Patents

Literature

263 results about "Vanadium trioxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vanadium Trioxide (V2O3) Vanadium trioxide (V2O3) is a high-purity product used in a variety of applications, including chemical and environmental catalysts, gas processing, coloring compounds, batteries, dye fixants, and vitamins.

Method for producing vanadium trioxide by adopting fluidized bed reactor

ActiveCN101880059AImprove efficiencySuitable for mass productionVanadium oxidesCombustion chamberFluidized bed

The invention relates to a method for producing vanadium trioxide by adopting a fluidized bed reactor, belonging to the field of the chemical industry and metallurgy. Heat is provided for reaction by a mode of preheating the materials containing vanadium to be 400-550 DEG C, the materials containing vanadium are preheated by adopting a two-stage cyclonic preheater, and high-temperature smoke generated by a combustion chamber provides heat. Gas with heat value of being larger than 1250kcal / Nm<3> is adopted to be reduced for 5-20 minutes at the temperature of 700-850 DEG C, and a vanadium trioxide product with vanadium grade of being more than 66% can be obtained. The method has the advantages of high reduction efficiency, good energy utilization and suitability for large-scale production of vanadium trioxide.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

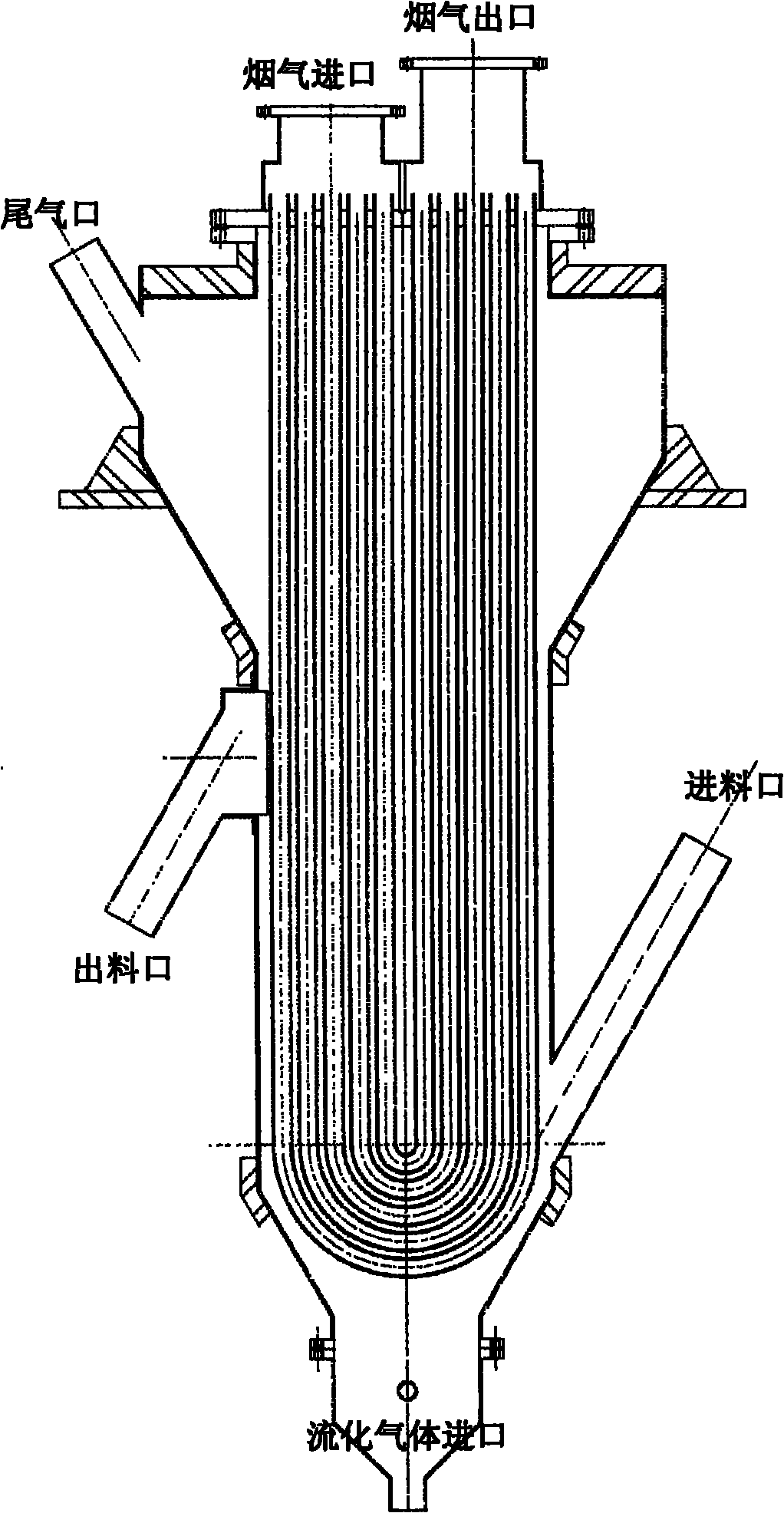

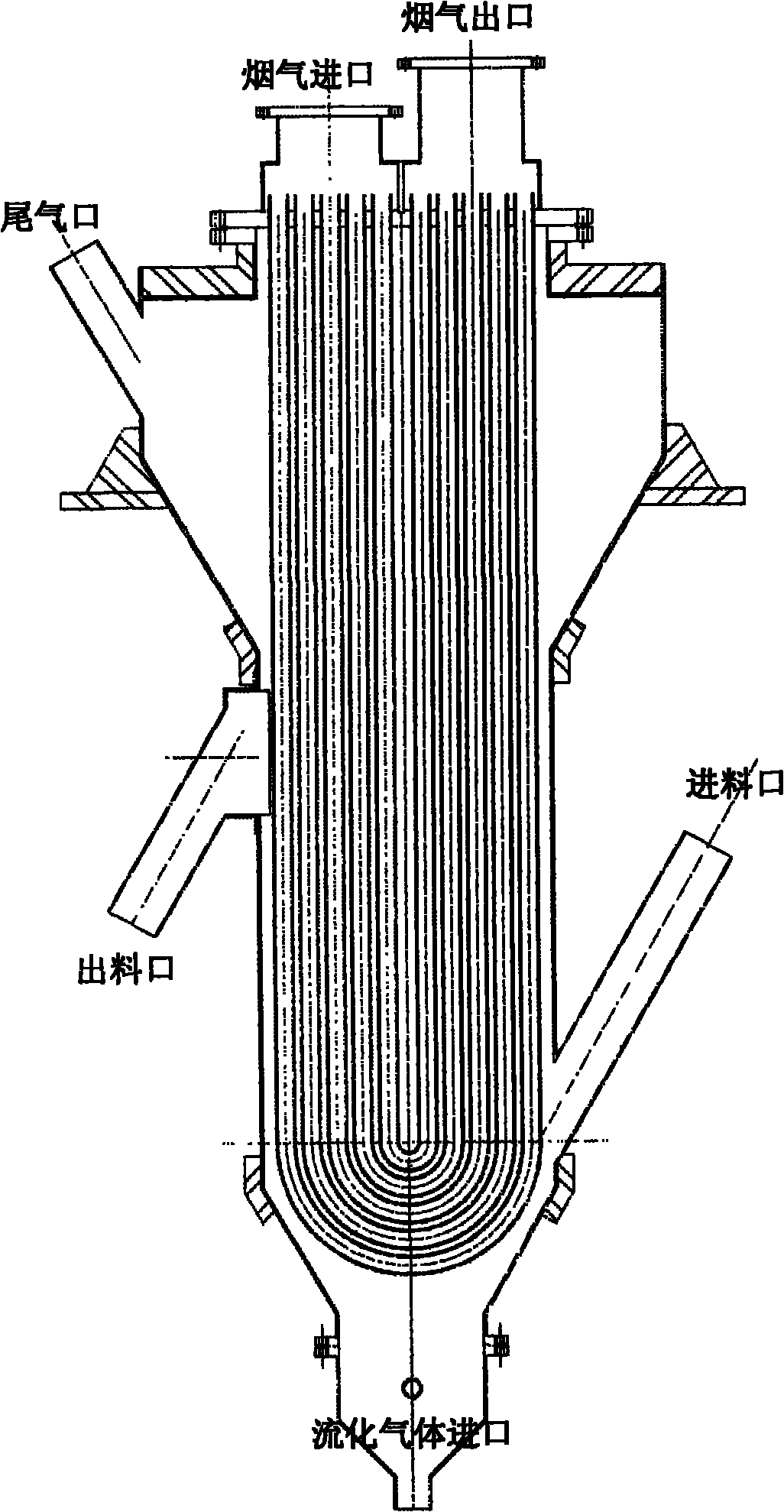

Fluidized reduction furnace for producing high-purity vanadium trioxide and production method

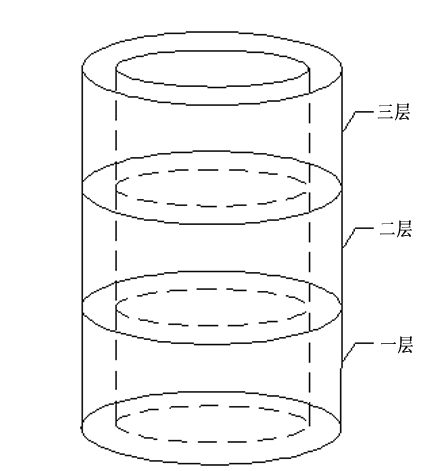

The invention relates to a fluidized reduction furnace for producing high-purity vanadium trioxide, which comprises a fluidized bed reactor and a built-in heat exchange component, wherein the heat exchange component is a tube type heat exchanger, and a heat exchange tube is vertically provided with at least two layers of sieve mesh plates to form at least three layers of fluidized reaction chambers. The invention also provides a fluidized reduction method for producing the high-purity vanadium trioxide. The fluidized reduction furnace and the fluidized reduction method have the advantages that firstly, materials in each layer are in a fully-mixed state, and material flow among the layers is in a plug flow state; secondly, the multi-stage fluidized reduction conditions are provided, raw materials enter from the lowermost layer, are reduced step by step and are purified gradually, and the running stability and the operating rate of equipment are improved in a manner of reduction step by step; and thirdly, the fluidized reduction furnace can be used for producing the high-purity vanadium trioxide, and the vanadium grade is larger than 67.9 percent.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Vanadium redox battery electrolyte

InactiveUS20040241552A1Loss in Coulombic efficiencyEvolution of hydrogen is thereby avoidedTantalum compoundsRegenerative fuel cellsVanadium redox batterySlurry

The present invention relates generally to the production of a vanadium electrolyte, including a mixture of trivalent and tetravalent vanadium ions in a sulphuric acid solution, by the reactive dissolution of vanadium trioxide and vanadium pentoxide powders, the surface area and particle size characteristics being controlled for complete reaction to produce the desired ratio of V(III) to V(IV) ions in the solution. The solution may be suitable for direct use in the vanadium redox battery, or the solution can provide an electrolyte concentrate or slurry which can be reconstituted by the addition of water or sulphuric acid prior to use in the vanadium redox battery.

Owner:UNISEARCH LTD

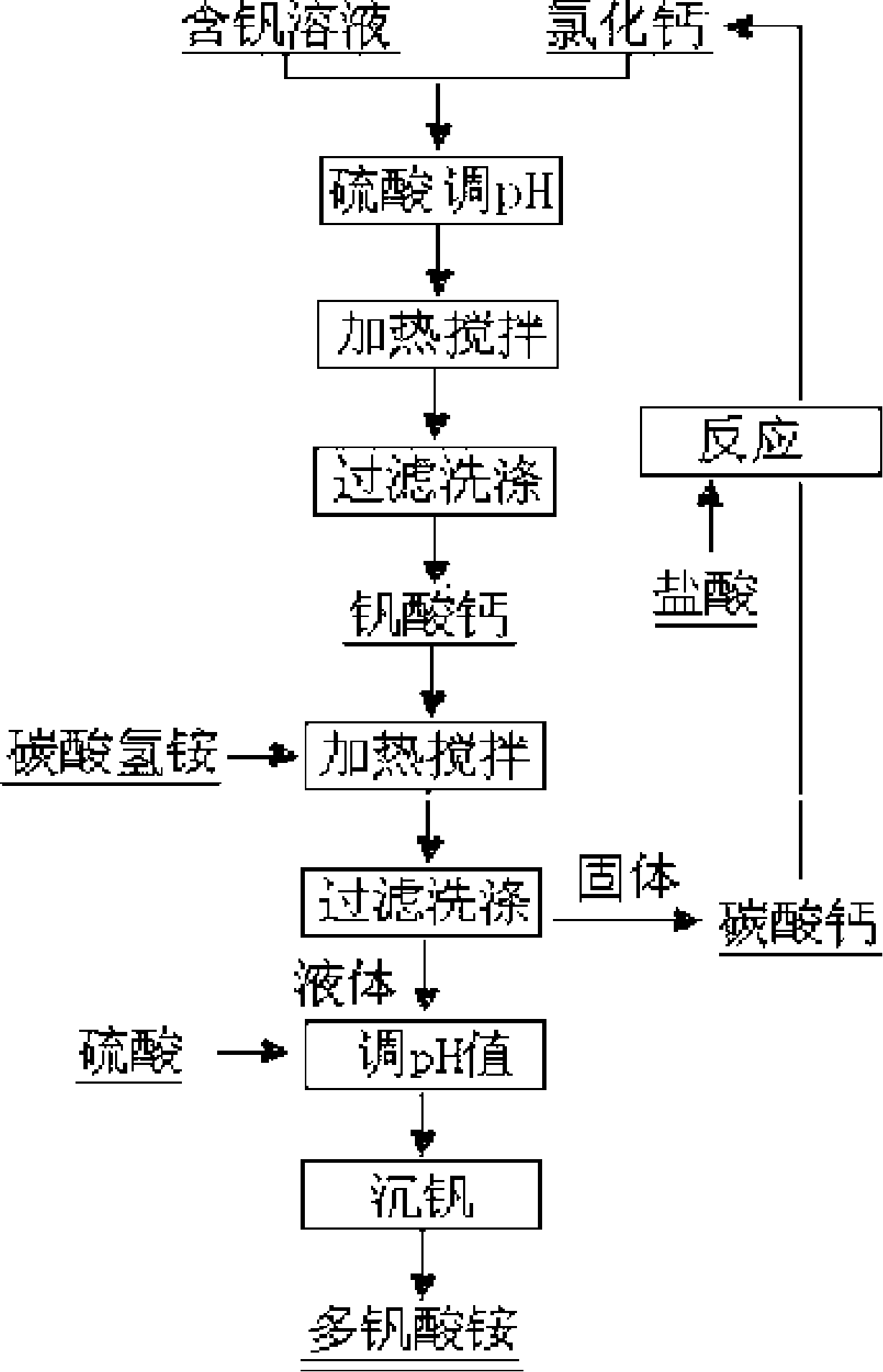

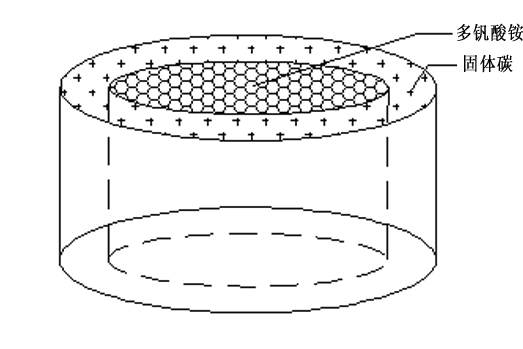

Preparation method of ammonium poly-vanadate

The invention belongs to the chemical engineering field, in particular relates to a method for preparing ammonium polyvandata with vanadium-containing solution. The method uses the vanadium-containing solution produced with the traditional sodium roasting-water immersing technology as the raw material. First, vanadium combines with added calcium compounds and produces calcium vanadate, which reacts with ammonium bicarbonate and transfers vanadium into the solution but transforms calcium into more insoluble calcium carbonate; the ammonium polyvandata is produced with the separated solution under appropriate pH and heating conditions. After redissolution of calcium vandata, the ammonium bicarbonate containing less than 0.1percent of SUM (Na2O+K2 O) can be obtained. The ammonium bicarbonate can be used for production of vanadium trioxide and vanadium pentoxide with exceedingly low contents of potassium and sodium; and the ammonia content of vanadium-precipitation waste water is only 60percent to 75 percent of vanadium-extraction waste water in traditional technologies. The invention has very promising application prospect.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

