobiological testing/measurementMarker-assisted selectionAgricultural science

The invention discloses a gene GW7 (SEQ ID NOs:1-4) for controlling the grain length and the grain width of rice and applications of the gene GW7. GW7 can control the grain length, the grain width and the grain length-width ratio of the rice, so that the grain quality of the rice is improved; after polymerization of GW7 and gs3, the yield of the rice can be obviously improved, and meanwhile, the quality of the rice can be improved. The invention also discloses a method for breeding crops with the increased yield by utilizing the gene GW7, and a marker-assisted selection pyramiding breeding method for breeding rice variety with the improved rice quality and yield. The gene GW7 has a wide application prospect in the high-yield and high-quality breeding of the crops such as the rice.

Owner:INST OF GENETICS & DEVELOPMENTAL BIOLOGY CHINESE ACAD OF SCI

Method for planting wheat

InactiveCN105210606AEasy to useReduce investmentSuperphosphatesMagnesium fertilisersAdditive ingredientPotassium

The invention discloses a method for planting wheat, which comprises following steps: (a). selecting seeds; (b). soaking seeds to accelerate buds; (c). sowing; (d). preparing the field; (e). planting and fertilizing; (f). and managing the field. The special fertilizer provided by the invention is acquired by blending humic acid, nitrogen, phosphorus and potassium; the use amount of the fertilizer added with manure is added and the use amount of chemical fertilizer is reduced, so the special fertilizer has the function of improving white harmful physic properties and the special fertilizer can also effectively provide three ingredients for crops; and by adopting the method provided herein, the land and the light and heat resources are fully utilized, thus improving the utilization rate of the ingredients, effectively increasing production, increasing grain weight and improving the grain quality; and the significance to environmental protection is great.

Owner:TONGLING WUTONGSHU AGRI DEV

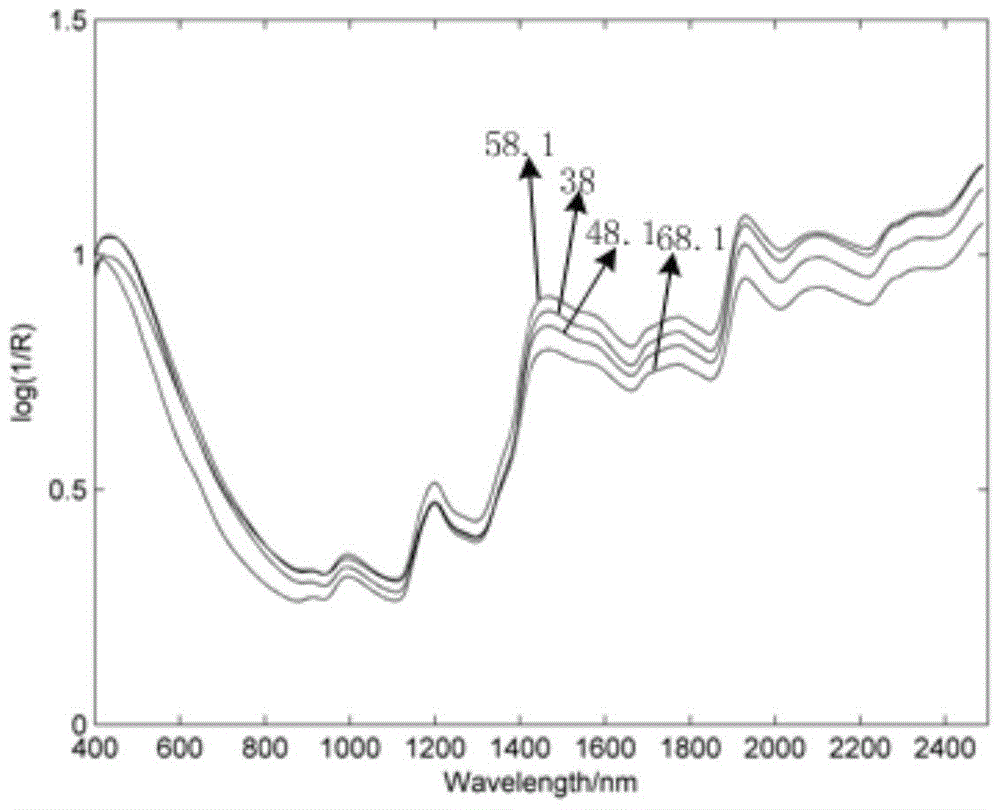

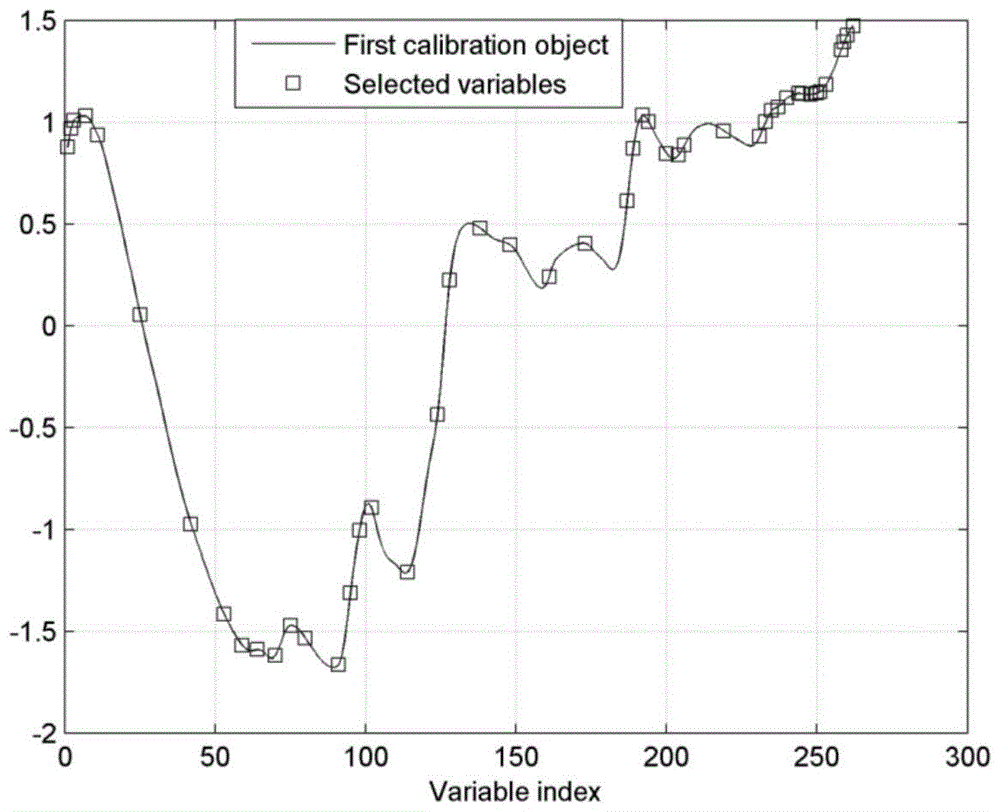

Method for rapidly nondestructively detecting wheat hardness based on near infrared spectrum technology and application

The invention discloses a method for rapidly nondestructively detecting wheat hardness based on a near infrared spectrum technology and application and belongs to the technical field of grain quality detection. The method comprises the steps of establishing a near infrared detection model of the wheat hardness, utilizing a near infrared spectrometer to scan to-be-detected wheat samples, obtaining a sample near infrared spectrum curve, and after performing data processing on the near infrared spectrum curve, determining the hardness of the to-be-detected wheat samples by utilizing the detection model according to obtained data. The method is low in cost, free of pollution, quick in detection speed and high in objectivity, online analysis can be achieved, the method is subjected to geographical limitations, and real-time detection can be performed.

