Physical preparation method of high density vanadium oxide powder

A vanadium oxide, high-density technology, applied in the direction of vanadium oxide, etc., can solve the problem of insufficient density of vanadium oxide, achieve the effect of good resistance to airflow, good contact reaction performance of furnace materials, and reduce gasification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

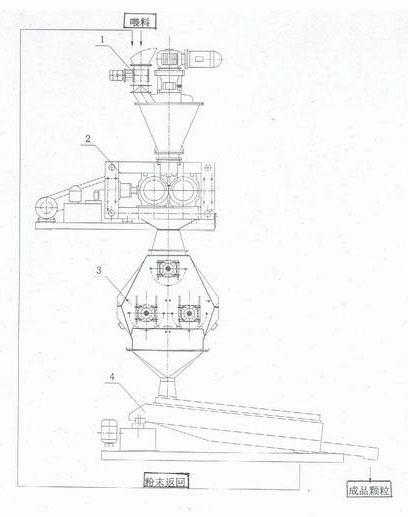

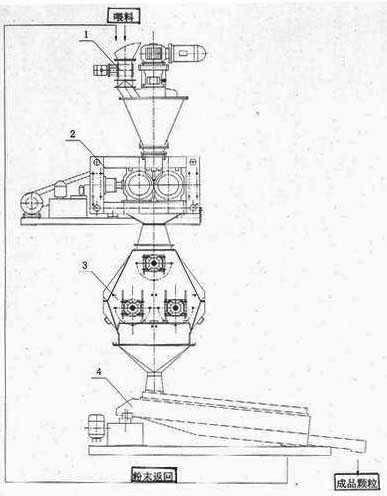

Image

Examples

Embodiment 1

[0027] Embodiment one: the density (bulk specific gravity) is 0.62g / cm 3 The powdered vanadium pentoxide is continuously added to the feeding system (the system is composed of a pre-feeder with a mechanical vibration device and a forced-feeding screw hopper to ensure the continuity, adequacy and Uniformity), and then the vanadium oxide is forced into the flaking machine and the crushing and sizing system by the feeding system. 2 The granulation process is completed under certain conditions, and the obtained product has a particle size of 0.3-10mm and a density (bulk specific gravity) of 1.45g / cm 3 .

Embodiment 2

[0028] Embodiment two: the density (bulk specific gravity) is 0.69g / cm 3 The powdered vanadium tetroxide is continuously added to the feeding system (the system is composed of a pre-feeder with a mechanical vibration device and a forced-feeding screw hopper to ensure the continuity, adequacy and Uniformity), and then the vanadium oxide is forced into the flaking machine and the crushing and sizing system by the feeding system. 2 The granulation process is completed under certain conditions, and the obtained product has a particle size of 0.3-10mm and a density (bulk specific gravity) of 1.74g / cm 3 .

Embodiment 3

[0029] Embodiment three: the density (bulk specific gravity) is 0.77g / cm 3 The powdered vanadium trioxide is continuously added to the feeding system (the system is composed of a pre-feeder with a mechanical vibration device and a forced-feeding screw hopper to ensure the continuity, adequacy and Uniformity), and then the vanadium oxide is forced into the flaking machine and the crushing and sizing system by the feeding system. 2 The granulation process is completed under certain conditions, and the obtained product has a particle size of 0.3-10mm and a density (bulk specific gravity) of 1.94g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com