Patents

Literature

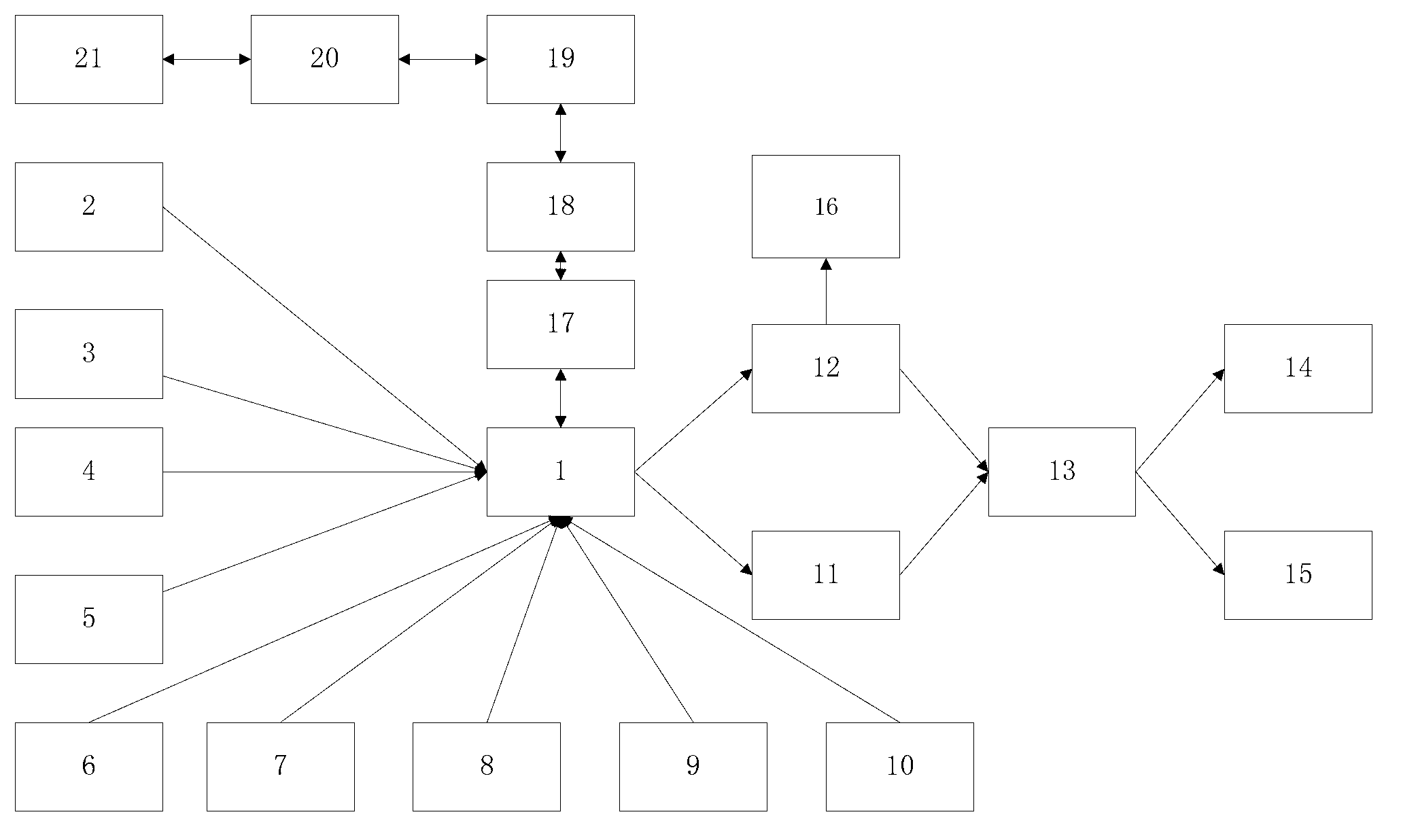

924 results about "Quality safety" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Whole-process monitoring and tracing system and method for quality safety of agricultural products

InactiveCN103310383ASatisfy retrospective inquiriesMeet the needs of retrospectively querying the relevant information of agricultural productsData processing applicationsWater qualityThe Internet

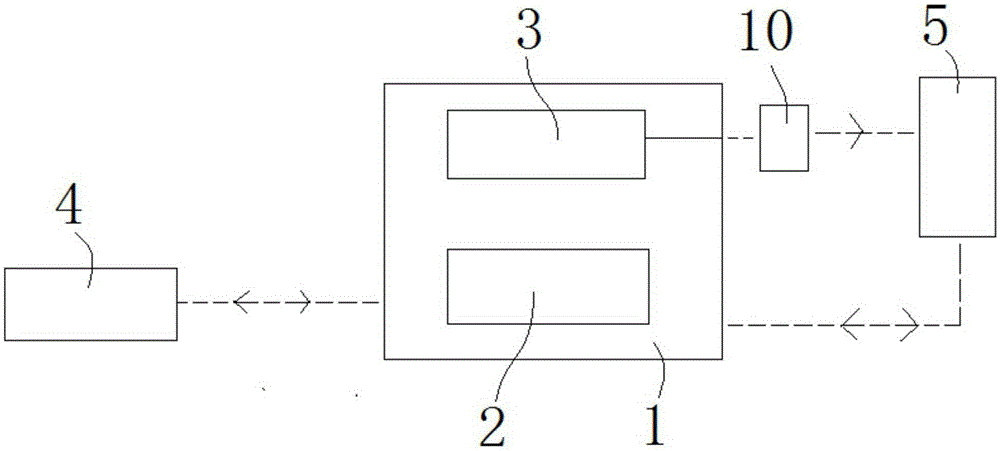

The invention discloses a whole-process monitoring and tracing system and method for the quality safety of agricultural products. The system comprises a cloud server which is connected with a client inquiry system, an agricultural product information acquisition pool and a monitoring system; the client inquiry system comprises a switch, a firewall, Internet, an authority authentication server and inquiry clients which are connected successively, wherein both-way communication is performed between the switch and the cloud server; and the agricultural product information acquisition pool comprises a forbidden pesticide inputting system, a basic information importing system, a water quality testing device, temperature and humidity sensors, a soil detection device, cameras, an air detection device, a pesticide detection device and a fertilizer detection device which are connected with the cloud server. The whole-process monitoring and tracing system and method have the advantages that the whole production process of agricultural products can be traced, and consumers can inquire about basic information of agricultural products through terminals.

Owner:莘县农业局

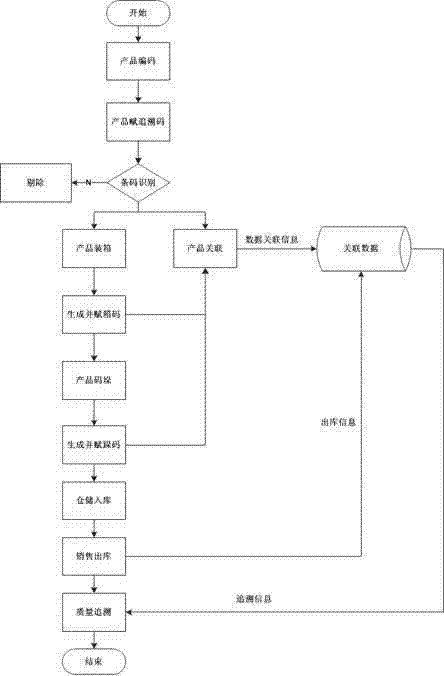

Quality safety tracing method for food processing enterprises

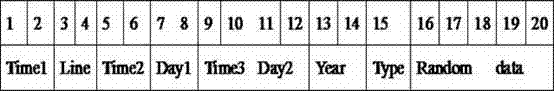

InactiveCN103761546ANo repeated codes appearMeet randomnessCo-operative working arrangementsDebit schemesProduction lineRelational database

The invention discloses a quality safety tracing method for food processing enterprises. The quality safety tracing method includes the steps that a laser coder generates random tracing codes according to a coding rule when a laser marking machine in a production line device is dynamically read in an on-line tagging mode; the laser marking machine carries out tracing mode marking on products on a production line, and two-dimension codes and plain codes are all marked on packages; a fixed reader is used for scanning and reading designated tagged code portions of the products; the two-dimension codes are successfully scanned and read, the tracing codes are recorded, and relevance between the tracing codes and commodity attribute information is completed; if the two-dimension codes fail to be scanned, the two-dimension codes will be removed through a removing device; the commodity tracing code information and the commodity attribute information are recorded into a relational database; after the products are packaged, package code data and product tracing code data are related; the products are stacked, stacking codes and tagged stacking codes are generated, and the stacking codes and the product package code data are related; the stacking codes are scanned, storage of the products is completed, delivery orders and the stacking codes are scanned to complete delivery, and the database records delivery information.

Owner:武汉华工赛百数据系统有限公司

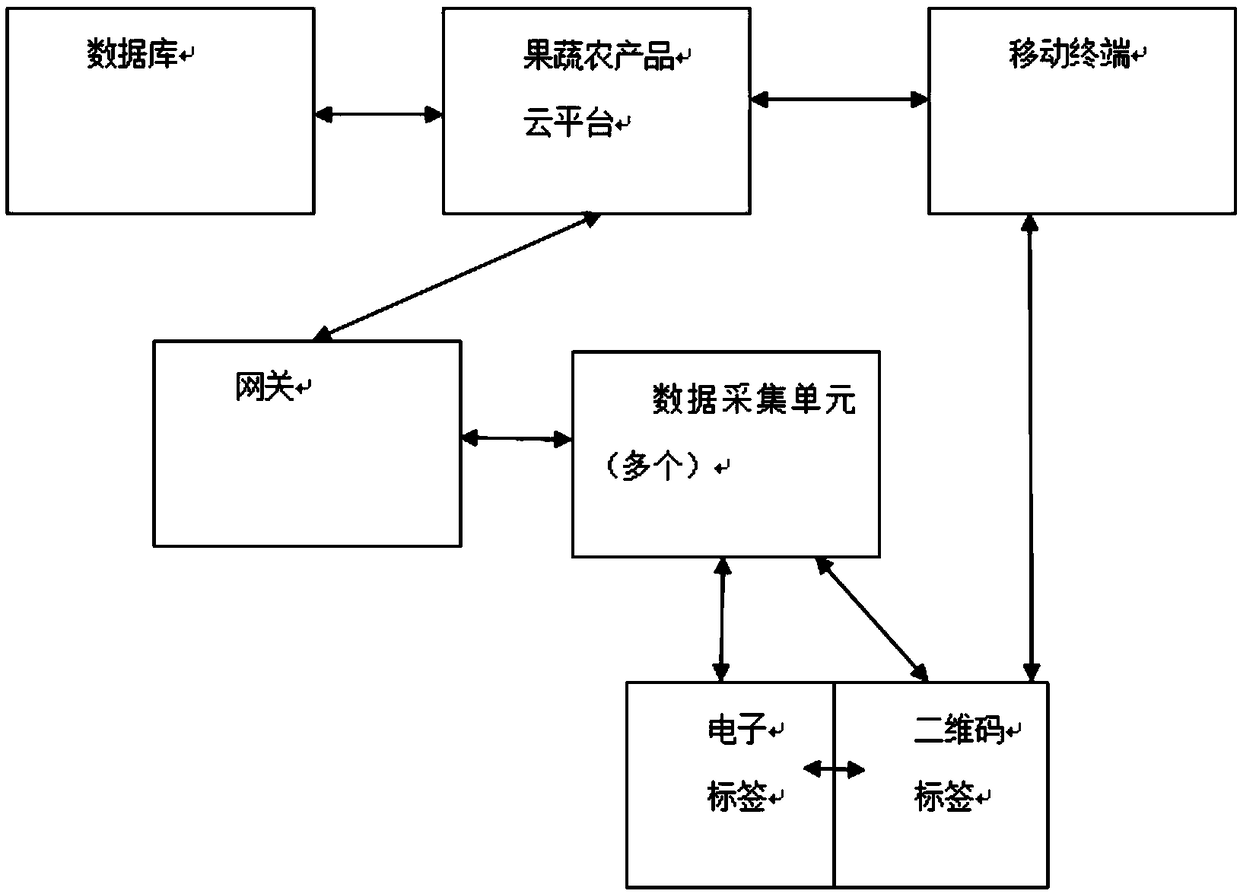

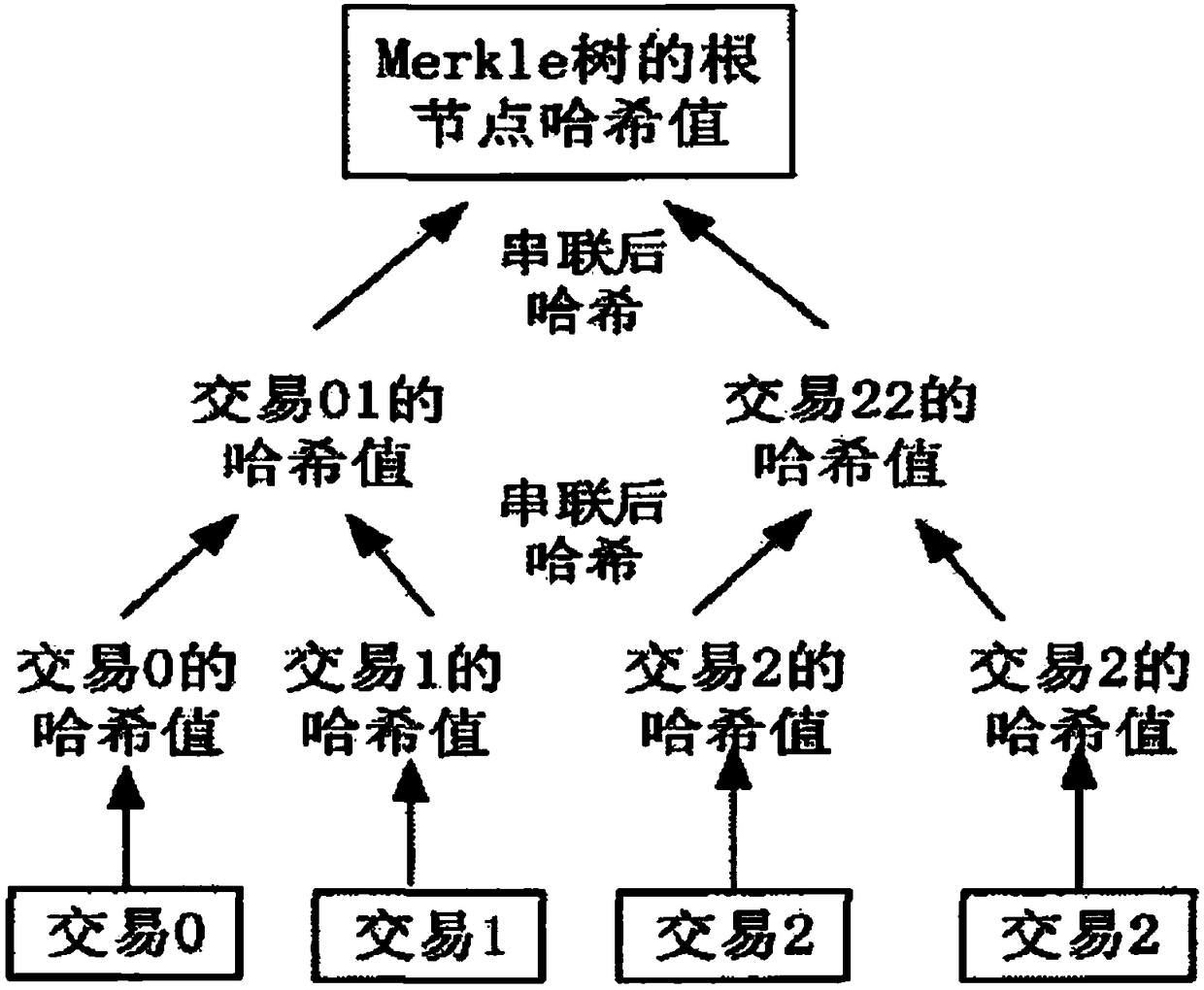

A fruit and vegetable agricultural product quality safety traceability system based on a block chain

InactiveCN109191003AGuaranteed not to be tampered withResolve integrityResourcesCommerceQuality safetyComputer science

The invention provides a fruit and vegetable agricultural product quality safety traceability system based on a block chain, which comprises a fruit and vegetable number generation module, a fruit andvegetable transaction generation recording module, a verification block chain module and a transaction block chain module. The invention utilizes the block chain technology, can ensure that the datain the whole link cannot be tampered with and cannot be replaced, records the whole transaction process through the transaction block chain and verifies the transaction behavior through the verification block chain, thereby solving the integrity and trustworthiness of the quality safety data in the fruit and vegetable agricultural product quality safety traceability system.

Owner:ZHONGKAI UNIV OF AGRI & ENG

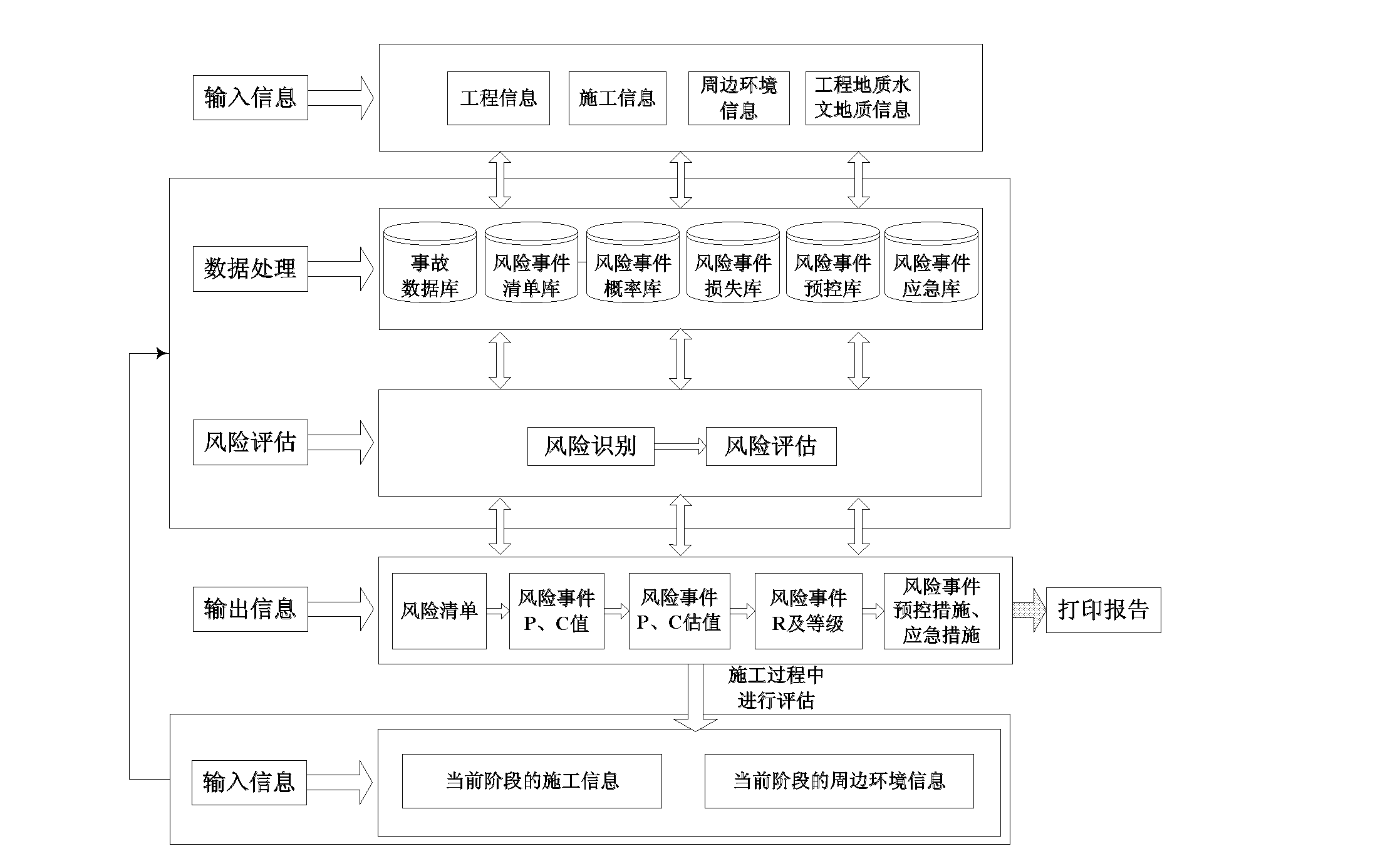

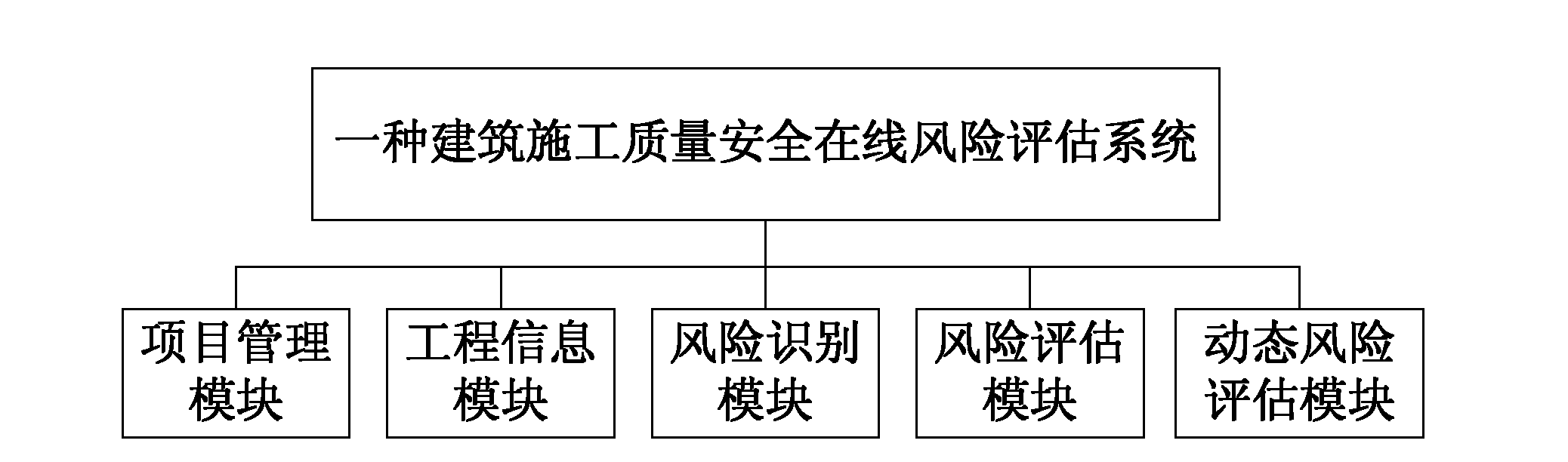

Building construction quality safety online risk assessment system

ActiveCN102521710AWith self-learning functionPromote self-learningResourcesRisk identificationEngineering

The invention provides a building construction quality safety online risk assessment system. The system comprises: a project management module, an engineering information module, a risk identification module, a risk assessment module and a dynamic risk assessment module. The project management module is used for information management of a building construction project and a case library. The engineering information module is used for general situation information management of the building construction project. The risk identification module can automatically identify a risk event and a risk factor according to an engineering general situation information system so as to form a risk list and a risk tree. The risk assessment module carries out data reasoning according to comparison of the project general situation information and the similar project information in a database, estimates a risk event generation probability and losses, determines a risk grade, determines an importance degree of the risk factor through a sensitivity analysis and automatically searches the database so as to obtain a pre-control measure and form a risk assessment report. The dynamic risk assessment module is used for risk tracking, monitoring and situation evaluation during an engineering construction process.

