Patents

Literature

100results about How to "Facilitated contact response" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

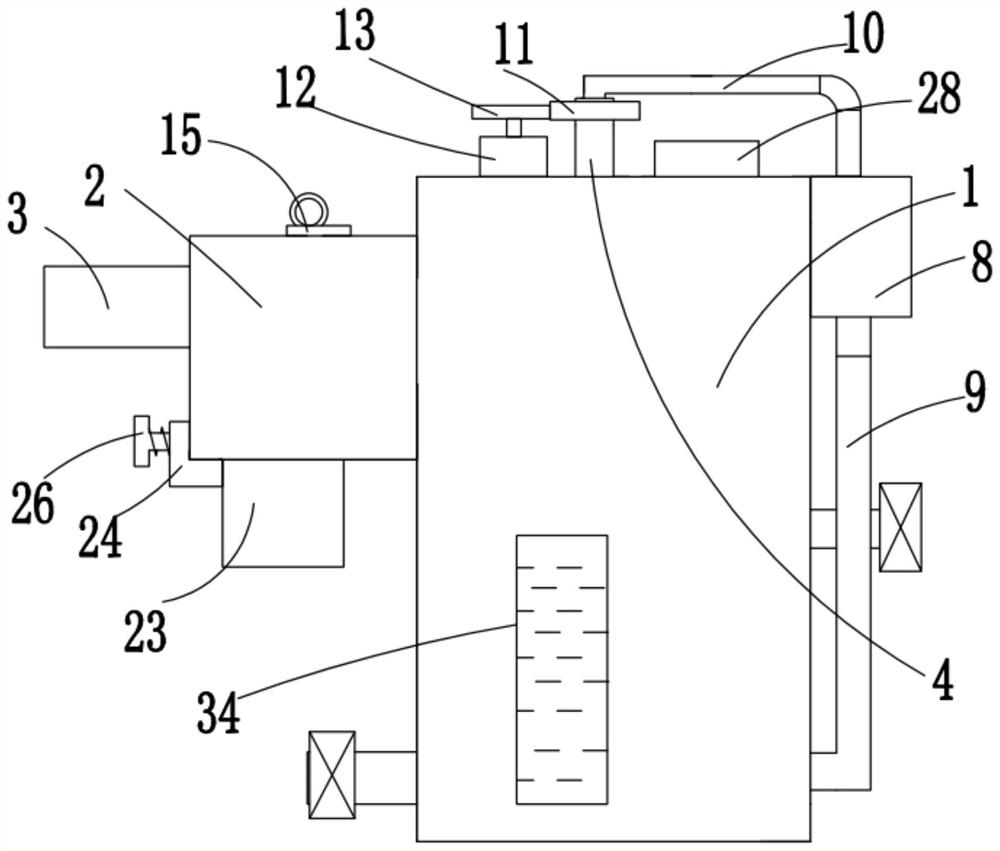

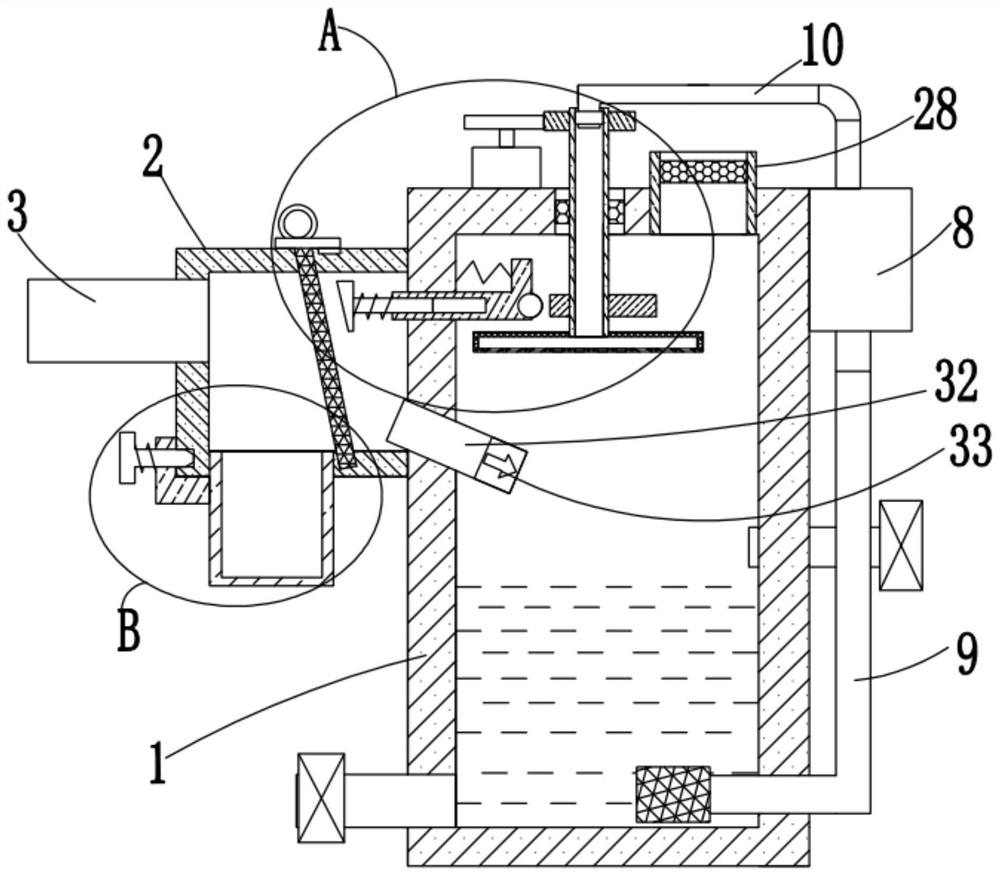

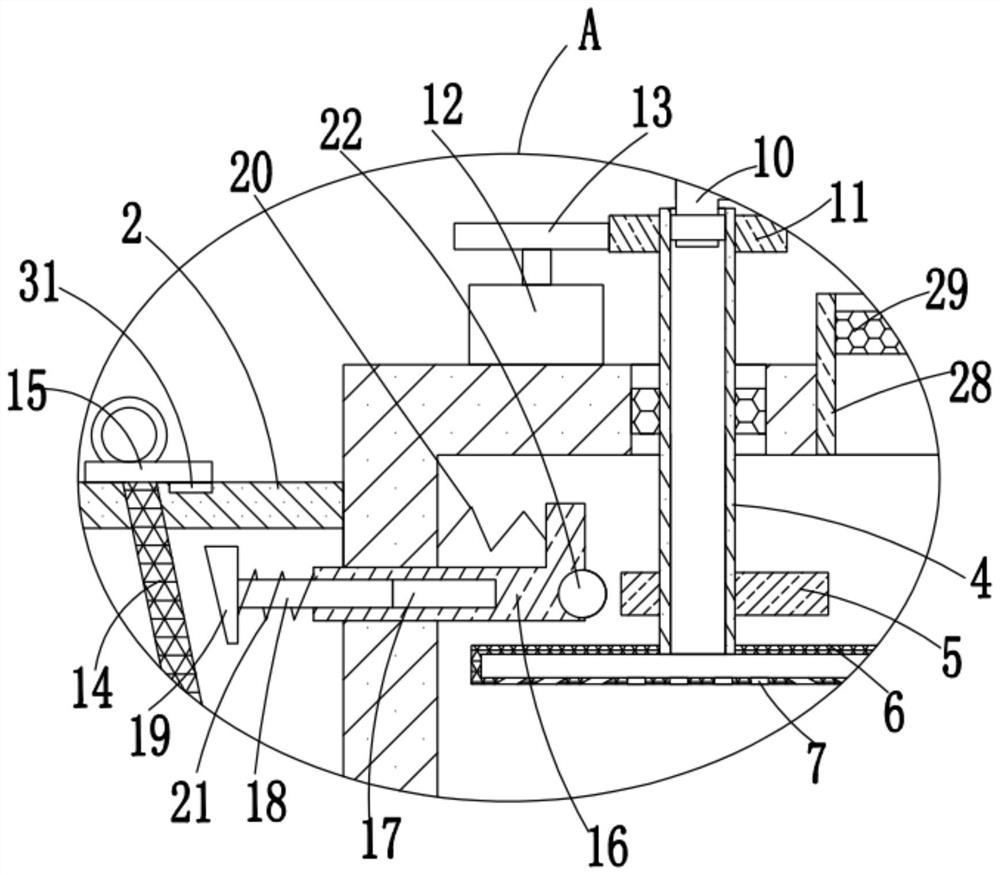

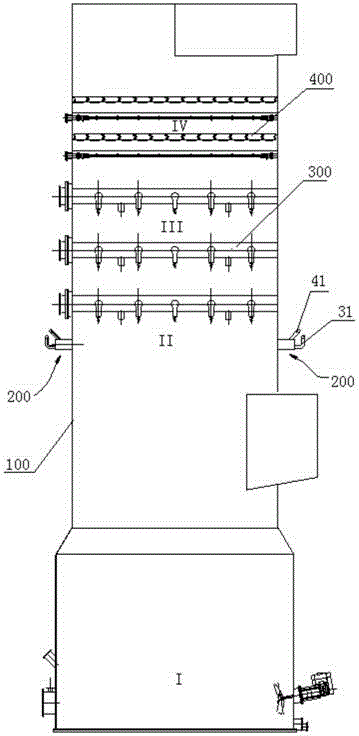

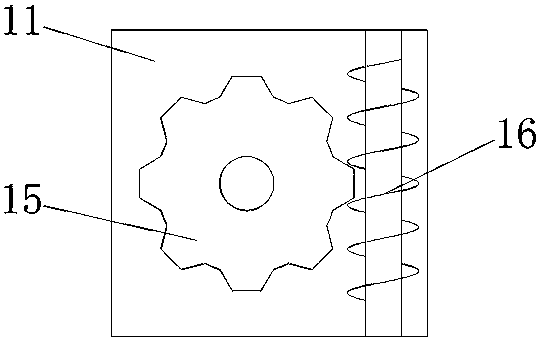

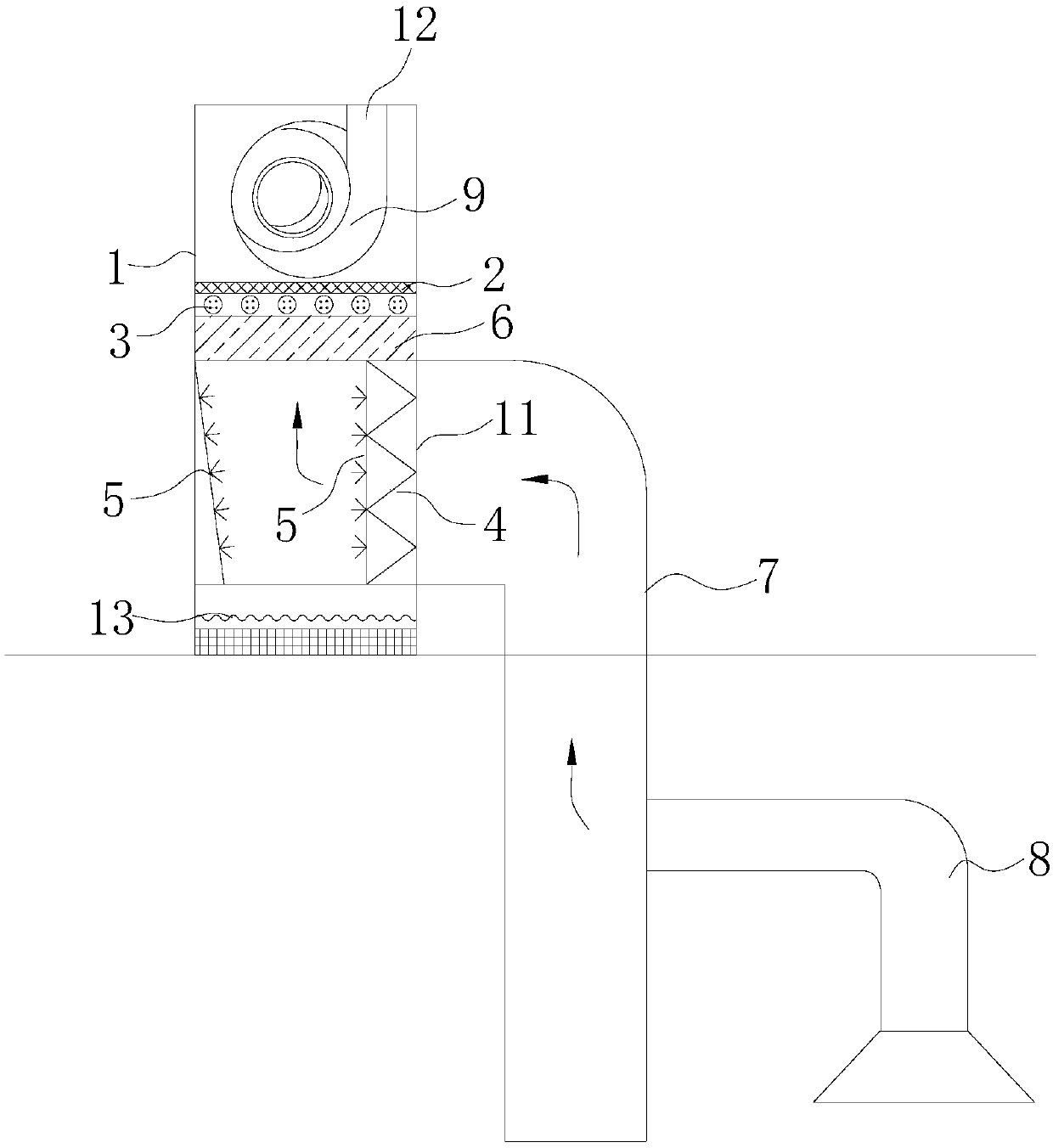

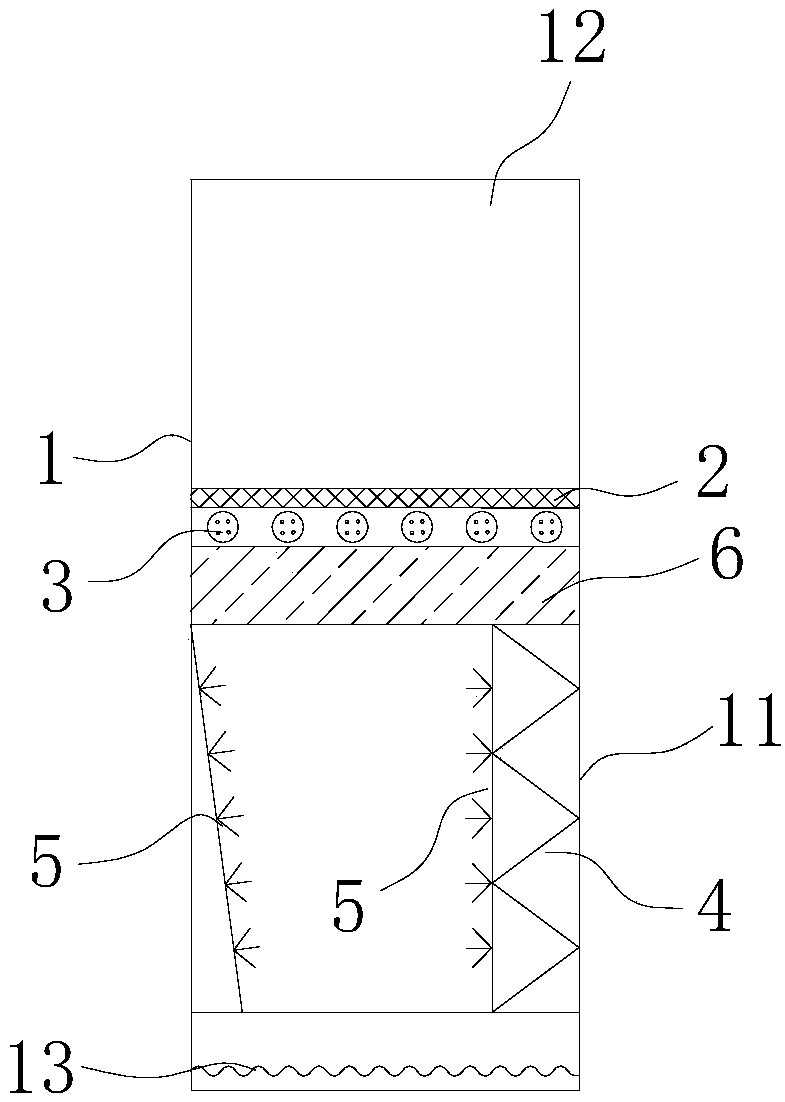

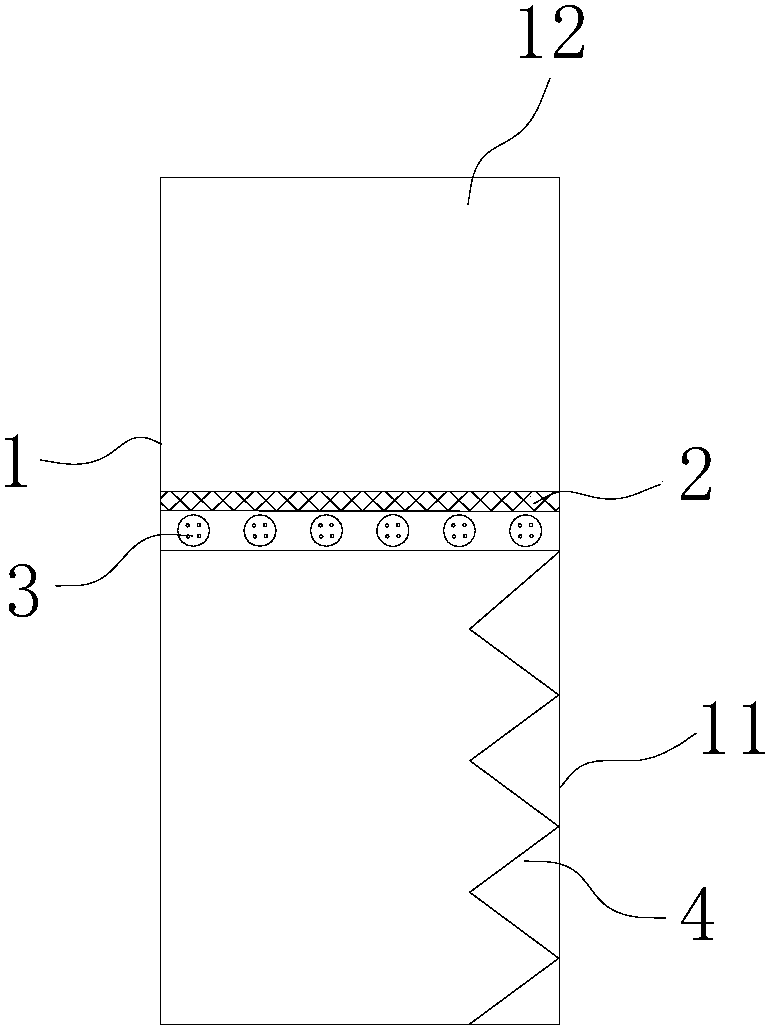

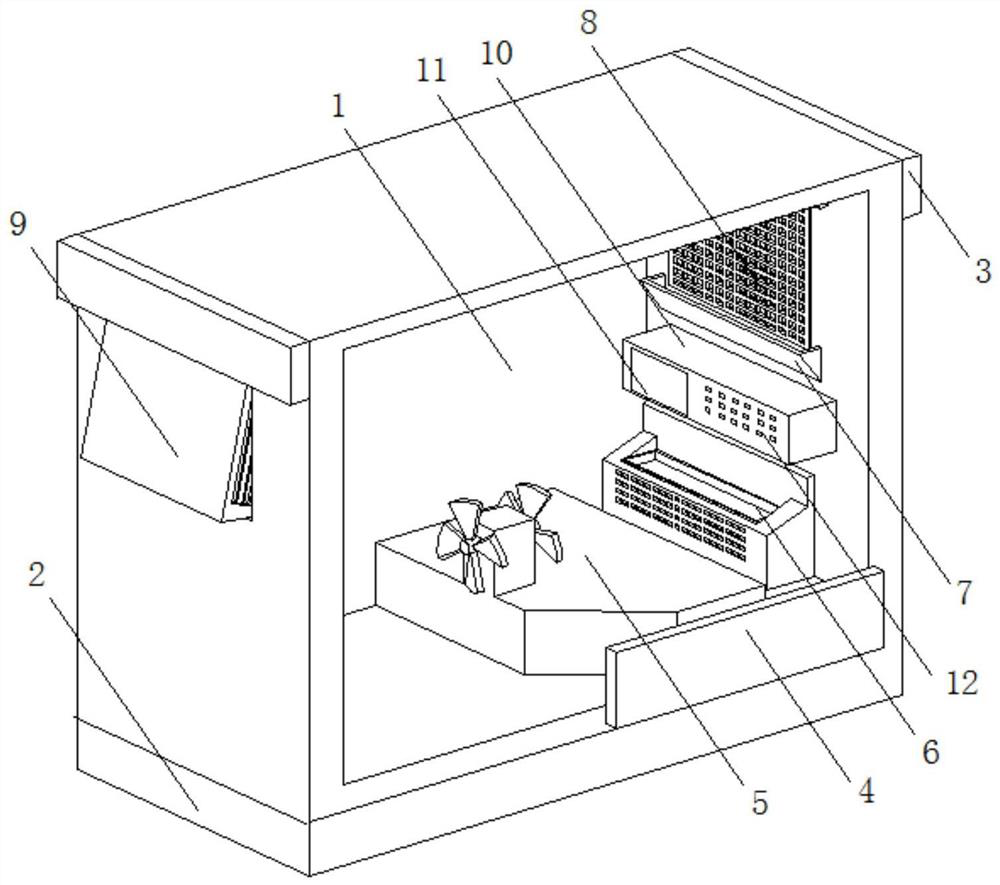

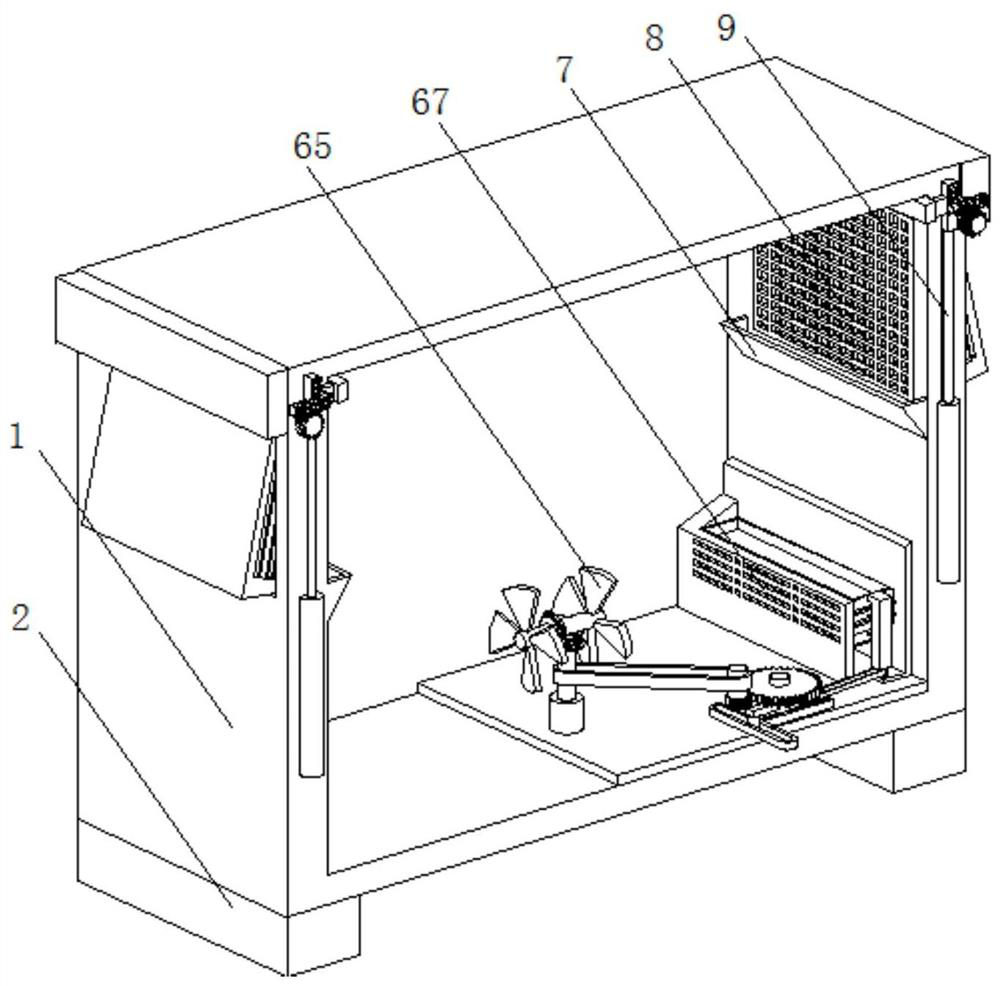

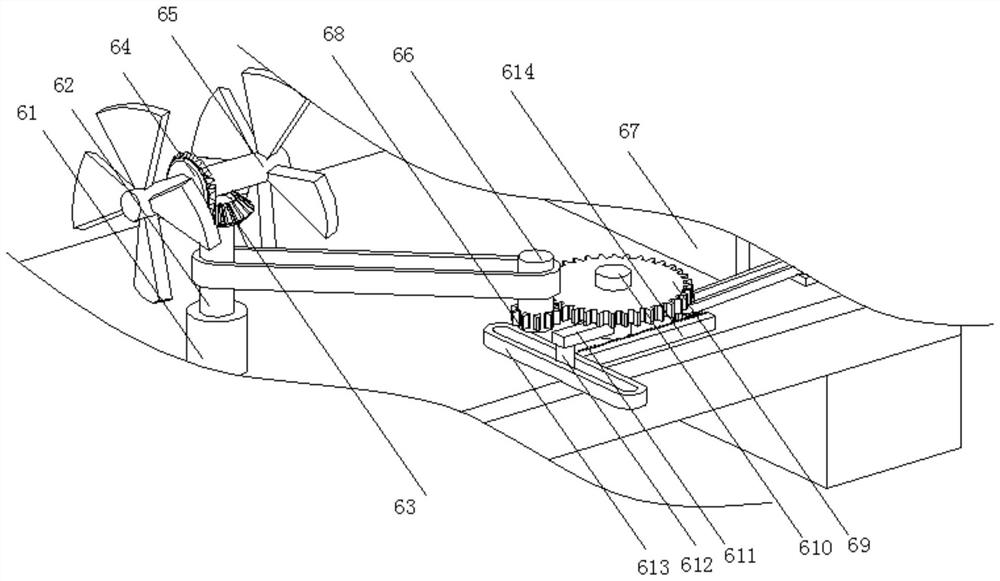

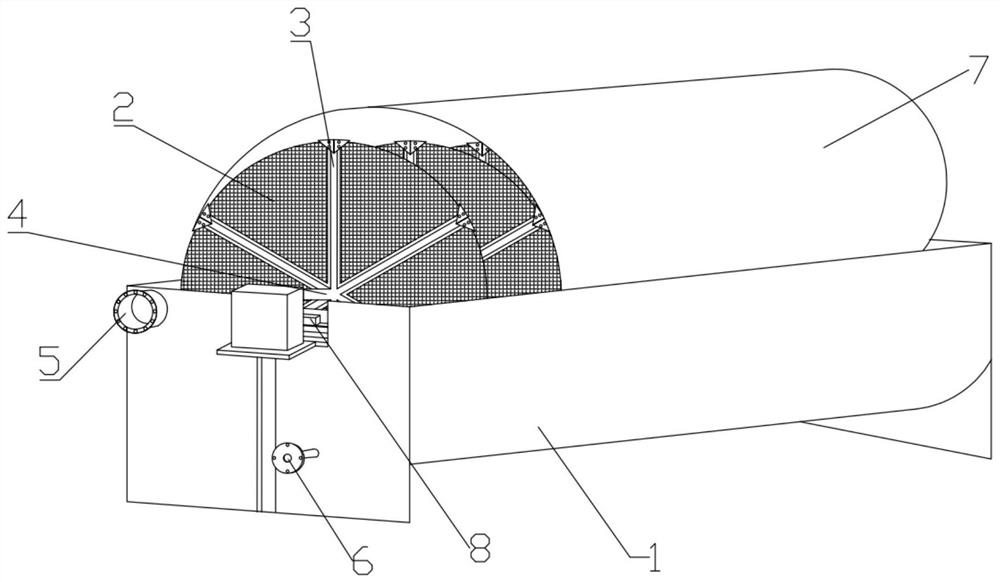

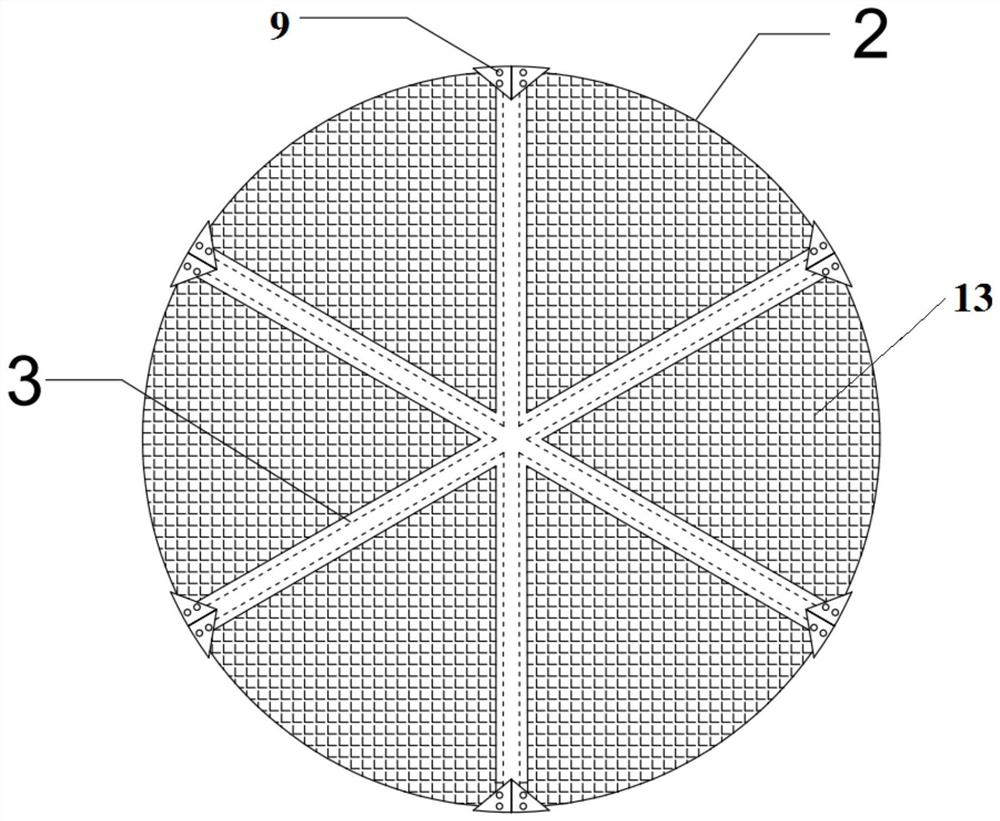

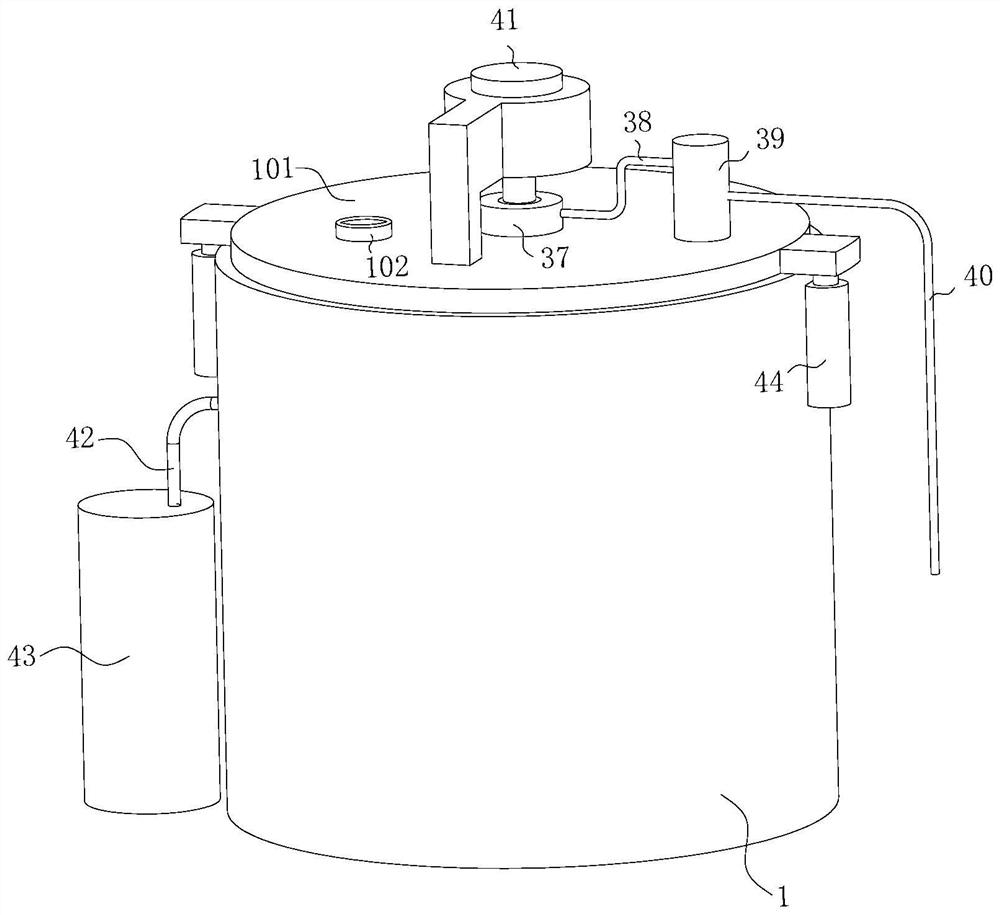

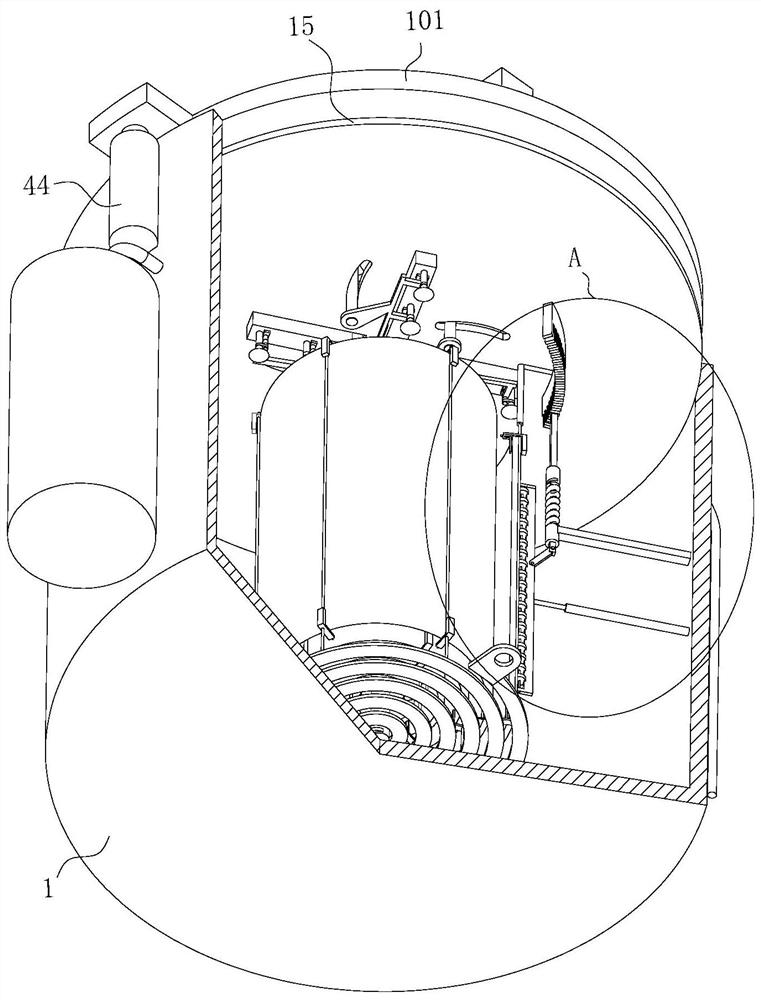

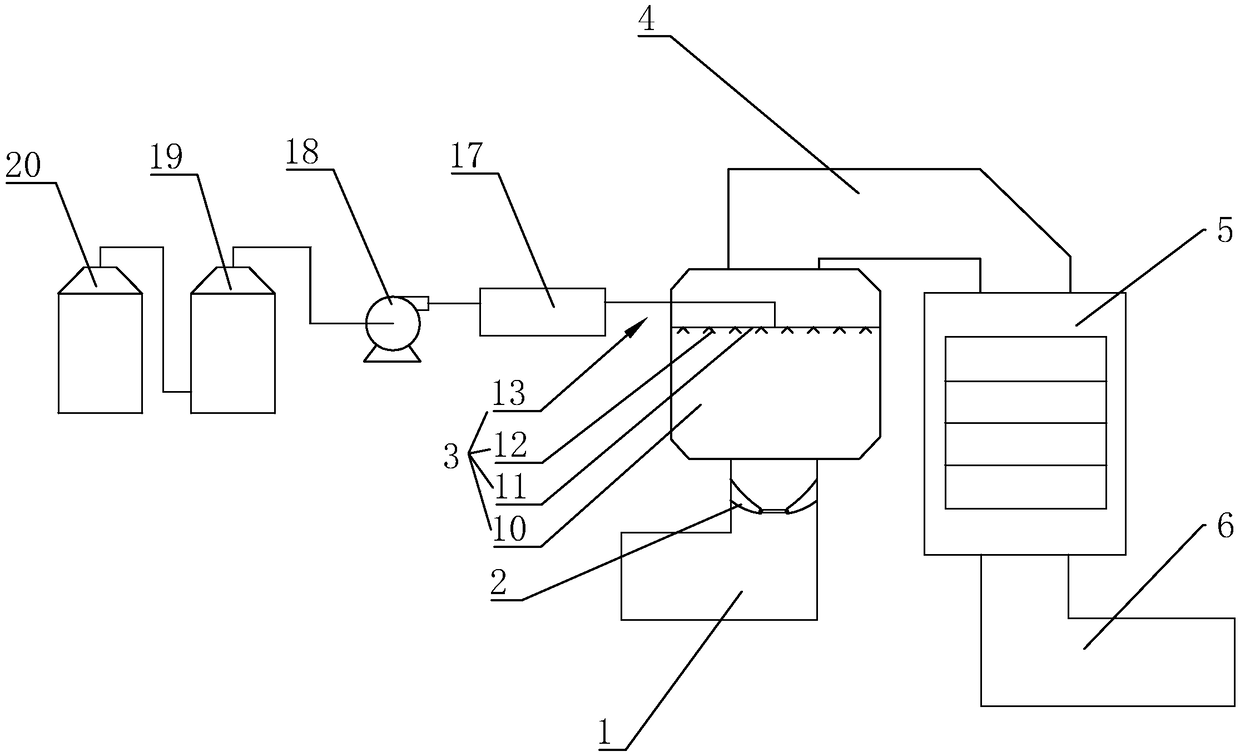

Industrial waste gas desulfurization, denitrification and dust removal equipment

InactiveCN111672307ASpread evenlyAvoid buildupDispersed particle filtrationTransportation and packagingExhaust fumesDust control

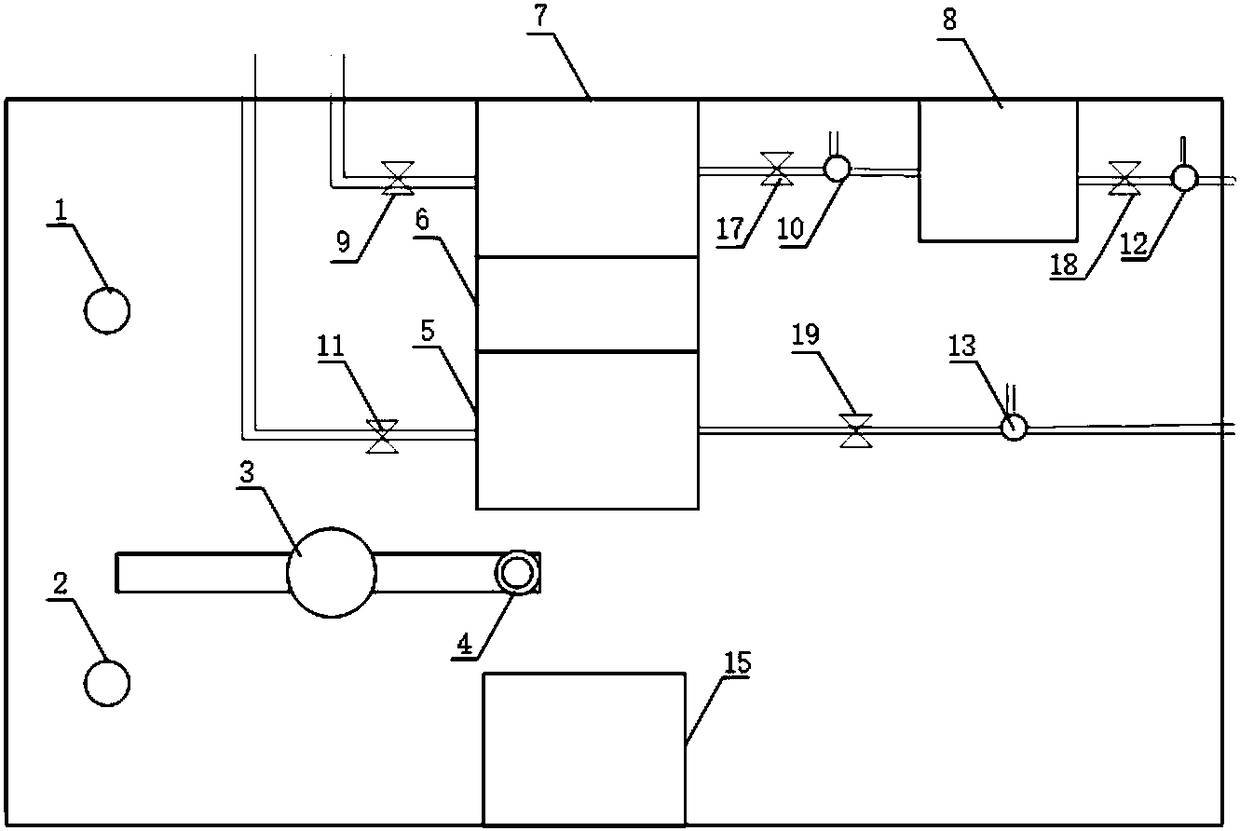

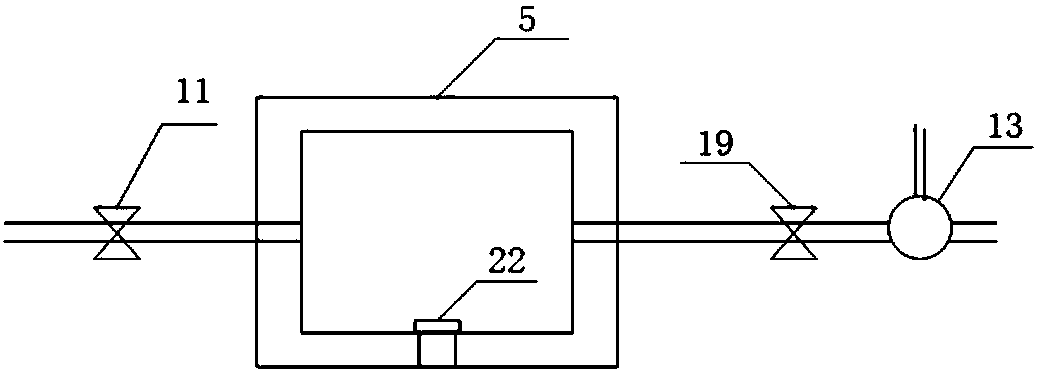

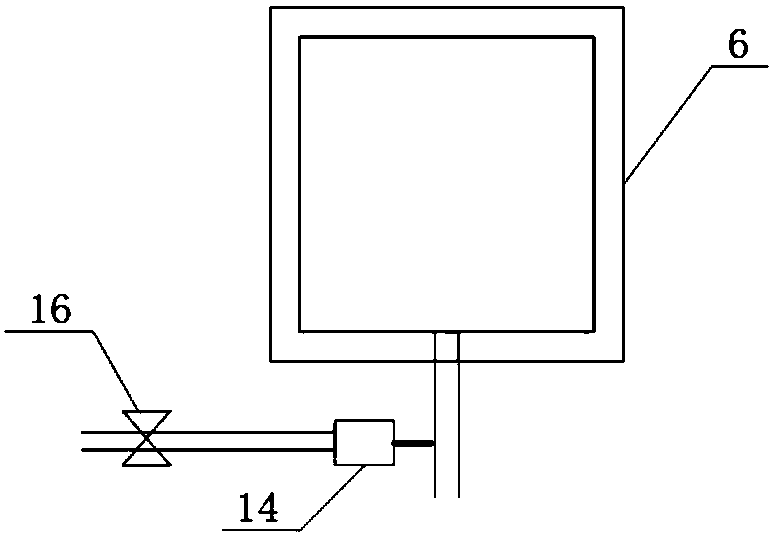

The invention discloses industrial waste gas desulfurization, denitrification and dust removal equipment. The equipment comprises a reaction box, the bottom of the left side of the reaction box is communicated with and is fixed with a drainage pipe, the right side of the reaction box is communicated with and is fixedly provided with a water inlet pipe, the ends, away from each other, of the drainage pipe and the water inlet pipe are communicated with and are fixedly provided with valves, the reaction box is filled with a treatment liquid, and the reaction box is provided with a rotary sprayingreaction mechanism and an efficient filtering and dust removing mechanism matched with the rotary spraying reaction mechanism. The design is reasonable, rotary spraying of the treatment liquid and synchronous vibration of the filter screen are facilitated, in a rotary spraying state, the sprayed treatment liquid can be uniformly dispersed in the reaction box, the dead angle phenomenon is reduced,the treatment reaction effect is improved, dust particles can be effectively prevented from adhering, accumulating and blocking the filter screen under the oscillation effect, the filtering efficiency is improved, the dust particles can be conveniently collected in a centralized manner and quickly taken out, and the use is facilitated.

