Patents

Literature

169results about How to "Large inner diameter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

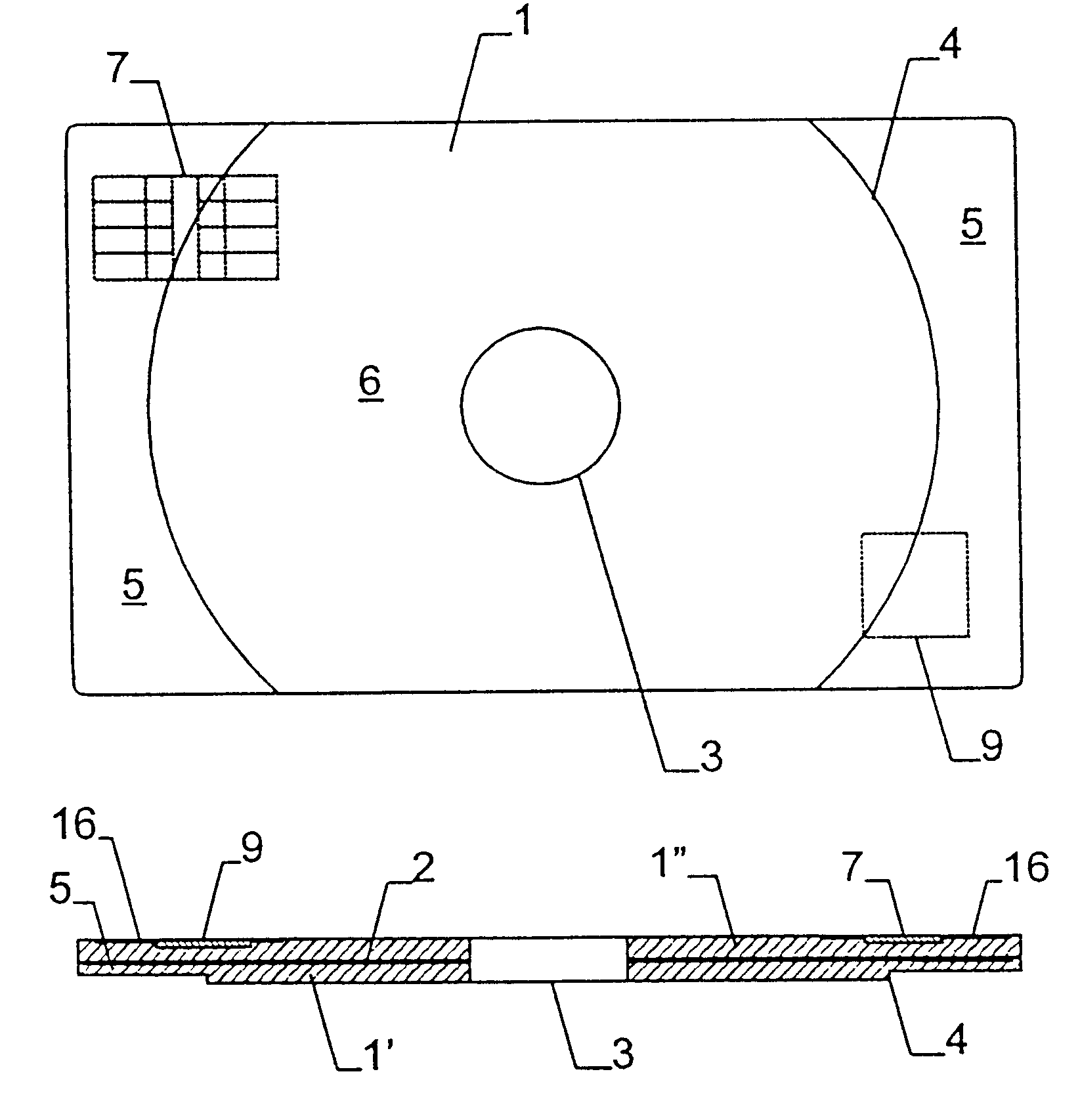

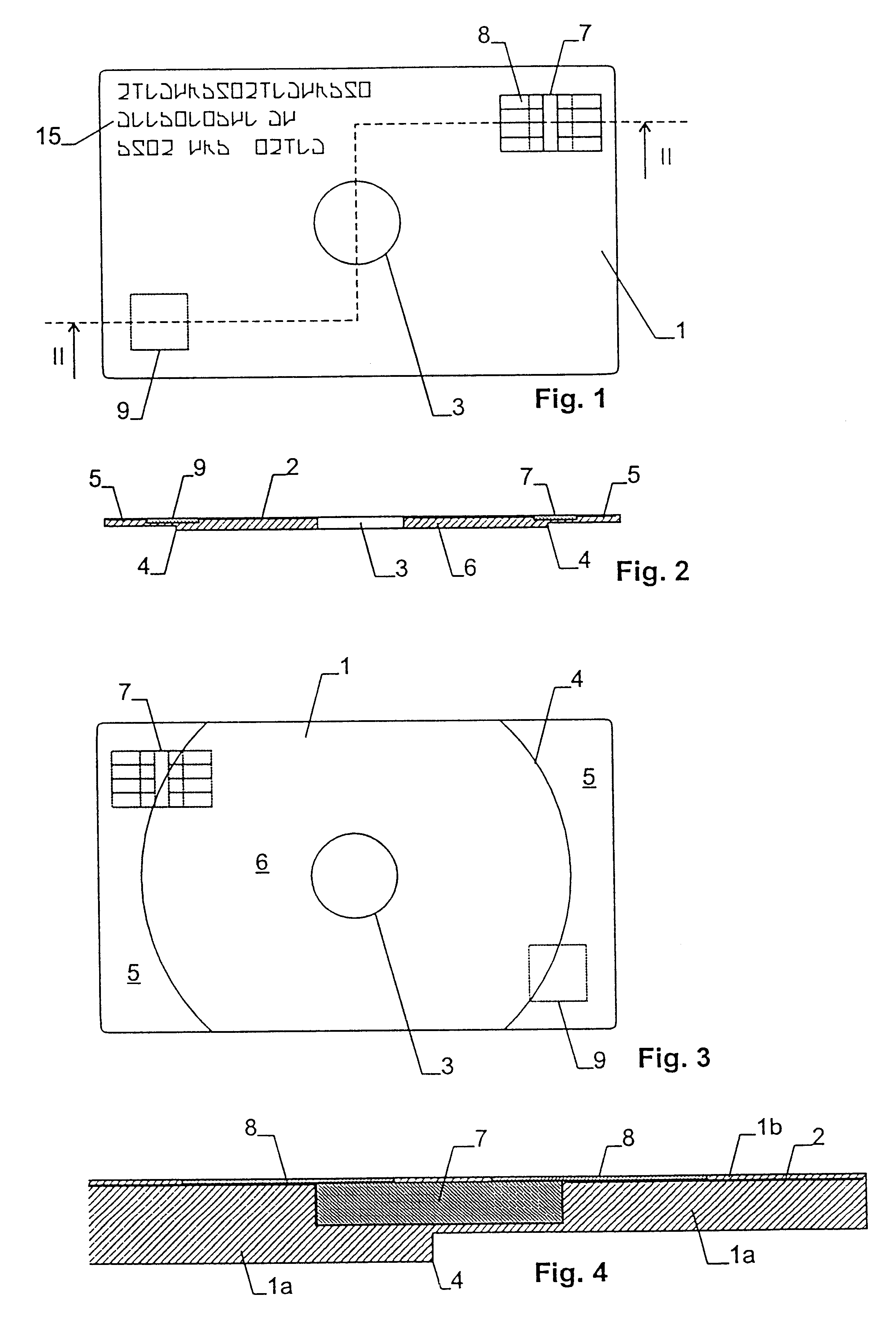

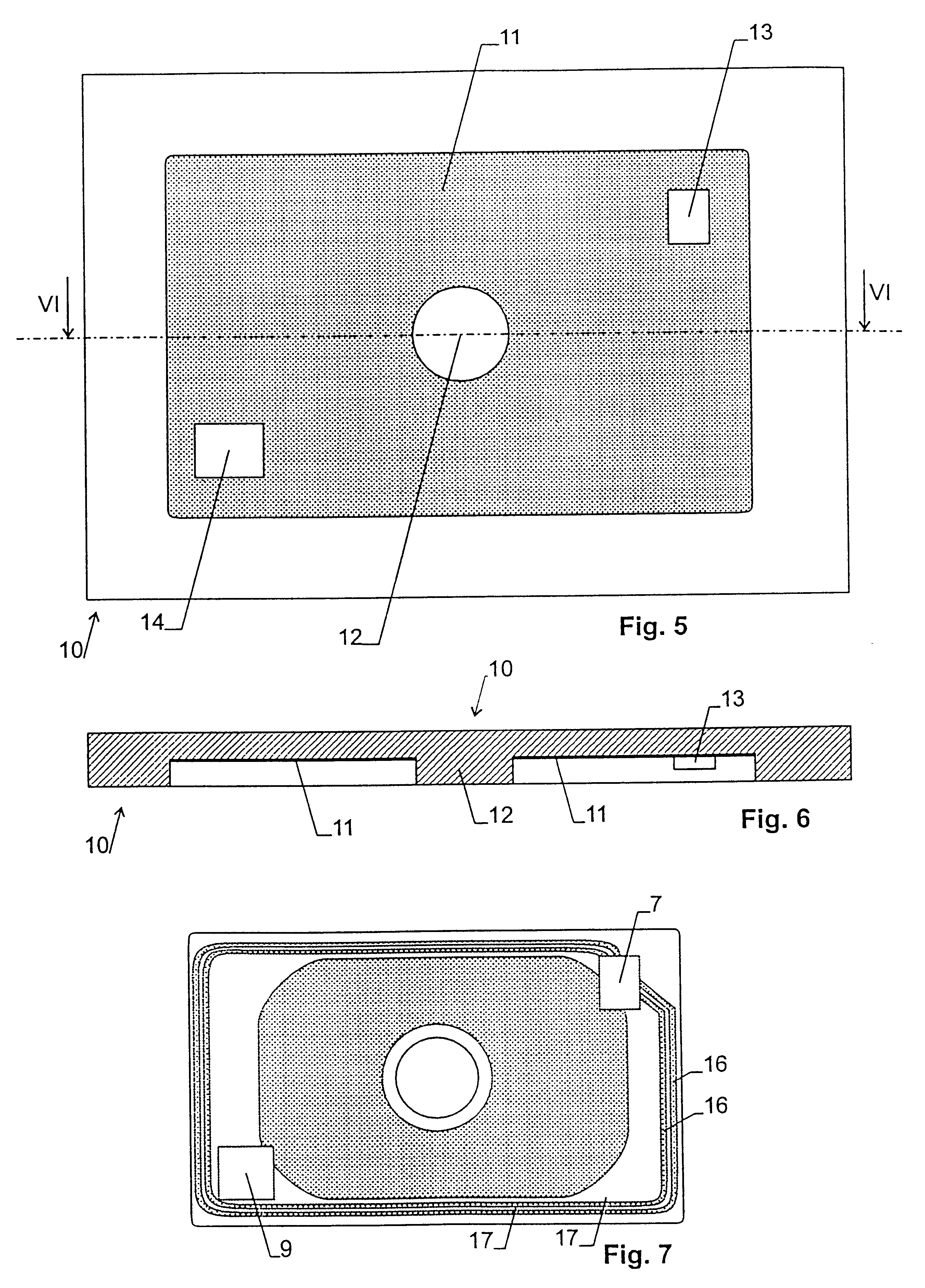

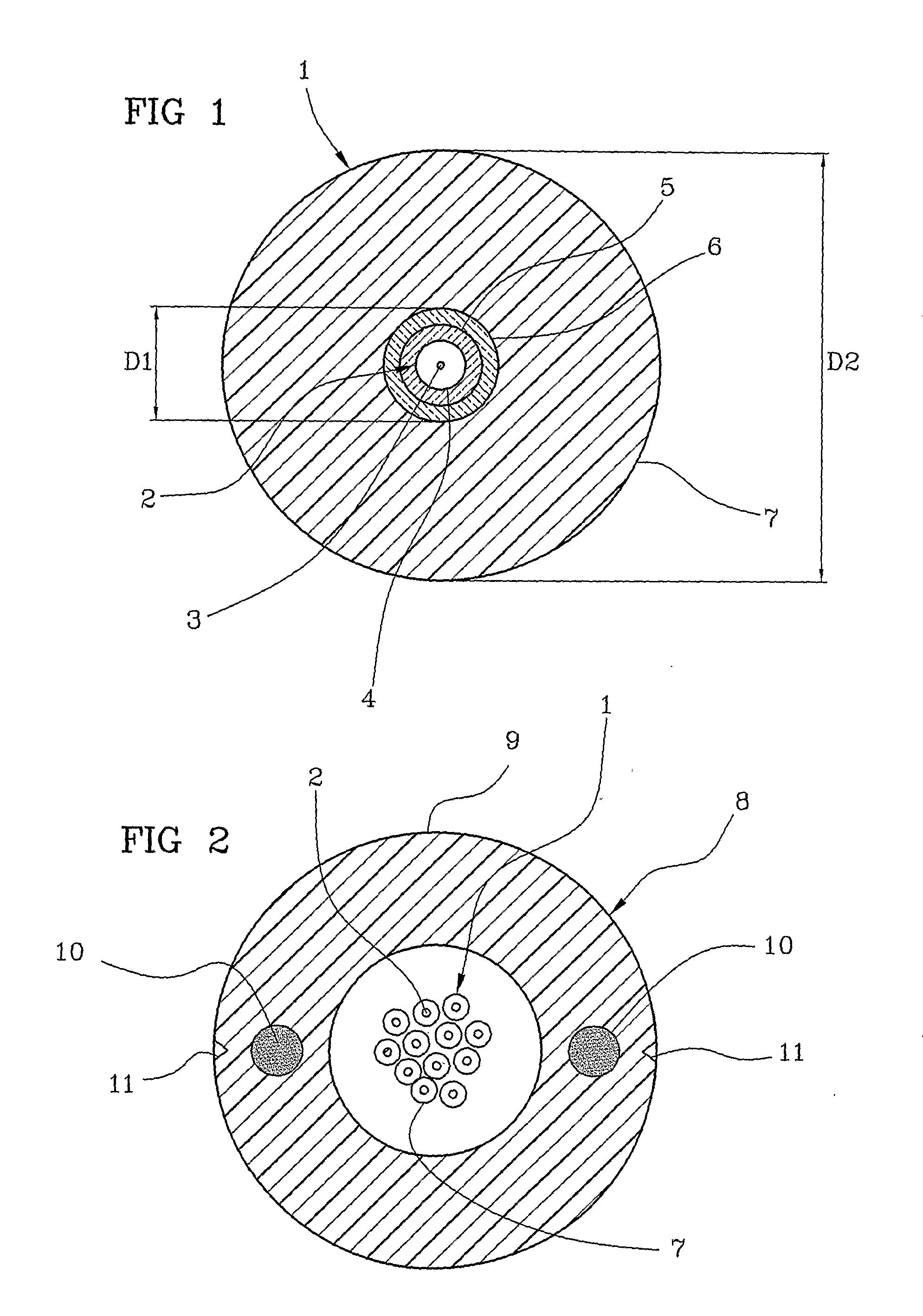

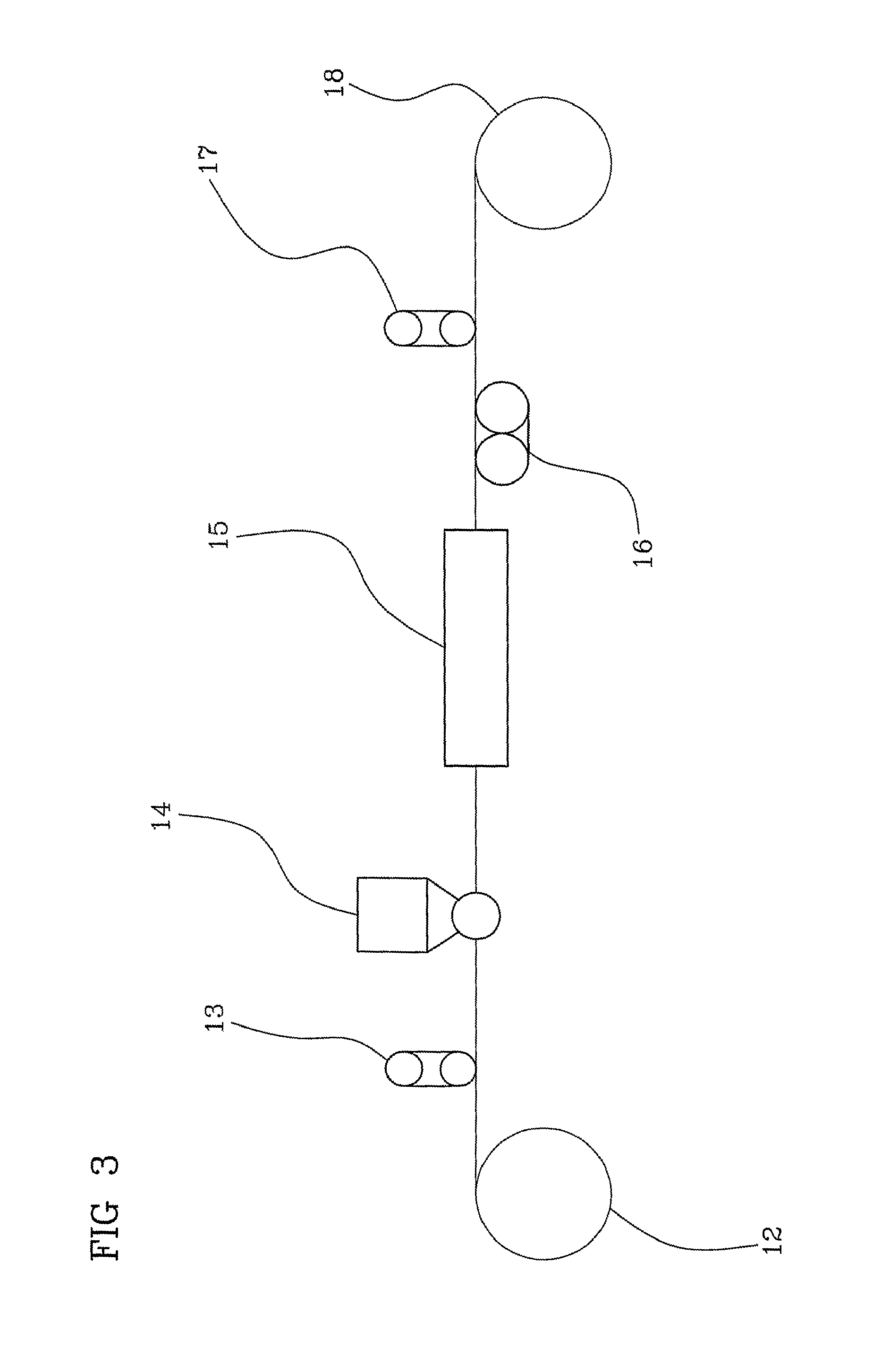

Carrier card capable of storing information data in CD or DVD formats

InactiveUS6542444B1Easy to manufactureEasy to installCombination recordingOther printing matterSemiconductor chipComputer science

A data carrier and a method of making the data carrier. The data carrier includes a plastic body, at least one metal layer arranged in or on the plastic body for carrying information encoded in one of CD and DVD format, a semiconductor chip arranged in the plastic body, a communication device for connecting the semiconductor chip with an external apparatus, and a mechanism for balancing an unbalance caused by the semiconductor chip. The method includes providing a matrix carrying the encoded information in a relief, the matrix including at least one projection, casting a first part of the plastic body against the matrix, forming the metal layer on a side of the first part of the plastic body disposed adjacent the matrix, forming at least one recess in the plastic body with the projection, and coating the metal layer with a second part of the plastic body, wherein the recess in the plastic body is capable of receiving the semiconductor chip.

Owner:OMD INT

Lockable enteral feeding adapter

Owner:UTAH MEDICAL PRODS

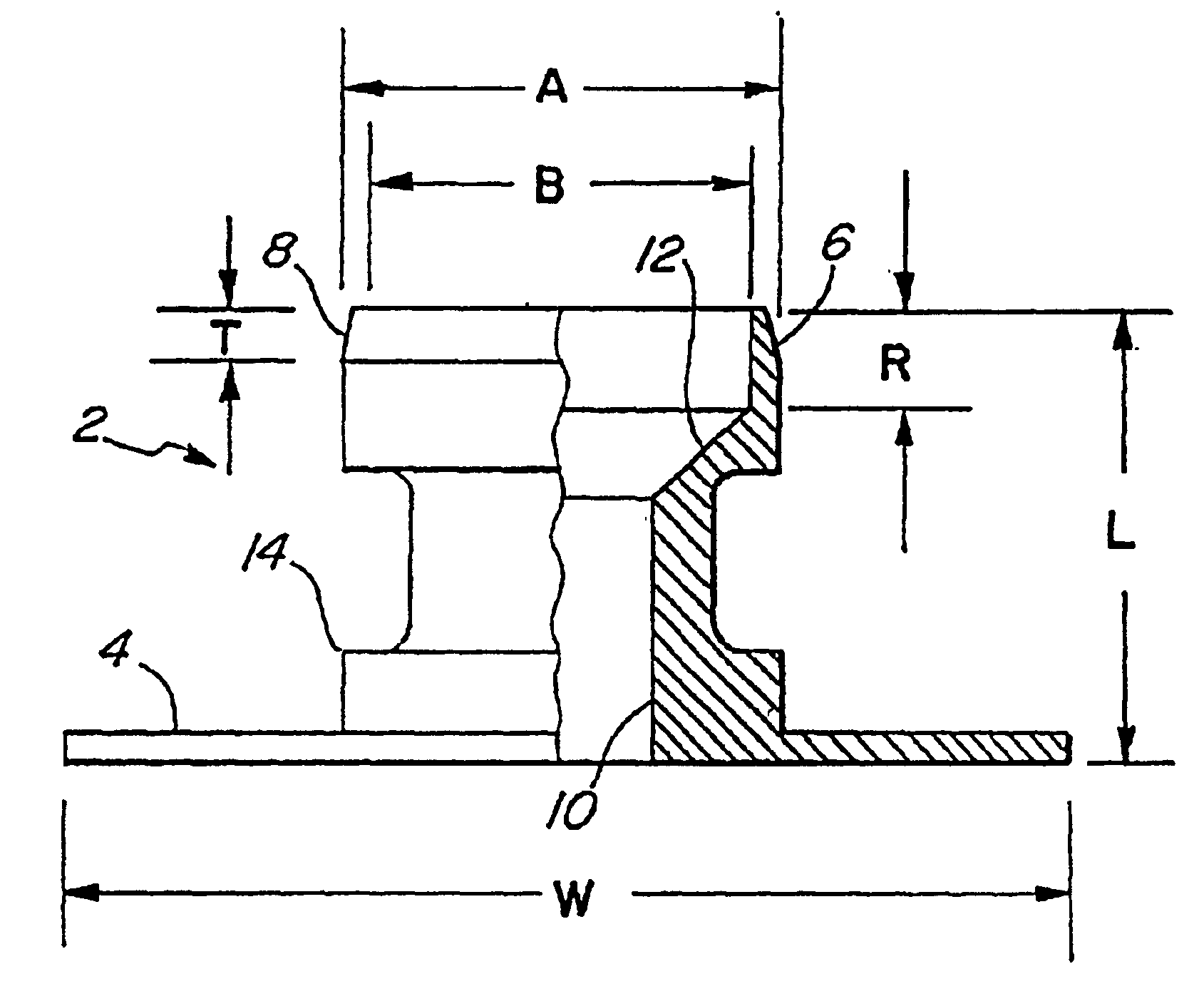

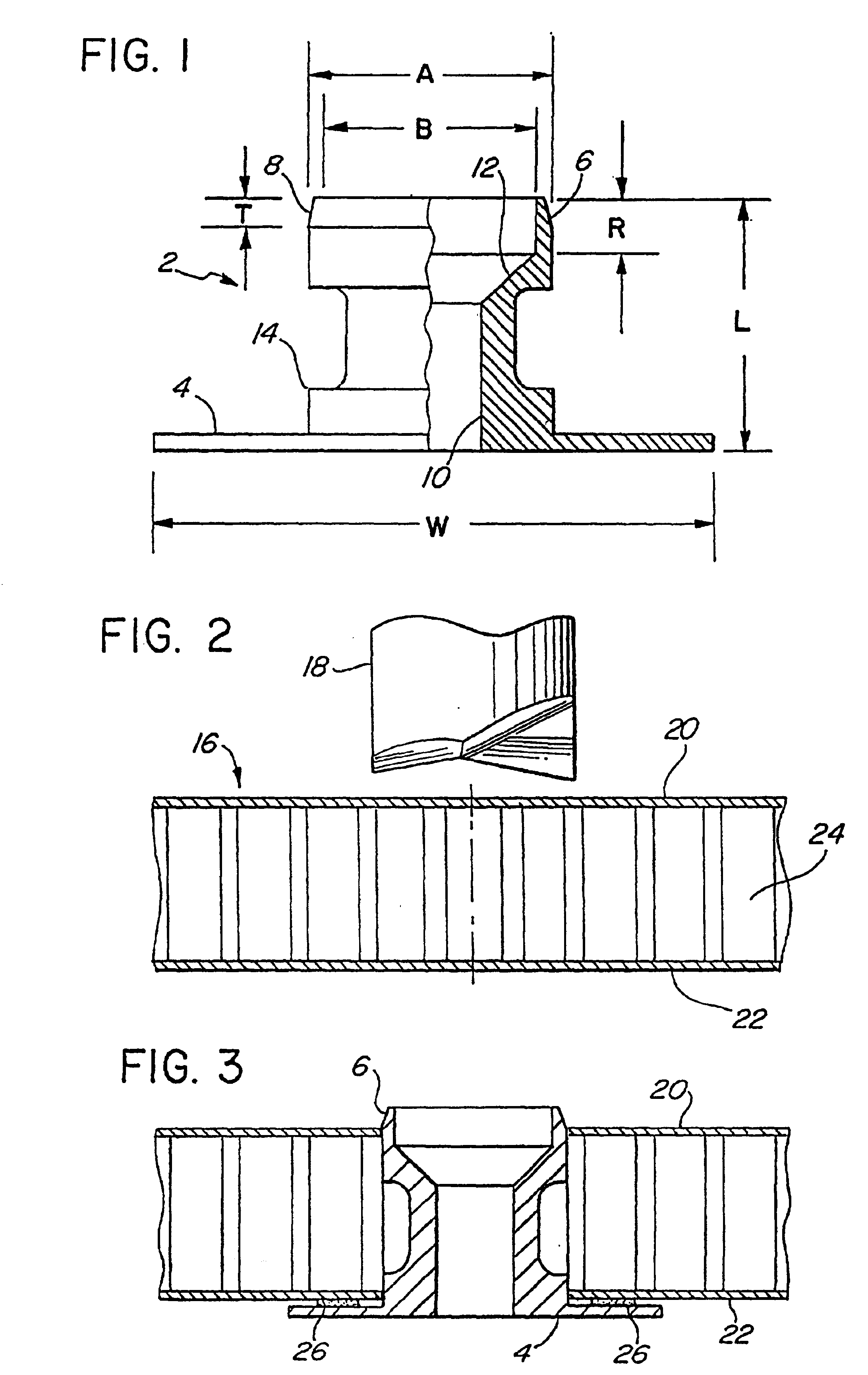

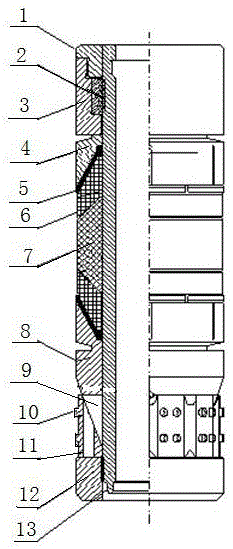

Flush panel spacer and method and apparatus of installing the same

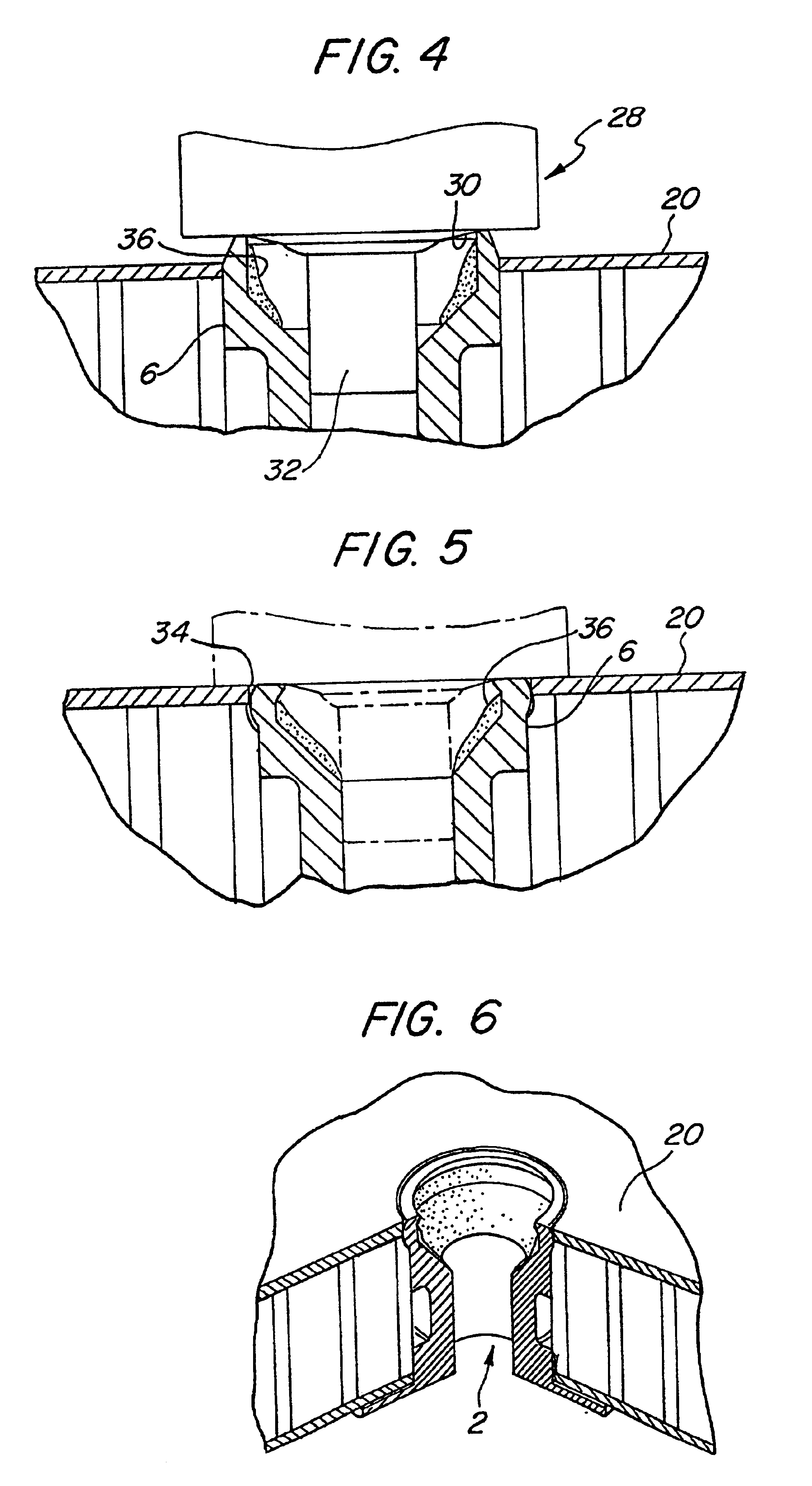

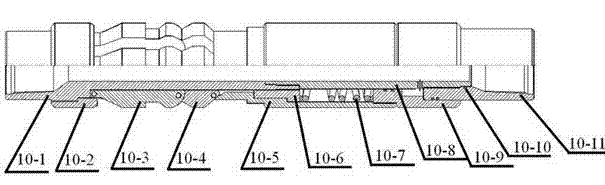

InactiveUS6862863B2Large inner diameterEasy to installSheet joiningBuilding componentsSealantSandwich panel

A method of installing an insert in a sandwich panel for mounting a fastener includes making a hole in the panel and inserting a spacer having a height greater than the thickness of the panel. An entrance rim of the spacer extends above an upper surface of the panel and a setting tool exerts a force on the entrance rim to force it into the hole and to position an upper edge of the entrance rim flush with the panel surface. The spacer can include an annular groove on an interior wall of the entrance rim to facilitate the cold working deformation during an installation in the panel and a hole engaging surface to align and maintain the spacer within the hole. An outer exterior surface of the entrance rim can be indented and coated with a first sealing compound to ensure a watertight seal with the panel. A second sealant material can be provided within the entrance rim for sealing with a head of any fastener extending through the spacer. An improved floor panel with spacer is accordingly provided for aircraft.

