Patents

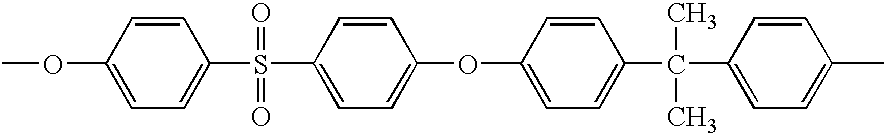

Literature

1264 results about "Hollow fibre membrane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

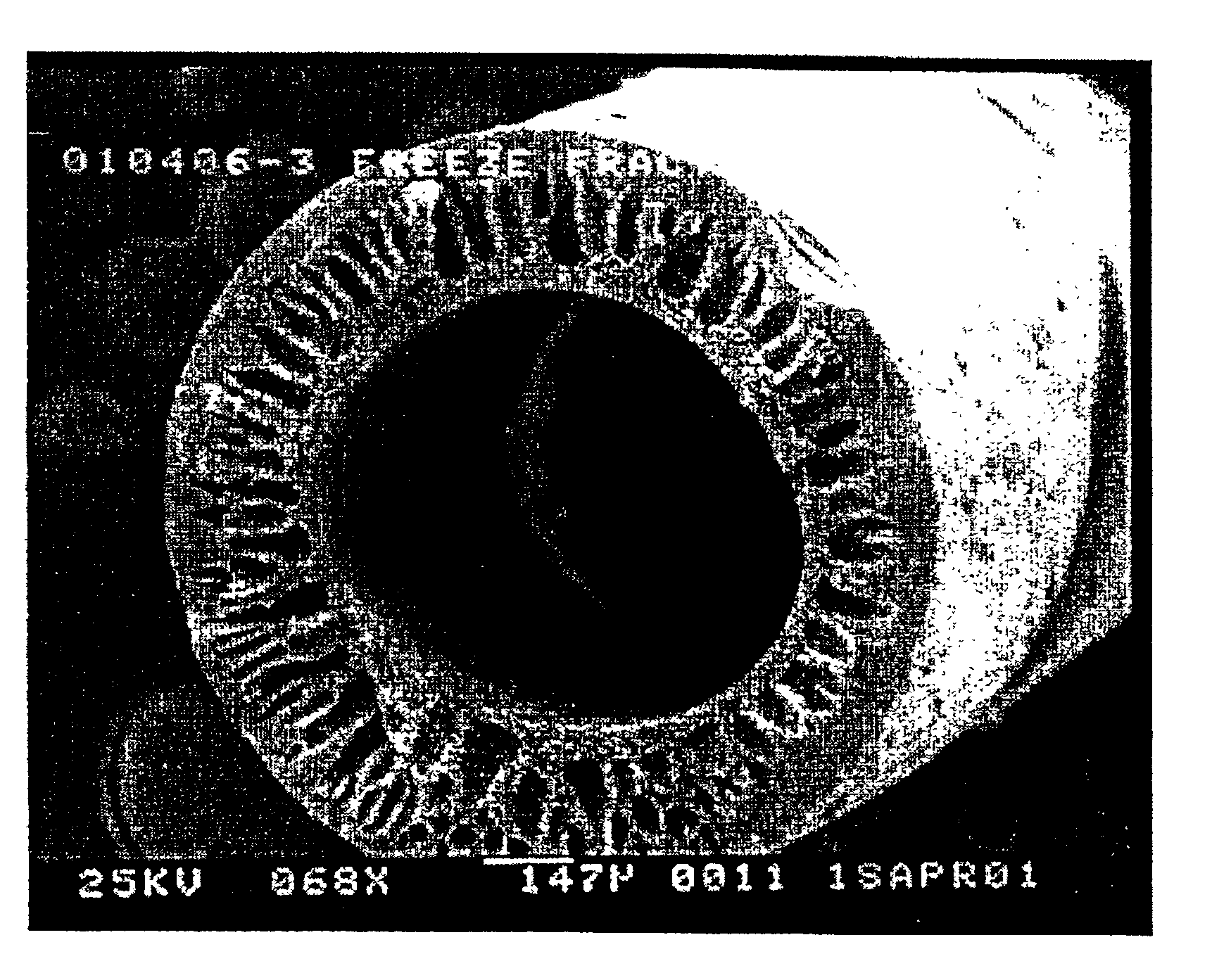

Hollow fiber membranes (HFMs) are a class of artificial membranes containing a semi-permeable barrier in the form of a hollow fiber. Originally developed in the 1960s for reverse osmosis applications, hollow fiber membranes have since become prevalent in water treatment, desalination, cell culture, medicine, and tissue engineering.

