Patents

Literature

158 results about "Gantt chart" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A Gantt chart is a type of bar chart that illustrates a project schedule, named after its inventor, Henry Gantt (1861–1919), who designed such a chart around the years 1910–1915. Modern Gantt charts also show the dependency relationships between activities and current schedule status.

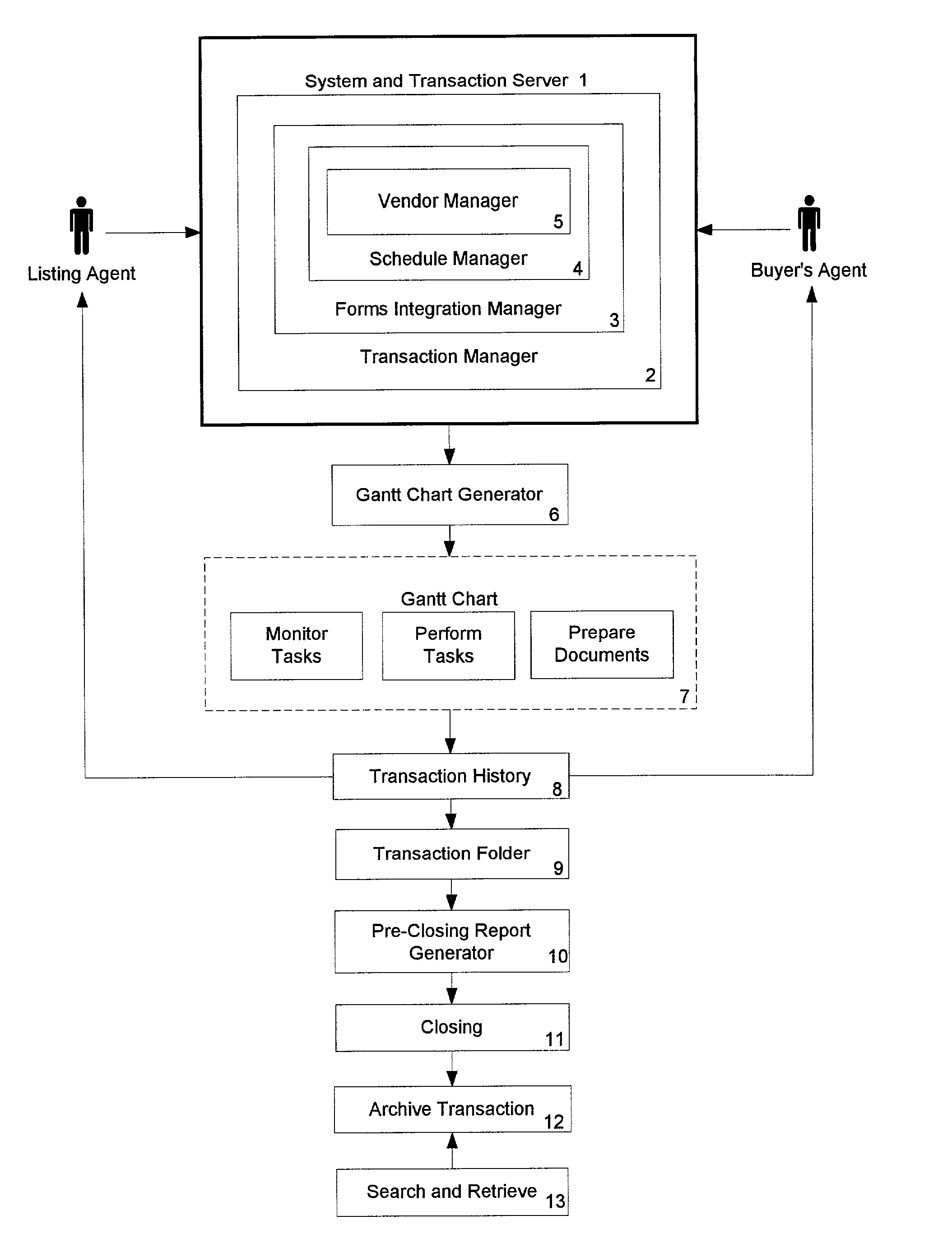

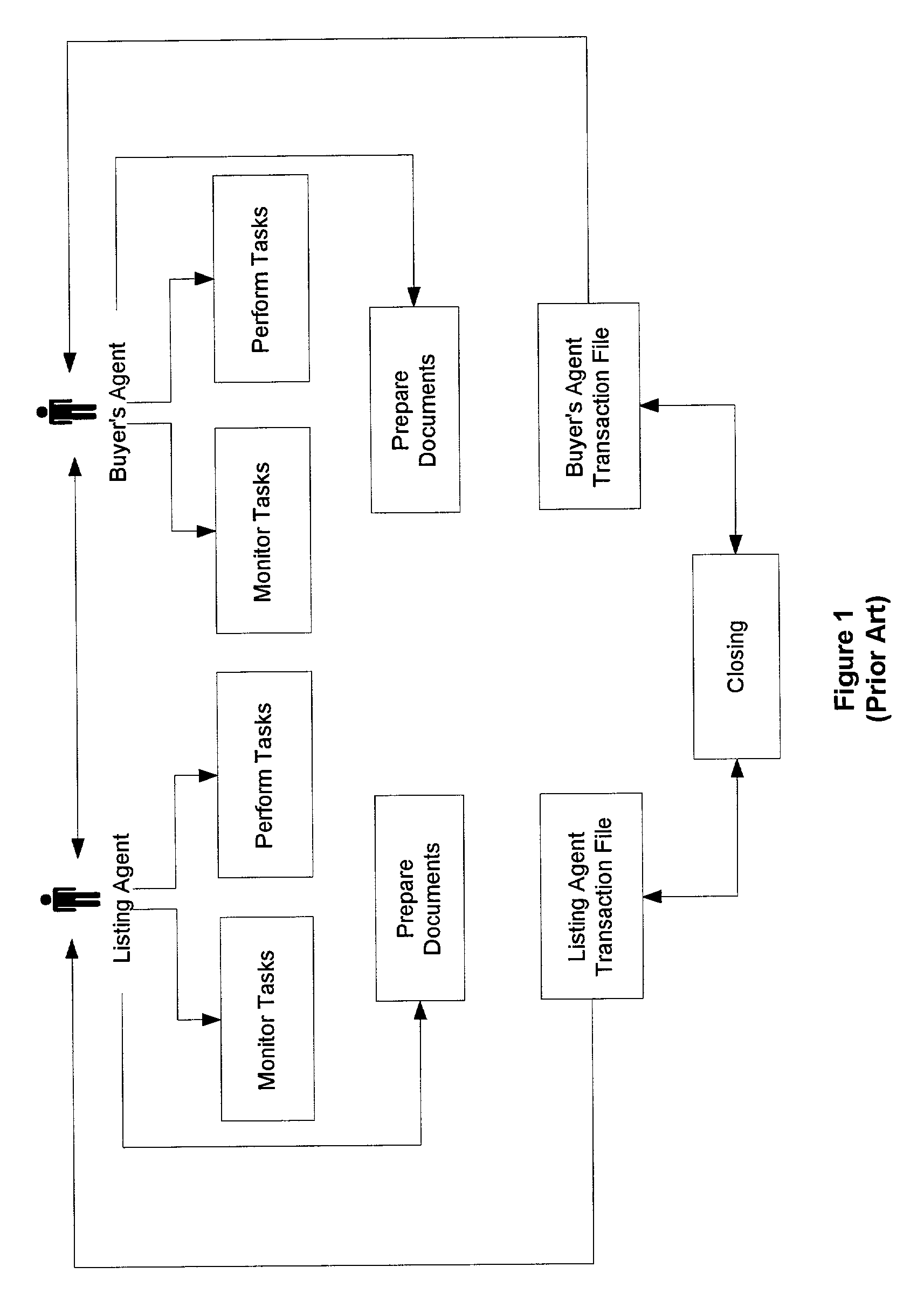

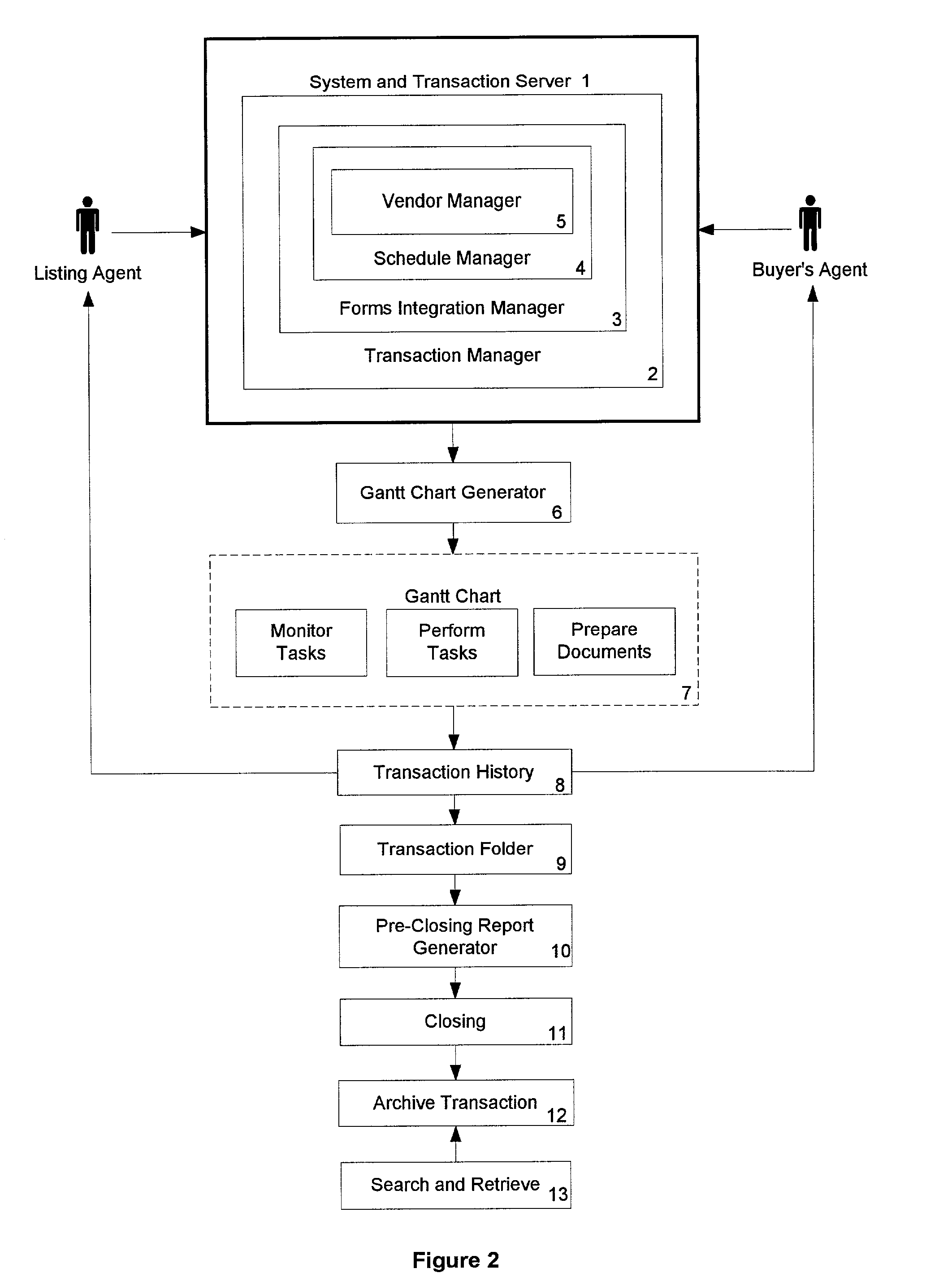

Method and system for managing and closing a real estate transaction

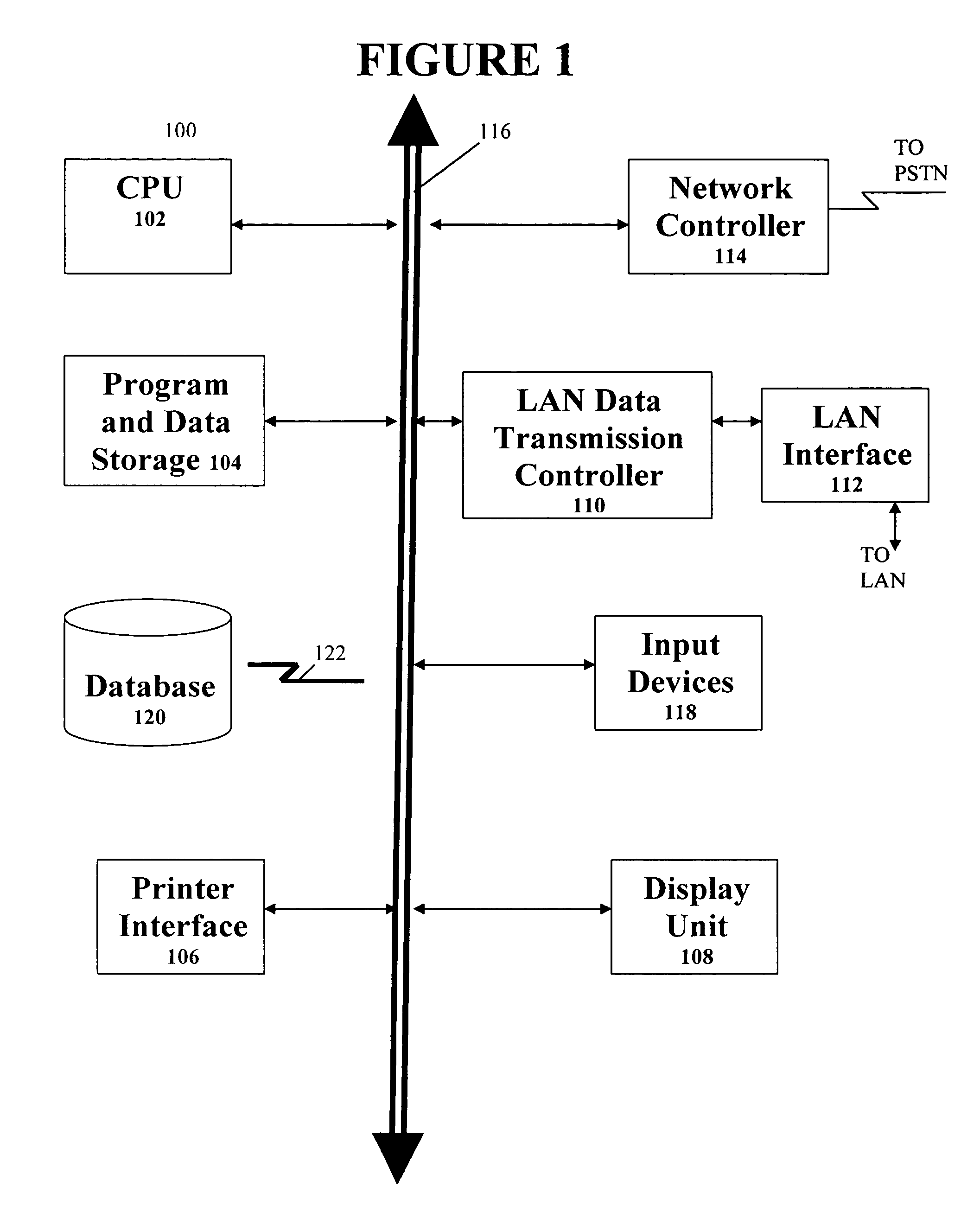

ActiveUS7353183B1Quickly scroll and “ pageData processing applicationsGantt chartVisual presentation

A computer implemented, interactive method and system for assisting real estate agents and their clients in managing and closing a real estate transaction. The invention includes the computer system's generation of a Gantt Chart which automatically tracks the entire real estate transaction, simultaneously providing each agent with the same visual presentation, on their own computer display device, of a description and status of each task to be performed by both agents in order to close the purchase and sale of a property. The Gantt Chart displays each task in a column on each agent's display device and adjacent to each task is a horizontal schedule bar which may contain at least one status indicator which indicates the status of its associated task. A document access indicator is also displayed as an icon adjacent to each task which involves the preparation and delivery of a real estate document. The agent selects the icon in order to display a desired document on the display device, and when the document is completed and delivered the Gantt Chart is automatically updated to indicate that the status of the task has changed. The Gantt Chart also provides each agent with access to a list of vendors to perform a task involving the utilization of a vendor service. As the agent and the selected vendor interact, the Gantt Chart is automatically updated to indicate the current status of obtaining the desired vendor service. When all tasks have been completed, the computer system achieves the complete history of the transaction and generates a pre-closing report. The system also provides each agent with the ability to simultaneously monitor and perform tasks for multiple transactions.

Owner:MOVE SALES INC

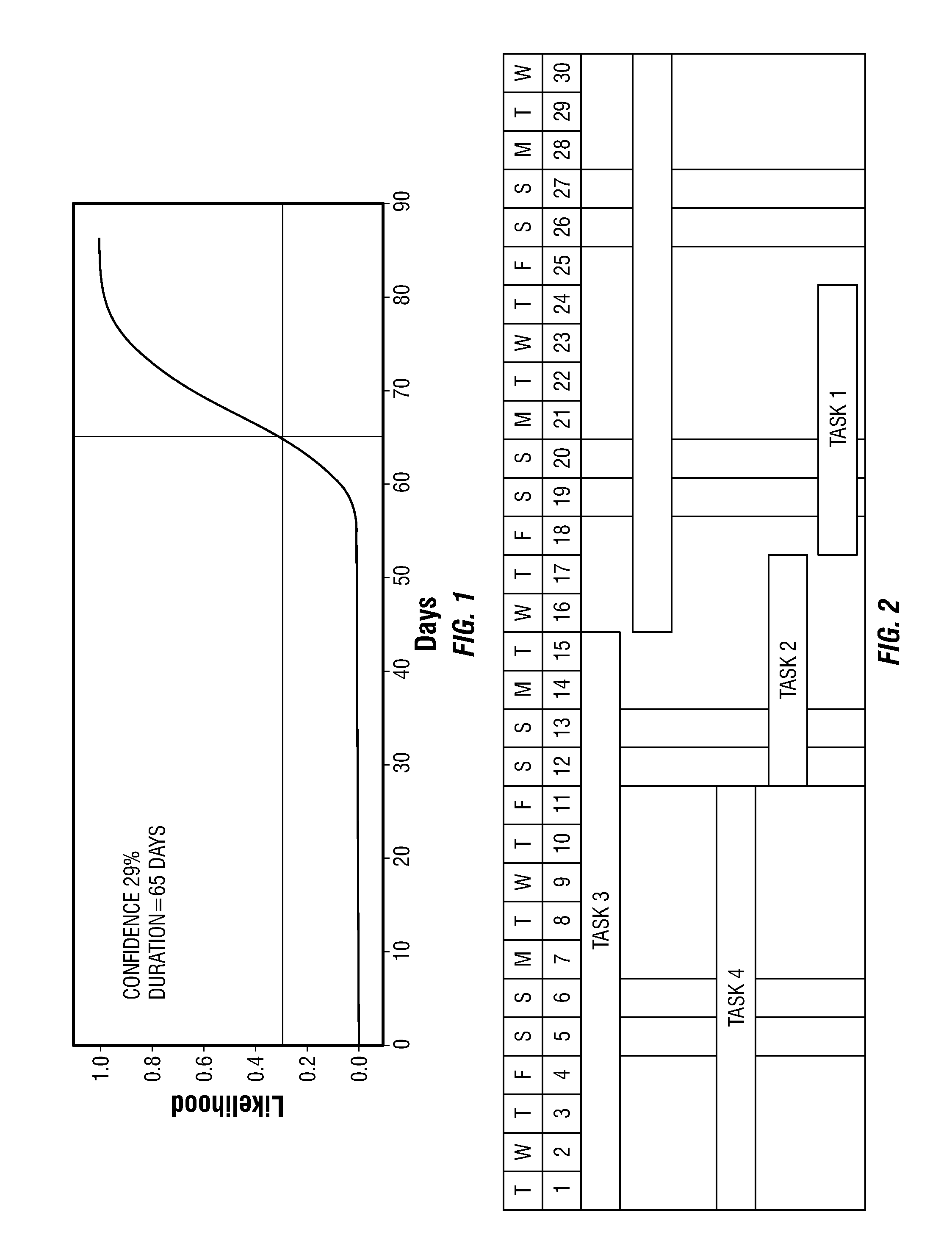

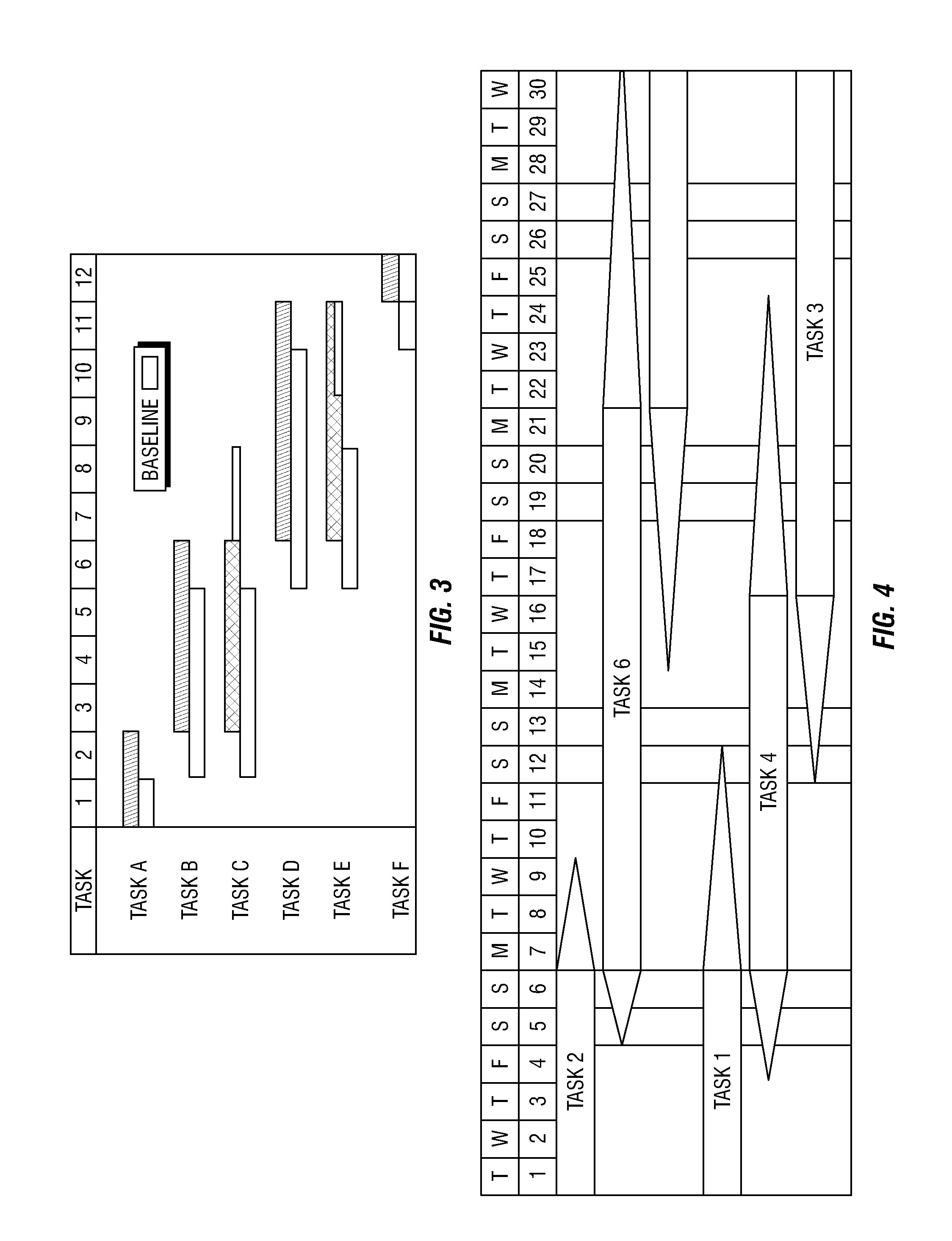

Method for project management

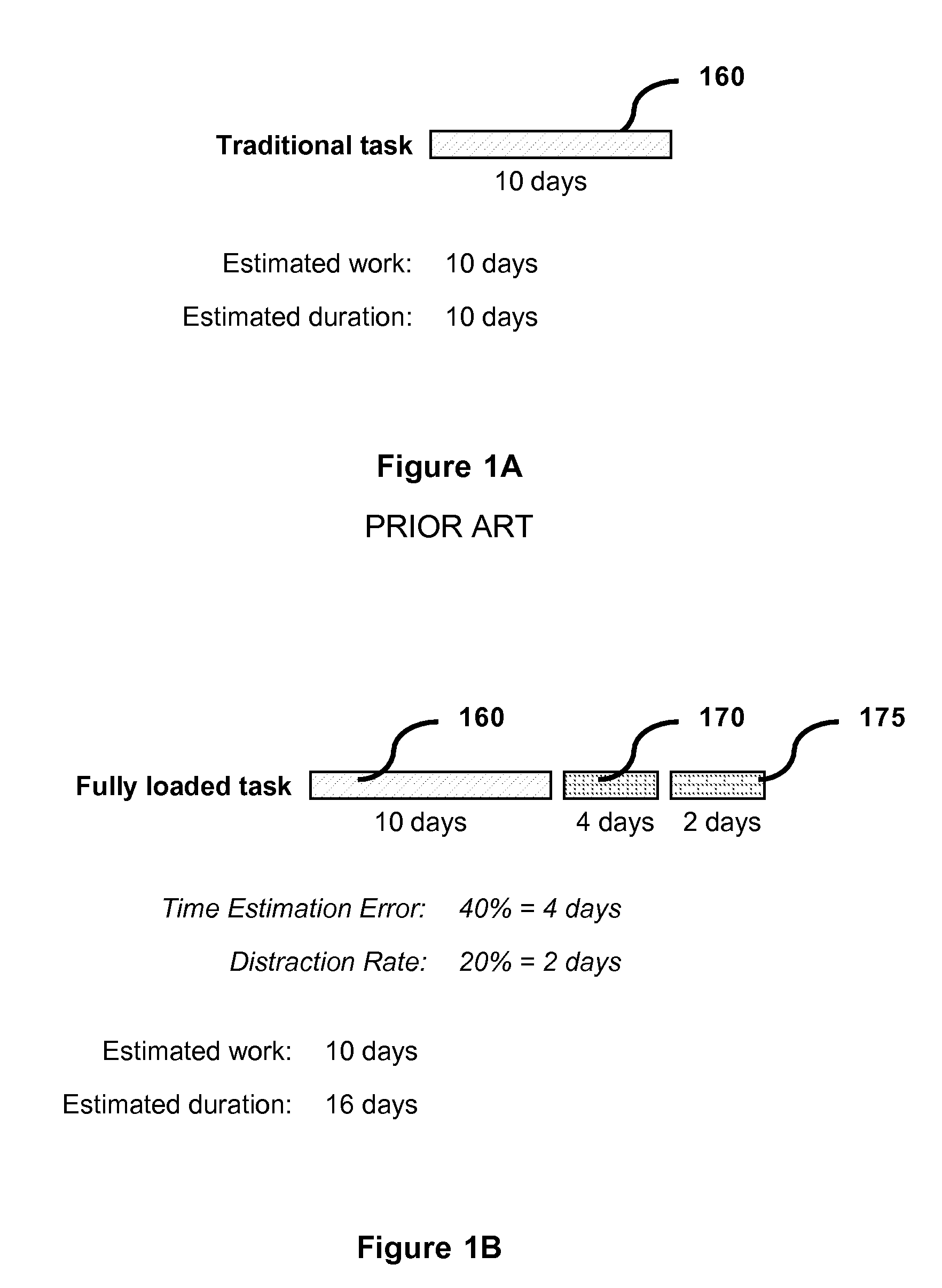

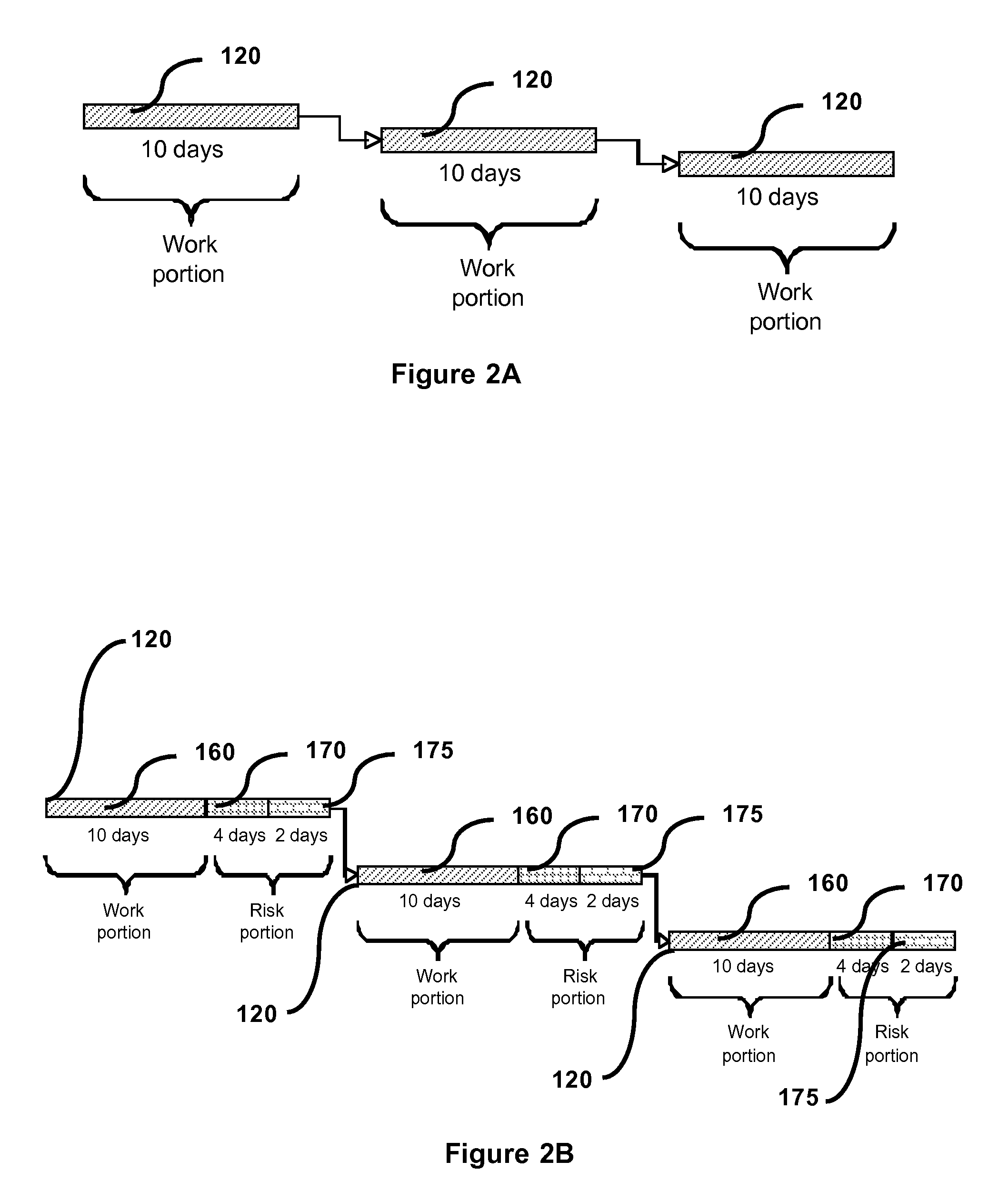

InactiveUS20070288283A1Improve realismReduce impactFinanceMultiprogramming arrangementsDistractionGantt chart

A method for project management that can be used to achieve a more accurate project schedule at the beginning of, and during the life of a project. The method can be built into a software product, or used manually.The method uses data collection, modeling, analysis, reporting and visualization to reduce the impact of risk in project scheduling and thereby improve the project's chances of a successful outcome (e.g. as measured by stronger adherence to: budget, deadline, quality and specifications).The method introduces time estimation error, distraction rate and schedule confidence into the project schedule and provides for visualization of the schedule in the form of Gantt charts in difference views organization by component, by team member and by project.

