Patents

Literature

45results about How to "Closely guarded" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wound dressing material containing silk fibroin and sericin as main component and method for preparing same

There is provided a novel wound dressing material which has biocompatibility and infection controllability as essential properties required for such a material, especially excellent flexibility and water absorption properties, thereby accelerating smooth regeneration of a skin defect without stripping off the regenerating skin while removing the material from the skin. A healing agent is added to the wound dressing material which comprises an amorphous film of a crystallinity below 10% and contains fibroin and sericin as a main component.

Owner:NAT INST OF AGROBIOLOGICAL SCI +1

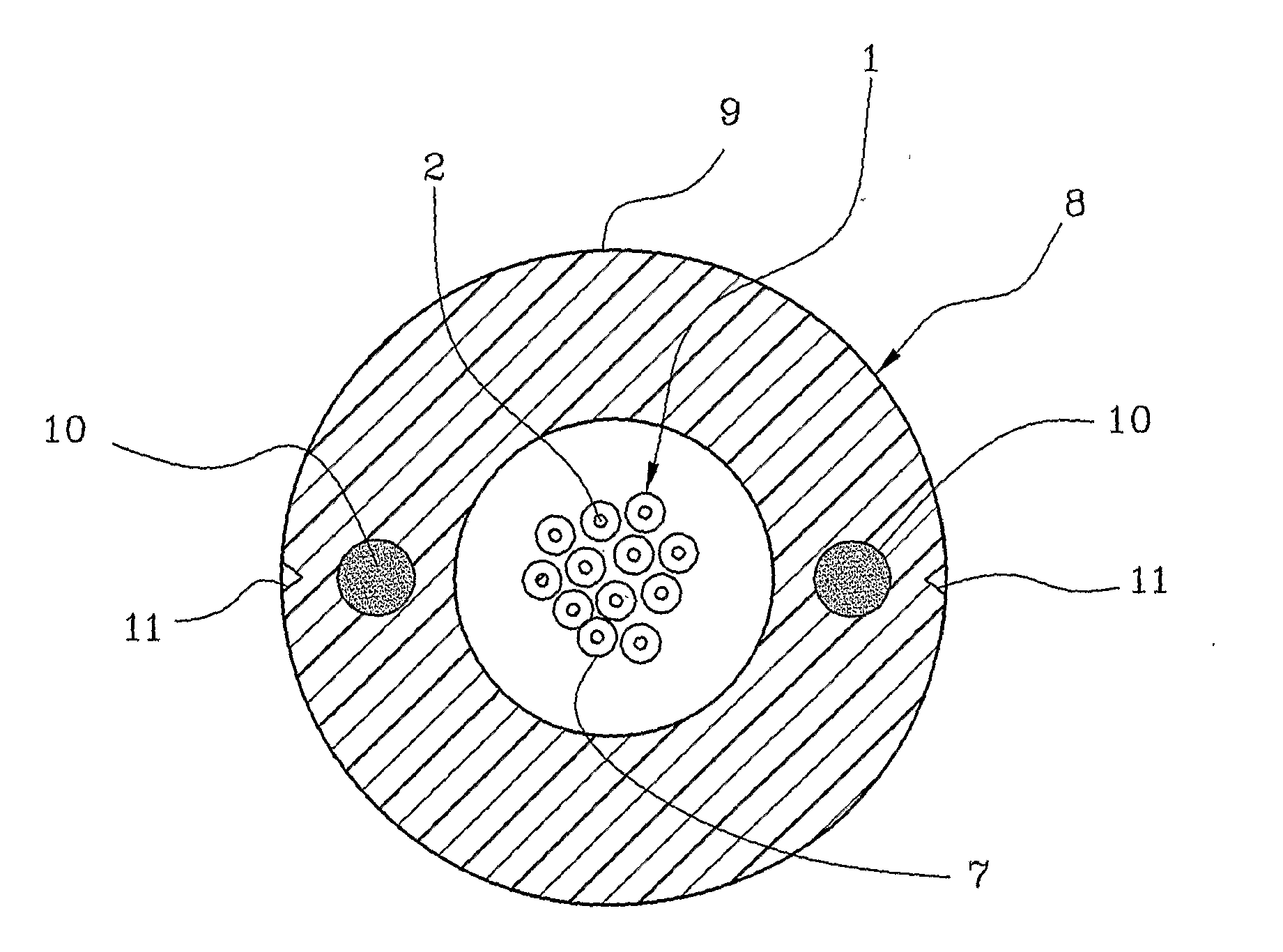

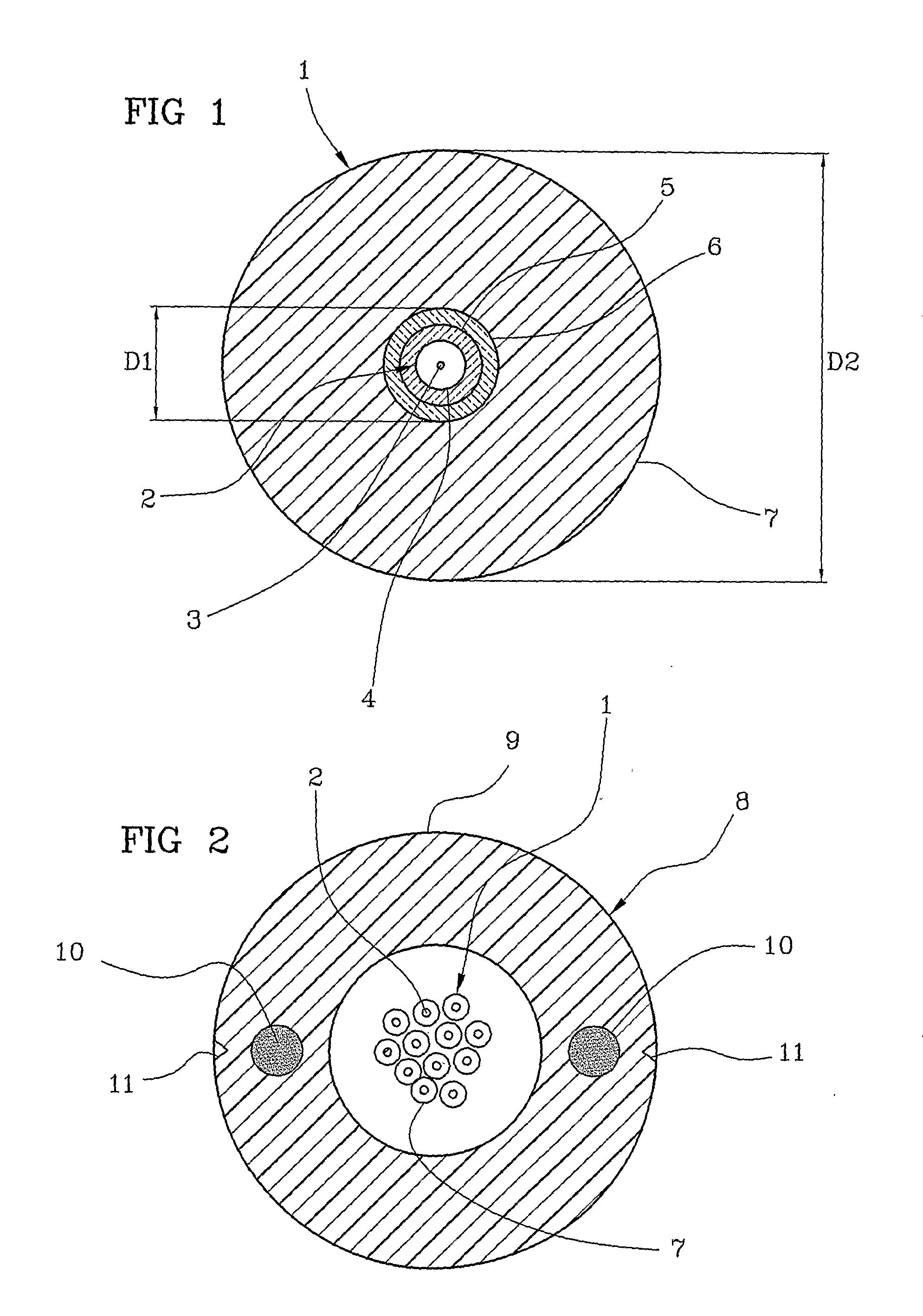

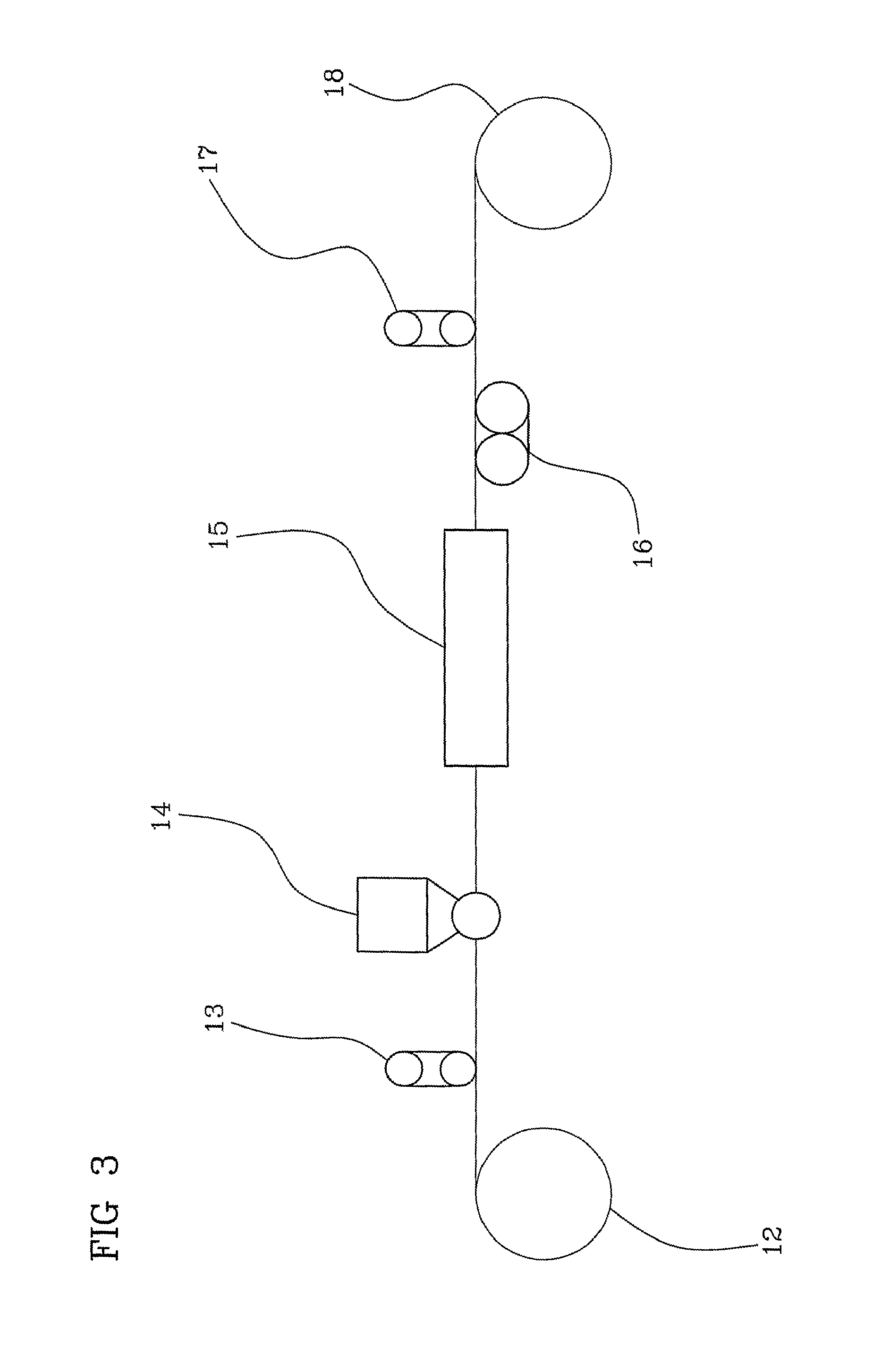

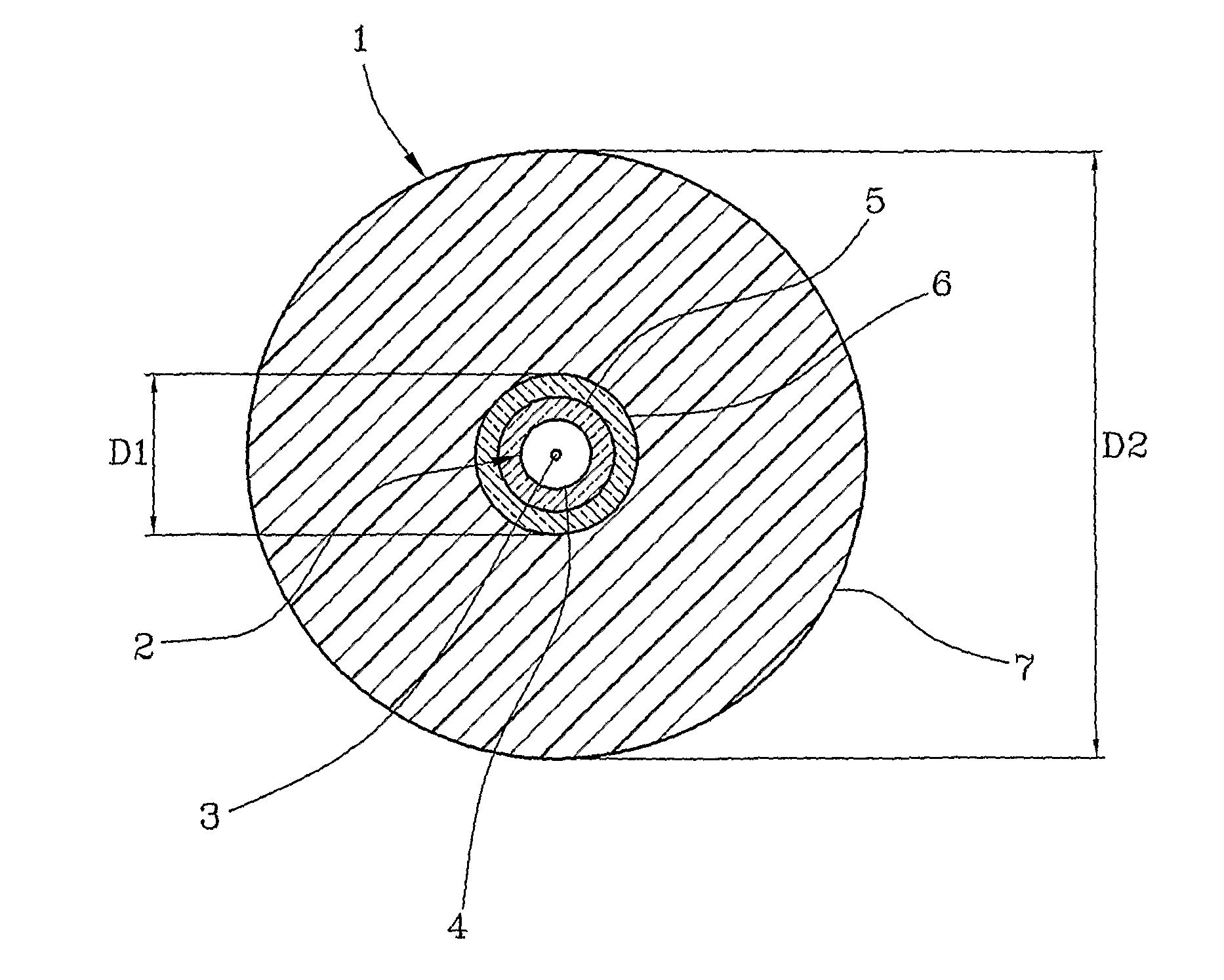

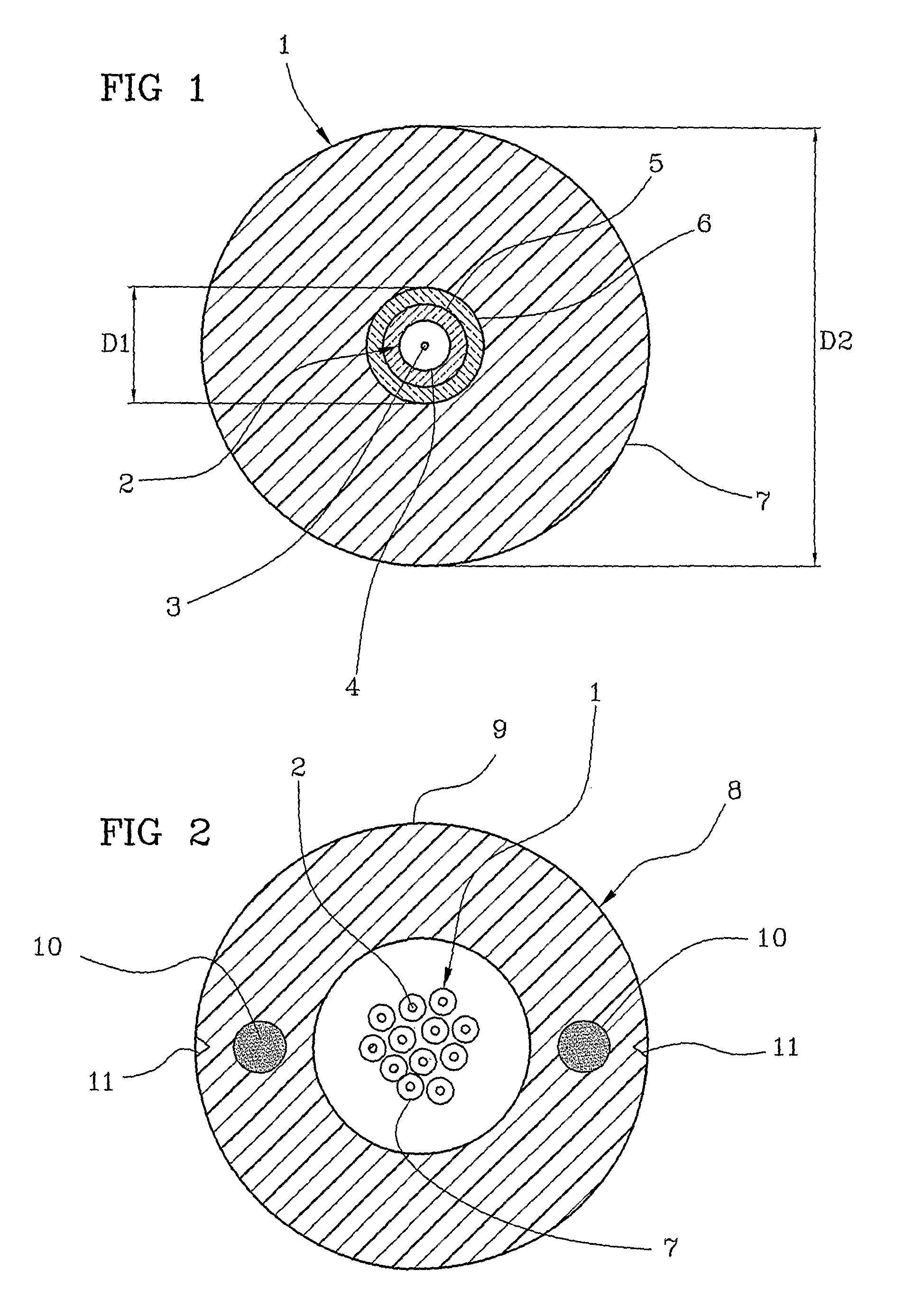

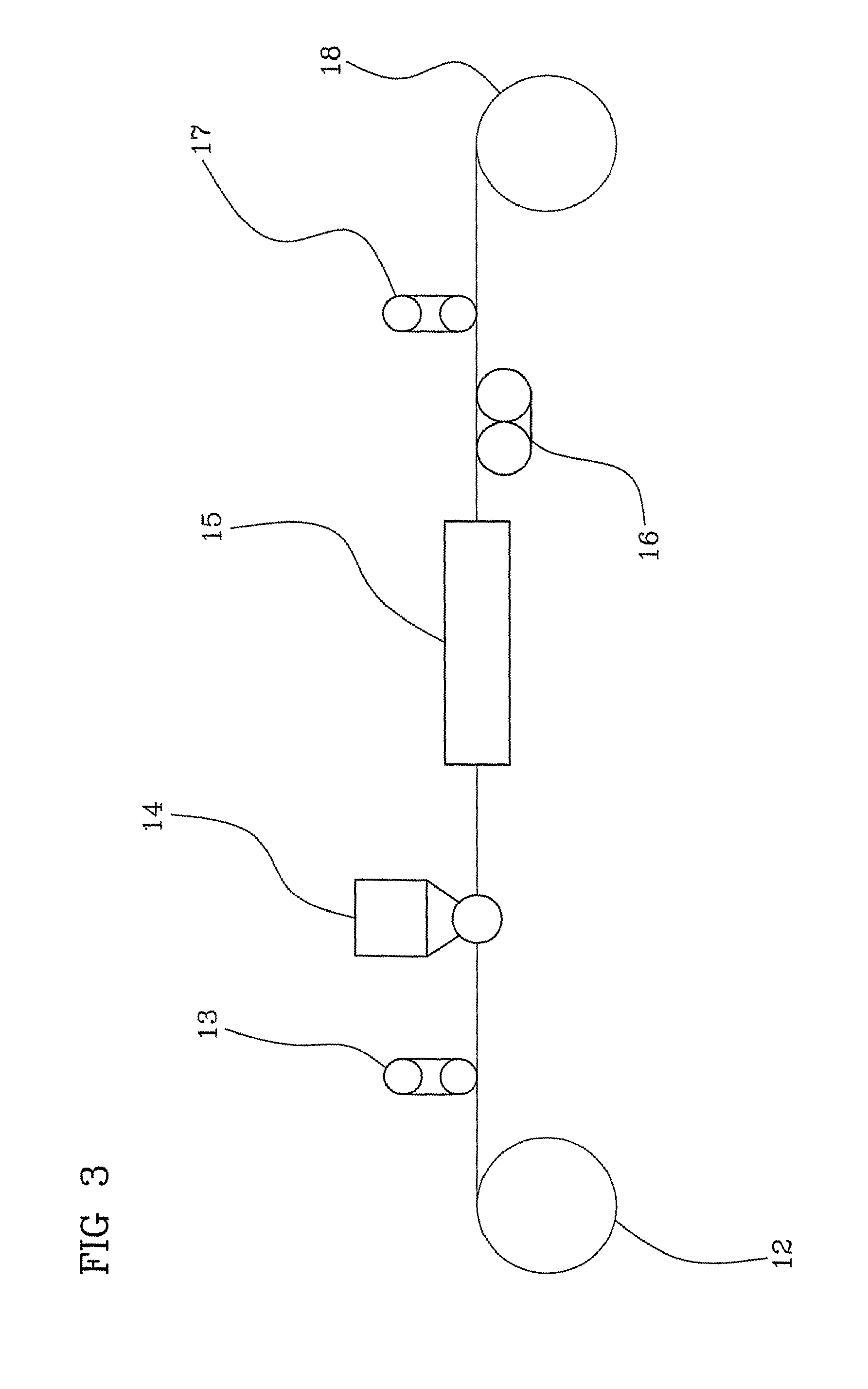

Telecommunication cable equipped with tight-buffered optical fibers

ActiveUS20100254668A1Reduce installationClosely guardedOptical fibre with multilayer core/claddingFibre mechanical structuresFiberTelecommunications cable

A telecommunication cable is equipped with at least one optical fiber coated by a tight buffer layer made from a polymeric material having an ultimate elongation equal to or lower than 100% and an ultimate tensile strength equal to or lower than 10 MPa. The above combination of features of the polymeric material forming the buffer layer provides an optical fiber which is effectively protected during installation operations and during use, and at the same time can be easily stripped by an installer without using any stripping tools, simply by applying a small pressure with his fingertips and a moderate tearing force along the fiber axis.

Owner:PRYSMIAN SPA

Elastic peelable glue and method for carrying out local electroplating protection by using same

The invention discloses elastic peelable glue and a method for carrying out local electroplating protection by using the same. The elastic peelable glue comprises the following components in parts by weight: 15-50 parts of styrene thermoplastic elastomer, 20-60 parts of mineral oil, 10-30 parts of tackifying resin and 0-2 parts of antioxidant. The method for carrying out the local electroplating protection by using the elastic peelable glue comprises the following steps of: putting the elastic peelable glue into a heating container with controllable temperature, wherein the elastic peelable glue can be used after being heated and melted, and temperature is controlled to be between 140 DEG C and 180 DEG C; dipping a workpiece to be electroplated into the melted protection glue; after the workpiece is completely dipped, taking the workpiece out and putting into cold water for cooling for 5-15 minutes; and then carrying out a subsequent electroplating working procedure. The elastic peelable glue has the advantages of environmental protection, easy peeling and recycling, and the method has simple operation and easy control and can improve the production efficiency and reduce the production cost.

