Patents

Literature

232 results about "Chymosin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chymosin /ˈkaɪməsɪn/ or rennin /ˈrɛnɪn/ is a protease found in rennet. It is an aspartic endopeptidase belonging to MEROPS A1 family. It is produced by newborn ruminant animals in the lining of the abomasum to curdle the milk they ingest, allowing a longer residence in the bowels and better absorption. It is widely used in the production of cheese. Bovine chymosin is now produced recombinantly in E. coli, Aspergillus niger var awamori, and K. lactis as alternative resource.

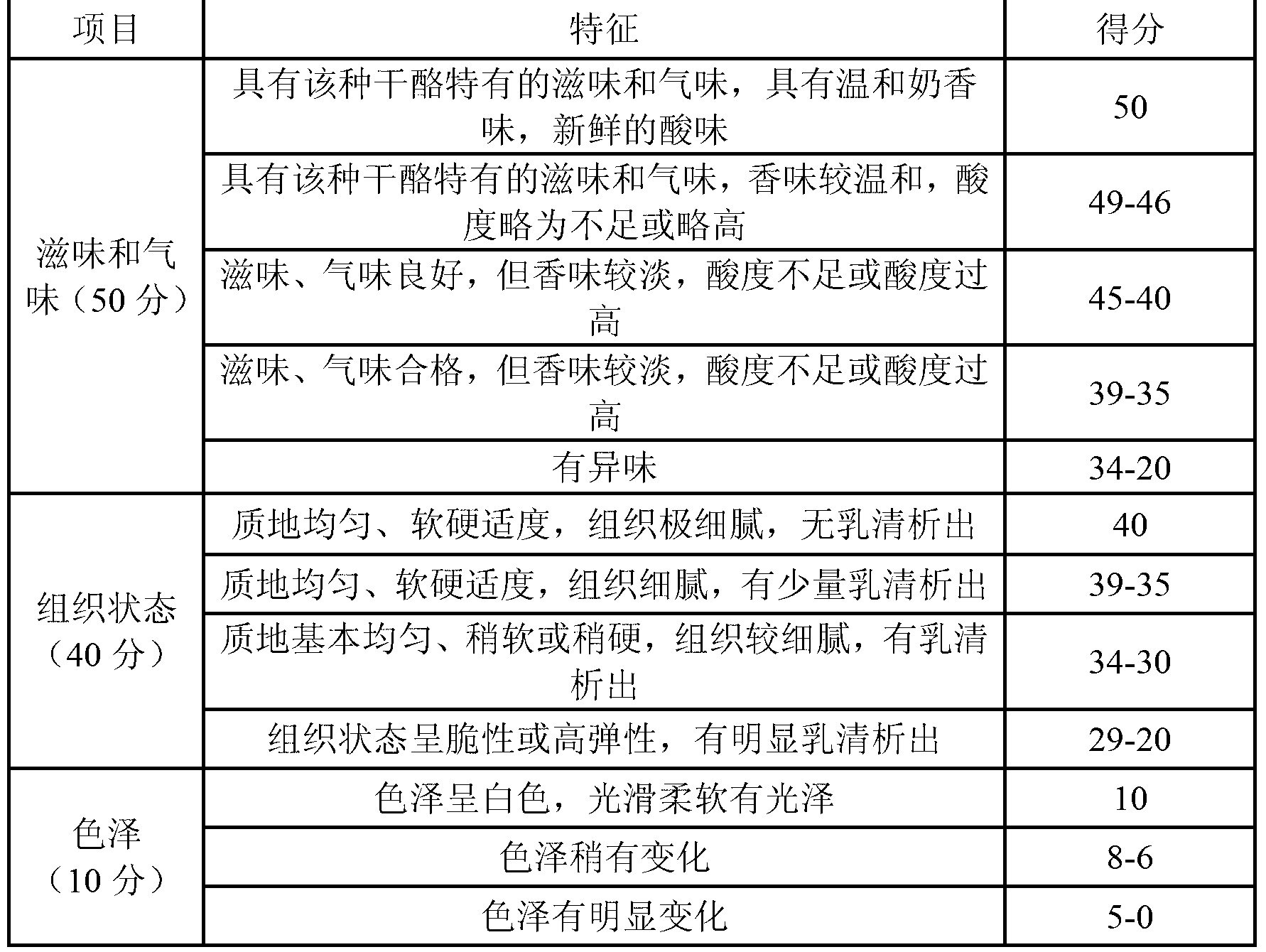

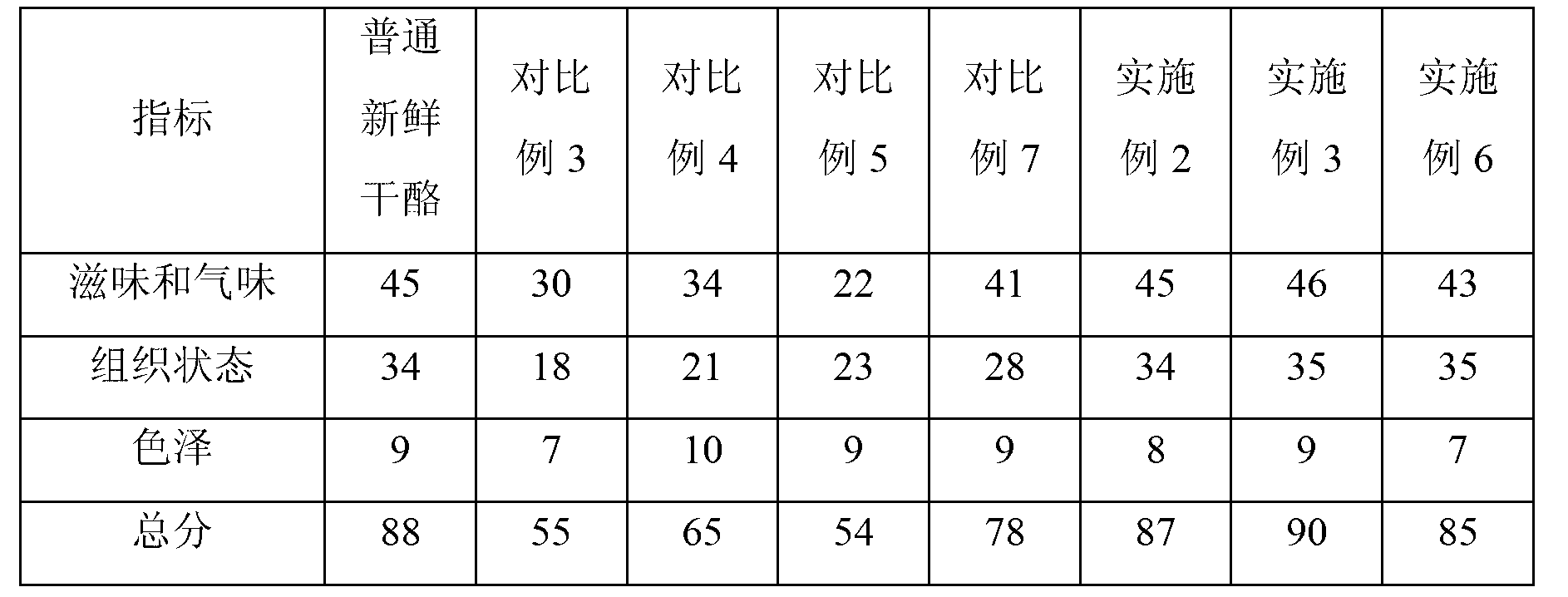

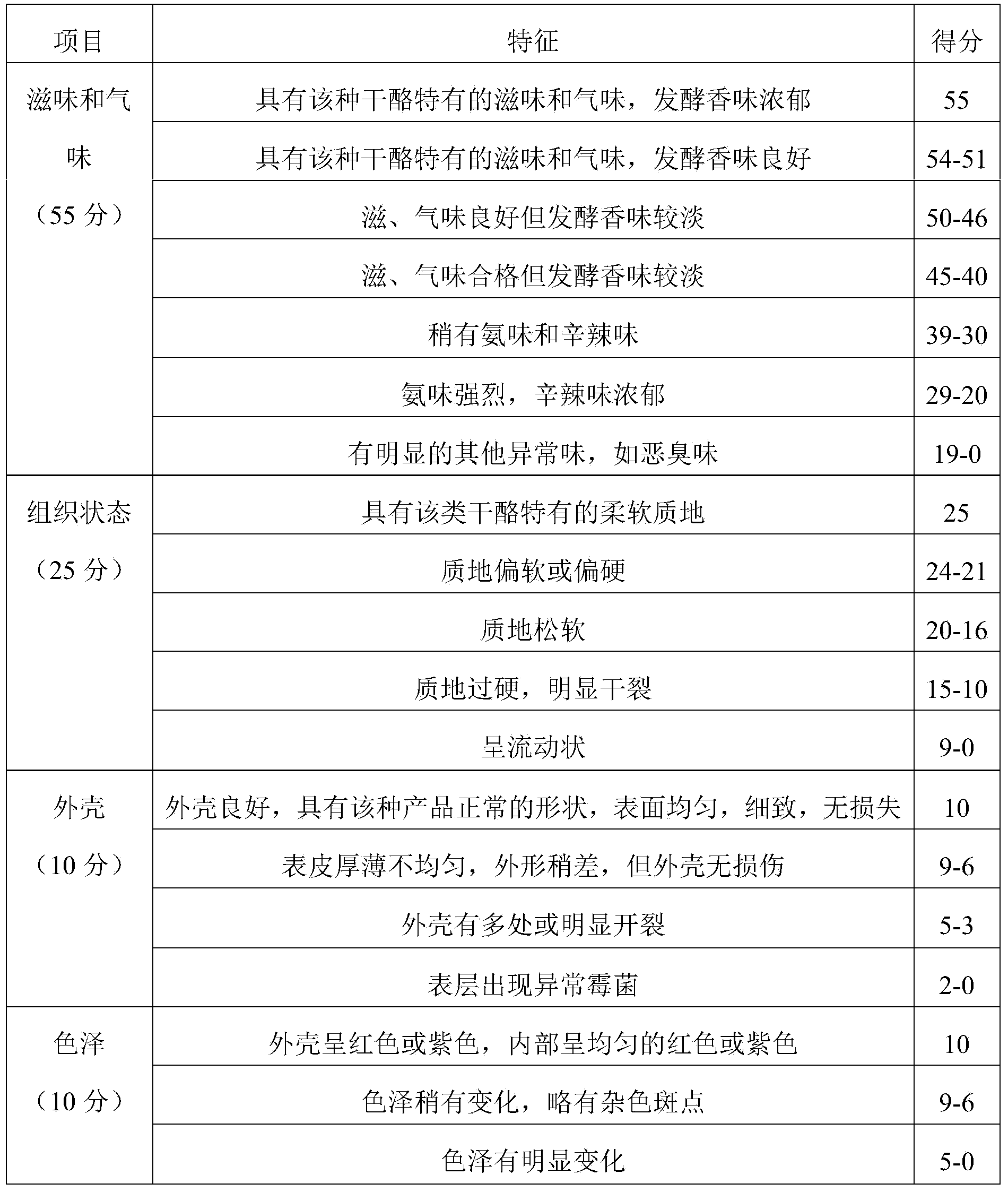

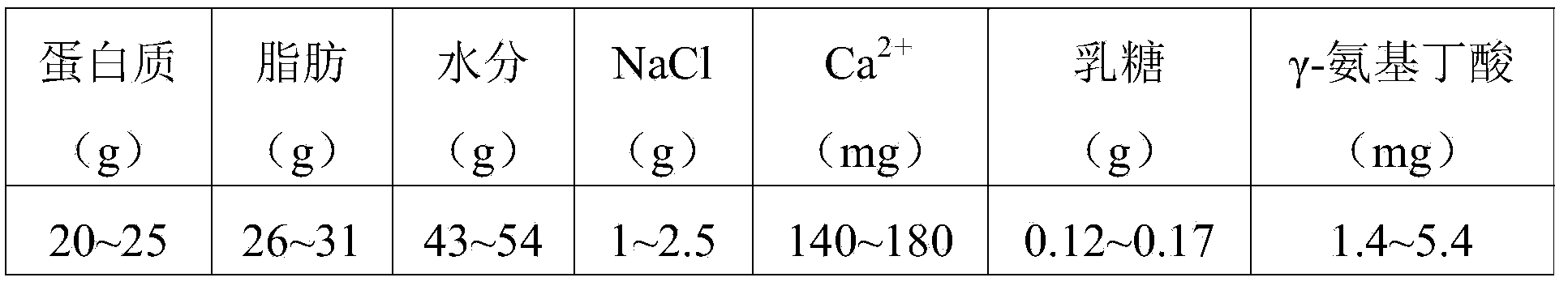

Preparation method of monascus sp. cheese and product thereof

ActiveCN103444878ABreakthrough understandingImprove immunityCheese manufactureNutritive valuesFlavor

The invention discloses a preparation method of monascus sp. cheese and a product of the monascus sp. cheese. The preparation method comprises the following steps: (1), sterilizing raw milk and then cooling to obtain treated milk, inoculating a lactic acid bacteria starter in the treated milk, adding chymosin when fermenting until pH is 6.0-6.5, curdling for 30-40min to obtain curd; (2), cutting the curd into blocks, stirring and discharging whey, adding salt in the curd after discharging the curd, and feeding into a mould after uniformly stirring; (3), carrying out or not carrying out pressing after feeding in the mould, overturning for 5-10 times at a frequency of 15-30min / times, and standing to ensure that the whey is discharged; and (4), cutting the curd into curd blocks, uniformly spraying a monascus fermentation liquor on the surface of the curd blocks, loading in a container, and curing to obtain the monascus sp. cheese. The monascus sp. cheese disclosed by the invention belongs to natural mould aged cheese; the quality and the flavor of the cheese are effectively improved by using the monascus sp., and the nutritional value of the cheese is increased; the preparation method is simple, convenient and easy to popularize and apply.