Owner:DEVSHOP

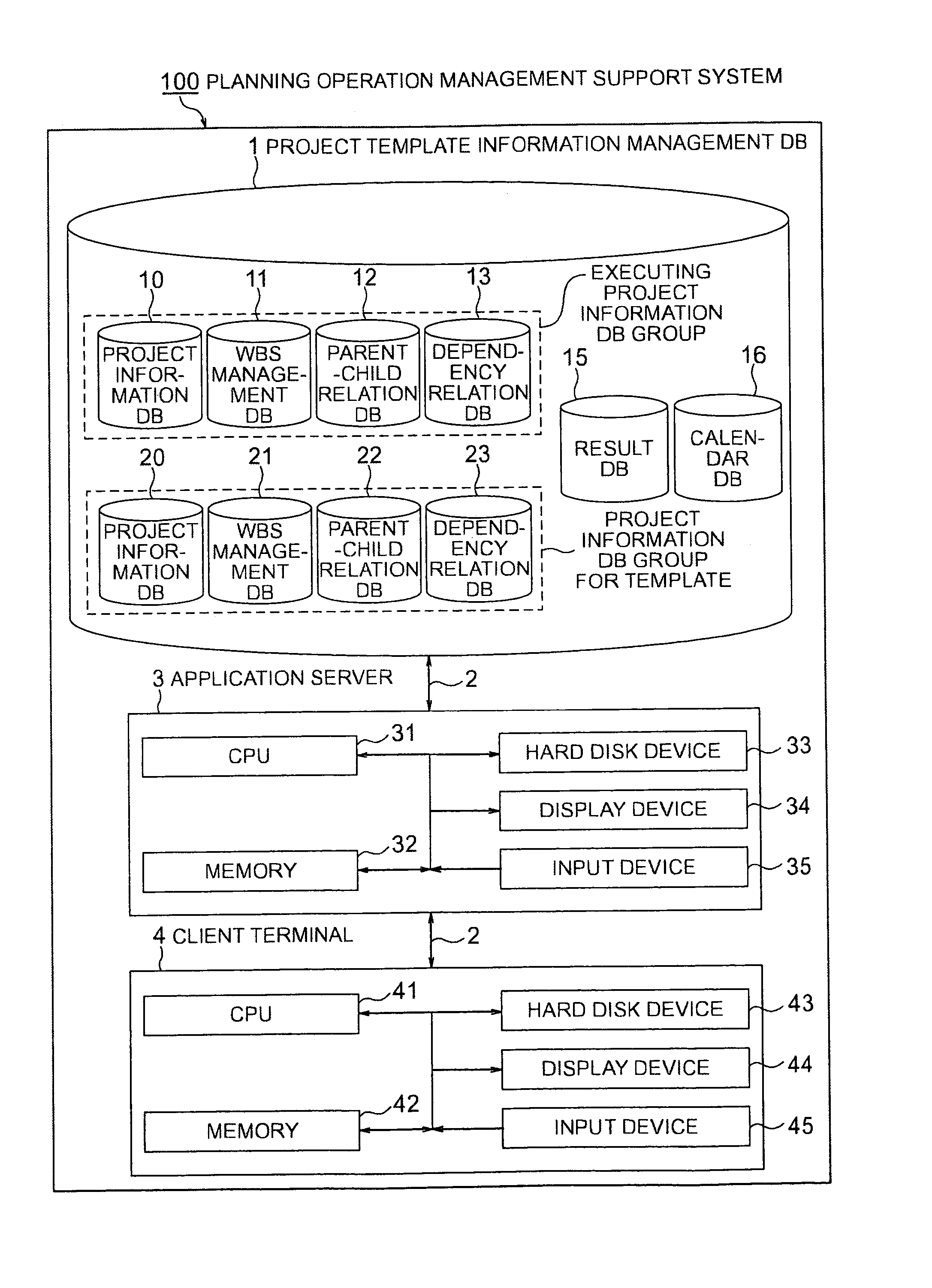

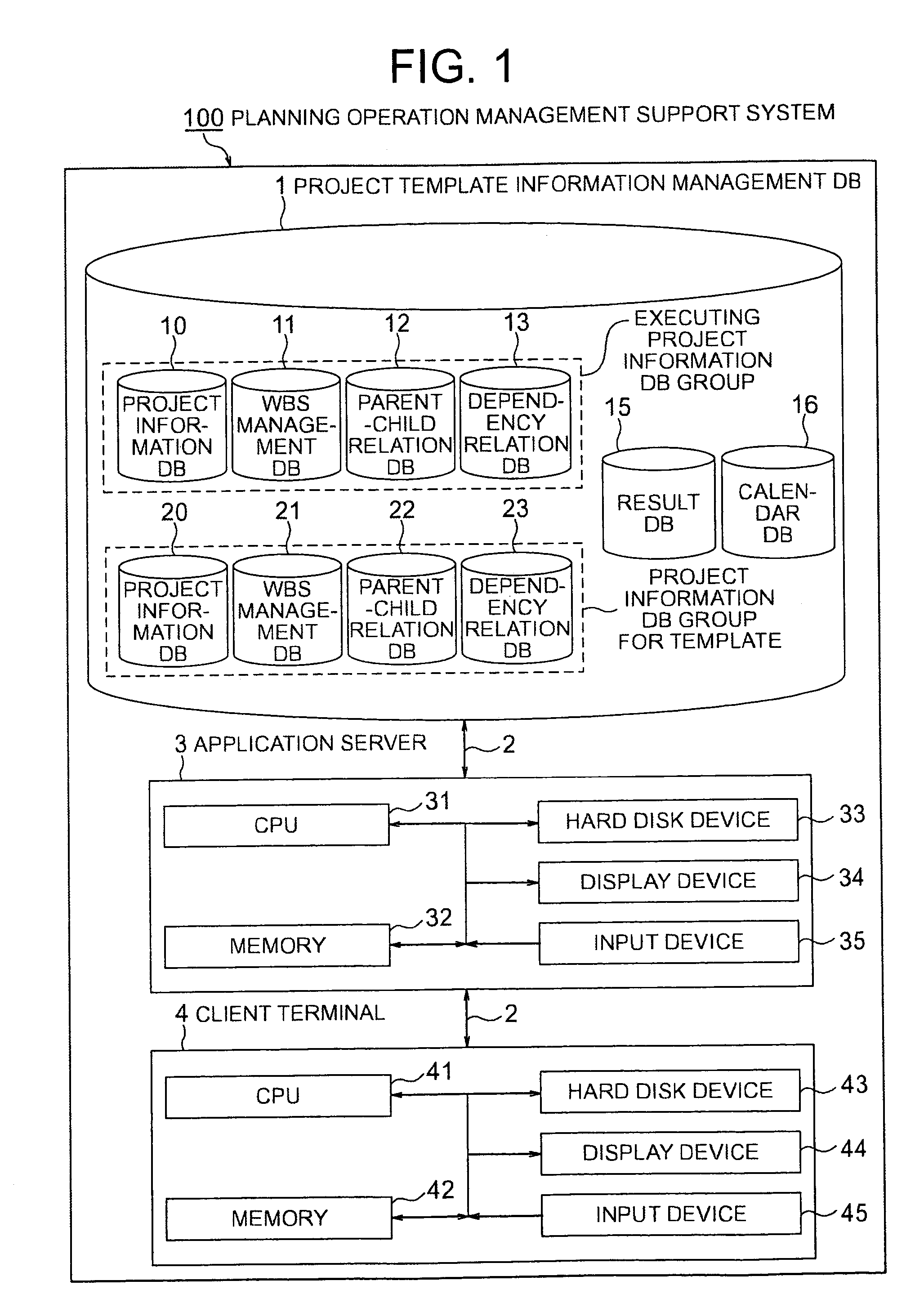

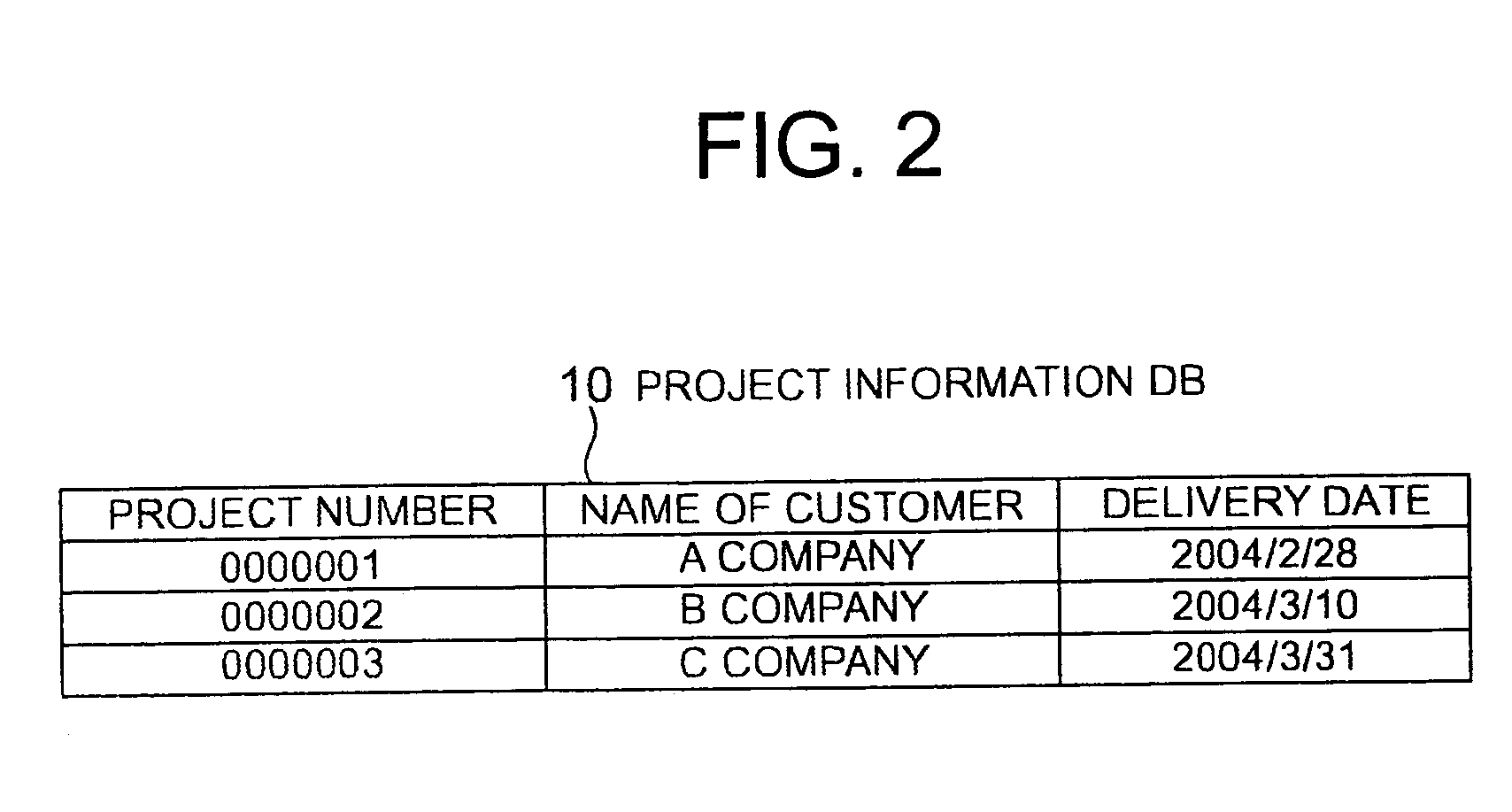

Planning operation management support system, and planning operation management support program

ActiveUS20050216111A1Performed easily and accuratelyEasy to correctResourcesSpecial data processing applicationsGantt chartManagement support systems

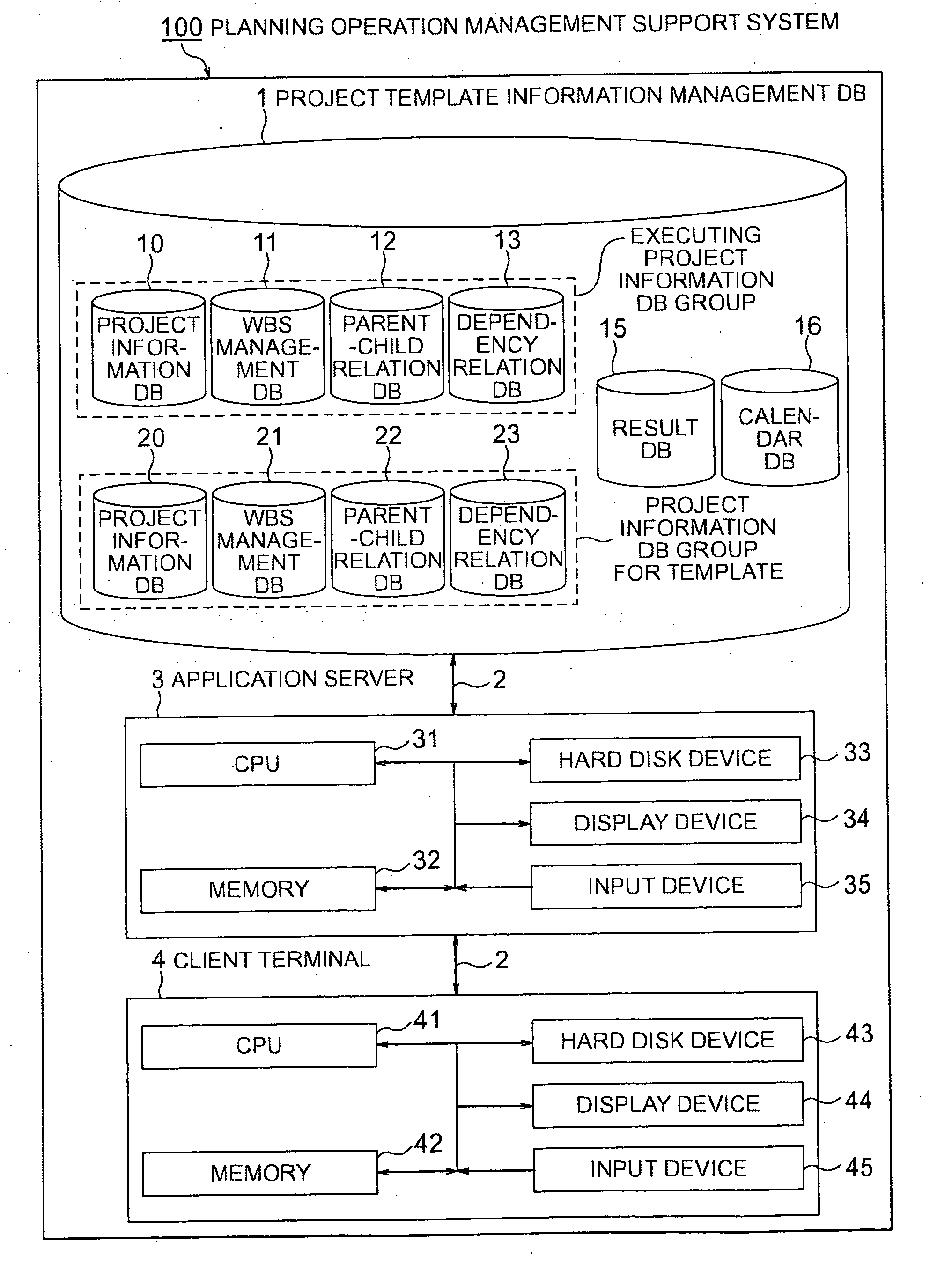

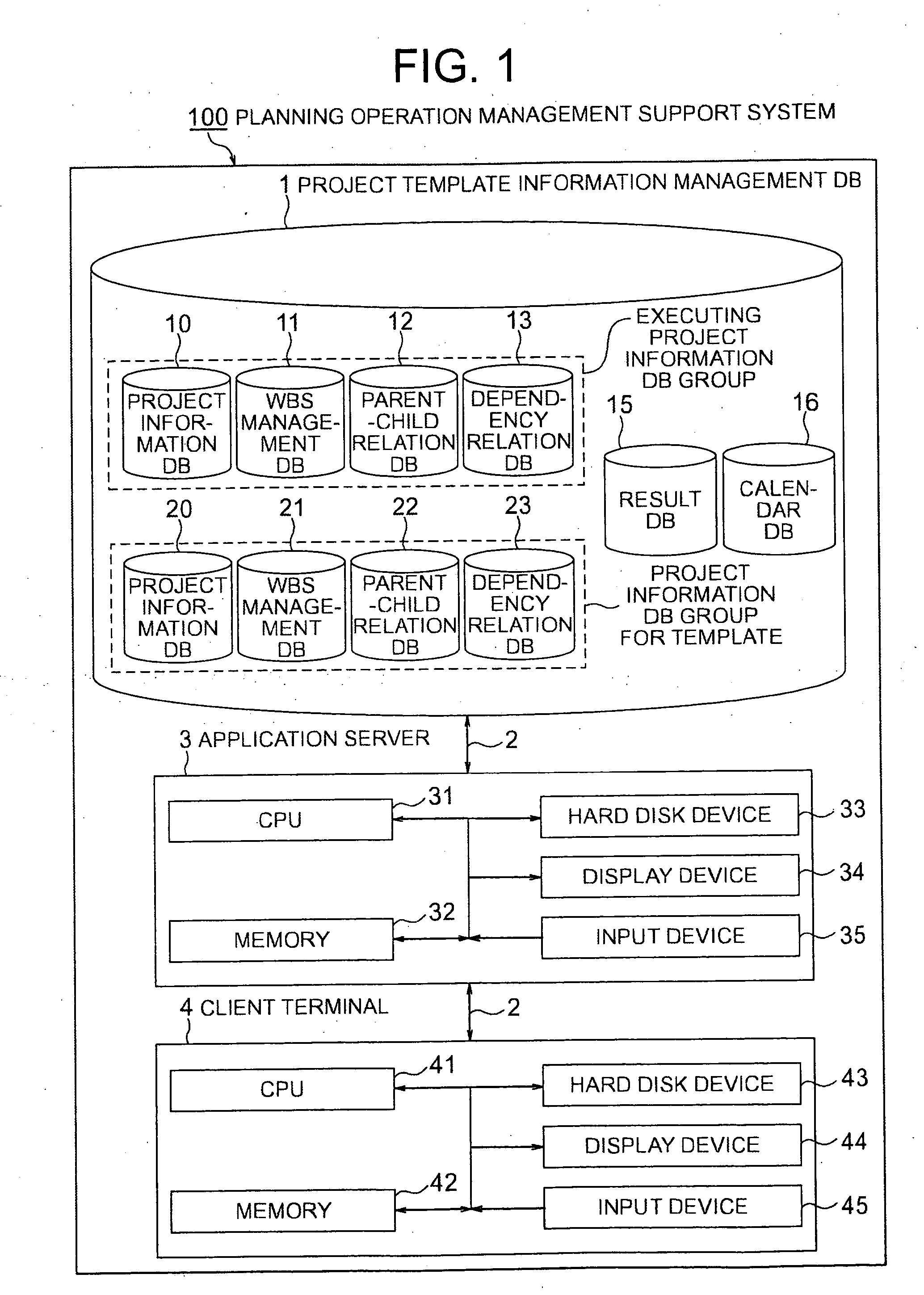

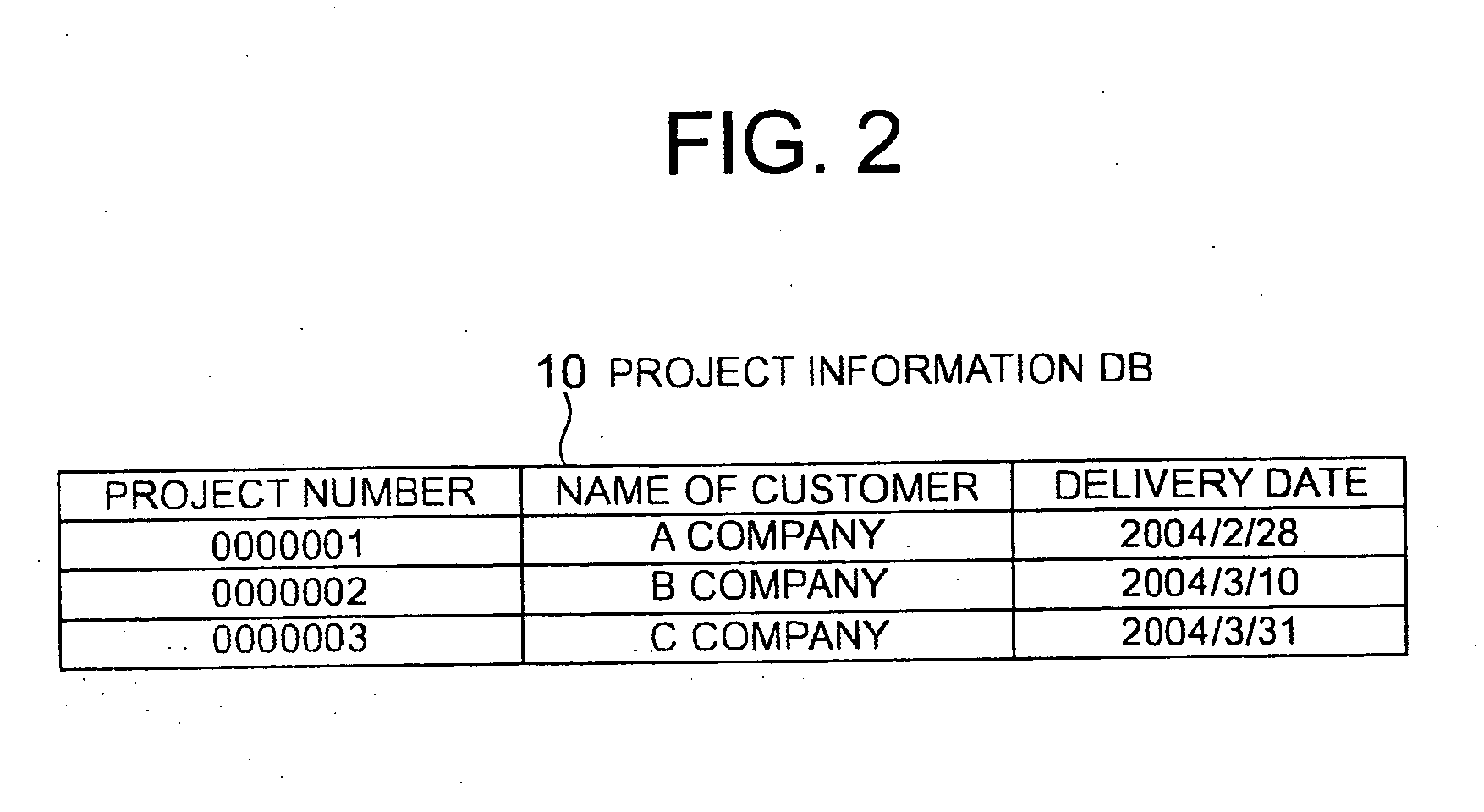

A project template information management database 1 of a planning operation management support system includes: database groups from 20 to 23 saving setting information of planning operations performed in the past, names of process flows in the respective layers (task name), lead times (lead time) required for the respective process flows (task), and dependency relations between the process flows (task), as templates by the respective customers; a result database 15 storing trading results with customers in the past; and a calendar database 16 storing calendar information setting actual working days when workers in charge of the respective process flows carry on a work, and holidays. A client terminal 4 includes: an input device 35 inputting new project names, customer names, and delivery dates; and a CPU41 calling a corresponding customer's template from the project template information management database 1 by inputting the customer name, the name of the new project, and the delivery date, creating a new project information, and displaying the Gantt chart on the screen.

Owner:SUMITOMO WIRING SYST LTD +1

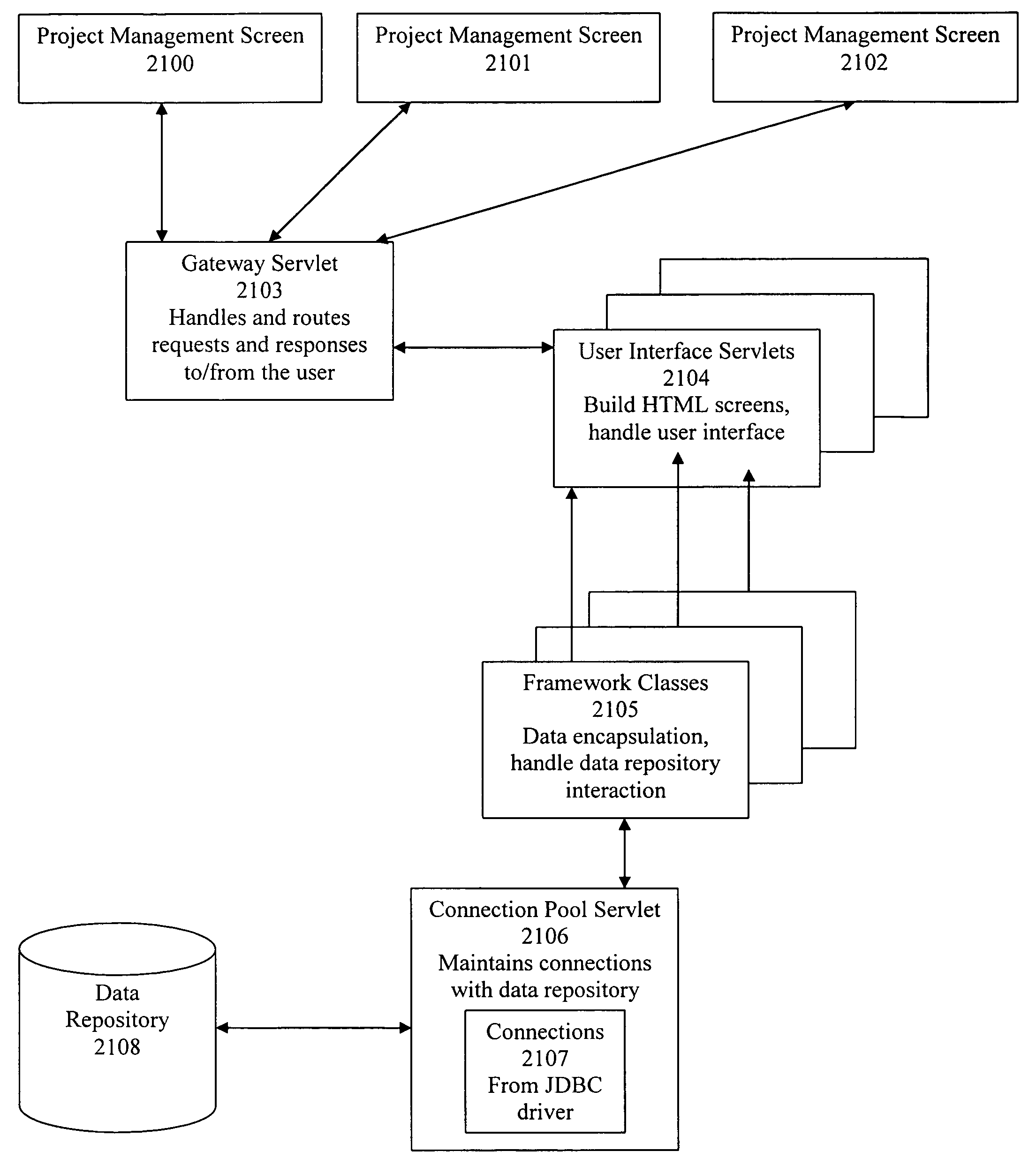

Progress management system

InactiveUS20070073575A1Easily visually monitoredEasy to monitorMultiprogramming arrangementsResourcesGraphicsGantt chart

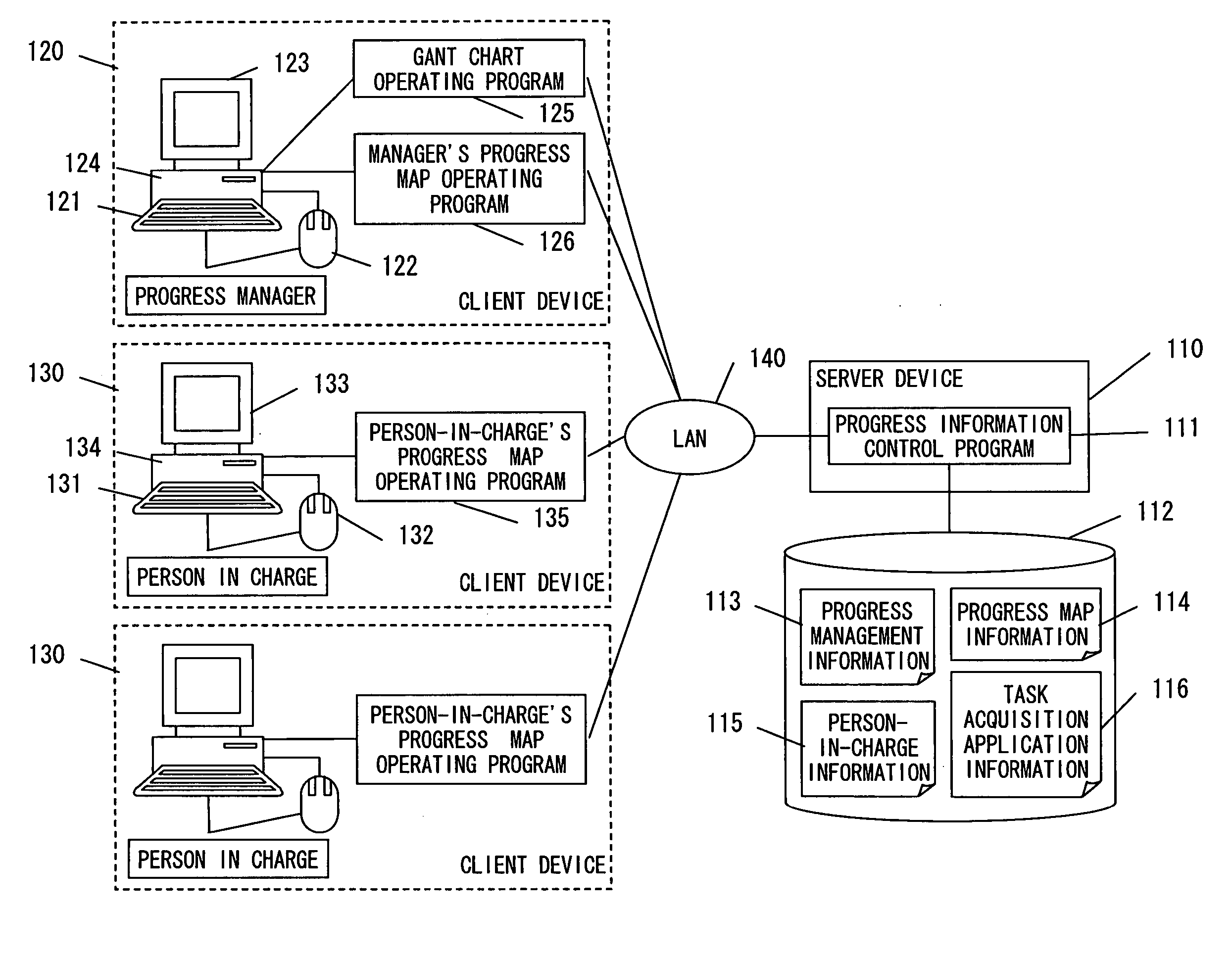

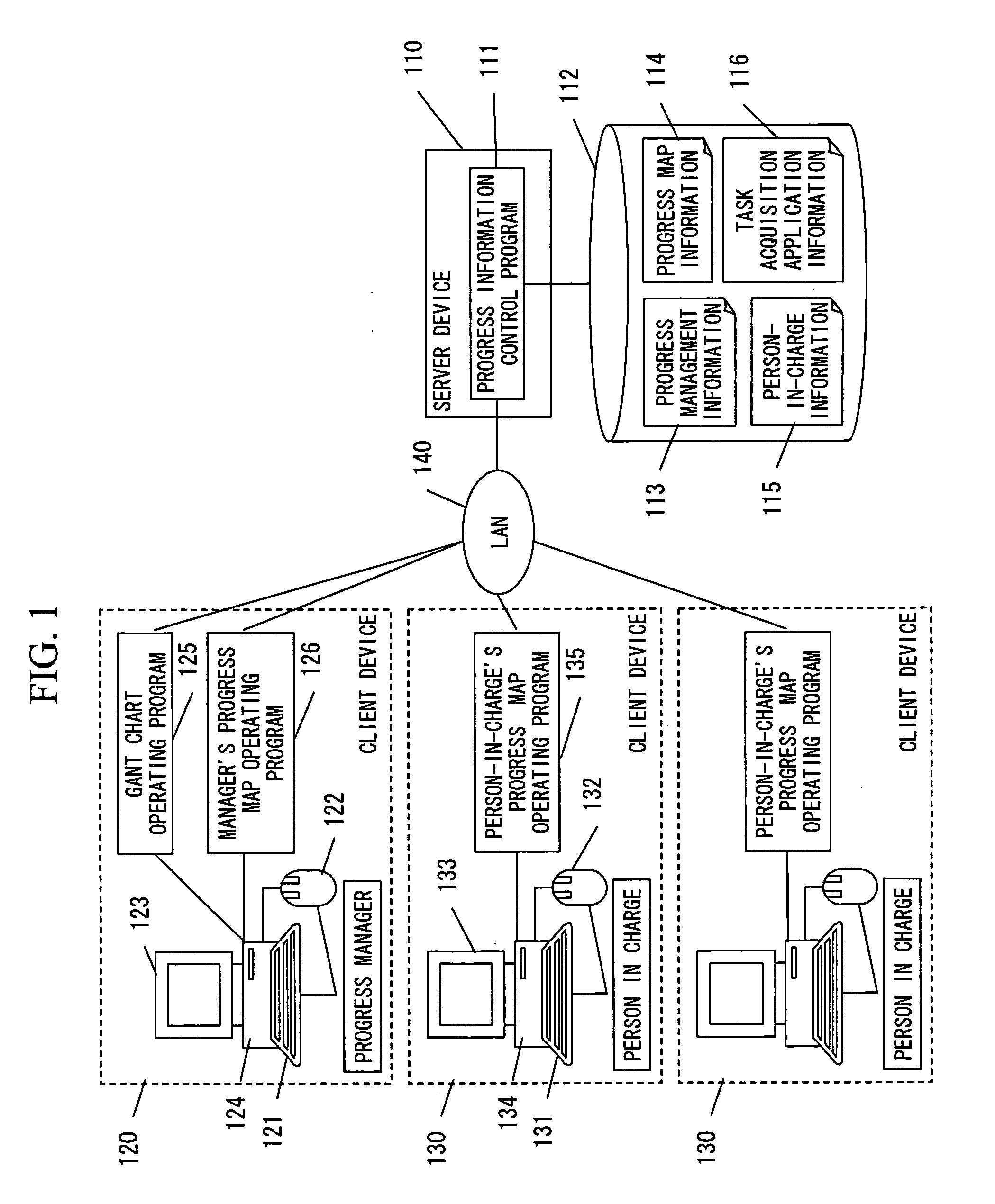

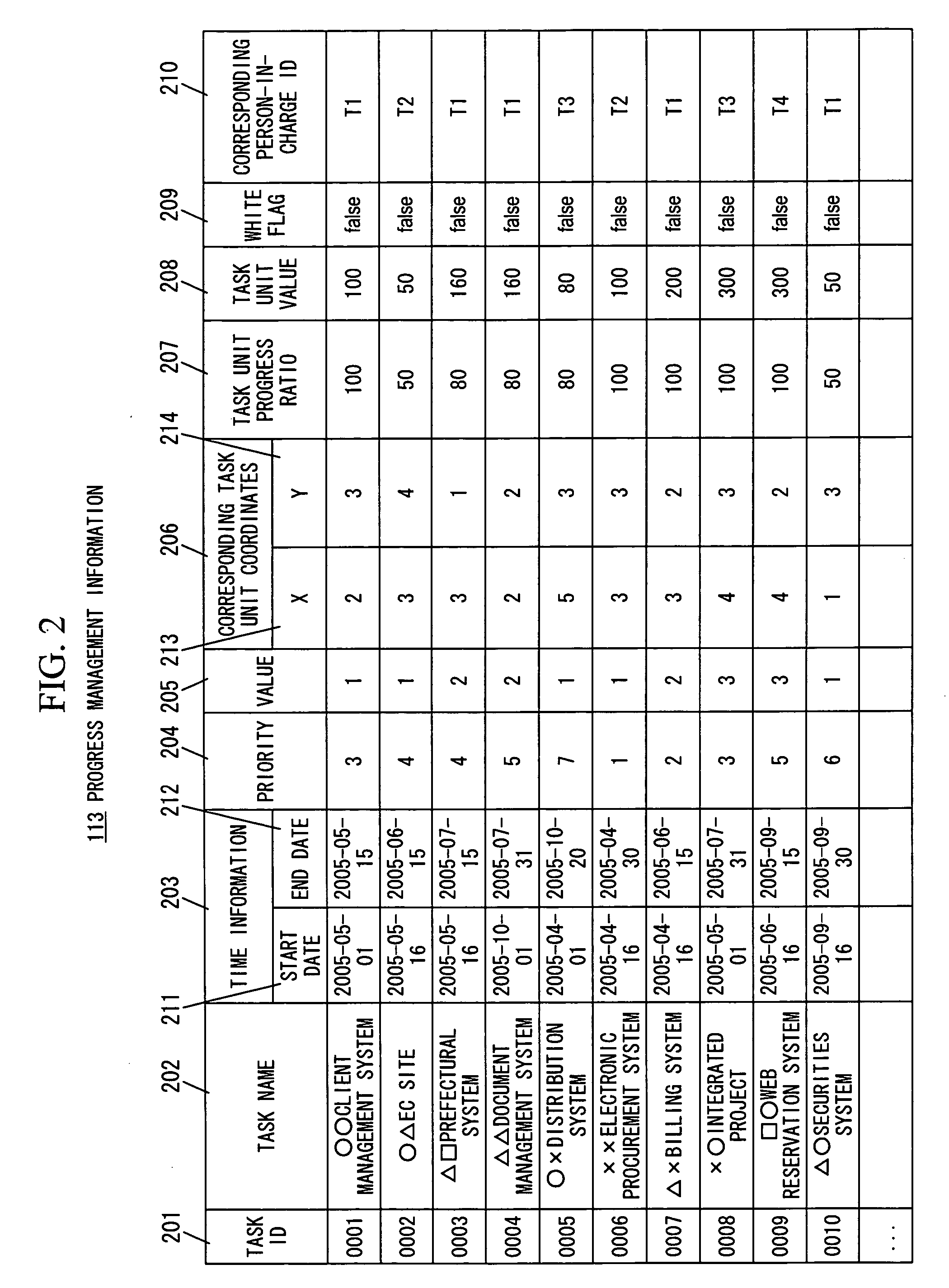

A progress management system employing a progress map that enables the visual monitoring of the progress status of an overall operation, the amount of each task, progress status or the like for each person in charge, in addition to the status of progress of each task, on a single screen. A progress management screen 2100 includes a progress map display portion 2110 and a person-in-charge list display portion 2120. The progress map display portion 2110, based on a Gantt chart, shows a progress map consisting of task units 2111 indicating individual tasks and a connection line connecting adjacent task units 2111 in a graph structure. On a task unit 2111, persons in charge of associated tasks, progress ratio 2112, and a task unit value 2114 based on the progress ratio 2112 and value 2113 are displayed. In the person-in-charge list display portion 2120, a list of persons in charge with associated task units and a sum of task unit values for each person in charge are displayed as a person-in-charge result value 2121.

