Patents

Literature

96 results about "Torpedo" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A torpedo is an explosive device used, especially in the early days of the petroleum industry, to fracture the surrounding rock at the bottom of an oil well to stimulate the flow of oil and to remove built-up paraffin wax that would restrict the flow. Earlier torpedoes used gunpowder, but the use of nitroglycerin eventually became widespread. The development of hydraulic fracturing rendered torpedoes obsolete, and is the primary fracturing process used today.

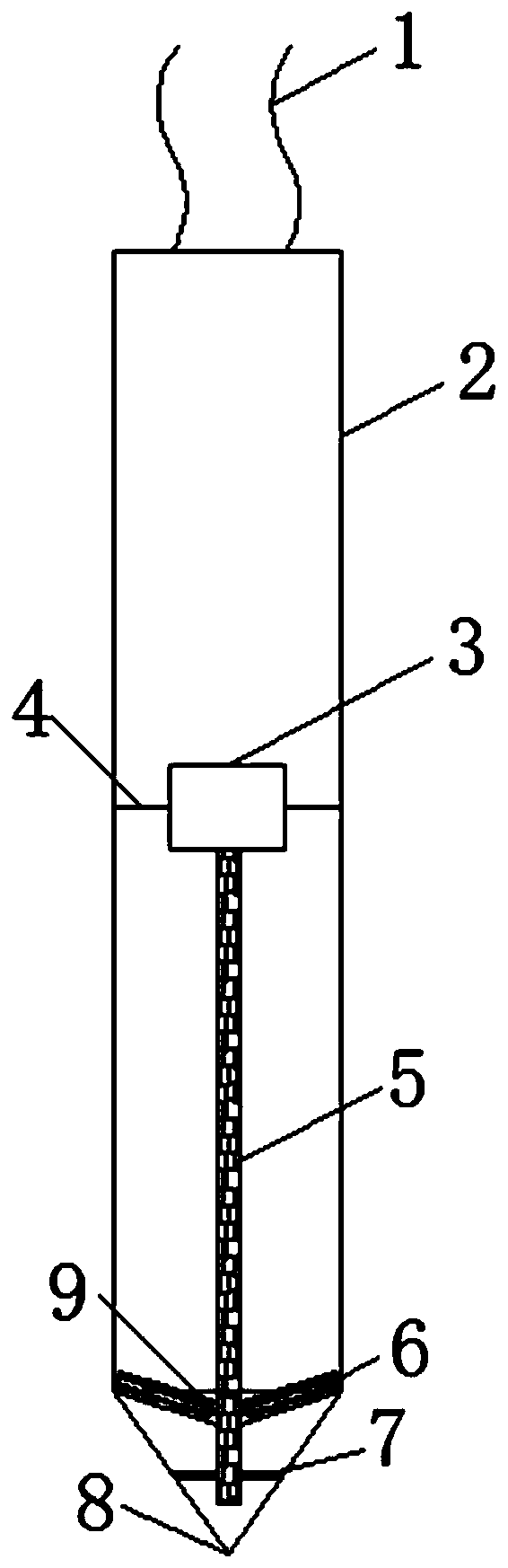

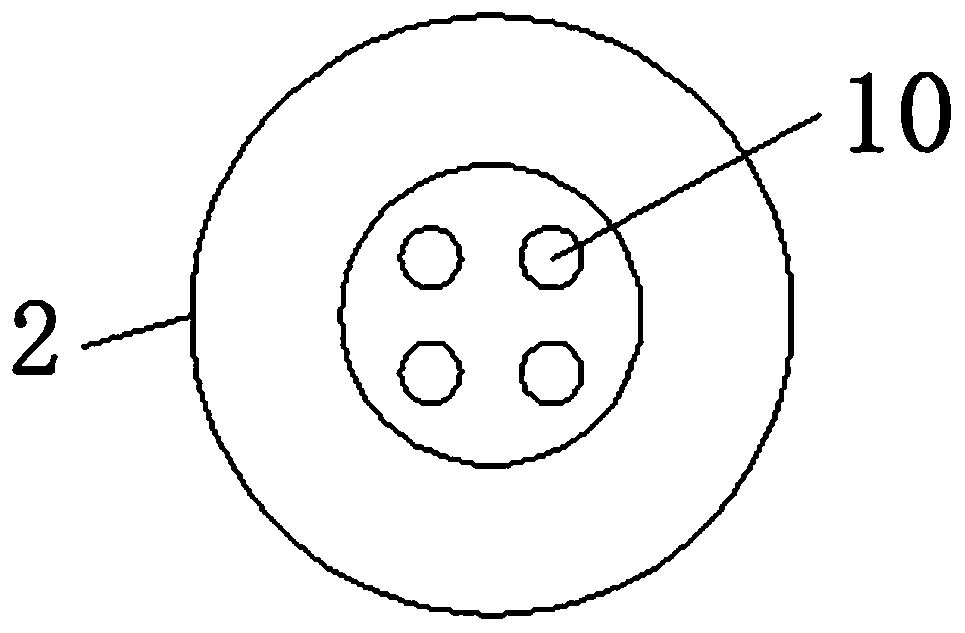

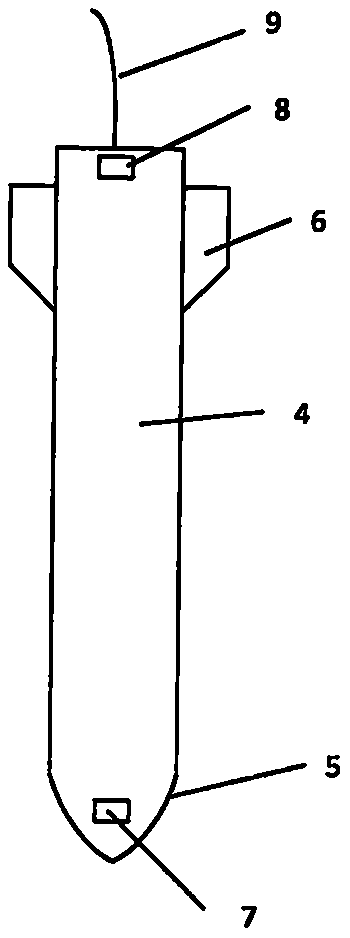

Torpedo anchor capable of increasing anchoring length

PendingCN111055967AMeet the pullout performance requirementsPrevent disengagementAnchorsTorpedoElectric machinery

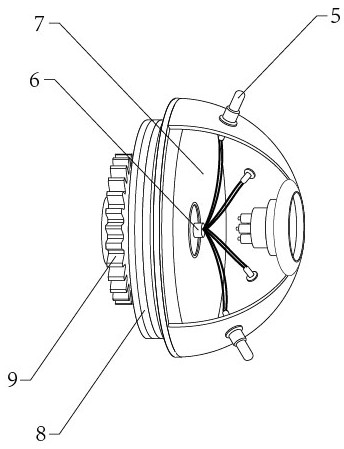

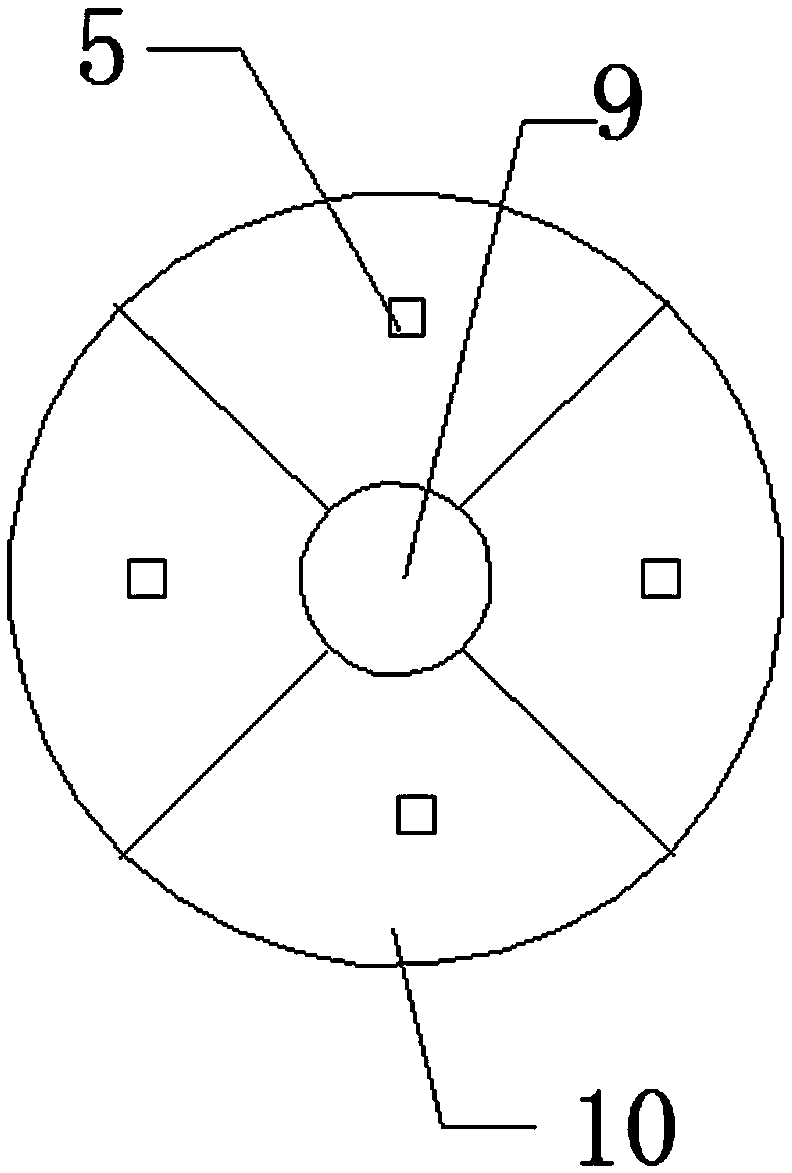

The invention relates to a torpedo anchor capable of increasing the anchoring length. The anchor comprises an anchor body (2) and an anchor head (8) which are mutually clamped, a screw (5) is arrangedin the anchor body (8), one end of the screw (5) is connected with the anchor head (8) through a nut (7), a motor (3) is fixed at the other end and connected with the anchor body (2) through a connecting rod (4), and a rotary blade (6) is arranged on the rod body of one end, closed to the nut (7), of the screw (5). Compared with the prior art, the torpedo anchor has the advantages that the anchoring length is increased by cutting a soil layer, and the pulling resistance of the torpedo anchor is improved.

Owner:TONGJI UNIV

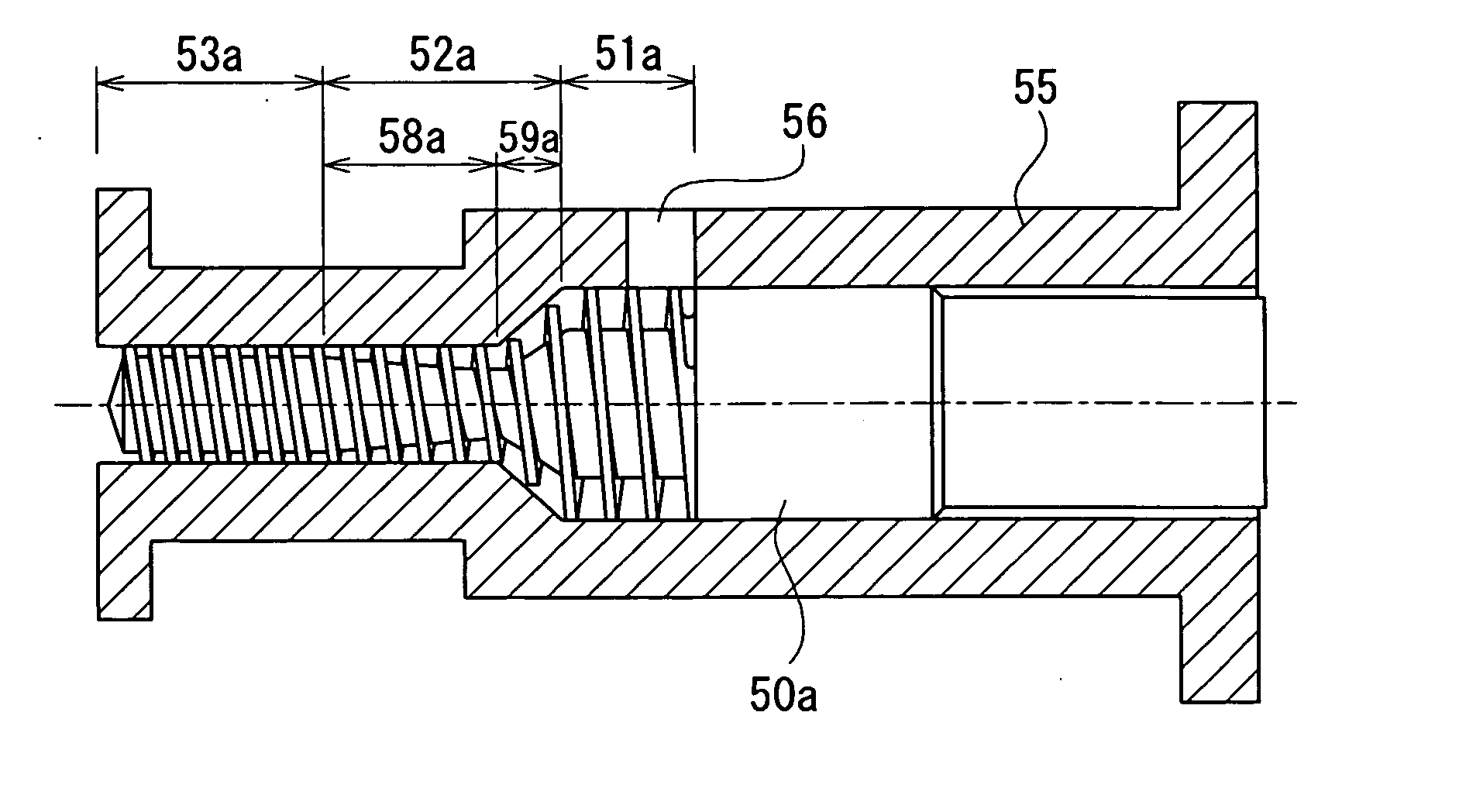

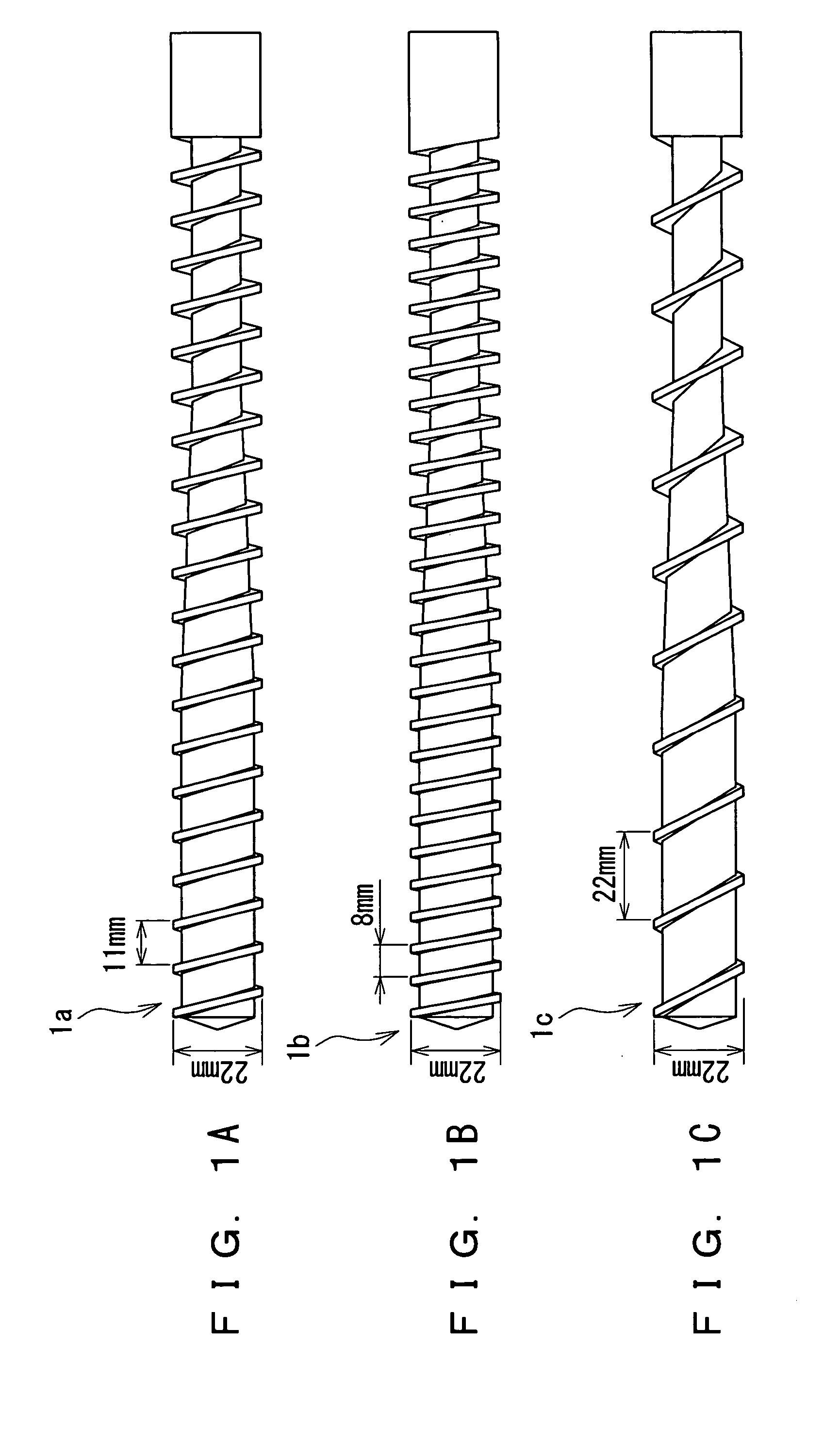

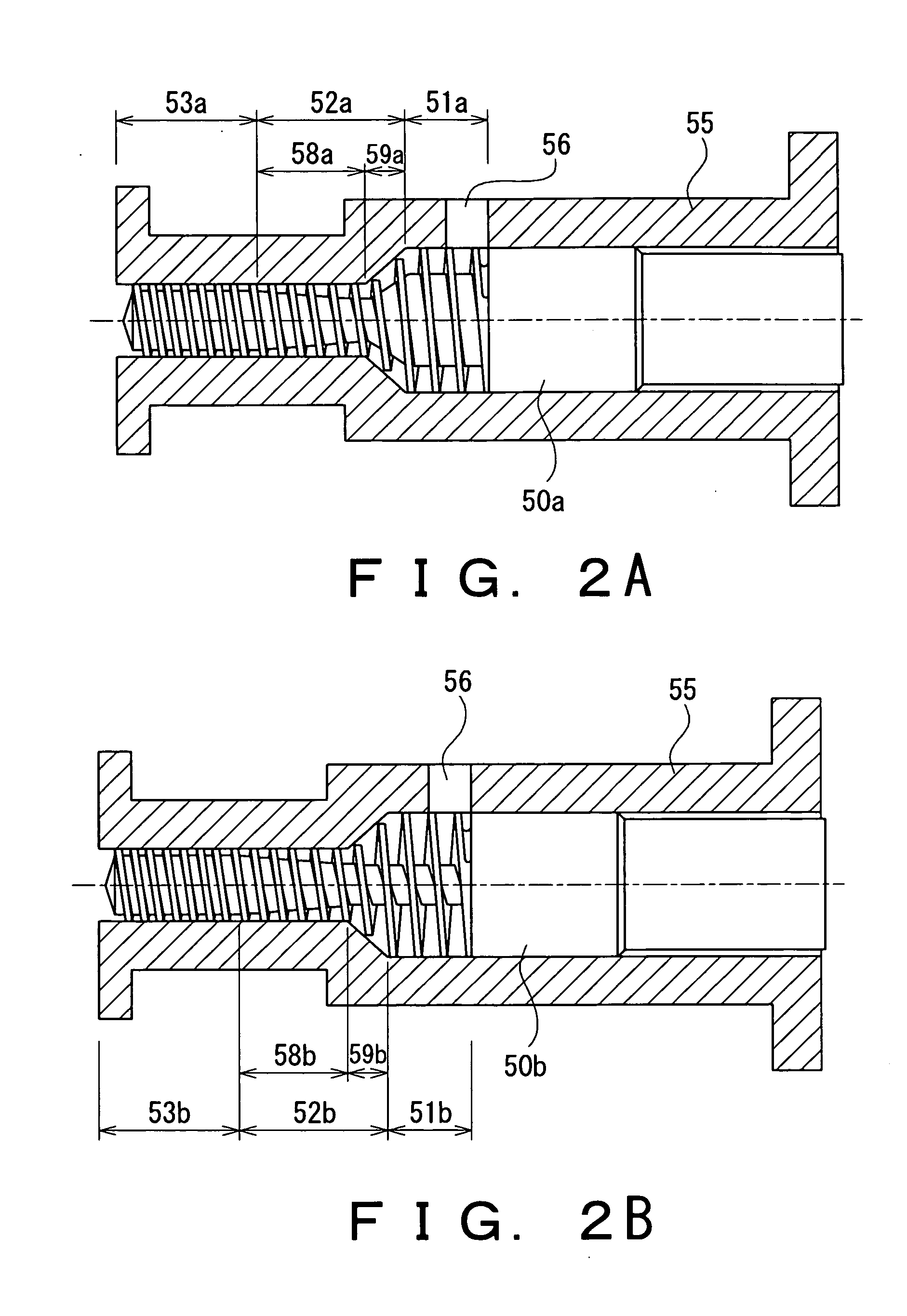

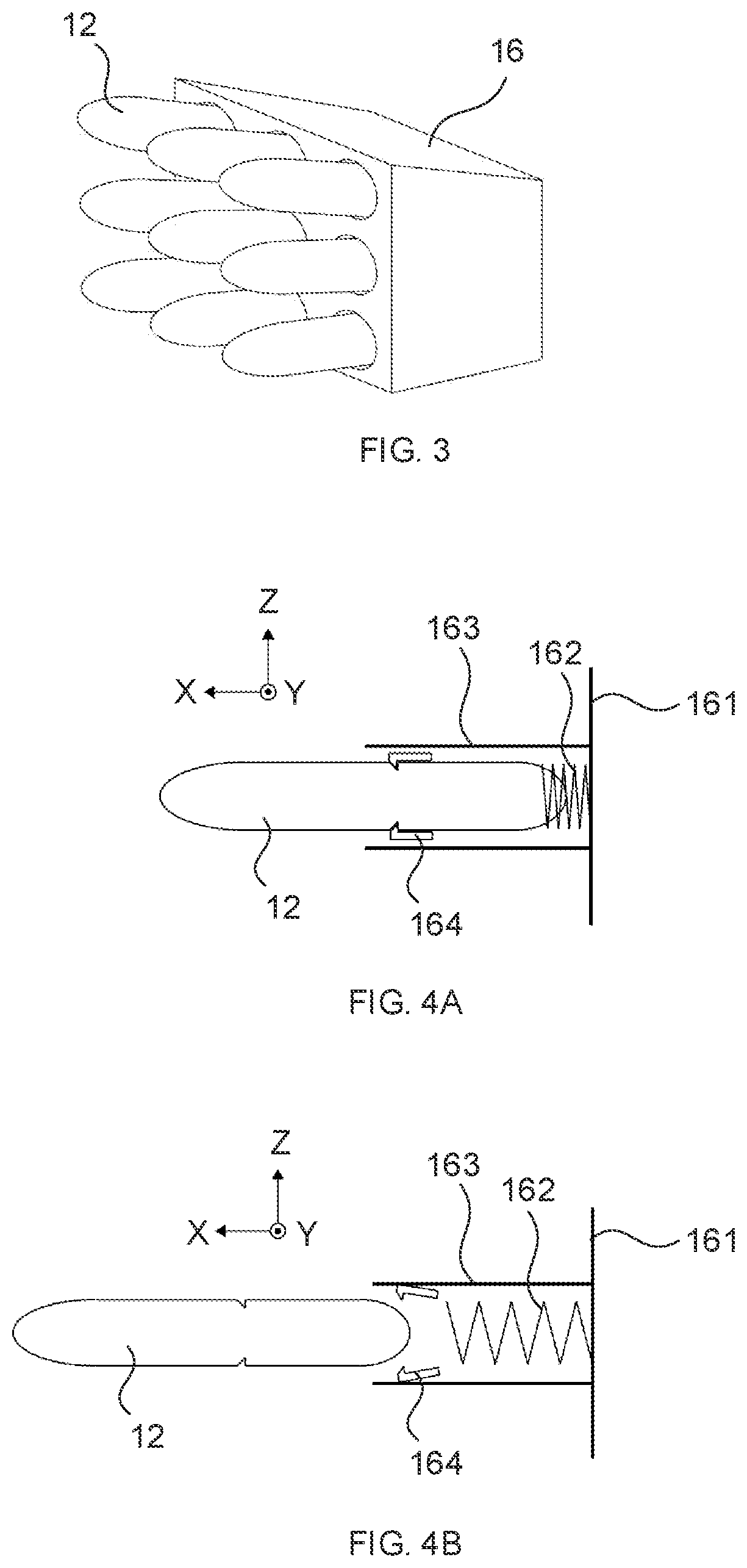

Screw for plastication of resin material and a plasticizing mechanism

InactiveUS20070104021A1Equipment costGuaranteed smooth progressRotary stirring mixersMixing/kneading with horizontally-mounted toolsPolymer scienceTorpedo

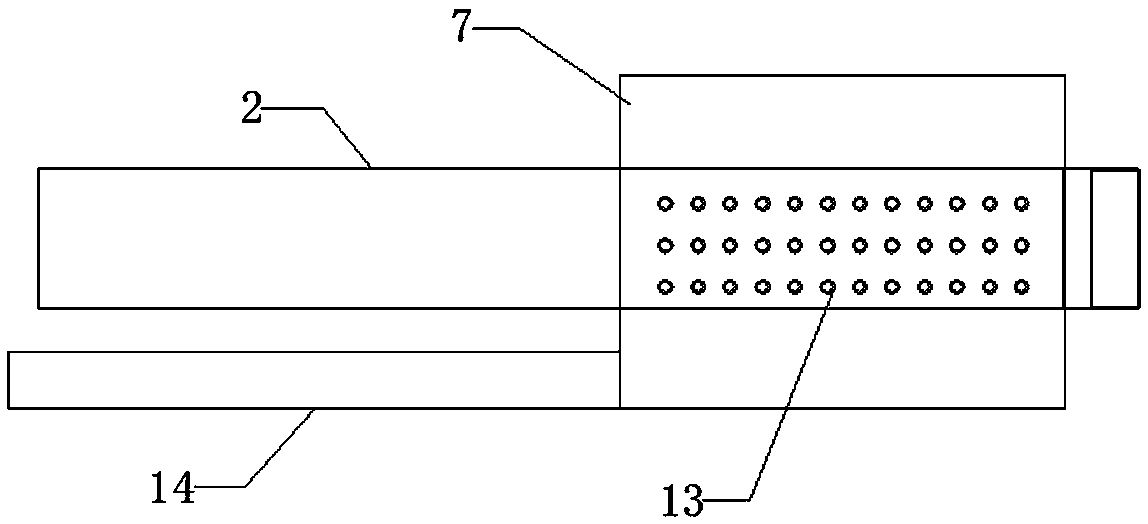

To provide a screw for injection molding and a plasticizing device which can ensure downsizing of the plasticizing device by decreasing an L / D ratio as well as keeping a molten resin to be discharged while stably molten and discharged. In the screw 1a, 1b, 1c, the L / D ratio obtained by dividing an effective length L by an external diameter D is 10 or less, and a flight pitch is designed so that a thread length falls within a range of 30 to 300% of a screw with a square pitch having the same diameter and the L / D ratio of 20 to 24. A torpedo plate 13 with a through-hole is installed in the vicinity of the top end of the screw, inside the through-hole arranged is a spindle-shaped torpedo 12 supported by one or more supporting pieces, and between an internal surface of the through-hole and an outer surface of the torpedo 12, formed is a path 17 of plasticized resin material.

