Patents

Literature

472results about How to "Speed up production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

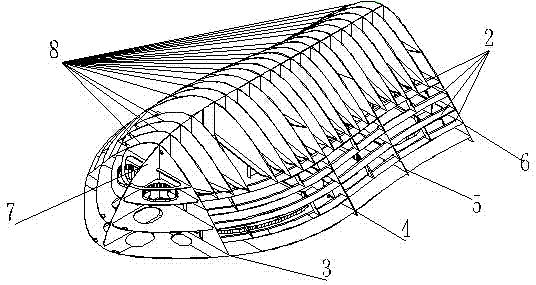

Building block type aircraft carrier

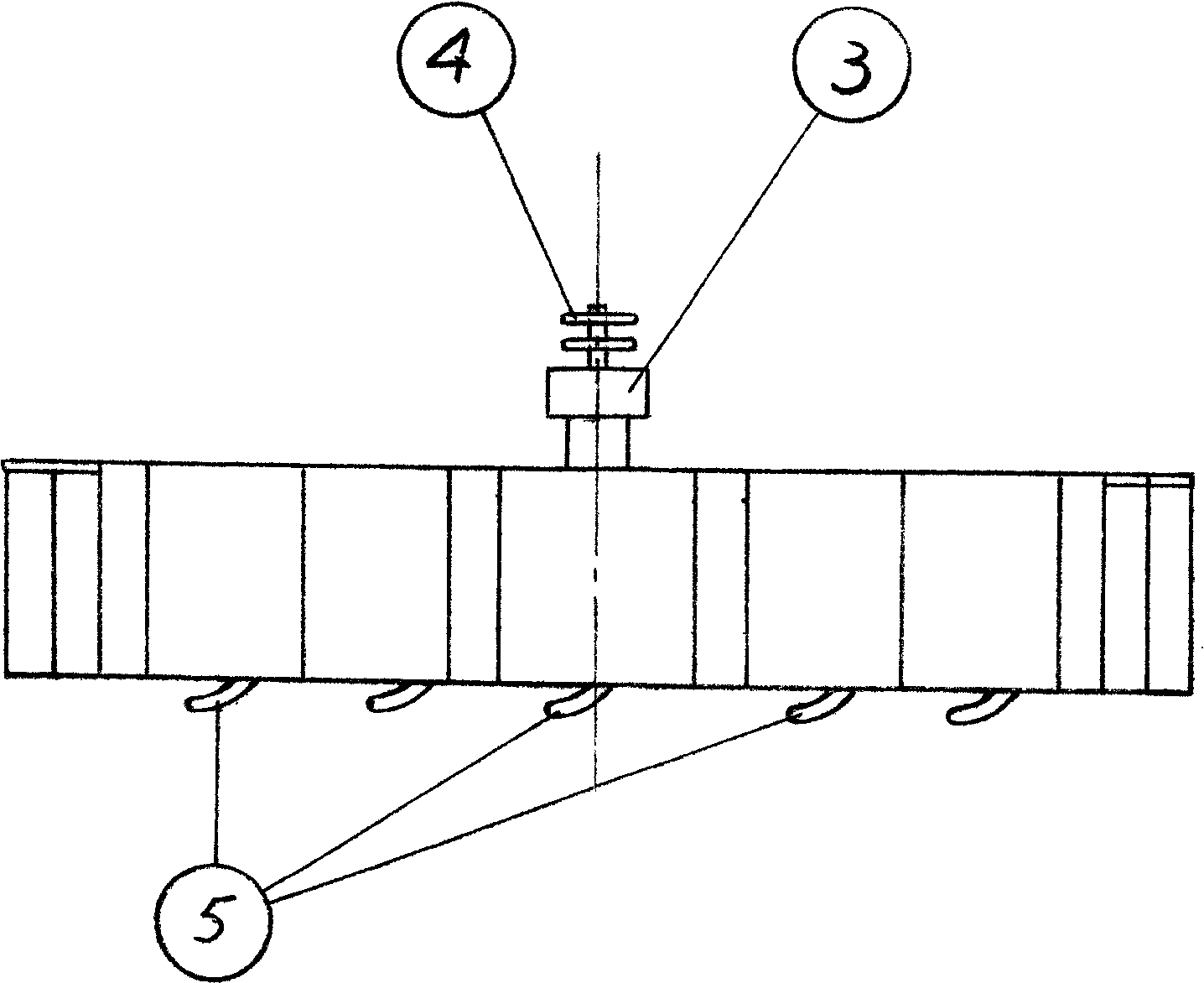

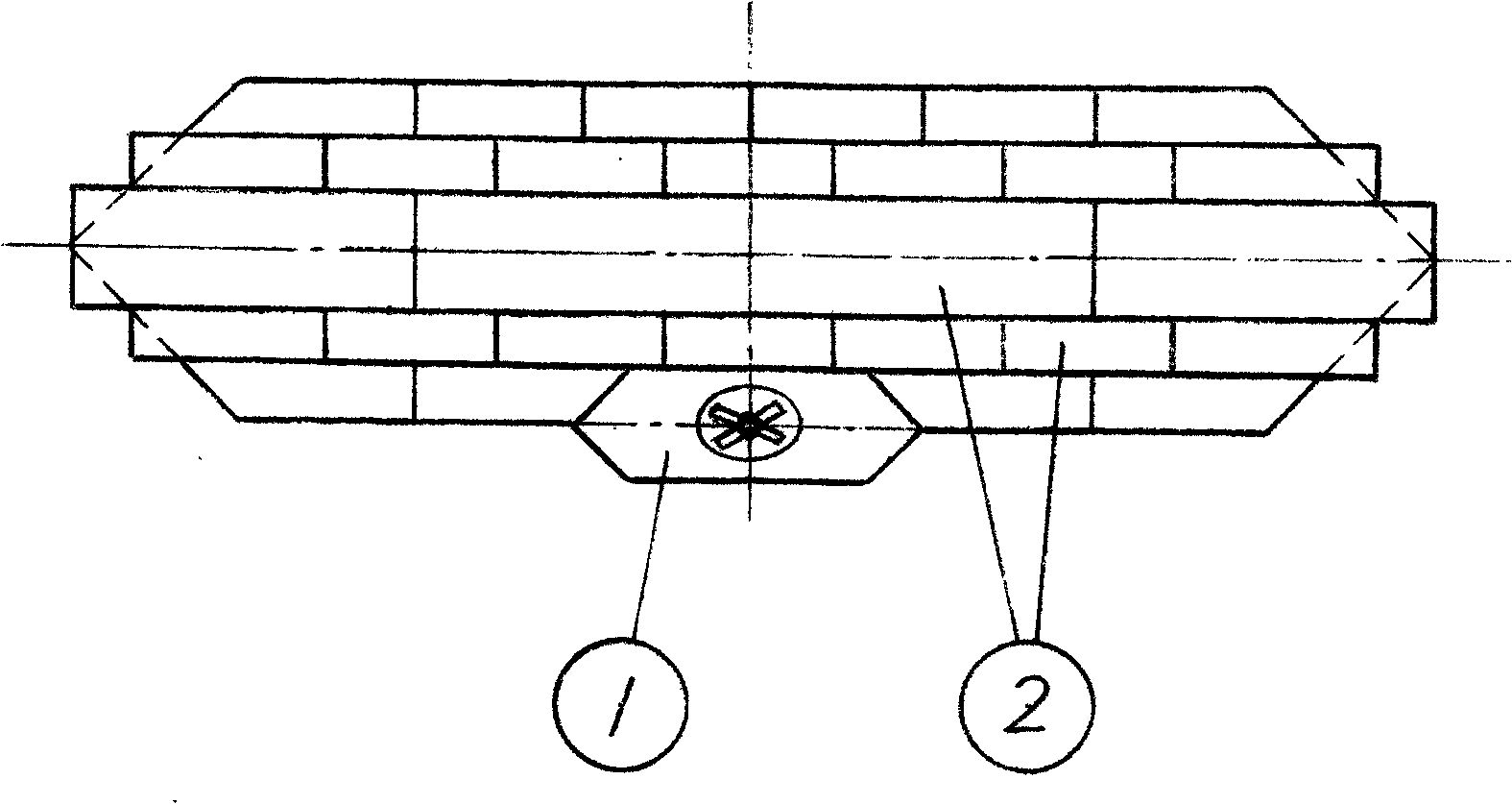

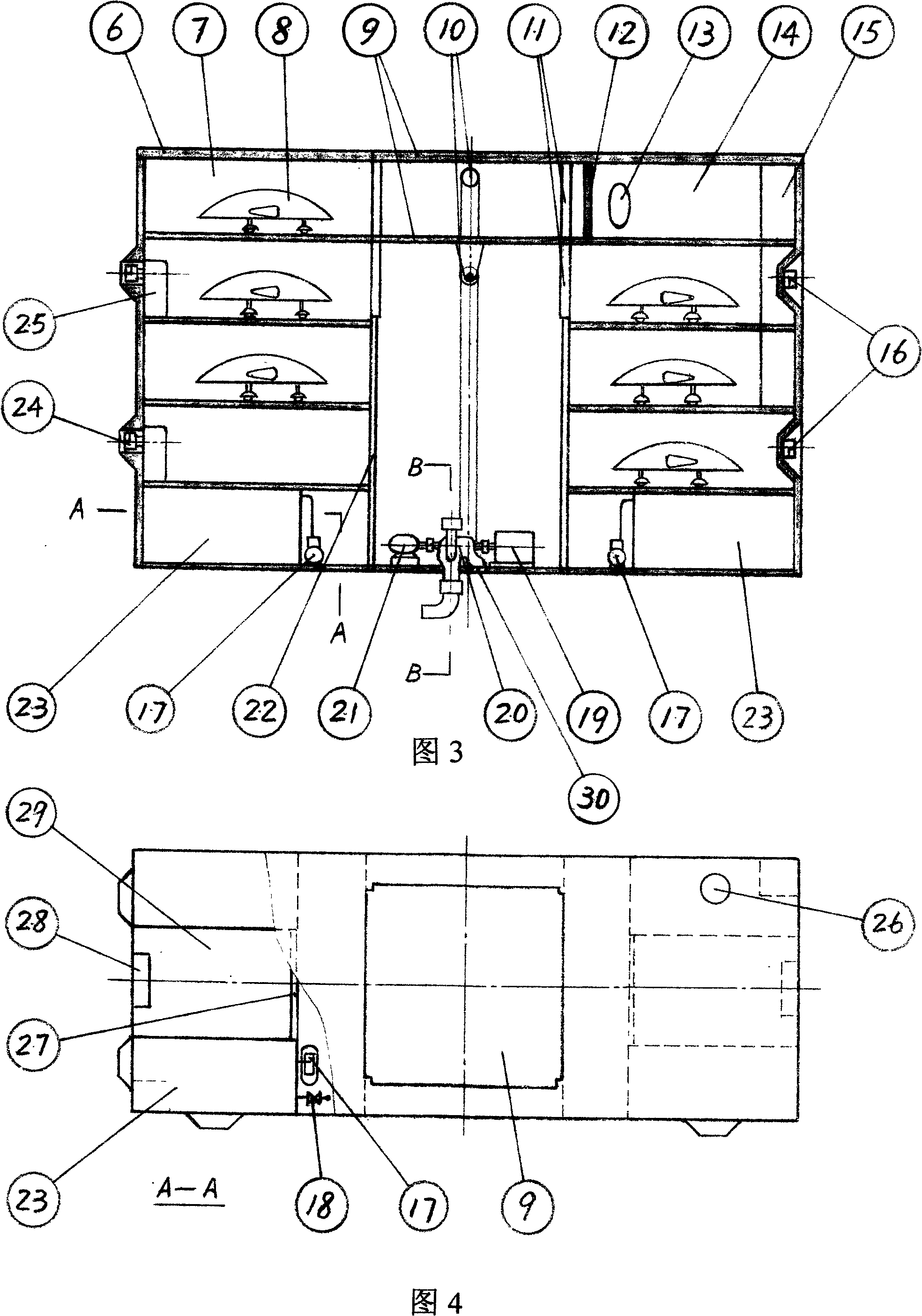

The invention provides a building block typed aircraft carrier which consists of a commanding ship and a plurality of unit ships. The whole shape of the commanding ship and the aircraft carrier is a shuttle-shaped multi-prism. The commanding ship is provided with a nuclear power device and a diesel electric hybrid power device. The unit ship is provided with the diesel electric hybrid power device. The connection and disconnection between the commanding ship and the unit ships are realized by a Zhantianyou which is arranged on the side wall of the ship body. Each unit ship is sealed; the underfloor area is provided with a water tank which can adjust the water accumulation quantity; a telescopic periscope is arranged below a deck. The aircraft carrier can disperse to prowl, can pass through narrow water passage, can float out of the water surface and be quickly assembled when achieving the destination, so as to realize the surprise attack. The flying deck is provided with a unique aircraft takeoff ejector and a unique aircraft landing damp. The aircraft carrier can realize emergency stop, backing movement and turning in-situ, which can lead the aircraft to always take off and land against the wind.

Owner:左学禹

Resistance welding superposition technology for PCB thick copper lines

ActiveCN101534612AIncreasing the thicknessInhibit sheddingNon-metallic protective coating applicationProduction scheduleCooking & baking

The invention discloses a resistance welding superposition technology for PCB thick copper lines, comprising the steps of: at first, printing resistance welding ink on the surface of a PCB and forming a first resistance welding layer via screen printing resistance welding; and pre-drying while remaining 75 DEG C and semi-hardening the first resistance welding layer after cooling; then printing the resistance welding on the first resistance welding layer once again in order to form a second resistance welding layer; pre-drying once again while remaining 75 DEG C and semi-hardening the first resistance welding layer and the second resistance welding layer after cooling; eventually, hardening the resistance welding layer and the second resistance welding layer completely subsequent to the segmented baking of the semi-hardened PCB. The invention requires only one-time resistance welding pattern transfer and high-temperature baking by the superposition printing on the thickness of the resistance welding, which increases the thickness of the resistance welding layer, thickens, in particular, the thickness of the resistance welding layer at corners of the lines, and avoids the problems of resistance welding blistering and falling in thermal impact procedures of post-processing procedure, and meanwhile, using the inventive technology shortens production procedure dramatically, speeds up production schedule and lowers production cost.

Owner:SHENZHEN BOMIN ELECTRONICS

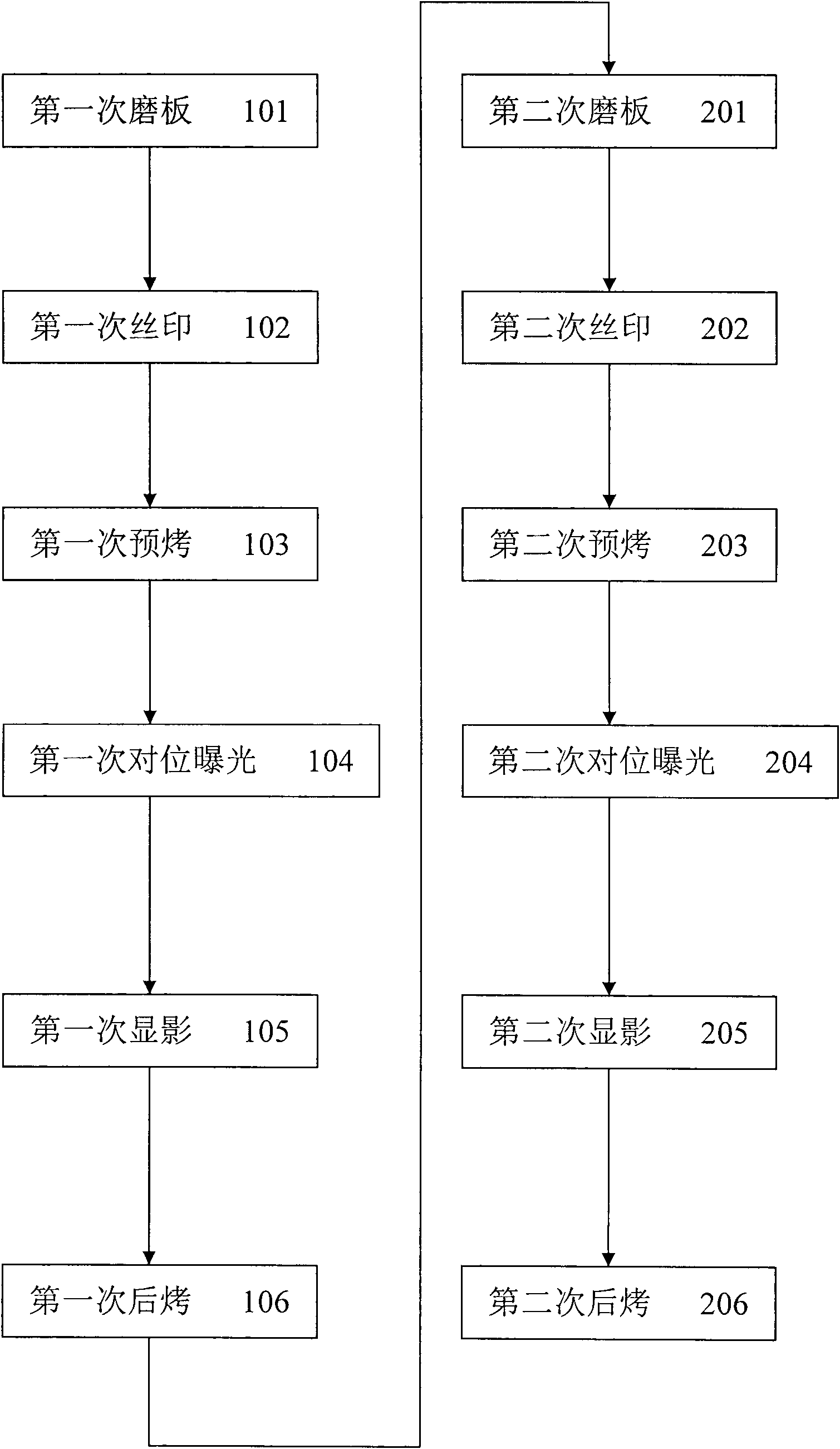

Production technology of PCB (Printed Circuit Board) solder mask

ActiveCN101668390AIncrease productivityImprove product qualityNon-metallic protective coating applicationCooking & bakingProduction schedule

The invention relates to a production technology of a PCB (Printed Circuit Board) solder mask, which comprises the following steps of: a first board grinding, a first silk screen, a first pre-braking,a first contraposition exposure, a first development, a first post-baking, a second board grinding, a second silk screen, a second pre-braking, a second contraposition exposure, a second developmentand a second post-baking, wherein the mesh number of the first silk screen is larger than that of the second silk screen, and the windowing size of the first contraposition exposure is larger than that of the second contraposition exposure. The production technology of the PCB solder mask better eliminates the harmful defects in the solder mask production process that green oil and the like easilysolders an oil plughole, the developing is dirty, the circuit becomes red, and the lateral erosion of a film printing and development is large and the like, thereby improving the production efficiency and the production quality, speeding up the production schedule and reducing the production cost.

Owner:大连崇达电子有限公司

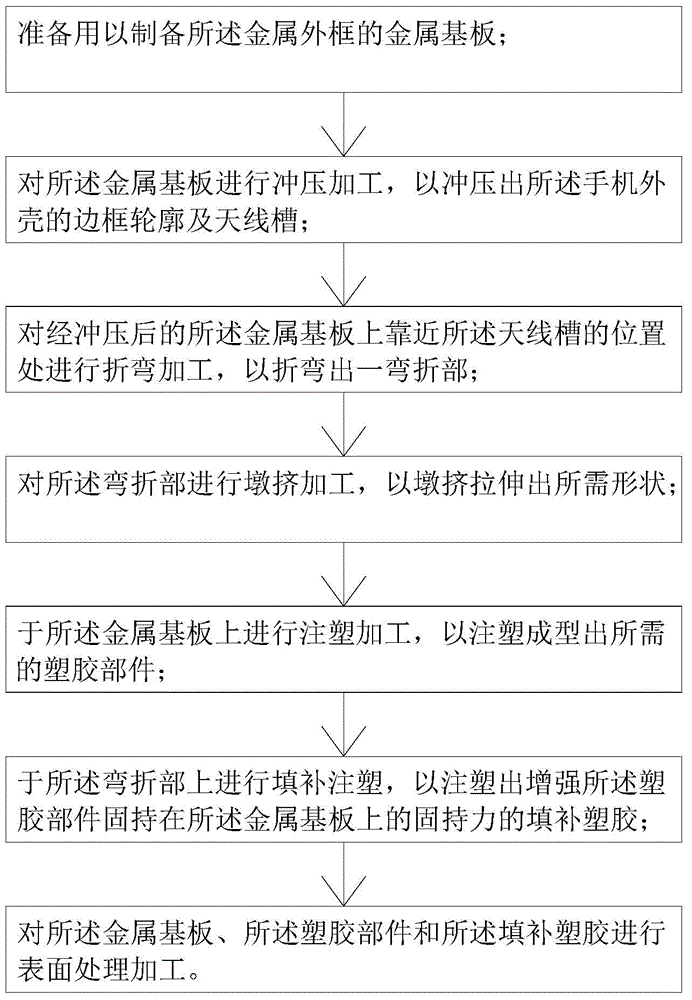

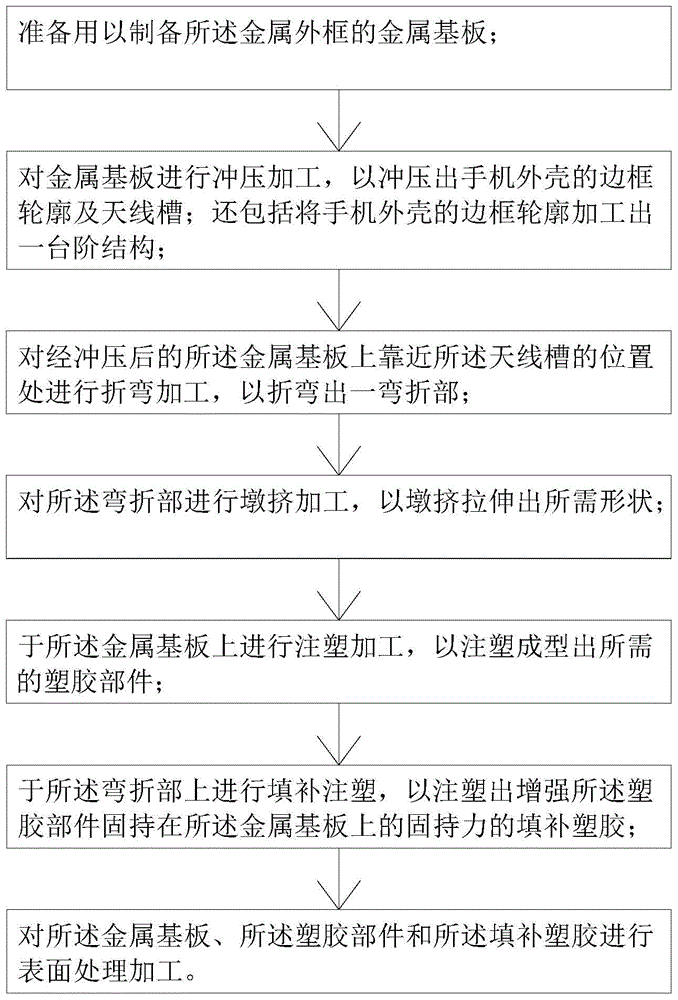

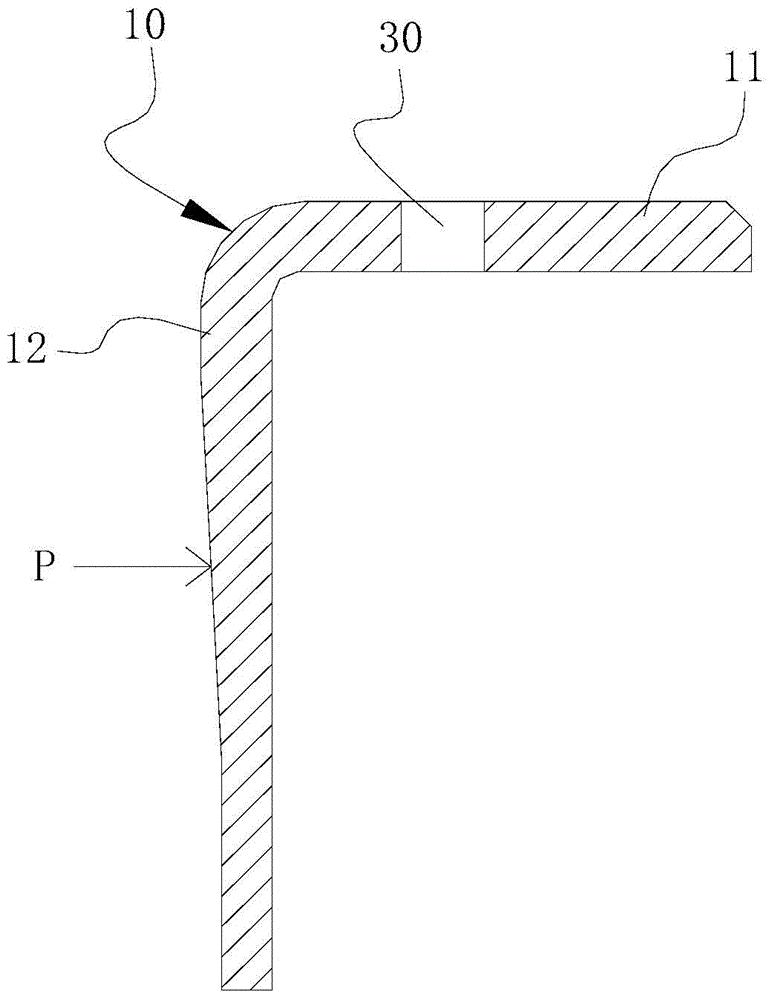

Mobile phone shell and manufacturing method thereof

ActiveCN104468885AHigh strengthReduce weightDomestic articlesTelephone set constructionsEngineeringInjection molding machine

The invention discloses a method for manufacturing a mobile phone shell. The method comprises the steps of preparing a metal substrate used for manufacturing the mobile phone shell; punching the metal substrate; bending the position, close to an antenna slot, of the punched metal substrate to obtain a bent part; conducting upsetting and extrusion on the bent part; conducting injection molding on the metal substrate to obtain a required plastic part; conducting filling injection molding on the bent part; conducting surface treatment on the metal substrate, the plastic part and filled plastic. By punching the metal substrate firstly, then conducting bending, upsetting and extrusion on the position, close to the antenna slot, of the metal substrate, obtaining the required plastic part through injection molding on the metal substrate, conducting plastic supplement, and finally conducting surface treatment on the whole workpiece, the method has the advantages that time for conducting surface treatment on the metal substrate can be shortened and production cost can be saved compared with the prior art. The invention further provides a mobile phone shell.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Routine paraffin wax flaking HE dyeing non-xylol whole-course treatment liquid for biological organization sample

InactiveCN101344467AThoroughly dehydratedSpeed up productionPreparing sample for investigationParaffin waxNon toxicity

The invention aims at providing a pathological diagnosis reagent, which is mainly used for processing various tissue samples in the pathology department in all levels of hospitals, can satisfy the requirements of a global non-xylene HE dyeing treating fluid of routine paraffin slices of biological tissue samples that is required in the slicing technique of the tissue samples with manual operation or operation of an automatic dehydrator and in the HE dyeing technique of cast-off cells, and is separated into two parts of tissue dehydration and section staining. As a novel conservation-conscious environmental protection technique, the pathological diagnosis reagent quickens splicing speed and simultaneously leads the tissue not to become over shrunk, hardened, split and crisp and leads the cells and the tissue structure to be closer to original patterns; the pathological diagnosis reagent has more complete tissue dehydration and adopts various novel mixed reagents that are pure analyzing organic chemical reagents with low volatility or non-volatility, non-toxicity and non-pollution, thus replacing originally widely used xylene reagents that have toxicity and heavy environmental pollution and eliminating occupational diseases that are caused by the xylene reagents in the global slicing of tissue sample preparation and tissue slice HE dyeing.

