Vanadium trioxide production method

A technology of vanadium trioxide and production method, applied in vanadium oxide and other directions, can solve the problems of complex production process, high production cost, low safety factor, etc., and achieve the effects of strong operability, low manufacturing cost and high safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

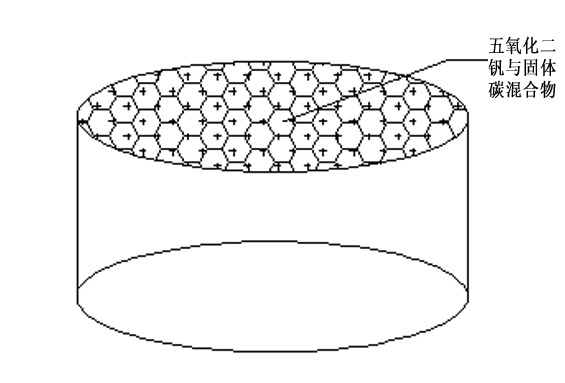

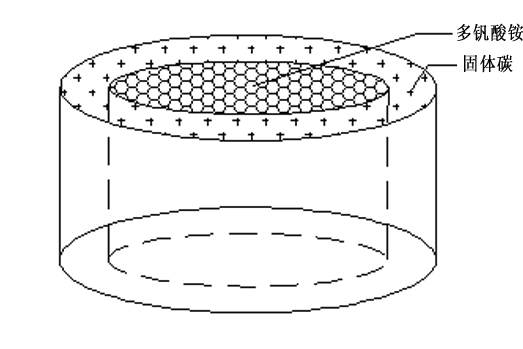

[0023] Add the ammonium polyvanadate external reducing agent-graphite powder with a particle size of 0.01-5mm into the heating furnace made of nickel alloy, and the graphite powder is mixed around the ammonium polyvanadate, such as figure 1 shown. The weight ratio of ammonium polyvanadate to graphite powder is 10:4, the heating temperature is 800°C, and the reduction time is 5 hours, so that the material undergoes a reduction reaction in the heating furnace to form vanadium trioxide, and the material is naturally cooled under airtight conditions Bring to room temperature and bake. The obtained vanadium trioxide product ∑V67.39%, the recovery rate of vanadium is 99.3%.

Embodiment 2

[0025] Add the ammonium polyvanadate external reducing agent graphite powder with a particle size of 0.01 to 5mm into the heating furnace made of nickel alloy, and the graphite powder is mixed around the ammonium polyvanadate, such as figure 1 shown. The weight ratio of ammonium polyvanadate to graphite powder is 100:1, the heating temperature is 1150°C, and the reduction time is 1h, so that the material undergoes a reduction reaction in the heating furnace to form vanadium trioxide, and the material is cooled under the protection of an inert gas Bring to room temperature and bake. The obtained vanadium trioxide product ΣV67.03%, the recovery rate of vanadium is 99.1%.

Embodiment 3

[0027] Ammonium polyvanadate with a particle size of 0.01-5mm is externally mixed with a reducing agent-coke, and coke is mixed around the ammonium polyvanadate, such as figure 1 As shown, the weight ratio of ammonium polyvanadate to coke is 4:1, and it is added into a heating furnace made of nickel alloy. The heating temperature is 1000°C, and the reduction time is 1h, so that the material undergoes a reduction reaction in the heating furnace. Vanadium trioxide is generated, and the material is cooled to room temperature under the protection of an inert gas. The obtained vanadium trioxide product ∑V67.58%, the recovery rate of vanadium is 99.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com