Quality safety tracing method for food processing enterprises

A technology of quality safety and food processing, applied in the direction of cooperative operation devices, debit schemes, payment schemes/models, etc., can solve the problems of unreadable commodity codes, lower production efficiency, and inability to eliminate unqualified products, etc., to improve The effect of reading efficiency and accuracy, ensuring authenticity and effectiveness, and improving storage work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

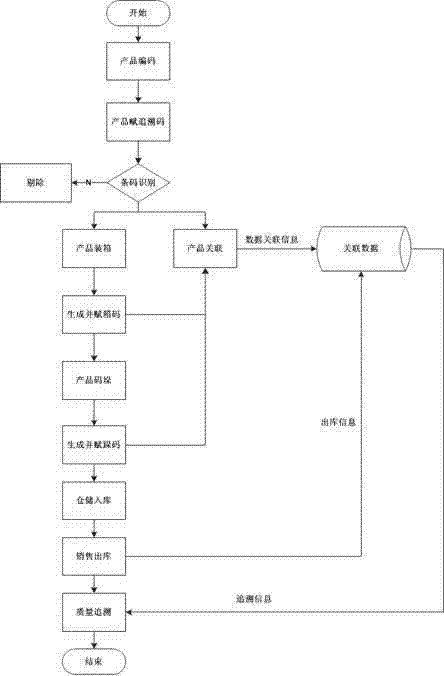

[0042] like figure 1 As shown, it is the method of the present invention for the quality and safety of food processing enterprises, which conforms to the assembly line operation of high-speed production, establishes product life cycle files, establishes seamless links between various links, and realizes the associated management of label information transmission and exchange. It is beneficial to realize the tracking and tracing of the whole supply chain. Realize production process control and improve production efficiency. Specifically include the following steps:

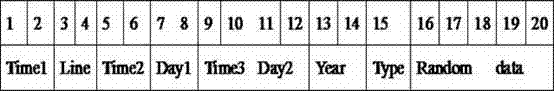

[0043] 1. Product code, the rules are as follows:

[0044]When food processing is packaged into small packages (bags or bottles), it is necessary to attach a unique identification code-traceability code to each single-product small package. The design traceability code adopts 20 digits, and can be generated simultaneously according to different production lines without duplication In order to simplify the operat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com