Patents

Literature

564 results about "Stored grain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

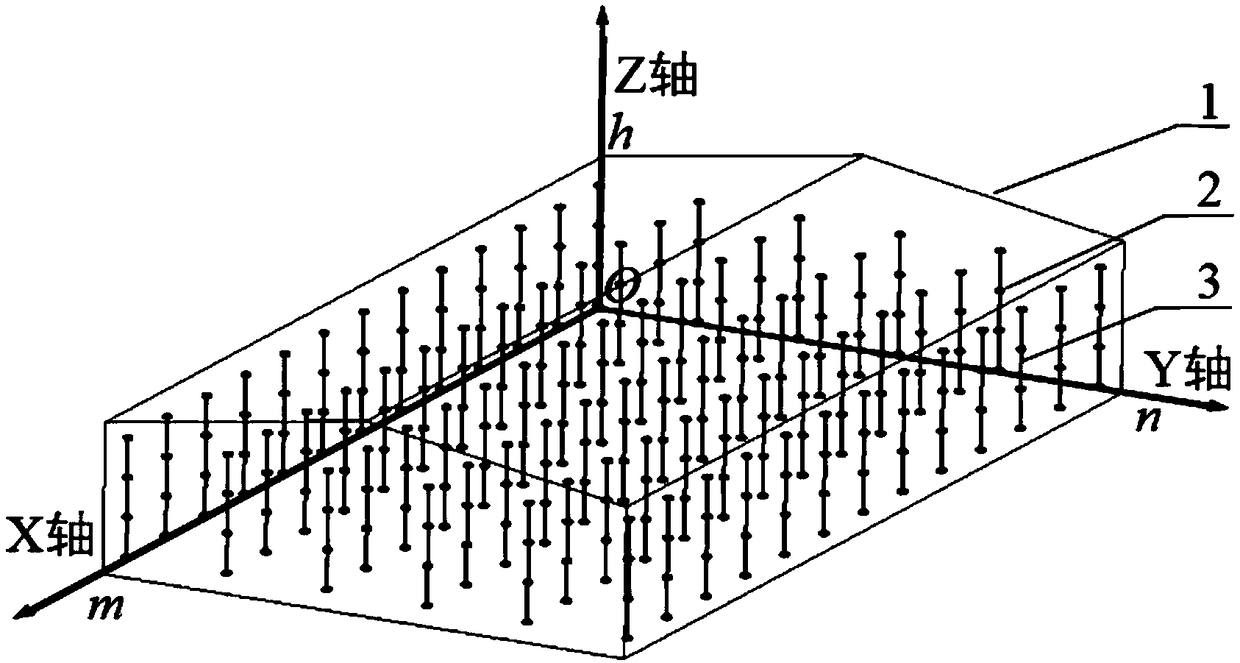

Method for detecting quantity of stored grains in granary based on pressure sensor

InactiveCN101907481AGuaranteed detection effectHigh measurement accuracyWeighing apparatus for materials with special property/formProcess engineeringForce sensor

The invention relates to a method for detecting the quantity of stored grains in a granary based on a pressure sensor, belonging to the technical field of detection. The detection method in the invention can calculate pressure values of the bottom surface and the side surfaces of the granary by adopting the output values of the pressure sensor according to the arrangement modes of pressure sensors of different types, and calculates the quantity of the stored grains in the granary based on an established model. The detection method in the invention has high measurement precision, strong practicability and low detection cost, can meet the actual requirements on detecting the quantity and distribution of the stored grains in nationwide granaries on line in real time, provides a technical means for accurately mastering the quantity of the stored grains in China in real time and gives services to guaranteeing the grain safety of China.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

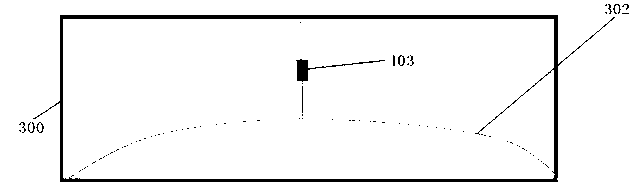

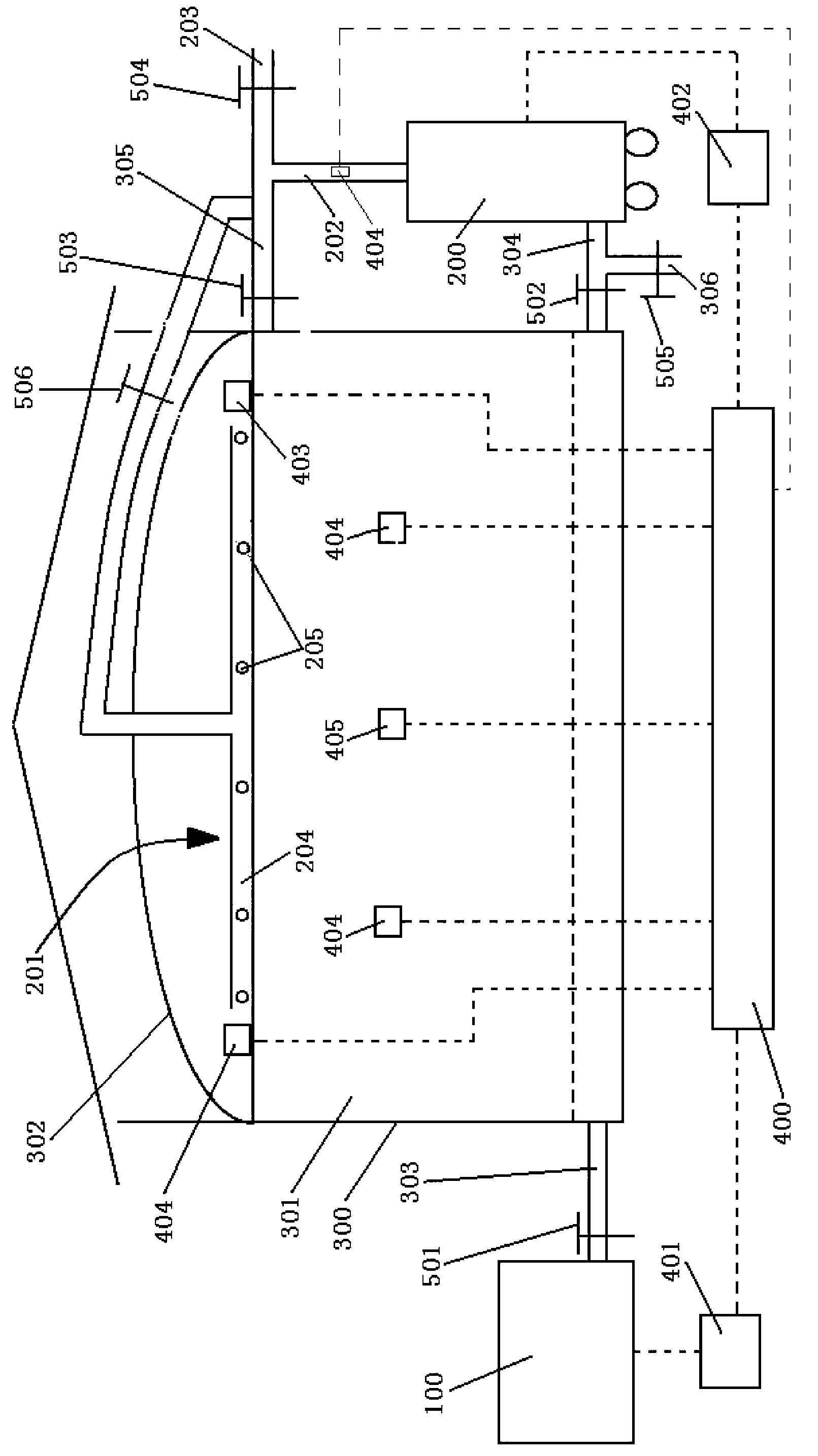

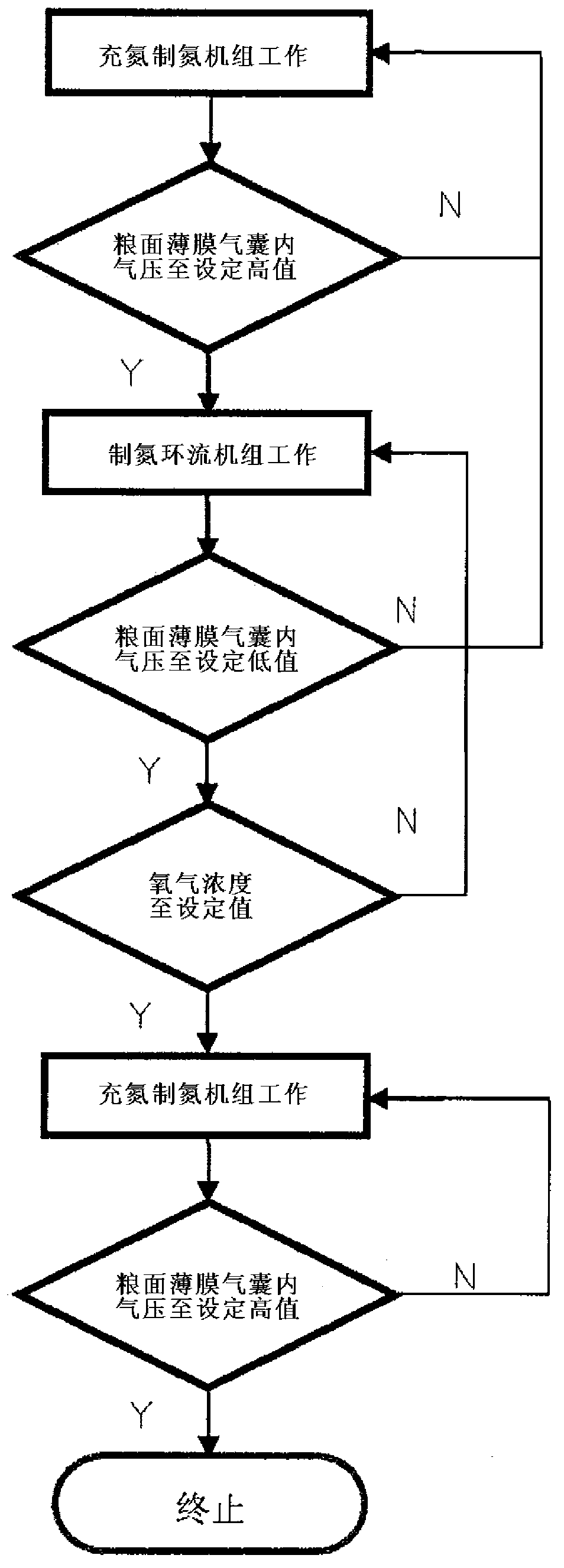

Circular inflation modified atmosphere grain storage device and method using device

InactiveCN102907220AGuaranteed qualityImprove work efficiencyAgriculture tools and machinesFood processingAutomatic controlStored grain

The invention discloses circular inflation modified atmosphere grain storage device and method using the device. The device comprises a nitrogen inflation system, a nitrogen preparation circulation system, a grain barn system and an automatic control system. The nitrogen inflation system comprises a nitrogen inflation / preparation unit. The circulation system comprises a nitrogen preparation circulation unit and a circulation pipeline. The grain barn system comprises a barn body, a grain pile, a grain face film gasbag disposed above the grain pile, and a grain storage ventilation pipeline, a nitrogen inflation pipeline, a circular nitrogen inflation pipeline and a gas outlet pipe disposed in the grain pile. The automatic control system comprises a central processor, a nitrogen inflation / preparation unit control module, a nitrogen preparation circulation unit control module, a pressure sensor, an oxygen concentration sensor, and a grain pile temperature / humidity sensor. By cooperative operation of the nitrogen inflation system and the circulation system, the device and the method greatly improve working efficiency, save energy consumption, guarantee grain storage quality, and achieve significant pest killing effect.

Owner:ACAD OF STATE GRAIN ADMINISTRATION +1

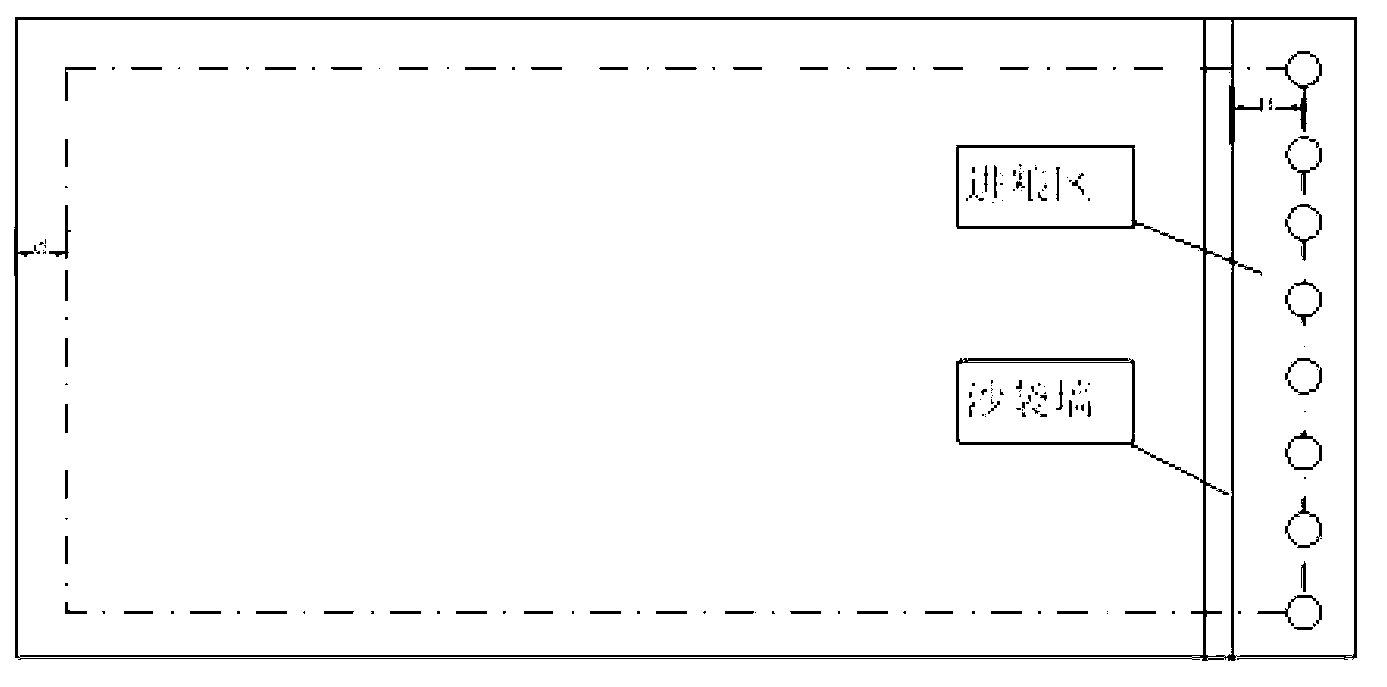

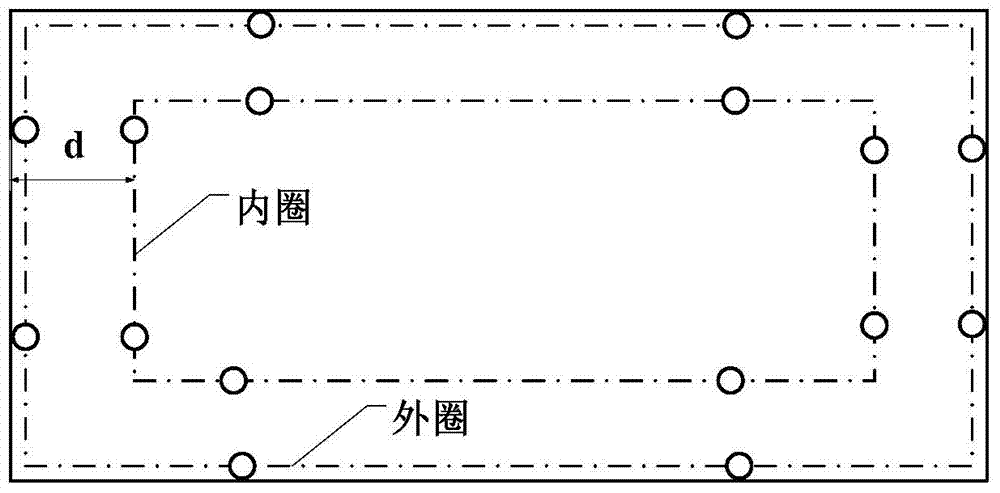

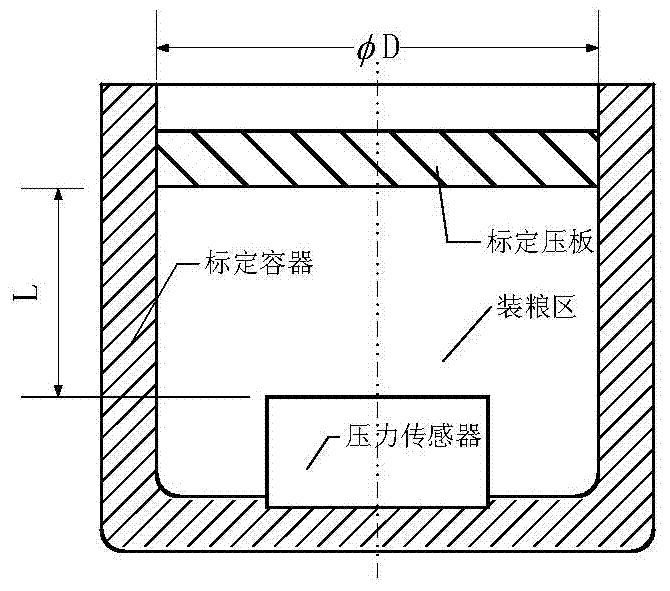

Grain storage quantity detection method for horizontal warehouse and shallow silo

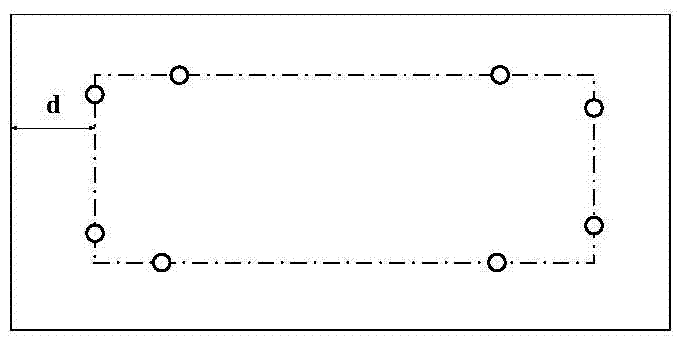

InactiveCN102706417ALow costReduce workloadWeighing apparatus for materials with special property/formGrain storageSurface pressure

The invention relates to a grain storage quantity detection method for horizontal warehouses and shallow silos. The grain storage quantity detection method comprises the following steps of: firstly selecting specific pressure sensors to lay a grain warehouse pressure sensor detection network; distributing the pressure sensors along the side wall of the grain warehouse in the mode that all the pressure sensors are evenly-spaced laid at d meter distance from the side wall; and determining whether a grain warehouse is calibrated or not so as to obtain a calibration parameter and a grain warehouse weight prediction model, spreading the top surface of a grain pile in the grain warehouse after the grain warehouse is fully filled with the grain, detecting the average output valve of the pressure sensor at the bottom of the grain warehouse, and detecting the grain storage quantity of the grain warehouse according to an actually-tested bottom surface area of the grain warehouse, a bottom surface area of the calibrated grain warehouse and calibrated parameters by using a model so as to obtain an estimated value of the weight of the grain warehouse. According to the grain storage quantity detection method provided by the invention, the pressure sensors are required to be arranged on the bottom surface of the grain warehouse, and a compensating item of a side grain warehouse friction action is added into a bottom surface pressure estimating model in order to avoid using the side pressure sensor and accurately obtain the estimated value of the pressure of the bottom surface of the grain warehouse, so that the quantity of the sensors is obviously reduced, and the device detection cost and the installation and maintenance cost are reduced.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