Owner:HEILONGJIANG UNIV

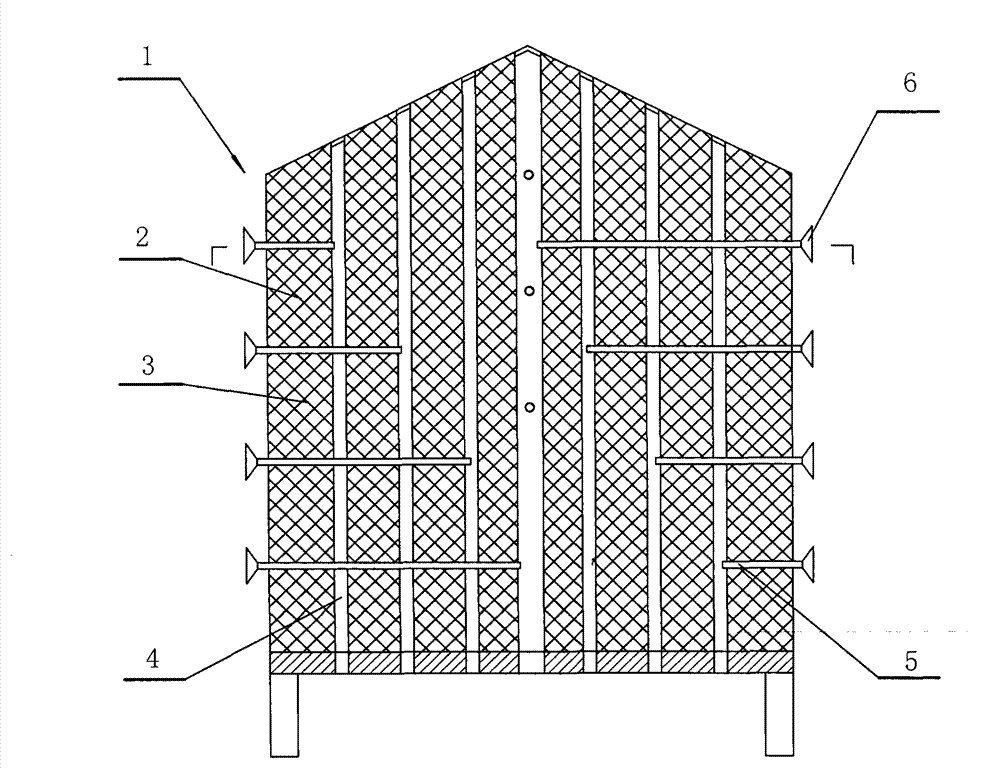

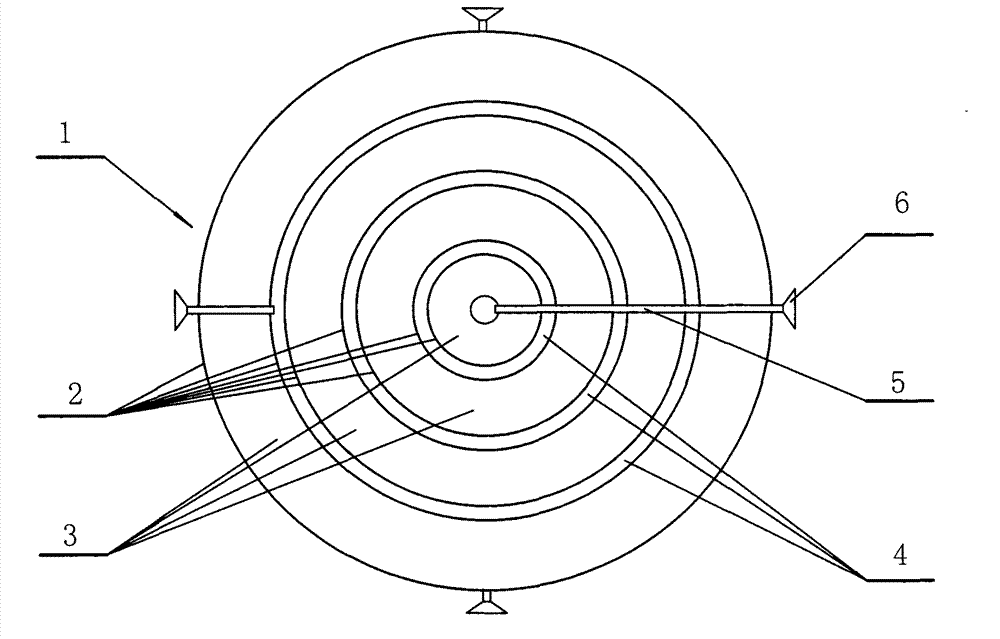

Grain storage air drying bin

ActiveCN103238423ADry fastLong term storageAgriculture tools and machinesHarvested fruit hanging devicesGrain storageEngineering

The invention relates to an energy-saving device, namely a grain storage air drying bin. The grain storage air drying bin mainly comprises a cylinder bin body (1) and is characterized in that the outer wall of the bin body (1) is formed by screen meshes (2). A space in the bin body (1) is separated by the screen meshes (2) to form a plurality of grain storage cavities (3) and air ducts (4). Each grain storage cavity (3) is adjacent to at least one air duct (4). A plurality of ventilating pipes (5) are inserted into the air ducts (4) from the outside of the bin body (1). The grain storage air drying bin has the advantages that the bin body is of a screen mesh structure provided with the air ducts inside, good in ventilation, applicable to fast drying of grains and long-term grain storage, low in cost, and convenient to operate, grains can be dried fast to avoid mildew, and conditions for grain storage scattering, successive selling, storage tension relieving, grain quality guaranteeing and market supply stabilizing are provided for farmers.