Owner:AUTONETWORKS TECH LTD +2

Automatic oiling device for inner side guide rail of special pipeline

ActiveCN111842038ALow costRealize simultaneous oiling and maintenanceLiquid surface applicatorsCoatingsTorpedoOil quality

The invention discloses an automatic oiling device for an inner side guide rail of a special pipeline, and belongs to the technical field of guide rail oiling. The automatic oiling device for the inner side guide rail of the special pipeline comprises a support frame, an oiling component, a travelling mechanism and a guide component, by making use of reliable support provided for the oiling component by the support frame after being arranged on the travelling mechanism, and corresponding matching between each oiling unit in the oiling component and each guide rail in the pipeline, and furtherby reliable travelling of the travelling mechanism on a longitudinal direction of the pipeline, synchronous oiling maintenance for each guide rail in a torpedo launching pipeline can be realized in cooperation with corresponding guiding of the guide component. The automatic oiling device for the inner side guide rail of the special pipeline, provided by the invention, is simple in structure and simple and convenient to operate, can effectively adapt to a guide rail setting environment in the torpedo launching pipeline, can simultaneously complete oiling maintenance operations for each guide rail in the pipeline, effectively improves oiling efficiency and oiling quality of the guide rail, reduces oiling maintenance cost of the torpedo launching pipeline, guarantees reliable running and function stability of the pipeline, and has better application prospect and promotion value.

Owner:HUBEI SANJIANG SPACE XIANFENG ELECTRONICS&INFORMATION CO LTD

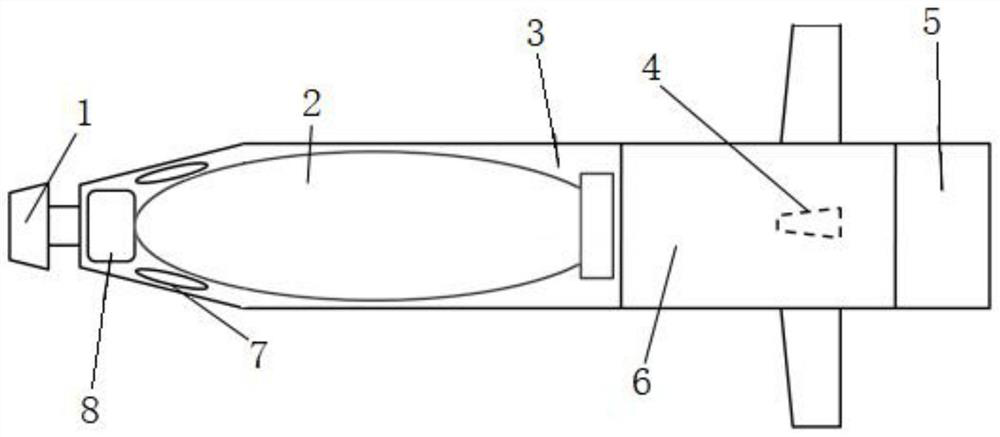

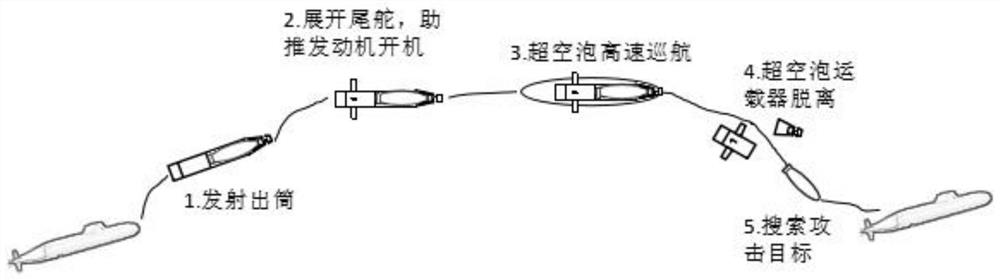

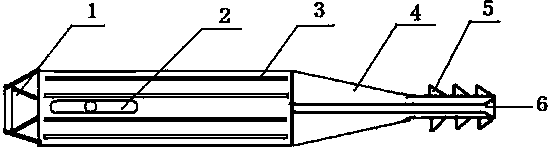

Supercavitation sailing vehicle

ActiveCN113091531AShort reaction timeIncrease rangeDirection controllersMarine torpedoesTorpedoMarine engineering

The invention provides a supercavitation sailing vehicle. The supercavitation sailing vehicle comprises a cavitator, a torpedo, an internal load, a tail control surface, a main engine and a boosting engine; the right end of the cavitator is connected with the internal load; the right end of the internal load is fixedly connected with the main engine; the right end of the main engine is fixedly connected with the boosting engine; the tail control surface is installed on the outer side of the main engine; and the torpedo is arranged in the internal load. According to the invention, the range and speed are increased by using the drag reduction characteristic of the supercavitation; conventional underwater weapons such as a light sound self-guided torpedo can be carried in the vehicle to remotely and quickly attack an enemy target; and the response time of the enemy target is shortened.

Owner:SHANGHAI INST OF ELECTROMECHANICAL ENG

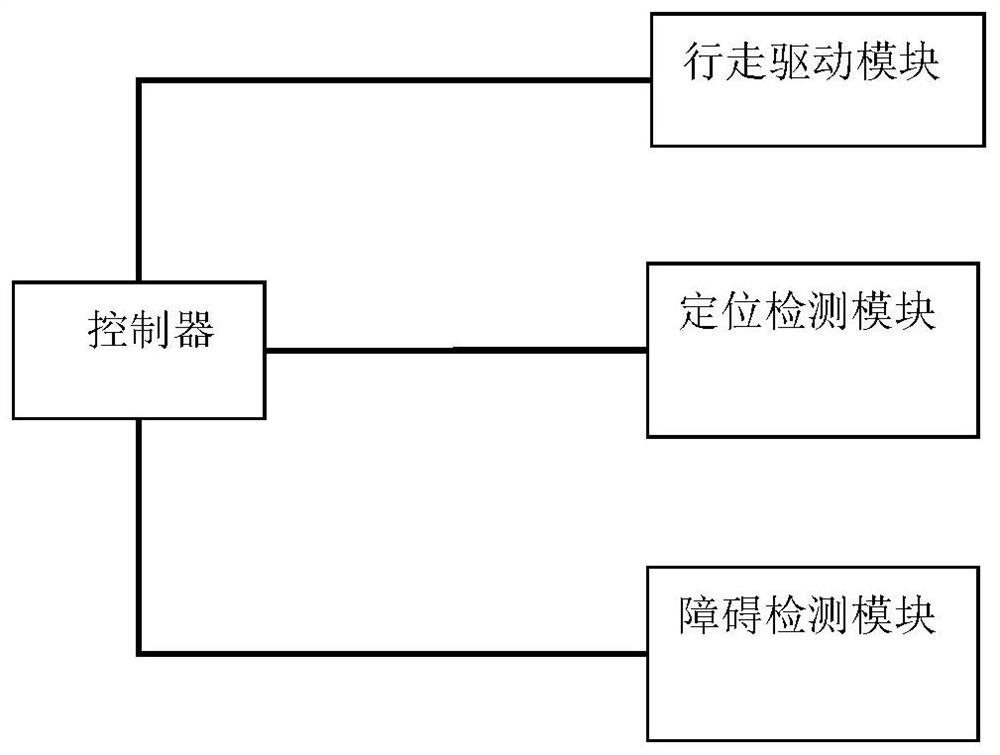

Concrete torpedo ladle automatic positioning control method, control system and storage medium

PendingCN111830975AReduce manual adjustment operationsImprove efficiencyPosition/course control in two dimensionsVehiclesTorpedoControl system

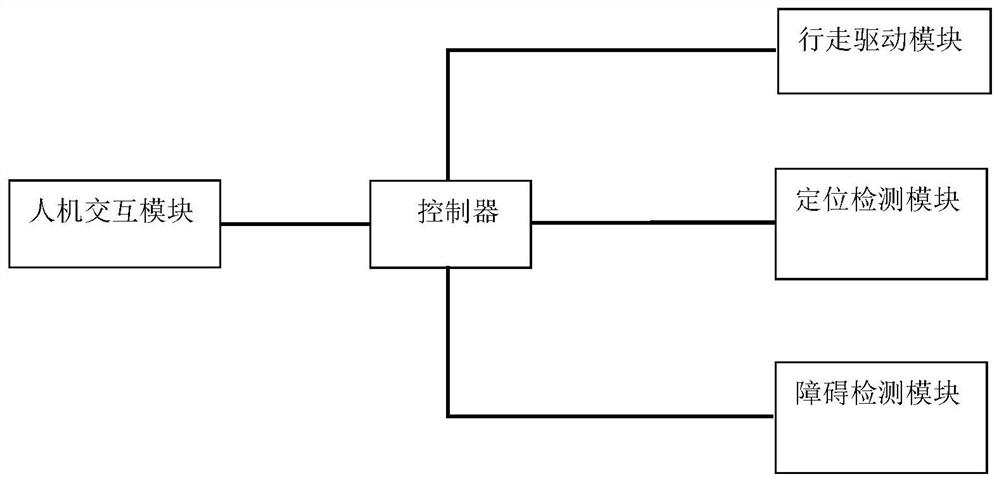

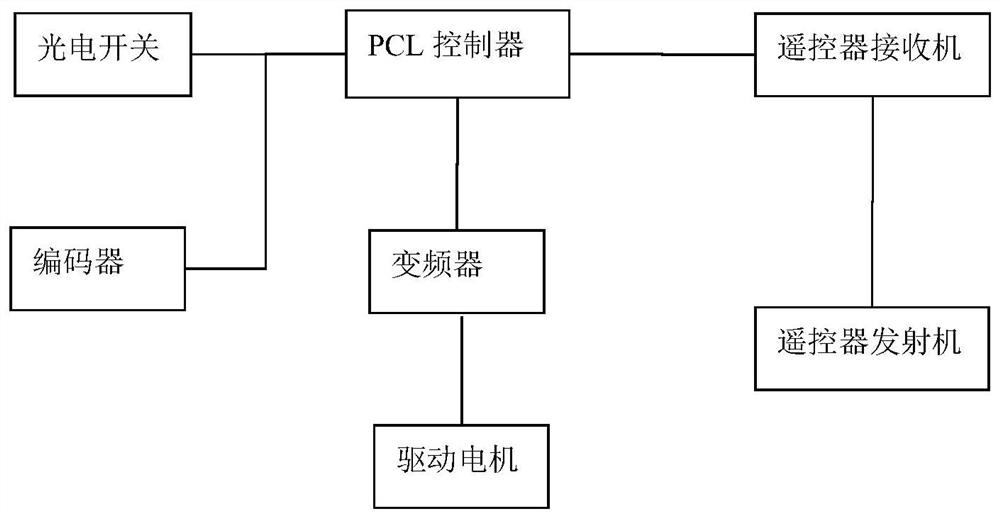

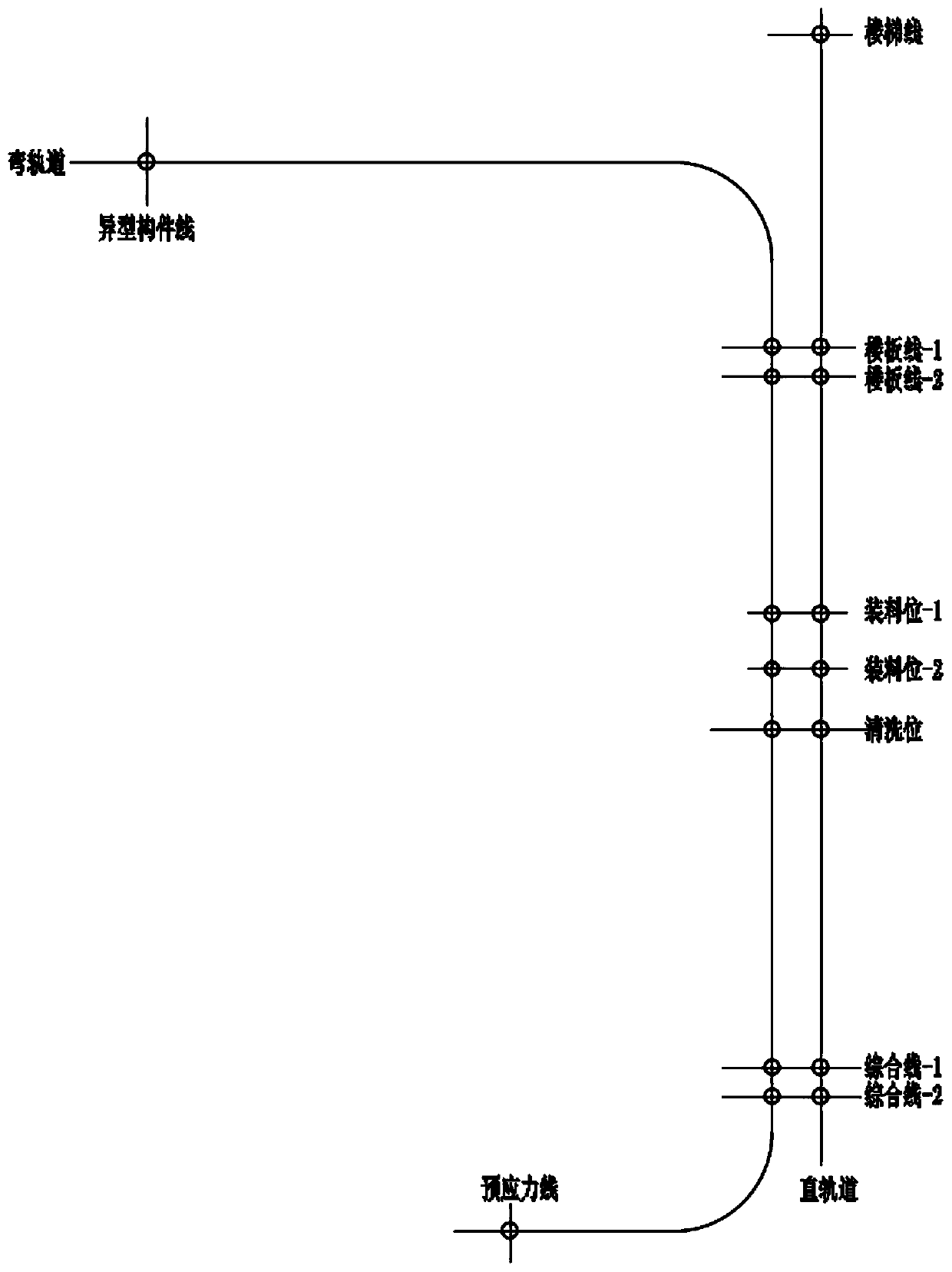

The invention discloses a torpedo ladle automatic positioning control method, which comprises the steps: obtaining positioning parameters of a target position of a torpedo ladle and the current position of the torpedo ladle; controlling the torpedo ladle to operate by adopting a speed control algorithm; judging whether the torpedo ladle reaches the target position or not through a limiting function; if so, controlling the torpedo ladle to stop running, and resetting the positioning parameters; and if not, adopting the speed control algorithm continuously to control the torpedo ladle to operateuntil the torpedo ladle reaches the target position. The invention further provides a torpedo ladle automatic positioning control system, which comprises a walking driving module, a controller and aposition detection module. The walking driving module is used for executing a command issued by the controller and driving the torpedo ladle to walk; the position detection module is used for detecting the current position of the torpedo ladle and feeding back the current position to the controller; and the controller comprises a processor, a memory, and a computing program stored on the memory and executable by the processor. According to the scheme, the torpedo ladle can be automatically and accurately positioned, manual adjustment operation can be reduced, efficiency is improved, and the automation degree is high.

Owner:筑友智造智能科技有限公司

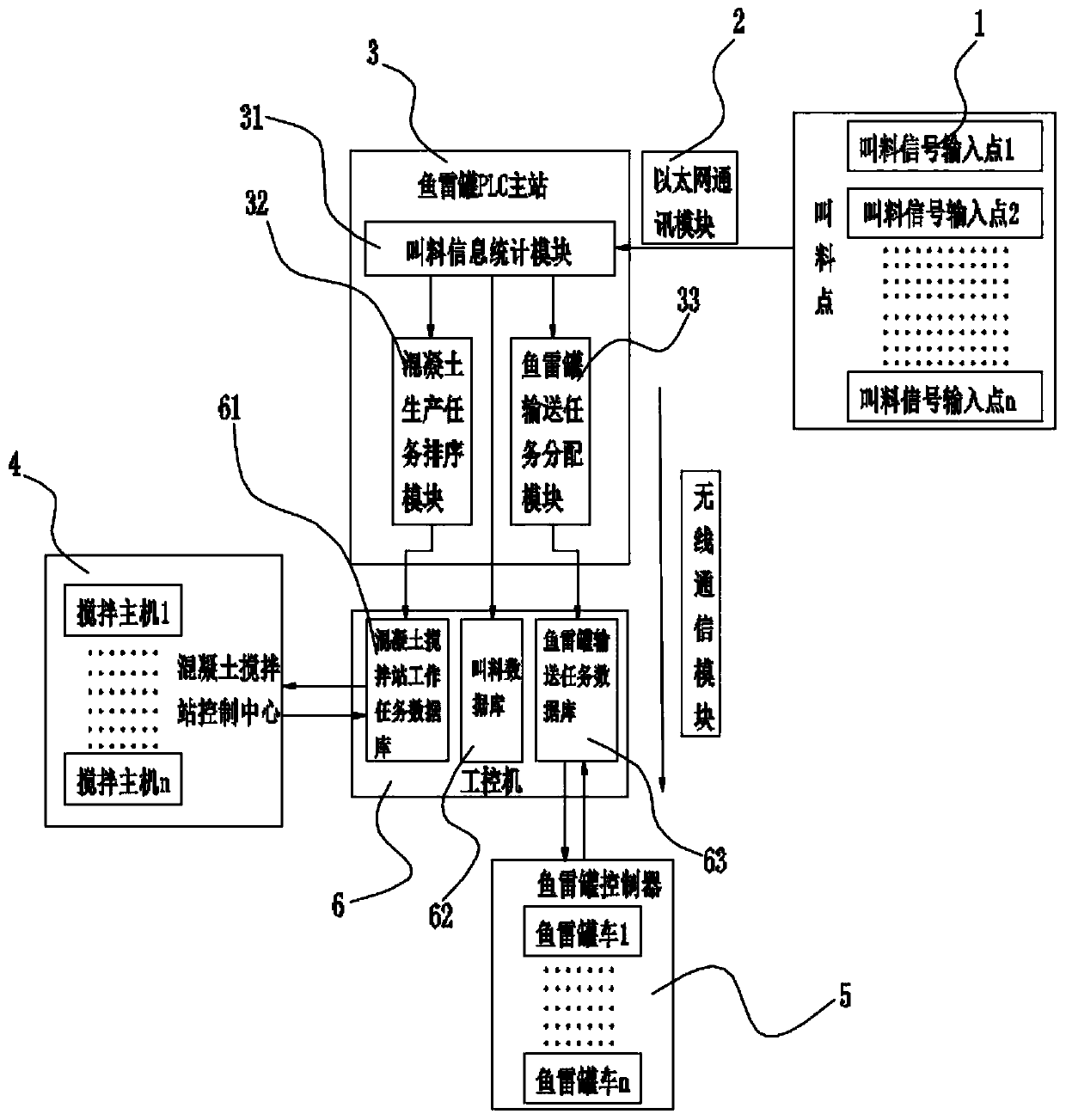

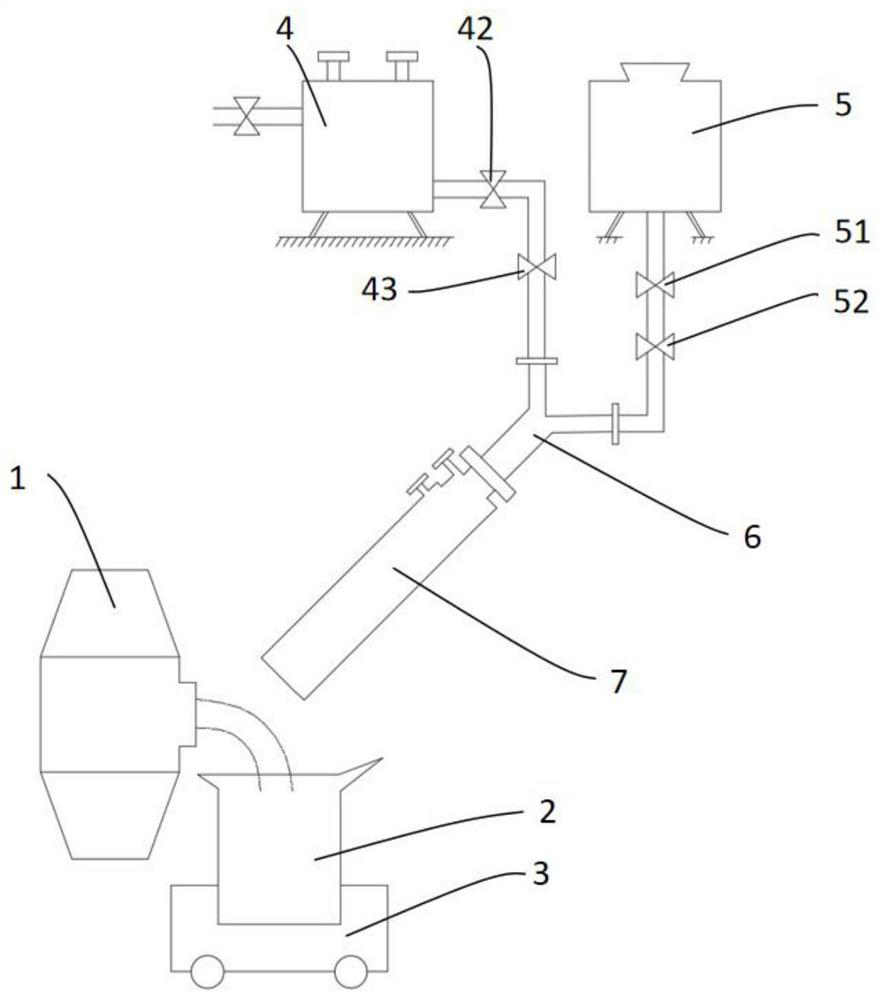

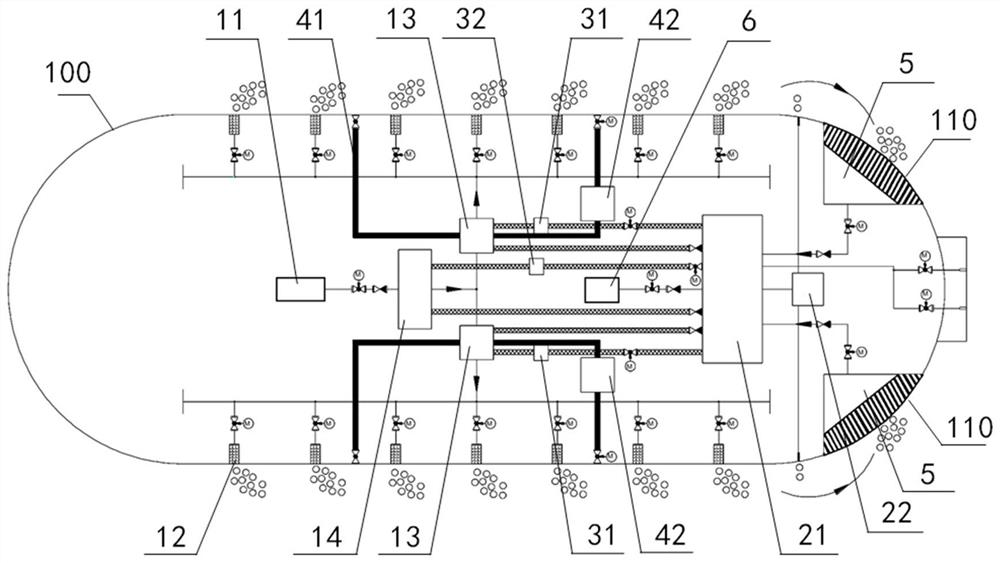

Torpedo ladle master station control system and concrete distribution system as well as distribution method

