Patents

Literature

751results about How to "Improve work rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

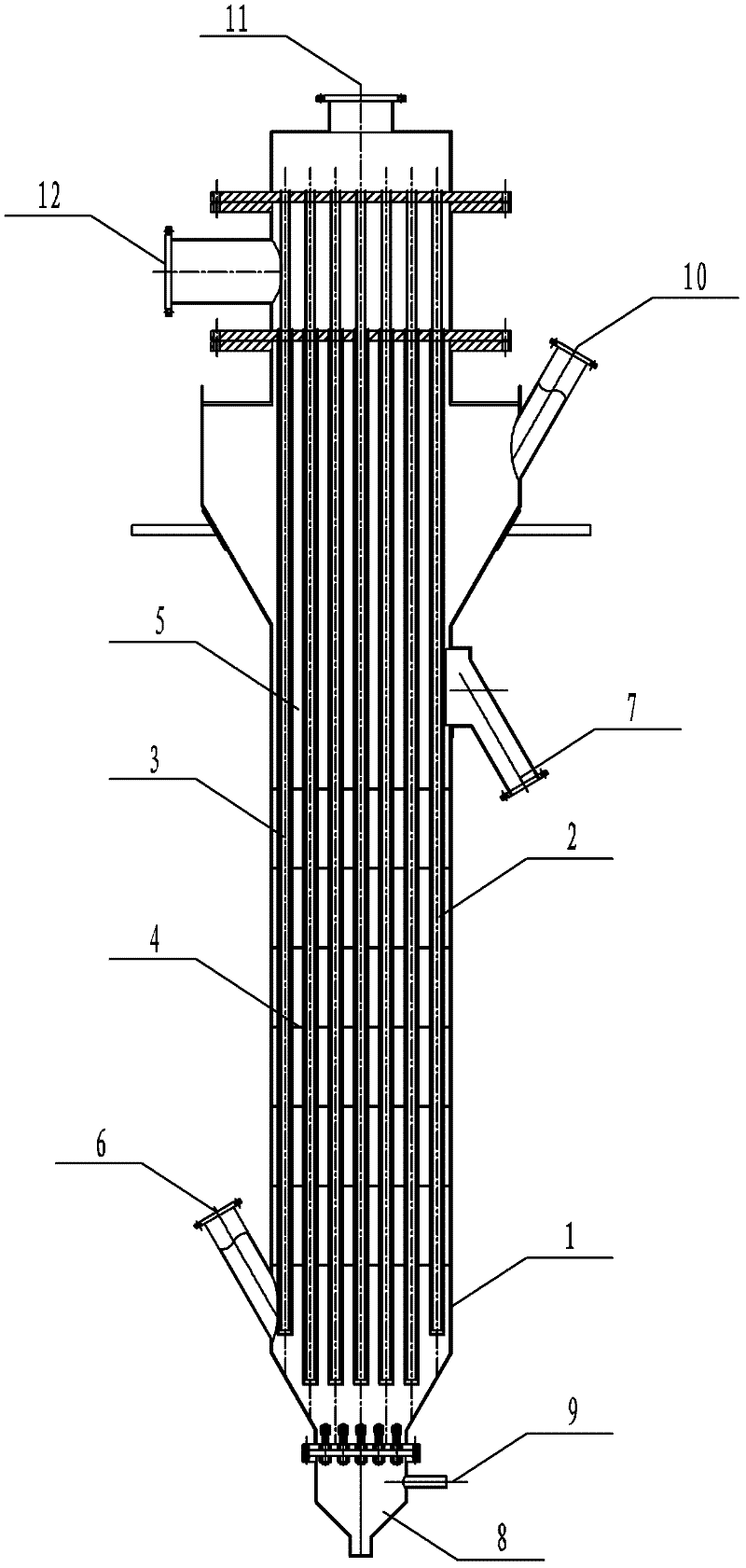

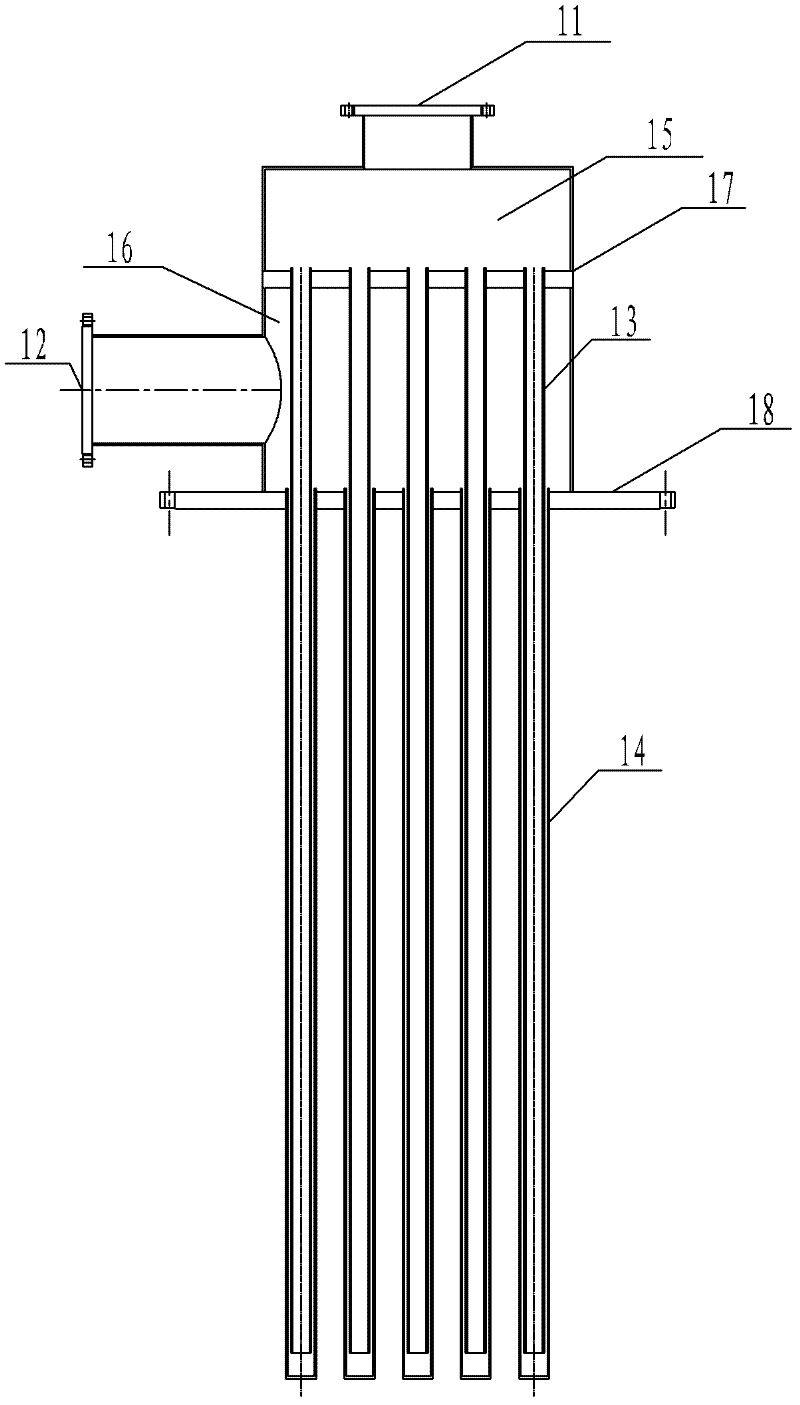

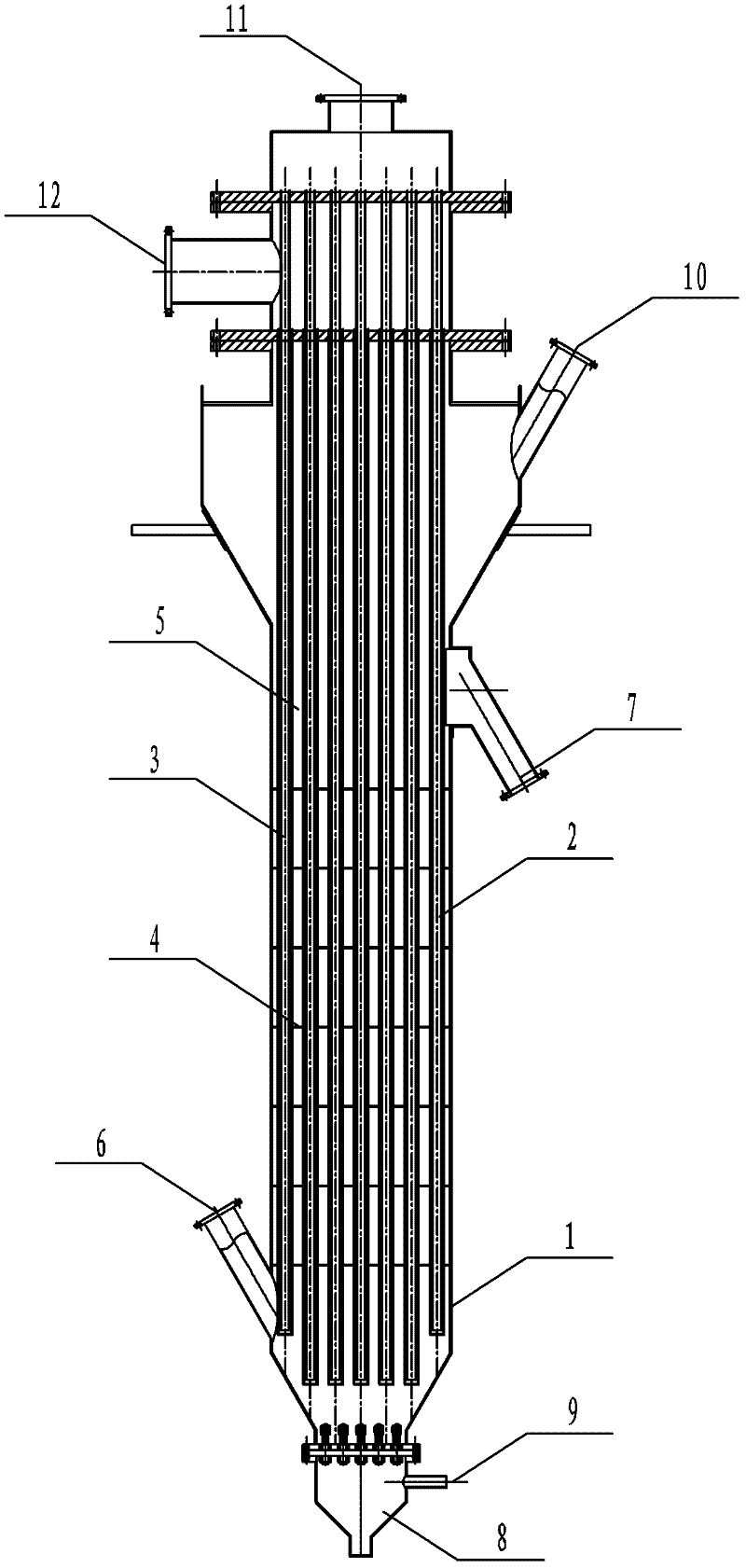

Fluidized reduction furnace for producing high-purity vanadium trioxide and production method

The invention relates to a fluidized reduction furnace for producing high-purity vanadium trioxide, which comprises a fluidized bed reactor and a built-in heat exchange component, wherein the heat exchange component is a tube type heat exchanger, and a heat exchange tube is vertically provided with at least two layers of sieve mesh plates to form at least three layers of fluidized reaction chambers. The invention also provides a fluidized reduction method for producing the high-purity vanadium trioxide. The fluidized reduction furnace and the fluidized reduction method have the advantages that firstly, materials in each layer are in a fully-mixed state, and material flow among the