Two-stage circulating fluidized bed desulfurization system and desulfurization process thereof

A circulating fluidized bed and desulfurization system technology, applied in chemical instruments and methods, direct contact heat exchangers, dispersed particle filtration, etc., can solve the problem of increasing ash concentration in the tower, increasing the layout elevation, and large operating resistance of the desulfurization tower and other issues, to achieve the effect of reducing the height of the tower, reducing the overall elevation, and improving the overall utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

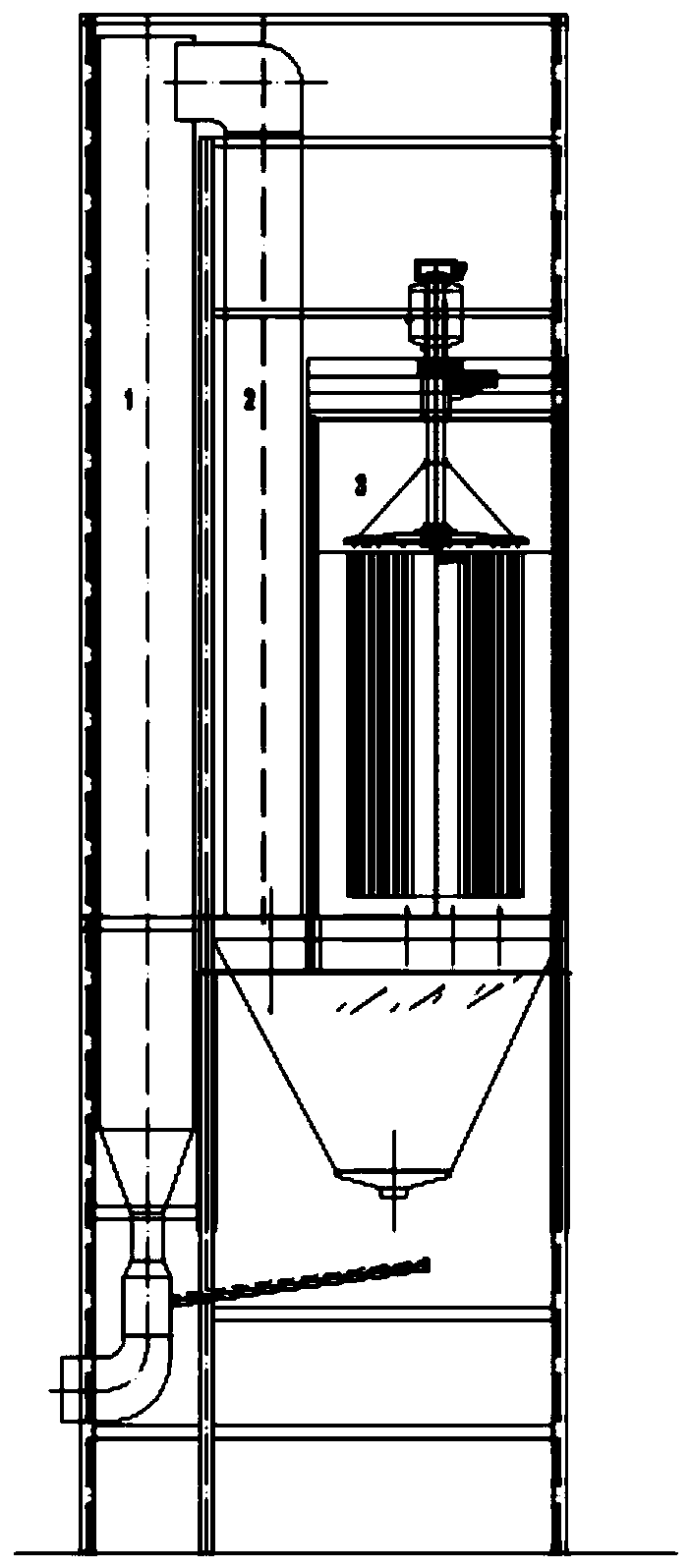

[0051] As an implementation mode, the desulfurized ash discharged from the bottom of the down tower along with the flue gas enters the bag filter, and after being filtered by the bag filter, the desulfurized ash is returned to the Venturi section of the up tower.

[0052] Among them, the structure of the bag filter is an existing structure, and those skilled in the art can specifically select the model of the bag filter according to the actual situation.

[0053] As an implementation mode, the position of the Venturi section of the upward tower after being filtered by the bag filter is set as the first position; the position of the desulfurizer added to the Venturi section of the upward tower is set as the second position; The height of the two positions is the same.

[0054] As an embodiment, an atomizing device is provided at the bottom of the ascending tower and above the Venturi section, and the atomizing device is used to atomize humidifying water to reduce the temperatur...