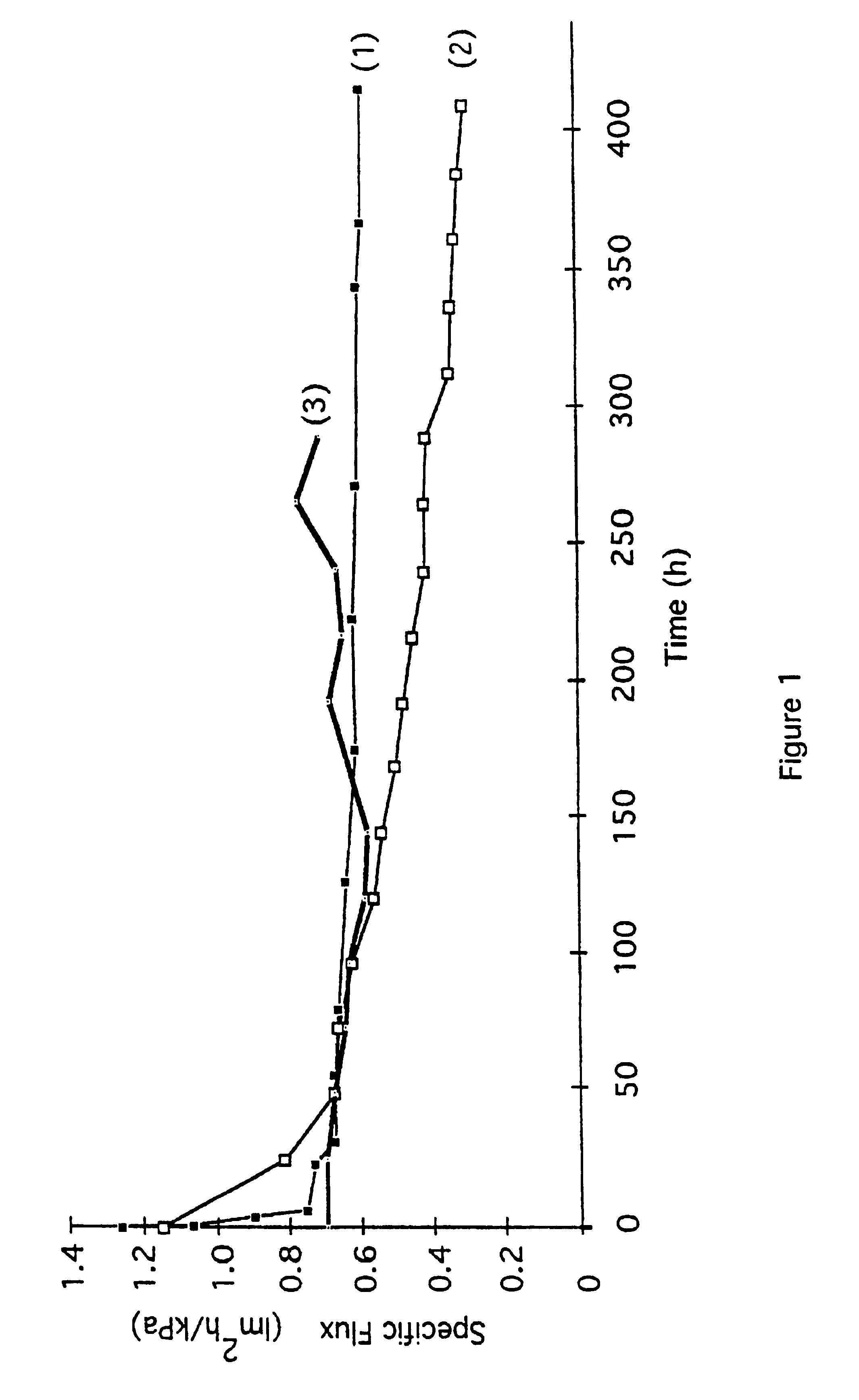

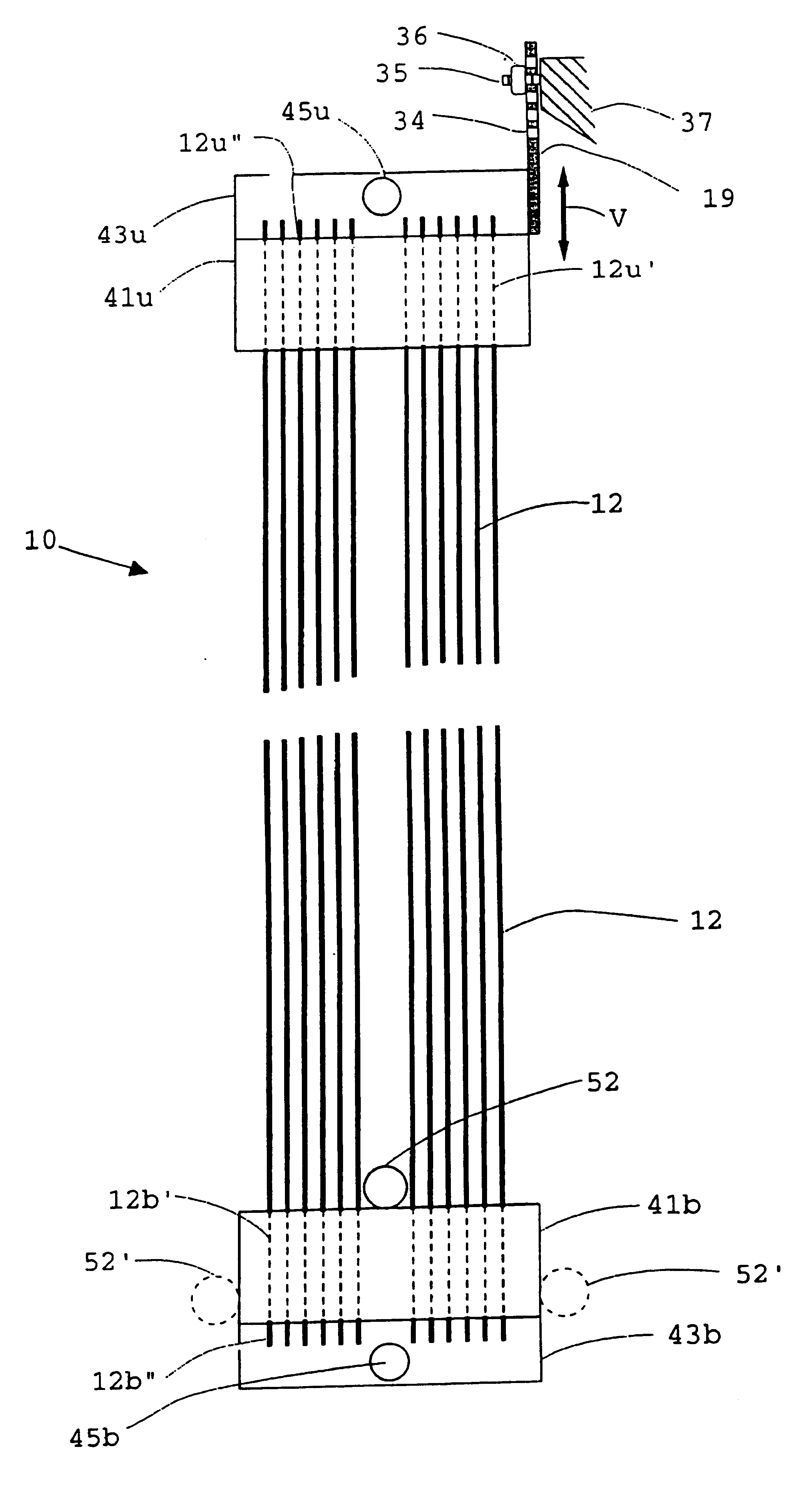

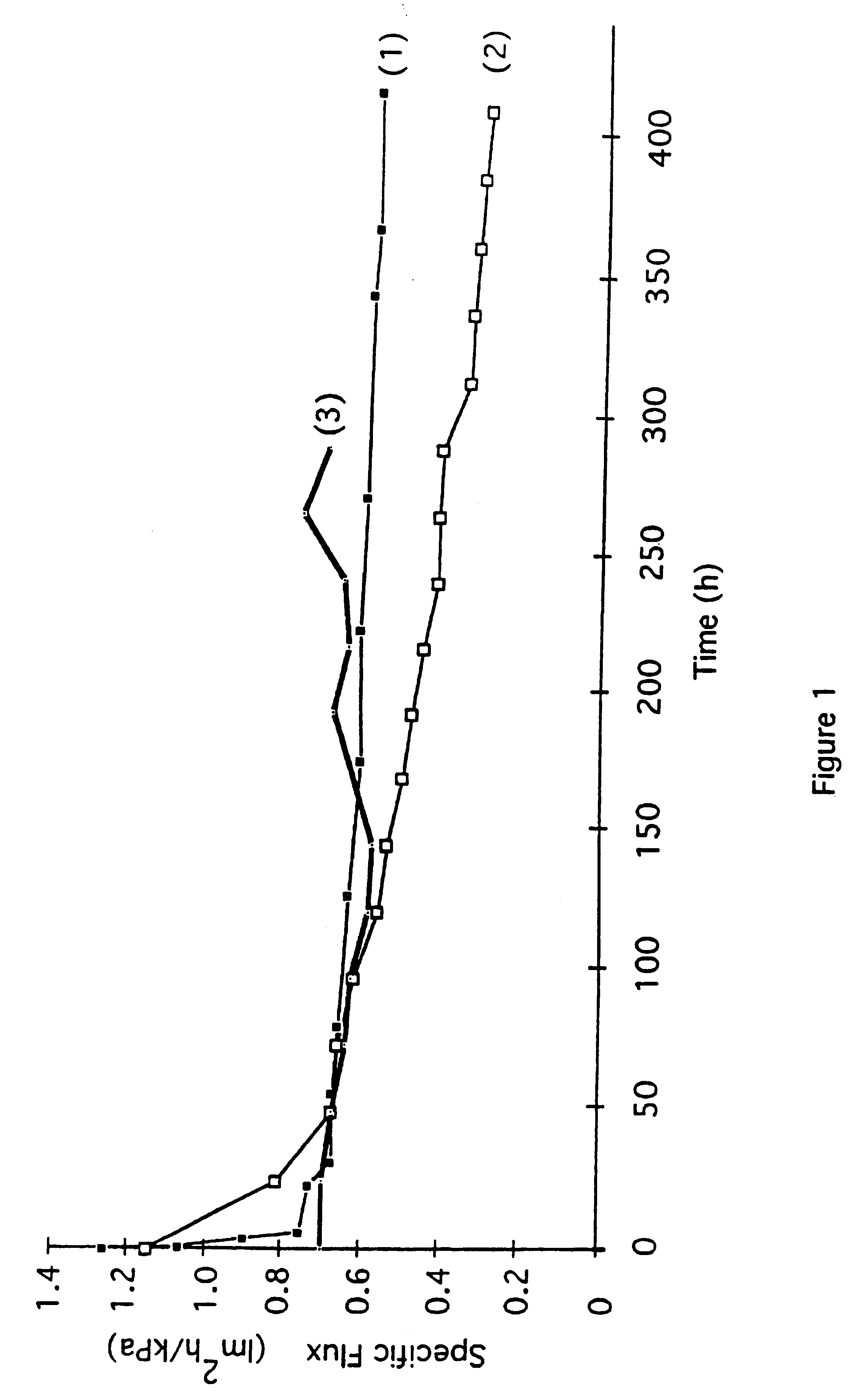

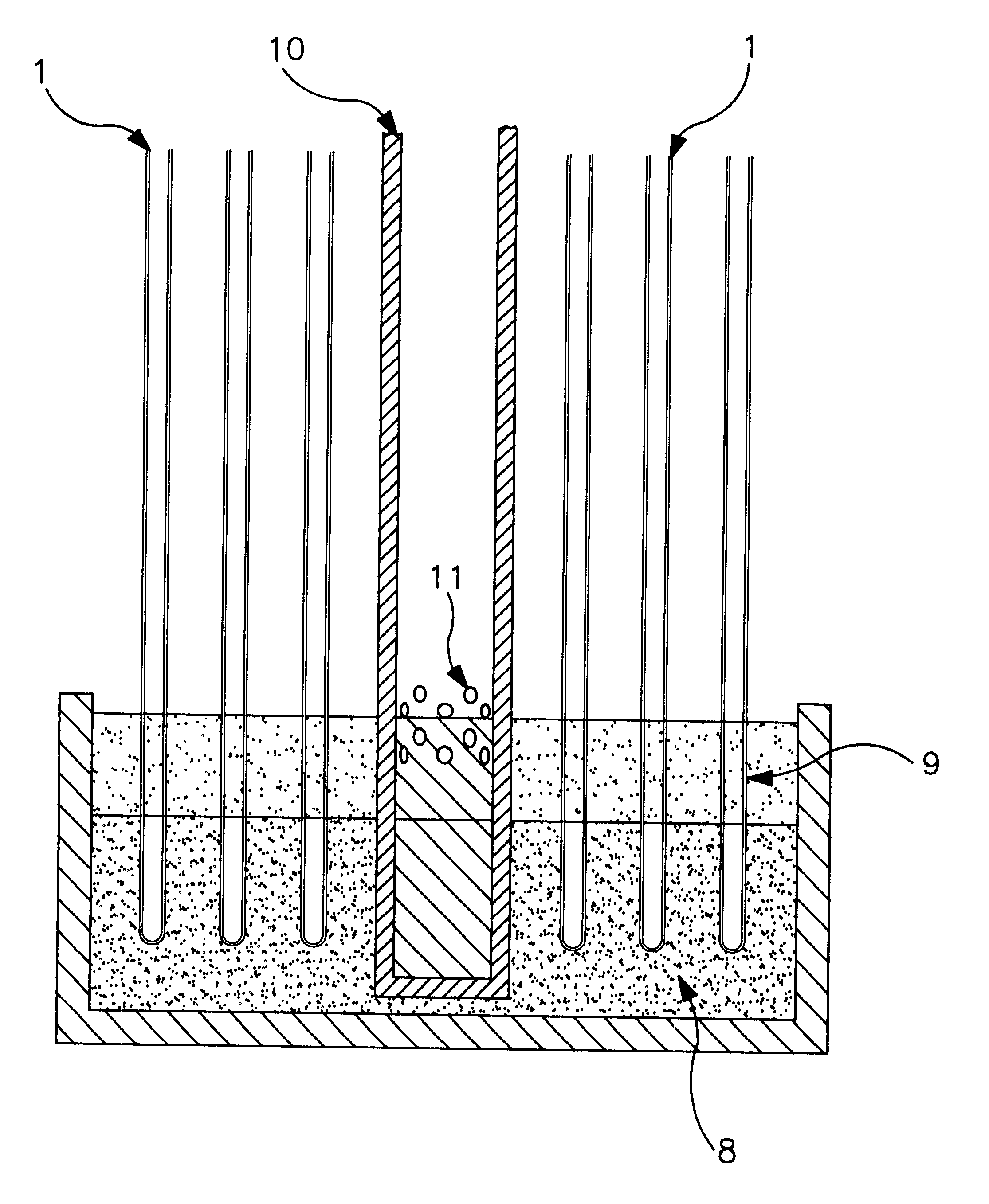

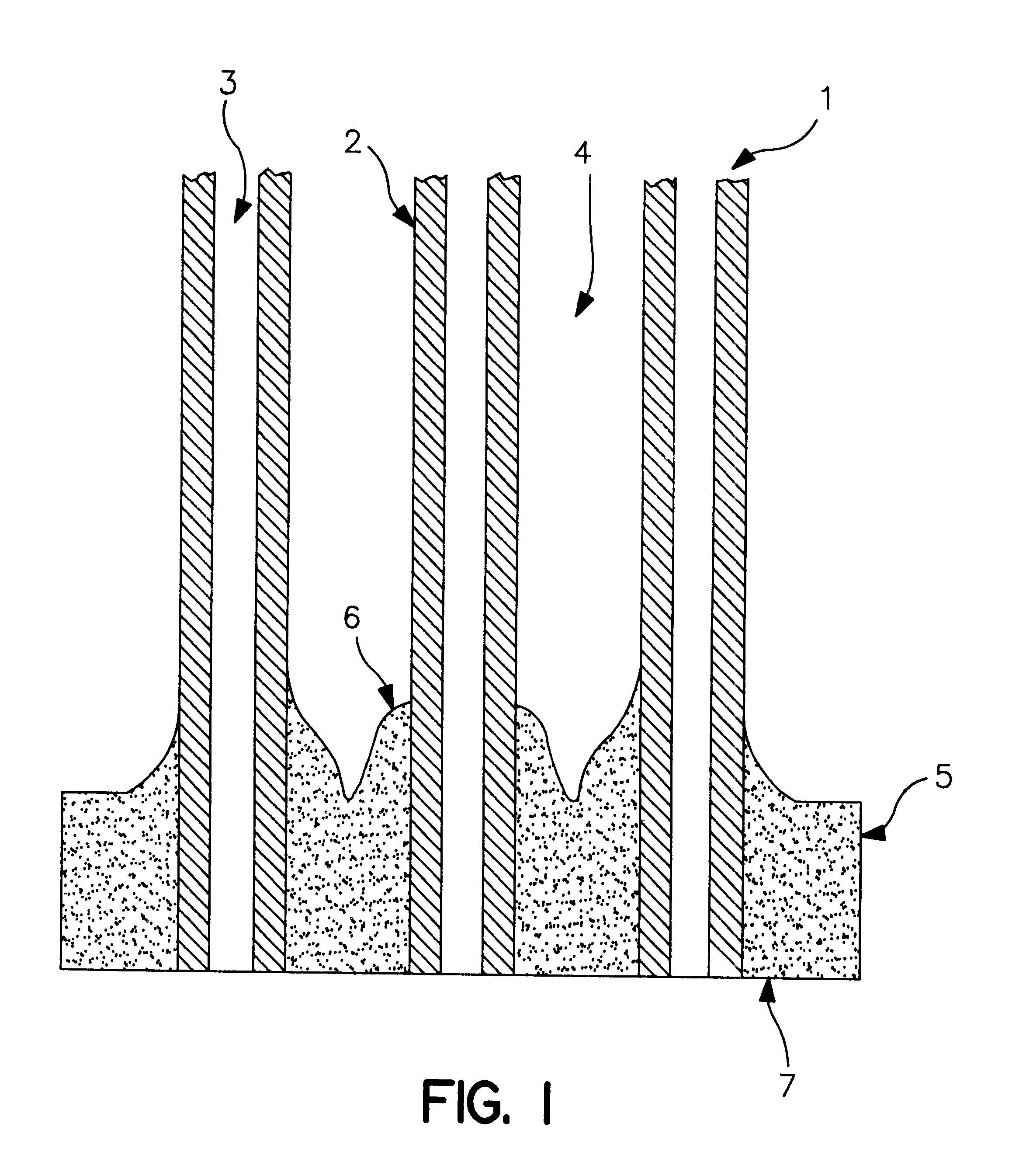

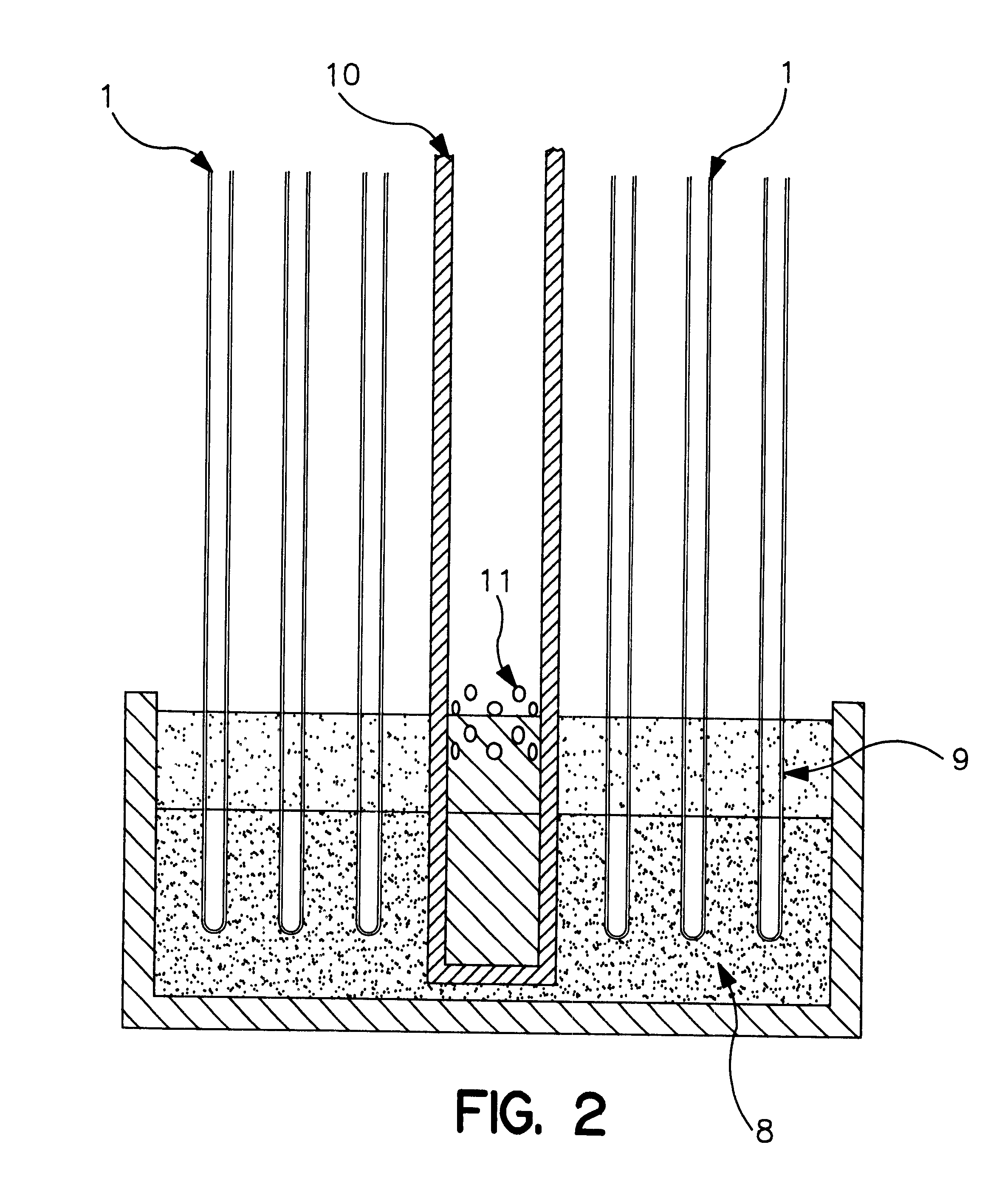

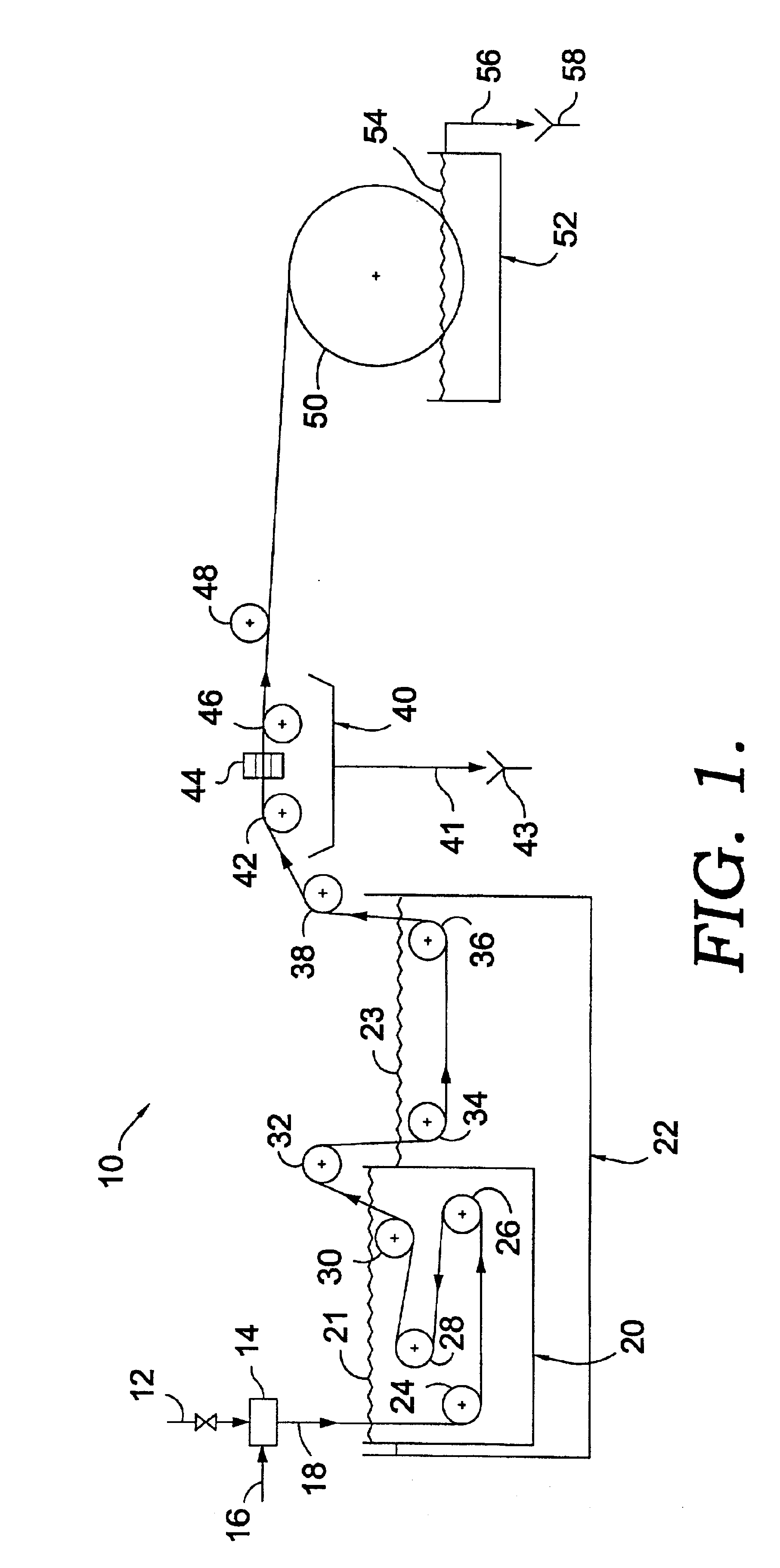

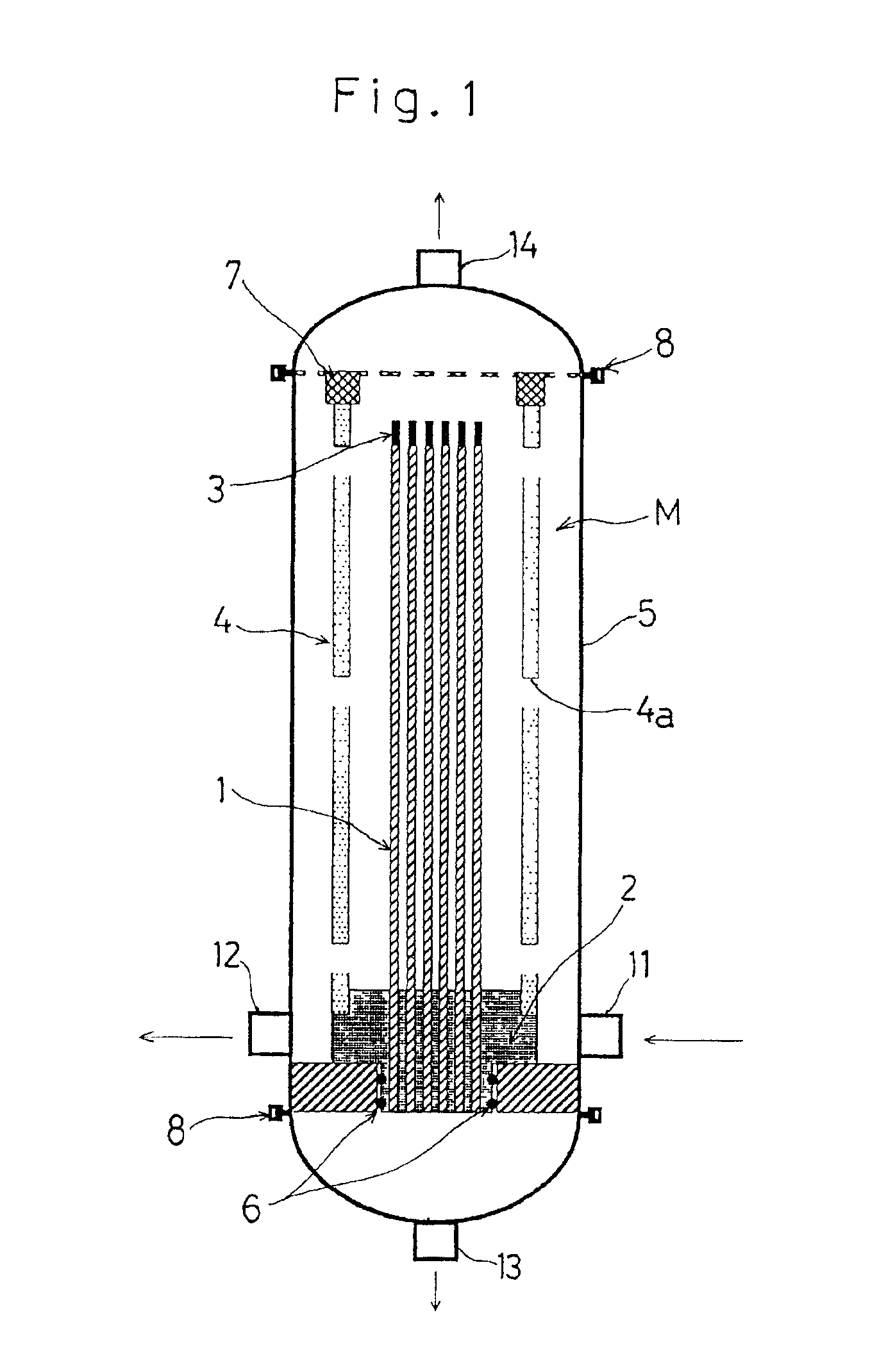

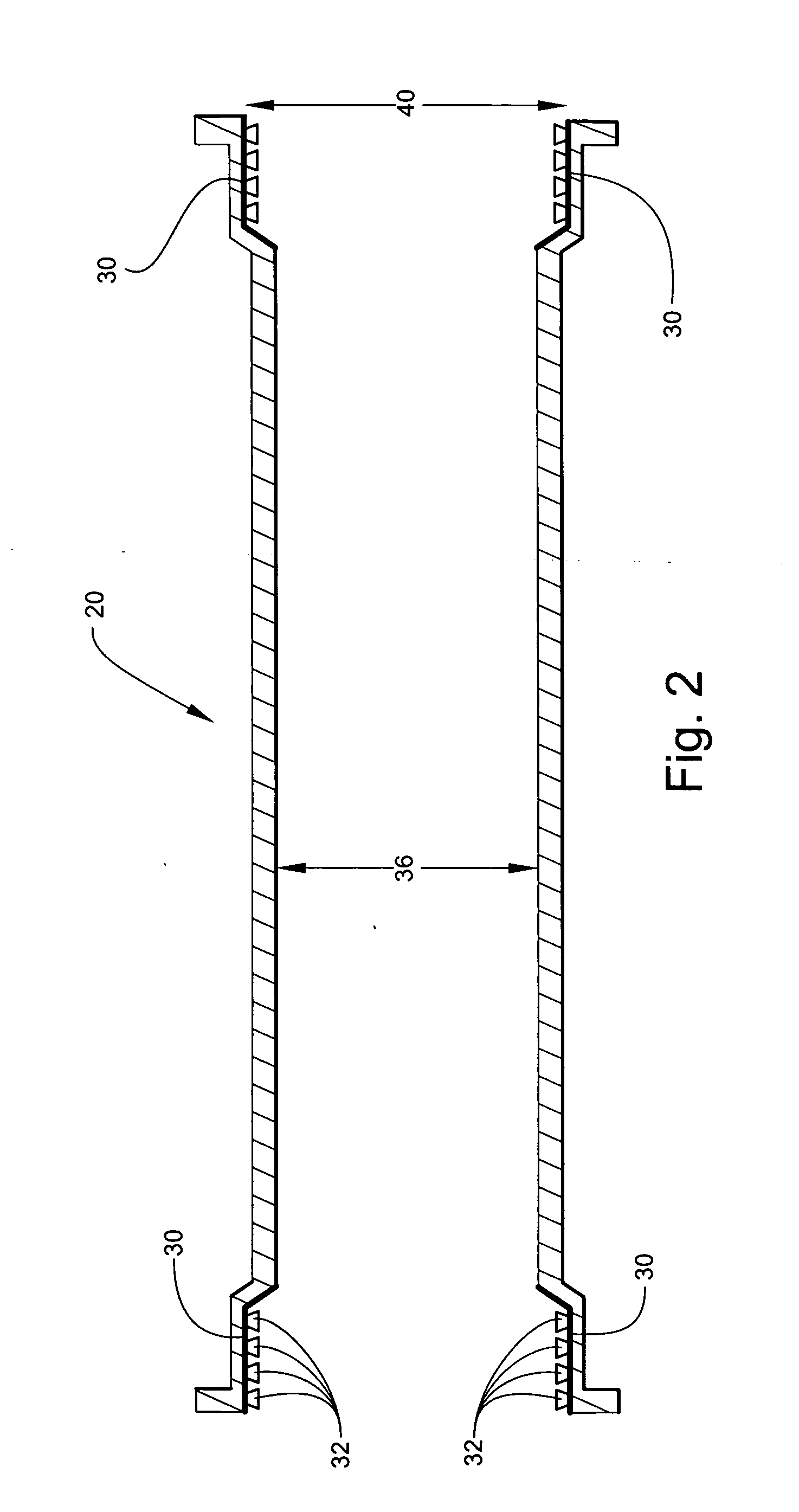

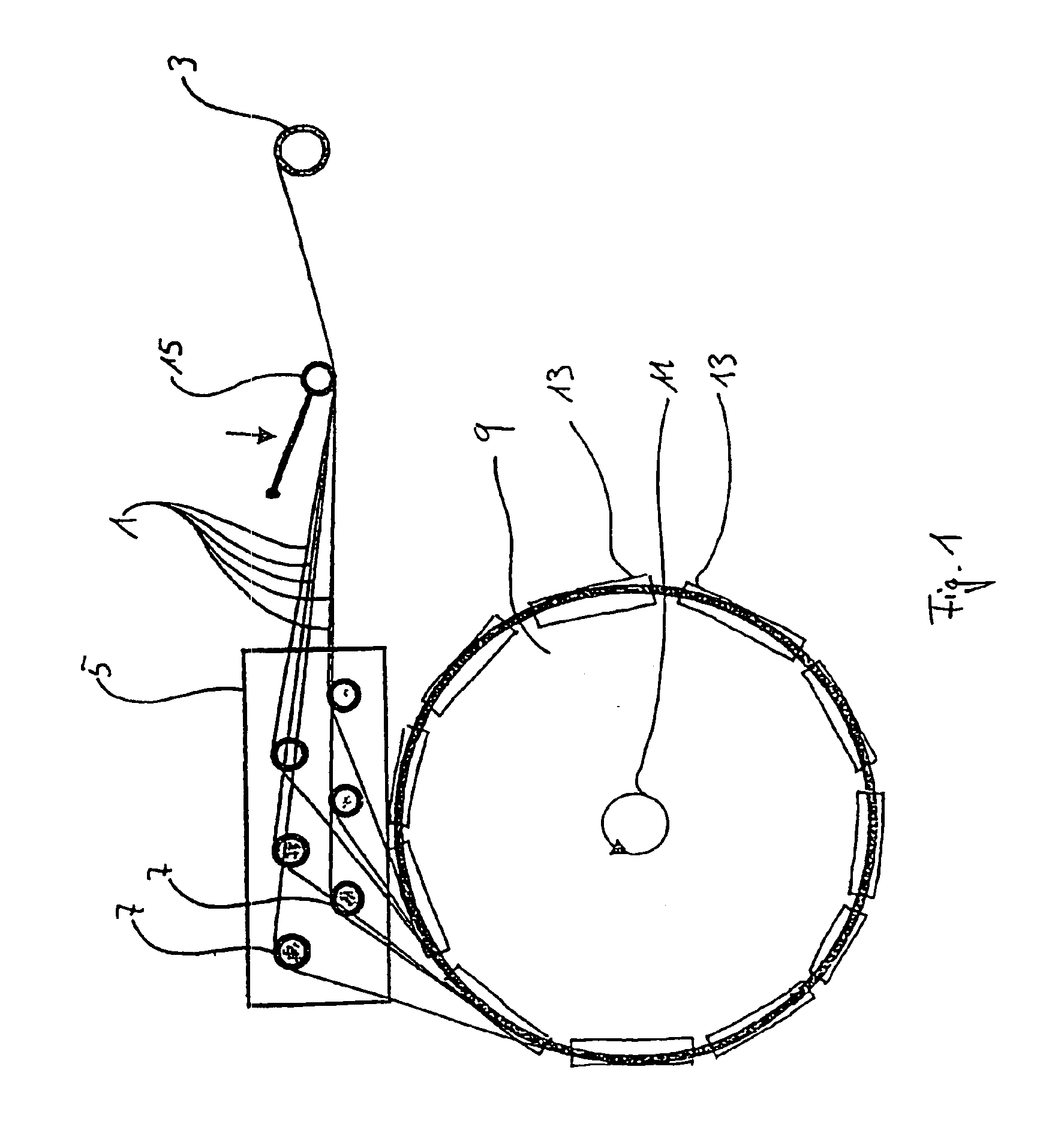

Vertical skein of hollow fiber membranes and method of maintaining clean fiber surfaces while filtering a substrate to withdraw a permeate

A vertical skein of "fibers", opposed terminal portions of which are held in headers unconfined in a modular shell, is aerated with a gas-distribution means which produces a mass of bubbles serving the function of a scrub-brash for the outer surfaces of the fibers. The membrane device is surprisingly effective with relatively little cleansing gas, the specific flux through the membranes reaching an essentially constant relatively high value because the vertical deployment of fibers allows bubbles to rise upwards along the outer surfaces of the fibers. Further, bubbles flowing along the outer surfaces of the fibers make the fibers surprisingly resistant to being fouled by build-up of deposits of inanimate particles or microorganisms in the substrate provided that the length of each fiber is only slightly greater than the direct center-to-center distance between opposed faces of the headers, preferably in the range from at least 0.1% to about 5% greater. For use in a large reservoir, a bank of skeins is used with a gas distributor means and each skein has fibers preferably >0.5 meter long, which together provide a surface area >10 m2. The terminal end portions of fibers in each header are kept free from fiber-to-fiber contact with a novel method of potting fibers.

Owner:ZENON TECH PARTNERSHIP

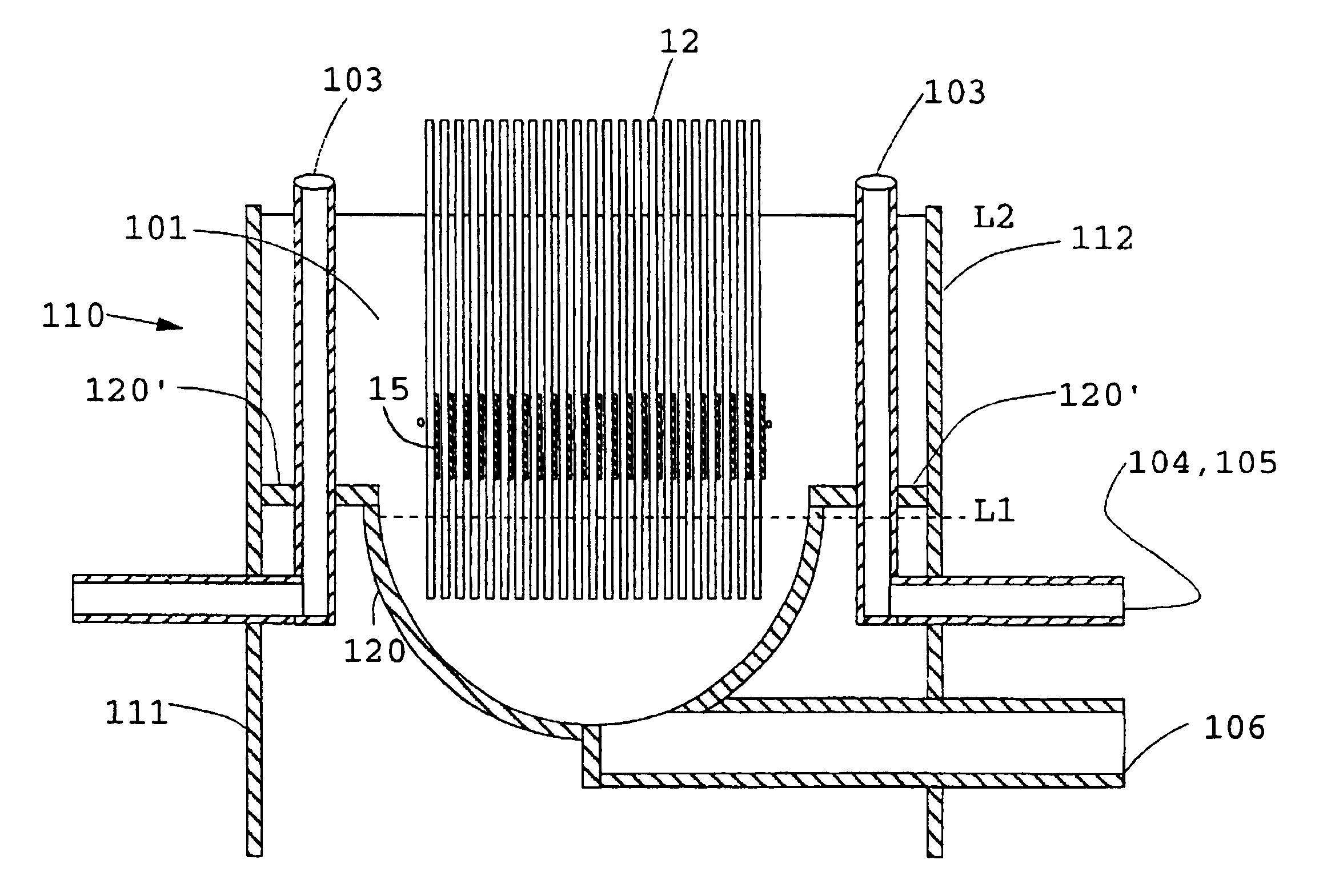

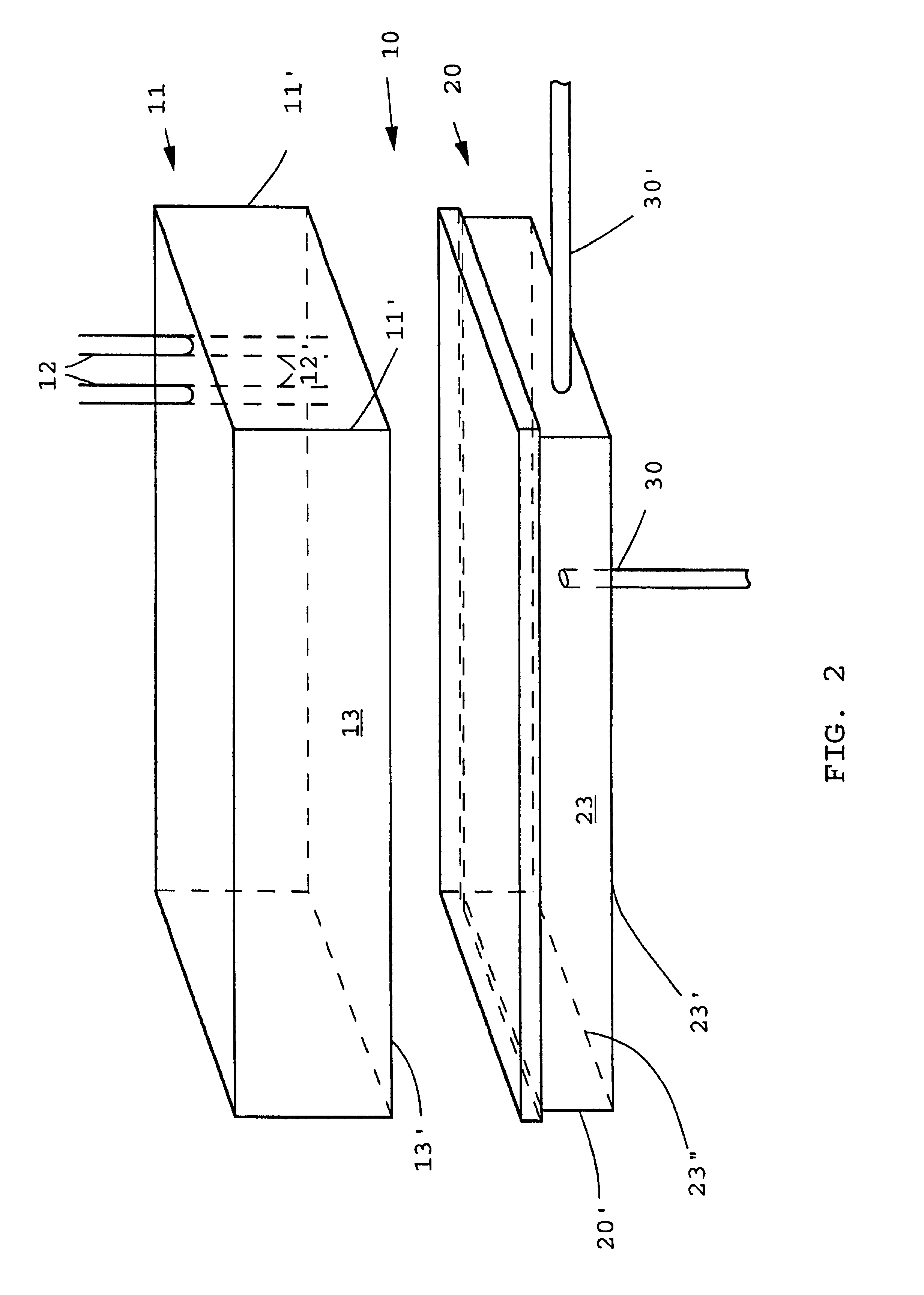

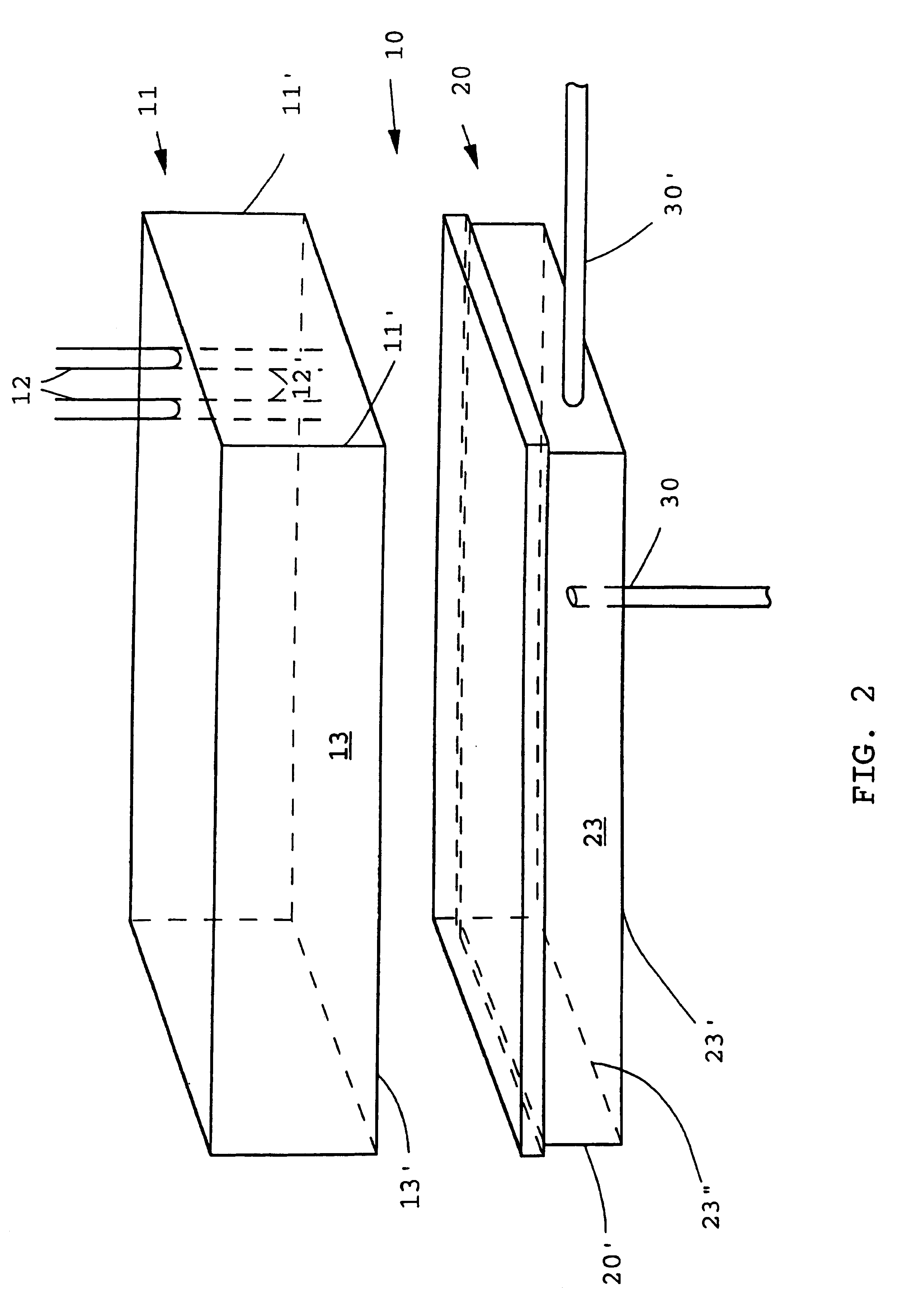

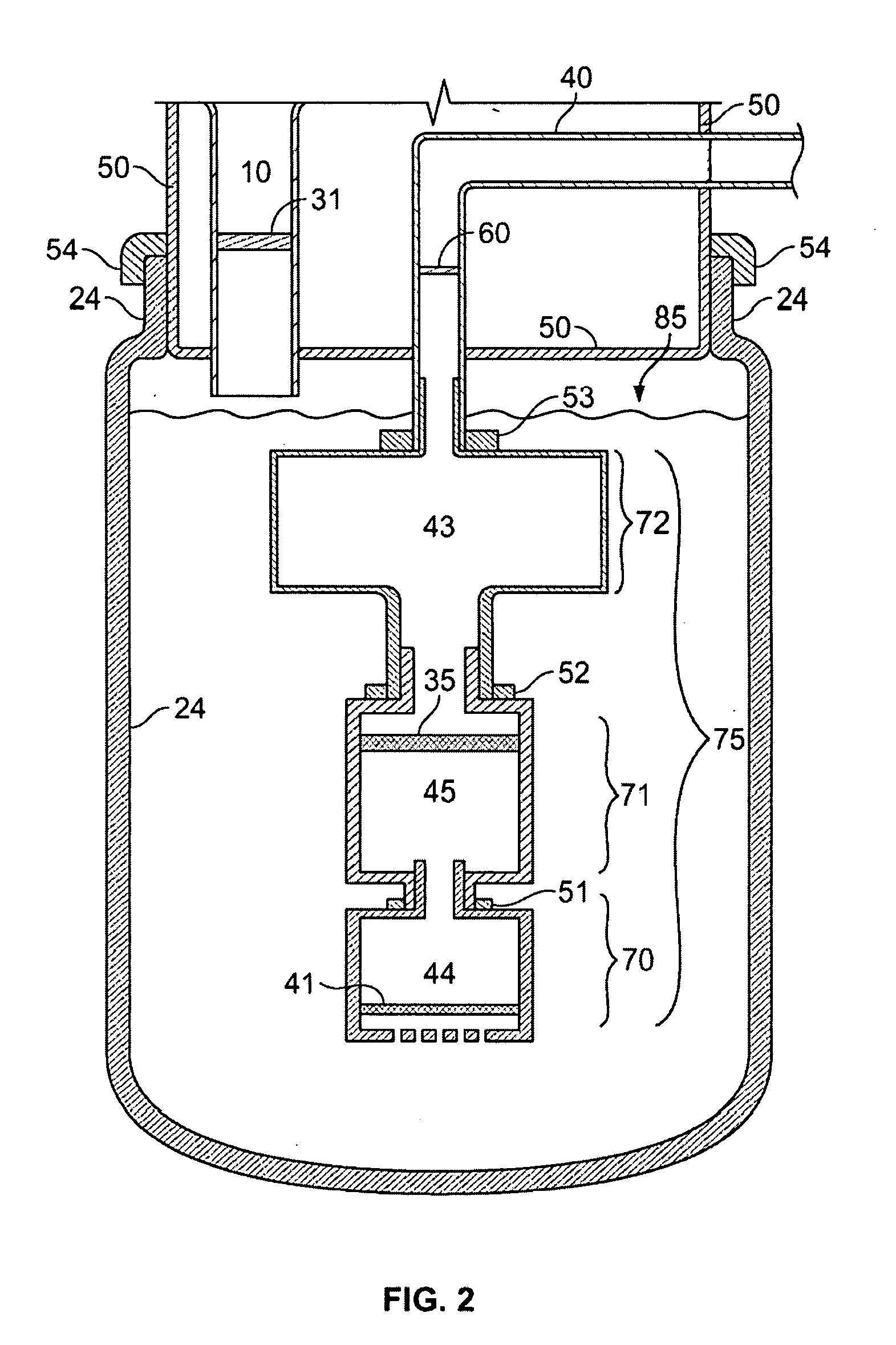

Apparatus for withdrawing permeate using an immersed vertical skein of hollow fibre membranes

An apparatus for treating a multi component liquid substrate while leaving particulate matter therein as a skein of hollow fiber filtering membranes immersed in the substrate which is contained in a non-pressurized reservoir. A pumping fluid communication with the lumens of the membranes draws a component of the substrate as permeate through the membranes by applying a section to the lumens of the membranes. In various embodiments, an aeration system as a gas distributor for discharging air directly into the substrate within the skein, upper and lower headers of the skein are spaced apart by a gas tube, and a gas distribution system has through passages through the lower header to discharge bubbles into the substrate above the lower header.

Owner:ZENON TECH PARTNERSHIP

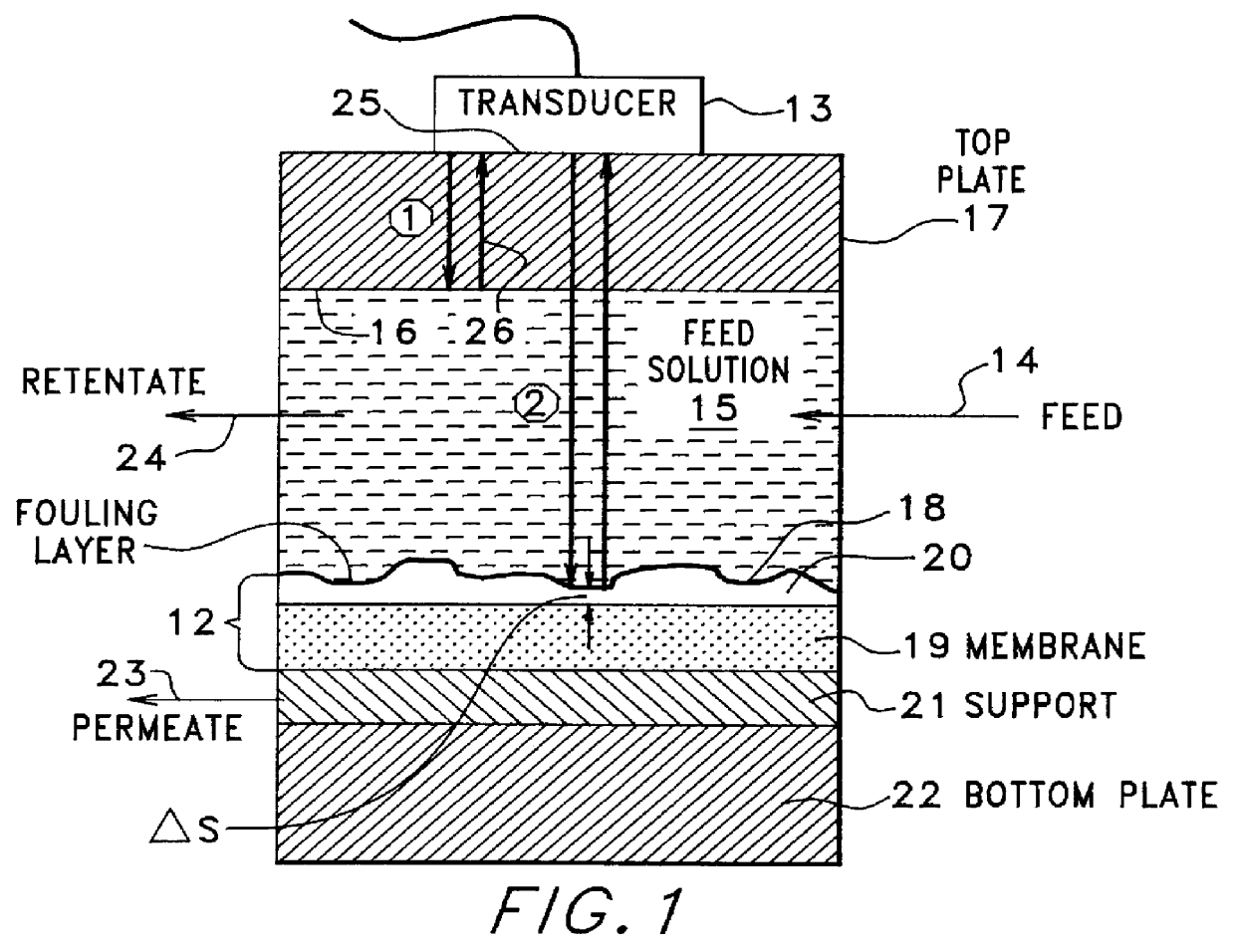

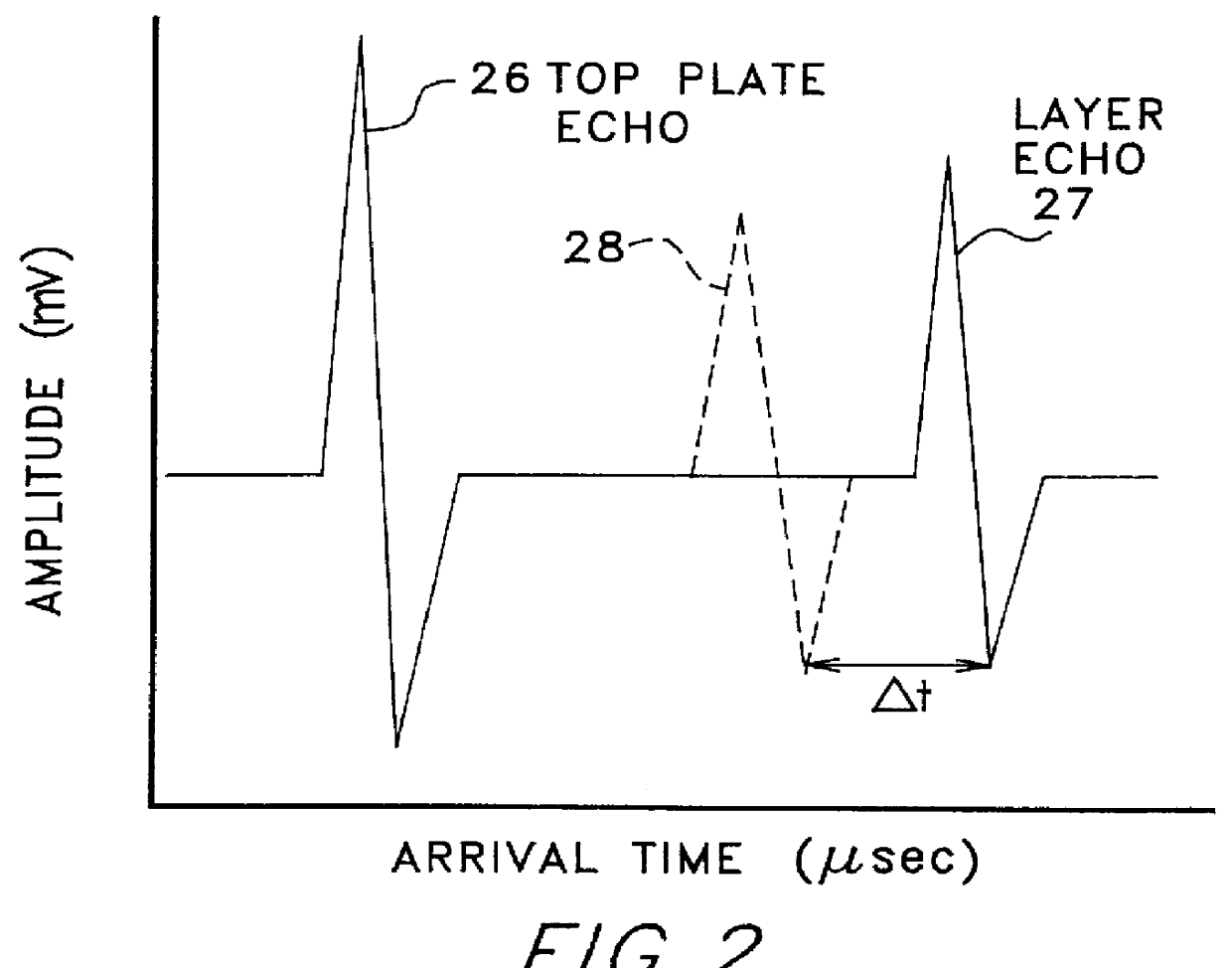

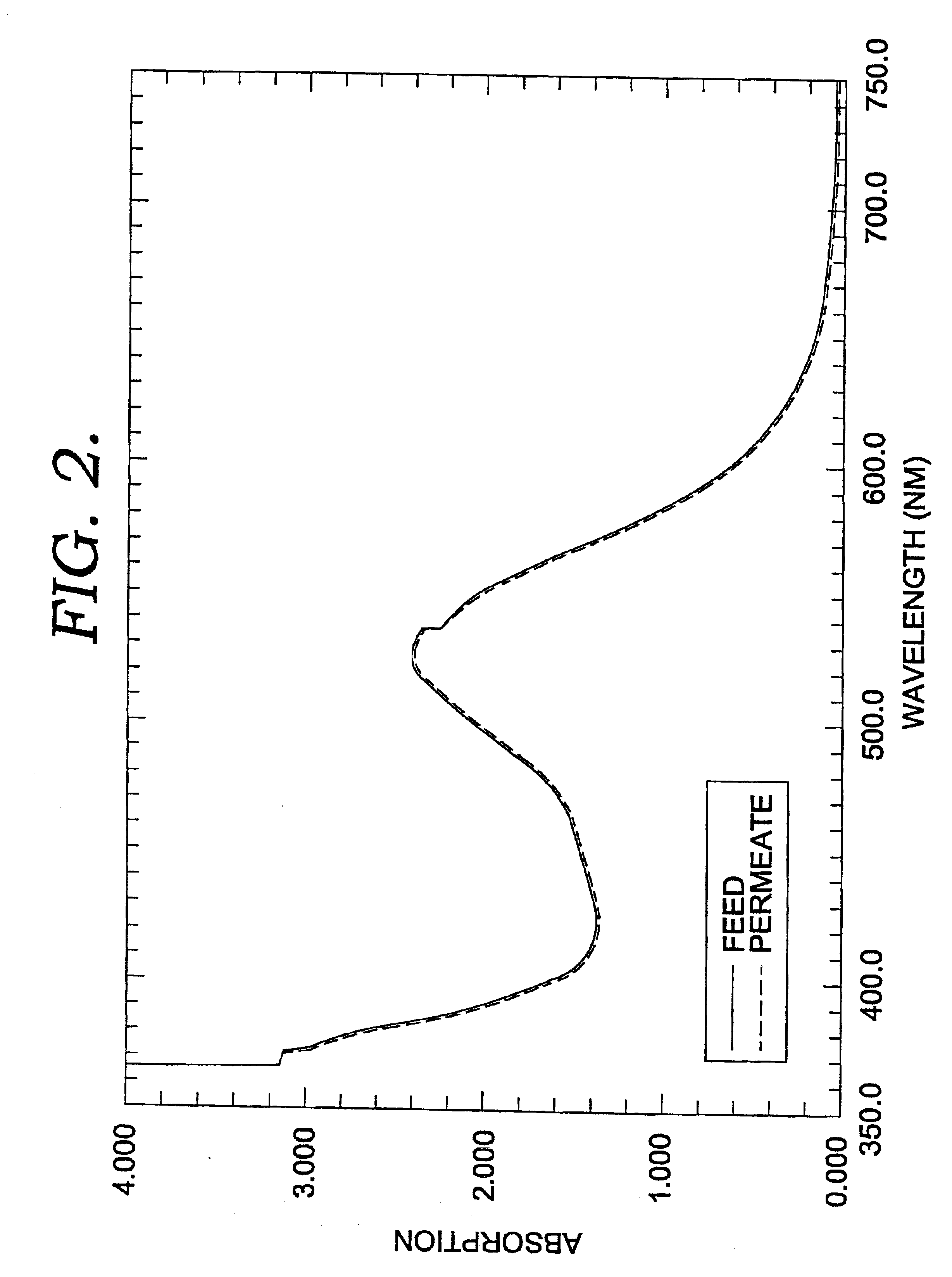

Method and apparatus for determining the state of fouling/cleaning of membrane modules

InactiveUS6161435AVibration measurement in solidsAnalysing fluids using sonic/ultrasonic/infrasonic wavesTime domainSpiral wound

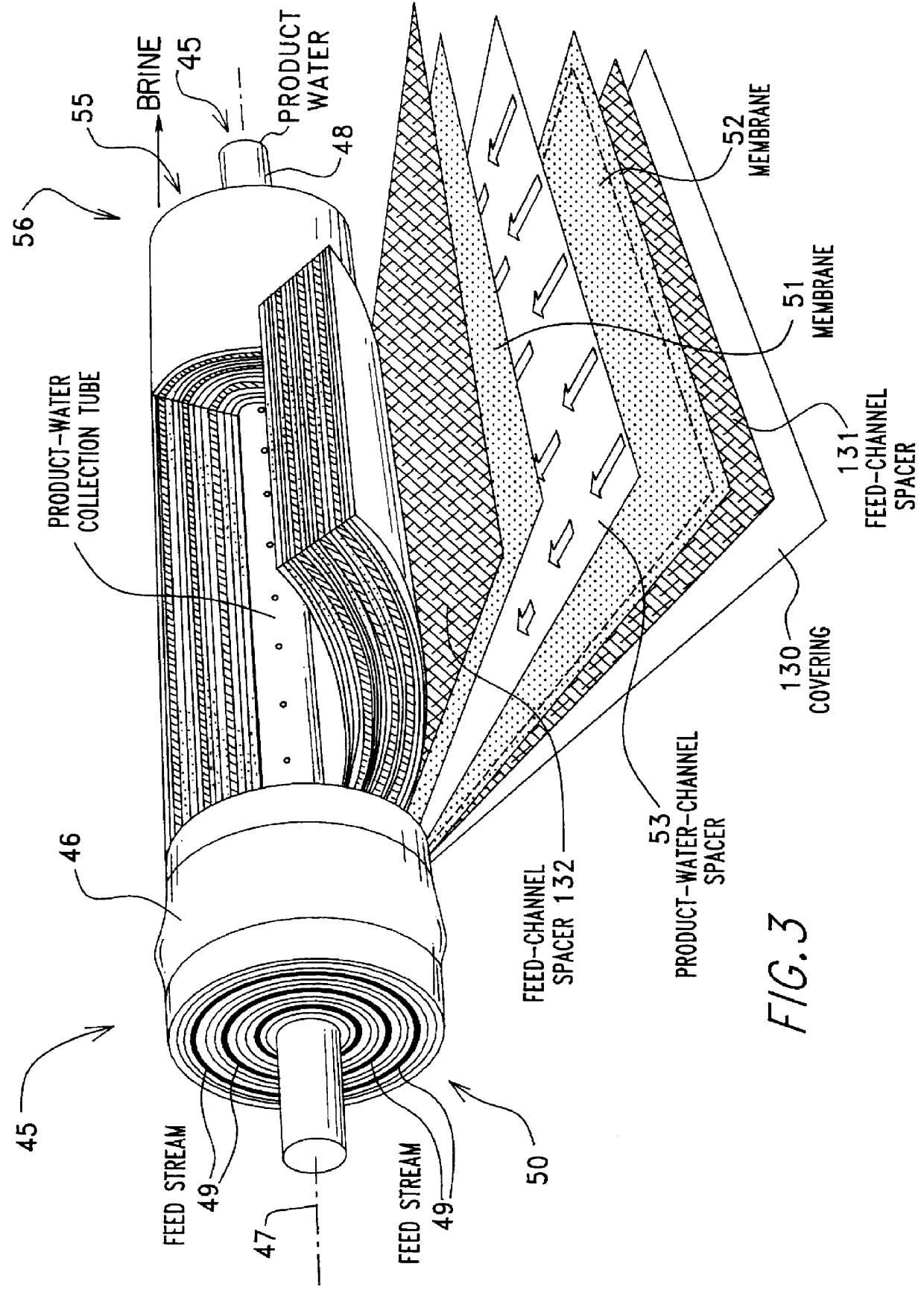

The fouling state of a polymeric membrane within the high pressure housing of a spiral wound or a hollow fiber membrane module is determined. An ultra sonic transducer positioned with its emitting face in physical engagement with the outer surface of the housing is pulse energized by a pulser / receiver device. A membrane echo signal is detected by a receiver of the pulser / receiver device. A reference echo signal indicative of a fouled or an unfouled state of the membrane is compared to the echo signal to determine the membrane fouling state. The echo to reference comparing step can be based upon comparing amplitude domain signals, comparing time-domain signals, comparing combinations of amplitude domain and time-domain signals, and comparing transformations of amplitude domain and time-domain signals. A clean or a fouled reference echo can be provided from a clean or a fouled membrane and then stored for use during a liquid separation process, or a clean reference echo signal can be obtained on-line from a second transducer whose echo signal is derived from an area of the membrane known to remain relatively unfouled during the liquid separation process, or a clean or fouled reference echo signal can be provided for later use during a cleaning process or during a liquid separation process. Multiple transducers and a switching network can sample the fouling state at different positions within the membrane module.

