Instant cheese and preparation method thereof

A technology of cheese and food habits, applied in the field of dairy products, to achieve the effect of high utilization rate of raw materials, soft taste and smooth texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

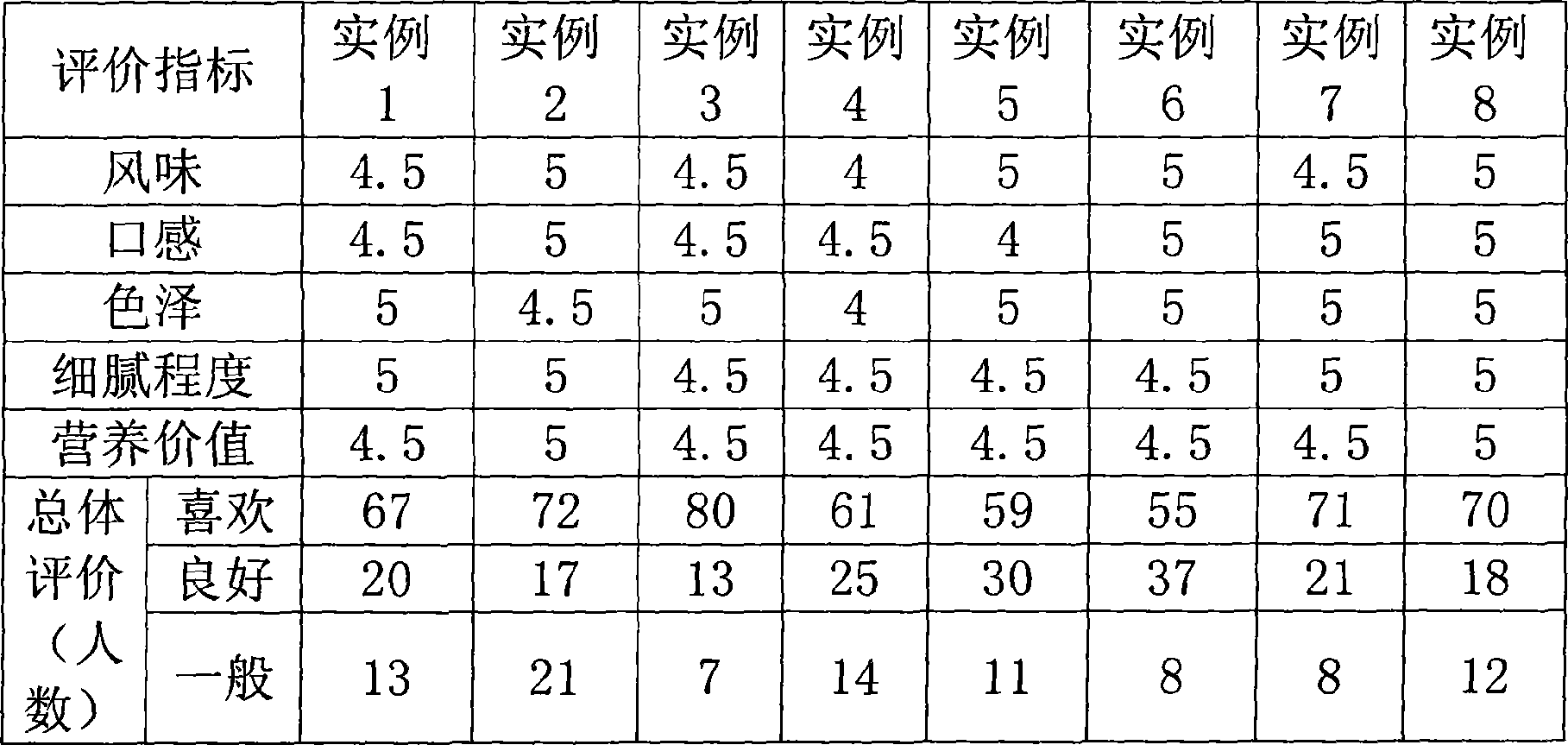

Examples

Embodiment 1

[0039] A ready-to-eat cheese comprising the following ingredients:

[0040] Concentrated fresh milk: about 60 parts by weight, formed by concentrating 100 L whole fat fresh milk to 40% of the original volume, and adding 0.13 parts by weight of lactase during the treatment before concentration.

[0041] Transglutaminase: 0.3 parts by weight;

[0042] 0.035 parts by weight of rennet.

[0043] A preparation method of instant cheese, the steps are:

[0044] (1) Add lactase to whole fresh milk and place it in a water bath at 37°C for 2 hours;

[0045] (2) heating the treated whole fresh milk to 63° C., and pasteurizing it for 0.5 hour;

[0046] (3) Vacuum concentrating the sterilized whole fresh milk to 40% of the original volume to form concentrated fresh milk;

[0047] (4) Cool the concentrated fresh milk to 30°C, add the standard solution of transglutaminase powder and rennet, fully mix and stir to form a mixture;

[0048] (5) Treat the above mixture in a 30°C water bath fo...

Embodiment 2

[0051] A ready-to-eat cheese comprising the following ingredients:

[0052] Concentrated fresh milk: about 60 parts by weight, formed by concentrating 100 L whole fat fresh milk to 40% of the original volume, and adding 0.15 parts by weight of lactase during the treatment before concentration.

[0053] Transglutaminase: 0.3 parts by weight

[0054] Rennet: 0.035 parts by weight.

[0055] Random mixing of chocolate and almonds: 4 parts by weight.

[0056] A preparation method of instant cheese, the steps are:

[0057] (1) Add lactase to whole fresh milk and place it in a water bath at 37°C for 2 hours;

[0058] (2) heating the treated whole fresh milk to 63° C., and pasteurizing it for 0.5 hour;

[0059] (3) Vacuum concentrating the sterilized whole fresh milk to 40% of the original volume to form concentrated fresh milk;

[0060](4) Add sterilized additives: chocolate and almonds (whole or broken);

[0061] (5) Cool the concentrated fresh milk to 30°C, add the standard s...

Embodiment 3

[0065] A ready-to-eat cheese comprising the following ingredients:

[0066] Concentrated fresh milk: about 60 parts by weight, formed by concentrating 100 L whole fat fresh milk to 40% of the original volume, and adding 0.15 parts by weight of lactase during the treatment before concentration.

[0067] Transglutaminase: 0.3 parts by weight

[0068] Rennet: 0.035 parts by weight.

[0069] Additive: 0.01 parts by weight of β-carotene.

[0070] A preparation method of instant cheese, the steps are:

[0071] (1) Add lactase to whole fresh milk and place it in a water bath at 37°C for 2 hours;

[0072] (2) heating the treated whole fresh milk to 63° C., and pasteurizing it for 0.5 hour;

[0073] (3) Vacuum concentrating the sterilized whole fresh milk to 40% of the original volume to form concentrated fresh milk;

[0074] (4) Add additives: β-carotene;

[0075] (5) Cool the concentrated fresh milk to 30°C, add the standard solution of transglutaminase powder and rennet, fully...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com