Patents

Literature

413 results about "Lactase" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

This product is an enzyme supplement used to help people who have trouble digesting milk and other dairy products (lactose intolerance).

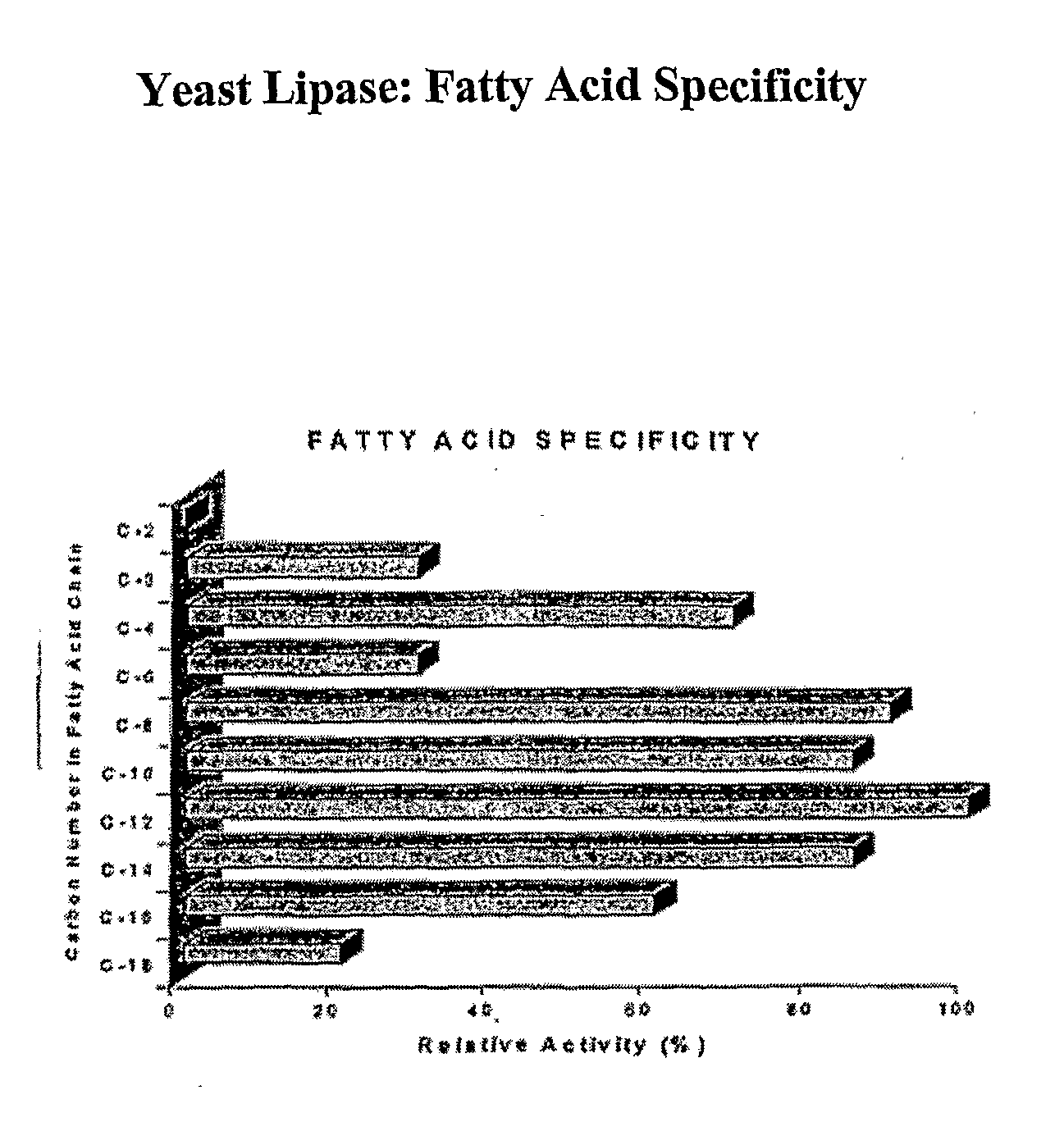

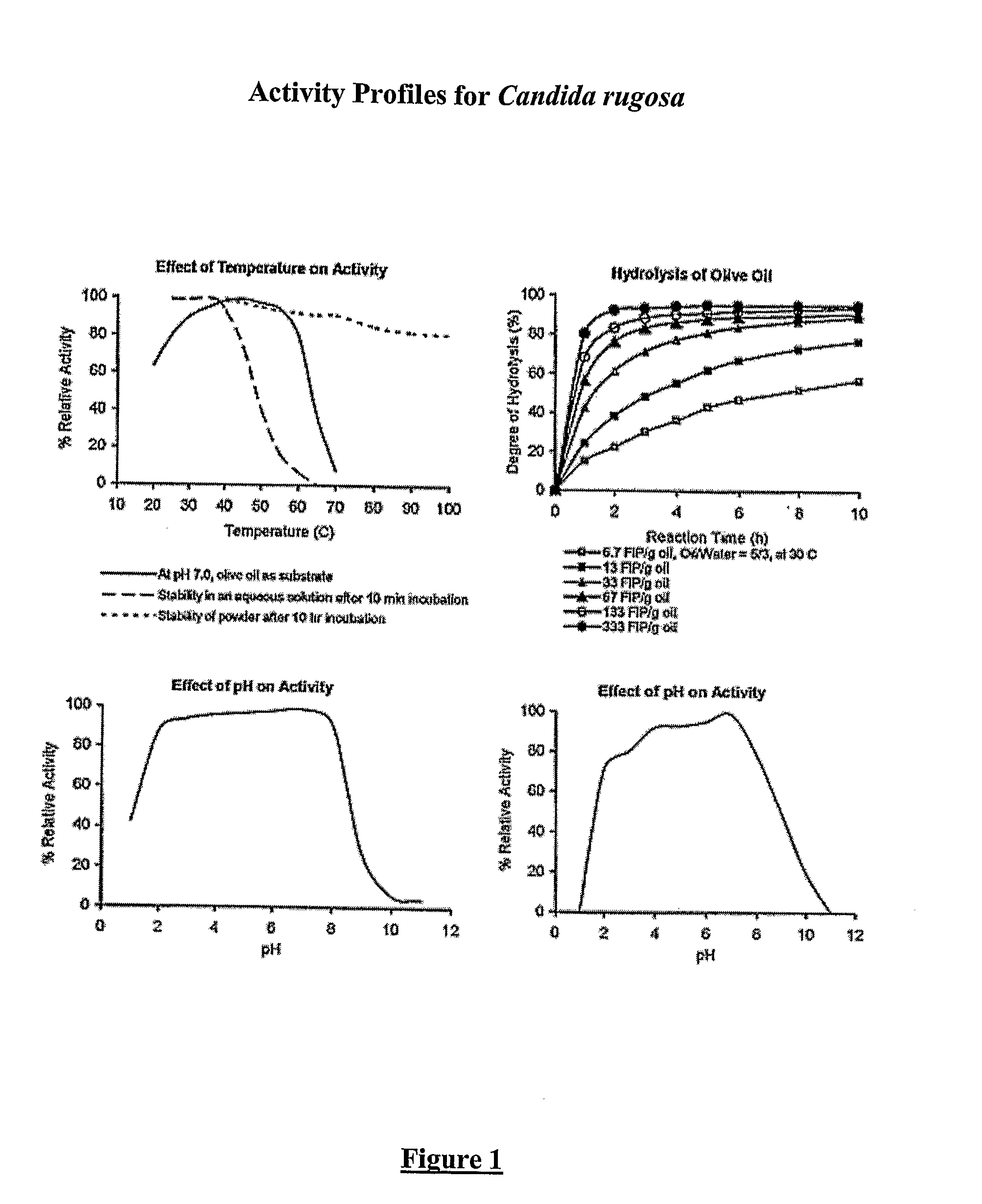

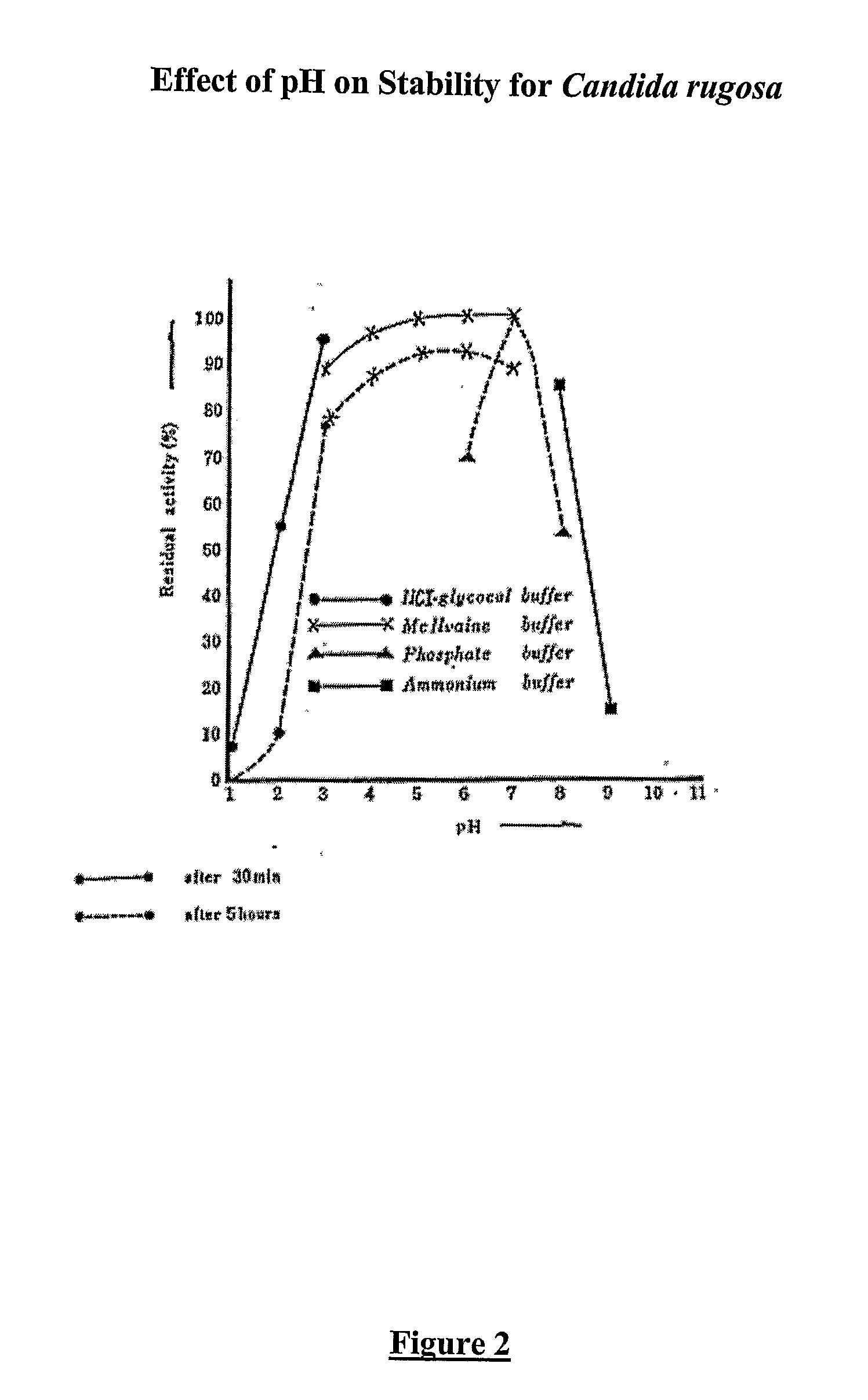

Composition With a Fungal (Yeast) Lipase and Method For Treating Lipid Malabsorption in Cystic Fibrous as Well as People Suffering From Pancreatic Lipase Insufficiency

The invention provides compositions and methods for treating pancreatic enzyme insufficiency, such as the pancreatic enzyme insufficiency associated with cystic fibrosis. The invention also provides compositions comprising lipase from Candida cylindracea, alone or in combination with amylase or amyloglucosidase, protease and / or lactase. Furthermore, the invention discloses methods for treating pancreatic enzyme insufficiency comprising administering compositions to patients in need thereof.

