Bridge plug for fracturing of casing pipe

A fracturing and casing technology, which is applied in the direction of production fluid, wellbore/well parts, earthwork drilling and production, etc. It can solve the problems of high operating cost, difficult drilling and grinding, and high risk of drilling and grinding, so as to avoid drilling and grinding operation, and the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

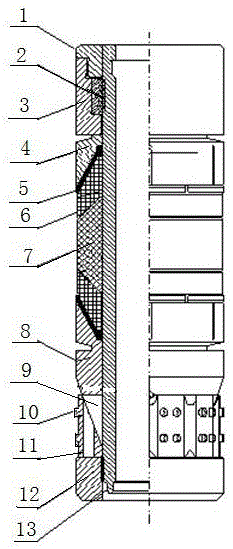

[0025] This embodiment provides a bridge plug for casing fracturing, such as figure 1 As shown, it includes a central rod 13 and an upper joint 1 and a lower joint 12 respectively connected to the upper and lower ends of the central rod 13. The middle part of the central rod 13 is covered with a cylindrical long rubber tube 7 and a short rubber tube 6. The upper and lower ends of the long rubber tube 7 are respectively symmetrically provided with short rubber tubes 6 in turn, and the upper and lower parts of the central rod 13 are respectively covered with an upper support sleeve 4 and a lower support sleeve 8, and the upper support sleeve 4 and the lower support sleeve 8 are respectively fixed. There is a rubber cartridge seat 5, and the short rubber cartridges 6 located at the upper and lower ends of the long rubber cartridge 7 are installed on the rubber cartridge seat 5;

[0026] A seat ring 3 is arranged between the upper support sleeve 4 and the upper joint 1, and the up...

Embodiment 2

[0031] On the basis of Embodiment 1, a locking mechanism is also provided in this embodiment. In this embodiment, the inner wall of the seat ring 3 is stepped, and a locking block 2 is arranged on the step, and the locking block 2 is sleeved on the central rod 13 Above, the upper and lower ends of the locking block 2 are respectively limited by the steps of the upper joint 1 and the inner wall of the seat ring 3 .

[0032] The locking block 2 is a cylindrical structure, and the locking block 2 and the central rod 13 are connected by a horse-tooth button.

[0033] The locking mechanism of this embodiment adopts the form of horsetooth buckle connection to form unidirectional stress. Here, the horsetooth buckle connection adopts the form of two positive and negative horsetooth buckles. The tooth buckle, the locking block 2 is a positive horse tooth buckle, so that the seat ring 3 and the upper support sleeve 4 are only subjected to downward stress and can only move downward, prev...

Embodiment 3

[0035] On the basis of Embodiment 1 and Embodiment 2, in this embodiment, there are at least three guide pins 9, which are evenly distributed in the circumferential direction on the lower end of the lower support sleeve 8; Four anchor flukes 10 are arranged on the slips.

[0036] Slips 11 are composed of multiple single-piece slips, so that during the continuous upward movement along the guide pin 9 and along the lower support sleeve 8, the slips 11 will slowly break into single single-piece slips, and the single-piece slips The four flukes 10 move radially with the single slip until the flukes 10 are anchored to the inner wall of the casing.

[0037] The connecting surfaces between the upper support sleeve 4, the rubber cylinder seat 5, the short rubber cylinder 6, the long rubber cylinder 7 and the lower support sleeve 8 are slopes, and these slopes are inclined to the middle long rubber cylinder 7.

[0038] The bevel-shaped end surface setting of this embodiment can make t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com