Imitated cheese and its preparation method

A cheese and product technology, which is applied in the field of imitation cheese and its preparation, can solve the problems of limited use of processed cheese raw materials, reduced wire drawing performance, and high refrigeration cost, and achieves the advantages of reducing costs and food safety risks, being easy to operate, and having a simple preparation method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

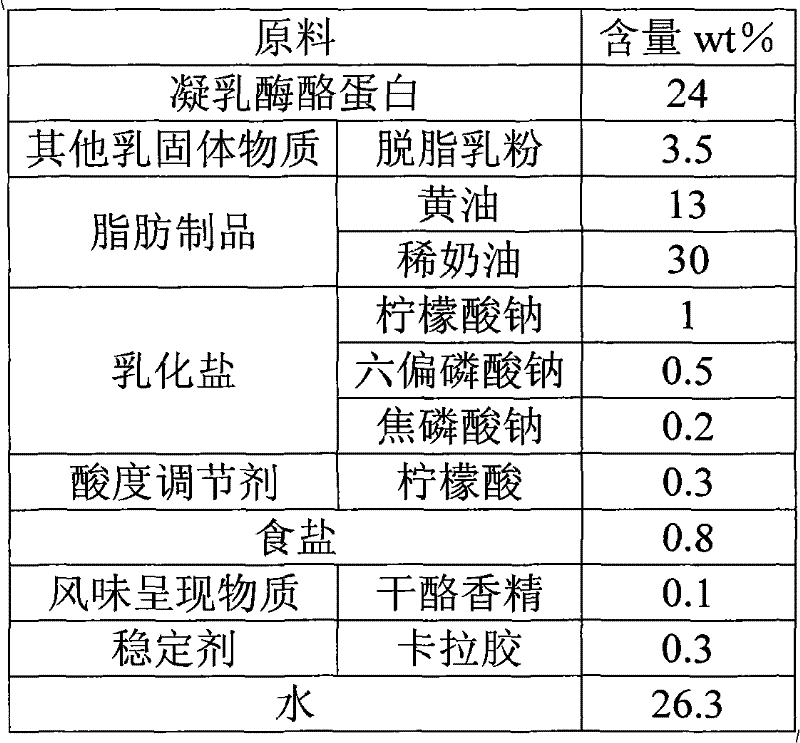

[0039] Raw material formula:

[0040]

[0041] Preparation:

[0042] ① According to the above formula, put the raw materials into the melting pot, and without heating, use a blunt knife with a blade thickness of 2mm to shear and stir at 1000rpm for 4min to obtain a premixed slurry;

[0043] ② Stir the pre-mixed slurry at a speed of 1000rpm, heat the steam directly to a temperature of 80°C, and then keep it warm for 6 minutes until the wire drawing appears;

[0044] ③Hot-filled aseptic packaging, cooled, and refrigerated.

[0045] After testing, the indicators of the obtained imitation cheese are: 23.1% protein; 22.7% fat; 47.9% moisture; pH 5.2.