Owner:BRIGHT DAIRY & FOOD

Imitated cheese and its preparation method

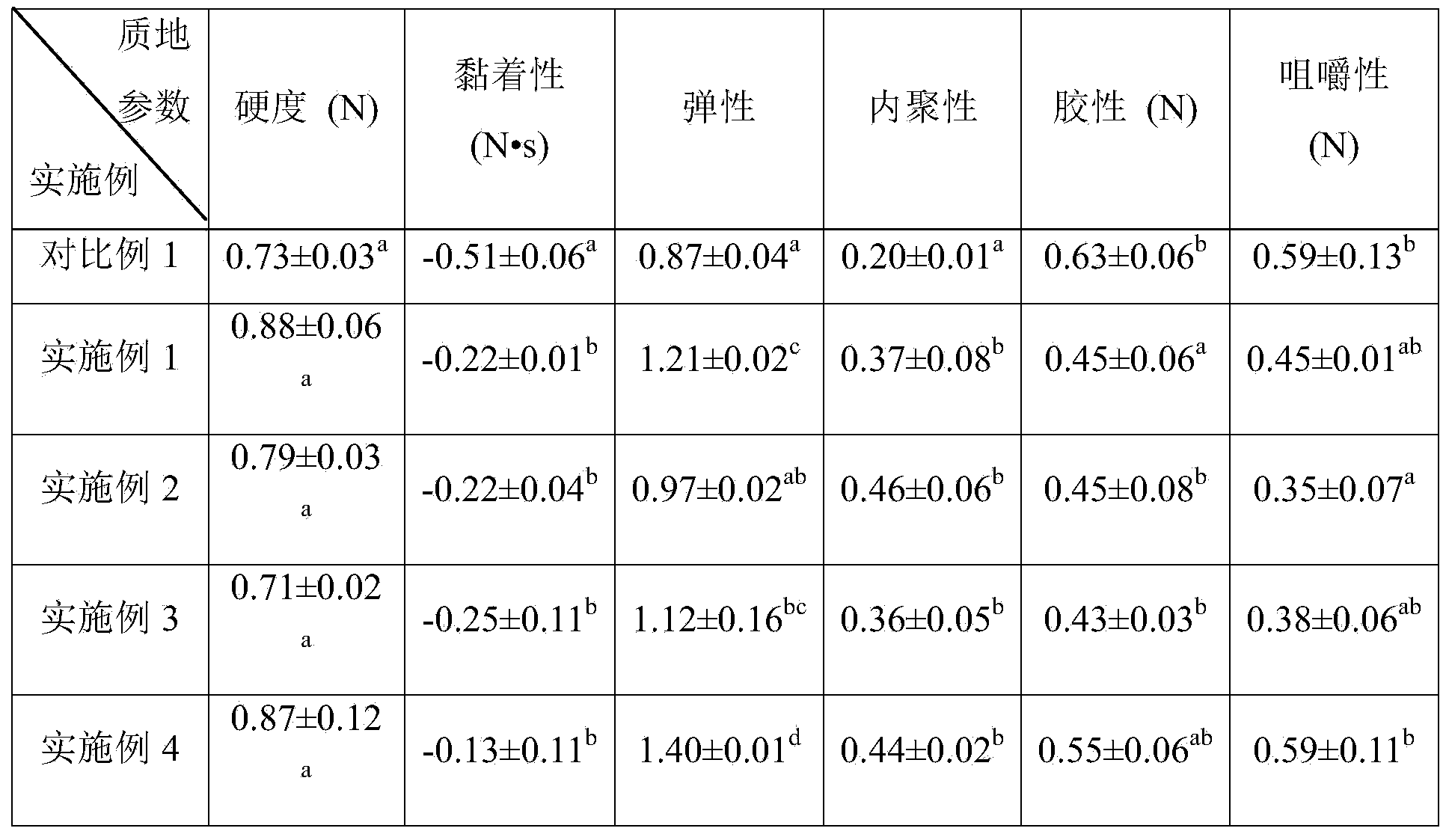

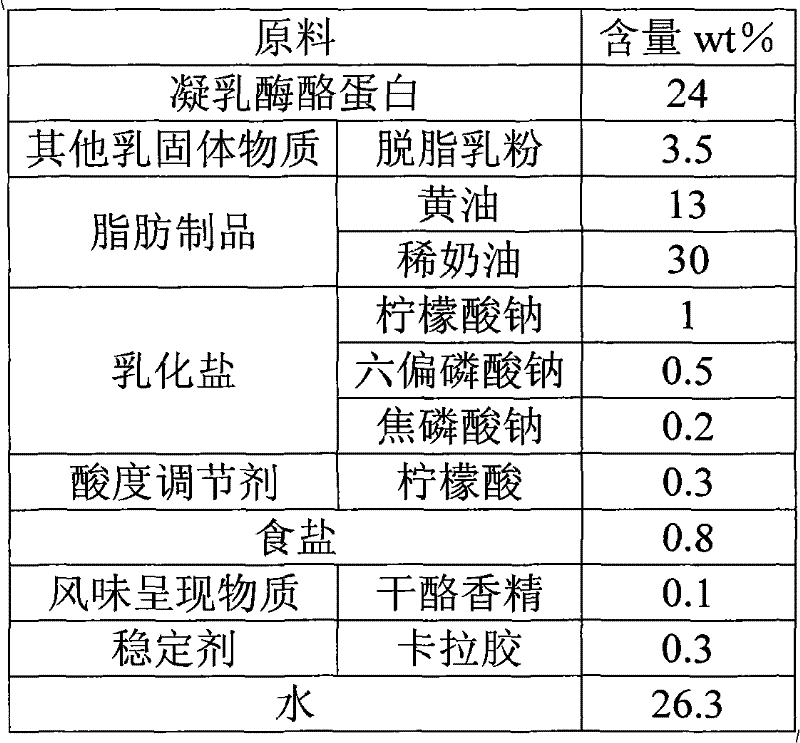

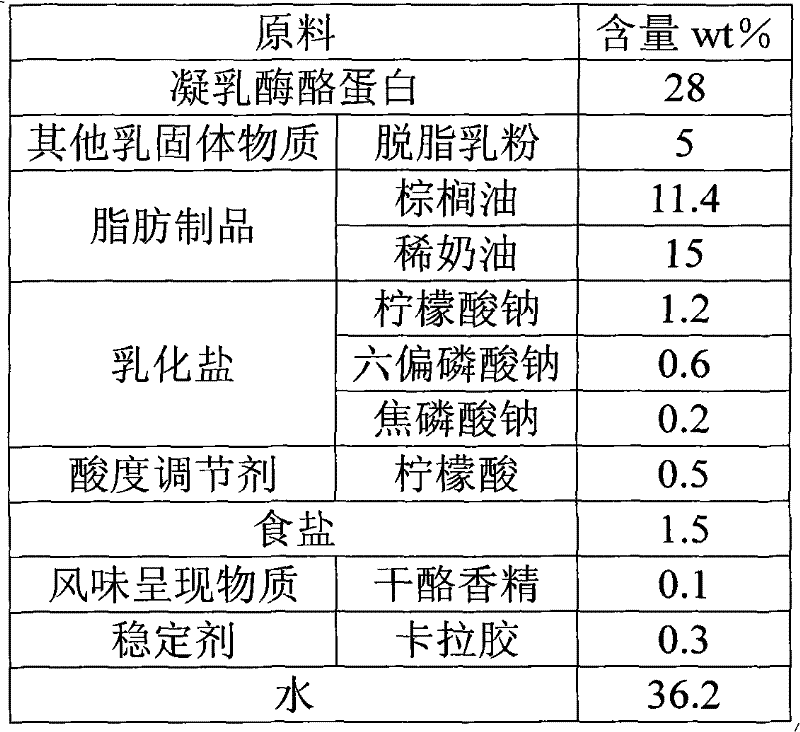

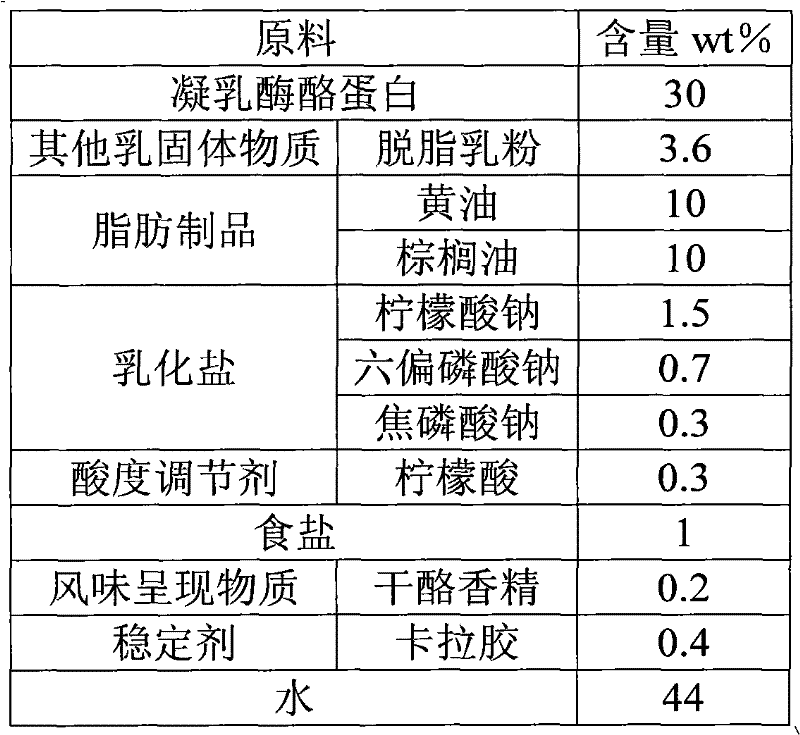

The invention discloses a preparation method of an imitated cheese, comprising the following steps of: (1) shearing and premixing raw materials consisting of, by weight, 21-30% of chymosin casein,1-5% of other milky solid substances excluding the chymosin casein, 20-60% of a fat product, 1-3% of an emulsifying salt and 11-44% of water, wherein the emulsifying salt is phosphate and / or citrate; (2) stirring and emulsifying a slurry obtained by premixing; and (3) molding and cooling. The method provided by the invention is simple, fast and easy to operate. The imitated cheese prepared by the method can maintain the original local flavor and functional properties of the classic natural Mozzarella cheese. In addition, the applied raw materials and the product are easy to store, and the wire drawing performance of the product will not be changed with the storage time, thus effectively reducing cost and food safety risk.

Owner:BRIGHT DAIRY & FOOD

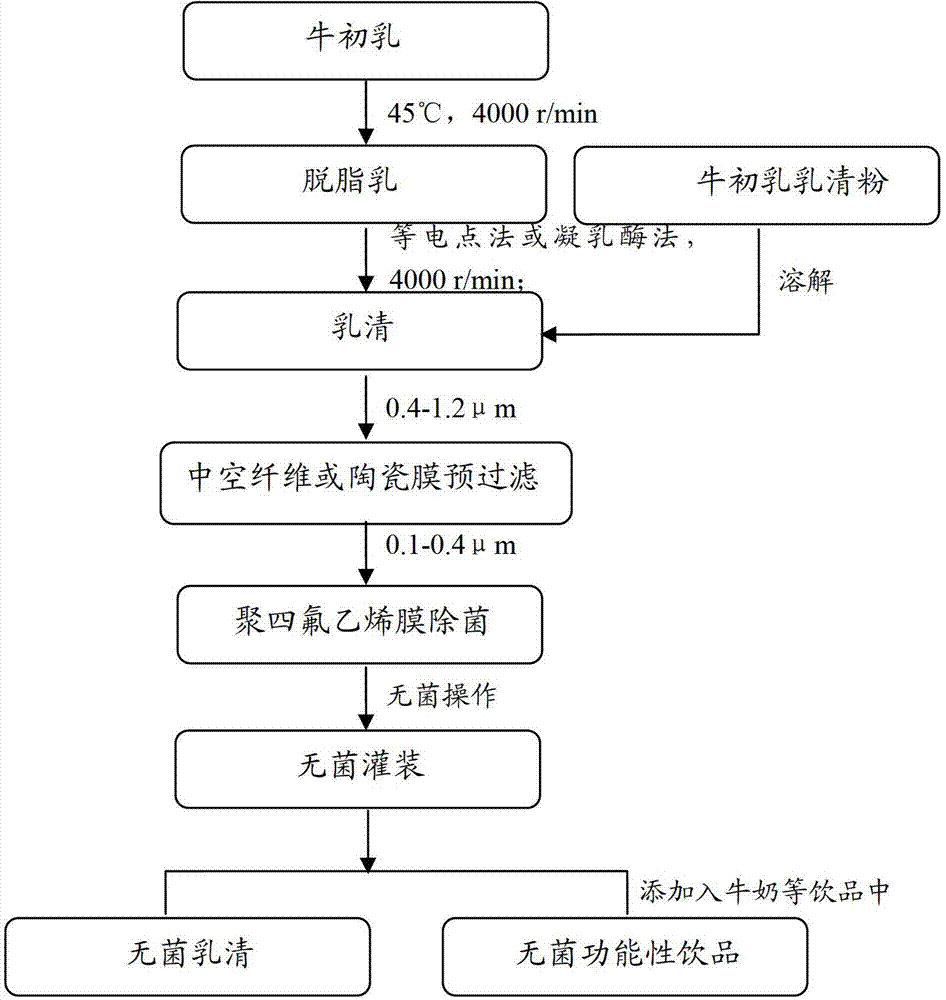

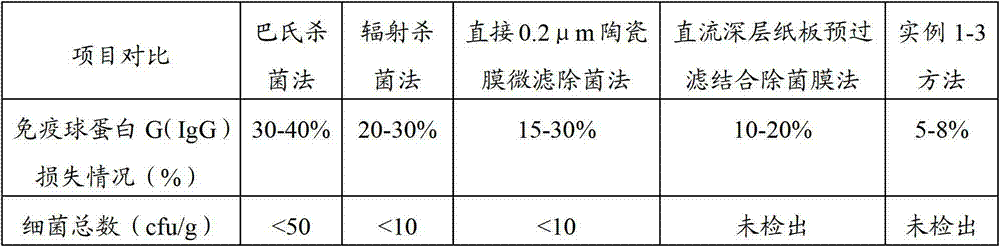

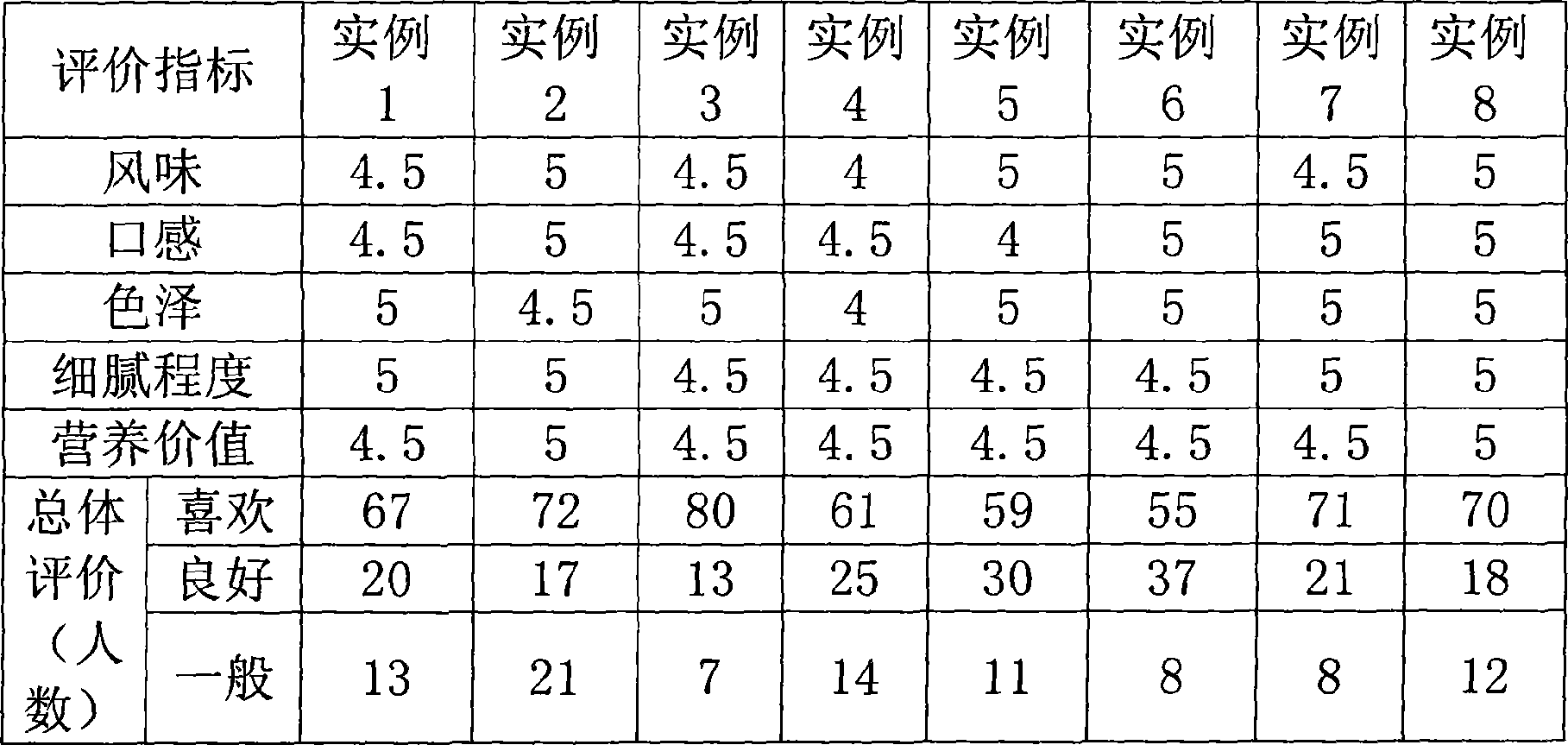

Sterile bovine colostrum whey with natural immunocompetence and preparation method and application thereof

ActiveCN103039630AAvoid sex changeAttenuation Concentration RatioWhey manufactureHollow fibre membraneFruit juice

The invention relates to sterile bovine colostrum whey with natural immunocompetence, and a preparation method and an application thereof. The preparation method comprises the steps of centrifuging bovine colostrum, removing fat to obtain defatted bovine colostrum, settling casein in the defatted bovine colostrum by an isoelectric point method or a chymosin method, obtaining whey liquid, or dissolving bovine colostrum whey powder to obtain the whey liquid, pre-filtering with a hollow fiber membrane or a ceramic membrane, removing the residual fat, casein and most thalli in the whey, conducting filtration sterilization with a polytetrafluoroethylene membrane filter, filling under a sterile condition, and obtaining the sterile bovine colostrum whey. The sterile bovine colostrum whey is degermed by a polytetrafluoroethylene degerming membrane based on pre-filtering, the handling capacity of feed liquid is increased, the service life of the membrane is prolonged, the membrane cost is saved, and the sterile bovine colostrum whey is suitable for industrial production. The content of immunoglobulin in the obtained whey is high; sterile requirements can be met; and the whey can directly serve as an immunoglobulin-rich whey product, and can also be added to beverages such as milk and fruit juice to be made into functional beverages.

