Online imaging man-machine interaction scheduling method for steel making and continuous casting production process

A production process and production scheduling technology, applied in the field of steelmaking and continuous casting, can solve the problem of not providing an online graphical human-computer interaction scheduling method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

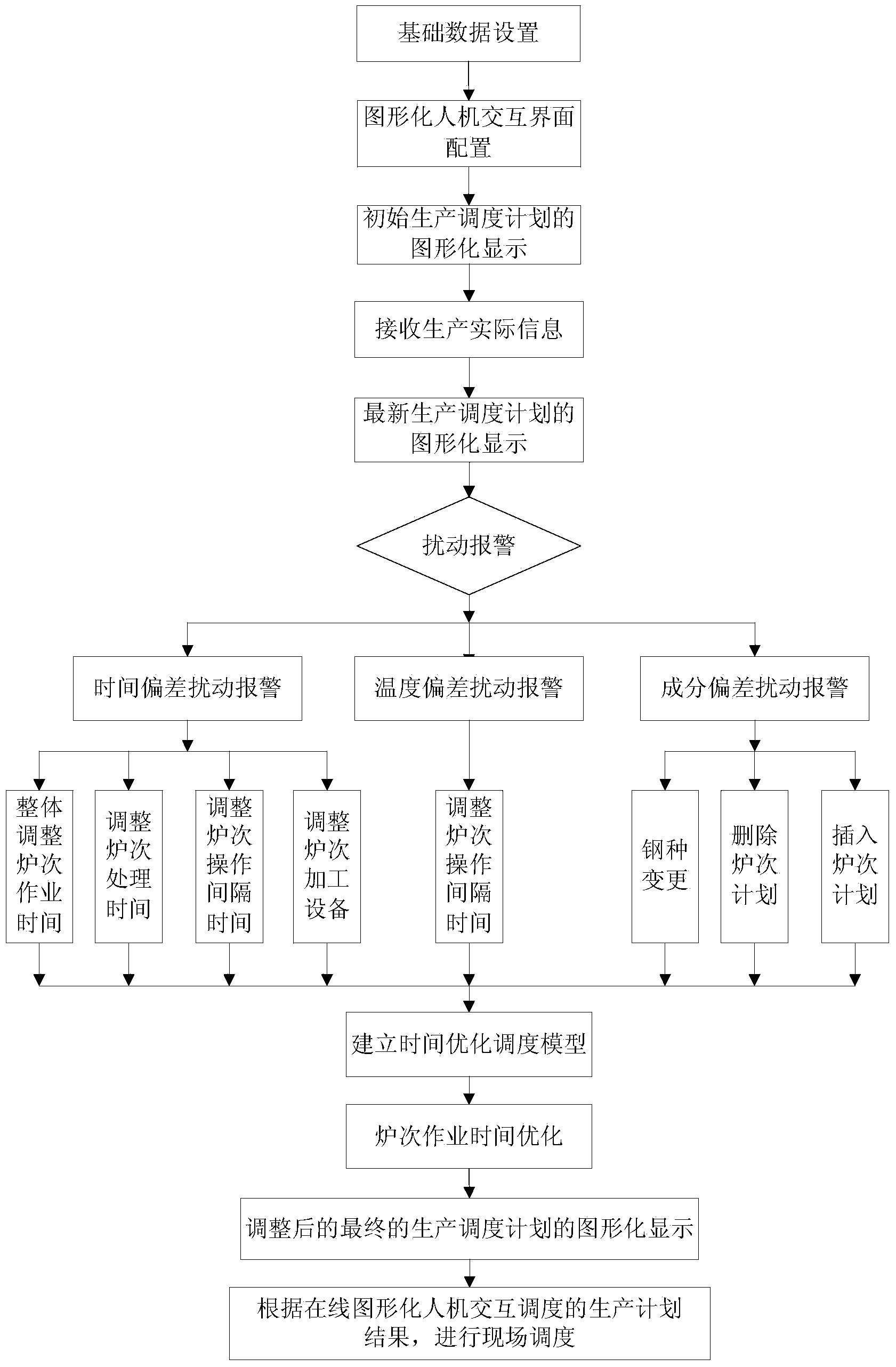

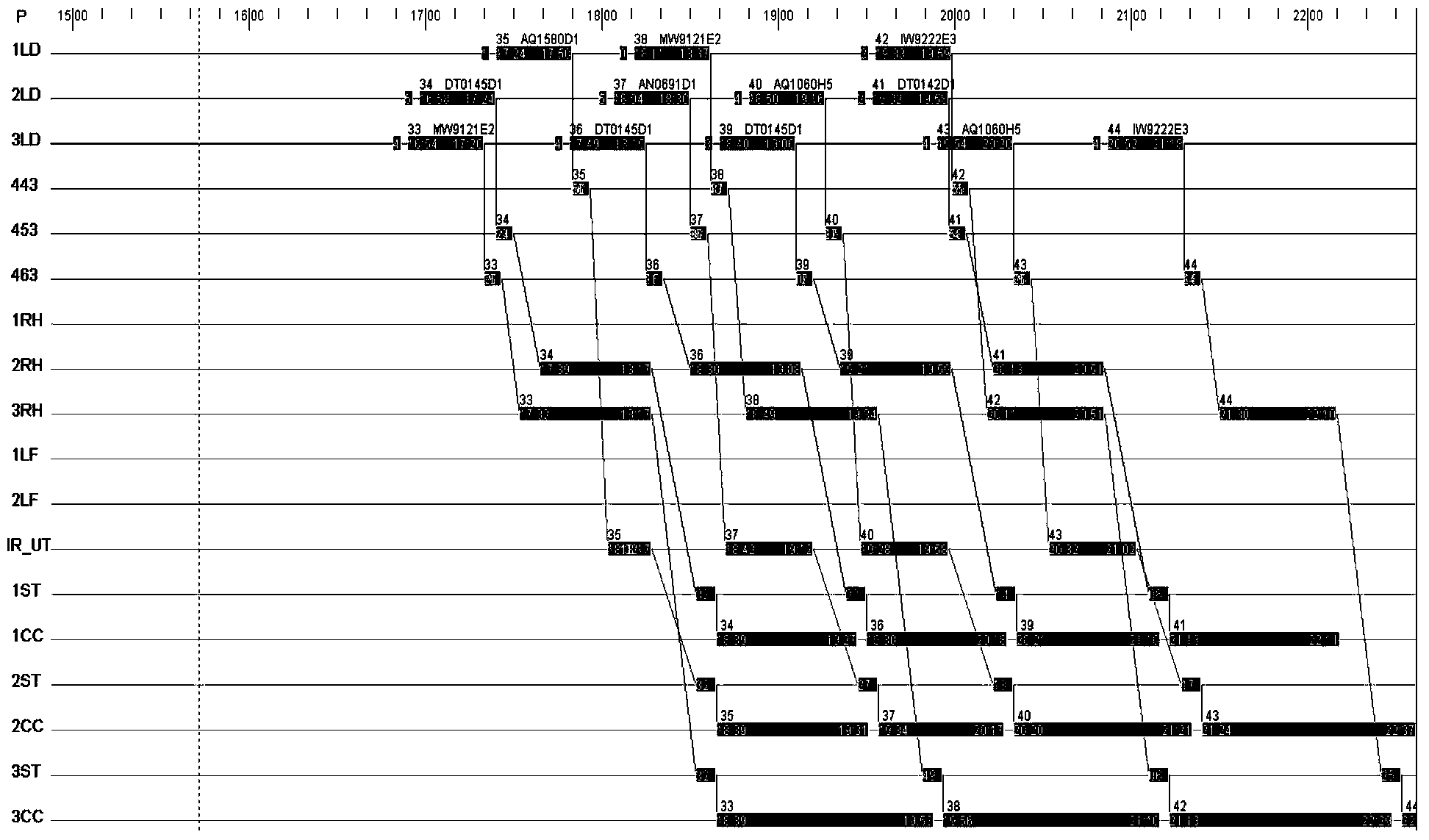