Owner:SHANGHAI JIANKE ENG CONSULTING

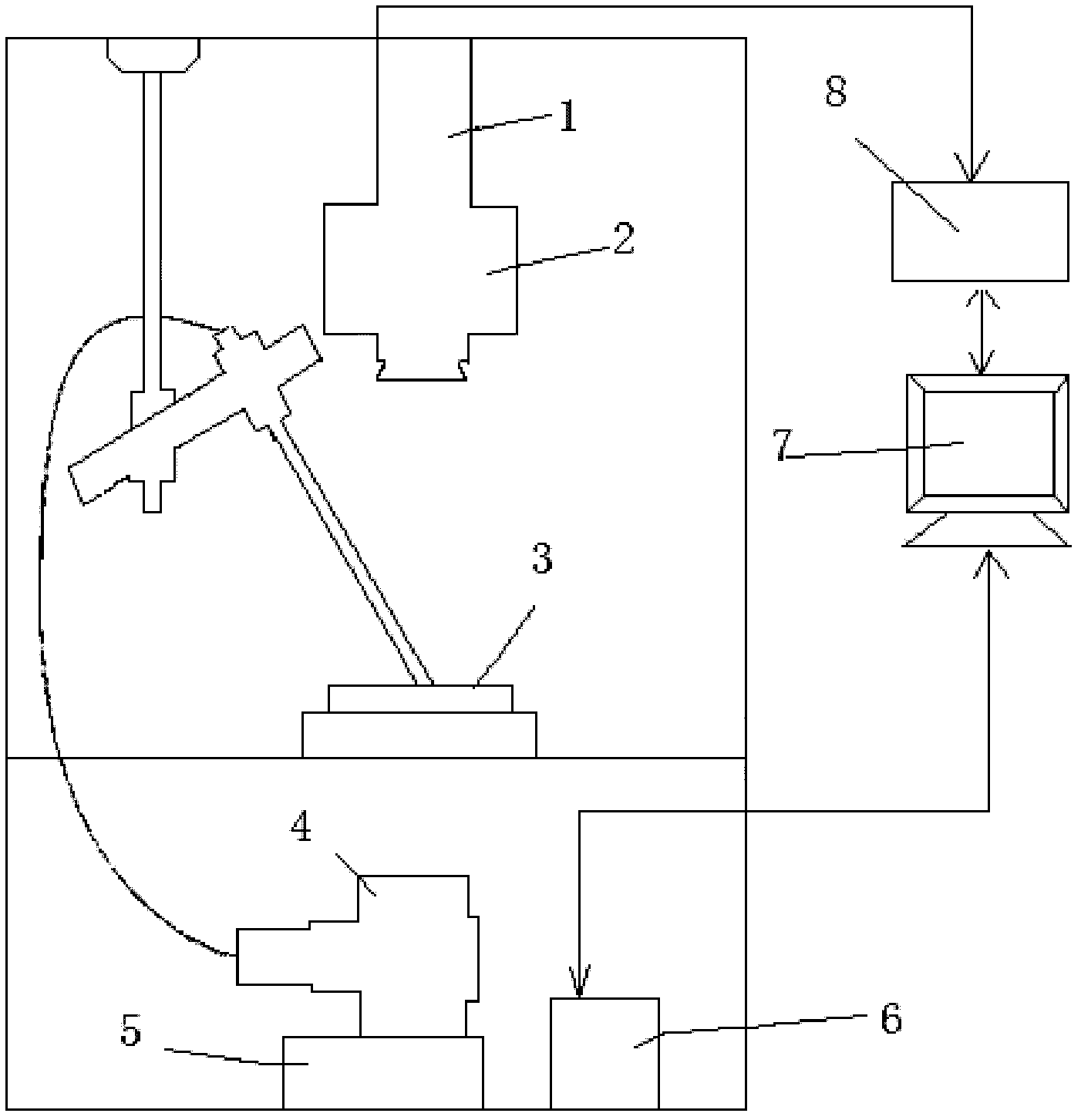

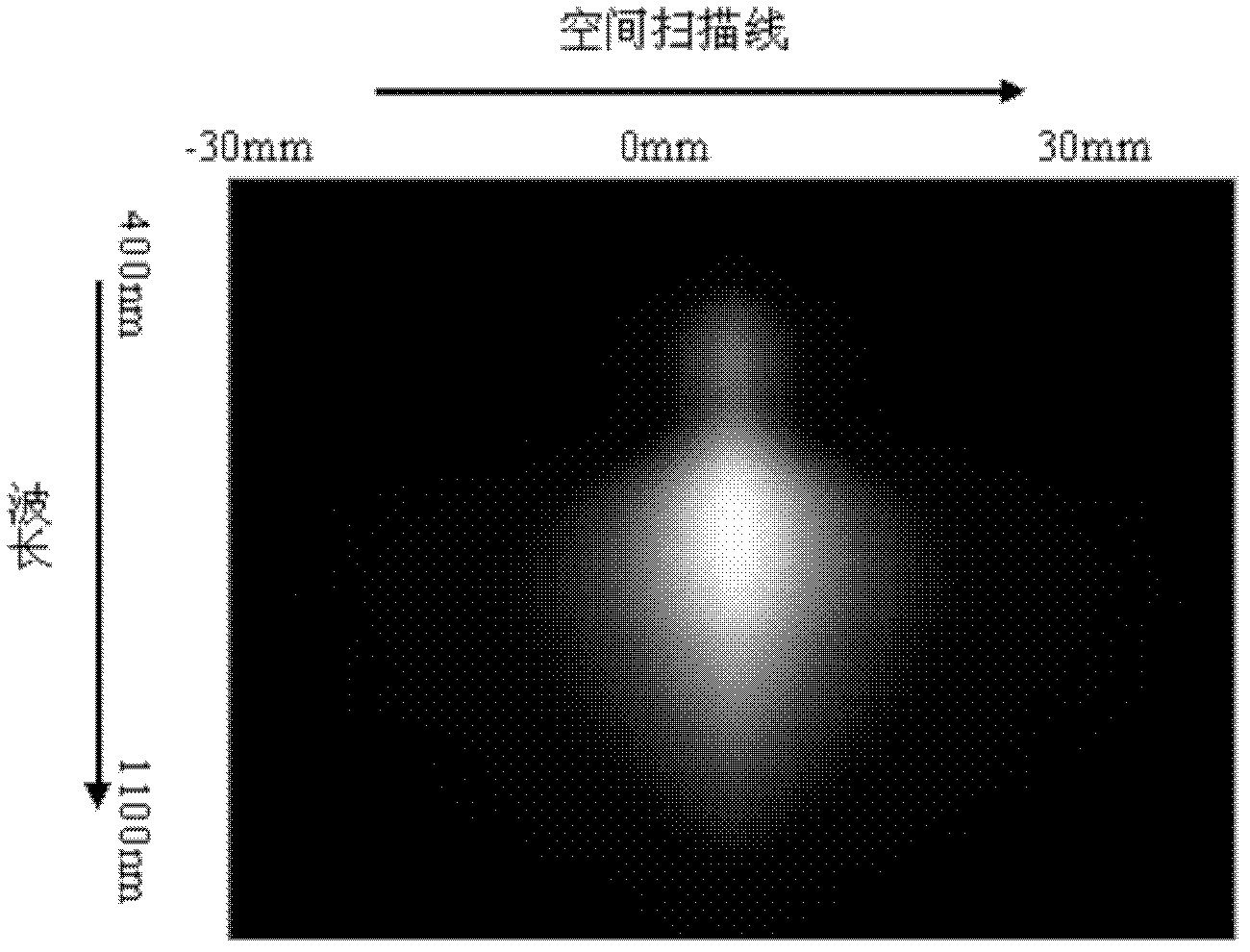

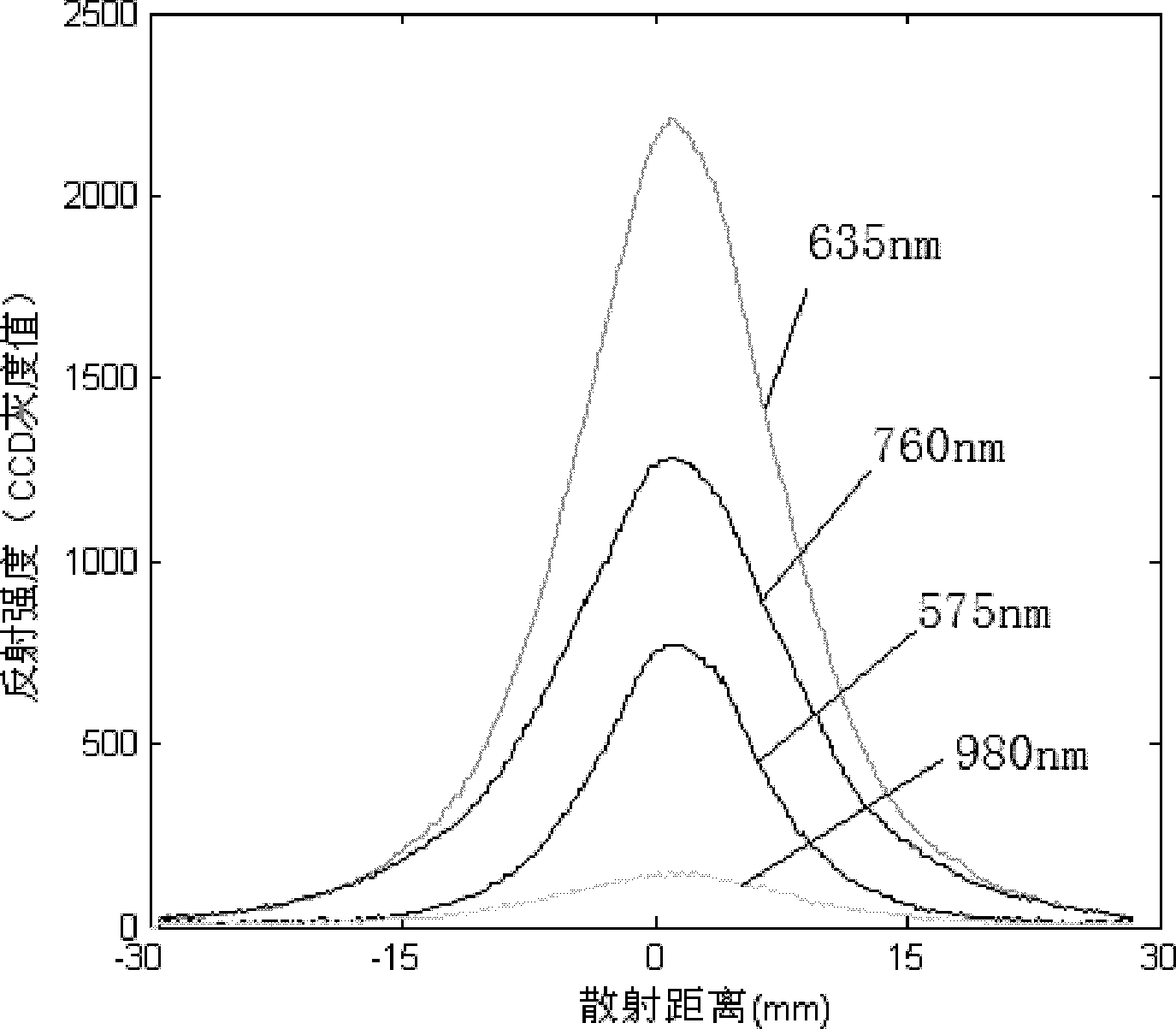

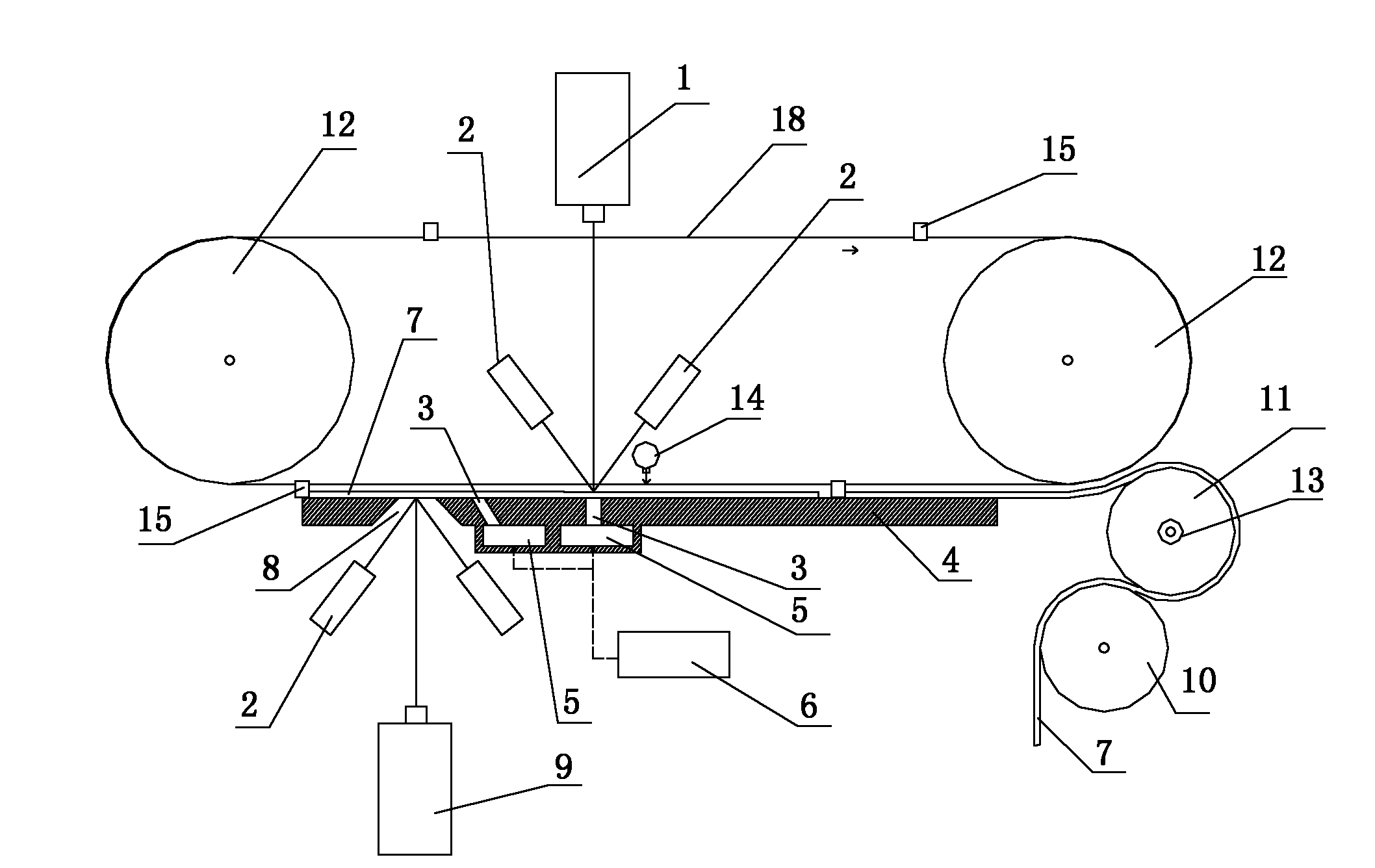

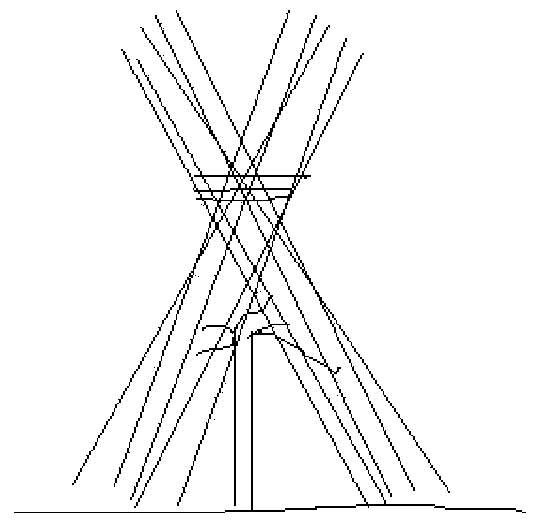

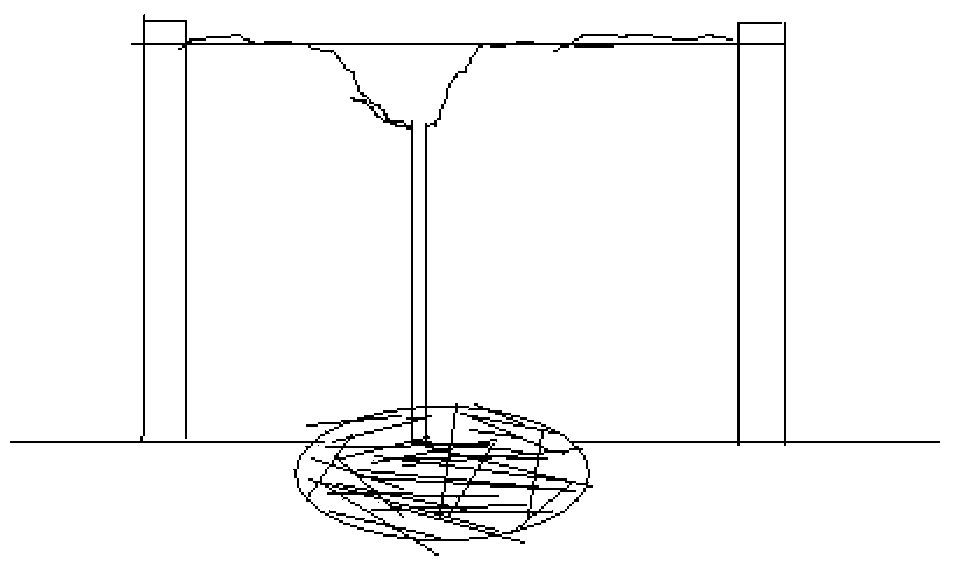

System and method used for rapidly evaluating freshness of raw meat products

InactiveCN102323267ANon-destructive testingMaterial analysis by optical meansNitrogenBusiness forecasting

The invention belongs to the technical field of meat product quality safety testing, and provides a system and a method used for rapidly evaluating the freshness of raw meat products. The system is composed of an imaging spectrometer, a CCD digital camera, a tungsten halogen lamp direct current point light source, a light source stabilizing device, a camera controller, a computer and an image collecting chip. The method provided by the invention comprises steps that: the CCD digital camera, the imaging spectrometer and the camera controller are used for collecting hyper-spectral images of the surfaces of pork; evaluation and grading are carried out according to measured physical and chemical parameters; the hyper-spectral images are analyzed by using mathematical techniques, and a forecasting model used for evaluating pork freshness is established. With the system and the method provided by the invention, rapid and lossless detections can be carried out upon raw meat freshness parameters such as volatile basic nitrogen, pH value and color.

Owner:CHINA AGRI UNIV

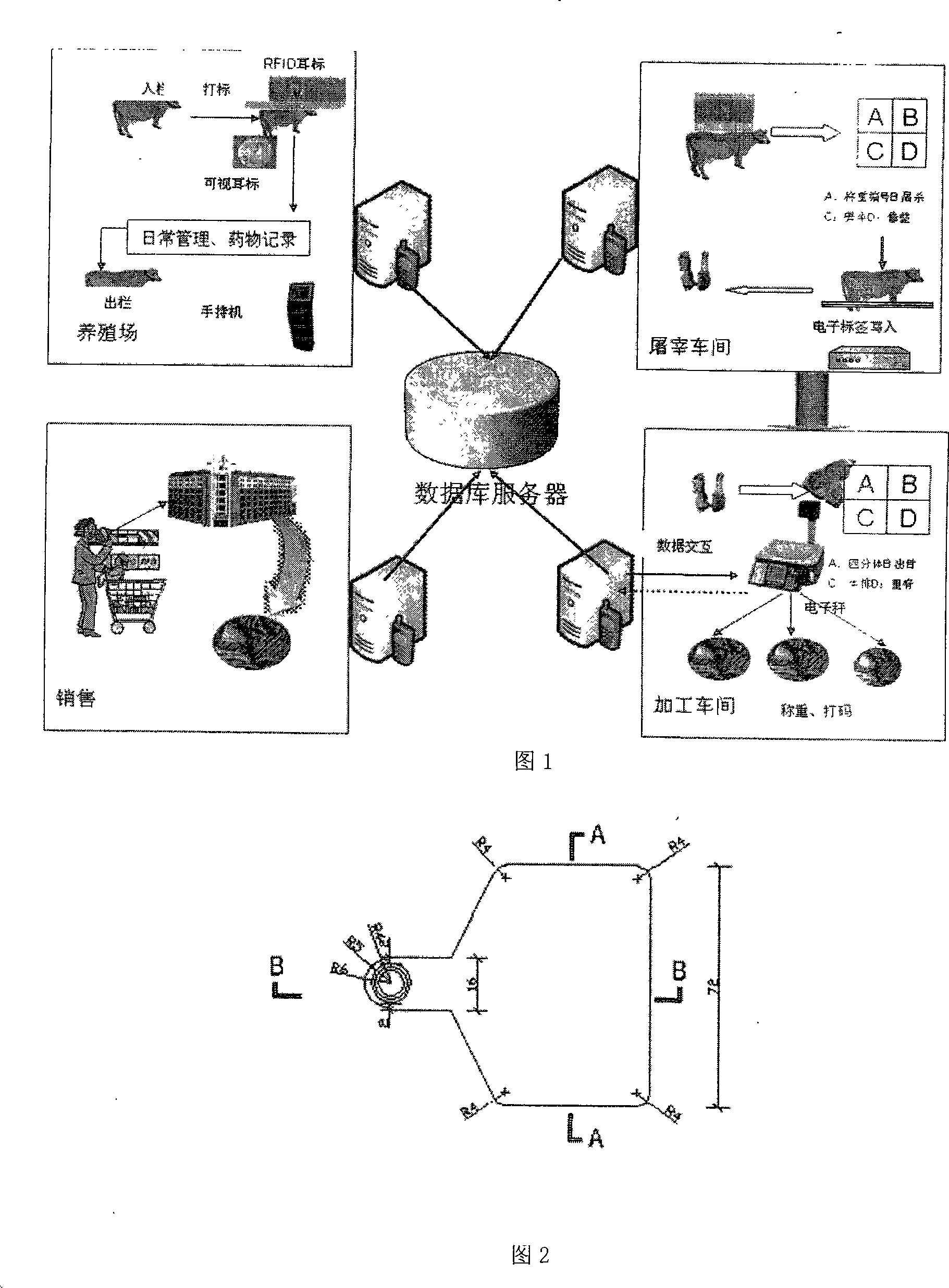

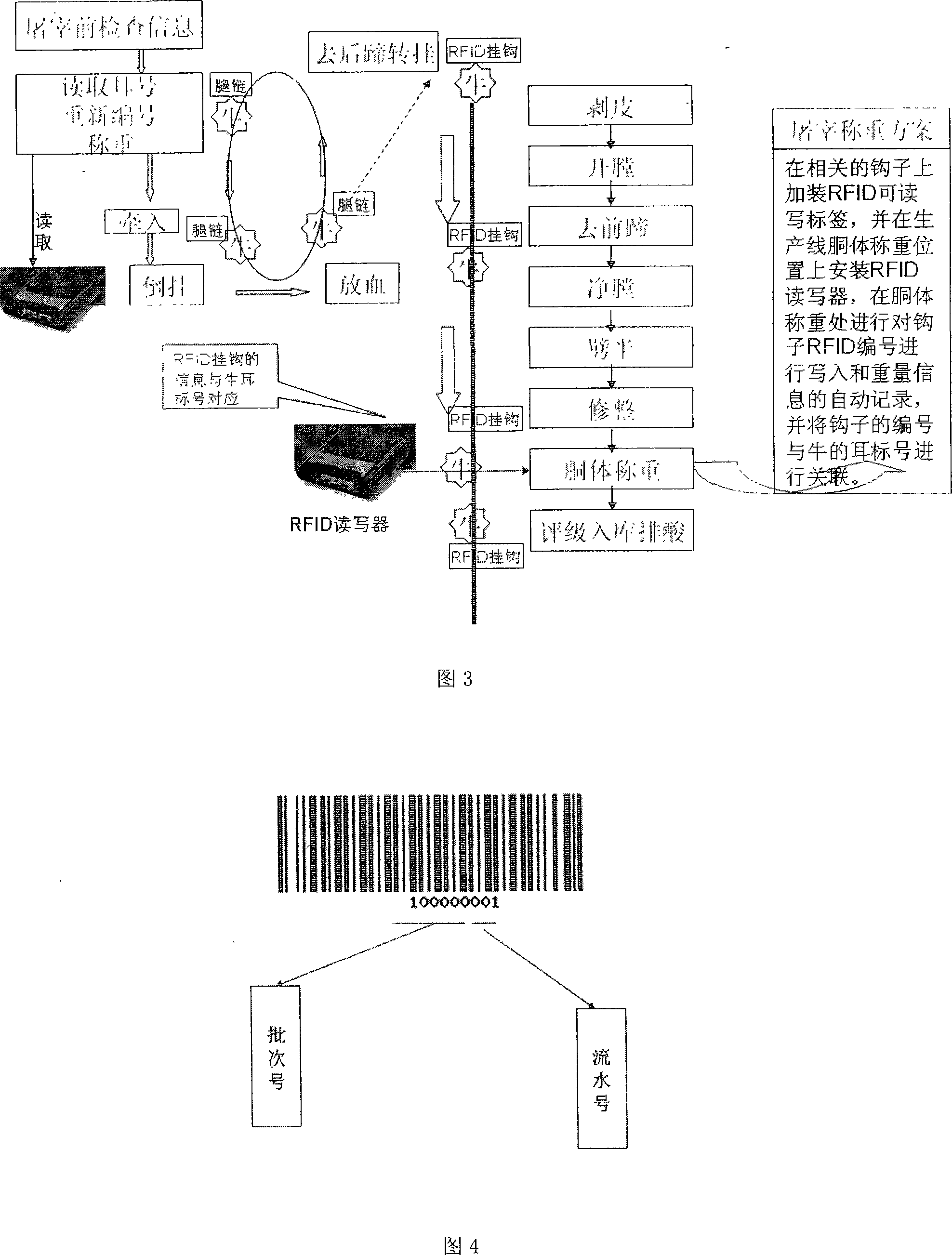

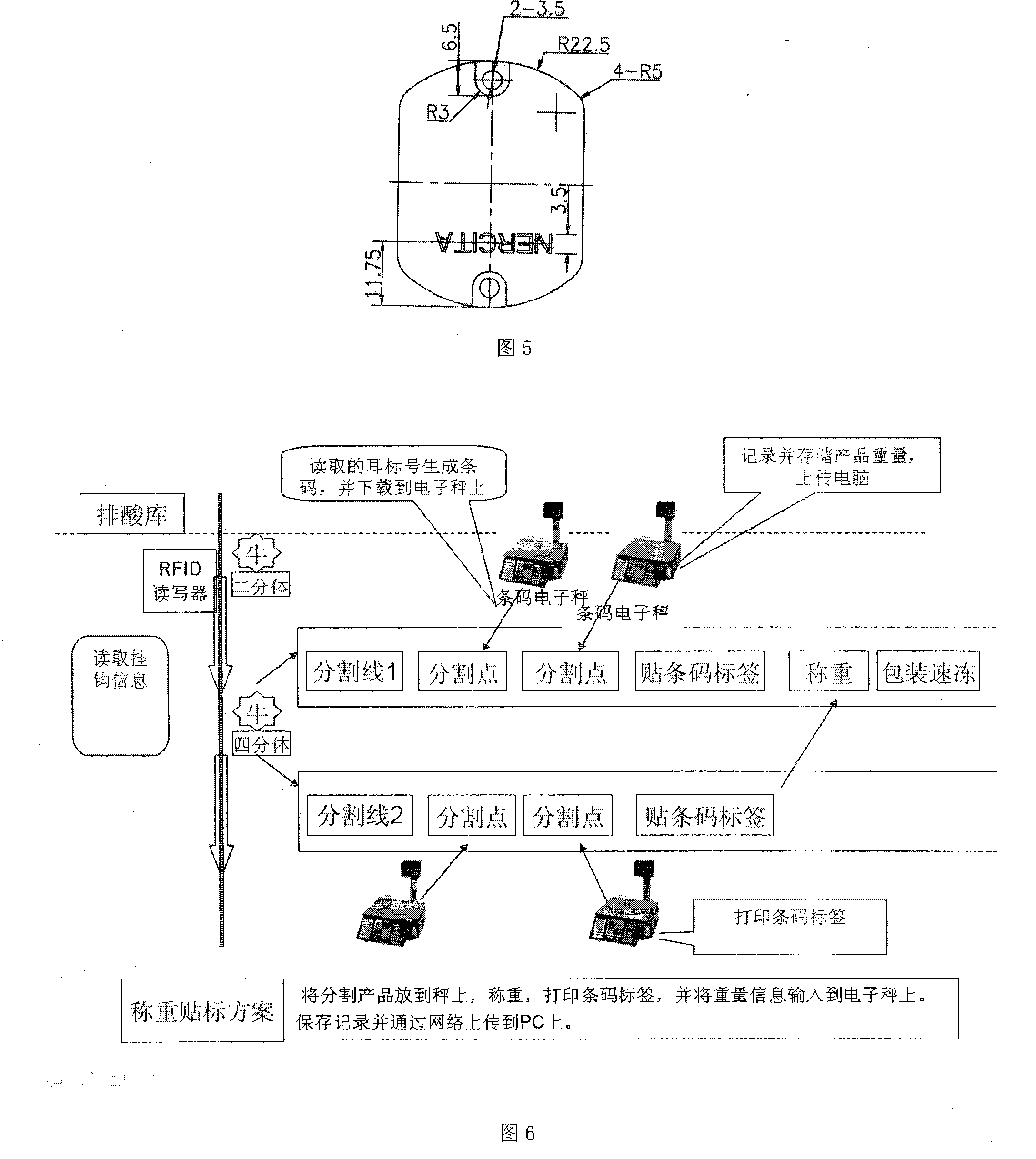

Method and system for whole course tracing and retroacting beef product quality safety

InactiveCN101201928AImprove management levelFully automatedData processing applicationsCo-operative working arrangementsAgricultural scienceEar tag

The invention relates to a whole process tracking and tracing method and system thereof for quality safety of beef products, which belongs to digitization category of beef product quality safety. The invention adopts a 134.2 KHz electronic ear tag to mark individual cattle in beef cattle breeding period and a breeding management subroutine to record the situation of immunization, epidemic prevention and feeding diseases, in beef cattle breeding period; in butchering period, the system realizes the transformation from a breeding ear tag to a new ear tag; hooks on a butchering line are provided with 915M electronic labels, when weighing carcasses, number and types of inspection labels as well as 'new ear tag No.' are written on corresponding labels on hooks; when the carcasses are sent from an acid discharge storehouse to a cut line, the system realizes the transformation from the 915M electronic label to a bar code and automatically delivers data to an electric balance by a UDP protocol in wireless mode to realize the organic integration of management, control and production through printing program by an embedded bar code. The invention compactly combines software, hardware, the electronic label with low or high frequency, the bar code, and system management software to realize the seamless integration of production operation and marking management, thus greatly improving working efficiency.

Owner:BEIJING RES CENT FOR INFORMATION TECH & AGRI

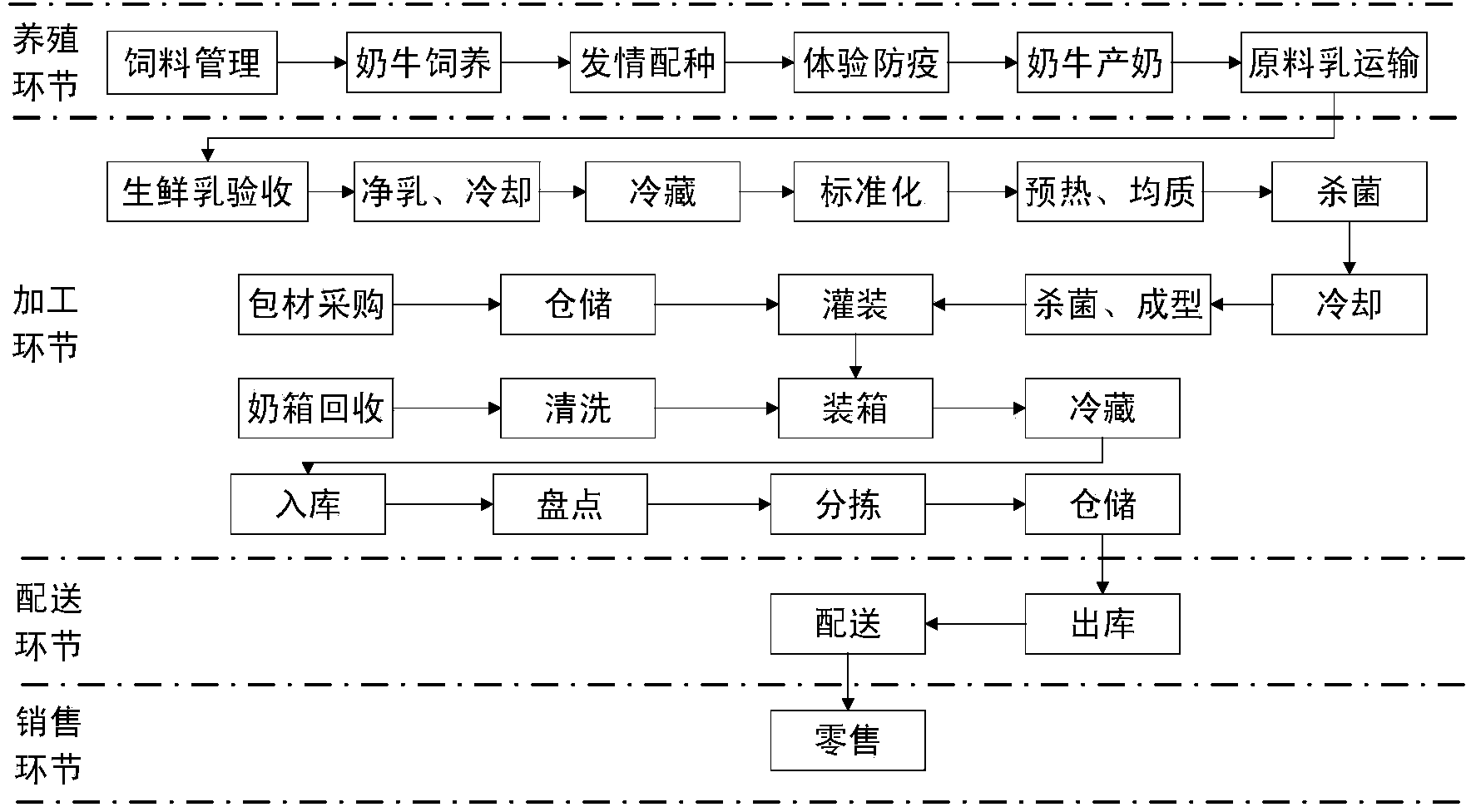

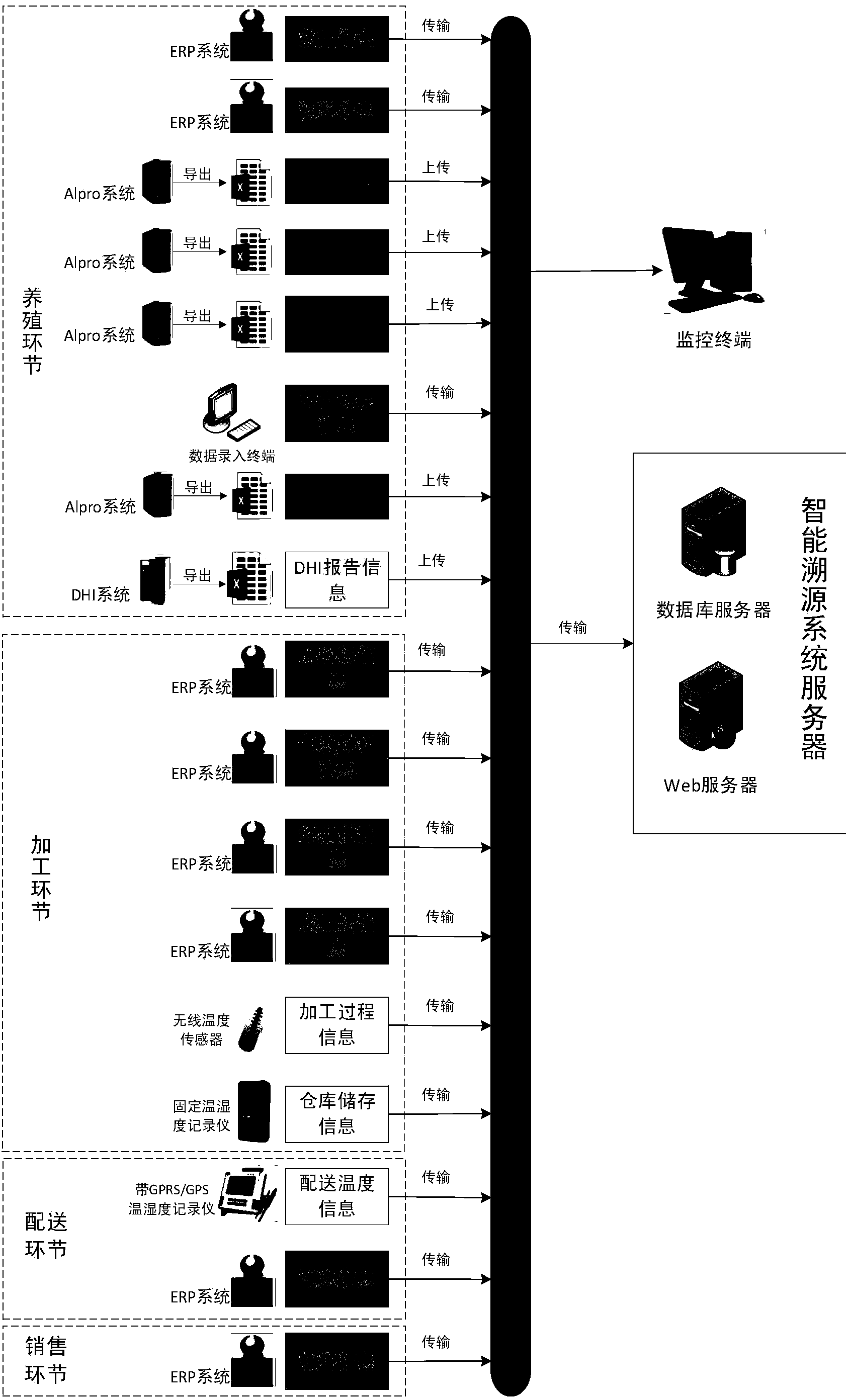

Dairy product quality safety full-life-circle intelligent traceability method based on Internet of things

The invention discloses a dairy product quality safety full-life-circle intelligent traceability method based on the Internet of things. The method comprises the following steps: the step S1 in which various cow breeding information is acquired in the breeding link; the step S2 in which various material and processing information is acquired in the processing link; the step S3 in which the raw milk and finished milk temperature information is acquired in the distribution link; the step S4 in which the order, customer and distribution information is acquired in the marketing link; the step S5 in which a traceability method in which a two-dimensional bar code and a traceability code are combined is adopted, wherein the two-dimension code is used on a large package, and the traceability code is used on a small package, and a traceability platform is established to perform traceability. According to the traceability method of the invention, an appropriate technology is selected when the enterprise actual situation is taken into account, and at the same time, the existing enterprise information system is used to acquire most of the traceability information, so that a lot of equipment and labor cost can be reduced. Additionally, the intelligent traceability system can be used to realize the visualization of the whole dairy product supply chain, so great utilization values can be provided for dairy product enterprises and supervision departments to facilitate the enterprises and the supervision departments to find problems timely, so that the loss can be effectively reduced.

