Bacillus amyloliquefaciens D4 and method for producing chymosin by fermentation of same

A technology of amylolytic spores and chymosin, which is applied in the field of bioengineering and can solve the problems of difficult extraction of fermentation products, long fermentation period, and easy damage of mycelium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

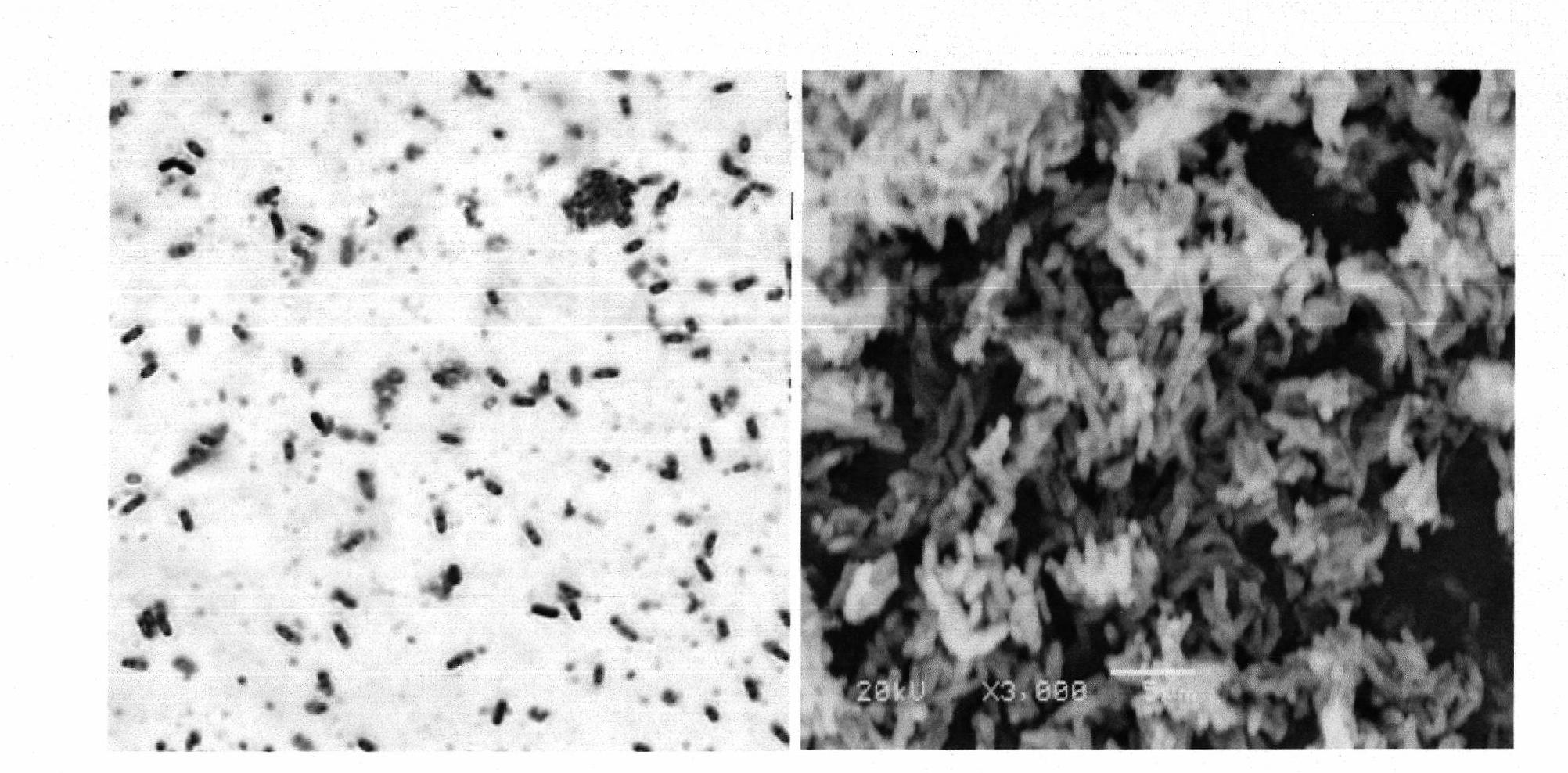

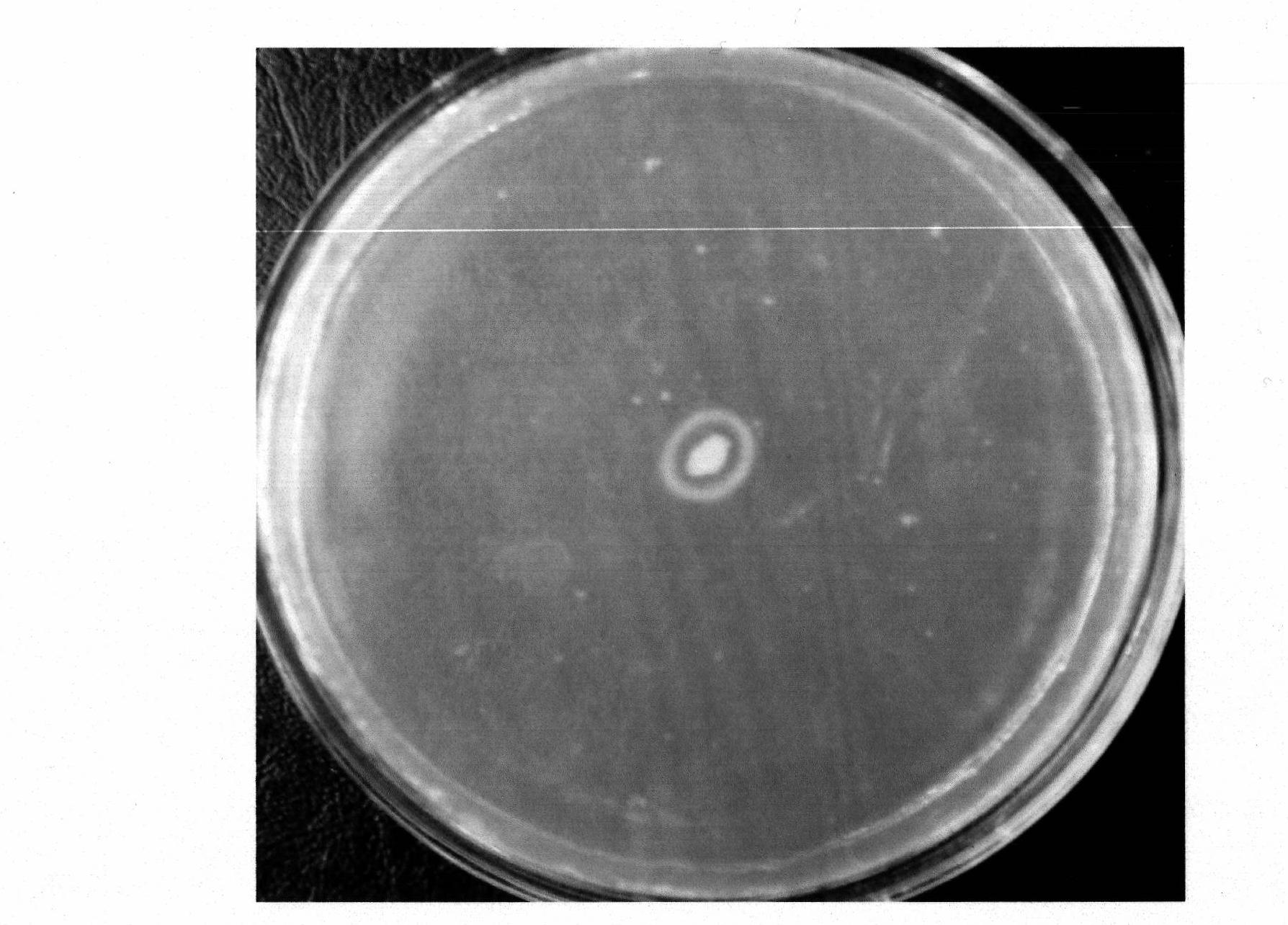

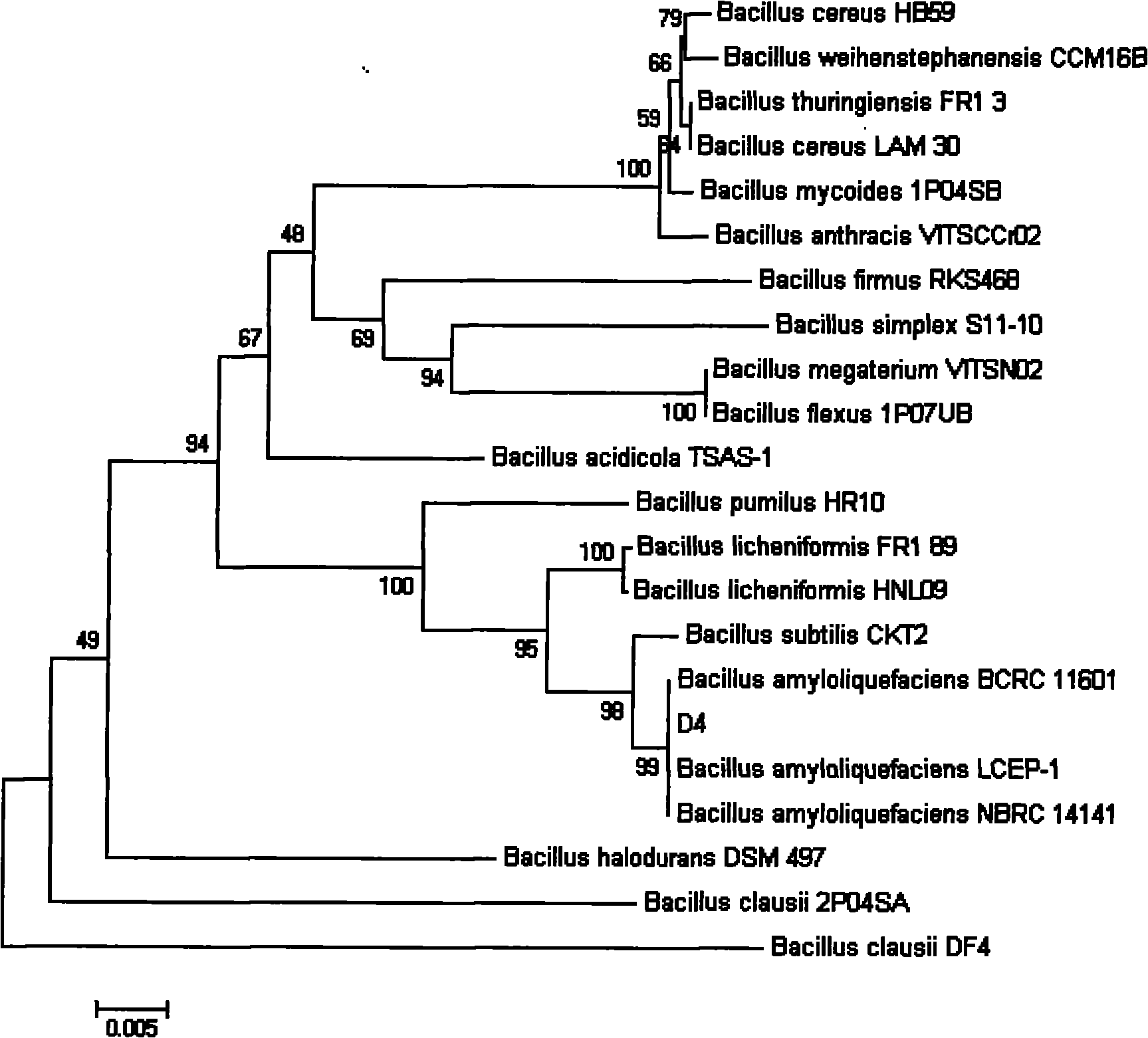

Method used

Image

Examples

Embodiment 1

[0077] Scrape the two-ring strains from the inclined surface, inoculate them in a 250ml Erlenmeyer flask with 70ml seed medium for seed culture. The conditions are as follows: the culture time is 13 hours, the temperature is 37° C., and the rotation speed of the shaker is 240 r / min. Then insert 3% inoculum into a 250ml Erlenmeyer flask with 50ml fermentation medium for fermentation. The conditions are as follows: the fermentation time is 48 hours, the temperature is 37° C., and the rotating speed of the shaker is 180 r / min, and the fermentation liquid with an enzyme activity of 2310.2 SU / ml can be obtained.