Owner:赵晓辉

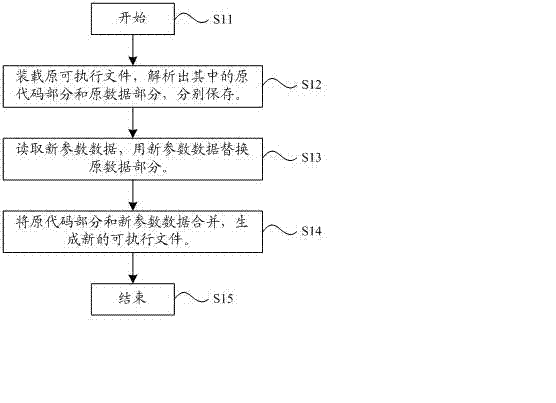

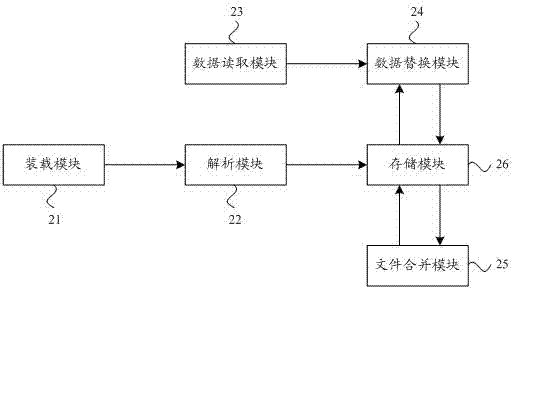

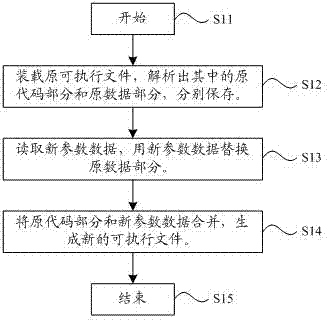

Generation method and device of executable file

InactiveCN102508660AEnsure safetySpeed up productionSpecific program execution arrangementsOriginal dataNew Executable

The invention discloses a generation method and device of an executable file. The generation method comprises the following steps: loading the original executable file and parsing out an original code part and an original data from the original executable file according to the creation rules of the original executable file; reading new parameter data which is required for the executable file to be generated and substituting the new parameter data for the original data part; and merging the original code part with the new parameter data and generating the new executable file. According to the method disclosed by the invention, data parameters can be modified on the basis of not modifying program codes, then the new executable file can be obtained, the participation of design staff of a source program is not required during the whole process, codes are less prone to being modified mistakenly, and the whole product production scheduling can be improved.

Owner:HISENSE BROADBAND MULTIMEDIA TECH

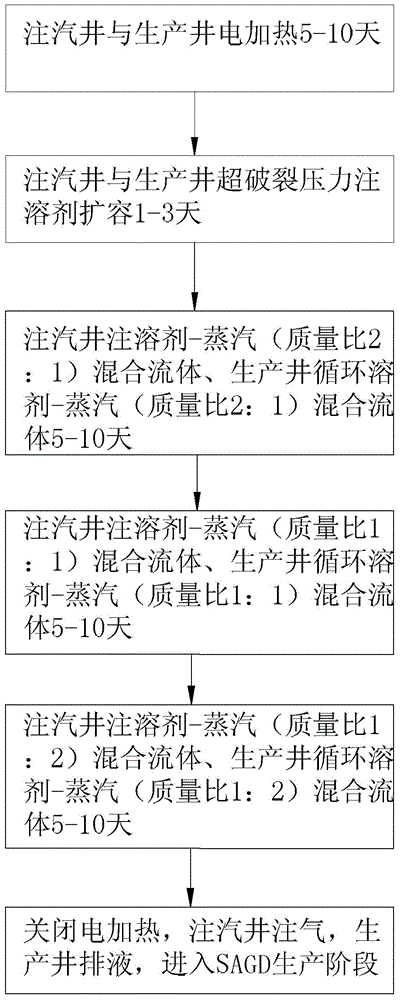

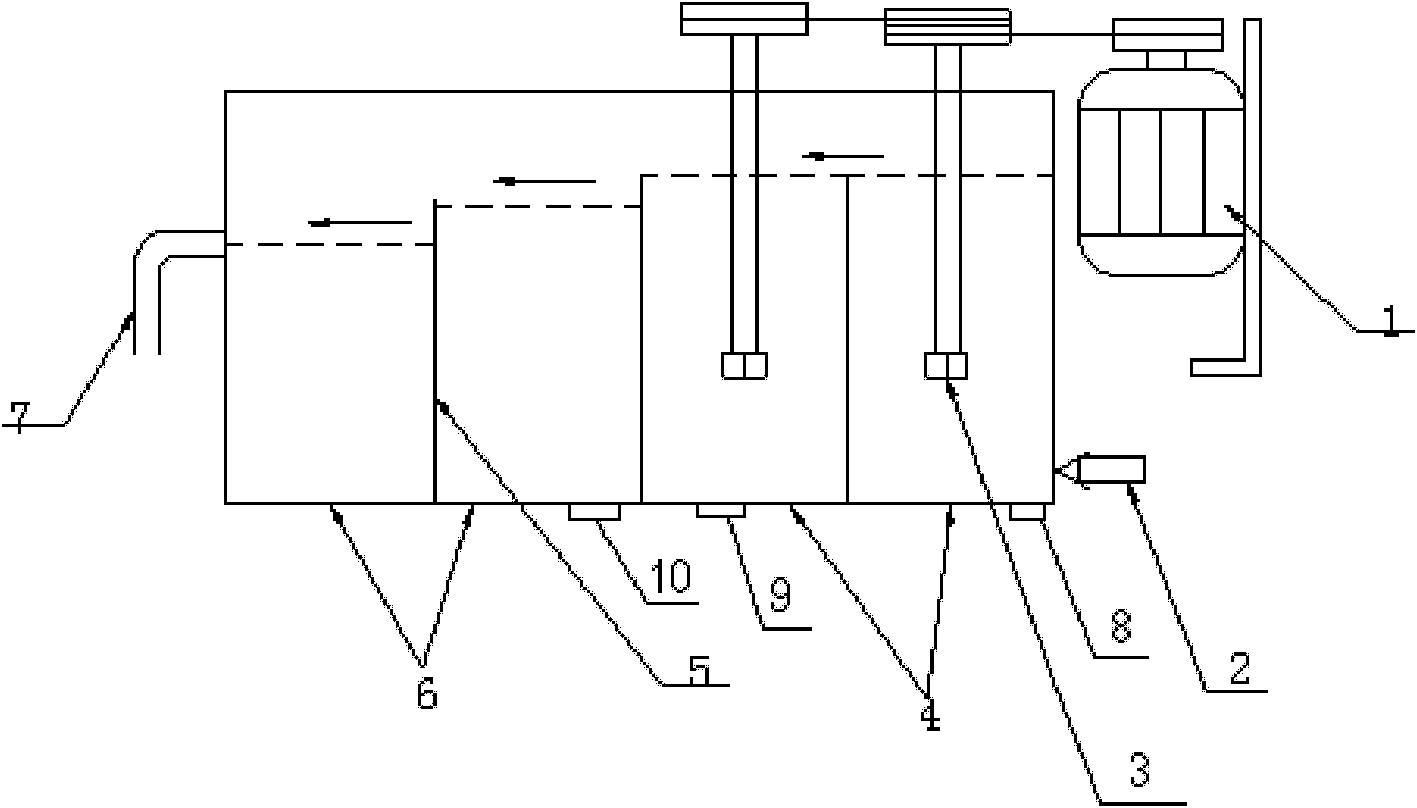

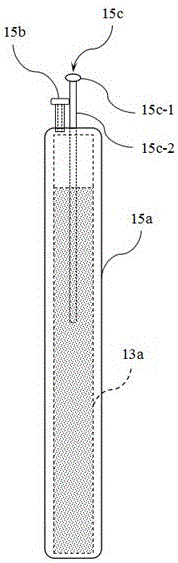

Rapid start method for heavy oil reservoir steam assisted gravity drainage

ActiveCN104453805ABuild pressure connectionIncrease the range of viscosity reductionFluid removalSolventInjection well

The invention discloses a rapid start method for heavy oil reservoir steam assisted gravity drainage. The rapid start method for heavy oil reservoir steam assisted gravity drainage comprises the following steps that (1) a steam injection well and a producing well are electrically heated at a large power; (2) a solvent is injected into a long oil pipe and a short oil pipe of the steam injection well and a long oil pipe and a short oil pipe of the producing well at the same time; (3) a solvent and steam liquid mixture is injected into the long oil pipe and the short oil pipe of the steam injection well at the same time, the solvent and steam liquid mixture is injected into the long oil pipe of the producing well, and the short oil pipe of the producing well discharges liquid; (4) electric heating is stopped, pure steam is injected into the long oil pipe of the steam injection well and the short oil pipe of the seam injection well at the same time, and the long oil pipe and the short oil pipe of the producing well discharge liquid at the same time. Compared with a conventional preheating start method, time is shortened by over two thirds, so that the heat energy utilization rate is greatly increased, rapid preheating start of SAGD can be achieved, and the production speed of SAGD is increased. In addition, through rapid solvent volume expansion and super fracture pressure injection, an even oil drainage channel can be established, and the purposes of increasing the yield and the recovery rate are achieved.

Owner:PETROCHINA CO LTD

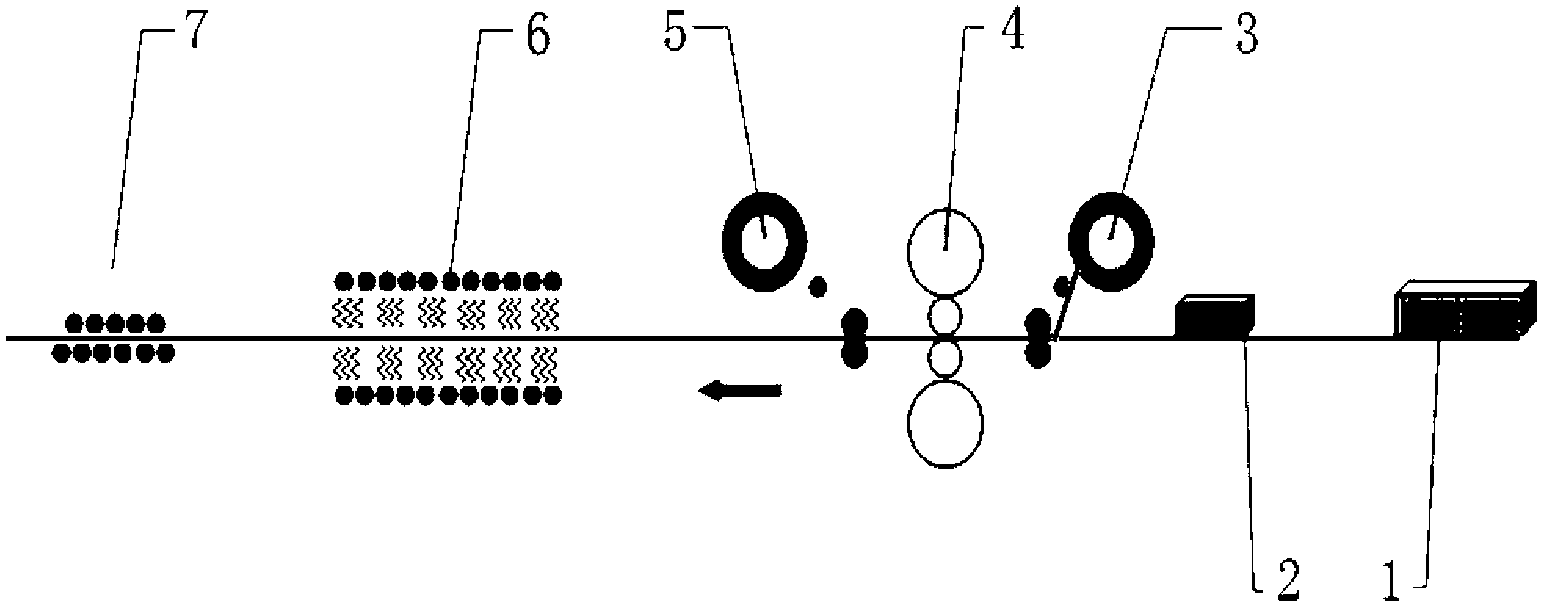

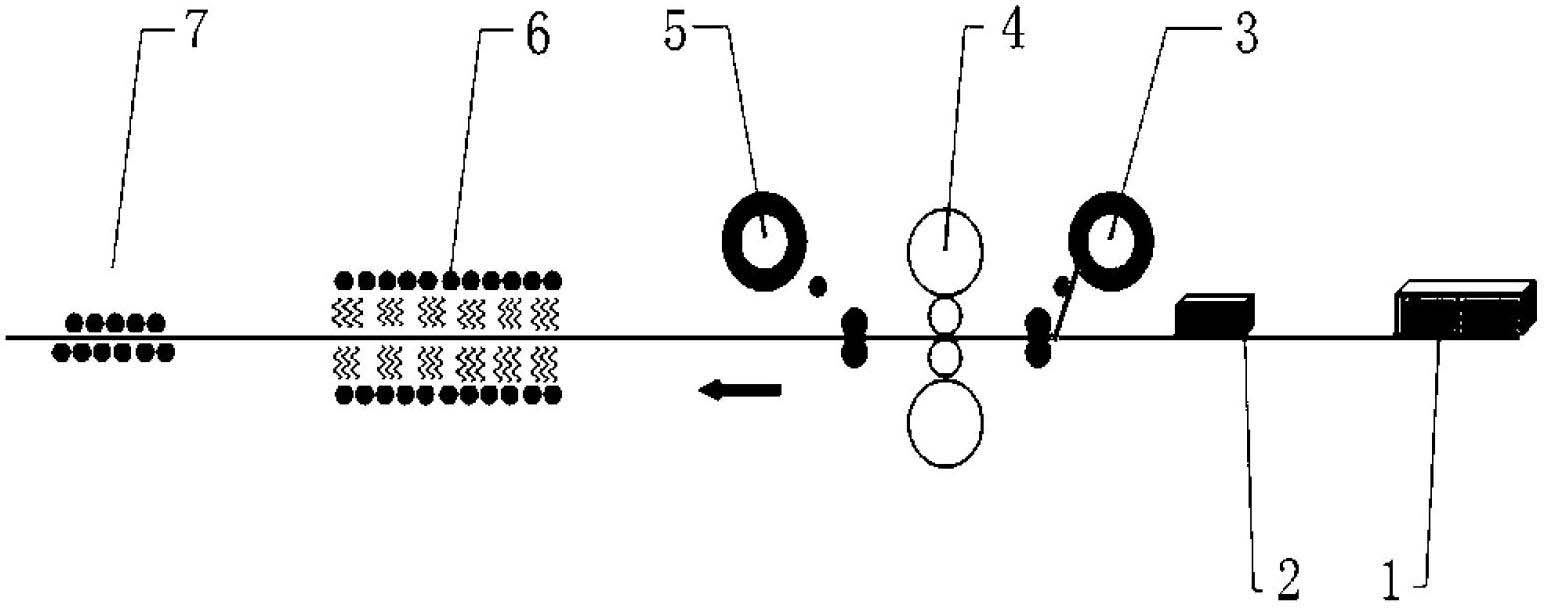

Plate shape control method of hot-rolling and coiled-rolling steel plate of single-rack steekle mill

ActiveCN102699023AImprove the rolling rateSpeed up productionRoll force/gap control deviceTemperature control deviceSteel platesShape control

The invention belongs to the field of steel rolling and discloses a plate shape control method of a hot-rolling and curved-rolling steel plate of a single-rack steekle mill. The plate shape control technology of the hot-rolling and curved-rolling steel plate of the single-rack steekle mill is realized by the steps of adjusting a heating system, optimizing temperature setting of a coiler furnace, adjusting coiled-rolling tension force of the coiler furnace, optimizing a down-pressing system, utilization of bending rolling force of a milling machine and a straightening machine as well as a roller convex degree of a working roller, improving temperature of cooling water which keeps a thin coiled-rolling plate, using an edge shielding function of a laminar flow cooling system, comprehensively adjusting straightening process of edge rollers and bending rollers of a hot straightening machine and the like. When a long billet with a thickness of 150 mm to 220 mm and a steel plate with a rolling thickness not greater than 12 mm are used, the plate shape control method disclosed by the invention has the advantages of synthetically controlling plate shape of the coiled-rolling steel plate and optimizing mechanical properties of the coiled-rolling plate.

Owner:NANJING IRON & STEEL CO LTD

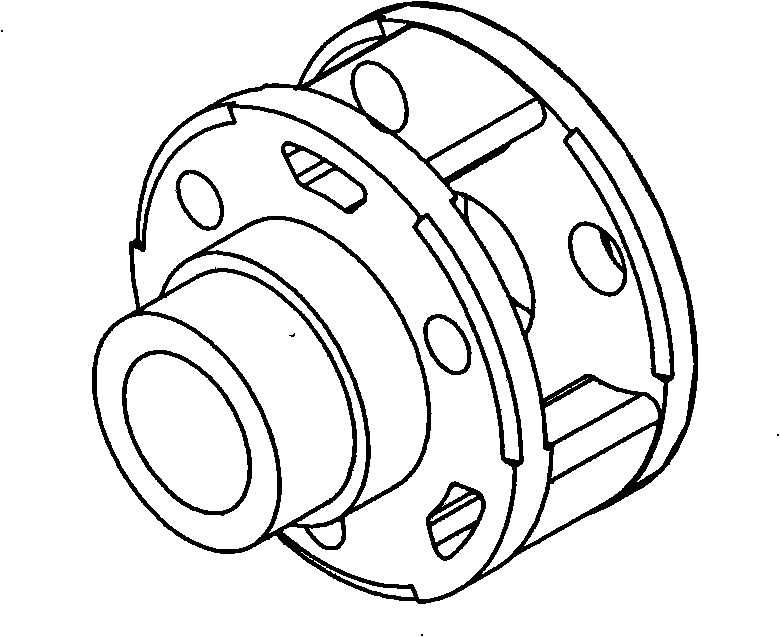

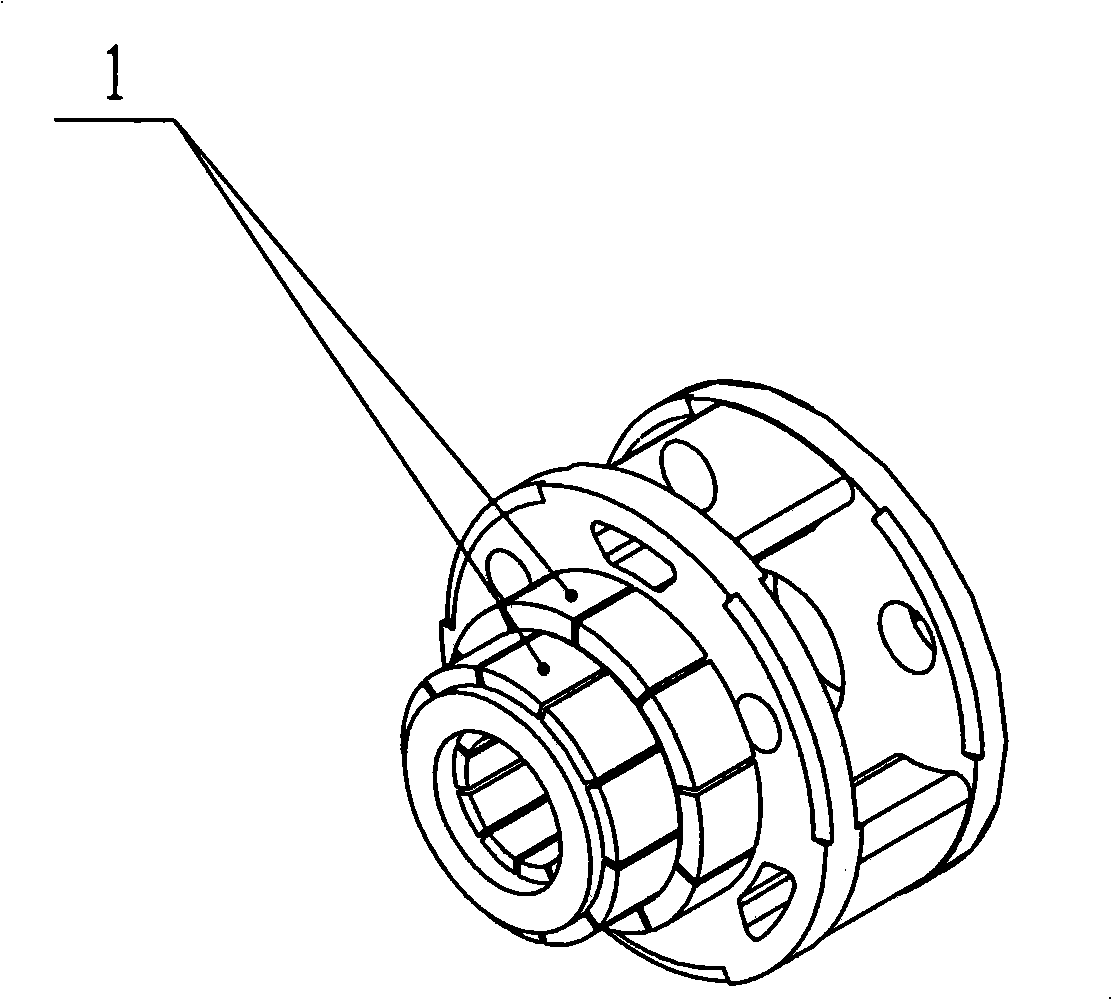

Method for producing nodular cast iron planetary supporter

ActiveCN101343711AHigh tensile strengthHigh yield strengthGearing detailsDuctile ironMechanical property

The invention discloses a nodular cast iron planet carrier production method. The nodular cast iron planet carrier production method comprises a smelting iron fluid working procedure, a nodulizing working procedure, an inoculation working procedure and a casting working procedure; after the casting working procedure is finished, when the planet carrier in put into the casting mould, the temperature of T1 is maintained within 790 to 810 DEG C, the planet carrier casting product is taken from the casting mould and the temperature is rapidly reduced; when the temperature T1 of the planet carrier casting product is reduced to the temperature of T2, that is within 490 to 510 DEG C, the planet carrier casting product is hanged into a heat retaining vessel, and then after casting sand is covered on the planet carrier casting product, the thermal retardation is continued; when the temperature T2 of the planet carrier casting product is maintained to the temperature T3, that is within 190 to 210 DEG C, the planet carrier casting product is taken out from the heat retaining vessel and the cleaning work is performed; and finally, the stress removing and annealing working procedure is performed to the planet carrier casting product. The nodular cast iron planet carrier production method has the advantages that the operation is simple, the energy consumption is less, the cost is low, the production cycle is short, the costing product distortion is not easy, and the planet carrier casting product contains pearlyte of more than 80 percent to reach the mechanical property requirements.