Owner:SOUTH CHINA UNIV OF TECH +2

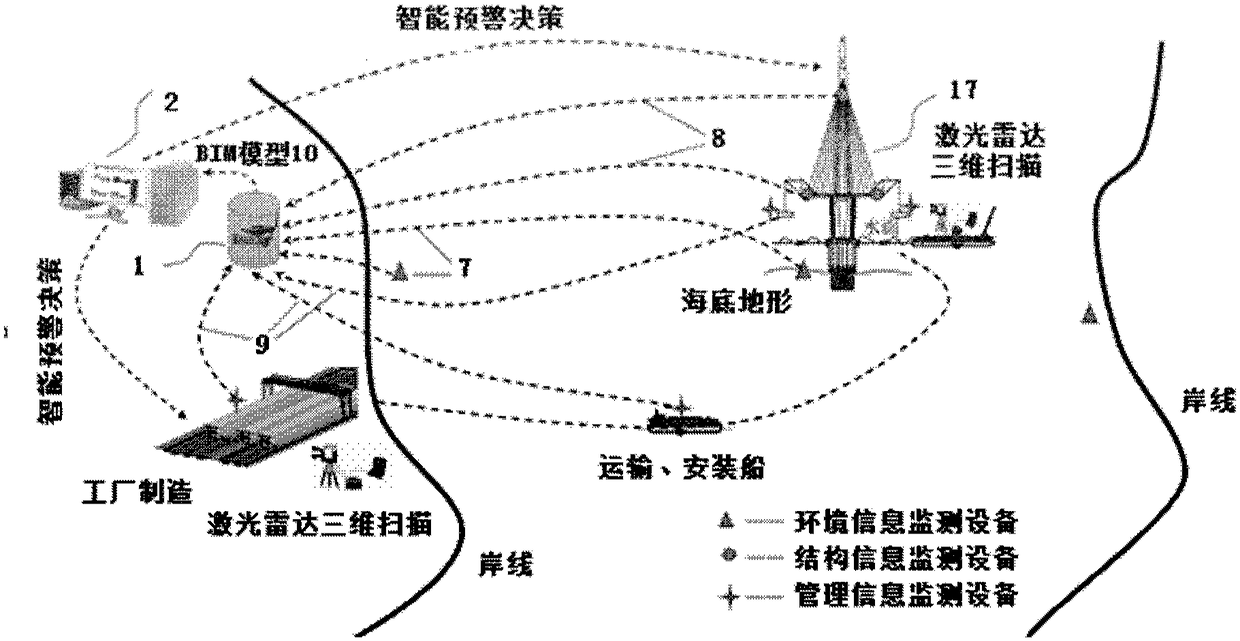

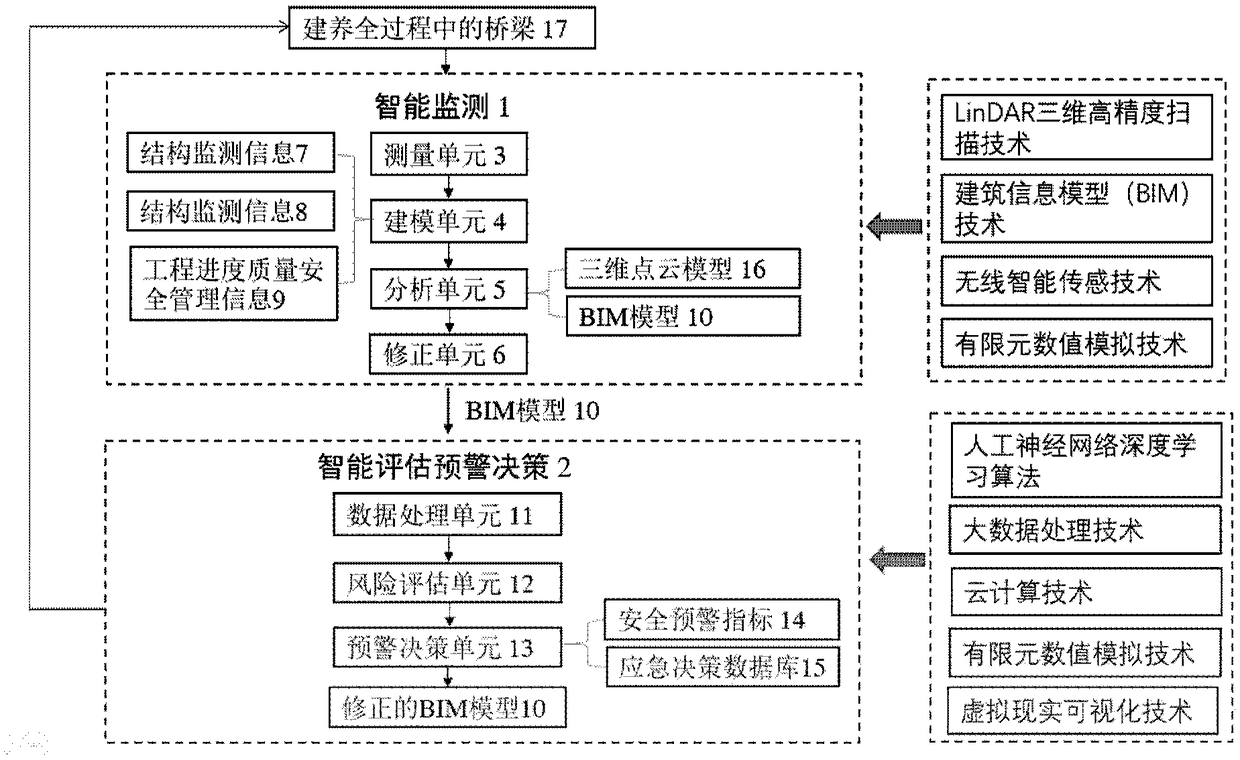

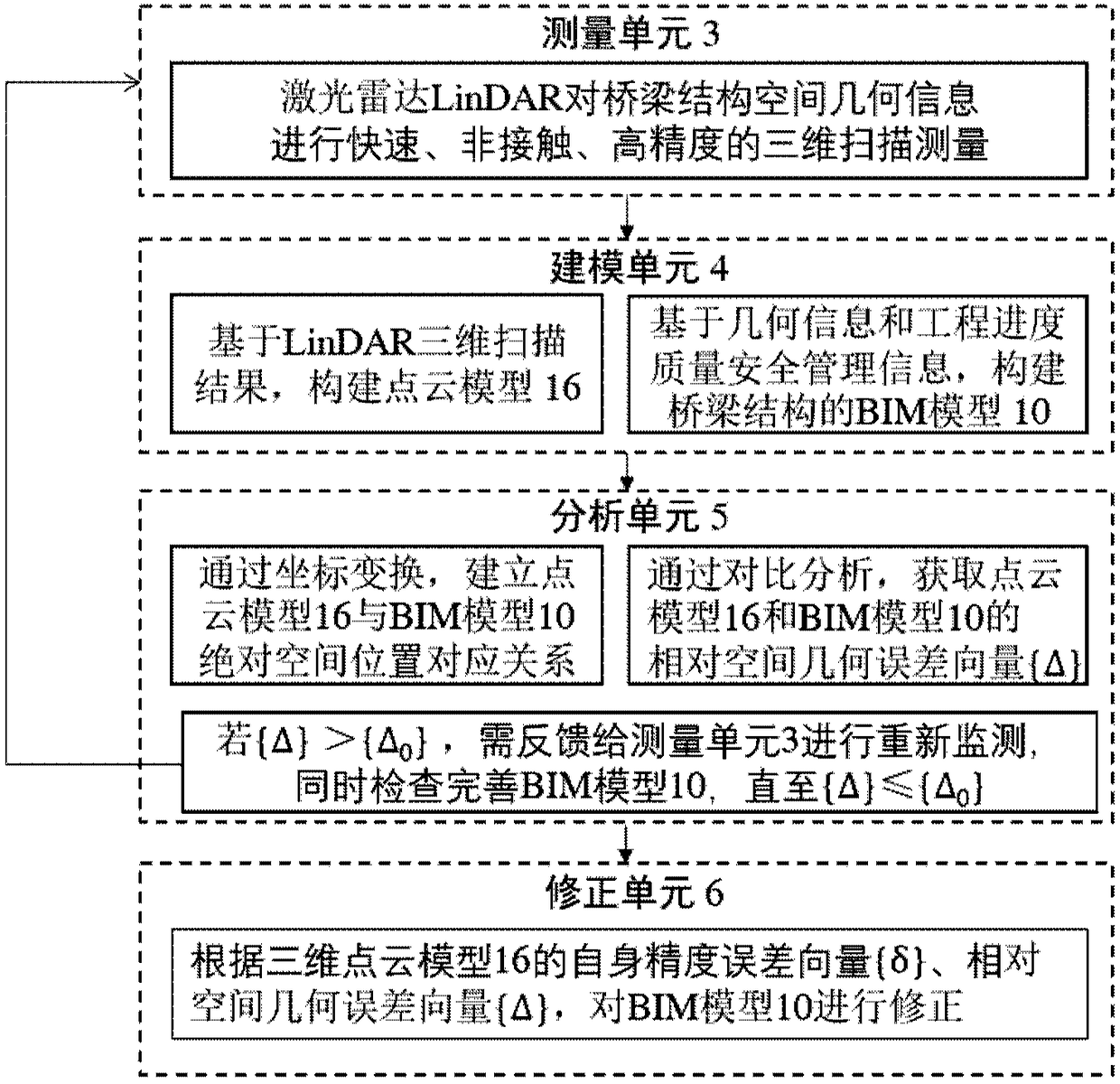

Bridge construction and maintenance whole-process intelligent monitoring, assessment, alarming and decision-making system and method

PendingCN108460231ARealize online real-timeHigh precisionGeometric CADInput/output for user-computer interactionStructural monitoringProcess quality

Disclosed is a bridge construction and maintenance whole-process intelligent monitoring, assessment, alarming and decision-making system and method. The bridge construction and maintenance whole-process intelligent monitoring, assessment, alarming and decision-making system is composed of an intelligent collecting module and an intelligent assessment, alarming and decision-making module, wherein the intelligent collecting module integrates laser radar three-dimensional high-precision scanning technology, building information model technology and wireless intelligent sensing technology and intelligently collects multi-source heterogeneous multi-dimensional high-precision information during a bridge construction and maintenance whole process such as environment monitoring information, structure monitoring information and project process quality safety management information; the intelligent assessment, alarming and decision-making module integrates big data processing technology, cloud computing technology, artificial neural network algorithms and virtual reality technology and structures multi-stage safety alarming indexes and emergency decision-making database to perform online, real-time, high-precision, visual and intelligent assessment analysis, alarming and decision-making on structure and traffic safety performance of the bridge construction and maintenance whole process.The bridge construction and maintenance whole-process intelligent monitoring, assessment, alarming and decision-making system covers the bridge construction and maintenance whole process and has the advantages of being high in efficiency and precision, visualized, intelligent and the like.

Owner:CCCC HIGHWAY BRIDNAT ENG RES CENT

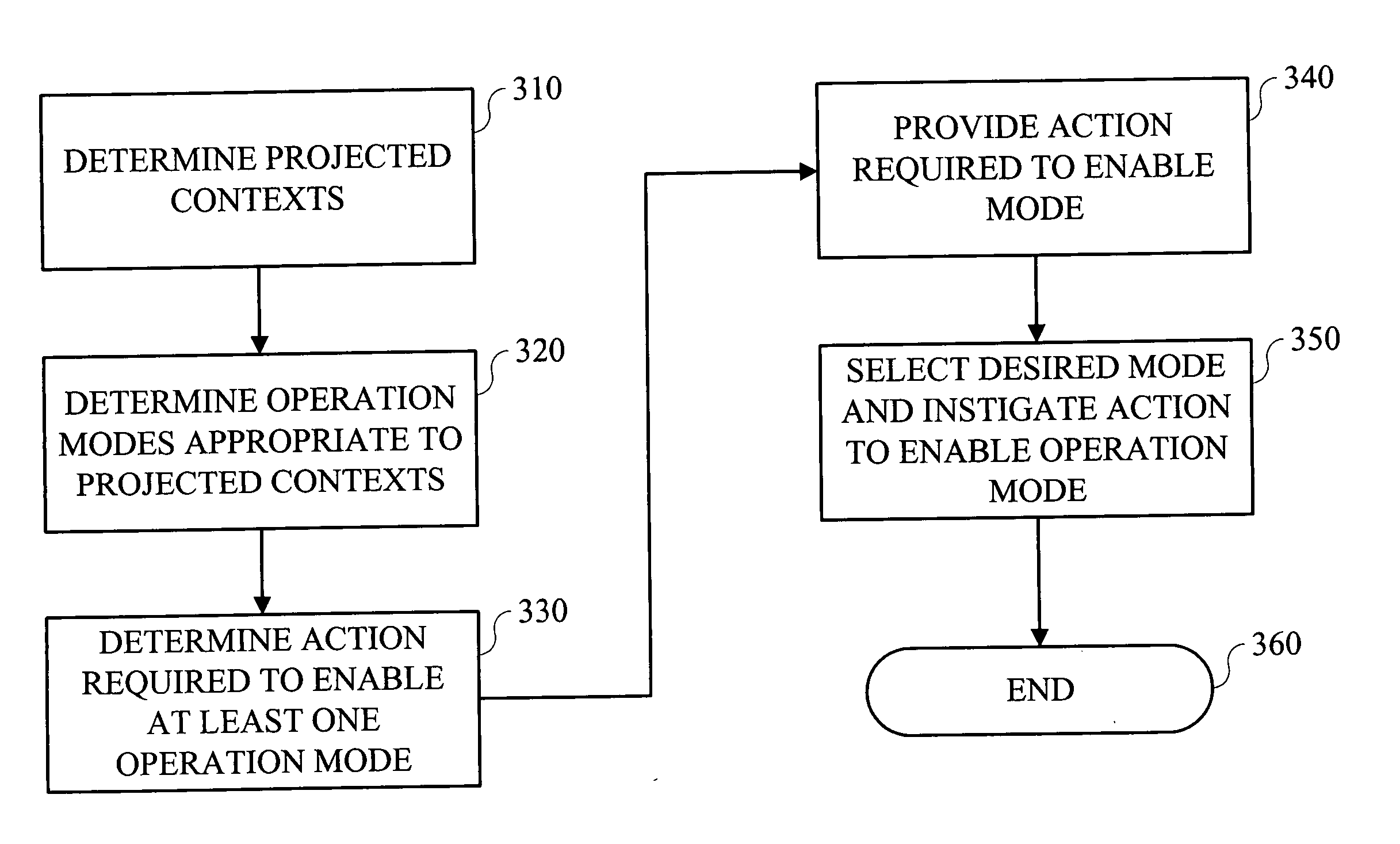

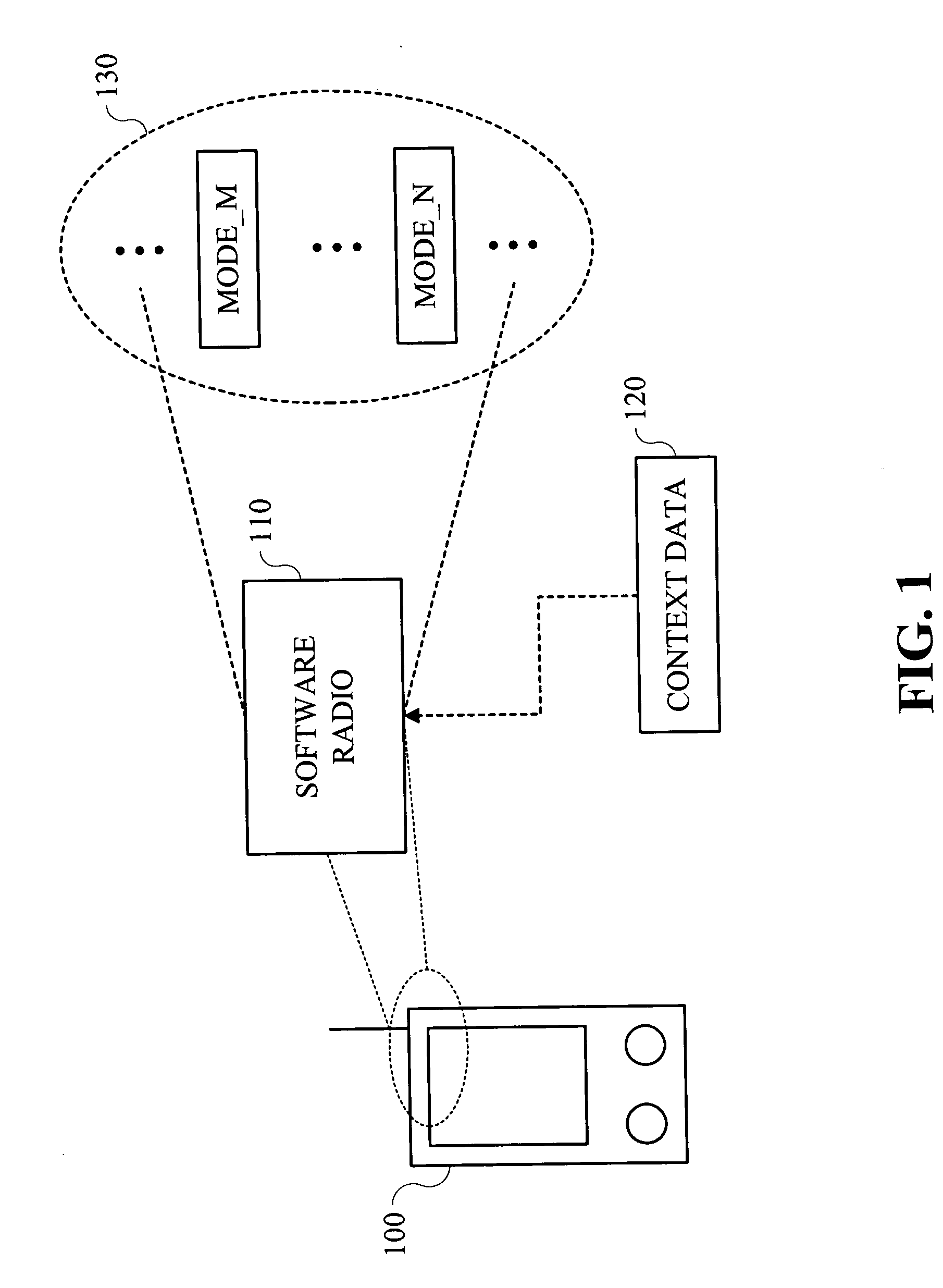

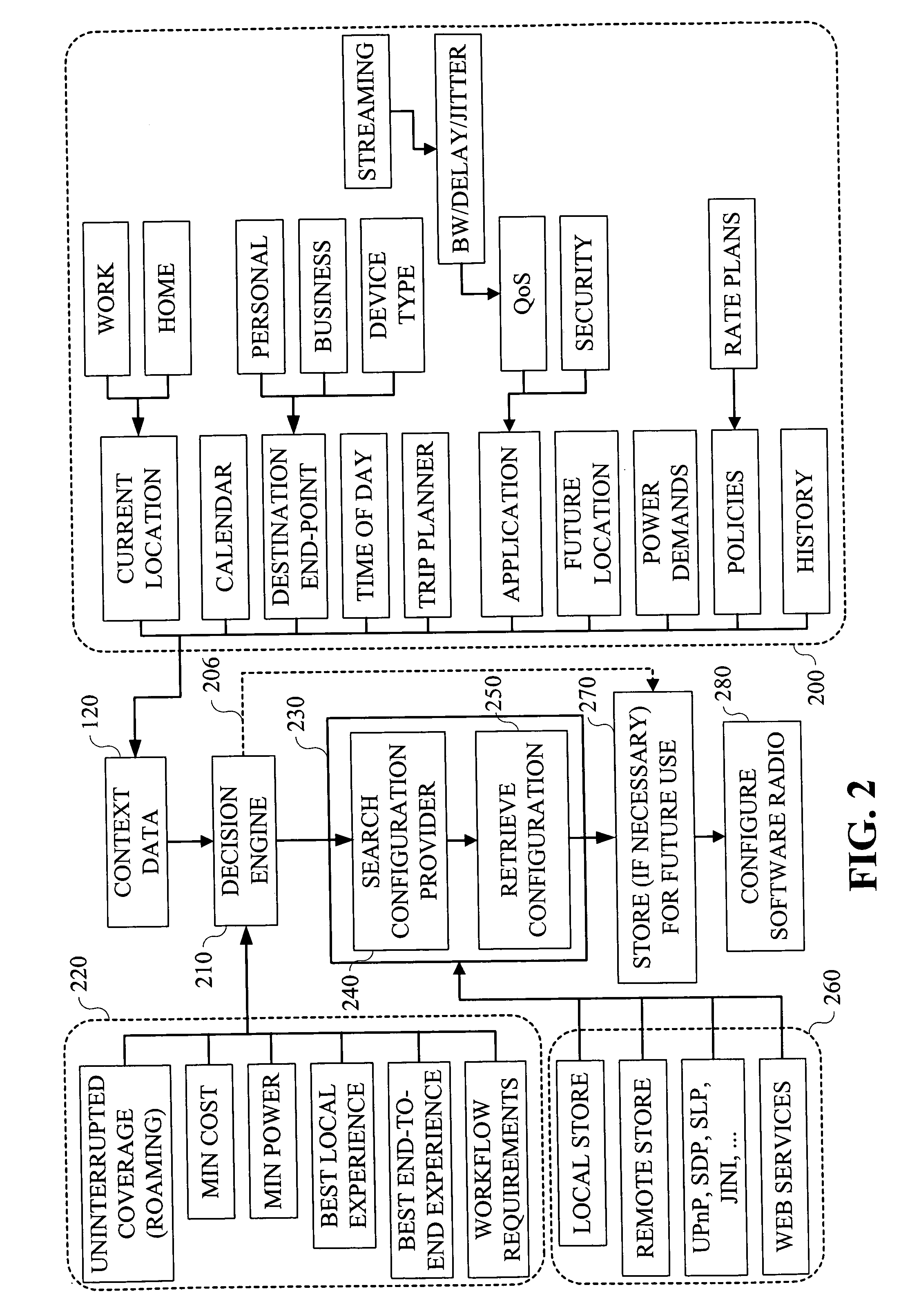

Method and apparatus for preconditioning mobile devices for network and other operations

ActiveUS20050130653A1Radio/inductive link selection arrangementsSubstation equipmentComputer hardwareQuality of service

Techniques are provided for providing automated configuration of computing devices. More particularly, principles of the invention may use anticipated context to precondition a device whose operational mode is alterable via computer controllable operations. Anticipated context may be affected by any number of parameters including, but not limited to, current location, time of day, destination end-point, e.g., phone number to be called, past history, subscription rate plans, power requirements of device, application demands with respect to quality-of-service (QoS), security, calendar information, and so on. Further, principles of the invention may use locally derived knowledge about the intended use of a device and dynamically enable it in a desirable mode of operation using locally reachable configuration parameters stored in advance based on the anticipated context for the operation of the device. Still further, principles of the invention may dynamically locate necessary configuration parameters via a service discovery process.