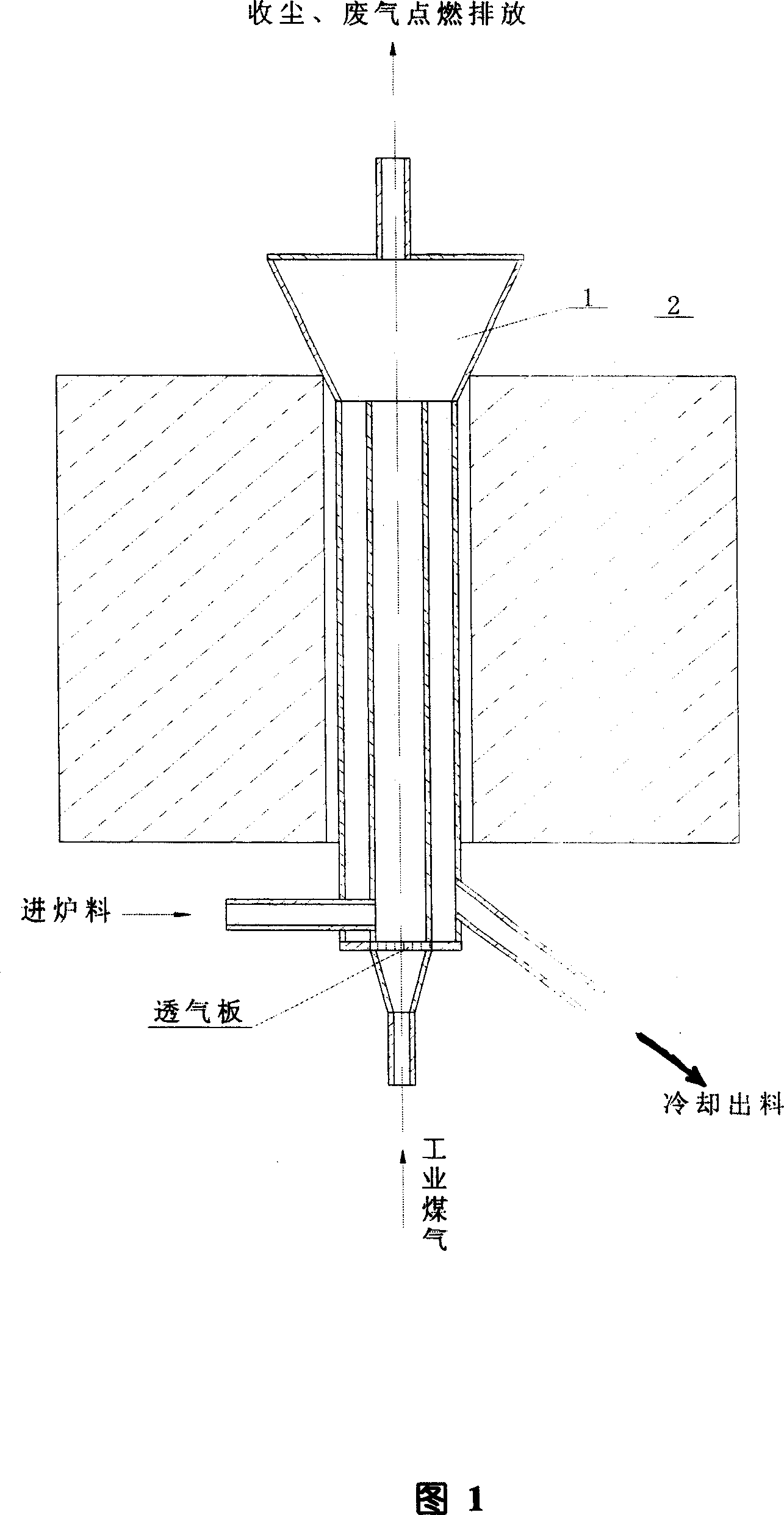

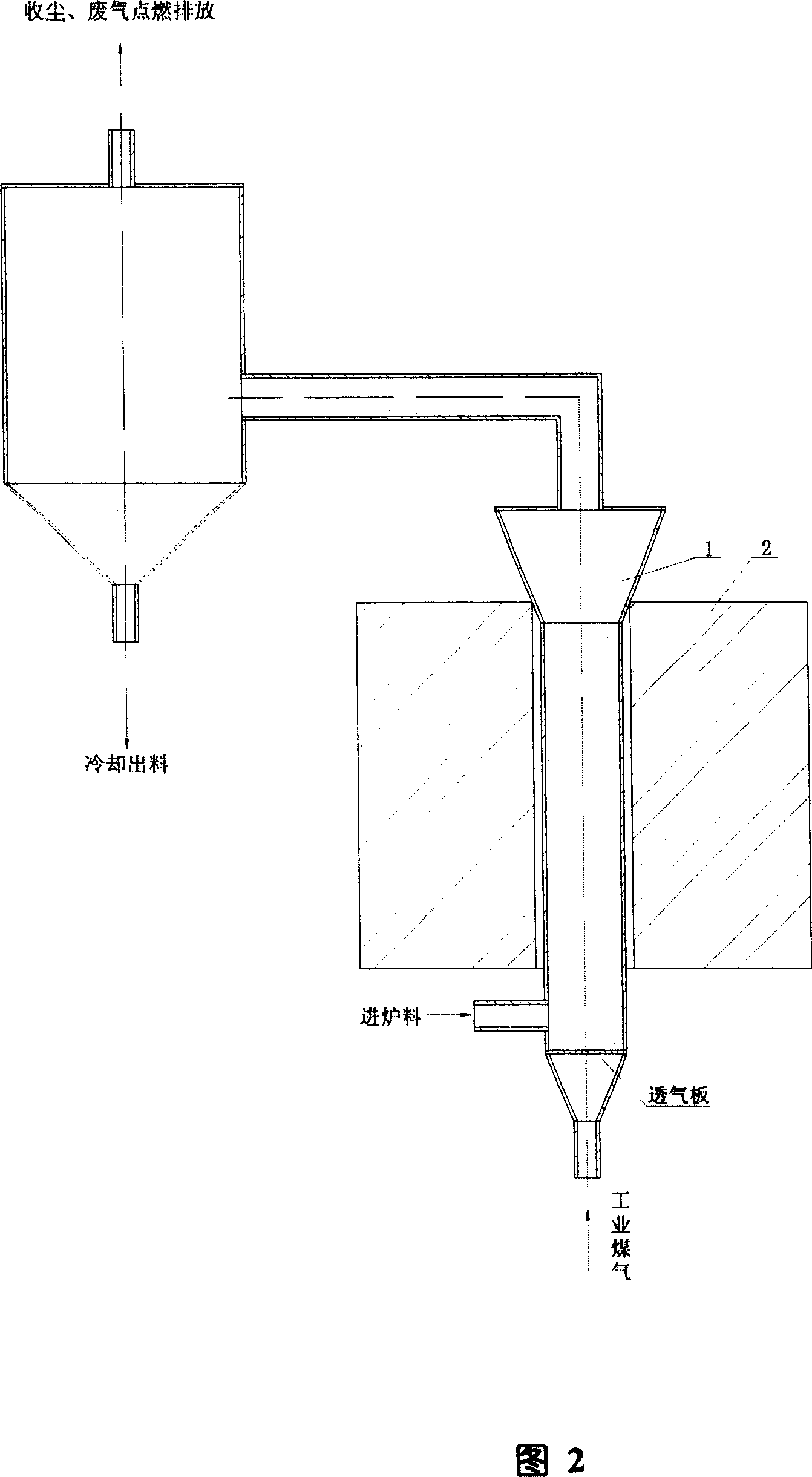

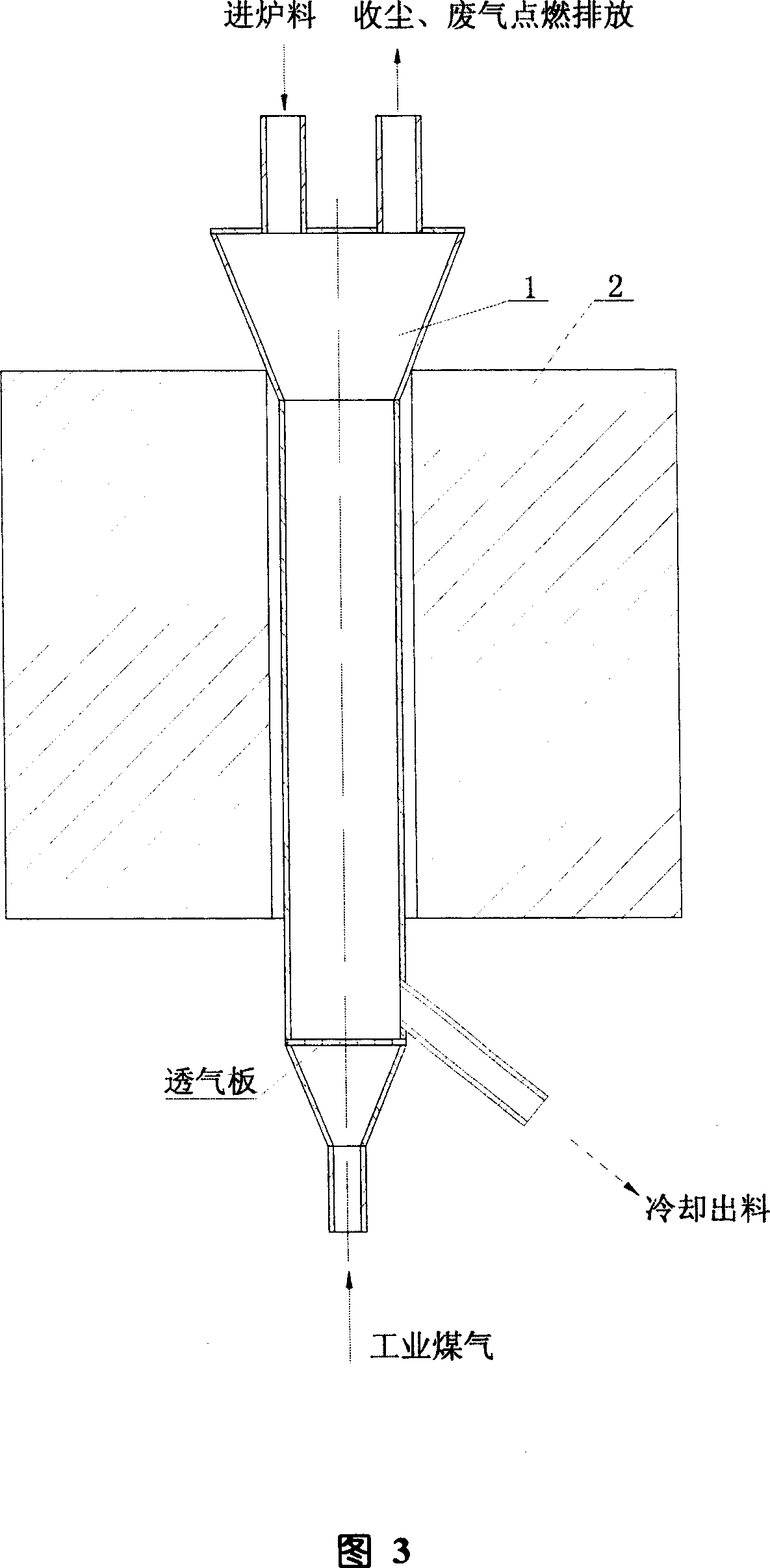

Method for producing vanadium trioxide

A process for preparing V2O3 includes such steps as adding the powdered ammonium vanadate or V2O5 into the furnace pipe of an externally heated fluidized furnace, filling industrial gas in the furnace pipe while heating it to 600-650 deg.C, reducing reaction for 3-9 min, and cooling in the condition of isolating air.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Synthesis of lithium ion battery anode material vanadium lithium phosphate using sol-gel method

InactiveCN1785798ALower valenceReduce pollutionCell electrodesPhosphorus compoundsLithium carbonatePhysical chemistry

The present invention relates to method for synthesizing positive electrode material vanadium lithium phosphate of lithium ion cell by using sol-gel process. Said method includes the following steps: adopting sol-gel reaction, using vanadium pentoxide or vanadium trioxide, ammonium dihydrogen phosphate, lithium carbonate and citric acid as raw material to synthesize precursor body of lithium ion cell positive electrode material Li3V2(PO4)3, then under the protection of inert gas roasting said precursor body to make V5+ be completely reduced into V3+ and simultaneously produce product Li3V2(PO4)3.

Owner:NANKAI UNIV

Method for preparing vanadium oxide

InactiveCN103146930AAchieve recyclingReduce consumptionProcess efficiency improvementHigh phosphateSlag

The invention provides a method for preparing vanadium oxide, which comprises the following steps of: mixing vanadium slag with calcium oxide or limestone to form a mixed material; roasting the mixed material to obtain calcified clinker; leaching the calcified clinker by using C2O4<2-> and 35-70 g / L of oxalate solution at 80-95 DEG C; after leaching, carrying out solid-liquid separation to obtain vanadium-containing leachate and residues; removing silicon from the vanadium-containing leachate, so that the silicon concentration in the vanadium-containing leachate is less than 0.1 g / L, then adding ammonium oxalate into the vanadium-containing leachate, adjusting the mol ratio of NH4<+> to TV to 2-3.5, precipitating ammonium metavanadate, and filtering to obtain ammonium metavanadate and vanadium precipitation wastewater; and oxidizing, roasting and deaminizing ammonium metavanadate to prepare vanadium pentoxide or reducing to prepare vanadium trioxide. According to the invention, on the premise of satisfying environment-friendly requirements, preparation of vanadium oxide from ordinary vanadium slag and high-calcium and high-phosphate vanadium slag is realized; furthermore, consumption of reagents can also be reduced; and the production cost is reduced.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Dust removal and waste gas decomposition double-effect filter material and preparation method thereof

ActiveCN102512878AHigh catalytic activityImprove permeabilitySynthetic resin layered productsDispersed particle separationFiberDecomposition

The invention discloses a dust removal and waste gas decomposition double-effect filter material and a preparation method thereof. The filter material comprises a raw felt, catalyst powder and a coating. The filter material utilizes the raw felt as a carrier, the catalyst powder is adhered to the inside of the raw felt, and the coating is coated on the surface of the raw felt and is of a polytrifluorochloroethylene microporous film structure. The catalyst powder is in a grade of nanometer or micron and is selected from one or more of vanadium pentoxide, vanadium trioxide, tungsten trioxide, titanium dioxide and manganese dioxide. By utilizing the preparation method to prepare the filter material, the process is simple and easy to implement, and processing costs of preparation of catalyticfibers, film covering and the like are reduced. In addition, compared with a polytetrafluoroethylene microporous film, running resistance is low, and difficulties in follow-up sewing, transportation,installation and the like of the filter material are reduced simultaneously.

