Patents

Literature

37results about How to "Low overall length" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

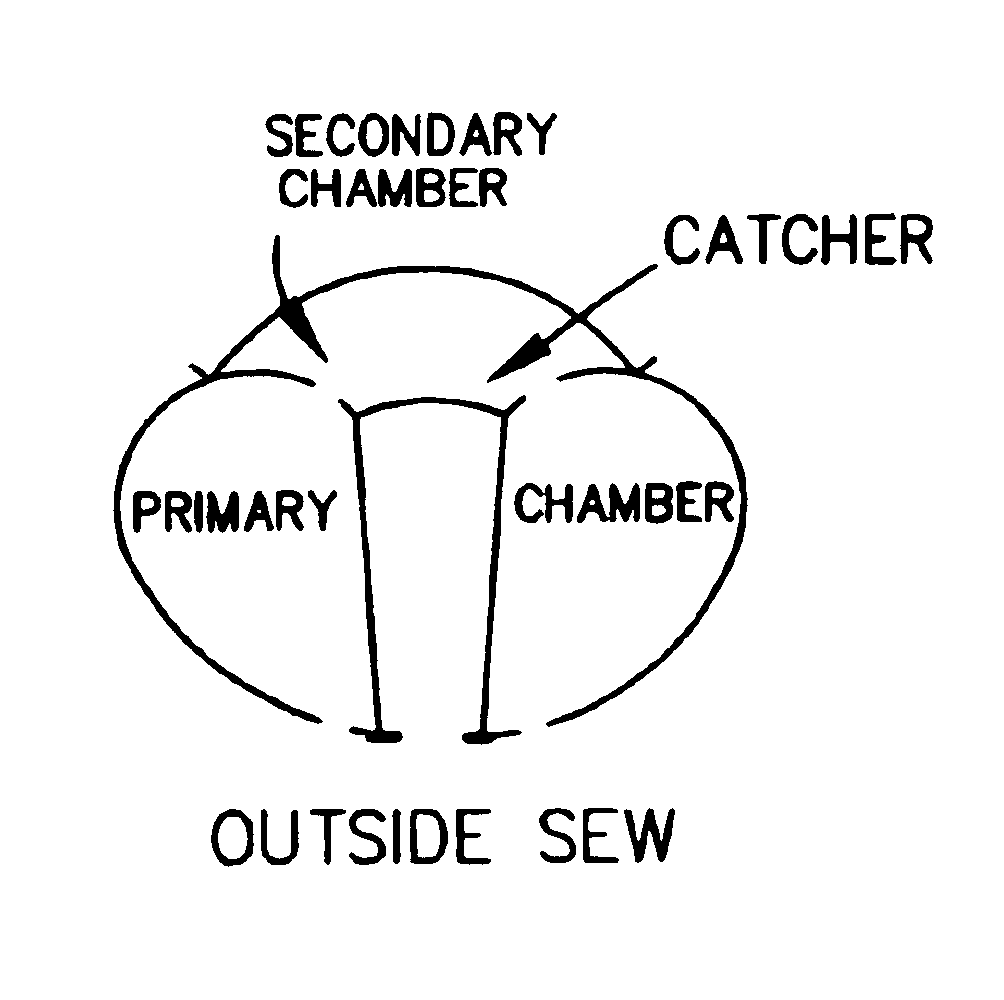

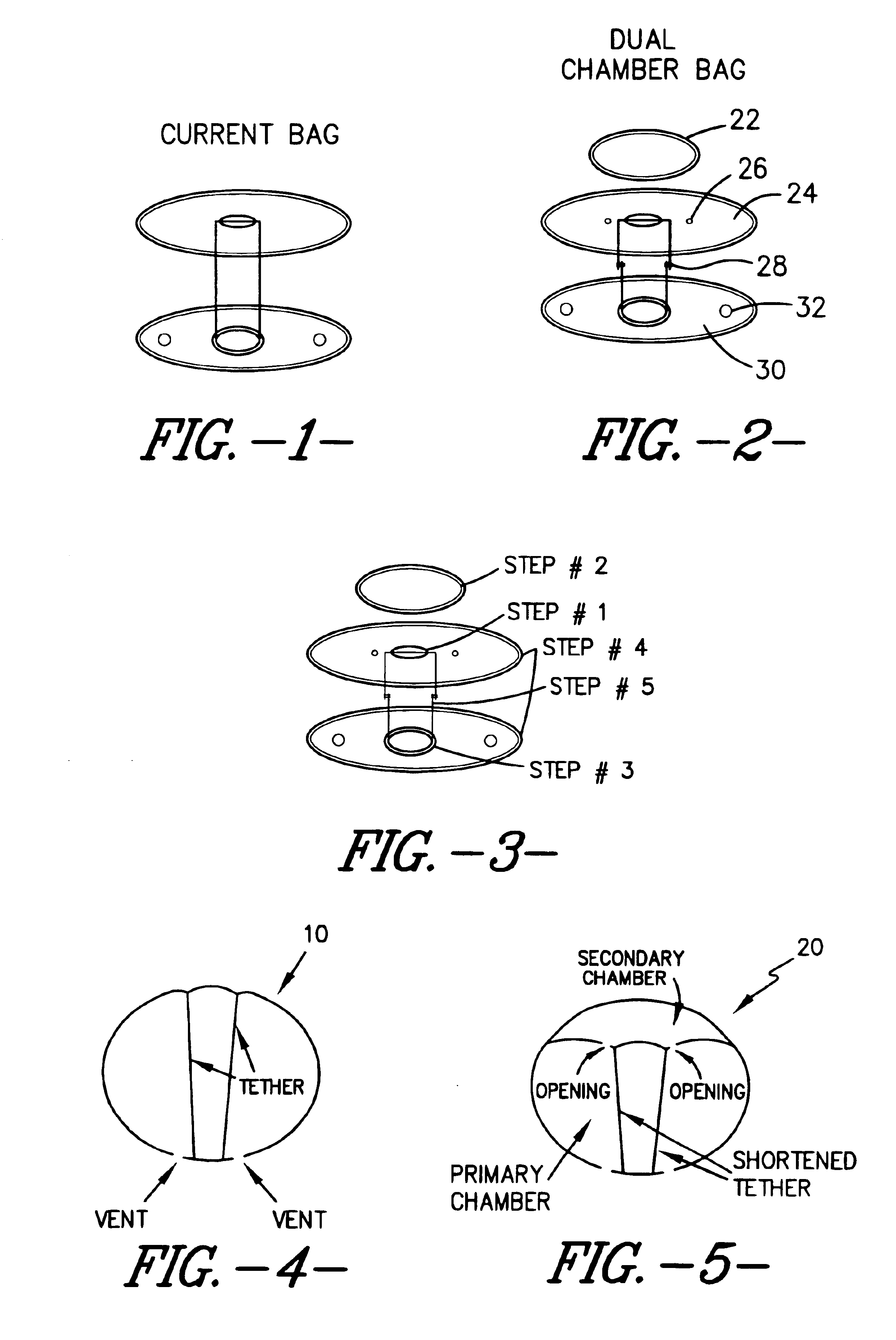

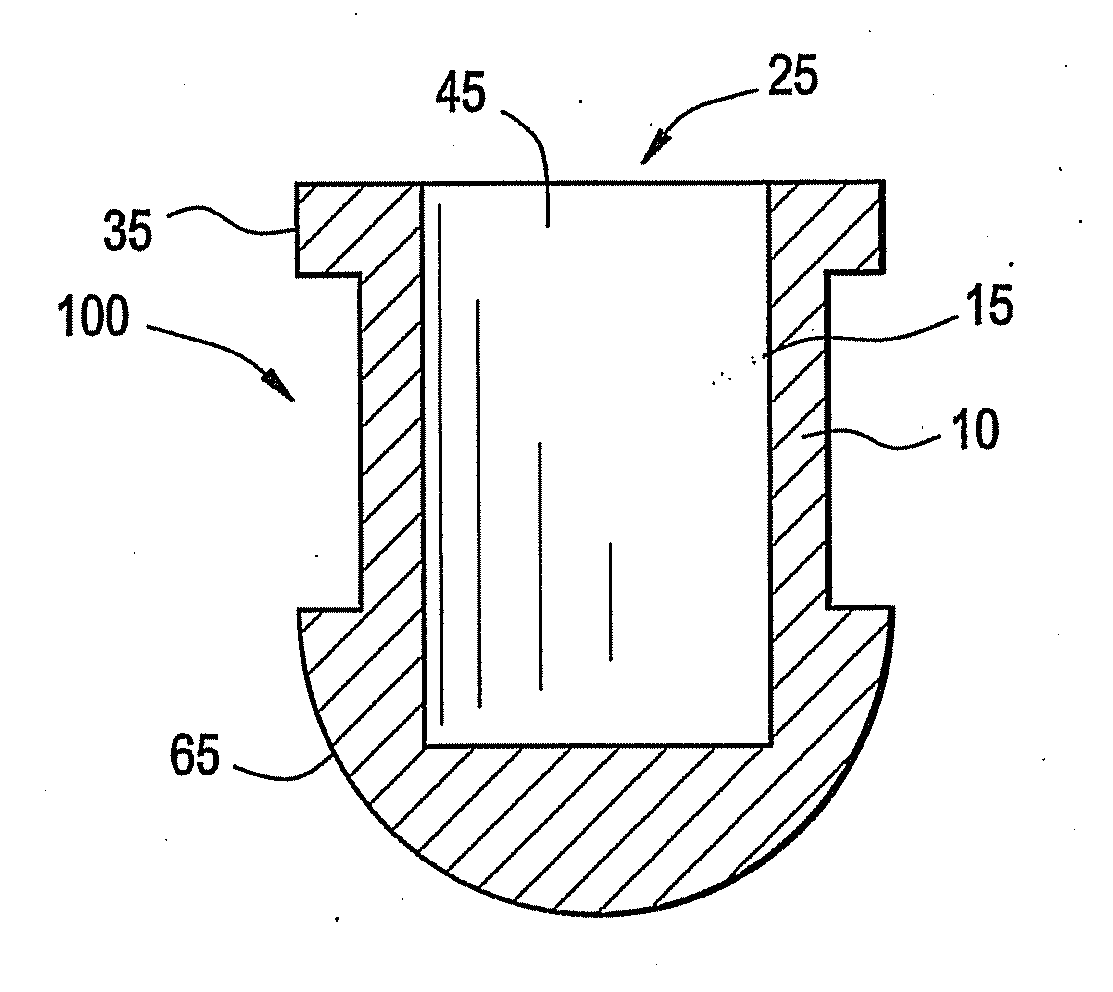

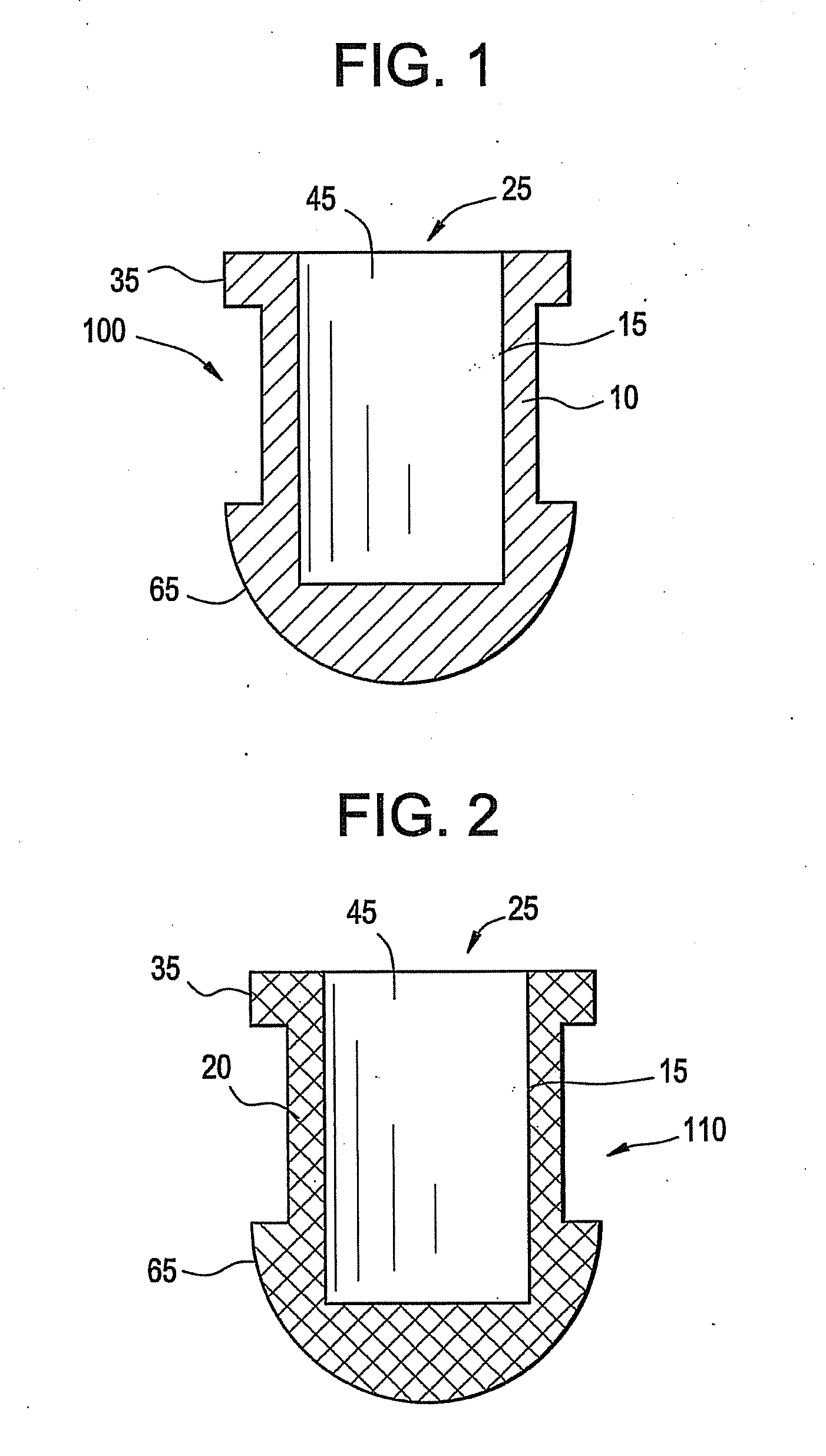

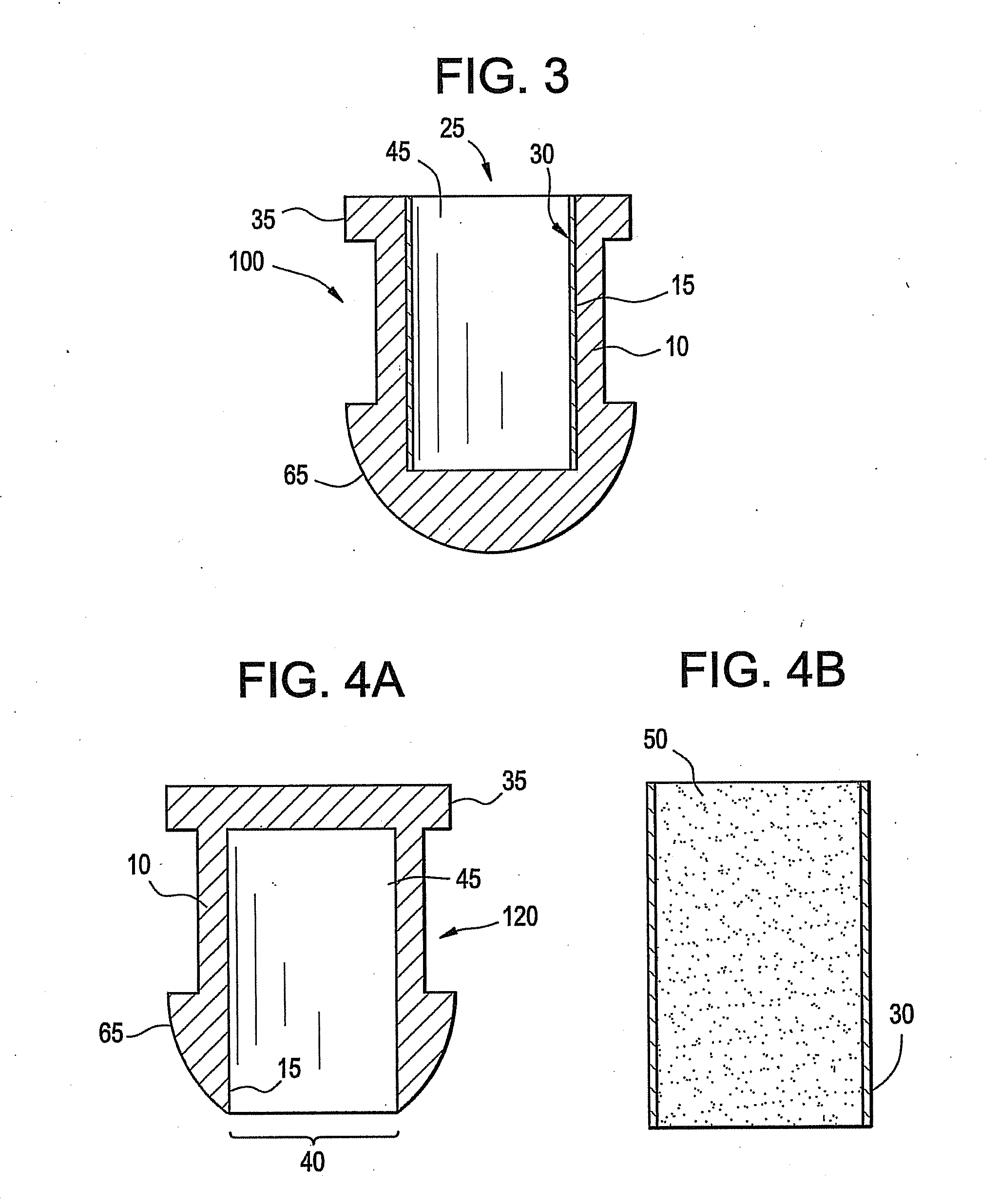

Multiple chamber airbags and methods

InactiveUS6962363B2Low amount and weightMinimally labor-intensive to manufacturePedestrian/occupant safety arrangementEngineeringSingle chamber

A two or more chambered airbag provides much improved safety and / or performance. A modified single chamber airbag can be used as the primary chamber of the two-chamber airbag. A piece of fabric of appropriate size is sewn to the inside or outside surface of the front panel of the primary chamber to create the secondary chamber. One or more apertures are opened between the primary and secondary chambers. In order for the secondary chamber to inflate properly, the tethers of the primary chamber are shortened to 50% to 80% of their original length. The size or location of the tether sewing to the inner surface of the front panel of the primary chamber is also adjusted to create a desired shape of the secondary chamber when deployed.

Owner:MILLIKEN & CO

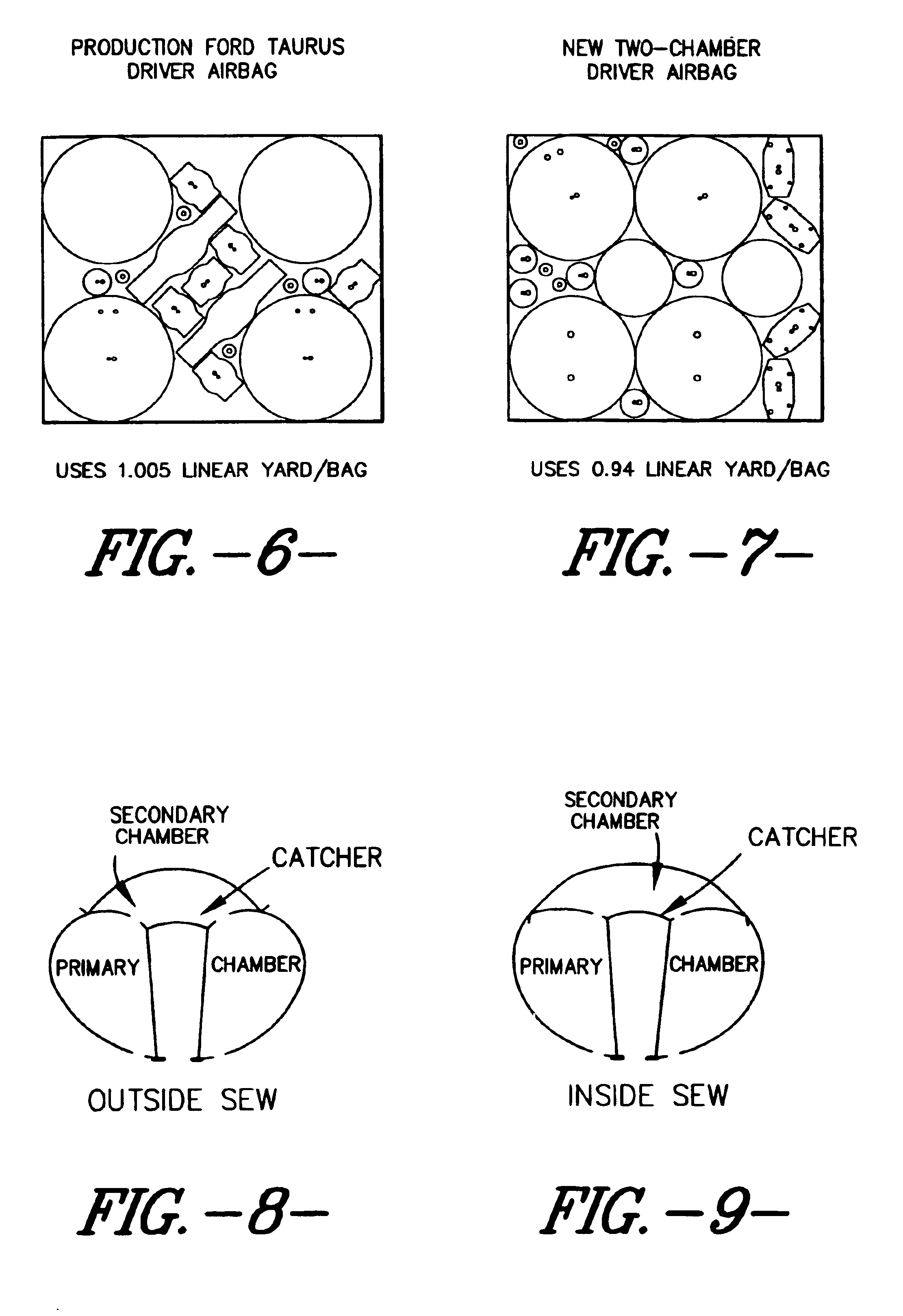

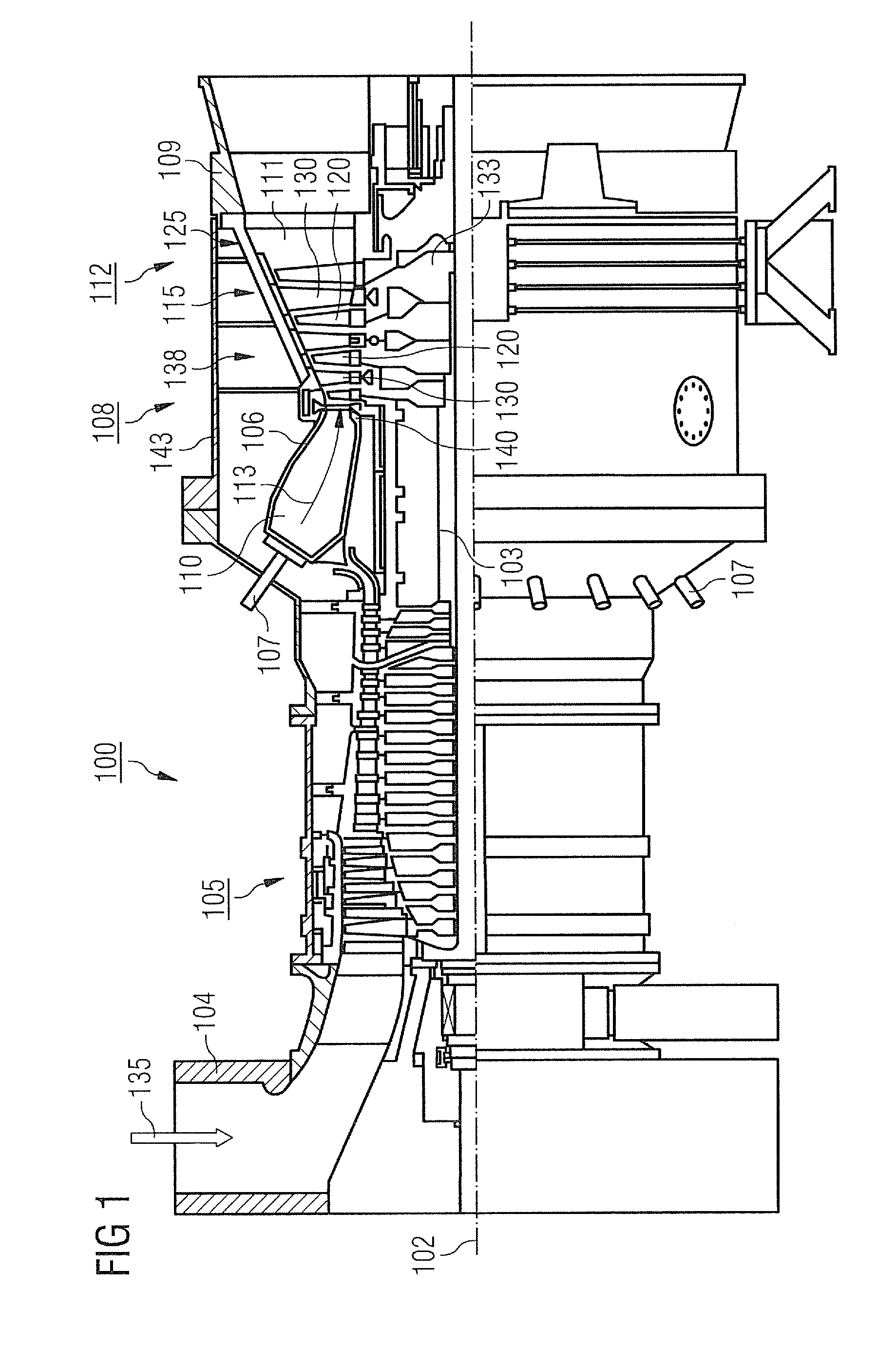

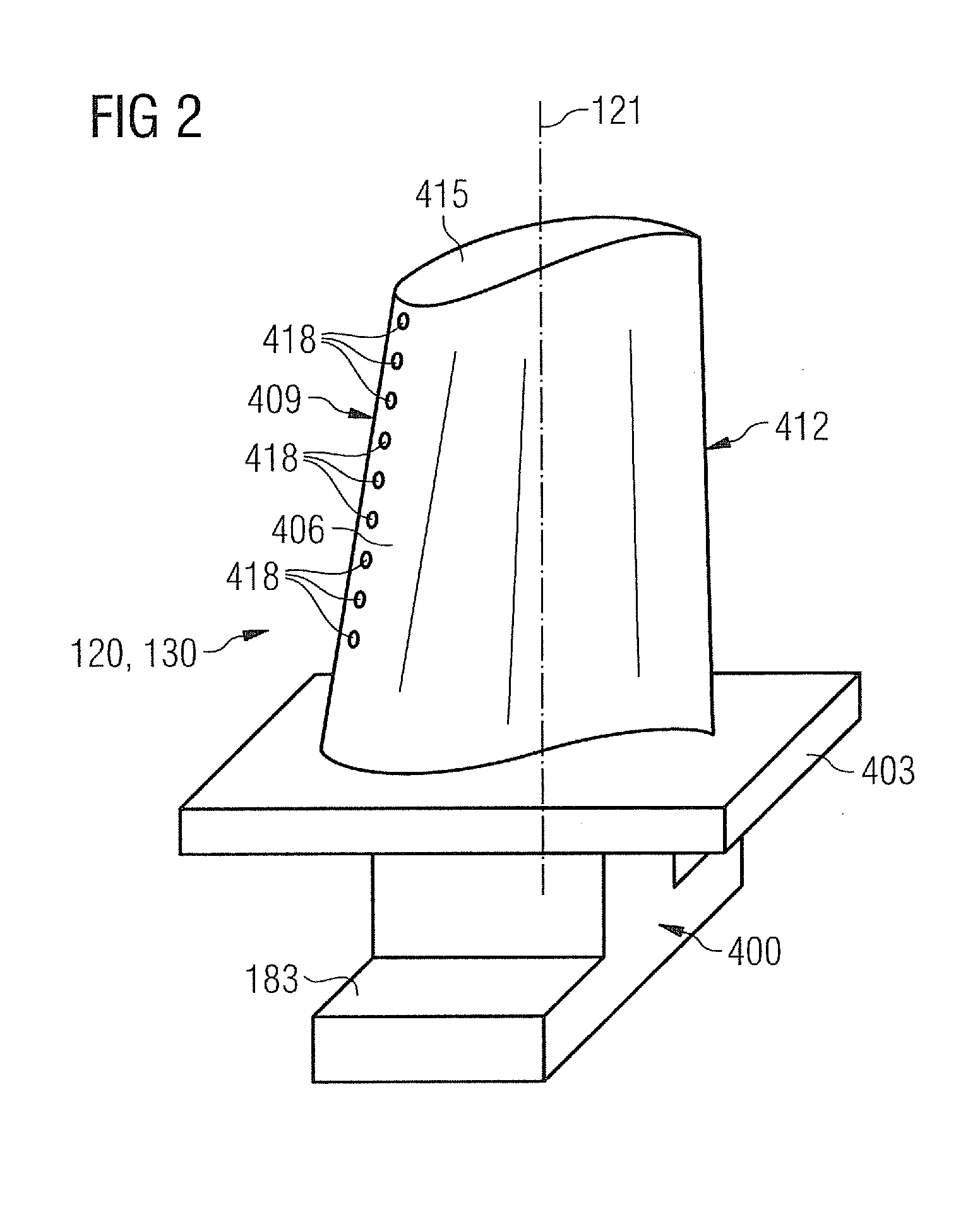

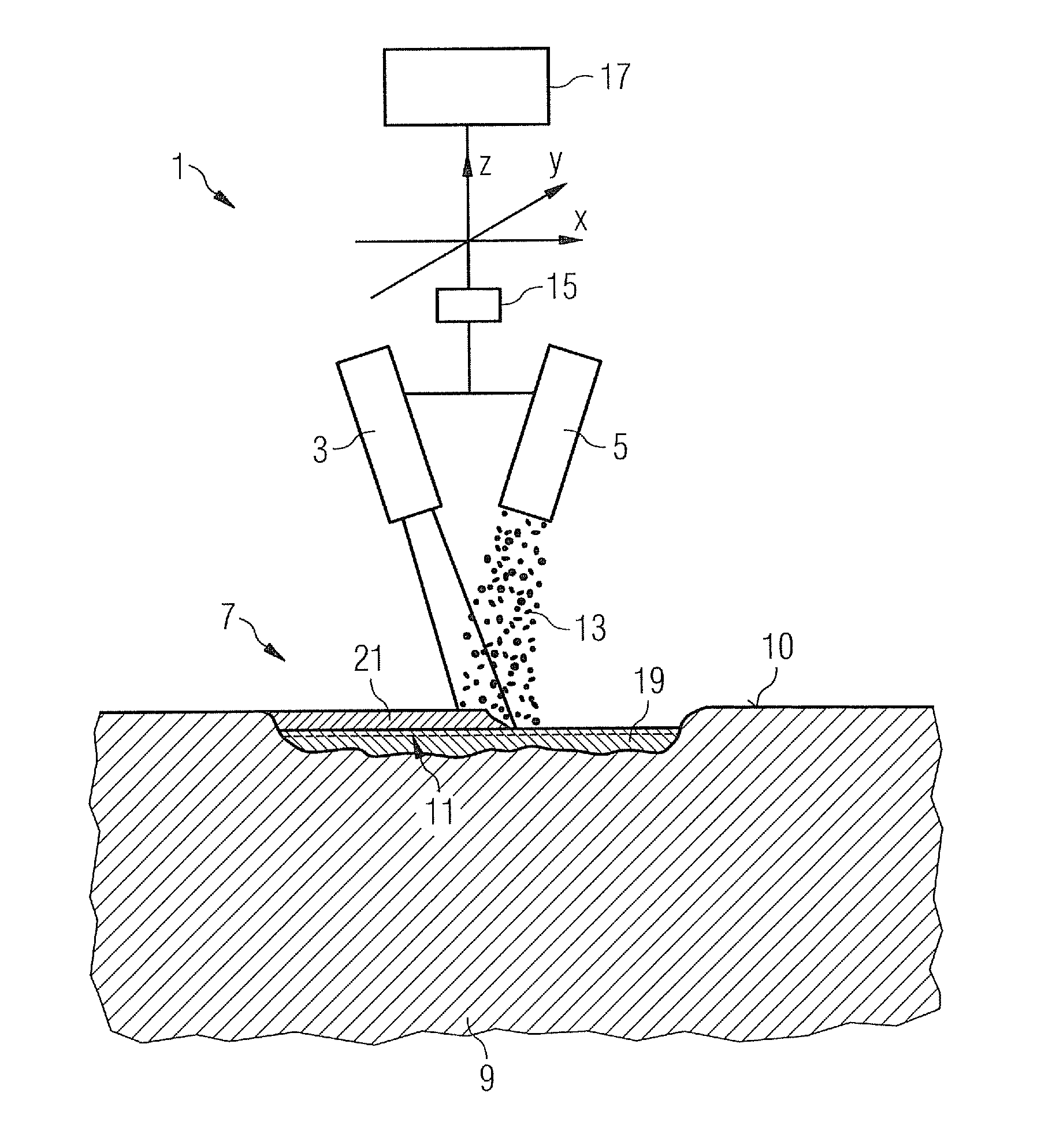

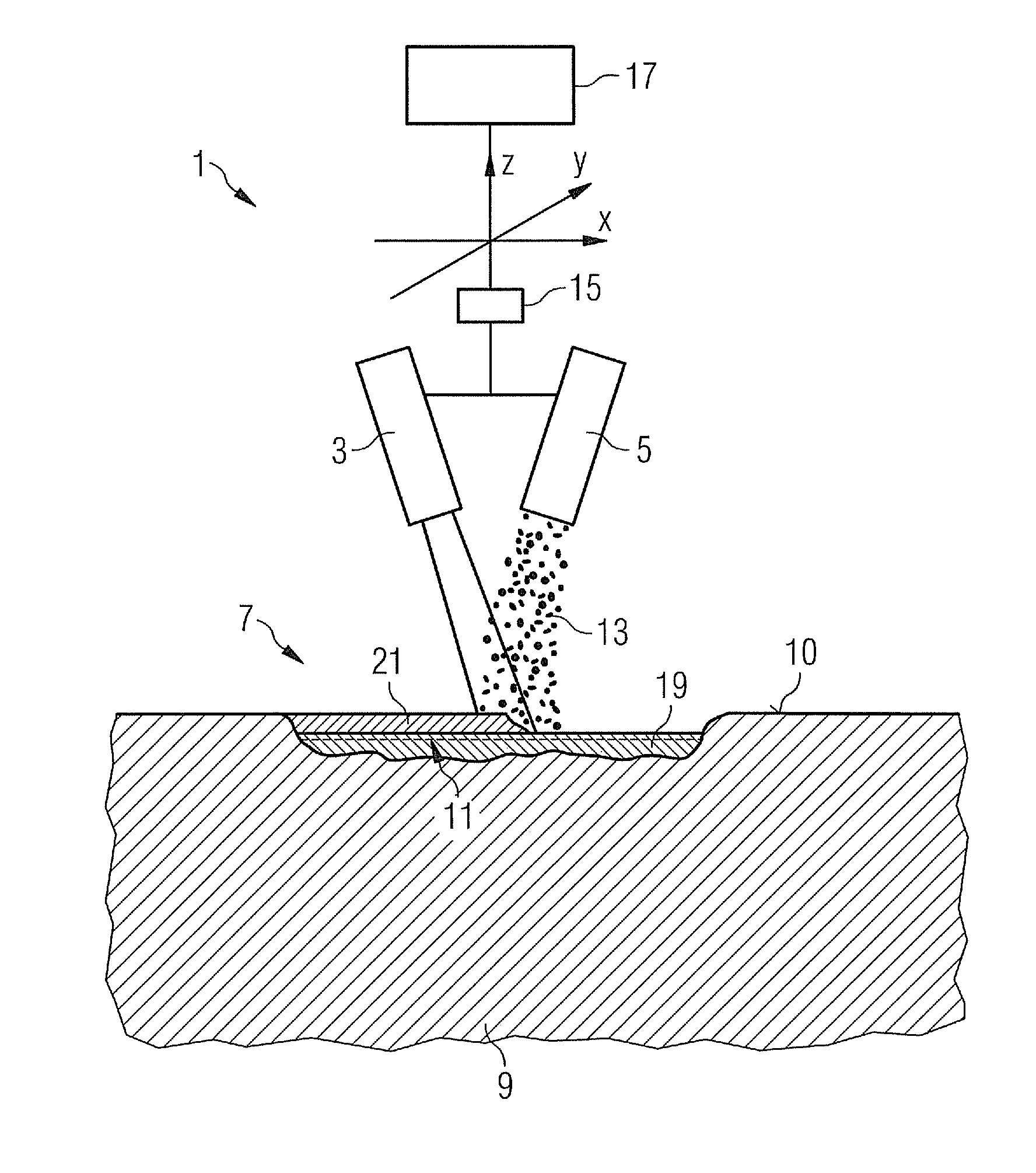

Method for welding workpieces made of highly heat-resistant superalloys, including a particular mass feed rate of the welding filler material

InactiveUS20120267347A1Improve cooling effectIncrease chanceTurbinesEngine manufactureHeat resistanceRelative motion

A welding method for welding workpieces made of highly heat-resistant superalloys is provided. The method includes generating a heat input zone on the workpiece surface by means of a heat source, feeding welding filler material into the heat input zone by means of a feeding device, and generating a relative motion between the heat source and the feeding device on one hand and the workpiece surface on the other hand by means of a conveying device. Furthermore, according to the welding method, the mass feed rate is ≦350 mg / min.