layers is in a plug flow state; secondly, the multi-stage fluidized reduction conditions are provided, raw materials enter from the lowermost layer, are reduced step by step and are purified gradually, and the running stability and the operating rate of equipment are improved in a manner of reduction step by step; and thirdly, the fluidized reduction furnace can be used for producing the high-purity vanadium trioxide, and the vanadium grade is larger than 67.9 percent.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for continuous casting, continuoccs rolling intermediate and thin sheet blanket

InactiveCN1483521ASmall temperature differenceImprove surface qualityMetal rolling arrangementsAutomatic controlThin slab

The production method of sheet billet conticasting tandem-rolling coil sheet is characterized by that said invention adopts the following technical measures: using conticasting machine and making pulling rate of casting blank low, and making the blank material have reasonable section; compactly arranging conticasting machine and heating furnace, making the conticasting blank output roller conveyer and inlet roller conveyer of heating furnace have double purpose, making inlet temp. of casting blank be above 900 deg.C; adopting double furnace and hating; and adopting small-cross charging and tapping process; two-high reversing rougher for three passes, four-high reversing rougher for one pass; and adopting thermal coiler box process of workpiece so as to raise coil sheet quality and reduce its production cost.

Owner:ANGANG STEEL CO LTD

Process for producing metal foam and metal body produced using this process

The invention relates to a process for producing metal foam and to a metal body produced using this process.The object is achieved by a process for producing metal foam by adding a blowing agent to a metal melt, wherein the metal melt is introduced into the die cavity of a metal die-casting machine and is foamed using a blowing agent which releases gases and is solid at room temperature.