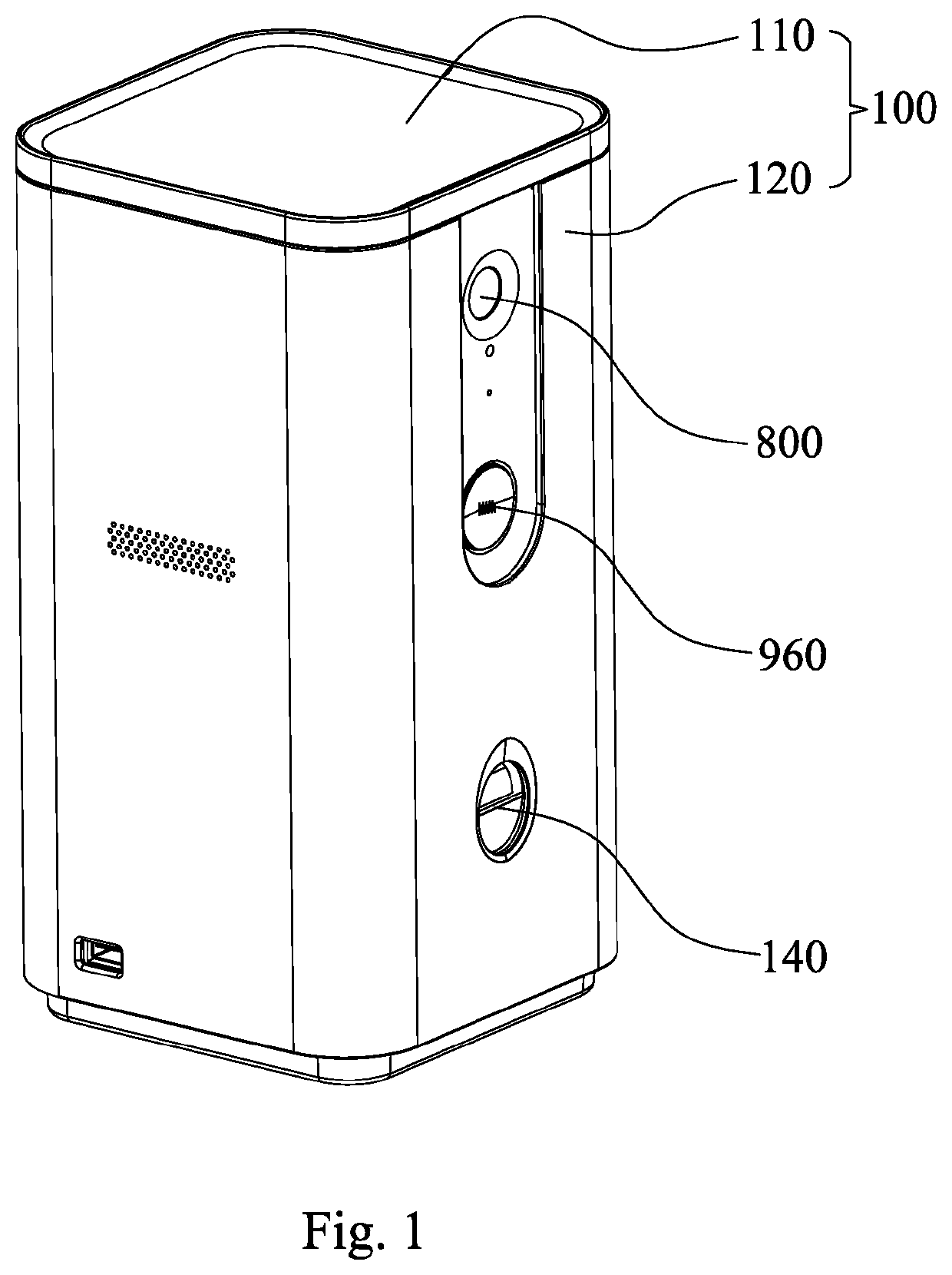

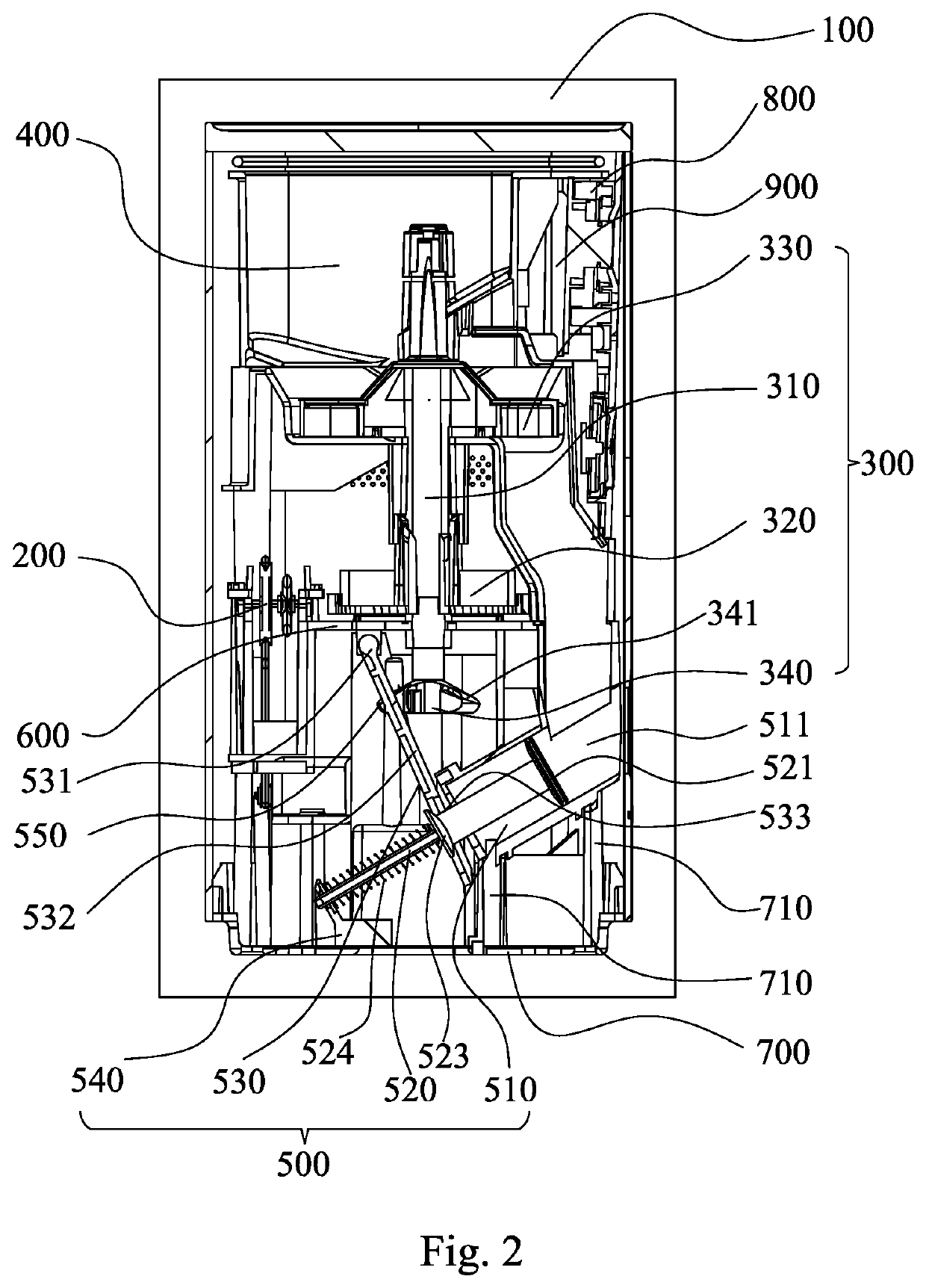

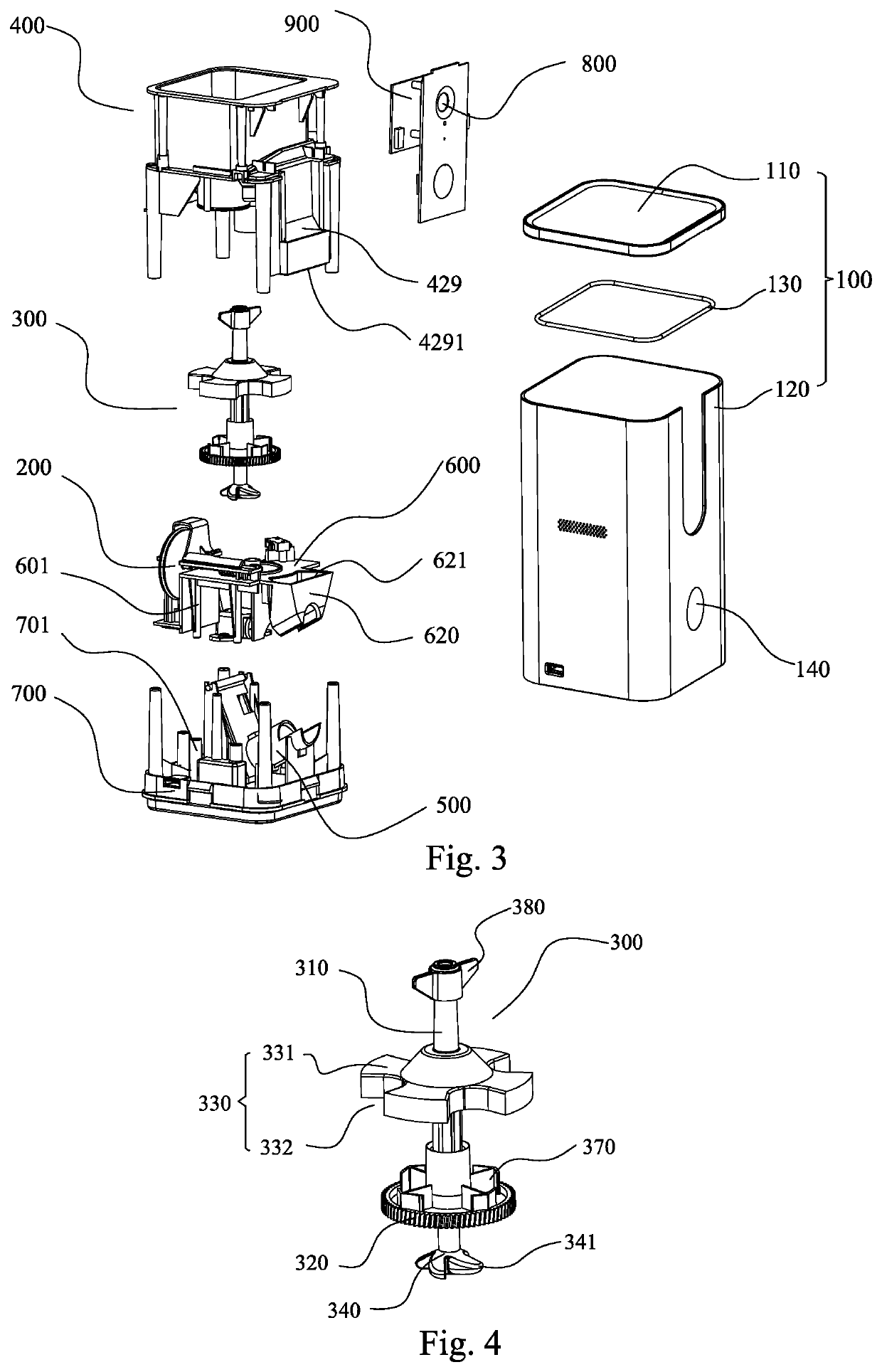

Smart pet feeder

ActiveUS20200100460A1Improve feeding effectAnimal feeding devicesOther apparatusGear wheelGrain storage

The smart pet feeder includes a housing, and a grain storage component, a driving component and a rotating component, arranged therefor in the upper part, the middle part and the lower part of the housing; a rotating component is arranged in the housing, and the rotating component has a supporting column, the upper part, of it is provided with a wheel, the lower part of it is provided with a driving gear, the bottom end of it is provided with a cam; the upper part is extended into the grain storage component, and the wheel is contained in the grain storage component; the driving gear is rotatably connected with the driving component, the cam is connected with the throwing component.

Owner:DOGNESS GRP LLC

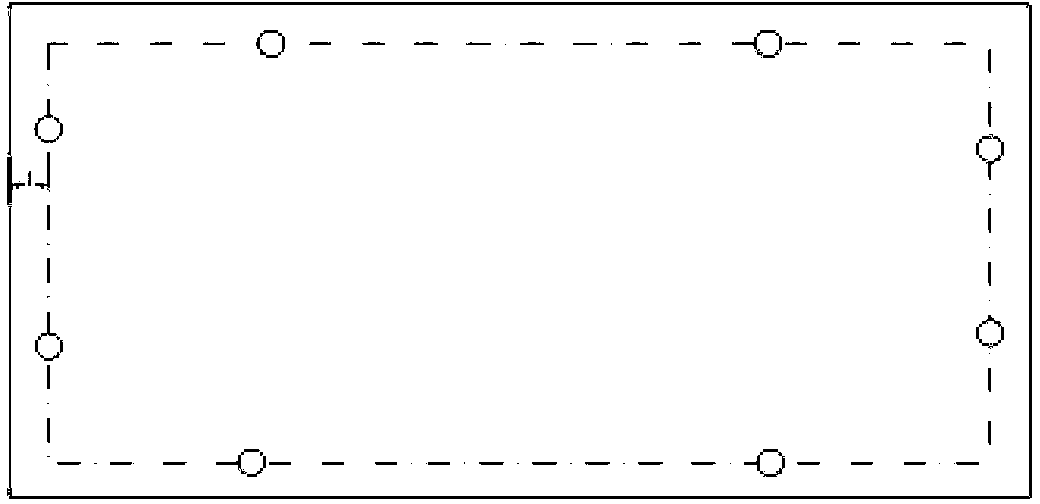

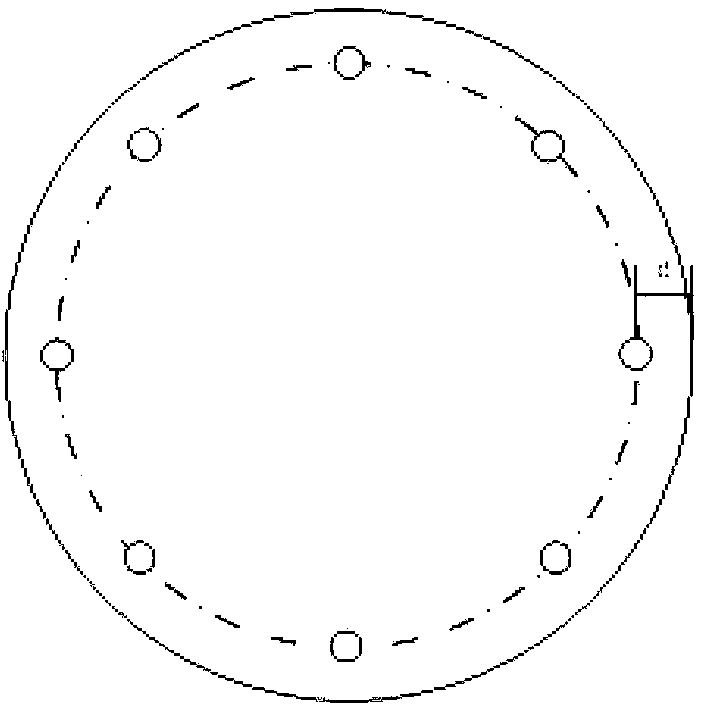

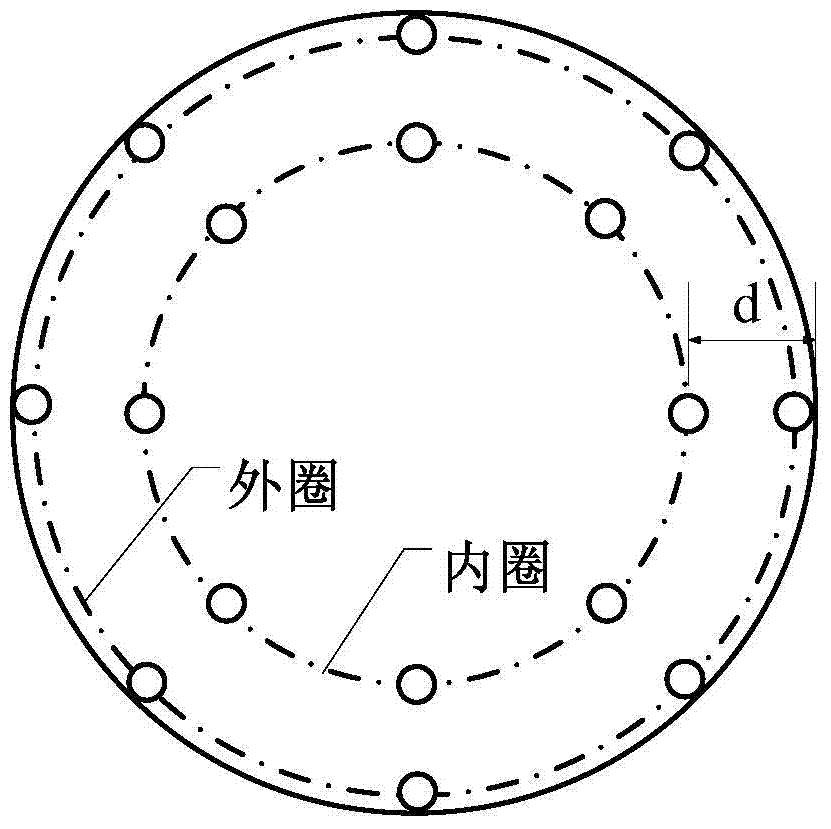

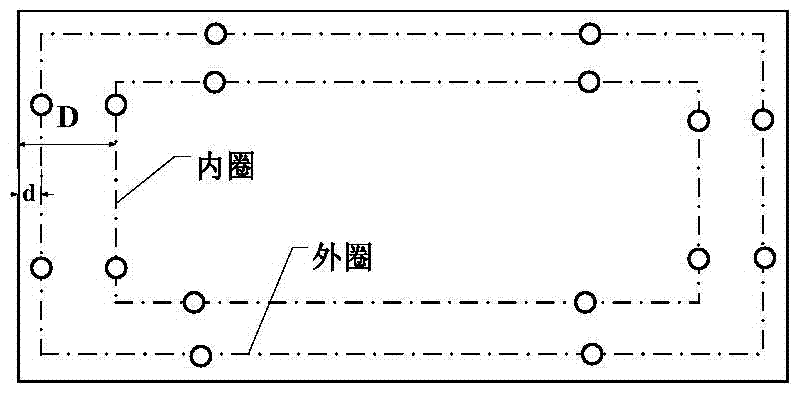

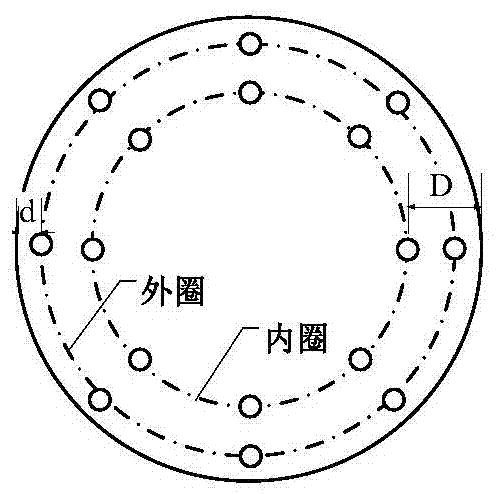

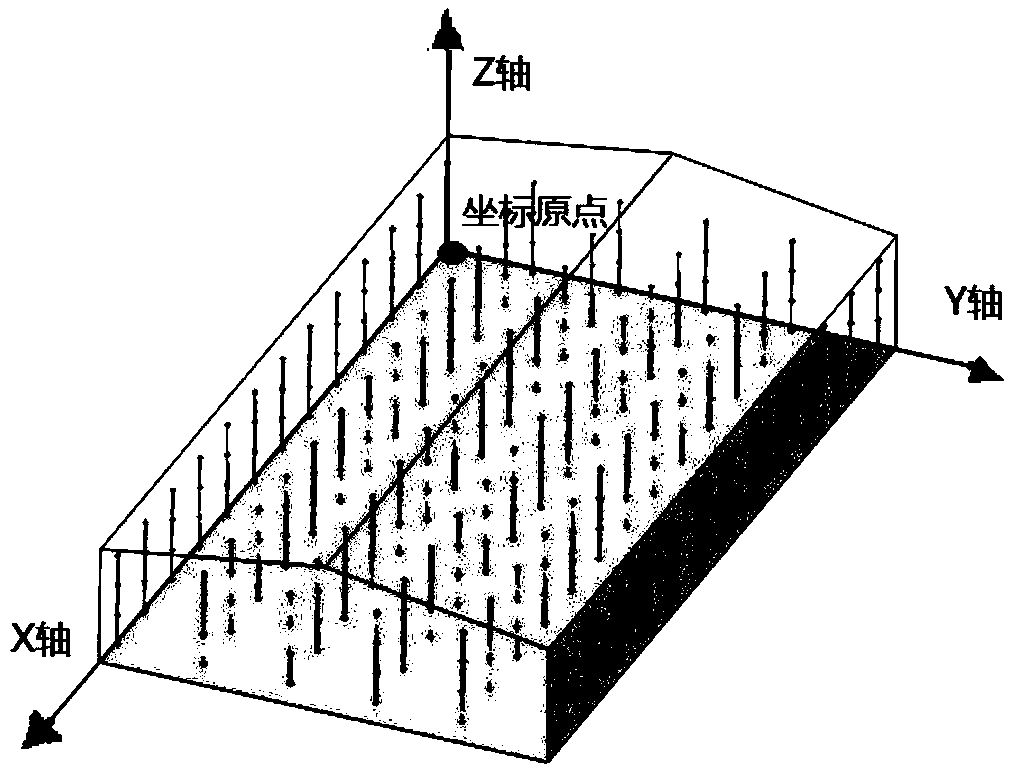

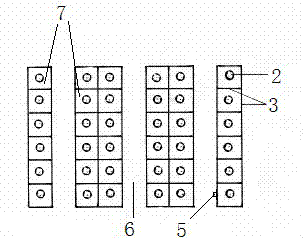

Granary, stored grain weight detection system and method and sensor arrangement method

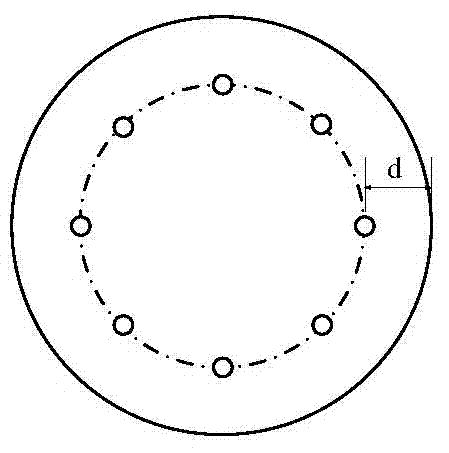

ActiveCN104296847AReduce usageLow costWeighing apparatus for materials with special property/formGrain weightEngineering

The invention relates to a granary, a stored grain weight detection system and method and a sensor arrangement method, and provides the granary stored grain weight detection method based on the arrangement of two loops of sensors arranged on the bottom. The core technology comprises arrangement of inner and outer two loops of bottom pressure sensors, grain pile weight detection model based on bottom pressure intensity and side pressure intensity mean value estimation, and system calibration and modeling method and the like. The method has the advantages of high detection precision, low requirement for the performance of sensors, high applicability, simple device, convenient use and maintenance, and facilitating to carry out remote online granary quantity detection and granary condition monitoring and the like, and the demand for carrying out remote online quantity detection of grains stored in commonly-used granaries can be met. Since the detection method can be suitable for quantity detection of stored grains in a plurality of granary structures, the method has huge application value, and provides a new technological means for guaranteeing nation grain quantity safety.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

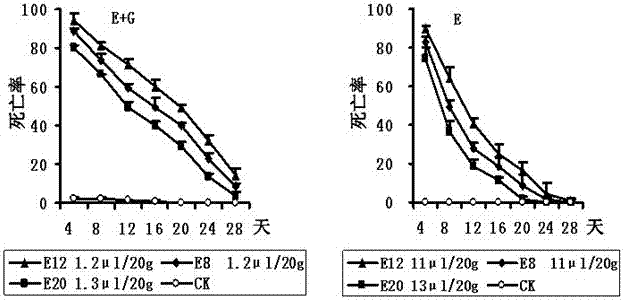

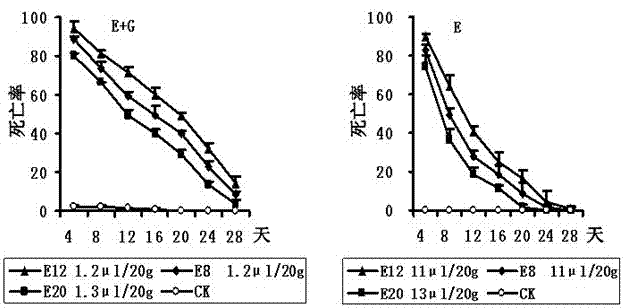

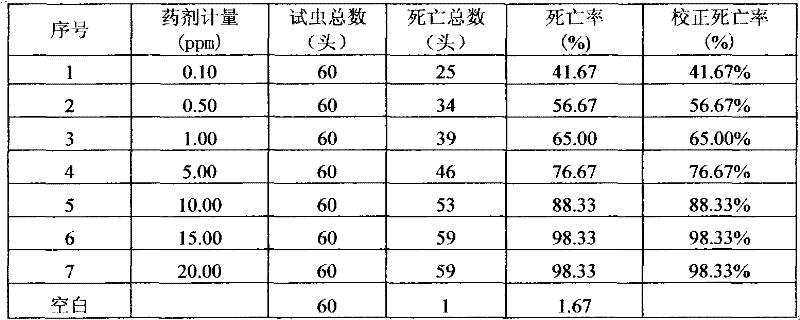

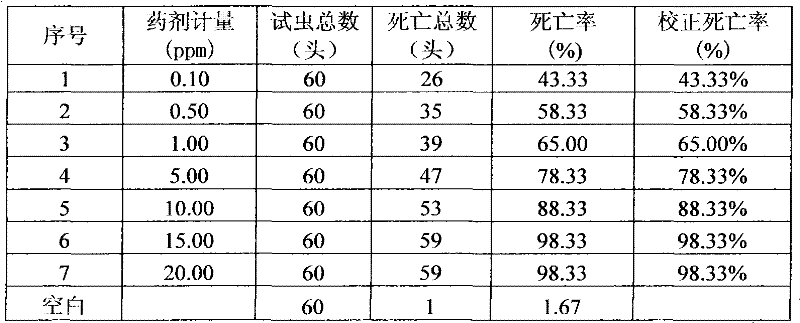

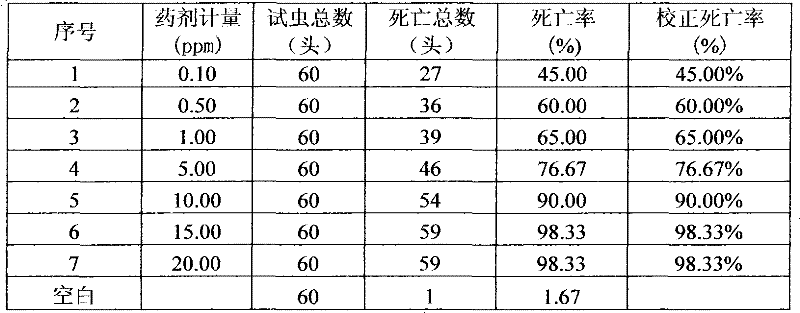

Method for controlling grain pest by using essential oil

InactiveCN102388958AReduce volatilityGood effectEdible seed preservationAgricultural engineeringPesticide use

The invention discloses a method for controlling grain pest by using essential oil. In the method, the essential oil and kieselguhr are mixed and used for controlling the grain pest. Compared with other methods for controlling the grain pest by using the essential oil, the method has the advantages that the kieselguhr is used as a carrier, and the volatilization of the essential oil can be delayed, so that the effects of the essential oil can be improved and efficiency duration can be prolonged; and by the method for controlling the grain pest by using the essential oil, the using amount of the essential oil can be greatly reduced and the pest killing effect of the essential oil is not influenced, and the pesticide using cost can be effectively reduced. The method has very wide application prospect in the agricultural technical fields of controlling the grain pest and the like.