Owner:SPS TECH LLC

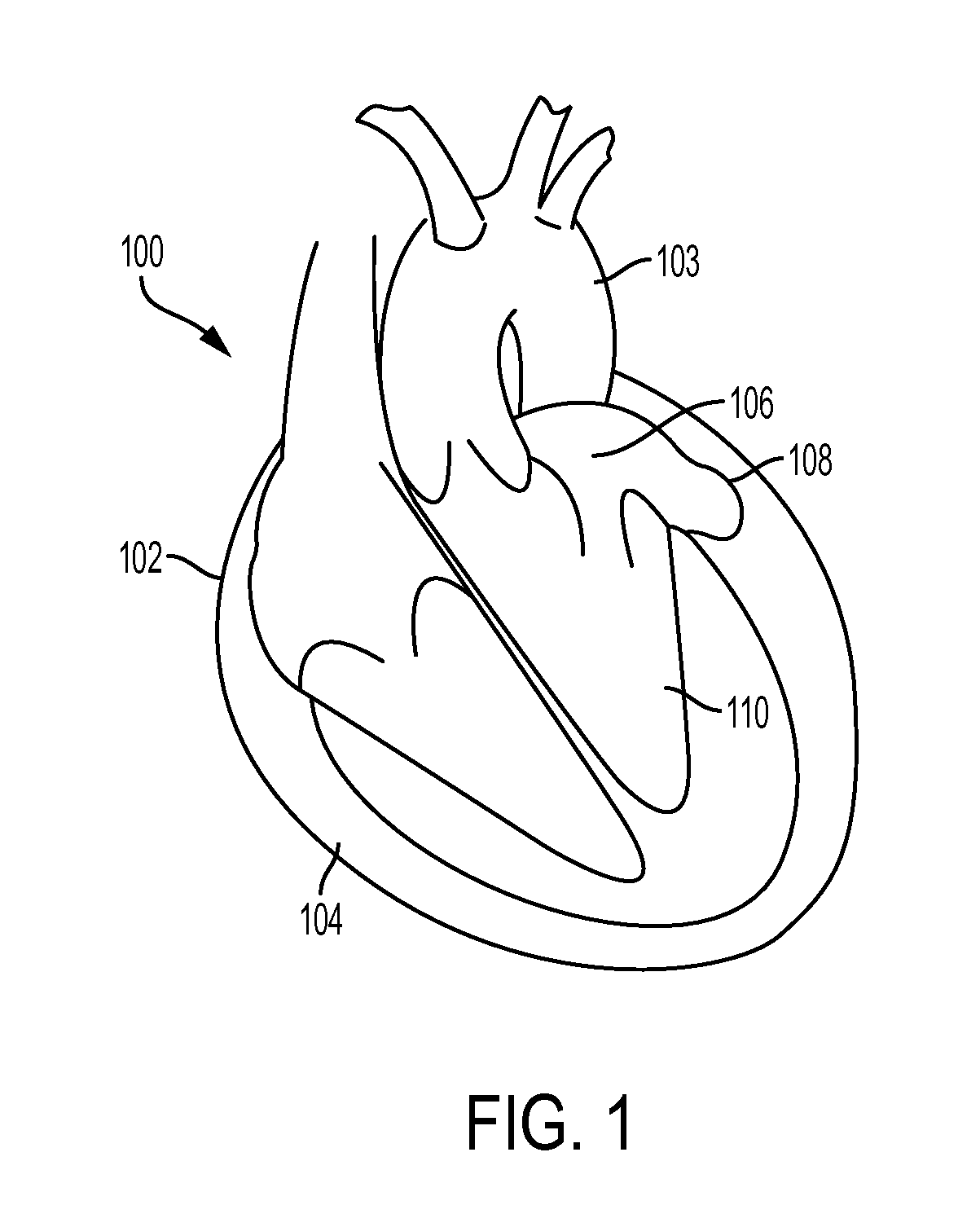

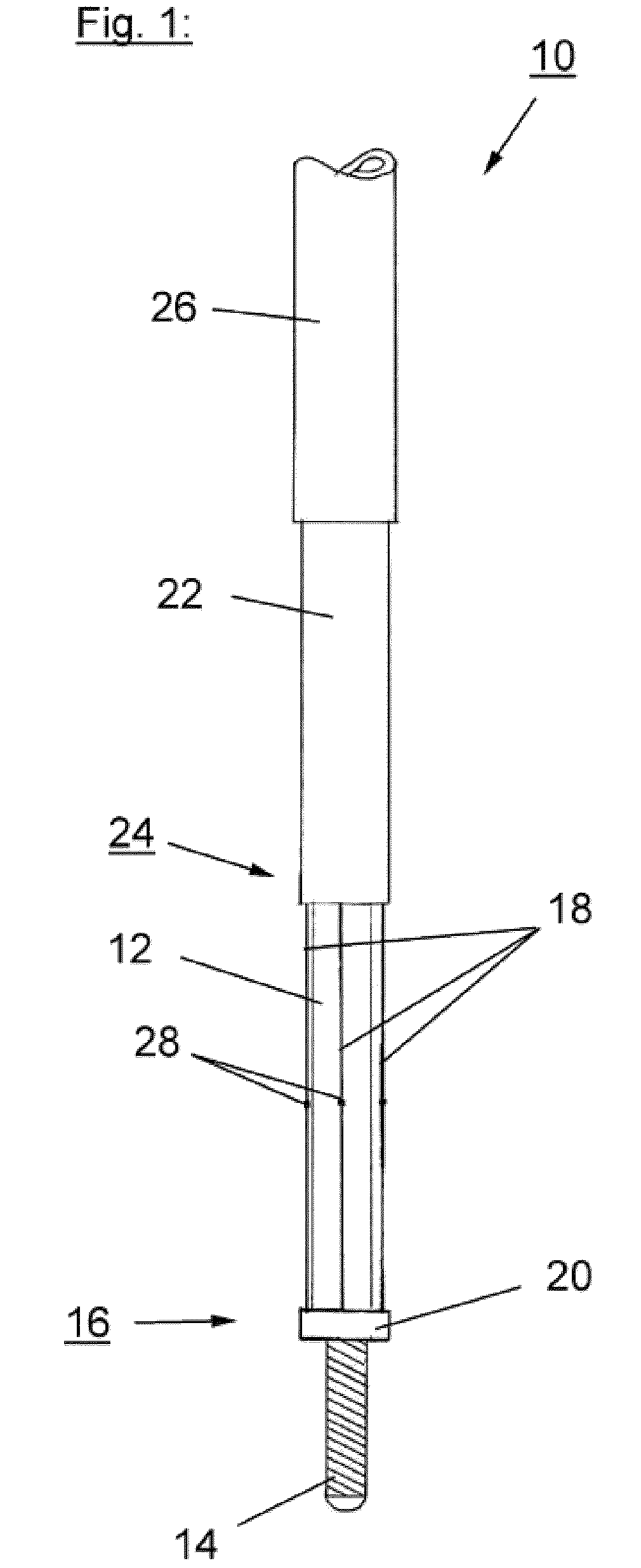

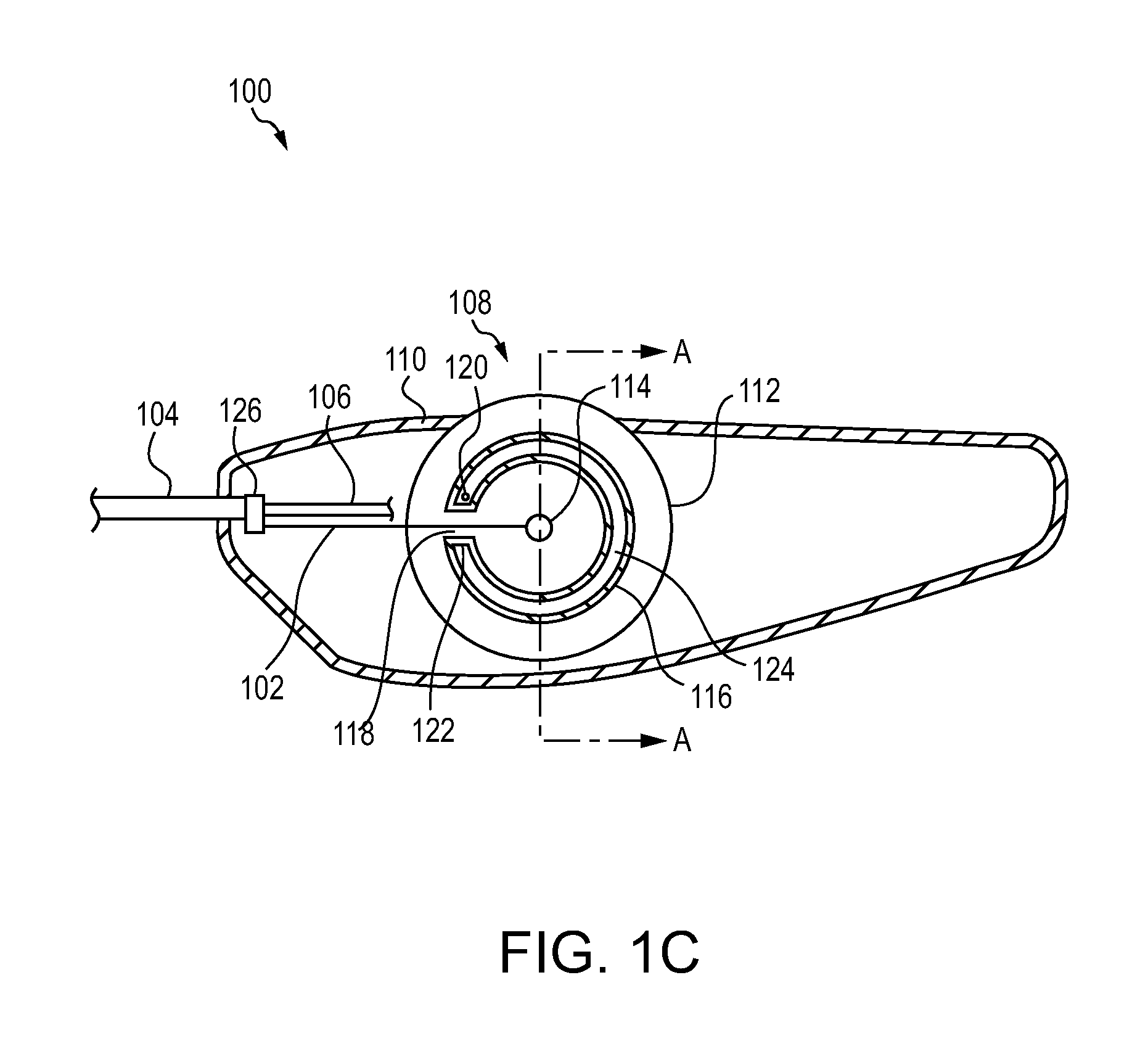

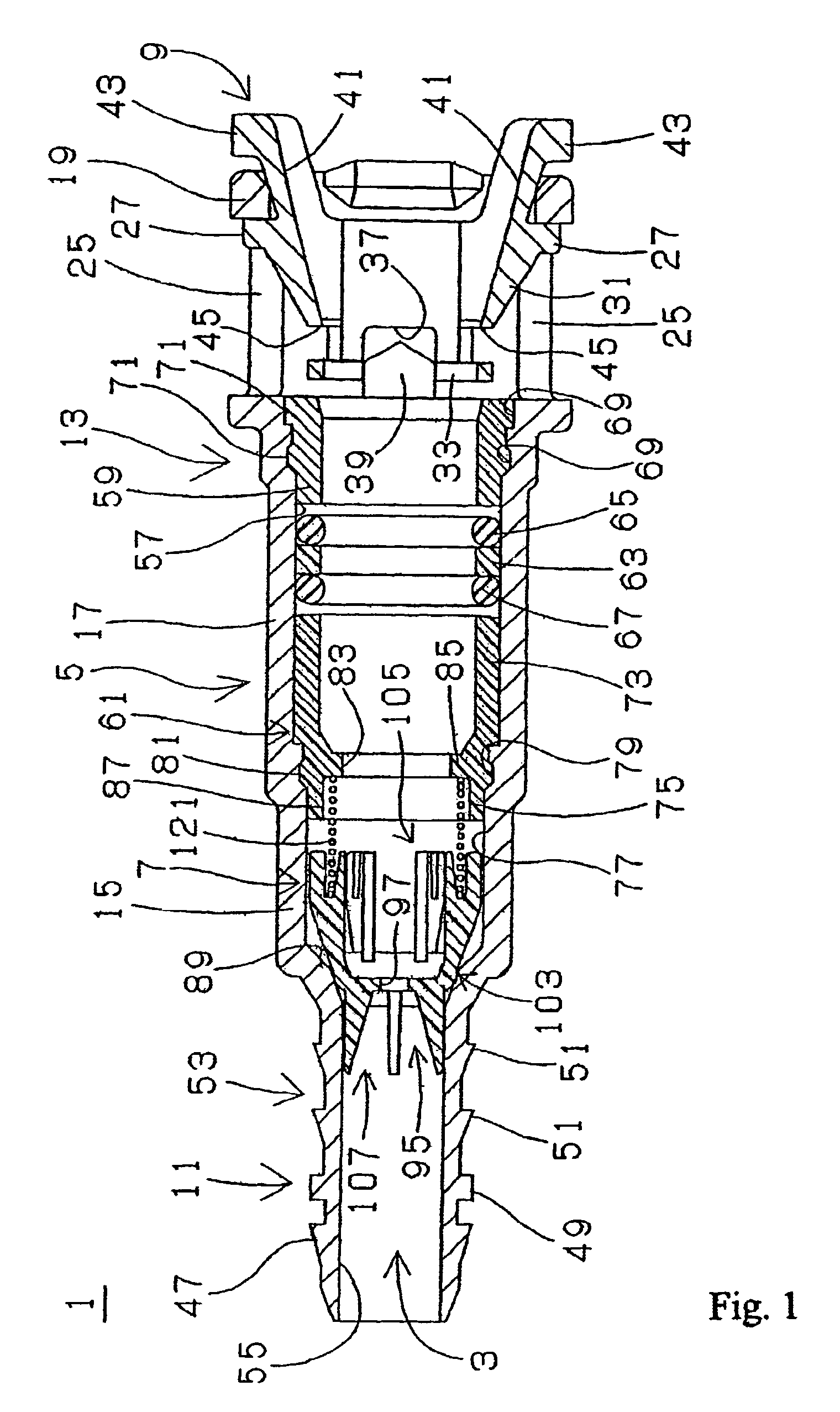

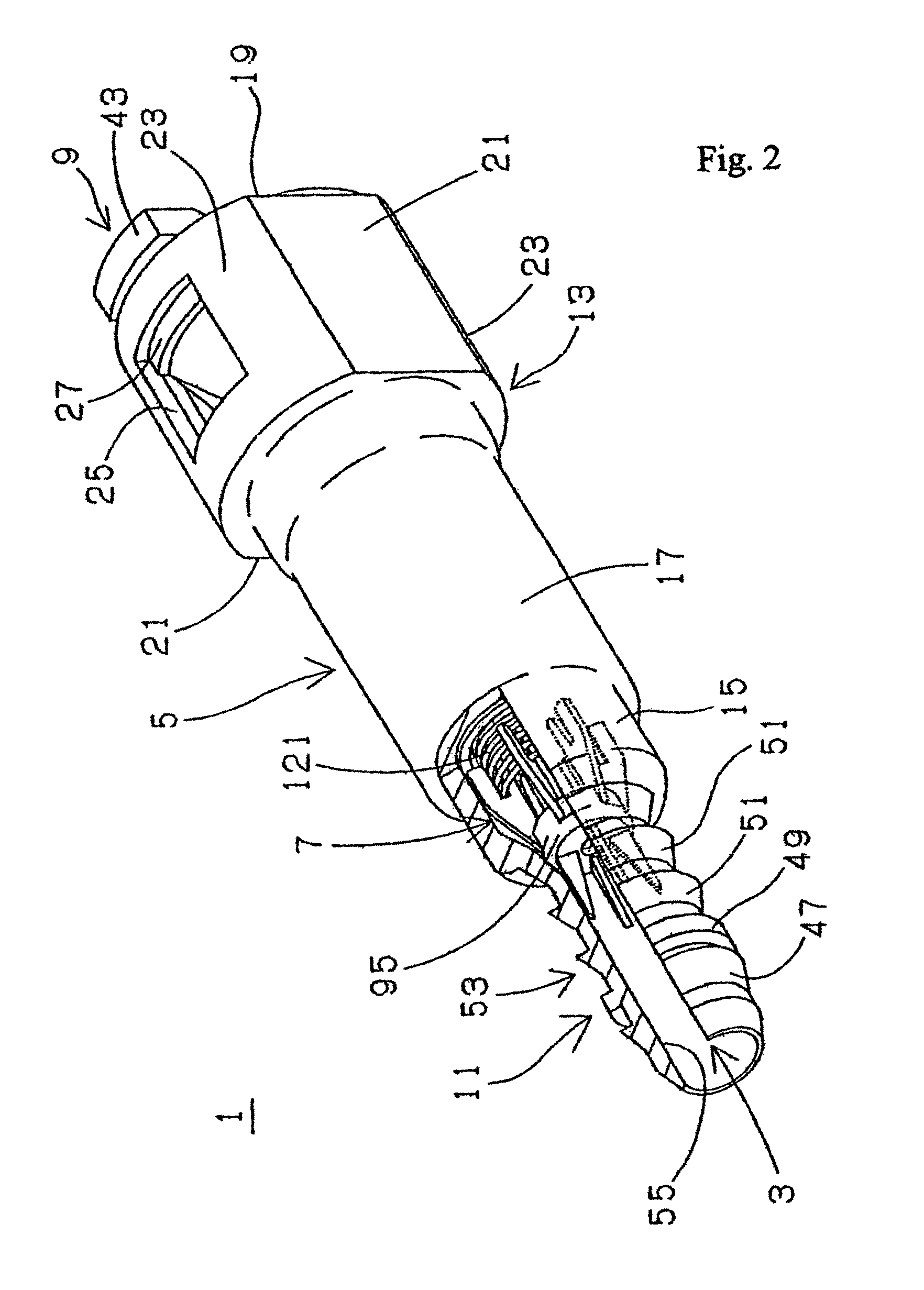

Scoring catheter and method for treating diseased heart valves

ActiveUS20090306582A1Prevents and reduces adverse and inflammatory effectLarge inner diameterCannulasDilatorsHeart valveDiseases heart valve

The present invention provides a valvuloplasty catheter which has a scoring element at its distal part to score stenotic, calcified heart valves in radial direction and to make the single valve flaps / leaflets work again. In addition to this, the device could comprise an attached balloon to post-dilate the valve after the scoring procedure. To reduce a future recalcification, the scoring element and / or the balloon have a pharmacologic coating on their outer surface.

Owner:BAVARIA MEDIZIN TECH

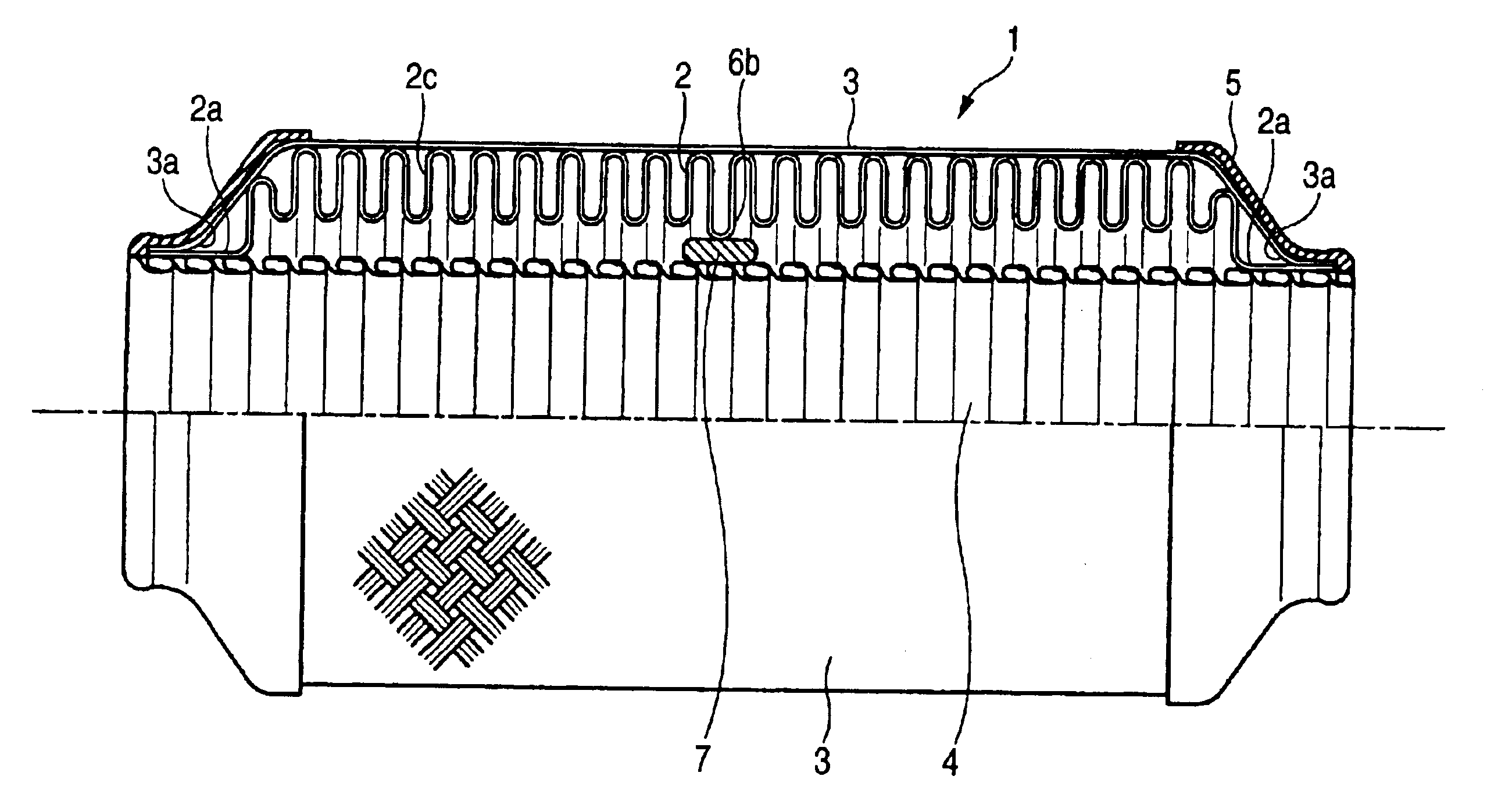

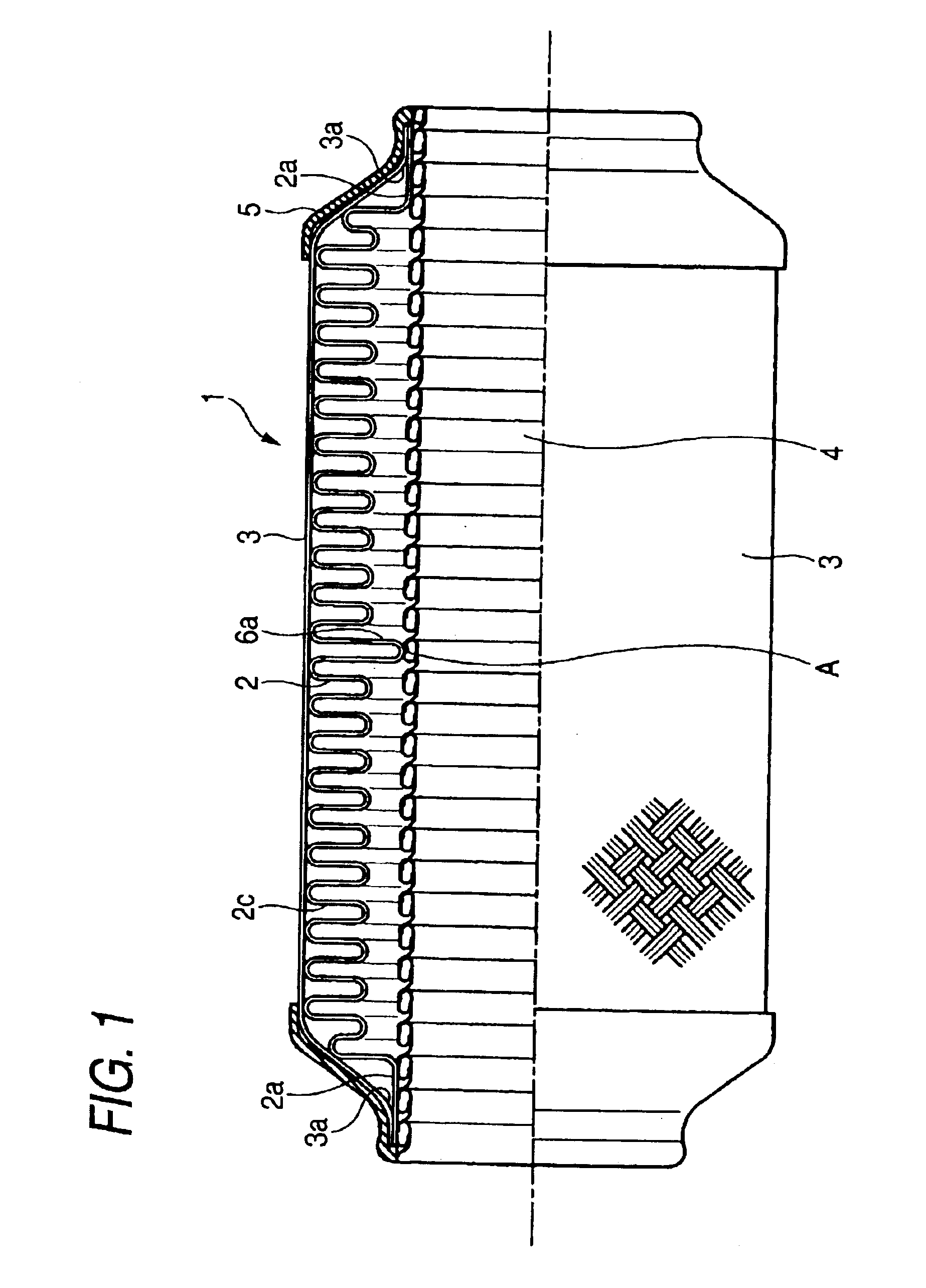

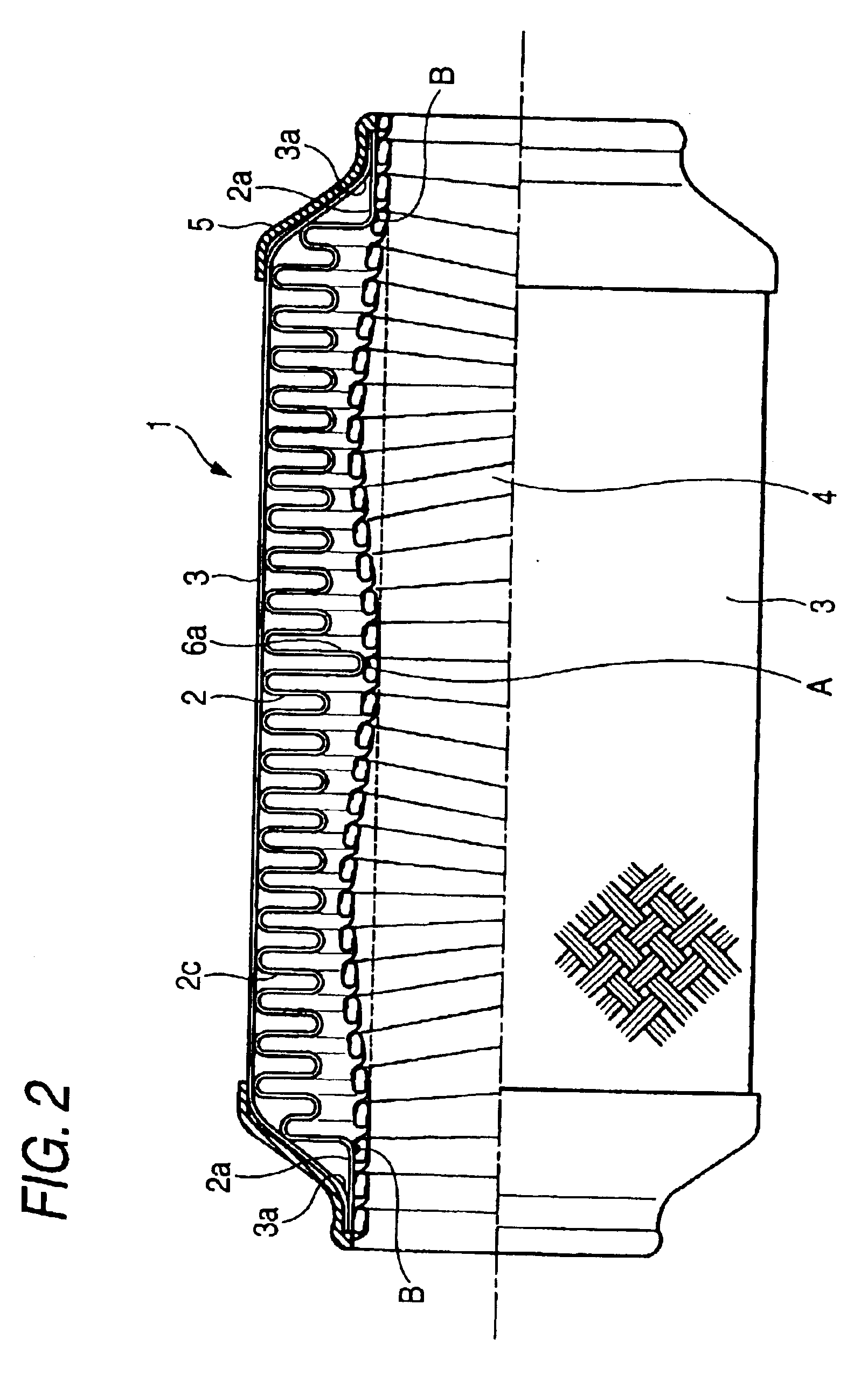

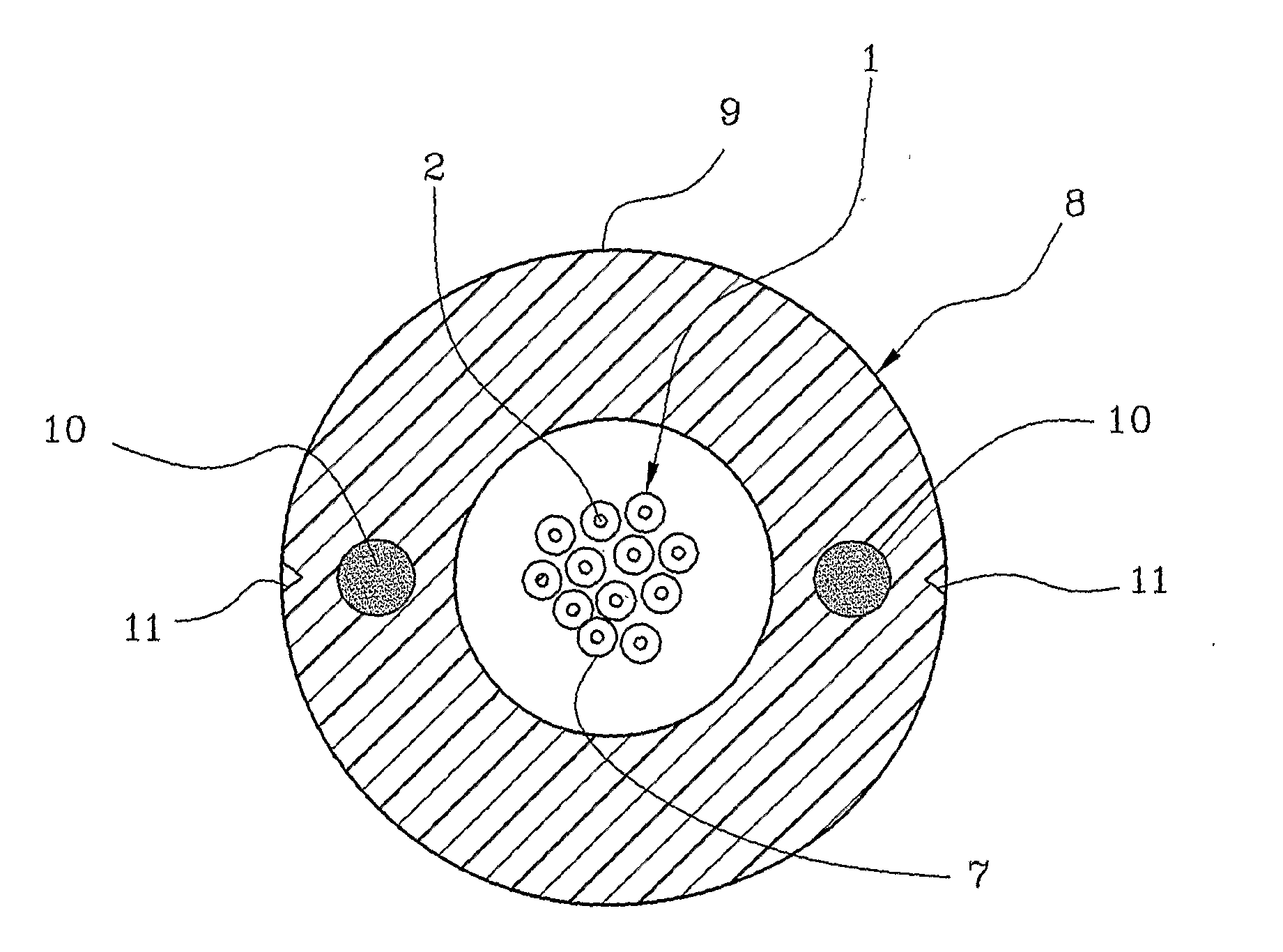

Flexible tube

InactiveUS6848478B2Limitation of vibration amplitudeLarge inner diameterExhaust apparatusSilencing apparatusVibration amplitudeEngineering

A small-diameter part in the vicinity of a center of a bellows portion in an axial direction has a smaller diameter. A tip end of the small-diameter part contacts at a point A with an outer peripheral face of an interlock pipe. The interlock pipe vibrates with using the point A and points B in both ends as fulcrums. The addition of the point A reduces distance between the fulcrums. In accordance with this reduction, deflection amount of the interlock pipe is reduced and vibration amplitude of the interlock pipe is decreased. Therefore, the interlock pipe does not contact with the bellows portion so that troubles such as noises can be prevented from occurring.

Owner:CALSONIC KANSEI CORP

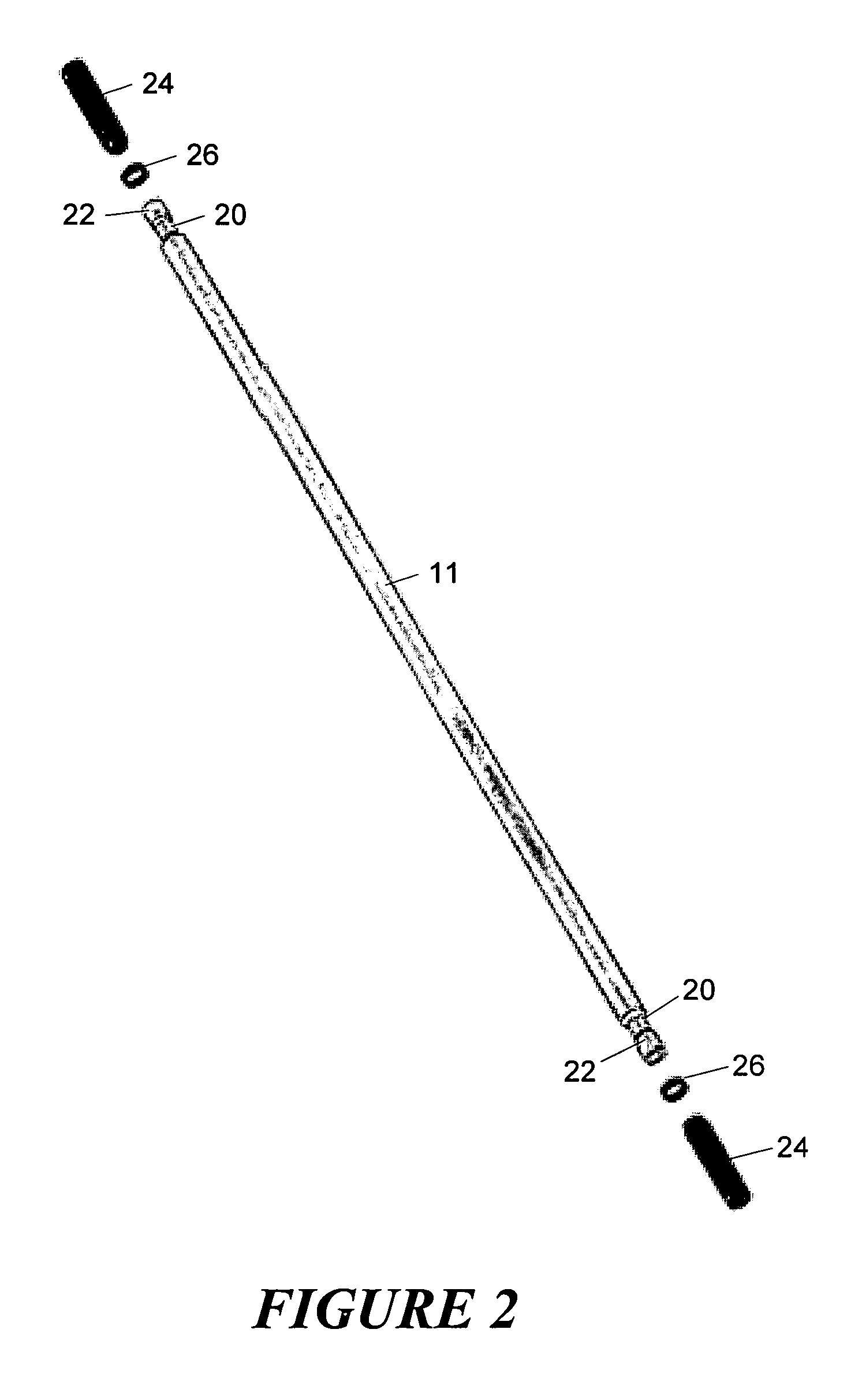

Telecommunication cable equipped with tight-buffered optical fibers

ActiveUS20100254668A1Reduce installationClosely guardedOptical fibre with multilayer core/claddingFibre mechanical structuresFiberTelecommunications cable

A telecommunication cable is equipped with at least one optical fiber coated by a tight buffer layer made from a polymeric material having an ultimate elongation equal to or lower than 100% and an ultimate tensile strength equal to or lower than 10 MPa. The above combination of features of the polymeric material forming the buffer layer provides an optical fiber which is effectively protected during installation operations and during use, and at the same time can be easily stripped by an installer without using any stripping tools, simply by applying a small pressure with his fingertips and a moderate tearing force along the fiber axis.