Owner:张建臣 +1

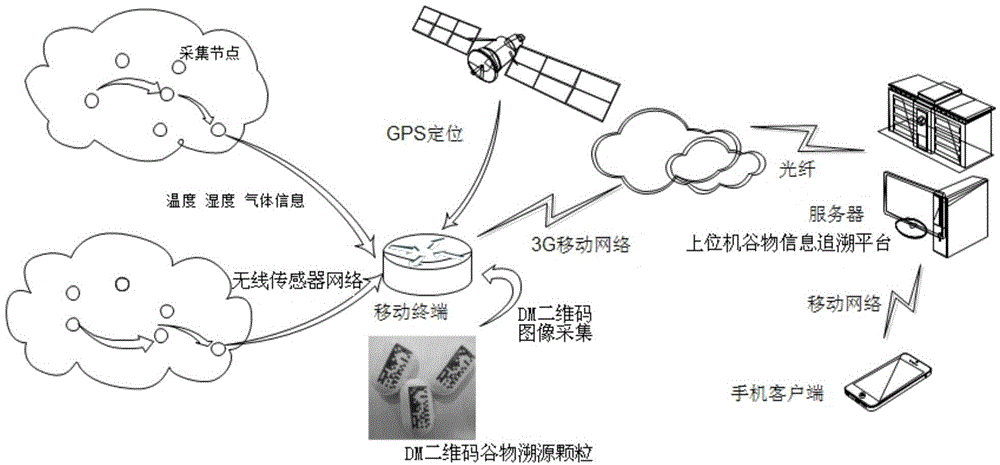

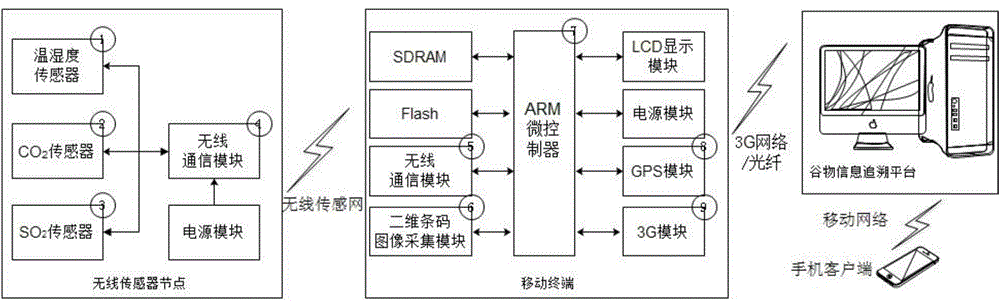

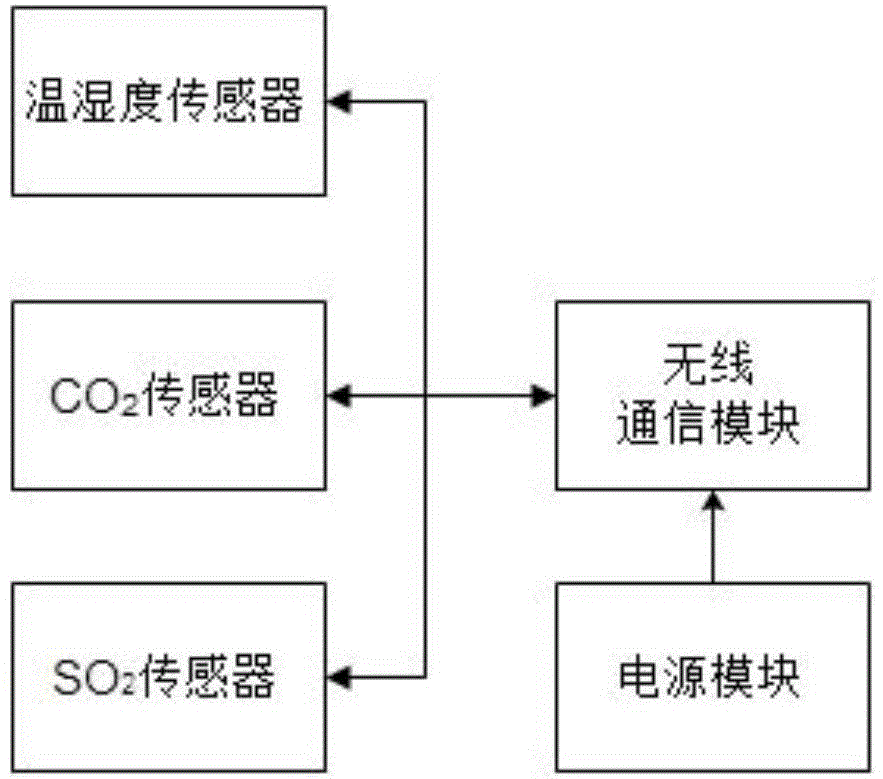

Precise information acquisition and tracing system and tracing method based on DM (Data Matrix) two-dimension code grain tracing particles

InactiveCN104867023AAccurate full traceabilityAccurately realize full traceabilityCo-operative working arrangementsCommerceGeneral Packet Radio ServiceThe Internet

The invention discloses a precise information acquisition and tracing system and a tracing method based on DM (Data Matrix) two-dimension code grain tracing particle, which take the food-grade DM two-dimension code grain tracing particles as a carrier of a grain producing area information identifier, and develop automatic acquisition and transmission based on information of each link for ARM (Advanced RISC Machines) grain tracing as a rapid full-range grain tracing system with low cost to provide an effective manner for guaranteeing the grain quality and the safety production. The tracing system comprises an environment information acquisition node, a wireless sensor network, a mobile terminal provided with a wireless communication module, a GPRS (General Packet Radio Service) locating module and a DM two-dimension code image capture module, and an upper computer grain information tracing platform. The upper computer grain information tracing platform recognizes and decodes a plurality of DM two-dimension code areas in received grain images to obtain grain production mark information, stores the grain production mark information, the grain environment information and the position information together, and publishes on the internet. A user can search related grain information through a mobile phone client.