Owner:RIYUE HEAVY IND

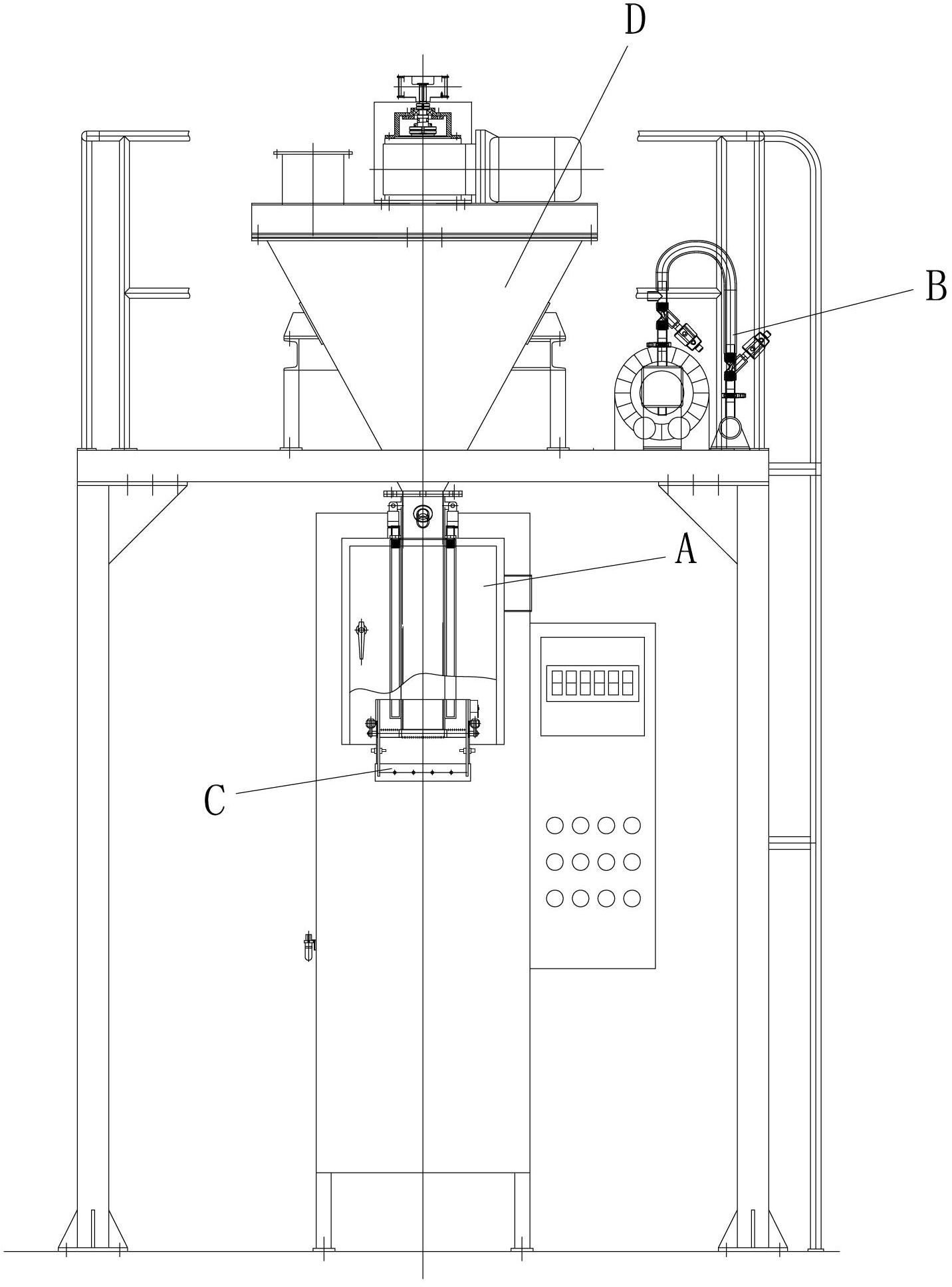

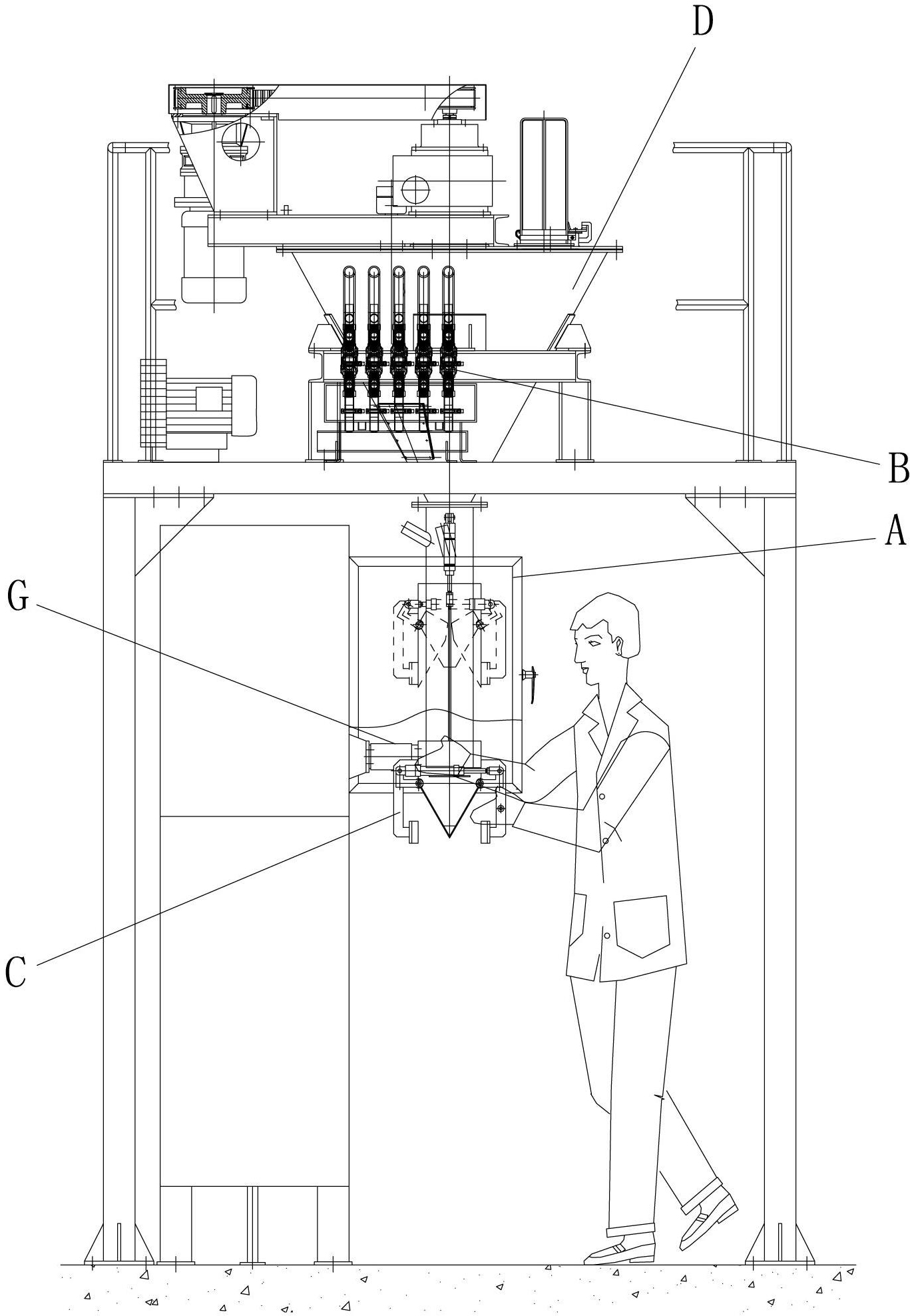

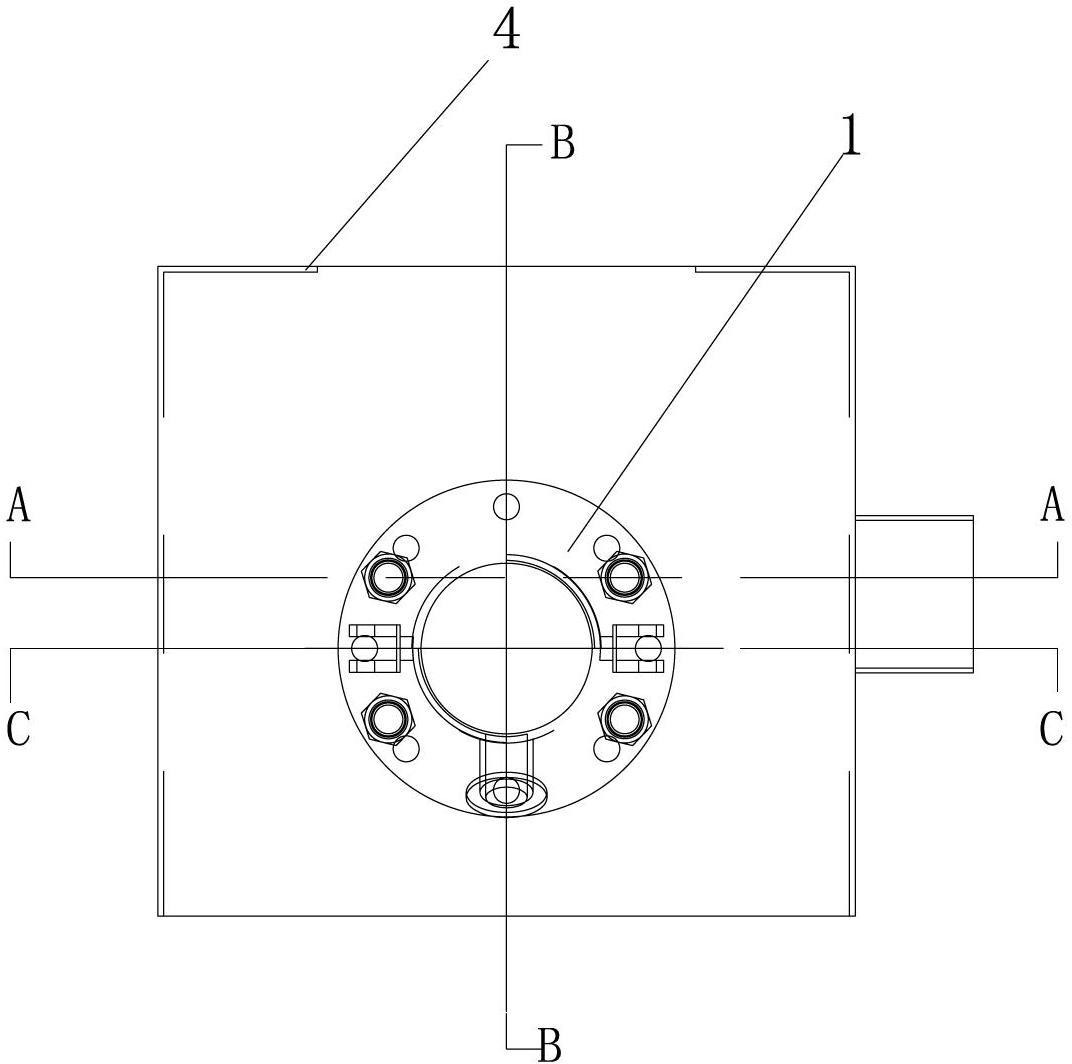

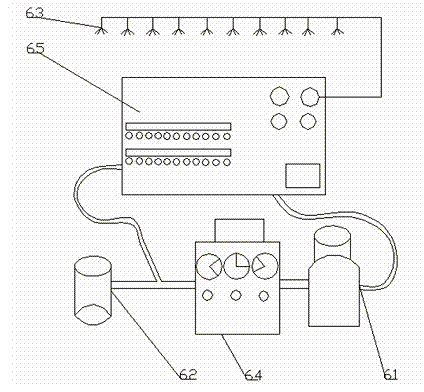

Operating method of powder material packing scale

The invention relates to an operating method of a powder material packing scale, which is suitable to solve the problems that the packaging bag is unable to be vertically placed and the rated quantity of materials are difficultly put into the bag within a normal time when powder materials with high gas contents enter a packaging bag; and the dust is easy to fly everywhere, after the packaging equipment is used, a better effect is obtained, and the efficiency is improved. The packaging scale comprises a degassing blanking device which is arranged on an outlet at the bottom of a hopper, an air suction blowing combination valve group and a vacuum pump which are used for degassing, blowing and blockage removing and are connected with the degassing blanking device, and a pneumatic bag-clamping lifting mechanism which is arranged at the bottom of the degassing blanking device; and the degassing blanking device comprises a blanking barrel, integrated microporous filter elements are arranged at both the inner wall and the outer wall of the blanking barrel, and the pore diameters of the filter elements can be set according to the sizes of material particles, and can range between 50 mum and 1mum. Ports which are communicated with a clearance between the inner wall of the blanking barrel and the inner filter elements are arranged in the outer wall of the blanking barrel; and the ports are connected with air suction blowing combination valves.

