Patents

Literature

318 results about "Rock flour" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rock flour, or glacial flour, consists of fine-grained, silt-sized particles of rock, generated by mechanical grinding of bedrock by glacial erosion or by artificial grinding to a similar size. Because the material is very small, it becomes suspended in meltwater making the water appear cloudy, which is sometimes known as glacial milk.

Big pig premix and application method thereof

ActiveCN101579061ABalanced nutrient supplyComprehensive nutrition supplyFood processingAnimal feeding stuffLean meatPhytase

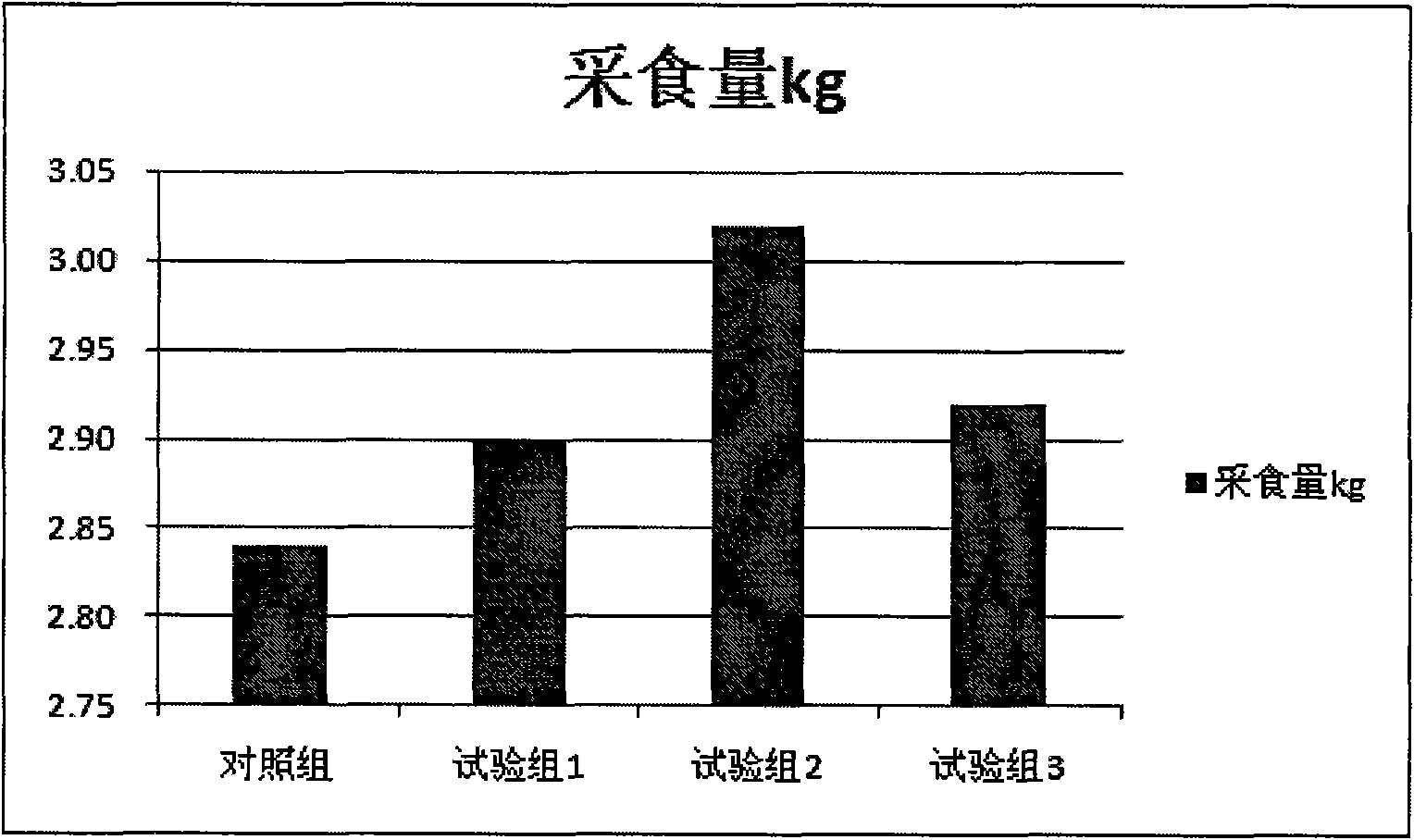

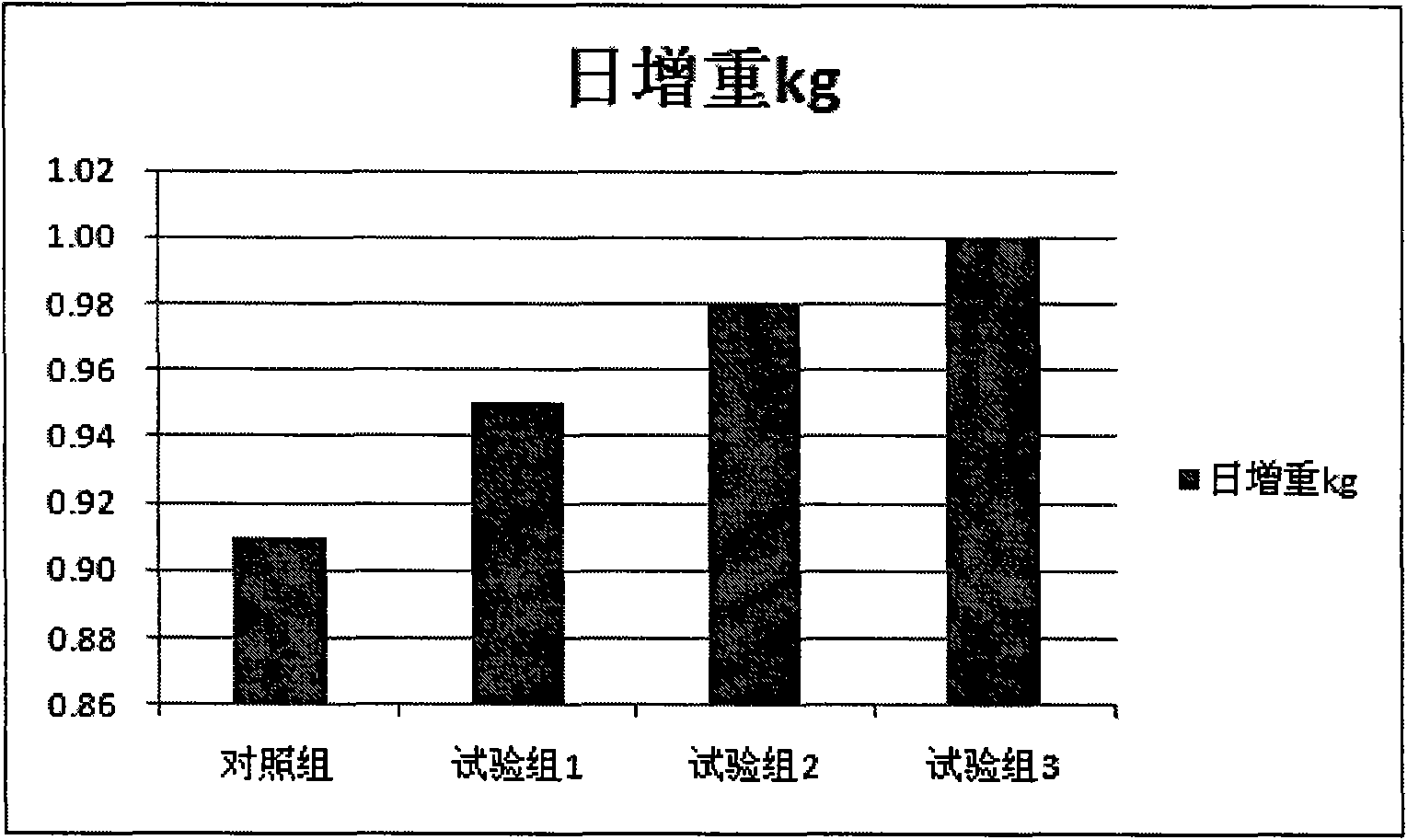

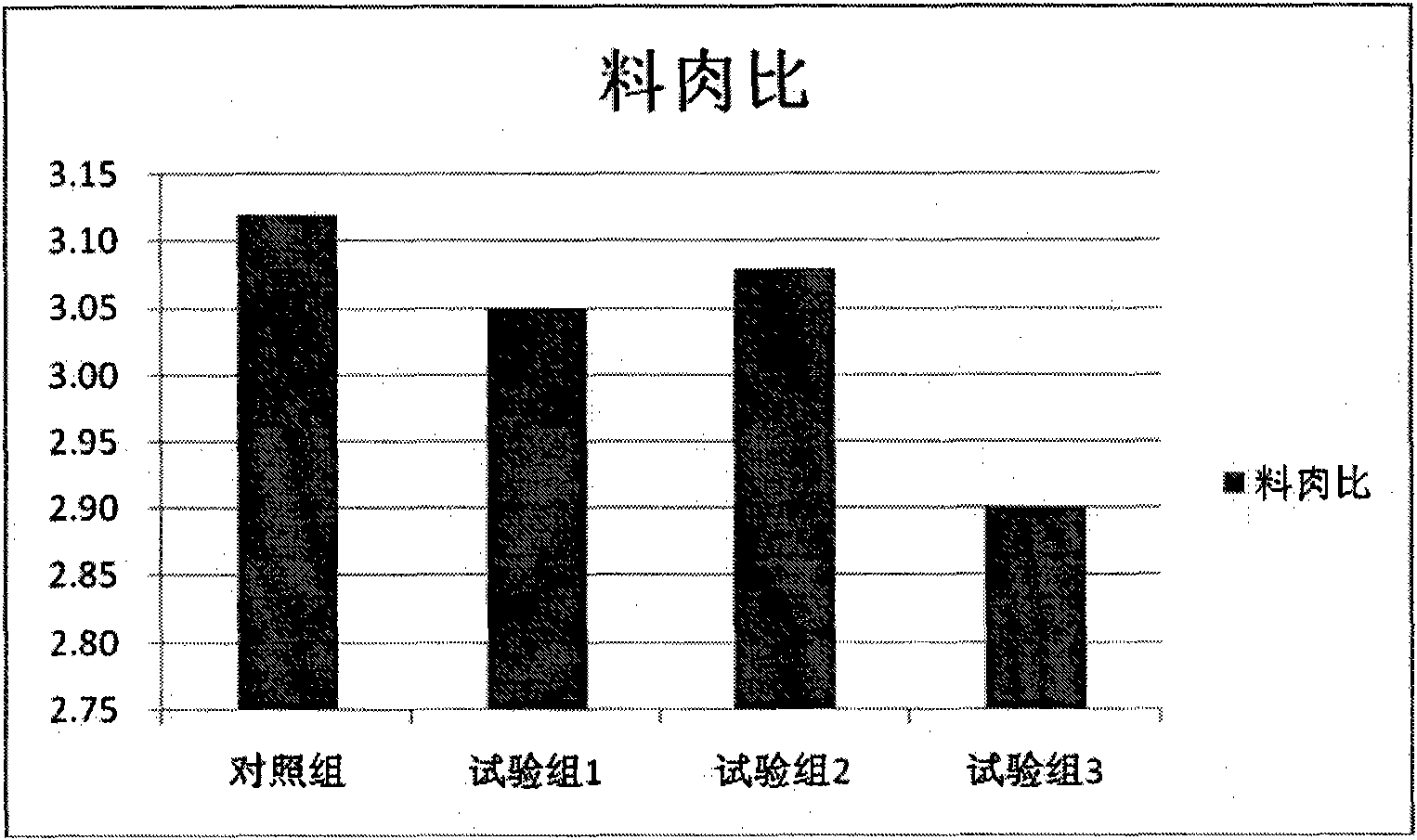

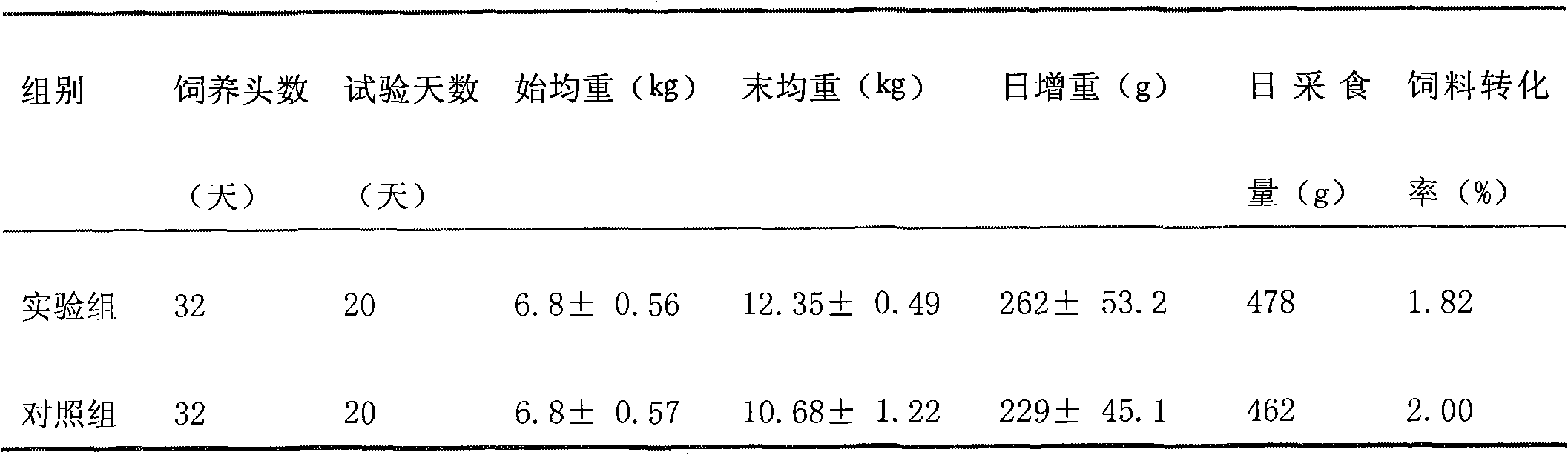

The invention belongs to the animal sitology technical field, in particular to big pig premix and an application method thereof. The premix mainly comprises the following components: iron element, copper element, zinc element, manganese element, iodine element, cobalt element, selenium element, composite vitamine premix, DL-methionine, lysine, threonine, cholinehydrochloride, calcium hydrophosphate, rock flour, salt, carrier and phytase. The big pig premix and conventional basic ration are used to prepare big pig compound feed to feed big pigs with conventional process, and the content of the big pig premix in the big pig compound feed is 4% according to the weight percentage. The big pig premix provided by the invention is simple and safe to use; after feeding big pigs, the fodder-meat rate can be reduced, the big pig growth speed and lean meat percentage are increased and the meat quality safety can be improved.

