Open hole staged fracturing well completion pipe string provided with controllable valve and hydraulic control switching pipe string

A staged fracturing and hydraulic control switch technology, which is applied in the direction of wellbore/well components, production fluid, wellbore/well valve device, etc., can solve the problem of restricting unconventional oil and gas resources in low permeability reservoirs, well completion and fracturing The complex structure of the integrated pipe string, the number of segments and the limitation of fracturing scale can achieve the effects of saving perforation operation cost and operation time, reducing construction cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

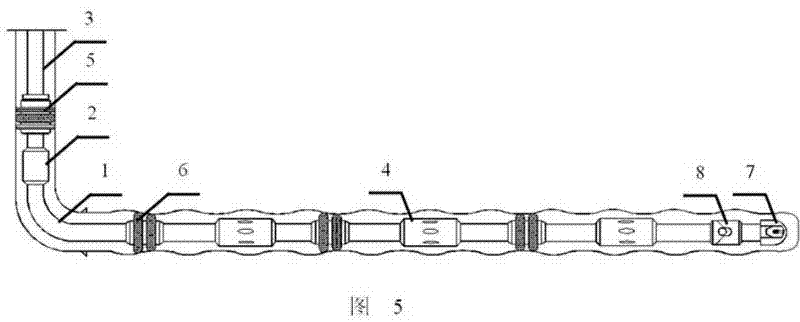

[0019] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0020] The open-hole staged fracturing completion string with controllable valves is connected sequentially from top to bottom with the casing 1, the drill pipe feeding tool 3, the top hanging packer 5, the hydraulic control switch retention tube 2, and the openable close control valve 4 and and It is connected with open hole fracturing packer 6 , wellbore isolation valve 8 and bottom circulation valve 7 . Connect at least one set of switchable control valves 4 and and It is connected to the open hole fracturing packer 6 . When fracturing and completing multi-stage formations, it is necessary to configure multiple sets of switchable control valves 4 and open hole fracturing packers 6 connected to them in the pipe string, and there is no need for a set of switchable control valves 4 at the bottom. Install the open hole fracturing packer 6 again.

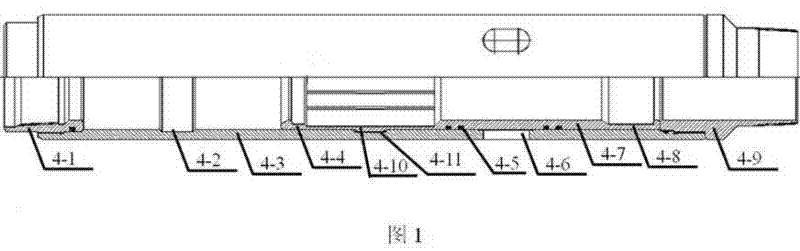

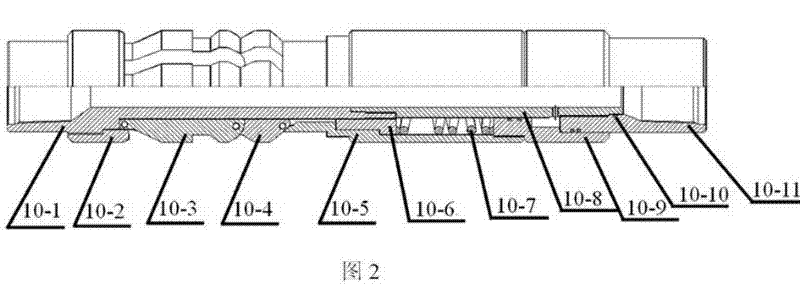

[0021] The swit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com