Owner:SOUTH CHINA AGRI UNIV

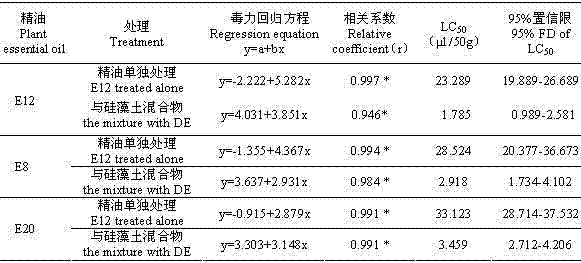

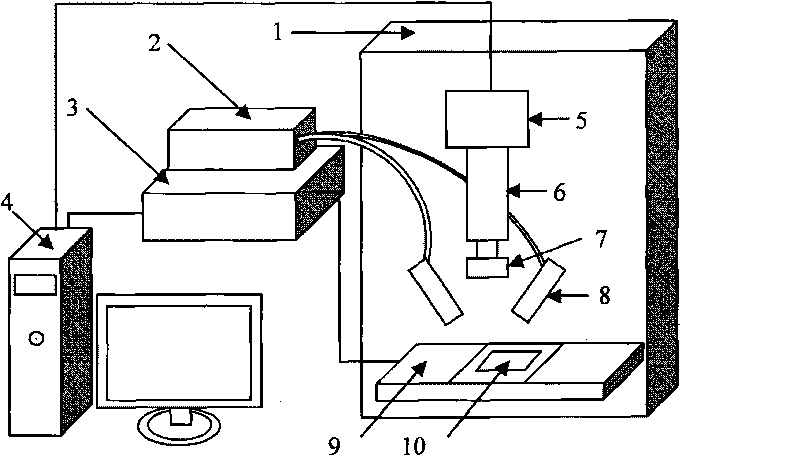

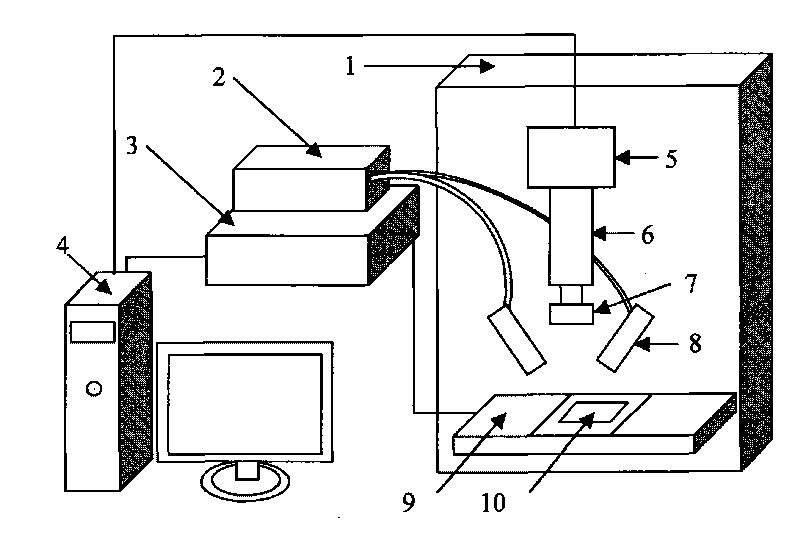

Device and method for detecting stored-grain insects based on visible light-near infrared binocular machine vision

InactiveCN101701915AAutomatic countingAccurate countWithdrawing sample devicesMaterial analysis by optical meansMachine visionCharacteristic space

The invention relates to a device and a method for detecting stored-grain insects, which consists of a stored-grain insect separation part, a stored-grain insect transmission part and a machine vision part, wherein the stored-grain insect separation part efficiently separates stored-grain insects from a grain sample by utilizing a screening motor to drive a vibrating screen; the stored-grain insect transmission part can transmit an acquisition box to an appointed position and can automatically clear screen underflows in the acquisition box; the machine vision part consists of a control module, a computer, a lighting box, a near infrared camera, a visible light CCD, a light source and corresponding software. The method for detecting stored-grain insects comprises the following steps of sequentially acquiring near infrared images and visible light images of the screen underflows for information fusion, extracting entire morphological characteristics and local morphological characteristics of the stored-grain insects, and automatically determining the kinds and the quantity of the live stored-grain insects by utilizing an optimized stored-grain insects characteristic space and identification software, thus realizing the real-time, precise and automatic detection of normal stored-grain insects.

Owner:JIANGSU UNIV

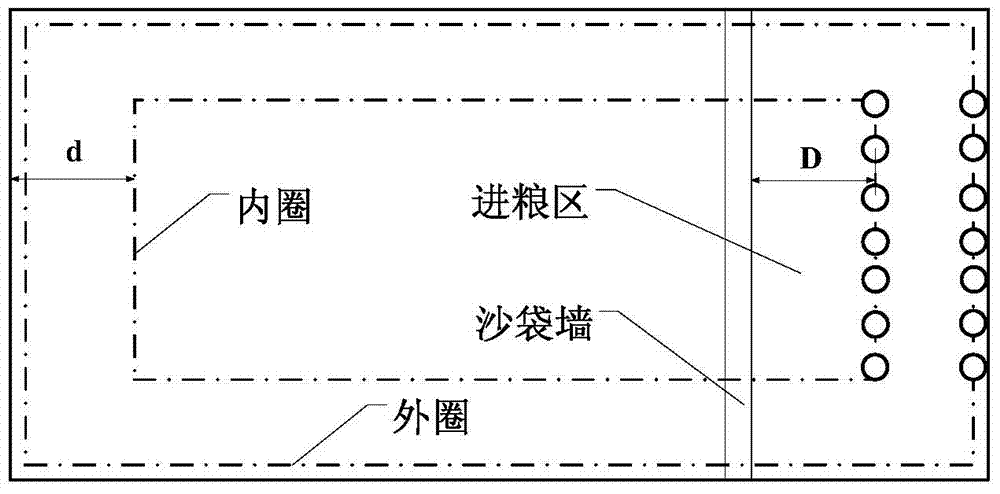

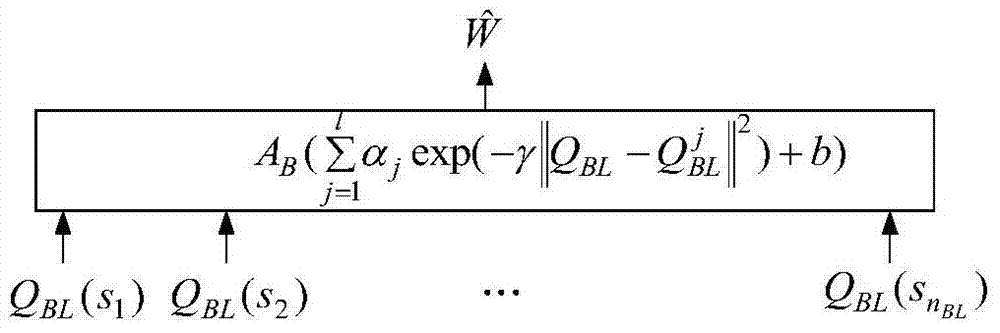

Grain bin stored-grain quantity detection method based on detection point pressure intensity value sequence

ActiveCN104330137AWeighing apparatus for materials with special property/formSupport vector regression modelEngineering

The invention relates to a grain bin stored-grain quantity detection method based on a detection point pressure intensity value sequence. A circle of pressure sensors are arranged on the bottom face of a grain bin and the vertical distance of each pressure sensor to a closest outer wall is d; and the output value of each sensor is detected and according to a detection model (as is shown in the specification), the stored-grain weight estimation W<^> of the grain bin is calculated. According to characteristics of pressure intensity distribution of the bottom face of the grain bin and change of pressure intensity measurement values, the invention proposes the grain bin stored-grain quantity detection method of a support vector regression model, based on the detection point pressure intensity value sequence. According to a corresponding sensor arrangement method, the core technology of the method includes two parts: the support vector regression grain bin stored-grain quantity detection model based on the detection point pressure intensity value sequence and a system calibration and modeling method. The grain bin stored-grain quantity detection method has the characteristics of being high in detection precision, high in universality and adaptive to stored-grain quantity detection of a plurality of kinds of grain bin structure types and the like.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Method and device for detecting stored-grain insects based on near infrared super-spectral imaging technology

InactiveCN101701906AGuaranteed recognition accuracyAutomatic countingColor/spectral properties measurementsIndiumLength wave

Owner:JIANGSU UNIV

Grain bin stored-grain quantity detection method based on structure self-adapting detection model

ActiveCN104330138AWeighing apparatus for materials with special property/formGrain weightEngineering

The invention relates to a grain bin stored-grain quantity detection method based on a structure self-adapting detection model. Two circles of pressure sensors are arranged on the bottom face of a grain bin and output values of the sensors are detected and according to the detection model (as is shown in the specification), the grain bin stored-grain weight estimation W<^> is calculated. The method has the characteristics of being high in detection precision and adaptive to stored-grain quantity detection of a plurality of kinds of grain bin structure types and the like.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

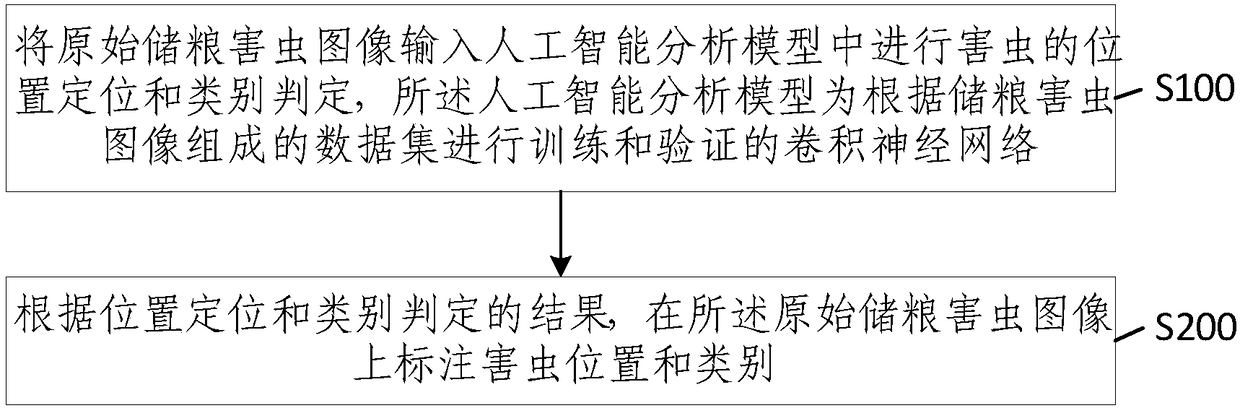

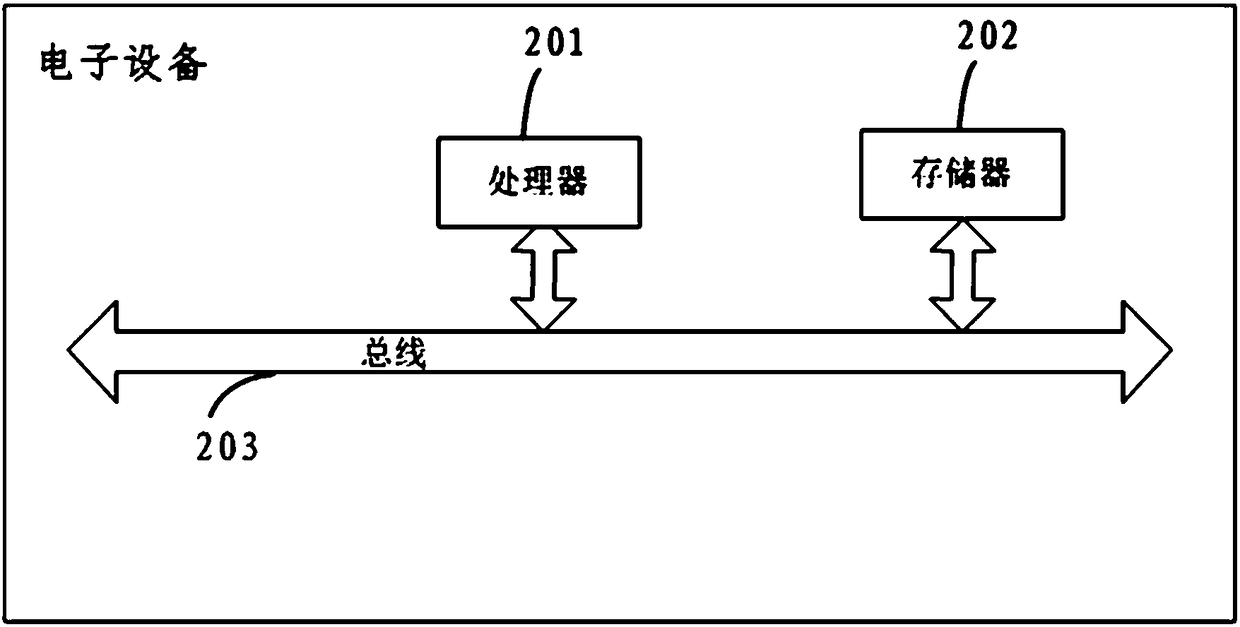

Method and device for detecting and identifying stored grain insects

InactiveCN108615046AHigh precisionImprove efficiencyData processing applicationsCharacter and pattern recognitionAnalytic modelData set

The invention provides a method and device for detecting and identifying stored grain insects. The method comprises the steps of inputting an original stored grain insect image into an artificial intelligence analysis model to perform location positioning and category judgment on insects, wherein the artificial intelligence analysis model is a convolutional neural network which is trained and verified according to a data set formed by the stored grain insect image; and labeling the insect location and category on the original stored grain insect image according to a location positioning and category judgment result. According to the invention, a model capable of correctly positioning and identifying various stored grain insects is trained according to a deep leaning based target detectionalgorithm and collected stored grain insect data, thereby avoiding the drawbacks of poor robustness and generalization of manual design features, and improving the accuracy and efficiency of detectionand identification.

Owner:BEIJING UNIV OF POSTS & TELECOMM

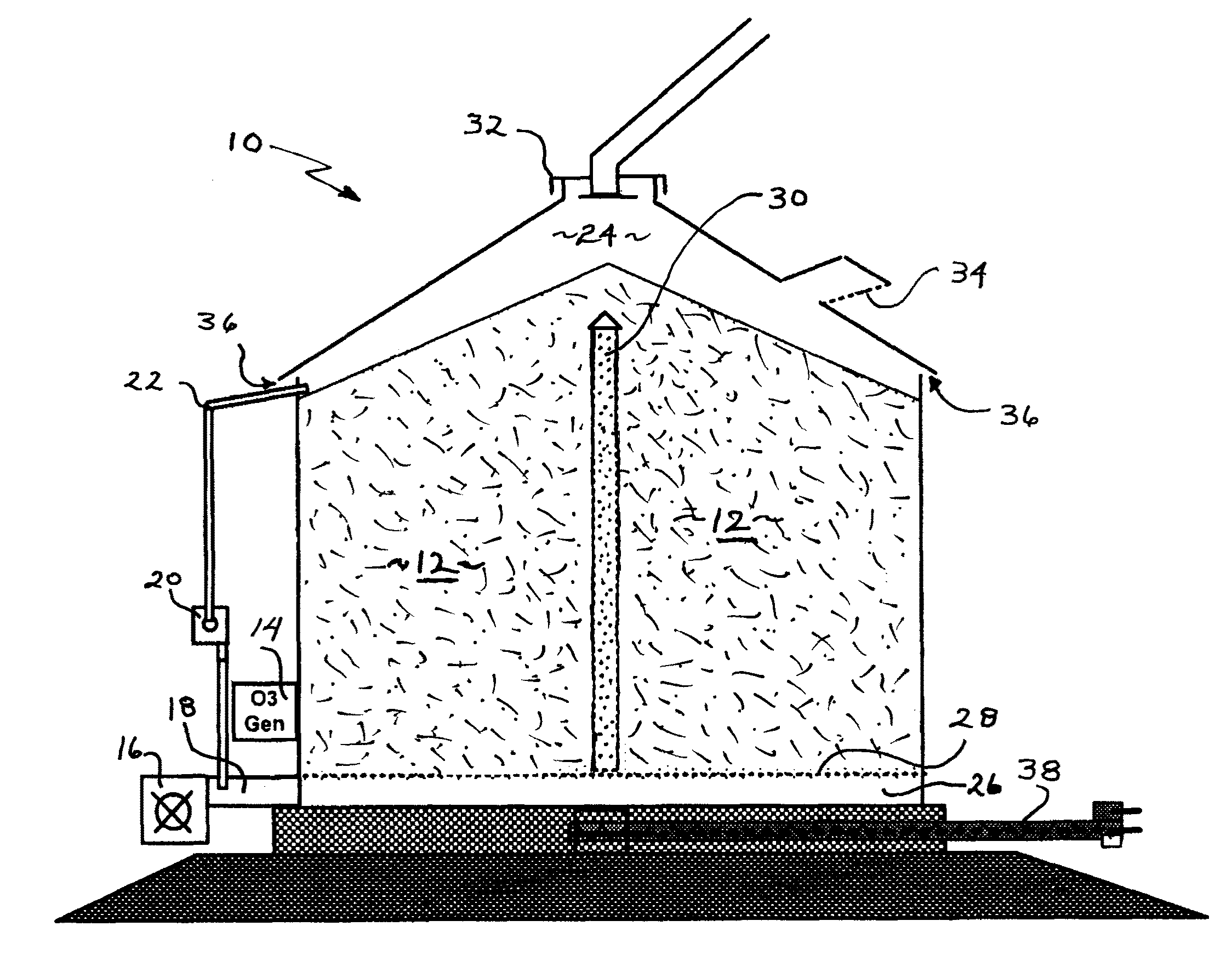

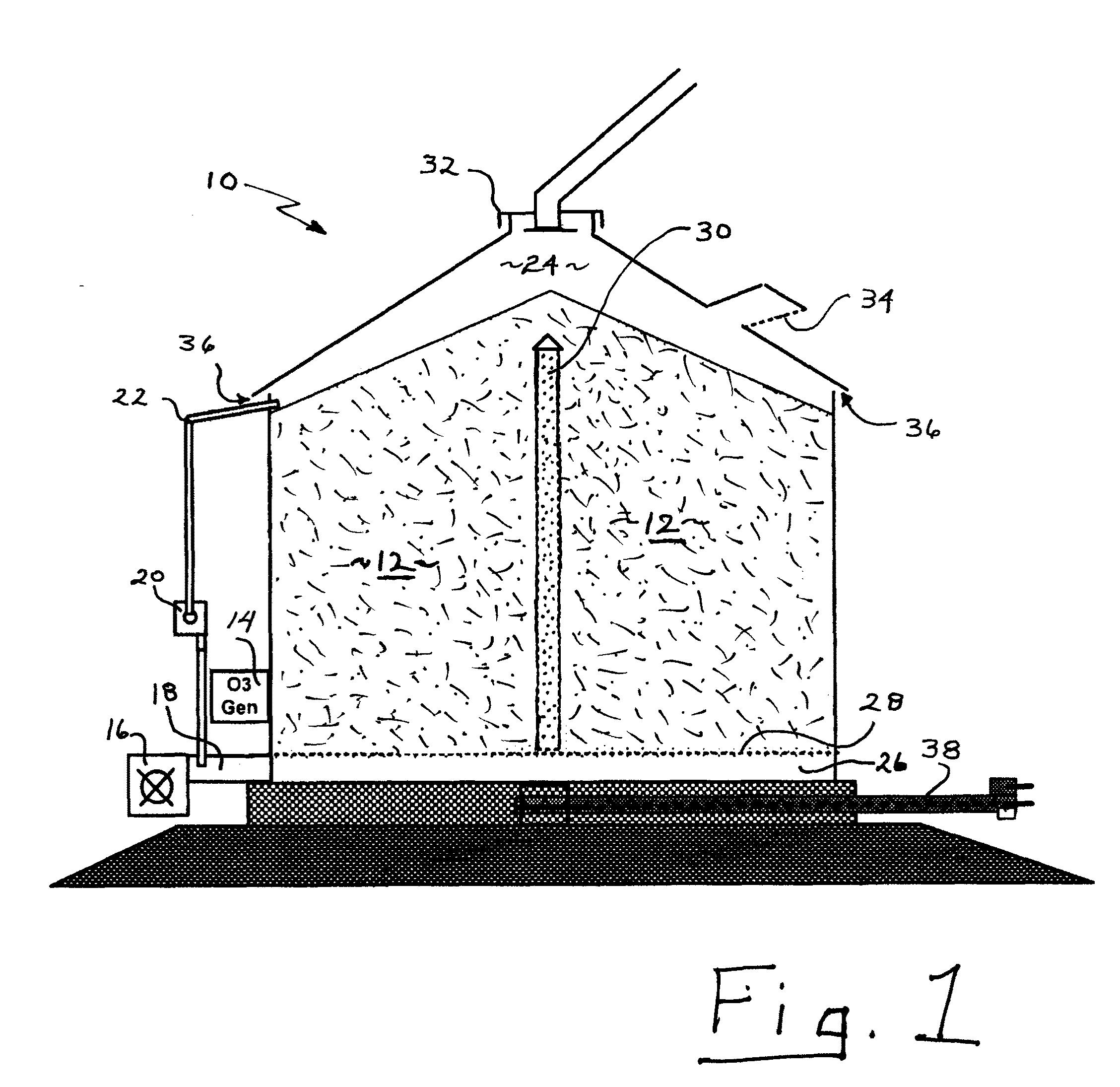

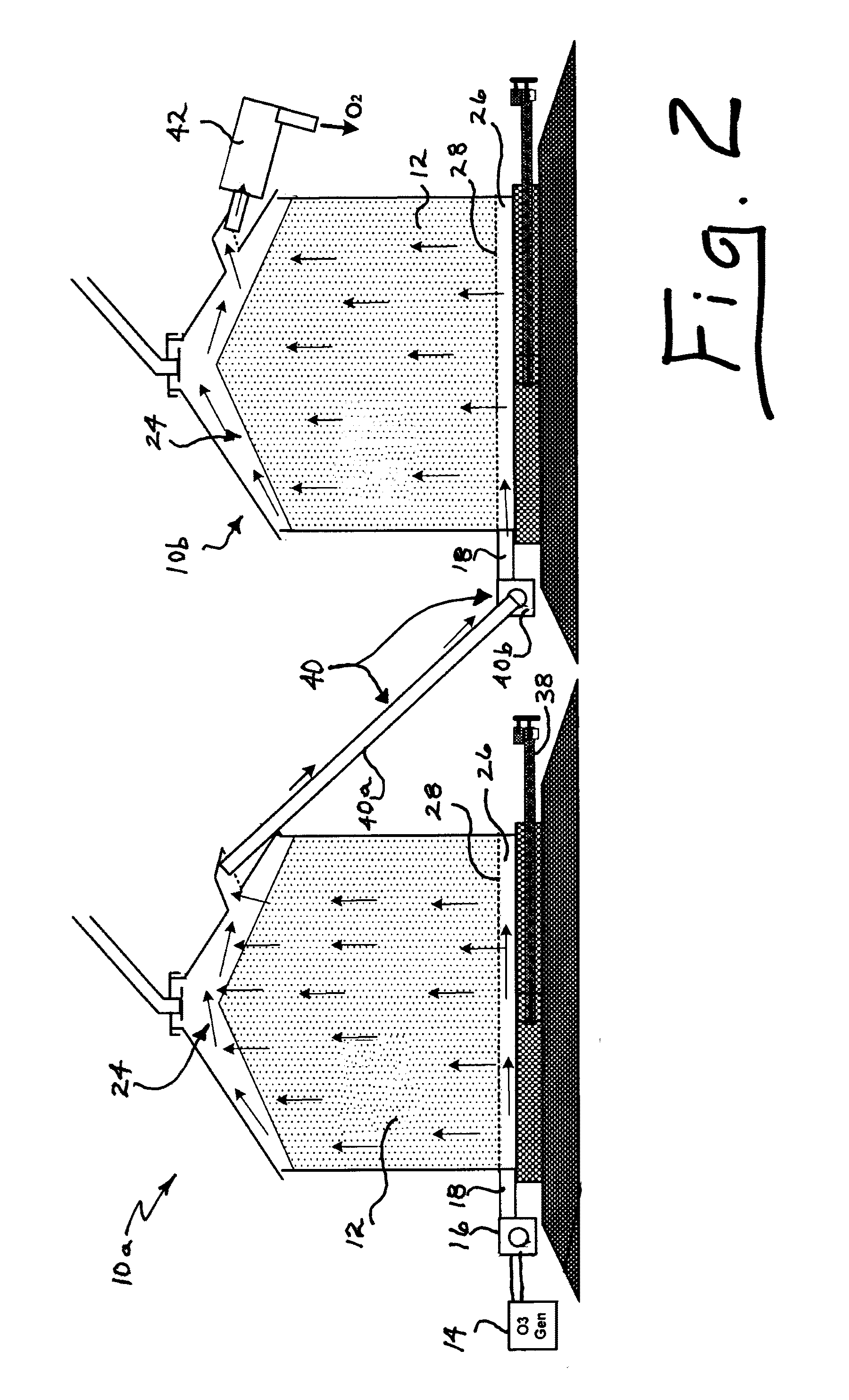

Fumigation and sanitation of biological products storage systems using ozone

InactiveUS20090117016A1Avoid damageFood preservationEnergy based chemical/physical/physico-chemical processesEngineeringBiologic Products

An apparatus and method are provided for elimination of mold, pests, insects and the like from bulk, stored grain and milled grain products and other biological items by pushing an ozone-containing atmosphere up through the grain or biological items and providing and maintaining an ozone-containing atmosphere in contact with the upper surface of the grain or biological items and maintaining an ozone-containing atmosphere in the spaces of the storage contained that are below the grain or biological items.