Owner:河南雄峰科技股份有限公司

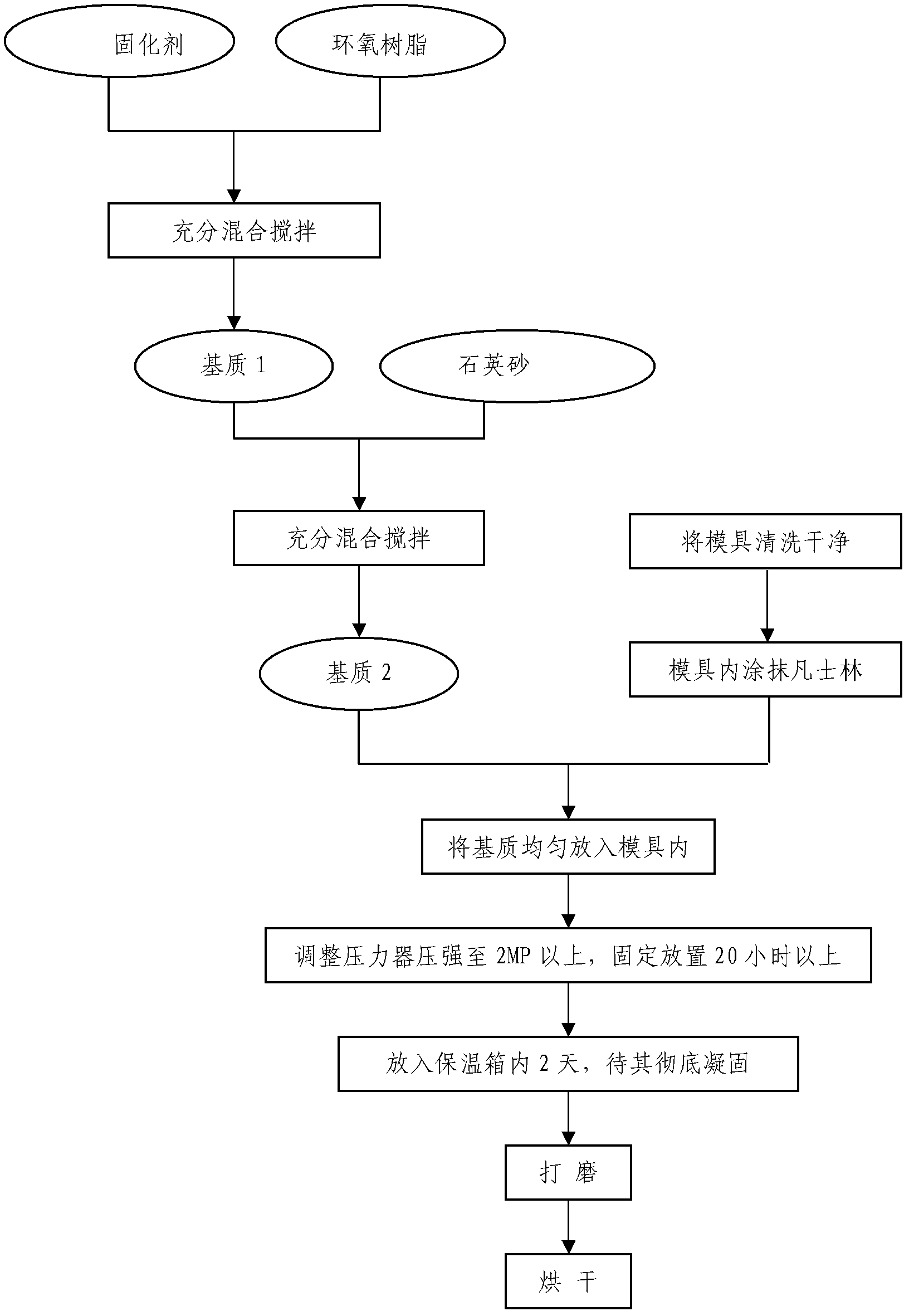

Novel microbial fermentation bed mattress material and preparation method thereof

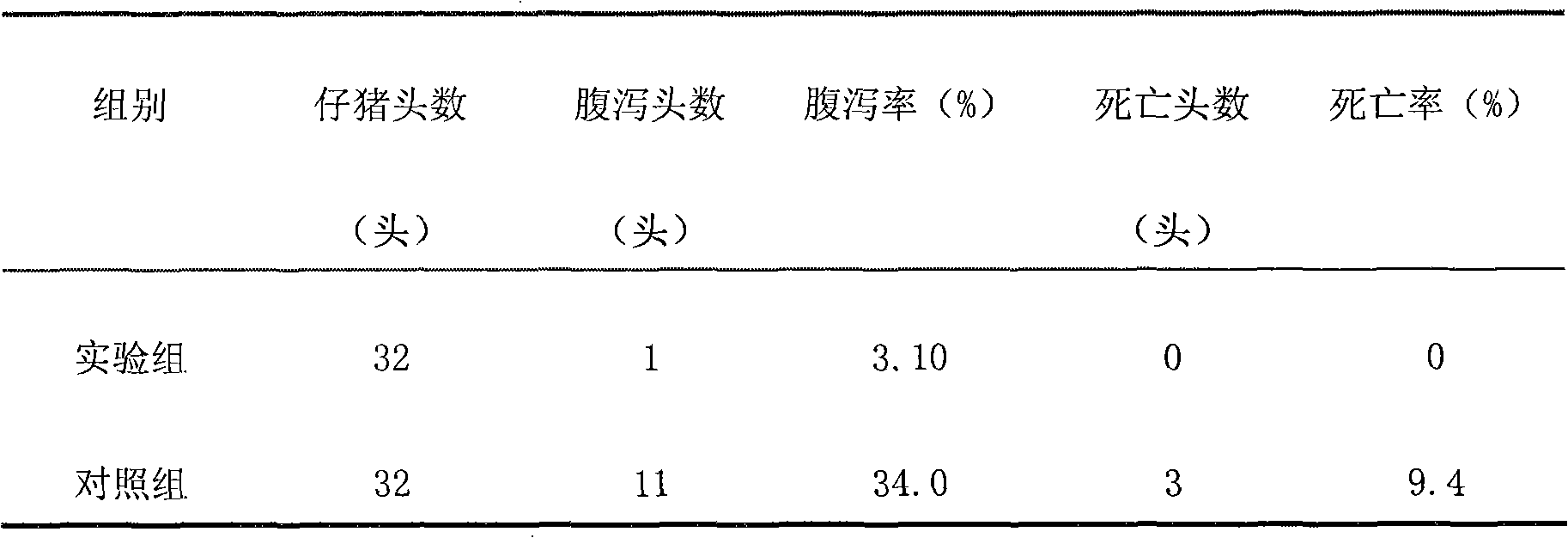

The invention discloses a novel microbial fermentation bed mattress material, which comprises a top fermentation padding and a bottom fermentation bed, wherein the thickness of the top fermentation padding is 70-80cm and the top fermentation padding contains a padding blended with a microbial fermentation bacterium agent. The novel microbial fermentation bed mattress material is characterized in that each cubic meter of the fermentation padding comprises the components as follows: 80-100kg of saw dust, 60-80kg of rice husk mixture, 60-80kg of straw mushroom residues and alcohol residues, 10-15kg of rice bran or bran, 50-100kg of water, 50-100kg of soil and rock flour, 0.5-0.8kg of microbial fermentation bacterium agent, and 0.5-0.8kg of crude salt. The preparation method of the material comprises the following steps: 1) preparing a bacterium agent; (2) mixing a padding; (3) composting and fermenting; (4) preparing a fermentation padding; and (5) preparing a fermentation bed mattress. The preparation method of the novel microbial fermentation mattress material is simple and feasible, low in cost and low in morbidity of pigs. The replaced fermentation mattress material can be used for composting, thus realizing zero emission, no pollution and environmental friendliness and being suitable for popularization and application under high temperature and high humidity environments.

Owner:JIANGSU KANGLE FARMING

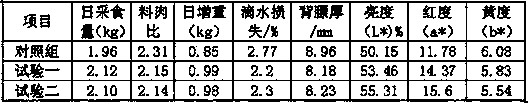

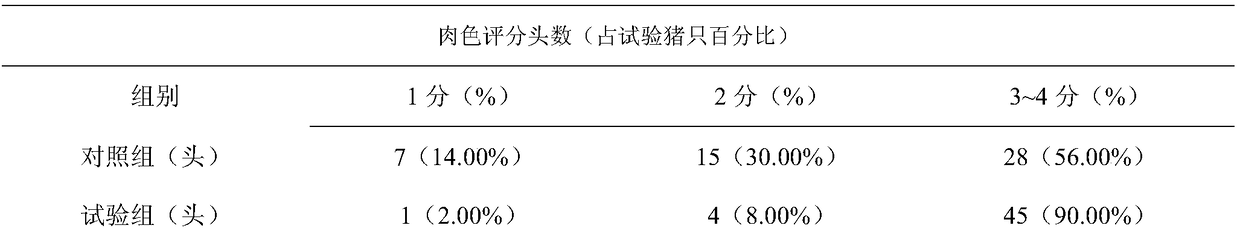

Coarse cereal type growing and fattening pig compound feed for promoting growth and improving meat quality

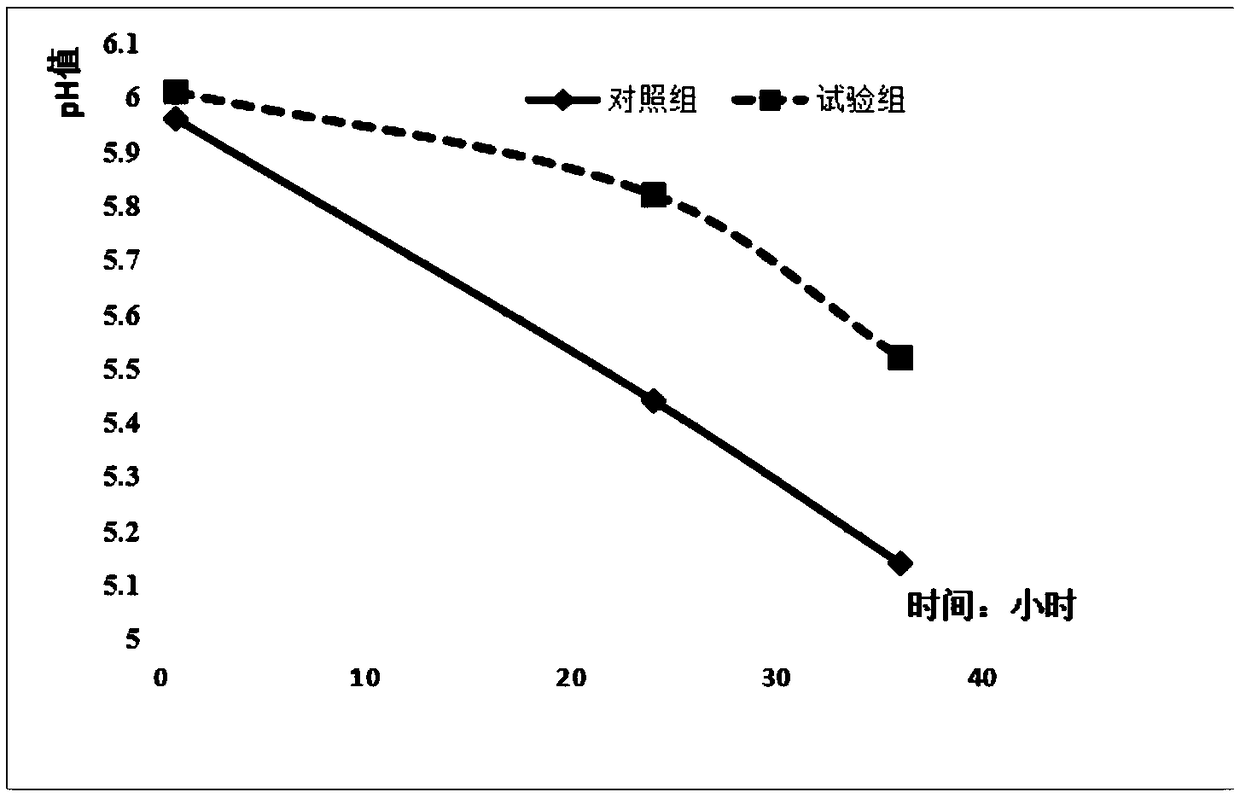

The invention discloses coarse cereal type growing and fattening pig compound feed for promoting the growth and improving the meat quality. The coarse cereal type growing and fattening pig compound feed is prepared from the compositions of corn, barley, broomcorn, bean pulp, phosphatide oil powder, orange peel dreg, calcium hydrogen phosphate, rock flour, salt, vitamin E, lysine, threonine, plant extract, probiotics, choline chloride, multiple vitamins, multiple microelement pre-mixed feed and the like through mixing. The coarse cereal type growing and fattening pig compound feed disclosed by the invention has the advantages that the source of the feed is rich, no pollution, residue and side effects are generated, the cost is low, the processing is convenient, and the storage is easy; while rapid growth speed is ensured, an eye muscle area is increased, and the backfat thickness is reduced; the meat quality is improved while the lean meat percentage is increased; the pH (Potential of Hydrogen) value of meat is normal, the meat color grade is improved, marble veins are formed, the tenderness is increased, the rate of water loss is reduced, the cooked meat percentage is increased, and the storage loss is reduced.

