Grain storage air drying bin

A technology of drying warehouse and grain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

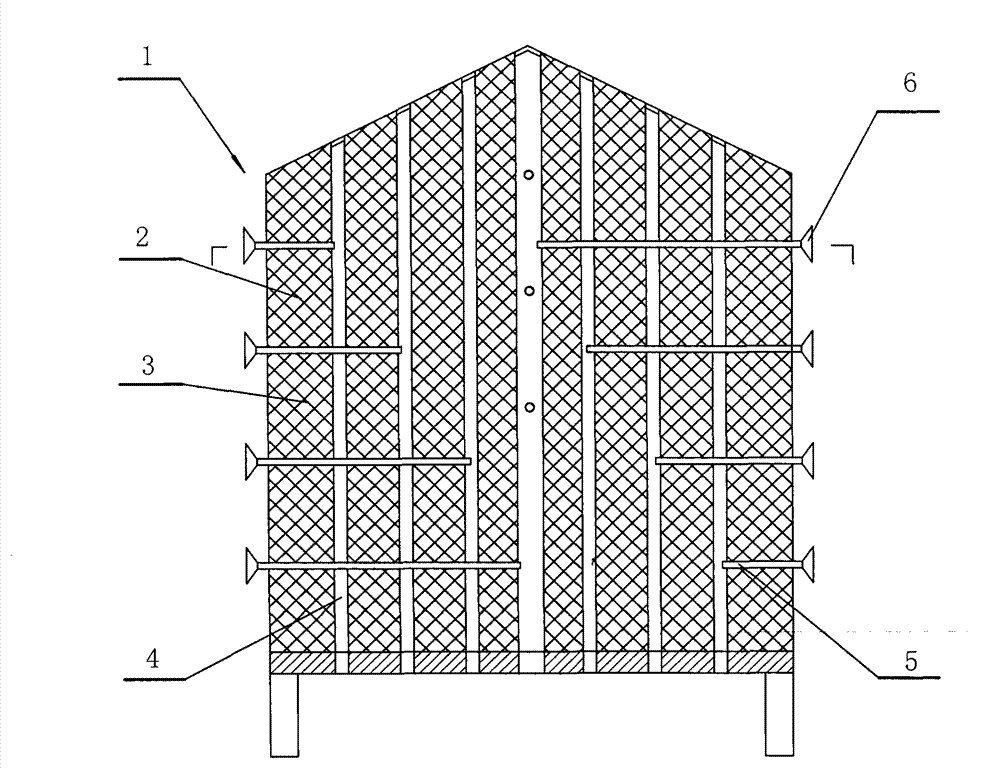

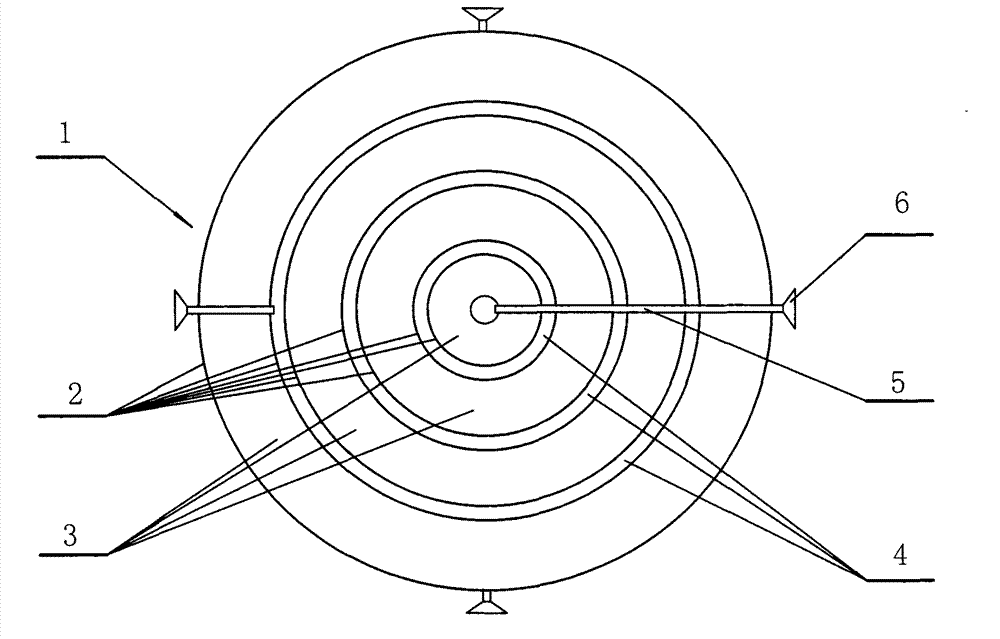

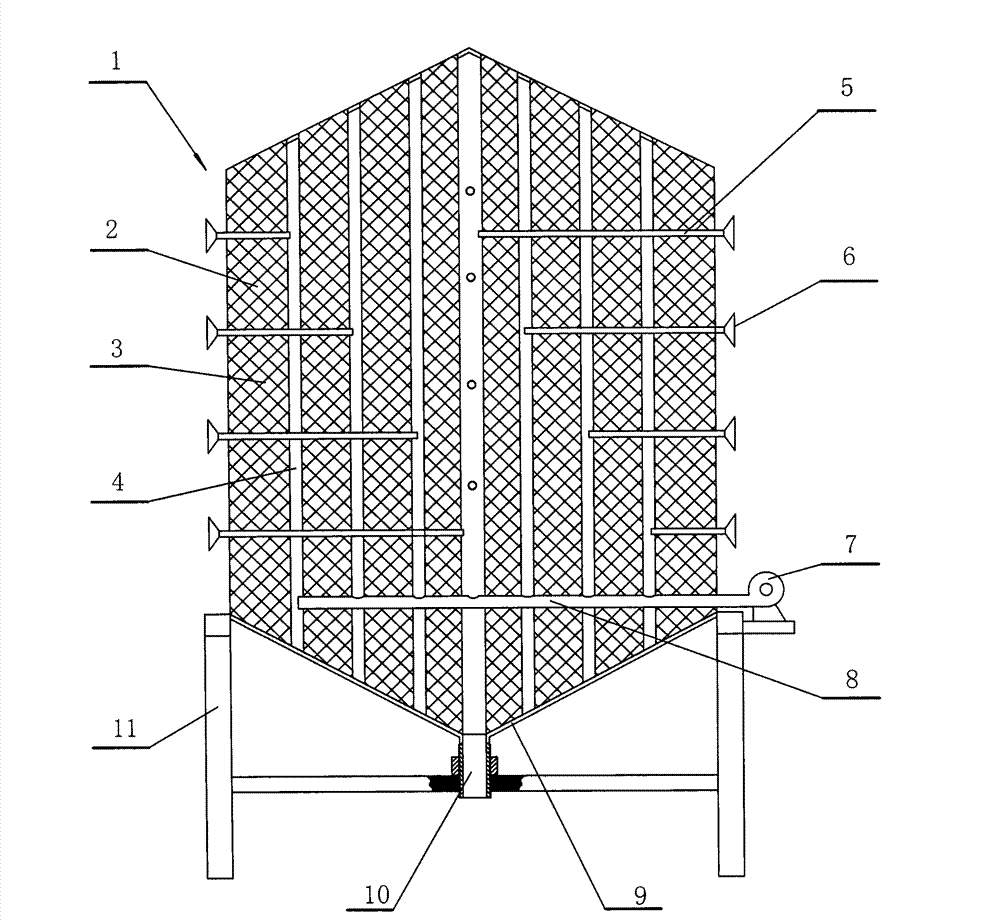

[0046] The general idea of the present invention is: use screen to encircle the storehouse body of filling grain, and the inside of storehouse body is divided into a plurality of ventilation passages with screen, so that air flow circulates in the storehouse body, strengthens the drying effect of grain. The following introduces eight embodiments centering on this idea.

[0047] The first embodiment: as figure 1 , 2 As shown, the main body of the grain storage air-drying warehouse is a cylindrical warehouse body 1, and the periphery of the warehouse body 1 is surrounded by a screen 2. Of course, a framework with higher strength can also be used to support the screen 2. The inside of the warehouse body 1 is provided with multi-layer screens to separate a plurality of cavities. Wherein the wider cavity is the grain storage chamber 3, and the narrower cavity is the ventilation channel 4. For the circular bin body 1, it is best as figure 2 As shown, the grain storage cavity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com