Owner:DAEDALUS GRP LLC

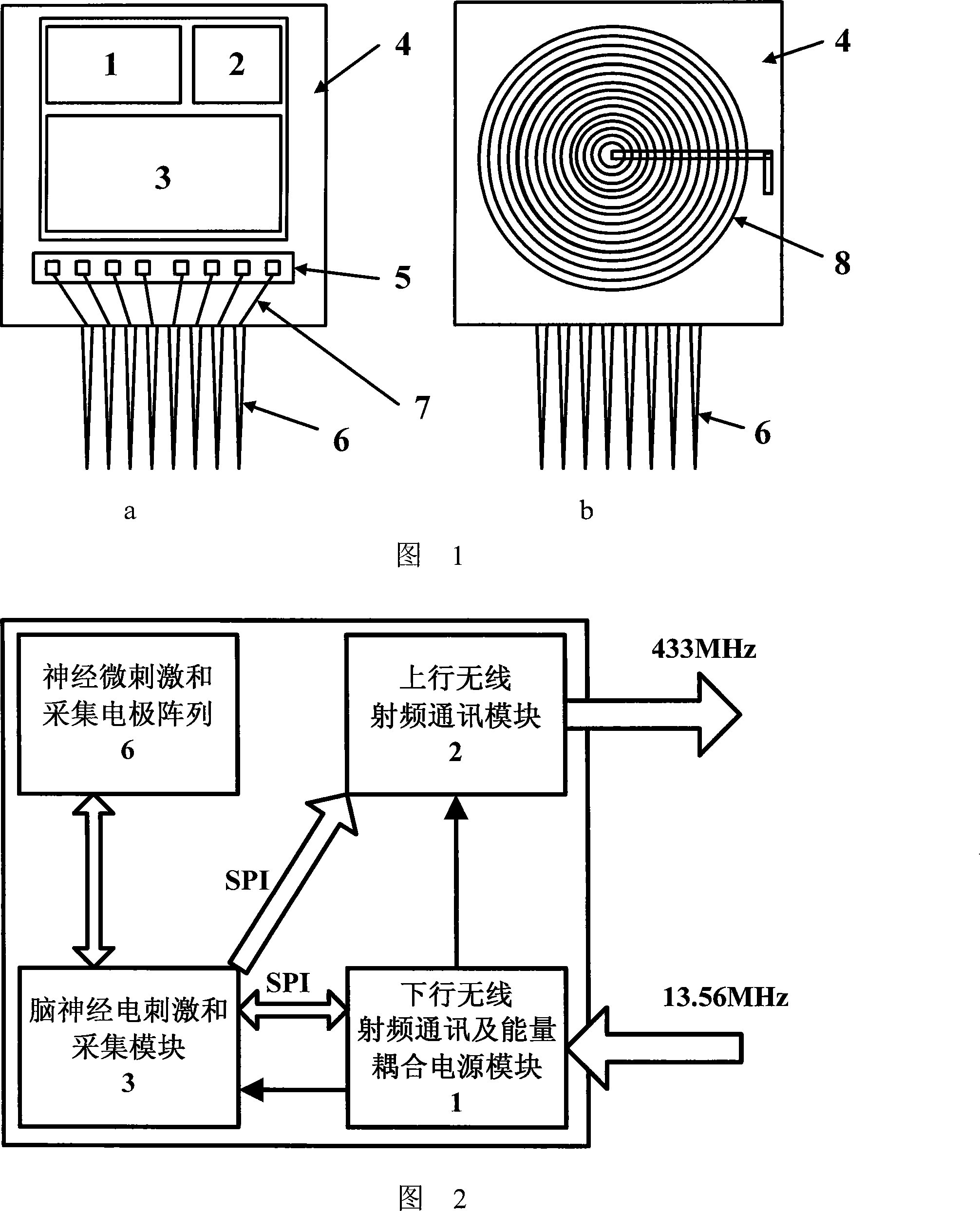

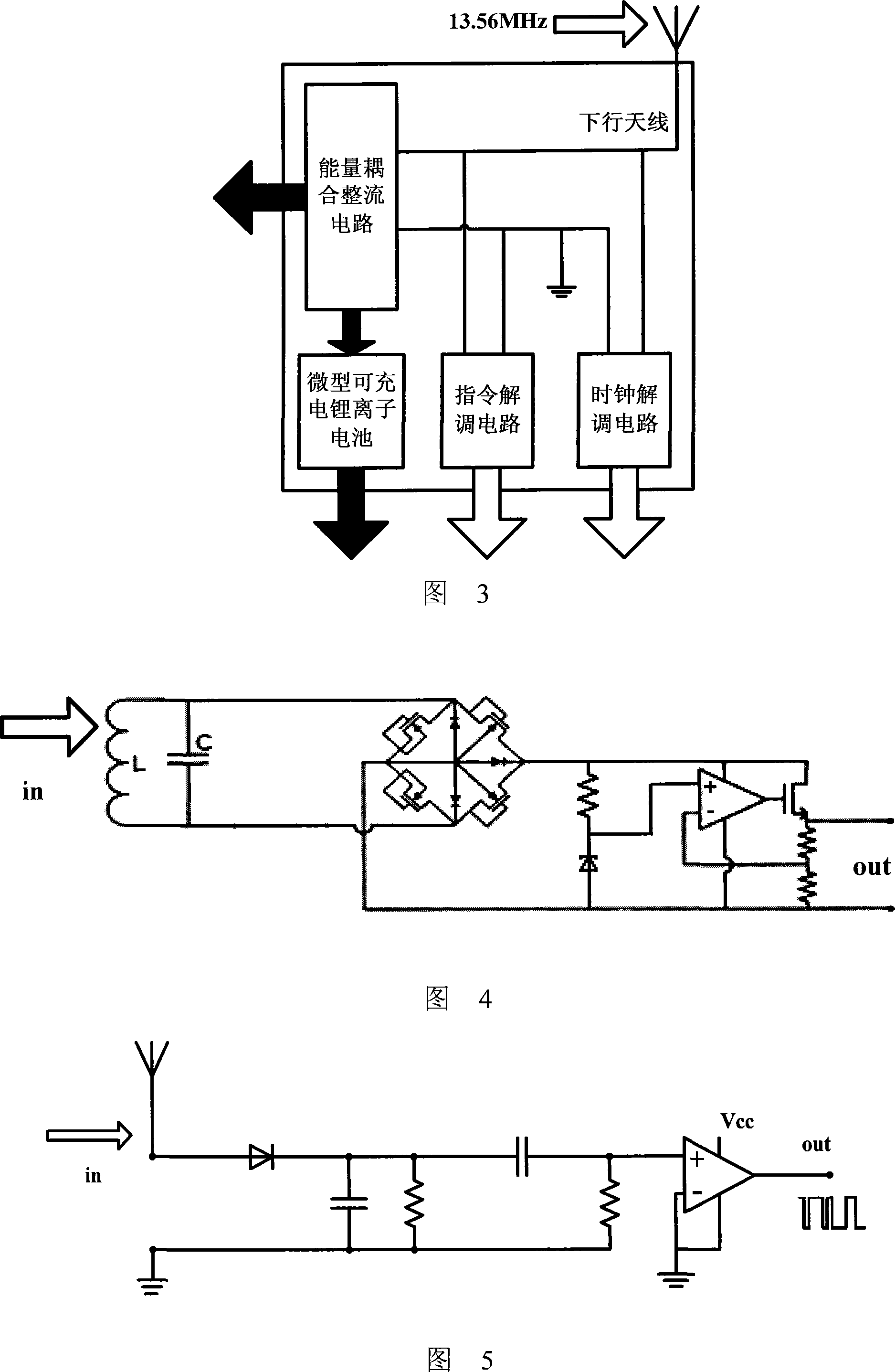

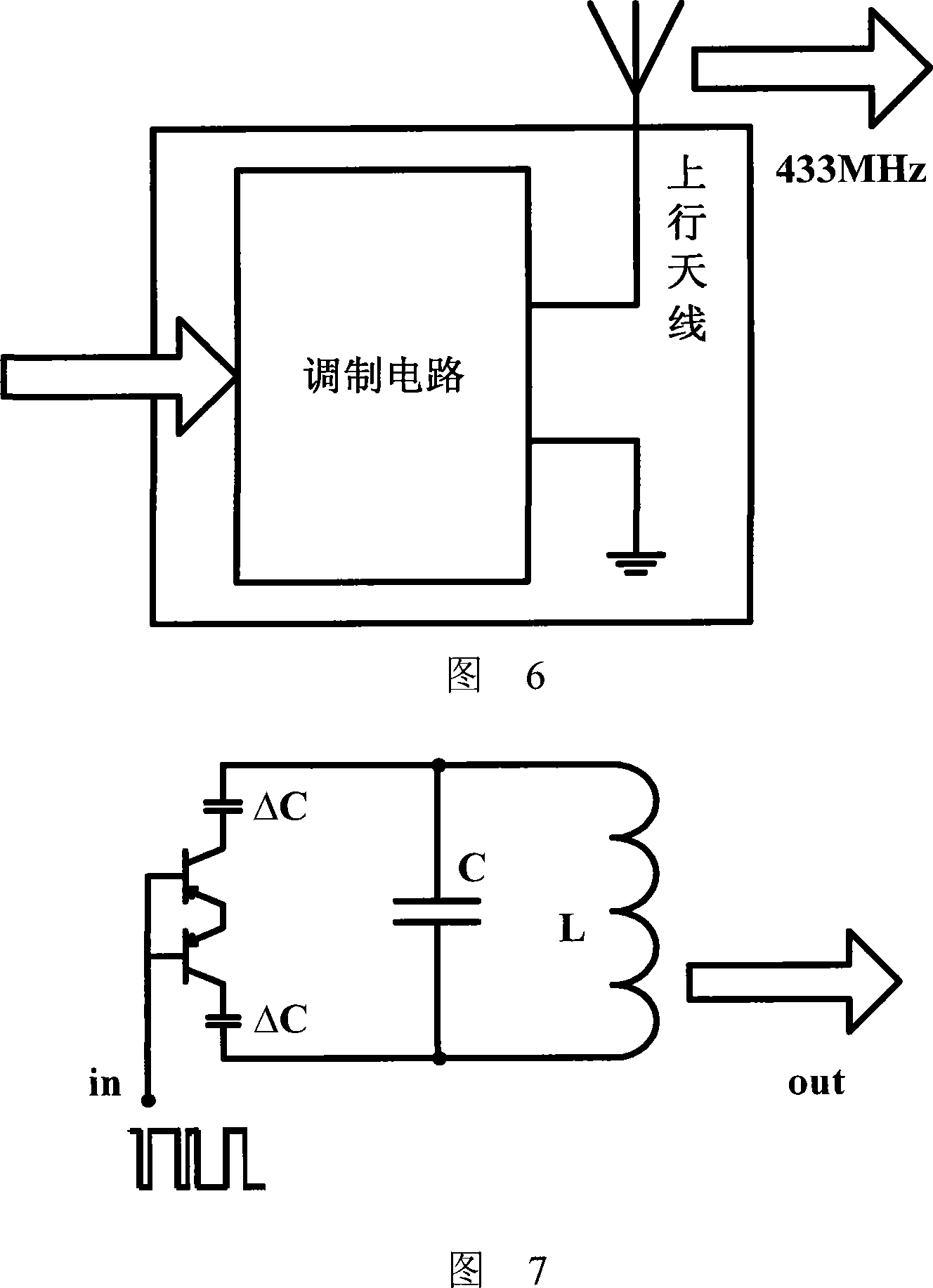

Implantation type nerve micro-stimulus and gathering remote-controlled chip

InactiveCN101185789AControl behaviorReduce riskElectric signal transmission systemsInternal electrodesRadio frequency energyCranial nerves

The invention discloses an implantable nerve micro-stimulation and collection remote control chip. The invention includes a brain nerve electrical stimulation and collection module, a nerve micro-stimulation and collection electrode array, an uplink wireless radio frequency communication module and a downlink wireless radio frequency communication and an energy coupling power supply module; the whole remote control device is arranged in the animal brain; the downlink wireless radio frequency communication and energy coupling power supply module receives the command which is send in from the outside, the brain nerve electrical stimulation and collection module is controlled to generate the stimulation signal and is responsible for the energy supply of the whole implantable chip remote control device by utilizing the radio frequency energy coupling principle after the analysis; the uplink wireless radio frequency communication module carries out the wireless output of the nerve electrical signal which is sent in by the brain nerve electrical stimulation and collection module; by implanting the chip in the animal brain, the invention can lead to a more compact system for collecting and controlling the physiological signals of animals, reduce the influence of the outside devices on the animals and increase the concealment and quality safety of the future practical field.

Owner:ZHEJIANG UNIV

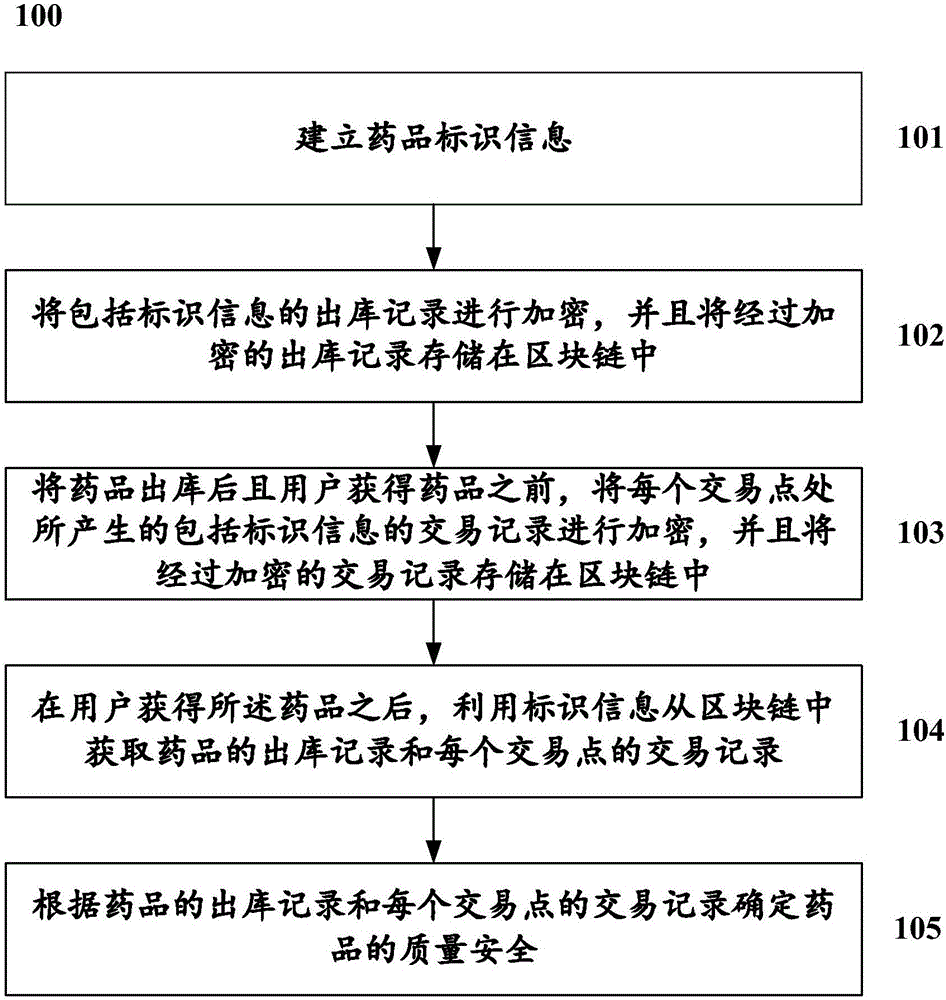

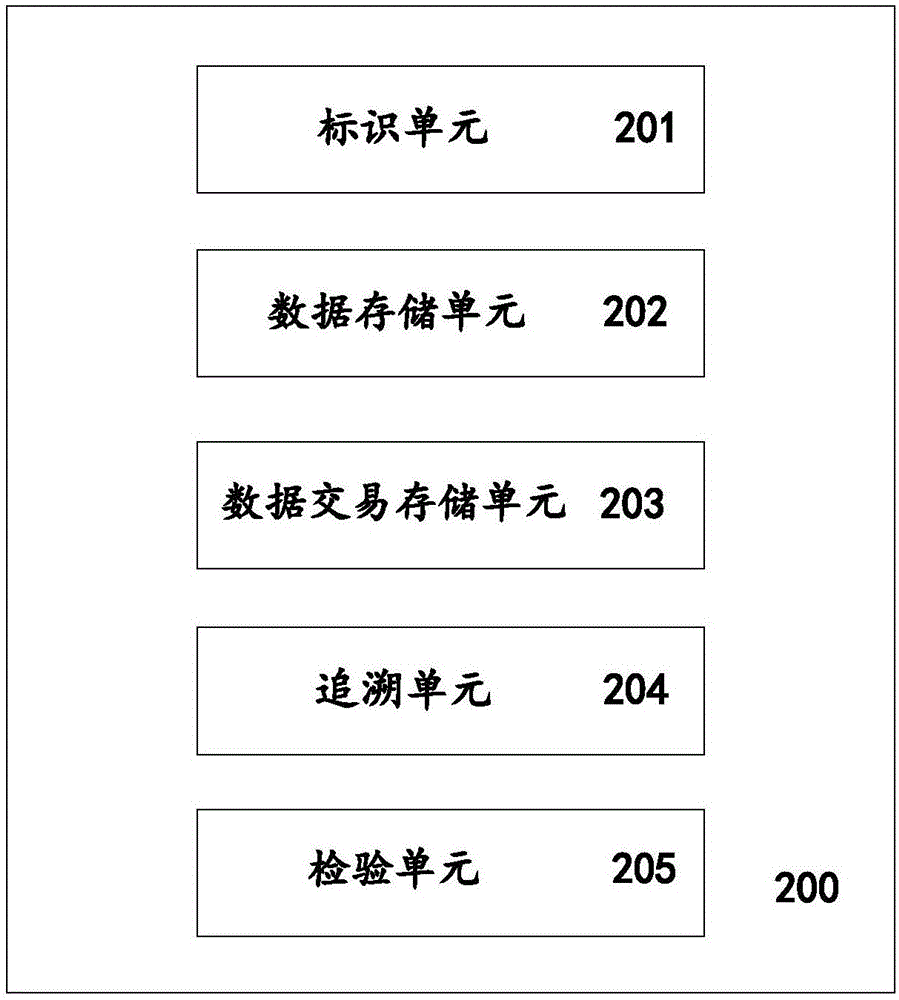

Method and system for performing whole-process monitoring on drug quality safety based on block chain

InactiveCN106779742ARealize full trackingRealize traceability managementCommerceQuality safetyDatabase

The invention discloses a method for performing whole-process monitoring on drug quality safety based on a block chain. The method comprises the steps that identification information of a drug is established; an ex-warehouse record comprising the identification information is encrypted, and the encrypted ex-warehouse record is stored in the block chain; after the drug leaves a warehouse and before a user obtains the drug, a transaction record comprising the identification information and generated at each transaction point is encrypted, and the encrypted transaction records are stored in the block chain; after the user obtains the drug, the identification information is utilized to acquire the ex-warehouse record of the drug and the transaction record at each transaction point from the block chain; and quality safety of the drug is determined according to the ex-warehouse record of the drug and the transaction record at each transaction point. According to the technical scheme, whole-process tracking and safety tracing of the drug in all links including safety production, circulation and usage are realized.

Owner:HUADI COMP GROUP

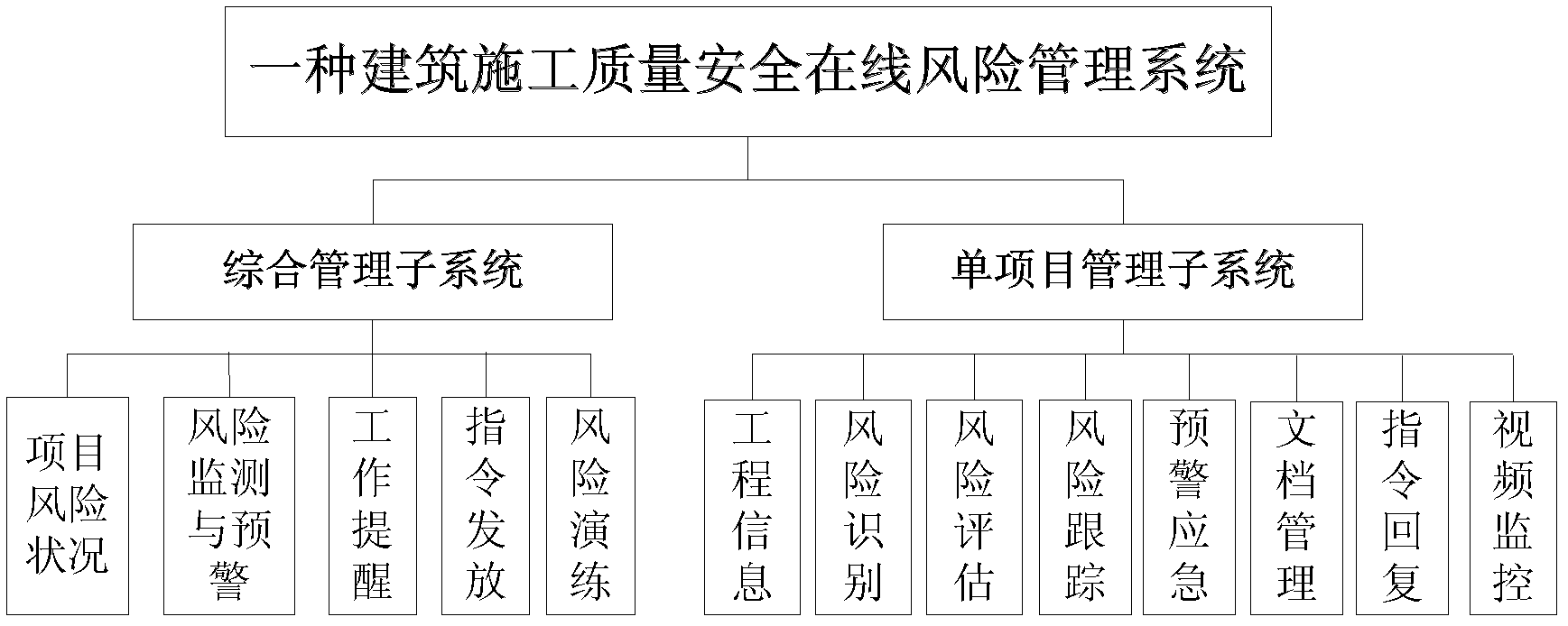

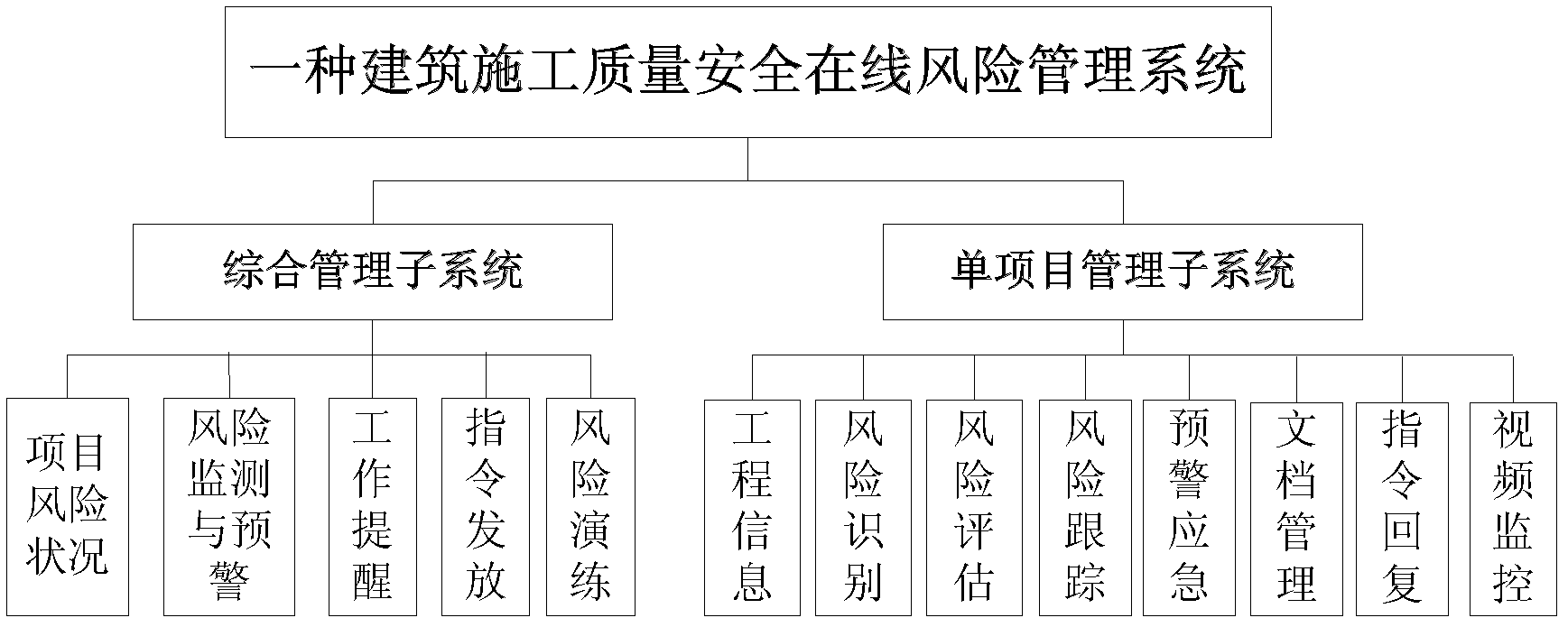

Building construction quality safety online risk management system

ActiveCN102521709APowerful self-learning mechanismPowerful self-learning functionResourcesVideo monitoringProject management

The invention provides a building construction quality safety online risk management system, which relates to the technical field of risk management of building engineering and comprises a general subsystem and a single project management subsystem. The general management subsystem consists of a project risk condition function module, a risk monitoring and early warning function module, a work reminder function module, an instruction issuing function module, an emergency practice function module and the like, and is used for browsing relevant information of all the projects undertaken by a company, transmitting instructions to project departments and checking daily work of the project departments; and the single project management subsystem comprises an engineering information function module, a risk identification function module, a risk assessment function module, a risk tracking function module, an early warning emergency function module, a document management function module, a work reminder function module, an instruction reply function module, a video monitoring function module and the like, and is used for realizing risk identification, assessment and tracking and early warning emergency by the aid of engineering situation information and remotely monitoring an engineering field. An online risk assessment system, a remote monitoring system and a risk management information platform are integrated in the building construction quality safety online risk management system, and real-time management and whole-process management for risks of large-size building construction engineering projects are realized.

Owner:SHANGHAI JIANKE ENG CONSULTING

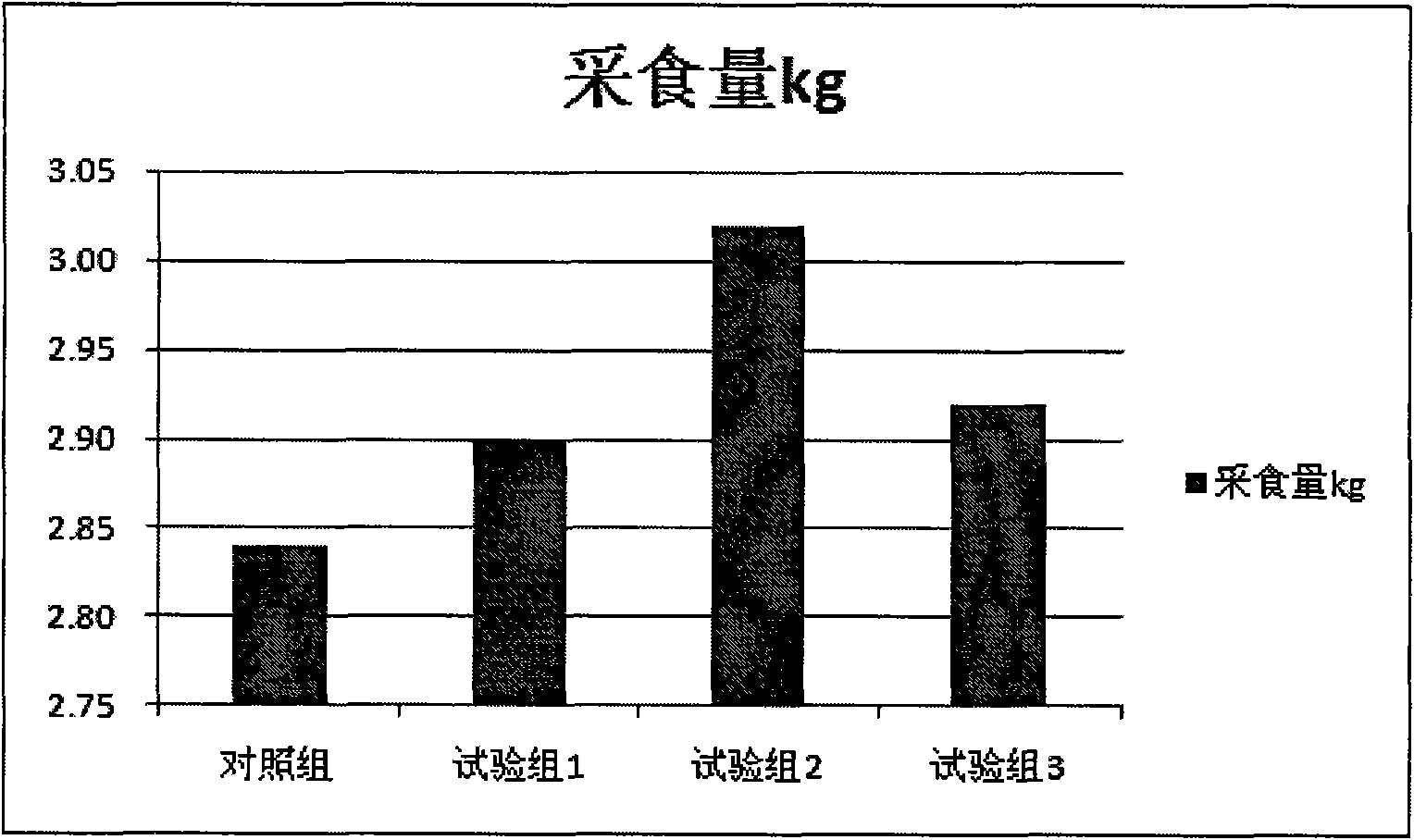

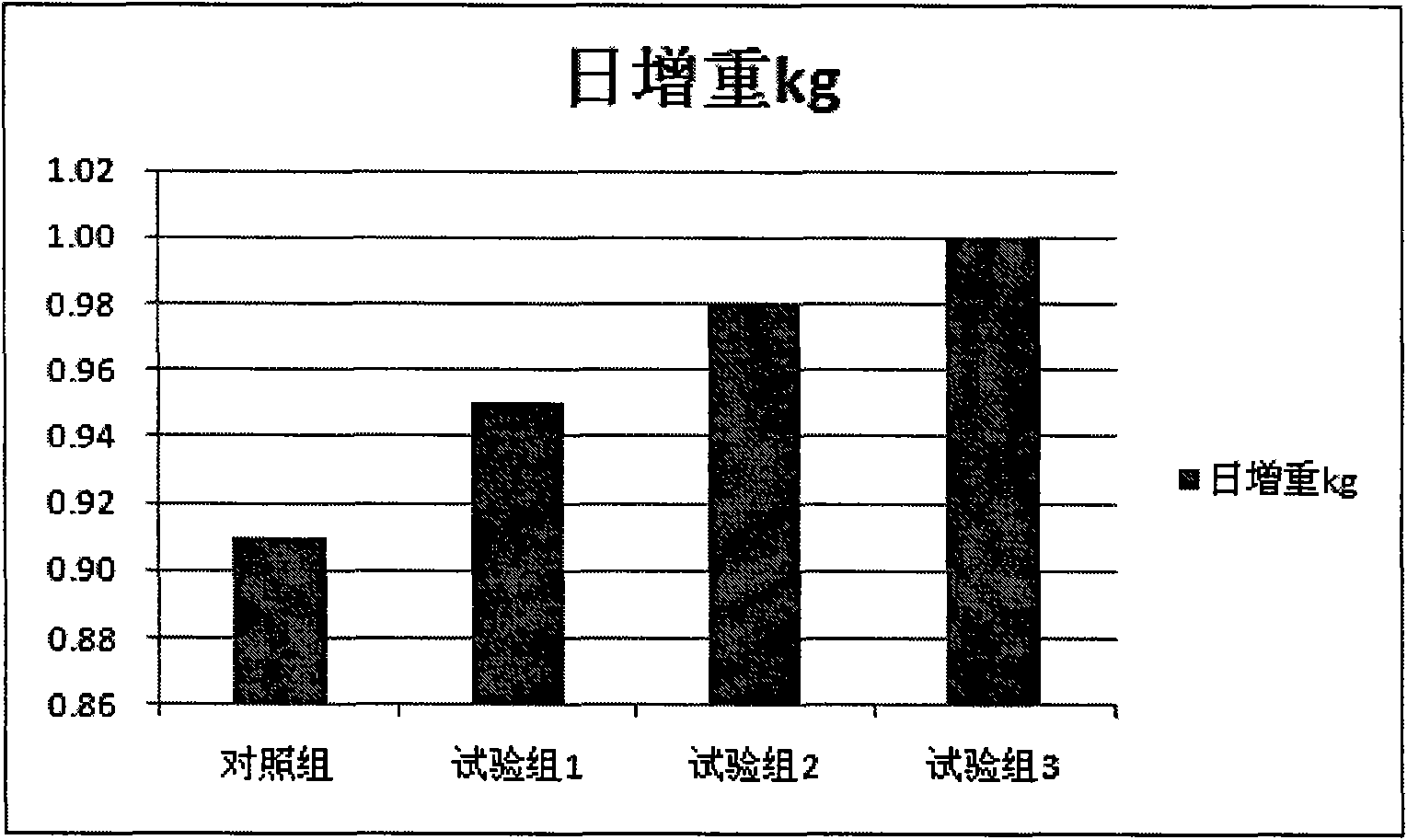

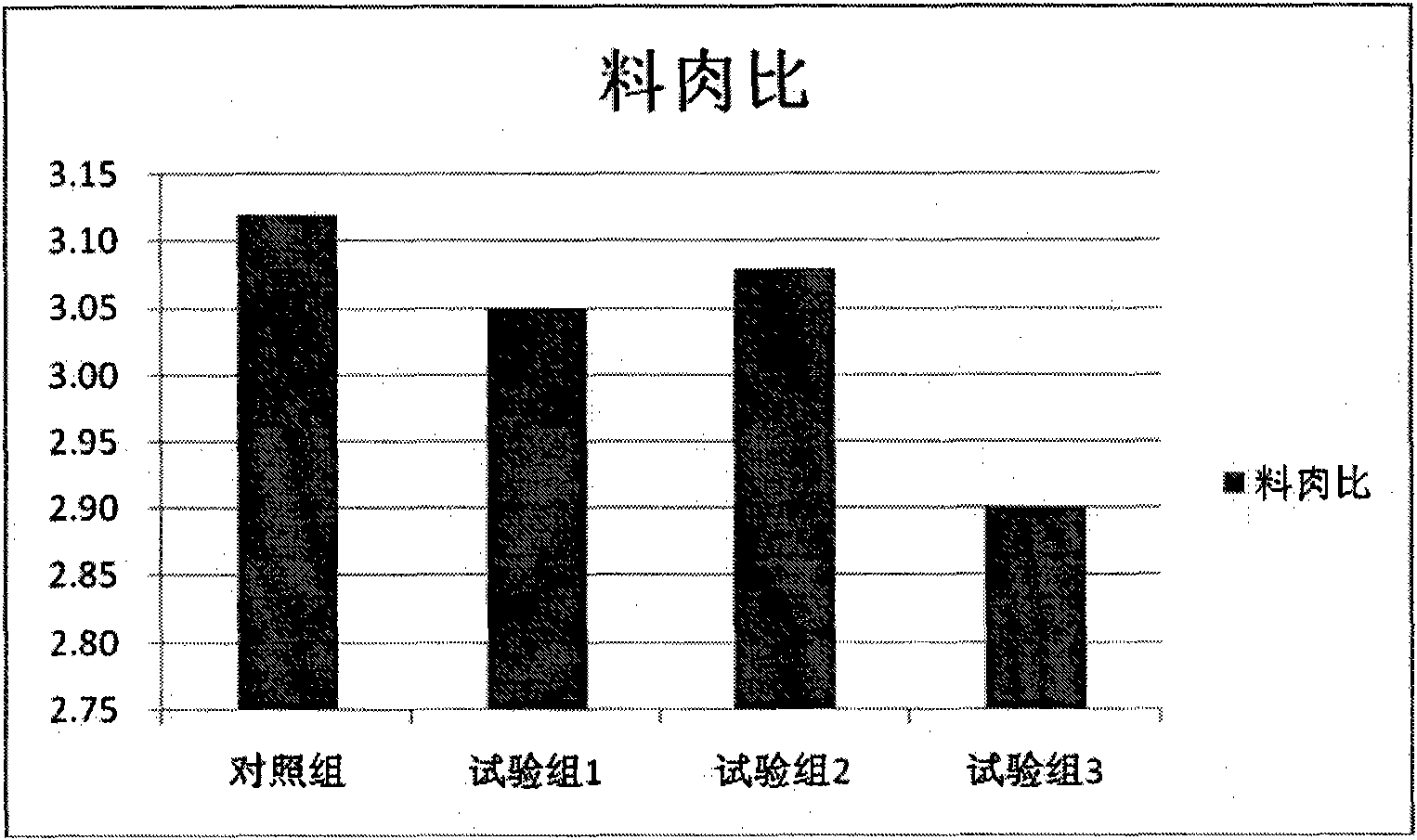

Big pig premix and application method thereof

ActiveCN101579061ABalanced nutrient supplyComprehensive nutrition supplyFood processingAnimal feeding stuffLean meatPhytase

The invention belongs to the animal sitology technical field, in particular to big pig premix and an application method thereof. The premix mainly comprises the following components: iron element, copper element, zinc element, manganese element, iodine element, cobalt element, selenium element, composite vitamine premix, DL-methionine, lysine, threonine, cholinehydrochloride, calcium hydrophosphate, rock flour, salt, carrier and phytase. The big pig premix and conventional basic ration are used to prepare big pig compound feed to feed big pigs with conventional process, and the content of the big pig premix in the big pig compound feed is 4% according to the weight percentage. The big pig premix provided by the invention is simple and safe to use; after feeding big pigs, the fodder-meat rate can be reduced, the big pig growth speed and lean meat percentage are increased and the meat quality safety can be improved.