Owner:PRYSMIAN SPA

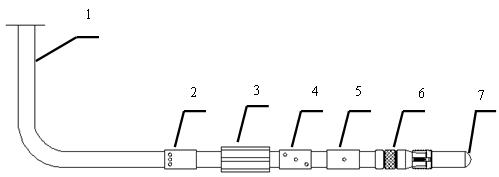

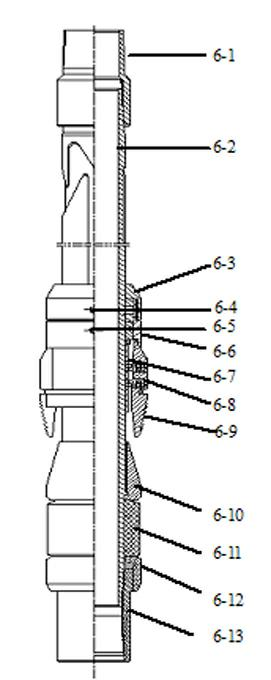

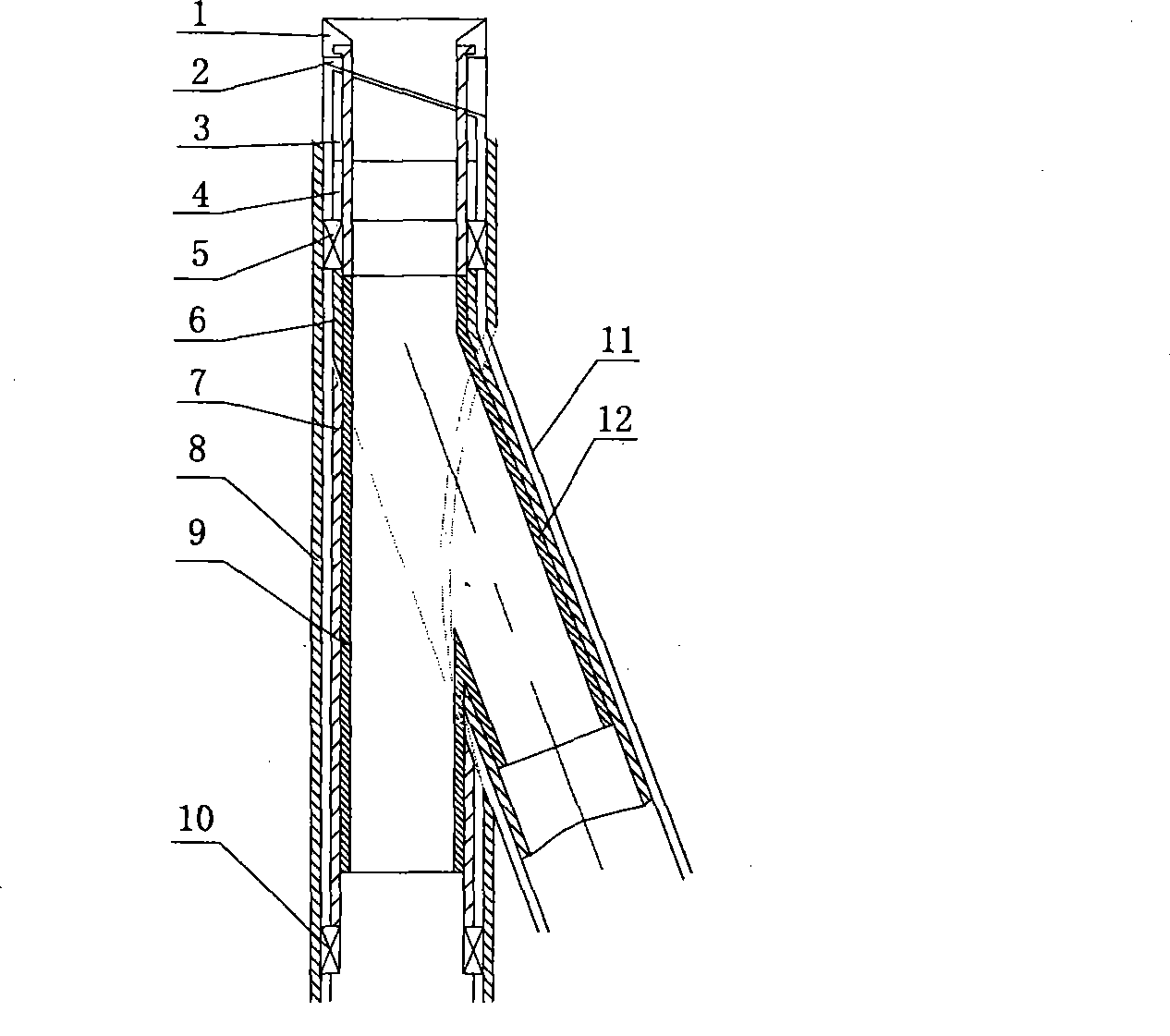

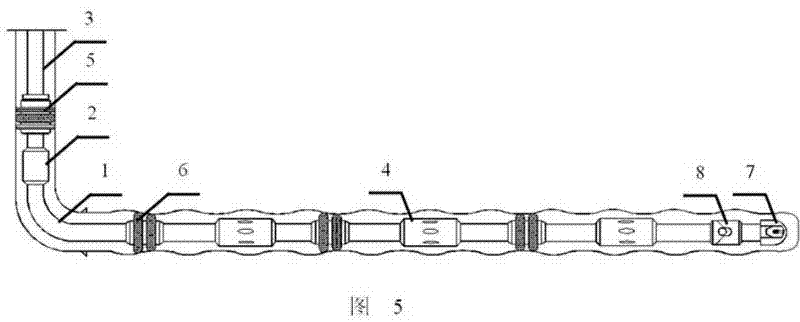

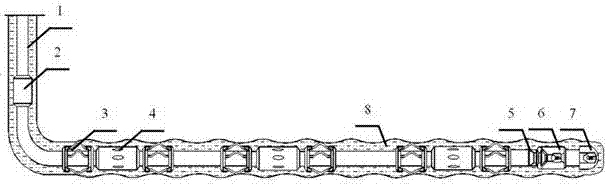

Continuous oil pipe sectional sand-blasting perforation casing fracturing pipe column and casing fracturing method

ActiveCN102691493ARemarkable effectSignificant progressDrilling rodsFluid removalSand blastingHorizontal wells

The invention discloses a continuous oil pipe sectional sand-blasting perforation casing fracturing pipe column and a casing fracturing method, which are suitable for application in vertical wells and horizontal wells in the petroleum industry, in particular for sectional fracturing of unconventional oil-gas reservoir horizontal wells such as tight sandstone wells. The fracturing pipe column comprises a safety joint, a centralizer, a hydraulic jet tool and a reverse circulation valve, which are connected to a continuous oil pipe in sequence, wherein a mechanical continuous oil pipe fracturing packer is connected below the reverse circulation valve. The sectional casing fracturing method is used for placing the fracturing pipe column provided with the mechanical continuous oil pipe fracturing packer into a casing in a well through the continuous oil pipe; and by the method, a fracturing well section closest to the bottom of the well is fractured at first, and then the fracturing well section is packed by using the mechanical continuous oil pipe fracturing packer. By the continuous oil pipe sectional sand-blasting perforation casing fracturing pipe column and the casing fracturing method, a sand stopper is not needed as an isolation section, so that the sand stopper is not needed to be subjected to back flushing, the production cost is reduced, and multi-layer section fracturing operation for a short horizontal well section or straight well section can be realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

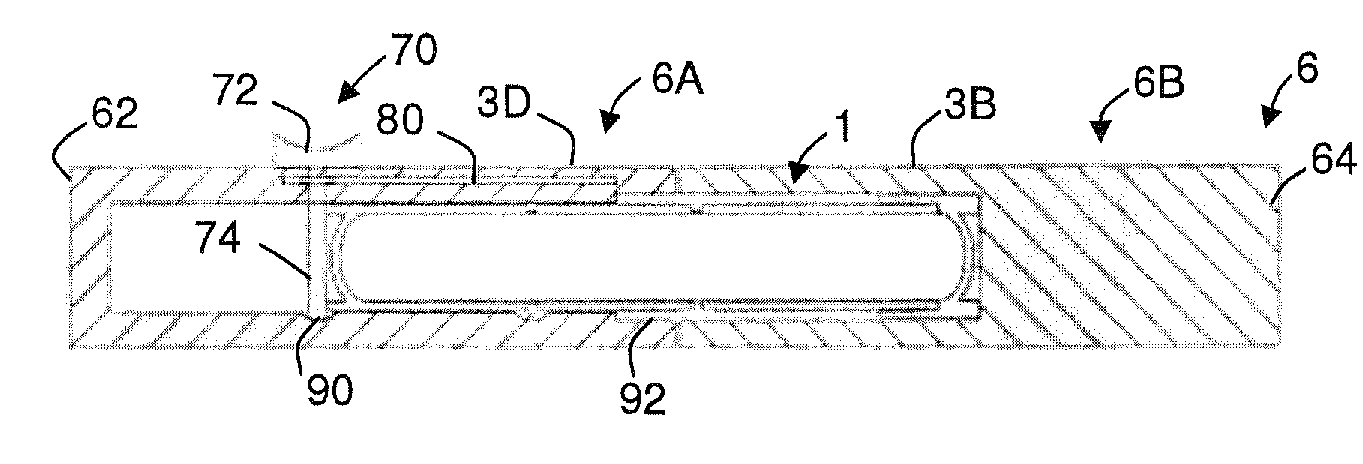

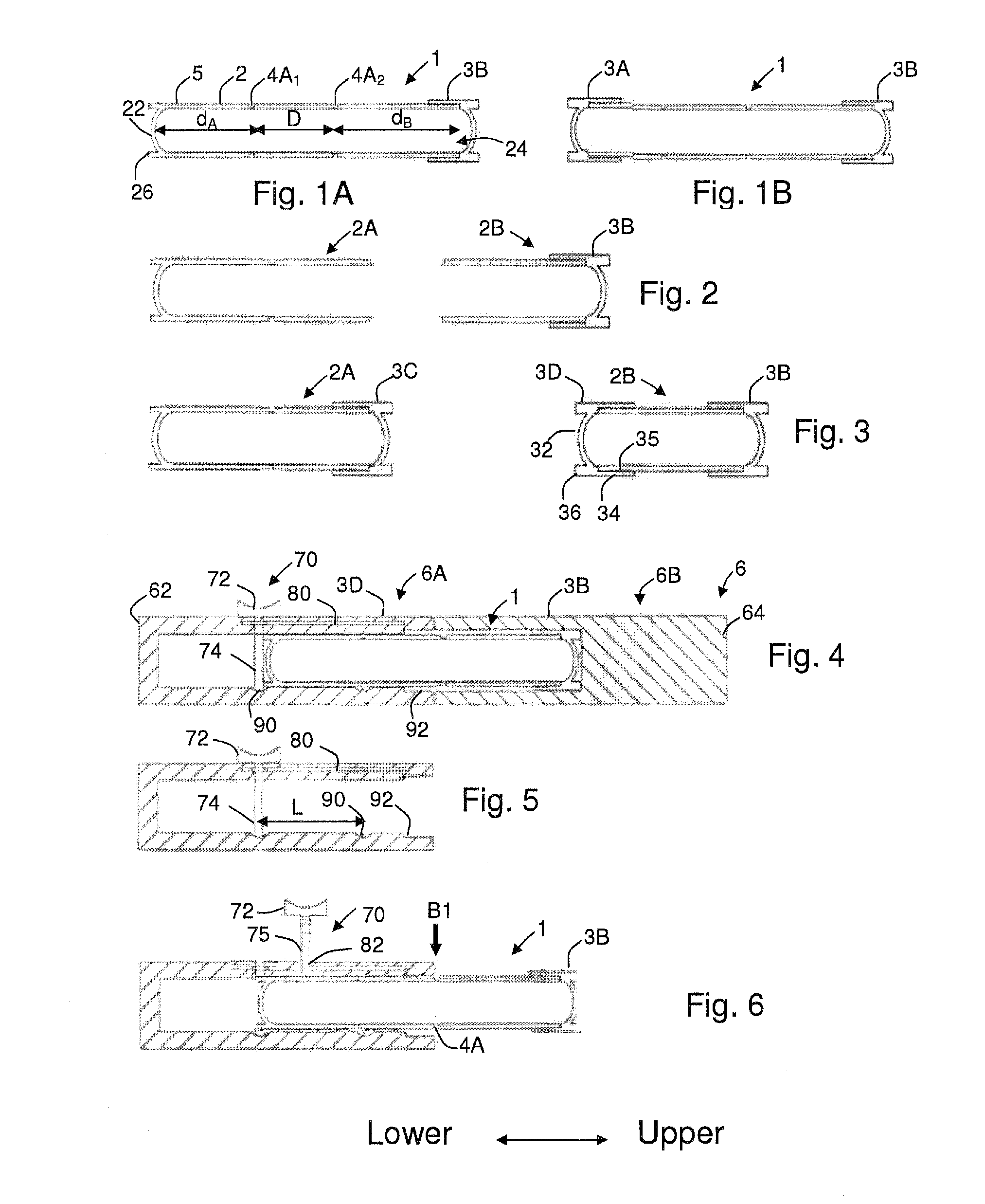

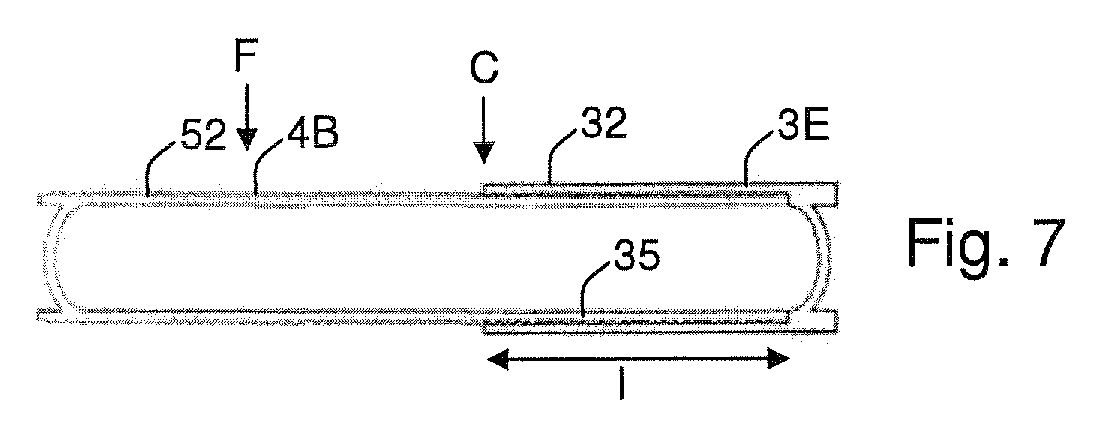

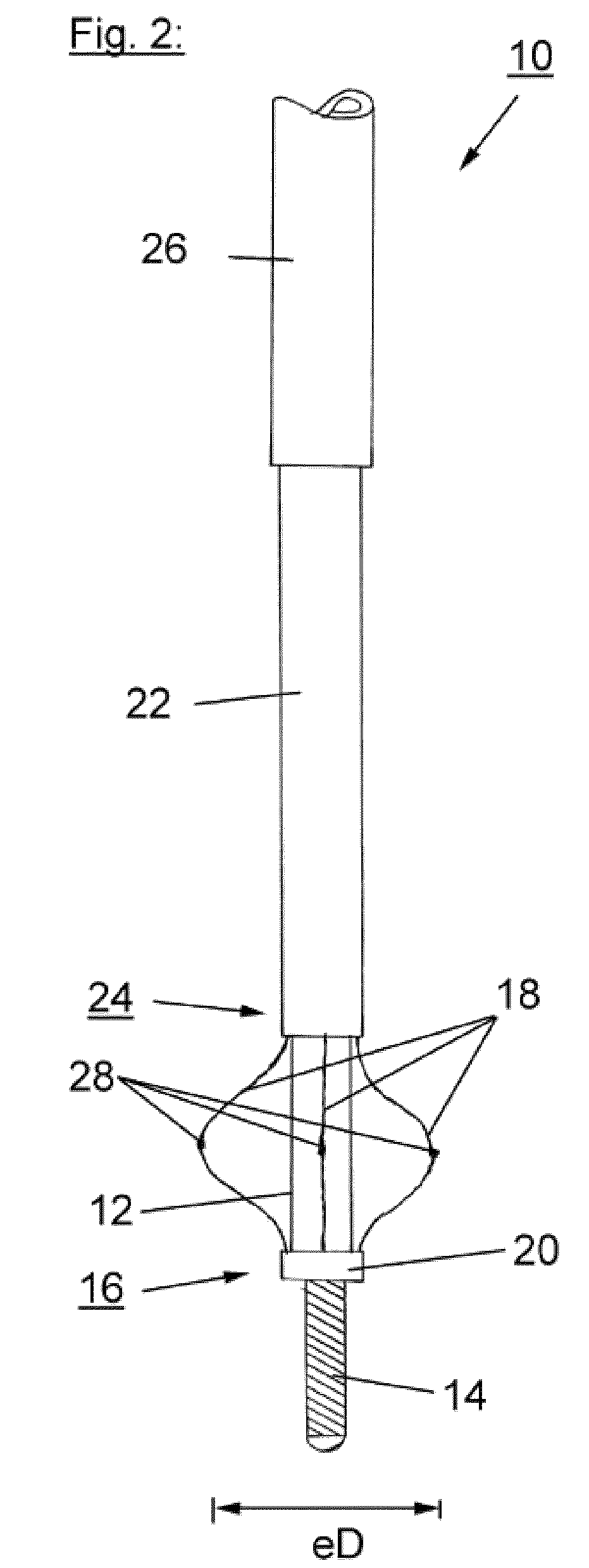

A storage vessel and a break tool for dividing such vessel

InactiveUS20100303688A1Low production costEasy to emptyPreparing sample for investigationLaboratory glasswaresScrew thread

The present invention concerns a breakable multi-specimen storage vessel. The vessel comprises a tubular container (2) comprising a lower end (2A) and an upper end (2B). At least said upper end (2B) has an open end opening (2C). The length of said container (2) is continuously formed and provided with break portions (4A, 4B) at predetermined positions alongside thereof. Said container (2) is adapted to be broken into a plurality of specimens. Further, an external surface of said container (2) may be provided with a screw thread (5). Said screw thread (5) is provided extending longitudinally along substantially the entire length of said tubular container (2) and said internal surface is substantially smooth. The invention further relates to a break tool (6) for breaking off specimens from a multi-specimen storage vessel such as a storage vessel according to the invention.