Owner:UNIV TECH

Hollow fiber membrane tubesheets of variable epoxy composition and hardness

InactiveUS6290756B1High strengthIncreased durabilitySemi-permeable membranesLaminationEpoxyHollow fibre membrane

Multicomponent hollow fiber membrane tubesheets are disclosed that provide for improved membrane performance, particularly at high operating pressures. The multicomponent tubesheets have an epoxy resin having, when cured, different degrees of hardness in different portions of the tubesheet. Methods for producing such multicomponent tubesheets are also provided.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

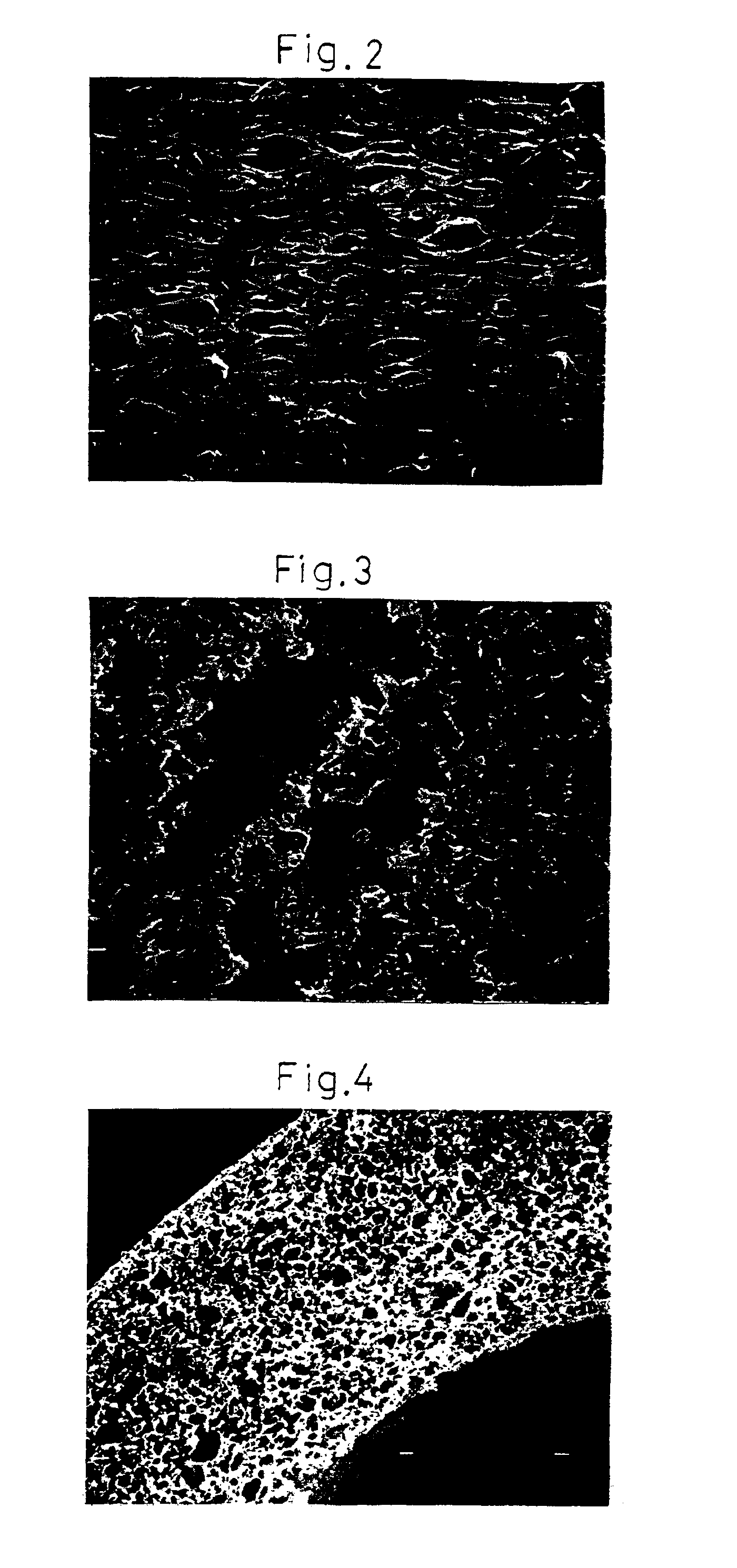

Hollow fiber microfiltration membranes and a method of making these membranes

InactiveUS6890435B2Narrow pore size distributionHigh mechanical strengthSemi-permeable membranesMembranesFiberHollow fibre membrane

A hollow fiber microfiltration (MF) membrane is provided. The casting solution used to make this membrane includes a fiber-forming polymer having a degree of polymerization greater than about 1000, a water-soluble polymer, an anhydride with about 2 to 12 carbon atoms, and a solvent. The membrane is formed by mixing and heating these components to form a viscous dope and then extruding the dope through an annular orifice to form a hollow fiber MF membrane. The hollow fiber membrane is then fed through a coagulation bath and two leaching baths. The membrane is especially useful for filtering liquids, such as wine and juice, so as to remove bacteria, gel, and solid particles from the liquids.

Owner:KOCH MEMBRANE SYST

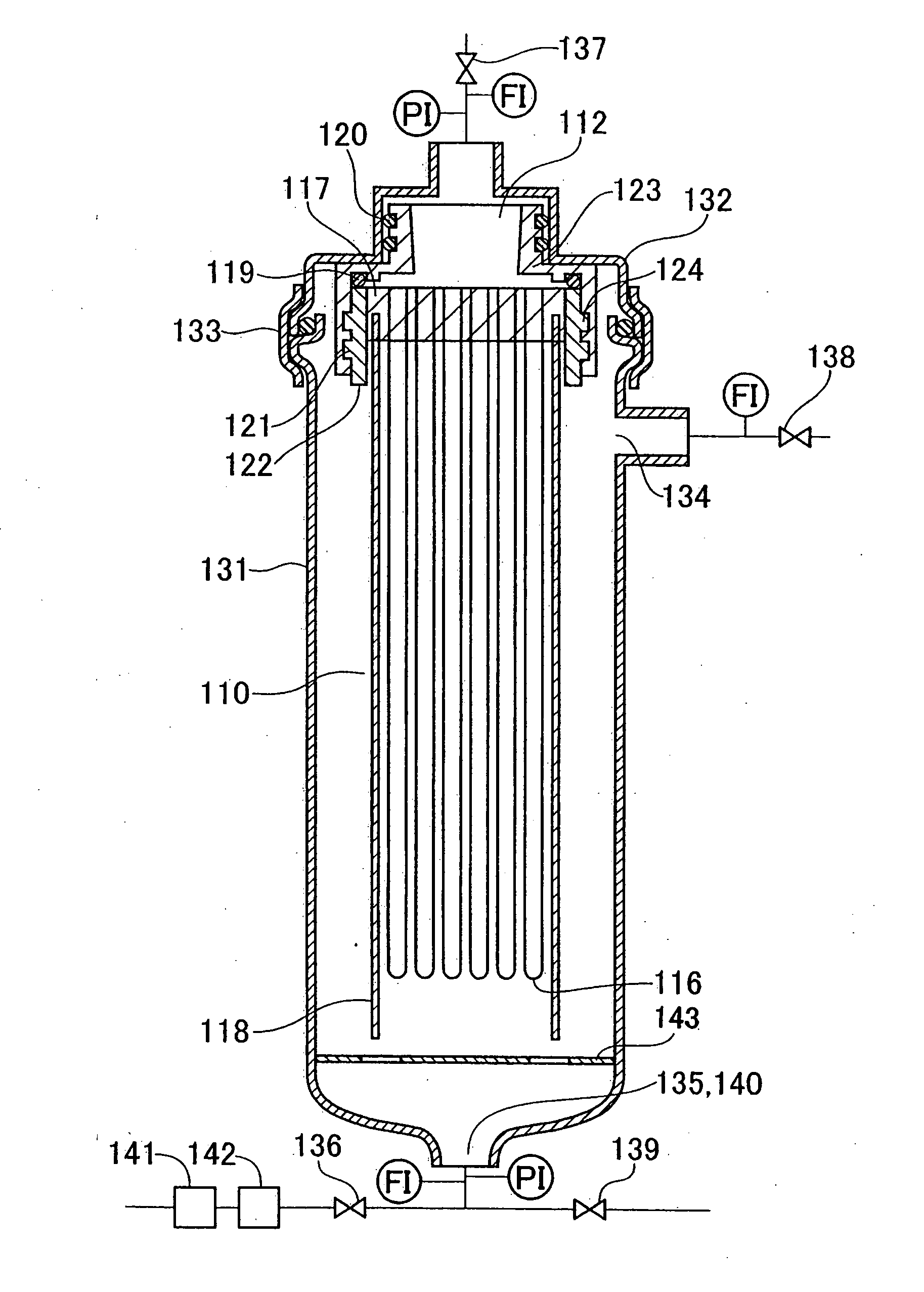

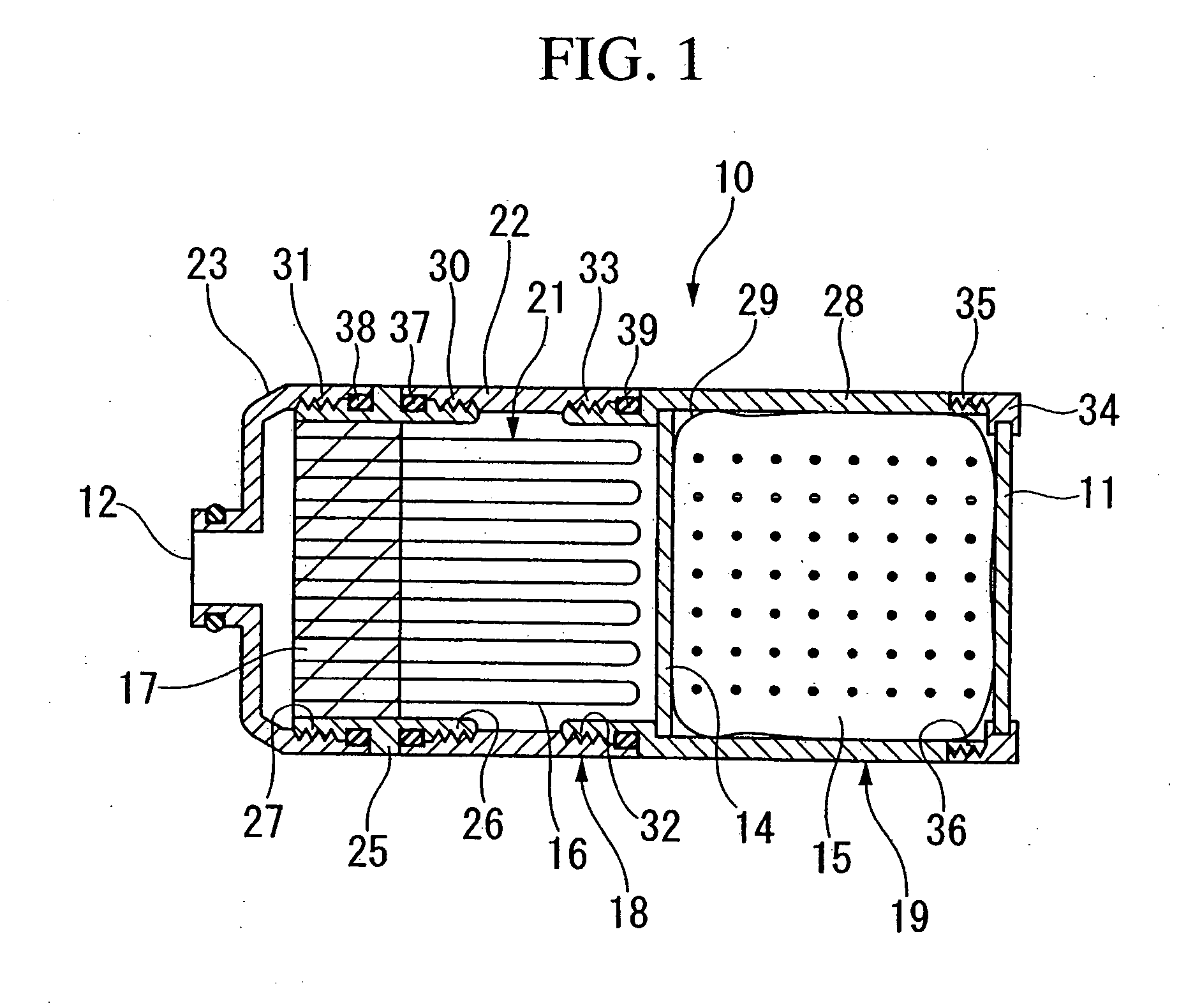

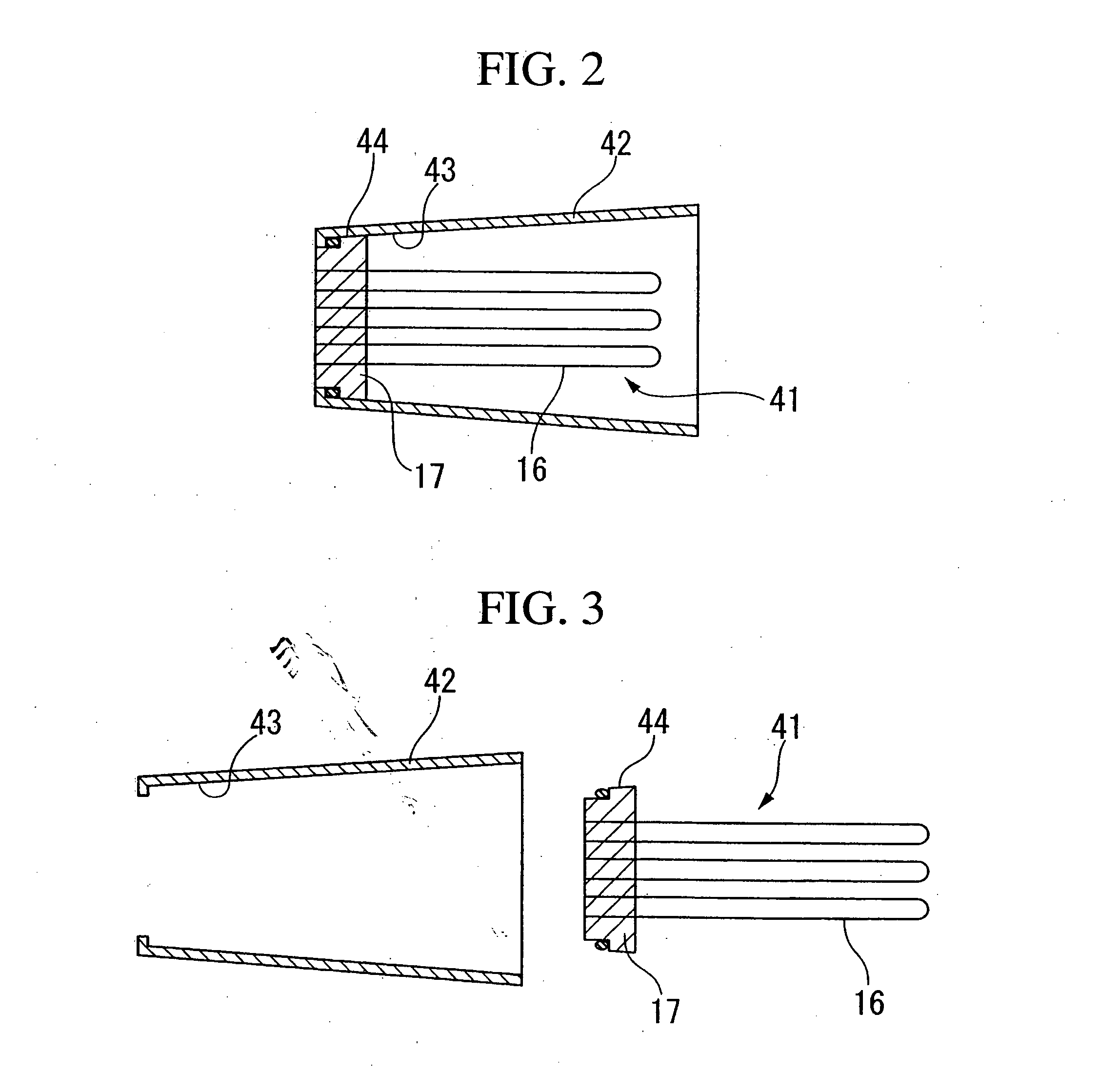

Water purification cartridge, water purifier and method for cleaning water purifier

InactiveUS20040245174A1Simple structureEasy to cleanMembranesUltrafiltrationHollow fibre membraneFiber

An object of the present invention is to provide a water purification cartridge in which the decreased function of the hollow fiber membranes is restored by cleaning and of which the operating cost of a purification treatment of raw water decreases. The present invention provides a water purification cartridge comprising a hollow fiber membrane element comprising a plurality of hollow fiber membranes bent in a U-shape and a potting material for binding both ends of the hollow fiber membranes so as to maintain the open states of the hollow fiber membranes and a cylindrical hollow fiber membrane case for covering the hollow fiber membranes, wherein the hollow fiber membrane element is detachably installed in the hollow fiber membrane case so that a fluid-tight state is maintained between the primary side and the secondary side of the hollow fiber membranes.

Owner:MITSUBISHI RAYON CO LTD

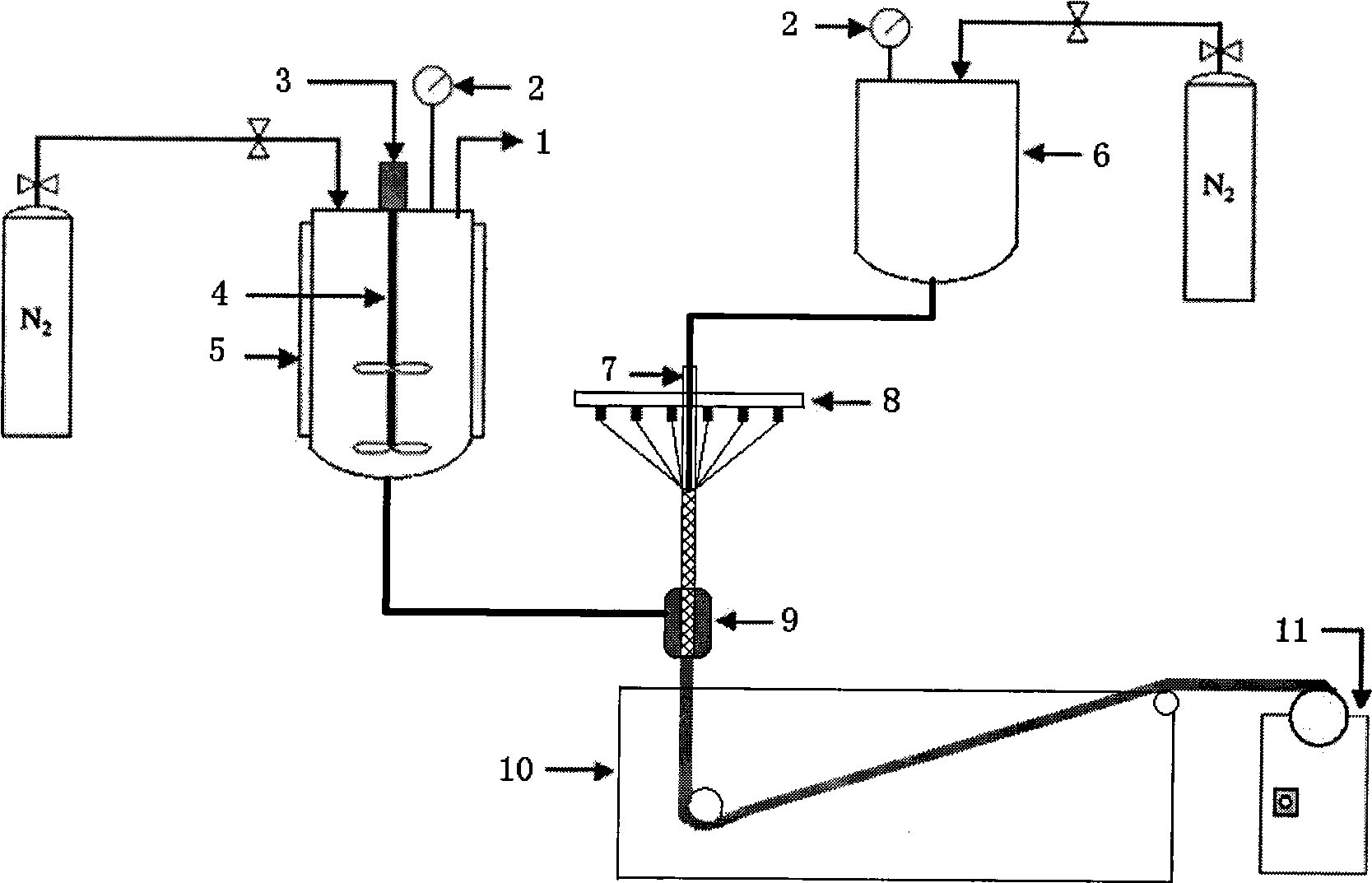

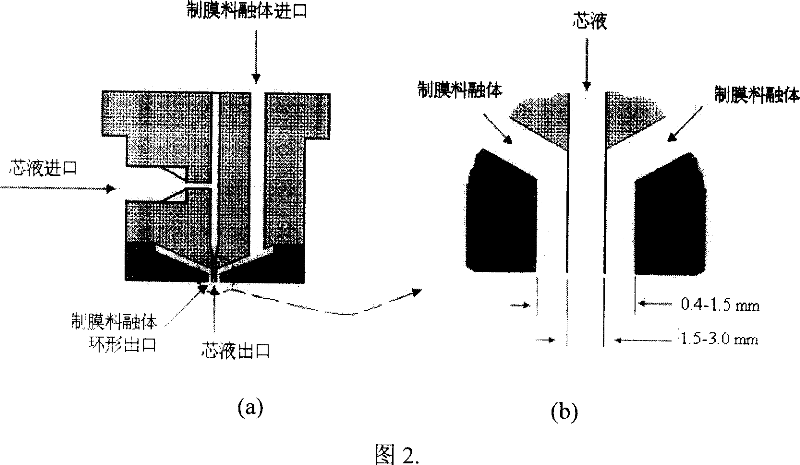

Method for preparing fiber braided tube embedded enhanced type polymer hollow fiber microporous membrane

ActiveCN101543731AControl the amount of infiltrationSolve technical problems that are easy to blockSemi-permeable membranesFiberHollow fibre membrane

The invention discloses a method for preparing a fiber braided tube embedded enhanced type polymer hollow fiber microporous membrane, which is characterized by adopting a fiber-braiding and coextrusion integrative membrane forming process, namely a core liquid tube is fixed in the middle of the braded tube, a fibrous bundle is braided into a fiber braided tube along the core liquid tube, then casting film liquid, core liquid and the fiber braided tube are co-extruded by an extrusion die, and the fiber braided tube embedded enhanced type polymer hollow fiber microporous membrane is prepared bya phase transformation method. The method successfully embeds the fiber braided tube into the body of the hollow fiber microporous membrane and introduces the core liquid into the inner cavity of thebraided tube, and effectively controls the inside diameter of the hollow fiber microporous membrane, so that the technical problems that in the prior coating process of preparing a fiber braided tubeenhanced type hollow fiber membrane, a polymer layer is easy to break away from the fiber braided tube, the hollow fiber inner cavity is easy to be blocked, and the like are solved, thus the polymer hollow fiber microporous membrane with high backwashing pressure, high mechanical strength, high flux, high retention performance and hydrophilic property is obtained.

