System and method for detecting front and back face qualities of imprinted Renminbi (RMB) large-page product

A detection system and product technology, applied in coin inspection, measuring devices, handling coins or valuable banknotes, etc., can solve the problems of insufficient machine inspection capabilities of small-denomination products, inability to accurately locate small openings of waste products, etc., to reduce paper fluctuations, Quality and safety, the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

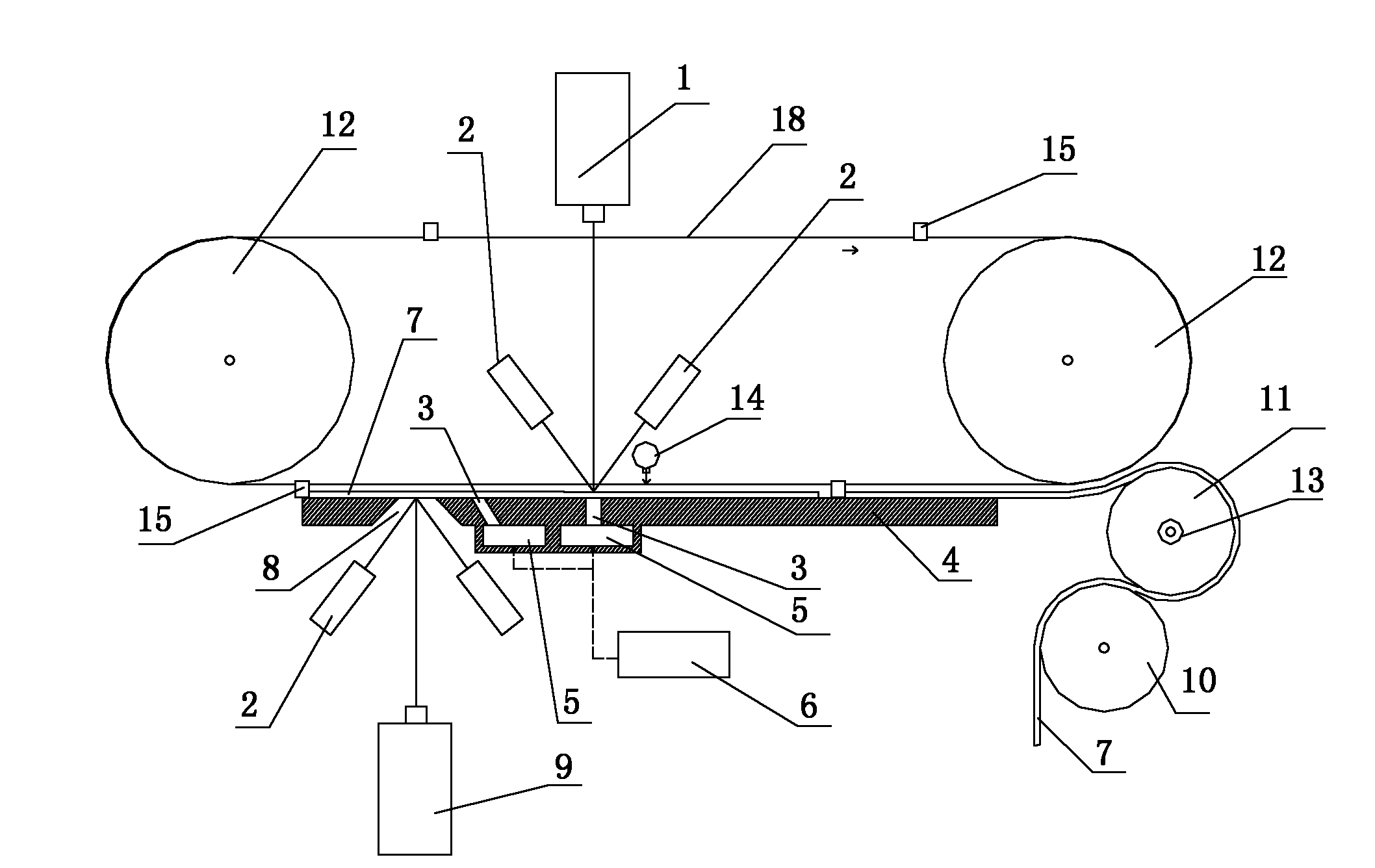

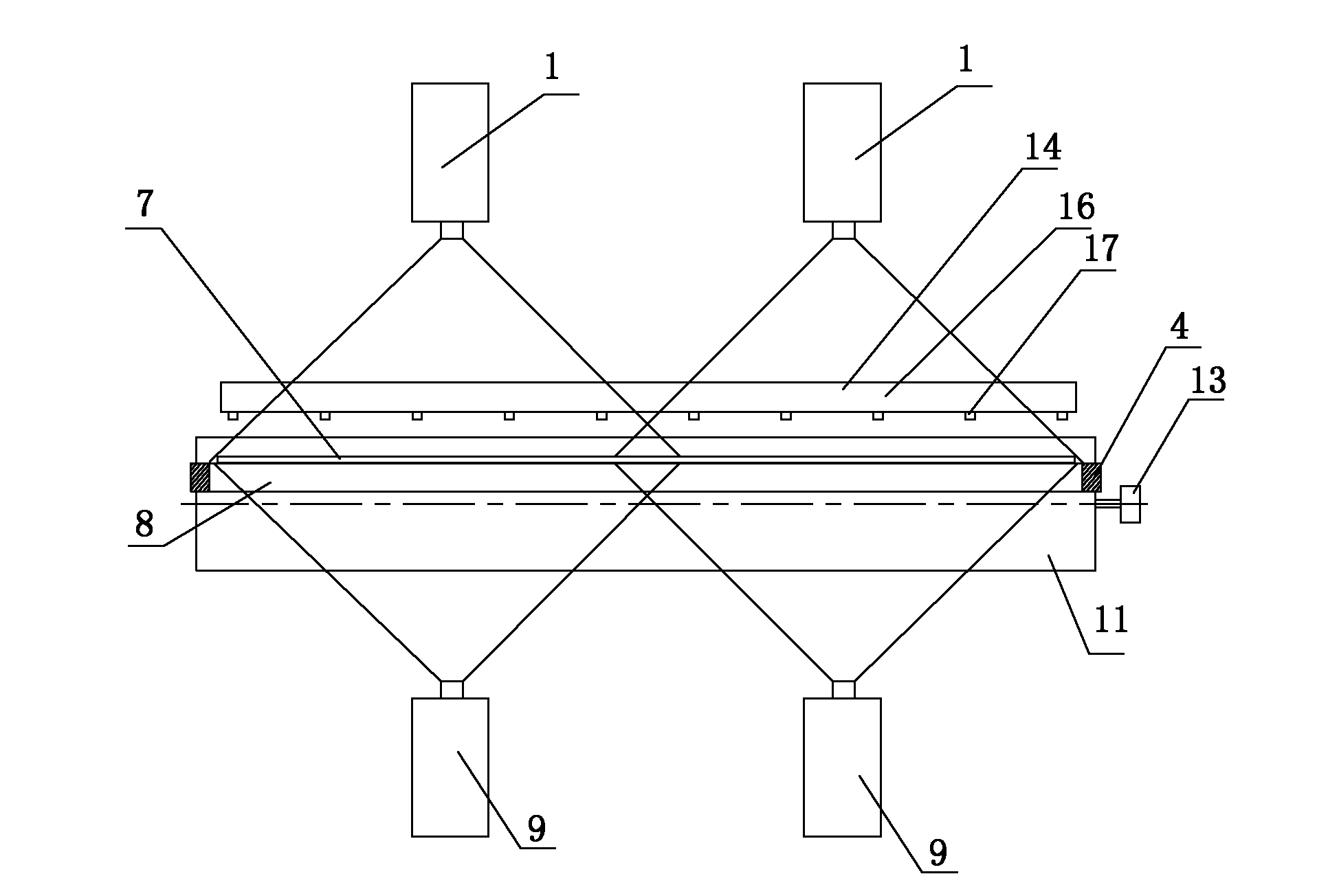

[0027] The detection system of the present invention includes a transmission device, a flattening device and a detection device; the transmission device includes a detection roller 11 connected to the paper output sprocket 10 of the printer, and two gripper row sprockets 12 connected to the detection roller 11 , the transmission chain 18 arranged between the two gripper teeth row sprockets, the plurality of evenly distributed gripper teeth rows 15 arranged on the transmission chain; A piece of product is dragged from the flattening device; the flattening device includes a suction plate 4 arranged under the two gripper row sprockets 12, and two long rows of suction holes 3 arranged on the suction plate and evenly distributed horizontally 1. The air blowing device 14 arranged above the air suction plate and arranged horizontally; the air suction hole 3 communicates with the air pump 6, and the air blowing device can blow air on the air suction plate; the detection device includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com