PendingCN111546503ARealize intelligenceEasy to manageDischarging apparatusCeramic shaping plantsProduction lineTorpedo

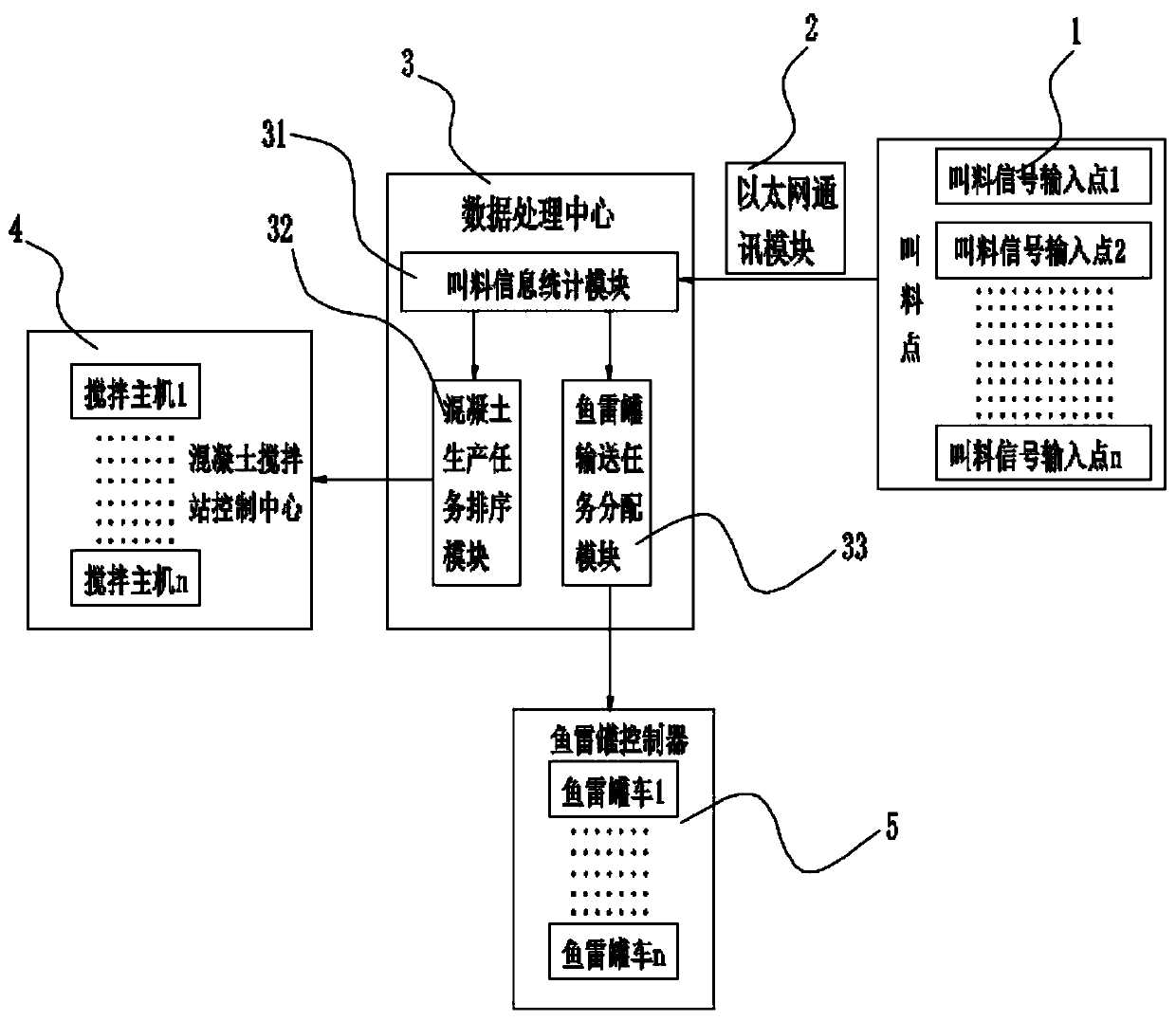

The invention discloses a torpedo ladle master station control system which comprises a data processing center, wherein the signal input end of the data processing center communicates with the signaloutput ends of a plurality of material calling signal input points; and the data processing center is responsible for the statistics, the arrangement and the sorting of input information from the material calling signal input points, as well as is capable of generating a concrete stirring task and a torpedo ladle conveying task, transmitting the concrete stirring task to a concrete stirring station control center, and transmitting the torpedo ladle conveying task to a torpedo ladle controller. The invention further relates to a concrete distribution system as well as distribution method. The concrete distribution system comprises the torpedo ladle master station control system. Through the torpedo ladle master station control system and the concrete distribution system as well as distribution method, a production line, a concrete stirring station and a torpedo ladle car can share information and unify organically; the concrete distribution system in which the concrete stirring stationhas the automatic proportional stirring function and a torpedo ladle car has the automatic distribution function can be controlled; and the concrete conveying efficiency can be improved.

Owner:CHONGQING ZHONGKE CONSTR GROUP

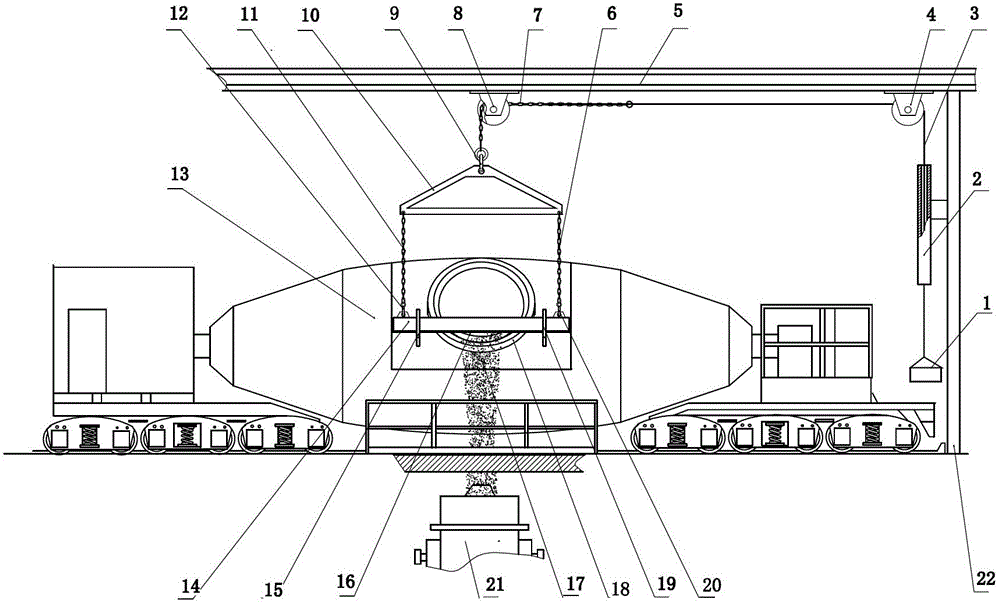

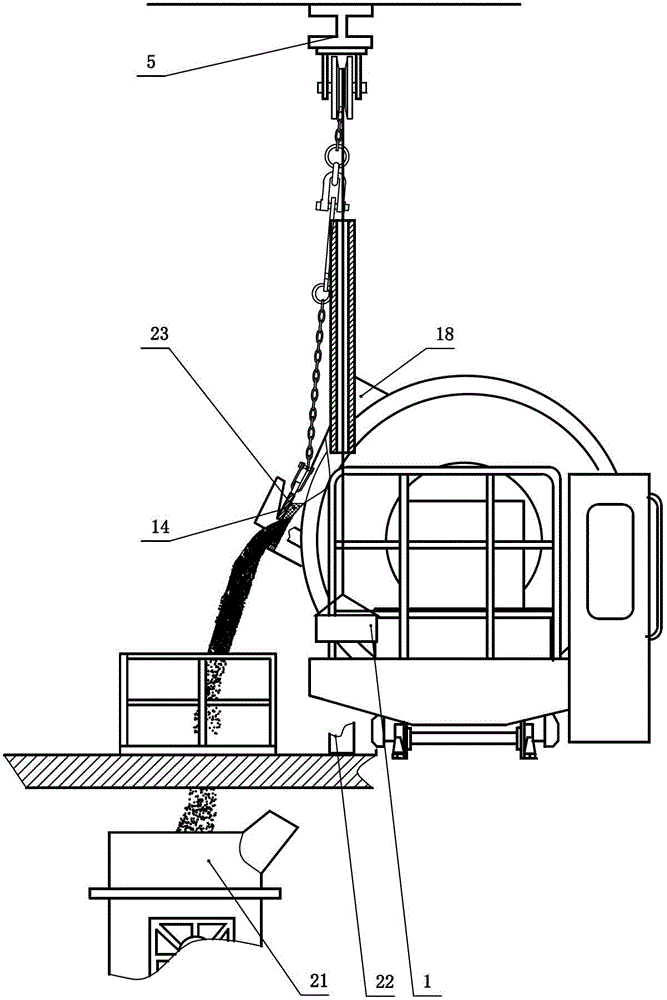

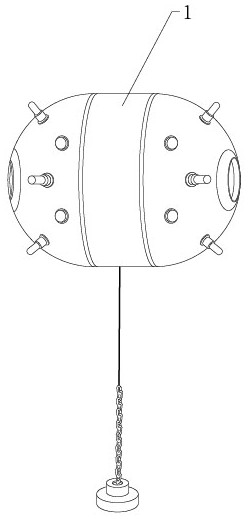

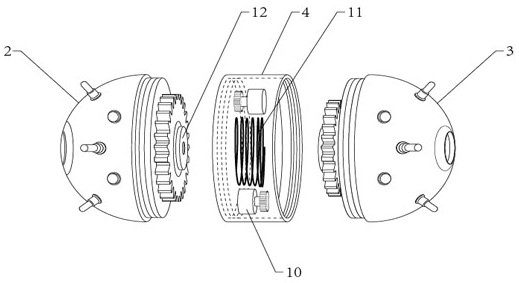

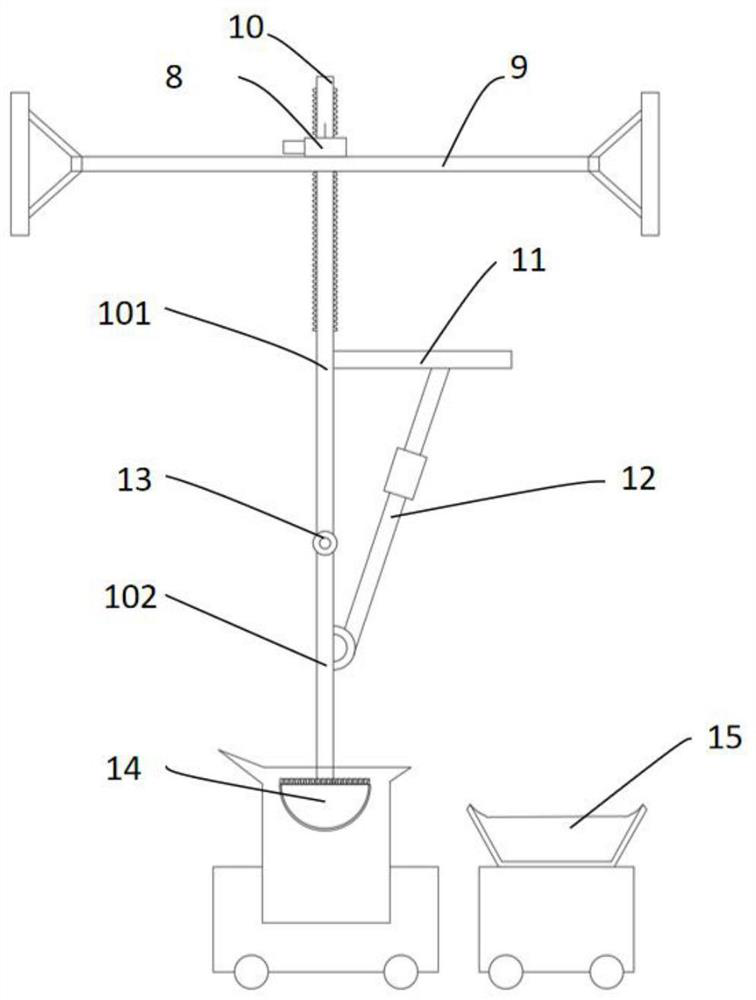

Slag-blocking system for torpedo ladles

InactiveCN103143703AImprove pass rateSimple structureMelt-holding vesselsCasting cleaning apparatusTorpedoClassical mechanics

A slag-blocking system for torpedo ladles comprises a counterweight, the counterweight is connected with one end of a wire rope, the other end of the wire rope passes through a guiding pipe fixed on a supporting upright and a guiding fixed pulley, and is then connected with one end of a hanging chain, and the other end of the hanging chain passes through a fixed pulley, and is then connected with a U-shaped hanging clamp; both the guiding fixed pulley and the fixed pulley are fixed on an I-shaped crossbeam; the bottom of the U-shaped hanging clamp is connected with a balancing frame, and the right end of the balancing frame is connected with a right chain, and is connected with the right side of a slag-blocking plate through a right U-shaped clamp; and the left end of the balancing frame is connected with a left chain, and is connected with the left side of the slag-blocking plate through a left U-shaped clamp. The slag-blocking system is characterized in that: both ends of the slag-blocking plate are placed in a right L-shaped positioner and a left L-shaped positioner and locked, both the right L-shaped positioner and the left L-shaped positioner are welded on both sides of a tap hole of a torpedo ladle, so that the slag-blocking plate can be turned along with the torpedo ladle, and moreover, a tapping gap is kept between the slag-blocking plate and the lower edge of the tap hole.

Owner:夏俊双

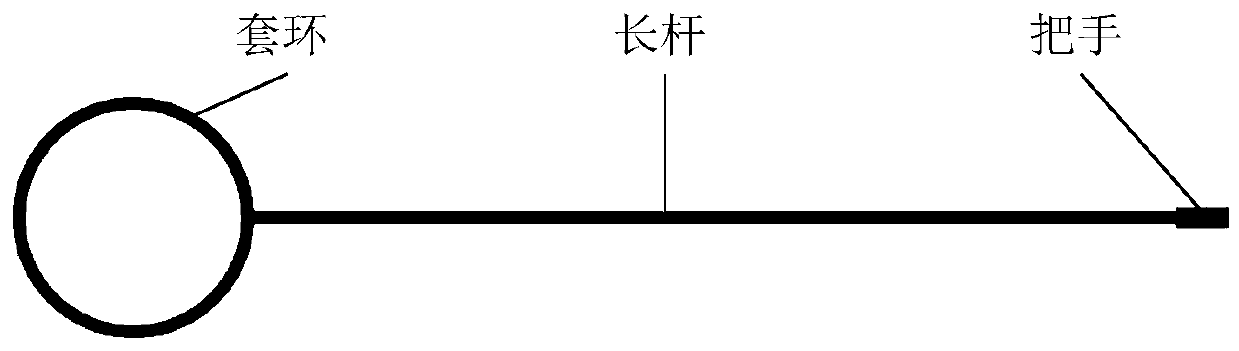

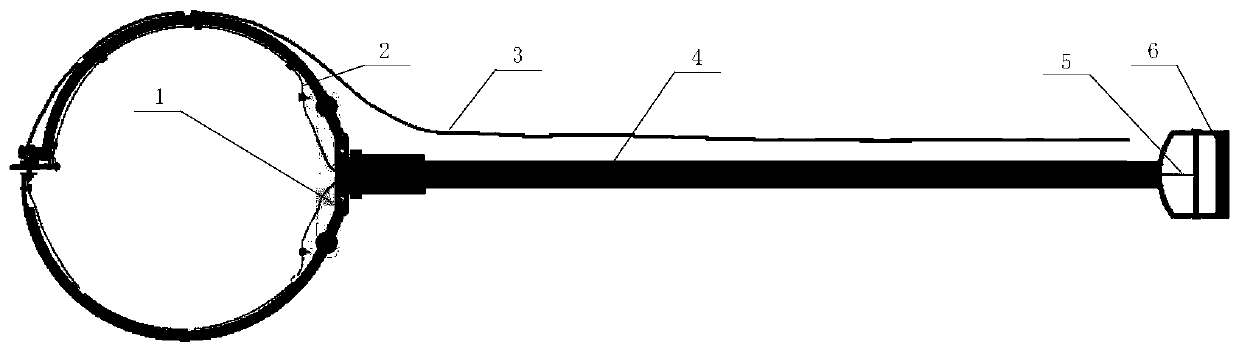

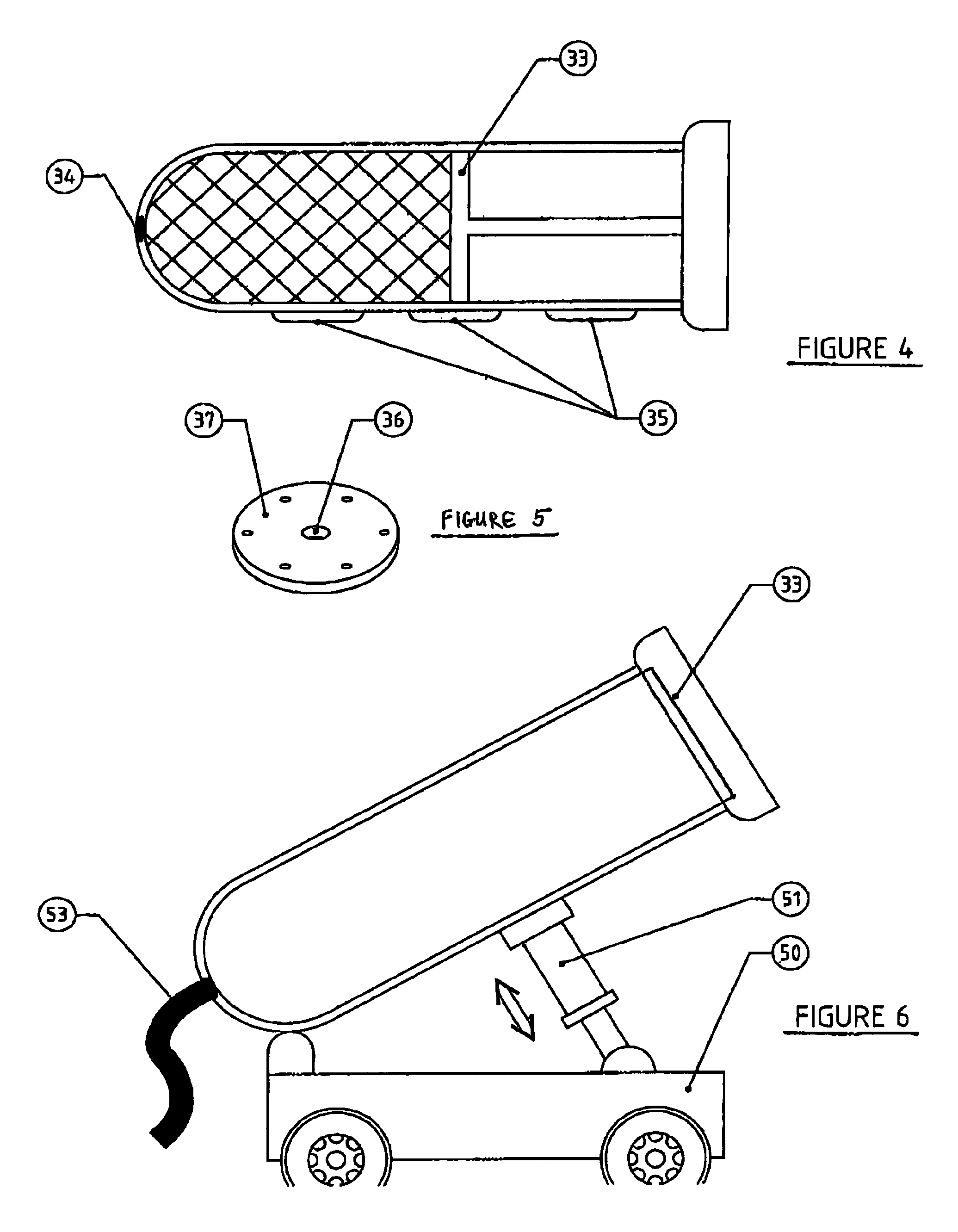

Quick-type torpedo recovery tool

The invention relates to a quick-type torpedo recovery tool, and belongs to the technical field of recovery of aircrafts of exercise torpedoes. The tool comprises a torpedo sleeveing mechanism, a ropetying assembly, a long rod and a torpedo recovery handle, wherein one end of the long rod is fixedly provided with the torpedo sleeveing mechanism, and the other end of the long rod is provided withthe torpedo recovery handle; the rope tying assembly is installed on the torpedo sleeveing mechanism in a detachable mode, and the torpedo sleeveing mechanism comprises an upper half ring, a lower half ring and a connecting rod mechanism; and the upper half ring and the lower half ring are combined to form a complete circular ring structure, the upper half ring and the lower half ring are fixed toone end of the long rod through the connecting rod mechanism, and the connecting rod mechanism controls the opening / closing states of the upper half ring and the lower half ring which act as a sleevering of the torpedo recovery tool, so that torpedoes are clamped. The tool is designed under the condition that remote automatic torpedo sleeveing operation is realized while the light mass is met.