Owner:河南雄峰科技股份有限公司

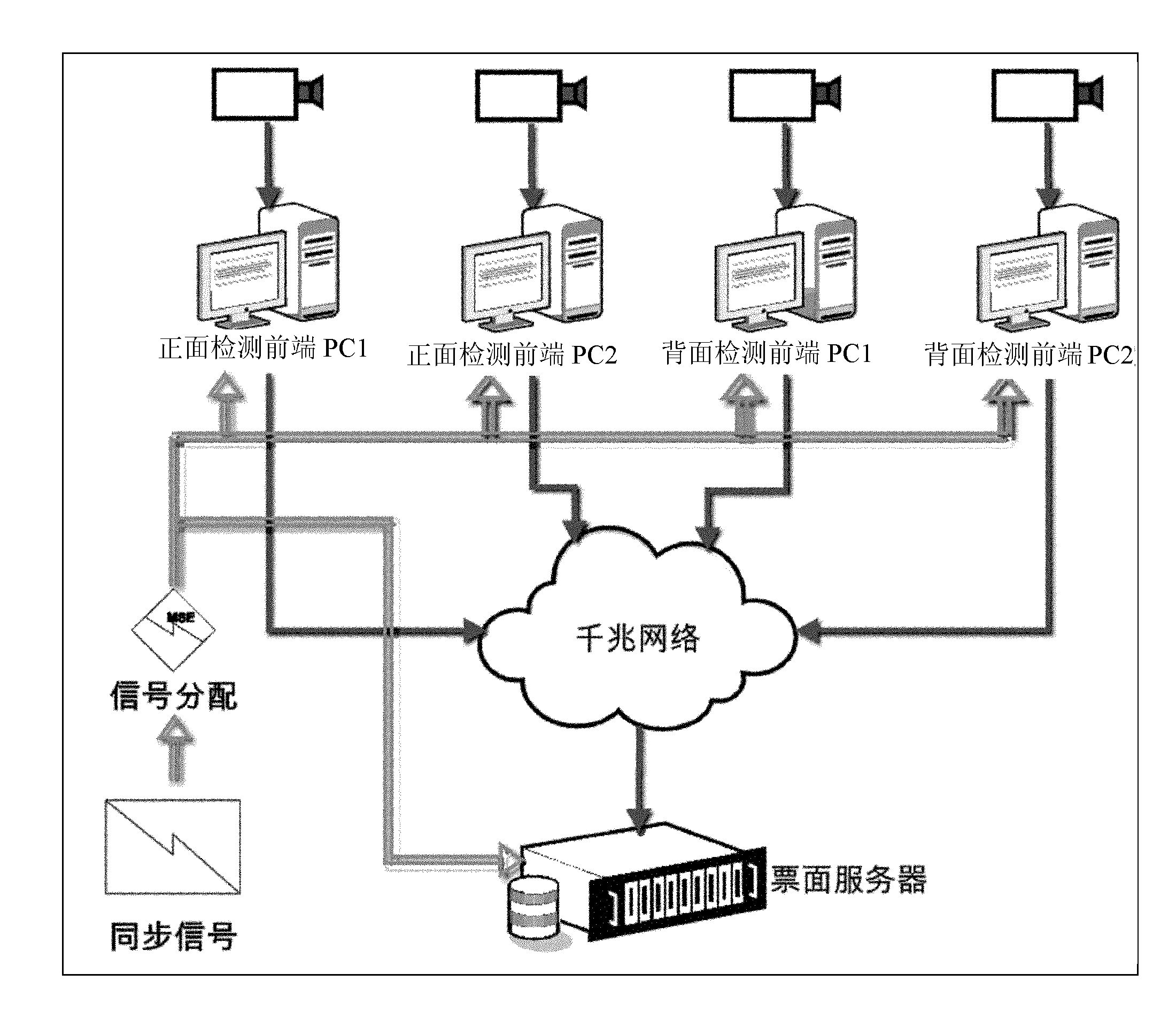

System and method for detecting front and back face qualities of imprinted Renminbi (RMB) large-page product

ActiveCN102136165AFactory quality and safetyReduce detection capacity dropCoin testingMaterial analysis by optical meansEngineeringQuality safety

The invention relates to a system and method for detecting front and back face qualities of an imprinted Renminbi (RMB) large-page product. The method comprises the following steps of: arranging a front face detecting unit and a back face detecting unit on a paper collecting part of an imprinter respectively; and transmitting a pulse signal by using an encoder which is synchronous to a system detection drum to trigger a colored linear array CCD (Charge Coupled Device) camera to acquire an image, wherein the reduction in the detection capability of the system, caused by paper fluctuation, can be reduced to the maximum extent by using a flattening device. By adopting the system and method, products with severe quality problems caused by an imprinting procedure per se and a series of products with continuous remarkable quality problems (such as paper holes, break angles, oil stains, number strike-through and the like) can be intercepted, and products with remarkable and severe quality problems in an offset printing procedure and a gravure procedure can be controlled according to a detection result, better technical supplements are provided for the conventional running computer retrieval process, and the front and back face qualities of the important imprinted RMB product can be checked, scraps can be positioned accurately, and the delivery quality safety of the product is ensured.

Owner:XIAN BANKNOTE PRINTING +1

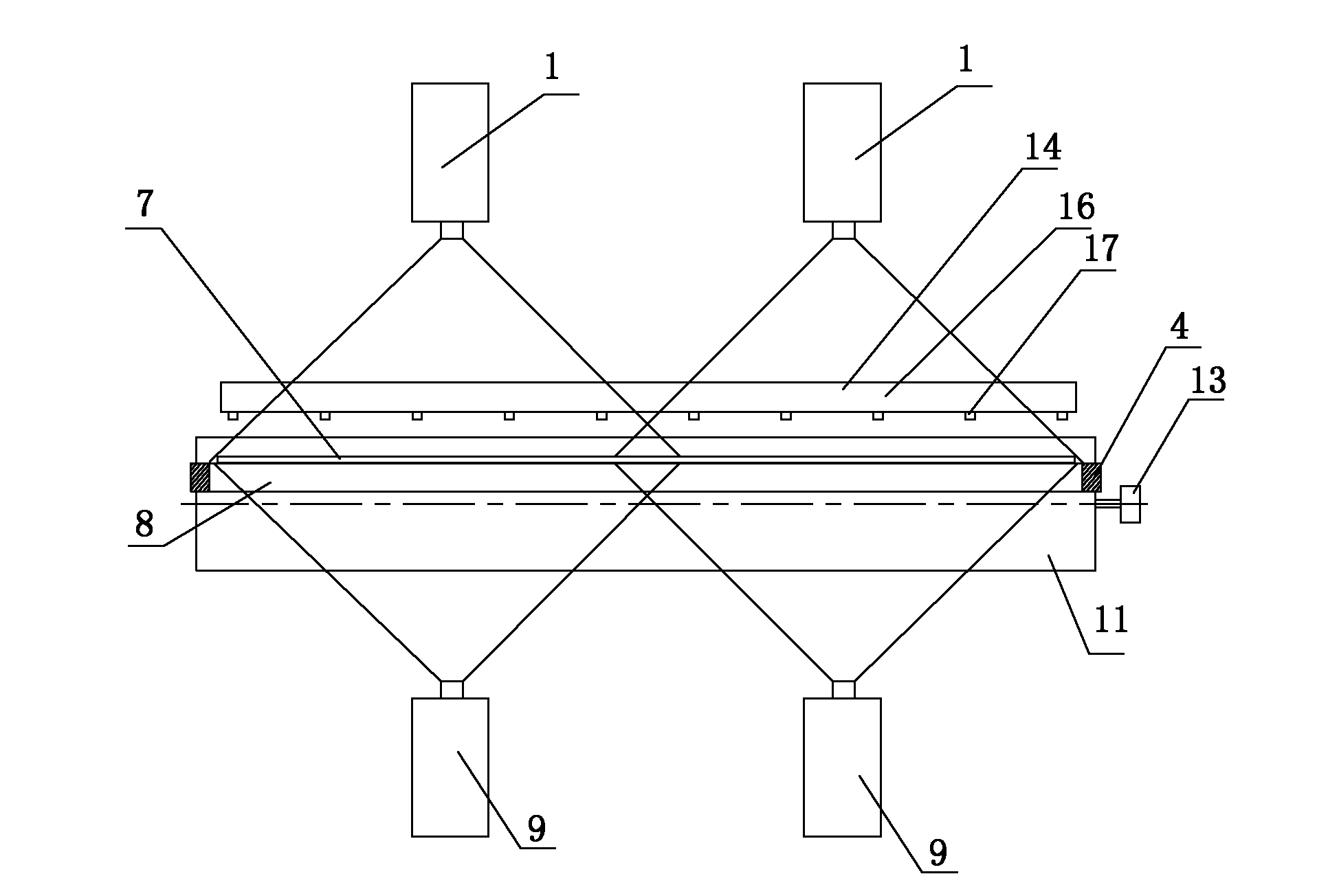

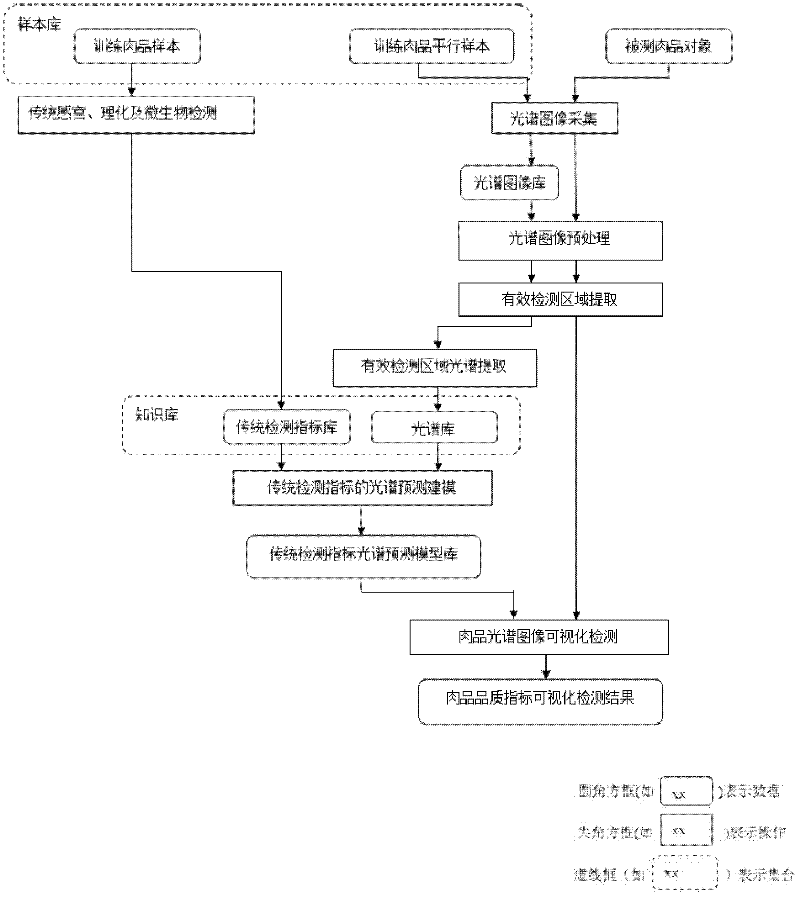

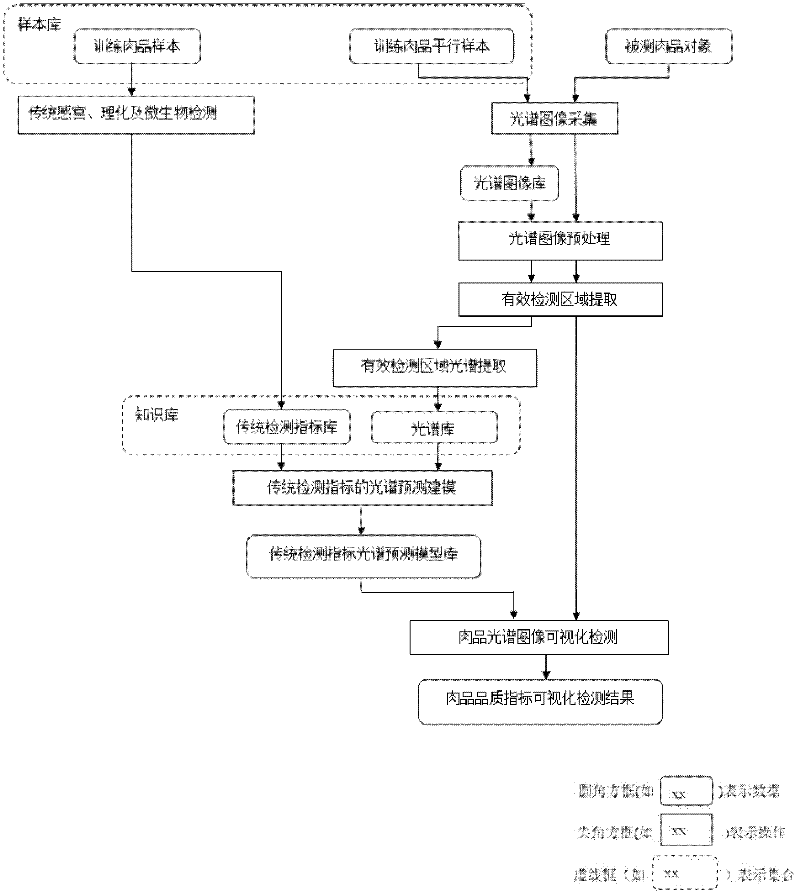

Spectral image-based meat quality visual non-contact detection method

InactiveCN102564964ABreak through subjectivityBreakthrough speedColor/spectral properties measurementsEvaluation resultWater activity

The invention discloses a spectral image-based meat quality visual non-contact detection method. By means of spatial distribution information and spectral characteristic information which are contained in a spectral image and reflect the characteristics of an object to be detected, multiple indexes of meat quality (such as water content, water activity, volatile basic nitrogen, meat color, microorganism counts, acid value and pH value) are respectively or comprehensively evaluated, and evaluation results are given in an image mode according to spatial distribution conditions of specific indexes in the object to be detected. The method can be used for quick and non-contact inspection of meat production, processing, storage, transportation and marketing links, inspection results are accurate and objective, and the expression mode is intuitive, so that a guarantee means for supervising the production and marketing quality safety of meat is provided.

Owner:沛县汉腾建设发展有限公司

Kiwifruit tree planting method

InactiveCN104106440APrevent sunburnCut off the transmission routeCultivating equipmentsHorticultureDiseaseExtreme weather

The invention discloses a kiwifruit tree planting method. Connected greenhouses are used for cultivation, greenhouse films and arrangement of the greenhouses are adjusted along with change of seasons, the four-prevention measures including anti-freezing measures taken in winter and spring, rain sheltering and disease preventing measures taken in the rainy season, and cooling and sun blocking measures and windproof measures taken in midsummer are adopted, matched labor-saving tree cultivating management is performed, the capacity for coping with extreme weather in rainy and high-temperature areas in the south is effectively improved, and the high temperature and high humidity disease problem and the like which are difficult to solve in open field cultivation and traditional facility cultivation are solved. Due to the adoption of the method, the kiwifruit disease transmission route can be effectively cut off, input cost is low, manpower is saved, the survival rate of kiwifruit trees reaches 95.2%, the average single weight of red kiwifruits can reach 86 g under the situation that no swelling agents are applied, and the largest single fruit weight reaches 103.5 g; the soluble solid reaches 17.4% to 19.1%; the fruit cleanness is obviously improved, use of swelling agents and high-poison and mediate-poison pesticide is effectively eradicated, and quality safety of the fruits is guaranteed.

Owner:SHANGHAI ACAD OF AGRI SCI

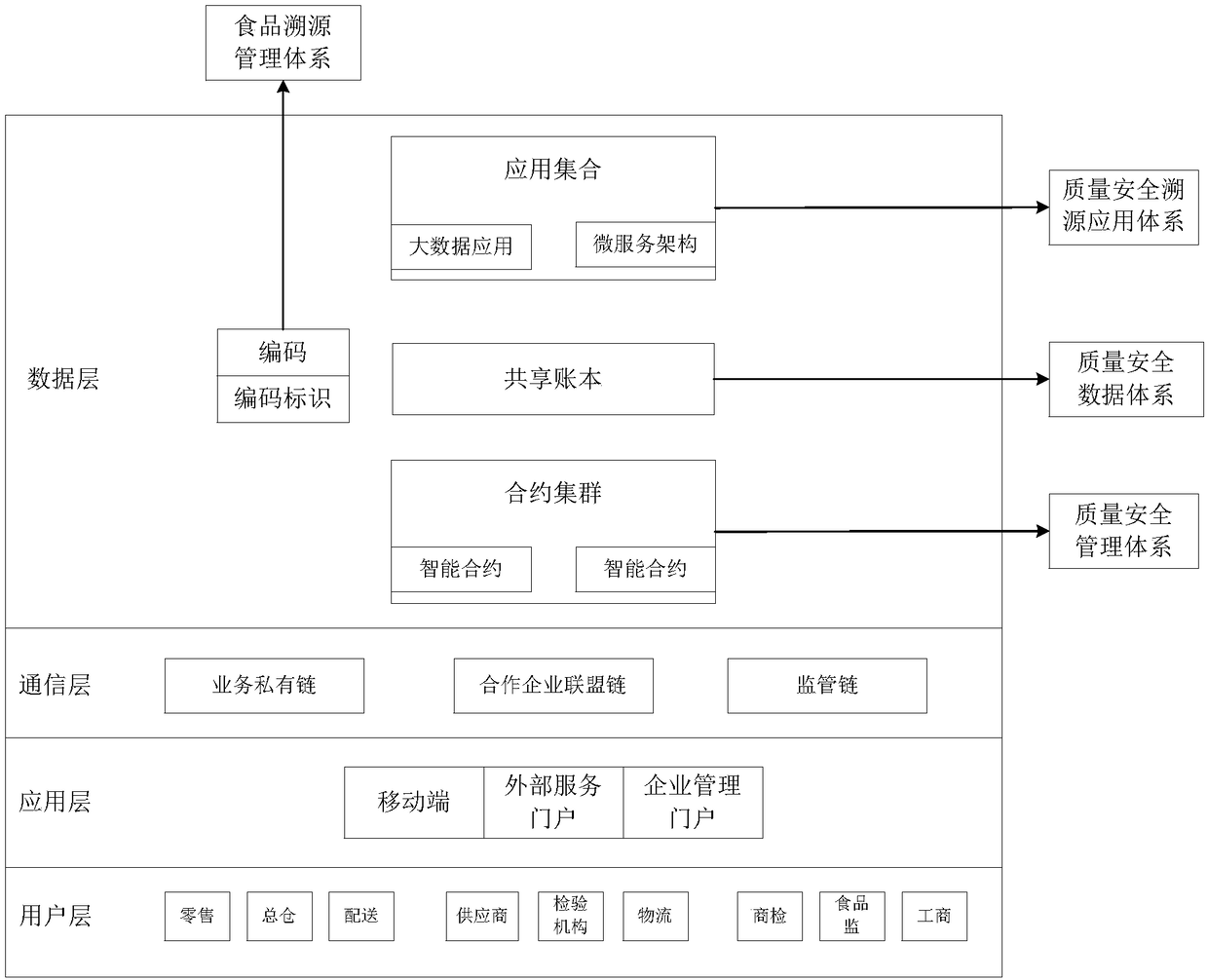

Food safety traceability system and method based on blockchain technology

InactiveCN108764695AImprove securityImprove stabilityFinanceDigital data protectionFood safetyData system

The invention provides a food safety traceability system and method based on blockchain technology. The food safety traceability system implants a blockchain into a food traceability architecture. Thefood safety traceability system comprises a user layer, a communication layer, a data layer, and an application layer. The user layer includes participants and business departments having different functions. The communication layer is a blockchain network. The data layer includes a shared ledger stored in the blockchain network. The application layer is used for embedding an application or protocol and providing a human-machine interaction interface, and includes a quality safety data system, a food traceability management system, a quality safety management system, and a quality safety traceability application system. The food safety traceability system and method have good safety, good stability, convenient operation, high work efficiency and good openness.

Owner:江苏涞哲信息科技有限公司

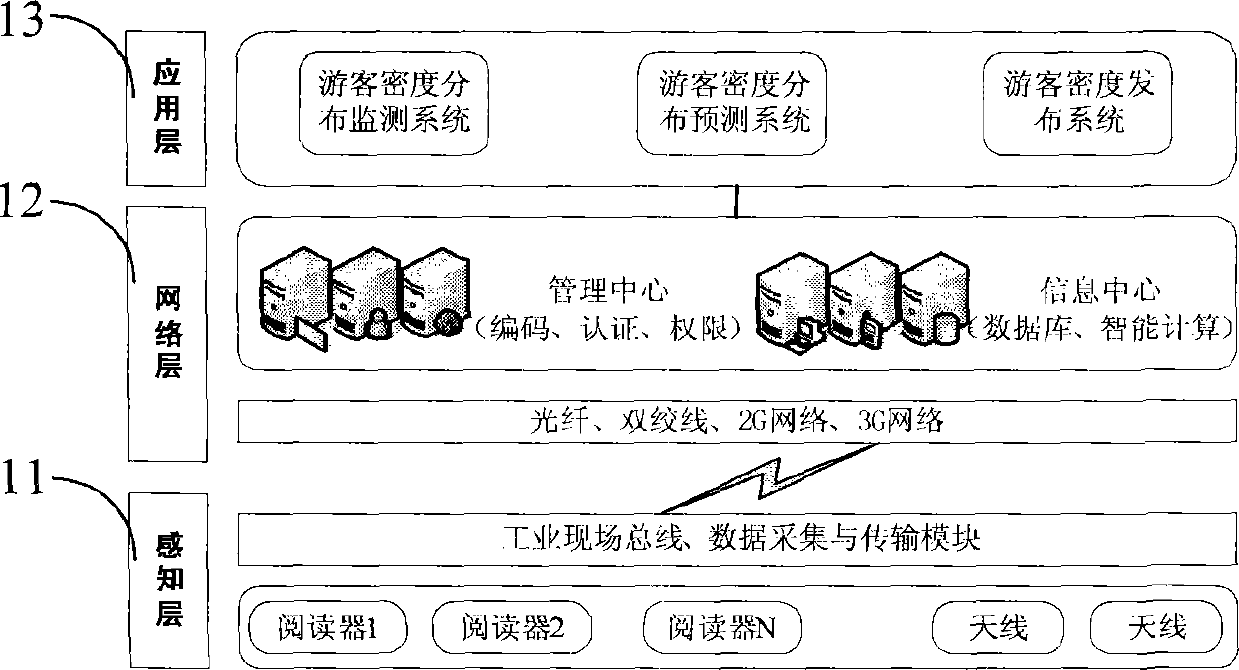

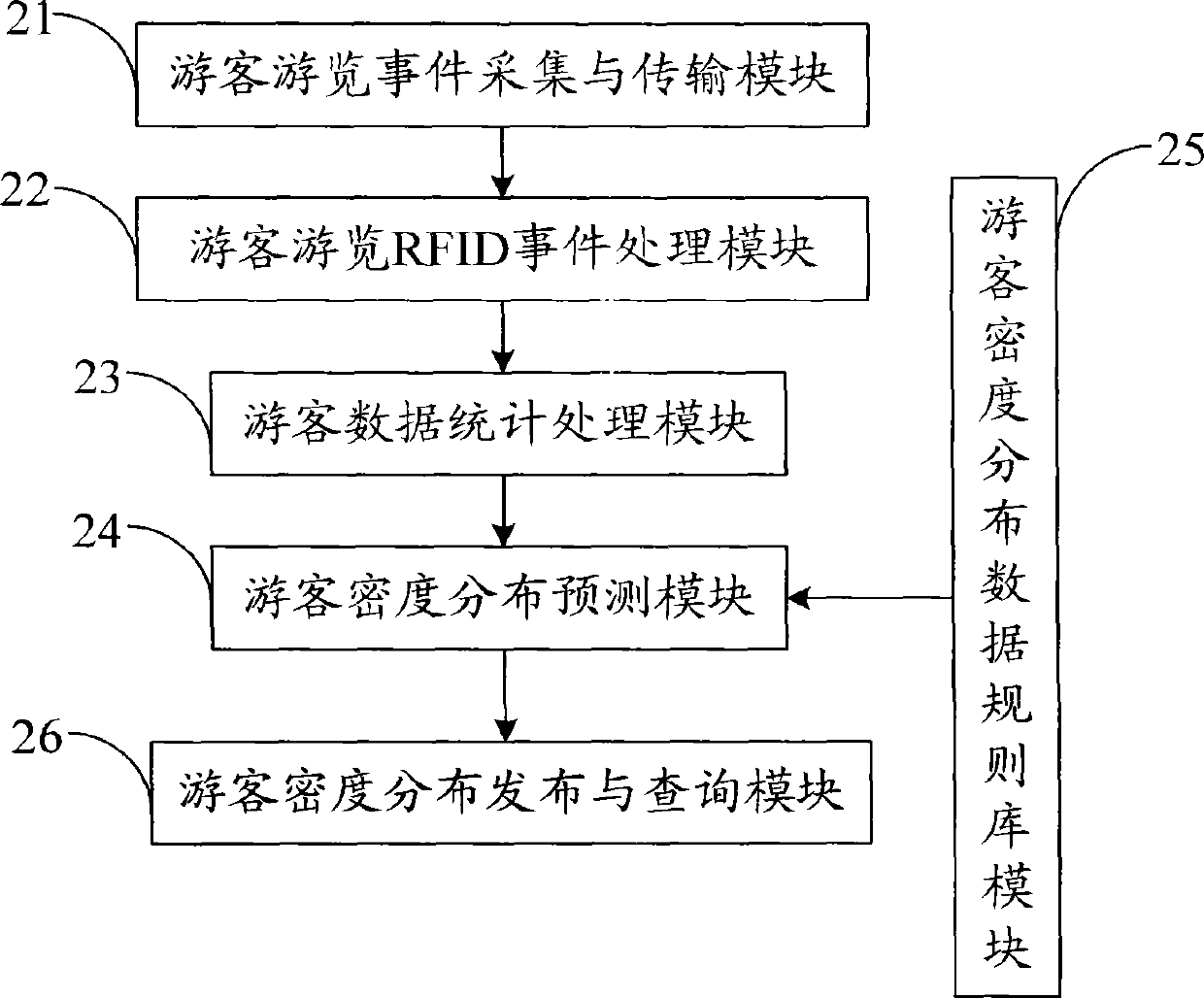

Method and system for statistics and process of tourist density distribution

InactiveCN103136703AAvoid quality of playReasonable distributionData processing applicationsDensity distributionCrowds

The invention belongs to the technical field of data processing, and provides a method and a system for statistics and process of tourist density distribution. Scenic spots and the tourist density distribution in a scenic spot are counted automatically by obtaining flow time, view and admire time, view and admire position and state information of tourists in the scenic spot are obtained. Circulating speed and direction of visit of the tourists are predicted through a density distribution prediction model so as to provide scientific basis for the scenic spots or visiting sequence of the tourists, and bad playing quality of the tourists caused by crowd is avoided. Tourism resources can be distributed reasonably through real-time distribution of tourist density and split-flow and guidance with proper measures, the tourist environment is further protected, damages of tourist activities to the environment and facilities are reduced, management ability of the scenic spots is enhanced, the product quality safety level of tourism products is improved, sound development of tourism industry is promoted, and the method and the system have great significance on personalized service of the scenic spots.