[0088] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

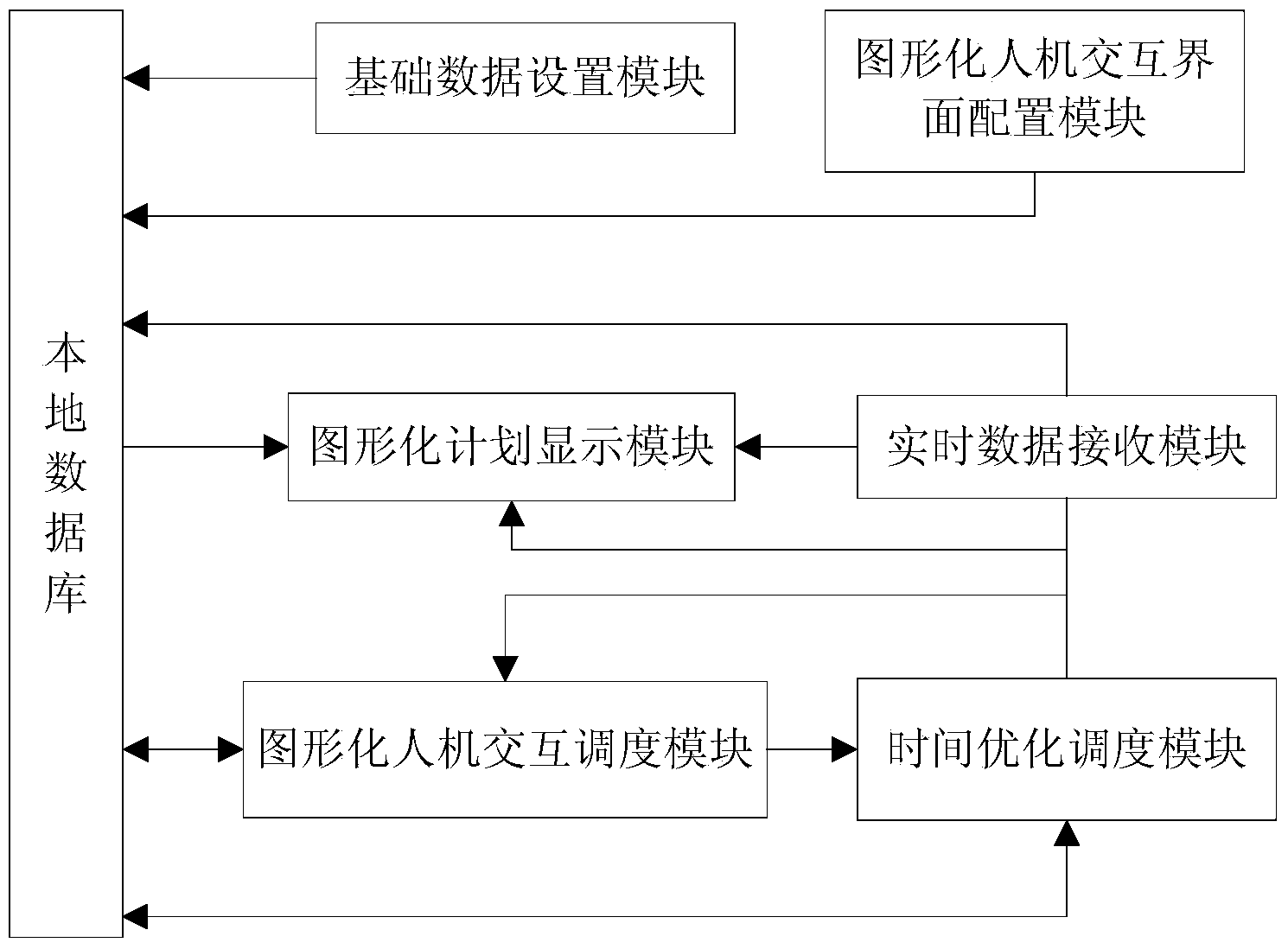

[0089] The steelmaking-continuous casting production process online graphic human-computer interaction scheduling method of the present embodiment of the present invention is realized by using the steelmaking-continuous casting production process online graphic human-computer interactive scheduling system, such as figure 1 As shown, the system includes a basic data setting module, a graphical human-computer interaction interface configuration module, a graphical plan display module, a real-time data receiving module, a graphical human-computer interaction scheduling module, a time optimization scheduling module and a local database;

[0090] The basic data setting module is used to set the graphical human-computer interaction interface to display basic data, including equipment code, equipment name, equipment type, minimum allowa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com