Owner:NANJING AGRICULTURAL UNIVERSITY

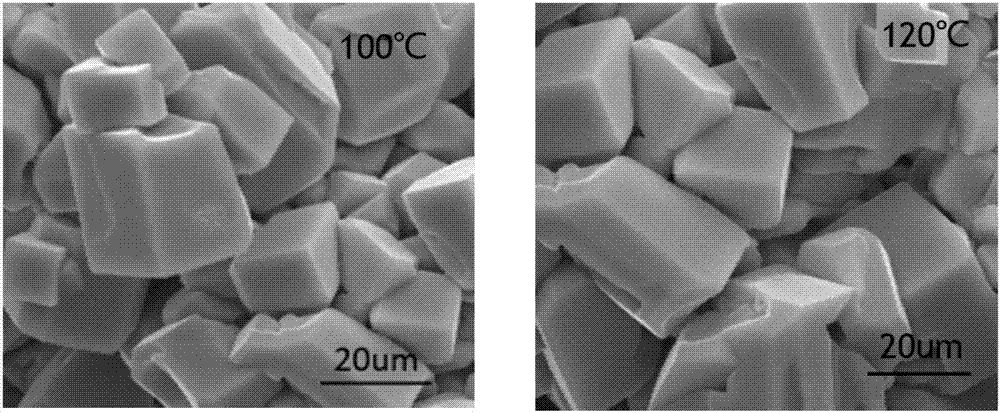

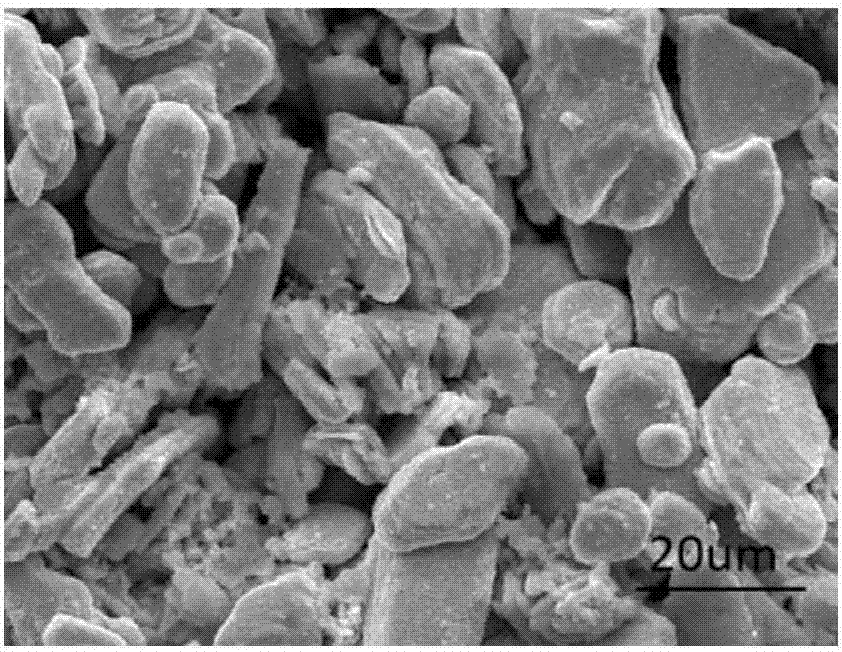

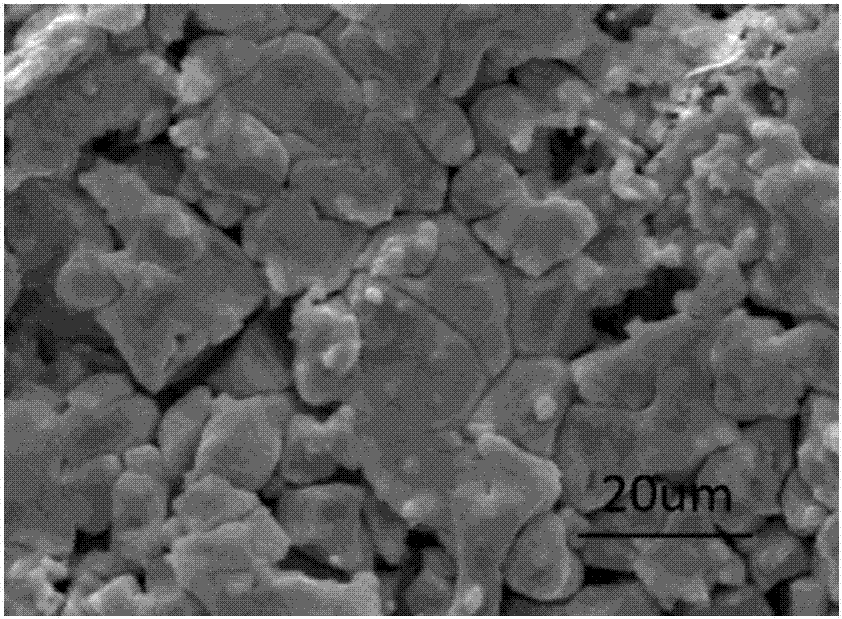

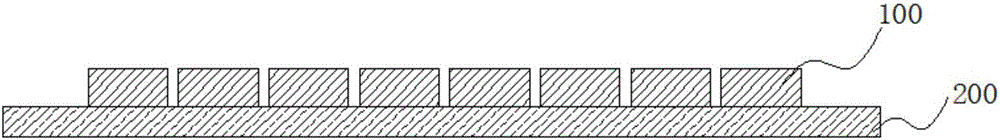

Preparation method of large-grained iodide perovskite thin film

InactiveCN107046098AGood size uniformityGood film coverageSolid-state devicesSemiconductor/solid-state device manufacturingMicron scaleIodide

The invention discloses a preparation method of a large-grained iodide perovskite thin film. The preparation method comprises the steps of: adding methylammonium iodide and iodide powder into methanol for ultrasonic treatment, so that the raw materials are dispersed into tiny particles for sufficient reaction, and finally a micron-scale large-grained quality perovskite thin film is obtained through grinding. The perovskite thin film prepared by adopting the preparation method has the advantages that the grain size evenness is good, the thin-film cover degree is high, the thin film thickness is easy to control, the grain size is large, the thin film can reach micron-scale, the large grains can effectively reduce density of a grain boundary, and the transport rate of carriers is increased. The efficiency of a battery prepared by adopting the thin film is increased from 7.79% to 10.13%, namely, is increased by 2% than that of the conventional method.

Owner:NANJING UNIV OF SCI & TECH

Film-expanding grain-eliminating method of wafer and wafer production method

ActiveCN106816404AAvoid collisionAvoid scratchesSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringSemiconductor

The invention provides a film-expanding grain-eliminating method of a wafer and a wafer production method, wherein the film-expanding grain-eliminating method and the wafer production method relate to the technical field of semiconductor wafer processing. The film-expanding grain-eliminating method comprises the following steps of (a), supplying a wafer and cutting the wafer into a plurality of crystal grains which adhere a bottom film; (b), performing expansion on the bottom film on which the plurality of crystal grains are adhered, and eliminating the unqualified grain particles; and (c), baking the bottom film for restoring the bottom film to a state before film expansion. The film-expanding grain-eliminating method settles technical problems of edge breaking and scratch of adjacent crystal grains, severe crystal grain quality reduction and incapability of normally performing subsequent processes caused by mutual collision between the unqualified crystal grains and the adjacent crystal grains in an unqualified crystal grain eliminating process after the wafer is cut into crystal grains by a wafer manufacturer. Distance increase between the crystal grains is realized through film expansion so that the unqualified crystal grains do not collide with adjacent crystal grains in the eliminating process, thereby realizing technical effects of ensuring high crystal grain quality and facilitating subsequent normal execution of a subsequent packaging process.