Owner:HEILONGJIANG KANPURE BIOTECH

Instant cheese and preparation method thereof

The invention relates to an instant cheese and a preparation method thereof. The preparation method comprises the steps: using full-cream fresh milk as main material, pasteurizing the milk after being hydrolyzed through lactase, and concentrating the full-cream fresh milk to 35-40 percent of the original volume in vacuum. The preparation method of the instant cheese has the core points that transglutaminase is added at 35 DEG C, and milk proteins are linked to form a protein network under the action of the transglutaminase, thereby forming a uniform and stable gel system easily. Then, chymosin is added for promoting gel to form , and uniform, stable and delicate instant cheese can be obtained in a water bath for half hour at about 30 DEG C. The invention is simple and easy for operation, and can be used for development of various application products on the theoretical basis, including breakfast cereal cheese, jelly cheese and the like. Moreover, the instant cheese can meet the requirements of consumers for taste, texture, nutrition, and the like.

Owner:TIANJIN UNIV OF SCI & TECH

Novel string cheese and preparation method thereof

InactiveCN102090457AAdd hot water to scaldShorten acidification timeCheese manufactureFiber structureFlavor

The invention relates to novel string cheese and a preparation method thereof. The preparation method comprises the following steps of: making a cheese coagulum by using lactic acid bacteria and acidulant chymosin; performing steam jet or hot-water hot iron on the cheese coagulum; stretching at a high temperature to obtain a cheese block mass; adding emulsifying salt, table salt and seasoner into the cheese block mass; and extruding to obtain a product, wherein the product can be eaten without being cooked and has a hand-torn string texture and various flavors. On the basis of a Mozzarella cheese technology and the novel string cheese and the preparation method thereof, the acidulant is used, the hot-water hot iron is performed, a minor-diameter long-distance outlet molding method is used, and the positive effects of shortening acidification time, increasing the adaptability to production conditions and improving the uniformity and the stability of a cheese fiber structure are achieved.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Monascus cheese, monascus purpureus and culture method of monascus purpureus

ActiveCN104585333AHigh content of active metabolitesIncrease contentFungiMicroorganism based processesNutritive valuesFood flavor

The invention discloses monascus cheese and a preparation method thereof.The preparation method of the monascus cheese comprises the following steps of: (1) inoculating a lactic acid bacterium fermentation agent to sterilized raw milk at 28-32 DEG C for fermentation till a pH (potential of hydrogen) value is 6.2-6.6, (2) adding chymosin, curding to form curd after stirring, (3) cutting the curd to form curd blocks, (4) draining the curd blocks till the pH (potential of hydrogen) value is 5.4-5.8, putting into a mold for forming, standing, and turning over regularly, and (5) soaking the curd blocks obtained in Step (4) with saline, then standing, spraying monascus spore liquid, and curing, wherein a monascus strain is monascus purpureus BD-M-1 strain with the collection number of CGMCC (China General Microbiological Culture Collection Center) No. 8120. The monascus cheese improves the texture and flavor of cheese, and adds a nutritive value of the cheese, and the preparation method is simple and convenient.

Owner:BRIGHT DAIRY & FOOD

Commercial production of chymosin in plants

InactiveUS7390936B1Improve the level ofHydrolasesOther foreign material introduction processesBiotechnologyPlanting seed

A method for the commercial production of chymosin which involves the recombinant expression of chymosin in plant seeds, that enables chymosin to accumulate to at least 0.5% (w / w) of total seed protein is described. An improved method for the isolation of chymosin from the seed is also described.

Owner:CONCEPT CAPITAL MANAGEMENT +1

Formula for secondarily preparing yoghourt with high-index base stock, preparation technique and use method thereof

The invention provides a formula for secondarily preparing yoghourt with high-index base stock. The formula comprises the following components by weight part: 80-100 parts of milk, 0-15 parts of white granulated sugar, 0-5 parts of single cream, 0-5 parts of concentrated whey protein, first fermentation culture, secondary fermentation culture, 0-0.5 part of stable thickening emulgator, nutrient supplement, glutamine transaminase, lactase and chymosin. The formula has the beneficial effects that the fermentation base stock is uniformly produced, the products in different forms are variously produced, the formula is conveniently sold in catering terminal, the formula can meet the requirements of various clients and much more yoghourt need not be stored.

Owner:ZHEJIANG INM FOOD

Method for processing seabuckthorn yogurt slices

InactiveCN101773160AGuaranteed sensory qualityImprove product qualityMilk preparationFruit juiceMagnesium stearate

The invention relates to a method for processing seabuckthorn yogurt slices, which belongs to the technical field of nutrition health-care food processing and solves the technical problem that the mouthfeel of the seabuckthorn is sour. Due to the method, the seabuckthorn yogurt slices with total nutrition and suitable sourness and sweetness are produced by mixing with milk and through the fermentation of lactobacillus. The technical scheme comprises the key point of the production of the seabuckthorn yogurt slices. The key point of the process is to determine parameters of milk curd, additive formation and drying condition. The optimal parameters of the milk curd comprise that: the pH value is adjusted to be 6.0; 0.02 percent CaCl2 and 2g / L chymosin sequentially are added; slow stirring is performed; the mixture is maintained for 2.5 to 3 hours; the materials are sieved by an 80-mesh sieve; and water in whey and fruit juice are discharged. The optimal formula of the additive comprises 2 percent of whole milk powder, 6 percent of white granulated sugar powder, 1.5 percent of magnesium stearate, 15 percent of maltodextrin, 0.10 percent of citric acid and 0.2 percent of CMC-Na. The optimal parameter of the drying condition is 24 hours in vacuum. The method is mainly used for promoting the development of the processing technique of the seabuckthorn and dairy products, filling the blank of single seabuckthorn products or dairy products, changing the traditional production process of the seabuckthorn and providing safe and high-quality seabuckthorn yogurt slice products for the market.