Owner:南京际华三五二一环保科技有限公司

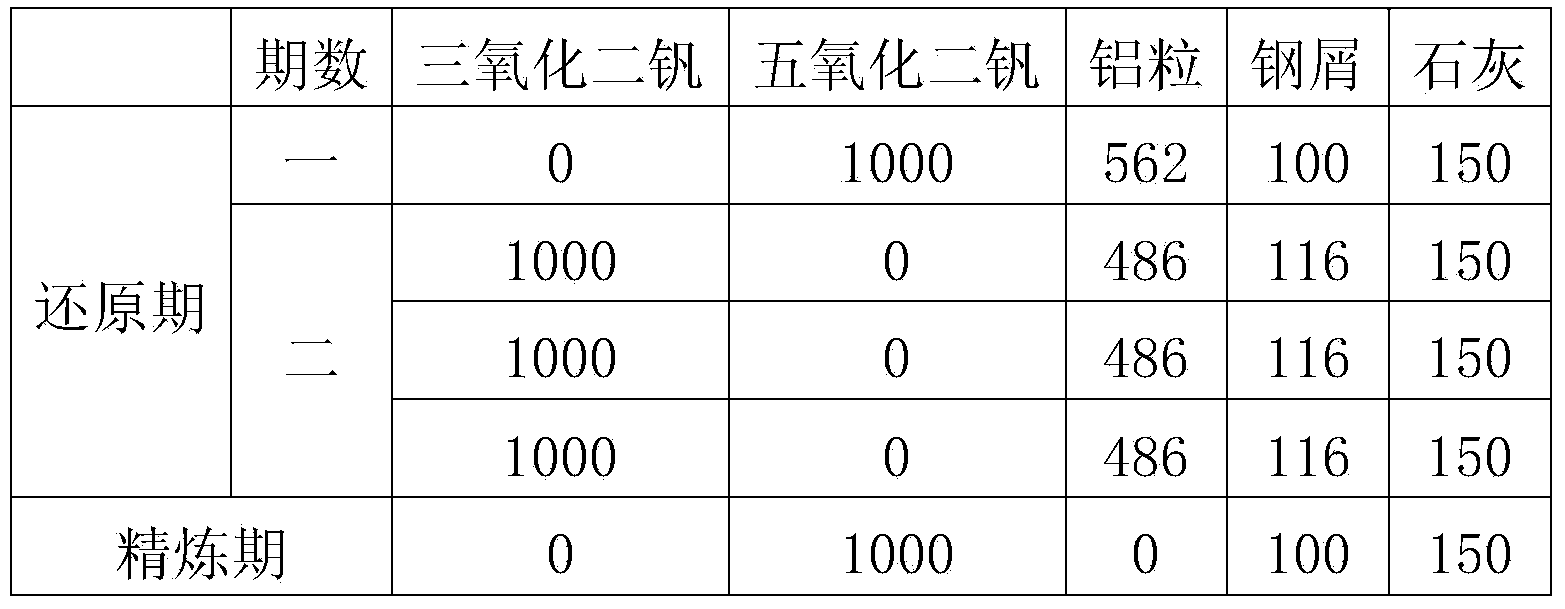

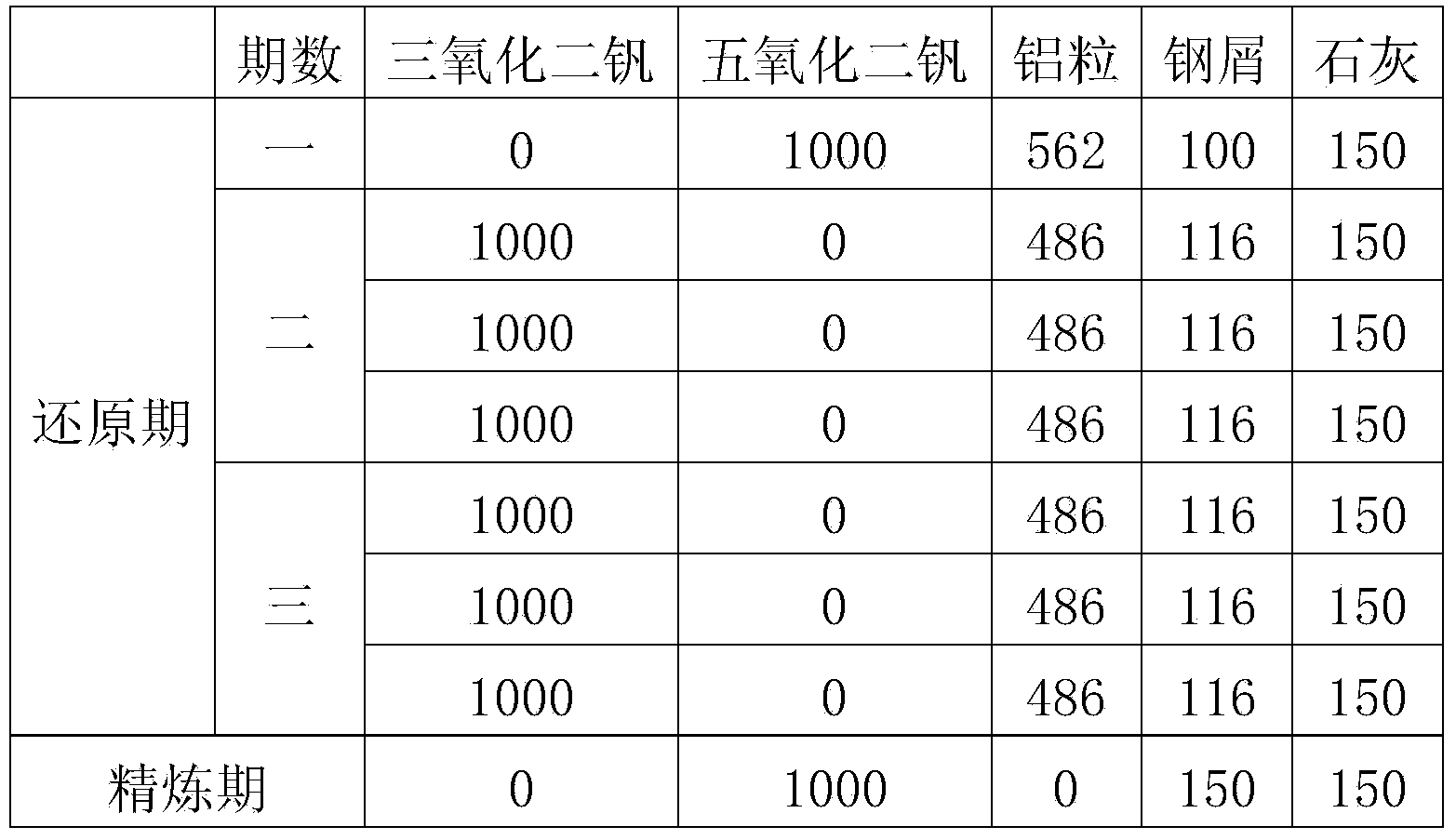

High vanadium ferroalloy smelting method and ingot mould for smelting high vanadium ferroalloy

ActiveCN103757171AReduce coolingOvercoming difficult follow-up problemsProcess efficiency improvementReduction treatmentElectric arc furnace

The invention discloses a high vanadium ferroalloy smelting method. The method comprises the steps of adding cold-state vanadium-rich slag and limestone to the bottom of an electric arc furnace, adding a phase-I mixture consisting of vanadium pentoxide, aluminum particles, limestone and steel cuttings and smelting; returning heat-state vanadium-enriched slag of last batch into the electric arc furnace and discharging slag when vanadium content in smelting slag is less than 0.5%; adding a phase-II mixture consisting of vanadium trioxide, aluminum particles, limestone and steel cuttings, smelting, discharging slag when vanadium content in smelting slag is less than 0.5%, and before discharging the slag, adding aluminum or aluminum-magnesium alloy for reduction treatment; adding a refining mixture consisting of vanadium pentoxide and limestone or iron scale and limestone, smelting, controlling temperature of vanadium-iron alloy liquid in the furnace to be above 1900 DEG C, discharging the vanadium-iron alloy liquid and the vanadium-enriched slag when vanadium content is 78-82% and aluminum content is less than 1.5% in the vanadium-iron alloy liquid, pouring the vanadium-iron alloy liquid into an ingot mould which is preheated to be above 500 DEG C, and cooling, demoulding and breaking to obtain high vanadium ferroalloy which contains more than 80% of vanadium.

Owner:攀钢集团西昌钒制品科技有限公司

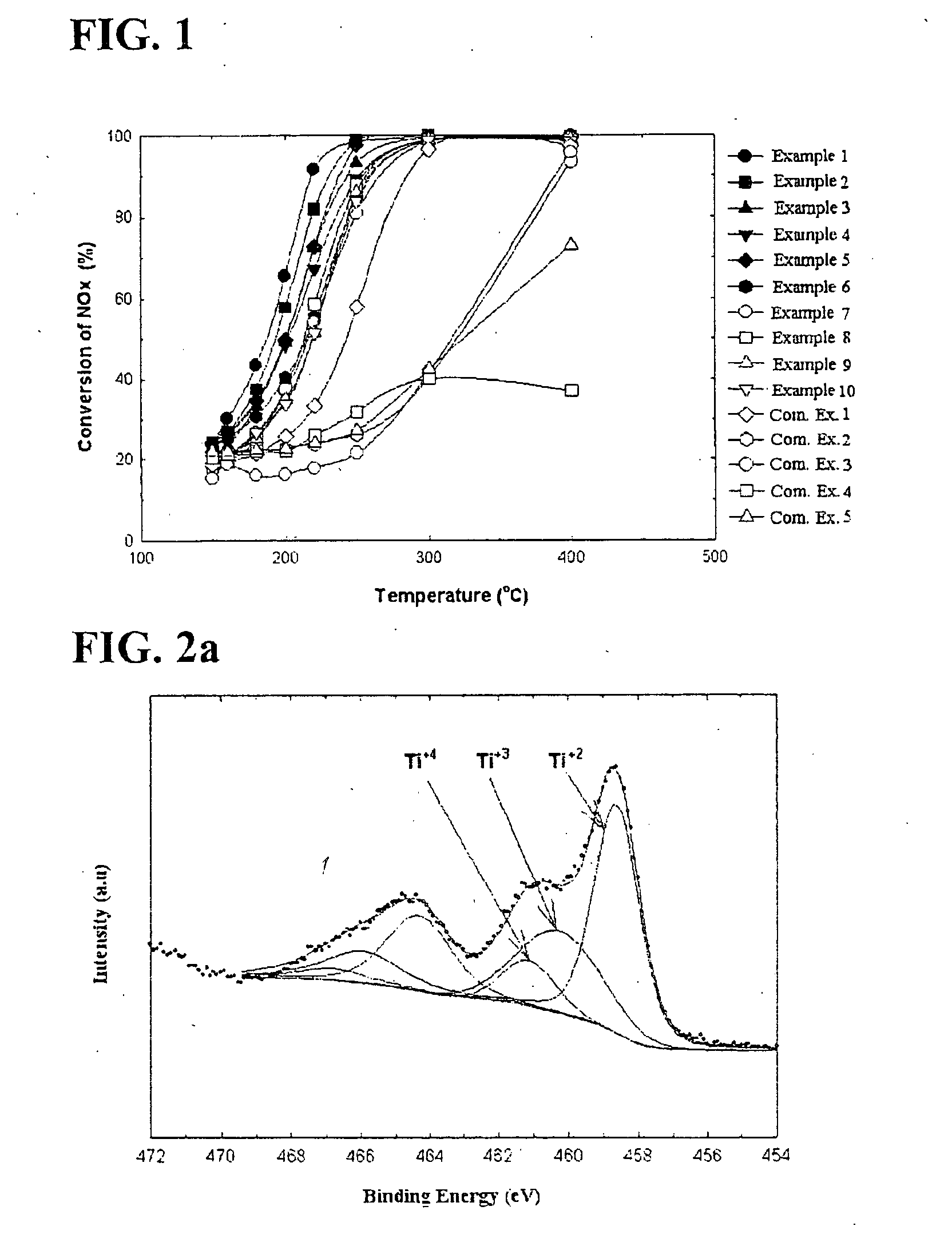

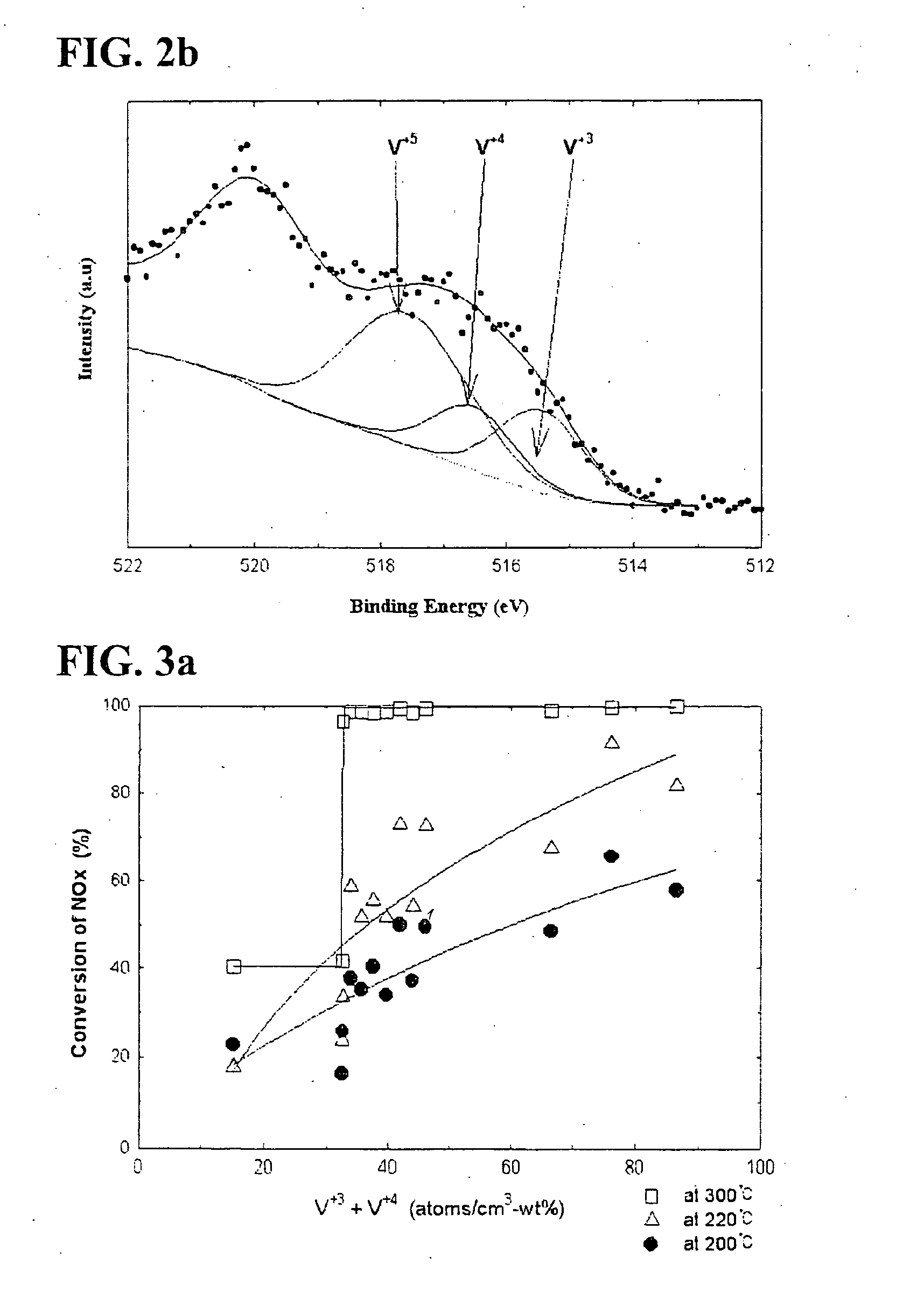

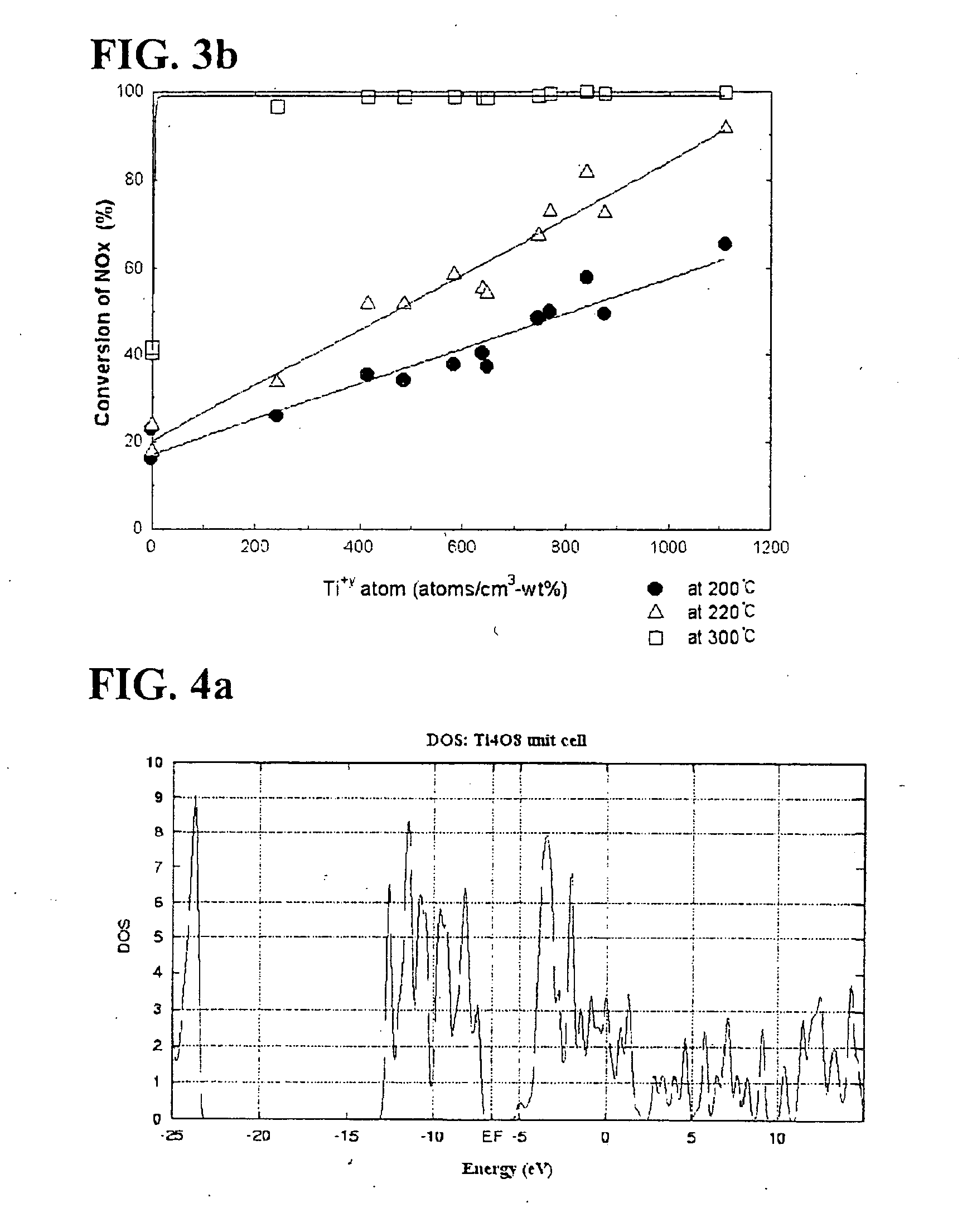

Vanadium/titania-based catalyst for removing introgen oxide at low temperature window, and process of removing nitrogen oxide using the same

InactiveUS20050069477A1High activityNitrogen compoundsOther chemical processesFlue gasNitrogen oxide

Disclosed is a vanadium / titania-based catalyst for removing nitrogen oxides, and a process for removing nitrogen oxides in a flue gas using the same. The vanadium / titania-based catalyst containing a vanadium trioxide and / or vanadium tetraoxide has excellent activity to remove nitrogen oxides in a wide temperature range, particularly, at the low temperature window.