Owner:孙琳

Normal temperature de-arsenic agent

ActiveCN101485971AGood dispersionIncrease contactOther chemical processesActive componentRoom temperature

The invention relates to a normal temperature dearsenifying agent, which consists of active components and a carrier, wherein the carrier is clay; and the active components comprise manganese dioxide and ferric oxide. Particularly, the dearsenifying agent consists of the following components in percentage by weight: 20 to 55 weight percent of manganese dioxide, 10 to 45 weight percent of ferric oxide, and 10 to 35 weight percent of the carrier. Based on the dearsenifying agent, the invention further discloses a method for preparing the dearsenifying agent, and the dearsenifying agent prepared by the method has higher arsenic capacity.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

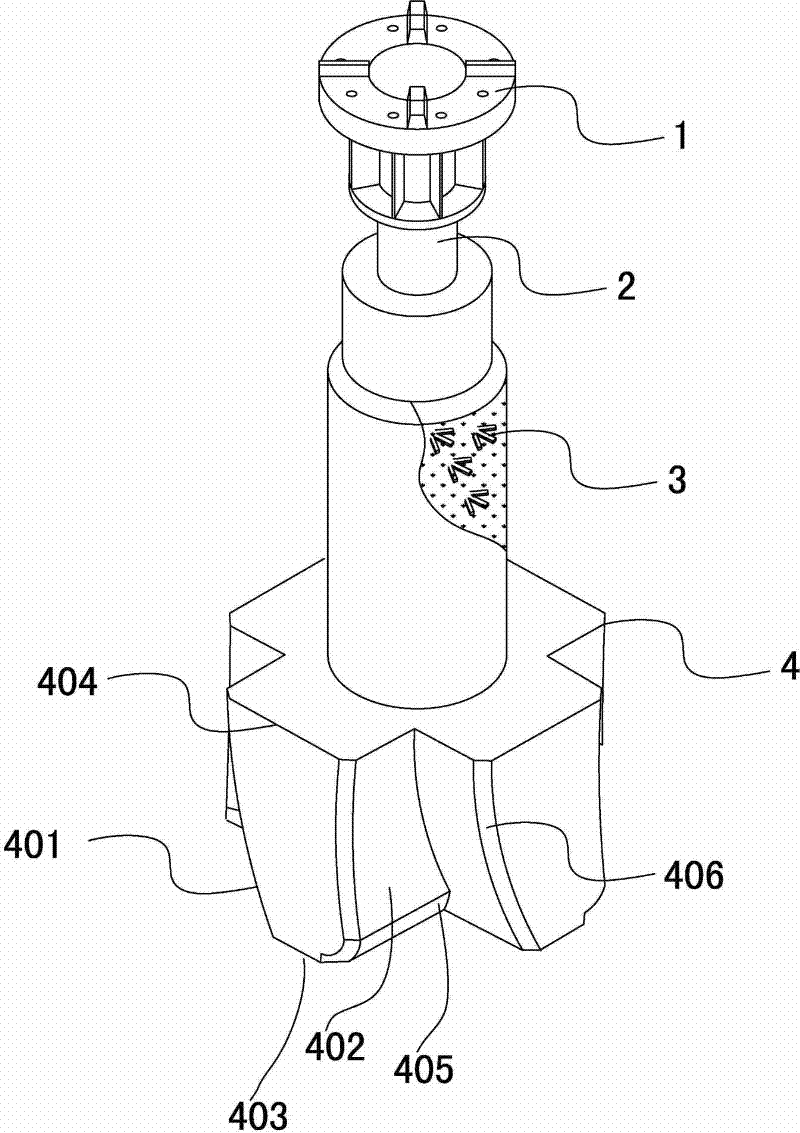

KR stirring paddle and manufacture method thereof

ActiveCN103014218APromote desulfurization reactionTo achieve the purpose of deep desulfurizationStirring devicesEngineeringHot melt

The invention discloses a KR stirring paddle and a manufacture method thereof. The KR stirring paddle is used in a hot-melt ladle desulfuration process and comprises a stirring shaft, paddles, a ventilating pipeline and ventilating holes, wherein the paddles are arranged on one end of the bottom of the stirring shaft, the core part of the stirring shaft is hollow and is used as the ventilating pipeline, the ventilating holes are formed in the paddles, one ends of the ventilating holes are communicated with the ventilating pipeline, the other ends of the ventilating holes are opened in the surfaces of the paddles, and one end of the top of the stirring shaft is connected with a gas supply device for supplying gas to the ventilating pipe. According to the invention, through the KR stirring paddle, the gas is introduced from the ventilating pipeline and is discharged from the ventilating holes, the discharged gas plays a role of reinforcing the stirring of molten ion to ensure that the molten iron is in well contact with a desulfurizing agent for reaction, therefore the desulfurization of the molten iron is accelerated, and the purpose of deep desulfurization of the molten iron is reached.

Owner:DAYE SPECIAL STEEL CO LTD

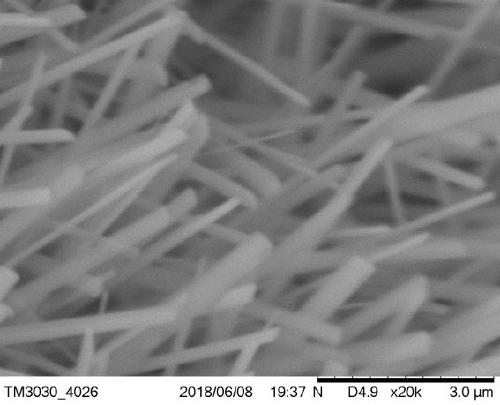

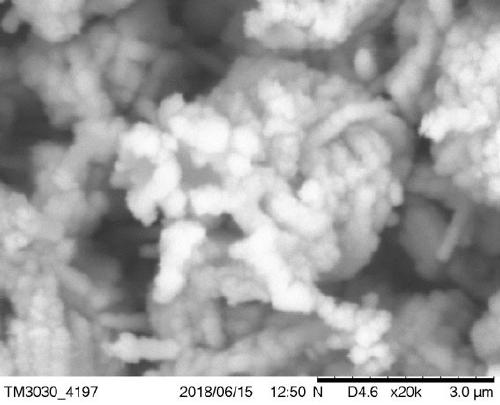

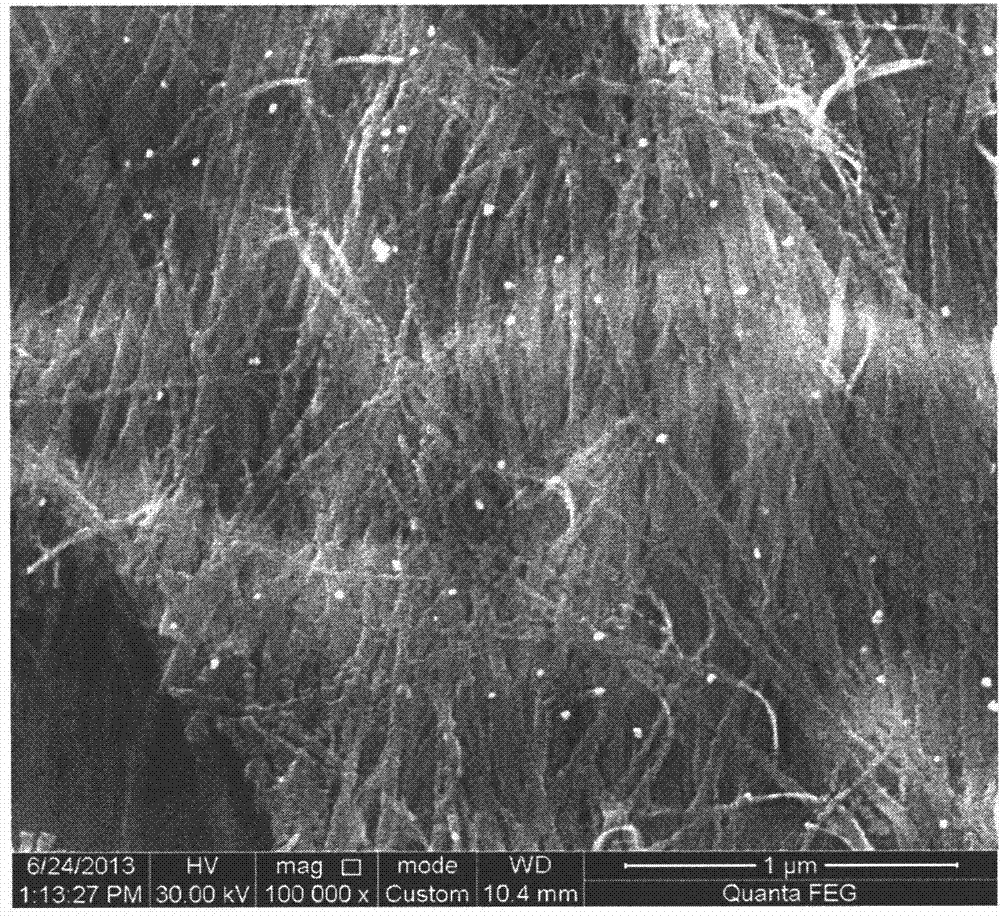

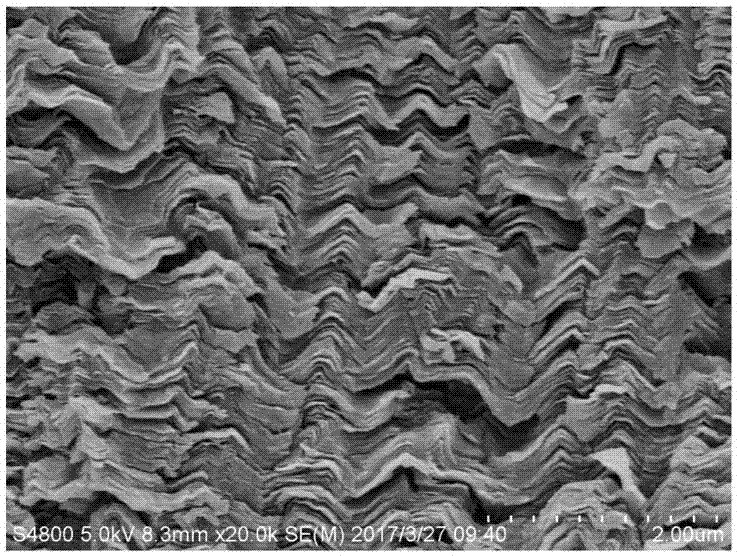

MoS2@Cu2S@ copper foam composite nanometer material and preparation method and application thereof

ActiveCN108950585AEasy to operateMild reaction conditionsNanotechnologyLiquid/solution decomposition chemical coatingElectrolysisMolybdate

The invention discloses a MoS2@Cu2S@ copper foam composite nanometer material and a preparation method and application of the MoS2@Cu2S@ copper foam composite nanometer material. The preparation method of the MoS2@Cu2S@ copper foam composite nanometer material comprises the following steps that (1) Cu(OH)2 nano-array rods are prepared on copper foam through a solution etching method; (2) the Cu(OH)2 nano-array rods obtained in the first step are used as a template and dipped into a crystalline hydrous molybdate and thiourea mixed solution, MoS2@Cu2S nano-array rods are generated through conversion by means of a hydrothermal synthesis method, and the composite nanometer material is obtained. The MoS2@Cu2S@ copper foam composite nanometer material is prepared by the adoption of the preparation method. A water electrolysis hydrogen evolution catalyst comprises the MoS2@Cu2S@ copper foam composite nanometer material. The MoS2 having good hydrogen evolution activity are grown on the surfaces of the Cu2S nano-array rods in an in-situ manner by means of a hydrothermal process, so that the electro-catalytic property of the composite is improved through the good electron conduction capacityof sulfide, and therefore by the adoption of in-situ growth of the MoS2@Cu2S on the surface of the foam copper, the electro-catalytic property of the composite can be collaboratively improved.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

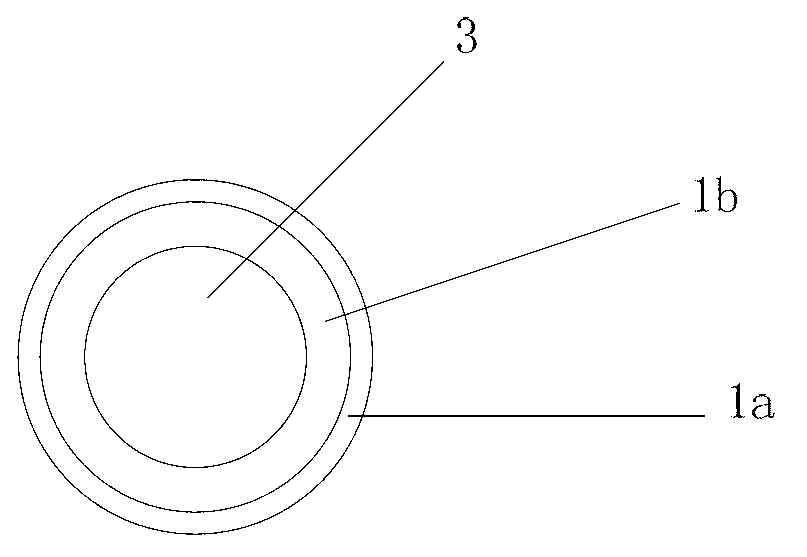

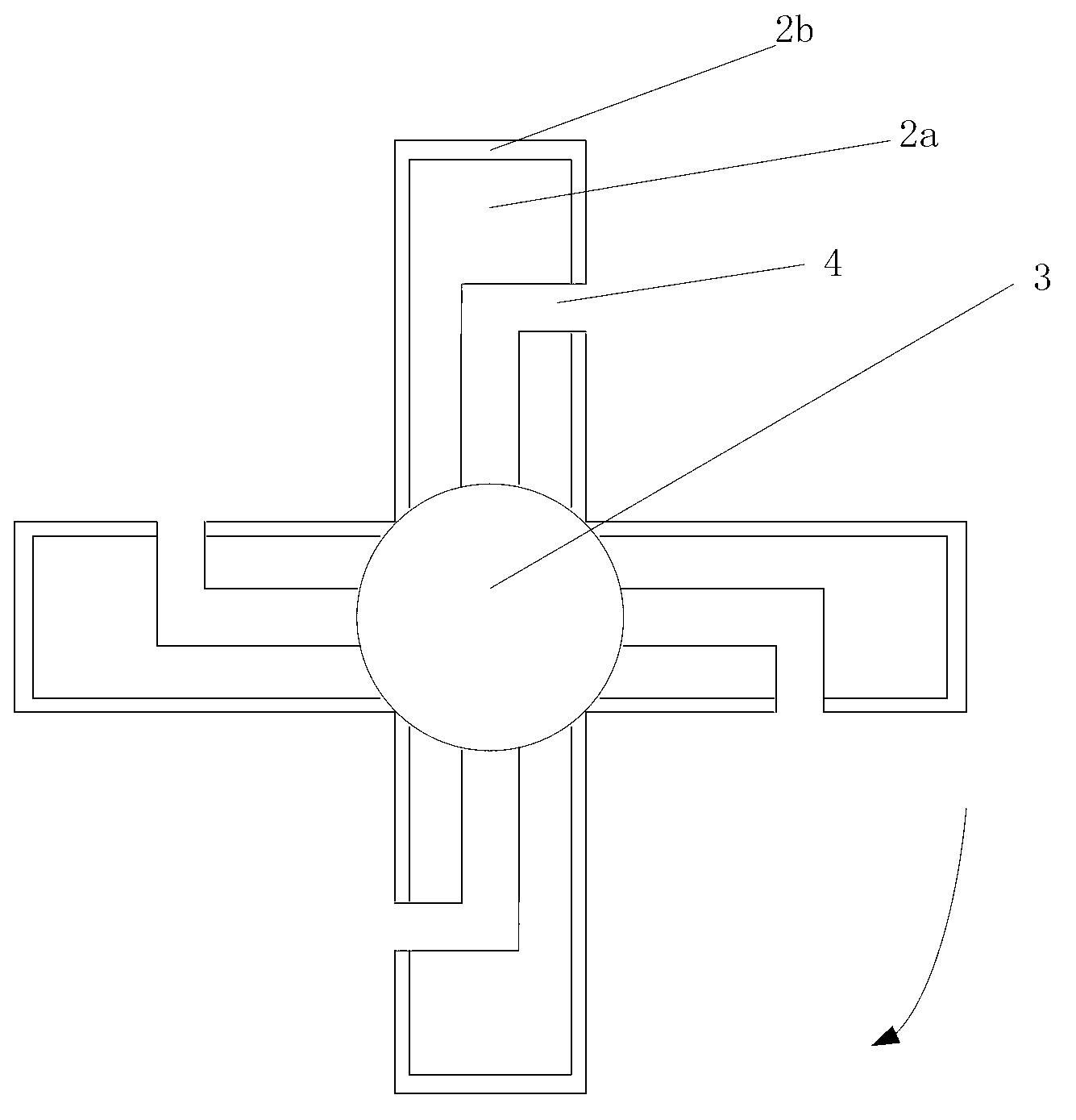

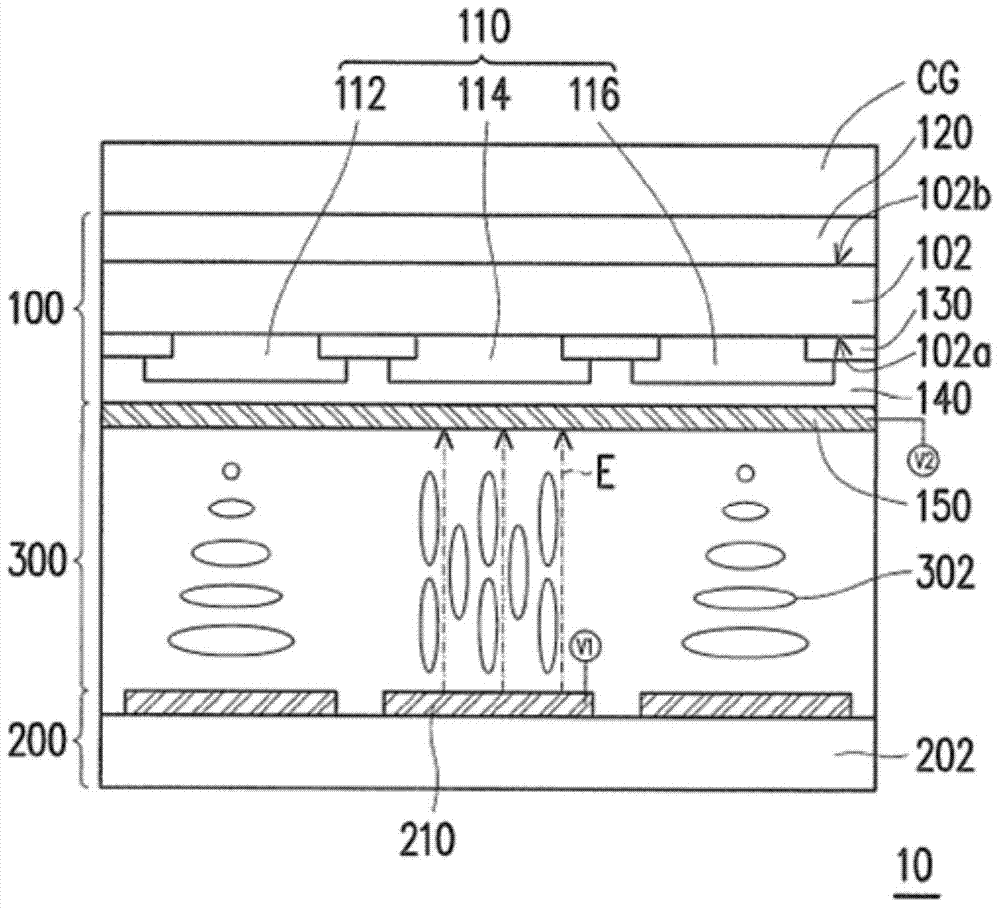

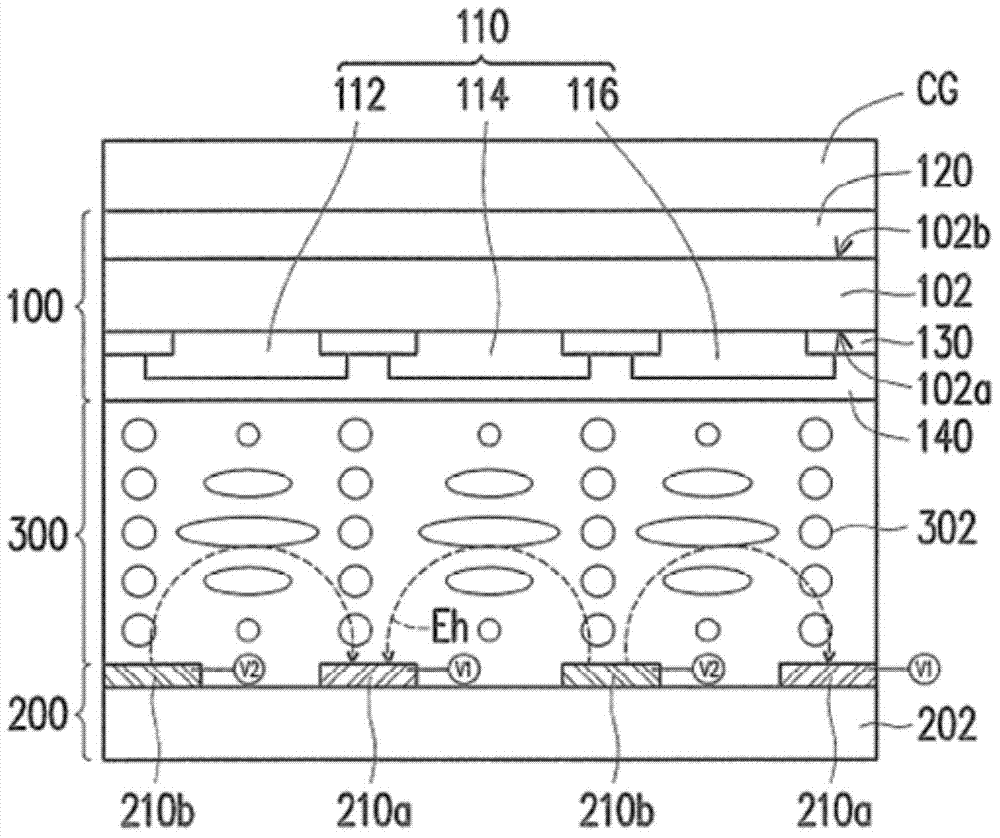

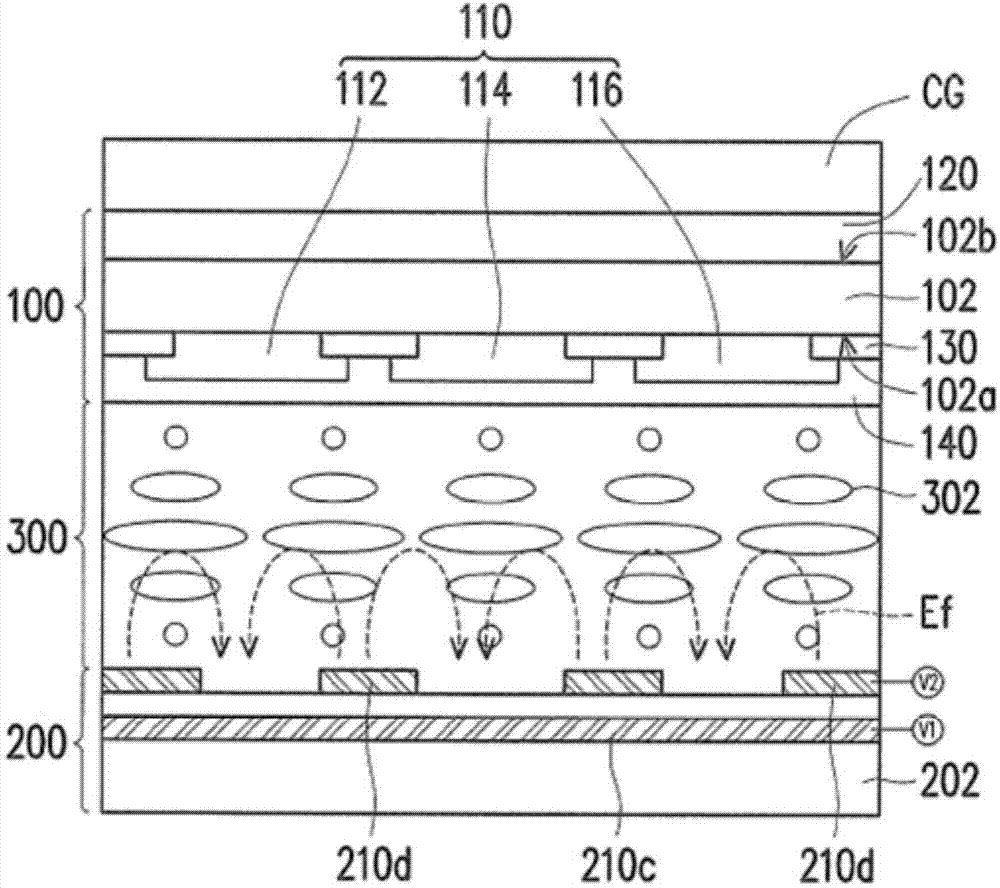

Device substrate

InactiveCN104731423AFacilitated contact responseImprove conductivityInput/output processes for data processingElectrical conductorEngineering