Owner:SICHUAN TEQU INVESTMENT

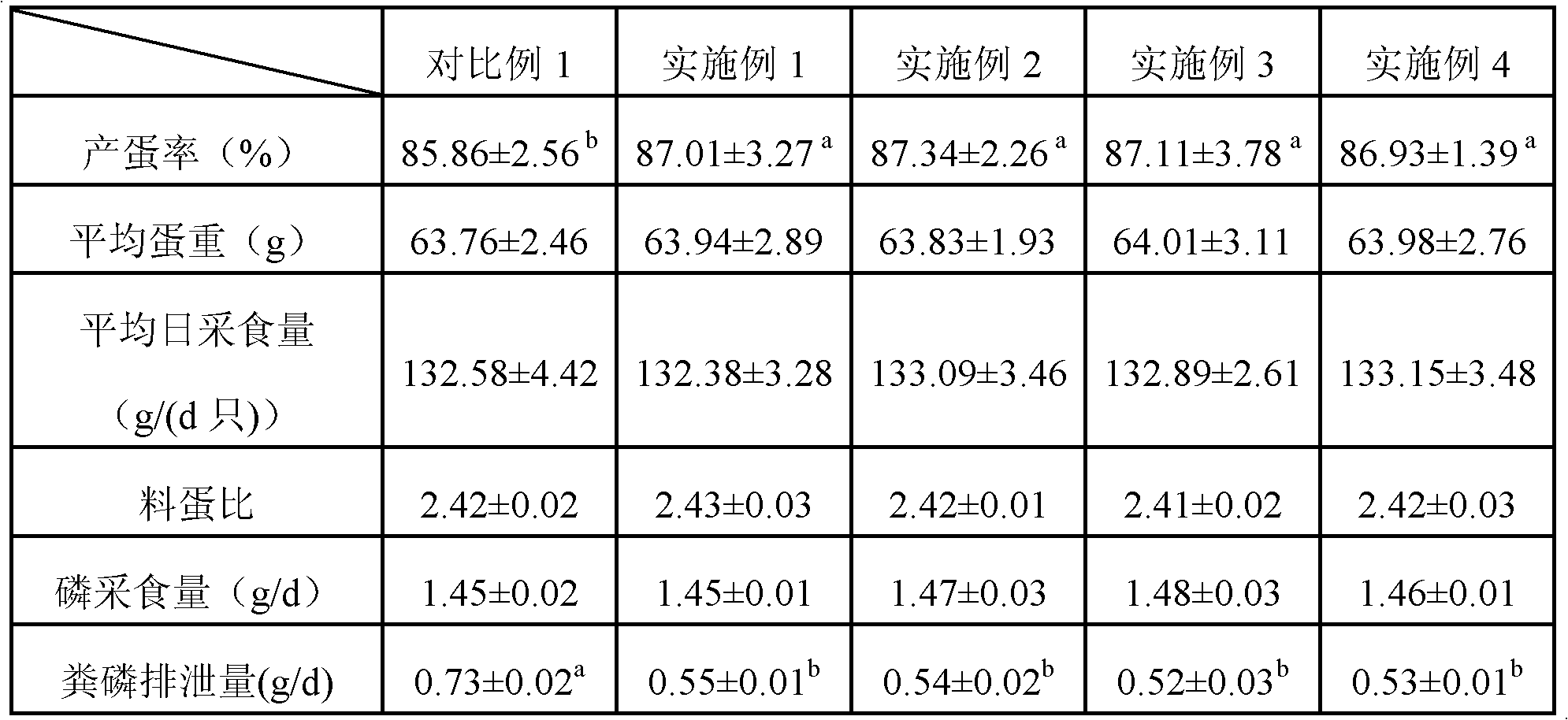

Compound feed for egg-laying duck and preparation method thereof

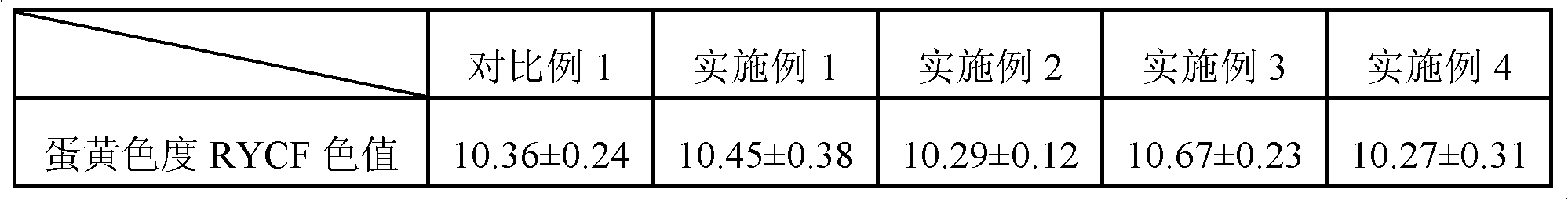

ActiveCN102626187AIncrease egg productionImprove securityFood processingAnimal feeding stuffYolkAnimal science

The invention discloses compound feed for an egg-laying duck and a preparation method thereof. Every 1000kg of the compound feed comprises the following materials: 336-425kg of wheat, 85-150kg of barley, 74.45-94.45kg of wheat middling, 43-100kg of rice bran, 20kg of cotton seed meal, 20kg of rapeseed meal, 15-33kg of corn protein powder, 80-120kg of American DDGS (distillers dried grains with soluble), 50-60kg of soybean meal, 11-15kg of soybean oil, 0.8kg of methionine, 0.75kg of threonine, 4.3kg of lysine, 60kg of rock flour, 20kg of shell powder, 5kg of calcium hydrophosphate powder, 3kg of salt, 1kg of egg-laying duck microelements, 0.2kg of egg-laying duck multiple vitamins, 1kg of choline, 3kg of humic acid, 0.4kg of complex enzyme, 0.1kg of Chang Lexin and 5kg of medlar. The preparation method comprises that the feed is mixed in class and finally a feed product is obtained. The compound feed disclosed by the invention contains no medical additive, reduces drug residue in an animal product and pollution to the environment, enhances safety of the feed and improves chromaticity of egg yolk and laying rate of the egg-laying duck, and minimization on cost input of the feed and maximization on benefits are realized.

Owner:SHANGHAI NONGHAO FEED

Pig fattening feed

InactiveCN101965922AIncrease profitIncrease economic incomeFood processingAnimal feeding stuffVitamin K3Corn meal

The invention relates to a pig fattening feed and belongs to the technical field of animal feeds. The pig fattening feed mainly solves the technical problems of overmuch fatty pork, high cost and low income which are caused by adopting concentrated feed to fast fatten pigs when the pigs are fattened before being taken to markets in the conventional feedlots. The pig fattening feed is prepared by mixing the following raw materials in a certain proportion: corn flour, soybean meal, bran, rock flour, calcium hydroxide, salt and premix, wherein the premix consists of vitamin A, vitamin B1, vitamin B2, vitamin B6, vitamin B12, vitamin D3, vitamin E, vitamin K3, biotin, niacin, calcium pantothenate, folic acid, choline chloride, ferrous sulfate, copper sulfate, manganese sulfate, zinc sulfate, potassium iodide and sodium selenite. The pig fattening feed has the advantages of high feed utilization efficiency, low cost and high income.

Owner:沁源县灵兴养殖专业合作社

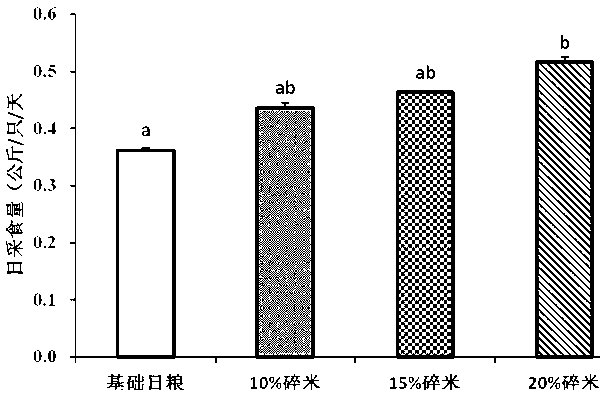

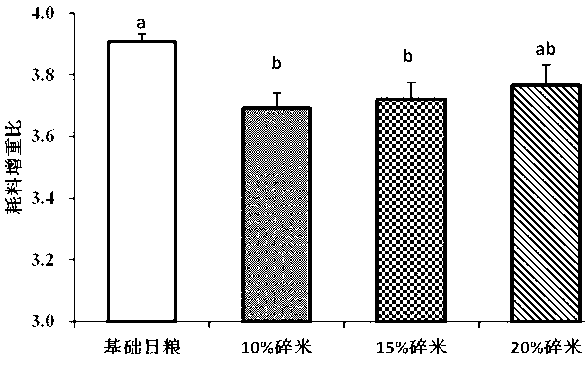

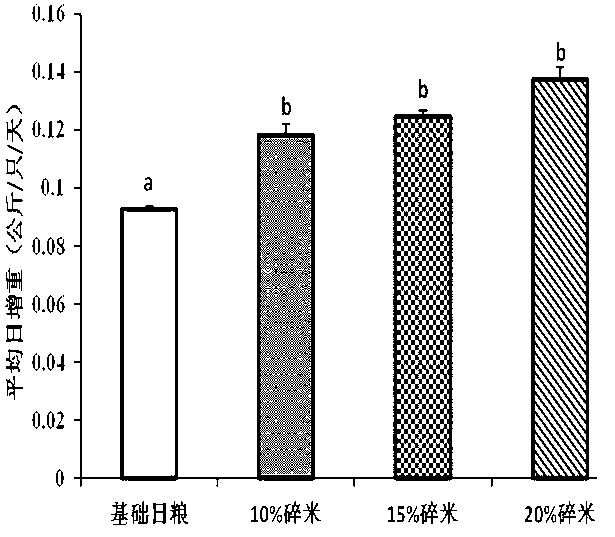

Meat chicken feed and processing method thereof

InactiveCN101991012AAddressing Anti-Nutritional ProblemsImprove digestibilityAnimal feeding stuffAccessory food factorsAnimal scienceFeed conversion ratio

The invention discloses meat chicken feed and a processing method thereof. The feed comprises the following components in percentage by weight: 58 percent of corn, 3 percent of wheat flour, 5 percent of bean pulp, 5 percent of vegetable meal, 5 percent of cotton meal, 5 percent of colza cake, 5.8 percent of peanut cake, 5 percent of bulked soybean, 2.8 percent of corn protein powder, 1.0 percent of lard oil, 1.2 percent of rock flour, 1.5 percent of calcium hydrophosphate, 0.21 percent of edible salt, 0.53 percent of lysine, 0.12 percent of methionine, 0.14 percent of threonine, 0.2 percent of composite bio-enzyme preparation, and 0.5 percent of premix. The processing method comprises: crushing and / or grinding the components of the feed; feeding the raw materials into a mixer for mixing; and packaging the mixed feed in bags. By adding an additive, the feed conversion rate and feed quality stability of the feed are improved and the use amount of mixed meal proteins is reduced; therefore, the cost of the feed is reduced, and the growth performance of the meat chickens can be maintained or improved.