Owner:KOREA ELECTRIC POWER CORP

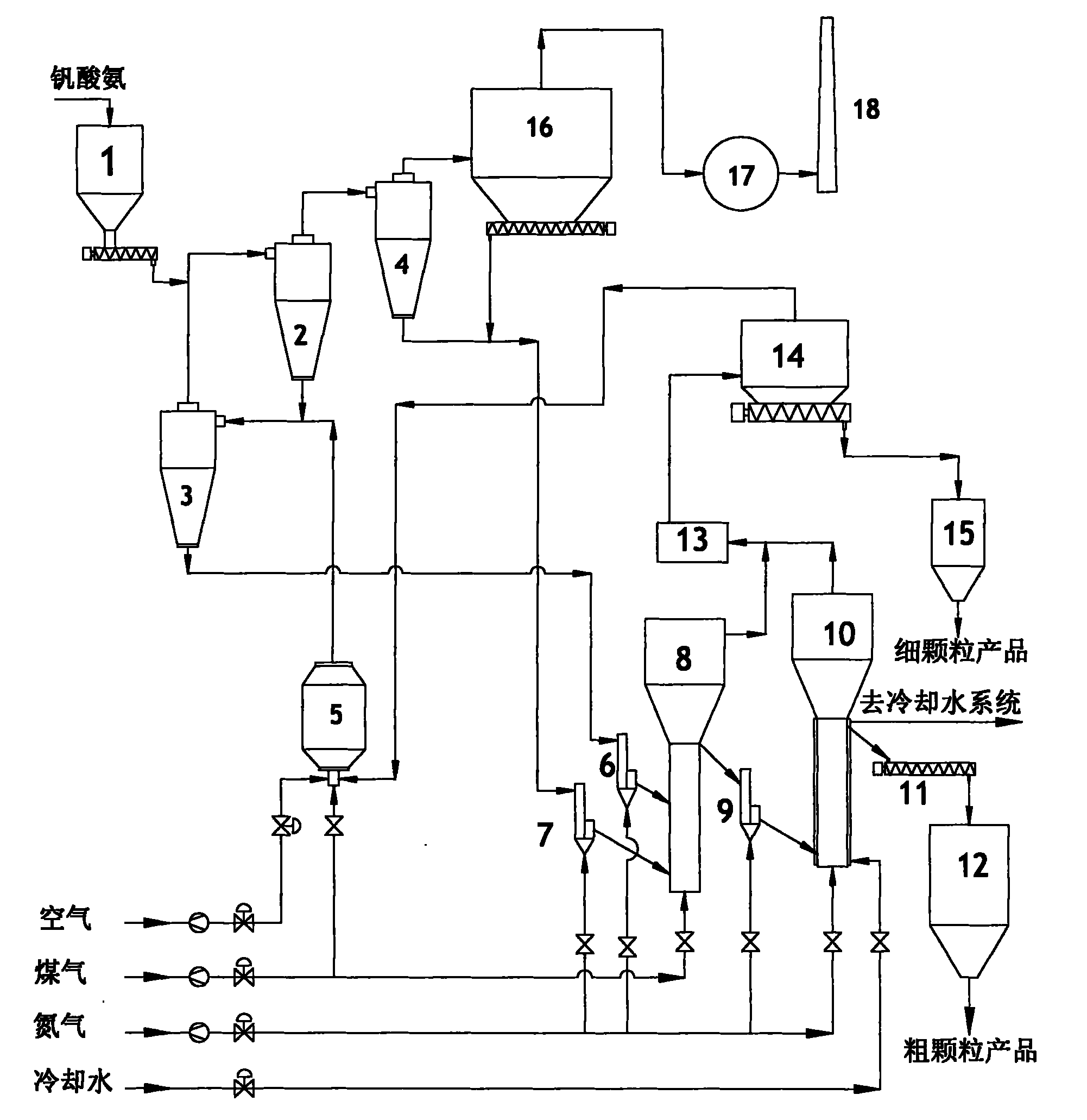

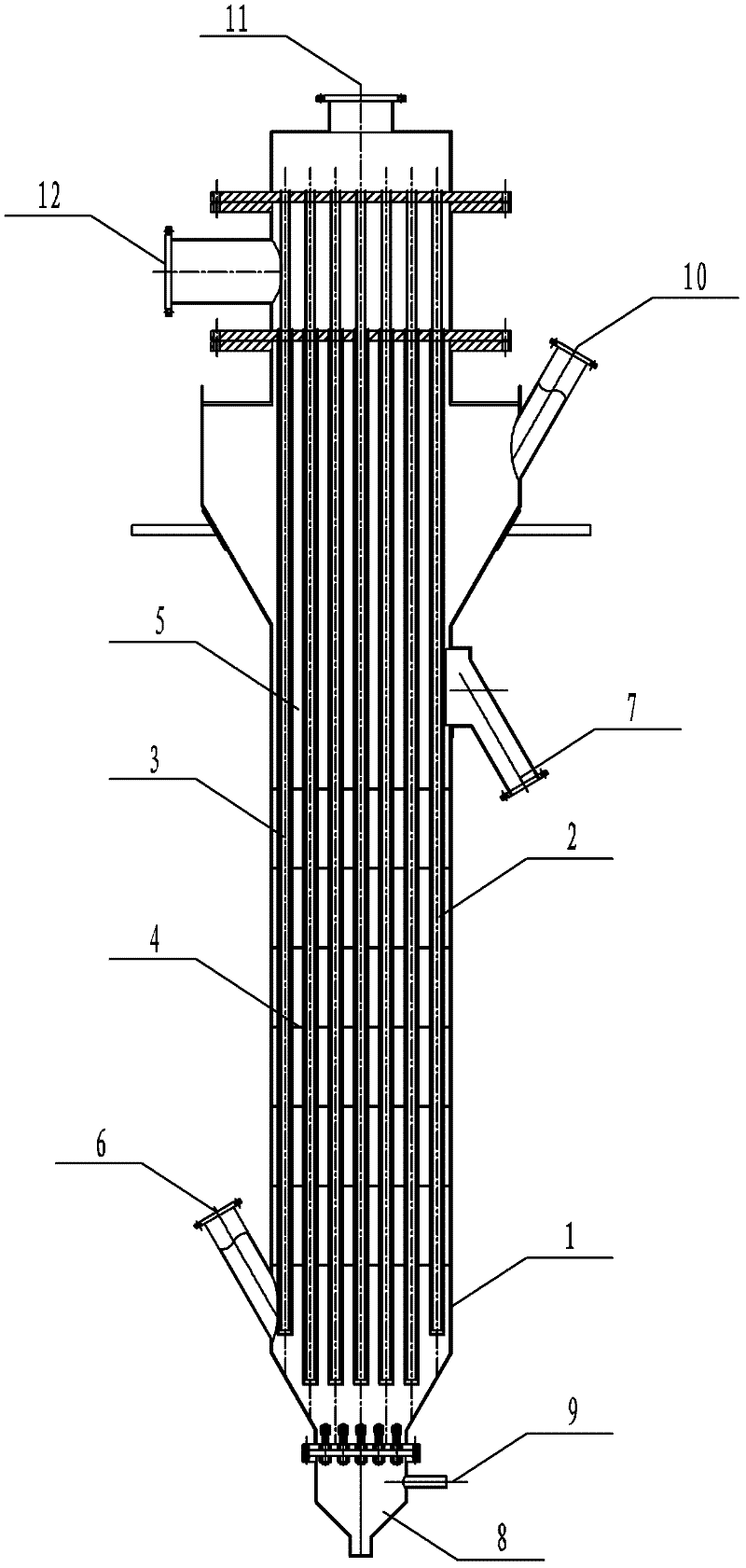

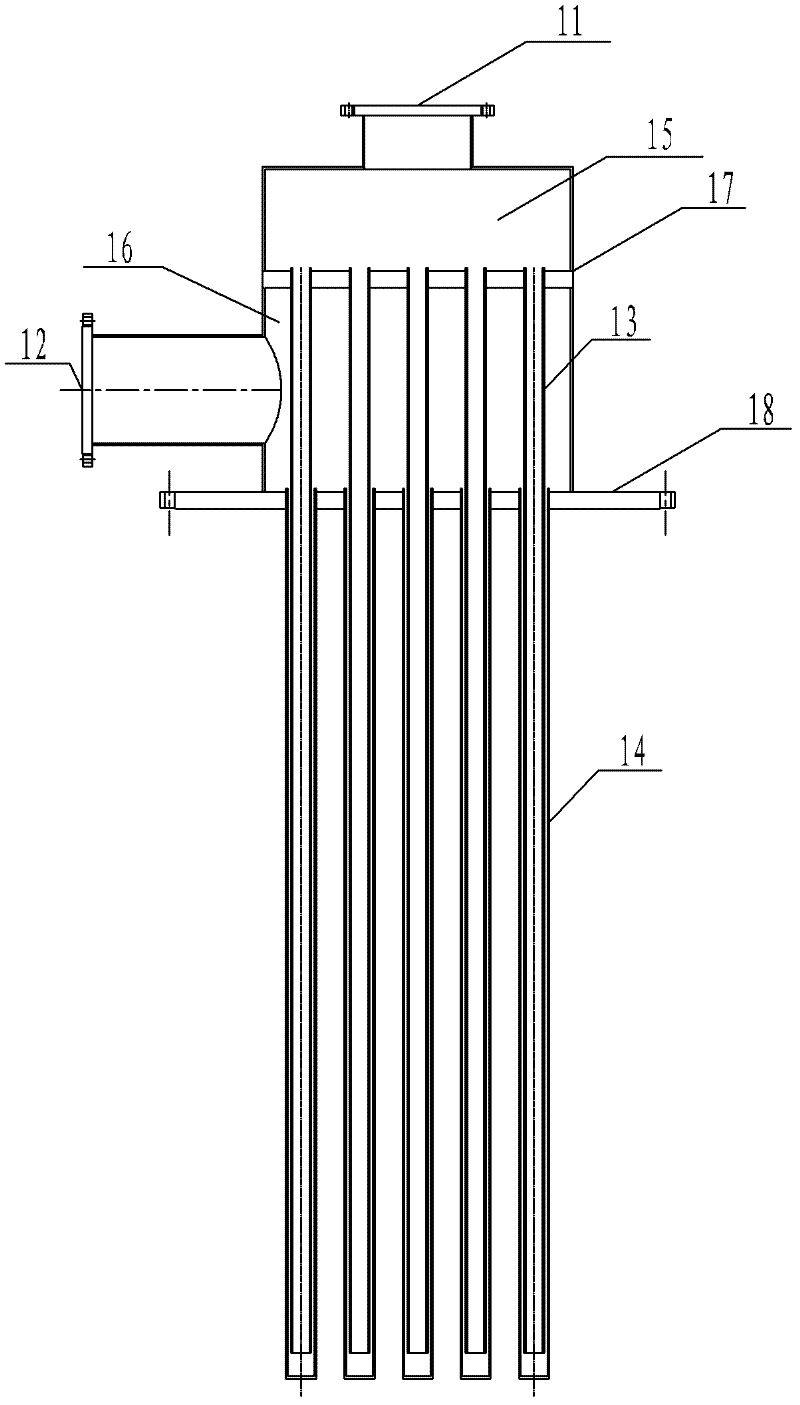

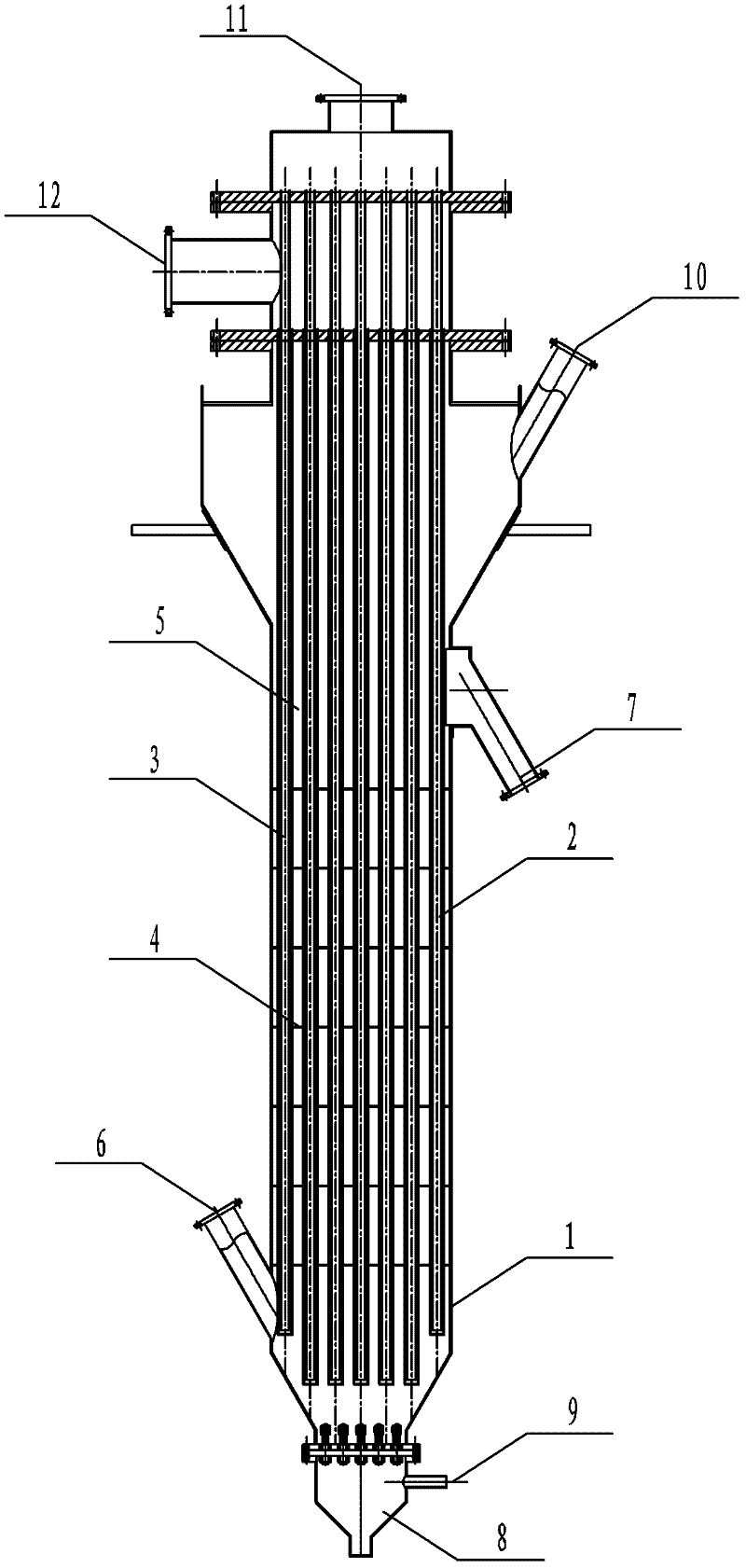

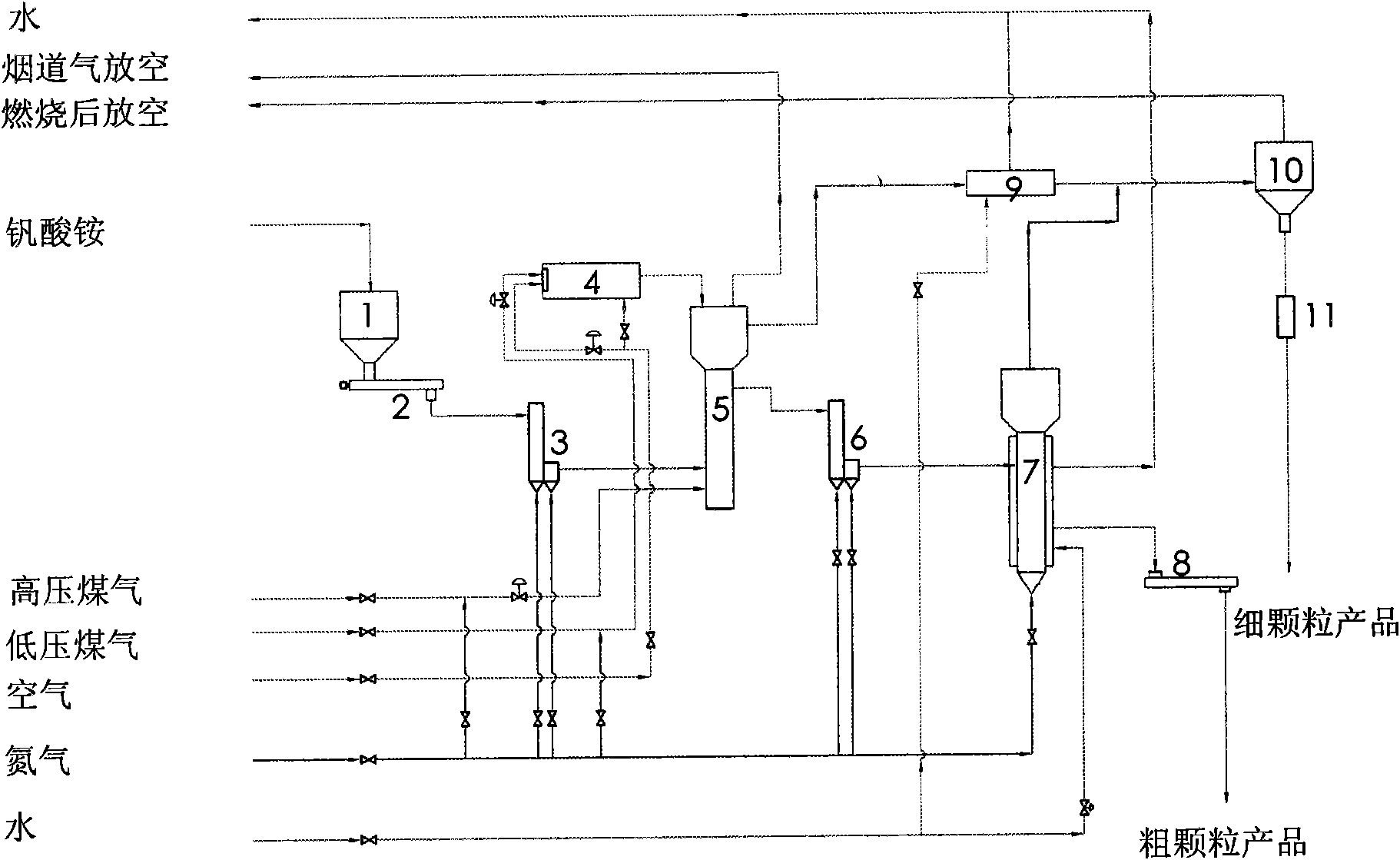

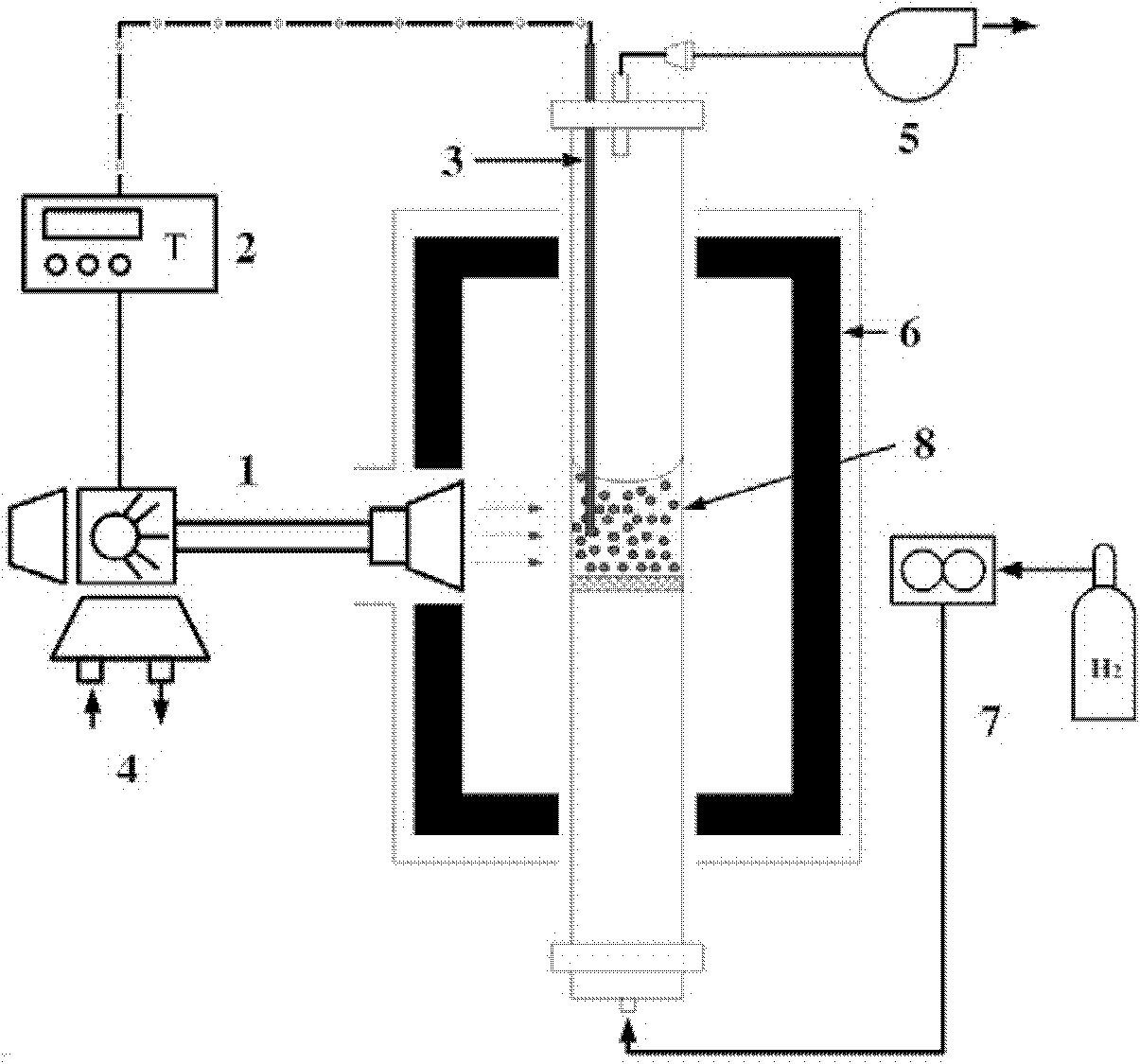

System and method for producing vanadium trioxide

The invention discloses a system and a method for producing vanadium trioxide, and belongs to the technical field of chemical industry. The system comprises a fluidized reduction furnace, a feeding system, a combustion system, a cooling system, a tail gas treatment system, and a discharging system. A heat exchange member is arranged inside the fluidized reduction furnace, and is in a U shape; the heat exchange member makes flue gas and materials exchange heat in a mode of coupling reverse flow with cross flow; the fluidized gas enters the furnace from a fluidized air inlet and the raw materials enter the furnace from a feed inlet; the fluidized gas moves from bottom to top to suspend the raw materials in the furnace body and drive the raw materials to move upwards and be discharged from a discharge hole, and the reaction tail gas is exhausted from a tail gas outlet; the heat exchange member has the functions of improving the fluidized state and exchanging heat simultaneously; and high-temperature flue gas enters the furnace from a flue gas inlet, and after heat exchange, the high-temperature flue gas is exhausted from a flue gas outlet. The system for producing the vanadium trioxide has the advantages of applicability to mass production of vanadium trioxide, good device tightness, high safety, high reaction efficiency, vanadium recovery rate of over 99.4 percent, and vanadium grade in the vanadium trioxide of 67.9 percent.

Owner:深圳中科九台资源科技有限公司

Method for preparing electrolyte for vanadium redox flow battery

InactiveCN1828991AImprove solubilityIncrease energy densityHybrid cell detailsRegenerative fuel cellsSolubilityAlkaline earth metal

The present invention relates to a preparation method for electrolyte of vanadum oxidation-reduction liquid stream. It contains 1, putting weight ratio 1.5-2.5 :1 vanadium trioxide and vanadium pentoxide powder in furnace and calcination at 200-700 degree centigrade, to make yellow powder became black powder to obtain multivalent vanadum compound, wherein quadravalence vanadum greater than total vanadum by 50 per cent, 2, adding distilled water in specific gravity 1.84 concentrated sulfuric acid to proceed 2 : 1 diluting then adding above-mentioned compound, according to mass fraction preparation to 65-75 per cent concentration vanadyl sulfate solution, wherein