Owner:CHANGZHOU CHANGHENG DEYU POWDER INTEGRATIVE SYST

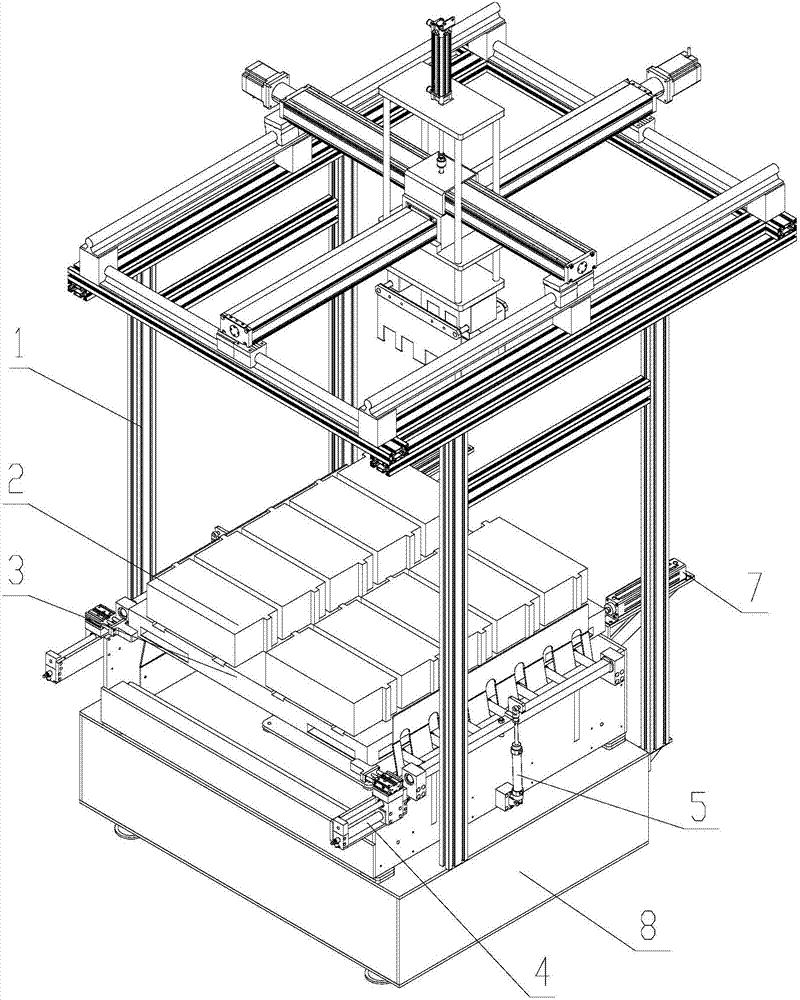

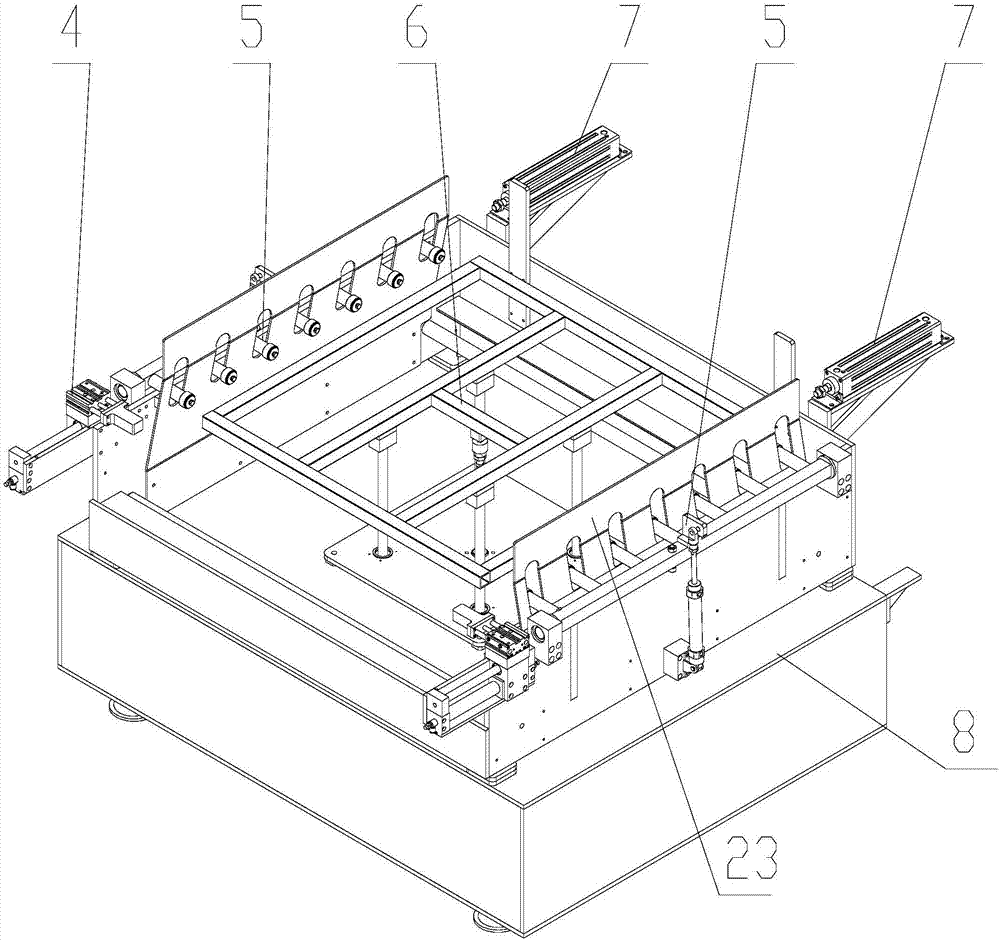

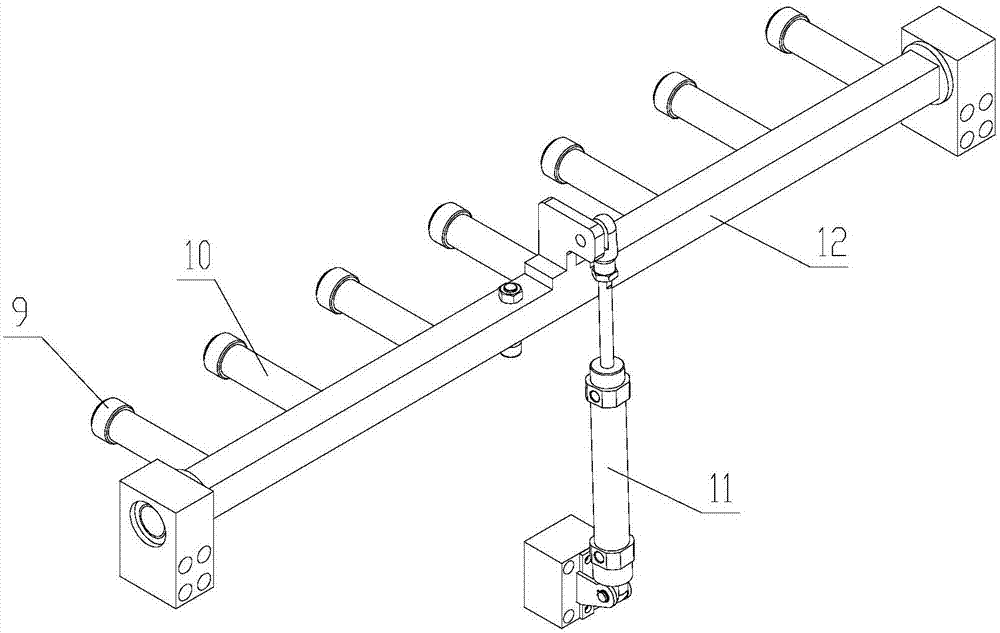

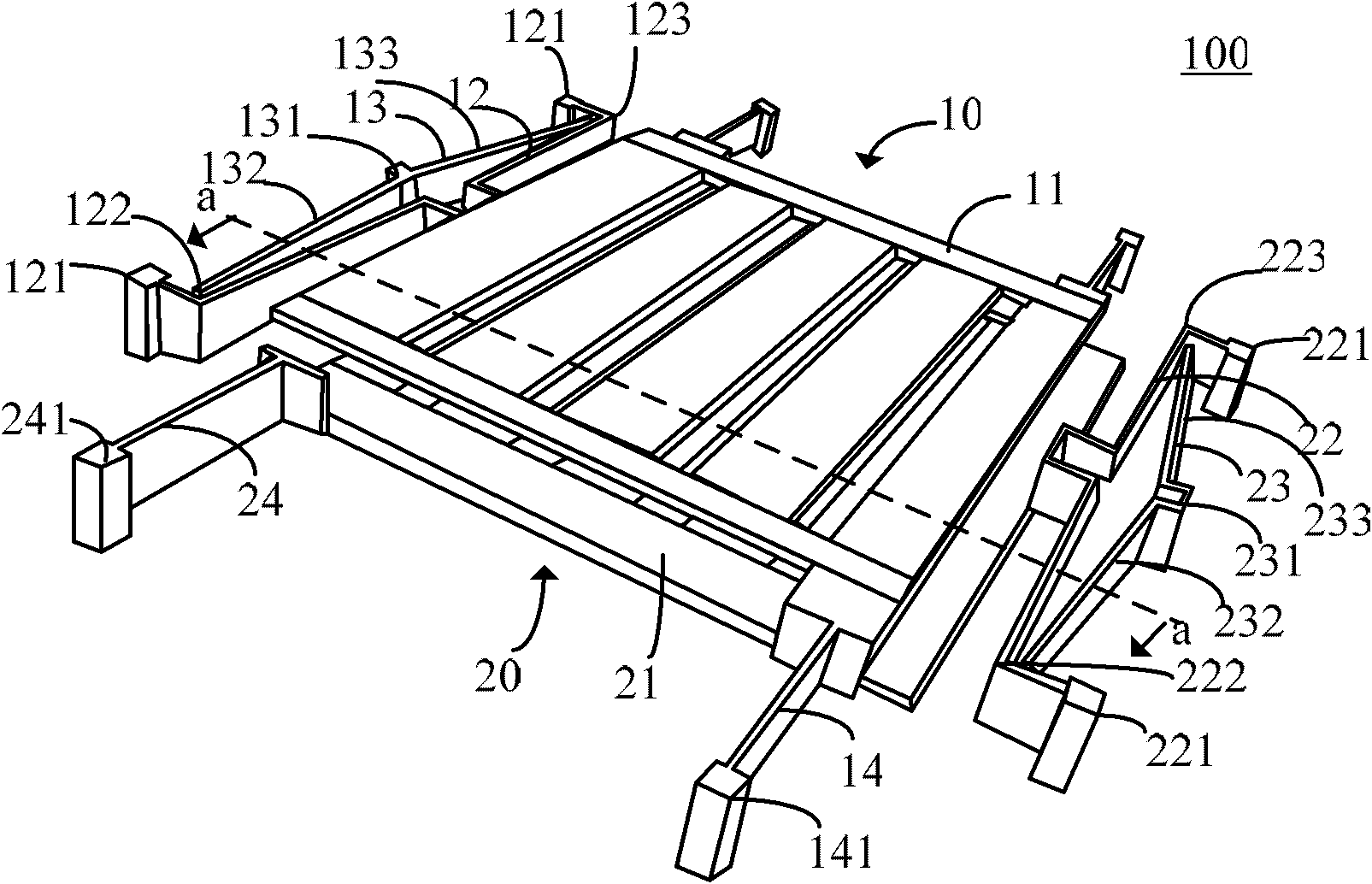

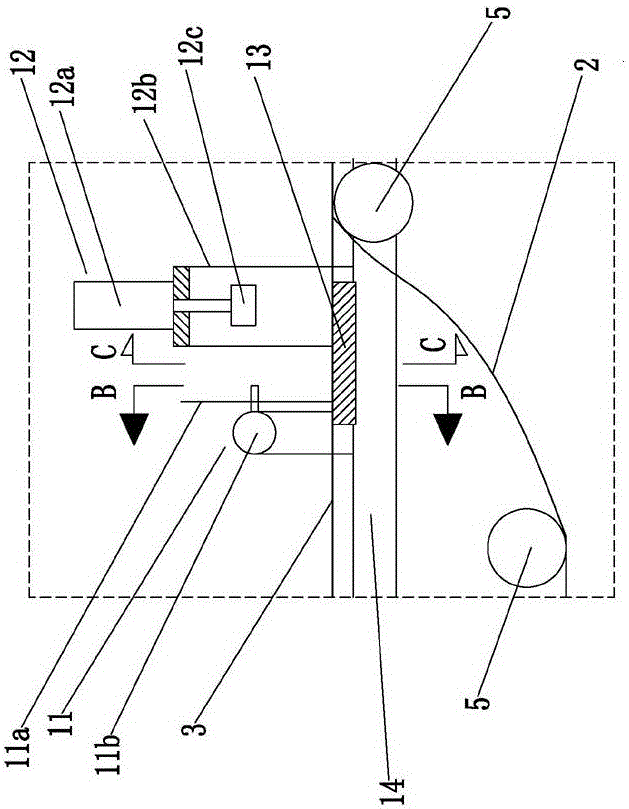

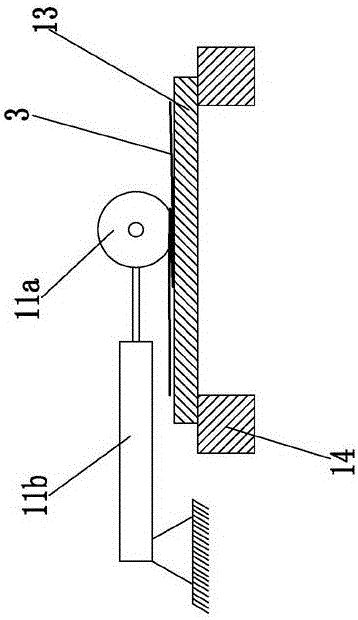

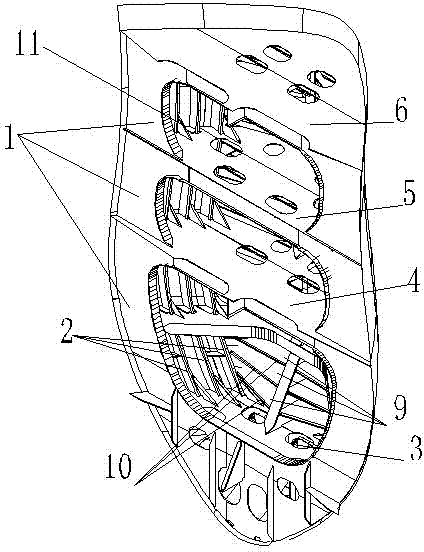

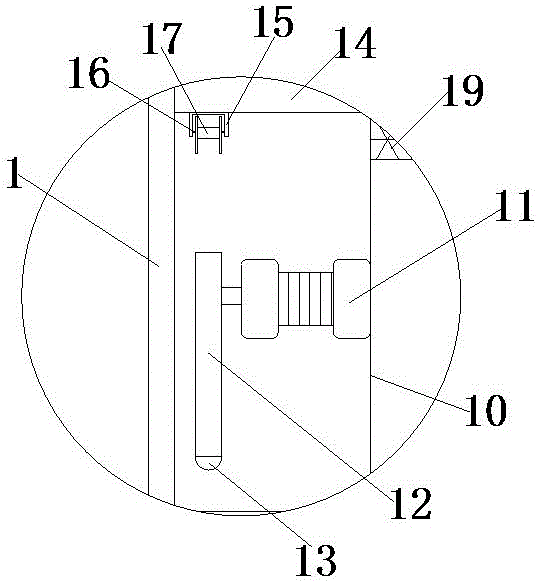

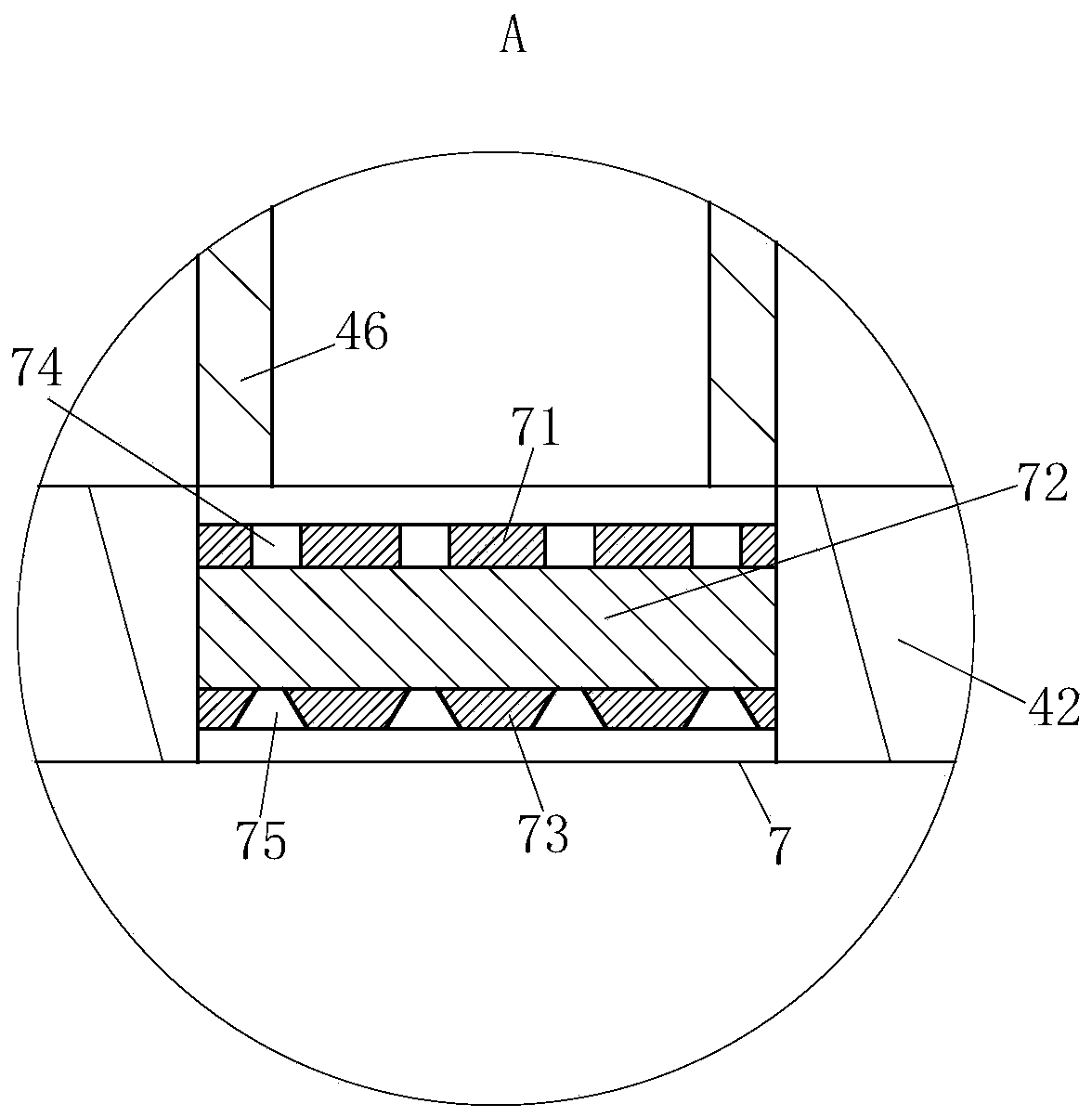

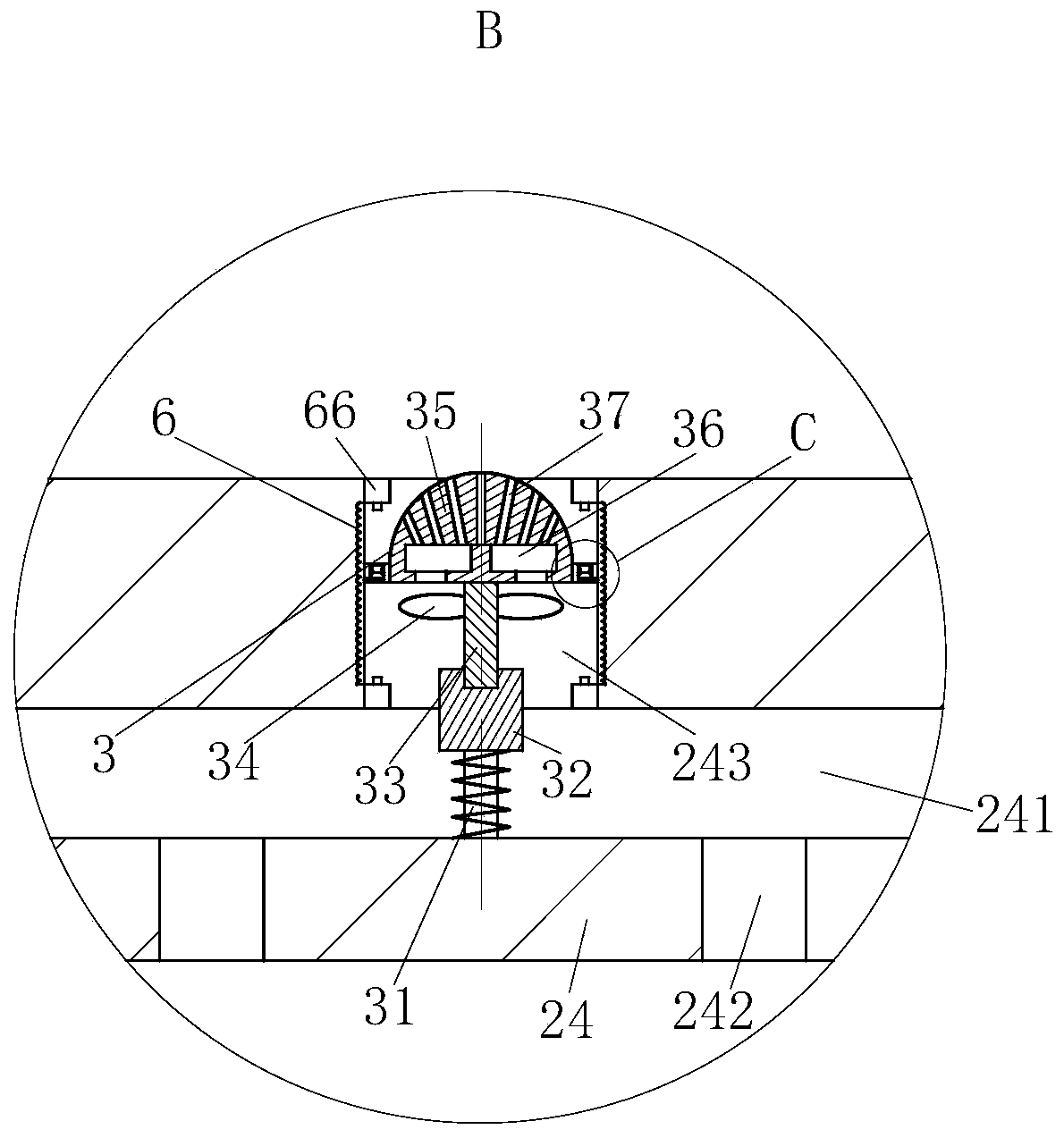

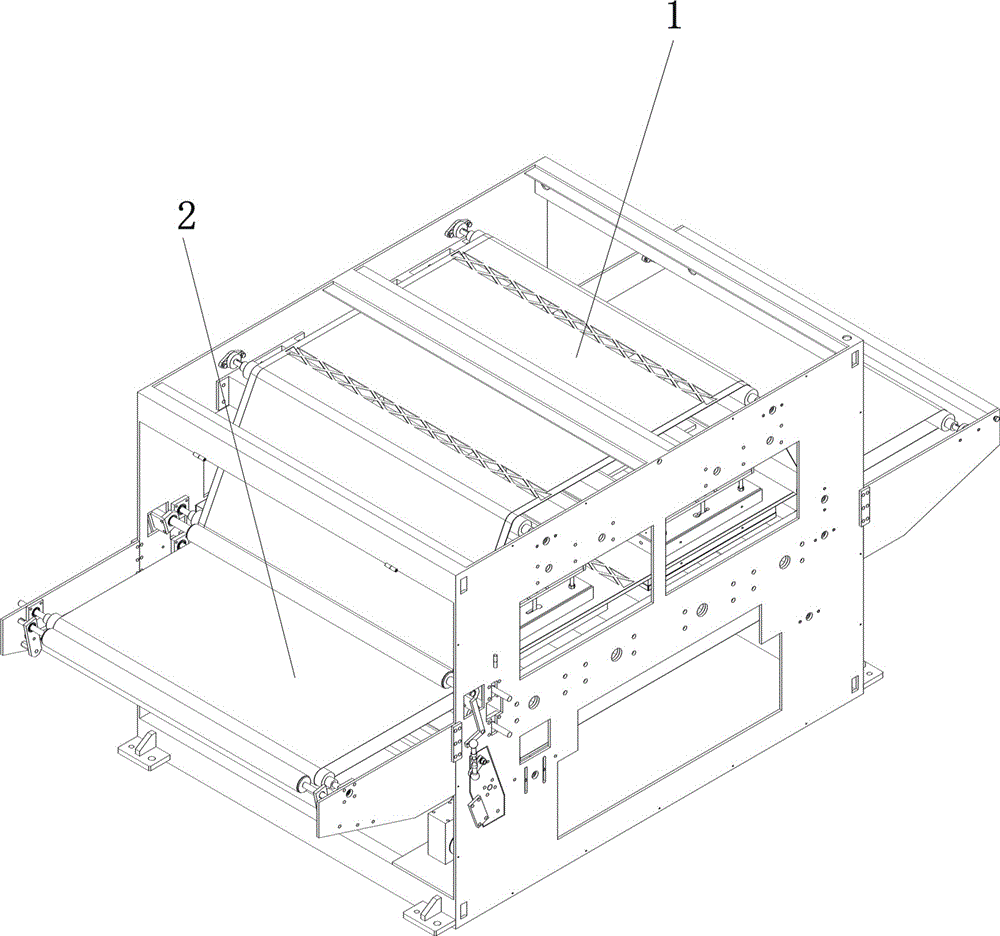

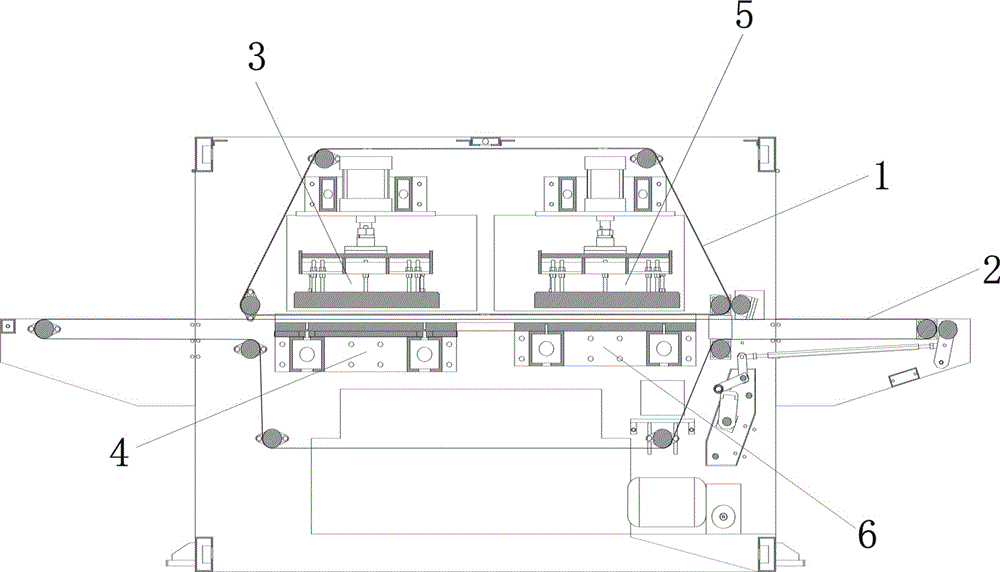

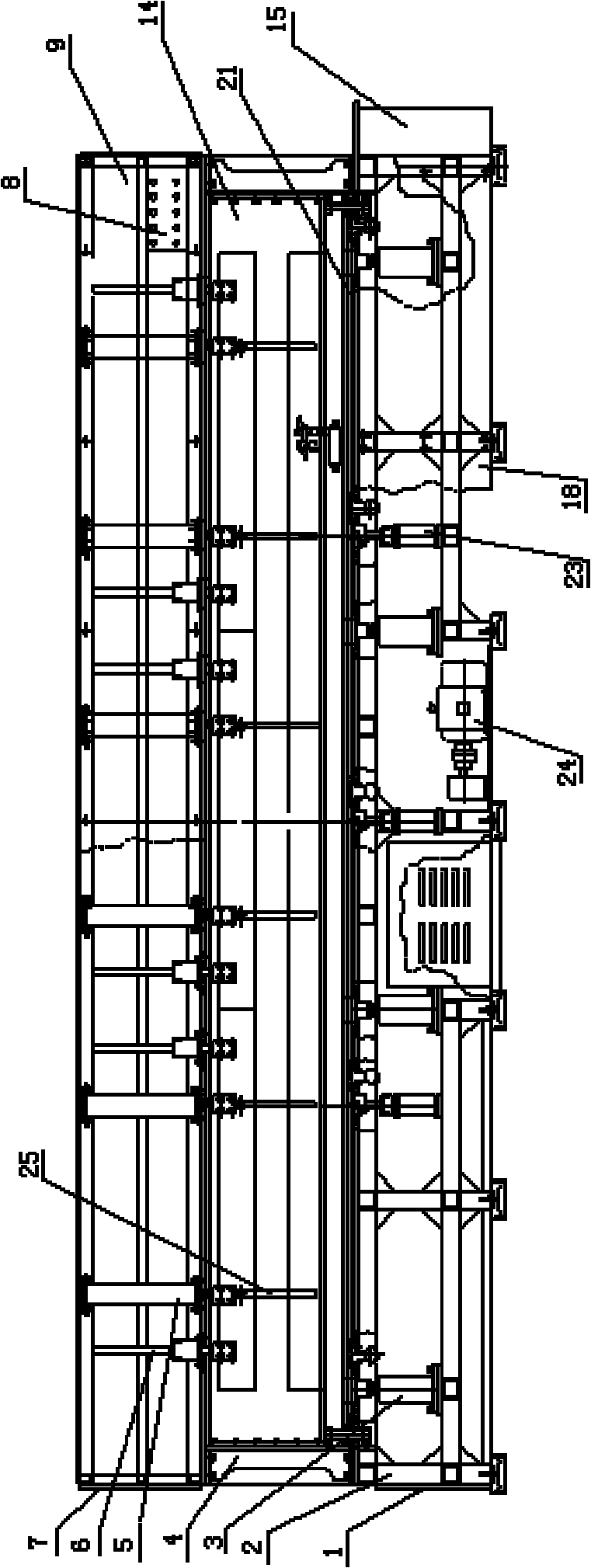

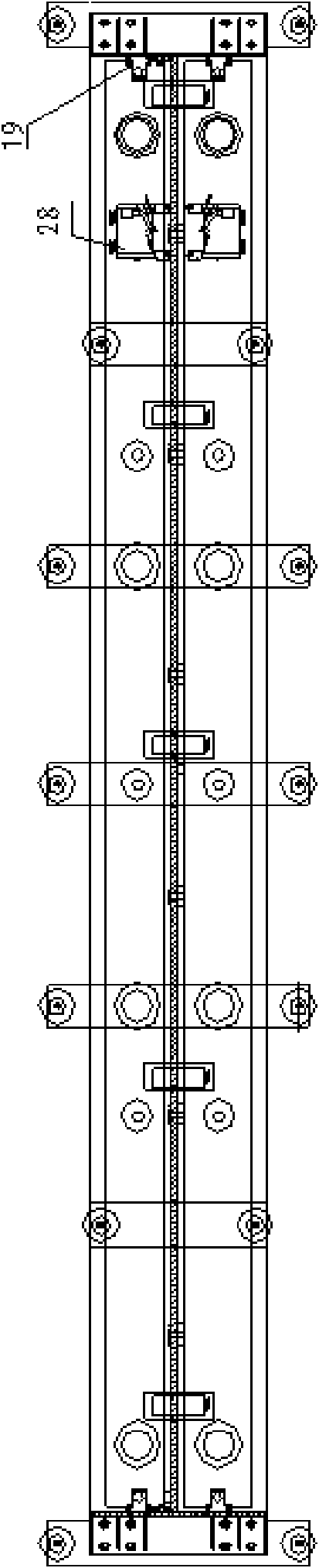

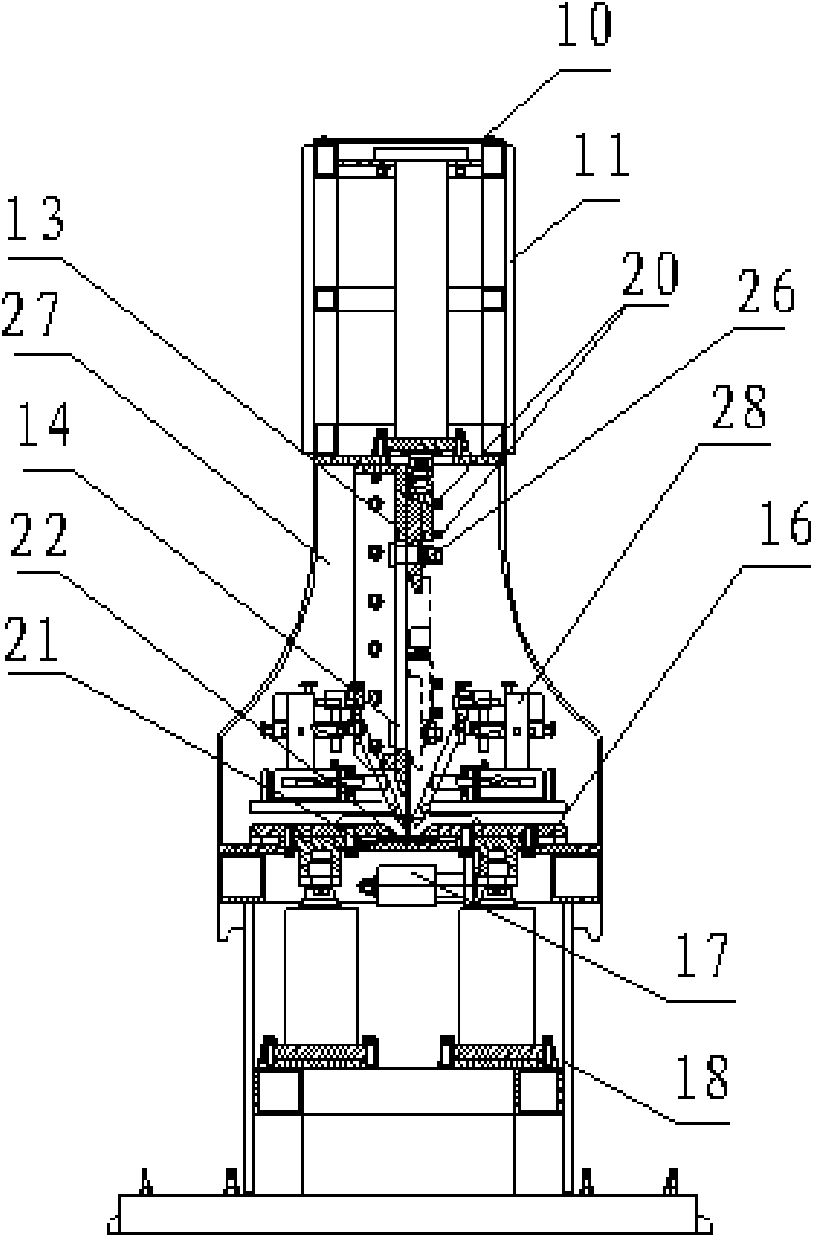

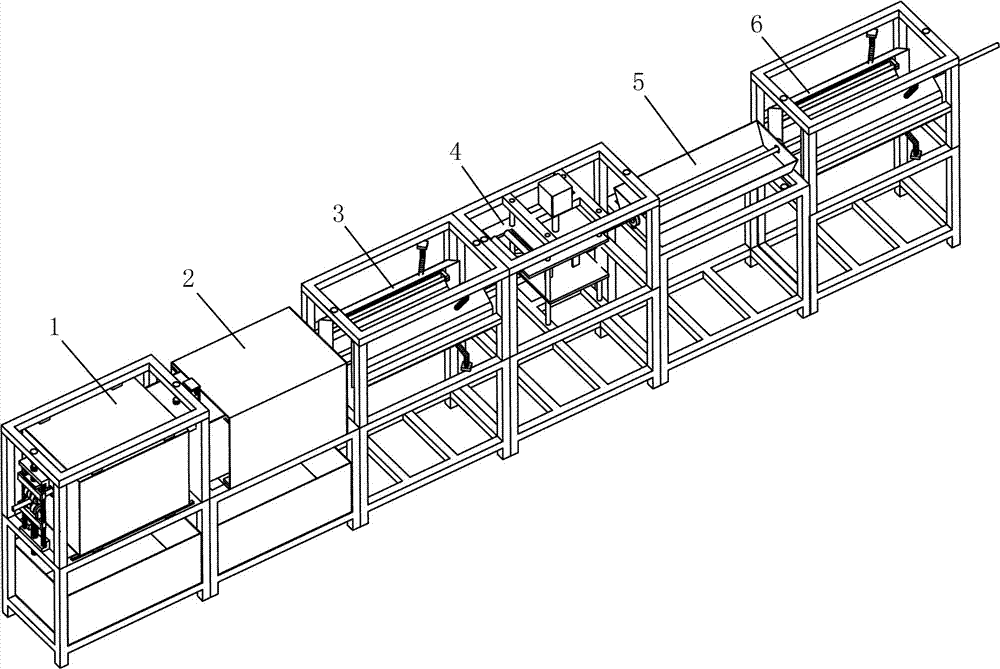

Automatic stacking device for storage battery electrode plates

PendingCN107381075AHigh degree of automationReduce labor intensityLead-acid accumulator electrodesStacking articlesProduction lineManipulator

The invention discloses an automatic stacking device for storage battery electrode plates. The automatic stacking device comprises a rack, a lifting mechanism, supporting and positioning assemblies, a manipulator assembly and pushing mechanisms. The lifting mechanism is used for storing an electrode plate heap tray and controlling the electrode plate heap tray to ascend and descend. The supporting and positioning assemblies are used for supporting and positioning the electrode plate heap tray. The manipulator assembly is used for automatically carrying electrode plate heaps into the electrode plate heap tray. The pushing mechanisms are used for pushing out the electrode plate heap tray. The lifting mechanism is arranged in the rack, the supporting and positioning assemblies are fixed to the rack and located on the two sides of the lifting mechanism, the manipulator assembly is detachably fixed to the rack and located above the lifting mechanism, and the pushing mechanisms are arranged on one side of the rack. By means of the automatic stacking device, automated stacking can be achieved, the labor intensity of workers is lowered, work efficiency is improved, the automated degree of a production line is increased, the production progress is accelerated, and the automatic stacking device is simple in structure, convenient to machine and manufacture and convenient to use.

Owner:中国船舶重工集团衡远科技有限公司

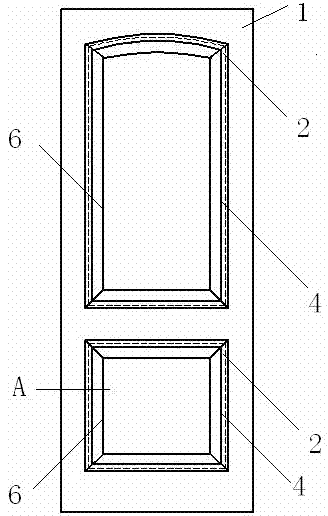

Wooden door processing technology for conveniently improving production efficiency

ActiveCN103029194AReduce size requirementsEfficient use ofWood working apparatusUltravioletEngineering

The invention discloses a wooden door processing technology for conveniently improving production efficiency, which comprises the following processing technologies of: (1) a processing technology for a door leaf of a wooden door; and (2) a processing technology for a doorframe 16 of the wooden door. Both the processing technologies comprise the following steps of: (1) a process of processing and forming each component in advance, wherein a door leaf frame and a flexible cord frame are formed in a splitting manner; (2) a process of painting each component, i.e. painting the parts with large painting areas and flat surfaces in a manner of adopting a machine to carry out roll coating and enabling each part which is painted in a manner of adopting the machine to carry out roll coating to be irradiated by ultraviolet (UV) and be subjected to drying treatment; and (3) an assembling process, i.e. assembling the parts which are completed in the painting process in the step (2) according to a special corresponding structure obtained in the step (1) of processing and forming in advance so as to respectively obtain the door leaf of the wooden door and the doorframe of the wooden door. According to the invention, labor cost can be reduced, controllability of product quality is improved and wooden door production efficiency is greatly improved.

Owner:重庆积艺智能家居有限公司

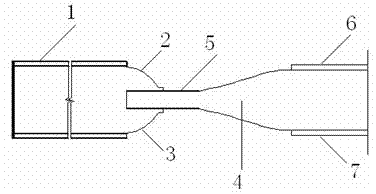

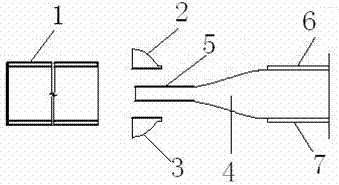

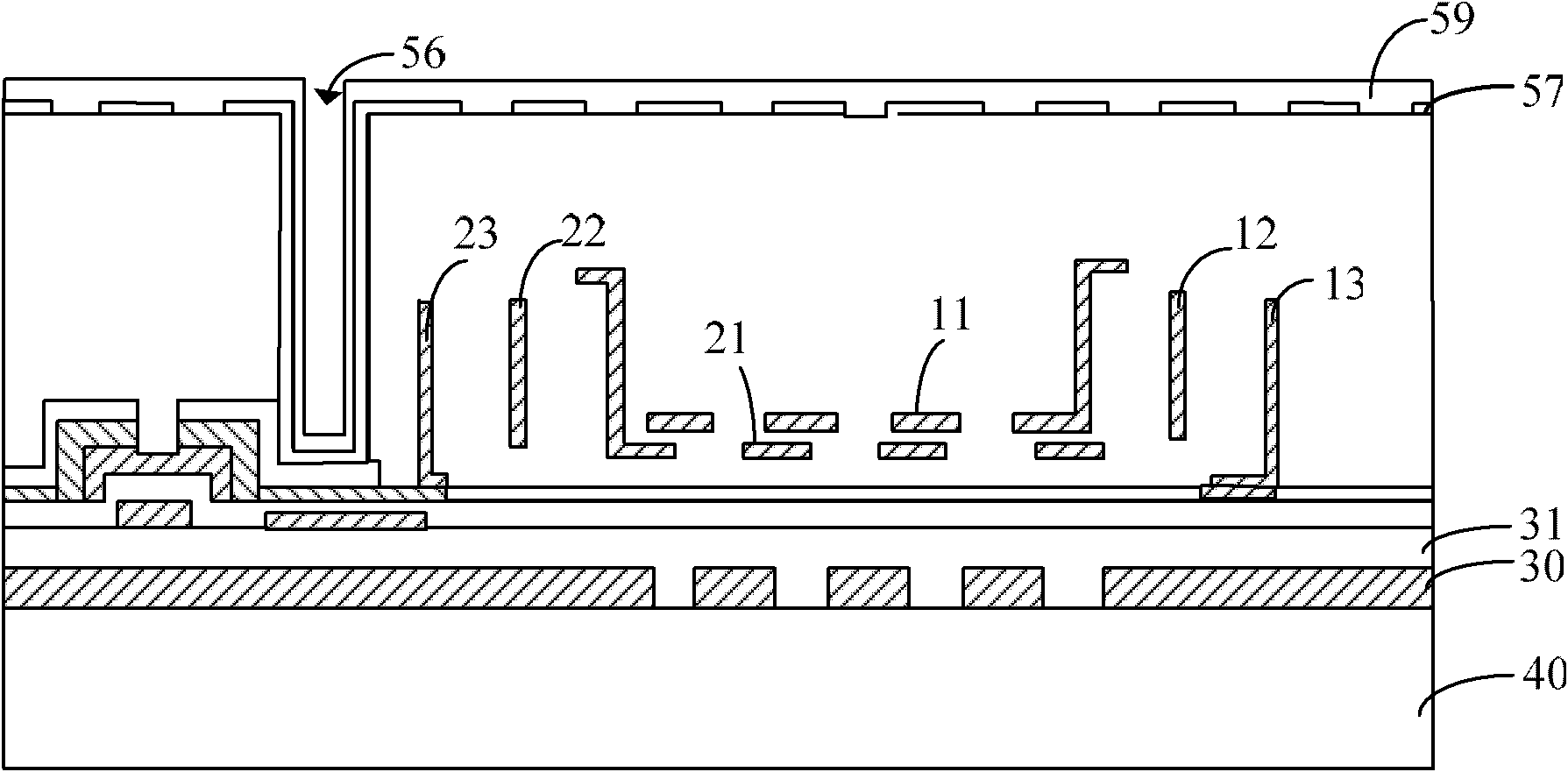