Owner:NANJING PERFECTA CHEM

Telecommunication cable equipped with tight-buffered optical fibers

ActiveUS8494326B2Reduce installationClosely guardedOptical fibre with multilayer core/claddingFibre mechanical structuresFiberTelecommunications cable

Owner:PRYSMIAN SPA

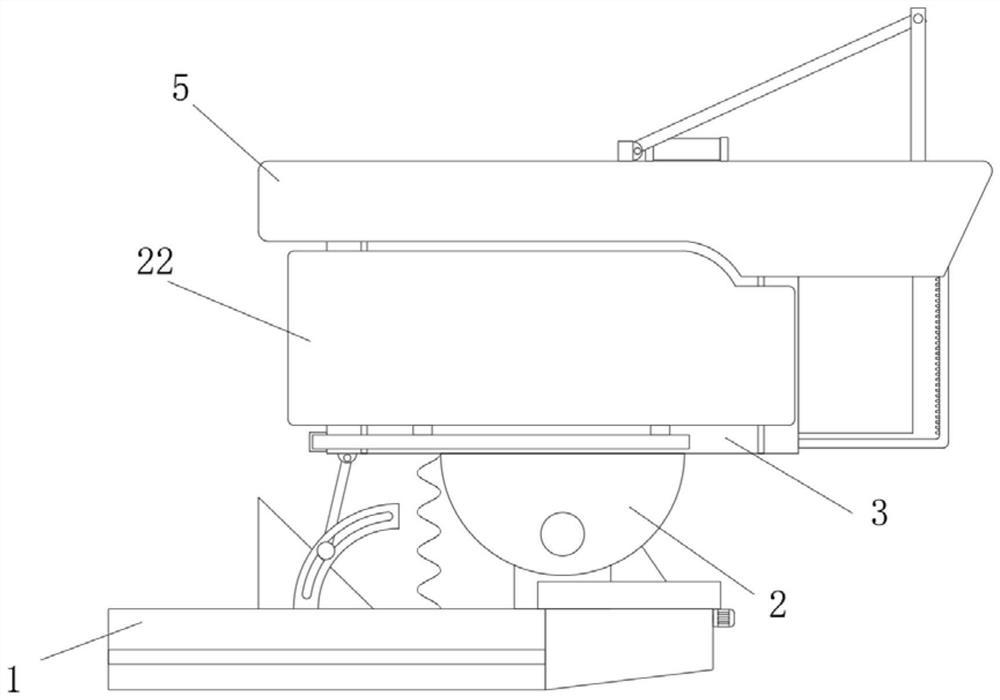

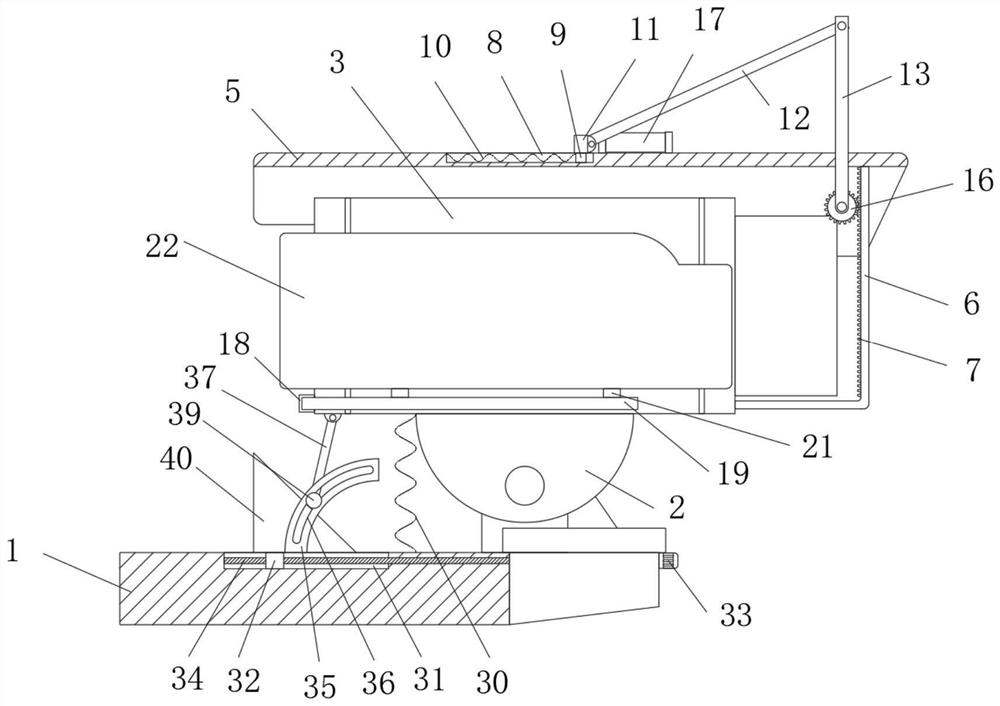

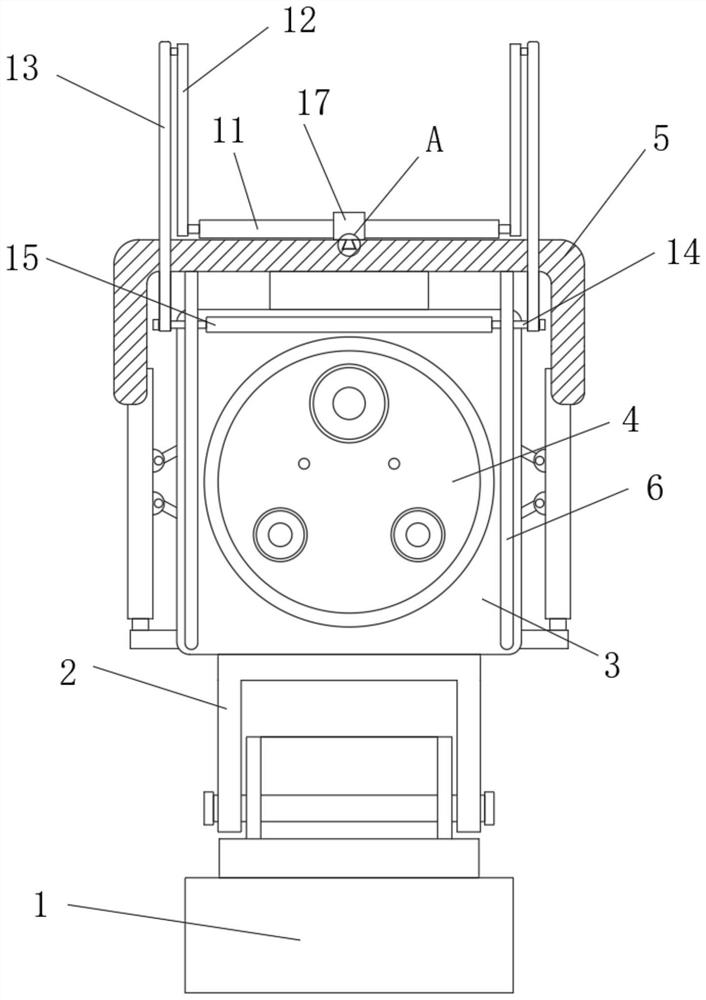

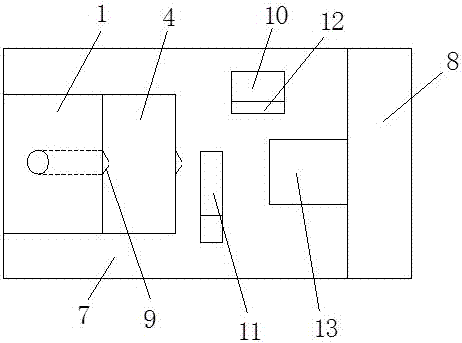

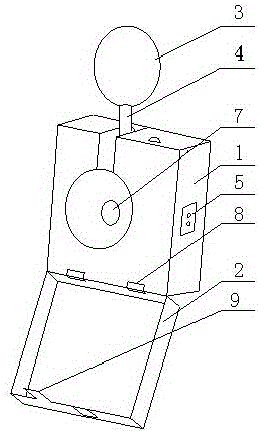

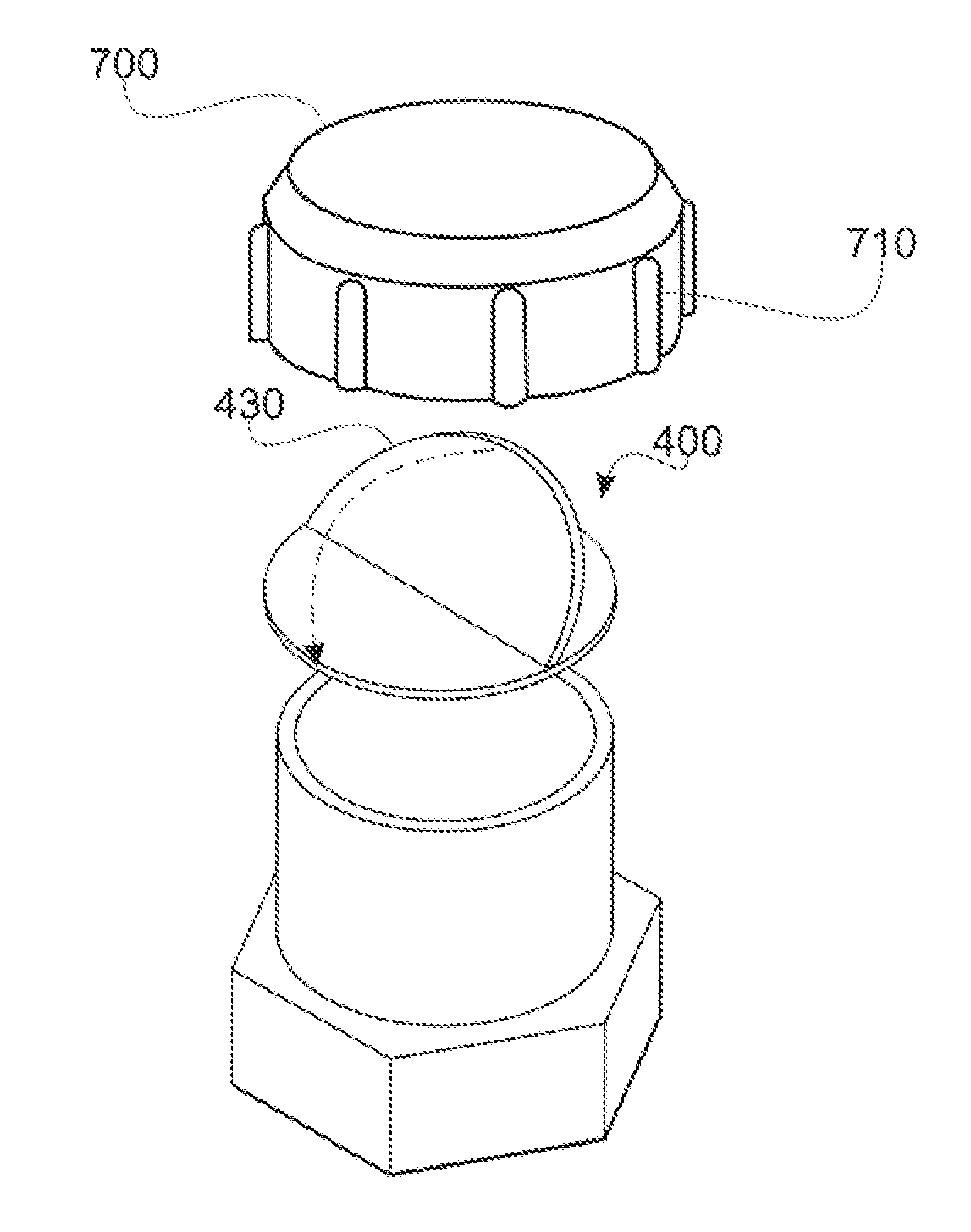

Monitoring equipment with protection mechanism

PendingCN112197126AReduce blind spotsImprove practicalityTelevision system detailsNon-rotating vibration suppressionProtective glassesStructural engineering

The invention relates to the technical field of monitoring equipment, in particular to monitoring equipment with a protective mechanism. The monitoring equipment with the protective mechanism comprises a mounting bracket, a movable mounting seat is movably mounted on the right side of the upper surface of the mounting bracket, and a camera body is mounted on the upper surface of the movable mounting seat. Protective glass is mounted on the right side of the camera body, a protective cover plate is installed on the upper surface of the camera body, an L-shaped fixing rod is installed on the right side of the lower surface of the protective cover plate, the end, away from the protective cover plate, of the L-shaped fixing rod is connected to the right side of the camera body, and a pluralityof teeth are sequentially arranged and installed on one side of the L-shaped fixing rod. The side face of the monitoring equipment can be protected through mutual cooperation of the structures, damage caused by impact or extrusion in the transportation or use process is prevented, the angle of the monitoring equipment can be conveniently adjusted, the protective glass can be conveniently cleaned,and the definition of an output image of the monitoring equipment is guaranteed.

Owner:田友云

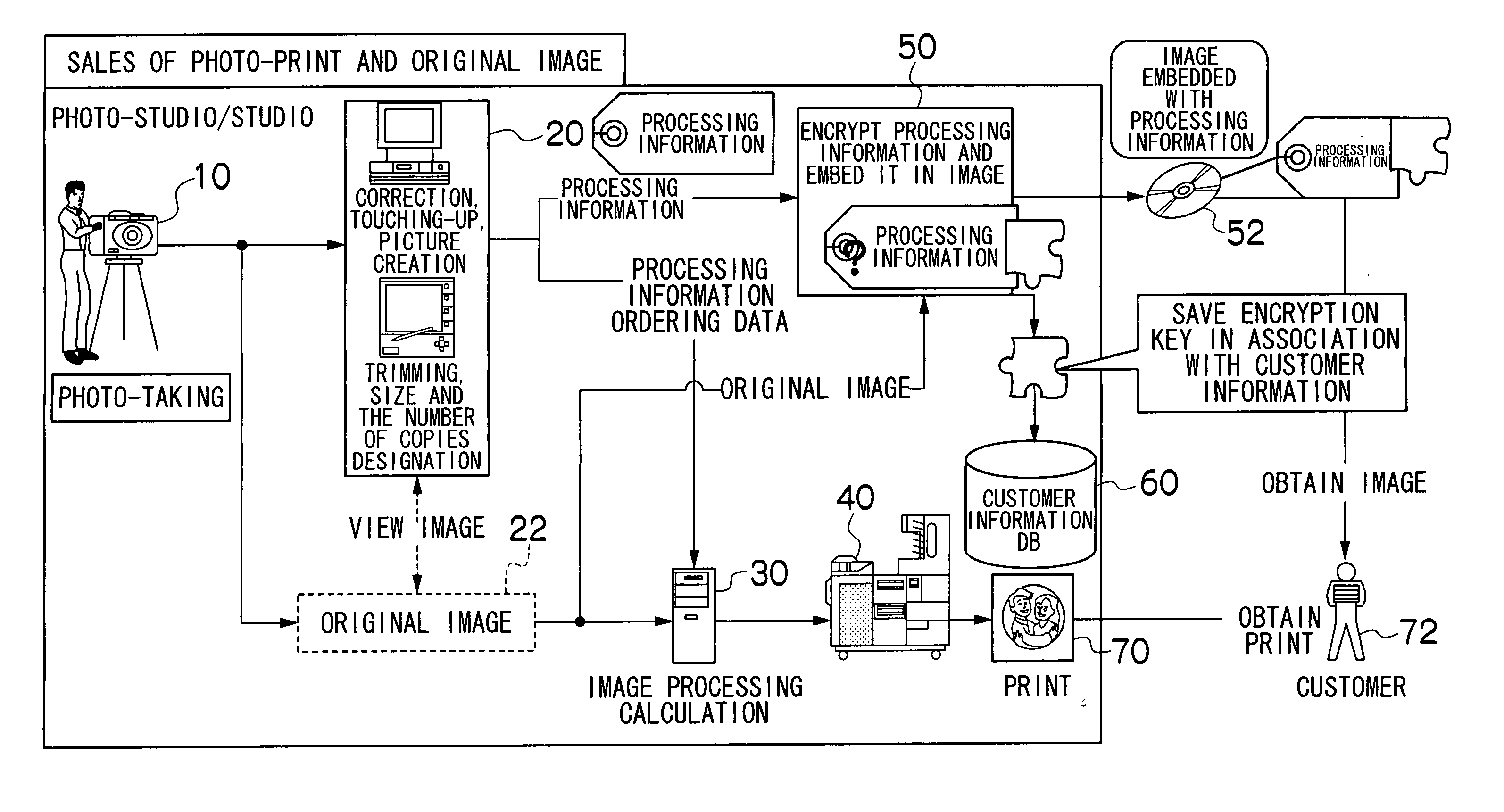

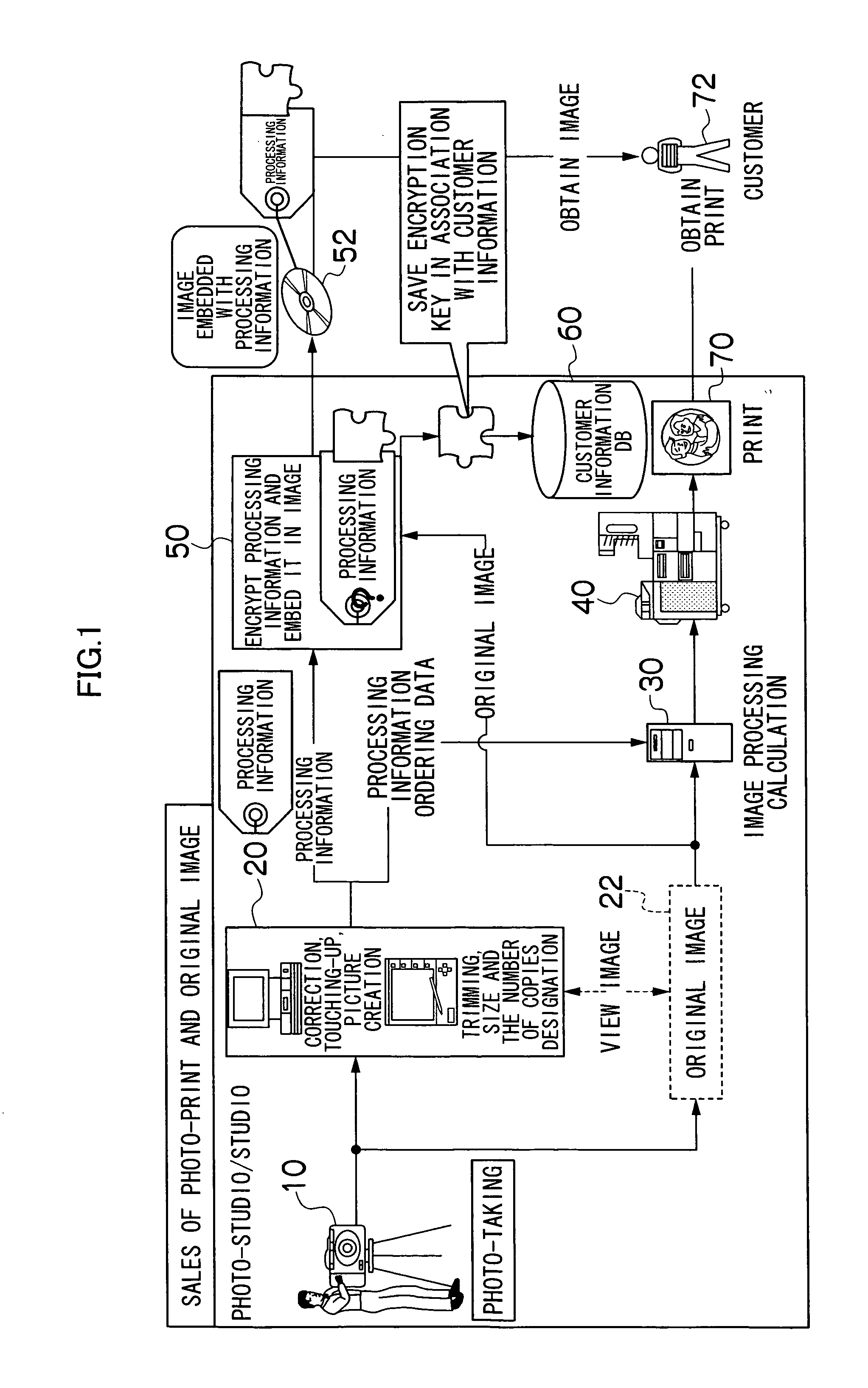

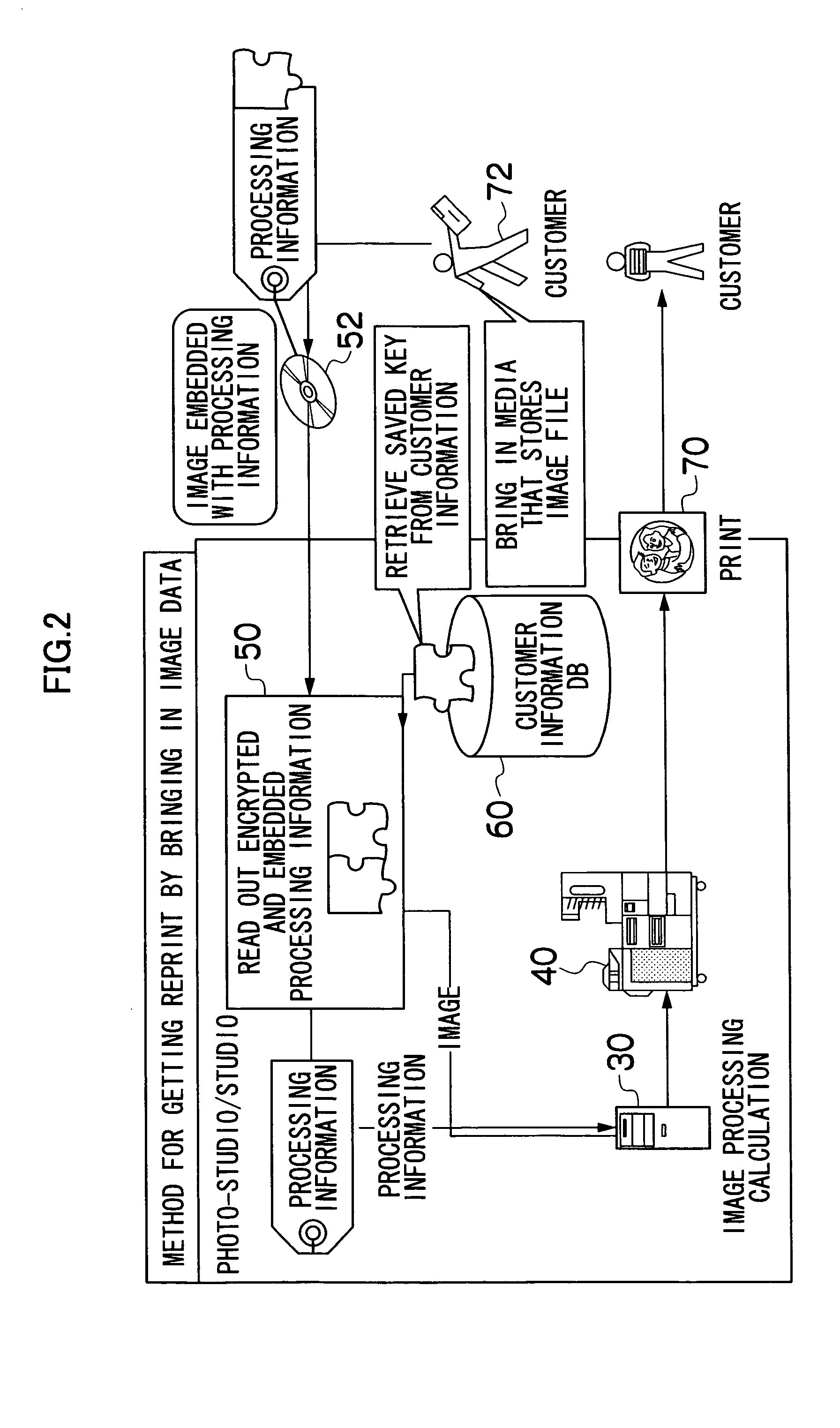

Digital image providing system

InactiveUS20060017968A1Protect informationClosely guardedTelevision system detailsData processing applicationsImaging processingComputer graphics (images)

The present invention provides a digital image providing system comprising a processing information obtaining device which obtains processing information for performing required image processing on an original image of a customer taken at a photo-studio, an encrypting device which encrypts the obtained processing information, a decrypting device which decrypts the encrypted processing information, and a device which records the original image of the customer and the encrypted processing information of the original image in association with each other on a recording medium to be provided for the customer or uploads them to a server accessible to the customer.