Owner:ADAPTIVE OZONE SOLUTIONS

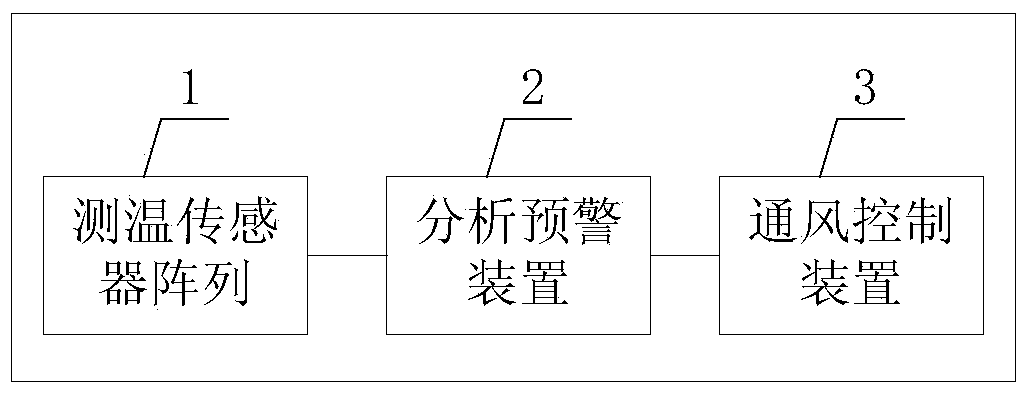

Grain pile dewing early-warning, prevention and control system and method based on temperature field and humidity field coupling

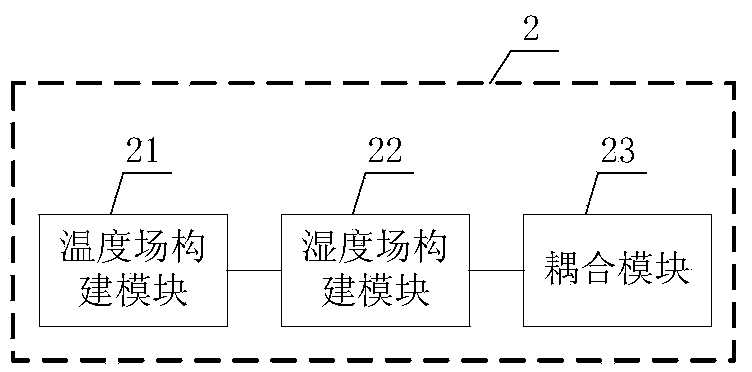

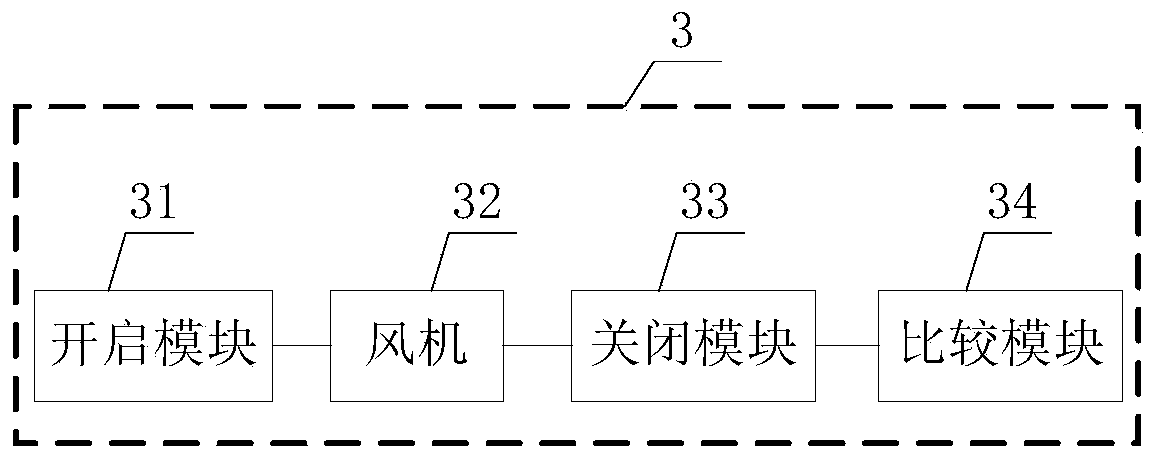

ActiveCN104007776AAvoid mildew lossReduce expensesMeasurement devicesSimultaneous control of multiple variablesSensor arrayMeasurement point

The invention discloses a grain pile dewing early-warning, prevention and control system and method based on temperature field and humidity field coupling. The early-warning, prevention and control system comprises a temperature measurement senor array, an analyzing and early-warning device and a ventilation control device which are sequentially and electrically connected. The temperature measurement senor array comprises a plurality of regularly arranged temperature sensors, the temperature sensors are arranged at different positions in a grain pile, and each temperature sensor is located at an actual measurement point in the grain pile. The analyzing and early-warning device comprises a temperature field building module, a humidity field building module and a coupling module, and the temperature field building module is sequentially and electrically connected with the humidity field building module and the coupling module. The early-warning, prevention and control system and method can predict the time when dewing may occur in the grain pile in several days or tens of days and the positions where dewing may occur in the grain pile in several days or tens of days, thereby avoiding mildew losses, lowering expenditure and guaranteeing the quantity and quality safety of stored grain.

Owner:ACAD OF NAT FOOD & STRATEGIC RESERVES ADMINISTRATION

Method for detecting insect pests in stored grains by means of terahertz imaging technology

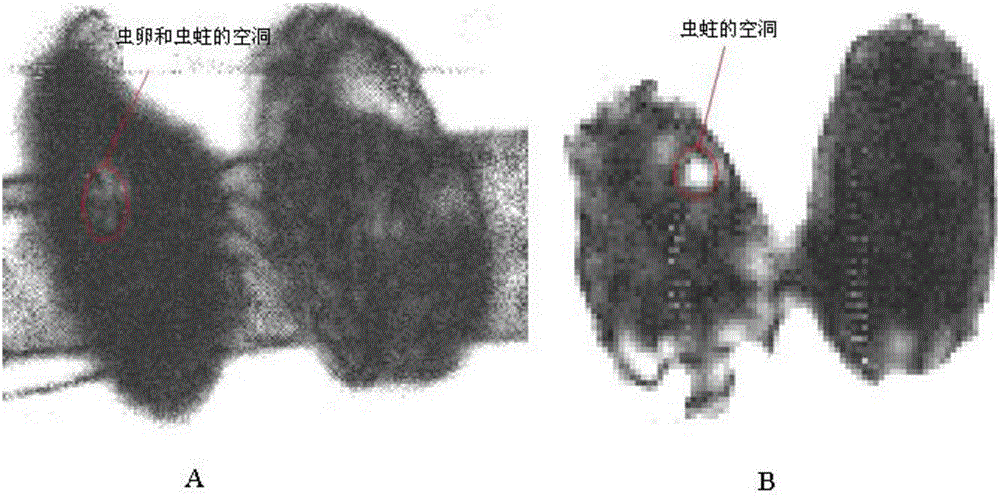

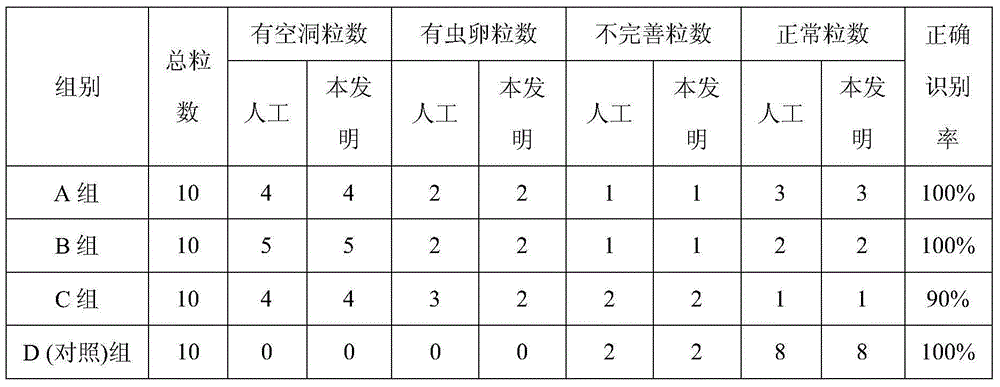

InactiveCN104990888ASimple and fast operationImprove detection accuracyMaterial analysis by optical meansInsect pestImaging technology

The invention discloses a method for detecting insect pests in stored grains by means of the terahertz imaging technology. The method comprises the steps that 1, stored grains not damaged by insect pest eggs or larvae are collected as standard grains, and terahertz spectral imaging detection is carried out on the standard grains; 2, stored grain samples to be detected are collected, and terahertz spectral imaging detection is carried out on the stored grain samples; 3, stored standard grain terahertz images obtained in the step 1 and to-be-detected stored grain sample terahertz images obtained in the step 2 are compared and analyzed, and whether the stored grain samples to be detected have insect pest eggs or larvae or not is determined through analysis. The method has the advantages of being easy, convenient and rapid to implement, efficient, high in detection accuracy and the like, can rapidly and accurately detect insect pest eggs or larvae in the stored grains in the early insect pest period, has the important practical significance in ensuring stored grain safety and quality and reducing economic losses, and has good market application prospects.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Bacteriostatic mildew-resistant insecticidal sustained release agent prepared from sol/gel also used as insect attractant

The invention relates to a bacteriostatic mildew-resistant insecticidal sustained release agent prepared from a sol / gel also used as an insect attractant. The agent is prepared into a sol plastic and a sol forming preparation with a microemulsion technology, a sol technology and the like according to different use conditions. The agent which treats an insect growth regulator (IGR) as a main component and essential oil and / or a low-toxicity high-efficiency insecticide, a bactericide, a penetrant, a water-soluble solvent, a stabilizing agent, an insect attractant, a film forming sustained release agent and the like as assistant components to satisfy prevention and control demands of different places. The agent of the invention, which has the advantages of wide insecticidal spectrum, low toxicity and high efficiency, ovum killing, insect growth inhibition, long persistent period, difficult resistance generation, bacteriostasis and mildew resistance, and low residual, can eliminate the pollution caused by unbalanced drug application, and is in favor of the ecological environment. The agent which is used for killing, preventing and controlling pests, mites and mildews on storage objects of stored grains, tobaccos, medicines, leathers, clothes, books, archives, history relics and the like and plants can reduce the loss caused by the pests and the mildews of the stored objects, the grains and the plants.

Owner:周端午

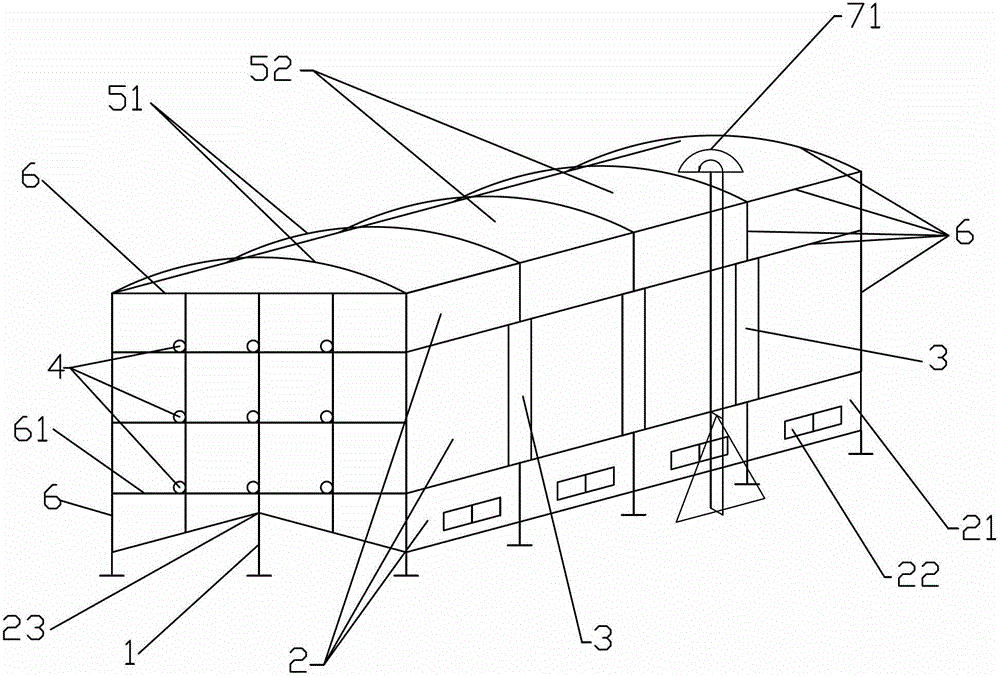

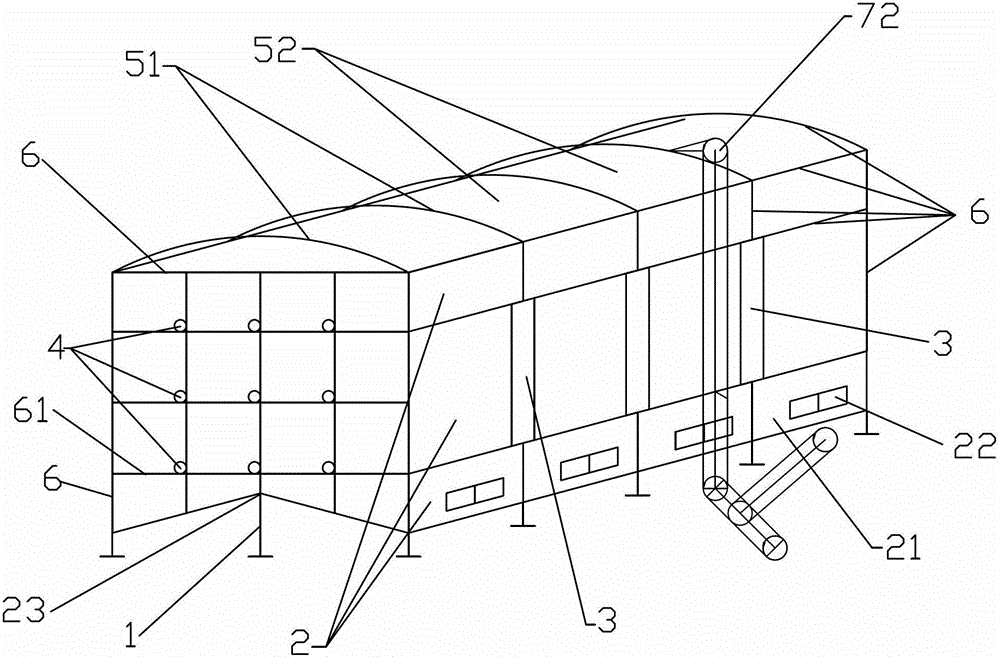

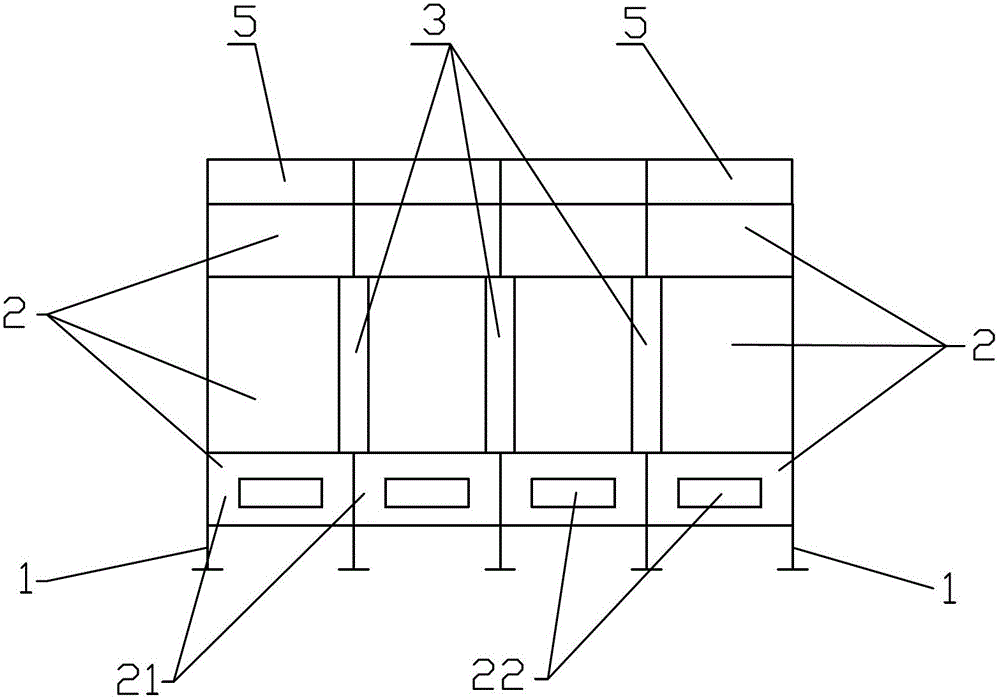

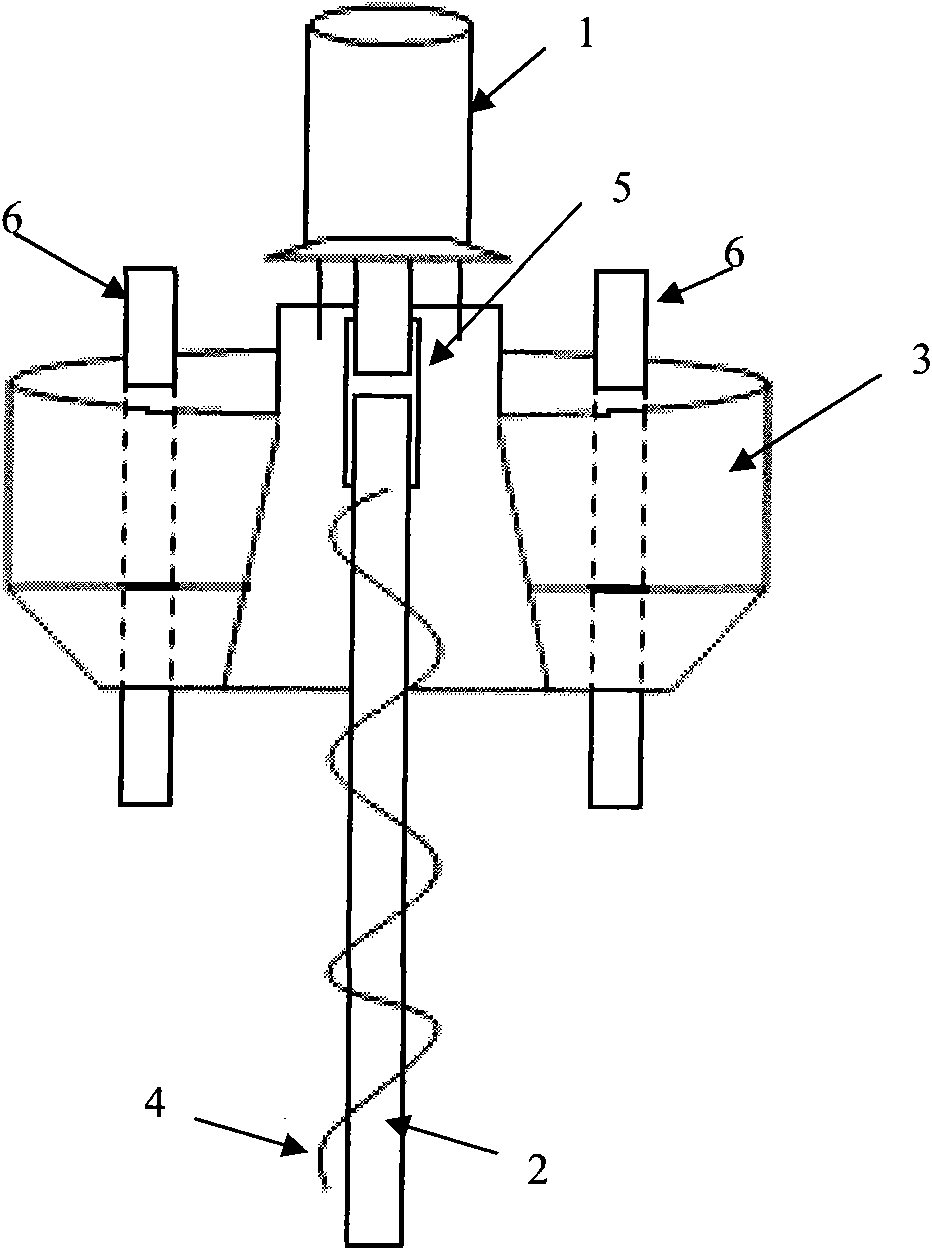

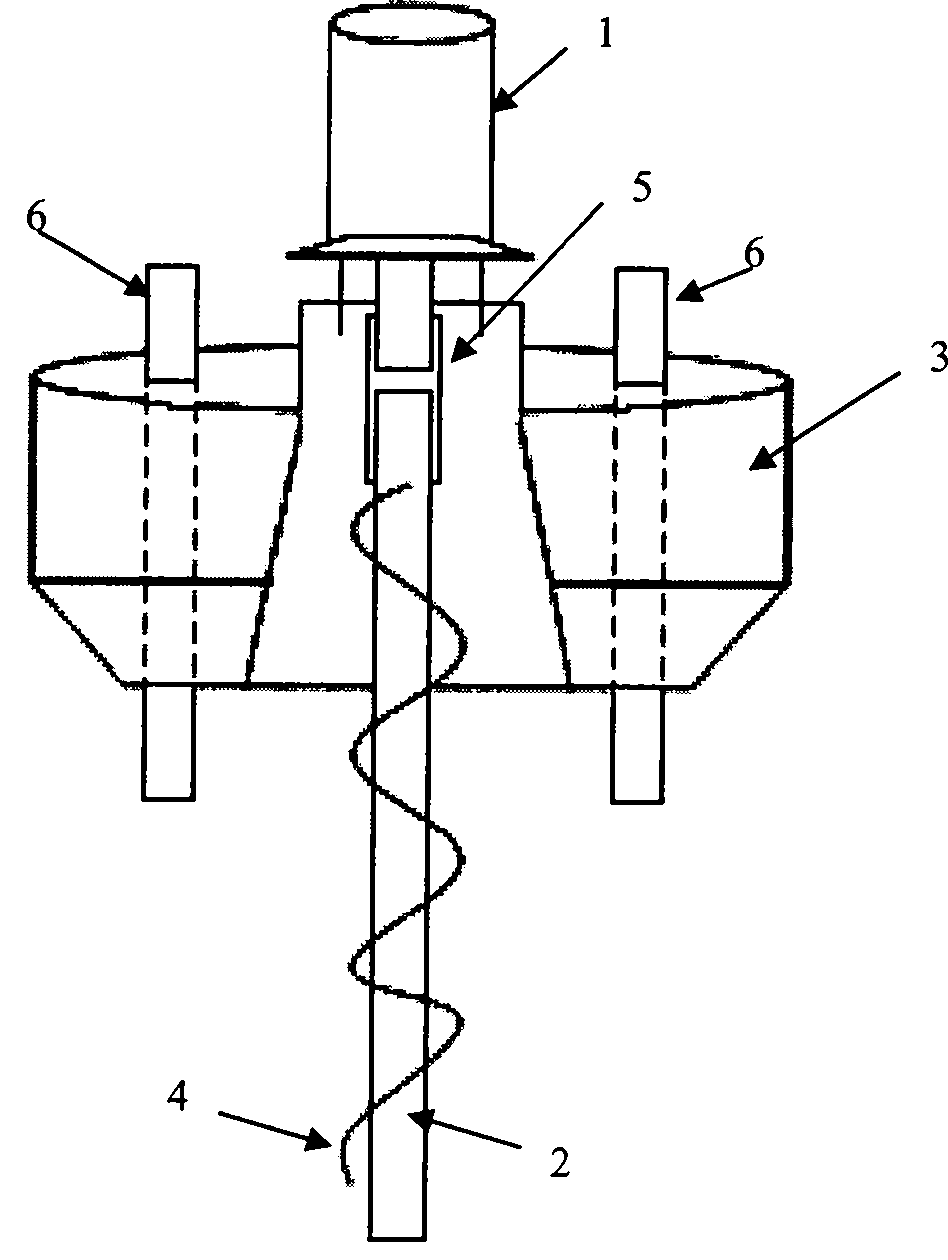

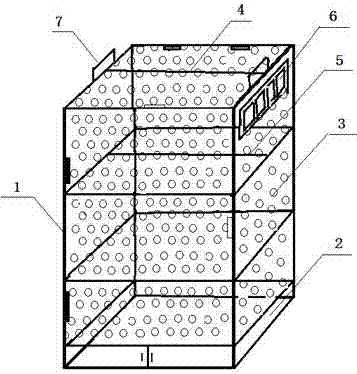

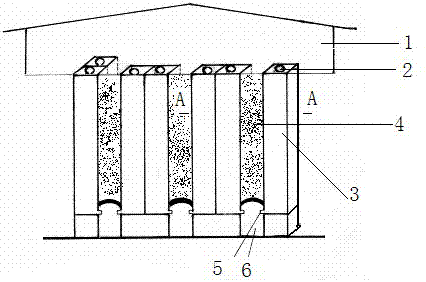

Stereoscopic combined grain airing and storage barn and grain airing, drying and storage method