Owner:HITACHI SOFTWARE ENG

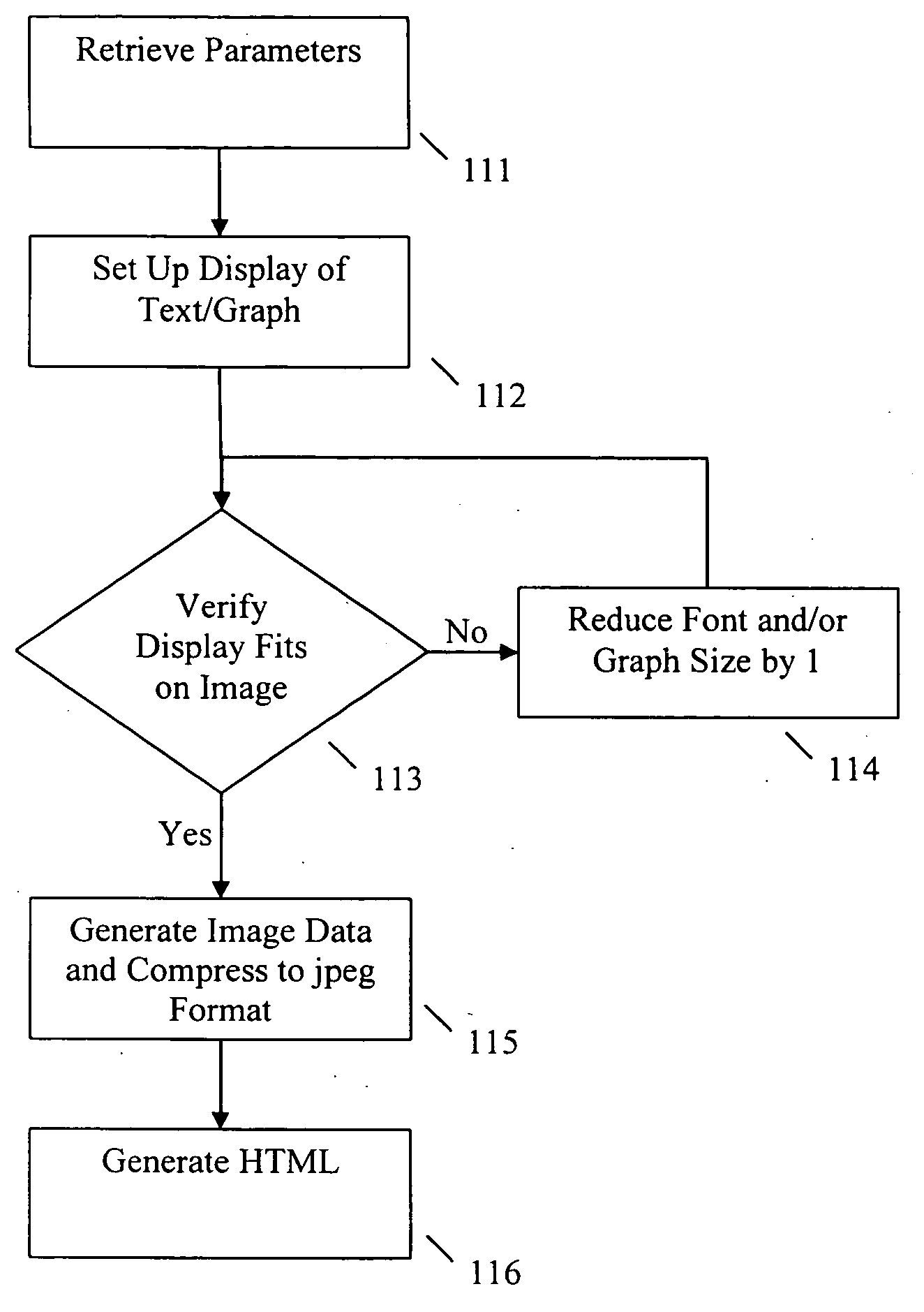

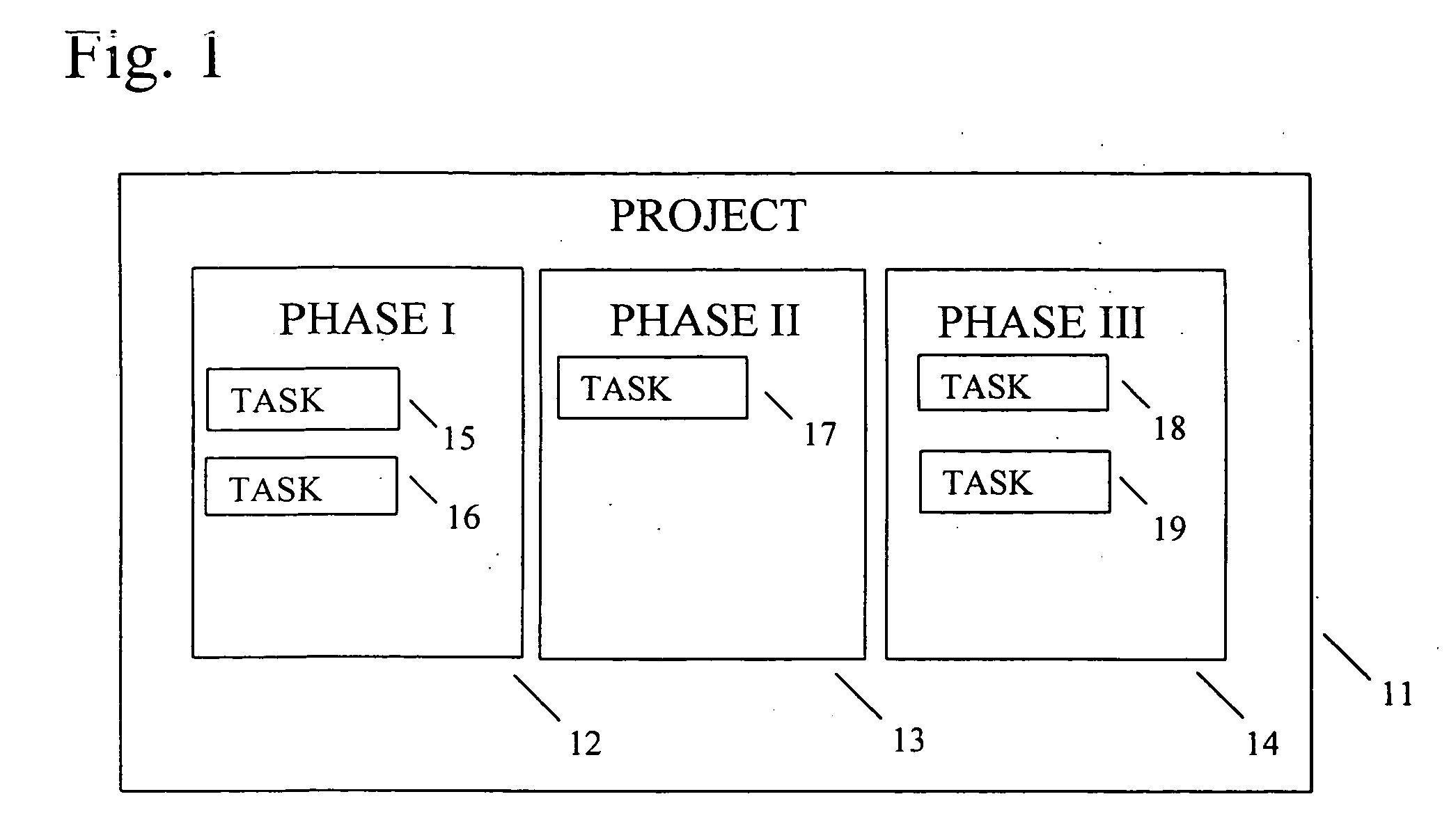

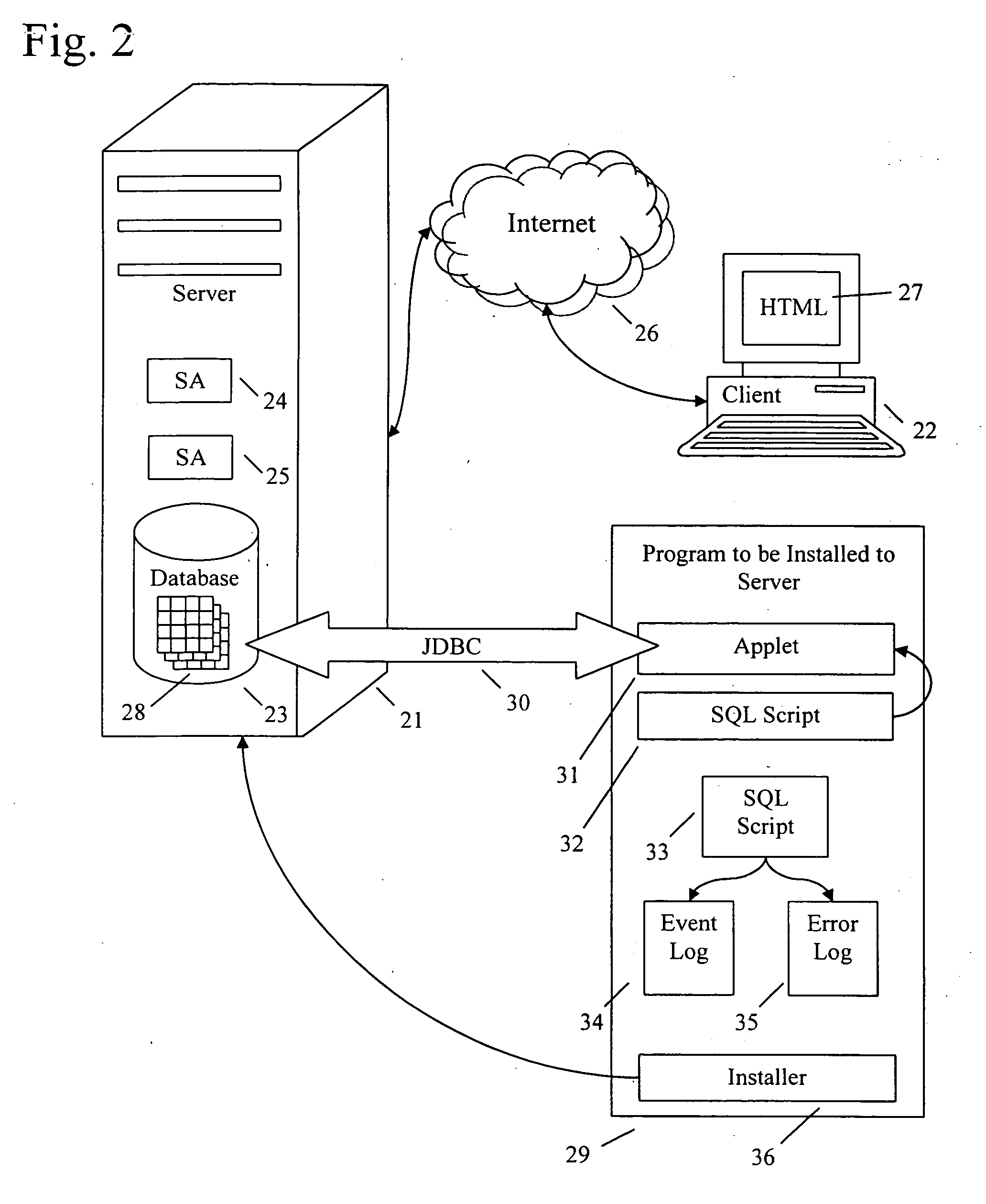

Apparatuses and methods for dynamic creation of phase gantt charts

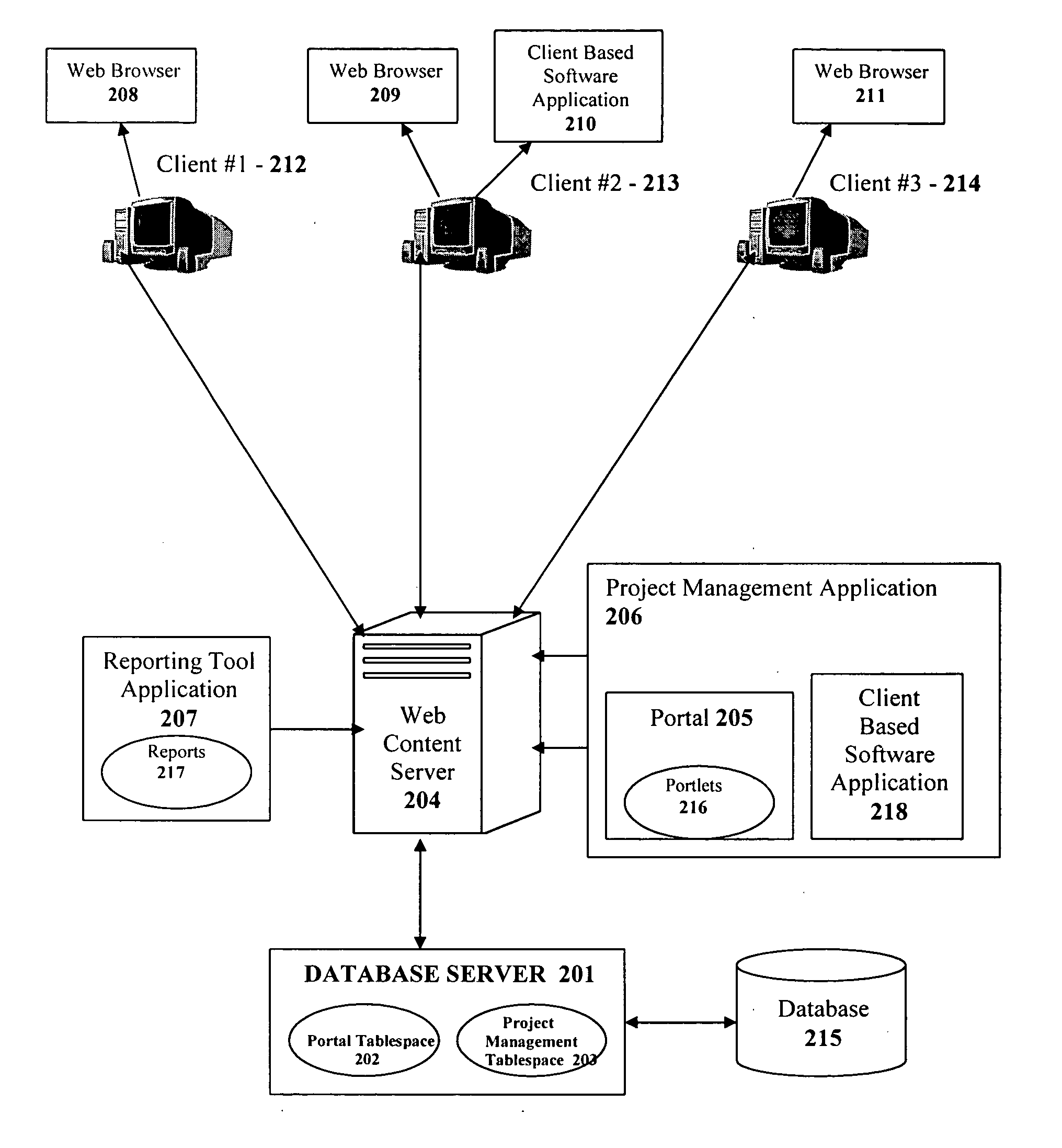

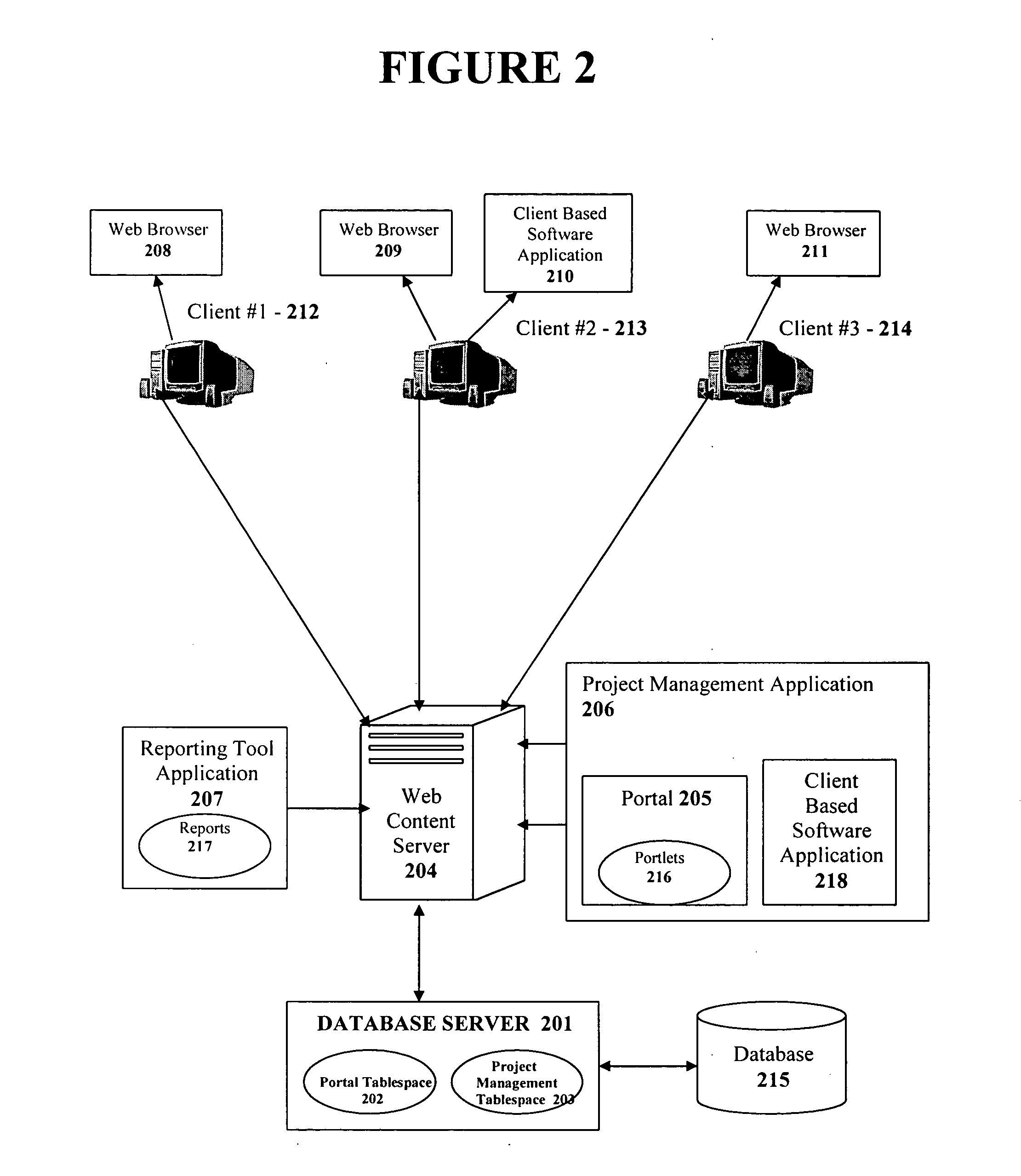

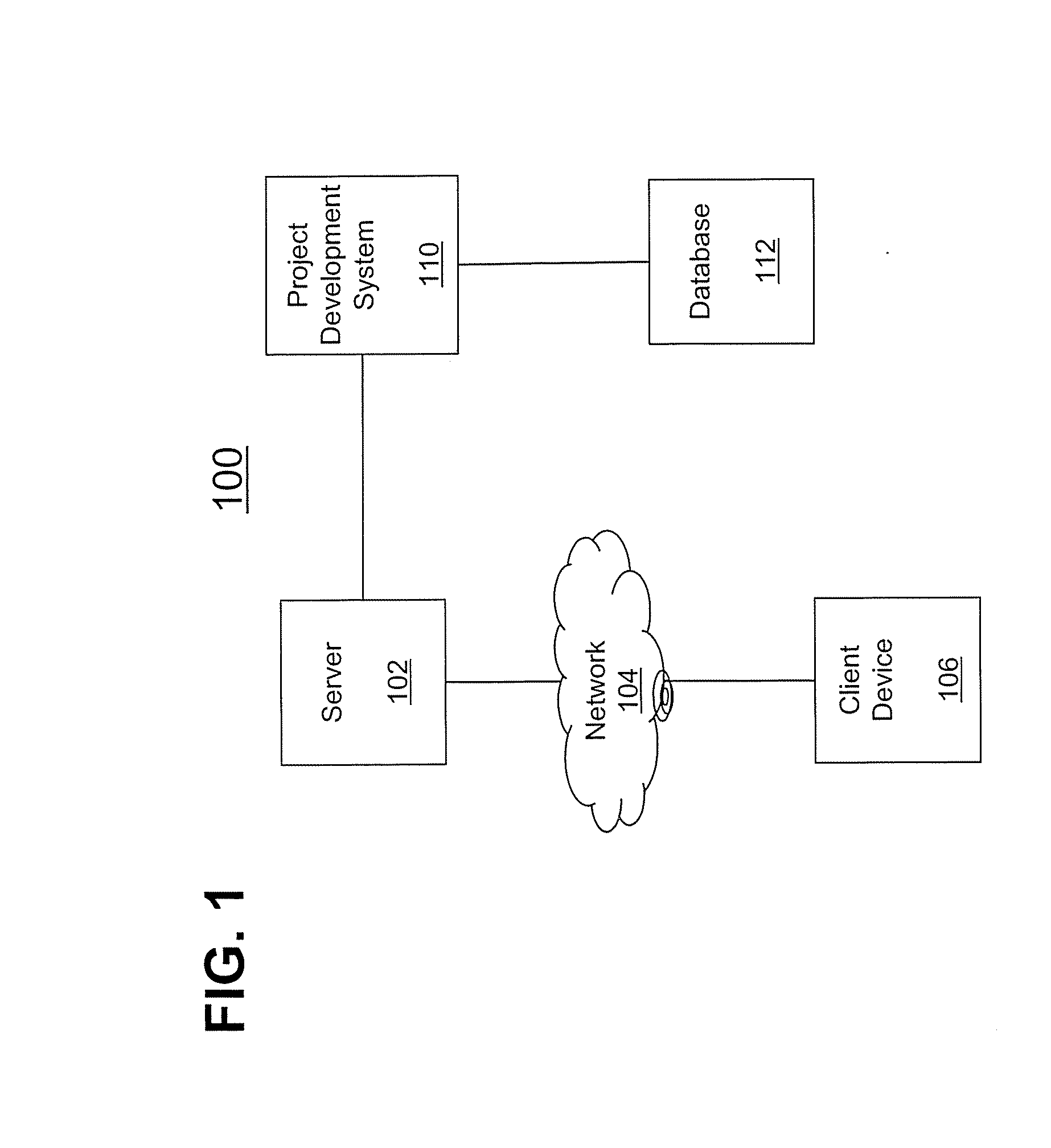

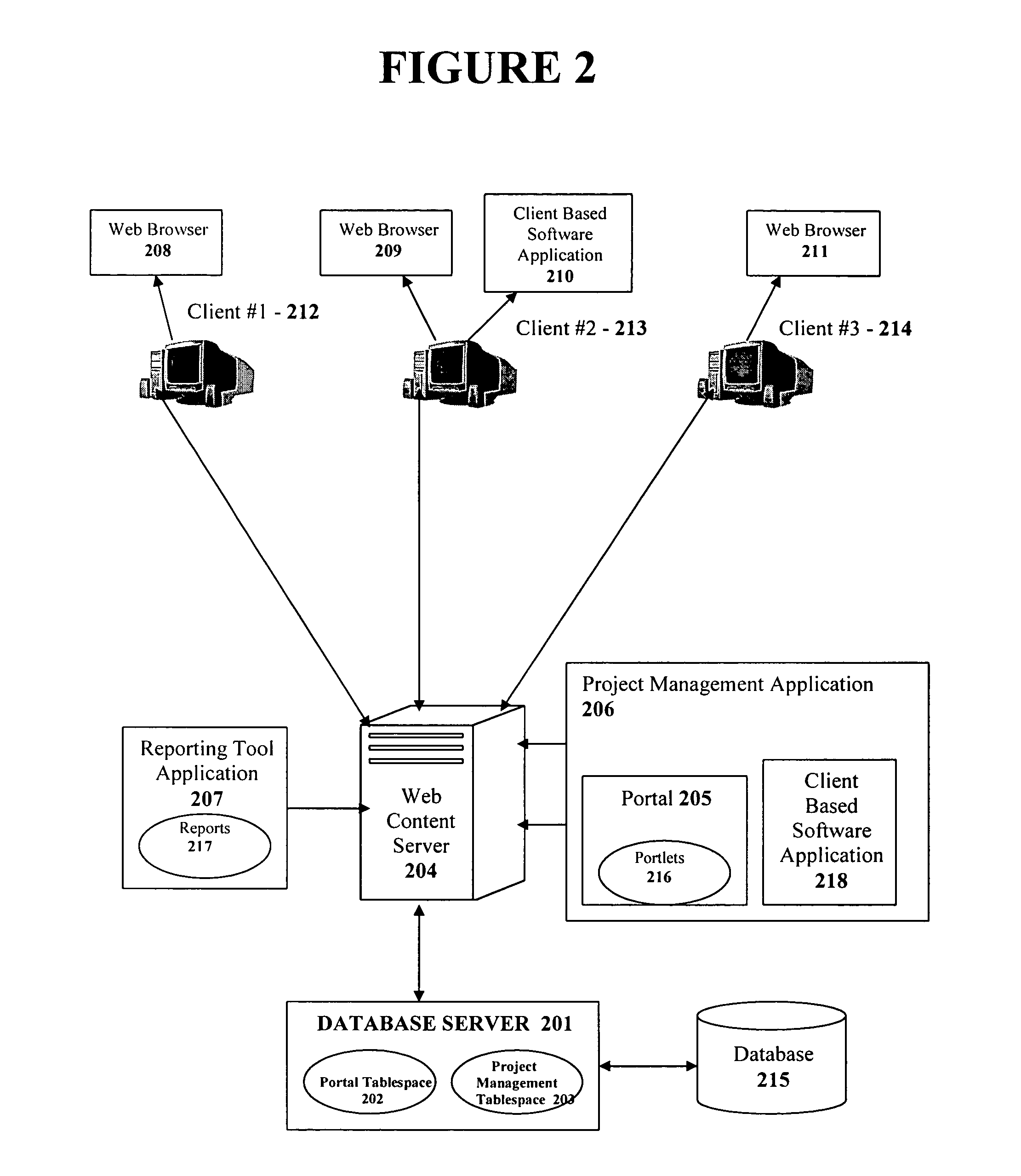

A method for dynamic creation of a phase Gantt chart, includes entering project management data into a repository, receiving a request from at least one client to obtain the project management data and generating the phase Gantt chart in response to the received request based on the project management data stored in the repository.