Owner:HENAN MUHE GROUP FEED

Thermoplastic polyurethane floor tile and technique for producing the same

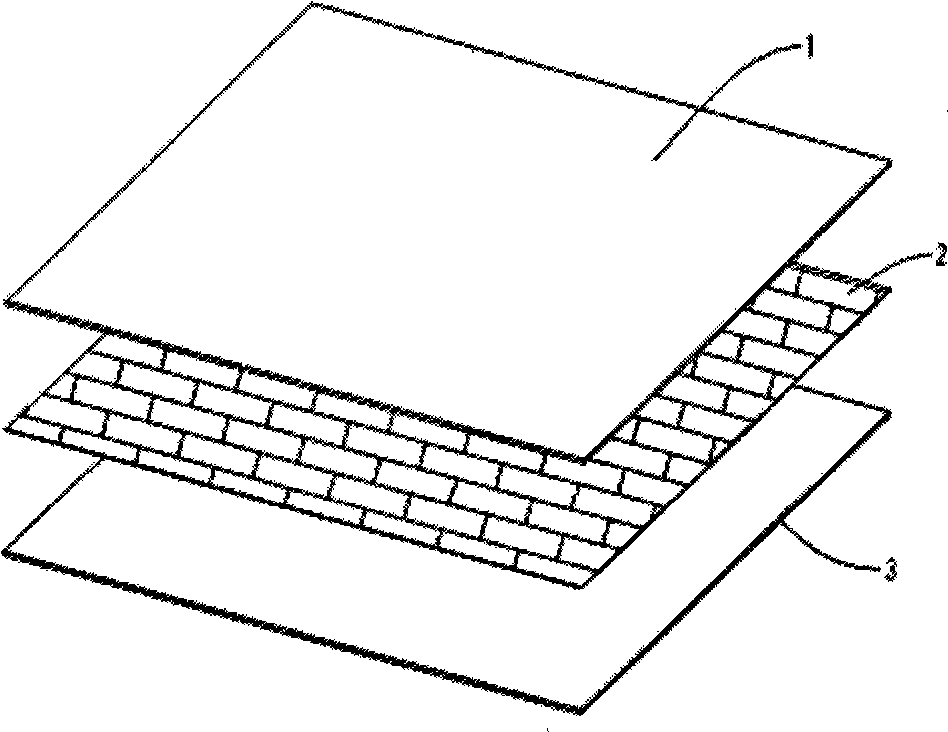

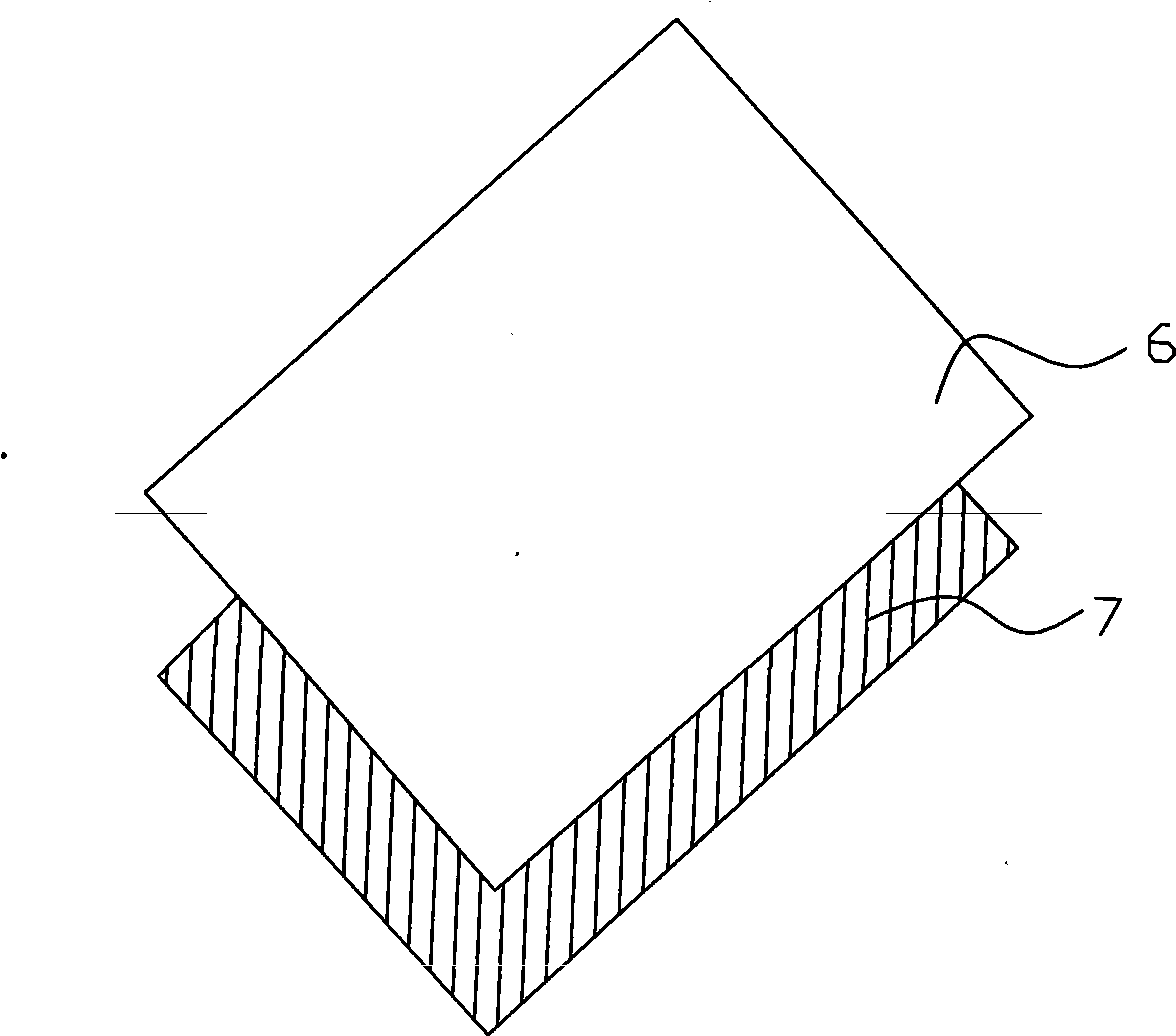

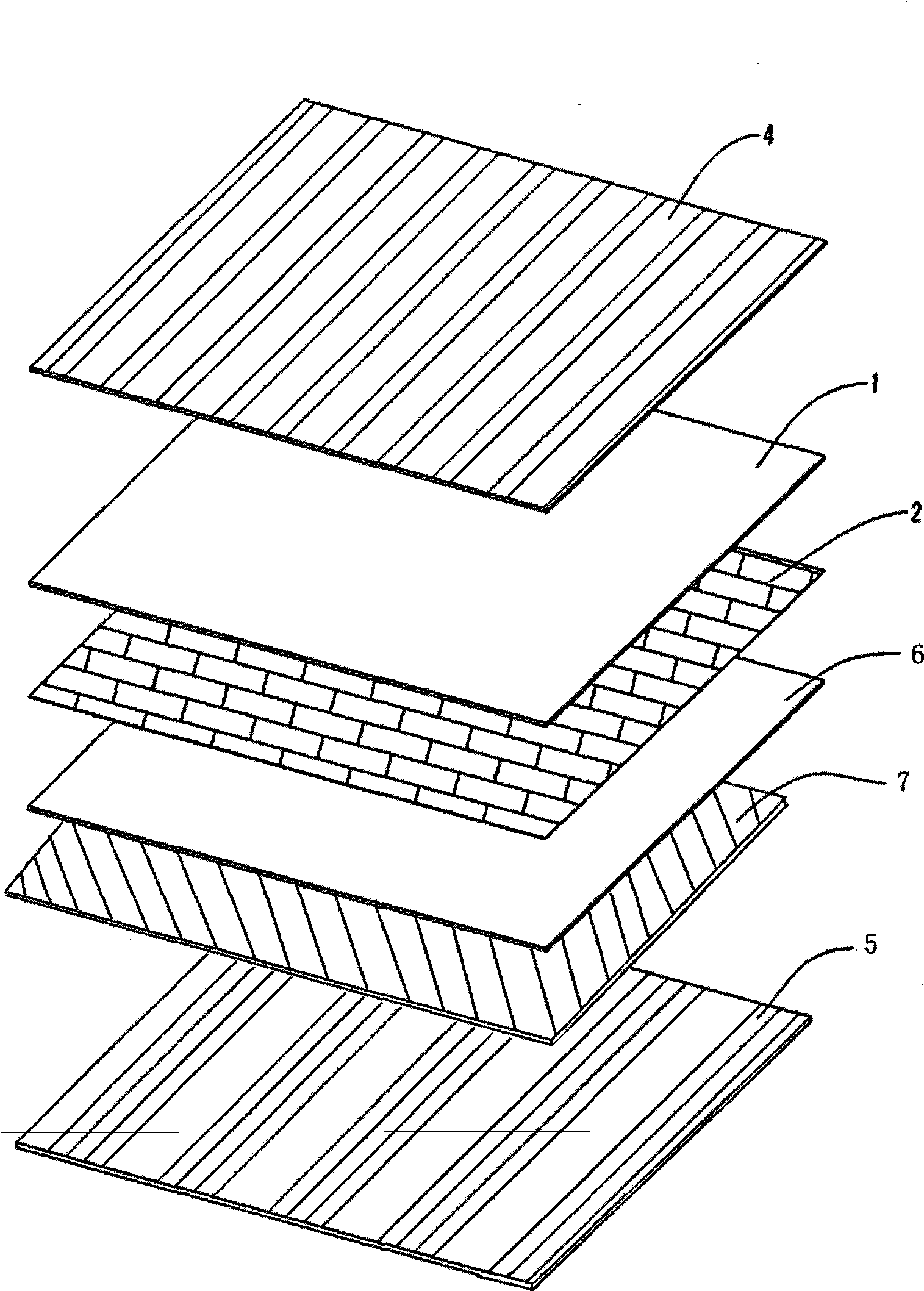

InactiveCN101509313AEasy to processReduce energy consumptionFlooringThermoplastic polyurethaneMoisture absorption

The invention provides a thermoplastic polyurethane floor tile and a producing technique thereof. The floor tile comprises a wearing layer, a printing layer and a base layer, which are compounded together from top to bottom in sequence to be integral, wherein the wearing layer is made of TPU sheets with the thickness of 0.1-2.0mm, the printing layer is made of TPU films with the thickness of 0.05-1.0mm and patterns on the surface, and the base layer is made of sheets mixed and rolled by TPU and rock flour. The producing technique is completed by the following steps: layered material processing, hot pressure laminating semi-finished products slotting and trimming, cleaning and packaging. The hot compounded floor tile of the invention produced by fully using the physical and chemical properties of the thermoplastic polyurethane has characteristics of high surface hardness, wearing resistance, skid resistance, no moisture absorption, no mould, good glossiness, abundant patterns, light weight, simple and convenient construction and recyclability.

Owner:M&L INT

Premixed feed for improving eggshell quality of hyline brower laying hen

ActiveCN102178083AGood colorHigh strengthAnimal feeding stuffAccessory food factorsSodium bicarbonateAnimal science

The invention relates to premixed composite feed for improving eggshell quality of a hyline brower laying hen. The premixed composite feed comprises the following components in parts by weight: calcium hydrophosphate, rock flour, salt, sodium bicarbonate, choline, composite trace element, composite vitamin, lysine, methionine, fish meal, hemocyte protein powder, corn germ meal, probiotics and phytase. The invention can effectively improve the eggshell color and the eggshell intensity and reduce the egg damage rate by 3-5 percent by combining various technologies, preparing various vitamins and trace elements independently and combining the proportion and dosage of the hemocyte protein powder, the sodium bicarbonate, organic iron, and the like, thereby solving the problems of poor eggshellcolor, poor eggshell quality, and the like generated after 200-250 days of egg laying along with the ageing of laying hens in days in the laying hen culture and bringing great economic benefits to culturists.

Owner:荆州市和美华生物科技有限公司

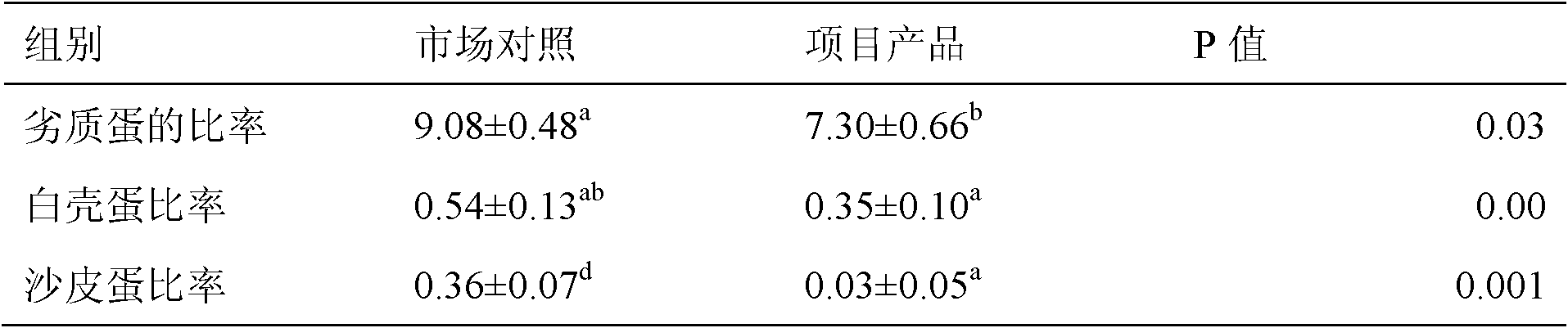

Dense sandstone physical model and manufacture method thereof

The invention provides a dense sandstone physical model and a manufacture method thereof. The method comprises: particle rock flour, epoxy resin in low viscosity and a curing agent are evenly mixed according to a certain ratio and placed into a mold to conduct pressing processing, pressure is over 2MPa, the pressure is maintained so that an even mixture is solidified to a block, and the mixture is taken out and baked to be completely solidified so that a dense sandstone physical model is obtained. According to earthquake physical model technology characteristics and based on relation between practical stratum features and the laboratory model manufacture, the problems may occur in the process of sandstone model design and manufacture are solved so that the technology can be well used for developing sandstone reservoir stratum earthquake wave response simulation research.