InactiveCN102907221AAvoid demandFlexible structureAgriculture tools and machinesHarvested fruit hanging devicesMoisture absorptionEngineering

A stereoscopic combined grain airing and storage barn comprises a base support (1) and at least two grain airing and storage units (2), the grain airing and storage units are mutually connected to be combined into a grain airing and storage barn body, a top cover (5) and grain inlets (52) are arranged on the upper portion of the grain airing and storage barn body, the side wall of each grain airing and storage unit (2) is of a mesh structure, a ventilating duct (3) is arranged between each two adjacent grain airing and storage units (2), and grain outlets (21) are arranged on the lower portions of the grain airing and storage units (2). The invention further discloses a grain airing method using the storage barn. The grain airing and storage barn achieves safe and energy-saving airing and drying of high-moisture grains of peasant households or acquiring enterprises; labor intensity for enabling new harvested grains to go in and out of the barn during airing and drying is reduced, and cost is also lowered; mildew and heat emission of the new harvested grains during airing, drying and storage are avoided; and soaking of the grains by rain during airing and drying and moisture absorption and damp getting of the stored grains can be prevented.

Owner:ACAD OF STATE GRAIN ADMINISTRATION +1

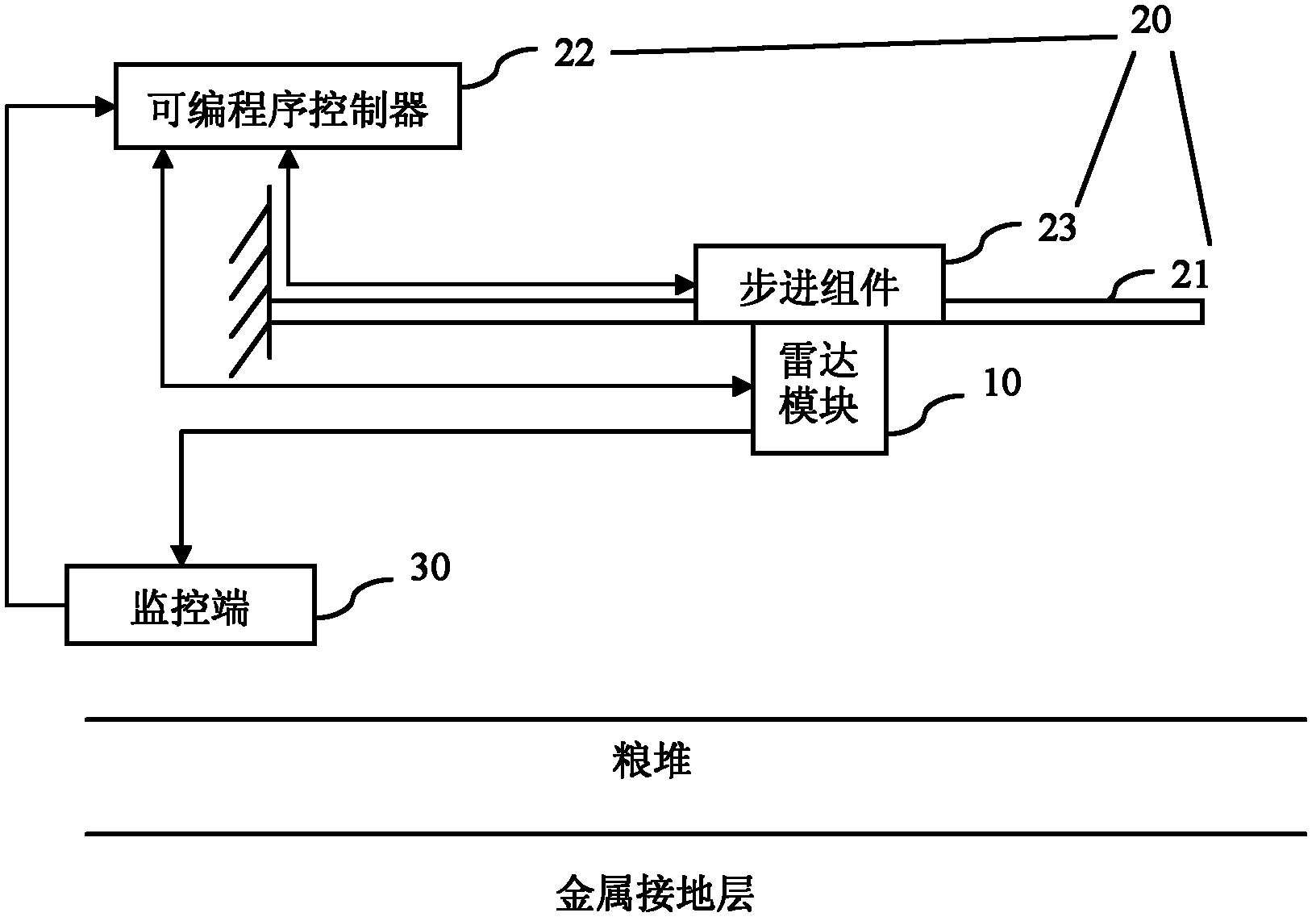

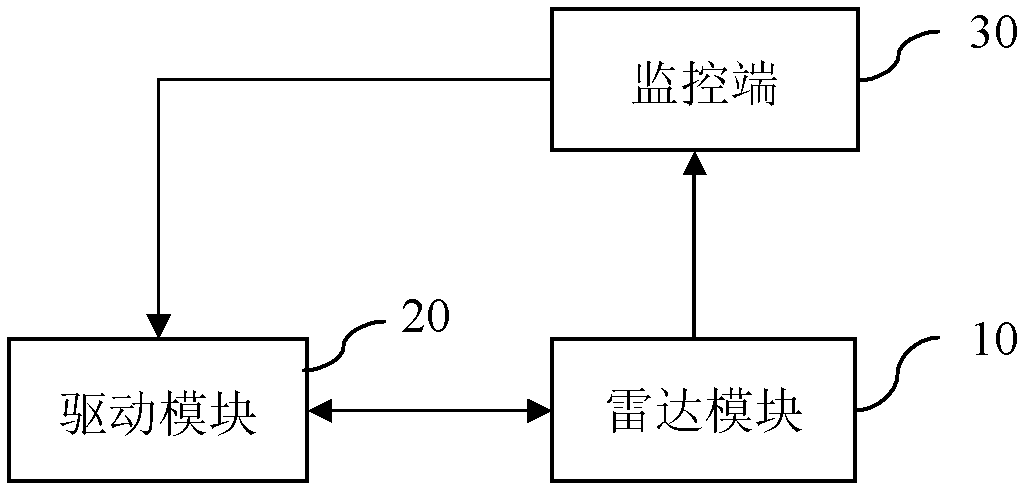

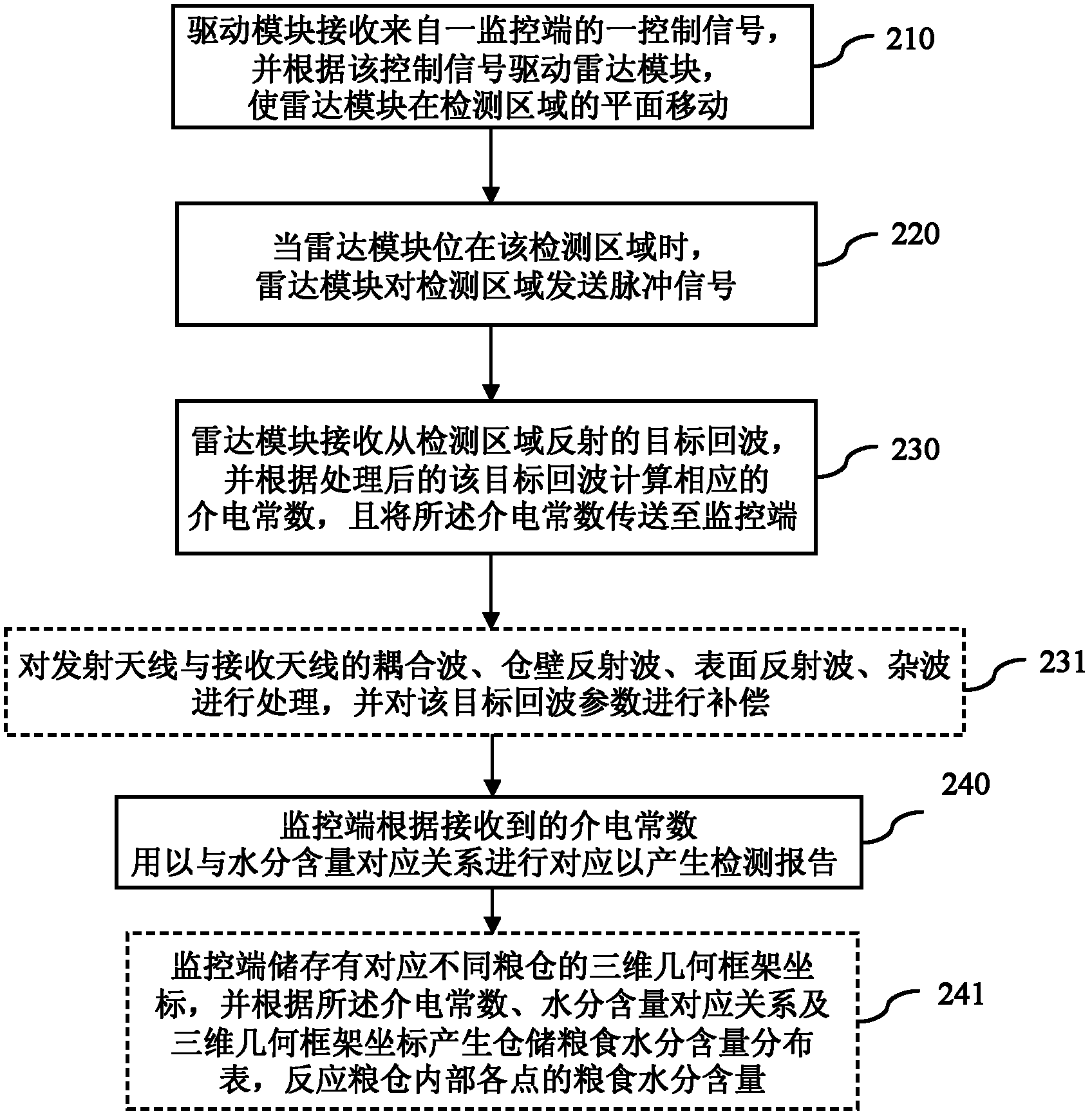

Apparatus for online detection of content of water in stored grains, and method thereof

ActiveCN103175852AImprove management efficiencySolve the problem of actual food situationMaterial analysis using wave/particle radiationMoisture content investigation using microwavesControl signalComputer module

The invention discloses an apparatus for the online detection of the content of water in stored grains based on a ground penetrating radar technology, and a method thereof. The apparatus comprises a radar module, a drive module and a monitoring end. The drive module receives a control signal from the monitoring end and drives the radar module according to the control signal to make the radar module move in a plane of a detection zone; when the radar module is in the detection zone, the radar module sends a pulse signal to the detection zone; the radar module receives a target echo reflected from the detection zone, calculates according to a processed target echo to obtain a corresponding dielectric constant, and transmits the dielectric constant to the monitoring end; and the monitoring end corresponds the relationship between the received dielectric constant and a water content to generate a detection report. The apparatus and the method improve the technical effect of the management efficiency of the storage and transportation environment of the grains.

Owner:AEROSPACE INFORMATION

Application of anti-mildew bacillus strain and antimicrobial product thereof in corn storage

ActiveCN103333828AGuarantee and improve qualityStrong growthBacteriaEdible seed preservationSporePreservative

The invention provides an anti-mildew bacillus strain, namely Bacillus subtilis LPL-NM45 of which the collection number is CGMCC No.7762. The invention also provides a method for extracting an antimicrobial product of the Bacillus subtilis LPL-NM45. The Bacillus subtilis LPL-NM45 and the antimicrobial product thereof have strong inhibiting effect on growth of mildew and germination of spores in grain storage (especially corn storage). In case of the identical spraying dosage, the Bacillus subtilis LPL-NM45 and the antimicrobial product thereof can more effectively inhibit the growth of mildew in the storage process of high-water-content corns in comparison with the conventional chemical preservative used in grains, and guarantee the safety of the grains, thus having favorable prospects of being used as mildew inhibitors for grains.