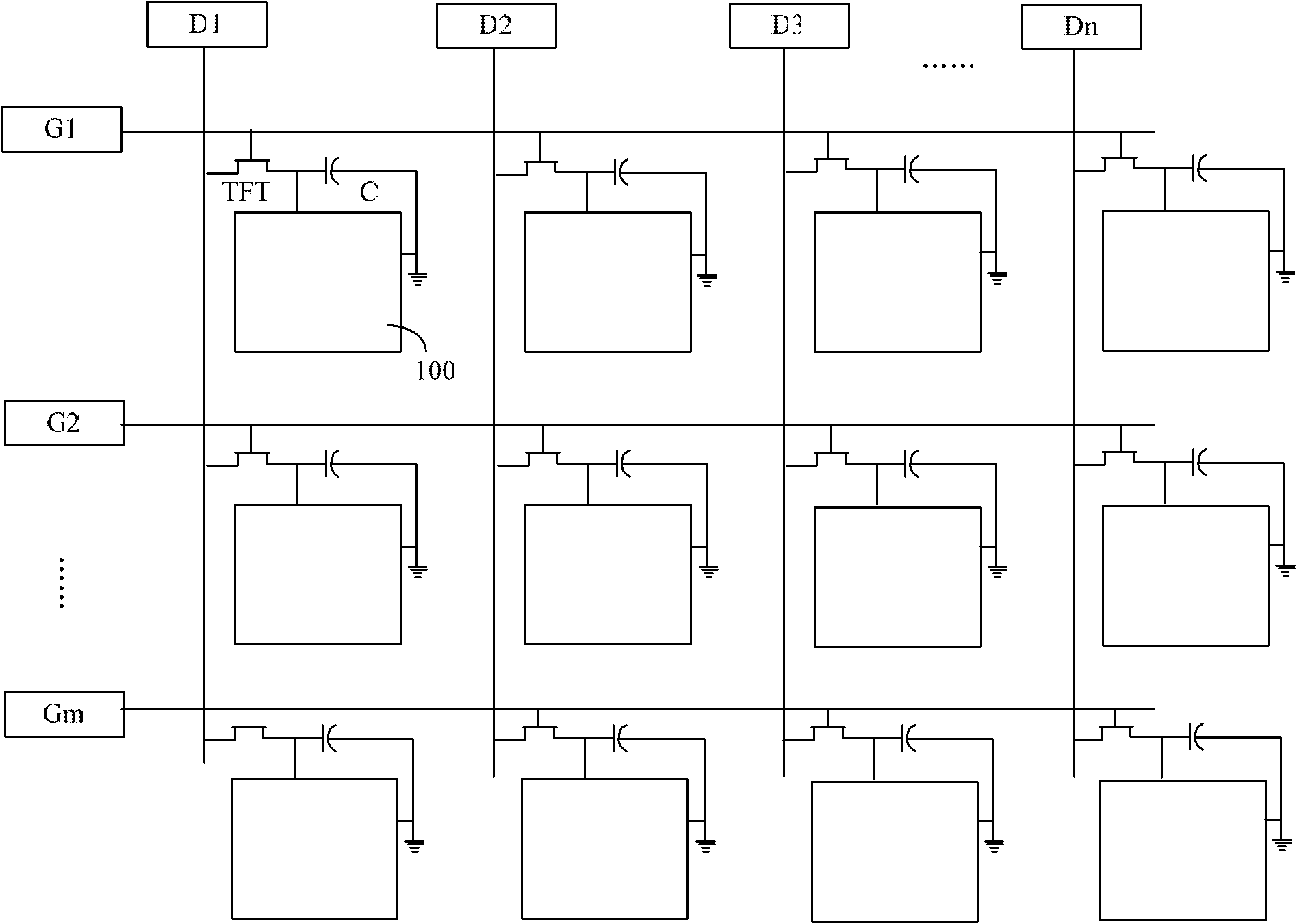

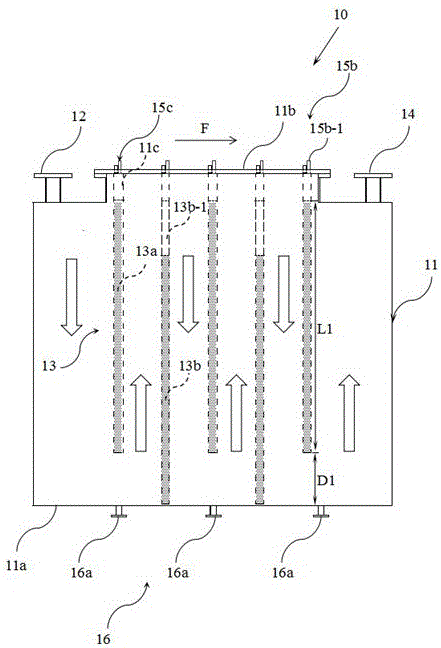

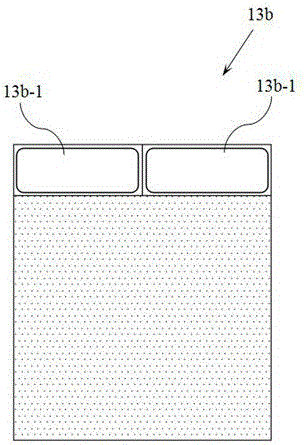

Display device with mems light valve and method of forming the same

ActiveCN102279463AHigh sensitivityEasy to controlStatic indicating devicesSubstation equipmentGratingDisplay device

The invention discloses a display device provided with a micro-electromechanical system (MEMS) light valve and a forming method thereof. The display device comprises a substrate as well as a fixed grating and the MEMS light valve which are positioned on the substrate, wherein the MEMS light valve is used for controlling the open and closure of the fixed grating, comprises a first light valve and a second light valve, and controls the open and closure of the fixed grating by controlling the movement of the first light valve and the second light valve; and the moving directions of the first light valve and the second light valve are opposite. The display device can be used for improving the sensitivity of the MEMS light valve.

Owner:XIAN YISHEN OPTOELECTRONICS TECH CO LTD

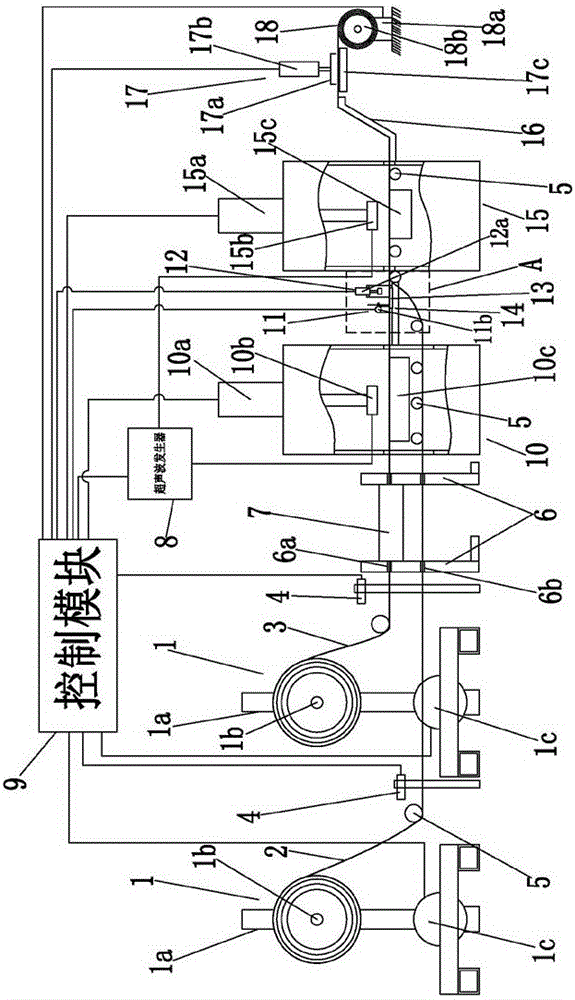

Disposable slipper producing device

The invention discloses a disposable slipper producing device in the technical field of disposable slipper production. The disposable slipper producing device comprises two feed devices, a vamp edge folding device, an ironing device capable of ironing and forming a bent vamp fabric, a die press capable of pressing the vamp fabric and a sole fabric together, an inclined slope type guide table, a final forming device capable of directly shearing out a finished product, and a winding device, further comprises a plurality of feed rollers which abut against the vamp fabric and the sole fabric and are used for controlling the conveying directions and relative positions of the vamp fabric and the sole fabric, and further comprises a control module and an ultrasonic generator. The ultrasonic generator is connected with an ironing die head and a forming die head through control lines and can control the heating temperatures of the ironing die head and the forming die head. The control module is connected with the ultrasonic generator, an ironing drive mechanism, a horizontal push-pull mechanism, a vertical lifting mechanism, a die head drive mechanism, a forming drive mechanism and a winding drive mechanism through control lines. The automation of the whole production process of disposable slippers can be achieved.

Owner:YANGZHOU MEINENGLIANG PLASTIC DAILY CHEM

Process for manufacturing ice zone bulbous bow reinforcing structure by sections

ActiveCN104760662AShorten the construction periodIncrease productivityHull stemsEngineeringMechanical engineering

The invention relates to a process for manufacturing an ice zone bulbous bow reinforcing structure by sections. An angle steel combined horizontal tangent rib frame is adopted during bulbous bow sectioning, and a strong rib frame is used as a reference surface for lying manufacturing. The process for manufacturing by sections comprises the following steps: sectioning; putting a strong rib frame large assembly on a jig; putting a first layer platform large assembly on the jig and assembling; putting a second layer platform large assembly on the jig and assembling; putting a third layer platform large assembly on the jig and assembling: assembling a third layer platform plate and a third strong rib frame assembly into the third layer platform large assembly; putting a fourth layer platform large assembly on the jig and assembling; assembling a third middle longitudinal girder assembly and a fourth middle longitudinal girder assembly into a whole; mounting ribs; mounting an external plate. The process has the advantages that the angle steel combined horizontal tangent rib frame is adopted, and the strong rib frame is used as the reference surface for lying manufacturing, so that the production efficiency is improved, the period for constructing the bulbous bow by sections is shortened, and the shipbuilding speed is increased.