Owner:SIEMENS AG +1

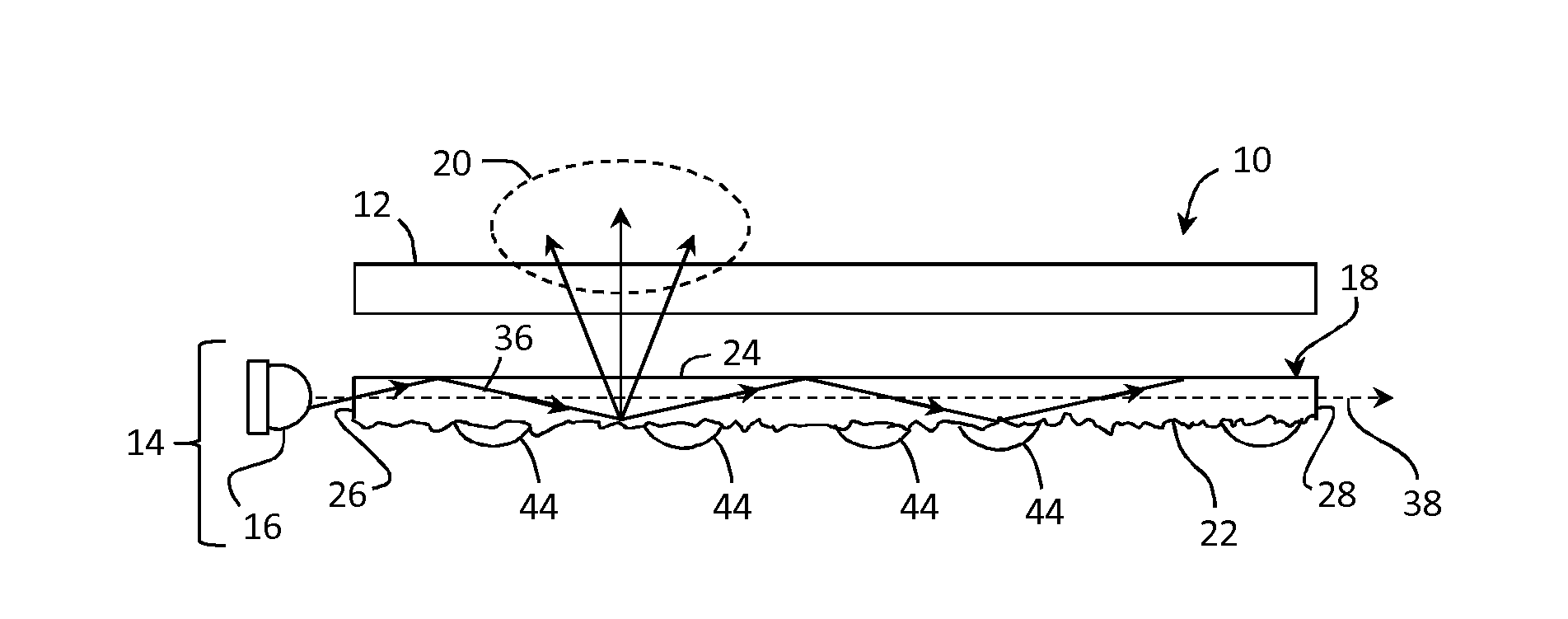

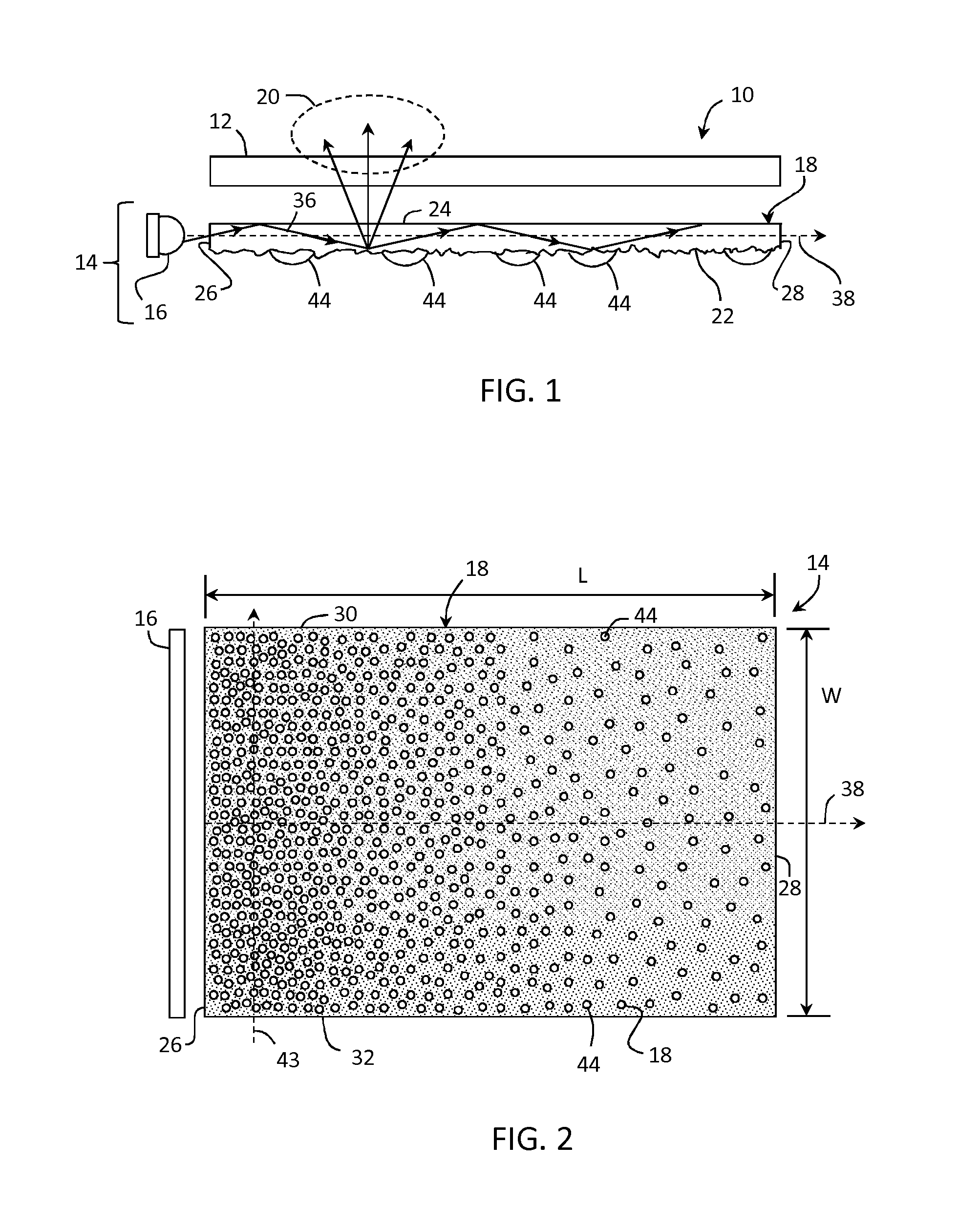

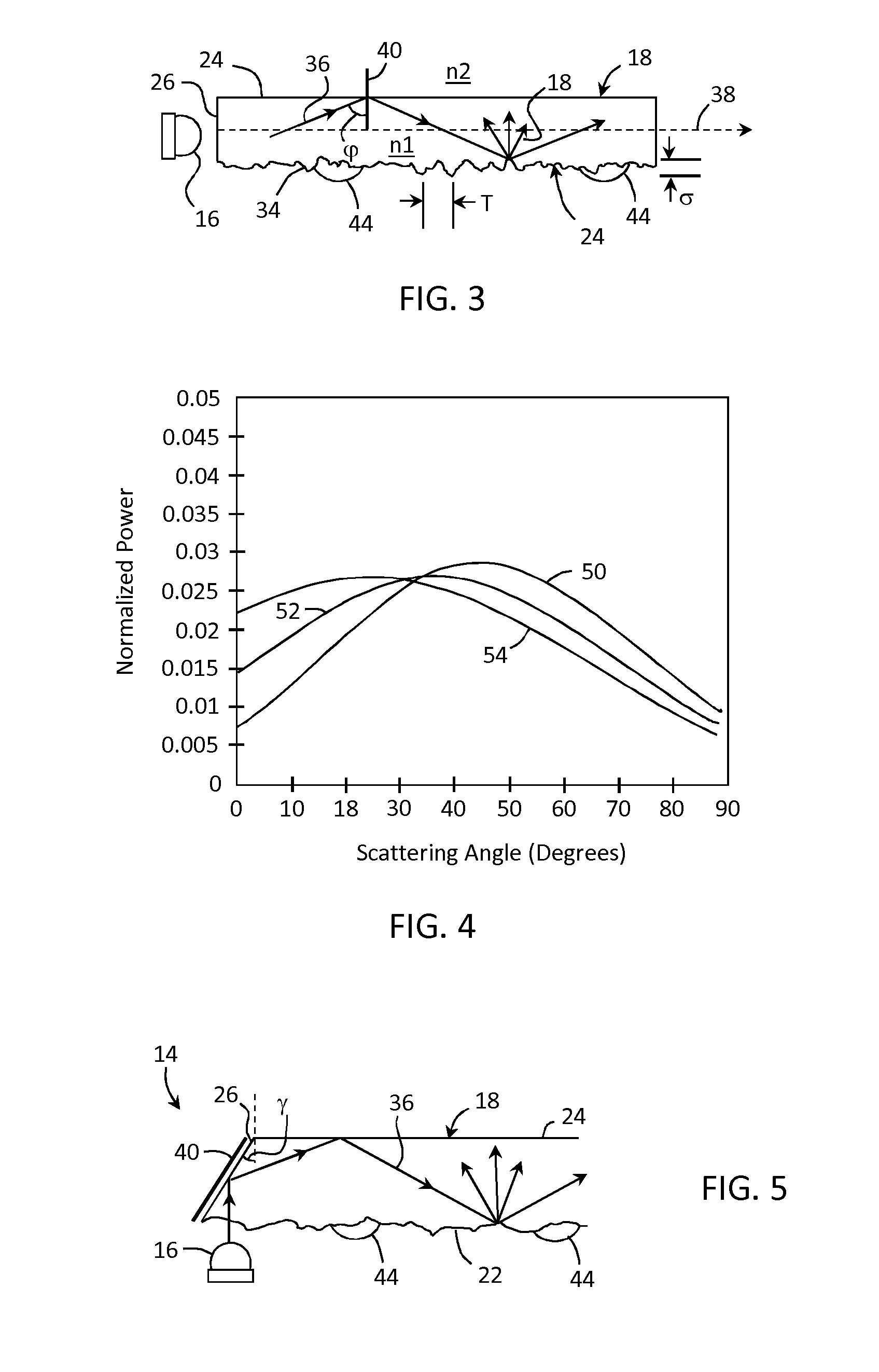

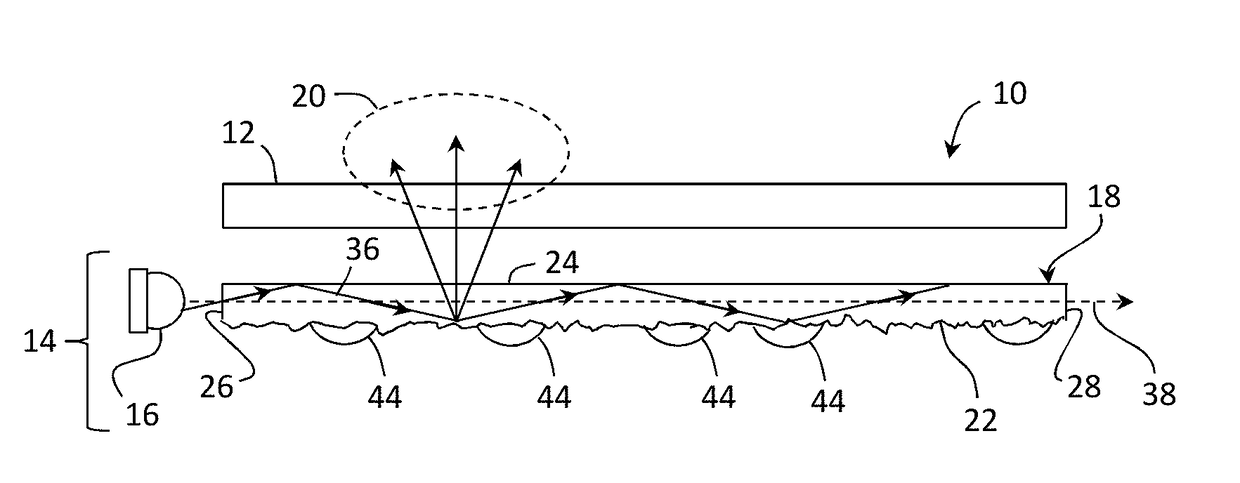

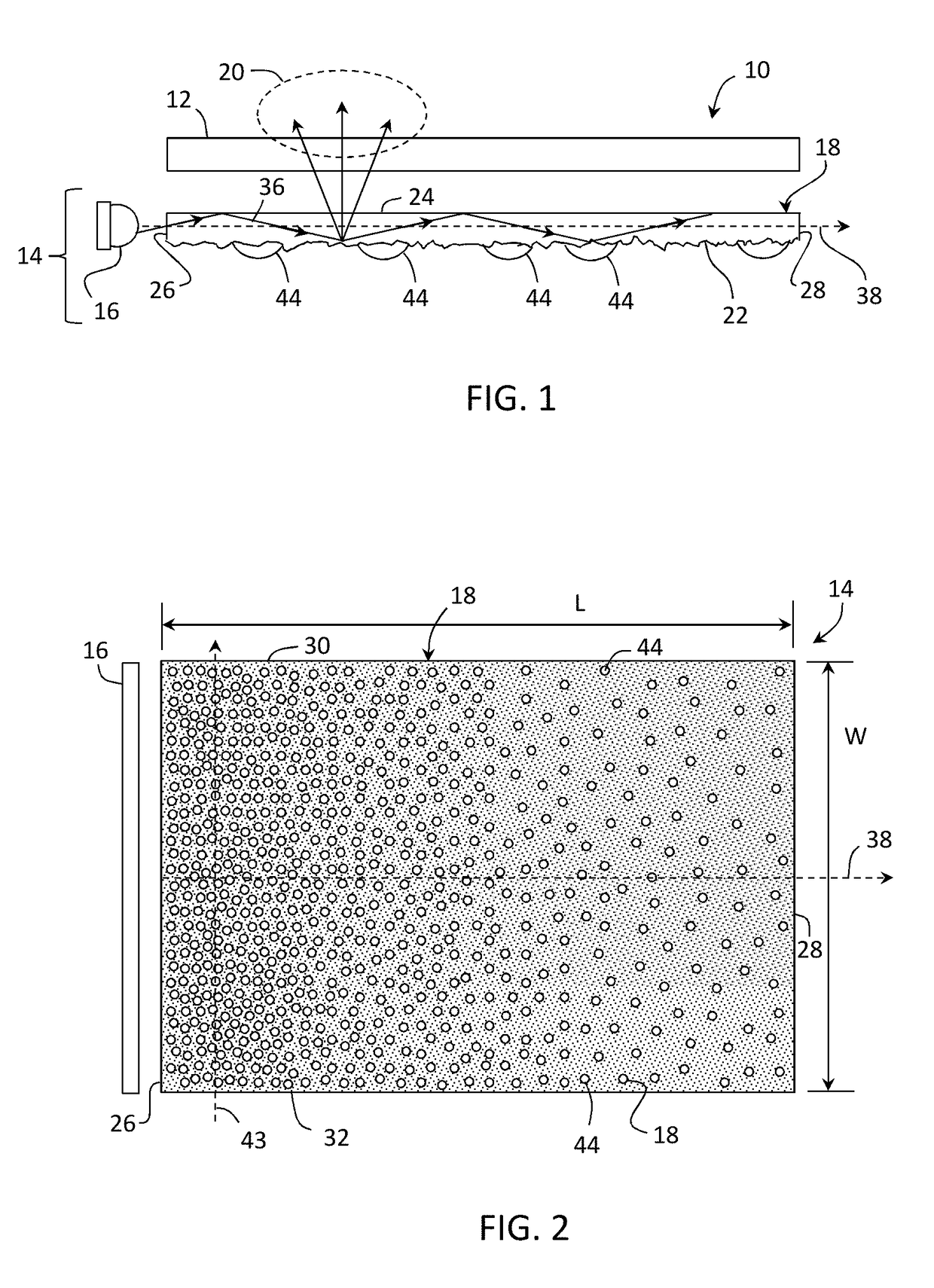

Textured surfaces for display applications

ActiveUS20160313494A1Provide protectionHigh light transmittanceMechanical apparatusDiffusing elementsLight guideDisplay device

A substrate with a textured surface is disclosed. The substrate may be, for example, a light emitter comprising a light guide, for example a backlight element for use in a display device, wherein a surface of the light guide, for example a glass substrate, is configured to have a textured surface with a predetermined RMS roughness and a predetermined correlation length of the texture. A plurality of light scatter supressing features can be provided on the textured surface. Textured surfaces disclosed herein may be effective to reduce electrostatic charging of the substrate surface. Methods of producing the textured surface are also disclosed.

Owner:CORNING INC

Biocompatible wire battery

ActiveUS20130034760A1Reliable and stable powerEasy to useFinal product manufactureSmall-sized cells cases/jacketsActive componentElectrochemistry

A rechargeable electrochemical battery in the form of a single or multi-stranded wire assembly may be utilized as a power source for any number of implantable or non-implantable medical devices. As the wire form battery may be scaled to micro size, it may be utilized to power medical devices that were traditionally non-active devices, but which may be enhanced with active components. The wire form battery may be cut to size for a particular application which provides the same open circuit voltage regardless of how the wire is ultimately configured and the length of the wire utilized. Although the battery is in wire form, various arrangements of the components within the battery are also possible.

Owner:JOHNSON & JOHNSON VISION CARE INC

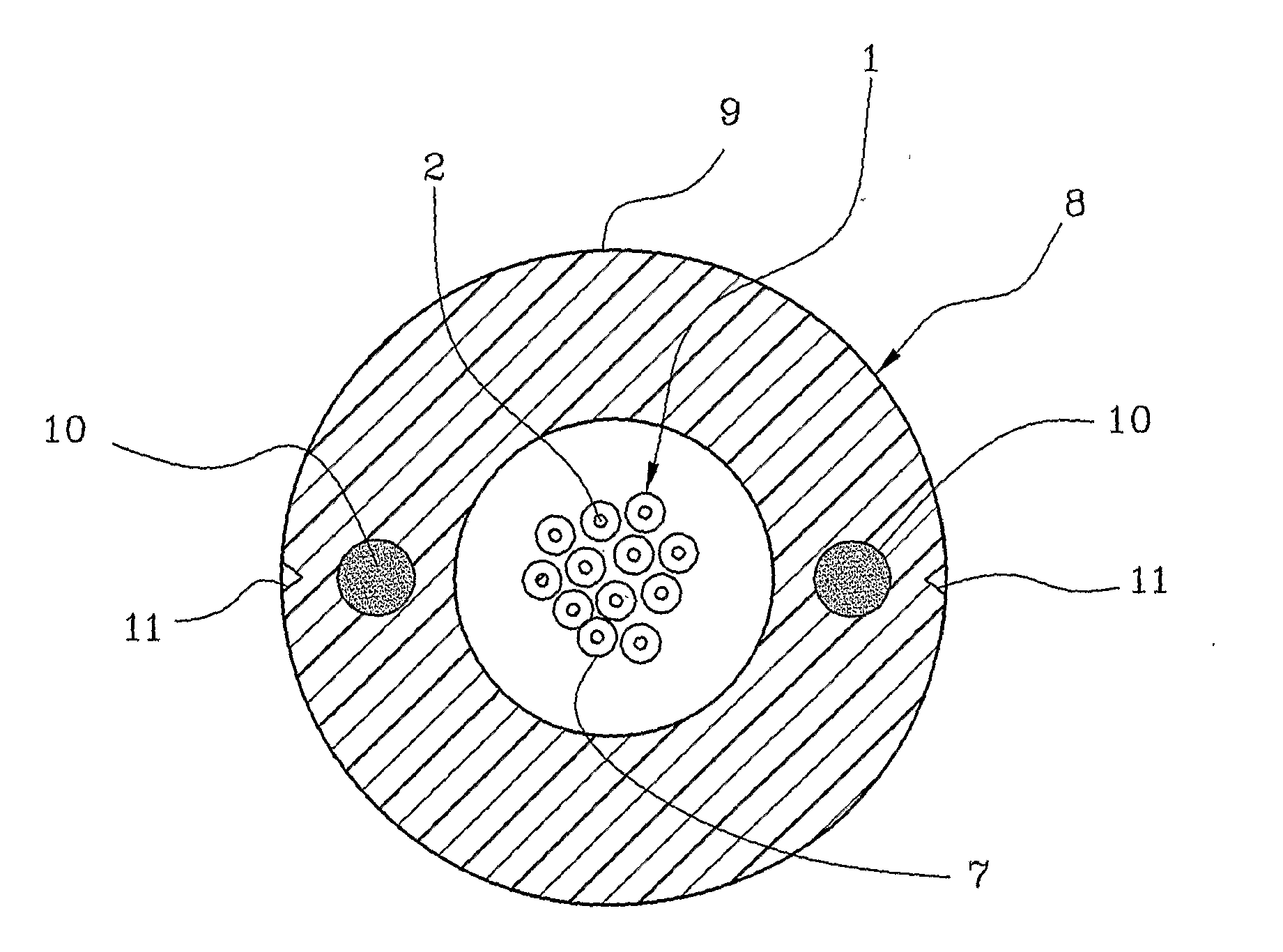

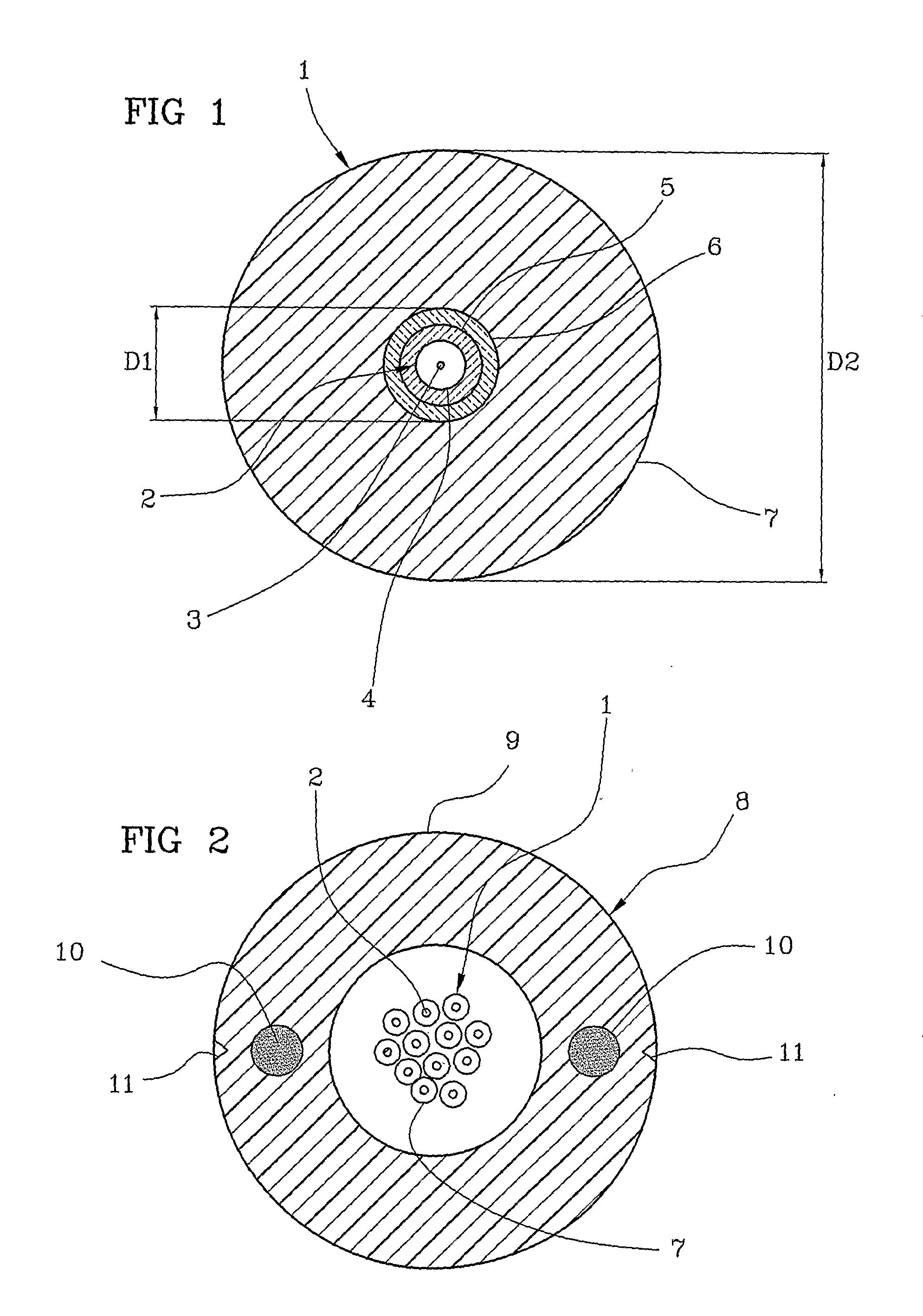

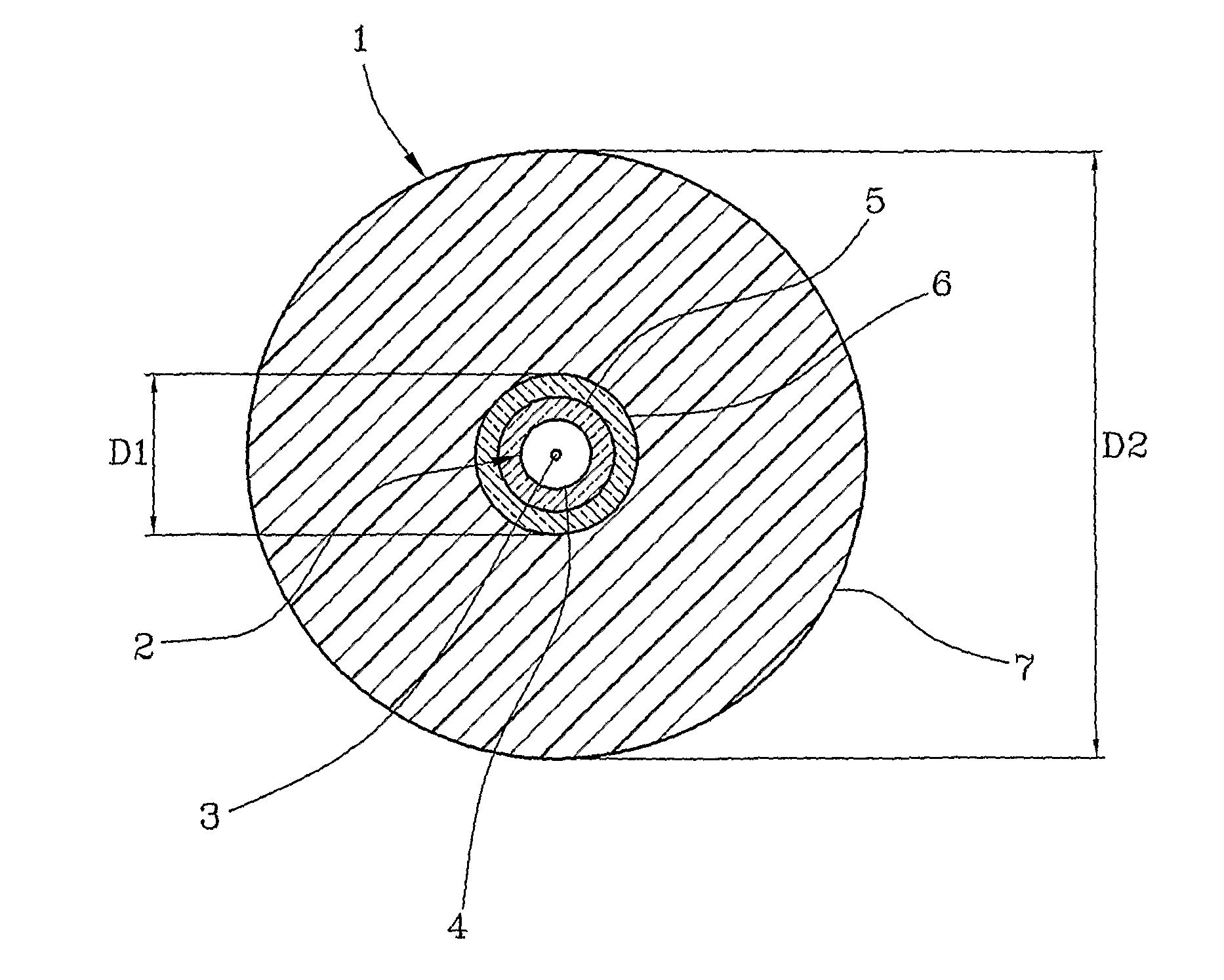

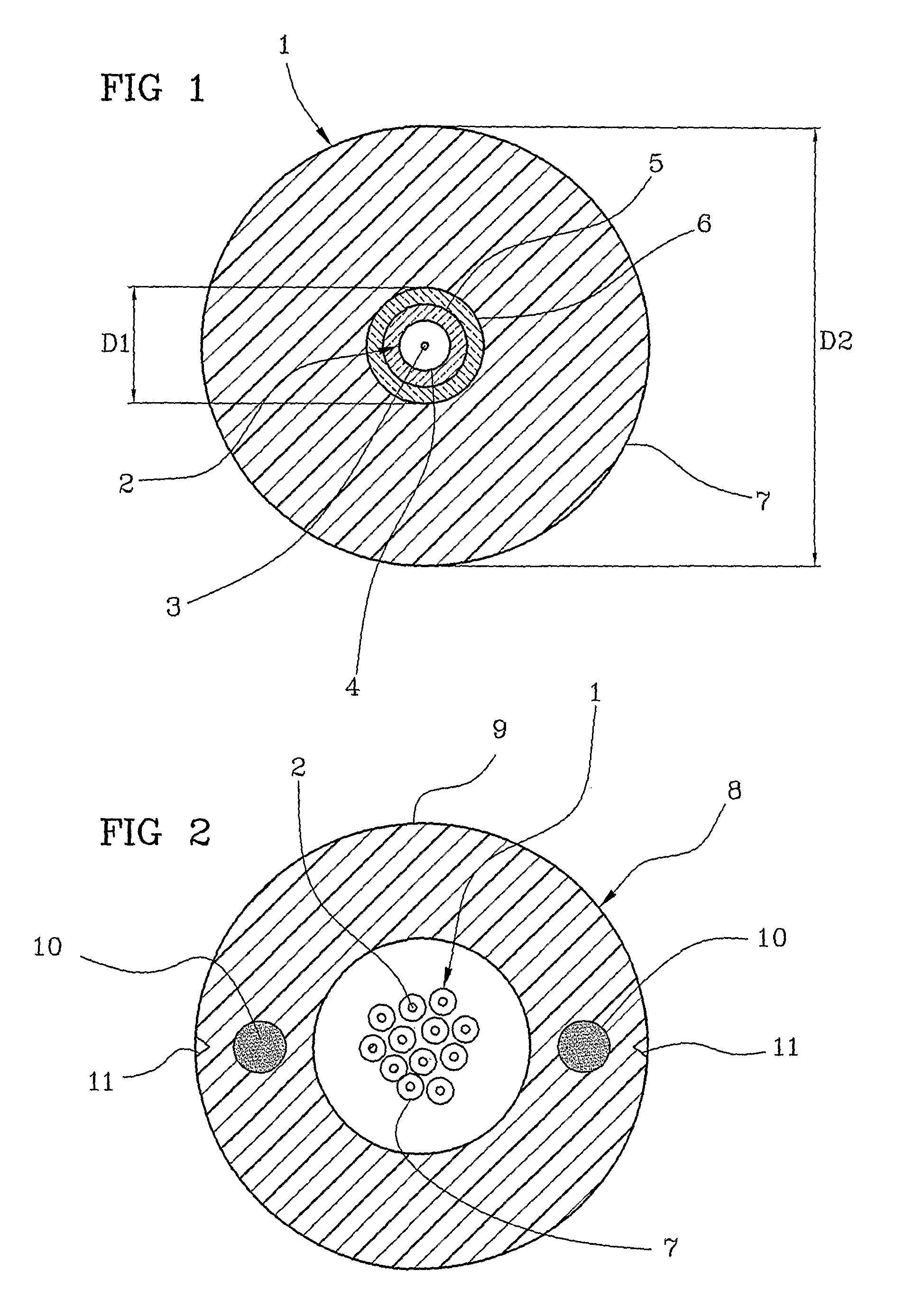

Telecommunication cable equipped with tight-buffered optical fibers

ActiveUS20100254668A1Reduce installationClosely guardedOptical fibre with multilayer core/claddingFibre mechanical structuresFiberTelecommunications cable

A telecommunication cable is equipped with at least one optical fiber coated by a tight buffer layer made from a polymeric material having an ultimate elongation equal to or lower than 100% and an ultimate tensile strength equal to or lower than 10 MPa. The above combination of features of the polymeric material forming the buffer layer provides an optical fiber which is effectively protected during installation operations and during use, and at the same time can be easily stripped by an installer without using any stripping tools, simply by applying a small pressure with his fingertips and a moderate tearing force along the fiber axis.

