Internal Heat Exchanger for an Air Conditioning System

a heat exchanger and air conditioning technology, applied in the direction of heat exchange apparatus, tubular elements, stationary tubular conduit assemblies, etc., can solve the problems of increasing the heat exchange capacity maintaining the overall length of the heat exchanger at the same time, and achieve the effect of preventing leakag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

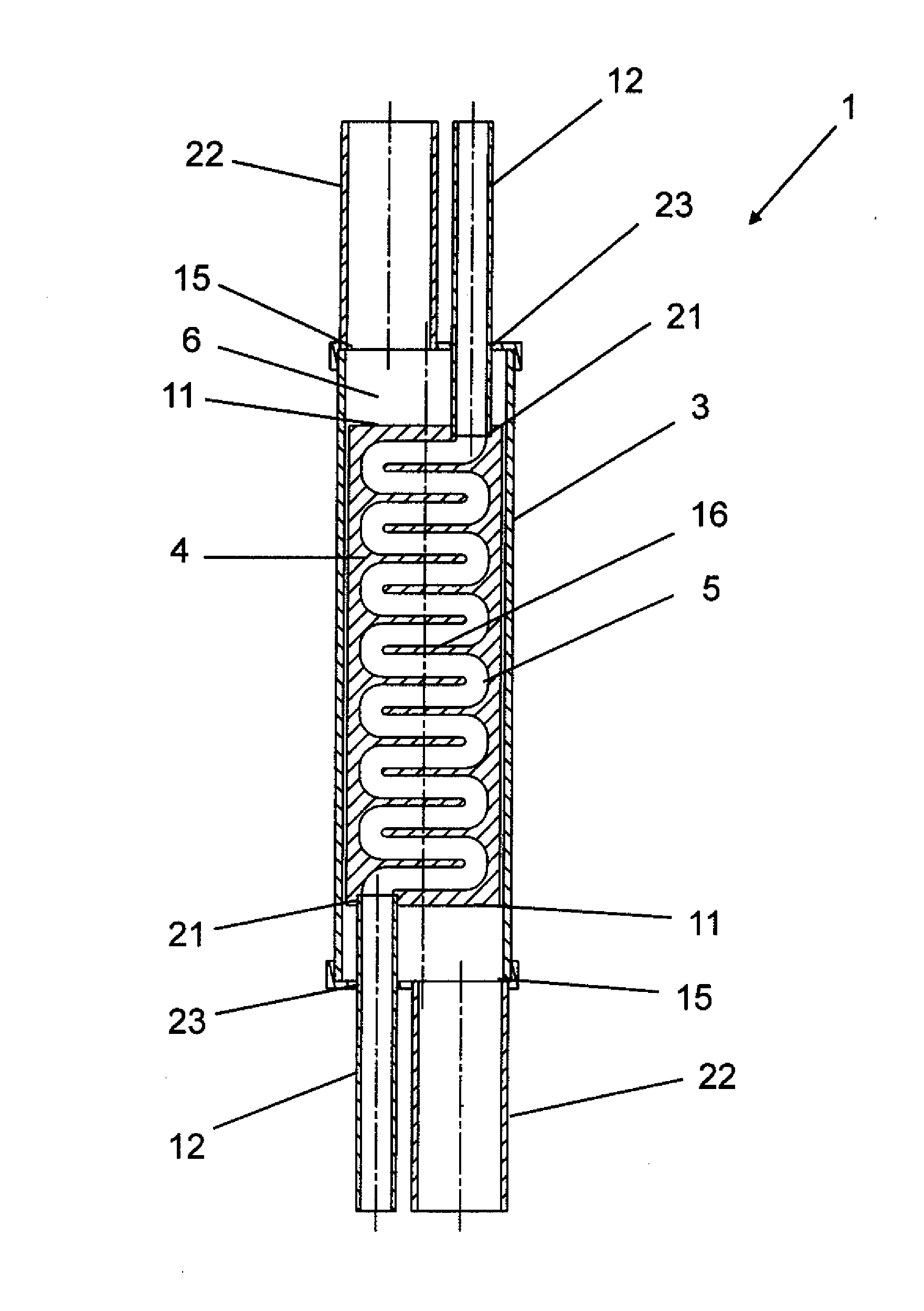

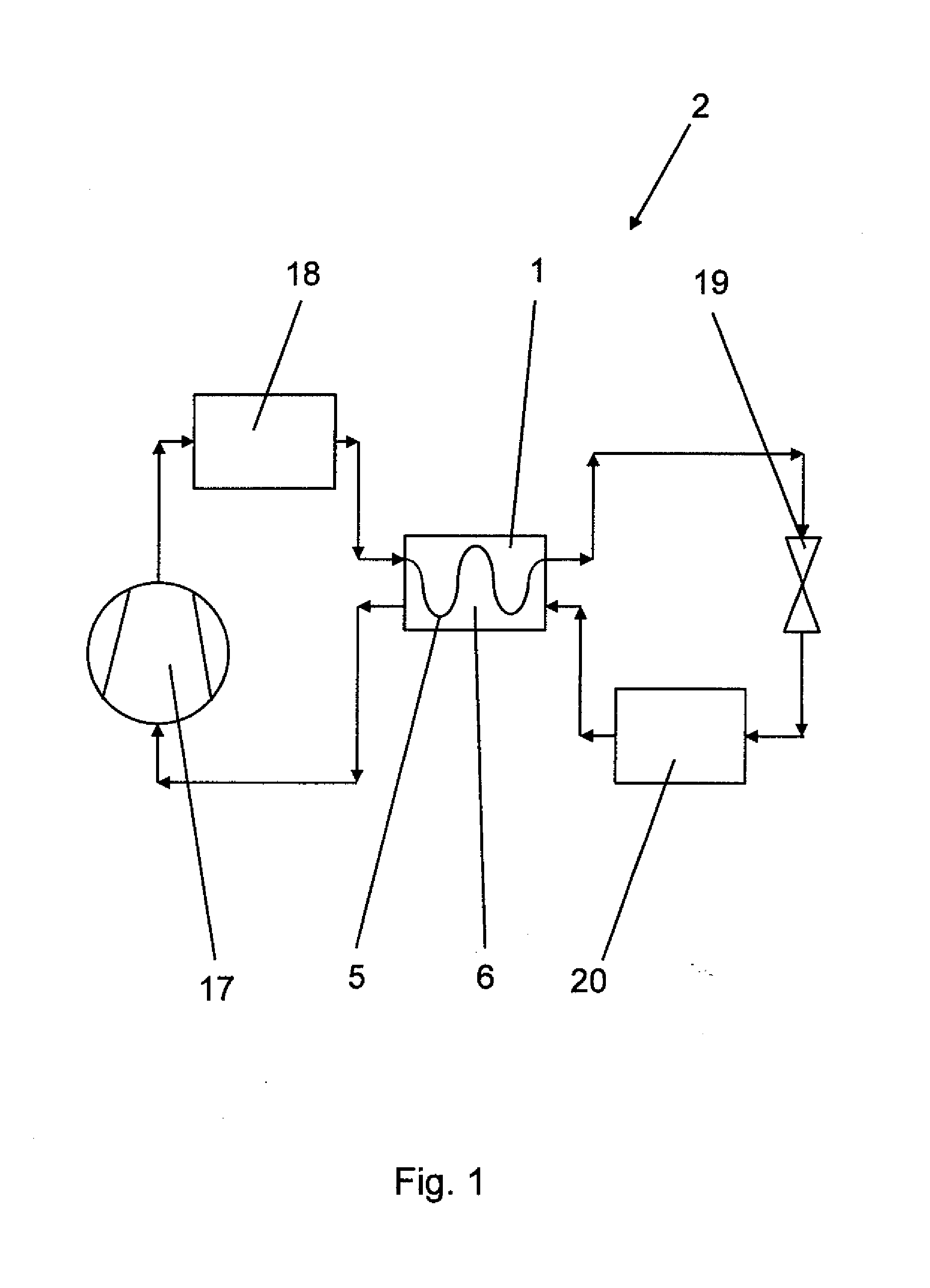