total vanadum concentration in 25-45 per cent, 3, adding 1-10 per cent concentration alkali salt or alkali salt and alkaline earth metal salt. Said invention adds additive in vanadyl sulfate solution, which not only raising vanadum ion solubility, preferably solving crystallizing jamming battery flow field problem in charge discharge process, but also reducing vanadium ion osmotic problem in film, greatly raising battery energy source efficiency.

Owner:缪强

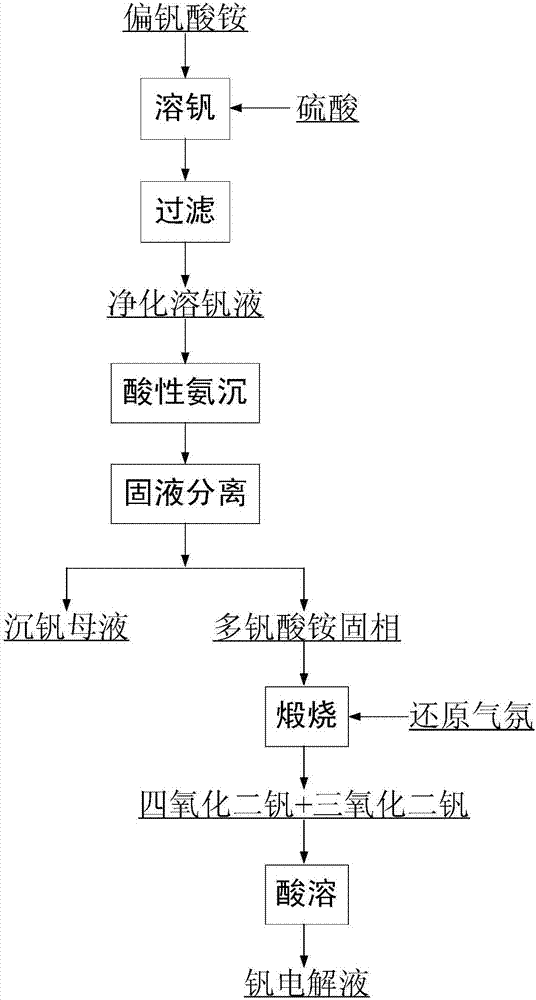

Vanadium electrolytic solution and preparation method thereof

ActiveCN106941186AMeet the requirements of the electrolyteReduce lossesRegenerative fuel cellsSecondary cellsAmmonium metavanadateImpurity

The invention relates to a vanadium electrolytic solution preparation method, which comprises: (1) using ammonium metavanadate with a purity of 99.0-99.5 wt% as a raw material, dissolving, filtering to obtain a purified vanadium dissolving solution, and carrying out acid ammonia precipitation to obtain an ammonium polyvanadate solid phase; (2) calcining the ammonium polyvanadate solid phase in a reducing atmosphere to obtain the mixture containing vanadium tetraoxide and vanadium trioxide, wherein a molar ratio of vanadium tetraoxide to vanadium trioxide is (0.95-1.05):1; and (3) carrying out acid dissolving on the mixture to obtain the vanadium electrolytic solution. According to the present invention, when the vanadium concentration of the vanadium electrolytic solution is 2 mol / L, the contents of impurities such as silicon, calcium and aluminum can be respectively reduced to less than 7 ppm, less than 10 ppm and less than 10 ppm, the total impurity content is less than 65 ppm, and the requirement of the vanadium battery vanadium electrolytic solution can be met; and compared to the acid and alkaline alternating impurity removing method, the method of the present invention has the following advantages that the vanadium loss can be significantly reduced, the vanadium recovery rate is more than 96.6%, the vanadium valence in the obtained vanadium electrolytic solution is +3.5, and the obtained vanadium electrolytic solution can be used directly as the vanadium battery electrolytic solution without activation.

Owner:HEBEI IRON AND STEEL

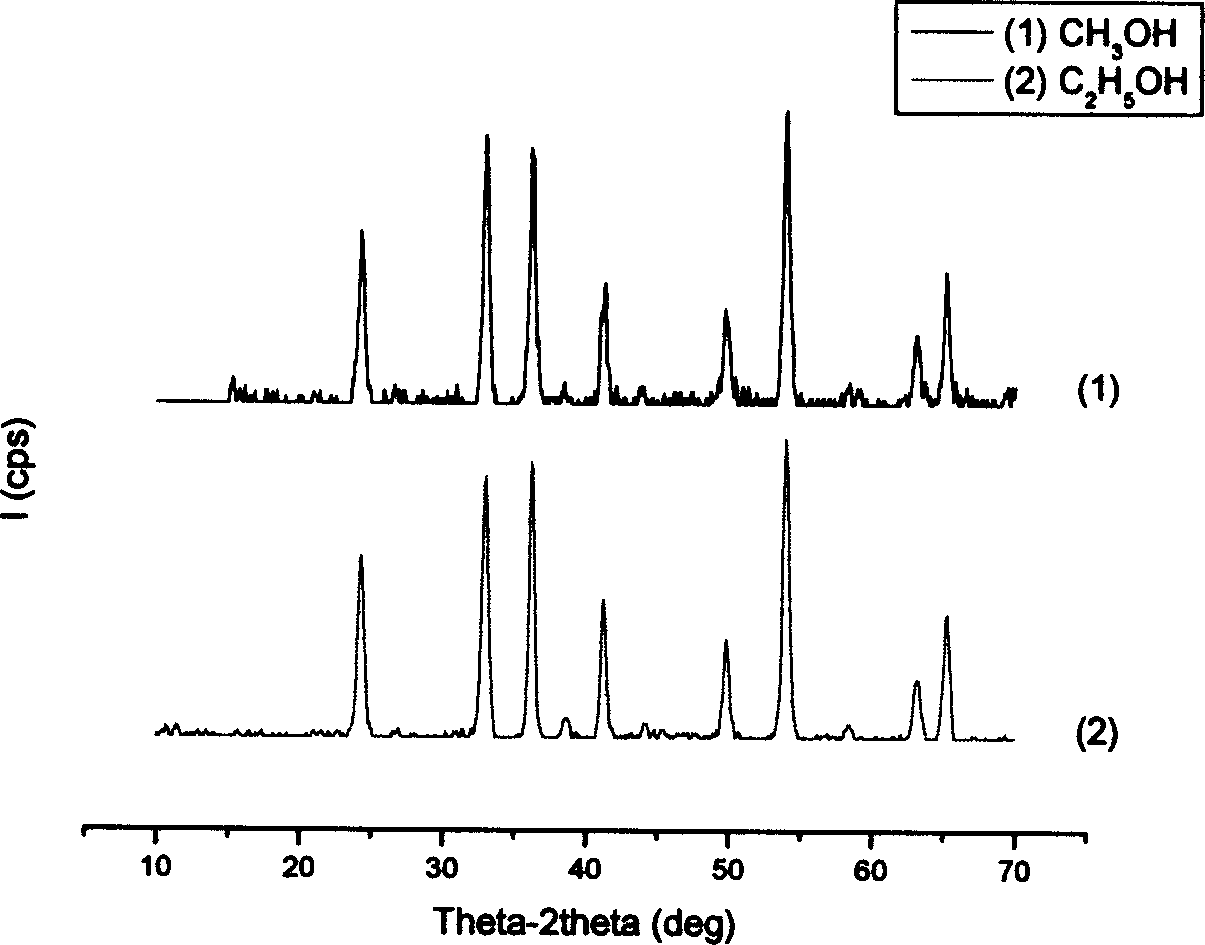

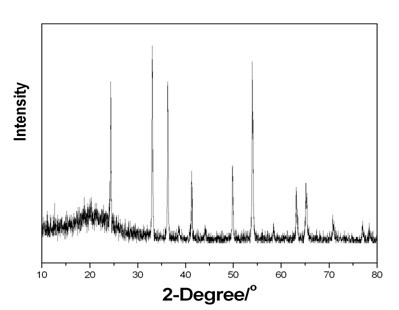

Process for preparing crystal vanadium trioxide

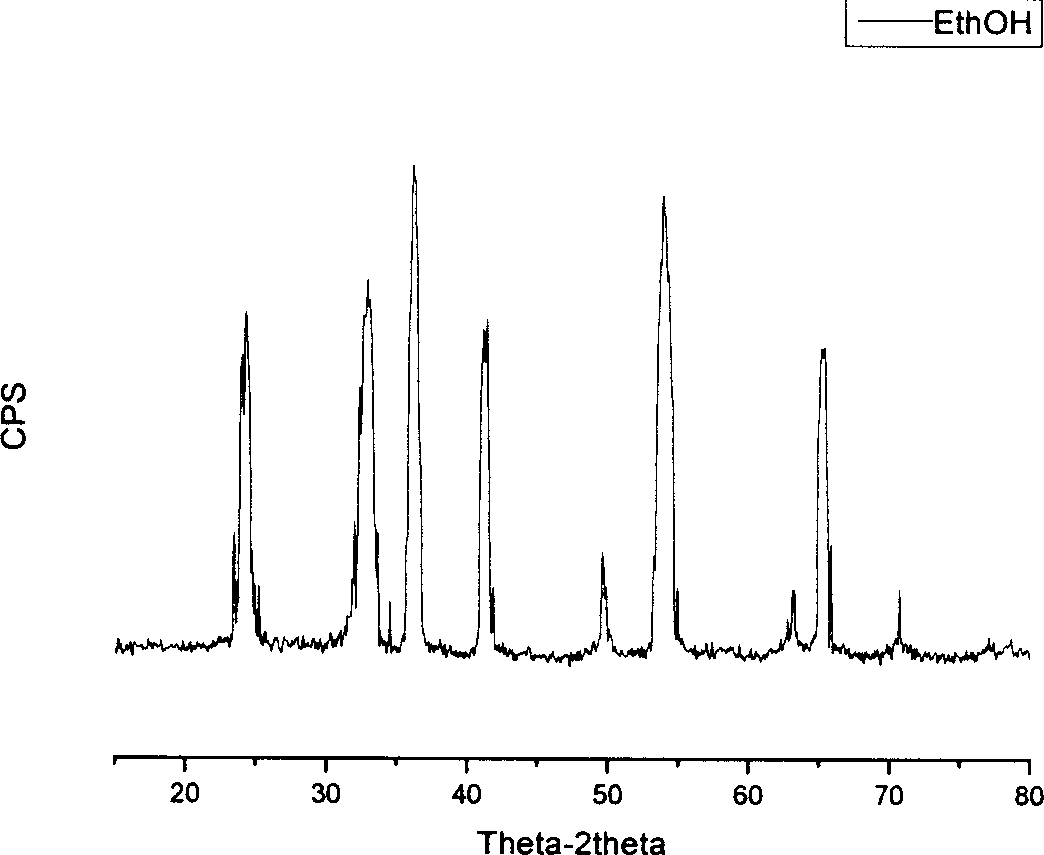

A process for preparing crystalline V2O3 includes such steps as dispersing V2O5 powder in proper organic solvent, adding to high-pressure tubular reactor, reacting at a certain temp under a certain pressure, and removing solvent.