Owner:FUJIFILM CORP

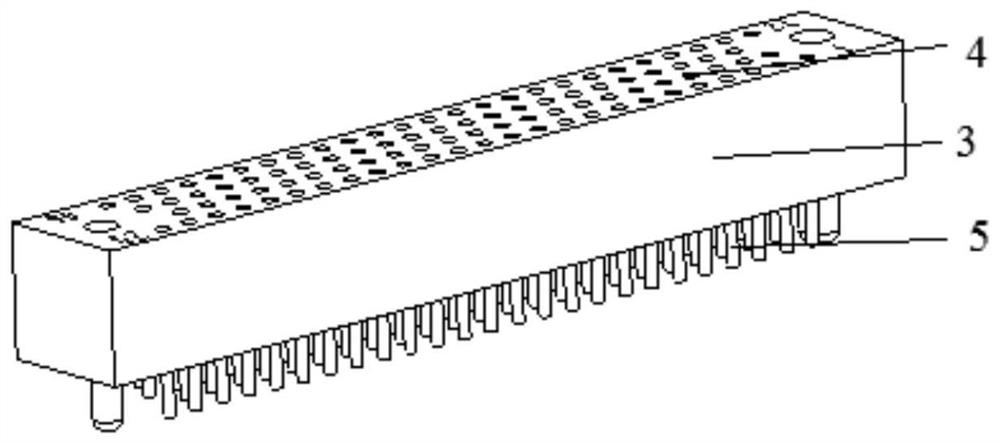

Communication cable interface protection apparatus

PendingCN108808344AReduce mutual interferenceReduce connectivityCouplings bases/casesBody contactHardness

The invention relates to the technical field of cable protection, and discloses a communication cable interface protection apparatus. The communication cable interface protection apparatus comprises alower box body, an upper box body, buckles and a cable; the cable enters from middle positions of two ends of the lower box body and is connected with the lower box body, one side of the upper box body contacts one side of the lower box body, the middle positions of two ends of the upper box body are connected with the cable in a clamping manner, and a plurality of buckles are provided and are respectively uniformly arranged on the sides of the lower box body and the upper box body; and the buckles which are uniformly arranged on the upper box body and the lower box body can effectively ensure the sealing reliability; a reinforcing rib A and a reinforcing rib B are arranged to improve the structure strength and the hardness of the upper box body and the lower box body and improve the safety of use, and the communication cable interface protection apparatus has the characteristics of compact structure, convenience in disassembling and installation, well protection and reliability in use; after the communication cable interface protection apparatus is used, an interface of a cable can be protected in a waterproof and damp-proof manner; and moreover, the communication cable interfaceprotection apparatus is easy to disassemble and install, convenient for the later maintenance and examination, and capable of improving the practicability of the cable and ensuring the normal communication.

Owner:佛山长意云信息技术有限公司

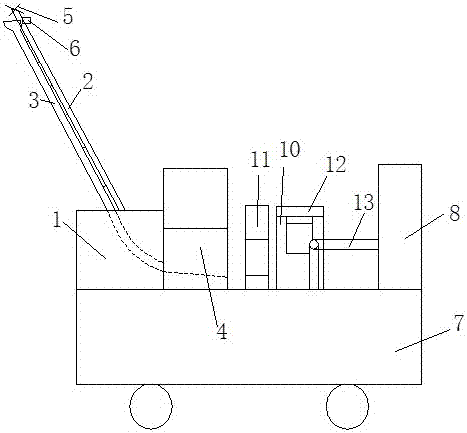

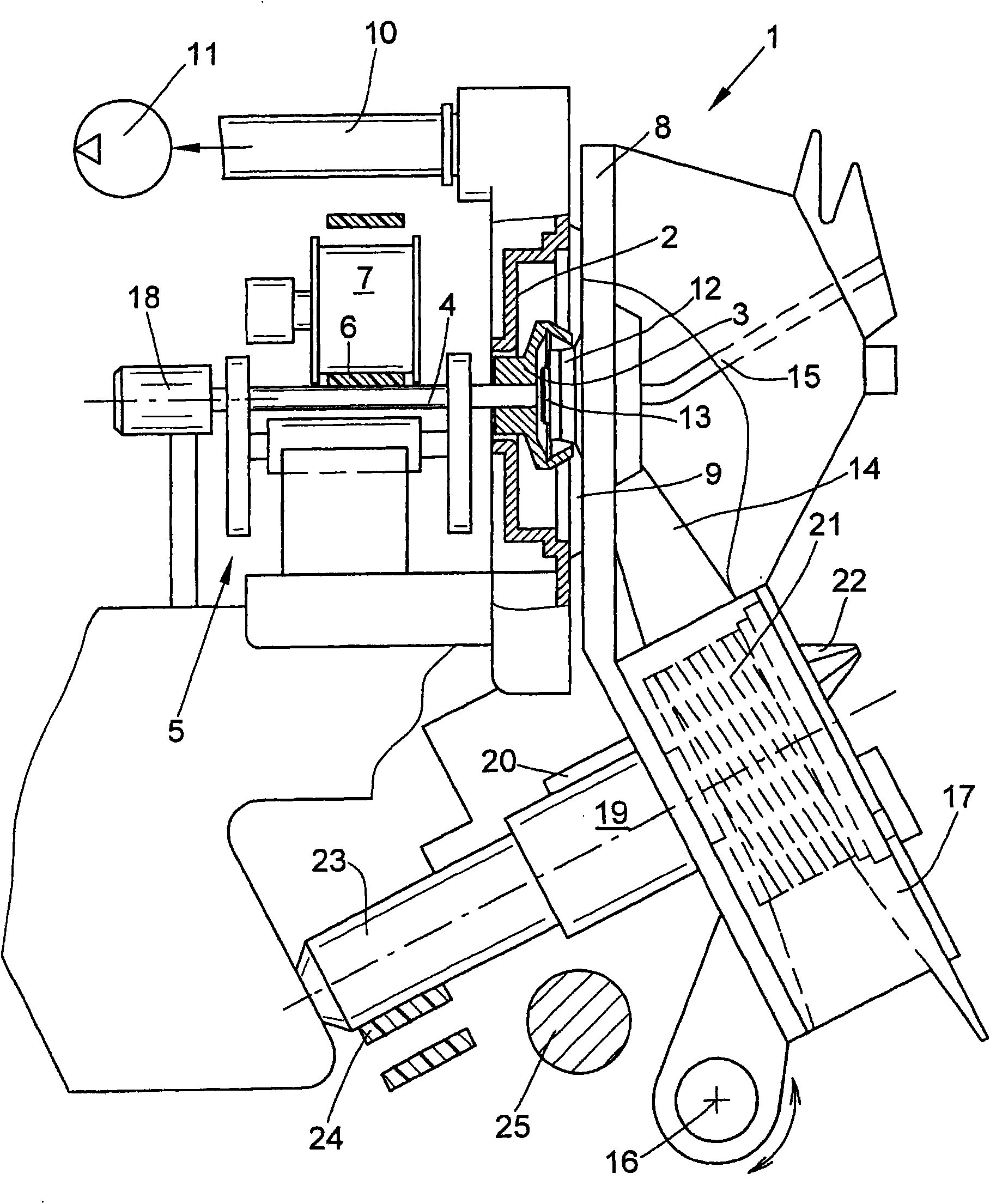

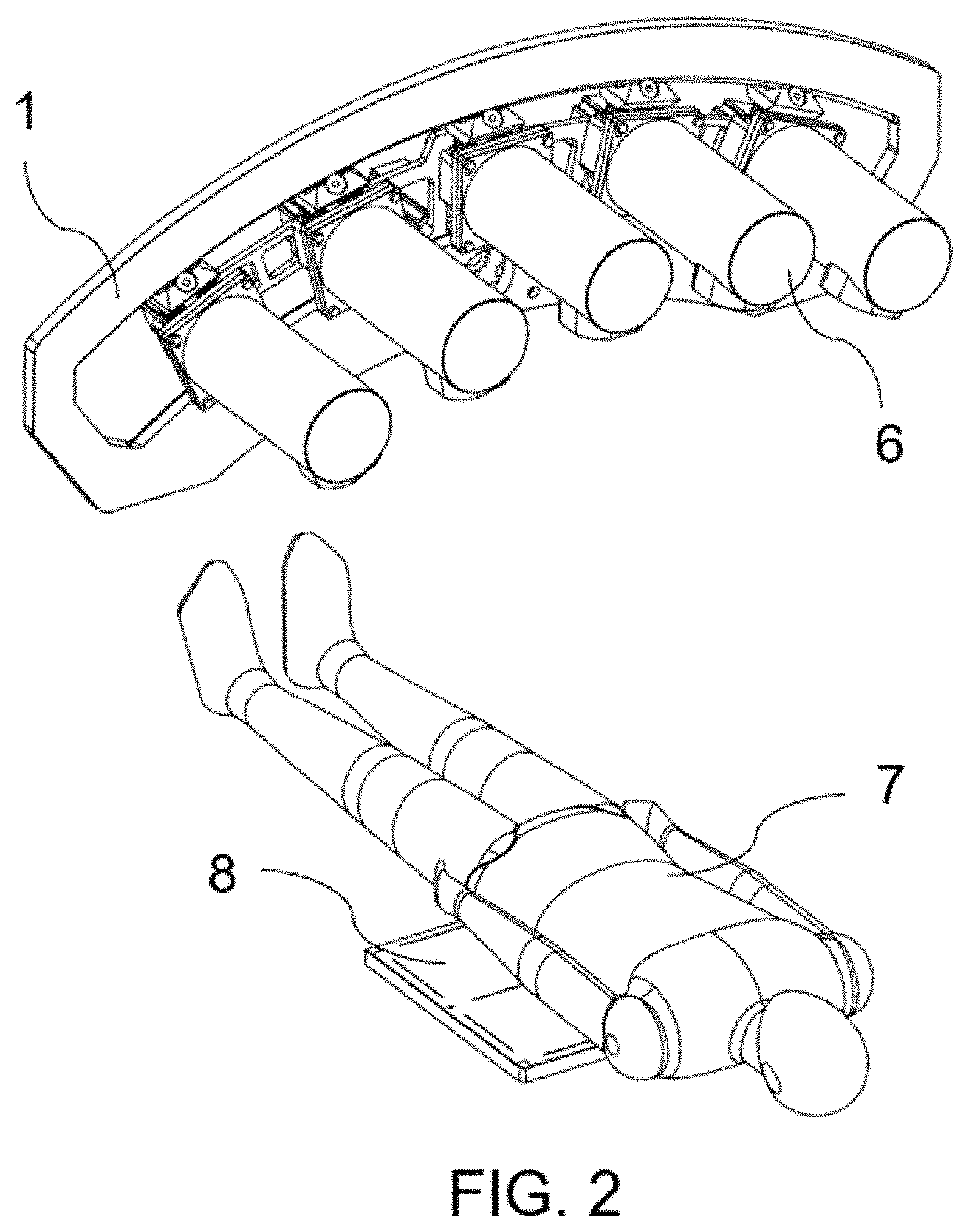

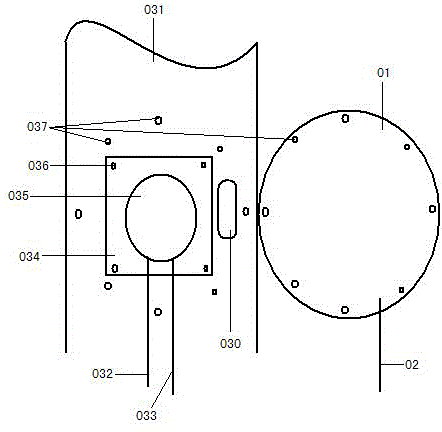

Automatic fruit picking device

InactiveCN107235176AFlexible fruit pickingEasy to movePackaging fruits/vegetablesPicking devicesIndustrial engineering

Owner:ZHENJIANG JUNENG ELECTRICAL

Emergency illuminating lamp

InactiveCN104964231AReduce volumeClosely guardedElectric circuit arrangementsGlobesWear resistantEngineering

The invention provides an emergency illuminating lamp. The emergency illuminating lamp comprises a box body and a cover body matching the shape of the box body, the box body is connected with a lamp holder, the lamp holder is hinged to the box body through a connecting member capable of pivoting on the box body, a position, corresponding to the lamp holder, in the box body is provided with a lamp holder arranging groove, a storage battery is disposed in the box body, the lamp holder is electrically connected with the storage battery through a control circuit, the bottom of the box body is provided with a telescoping plug and a slot mating the plug, the plug is electrically connected with the control circuit, the inner surface of the lamp holder arranging groove is provided with an oxhide wear-resistant pad, and the outside surface of the box body bottom is provided with a wall-hanging hole. The emergency illuminating lamp is small in size, convenient to transport, mount and use, and the lamp holder can be tightly protected.

Owner:柳州市蓝光电源科技有限责任公司

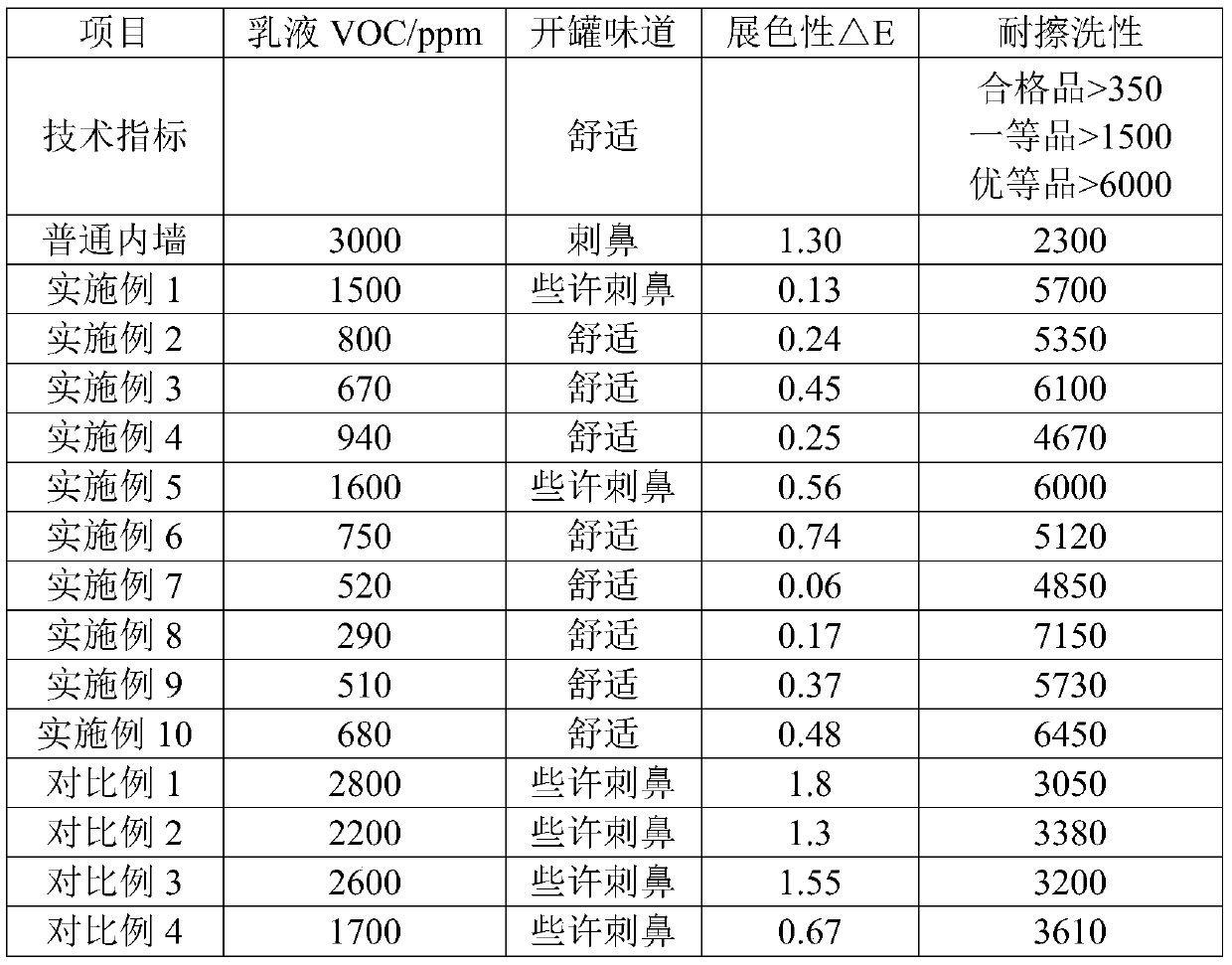

Ammonia-free low-VOC interior wall emulsion and preparation method thereof

ActiveCN110483677AImprove general performanceGood scrub resistanceCoatingsPolymer scienceFunctional monomer

The invention relates to an ammonia-free low-VOC interior wall emulsion and a preparation method thereof. The invention belongs to the technical field of building coatings. The emulsion is prepared from the following components in percentage by mass: 30-55% of water, 0.5%-3% of an emulsifier, 0.1%-3% of persulfate, 0.1%-3% of tert-butyl hydroperoxide, 0.1%-3% of a reducing agent, 10%-60% of styrene, 5%-30% of butyl acrylate, 0.5%-3% of acrylic acid, 0.5%-3% of methacrylic acid, 0.1%-6% of a functional monomer I and 0.1%-6% of a functional monomer II, wherein the functional monomer I is 2-methacryloyloxyethyl phosphate, and the functional monomer II is one or a mixture of more than two of ethylene glycol dimethacrylate, diethylene glycol dimethacrylate, 1, 3-butanediol dimethacrylate, 1, 4-butanediol dimethacrylate and allyl methacrylate. The interior wall emulsion has the advantages of no ammonia, low VOC, effective improvement of the smell, low energy consumption, consideration of theglass transition temperature and the lowest film forming temperature, and improvement of the scrubbing resistance and other performances of the emulsion.

Owner:GUANGDONG HENGGUANG CHEM CO LTD

Elastic peelable glue and method for carrying out local electroplating protection by using same

The invention discloses elastic peelable glue and a method for carrying out local electroplating protection by using the same. The elastic peelable glue comprises the following components in parts by weight: 15-50 parts of styrene thermoplastic elastomer, 20-60 parts of mineral oil, 10-30 parts of tackifying resin and 0-2 parts of antioxidant. The method for carrying out the local electroplating protection by using the elastic peelable glue comprises the following steps of: putting the elastic peelable glue into a heating container with controllable temperature, wherein the elastic peelable glue can be used after being heated and melted, and temperature is controlled to be between 140 DEG C and 180 DEG C; dipping a workpiece to be electroplated into the melted protection glue; after the workpiece is completely dipped, taking the workpiece out and putting into cold water for cooling for 5-15 minutes; and then carrying out a subsequent electroplating working procedure. The elastic peelable glue has the advantages of environmental protection, easy peeling and recycling, and the method has simple operation and easy control and can improve the production efficiency and reduce the production cost.

Owner:NANJING PERFECTA CHEM

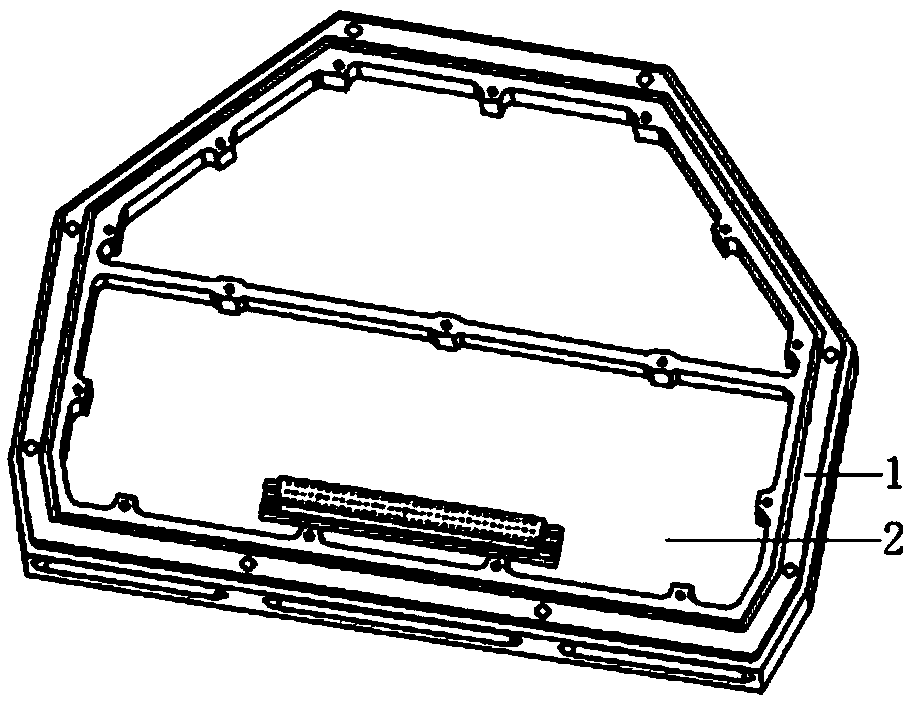

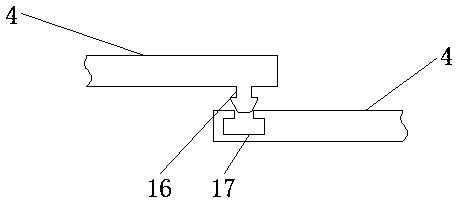

Outer frame protection tool and method during spray coating of printed parts

InactiveCN108993792ALow costQuality improvementLiquid surface applicatorsSpraying apparatusSpray coatingEngineering

The invention discloses an outer frame protection tool and method during spray coating of printed parts. The tool comprises a tool upper layer and a tool lower layer; the tool upper layer and the toollower layer are detachably connected, and the printed parts are placed between the tool upper layer and the tool lower layer; an upper layer through hole is formed in the tool upper layer, and whether an upper layer middle groove is arranged is determined according to requirements; a lower layer through hole and a lower layer middle groove are formed in the tool lower layer, and the middle grooveis used for containing the outer frame; and the inner edge of the upper layer through hole and the inner edge of the lower layer through hole extend out of the inner side of the inner edge of the upper side and the inner side of the inner edge of the lower side of the outer frame by 0-2 mm; the tool upper layer and the tool lower layer adopt an anti-static EVA material. The tool has the advantages that the tool is light and handy, has tenacity and does not damage products, operation is simple, fixing in unnecessary, labor and materials are saved, and at the same time quality and efficiency ofthe product are improved; meanwhile, cost of the whole tool is low, anti-static property and reusable property are achieved, simplicity, efficiency and practicality are realized; and the tool is particularly suitable for batch production and spray coating protection of electronic products which are complex in structure and not easy to protect.