Owner:PRYSMIAN SPA

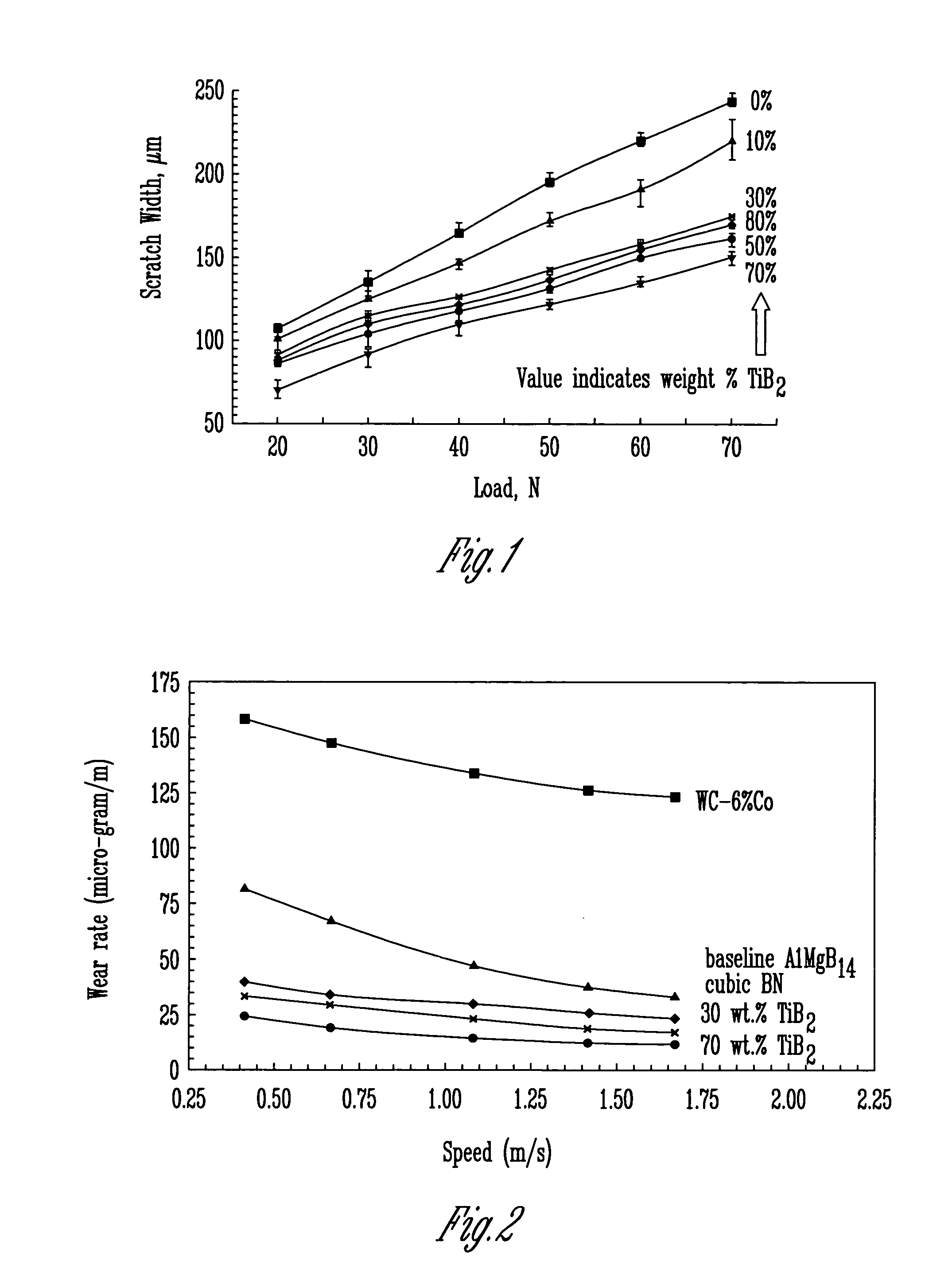

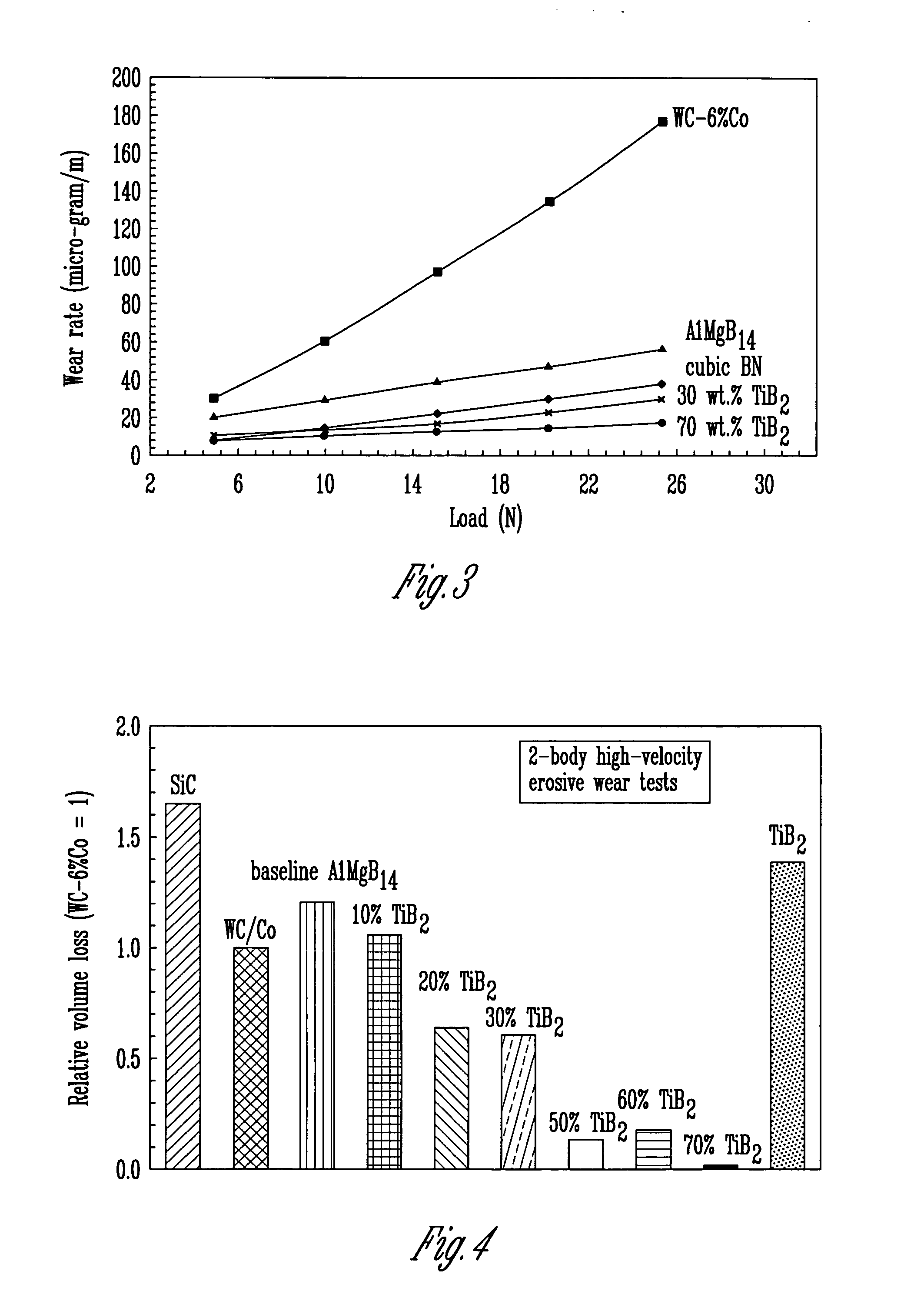

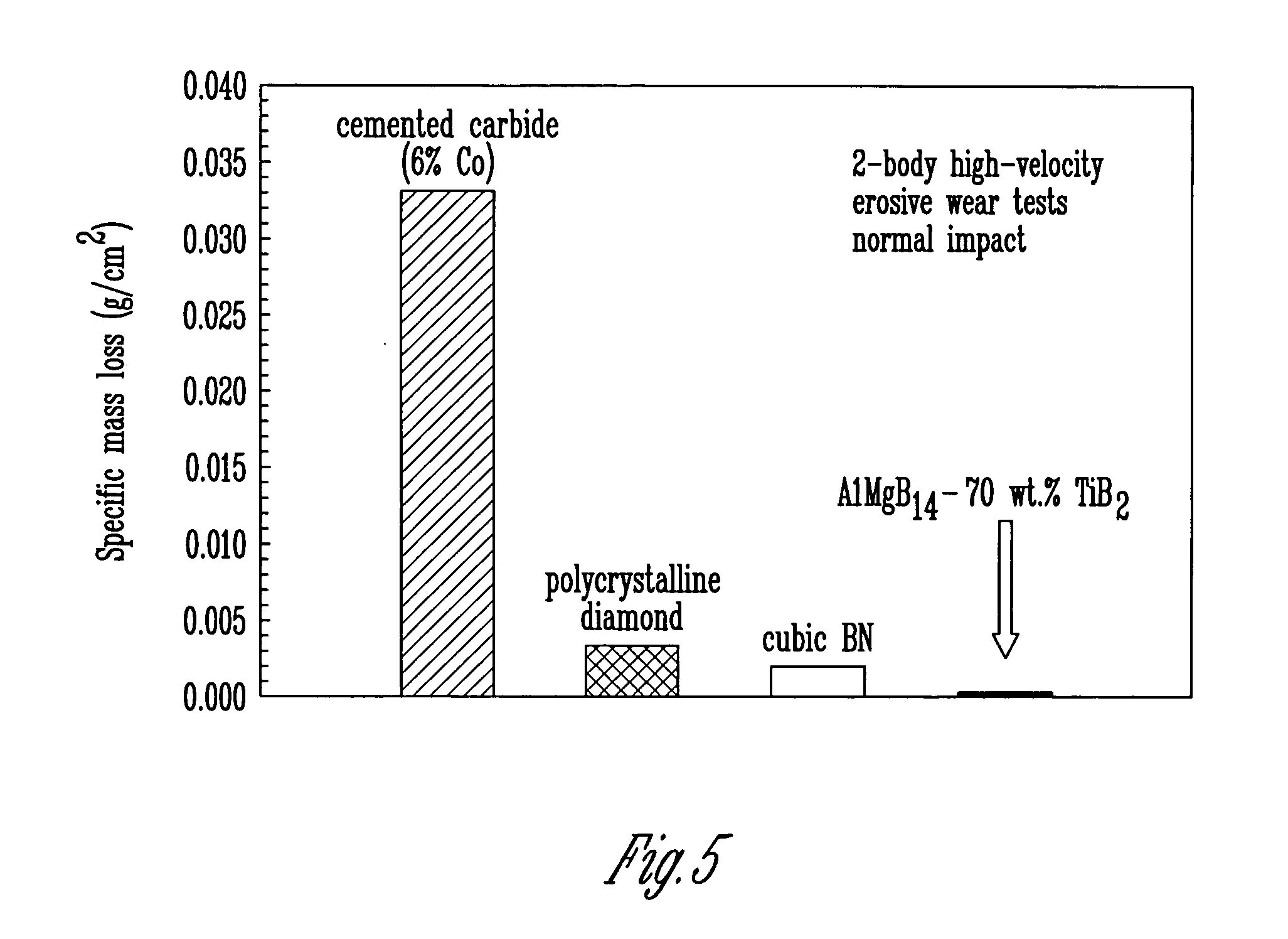

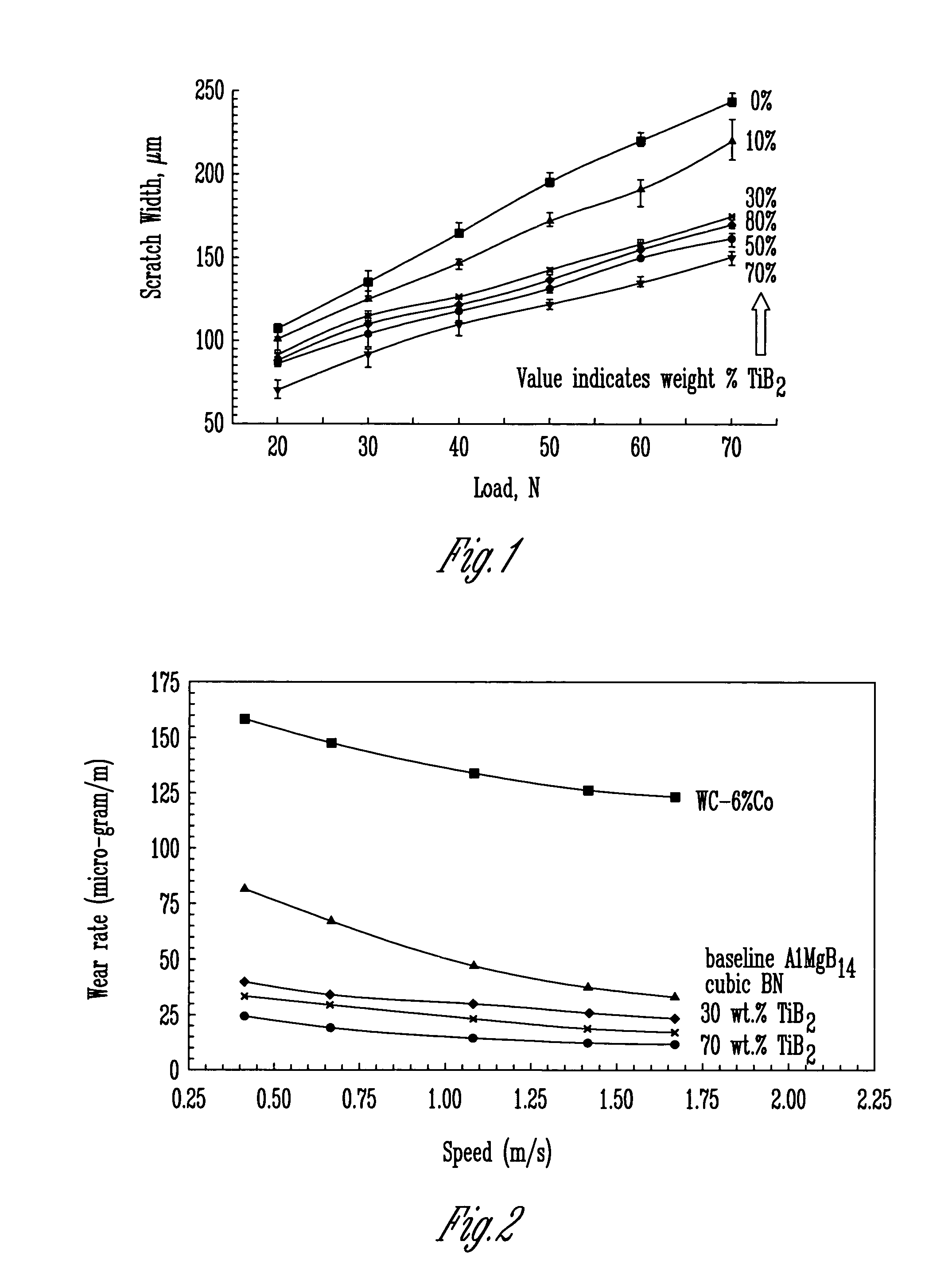

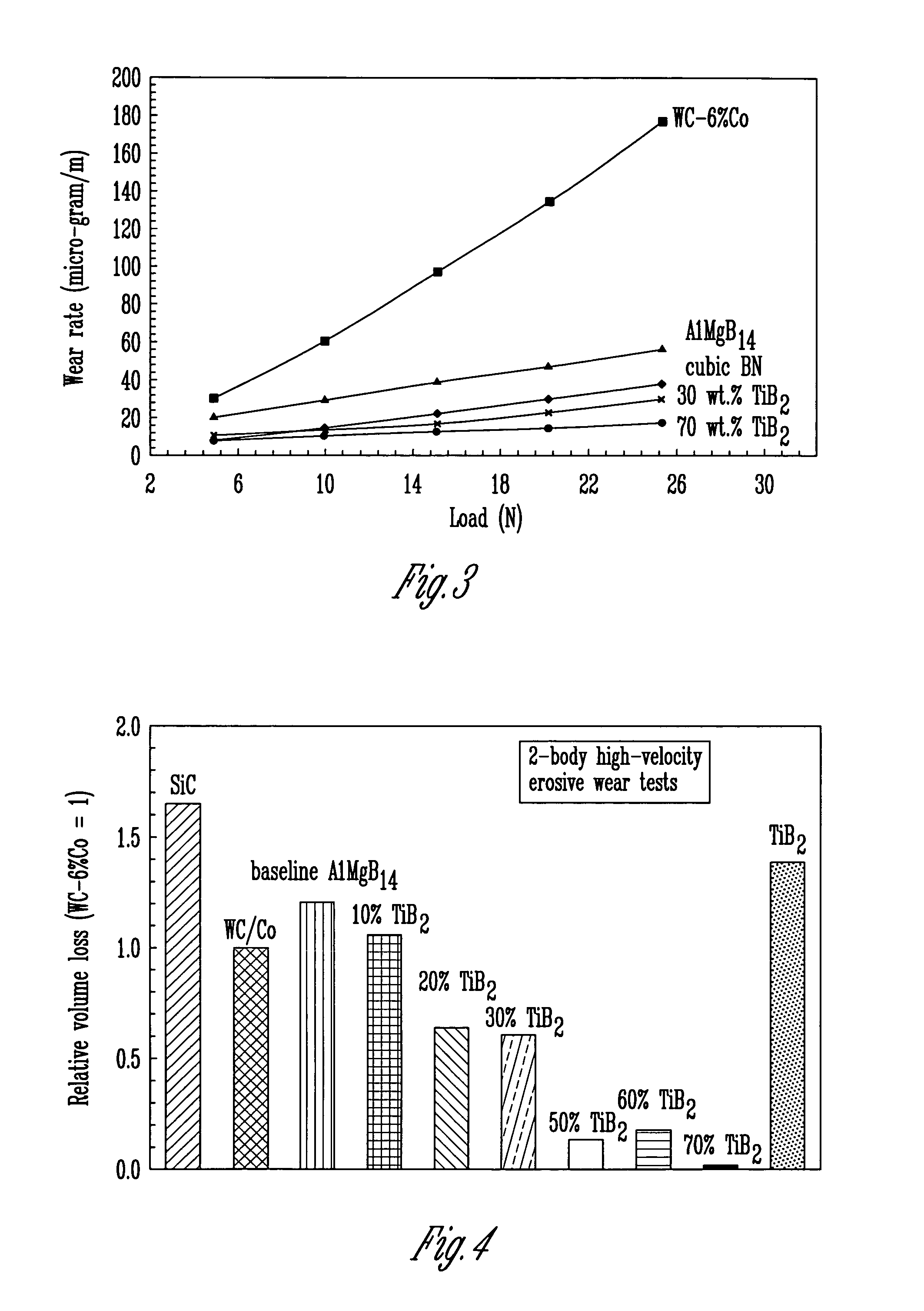

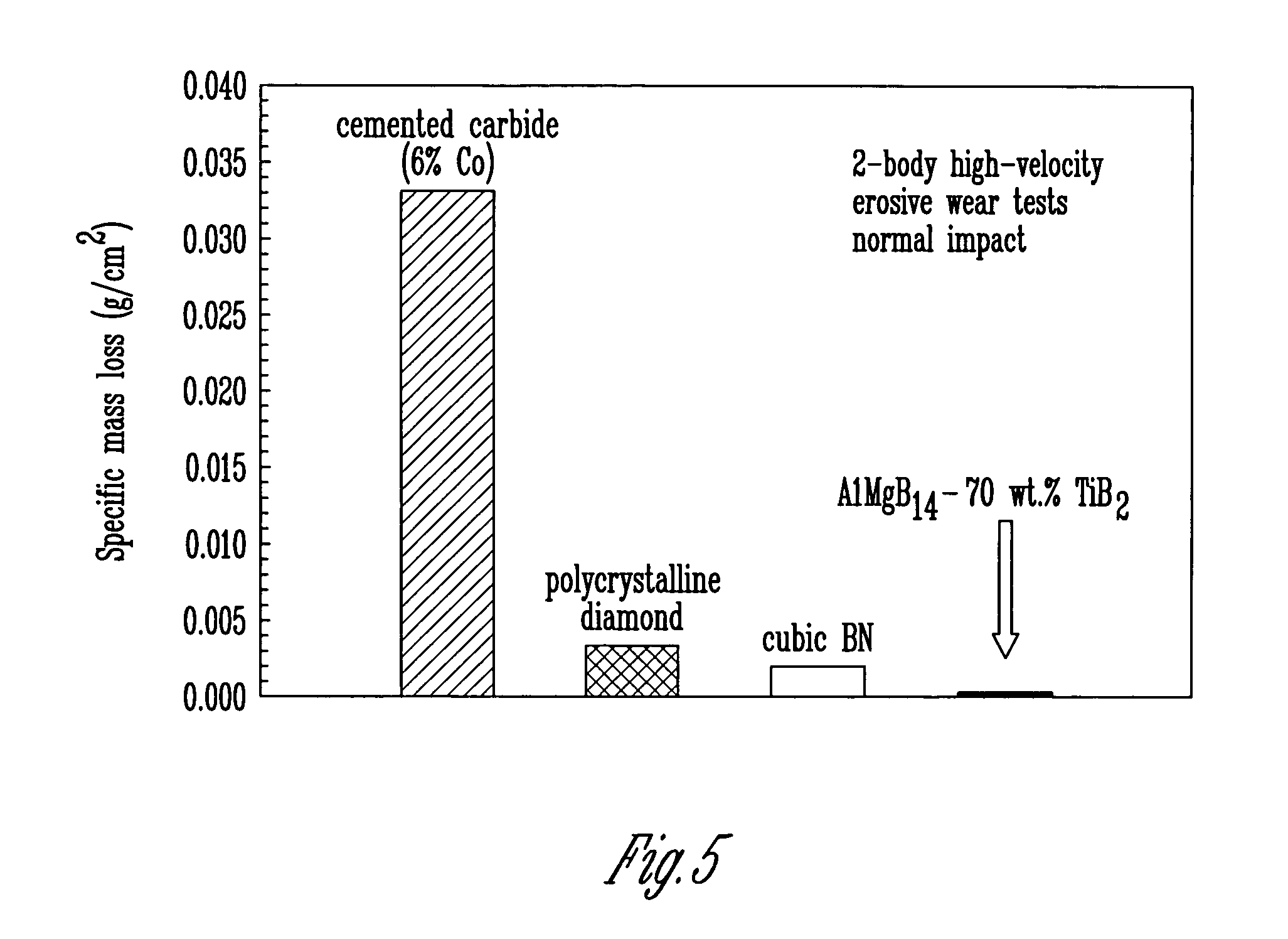

Wear-resistant boride composites with high percentage of reinforcement phase

ActiveUS20070151167A1Improve wear resistanceLow overall lengthPigmenting treatmentOther chemical processesBorideCeramic composite

A highly wear resistant sintered, hot pressed, or otherwise compacted ceramic composite material is described, consisting of two discrete phases of the form AlxMgyB14 where x and y≦1 or like hard, orthorhombic compounds, and TiB2 or like Group IVB transition metal di-borides, and with an unexpectedly high content of transition metal di-boride in the range from 40 to 90 percent (28 to 85 volume percent).

Owner:IOWA STATE UNIV RES FOUND

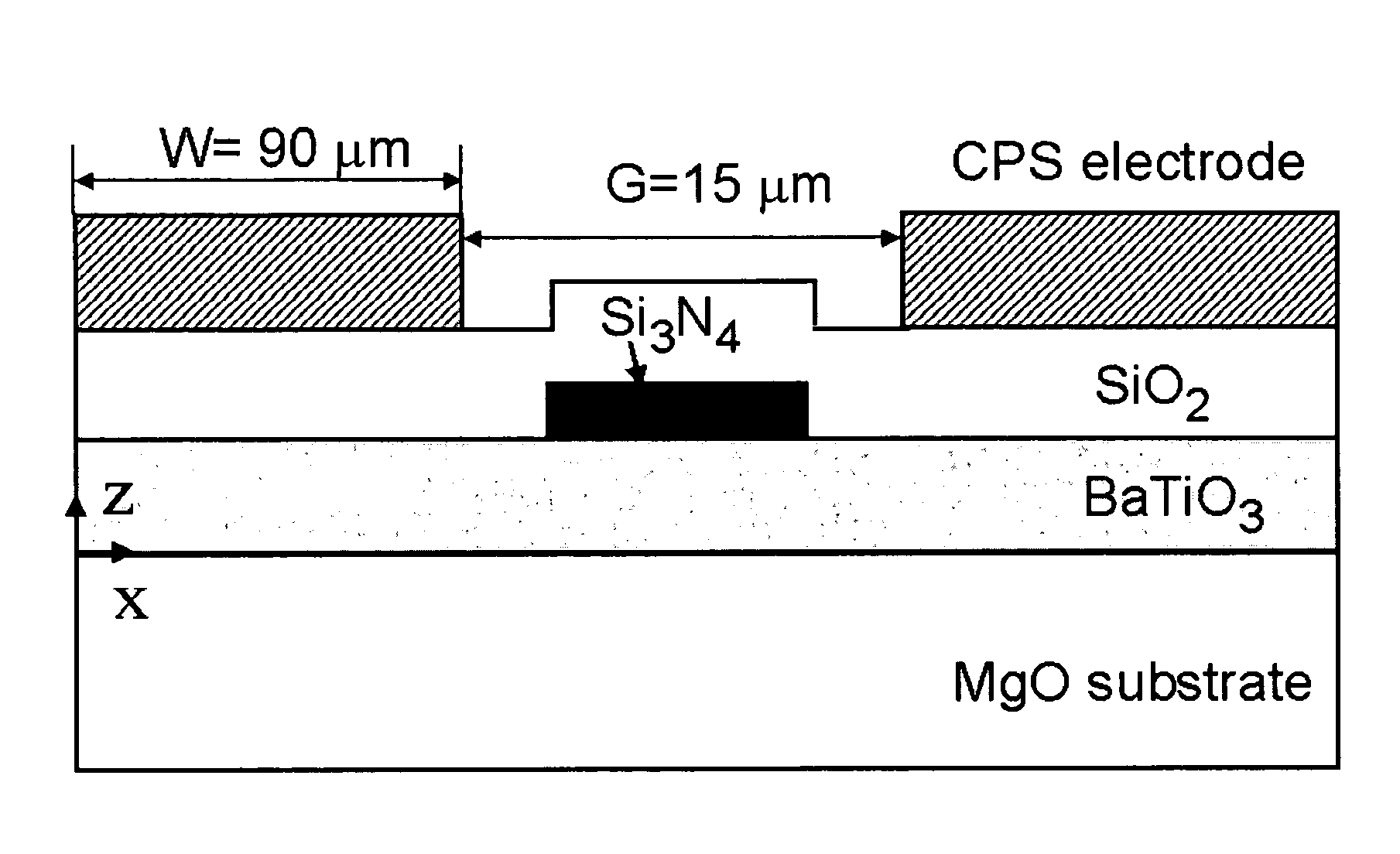

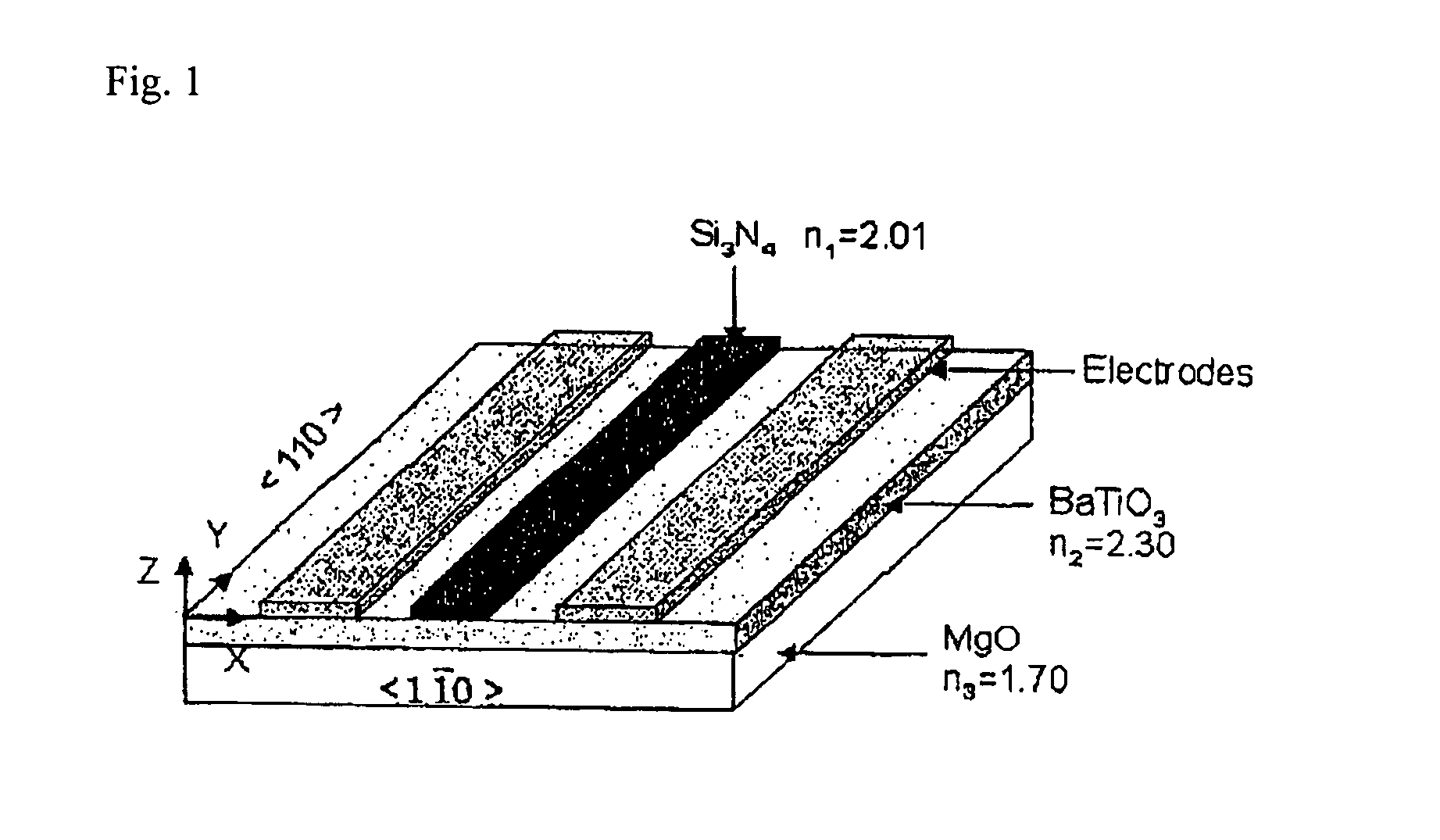

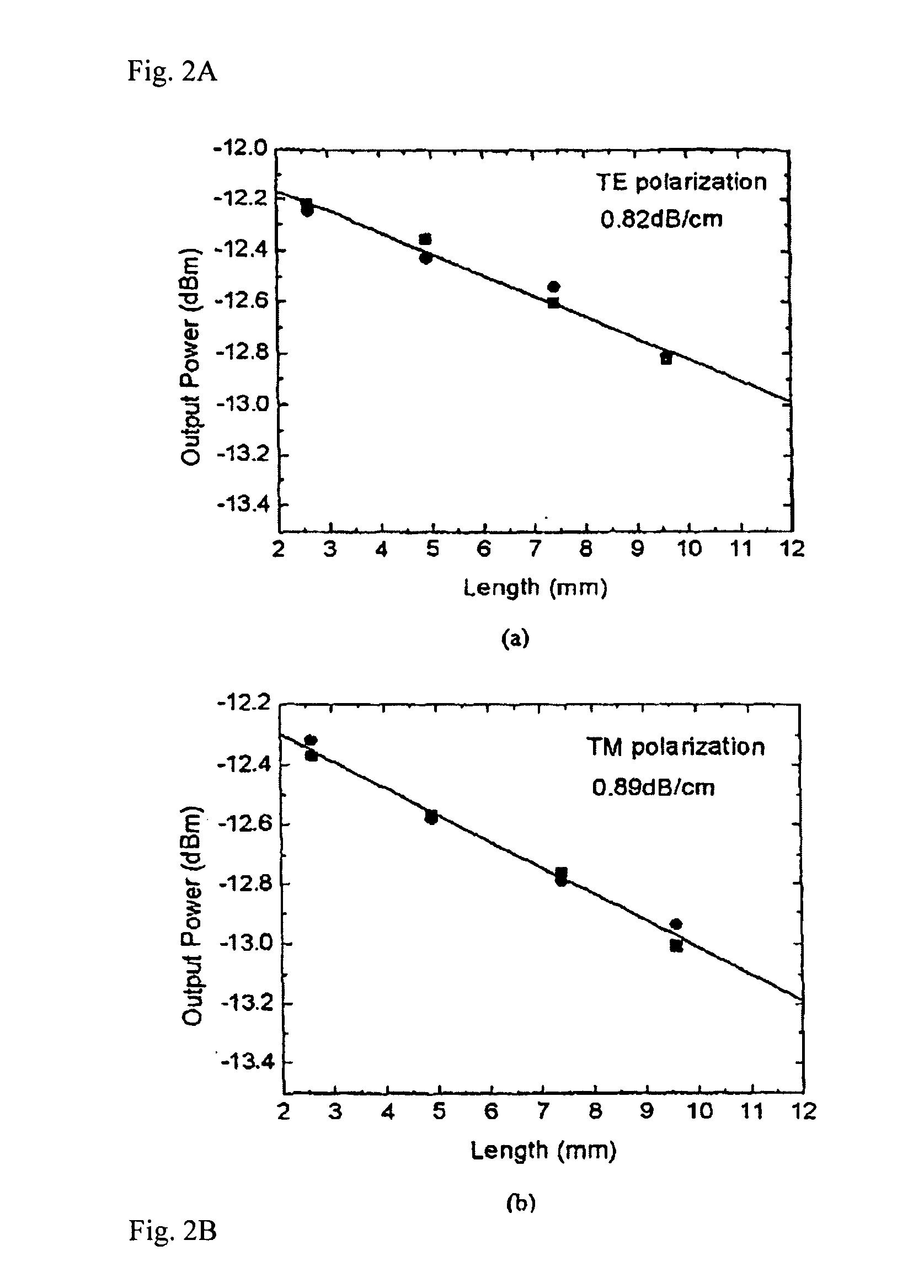

BaTiO3 thin film waveguides and related modulator devices

InactiveUS7224878B1Reduce polarizationReduce the driving voltageNanoopticsOptical waveguide light guideWaveguideElectro-optic modulator