Owner:BIO CAT

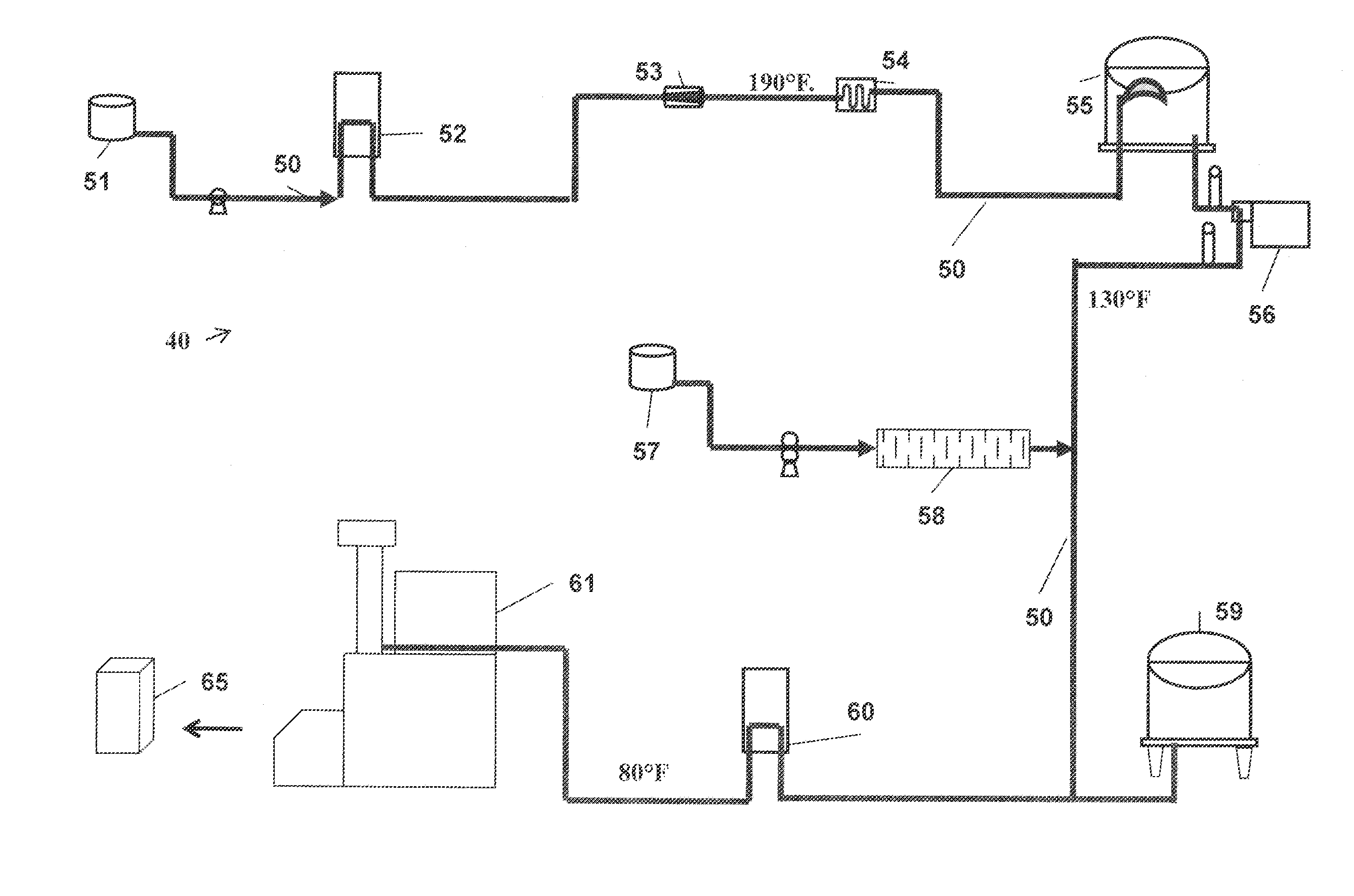

Process For Making A Shelf-Stable Milk Based Beverage Concentrate

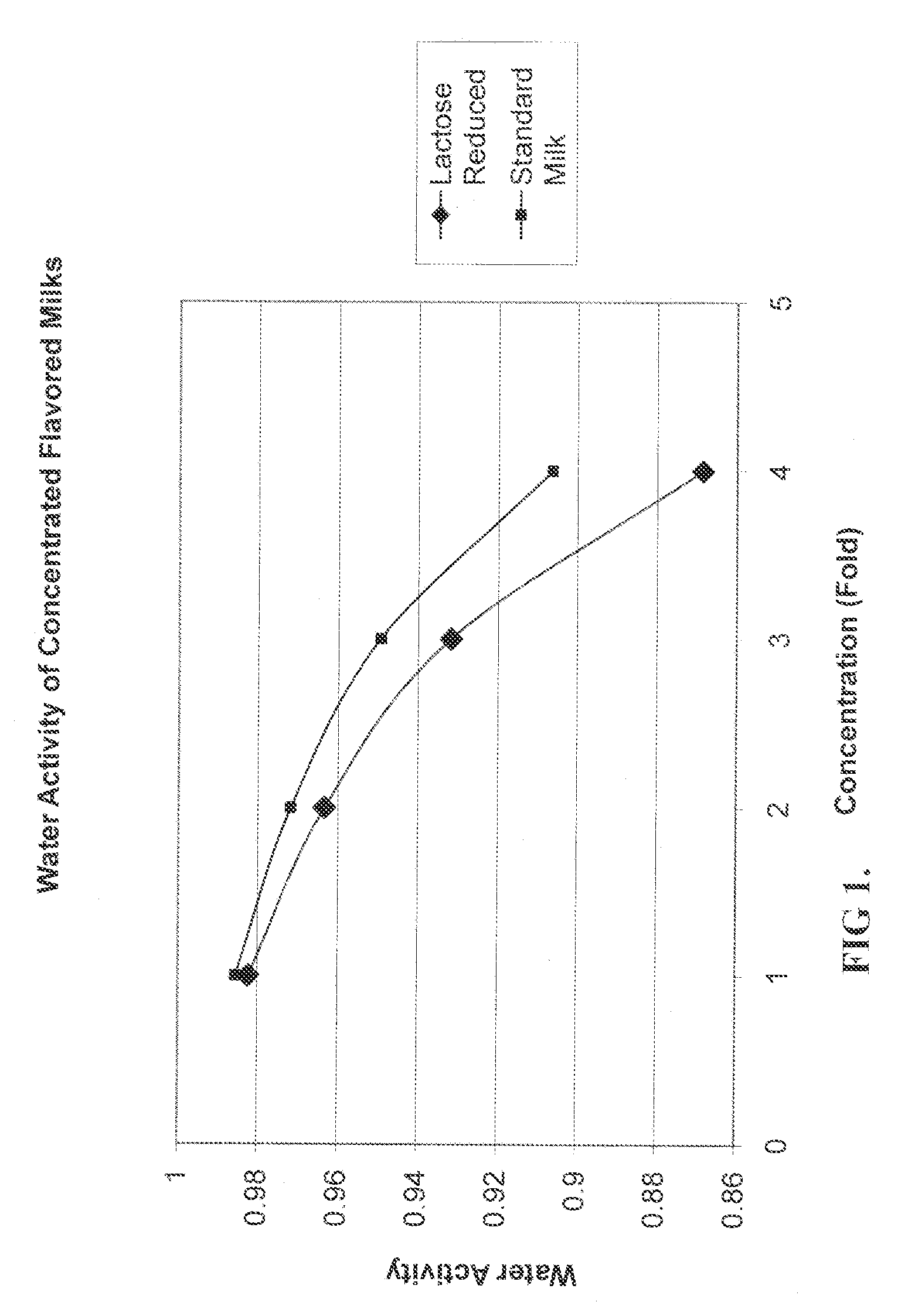

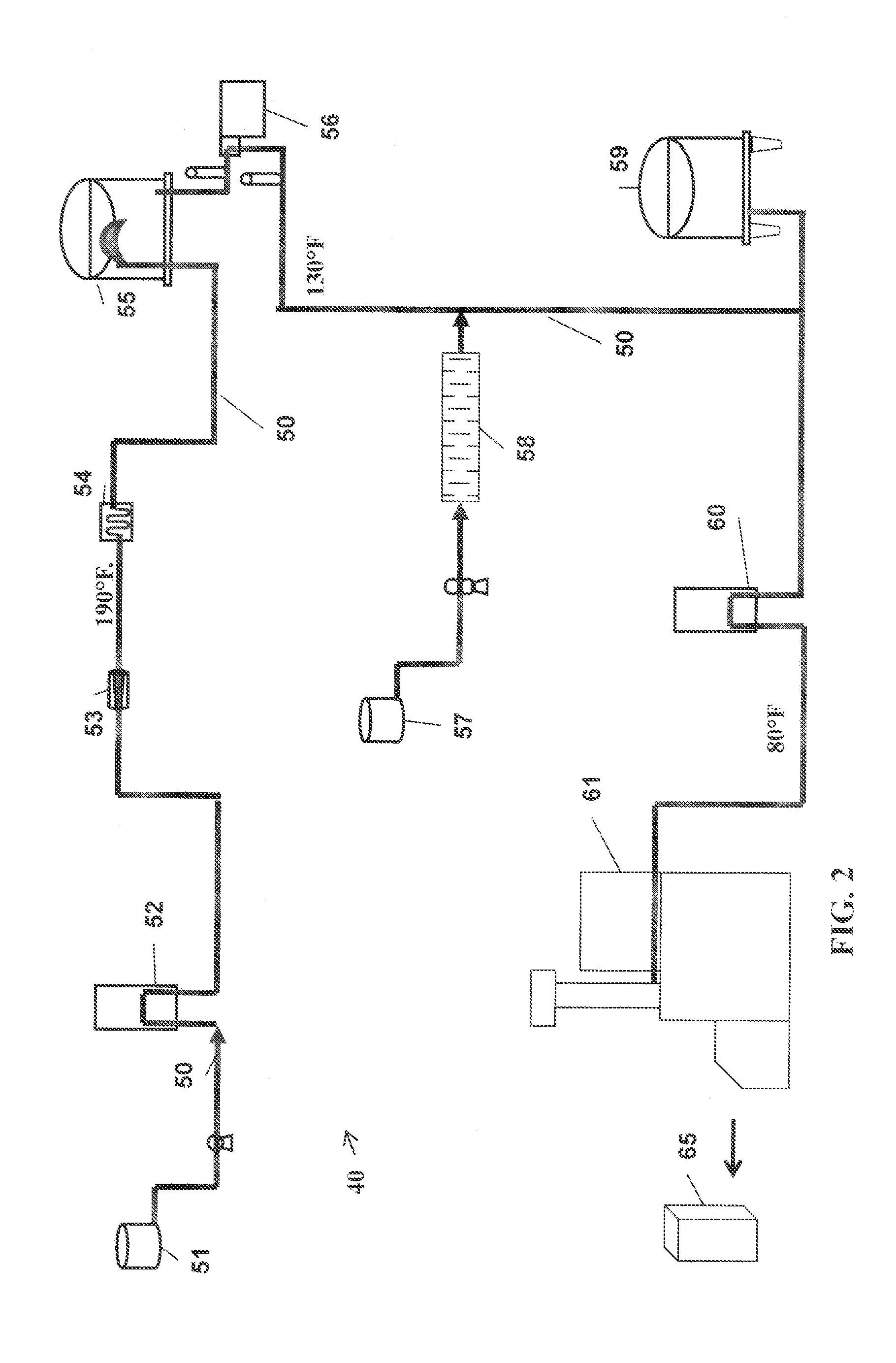

InactiveUS20090317514A1Minimizes thermal exposureLower water activityMilk preparationMilk preservationLactaseWater activity

A concentrate, system and low-temperature process for preparing a shelf-stable milk concentrate that does not require ultra-high temperature thermal processing for control of the microbiology of the product is disclosed herein. The method preferably incorporates aseptic technology and the enzymatic reduction of lactose to control water activity. The method preferably includes the enzymatic conversion of the lactose in the milk to its component sugars glucose and galactose, which preferably changes the colligative properties of the concentrate, decreases the amount of free water, and reduces the osmolarity.

Owner:DAIRYVATIVE TECH

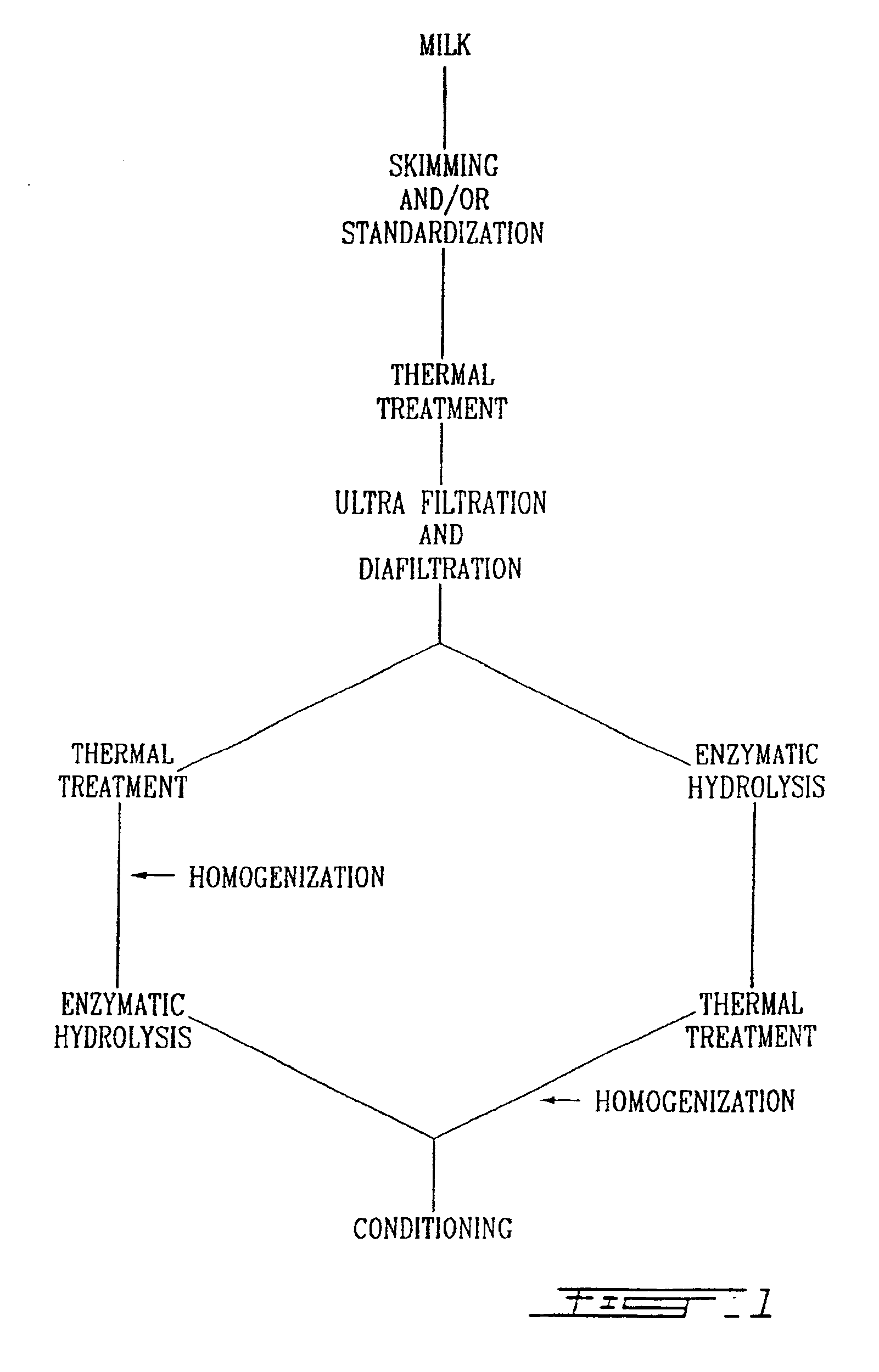

Process for making a lactose-free milk and milk so processed

InactiveUS6881428B2Affecting tasteLactose is reduced or substantially eliminated from milkMilk preparationWort preparationBiotechnologyLactose free milk

This invention relates to a process for producing a lactose-free milk which does not confer a sweet taste to the milk normally resulting from the hydrolysis of lactose into monosaccharides. The process comprises the step of reducing the lactose content of the milk to about 3% prior to hydrolysis with lactase. When the milk is skimmed milk, the protein content may be increased to about 3.8-4.0% or greater, which further improves the organoleptic properties of the milk. Milk so processed and dairy products derived therefrom are also disclosed and claimed.

Owner:AGROPUR COOP

Composite plant enzyme containing probiotics and application of composite plant enzyme

ActiveCN103876155APromote body metabolismWide range of conditionsFood ingredient functionsFood preparationBiotechnologyLactase

The invention discloses a composite plant enzyme containing probiotics and an application of the composite plant enzyme. The composite plant enzyme comprises amylase, lipase, protease, cellulase, beta-dextranase, xylanase and lactase. The composite plant enzyme is obtained by discontinuously feeding materials and fermenting for a plurality of periods, selecting a plurality of types of fruits and vegetables, and edible and medical plants as fermentation substrates and taking a plurality of types of probiotics / yeasts as fermentation inoculation substances through a plurality of grades of deep fermentation. The composite plant enzyme contains seven enzymes needed by a human body at the same time so that the plant enzyme has the synergistic effects of promoting in-vivo metabolism and decomposing toxic substances; the plant enzyme contains a high-activity compound enzyme and has a wide acting condition, good adaptability, and good stability, acid-base resistance and high-temperature resistance; the plant enzyme can effectively and rapidly improve the biochemical reaction speed and can be used as a raw material to be applied to foods and chemicals for daily use.

