Method for implementing branch well window seal by using metal expansion tube

A technology for metal expansion and branch wells, which is applied in sealing/isolation, directional drilling, earthwork drilling and production, etc. It can solve the problems of difficult completion of branch wells and poor cementing quality at the joints of branch wells, so as to increase the pressure Sealing and mechanical support, the effect of good sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

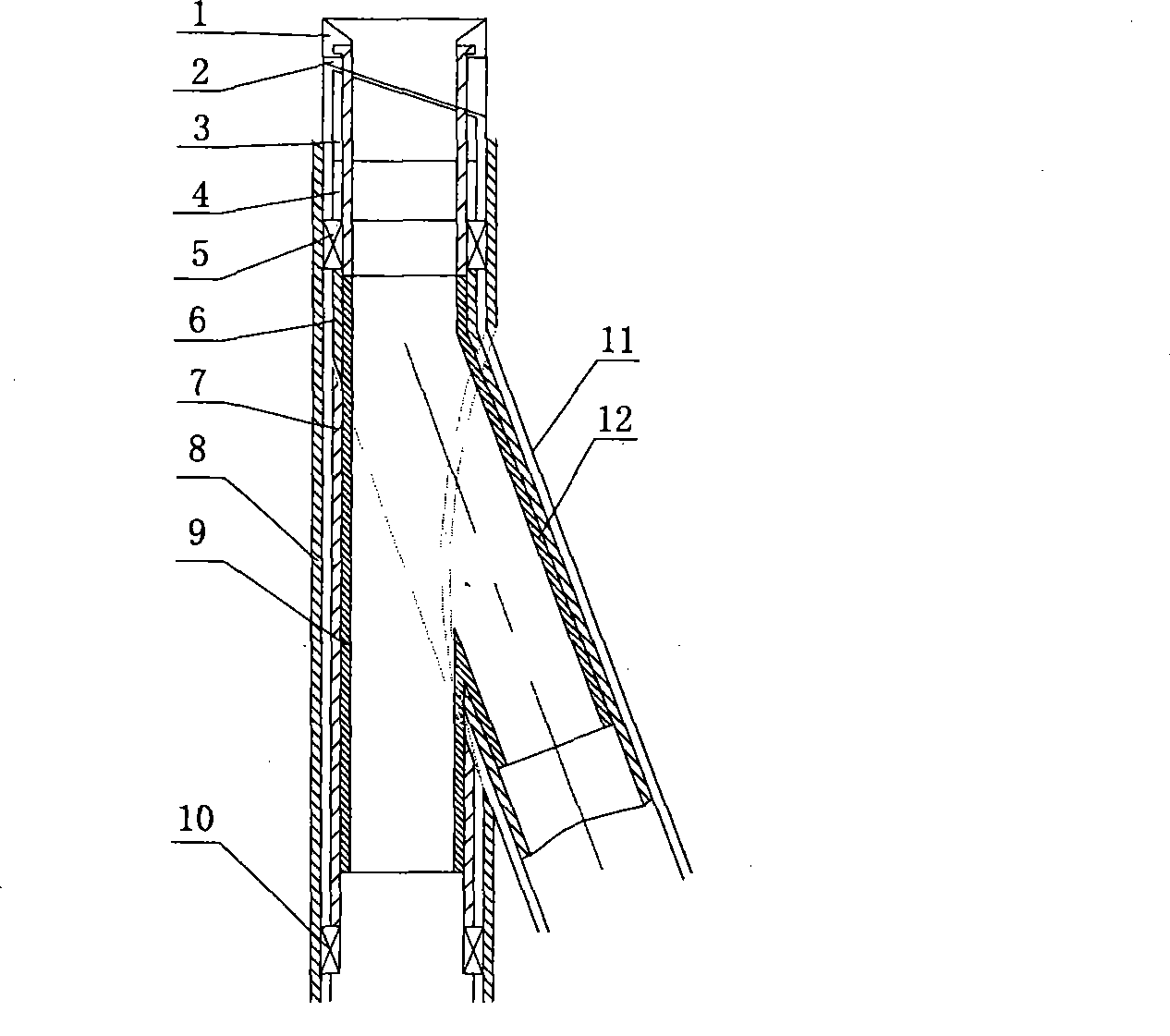

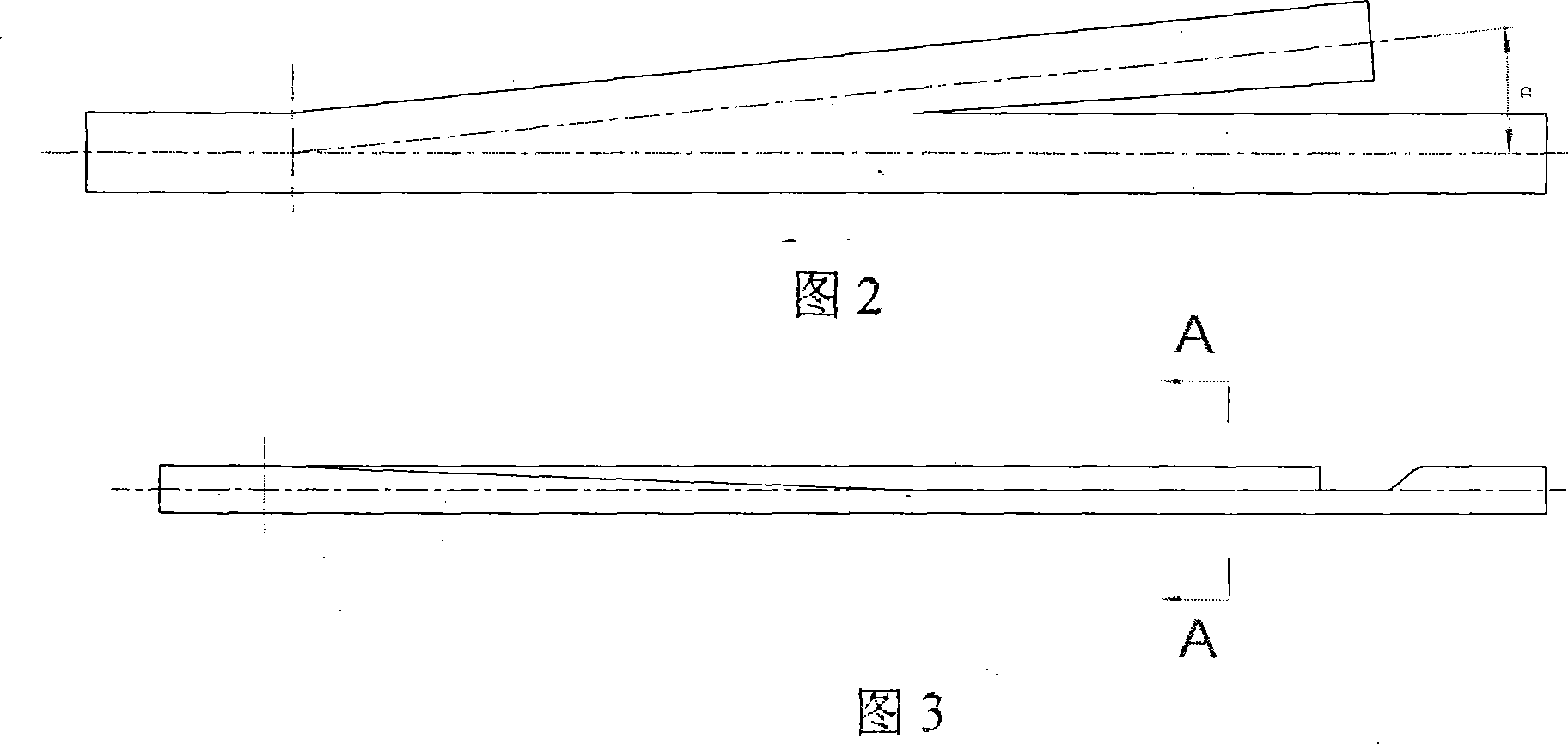

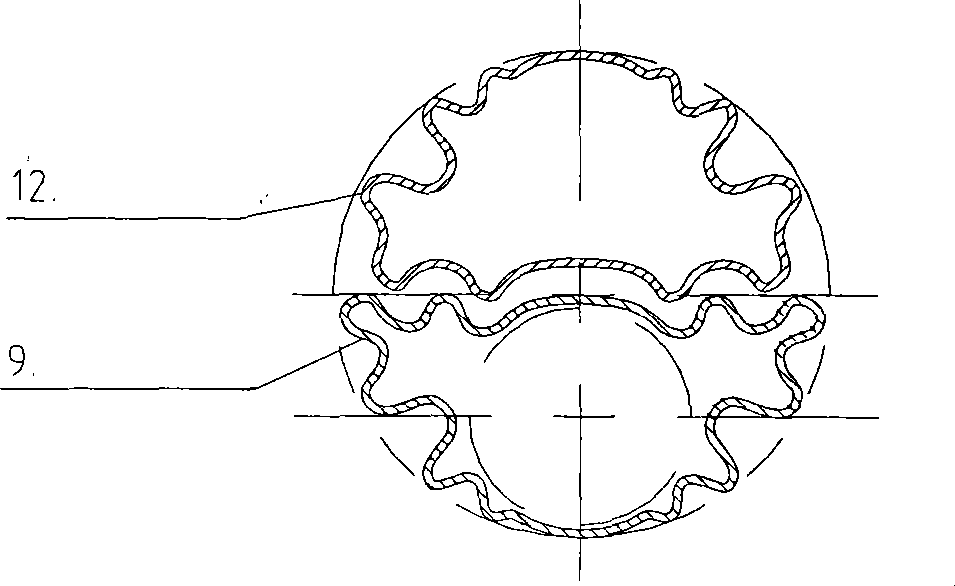

[0015] A method for sealing the windows of branch wells with metal expansion tubes. The sealing method is explained mainly through the window sealing structure of branch wells, the positioning and directional feeding device and the running system of bifurcated metal expansion tubes: firstly, it is completed according to the existing branch well drilling method The main wellbore is drilled and run into the main wellbore string, and then the whipstock is run to the designed window opening position to sidetrack and open the window and complete the drilling of the branch wellbore. The hole suspension device is hooked on the upper part of the hollow deflector, and the pre-deformed bifurcation sealing device is lowered to the window position by the feeding device, and the shape recovery and expansion sealing of the sealed metal expansion tube are realized by the expansion tube running system. figure 1 , the sealing structure of the branch well window, which consists of the introductio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com