[0078] The composition of the seed medium is: beef extract 3g / L, peptone 10g / L, NaCl 5g / L, pH 7.0;

[0079] The liquid submerged fermentation medium is composed by mass percentage: 18% of bran extract, 3% of glucose, 2% of skim milk, 0.2% of disodium hydrogen phosphate, 0.1% of casein, 0.10% of magnesium sulfate, and distilled water as the balance;

[0080] The preparat...

Embodiment 2

[0082] Scrape the two-ring strains from the inclined surface, inoculate them in a 250ml Erlenmeyer flask with 70ml seed medium for seed culture. The conditions are: the culture time is 13 hours, the temperature is 37° C., and the rotation speed of the shaker is 220 r / min. Then insert 3% inoculum into a 250ml Erlenmeyer flask with 50ml fermentation medium for fermentation. The conditions are as follows: the fermentation time is 48 hours, the temperature is 37° C., and the rotating speed of the shaker is 175 r / min, and the fermentation liquid with an enzyme activity of 2308.5 SU / ml can be obtained.

[0083] The composition of the seed medium is: beef extract 3g / L, peptone 11g / L, sodium chloride 5g / L, pH7.0;

[0084] The liquid submerged fermentation medium is composed by mass percent: 14% of bran extract, 5% of glucose, 2% of skim milk, 0.2% of disodium hydrogen phosphate, 0.1% of casein, 0.10% of magnesium sulfate, and distilled water as the balance. The preparation method of...

Embodiment 3

[0086] Scrape the two-ring strains from the inclined surface, inoculate them in a 250ml Erlenmeyer flask with 70ml seed medium for seed culture. The conditions are as follows: the culture time is 13 hours, the temperature is 37° C., and the rotation speed of the shaker is 200 r / min. Then insert 3% inoculum into a 250ml Erlenmeyer flask with 50ml fermentation medium for fermentation. The conditions are as follows: the fermentation time is 48 hours, the temperature is 37° C., and the rotating speed of the shaker is 170 r / min, and the fermentation broth with an enzyme activity of 2214.7 SU / ml can be obtained.

[0087] The composition of the seed medium is: beef extract 3g / L, peptone 12g / L, sodium chloride 5g / L, pH7.0;

[0088] Liquid submerged fermentation medium composition: 10% of bran extract, 8% of glucose, 2% of skim milk, 0.2% of disodium hydrogen phosphate, 0.1% of casein, 0.10% of magnesium sulfate, and distilled water as the balance. The preparation method of the bran ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com