Owner:XIAN MICROELECTRONICS TECH INST

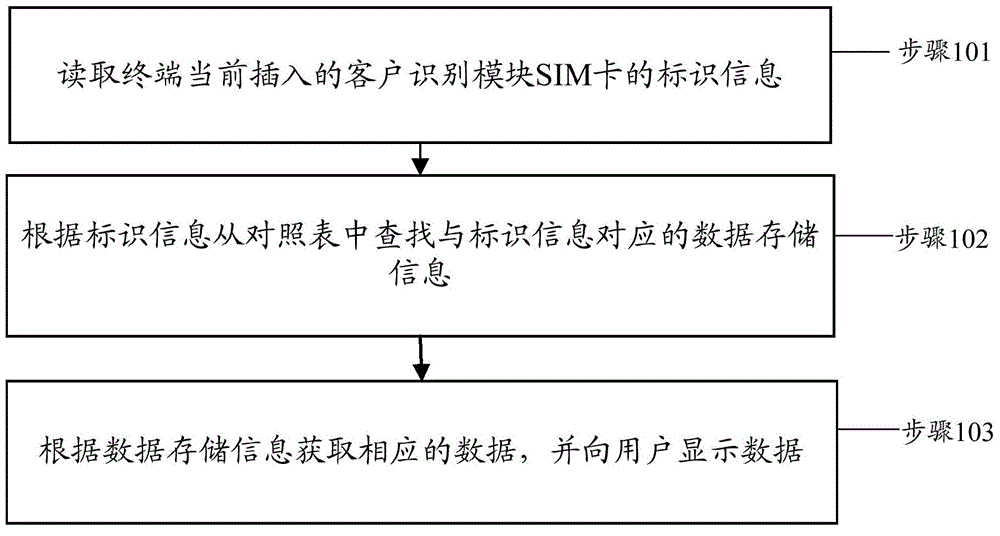

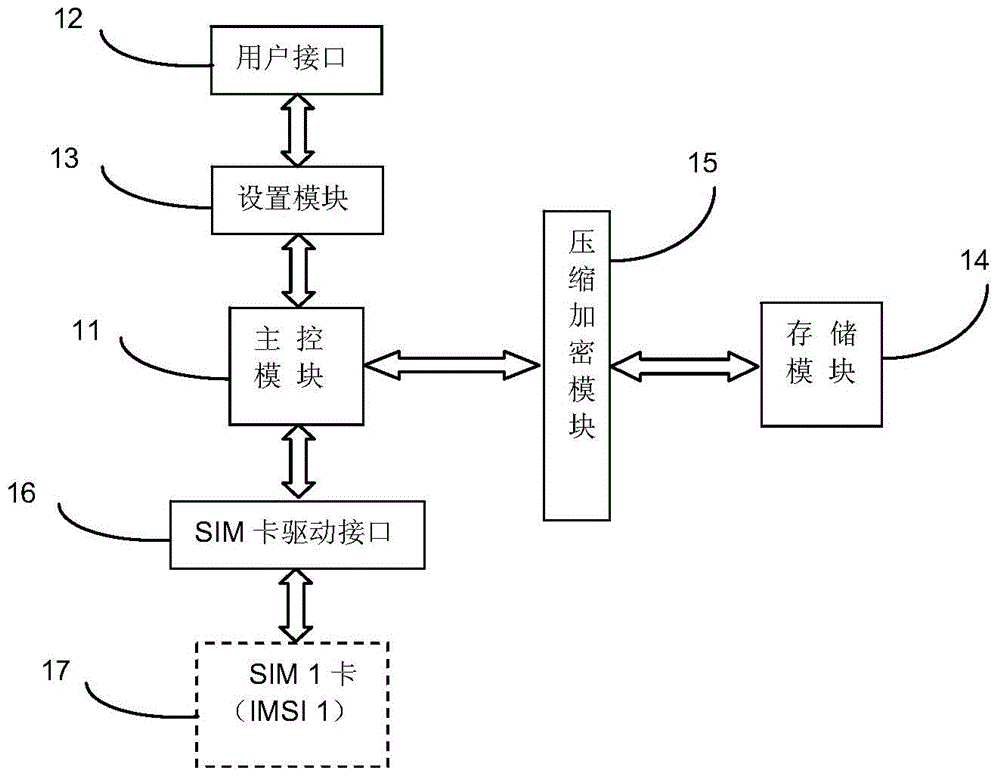

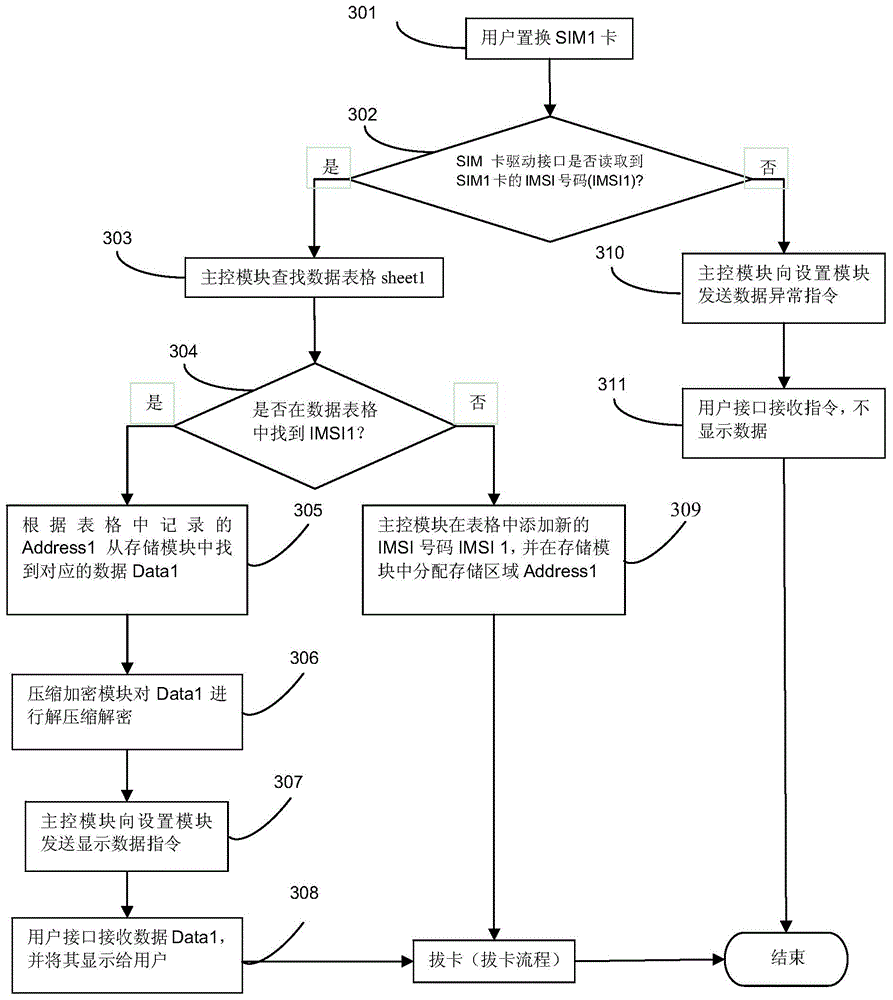

Data processing method and device

InactiveCN105323365AAddressing protection issues with serious security gapsClosely guardedSubstation equipmentSecurity arrangementComputer moduleComputer terminal

The invention discloses a data processing method and device. The method comprises the following steps: reading identification information of a customer identification module SIM card inserted to a terminal currently; searching from a comparison table for data storage information corresponding to the identification information according to the identification information; and obtaining corresponding data according to the data storage information and displaying data to the user. With the technical scheme, the data of the user can be protected more strictly.

Owner:ZTE CORP

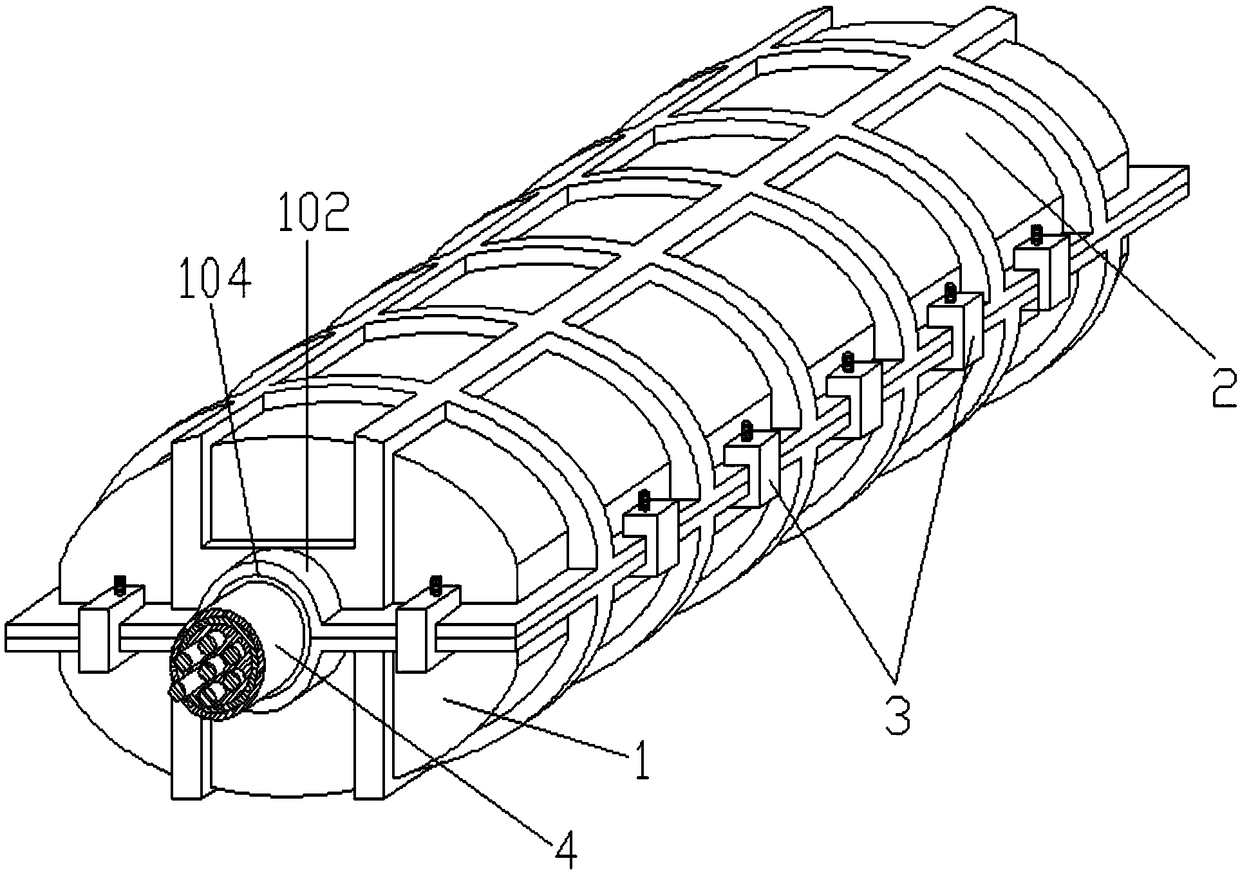

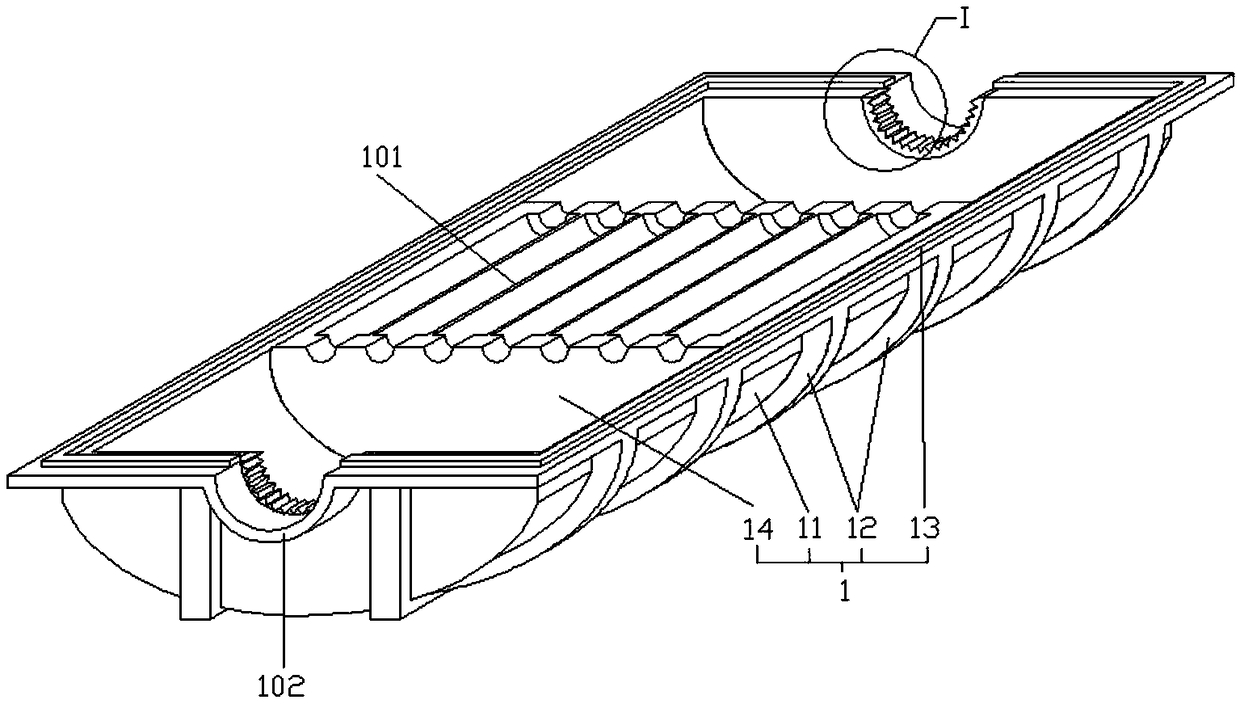

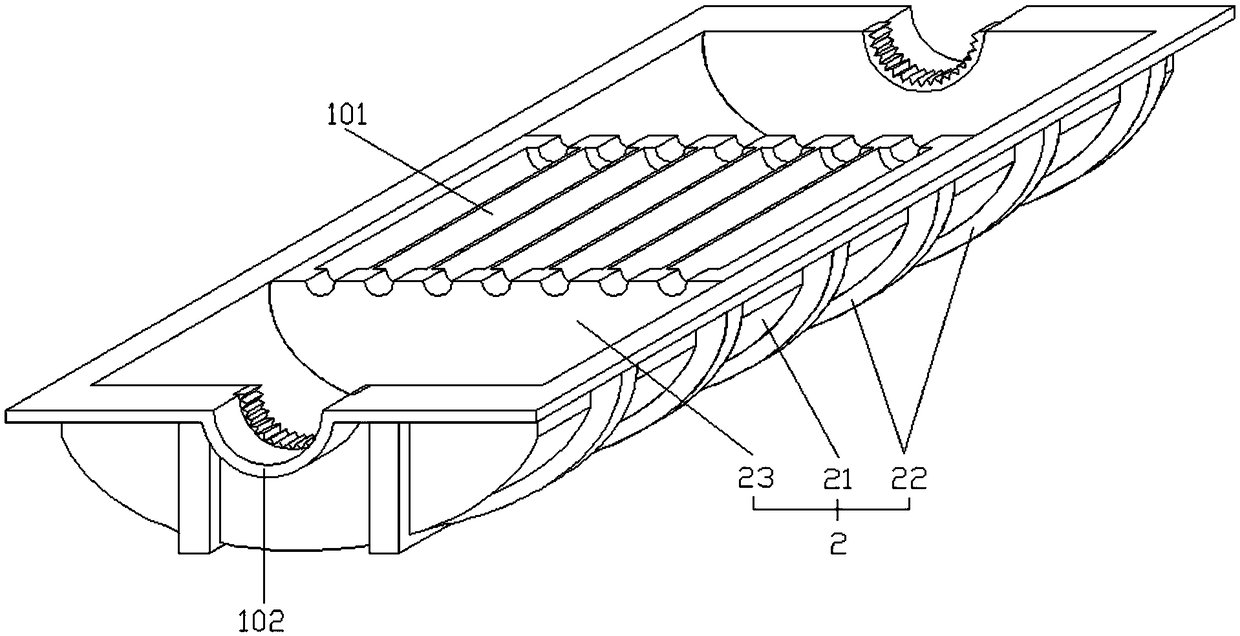

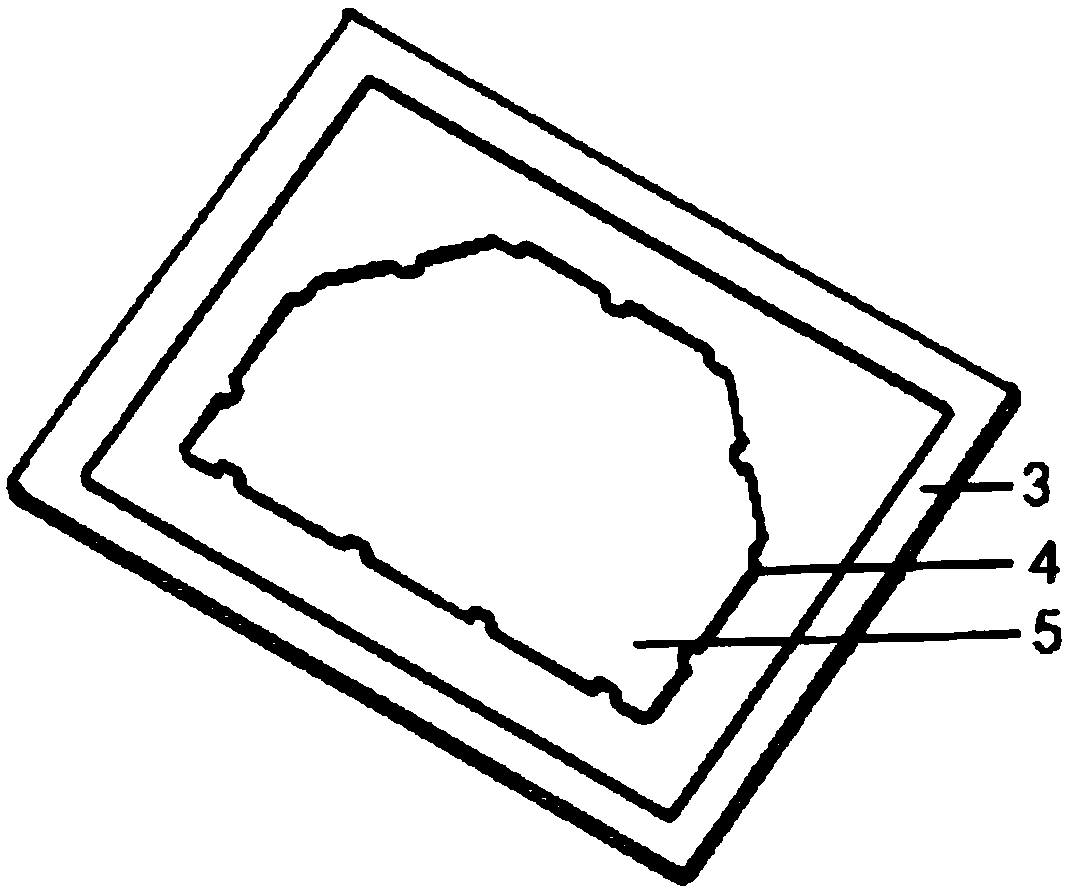

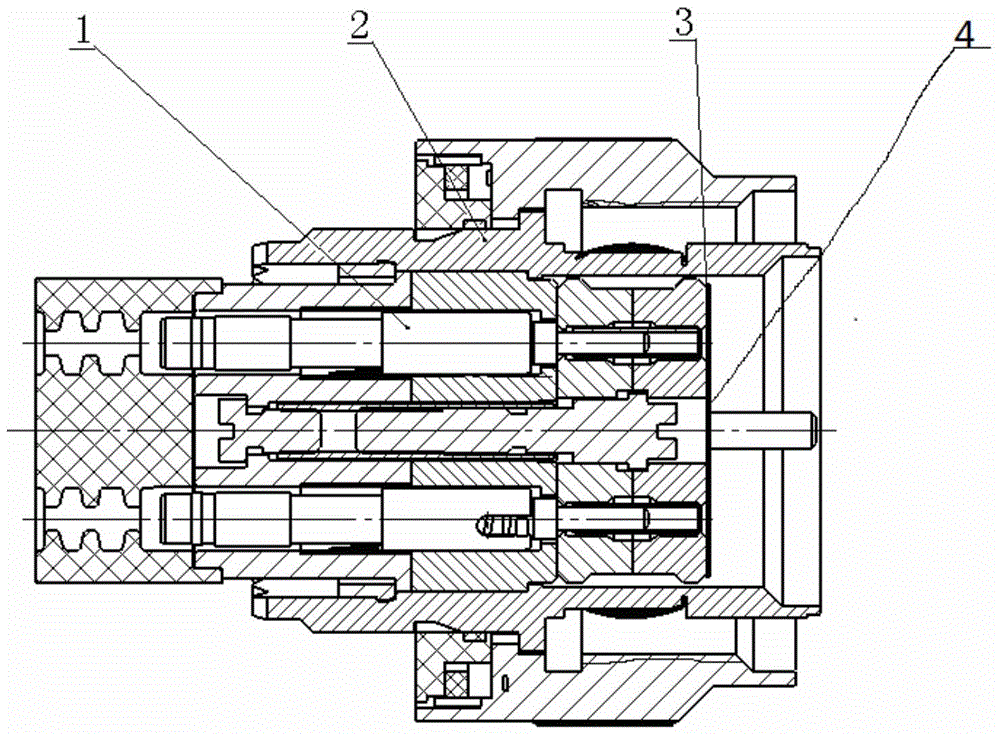

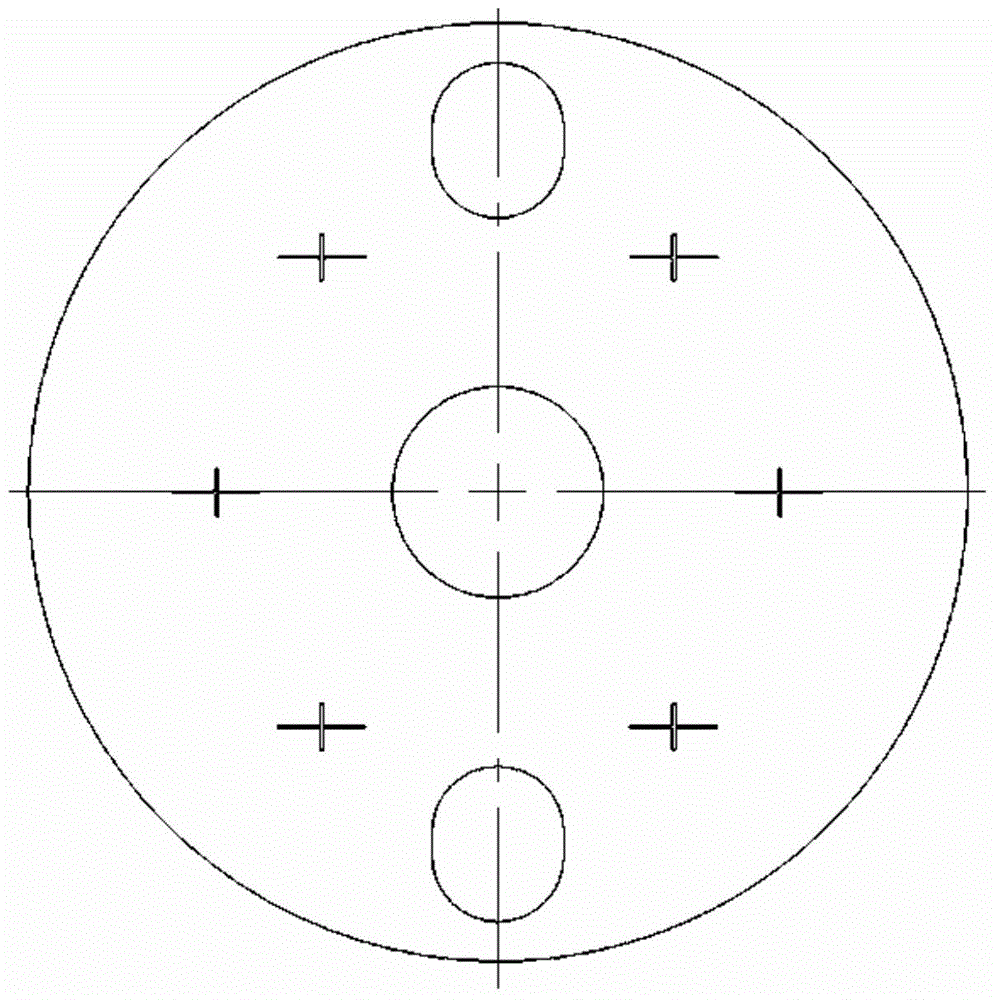

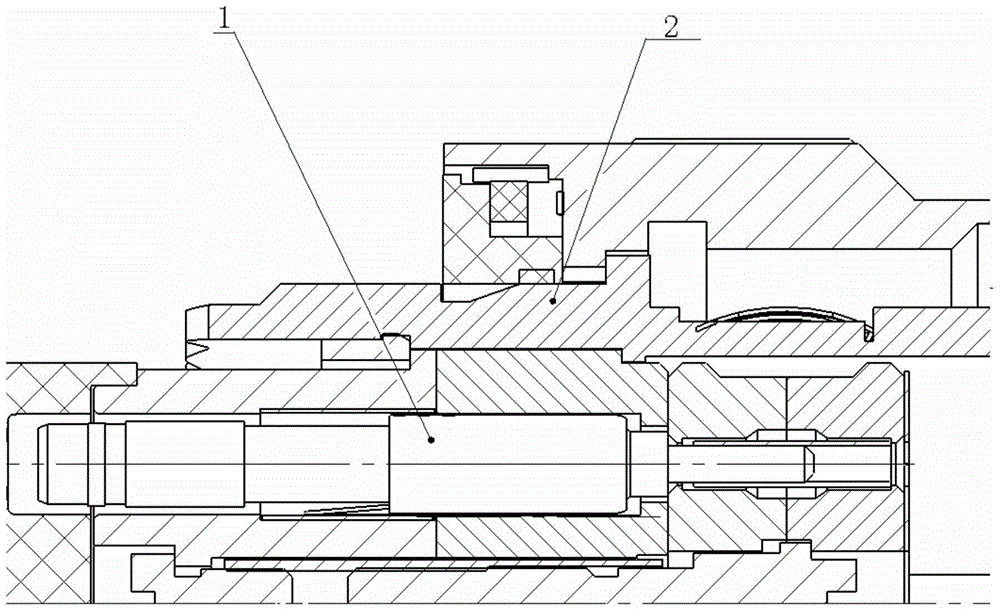

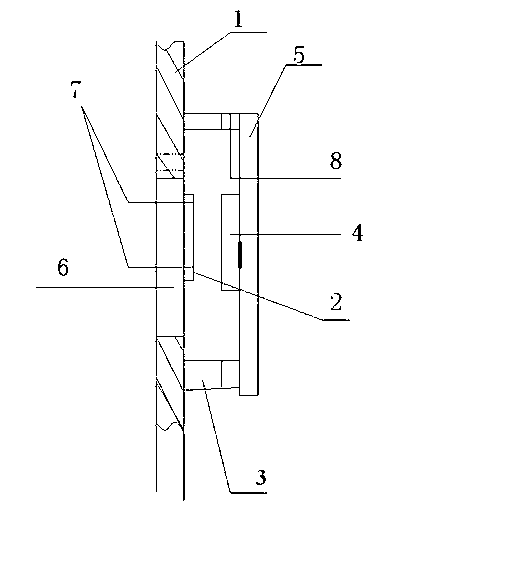

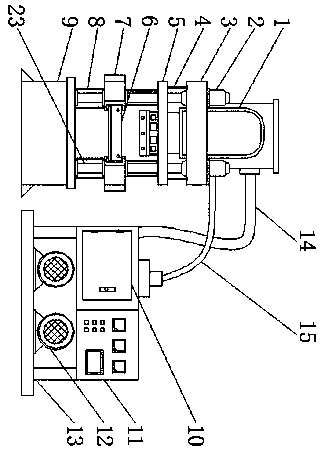

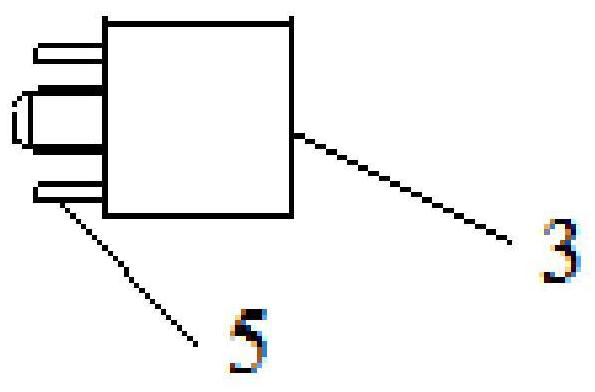

Automatic dustproof structure of optical fiber connector

ActiveCN105629392AGuaranteed docking effectClosely guardedCoupling light guidesButt jointEngineering

Disclosed is an automatic dustproof structure of an optical fiber connector. The automatic dustproof structure is composed of optical fiber insertion pins (1), optical fiber plugs (2) and dustproof non-woven fabric (3); the optical fiber insertion pins (1) are installed in the optical fiber plugs (2); the dustproof non-woven fabric (3) is adhered to the end portions of the optical fiber plugs (2) by using silicone rubber (4); the dustproof non-woven fabric (3) is provided with cross hole structures; the hole position coordinates of the cross hole structures are consistent with the insertion hole position coordinates of the optical fiber plugs (2); the profile dimensions of the cross hole structures are consistent with the profile dimensions of the optical fiber insertion pins (1); and the cross hole structures are closed holes. According to the automatic dustproof structure of the optical fiber connector, the structures of the optical fiber plugs are not changed, plugging, unplugging, butt joint and self-cleaning of optical fibers is realized through the dustproof non-woven fabric; the ceramic end surfaces of the optical fiber insertion pin ends of fiber socket ends can be cleaned through the dustproof non-woven fabric during a butt joint process, so that the butt joint effect of the optical fiber connector is guaranteed.