Owner:田雷

Milk powder

The milk powder is prepared with the materials including: fresh milk or milk powder, defatted milk powder or defatted milk, lactase, desalted whey powder, whey protein powder and / or soybean protein powder, vegetable oil, phospholipid, oligose, honey, calcium lactase, CPP, wolfberry fruit, vitamins and minerals. The product may avoid lactose intolerance, has the effects of resisting fatigue, resisting senility, raising memory and improving gastrointestinal tract function, and has the advantages of no cane sugar, high calcium content and low lactose content.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

Nutritious powder for hypoglycemia patient

InactiveCN1810161AHigh nutritional valueIncrease nutritionMilk preparationVegetable proteins working-upLactaseIsomaltooligosaccharide

The nutritious powder with low blood sugar creating index is prepared with fresh milk, no-sugar whole fat soybean powder, concentrated soybean protein, puffed lotus seed powder, isomaltose, fructose, selenium-rich yeast, resistant starch and soluble diet fiber, and through preparing materials, adding lactase to hydrolyze lactose, mixing materials, sterilizing, concentrating, spray drying, cooling and sieving. The nutritious powder has rich nutrients and low blood sugar creating index, contains diet fiber and organic selenium, and may be utilized easily by probiotics in human body to improve intestinal tract micro environment.

Owner:黑龙江省农业科学院食品加工研究所

Inactivated lactobacillus micro-ecological preparation and preparation method thereof

ActiveCN101612169AInhibition is effectiveEfficient killingBacteria material medical ingredientsAnimal feeding stuffMetaboliteLactase

The invention discloses an inactivated lactobacillus micro-ecological preparation and a preparation method thereof. The preparation comprises the following components in portion by mass: 10 to 60 portions of inactivated lactobacillus cell and lactobacillus fermentation product, and 30 to 50 portions of excipient, wherein the inactivated lactobacillus cell accounts for 10<8> to 10<9> cells per gram. The inactivated lactobacillus cell resists high temperature, gastric acid and bile, and has synergistic action with antibiotics; in addition, metabolic products produced in a lactobacillus fermentation process such as lactic acid, like bacteriocin and the like can effectively inhibit or kill enteric pathogenic bacteria of people or animals; and enzymes such as amylase, lactase and the like are helpful for digestion of the animals. The inactivated lactobacillus micro-ecological preparation effectively and economically solves the problem puzzling the prior viable bacteria micro-ecological preparation.