Owner:中国船舶重工集团公司第七0五研究所

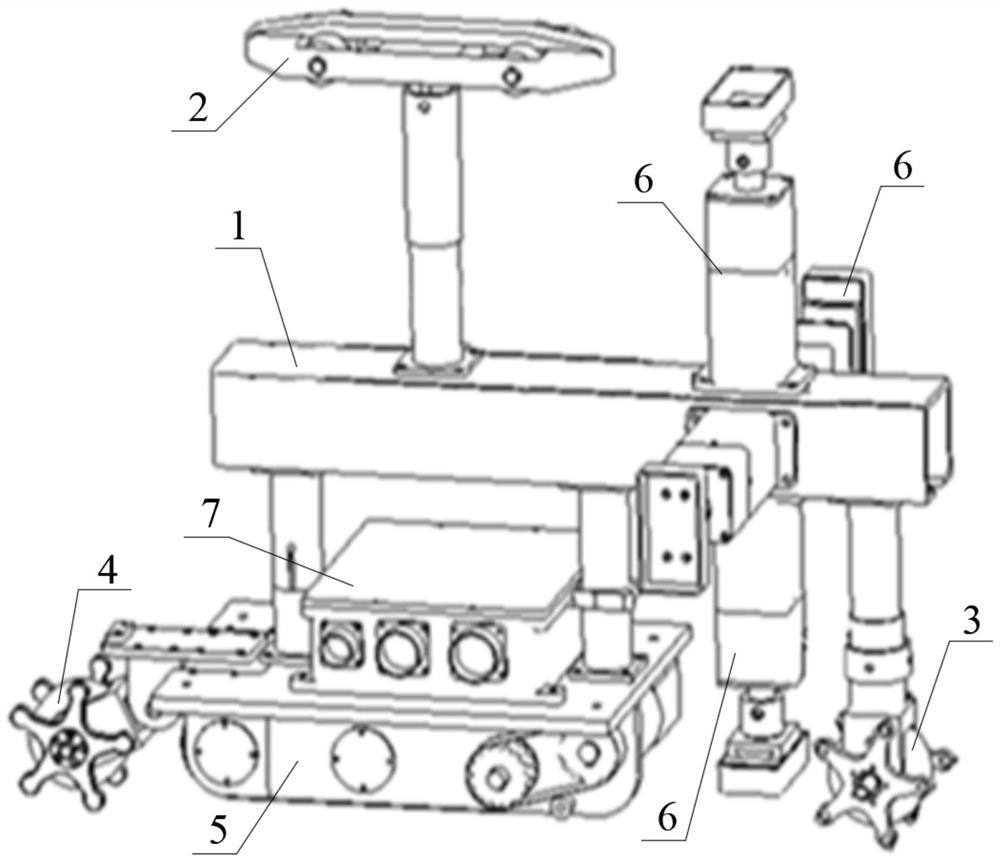

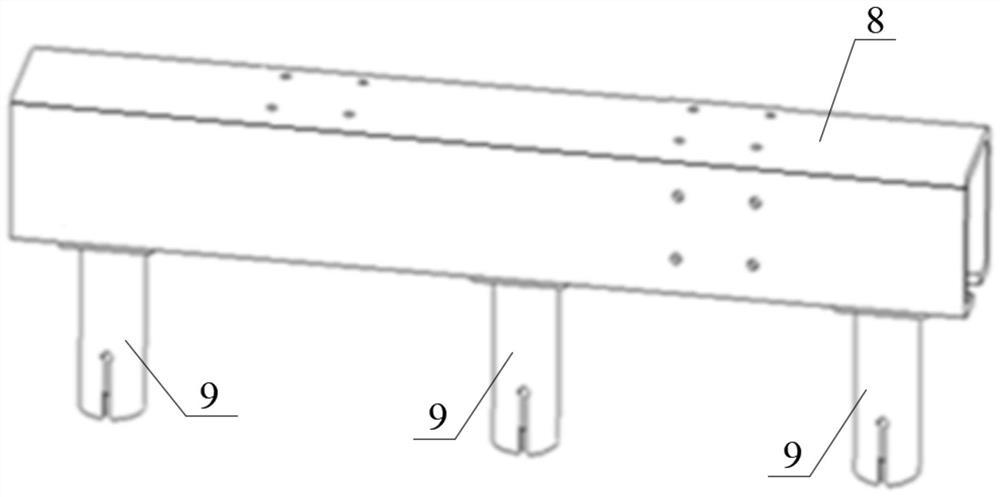

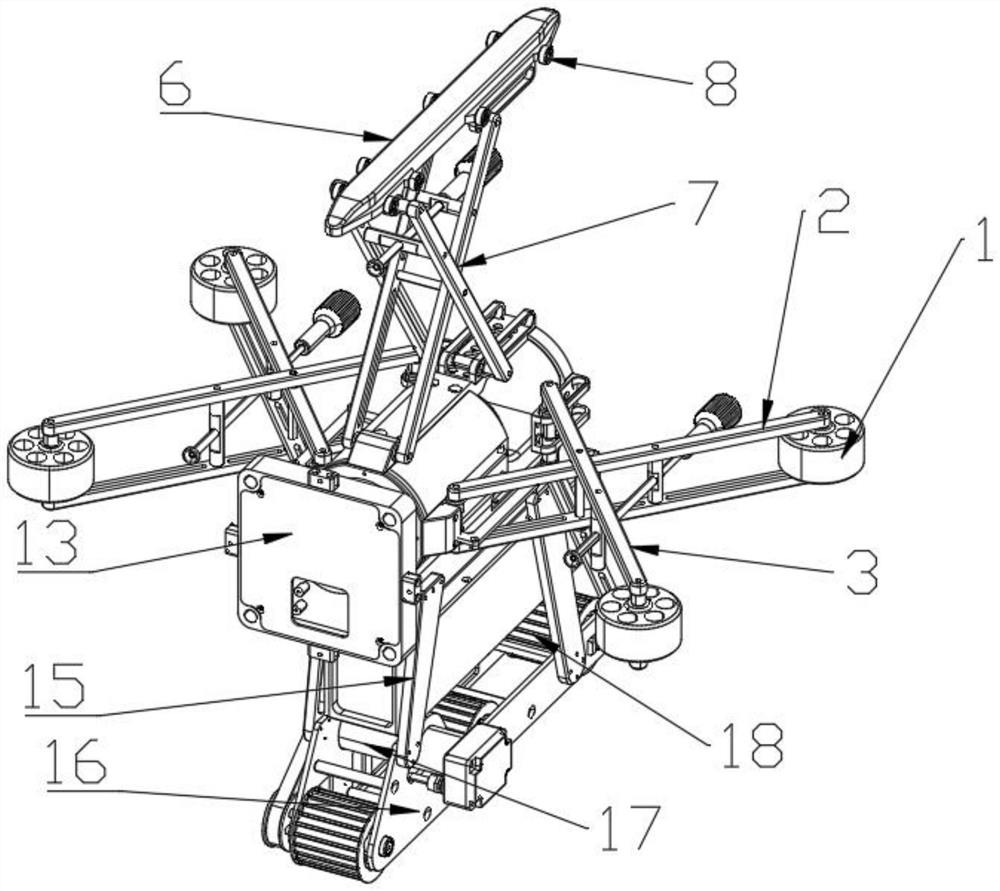

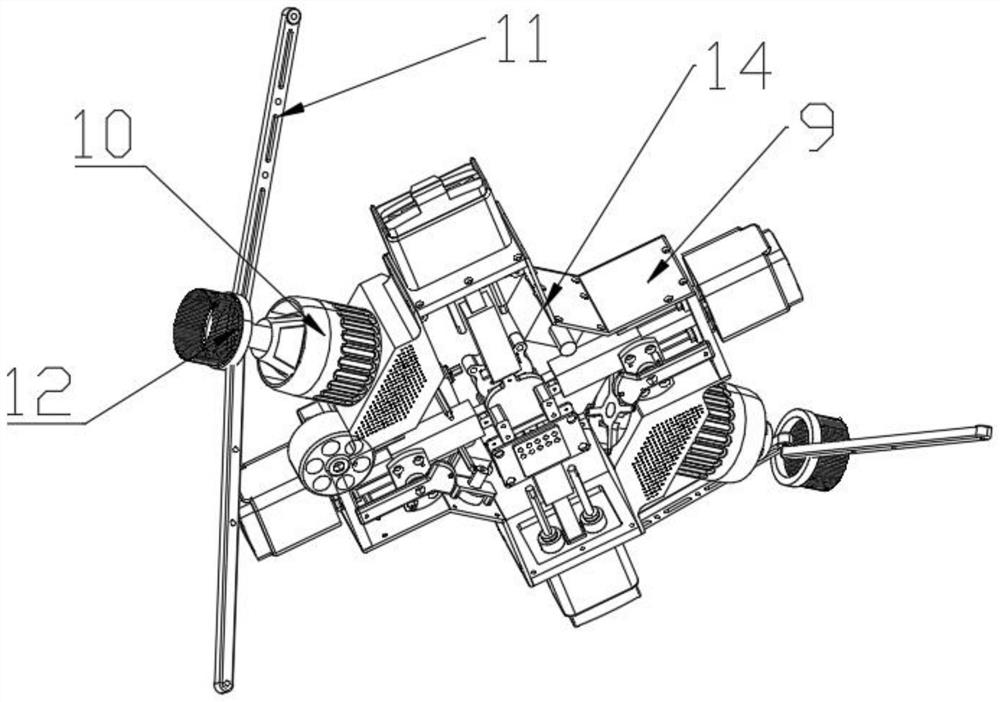

Torpedo pipeline maintenance equipment

ActiveCN114643170AEasy to adjustFast real-time monitoringLiquid surface applicatorsTorpedo launchersTorpedoWorking environment

The invention discloses torpedo pipeline maintenance equipment. Comprising carrying equipment capable of autonomously walking along the interior of a pipeline, a supporting mechanism adjustably arranged on the carrying equipment and used for supporting the carrying equipment, a functional module which is designed to be separated from the carrying equipment and provides a cleaning or oil coating or water absorbing or rust removing function for the carrying equipment, and a quick changing device for quickly disassembling, assembling and connecting the functional module and the carrying equipment, the device has the beneficial effects that the device is small in size and convenient to get off the boat, a supporting mechanism of the device can be rapidly adjusted according to the actual working environment, the device can be stably supported in the advancing process of the device, functions are complete, and the device has multiple functions of cleaning, rust removal, water absorption and oil coating; the functions of the equipment are modularly designed, the equipment and the carrying equipment are separately designed, and the carrying equipment is connected with the function modules through the quick-change devices, so that disassembly, assembly and replacement are facilitated.

Owner:天津市航天安通电子科技有限公司

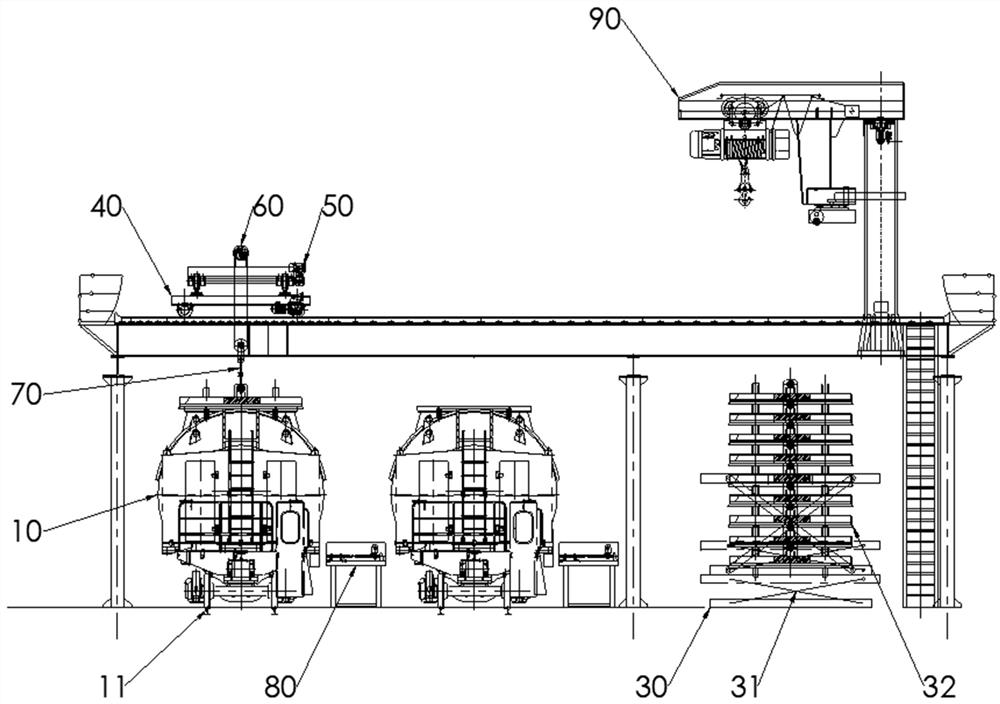

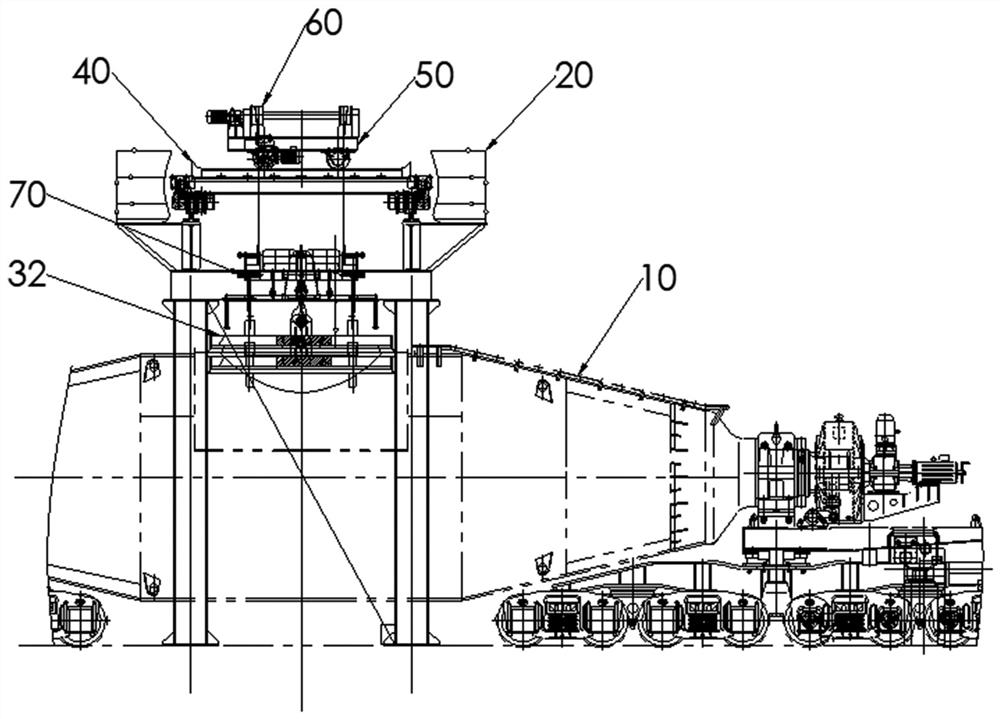

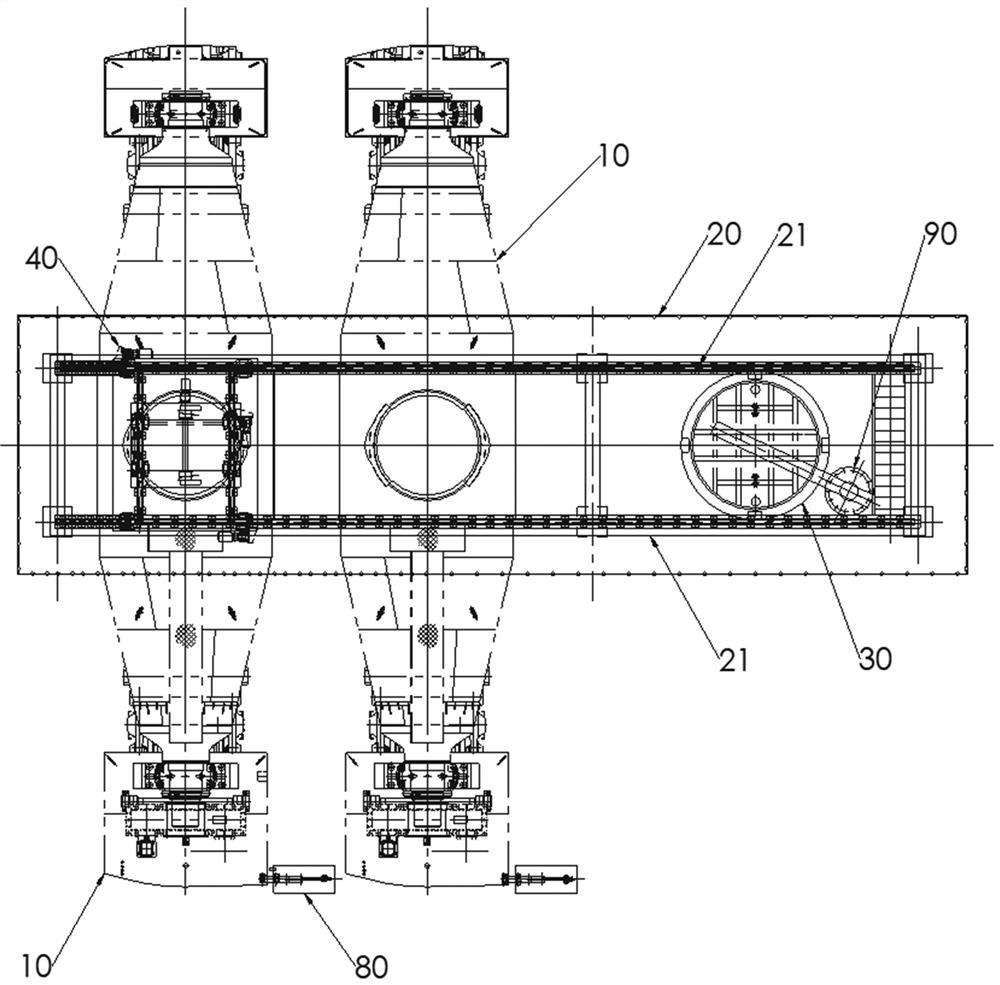

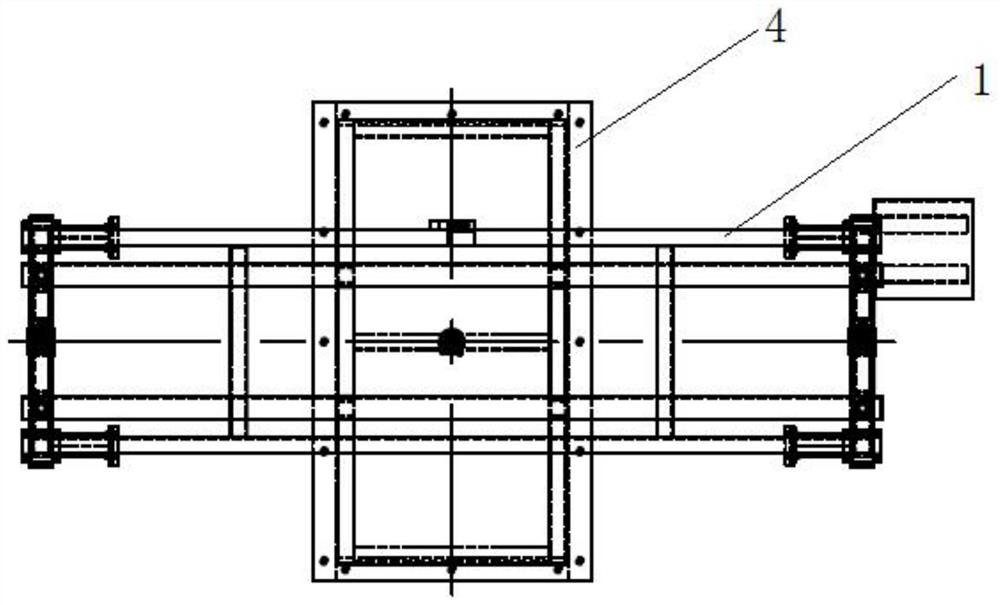

Tank cover conveying system of torpedo tank car

PendingCN114713806AIncrease the level of automationIncrease productivityMelt-holding vesselsConveyorsTorpedoMarine engineering

The invention discloses a tank cover conveying system of a torpedo tank car. The tank cover conveying system comprises a cross beam, a tank cover storage position, a first moving mechanism, a second moving mechanism, a grabbing mechanism, a detection device and a controller. The cross beam extends in the first direction and stretches across one or more first rails where the torpedo tank car runs, and the cross beam is suspended above the first rails. The first moving mechanism is movably arranged on the cross beam; the second moving mechanism is movably arranged on the first moving mechanism; the grabbing mechanism is connected with the second moving mechanism and used for grabbing or releasing the can cover. The detection device is arranged at a position adjacent to the first track and is used for detecting the position of the torpedo tank car; the controller is connected with the detection device, the grabbing mechanism, the first moving mechanism and the second moving mechanism. According to the system, the purpose of automatically covering or uncovering the torpedo tank car is achieved, the automation level and the production efficiency of a steel plant in the covering and uncovering link can be remarkably improved, and the production cost is reduced.

Owner:QINHUANGDAO QINYE HEAVY IND

Underwater propeller

InactiveCN103697771AReduce resistanceMarine torpedoesSelf-propelled projectilesTorpedoElectric machine

The invention provides a torpedo propeller. The torpedo propeller is characterized in that 3-5 layers of bubble generators are arranged at the head of a torpedo, a suction port is formed in the middle of the head of the torpedo, a high-power generator with oxidants and fuel is arranged inside the torpedo, combustion waste gas is diluted in water and is turned into weak electric conductors, a super-conducting magnetic field with the magnetic flux higher than 5 Tesla can be generated by the high-power generator, the polar water which is filled into the torpedo from the suction port is propelled and is backwardly ejected, a contractible empennage is arranged at the tail of the torpedo, and gas guide grooves are formed in a body of the torpedo. The torpedo propeller has the advantages that the torpedo can be electromagnetically propelled by the aid of high power, bubbles can be generated at the front of the torpedo after the torpedo is propelled at a certain speed, the resistance on the torpedo can be reduced, accordingly, the torpedo can be durably propelled at the certain high speed for a long time, and the torpedo propeller is applied to anti-ship and anti-aircraft torpedoes.

Owner:SUZHOU NIUWU ERGUAN ELECTRICAL APPLIANCE TECH

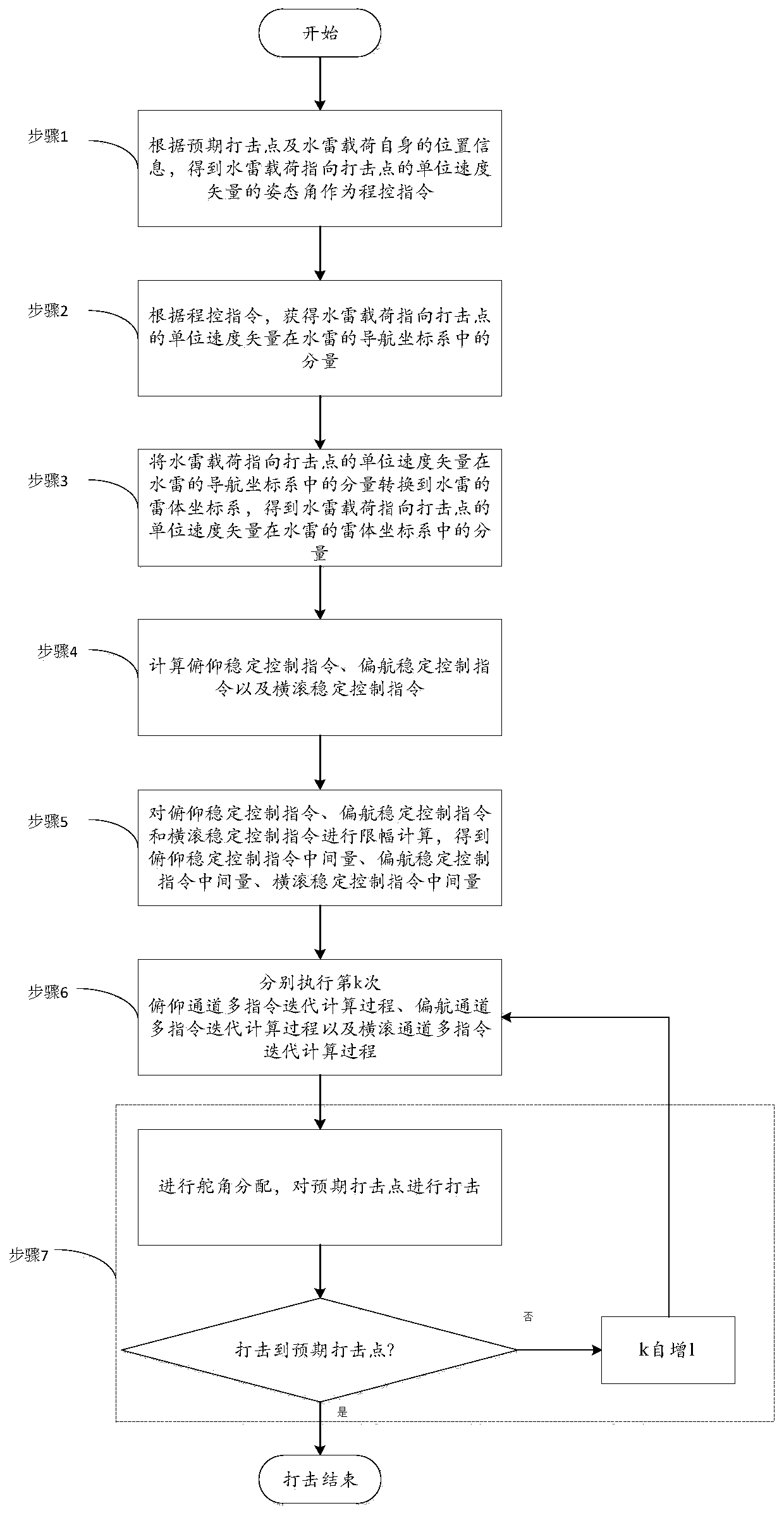

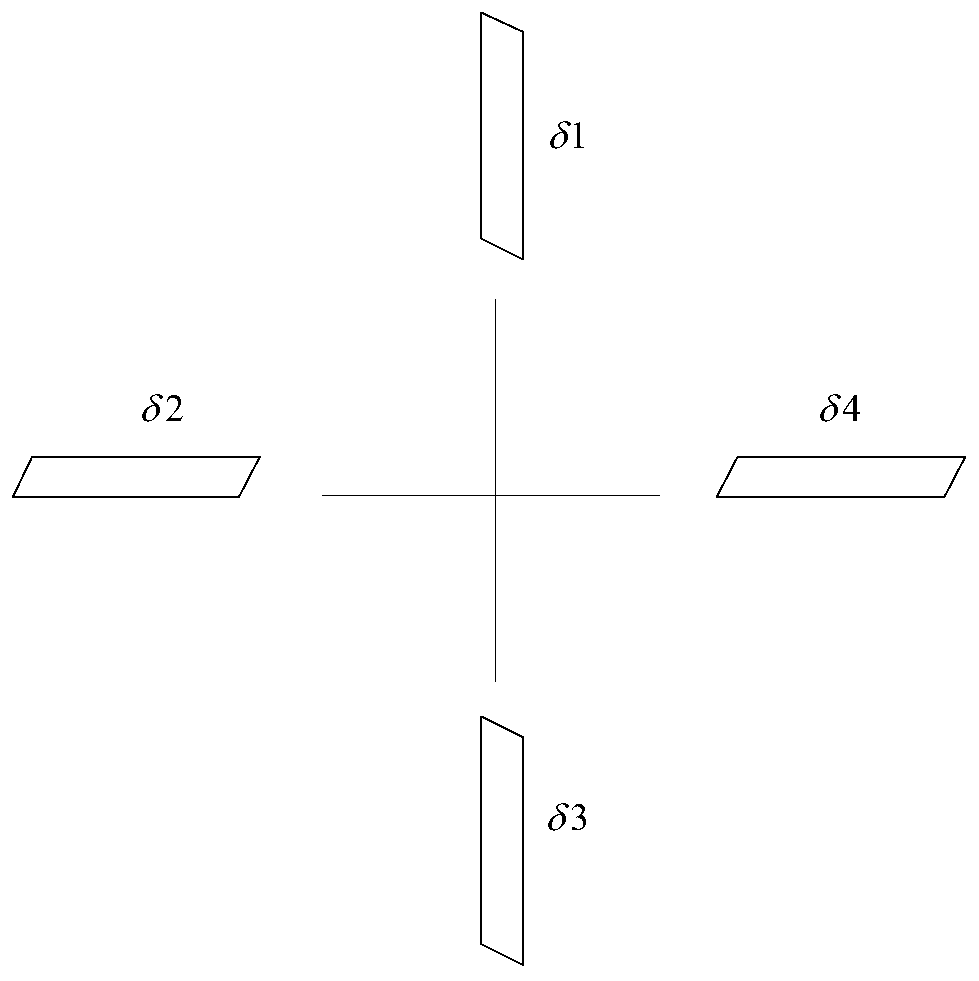

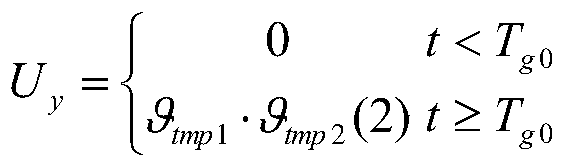

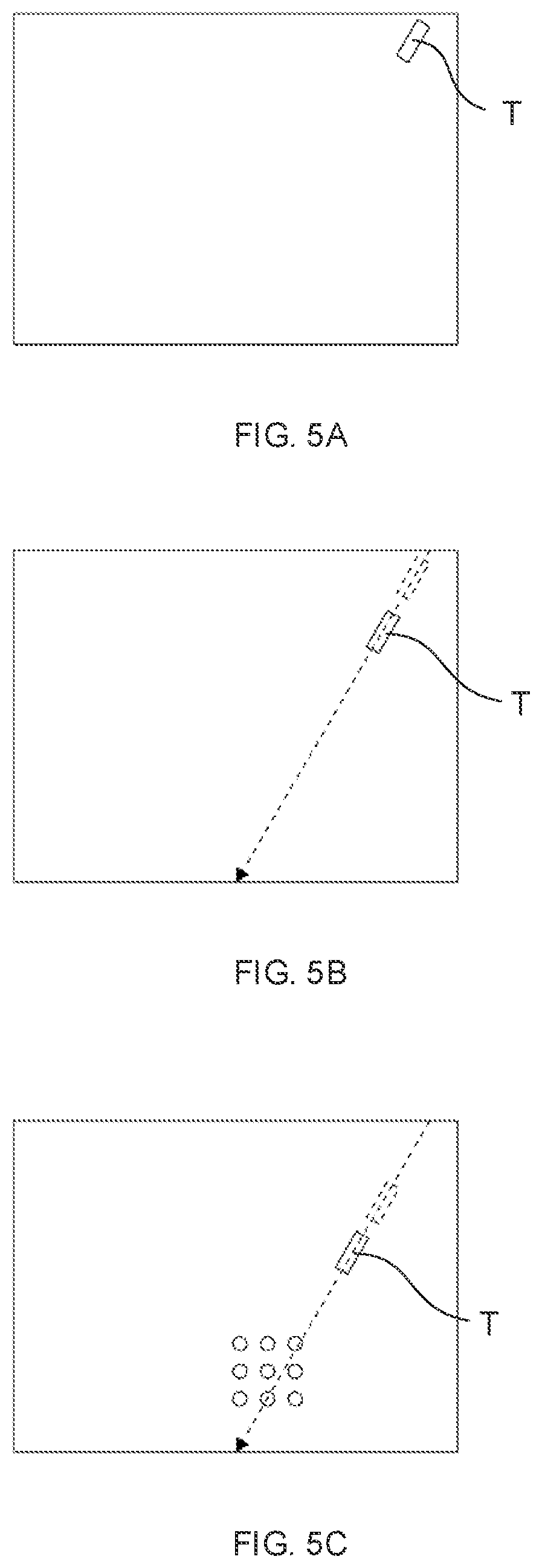

Real-time correcting method for torpedo high-speed striking

ActiveCN111256545AReal-time correctionEasy to controlSelf-propelled projectilesTorpedoStabilization control

The invention discloses a real-time correcting method for torpedo high-speed striking, and belongs to the technical field of trajectory control. The real-time correcting method comprises the followingsteps that firstly, according to an expected striking point and position information of a torpedo load, a pitching control instruction, a yaw control instruction and a roll stable control instructionare calculated, then the stable control instructions are clipped, and rudder instruction iterative computing process of a pitching channel, a yaw channel and a roll channel are executed, then rudderangle assignment is carried out on a rudder instruction for each channel so as to achieve the control of a torpedo load steering engine, so that the torpedo load is aimed at the expected striking point for striking. According to the process, in the rudder instruction iterative computing process of each channel, a calculation model considering channel angular rate and one stable control instructionis established, finally rudder angle distribution is carried out on the calculated rudder instruction of each channel to realize steering engine control, and the steering engine control is correctedin real time according to a striking result so that the real-time correction of the torpedo high speed can be realized, and the striking precision is further improved.