Owner:BUHLER DRUCKGASS AG

Mineral separation process of magnetic iron ore

ActiveCN101480632AReduce energy consumptionFine Concentrate SizeSievingScreeningMagnetiteMaterials science

The invention discloses a beneficiation method for a pure magnetic iron ore. A crude ore is sequentially treated according to the steps such as first crushing, first-stage dry-type magnetic dressing, medium crushing, second-stage dry-type magnetic dressing, fine crushing and third-stage dry-type magnetic dressing, fine ore is obtained after a great amount of gangues are thrown by the third-stage dry-type magnetic dressing and sent to a grinding head sieve to be griddled and separated, granules griddled by the grinding head sieve are treated in a first-section magnetic dressing process, rough ore griddled by the grinding head sieve is treated in a first-section ball grinding and then enters the first-section magnetic dressing process; ore aggregates obtained from the first-section magnetic dressing process are treated in a second-section ball grinding after discharging gangue sands till the granularity of ore powder is -200meshes being more than or equal to 60 percent, ore powder generated from the second-section ball grinder are treated in second-section magnetic dressing, ore aggregates generated from the second-section magnetic dressing are treated in a high-frequency sieve after discharging gangue sands, products positioned on the high-frequency sieve are filtered to obtain ore concentrate, and products positioned below the high-frequency sieve are treated with desliming and then treated with floatation. The invention adopts two sections of grinding ore open-way processes and distinguishes the ore aggregates during the ore dressing process, thereby greatly reducing the energy consumption of a system, lowering the production cost and enhancing the utility ratio of equipment.

Owner:安徽大昌矿业集团有限公司

Method for producing synthetic rutile

InactiveCN101244841AAvoid pollutionReduce manufacturing costTitanium dioxideIlmenitePollution prevention

The invention relates to a production method of artificial rutile, belonging the technical field of chemical engineering, which provides a method of producing high-taste artificial rutiles made of raw ilmenite containing Mg with high Ca contents and has good production continuousness, low energy consumption and less pollution. The production method provided by the invention comprises the following steps: a. ilmenite concentrate is oxidized and roasted at 800-1100 DEG C, and then reduced and roasted at 600-900 DEG C; b. the reduced and roasted ilmenite concentrate is leached by hydrochloric acid with 18-24 percent concentration under normal pressure; c. cleaned and filtered; d. the filter cake is collected and calcined. The production method can used for producing artificial rutile, and has the advantages of low production cost, environmental pollution prevention, low production energy consumption, and easy capacity for continuous production, thereby enjoying wide application prospect.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