Owner:WINTEK CORP

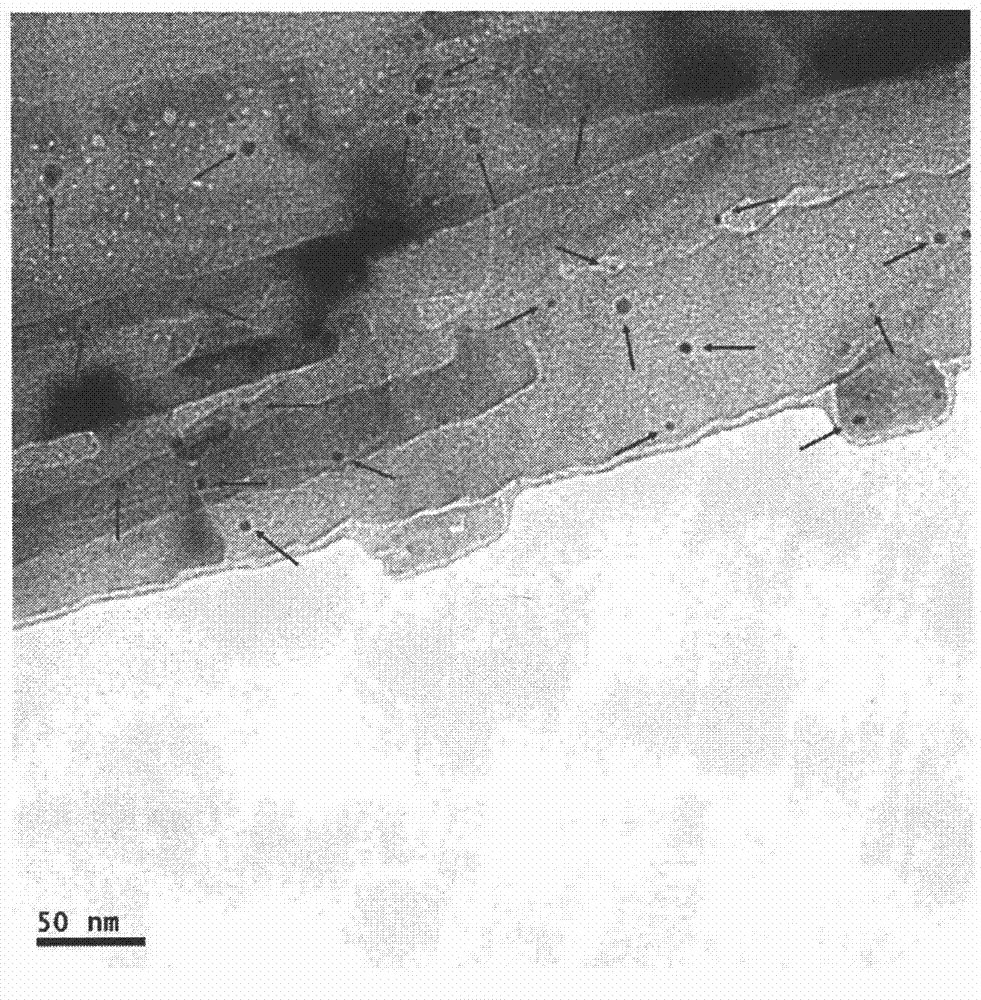

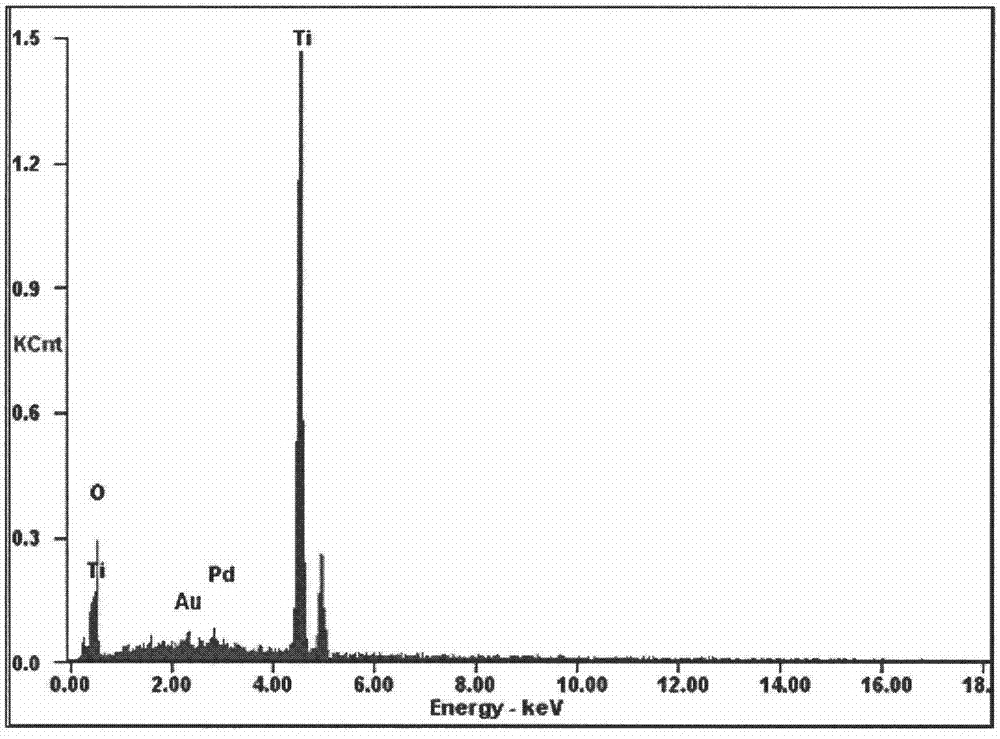

Preparation method of Au-Pd/TiO2 NBs photocatalyst

ActiveCN104492431AGood for recyclingAvoid water pollutionWater/sewage treatment by irradiationWater contaminantsPhotocatalytic degradationIon

The invention discloses a preparation method of an Au-Pd / TiO2 NBs photocatalyst, which comprises the following steps: with a titanium sheet as a matrix, performing anodic oxidation treatment on the titanium sheet to prepare TiO2NBs; before anodic oxidation, performing ultrasonic cleaning of the titanium sheet in ethanol and acetone respectively, performing acid pickling, washing with deionized water and drying, wherein a two-electrode system is adopted for the anodic oxidation; calcining in air; modifying the TiO2NBs prepared in the step I with Au-Pd bimetallic nanoparticles; adopting a three-electrode system in which chloroauric acid and a palladium chloride aqueous solution are used as Au and Pd sources; and depositing Au and Pd in turn and drying. The photocatalyst prepared by the method disclosed by the invention is fixed on the titanium matrix, the water body pollution caused by non-thorough recovery is avoided, a contactable surface area is larger, the contact reaction between organic pollutant molecules and the photocatalyst is facilitated, the photocatalytic degradation property of the photocatalyst is remarkably promoted, reaction conditions are mild, and the process flow is simple and easy to control.

Owner:QINGDAO AGRI UNIV

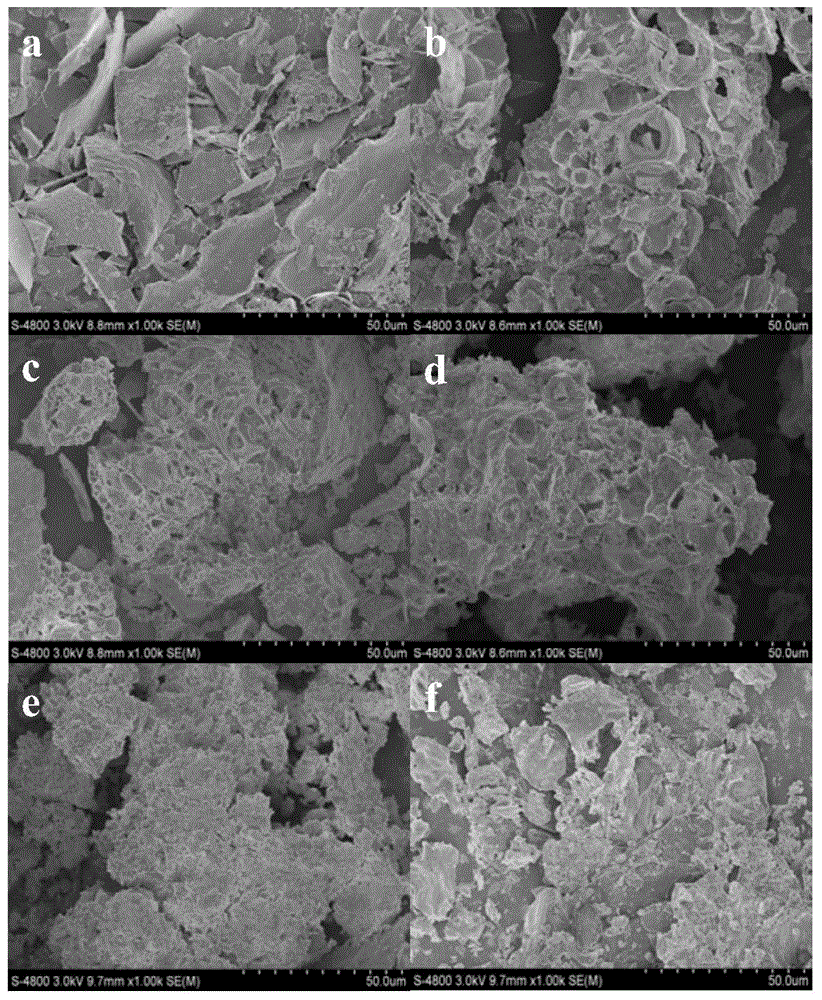

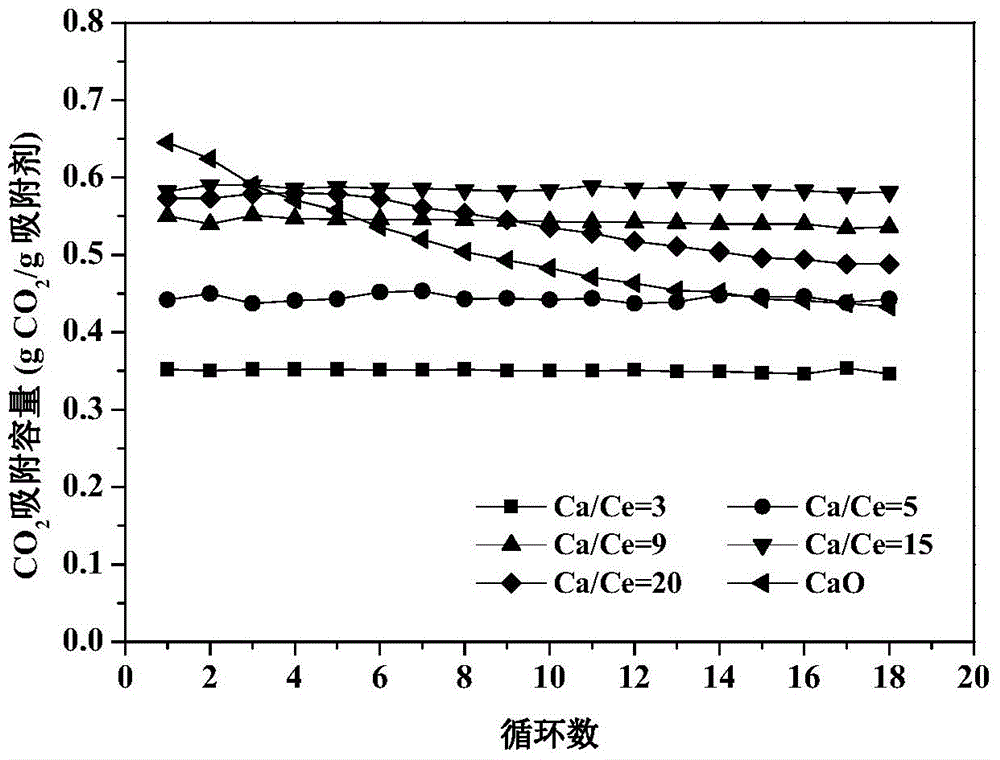

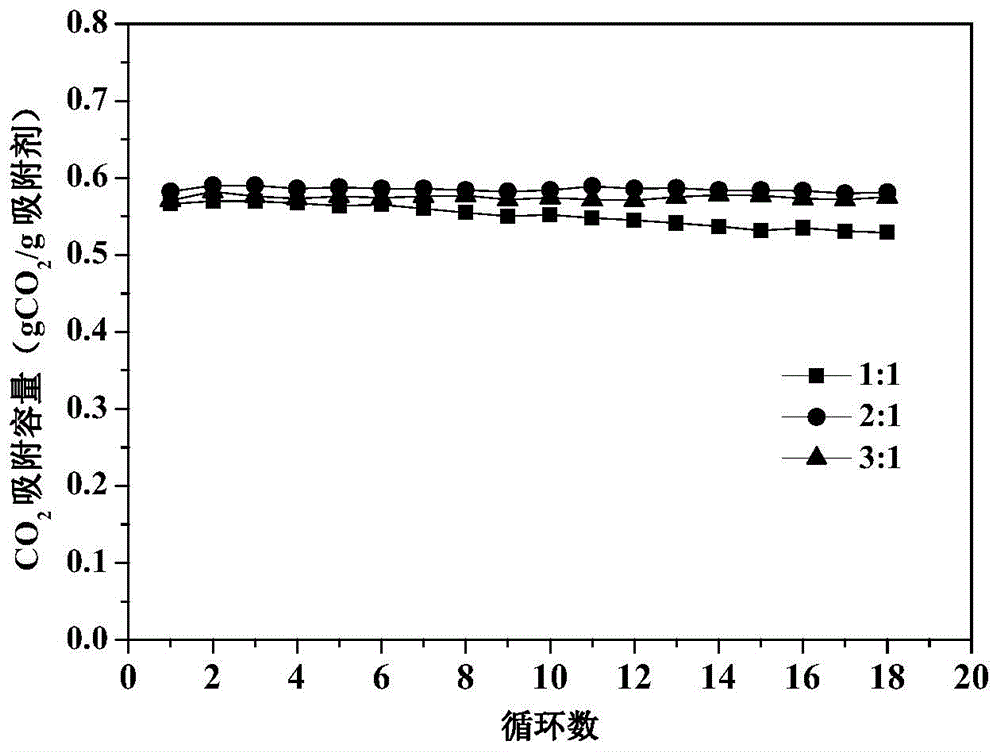

Calcium oxide based high-temperature carbon dioxide adsorbent material doped with inert component and preparation method

InactiveCN104785195AReduce grain sizeFacilitated contact responseOther chemical processesDispersed particle separationWater bathsCerium nitrate

The invention discloses a calcium oxide based high-temperature carbon dioxide adsorbent material doped with an inert component and a preparation method. The inert component is cerium oxide, and an active component for adsorbing carbon dioxide is calcium oxide. A calcium oxide based adsorbent is prepared with a sol-gel method, and cerium nitrate and calcium nitrate are precursors; citric acid is introduced, the mixture is sufficiently complexed in a water bath process, and calcium and cerium are uniformly dispersed; a large amount of gas is generated in a roasting process, and loose and porous morphology is formed. The material has the characteristics of excellent stability, high adsorption capacity, high molar conversion of calcium oxide and high adsorption rate when adsorbing carbon dioxide at the high temperature; the preparation process is simple, the cost is low, and the requirement for the preparation is lower; the adsorbent has a wider industrial application prospect when used for adsorbing carbon dioxide at the high temperature.

Owner:TIANJIN UNIV

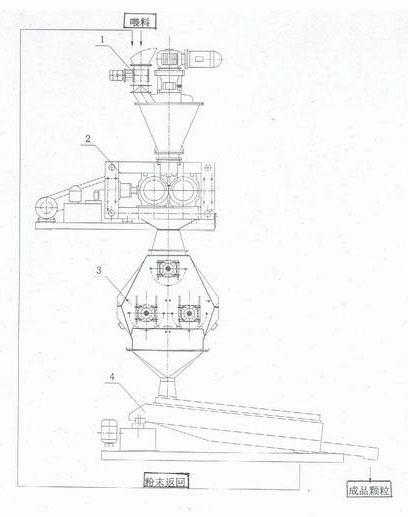

Physical preparation method of high density vanadium oxide powder

ActiveCN102372304AImprove automation performanceGood against airflowVanadium oxidesTitanium nitrideAlloy

The invention relates to a physical preparation method of high density vanadium oxide powder. Prepared high density (bulk density) vanadium oxide can be used to smelt vanadium-contained alloys and prepare metal vanadium as an additive or a main raw material. The physical preparation method is characterized in that: routine vanadium oxide powder is added to 0.1 wt% of a nonionic surfactant pulvis at a temperature of -20-120DEG C to improve the density and the stability of granulation and enhance the exhaust effect; mechanical pressurization, dry flaking, and granulation are directly carried out to prepare vanadium oxide particles with the granularity of 0.3-10mm; and in the process of flaking and granulation, the mechanical pressurization strength applied to the vanadium oxide powder is 10-125N / cm<2>, and the bulk density of granulated vanadium oxide is improved to 1.4-2.1g / cm<3> from routine 0.6-1.2g / cm<3>. High density vanadium oxide which has good airflow resistant effects and good furnace charge contact reacting performances allows the gasification and fly loss of vanadium oxide to be reduced, the smelting efficiency to be improved, and the density and the reaction efficiency of vanadium nitride products to be obviously improved in the production of vanadium nitride; and the density of the vanadium nitride products is far greater than the density of vanadium oxide products produced by chemical methods.