Owner:WUHAN UNIV

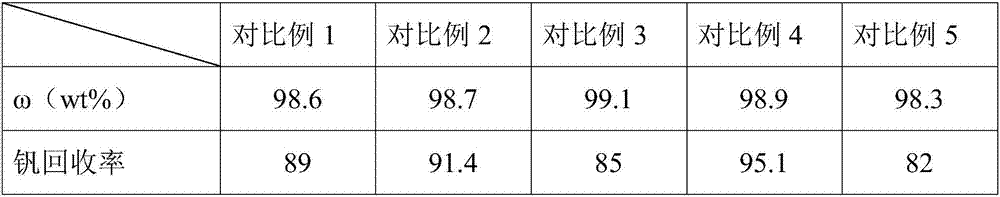

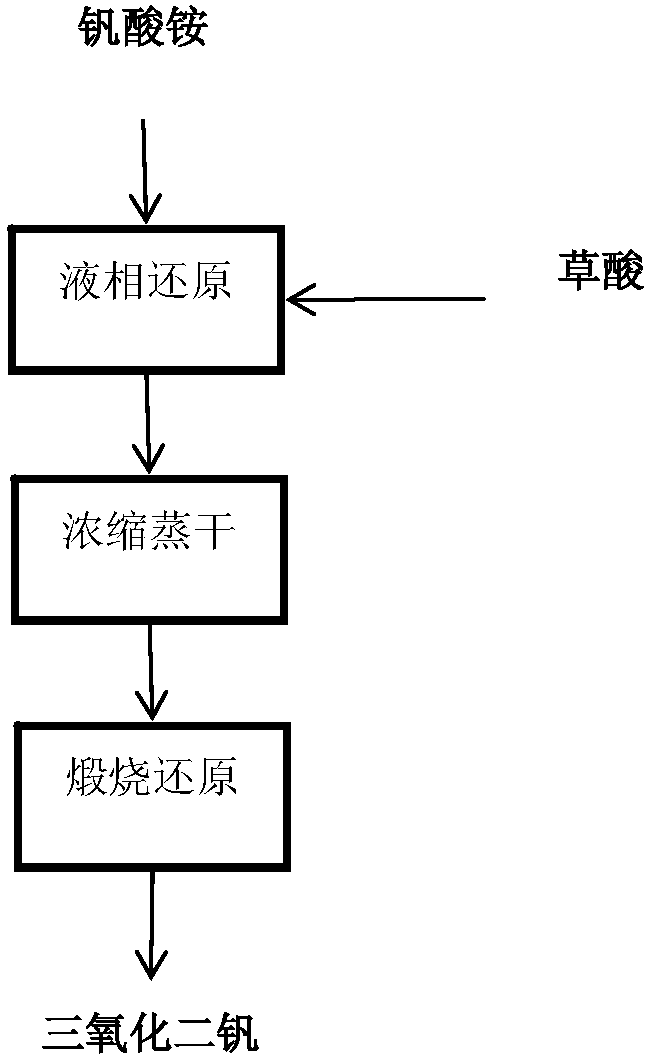

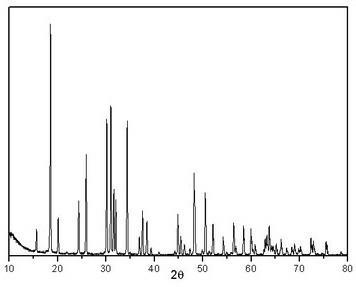

Preparation method of vanadium trioxide

ActiveCN107662946AReduce manufacturing costEasy to operateRegenerative fuel cellsVanadium oxidesOxalateDistillation

The invention discloses a preparation method of vanadium trioxide suitable for a vanadium battery. The preparation method comprises the following steps: enabling ammonium vanadate with a vanadium valence state of +5 valence and oxalic acid or solvent complex of the oxalic acid to have liquid-phase reduction in a reaction solvent, drying by distillation a reaction solution, and calcining, thus obtaining the vanadium trioxide. According to the preparation method, the +5-valence ammonium vanadate which is relatively low in price and available is adopted as a raw material to be reduced by the oxalic acid and to be calcined, thus obtaining the vanadium trioxide with purity reaching up to 99 percent, and except for the transfer loss in the production process, the yield of vanadium has no other loss. The production process is simple in operation, low in energy consumption, safe, low in requirement on equipment, suitable for industrialized mass production and capable of significantly decreasing the production cost of the vanadium trioxide.

Owner:PANZHIHUA UNIV

Production method of vanadium-nitrogen alloy

InactiveCN103243254AReduced temperature control requirementsReduce manufacturing costTemperature controlAlloy

The invention provides a production method of a vanadium-nitrogen alloy. The method comprises the following steps of: a) reducing vanadium pentoxide to vanadium tetraoxide; b) adding carbon powder into vanadium tetraoxide and then carrying out dry powder extrusion on the resulting mixture for ball forming; and c) feeding the formed ball into a medium frequency vertical furnace, vacuumizing the furnace to be lower than 300Pa, and heating the ball inside the furnace to 1000 DEG C, introducing nitrogen into the furnace, preserving the positive pressure of 0.8-1.0MPa, increasing the temperature to 1200-1500 DEG C, and preserving heat for 3-5 hours; preserving the positive pressure of the nitrogen to 0.3-0.5MPa, increasing the temperature to 1500-1600 DEG C, and preserving heat for 1 hour; at last cooling the material to be lower than 200 DEG C and discharging the material, wherein the product is the vanadium-nitrogen alloy. The method conquers the defects that vanadium pentoxide is low in melting point, temperature control demand is strict, vanadium trioxide is unstable in normal state and is easily oxidized in the existing vanadium-nitrogen synthesis production process, and is relatively loose in temperature control demand, simple in equipment, good in product quality, stable in production process, and low in production cost.

Owner:湖南汉瑞新材料科技有限公司

Preparation method for NaV2O5

InactiveCN102557131AReduce riskShorten sintering timePolycrystalline material growthVanadium compoundsArgon atmosphereNitrogen gas

The invention relates to a preparation method for NaV2O5. According to the invention, sodium carbonate (Na2CO3), vanadium trioxide (V2O3) and vanadium pentoxide (V2O5) are used as raw materials and are mixed according to a mole ratio of 2: 1: 3, and an obtained mixture is sintered in an inert gas atmosphere like a high purity nitrogen atmosphere or an argon atmosphere at a temperature of 600 to 800 DEG C for 10 h so as to obtain NaV2O5 polycrystalline powder. According to the invention, nontoxic Na2CO3 is used to substitute a raw material with great toxicity, NaVO3, used in traditional preparation methods, which enables hazards of an experiment to be reduced and sintering time to be greatly shortened, so the method has great significance to future industrial production and incomparable advantages compared to traditional methods.

Owner:JILIN NORMAL UNIV

Method for preparing metal vanadium

The invention relates to a method for preparing metal vanadium, and belongs to the field of metallurgy. The technical problem to be solved is to provide a method for preparing the metal vanadium with low production cost. The method for preparing the metal vanadium comprises the following steps of: a, preparing crude vanadium, namely igniting and reducing vanadium trioxide and vanadium pentoxide serving as raw materials by using Al powder as a reducing agent to obtain the crude vanadium and slag, wherein the weight ratio of the vanadium trioxide to the vanadium pentoxide is 1:1-2, and the using amount of the Al powder is 0.6 to 0.9 time the theoretical using amount of the raw materials when the raw materials are completely reduced into vanadium (V) (the theoretical using amount is the using amount of the Al powder required for completely reducing the vanadium trioxide and the vanadium pentoxide serving as the raw materials into the metal vanadium); and b, refining, namely performing vacuum refining to obtain the metal vanadium.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

Production method of vanadium-aluminium alloy

The invention belongs to the field of metallurgy, and particularly relates to a production method of vanadium-aluminium alloy. The invention aims to solve the technical problem of providing the production method of vanadium-aluminium alloy. By using the method, no heat removal agent and heat assisting agent need to be added, and the content of Fe and Si in the prepared product is below 0.30wt%. The production method of vanadium-aluminium alloy is characterized in that raw materials are ignited and reduced in a reaction device to obtain vanadium-aluminium alloy and slag; vanadium oxide and metallic aluminium serve as raw materials, wherein the vanadium oxide is composed of vanadium trioxide and vanadium pentoxide, and the ratio of V to O in the vanadium oxide is equal to 1:(1.70-2.30). Finally, the vanadium-aluminium alloy contains 75-85wt% of V, less than or equal to 0.30wt% of Fe and less than or equal to 0.30wt% of Si, thereby satisfying the requirement on further subsequent processing. The method has the advantages of simple technology and low cost, and is especially suitable for mass production on a large batch; and meanwhile, the proportion of the raw materials is properly adjusted, and heat removal agent and heat assisting agent do not need to be added so as to prevent the pollution on alloy ingredients.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +2

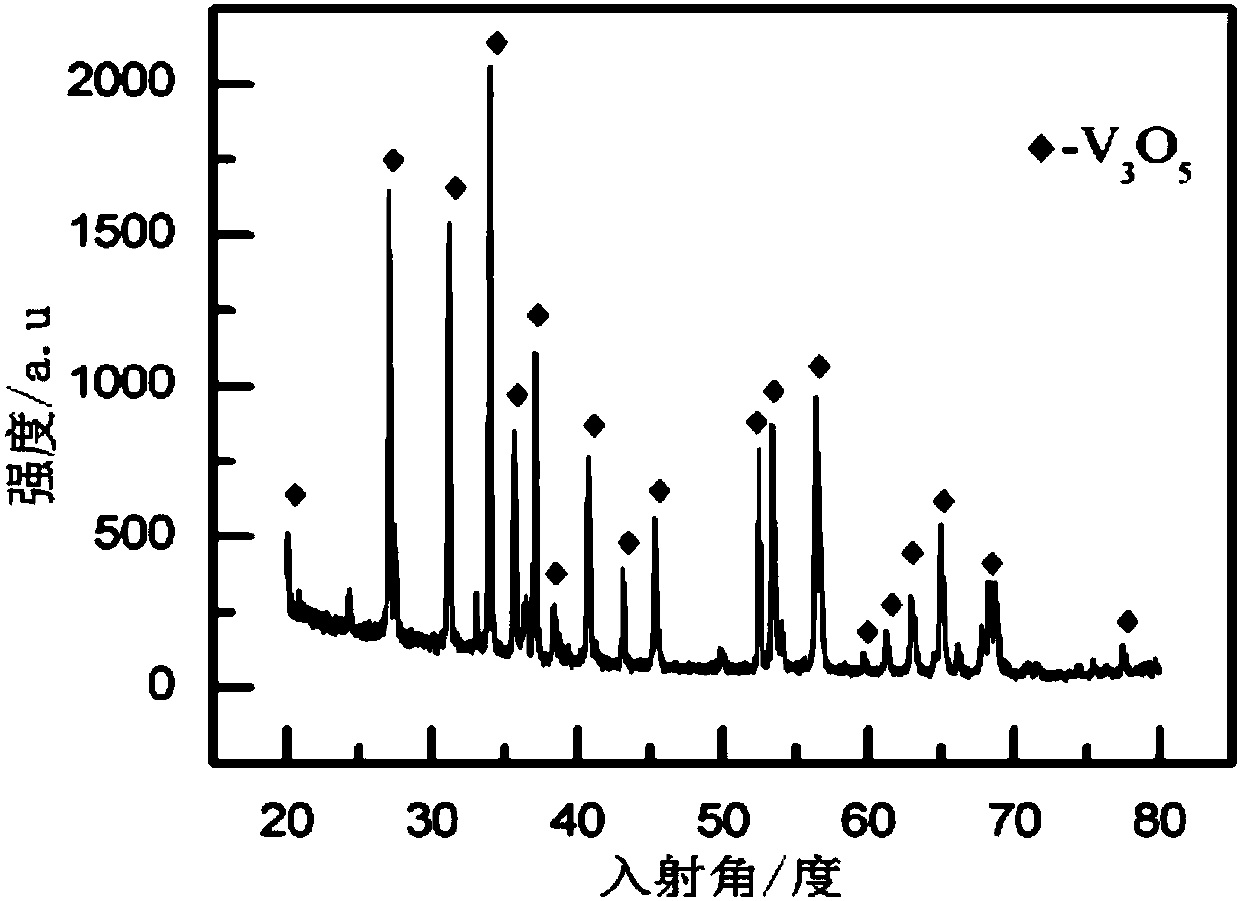

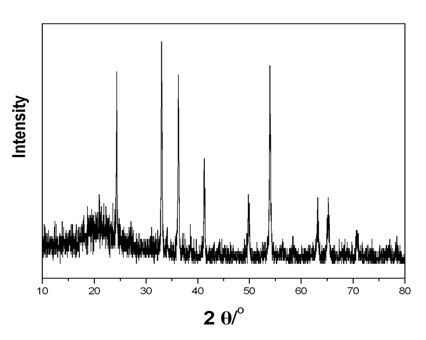

Preparation method for vanadium trioxide doped powder material

The invention discloses a preparation method for a vanadium trioxide doped powder material. The preparation method comprises the following steps of: by using a certain amount of ammonium metavanadate, oxalic acid, a doping agent and water as raw materials, uniformly mixing the raw materials according to quantitative proportions, then transferring the mixture to a polytetrafluoroethylene hydrothermal kettle for hydrothermal reaction, and after finishing reaction, centrifuging, washing, vacuumizing and calcining the mixture in an inertia atmosphere to obtain the vanadium trioxide powder doped powder material. The phase-transition temperature of the V2O3 doped powder can be effectively controlled by adjusting the doping amount of atoms. The preparation method for the vanadium trioxide doped powder material has the advantages of simple technological process, good product quality, low cost, environmental friendliness, easiness in control and capability of realizing the large-scale industrial production.

Owner:WUHAN UNIV

Conductive heating coating

The invention discloses a conductive heating coating which comprises the following components in parts by weight: 24-36 parts of lithium silicate, 20-30 parts of graphite nodules, 16-18 parts of vanadium trioxide, 10-20 parts of azo-dicarbonamide, 8-12 parts of zinc oxide, 4-12 parts of benzoyl peroxide, 12-18 parts of dibutyl phthalate, 10-20 parts of triphenyl phosphate, 4-8 parts of isopropyl acrylate, 12-16 parts of epoxy resin, 8-12 parts of butyl acetate, 4-12 parts of ethylene glycol, 2-8 parts of ethylene glycol monohexyl ether, 4-8 parts of dimethyl ethanolamine, and 4-6 parts of zirconate calcium carbonate. The conductive heating coating provided by the invention is simple in manufacturing; the adopted production raw materials are non-toxic, therefore, the coating is good in application effect, and environment-friendly; and a conductive paint film formed by the coating has good electric conductivity.

Owner:姜云华

Preparation method of vanadium-aluminum alloy

The invention discloses a preparation method of a vanadium-aluminum alloy, which can lower the producing cost of the vanadium-aluminum alloy. In the method, vanadium trioxide and vanadium pentoxide are taken as raw materials, Al powder is taken as a reducing agent and the vanadium-aluminum alloy and slag are obtained by igniting and reducing, wherein the weight ratio of the vanadium trioxide to the vanadium pentoxide is 1:1-2; and the using amount of the Al powder is 1.2 to 1.5 times of V ideal using amount (namely, the using amount of the Al powder needed for fully reducing the vanadium trioxide and the vanadium pentoxide into metal vanadium) of fully reduced raw materials. Compared with the conventional process, the method has lower cost and is fully accordant with the requirement on mass industrial production; moreover, the produced vanadium-aluminum alloy has low impurity content; a final vanadium-aluminum alloy comprises the following components in percentage by weight: 75 to 85 percent of V, less than or equal to 0.3 percent of Fe and less than or equal to 0.3 percent of Si; and the requirements on further subsequent processing are met.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

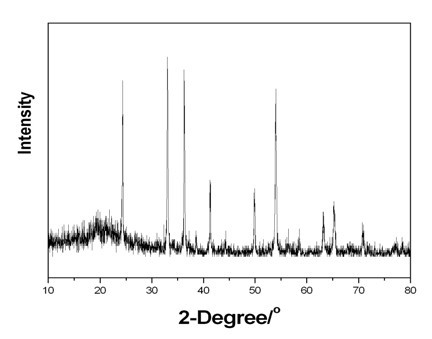

Process for preparing nano grade vanadium trioxide

InactiveCN1724386ALow reaction temperatureLow priceNanostructure manufactureVanadium oxidesReaction temperatureSolvent