Owner:XINJIANG UNIVERSITY

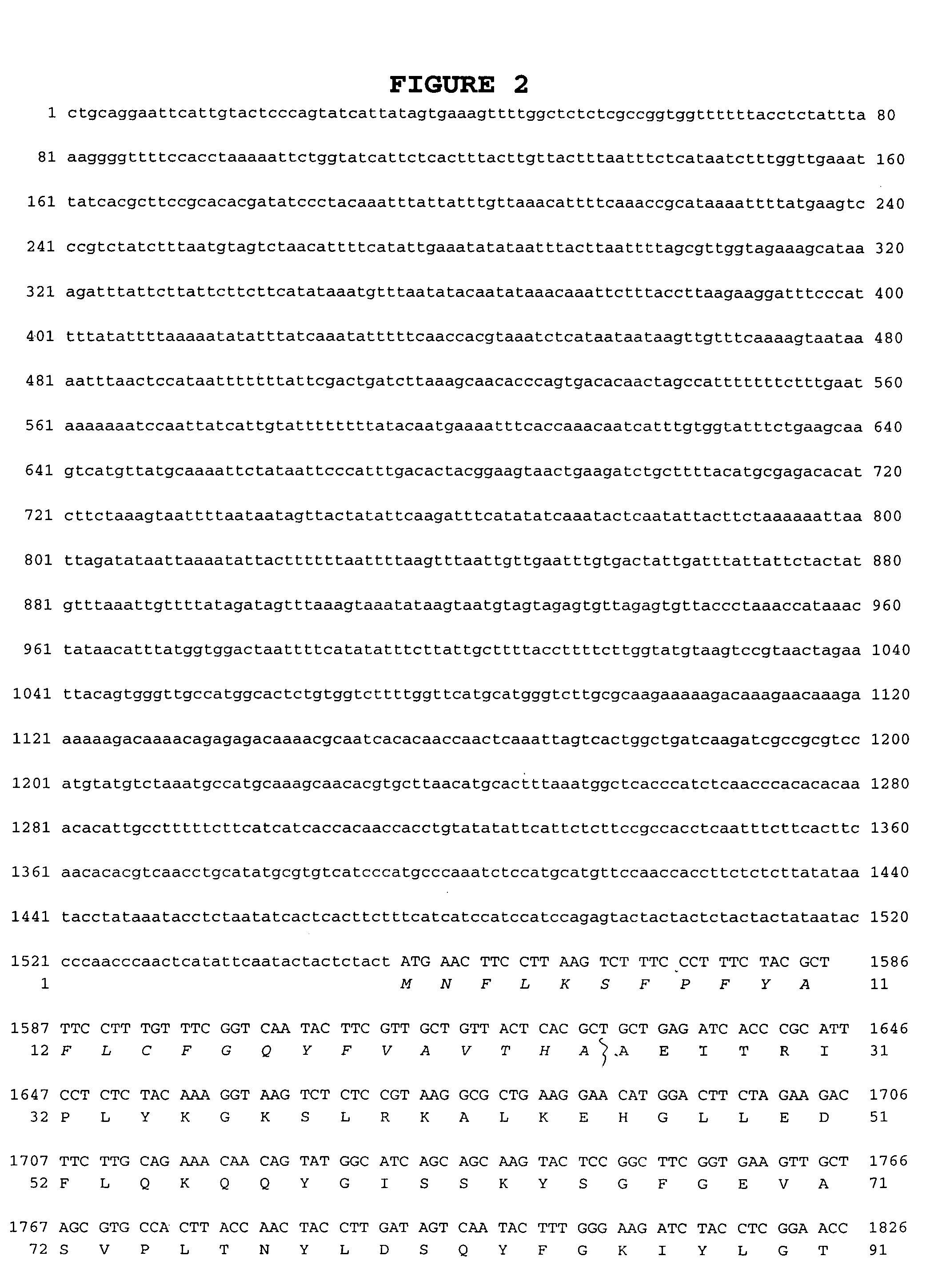

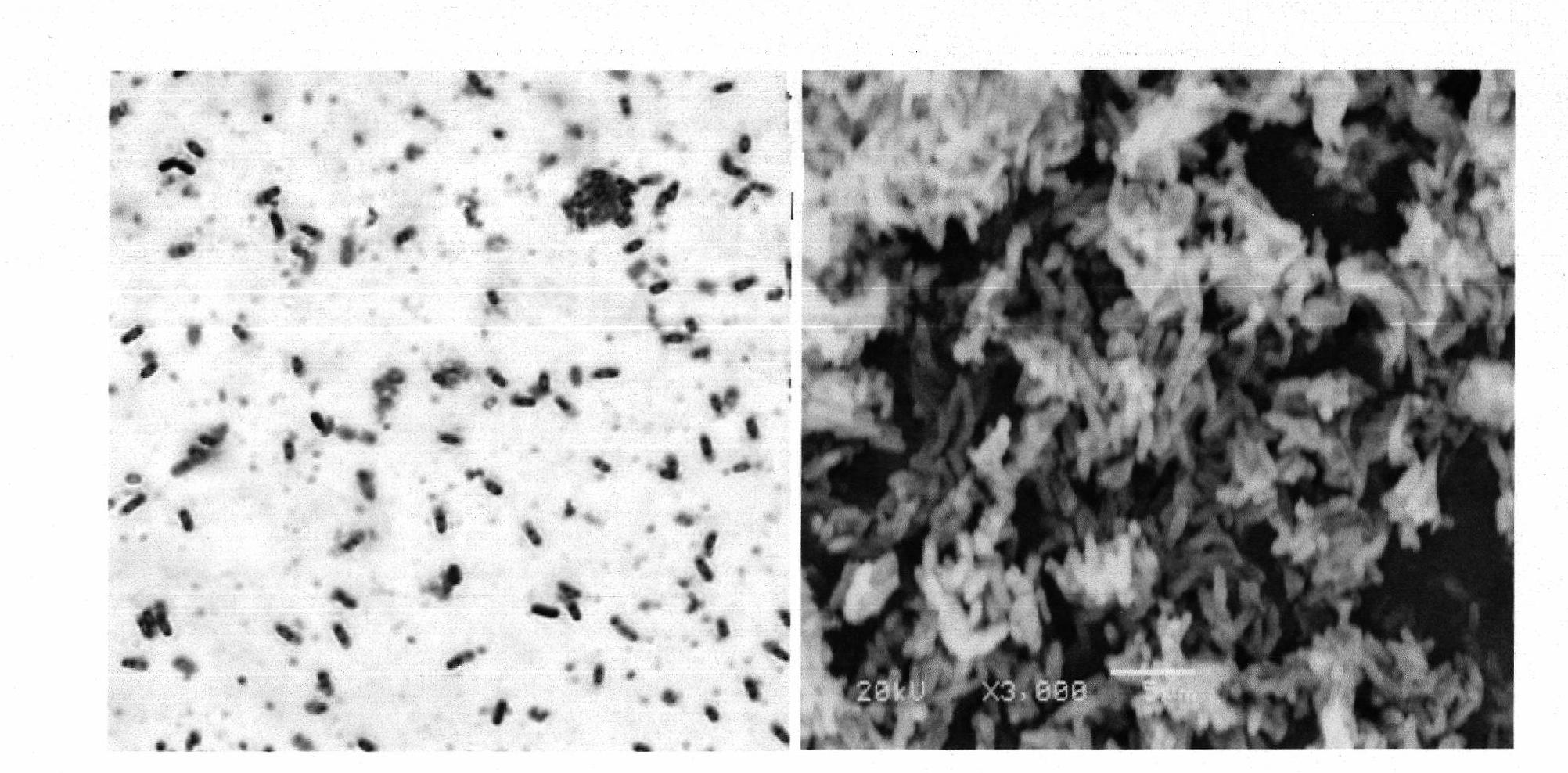

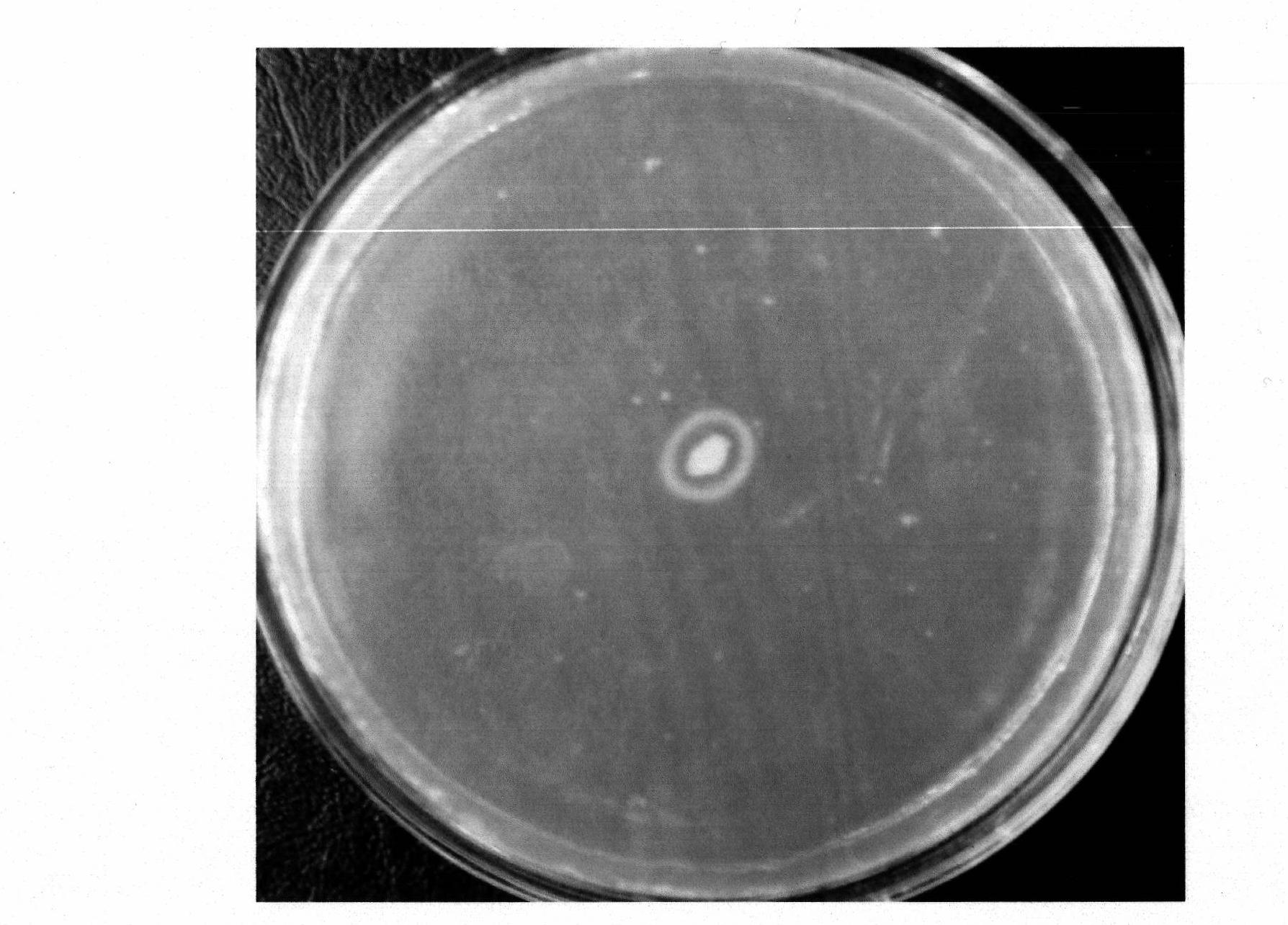

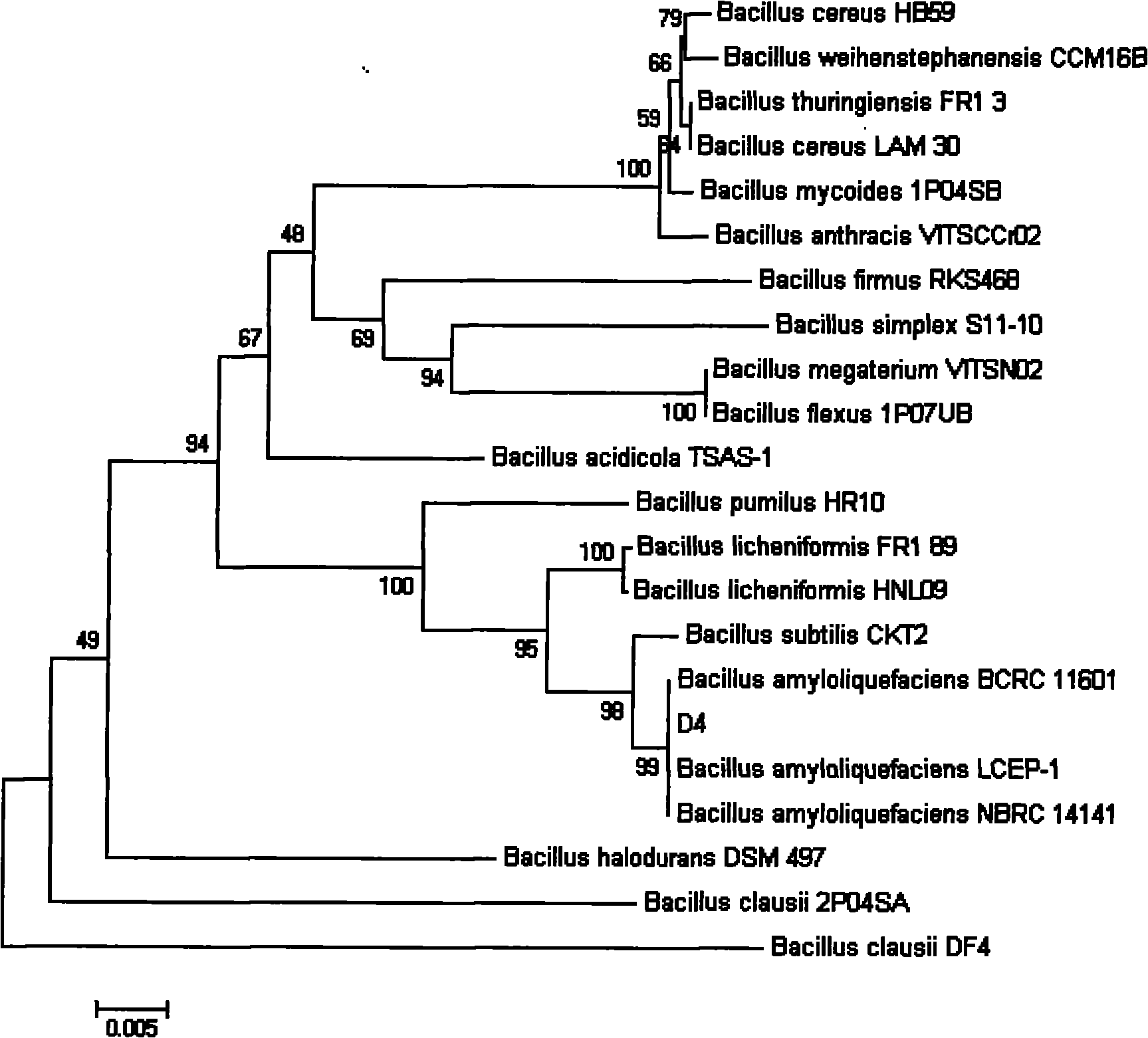

Bacillus amyloliquefaciens D4 and method for producing chymosin by fermentation of same

The invention discloses bacillus amyloliquefaciens D4 and a method for producing chymosin by fermentation of the same. The strain is screened from yak pasturing environmental soil of Gannan Tibetan Autonomous Prefecture of Gansu Province by adopting a casein culture medium, the chymosin can be obtained by deep fermentation of shake flask liquid, and the activity of the chymosin can reach 2,310.2SU / ml. The chymosin can be used for producing cheese and casein.

Owner:GANSU AGRI UNIV

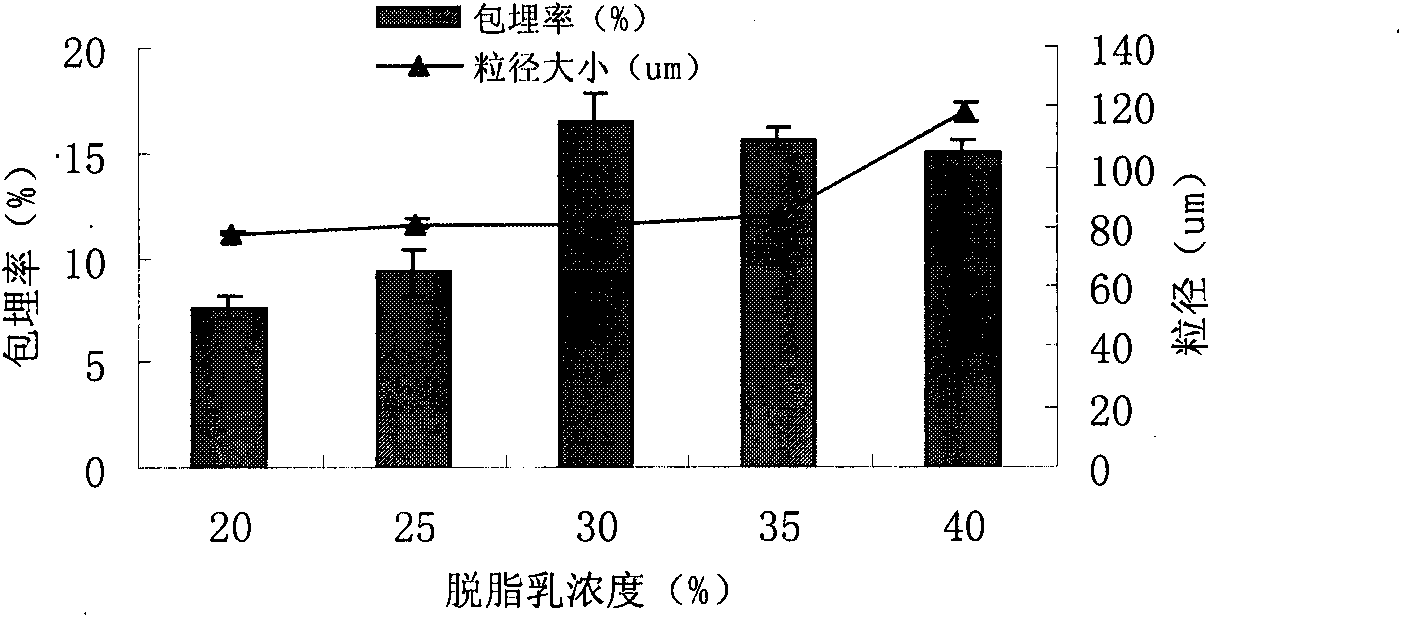

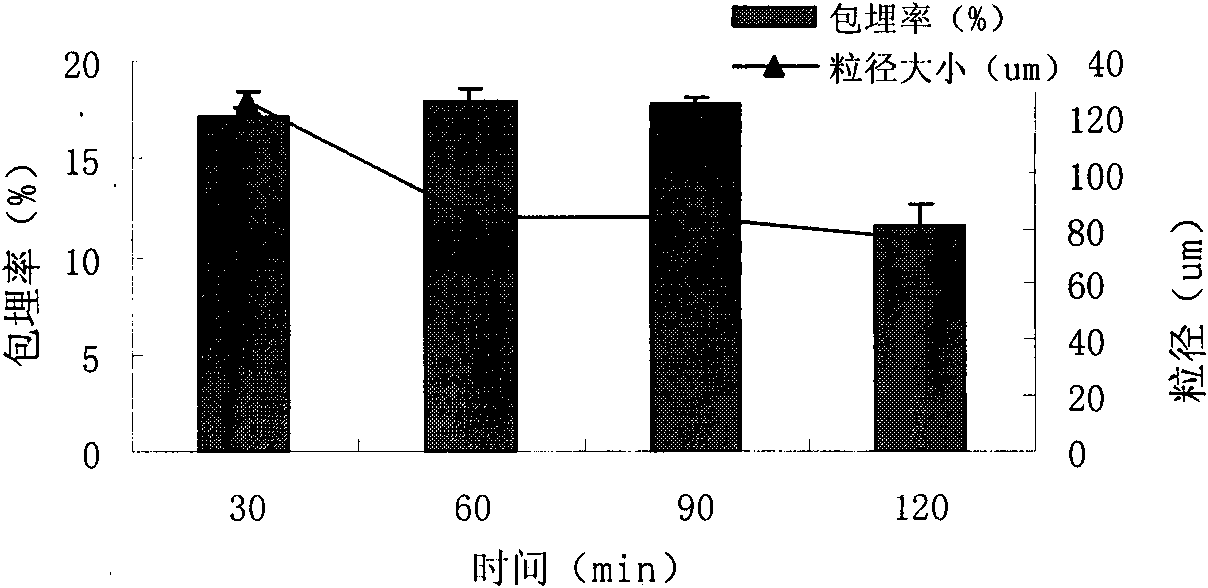

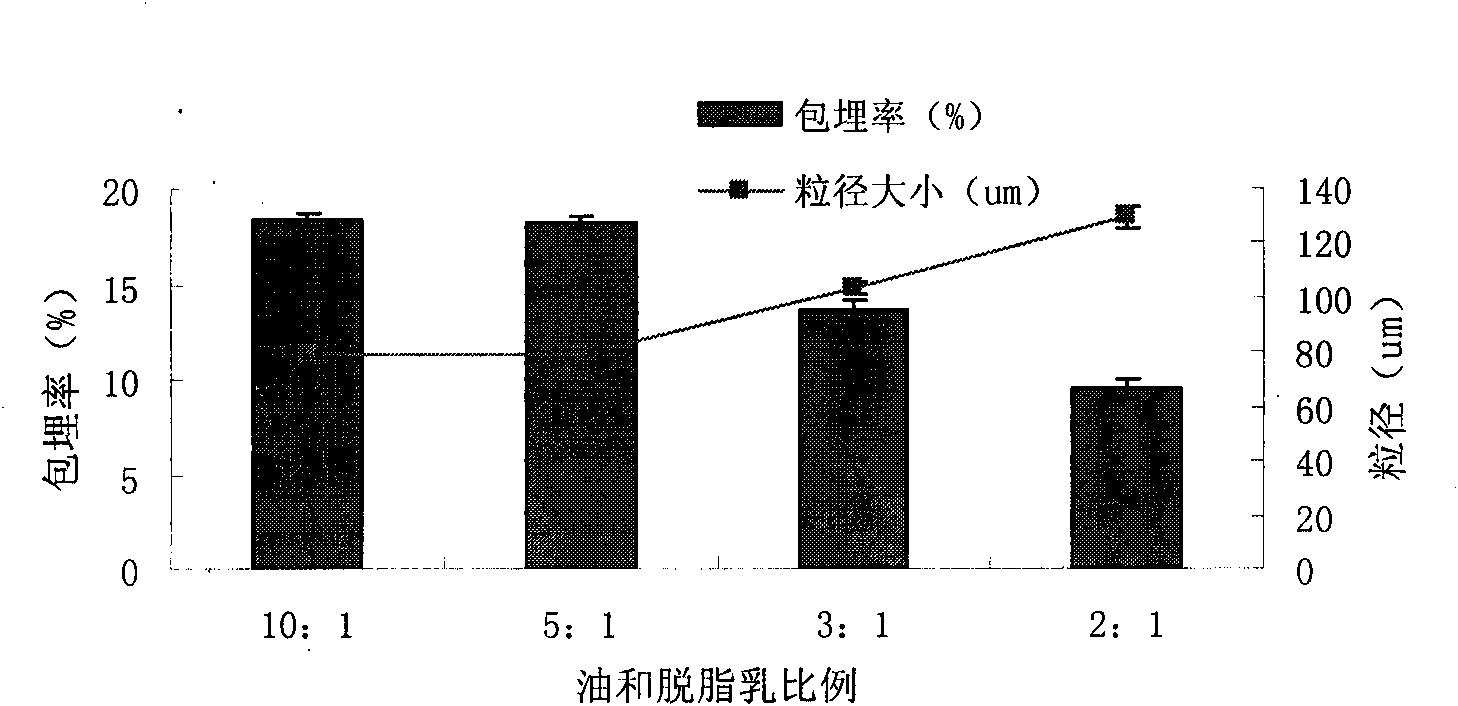

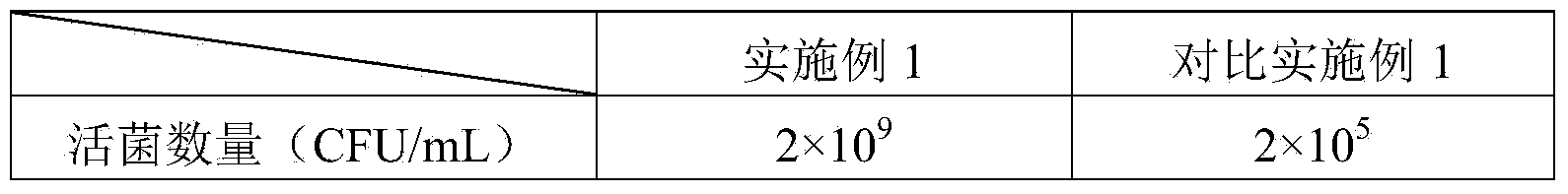

Method for preparing micro-encapsulation bifidobacteria

InactiveCN101597604AEfficient releaseNot subject to airMicroorganism based processesOn/in organic carrierSolubilityVegetable oil

The invention discloses a method for preparing micro-encapsulation bifidobacteria, which adopts skimmed milk as a wall material source for a phase separation coagulation method, and forms a microcapsule through the interaction between chymosin and lactoprotein. The technical proposal of the method comprises that: the fat-milk concentration is between 20 and 40 percent, the chymosin acting time is between 30 and 120 minutes, the vegetable oil mixing ratio is 10:1-2:1, and the stirring rotation speed during emulsification is between 100 and 1,000 revolutions per minute. The micro-encapsulation bifidobacteria prepared by the method have the advantages of high embedding rate, suitable grain size, high enteric solubility, good safety and the like, and can effectively promote the renovation and the industrialization of a bifidobacteria micro-encapsulation preparation technique.