Owner:NORTHWESTERN UNIV

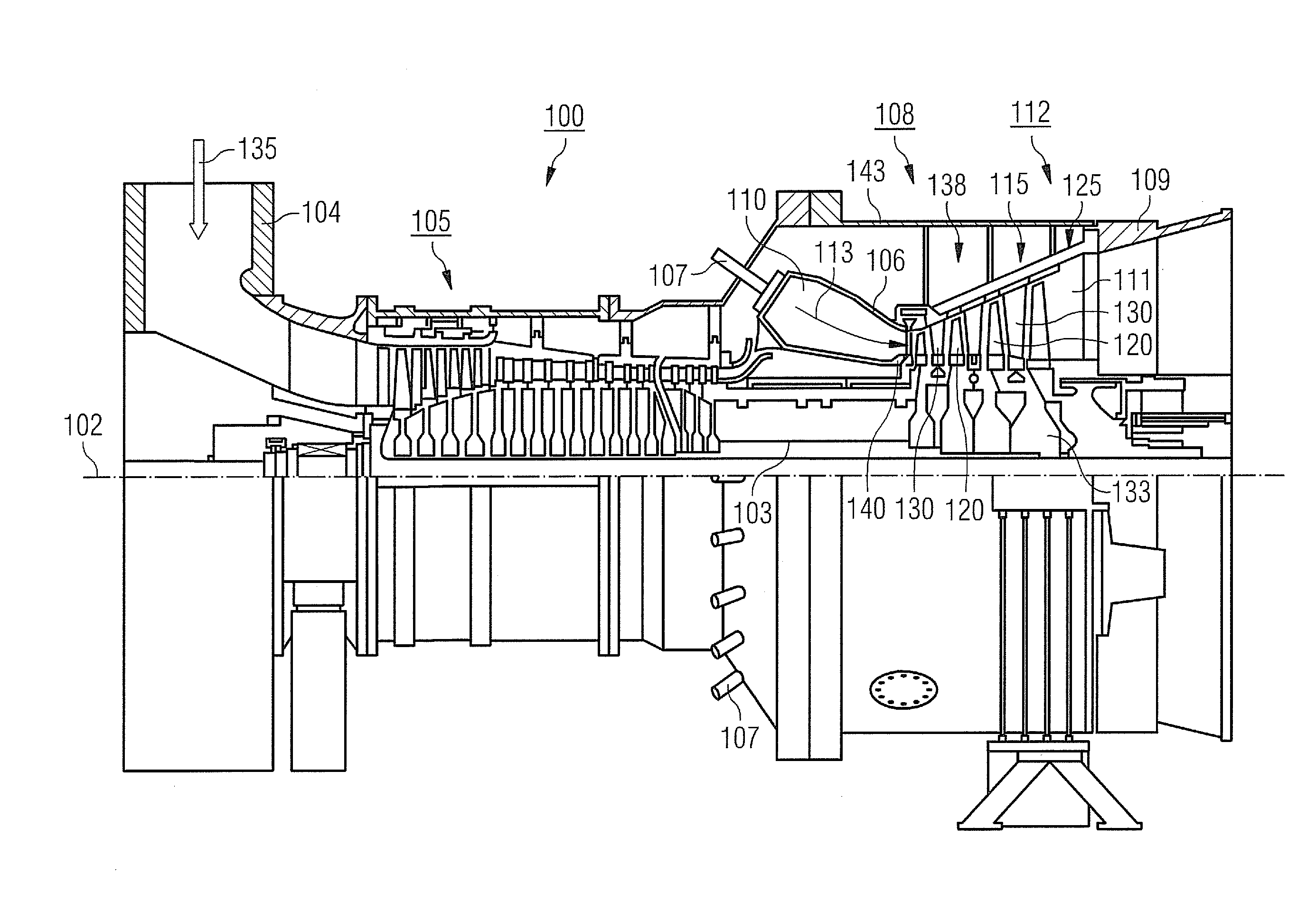

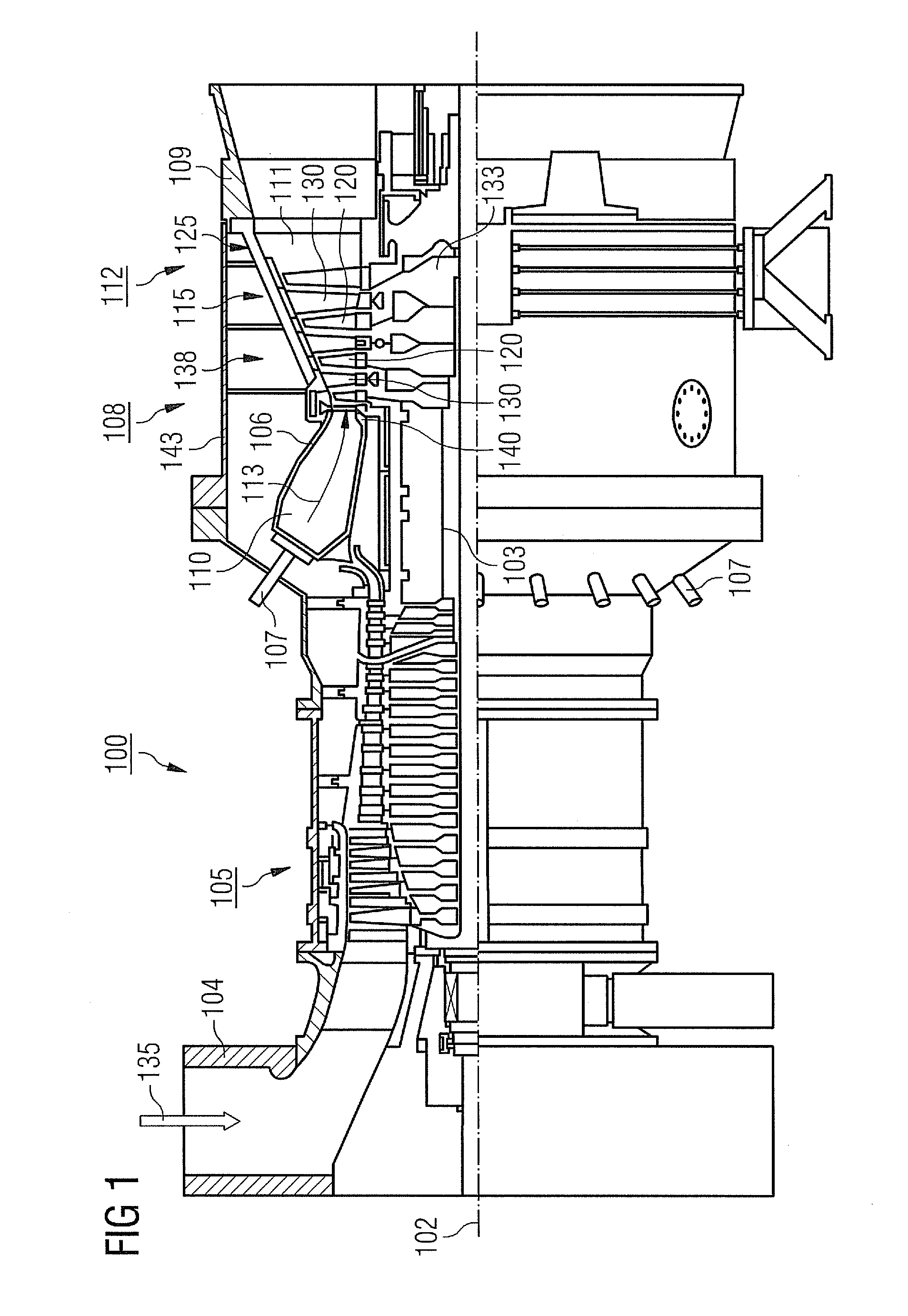

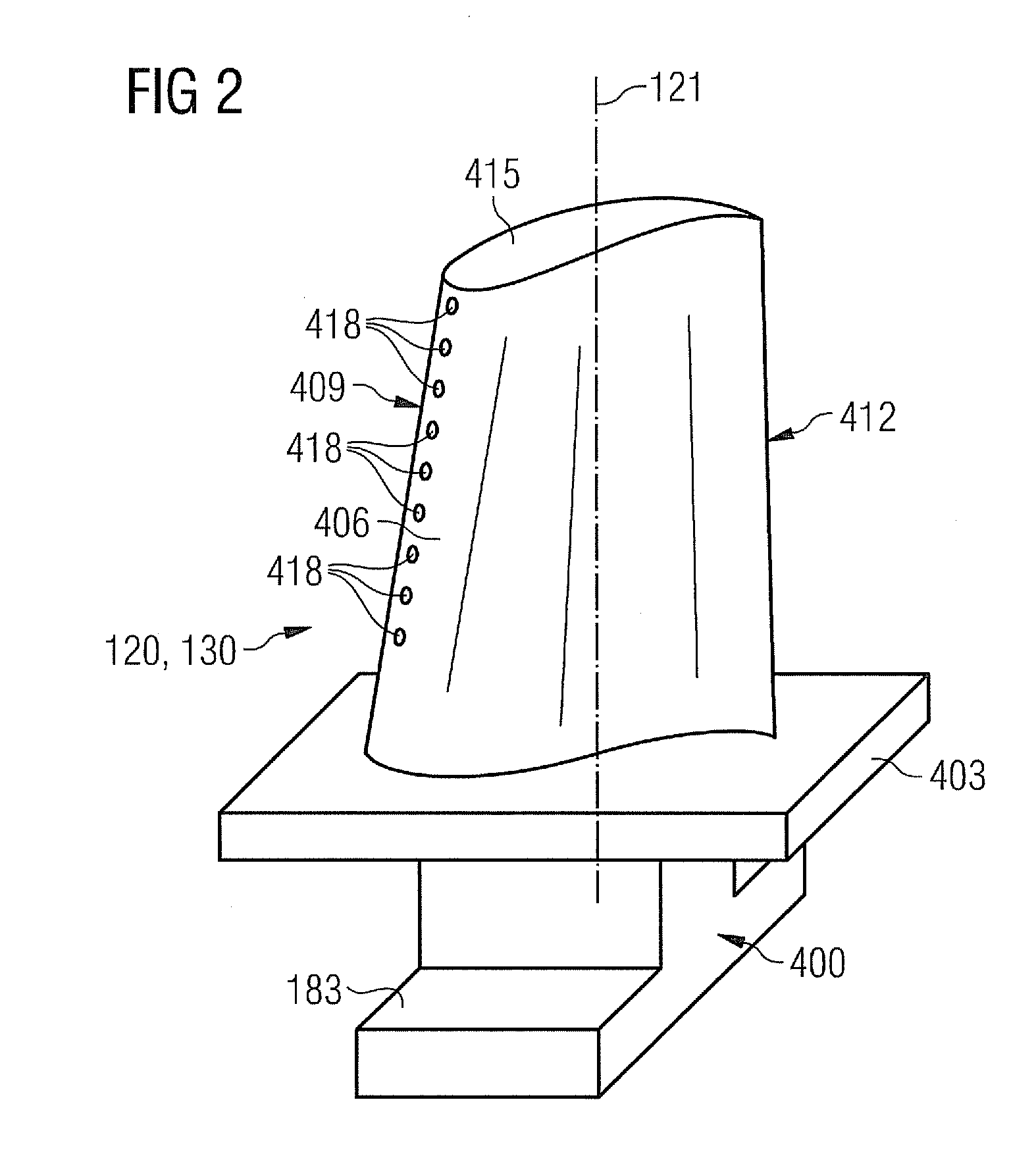

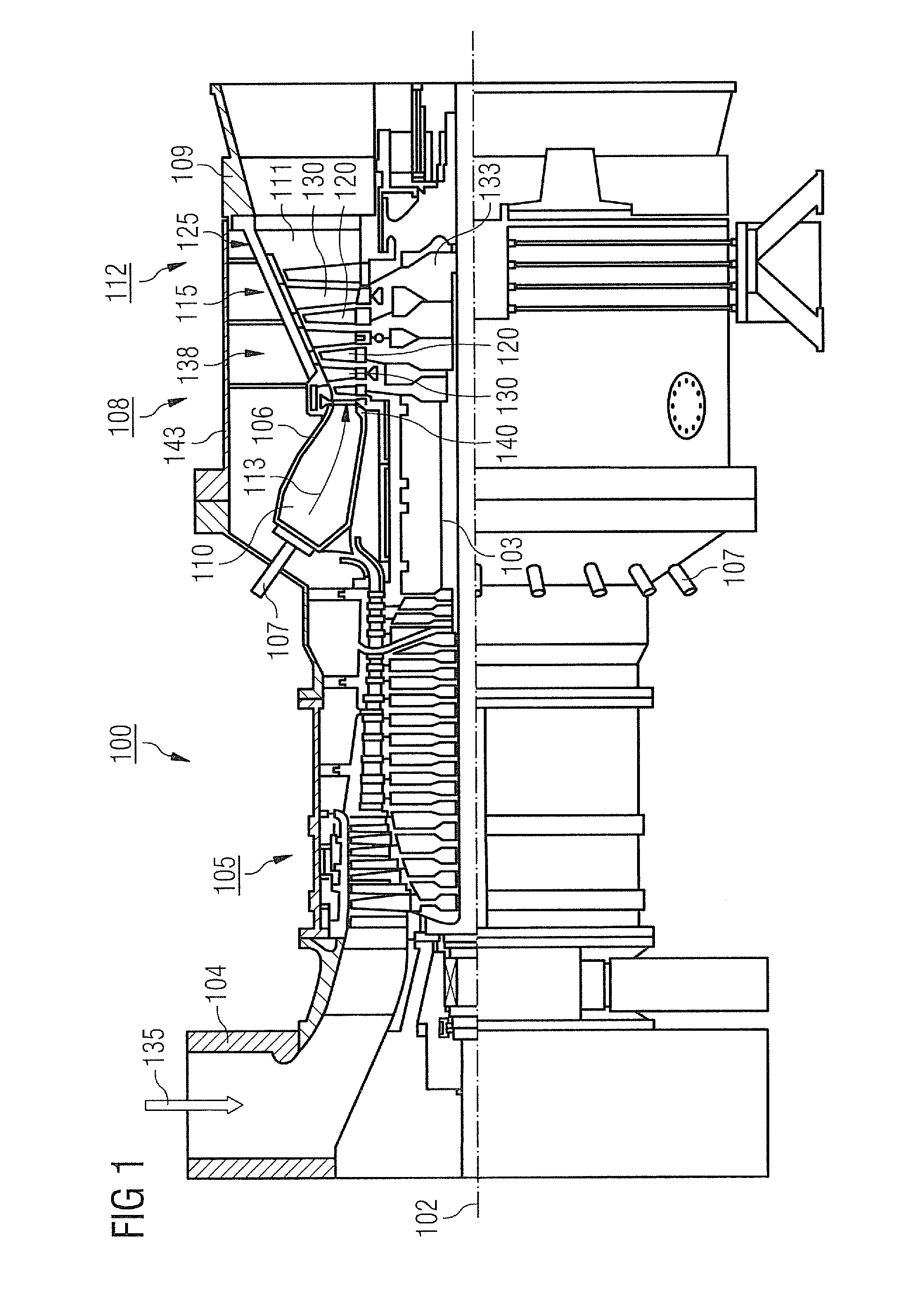

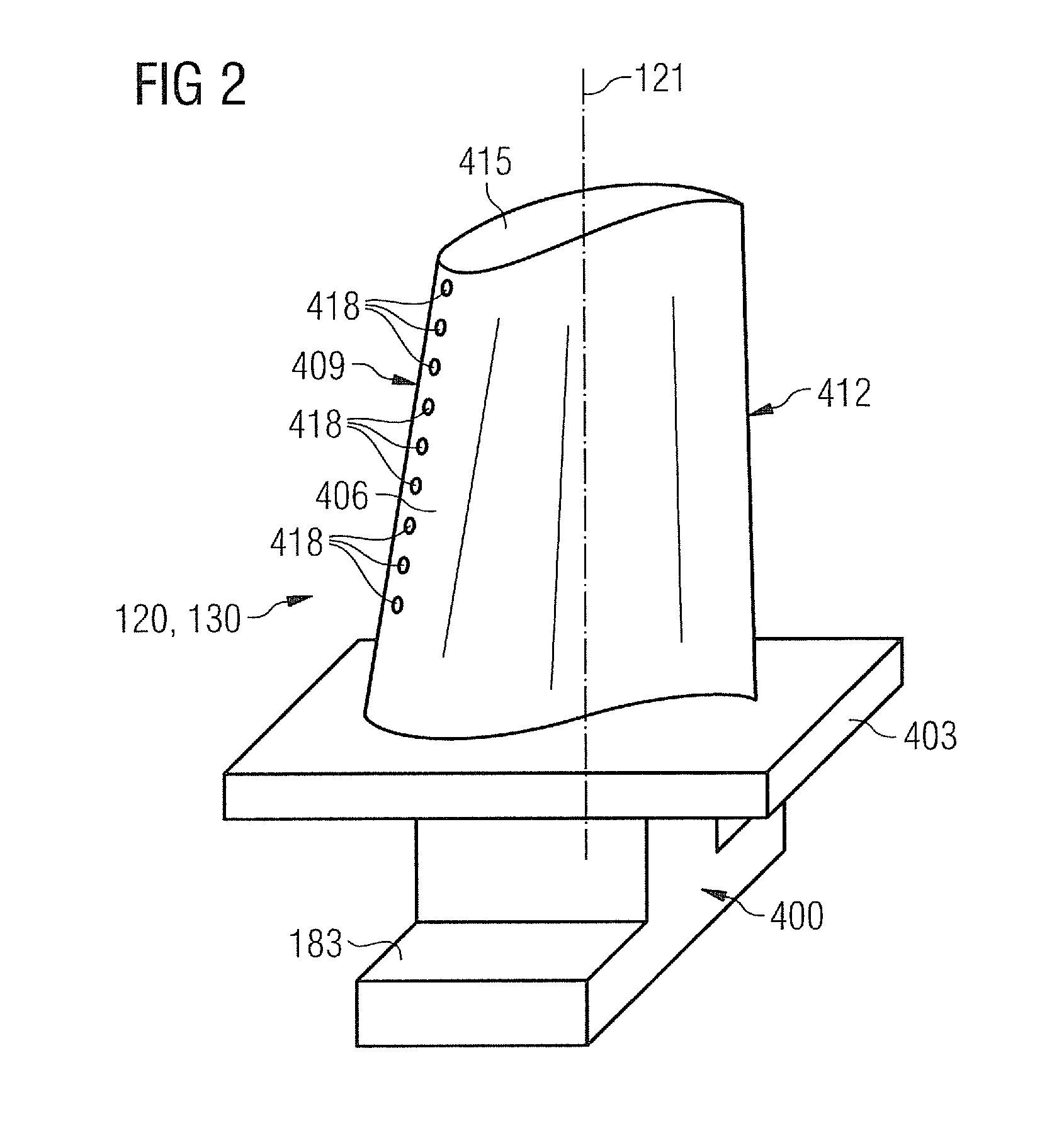

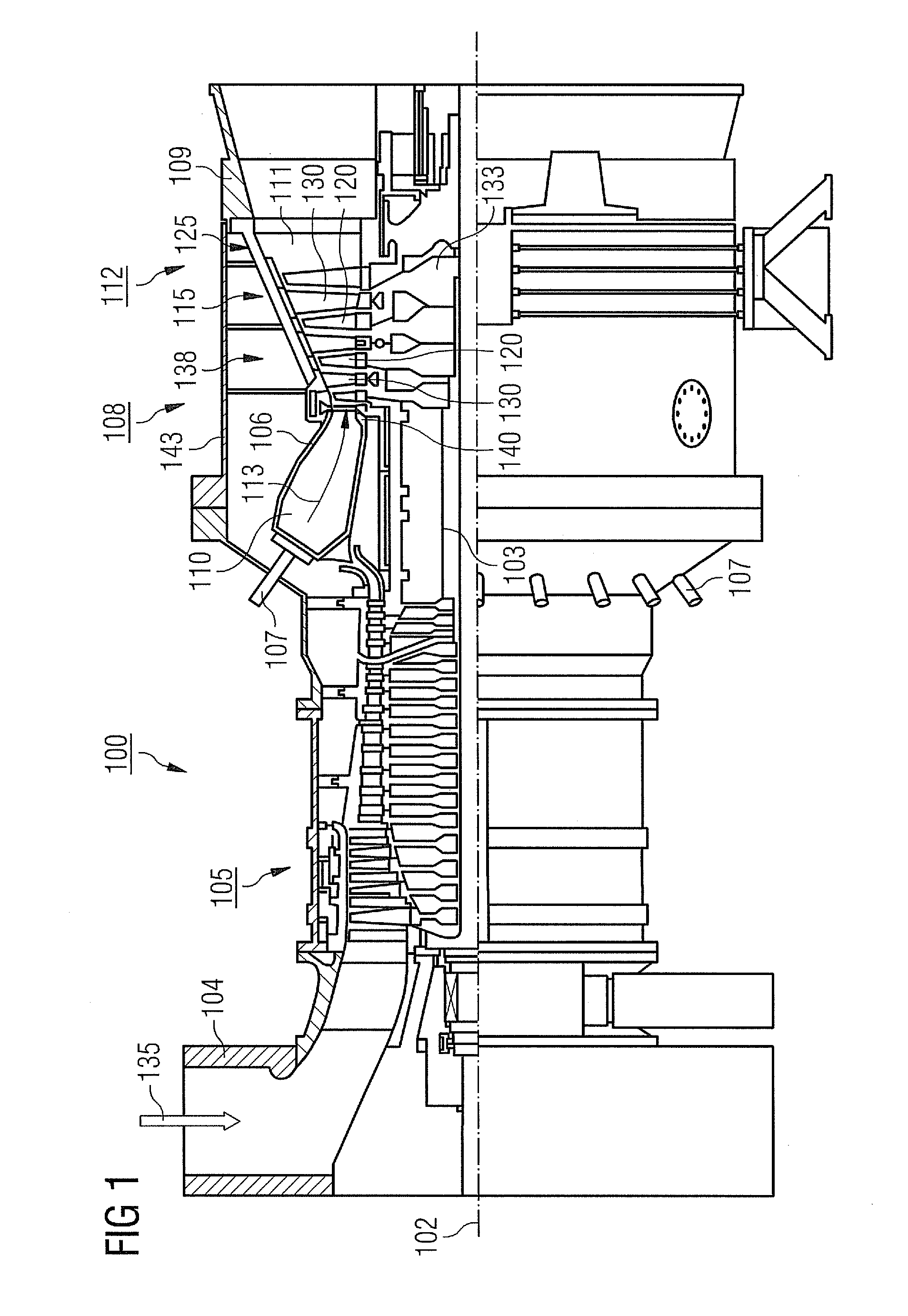

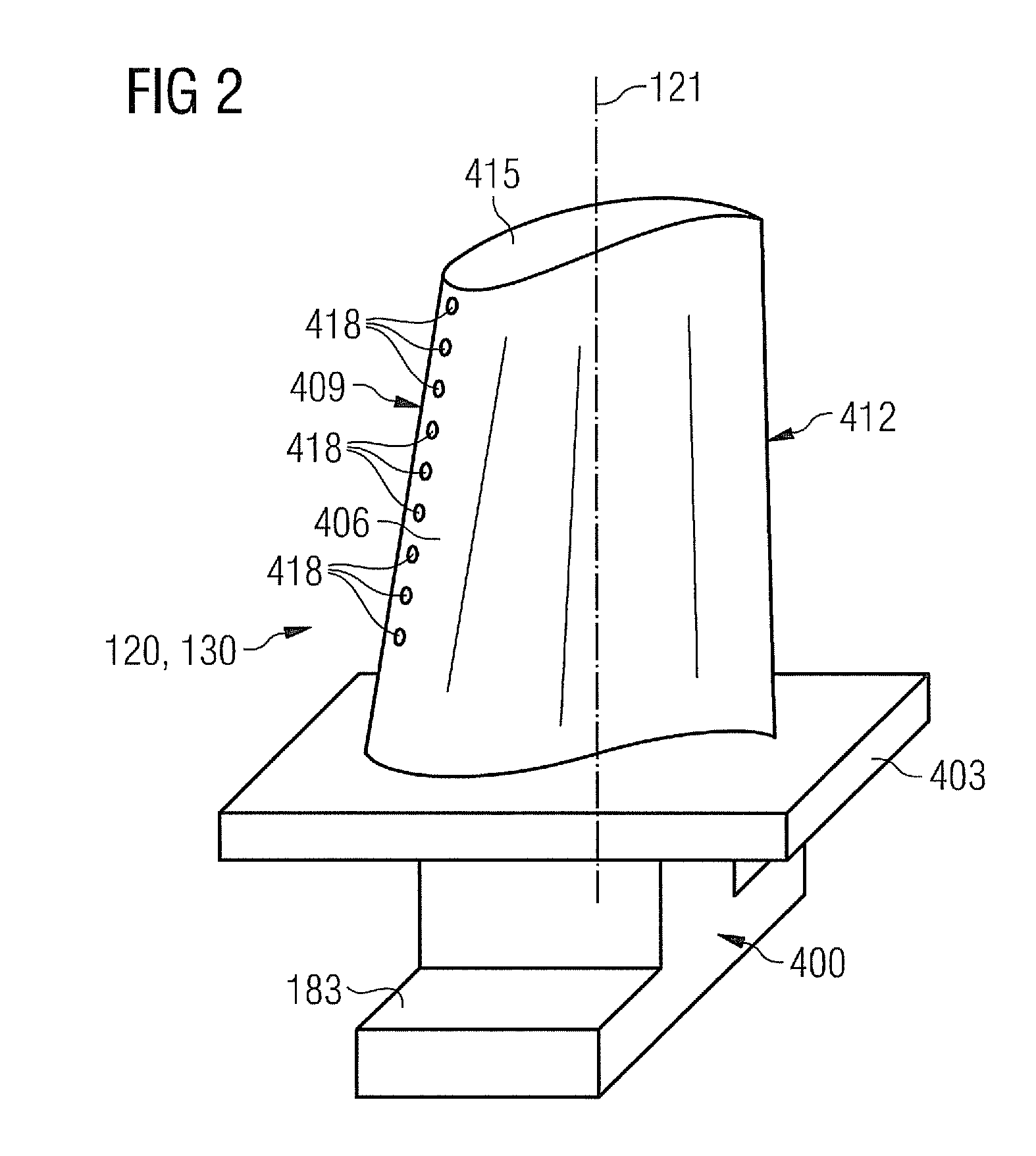

Method and Apparatus for Welding Workpieces of High-Temperature Superalloys

ActiveUS20110089150A1Improve cooling effectIncrease chanceTurbinesEngine manufactureEngineeringSuperalloy

A welding apparatus for welding workpieces of high-temperature superalloys is provided. The welding apparatus includes a heat source for producing a heat input zone on the workpiece surface, a supplying device for supplying welding filler into the heat input zone and a transporting device for producing a relative movement between the heat source and the supplying device on the one hand and the workpiece surface on the other hand. The welding apparatus further includes a control unit with a control program, which carries out the relative movement in such a way that the welding power and the diameter of the heat input zone are set such that the cooling rate during the solidifying of the material is at least 8000 Kelvins per second.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV +1