Owner:WUHAN UNIV

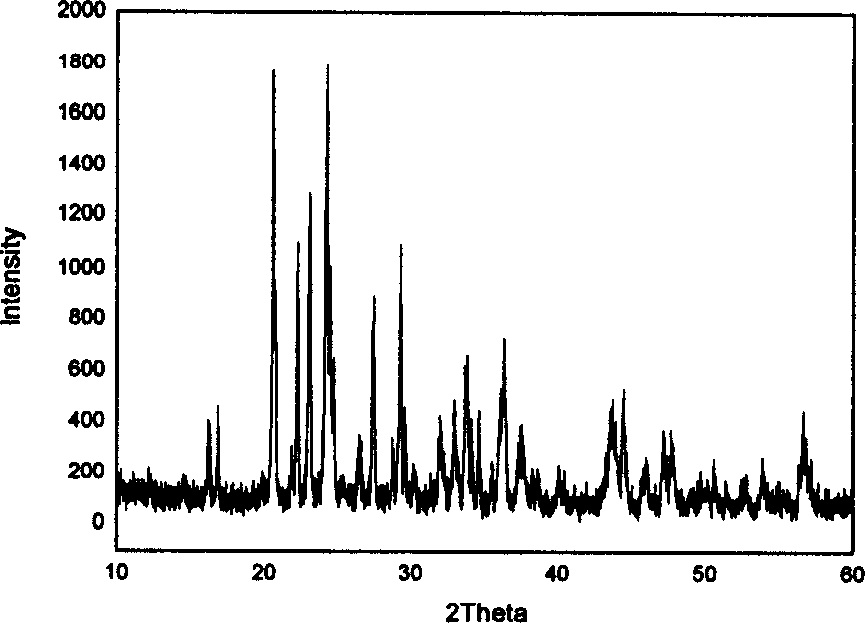

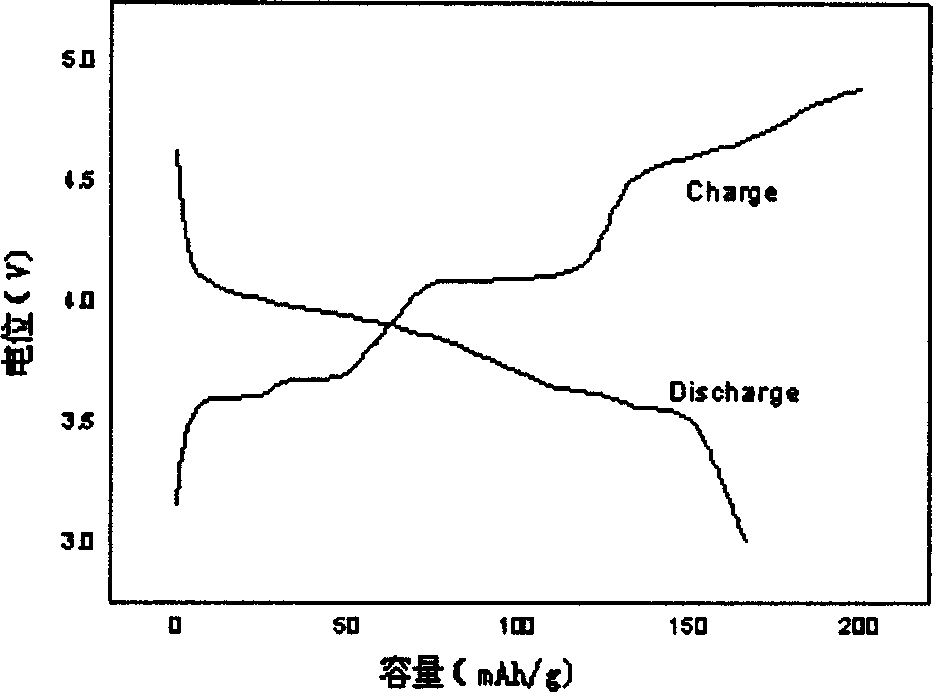

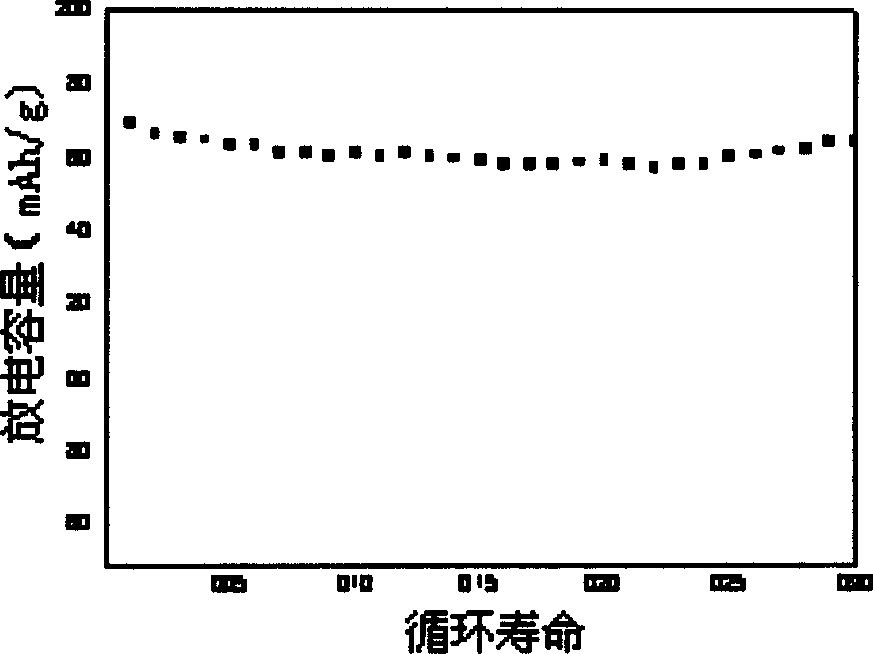

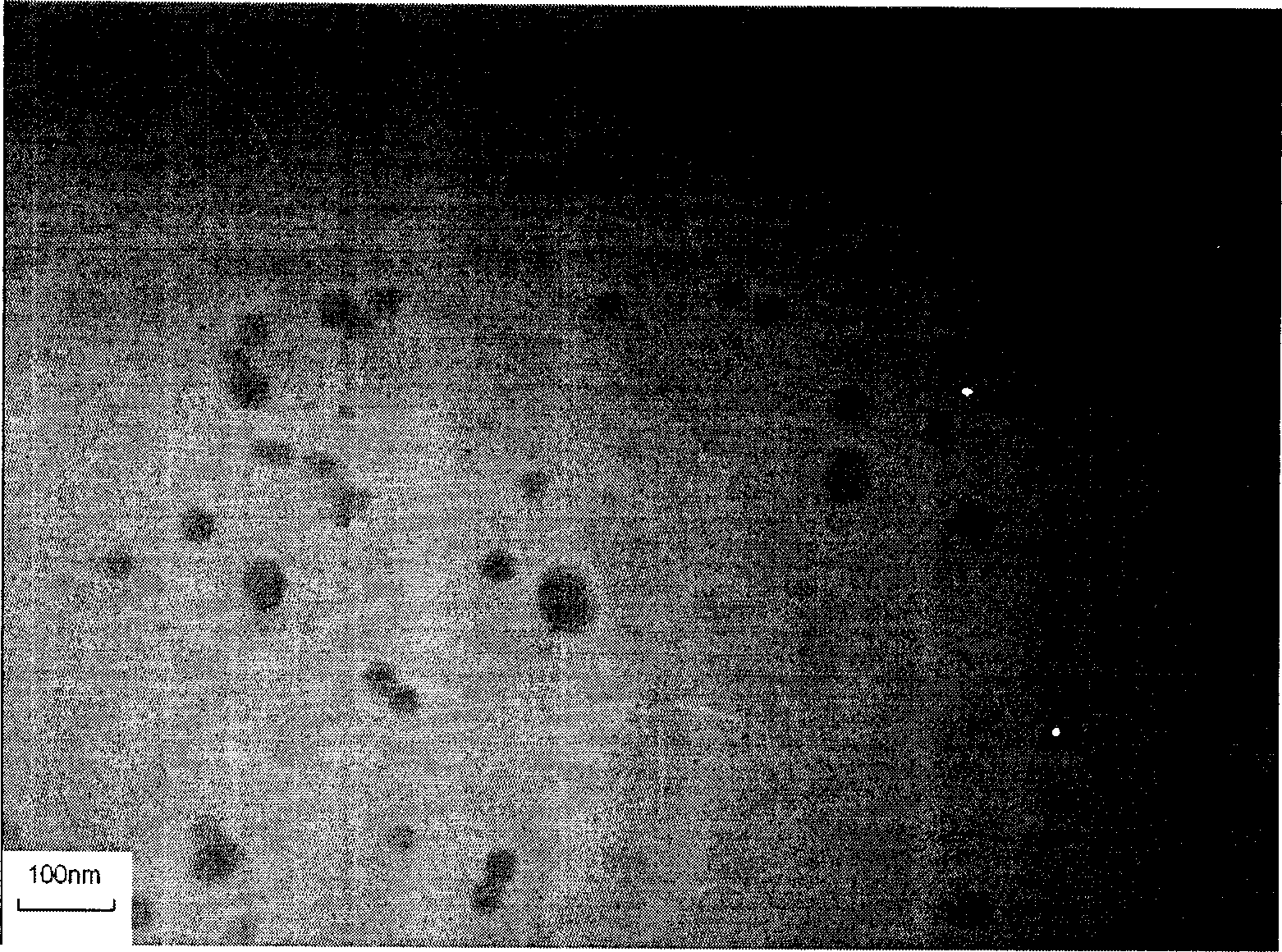

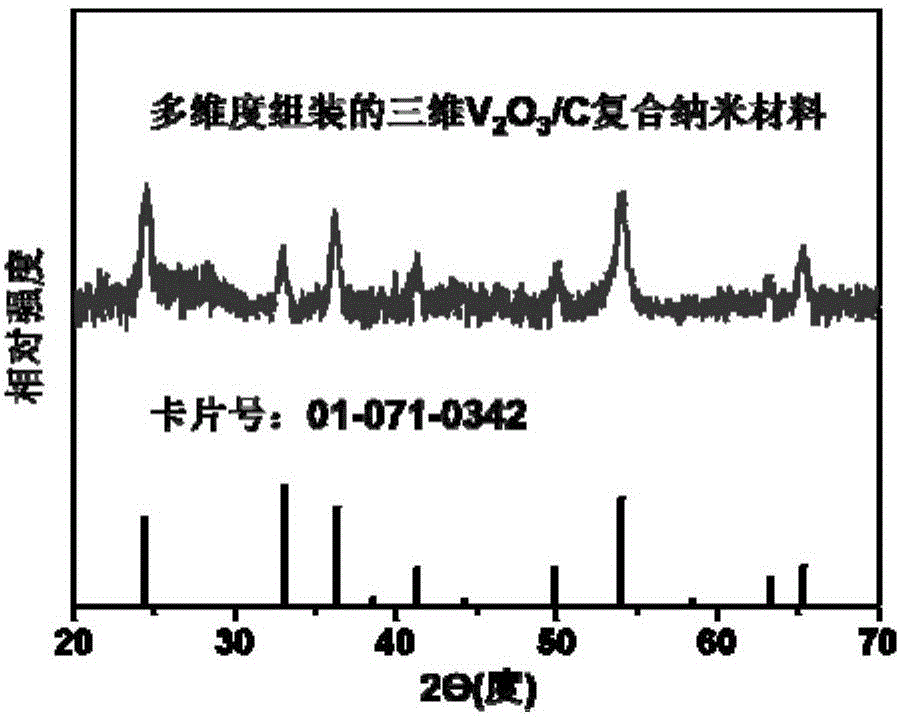

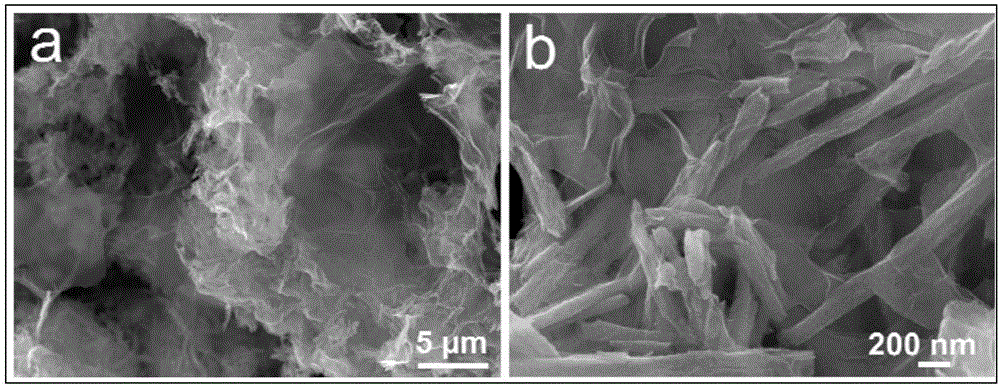

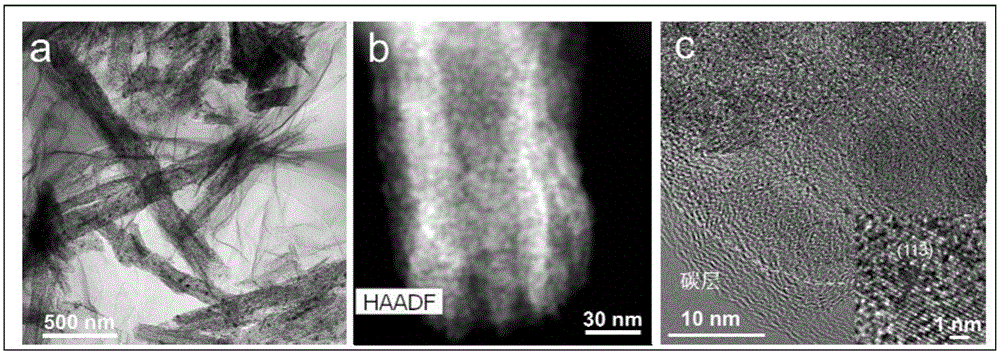

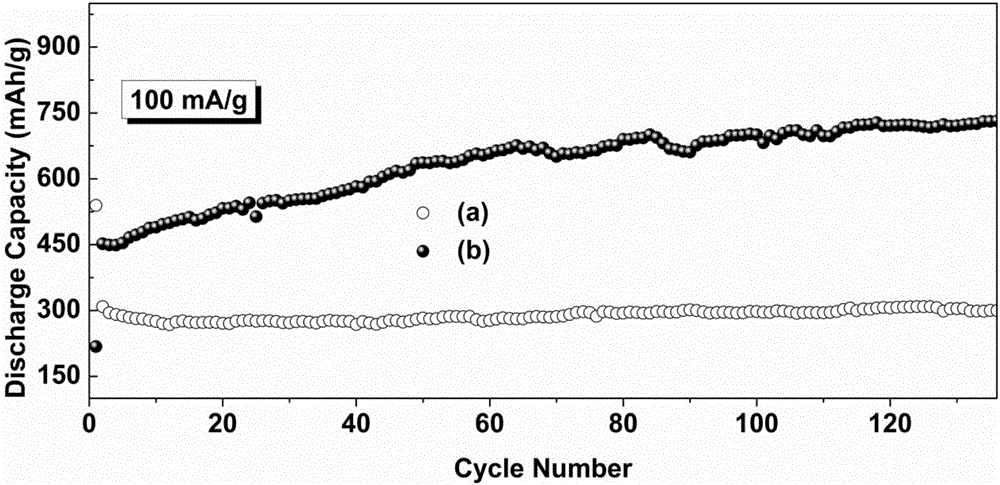

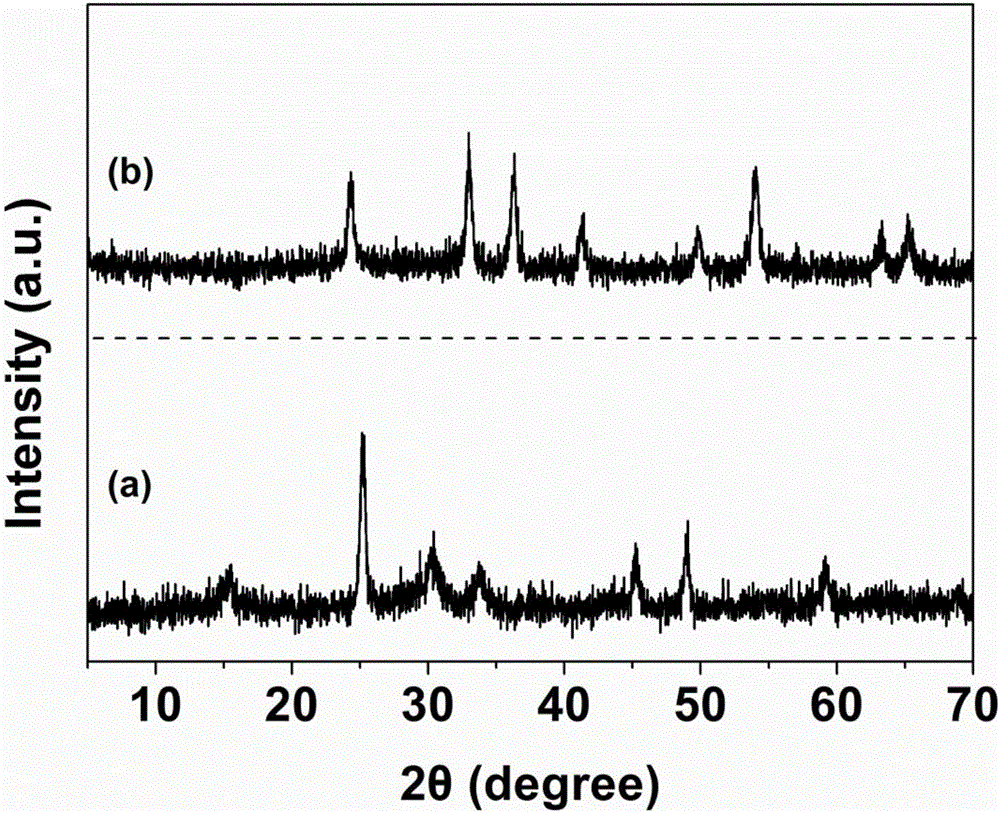

Multi-dimensional assembled three-dimensional vanadium trioxide/carbon composite nano material as well as preparation method and application thereof

ActiveCN106450219AImproved magnification performanceImprove cycle lifeCell electrodesCarbon compositesNano structuring

The invention relates to a multi-dimensional assembled three-dimensional vanadium trioxide / carbon composite nano material as well as a preparation method and application thereof. The structure can be used as a high-power and long-life sodium ion battery cathode active material and is formed by embedding zero-dimensional V2O3 nano particles into a one-dimensional carbon nano tube and further clamping and embedding the carbon nano tube into a reduced graphene oxide network; the particle size of the V2O3 particles is 8 to 20 nm; the diameter of the carbon nano tube is 100 to 150 nm, and the carbon nano tube is 1 to 3 [mu]m in length; reduced graphene oxide is 3 to 5 nm in thickness. The multi-dimension assembled three-dimensional vanadium trioxide / carbon composite nano material has the beneficial effect that based on the synergistic effect of a multidimensional nano structure, the multi-dimension assembled three-dimensional V2O3 / C composite nano material is obtained through a liquid phase method and a calcination method. When used as the sodium ion battery cathode active material, the multi-dimensional assembled three-dimensional V2O3 / C composite nano material is excellent in circulating stability and high-magnification characteristic, and is a potential application material of a high-power and long-life sodium ion battery.