Owner:HEBEI IRON AND STEEL

Surface cleaning method before brazing repairing of single crystal turbine guide vane crack

InactiveCN109434233AWill not recrystallizeEfficient removalSoldering apparatusGas phaseSurface cleaning

The invention relates to a surface cleaning method before brazing repairing of a single crystal turbine guide vane crack. The surface cleaning method before brazing repairing of the single crystal turbine guide vane crack is characterized in that a method combining physics and chemistry is adopted to remove a carbon deposition layer and an aluminizing layer on the surface of a vane, to remove an oxidation film on the surface of the crack and to provide a clean surface for final brazing repairing. The surface cleaning method comprises the steps of (1) sand blasting treatment, (2) chemical cleaning, (3) aluminized coating stripping, (4) gas phase fluorinion cleaning, and (5) vacuum purification treatment. The surface cleaning method before brazing repairing of the single crystal turbine guide vane crack is suitable for an alitizing single crystal high temperature alloy turbine guide vane, the vane after being cleaned through the surface cleaning method has a good brazing repairing effect, and a repaired vane body has no recrystallization; the surface cleaning technical problem of single crystal high temperature alloy turbine guide vane non-recrystallization repairing is solved, and conspicuous innovativeness is achieved.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

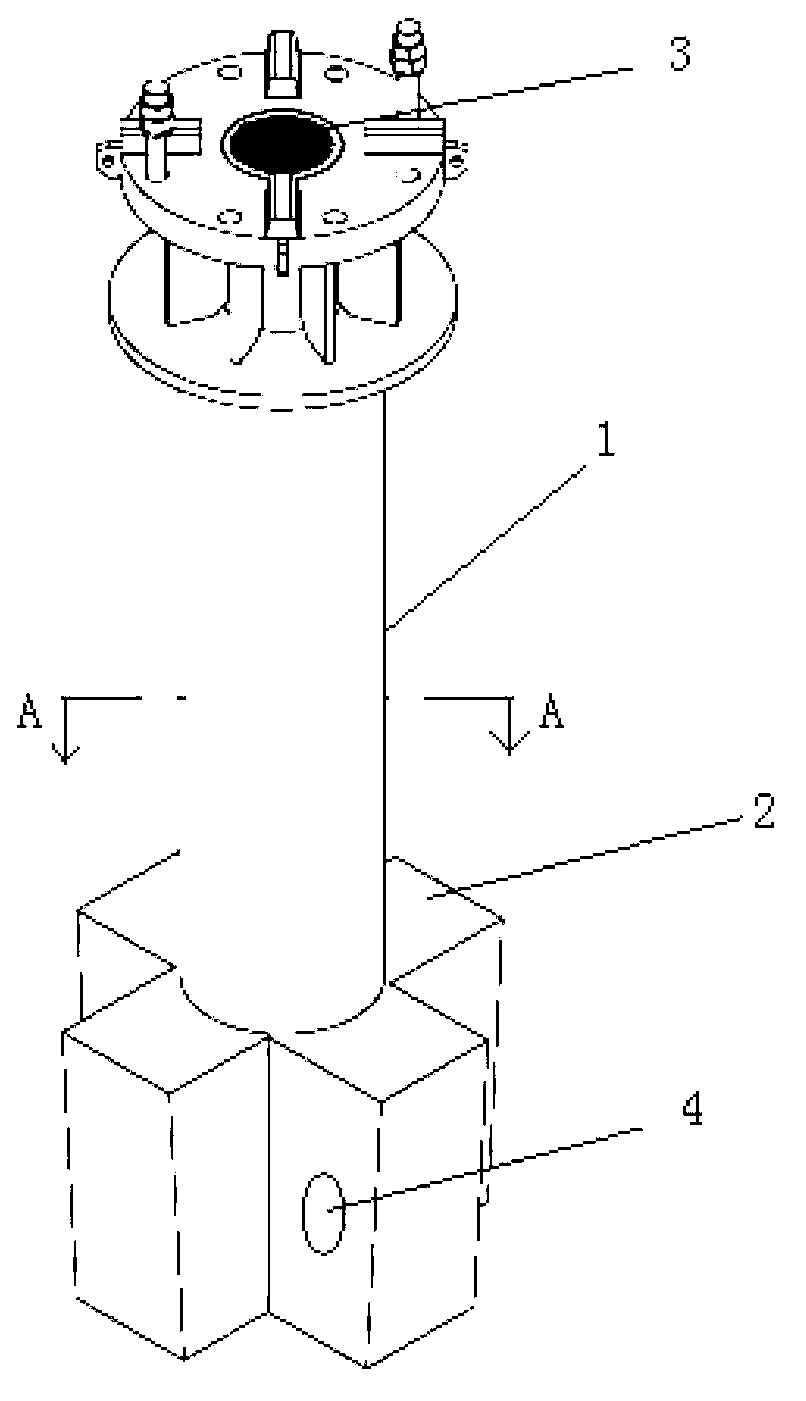

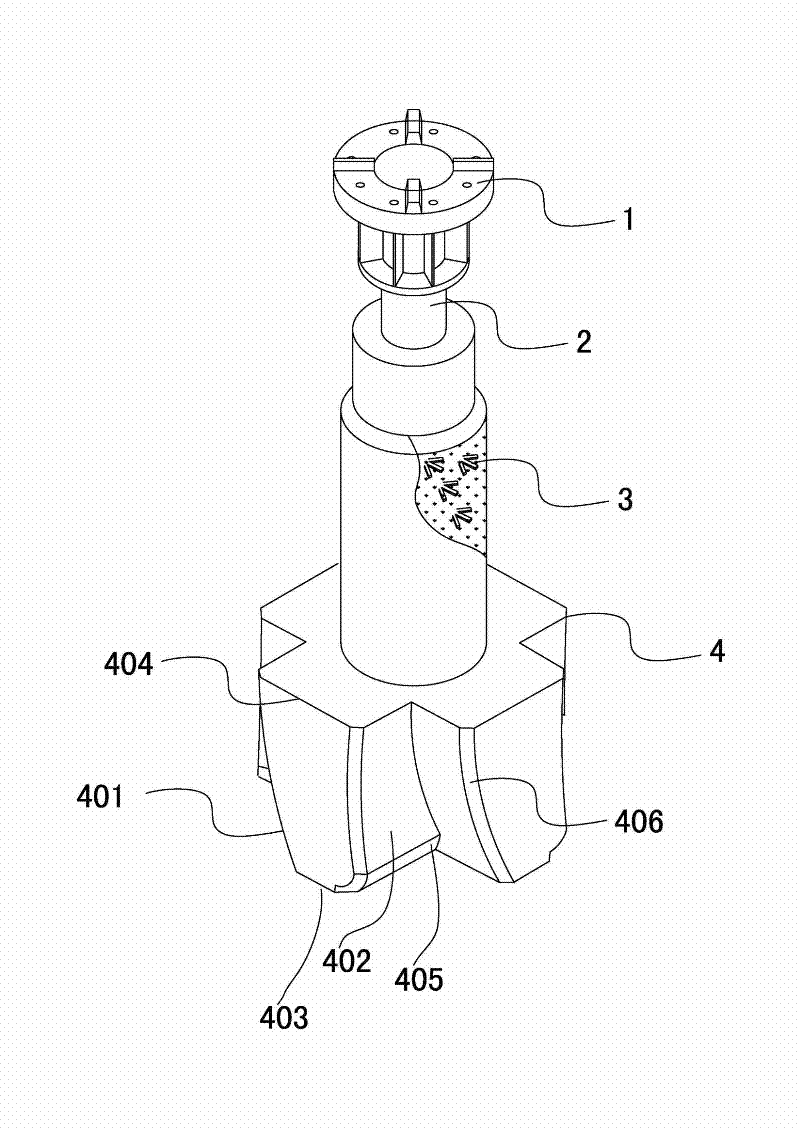

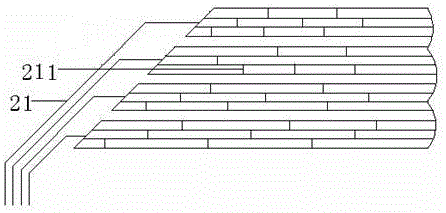

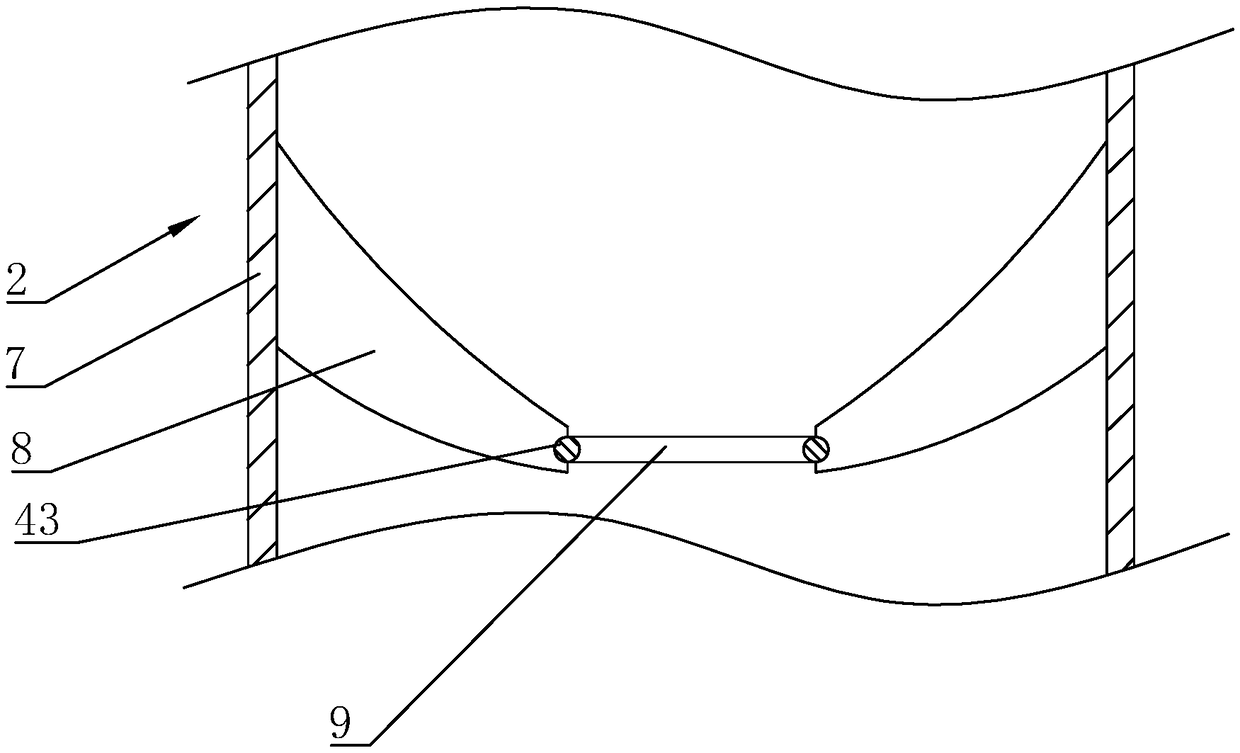

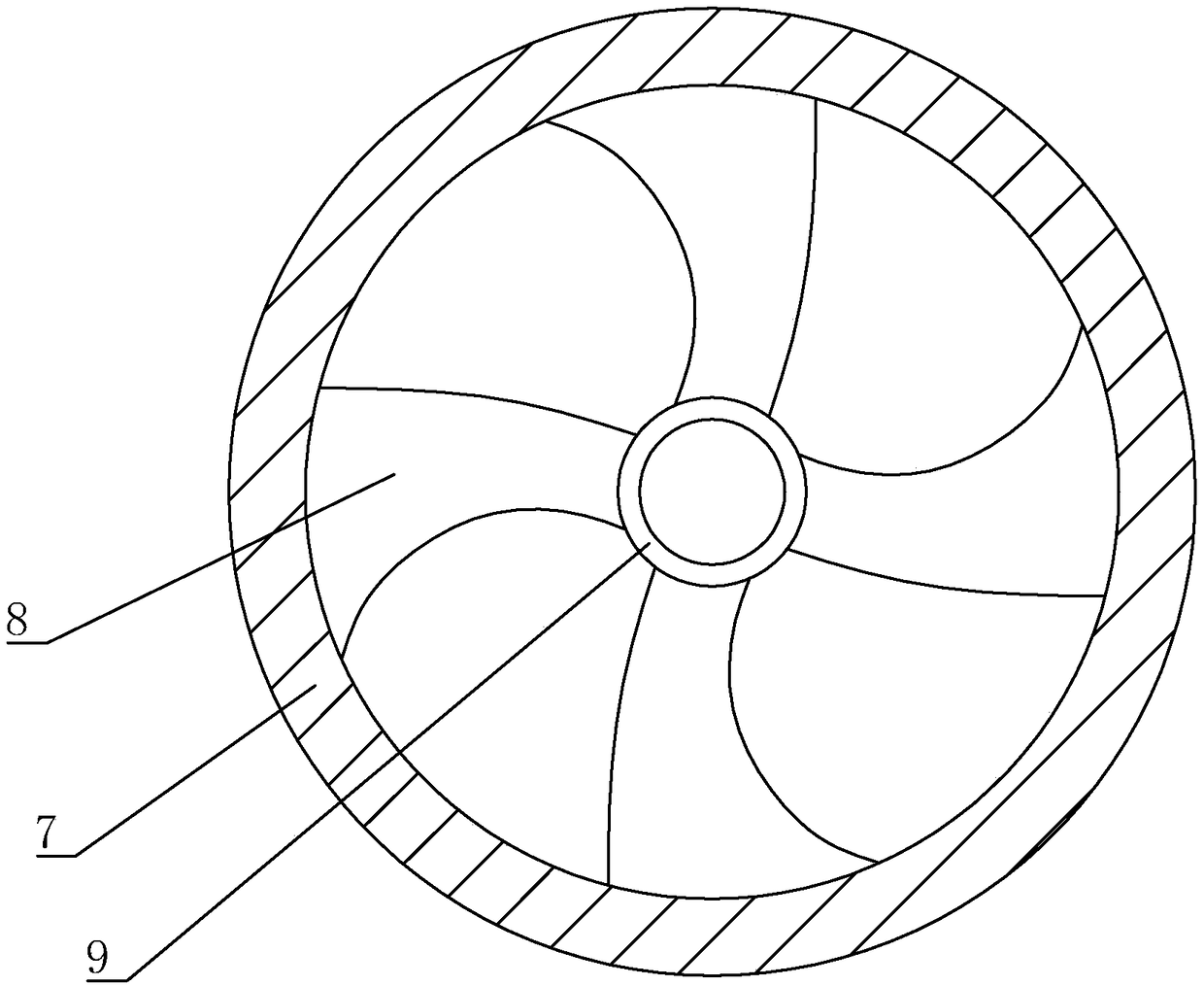

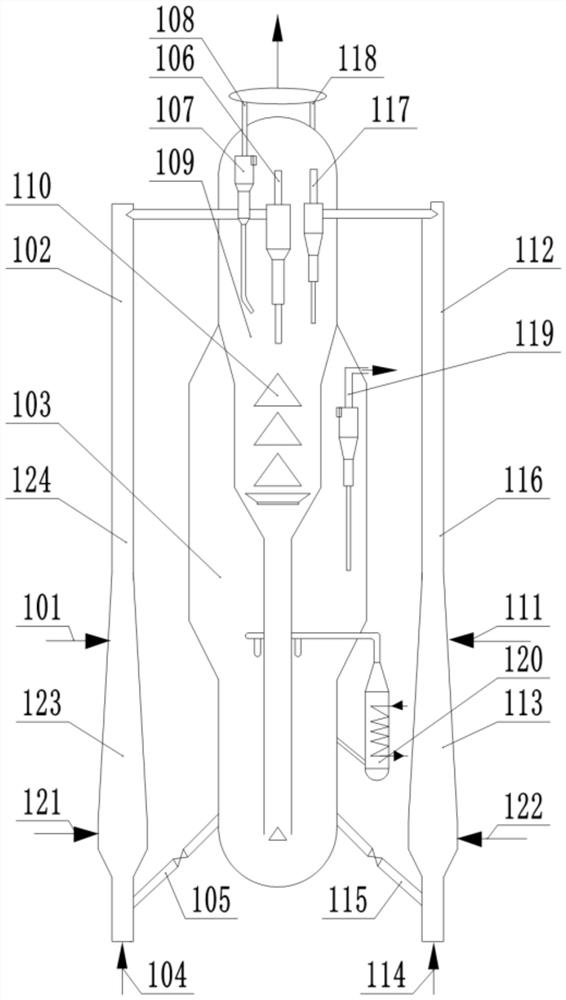

Stirring device for Kambara reactor (KR) molten iron desulfurization

The invention belongs to the field of desulfurization devices in metallurgy and foundry industry, and in particular relates to a stirring device for Kambara reactor (KR) molten iron desulfurization. The stirring device comprises a flange connecting piece (1), a stirring shaft (2) fixedly connected with the flange connecting piece (1), and a stirring blade (4) fixedly connected with the lower part of the stirring shaft (2), and is characterized in that: an iron facing surface (401) of the stirring blade (4) is a convex arc surface; an iron backing surface (402) of the stirring blade (4) is a convex arc surface; the width a of a blade bottom (403) of the stirring blade (4) is smaller than the width b of a blade top (404) of the stirring blade (4); a convex arc surface is formed at an included angle between the blade bottom (403) of the stirring blade (4) and the iron backing surface (402); the stirring blade (4) has a three-blade structure; and a convex arc surface is formed at a side wall external corner (406) of the stirring blade (4). The stirring device has a simple structure, long working life and an ideal stirring effect and is low in cost.

Owner:营口东邦环保科技股份有限公司

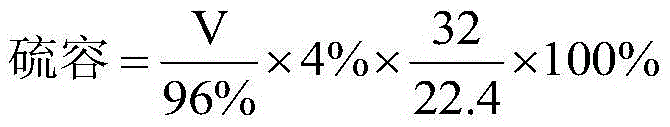

Magnetic ferric oxide desulfurizer and preparation method thereof

ActiveCN105597516AHigh sulfur capacityEasy accessGaseous fuelsDispersed particle separationCooking & bakingHigh pressure

The invention discloses a magnetic ferric oxide desulfurizer and a preparation method thereof. The preparation method comprises the following steps that 1, ferric oxyhydroxide, a binder and an auxiliary are mixed to be uniform, and a mixture I is obtained, wherein the auxiliary adopts coal ash and / or volcanic ash; 2, the mixture I, peptizer and water are mixed to be uniform, and a mixture II is obtained; 3, the mixture II is formed and dried; 4, baking is conducted on a dried forming composition, and the magnetic ferric oxide desulfurizer is obtained. The prepared magnetic ferric oxide desulfurizer has a porous structure and is high in mechanical strength and capable of making full contact with sulfur-containing gas, and the desulfurization efficiency is improved. Desulfurization can be conducted under the working conditions of room temperature to medium temperature, normal pressure to high pressure, high hydrogen sulfide content, high moisture content and different feed gases, in the desulfurization process, the strength of a desulfurizing agent is not reduced, argillation and hardening phenomena do not exist, and the high desulfurization activity is kept all the way.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Method for preparing pyrolytic boron nitride material

InactiveCN107265416AIncrease productivityFast deposition growthNitrogen compoundsBoron nitrideChemical vapor deposition

The invention discloses a method for preparing a pyrolytic boron nitride material. The method comprises the following steps: putting a substrate mold in an air-carrying atmosphere carrying borazine vapor under a vacuum condition, and pyrolyzing borazine which constantly deposits on the depositing surface of the substrate mold by adopting a chemical vapor deposition method to form the pyrolytic boron nitride material. The preparation method of the pyrolytic boron nitride material has the advantages of simple and easily controlled process, low cost, low energy consumption, high yield, environmental friendliness and the like.

Owner:NAT UNIV OF DEFENSE TECH

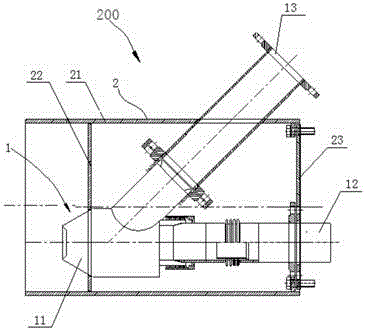

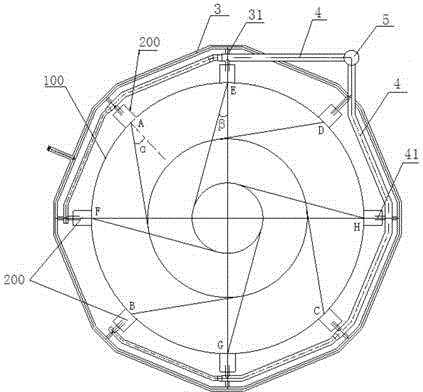

Desulfurization device

The invention discloses a desulfurization device comprising a desulfurization tower body (100). At least one set of atomizers (200) is arranged on the tower wall of the desulfurization tower body (100). A plurality of atomizers (200) in each atomizer set are circumferentially arranged on and along the tower wall, such that slurry ejected by each set of the atomizers form a swirl in the desulfurization tower body (100). With the desulfurization device provided by the invention, flue gas can be mixed well with the slurry; the contact time of the flue gas and the slurry can be prolonged; and a contact reaction of the flue gas and the slurry can be facilitated. Therefore, desulfurization efficiency can be improved, and circulating slurry utilization rate can be improved, such that circulating slurry demand can be reduced, and desulfurization energy consumption can be reduced.

Owner:北京楚天瑞平环保科技有限责任公司

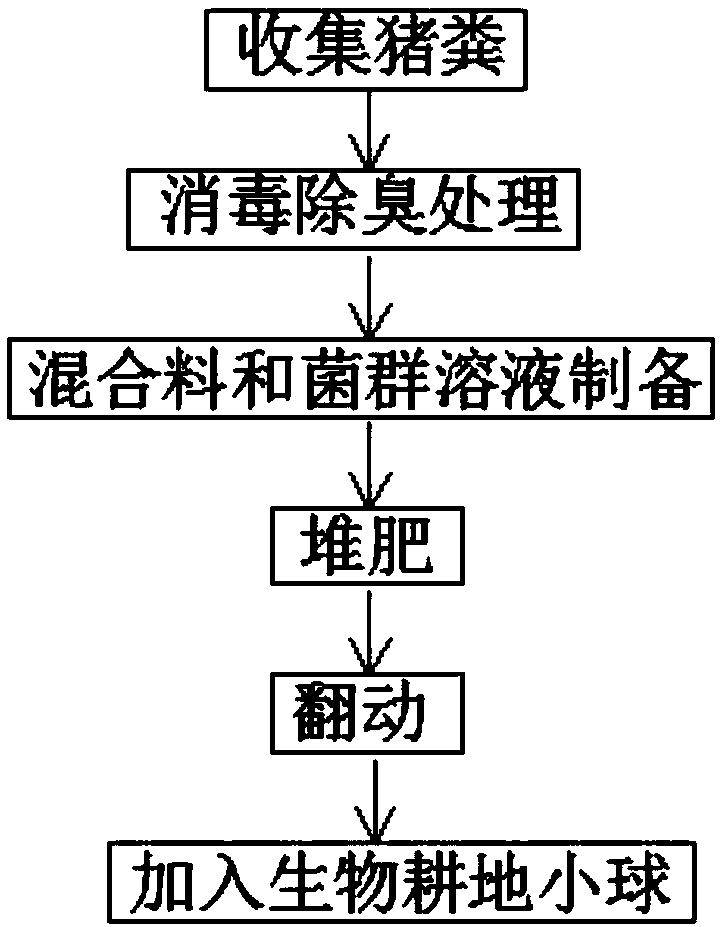

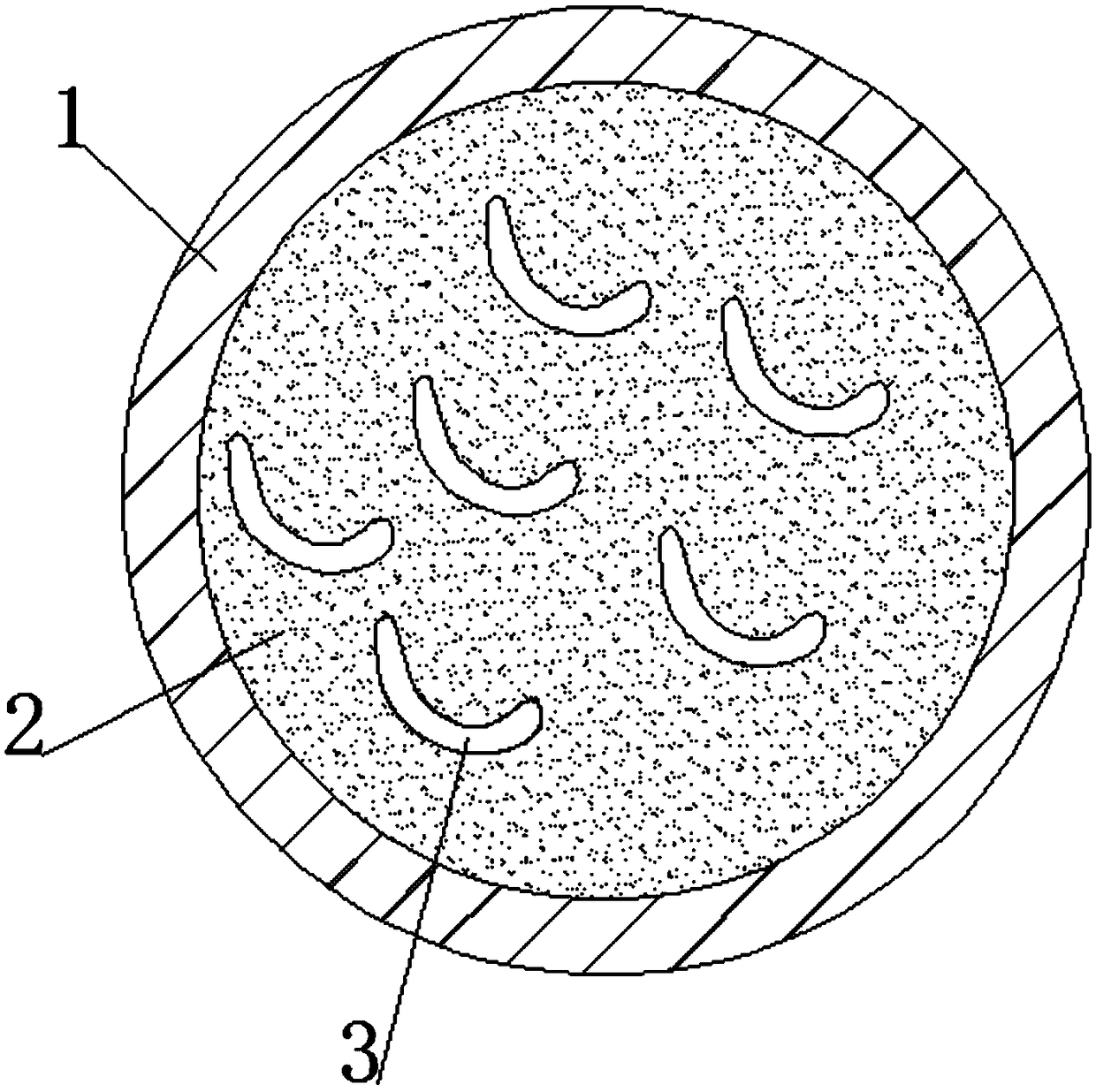

Method for making bio-organic fertilizer by utilizing pig manure

InactiveCN109438015APromote absorptionFewer crushing stepsExcrement fertilisersBioloigcal waste fertilisersMicroorganismBiotechnology

The invention discloses a method for making a bio-organic fertilizer by utilizing pig manure, and belongs to the field of organic fertilizers. The method for making the bio-organic fertilizer by utilizing the pig manure is characterized in that the organic fertilizer comprises the following ingredients in parts by mass: 200-220 parts of pig manure, 60-80 parts of plant ash, 100-110 parts of pond bottom sludge, 20-30 parts of oil cakes, 50-60 parts of crop straw, 3-5 parts of microbial flora, 20-30 parts of rotted crop fruits, 8-10 parts of wormcast and 30-40 parts of rice bran; an effect of processing the pig manure into the organic fertilizer in the form of composting is realized; through the use of biological land cultivating balls, earthworm cocoons in the biological land cultivating balls are hatched into earthworms, and biological soil digging can be performed on soil near the organic fertilizer and roots and stems of crops, so that the cost and the sum of labor of artificial soildigging are greatly reduced, the absorption of the organic fertilizer by the roots and stems of the crops is more easily, the step of crushing the organic fertilizer after composting is omitted, andthus the work efficiency is significantly increased.