Owner:1CRYOBIO +1

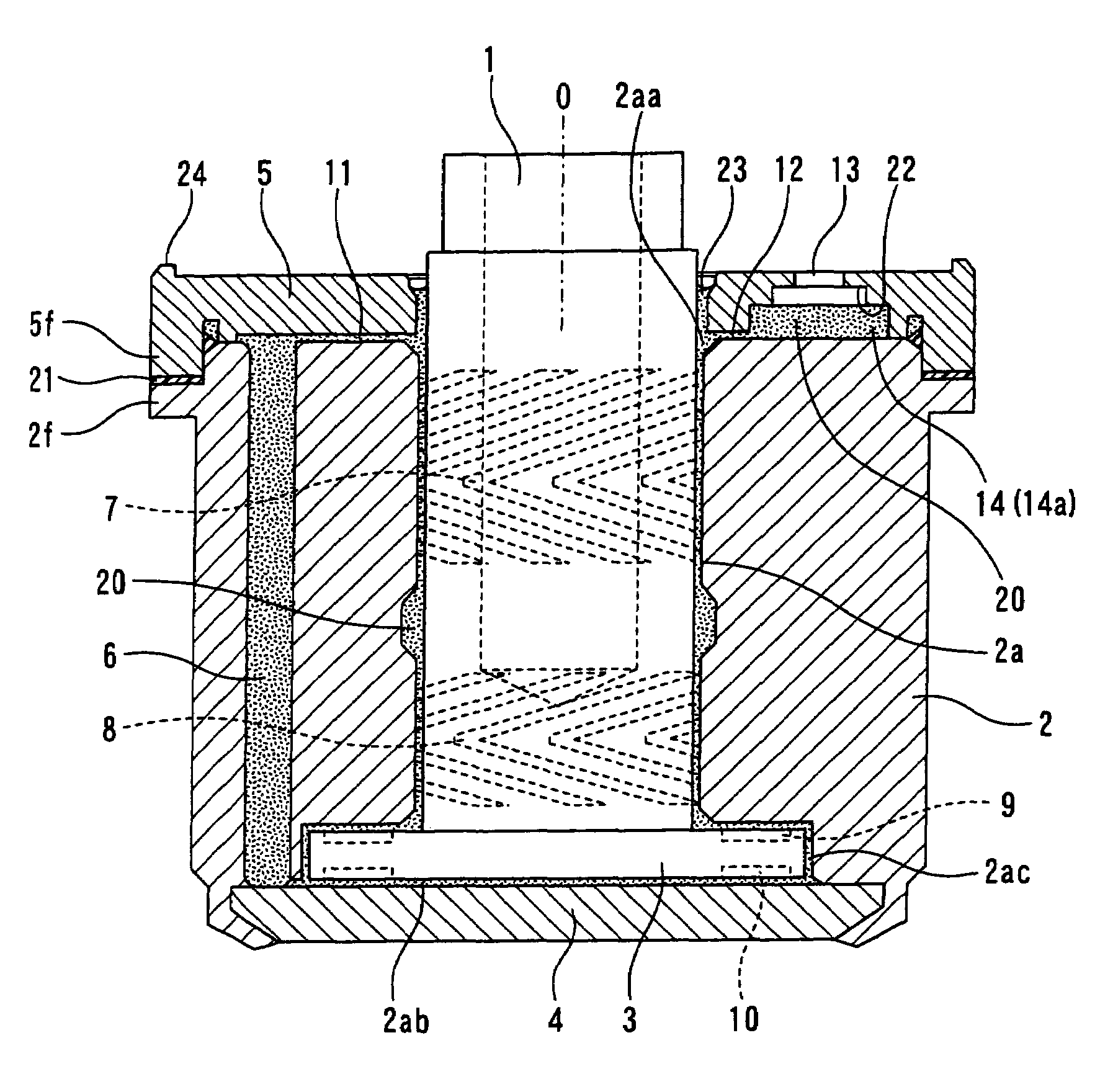

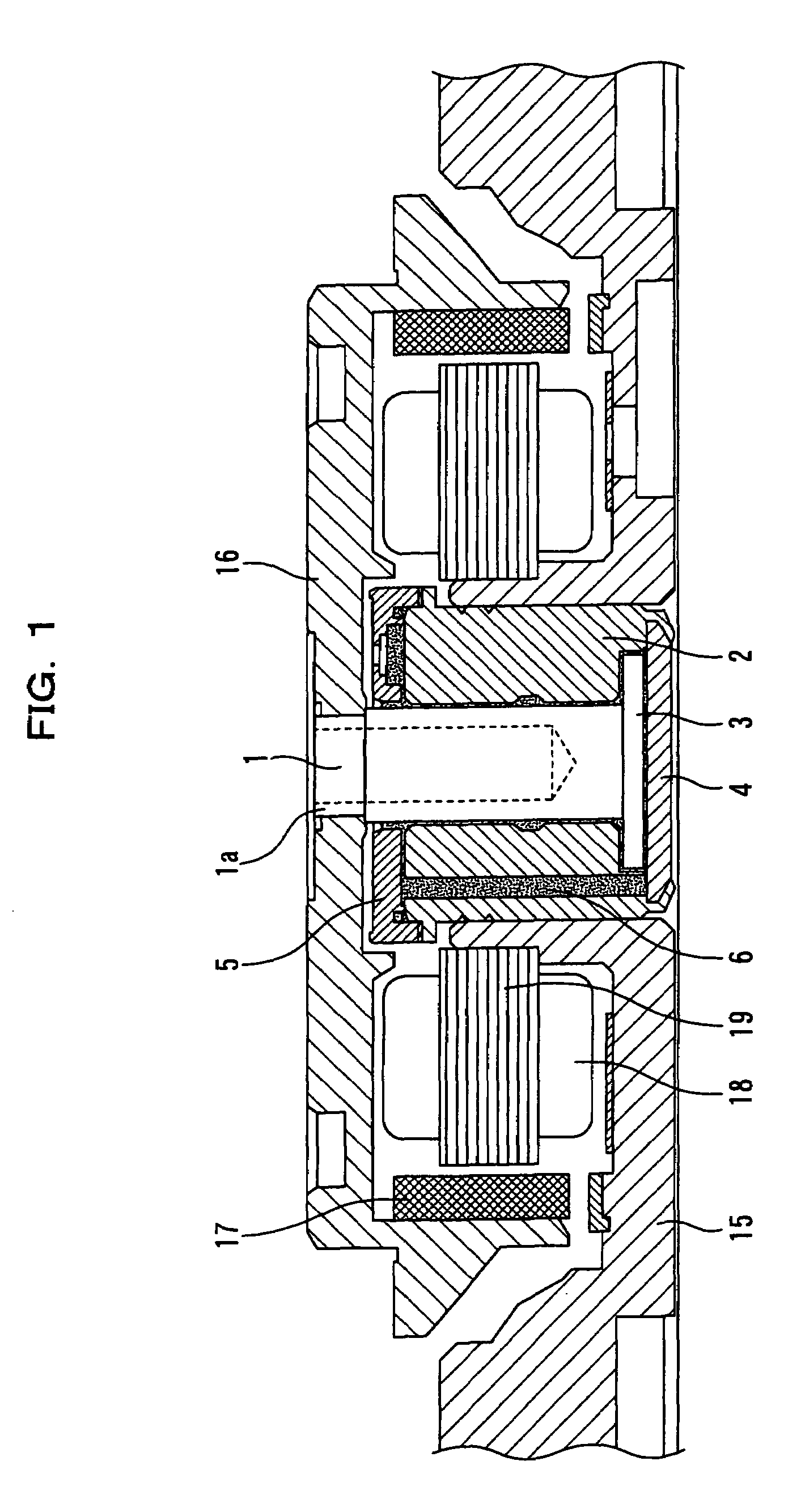

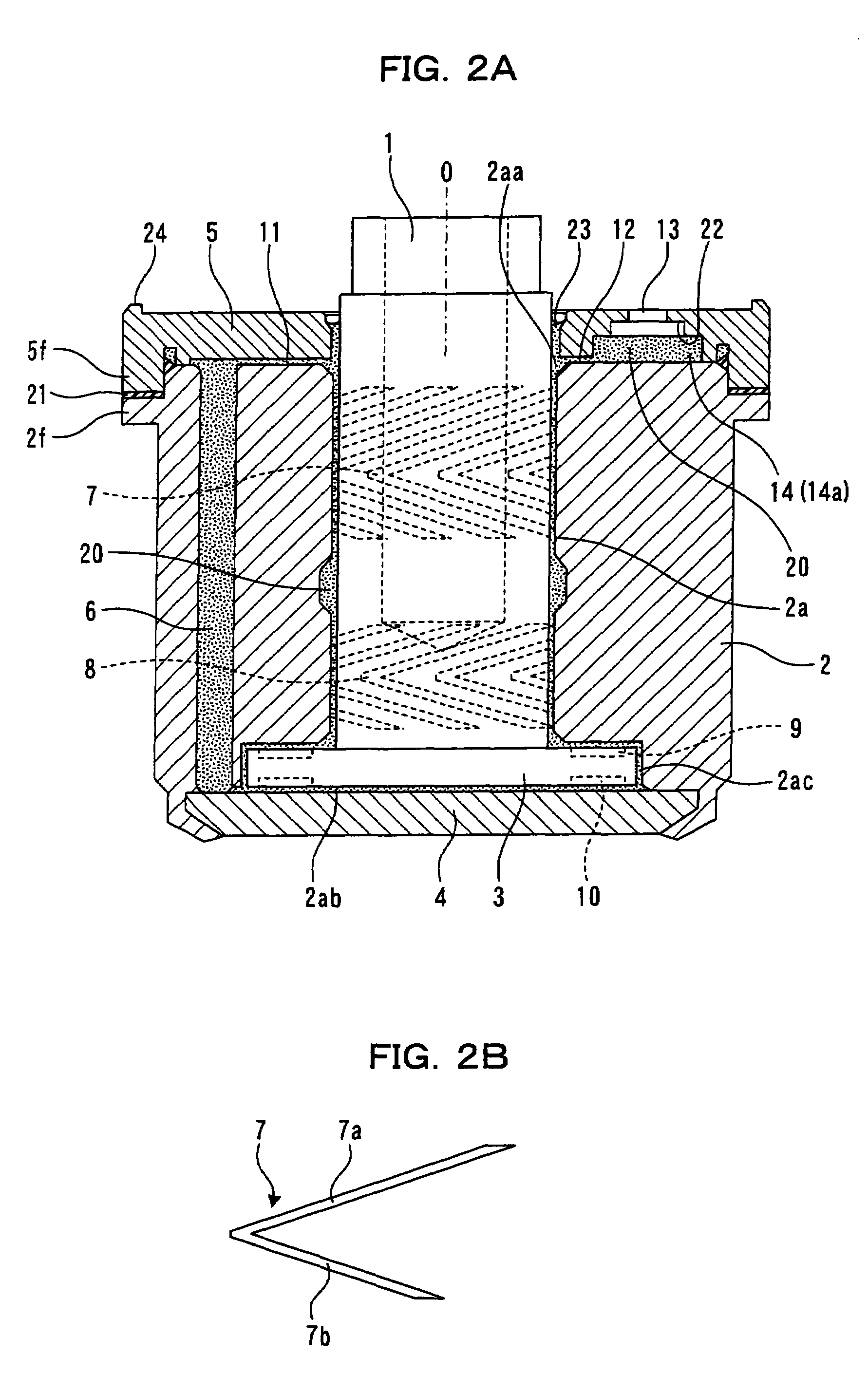

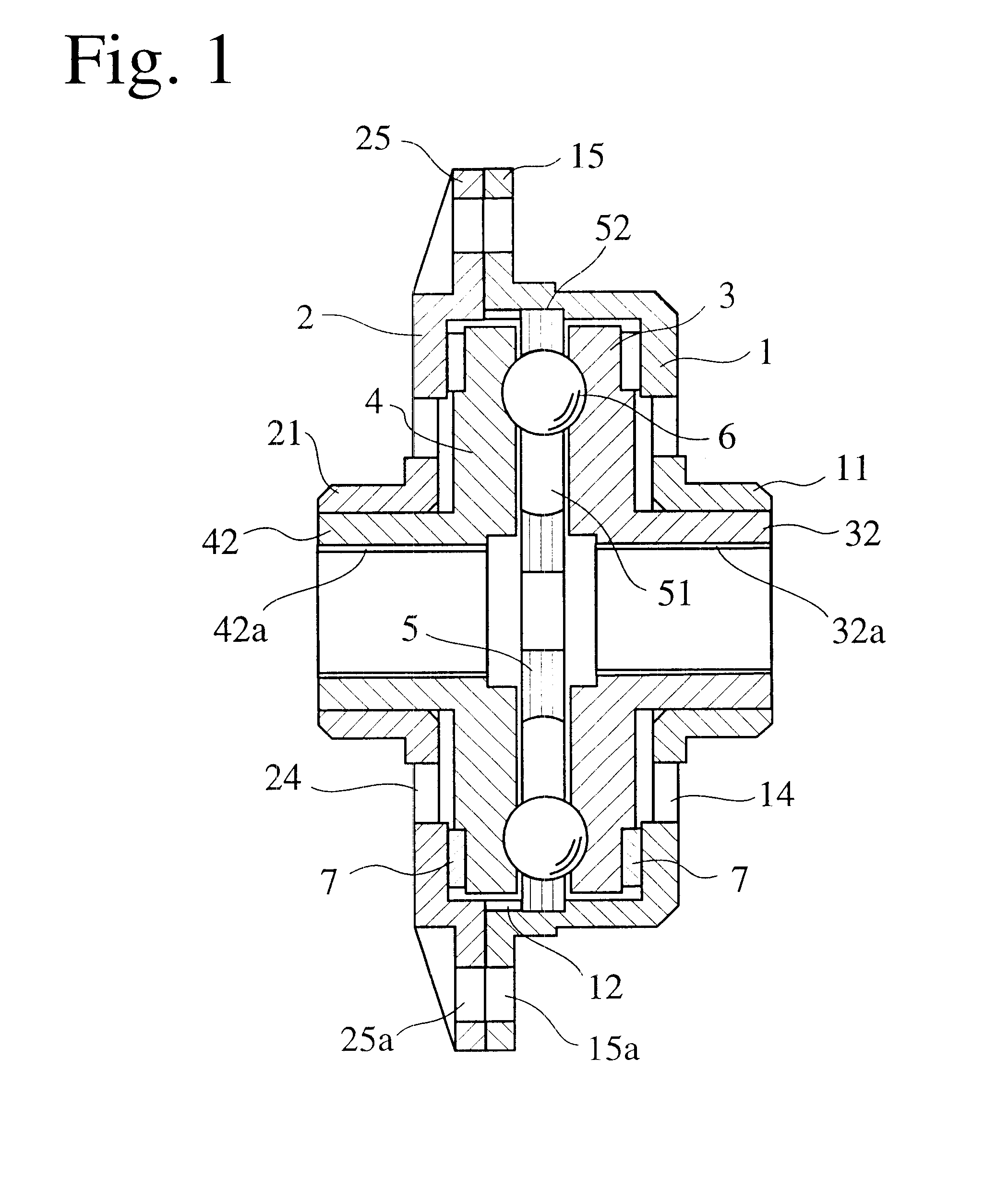

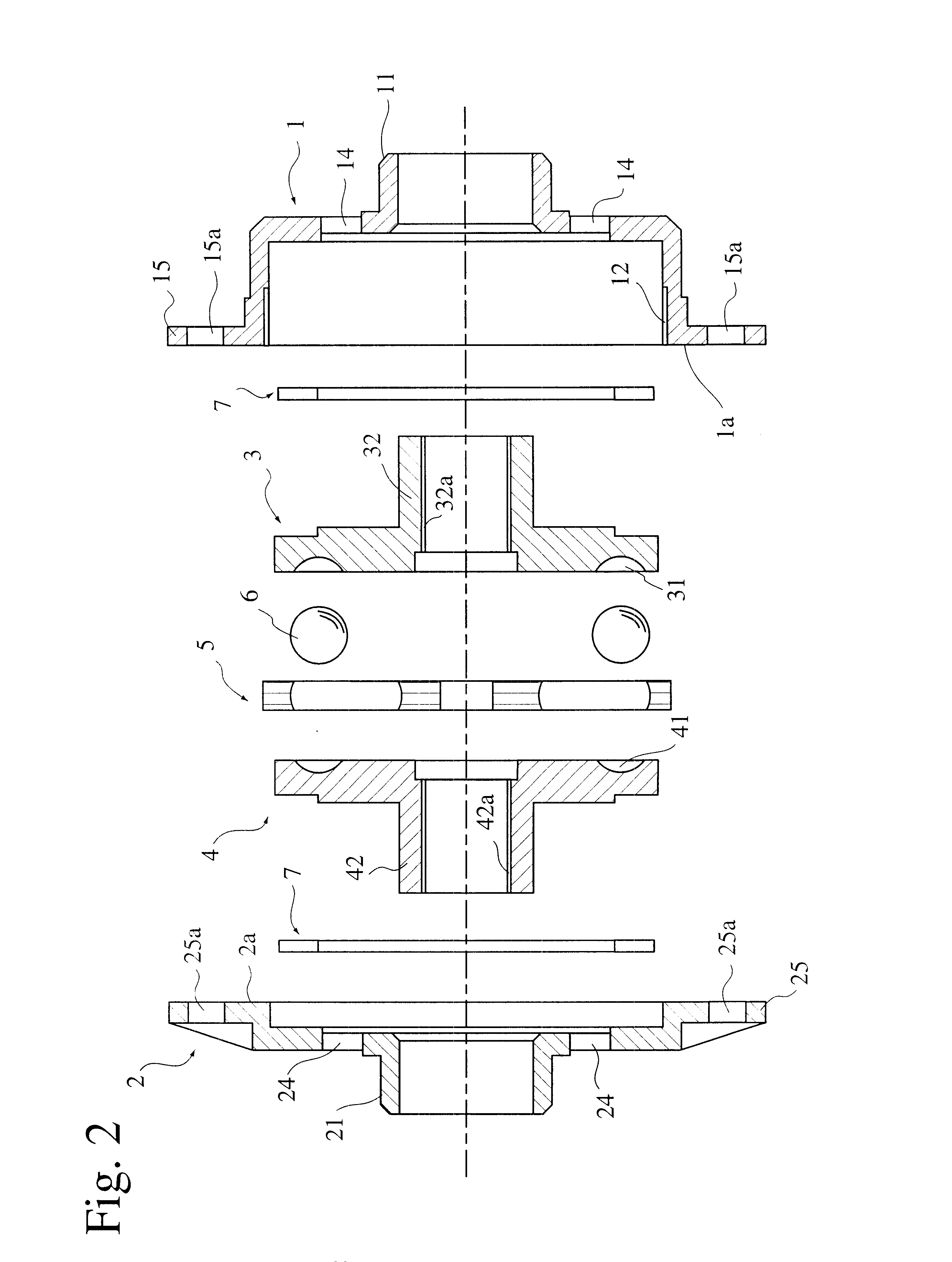

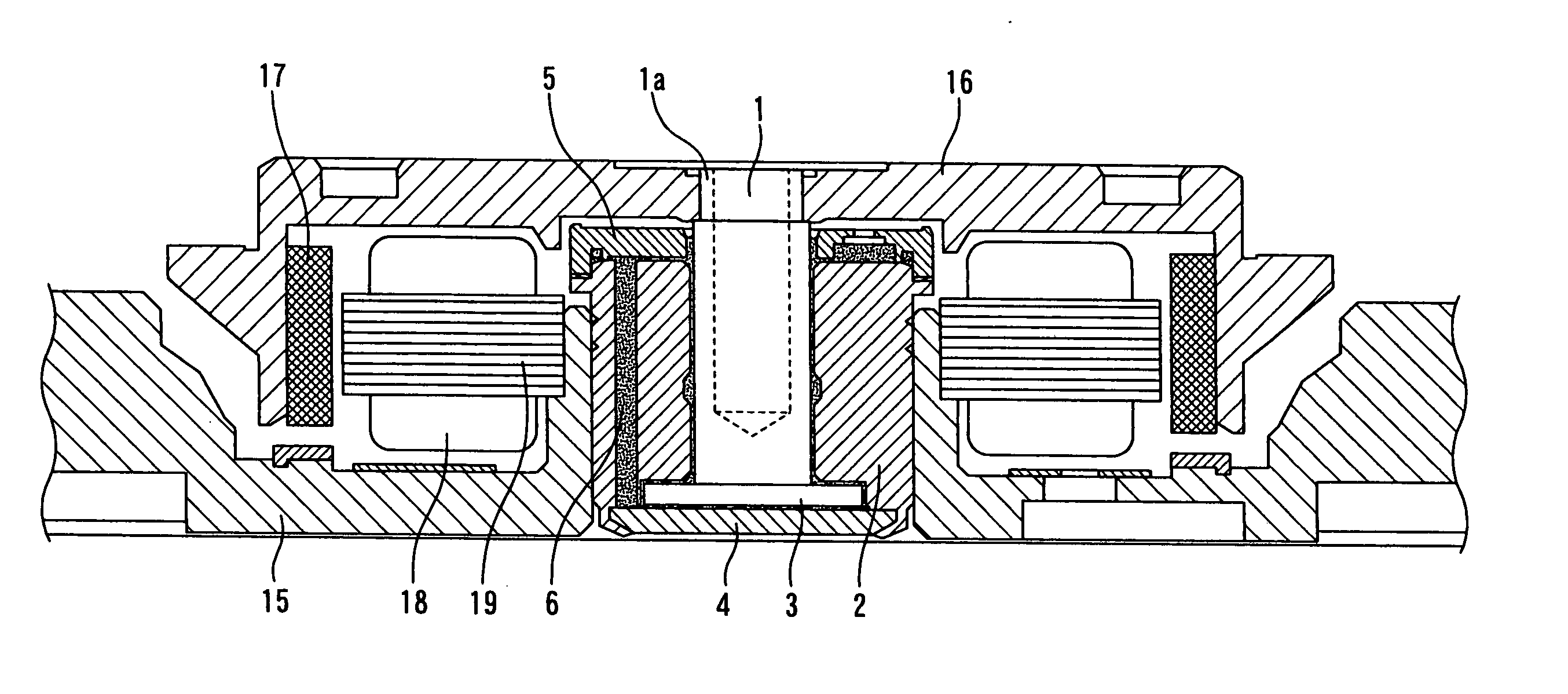

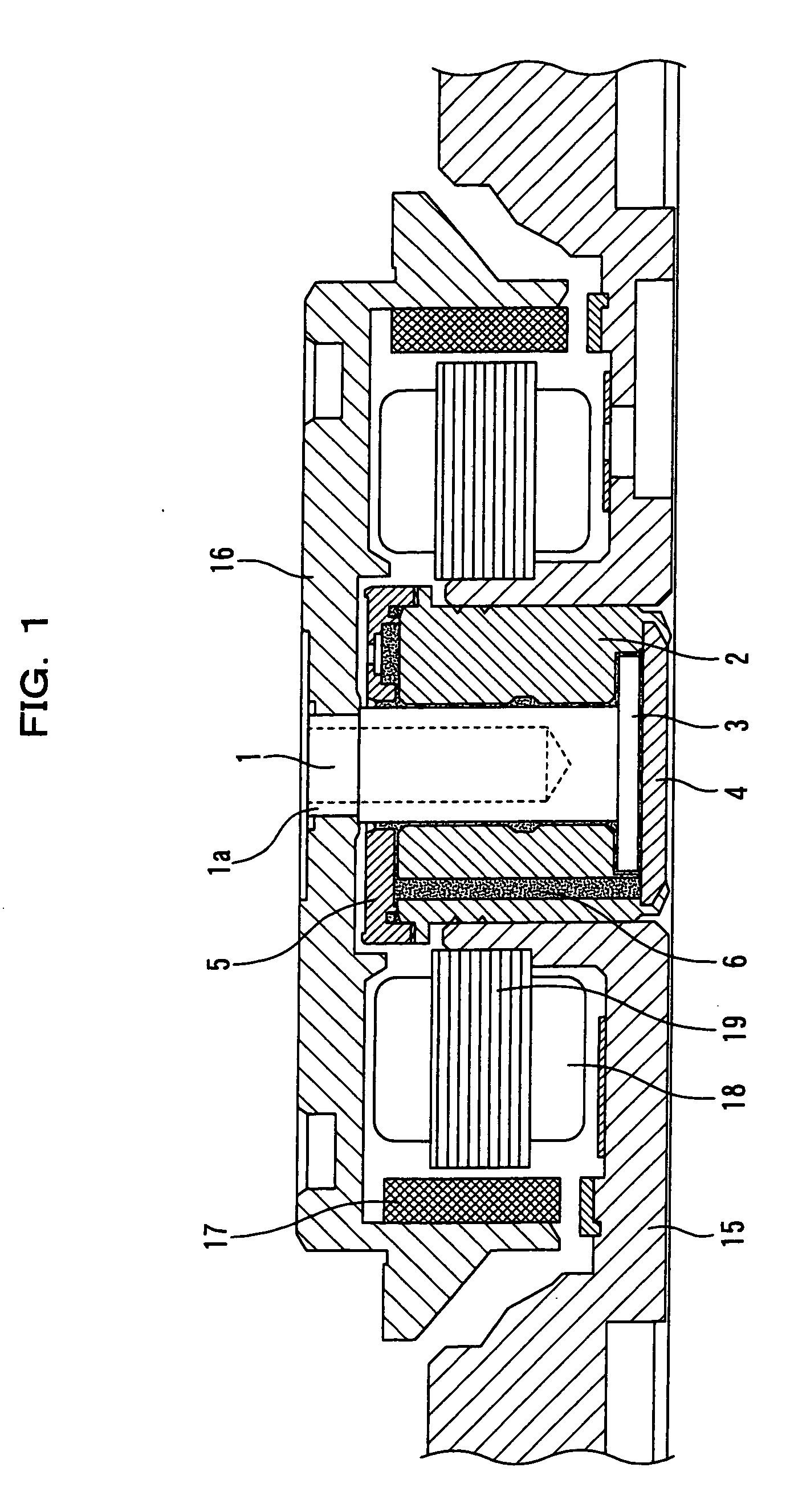

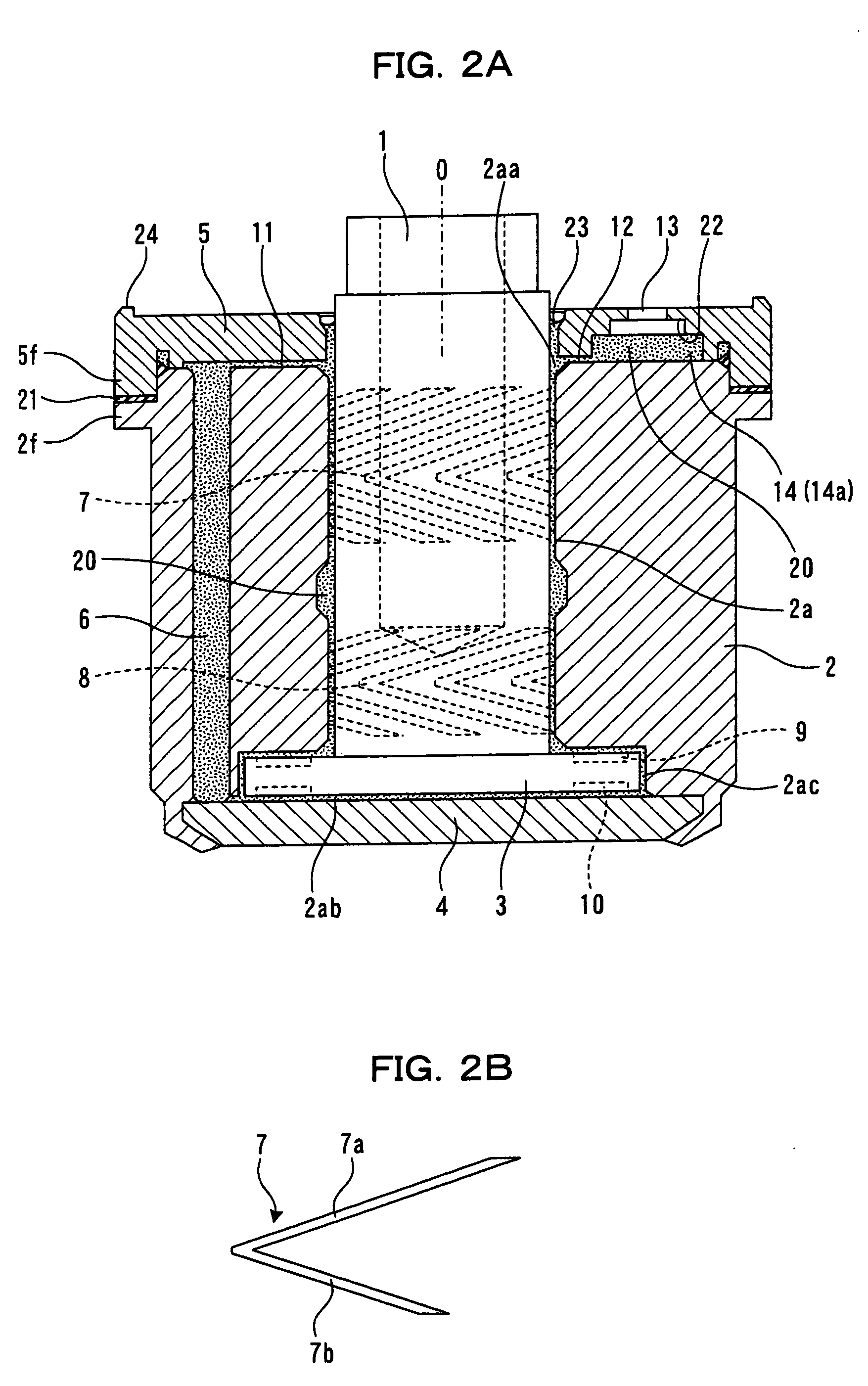

Hydrodynamic bearing device

ActiveUS7241050B2Efficient removalMaintained satisfactorilyShaftsBearing componentsWorking fluidCapillary Tubing

Owner:PHC HLDG CORP

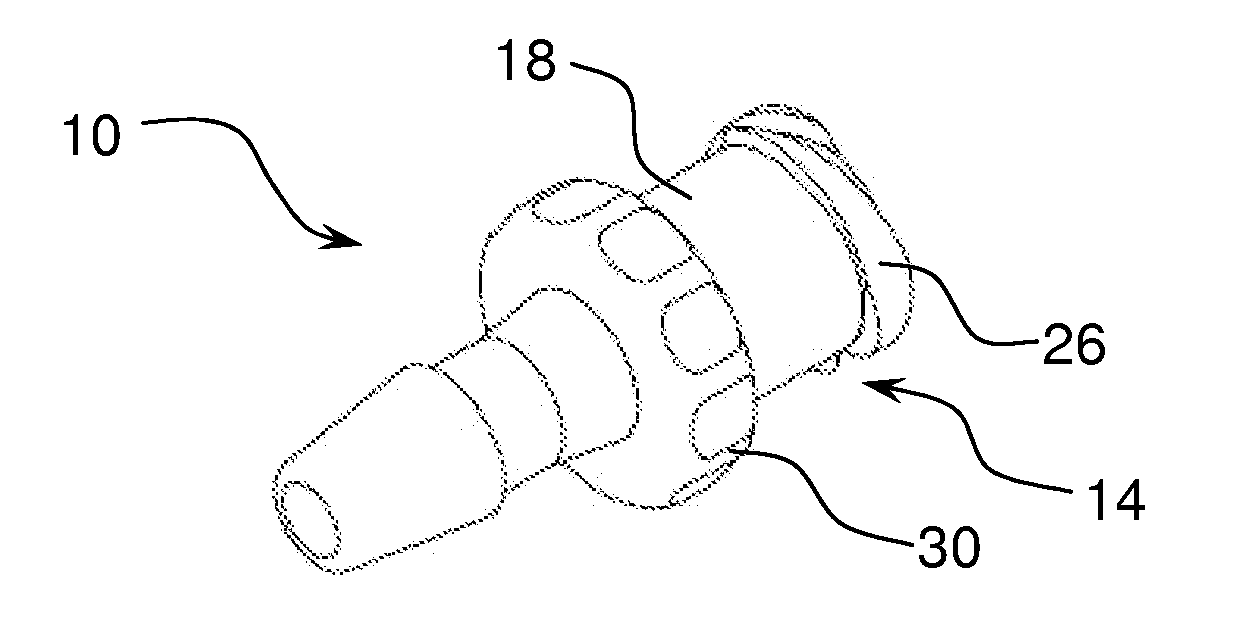

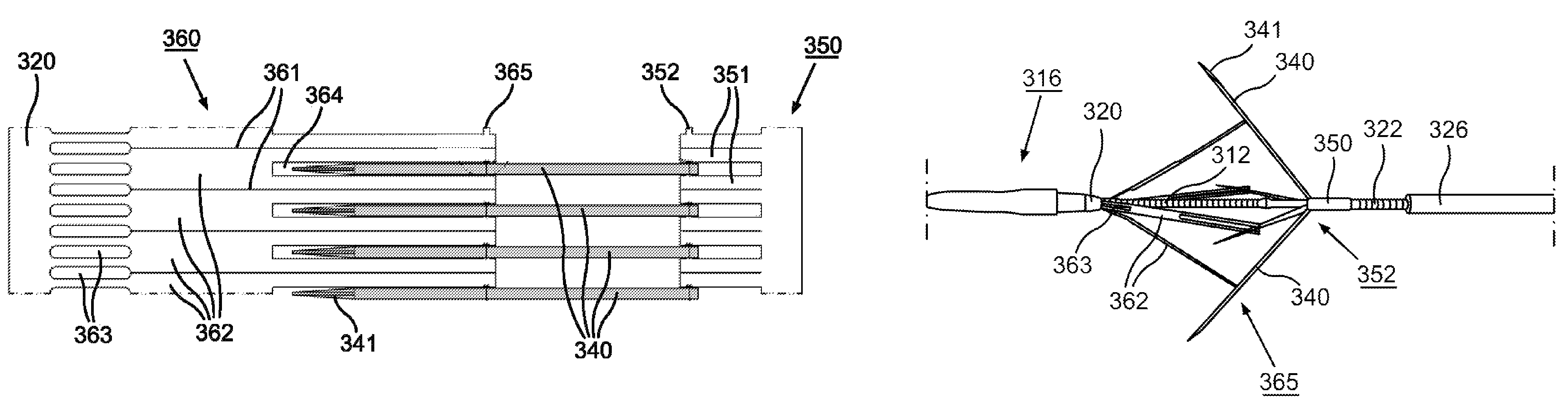

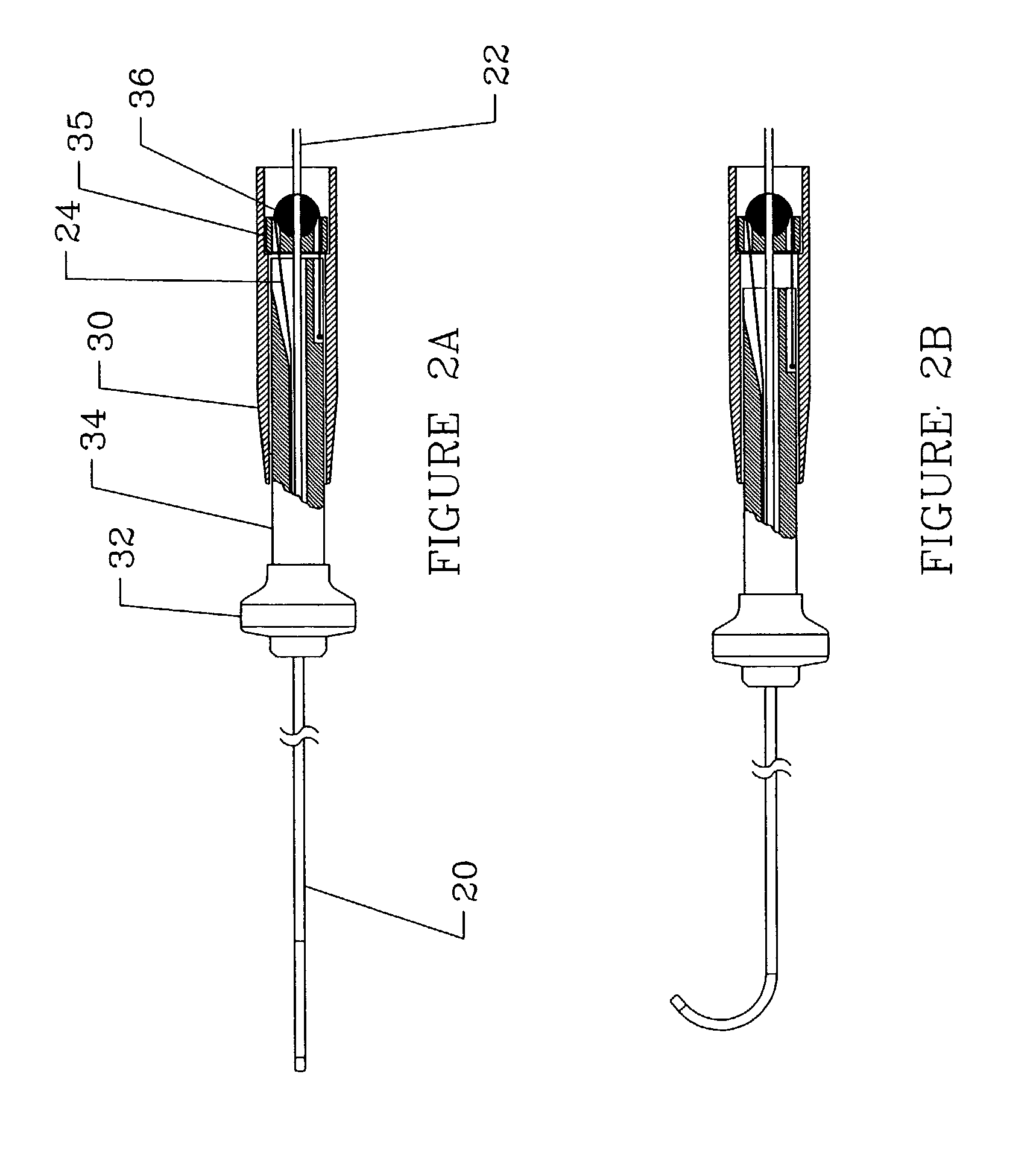

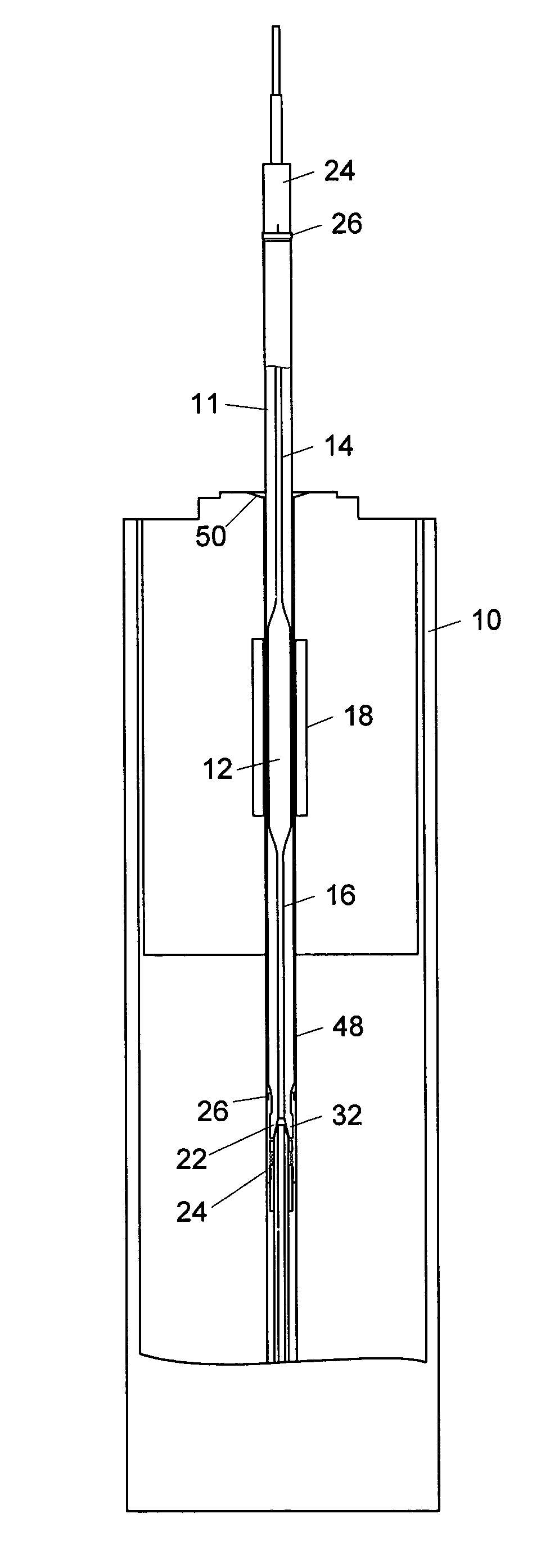

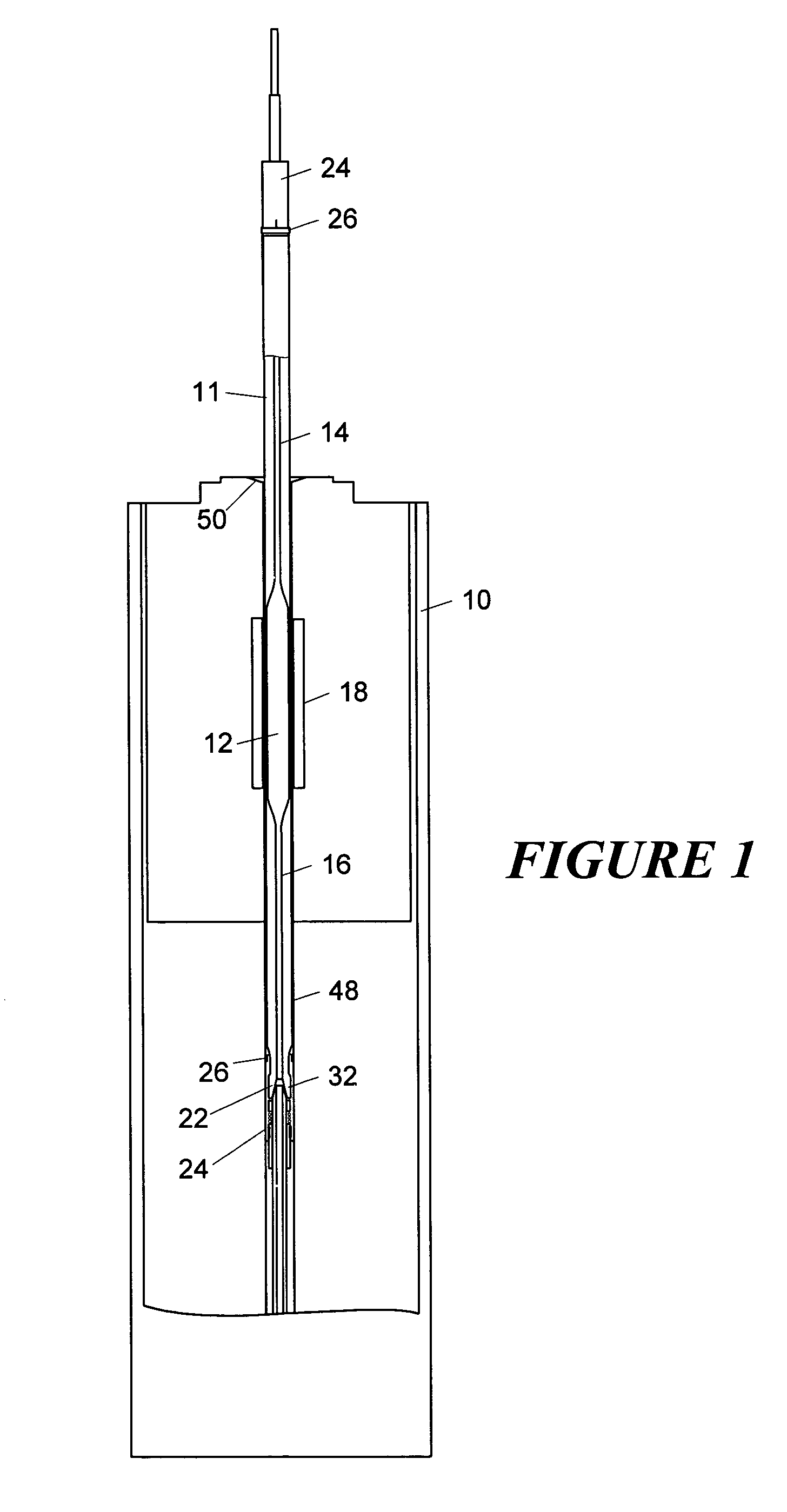

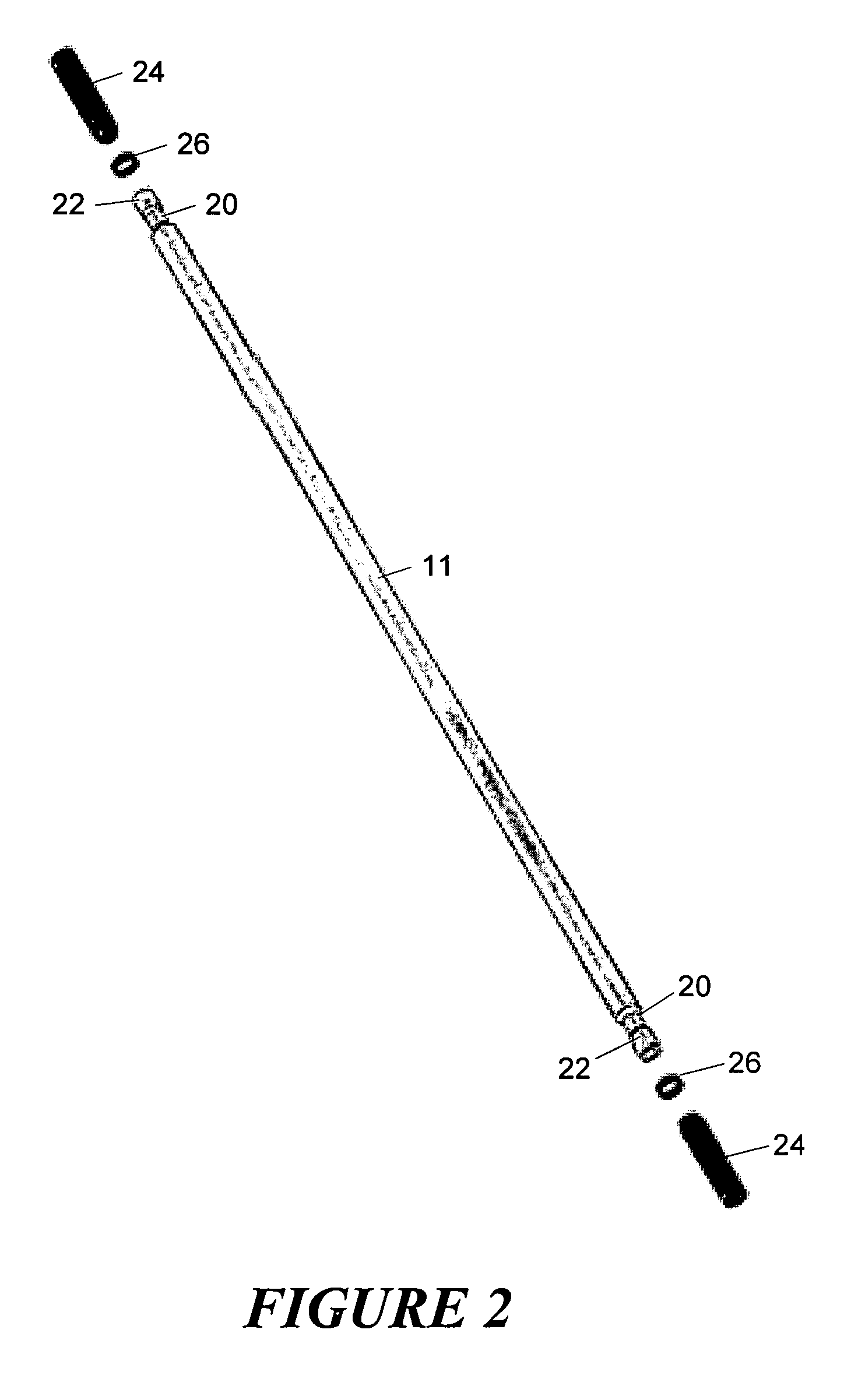

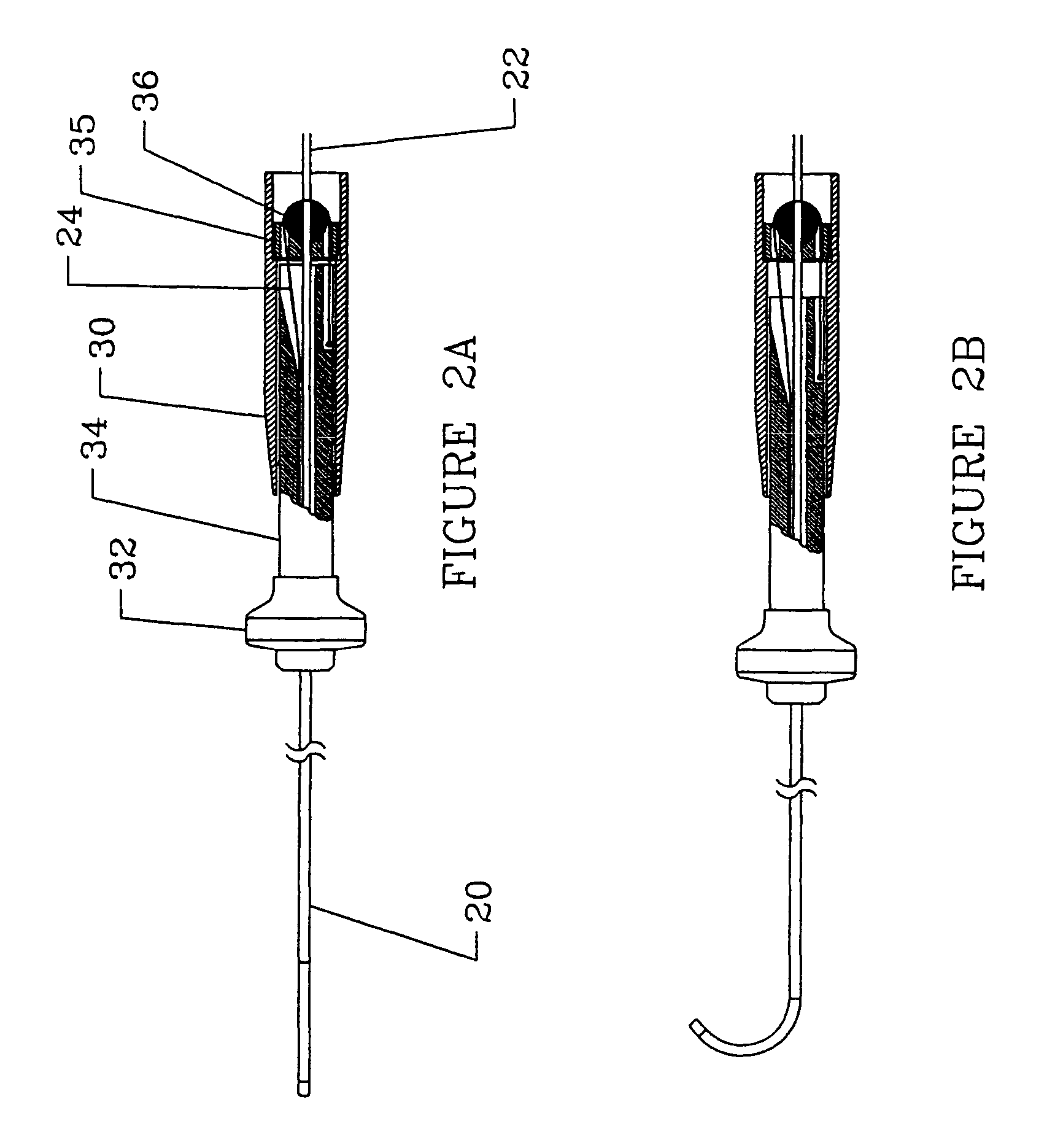

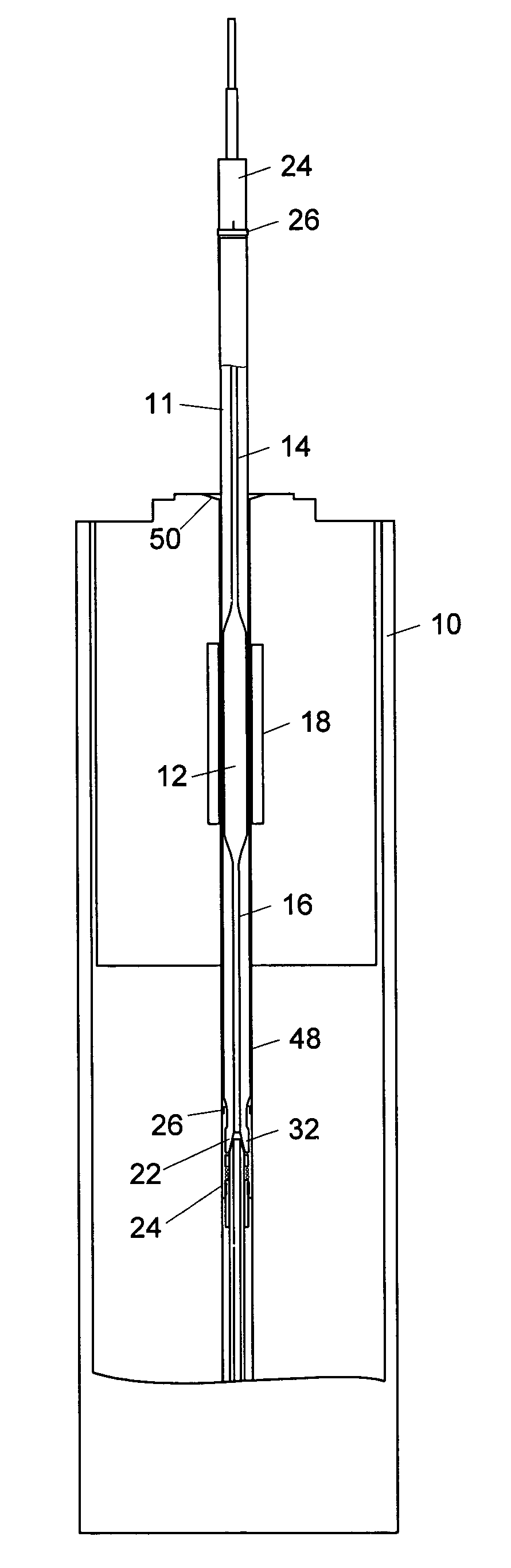

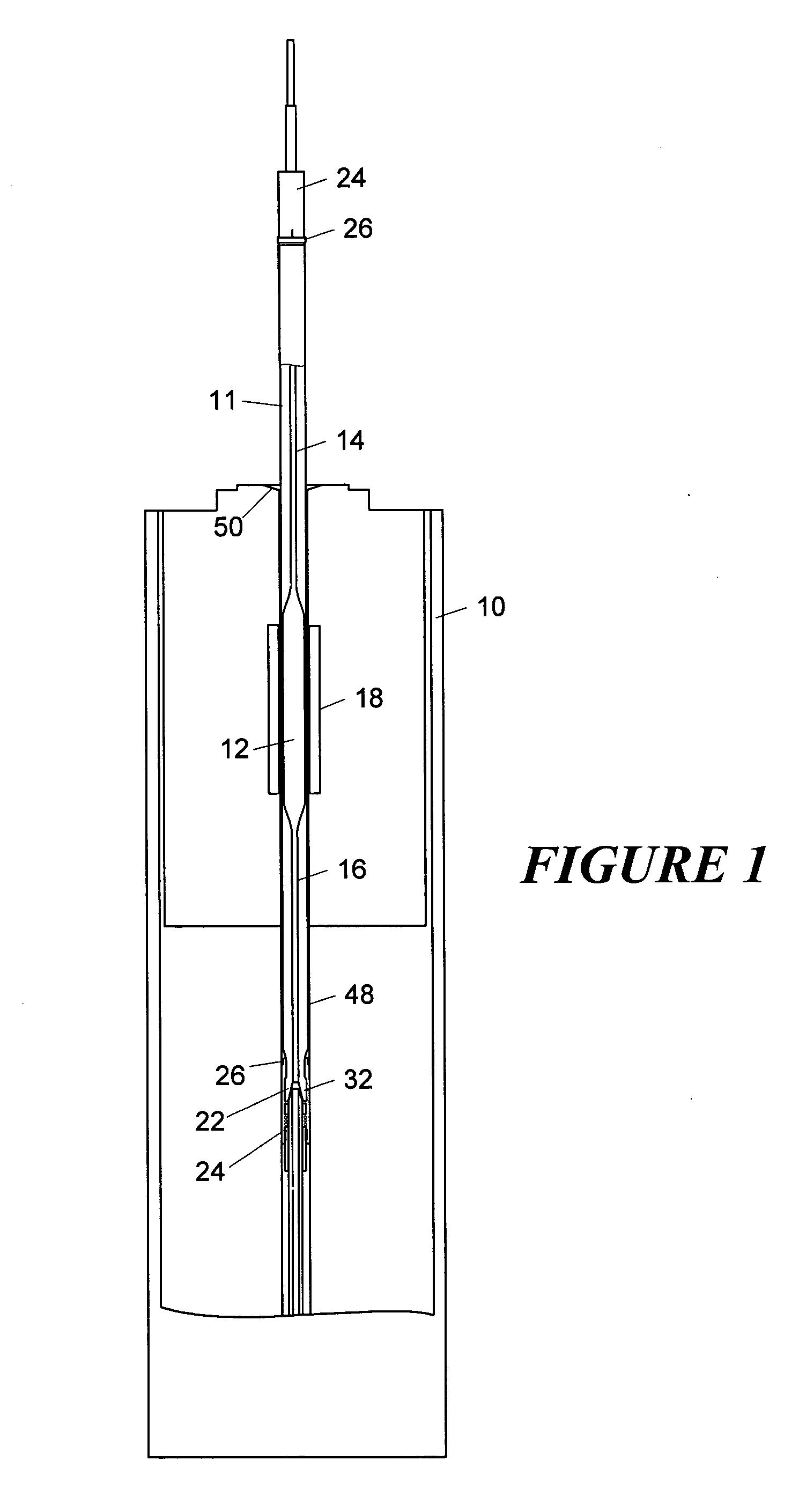

Pericardial access devices and methods

Described here are devices, systems, and methods for accessing the pericardial space through the pericardium. The access devices may include a plurality of elongate members having lumens that may be advanced together through the body to the pericardium. The elongate members may have different lengths and may be slideably positioned one within the lumen of another. At least one of the elongate members may comprise a distal tip configured to pierce tissue. In some instances, the access devices may also comprise a locking member to constrain the position of one elongate member relative to another.

Owner:SENTREHEART LLC

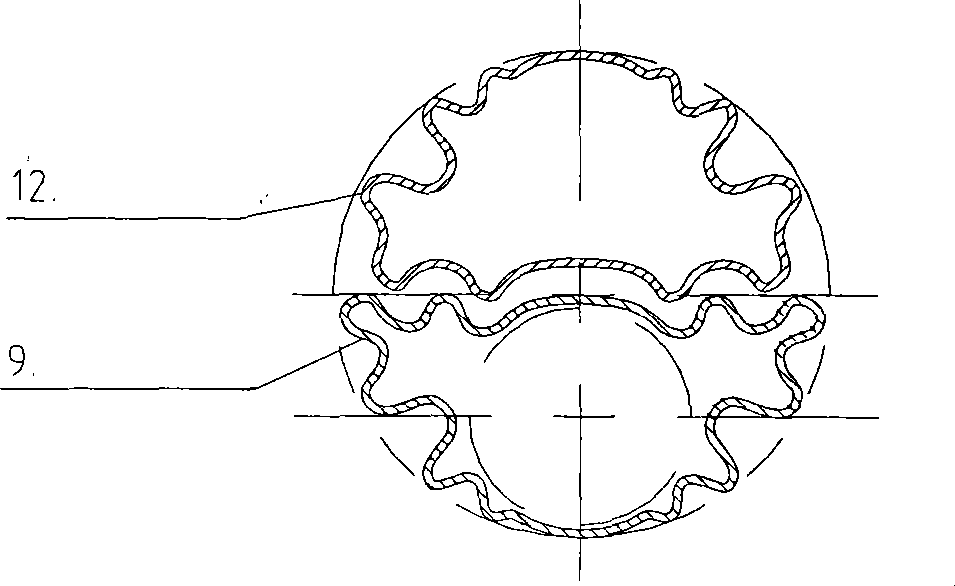

Differential device and method of manufacturing the device

InactiveUS6463830B1Reduce wearIncreased durabilityGearboxesDifferential gearingsRadial positionMechanical engineering

The differential apparatus comprises (a) a casing rotated by a driving force from outside; (b) a pair of opposing disc plates coaxially disposed in the casing, an opposing surface of each disc plate being formed with a circumferentially continuous groove winding such that a radial position changes at a constant period; (c) a plurality of balls rolling in opposing winding continuous grooves of both disc plates; and (d) a ball holder rotating integrally with the casing and having a plurality of radially extending guide holes, each guide hole movably receiving each ball, wherein the winding continuous groove of each disc plate circumferentially continuously has first guide regions each extending from a radially outer position to a radially inner position of each disc plate and second guide regions each extending from a radially inner position to a radially outer position, inflected regions each connecting each first guide region and each second guide region being larger in width and / or depth than the first guide regions and the second guide regions, whereby a contact stress between the balls and the winding continuous groove is decreased in the inflected regions.