Owner:WUHAN UNIV OF TECH

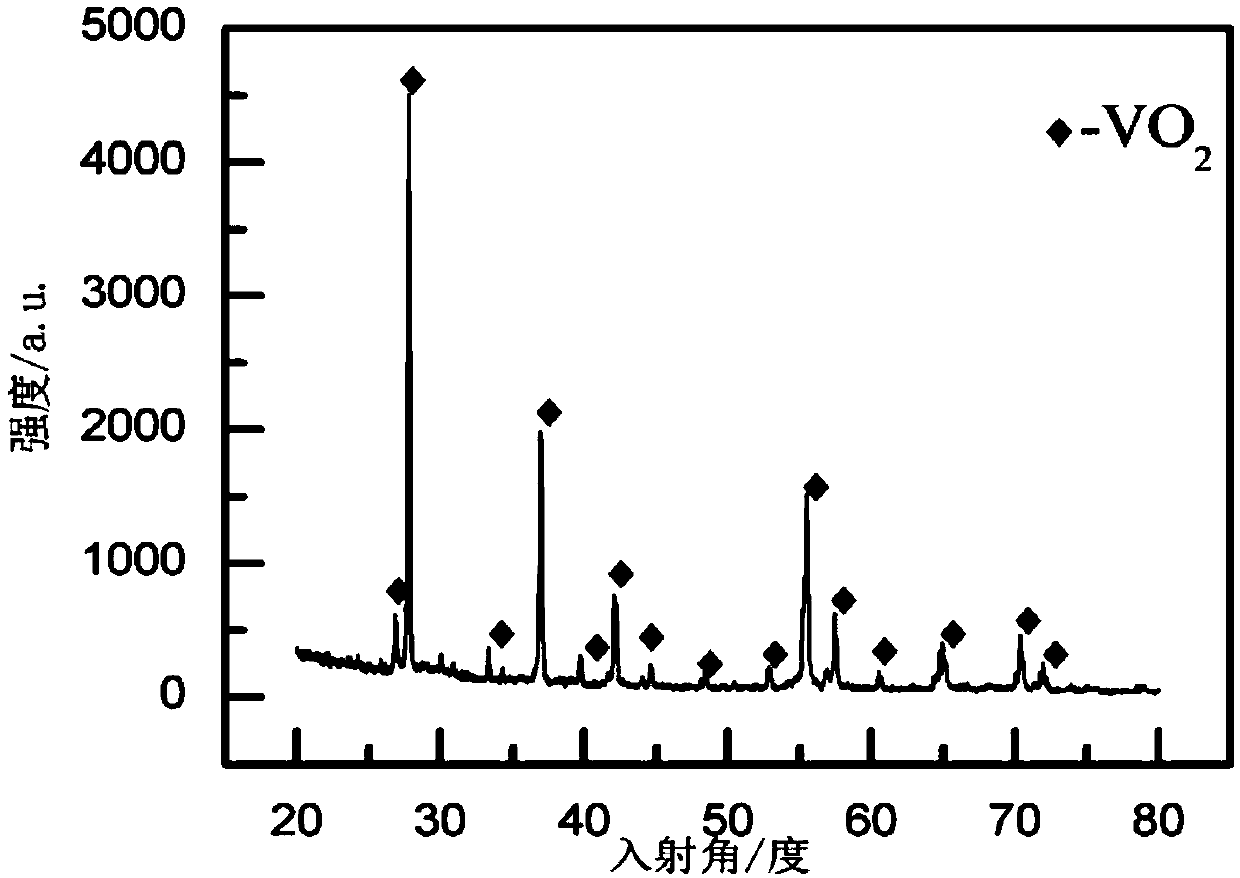

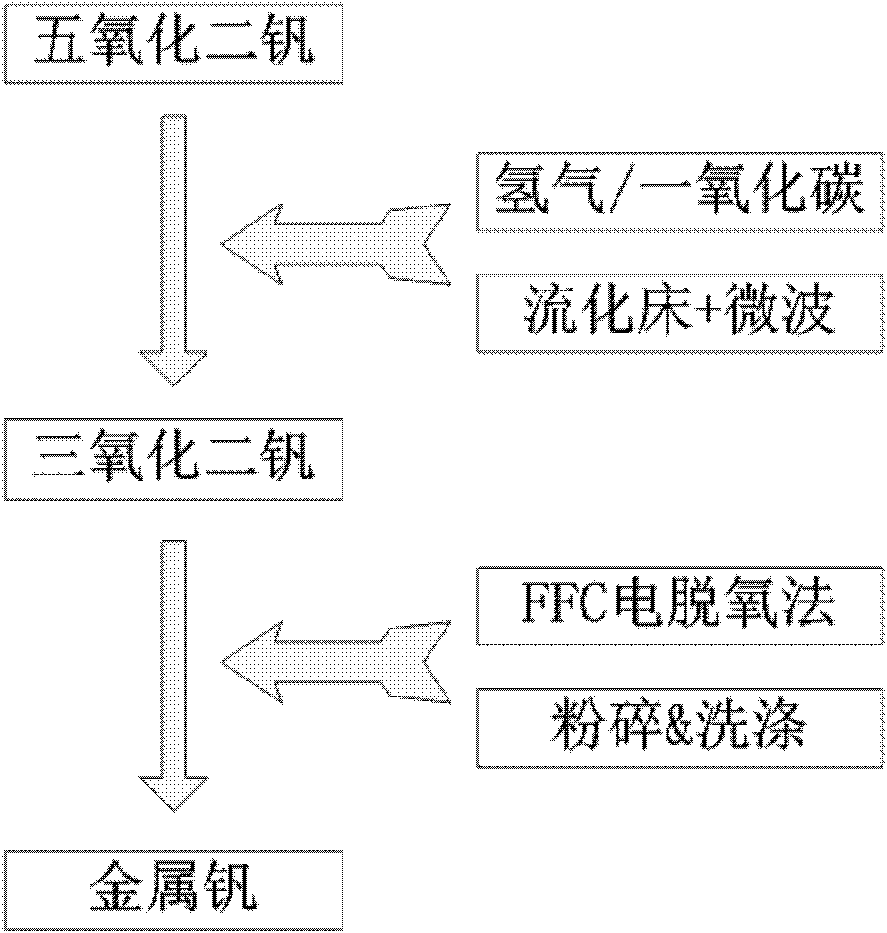

Vanadium metal smelting process

The invention discloses a vanadium metal smelting process. The process prepares vanadium metal by combining a microwave fluidized bed technology and a flexible flat cable (FFC) electric deoxidation technology and using vanadium pentoxide as a raw material. The method comprises the following steps of: directly reducing the vanadium pentoxide with low melting point (the melting point is 690 DEG C) into vanadium trioxide in short time at the temperature of between 600 and 650 DEG C by using the characteristics of high heating efficiency, quick temperature rise and gas-solid contact of a microwave fluidized bed and adopting hydrogen and / or carbon monoxide as reducing gas; directly preparing the vanadium trioxide which has high melting point into an oxide cathode by molding and sintering processes; and performing FFC electric deoxidation on the oxide cathode in molten salt of calcium chloride or mixed molten salt of calcium chloride and sodium chloride, crushing the electrolyzed cathode by using ultrasonic wave, then performing water washing, acid washing and alcohol washing to remove impurities, and finally obtaining the vanadium metal with purity of over 99 percent, wherein the current efficiency is kept over 70 percent, the energy utilization rate of microwave heating equipment is over 80 percent, and the electrolysis energy consumption is 10kwh to 13kwh / kg.

Owner:UNIV OF SCI & TECH BEIJING

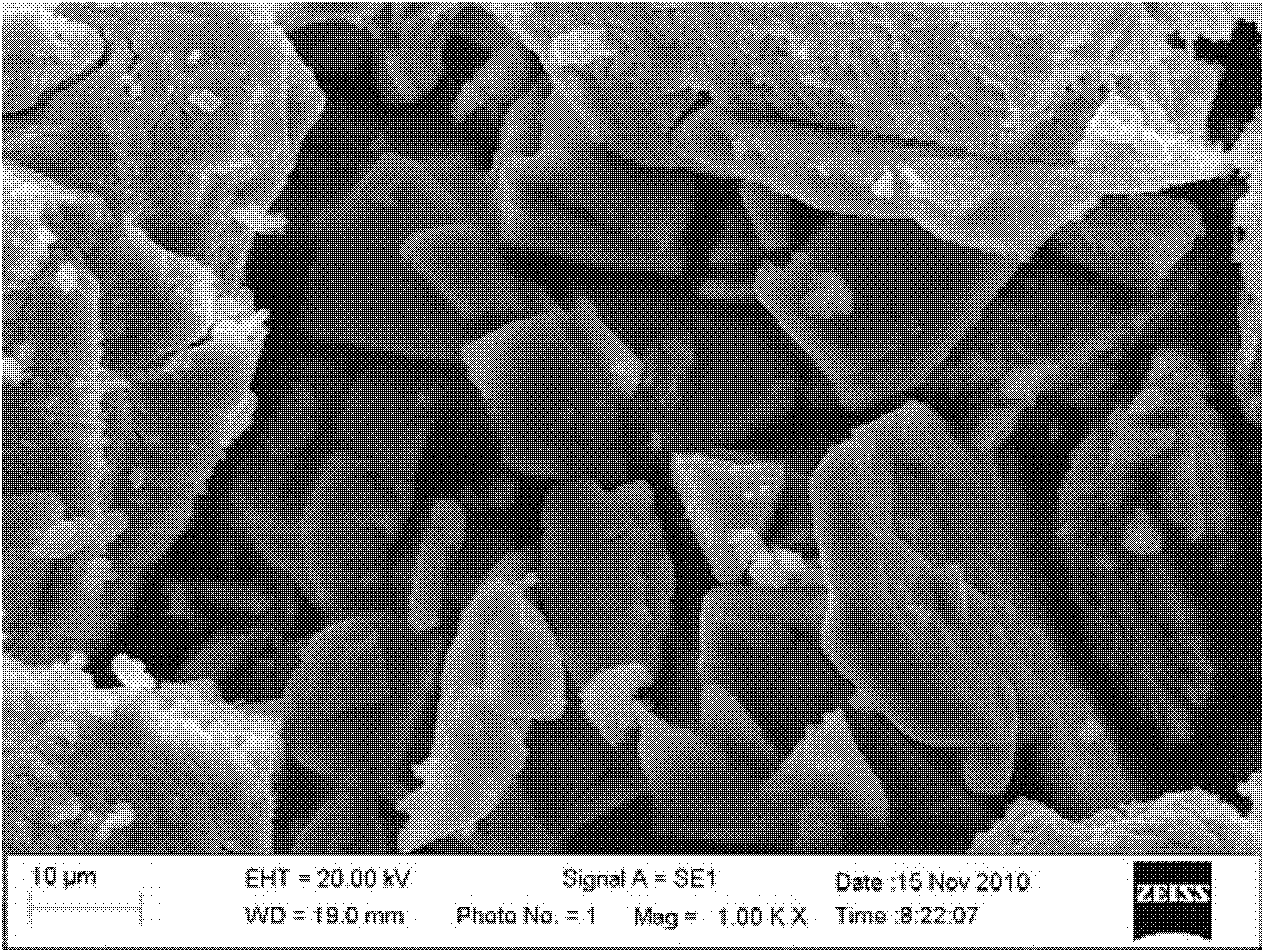

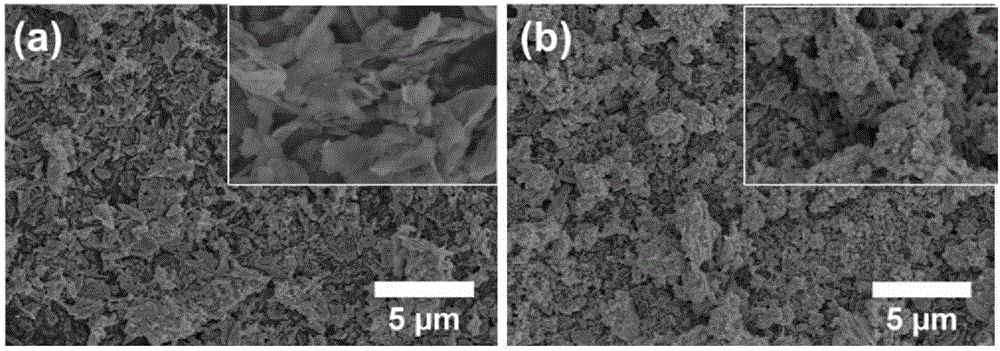

Carbon-coated vanadium trioxide nano material preparing method and lithium ion batteries

ActiveCN106025276AHigh crystallinityThe structure is easy to controlCell electrodesSecondary cellsMicro nanoNanoparticle

The invention discloses a carbon-coated vanadium trioxide (V2O3) nano material preparing method. The method comprises that different morphologies of carbon-coated VO2(B) (VO2(B)@C) nano materials synthesized by a high temperature mixed hydrothermal method are used as precursors, then the precursors are calcined to obtain V2O3 nano materials having different morphologies and including V2O3 nanoparticles and a three-dimensional (3D) hierarchical porous V2O3@C micro-nano structure. The prepared materials can be used as electrode materials of lithium ion batteries, wherein the 3D hierarchical porous V2O3@C micro-nano structure shows extremely excellent electrochemical performance; and the prepared materials have highly broad application prospects.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

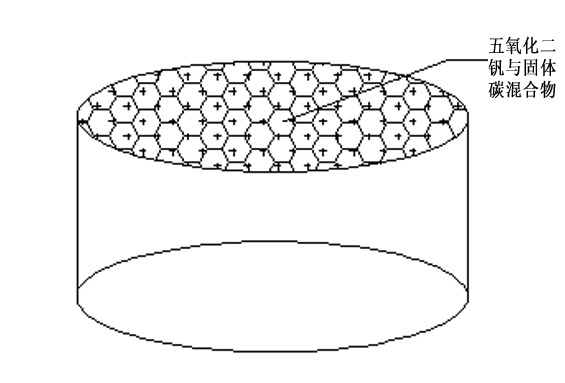

Vanadium trioxide production method

The invention discloses a vanadium trioxide production method. In the method, ammonium polyvanadate or vanadium pentoxide of which the particle size is 0.01 to 5 millimeters and solid carbon are added into a heating furnace according to a weight ratio ranging from 100:40 to 100:1, the heating temperature is 800 to 1,150 DEG C, the reduction time is 1 to 5 hours, the materials are reduced in the heating furnace to form vanadium trioxide, and the materials are cooled under a closed condition to room temperature and discharged. The vanadium trioxide production method has the advantage that compared with preparation of vanadium trioxide by using a gas reducer and a dynamic process, the preparation of vanadium trioxide by using a solid reducer and a static reducing method reduces manufacturing cost, simplifies process, improves operability, has a high safety coefficient, eliminates a gas leakage risk, can obtain high-quality vanadium trioxide product of which the all vanadium grade reaches over 67 percent and can realize industrial production.

Owner:CITIC JINZHOU METAL

Production method of vanadium trioxide

The invention discloses a production method of vanadium trioxide, comprising the following steps: heating in a reducing atmosphere or under inert gas protection at the temperature of 600-900 DEG C, and keeping reduction time for 5-60 minutes; and naturally cooling or forcibly cooling under an isolated air condition. The method has the advantages that amino-containing vanadate is taken as a raw material and heated by industrial microwave, and an appropriate amount of reductant can be added or not, thus greatly saving usage amount of the reductant, shortening reduction time, reducing reduction temperature, simplifying production process, lowering production cost, and obtaining high-purity vanadium trioxide.

Owner:CHANGSHA SYNO THERM

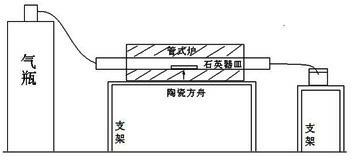

Method for preparing electrolyte for all-vanadium redox flow battery

InactiveCN102074719ASimplify the assembly processAvoid wastingRegenerative fuel cellsVanadium redox batteryTube furnace

The invention provides a method for preparing electrolyte for an all-vanadium redox flow battery, which comprises the following steps of: uniformly mixing vanadium trioxide with vanadium pentoxide according to the weight ratio of 6-9:1, adding the mixture into a certain amount of concentrated sulfuric acid, arranging the mixed solution into a tube furnace, performing calcination at 100 to 250 DEG C, and dissolving a calcination product into 2 to 5 mol / L sulfuric acid solution to obtain the electrolyte for the vanadium battery, wherein each of trivalent vanadium and tetravalent vanadium accounts for 50 percent of the concentration of the total vanadium. The method for preparing the electrolyte is simple, and solves the problems of wasting of resources and secondary pollutions.

Owner:PANZHIHUA UNIV

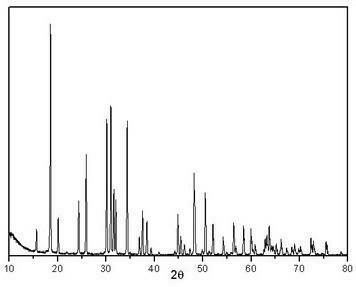

Preparation method of electrolyte for all-vanadium redox flow battery

ActiveCN103904343AIncrease profitShort processRegenerative fuel cellsFuel cell detailsVanadium redox batteryMass ratio

The invention relates to a preparation method of electrolyte for an all-vanadium redox flow battery, which belongs to the field of the preparation of the electrolyte. The invention aims at solving the technical problem for providing a chemical preparation method of electrolyte for the all-vanadium redox flow battery. The preparation method comprises the following steps of a, mixing a mixture and sulfuric acid to be reacted for 10minutes to 40 minutes at the temperature of 75 to 95 DEG C to obtain a mixed liquid, wherein the mixture contains vanadium trioxide and vanadium pentoxide in a mass ratio of (2.5-4):1; b, adding deionized water into the mixed liquid to be reacted for 5 minutes to 20 minutes at the temperature of 75 to 95 DEG C, and filtering the mixed liquid, wherein the filtered liquid is the electrolyte for the vanadium battery. The preparation method is short in process flow, simple in equipment, short in consumption time, high in utilization rate of raw materials, low in cost and capable of avoiding secondary pollution, the prepared electrolyte is used as a positive and negative electrolyte of the battery, the assembling procedure of the battery can be simplified, and the working efficiency can be increased.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com