Preparation methods of animal active microecological fermented concentrated feed and compound feed

A technology for concentrated feed and compound feed, applied in the field of feed microorganisms, can solve the problems of general synergy relationship, low preservation activity and fermentation activity, and slight fermentation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0104] A kind of preparation method that the present invention is used to prepare the fermentation strain of animal active probiotics concentrated feed and compound feed, the steps of this method are as follows:

[0105] The strains used in the feed product of the present invention are mainly Saccharomyces cereviciae, Schizosaccharmyces pombe Linder, Candida krusei, Zygosaccharomyces bailii, etc. Yeast and acetic acid bacteria such as Acetobacter xylinum, Acetobacter xylinoides, Bacterium gluconicum, Acetobacter ketogenum, and Acetobacter suboxydans. The fermentation strains described in the present invention are one or more of the above-mentioned microorganisms, which need to be prepared through processes such as seed collection, separation, purification, expansion, mixing, and bottling. Now, taking yeast as an example, the separation, purification, and expansion It has been explained:

[0106] (1) Preparation of PDF solid medium

[0107] A. Culture medium composition:

[...

Embodiment 2

[0120]The present invention provides a method for preparing fermented growth promoters for animal active micro-ecological concentrated feeds and compound feeds, and its components and weight percentages are one of the following schemes:

[0121] (1) Lactic acid powder 5%

[0123] Ammonium hydrogen phosphate 2%

[0124] Urea 25%

[0125] Carrier (wheat bran) 66%

[0126] (2) Lactic acid powder 4%

[0127] Yeast powder 3%

[0128] Ammonium hydrogen phosphate 2%

[0129] Urea 25%

[0130] Carrier (wheat bran) 66%

[0131] (3) Lactic acid powder 6%

[0132] Yeast powder 2%

[0133] Ammonium hydrogen phosphate 3%

[0134] Urea 24%

[0135] Carrier (wheat bran) 65%

[0136] (4) Lactic acid powder 5%

[0137] Yeast powder 4%

[0138] Ammonium hydrogen phosphate 3%

[0139] Urea 28%

[0140] Carrier (wheat bran) 60%

[0141] (5) Lactic acid powder 7%

[0142] Yeast powder 3%

[0143] Ammo...