Owner:TONGXIANG JIANMIN FILTER MATERIALS

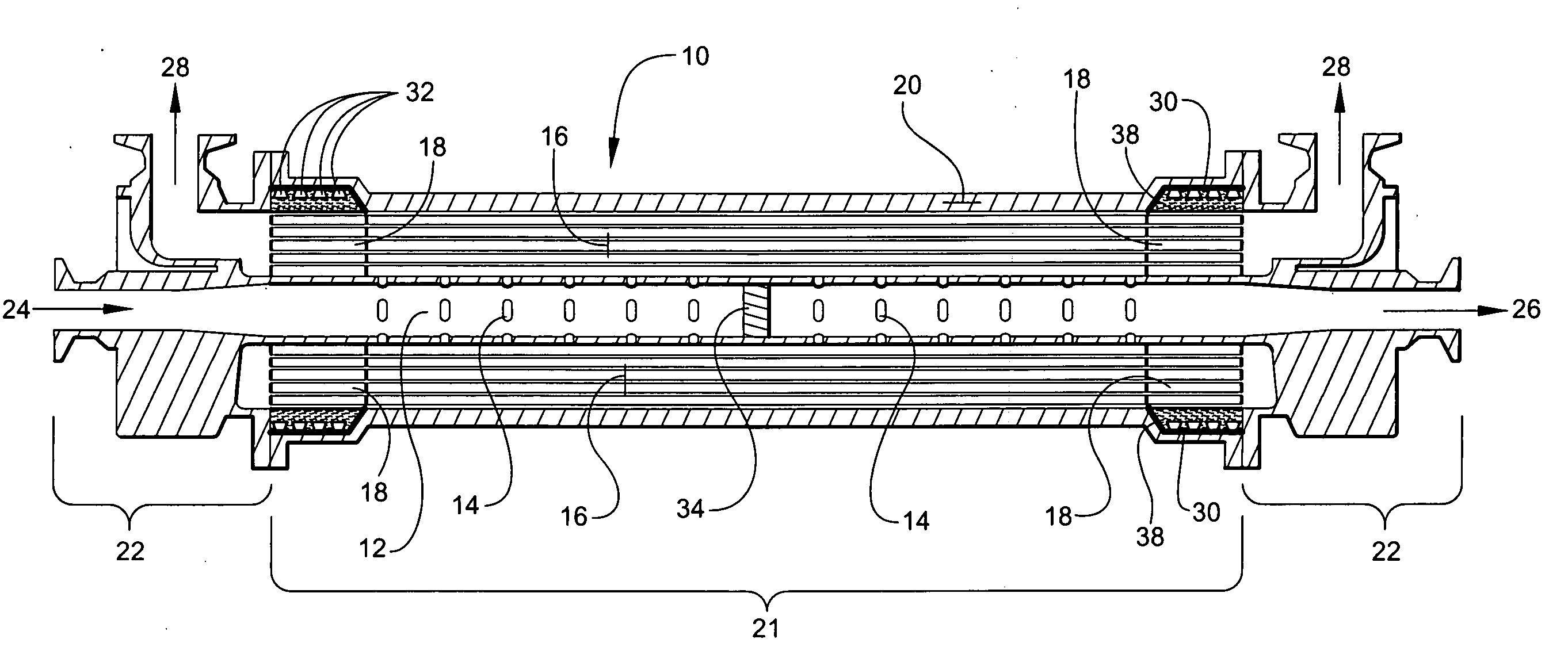

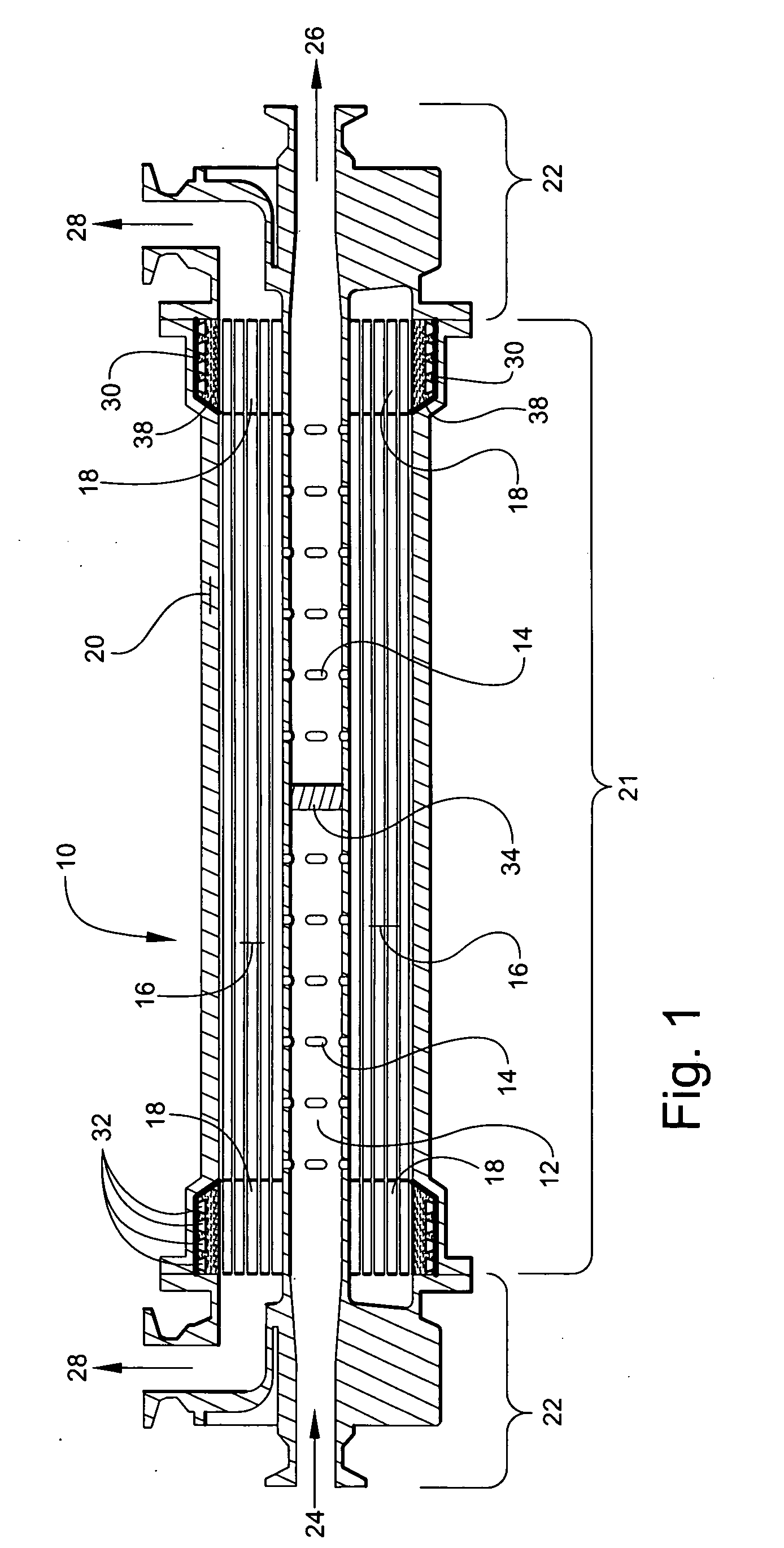

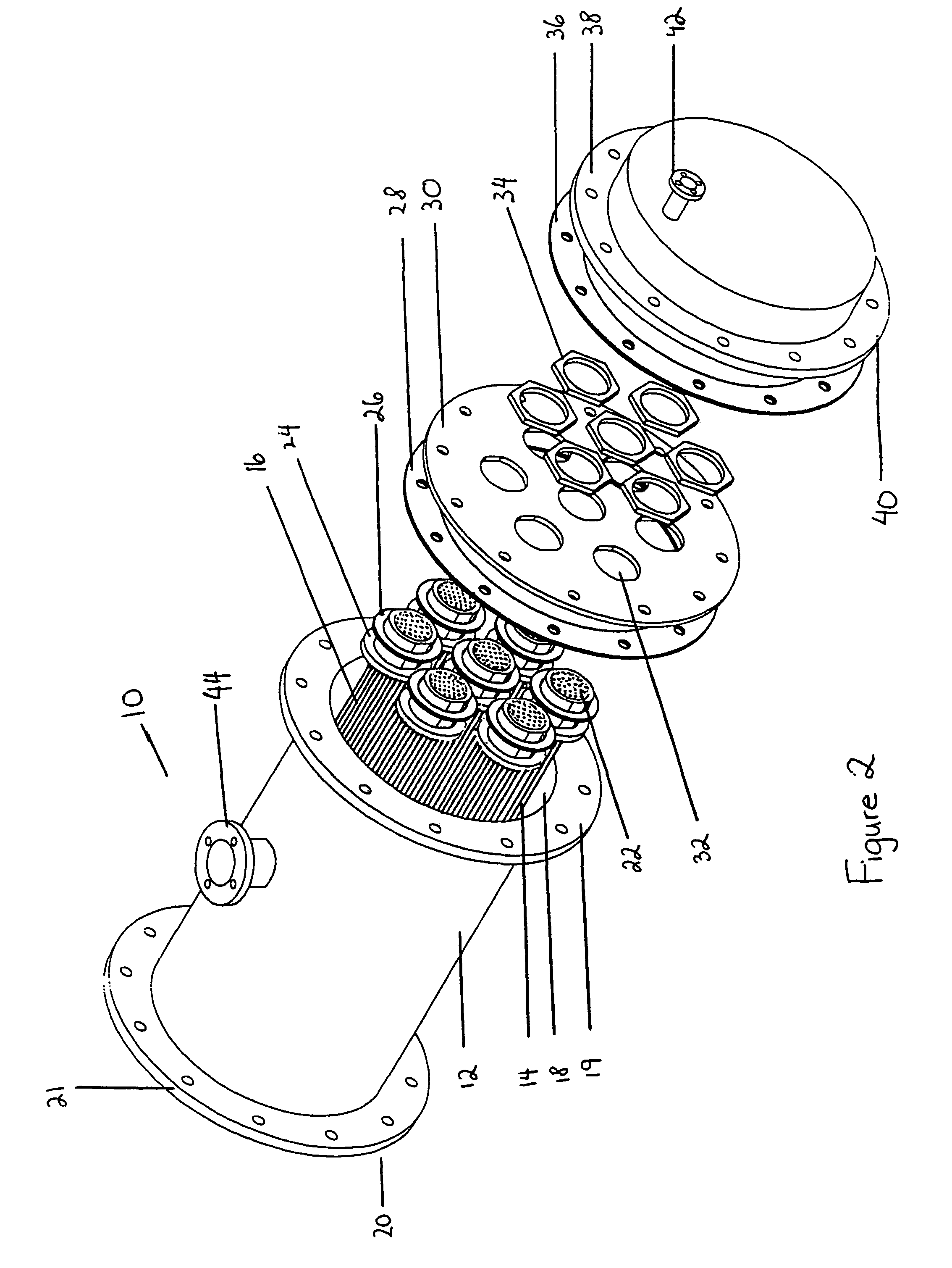

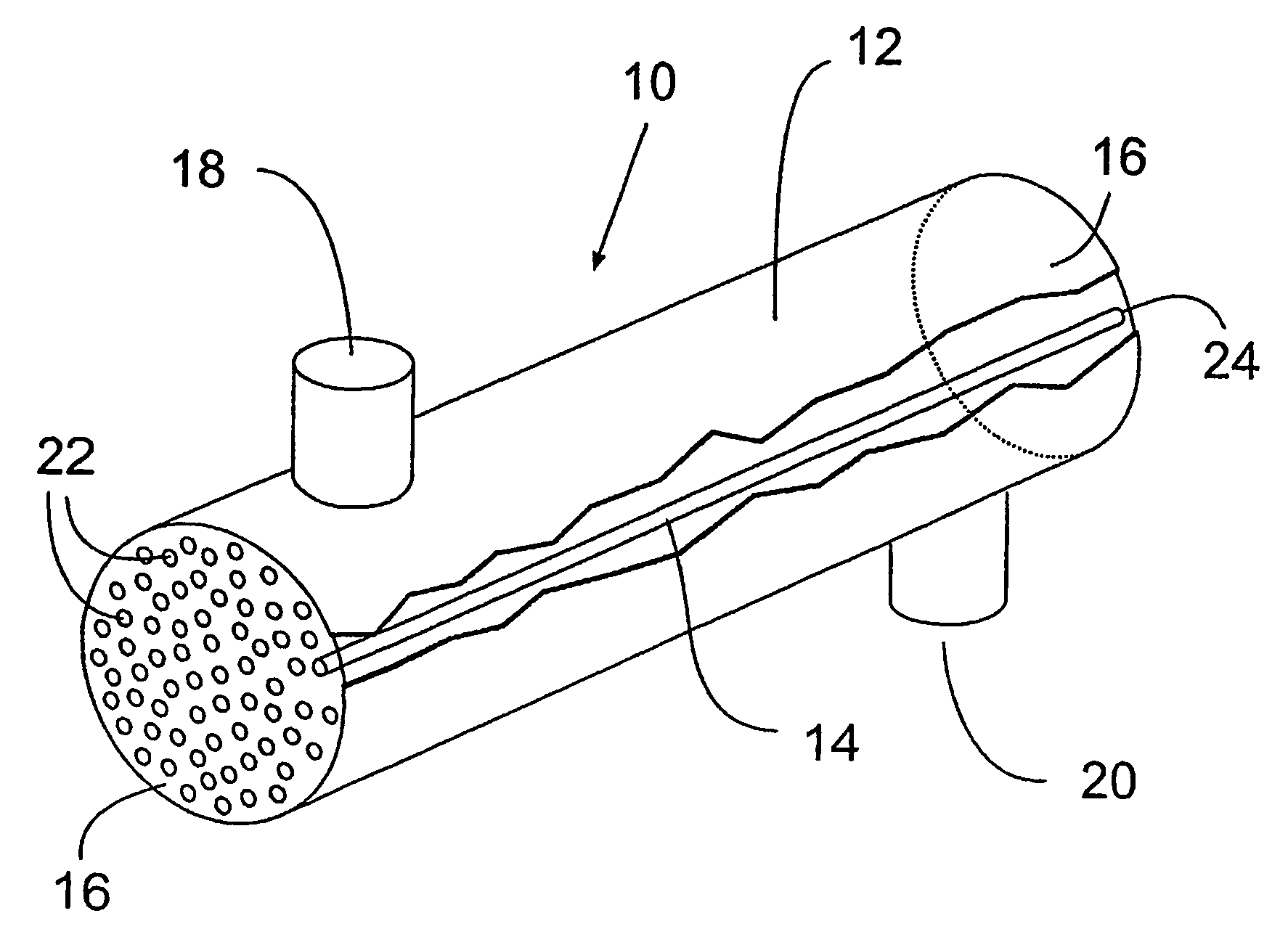

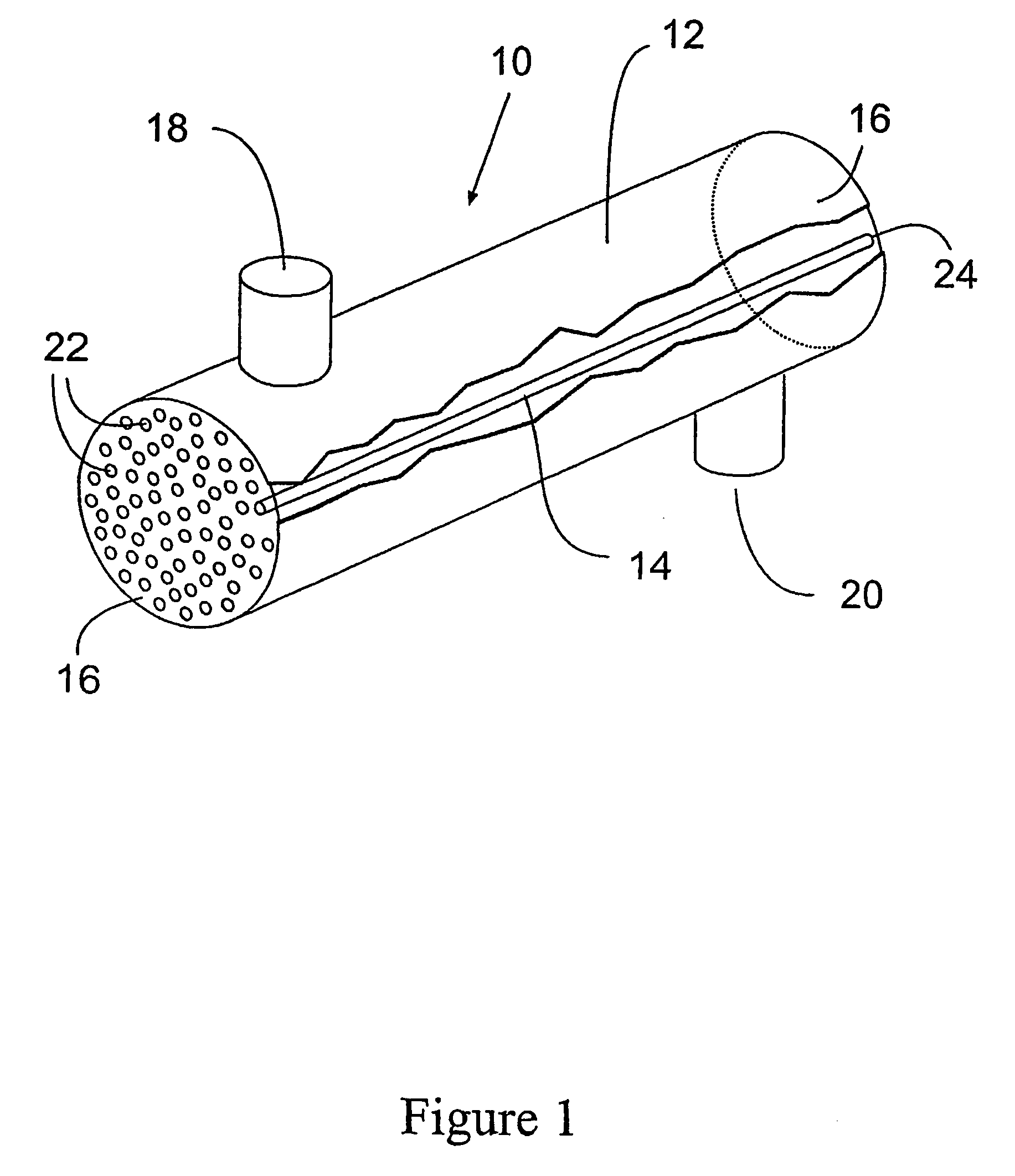

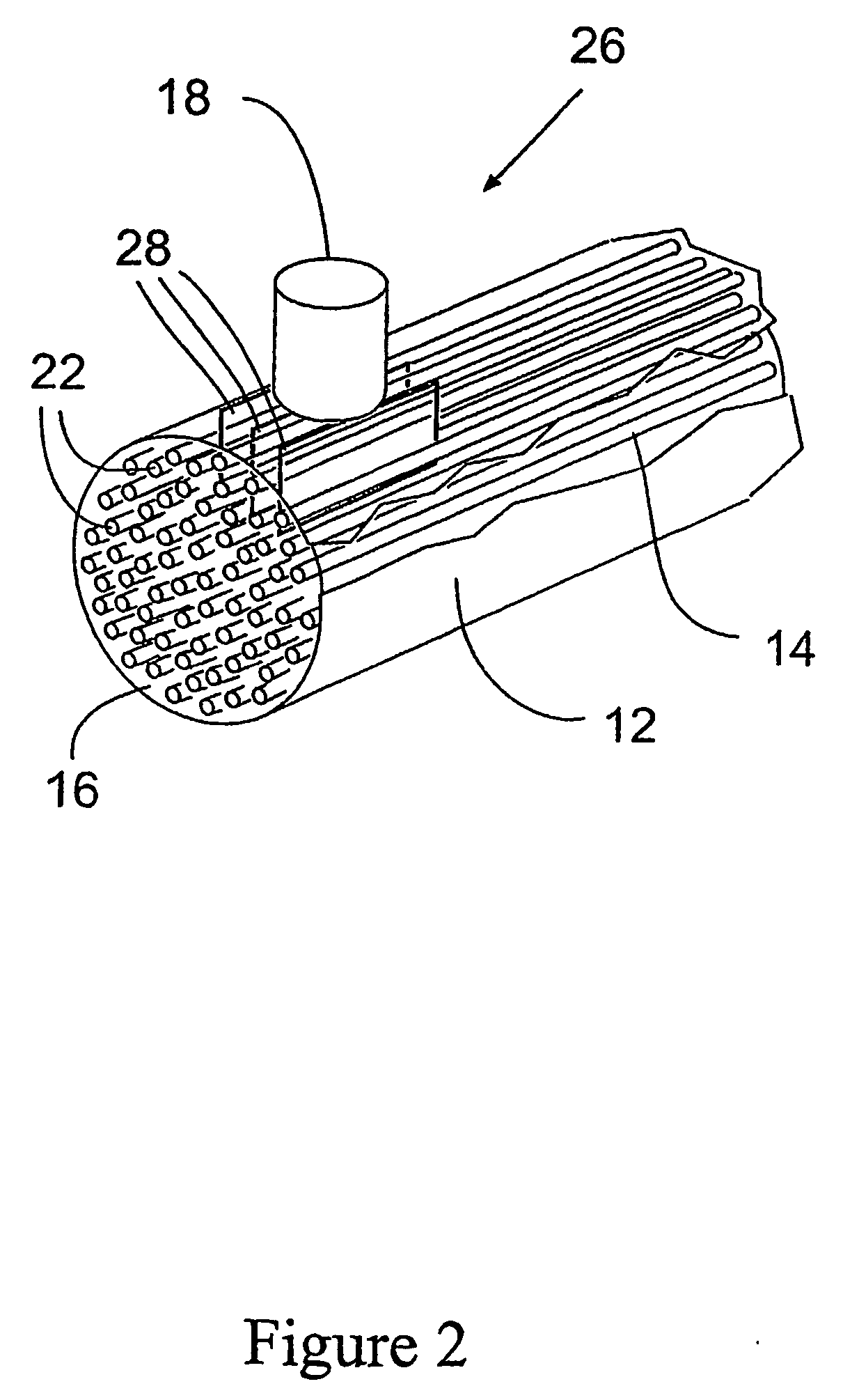

Membrane contactor and method of making the same

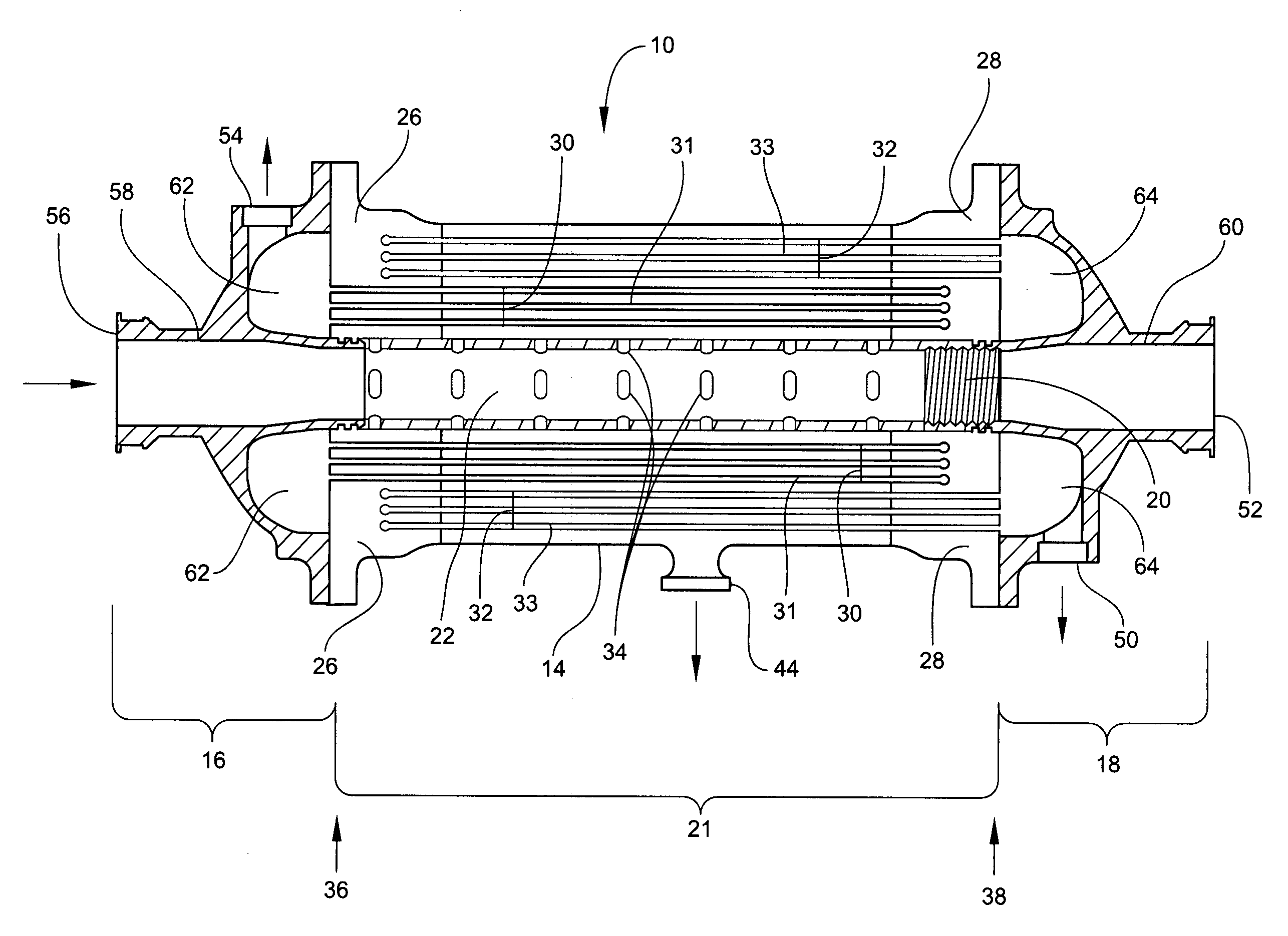

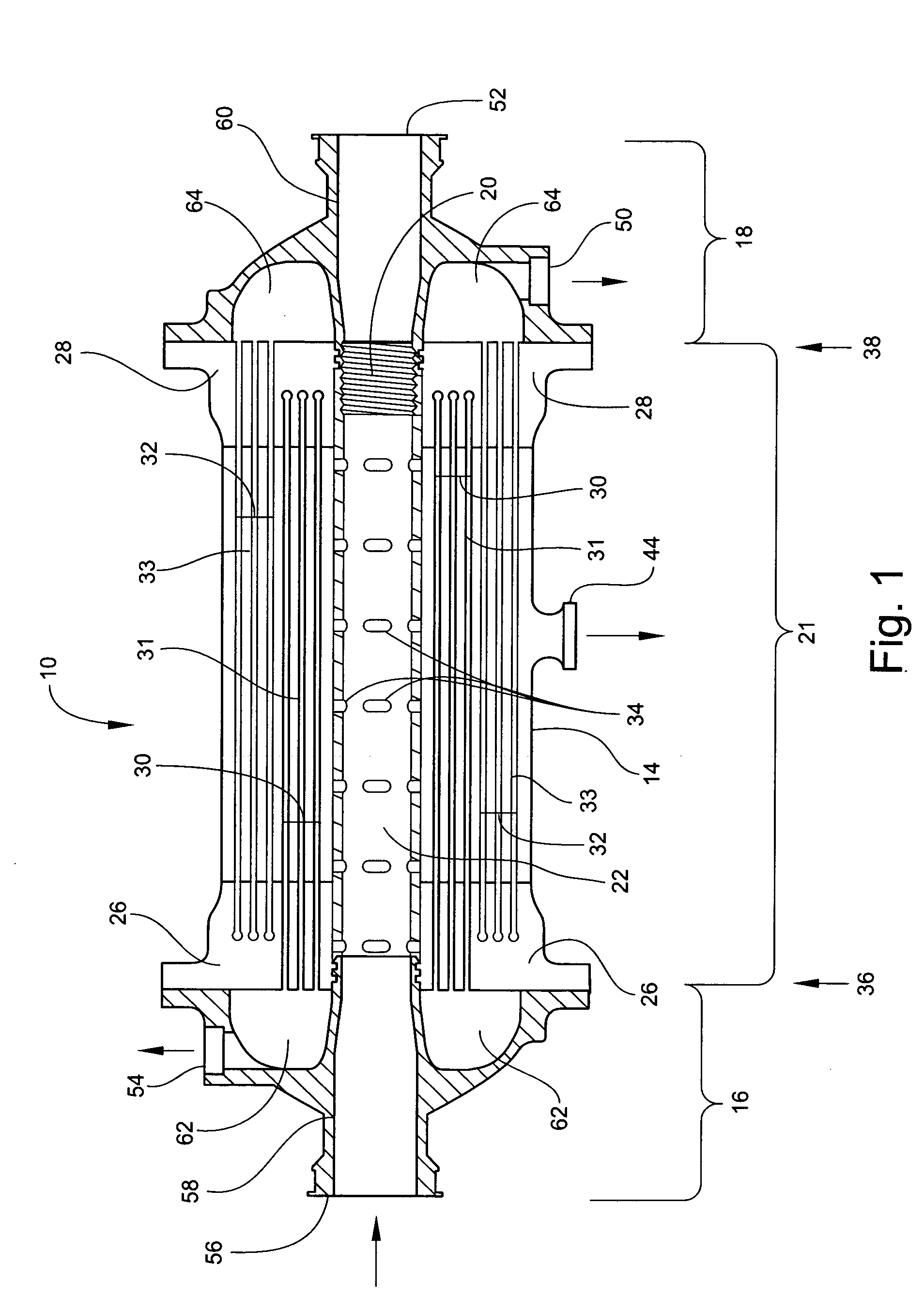

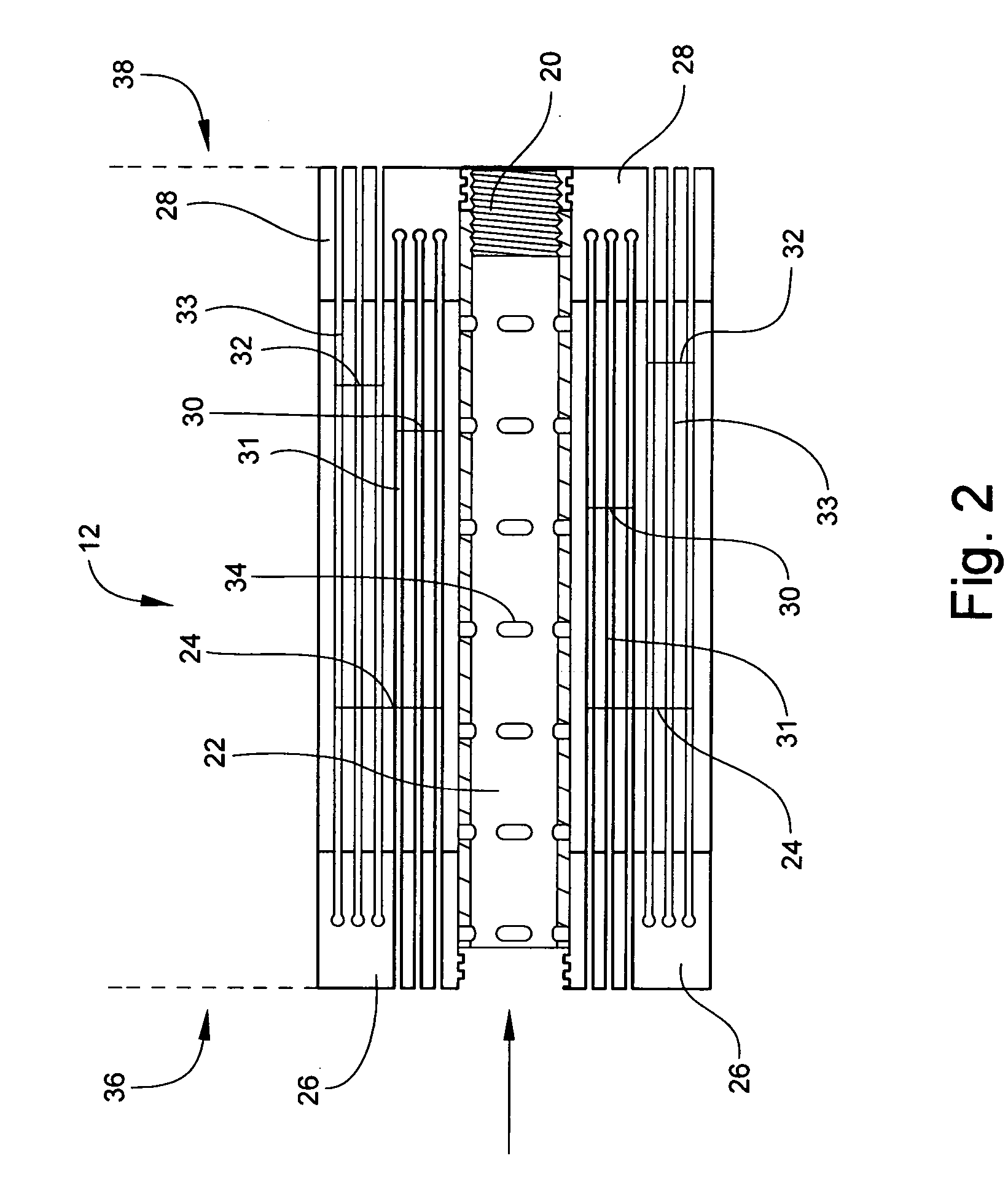

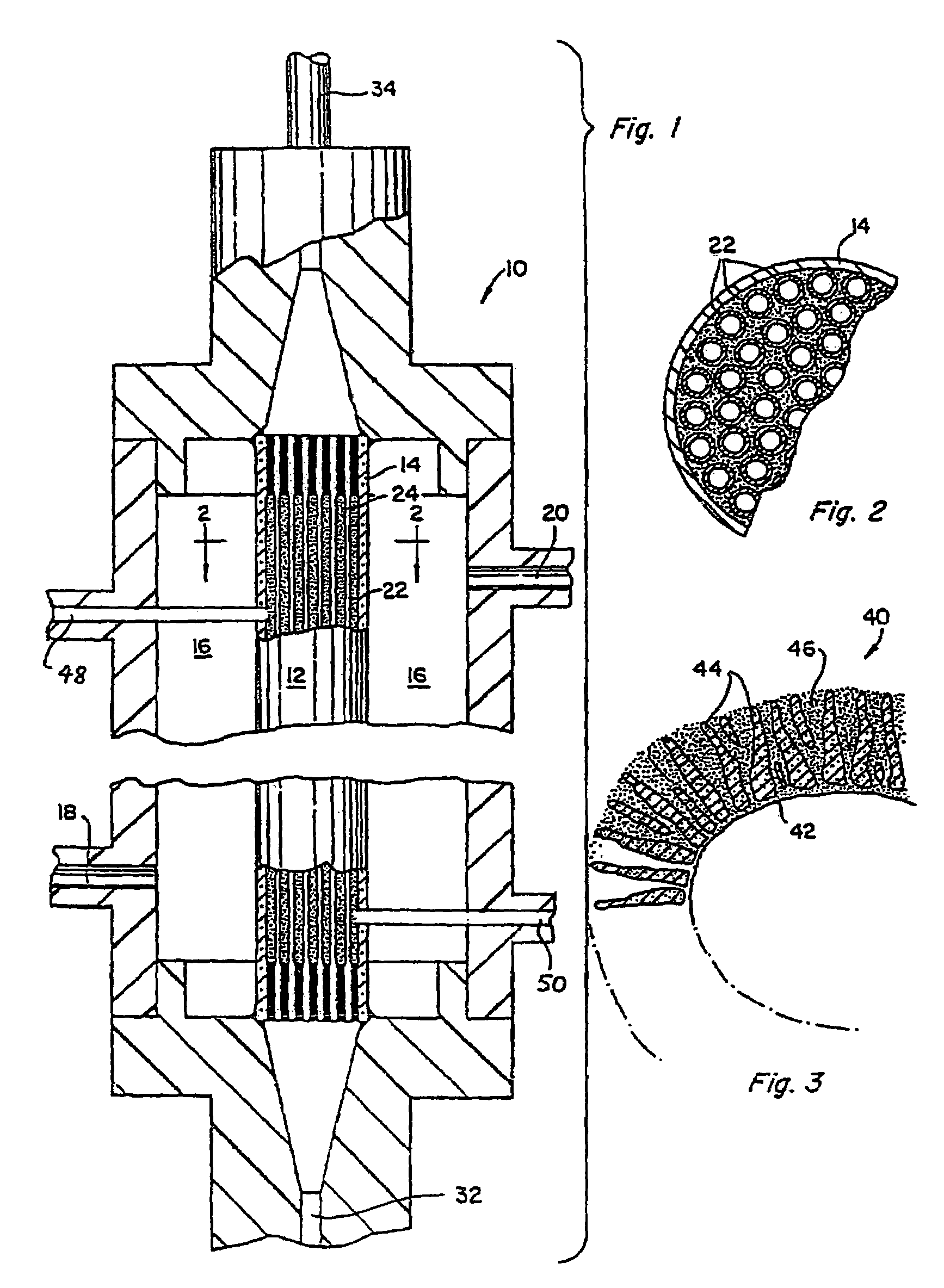

A hollow fiber membrane contactor includes a perforated center tube, a first mat comprising a first hollow fiber membrane, a second mat comprising a second hollow fiber membrane, a first tube sheet, a second tube sheet, a shell, and end caps. The first and second hollow fiber membranes are dissimilar. The first and second mats surround the center tube, and the first and second tube sheets affix the first and second mats to the center tube. The first hollow fiber membrane has a first lumen, and the second hollow fiber membrane has a second lumen. The first lumen may be open at the first tube sheet and closed at the second tube sheet while the second lumen may be open at the second tube sheet and closed at the first tube sheet. The shell surrounds the first and second mats, and it is sealed to the tube sheets. The end caps are affixed to the shell thereby defining headspaces therebetween the tube sheets and the end caps.

Owner:CELGARD LLC

Polysulfone-base hollow-fiber hemocathartic membrane and processes for the production thereof

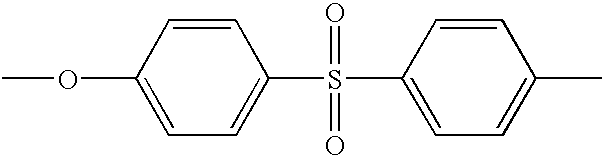

InactiveUS6432309B1Good blood compatibilityEasy to separateSemi-permeable membranesMembranesFiberHollow fibre membrane

Provided are a polysulfone type blood-purifying membrane which is improved in blood compatibility and separation properties and less in polyvinyl pyrrolidone eluting in the internal surface of the hollow fiber membrane, as well as a process for producing the same.

Owner:ASAHI KASEI MEDICAL CO LTD

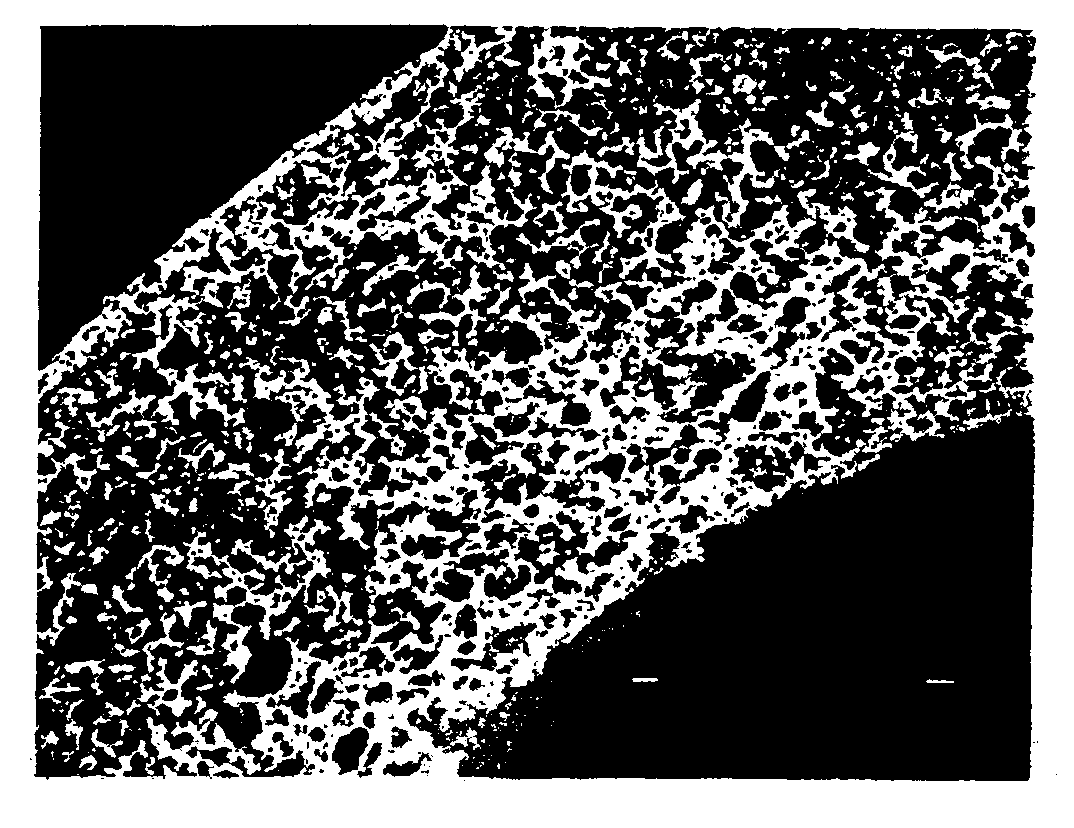

Porous hollow fiber membranes and method of making the same

InactiveUS6890436B2Improve filtering effectLow costMembranesSemi-permeable membranesHollow fibre membraneFiber

A porous hollow fiber membrane having a particle cutoff within the range of 1 to 10 μm and a pure water permeate flow equal to or higher than 30,000 L / m2 / hr / 100 kPa. This porous hollow fiber membrane can be prepared by a method including, while a spinning dope containing a base polymer as a material for forming the porous hollow fiber membrane, an additive used for facilitating a phase separation of the spinning dope, a solvent compatible with both the base polymer and the additive and a mass of microparticles insoluble to the compatible solvent and uniformly dispersed in a liquid medium and having an average particle size within the range of 1 to 20 μm, and a coagulating liquid for forming the hollow fiber membrane is used, a step of forming the hollow fiber membrane according to a dry-wet spinning method or a wet spinning method, and a step of extracting and removing the microparticles by immersing the hollow fiber membrane, which has been spun, into an extracting solution effective to dissolve the microparticles, but ineffective to dissolve the base polymer.

Owner:KURARAY CO LTD

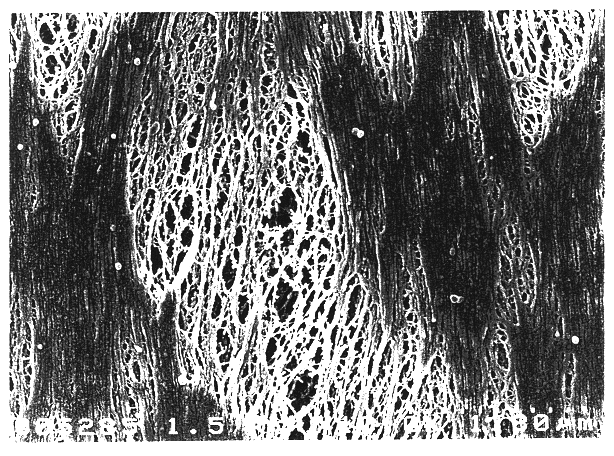

Method for preparing reticular fiber reinforced hollow fiber membrane of polyvinylidene fluoride

InactiveCN1864828AAperture size controllableStrong blast resistanceSemi-permeable membranesBursting strengthHollow fibre membrane

The invention discloses a method for preparing intensified netted hollow fiber membrane, belonging to technology for preparing hollow fiber membrane. The process comprises: taking polyvinylidene fluoride as membrane material, N,N-dimethyl formamide as disslovant, polyvinyl pyrrolidon as additive, preparing membrane liquid according to a certain proportion among them; textiling hollow fiber membrane under certain temperature, pressure and dragging speed; braiding net with synthetic fiber out of hollow fiber membrane, putting intensified hollow fiber membrane sequentially through membrane producing liquid and coagulating bath; coating and congealing under certain temperature, pressure and dragging speed, and getting final product. The invention is characterized in that there is no clogging, the flow resistance is small, stretching intensity amounts to 10-50 MPa, bursting strength is 0.5-1 MPa, and the process is continous and easy for industrialization.

