Porous material-polymer gas separation composite membrane

A porous material and gas separation technology, applied in the direction of semi-permeable membrane separation, membrane technology, chemical instruments and methods, etc., can solve problems such as poor mechanical properties, and achieve the goal of overcoming poor mechanical properties, high gas separation performance, and high mechanical strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

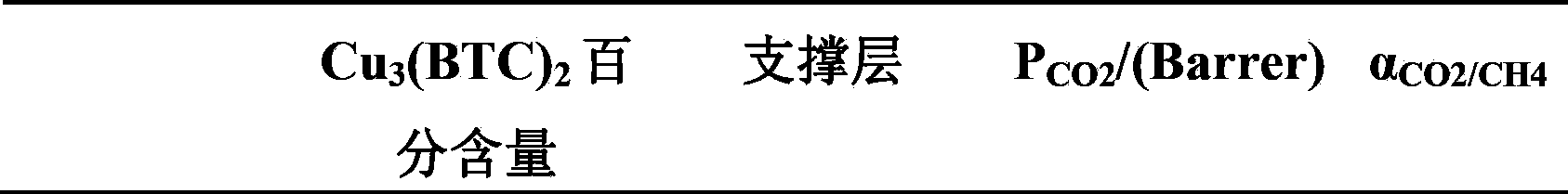

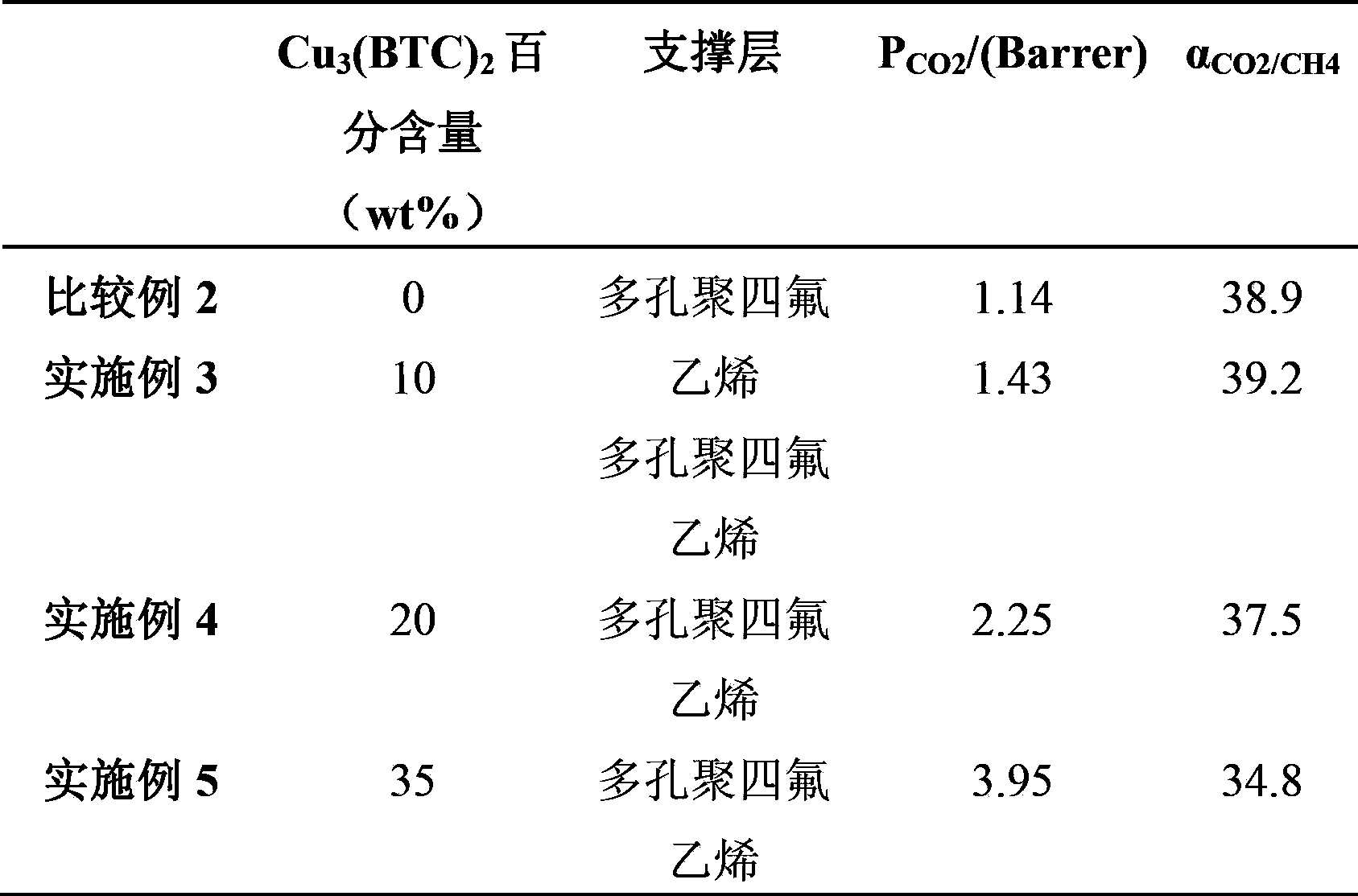

[0016] Example 1: Cu 3 (BTC) 2 -Polysulfone gas separation composite membrane

[0017] (1) Cu 3 (BTC) 2 Solution preparation: 0.3g Cu 3 (BTC) 2 After activation, it is uniformly dispersed in chloroform organic solvent; (2) Preparation of polymer solution: polysulfone is dissolved in chloroform organic solvent after drying and pretreatment, and the solid content of the solution is 8wt%; (3) Preparation of casting solution: 17g polysulfone polymer solution was added in batches to Cu 3 (BTC) 2 solution, remove the excess solvent, and finally obtain Cu with a solid content of 10wt%. 