Embodiment 3

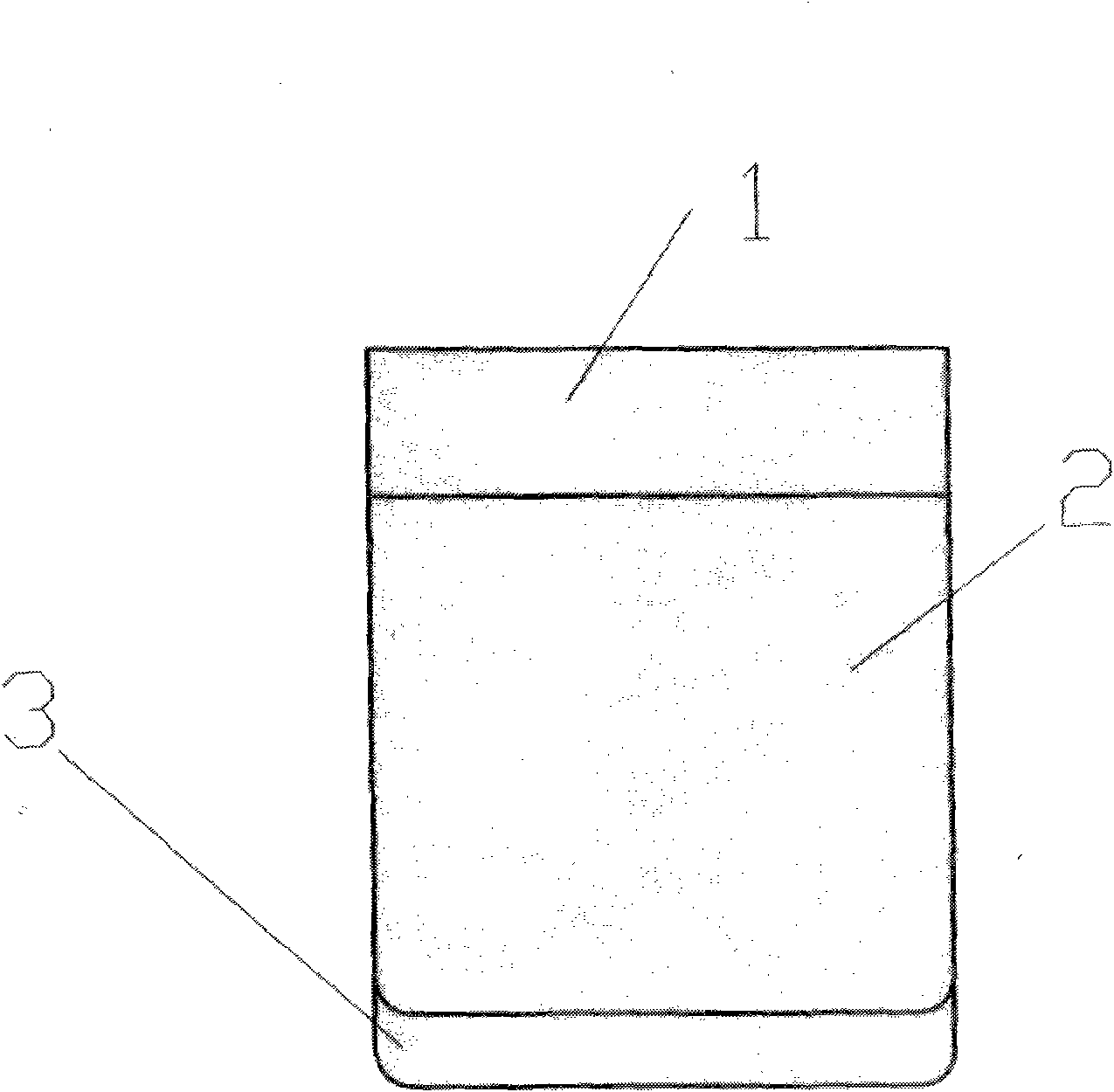

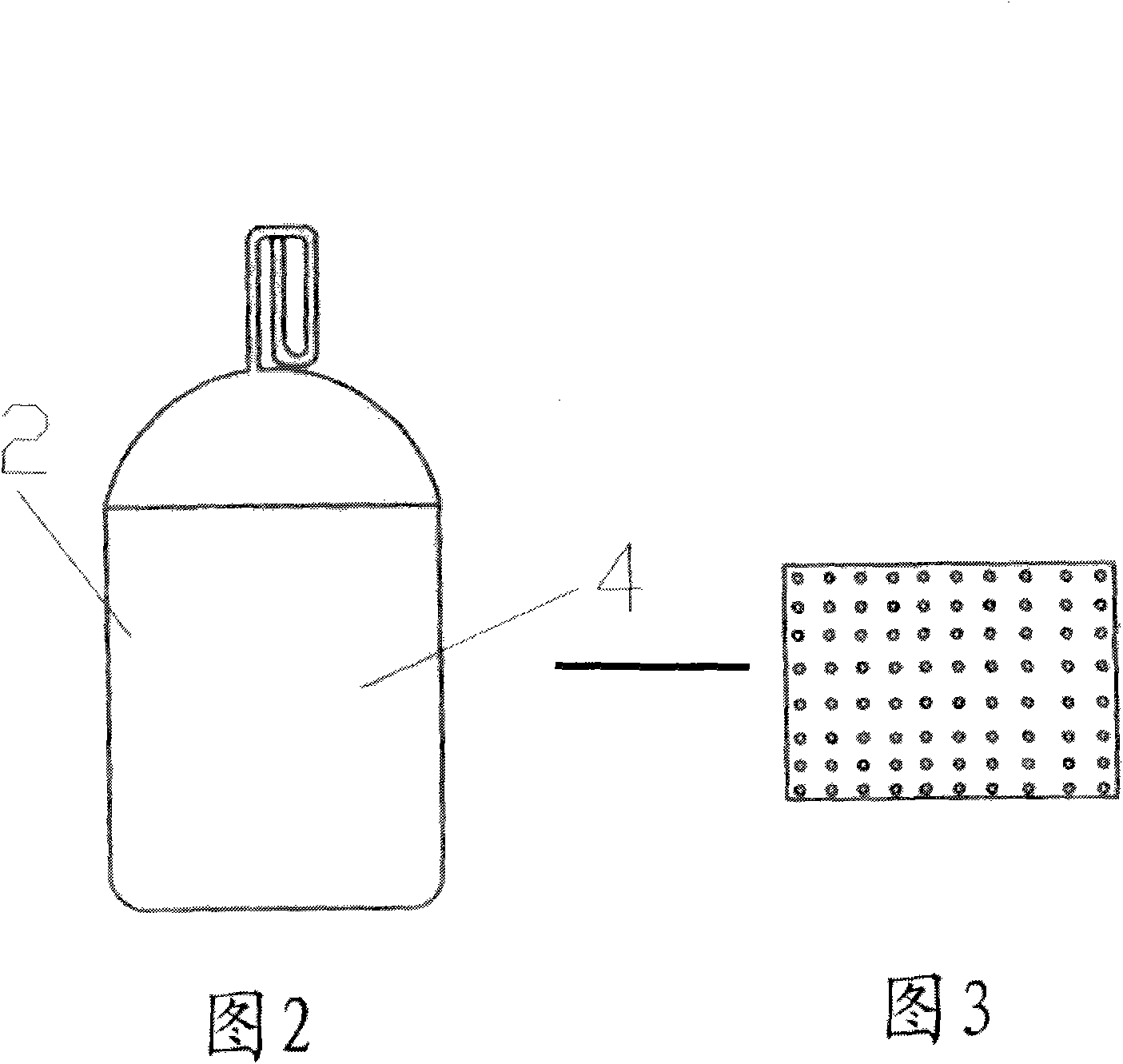

[0147] The invention provides a method for making a two-way air-permeable fermentation packaging bag for preparing animal active micro-ecological concentrated feed and compound feed, see attached figure 1 - attached image 3 , including a tube bag 2, one end of the tube bag 2 is provided with a bag heat seal 1, the other end of the tube bag 2 is a heat seal line 3 at the bottom of the bag, and a large number of micropores 4 are evenly distributed on the tube bag film; The material is a two-way breathable fermentation packaging bag made of a plastic microporous film prepared by stretching into holes. The steps for making the fermentation packaging bag are as follows:

[0148] First, the production method of PE microporous membrane

[0149] Polyethylene and selected from CaCO 3 , SiO 2 , clay, TiO 2 One or more inorganic compounds are mixed and then processed by stretching.

[0150] 2. Technical parameters of PE microporous membrane

[0151] The technical parameters of its...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com