Owner:任发政

Fresh cheese rich in probiotics and preparation method thereof

The invention provides a fresh cheese rich in probiotics. The fresh cheese comprises the following raw materials in parts by weight: cow milk 60-70, skimmed milk powder 8-15, whipping cream 8-10, white granulated sugar 8-10, stabilizer 0-1, jam 0-15, Lactobacillus casei starter 1-3, and Streptococcus lactis and Streptococcus cremoris mix direct vat set starter dilution 0.3-0.5. The invention also provides a preparation method of the fresh cheese. Proteins are coagulated through mix fermentation of several kinds of Lactobacillus, and chymosin, acidulant and coagulator are not necessary; the generation of sticky matter and the use of the stabilizer make a whey draining step be not necessary after coagulation; the taste of the cheese is improved by a stirring step, seasonings can be added during the stirring process, and the kinds of products are increased; and the fresh cheese can be produced by the existing yoghourt processing equipment. The theoretical production rate of the fresh cheese is 100%. The fresh cheese is rich in probiotics, and the content of the probiotics reaches more than 107 cfu / mL.

Owner:HUNAN AGRICULTURAL UNIV

Bacillus subtilis capable of stably producing chymosin with high yield by mutation and application

InactiveCN101665779AShorten the production cycleReduce fermentation costsBacteriaHydrolasesSporeMutation breeding

The invention discloses a bacillus subtilis capable of stably producing chymosins with high yield by mutation and an application. The original strain used is a bacillus subtilis which is obtained by the screening of a laboratory and used for producing products such as cheeses and the like by fermentation, and is preserved in China Center for Type Culture Collection (CCTCC) in February 2008, with the preservation name of bacillus subtilis QL-2 (Bacillus subtilis QL2) and the preservation No. of M208023. The mutation breeding comprises the following steps of: taking the bacillus subtilis QL-2 which is preserved in CCTCC with the culture preservation No. of M208023 as the original strain, and then culturing the bacillus subtilis QL-2 on a rejuvenation culture medium and a fermentation culture medium in sequence so as to obtain the original strain suspension; using a vortex device to make the strain suspension into single spore suspension; and then conducting ultraviolet mutation and culture for a plurality of times to the single spore suspension; and finally obtaining the bacillus subtilis YB-3 (Bacillus subtilis YB-3 , CCTCC NO: M209075) capable of stably producing chymosins with high yield. The bacillus subtilis capable of stably producing chymosins with high yield can be used for preparing chymosin crude enzymes by liquid fermentation, which can be used for preparing cheeses and caseins, and shortens the clotting time of milk.

Owner:LANZHOU UNIVERSITY

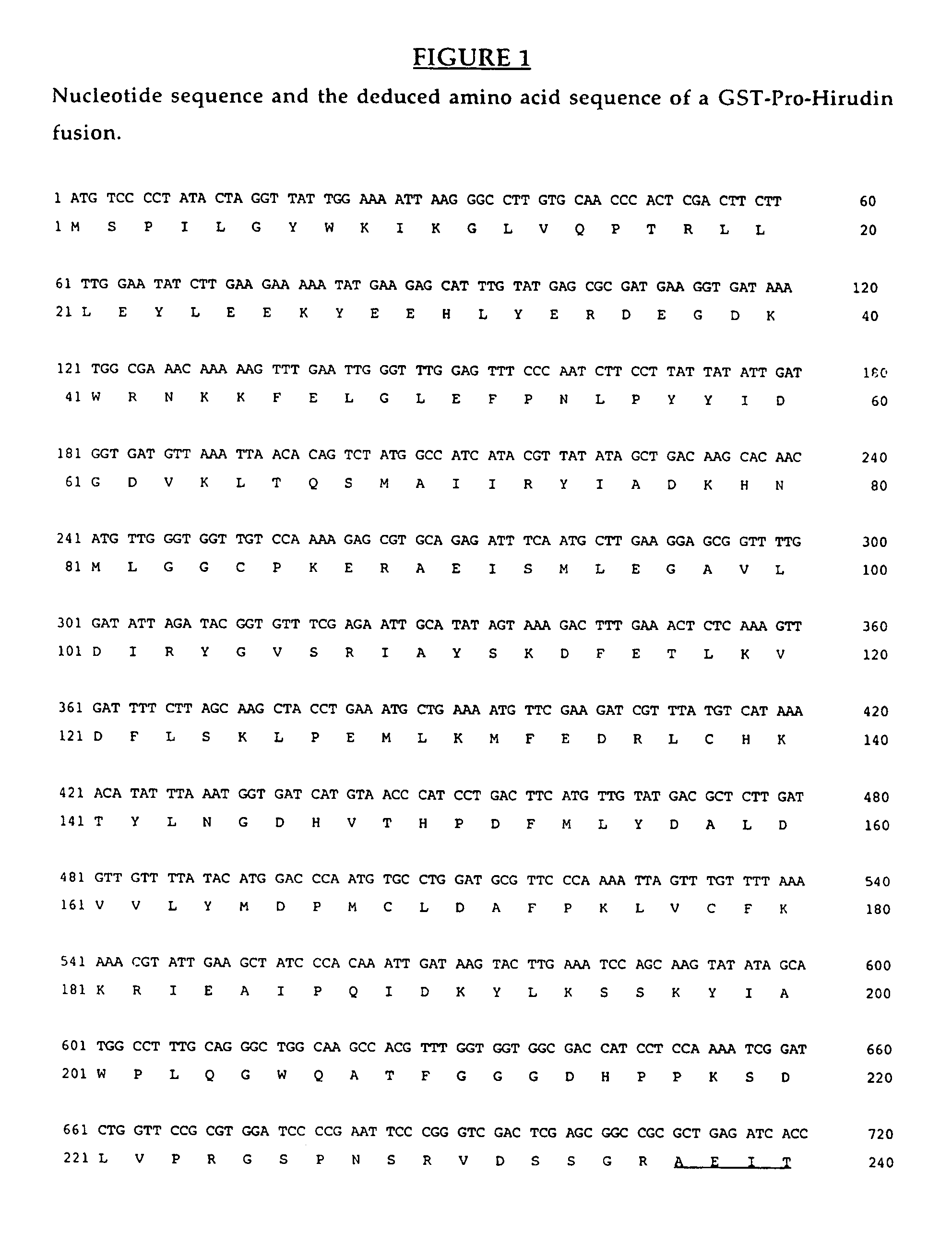

Method for producing and cleaving a fusion proteins with an n-terminal chymosin pro-peptide

An improved method for recovering recombinantly produced polypeptides is described. The method involves expressing the recombinant polypeptide as a fusion protein with a pro-peptide. The pro-peptide-polypeptide fusion protein can be cleaved and the recombinant polypeptide released under the appropriate conditions.

Owner:SEMBIOSYS GENETICS INC

Fresh cheese and preparation method thereof

The invention discloses a fresh cheese and a preparation method thereof. The preparation method comprises the following steps: 1, carrying out heat treatment of whey, and enriching denatured whey proteins to obtain a whey concentrate having 10-12% of dry matters; 2, adding the whey concentrate to raw milk, carrying out heat treatment, and cooling to obtain treated milk; 3, inoculating a starter, fermenting to the pH value of 5.4-5.5, adding chymosin, uniformly stirring, allowing the obtained mixture to stand, and continuously fermenting to the pH value of 4.6-4.7 for forming clotted milk; and 4, cutting the clotted milk, heating the system to 52-55DEG C in a 1-2DEG / min manner, carrying out heat treatment for 3-5min, heating to 58-60DEG C in a 0.3-0.5DEG C / min manner, carrying out heat treatment for 1-2min, cooling to 20-22DEG C, and discharging whey to obtain the fresh cheese. The fresh cheese has the advantages of substantially increased protein recovery rate and yield, good quality good mouthfeel, and effectively increased nutritional values and absorption rate, and can well satisfy modern nutritional requirements.

Owner:BRIGHT DAIRY & FOOD CO LTD

Preparation method of soft cheese

The invention discloses a preparation method of soft cheese and belongs to the field of dairy food processing. The method comprises the following steps: performing standardization; performing pasteurization; fermenting lactic acid bacteria; performing chymosin curding; discharging whey; performing molding; inoculating monascus firstly, and after a time, inoculating a mixed fungus liquid of geotrichum canididum and camembert blue mould, or inoculating monascus and the mixed fungus liquid of geotrichum canididum and camembert blue mould at one step; selecting proper ripening conditions. According to the method, monascus and white mould are mixed and ripened to prepare white mould soft cheese, so that the cheese is permeated with certain monascus color, can effectively improve the heavy flavor and taste of traditional white mould cheese, has good plasticity and is suitable for Chinese to eat.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Fresh fruity cheese and production method thereof