Owner:COMP ASSOC THINK INC

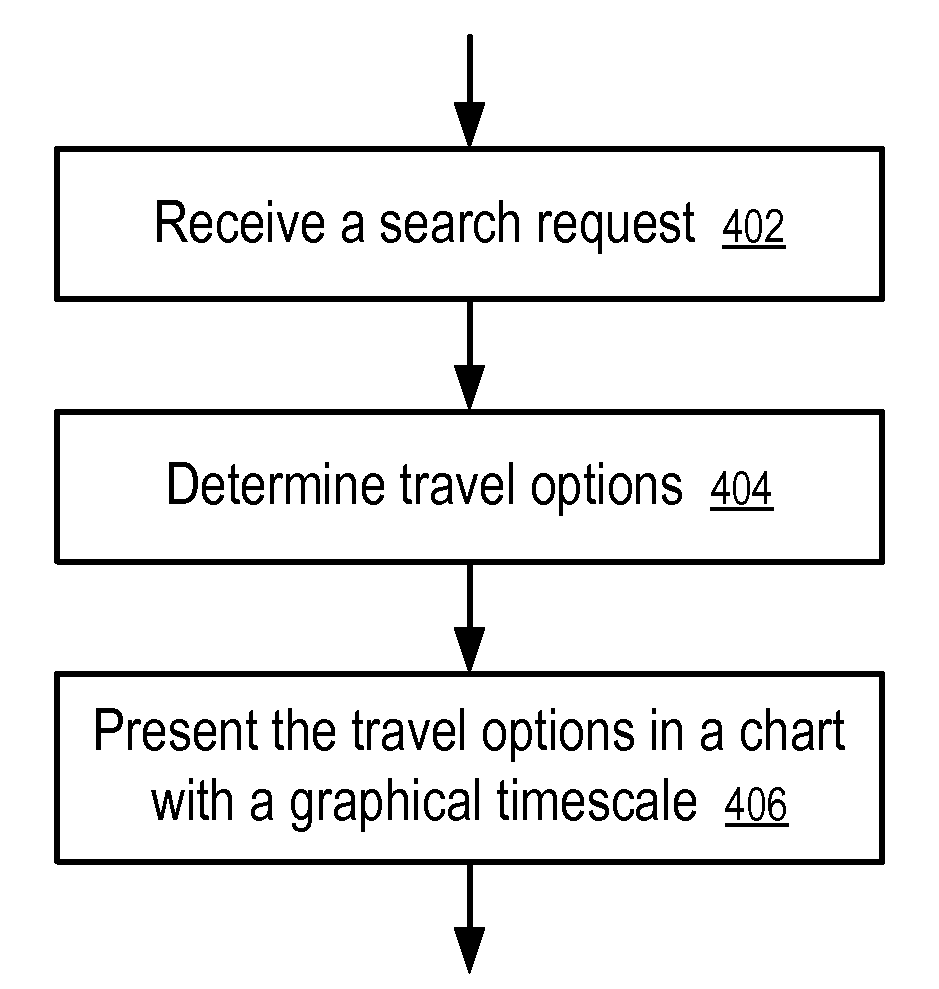

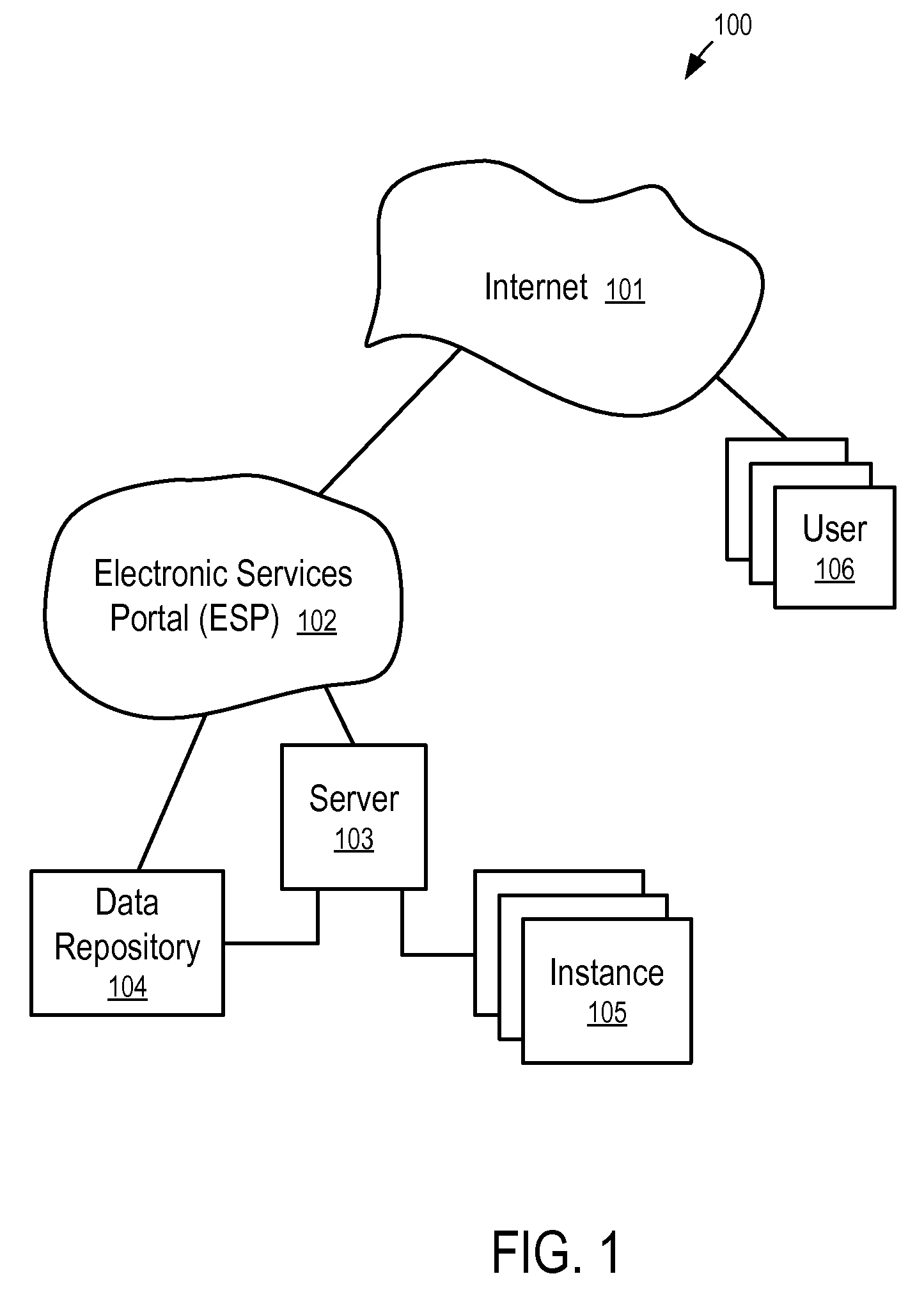

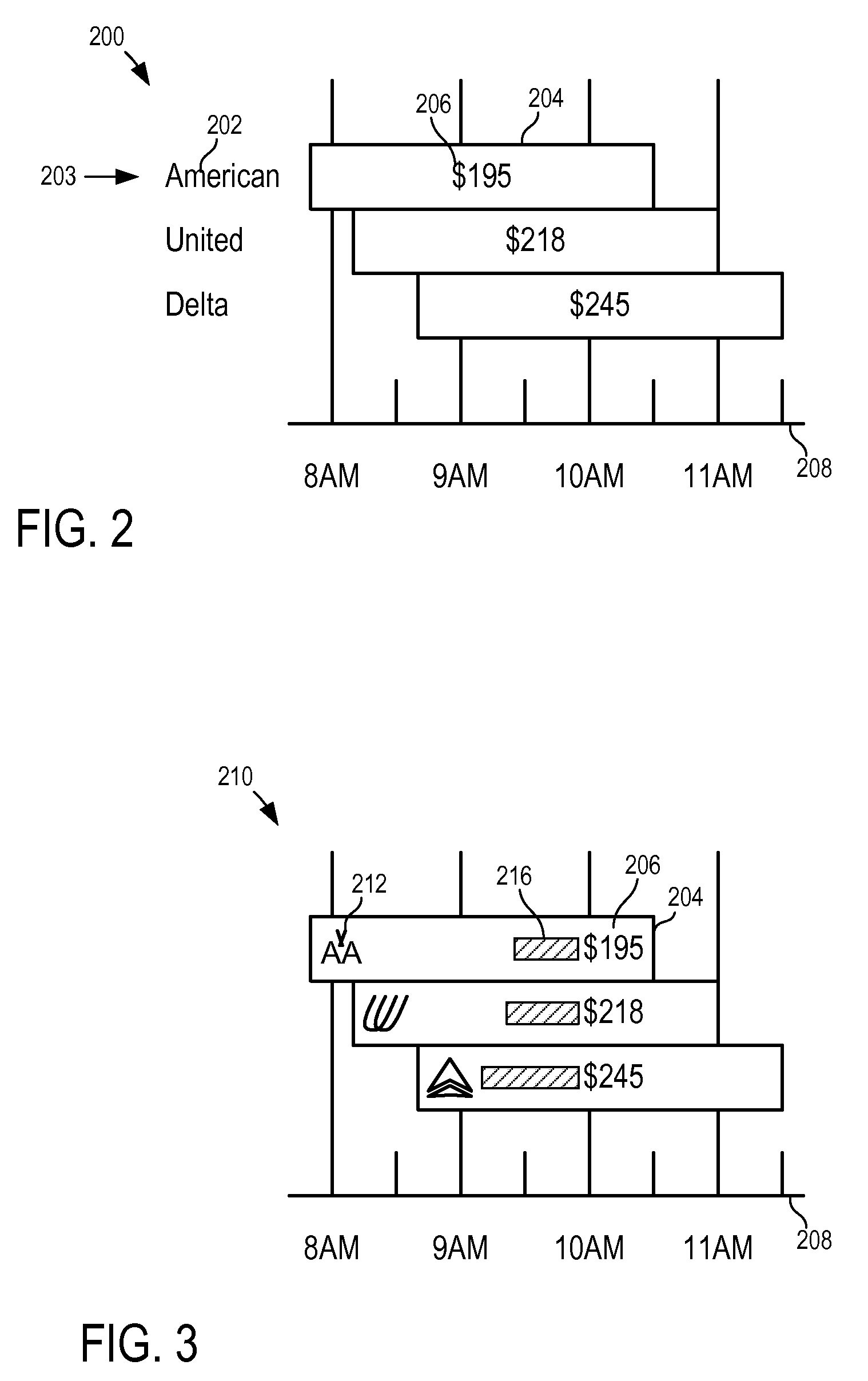

Systems and Methods to Present Travel Options

Systems and methods to present travel options in response to a search request. In one aspect, after a computer system receives a search request from a user, the computer system determines a plurality of travel options in response to the search request. The computer system then presents the travel options using a chart having a dimension graphically representing travel times of the travel options, such as in a Gantt chart with a graphical timescale, which may have a representation of an analog clock.

Owner:REARDEN COMMERCE

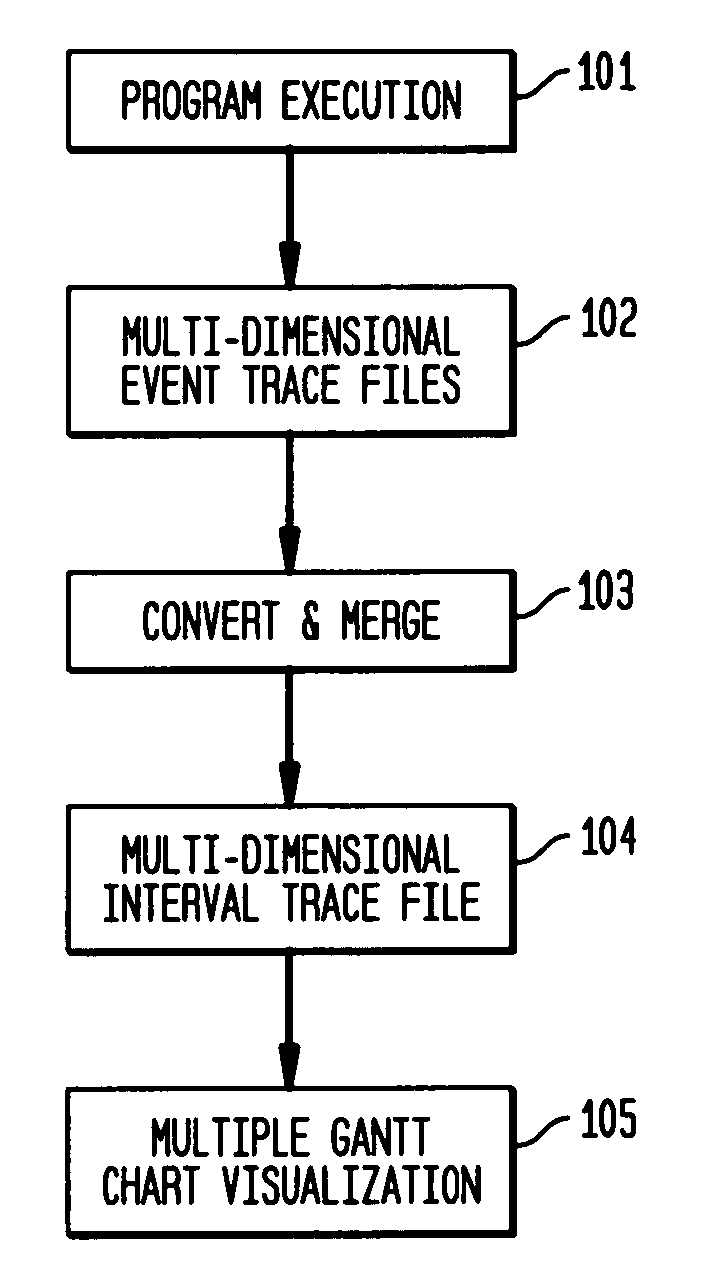

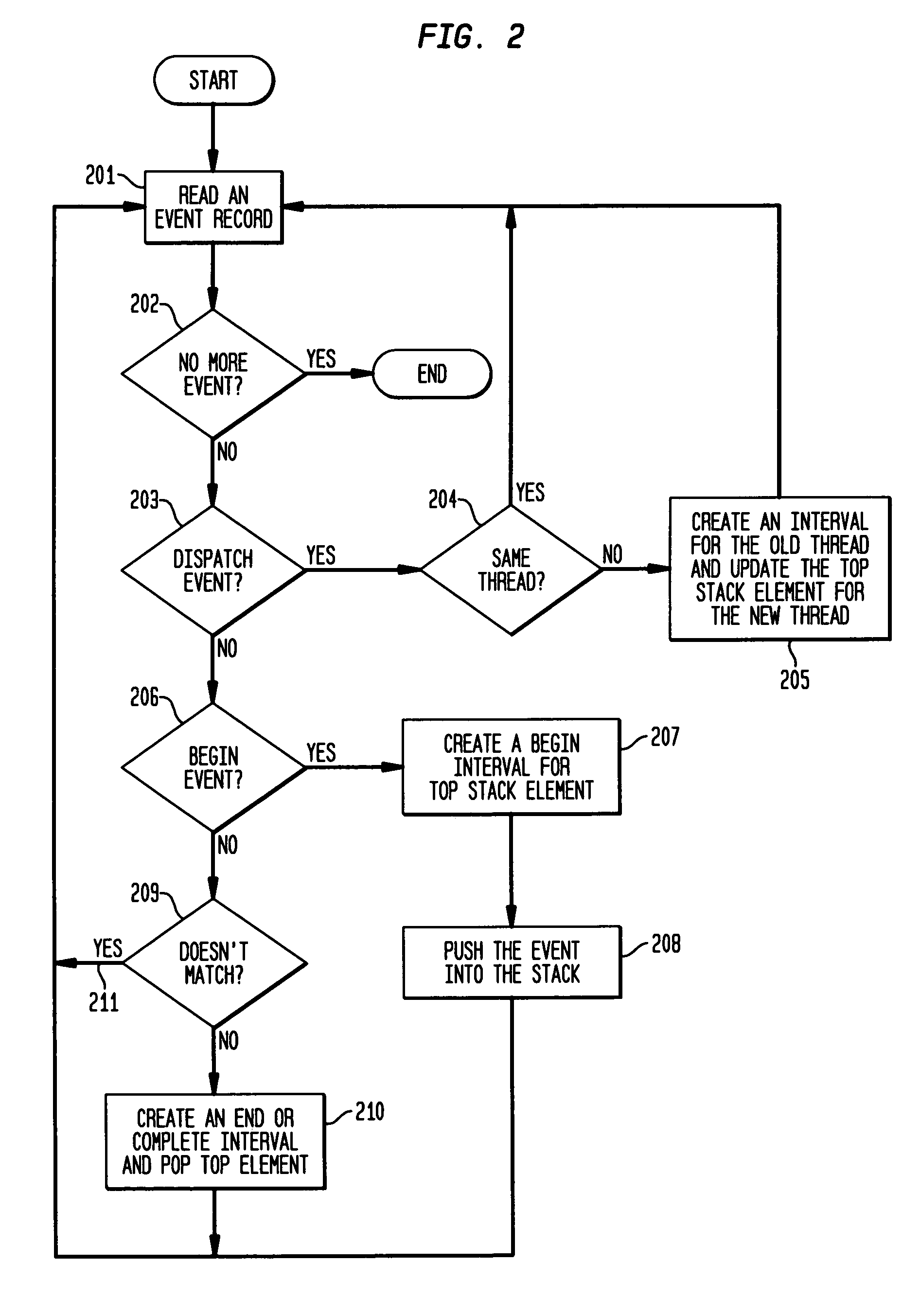

System and method on generating multi-dimensional trace files and visualizing them using multiple Gantt charts

InactiveUS7131113B2Elimination of trace file explosionEasy to understandError preventionError detection/correctionGantt chartMultiple dimension

A system and method for visualizing data in two-dimensional time-space diagrams including generating multi-dimensional program trace files, converting and merging them into interval trace files, and generating multiple time-space diagrams (multiple Gantt charts) to visualize the resulting multi-dimensional interval trace files. The needed events and trace information required to form multi-dimensional event traces are described in event trace files typically gathered from running programs, such as parallel programs for technical computing and Web server processes. The method includes converting event traces into interval traces. In one selectable design, the two-dimensional time-space diagrams includes three discriminator types (thread, processor, and activity) and six discriminator-legend combinations, capable of producing seven possible views. The six discriminator-legend combinations are thread-activity, thread-processor, processor-thread, processor-activity, activity-thread, and activity-processor. Each discriminator-legend combination corresponds to one time-space diagram, except that the thread-activity combination has two possible views: Thread-Activity View and Connected Thread-Activity View.

Owner:IBM CORP

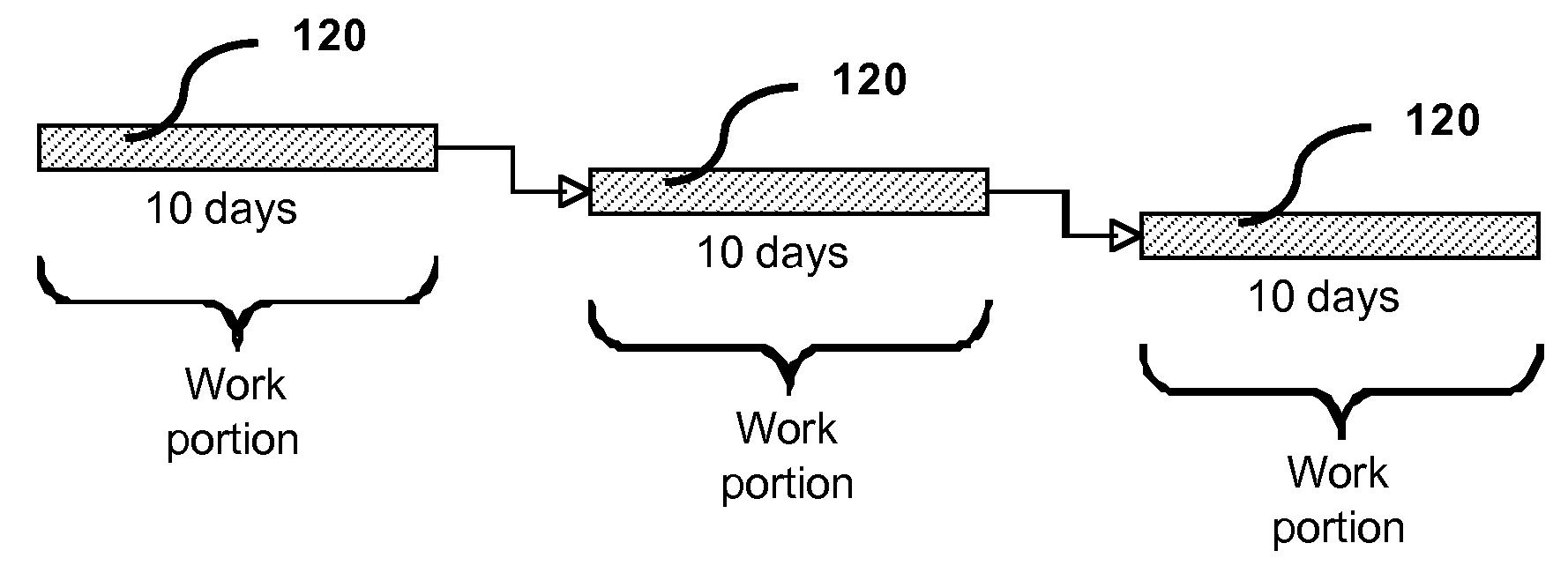

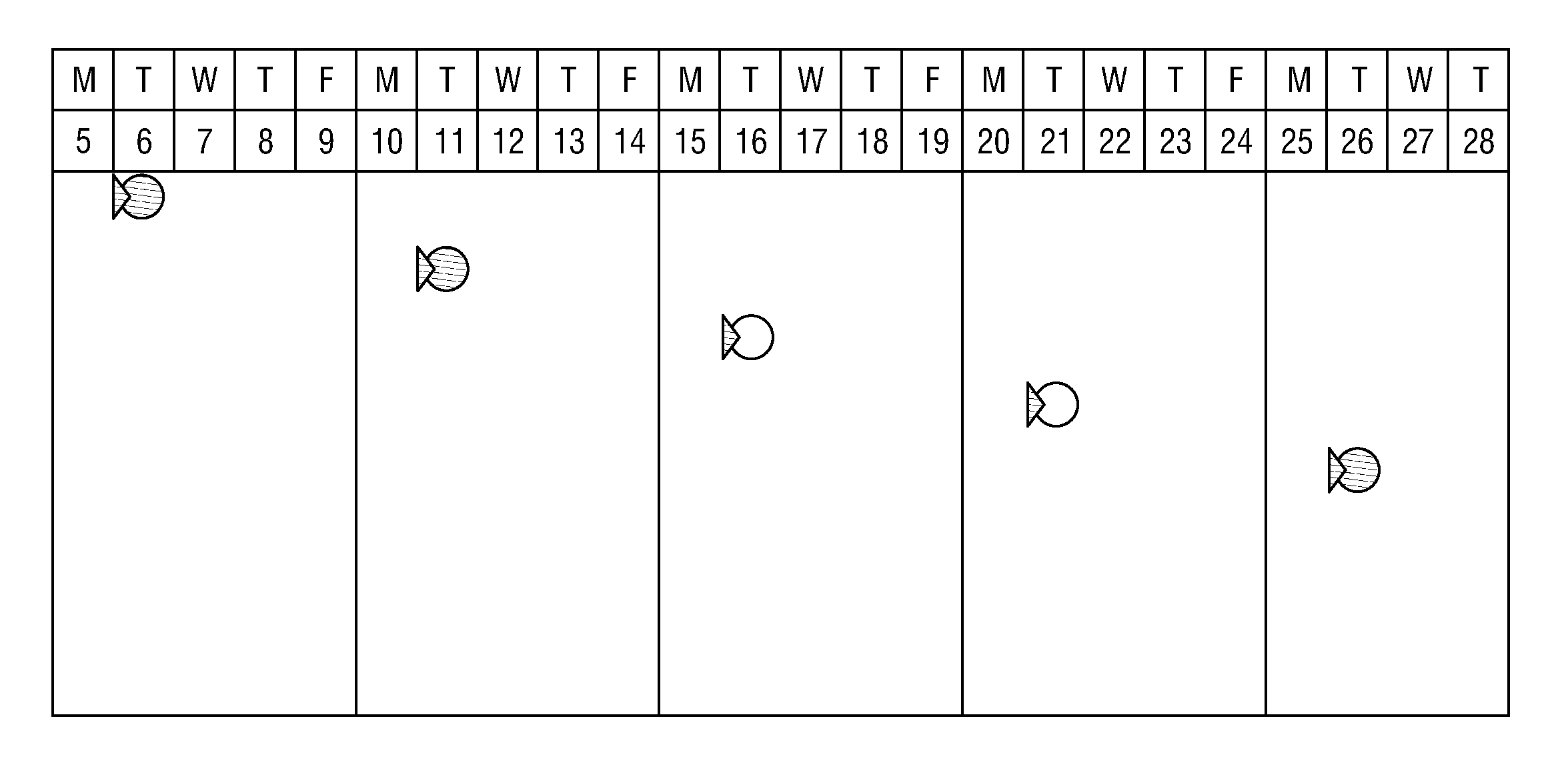

Determining a Critical Path in Statistical Project Management

An apparatus for a Gantt chart includes a processing unit which determines a range of dates for an end date for completing a task. The range comprises a first date and a final date. The apparatus includes a display which shows the range of dates for the task completion. A method for a Gantt chart includes the steps of determining a range of dates for an end date for completing a task with a processing unit. The range comprises a first date and a final date. There is the step of showing on a display the range of dates for the task completion. There is the step of showing on a display the range of the end date. An apparatus for establishing a project's performance. A method for establishing a project's performance.

Owner:TELEFON AB LM ERICSSON (PUBL)

System and method for displaying gantt charts with other project management tools

ActiveUS8245153B2Easy to controlReduce the amount requiredResourcesInput/output processes for data processingGraphicsGantt chart

Owner:INT BUSINESS MASCH CORP

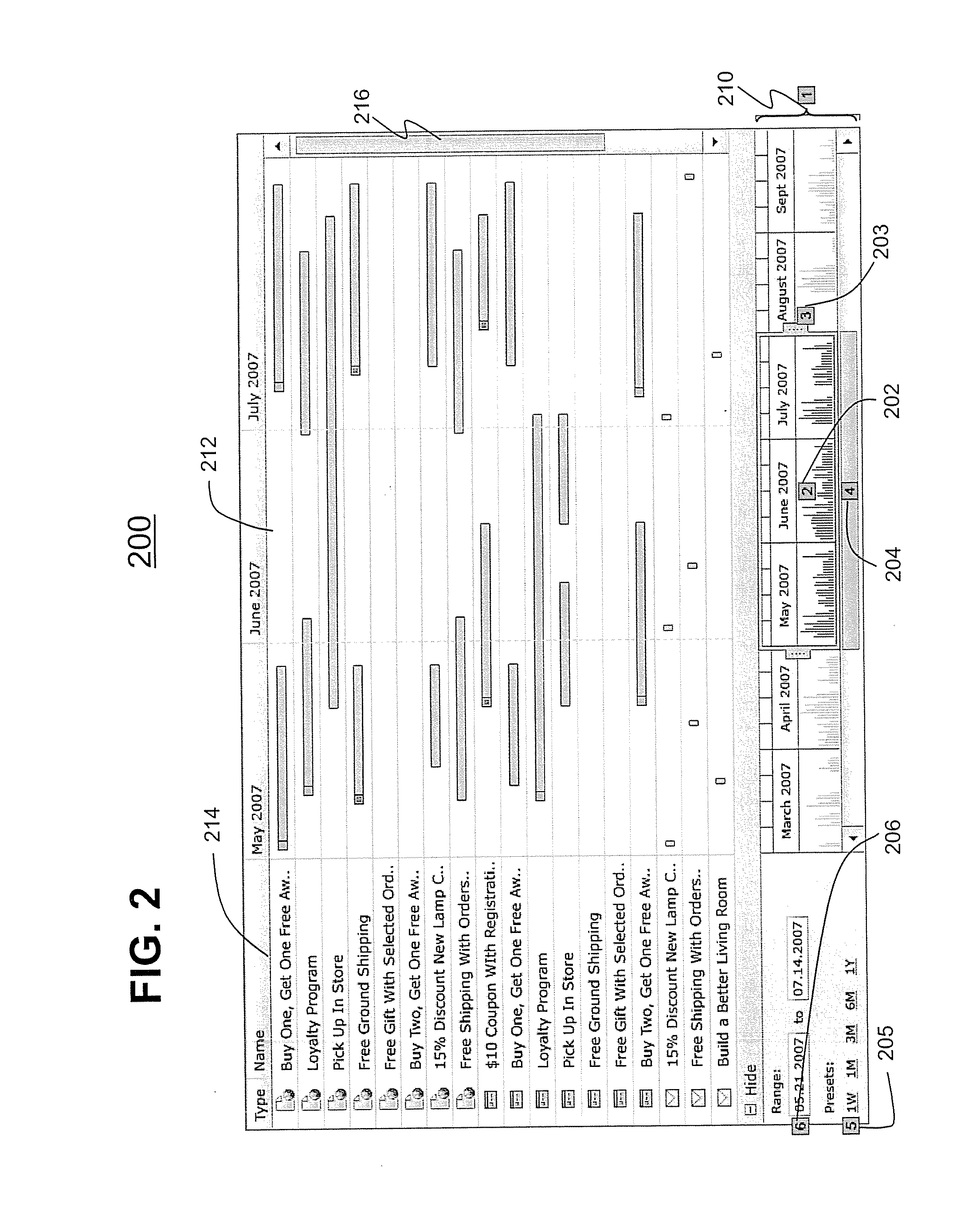

Gantt chart map display and method

ActiveUS20090193353A1Easy to controlEasy to seeResourcesInput/output processes for data processingGantt chartGraphics