Owner:中国船舶重工集团有限公司第七一0研究所

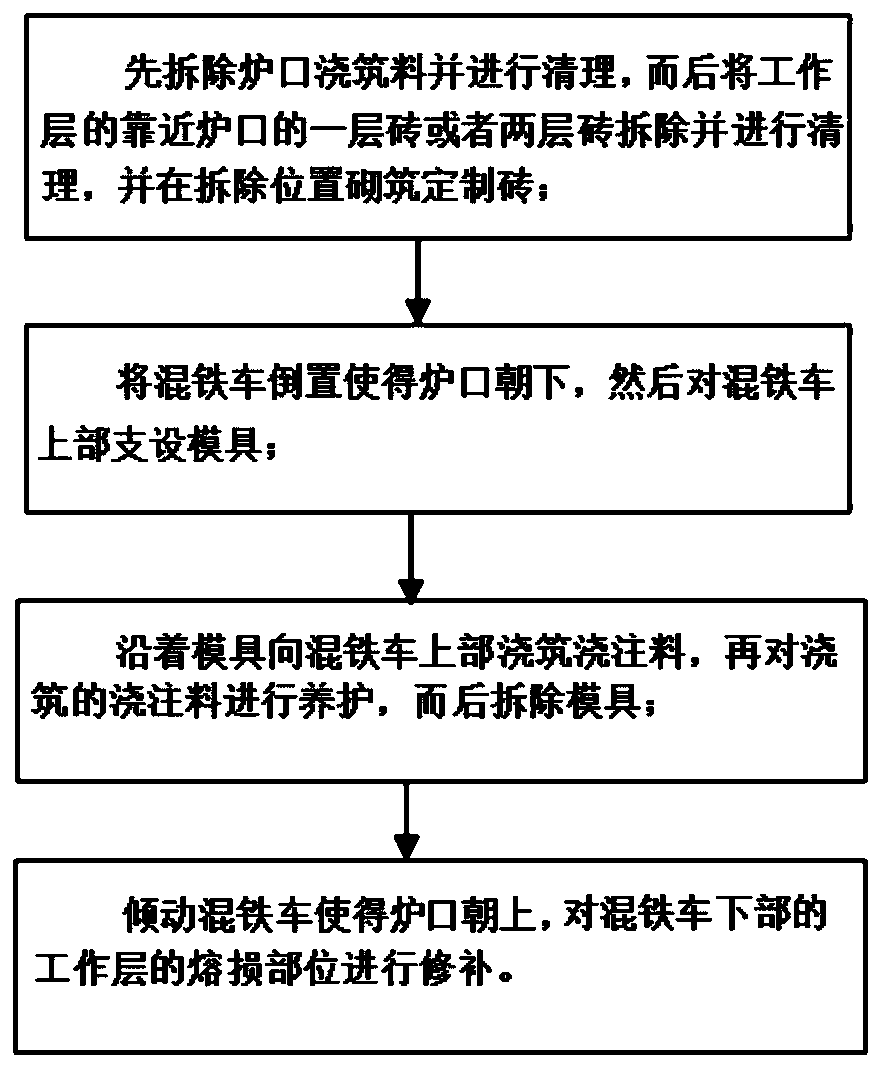

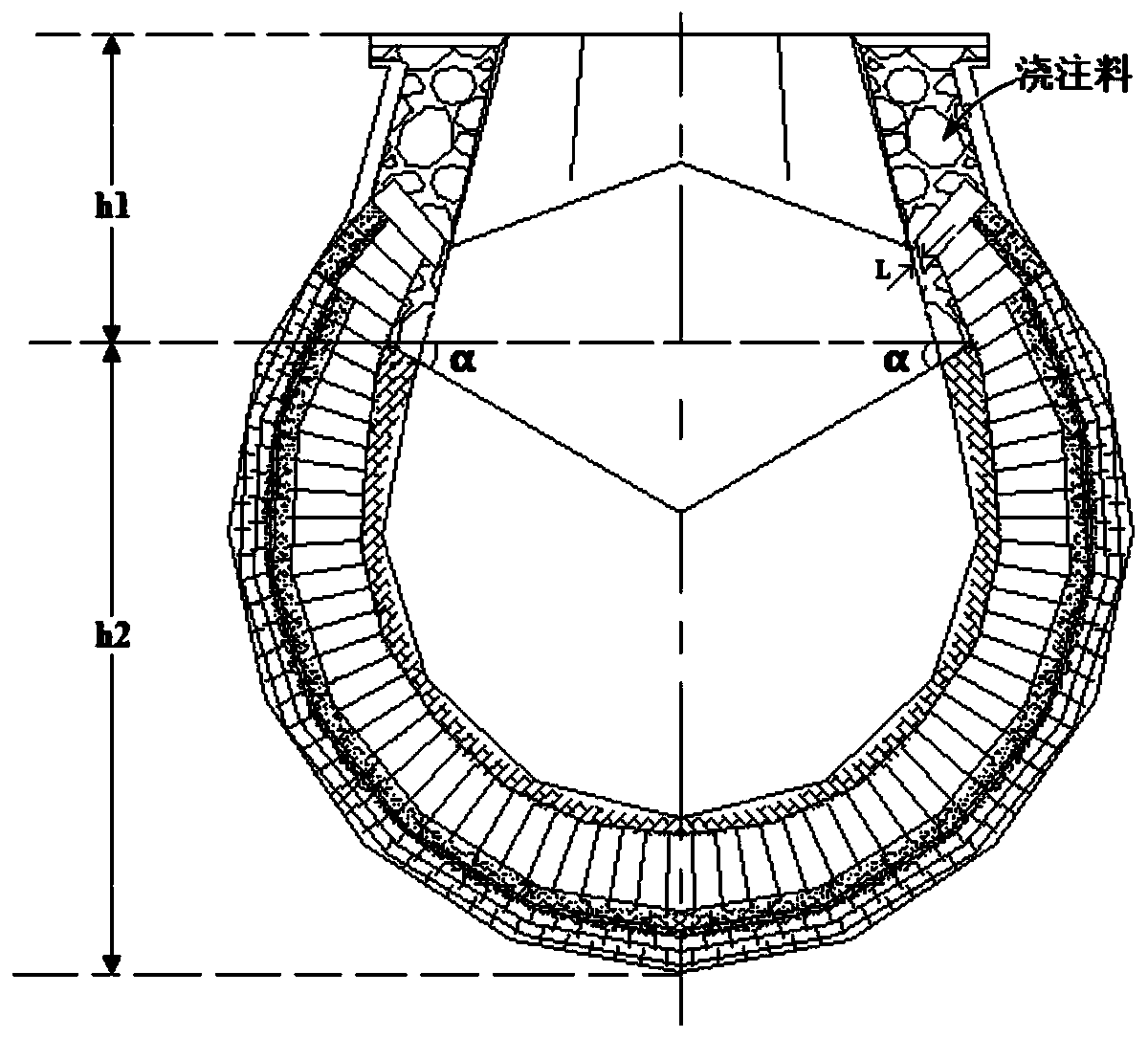

Repairing method for torpedo ladle lining

The invention discloses a repairing method for a torpedo ladle lining, and belongs to the technical field of metallurgical technologies. The repairing method comprises the steps of firstly removing apouring material of a furnace mouth, conducting cleaning, then removing one layer of bricks or two layers of bricks at the position, near the furnace mouth, of a working layer, conducting cleaning, and building customized bricks at the removed position; then inversing a torpedo ladle to enable the furnace mouth to be downward, and erecting a mold on the upper portion of the torpedo ladle; then pouring a pouring material on the upper portion of the torpedo ladle along the mold, then curing the poured pouring material, and removing the mold; and finally, turning over the torpedo ladle to enablethe furnace mouth to be upward, and repairing a melting loss part, at the lower portion of the torpedo ladle, of the working layer. The repairing method aims to overcome the shortcoming that in the prior art, when a corroded torpedo ladle lining is repaired, the repaired torpedo ladle lining is poor in quality; and by means of the repairing method, the compactness of the pouring material can be improved, the corrosion resistance of the torpedo ladle lining can be improved, the quality of the repaired torpedo ladle lining is improved, and the service life of the repaired torpedo ladle lining isprolonged.

Owner:ANHUI MASTEEL ENG & TECH GRP

Small mine

PendingCN112729025ACombining autonomous attack featuresBreak the single-point attack methodMarine minesDetonatorSonar

The invention discloses a small mine which comprises a small mine body, a left shell, a right shell, a middle shell, fuses, an electric detonator, an explosive chamber, a threaded connector, a gear, a motor, a spring, a propeller device, a nozzle opening, a combustion channel, an explosive column, a heat insulation layer, an ignition device and a sealing heat protection ring. The small mine body is provided with the left shell and the right shell in left-right symmetry, the left shell and the right shell are connected and installed through the middle shell, the left shell and the right shell are the same in structure, and the fuses are installed on the left shell and the right shell respectively. The mine has the advantages that a target can be locked or nearby mine explosion can be sensed through sonar of the mine, the left shell and the right shell are separated from each other and become independent small mine individuals respectively, automatic navigation attacking is achieved, the single-point attacking mode of a traditional mine is broken through, and the hit rate and destructive power of undersea attacking are improved; and propeller devices are installed in the left shell and the right shell respectively and can be aligned with a target to implement attacks, and destructive power is increased in combination with the autonomous attack characteristic of a torpedo.

Owner:浙江铭品海工智能科技有限公司

Automatic tank dumping system for torpedo type molten iron vehicle tilting device and technological method thereof

PendingCN112475277AAvoid safety accidentsImprove production safetyMolten metal supplying equipmentsCasting parameters measurement/indication devicesTorpedoEngineering

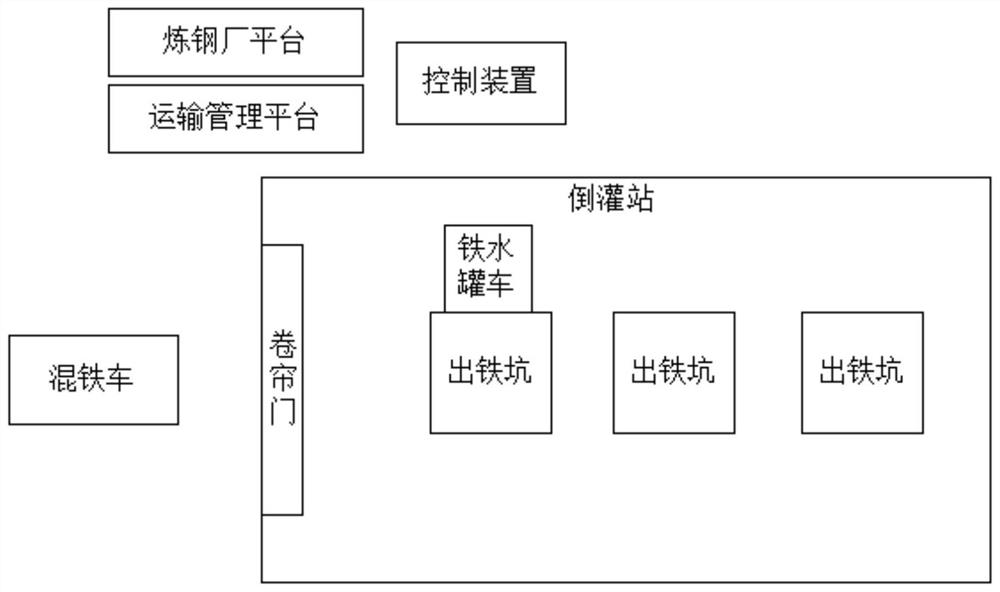

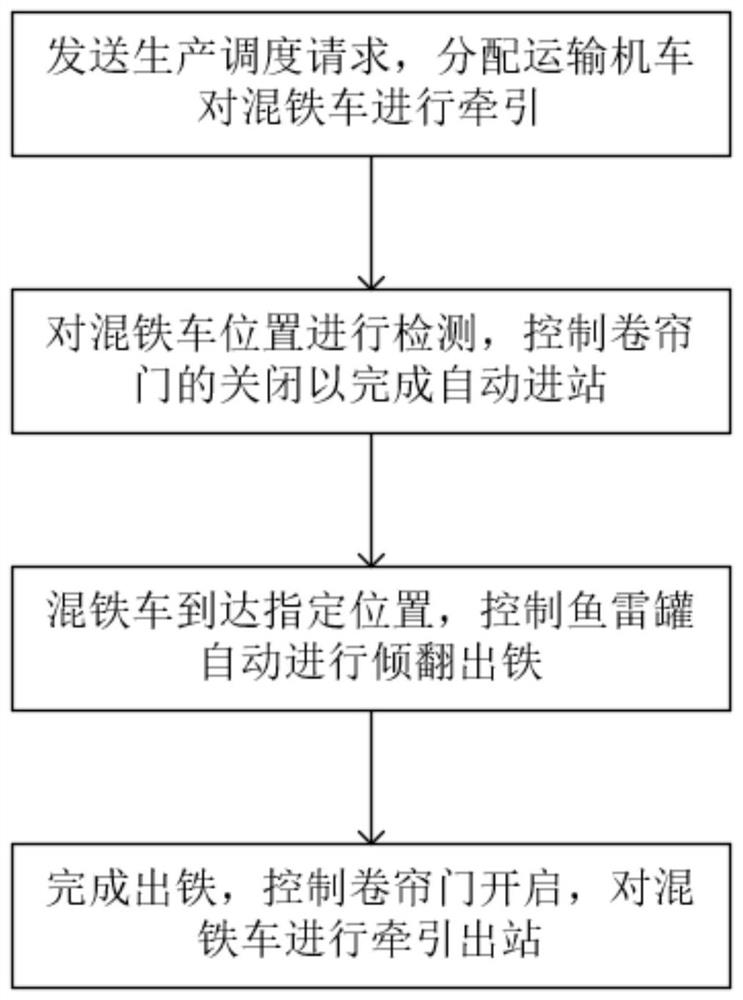

The invention discloses an automatic tank dumping system for a torpedo type molten iron vehicle tilting device and a technological method thereof, and overcomes the defect that great potential safetyhazards exist in manual operation of a station of a tank dumping station at present. According to the technical scheme, a roller shutter door is controlled to be automatically closed by detecting theposition of the molten iron vehicle tilting device; and in addition, a control device is matched with a position monitoring device and a tapping detection device to realize automatic tapping control operation. The automatic tank dumping system for the torpedo type molten iron vehicle tilting device and the technological method thereof have the advantages that the operation is more automatic and intelligent, and the production is safer.

Owner:上海梅山工业民用工程设计研究院有限公司

Operation method for reducing iron loss of molten iron torpedo ladle

InactiveCN111607677AReduce consumptionIncrease productionSteel manufacturing process aspectsIncreasing energy efficiencySteelmakingTorpedo

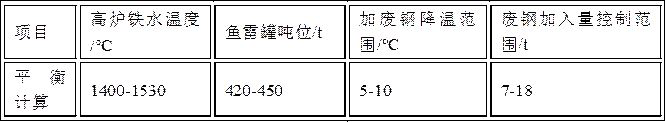

The invention discloses an operation method for reducing the iron loss of a molten iron torpedo ladle. The operation method comprises the following steps of processing scrap steel into a crushed material by adopting a crushing mode, controlling the size to be within 100 mm*100 mm, controlling the bulk specific gravity of the crushed material to be more than 1.60 t / m<3>, transporting scrap steel toa molten iron torpedo ladle iron adding position bin, calculating the scrap steel adding amount meeting the steelmaking temperature requirement according to the tapping temperature of blast furnace molten iron, enabling the blast furnace molten iron temperature to range from 1400 DEG C to 1530 DEG C, the torpedo ladle tonnage to range from 420 t to 450 t, the scrap steel adding cooling range to range from 5 DEG C to 10 DEG C and the scrap steel adding amount control range to range from 7 kg / t to 18 kg / t, adding the scrap steel into the torpedo ladle through a rotating chute in the earlier stage of blast furnace iron adding, using the stirring effect of the molten iron in the later period of torpedo ladle iron mixing, and promoting melting of the scrap steel in the torpedo ladle. Accordingto the operation method, a chemical reaction generated by adding slag such as pellets and dolomite in the smelting process can be reduced, and the frequency of manual intervention in oxygen lance operation in the smelting process is reduced.

Owner:XINJIANG BAYI IRON & STEEL

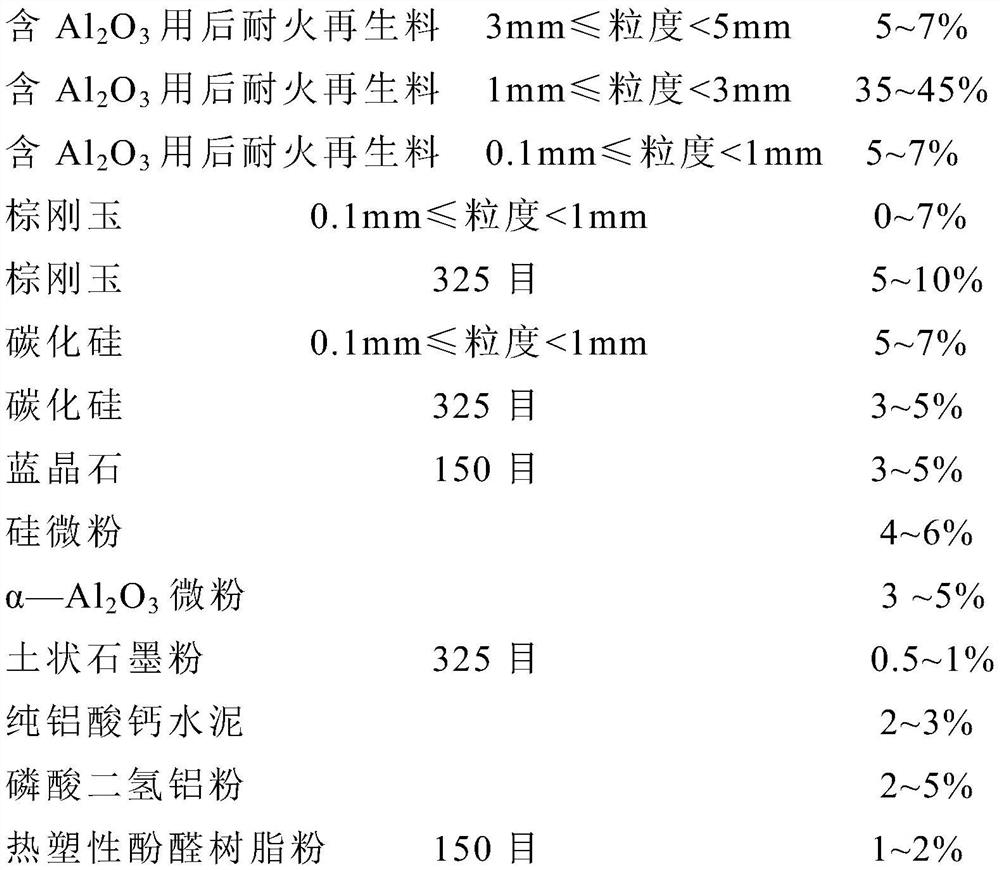

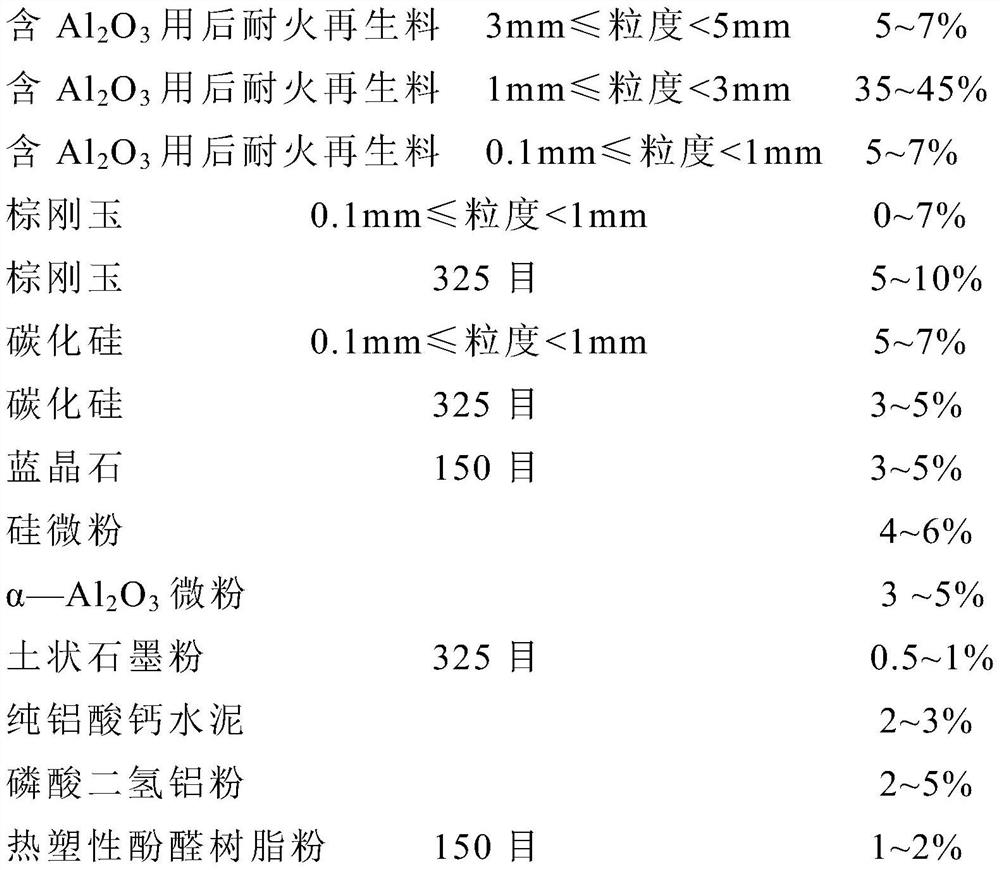

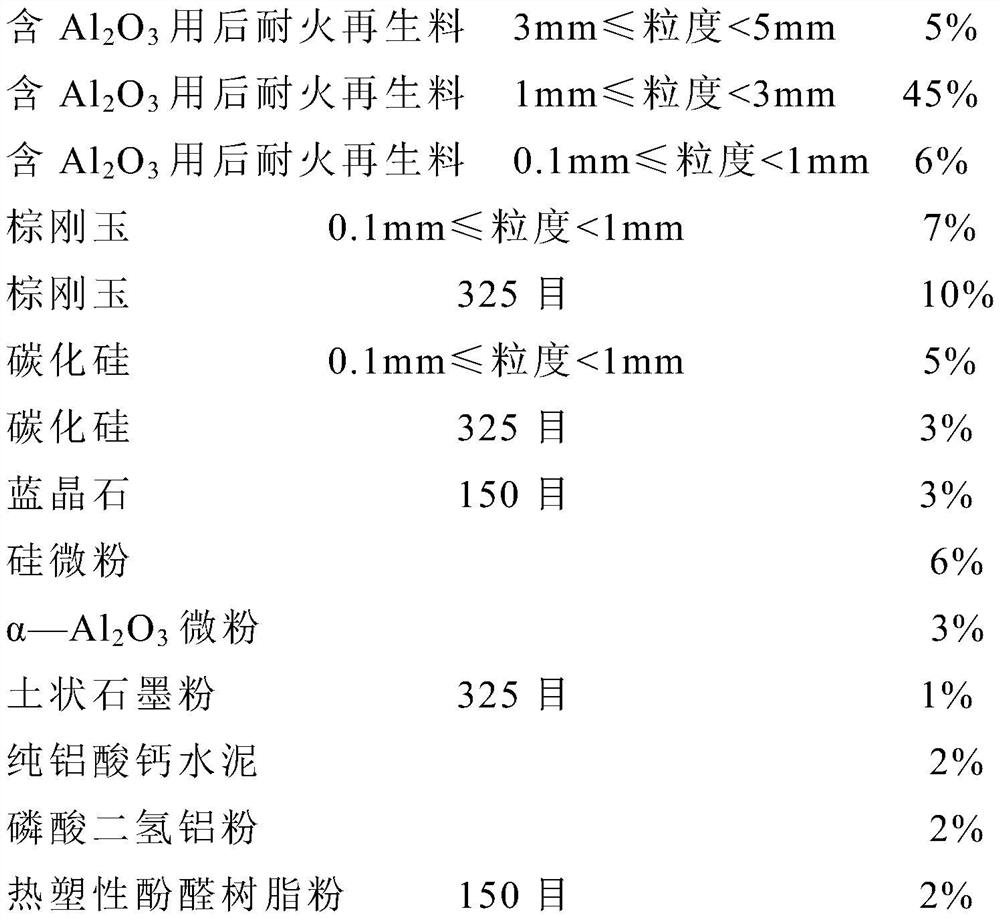

Torpedo ladle lining smearing repair material, preparation method and use method

PendingCN111943693AExcellent performance indexExtended service lifeMelt-holding vesselsCarbon filmTorpedo

The invention discloses a torpedo ladle lining smearing repair material, a preparation method and a use method. The torpedo ladle lining smearing repair material comprises three Al2O3-containing usedrefractory reclaimed materials with different granularities and two brown fused alumina with different granularities, and the surfaces of the three Al2O3-containing used refractory reclaimed materialswith different granularities and the two brown fused alumina with different granularities are coated or partially coated with nano carbon films; wherein the thickness of the nano carbon film is 20-200 nanometers, and the fixed carbon content of the nano carbon film is more than or equal to 90%. The repair material has the characteristics of low raw material cost, wide renewable resource source, excellent thermal shock resistance, high interface bonding strength of a repairing layer, strong slag iron erosion resistance, simplicity and convenience in preparation and application and the like. Bymeans of the repair material, the service life of the torpedo ladle is prolonged, the consumption and maintenance cost of torpedo ladle refractory materials are reduced, the heat preservation and insulation performance of the torpedo ladle refractory material lining is improved, and the temperature drop of molten iron is reduced.