Owner:广东巴斯德环境科技有限公司

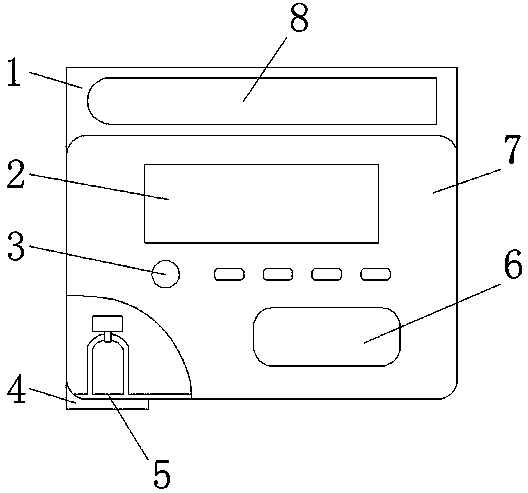

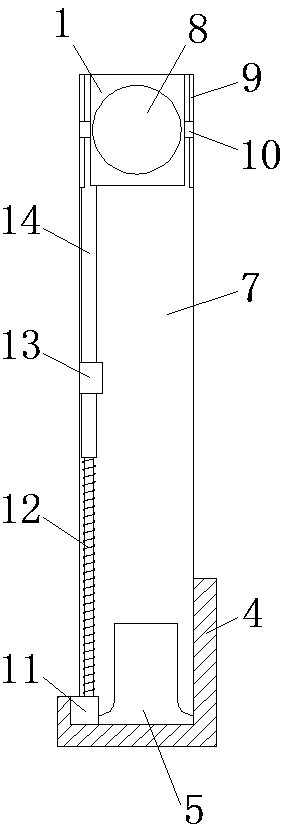

Blood glucose detector used for surgical department

InactiveCN107817344AThe blood collection process is fastEase of contact reactionDiagnostic recording/measuringSensorsSurgical departmentEngineering

The invention discloses a blood glucose detector for surgery, which comprises a box body, a storage box and a protective cover, a groove is arranged on the top of the box body, a storage box is arranged in the groove, a blood collection pen is placed in the storage box, a box The middle part of one side of the body is respectively equipped with a display, buttons and a storage box. The bottom of the box body is provided with a test paper receiving port, and the outer cover of the test paper receiving port is provided with a protective cover, which is connected to the box body through a rotating part. , the present invention is provided with a storage box for storing the blood collection pen and a storage box for storing the test paper, so as to prevent patients from forgetting to carry the blood collection pen or test paper when going out and miss the time of blood collection, and the protective cover can effectively protect the test paper receiving port from receiving Damage to the external environment facilitates contact and reaction between the blood and the sensor in the receiving port of the test paper, thereby ensuring the detection accuracy of the blood glucose detector.

Owner:廖仁良

Fume purification device and central fume purification equipment

PendingCN108050565AReduce the degradation and purification efficiencyReduce the frequency of cleaning and maintenanceDomestic stoves or rangesLighting and heating apparatusFlueActive carbon

The invention provides a fume purification device and central fume purification equipment, and relates to the technical field of purification equipment. The fume purification device comprises a ventilation pipe, an active carbon carrier layer is arranged in the ventilation pipe, the shape of the active carbon carrier layer is matched with the cross section shape of the ventilation pipe, and a photocatalyst corresponding to the ultraviolet rays is loaded on the active carbon carrier layer; an ultraviolet lamp is arranged in the ventilation pipe, and the ultraviolet lamp corresponds to the active carbon carrier layer; the central fume purification equipment comprises a public gas flue, an exhaust fan and the fume purification device; and the gas outlet end of the public gas flue is communicated with a gas inlet of the ventilation pipe, and a plurality of fume collecting hoods are communicated with the public gas flue. The fume purification device has good purification effect on VOCs element in the fume gas, the content of the VOCs element in the gas which is exhausted out of the ventilation pipe is greatly decreased, and pollution to the environment by the exhausted gas is reduced.

Owner:HANGZHOU ROBAM APPLIANCES CO LTD +1

Device for detecting carbon content of fly ash in coal-fired power generation boiler

InactiveCN108593853ARaise the sintering temperatureAvoid the phenomenon of sticking to each otherWeighing by removing componentProcess engineeringFly ash

The invention discloses a device for detecting the carbon content of fly ash in a coal-fired power generation boiler and belongs to the technical field of detection of carbon content of fly ash. The device for detecting the carbon content of the fly ash in the coal-fired power generation boiler comprises a drying furnace, a burning furnace, a burning container and a lifting rotary tray, wherein one end of the drying furnace is communicated with an inert gas supply mechanism through a pipeline, and the other end of the drying furnace is communicated with a vacuum pump I through a pipeline; oneend of the burning furnace is communicated with an oxygen supply mechanism through a pipeline, the other end of the burning furnace is communicated with one end of a sealed container through a pipeline, and the other end of the sealed container is communicated with a vacuum pump II through a pipeline; the lifting rotary tray is used for transporting the burning container. The invention aims to overcome the defects of low measurement accuracy and reliability of the conventional technology for detecting the carbon content of the fly ash in the coal-fired power generation boiler, provides the device for detecting the carbon content of the fly ash in the coal-fired power generation boiler, and improves the accuracy and the reliability of measurement on the carbon content of the fly ash.

Owner:马鞍山市特种设备监督检验中心 +1

LCD (liquid crystal display) integral touch device with an external copper process

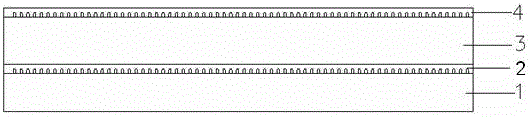

InactiveCN105717683AReduce processImprove yieldNon-linear opticsInput/output processes for data processingLiquid-crystal displayTransmittance

The invention relates to an integrated touch device with an external copper process for an LCD liquid crystal display. It includes an upper glass substrate and a sensing pattern layer; the surface of the upper glass substrate is copper plated with a first metal grid conductive layer, the first metal grid conductive layer is coated with an OC insulating layer, and the copper on the OC insulating layer is plated with a second metal grid conductive layer; the first metal grid conductive layer directly forms the first metal grid circuit, and forms the electroplating driving electrode pattern through the driving electrode unit; the second metal grid conductive layer directly forms the second metal grid circuit, and forms the second metal grid circuit directly through the driving electrode unit The sensing electrode unit forms an electroplating sensing electrode pattern; the electroplating driving electrode pattern and the electroplating sensing electrode pattern constitute the distribution of the sensing pattern layer. The present invention can reduce channel impedance, reduce power consumption, and improve transmittance without reducing pitch; in the case of a flexible integrated touch device, it can reduce the change of impedance when bending or stretching.

Owner:赵宗轩

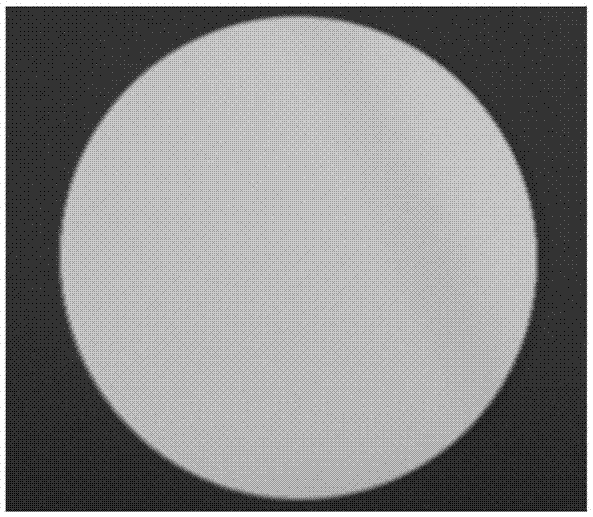

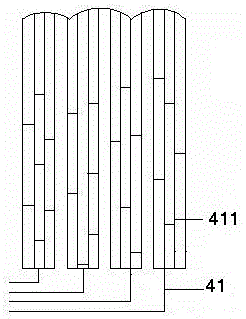

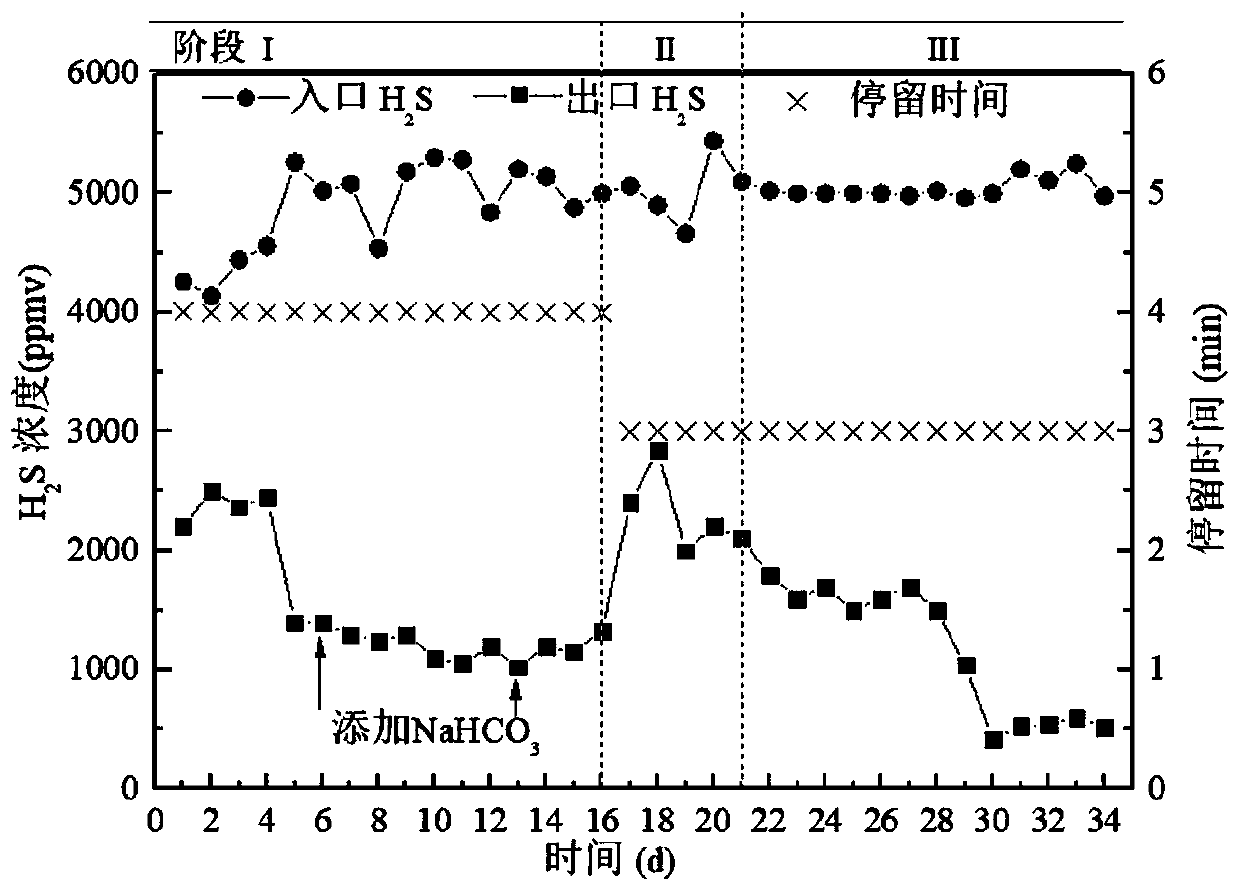

Gas circulation biological bubble tower methane/natural gas biological desulfuration method

ActiveCN109908717AImprove oxygen solubilityReduce entryDispersed particle separationGaseous fuelsProduct gasProcess engineering

The invention discloses a gas circulation biological bubble tower methane / natural gas biological desulfuration method and belongs to the technical field of environment-friendly pollution treatment. The gas circulation biological bubble tower methane / natural gas biological desulfuration method comprises the steps of mixing methane / natural gas containing hydrogen sulfide with air or oxygen, allowingmixed gas to enter into a reactor for purification through a bubble diffuser from the bottom of a biological bubble tower reactor, dividing the purified methane / natural gas into two parts, allowing one part to circularly back flow through a gas circulation pump and enter the reactor with the mixed gas, and directly discharging the other part from the top of the reactor. The method basically converts H2S into elemental S, and significantly reduces post-treatment cost and secondary pollution risks; in particular, the methane is purified circularly; the desulfurization efficiency is greatly improved; and a yield of elemental sulfur is increased.

Owner:SICHUAN UNIV

Intelligent switch cabinet and use method thereof

ActiveCN112952622ASafeguard the operating environmentExtended service lifeSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsDust controlEngineering

The invention relates to the technical field of switch cabinets, and discloses an intelligent switch cabinet, which comprises a cabinet body, wherein a base is welded to the bottom of the cabinet body, side bases are welded to the two sides of the cabinet body, a cabinet door is fixedly installed on the front portion of the cabinet body, an installation bottom box is connected to the interior of the cabinet body through bolts, a dehumidification and heat dissipation mechanism is arranged in the installation bottom box, a dust collection box is clamped to the inner wall of the cabinet body, a separation net is fixedly connected to the portion, located above the dust collection box, of the cabinet body through bolts, and a dust removal and heat dissipation mechanism is arranged in the cabinet body. According to the intelligent switch cabinet and the use method thereof, the effects of dehumidification and heat dissipation of the interior of the cabinet body are achieved through mutual operation of all structures in the dehumidification and heat dissipation mechanism and the dust removal and heat dissipation mechanism, and moisture and hot air in the cabinet body are absorbed and dissipated, so that the effect that the operation environment of internal elements is safe is guaranteed, and the service life of the electric appliance element is prolonged.

Owner:孙冶

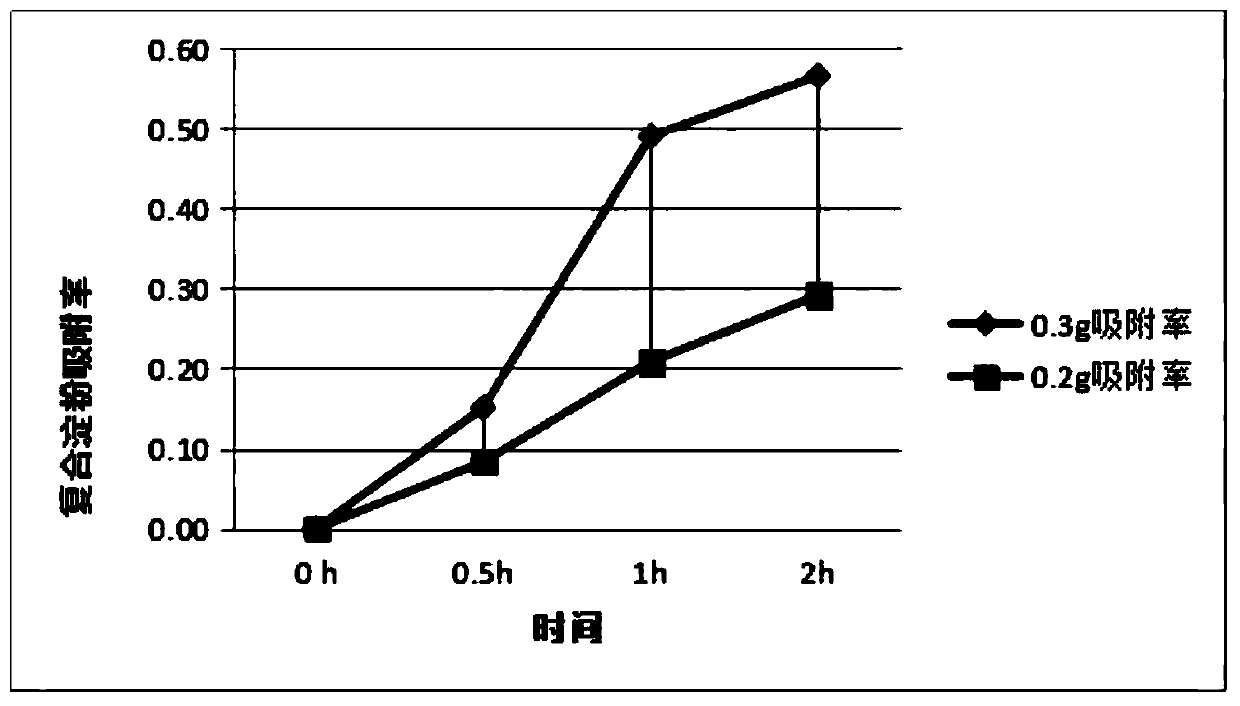

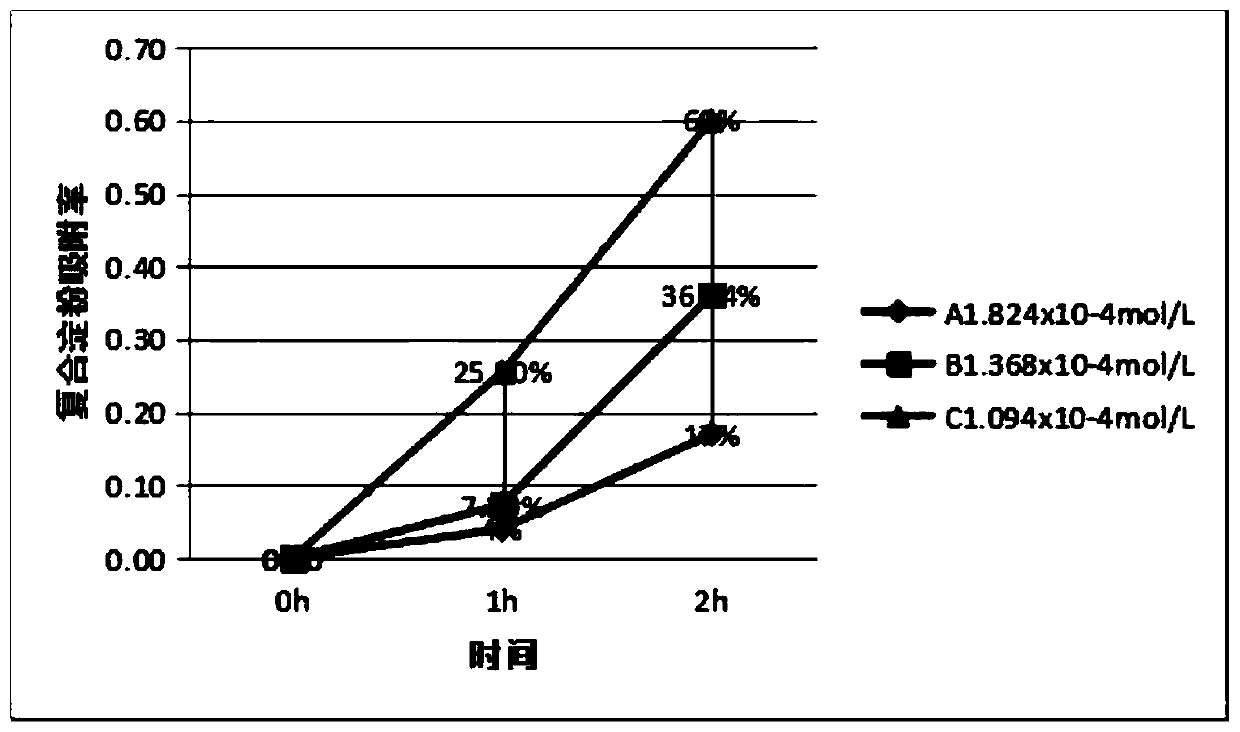

Method for preparing starch-beta-cyclodextrin microspheres based on reversed-phase latex method

The invention belongs to the technical field of preparation of starch-beta-cyclodextrin microspheres, and provides a method for preparing starch-beta-cyclodextrin microspheres based on reversed-phaselatex method. The preparation method comprises the following steps: step 1, starch pretreatment: firstly, uniformly dispersing starch into a softening and moistening solution for 1-2 hours of immersion, then centrifuging and drying, then adding 25-35U / g of starch branching enzyme, then reacting for 1-2 hours at 55-65 DEG C, and finally washing with water, centrifuging and drying, so as to obtain afinished product. According to the prepared novel jasmine essence sustained release agent-starch-beta-cyclodextrin microspheres prepared using the reversed-phase latex method, the starch and the beta-cyclodextrin are both taken as the main materials to prepare the sustained-release agent, and the advantages of the starch and the beta-cyclodextrin are achieved at the same time, adsorption sites onthe surface of the microspheres are increased, essence adsorption capacity is increased, and the sustained-release effect is optimized.