Owner:PETROCHINA CO LTD +1

Broiler feed capable of enhancing immunity

InactiveCN104413284AInhibitionAvoid spreadingFood processingAnimal feeding stuffDiseaseBiotechnology

The invention relates to a broiler feed capable of promoting absorption and enhancing immunity. The broiler feed is composed of a main material and traditional Chinese medicine additives, wherein the main material of the feed comprises the following raw material components by weight: 40kg of corns, 5kg of sorghums, 10kg of wheat bran, 4kg of bean flour, 15kg of bean cakes, 2kg of fish meal, 3kg of bone meal, 0.2kg of table salt and 1.2kg of rock flour. The broiler feed has the advantages of rationalizing the ratio of all the raw material components of the feed and adding various traditional Chinese medicine components as the additives on the basis of keeping domestic animals growing in a good condition according to the characteristic that broilers easily suffer from infectious diseases in the growing period, so that the occurrence and propagation of infectious diseases most easily infected by the broilers are effectively inhibited. Meanwhile, the feed also has the effects of helping digestion to remove stasis, reinforcing qi and nourishing blood, expelling parasites, inhibiting bacteria and resisting to diseases as well as improving the disease resistance of an organism, and is capable of avoiding the intake of synthetic auxins and antibiotics, low in toxicity and few in side effect.

Owner:TIANJIN HAOYU KAIMULE TECH

Beef concentrate supplement and preparation method thereof

ActiveCN101919504AFast growthNutritional balanceFood processingAnimal feeding stuffAntioxidantRapeseed

The invention relates to a beef concentrate supplement and a preparation method thereof. The beef concentrate supplement consists of corn, cottonseed meal, rapeseed meal, sesame cake, sunflower seed meal, rock flour, calcium hydrophosphate, soda, rumensin, micro-ecological preparation for raising, rumen bypass fat, rumen bypass lysine, magnesium oxide, antioxidant, molasses and premix special for beef. By strict raw material selection and reasonable formula setting, the beef concentrate supplement has balanced and comprehensive nutrition, strong pertinence and good palatability, and can effectively improve the growth speed of the beef.

Owner:NINGXIA DABEINONG TECH IND

Preparation methods of animal active microecological fermented concentrated feed and compound feed

The invention provides a preparation method of an active microecological fermented concentrated feed. The microecological fermented concentrated feed comprises the following components in percentage by weight: 1.5-5% of wheat bran, 70-90% of bean pulp, 3-5% of cottonseed meal, 5-8% of rapeseed meal, 3-6% of rock flour, 2-3.5% of calcium hydrophosphate, 1-2% of table salt, 0.3-0.7% of trace elements, 0.05-0.1% of compound vitamin, 0.5% of cane sugar prepared by the traditional method and 0.2% of fermentation promoter. The preparation method of the microecological fermented concentrated feed comprises the following steps of: 1, activating strains and preparing disinfectant fluid; 2, mixing the activated strains and the disinfectant fluid with the components, filling the mixture in a fermentation packaging bag and heat-sealing the packaging bag; 3, fermenting for 3-15 days at normal temperature to obtain the finished microecological fermented concentrated feed. In addition, the inventionalso provides a preparation method of an active microecological fermented compound feed and manufacture (preparation) methods of a fermentation packaging bag, fermentation strains and a strain growthpromoter used in the preparation process of the active microecological fermented concentrated feed. Due to adoption of the technology disclosed by the invention, namely a bidirectional-breathe feed packaging fermentation technology based on the designs of the fermentation strains, the strain growth promoter, the fermentation packaging bag and the feed formulas and combining anaerobic fermentationand aerobic fermentation, the prepared feeds have good palatability, high nutritional value and good animal feeding effect and are novel safe feeds without medicines such as antibiotics, hormones andthe like.

Owner:ANLONG KANGTIAN ECOLOGY IND DEV

Suckling pig creep feed

The invention discloses suckling pig creep feed which comprises the following components in percentage by weight: 40.5 to 54.5 percent of swelled corn, 4 to 8 percent of swelled bean pulp, 6 to 11 percent of swelled soy, 4 to 7 percent of fish meal, 4 to 8 percent of plasma proteins, 2.5 to 4 percent of plant oil, 4 to 8 percent of fermented soy, 8 to 12 percent of whey powder, 2 to 3 percent of goldbeater skin protein and 4 to 5.5 percent of a pre-mixed material, wherein the pre-mixed material consists of an additive and a pre-mixing agent; the additive comprises the following components in percentage by weight: 0.1 to 0.2 percent of choline, 0.1 to 0.2 percent of an acidifying agent, 0.5 to 1 percent of sugar powder, 0.1 to 0.15 percent of protease, 0.8 to 1 percent of a mineral additive, 0.15 to 0.2 percent of diaminocaproic acid, 0.1 to 0.2 percent of methionine, 0.25 to 0.35 percent of soda acid, 0.1 to 0.15 percent of vitamin and 0.1 to 0.15 percent of an assistant production agent; and the pre-mixing agent comprises the following components in percentage by weight: 0.5 to 1 percent of rock flour, 1 to 1.5 percent of calcium hydrophosphate and 0.2 to 0.3 percent of salt. According to the suckling pig creep feed, the cost of the feed can be reduced; the immunity of suckling pigs can be improved; and the appetite of the suckling pigs can be promoted.

Owner:HAINING ZHENONG FEED

Premixed feed for micro-ecological wheat middling type pigs

InactiveCN102178104AImprove digestive systemLow costAnimal feeding stuffAccessory food factorsBiotechnologyPhytase

The invention relates to a feed using wheat middling instead of all corn and partial bean pulp in compound feed raw materials for pigs. The feed comprises the following components in parts by weight: 300 to 500 parts of two-starter apozymase, 3 to 5 parts of probiotics, 60 to 80 parts of composite trace elements, 6 to 8 parts of vitamin complex, 30 to 50 parts of grease, 13 to 15 parts of phytase, 60 to 80 parts of lysine, 4 to 6 parts of sweetener, 80 to 120 parts of calcium hydrophosphate, 8 to 12 parts of choline, 80 to 100 parts of edible salt, 80 to 100 parts of medical stone, and 60 to 120 parts of rock flour. In the feed, micro-ecological preparations (namely the two-starter apozymase and probiotics) are added into the feed, and can sufficiently lead the pigs to digest and absorb wheat middling, so that users can use the wheat middling serving as an energy protein raw material instead of all the corn and partial bean pulp, the feed cost is remarkably reduced, and the economical benefit is remarkably improved.

Owner:TAIAN XINKE FEED

Low-protein compound feed for geese

ActiveCN103141698AMeet growth needsIncrease appetiteFood processingAnimal feeding stuffBiotechnologyAnimal science

The invention provides a low-protein compound feed for geese. The low-protein compound feed contains the following raw materials in parts by weight: 30-41 parts of corn, 21-25 parts of rice bran meal, 10-20 parts of broken rice, 5 parts of wheat bran, 5 parts of flour, 5 parts of tapioca, 5 parts of corn wine dregs, 2-3 parts of bean pulp, 1.2 parts of rock flour, 1 part of calcium hydrophosphate, 1 part of salt, 1 part of sulfate lysine, 1 part of a mineral substance premix for the geese and 1 part of vitamins for the geese. The preparation of the feed comprises the steps of: weighing the raw materials according to a proportioning, putting the raw materials in a stirrer, and completely stirring and mixing the raw materials, so as to obtain a finished product. The low-protein compound feed for the geese is low in feed cost, rich in various nutrition ingredients, and capable of enhancing the appetite of the geese, so that the geese can grow more fast and the female geese can lay more eggs after eating the low-protein compound feed. Besides, the immunity function of the geese is greatly enhanced and the disease prevention capability, the curing capability and the anti-virus capability of the geese are enhanced after the geese eat the compound feed.

Owner:GUANGDONG YUWEI AGRI GRP +1

Feed for mouth-open period of chickens as well as preparation method and application method thereof

ActiveCN102178090ANutritional balanceImprove digestibilityFood processingAnimal feeding stuffBiotechnologyWeight gaining

The invention discloses a feed for mouth-open period of chickens as well as a preparation method and an application method thereof. The feed for the mouth-open period of the chickens is prepared from the following raw materials in parts by weight: 50-70 parts of corn, 25-35 parts of dehulled soybean meal, 2-4 parts of grain dust, 2-4 parts of maize protein powder, 0.2-0.6 part of lysine, 0.1-0.5 part of methionine, 1.0-3.0 parts of calcium hydrophosphate, 0.8-2 parts of rock flour, 1-3 parts of soybean oil, 0.35 part of salt, 1 part of a chicken premix, 0.1 part of composite micro-ecological inoculum for poultry, 0.01 part of complex enzyme for poultry and 0.02 part of a colorant. The feed for the mouth-open period of the chickens can be applied to chickens which are 1-5 days old. Tests prove that the feed for the mouth-open period of the chickens has a feeding attraction effect on the newly hatched chickens, can be used for reducing the diarrhea rate and death rate of the chickens and is beneficial to the weight increment of the chickens.

Owner:云南西南农牧集团股份有限公司 +2

Special concentrated compound nutritive licking block for Tibet yak and manufacturing method thereof

InactiveCN102172263AAvoid deathImprove aestheticsAnimal feeding stuffWorking-up animal fodderBrickQuinoline

The invention discloses a special concentrated compound nutritive licking block for Tibet yak and a manufacturing method thereof. The concentrated compound nutritive licking block is prepared from the following raw materials in parts by weight: 300-450 parts of gelatinized corn urea, 100 parts of virus-free rapeseed cakes, 100 parts of brewex's grains, 150 parts of green syrup, 50-100 parts of attapulgite clay, 50 parts of rock flour, 20-40 parts of tannin, 55 parts of table salt, 100 parts of calcium hydrophosphate, 0.02 parts of potassium iodide, 6 parts of magnesium oxide, 6.3 parts of potassium chloride, 0.15 part of ferrous sulfate, 0.34 part of monohydrate zinc sulphate, 0.125 part of anhydrous cupric sulfate, 0.07 part of manganese sulfate, 0.025 part of cobalt chloride, 0.01 part of sodium selenite, 5-10 parts of acetoxy quinoline acid, and 25-50 parts of modified starch. The invention provides a preparation process of the licking block. The licking block provided by the invention has the advantages of comprehensively supplementing the energy, proteins, and various lacked mineral nutritive elements of yak in winter and spring and effectively improving the production properties and snowstorm resisting ability of the yak.

Owner:LANZHOU UNIVERSITY

Special fodder for goose fattening stage

InactiveCN105076782AHigh energyHigh protein contentFood processingAnimal feeding stuffAnimal sciencePhytase

The invention discloses special fodder for the goose fattening stage. The special fodder comprises, by weight, 10-20 parts of corn, 20-30 parts of wheat, 15-30 parts of rice bran, 0.5-2 parts of lard oil, 2-5 parts of sweet potato leaves, 1-2 parts of grape seed oil, 10-30 parts of corn protein powder, 1-2 parts of fish meal, 1-3 parts of soybean protein concentrate, 5-10 parts of chrysanthemum dregs, 5-15 parts of dried blood, 2-6 parts of fermentation biological protein, 0.5-1.5 parts of feather meal, 2-5 parts of cotton dregs, 5-15 parts of maize germ pulp, 0.5-2 parts of rock flour, 1-5 parts of se-enriched yeast, 2-6 parts of Chinese herbal medicine additives, 0.2-0.8 part of compound enzyme, 0.2-0.8 part of phytase, 0.01-0.04 part of white ginseng, 0.1-0.5 part of armillaria mellea, 0.01-0.05 part of rhizopus oryzae, 0.02-0.08 part of lysine and 0.02-0.09 part of methionine. The special fodder is green, healthy, balanced in nutrition, remarkable in weight put-on effect and low in cost.