Embodiment 2

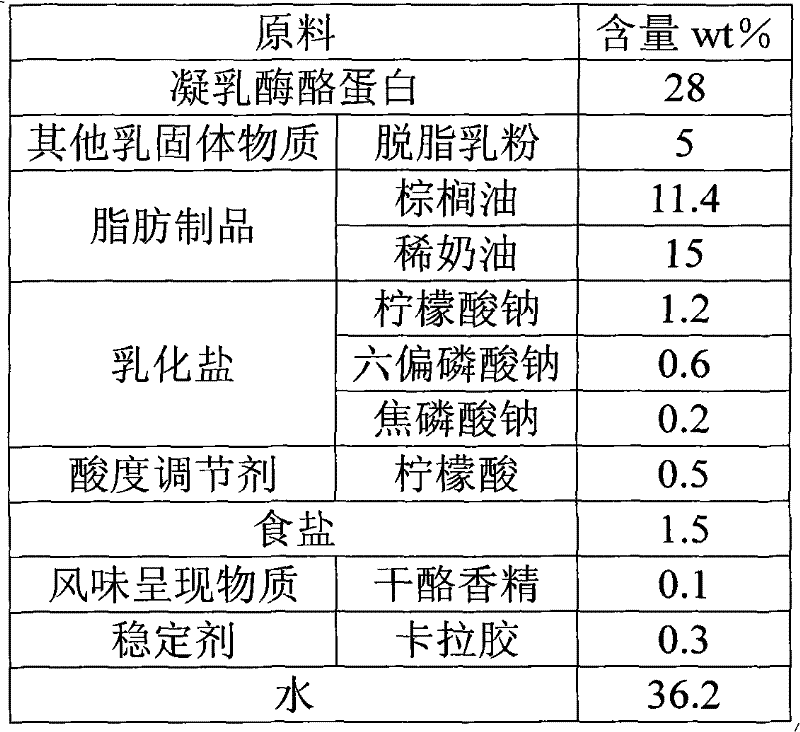

[0047] Raw material formula:

[0048]

[0049] Preparation:

[0050] ①According to the above formula, put all the raw materials into the melting pot, and without heating, use a blunt knife with a blade thickness of 10mm to shear and stir at 1500rpm for 3min to obtain a premixed slurry;

[0051] ② Stir the pre-mixed slurry at a speed of 800rpm, heat the steam directly to a temperature of 80°C, and then keep it warm for 8 minutes until the wire drawing appears;

[0052] ③Hot-filled aseptic packaging, cooled, and refrigerated.

[0053] After testing, the indicators of the obtained imitation cheese are: 26.9% protein; 17.7% fat; 47.6% moisture; pH 5.9.

Embodiment 3

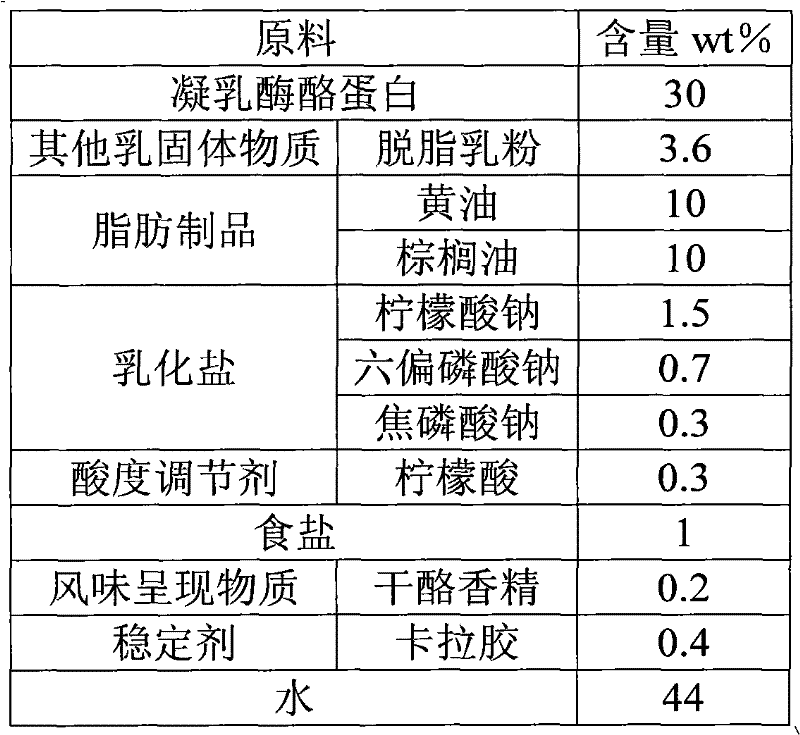

[0055] Raw material formula:

[0056]

[0057] Preparation:

[0058] ①According to the above formula, put all the raw materials into the melting pot, and without heating, use a blunt knife with a blade thickness of 10mm to shear and stir at 1500rpm for 3min to obtain a premixed slurry;

[0059] ② Stir the pre-mixed slurry at a speed of 800rpm, heat the steam directly to a temperature of 80°C, and then keep it warm for 8 minutes until the wire drawing appears;

[0060] ③Hot-filled aseptic packaging, cooled, and refrigerated.

[0061] After testing, the indicators of the obtained imitation cheese are: 27.9% protein; 18.8% fat; 50.0% moisture; pH 5.3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com