Owner:南通华川交通装备有限责任公司

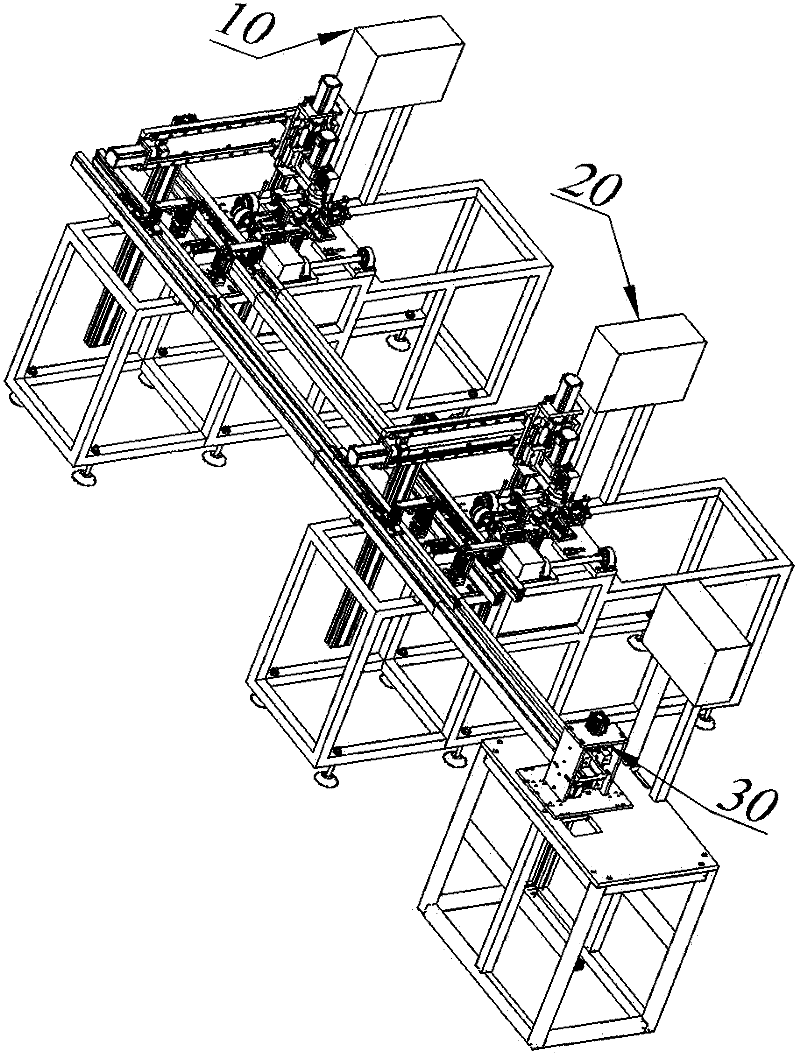

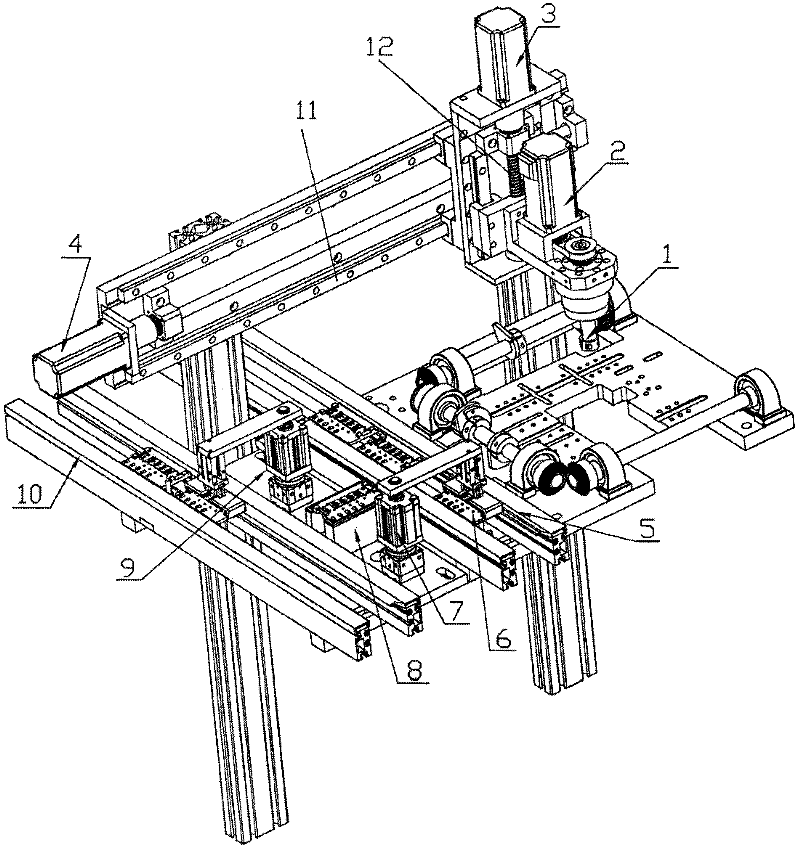

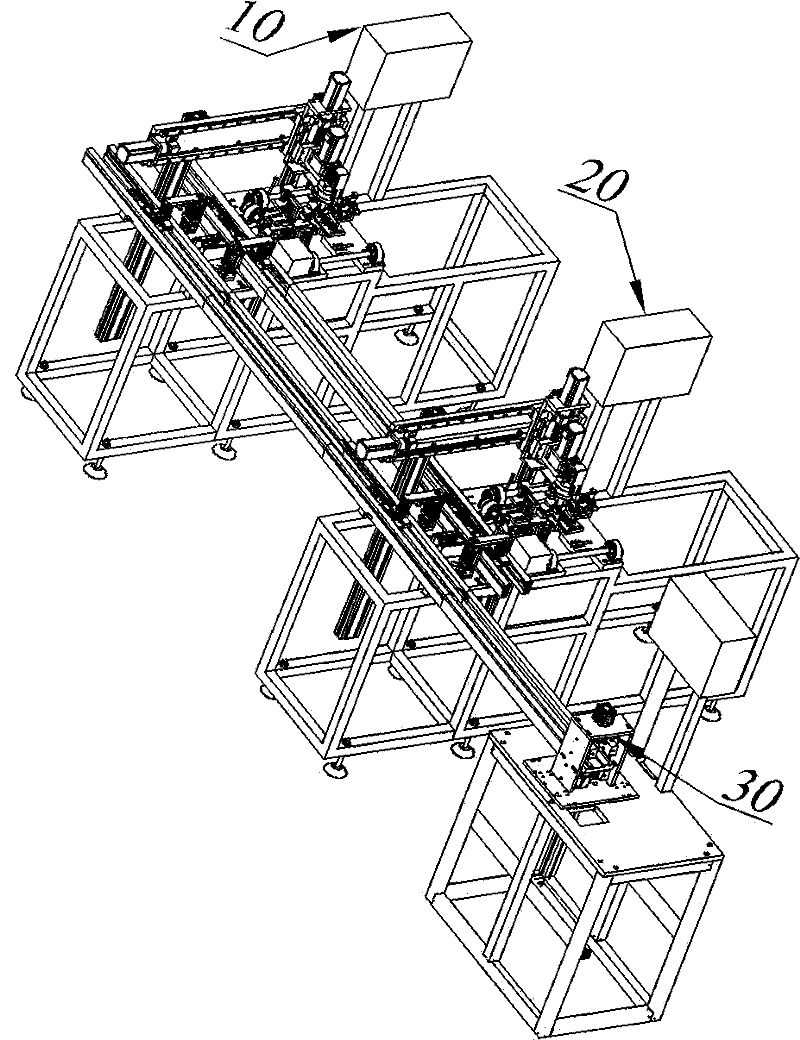

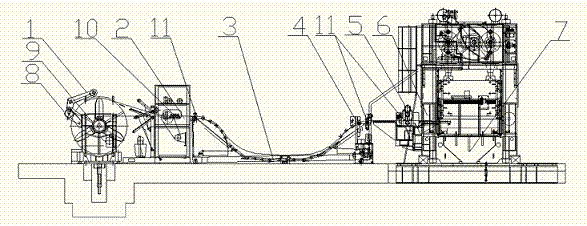

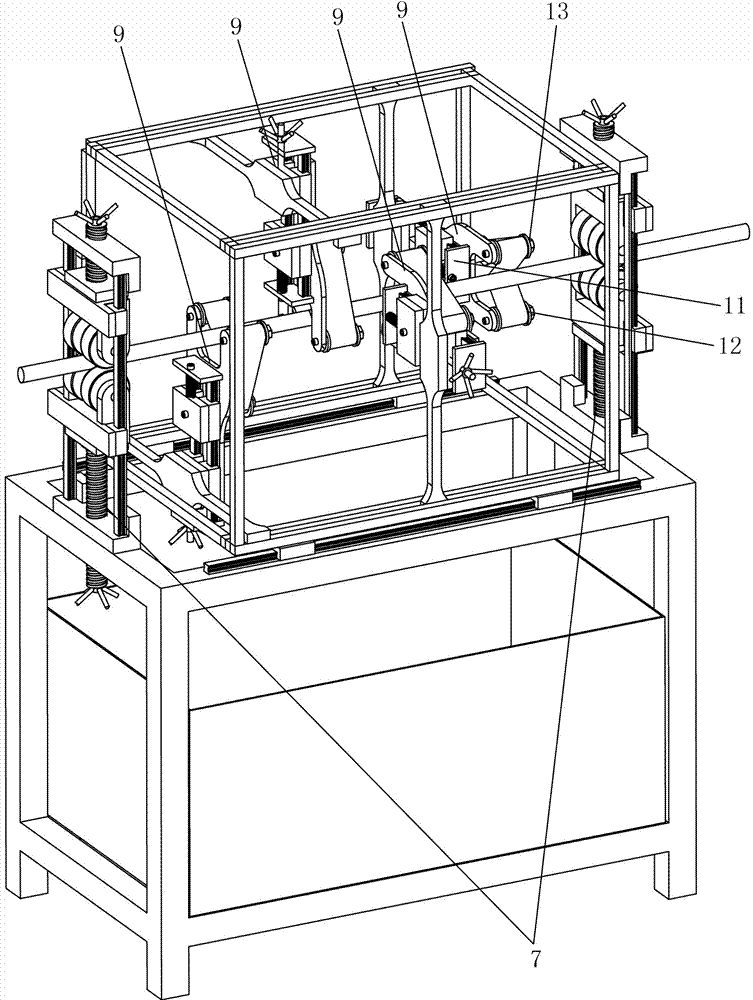

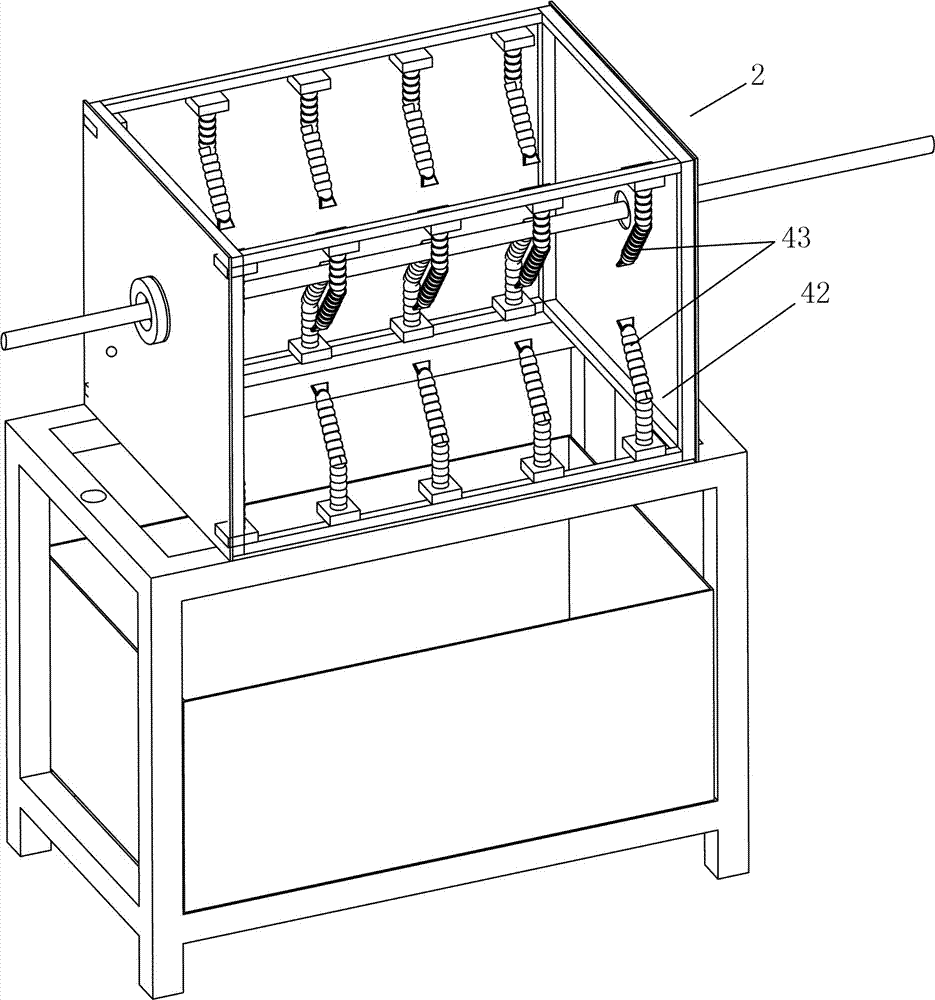

Automated winding and spot welding production line

ActiveCN102554524AHigh precisionReduce labor costsWelding/cutting auxillary devicesAuxillary welding devicesProduction lineWinding machine

The invention discloses an automated winding and spot welding production line, which comprises a winding unit and a spot welding machine. The winding unit comprises a frame, a winding machine and a jig plate conveying device, wherein the winding machine and the jig plate conveying device are arranged on the frame, the winding machine is capable of moving along the frame to place a wound coil in a jig plate, and the jig plate is conveyed to a worktable of the spot welding machine through the jig plate conveying device. By the aid of the scheme, the production line can be used for directly performing automated spot welding for the coil wound by the winding machine, labor cost is saved, production progress is accelerated, and the precision of the spot-welded coil can be improved more effectively.

Owner:BTCOIL ELECTRONICS (DONGGUAN) LIMITED

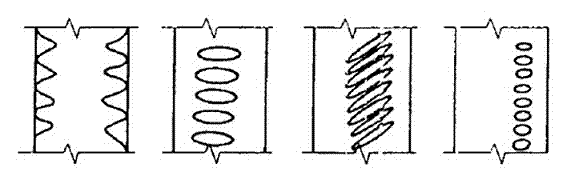

Method for molding multi-layer plate-type array-structure ceramic filter

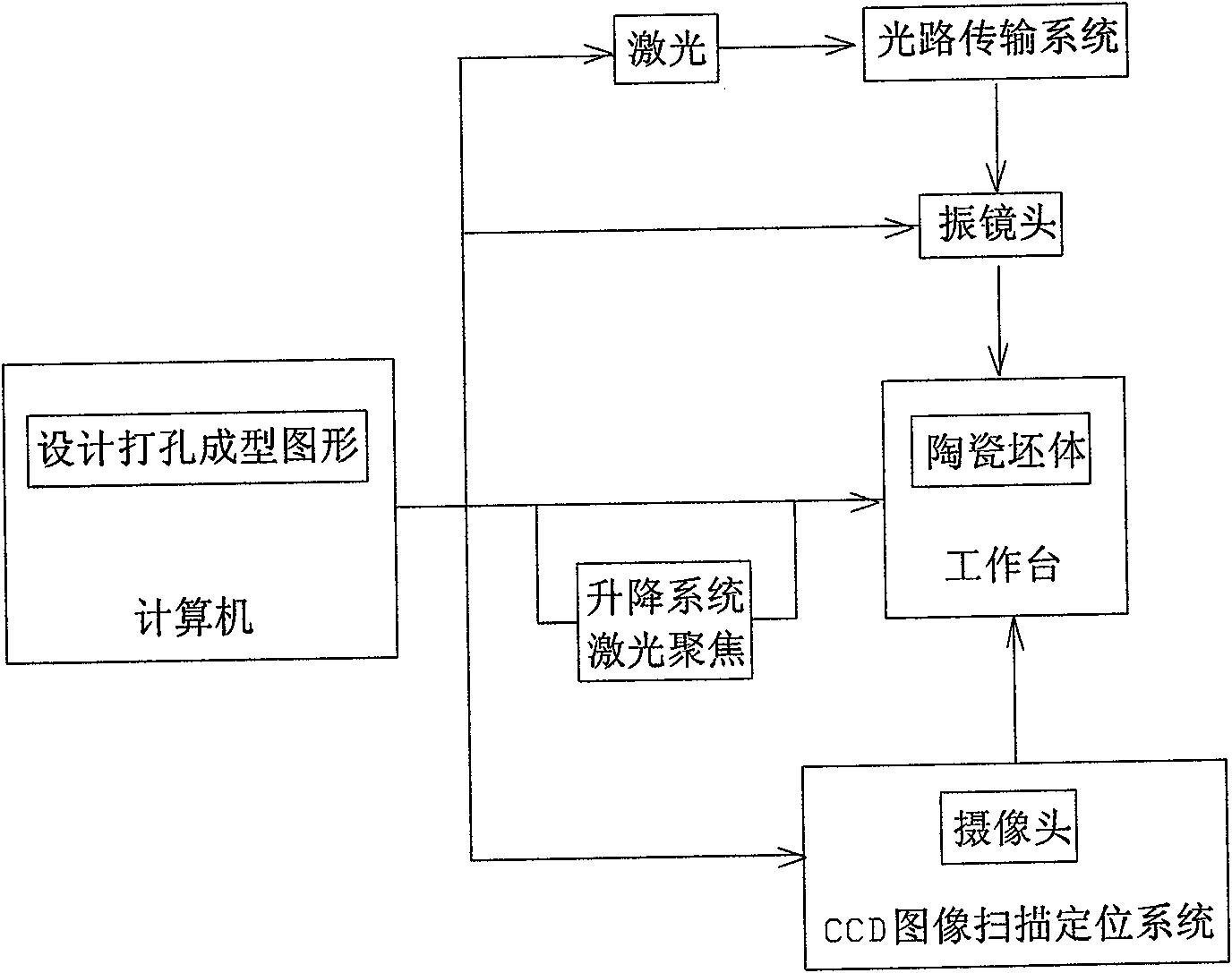

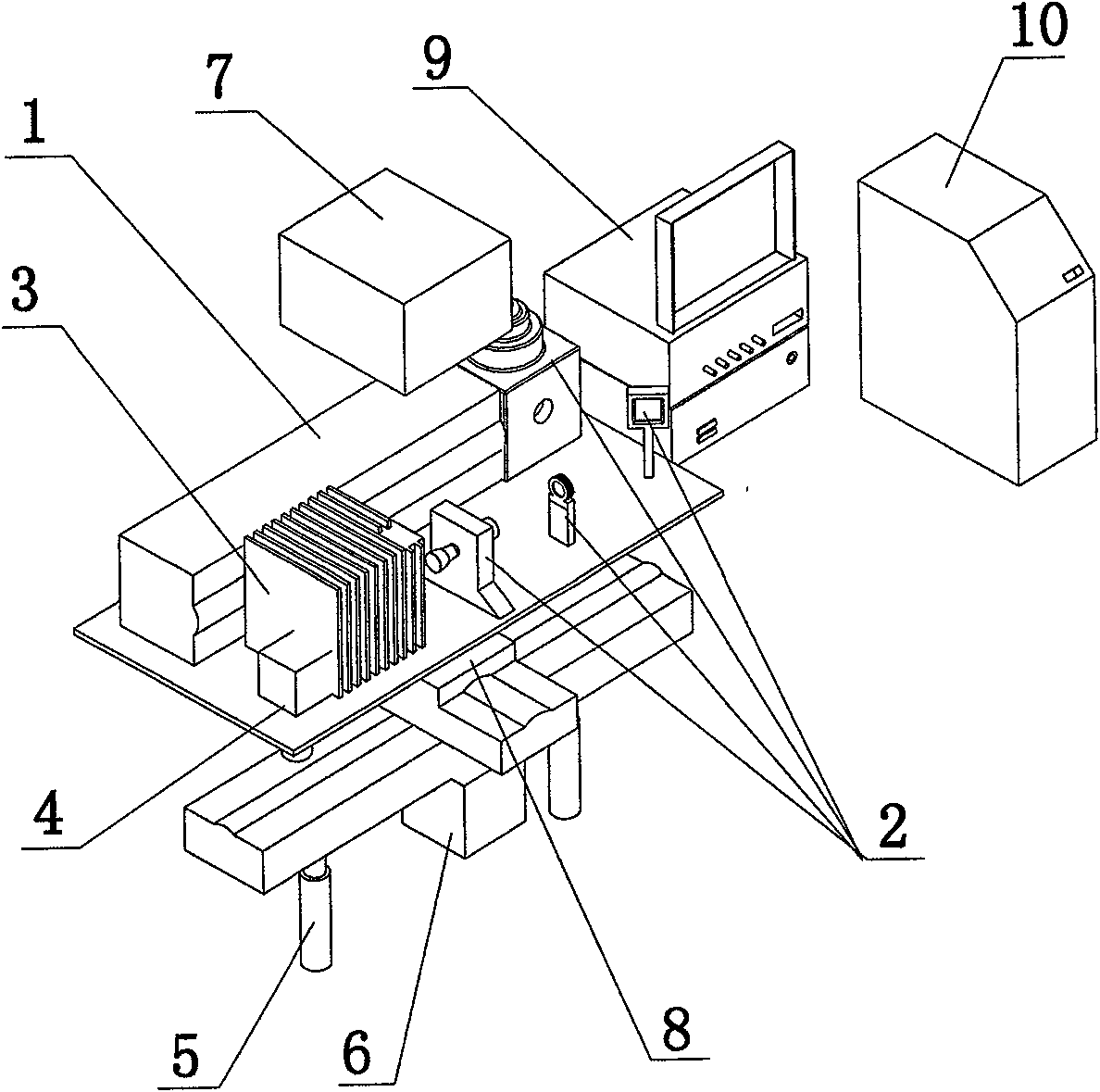

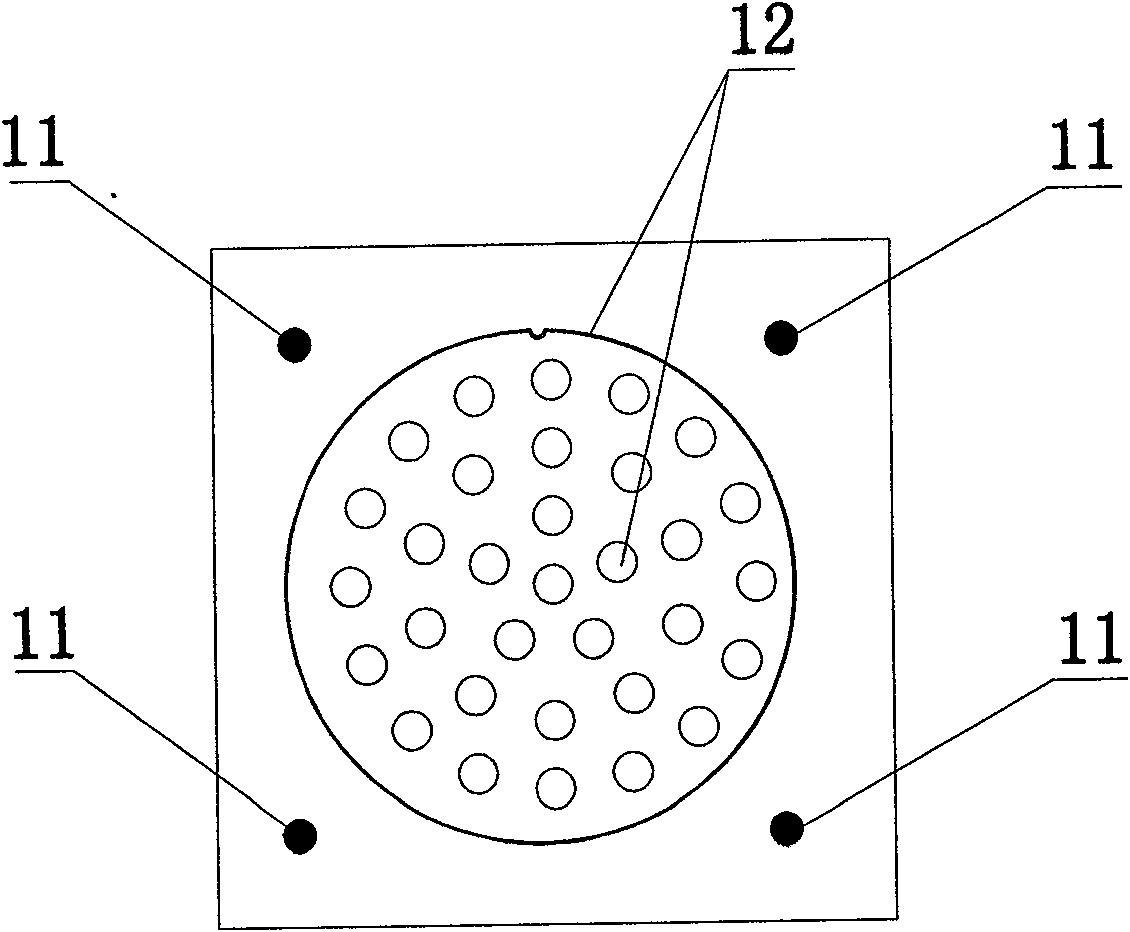

InactiveCN101673868AAvoid strainLong solution cycleImpedence networksWaveguide type devicesPunchingLight energy

The invention discloses a method for molding a multi-layer plate-type array-structure ceramic filter, relating to a processing and molding method of an electronic element, and comprising the followingmain steps: putting a ceramic body printed with positioning points on a working bench; loading the designed pattern for punching and molding by a computer, and setting parameters for the punching andcutting processes; setting the size of the light energy of a laser light source; controlling a machine vision system to scan the printed pattern on the ceramic body by the computer so as to automatically capture and recognize the positioning points, driving the working bench to move the ceramic body to a cutting position below the laser beam according to the positioning points, controlling a vibrating lens to move according to the position of the positioning points based on the designed pattern for punching and molding by the computer so as to carry out laser punching and cutting, and punching and cutting the inner hole and the outer profile of the ceramic body to mold the ceramic filter. The method for molding a multi-layer plate-type array-structure ceramic filter utilizes the laser toautomatically capture and cut, so that the cutting precision is high, the speed is high, and the damage on the surface of the filter is small. The method for molding a multi-layer plate-type array-structure ceramic filter is applicable to filters with requirements such as small space, high precision, large capacity, ultra-large thickness and diversity, and improves the production efficiency and the qualification rate of the filter products.