Owner:武汉钢铁有限公司

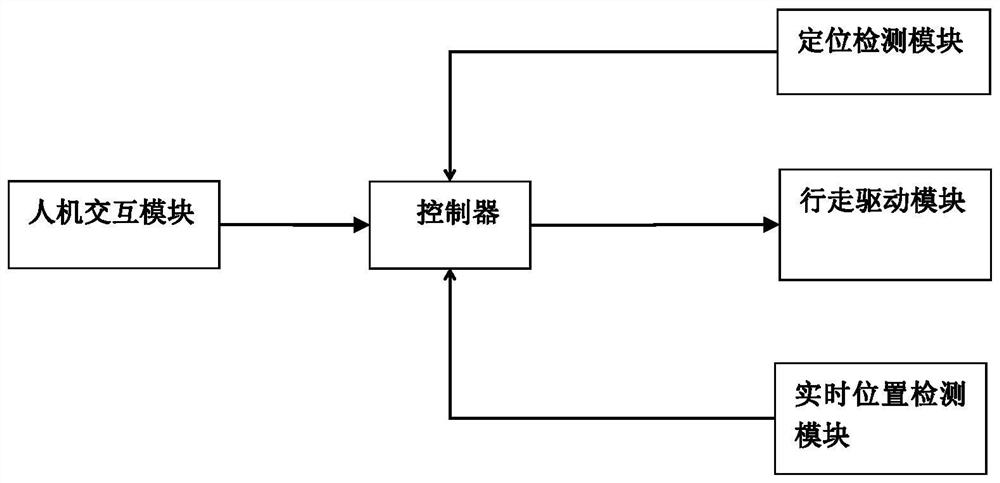

Concrete torpedo ladle on-site debugging method and debugging system and readable storage medium

ActiveCN112000076AImprove friendlinessSolve the problem of not startingProgramme controlElectric testing/monitoringTorpedoControl engineering

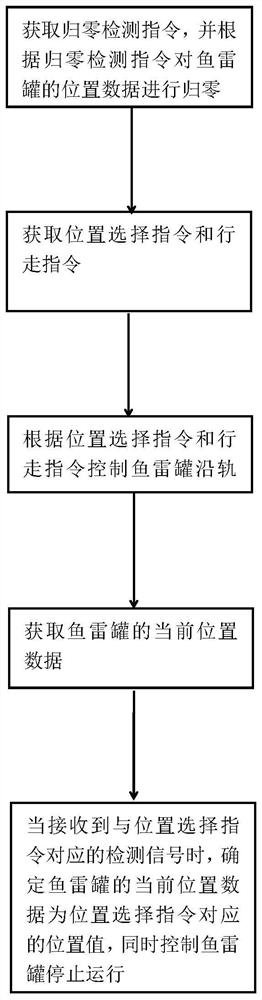

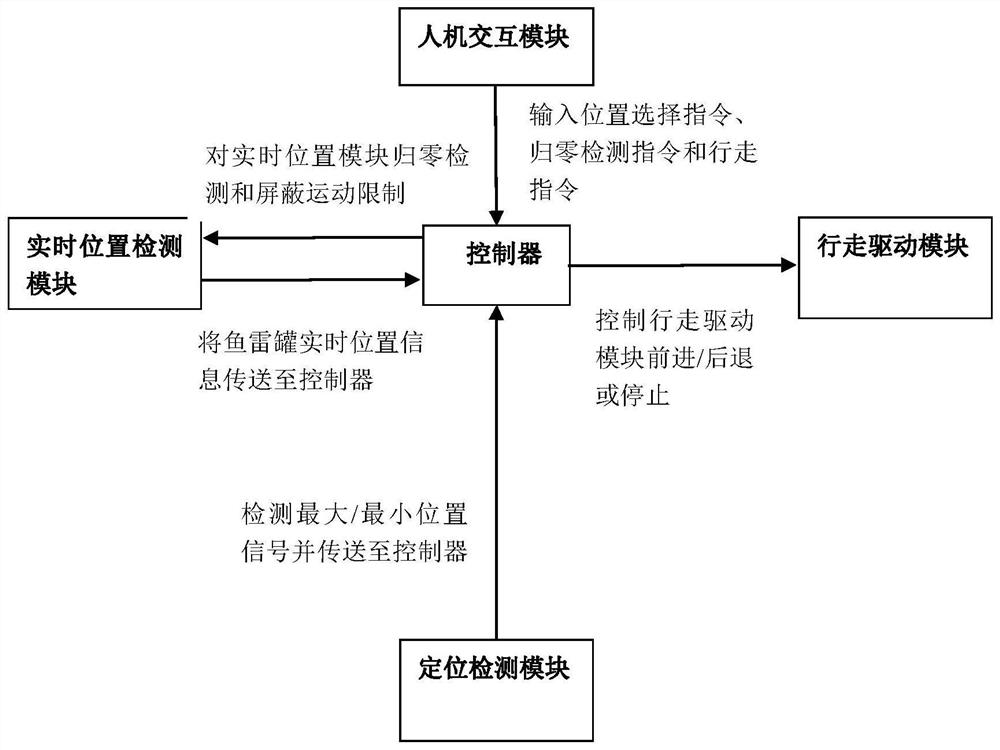

The invention relates to a torpedo ladle on-site debugging method comprising the following steps: acquiring a zeroing detection instruction, and zeroing the position data of a torpedo ladle accordingto the zeroing detection instruction; obtaining a position selection instruction and a walking instruction; controlling the torpedo ladle to operate according to the walking instruction; acquiring current position data of the torpedo ladle; and when a detection signal corresponding to the position selection instruction is received, determining that the current position data of the torpedo ladle isa position value corresponding to the position selection instruction. The invention further provides a torpedo ladle on-site debugging system. The torpedo ladle on-site debugging system comprises a walking driving module, a real-time position detection module, a positioning module and a controller. The walking driving module is used for executing a command issued by the controller; the real-timeposition detection module is used for detecting the current position of the torpedo ladle and feeding back the position to the controller; the positioning module is used for feeding back a detection signal corresponding to the position selection instruction to the controller when the torpedo ladle reaches the position corresponding to the position selection instruction; the controller includes a processor, a memory, and a computing program stored on the memory that is executable by the processor.

Owner:筑友智造智能科技有限公司

Guidance mode

InactiveCN103661948AEffective attackShort time intervalMilitary adjustmentOffensive depth chargesTorpedoMicrowave

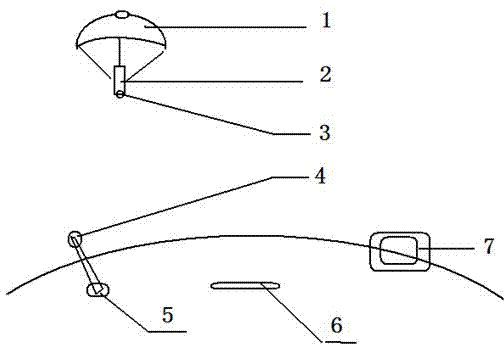

The invention provides a guidance method. The guidance method is achieved through transmission among an air relay point, a water surface relay point and an underwater relay point. The air relay point is pushed by compressed air to be transmitted to the 5-10KM high altitude and decelerated by a blue parachute to prolong the hanging time, then naval vessels are scanned by a microwave scanner, the coordinates and the moving directions of enemy naval vessels are calculated, then information is downloaded to LED lamps under the naval vessels, after light sensors of water surface miniature floats read signals of the LED lamps, target coordinate information is encrypted and intermittently transmitted through a long wave transmitter to be transmitted to torpedoes, amendments are continuously carried out before a guidance link is damaged, the amendments are memorized to calculate intercepting routes and intercepting points, and the torpedoes are guided to conduct intercepting operation. Microwaves, LED light and the like are adopted for recognizing a target, then the adjustment and the memory attacks are carried out, the time interval is short, the torpedoes can be guided to conduct the effective attacks, and the guidance mode is used for attacking the large-scale water surface naval vessels.

Owner:SUZHOU NIUWU ERGUAN ELECTRICAL APPLIANCE TECH

Intraductal totally wetted underwater electromagnetic emission device and working method thereof

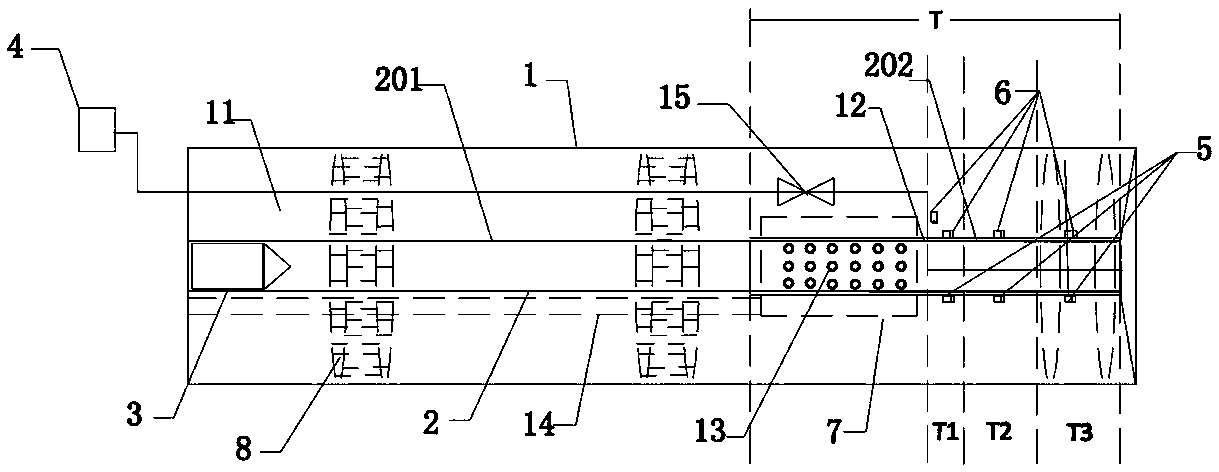

The invention relates to an intraductal totally wetted underwater electromagnetic emission device and a working method thereof. The emission device comprises an original torpedo emission tube, an electromagnetic gun tube, an electromagnetic gun, a gas-barrier-water system, a water pressure sensor, an air pressure sensor and a drainage box. The electromagnetic gun is arranged in the electromagneticgun tube, the electromagnetic gun tube is inlaid in the original torpedo emission tube by a supporting rack, the electromagnetic gun tube is formed by connecting a metal gun tube at the root and an insulating gun tube on an emission end part, and a projectile intraductal water entry totally wetted process is finished in the insulating gun tube. The projectile intraductal water entry totally wetted process is finished in the insulating gun tube comprises a water balance stage T1, an intraductal water entry wetted stage T2 and a totally wetted safe emission stage T3. The intraductal totally wetted underwater electromagnetic emission device achieves purposes of underwater launching of the electromagnetic gun and totally wetting the projectile out of a gun muzzle to enter into water, and reduces influence of a seawater environment on a flight path, so that the hitting precision is further improved. Near distance hitting and defence abilities are provided for an underwater submarine launching platform.

Owner:HENAN UNIV OF SCI & TECH

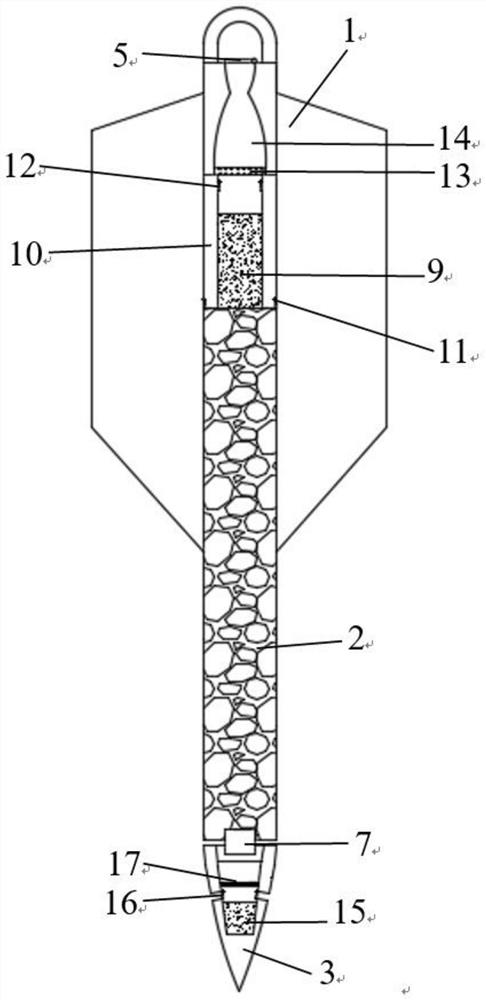

Thermatic torpedo for reinstatement materials

ActiveUS8757924B2Overcome problemsLess costlyRoads maintainenceCement mixing apparatusThermoformingBiomedical engineering

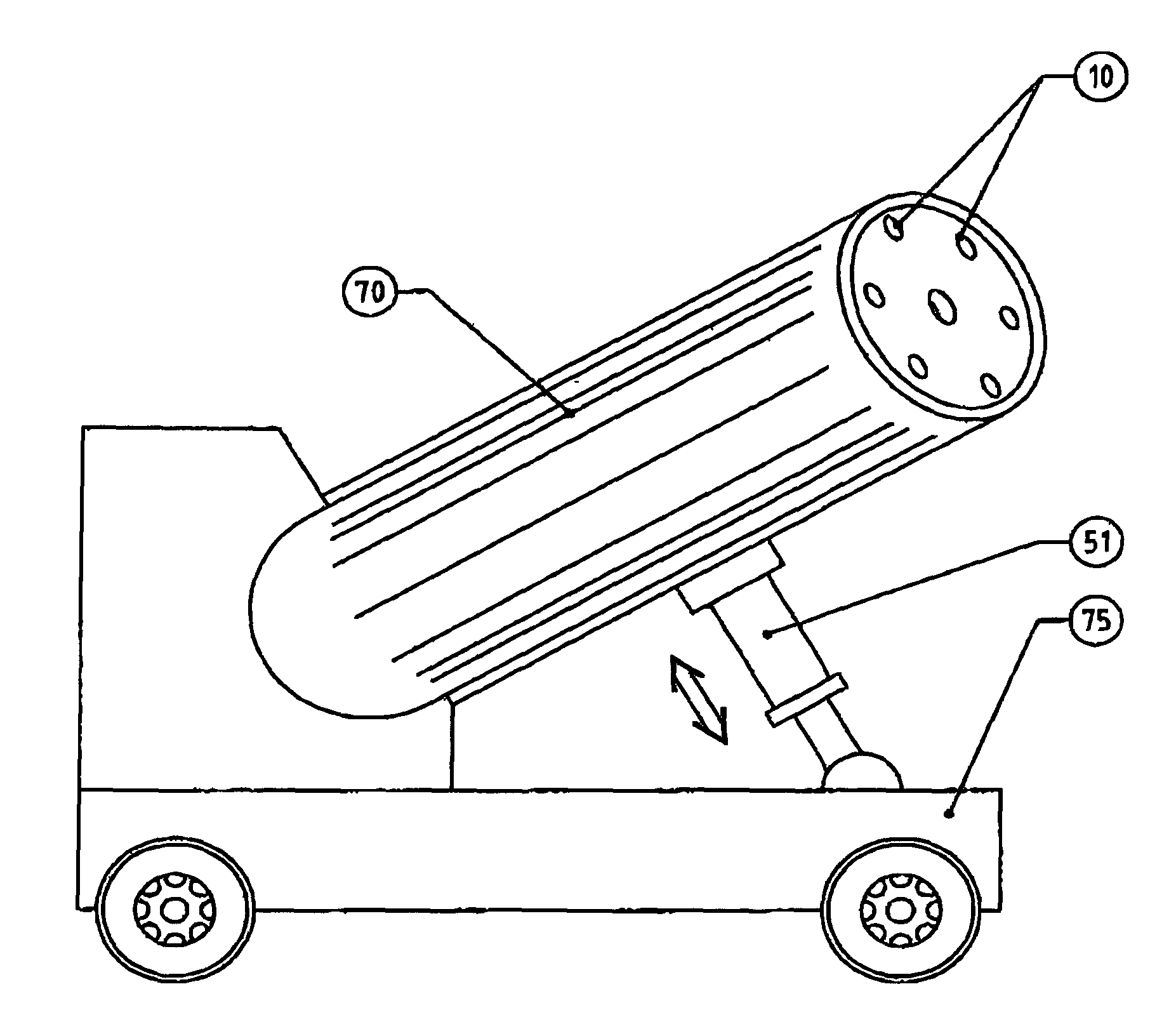

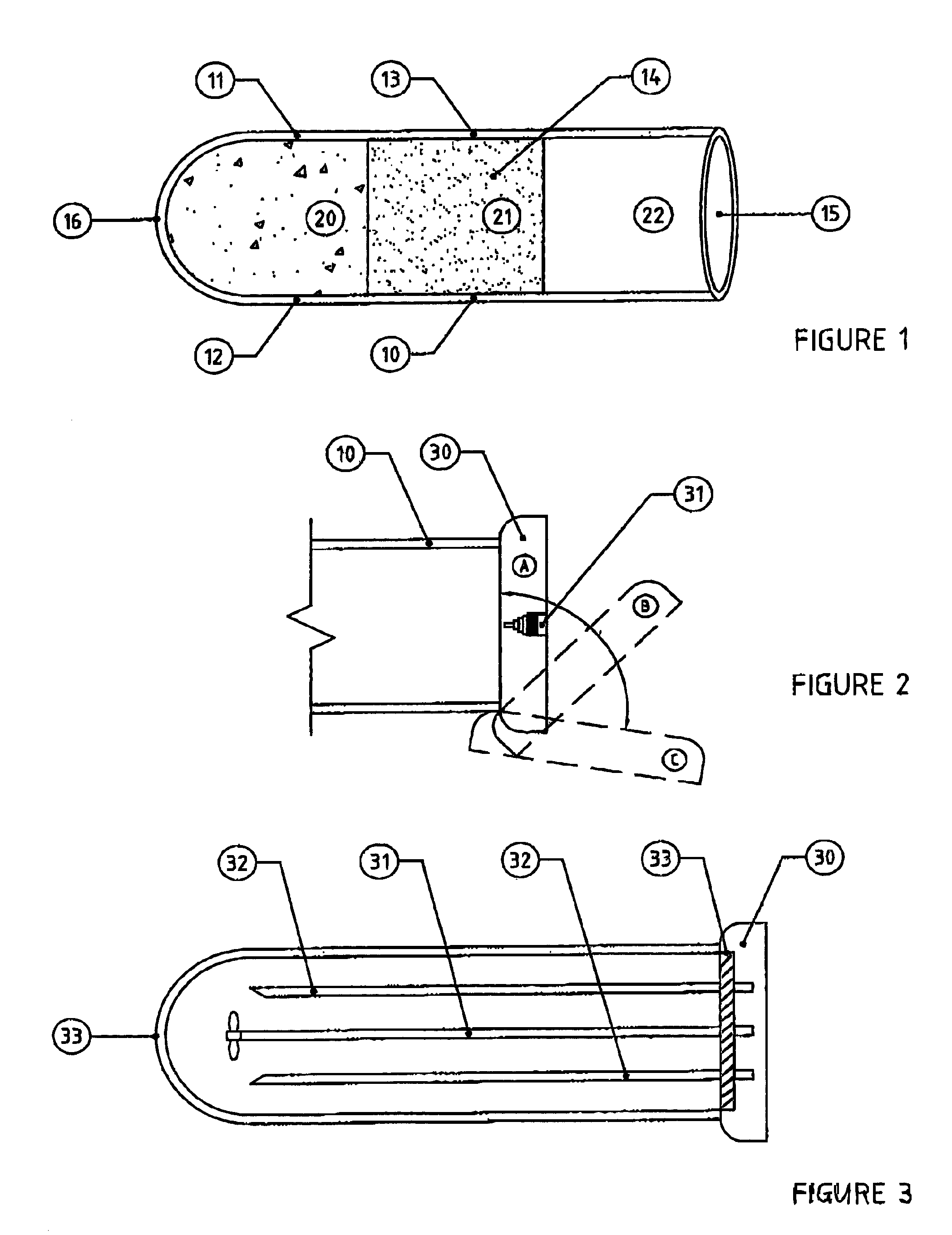

A thermic torpedo for preparing and delivering reinstatement materials has an internal chamber defining at least one compartment for containing graded aggregate and a second compartment for containing a stabilising agent, an external skin for insulating the contents of said internal chamber, a cap or lid for securely containing the contents of the torpedo in which is located at least one telescopic probe which can be driven through the compartments to heat and / or mix the contents thereof and at least one aperture through which the reinstatement materials may be expelled for delivery to a work site.

Owner:WRIGHT JAMES

Nano coating material used for permanent layer of torpedo ladle and preparation method thereof

The invention discloses a nano coating material used for a permanent layer of a torpedo ladle and a preparation method thereof and mainly solves the technical problems that a torpedo ladle in the prior art is high in heat conductivity coefficient and is large in temperature reduction of molten iron during transportation of the molten iron. The nano coating material is composed of, by weight, 55-65% of light-weight alumina, 2-4% of microbeads, 13-24% of pure calcium aluminate cement, 4-5% of magnesia, and 6-14% of nano Al2O3, all the components adding to 100% by weight in total. The permanent layer of the torpedo ladle, prepared from the nano coating material, has the heat conductivity coefficient of 0.024-0.032 W / (m*K) at 600 DEG C.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

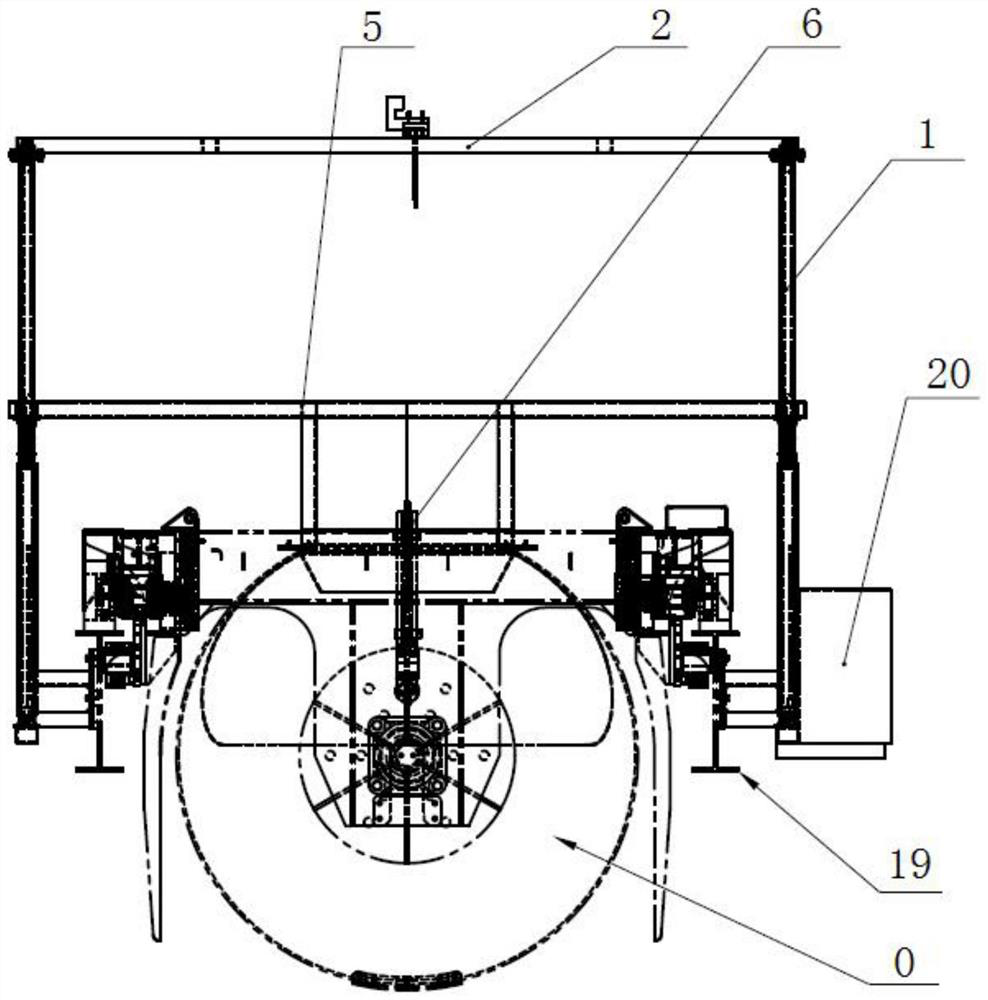

Automatic torpedo ladle cleaning device and cleaning method

The invention provides an automatic torpedo ladle cleaning device and a cleaning method. The automatic torpedo ladle cleaning device comprises supporting portals installed on conveying rails on the two sides of a torpedo ladle, a cross beam, a cover plate assembly, a lifting system, a cleaning system and an electrical system. The cross beam is transversely mounted at the tops of the supporting portals. The cover plate assembly is transversely mounted on the supporting portals. The lifting system is mounted on the supporting portals and used for driving the cover plate assembly to do lifting motion. The cleaning system is provided with a three-dimensional cleaning nozzle, a pipeline and a pump set, and the three-dimensional cleaning nozzle is installed at the bottom of the cover plate assembly, used for rotationally cleaning the inner side surface of a torpedo cylinder and externally connected with a water source through the pipeline and the pump set. The electrical system is electrically connected with the lifting system and the cleaning system. By means of the automatic torpedo ladle cleaning device and the cleaning method, the automatic cleaning efficiency of the torpedo ladle is remarkably improved, the manual operation risks are reduced, the safety coefficient is high, and the cleaning effect is good.