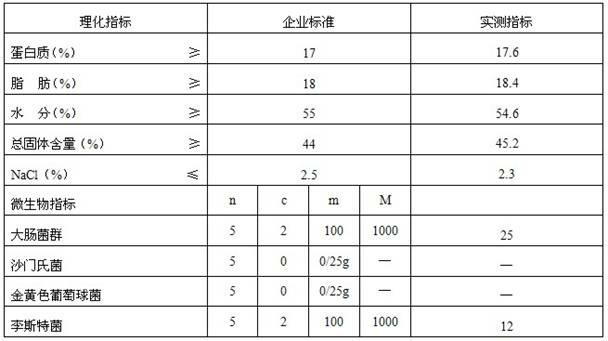

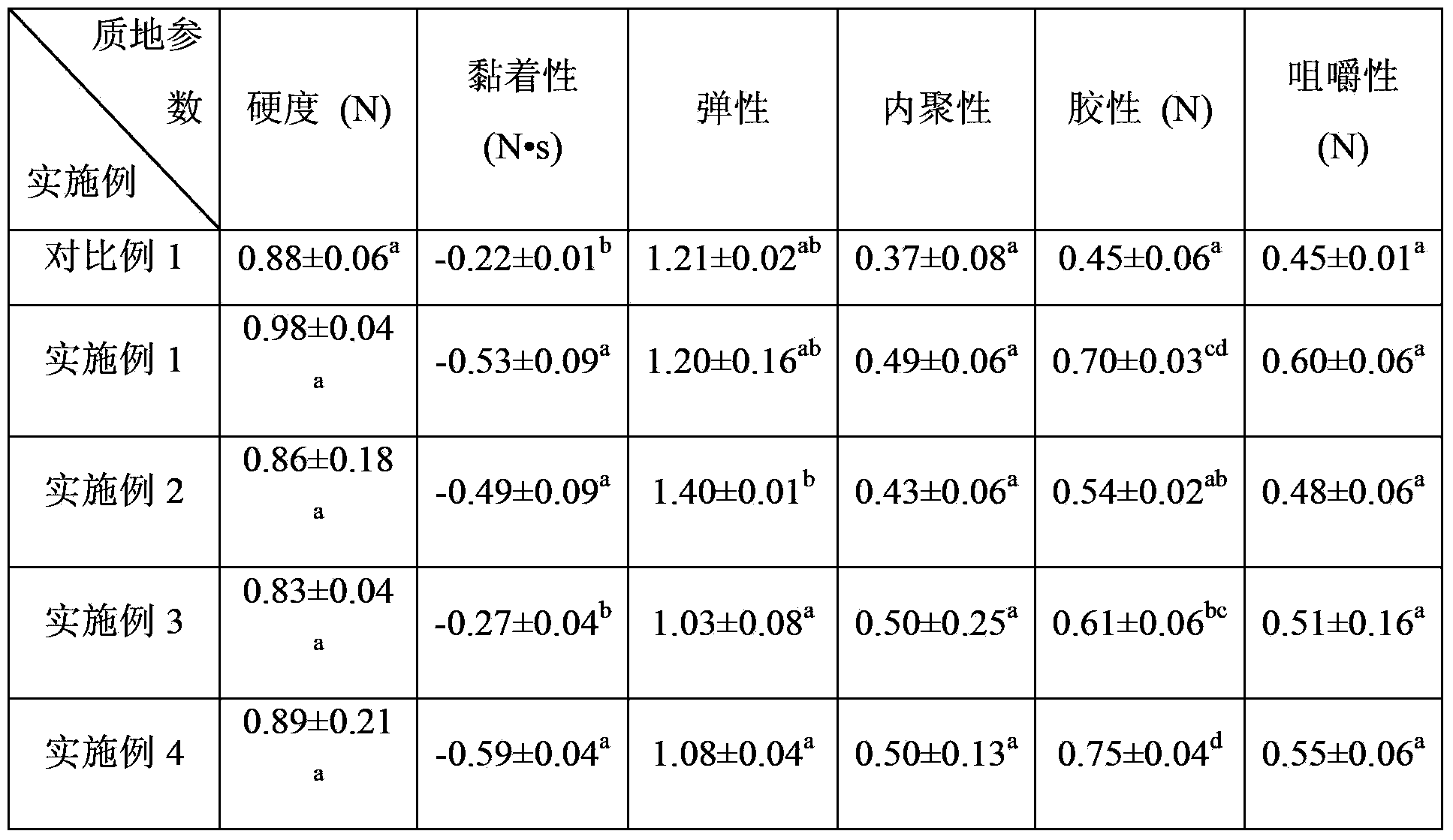

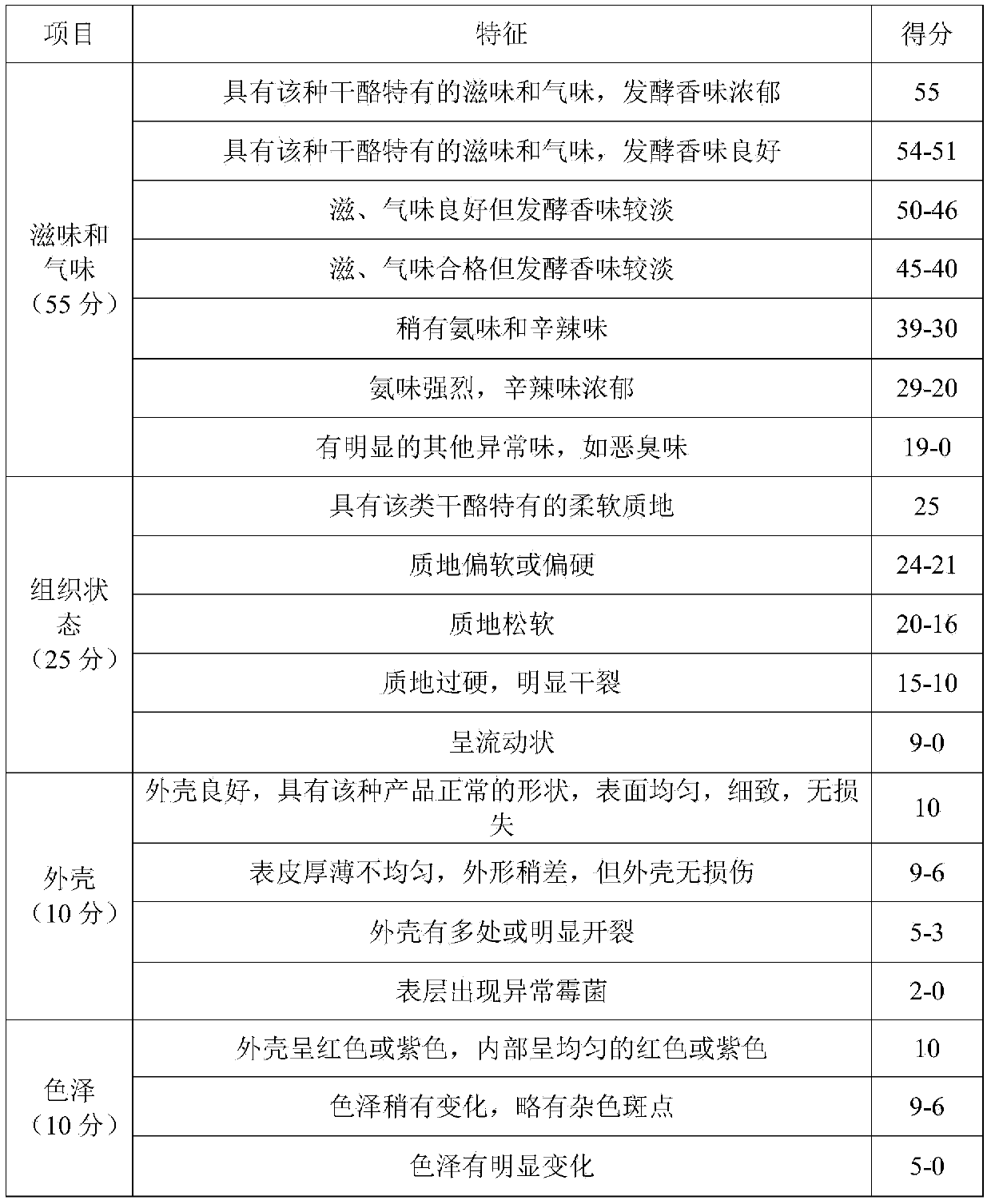

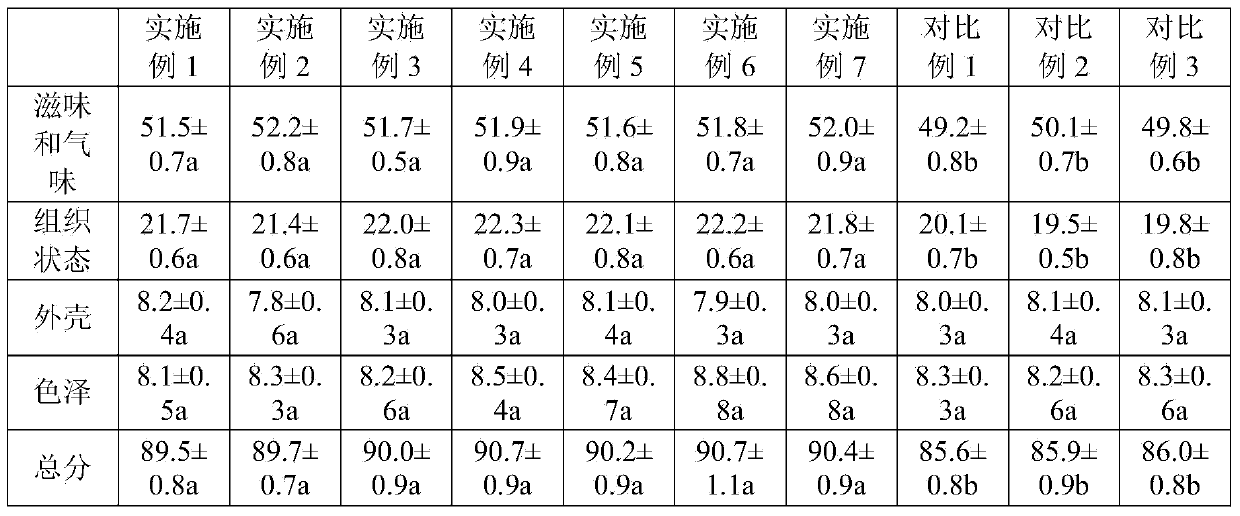

InactiveCN102429045ASuitable for needsIncrease heap operationCheese manufactureBiotechnologyChymosin

The invention discloses fresh fruity cheese and a production method thereof. Fresh brown cow milk is taken as raw material, and the fresh fruity cheese is produced through process steps of inspection, pretreatment, sterilization, fermentation, curding, cutting, cheddaring, seasoning, filling and the like. The Xinjiang brown cow milk is taken as the raw material in the fresh fruity cheese providedby the invention, an imported strain and domestic chymosin are combined for fermentation, and a variety of fruits are added, so that the fresh fruity cheese has the characteristics of soft flavor, prominent milk flavor and palatable sourness and sweetness. The innovation points of the fresh fruity cheese and the production method thereof, disclosed by the invention, are as follows: 1) the proteincontent in the fresh fruity cheese is not less than 17%, and the fat content is not less than 18%, which are much higher than those of traditional fruity cheese; 2) the operations of emulsification and cheddaring are added in the production process provided by the invention on the basis of a traditional fruity cheese process, and the product is strong in milk flavor, palatable in sourness and sweetness and delicate in taste; and 3) when the fresh fruity cheese is produced, the added high-quality chymosin can prolong the shelf life of the fresh fruity cheese to 60 days on an original basis, and the taste is more suitable for demands of domestic consumers.

Owner:XINJIANG YIPIN CASEIN

Preparation method and product of cheese by using monascus sp.

ActiveCN103431055ABreakthrough understandingImprove immunityCheese manufactureNutritive valuesMonascus sp.

The invention discloses a preparation method and a product of cheese by using monascus sp. The method comprises the steps of firstly, performing sterilization to raw milk, cooling the raw milk, so as to obtain treated milk, inoculating lactic acid bacteria starter to the milk to ferment the milk till pH is 6.0 to 6.5, and then adding chymosin to perform clabbering for 30 to 40min, so as to obtain curdled milk, secondly, cutting the curdled milk obtained in the first step into blocks, stirring the curdled milk to remove whey, then adding salt, uniformly stirring the curdled milk, and then putting the curdled milk into a die, thirdly, pressing or not pressing the curdled milk after the milk is put into the die, overturning the curdled milk for 5 to 10 times in the frequency of one time per 15-30 minutes, and standing the curdled milk, so as to further remove the whey, and fourthly, cutting the curdled milk into curdled milk blocks, spraying or coating a mixture of monascus sp. fermenting liquor and acidified rice paste on surfaces of the curdled milk blocks, putting the curdled milk blocks into a container, and curing the curdled milk blocks, so as to obtain the cheese by using monascus sp. The cheese by using monascus sp. belongs to natural mould cured cheese, and the method effectively improves the texture and the flavour of cheese through monascus purpureus, increases the nutritive value of cheese, is convenient and simple, and is convenient for popularization and application.

Owner:BRIGHT DAIRY & FOOD

Functional fresh cheese with special flavor and preparation method thereof

The invention discloses a functional fresh cheese with special flavor and a preparation method thereof. The preparation method comprises the following steps: a step of preparing red mud, hawthorn pulp and crude extracts of hawthorn leaf flavonoids and procyanidines; a step of sterilizing whole milk solution or fresh milks, adding the hawthorn pulp, calcium chlorides and chymosin and then curding, removing whey and performing enzymolysis to obtain curded blocks; a step of mixing purple potato powders, the red mud and the crude extracts of hawthorn leaf to obtain purple potato red mud; a step of uniformly mixing the purple potato red mud and the enzymolysis curded blocks, filling in a cookies mould or western pork ham mould, pressing and forming; and a step of packaging in vacuum and sterilizing to obtain finished products. The functional fresh cheese with special flavor has the advantages of special flavor, rich nutrition, oxidation resistance and immune modulating function and is rich in active substances such as flavonoid, peptide, anthocyanin and so on.

Owner:江苏宇航食品科技有限公司

A kind of cheese and its making technology

InactiveCN102293257AShorten the production cycleGreat tasteCheese manufactureAdditive ingredientSugar

The invention discloses a process for making cheese. The ingredients are as follows: the content of water is 69.95-61.4%, the content of skimmed milk powder is 15-17.5%, the content of cream is 10-14%, and the content of white sugar is 5%. -7%, the content of pectin is 0.03-0.5%, the content of agar is 0.02-0.05%, the content of lactic acid bacteria starter is 50-100u / T, and the content of rennet is 10-30 g / T; its production The process includes mixing materials, sterilization, inoculation, fermentation, homogenization, quick cooling and packaging. The invention uses milk powder as raw material to make cheese, shortens the production cycle to less than one day, and has good taste of the product.