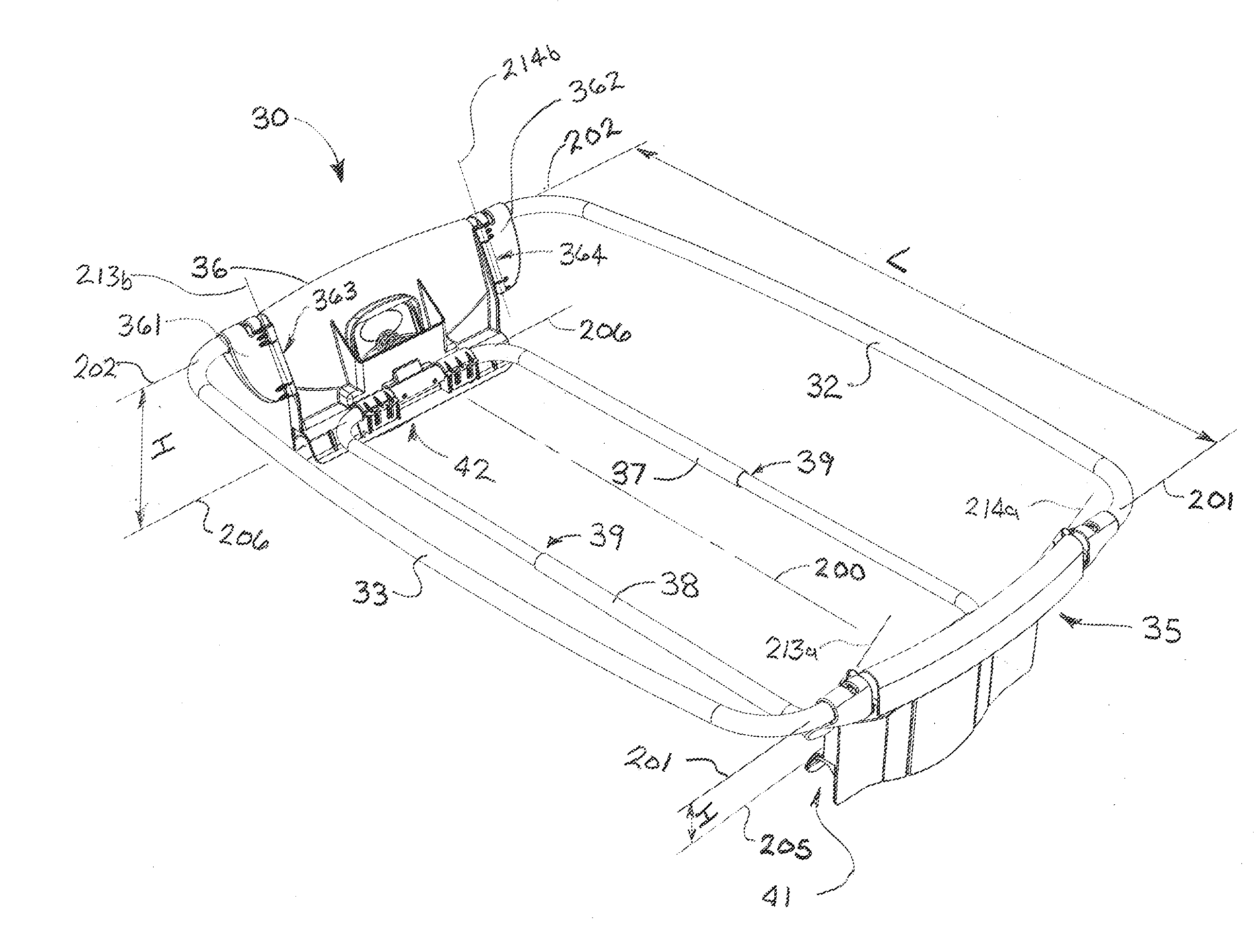

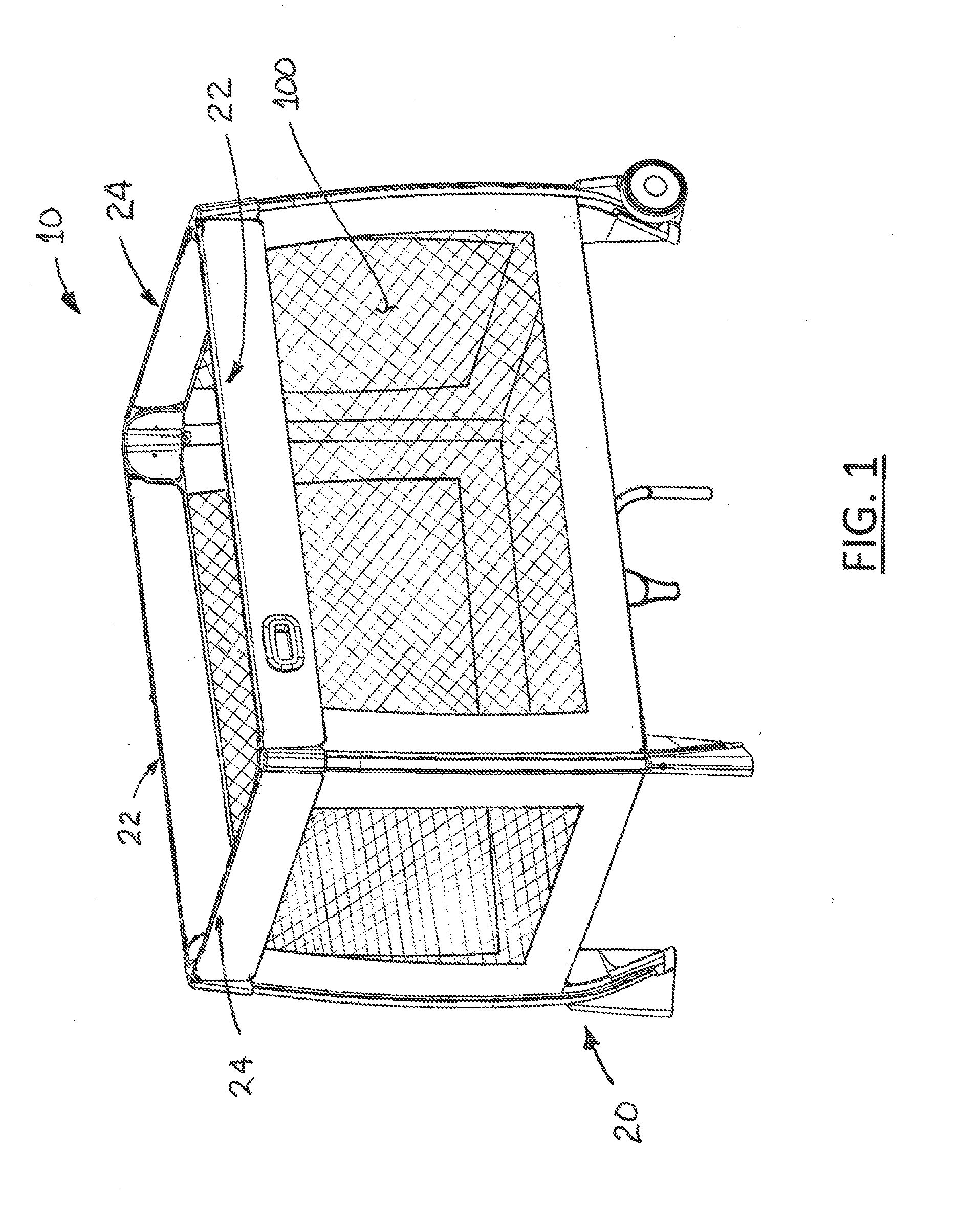

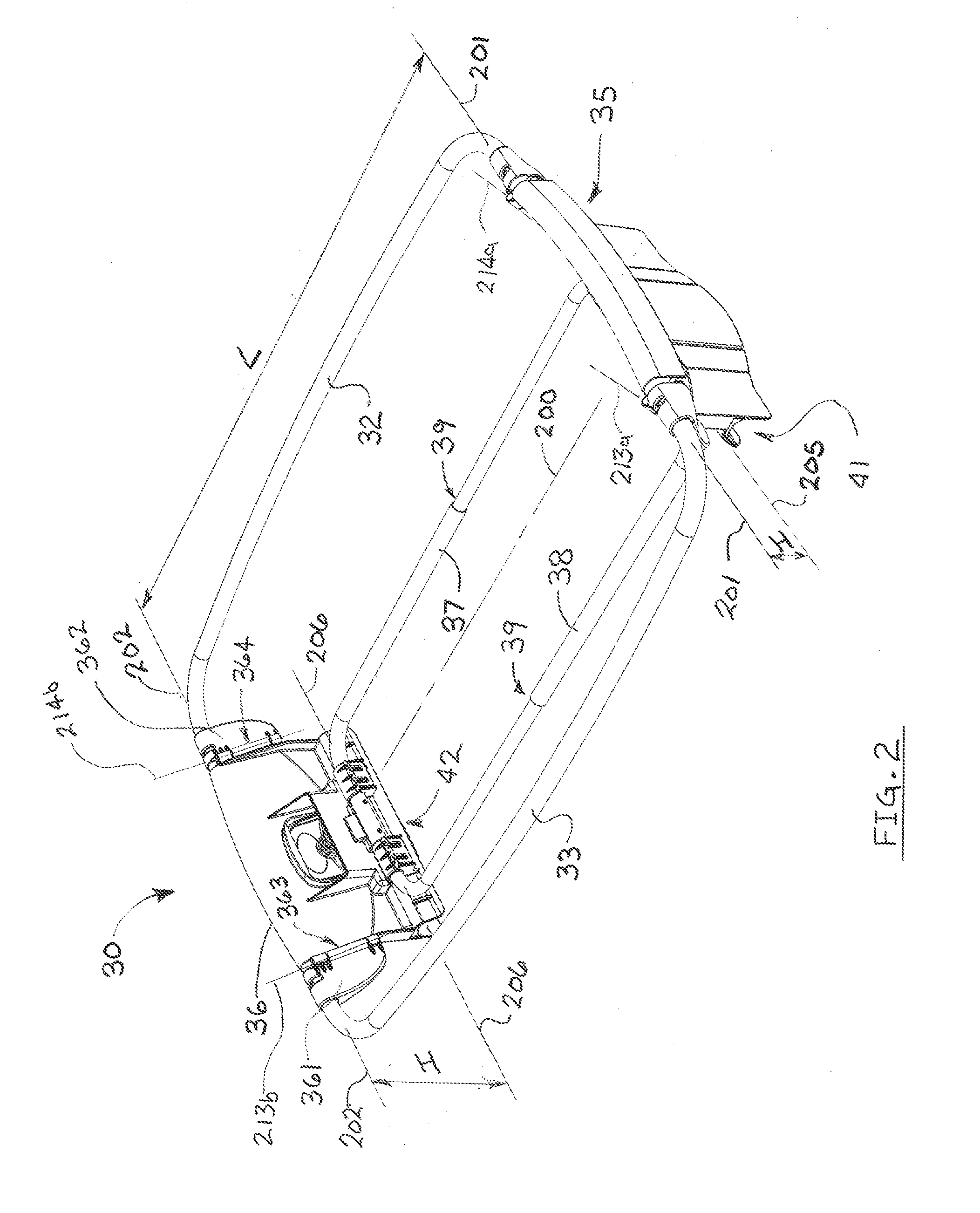

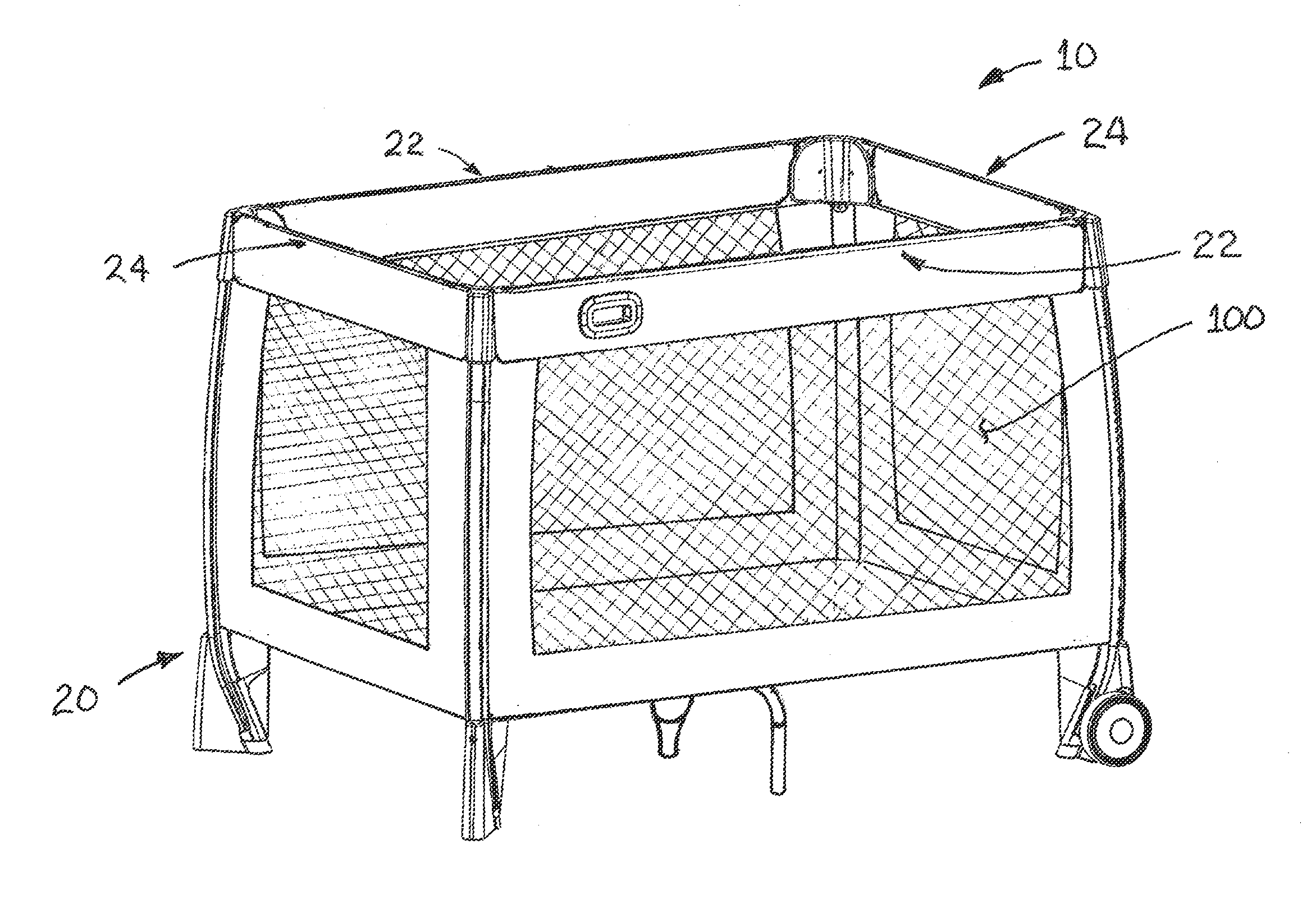

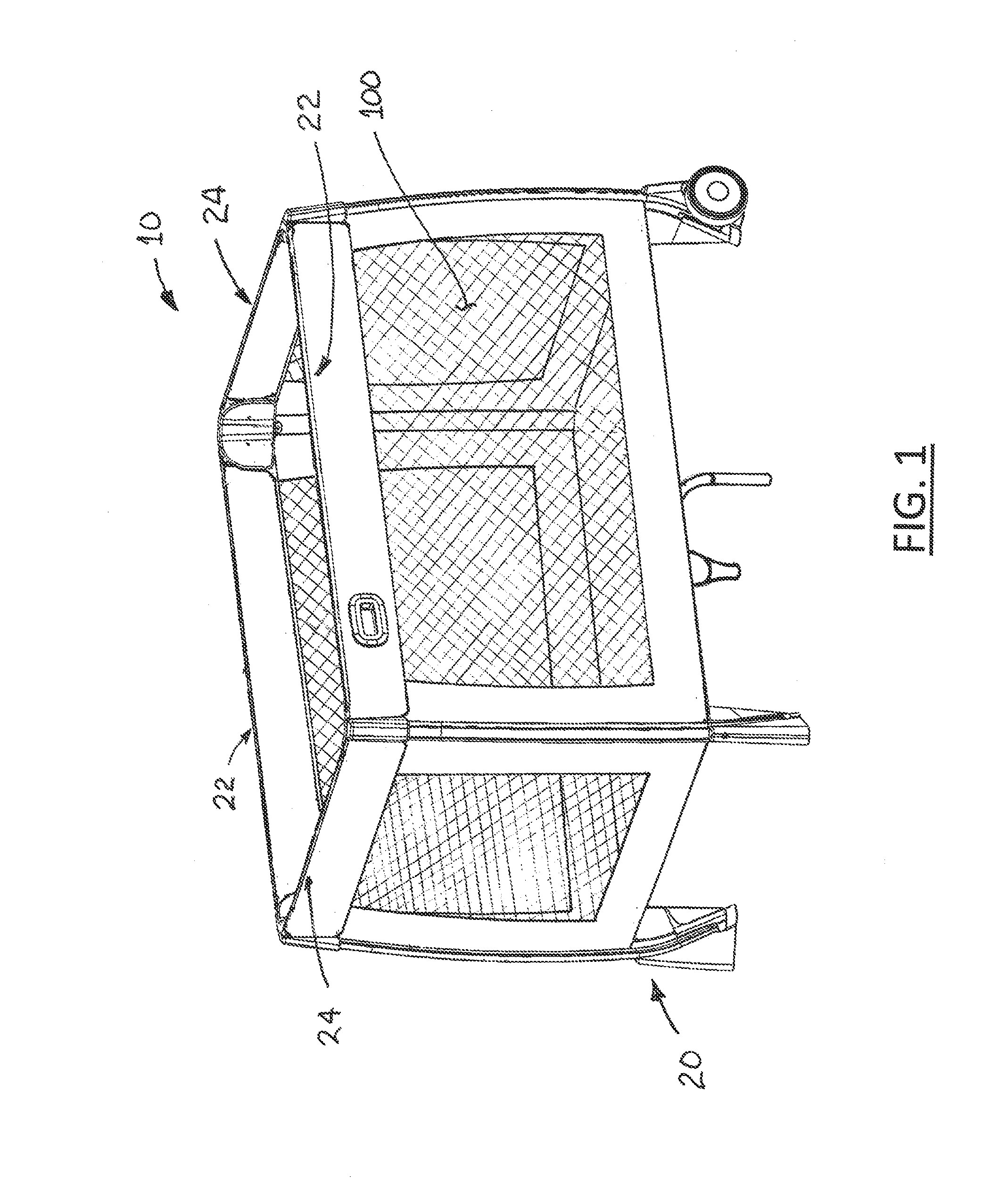

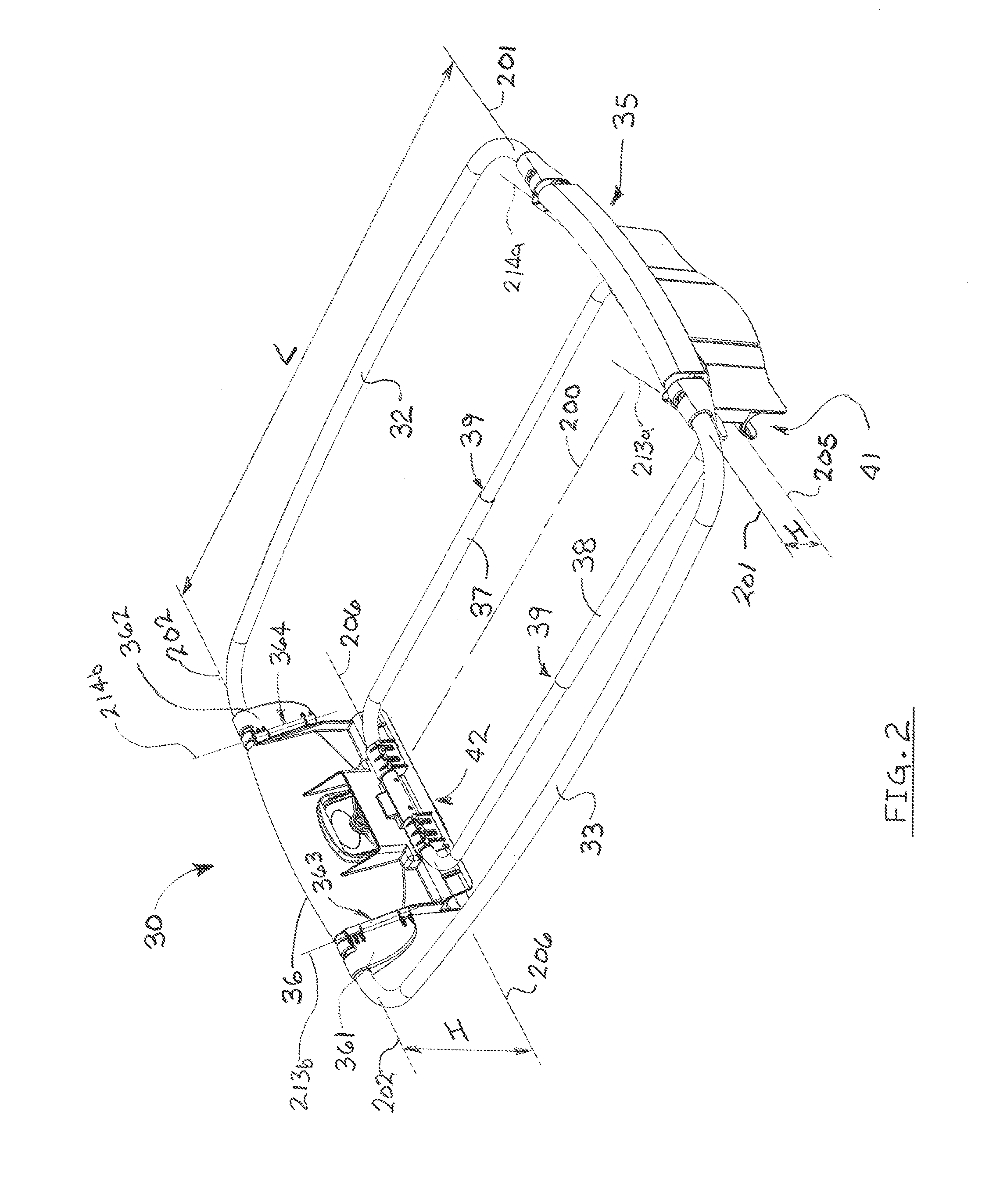

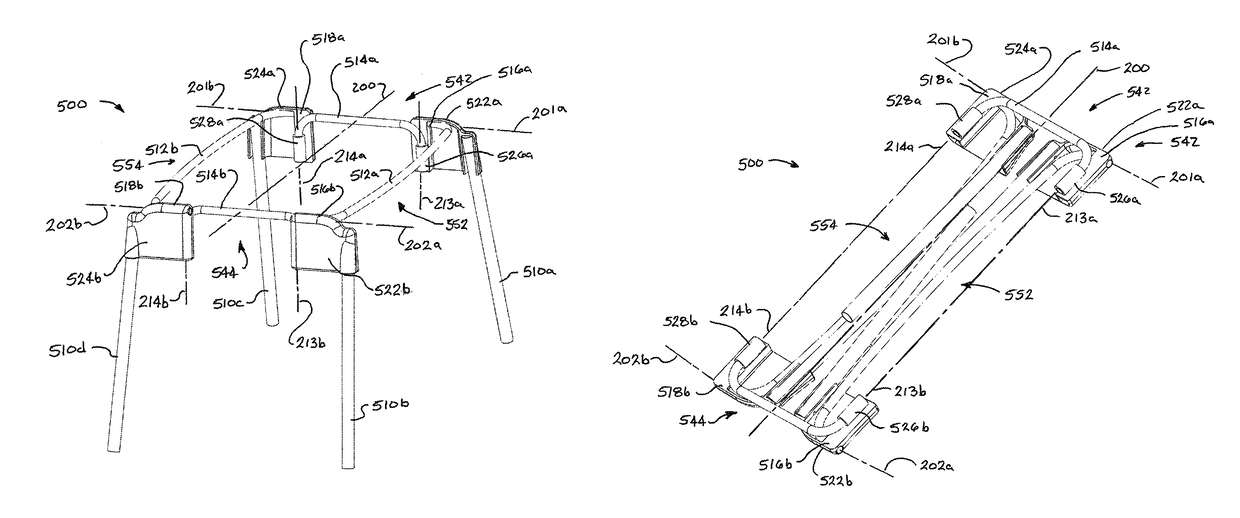

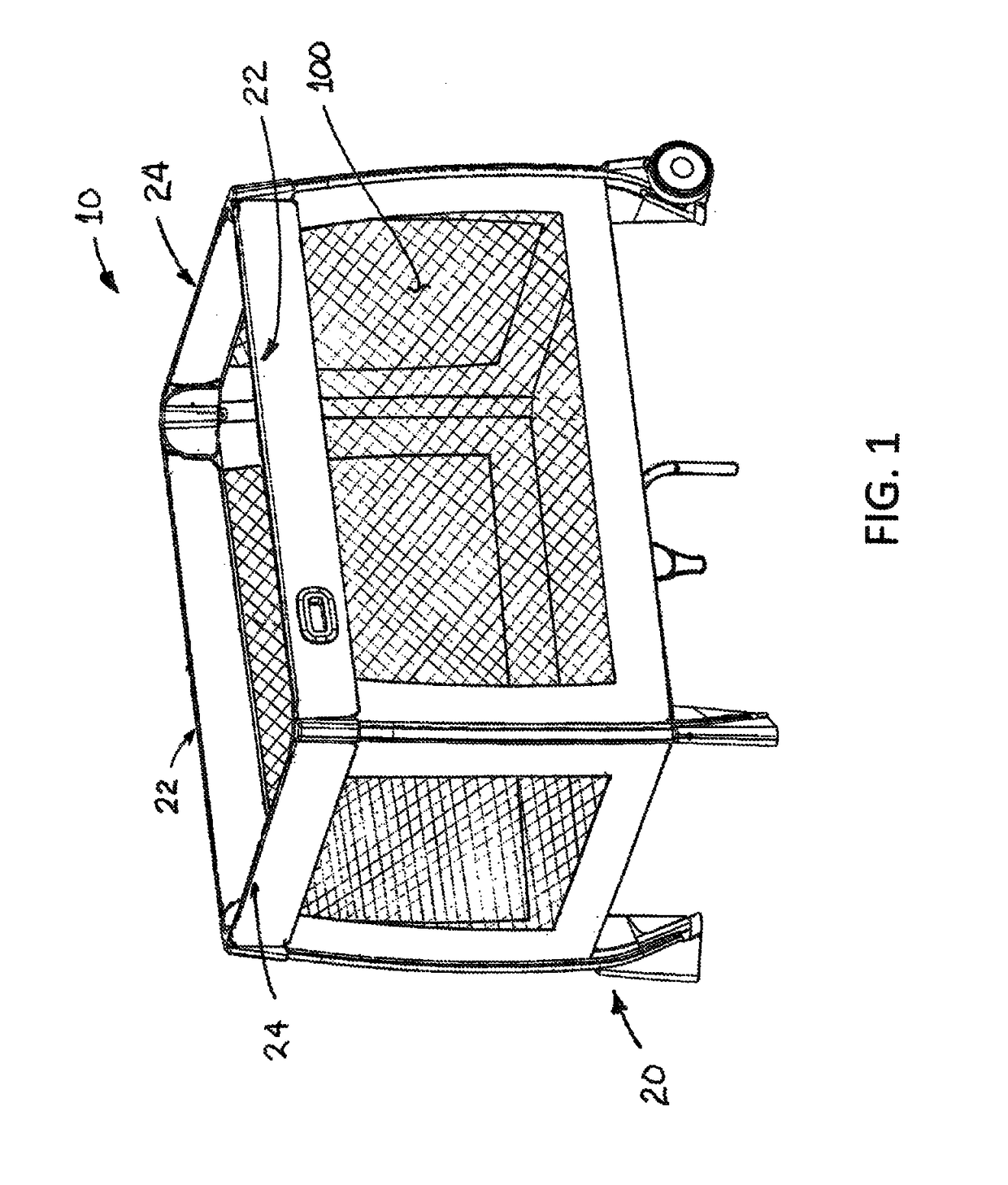

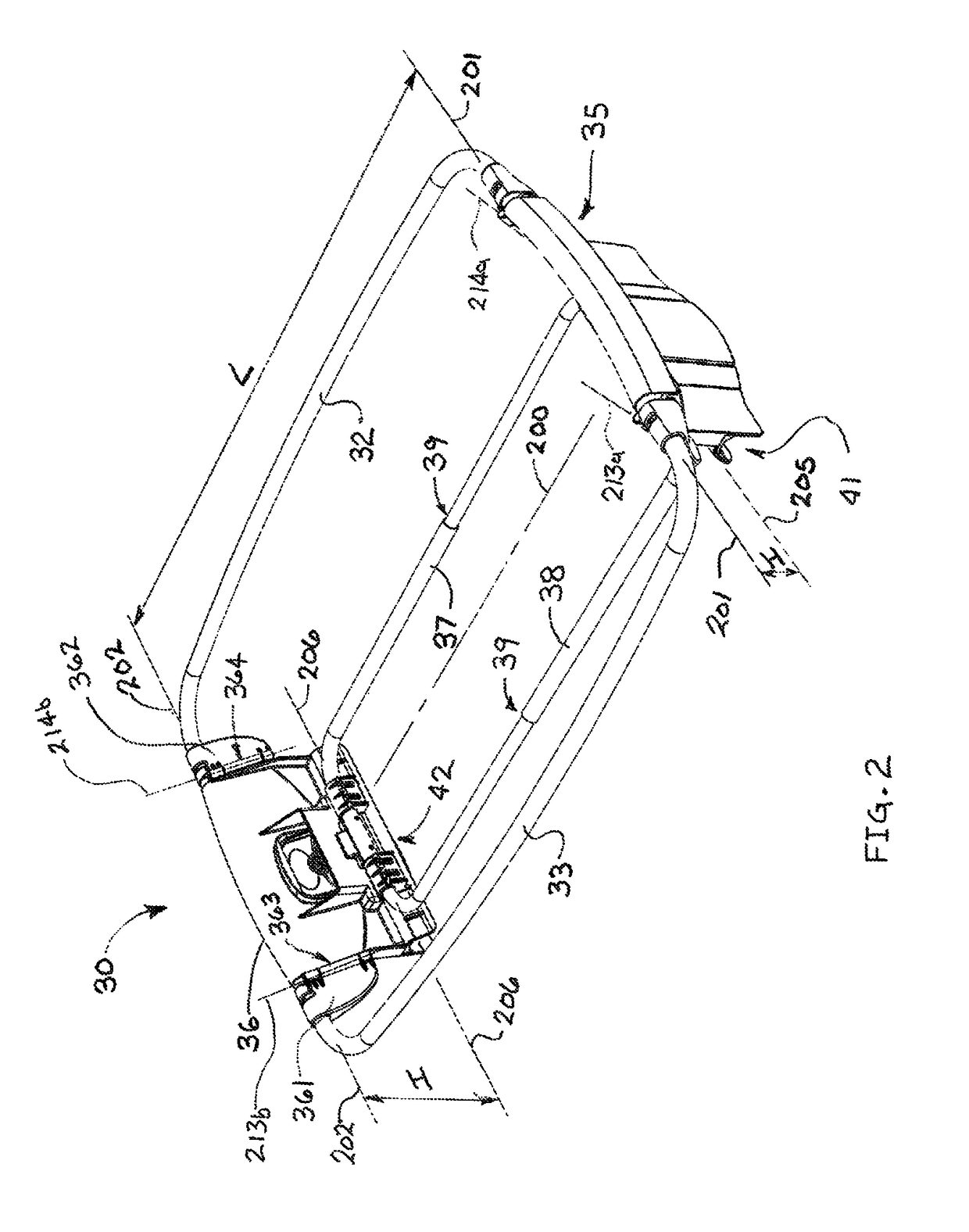

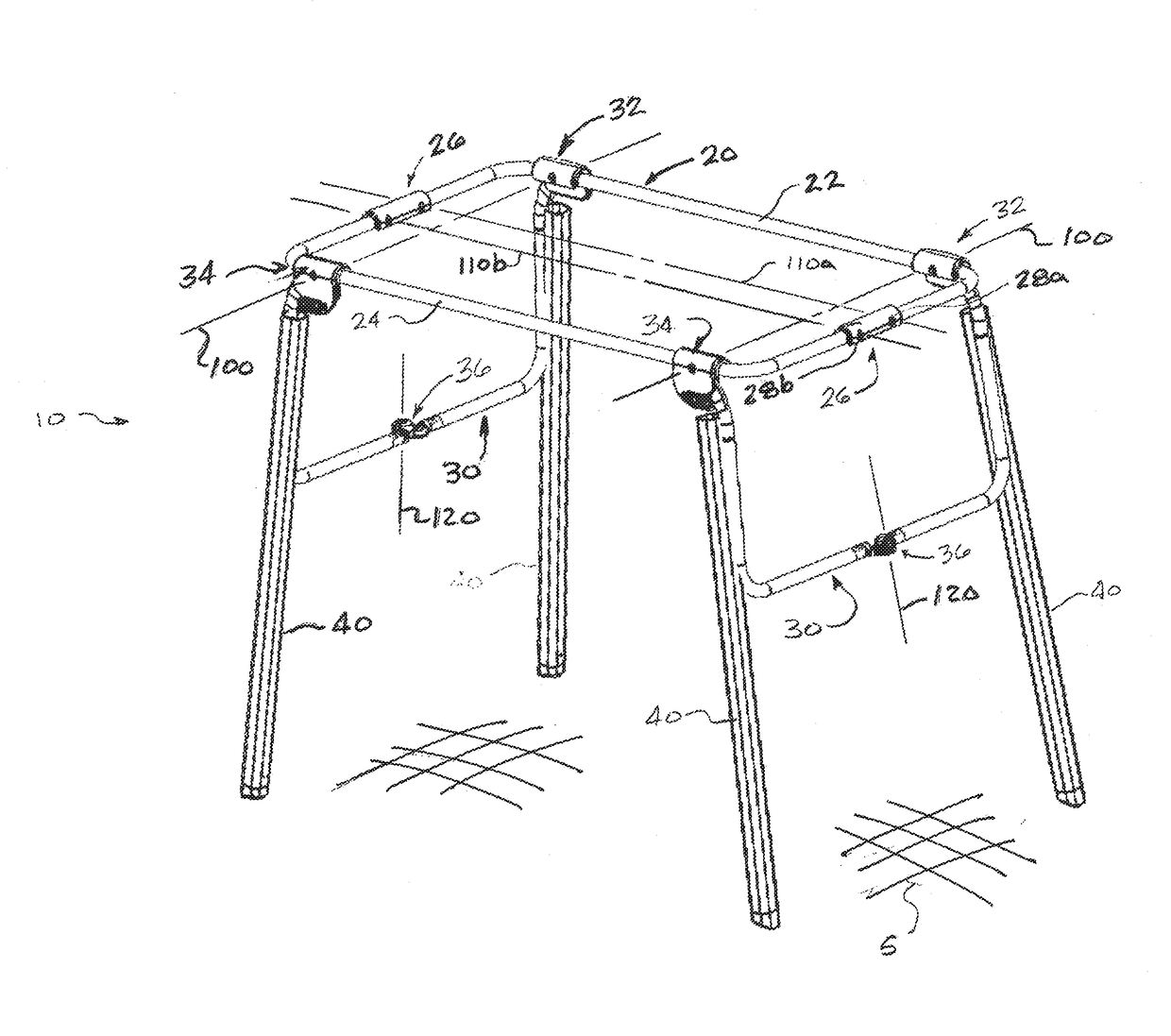

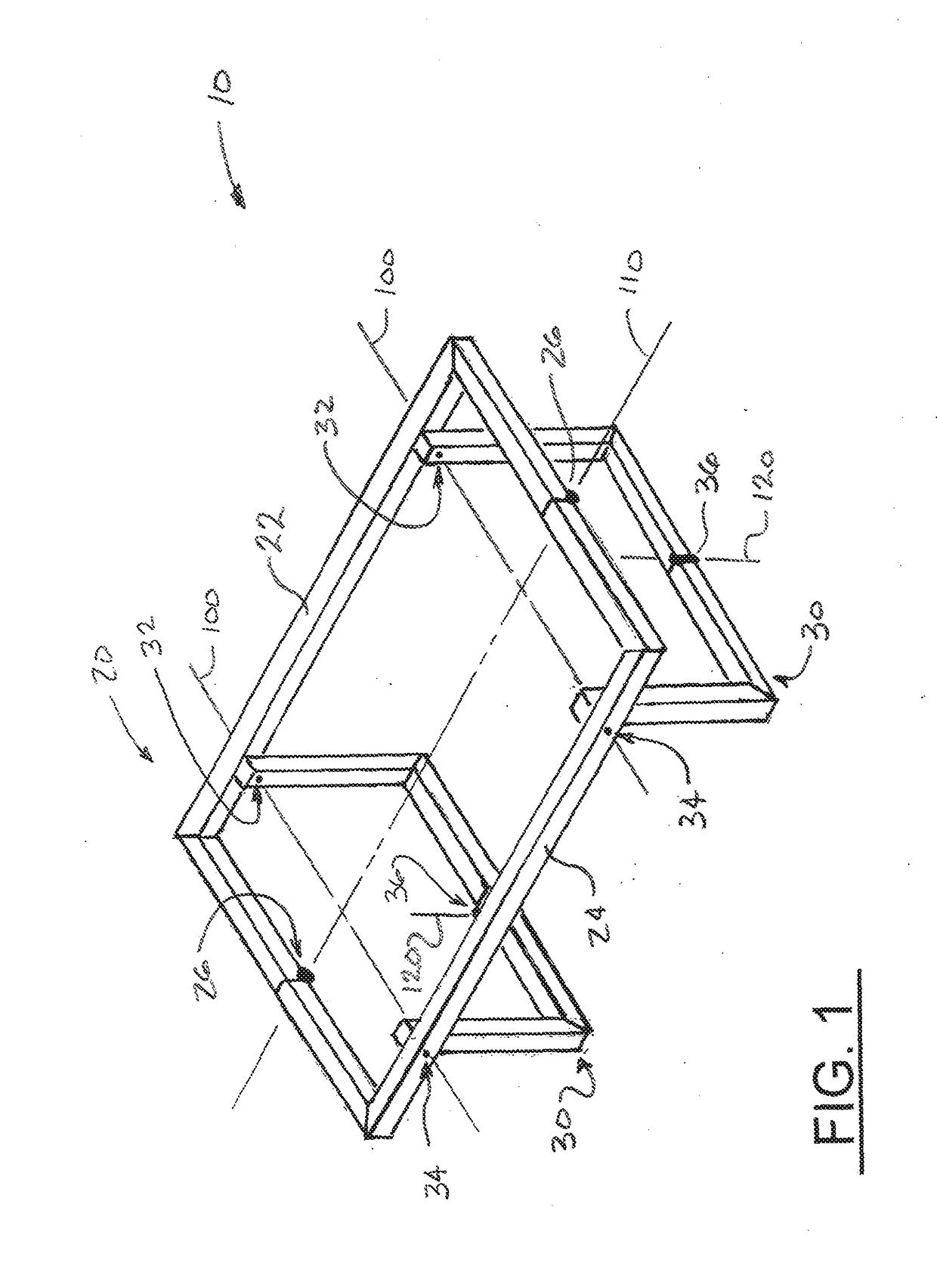

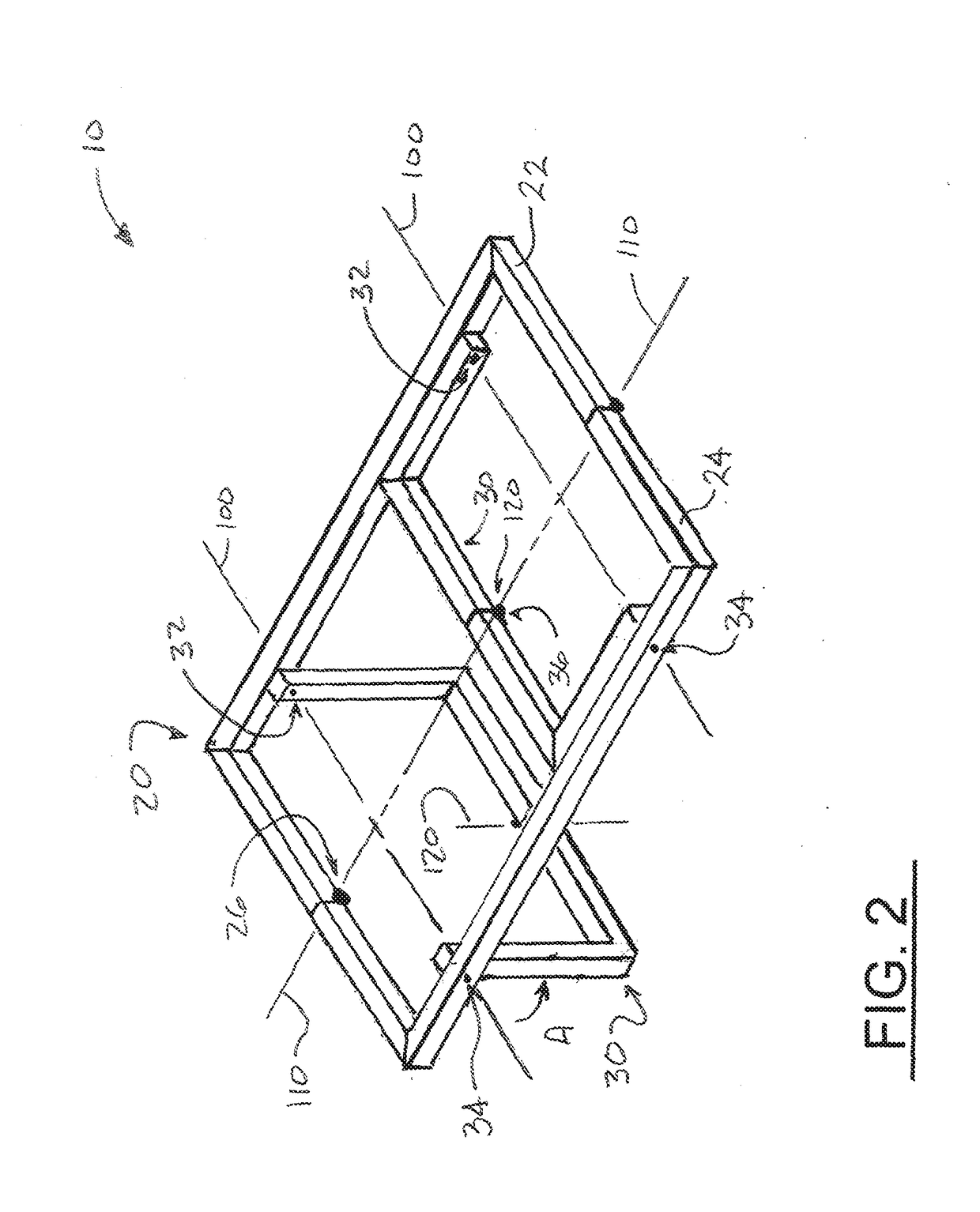

Bi-axially collapsible frame for a bassinet

ActiveUS20150216322A1Low overall lengthLength of may varyKids bedsCradleEngineeringStructural engineering

Owner:ARTSANA USA

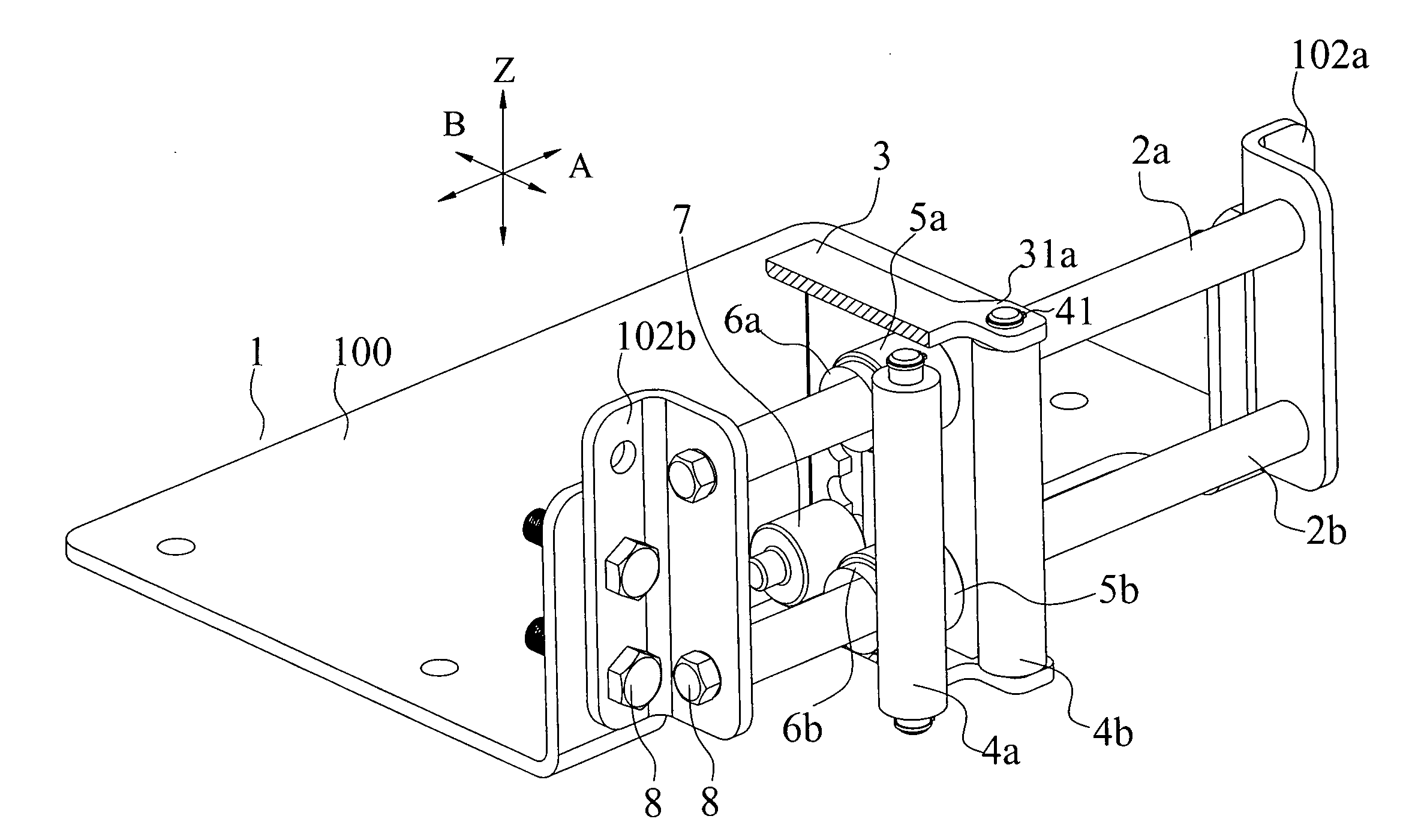

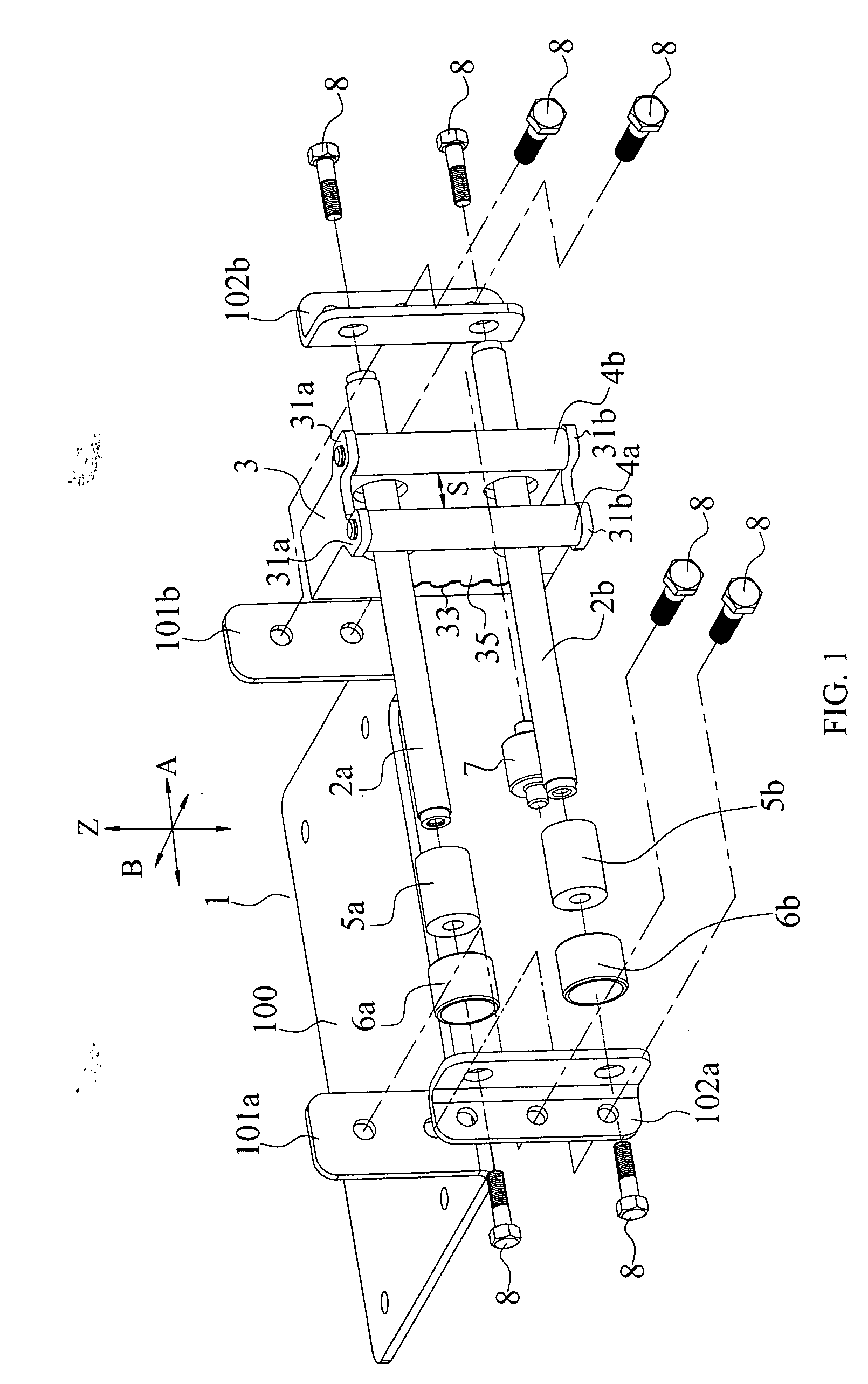

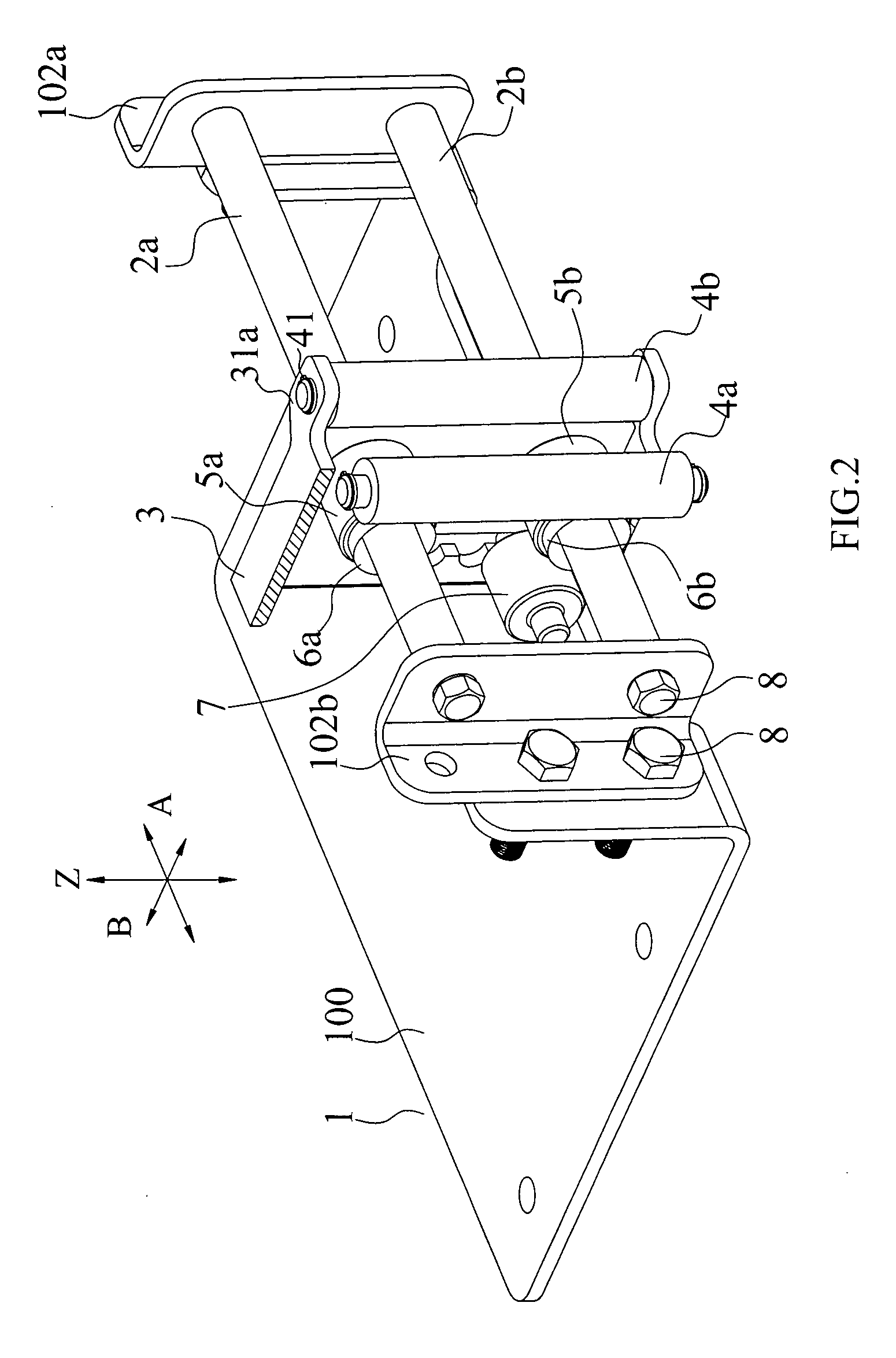

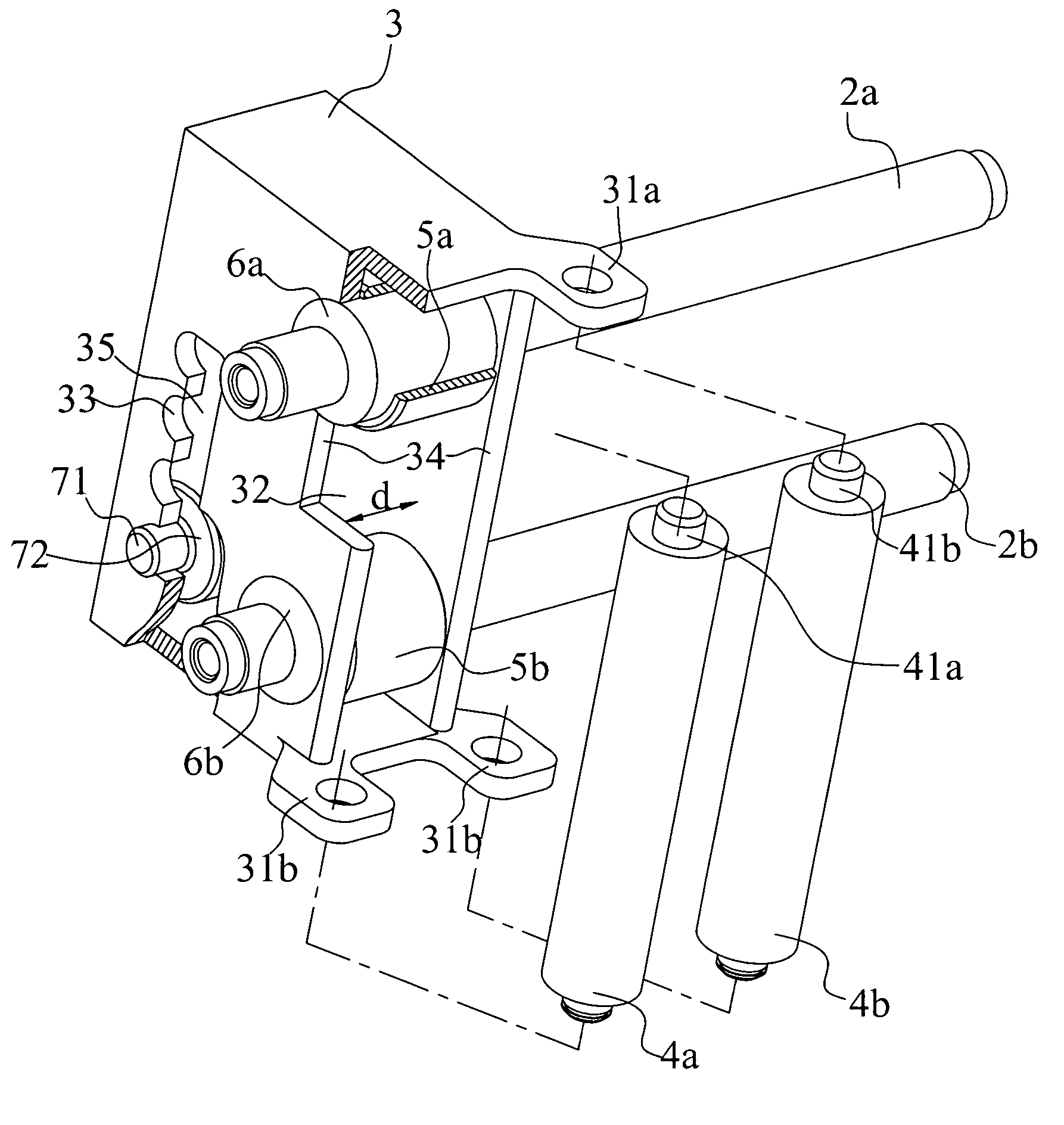

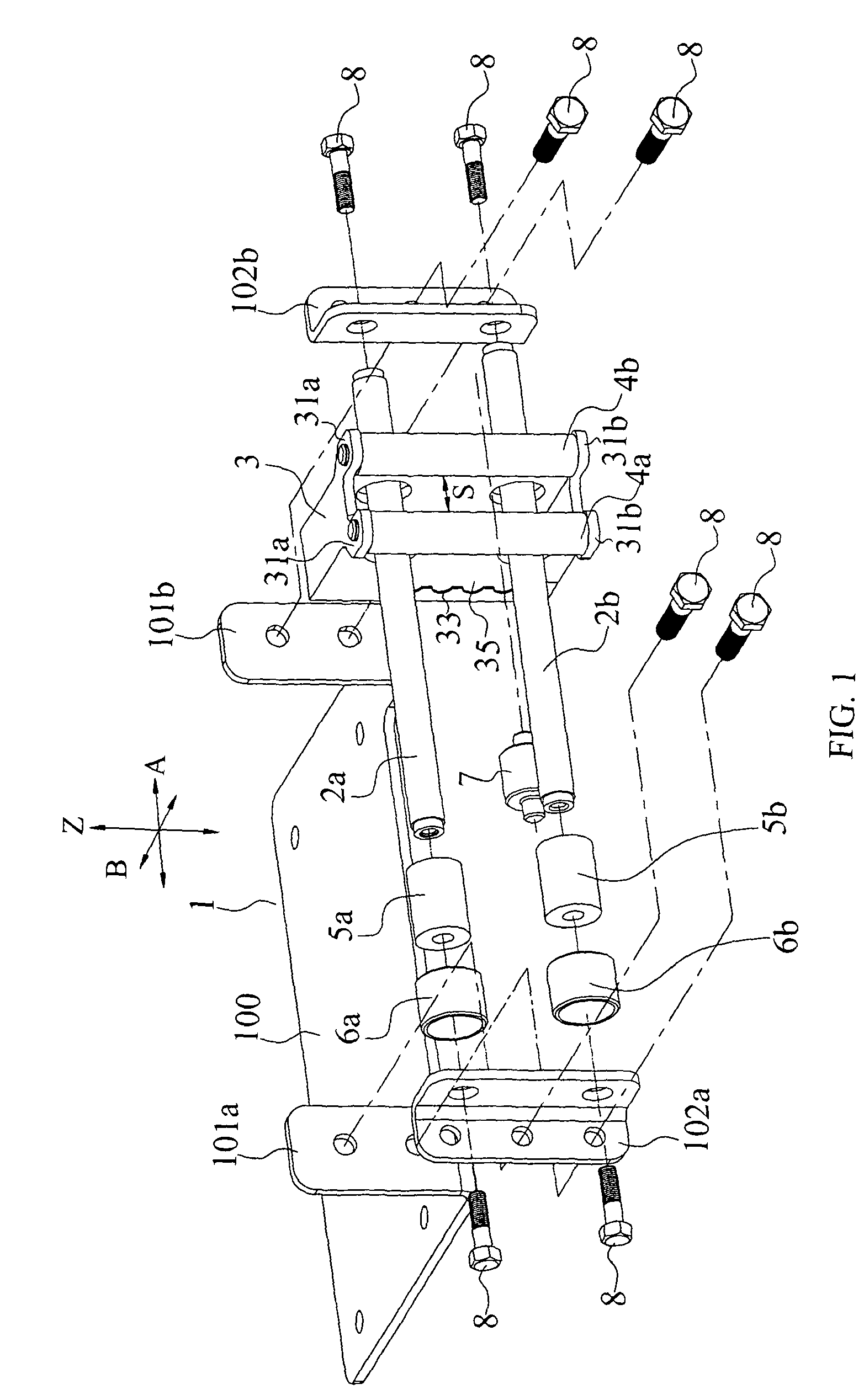

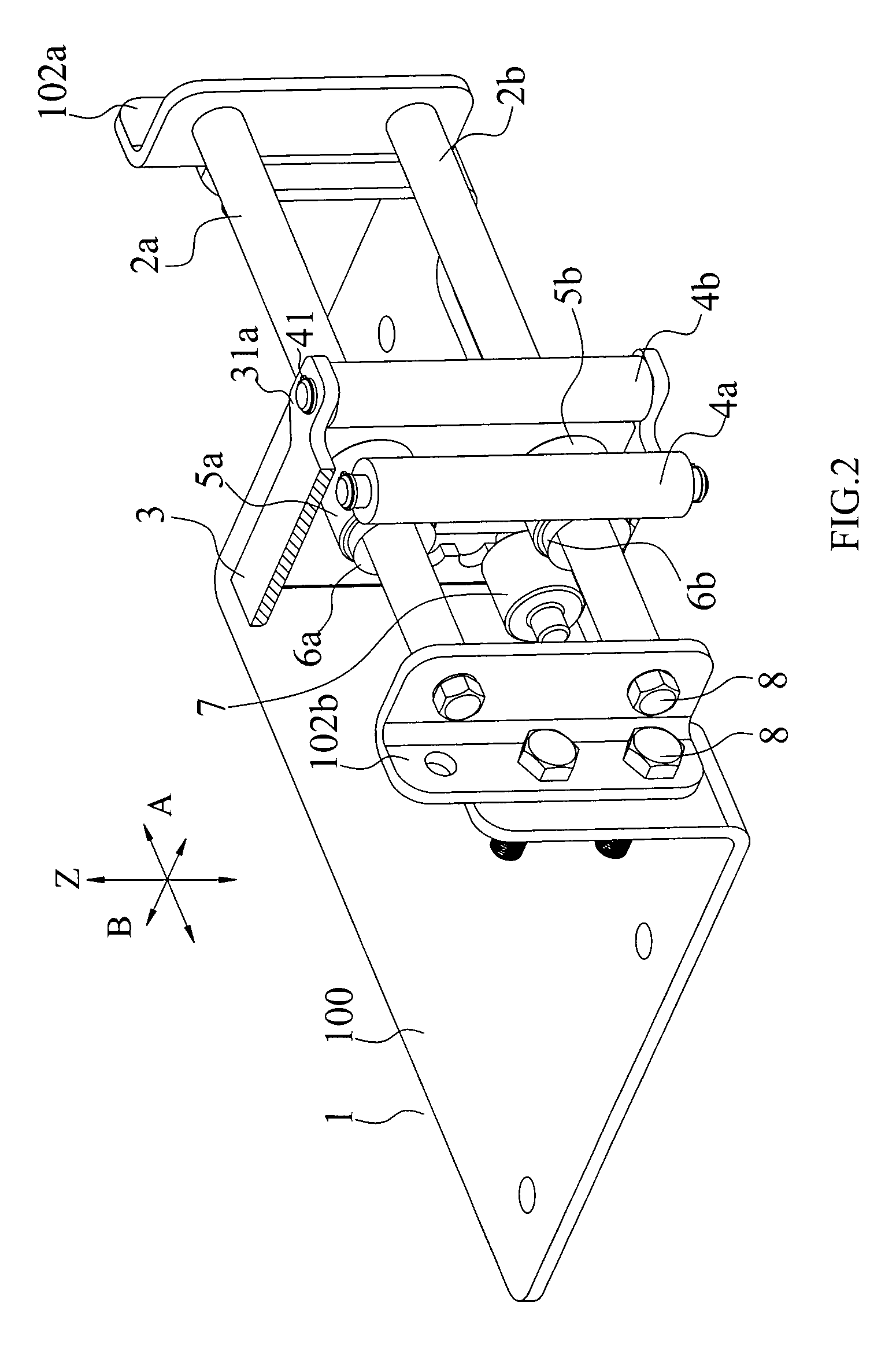

Cable guiding device

Owner:HANGZHOU TIANMING TECH CO LTD

Cable guiding device

Owner:HANGZHOU TIANMING TECH CO LTD

Collapsible accessory platform for a child's playard

A foldable frame for supporting a bassinet for fitment on a child's playard comprising a pair of longitudinally extending upper frame rails connected at each end to a one of pair of transversely extending end members for pivotal movement about the transverse axis. A longitudinally extending lower frame rail is connected at each end to the respective end members and spaced apart from the upper frame rails. The length of the lower frame may be adjusted enabling the end members to pivot inwardly from an unfolded position toward a folded position and reduce the spacing between the upper and lower frame rails. The upper frame rails further include a wing pivot at each end member connection which are aligned to allow the upper frame rails to pivot about a longitudinal axis and reduce the frame width when the frame is folded, but do not allow pivoting when the frame is unfolded.

Owner:ARTSANA USA

Telecommunication cable equipped with tight-buffered optical fibers

ActiveUS8494326B2Reduce installationClosely guardedOptical fibre with multilayer core/claddingFibre mechanical structuresFiberTelecommunications cable

Owner:PRYSMIAN SPA

Wear-resistant boride composites with high percentage of reinforcement phase

ActiveUS7517375B2Improve wear resistanceLow overall lengthPigmenting treatmentOther chemical processesBorideCeramic composite

A highly wear resistant sintered, hot pressed, or otherwise compacted ceramic composite material is described, consisting of two discrete phases of the form AlxMgyB14 where x and y ≦1 or like hard, orthorhombic compounds, and TiB2 or like Group IVB transition metal di-borides, and with an unexpectedly high content of transition metal di-boride in the range from 40 to 90 percent (28 to 85 volume percent).