Owner:CHINA AGRI UNIV

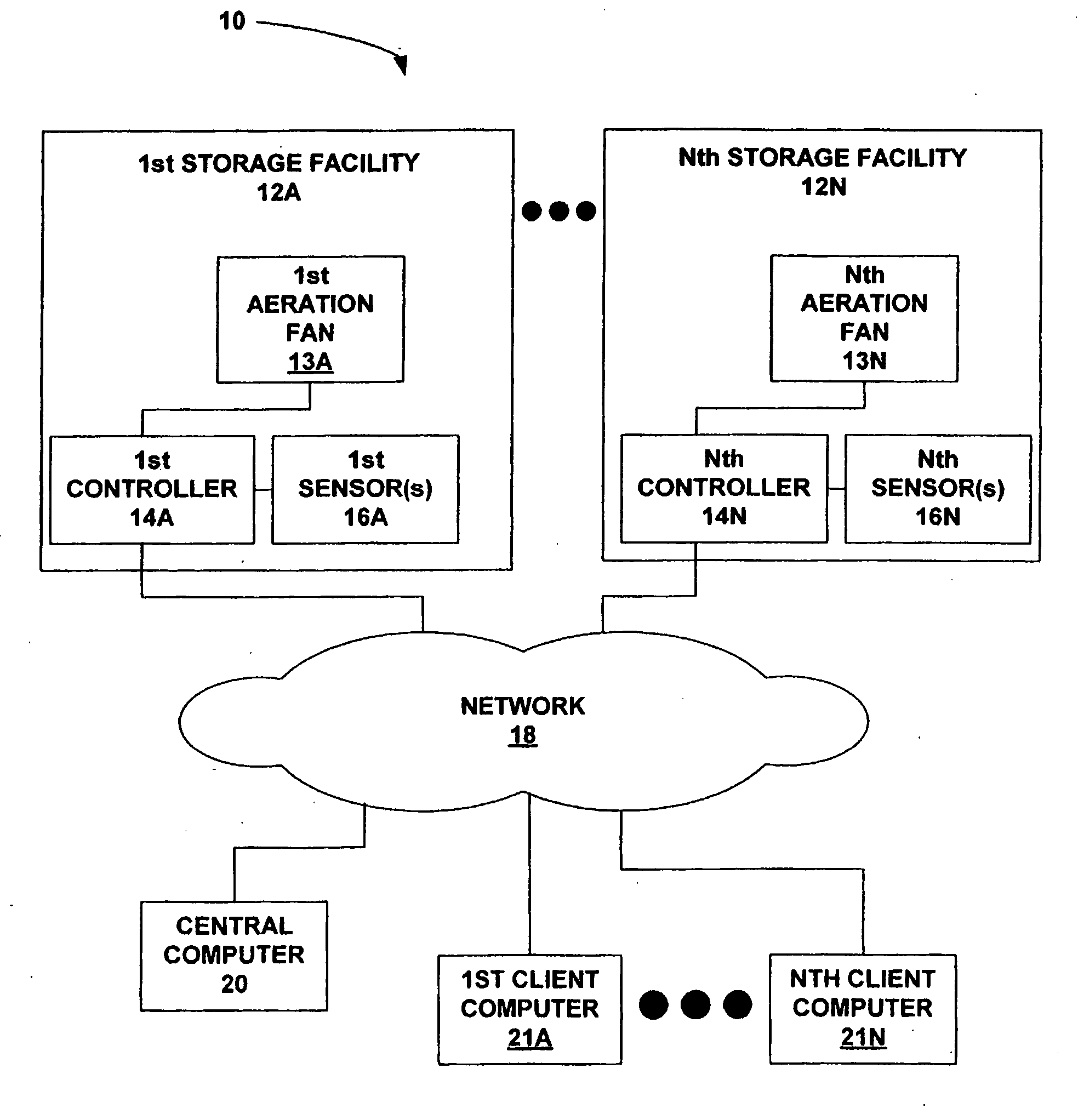

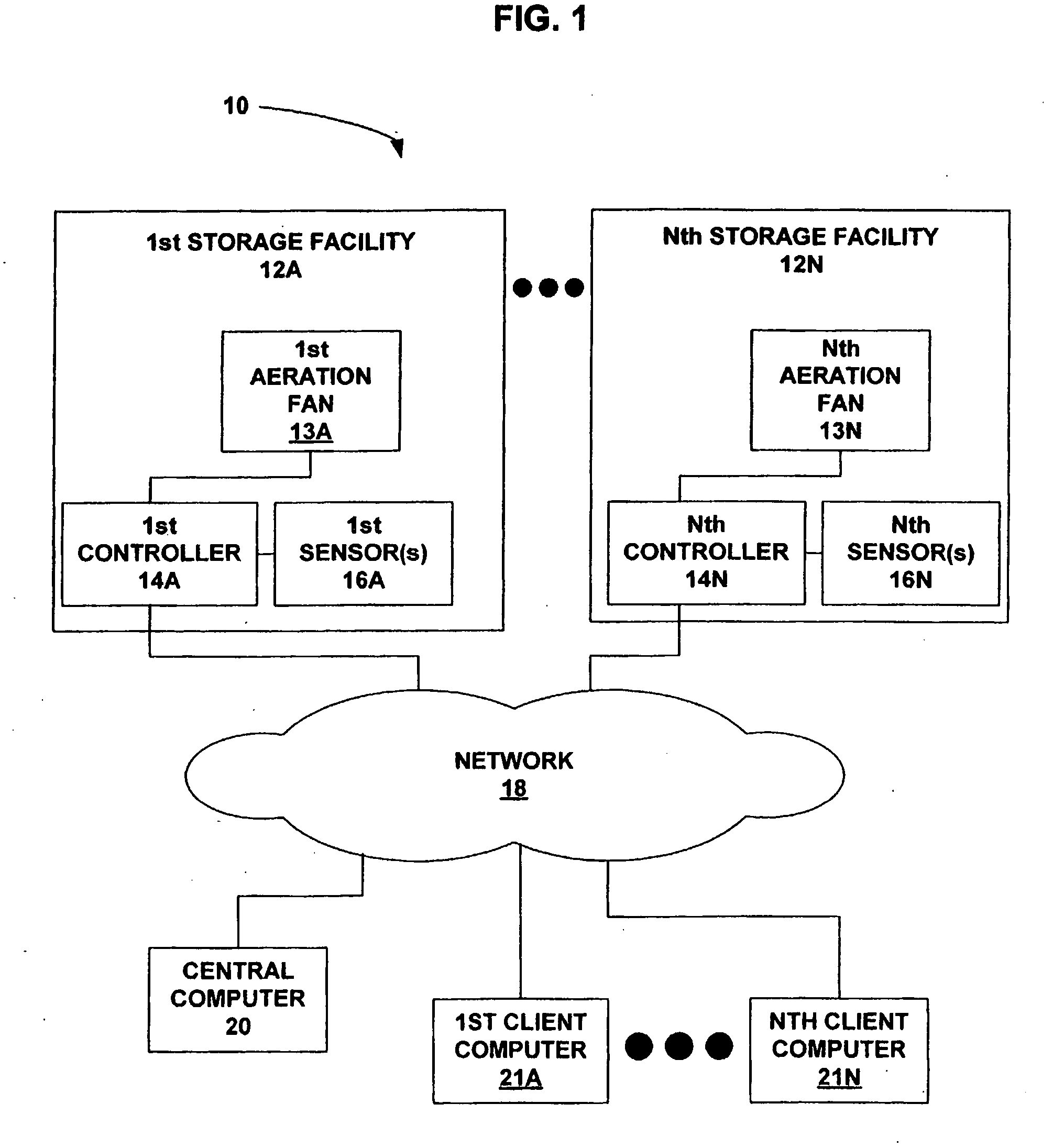

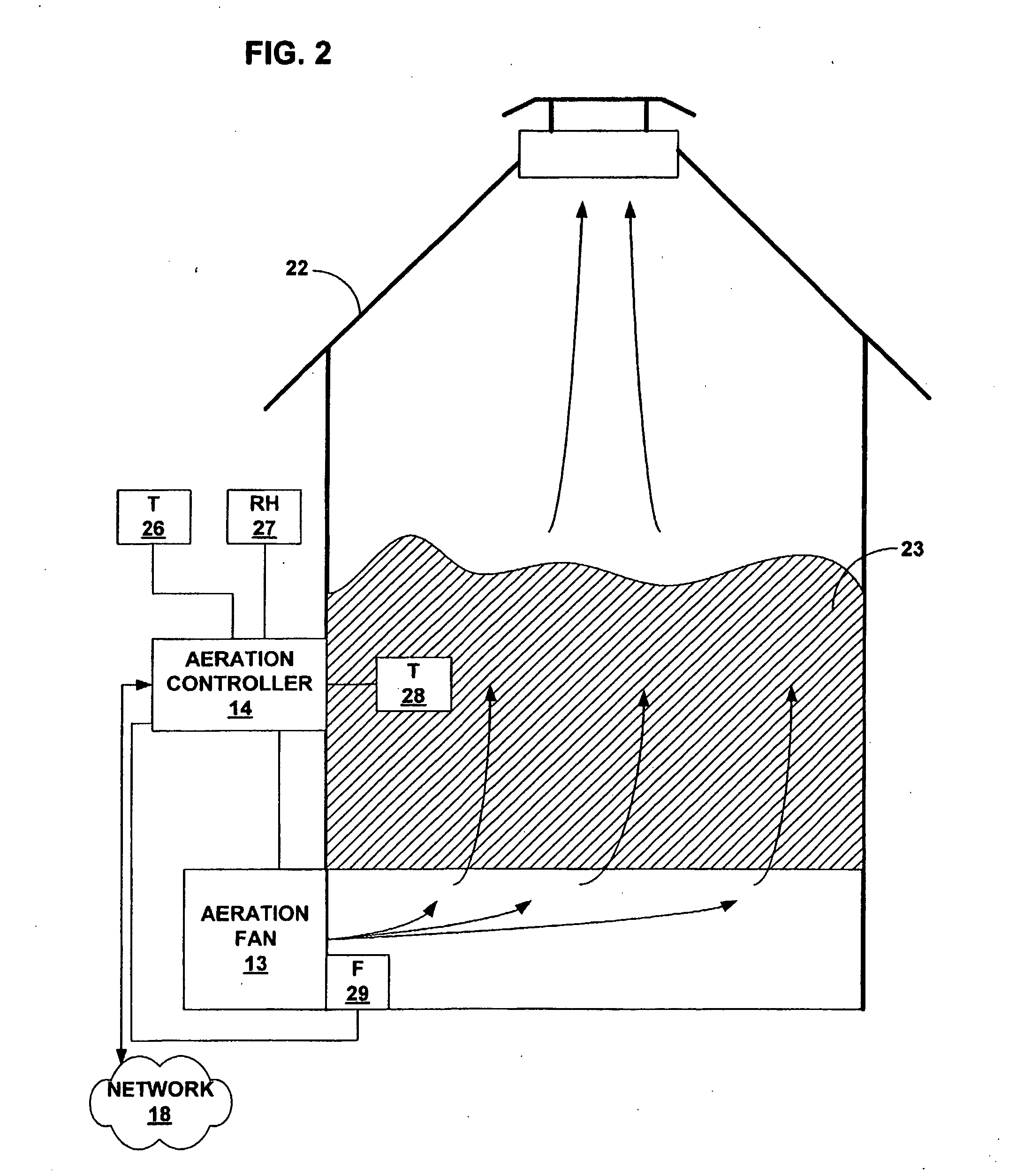

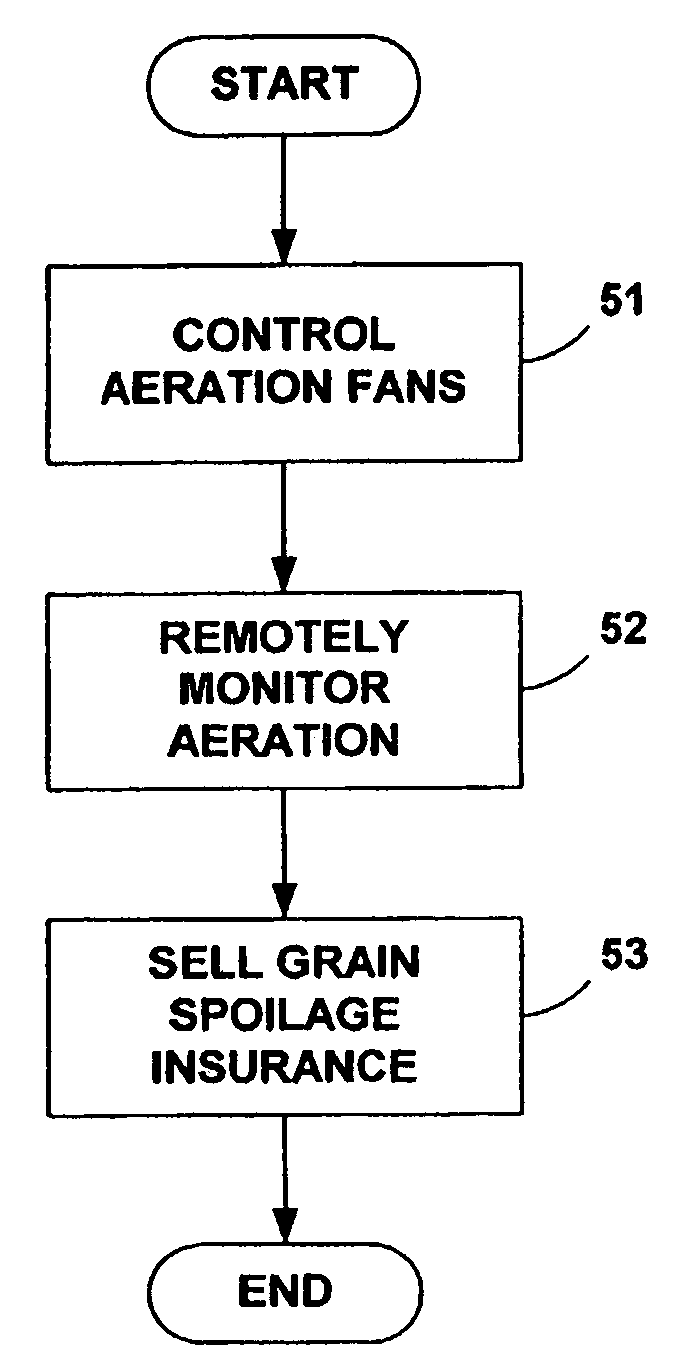

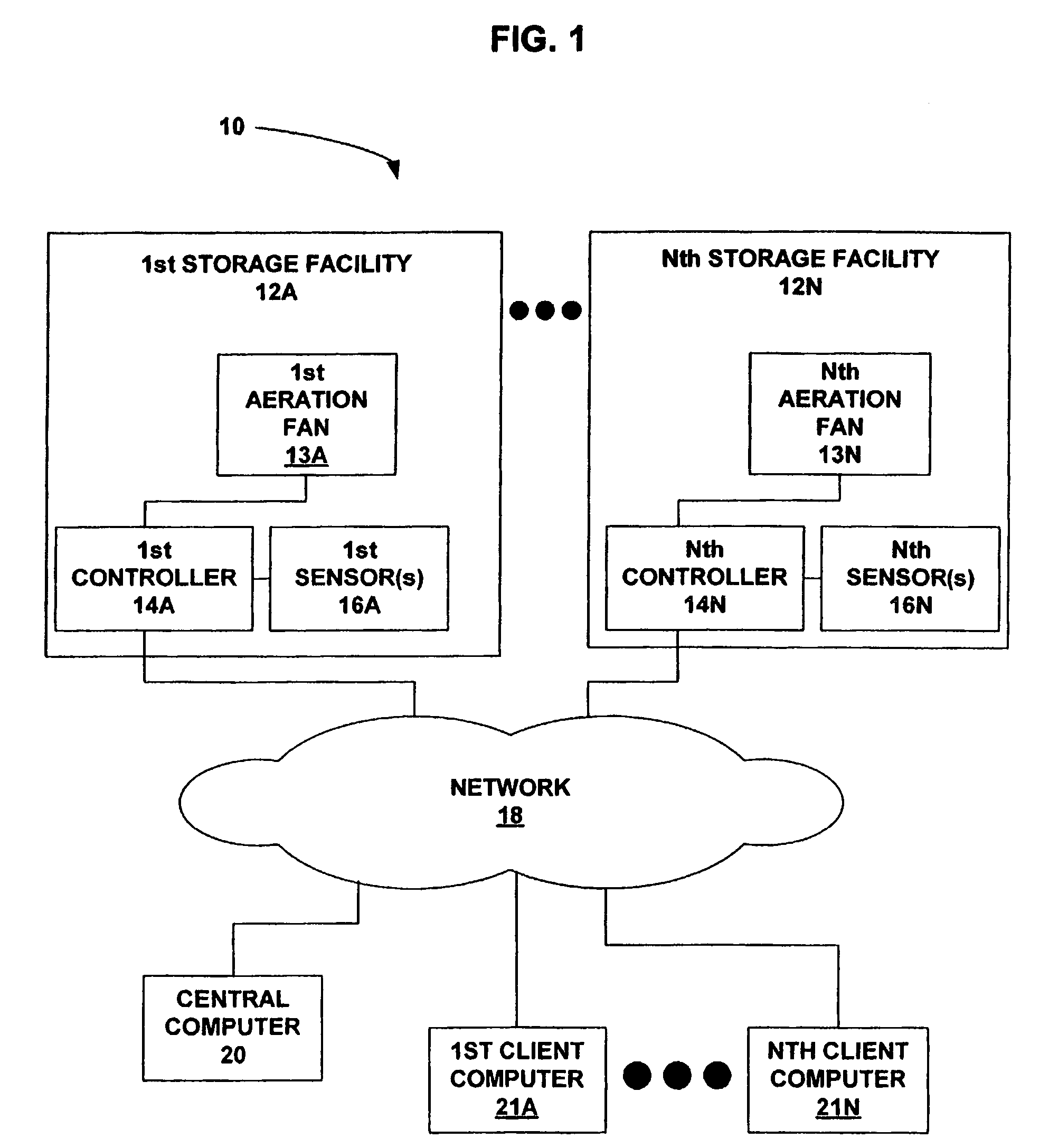

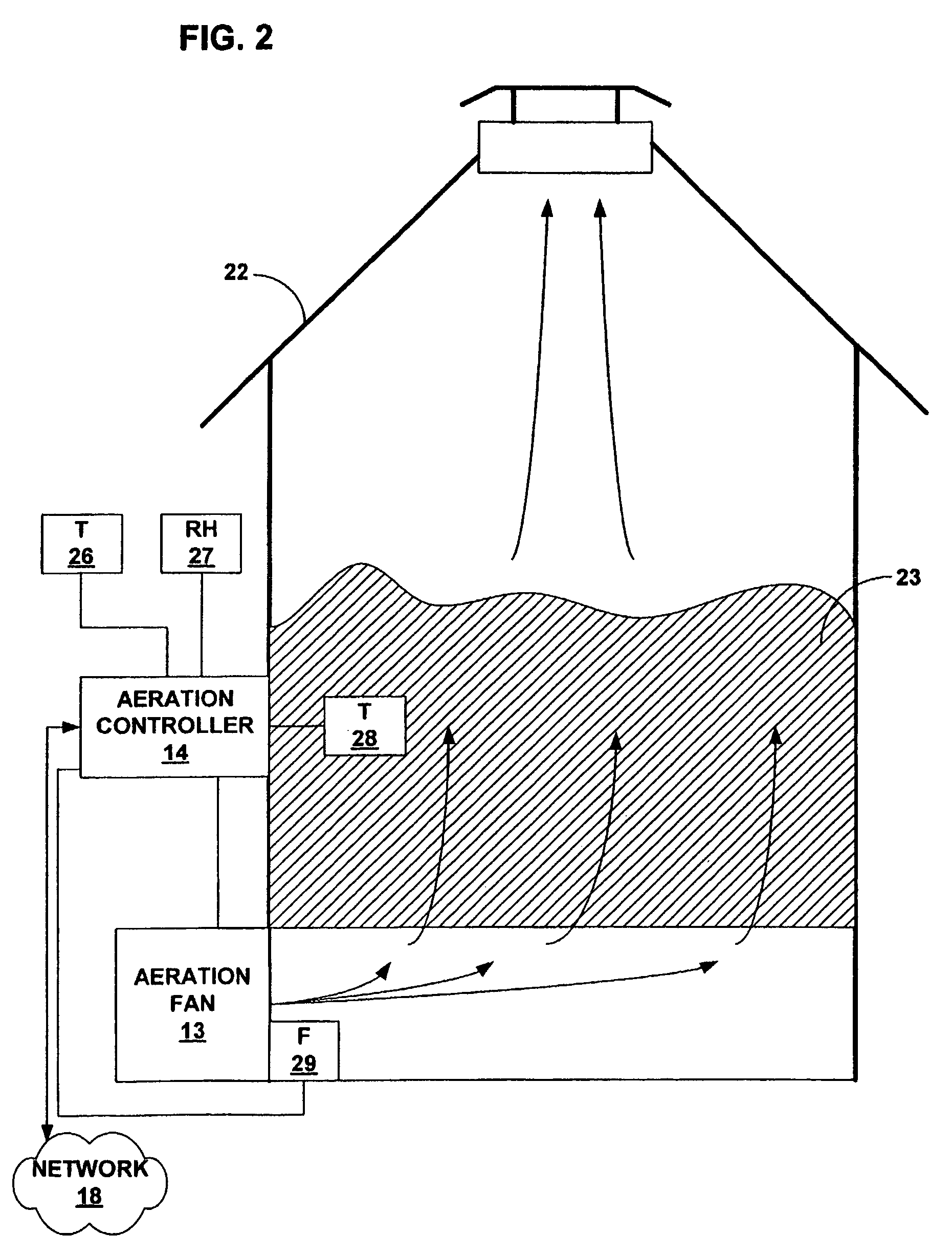

Grain aeration systems and techniques

InactiveUS20060111035A1Easy to manageAgriculture tools and machinesHand manipulated computer devicesAeration systemControl system

In one embodiment, the invention is directed toward a networked grain aeration control system. For example, the system can provide centralized monitoring of the aeration of a number of grain storage facilities, thereby improving the management of stored grain. The networked grain aeration control system can allow the custodian of the system to offer an aeration service. Farmers, or other individuals, cooperatives, or companies can purchase the aeration service at a cost proportionate to the amount of stored grain to be aerated and the duration of storage. In this manner, the purchaser of the aeration service can avoid relatively high fixed costs that can be associated with various aeration hardware.

Owner:TARGETED GRAIN MANAGEMENT

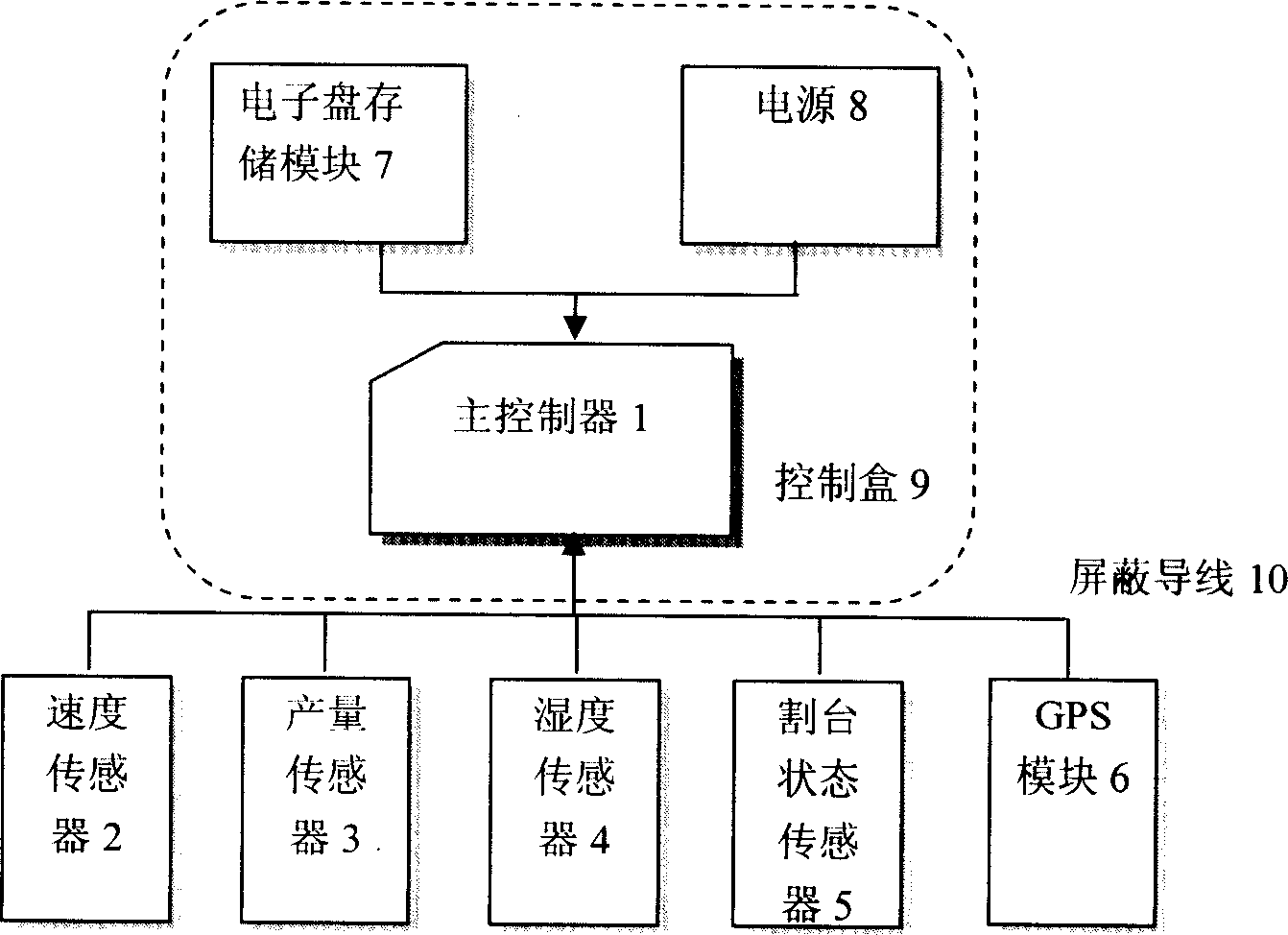

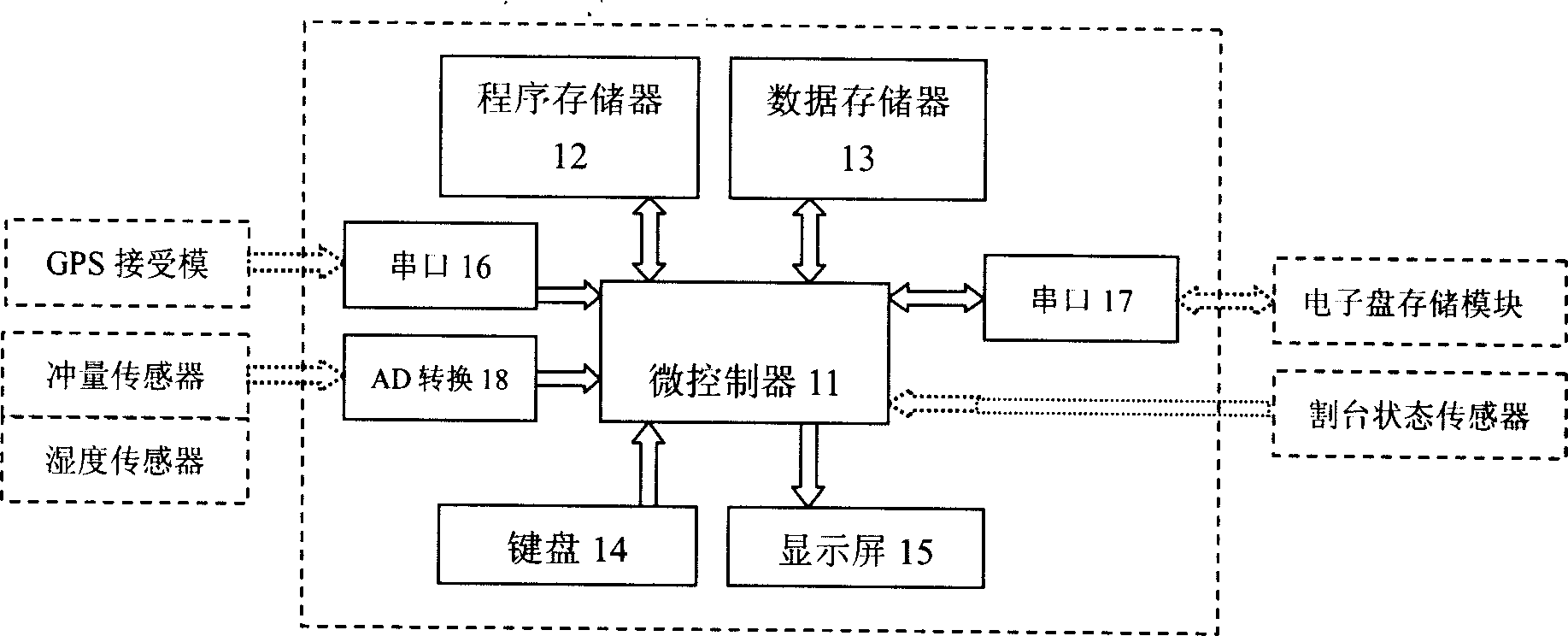

System for measuring yield of stored grain based on single chip nicrocemputer and electric tray

InactiveCN1695420ASolve earthquake resistanceReasonably equippedMowersWeighing apparatus for continuous material flowMeasurement deviceEngineering

A grains yield estimating system based on single-chip microprocessor and disc storage is composed of speed sensor for measuring the speed of harvester, impulsive yield sensor for real-time measuring the yield of grains, capacitor-type humidity sensor for measuring the humidity of grains, harvesting branch state sensor, GPS module, disc storage module and master controller.