Owner:CHENGDU HONGMING ELECTRONICS CO LTD

Method for purifying cobalt solution

ActiveCN101831547AReduce consumptionReduce organic contentProcess efficiency improvementSolventBromine

The invention relates to a method for purifying cobalt solution which can decrease the organic matter content in the cobalt solution to less than 10ppm. The method comprises the step of removing the organic matter from the cobalt solution through solvent extraction, wherein the cobalt solution is obtained by acid leach, extraction and re-extraction; the solvent contains extracting agent; the extracting agent is 1-bromine-3-chloropropane, carbon trichloride, carbon tetrachloride or 1-bromine-2-chloroethane. The improvement in the invention is that the solvent also contains solid cobalt naphthenate, the mass of which is 0.01% to 0.1% of the extracting agent mass. The invention has the following advantages of efficiently decreasing the organic matter content in the cobalt solution, obtaining the cobalt chloride satisfying the lithium battery, lowering the consumption of the solvent which is easy to regenerate, making up the defect of using activated carbon, obviously promoting the recovery in the process of processing cobalt due to no cobalt salt loss in the solvent and promoting the use ratio of cobalt.

Owner:GEM JIANGSU COBALT IND CO LTD

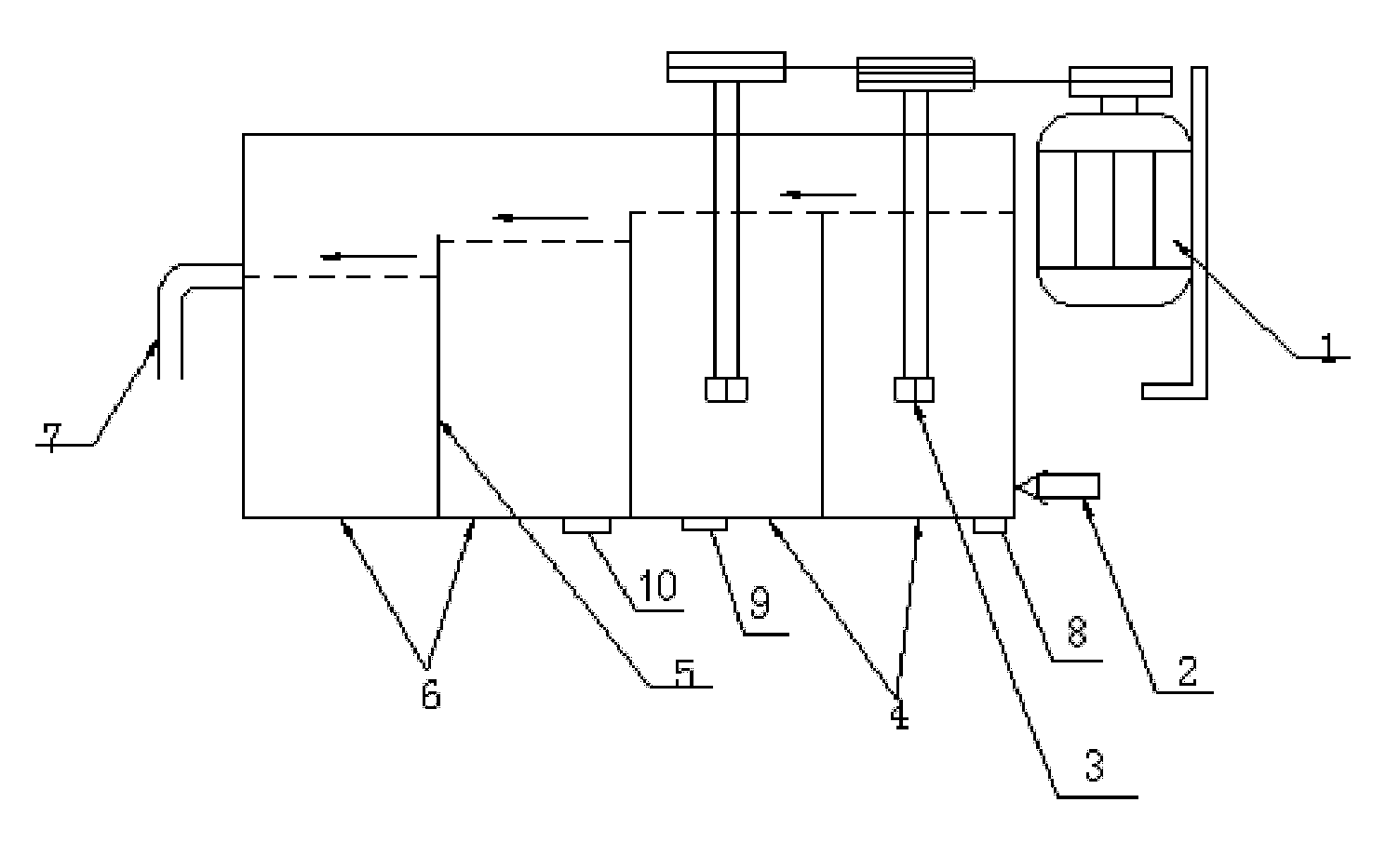

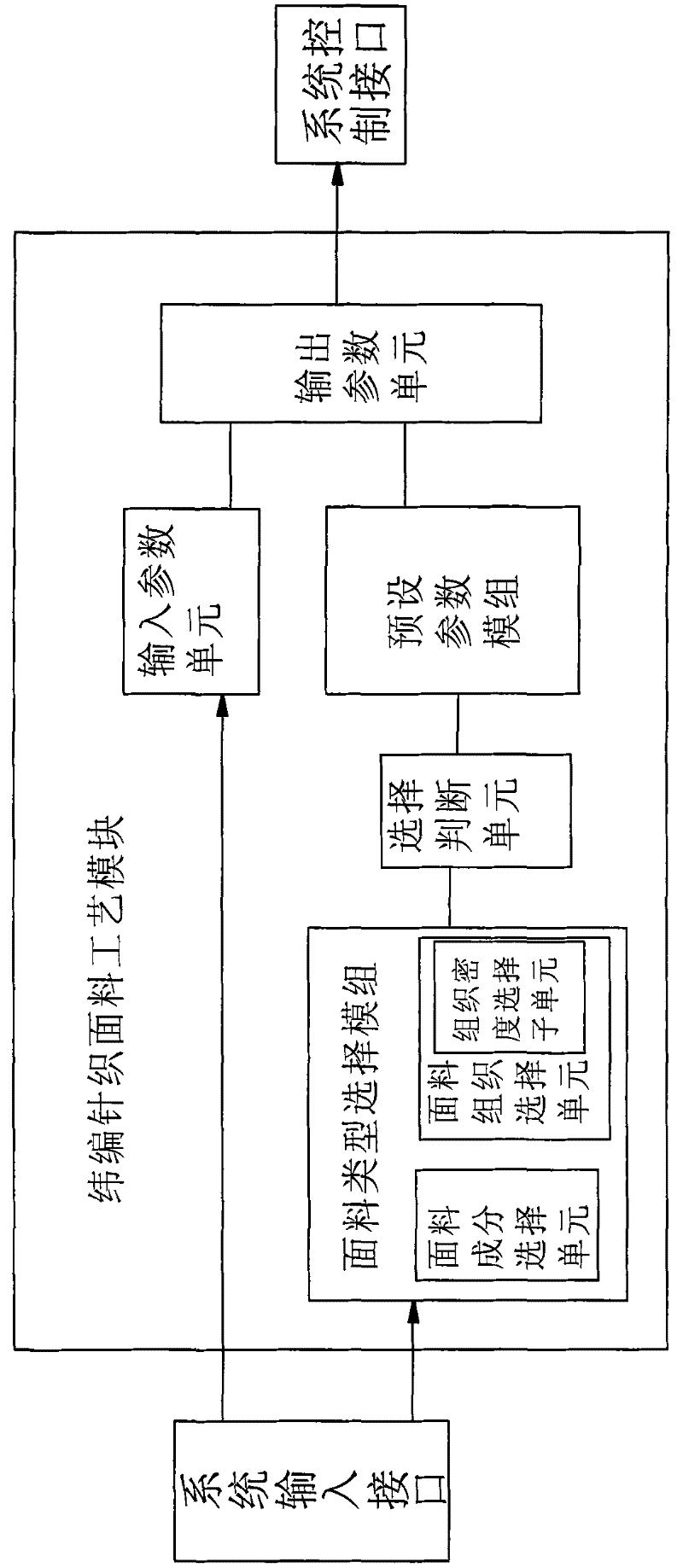

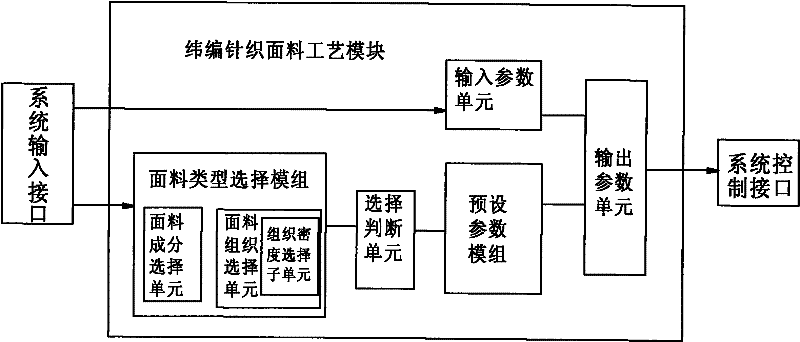

Unilayer cutting bed of weft-knitted fabric

InactiveCN101748592AShorten test timeReduce consumptionSevering textilesProcess moduleComputer module

The invention relates to a unilayer cutting bed, belongs to the field of textile machinery. The unilayer cutting bed of weft-knitted fabric comprises a cutting worktable and a cutting working head as well as a corresponding servo-control system, wherein the cutting working head comprises a cutting knife, a vibration motor of the cutting knife, an angle motor of the cutting knife, a cylinder, a motion driving mechanism of the cutting knife, an angle movement mechanism and a sharpen mechanism. The cutting bed is characterized in that the servo-control system comprises a process module of the weft-knitted fabric, wherein the process module comprises a fabric type selection module, a selection judging unit, a preset parameter module connected after the selection judging unit, and an input parameter unit as well as an output parameter unit; and the process module is connected with the input interface and the control interface of the servo-control system. The invention designs the process of the weft-knitted fabric into the module to be installed on the unilayer cutting bed in advance, sets the important parameters of the simplified cutting process, and thereby the determination of the cutting scheme can be completed only by fine adjustment, reducing the consumption and saving the cost.

Owner:SHANGHAI UNIV OF ENG SCI

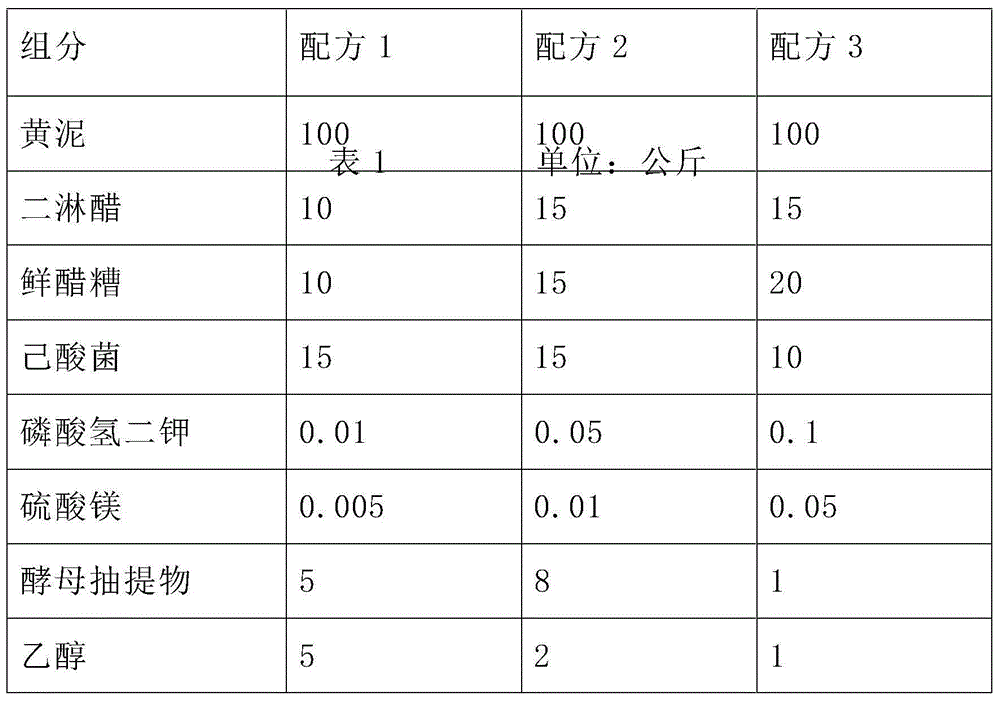

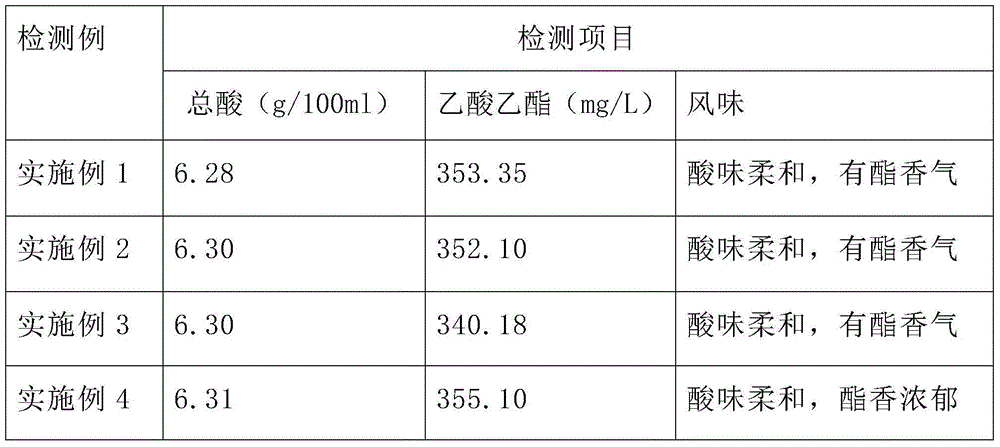

Cellar vinegar brewing technology

The invention provides a cellar vinegar brewing technology, which comprises the following steps: (1) moistening raw materials with water; (2) digesting; (3) saccharifying and alcoholizing; (4) performing acetic fermentation; (5) transferring vinegar culture into a vinegar cellar mud pool, sealing and performing secondary fermentation; (6) performing vinegar spraying: spraying vinegar into secondarily fermented vinegar culture; (7) refining: filtering and sterilizing the prepared vinegar; and (8) filling. By utilizing unique secondary fermentation technology of vinegar cellar mud, the vinegar cellar mud contains various microorganisms, vinegar culture is placed into the cellar pool under close environment, caproic acid bacteria, lactic acid bacteria, saccharomyces and the like have a series of reaction with acid and alcohol in the vinegar culture to generate more flavor components, the production time can be effectively shortened, and vinegar with excellent quality can be brewed within equal production time. The cellar vinegar product aged by utilizing a later-period ceramic tank is rich in various amino acid, organic acid and plural essential nutrient substances of a human body, any preservatives, additives or nutrients are not added, and the brewed vinegar is red and bright in color, clarified in posture, soft and mellow in sour, rich in nutrients and excellent in quality.

Owner:QIANHE CONDIMENT & FOOD CO LTD

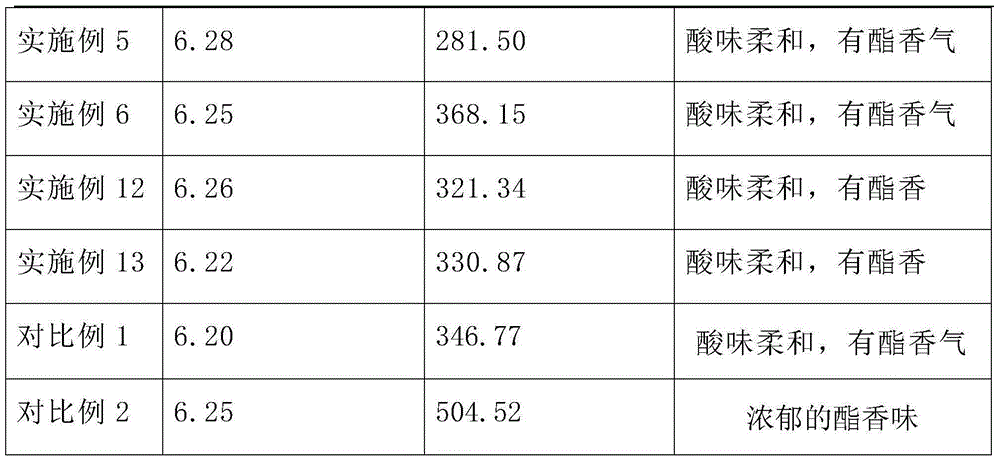

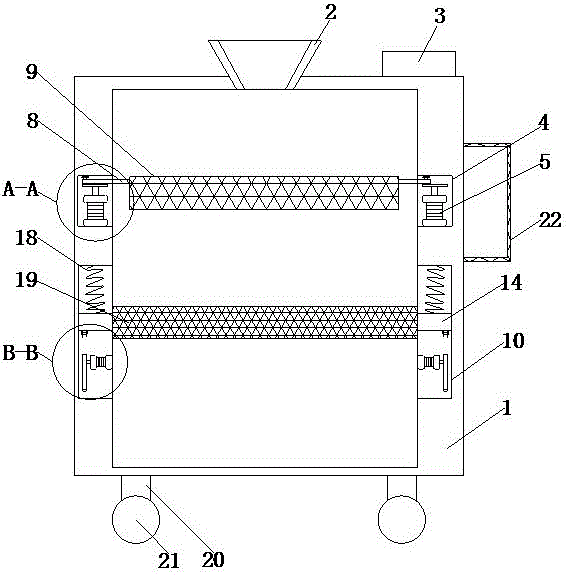

High-applicability screening machine for processing PVC- additives

The invention provides a high-applicability screening machine for processing PVC additives and relates to the field of processing of PVC additives. The high-applicability screening machine for processing the PVC additives comprises a box body; a feeding pipe is arranged at the top of the box body; a part, positioned at the right side of the feeding pipe, of the top of the box body is provided with a controller; the two sides of the box body are each provided with a first chamber body; the bottom of the inner wall of each first chamber body is fixedly connected with a first motor; an output end of each first motor is fixedly connected with a fixing disc; one side, far away from the output end of the corresponding first motor and positioned at the edge of the corresponding fixing disc, of each fixing disc is fixedly connected with a first fixing rod; the surface of each first fixing rod is sleeved with a first connecting rod. By two steps of screening, the high-applicability screening machine for processing the PVC additives has the advantages of effectively improving the screening quality, realizing complete screening so that the screened PVC additives are uniform in size, effectively reducing influences on production quality of PVC, effectively quickening the production schedule and realizing high applicability and high reliability.

Owner:WUXI RISHENG CHEM CO LTD

Aluminum coil stamping automation device and stamping method thereof

ActiveCN104759514AGuaranteed feed speedGuaranteed degree of deformationShaping toolsMetal-working feeding devicesControl engineeringProcess engineering

The invention discloses an aluminum coil stamping automation device and a stamping method thereof. The aluminum coil stamping automation device comprises an uncoiling mechanism, a leveling mechanism, a feeding mechanism, an oil injection mechanism and a machine tool which are arranged in turn; the uncoiling mechanism comprises a servo motor and a rolling wheel which are connected with each other; the rotational speed of the rolling wheel does not exceed 115 rounds every minute; the feeding mechanism comprises a servo motor and a feeding roller which are connected with each other; the clearance feeding of the feeding mechanism is performed and the feeding speed of the feeding mechanism and the stamping frequency of the machine tool are synchronized; a material lifting and conveying mechanism is arranged between the leveling mechanism and the feeding mechanism; a material buffering area is formed between the material lifting and conveying mechanism and the leveling mechanism; the deformation degree of aluminum coils does not exceed 30 I in the process that the aluminum coil are fed into the machine tool from the uncoiling mechanism. According to the aluminum coil stamping automation device and the stamping method thereof, the rotational speed of the feeding mechanism is controlled so as to effectively ensure that the deformation degree of the aluminum profile can be within the acceptable range in the production process, the quality of subsequent machining products is ensured, meanwhile the machining speed requirement can be met by the feeding speed of the materials, and the production efficiency is ensured.