3 (BTC) 2 - Polysulfone casting solution; (4) Cu 3 (BTC) 2 -Preparation of polysulfone gas separation composite membrane: After filtering and defoaming the casting solution, it is scraped on the porous polytetrafluoroethylene base membrane, and the solvent is volatilized to obtain Cu 3 (BTC) 2 - Polysulfone gas separation composite membrane.

[0018] Cu in this example 3 (BTC) 2 It is a ...

Embodiment 2

[0019] Example 2: Cu 3 (BTC) 2 -Polysulfone gas separation composite membrane

[0020] (1) Cu 3 (BTC) 2 Solution preparation: 0.9g Cu 3 (BTC) 2 After activation, it is uniformly dispersed in chloroform organic solvent; (2) Preparation of polymer solution: polysulfone is dissolved in chloroform organic solvent after drying and pretreatment, and the solid content of the solution is 10wt%; (3) Preparation of casting solution: 27g polysulfone polymer solution was added in batches to Cu 3 (BTC) 2 solution, remove the excess solvent, and finally obtain Cu with a solid content of 10wt%. 3 (BTC) 2 - Polysulfone casting solution; (4) Cu 3 (BTC) 2 -Preparation of polysulfone gas separation composite membrane: After filtering and defoaming the casting solution, it is scraped on the porous polytetrafluoroethylene base membrane, and the solvent is volatilized to obtain Cu 3 (BTC) 2 - Polysulfone gas separation composite membrane.

[0021] Cu in this example 3 (BTC) 2 - Cu in...