Owner:HITACHI METALS LTD

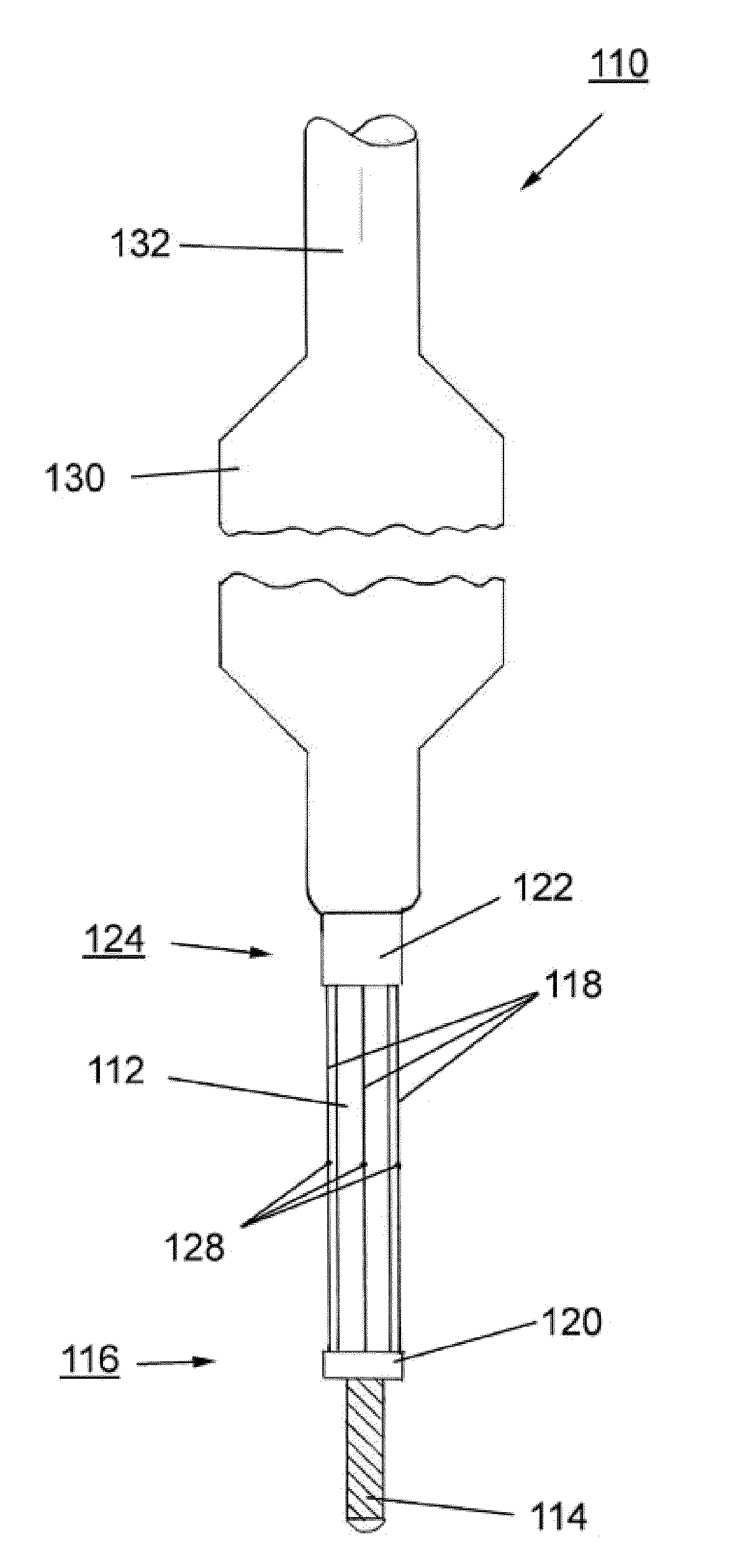

Scoring catheter and method for treating diseased heart valves

ActiveUS8398662B2Better crossingEasy to controlCannulasExcision instrumentsVALVE PORTDiseases heart valve

The present invention provides a valvuloplasty catheter which has a scoring element at its distal part to score stenotic, calcified heart valves in radial direction and to make the single valve flaps / leaflets work again. In addition to this, the device could comprise an attached balloon to post-dilate the valve after the scoring procedure. To reduce a future recalcification, the scoring element and / or the balloon have a pharmacologic coating on their outer surface.

Owner:BAVARIA MEDIZIN TECH

Hydrodynamic bearing device

ActiveUS20060023982A1Efficient removalMaintained satisfactorilyShaftsBearing componentsWorking fluidEngineering

Owner:PHC HLDG CORP

Method for implementing branch well window seal by using metal expansion tube

InactiveCN101413384AImprove sealingStable supportDirectional drillingSealing/packingWell cementingMetal

The invention relates to a method for realizing window sealing of a multilateral well by utilization of a metallic expansion tube, which is used for completion window sealing of an oil gas well. The method is mainly realized through a window sealing structure of the multilateral well, a positioning and orienting feeding device and a running system of a branched metallic expansion tube. The method comprises the following steps: firstly, drilling of a main wellbore is completed by the drilling method of the multilateral well, and a main wellbore pipe column is run into the ground; and secondly, a whipstock is run into a designed windowing position, drilling of a branched wellbore is completed through side tracking windowing, a completion pipe column of the branched wellbore is hung on the upper part of a hollow wedge deflection tool through a pre-opening suspension device, a predeformed branched sealer is run into the window position by utilization of the feeding device, and shape recovery and inflatable seal of the hermetical metallic expansion tube are realized through the feeding system of the branched metallic expansion tube. The method solves the problems in the prior art of poor cementing quality on a joint of the multilateral well due to large difficulty of branched completion and particularly the problem of sealing of a windowing position of the multilateral well. The method can be widely used in completion window sealing operation of the multilateral well of the oil gas well.