Owner:沈阳兴华航空电器有限责任公司

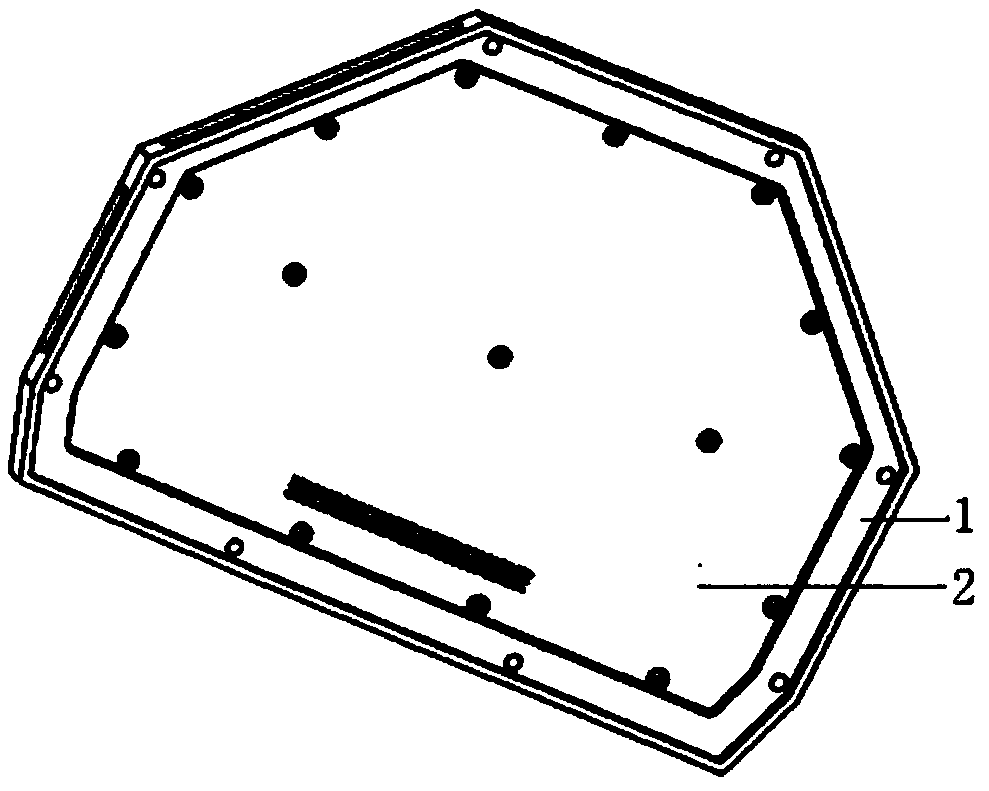

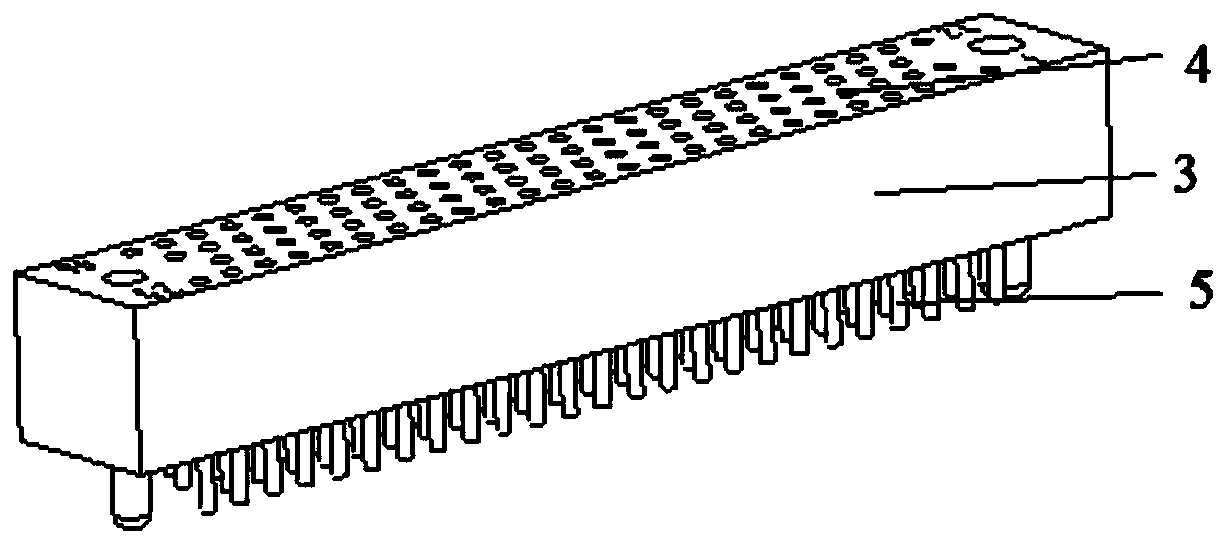

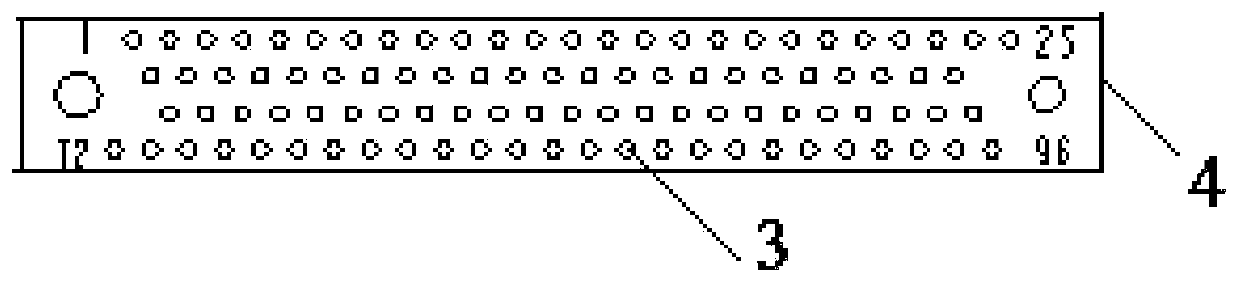

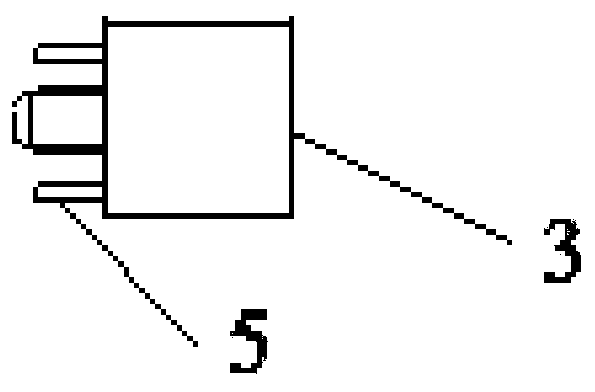

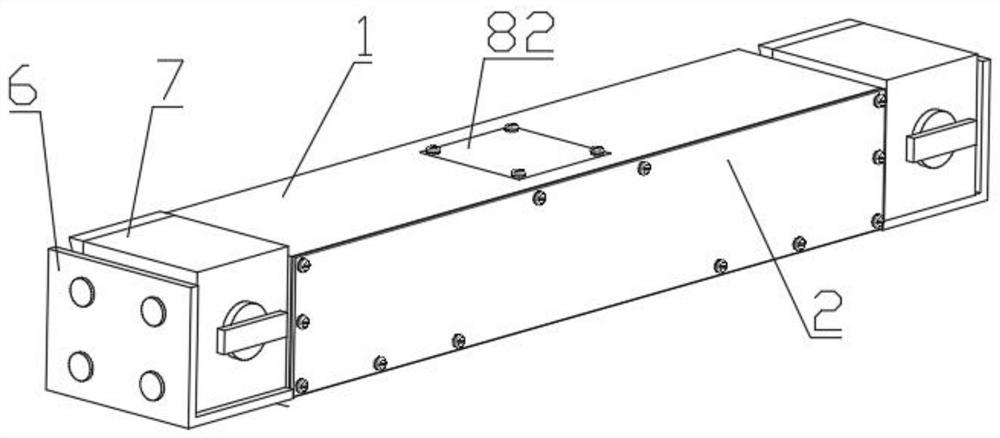

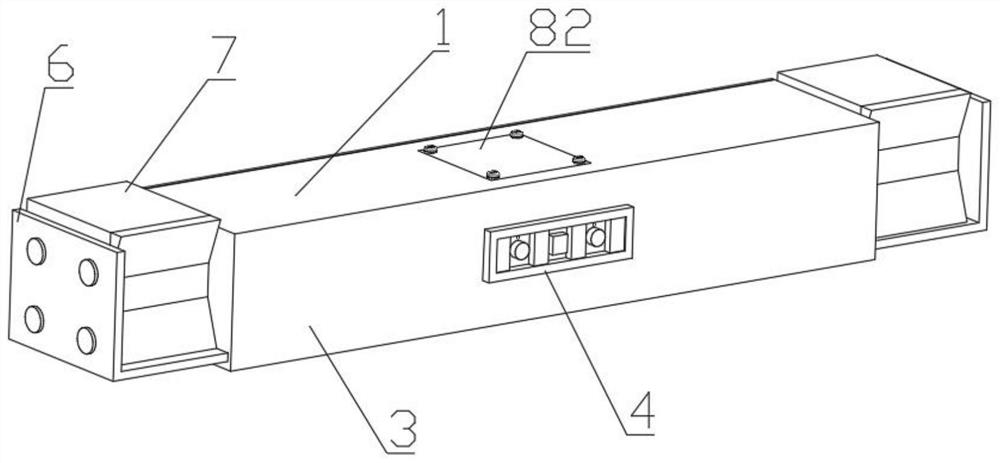

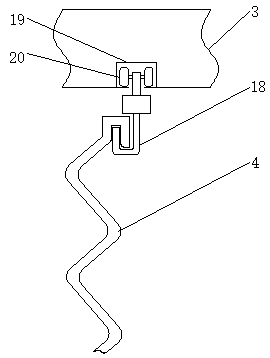

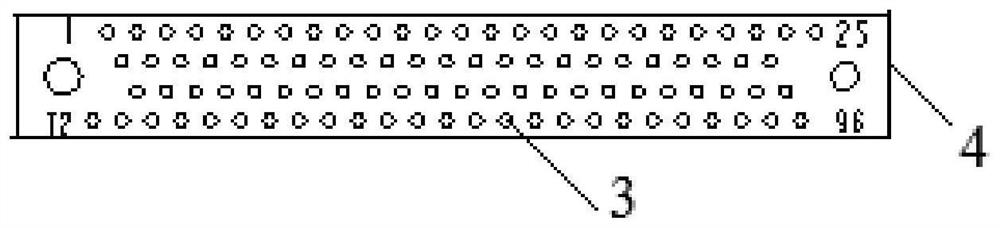

Protection tool and method for square socket during spraying of printed piece

ActiveCN110639726AWon't hurtImprove quality and efficiencyLiquid surface applicatorsSpraying apparatusStructural engineeringMechanical engineering

The invention discloses a protection tool and method for a square socket during spraying of a printed piece. The tool comprises a protective shell and a sealing layer; the protective shell is in a long strip shape; a shape of a cavity of the protective shell is the same as that of a square socket shell; the two ends, in a length direction, of the protective shell are arranged in an opening manner;and a shape of each opening portion of the protective shell is the same as that of the cross section of the square socket shell; the lower end of the protective shell is folded inwards and horizontally extends in a width direction of the protective shell; and the sealing layer is a flexible material and seals at the openings of the protective shell. The method comprises the following steps that firstly, the protection tool is buckled on the square socket shell after extending outwards; after the protection tool is restored to an original shape, whether the protection tool is stable or not andwhether the bottom of the square socket shell is wrapped or not are checked; after confirmation, a spraying process of the printed piece is performed; and after the spraying process of the printed piece is finished, the protection tool is removed from the printed piece. The protection tool and method are especially suitable for protection of a spraying process for the printed piece with the square socket in mass production.

Owner:XIAN MICROELECTRONICS TECH INST

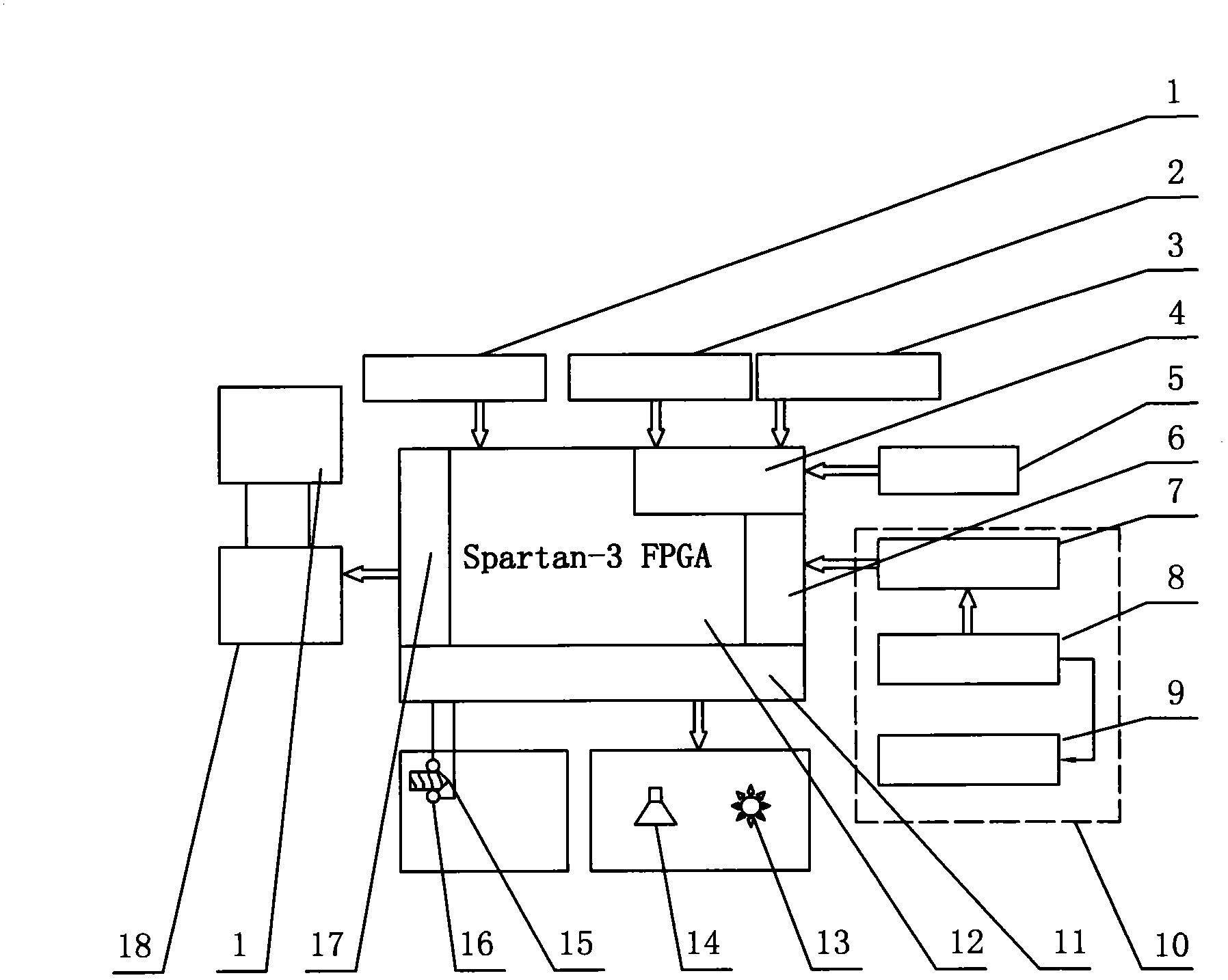

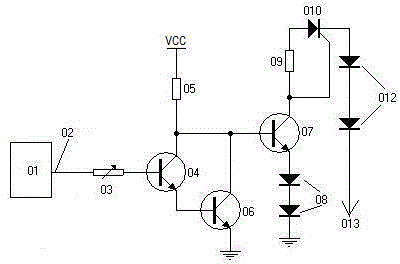

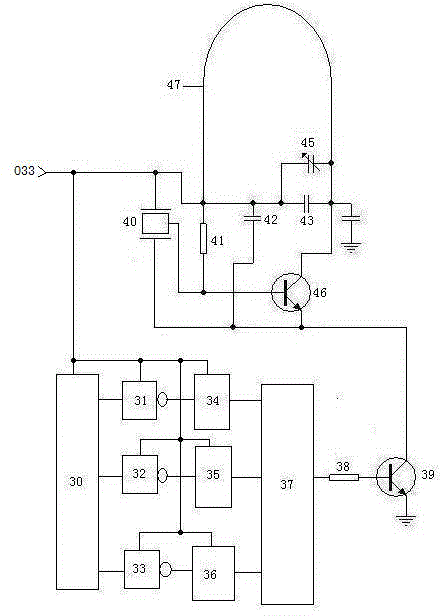

Anti-infringement detection and protection system for general automatic control apparatus

ActiveCN103424139ASimple circuit structurePrevent illegal destruction or infringing copyingMeasurement devicesAutomatic controlMaterial resources

The invention discloses an anti-infringement detection and protection system for a general automatic control apparatus and belongs to an instrument in the field of photoelectric detection. In the system, three protection measures including detection of whether a spiral device is displaced, brightness change detection by a brightness detection module, and distance finding by an ultrasonic ranging module are adopted, and a sound maintenance device for a secret key coupling detection circuit is arranged, so that the general automatic control apparatus can be monitored real time and protected rigorously, thus the general automatic control apparatus is effectively prevented from illegal damage or unauthorized copying, the practicality is high, the safety and reliability of a product are improved, labor resources and material resources are saved, enterprise benefits are protected, and market order is stabilized.