Owner:ZHONGZHOU UNIV

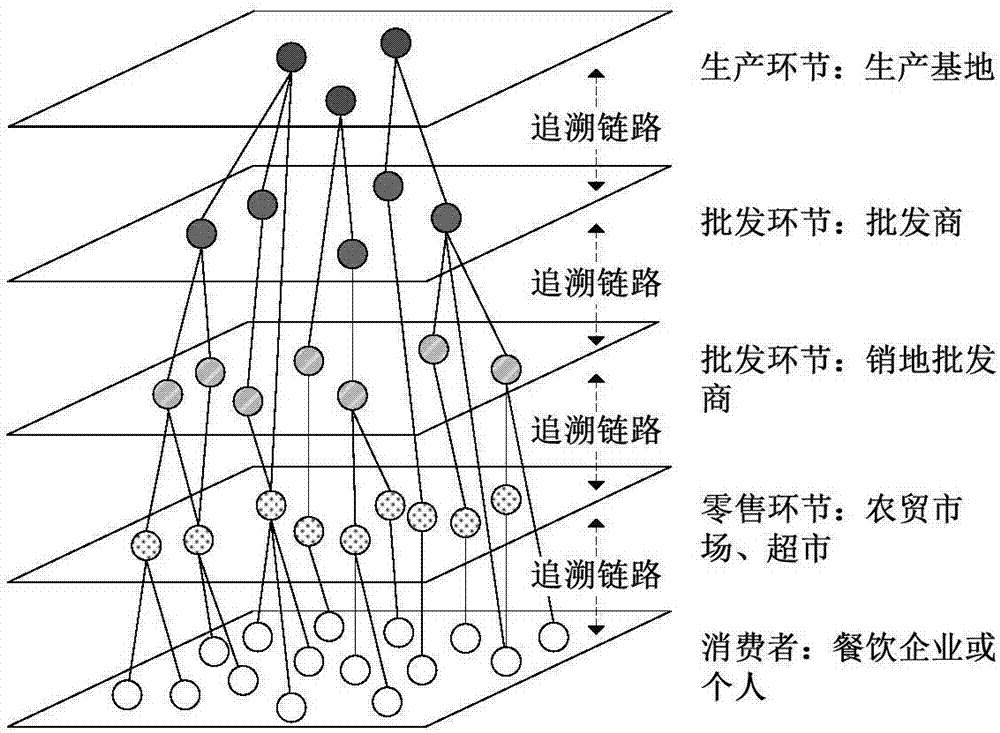

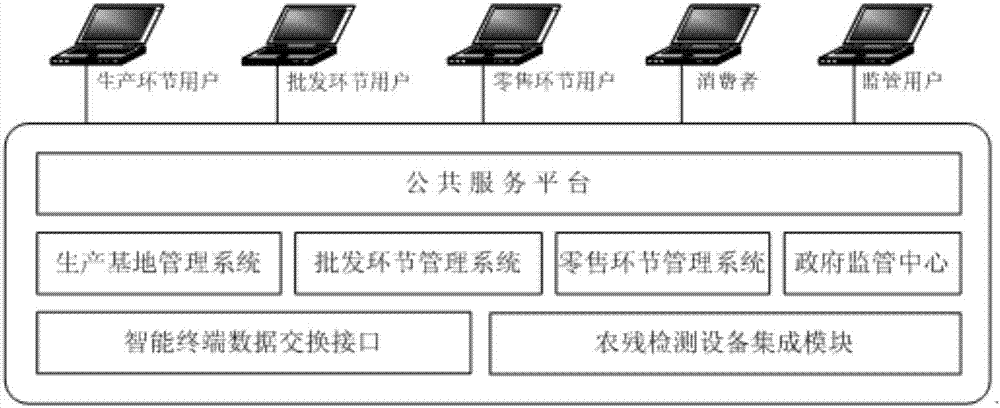

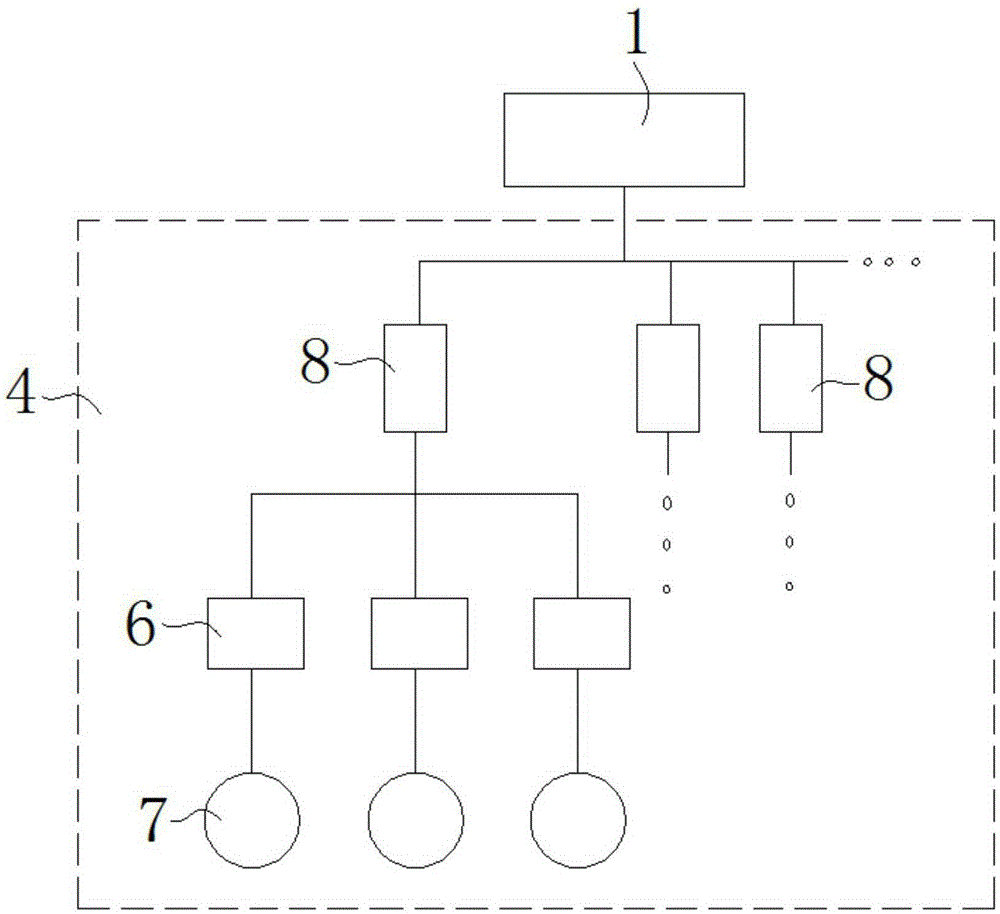

Agricultural product quality safety traceability supervision system based on two-dimensional codes and realization method thereof

InactiveCN107093083AReduce labor burdenReduce economic costsCommerceRecord carriers used with machinesDatabase serverLink management

The invention discloses an agricultural product quality safety traceability supervision system based on two-dimensional codes, comprising a production base management system, a wholesale link management system, a retail link management system, a customer service system, a government supervision center, a public service platform, and a system server. The system server comprises a database server. The production base management system, the wholesale link management system, the retail link management system, the customer service system, the government supervision center and the public service platform are in communication connection with the system server. The whole process 'from field to table' can be traced. Where agricultural products come from and where agricultural products go constitute a piece of sales chain information. A traceable chain consisting of source tracing and down tracking is formed. The problem that agricultural product quality safety information is asymmetric and responsibilities are not clear is well solved. The quality safety of agricultural products can be supervised and traced in the whole process from the production base to the market. Thus, people rest assured buying agricultural products.

Owner:JIANGSU AGRI ANIMAL HUSBANDRY VOCATIONAL COLLEGE

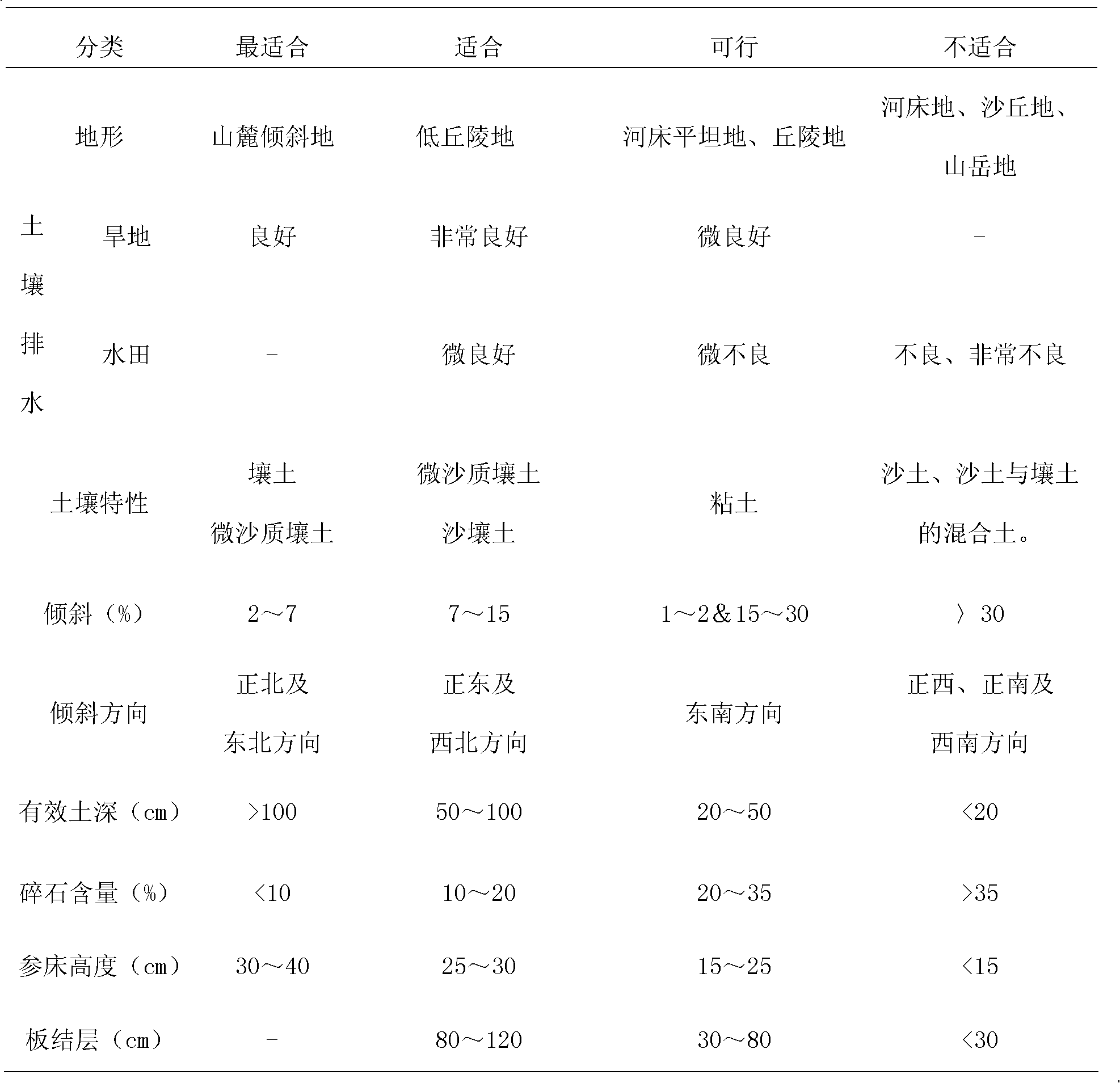

Standard planting method of non-forest ginseng

InactiveCN102138427ASolve pesticide residuesSolve the problem of excessive heavy metal contentHorticultureEcological environmentPesticide residue

The invention relates to a planting method of Chinese medicine, namely a standard planting method of non-forest ginseng. The method comprises the following steps: (1) land selection; (2) soil improvement; (3) selection of ginseng seeds and germination treatment; (4) making a soil bed; (5) seeding; (6) erecting a frame; (7) collecting seedlings; and (8) transplanting the seedlings and the like. The planted ginseng is transferred from a wild mountainous region to a non-forest flat land; and all links from land selection, soil detection and soil improvement to the selective application of a fertilizer of the improved soil, the application of the key technology of each production link, the ginseng preparation and the like comfort to the Chinese medicine GAP (good agricultural practice) production and quality management standard and standard production operation procedure, and the production and quality safety of the non-forest ginseng is guaranteed; and the technology not only can effectively protect the ecological environment and powerfully improve the land utilization rate, but also can solve the problems of pesticide residue and super-standard heavy metal content in the traditional ginseng planting process, thereby ensuring the quality of the ginseng raw medicine product.

Owner:吉林省集安益盛药业股份有限公司

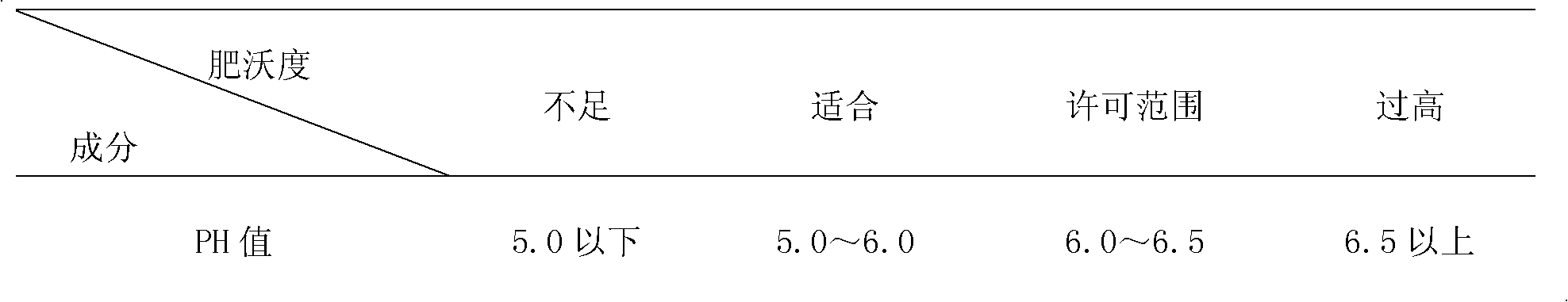

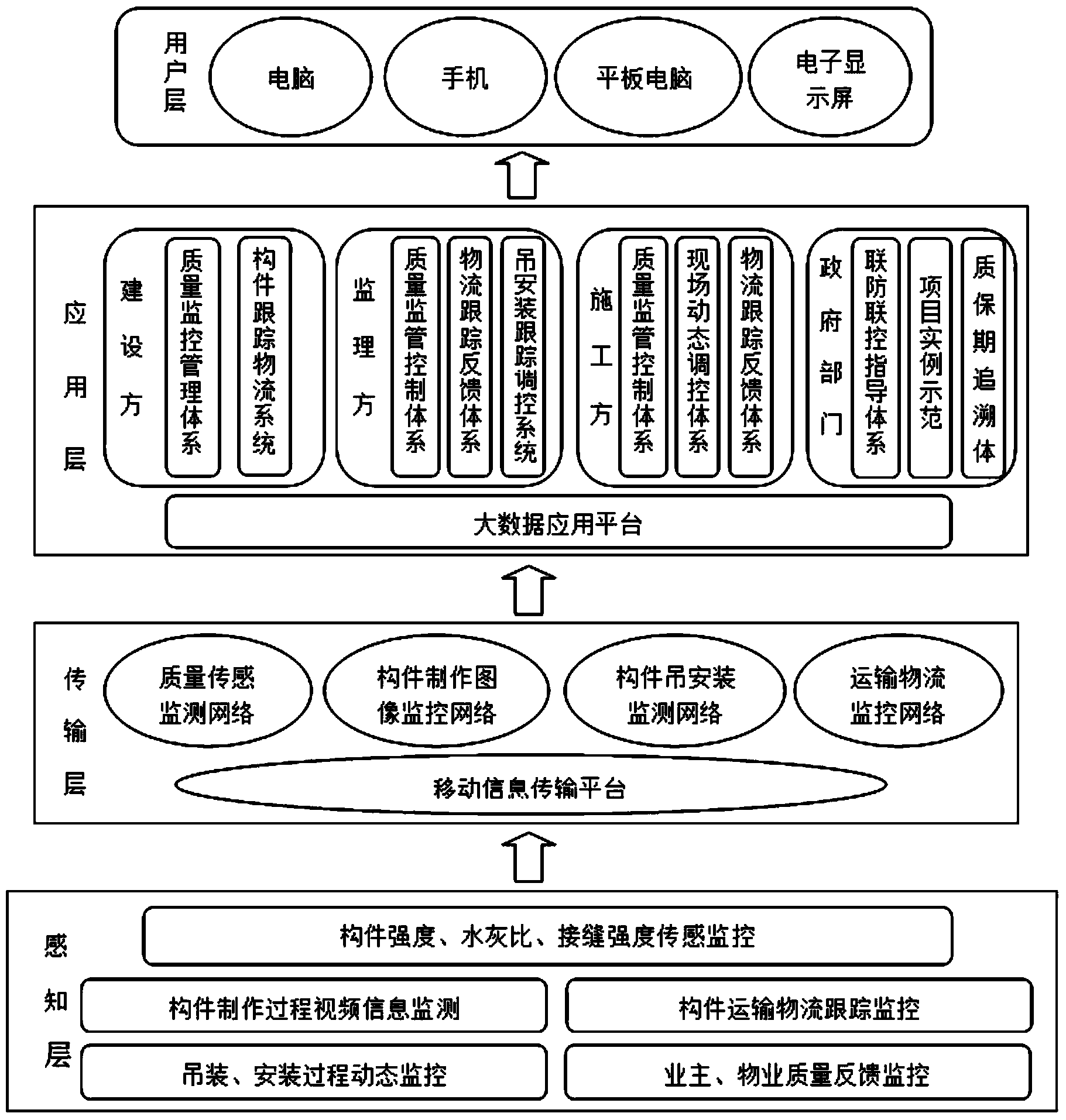

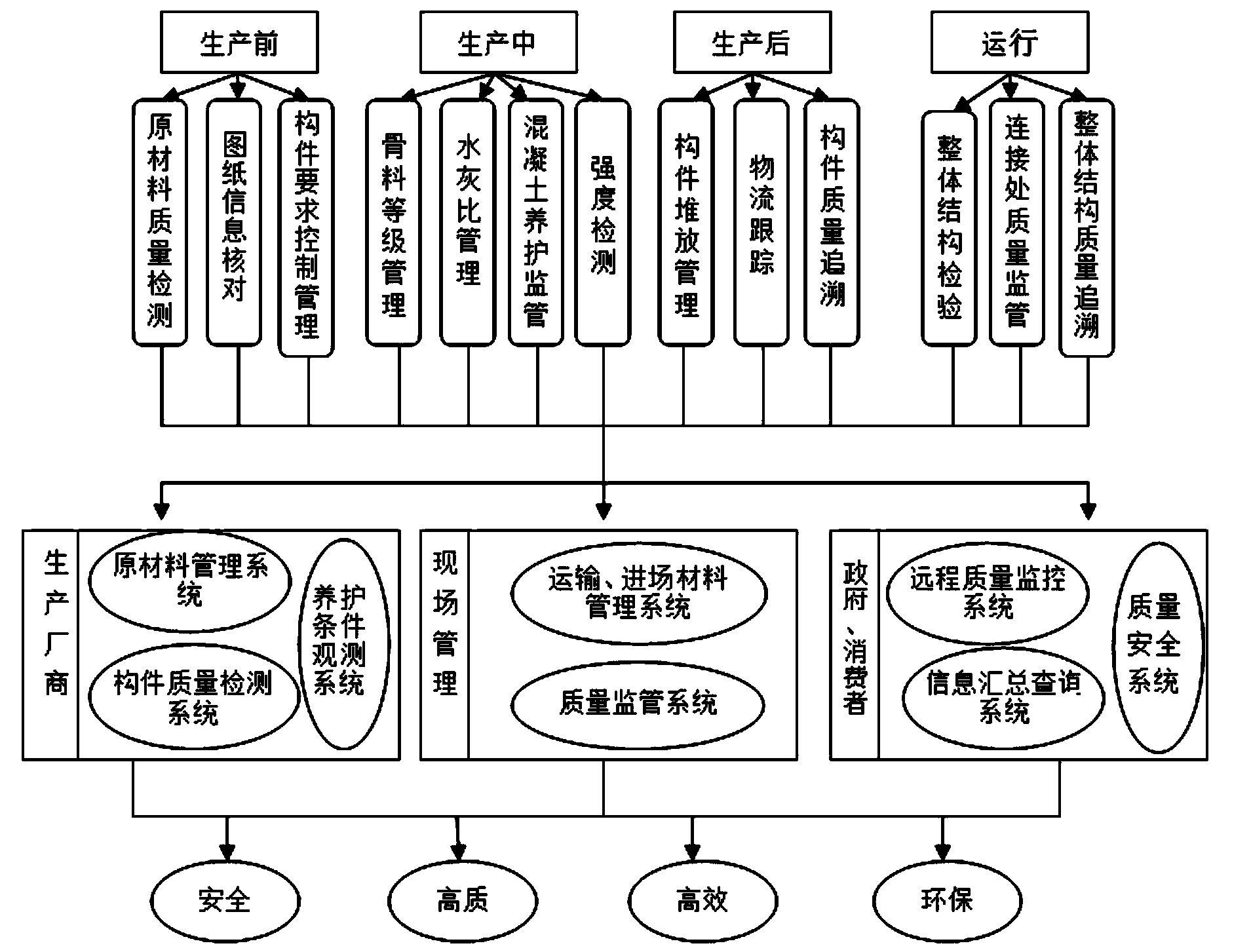

Assembly type concrete whole-process monitoring system based on Internet of Things

InactiveCN103957260AQuality improvementReduce investmentNetwork topologiesData switching networksDynamic monitoringThe Internet

The invention provides an assembly type concrete whole-process monitoring system based on the Internet of Things. An Internet of Things model conforming to assembly type concrete development is established, a perceiving structure in the assembly type concrete producing and constructing process is constructed, a low-cost and environmental-friendly transmission network is built and a cloud calculation big data service platform of the assembly type concrete and an intelligent decision and information feedback system are built according to the whole production process of pre-production, during-production, post-production and operation of the assembly type concrete based on the technologies of sensors, radio frequency, wireless communication and the like for the problems of quality safety and logistics tracing in the links of manufacturing, transporting and installing of the assembly type concrete. Quality monitoring and controlling over the production process, logistics tracing on members and dynamic monitoring and controlling over the hoisting installation process are achieved, and the whole process from manufacturing to completing of the assembly type concrete is monitored, controlled and traced.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL +1

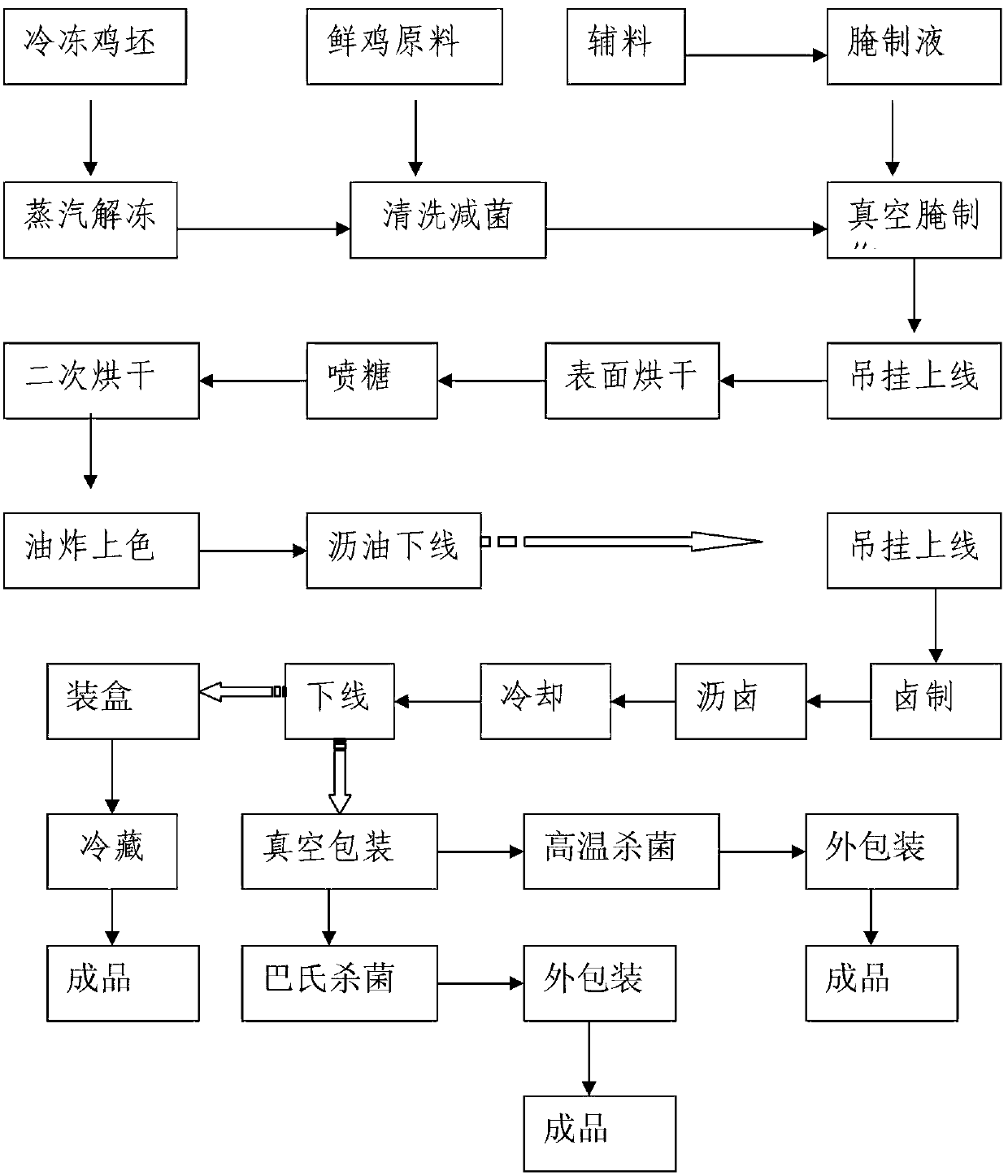

Automatic braised chicken production system and automatic braised chicken production process

ActiveCN103340431AOutstanding fragranceReduce the initial bacterial countClimate change adaptationFood preparationFlavorMaterial resources

The invention provides an automatic braised chicken production system and an automatic braised chicken production process. The automatic braised chicken production system comprises pretreatment equipment, coloring and frying equipment, marinating equipment and finished product packaging equipment. The automatic braised chicken production process comprises the flows of preparing a raw material, namely a frozen killed chicken, quickly unfreezing, cleaning and decontaminating, curing to be tasty, hanging on a line, carrying out surface drying, sugar spraying, re-drying, frying and coloring, draining oil, taking off the line, re-putting on the line, marinating, draining marinade, cooling, taking off the line and packaging, carrying out secondary sterilization, externally packaging and producing a finished product, wherein a cold killed chicken does not need to be quickly unfrozen. The automatic braised chicken production system is high in degree of automation, a large number of labor and material resources can be saved, and quality safety control and standard level improvement are facilitated. A product which is produced through the automatic braised chicken production process has a golden appearance, is crispy, is fresh, tender and delicious, is nutrient-rich, and is stable in quality. The industrial development of a traditional flavor braised chicken product is greatly promoted.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