Owner:BIOFORTE BIOTECHNOLOGY (SHENZHEN) CO LTD

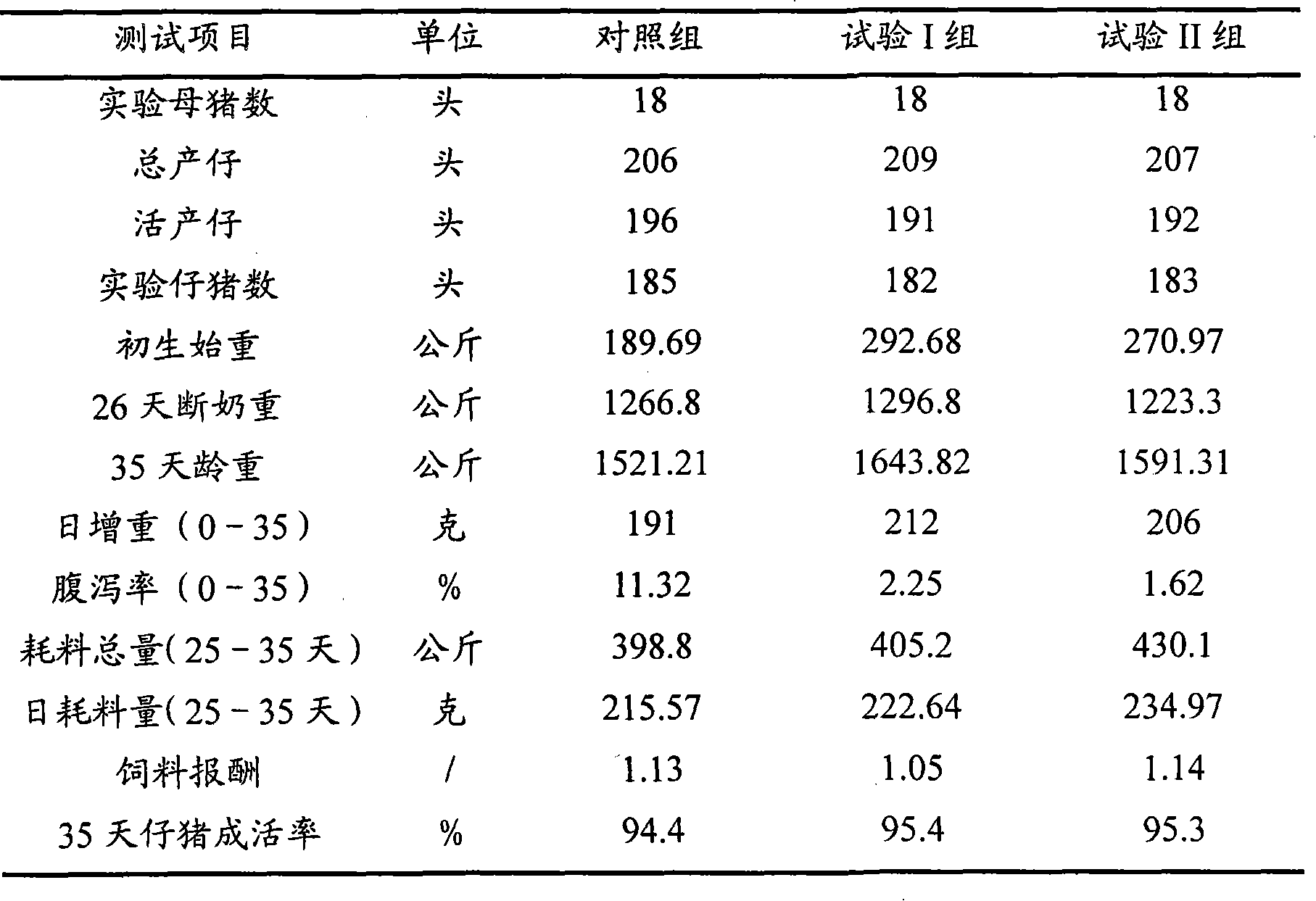

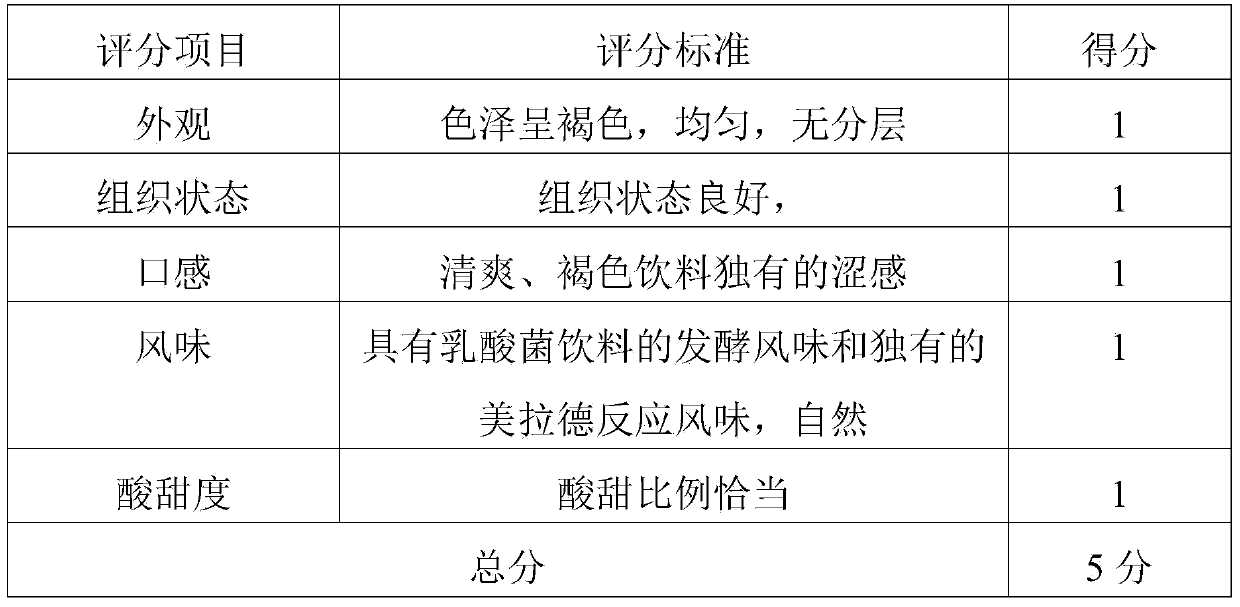

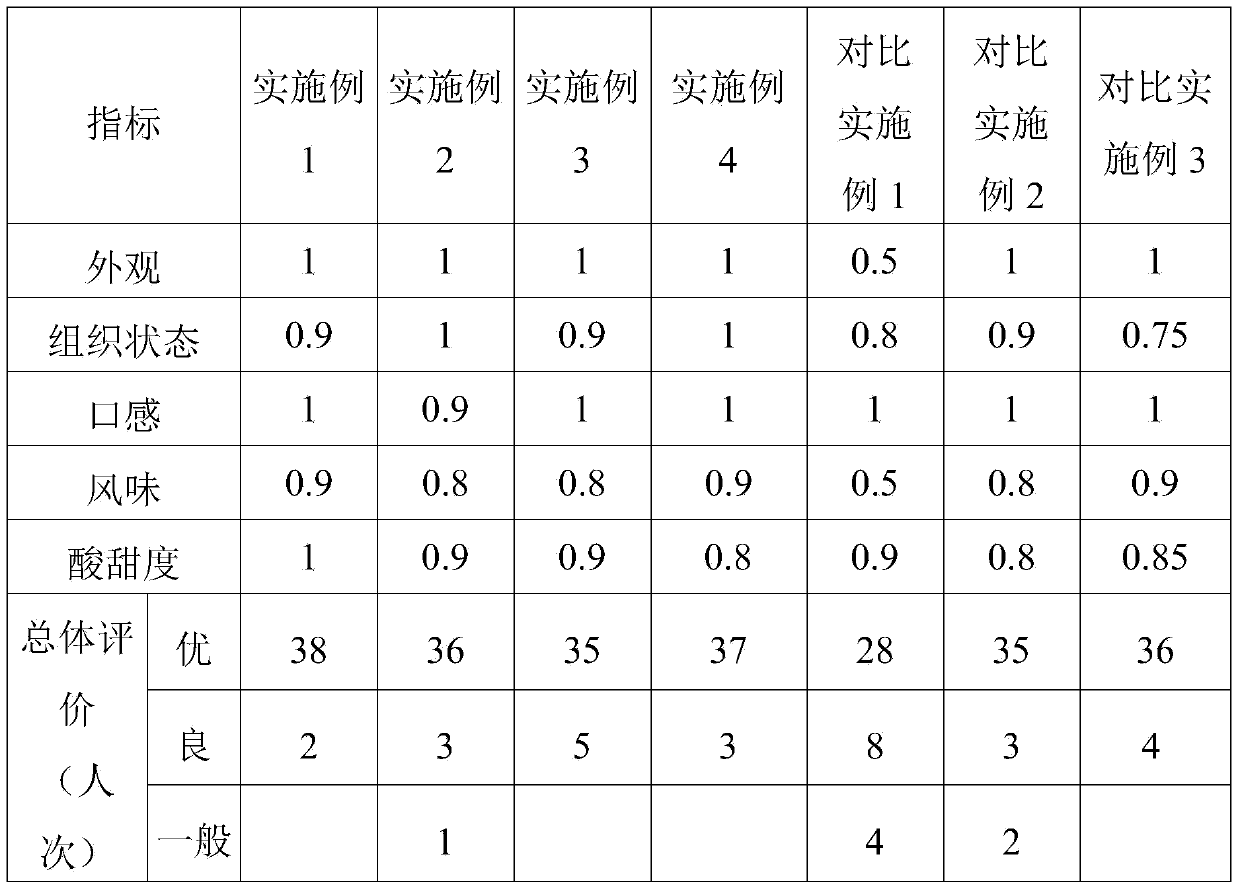

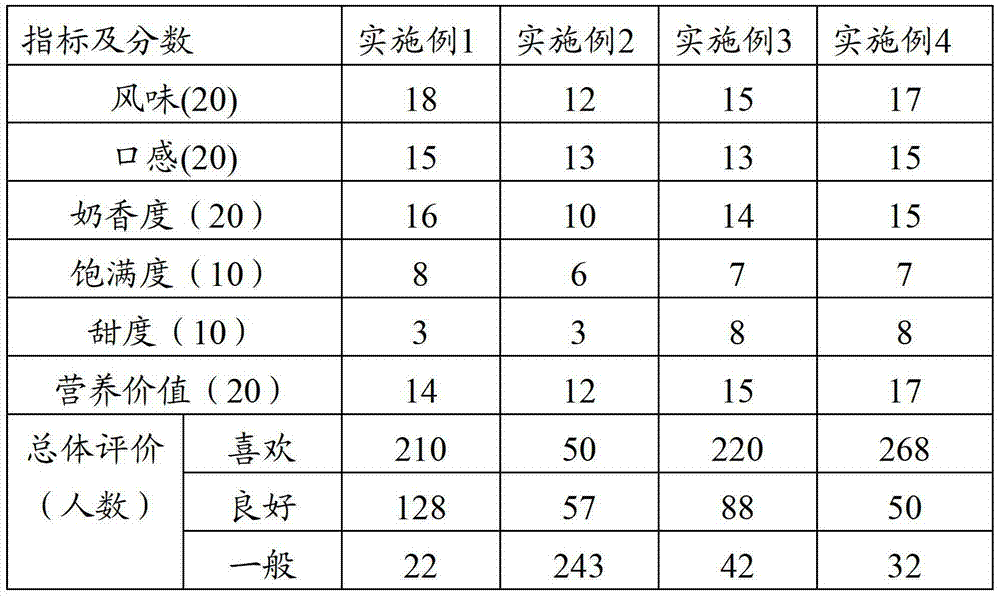

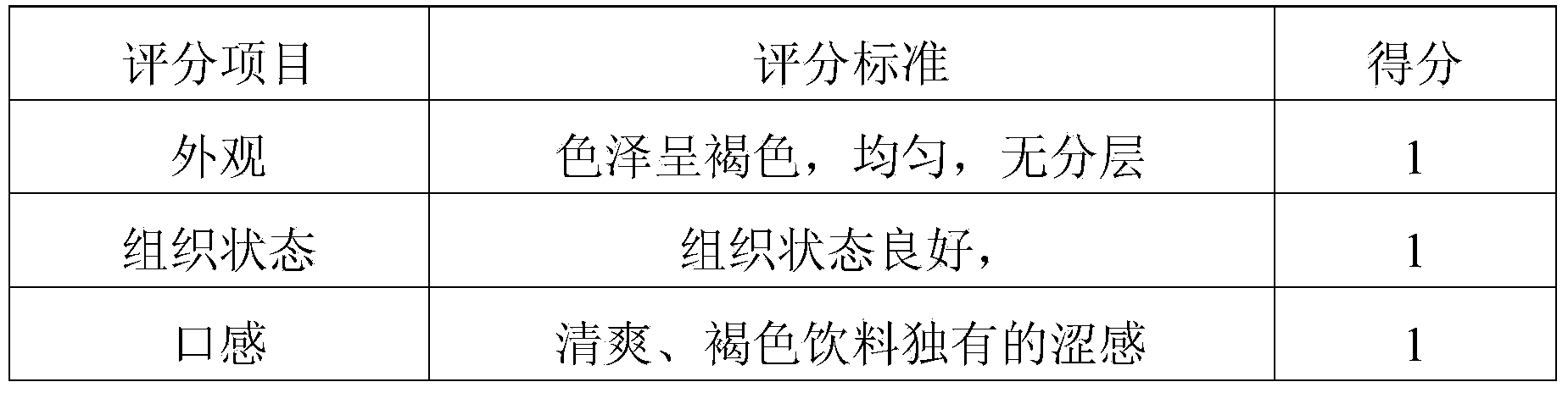

Brown lactic acid bacteria drink and preparation method thereof

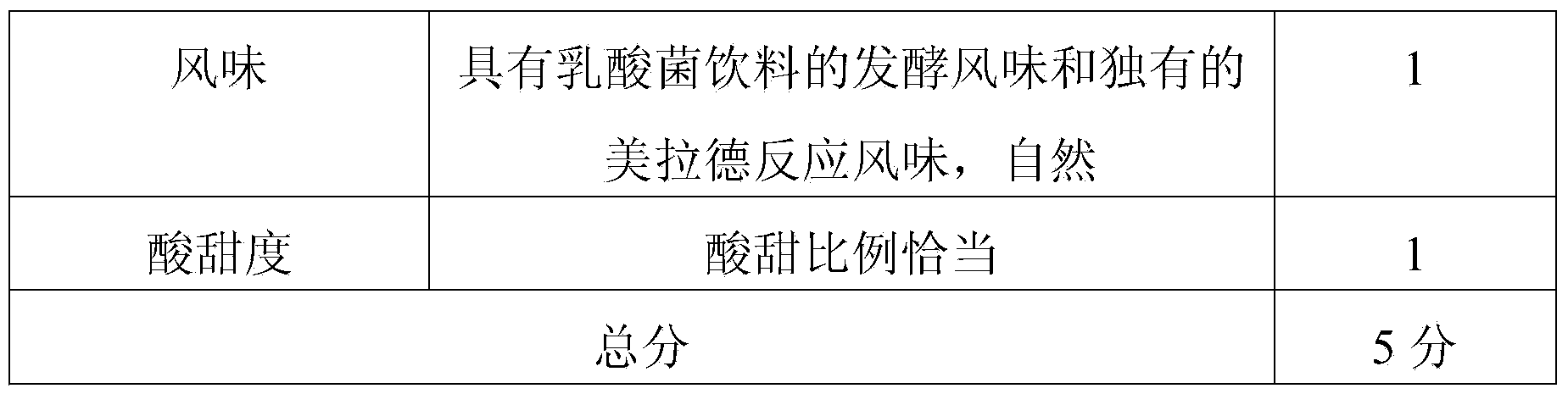

ActiveCN104186651ALower sugar contentImprove textureMilk preparationMaillard reactionLactic acid bacterium

The invention discloses a brown lactic acid bacteria drink and a preparation method thereof. The preparation method comprises the following steps: (1) uniformly mixing a raw material A to obtain a mixed liquid A and standing the mixed liquid A for 1-10h under the temperature condition of 4-40 DEG C to obtain a sizing agent A, wherein the raw material A comprises 8%-16% of milk powder, 0.02%-0.2% of lactase and water; (2) carrying out maillard reaction on the sizing agent A, cooling, uniformly mixing with a lactic acid bacteria starter, fermenting, turning over matters in a vat, homogenizing and cooling to obtain a fermented milk-based material; and (3) mixing an uniformly mixed additive B and the fermented milk-based material in the step (2) to obtain a mixed liquid B, adjusting the acidity and homogenizing so as to obtain the drink, wherein the additive B comprises an emulgator, a stabilizer and water. The preparation method is simple, the fermentation time is shortened, reducing sugar or pigment is not additionally added, and the prepared brown lactic acid bacteria drink is low in sugar content, and has good stability in shelf life.

Owner:BRIGHT DAIRY & FOOD

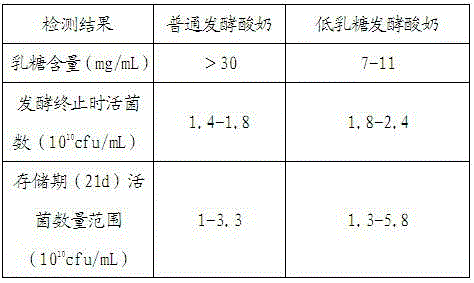

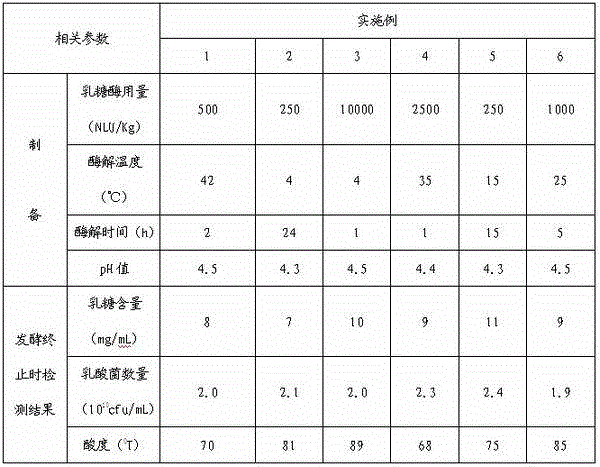

Preparation method for low-lactose fermented dairy product

The invention discloses a preparation method for a low-lactose fermented dairy product. The preparation method has two modes; in one of the modes, lactase is added into milk and ferment is inoculated at the same time, so that the low-lactose fermented dairy product is prepared; in the other mode, lactase is first added into fresh milk, so that lactose is hydrolyzed into glucose and galactose, and ferment is then inoculated, so that the fermented dairy product is prepared. The low-lactose fermented dairy product prepared by the preparation method not only has the characteristics of low lactose content and high viable count, but also has the specific flavor and taste of fermented milk, the change of acidity is little in the process of later storage, and the taste is good. The preparation method is applicable to the preparation of low-lactose fermented dairy products.

Owner:JUNLEBAO DAIRY GRP CO LTD

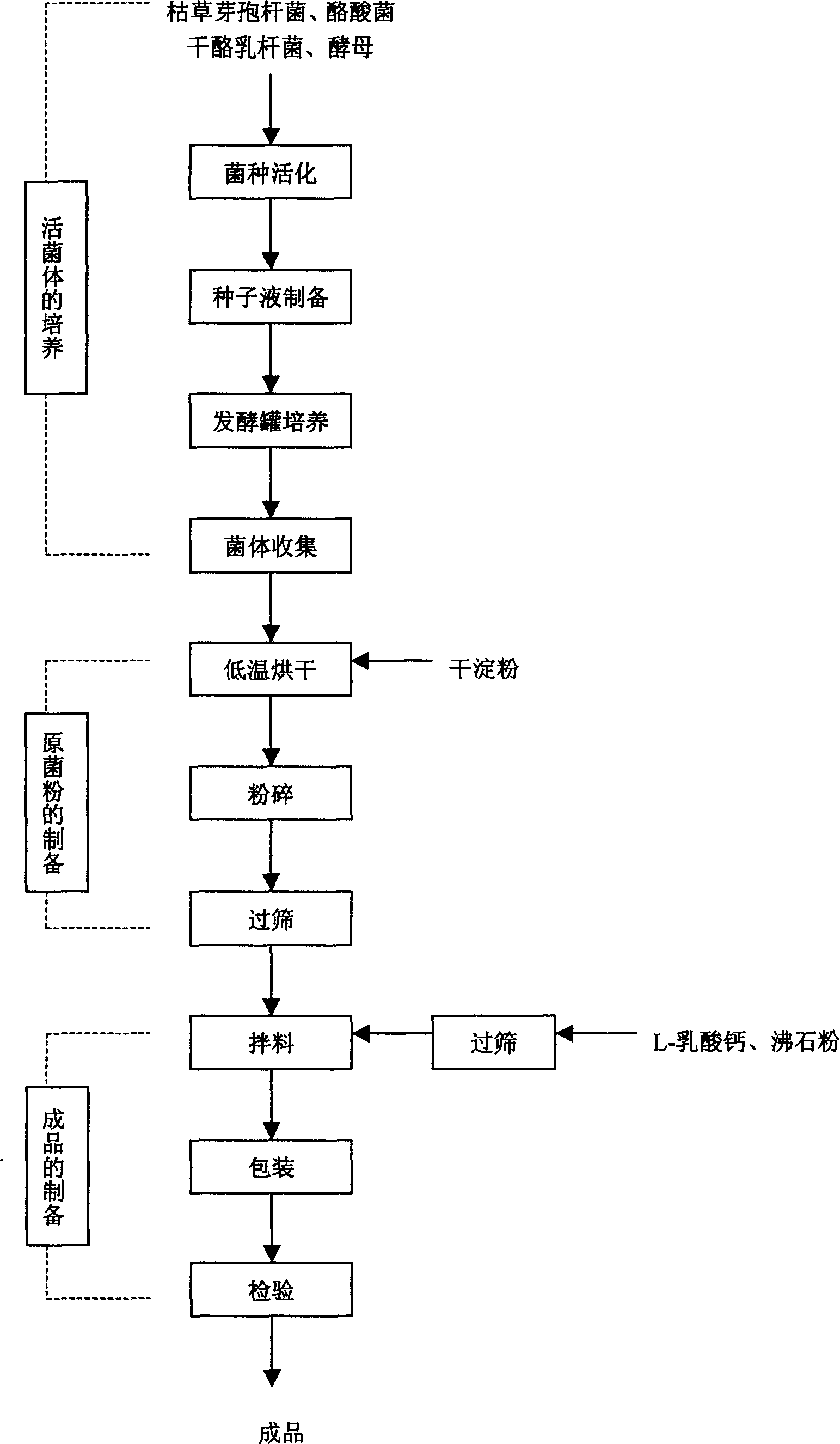

Microecological preparation-tetragenous viable bacteria preparation and method for preparing same

InactiveCN1844364AQuick activationImprove reproductive abilityFungiBacteriaLactaseFresh water organism

This invention relates to a micro-ecological agent and the preparation method thereof, belonging to the micro-ecological agent technological field. The preparation of the active bacteria agent of this invention comprises: using L-calcii lactas and four useful micro-organisms of clostridium bytyricum, Lactobacillus casei, bacillus subtilis and saccharomycete as characteristic elements, cultured purely or mixedly by means of universal fermentator, producing active bacteria powder by freeze-drying, and acquiring the finished products by double crossing of the powder at a specific proportion. By using the anaerobic and aerobic characteristics of related bacterial strains, this agent has the following merits: playing the synergy effect in enhancing the disease resistance of marine animals and the water purification of aquaculture, substituting antibiotics fully or partly for the disease prevention and cure in fresh water aquiculture and mariculture, and improving the economic benefits of aquaculture. The L-calcii lactase component can accelerate the husking growth and prevent the disease of soft husk of shellfish marine animals like shrimp and crab. This agent is characterized of being nontoxic, free from side effects, nonpersistent, without secondary pollution and no drug tolerance, and will have a wide commercial application in the fresh water aquiculture mariculture.