Owner:SHANGHAI JIAO TONG UNIV

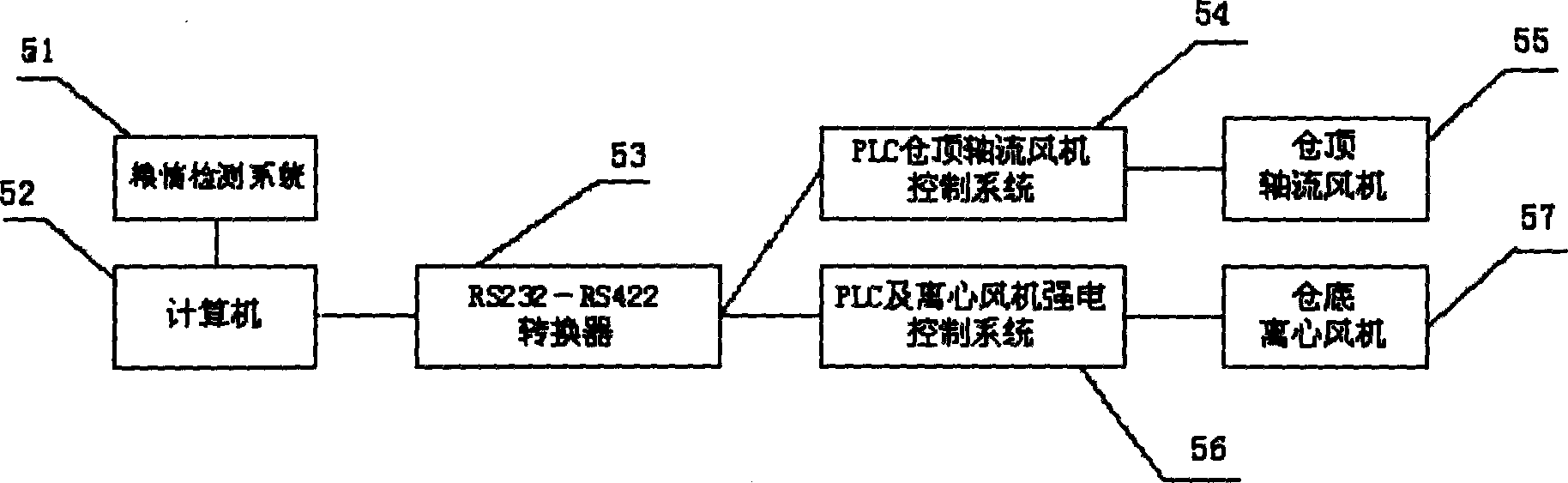

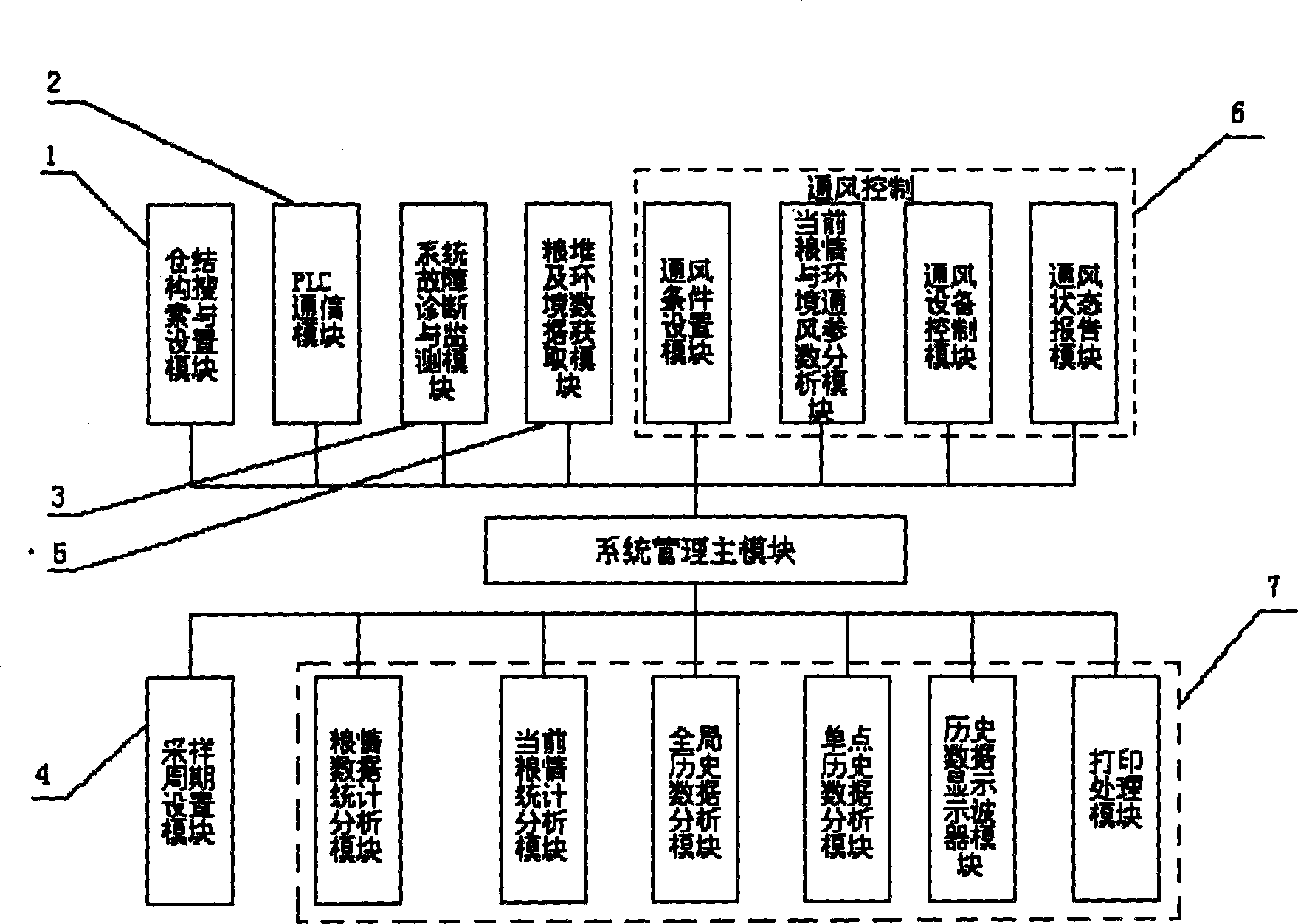

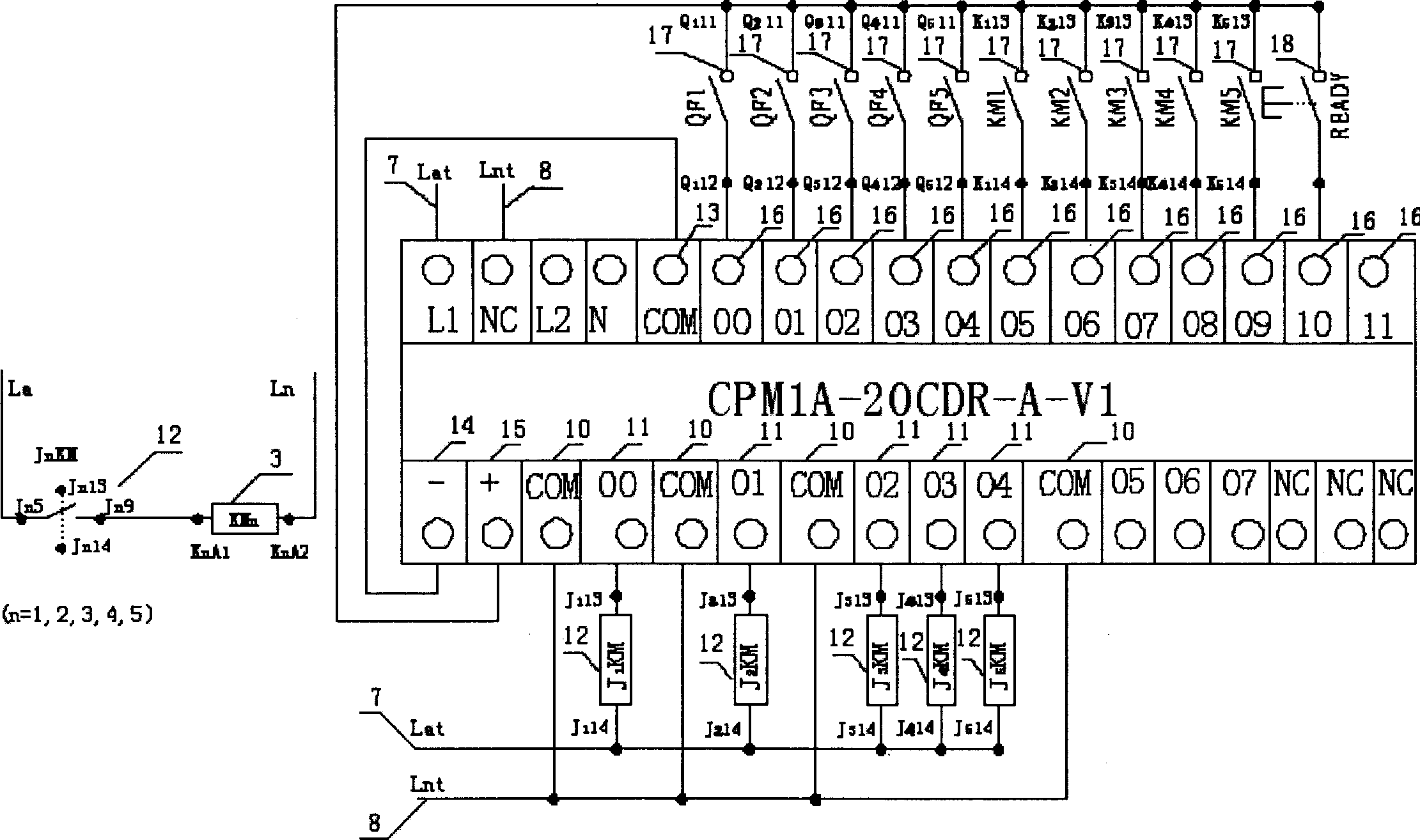

Intelligent management control system and method for mechanical ventilation in grain storage

InactiveCN1808318AFully automatedRealize intelligenceComputer controlTesting/monitoring control systemsAutomatic controlControl system

Disclosed is a grain storing mechanism venting intelligent management control system and the method for control thereof. The system comprises a computer for storing, PLC storehouse roof axial flown fan control system, PLC centrifugal flown fan control system which are connected on the RS232-RS422 converter; the computer is connected to the grain situation detecting system; the PLC storehouse roof axial flown fan control system is connected with storehouse roof axial flown fan and the LC centrifugal flown fan control system is connected with storehouse ground centrifugal flow fan. The function of the management control software is realizing automatic control of the venting process of the storehouse and recording the grain situation changes.

Owner:LIAONING RES INST OF GRAIN SCI

Grain aeration systems and techniques

InactiveUS7472070B2Easy to manageSpace heating and ventilationTemperatue controlAeration systemControl system

Owner:TARGETED GRAIN MANAGEMENT

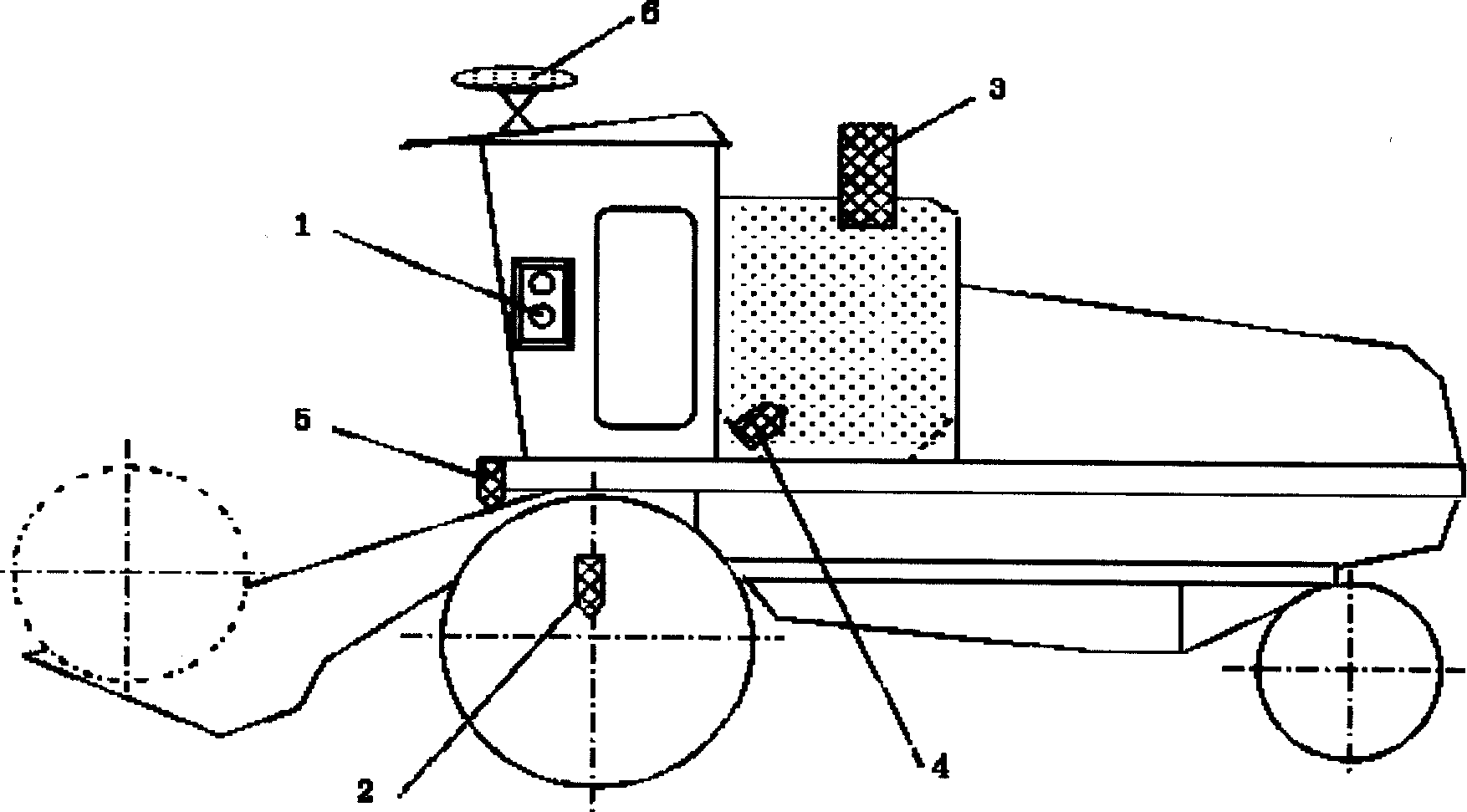

Automatic-traveling grain turning over machine

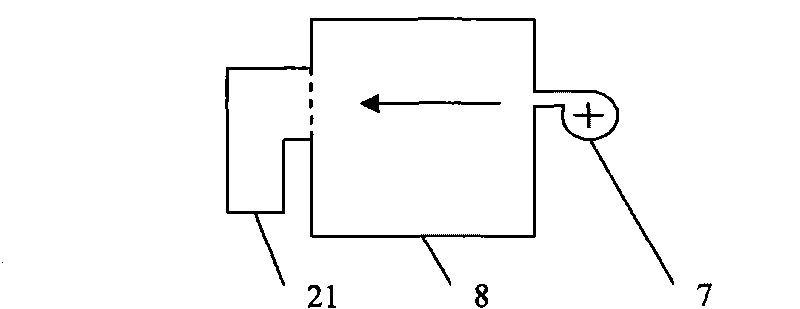

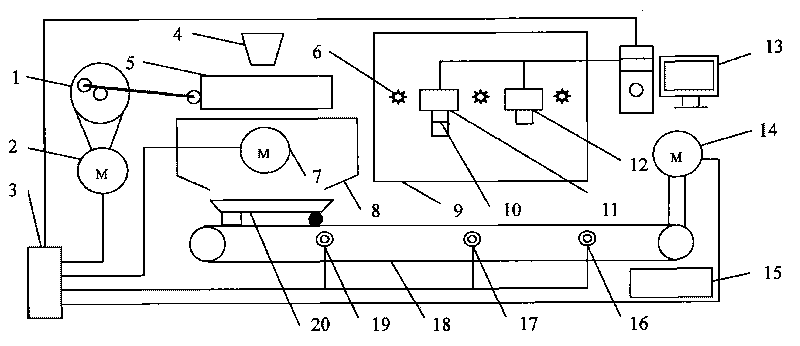

InactiveCN102084895AReduce volumeSimple and fast operationSeed preservation by dryingEngineeringUltimate tensile strength

The invention discloses an automatic-traveling grain turning over machine, of which the main structure is composed of a motor, an auger, a box body and the like. The automatic-traveling grain turning over machine turns over the grain through a stirrer so as to ventilate and cool the grain better, and simultaneously, since paddles have the pushing function, the grain flowing out from a grain port of the box body generates a forward pushing force to drive the machine to automatically travel forward, and the traveling direction of the grain turning over machine is changed by two direction regulating rods on the box body, the automatic-traveling grain turning over machine can be used for ventilating the grain in a ground warehouse better, improving storage quality of the stored grain and greatly saving labor intensity, and is featured by practicability, quickness and high efficiency.

Owner:王远成 +2

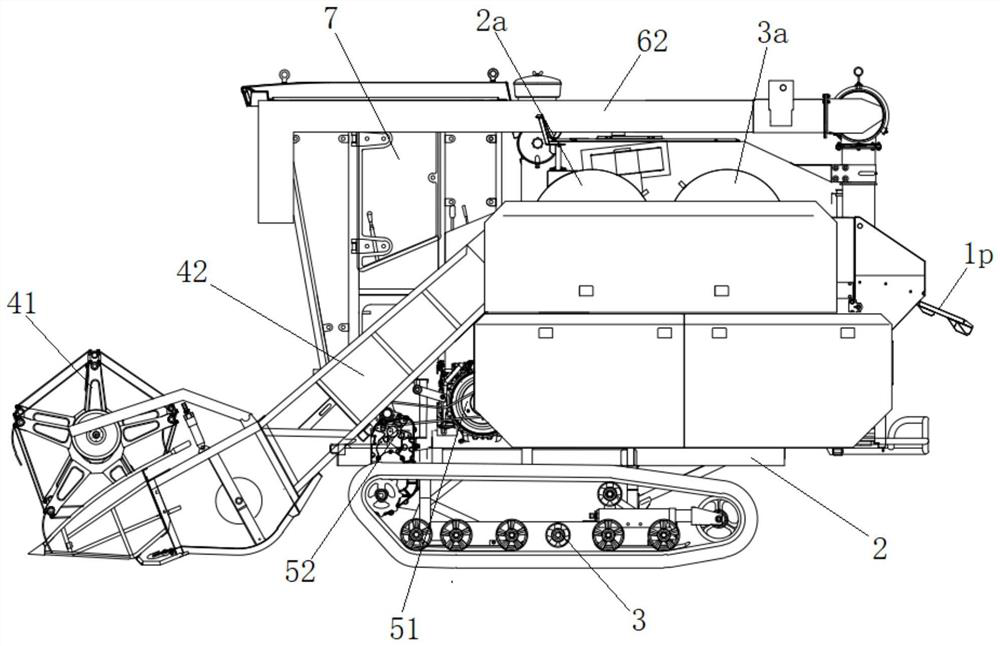

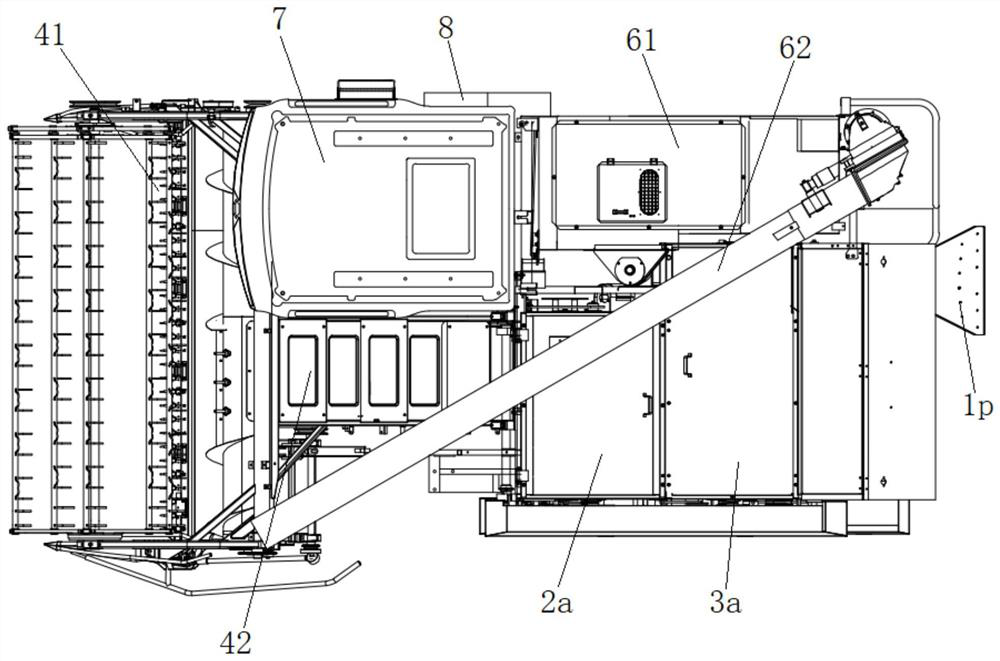

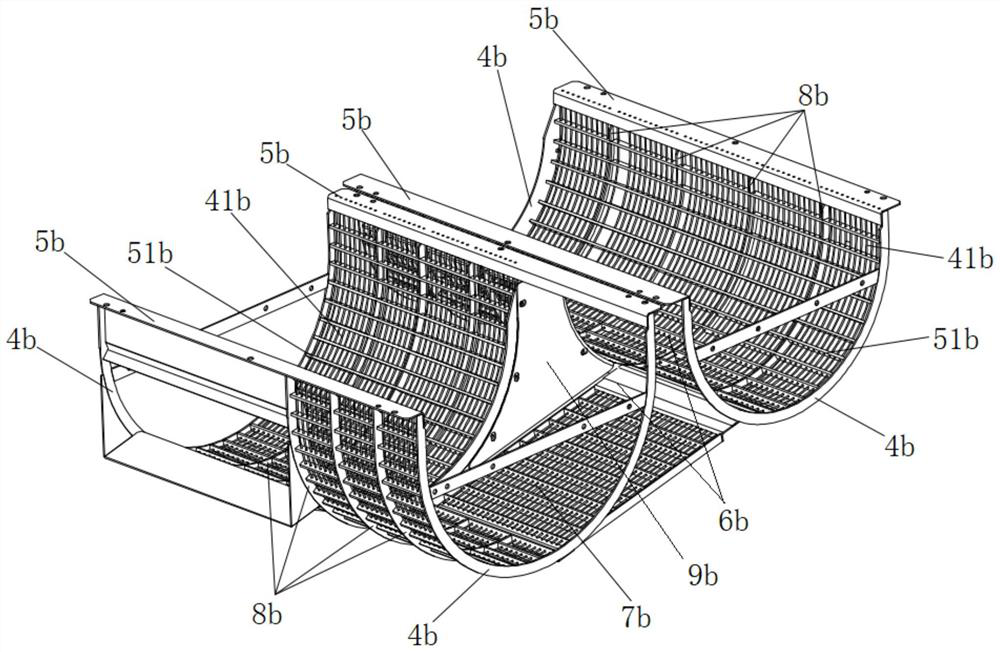

Combine harvester

PendingCN112690086ASmooth feedingGuaranteed stabilityMowersThreshersAgricultural engineeringGrain storage

The invention provides a combine harvester. A feeding port is formed in the middle of a frame, so that a connecting port between a crop conveying structure communicated with the feeding port and a header is located at the position, close to the middle, of the header, and crops are fed into the connecting port from the two sides of the header more evenly; and meanwhile, a scattering structure is arranged close to a grain storage assembly, the crops enter from the middle of the front end of the harvester and are partially scattered out from the middle of the tail end of the harvester through the n-shaped threshing direction of a double-helix threshing conveying system, and the stability of the gravity center of the combine harvester is guaranteed. A cleaning transmission system is arranged at the outer side of a threshing system, centralized transmission is achieved, and installation and debug are convenient. The whole harvester is compact in structure, small in occupied space, high in maneuverability and remarkable in operation efficiency, and the gravity center is always kept stable in the empty operation and harvesting operation process.