Owner:JILIN MAGIC SEMICON

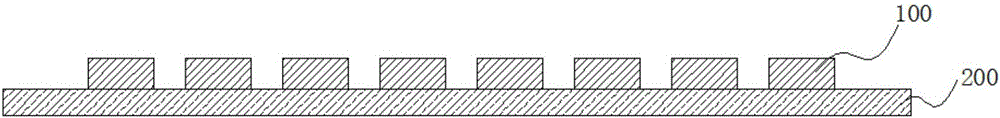

Short technological process of preparing metal grains

The short technological process of preparing metal grains includes the first preheating treatment of ingot at 100-120 deg.c; smelting ingot at temperature 15-25 deg.c over the melting point of the metal inside one melting furnace, conveying metal liquid via ceramic pipe to a holding furnace, maintaining the temperature of the holding furnace at 25-28 deg.c over the melting point of the metal, dropping metal liquid through quantitative dropping spouts in the bottom of the holding furnace to cooling water at 15-40 deg.c inside the cooling box below the holding furnace to form metal grains with the retention time of metal grains in water being 10-18 sec, and conveying the metal grains with a bucket elevator to the packing box. Compared with available technology, the present invention has the advantages of short production period, 15-20 % lower power consumption, high efficiency, and high metal grain quality.

Owner:XI AN JIAOTONG UNIV

Biological organic fertilizer special for grain and preparation method of biological organic fertilizer

InactiveCN107935657AReduce pollutionThe generation process is simpleExcrement fertilisersBioloigcal waste fertilisersPoultry manureFermentation

The invention discloses biological organic fertilizer special for grain and a preparation method of the biological organic fertilizer. Fresh livestock and poultry manure, natural turf soil and agricultural waste are mixed evenly for fermentation, and the fermented mixture is compounded with biochar, humic acid, clay and the like to prepare the organic fertilizer, wherein the weight ratios of the basic components are as follows: 10-15 parts of the turf soil, 60-70 parts of the livestock and poultry manure, 5-10 parts of the humic acid, 15-20 parts of the agricultural waste, 5-10 parts of the clay, 5-10 parts of the biochar and 0.1-0.5 part of biological agents; the preparation method comprises the steps of fermentation, mixing, granulation, drying, cooling, screening and packaging. The biological organic fertilizer special for the grain has the advantages of rich raw materials, a simple process and low cost, has the effects of promoting grain growth, improving the grain quality and edible quality of millet, and improving the soil fertility, and solves the problems of loss of nutrients in the livestock and poultry manure and agricultural waste and pollution of the livestock and poultry manure and agricultural waste to the surrounding environment, thereby turning waste into treasure.

Owner:吉林省松岭有机肥业科技有限公司

Synergic composite nitrogen fertilizer and preparation method thereof

The invention relates to a synergic composite nitrogen fertilizer and a preparation method thereof. The synergic composite nitrogen fertilizer is prepared by mixing the following raw materials in percentage by weight: 20-40% of urea, 25-50% of ammonium sulfate, 0-50% of ammonium chloride, 10-20% of magnesium sulfate and 3-8% of a nitrogen fertilizer synergist. The synergic composite nitrogen fertilizer provided by the invention not only can effectively improve the utilization of the nitrogen fertilizer, but also has the functions of supplementing secondary elements including sulfur, magnesium and the like; the synergic composite nitrogen fertilizer has the functions of rapid effect, slow release, long effect and the like, and has the effects of improving the yield of crops, improving the grain quality, overcoming the soil hardening, and enhancing the cold-resisting, drought-resisting and lodging-resistance capabilities of the crops.

Owner:PIZHOU JINCHENG FERTILIZER IND CO LTD

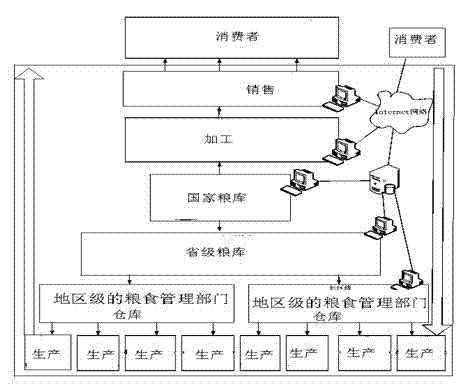

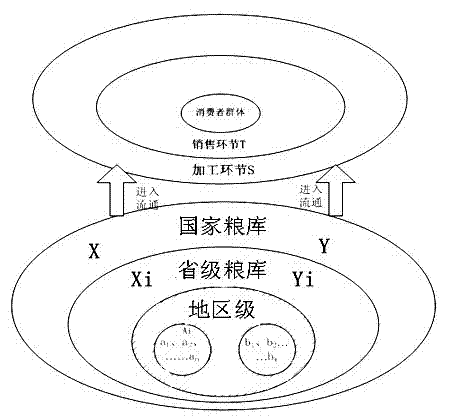

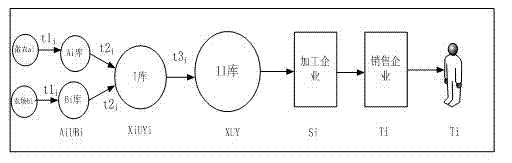

Grain safety traceability method based on time sequence

InactiveCN102521780AEffective supervisionEfficient managementData processing applicationsRecord carriers used with machinesQuality safetyComputer science

The invention discloses a grain safety traceability method based on a time sequence. The method comprises the following steps of: establishing a grain safety traceability information converging model in a computer, wherein the model comprises level-by-level progressive information sources from upstream to downstream,; constructing grain quality safety tracing sequence information by taking storage time of a local grain management department and the allocation time variable of a national grain depot as parameters, and configuring sequence information on grain products; and tracing all information of the grain products by virtue of the computer through network according to sequence information on the grain products by a consumer. According to the grain safety traceability method based on the time sequence, disclosed by the invention, the grain safety traceability information converging model is established, thus the consumer is ensured to exactly trace the grain information from the downstream to the upstream level by level, and effective and fast query of the grain information is realized.

Owner:NANJING UNIV OF FINANCE & ECONOMICS

Grain quality sensor

A grain quality sensor comprising a photosite array, an illumination source, a filter, and an electronics module, wherein the illumination source directs light onto a crop sample, wherein the filter limits passage of light into different parts of the photosite array such that certain locations on the photosite array only receive certain wavelengths of light reflected or fluoresced by the crop sample, wherein an electronics module is electrically connected to the photosite array and capable of determining which parts of the photosite array received light and the wavelengths of the light received, wherein the electronics module can analyze the optical data received by the photosite array, and wherein the analysis of the optical data is used to determine the composition of the crop sample.