Owner:江苏省苏微微生物研究有限公司

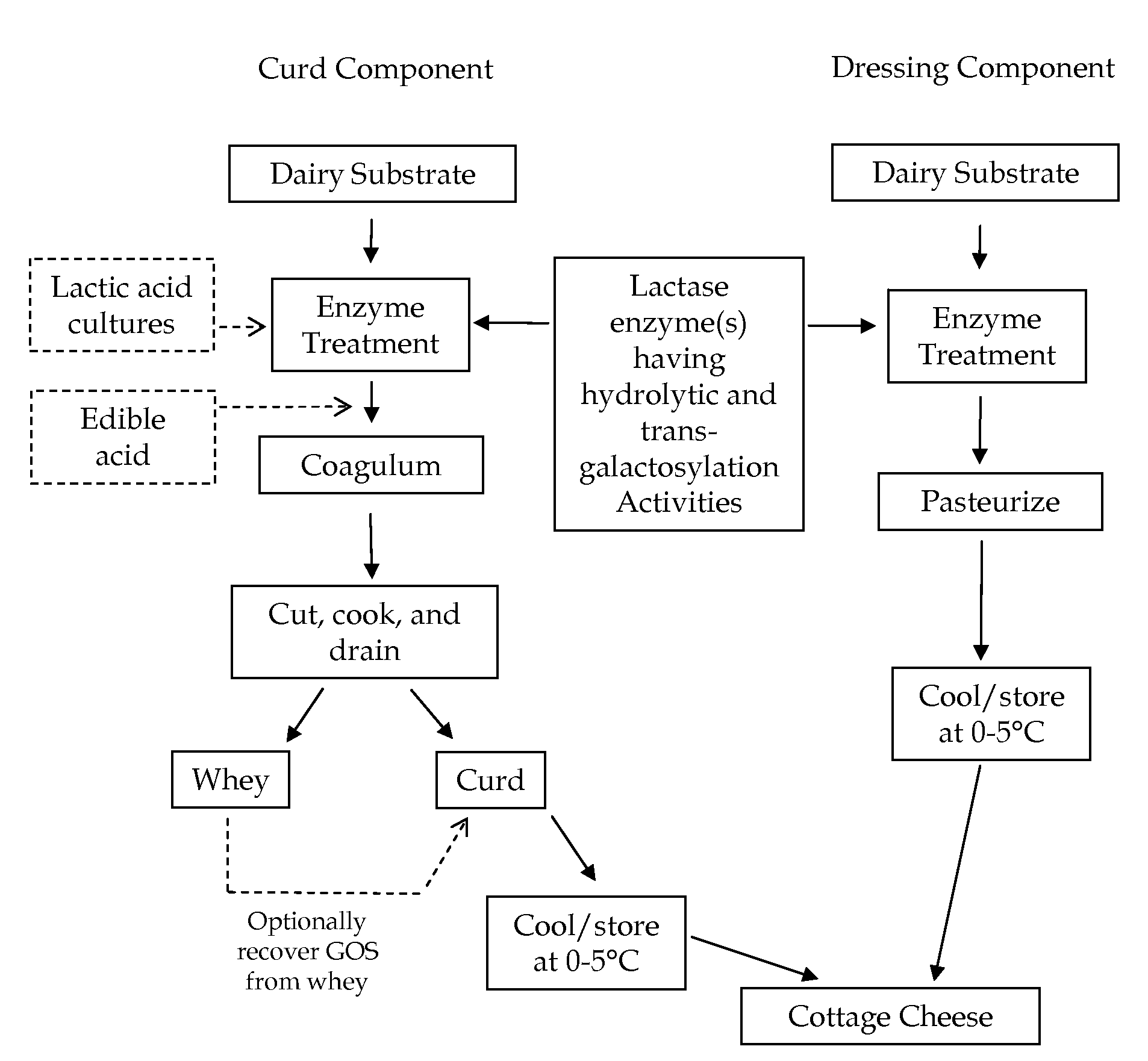

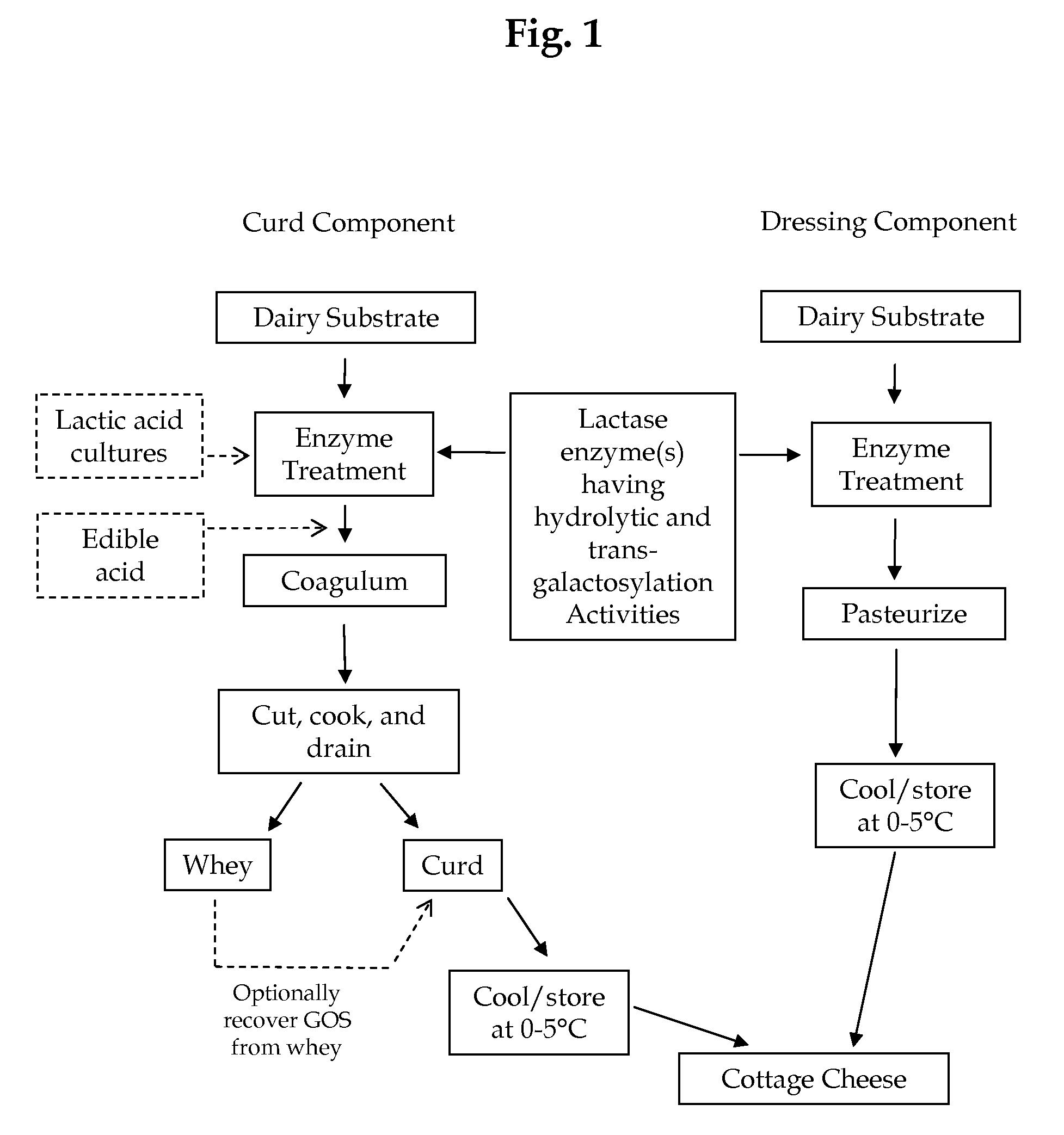

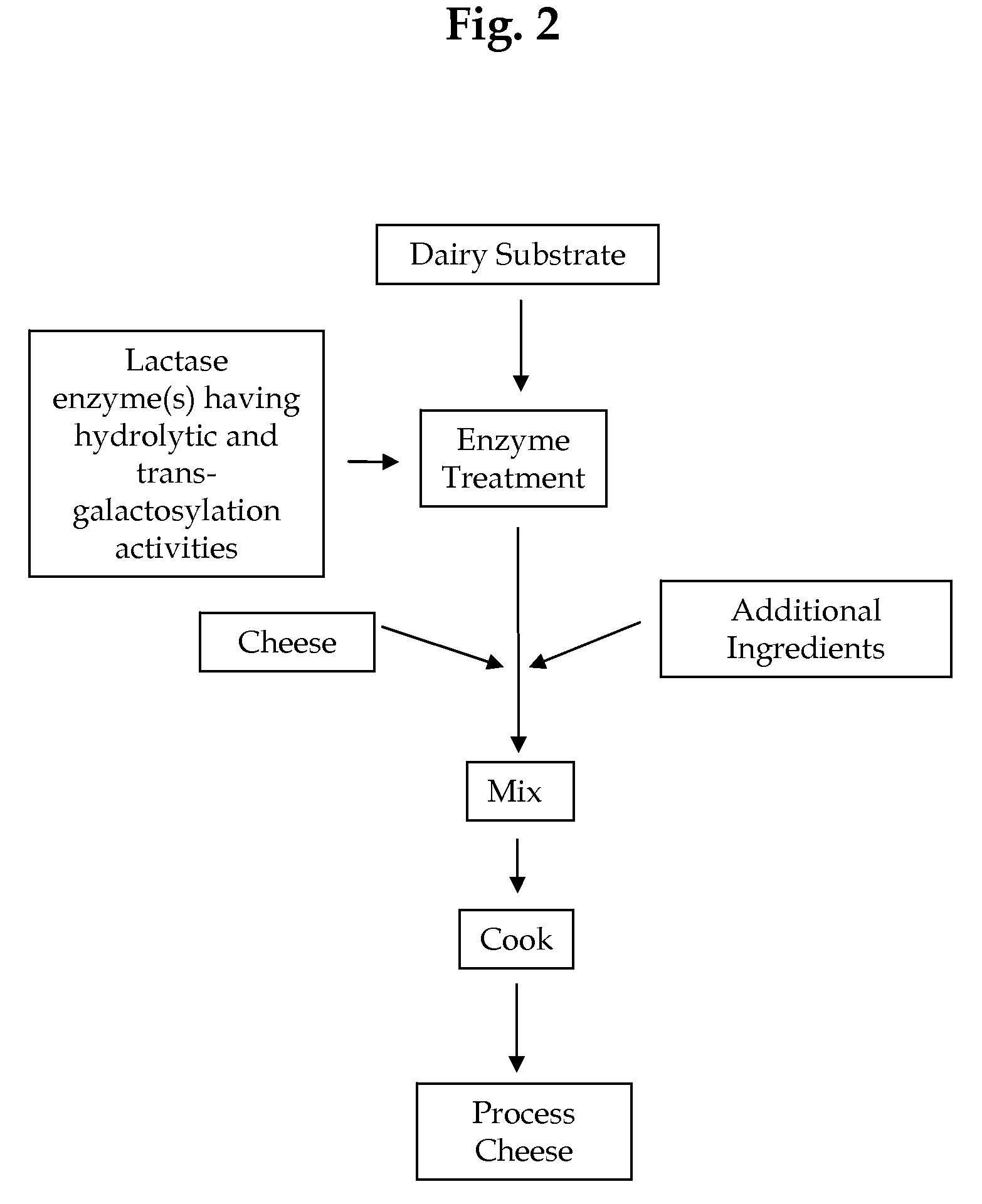

Cheese Products Containing Galacto-Oligosaccharides And Having Reduced Lactose Levels

InactiveUS20090297660A1Lower Level RequirementsReduce lactose levelMilk preparationWhey manufactureLactaseGalactooligosaccharide

The processes described herein are directed to cream cheese products containing galacto-oligosaccharides and having significantly reduced lactose levels. More specifically, lactose-containing dairy substrates are contacted with lactase enzyme(s) having hydrolytic and trans-galactosylation activities effective for converting at least 20 percent of the lactose in the dairy substrate to galacto-oligosaccharides. The enzyme-treated dairy substrate is then processed into galacto-oligosaccharide containing cream cheese products having reduced lactose levels. The cream cheese products provided herein have excellent nutritional and organoleptic properties.

Owner:KRAFT FOODS INC

Lactose-reduced dairy compositions and related methods

Compositions for ameliorating the symptoms associated with lactase deficiency, the composition including a lactose reduced dairy product, and an effective amount of a probiotic, a prebiotic, or a mixture thereof. The lactose reduced dairy product is selected from a fluid milk, a smoothie, a liquado, ice cream, yogurt, and a yogurt drink. Methods for treating lactose intolerance in a patient in need thereof, the method includes providing a composition having a lactose reduced dairy product, and an effective amount of a probiotic, a prebiotic, or a mixture thereof. The lactose reduced dairy product is selected from a fluid milk, a smoothie, a liquado, ice cream, yogurt, and a yogurt drink.

Owner:MCNEIL NUTRITIONALS

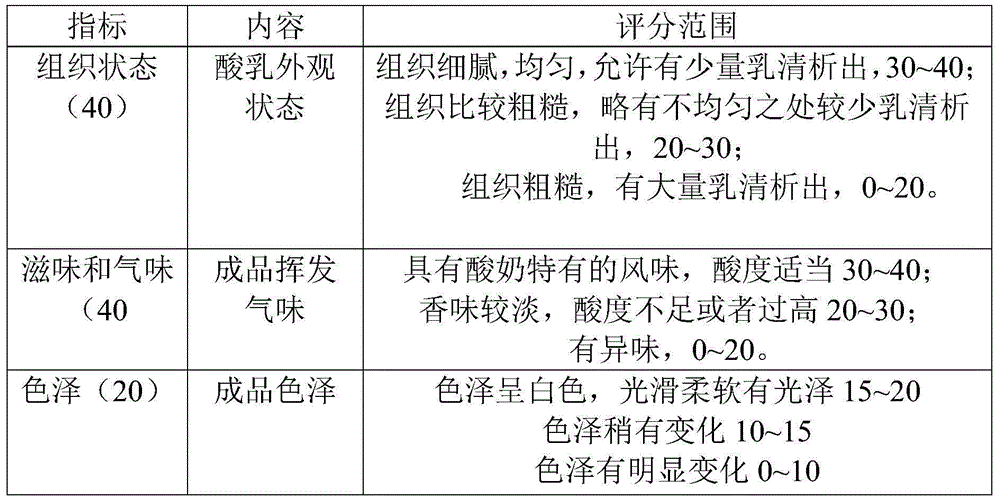

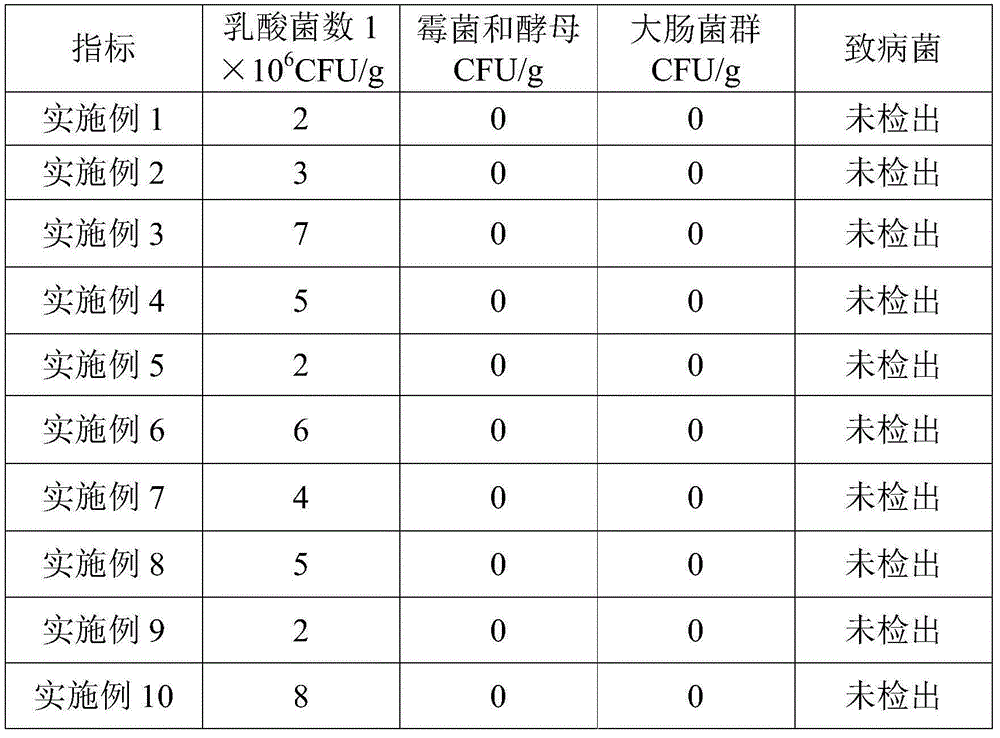

Additive-free high-protein yogurt and making method thereof

ActiveCN105010530AThe state of organization is smoothDelicate tissue stateMilk preparationSucroseLactase

The invention provides additive-free high-protein yogurt and a making method thereof. The method relates to raw materials including raw milk, single cream, a leavening agent and lactase. The method includes the steps that (1) the raw milk is degreased at the temperature of 40-50 DEG C, ultrafiltration and concentration are carried out after microfiltration sterilization, then the raw milk is mixed with the single cream, the protein content is made to be 4%-6% and the fat content is made to be 4%-7%; afterwards, homogeneity is performed, heat treatment is conducted for 5-10 minutes at the temperature of 90-95 DEG C, and cooling is conducted till the temperature is 38-45 DEG C; (2) 100-200 U / 1000 kg of leavening agent and 1000-3000 NLU / L of lactase are added to be stirred for 5-10 minutes, and the temperature rises to 38-45 DEG C so that filling can be conducted; (3) fermentation is carried out at the temperature of 38-45 DEG C and stops till the pH value is 4.4-4.55, curing is conducted for 12-24 hours after cold storage at the temperature of 2-6 DEG C is completed, and accordingly the additive-free high-protein yogurt is obtained. By the adoption of the method, the quality of the raw milk is greatly improved, the obtained yogurt is high in protein concentration and does not contain sucrose, and the yogurt further has good mouthfeel and flavors.