Owner:JIANGSU WORLD AGRI MACHINERY

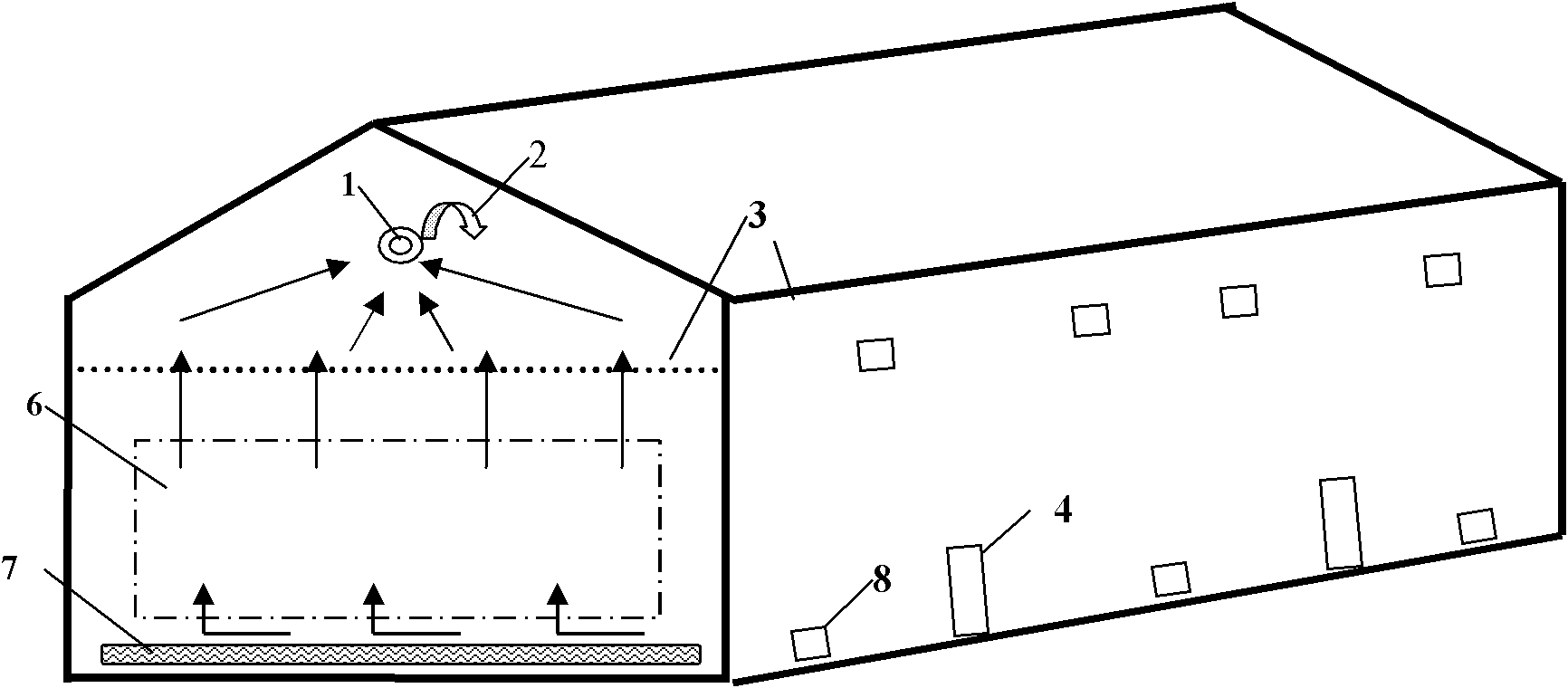

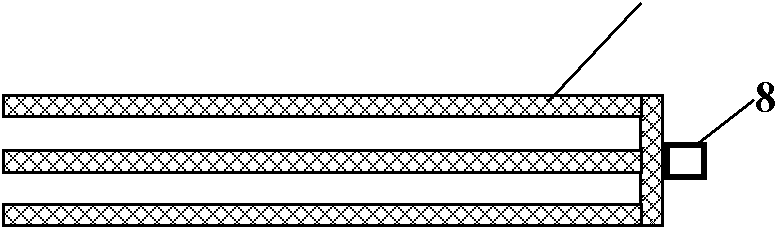

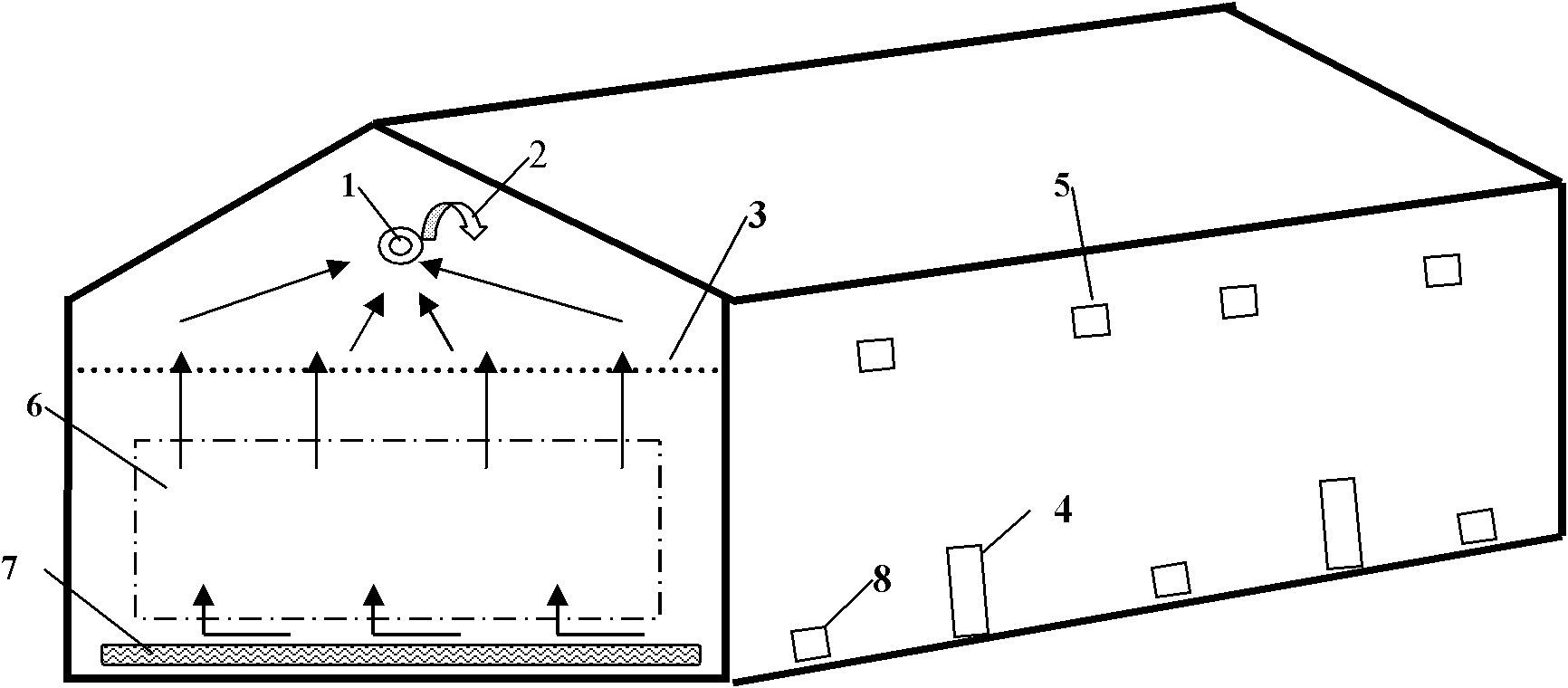

Stored grain temperature adjusting method

InactiveCN101919442ASpeed up heat dissipationEfficient use ofFood processingSeed preservation by freezing/coolingTemperature controlCold air

The invention discloses a stored grain temperature adjusting method, which comprises the following steps of: A, closing all windows and ventilation openings of a warehouse to make the warehouse in a sealed state; and B, starting an axial flow fan on the top of the warehouse to make the whole warehouse and grain piles form negative pressure, discharging the accumulated temperature of the warehouse space part, and making the cold air of the cold cores of the grain piles move to the upper layers the grain piles so as to reduce the grain temperature of the upper layers of the grain piles and the temperature in the warehouse and meet the temperature requirement of temperature-controlled stored grain. The method also comprises a step of compensating cold quantity by using a refrigerator, wherein the axial flow fan on the top of the warehouse is started in the step B, when the accumulated temperature of the warehouse space and the grain temperature of the upper layers of the grain piles is reduced by not more than 28 DEG C, the ventilation openings of a ground cage ventilation pipe network of the warehouse are opened and linked with the refrigerator, and the refrigerator is started for refrigeration, so the stored grain temperature can be reduced and the requirement of standard low-temperature grain storage is met. Because a sealed system is adopted and the negative pressure is formed in the warehouse and the grain piles, the radiating speed of the granary is improved, the cold sources of the cold cores of the grain piles are effectively utilized, the energy is saved and the operating cost is reduced.

Owner:陈国利 +4

Stored grain pest trapper with temperature control pest killing device

InactiveCN106954605AExtend and optimize construct performanceIn line with development ideasInsect catchers and killersTemperature controlLow voltage

The invention relates to a stored grain pest trapper with a temperature control pest killing device. The stored grain pest trapper comprises a trapper body device, a pest attraction device located at the upper part in the trapper body device, and the temperature control pest killing device located below the pest attraction device, wherein the trapper body device comprises a body frame, an upper layer fitting rack and a lower layer fitting rack; the body frame is internally provided with the upper layer fitting rack and the lower layer fitting rack in an upper and lower structure; the pest attraction device comprises an attraction lamp component and an attraction core component; the temperature control pest killing device comprises a low-voltage electric heating body, an electric appliance control box, a power supply adapter, a temperature controller and a timer; the electric appliance control box is arranged on one side of the body frame and internally provided with the power supply adapter, the timer and the temperature controller; the timer and the temperature controller are connected with the low-voltage electric heating body; the power supply adapter is connected with the timer, the temperature controller and the low-voltage electric heating body; and the trapper has the characteristics of reasonable structure, strong trapping function, advanced control mode, reliable safety performance and simplicity and convenience in operation.

Owner:中央储备粮盐城直属库有限公司

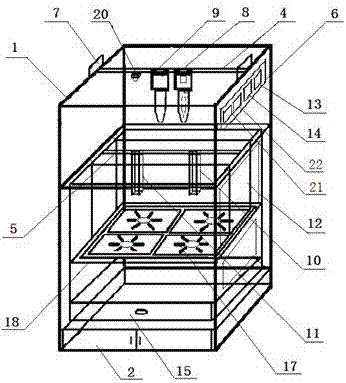

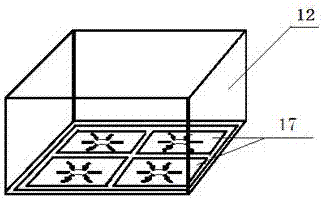

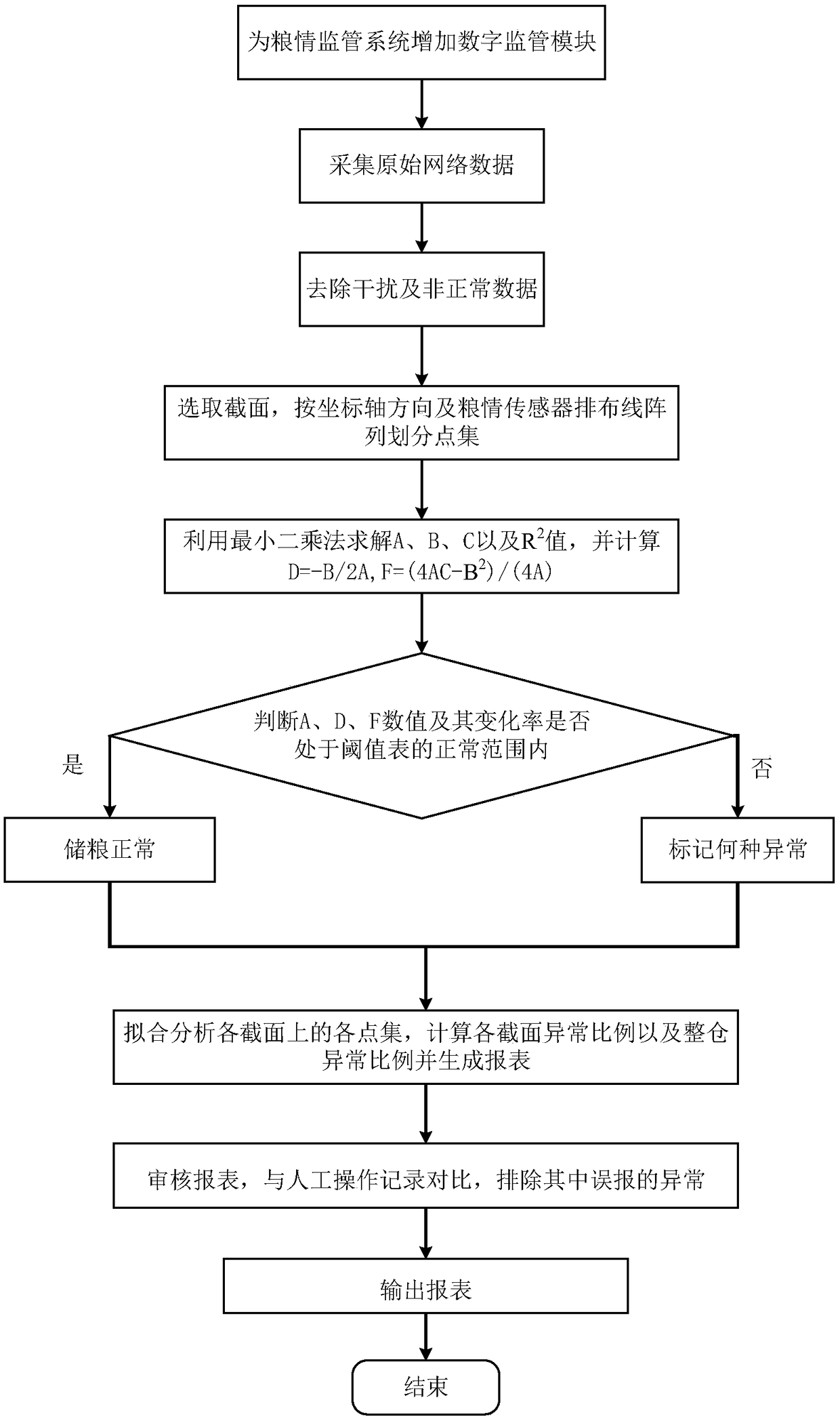

ABC strategy method suitable for stored grain digital supervision

The invention discloses an ABC strategy method suitable for stored grain digital supervision. The method comprises the steps of 1, determining a sampling range and a temperature measuring point of stored grain storage, and determining a temperature measuring sensor position in the sampling range and a grain temperature tested by a temperature measuring sensor; 2, building a fitting function F(i,j,k,d) of the temperature measuring sensor position and the grain temperature, wherein F(i,j,k,d)=A(i,j,k,d)j2+B(i,j,k,d)j+C(i,j,k,d); 3, calculating a deviation of the fitting function in the spatial position of the temperature measuring sensor and coefficients A(i,j,k,d), B(i,j,k,d) and C(i,j,k,d) of the fitting function when the deviation reaches a minimum value, and calculating a parameter D(i,j,k,d)and a parameter F(i,j,k,d); 4, judging and analyzing the coefficients and the parameters; and 5, summarizing abnormal conditions occurring in the step 4, calculating an abnormal proportion of a certain section in a granary and an abnormal proportion of the whole granary, and performing output.

Owner:JILIN UNIV +1

Application of melaleuca ahemifolia essential oil to control of stored-grain insect pests

Application of melaleuca ahemifolia essential oil to control of stored-grain insect pests belongs to the technical field of biotechnology. According to the grain storage and production realities, the stored-grain insect pests (tribolium confusum and sitophilus zeamais) are repelled, touched out and fumigated. Compared with three essential oil single items and the mixing formula thereof, which are reported in the disclosed patent 201510340845.X, the melaleuca ahemifolia essential oil has a better control effect on the stored-grain insect pests (tribolium confusum and sitophilus zeamais), particularly has a remarkable fumigating insecticidal function, and is long in lasting period and low in probability of resistance to drugs. The melaleuca ahemifolia essential oil is rich in raw material source, low in cost and environmentally friendly, has the potential of being developed into a stored-grain insect pest fumigating agent, and has a very wide application prospect in controlling red-grain insect pests.

Owner:ANHUI AGRICULTURAL UNIVERSITY

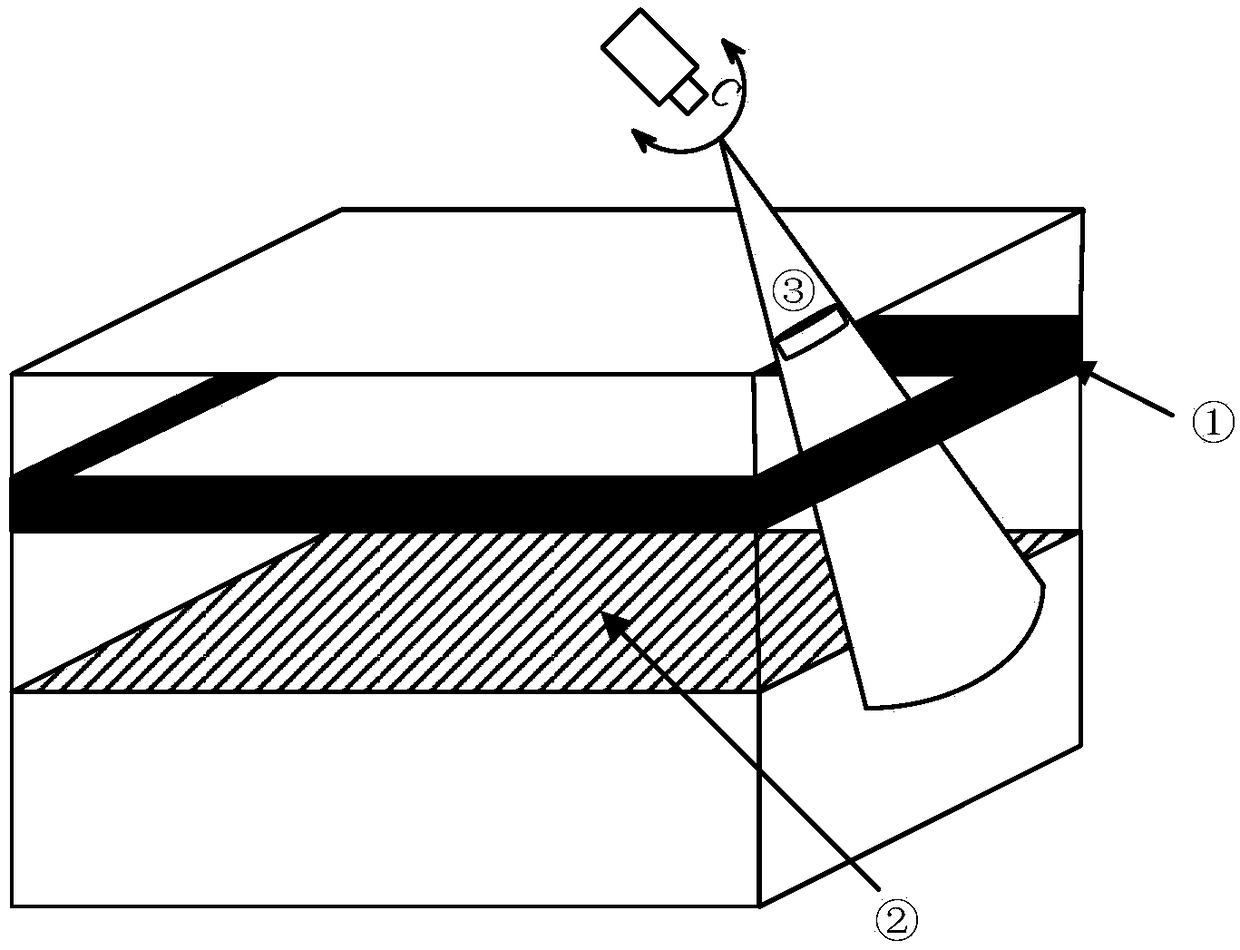

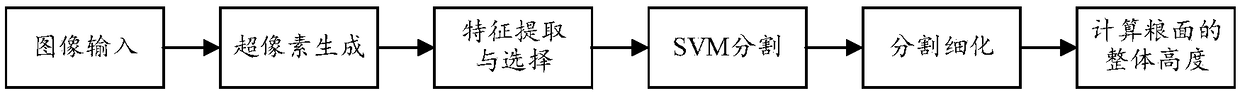

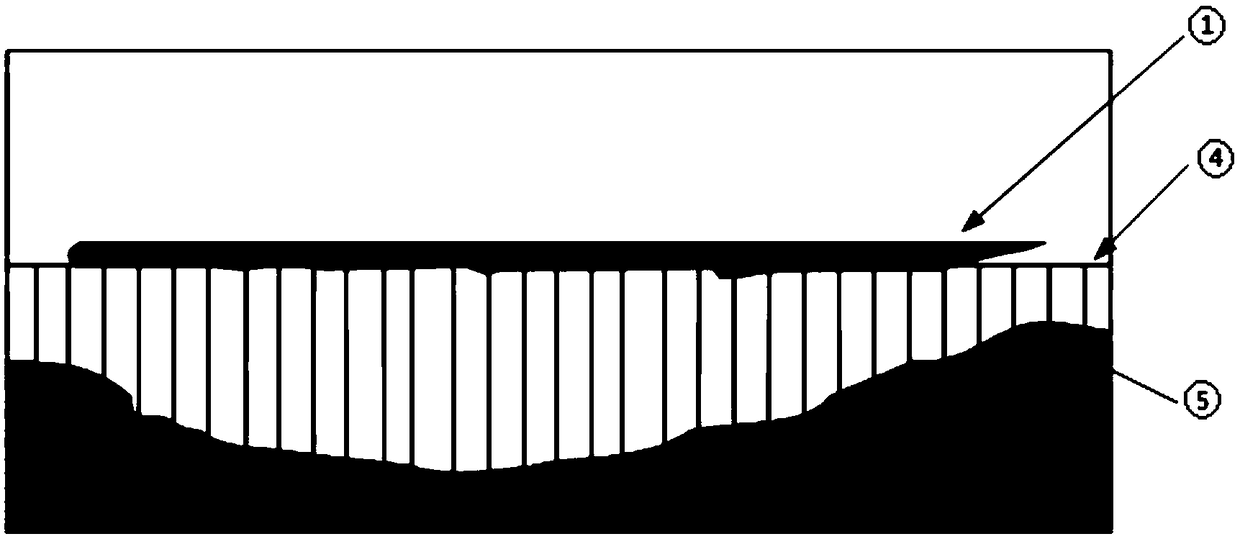

A computer vision-based automatic monitoring method for grain storage quantity change in granary

ActiveCN109472261AReduce consumptionThe detection process is fastCharacter and pattern recognitionLogisticsGrain storageVision based

The invention provides an automatic monitoring method of grain storage quantity change based on computer vision, belonging to the technical field of grain storage detection. The invention firstly collects the grain surface image at the grain mouth; The grain surface image comprises a reference line above the grain ration surface, wherein the reference line is a grain loading line or a marking line; The whole height of the grain surface is calculated by processing the grain surface image, and is compared with the whole height of the grain surface calculated at a predetermined time or at a previous time; If the overall height of the grain surface drops, the amount of stored grain in the warehouse is judged to be reduced. As oppose to that prior art which requires the continuous detection ofthe amount of grain in the entire granary, The invention only needs to detect the grain surface information at the grain mouth, and compares the calculated whole grain surface height with the preset primary or previous calculation result, so as to judge whether the grain storage quantity in the granary is changed, and has the advantages of fast detection speed and low energy consumption.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

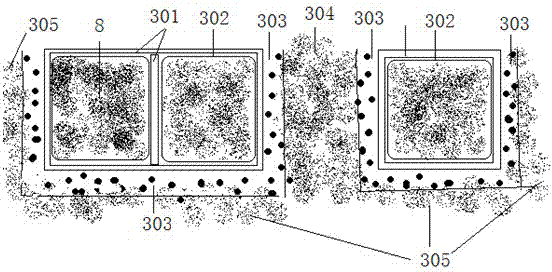

Underground bionic honeycomb granary

ActiveCN102287068AAdvanced ideasReasonable and unique structureAgricultural buildingsClimate change adaptationBrickAgricultural engineering

The invention belongs to the technical field of grain storage, and in particular relates to an underground bionic honeycomb granary and a grain storage method. The granary is designed through the reference and absorption of the original ecological honeycomb structure principle and comprises a granary body positioned below the ground surface, wherein the granary body consists of a plurality of rows of honeycomb silos among which gaps are formed in the transverse direction; each row of honeycomb silo comprises a plurality of silos which are tightly arranged along the longitudinal direction in turn; a silo upper opening is formed at the upper end of each silo and is provided with a closed cover; each silo comprises a reinforced concrete layer or a brick-concrete masonry layer; a polyethylenefilm layer is arranged in each silo; a spodosol layer is backfilled in an outer wall gap of each silo; and soil or sandstone or a soil and sandstone mixed material is backfilled among the spodosol layers. Grain is stored in the polyethylene film layers and isolated from outside, so that four ecological factors such as moisture, temperature, oxygen and light rays which can cause the deterioration of the stored grain are inhibited from the source, the stored grain is free from insects, mildew, rat damage, fires, floods and earthquakes, and the shelf life of the stored grain is prolonged by morethan one time.

Owner:蔡天印

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com