Owner:TIANJIN UNIV

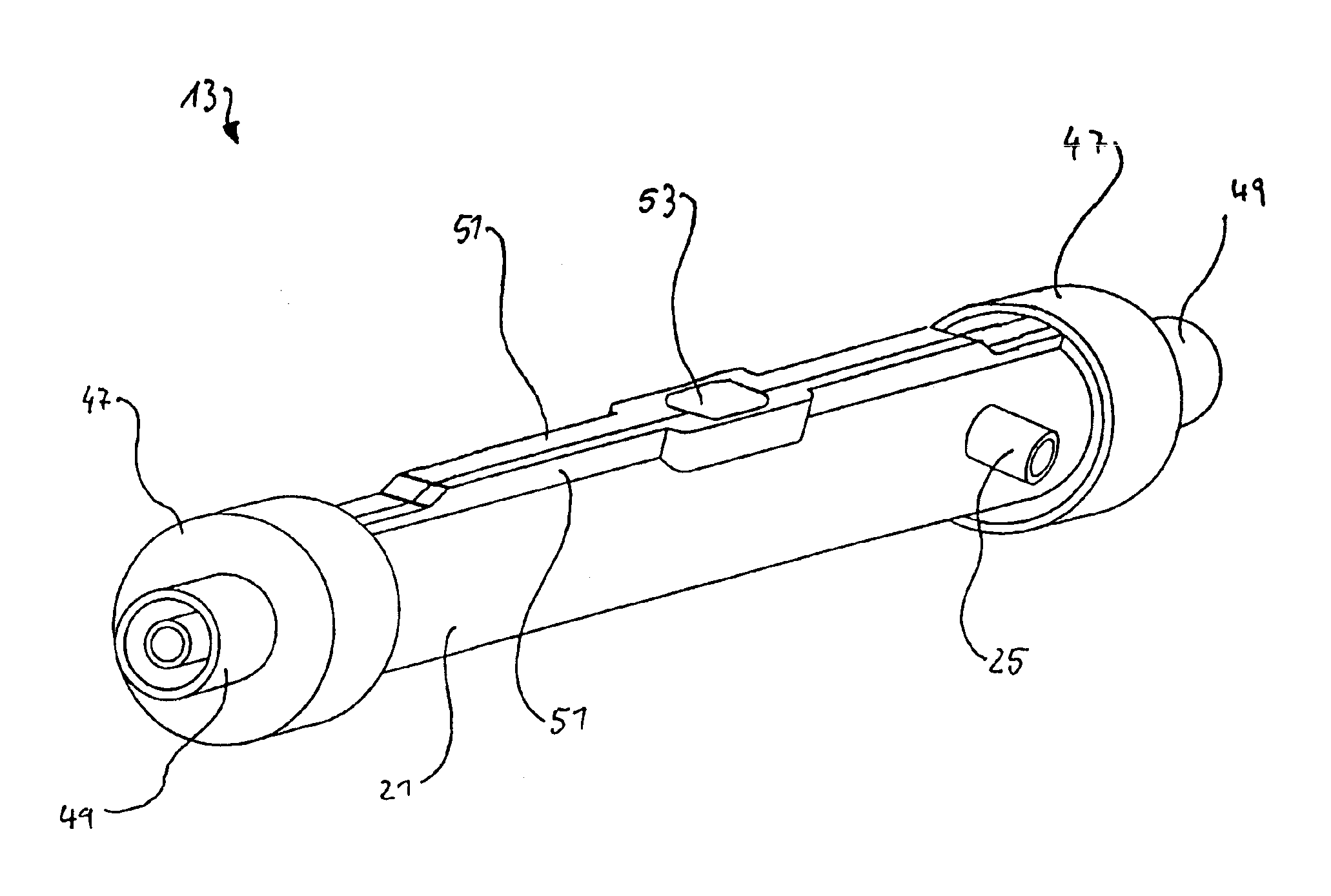

Hollow fiber membrane contactor and method of making same

The instant invention is a hollow fiber membrane contactor, and method of making same. The hollow fiber membrane contactor includes (1) a shell, said shell having a internal bonding surface, an interlocking geometry ring being provided on said internal bonding surface; (2) a unitized structure; (3) a potting material joining said unitized structure to said shell at said interlocking geometry ring thereby forming an interlocking seal therebetween; and (4) end caps, said end caps being adjoined to lateral ends of said shell. The method of making a hollow fiber membrane contactor includes (1) providing a shell, said shell having a internal bonding surface; (2) providing an interlocking geometry ring on said internal bonding surface; (3) forming a unitized structure; (4) placing the unitized structure into said shell (5) potting said unitized structure to said shell at said interlocking geometry ring thereby forming an interlocking seal therebetween; and (6) adjoining end caps to lateral ends of said shell.

Owner:3M INNOVATIVE PROPERTIES CO

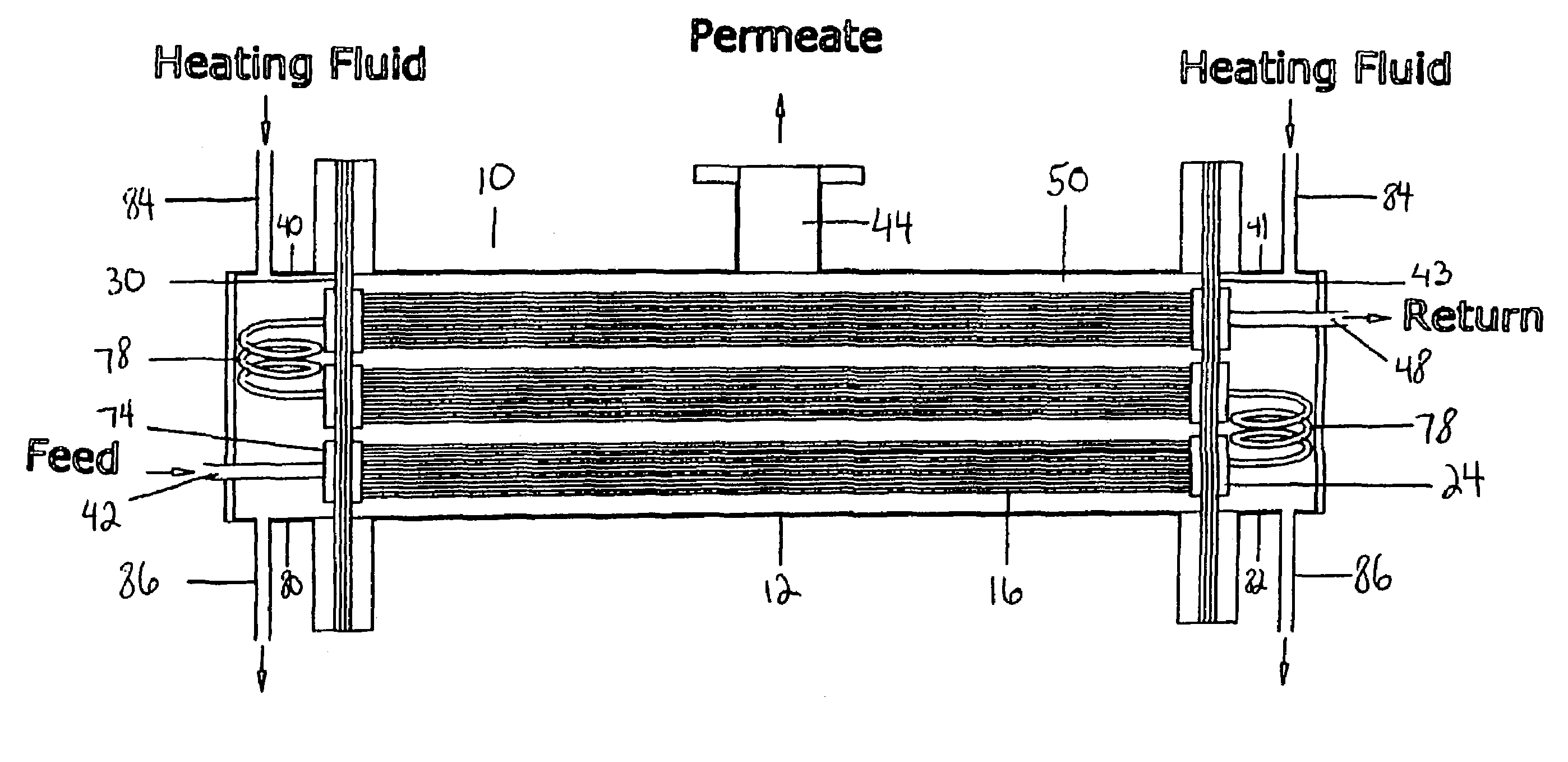

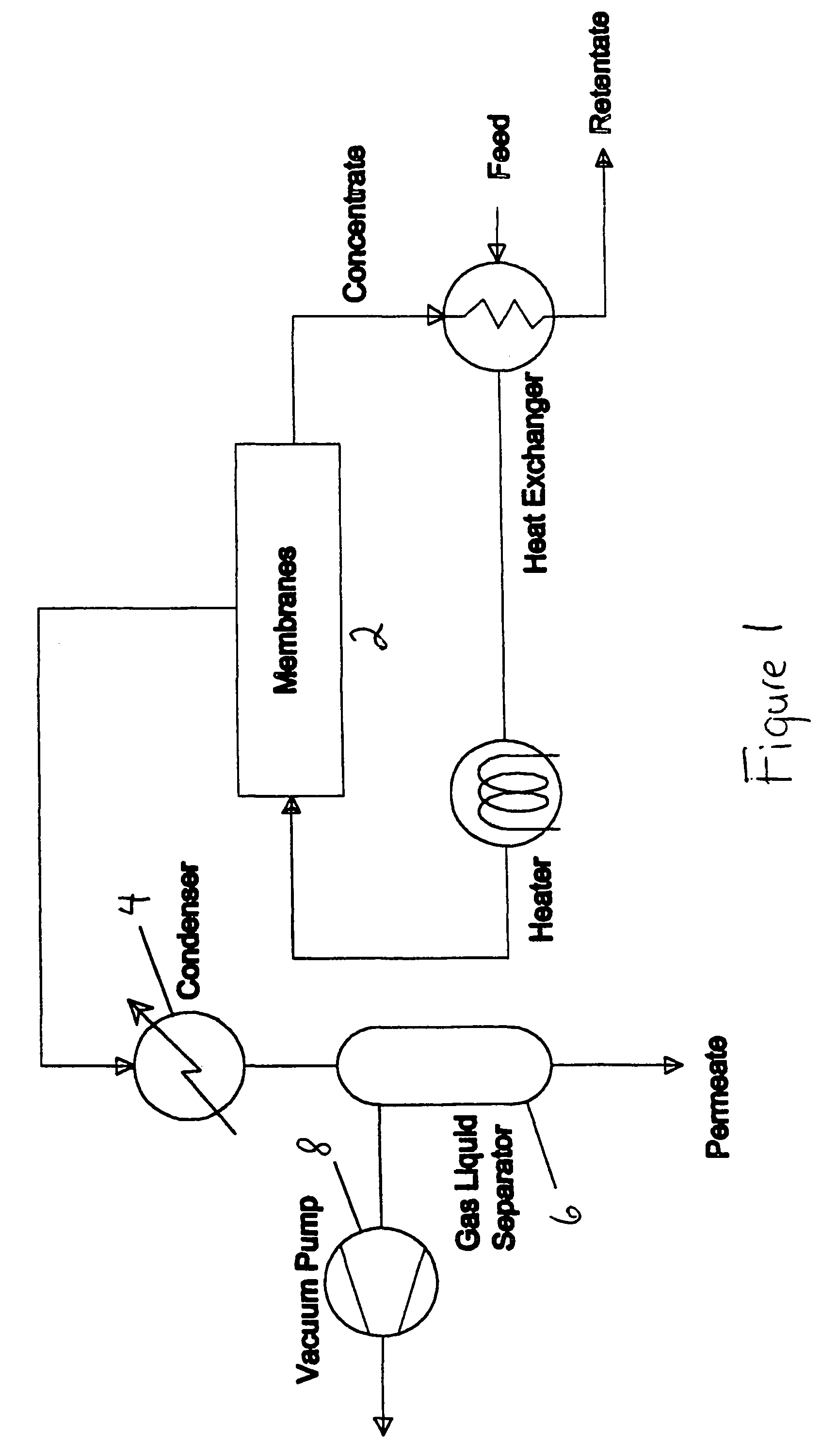

Membrane-assisted fluid separation apparatus and method

InactiveUS7459084B2Easy to disassembleReduce complexityMembranesGeneral water supply conservationFiberHigh concentration

This present invention relates to a fluid separation module adapted to separate a given fluid mixture into permeate and retentate portions using bundles of hollow fiber membranes. The membranes may be composed of different kinds of membranes depending on the application being used to separate the fluid mixture. The fluid separation module may be used to separate fluid mixtures by a number of different processes, including but not limited to, pervaporation, vapour permeation, membrane distillation (both vacuum membrane distillation and direct contact membrane distillation), ultra filtration, microfiltration, nanofiltration, reverse osmosis, membrane stripping and gas separation. The present invention also provides an internal heat recovery process applied in association with those fluid separation applications where separation takes place by evaporation through the membrane of a large portion of the feed into permeate. Desalination and contaminated water purification by means of vacuum membrane distillation are just two examples where the internal heat recovery process may be applied. In these two examples, large portions of the feed are separated by membranes into a high purity water permeate stream by evaporation through the membranes and into a retentate stream containing a higher concentration of dissolved components than present in the feed. In this process the permeate vapour that is extracted from the fluid separation module is compressed by an external compressor to increase the temperature of the vapour higher than the temperature of the feed entering the separation module. Heat from the permeate vapour at the elevated temperature is transferred back to the incoming feed fluid mixture entering the fluid separation module in a condenser / heat exchange.

Owner:LOEB INVESTORS CO 166 LP +1

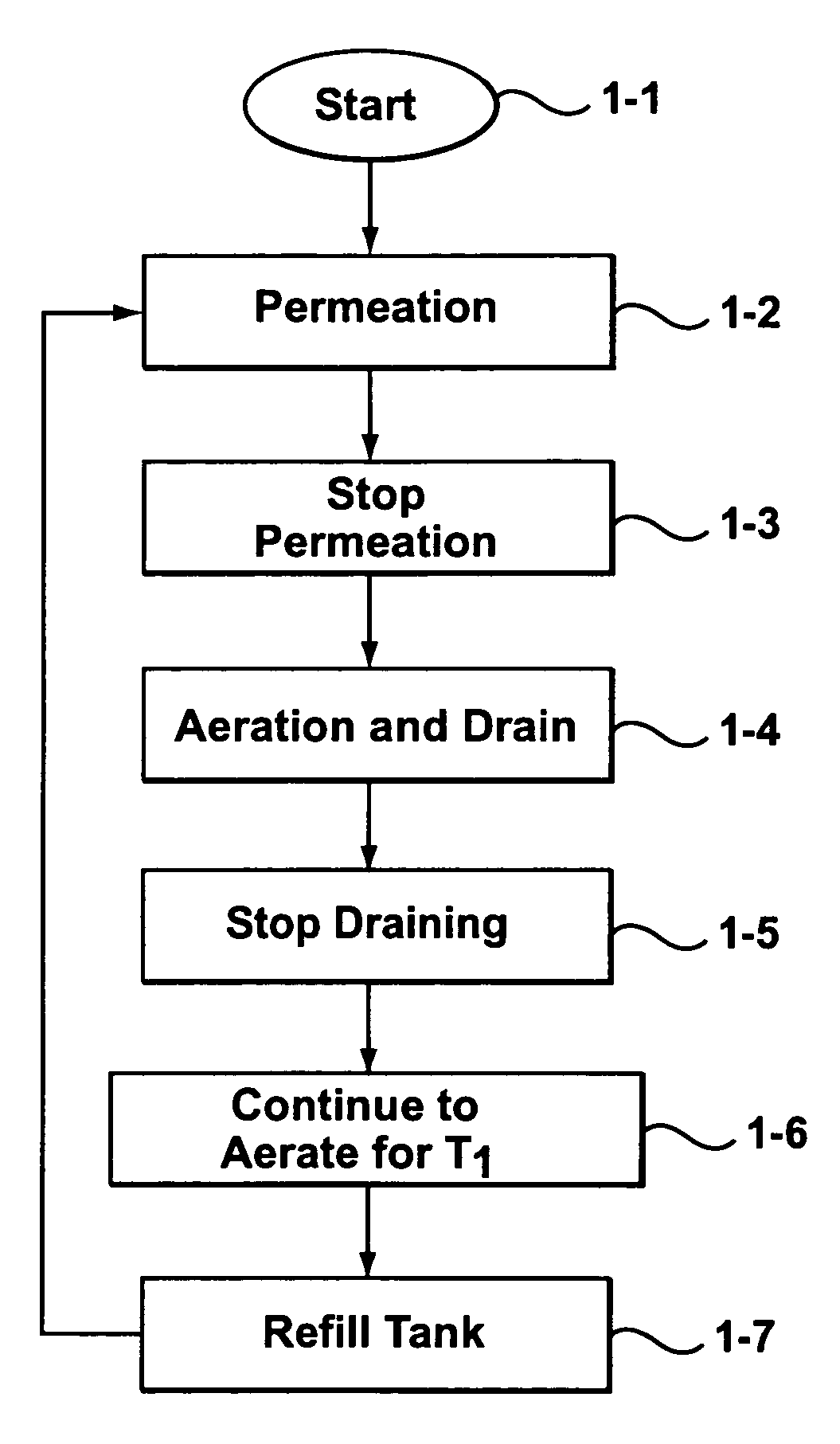

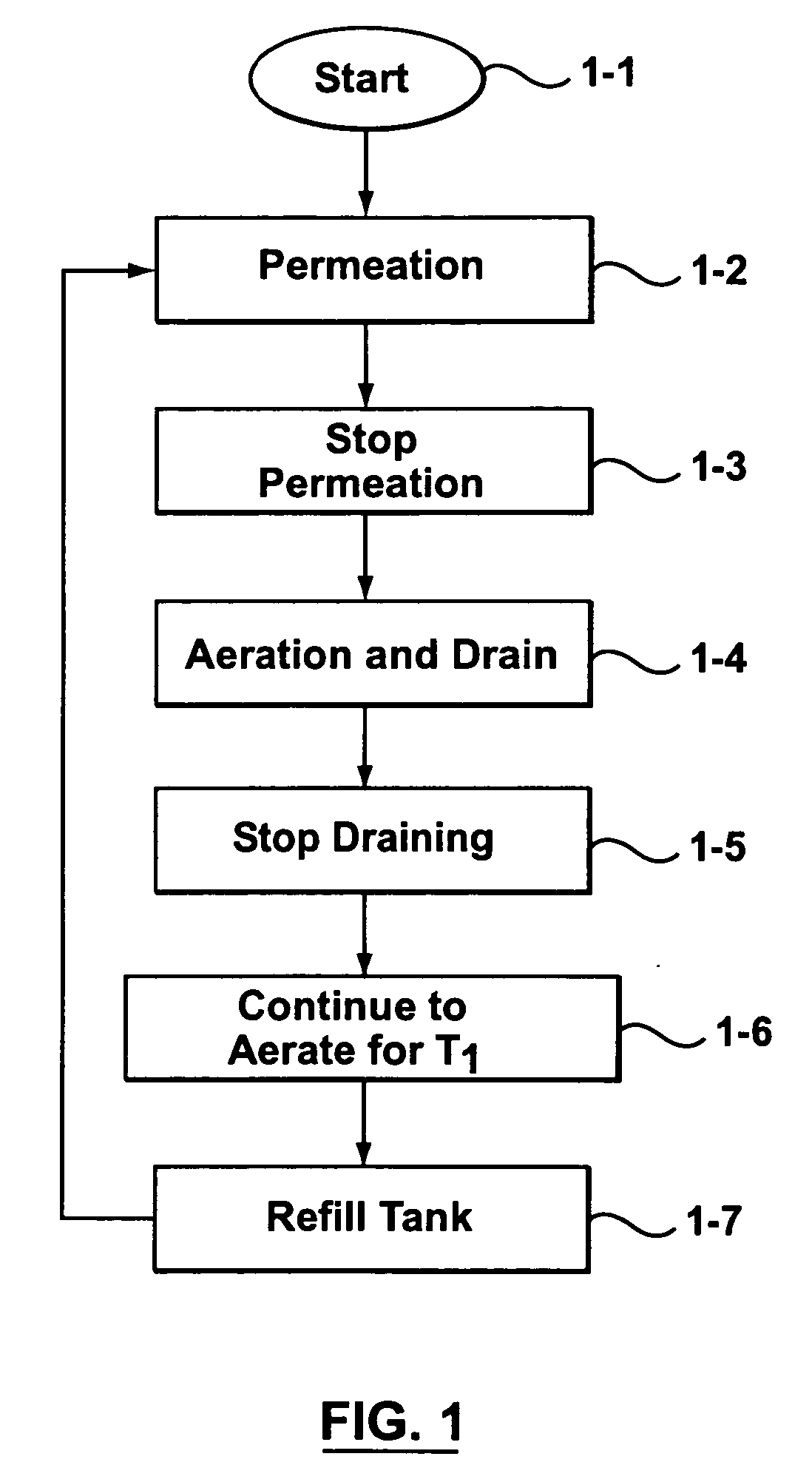

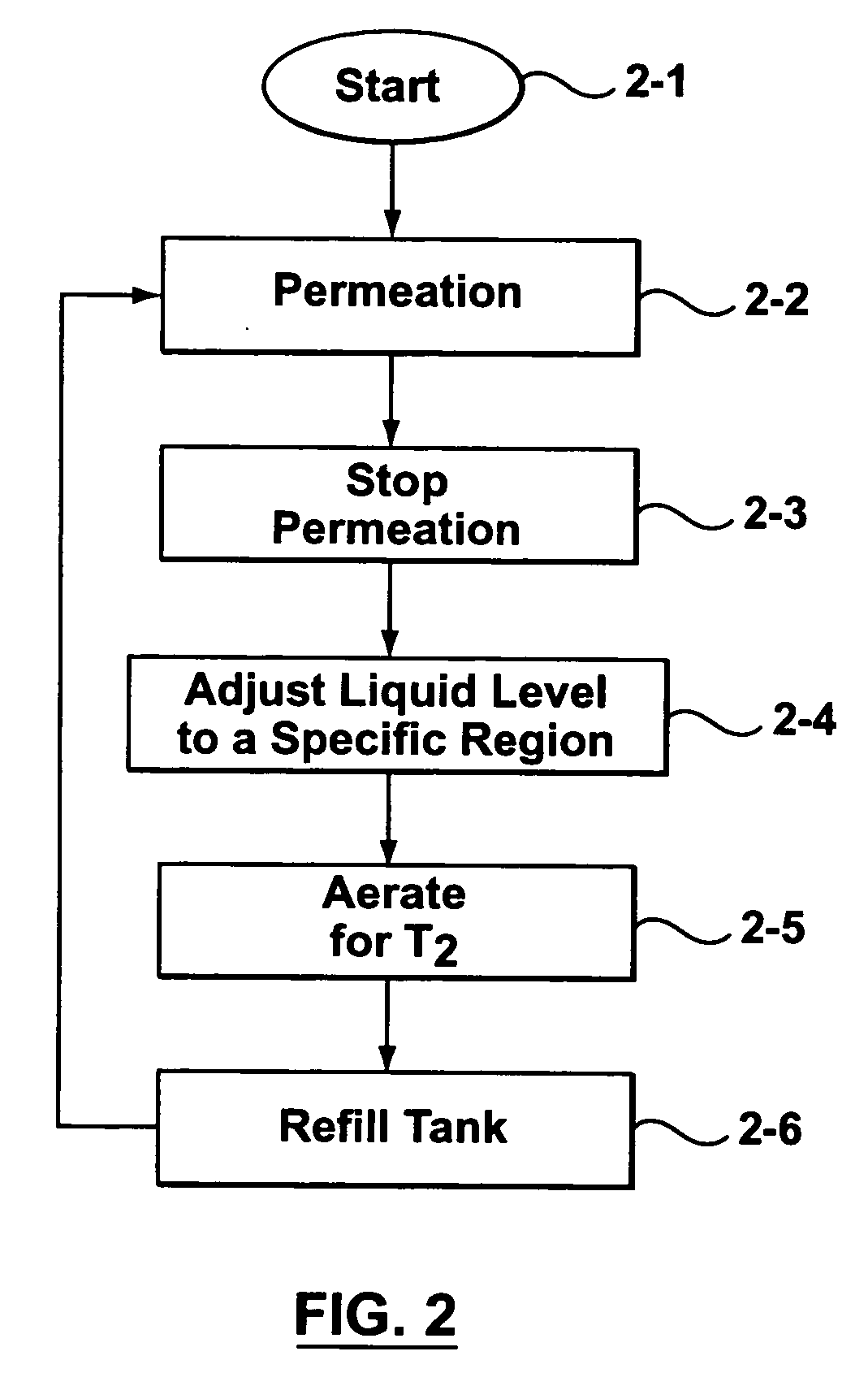

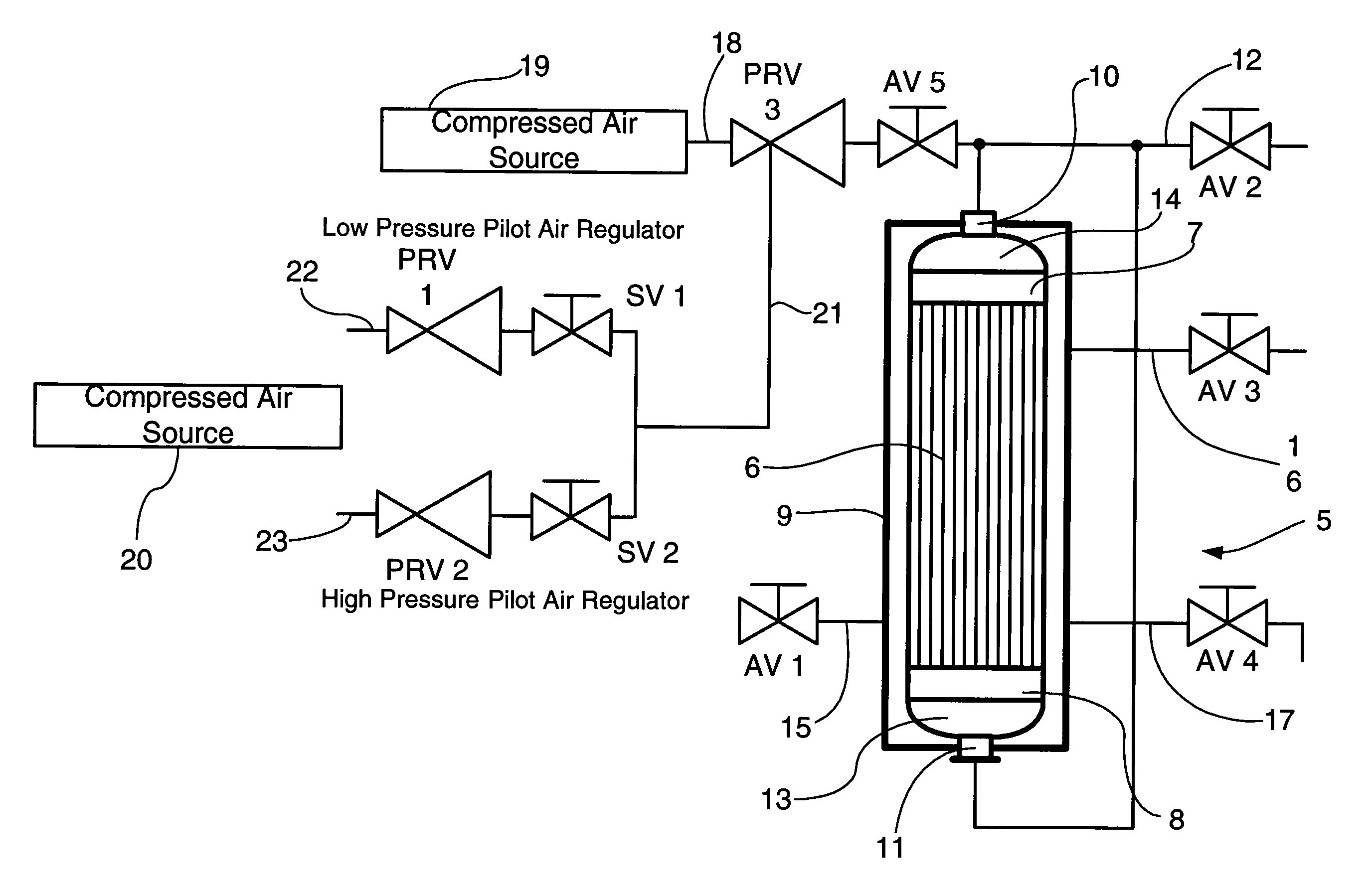

Membrane filter cleansing process

InactiveUS20060065596A1Reduce accumulationLower the liquid levelMembranesSemi-permeable membranesFiberHollow fibre membrane

Immersed hollow-fiber membrane filtration systems sometimes encounter process problems as a result of solids accumulation in and around the hollow fibers. The solids can accumulate to the point where they begin to dewater and form a mud like substance known as sludge. In some embodiments of the invention there is provided a process for substantially preventing the accumulation of sludge build-up on membrane fibers and / or cleansing membrane fibers that have been fouled by a substantial sludge build-up. Many of these embodiments involve aerating a membrane tank in which the membrane fibers are immersed after the water level has been reduced to near the level of solids accumulation. In some embodiments of the invention, the energy released by bursting bubbles at the liquid-air interface is employed to prevent fouling of membrane fibers and / or cleanse fouled membrane fibers.

Owner:ZENON TECH PARTNERSHIP

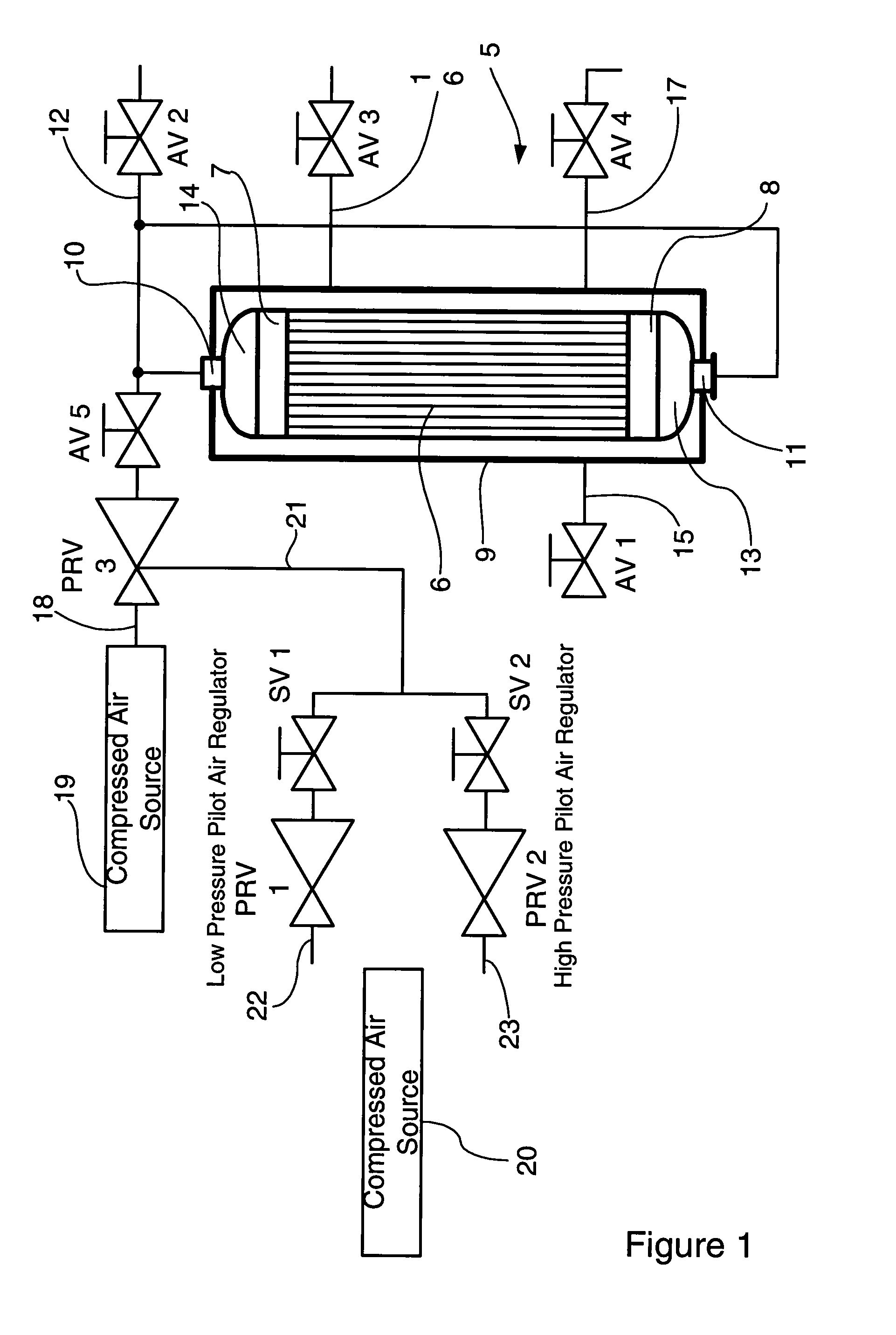

Membrane System Backwash Energy Efficiency

ActiveUS20110139715A1Improve efficiencyLow costMembranesSpecific water treatment objectivesFiberHollow fibre membrane

A method of backwashing a membrane filtration system comprising at least one permeable membrane, preferably a hollow fibre membrane, the method comprising the step of applying a pressurised gas at a variable pressure to permeate remaining present in the system when filtration process is stopped or suspended to provide liquid for backwashing pores of the permeable membrane during a backwashing process. Also provided are methods of filtering solids from a liquid suspension using alternating liquid backwash pressures.

Owner:EVOQUA WATER TECH LLC

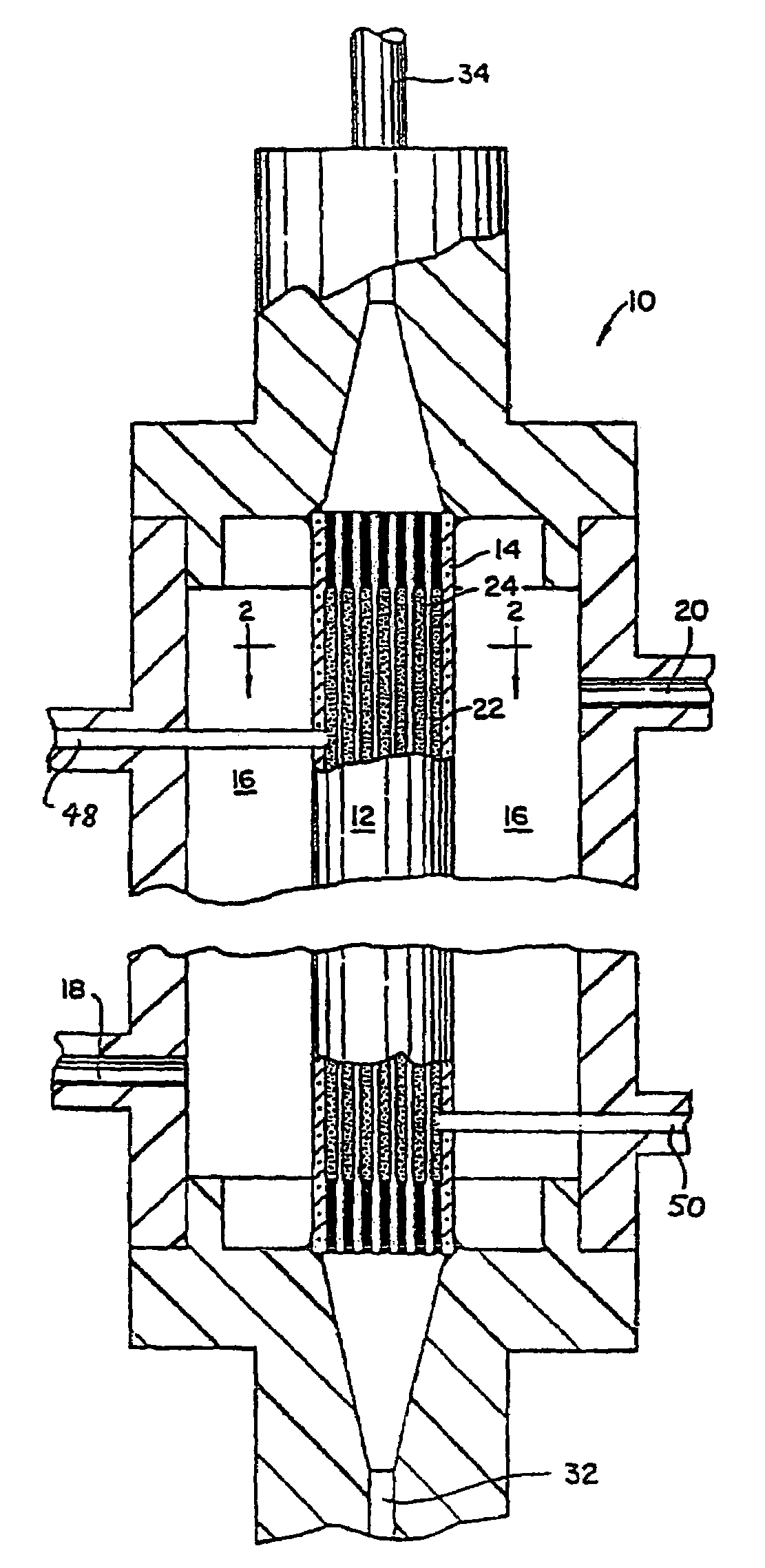

Hollow fiber membrane contact apparatus and process

InactiveUS20050230856A1Pressure dropPromotes turbulent liquid flowCarburetting airSemi-permeable membranesHollow fibre membraneBiomedical engineering

The present invention provides a perfluorinated thermoplastic hollow fiber (14) membrane gas-liquid shell side contactor (10) and a process for manufacturing the contactor (10) is described. The present invention also provides a device including a gas-liquid contactor (10) for producing ozonated water.