Owner:筑友智造智能科技有限公司

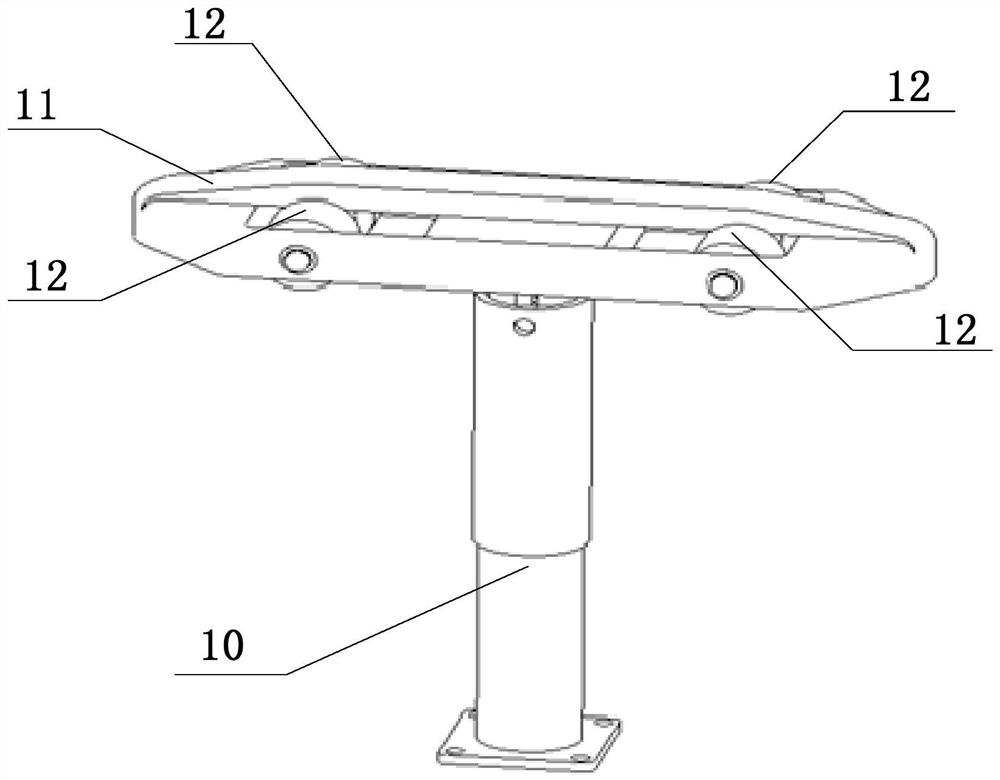

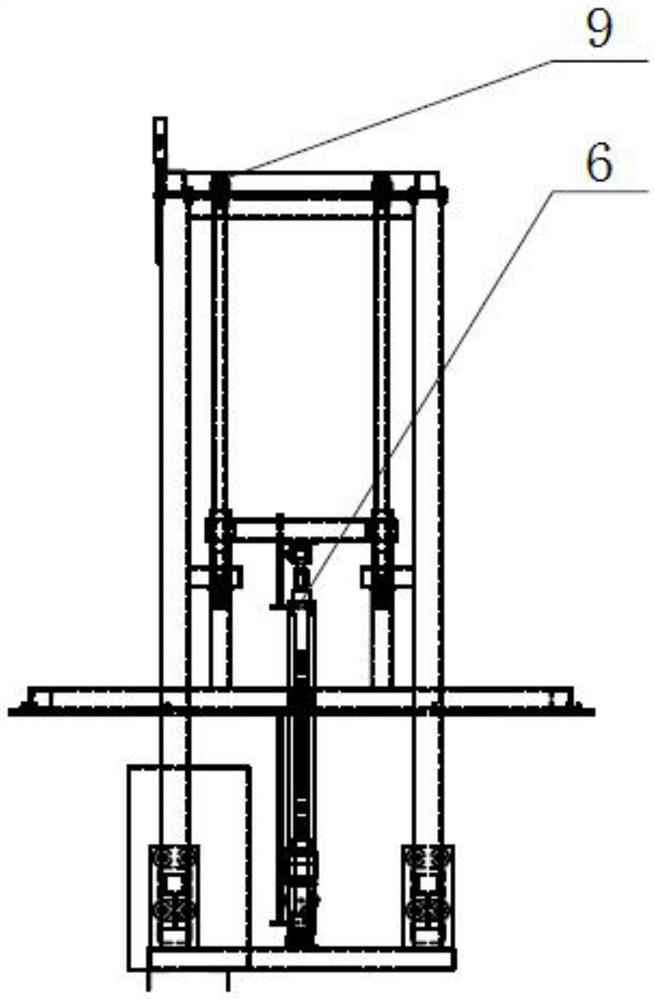

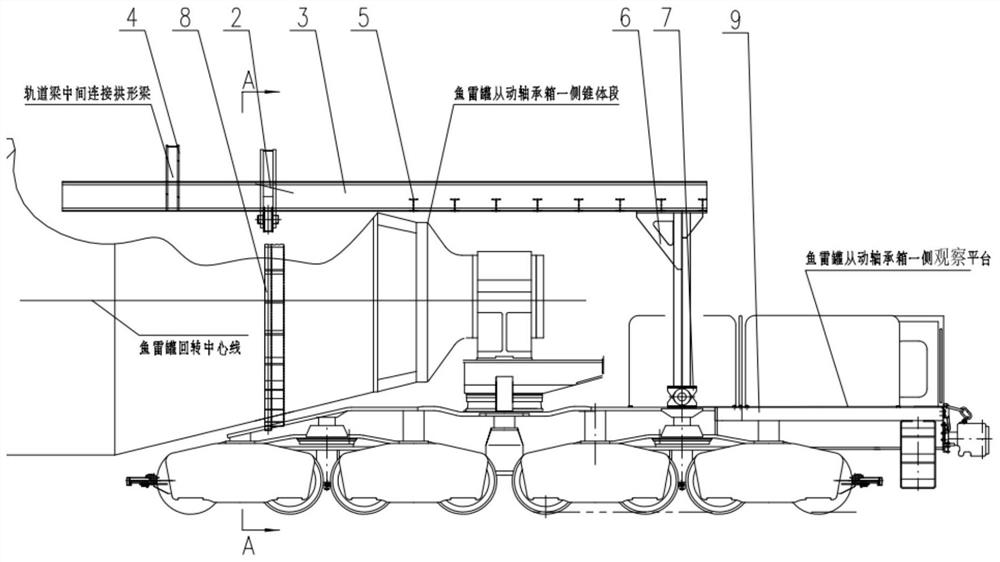

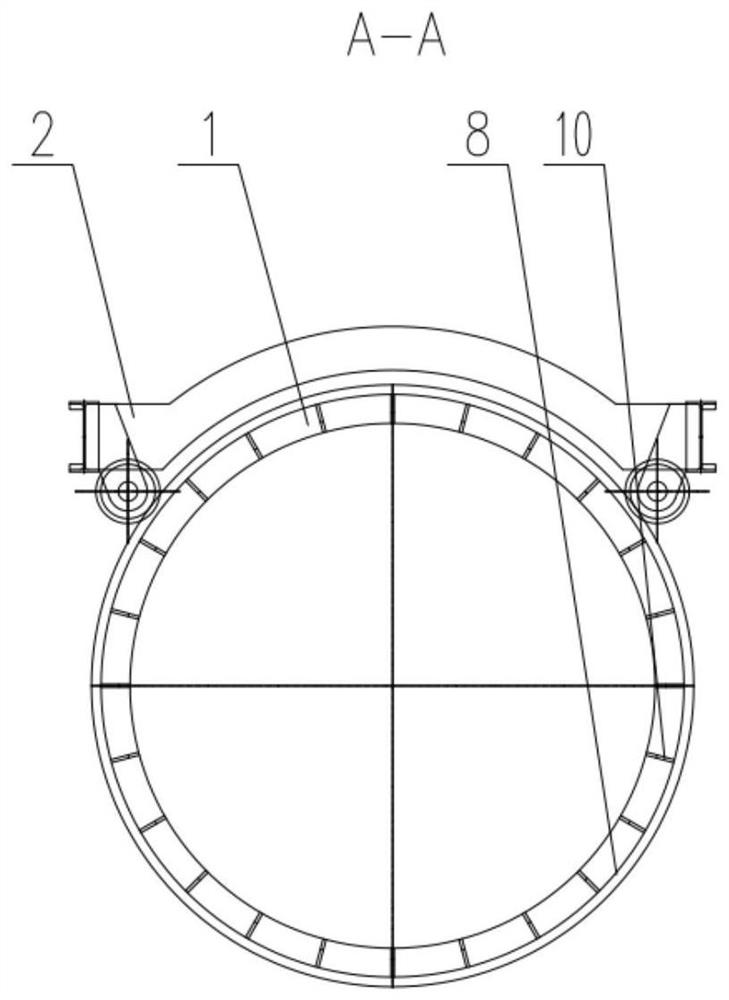

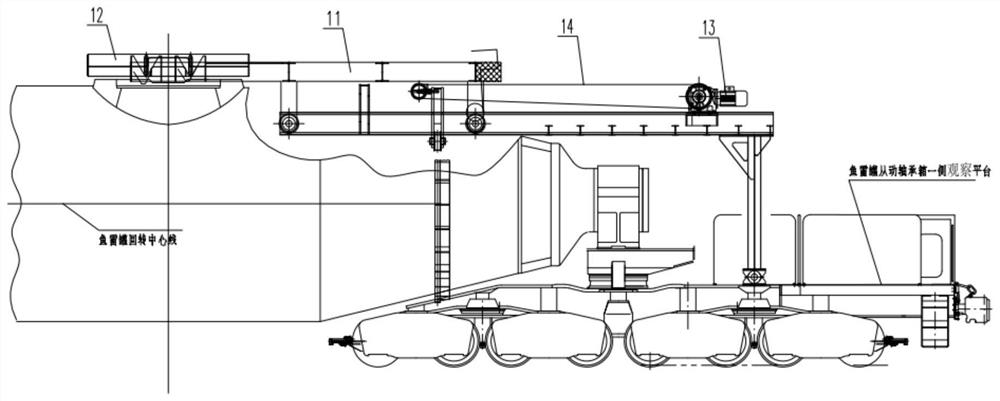

Ultra-low clearance vehicle-mounted uncovering machine above torpedo ladle opening

The invention discloses an ultra-low clearance vehicle-mounted uncovering machine above a torpedo ladle opening, and belongs to the technical field of molten iron transportation. Under the conditions that the clearance above the torpedo ladle opening is not greater than 460 mm and the slag height of a ladle opening water nozzle is within 150 mm, the heat preservation through covering and normal uncovering and capping can still be performed. A flat car track is composed of an annular track 1, an arch-shaped floating column leg 2 with trundles, a horizontal track main beam 3, a track beam middle connecting arch beam 4, a driving device mounting platform 5, a column leg 6 with a hinged joint and a hinged seat 7. According to the ultra-low clearance vehicle-mounted uncovering machine, a single-drive corbel trolley 11 automatic capping and uncapping technology, a tank cover self-weight homing tank opening heat preservation and anti-slip technology and a vehicle-mounted triboelectric track multi-point current collection and multi-person operation technology are comprehensively adopted. The ultra-low clearance vehicle-mounted uncovering machine has the advantages that the torpedo ladle is shielded by the cover in the conveying and placing process, the project implementation has small influence on production, the popularization value is high, an accident plan is simple and practical, and the ultra-low clearance vehicle-mounted uncovering machine is a direct and effective means for saving energy, reducing the consumption of refractory materials and heat preservation covering agents, reducing environmental pollution, prolonging the service life of the refractory materials of the torpedo ladle and reducing the turnover number of the torpedo ladle.

Owner:何正山 +1

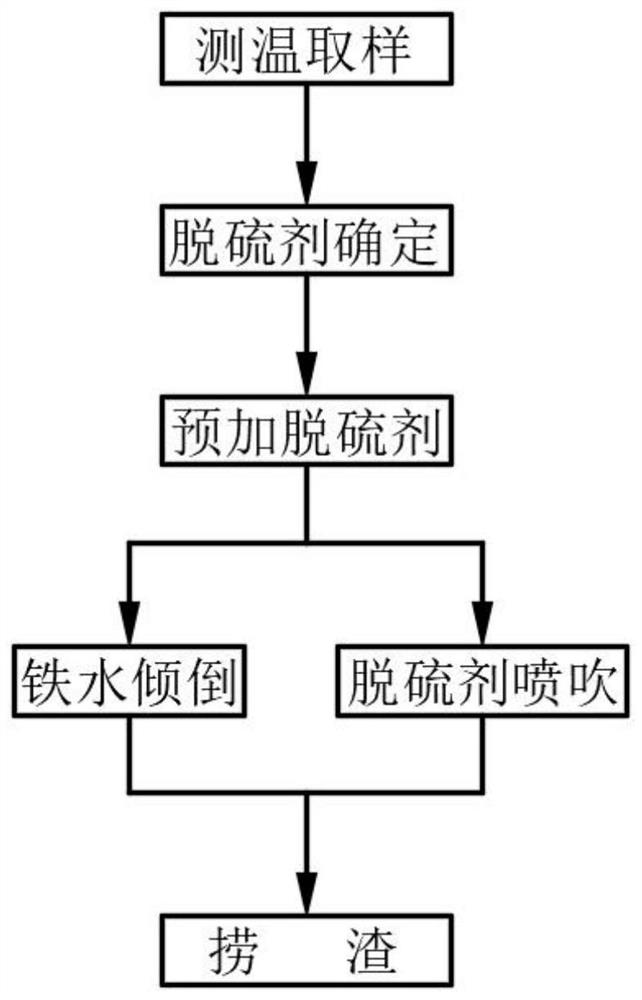

Molten iron desulfurization pretreatment process and method

The invention relates to a molten iron desulphurization pretreatment process and method, belongs to the technical field of molten iron desulphurization processes, and solves the problems of poor desulphurization effect, large slag salvaging iron loss and the like of a molten iron desulphurization process. The method comprises the following steps: S1, temperature measurement and sampling are conducted, specifically, temperature measurement and sampling are conducted on molten iron; S2, the injection amount is determined, and the total demand quantity of a desulfurizing agent is determined according to the content of initial sulfur and the type requirement of the steel type; S3, the desulfurizing agent is pre-added, specifically, the desulfurizing agent with the basic demand quantity is pre-added to the bottom of a molten iron ladle; S4, molten iron pouring and desulfurizing agent injection are conducted, specifically, the molten iron in a torpedo ladle is poured into the molten iron ladle, and meanwhile a spraying gun is used for being aligned with falling molten iron flow to spray out the desulfurizing agent; and S5, slag salvaging is conducted, specifically, desulfurization slag floating on the surface of the molten iron is salvaged away from the molten iron ladle through a special slag salvaging machine. According to the method, the desulfurizing agent is released in two directions to react with the molten iron, desulfurization is carried out in a mode of pouring the molten iron while injecting, desulfurization is carried out in cooperation with existing equipment, special slag salvaging equipment is manufactured for salvaging slag, and therefore the purposes of efficient and rapid desulfurization and slag salvaging are achieved.

Owner:吕梁建龙实业有限公司

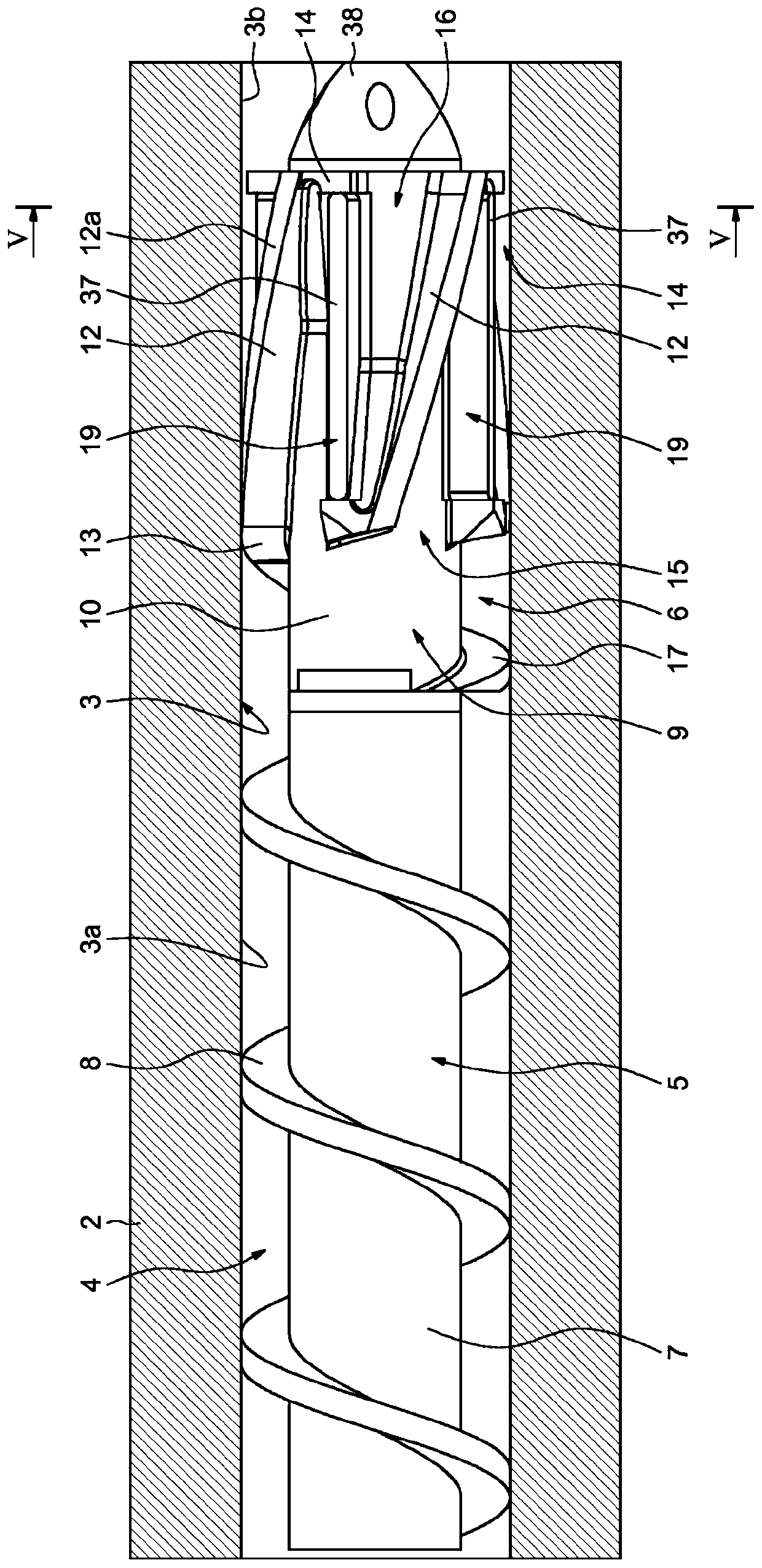

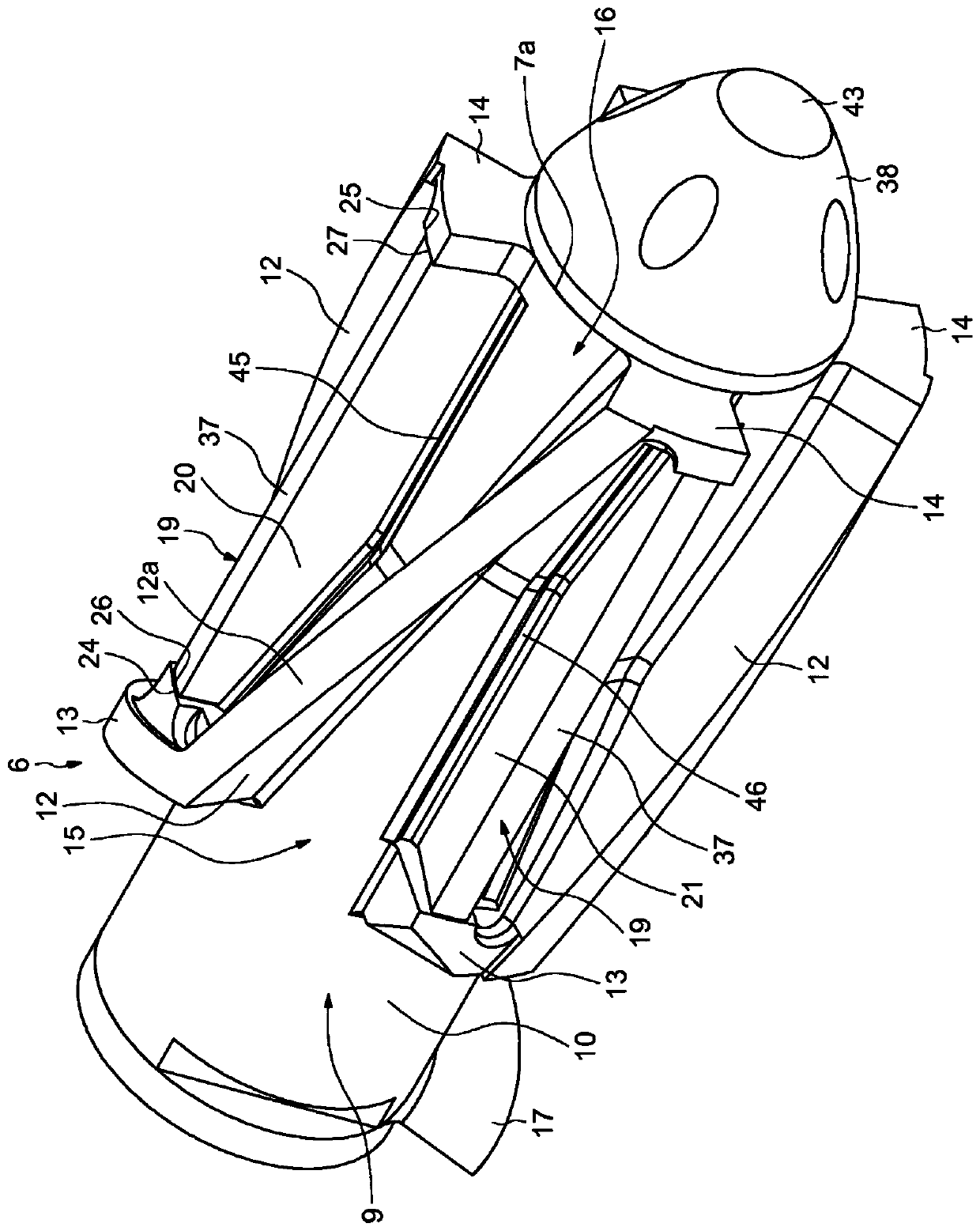

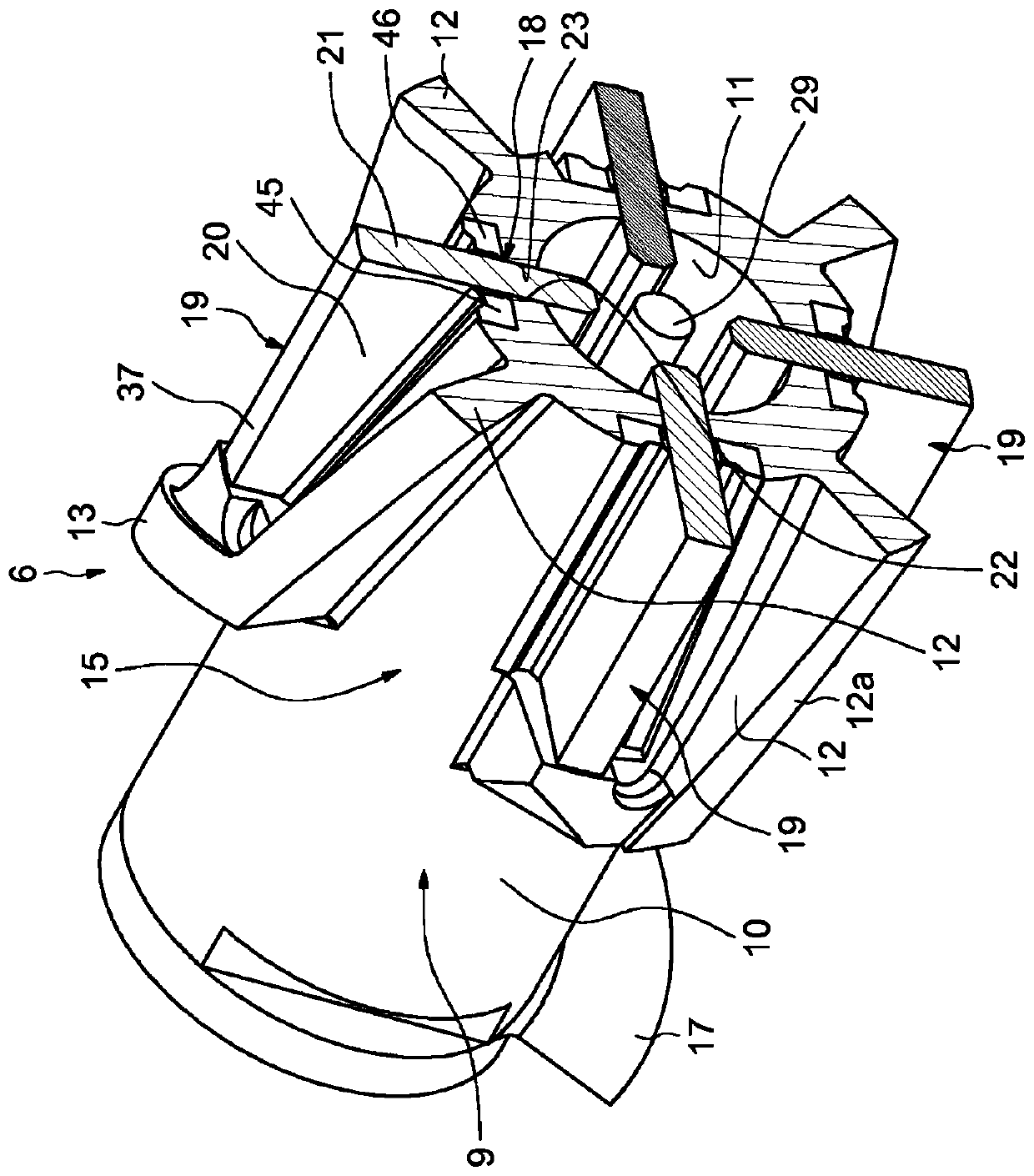

Torpedo for extruder

Torpedo for extruder, comprising: a longitudinal body (9) provided at the periphery thereof with a plurality of thread portions (12) protruding outwards and spaced apart in the circumferential direction, a plurality of sluice blades (19) movably mounted on said longitudinal body and partially engaged in slits (18) of said longitudinal body, said longitudinal body (9) and said sluice blades (19) being provided with complementary radial guiding surfaces (13, 14, 18) in contact on one another, and adjustment means (28) for radially moving said sluice blades relative to said longitudinal body. Thesluice blades respectively pass through the spaces between the thread portions. The thread portions (12) and the sluice blades (19) are provided with complementary radial guiding surfaces (13, 14, 18).