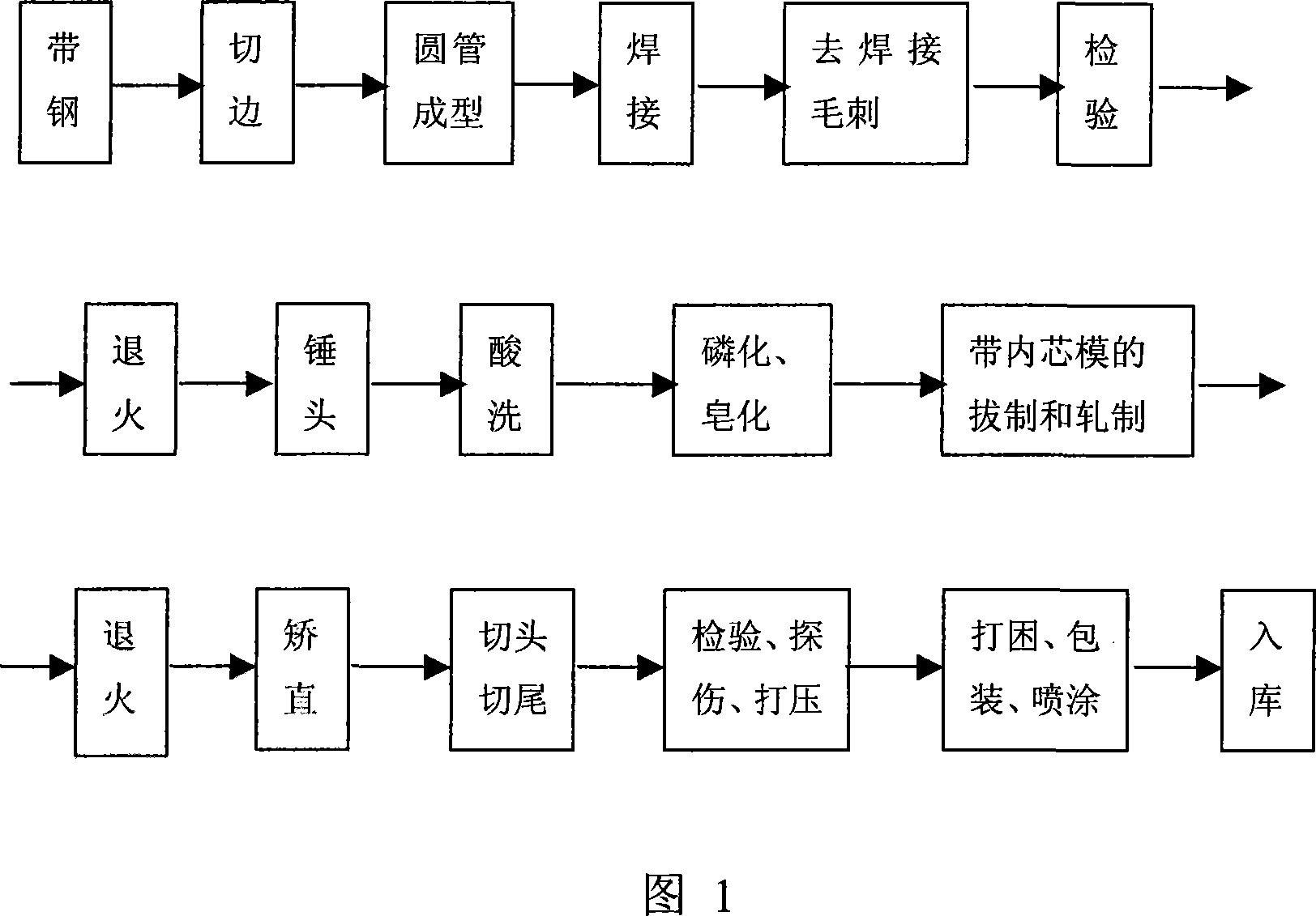

Cold drawing, cold rolling production method for high-accuracy weldless steel tube

InactiveCN101130197ASimple processLow costHigh frequency current welding apparatusChemical compositionStrip steel

The invention discloses a cold-drawing and cold-rolling manufacturing method of high-precision seamless steel pipe, which comprises the following steps: doing pipe formation procedure for the front part to cut edge of raw material steel, mould round tube, weld, remove the welded burr, detect the standard product to enter subsequent disposing procedure; doing back disposal procedure to heat, beat, wash through acid, phosphorized, saponify; rolling the mould with inner core; annealing; aligning; cutting head and tail; detecting flaw; bulging; testing; packing; storing. The invention saves energy and cost with simple operation and even wall thickness, which can replace common seamless steel pipe, low-middle pressure boiler pipe and steel pipe of the fluid completely.

Owner:李永立

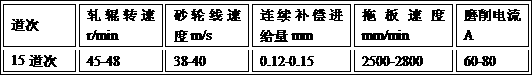

Grinding method for controlling roughness of surfaces of different rollers

ActiveCN103231289AReduce the frequency of roll changesExtend online timeRevolution surface grinding machinesNumerical controlSurface roughness

The invention relates to a roller grinding processing method, in particular to a grinding method for controlling the roughness of the surfaces of different rollers through sand wheels of the same type used on a numerical control roller grinding machine. The method comprises the following steps of: trimming the sand wheels to guarantee the balance of the sand wheels and the flatness and fineness of the working surfaces of the sand wheels; and after the sand wheels are trimmed, performing roller precision grinding in three steps, namely rough grinding, mediate grinding and fine grinding, wherein the grinding precision and the cylindricity of the rollers are smaller than 0.005mm, and the coaxiality is smaller than 0.005mm; and setting required grinding parameters according to different roughness requirement values, and carrying out grinding according to the roughness requirement values in three passes in a non-spark state. The method is simple and is easy to operate; the working efficiency of a machine tool and the working efficiency of a rolling machine can be improved; the roller replacement frequency of the rollers is reduced; the on-line time of the rollers is prolonged; the plate shape and the surface quality are improved; and therefore, the cost is reduced and the benefit is improved.