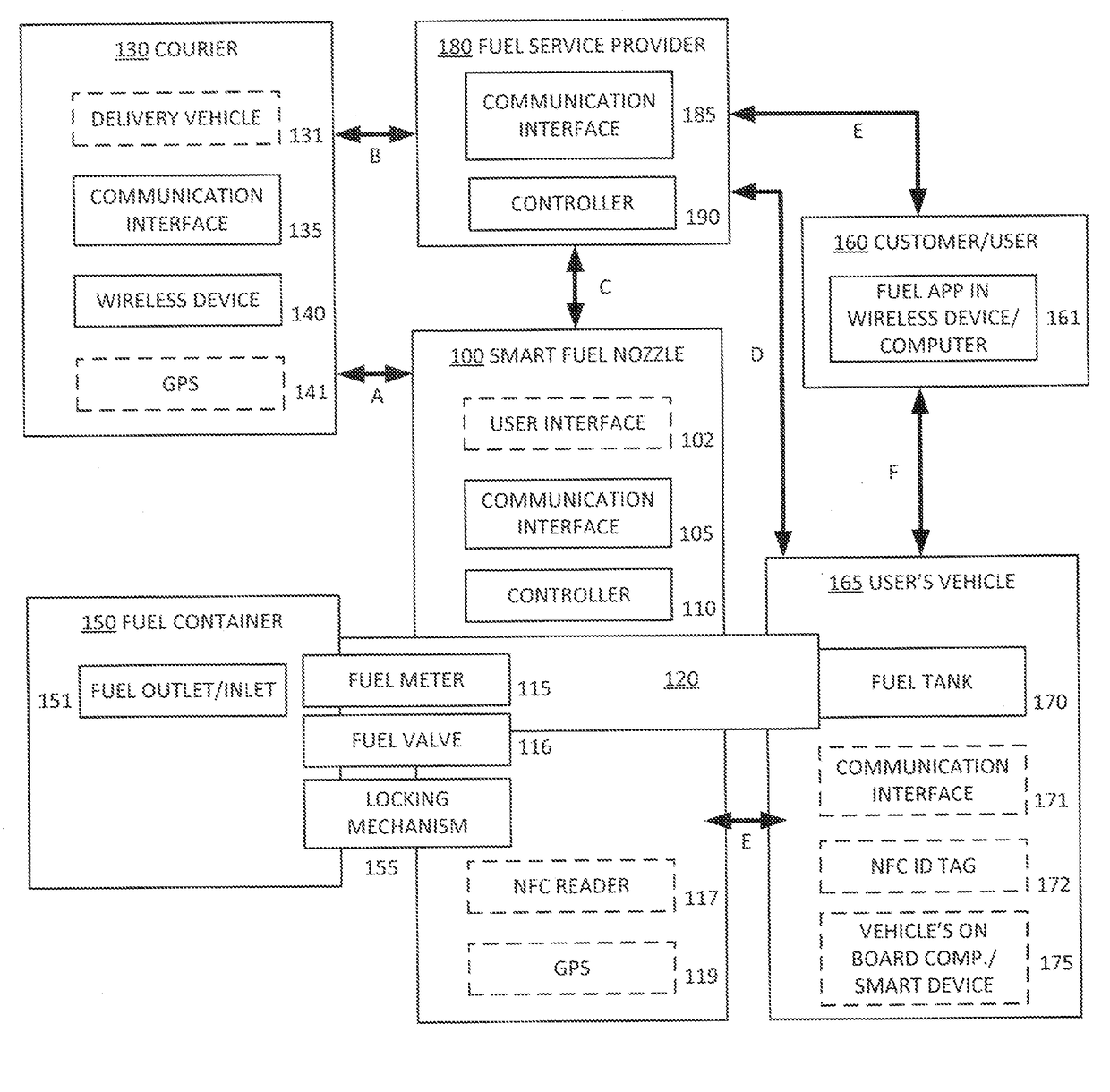

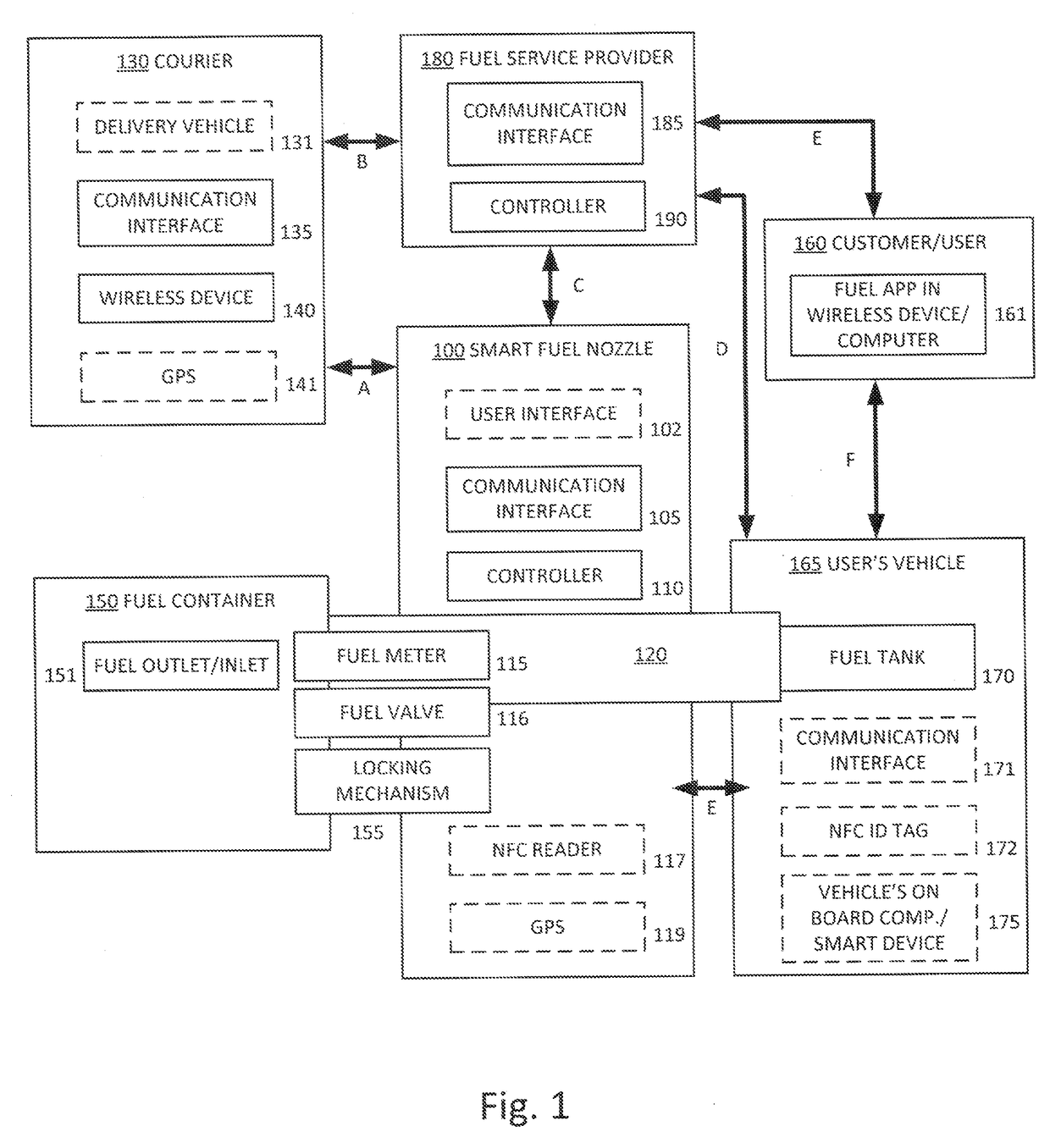

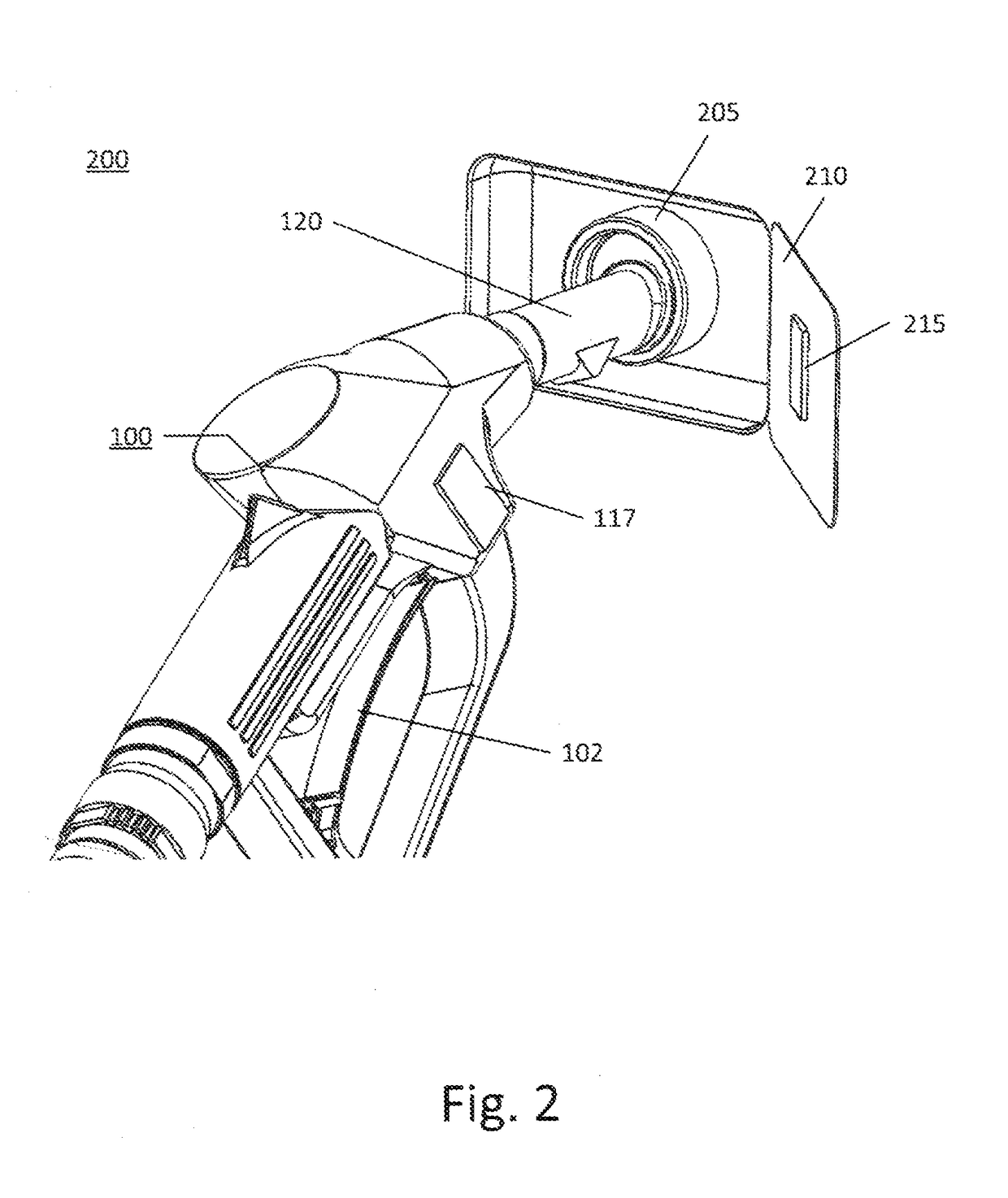

System and fuel nozzle for vehicle refueling

InactiveUS20170073211A1Grow customer baseGuaranteed uptimeComputer controlLiquid flow controllersSafe deliveryService provision

Embodiments of the present invention provide a system and associated smart fuel nozzle for improved fuel delivery to a vehicle. In particular, the smart fuel nozzle which can be in communication with a network including one or more of a fuel service provider, a courier's smart device, an user's device having an App, and in some embodiments, a vehicle's onboard computer / associated smart device. According to some aspects, the smart fuel nozzle can be used for controlled and monitored fuel delivery by a courier at the vehicle's location. According to some aspects, the ability to monitor the fuel being delivered can ensure proper delivery, quality of fuel, safe delivery, and automated order processing and / or confirmation.

Owner:PURPLE SERVICES

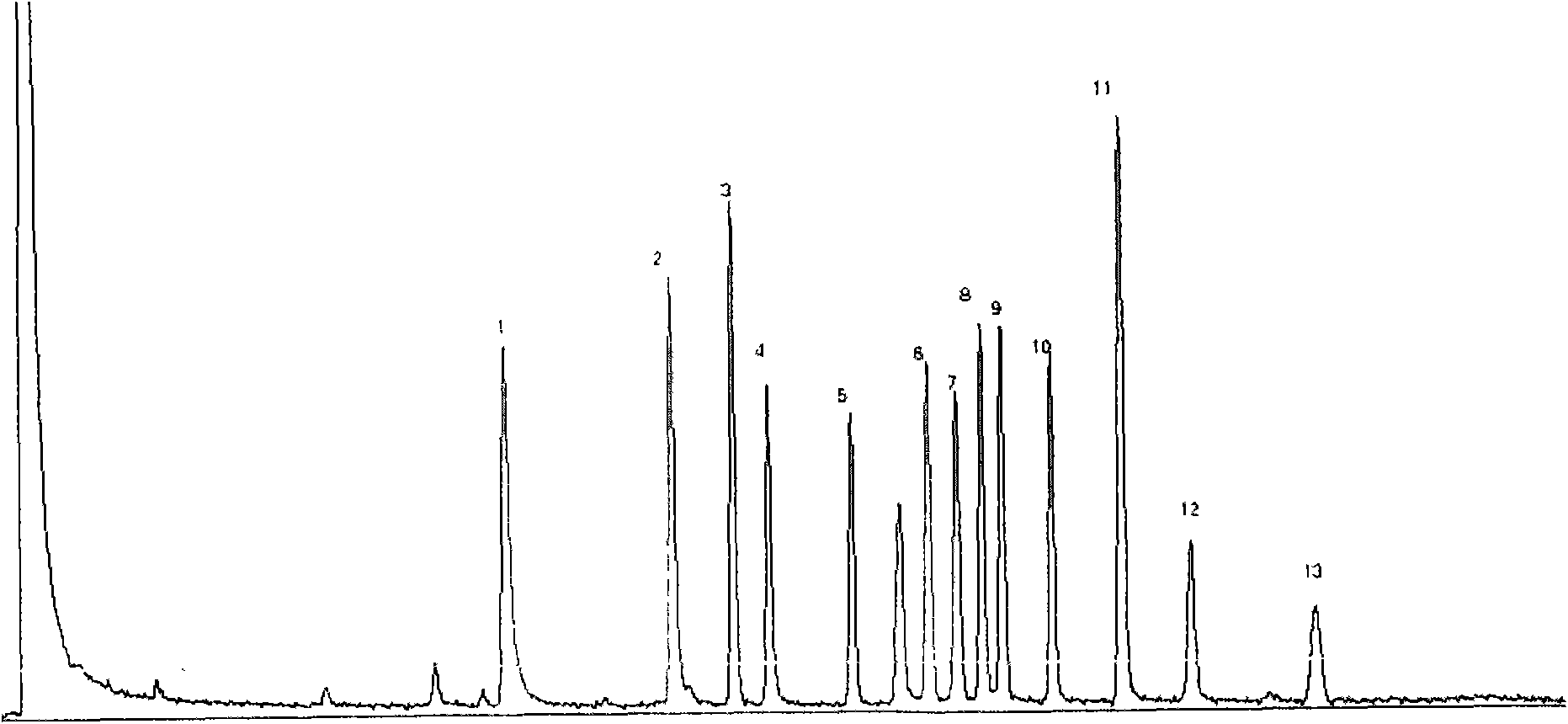

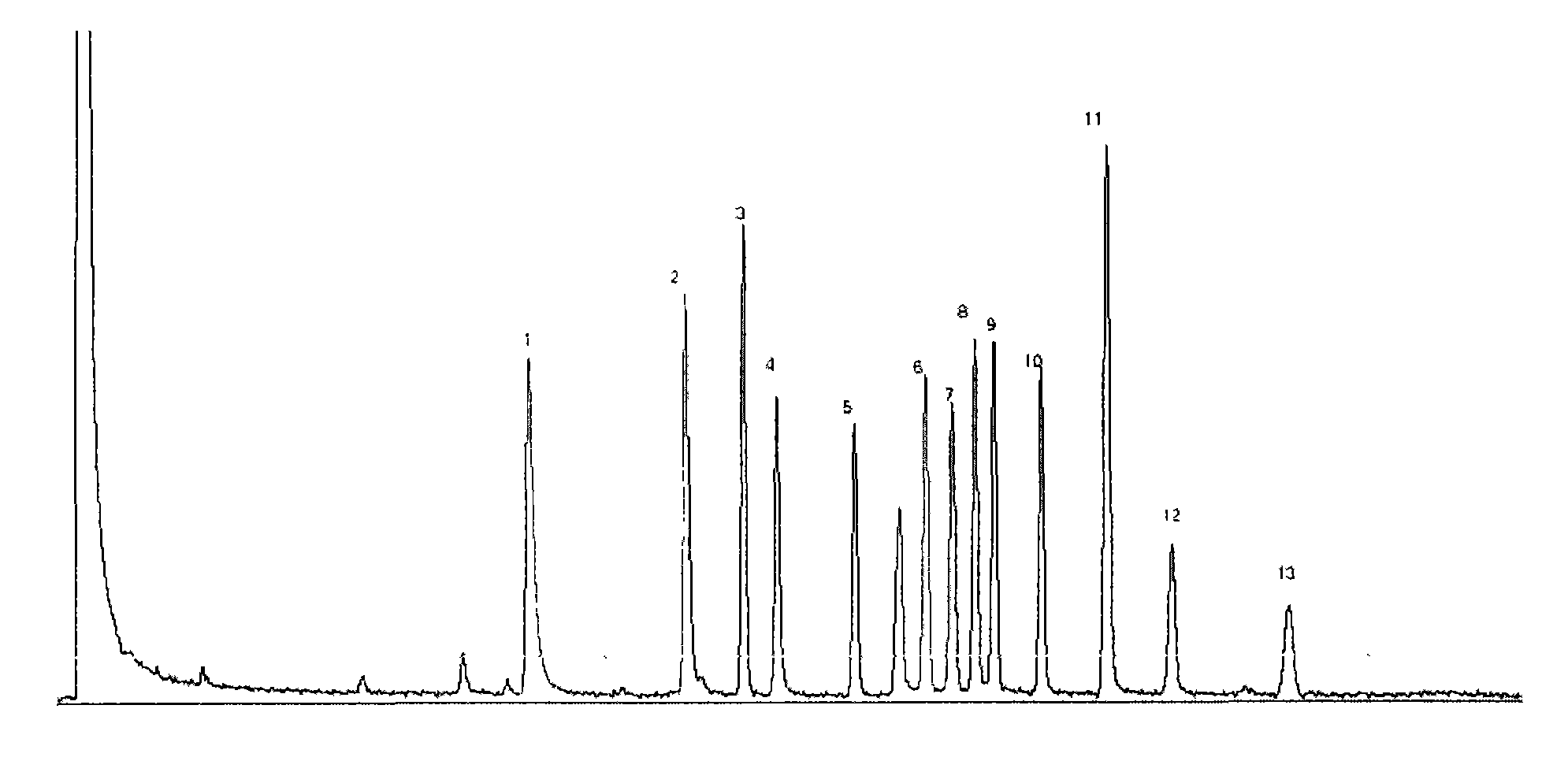

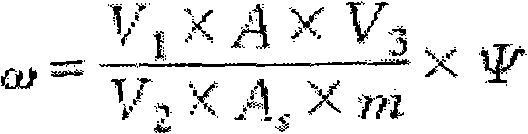

Method for detecting organophosphorus multi-pesticide residue in tea based on matrix effect compensation

InactiveCN101782558AHigh-precision detectionExtended maintenance cycleComponent separationPreparing sample for investigationGas phasePesticide residue

The invention relates to a method for detecting an organophosphorus multi-pesticide residue in tea based on matrix effect compensation, which belongs to the technical field of safety detection of foods. The method comprises the following steps of: (1) mixing a pesticide standard solution; (2) preparing a sample solution; (3) detecting a sample to be detected by a gas chromatogram and mixing the standard solution. The method is rapid, simple and economic, has high sensitivity, effectively reduces or eliminates the interference of a complex matrix derived from the tea on the detection of organophosphorus pesticide residues and provides a scientific basis for further improving an evaluation system of the quality safety of the tea.

Owner:TEA RES INST CHINESE ACAD OF AGRI SCI

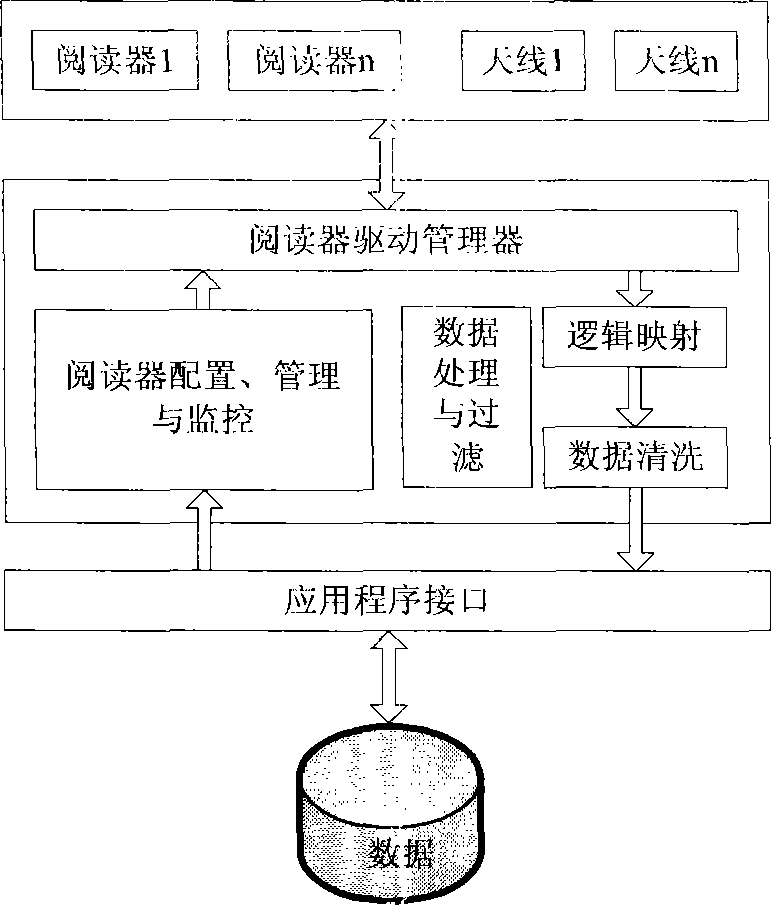

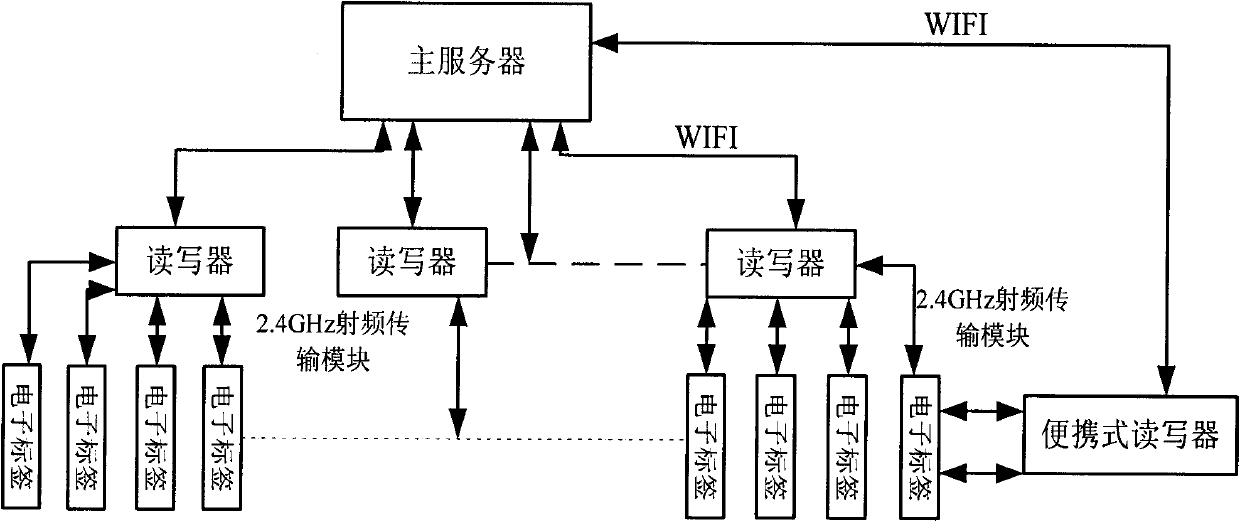

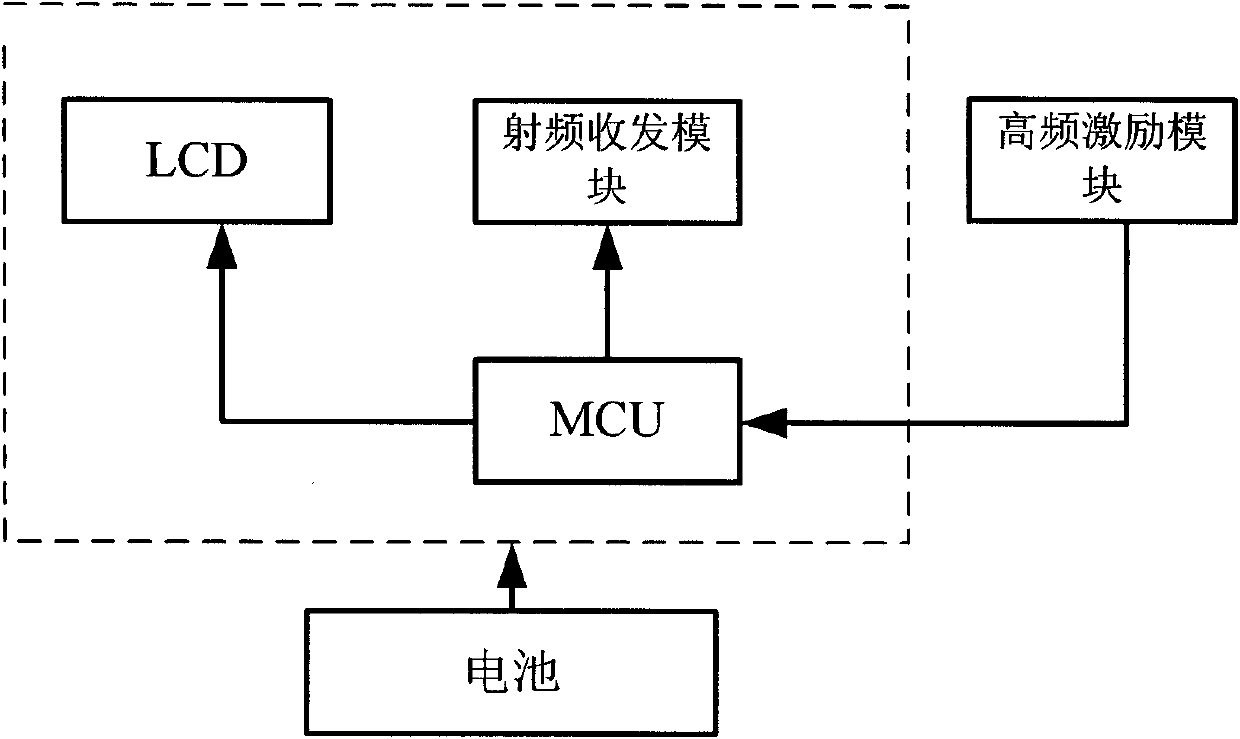

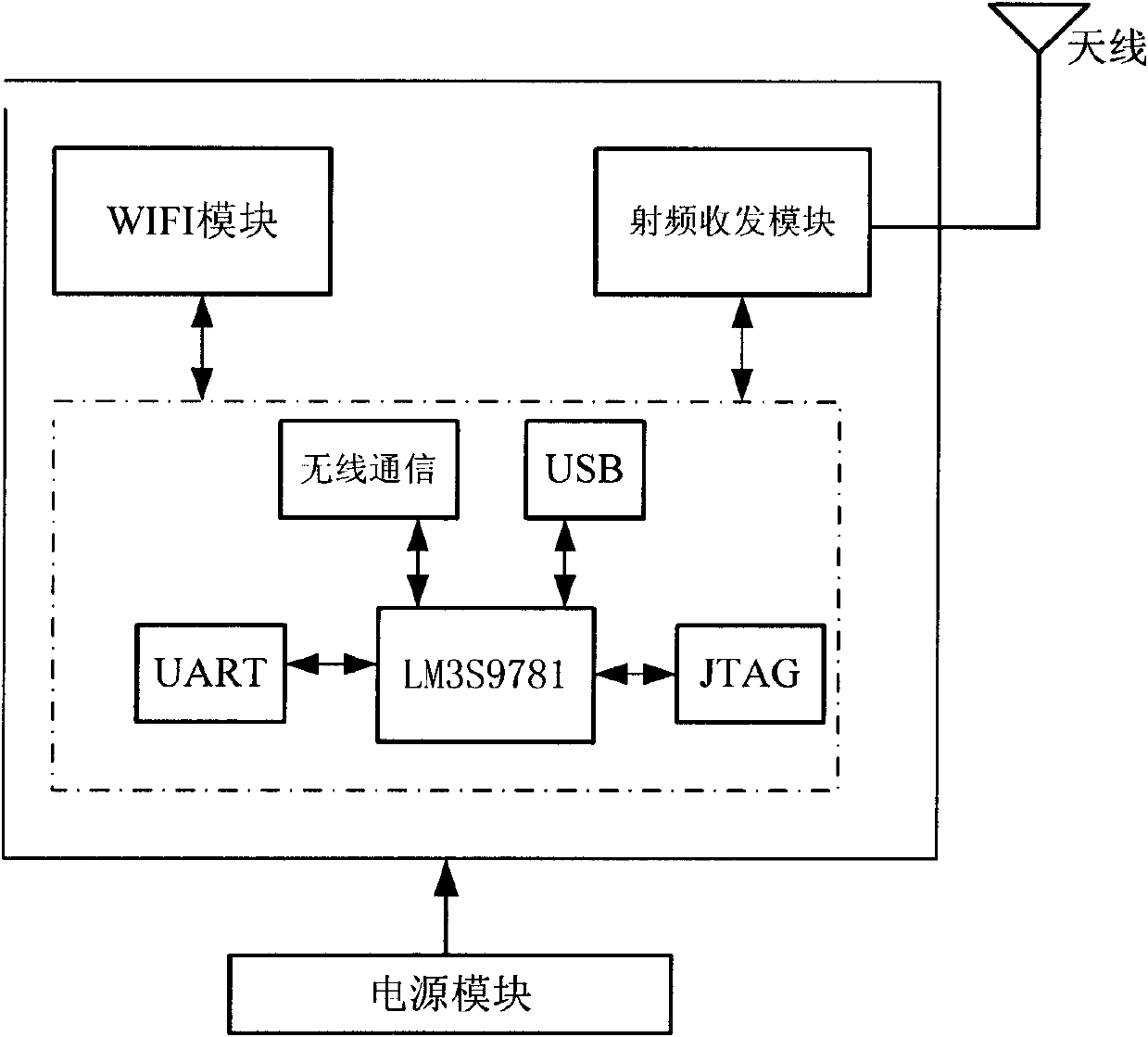

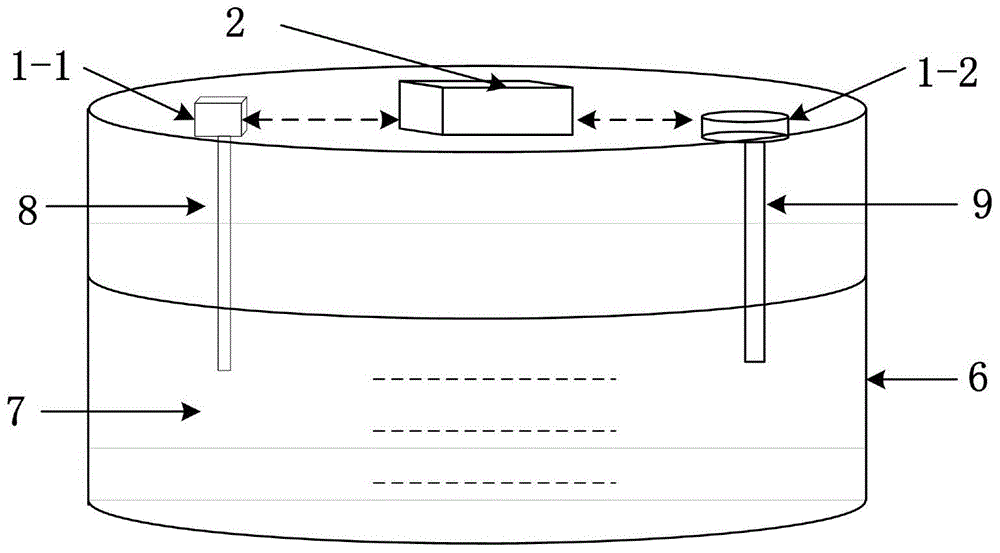

Internet of things data acquisition and transmission device and management method thereof

InactiveCN102169549AInstant updateConvenient process managementCo-operative working arrangementsData acquisitionTime effect

The invention provides an internet of things data acquisition and transmission device and a management method thereof. The data acquisition and transmission device that can trace the source of food raw materials, and ensure the effective traceability of the whole supply chain and work transparency among terminals is provided, and at least comprises an RFID (Radio Frequency Identification Device) label, a reader, a portable reader-writer and a main server. The data acquisition and transmission device has the beneficial effects of achieving convenience and excellent performance, being capable of updating production and circulation information of goods and foods in the process of operation immediately, enabling users to know the production and circulation trend of the goods and the foods, providing various food information channels related to quality safety management planes, being beneficial to goods process and transparent management and supervision of related quality and time effect, and greatly improving the present goods and food safety management systems.