Owner:ENTEGRIS INC

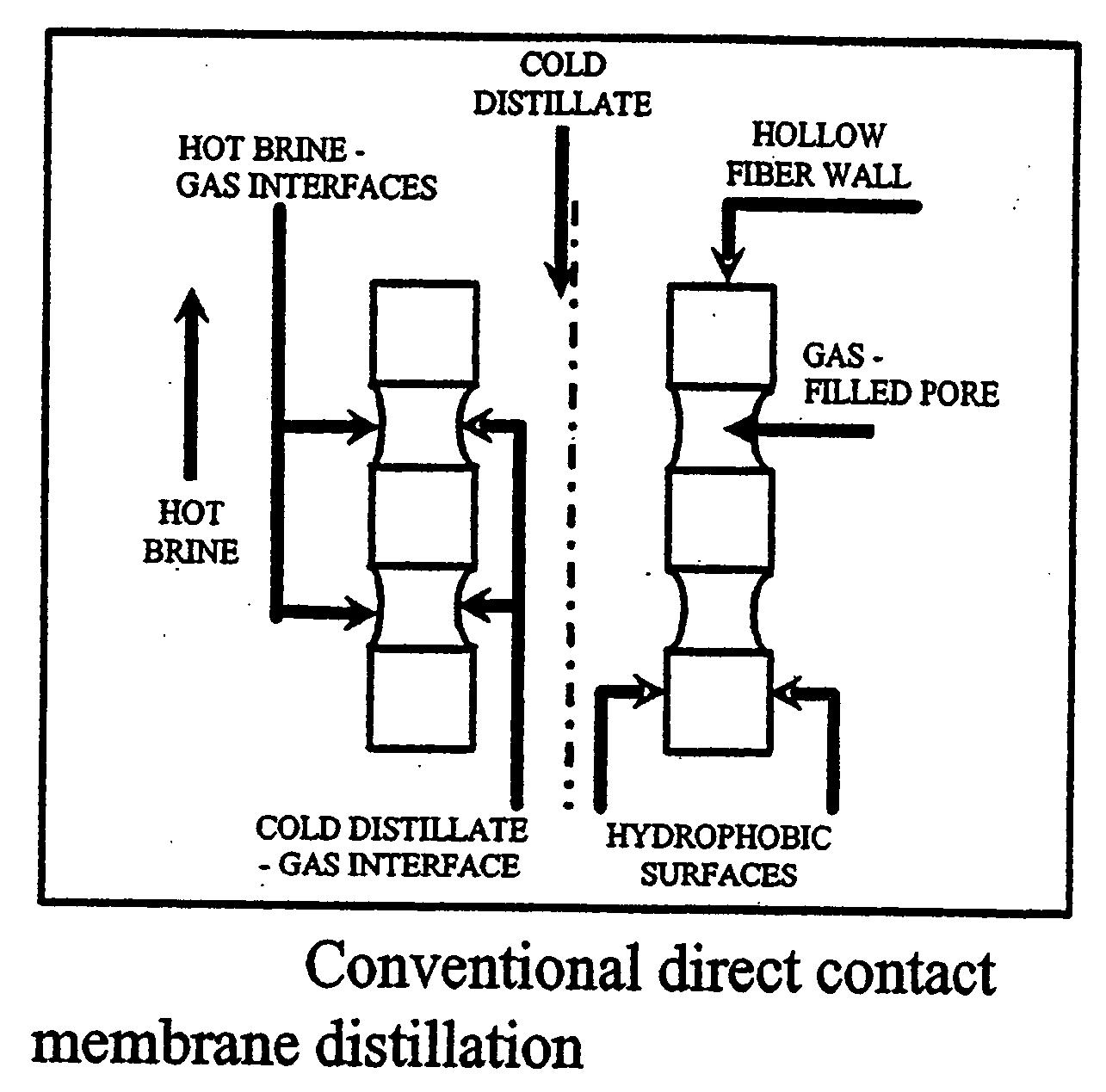

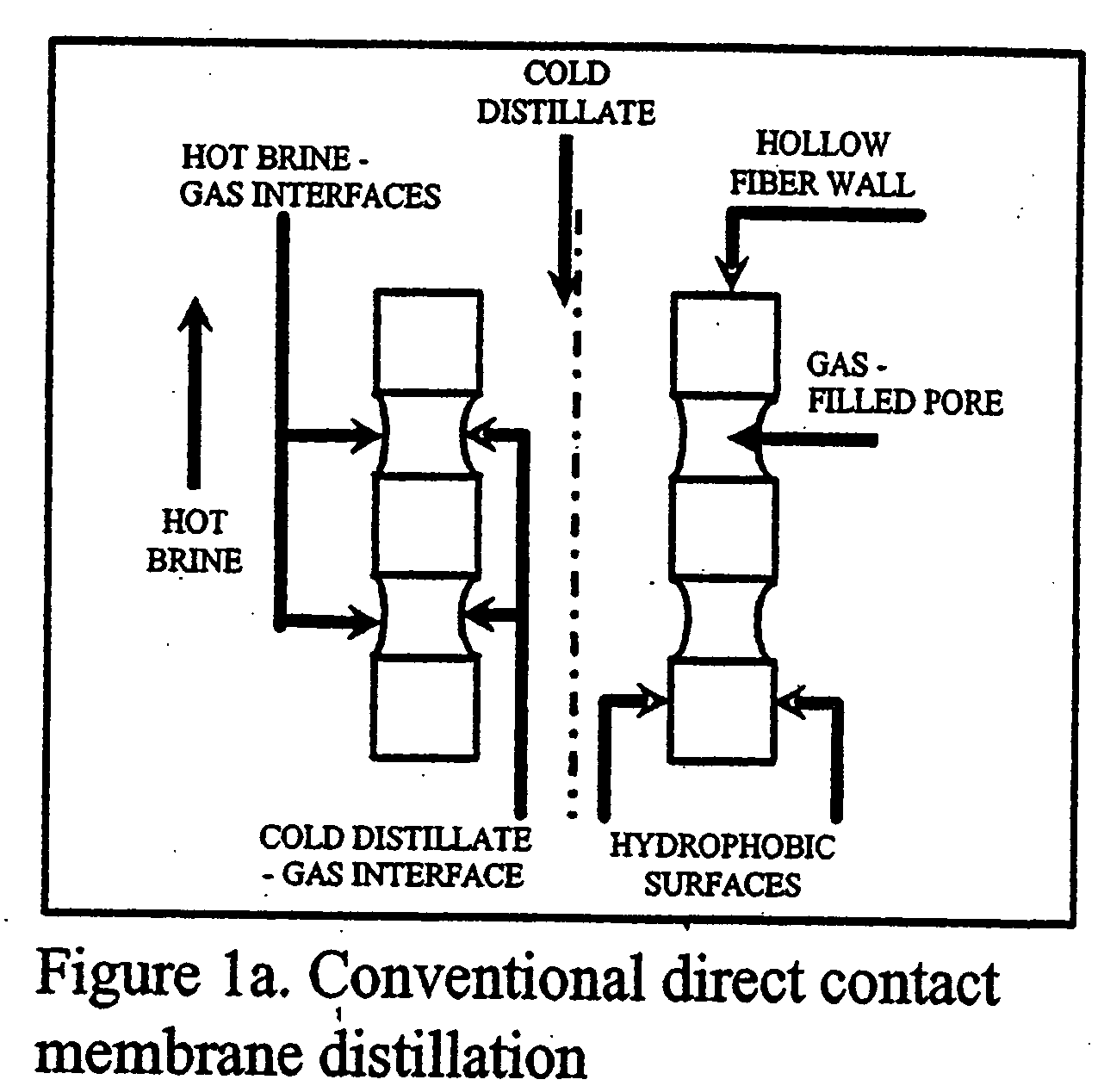

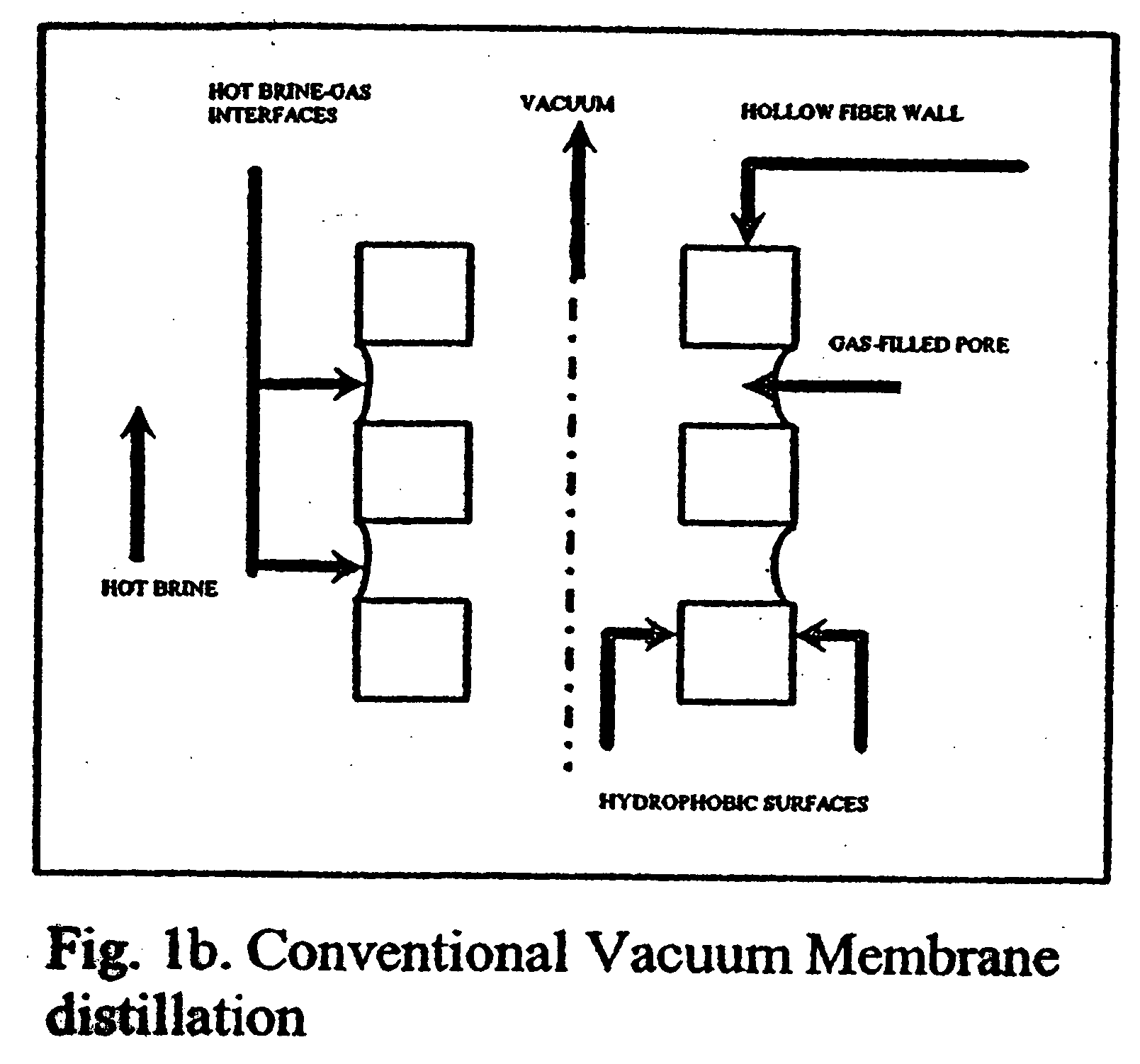

Devices and methods using direct contact membrane distillation and vacuum membrane distillation

ActiveUS20060076294A1Eliminate pore wettingReduce lossesGeneral water supply conservationSolid sorbent liquid separationFiberHollow fibre membrane

DCMD and VMD systems and methods for use in desalination applications are provided. The DCMD and VMD systems employ coated porous hydrophobic hollow fiber membranes. The coatings advantageously function to essentially eliminate pore wetting of the membrane, while permitting substantially unimpeded water vapor permeance through the fiber walls. The DCMD and VMD membranes are characterized by larger fiber bore diameters and wall thicknesses. The membranes substantially reduce the loss of brine sensible heat, e.g., heat loss via conductive heat flux through the membrane wall and the vapor space and, in exemplary embodiments, the brine-side heat transfer coefficient is dramatically enhanced by horizontal / vertical cross flow of brine over the outside surface of the coated fibers. Superior water vapor fluxes are achieved with the systems and methods.

Owner:NEW JERSEY INSTITUTE OF TECHNOLOGY

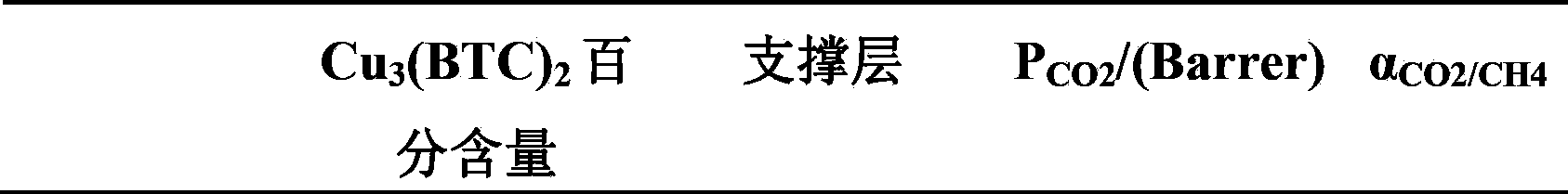

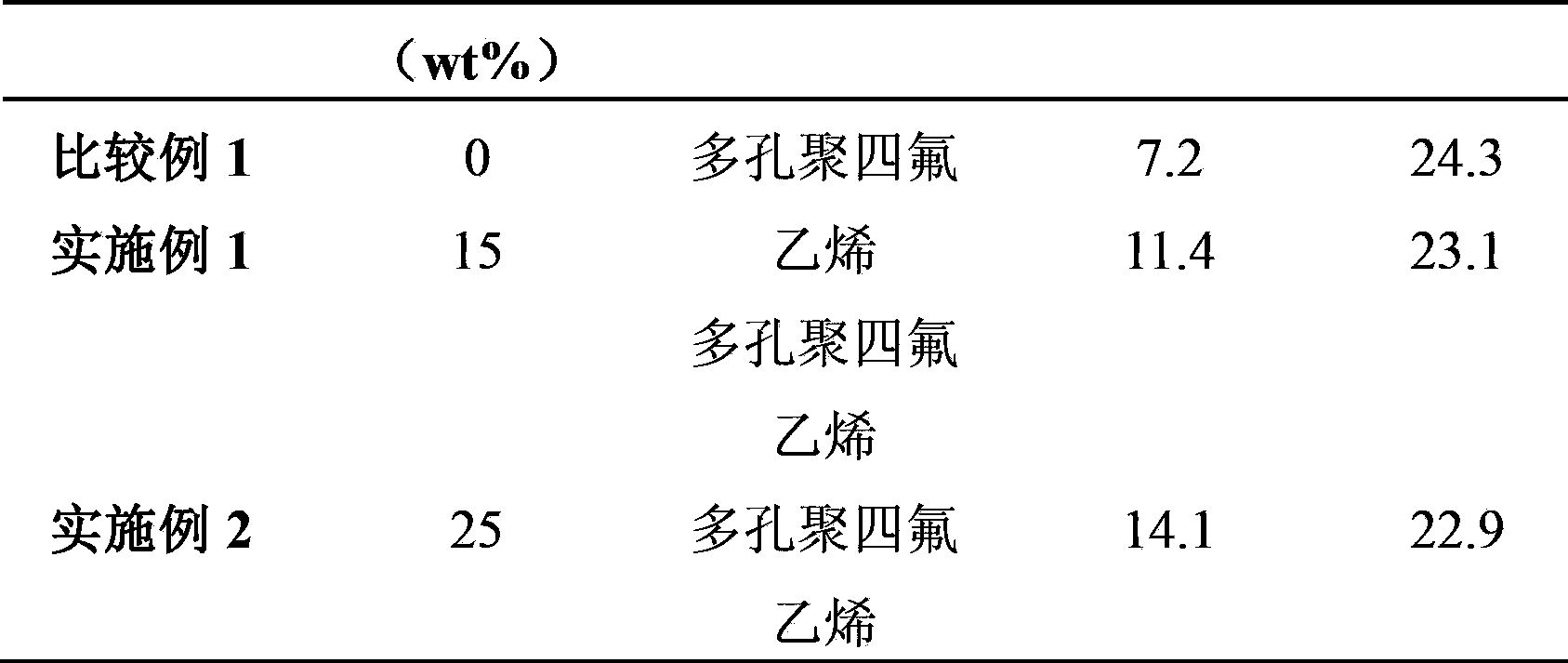

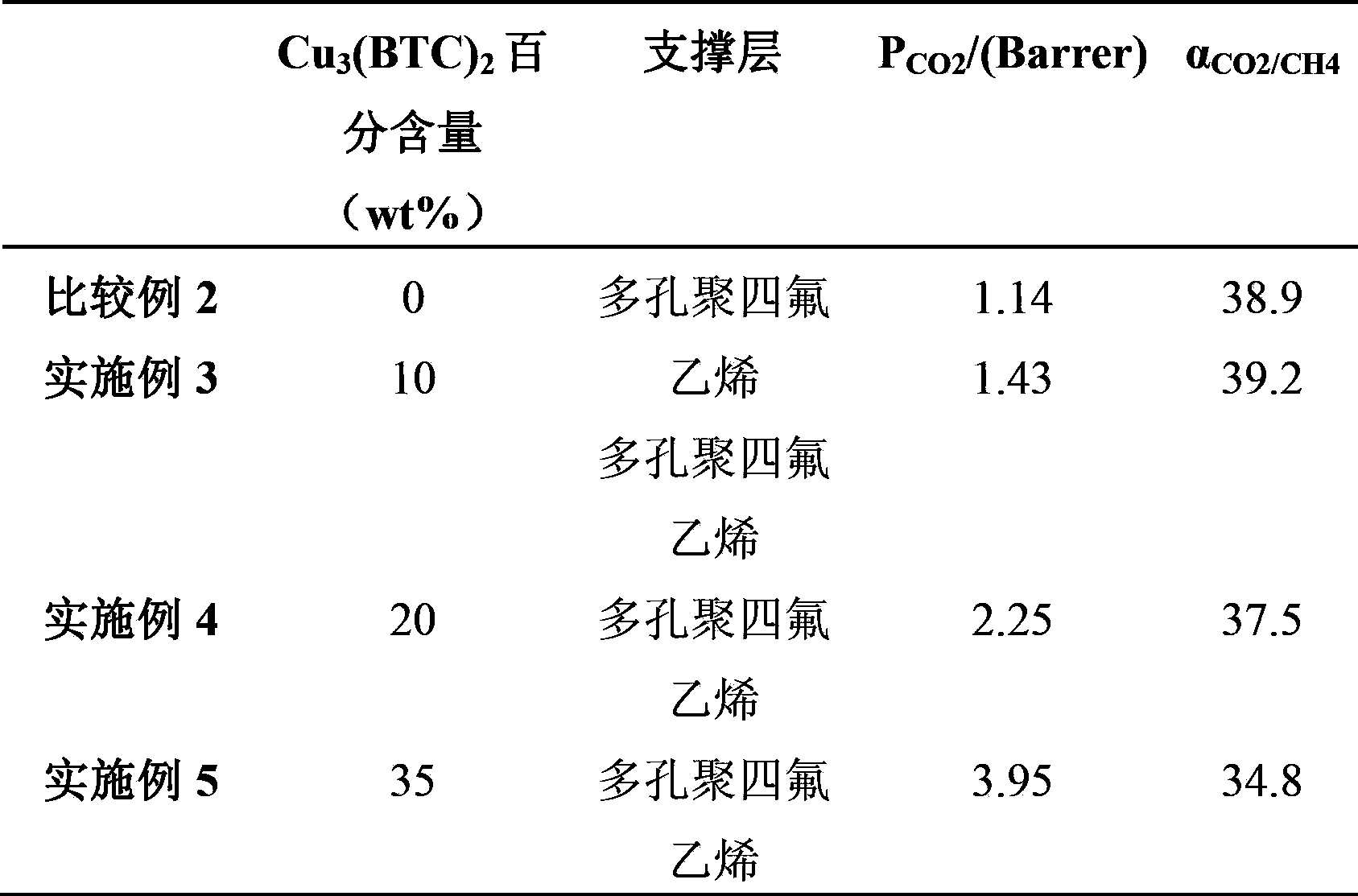

Porous material-polymer gas separation composite membrane

InactiveCN103846013ASimple materialImprove gas permeabilitySemi-permeable membranesDispersed particle separationHollow fibre membraneFiber

The invention belongs to the technical field of membranes and in particular relates to a porous material-polymer gas separation composite membrane. The composite membrane comprises a separation layer and a supporting layer, wherein a porous material-polymer hybrid membrane is adopted as the separation layer; one of a porous flat plate and a tubular or hollow fiber membrane is adopted as the supporting layer; the porous material of the separation layer is metal-organic frame materials (MOFs) with large specific surface area and high gas adsorption. The MOFs are added into the separation layer so that the gas permeation and selectivity of the membrane are obviously improved; the separation layer and the supporting layer are compounded so that the membrane keeps good mechanical property, and the separation layer is allowed to exist in a compact or asymmetric structure. The composite membrane provided by the invention has high gas separation property, good mechanical property and wide industrial application prospect.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

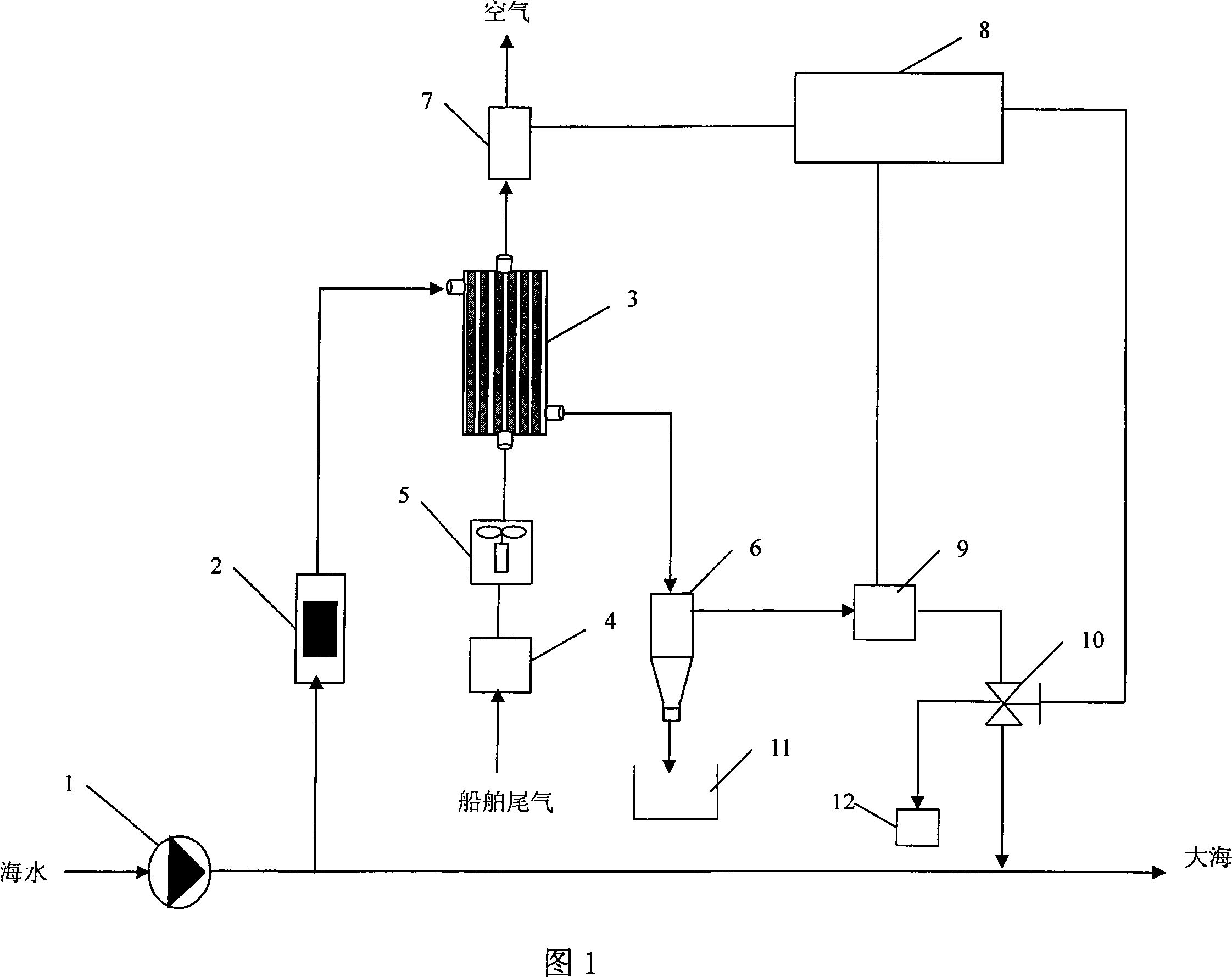

Device and method for treating ship tail gas with sea water washing

InactiveCN101104130AEfficient removalEasy to checkDispersed particle separationWater dischargeWater quality

The invention is a device and the method conducting seawater washing treatment to the ship exhaust gas which belongs to the ship exhaust gas treatment technical field. The ship exhaust gas after the dust-removing pretreatment is treated by seawater washing in a hollow fiber membrane contactor which serves as a syringe, a control system comprising an SO2 density monitor, a water quality monitor and a PLC programmable controller conducts real-time detection and storage to the SO2 density and waste water quality in the ship exhaust gas after treatment, as well as the control to the water discharging. The invention has beneficial effects that: water requirement is little by adopting the hollow fiber membrane contactor as the syringe, and the oxysulfide and particle substances in the ship exhaust gas can be effectively eliminated; and real-time monitoring, collection and storage of treatment effects of the ship exhaust gas and the seawater by adopting the PLC programmable controller facilitate the inspections of port states.

Owner:DALIAN MARITIME UNIVERSITY

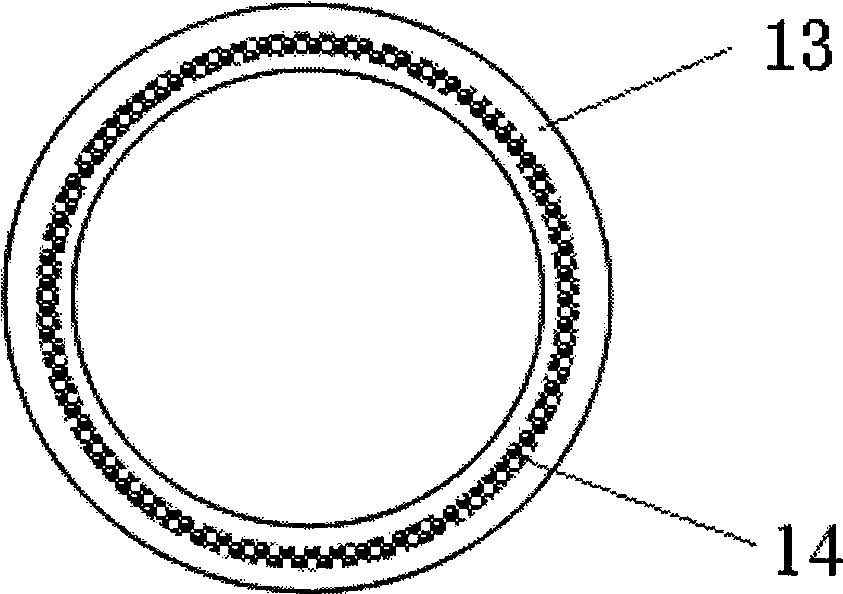

Process for preparing composite hollow fiber membrane

A preparation of composite hollow fiber membrane adopts solution phase transfer hollow fiber spinning process, makes poly(ethylene terephthalate) or polysulfone, solvent and pore-forming agent into a base membrane spinning solution of composite hollow fiber membrane, makes polyvinylidene fluoride or other copolymers or mixture of same, solvent and pore-forming agent into composite layer spinning solution of composite hollow fiber membrane and simultaneously extrudes the said two spinning solution and core solution in the hole of the spinneret central pipe through the spinneret for outside condensation bath. The solvents and pore-forming agents in the two kinds of spinning solutions prepared in said step (1) and (2) enters condensation solution phase and the polymers, as the composite layer and the base membrane materials, precipitates into polymer hollow fiber membrane due to phase transfer, producing high-strength and high-flux hydrophilic composite hollow fiber membrane.

Owner:江苏美能膜材料科技有限公司

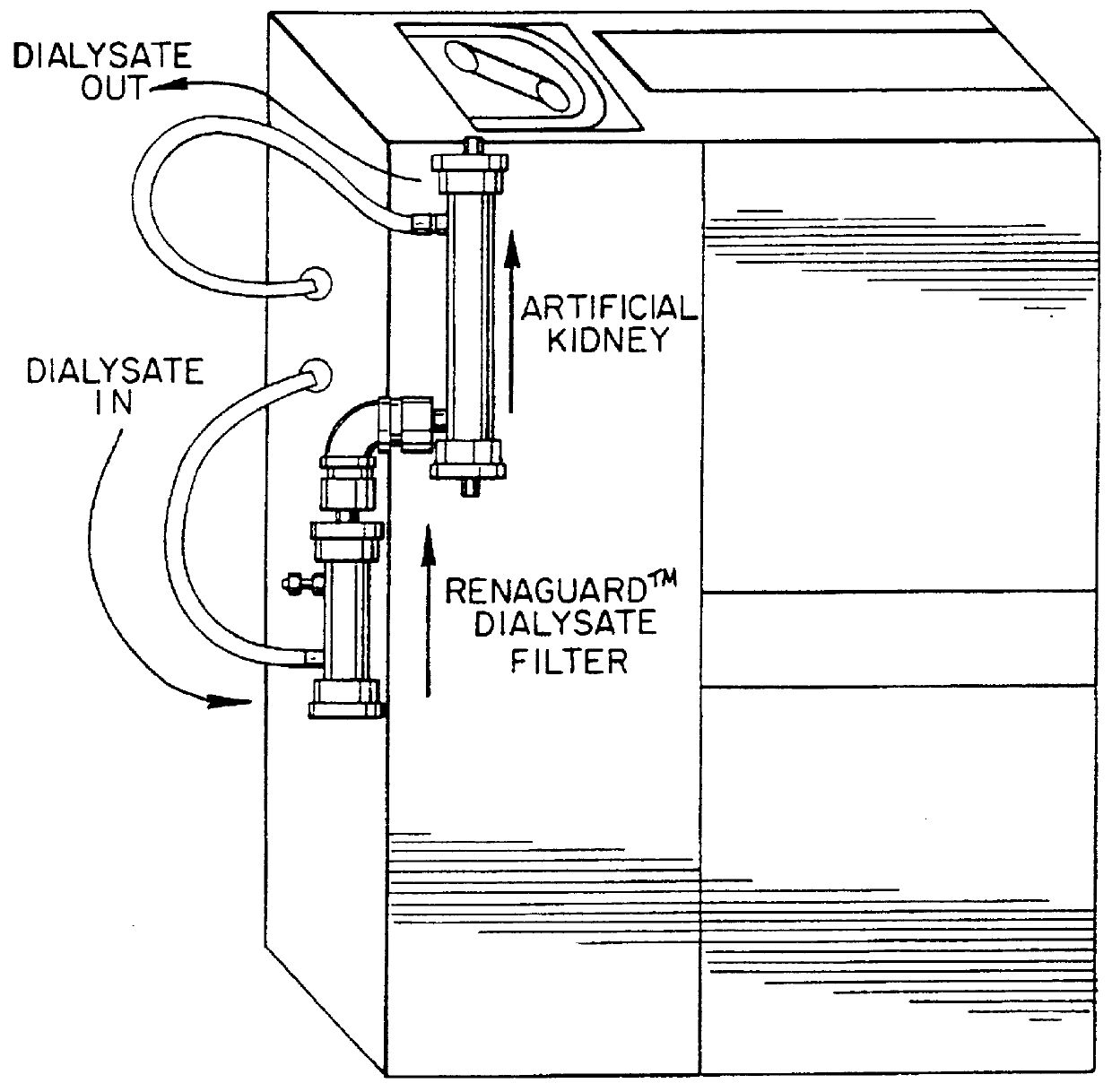

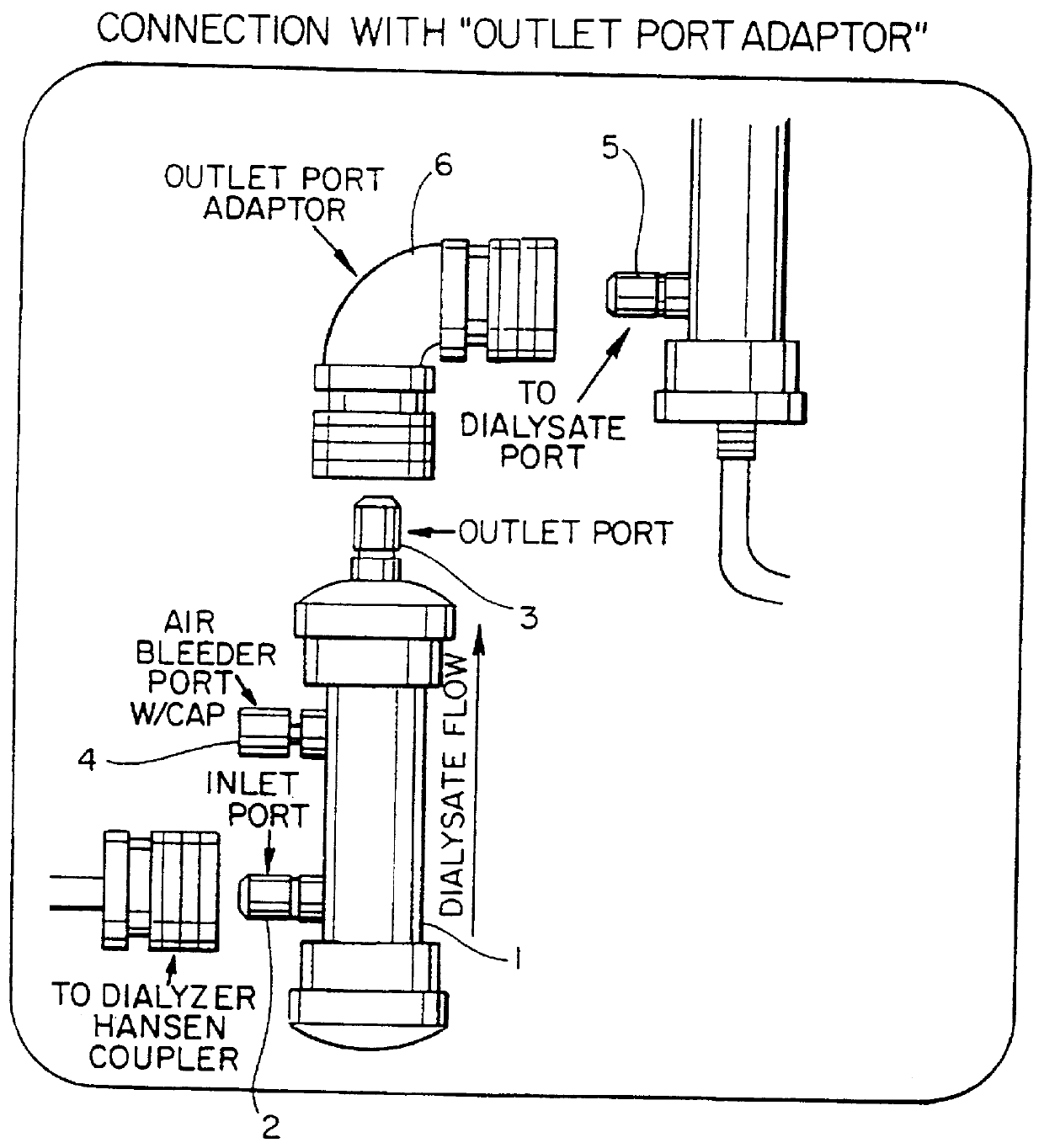

Dialysate filter including an asymmetric microporous, hollow fiber membrane incorporating a polyimide

InactiveUSRE36914E1Quickly and easily installEffective monitoringDialysisWater/sewage treatment bu osmosis/dialysisFiberHollow fibre membrane

A dialysate filter including asymmetric, microporous, hollow fiber membranes incorporating a polyimide. The dialysate filter connects to the dialysis machine immediately before the dialyzer ensuring complete filtration of the dialysate, easy visual inspection, quick installation and removal, and easy disinfection of the filter.