Owner:唐山瑞丰钢铁(集团)有限公司

Technique for continuously and flatly rolling welding seams of cold-rolled sheets

InactiveCN101658869APrevent the phenomenon of pinchingAvoid Printing DefectsRoll force/gap control deviceMetal rolling arrangementsHydraulic cylinderSheet steel

The invention relates to a technique for continuously and flatly rolling welding seams of cold-rolled sheets. A computer controls a hydraulic cylinder of a flat roll and front and back tension rolls of a leveler, adjusts rolling force and strip steel running speed, and adopts a control method for firstly slowing down the speed and then reducing the rolling force, and firstly recovering the rollingforce and then recovering the speed to realize the continuous and flat rolling of the welding seams of the cold-rolled sheets. The technique does not influence the production of previous and subsequent procedures, and eliminates punch marks of the welding seams on the flat roll, so the punch mark defects of the steel sheets are avoided, the surface quality of the steel sheets is improved, and a value of 2.6 million Yuan can be saved each year. The rolling force is reduced, so power consumption is reduced and energy is saved; and the technique dose not need increasing any equipment and investment, is simple and feasible, and has quick response.

Owner:ANGANG STEEL CO LTD

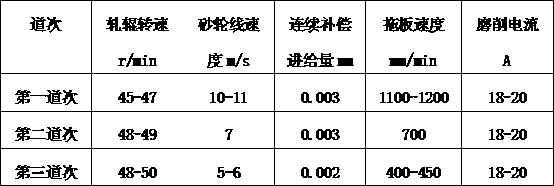

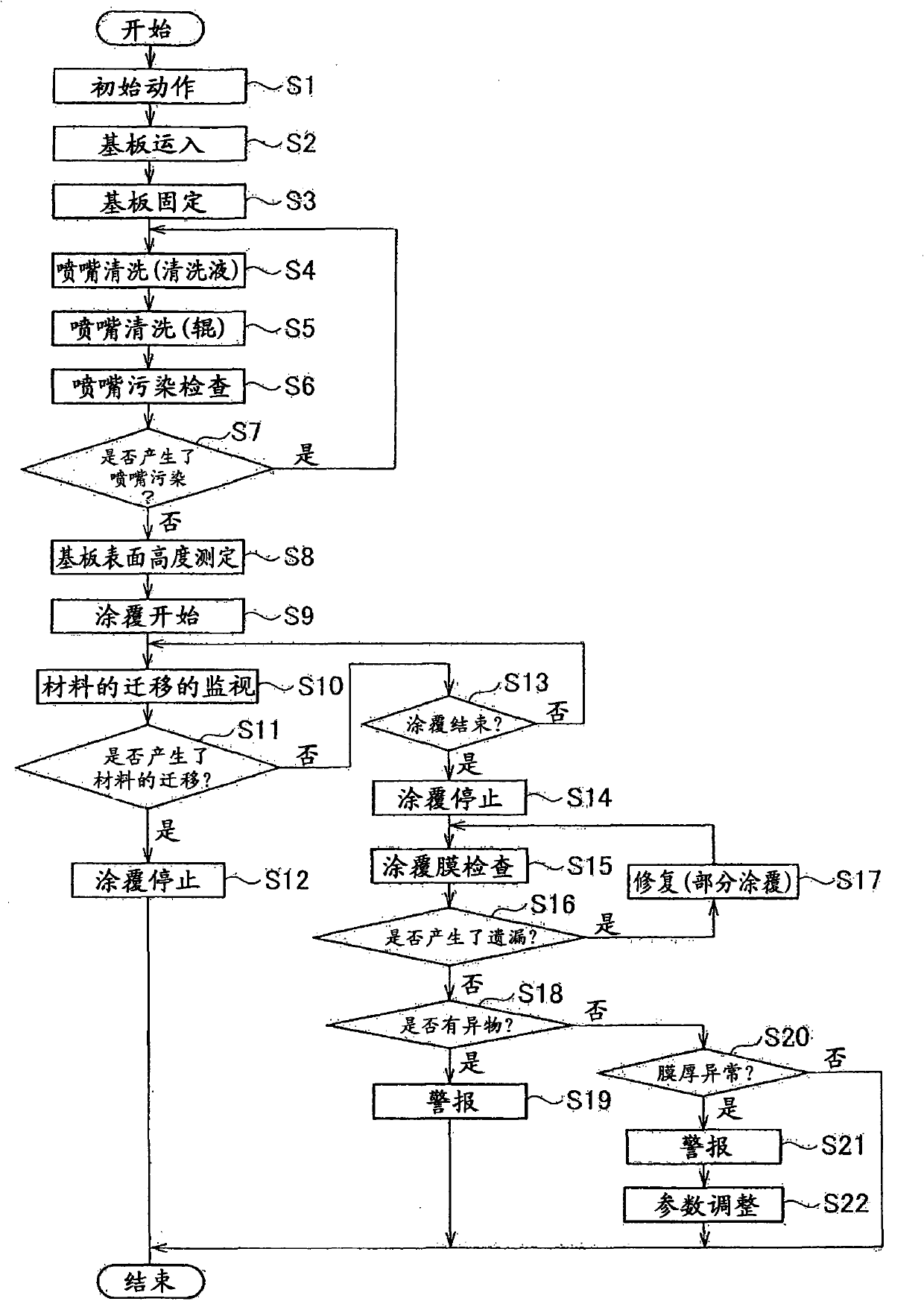

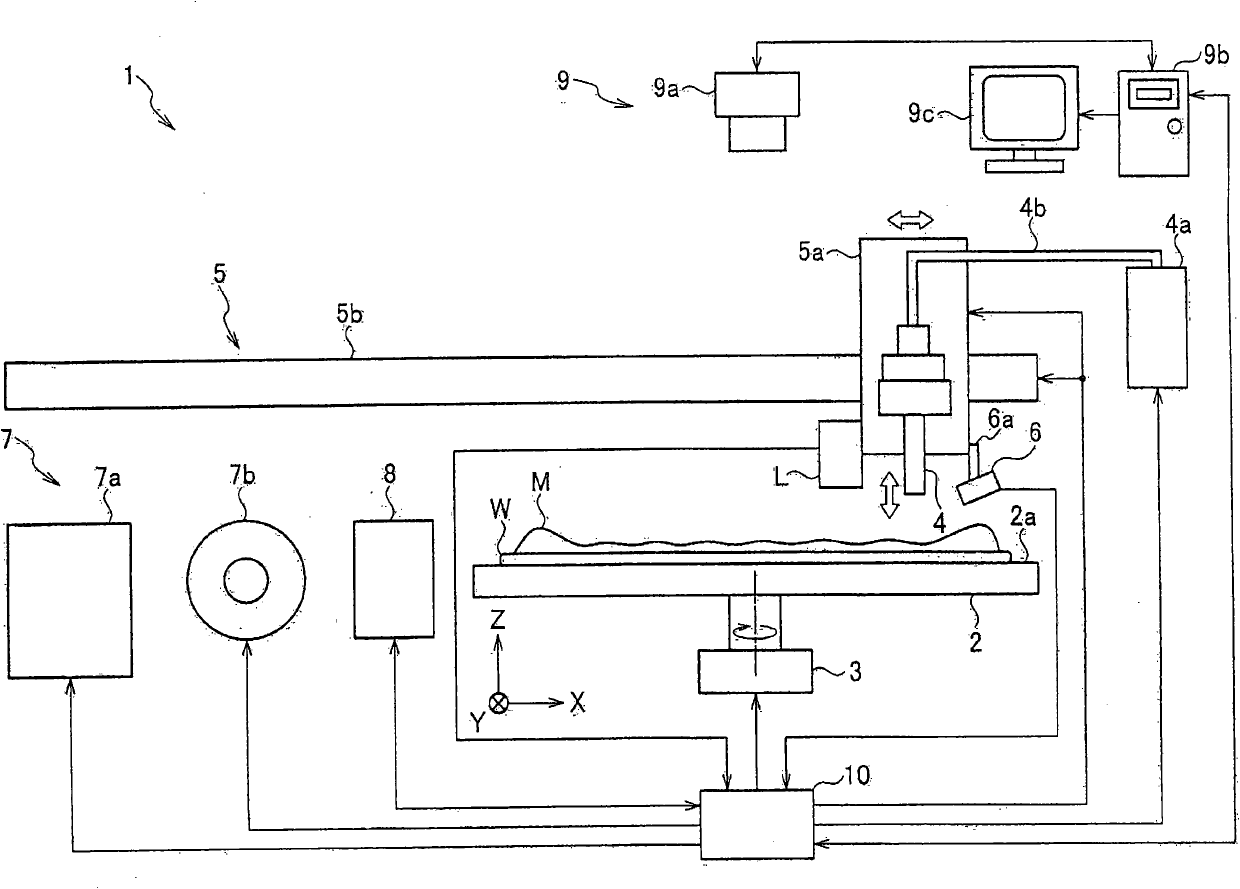

Film forming system and film forming method

ActiveCN101905205AImprove utilization efficiencyImprove work rateLiquid surface applicatorsSemiconductor/solid-state device manufacturingPhysicsEngineering

The invention increases the material utilization efficiency and operating rate and prevents reduction of film thickness uniformity owing to pollution on a nozzle. According to one embodiment, a film forming system includes: a stage including a placement surface on which an object to be coated is placed; a rotating mechanism rotating the stage in a rotational direction along the placement surface; an application nozzle discharging a material onto the object placed on the stage for application; a moving mechanism relatively moving the stage and the application nozzle along the placement surface in a cross direction crossing the rotational direction; a controller performing a control to rotate the stage on which the object is placed through the rotating mechanism while relatively moving the stage and application nozzle along the placement surface in the cross direction through the moving mechanism and applying the material to the object on the stage through the application nozzle; and a cleaning apparatus cleaning the application nozzle.