Owner:ANHUI BAIXIN FEED CO LTD

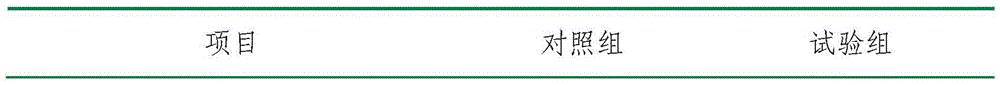

Complete formula feed capable of improving growth performance and meat quality of pigs

InactiveCN104323044AFast growth performanceImprove qualityAnimal feeding stuffBiotechnologySodium bicarbonate

The invention discloses complete formula feed capable of improving growth performance and meat quality of pigs. The complete formula feed comprises the following raw materials in parts by weight: 50-60 parts of corn, 8-12 parts of 43% bean pulp, 9-16 parts of wheat bran, 5-7 parts of middlings, 2-4 parts of peanut meal, 3-5 parts of rice bran meal, 2-4 parts of cottonseed meal, 1-3 parts of soya-bean oil, 1.2-1.3 parts of calcium hydrophosphate, 0.9-1 part of rock flour, 0.4 part of table salt, 0.1 part of sodium bicarbonate, 0.2 part of probiotics, 0.5-0.7 part of 65% lysine, 0.05 part of threonine, 0.05 part of 30% ethoxyquin, 0.01 part of high-temperature phytase 5000, 0.05 part of a mildew preventive and 1 part of premix. By virtue of the complete formula feed, the growing and fattening pigs have high growth performance on the basis of energy protein balance, calcium and phosphorous homeostasis, amino acid balance and electrolyte balance; the pork quality can be improved; the feed reward can be improved; the feeding cost can be reduced; high-quality pork can be obtained; therefore, the live pig feeding economic benefits are increased.

Owner:HENAN UNITED INVE FEEDSTUFF

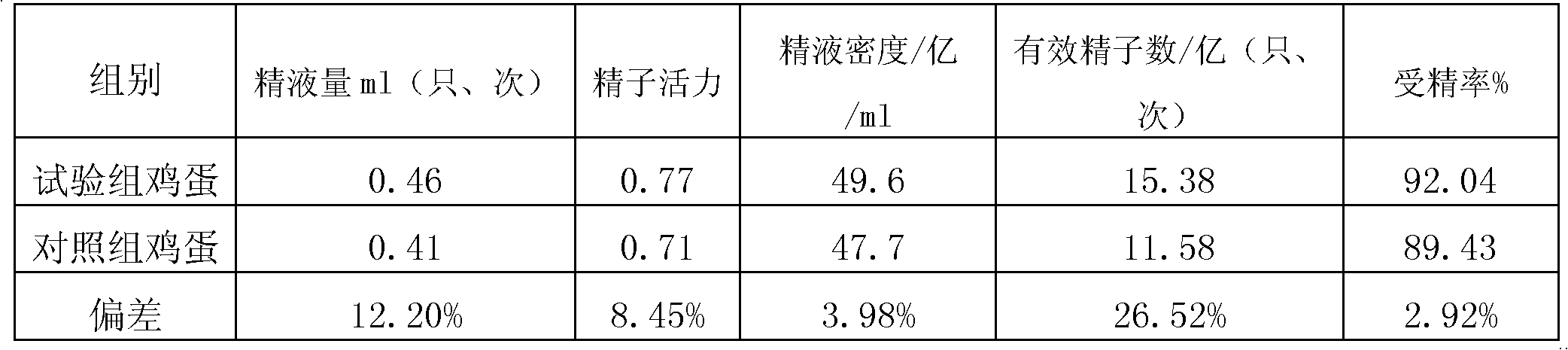

Feed for egg breeding cock

ActiveCN102178082AIncrease semen volumeImprove qualityAnimal feeding stuffAccessory food factorsBetaineAnimal science

The invention relates to a feed for egg breeding cocks. The feed consists of the following components in parts by weight: 220-260 parts of calcium hydrophosphate, 200-260 parts of rock flour, 50-60 parts of salt, 2-6 parts of betaine, 18-20 parts of choline, 40-45 parts of compound trace elements, 10-12 parts of compound vitamin, 25-30 parts of methionine, 300-420 parts of medical stone, 0.5-1 part of yeast chromium, 1-3 parts of bacillus subtilis, 1-3 parts of phytase and 2-5 parts of complex enzyme preparation. In the invention, nutritive additives and the like are added in the feed, thus producing the feed for egg breeding cocks; and the feed for egg breeding cocks can improve the semen volume and quality of the cocks so as to improve the fertilization rate, thus enhancing the benefit of poultry farms.

Owner:荆州市和美华生物科技有限公司

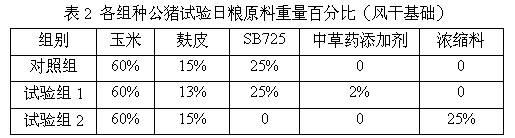

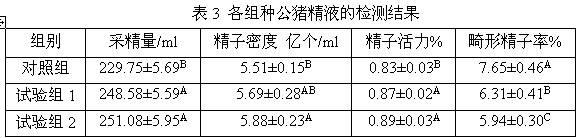

Chinese herbal medicinal additive for stock boar and concentrate feed containing same

ActiveCN102077927AIncrease the number ofIncrease vitalityAnimal feeding stuffBiotechnologyCalcium biphosphate

The invention relates to a Chinese herbal medicinal additive for stock boar and a concentrate feed containing the same. The Chinese herbal medicinal additive comprises the following raw materials in percentage by weight: 4 to 5 percent of epimedium herb, 4 to 5 percent of actinolite, 4 to 5 percent of motherwort herb, 3 to 4 percent of nutgrass galingale rhizome, 3 to 4 percent of south dodder seed, 3 to 4 percent of Chinese angelica, and 74 to 76 percent of bran shell powder. The concentrate feed contains the Chinese herbal medicinal additive, bean pulp, fish meal, fat powder, calcium hydrophosphate, rock flour, table salt, and the mineral elements of iron, copper, zinc, manganese, potassium and the like, and the auxiliary materials of frankincense type flavoring agent, antioxidant, mildew preventive, bran shell powder, zeolite powder and the like. The Chinese herbal medicinal additive or the concentrate feed can prevent the feet and leg problem of the boar, has the effects of enhancing vitality, feet and a body when added into the daily foundational diets of the stock boar, improves reproductive abilities and body immunity functions of the boar and prolongs the stock using age so as to greatly improve the economic benefit of farms.

Owner:河南雄峰科技股份有限公司

Light and high-strength wallboard made from fiber reinforced concrete and preparation method thereof

InactiveCN101713236AReduce usageImprove utilizationConstruction materialSolid waste managementCelluloseDecomposition

The invention relates to a light and high-strength wallboard made from fiber reinforced concrete which takes 30-40% of cement, 25-35% of rock flour, 20-30% of pulverized fuel ash, 5-9% of plant fiber, 1-3 per mill of concrete fiber, 1-1.5 per mill of white emulsoid, 1-1.5 per mill of acid amides, 3-5 per mill of cellulose calcium and 1-1.5 per mill of calcium stearate as raw materials. The plant fiber is paper fiber and / or straw fiber. Water is added to mix all the materials, so that the mixture obtains very good plasticity; then the mixture gets through the vacuum extruder and is squeezed out through a die orifice, forming a plate with a section; then the plate is cut into plates with a certain length, which are conveyed to a curing room for curing and molding. With the preparation method of the invention adopted, production processes can be reduced, waterproof and heat-preservation effect can be bettered, production cost can be lowered and pollution sources can be precluded. In addition, wasted paper at home can be used to replace the wasted paper imported from abroad so as to obtain cellulose produced by deliberation decomposition treatment, thus improving use ratio of straw and enjoying remarkable economic and social benefits.

Owner:陈兆平

Method for producing ecologic eggs rich in iodine and selenium

InactiveCN101578965AExcellent indicatorsPromote digestionAnimal feeding stuffAccessory food factorsBiotechnologyIodine

The invention relates to a method for producing eggs rich in microelements, in particular to a method for producing ecologic eggs rich in iodine and selenium, which comprises: selecting chickens with green shells; and using a concentrated feed comprising 65 portions of corns, 21 portions of soybeans, 8 portions of rock flour, 2.5 portions of proteins and 2 portions of calcium hydrophosphate to feed the chickens until the chickens can lay eggs. The method reserves important microelements and vitamins which are needed by human bodies in the green food ecologic eggs by a biological transformation method. The ecologic eggs can be digested and absorbed by human bodies, have a good taste and are the high-quality healthy food desired by people in the recent years.

Owner:KUNMING ZHAOGULONG STOCKBREEDING

Concentrated feeds for nursery pigs and preparation method

InactiveCN102028119ADealing With DiarrheaWeakened immunityFood processingAnimal feeding stuffBiotechnologyAntigen

The invention discloses 40 percent concentrated feeds for nursery pigs and a preparation method. The concentrated feeds comprise components such as dehulled soybean meal, low-antigen enzymatic vegetable protein, fish meal, choline chloride, an acidulant, an odorant, a flavor enhancer, decavitamins for piglets, composite organic trace elements for the piglets, lysine, methionine, probiotics such as lactic acid bacteria and yeasts, dicalcium phosphate, vegetable oil and rock flour. The feeds are convenient to use, use a small amount of antibiotics, not absorbed by the feeds, special for animals so as to ensure food safety, use the organic trace elements with higher bioavailability, do not contain high calcium, high phosphorus, high copper and high zinc, realize environmental friendliness, and can be prepared into perfect compound feeds for the nursery pigs by adding corn meal into the suggested formula for uniform mixing so as to completely satisfy the needs of the nursery pigs in nutrition, completely develop the growth potential of the nursery pigs and enhance economic performance.

Owner:北京资源亚太饲料科技有限公司

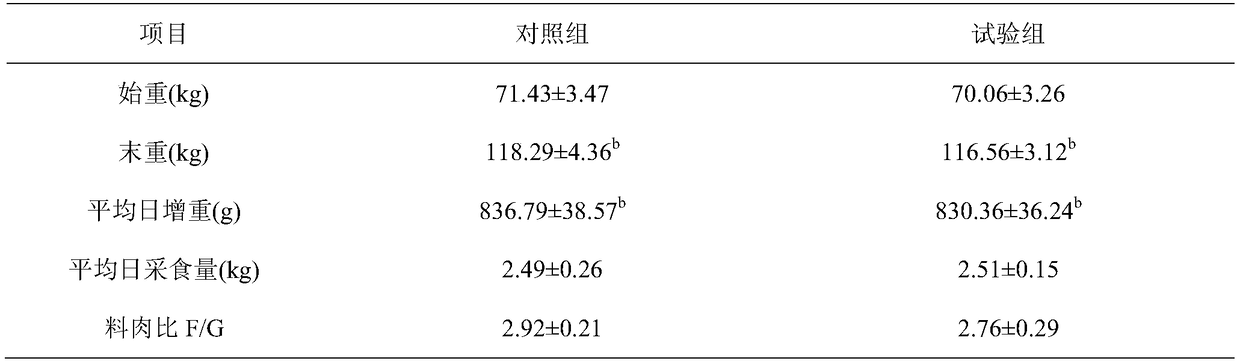

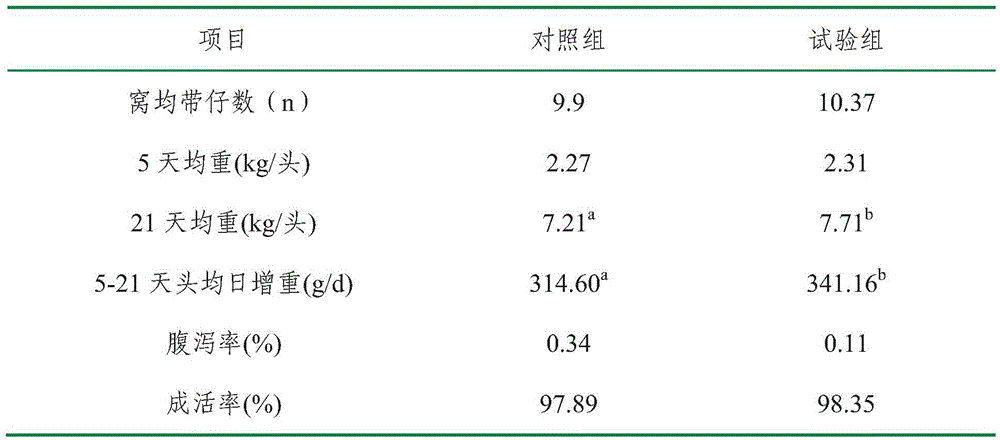

Special non-resistant low-protein broussonetia papyrifera fermented feed for finishing pigs and preparation method thereof

The invention discloses special non-resistant low-protein broussonetia papyrifera fermented feed for finishing pigs. The special non-resistant low-protein broussonetia papyrifera fermented feed is prepared from the following raw materials: maize, broussonetia papyrifera fermented materials, buckwheat short flour, soybean meal, cottonseed protein powder, grape seed meal, maize embryo meal, mulberryleaf powder, rock flour, 0.5 percent of composite multivitamins and composite multi-minerals for the finishing pigs, radix glycyrrhizae powder, feed-grade sodium chloride, acremonium terricola cultures, calcium hydrogen phosphate, coated cysteamine, chromium picolinate, meaical stone, expanded linseed, composite organic ferric agent, protease K, lactase, lysine, methionine, threonine, tryptophane, valine and sodium glutamate. The invention provides a preparation method of the special non-resistant low-protein broussonetia papyrifera fermented feed. The special non-resistant low-protein broussonetia papyrifera fermented feed and the preparation method of the special non-resistant low-protein broussonetia papyrifera fermented feed have the beneficial effects that by adopting the broussonetia papyrifera fermented feed, an utilization ratio of nutrient substances of feed raw materials can be increased, anti-nutrition factors are passivated, beneficial microorganisms are greatly bred and enriched, improvement and increase of quality of pork are promoted, a formula of the feed is reasonable, the cost is low, energy conservation and environmental protection are achieved, the growing-finishing effect is obvious, the pork is healthy, and the flavor is good.