Owner:IOWA STATE UNIV RES FOUND

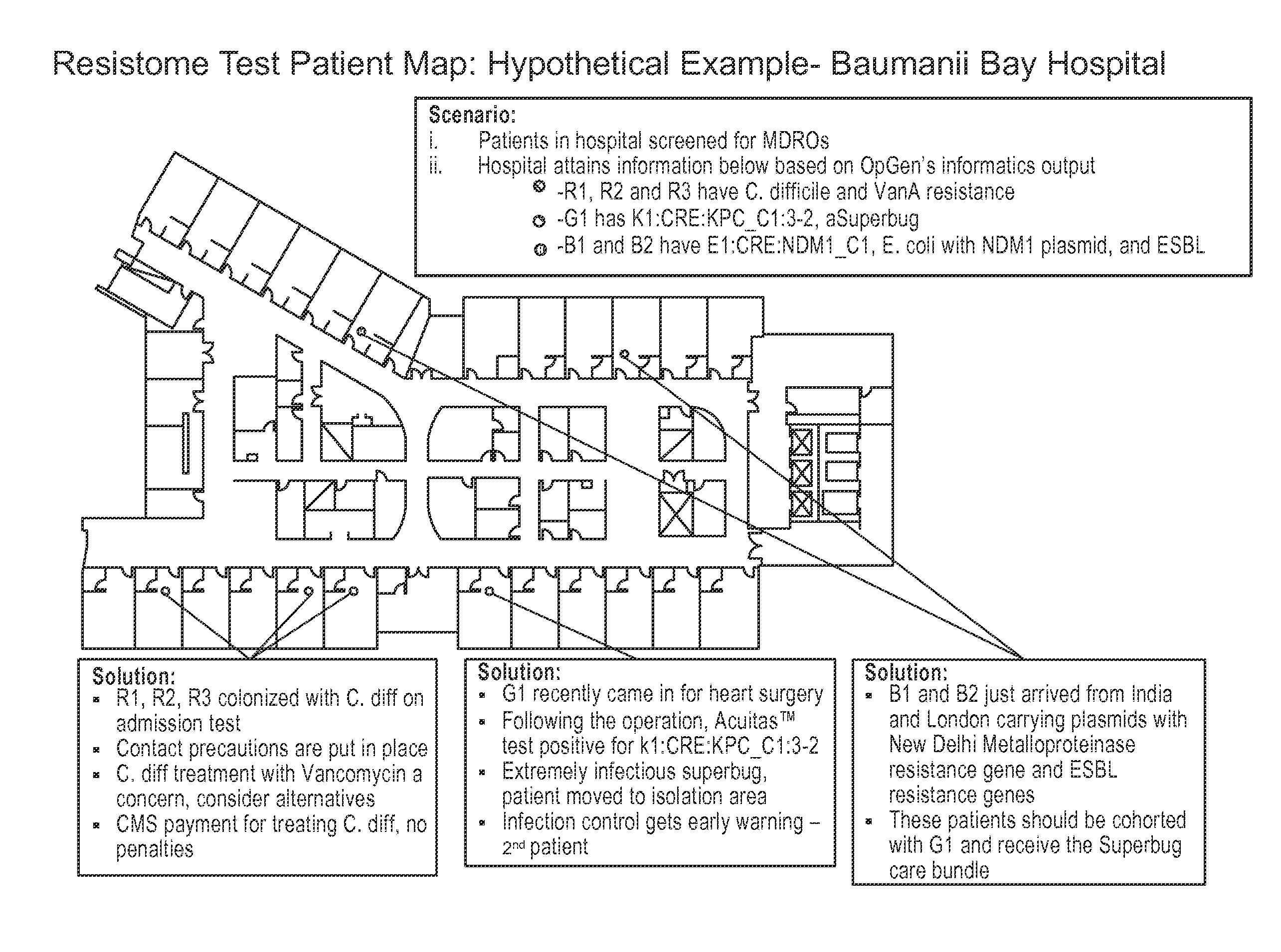

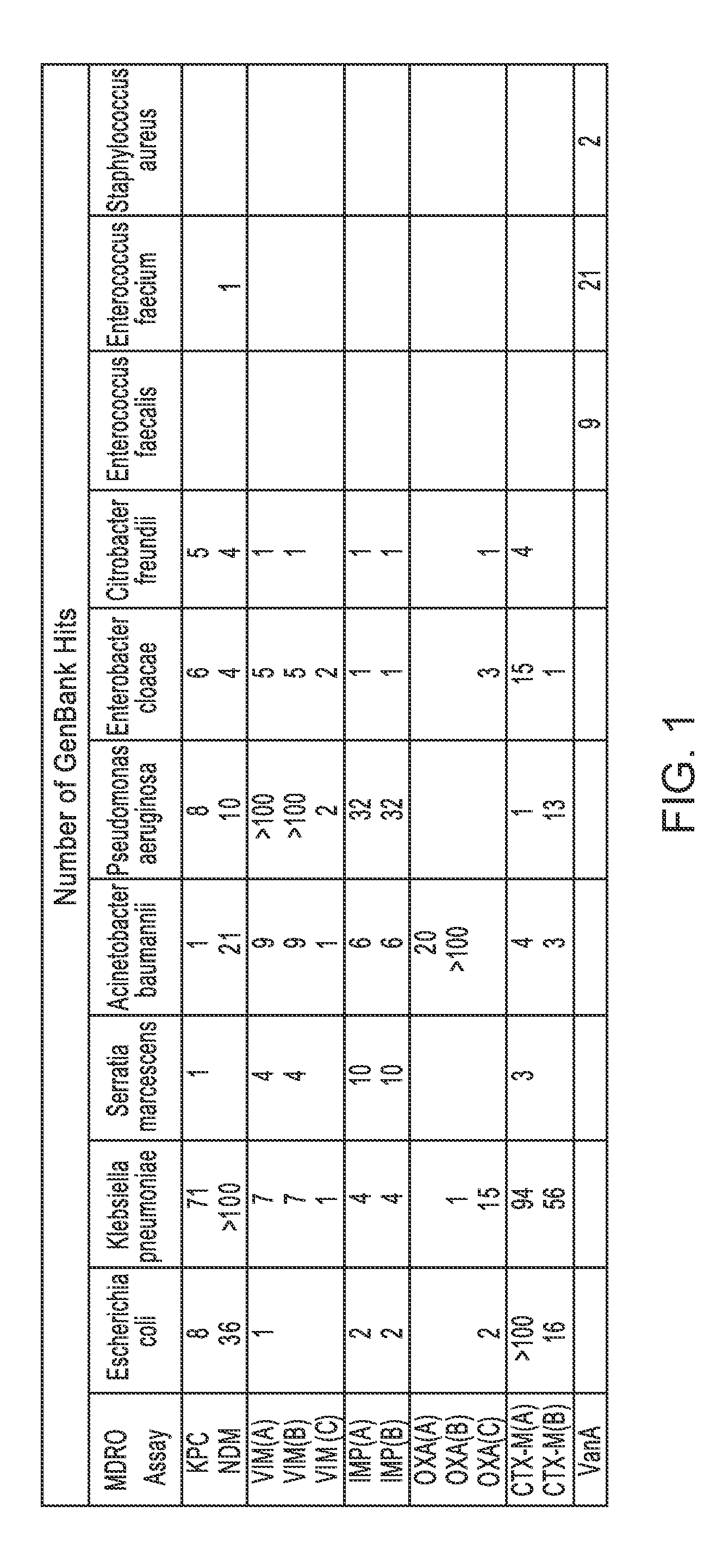

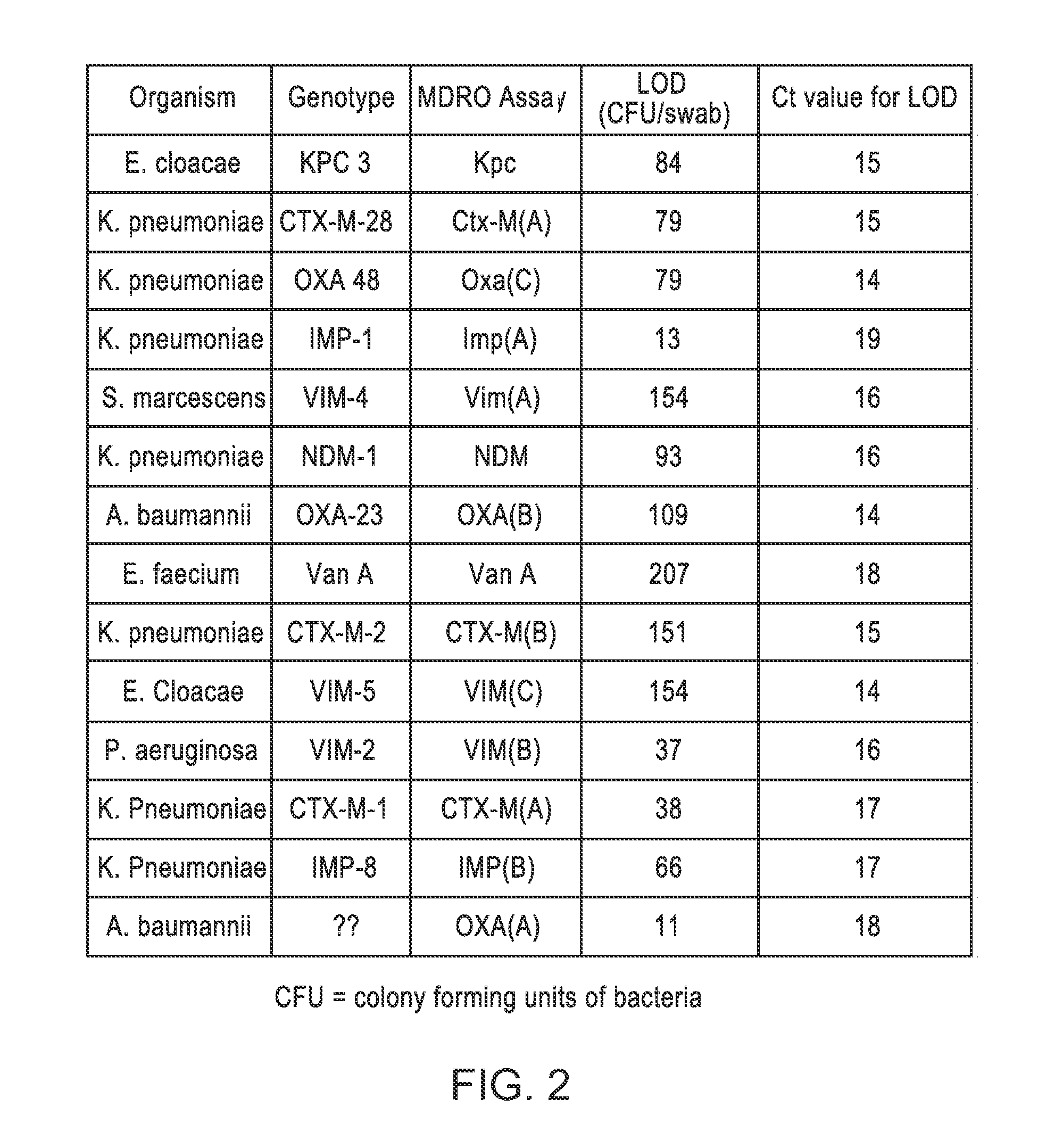

Methods of detecting multi-drug resistant organisms

InactiveUS20150259729A1Low overall lengthLow costDrug and medicationsMicrobiological testing/measurementMulti-Drug Resistant OrganismDrug resistance

The present invention provide methods using genes associated with multi-drug resistance for rapidly detecting a patient colonized or infected with an multi-drug resistant organism and administrating the appropriate precautions and / or treatment.

Owner:OPGEN INC

Bi-axially collapsible frame for a bassinet

ActiveUS9675182B2Low overall lengthLength of may varyKids bedsCradleEngineeringMechanical engineering

Owner:ARTSANA USA

Method for welding workpieces made of highly heat-resistant superalloys, including a particular mass feed rate of the welding filler material

InactiveUS9035213B2Improve cooling effectIncrease chanceTurbinesEngine manufactureHeat resistanceRelative motion

A welding method for welding workpieces made of highly heat-resistant superalloys is provided. The method includes generating a heat input zone on the workpiece surface by means of a heat source, feeding welding filler material into the heat input zone by means of a feeding device, and generating a relative motion between the heat source and the feeding device on one hand and the workpiece surface on the other hand by means of a conveying device. Furthermore, according to the welding method, the mass feed rate is ≦350 mg / min.

Owner:SIEMENS AG +1

Textured surfaces for display applications

ActiveUS20180059309A1Improve viewing angleReduce releaseMechanical apparatusDiffusing elementsLight guideDisplay device

A substrate with a textured surface is disclosed. The substrate may be, for example, a light emitter comprising a light guide, for example a backlight element for use in a display device, wherein a surface of the light guide, for example a glass substrate, is configured to have a textured surface with a predetermined RMS roughness and a predetermined correlation length of the texture. A plurality of light scatter suppressing features can be provided on the textured surface. Textured surfaces disclosed herein may be effective to reduce electrostatic charging of the substrate surface. Methods of producing the textured surface are also disclosed.

Owner:CORNING INC

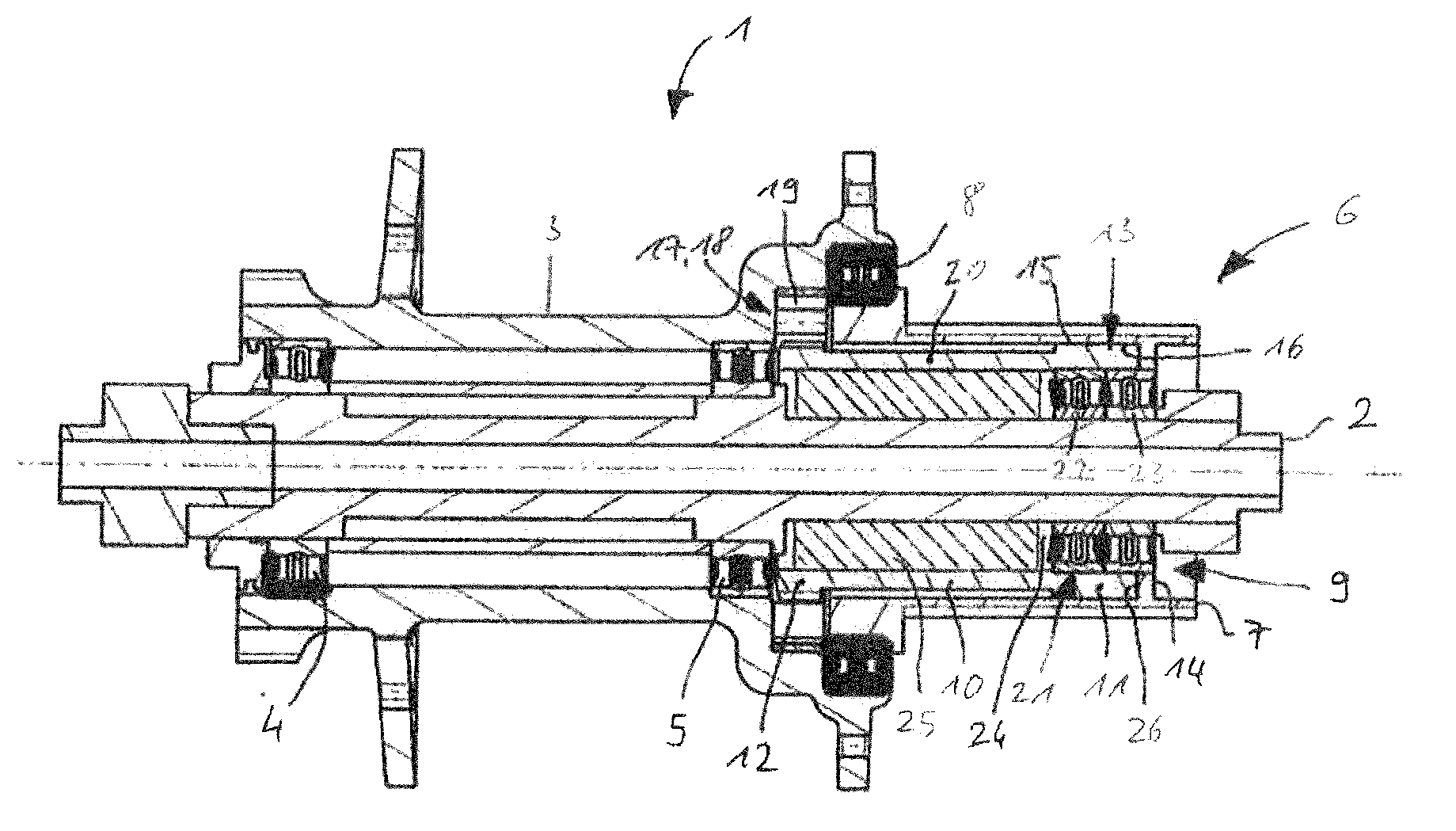

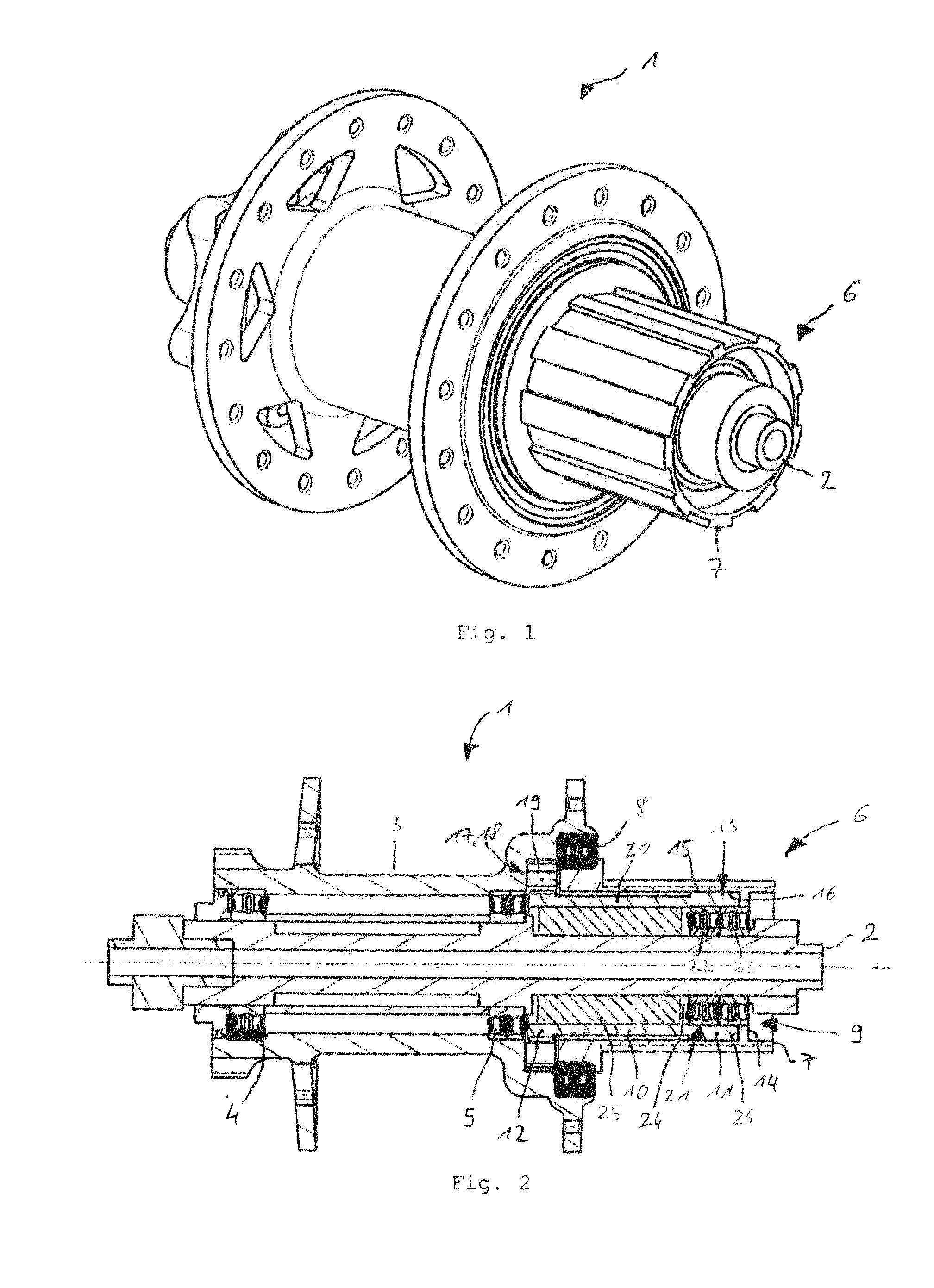

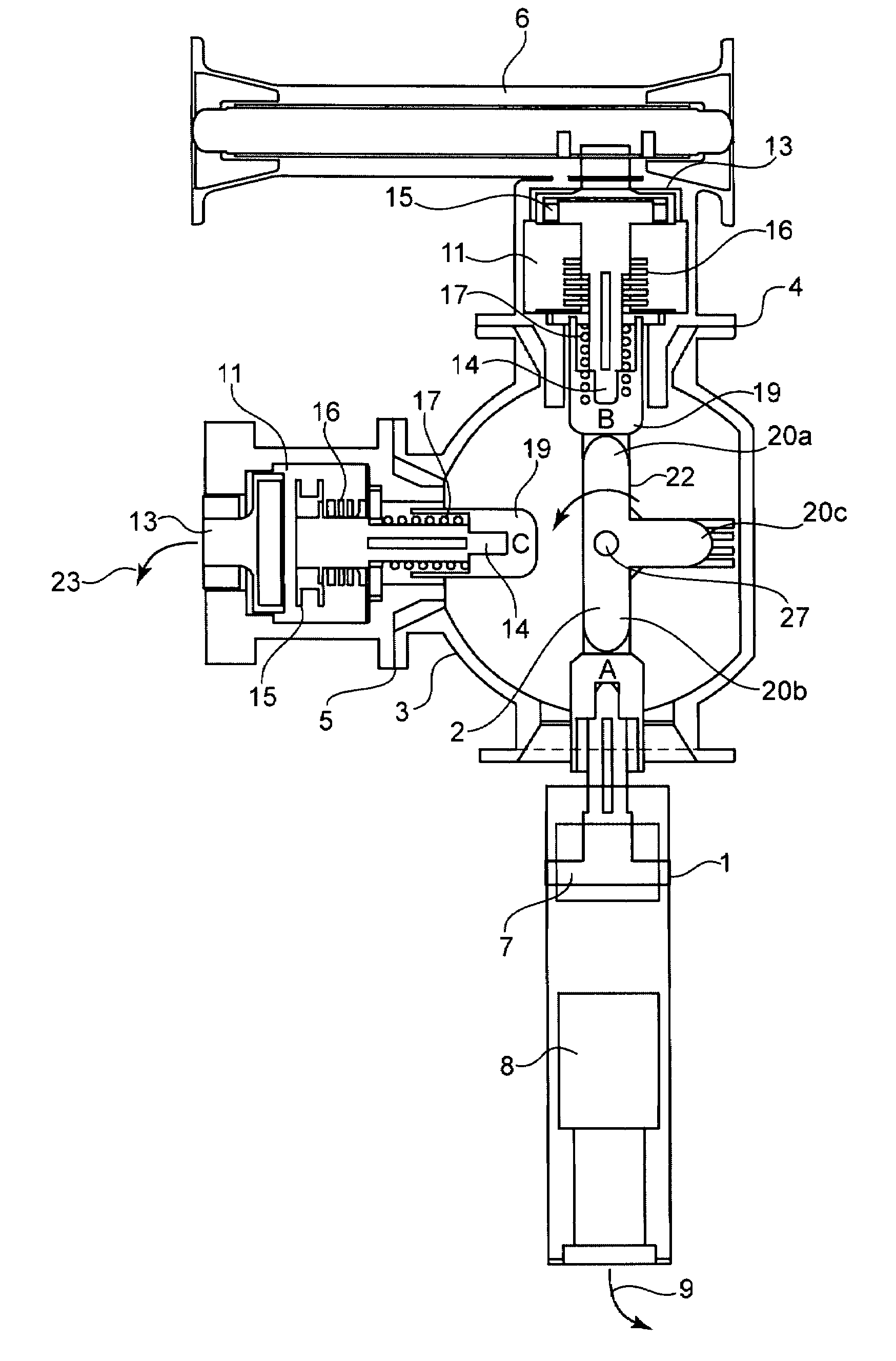

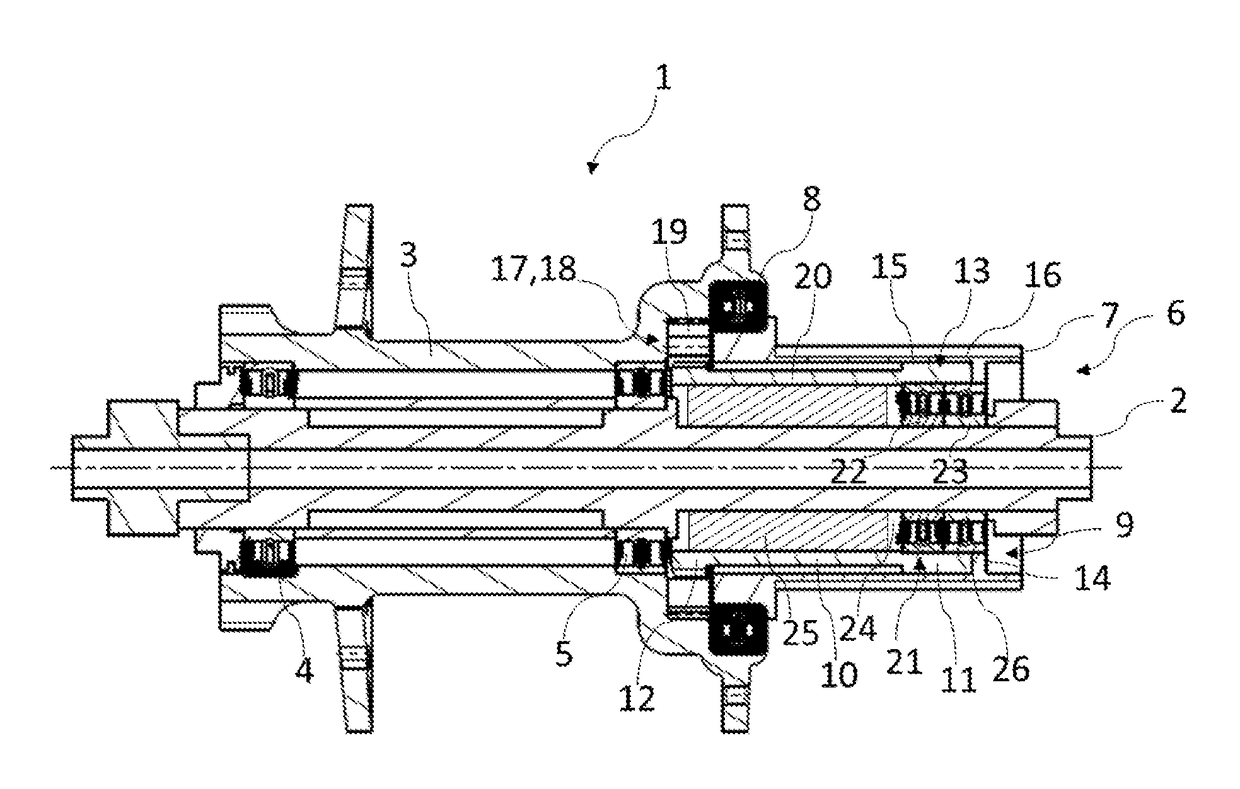

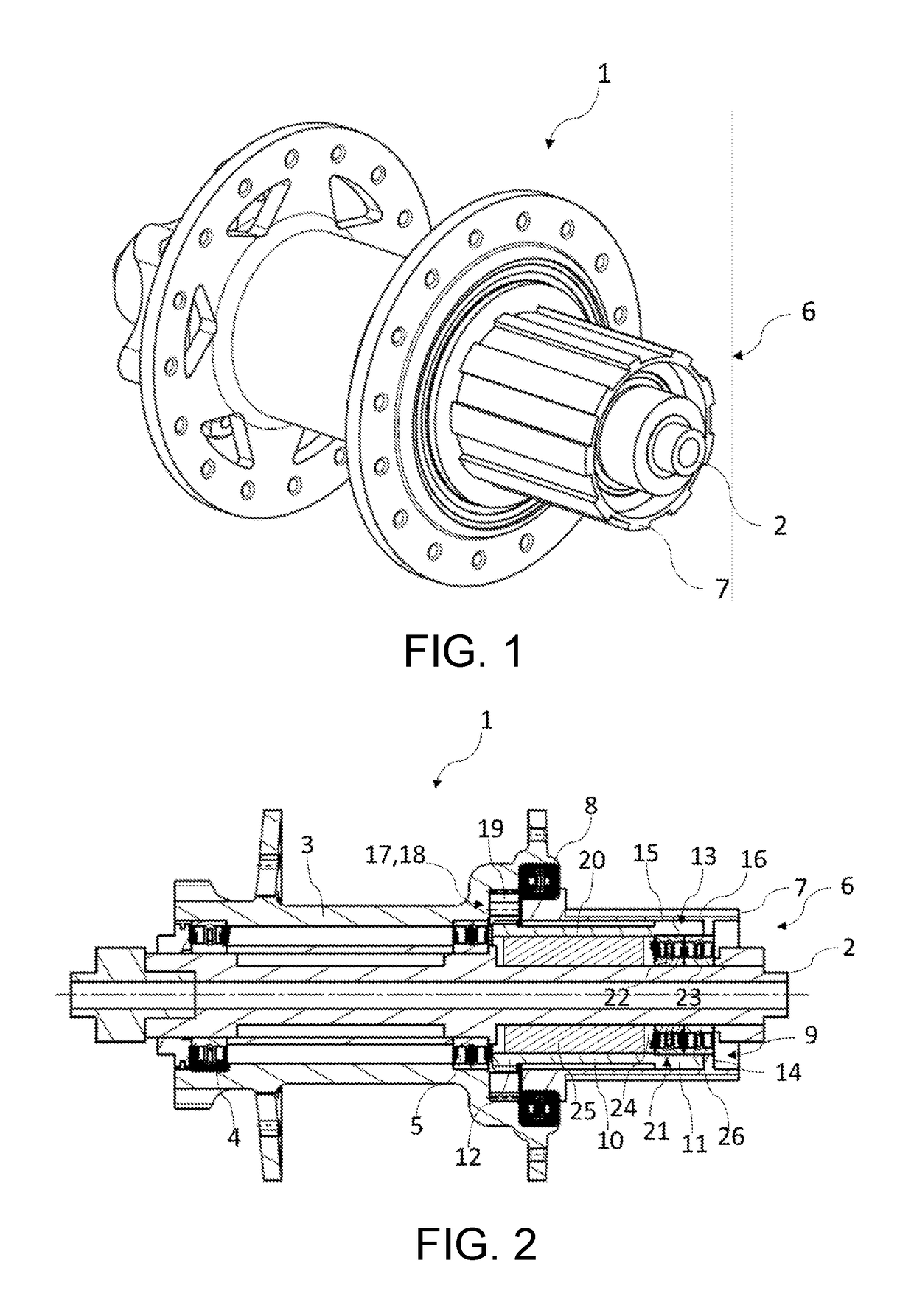

Wheel hub transmission unit for a drive wheel of a vehicle, drive wheel, and vehicle having an auxiliary drive

A wheel hub transmission unit for a drive wheel of a vehicle is provided. The wheel hub transmission unit includes a wheel axle, a pinion hub carrier concentrically arranged with respect to the wheel axle, a pinion mounted in a torsionally rigid manner onto said pinion hub carrier and configured to drive the drive wheel, and a torque transmission device having a transmission sleeve. The transmission sleeve is made from a magnetically coded material and includes a measuring area that is utilized to measure a torque by utilizing magnetic properties of the magnetically coded material of the transmission sleeve. An annular space is radially provided between the transmission sleeve and the wheel axle in the measuring area with a sensor coil being accommodated therein, the annular space being axially accessible from outside the transmission sleeve.

Owner:FAZUA GMBH

Process for dry-grinding a polysaccharide derivative

ActiveUS8973853B2Short dissolution rateEnergy optimizationGrain treatmentsMetallurgyPhysical chemistry

In a process for producing a particulate polysaccharide derivative by dry-grinding a moist polysaccharide derivative, one or more of the properties selected from median diameter, median length, bulk density and dissolution rate is controlled by controlling the temperature of the polysaccharide derivative prior to dry-grinding. Advantageously one or more of the properties selected from median diameter, median length, bulk density and dissolution rate of the particles after dry-grinding is adjusted to a first value by a first temperature of the polysaccharide derivative prior to dry-grinding and is adjusted to a second value by a second temperature.

Owner:NUTRITION & BIOSCIENCES USA 1 LLC +1

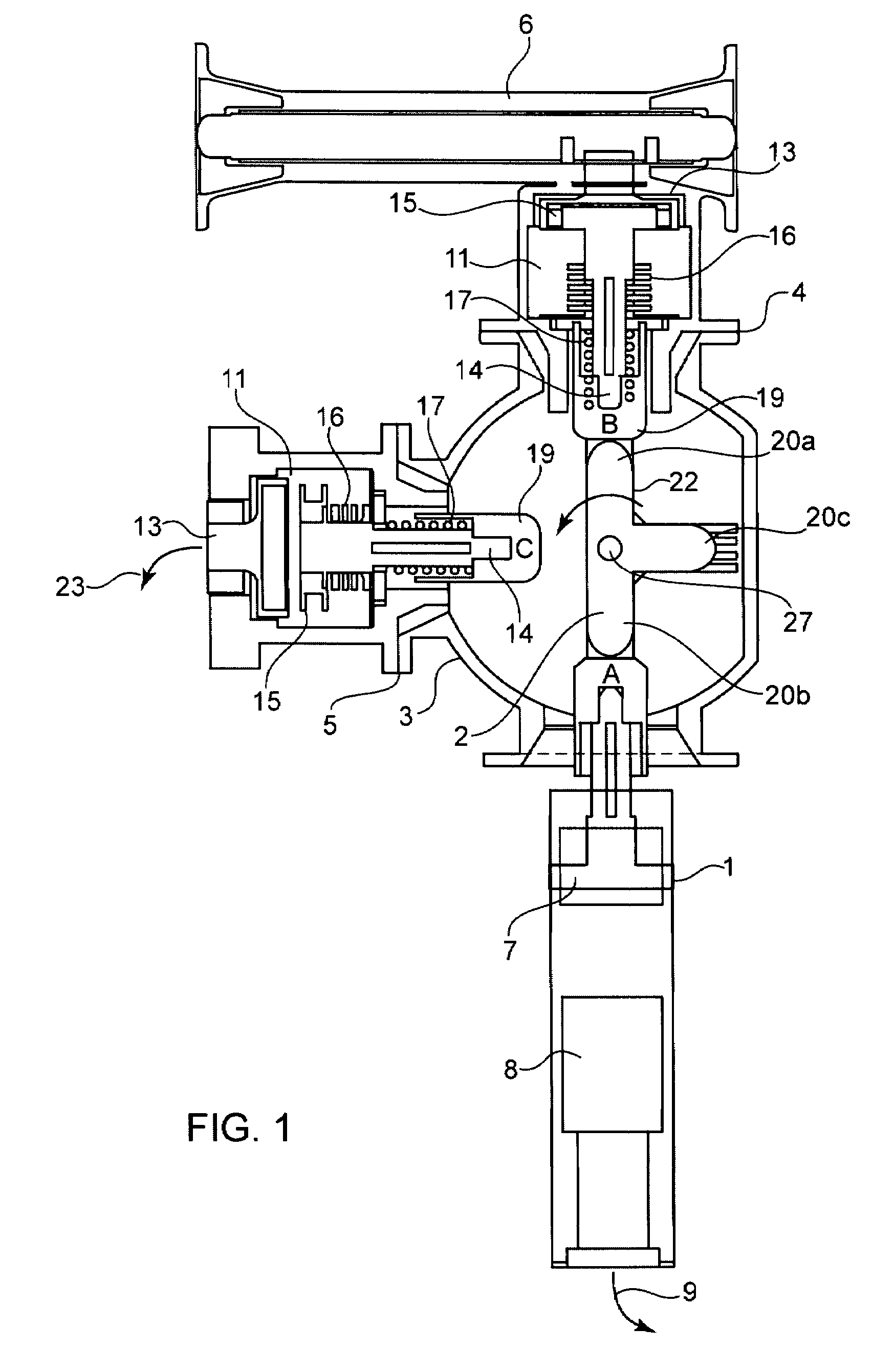

Electrical switching system

ActiveUS7679019B2Compact structureLow overall lengthSwitchgear arrangementsHigh-tension/heavy-dress switchesElectrical connectionEngineering

An electrical switching system, preferably a medium-voltage switching system, has a power switch or load switch, a disconnecting switch, and a grounding switch configured as a vacuum switching chamber. Low separation distance lengths and a more compact construction of a switching system is achieved by means of a housing in which the disconnecting switch, configured as a vacuum switching chamber, the grounding switch, and the power switch or load switch are disposed, and in which a central switch is disposed, with which the vacuum switching chambers of disconnecting switch and grounding switch can be mechanically activated. Electrical connections between connector contacts of power switch or load switch, disconnecting switch, and grounding switch can be produced.