Owner:MEDIVATORS INC

Universal water purifier unit assembly device

InactiveUS20080087596A1Easy to transportTreatment involving filtrationSolid sorbent liquid separationFiberWater filter

Owner:MARMON WATER SINGAPORE

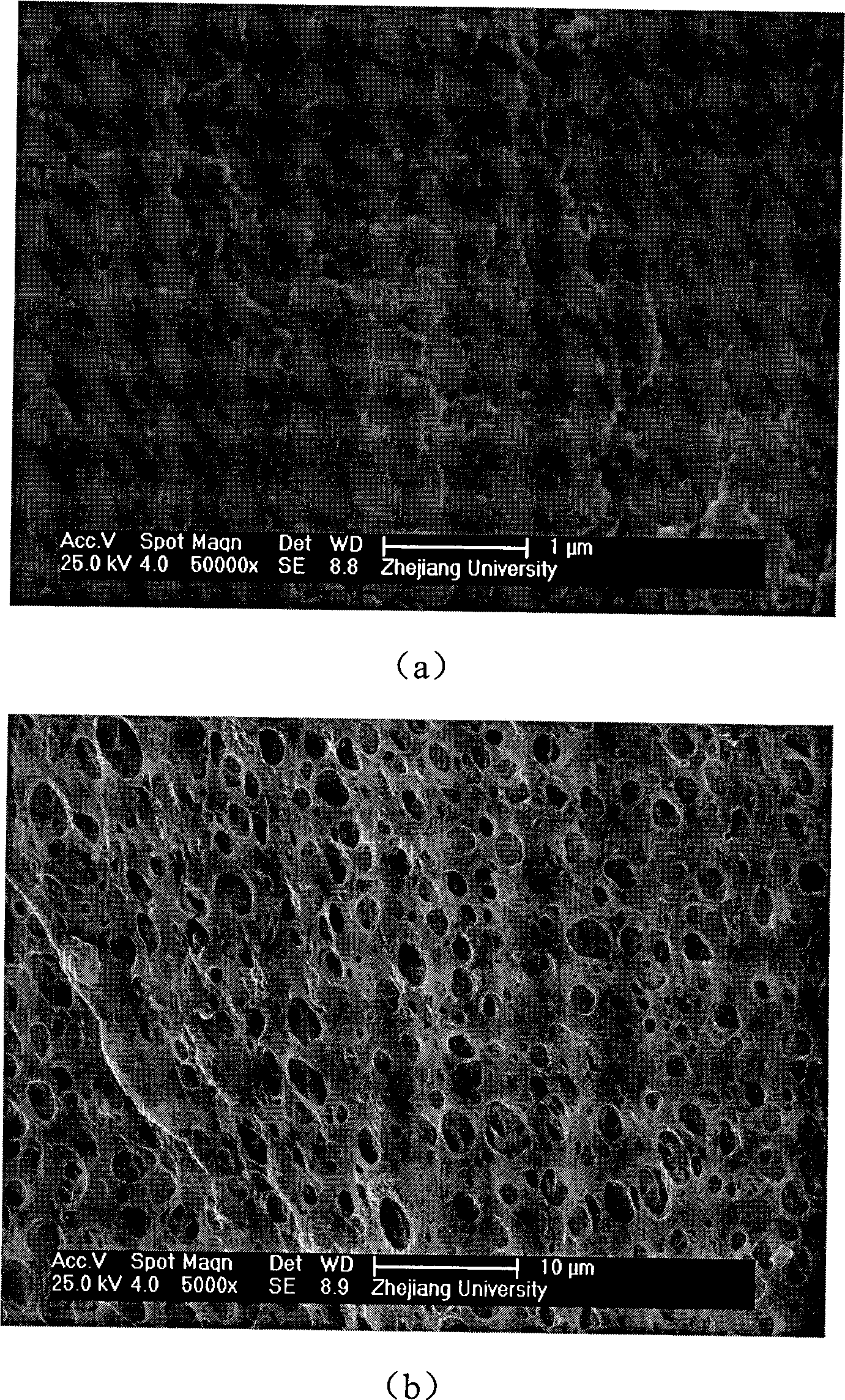

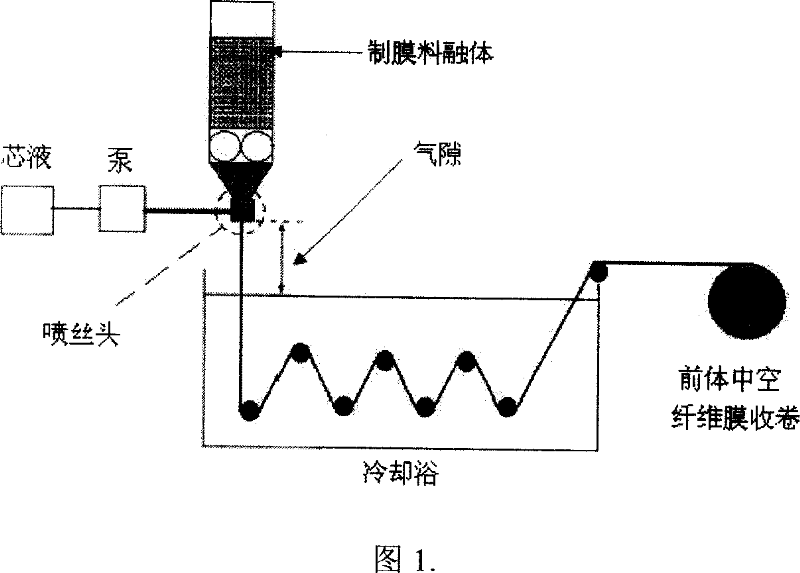

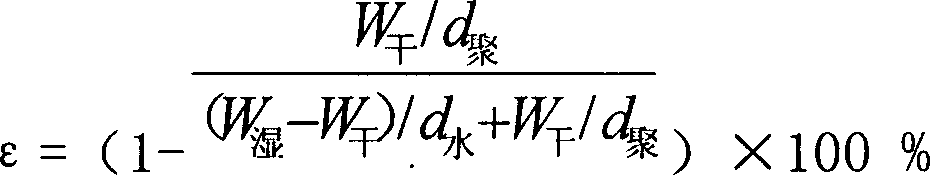

Hydrophilicity polyethylene hollow fiber micro-hole film and the preparation method

InactiveCN101036861AExtended cleaning cycleHydrophilic realizationSemi-permeable membranesFiberMolten state

The invention discloses hydrophilic polyethylene hollow fiber microporous membrane and preparation process thereof. Said membrane is characterized in that it mainly comprises polyethylene, amphoteric copolymer containing polyethylene oxide, and inorganic nano particles. The membrane preparing process is carried out based on thermally induced phpase separation and surface segregation principles, comprising the steps of (1) preparing membrane blank by fusion and blending of amphoteric copolymer containing polyethylene oxide, diluent, and inorganic nano particles; (2) preparing hollow fiber membrane precursor by hollow process spinning of membrane blank in molten state; (3) extracting diluent in hollow fiber membrane precursor by using organic solvent to obtain said hydrophilic polyethylene hollow fiber microporous membrane, wherein the porosity of said membrane is between 40% and 80%, and average pore diameter is between 0.1mum and 5.0mum. The microporous membrane in the invention has the characteristics of high hydrophilicity, narrow pore size distribution, high strength, and good chemical stability, and serves as micro-filtration and ultra-filtration membrane material with high performance, low cost, pollution resistance, and long serve life for water treatment.

Owner:ZHEJIANG UNIV

Method for producing hollow fiber film

InactiveCN1899678AImprove throughputUniform hole formationSemi-permeable membranesHollow fibre membraneNon solvent

The melt spinning process of producing hollow fiber membrane includes the first mixing inorganic particle, polymer pore creating agent, surfactant and non-solvent to constitute spinning composition, heating the composition to temperature higher than the smelting point of the polymer, the subsequent extruding the melt through spinning head and cooling to form hollow fiber, and final eliminating the inorganic particle, polymer pore creating agent, surfactant and non-solvent to produce the hollow fiber membrane. The spinning composition consists of polymer 20-90 wt%, inorganic pore creating agent 5-50 wt%, polymer pore creating agent 1-30 wt%, surfactant 0.05-20 wt%, and organic non-solvent 1-60 wt%.

Owner:TIANJIN POLYTECHNIC UNIV

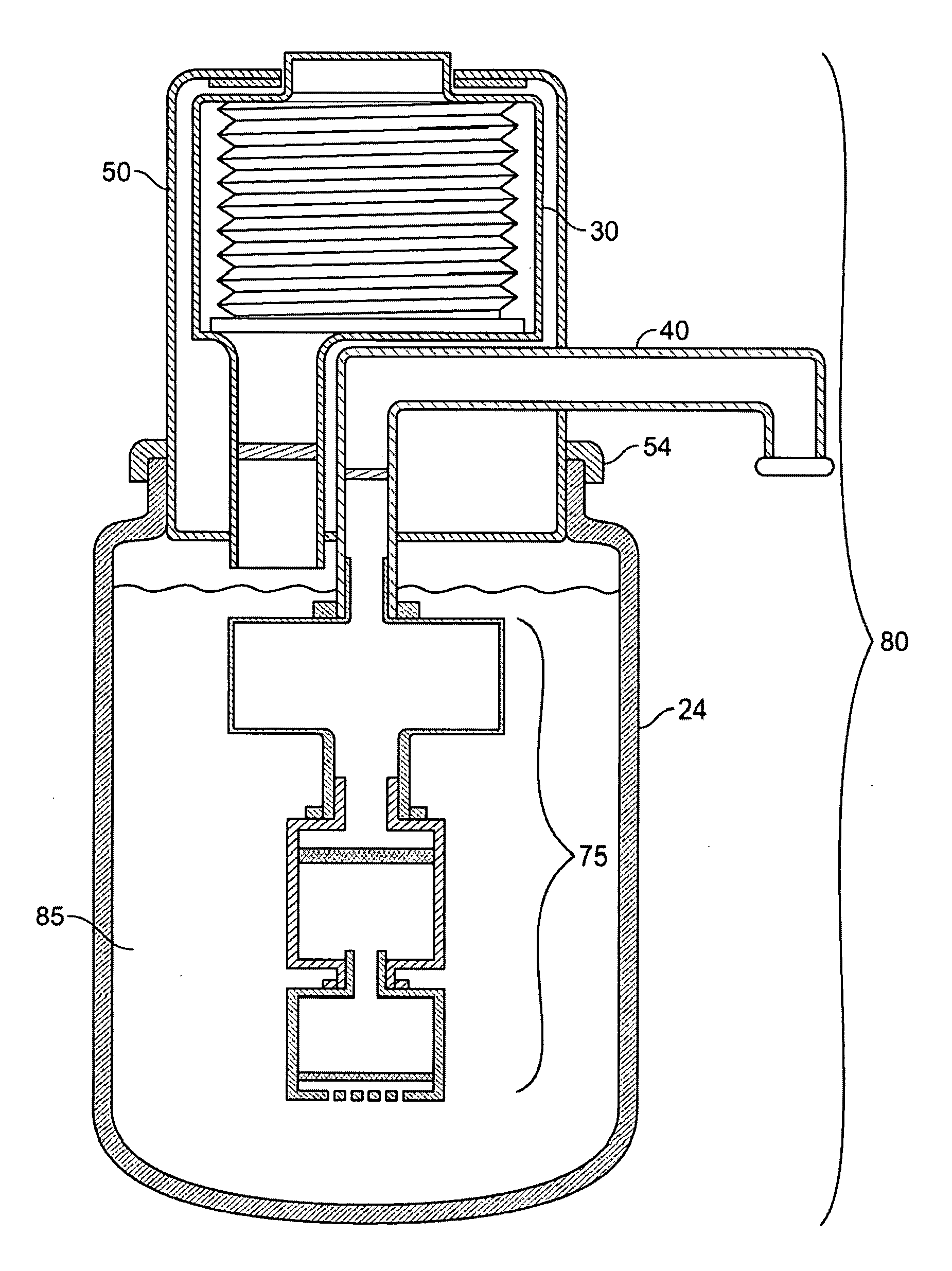

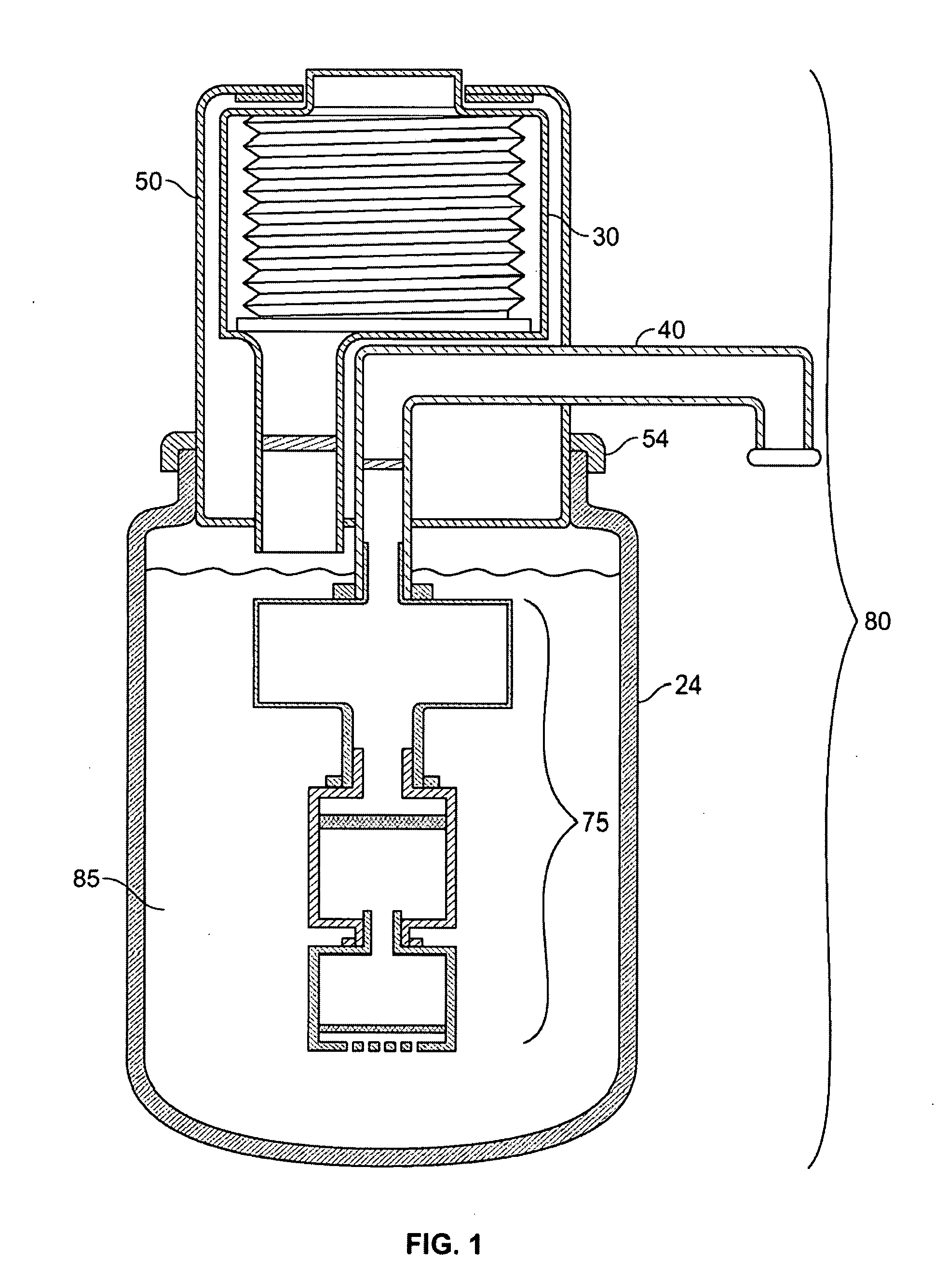

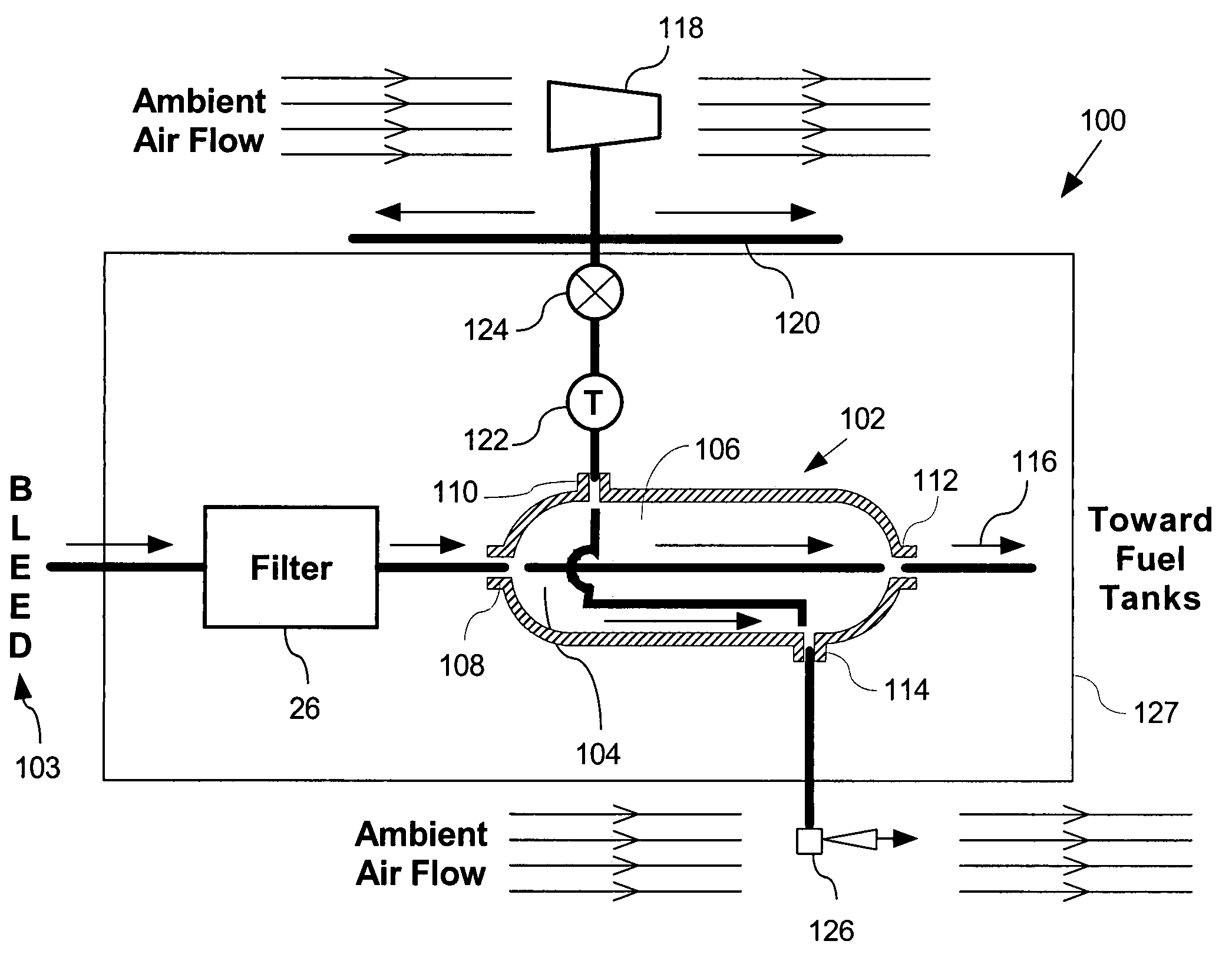

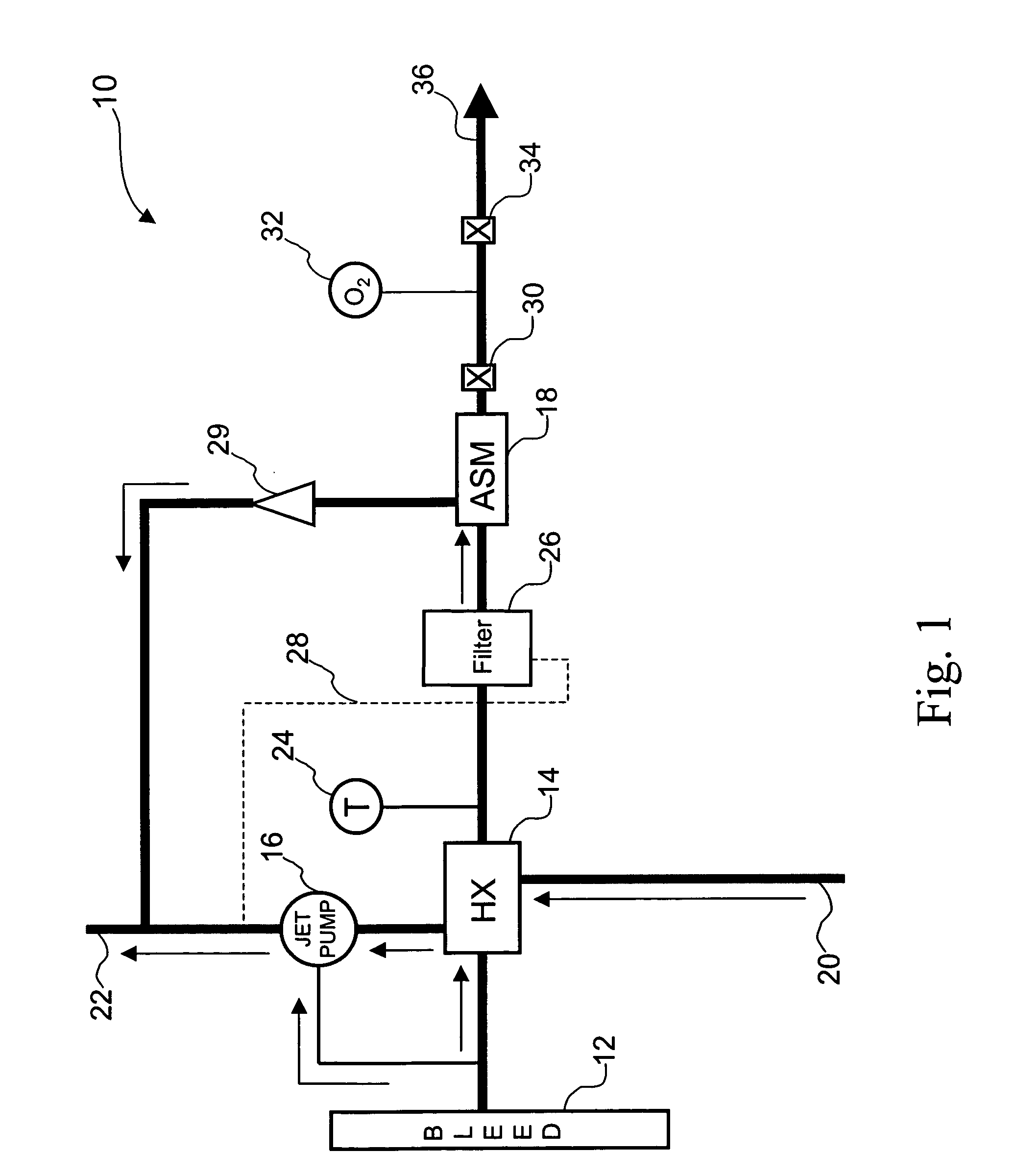

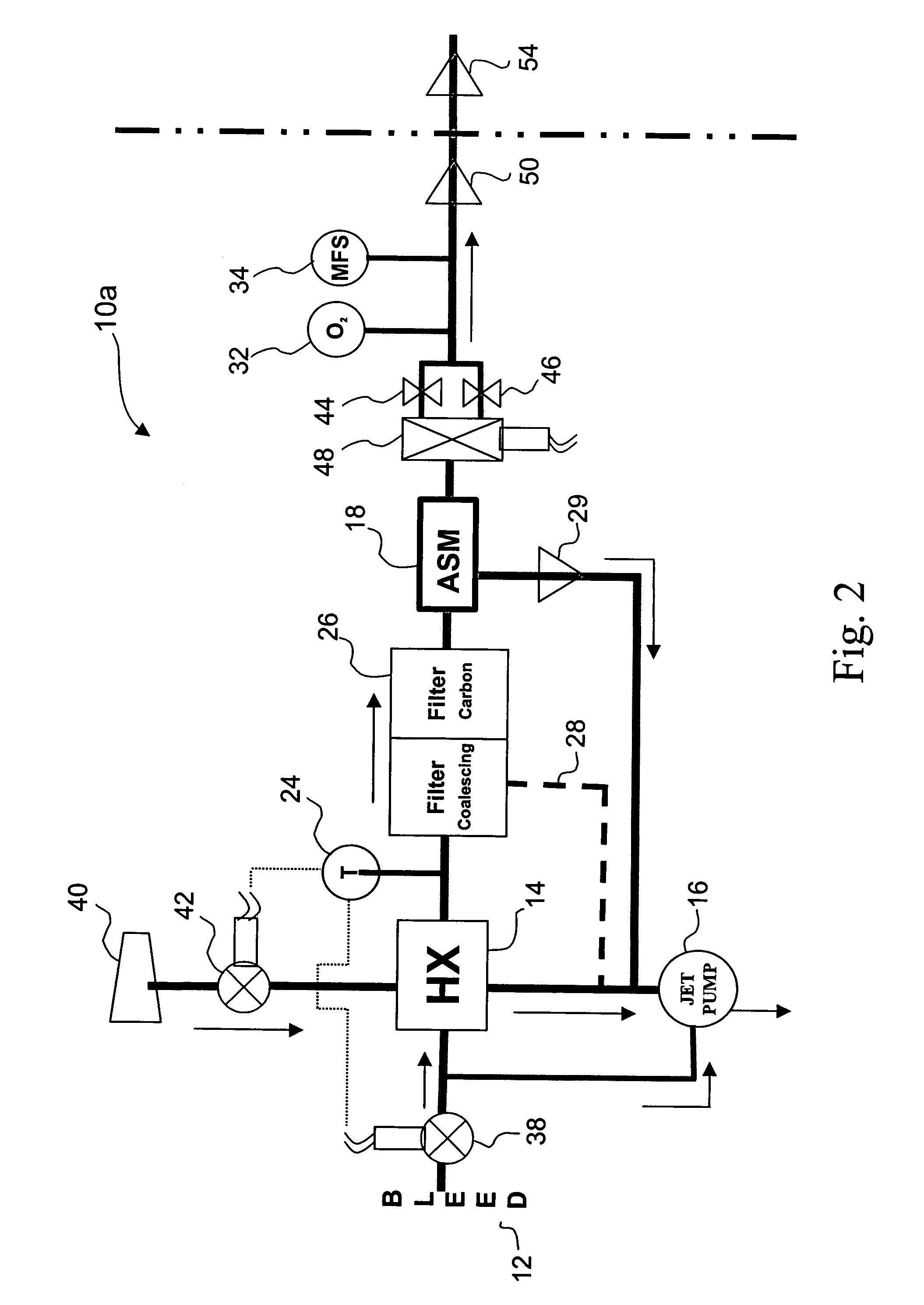

Cooling system for an on-board inert gas generating system

ActiveUS6997013B2Reduce the likelihood of burningImprove system performanceSolidificationLiquefactionHollow fibre membraneFiber

The inert gas generating system includes a compressed air source, a cooling air source, and a separation module. The separation module includes first and second inlets and outlets. The first inlet is coupled to the compressed air source. The first outlet is coupled to the first inlet via a bundle of hollow fiber membranes. The second inlet is coupled to the cooling air source, and the second outlet is coupled to the second inlet via a space surrounding the bundle of hollow fiber membranes.