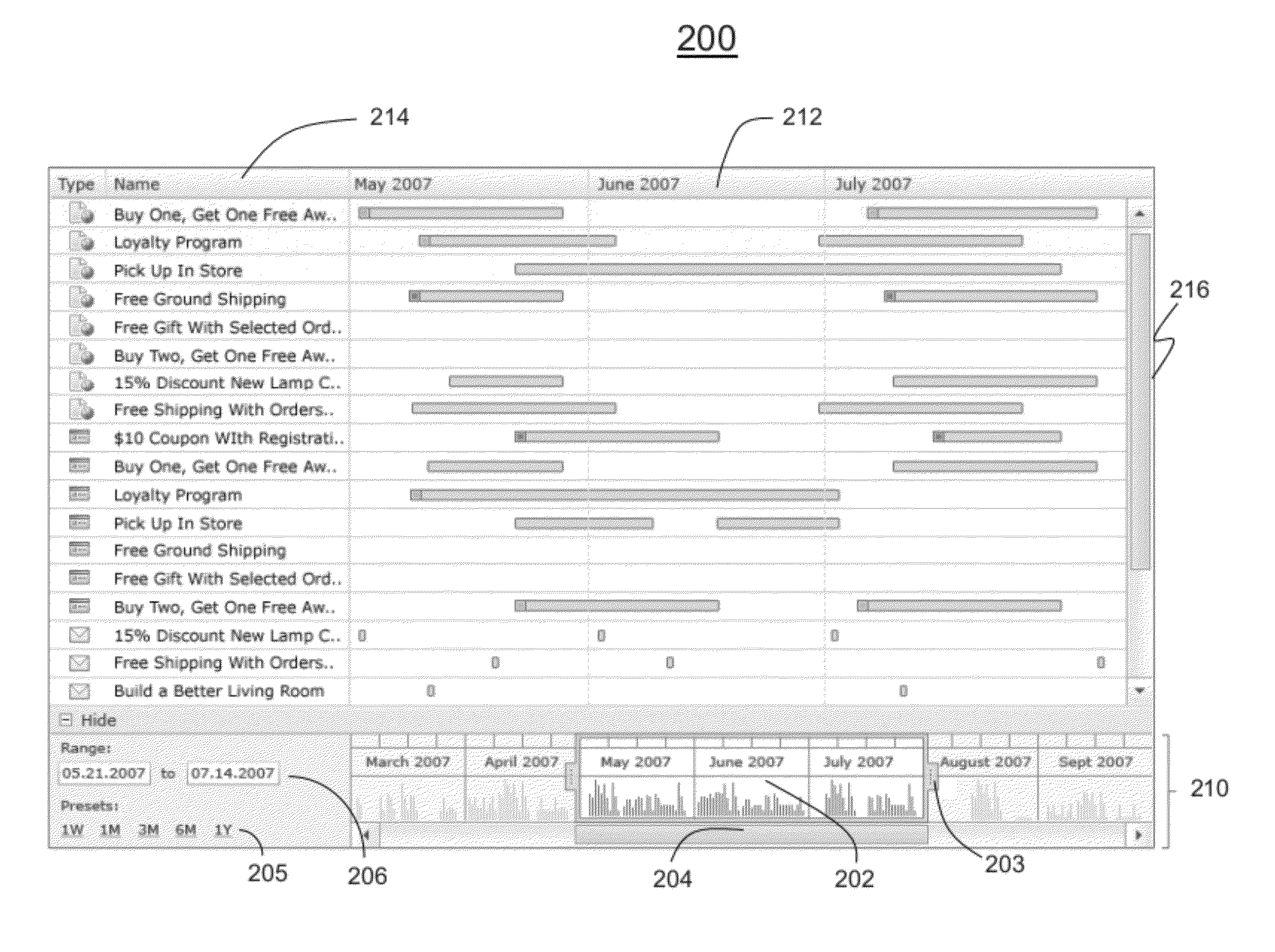

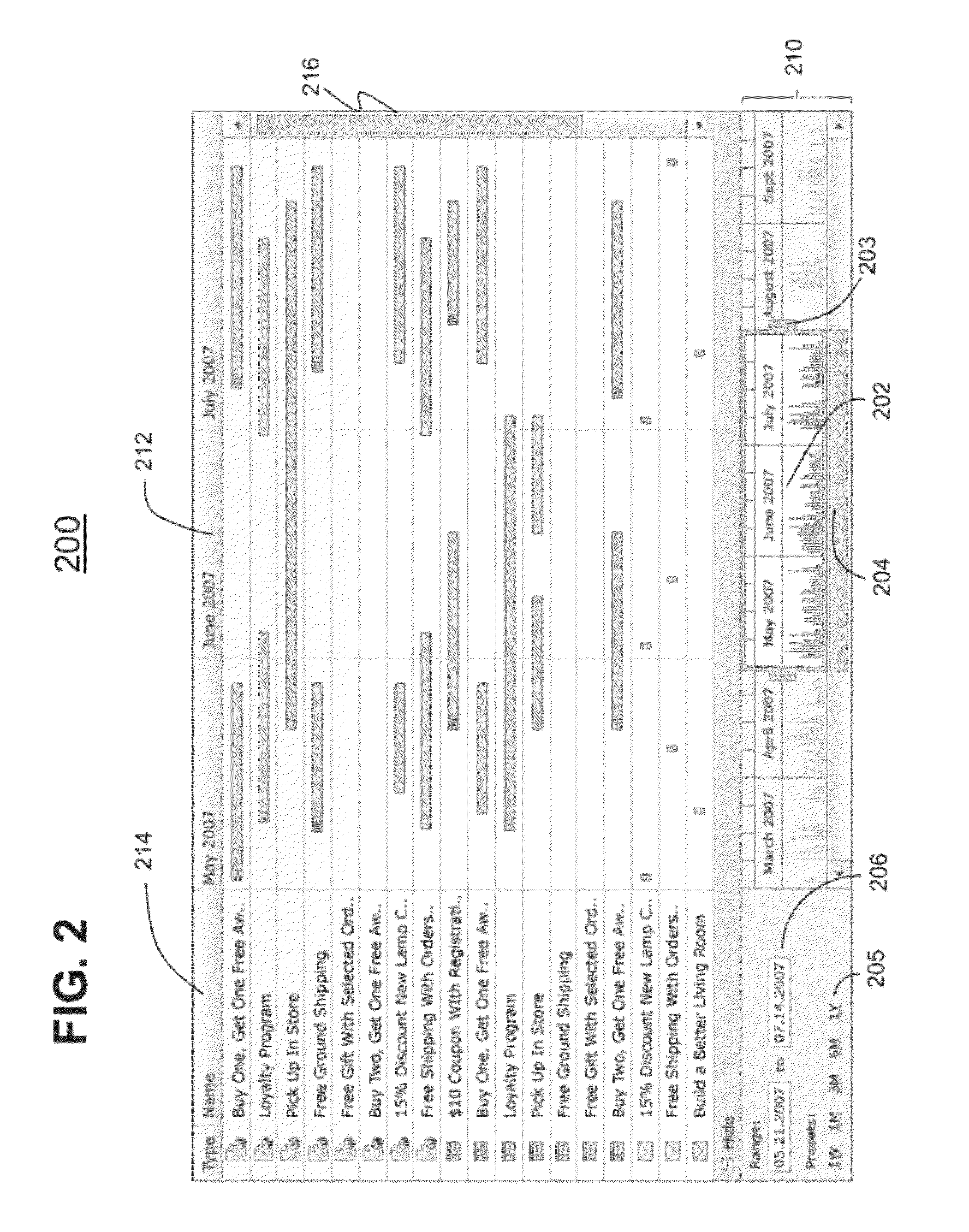

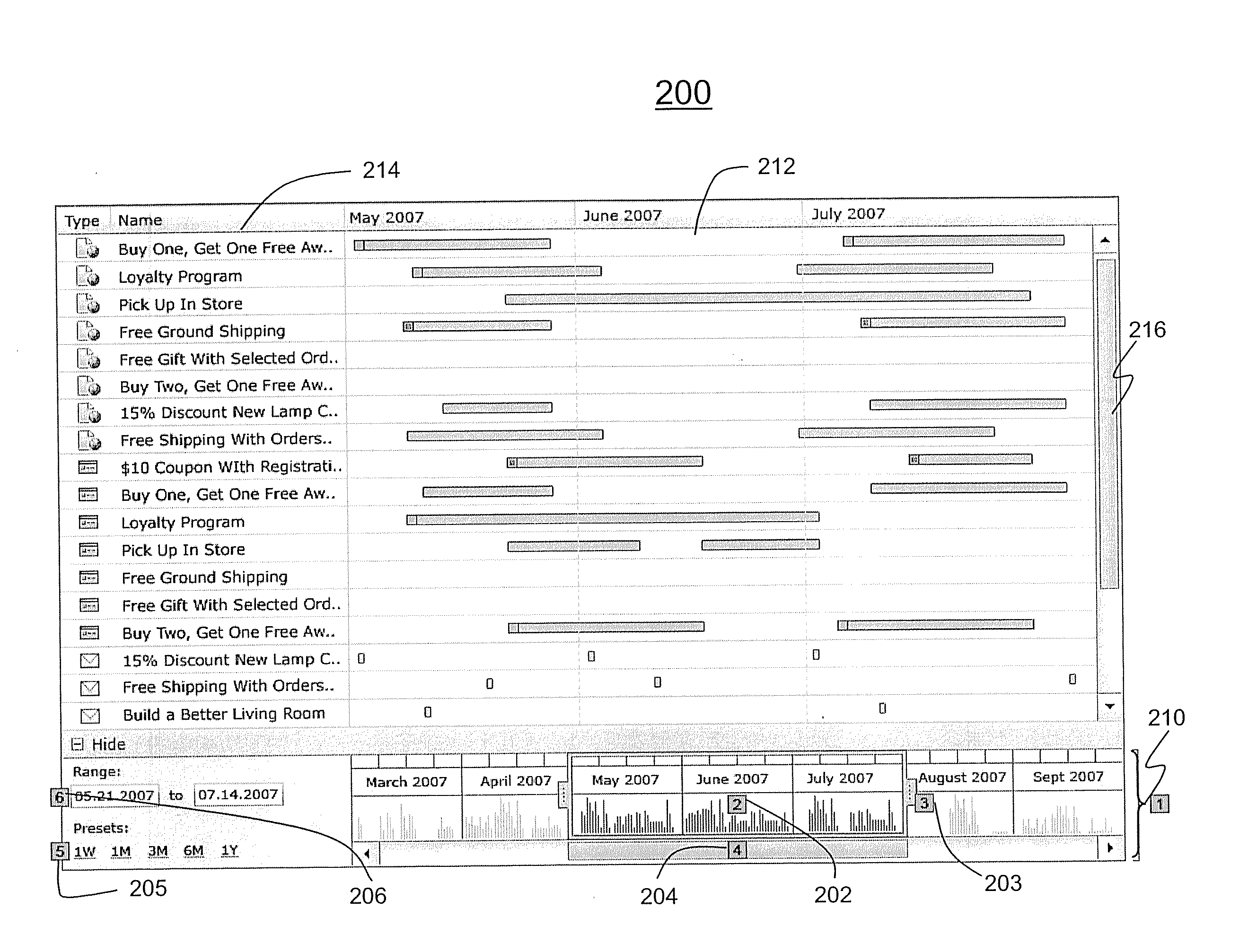

A graphical user interface for a Gantt chart map display (100) includes a list of projects (214), a corresponding activity timeline reflecting activity for each project, and a control (210) at a side or bottom area of the Gantt chart map display for manipulating date ranges viewable in the viewable area. The GUI further includes a selected date range control (204) providing a high level view (202) of the corresponding activity timeline displayed in the viewable area (212) above and can provide a high level view of corresponding activity beyond the scrollable view. A dynamic set of controls (205 and 206) enables preset filtered views of the Gantt chart with preset time frames such as days, weeks, months and years or predetermined date ranges entered by a user. The preset filtered view can also automatically re-sort and scale content on the Gantt chart into a viewable area to reduce scrolling.

Owner:IBM CORP

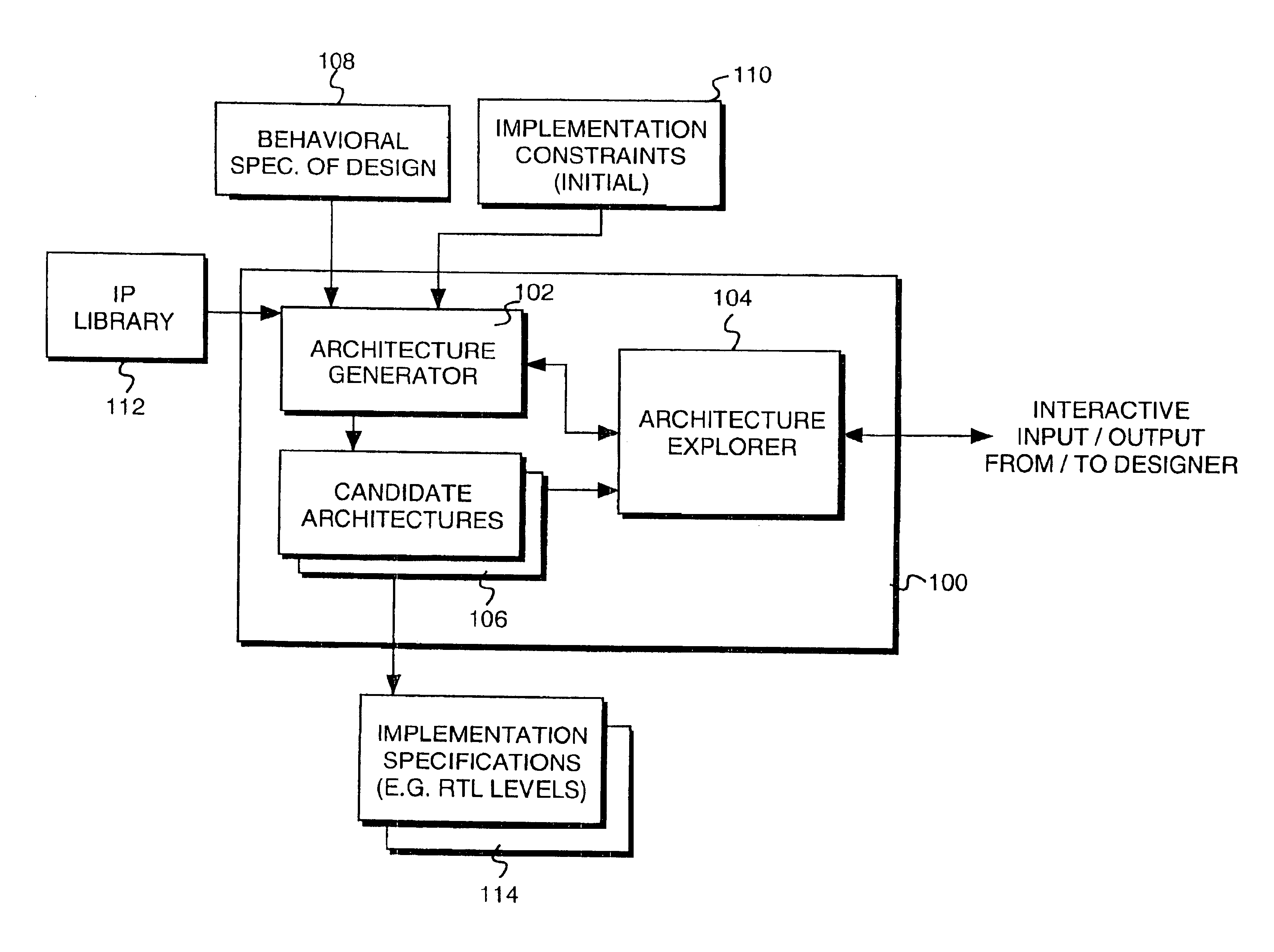

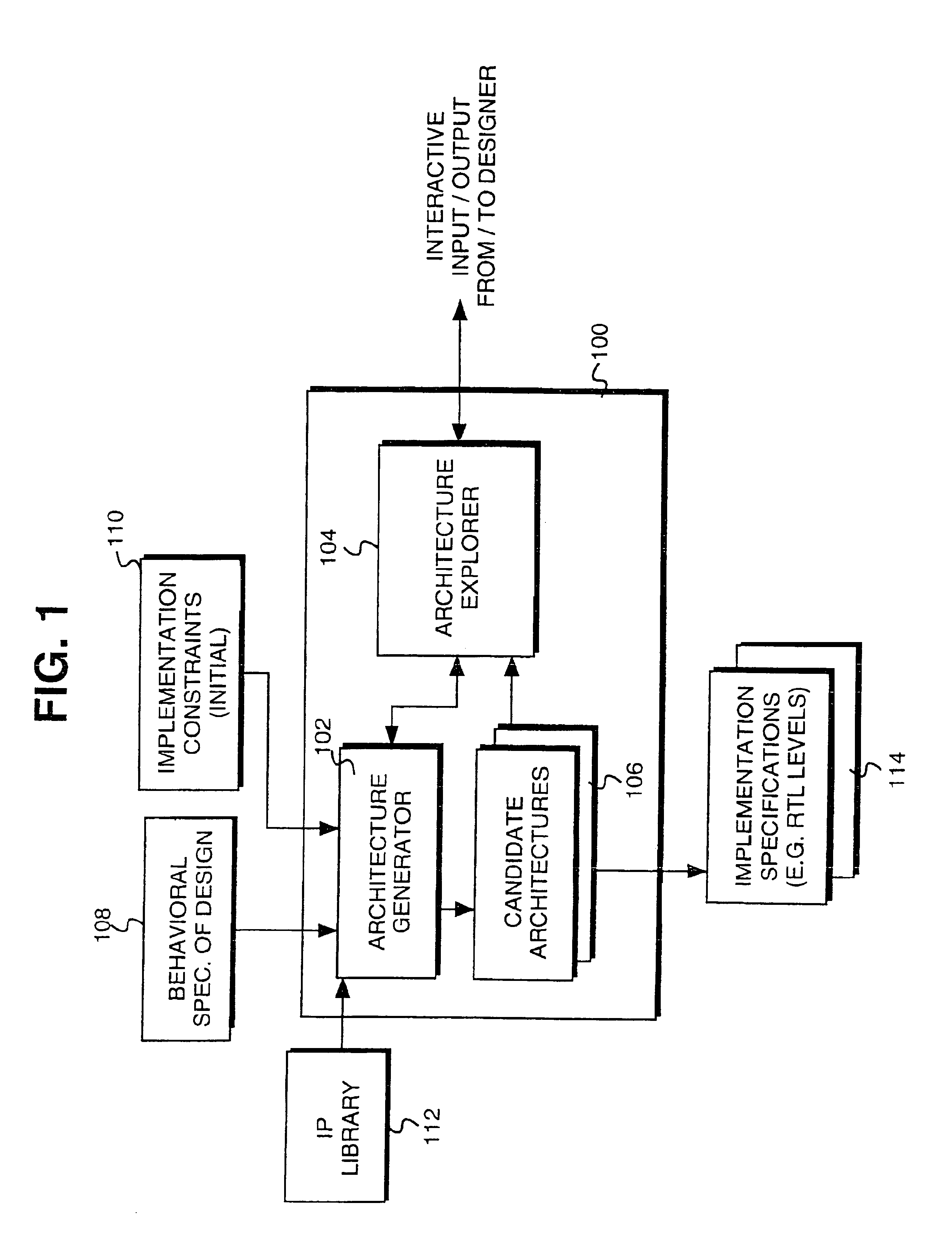

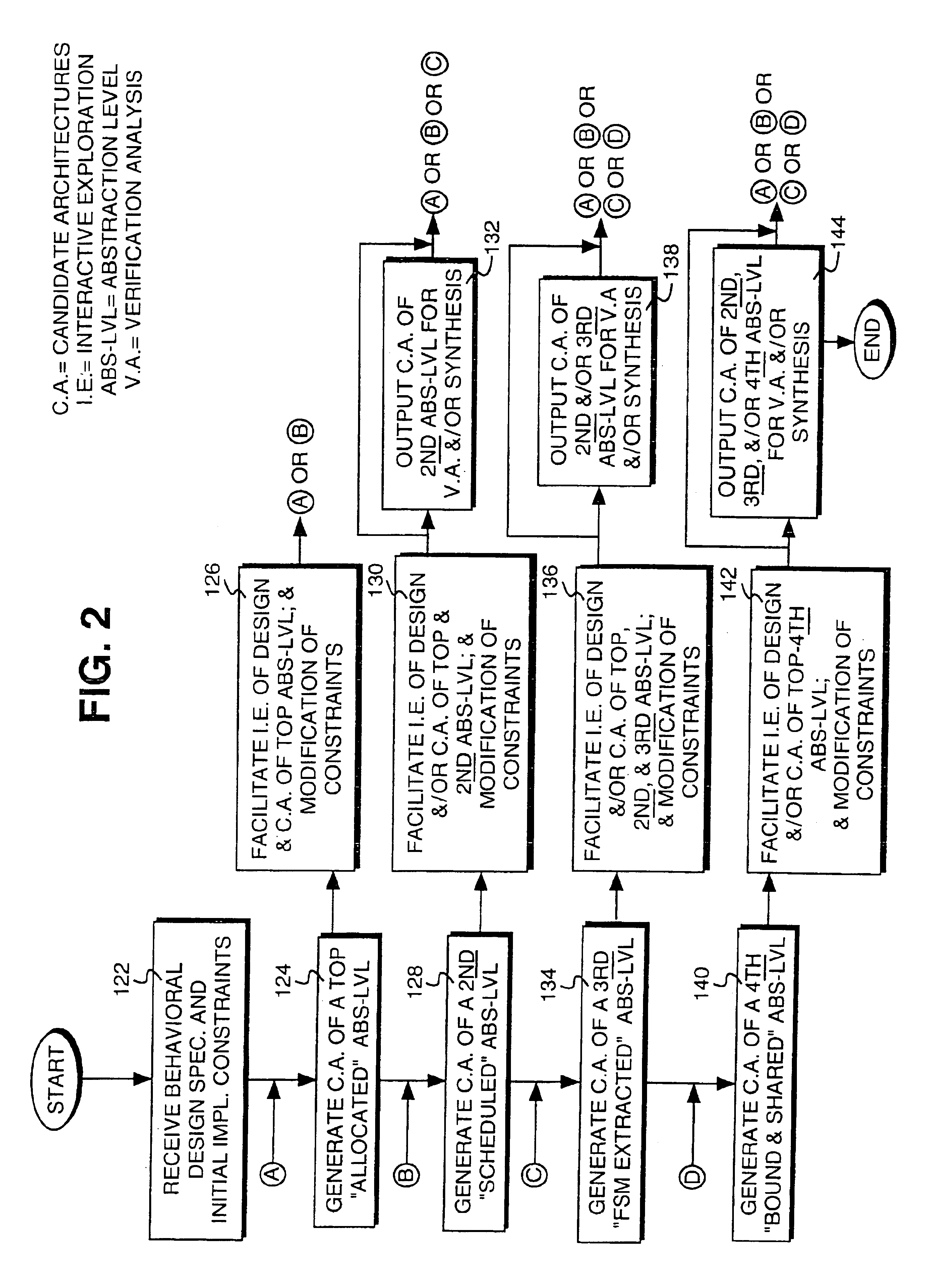

Facilitating guidance provision for an architectural exploration based design creation process

InactiveUS6917909B1To offer comfortComputation using non-denominational number representationCAD circuit designGraphicsGantt chart

Guidance provision to the creation of an electronic design is facilitated through a method that includes facilitating interactive exploration of the electronic design by a designer to aid the designer in formulating his / her guidance, and facilitating the designer in interactively providing the formulated guidance. In one embodiment, facilitation of interactive exploration by the designer include facilitating interactive cross-probing into a number of issues about the design, including generated candidate architectures for the design. In one embodiment, the issues available for cross probing include inter-dependencies of data and mobility of operations of the design, as well as occupation of hardware resources for the generated candidate architectures. In one embodiment, Gantt diagrams are employed to facilitate navigation by the designer in performing the interactive cross probing. Gantt diagrams graphically representing the generated candidate architectures are selectively presented to the designer. Data dependencies may be graphically depicted on the Gantt diagrams. Additionally, various aspects of the generated candidate architectures may be correlated back to the behavioral specification of the electronic design for the designer. In one embodiment, the designer may also modified the constraints on the electronic design interactively, applying the information the designer learned through the interactive exploration.

Owner:MENTOR GRAPHICS CORP

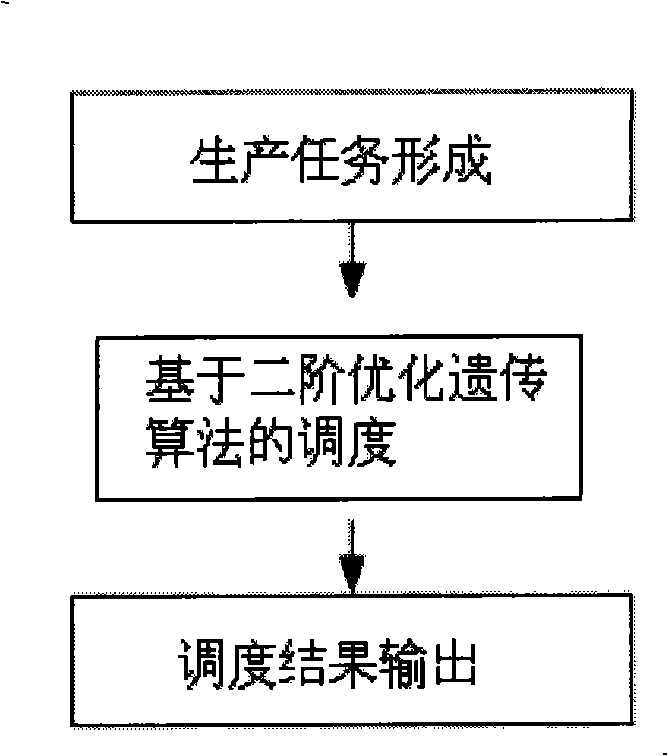

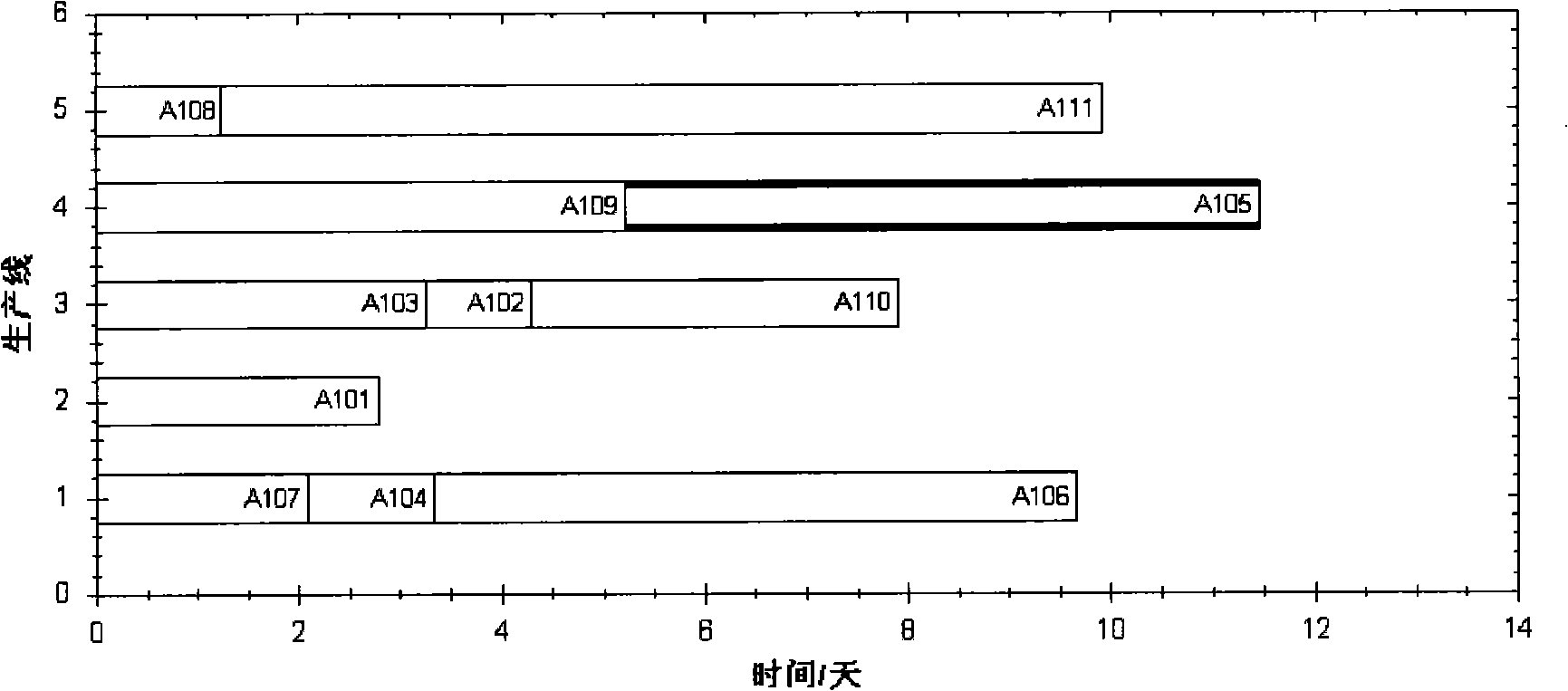

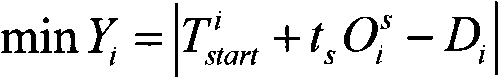

Method for scheduling workshop work facing to client requirement

InactiveCN101303749AFully automatedIncrease the level of automationResourcesGantt chartTemporal information

A workshop operation dispatching method facing to the client demands in the field of automatic control and information technology includes the following steps: step one, the client obtains license information by an authentication module and transfers demanding information to a proxy server by a browser; the proxy server clear up the demanding information of the client to form a workshop operation business list and transmit the list to an attaching decision module; the attaching decision module starts an attaching flow based on a binary optimizing inheritance arithmetic; step two, based on a binary optimizing inheritance arithmetic, sequencing on the workshop operation businesses is carried out to obtain an individual with a highest adaptation value; step three, outputting the result and carrying out decoding on the individual with the highest adaptation value to form a Gantt Chart, providing the corresponding time information of taking goods for the client as well as providing a detail schedule for implementing tasks for a workshop manager. The method can effectively carry out the workshop operation dispatching process and the automation of workshop operation is realized.

Owner:SHANGHAI JIAO TONG UNIV

Systems and methods for categorizing charts

InactiveUS20050039163A1Special data processing applicationsSpecific program execution arrangementsGantt chartComputer science

A method for managing a project including displaying, to a user, a Gantt chart illustrating one or more project items of the project as one or more corresponding bars, alerting the user when one of the one or more project items has a status of warning or critical, selecting one of the one or more corresponding bars, and displaying additional information pertaining to the project item corresponding to the selected one of the one or more corresponding bars.

Owner:CA TECH INC

Apparatuses and methods for dynamic creation of phase Gantt charts

A method for dynamic creation of a phase Gantt chart, includes entering project management data into a repository, receiving a request from at least one client to obtain the project management data and generating the phase Gantt chart in response to the received request based on the project management data stored in the repository.

Owner:COMP ASSOC THINK INC

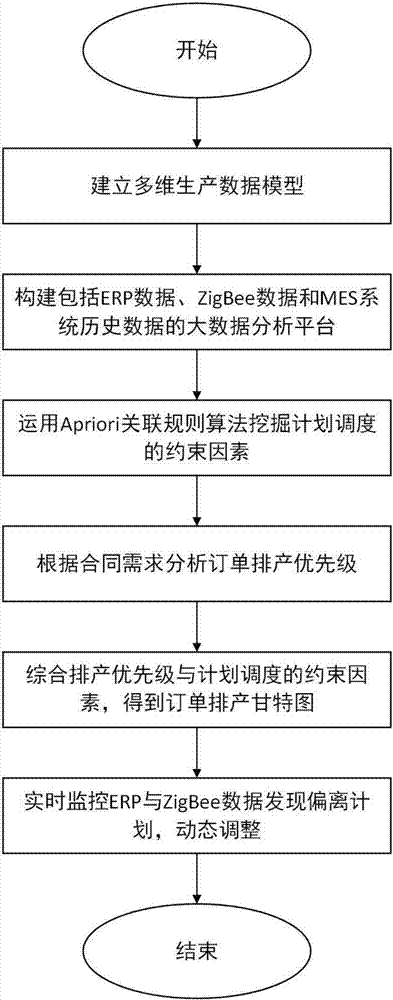

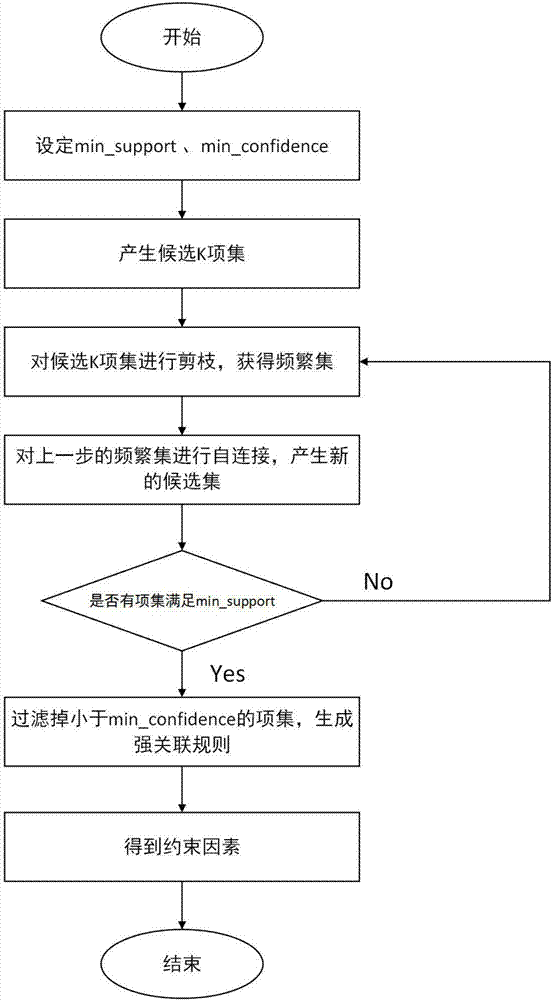

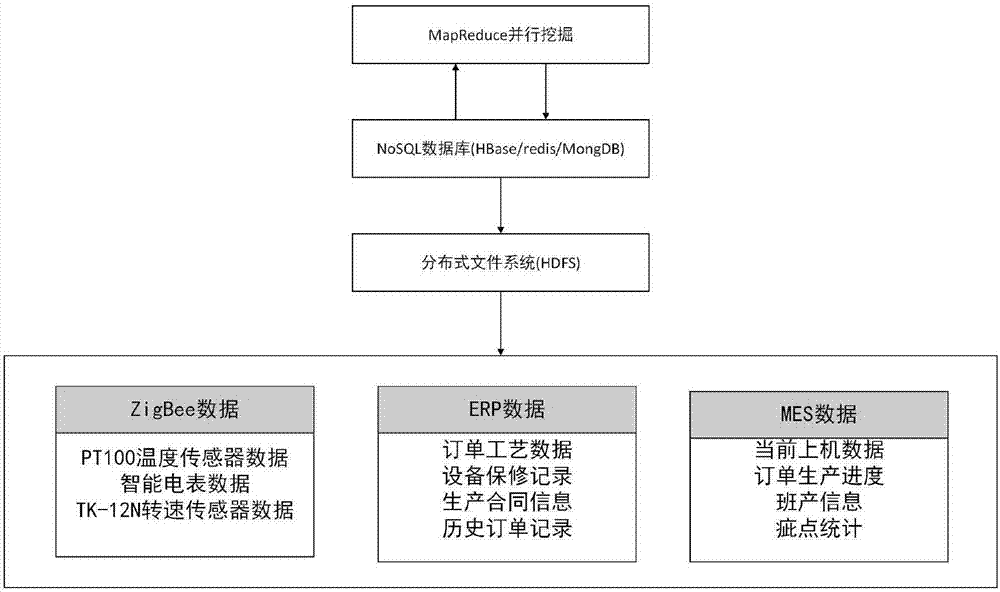

Knitting MES production planning and scheduling method based on big data mining

ActiveCN107168263AImprove the level of informatizationIncrease productivityTotal factory controlProgramme total factory controlGantt chartRequirements analysis

The invention discloses a knitting MES production planning and scheduling method based on big data mining, wherein the method belongs to the field of textile engineering application. The method comprises the following steps of S1, establishing a multidirectional knitting production data model; S2, establishing a big data analyzing platform based on a Hadoop distributed platform; S3, mining a planning scheduling restraining factor in a MapReduce frame by means of an Apriori correlation rule mining algorithm; S4, analyzing an order arranging priority according to a contract requirement; S5, integrating the arranging priority and the planning scheduling restraining factor, and obtaining an order arranging Gantt chart; and S6, performing real-time monitoring on ERP and ZigBee data, and when abnormities such as order delivery data change, knitting process updating and knitting machine sudden fault occur, dynamically adjusting a production plan.