Owner:SHEYANG SAIFU NDT EQUIP MFG

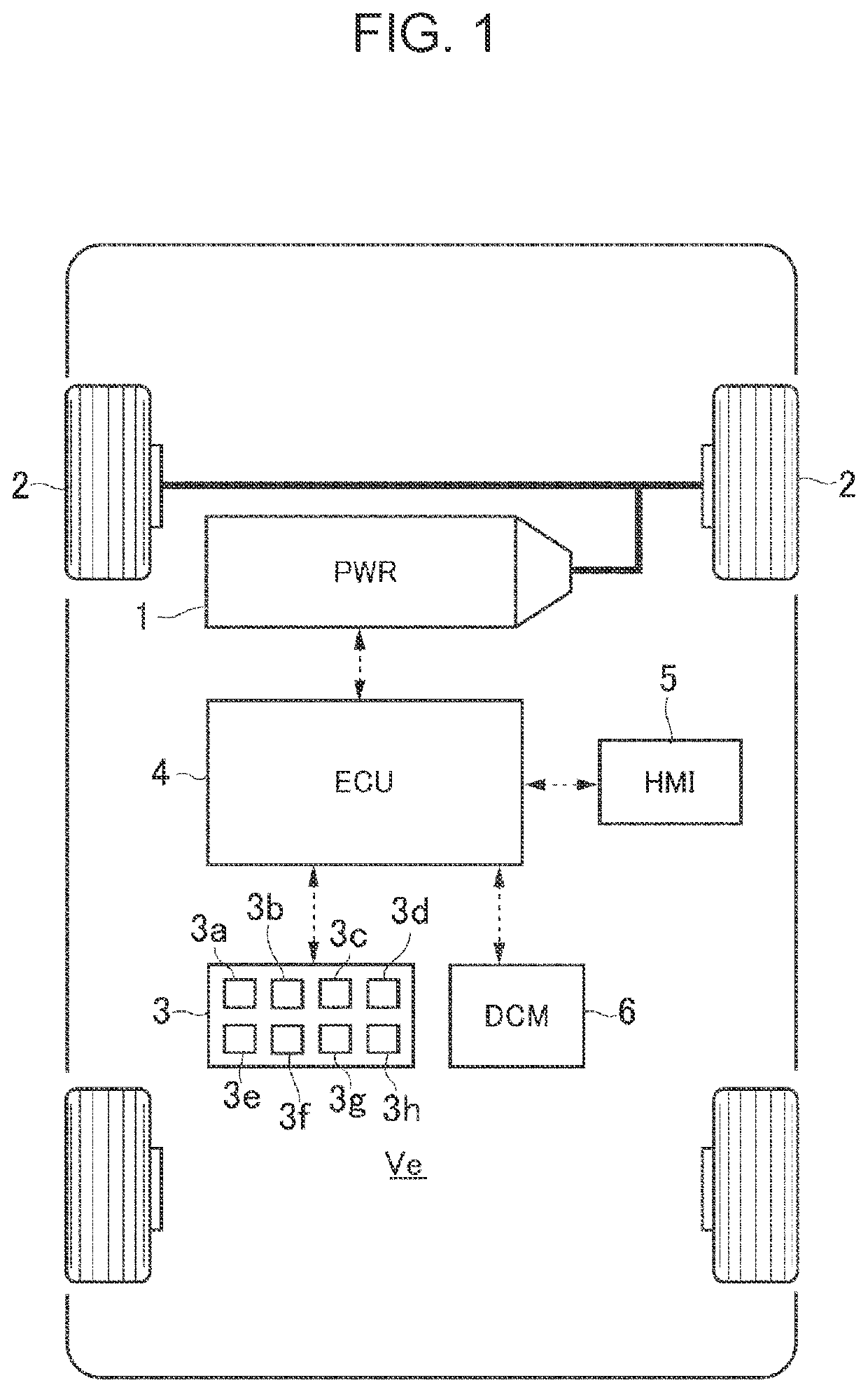

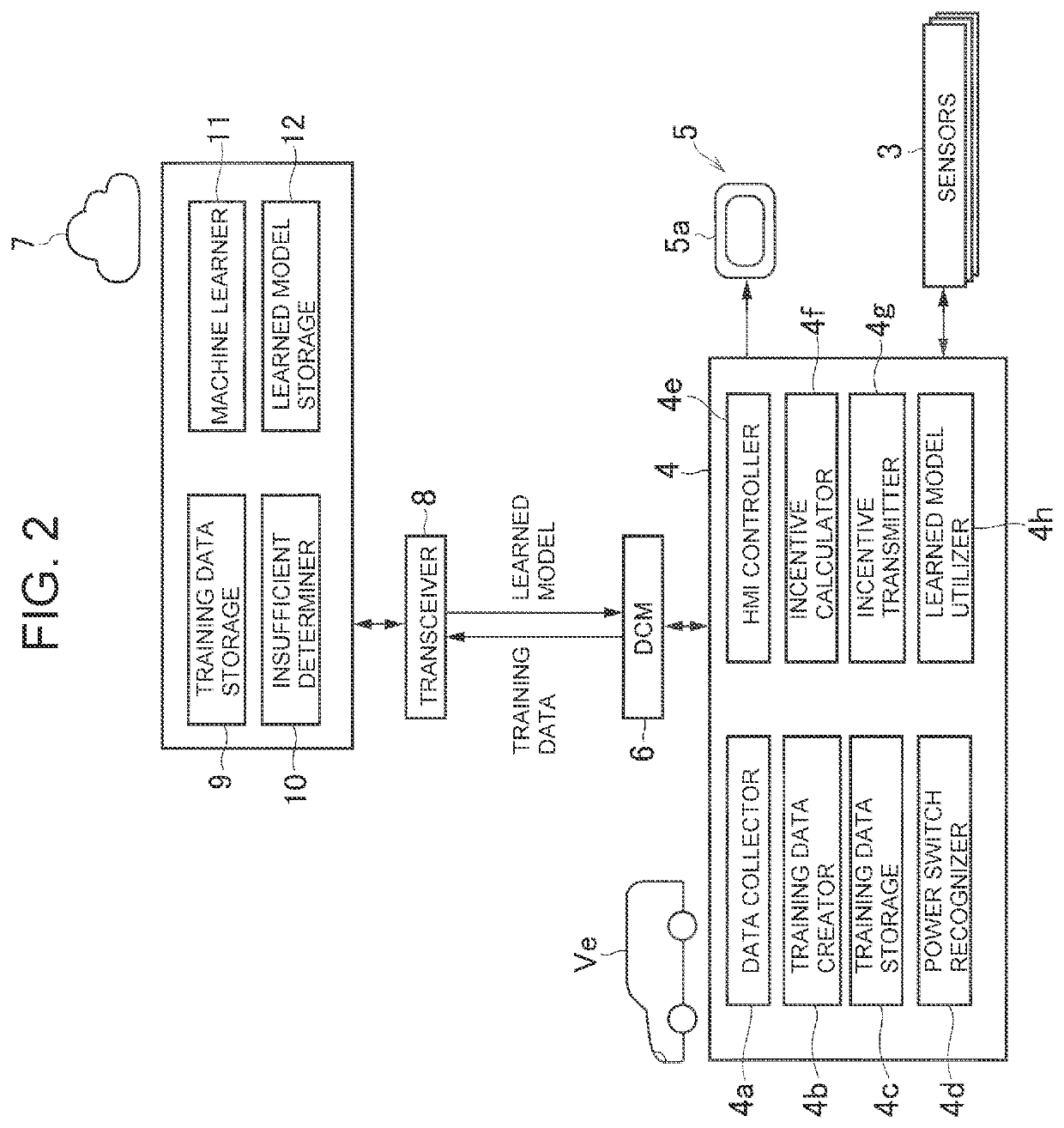

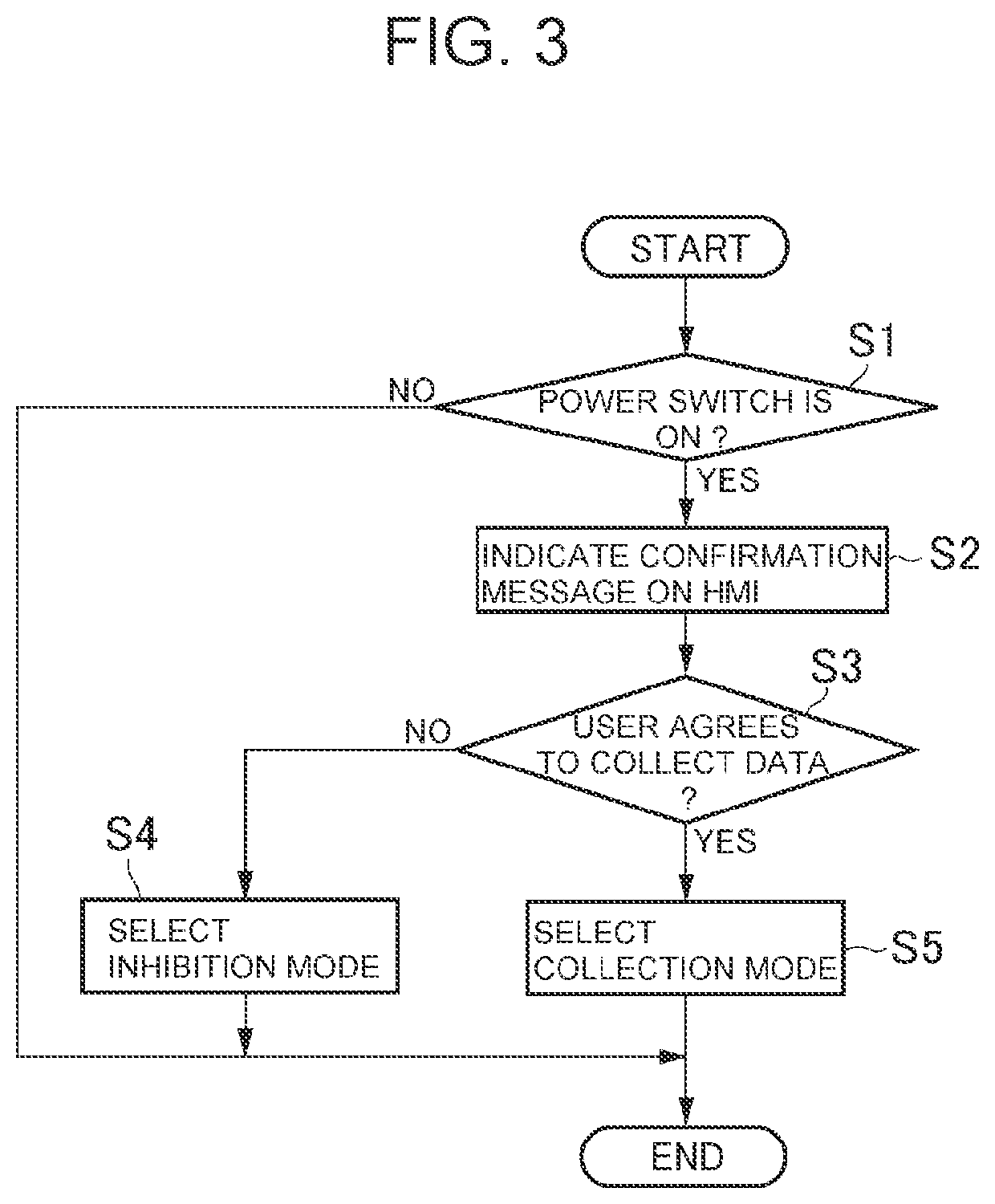

Data collection system for machine learning

PendingUS20210398159A1Closely guardedInput/output for user-computer interactionRegistering/indicating working of vehiclesMachine learningData harvesting

A data collection system for machine learning that is configured to collect data containing personal information from vehicles while administrating the collected personal information tightly. The data collection system comprises a control unit and a human-machine interface. The control unit comprises a power switch recognizer and a human-machine interface controller. The control unit is configured to collect data from the vehicle to perform machine learning while the power switch is on, and confirm an intention of the user to use the data of the vehicle for machine learning via the human-machine interface.

Owner:TOYOTA JIDOSHA KK

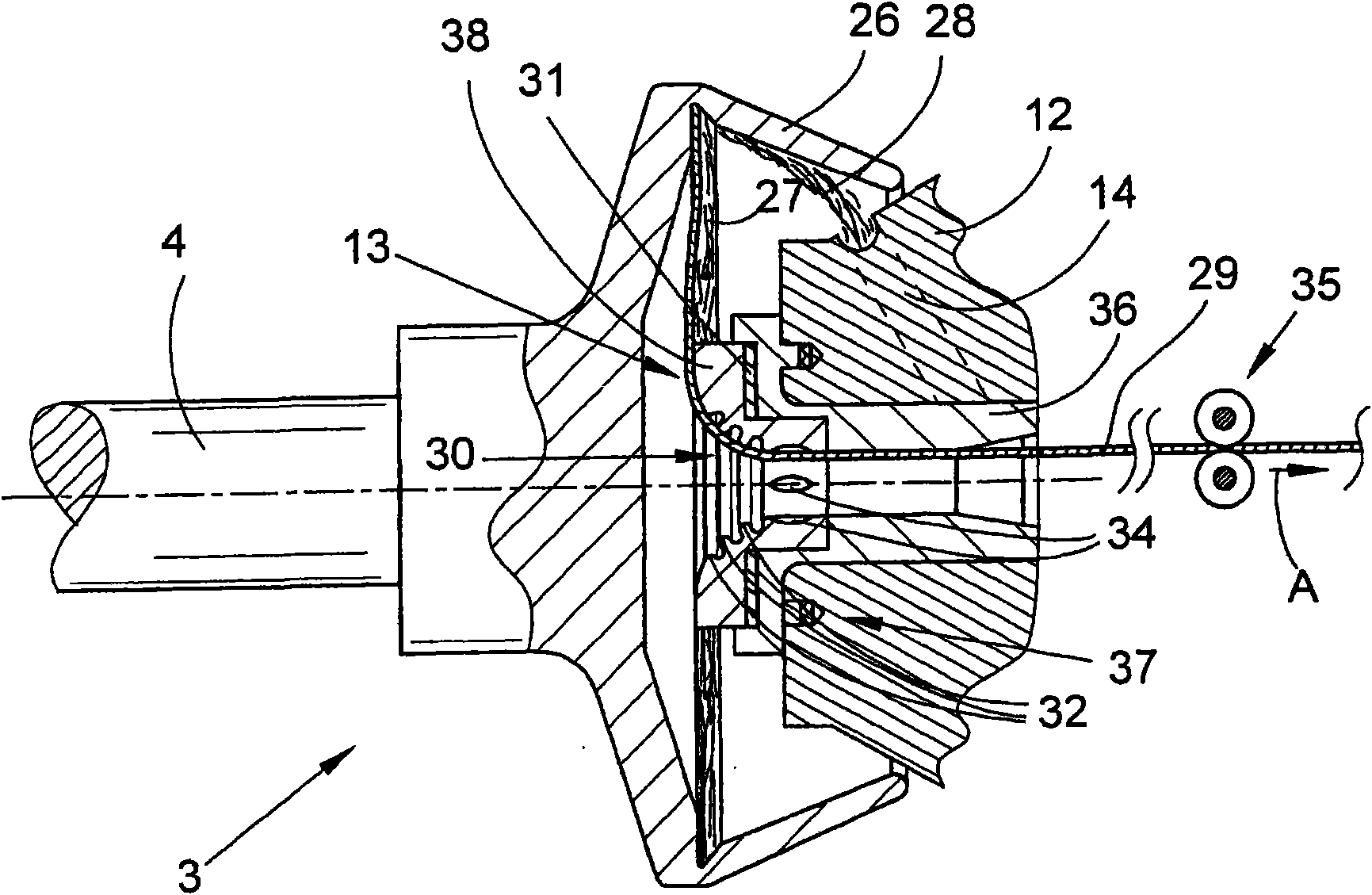

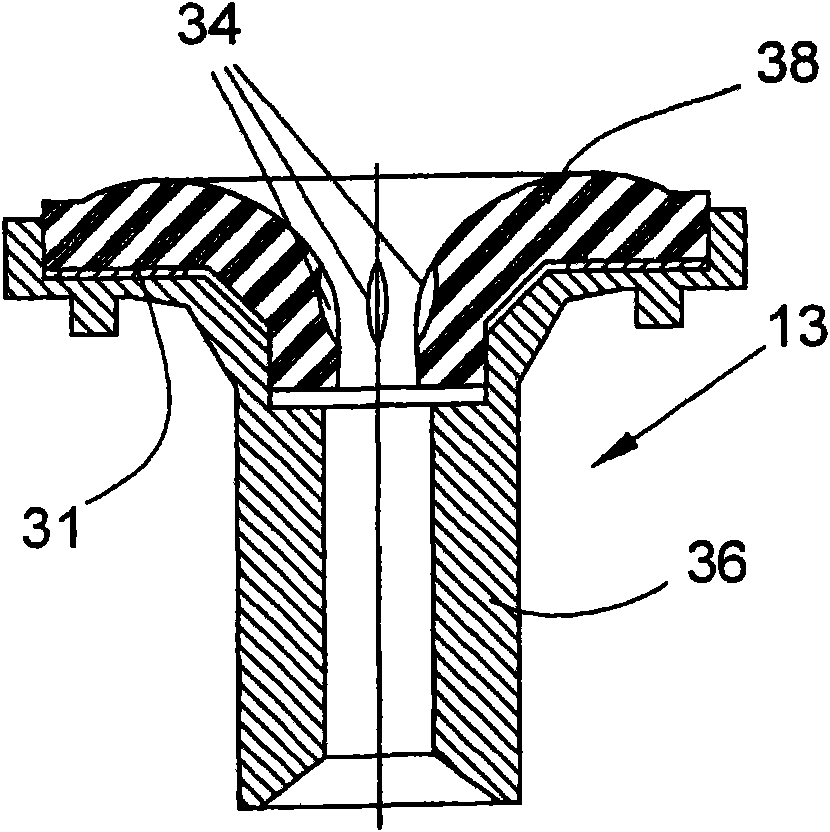

Yarn extraction nozzle

InactiveCN101560706AReduce wearService life exceedsContinuous wound-up machinesOpen-end spinning machinesYarnEngineering

The present invention relates to a yarn extraction nozzle of a free end rotor spinning device, comprising a nozzle base and a optically distinguished mark, which is used for distinguishing type of the yarn extraction nozzle, a nozzle insert made of ceramic is fixed on the nozzle base. According to the invention, the nozzle insert (38) is made of transparent sub-micron ceramic.

Owner:SAURER GERMANY GMBH & CO KG

Household protector with fine lightning protection property

InactiveCN103123734ACombine scienceIncrease active protectionBurglar alarm by openingEmergency protective arrangements for limiting excess voltage/currentEngineeringLightning

The invention discloses a household protector with a fine lightning protection property, and belongs to the technical field of public security. The household protector can be mainly and positively matched with existing patents and achievements of an inventor and becomes a novel protector. The household protector comprises a lightning protection power supply, a protection starting portion and an alarm portion, and a power supply circuit is characterized in that a line is simplified, has a fine voltage stabilizing circuit and is fine in lightning protection property, so that the household protector is fine in the lightning protection property. The alarm portion of the protector is placed in a house, the protection starting portion includes a displacement sensor installed on a door, and a magnetic sensor is fixed above a lock hole. By the aid of different installation processing methods, the household protector mainly has the advantages that the household protector is high in security and has a lot of features not belonging to the prior art, and the types of protectors are enriched.

Owner:蒋丹

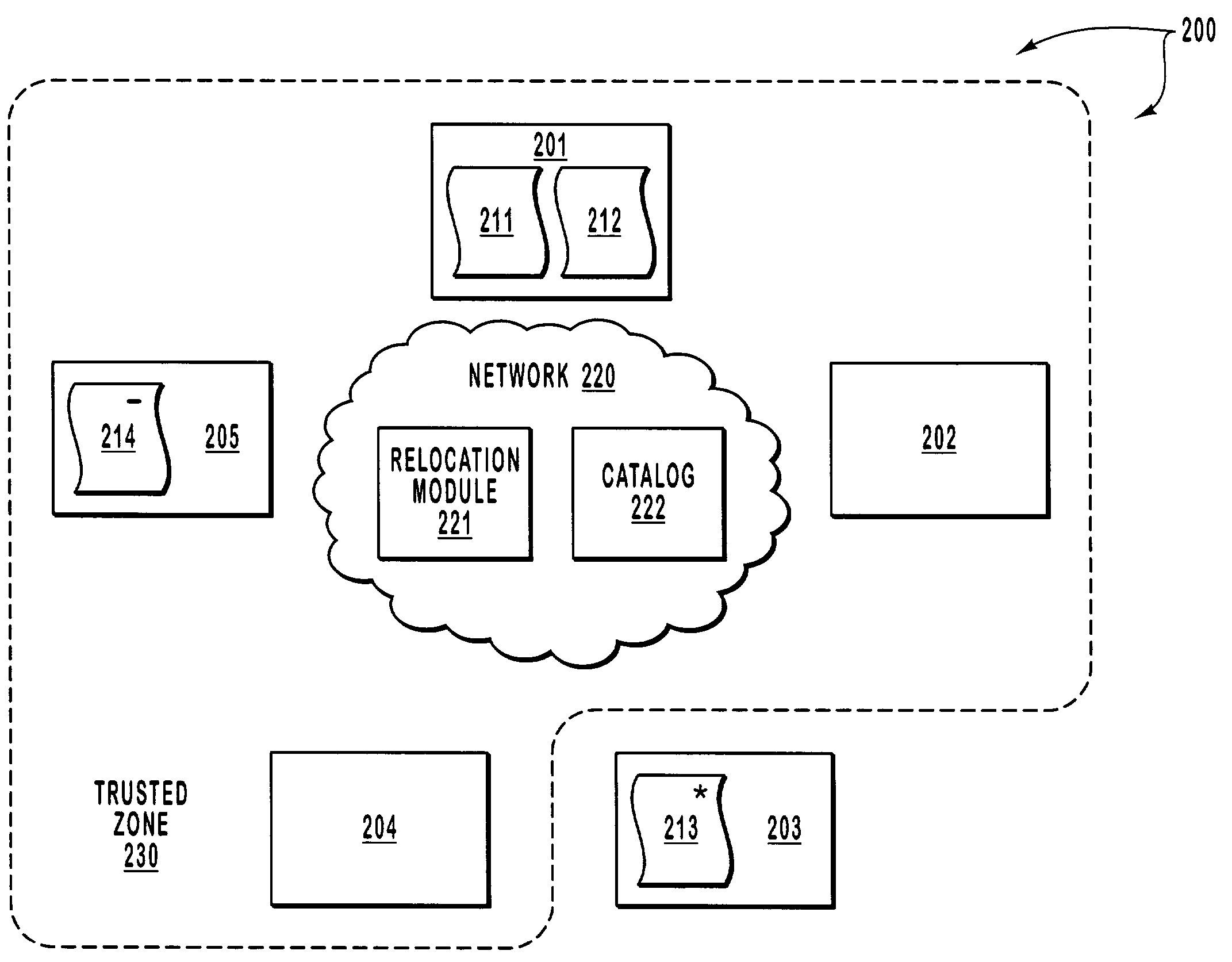

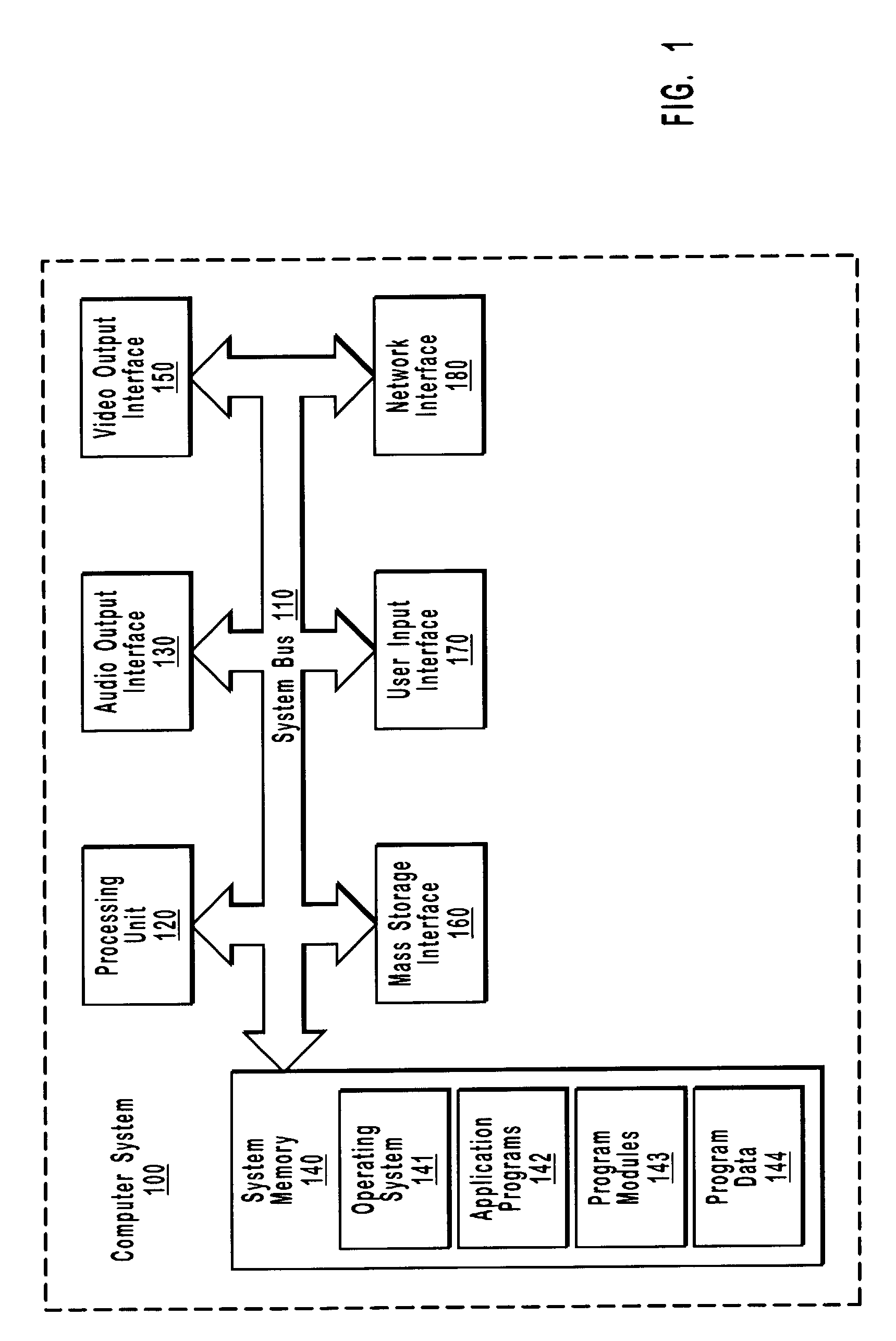

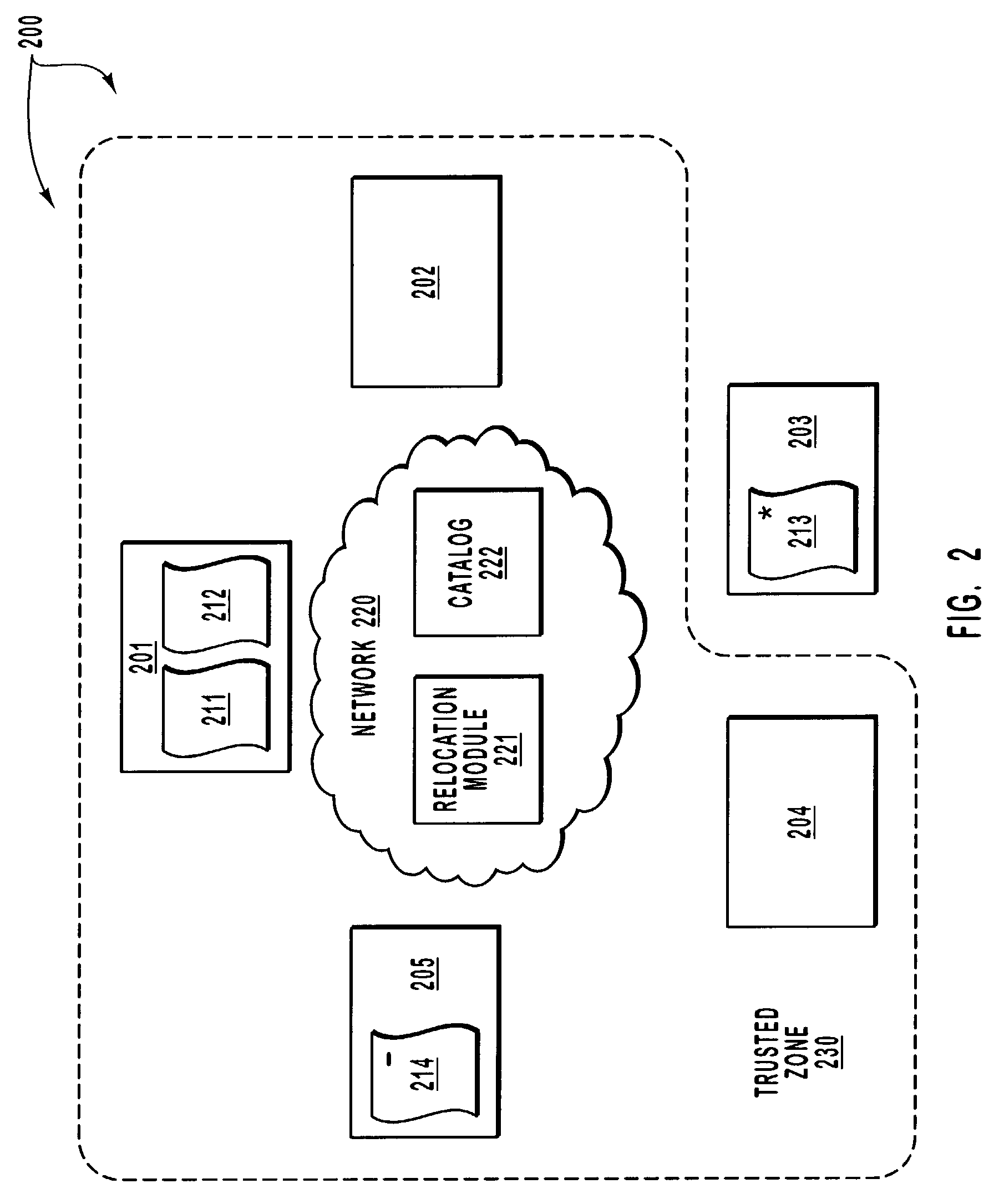

Hidden proactive replication of data

InactiveUS7631359B2Closely guardedOpportunities decreaseMemory loss protectionDigital data processing detailsExact locationComputer security

Moving replicas in a cryptographically secure manner such that the target location and timing of the movements are completely hidden from any user, or is kept as a secret by a limited number of users who have been given advanced notice of the new location and relocation time for a replica. A catalog of replica locations that describe the current location of the replicas is stored in encrypted form so as to prevent individuals from determining the exact location of the replicas. Since the location of the replicas is hidden at any given moment, attackers may not use the location of the replicas in order to attack all of the replicas at the same time. Accordingly, recovery mechanisms may have an opportunity to recover from any given attack by once again creating replicas from those replicas that had not been attacked.