Owner:CHENGDU TECHCAL UNIV

Heterogeneous Fenton reactor

InactiveCN113044950ARealize micro-electrolysisEasy to handleWater treatment compoundsWater/sewage treatment by oxidationPtru catalystEngineering

The invention discloses a heterogeneous Fenton reactor which is characterized in that in the reactor, a sewage tank is used for accommodating sewage to be treated; a disc is rotatably arranged in the sewage tank, at least one third of the disc is immersed in the sewage, a fixing support comprises n fixing rods which are arranged in a radial mode, each fixing rod comprises a first end located in the radial center and a second end opposite to the first end, the fan-shaped cage bodies are fixed between every two adjacent fixing rods, each fan-shaped cage body is of a net-shaped structure, the net-shaped structure is filled with an iron catalyst, and the mesh diameter of the net-shaped structure is smaller than the particle size of the iron catalyst; and a rotating shaft is erected on the sewage tank, the rotating shaft is connected with the radiation center, and the rotating shaft rotates to drive the disc to rotate. The heterogeneous Fenton reactor is large in effective contact area, high in liquid fluidity, free of catalyst loss, free of secondary pollution and low in cost.

Owner:CHINA UNIV OF MINING & TECH (BEIJING) +1

Sewage disposal system

InactiveCN101560015AEasy to handleImprove cycle performanceBiological water/sewage treatmentSewageSewage treatment

The invention discloses a sewage disposal system, comprising a water inlet, a water outlet and a gallery, wherein the gallery is internally provided with stuffing, the middle part of the gallery is provided with a straight partition wall, the gallery is divided into a water inlet gallery and a water outlet gallery by the straight partition wall, a side water outlet sieve is installed inside the water outlet gallery, and the side water outlet sieve and the straight partition wall are installed in the same direction. In the invention, the existing sewage disposal system is modified so that sewage can circularly flow inside the gallery, thereby prolonging the contact time of the sewage and the stuffing, and improving sewage disposal effect.

Owner:QINGDAO SPRING WATER TREATMENT

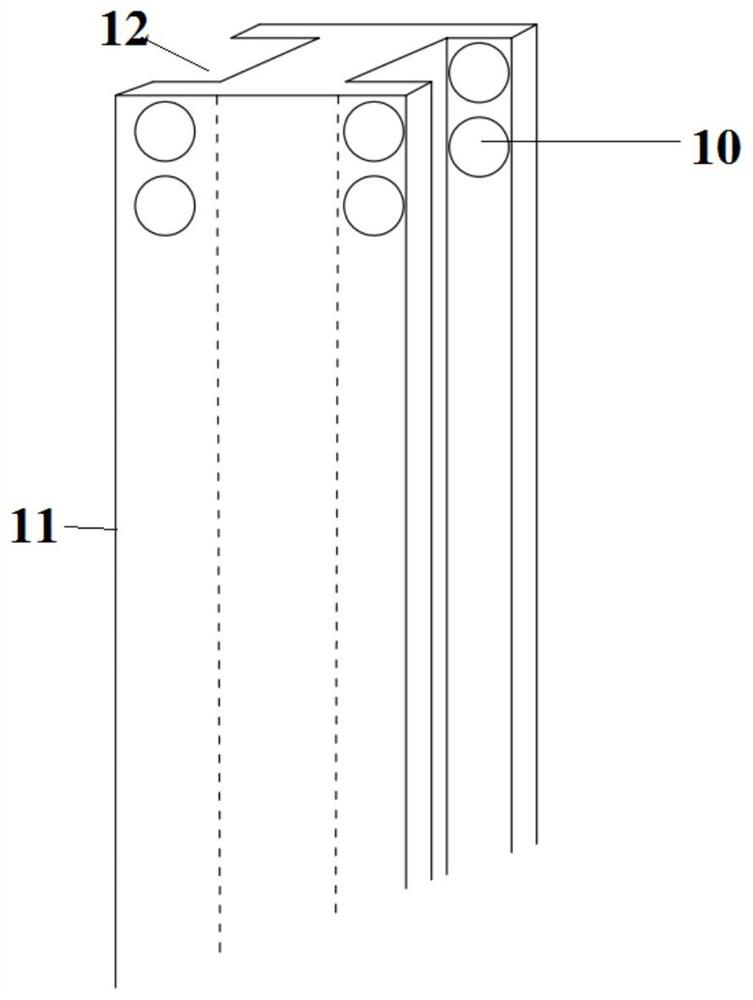

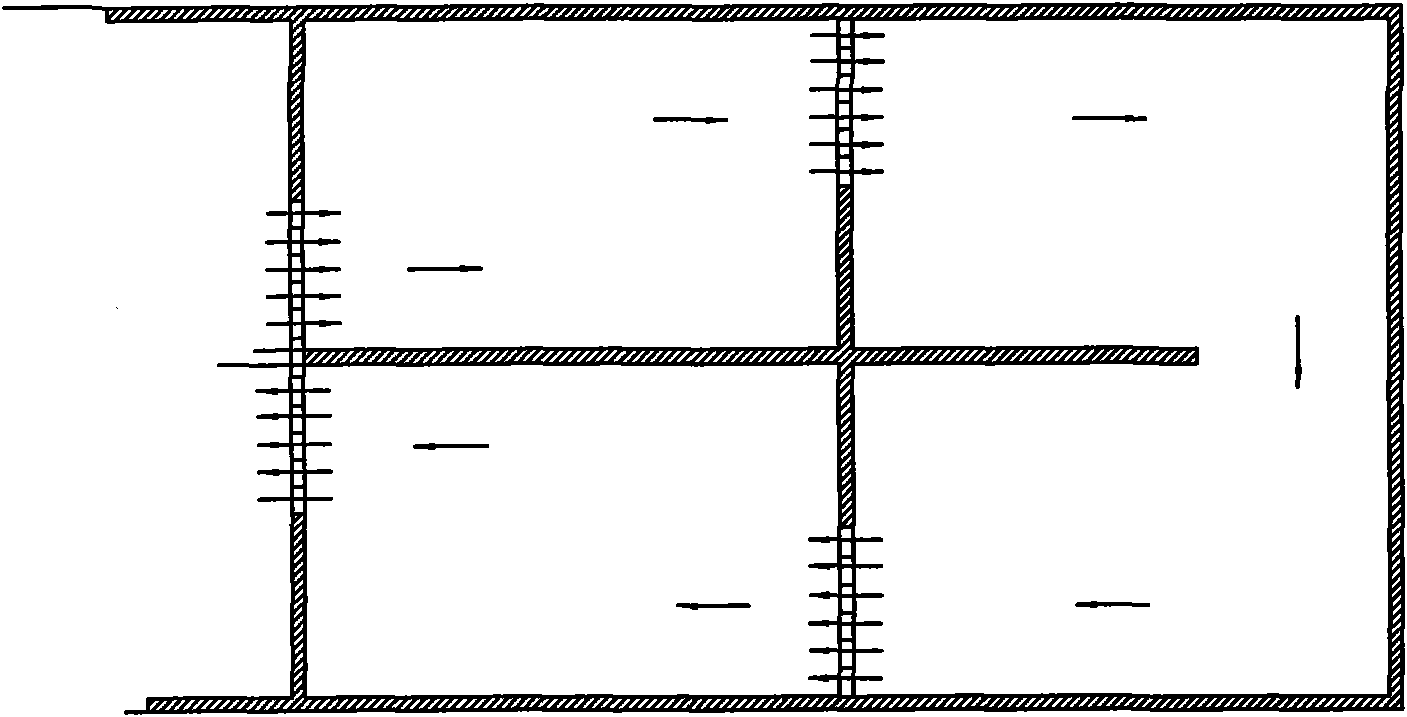

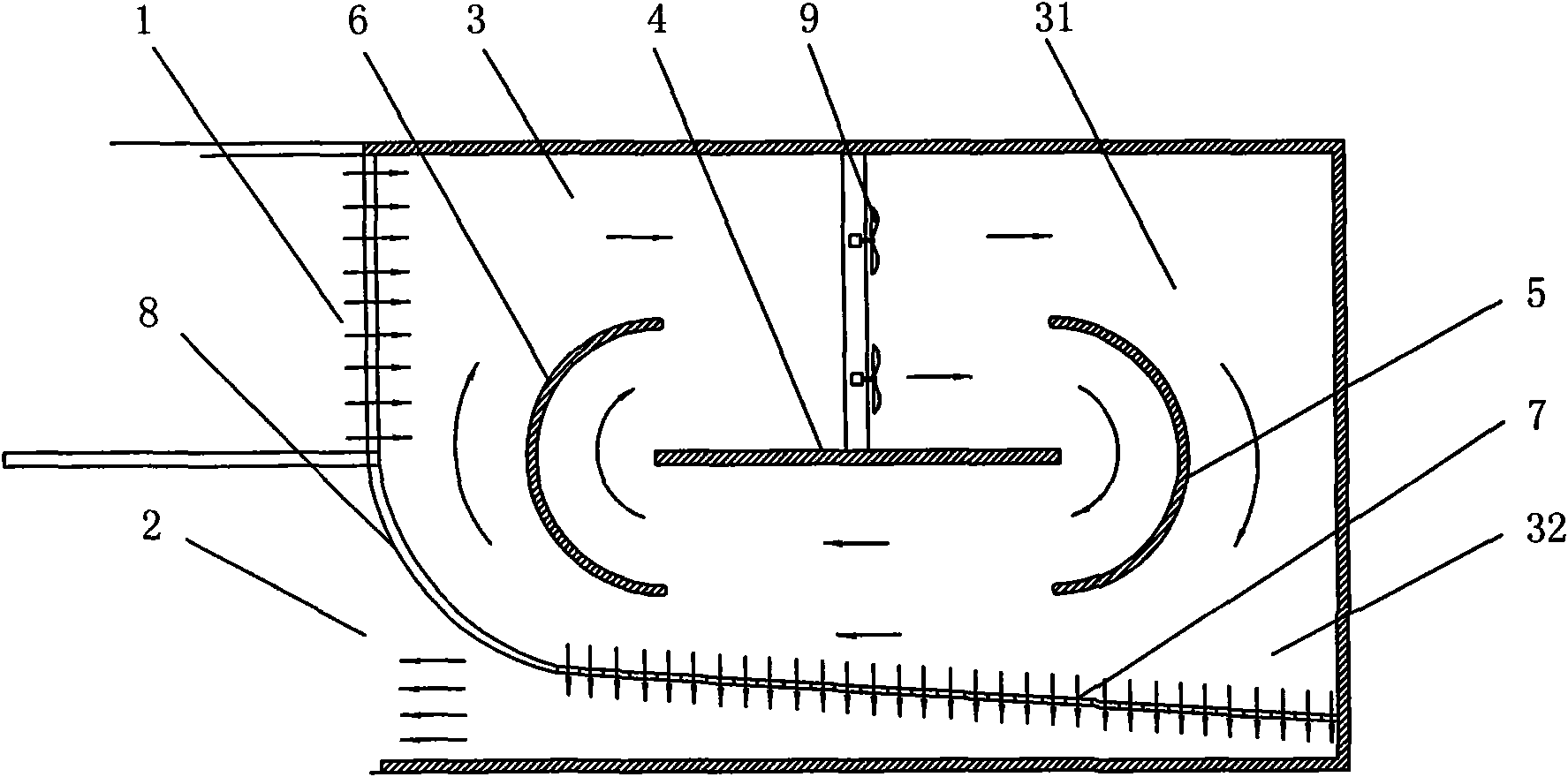

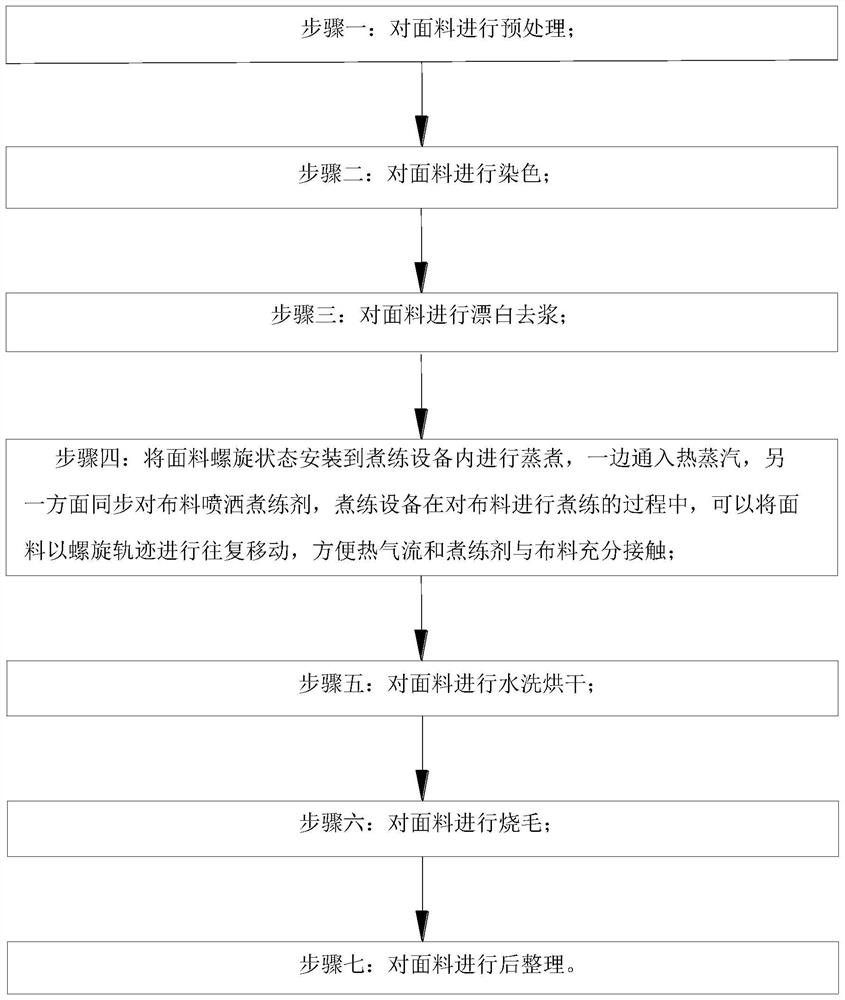

Energy-saving and environment-friendly fabric printing and dyeing process

InactiveCN112877966AEnhanced shakingFacilitated DiffusionSucessive textile treatmentsTextile treatment machine arrangementsProcess engineeringDyeing

The invention discloses an energy-saving and environment-friendly fabric printing and dyeing process in the technical field of fabric printing and dyeing. The process comprises the following specific step: 1, pretreating fabric. According to the process, the fabric does reciprocating contraction movement by taking a spiral track as a track under the action of a rotating disc, so that the fabric cannot be mutually adhered and stacked in a limited space, a good distance is always kept; the fabric moves in the spiral track while a cooking agent is sprayed, so that the distance change of the fabric is realized, entry of a cooking agent and introduction of hot air are facilitated by the distance change, the hot air and the cooking agent can be in good contact with the fabric on the inner side, then the moving cloth can generate vibration, the cloth is prevented from being adhered together, and therefore, the cooking agent can be in full contact with the fabric conveniently; and a spray pipe can be bent at different angles along with the rotation of the rotating disc, so that the spraying range of the cooking agent is wider, and the cooking agent can be fully contacted and reacted with the fabric.

Owner:叶阳

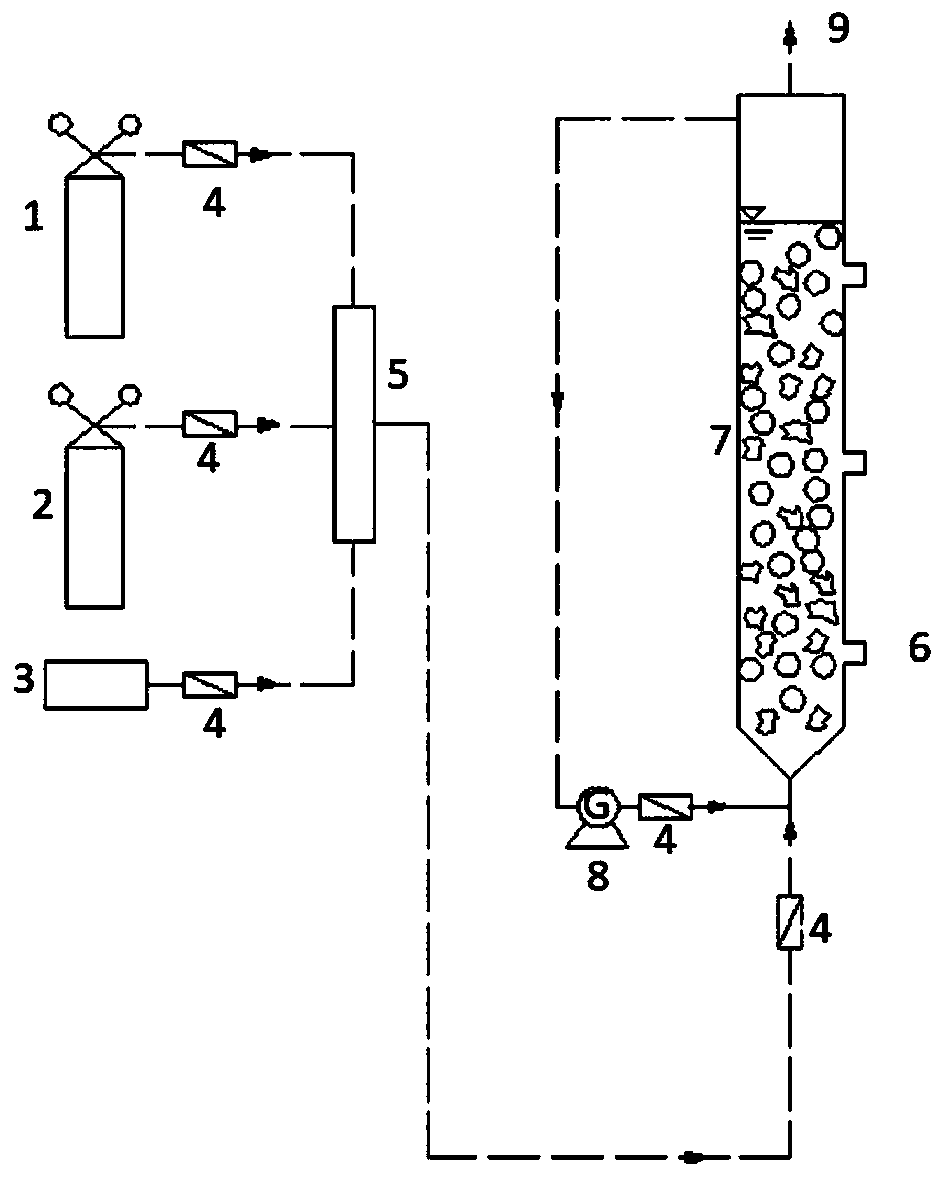

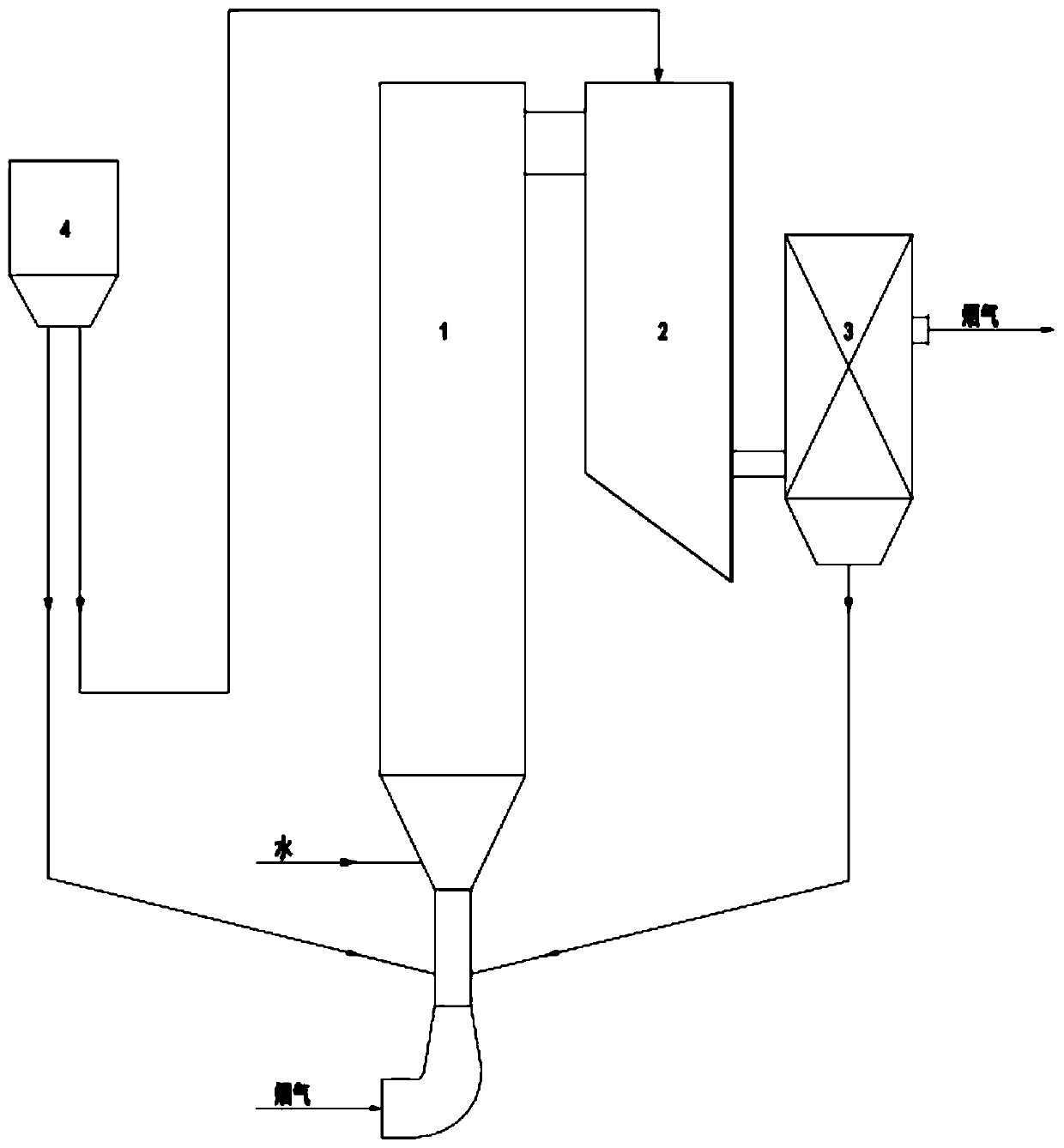

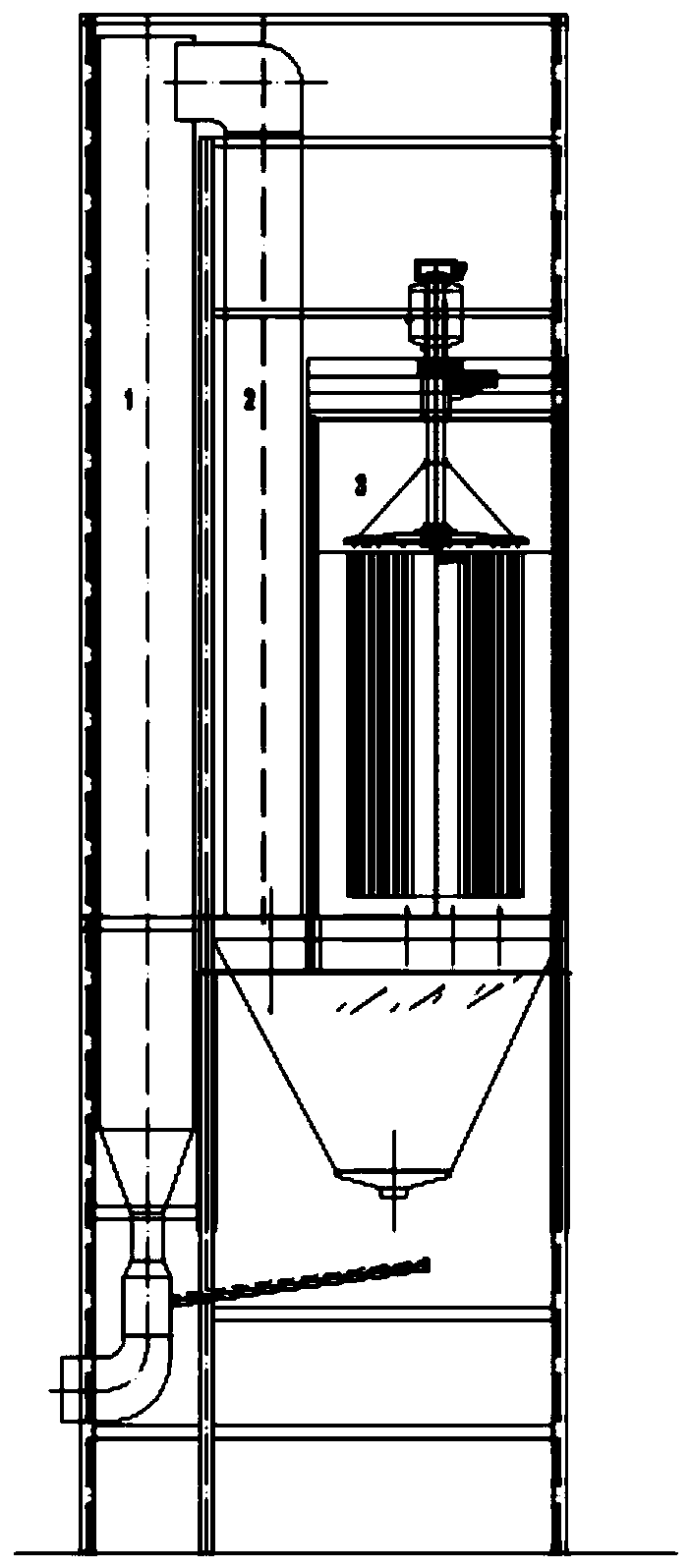

Two-stage circulating fluidized bed desulfurization system and desulfurization process thereof