Embodiment 2

[0059] This embodiment provides a two-stage circulating fluidized bed desulfurization process, including:

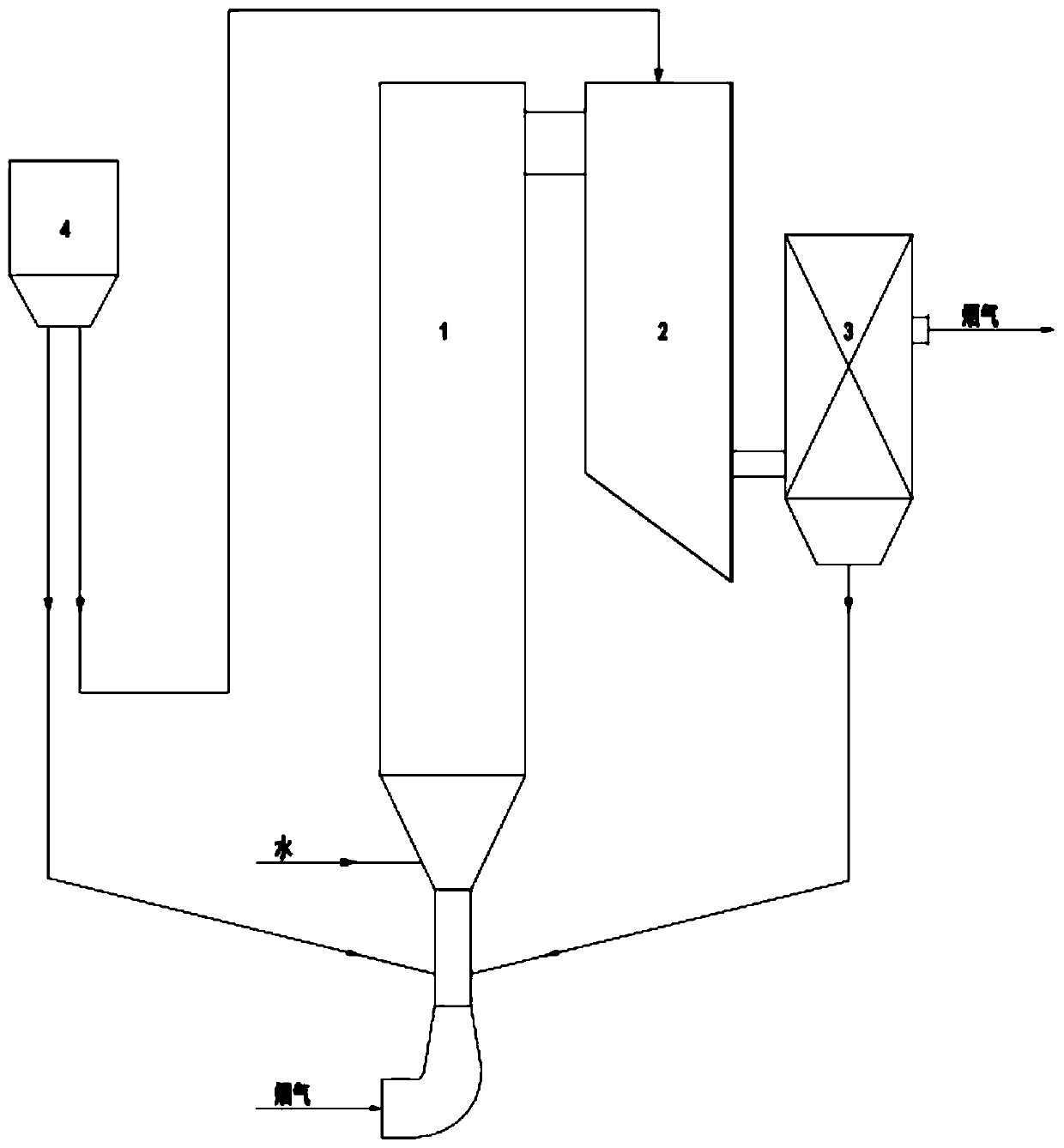

[0060] Add the desulfurizing agent in the desulfurizing agent chamber into the desulfurizing tower respectively from the Venturi section of the ascending tower and the top of the descending tower;

[0061] The flue gas enters the desulfurization tower from the bottom of the ascending tower for sulfuration reaction, the flue gas flows upward along the ascending tower, enters the top of the descending tower from the top of the ascending tower, and finally is discharged from the bottom of the descending tower;

[0062] During the vulcanization reaction, the flue gas reacts with the desulfurizing agent to produce desulfurization ash, part of the desulfurization ash carried by the flue gas flows back into the ascending tower from the top of the ascending tower due to gravity and inertial settlement, and becomes the desulfurizing ash of the internal circulation; The flue gas i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com