Owner:BRIGHT DAIRY & FOOD CO LTD

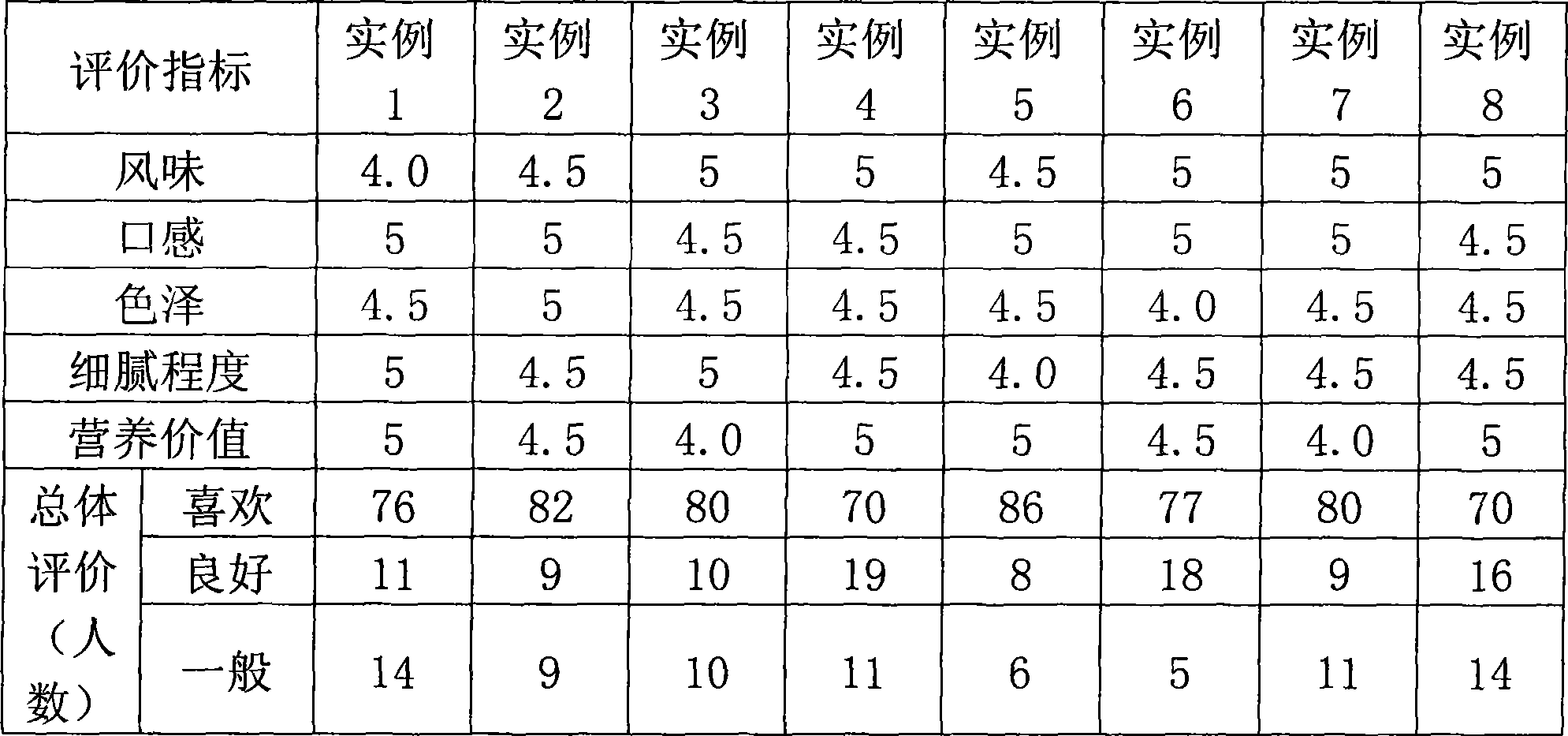

Non-fermentation type sour milk and preparation method thereof

The invention relates to non-fermentation type sour milk and a preparation method thereof. The non-fermentation type sour milk uses fresh cow milk as principal raw material. After being hydrolyzed by milk sugar, the cow milk is pasteurized and concentrated in vacuum to be 40 percent of the original volume. After the cow milk is cooled, probiotic powder is added. The invention has the core that transglutaminase is added at an optimal temperature; under the action of the transglutaminase, milk protein is connected together to form a protein network, thereby a uniform stable gelatin system is easily formed; delta-gluconolactone is then added, and the gelatin system and the delta-gluconolactone are heated at 35-40 DEG C in a water bath way for 2 to 3 hours so that the uniform, stable and exquisite non-fermentation type sour milk like a quark can be obtained. The invention has simple preparing process, no requirement for fermentation, and full utilization of resources. The non-fermentation type sour milk can be used as a base to develop various products, such as corn non-fermentation type sour milk for breakfast, jelly non-fermentation type sour milk, and the like, and can satisfy the requirements of consumers in nutrition, mouthfeel, texture, and the like.

Owner:TIANJIN UNIV OF SCI & TECH

Instant cheese and preparation method thereof

The invention relates to an instant cheese and a preparation method thereof. The preparation method comprises the steps: using full-cream fresh milk as main material, pasteurizing the milk after being hydrolyzed through lactase, and concentrating the full-cream fresh milk to 35-40 percent of the original volume in vacuum. The preparation method of the instant cheese has the core points that transglutaminase is added at 35 DEG C, and milk proteins are linked to form a protein network under the action of the transglutaminase, thereby forming a uniform and stable gel system easily. Then, chymosin is added for promoting gel to form , and uniform, stable and delicate instant cheese can be obtained in a water bath for half hour at about 30 DEG C. The invention is simple and easy for operation, and can be used for development of various application products on the theoretical basis, including breakfast cereal cheese, jelly cheese and the like. Moreover, the instant cheese can meet the requirements of consumers for taste, texture, nutrition, and the like.

Owner:TIANJIN UNIV OF SCI & TECH

Preblend of microcrystalline cellulose and lactase for making tablets

A preblend for making lactase tablets is prepared containing about 1-99% (preferably about 200-60%) by weight lactase and about 1-99% (preferably about 40-80%) by weight microcrystalline cellulose. Lactase used in the preblend may be in combination with up to about 4 parts (preferably about 0.5-2 parts) by weight cutting agent such as sugars, starches, cellulose, and inorganic salts for each part by weight lactase. About 0.5-4% by weight lubricant such as magnesium stearate may be present in the preblend. A preferred preblend contains about 9.6 weight percent lactase and about 90 weight percent microcrystalline cellulose, or about 2000 to about 9000 FCC lactase units and from about 40 to about 80 weight percent microcrystalline cellulose. Another preferred preblend contains about 9.6 weight percent lactase, about 30.0 weight percent microcrystalline cellulose and about 59.4 weight percent mannitol. Each preblend may also contain magnesium stearate. A preferred lactase is from Aspergillus oryzae and the microcrystalline cellulose preferably has an average particle size of about 10-200 μm.

Owner:MCNEIL PPC INC

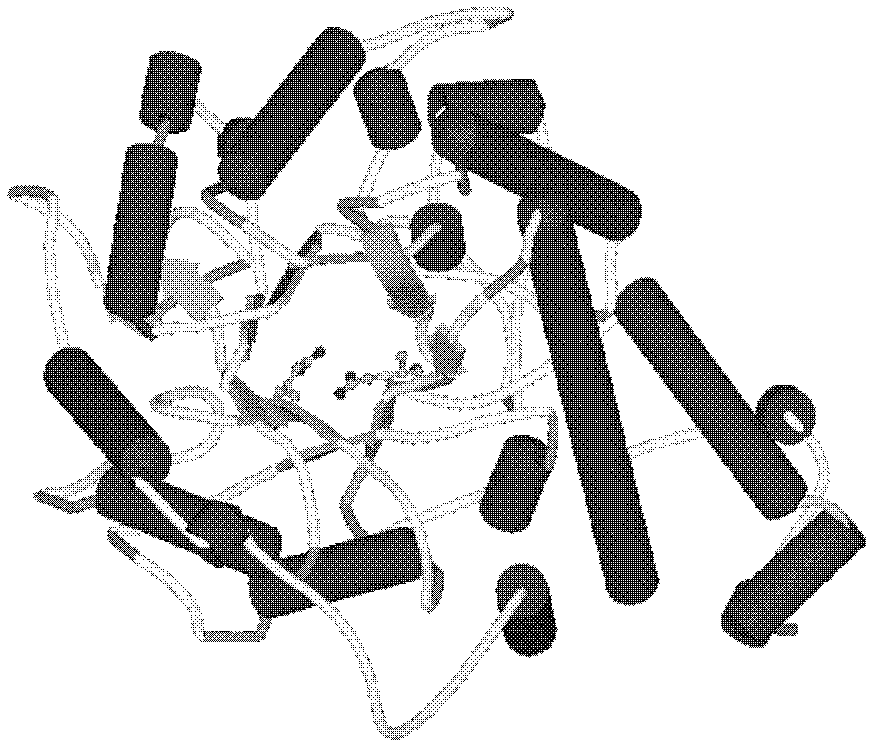

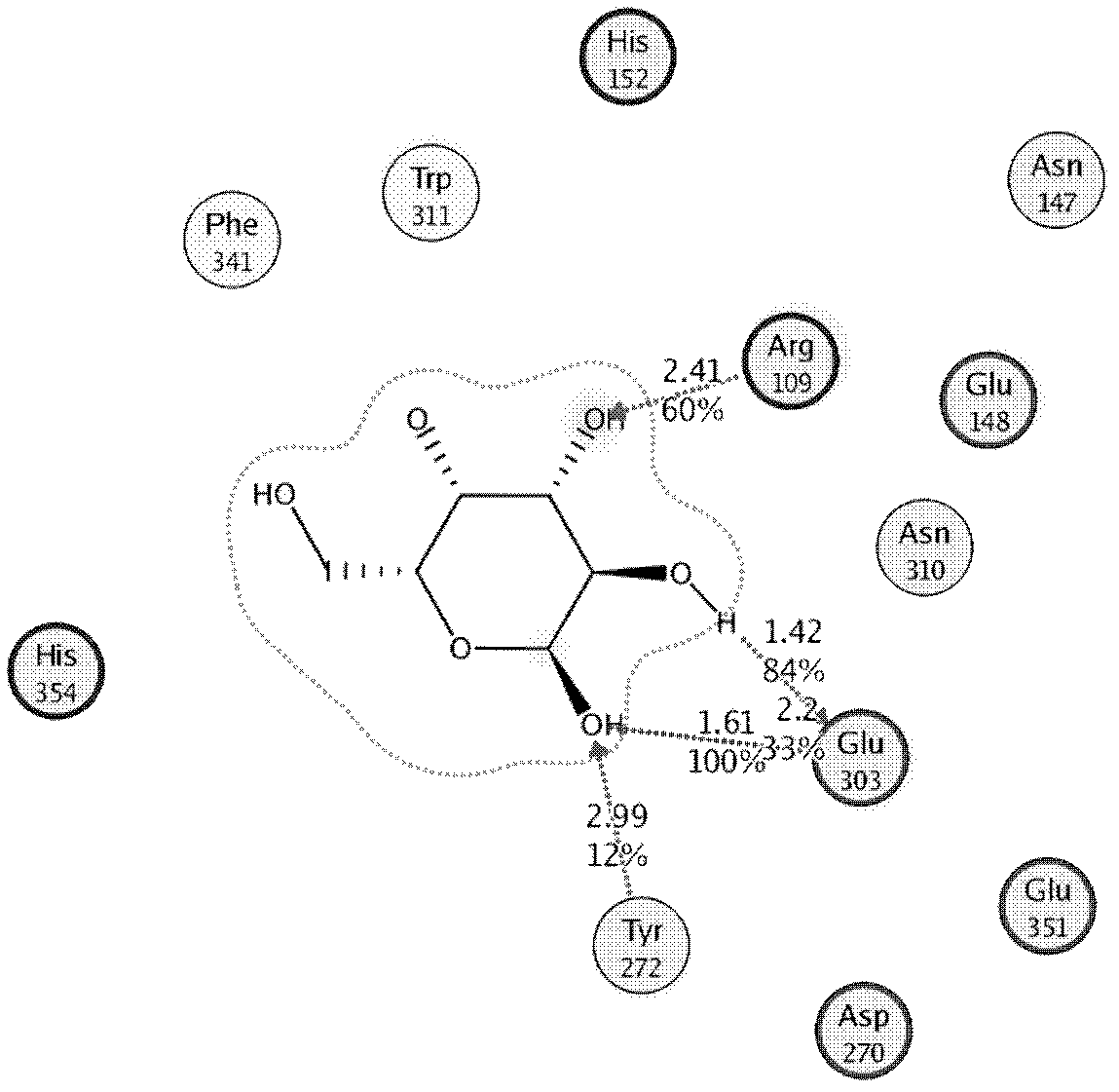

Construction of heat-resistant beta-galactosidase mutant

InactiveCN102250856AMaintain heat resistanceSuitable for hydrolysisMilk preparationMicroorganism based processesLactasePasteurization

The invention relates to construction of a heat-resistant beta-galactosidase mutant. When the heat-resistant beta-galactosidase (BgaB) mutant (BgaB-F341T) provided by the invention is used for a lactose hydrolysis process to produce low-lactose products, the inhibition action of the hydrolysis products to the hydrolytic activity of the enzyme can be effectively removed, so that the hydrolysis reaction is thoroughly carried out and the hydrolysis efficiency is improved; and when the heat-resistant beta-galactosidase (BgaB) mutant (BgaB-F341T) is used to replace medium-temperature lactase, the low-temperature hydrolysis process of low-lactose milk can be innovated. The hydrolysis temperature can be set at 55-60 DEG C, at the temperature, not only is the hydrolysis reaction speed high, but also common impure bacteria in the milk has stopped growing, therefore the product hygiene and quality problems caused by impure bacterial contamination can be effectively controlled; and in addition, by the high-temperature hydrolysis process using the heat-resistant lactase, the lactose hydrolysis and pasteurization processes can be combined, not only is the production cycle shortened, but also the energy consumption is reduced by taking full use of the waste heat from the pasteurization process, thus significantly saving production cost.