Owner:JIANGNAN UNIV

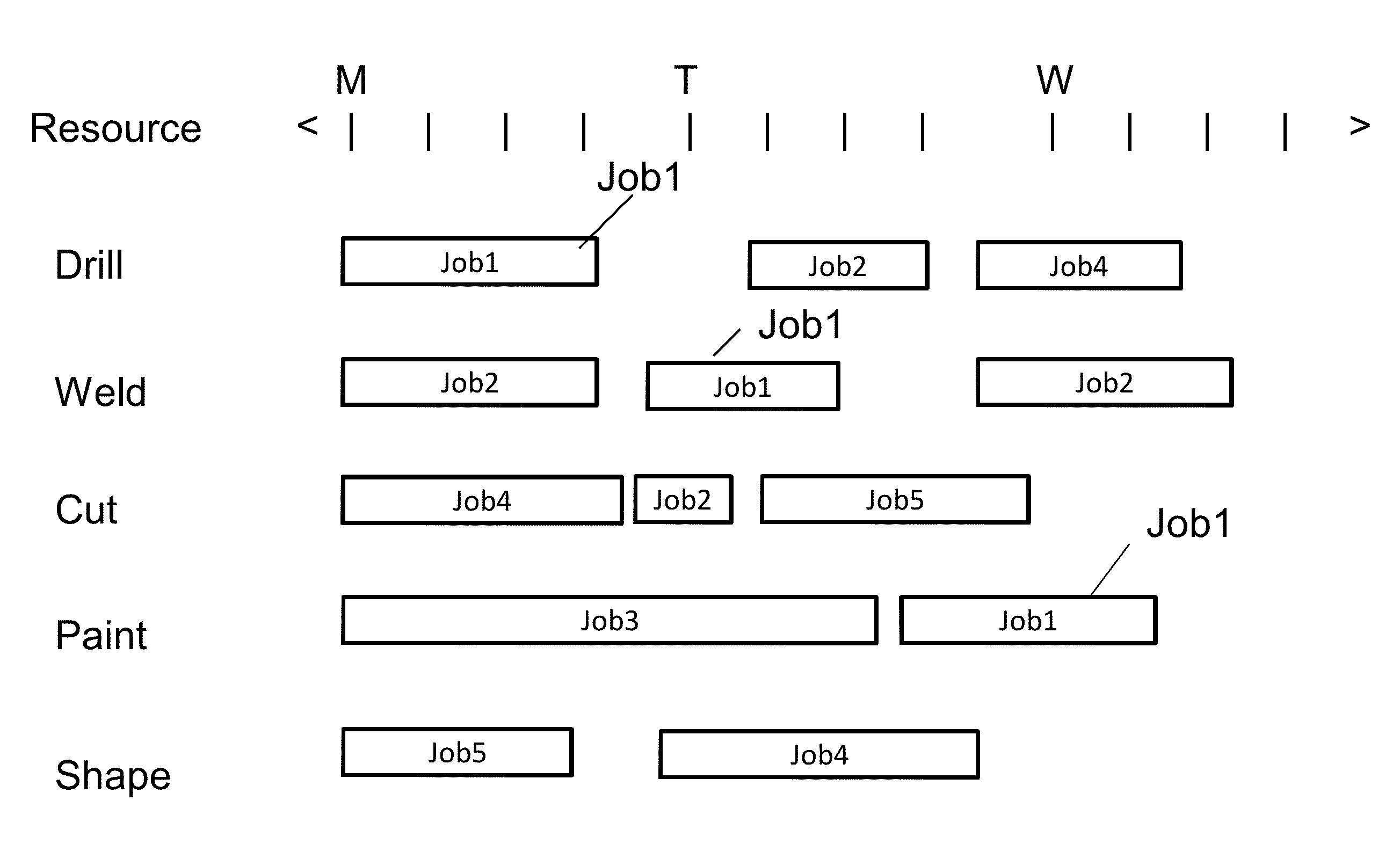

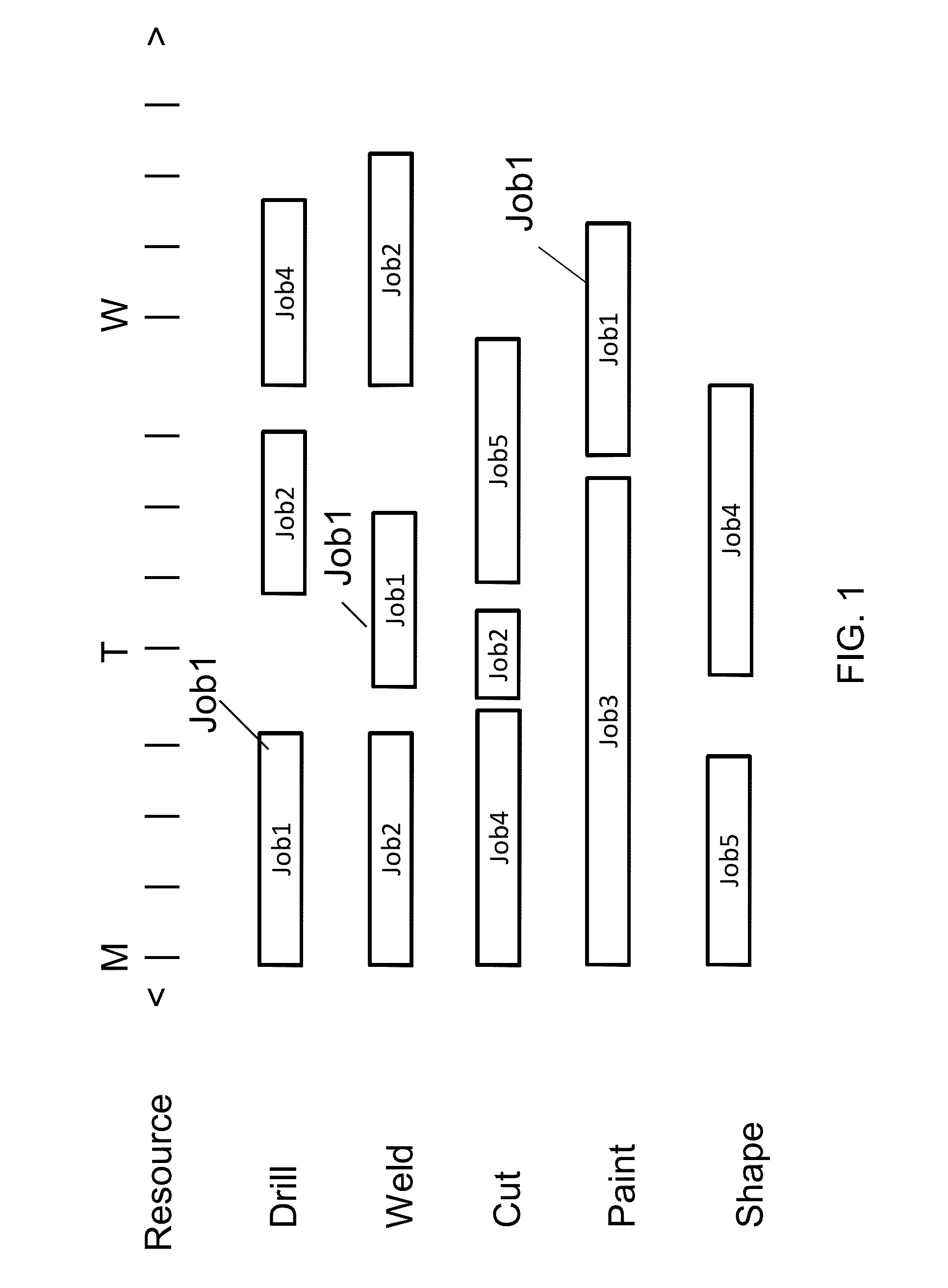

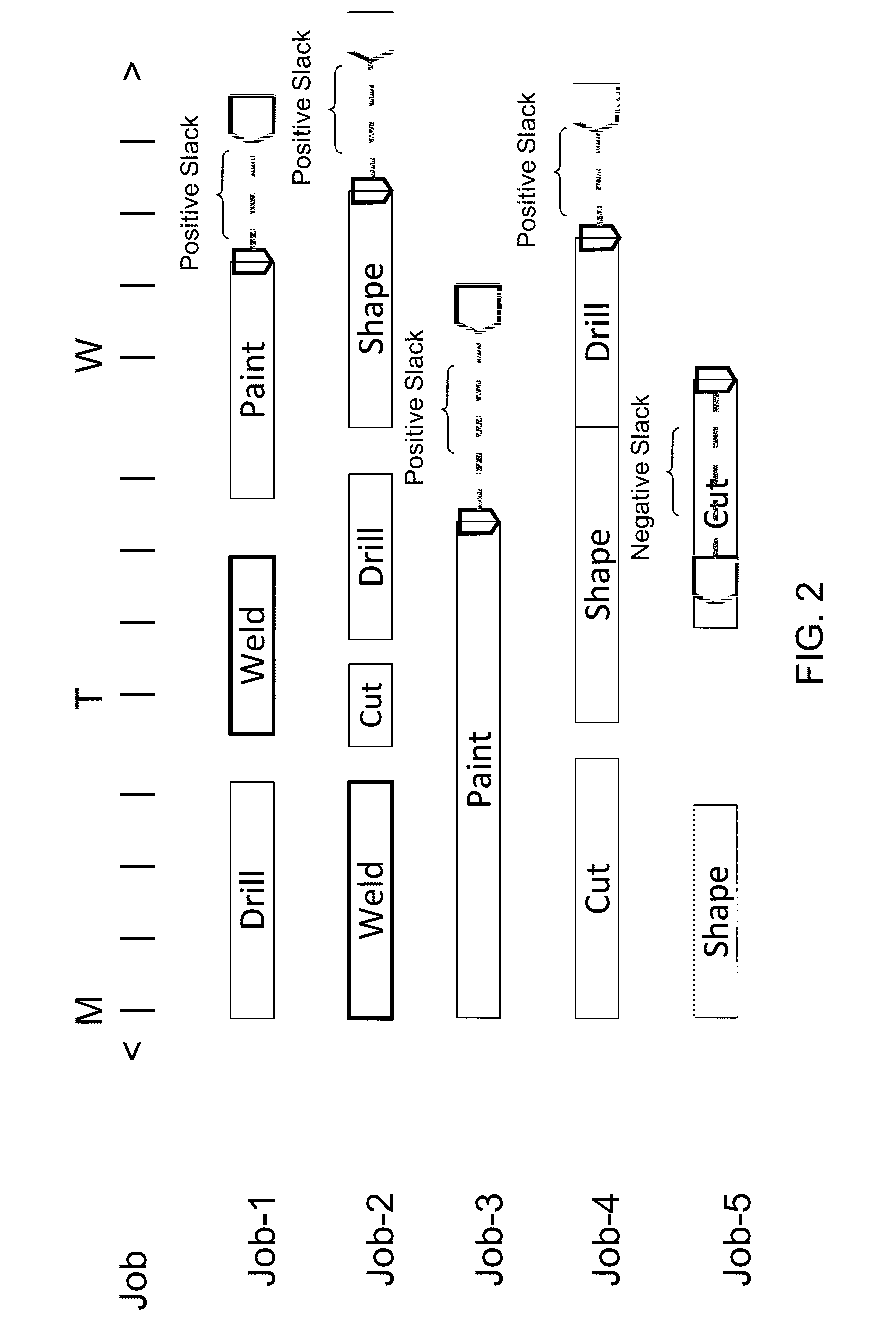

Simulation-based risk analysis for finite capacity scheduling

Scheduling software that provides both a deterministic schedule, such as shown in a Gantt chart or a work-to list (the role of traditional FCS software), along with additional information that can be used to judge the risk of the schedule when taking into account both the variations in task times, as well as the unplanned events. One embodiment of the present invention is a simulation model of a facility that incorporates the variations in task times and randomly generated events to provide stochastic estimates of risk measures. Another embodiment of the present invention may be the same model that is used to generate the deterministic schedule, however when generating the schedule the random variations and events are turned off, thereby generating a deterministic schedule. The same model can then be reused with the variations and random events turned on to generate risk measures for the associated deterministic schedule.

Owner:SIMIO

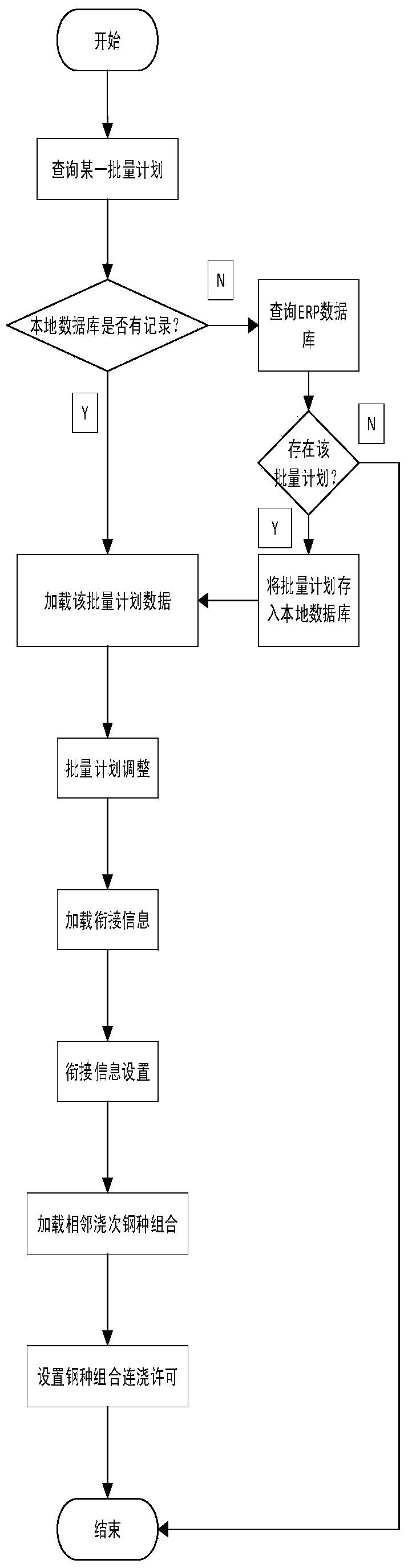

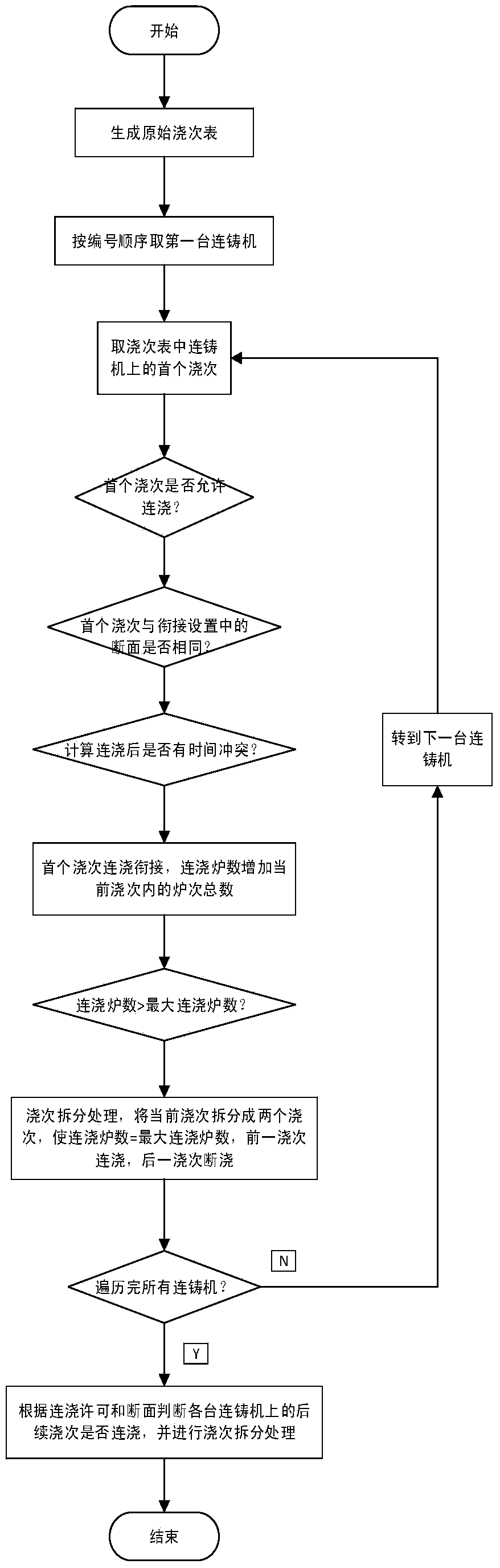

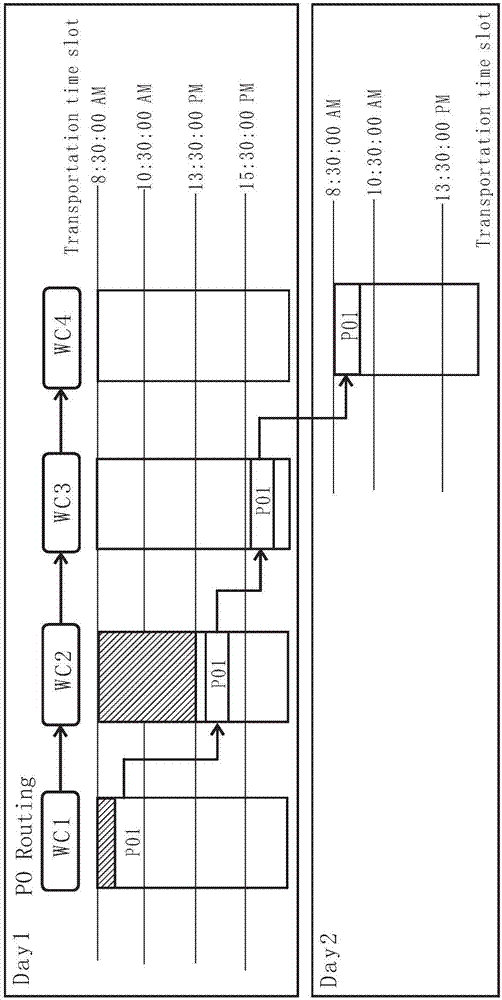

Timing sequence plan automatic making system for steelmaking workshop

ActiveCN103839114AFix articulation issuesImprove optimized search qualityForecastingSteelmakingGantt chart

The invention discloses a timing sequence plan automatic making system for a steelmaking workshop. The timing sequence plan automatic making system comprises a process parameter setting module, a system parameter setting module, a timing sequence plan requirement setting module, a requirement data preprocessing module, a timing sequence plan automatic making module and a timing sequence plan display module. The process parameter setting module is mainly used for providing various parameter setting functions. The system parameter setting module is mainly used for model parameters and algorithm parameters. The timing sequence plan request setting module downloads batched plans from the ERP, and stores the batched plans in a local database and provides the batched plan editing function at the same time. The timing sequence plan request preprocessing module serves as a bridge between the timing sequence plan requirement setting module and the timing sequence plan automatic making module, and is mainly used for extracting batched casting time plans, connecting information and steel type continuous casting permission information from the timing sequence plan requirement setting module. The timing sequence plan display module displays a timing sequence plan result Gantt chart obtained through calculation of the timing sequence plan automatic making module.

Owner:WISDRI ENG & RES INC LTD

Planning operation management support system, and planning operation management support program

ActiveUS7039480B2Performed easily and accuratelyEasy to correctResourcesSpecial data processing applicationsGantt chartManagement support systems

A project template information management database 1 of a planning operation management support system includes: database groups from 20 to 23 saving setting information of planning operations performed in the past, names of process flows in the respective layers (task name), lead times (lead time) required for the respective process flows (task), and dependency relations between the process flows (task), as templates by the respective customers; a result database 15 storing trading results with customers in the past; and a calendar database 16 storing calendar information setting actual working days when workers in charge of the respective process flows carry on a work, and holidays. A client terminal 4 includes: an input device 35 inputting new project names, customer names, and delivery dates; and a CPU41 calling a corresponding customer's template from the project template information management database 1 by inputting the customer name, the name of the new project, and the delivery date, creating a new project information, and displaying the Gantt chart on the screen.

Owner:SUMITOMO WIRING SYST LTD +1

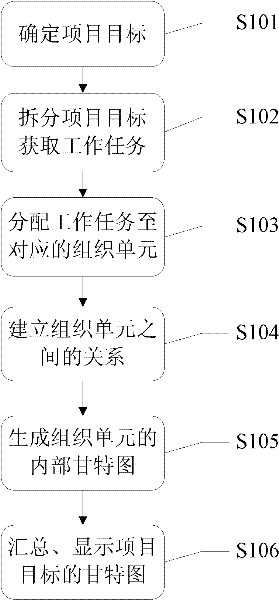

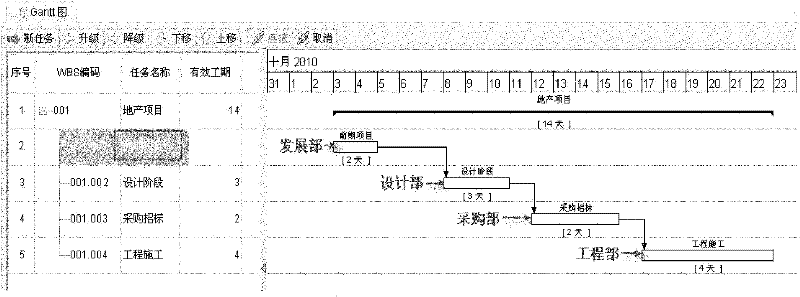

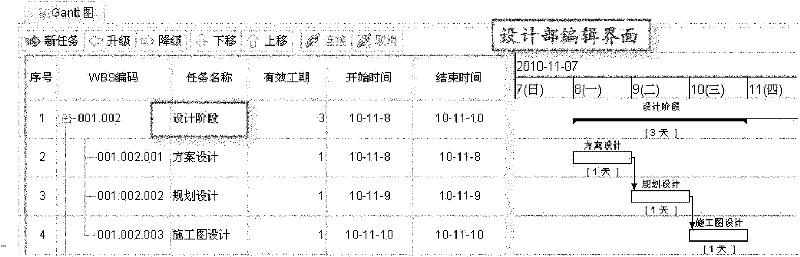

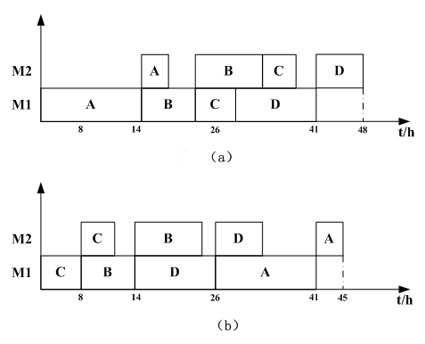

Gantt chart generating method and system

InactiveCN102541880AProper isolationProper data isolationSpecial data processing applicationsGantt chartWork task

The invention discloses a Gantt chart generating method and system. The method comprises the following steps of: splitting project objectives, and acquiring work tasks carrying construction periods, wherein upstream-downstream relations exist among the work tasks; distributing each work task into a corresponding organizational unit; detailing the work task in each organizational unit, generating an internal Gantt chart in each organizational unit; and summarizing organizational units, and automatically displaying internal Gantt charts in the organizational units on the same interface, so as to obtain a whole Gantt chart of the project objectives. By adopting the method and system disclosed by the invention, hierarchical control among the organization units and independent drawing on the internal Gantt charts can be realized, and finally the internal Gantt charts are automatically summarized and the Gantt charts of the whole project are displayed by the system. Data isolation and effective sharing are realized, and large-scale data interaction with a database is avoided, thus performance and efficiency of the system are improved.

Owner:KINGDEE SOFTWARE(CHINA) CO LTD

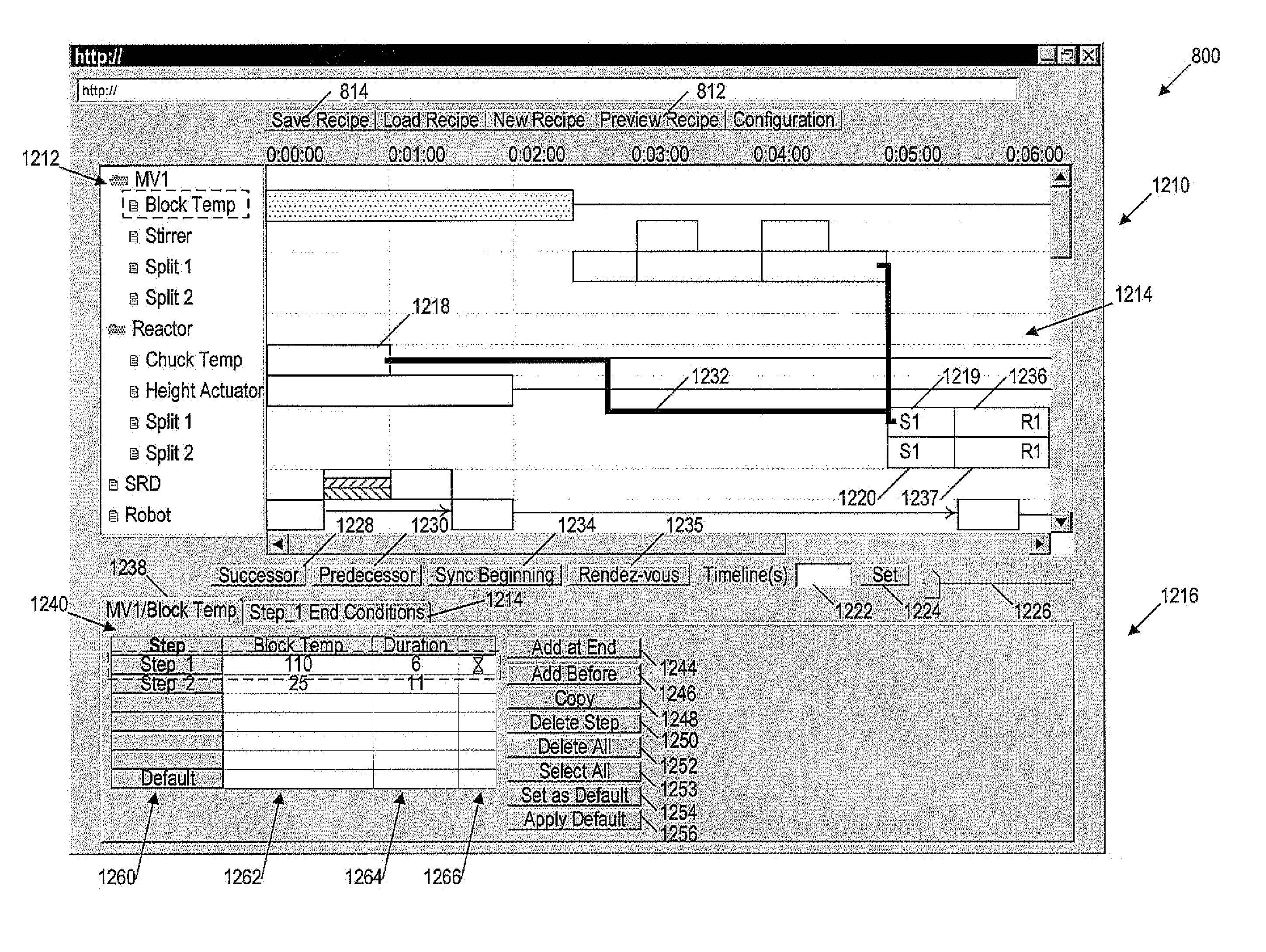

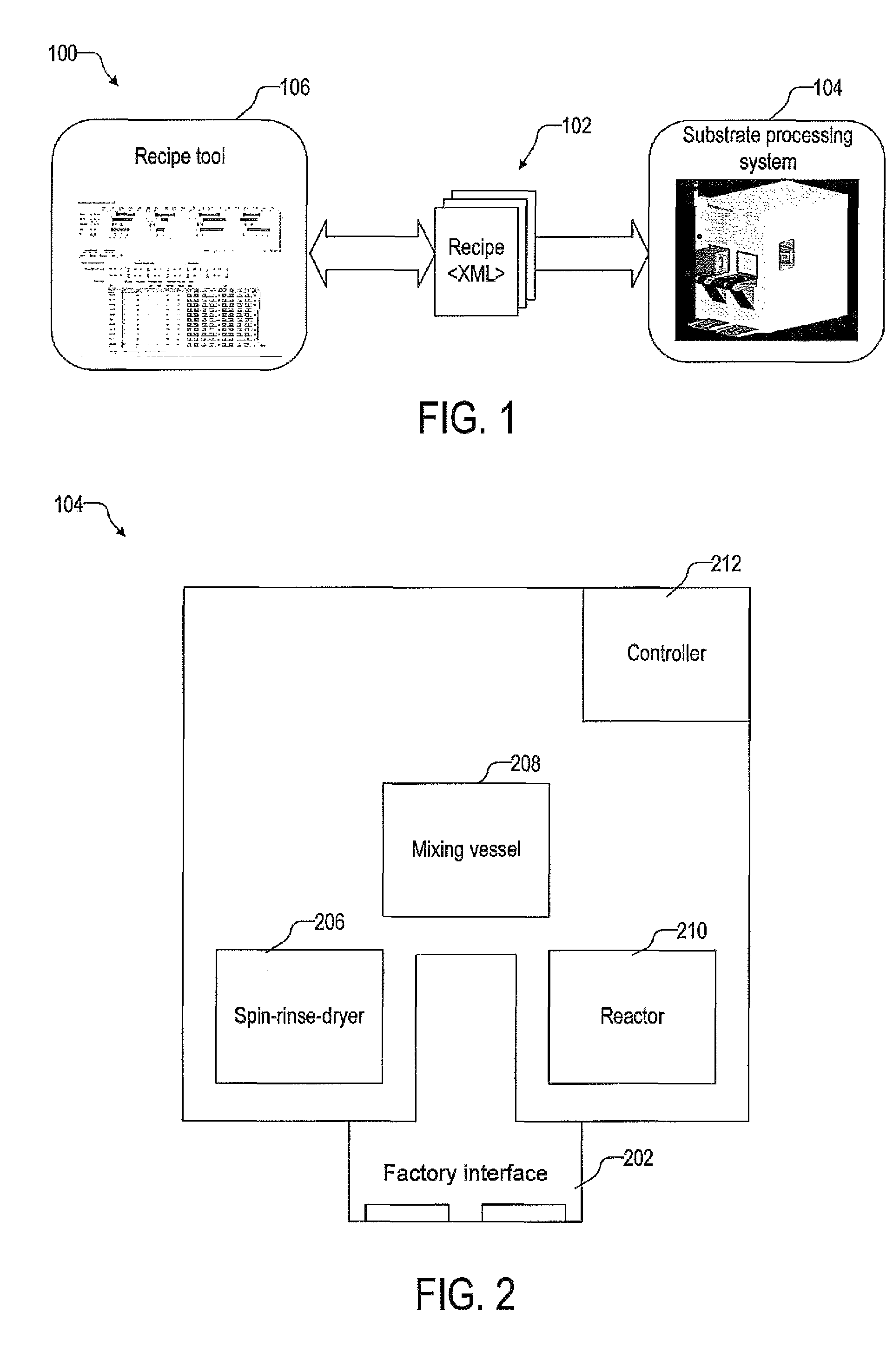

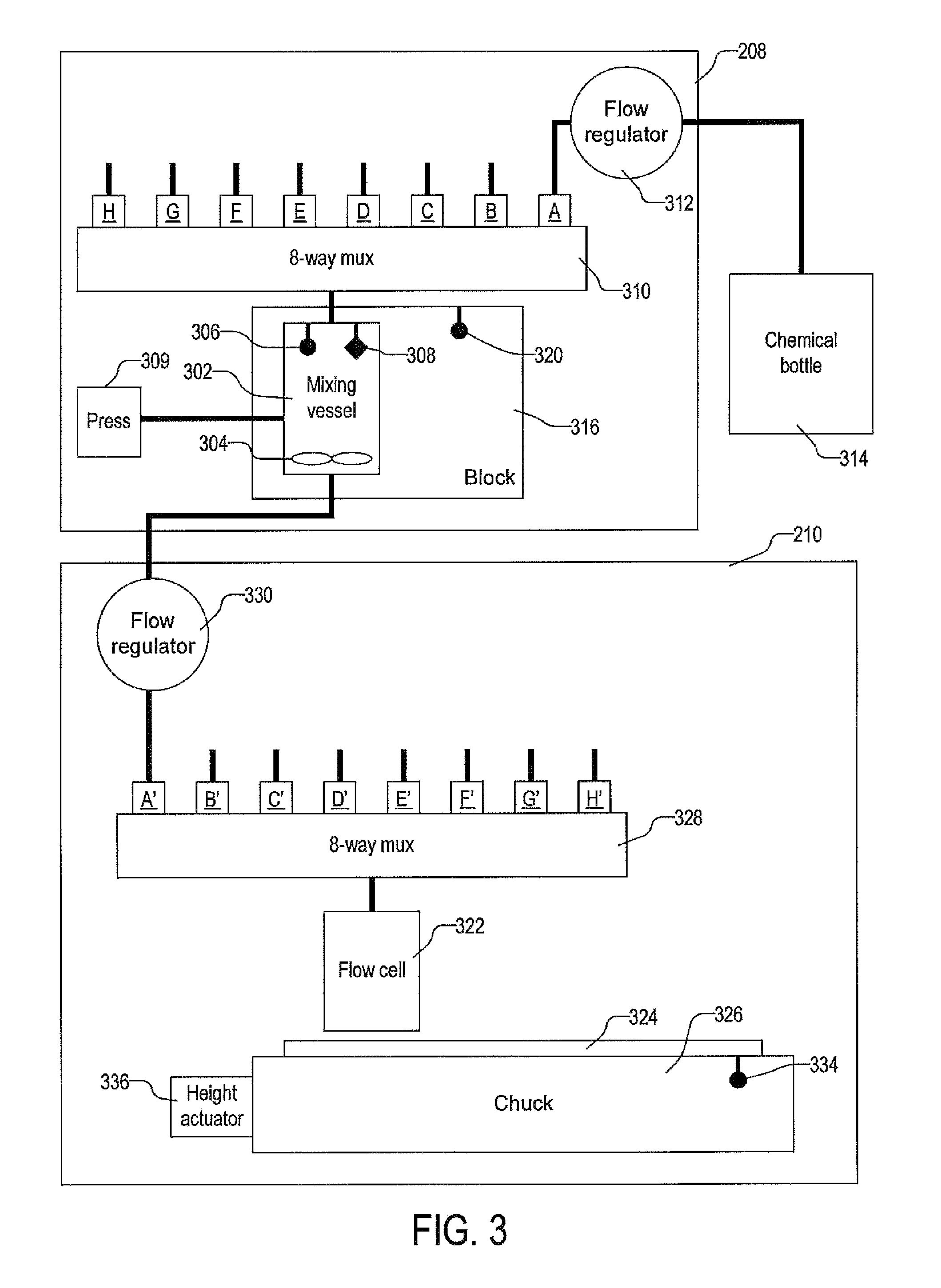

Substrate processing recipe manager

A method to graphically create a recipe for processing a substrate includes displaying graphical images that present processing operations to be performed on the substrate, allowing a user to set properties of the processing operations by manipulating the graphical images, and generating the recipe based on the properties of the processing operations set by the user and synchronizing the plurality of processing operations based on the properties. The graphical images may be time-bars in a Gantt-like chart that allows the user to see the sequence, the timing, and the durations of the processing operations.