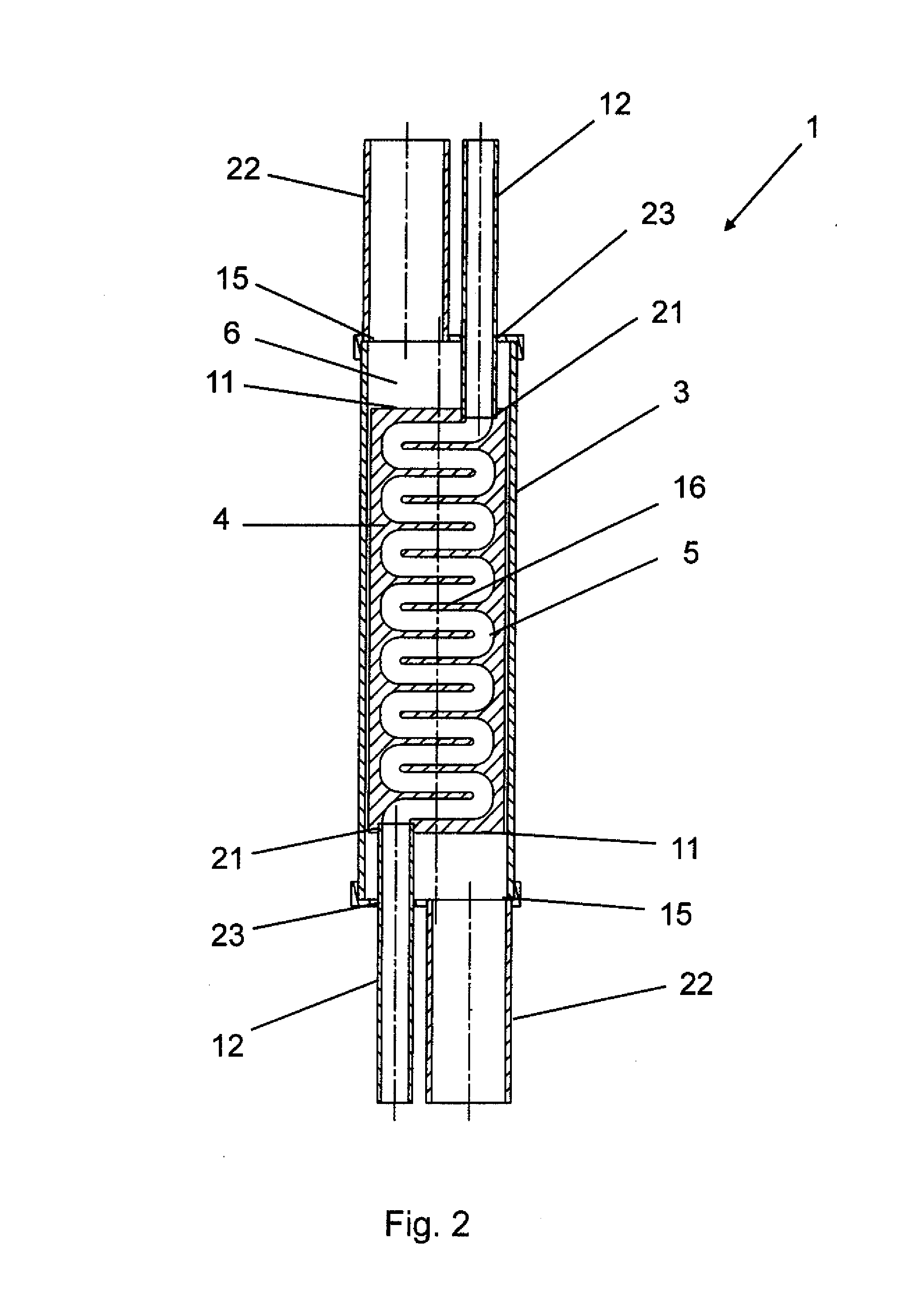

[0027]FIG. 1 presents a schematic view of the air conditioning circuit of a mobile air conditioning system 2, in particular the air conditioning system of a vehicle. The air conditioning system consists of a closed circuit piping arrangement between system components, in which a coolant circulates. The coolant is compressed by a compressor 17, and flows to a condenser 18, where the coolant is liquefied. After exiting the condenser, the coolant is liquid, and exhibits a temperature of 30° C. to 50° C. (Centigrade) at a pressure of 7 bar to 15 bar (Barometers). The liquefied coolant is now supplied to the first flow channel 5 of internal heat exchanger 1 according to the invention, where the coolant exiting the condenser 18 releases heat to the gaseous coolant exiting the evaporator 20 passes through the second flow channel 6. The liquid coolant then streams into the expansion valve 19, where the coolant pressure is reduced. The coolant absorbs heat in the evaporator 20, wherein it is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com