Owner:JIANGNAN UNIV +1

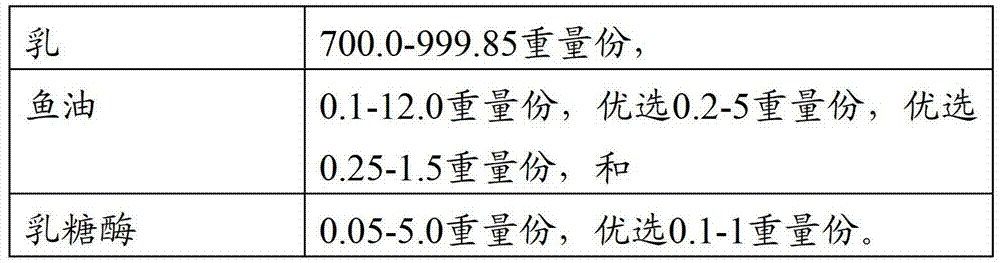

Low-lactose liquid milk product containing fish oil and production method thereof

InactiveCN103082000AFix stability issuesSolve the problem of drinking milkMilk preparationLactaseAntioxidant

The invention relates to a low-lactose liquid milk product containing fish oil and a production method thereof. The low-lactose liquid milk product containing fish oil is prepared from the following materials in parts by weight: 700.0-999.74 parts of cow milk, 0.1-12 parts of fish oil, 0-30 parts of oligosaccharide, 0-100 parts of dietary fiber, 0-3 parts of nutrients, 0.05-5 parts of lactase, 0-10 parts of an emulsifier, 0-5 parts of a thickener, 0-1 parts of an acidity regulator, 0.01-1 part of an antioxidant, 0-5 parts of edible essence, and the balance of pure water. According to the fish oil-containing low-lactose liquid milk product and the production method thereof, the stability problem of the fish oil in the liquid milk product is successfully solved by reasonably screening the proportion of various components, and the product taste and the content of the nutrients are stable within a shelf life. The high nutritional value of the product can satisfy the nutritional needs of the children, the youngsters, the office workers and the middle aged and elderly people, so the low-lactose liquid milk product containing fish oil has a strong market prospect of sale.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

Non-lactose lactic acid bacteria beverage and method for preparing beverage

ActiveCN103461486AImprove technical effectSolve the problem of impatienceMilk preparationLactic acid bacteriumLactase

The invention discloses a non-lactose lactic acid bacteria beverage and method for preparing the beverage. The method for preparing the beverage comprises the steps of 1) mixing 8%-16% of milk powder (fat<=1.5% and 28%-35% of protein) and 0.01%-0.2% of lactase with water, standing for 2-10h at the temperature of 4-10 DEG C, and obtaining reconstituted milk; 2) conducting heat preservation on the reconstituted milk for 1.5-2.5h at the temperature of 90-95 DEG C, evenly mixing the reconstituted milk with lactic acid bacteria, conducting fermentation for 60-120h, conducting cylinder reversing, homogenizing and cooling, and obtaining an acidified milk base stock, wherein the lactic acid bacteria comprises lactobacillus paracasei, and the additive amount of the lactobacillus paracasei is 1-6*106cfu / mL per milliliter of the reconstituted milk ; 3) conducting sterilization on aqueous solutions of sweet substances without the lactose, cooling the aqueous solutions to the temperature of 10-30 DEG C, mixing the aqueous solutions with the acidified milk base stock, and conducting acidifying and homogenizing. The non-lactose lactic acid bacteria beverage does not contain the lactose, and is sweet and sour, tasty and good in stability, texture, taste, special flavor and the like.

Owner:BRIGHT DAIRY & FOOD

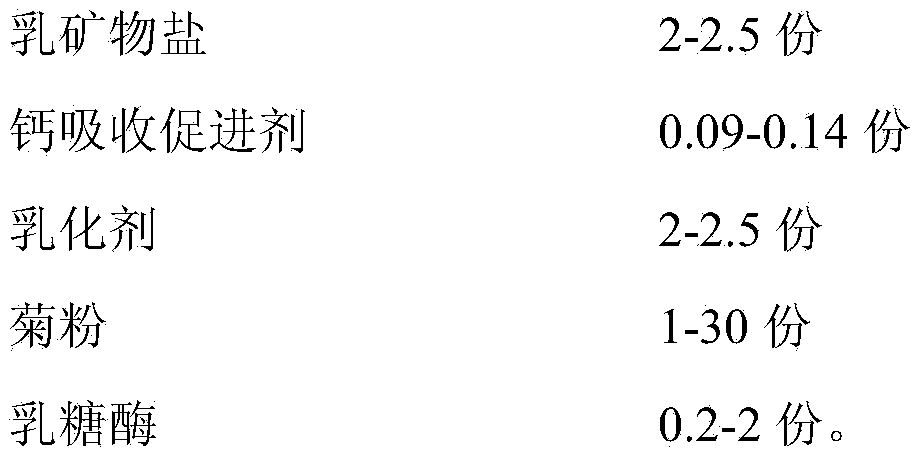

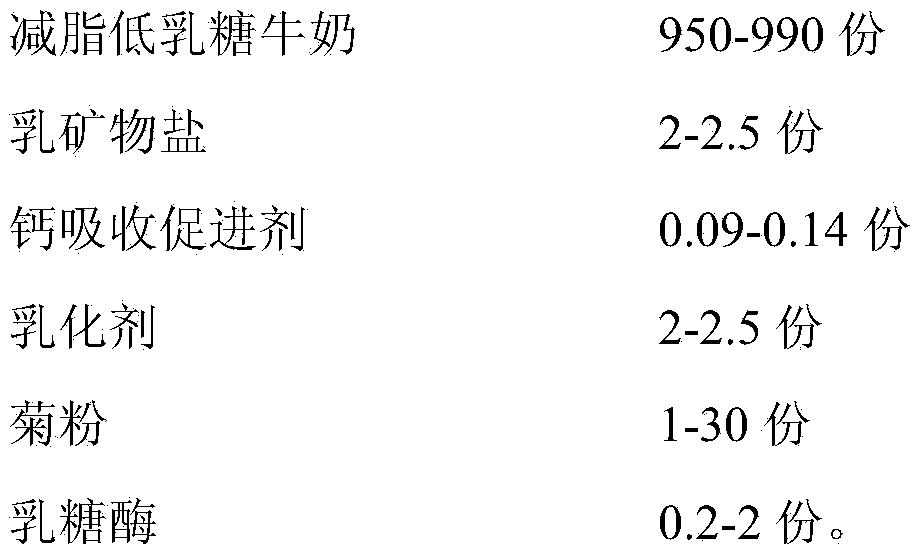

Fat-reduced, low-lactose and high-calcium milk and preparation method thereof

The invention belongs to the processing field of milk products and particularly relates to fat-reduced, low-lactose and high-calcium milk and a preparation method of the fat-reduced, low-lactose and high-calcium milk. The milk is prepared from fat-reduced and low-lactose milk, milk mineral salts, a calcium absorption accelerant, an emulsifying agent, inulin and lactase. The preparation comprises the steps of raw material preparation, material dissolving and after-treatment. The milk has no calcium precipitate, is smooth in taste and is mellow and rich; by particularly adding a dietary fiber, namely the inulin, the intestinal tract movement of middle and aged people can be accelerated, and body burdens can be alleviated; by degrading the lactose in cow milk into micromolecular galactose and glucose which are beneficially digested and absorbed, problems caused by lactose intolerance are avoided; meanwhile, vitamins and mineral substances which are necessary nutrient elements of the middle and aged people are added into raw milk of which the lactose is degraded, so as to process and prepare a required food suitable for the middle and aged people.