Owner:INTERMOLECULAR

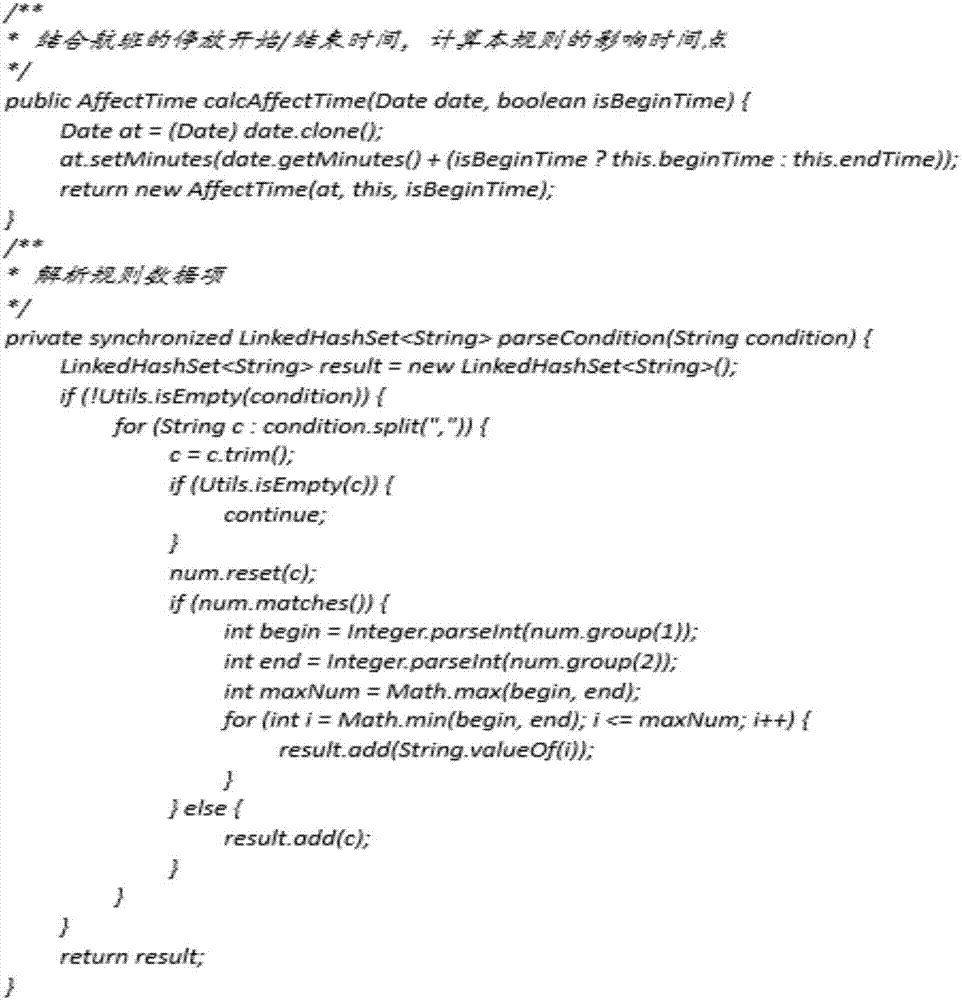

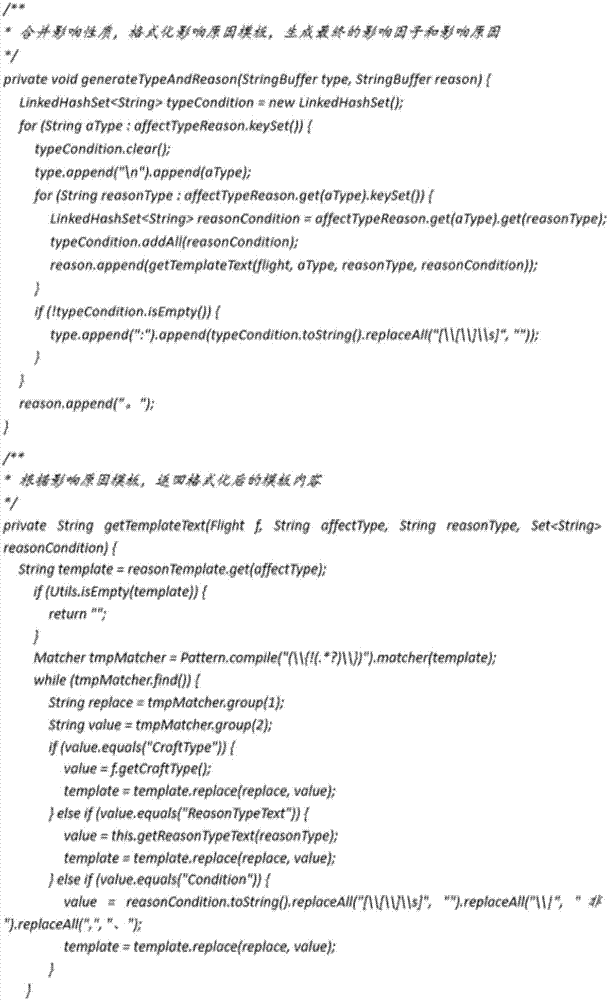

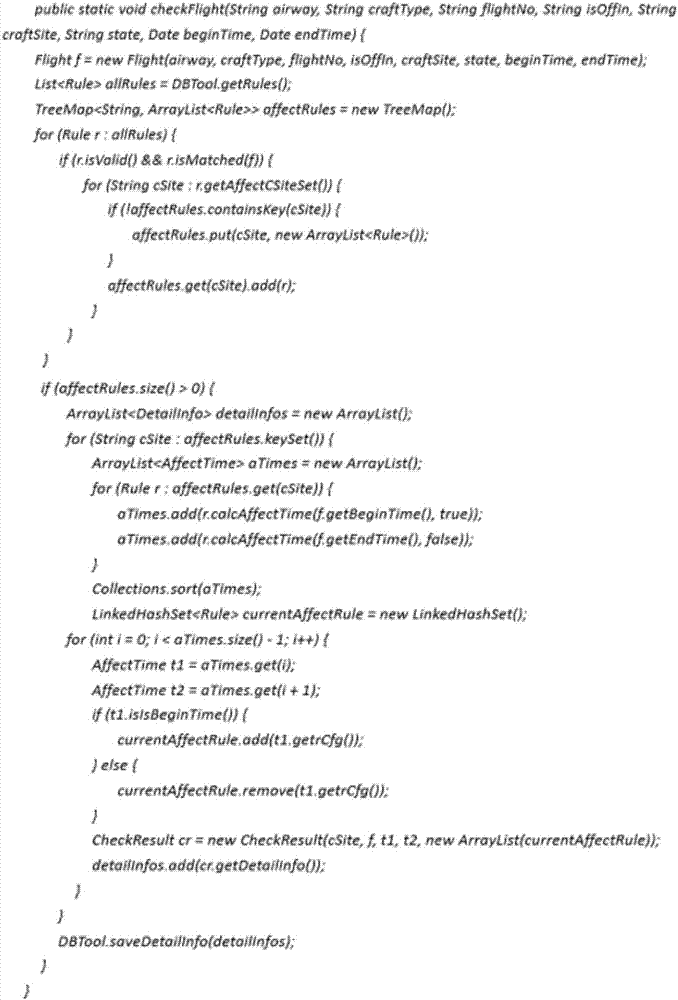

Civil aviation airport apron gate time-bound dynamic constraint method

ActiveCN107085976AImprove adaptabilityImprove acceleration performanceMultiple aircraft traffic managementGantt chartResource utilization

The invention discloses a civil aviation airport apron gate time-bound dynamic constraint method, relates to the technical field of civil aviation airport flight gate real-time allocation, adjustment and control based on the constraint conditions, and solves the technical problems in the prior art that only the fixed constraint is used, which cannot be efficiently and flexibly adaptive to the dynamically changed availability trend of the gates to be allocated. The optimized logic is presented through combined processing of the time-bound dynamic constraint and the fixed constraint and a true and false conflict algorithm and the Gantt chart so that the more accurate and reasonable and safer gate allocation and management strategy can be provided for the customers in real time, and the gate resource utilization rate and the apron safety can be enhanced.

Owner:民航成都信息技术有限公司

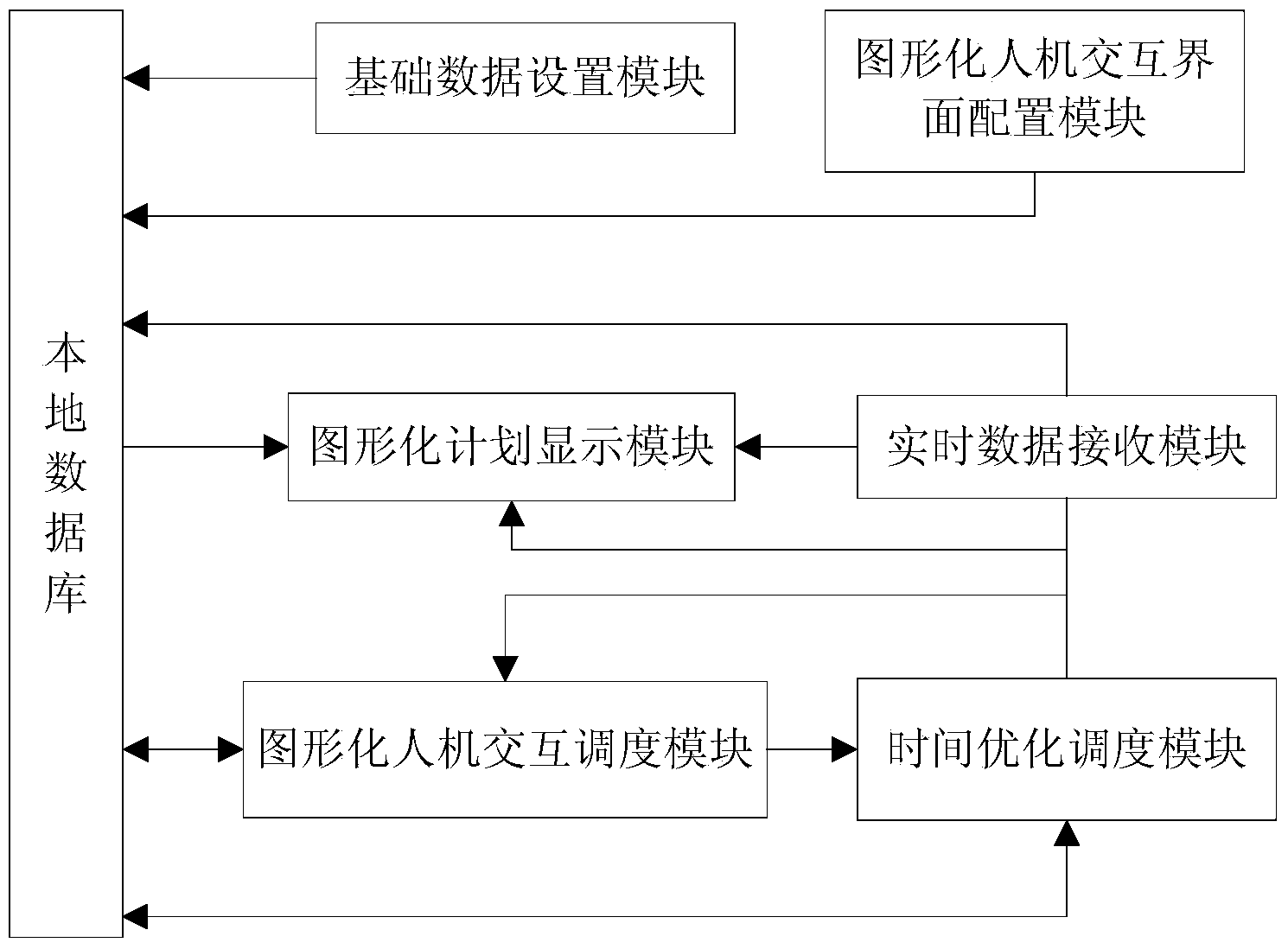

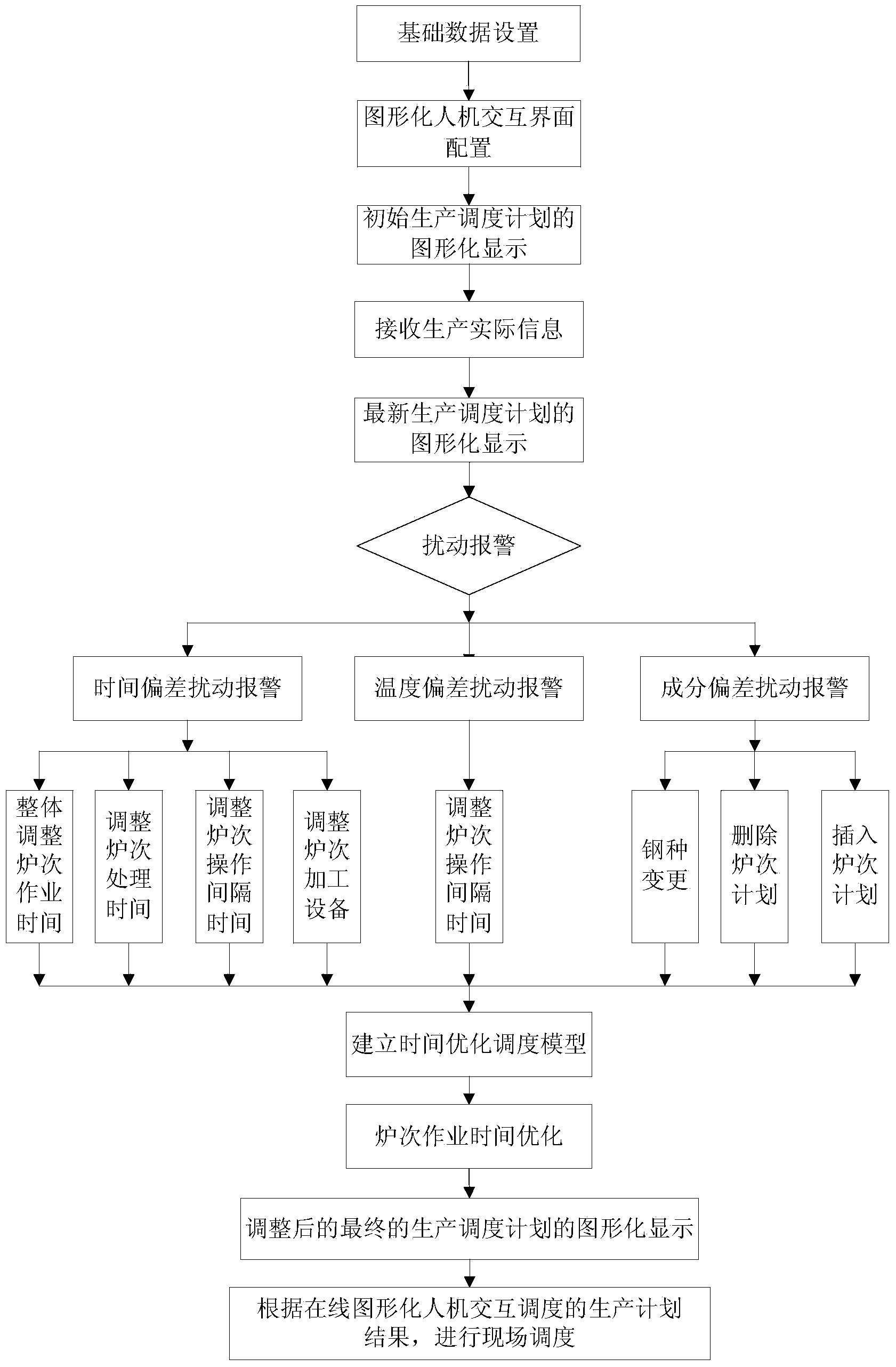

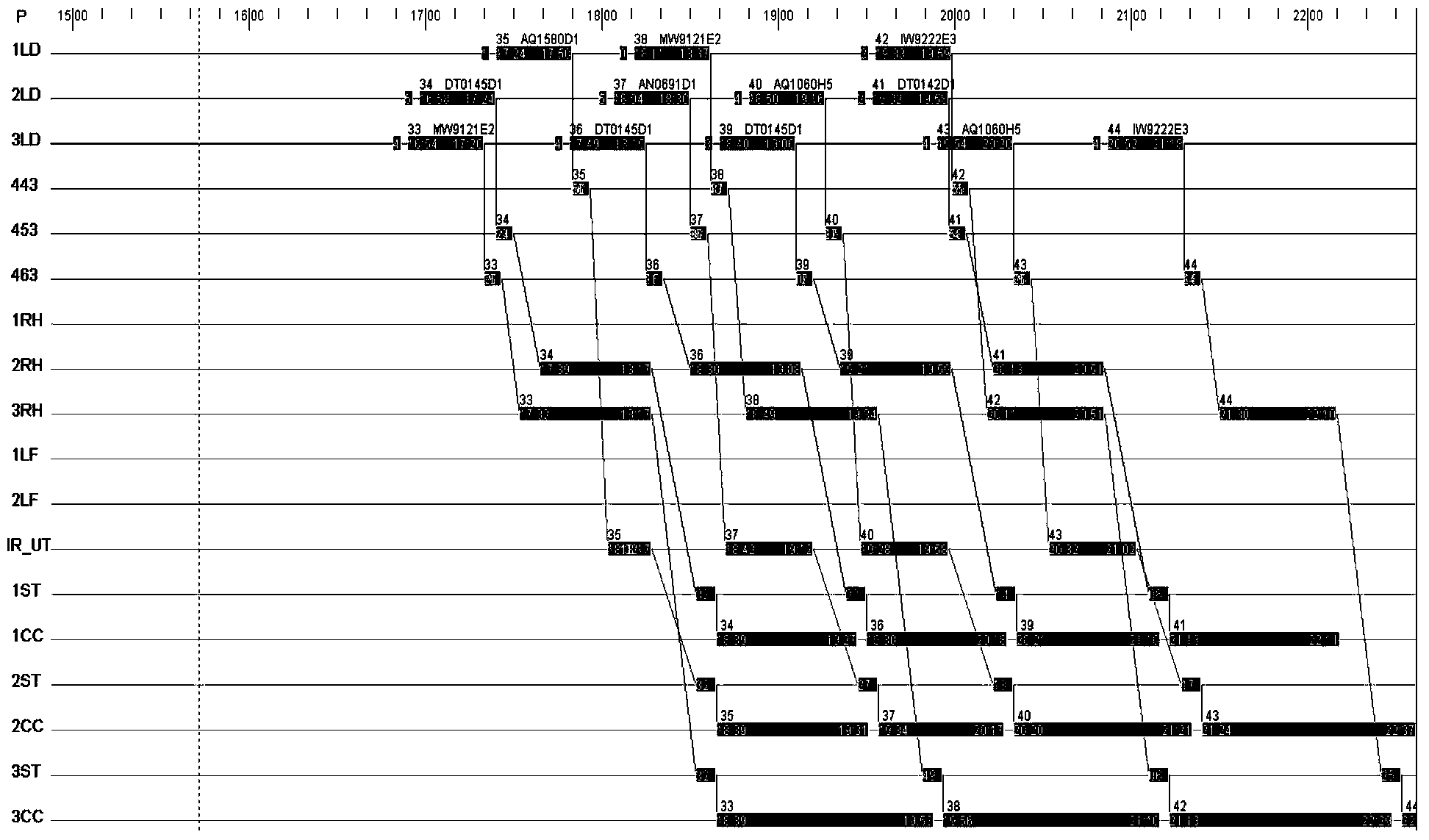

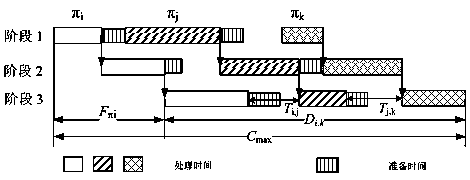

Online imaging man-machine interaction scheduling method for steel making and continuous casting production process

InactiveCN103646098AImprove optimization effectSpeed up dynamic schedulingSpecial data processing applicationsInput/output processes for data processingTime deviationGantt chart

The invention provides an online imaging man-machine interaction scheduling method for a steel making and continuous casting production process, and relates to the technical field of steel making and continuous casting. The method comprises steps as follows: initial steel making and continuous casting production scheduling plan data are acquired and displayed on a two-dimensional Gantt chart; actual production information of the steel making and continuous casting production process is acquired, and the disturbance condition is judged according to the actual production information of the steel making and continuous casting production process; and the initial steel making and continuous casting production scheduling plan data are adjusted according to time deviation disturbance, temperature deviation disturbance and ingredient deviation disturbance information, displayed in a two-dimensional Gantt chart manner and issued to a site for guiding production. In order to solve the problems that the plan adjustment speed is slow and the plan adjustment optimization degree is low due to the fact that the plan adjustment is manually entered by a scheduling worker of a steel making and continuous casting production scheduling system, an imaging man-machine interaction adjustment method based on the two-dimensional Gantt chart and online optimization of a time optimization scheduling model are combined, so that the online adjustment function of a scheduling plan is enhanced, and the scheduling plan optimization effect is improved.

Owner:NORTHEASTERN UNIV

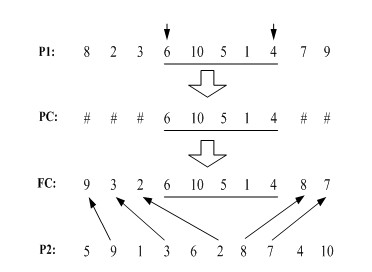

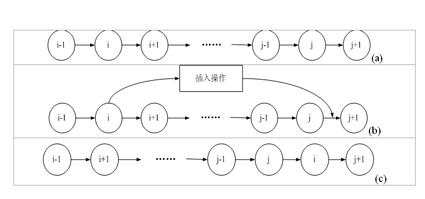

Method for scheduling machine part processing line by adopting discrete quantum particle swarm optimization

InactiveCN102073311AOptimal Scheduling SchemeEasy to operateBiological modelsTotal factory controlLocal search (optimization)Gantt chart

The invention discloses a method for scheduling a machine part processing line by adopting the discrete quantum particle swarm optimization, comprising the following steps: reading in the machine part processing process operation time, initializing a particle swarm, calculating the adaptation value of each particle, updating the individual optimal position and the global optimal position of each particle, carrying out global search on the basis of the discrete quantum particle optimization, carrying out local search and drawing a machine part processing sequence Gantt chart according to a global optimal scheduling scheme. The method disclosed by the invention improves the limitation of the traditional quantum particle swarm optimization in the production scheduling field, overcomes the defects that the quantum particle swarm is easy to be subjected to local optimization and has the advantages of high optimizing precision and high optimizing speed. The method is used for scheduling the machine part processing line, can solve to obtain an optimal scheduling scheme in a shorter time and is easy and convenient to operate. The principle has wide range of application and can be popularized to the producing and processing field of the manufacturing industry, the process industry and the like.

Owner:ZHEJIANG UNIV

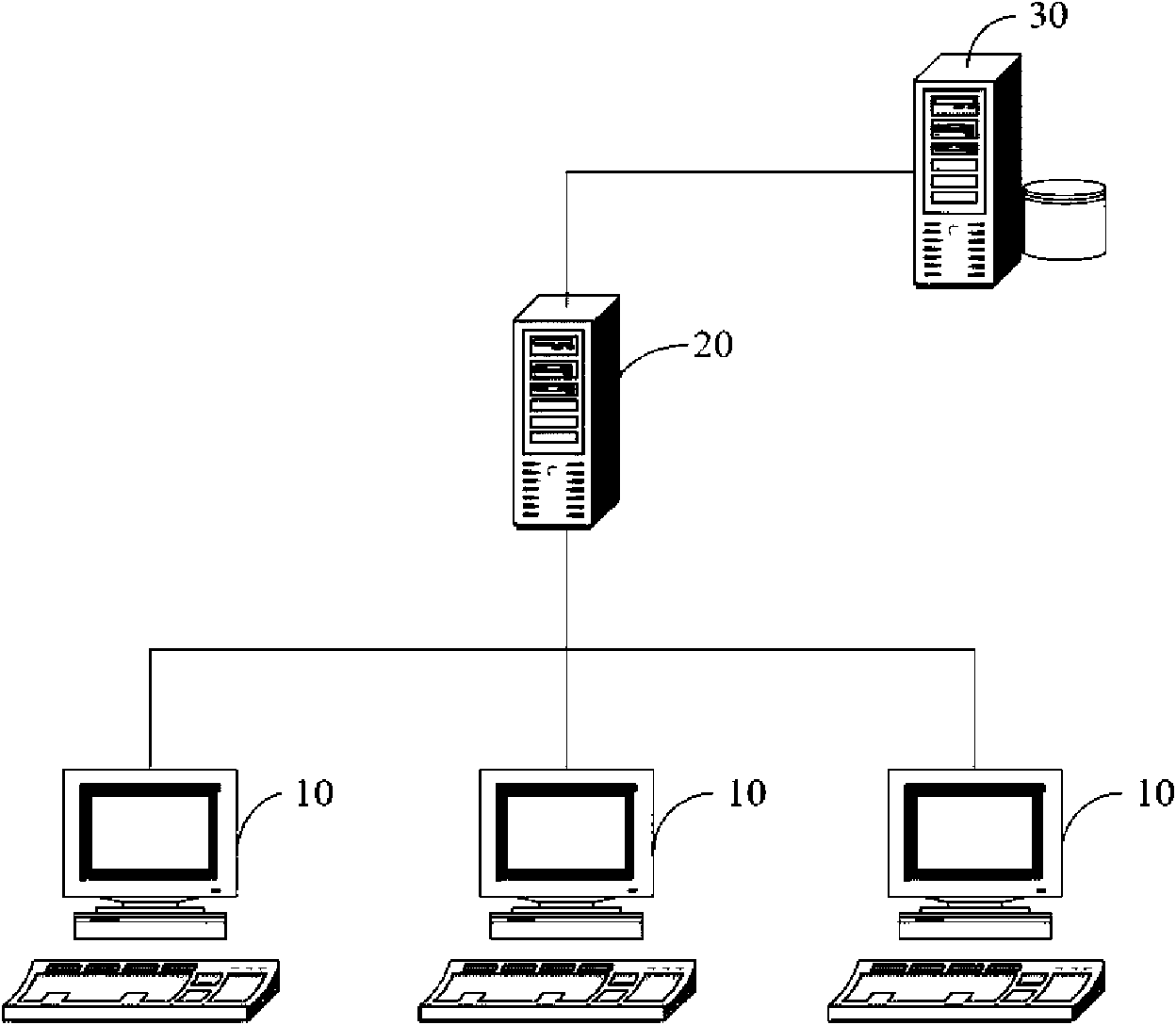

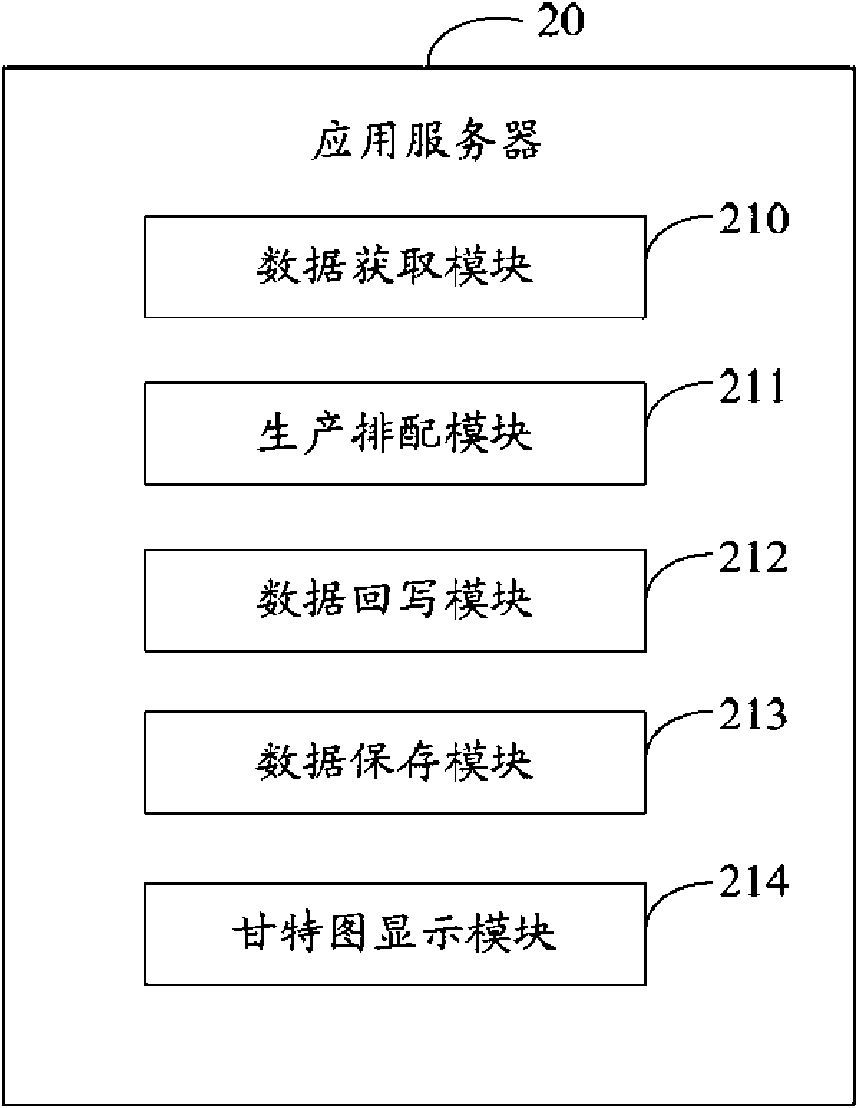

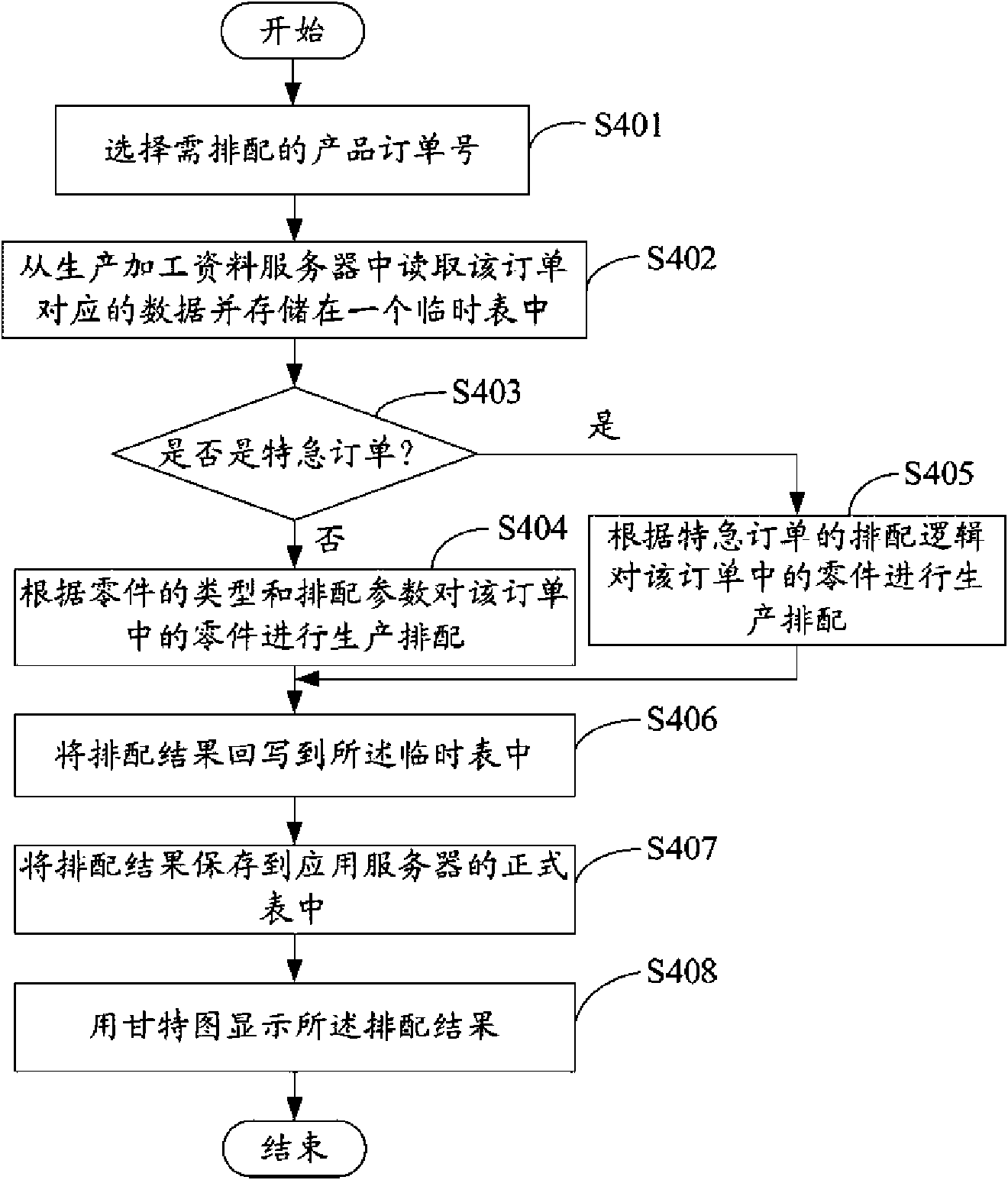

Production order arranging system and method

A production order arranging system and a method are disclosed. The method comprises the following steps of: selecting production order numbers to be arranged; according to the order numbers, reading data corresponding to the order from a production processing data server and storing the data in a temporary list, wherein, the data corresponding to the order comprise types of the order, parts included by the order, coding of each part and types of the parts; according to the types of the order, the types of the parts and arranging parameters of different types of the parts, implementing production arrangement on the parts in the order with an arranging result comprising time for starting processing and finishing processing the parts; storing the arranging result in a formal list; displaying the arranging result in Gantt chart. Utilization of the invention can rapidly complete the arrangement of the production orders, which improves the efficiency of the production arrangement.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