Owner:GANSU AGRI UNIV

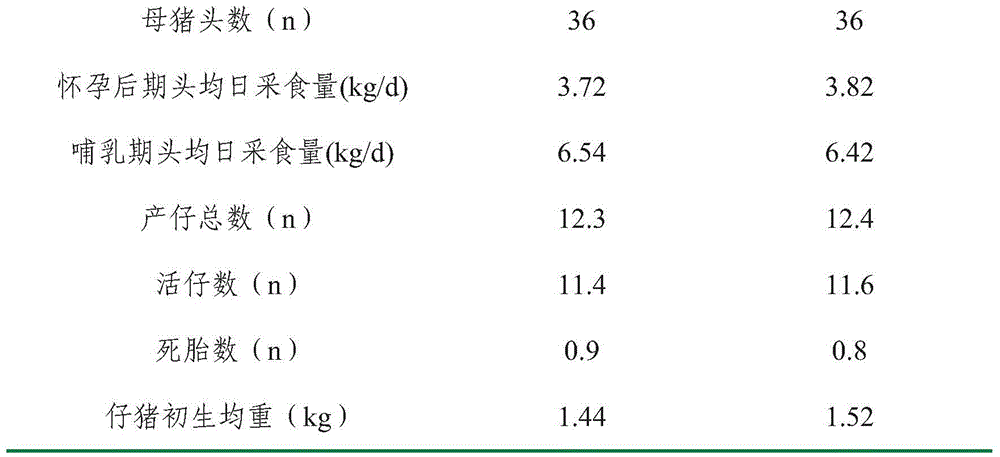

Compound lactating sow feed rich in omega-3 polyunsaturated fatty acid

InactiveCN105614101AGood detox effectImprove digestion and absorption rateFood processingAnimal feeding stuffAnimal scienceOMEGA-3 POLYUNSATURATED FATTY ACIDS

The invention provides compound lactating sow feed rich in omega-3 polyunsaturated fatty acid and improving the growth performance of the piglets. The feed is prepared from 300-700 parts of corn, 150-300 parts of soybean meal, 0-400 parts of wheat, 25-100 parts of bran, 25-50 parts of puffed flax seeds, 0-100 parts of degreased rice bran, 0-100 parts of DDGS, 0-50 parts of fish meal, 5-30 parts of soybean oil, 5-7 parts of calcium hydrophosphate, 10-15 parts of rock flour, 2.5-4.5 parts of salt and 10 parts of a premixed material. The feed can improve lactating capacity of sows, improve the growth performance of the piglets and improve immunity by increasing nutrition of the sucking piglets and therefore improve production efficiency.

Owner:ANYOU BIOTECH GRP

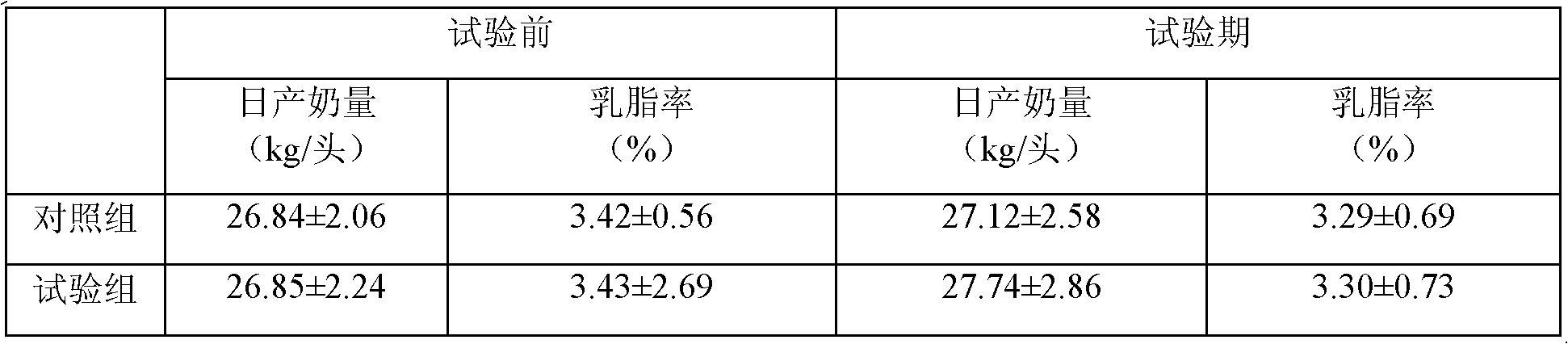

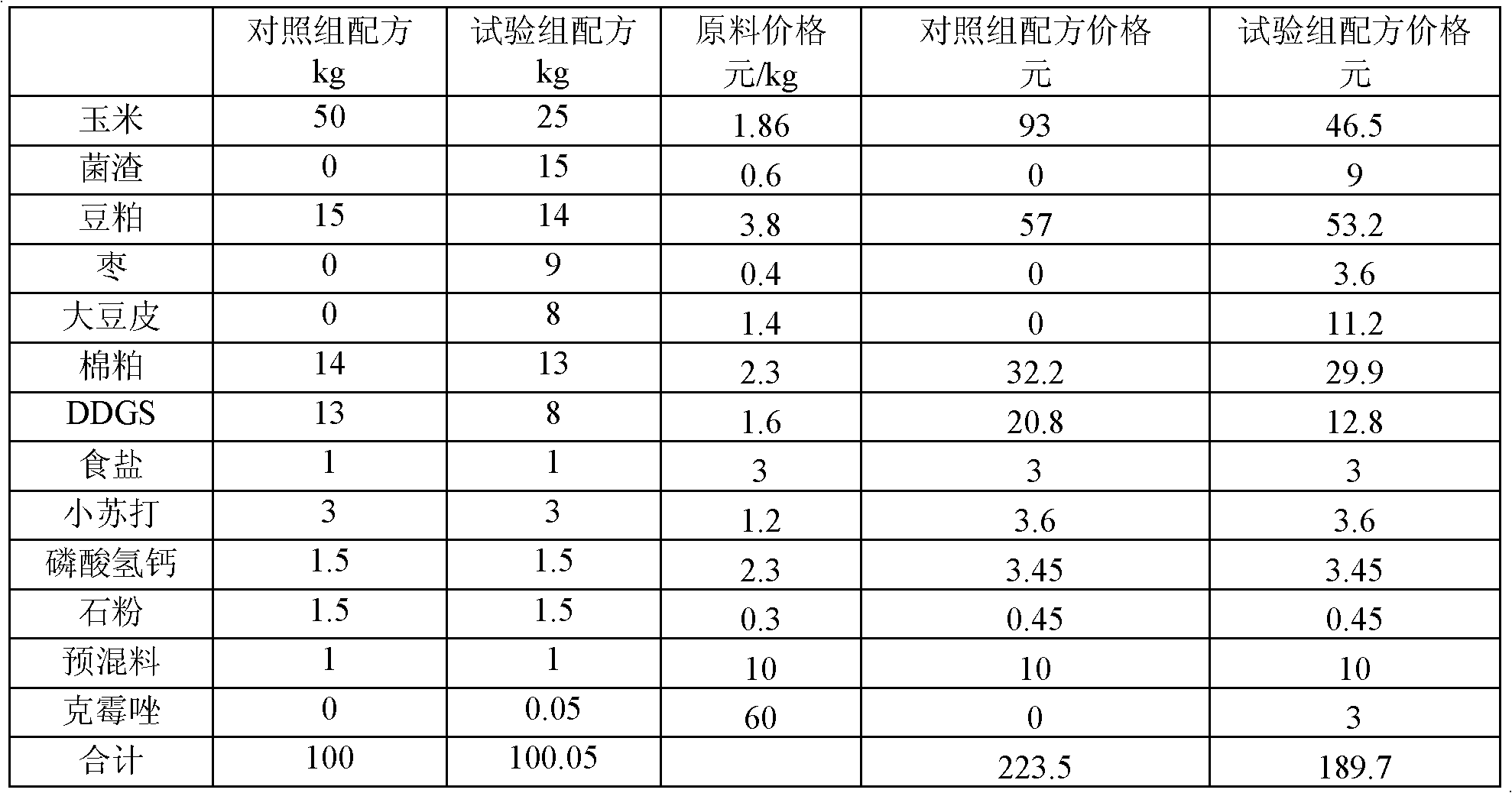

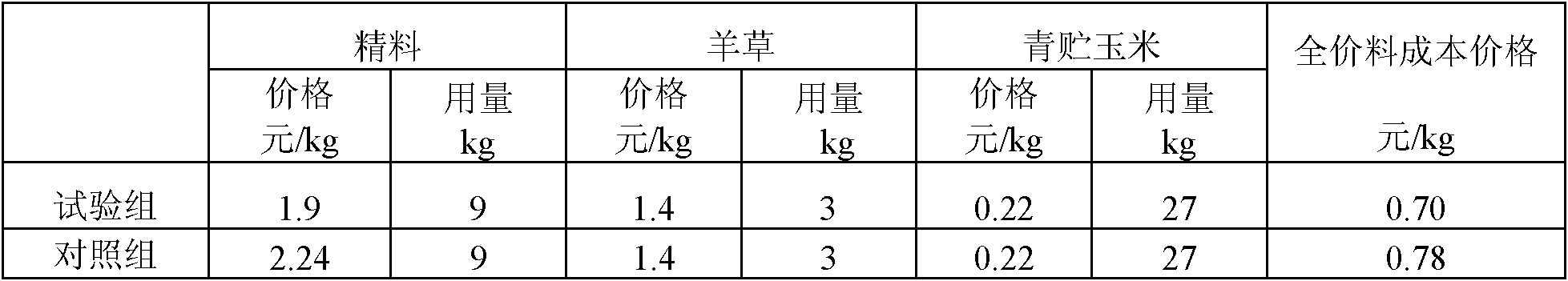

Needle mushroom fungus dreg feed for dairy cow

InactiveCN102125182ARealize added valueHarm reductionFood processingAnimal feeding stuffMycotoxinAdditive ingredient

The invention relates to a needle mushroom fungus dreg feed for a dairy cow. The needle mushroom fungus dreg feed is prepared by uniformly blending a needle mushroom fungus dreg concentrated feed for the dairy cow and a coarse feed in a weight ratio of (8-11):30, wherein the needle mushroom fungus dreg concentrated feed for the dairy cow is prepared from corn, needle mushroom fungus dreg, bean pulp, whole-grain inferior jujubes, soybean hulls, cottonseed meal, distillers dried grains with soluble (DDGS), salt, baking soda, calcium hydrophosphate, rock flour and premix in a certain proportion. In the invention, the needle mushroom fungus dreg feed for the dairy cow with balanced nutrient components is produced by the needle mushroom fungus dreg which is produced industrially and is used for partially replacing the corn and the bean pulp and performing compatibility on agricultural byproduct abandonment raw materials such as the soybean hulls, the whole-grain inferior jujubes, the DDGS and the like, antimold agents and the like; and the harm of mycotoxin is reduced, the feed utilization of large-scale fungus dreg is promoted, the cost of the concentrated feed for the dairy cow is obviously reduced, and the value of the fungus dreg is increased.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT SHANDONG ACADEMY OF AGRI SCI