Owner:GREENS BIOENG SHENZHEN

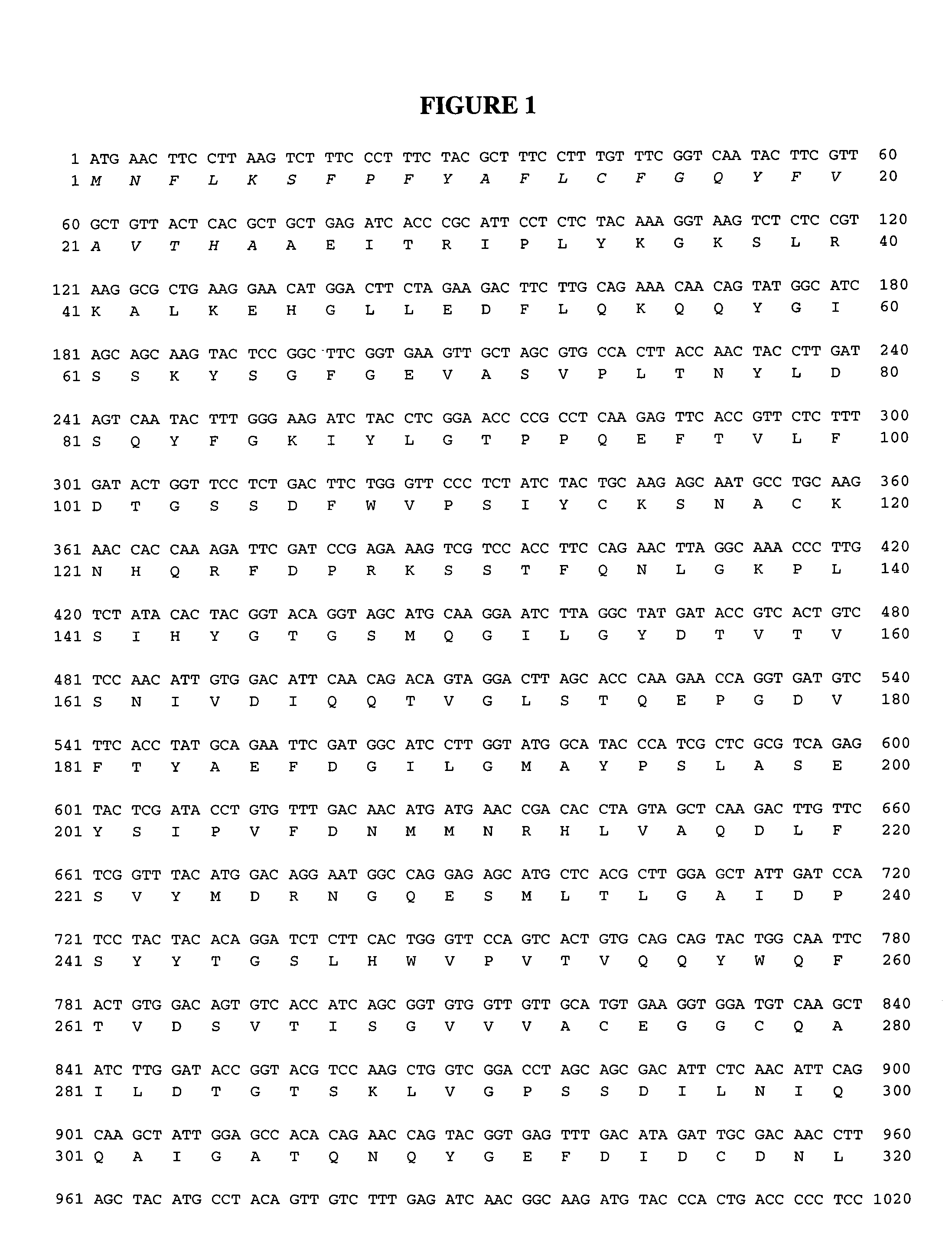

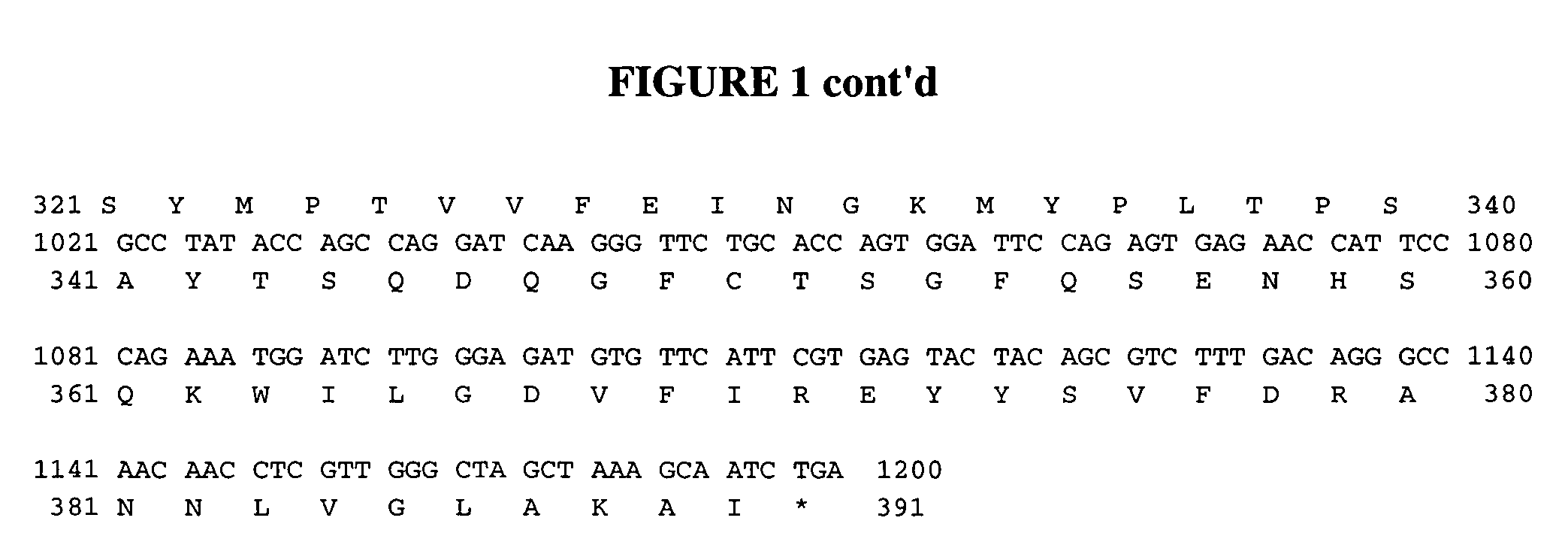

Recombinant calf-chymosin and a process for producing the same

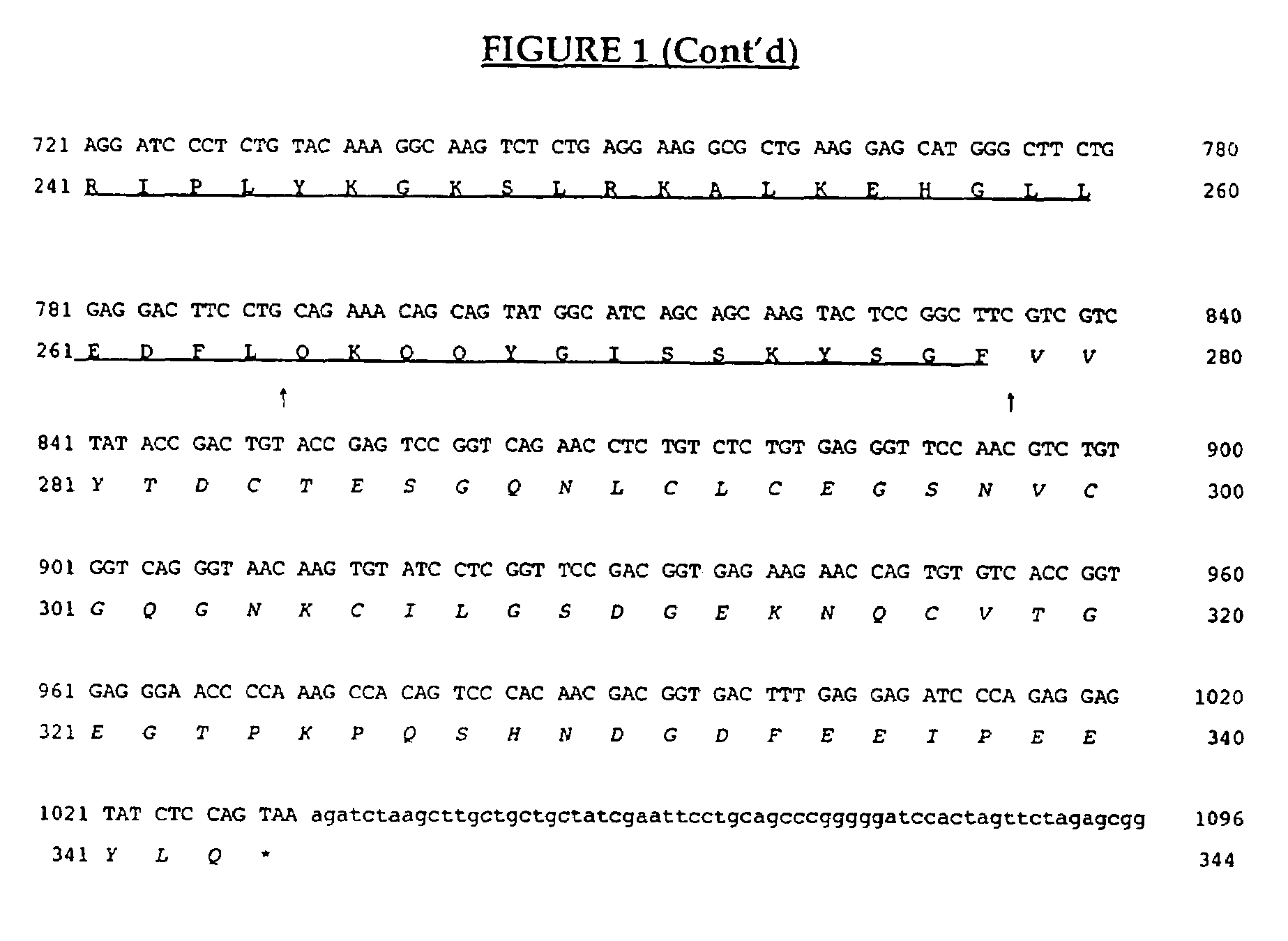

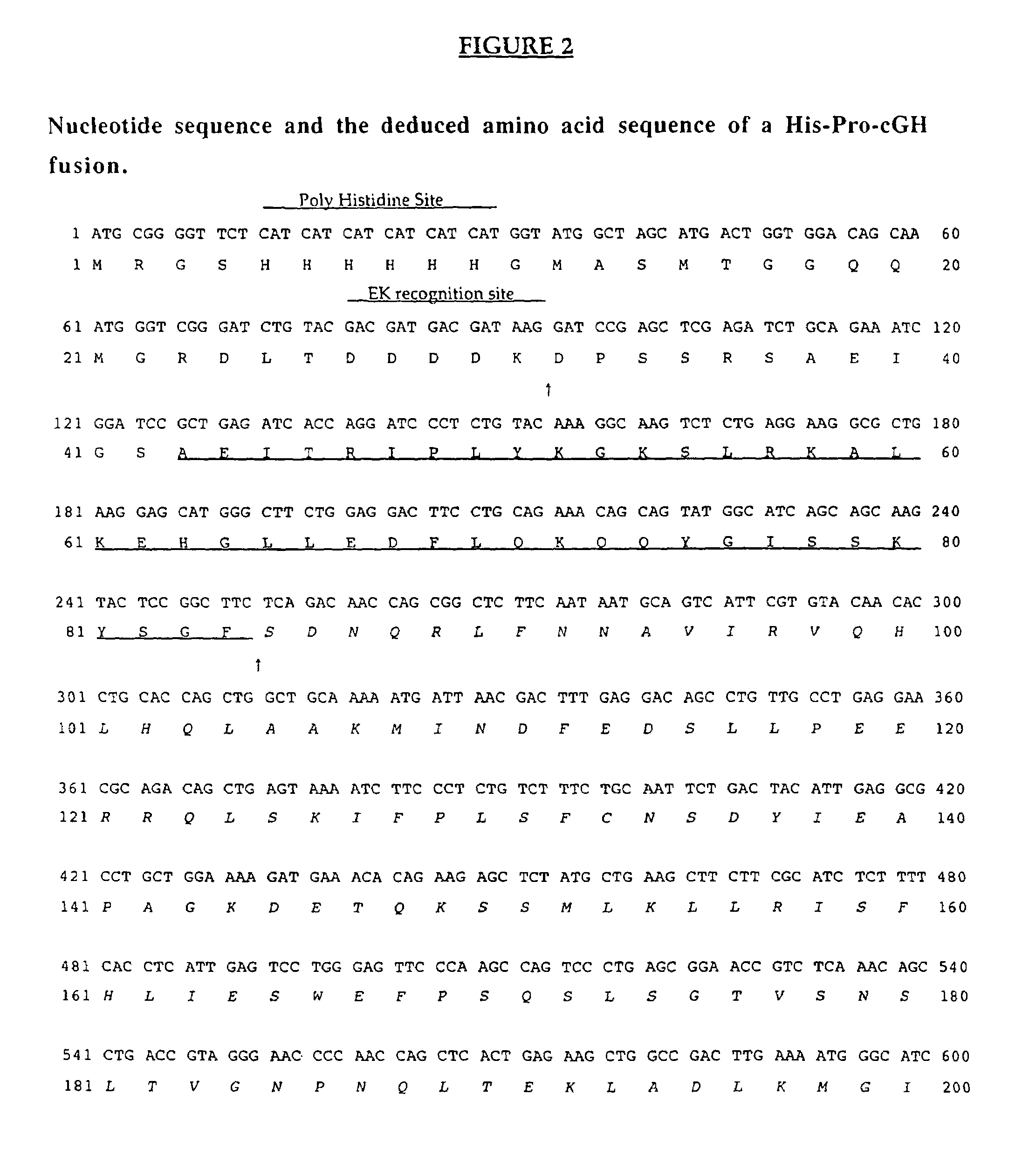

The present invention relates to a recombinant calf-Chymosin protein as set forth in SEQ ID No. 1; a recombinant calf-Chymosin gene as set forth in SEQ ID No. 2 encoding the protein comprising amino acid sequence of SEQ ID NO.1; an E. coli comprising the recombinant chymosin gene of SEQ ID No. 2; an expression vector pET21b comprising recombinant calf-chymosin gene as set forth in SEQ ID No. 2; and lastly a method for producing recombinant calf-chymosin protein as set forth in SEQ ID No. 1 which comprises steps of isolating calf-chymosin gene, cloning the same in bacterial expression vector pET21b, transforming said cloned vector into cells of E. coli, fermenting said E. coli to produce pro-chymosin, converting said pro-chymosin to chymosin and subsequently recovering the recombinant calf-chymosin.

Owner:SUDERSHAN BIOTECH

Monascus cheese with health function and preparation method of monascus cheese

The invention discloses a monascus cheese with the health function and a preparation method of the monascus cheese. The preparation method comprises the following steps: (1) inoculating sterilized raw milk by a lactic acid bacteria starter and a monascus spore liquid under the condition of 28-32 DEG C, adding or not adding red rice flour, and fermenting until the pH value is 6.2-6.4, wherein the monascus refers to a monascus purpureus bacterial strain with the preservation number of CGMCC No.8120; (2) adding chymosin, stirring for 5-10min, and curding for 25-30min so as to obtain curd; (3) cutting the curd and stirring for 15-30min to obtain curd blocks; and (4) removing whey from the curd blocks until the pH value is 5.4-5.8, putting the blocks into a mold for forming, steeping in salt water, overturning at regular time intervals, and cooking to obtain the monascus cheese.

Owner:BRIGHT DAIRY & FOOD

Tuckahoe-flavored functional cheese cake and preparation method thereof

InactiveCN102885163AGreat tasteRich tasteCheese manufactureFood preparationCow milkingRoom temperature

The invention discloses a tuckahoe-flavored functional cheese cake and a preparation method thereof. The preparation method is characterized by comprising the steps of preparing tuckahoe powder, and preparing lotus seed milk; carrying out sterilization on whole milk liquor or cow milk; adding the lotus seed milk, calcium chloride, chymosin and glutamine transaminase into the sterilized product; carrying out milk curding, whey removal, cutting and fermentation on the obtained mixture; adding the tuckahoe powder, blueberry powder, baking soda and salt or sugar into milk curds; and carrying out mixing, press molding, vacuum packing and sterilization on the obtained product so as to obtain a polypeptide and anthocyanin-like active factor containing tuckahoe-flavored functional cheese cake with antioxidation and immunoregulation functions. The quality guarantee period of the tuckahoe-flavored functional cheese cake at a low temperature or room temperature can be up to about 3-5 months. The tuckahoe-flavored functional cheese cake has the advantages that tuckahoe powder, lotus seed milk and blueberry powder are used for processing cheese cakes together, so that the nutritional value and functional properties of cheese cakes can be improved, and the taste of cheese cakes is enriched.

Owner:NINGBO UNIV

Fresh red rice cheese and preparation method thereof

The invention discloses fresh red rice cheese and a preparation method of the fresh red rice cheese. The preparation method comprises the following steps: (1) inoculating a monascus culture solution to sterilized raw milk at the temperature of 28-32 DEG C, and reducing the pH value to be 4.8-5.2; (2) adding 0.0002%-0.0005% of chymosin by mass percent, and fermenting until the pH value is 4.5-4.7, so as to obtain curd; (3) cutting the curd, raising the temperature to 49-54 DEG C within 120 minutes, carrying out washing by virtue of sterile water at 49-54 DEG C, and eliminating whey, so as to obtain curdled milk; and (4) washing the obtained curdled milk by virtue of the sterile water at 1-5 DEG C, draining away water, and filling the curdled milk into a container, so as to obtain the fresh red rice cheese. The fresh red rice cheese is gentle in flavor, long in guarantee period, high in nutrition value, rich in active functional components and conforms to the dietary habit of Chinese.

Owner:BRIGHT DAIRY & FOOD

Double-protein goat cheese and preparation method thereof

The invention discloses double-protein goat cheese. The cheese is prepared from raw materials including soybeans and goat milk, wherein soybean milk is obtained through grinding the soybeans, and the goat milk is fresh. The double-protein goat cheese consists of the following ingredients according to mass percent: 87.5%-92.5% of the fresh goat milk, 2.5%-7.5% of the soybean milk, 1%-1.5% of a leavening agent, 0.005%-0.02% of Cacl2, 0.3%-0.5% of transglutaminase, 0.1%-0.3% of chymosin and 1%-3% of salt. China has rich soybean resources, soybean products have a long history, but goat milk resources are not sufficient and high in cost. According to the cheese, the soybean milk substitutes part of the goat milk, so that the cheese cost can be lowered, animal and plant nutrition is complementary with each other, particularly, the animal and plant proteins are complementary with each other, and moreover, the flavor of the goat cheese can be changed to be better fit for the tastes of users.

Owner:INST OF ANIMAL SCI & VETERINARY MEDICINE SHANDONG ACADEMY OF AGRI SCI

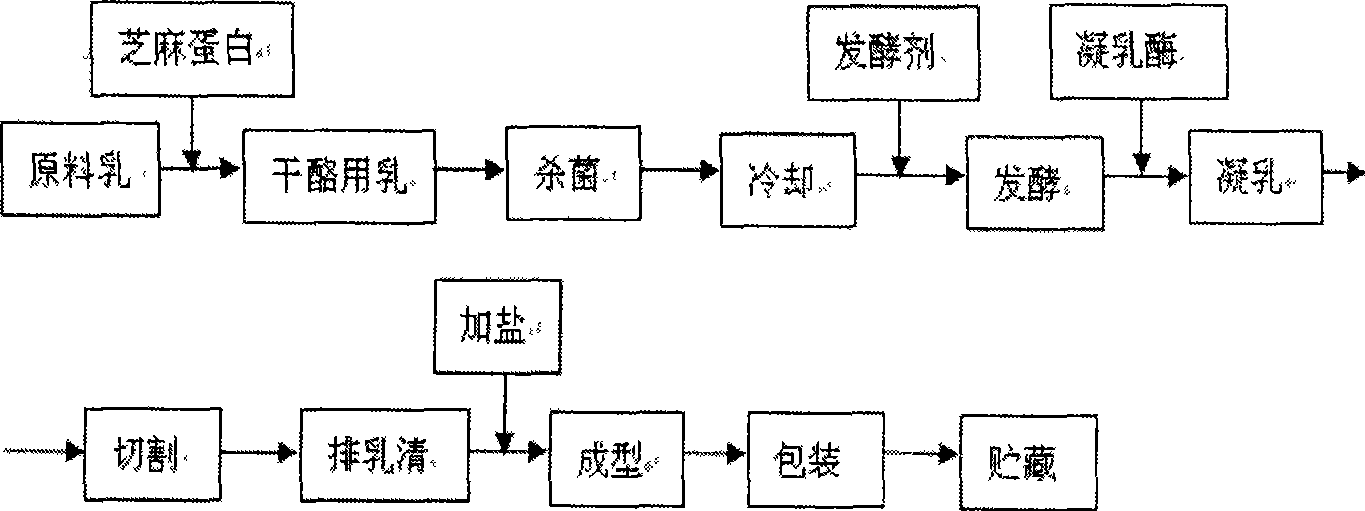

Original cheese containing sesame protein and preparation method thereof

InactiveCN101473872AImprove functional propertiesImprove textureCheese manufactureTotal proteinChymosin

The invention discloses an original cheese containing sesame protein and a preparing method thereof, belonging to the technical field of dairy processing. The original cheese is composed of the following components according to quality percentage: 20-25% of total protein and17-21% of fat, and the balance of water. The preparation method is as follows: a part of sesame protein is added in raw milk to replace a part of milk protein, the sesame protein is combined with the milk protein according to a certain proportion, and the cheese is prepared through the fermentation of the lactobacillus and the curding of the chymosin. The cheese prepared in the invention is similar to normal pure milk cheese in terms of physical and chemical characters, and has good quality and taste.