Owner:CNPC GREATWALL DRILLING ENG

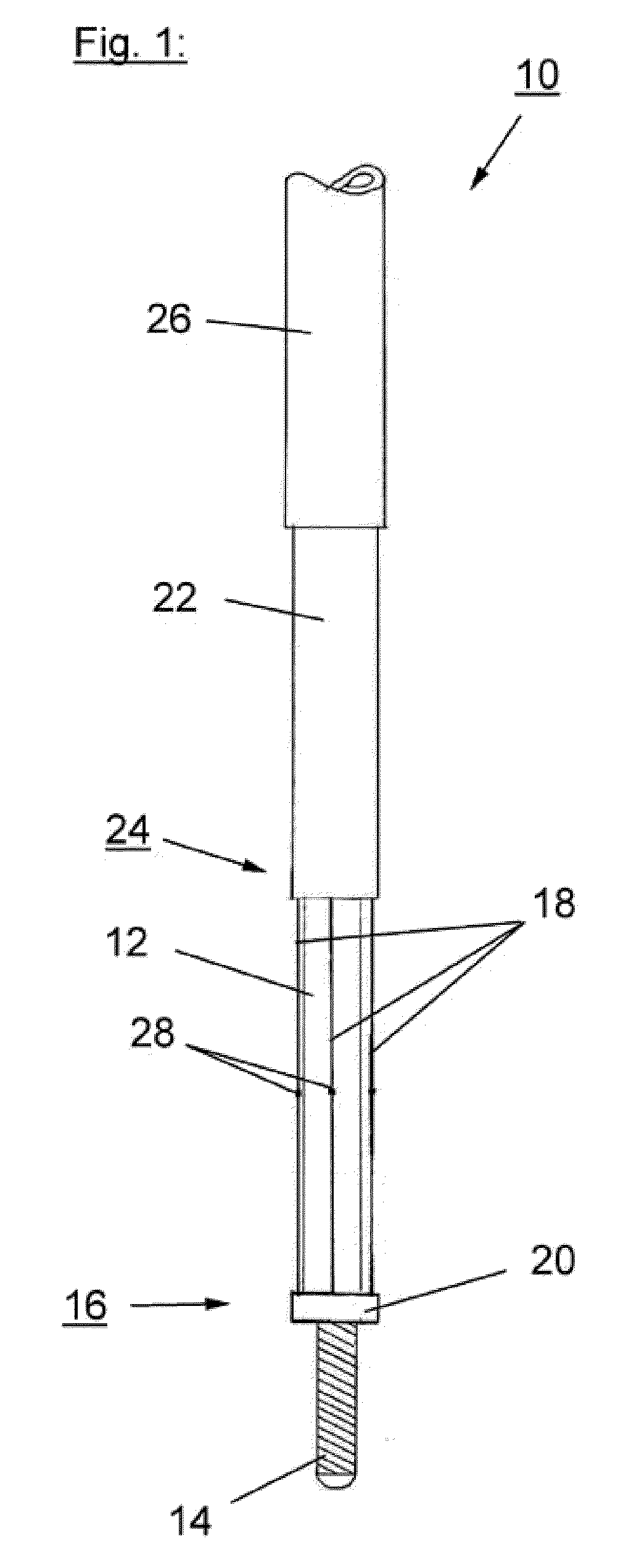

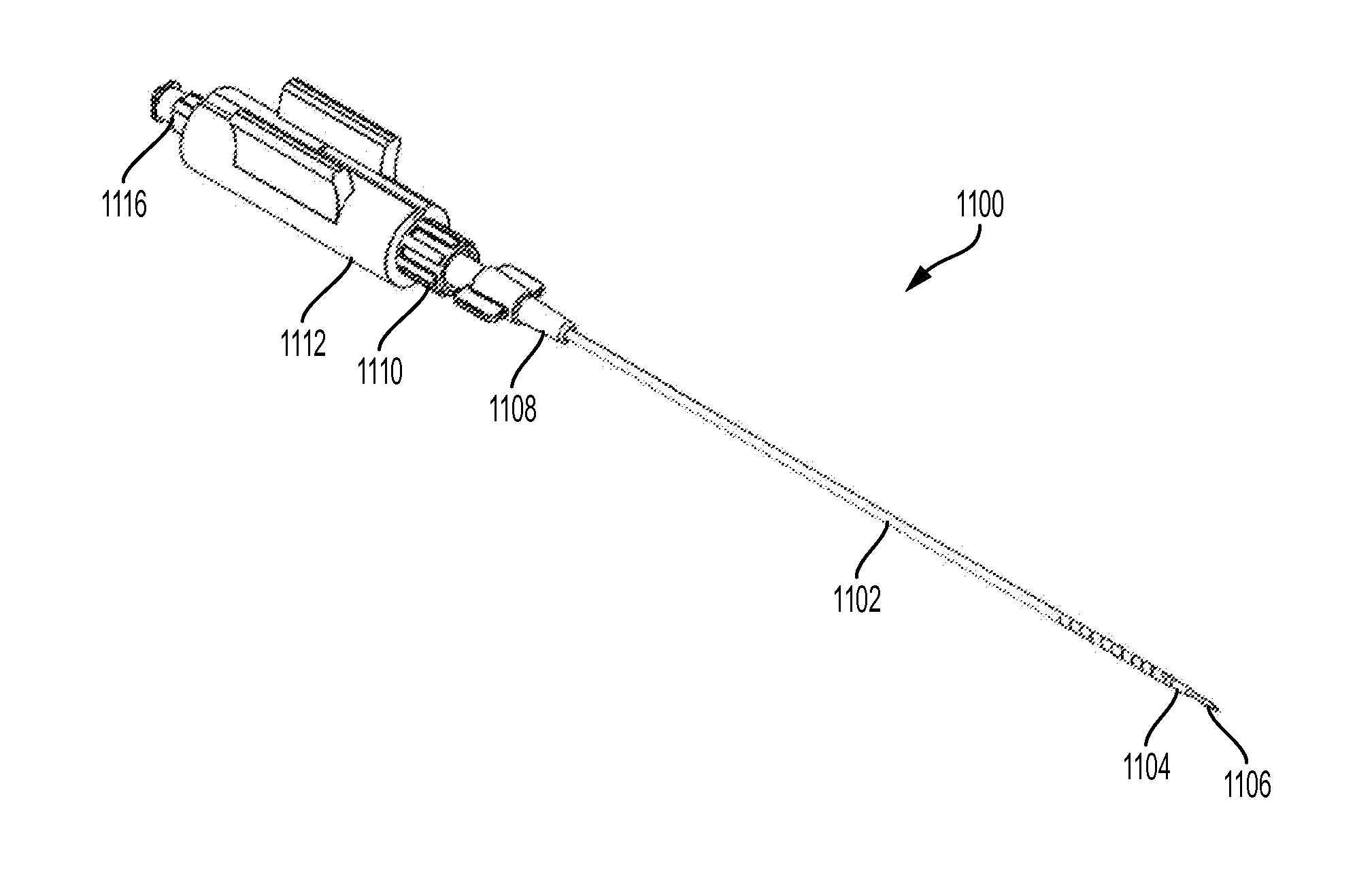

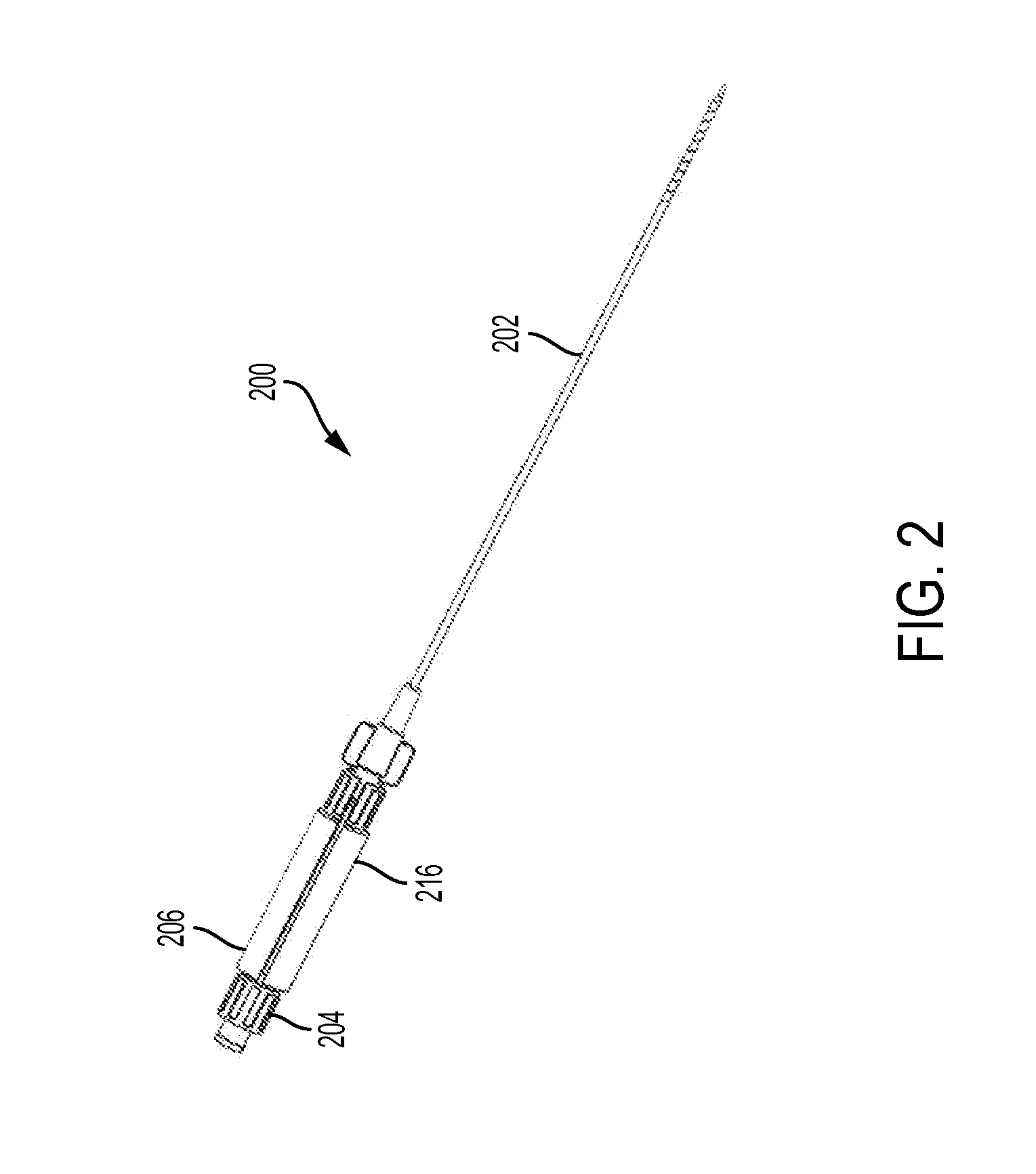

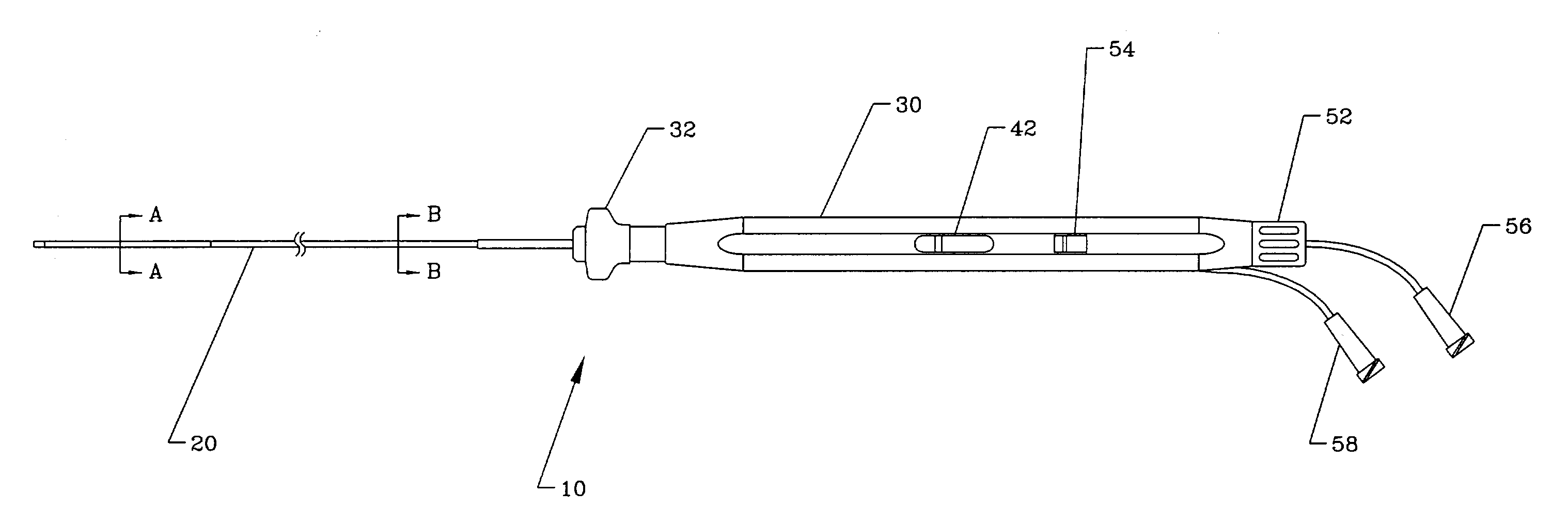

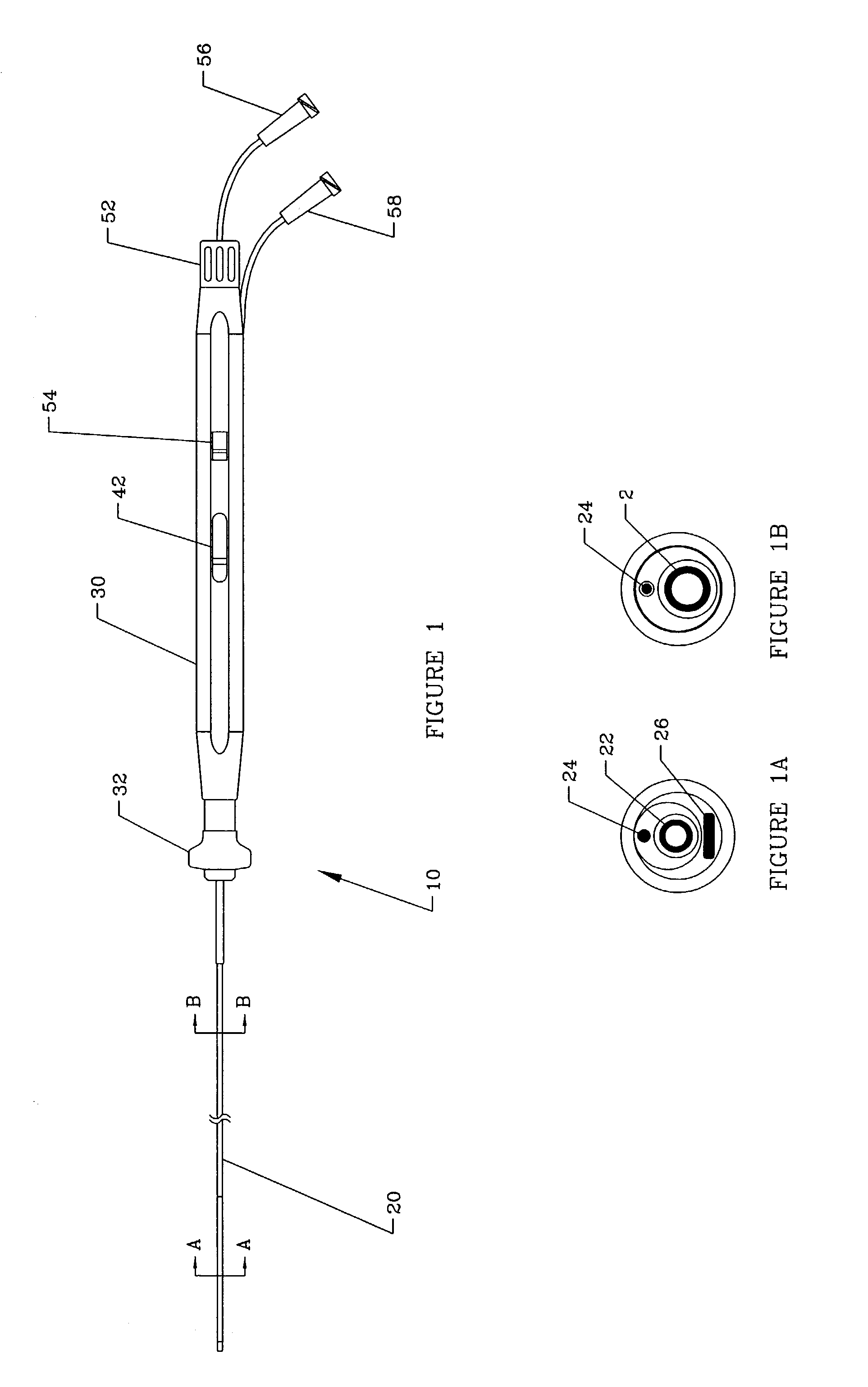

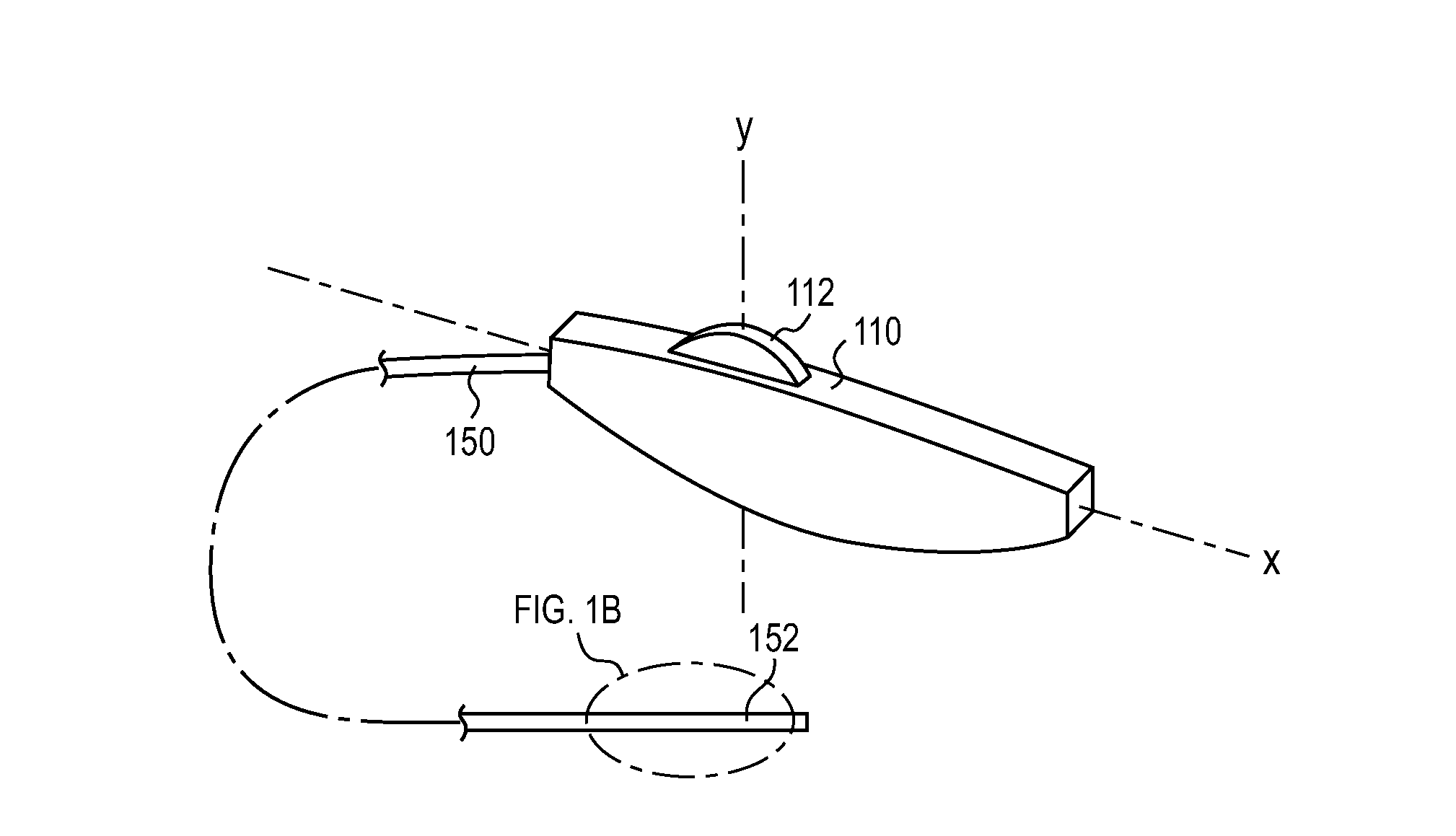

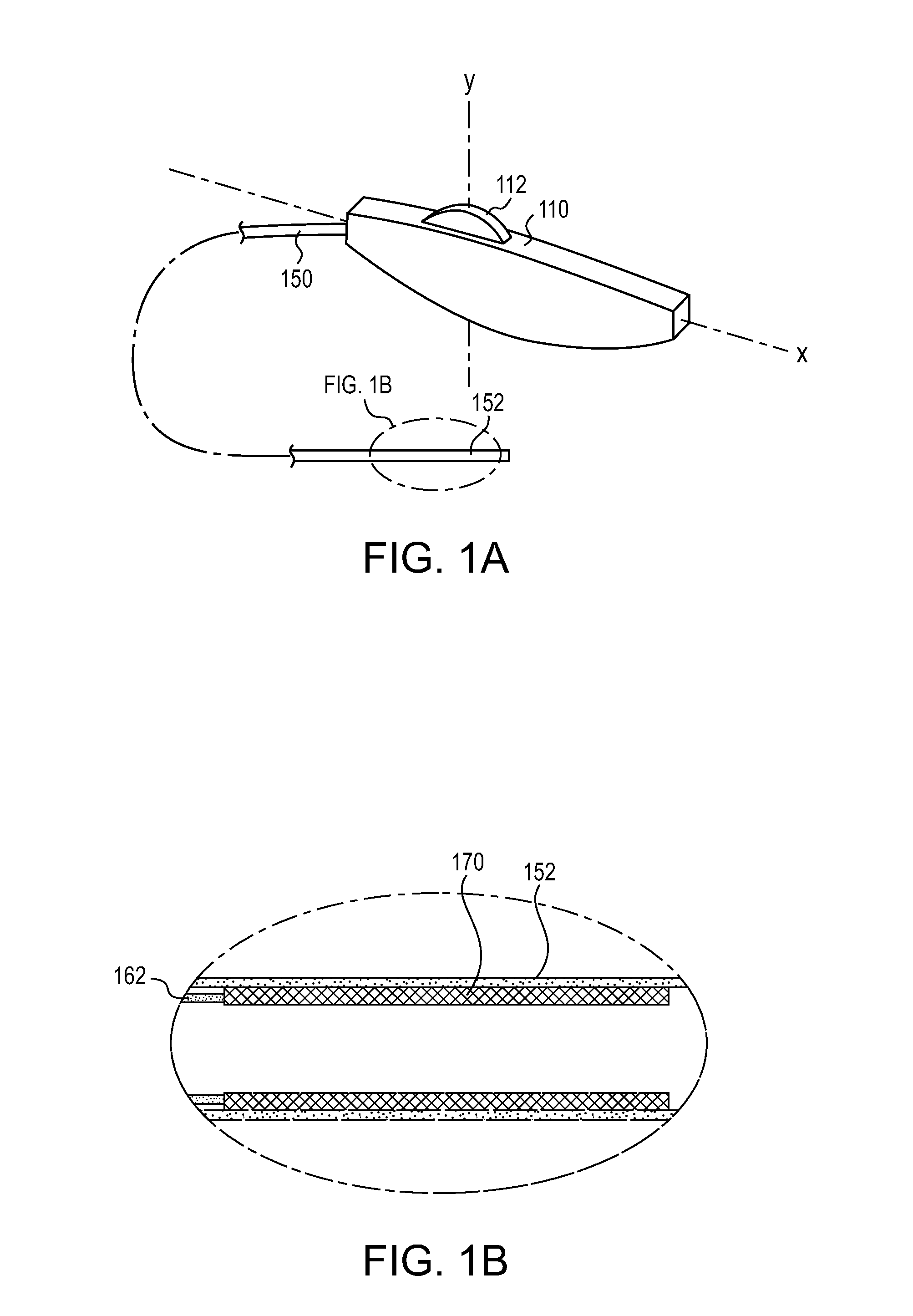

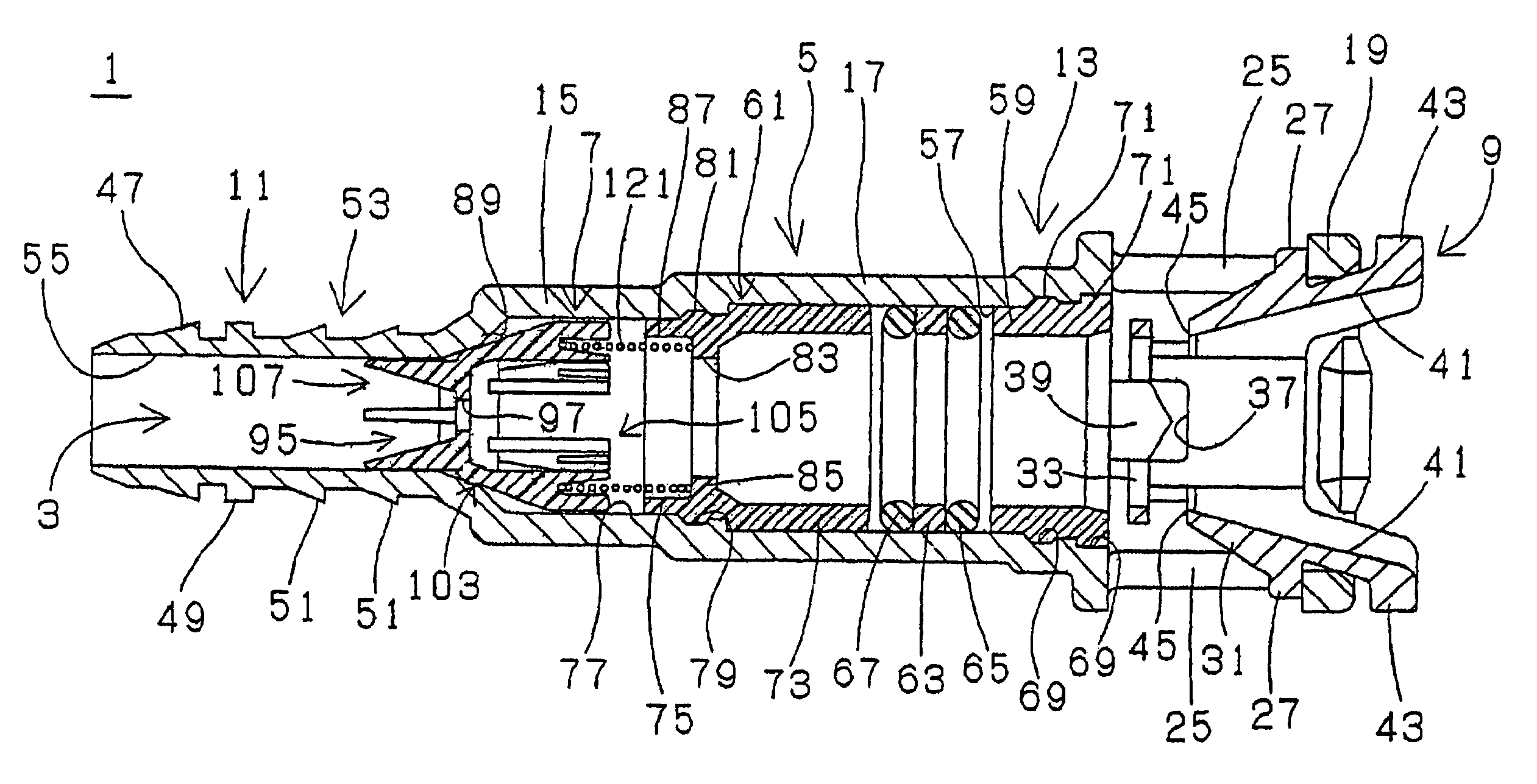

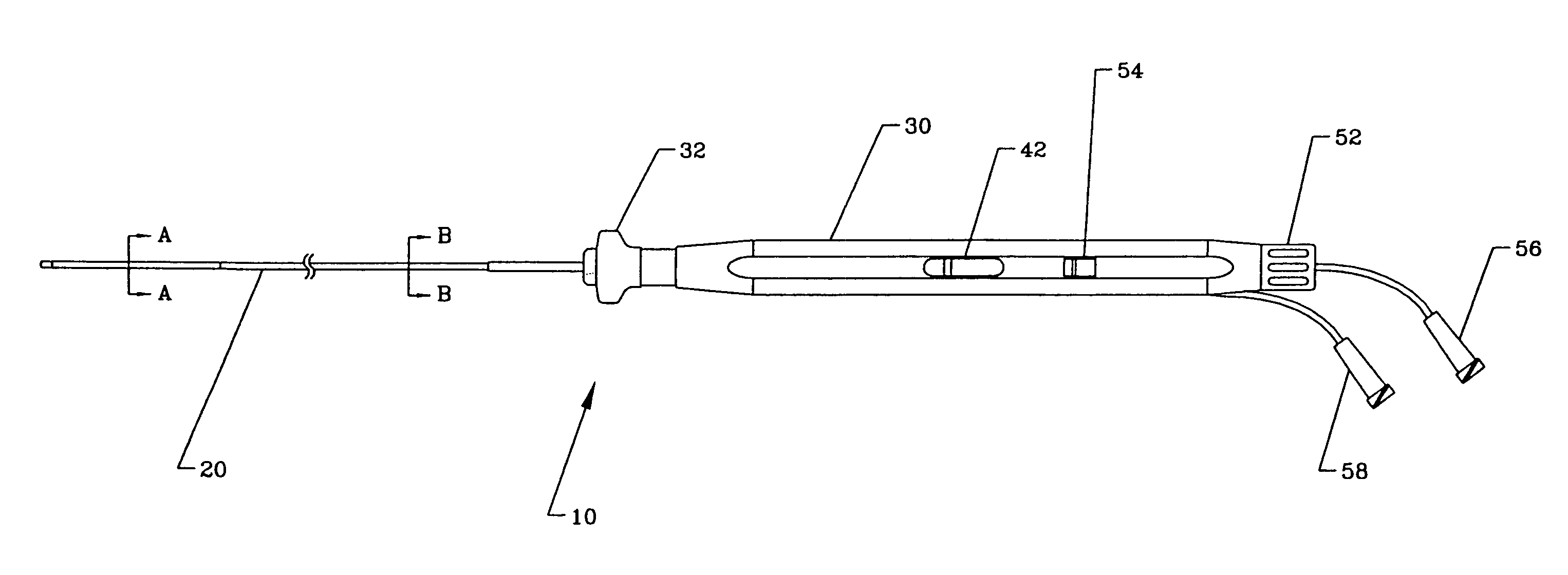

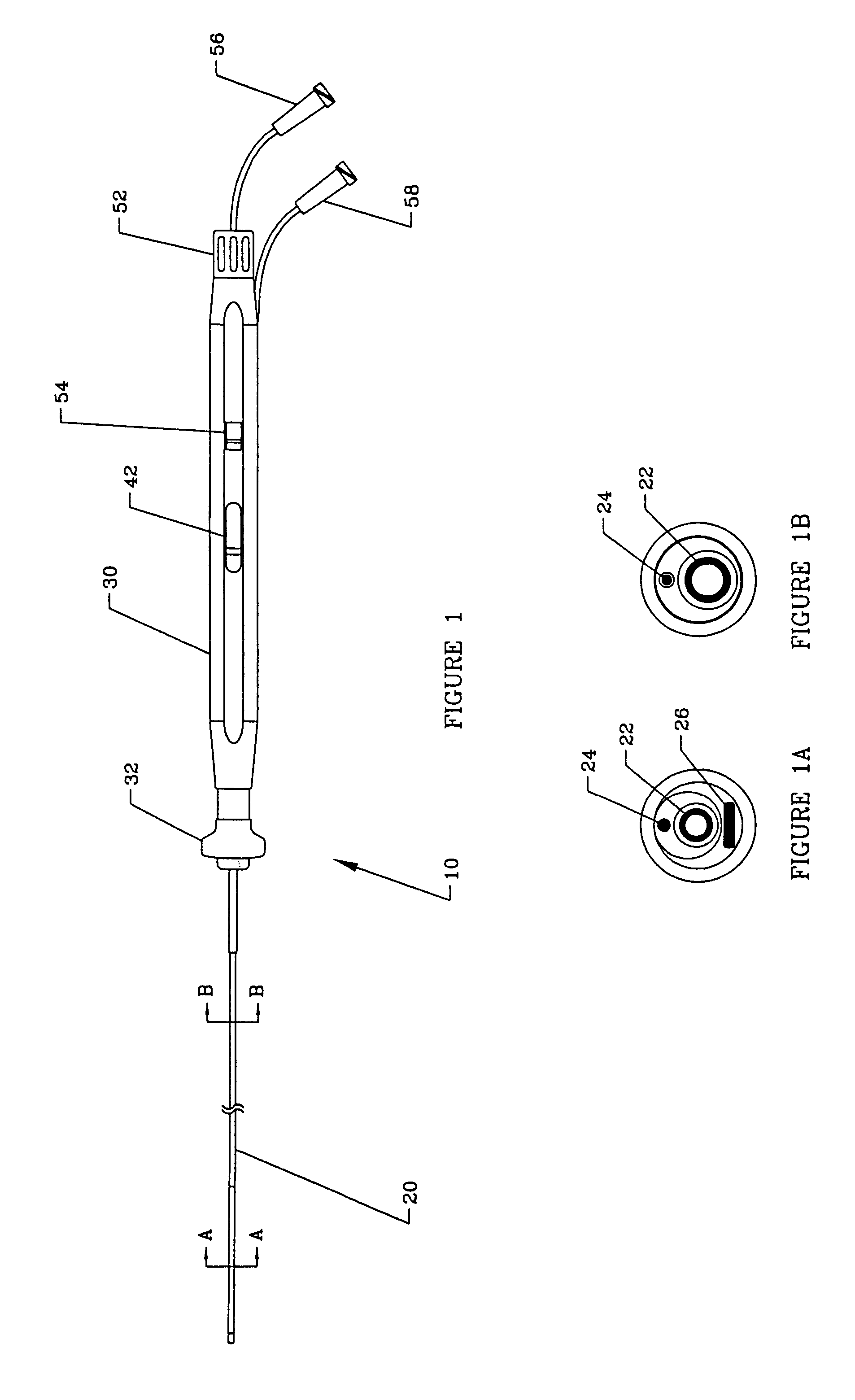

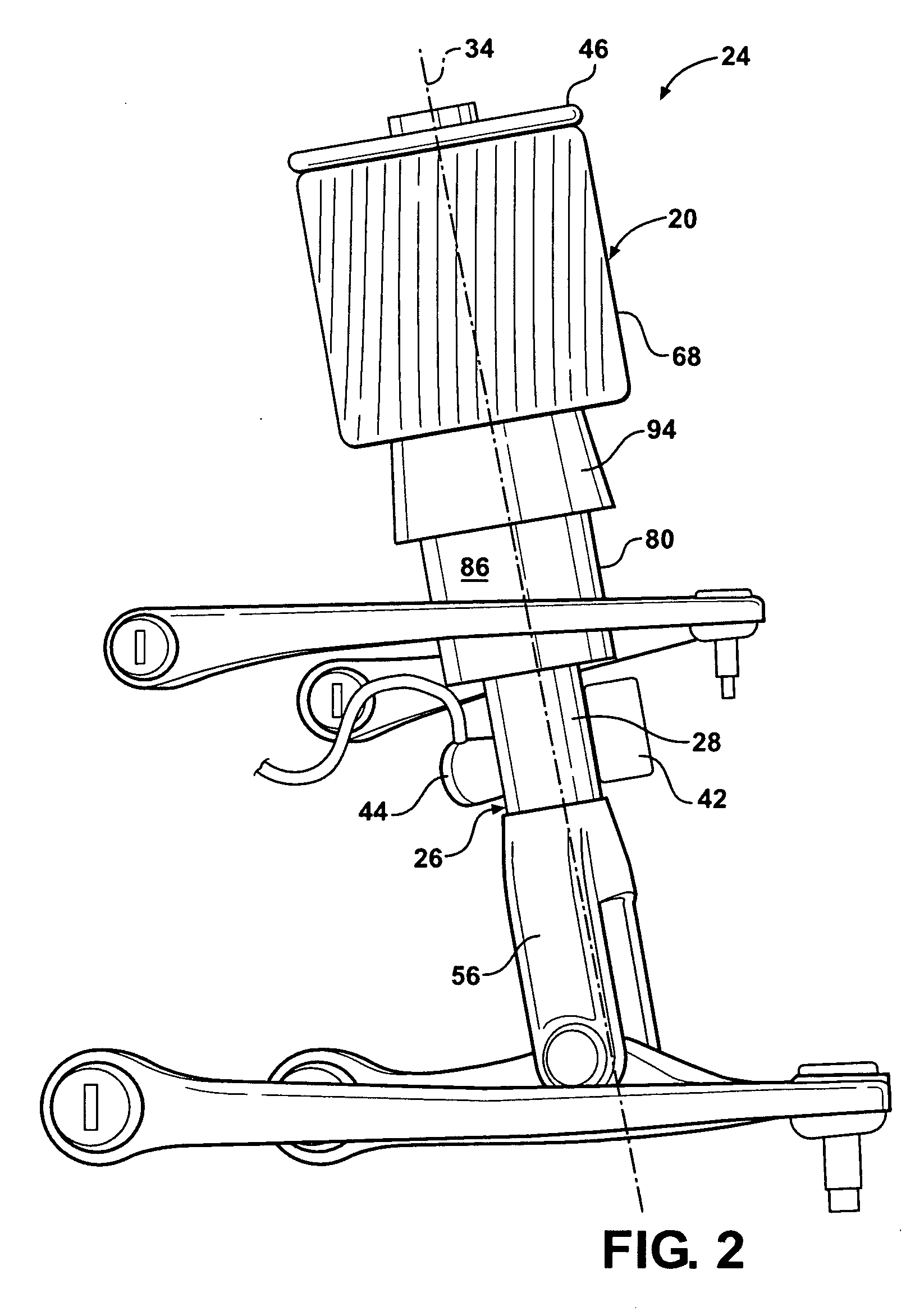

Deflectable microimplant delivery system

InactiveUS7033345B2Precise controlled deliveryLarge inner diameterInfusion syringesMedical devicesNeedle insertionCellular material

The present invention provides a deflectable catheter-based system for assisting in the delivery of therapeutic agents, cellular materials and the like to one or more sites in a target body tissue. The system provides for one or more injections to a predetermined needle insertion depth with a single core needle that can be advanced and retracted from the tip of the catheter. The catheter assembly includes a handle subassembly having a mechanism for setting and limiting the depth of insertion of the needle, a slide for moving the injection needle between retracted and extended positions, a return spring for biasing the needle to the retracted position, and a modified pulley mechanism for compensating for catheter shaft compression when the catheter is deflected.

Owner:ABBOTT CARDIOVASCULAR

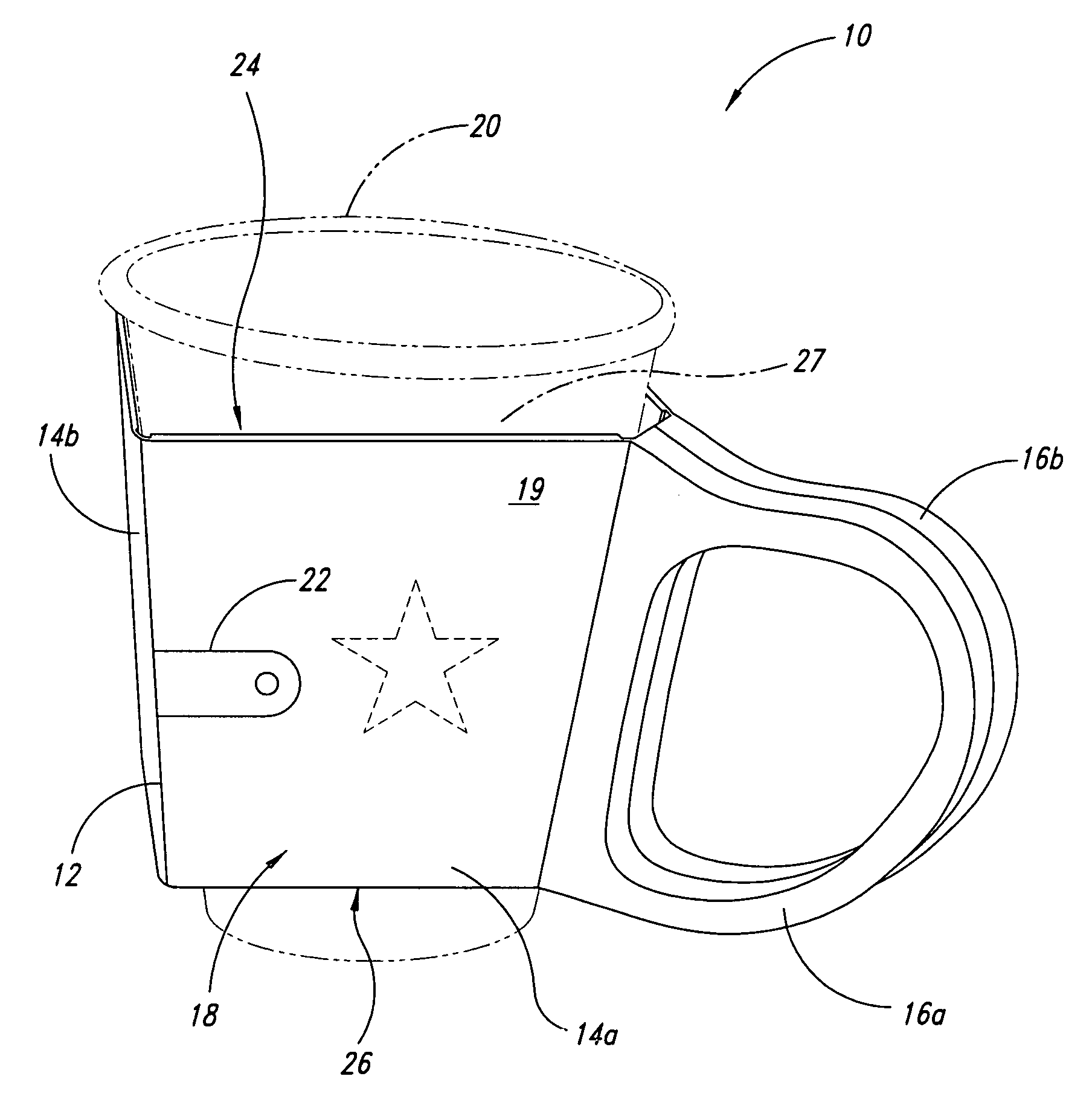

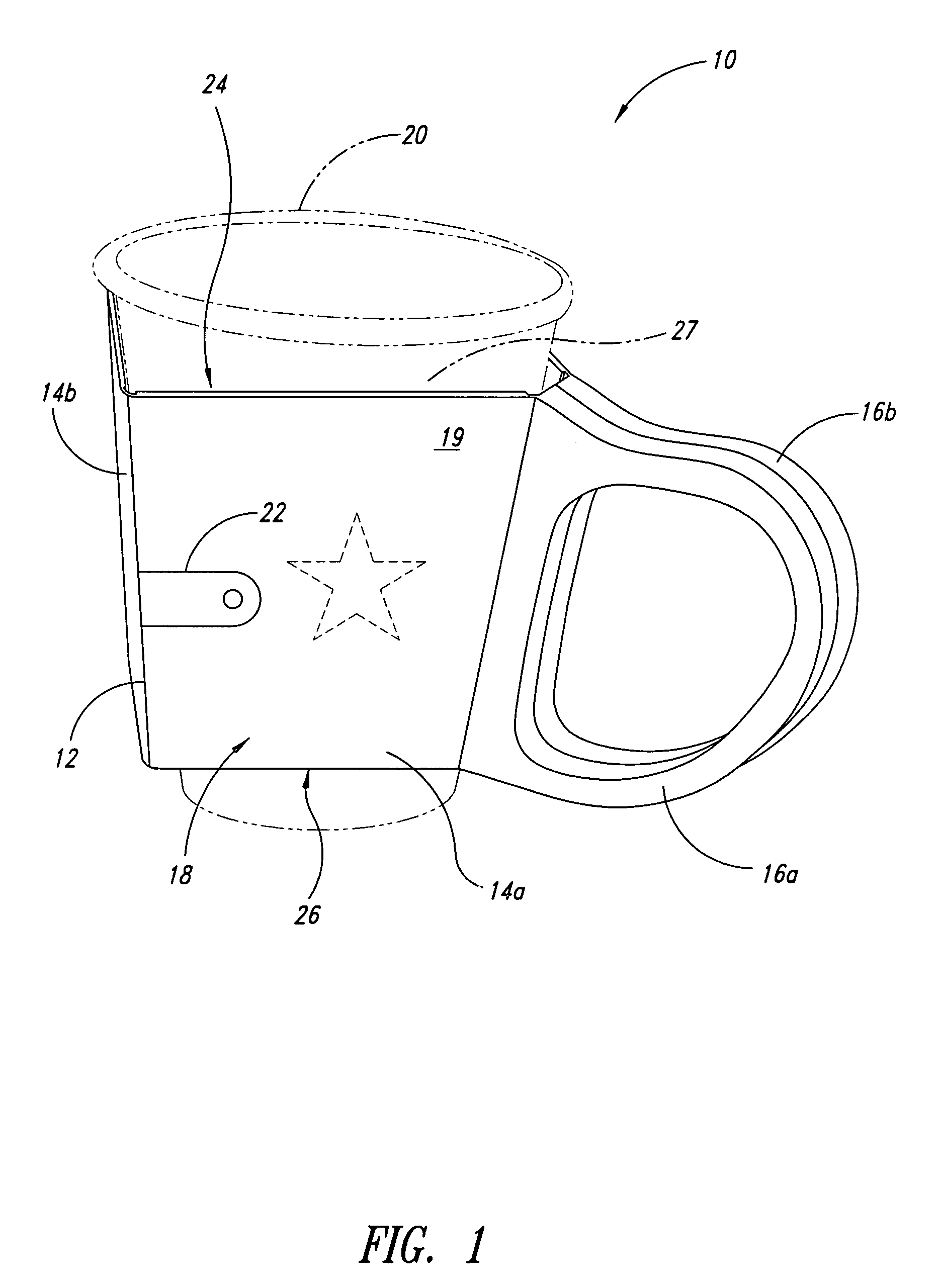

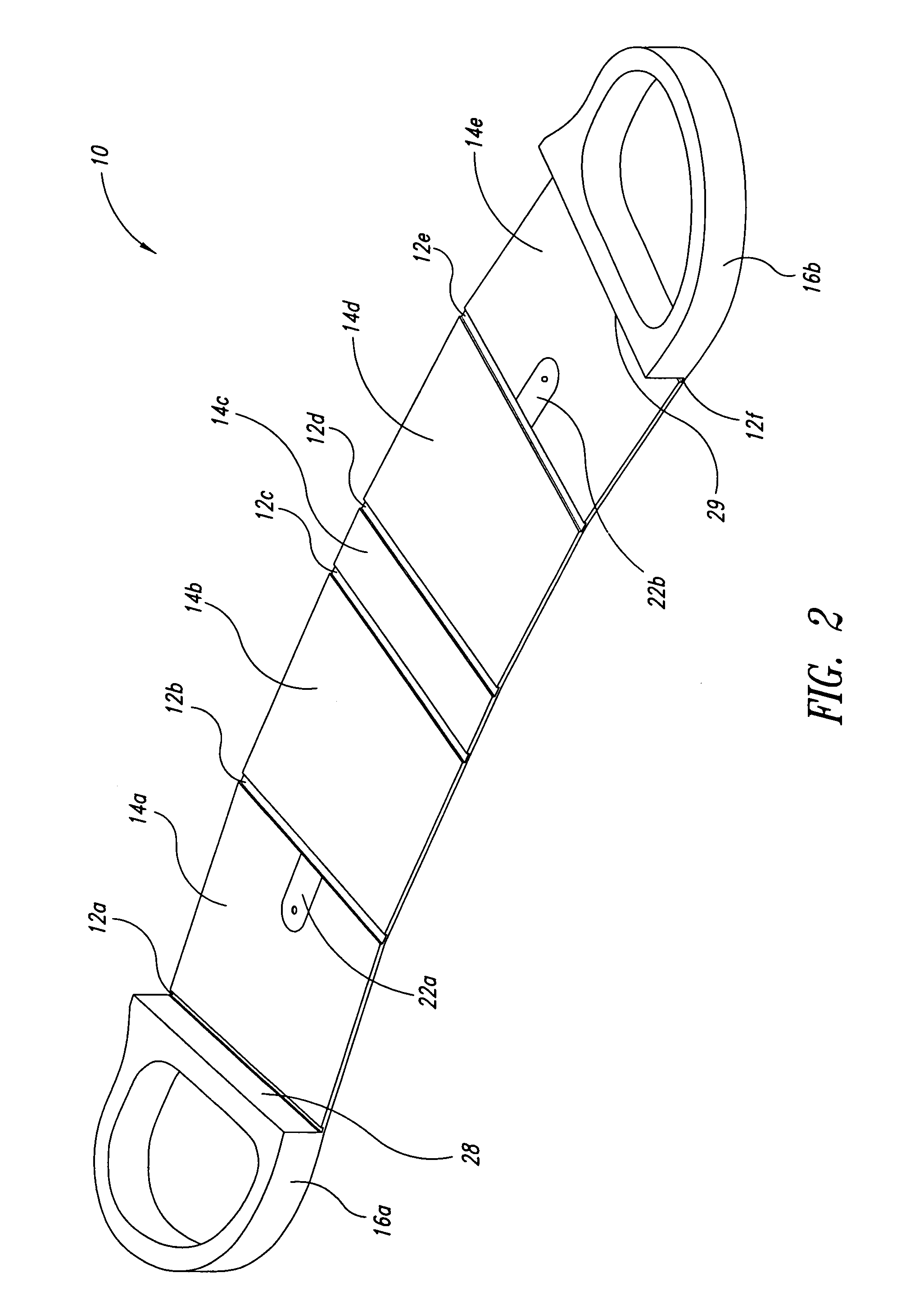

Collapsible handle for disposable cups

ActiveUS7080753B1Easily reducible in sizeLarge inner diameterLarge containersSealingEngineeringDisposable cup

The present invention provides a collapsible cup holder 10 having a plurality of hinges 12 intercoupling a plurality of rigid panels 14 and a handle 16 to form a collapsible ring 18. When the ring 18 is in an open position, the cup holder 10 can receive and retain a disposable container. When the ring 18 is in a closed position, the size of the holder 10 is reduced. The ring 18 is uniquely collapsible to provide an exposed, rigid panel surface that can be used to prominently display a decorative feature.

Owner:PACIFIC MARKET INT

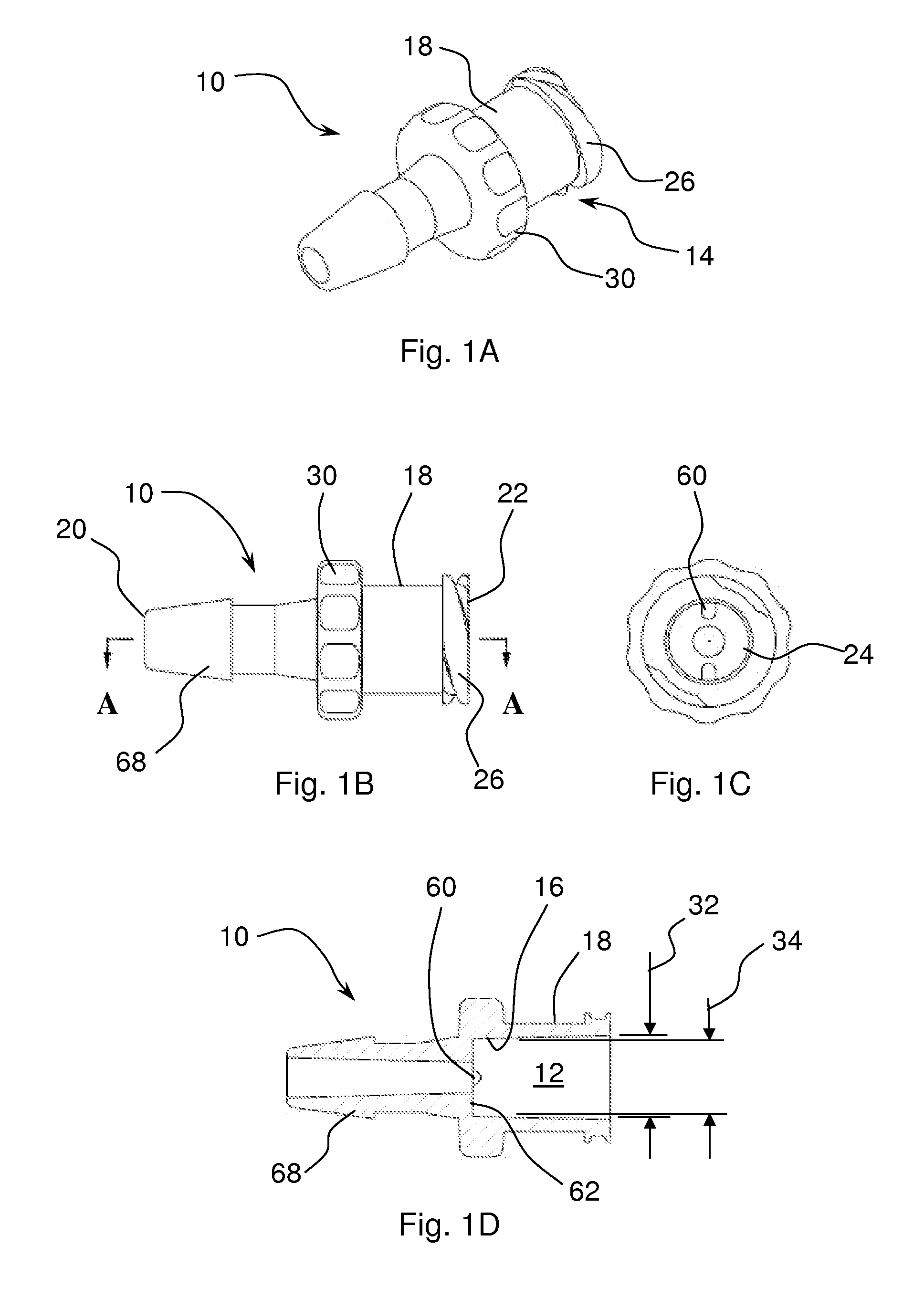

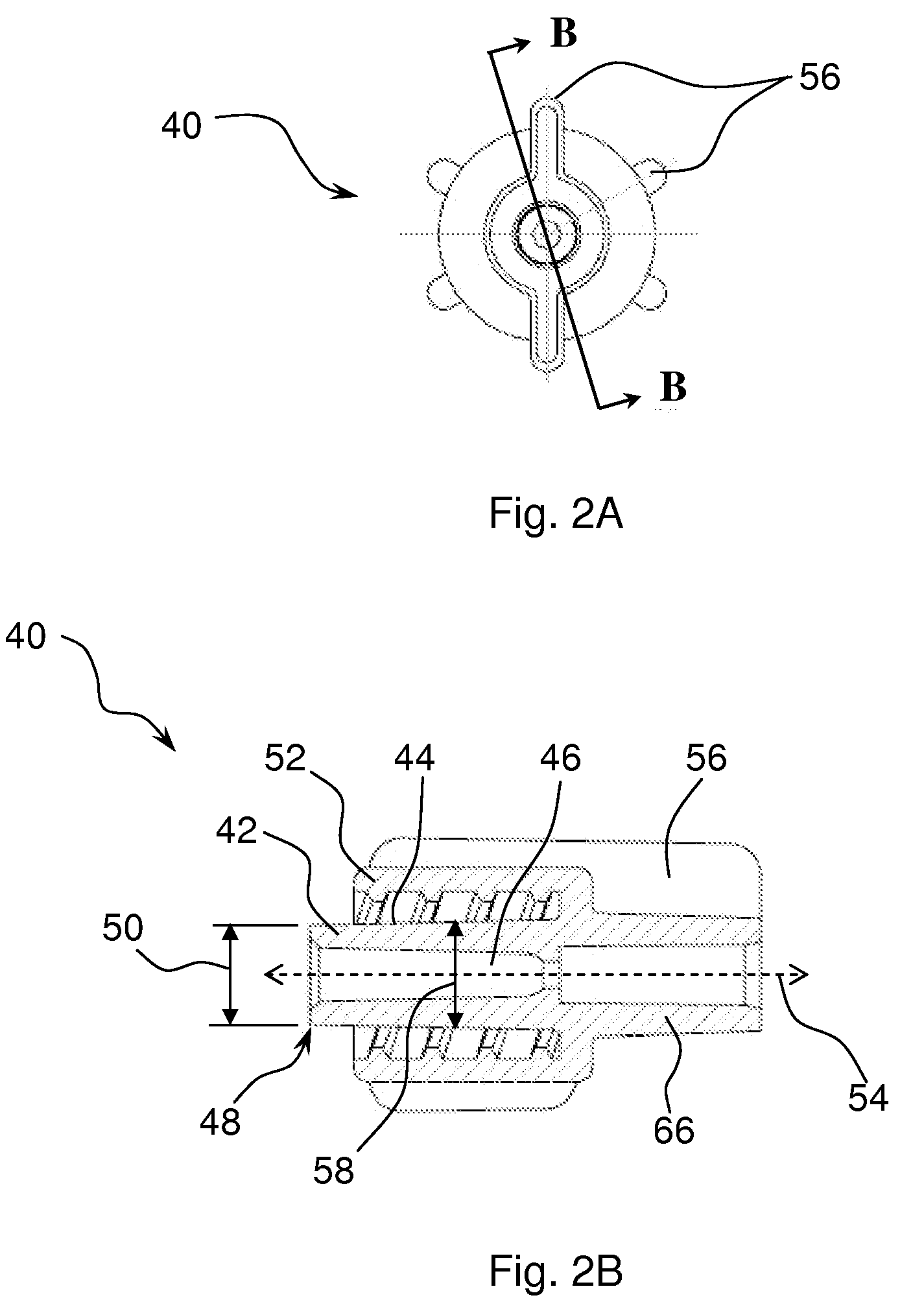

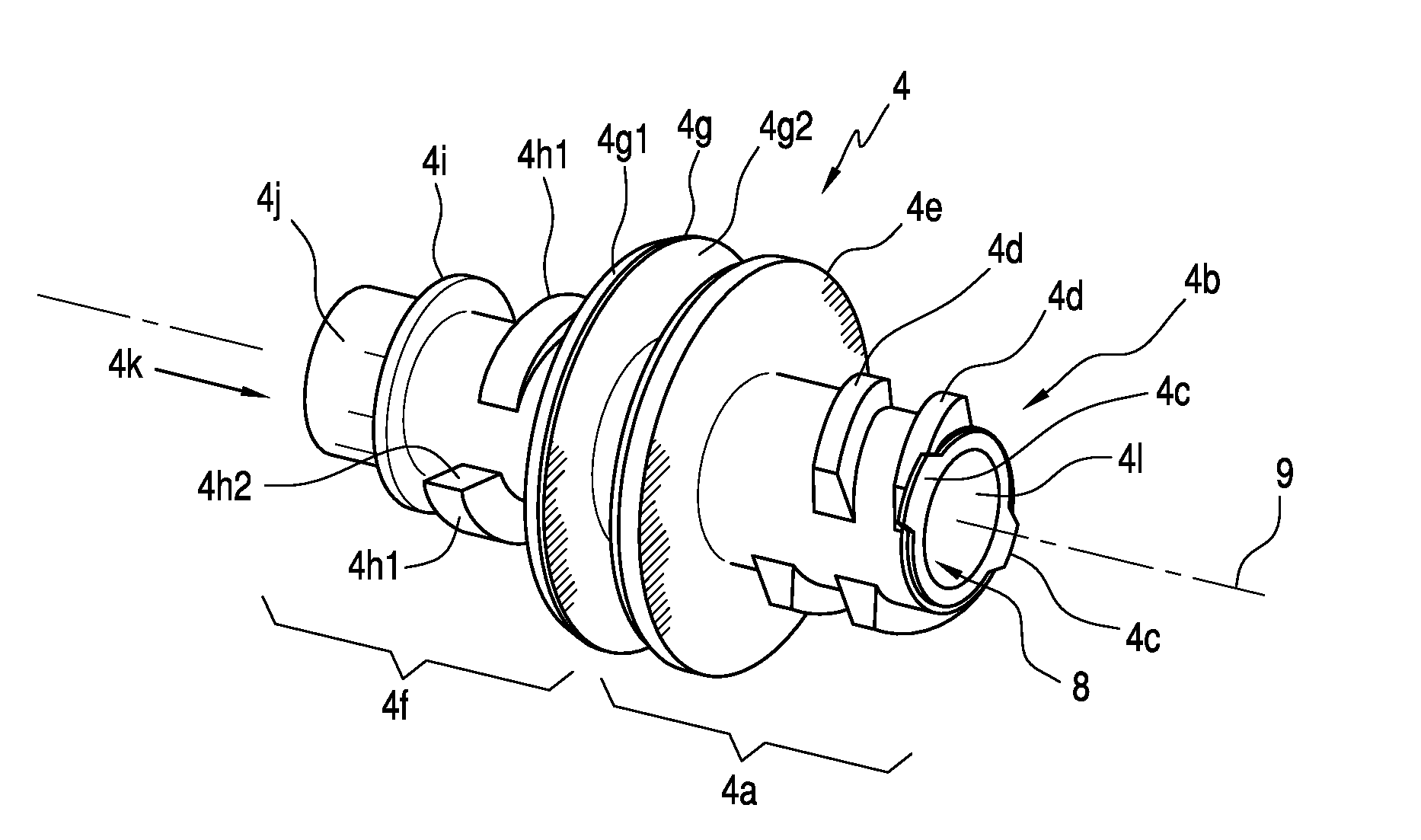

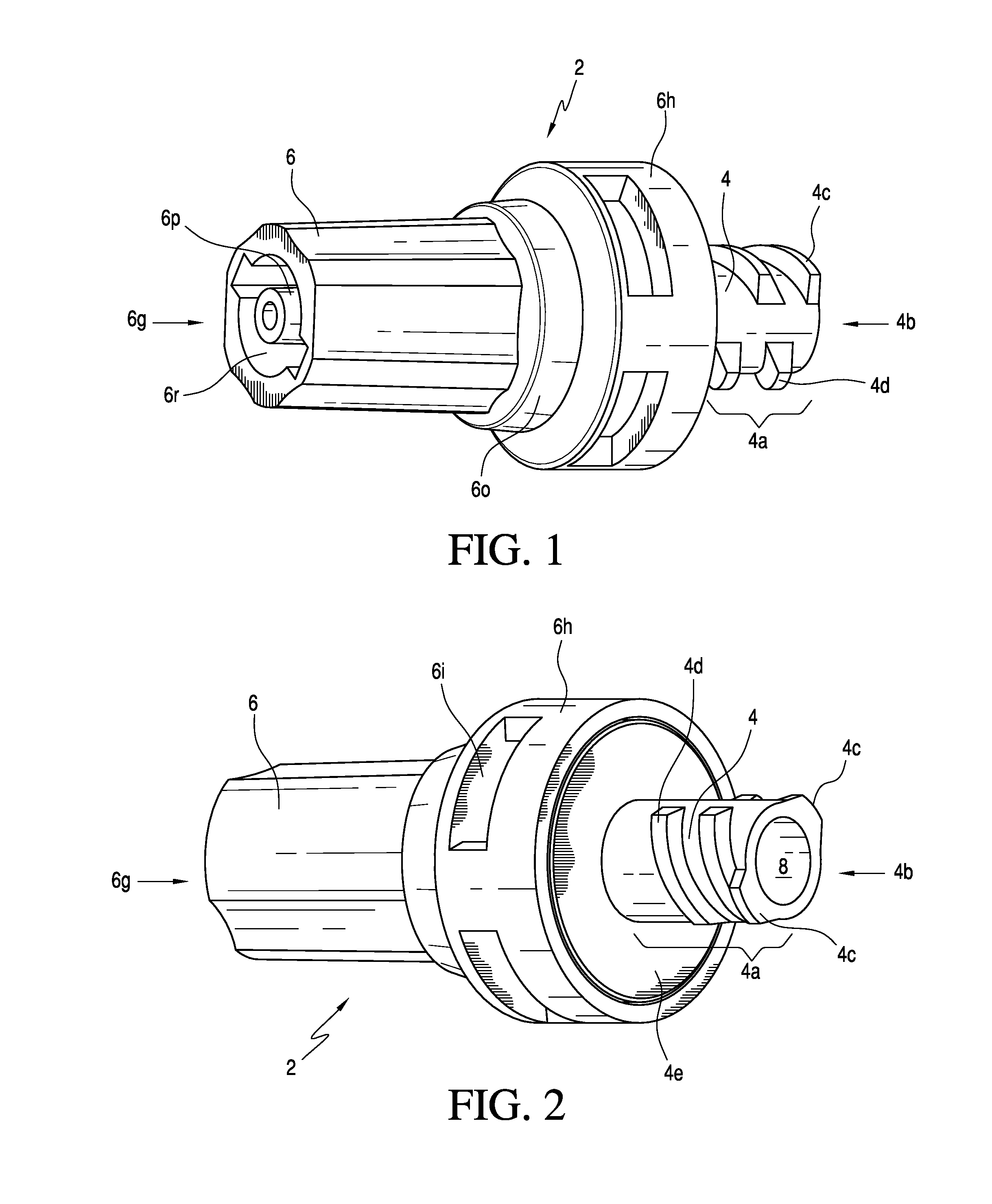

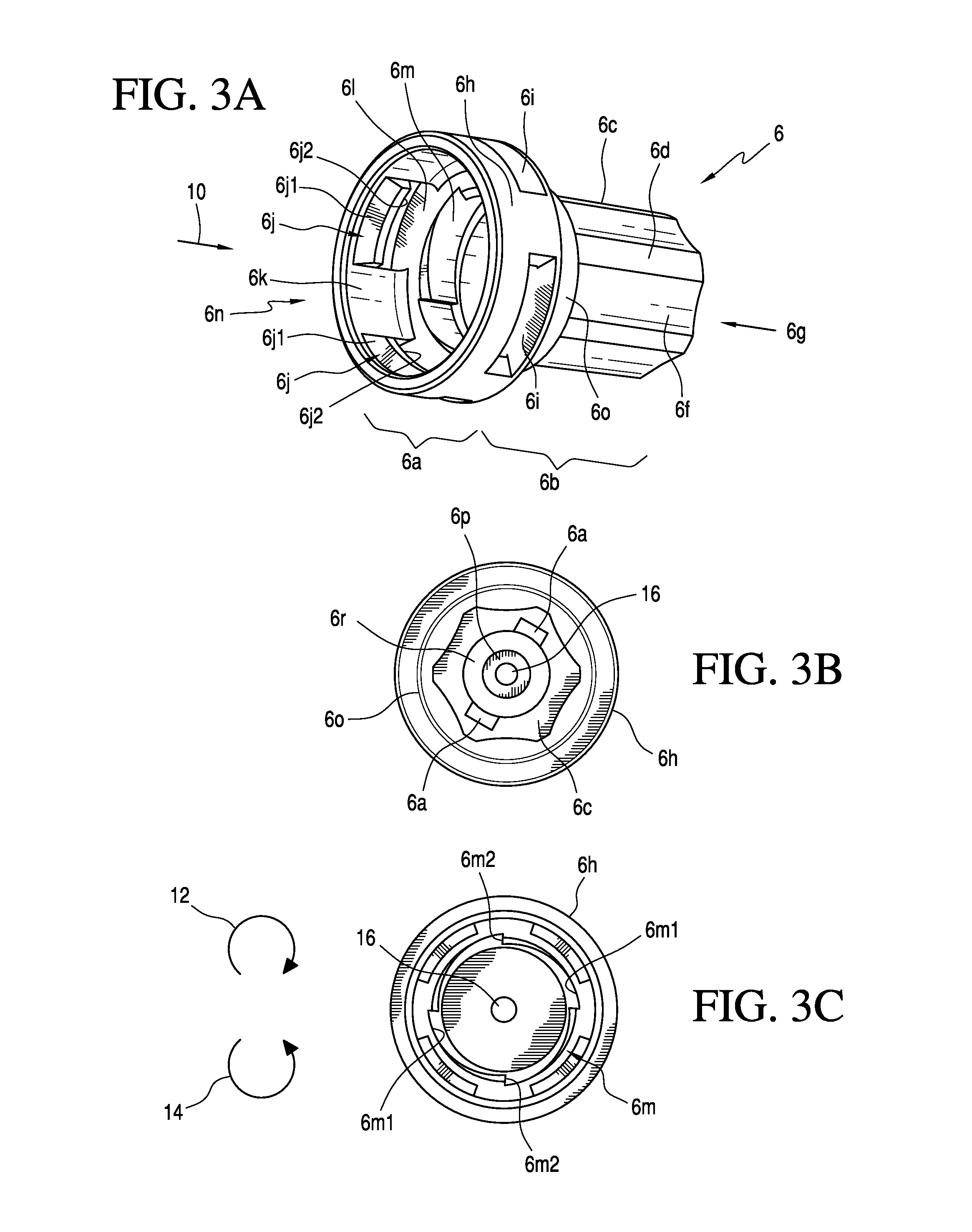

Adaptive connector

InactiveUS20140265319A1Prevent liquid leakageEasy to usePipe-jointsTube connectorsDistal portionEngineering

A connector has a first member with a distal portion non-removably coupled to a proximal portion of a second member. Respective through passages at the first and second members are in alignment to establish a through channel longitudinally along the connector. A seal in the connector prevents fluid leakage from the connector. A conventional fitting may be provided at one of the ends and a non-conventional fitting may be provided at the other end of the connector so that the connector may connect a device with a conventional fitting to a device with a non-conventional fitting. Once connected to the connector, the device with the conventional fitting is not removable from the connector. The first and second members are rotatable relative to each other about the longitudinal axis of the connector to enable rotational alignment of devices connected to the connector.