InactiveCN111249872ALower tower heightLower the overall elevationGas treatmentDispersed particle filtrationSulfur dioxideProcess engineering

The invention belongs to the field of flue gas treatment. The problem that the arrangement elevation of a desulfurization system is increased, a support structure is large and complex, and the operation resistance of the desulfurizing tower is large can be solved. According to the two-stage circulating fluidized bed desulfurization system and the desulfurization process provided by the invention,the advantage of high concentration of materials in an ascending tower and the advantage of high contact probability of fresh materials and sulfur dioxide in a descending tower are utilized, so that the height of the tower is reduced and the overall utilization rate of a desulfurizing agent is increased under the condition of ensuring the same residence time of flue gas. The desulfurization systemcomprises a desulfurization tower and a desulfurizing agent bin, wherein the desulfurizing tower comprises the ascending tower and the descending tower, and the top of the ascending tower is communicated with the top of the descending tower; the desulfurizing agent bin is respectively communicated with a venturi section connected with the bottom of the ascending tower and the top of the descending tower and is used for respectively adding a desulfurizing agent into the desulfurizing tower from the venturi section of the ascending tower and the top of the descending tower.

Owner:SHANDONG SHENHUA SHANDA ENERGY ENVIRONMENTAL

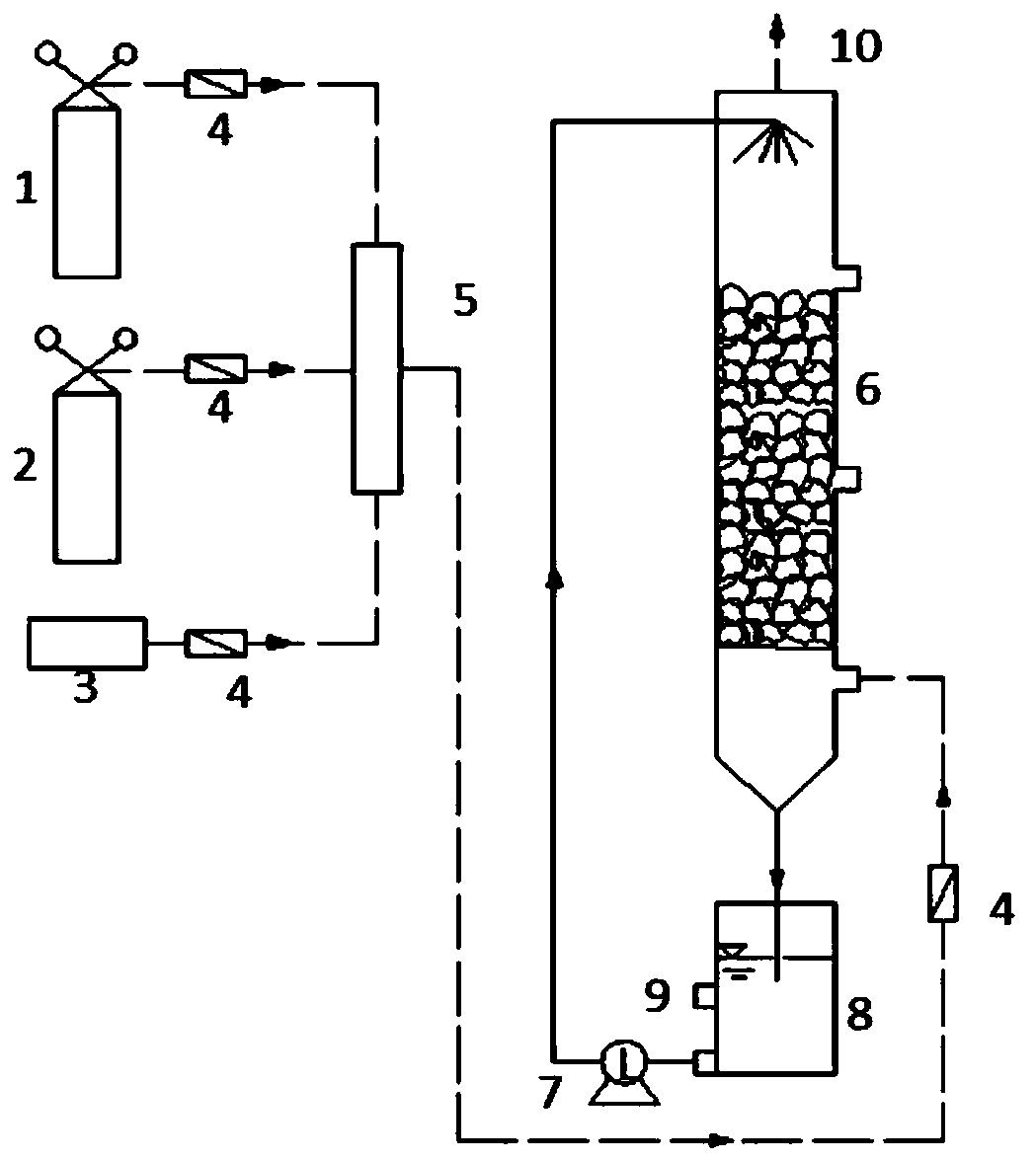

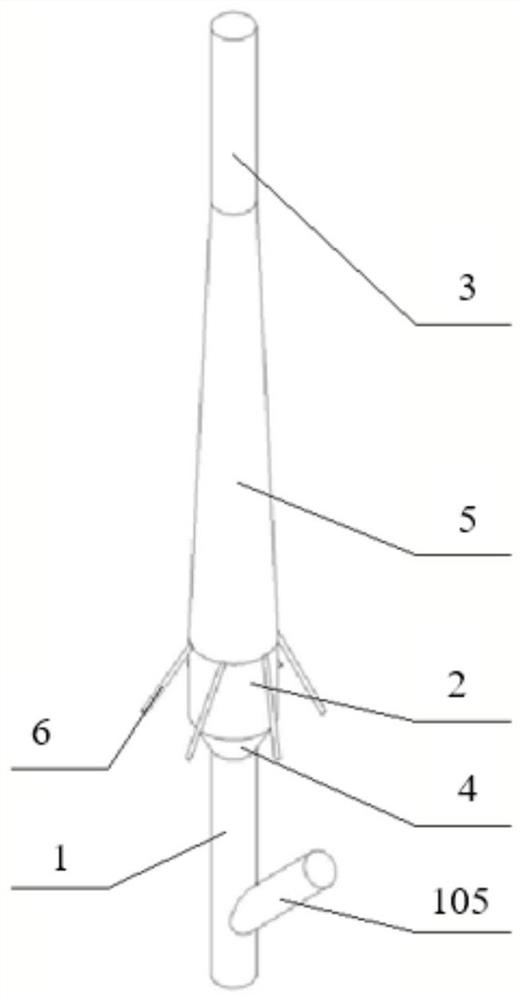

Cyclone redistribution denitration reactor for flue gas

ActiveCN109173720AEvenly distributedFacilitated contact responseGas treatmentDispersed particle separationCycloneFlue gas

The invention relates to the field of environmental protection devices, and concretely discloses a cyclone redistribution denitration reactor for flue gas. The cyclone redistribution denitration reactor comprises a flue gas inlet tube, a cyclone assembly for guiding flue gas, an ammonia spraying and mixing device, a connecting flue gas tube, a catalytic reaction device and a flue gas outlet tube which are sequentially interconnected, the cyclone assembly comprises a first shell, the flow guiding plates and a mounting plate, the flow guiding plates have a spiral fan blade shape, the flow guiding plates are connected to the inner wall of the first shell, and are arranged along the circumferential direction of the first shell, the quantity of the flow guiding plates is more than one, the rotating directions of all the flow guiding plates are same to each other, the mounting plate is positioned among all the flow guiding plates, and the mounting plate is fixedly connected to one ends, facing the center of the first shell, of all the flow guiding plates. Flue gas enters the cyclone assembly through the flue gas inlet tube, and moves along the flow guiding plates to form a uniform-rotating flue gas flow, so the flue gas is in a uniformly distributed state when moving to the ammonia spraying and mixing device, thereby the flue gas is well contacted and reacted with a reaction solutionsprayed by the ammonia spraying and mixing device, dead angles are reduced, and the denitration efficiency is improved.

Owner:ZHEJIANG TUNA ENVIRONMENTAL SCI & TECH

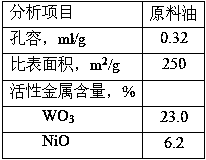

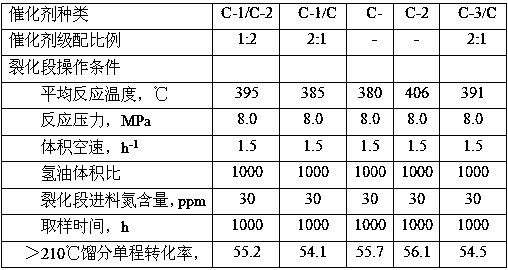

A Catalytic Diesel Hydrogenation Conversion Process

ActiveCN107304373BIncrease secondary crackingLow yieldMolecular sieve catalystsTreatment with hydrotreatment processesMolecular sieveHydrogenation reaction

The invention discloses a hydro-conversion technology for catalytic diesel oil. The technology comprises the following steps: firstly, putting a mixture of catalytic diesel oil and hydrogen into a hydrogenation reactor and performing hydrofining reaction, and then guiding into a cracking reactor and generating contact reaction with hydrocracking catalyst layers, wherein upper and lower catalyst layers are arranged in the hydrocracking reactor; the hydrocracking catalyst in the upper layer has the properties as follows: on the basis of the total weight of the catalyst, 10%-18% of MoO3, 2%-10% of Co, 40%-90% of modified Y-shaped molecular sieve, preferably 50-80%, and the balance of aluminum silicon carrier; the hydrocracking catalyst in the lower layer has the properties as follows: on the basis of the total weight of the catalyst, 15-30% of MoO3 or WO3, 2-15% of NiO, 10%-60% of modified Y-shaped molecular sieve, preferably 20-40%; the filling mass ratio of the hydrocracking catalysts in the upper layer and the lower layer is (1:5)-(5:1). The hydro-conversion technology disclosed by the invention can further increase the device liquid yield, can reduce the hydrogenation saturation of the generated gasoline component and can increase the octane value of the gasoline component under the condition of better meeting the requirement for the conversion rate of catalytic diesel oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Synthesis method of gamma-aminopropyl triethoxy silane

InactiveCN112239476AMild reaction conditionsRapid responseGroup 4/14 element organic compoundsPtru catalystTriethoxysilane

The invention discloses a synthesis method of gamma aminopropyl triethoxy silane, belongs to the technical field of organic silicon synthesis, and particularly relates to a synthesis method of gamma aminopropyl triethoxy silane. The method is characterized in that 3-chloropropyltriethoxysilane and ammonia water are used as reaction substrates, and ammonolysis reaction is performed according to themolar ratio of 3-chloropropyltriethoxysilane to ammonia water (calculated by ammonia) to a phase transfer catalyst to a buffer agent being 1: (3-5): 0.01: (1-2) to prepare gamma aminopropyltriethoxysilane. The invention has the advantages that the reaction time is shortened, and the product yield is increased; and meanwhile, the use amount of ammonia gas is reduced, the product purity is high, the post-treatment process is simple, and the method is green and environment-friendly.

Owner:SHANDONG YANGGU HUATAI CHEM

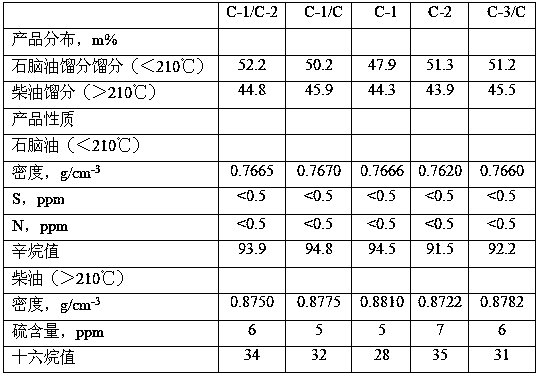

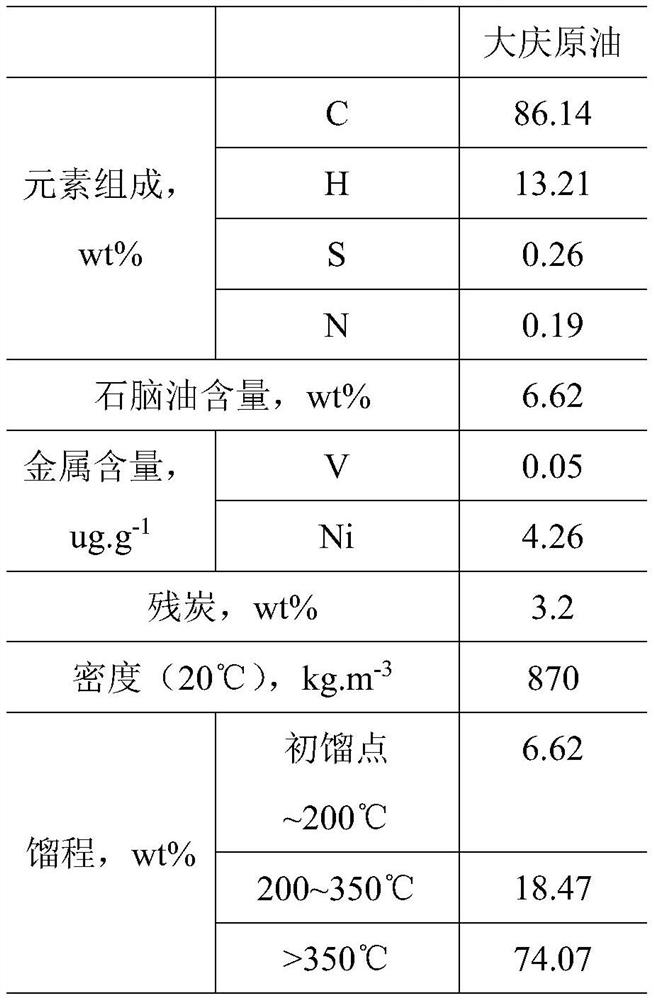

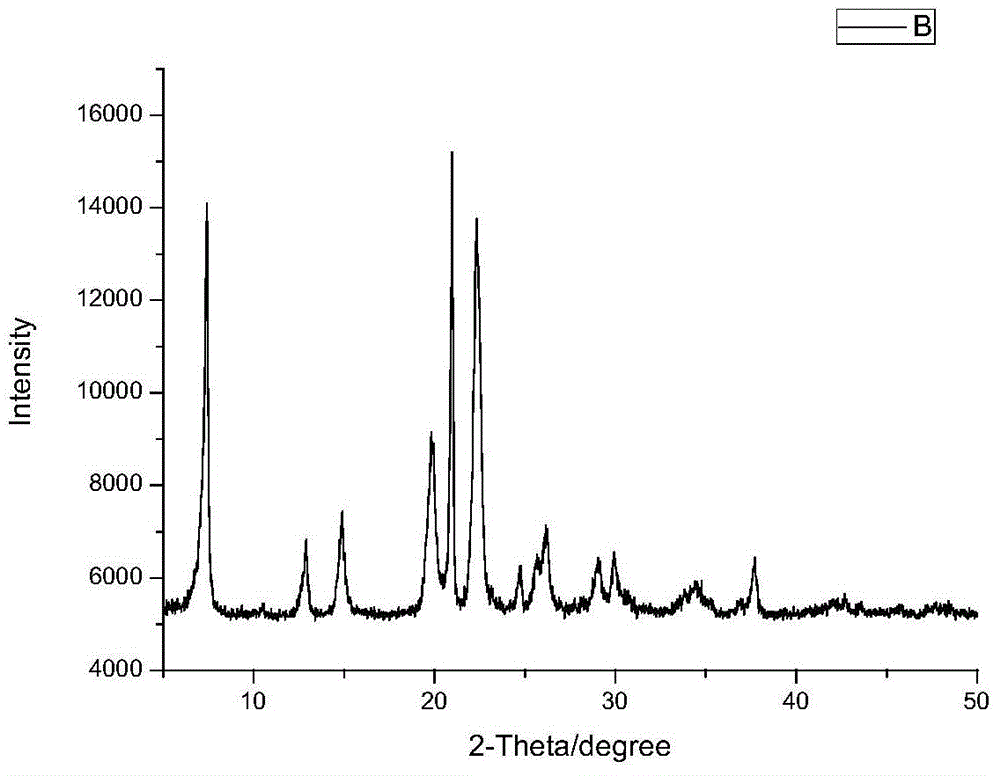

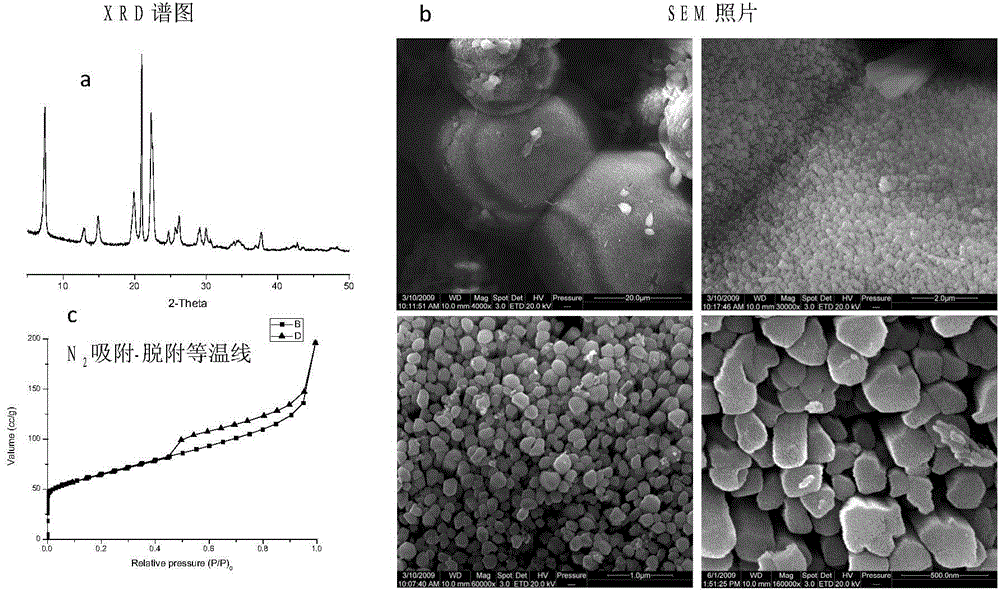

Method for preparing chemicals by double-tube parallel multi-zone catalytic conversion of crude oil

ActiveCN113462428AHigh yieldFacilitated contact responseCatalytic crackingTreatment with plural serial stages onlyCatalytic transformationPtru catalyst

The invention discloses a method for preparing chemicals by double-tube parallel multi-zone catalytic conversion of crude oil, the method comprises the following steps: directly feeding or desalting and dehydrating the crude oil, then dividing the crude oil into light and heavy components through a flash evaporation or distillation process, strengthening the contact reaction of oil gas and a catalyst by using two parallel novel structure reaction tubes, and performing zone control reaction, optimally combining feeding modes according to different properties of reaction materials, controlling suitable reaction conditions of different materials, and increasing the yield of low-carbon olefins and aromatic hydrocarbons.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Synthesis method of supported MoS2 catalyst

InactiveCN105753052AProcess economy is strongOperational securityMolybdenum sulfidesLarge poreMolecular sieve

The invention relates to a synthesis method of a supported MoS2 catalyst. The method comprises the following steps: preparing a macropore-mesopore-micropore composite hierarchical pore aluminum phosphate AFI molecular sieve carrier at normal pressure or a low authigenic pressure through adopting an ionothermal synthesis technology; and dipping the prepared hierarchical pore aluminum phosphate AFI molecular sieve carrier in a sulfur-containing mother liquor, drying the immersed carrier, and carrying out high temperature roasting to prepare the hierarchical pore molecular sieve supported MoS2 catalyst. The ionothermal synthesis technology has the advantages of recovery and repeated use of an ionic liquid, low synthesis cost, no discharge of acids, alkalis or waste liquids in the synthesis process, and environmental protection. The hierarchical pore molecular sieve supported MoS2 catalyst prepared in the invention has the advantages of large specific surface area, large pore volume, and potential application values in hydrodesulfurization, hydrocracking and other catalytic reactions.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com