Embodiment 3

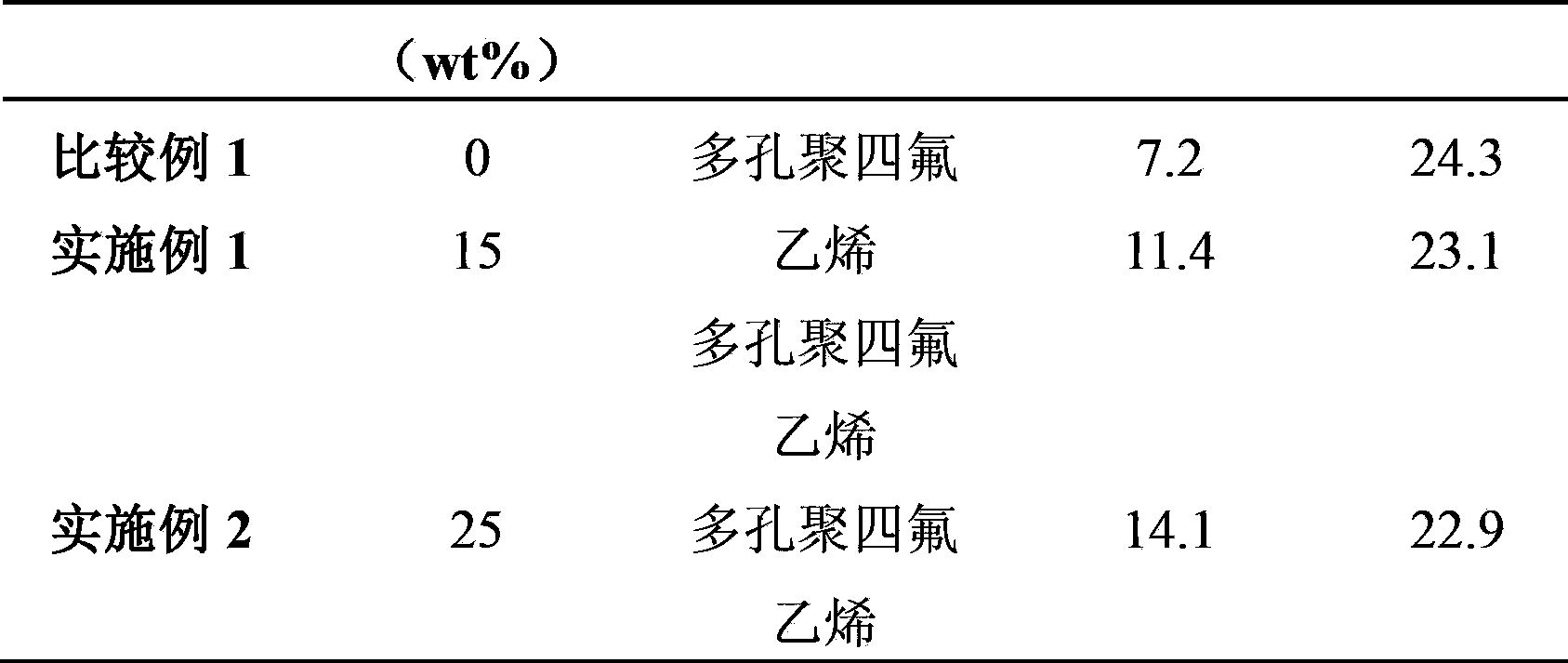

[0028] Example 3: Cu 3 (BTC) 2 -Ultem gas separation composite membrane

[0029] (1) Cu 3 (BTC) 2 Solution preparation: 0.3g Cu 3 (BTC) 2 After activation, it is uniformly dispersed in chloroform organic solvent; (2) Preparation of polymer solution: Ultem is dissolved in chloroform organic solvent after drying and pretreatment, and the solid content of the solution is 10wt%; (3) Preparation of casting solution: 27g The Ultem polymer solution was added batchwise to Cu3 (BTC) 2 solution, remove the excess solvent, and finally obtain Cu with a solid content of 10wt%. 3 (BTC) 2 -Ultem casting solution; (4) Cu 3 (BTC) 2 -Preparation of Ultem gas separation composite membrane: After filtering and degassing, the casting solution is scraped and coated on the porous PTFE-based membrane, and the solvent is volatilized to obtain Cu 3 (BTC) 2 -Ultem gas separation composite membrane.

[0030] Ultem in this example is a commercial polyimide material.

[0031] Cu in this exampl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com