Owner:SMITHS MEDICAL ASD INC

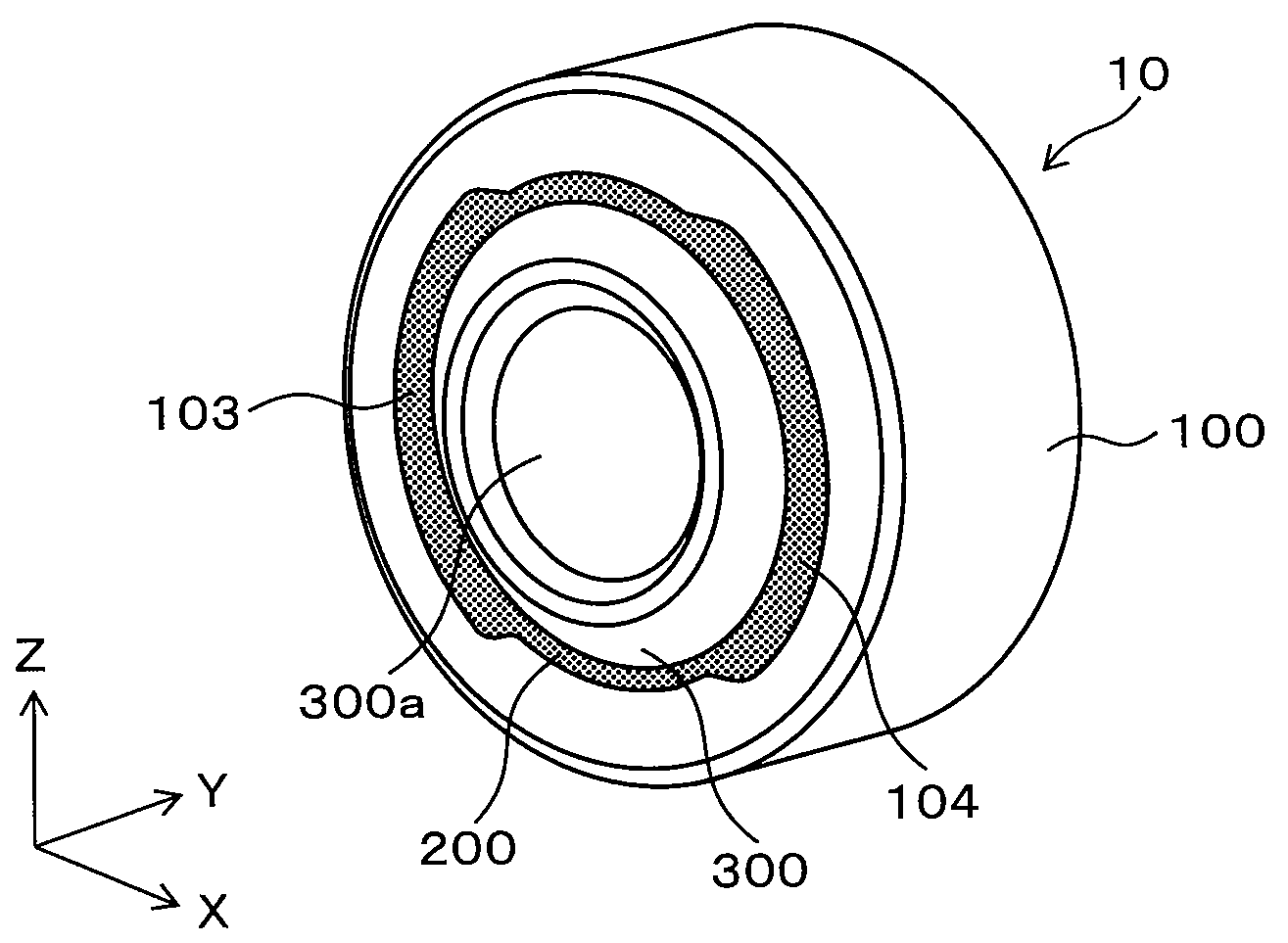

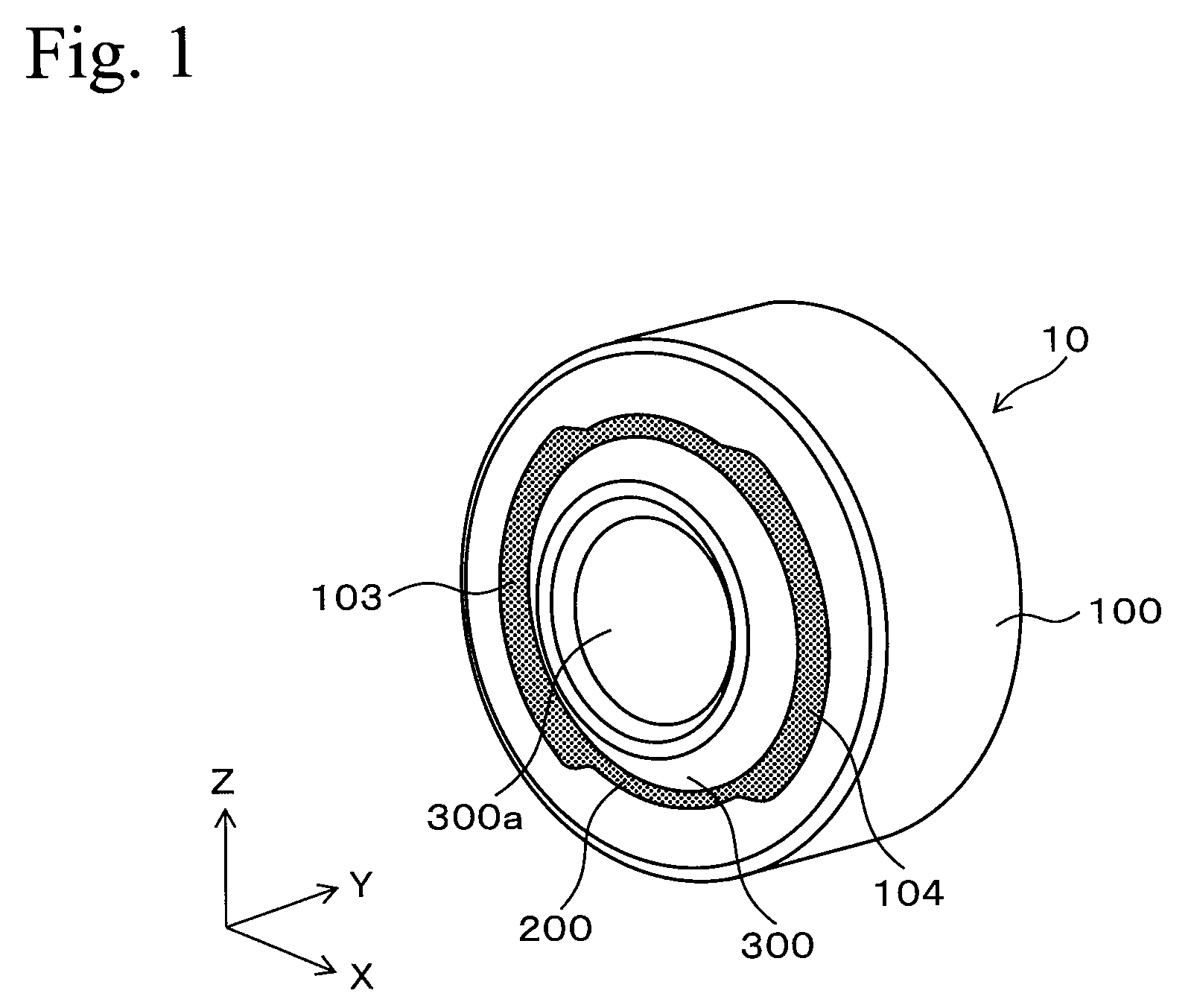

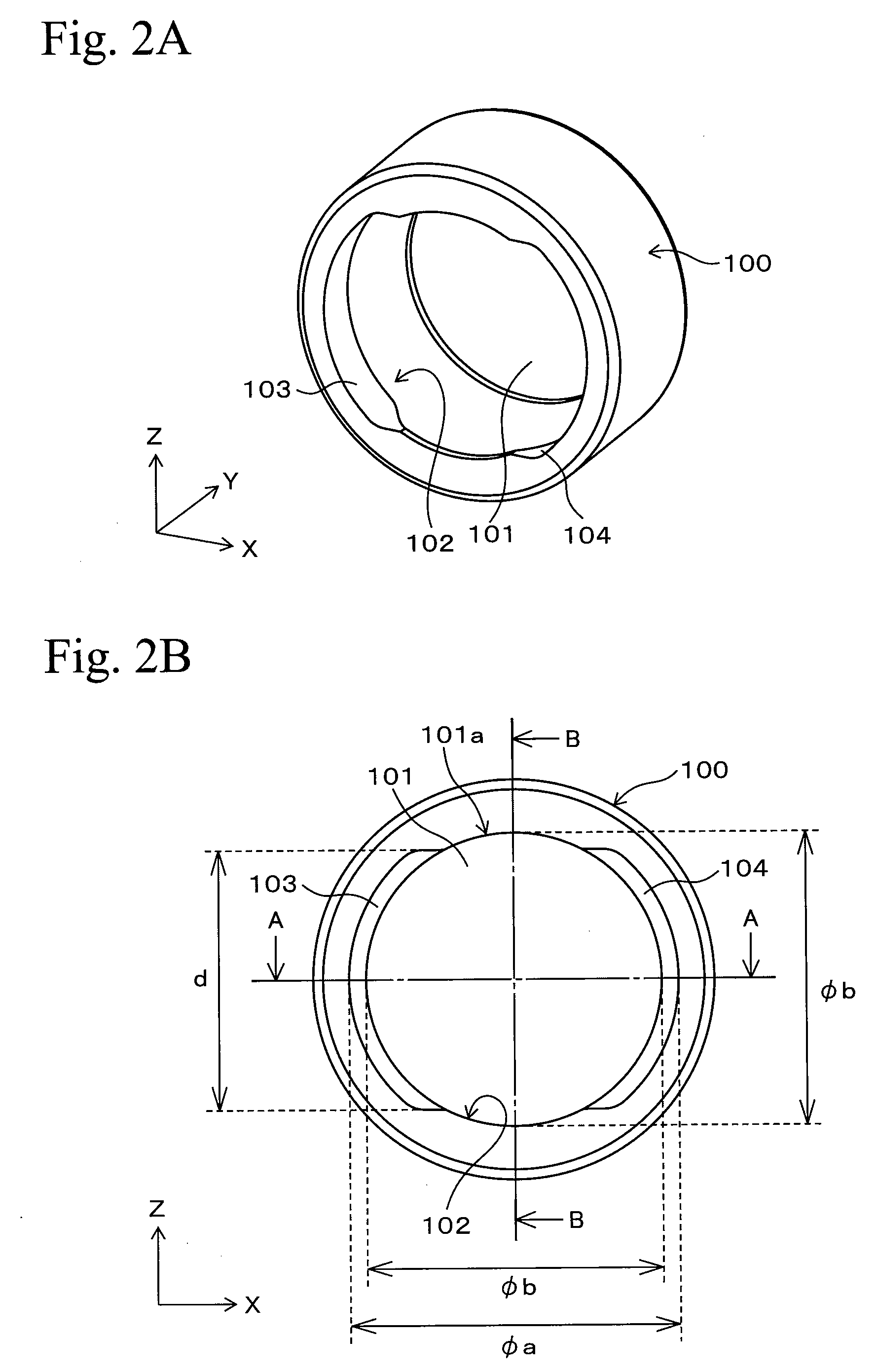

Spherical bearing with resin liner and rod end bearing

InactiveUS20090080818A1Large inner diameterDesign freedomRolling contact bearingsShaftsSpherical bearingEngineering

A spherical bearing with resin liner comprises an inner ring, an outer ring, an opening portion, a notched portion, and a resin liner portion. The inner ring has a convex spherical outer surface and a shape in which opposing end portions of a sphere are cut off, and the outer ring has a concave inner surface which faces the outer surface of the inner ring having a predetermined clearance therebetween. The opening portion is provided at the outer ring and has an inner diameter smaller than the outer diameter of the inner ring, and the opening portion communicates with a space surrounded by the inner surface of the outer ring. The notched portion is provided at an edge of the opening portion for inserting the inner ring into the outer ring, and the resin liner portion continuously fills the clearance and the notched portion.

Owner:MINEBEA CO LTD

Wire collection device for stent delivery system

ActiveUS20150057739A1Increases collection diameterLarge inner diameterStentsBlood vesselsEngineeringMechanical advantage

A wire collection device for a stent delivery system includes a plurality of nested wire collection drums with a first drum concentric in a second drum. A thumbwheel coupled to the first drum can rotate to actuate rotation of the first drum to collect the retraction wire around the diameter of the first drum. A catching mechanism can rotate about the first drum to engage a catch portion of the second drum and actuate rotation of the second drum to collect the retraction wire around the outer diameter of the second drum. This increases the collection diameter of the retraction wire to provide a mechanical advantage for sheath retraction.

Owner:COOK MEDICAL TECH LLC

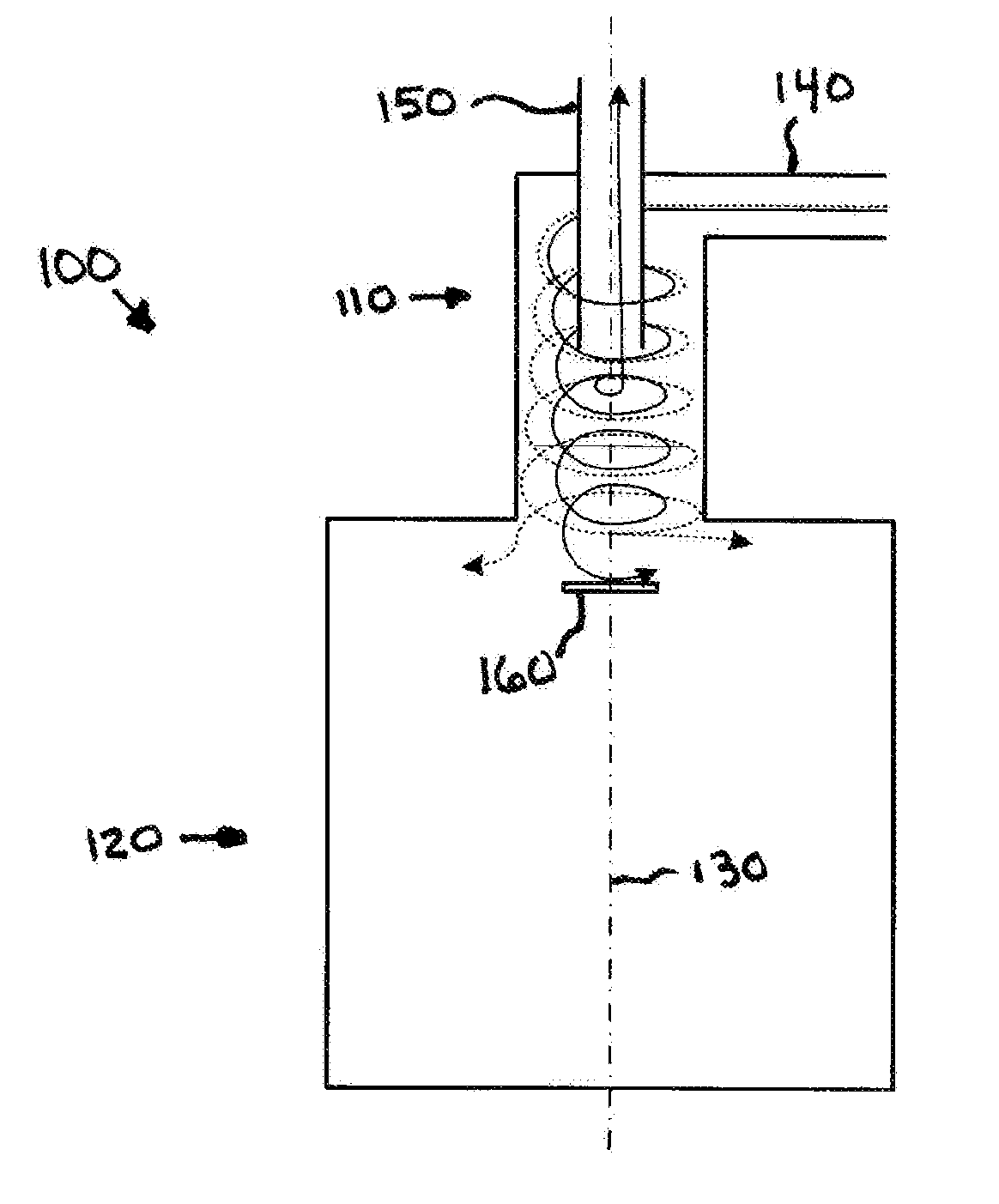

Systems and Methods for Separating Sand from Oil

InactiveUS20130134108A1Reduce erosionGreater taper anglesWater/sewage treatment by centrifugal separationReversed direction vortexHigh densityVolumetric Mass Density

Owner:TAPER LOK

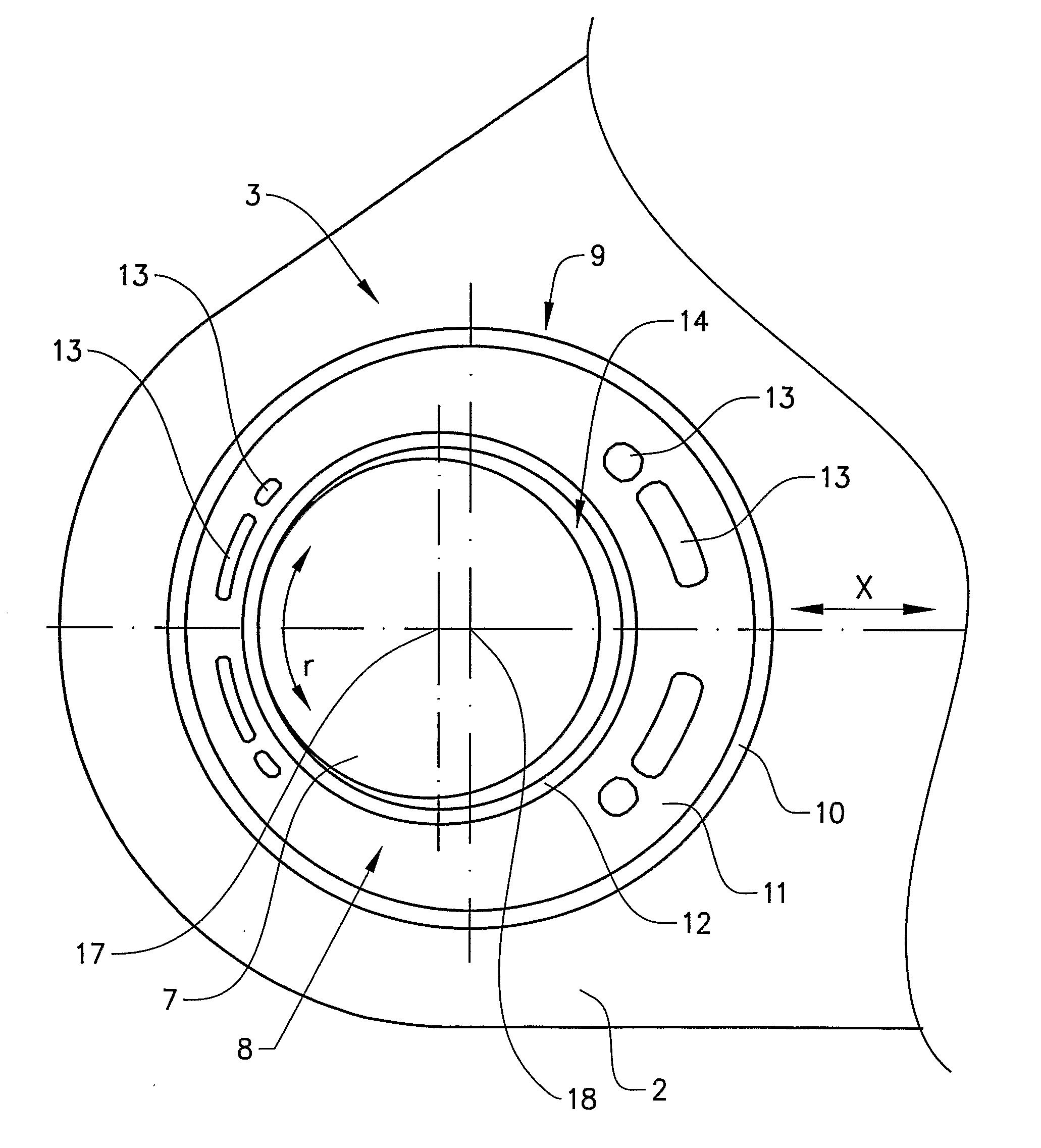

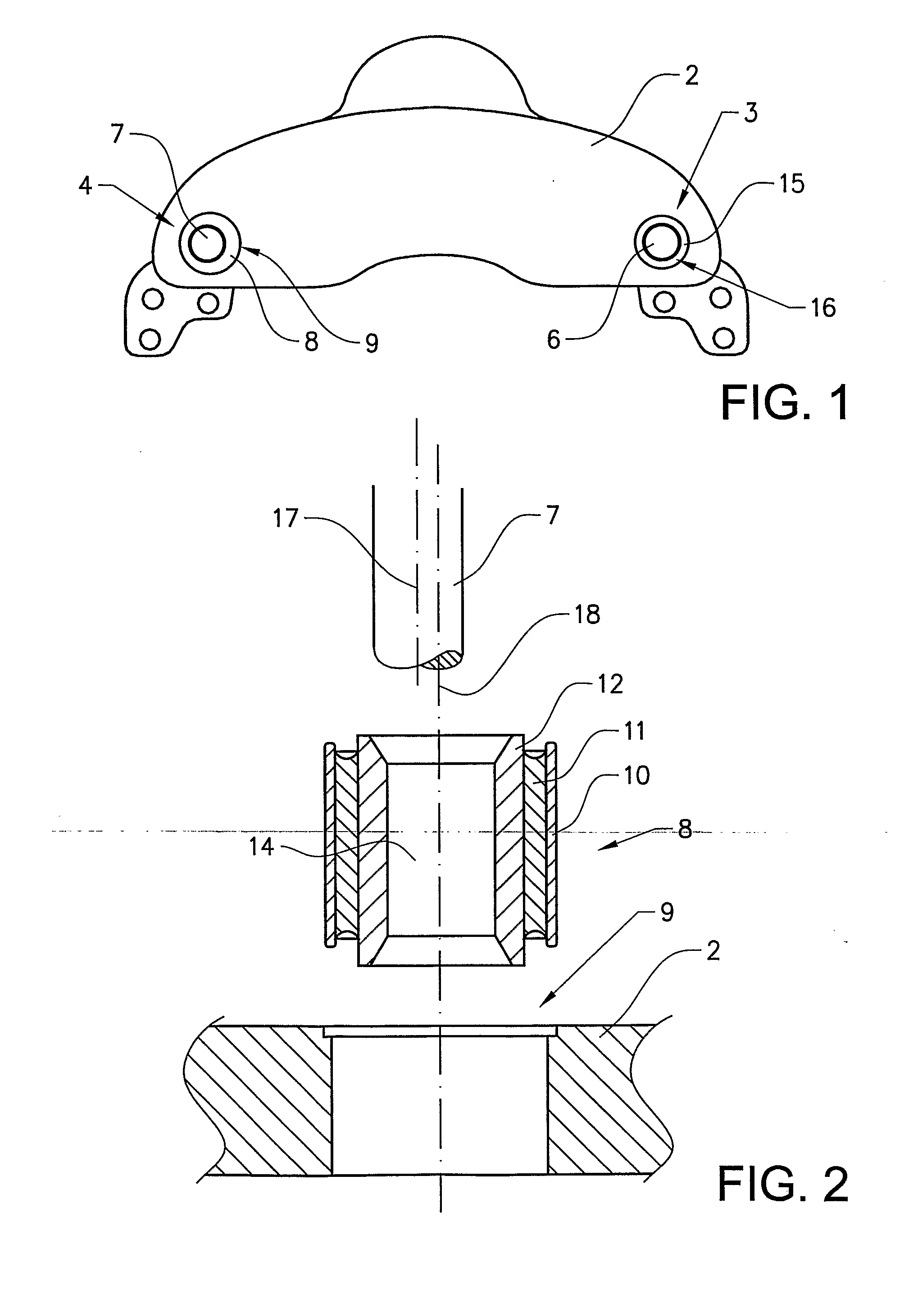

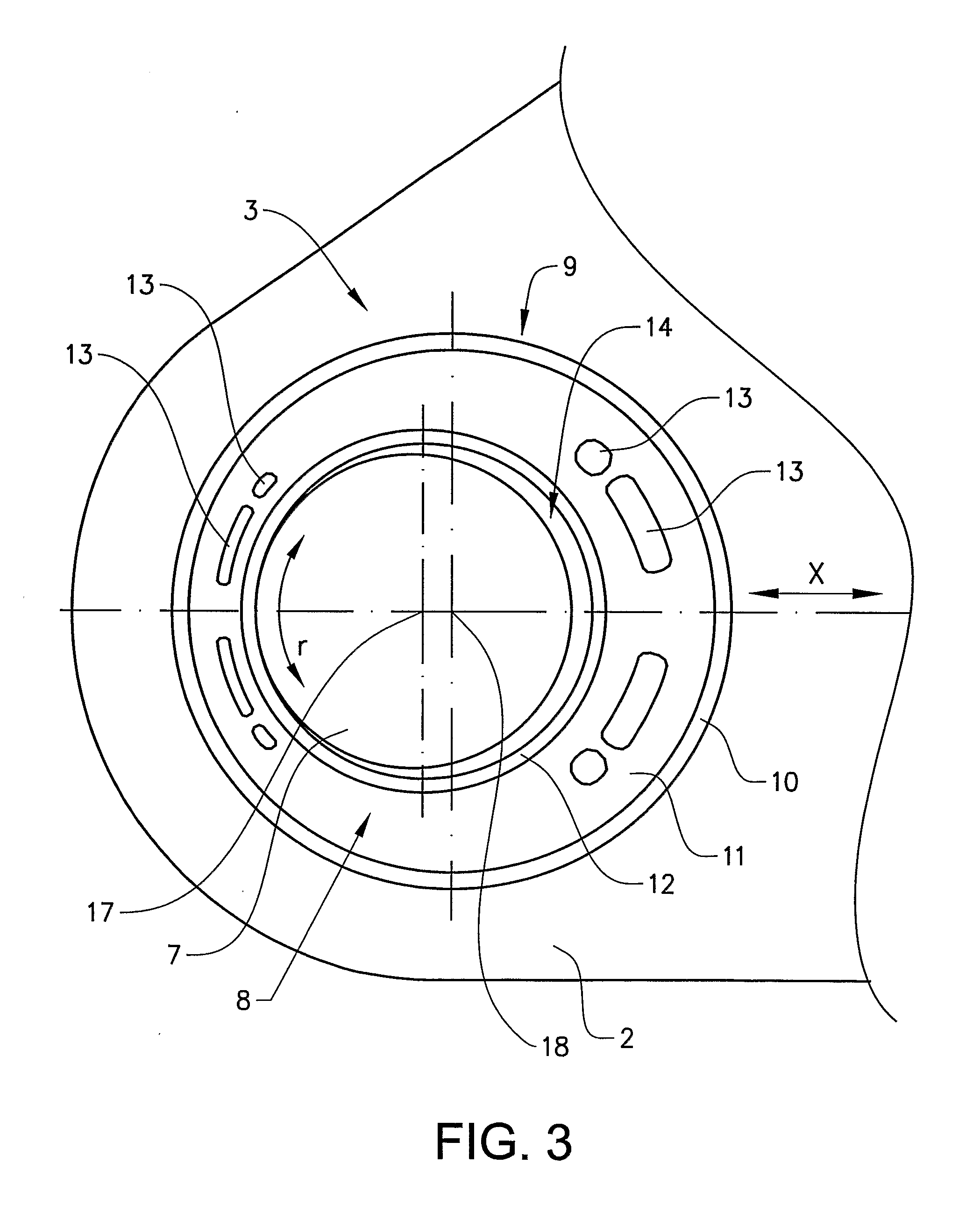

Sliding arrangement for a disk brake

InactiveUS20090200122A1Cancel noiseEliminate knockingNoise/vibration controlRolling contact bearingsEngineeringCalipers

A sliding arrangement for a disk brake includes a caliper adapted to engage a brake disk, and a first and a second support bearing for fixing the caliper to a brake support of the vehicle so that the caliper is axially slideable relative to the brake disk, where the first support bearing includes a first guide pin and a first guide bushing and the second support bearing includes a second guide pin and a second guide bushing, where the first guide pin and guide bushing have substantially no play between their sliding surfaces and the second guide pin and guide bushing have a play between their sliding surfaces, wherein the second guide bushing include an inner and an outer annular metal member with an annular member of resilient material therebetween, and wherein the bushing is mounted such that the center of the bushing is offset to the center of the guide pin. Hereby, brake noise created by vibrations when the brake is inactive is eliminated.

Owner:VOLVO LASTVAGNAR AB

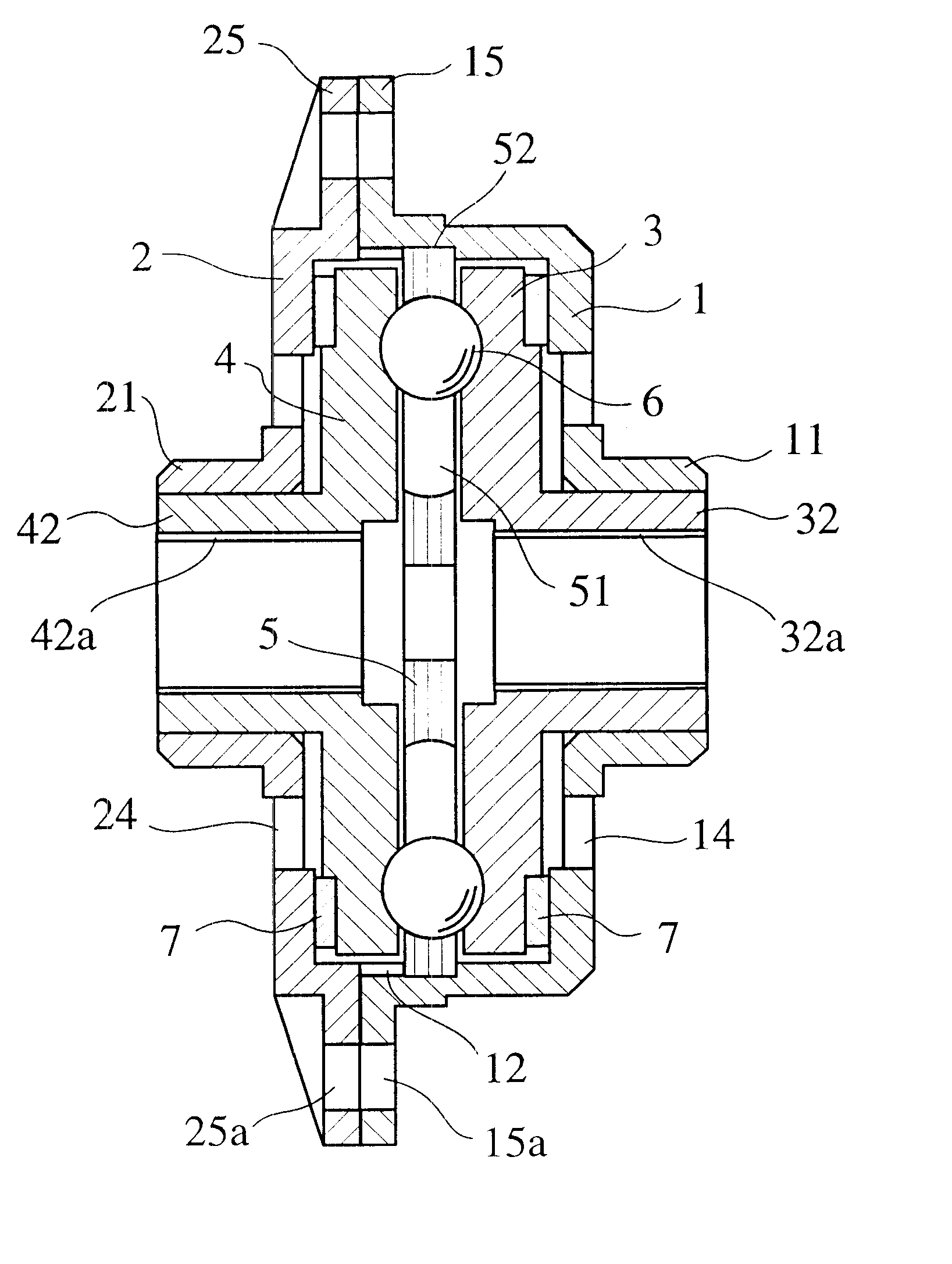

Connector equipped with a valve

ActiveUS7222637B2High trafficEfficient productionNon-fuel substance addition to fuelCheck valvesCoil springEngineering

A connector housing of a valve-equipped connector is integrally formed from a tube connection section at a first axial side; a pipe insertion section at a second axial side; and a valve housing section between the tube connection section and the pipe insertion section. The valve housing section is formed with an adequately large inner diameter. A main valve body and a compression coil spring for biasing the main valve body to the first axial side so that it abuts the inner surface of the housing are stored in the valve housing section. A cylindrical bushing is fitted to the first axial side of the pipe insertion section of the connector housing, and a valve cap for receiving a second axial end of the compression coil spring is formed integrally at the first axial end of the cylindrical bushing.