Owner:INTELLIGENT AGRI SOLUTIONS

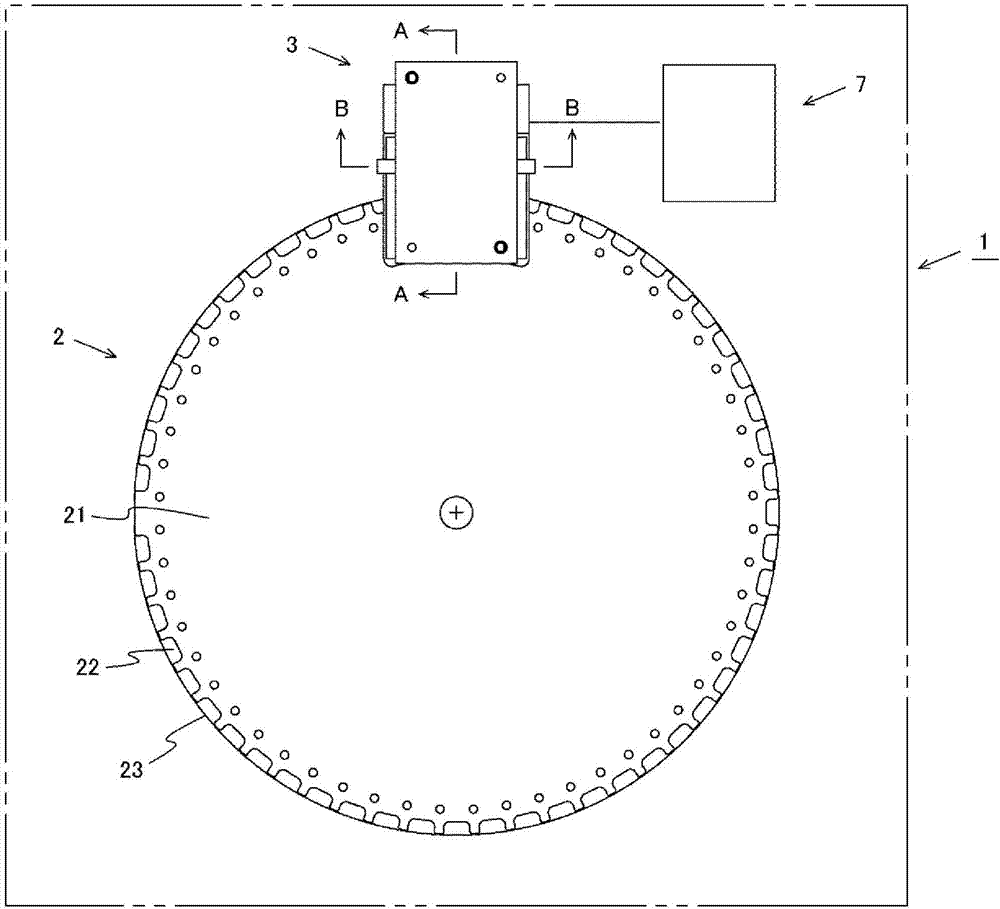

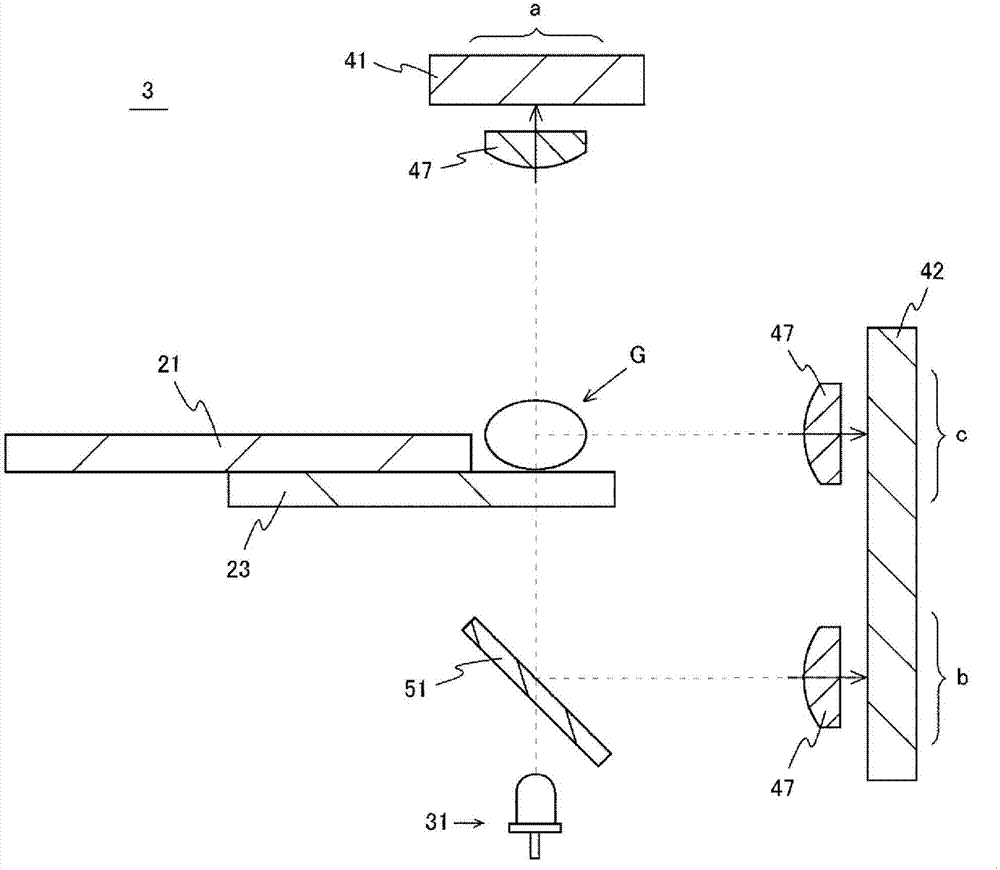

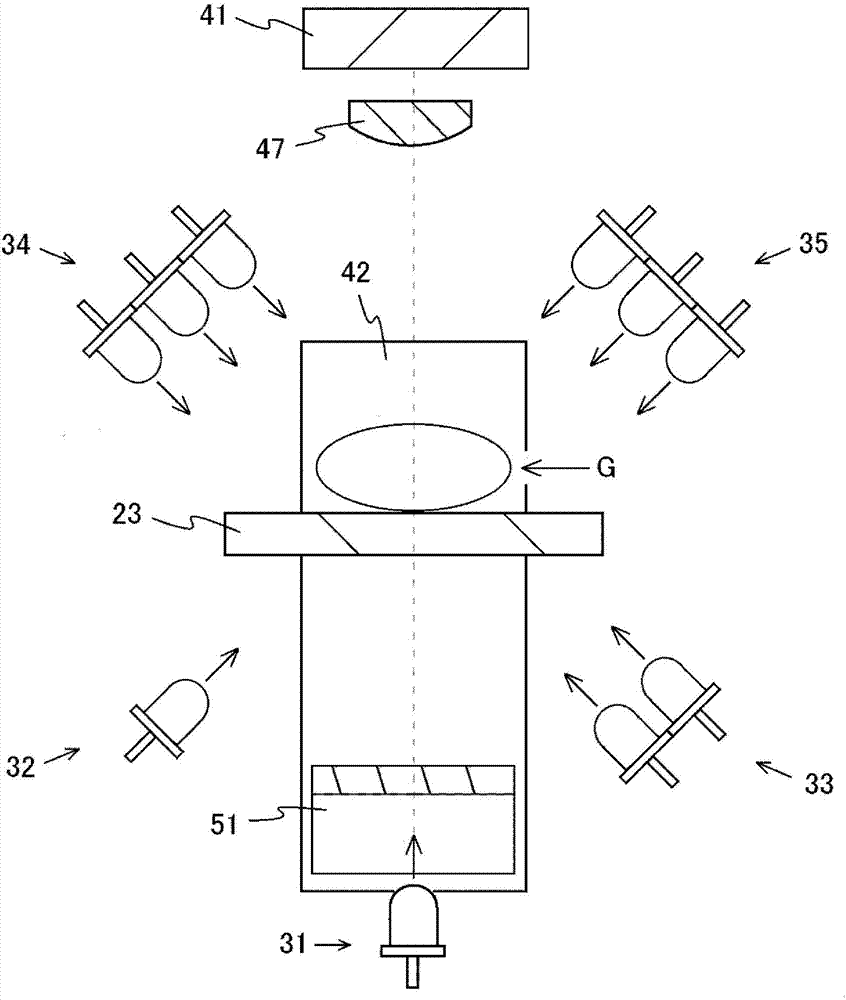

Grain quality discrimination device

The purpose of the present invention is to enhance the precision of quality discrimination of a grain G by a grain quality discrimination device. The present invention is provided with an optical unit 3 for radiating light to a grain G, receiving reflected light and / or transmitted light from the grain G through use of a light receiving sensor and obtaining information for quality measurement from a surface side and a back side of the grain G, and a quality discrimination unit 7 for discriminating the quality of the grain G on the basis of the information. The precision of quality discrimination of the grain G is enhanced by configuring the present invention so that the surface-side information and the back-side information are obtained simultaneously by a single optical unit 3, preventing misalignment of acquired information due to movement of the grain G or a change in the orientation thereof, removing a reference plate for correcting the information from the movement path of the grain to prevent contamination or damage, thereby preventing corruption of the information, and by also taking such measures as providing a special reference plate for lateral-face information of the grain G to increase the precision of the lateral-face information.

Owner:SATAKE CORP