Owner:奇昊汽车系统(苏州)有限公司

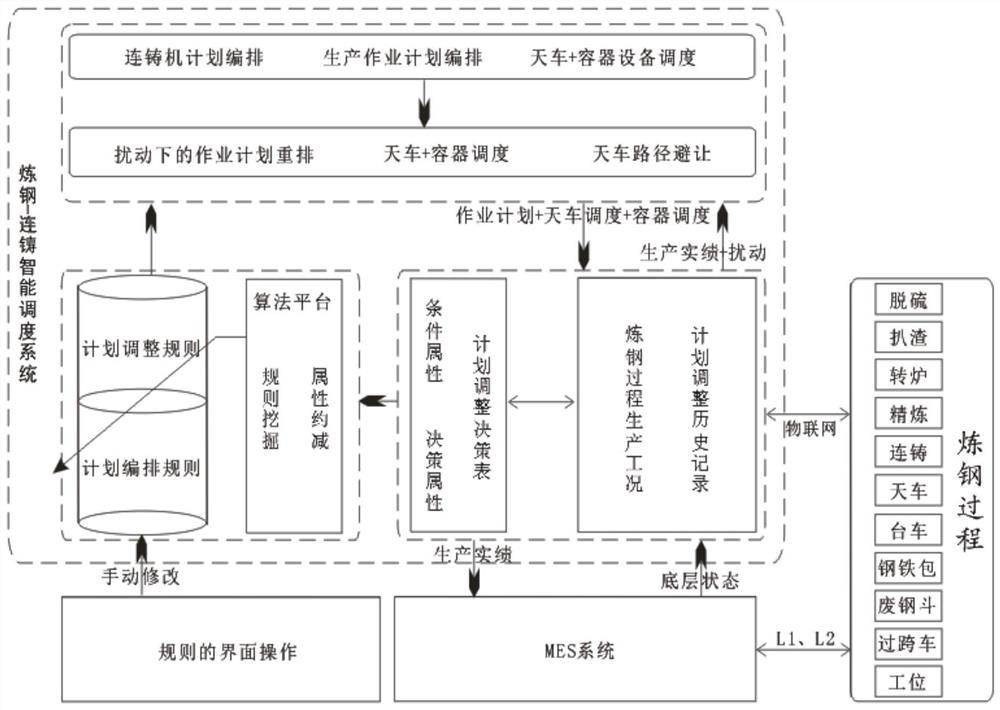

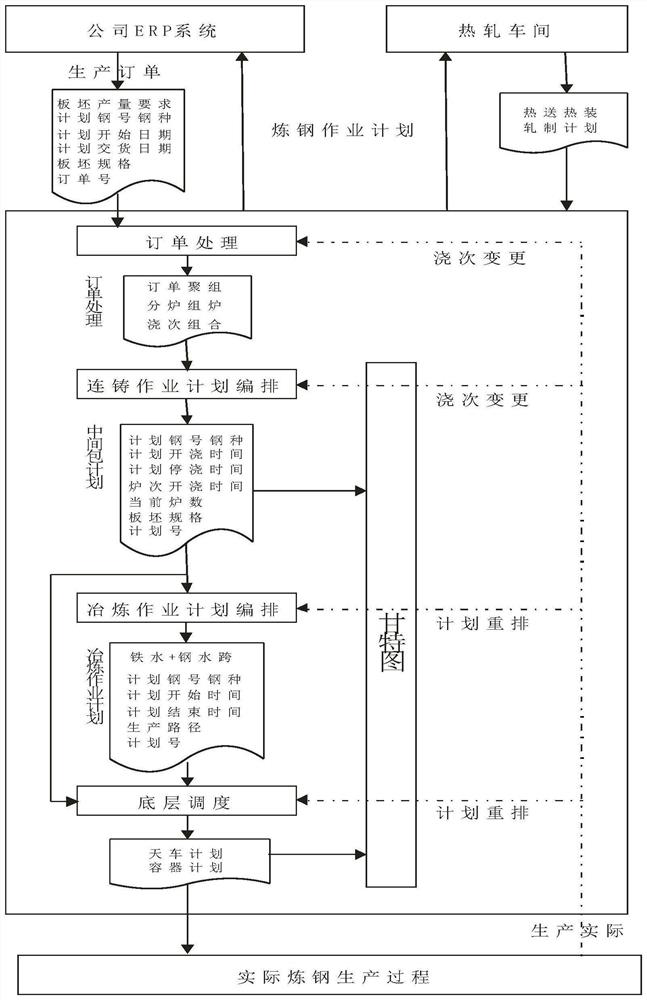

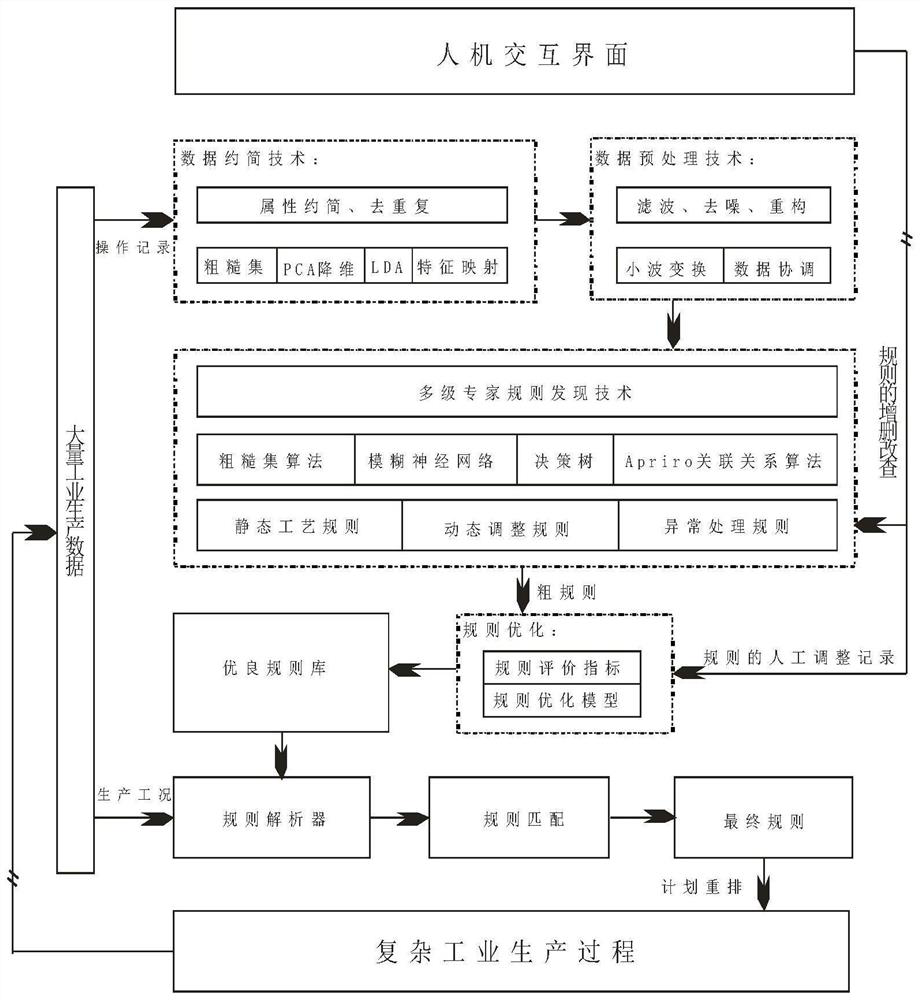

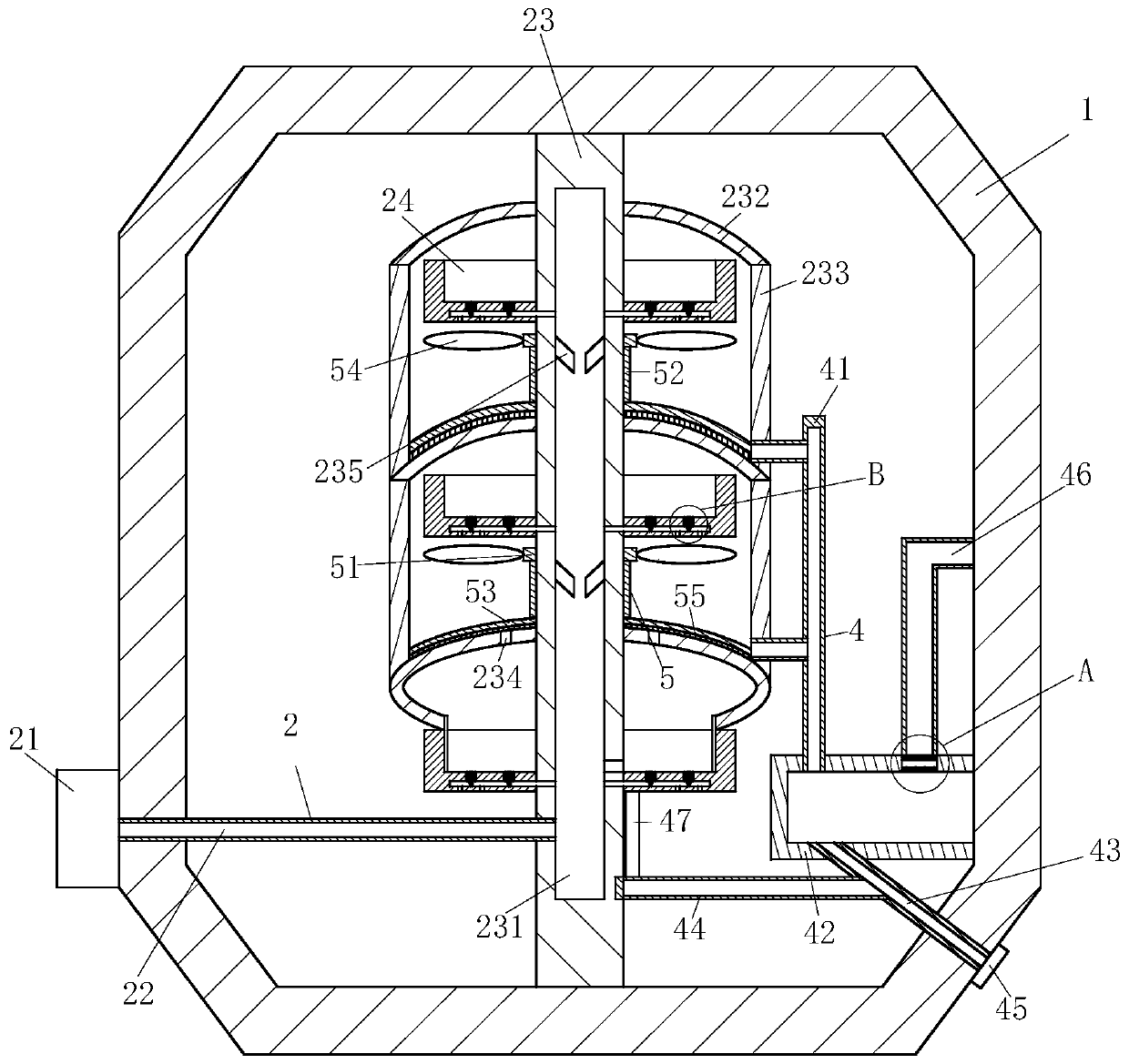

Steelmaking production plan intelligent scheduling method based on big data rule self-learning

The invention discloses a steelmaking production plan intelligent scheduling method based on big data rule self-learning, and the method mainly comprises the following steps: 1), forming a schedulingdecision table according to historical scheduling records, alignment time, scenes and scheduling operation; 2) rule mining: generating a rule base from historical records by adopting rule mining algorithms such as a rough set and deep learning; 3) plan arrangement: based on a continuous casting machine plan of actual data, based on a bottom layer equipment scheduling plan of container tracking technology, a production operation plan based on a time parallel back calculation method; 4) disturbance rearrangement: realizing intelligent rearrangement based on a rule description mode of'disturbance+ scene description + adjustment strategy 'and an expert rule base; and 5) plan display: displaying the operation plan through a Gantt chart, and providing dynamic interface adjustment. By means of the method, efficient and orderly operation of the steelmaking-continuous casting production process is ensured, the production and operation cost is reduced, energy is saved, consumption is reduced, the production efficiency is improved, and maximization of enterprise benefits is achieved.

Owner:HUNAN NORMAL UNIVERSITY

Chemical material finished product dehydration tank

ActiveCN109916155APrevent proliferationReduce moisture contentDrying gas arrangementsDrying machines with non-progressive movementsAir blowerDehydration

The invention belongs to the technical field of chemical machinery, in particular to a chemical material finished product dehydration tank comprising a frame body, a gas conveying mechanism, a diffusing mechanism, an air outlet mechanism, a dust removing mechanism, a circulation mechanism and a filtering mechanism; the gas conveying mechanism comprises a hot air blower, a gas conveying pipe and adispersing rod; the upper and lower ends of the dispersing rod are vertically and fixedly mounted on the upper and lower walls of the inner end of the frame body, the dispersing rod is internally provided with a dispersing groove, and the outer surface of the dispersing rod is evenly and fixedly connected with flow guide plates; the flow guide plates are arranged to be in a round cover shape, theflow guide plates are sealed through a circular pipe, a leaking hole is formed in the wall of the flow guide plate at the lowest end, and placing frames are arranged below the flow guide plates; the placing frames are arranged in round pipes, the inner sides of the placing frames are evenly and fixedly connected to the outer surface of the dispersing rod, and the lower walls of the placing framesare internally provided with gas separation grooves. The chemical material finished product dehydration tank is mainly used for solving the problems that an existing dehydration tank cannot completelydehydrate chemical materials, and energy is wasted in the dehydration process.

Owner:双键化工(泰兴)有限公司

Graphite type casting method of cylindrical titanium alloy piece

ActiveCN103658548ASolve crackingSolve defects such as poresFoundry mouldsFoundry coresSystems designGraphite

The invention discloses a graphite type casting method of a cylindrical titanium alloy piece. The method comprises the following processing steps: (1) designing a barrel-type titanium alloy piece casting system; (2) preparing a graphite mould; (3) removing air out of the graphite mould; (4) enabling the graphite mould to form a casting mould according to a casting forming picture; and (5) carrying out titanium alloy vacuum consutrode kish melting process. The graphite type casting method provided by the invention has the advantages that the barrel-type titanium alloy piece with the qualified surface quality and mechanical property is successfully formed by pouring based on the research on graphite casting technology of the barrel-type titanium alloy casting, a condition that the barrel-type titanium alloy piece depends on a machining preparation manner is avoided, the production cost is reduced, and the production efficiency is improved.

Owner:SHANGHAI SPACE PRECISION MACHINERY RES INST

Material bonding machine

PendingCN106626397AReduce labor intensityReduce the number of peopleEngineeringMechanical engineering

The invention discloses a material bonding machine. The material bonding machine is characterized in that the material bonding machine comprises an upper conveying belt and a lower conveying belt; materials are conveyed in a clamped mode through the upper conveying belt and the lower conveying belt; a hot upper die head or a hot upper die plate and a cold upper die head or a cold upper die plate are sequentially arranged in the upper conveying belt; a hot lower die head or a hot lower die plate and a cold lower die head or a cold lower die plate are sequentially arranged in the lower conveying belt correspondingly; the materials are subjected to hot pressing by the hot upper die head and the hot lower die head or the hot upper die plate and the hot lower die plate through the upper conveying belt and the lower conveying belt correspondingly, and then the materials are cooled by the cold upper die head and the cold lower die head or the cold upper die plate and the cold lower die plate through the upper conveying belt and the lower conveying belt correspondingly. The material bonding machine has the characteristics that the production speed is high, the staff number is small, and products are free of raised grains.

Owner:汕头市亿力机械设备有限公司

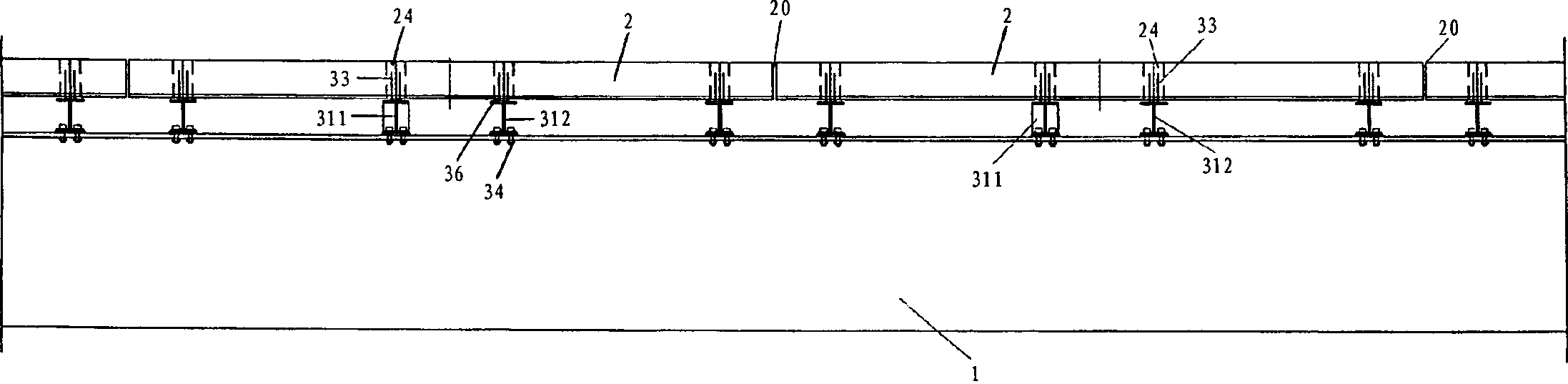

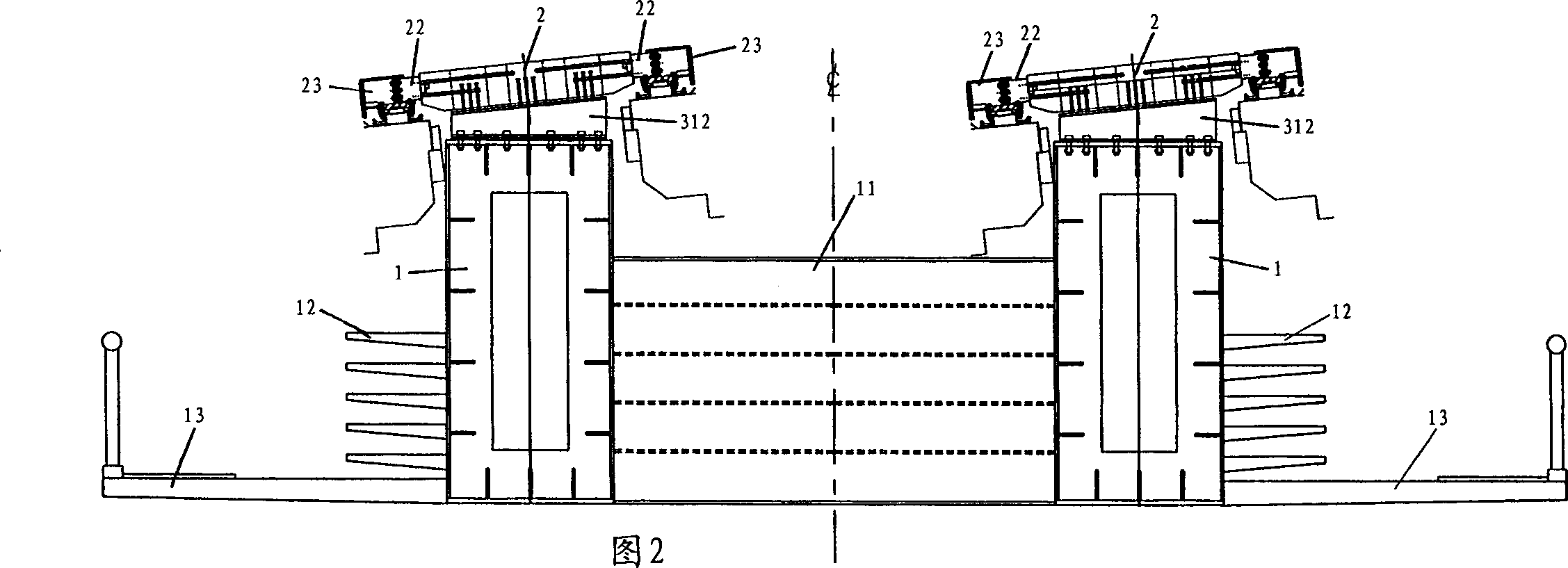

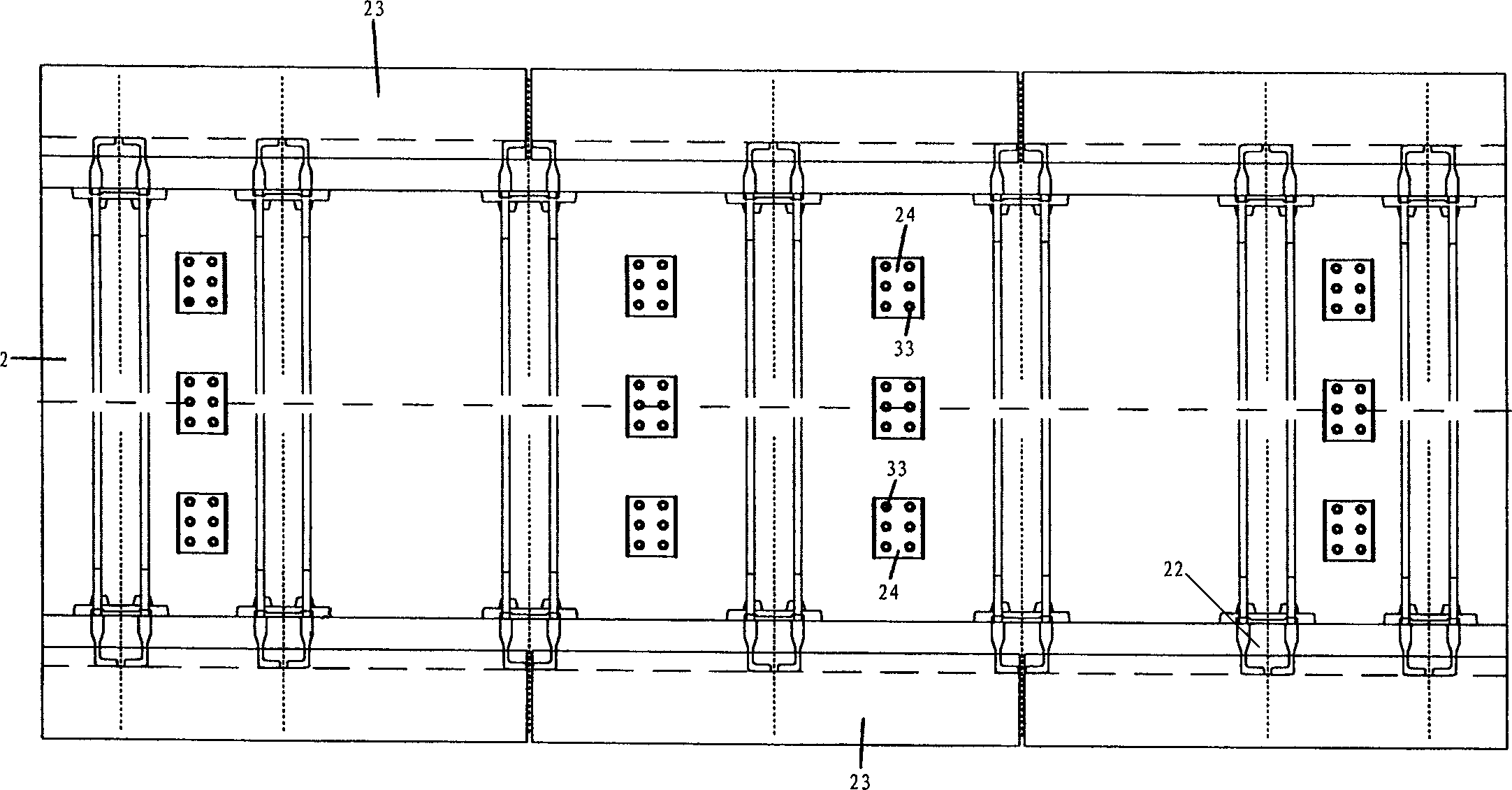

Rail structure of high-speed rail transportation

InactiveCN1350092ASpeed up productionSimplify the manufacturing processRailway tracksSheet steelExpansion joint

The track structure for high-speed rail traffic includes lower-layer bearing main beam and upper-layer rail level member, the rail level member is made up by using function zone steel member and self-body reinforced concrete plate beam which are connected into one body by means of connecting componnet. It is characterized by that (1). the reinforced concrete plate beam is a kind of small member, severl reinforced concrete plate beams are laid on the lower-layer main beam longitudinally along the line by means of connecting mechanism, between two reinforced concrete plate beams there is a certain expansion joint, (2), the describec connecting mechanism is formed from support steel beam, welding nail, high-strength bolt and steel soleplate, the support steel beam is connected with lower-layer bearing main beamm, the welding nail of top of supper steel beam is inserted into rear funnel of reinforced concrete plate beam, after the plate beam is positioned, concrete can be cast to make connection, and (3). for double-line rail, between sides of bearing main beam the support cross beam can be added.

Owner:SHANGHAI MAGLEV TRANSPORTATION DEVELOPMENT CO LTD

T-shaped aluminum soldering machine

ActiveCN101774099ASimple structureReduce labor intensityWelding/cutting auxillary devicesAuxillary welding devicesProduction scheduleEngineering

The invention relates to a T-shaped aluminum soldering machine, comprising an automatic soldering machine, wherein an upper rack is arranged on a lower rack in a connecting manner, the lower rack is horizontally provided with a workbench panel, lower platens are respectively arranged at the left and the right sides above the workbench panel, the lower part of the lower platen is connected with a first cylinder, and the first cylinder is arranged on the lower rack and is connected with a hydraulic system; and the upper rack is provided with a door frame plate which is vertical to the workbench panel and a second cylinder which is connected with the hydraulic system and an upper platen, the lower end of the upper platen is wedge-shaped, and the upper platen is close to the door frame plate and forms a wedge-shaped opening with the door frame plate at the lower end thereof. Compared with the prior art, the invention has the following technical effects: the invention has simple structure, no soldering deformation of a workpiece after automatic soldering and one-step realization of precision target, avoids using a corrective technology which is difficult to operate, lowers labor intensity, speeds up production schedule, improves production efficiency and ensures product quality.

Owner:WUCHANG SHIPBUILDING IND

Apparatus for removing magnetic foreign matters

ActiveCN106140458AEasy to cleanFully cleanedMagnetic separationCleaning using liquidsForeign matterBiochemical engineering

The invention provides an apparatus for removing magnetic foreign matters. The apparatus is characterized by having a shell, a feeding unit, a magnetic baffle plate assembly, a discharging unit, a washing unit and a liquid discharging unit, wherein the feeding unit is arranged on the upper part of the shell and used for a liquid material to enter the shell; the magnetic baffle plate assembly is installed in the shell and comprises at least one first magnetic baffle plate and at least one second baffle plate which are installed at the inner side of the top wall of the shell; the washing unit comprises at least one elastic inflatable membrane which sleeves on and is fit to each of the first magnetic baffle plate and second magnetic baffle plate, an inflation / deflation component which is installed on the shell, communicated with the inflatable membrane and used for inflating and deflating the inflatable membrane, and an ultrasonic vibration component which is installed on the shell and used for producing ultrasonic vibration; and the liquid discharging unit is arranged at the bottom of the shell and used for discharging washing liquid after washing the apparatus for removing the magnetic foreign matters. By adopting the apparatus for removing the magnetic foreign matters, the magnetic foreign matters removal effect and the washing efficiency can be improved, and the corrosion resistance is good.

Owner:JINGMEN GEM NEW MATERIAL

Automatic processing equipment and processing method for carbon fiber tube

ActiveCN106938425ASpeed up productionHigh degree of automationDrying solid materials with heatBelt grinding machinesFiberProduction schedule

The invention relates to an automatic processing equipment and a processing method for a carbon fiber tube. The automatic processing equipment comprises a polishing device, a washing device, a printing device, a gumming device and a drying device of which the processing centers are positioned on the same axis and which are sequentially arranged to form an automatic assembly line, wherein the polishing device comprises feeding mechanisms arranged on two sides of a rack and a positioning polishing mechanism arranged between the feeding mechanisms; and the printing device comprises a material supporting mechanism and a rolling printing mechanism which are mounted on the rack. The invention aims to provide the automatic processing equipment and the processing method for the carbon fiber tube, the polishing device, the printing device and a varnishing device are integrated, and traditional independent processing procedures, such as polishing, printing and varnishing, of the carbon fiber tube are integrated, so that automatic assembly line production is realized, the integral production schedule is greatly quickened, the production cycle is shortened, the production cost is lowered, the overall structure is simple, daily repair and maintenance are convenient, the degree of automation is high and the practicability is strong.

Owner:DONG GUAN JIN MING SPORTS EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com