Owner:PARKER INTANGIBLES LLC

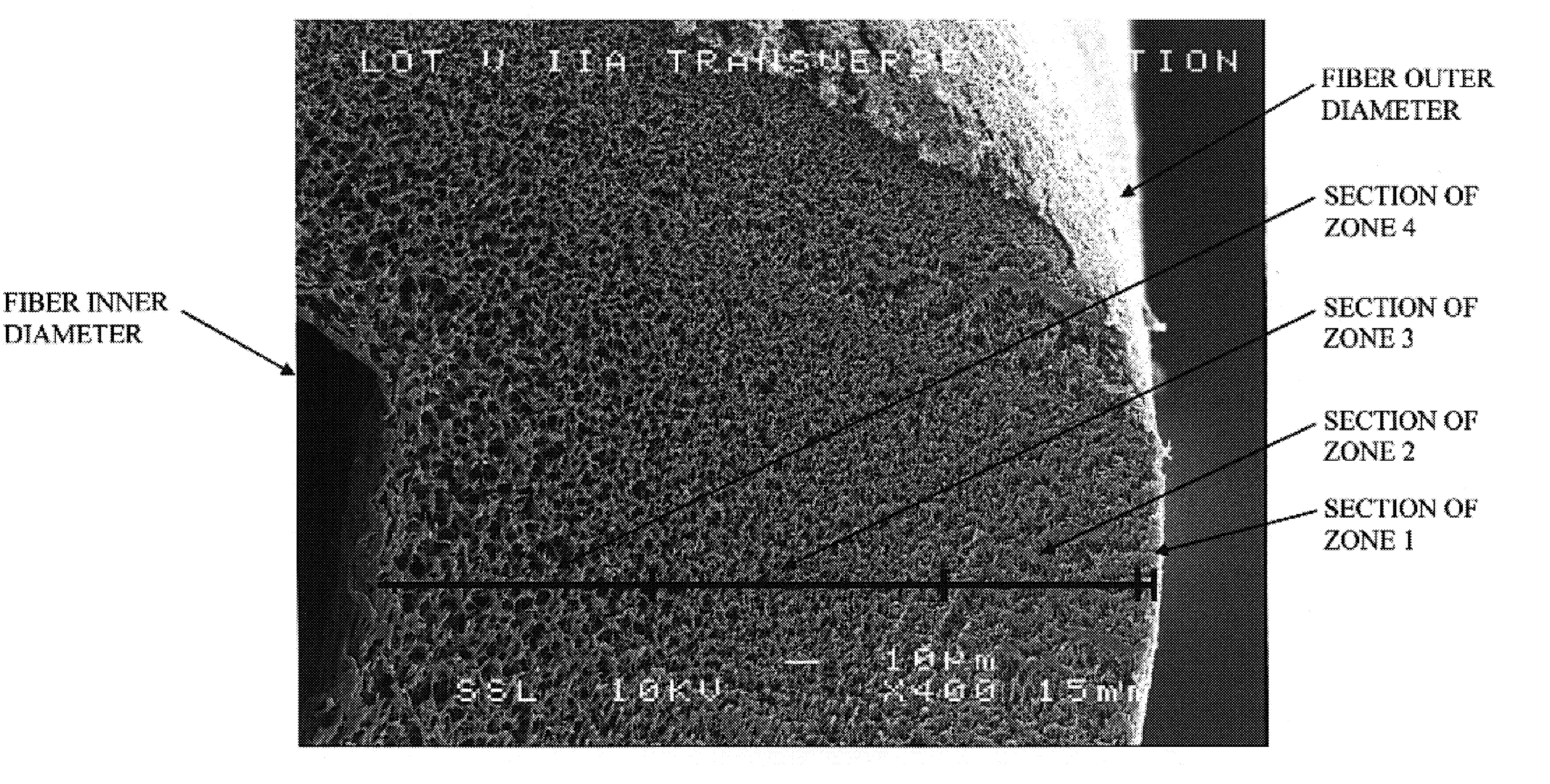

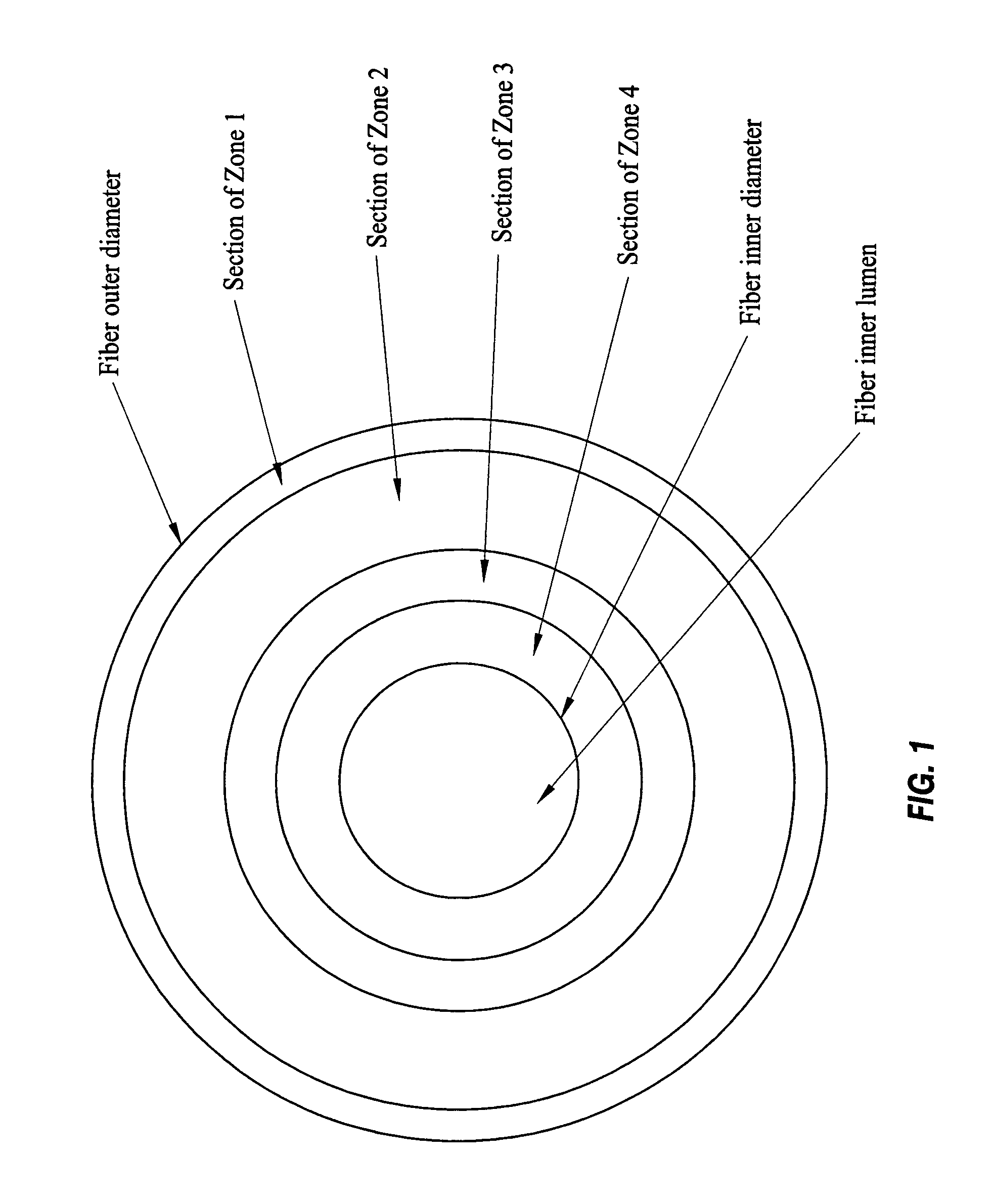

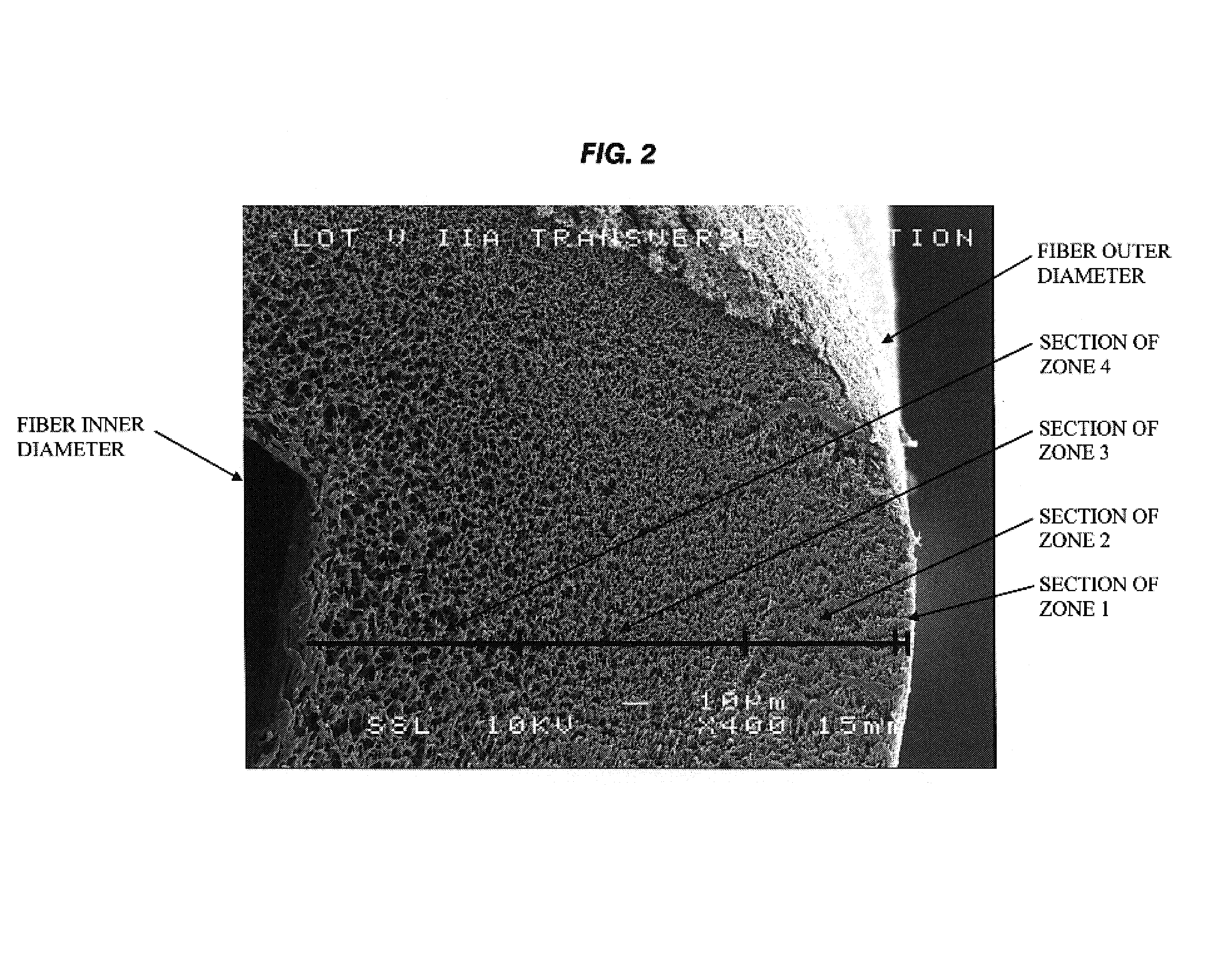

Specialized hollow fiber membranes for plasmapheresis and ultrafiltration

A plasmapheresis and / or ultrafiltration membrane comprises elongated hollow fibers each fiber having an interior lumen extending along the fiber length, the fiber wall having a plurality of zones between the inner and outer wall surfaces, each of the zones having a mass density different than the mass density of an adjacent zone. The fiber wall is characterized by having a lower mass density zone at the inner wall surface and a higher mass density zone at the outer wall surface. The fiber is further characterized by having an average elongation breaking force strength of at least about 0.2 lbs. and an average elongation of at least about 45%.

Owner:TRANSVIVO

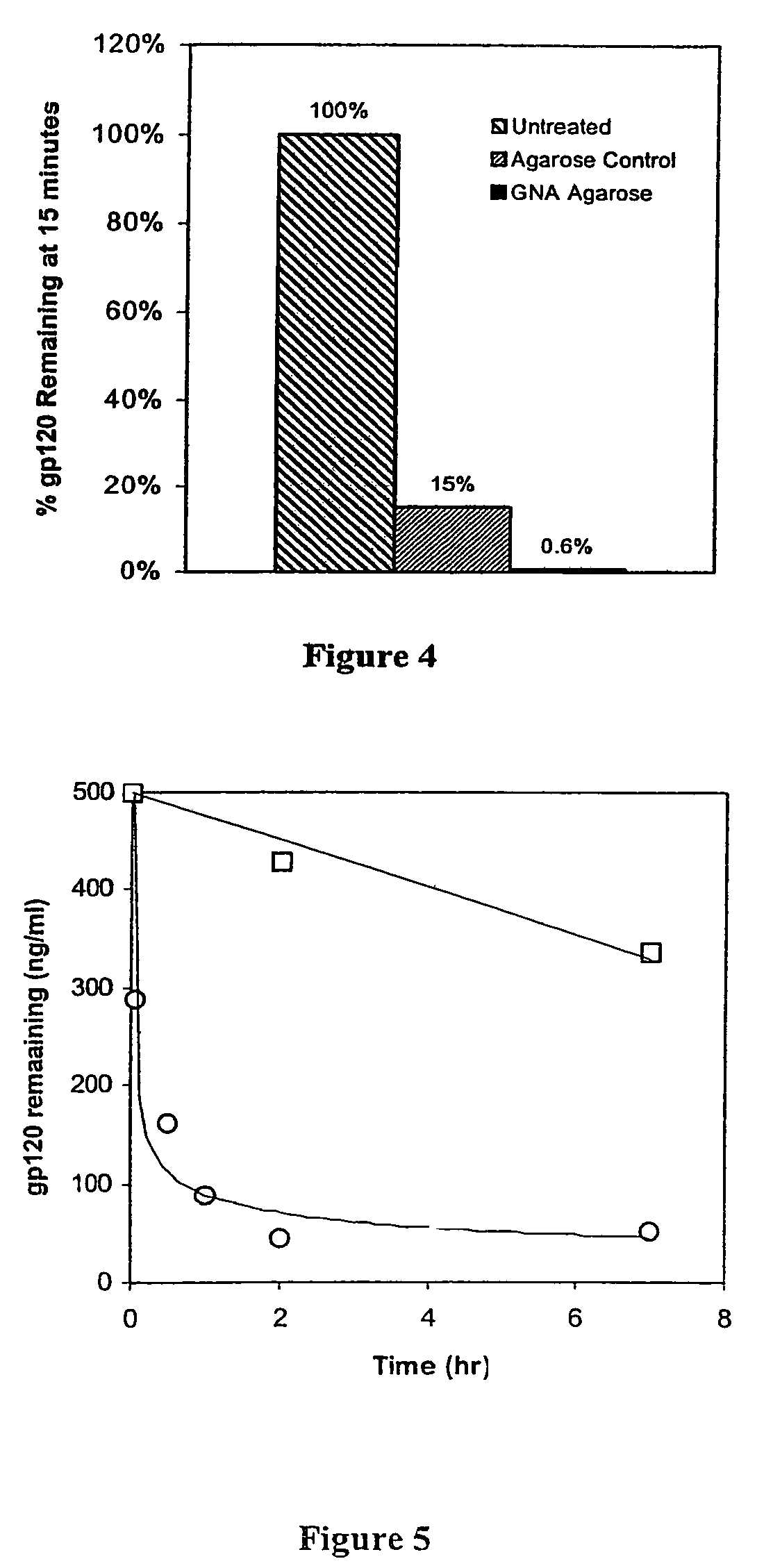

Method for removal of viruses from blood by lectin affinity hemodialysis

ActiveUS7226429B2Reduce loadReduce in quantityOther blood circulation devicesViral antigen ingredientsHemodialysisHigh mannose

The present invention relates to a method for using lectins that bind to pathogens having high mannose surface glycoproteins or fragments thereof which contain high mannose glycoproteins, to remove them from infected blood or plasma in an extracorporeal setting. Accordingly, the present invention provides a method for reducing viral load in an individual comprising the steps of obtaining blood or plasma from the individual, passing the blood or plasma through a porous hollow fiber membrane wherein lectin molecules are immobilized within the porous exterior portion of the membrane, collecting pass-through blood or plasma and reinfusing the pass-through blood or plasma into the individual.

Owner:AETHLON MEDICAL INC

Filters and method for producing filters

InactiveUS6951611B2Spend lessEasy to produceSemi-permeable membranesMembranesFiberHollow fibre membrane

Methods and apparatus are disclosed for producing hollow fiber membrane-containing filters. The methods include laying a plurality of hollow fibers in a first portion of a filter housing to form a bundle, forming first and second portions into a filter housing, sealing the portions together, connecting the plurality of hollow fibers together at at least one end of the filter housing, connecting the hollow fibers to the filter housing, and simultaneously adhering the first and second portions of the filter housing together by applying a potting compound thereto, and cutting the ends of the hollow fibers at at least one end thereof, whereby the hollow fibers include open ends.

Owner:GAMBRO DIALYSATOREN

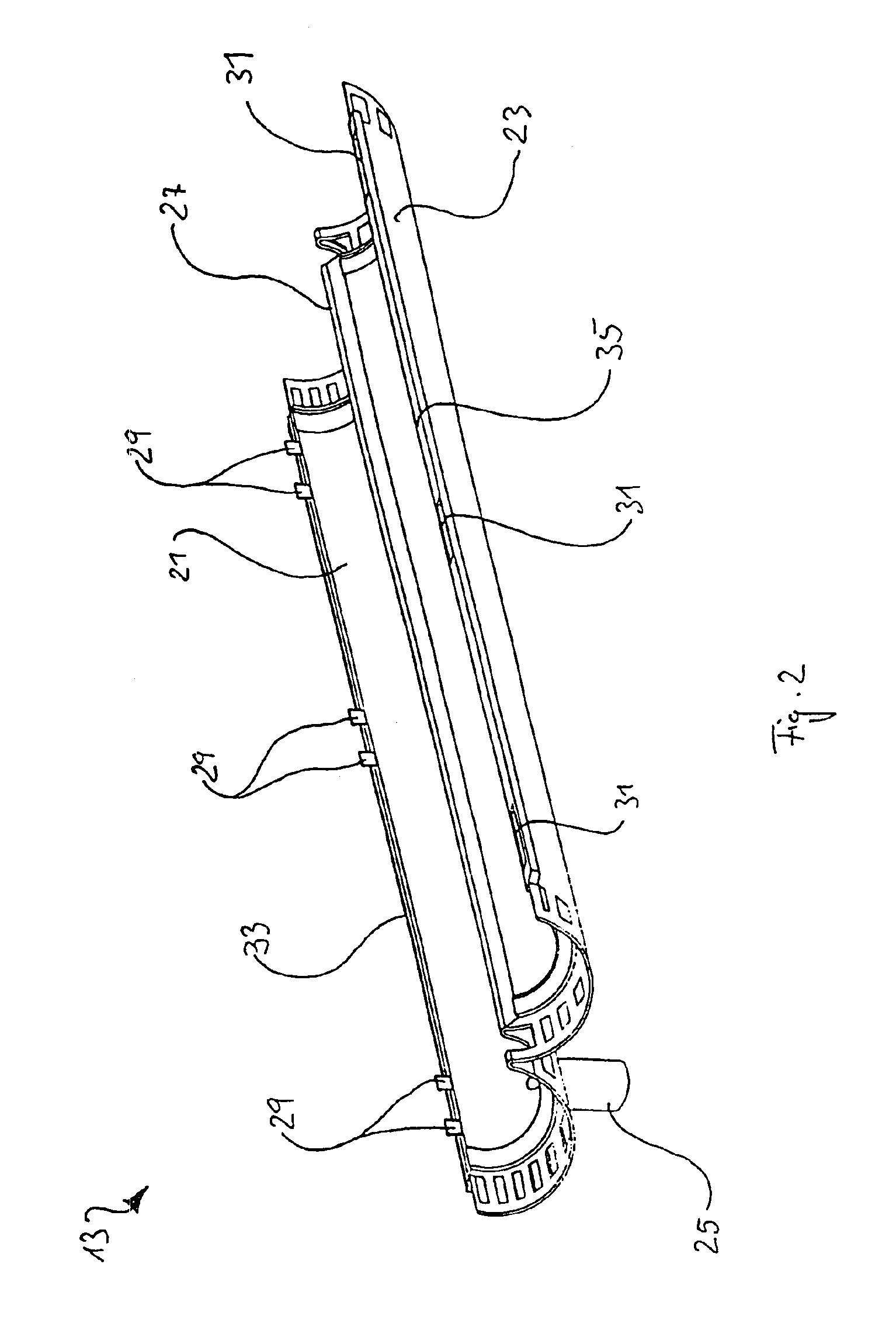

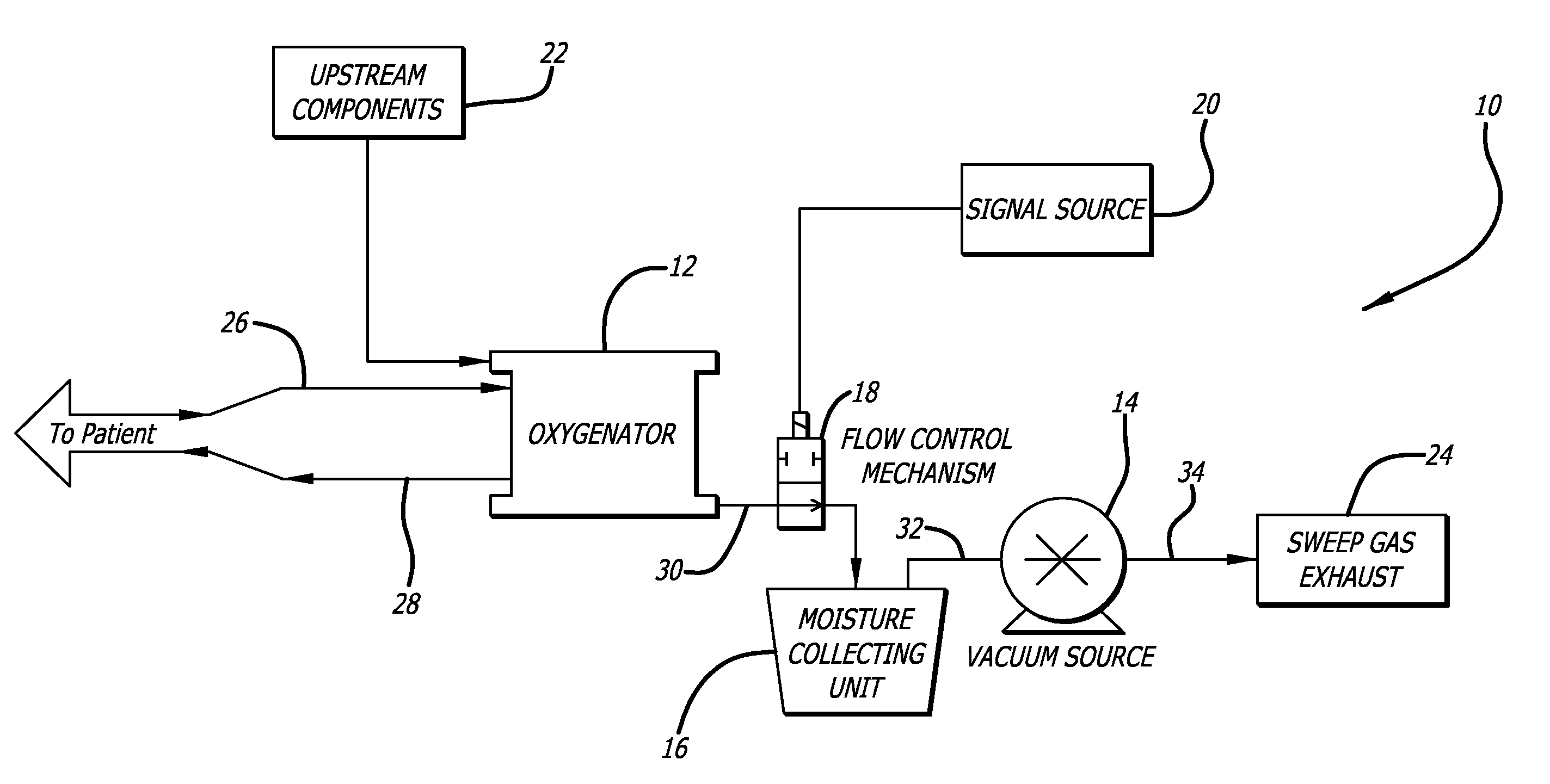

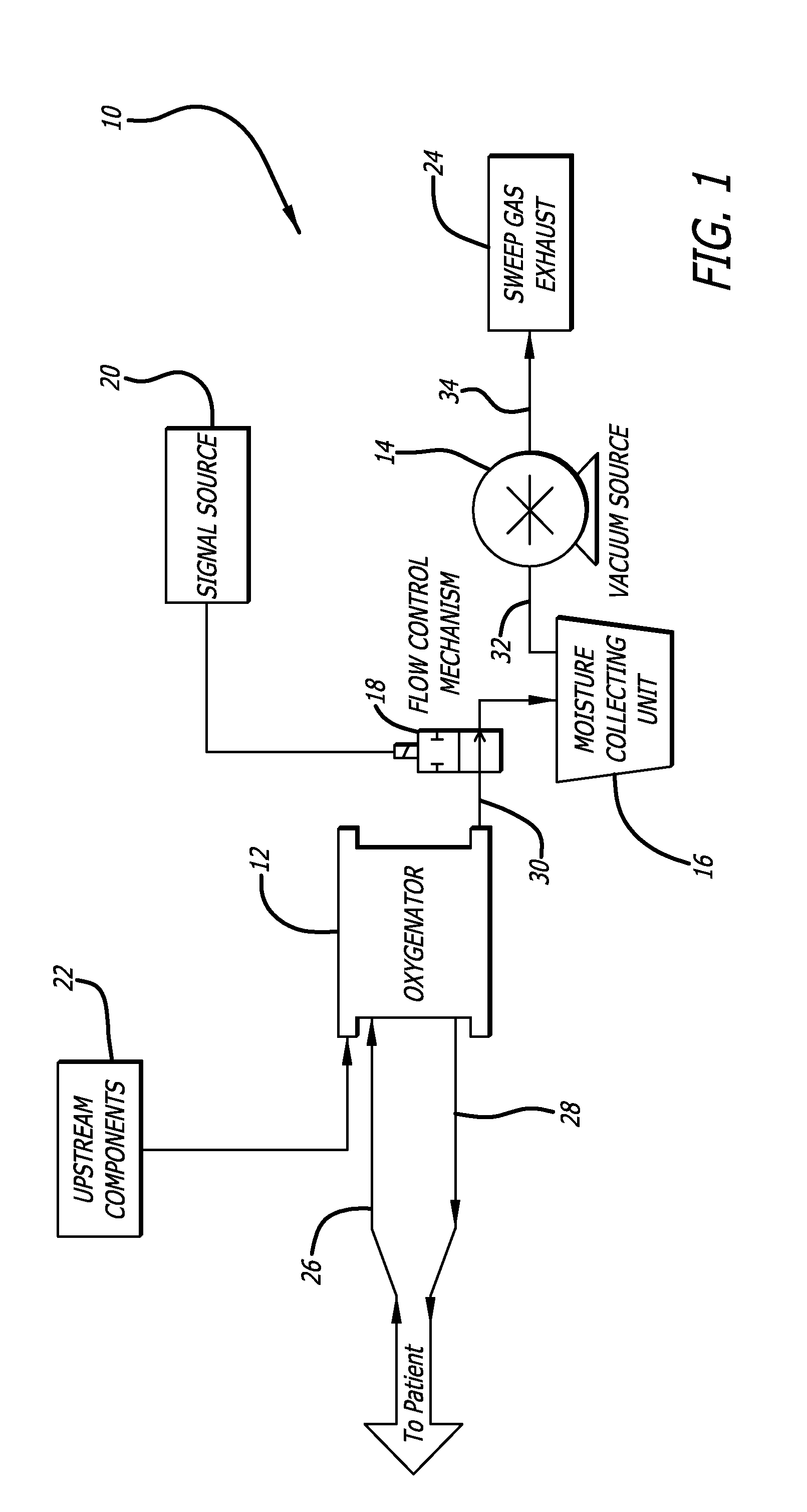

Method and system for purging moisture from an oxygenator

ActiveUS20100101657A1Improving gas exchange propertyImproves gas exchange propertyMembranesSemi-permeable membranesHollow fibre membraneFiber

A method and system for improving gas exchange properties of oxygenators which utilize hollow fiber membranes for removing carbon dioxide or adding oxygen to a patient's blood via extracorporeal circulation by removing moisture accumulating in the fibers are disclosed. The system utilizes a vacuum source for drawing sweep gas into the oxygenator, a moisture collection unit for storing moisture removed from the oxygenator, the moisture collecting unit being in communication with the oxygenator and the vacuum source and a flow control mechanism having an open position which allows sweep gas exiting the oxygenator to flow to the moisture collecting unit and a closed position which stops the flow of sweep gas from the oxygenator to the moisture collecting unit. The vacuum source draws sweep gas through the oxygenator and moisture collecting unit when the flow control mechanism is in the open position and the vacuum source creates a vacuum buildup in the moisture collecting unit when the flow control mechanism is in the closed position. The vacuum in the moisture collecting unit provides a sudden increase to the flow rate of the sweep gas to draw moisture with the sweep gas exiting the oxygenator when the flow control mechanism is returned to the open position.

Owner:ALUNG TECH INC

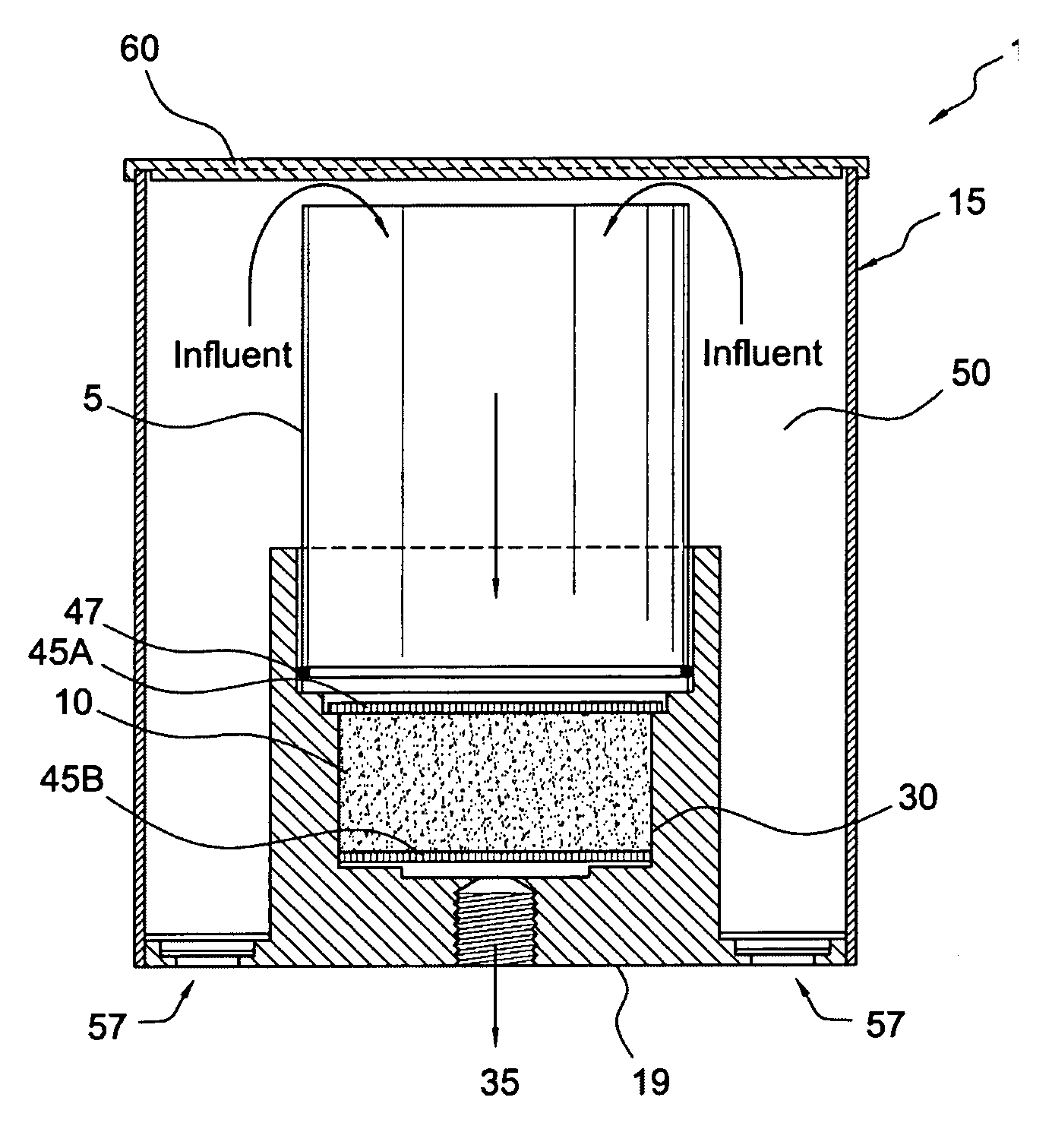

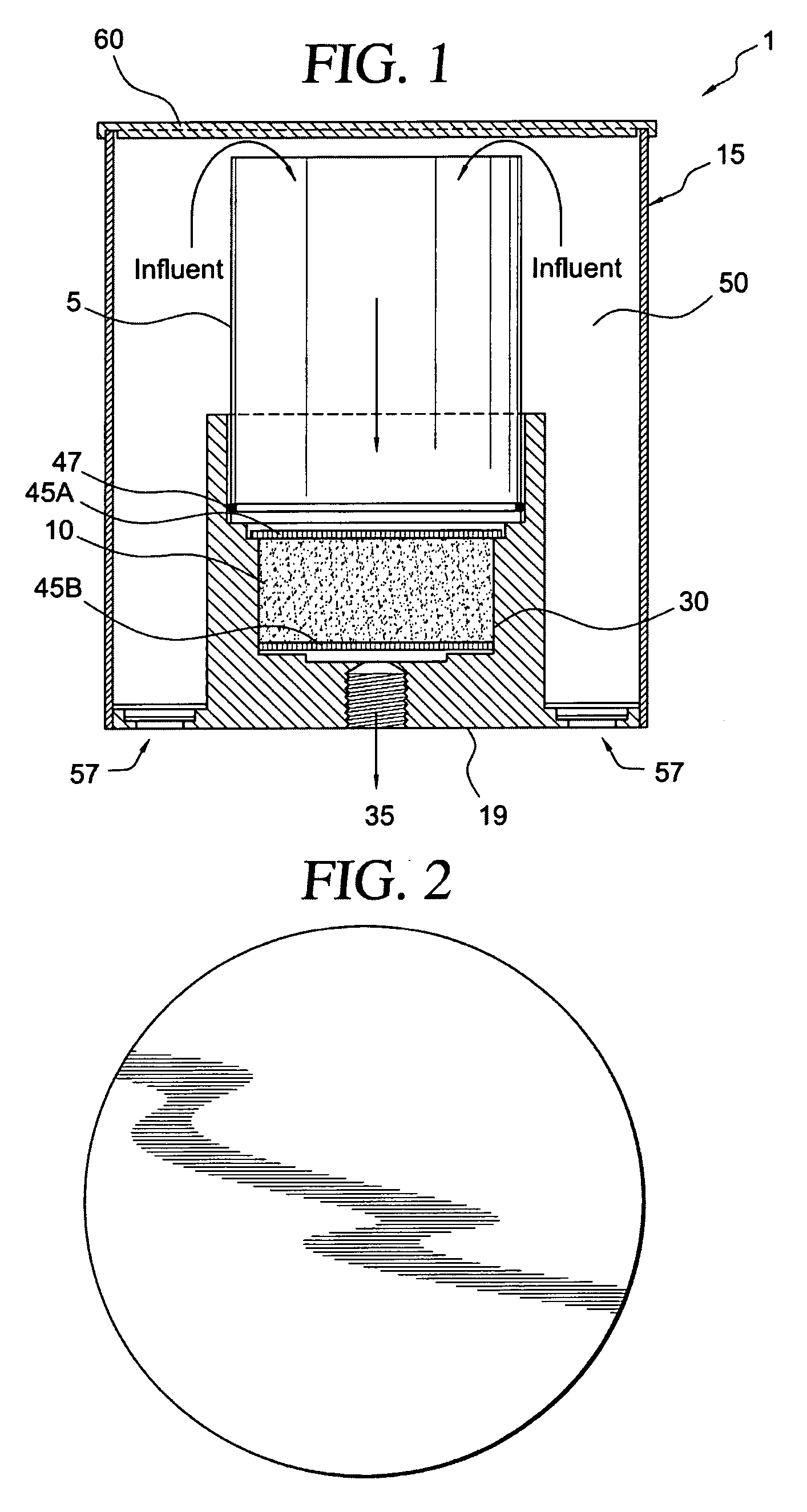

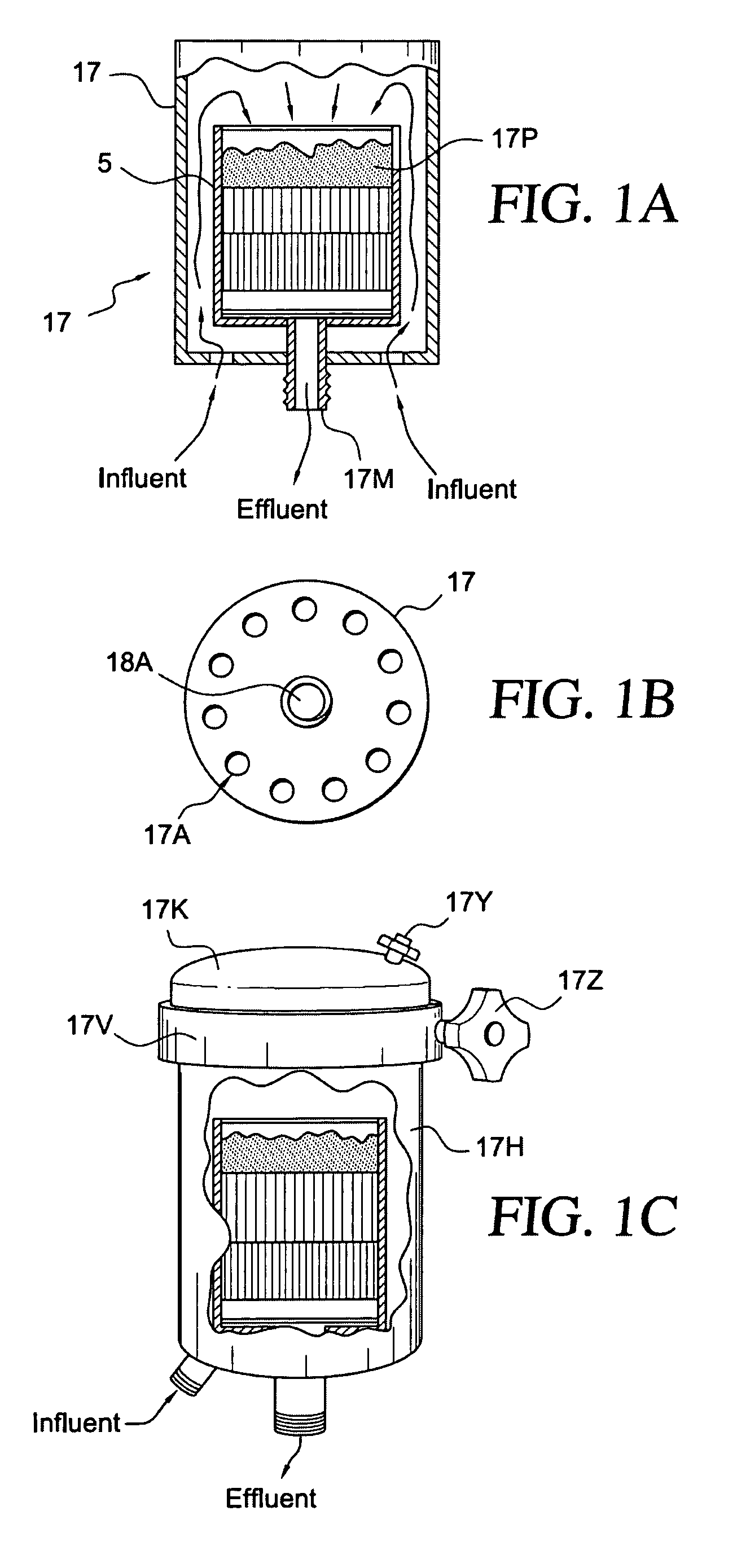

Microfiltration devices

ActiveUS20070062870A1Improve filtering effectImprove performanceSemi-permeable membranesMembranesHollow fibre membraneFiber

A method of treating a hollow fiber membrane microfiltration filter having an influent side and an effluent side to improve performance of the filter is disclosed. The method entails sealing imperfections in surfaces of the filter by flushing the filter with a liquid aqueous suspension of particulates. Filter cartridge devices also are disclosed. The devices may include a bactericidal chamber. A radial flow filter may be included in the devices. The filter cartridges may include a drain tube positioned within the filter for removing of effluent generated by the filter. A plurality of filter cartridges may be positioned on the drain tube.

Owner:STREAMLINE CAPITAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com