Owner:RAIL POWER SYST GMBH

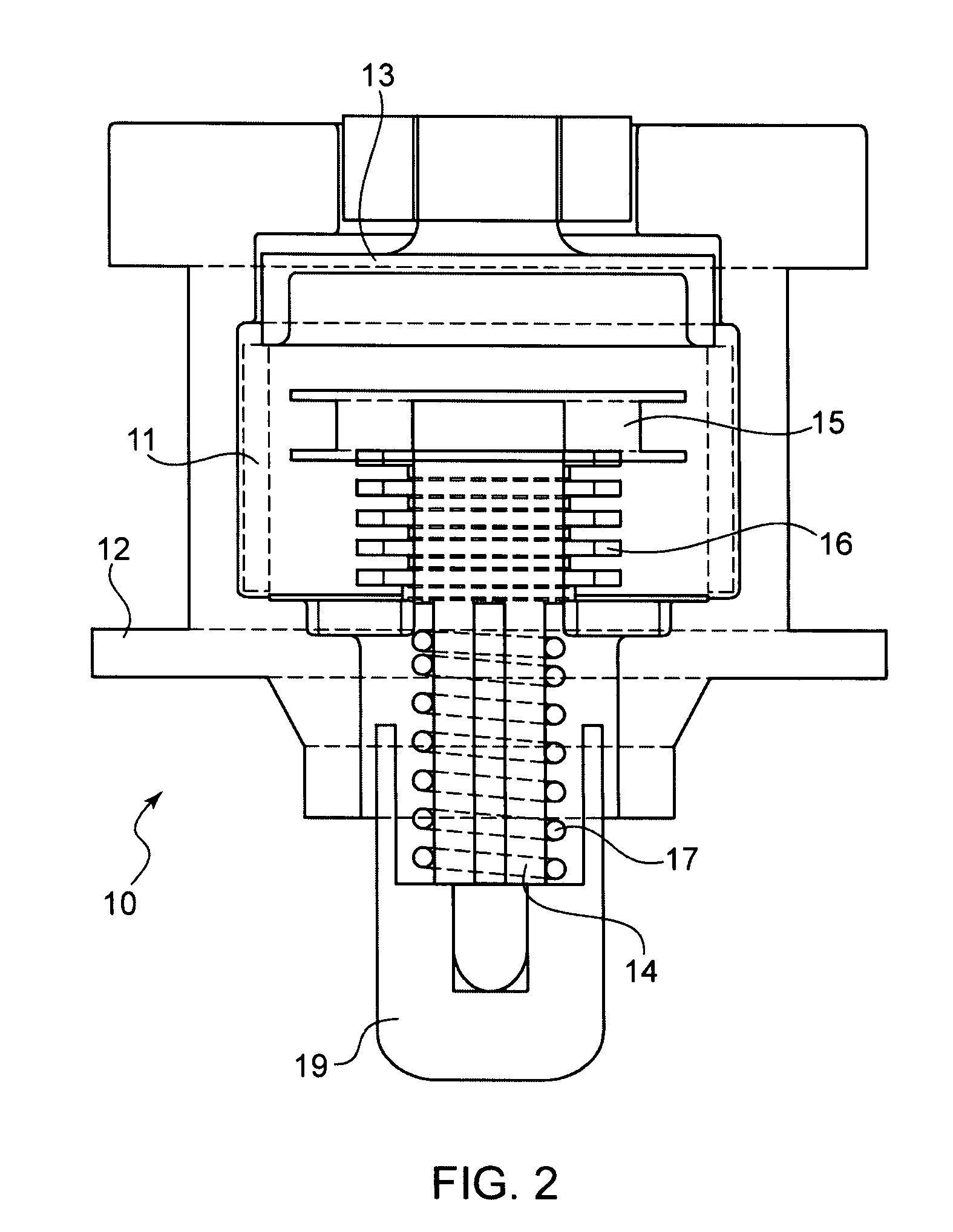

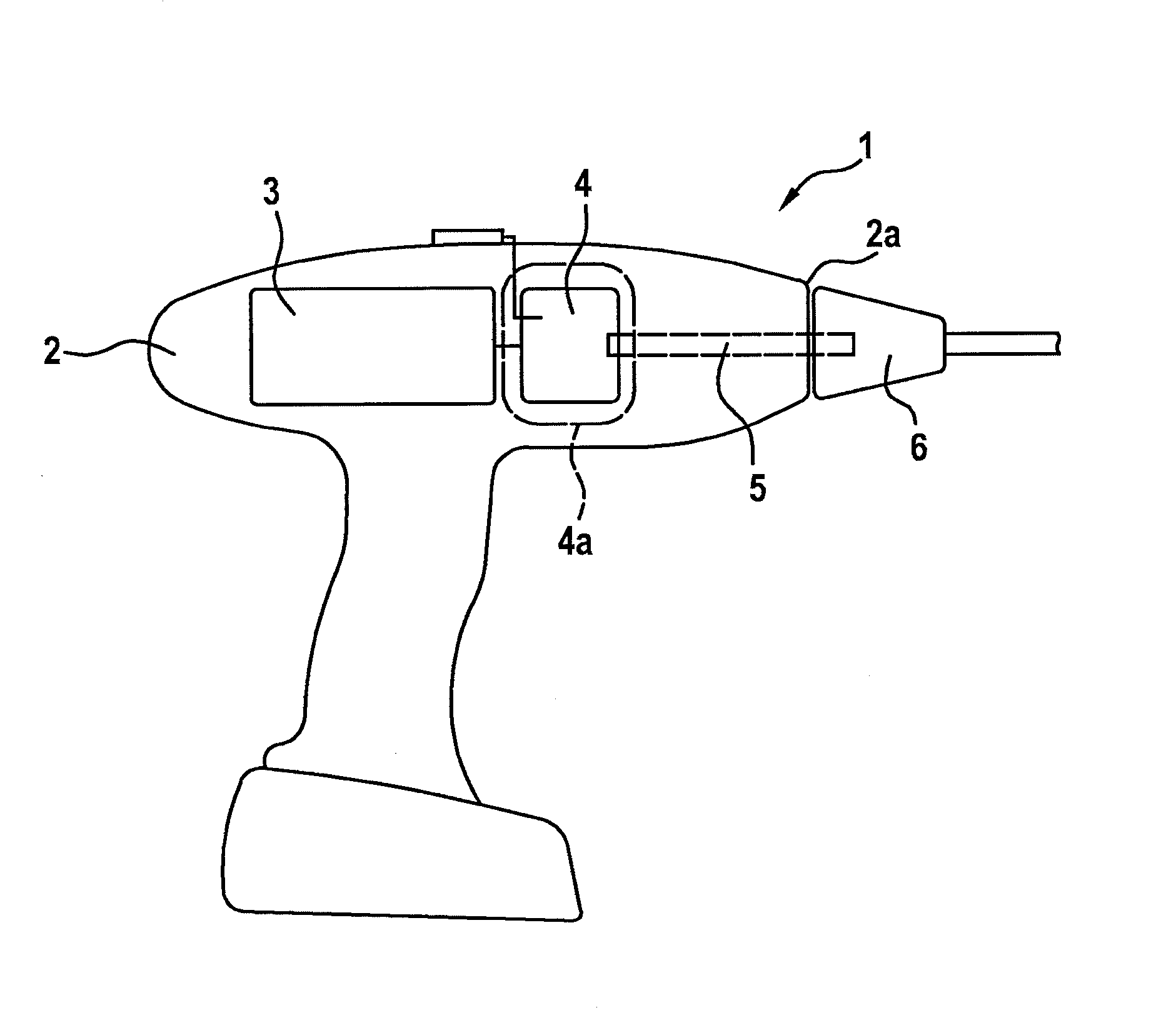

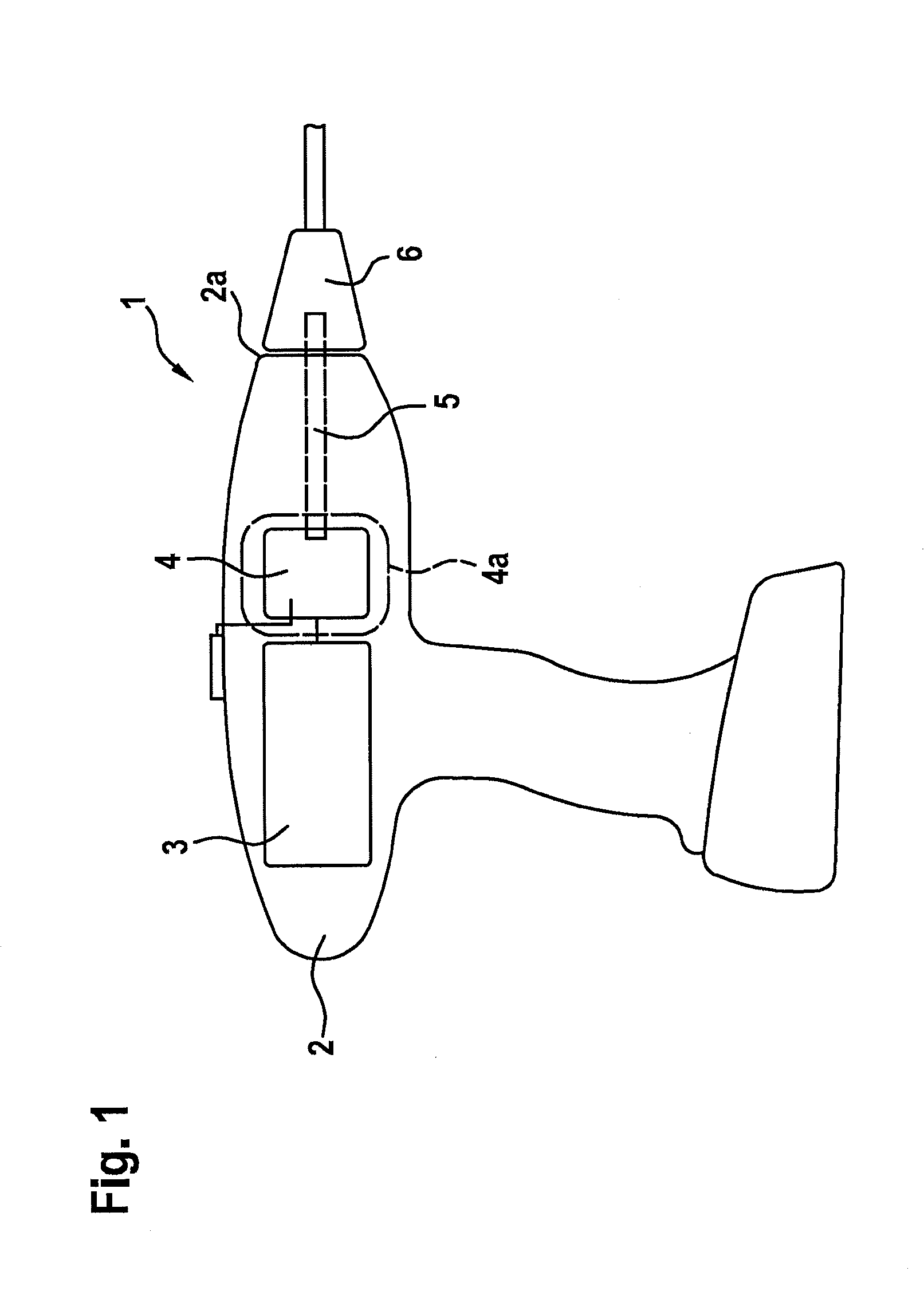

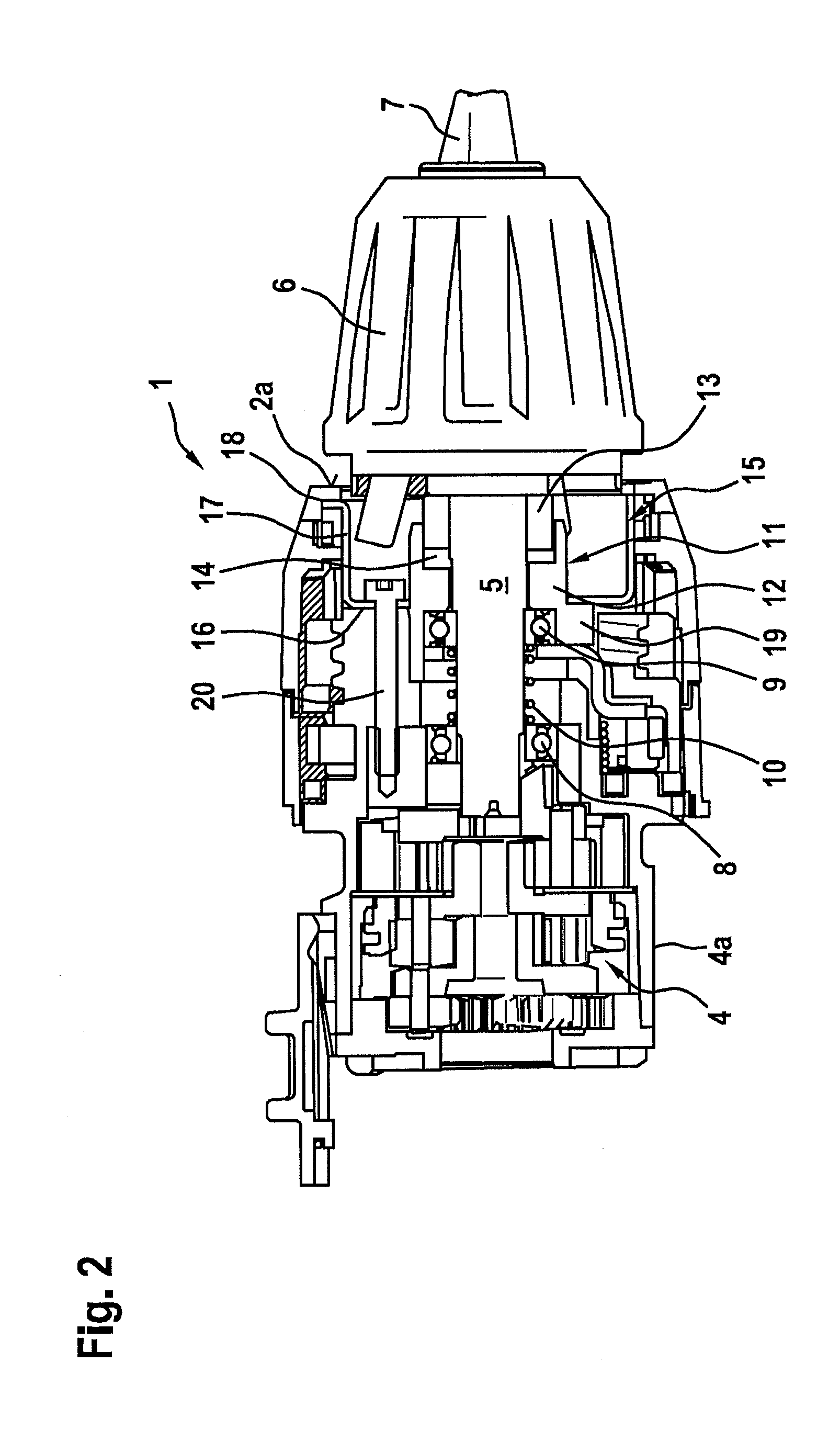

Handheld machine tool, in particular a hammer drill

ActiveUS20130248217A1Improve heat transfer performanceGood effectReciprocating drilling machinesConstructionsHand heldElectric machinery

A handheld machine tool has a drive motor for driving a tool holder, in which a tool is able to be accommodated. In addition, a cam-action mechanism for generating a hammer function is provided, which includes a cam-action mechanism holder and a notched disk. The cam-action mechanism holder is in contact with a heat-dissipating component situated inside the housing.

Owner:ROBERT BOSCH GMBH

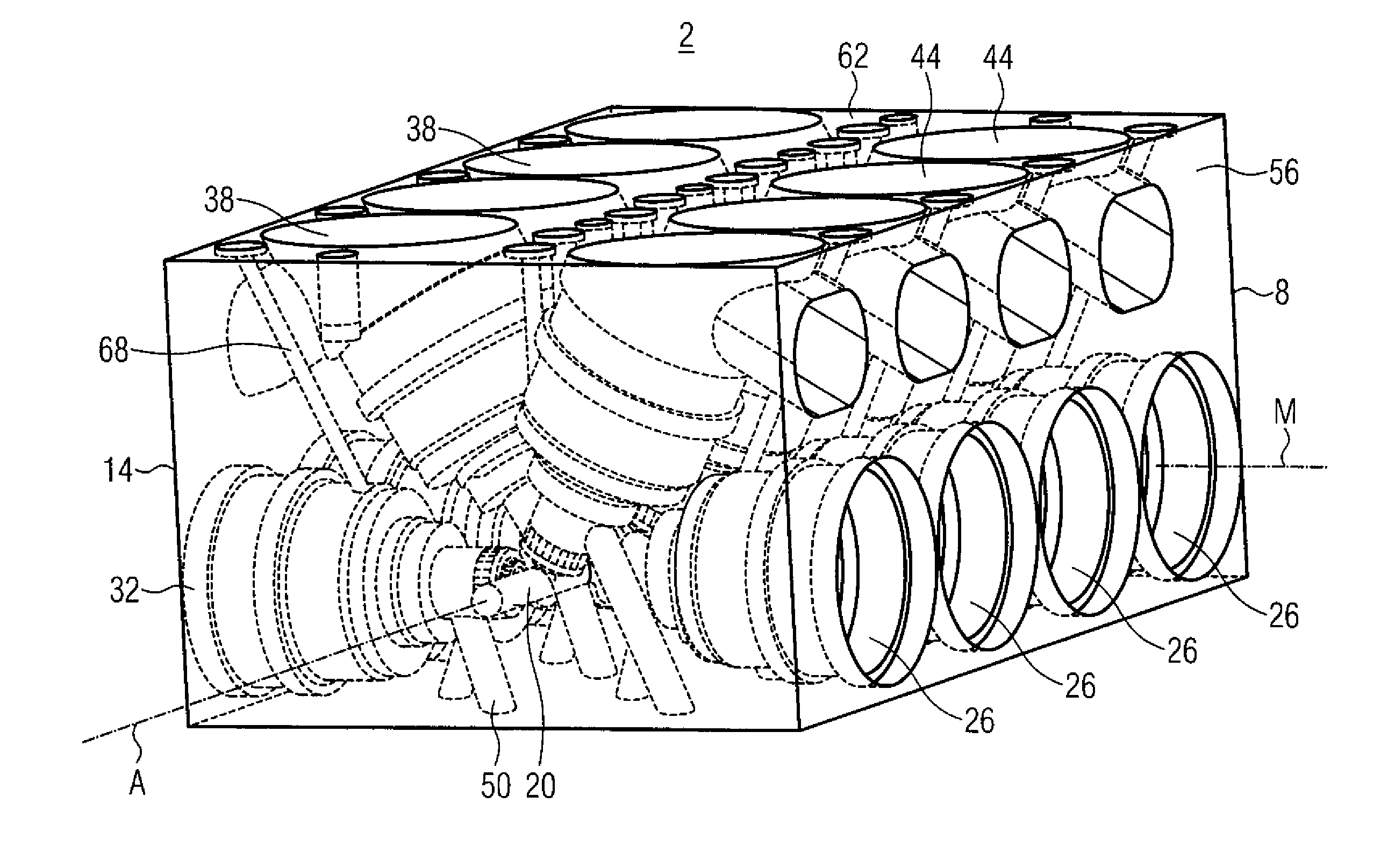

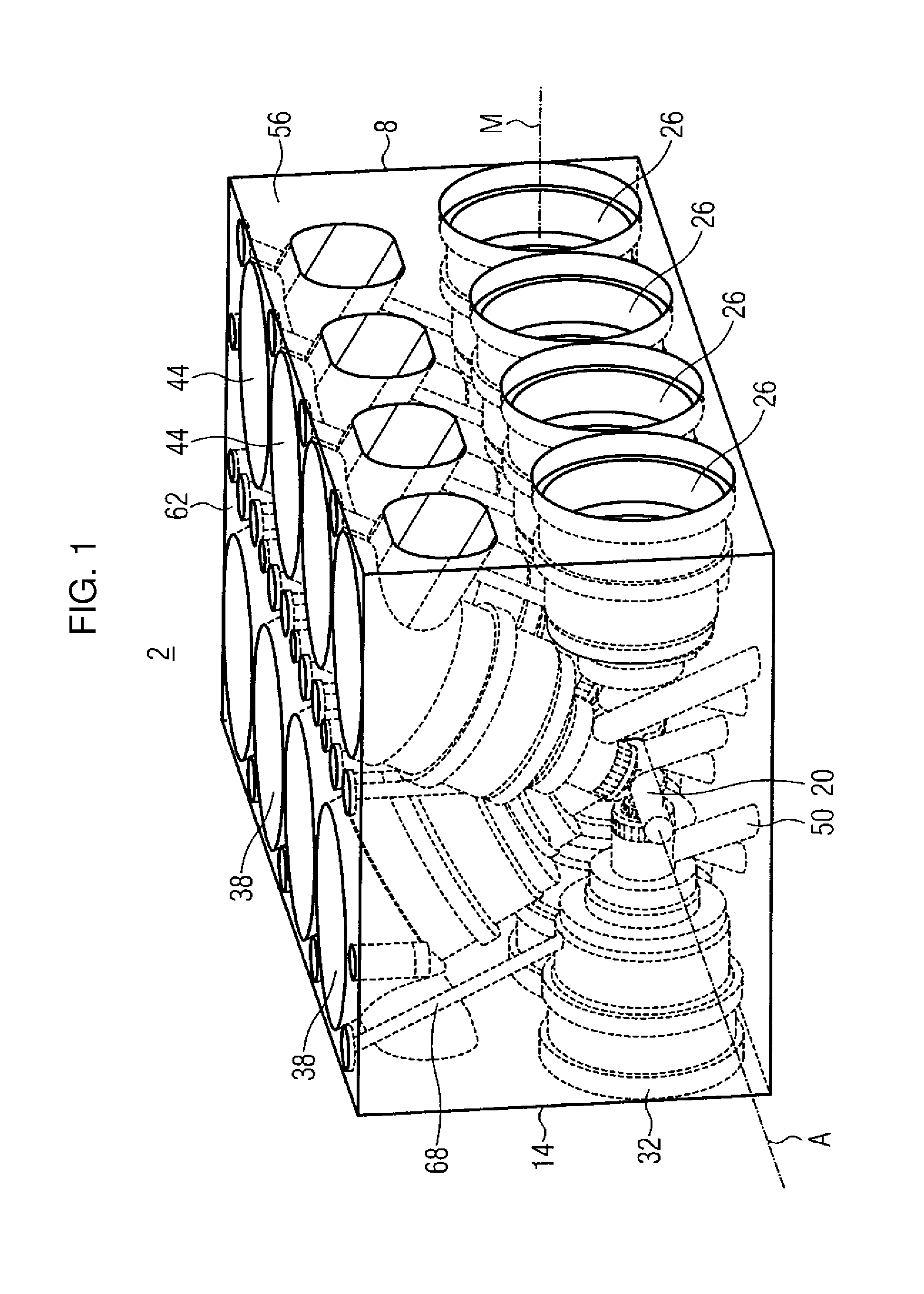

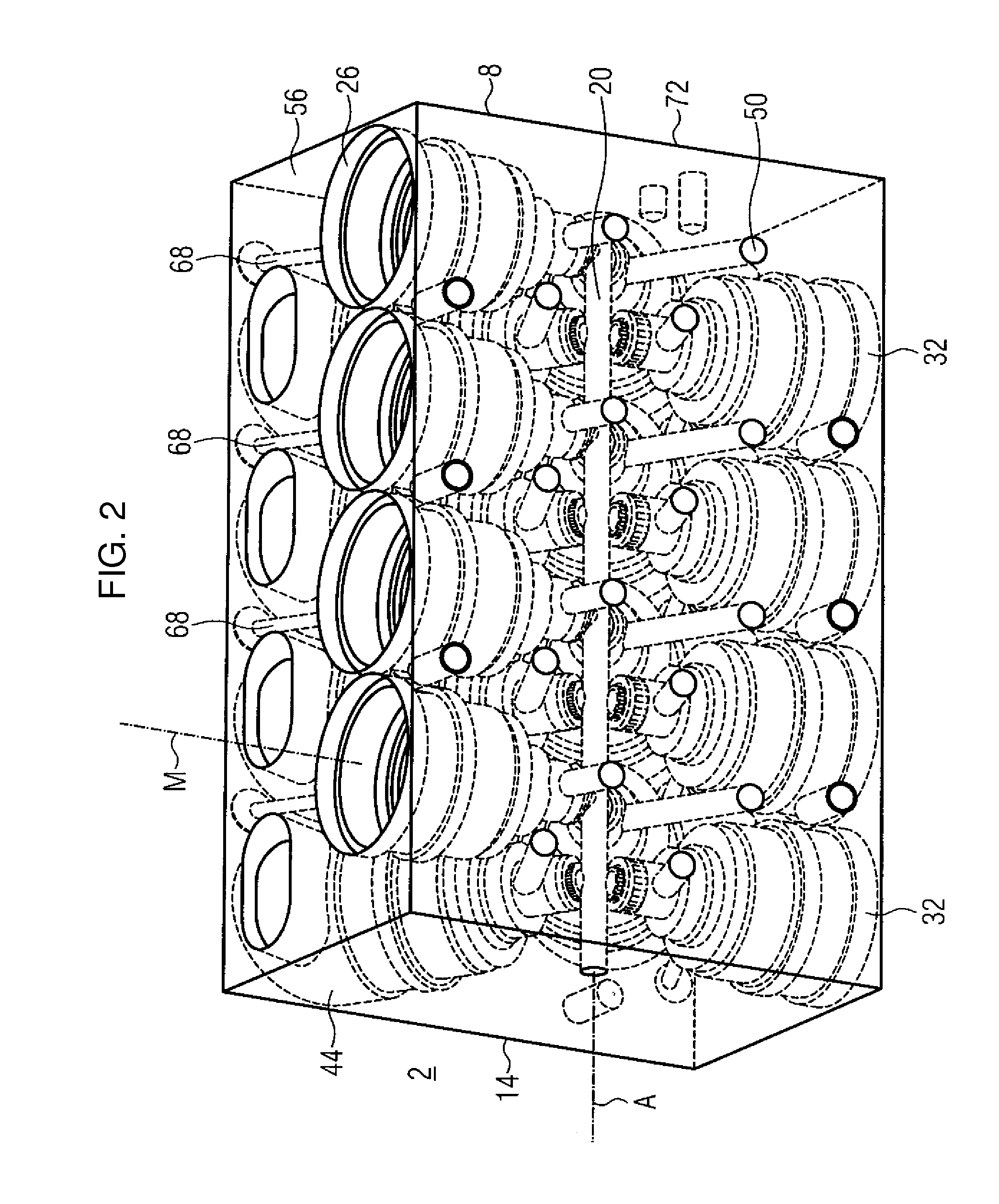

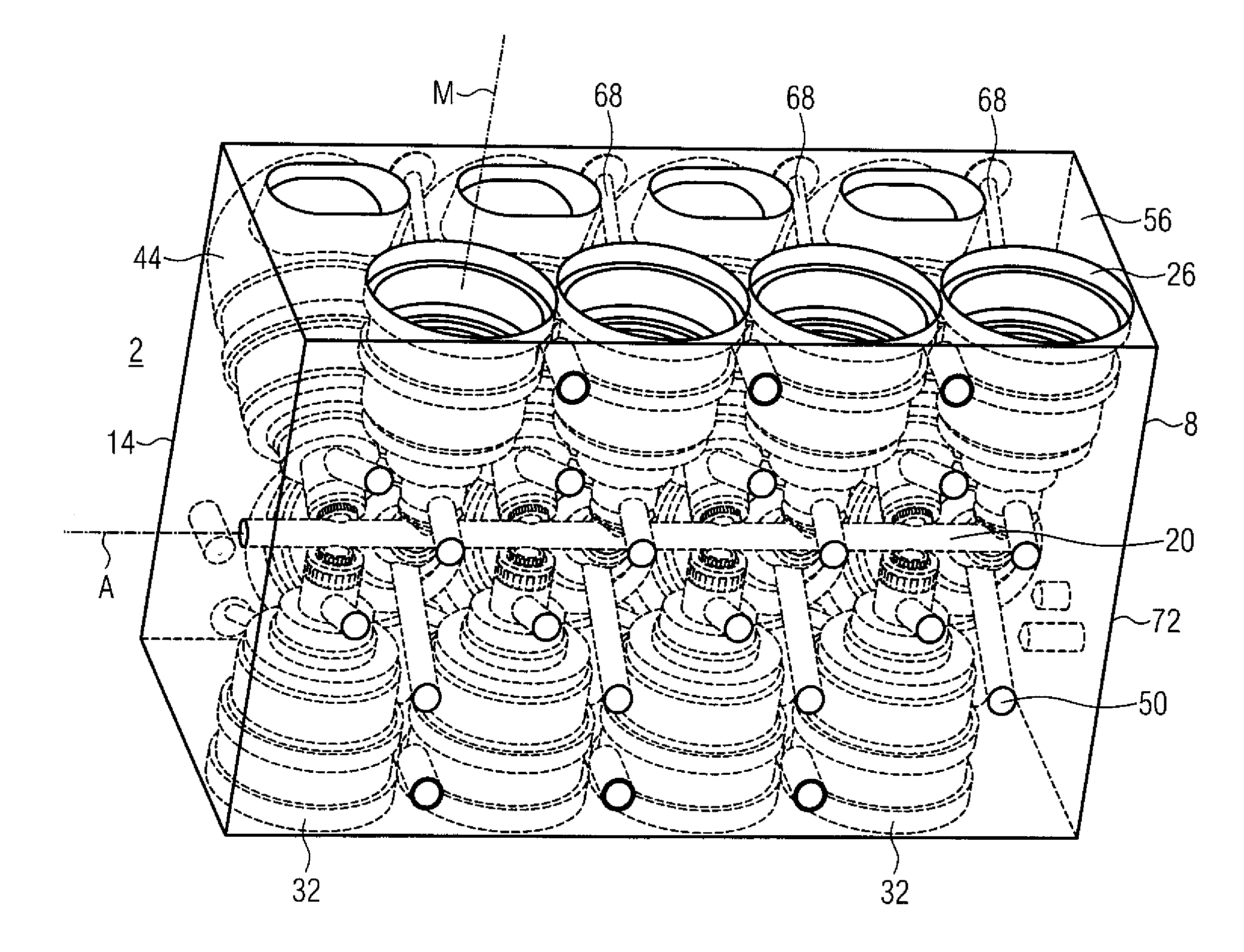

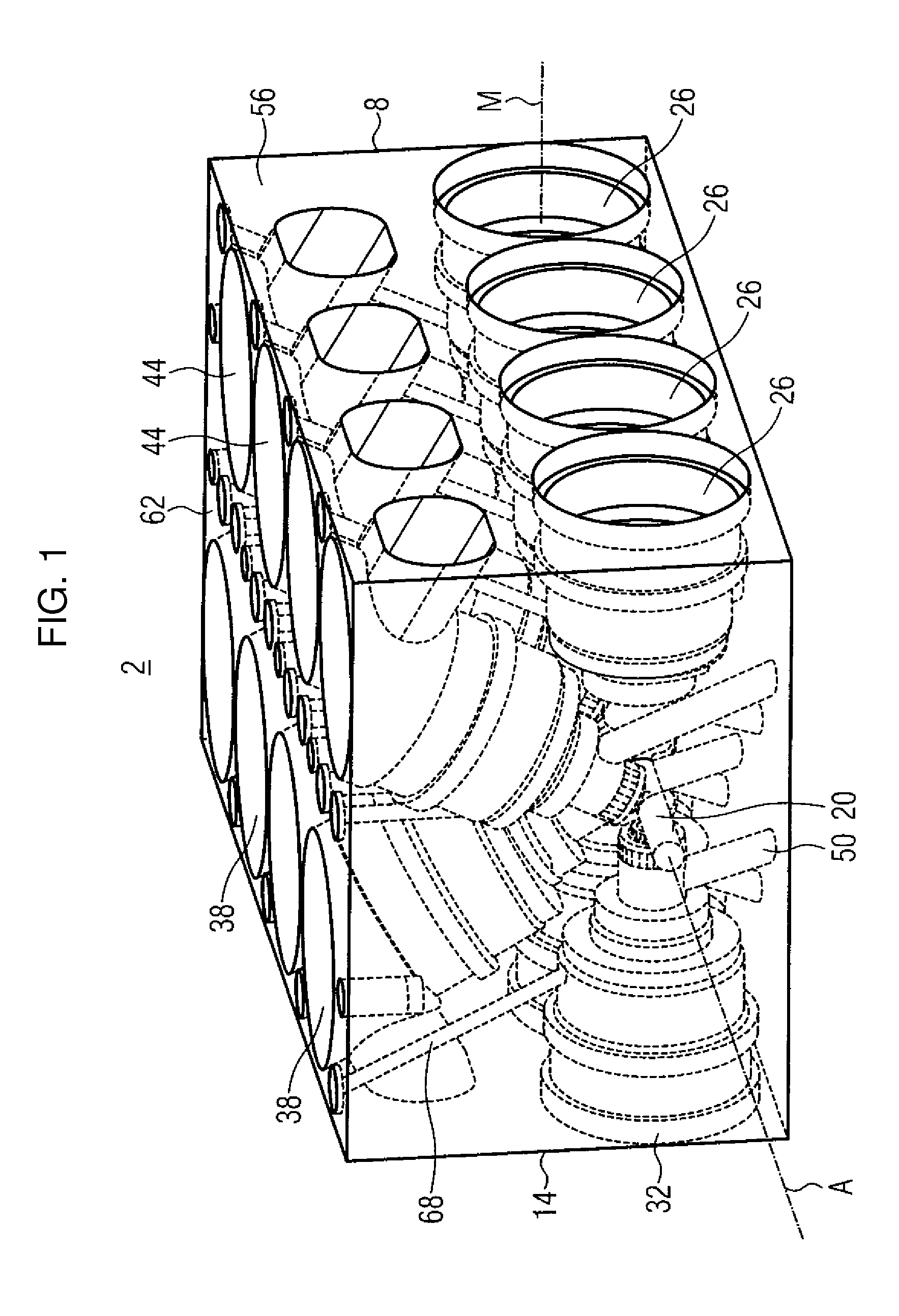

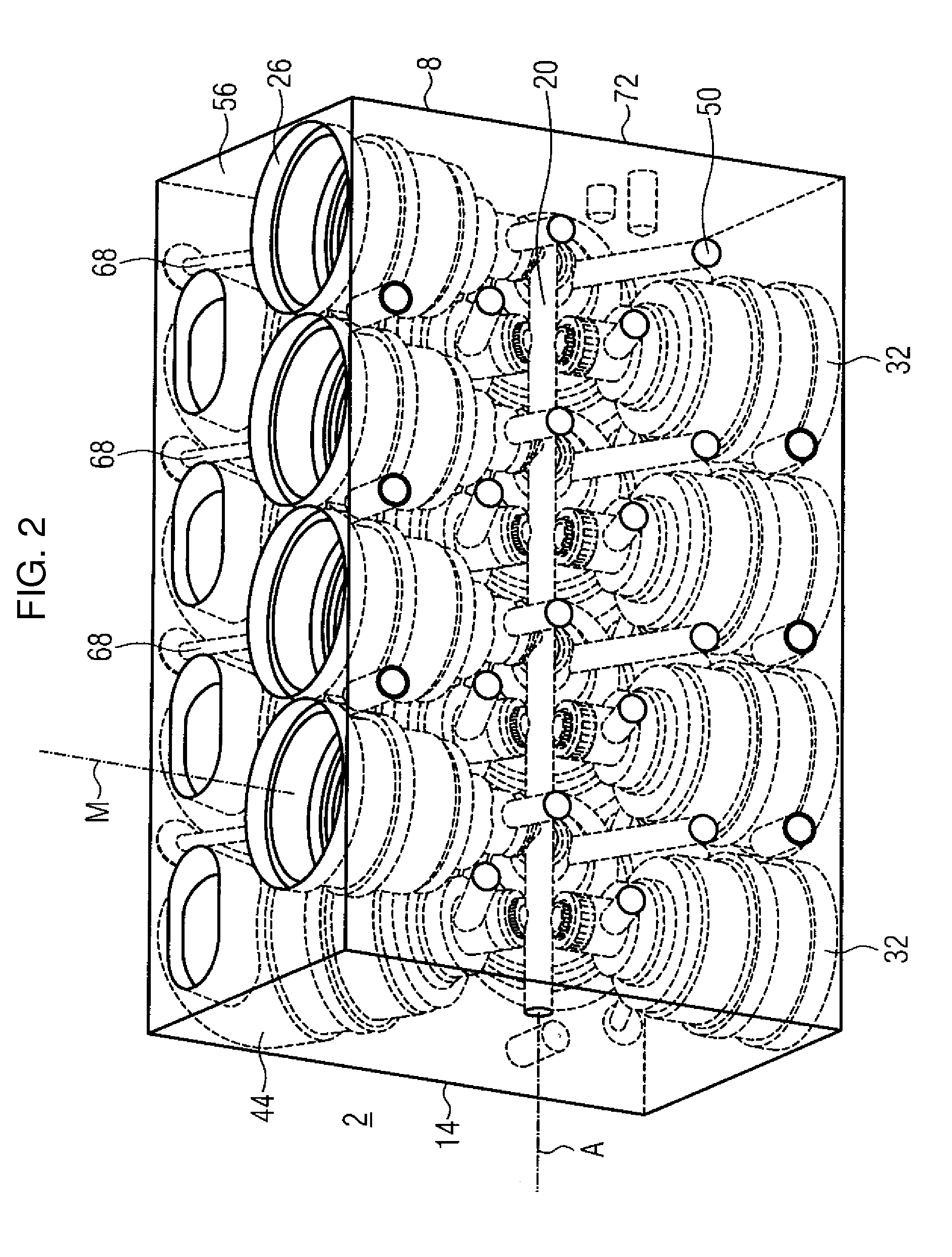

Color changer

InactiveUS20120055570A1Compact configurationLow overall lengthSpraying apparatusMultiple way valvesLine tubingEngineering

A color changer has a valve block for connecting a plurality of coating material lines to an application device. The valve block has a parallelepiped housing. The housing has a central color channel with an axial direction and contains valve bores for receiving valves and a length of a central color channel is as short as possible with a simultaneous supply of many paint feed lines. A first number of parallel valve bores open into the color channel at first openings, a second number of parallel valve bores open into the color channel at second openings on the opposite side of the color channel and offset in the axial direction with respect to the first number of valve bores. A third number of parallel valve bores open into the color channel at third openings and a fourth number of parallel valve bores open into the color channel at fourth openings.