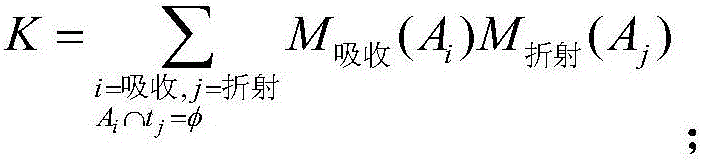

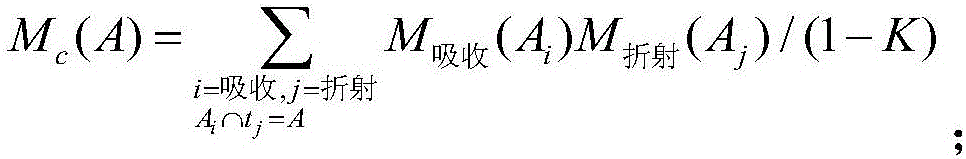

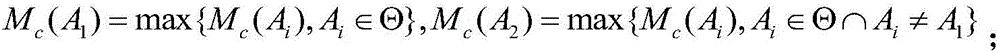

Wheat quality THz spectral classification method based on DS evidence theory

InactiveCN106778815AImprove recognition rateCharacter and pattern recognitionClassification methodsRefractive index

The invention discloses a wheat quality THz spectral classification method based on a DS evidence theory. The method comprises the following steps that: establishing a wheat classification probability output which aims at different-quality wheat absorption spectrums; establishing a wheat classification probability output which aims different-quality wheat refractive index spectrums; and establishing a DS evidence fusion rule. A multi-information fusion technology is adopted to fuse the adsorption spectrum information and the refractive index spectrum information of different-quality wheat samples, a wheat quality nondestructive testing model based on the multi-information fusion technology is established, and the DS evidence theory is adopted to fuse the output results of sub-classifiers and verify the output results for quality discriminatory analysis so as to lay a foundation for applying a THz technology to stored grain quality detection. By use of the method, an identification rate for different-quality wheat samples is improved.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Grain quality multi-index prediction method and device