Owner:CHINA AGRI UNIV

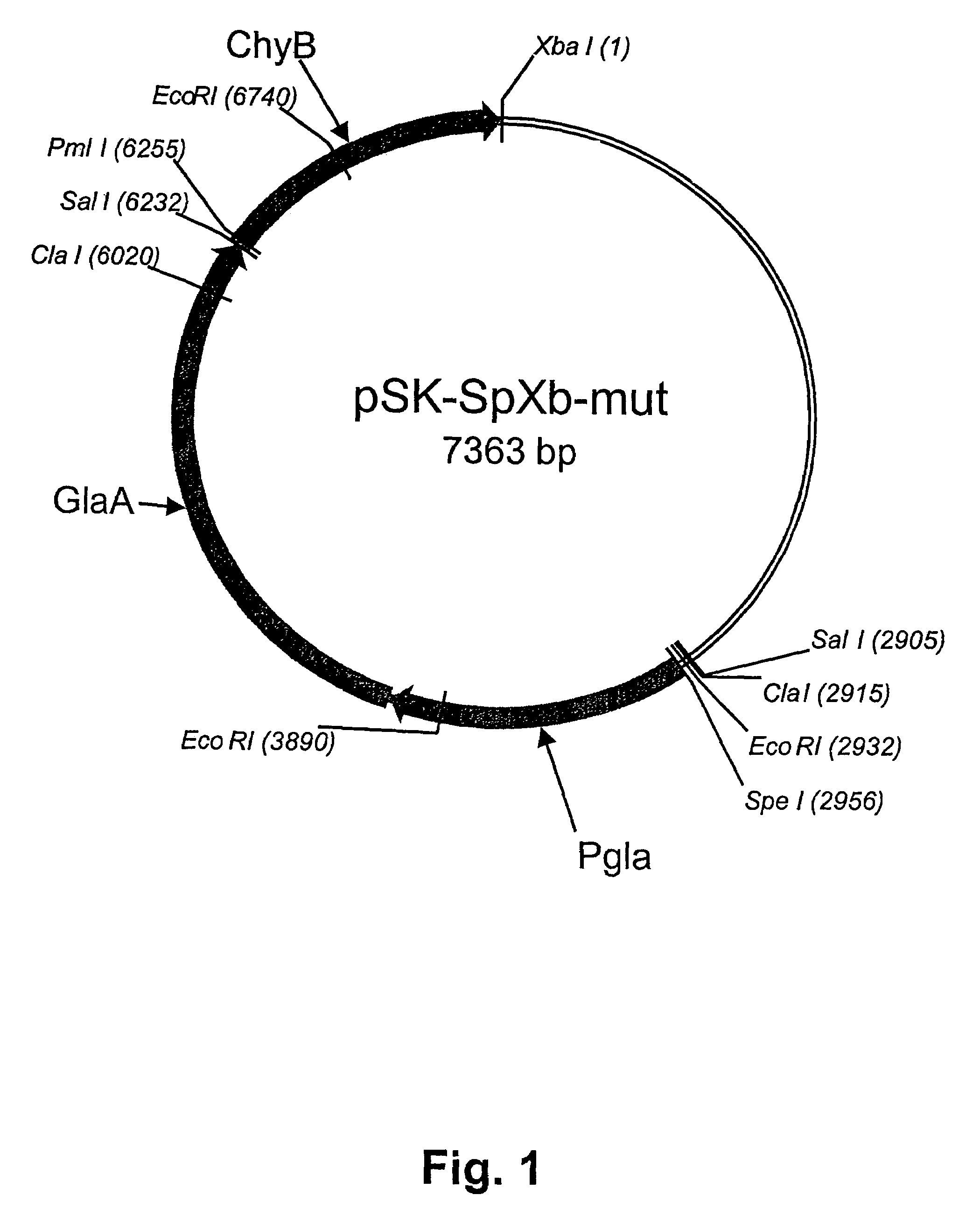

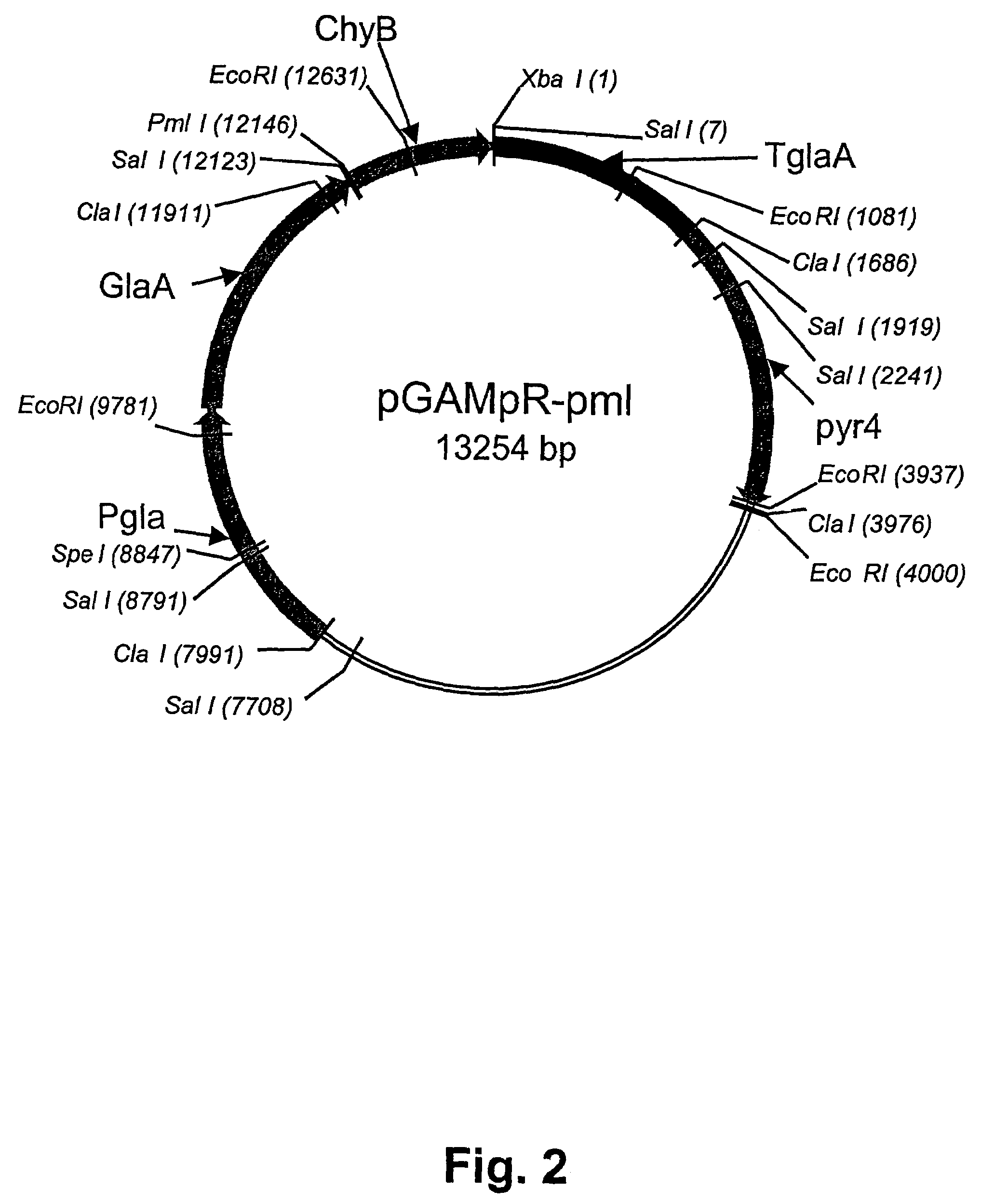

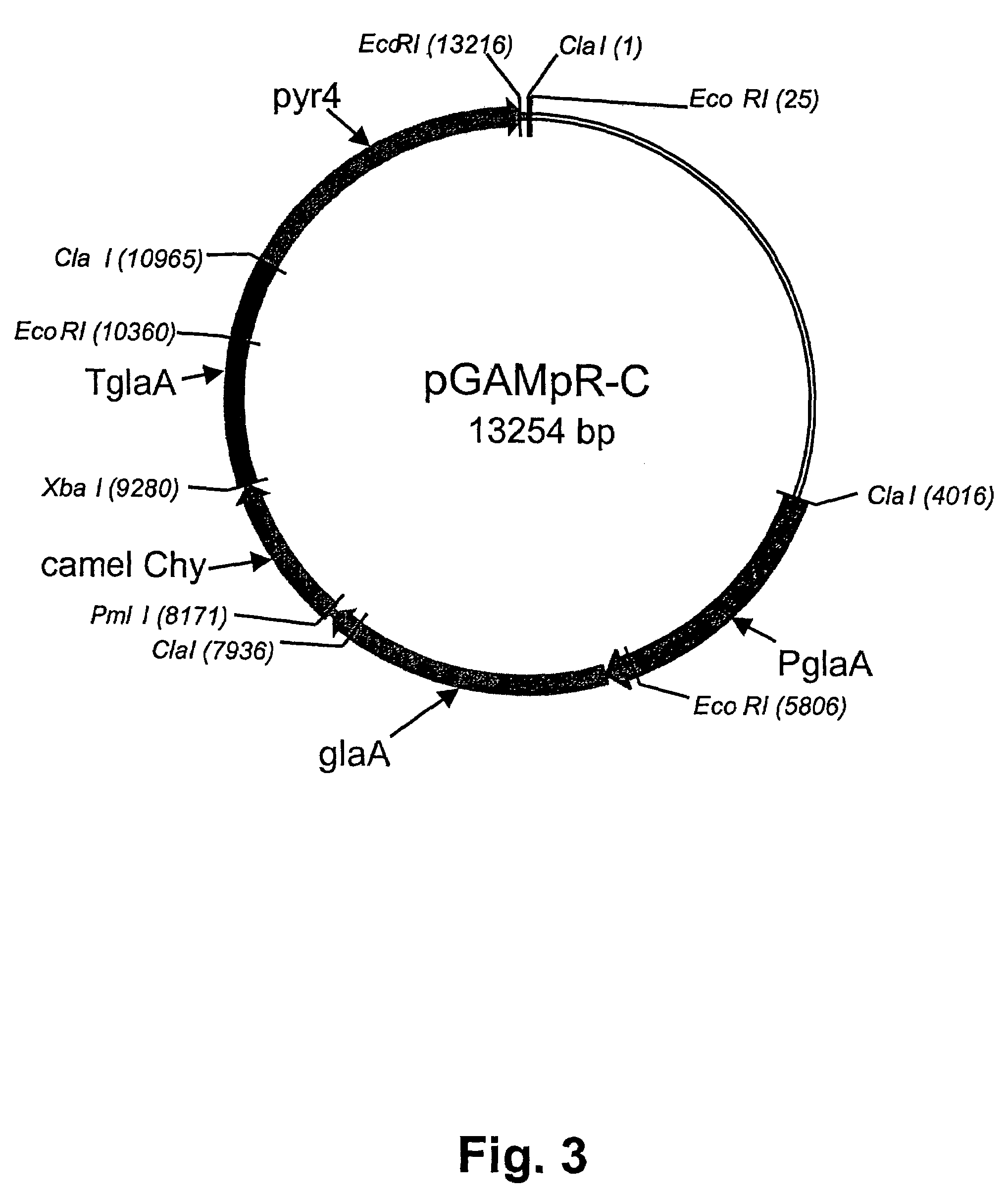

Method of producing non-bovine chymosin and use hereof

A method of recombinantly producing a non-bovine pre-prochymosin, prochymosin or chymosin derived from ruminant species including deer species, buffalo species, antelope species, giraffe species, ovine species and caprine species; Camelidae species such as Camelus dromedarius; porcine species; or Equidae species. The recombinant enzymes are used in milk coagulating compositions in cheese manufacturing based on cow's milk and milk from any animal species which are used in cheese manufacturing including camel's milk.

Owner:CHR HANSEN AS +1

Monascus cheese and preparation method thereof

The invention discloses monascus cheese and a preparation method thereof. The preparation method of the monascus cheese comprises the following steps: (1) inoculating lactic acid bacteria starter and monascus into sterilized raw milk at 28-32 DEG C, and pre-acidifying till the pH value is 6.2-6.4; (2) adding chymosin, stirring for 5-10 minutes, and curding for 25-30 minutes to obtain curd; (3) cutting the obtained curd, and stirring for 15-30 minutes to obtain curd pieces; (4) discharging the whey from the obtained curd pieces till the pH value is 5.4-5.8, mixing with salt, shaping by using a mold, turning over regularly so as to curing the monascus cheese. The monascus cheese prepared by using the preparation method disclosed by the invention is applicable to customers in China, is gentle in favor, outstanding in milk taste, and is easily accepted by customers in China as the spicy and irritating favor of the mold aged cheese is reduced, and industrial production can be easily achieved.

Owner:BRIGHT DAIRY & FOOD

Cheese beverage containing probiotics and preparation method thereof

ActiveCN103947764AKeep protein highGuaranteed nutritional valueCheese manufactureFruit juicePasteurization

The invention discloses a cheese beverage containing probiotics and a preparation method thereof. The preparation method comprises the following steps: (1) homogenizing raw milk and carrying out pasteurization at 72-76 DEG C for 10-15 seconds or intense heating treatment at 85-95 DEG C for 3-5 minutes to obtain treated milk; (2) cooling, adding a mesophilic fermenting agent and probiotics to ferment, and adding chymosin to continue fermentation after 15-30 minutes of fermentation till the pH is 4.6-5.0; (3) heating to 36-38 DEG C and discharging whey to obtain curds; and (4) sterilizing juice at 106-110 DEG C for 10-20 seconds, cooling, washing the curds by the juice from bottom to top, stirring while washing, and homogenizing to obtain the cheese beverage, wherein the homogenizing pressure is over 0.4MPa and the weight ratio of the curds to the juice is 1:9 to 5:5. The cheese beverage organically combines cheese, probiotics and juice, the survival amount of probiotics can be maintained, and the cheese beverage is abundant in nutrition and smooth in taste and is sweet and sour.

Owner:BRIGHT DAIRY & FOOD

Fat-free cheese, preparation method and raw material composition of fat-free cheese

ActiveCN102630758ASoft and smooth textureFresh and premium cheese flavorCheese manufactureMilk proteinChymosin

The invention discloses a raw material composition of a fat-free cheese. The raw material composition comprises the following components by weight percent: 70-89.9wt% of skimmed milk, 4.6-10wt% of milk protein powder, 1.5-2.5u / 100g of mesophilic lactic acid bacteria, 3.1-9.5wt% of white granulated sugar and 0.05-0.6wt% of stabilizing agent; the fat content in the skimmed milk is equal to or less than 0.3wt%; the protein content is 2.9-4.5wt%; and the fat content in the milk protein powder is equal to or less than 2.0wt%. The invention also discloses the fat-free cheese and a preparation method of the fat-free cheese. With the adoption of the fat-free cheese, chymosin is not added and whey is not discharged; the process is easy to come true; the fat-free cheese is appropriate in viscosity and good in mouthfeel and condition; the flavor of the cheese can be easily received by China consumers; and the requirements of parts of the consumers on nutrition and healthy food can be met.

Owner:BRIGHT DAIRY & FOOD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com