Owner:HONDA MOTOR CO LTD

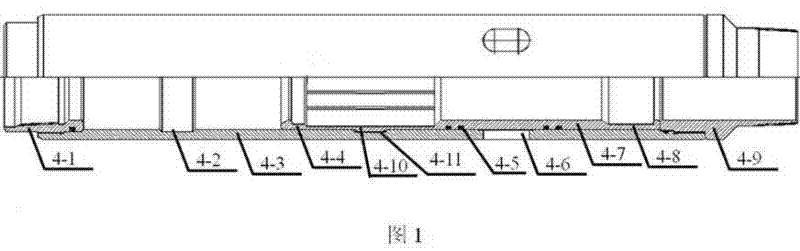

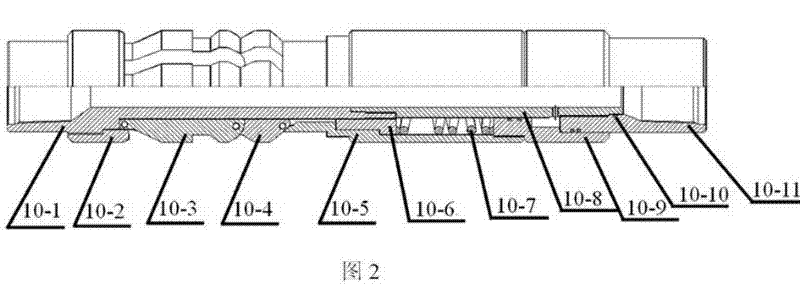

Open hole staged fracturing well completion pipe string provided with controllable valve and hydraulic control switching pipe string

ActiveCN102330546AIncrease the lengthLarge displacementFluid removalWell/borehole valve arrangementsHorizontal wellsCoiled tubing

The invention discloses an open hole staged fracturing well completion pipe string provided with a controllable valve and a hydraulic control switching pipe string, which are suitable for well completion processes of horizontal wells and straight wells. The hydraulic control switching pipe string is tripped to open and close the open hole staged fracturing well completion pipe string provided with the controllable valve, so that multilayer-section fracturing well completion construction is realized, and development requirements of low-permeability oil reservoirs and unconventional oil and gas resources are met. The pipe string is sequentially connected with a drill stem running tool, a top suspension packer, a hydraulic control switching retention cylinder, a switchable control valve, an open hole fracturing packer connected with the control valve, a shaft isolating valve and a bottom circulating valve from top to bottom by using a bushing. The hydraulic control switching pipe string comprises a hydraulic control switching tool and a continuous oil pipe; and a set of hydraulic control switching tool is connected to the bottom of the continuous oil pipe. The switchable control valve has the internal drift diameter of the same size; sand fracturing well completion can be performed on a stratum by using the bushing; and thus, requirements of large-displacement and large-scale fracturing reconstruction are met, the crack length, the crack number and the flow guide capacity are increased, and the production capacity and the recovery ratio are effectively increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

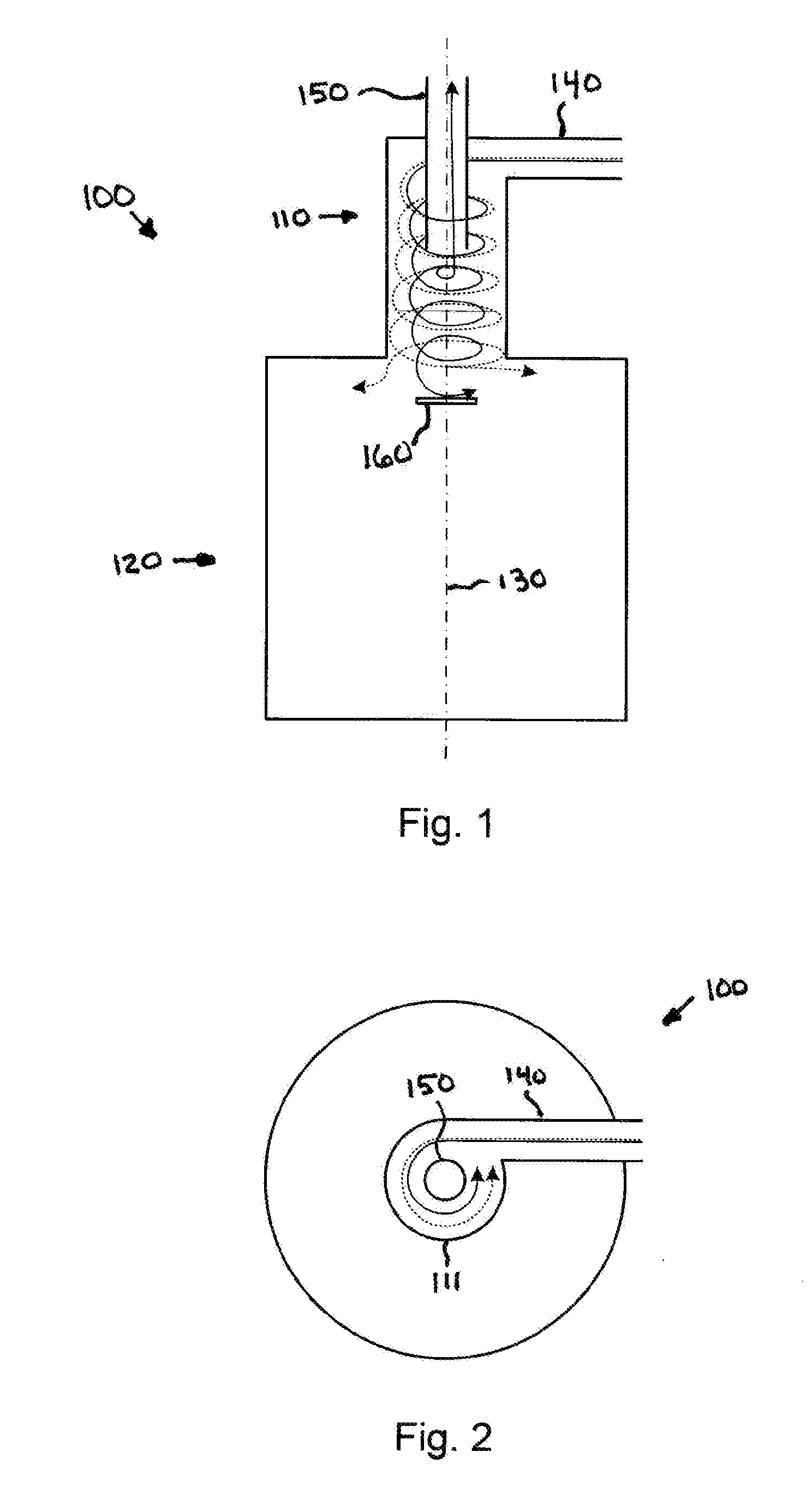

NMR spectrometer with flowthrough sample container

ActiveUS7145340B2Easy to introduceEasily and safely changeMagnetic measurementsElectric/magnetic detectionFlow cellResonance

A flow-through sample container, or flow cell, according to the present invention resides with the channel of magnetic resonance probe without being fixed thereto. The flow cell is removable from the spectrometer while leaving the probe in place, allowing easy cleaning of the probe channel and replacement of the flow cell. An insertion tool that houses the flow cell may be used to safely introduce it to the probe. Input and output capillaries serve as fluid pathways for fluid samples entering and leaving the flow cell, respectively. These capillaries may be connected to the flow cell with a manually operable connector, allowing easy disconnection of the flow cell from the input and output conduit. The capillaries enter through different ends of the spectrometer bore, so that the fluid samples flow enter one end of the spectrometer and exit through the other.

Owner:BRUKER BIOSPIN

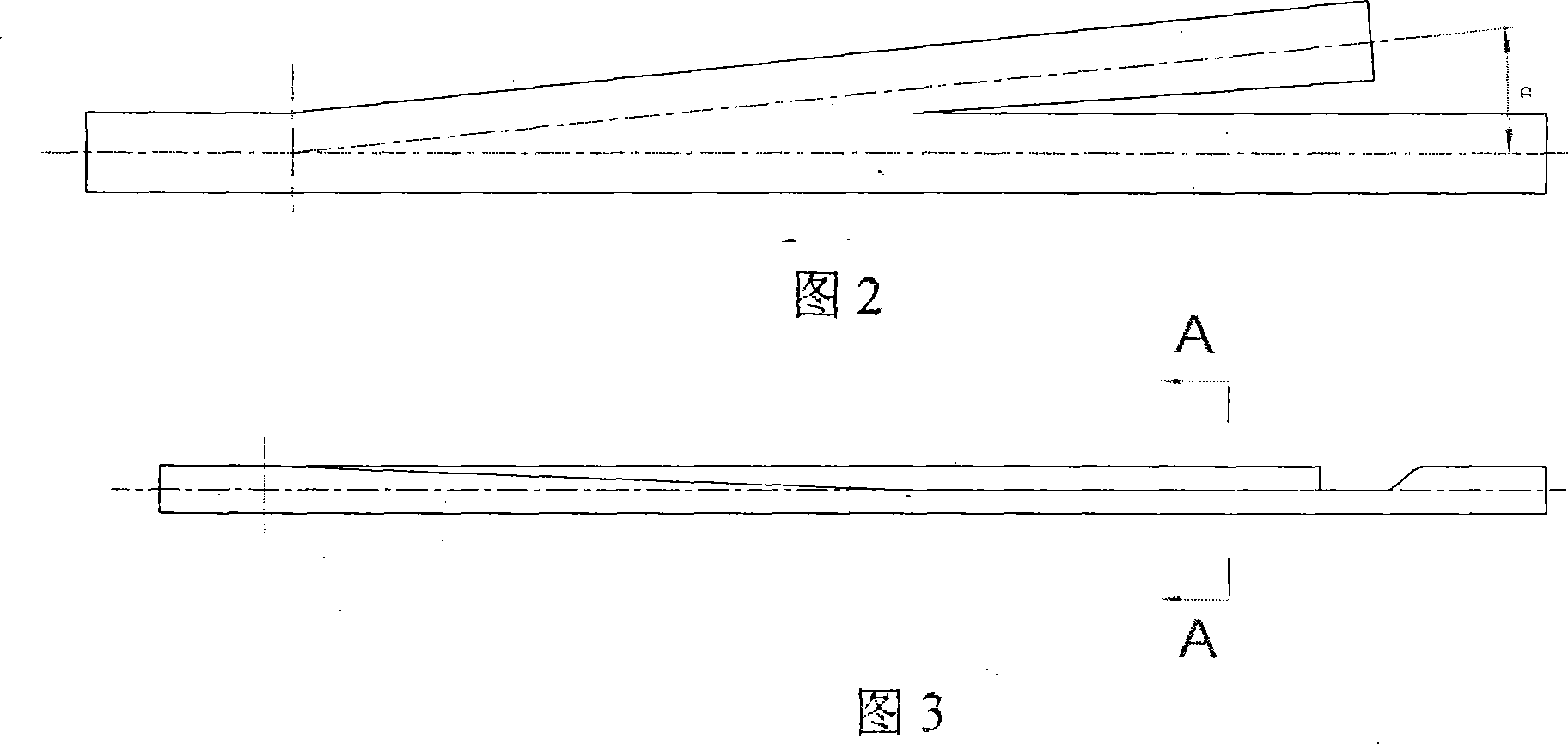

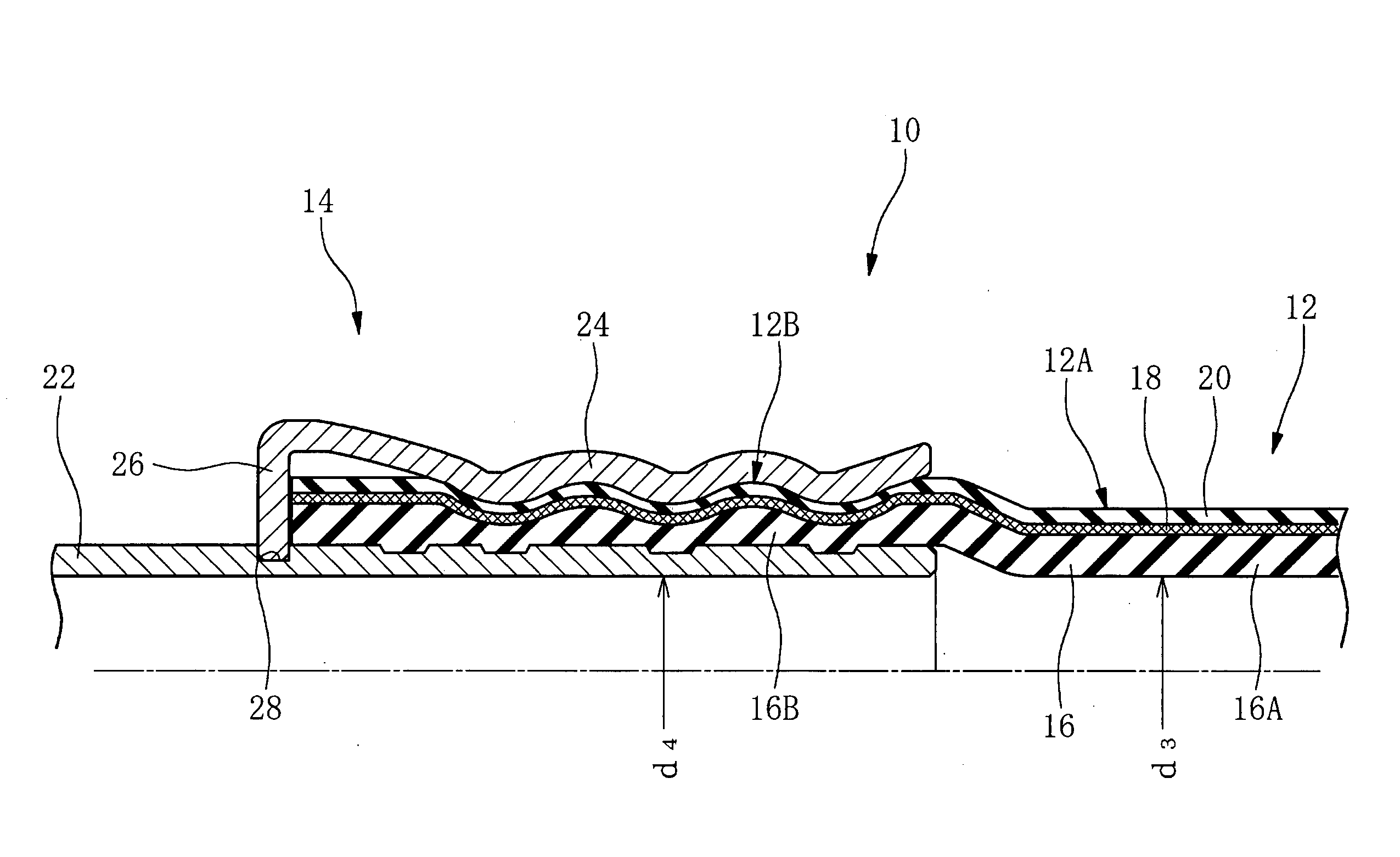

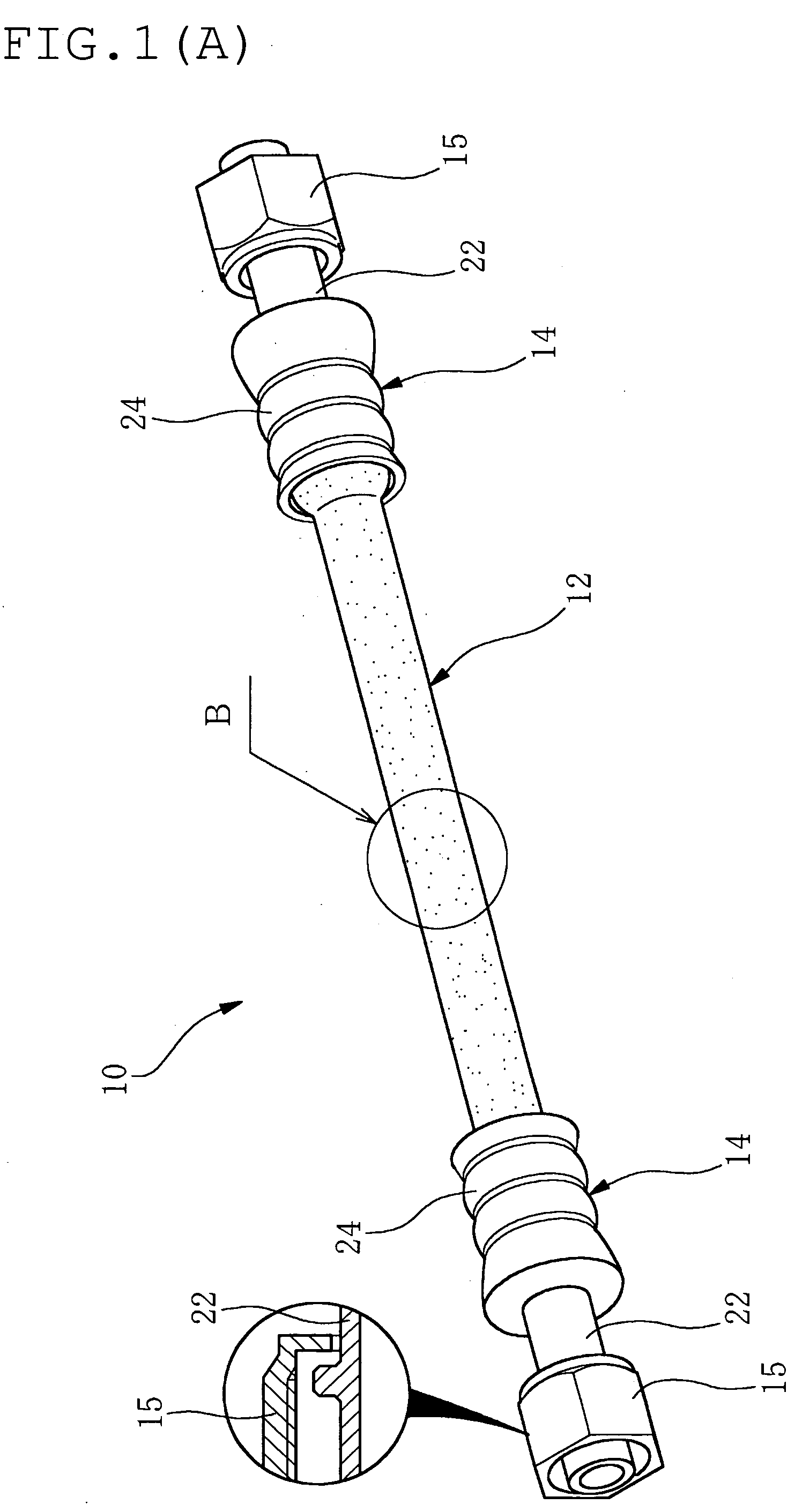

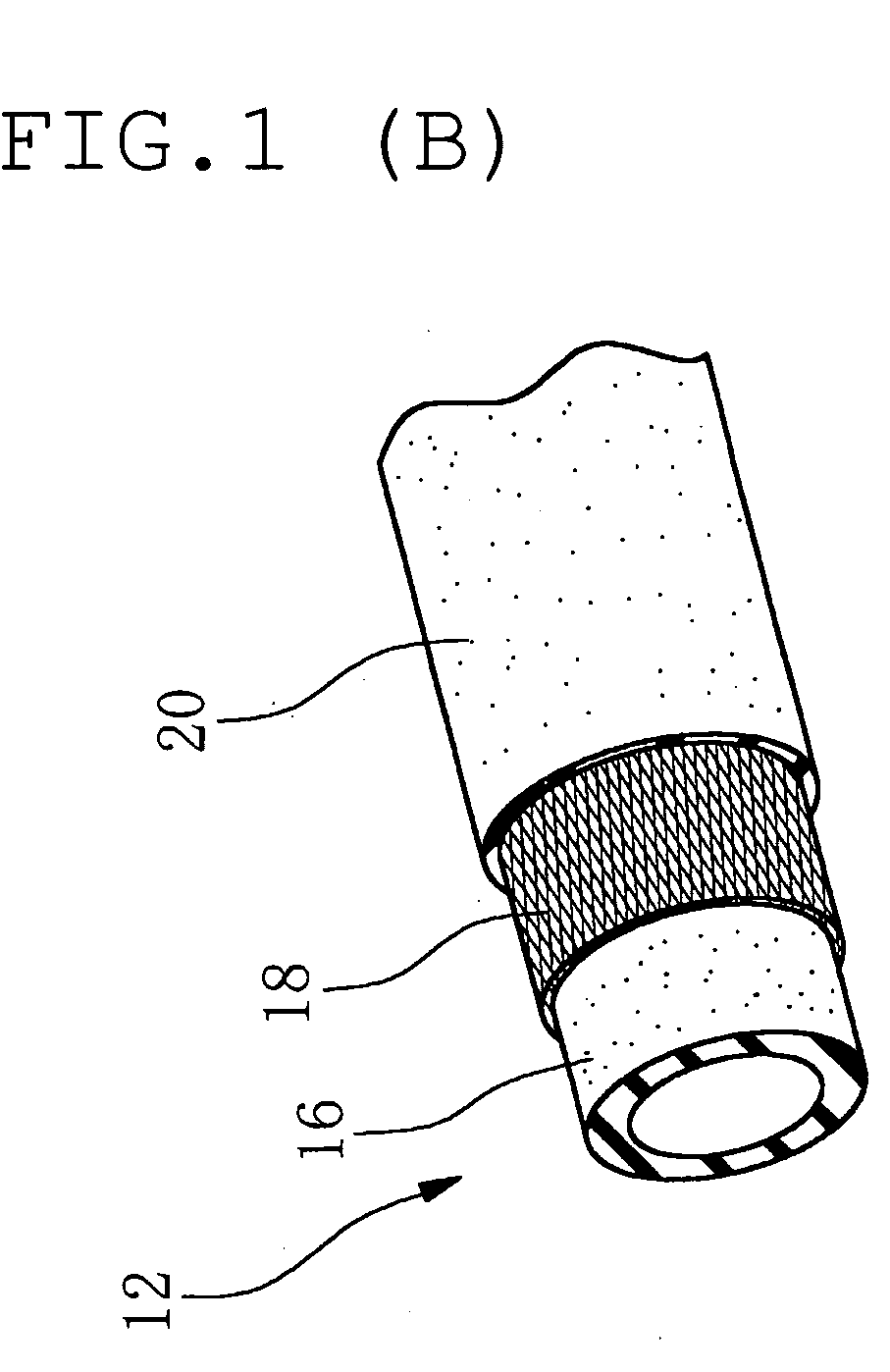

Pressure resistant vibration absorbing hose

A pressure resistant vibration absorbing hose has a hose body including an inner surface rubber layer, a reinforcing layer and an outer surface rubber layer and a joint fitting including a rigid insert pipe and a socket fitting. The joint fitting is attached to a swaged portion of an axial end portion of the hose body by securely swaging the socket fitting thereto. The inner surface rubber layer is formed by molding such that a swaged portion thereof is larger than a main portion thereof in diameter and a wall thickness of the swaged portion is equal to or larger than a wall thickness of the main portion, and after that, the reinforcing layer and the outer surface rubber layer are laminated to construct the hose body.

Owner:DENSO CORP +1

Controlled-valve placed well-cementing staged-fracturing well-completion string and hydraulically-controlled switch string

ActiveCN102410009AIncrease the lengthLarge displacementFluid removalWell/borehole valve arrangementsHorizontal wellsWell cementing

The invention discloses a controlled-valve placed well-cementing staged-fracturing well-completion string and a hydraulically-controlled switch string, which are suitable to be applied to a well-completion process for horizontal wells and vertical wells, and through tripping in the hydraulically-controlled switch string to start and close the controlled-valve placed well-cementing staged-fracturing well-completion string, multi-layer-and-section fracturing well-completion construction is realized, thereby meeting the needs of development on low-permeability oil reservoirs and unconventional oil / gas resources. The controlled-valve placed well-cementing staged-fracturing well-completion string, from top to bottom, is sequentially connected with a hydraulically-controlled switch tool detention cylinder, a switchable control valve and hydraulic casing centralizers connected with the two ends of the switchable control valve, a pressed settling valve and a bottom circulating valve by using a casing; and at least a set of switchable control valve and hydraulic casing centralizers connected with the two ends of the switchable control valve are equipped in the string. The hydraulically-controlled switch string comprises hydraulically-controlled switch tools and a continuous oil pipe, and a set of hydraulically-controlled switch tool is connected to the bottom of the continuous oil pipe. The switchable control valves are same in inner drift diameter (same in size), and can carry out well completion on stratums through the sand fracturing of the casing, thereby satisfying the needs of large-displacement and large-scale fracturing reformation.

Owner:CHINA PETROLEUM & CHEM CORP +1

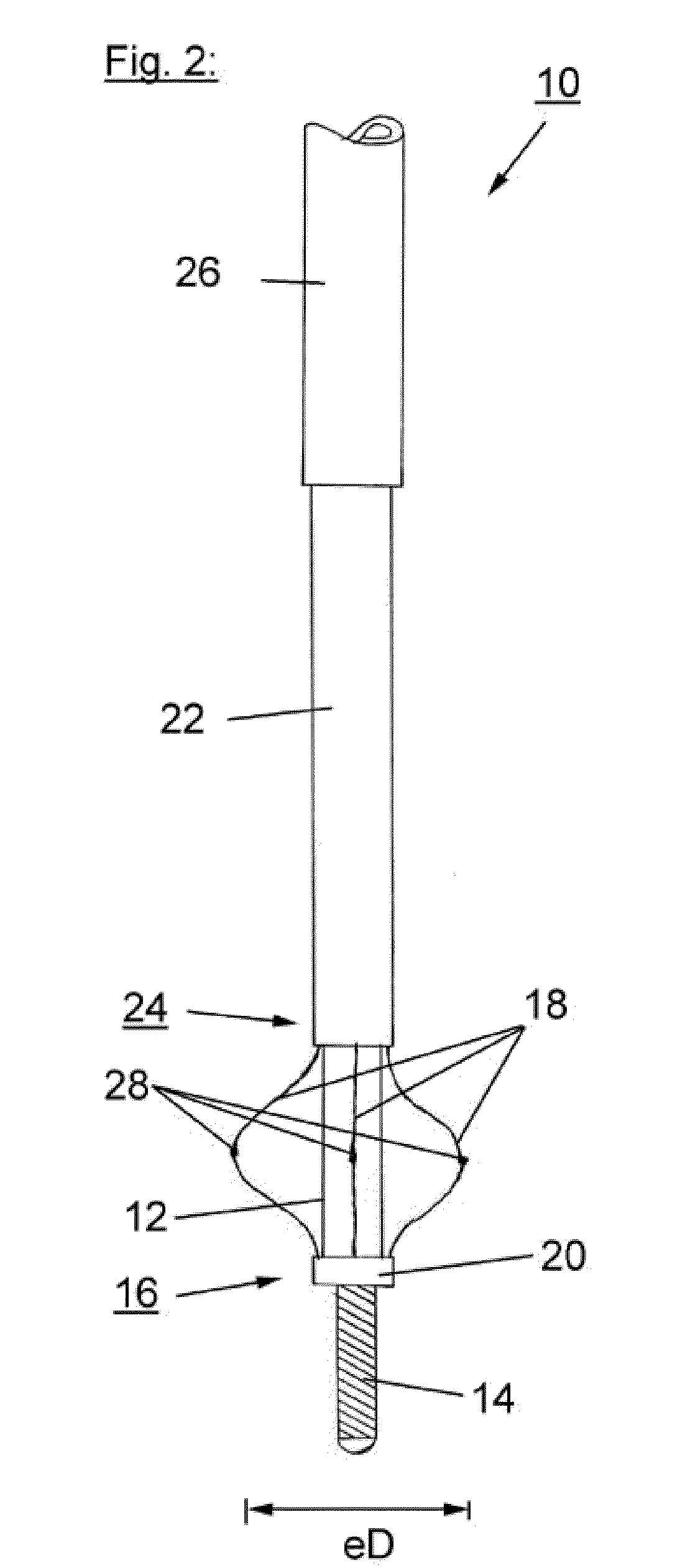

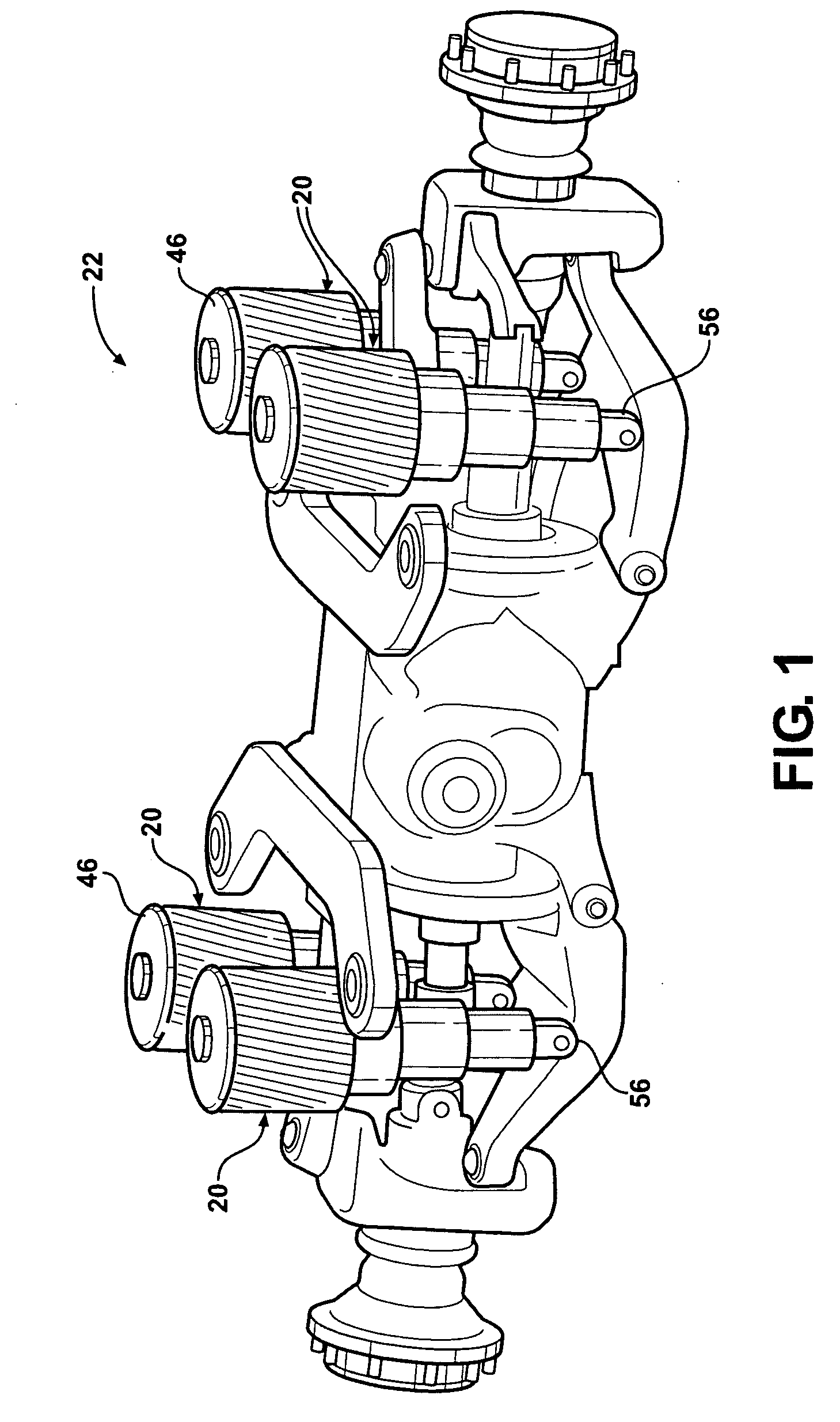

Deflectable microimplant delivery system

InactiveUS8002739B2Precise controlled deliveryLarge inner diameterMedical devicesCatheterSingle-coreGuide tube

The present invention provides a deflectable catheter-based system for assisting in the delivery of therapeutic agents, cellular materials and the like to one or more sites in a target body tissue. The system provides for one or more injections to a predetermined needle insertion depth with a single core needle that can be advanced and retracted from the tip of the catheter. The catheter assembly includes a handle subassembly having a mechanism for setting and limiting the depth of insertion of the needle, a slide for moving the injection needle between retracted and extended positions, a return spring for biasing the needle to the retracted position, and a modified pulley mechanism for compensating for catheter shaft compression when the catheter is deflected.

Owner:ABBOTT CARDIOVASCULAR

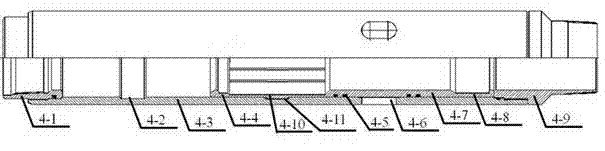

Bridge plug for fracturing of casing pipe

InactiveCN104989317AEliminate drilling and grinding operationsImprove reliabilityFluid removalSealing/packingWellboreLocking mechanism

The invention relates to a bridge plug for fracturing of a casing pipe. The bridge plug comprises a center rod, an upper connector and a lower connector. The upper connector and the lower connector are arranged at the upper end and the lower end of the center rod. The middle of the center rod is sleeved with a long rubber cylinder and short rubber cylinders. The upper portion and the lower portion of the center rod are sleeved with an upper supporting sleeve and a lower supporting sleeve respectively. Rubber cylinder seats are fixed to the upper supporting sleeve and the lower supporting sleeve respectively. The short rubber cylinders at the upper end and the lower end of the long rubber cylinder are installed on the rubber cylinder seats. A seat ring is arranged between the upper supporting sleeve and the upper connector, and the upper end and the lower end of the seat ring abut against the upper connector and the upper supporting sleeve respectively. A slip is arranged between the lower supporting sleeve and the lower connector and is provided with an anchor jaw. According to the bridge plug which is provided with the slip and a locking mechanism and used for fracturing of the casing pipe, the reliability of the bridge plug can be ensured, degradable materials are adopted, and degrading can be conducted as time goes by when certain shaft conditions are reached. The bridge plug for fracturing of the casing pipe has the advantages of being high in pressure bearing capability, free of plug drilling and large in diameter and can be used for transformation of multiple sections of a reservoir of a highly-deviated well and a horizontal well and put into production rapidly.

Owner:PETROCHINA CO LTD

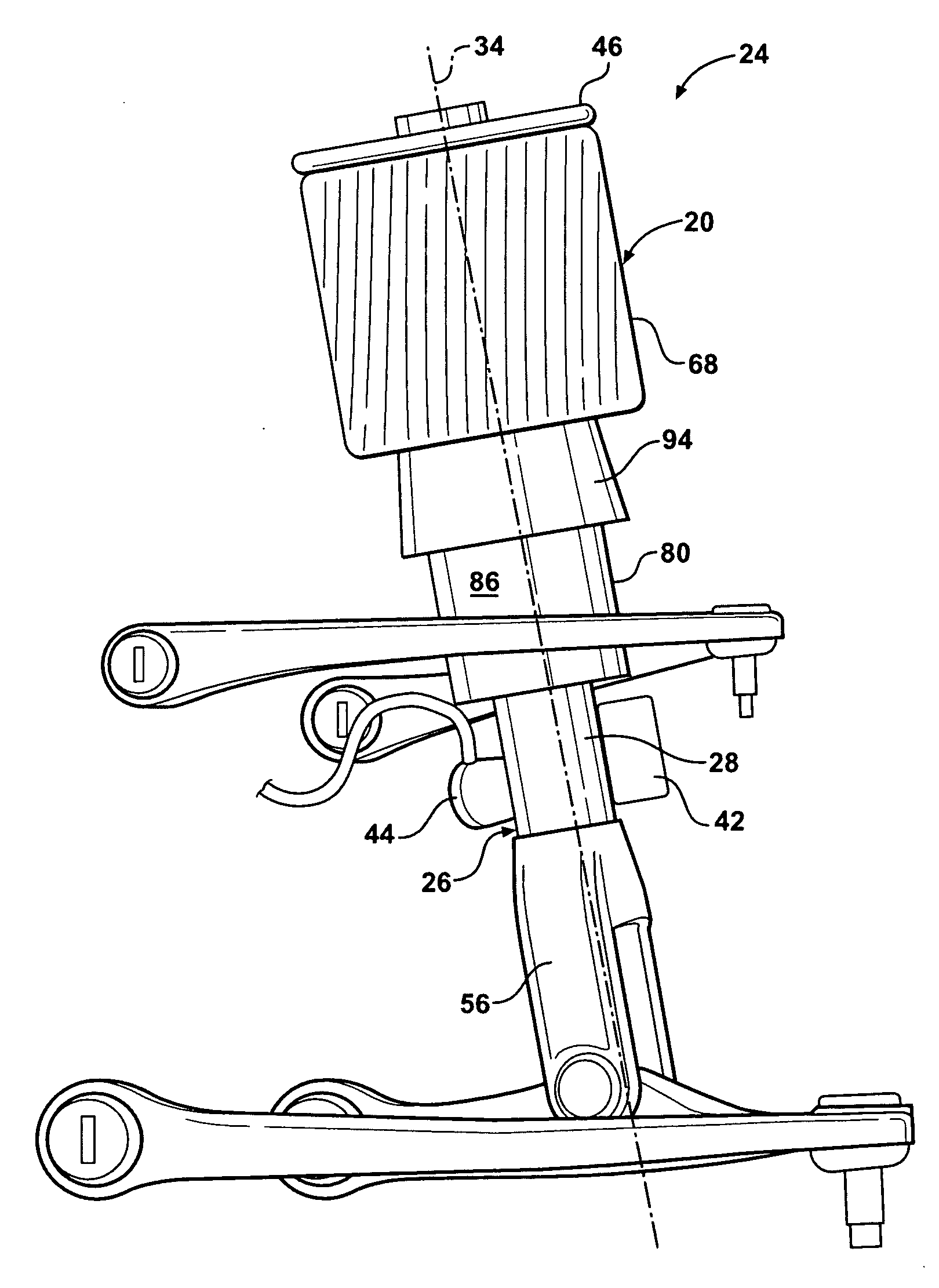

Strut assembly with air spring

ActiveUS20090212472A1Large inner diameterSmall sizeSpringsSprings/dampers design characteristicsAir springCoil spring

A strut assembly includes a damper having a housing and a rod moveable relative to the housing along a longitudinal axis. The strut assembly includes a flexible membrane configured to receive a pressurized gas to form an air spring. A coil spring defines an inner diameter with the housing disposed within the inner diameter to permit relative movement between the coil spring and the housing. The coil spring is at least partially disposed outside the flexible membrane relative to the longitudinal axis.

Owner:AXLETECH INT IP HLDG

NMR spectrometer with flowthrough sample container

ActiveUS20060091885A1Easy to rinseEasy to introduceMagnetic measurementsElectric/magnetic detectionEngineeringFlow cell

A flow-through sample container, or flow cell, according to the present invention resides with the channel of magnetic resonance probe without being fixed thereto. The flow cell is removable from the spectrometer while leaving the probe in place, allowing easy cleaning of the probe channel and replacement of the flow cell. An insertion tool that houses the flow cell may be used to safely introduce it to the probe. Input and output capillaries serve as fluid pathways for fluid samples entering and leaving the flow cell, respectively. These capillaries may be connected to the flow cell with a manually operable connector, allowing easy disconnection of the flow cell from the input and output conduit. The capillaries enter through different ends of the spectrometer bore, so that the fluid samples flow enter one end of the spectrometer and exit through the other.

Owner:BRUKER BIOSPIN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com