Owner:LACTEC

Method and apparatus for welding workpieces of high-temperature superalloys

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV +1

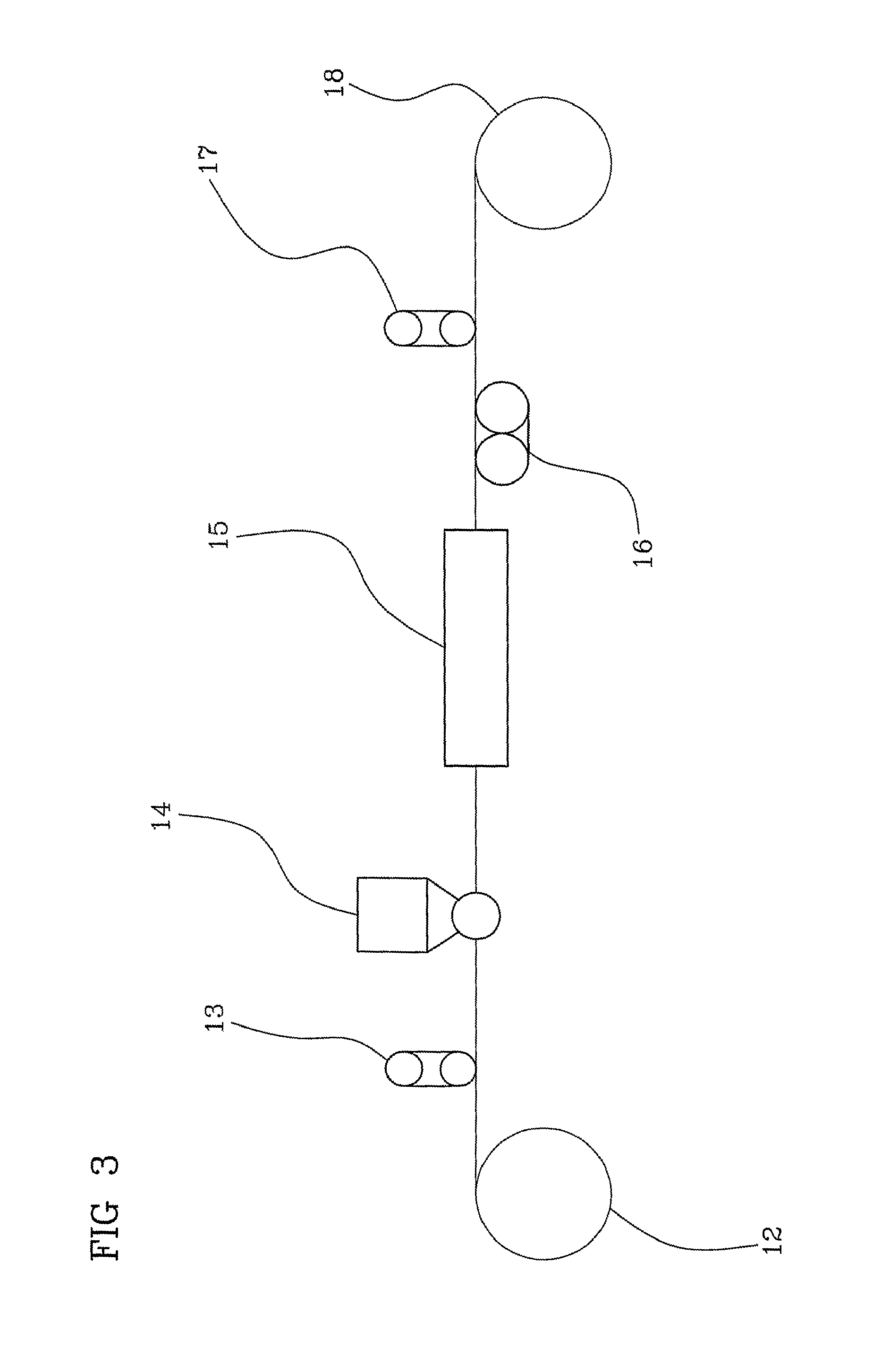

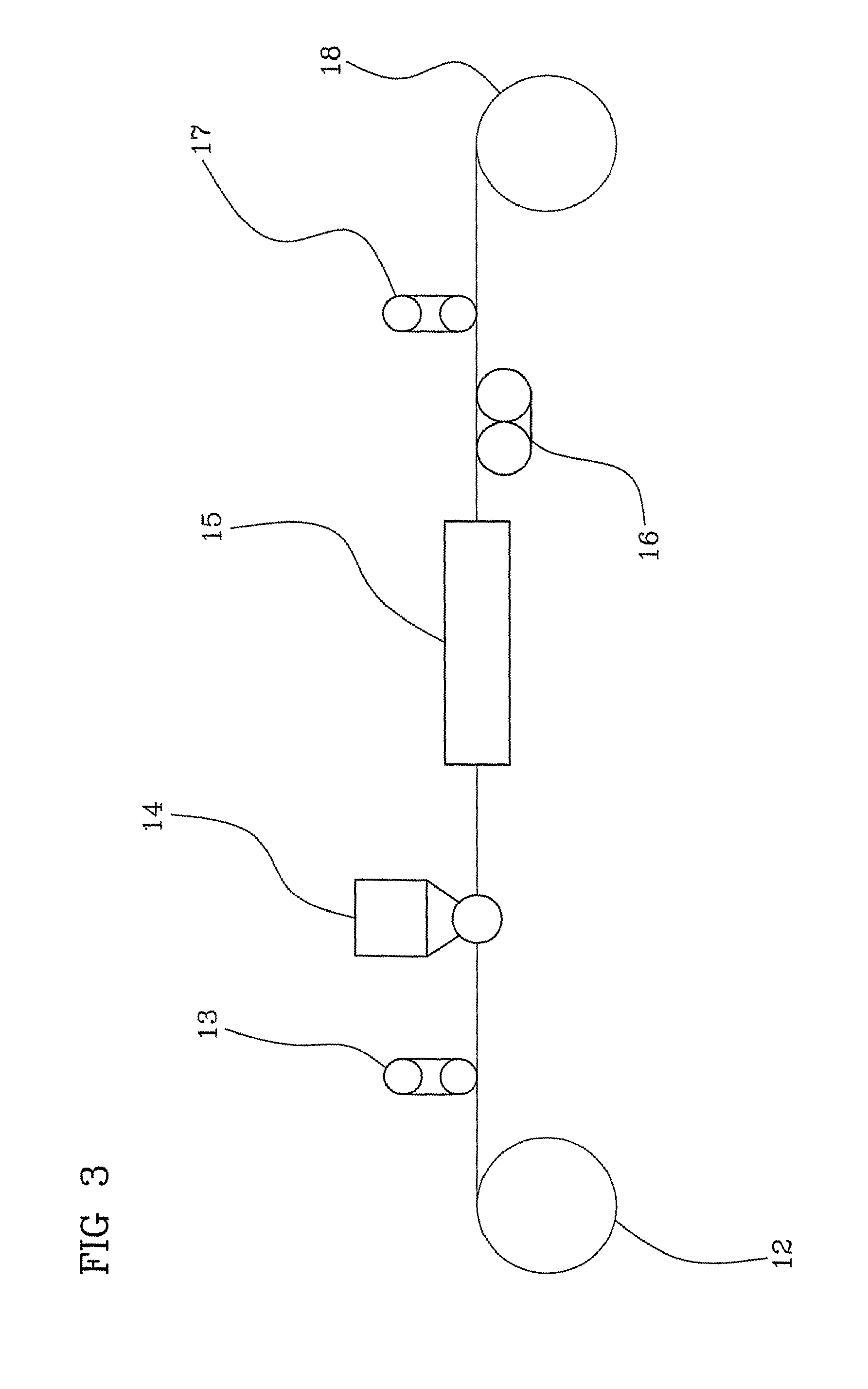

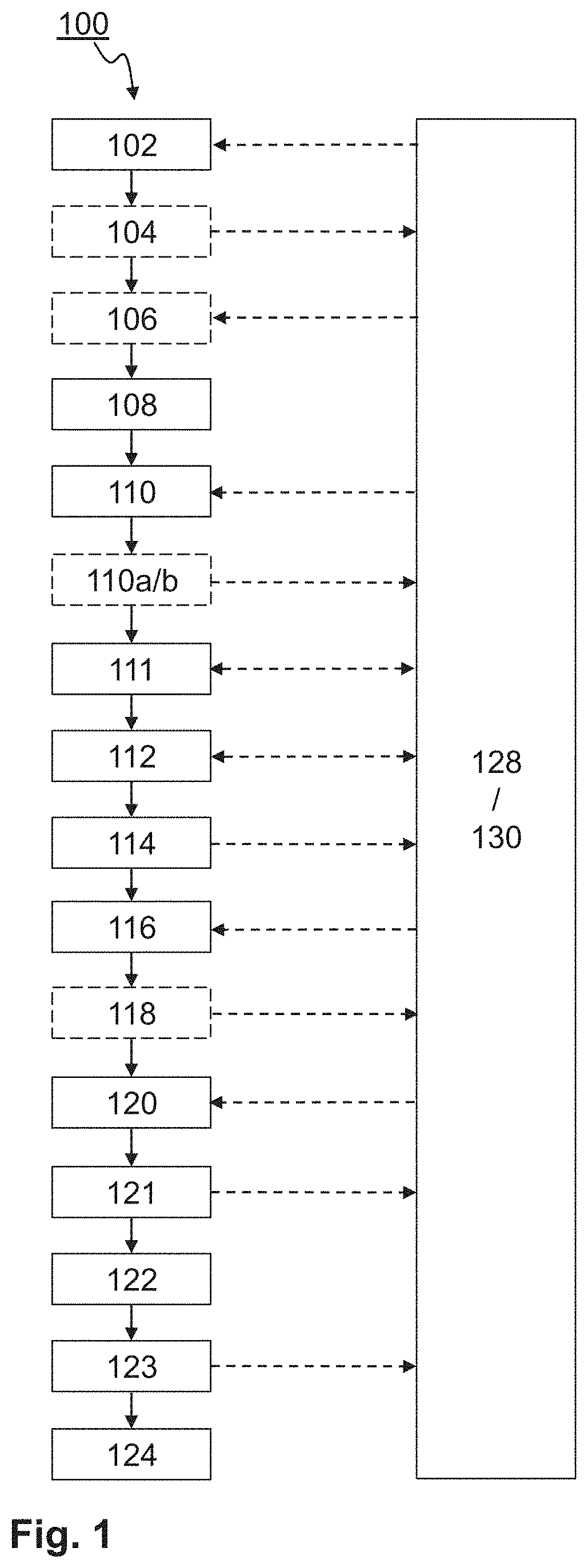

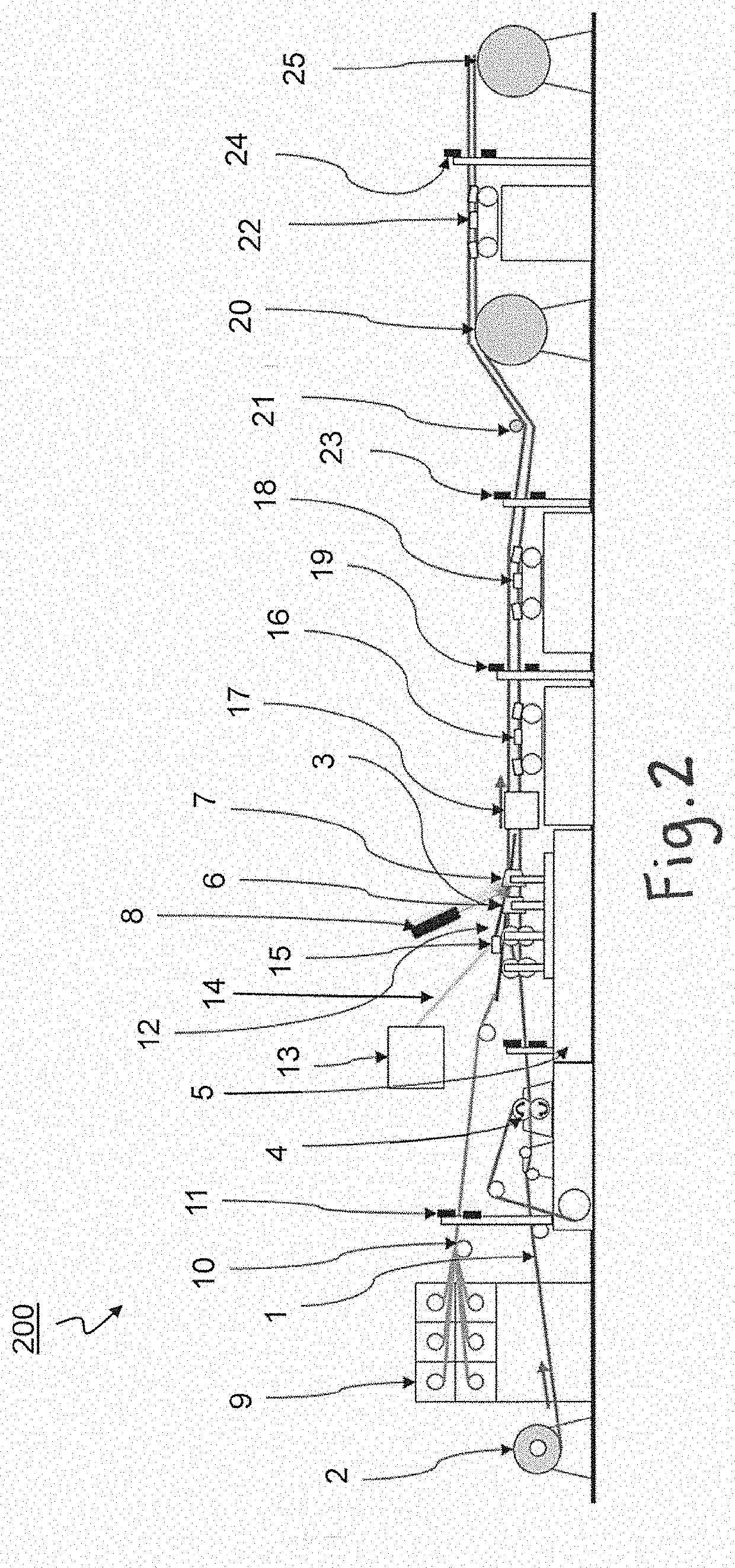

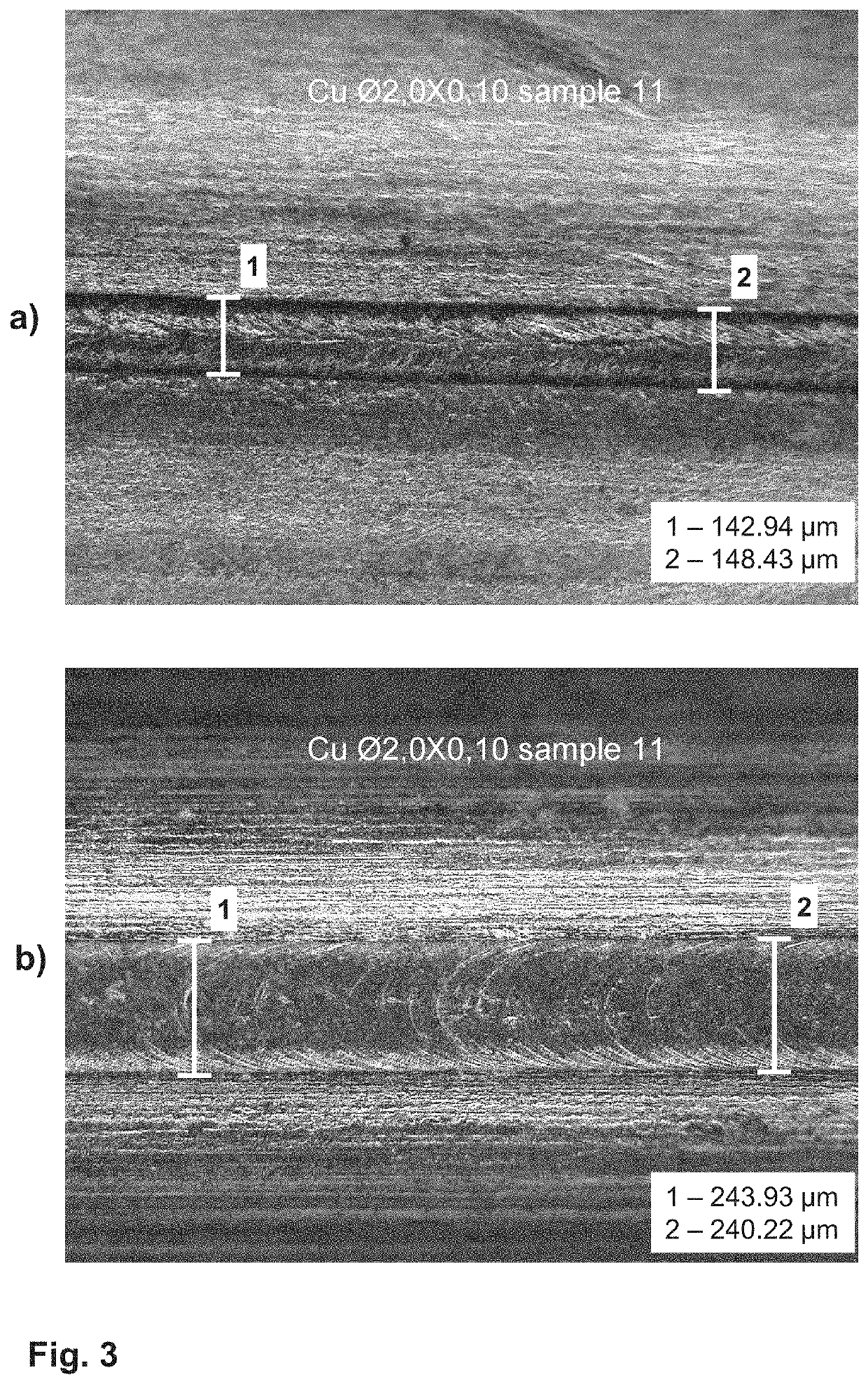

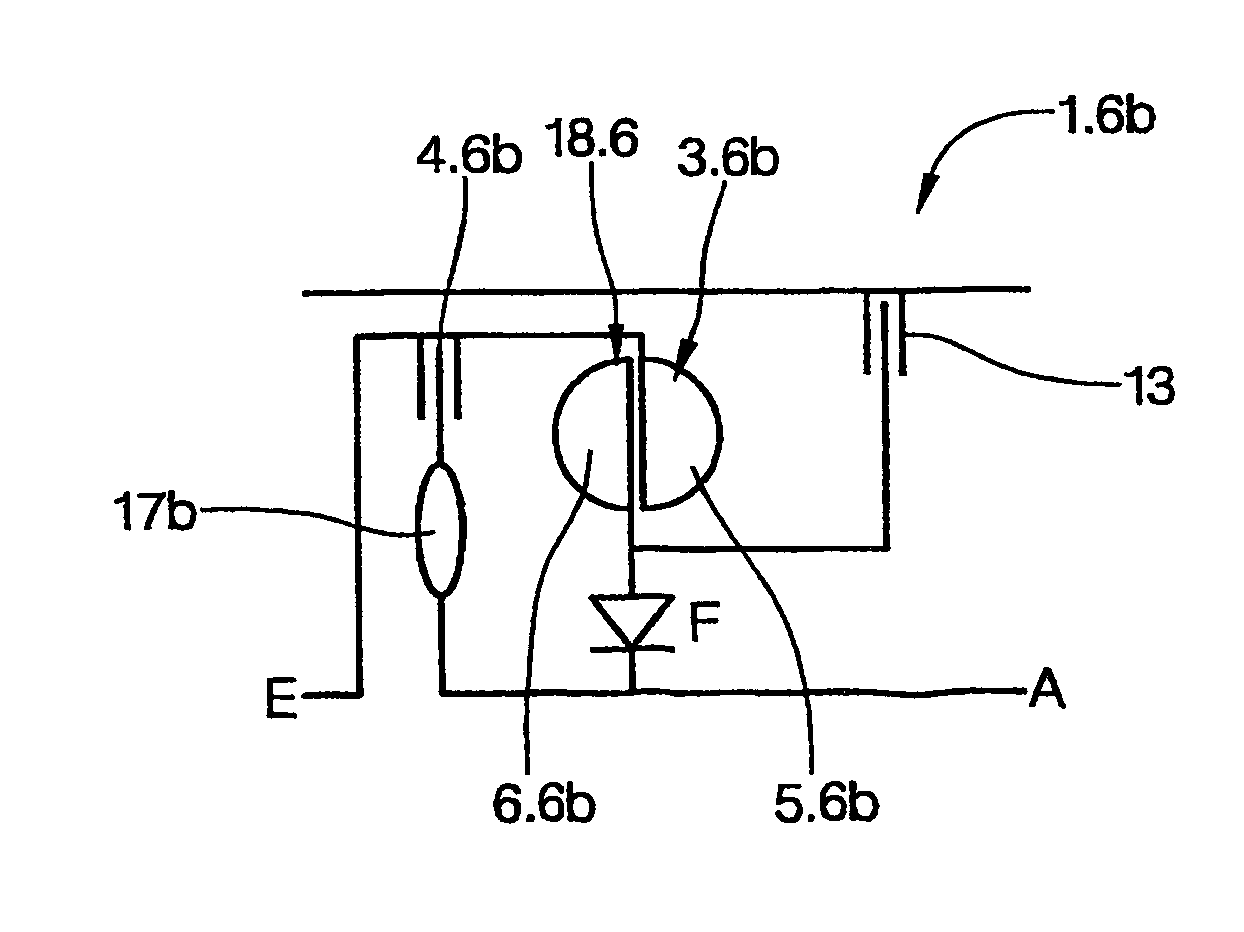

Method for the continuous production of optical fibre waveguides mounted in a thin-walled, radially closed metal tube

PendingUS20210154768A1Quality improvementReduce laser powerWelding/soldering/cutting articlesOptical waveguide light guideMetal stripsWaveguide

For the production of fibre waveguides mounted in a metal hollow profile, a flat metal strip is supplied to a deforming unit. The deforming unit is configured for continuously deforming the supplied flat metal strip into a shape corresponding to the hollow profile. The hollow profile is continuously welded along a longitudinal seam by means of a laser. A filler gel with a viscosity which increases with decreasing temperature, and one or more fibre waveguides, are introduced into the welded hollow profile in a continuous process via a guide or protective tube. In order to introduce the one or more fibre waveguides with an excess length into the hollow profile, the welded hollow profile is elastically stretched, is cooled, and is relaxed again. The finished product is received in a receiving unit. The continuous closed-loop control of the excess length of the fibre waveguides is performed inter alia through continuous open-loop control of the gel temperature, of the laser power and of the force exerted on the hollow profile for the elastic stretching.

Owner:NEXANS

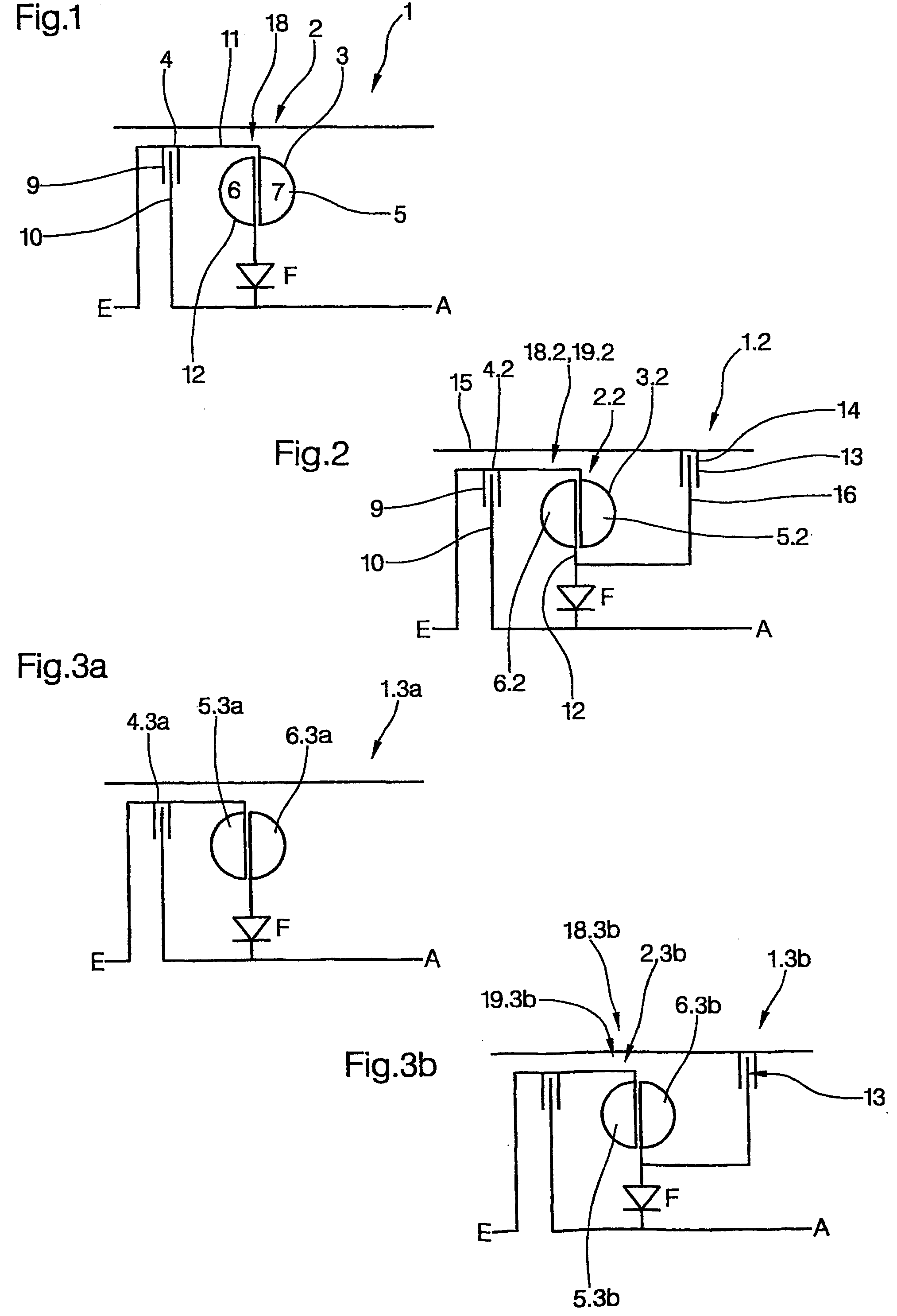

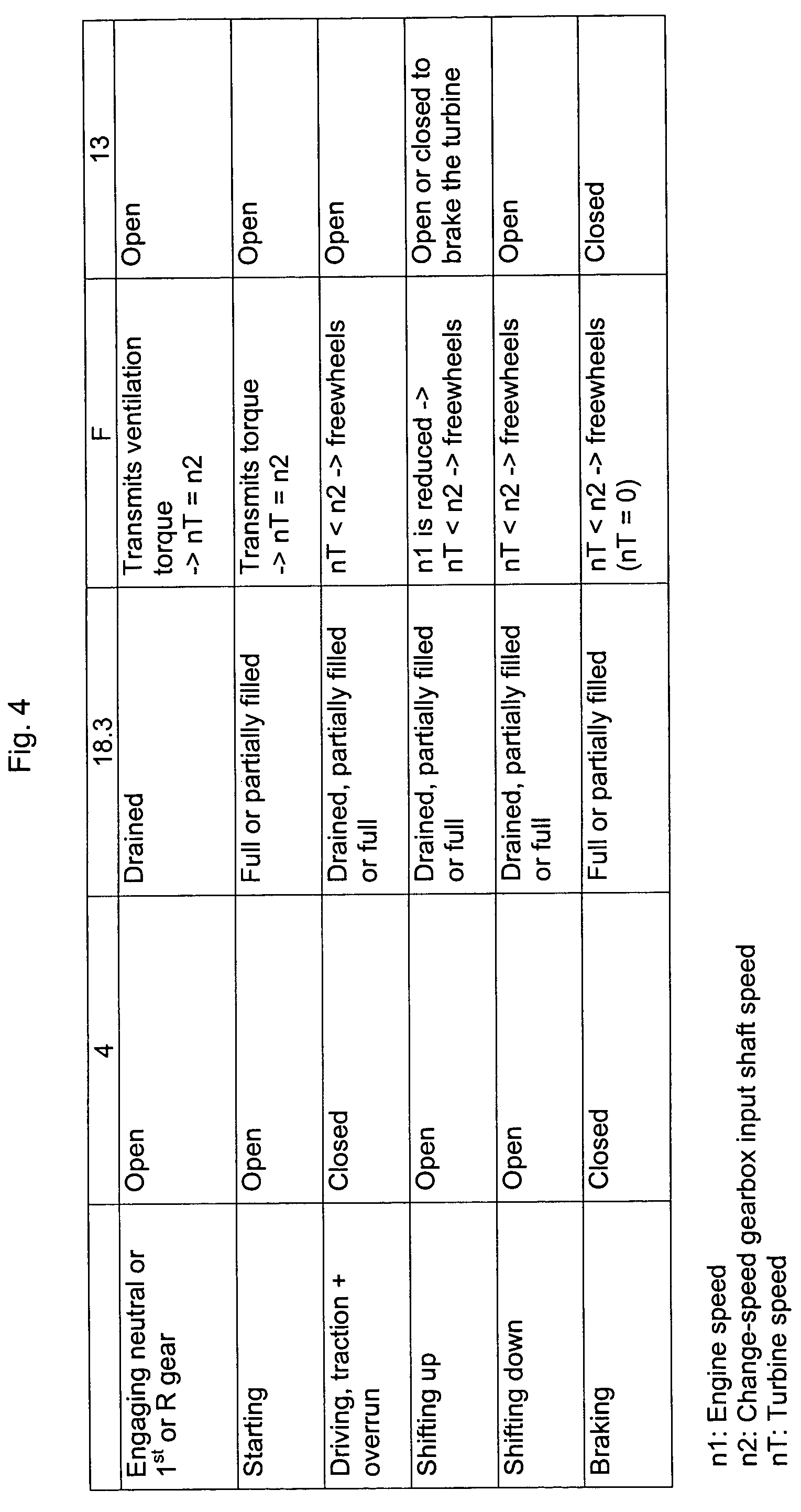

Starter unit

InactiveUS7160218B2Low controlLow designRotating vibration suppressionRotary clutchesEngineeringDriven element

A starter unit comprising: an input and an output; a starter element, configured as a hydrodynamic component comprising a drive element that can be coupled to the input in a rotationally fixed manner and a driven element that can be coupled to the output. A free wheel mechanism is located between the driven element of the starter element and the output.

Owner:VOITH PATENT GMBH

Wheel hub transmission unit for a drive wheel of a vehicle, drive wheel, and vehicle having an auxiliary drive

A wheel hub transmission unit for a drive wheel of a vehicle is provided. The wheel hub transmission unit includes a wheel axle, a pinion hub carrier concentrically arranged with respect to the wheel axle, a pinion mounted in a torsionally rigid manner onto said pinion hub carrier and configured to drive the drive wheel, and a torque transmission device having a transmission sleeve. The transmission sleeve is made from a magnetically coded material and includes a measuring area that is utilized to measure a torque by utilizing magnetic properties of the magnetically coded material of the transmission sleeve. An annular space is radially provided between the transmission sleeve and the wheel axle in the measuring area with a sensor coil being accommodated therein, the annular space being axially accessible from outside the transmission sleeve.

Owner:FAZUA GMBH

Color changer

InactiveUS8636029B2Compact configurationLow overall lengthServomotor componentsFrozen sweetsMechanical engineeringCoating materials

A color changer has a valve block for connecting a plurality of coating material lines to an application device. The valve block has a parallelepiped housing. The housing has a central color channel with an axial direction and contains valve bores for receiving valves and a length of a central color channel is as short as possible with a simultaneous supply of many paint feed lines. A first number of parallel valve bores open into the color channel at first openings, a second number of parallel valve bores open into the color channel at second openings on the opposite side of the color channel and offset in the axial direction with respect to the first number of valve bores. A third number of parallel valve bores open into the color channel at third openings and a fourth number of parallel valve bores open into the color channel at fourth openings.

Owner:LACTEC

Bi-axially collapsible frame for a child care support article

Owner:ARTSANA USA

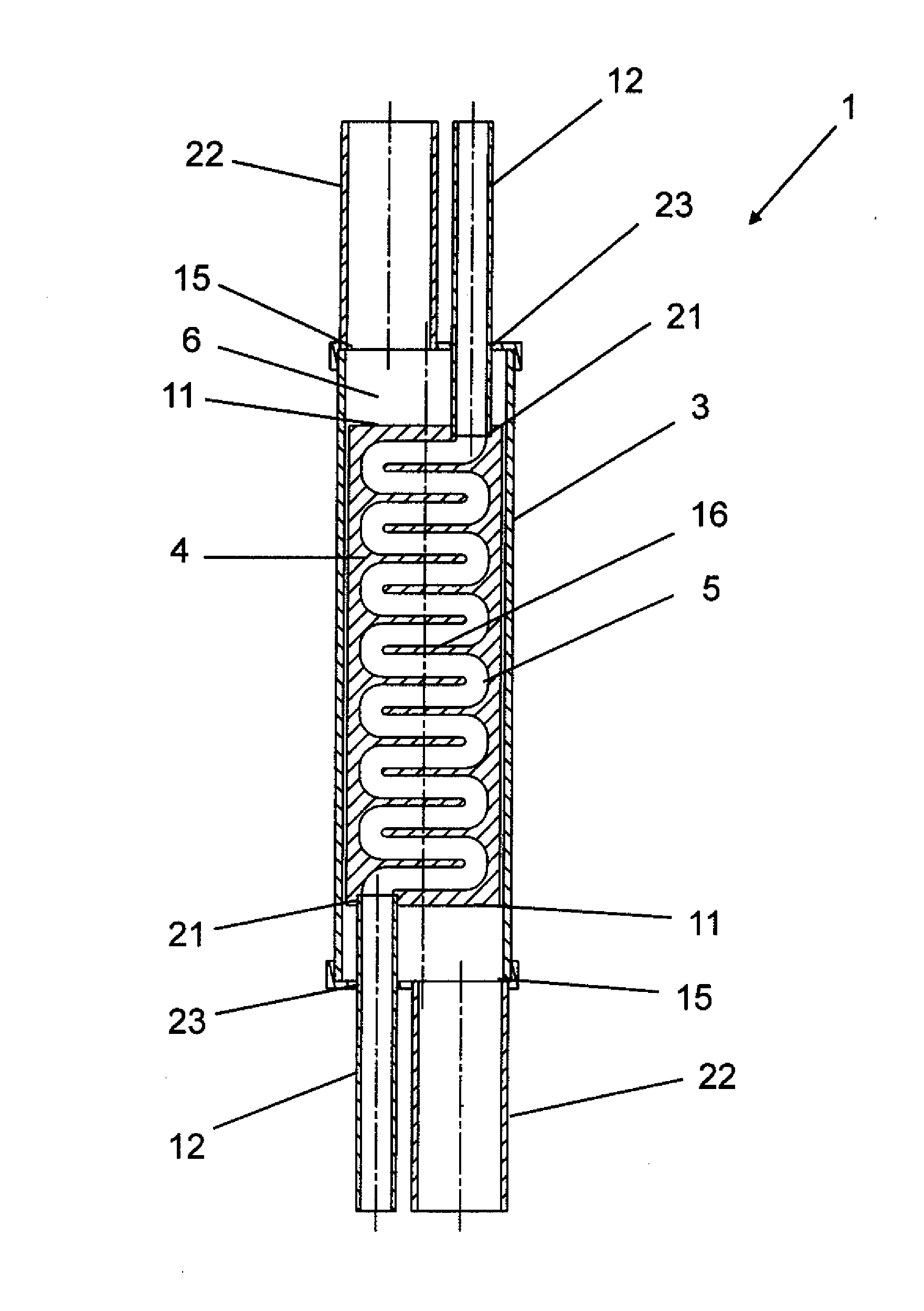

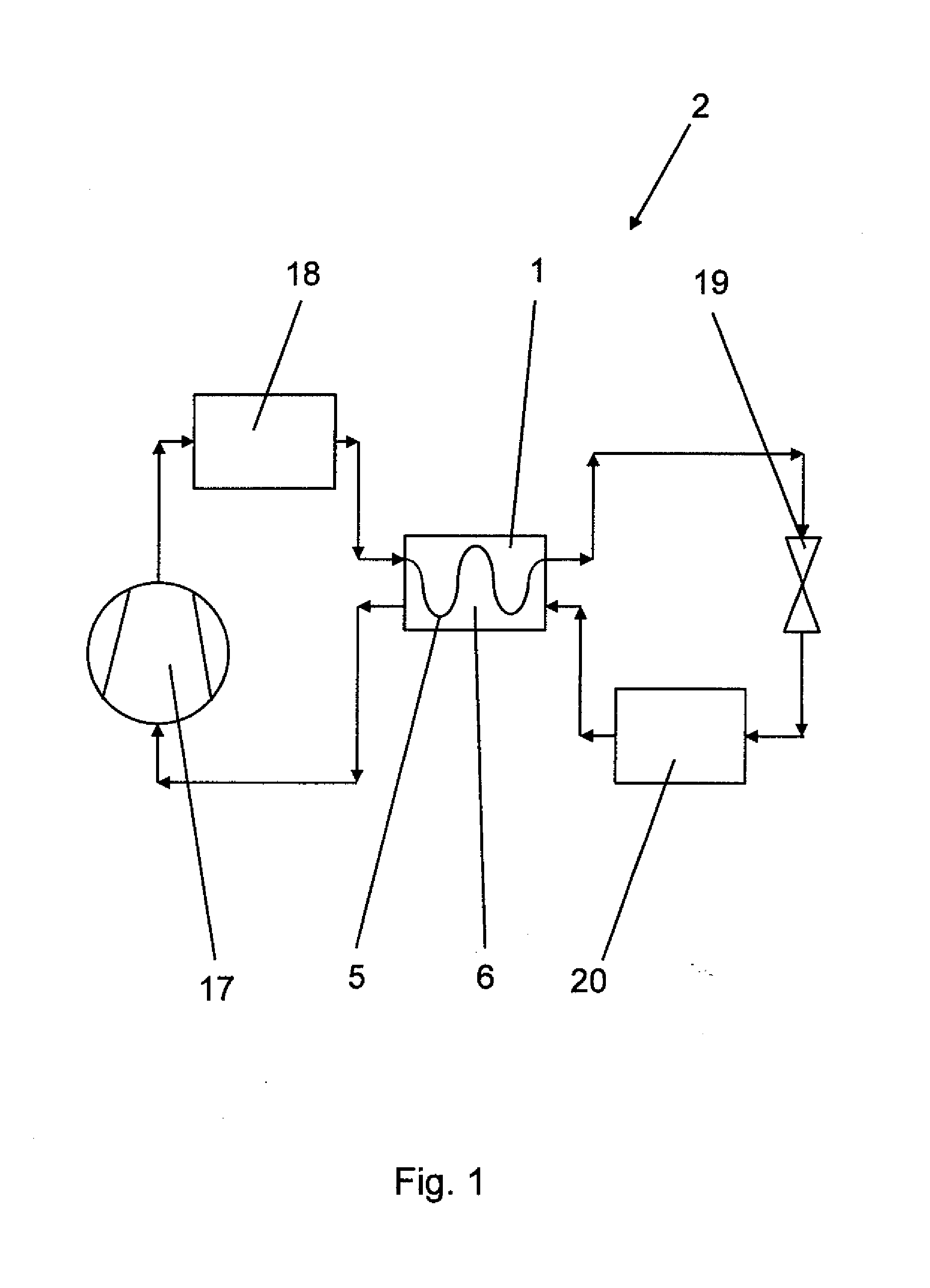

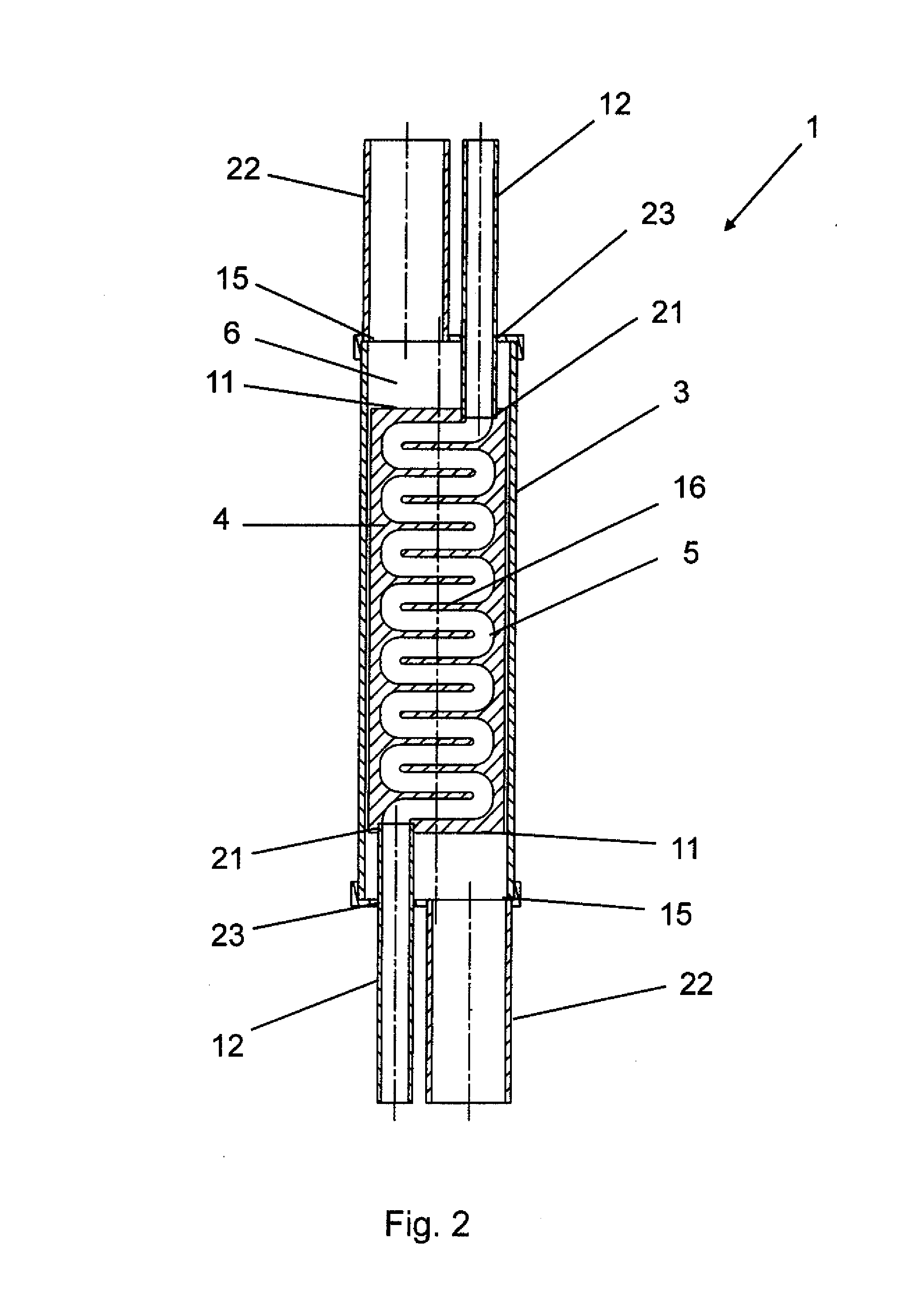

Internal Heat Exchanger for an Air Conditioning System

InactiveUS20140151004A1Prevent leakageImprove heat transfer performanceStationary tubular conduit assembliesHeat transfer modificationEngineeringAir conditioning

An internal heat exchanger for an air conditioning system, comprising an outer tube and a line structure arranged inside the outer tube defining a meandering serpentine first flow channel, with the second flow channel formed between the outer tube and the line structure. The first flow channel is formed by extruded components joined together to form a unitary structure inserted into the second flow channel which includes facing channel elements defining a serpentine path and two shells adhered to the channel elements defining the sides of the flow path and having fins extending perpendicular to the base disposed in the second flow channel.

Owner:TI AUTOMOTIVE ENG CENT HEIDELBERG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com