Owner:MICROSOFT TECH LICENSING LLC

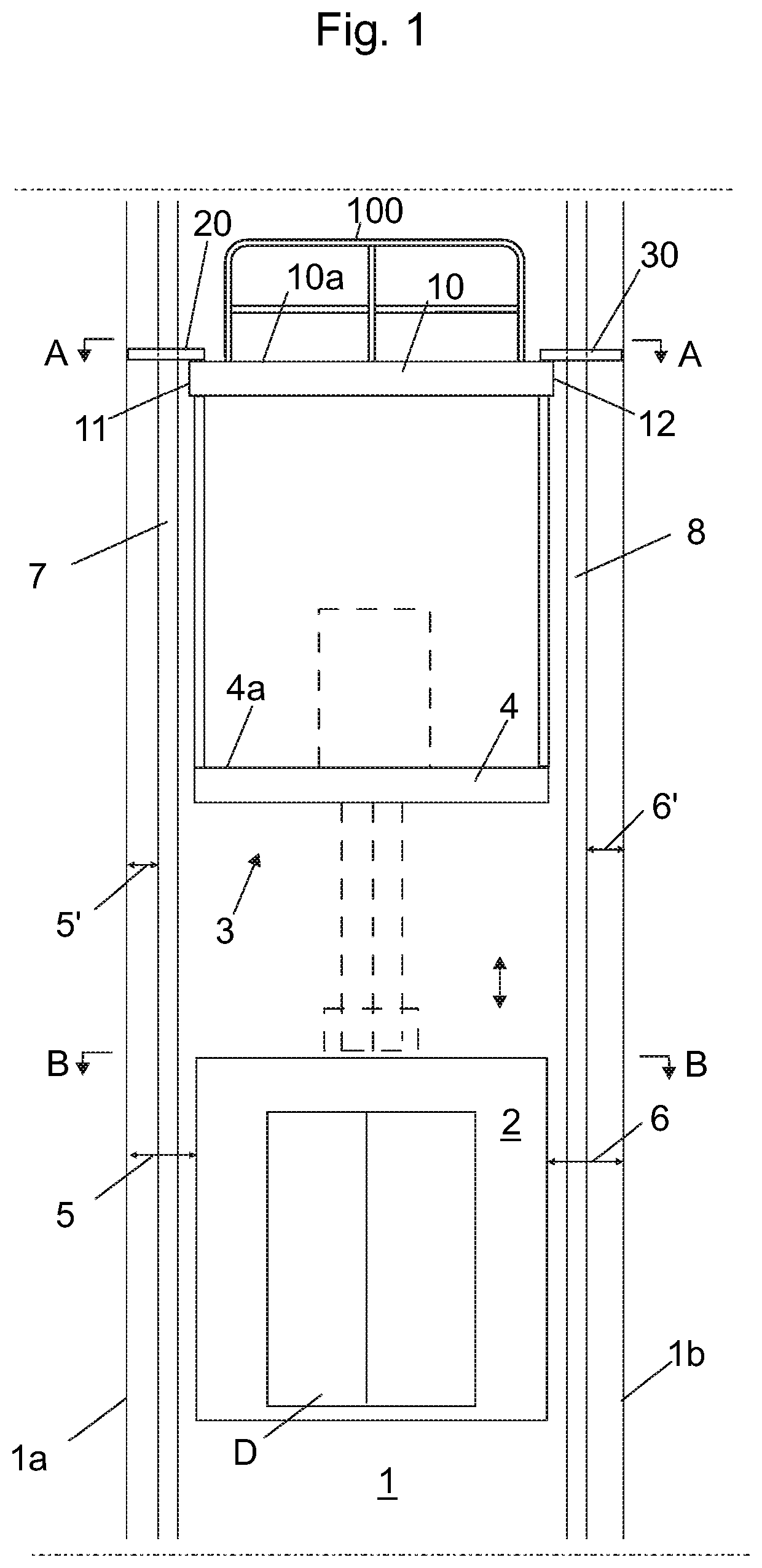

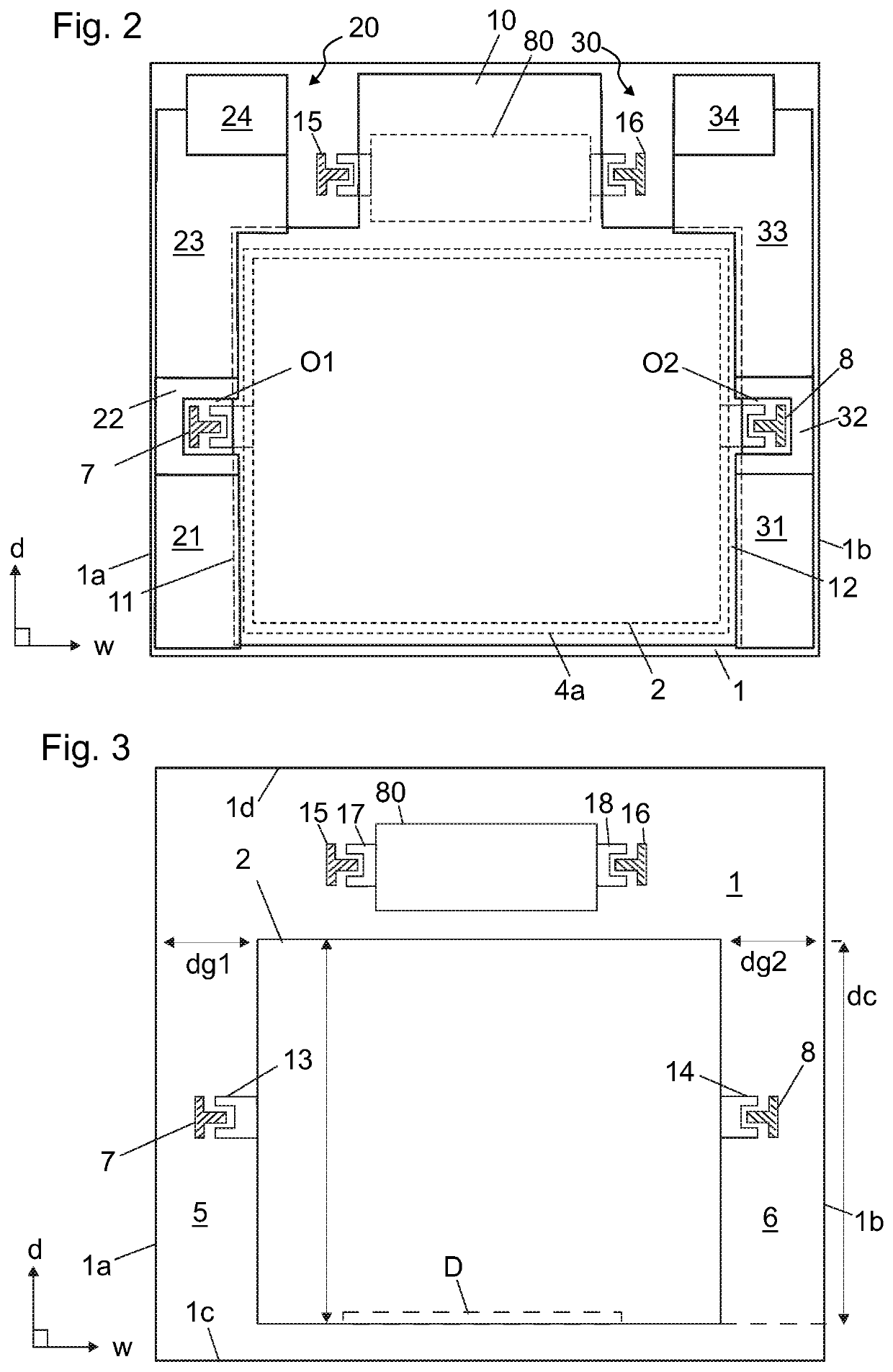

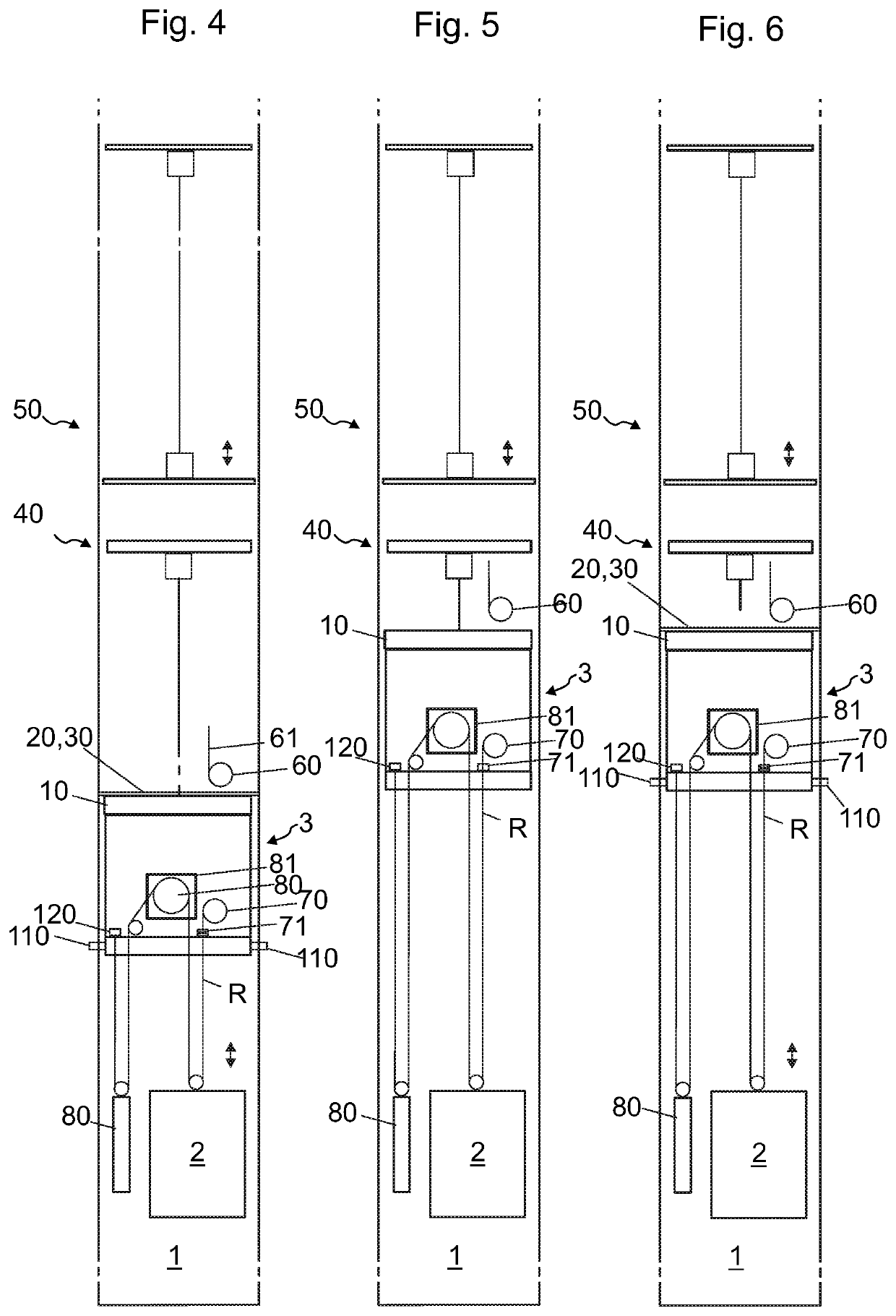

Elevator arrangement and method

ActiveUS10766744B2Save spaceExtended range of motionElevatorsBuilding material handlingControl theoryMechanical engineering

An elevator arrangement, in particular a construction time elevator arrangement, includes a hoistway; an elevator car mounted in the hoistway; and a vertically movable support structure in the hoistway for supporting the elevator car, the movable support structure being mounted above the elevator car in the hoistway. The vertically movable support structure includes a first working platform, having a planar working area, and a protective cover above the first working platform for protecting elevator components and / or people below it from falling objects. The protective cover covers most of the cross section of the hoistway.

Owner:KONE CORP

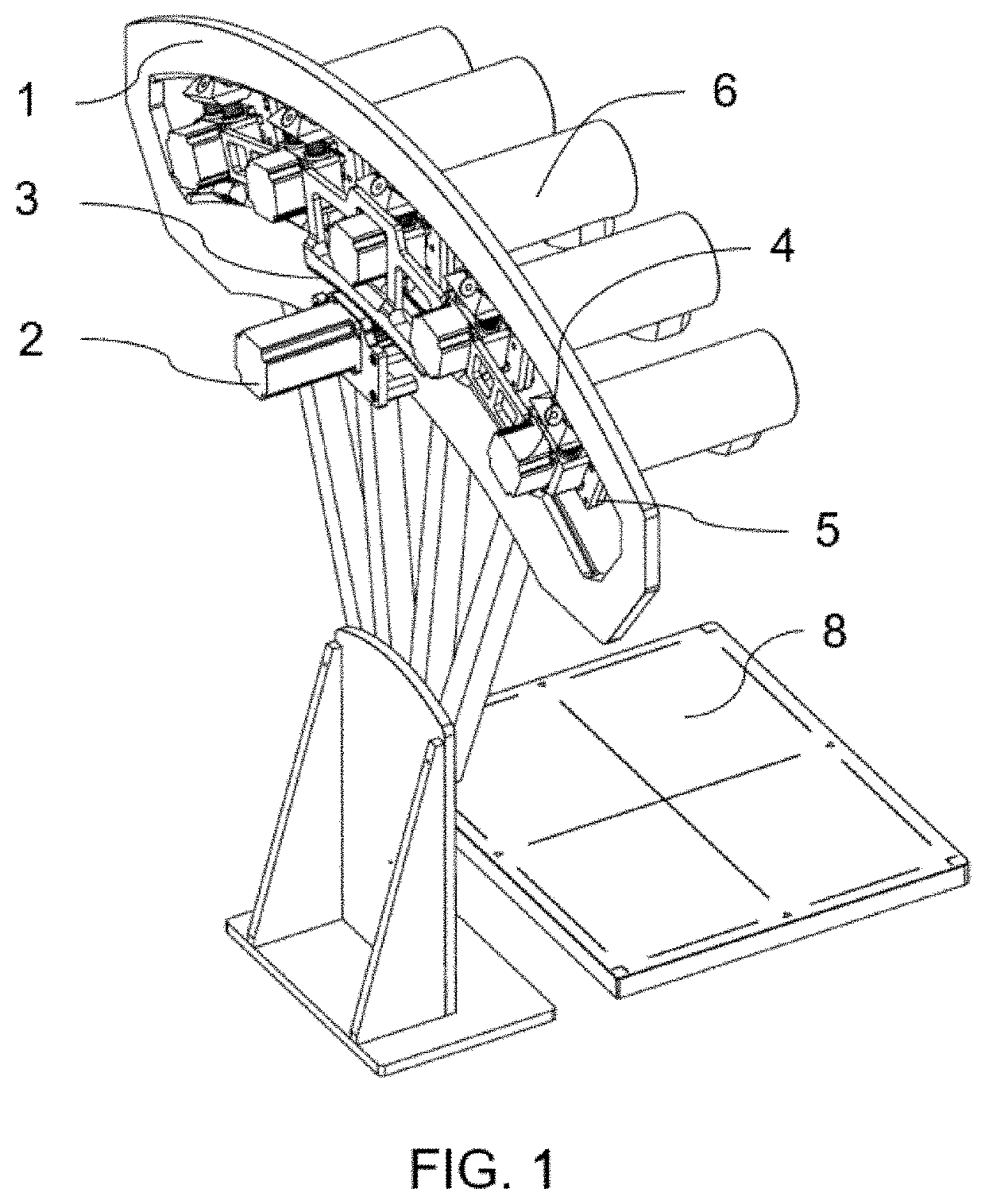

Artificial Intelligence Training with Multiple Pulsed X-ray Source-in-motion Tomosynthesis Imaging System

PendingUS20220313176A1Knowledge data base can be updatedReduced availabilityRadiation diagnosis data transmissionImage enhancementTomosynthesisPulmonary nodule

Disclosed are image recognition Artificial Intelligence (AI) training methods for multiple pulsed X-ray source-in-motion tomosynthesis imaging system. Image recognition AI training can be performed three ways: first, using existing acquired chest CT data set with known nodules to generate synthetic tomosynthesis Images, no X-ray radiation applied; second, taking X-ray raw images with anthropomorphic chest phantoms with simulated lung nodules, applying X-ray beam on phantom only; third, acquiring X-ray images using multiple pulsed source-in-motion tomosynthesis images from real patients with real known nodules and without nodules. An X-ray image recognition training network that is configured to receive X-ray training images, automatically determine whether the received images indicate a nodule or lesion condition. After training, image knowledge is updated and stored at knowledge database.

Owner:LIU JIANQIANG +3

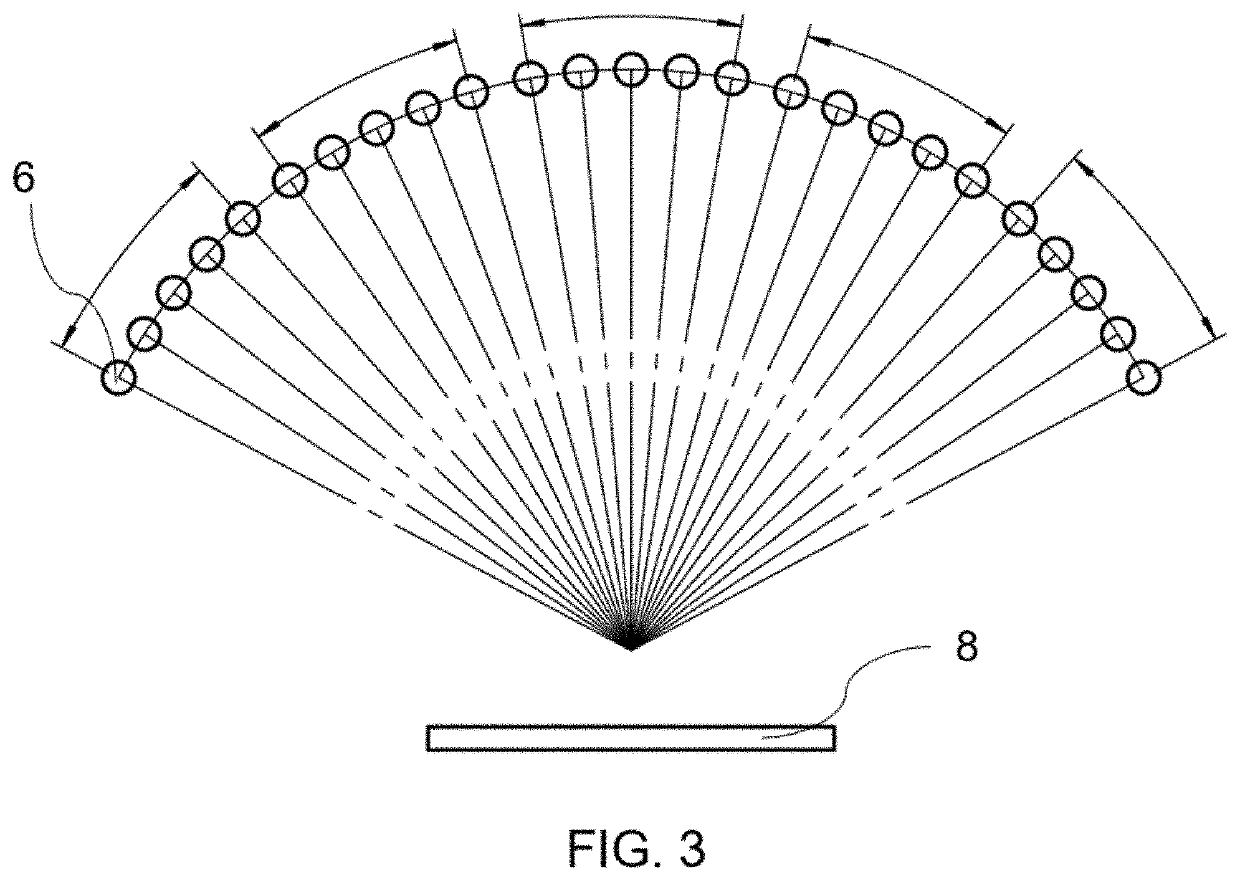

Efficient explosionproof halogen lamp and manufacturing method thereof

InactiveCN101599415AExtend your lifeClosely guardedLamp incadescent bodiesIncandescent lamp energy savingEffect lightEngineering

The invention is an efficient explosionproof halogen lamp, which comprises a lamp holder and a bulb. The invention is characterized in that the bulb is provided with a halogen lamp, a plus-minus electrode connecting rod and an insulating base; the insulating base is fixed on the lamp holder; the halogen lamp comprises a quartz bulb in which molybdenum plates and tungsten wires are mounted; the quartz is full of halogen gas; the plus-minus electrode connecting rod is fixed on the insulating base, one end thereof is separately connected with the plus electrode and the minus electrode of the lamp holder, and the other end thereof is separately connected with the molybdenum plates in the halogen lamp; and the bulb is full of inert gas. The invention also relates to a manufacturing method of the halogen lamp. The efficient explosionproof halogen lamp provided in the invention is a double-bulb lamp in structure, which has high luminous efficacy and about 30-50lm / w of lighting effect; the life service thereof is long and can reach 2000-3000 hours; the halogen lamp is convenient in use without explosion.

Owner:李韦玲

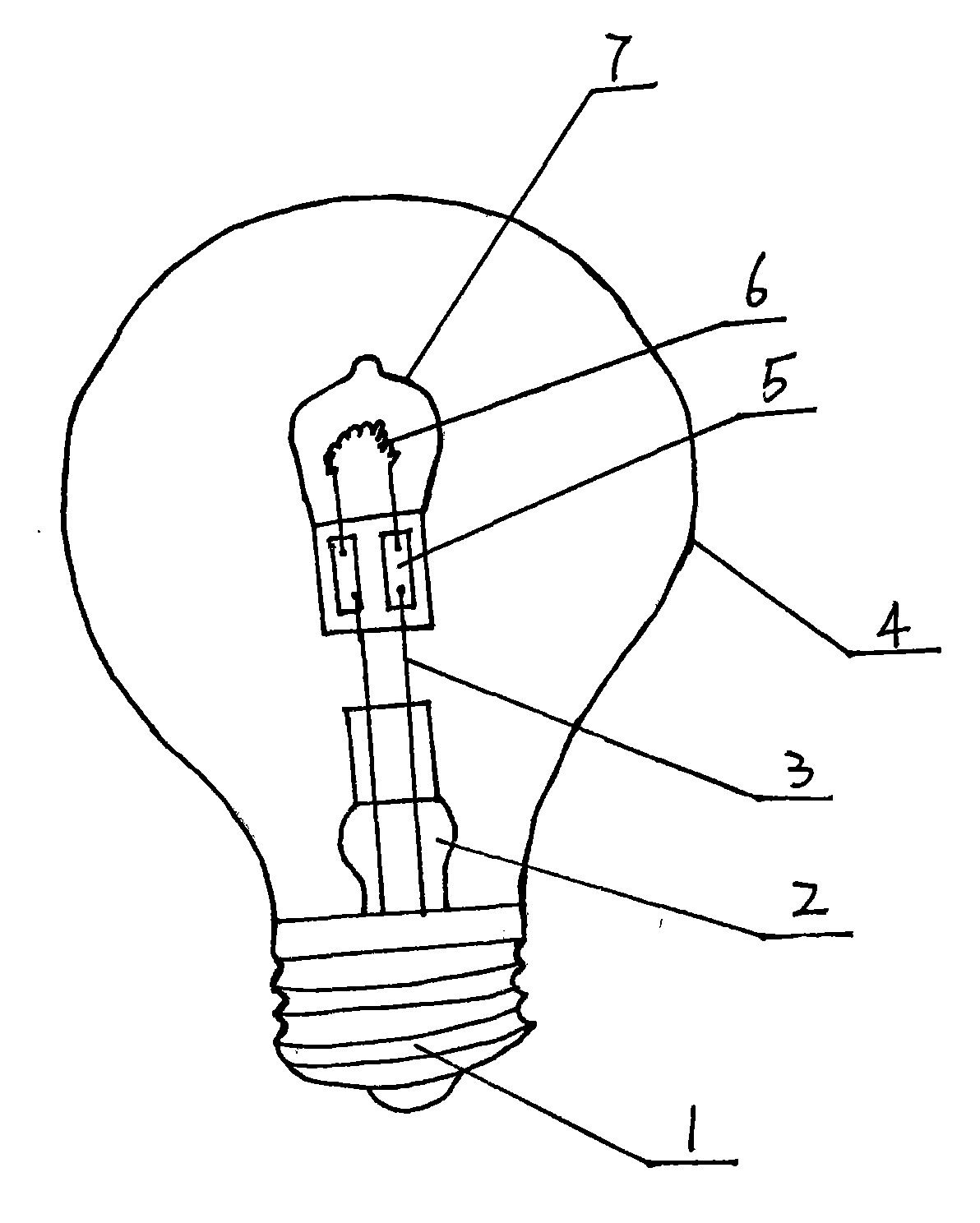

Anti-theft device with integrated telephone alarm

InactiveCN105809911AIncrease current gainHigh voltage gainAlarmsAlarm locksInterference resistanceEngineering

The invention provides an anti-theft device with an integrated telephone alarm, belonging to the technical field of anti-theft. The anti-theft device is formed by a contact piece, a warning start circuit, a lock switch, a field warning circuit, a radio multi-code transmitter circuit, and the integrated telephone alarm. When a hand touches the contact piece, a touch signal is generated, after the signal is amplified by the warning start circuit, the field warning circuit is started to emit warning, if stop is failed, the contact piece is loose, the lock switch immediately emits an alarm start signal, while the field warning circuit is started, the radio multi-code transmitter circuit with strong interference resistance and reduction of weather and surrounding environmental influences is started, the relevant personnel is notified by the integrated telephone alarm, and the anti-theft performance of security anti-theft door type products is improved further.