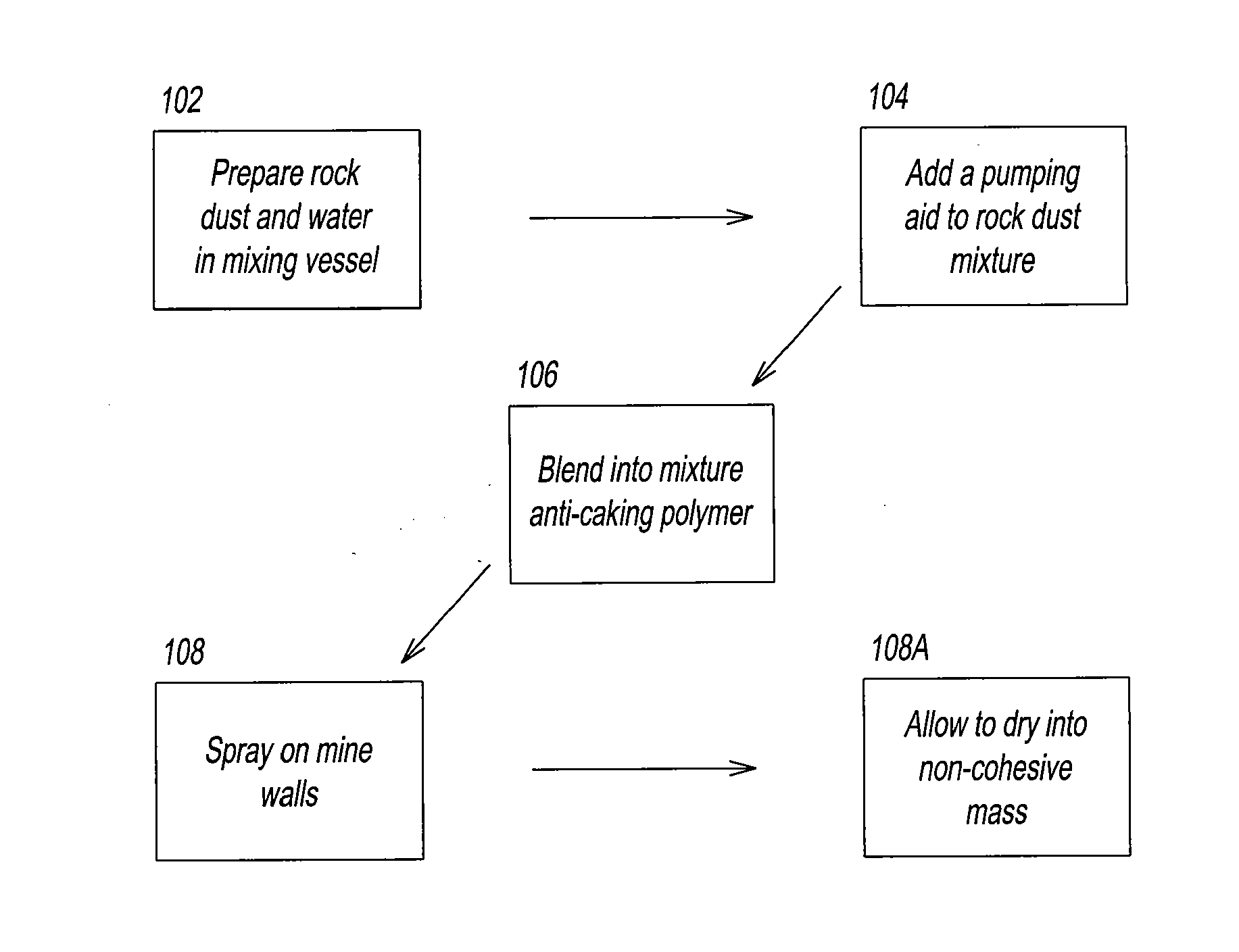

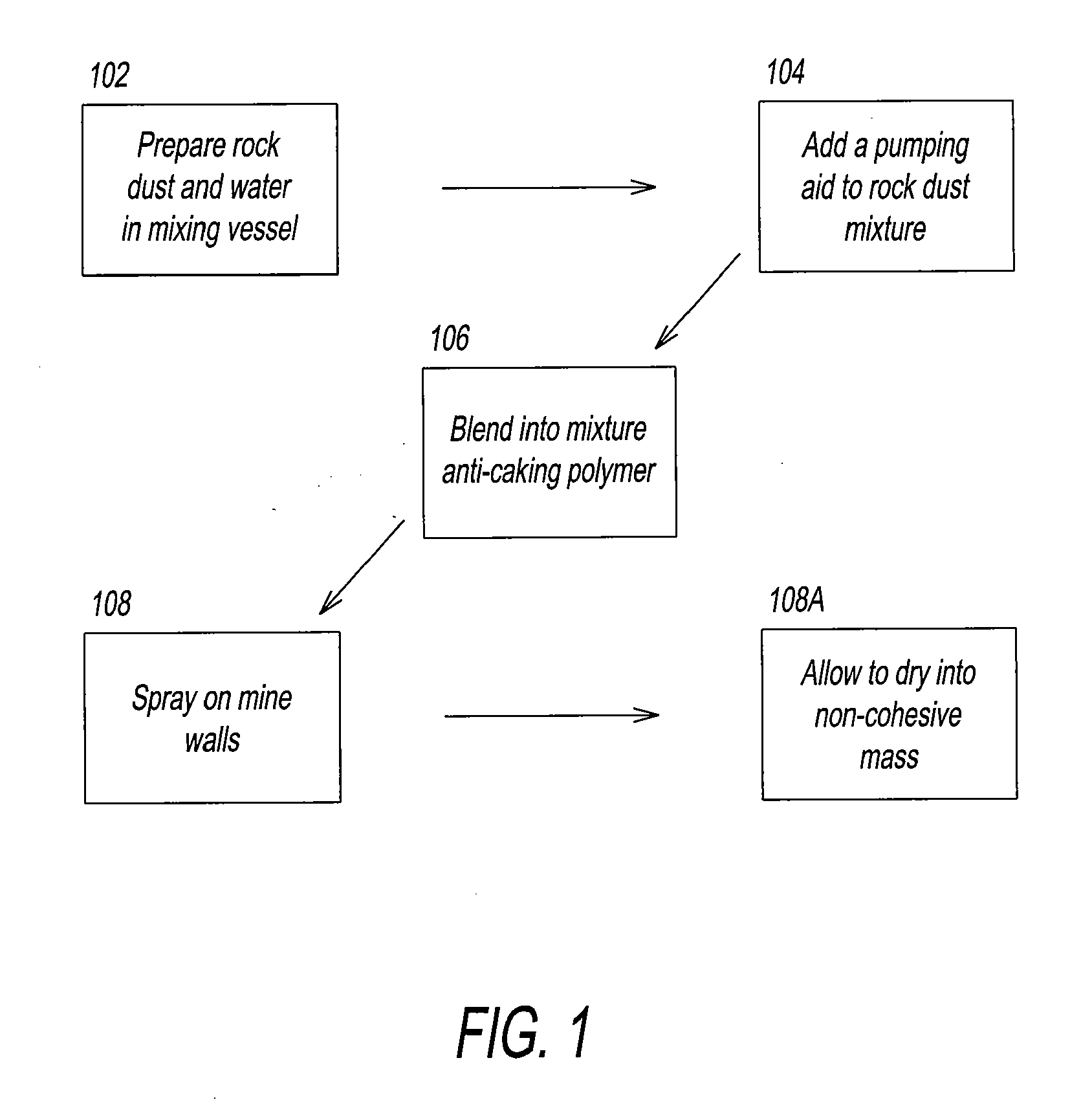

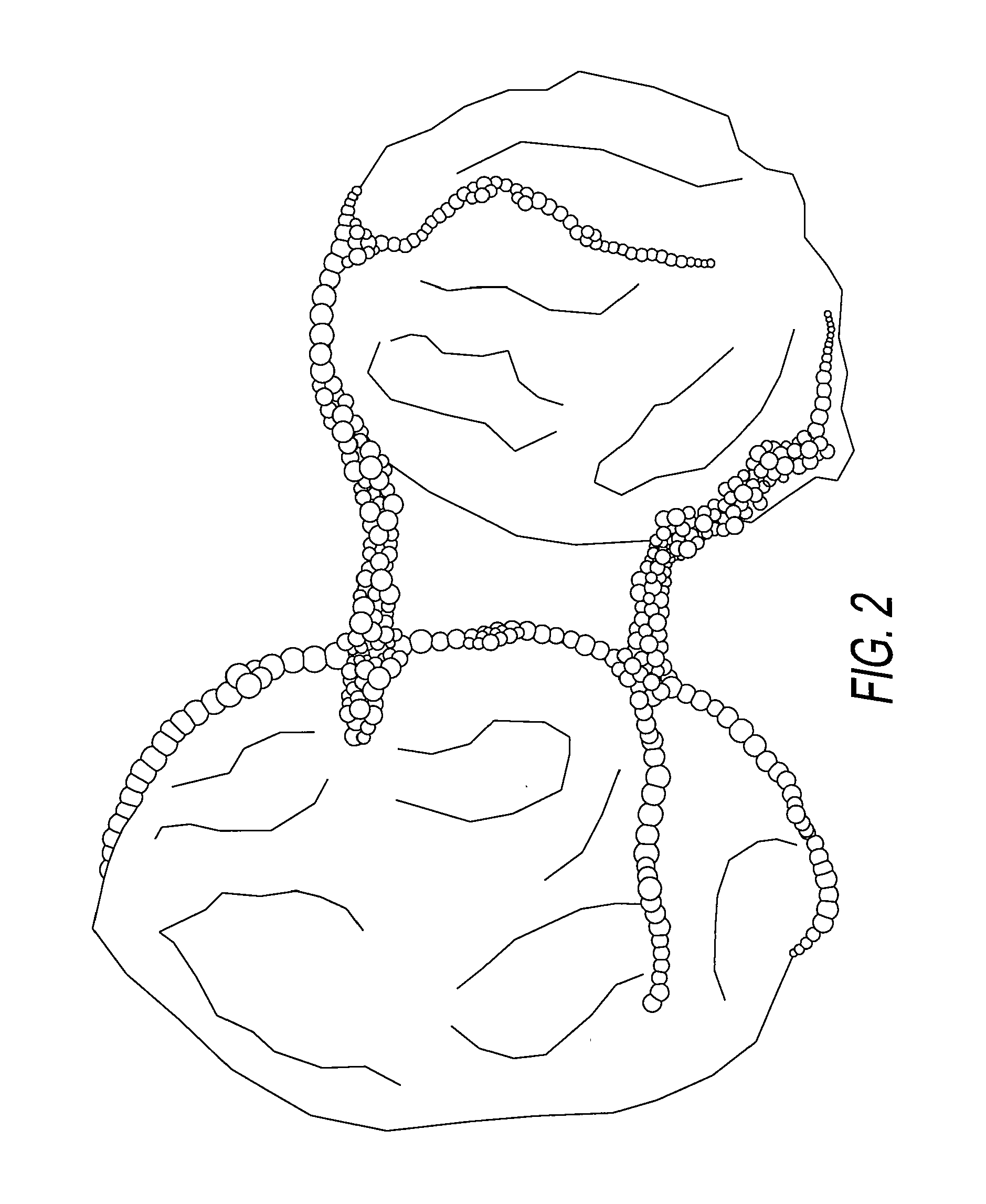

Rock dusting compositions and methods of use thereof

ActiveUS20120181051A1Prevent the spread of flamesSolve the lack of adhesionPretreated surfacesFire rescueMineral dustMining engineering

A rock dusting composition composed of rock dust, e.g., limestone or other mineral dust, water, pumping aid, and polymer, e.g., acrylamide homopolymers, acrylamide copolymers, and combinations thereof, and a method for applying the composition to the surface of a mine. The composition has a water content and a polymer content sufficient to allow the polymer to (i) disperse water molecules within the composition and, upon drying of the composition, (ii) dissipate forming void spaces in the dried composition. The composition is useful for suppressing propagation of a flame and / or fire caused by ignition of coal dust and / or gas within a coal mine.

Owner:DSI UNDERGROUND IP HLDG LUXEMBOURG S A R L

Spotted deer feed additive

InactiveCN101912054AIncrease profitFast growthAnimal feeding stuffAccessory food factorsCysteamineFeed additive

The invention provides a spotted deer feed additive. The additive for basic feed comprises the following components by mass: 100 to 300 grams of complex enzyme, 250 to 2,000 grams of amino acid-trace element chelate, 35 to 55 grams of cysteamine, 500 to 800 grams of sodium chloride, 180 to 1,500 grams of vitamins, 1 to 2 kilograms of fish bone meal, 200 to 450 grams of astragalus root, 50 to 300 grams of sodium selenite-vitamin E premix, 20 to 60 grams of rock flour, 10 to 30 grams of zeolite powder, 10 to 20 grams of honey and 15 to 25 grams of carotene. The spotted deer feed additive is specially used in artificial raising and propagating of spotted deer. The additive has green, environmentally-friendly and pollution-free effects and effects of effectively balancing and coordinating with various nutrients in the feed and improving growth speed, feed utilization rate and productive performance. In the invention, expensive apparatuses are not used, the operation is simple, the use is convenient, the raw materials are readily available and the cost is low.

Owner:HEILONGJIANG ACAD OF SCI INST OF NATURAL RESOURCES

Waste earth and coal gangue fired hollow brick

InactiveCN105669167AReduce consumptionIntrinsic quality is stableCeramic materials productionClaywaresFiberCarbon fibers

A waste earth and coal gangue fired hollow brick is characterized by being made from the following components according to parts by weight: 40% of sludge, 25% of waste rock flour, 20% of coal gangue, 0.5% of plant straw powder, 3% of modified ceramic powder, 3% of sea mud, 1.5% of colored stone sand, 1.5% of violet sand, 0.5% of polyurethane powder, 0.5% of wood-plastic powder, 1.5% of aluminum silicate fiber, 1.5% of borax, 0.5% of sepiolite powder, 0.5% of carbon fiber, and 0.5% of kaolin.It is possible to save consumption of raw materials and ensure intrinsic quality stability of a formed blank; forming pressure is high, and blank strength is high; self-heat of the coal gangue is used in combustion, saving energy and reducing pollution; the coal gangue hollow brick produced by the process of the invention reduces self-weight of a building structure, improves building functionality and has good thermal insulation and acoustic insulation.

Owner:JINZHAI GAOFENG NEW BUILDING MATERIAL CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com