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

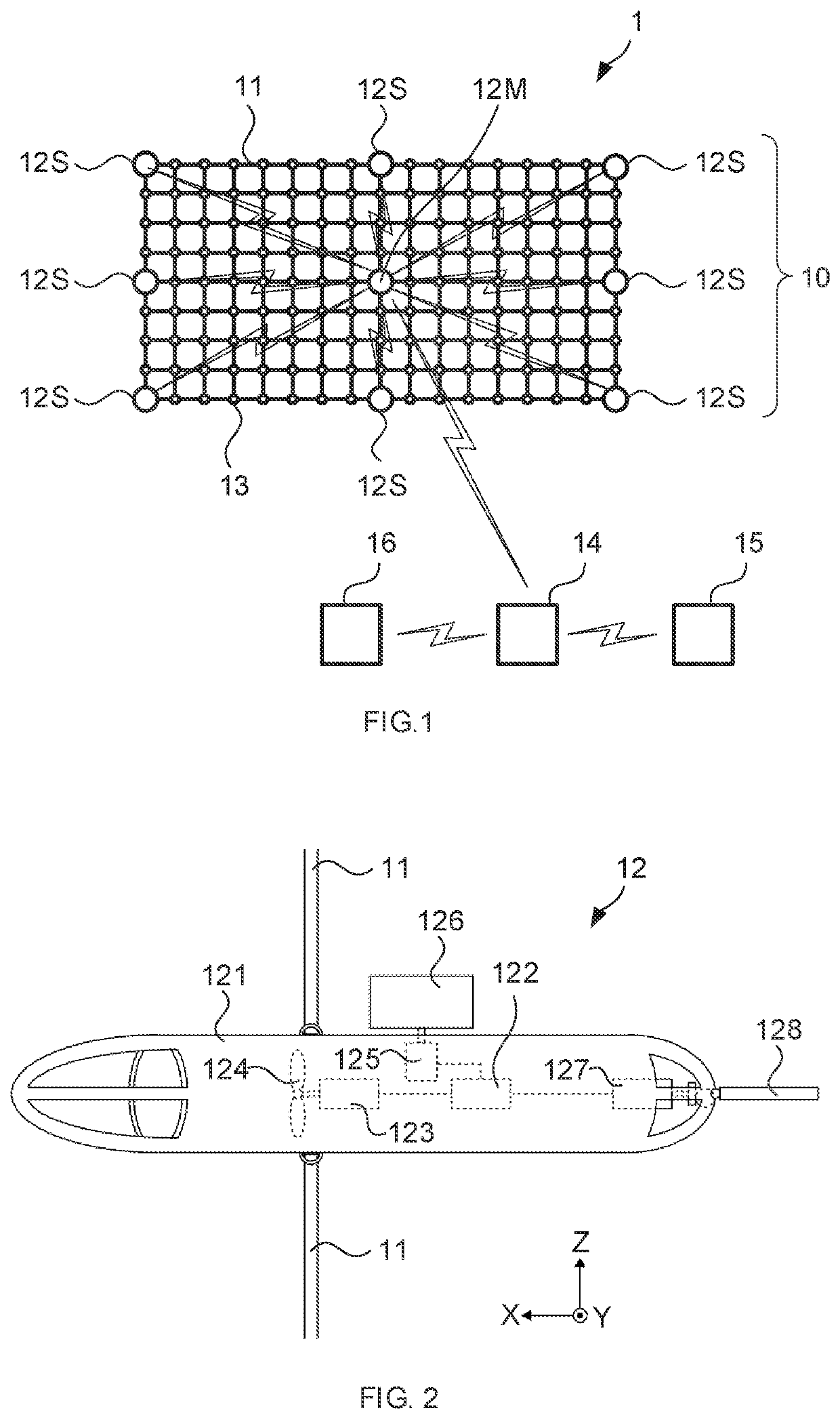

Self-hidden bubble curtain protection system and underwater vehicle

PendingCN114348218ARealize self-recyclingImprove concealmentDefensive equipmentOffensive equipmentShock waveTorpedo

The invention relates to the technical field of ships, and provides a self-hidden bubble curtain protection system and an underwater vehicle. The self-hidden bubble curtain protection system comprises a steam supply device, a vacuumizing device and a plurality of nozzles, the steam supply device is connected with the multiple nozzles through steam paths, the multiple nozzles are used for being arranged on a protection body and spraying bubbles to the outside of the protection body, the vacuumizing device is used for being communicated with a water inlet in the protection body, and the multiple nozzles are arranged on the protection body. And therefore, negative pressure can be formed at the water inlet relative to the outside of the protection body. When the self-hidden bubble curtain protection system is applied to the underwater vehicle, the bubble curtain can be provided to absorb shock waves when the underwater vehicle is attacked by external weapons such as torpedoes; and the problems of secondary exposure and wake flow aggravation of the underwater vehicle body can be relieved, and the survivability of the underwater vehicle is improved.

Owner:NO 719 RES INST CHINA SHIPBUILDING IND

System for protecting ships from torpedoes

ActiveUS11333466B2Improve protectionMove quicklyDefence devicesDefensive equipmentTorpedoMarine engineering

Owner:FUKUNAGA MIKIO

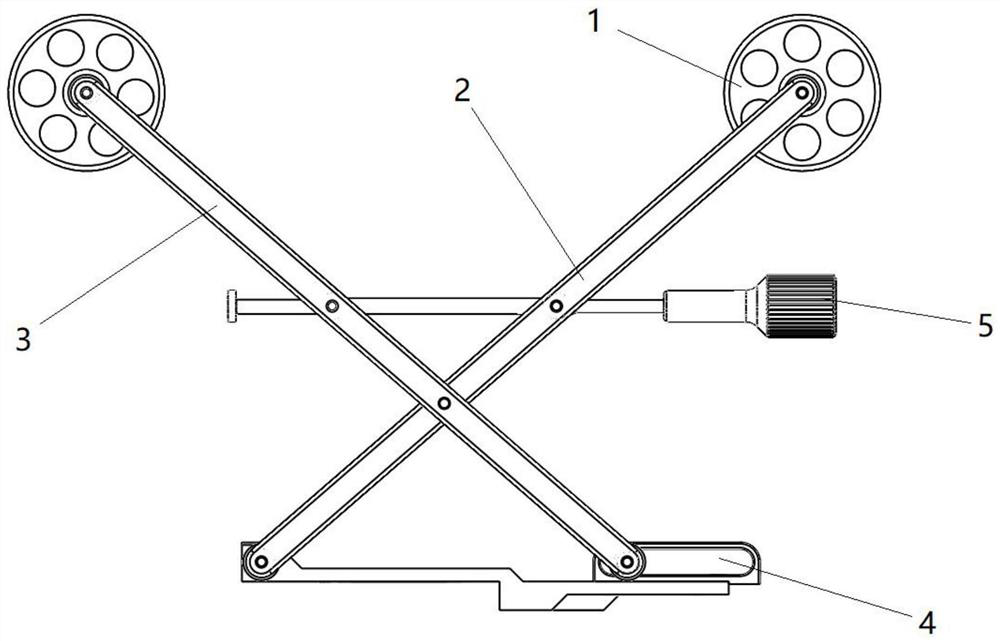

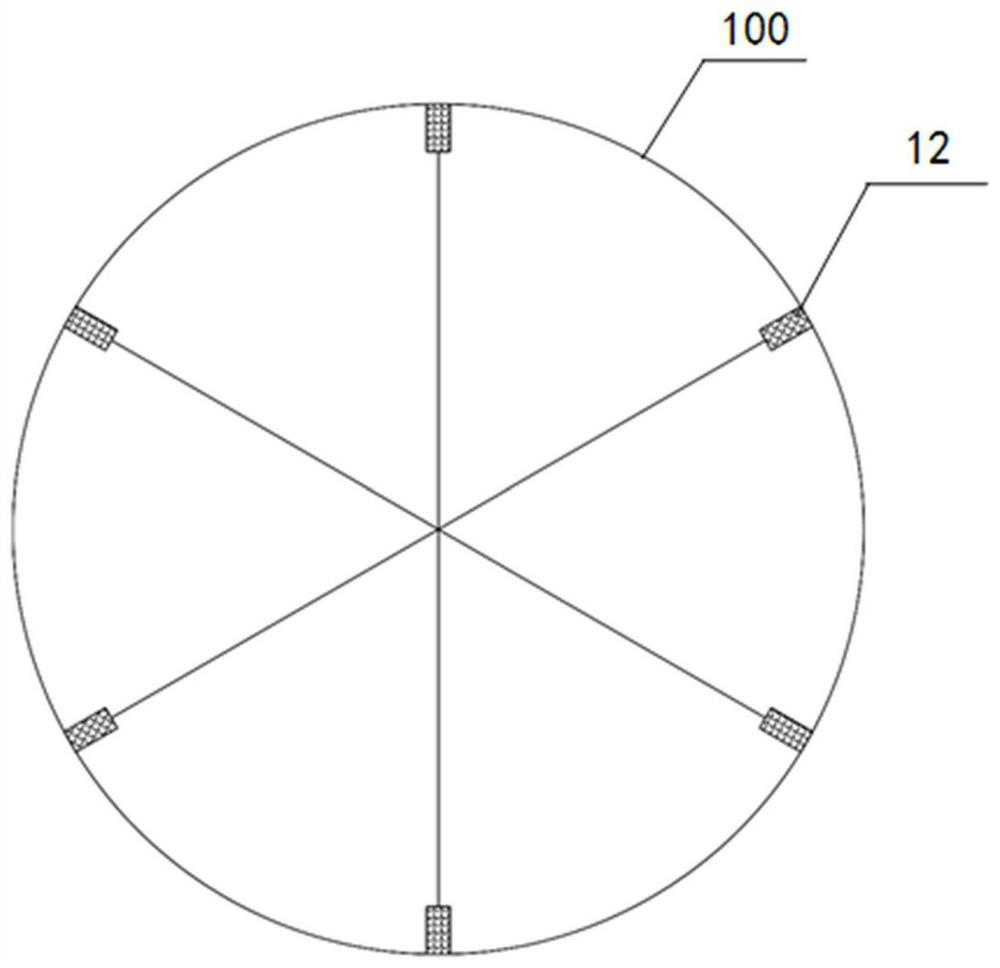

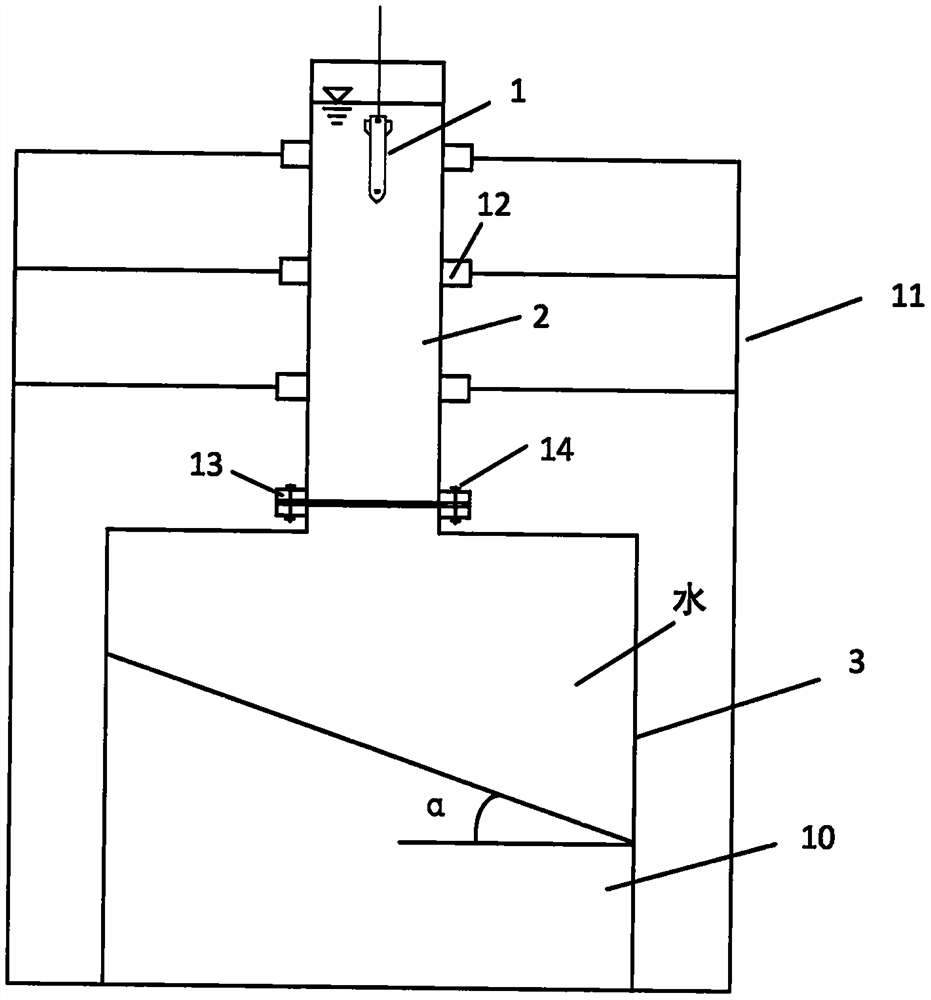

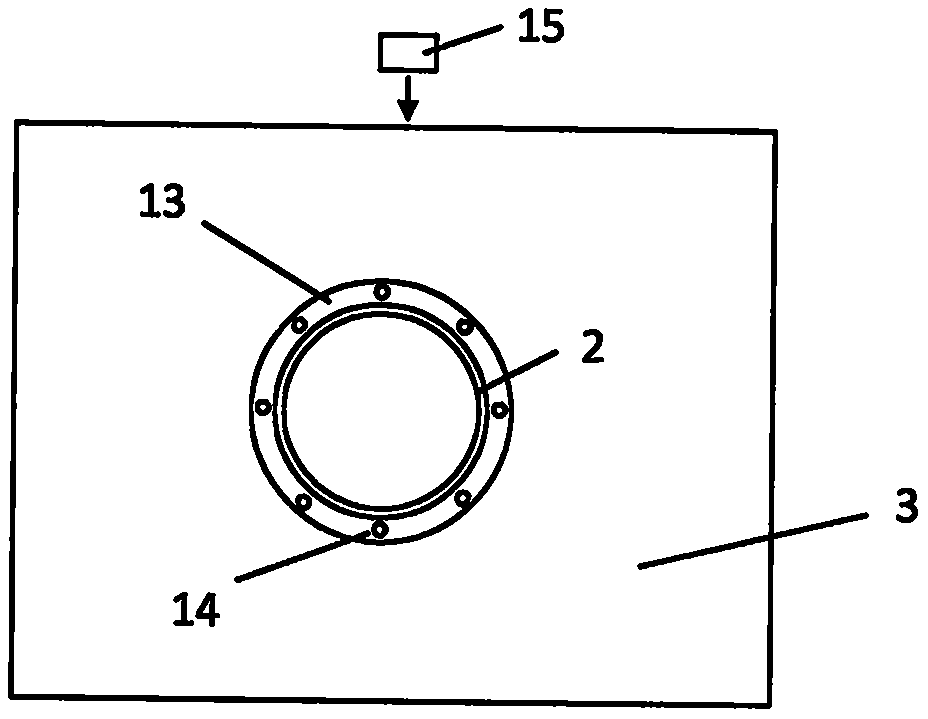

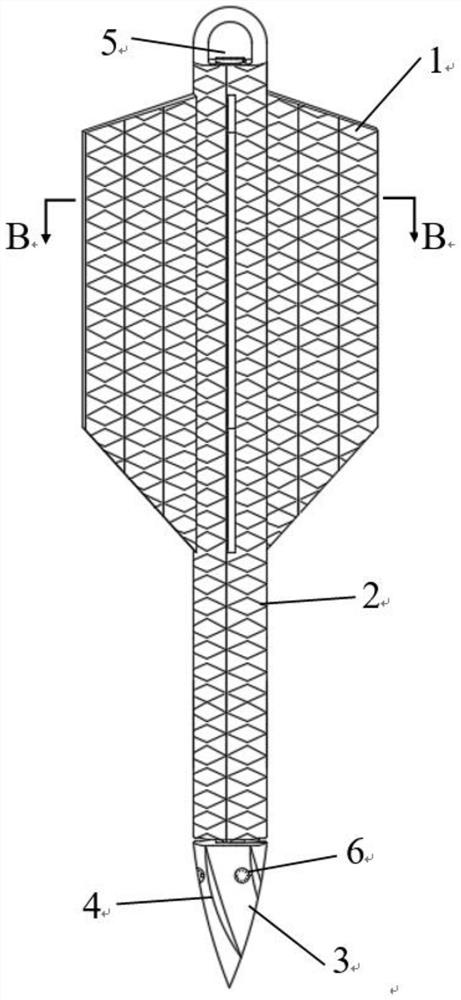

Model test device and test method for measuring penetration attitude of torpedo anchor in seabed slope

PendingCN114838926APrecise positioningSolve the problem that the pull-out bearing capacity cannot be effectively exertedMachine part testingAngle measurementMarine terraceTorpedo

The invention provides a model test device and a test method for measuring the penetration attitude of a torpedo anchor in a seabed slope. The device comprises a torpedo anchor, a cylinder, a soil box, an anchor body, an anchor head, a tail wing, a positioner A, a positioner B, a pull rope, a slope, a bracket, a fixing ring, a flange plate, a bolt and a signal detector. The influence of the slope angle alpha and the penetration speed v on the penetration posture and the penetration depth is determined by simulating the penetration posture of the torpedo anchor after the torpedo anchor penetrates into the seabed slope, so that an analysis basis is provided for researching the penetration posture and the penetration depth of the mooring foundation of the ocean platform in a seabed slope area. The problem that the uplift bearing capacity of a mooring foundation cannot be effectively exerted due to the fact that the penetration posture of a torpedo anchor in a slope stratum is poor or the penetration depth is insufficient is solved.

Owner:NANJING FORESTRY UNIV

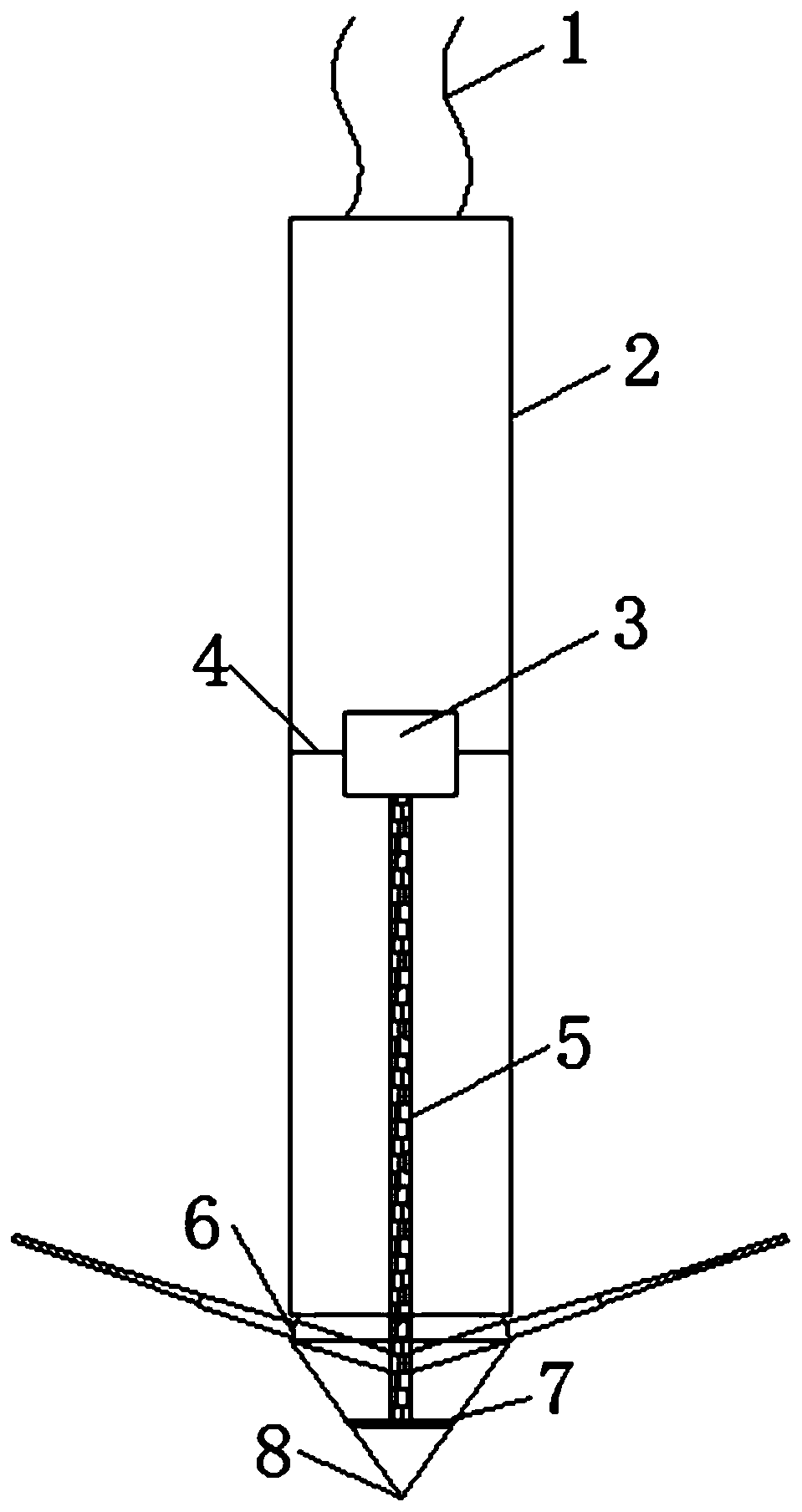

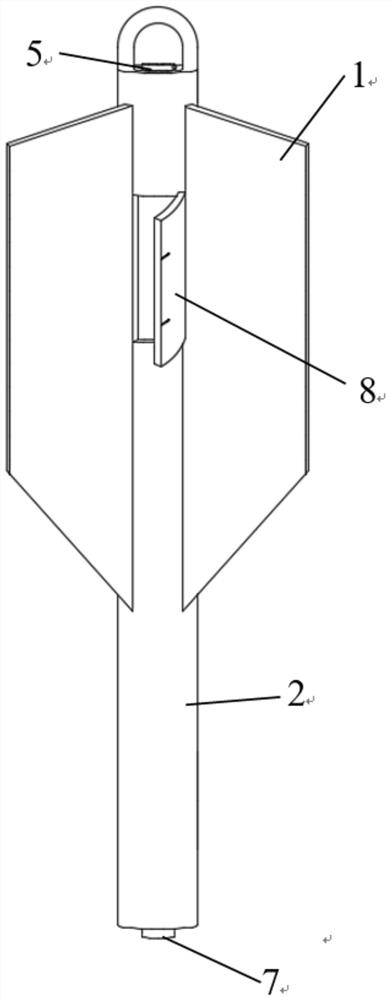

A bionics-based dynamic torpedo anchor and its installation method

ActiveCN112141268BImprove the pull-out capacityExpand the scope of applicable soilAnchorsAnchoring arrangementsTorpedoBiomimetics

The invention discloses a bionics-based dynamic torpedo anchor and an installation method thereof, belonging to the technical field of deep-sea mooring. Including rotating anchor tip, anchor rod, anchor wing and simple water ramjet engine part; the invention combines the traditional torpedo free-fall movement and installs the simple water ramjet engine at the same time, so that it can obtain a greater initial penetration speed and improve the penetration rate of the torpedo anchor. Depth; add negative Poisson’s ratio materials to the anchor rod and anchor wing, and use the characteristics of negative Poisson’s ratio materials to shrink under compression and expand under tension to reduce penetration resistance and improve uplift bearing capacity. The invention has the advantages of high initial penetration speed, deep installation penetration and high pullout bearing capacity.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com