Owner:CHONGQING NINGLAI SCI & TRADE

Polyurethane pouring sealant for wind driven generator rotor coating protection and preparation method thereof

PendingCN113683997AClosely guardedGood waterproof performanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesChemistryActive agent

The invention discloses a polyurethane pouring sealant for wind driven generator rotor coating protection. The polyurethane pouring sealant comprises a component A and a component B, wherein the component A comprises resin, filler and auxiliary agents, the component B is a curing agent, and the mass ratio of the component A to the component B is 100:30 when the component A and the component B are mixed. A preparation method of the polyurethane pouring sealant for wind driven generator rotor coating protection comprises the following steps: preparation of the component A: taking 45-55 parts of polyol, 0.5-2 parts of a surfactant, 0.1-1 part of a wetting dispersant, 0.1-1 part of a leveling agent, 0.1-1 part of an adhesion promoter and 0.1-1 part of an antifoaming agent, and fully stirring and uniformly mixing; then adding 30-40 parts of calcium carbonate powder, 1-5 parts of titanium dioxide and 5-10 parts of a dewatering agent, and fully dispersing by using a high-speed dispersion machine; and after uniformly dispersing, stirring in vacuum to obtain the component A; and preparation of the component B: taking 97-99 parts of MDI-50 and 1-3 parts of a drying dewatering agent, and performing vacuum stirring to obtain the component B.

Owner:浙江博菲电气股份有限公司

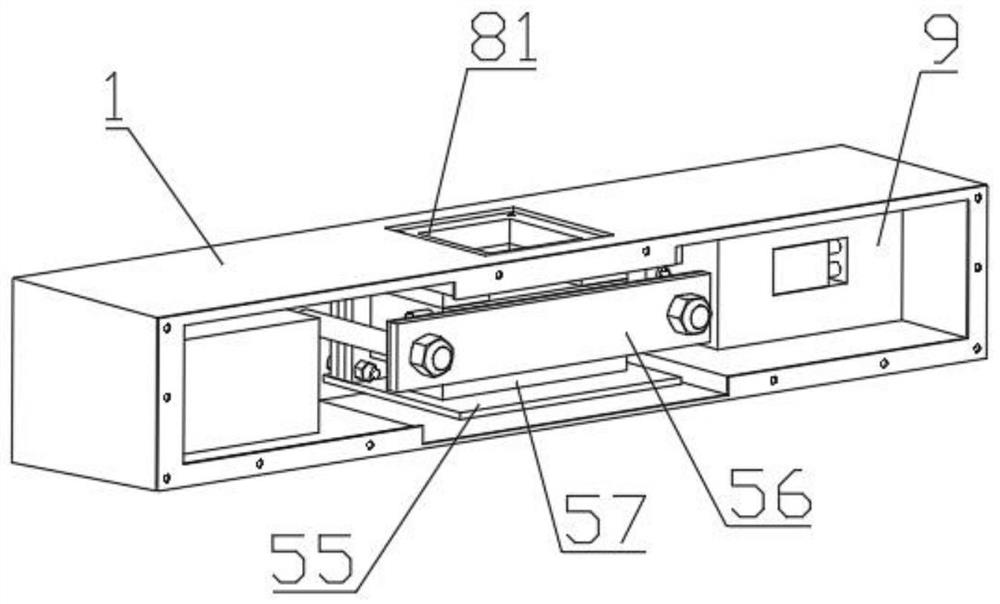

Ultrasonic monitoring device for residual stress of steel structure

ActiveCN112798164AReduce volumeEasy to installProcess efficiency improvementApparatus for force/torque/work measurementInformation processingProcess engineering

The invention belongs to the technical field of ultrasonic detection and particularly relates to a steel structure residual stress ultrasonic monitoring device. The device comprises a positioning box, a detection device, a power supply device and an information processing and transmitting device, wherein the positioning box is fixed to a steel structure, and the detection device, the power supply device and the information processing and transmitting device are installed in the positioning box. The device is simple in installation, convenient to carry and tight in protection, can be well attached to the surface of the steel structure, can guarantee real-time online monitoring of the residual stress of the steel structure, effectively improves the detection quality of the residual stress of the steel structure, saves the detection time of the residual stress of the steel structure, and improves detection efficiency of the residual stress of the steel structure.

Owner:SHIJIAZHUANG TIEDAO UNIV

Forming pressing-fit machine for car brake pad

The invention relates to a forming pressing-fit machine for a car brake pad. The forming pressing-fit machine comprises a primary hydraulic column. A primary oil pipe is connected to the right side ofthe primary hydraulic column, and an oil tank is connected to the right side of the primary oil pipe. The top of the oil tank is connected with a secondary oil pipe, and the left side of the top of the secondary oil pipe is connected with a secondary hydraulic column. The bottom of the secondary hydraulic column is provided with a piston rod, and a buckle is arranged at the left end of a first dustproof cover. A groove is formed in the right end of the first dustproof cover, and the top end of the first dustproof cover is connected with a hook. The top of the hook is connected with a roller,and a through groove is formed in the outer side of the roller. An upper beam is arranged on the outer side of the through groove, and a baffle is arranged at the bottom of the right end of the through groove. A sliding beam is arranged at the bottom of the first dustproof cover, and the bottom of the sliding beam is connected with a fixing strip and provided with a second dustproof cover. The portions, between the upper beam and the sliding beam, between the sliding beam and a lower beam as well as between the lower beam and a base and exposed to air, of the piston rod can be protected through structures of the first dustproof cover and the second dustproof cover, operating of the forming pressing-fit machine is more stable, and the service life is longer.

Owner:东莞市罗兰制动技术有限公司

A protective tooling and method for a square socket when spraying printed parts

ActiveCN110639726BWon't hurtImprove quality and efficiencyLiquid surface applicatorsSpraying apparatusMechanical engineeringIndustrial engineering

Owner:XIAN MICROELECTRONICS TECH INST

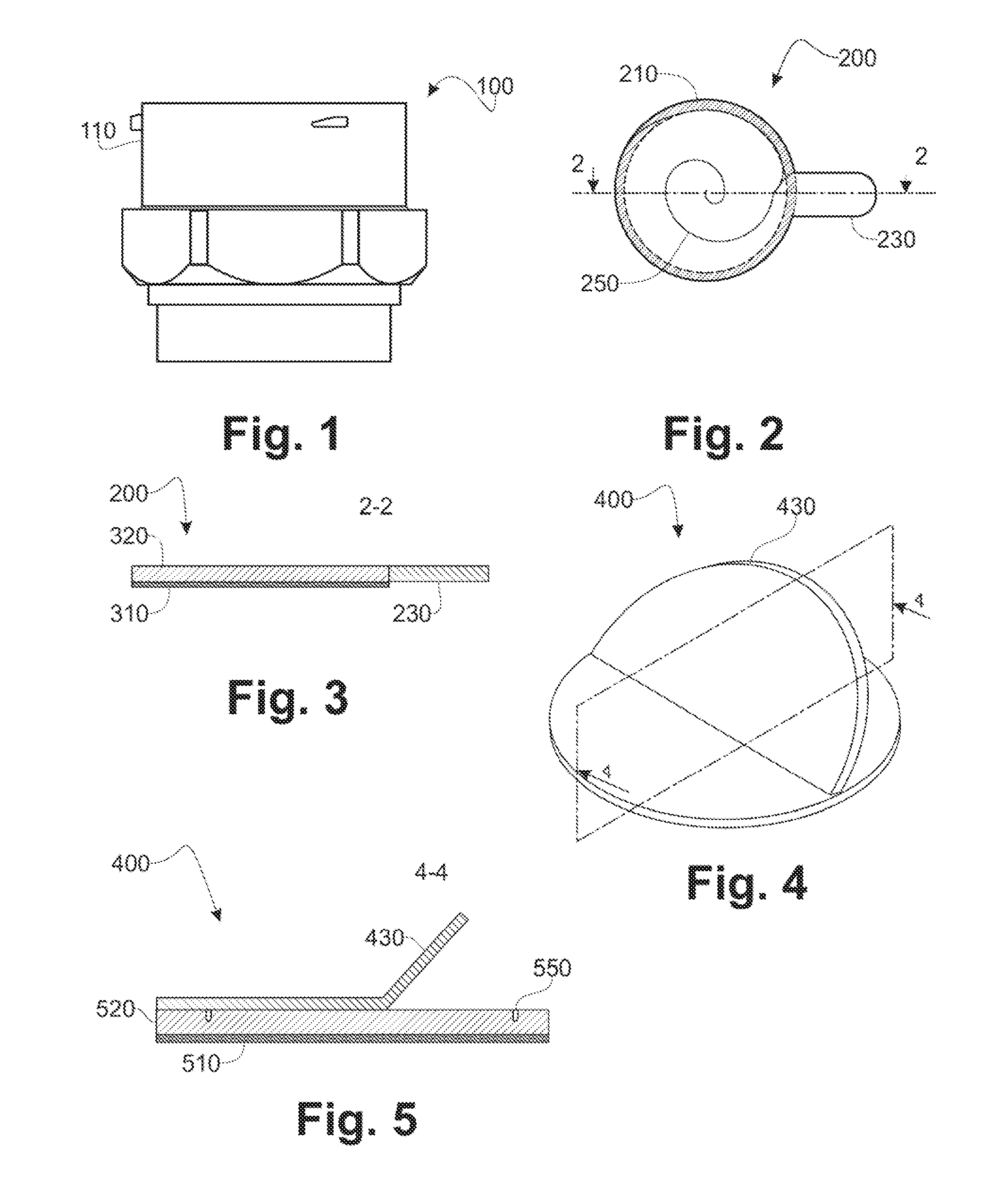

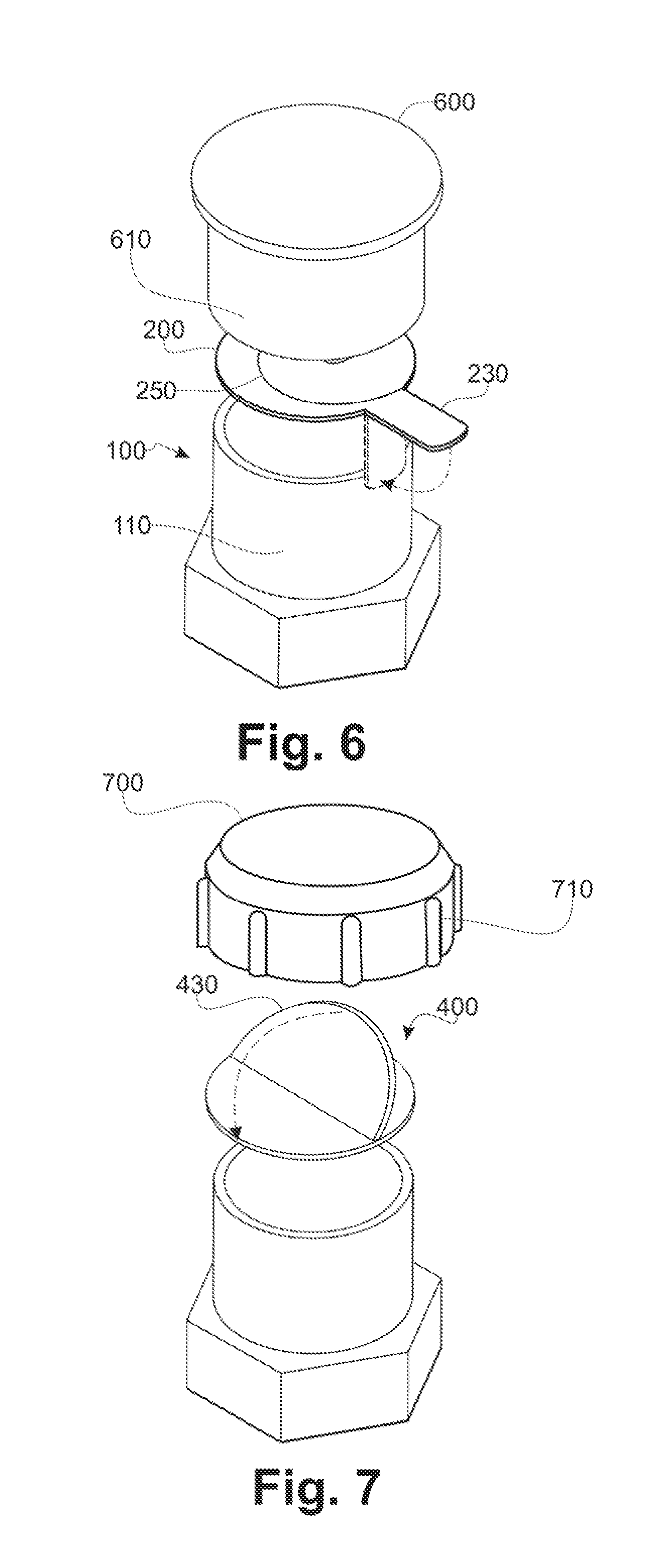

Protection device for an optical connector comprising a membrane seal

ActiveUS20150277061A1Easily removeEasily cutCoupling device detailsOptical articlesMechanical engineeringSemi transparent

A connector having a ferrule, and a translucent or transparent covering membrane sealingly bonded with the ferrule by a paste zone and blanking the opening of the connector. The covering membrane being detachable from the ferrule by peeling and having a strip for gripping the membrane during peeling. The covering membrane having a line defining an easy cutting path to prevent its re-installment on the ferrule after its peel off.

Owner:SOURIAU

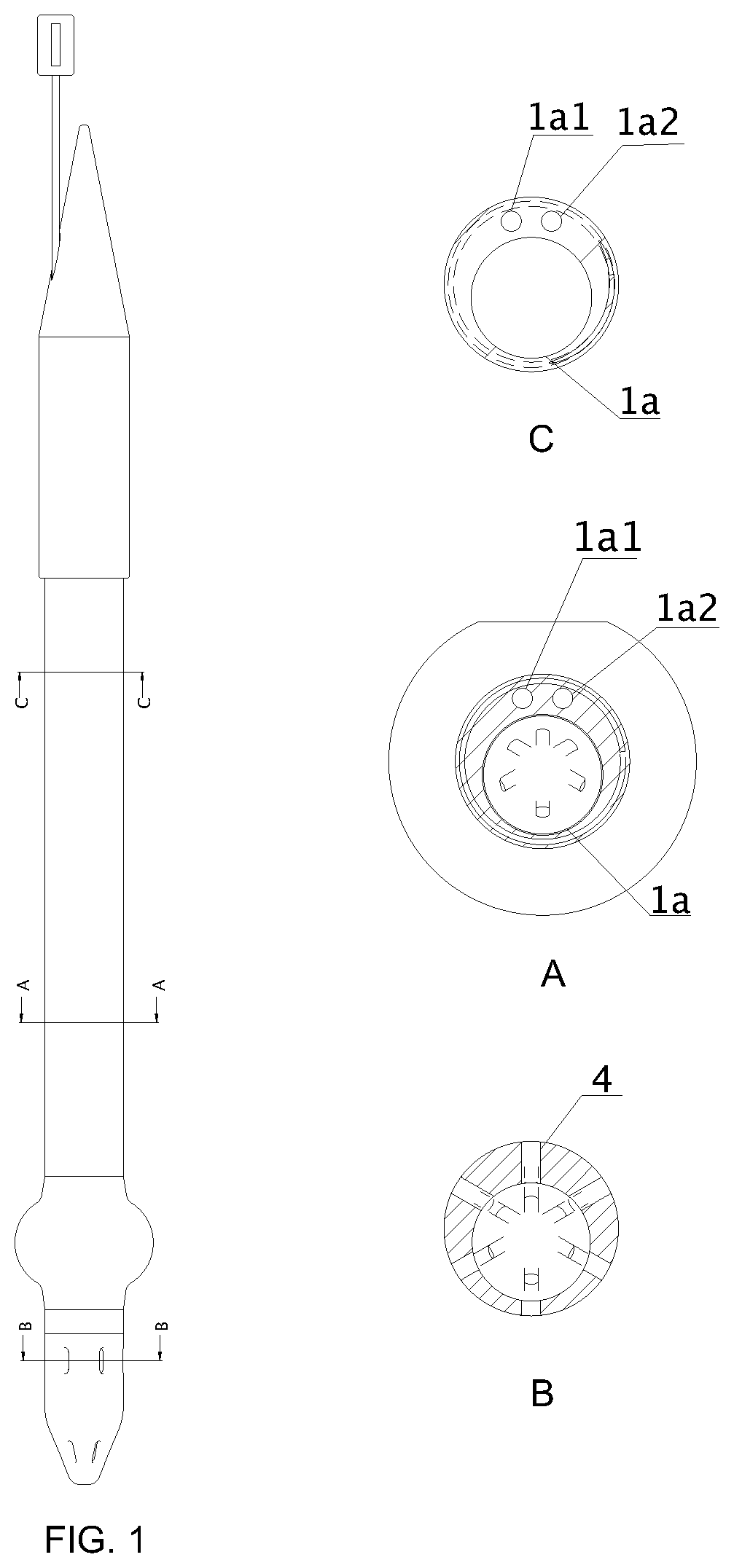

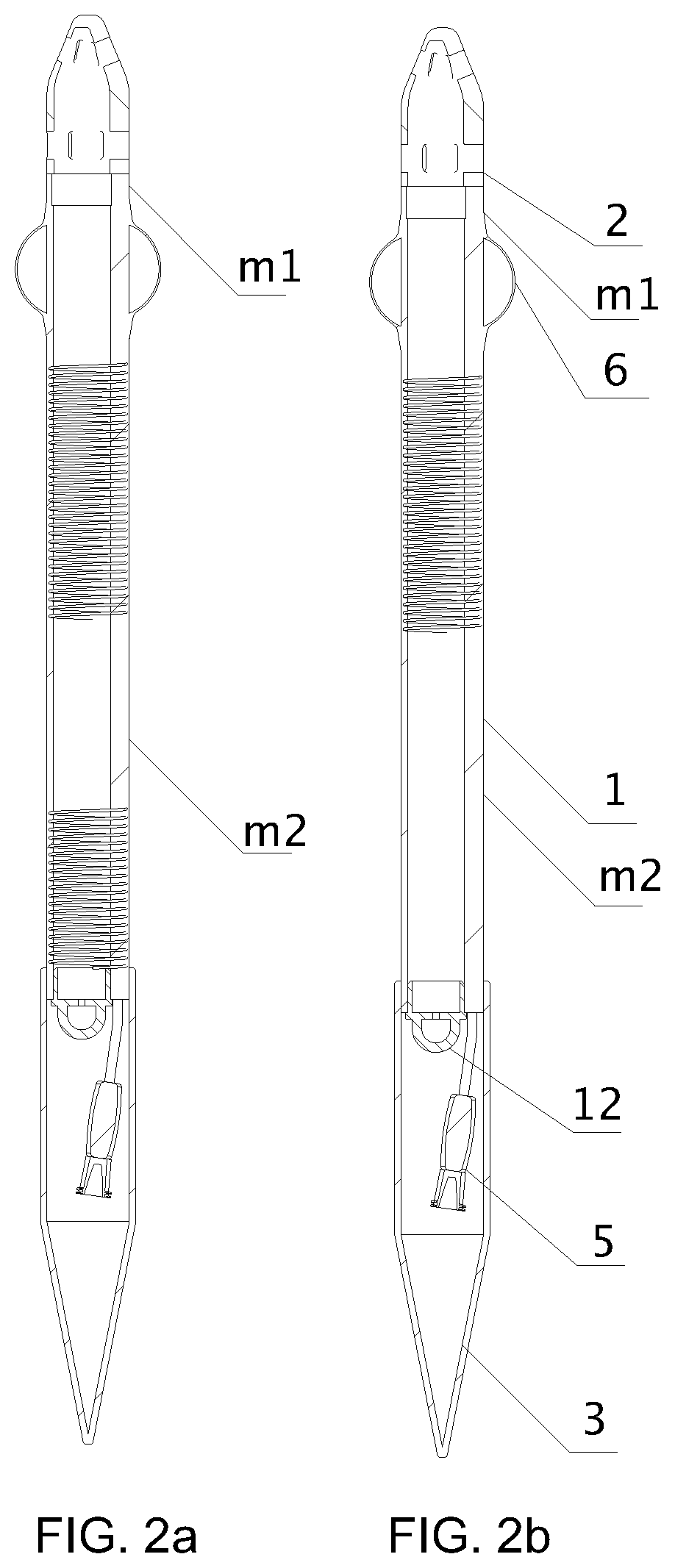

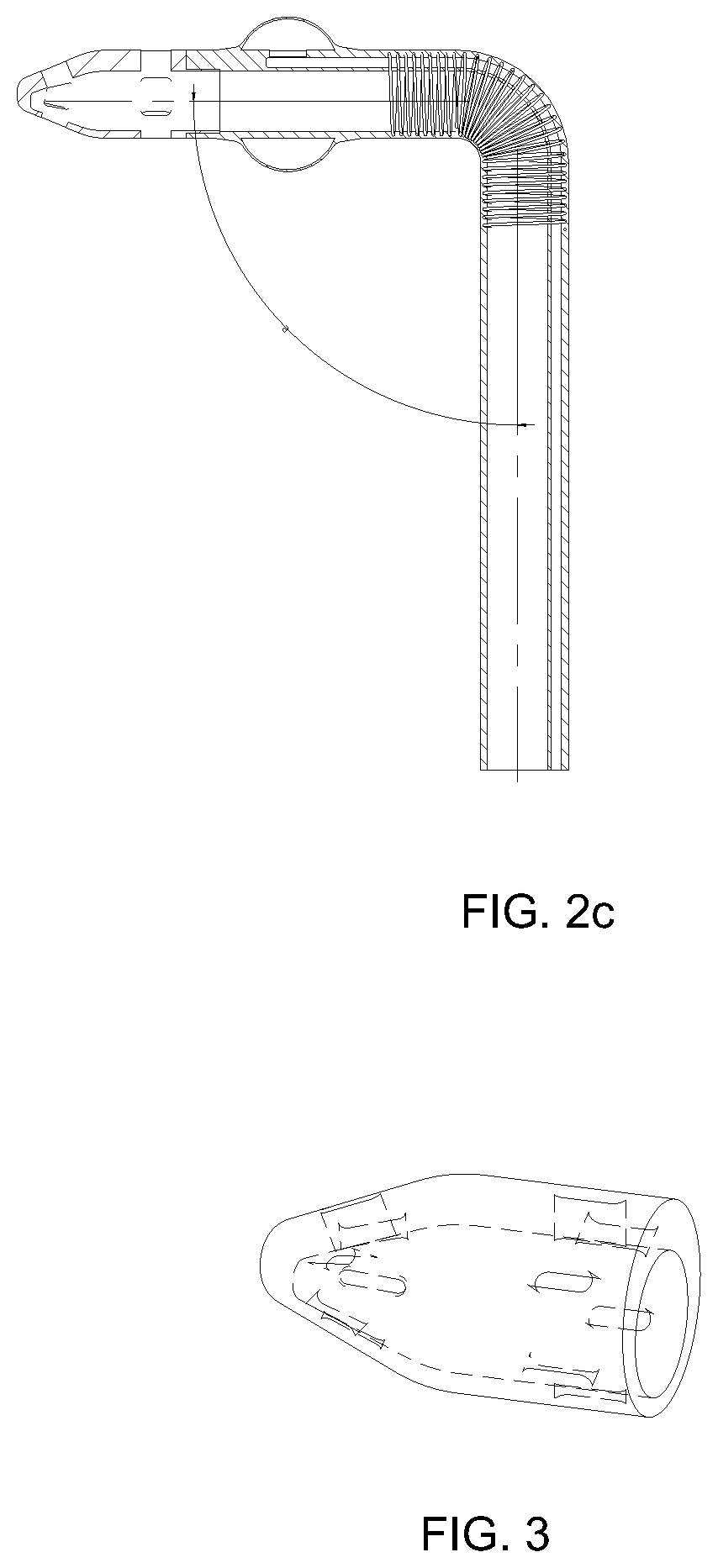

Cannula for percutaneous minimally invasive cannulation of the vena cava

A cannula comprising a plastic tube having three longitudinal chambers, including a main chamber, a first lateral chamber and a second lateral chamber, and at least one reinforced section ensuring constant internal diameter, wherein the cannula is equipped from the distal side with a round end narrowing towards the end, in which there are longitudinal holes of a size enabling free venous blood flow, and a balloon. A fragment of the reinforced tube section located below the balloon is bent under an angle α of approximately 90°. From the proximal side, the tube ends with a flexible cone, sealing the cannula tightly, inside which there is a valve closing the main chamber and a port for inflating the balloon connected to the first lateral chamber.

Owner:MEDINICE SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com