Owner:SHANDONG DEYI DAIRY IND

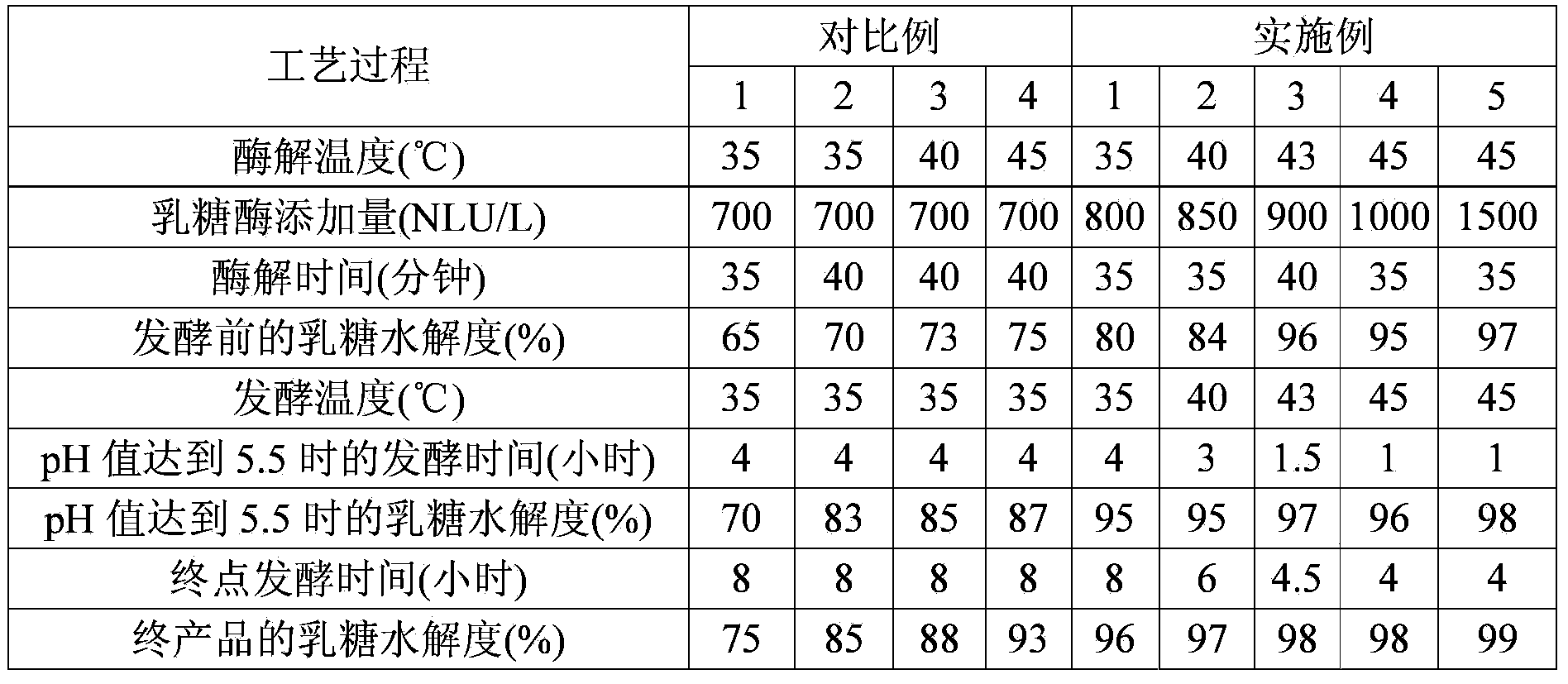

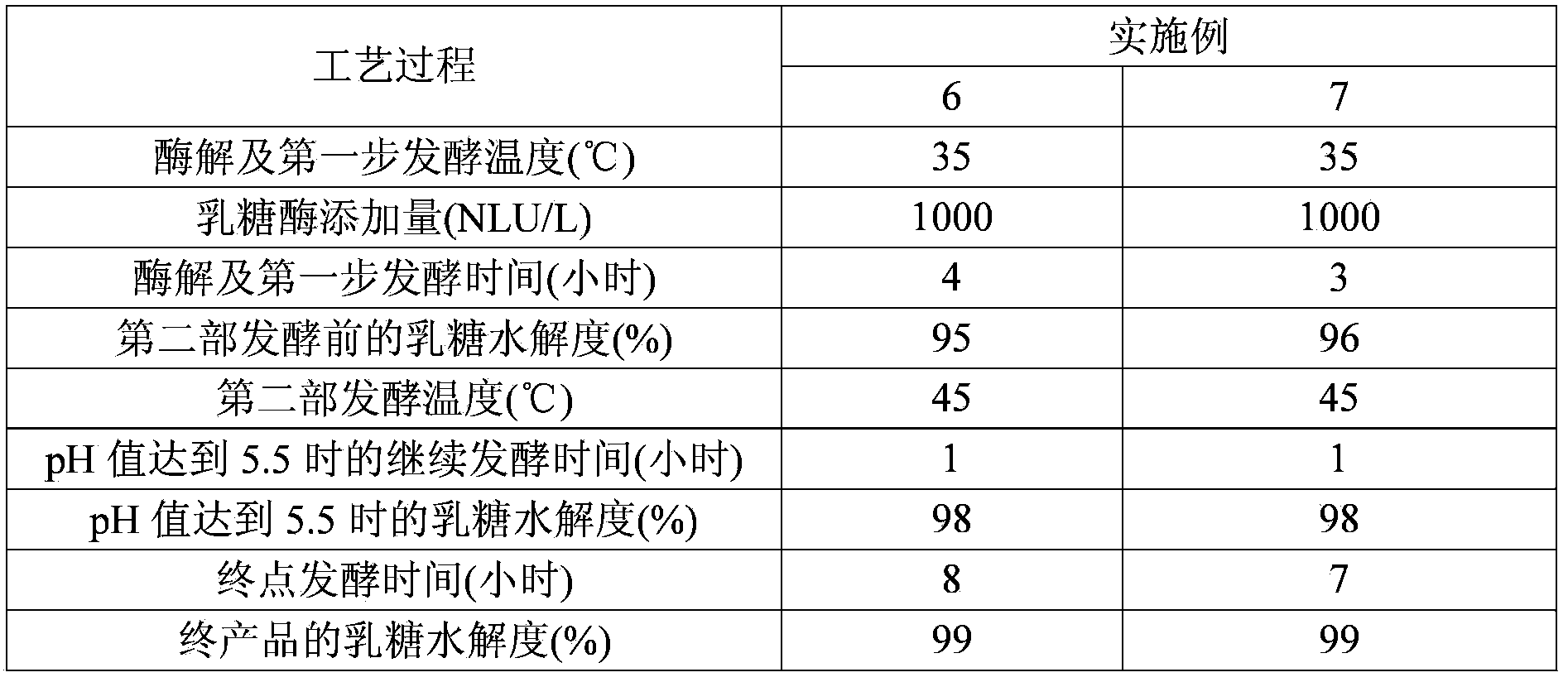

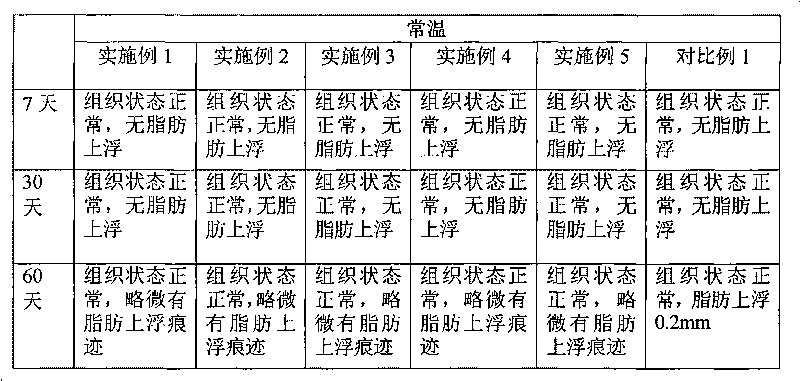

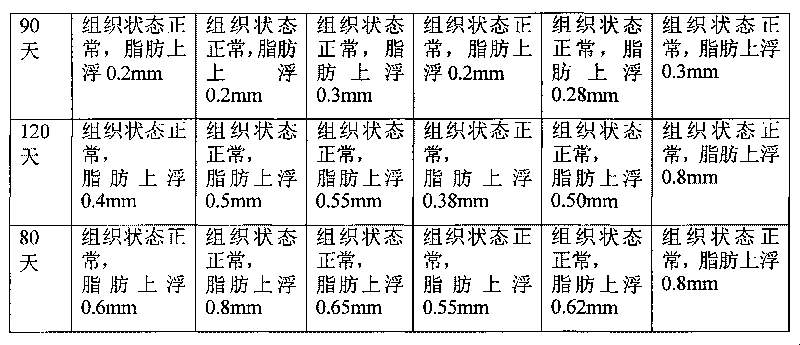

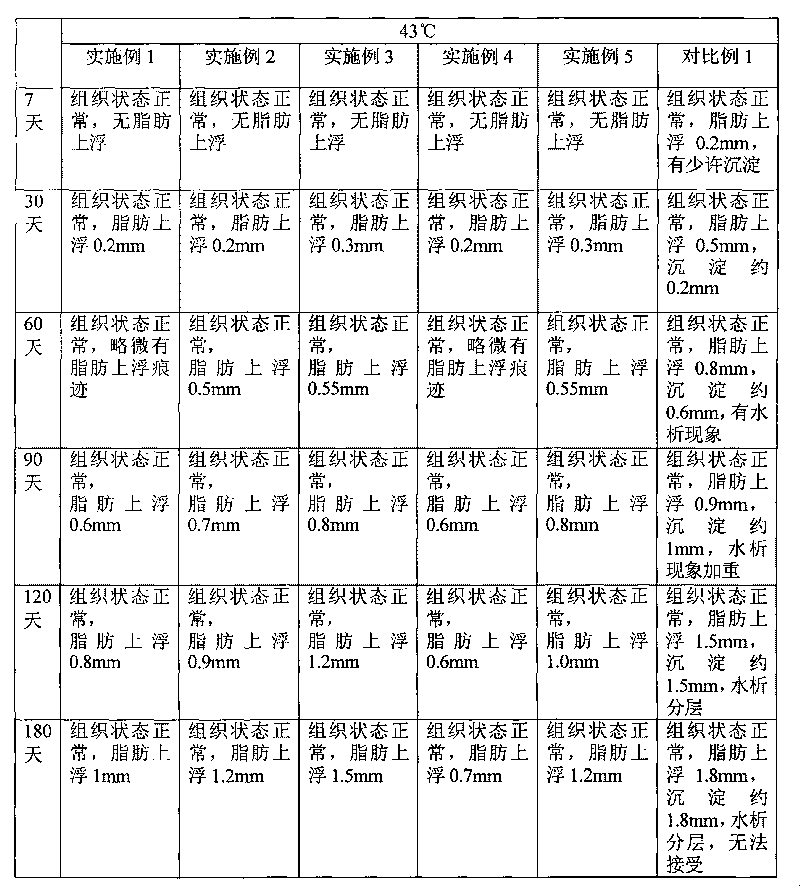

Preparation method of lactose-free fermented dairy product

The invention provides a preparation method of a lactose-free fermented dairy product. The method comprises the following steps: blending, homogenizing, sterilizing, carrying out enzyme-hydrolyzing, fermenting, filling and refrigerating all the raw materials in sequence to obtain the lactose-free fermented dairy product, wherein the enzymatic hydrolysis and fermentation steps comprise the following processes: adding lactase at the temperature of 35-40 DEG C, hydrolyzing till the degree of hydrolysis is above 80 percent, and then adding stains; or adding lactase at the temperature of 41-45 DEG C, hydrolyzing till the degree of hydrolysis is above 95 percent, and then adding stains; fermenting till the pH value of feed liquid is 5.5, starting to inactivate the lactose and ending the fermentation when the pH value of the feed liquid is 4.3-4.5; or adding lactose and medium temperature strains at the temperature of 30-35 DEG C, fermenting till the pH value of feed liquid is 5.5, then rising the temperature to 40-45 DEG C and adding thermophilic stains, and ending the fermentation when the pH value of the feed liquid is 4.3-4.5. The preparation method has the benefit that through addition of the lactose and improvement of a fermented milk preparation process, the lactose-free fermented dairy product can be effectively prepared and obtained.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

Method for preparing milk flavour using composite enzyme preparation

The present invention relates to a preparation process of milky essence. Natural butter as main material is prepared into the milky essence through diluting with water, stirring to emulsify, pasteurizing, cooling, enzymolysis, killing enzyme and concentrating. The preparation process features the enzymolysis with composite enzyme preparation comprising lipase as main component as well as one or several of proteinase, grape oxidase, hydrogen peroxidase and lactase and in the added amount of 0.2-10 wt% of main material, at 35-55 deg.c for 4-16 hr. The milky essence of the present invention has natural and mild fragrance and obviously improved quality compared with traditional product, and is used as ideal natural food additive.

Owner:天津市诺奥科技发展股份有限公司

Low-lactose milk and preparation method thereof

The invention relates to milk and a preparation method thereof, in particular to a lactase hydrolytic milk and the preparation method thereof, which belongs to a field of human daily necessary (agriculture, light industry and medical science) food and milk drink technology. The preparation method of lactase hydrolytic milk of the invention comprises the production technique of conventional liquid milk, wherein, a lactase hydrolytic step is added between the steps of pasteurization and UHT (ultra heat treated) sterilization. The product of the invention reduces the product lactose content via adding the lactase technique, thus improving the better milk absorption of the consumers.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

Formulated acidic low-lactose liquid milk product and producing method thereof

ActiveCN101703104AOvercome the defect of low hydrolysis rateIncrease hydrolysis rateMilk preparationCarboxymethyl celluloseLactase

The invention relates to the field of milk products, in particular to a formulated acidic low-lactose liquid milk product and a producing method thereof. The formulated acidic low-lactose liquid milk product contains the following raw materials by weight percent: 30 to 98.9 percent of milk, 0.31 to 1 percent of stabilizing agent, 0.3 to 0.6 percent of acidity regulator, and 0.01 to 0.1 percent oflactase of aspergillus oryzae, wherein the stabilizing agent comprises thickener and / or emulsifier, and the thickener comprises larger than or equal to 0.3 percent of low-viscosity sodium carboxymethyl cellulose by weight percent. The invention overcomes the limitation in the prior art that only neutral low-lactose milk can be produced, creatively adopts the lactase of aspergillus oryzae, provides acidic low-lactose liquid milk beverage and flavoured milk, and ensures the situation that the people suffering from lactose intolerance can drink the products becomes feasible.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

Formula for secondarily preparing yoghourt with high-index base stock, preparation technique and use method thereof

The invention provides a formula for secondarily preparing yoghourt with high-index base stock. The formula comprises the following components by weight part: 80-100 parts of milk, 0-15 parts of white granulated sugar, 0-5 parts of single cream, 0-5 parts of concentrated whey protein, first fermentation culture, secondary fermentation culture, 0-0.5 part of stable thickening emulgator, nutrient supplement, glutamine transaminase, lactase and chymosin. The formula has the beneficial effects that the fermentation base stock is uniformly produced, the products in different forms are variously produced, the formula is conveniently sold in catering terminal, the formula can meet the requirements of various clients and much more yoghourt need not be stored.

Owner:ZHEJIANG INM FOOD

Production of curing lactase

ActiveCN1818061AReduce manufacturing costHydrolasesOn/in organic carrierFreeze thawingKluyveromyces fragilis

The invention is about the production method for the immobilized lactase. It includes: (1) prepare the kluyveromyces Fragilis suspension, (2) breaking the cell wall by the enzyme, (3) breaking the cell wall by freeze-thaw, (4) breaking the cell wall by high-pressure homogenizer, (5) preparing the immobilized carrier liquid, (6) preparing the immobilized carrier liquid for lactase, (7) preparing the immobile liquid, (8) immobilization. So the low lactin milk is produced by the immobilized lactase, it can treat it continuously and the enzyme can't run off. So it can decrease the cost.

Owner:哈尔滨美华生物技术股份有限公司

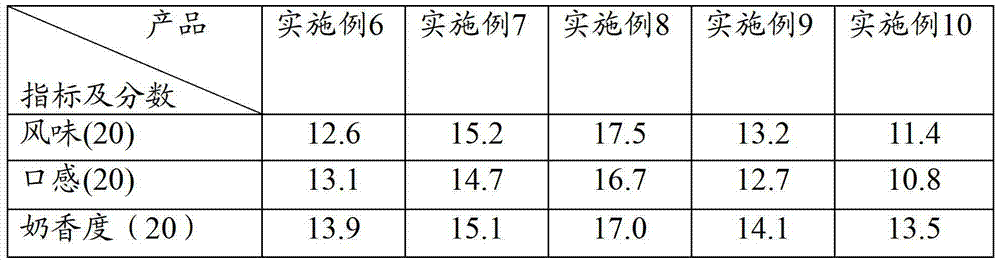

Low-sugar brown lactobacillus drink and preparation method thereof

The invention discloses a low-sugar brown lactobacillus drink and a preparation method thereof. The preparation method comprises the following steps: (1) mixing raw milk with lactase, and standing to obtain mixed liquid; (2) producing Maillard reaction of the mixed solution to obtain browned liquid; (3) cooling the browned liquid, fermenting, and cooling to obtain a fermented milk base material; (4) mixing sugar water liquid with the fermented milk base material, and homogenizing to obtain the low-sugar brown lactobacillus drink, wherein the sugar water liquid is prepared by mixing water with an additive A, sterilizing and cooling. According to the preparation method, lactose is decomposed by a bio-enzyme technology, and the effect of the Maillard reaction can be achieved without addition of reducing sugar, such as exogenous glucose; the low-sugar brown lactobacillus drink is relatively natural and mild in mouth feel, and an emulsifier can be reduced and even is no longer used according to the actual situation.

Owner:BRIGHT DAIRY & FOOD CO LTD

Whole-grain rice enzymolysis infant milky rice powder and manufacturing method thereof

InactiveCN106136052AImprove the efficiency of surface gelatinizationConducive to the efficiency of enzymatic hydrolysis operationMilk preparationSugar food ingredientsAmylaseBiotechnology

The invention relates to the field of baby foods, in particular to whole-grain rice enzymolysis infant milky rice powder. Whole-grain rice which substitutes for polished rice is supplemented with cow milk materials to serve as raw materials of baby foods, nutrients of husks, aleurone layers and grain embryos in whole-grain rice are used completely, and comprehensive nutrition is guaranteed due to joint addition of animal and vegetable materials. By protease, lactase and amylase for enzymolysis, enzymolysis of allergenic protein, lactose and starch is realized to make the allergenic protein, the lactose and the starch easier to digest and absorb, and transitional period of baby foods can be effectively shortened for infants.

Owner:SHANTOU PEIZHI FOOD

Lactase-containing modified milk powder capable of regulating intestinal function and preparation method of lactase-containing modified milk powder

InactiveCN107897381AAddress intolerance symptomsMilk preparationMilk preservationLactaseLactose intolerance

The invention provides lactase-containing modified milk powder capable of regulating an intestinal function and a preparation method of the lactase-containing modified milk powder is prepared from thefollowing components in percentage by weight: 50 to 80 percent of milk powder, 5 to 30 percent of a milk protein type raw material and / or a carbohydrate type raw material, 5 to 15 percent of prebiotics, 1 percent to 5 percent of lactase and 0.3 to 1.5 percent of probiotic bacteria. The invention further comprises the preparation method of the lactase-containing modified milk powder capable of regulating the intestinal function. The lactase-containing modified milk powder capable of regulating the intestinal function, provided by the invention, contains the lactase, the probiotic bacteria andthe probiotics, so that the intestinal micro-ecology and a digestion system are easy to regulate; after being matched with milk products containing other lactose, the lactase-containing modified milkpowder can assist the lactose decomposition and the effect of alleviating lactose intolerance symptoms is realized.

Owner:AUSNUTRIA DAIRY CHINA

Method of preparing low lactose milk

ActiveCN101223912AIncrease hydrolysis rateDecompose fullyMilk preparationFood preparationLactose intoleranceDietary fiber

The invention relates to a low-lactose milk preparation method which comprises the following steps: (1) mechanical impurities of raw milk are removed by milk purification technique; (2) raw milk after purification is sterilized at ultra-temperature or pasteurized and then cooled to temperature below 8 DEG C; (3) milk compound is prepared; (4) the prepared milk compound is sterilized at ultra-temperature or pasteurized and cooled; (5) lactase preparation is added under aseptic condition; (6) the milk is bottled sterilely. The milk compound in step (3) also comprises: 0.1-10 wt parts of dietary fiber for increasing the health care function of the milk and further comprises essence less than 2 parts by wt. The method of the invention overcomes the shortcoming of low lactose hydrolysis rate of the prior technique. The product prepared by the method of the invention has good stability, and is particularly suitable for people with severe lactose intolerance symptom. The invention is also added with dietary fiber in the formula.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com