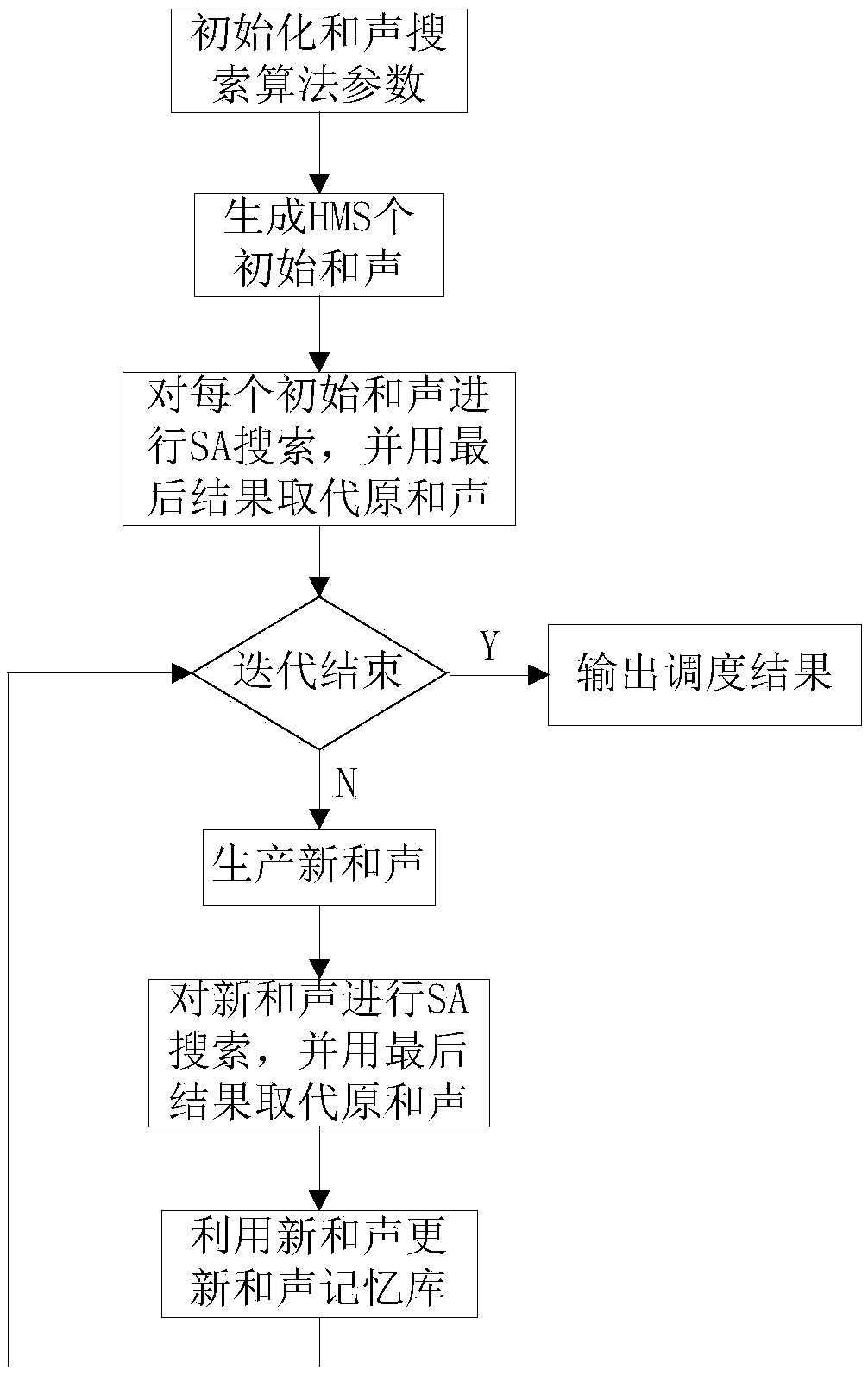

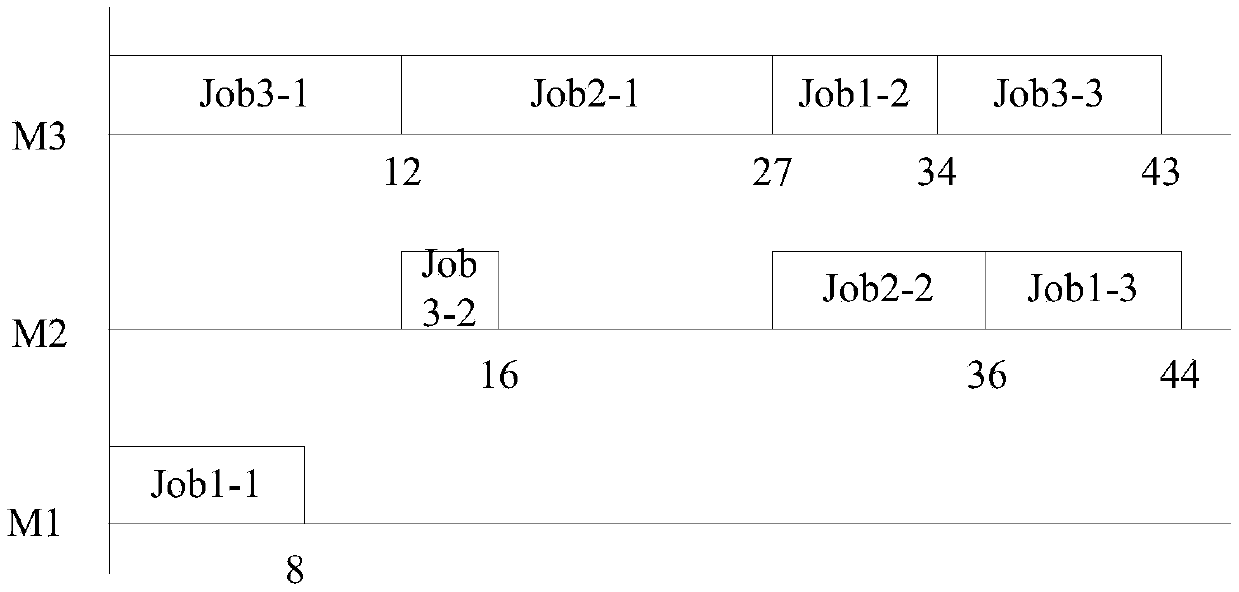

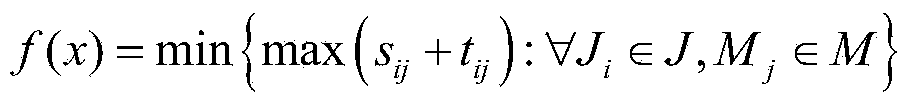

Hybrid intelligent scheduling optimization method of manufacturing enterprise workshop

The invention discloses a hybrid intelligent scheduling optimization method of a manufacturing enterprise workshop. The method comprises the following steps of: initializing related parameters of an HS algorithm and an SA algorithm; according to different production tasks, inputting processing information relating to each task; using a coding mode based on working procedures to code questions, and then utilizing a random generation mode to generate harmony memory HM initial solutions; utilizing the SA algorithm to carry out neighborhood transformation on all the initial solutions, if the solutions after the transformation are better than the initial solutions, then receiving the solutions after the transformation; and if not, then receiving the solutions after the transformation with a probability which successively decreases with a temperature in the SA algorithm; utilizing three kinds of mechanism, such as harmony memory learning, variable fine tuning and new tone random generation, to generate new solutions; utilizing the SA algorithm to carry out neighborhood transformation on the new solutions and to determine whether to receive the new solutions; establishing a target optimization function, and updating the HM according to an optimization result; and if a maximum iteration number is reached, outputting an optimal harmony solution, and drawing a scheduling Gantt chart of the system. The hybrid intelligent scheduling optimization method has the advantages that the hardware requirements are low, and the optimal solution can be found easily.

Owner:NANJING UNIV OF SCI & TECH

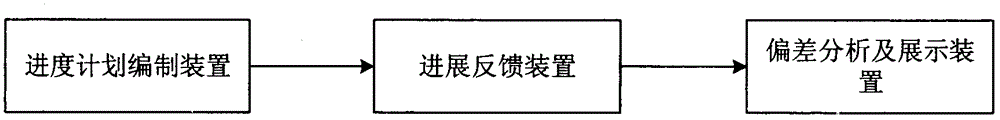

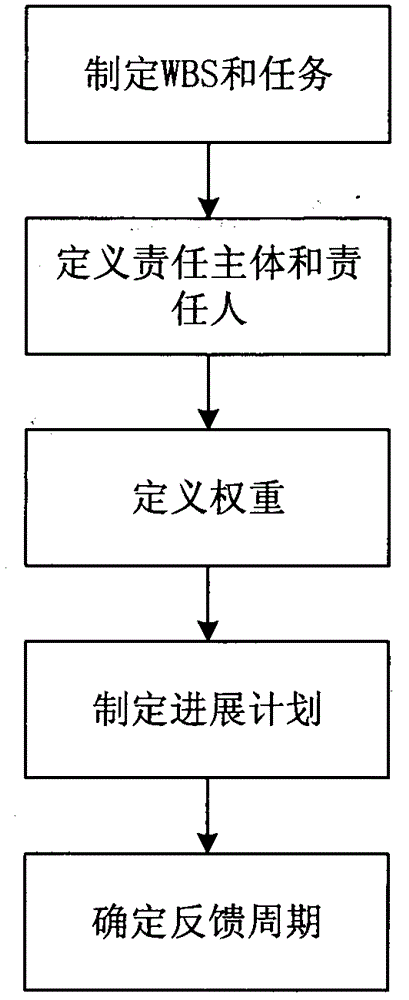

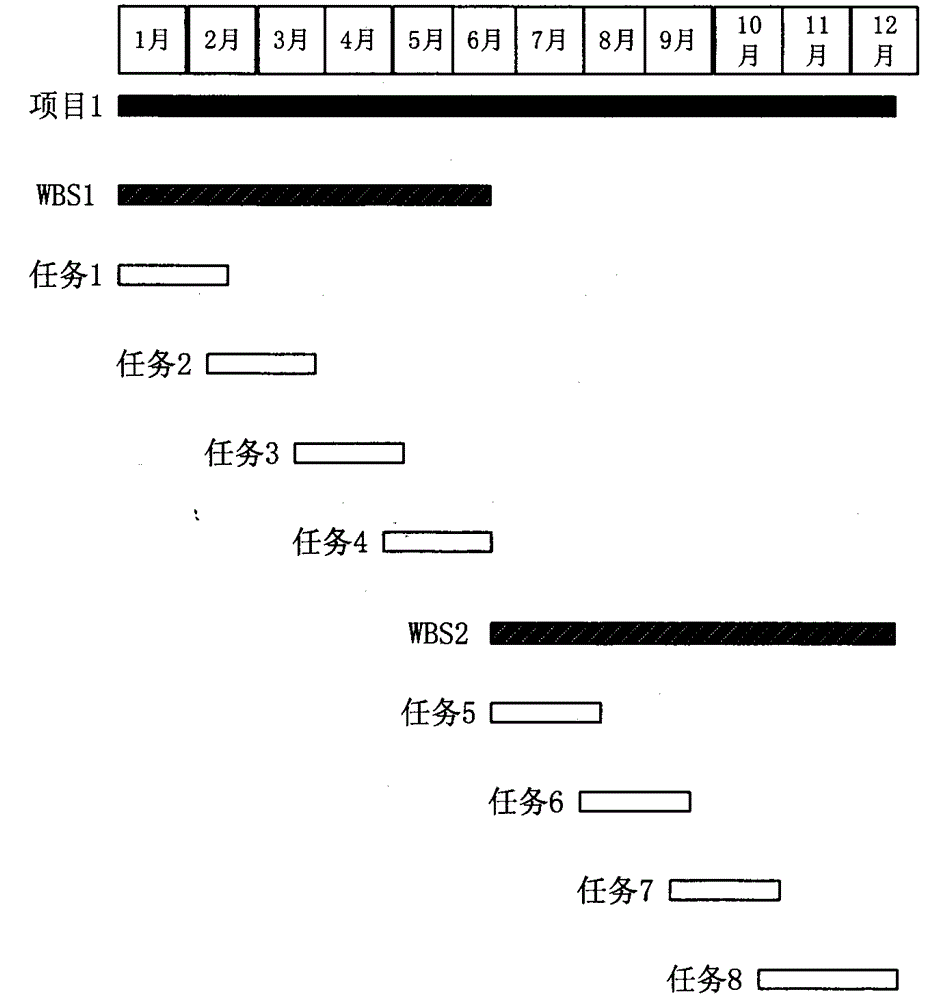

Method and system for project management process feedback and deviation analysis

ActiveCN104636880AEasy to controlImprove visualizationOffice automationResourcesGantt chartProject management process

The invention relates to a method and a system for project management process feedback and deviation analysis. The method comprises the following steps of 1, progress plan planning; 2, progress feedback; 3, deviation analysis and display. The method and the system have the advantages that the progress feedback realizing quantitative and qualitative combination is realized, meanwhile, the integral progress feedback integrating the generated problem, the current actual progress and the future risk is realized, the progress and the weight of all subordinate tasks are integrally considered, high-level stage WBS (work breakdown structure) and project actual progress are formed through summarizing, the task and WBS actual progress and time plan are used for comparison, and a respective actual execution deviation is formed, and is directly displayed in a Gantt chart.

Owner:南京远光广安信息科技有限公司

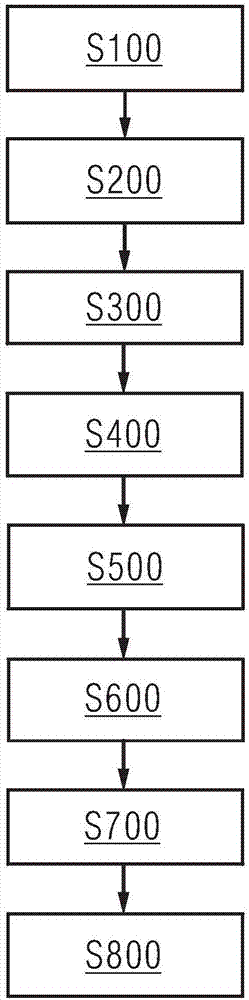

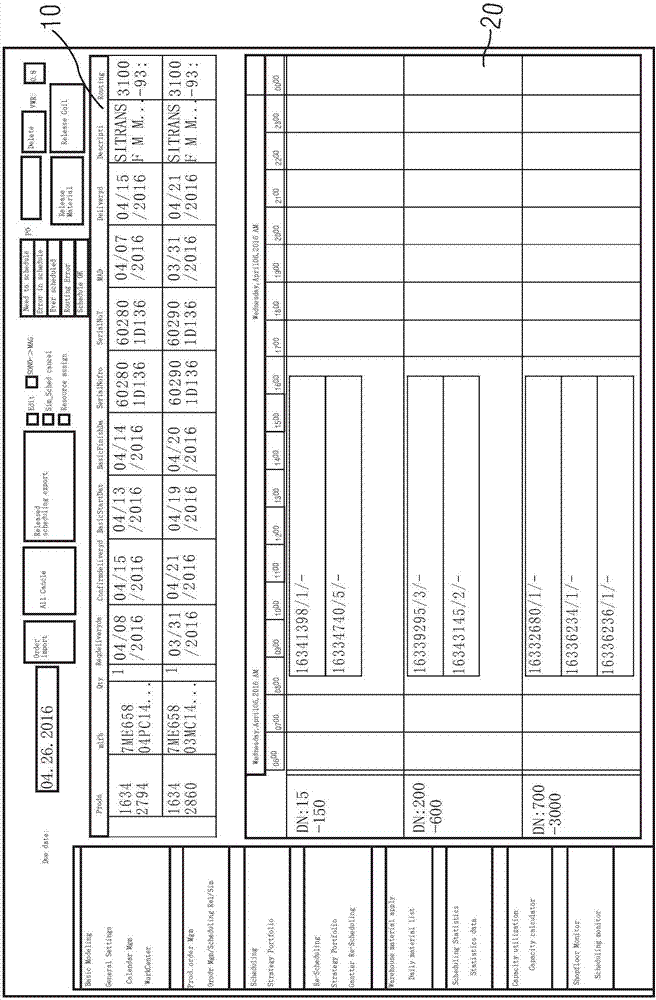

Production scheduling method and system for production line

The invention relates to a production scheduling method and system for a production line. The method comprises the following steps that: obtaining main data (D); scanning and sorting the main data (D), and generating a list, wherein the list (10) comprises order forms to be subjected to production scheduling; obtaining a modeling parameter (P) of the production line, and establishing a model which maps the production line; displaying the list (10) and a first Gantt chart, wherein the first Gantt chart (20) can display the order form under the production scheduling; detecting a dragging operation for the order forms in the list (10); when a detection result shows that the order form in the list (10) is dragged into the first Gantt chart (20), carrying out simulation according to the model of the production line to judge whether the order form can be executed or not; when the order form can be executed, transferring the order form to the first Gantt chart (20) from the list (10); and when the order form can not be executed, outputting alarm information.

Owner:SIEMENS SENSORS & COMM

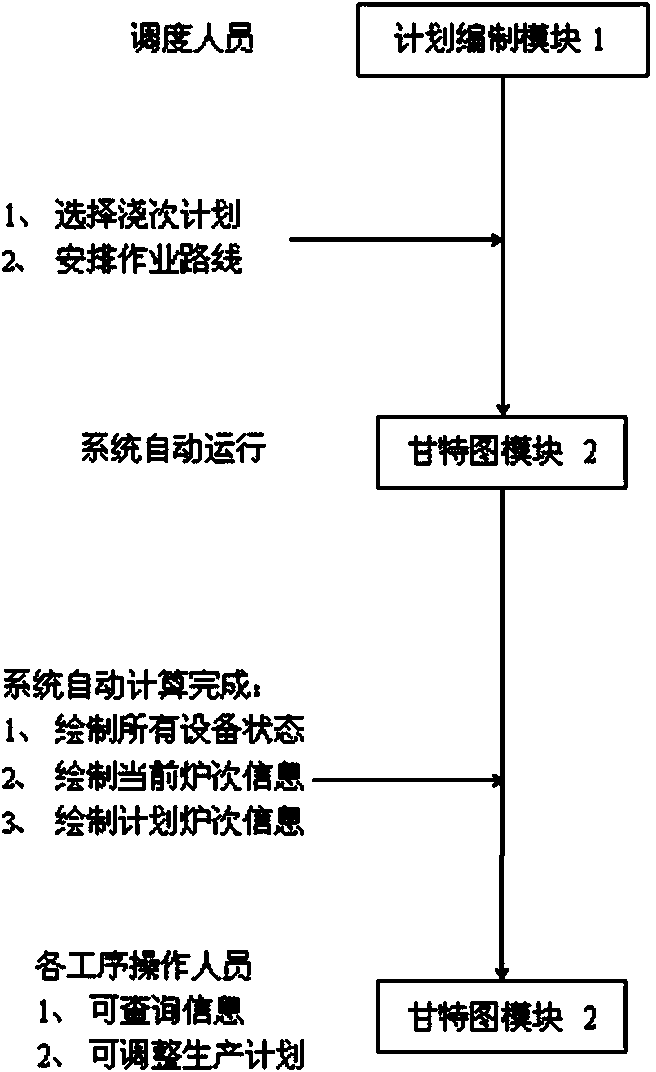

Steelmaking working procedure management system and method

InactiveCN104102982ASolve information silosProduction completeResourcesManufacturing computing systemsGantt chartSteelmaking

The invention discloses a steelmaking working procedure management system and method. The steelmaking working procedure management system comprises a terminal module, a planning module, a Gantt chart module and a data storage module. The method comprises the following steps: adding a production plan; drawing all equipment state diagrams of the production line according to a practical production line equipment situation; plotting current production heat information; calculating the production beginning time and ending time of the heat in each working procedure according to the situation of each production working procedure; and drawing in the state diagrams. The invention can visually, integrally and effectively arrange plans, organize production and transfer production information among all posts, so that steelmaking production is enabled to be accurate and effective, a production process can be clearly, integrally and definitely recorded, a production process monitoring level is improved, production personnel can precisely master a rhythm of production, control production quality and improve a production level.

Owner:WUKUN STEEL

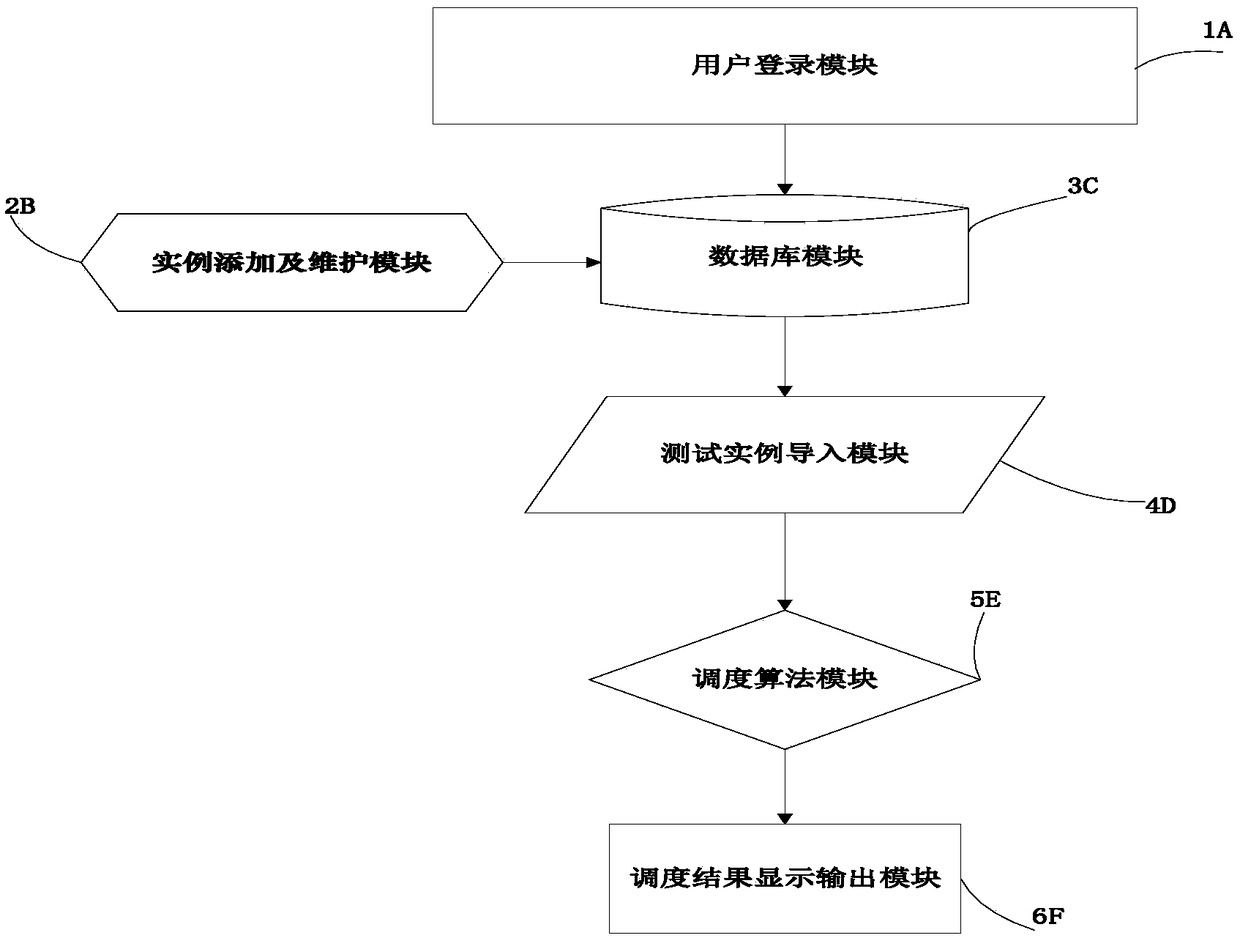

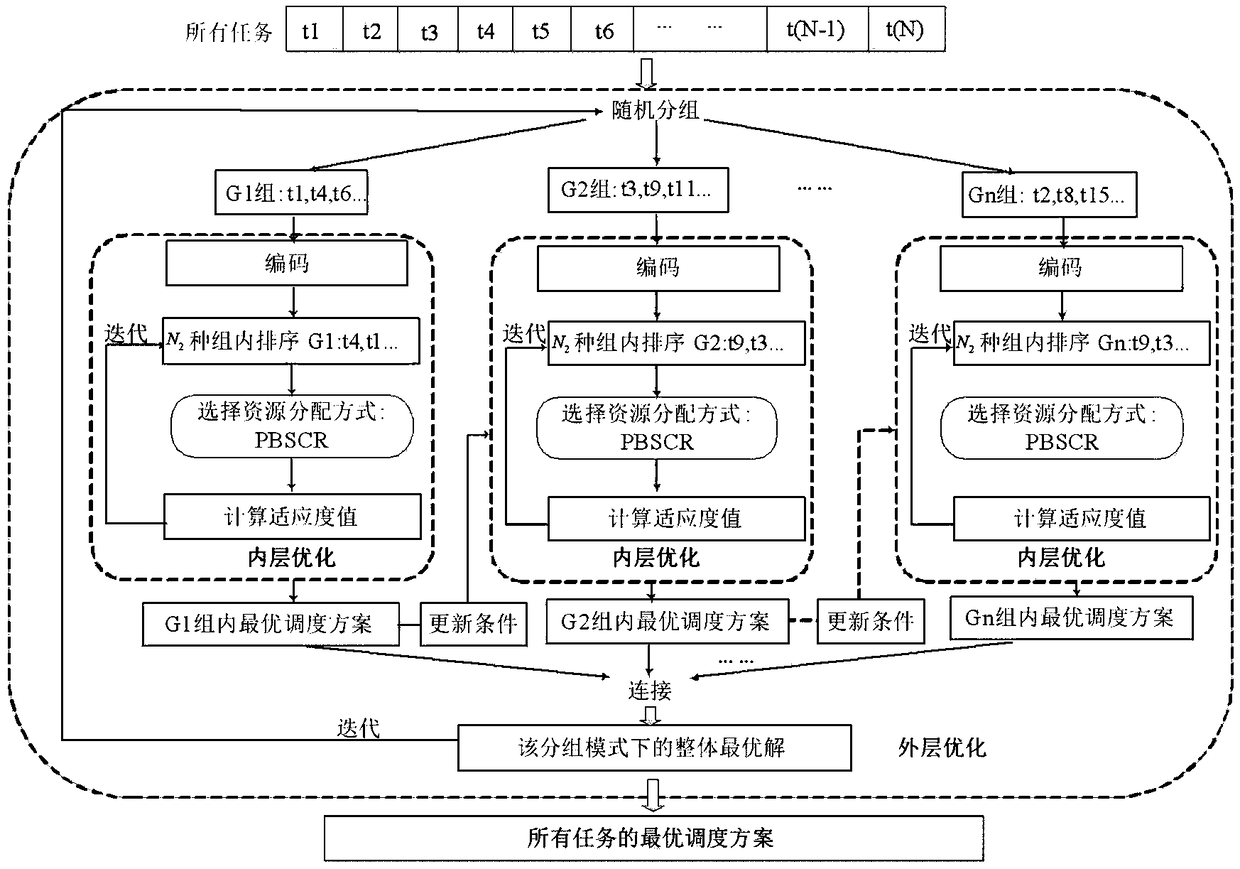

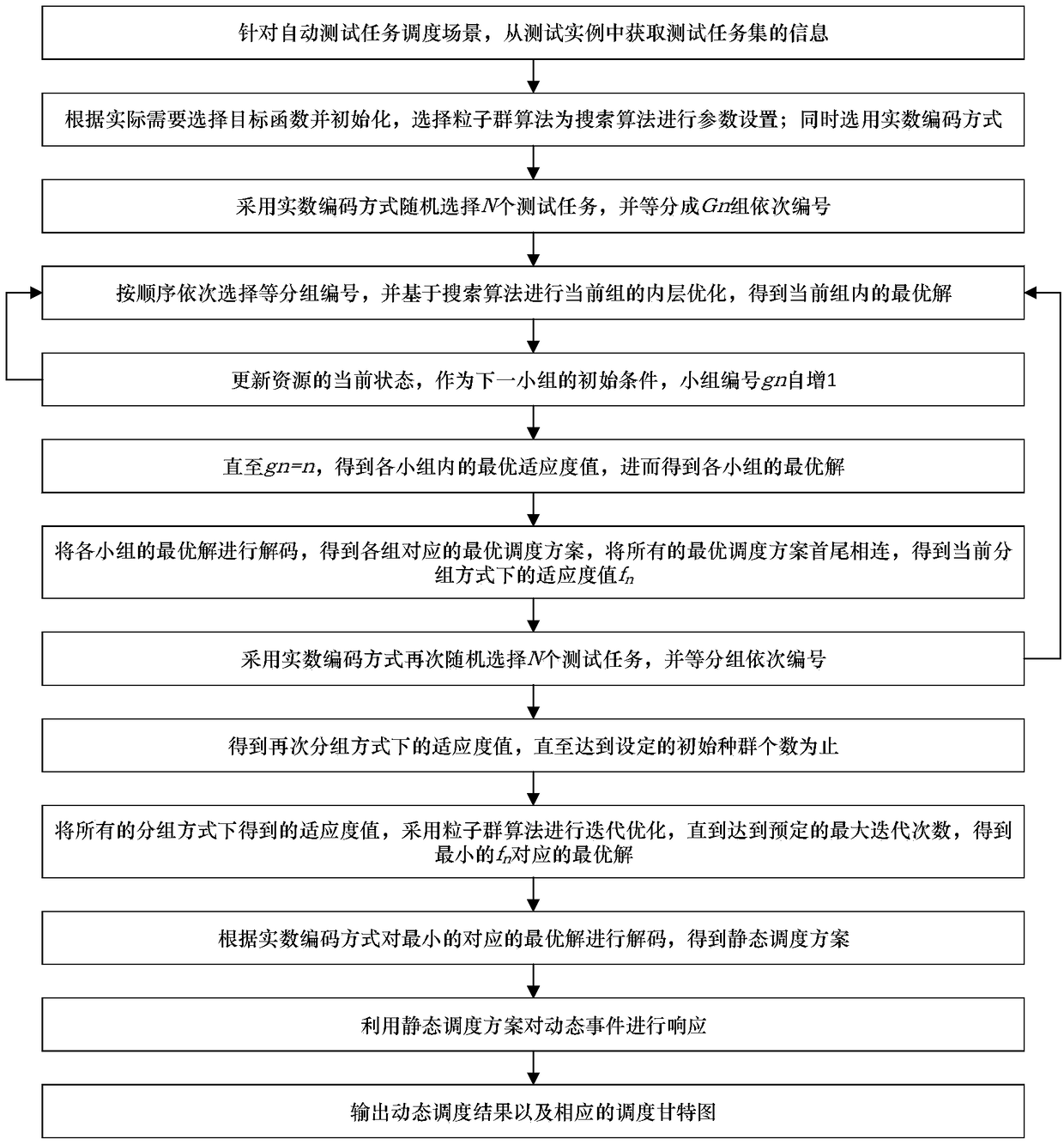

A dynamic test task scheduling method and scheduling platform based on a greedy grouping strategy

ActiveCN109409763AEasy to upgrade and maintainImprove performanceArtificial lifeResourcesGantt chartReal arithmetic

The invention discloses a dynamic test task scheduling method and scheduling platform based on a greedy grouping strategy, and belongs to the field of automatic test system dynamic task scheduling. The scheduling platform comprises a user login module, an instance adding and maintaining module, a database module, a test instance import module, a scheduling algorithm module and a scheduling resultdisplay output module; and obtaining information of the test task set, randomly selecting N test tasks in a real number coding mode to equally divide the test tasks into Gn groups, and carrying out inner layer optimization to obtain an optimal solution of each group. And decoding the optimal solution of each group to obtain an optimal scheduling scheme, and connecting all the optimal scheduling schemes end to end to obtain a fitness value fn. And repeating the above method until the outer layer reaches the set number of initial populations, performing iterative optimization to obtain an optimal solution corresponding to the minimum fn, decoding the optimal solution to obtain a static scheduling scheme, responding to the dynamic event, and outputting a dynamic scheduling result and a scheduling Gantt chart. The understanding quality is improved, and the system is convenient to maintain and upgrade.

Owner:BEIHANG UNIV

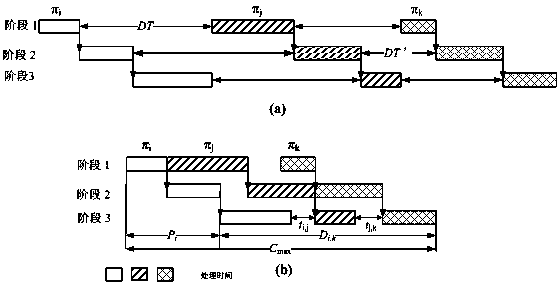

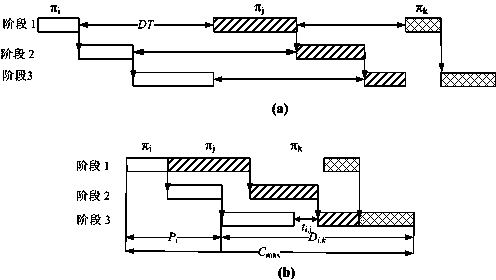

Multi-constraint wait-free hybrid running water scheduling modeling method based on idle matrix

InactiveCN104217287AReduce complexityReduce the difficulty of solvingResourcesGantt chartComputer science

The invention discloses a multi-constraint wait-free hybrid running water scheduling modeling method based on an idle matrix. The multi-constraint wait-free hybrid running water scheduling modeling method comprises the following steps: firstly, carrying out constraint preprocessing: for a constraint which exhibits processing unit skipping, setting the processing time of a task on a unit as 0, adding a big penalty term when a target function value is calculated for the constraint which exhibits preorders or conversion forbidding, and adding the preparation time after previous task processing time for preparation time which exhibits sequential dependency; secondly, for a stage with a parallel machine, processing by adopting a soft compression regulation method based on a Gantt chart to construct the idle matrix; and finally, on the basis of the idle matrix, constructing a scheduling model according a scheduling target. A wait-free hybrid running water scheduling problem with the complex constraint is converted into a common wait-free running water scheduling problem without the constraint, and the scheduling model is established on the basis of the idle matrix so as to lower the complexity and the solving difficulty of the model.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com