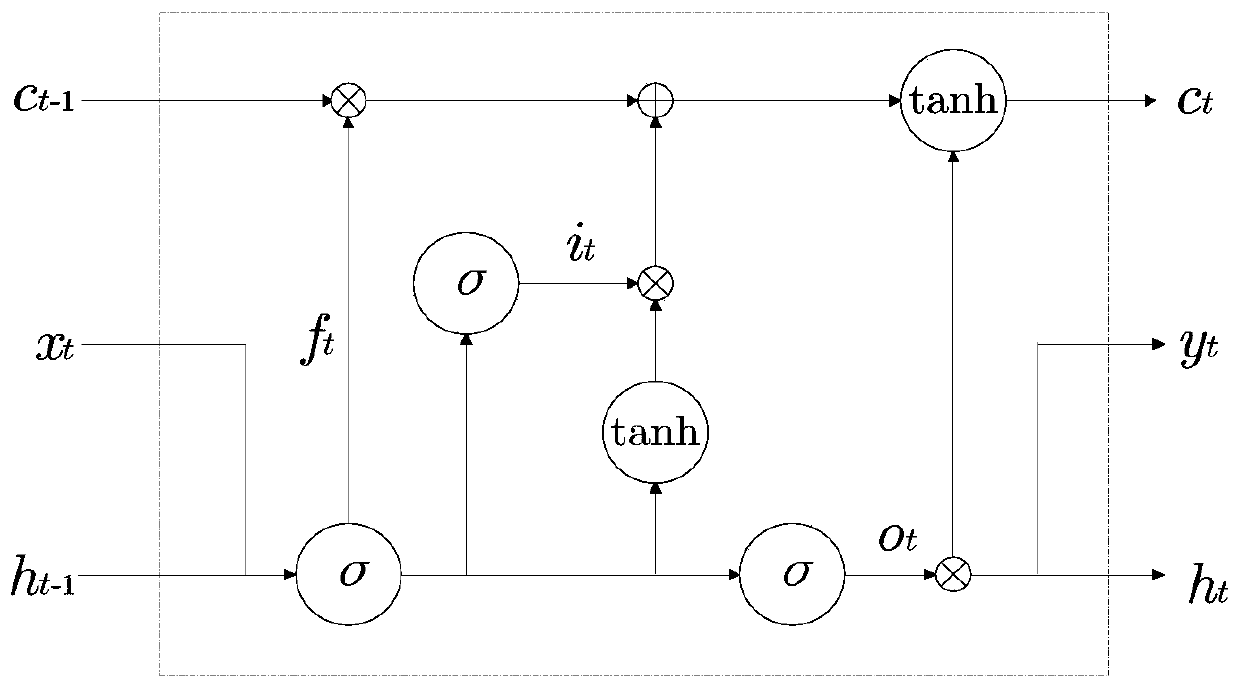

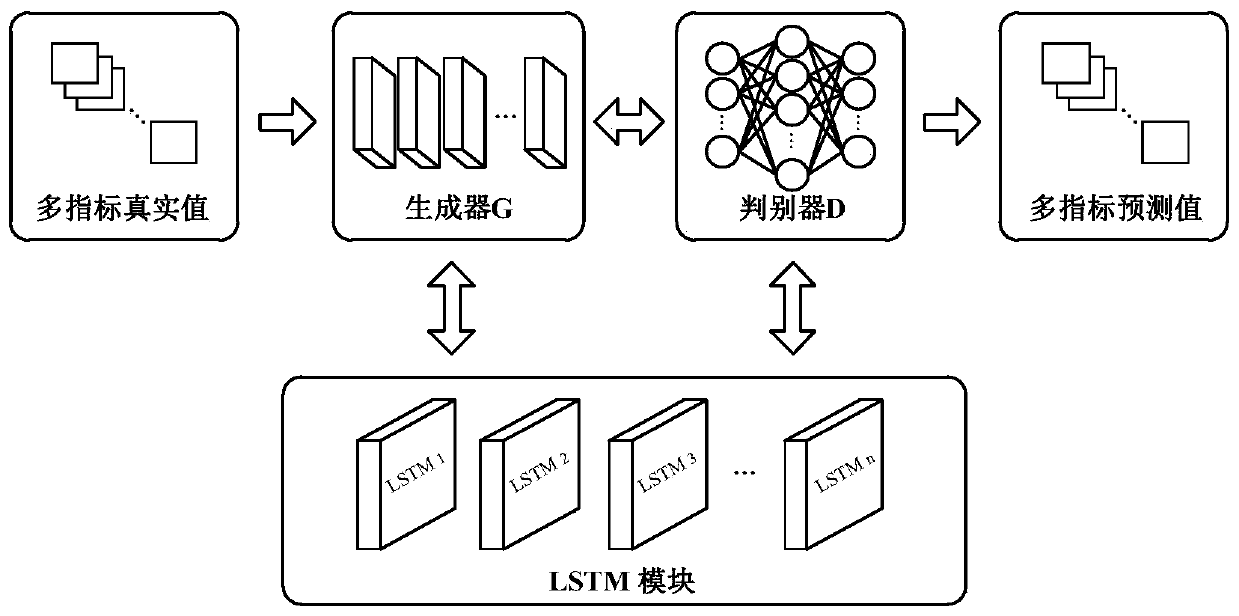

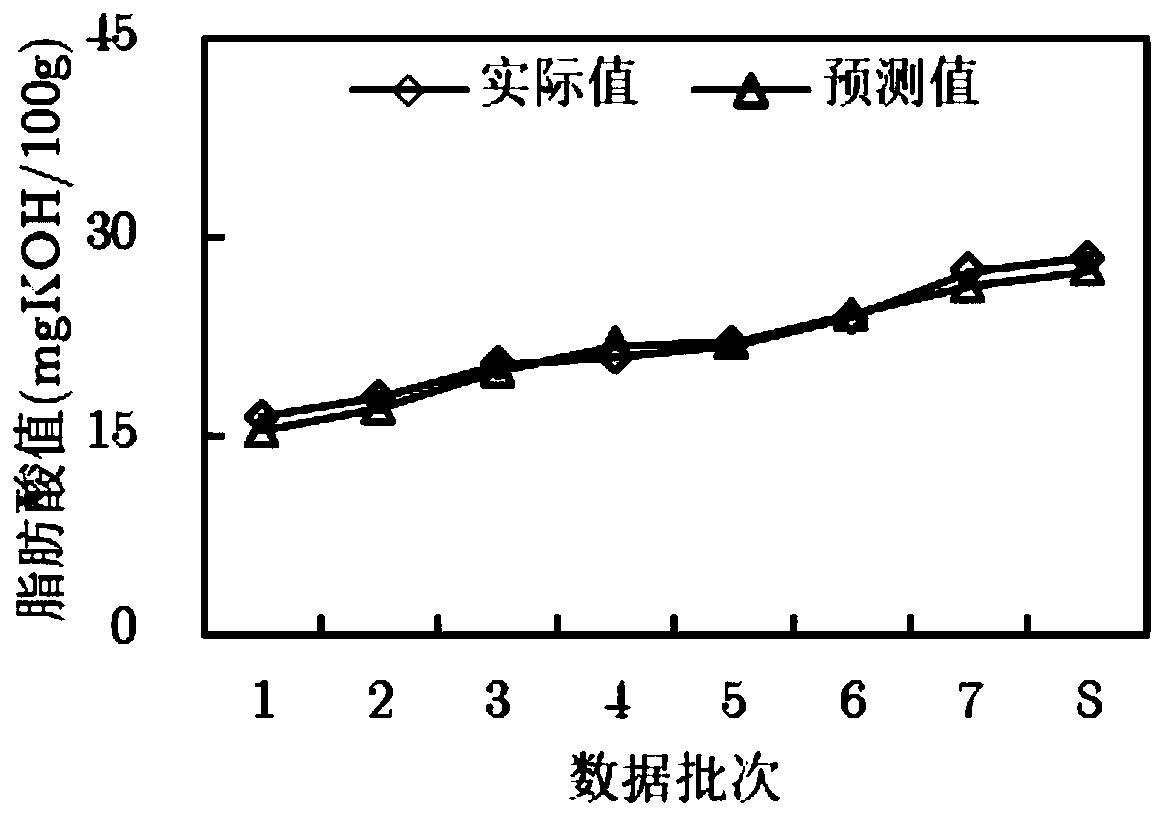

ActiveCN111144552AImprove accuracyPredicted values are accurateForecastingResourcesAlgorithmOutcome predictor

The invention relates to a grain quality multi-index prediction method and apparatus. The method comprises the steps of obtaining N kinds of grain quality index time series data; inputting the N typesof grain quality index time series data into a trained LSTM-GAN prediction model to obtain a prediction value of each index; wherein the LSTM-GAN prediction model comprises an LSTM model and a GAN model; wherein the LSTM model at least comprises N LSTM units; wherein N is the type number of the indexes; inputting the grain quality index time series data of each category in the training set into the corresponding LSTM unit for prediction; a prediction result is sent to the GAN model; and determining corresponding state information by integrating the prediction result of each index through theGAN model, and adjusting the parameters of each LSTM unit according to the state information corresponding to the real index data in the training set, so that the prediction error meets the requirement, and the training of the LSTM-GAN prediction model is realized. According to the method, the relevance and interaction of various grain quality indexes are considered, so that the accuracy of a prediction result is improved.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com