Owner:上海绿度信息科技股份有限公司

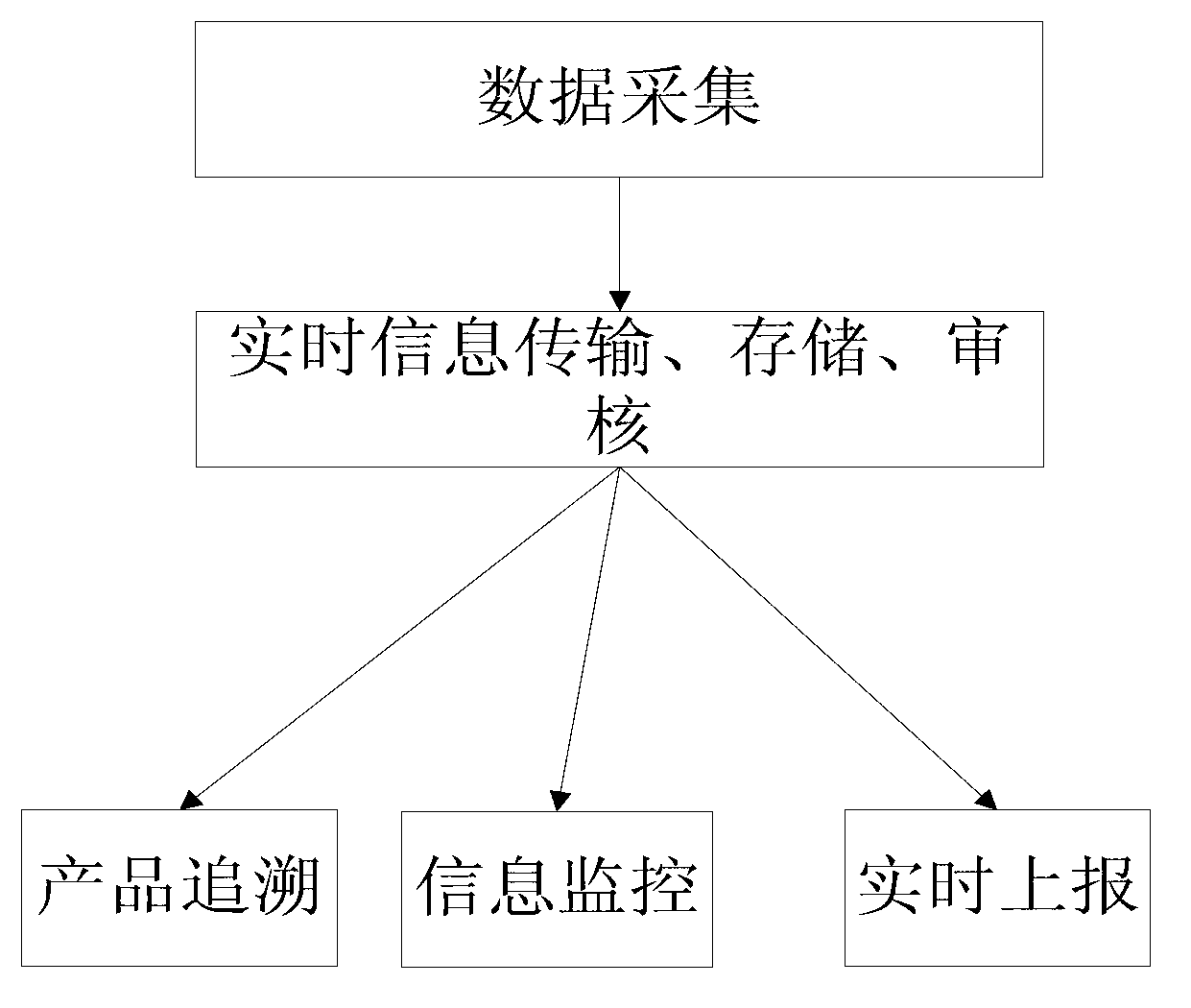

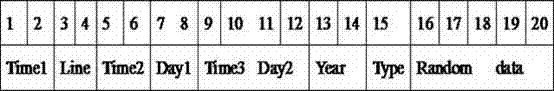

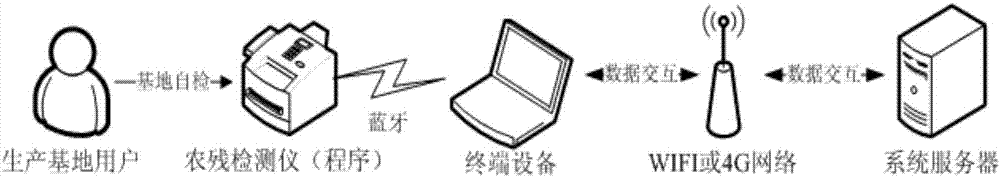

Agricultural internet of things agricultural product quality safety tracing method and internet of things system thereof

The invention relates to an agricultural internet of things agricultural product quality safety tracing method. The method comprises the steps that: agricultural product production information of all stages from seed selection to product selling are collected and transmitted to an internet of things cloud platform through an internet; the internet of things cloud platform sends the agricultural product production information to a central database for storage; the agricultural product production information forms an information group, and the internet of things cloud platform generates unique code information representing the information group; in an agricultural product packaging stage, a two-dimension code or electronic label with the code information is arranged on the package of the agricultural product; and a user obtains the code information through an intelligent terminal and transmits the code information to the internet of things cloud platform, and the internet of things cloud platform extracts the information corresponding to the code information from the central database and sends the information to the intelligent terminal. An agricultural product tracing system is characterized in that the detailed database is established from the seed stage to the product stage, the agricultural products are planted and processed in a standard manner, and a large amount of experiment data is provided.

Owner:北京东方海岸物联网科技有限责任公司

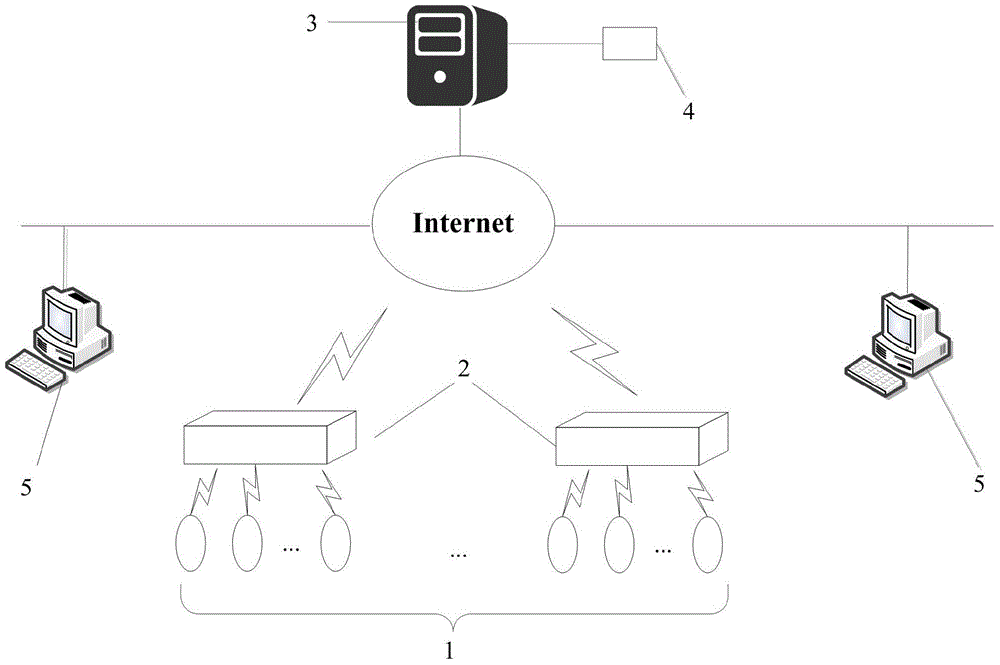

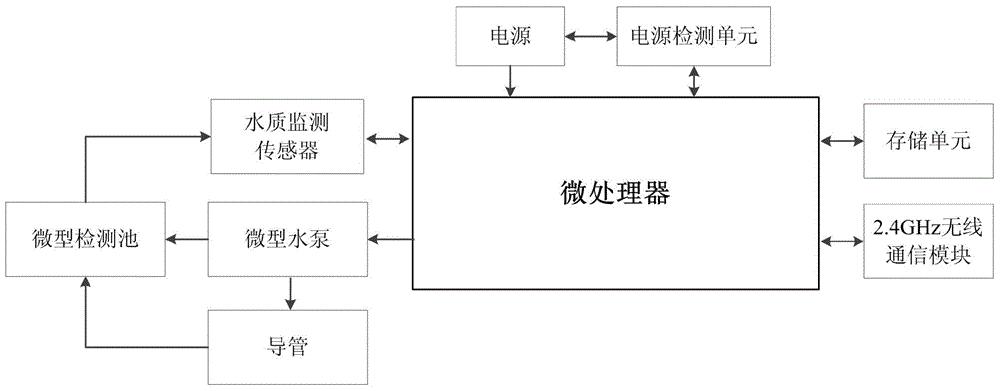

Remote supervising system and method for city secondary water supply quality safety

ActiveCN105092811ARealize the alarmEnable real-time supervisionTesting waterGeneral Packet Radio ServiceModem device

The invention discloses a remote supervising system and method for city secondary water supply quality safety. By the aid of the remote supervising system and method, centralized and unified management of all supervised areas can be realized. The system comprises wireless water quality monitoring sensors, water quality monitoring base stations, a WEB system server, a GSM modem module and client computers, wherein the wireless water quality monitoring sensors communicate with the water quality monitoring base stations through a wireless network, the water quality monitoring base stations are in remote communication with the WEB system server through the Internet or a GPRS (general packet radio service) network, the GSM modem module is connected with the WEB system server through a serial port, and the WEB system server is connected with the multiple client computers through the Internet. With the adoption of the remote supervising system and method, all running information in the monitored areas can be issued to users through the Internet, and real-time supervision on different scales of secondary water supply reservoir water quality in different regions is realized, so that secondary water supply safety and water quality supervision timeliness are further improved.

Owner:ANHUI XINHE DEFENSE TECH JOINT CO LTD

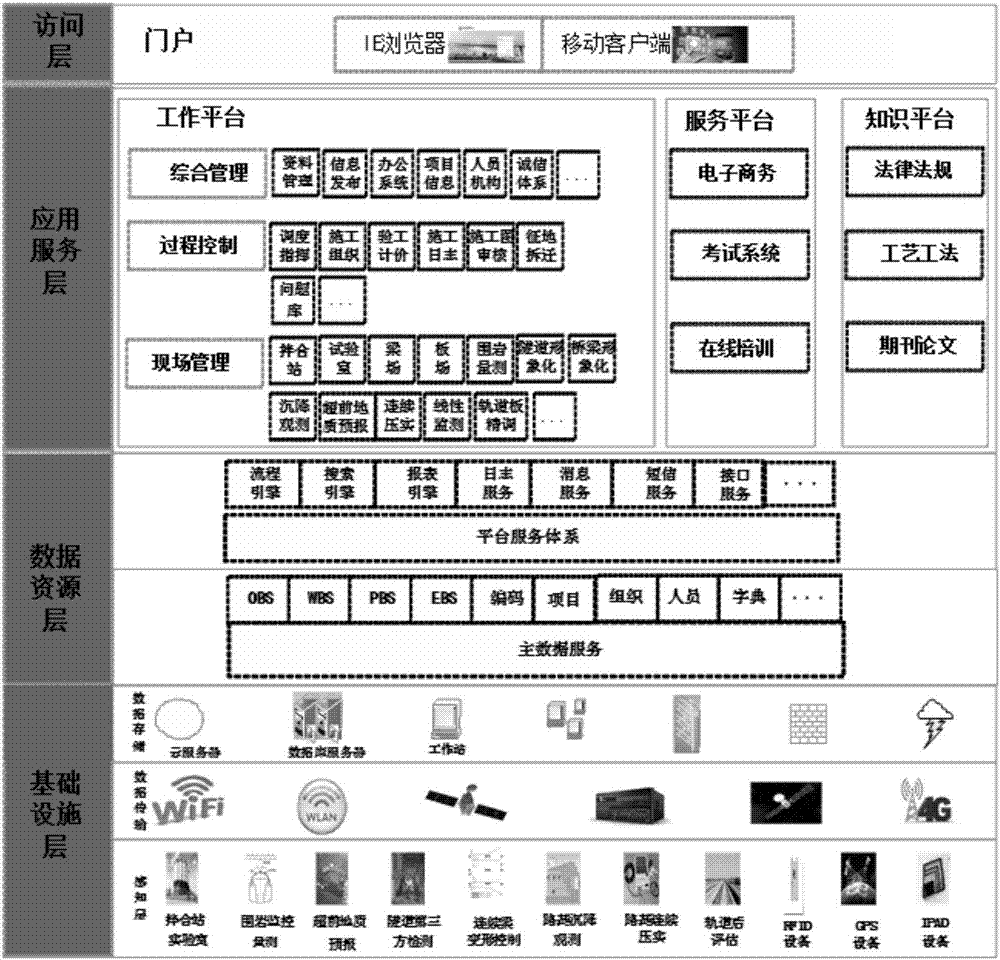

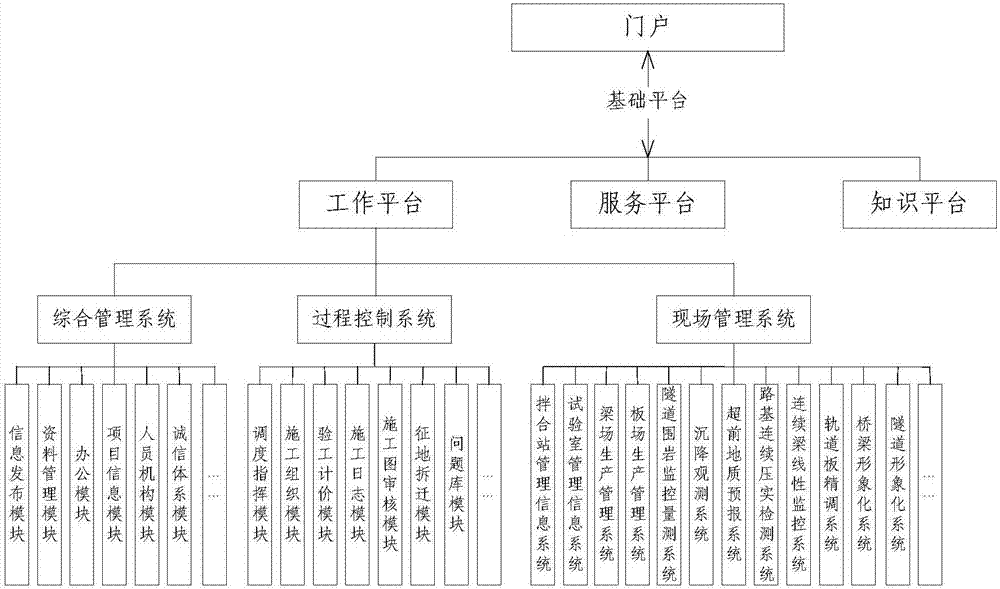

Railway project management platform system

PendingCN107146065AImprove management levelOrderly and efficient advancementCo-operative working arrangementsOffice automationInformatizationProcessing type

The invention provides a railway project management platform system. The system comprises an infrastructure layer, a data resource layer, a business application layer and an access layer, wherein the infrastructure layer is used for collecting, transmitting and storing railway project parameters; the data resource layer is used for processing the railway project parameters according to preset processing types and performing storage; the business application layer is used for managing railway project comprehensive information, controlling a railway project construction process and managing railway project field devices according to the railway project parameters; and the access layer is used for providing an identity authentication entry of the system. According to the railway project management platform system, through an integrated, standardized, intelligentized and service-oriented unified open management platform suitable for modern railway informatization construction, standardized construction is facilitated, a construction process is effectively supervised, the quality safety risk is prevented, the management level of a construction project is improved, and the ordered efficient promotion of the construction project is realized.

Owner:INST OF COMPUTING TECH CHINA ACAD OF RAILWAY SCI +2

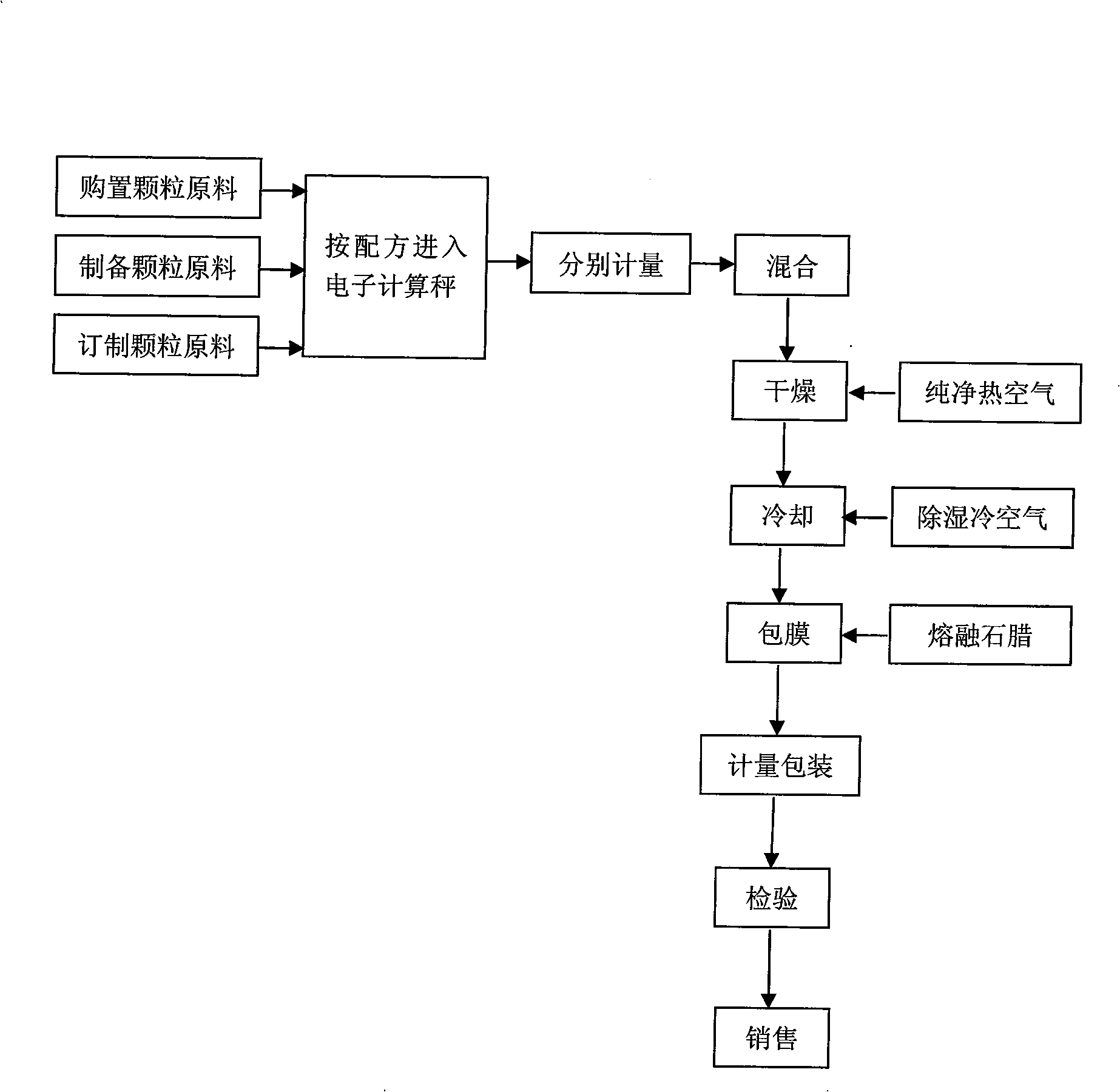

An ecological BB fertilizer

ActiveCN101514133AEfficient use ofReduce dosageAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersBiological StressEcological environment

The invention discloses an ecological BB fertilizer, relating to a mutifunctional ecological environment friendly compound fertilizer, which is formed by mixing functional urea, controllable slow release sulfurcoated urea, monoammonium phosphate, diammonium phosphate, potassium sulfate particle (or potassium chloride), agricultural magnesium sulfate particle, ammonium sulfate, bio-organic inorganic compound fertilizer, endophytic PASP fertilizer synergist DA-6, plant growth regulator and trace elements. Special ecological BB fertilizer for different plants can be prepared by soil testing formula, according to different farm crops and different soil structure. The ecological BB fertilizer can take effect for 3-120 days, the nutrition release is balanced, biological stress of the farm crop such as drought resistance, cold resistance, salt resistance, or the like can be improved. The product of the invention has great operation significance for increasing yield of grain, reducing production cost, steadily increasing grain production, keeping rural incomes growing, improving utilization rate of the fertilizer, reducing fertilizer waste, protecting ecological environment, guaranteeing farm crop quality and safety, and ensuring sustainable development of the agriculture.

Owner:苏州盛泽科技创业园发展有限公司

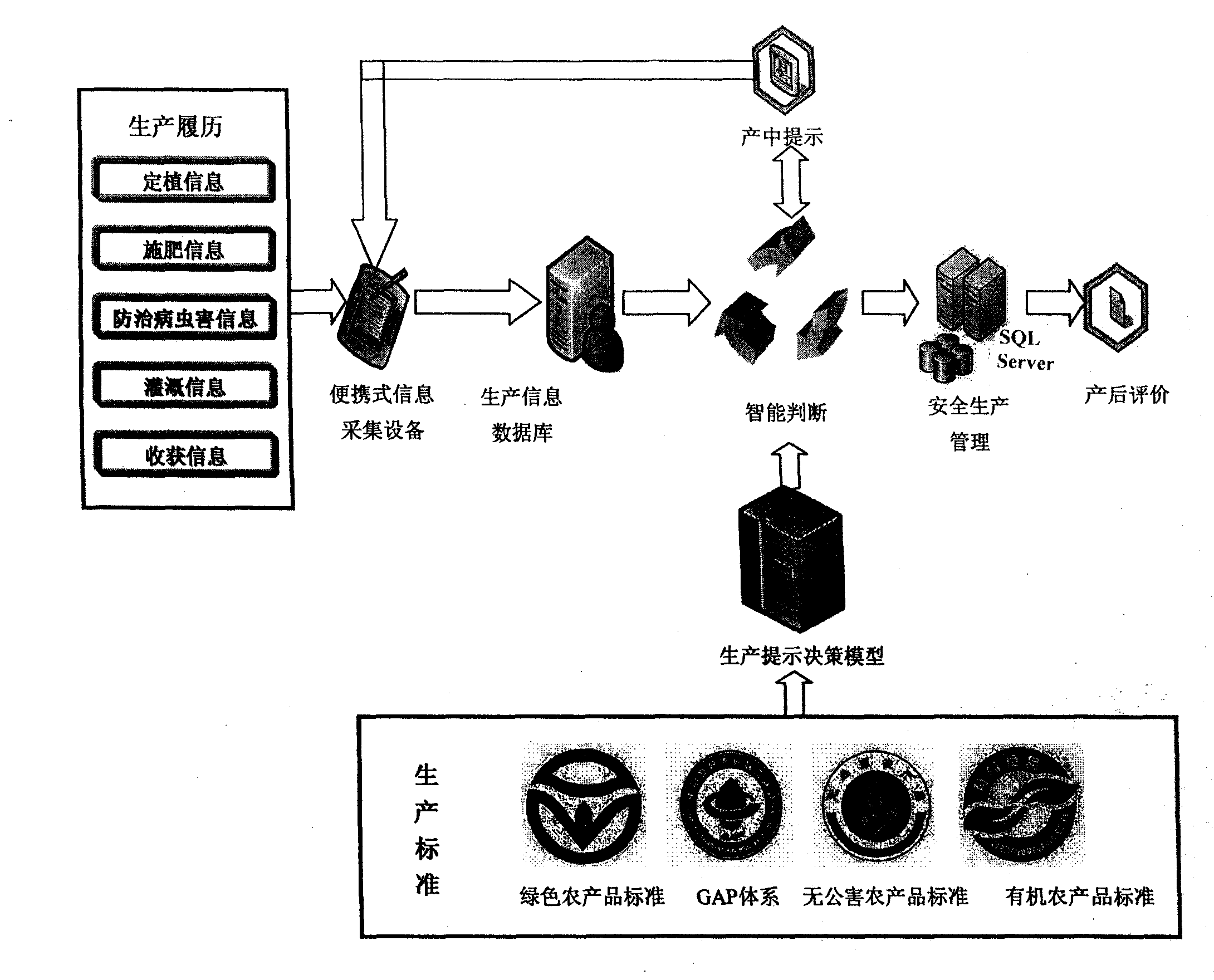

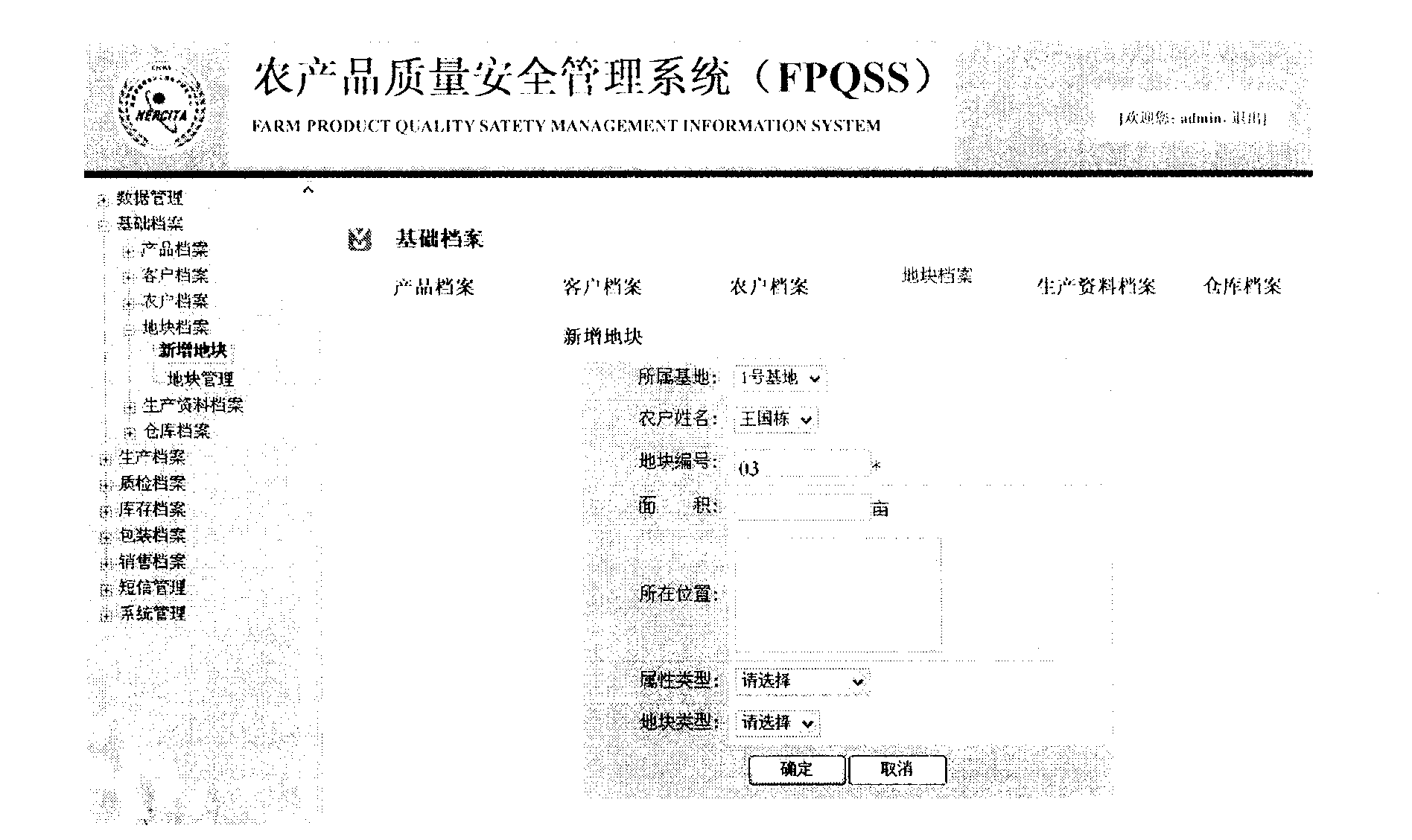

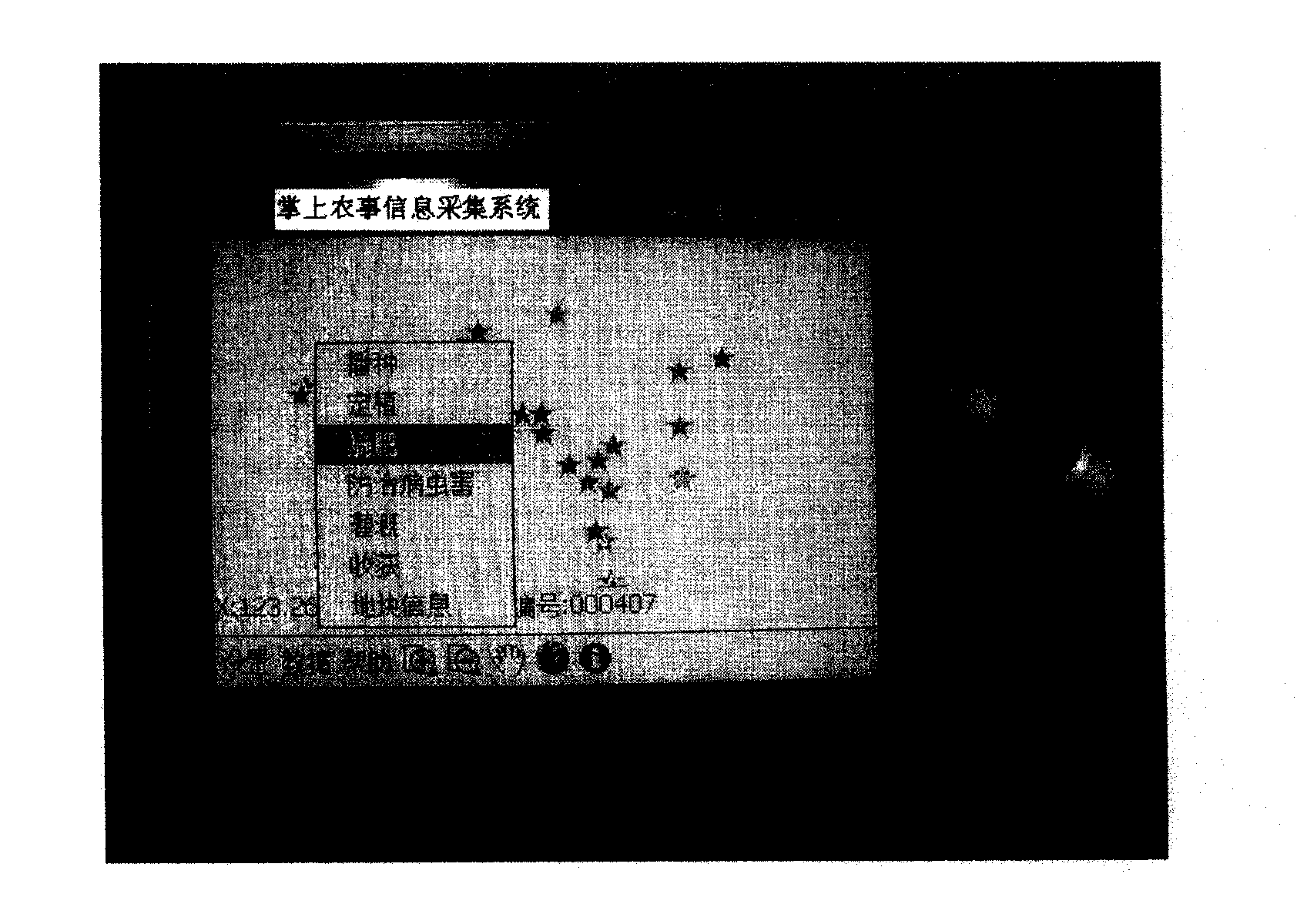

Management method and system of farming information collection and safe production of fruit-and-vegetable agricultural products

InactiveCN101840530AEnrich the technical framework of pollution-free certificationGet rid of incomplete recordsResourcesCollection systemQuality safety

The invention discloses management method and system of farming information collection and safe production of fruit-and-vegetable agricultural products, belonging to the technical field of whole-process tracking and tracing of the fruit-and-vegetable agricultural products. By taking GAP (Good Agriculture Practices) as a reference, and non-pollution, green and organic standards as basis and using a PDA (Personal Digital Assistant) and an intelligent mobile phone as carriers, a production operation prompt model of the fruit-and-vegetable agricultural products is constructed, the managing method of the farming information collection and safe production is provided and comprises the steps of downloading of basic information, collection of production information, uploading of production information, management of production information, decision of production process, feedback of decision information and evaluation of production process, and a handheld farming information collection system based on a portable terminal and the managing system of the safe production based on a B / S (browser-server) framework are developed. The comprehensive management combining safe production file record of agricultural products, control of production process and early-warning of production operation has great significance on scientific decision program, quality safety level improvement of the agricultural products and whole-process tracing of the agricultural products.

Owner:BEIJING RES CENT FOR INFORMATION TECH & AGRI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com