Owner:KK TOSHIBA

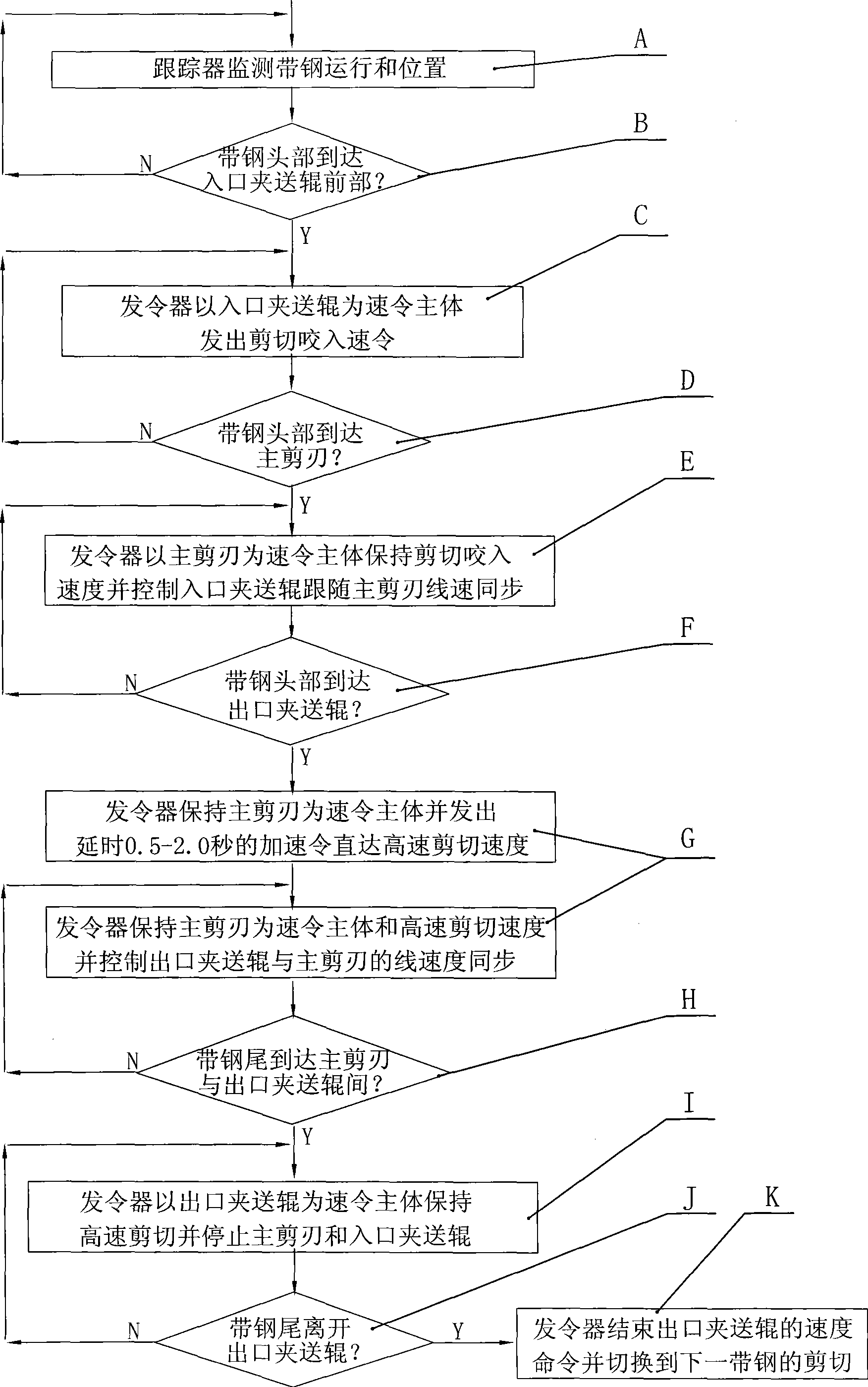

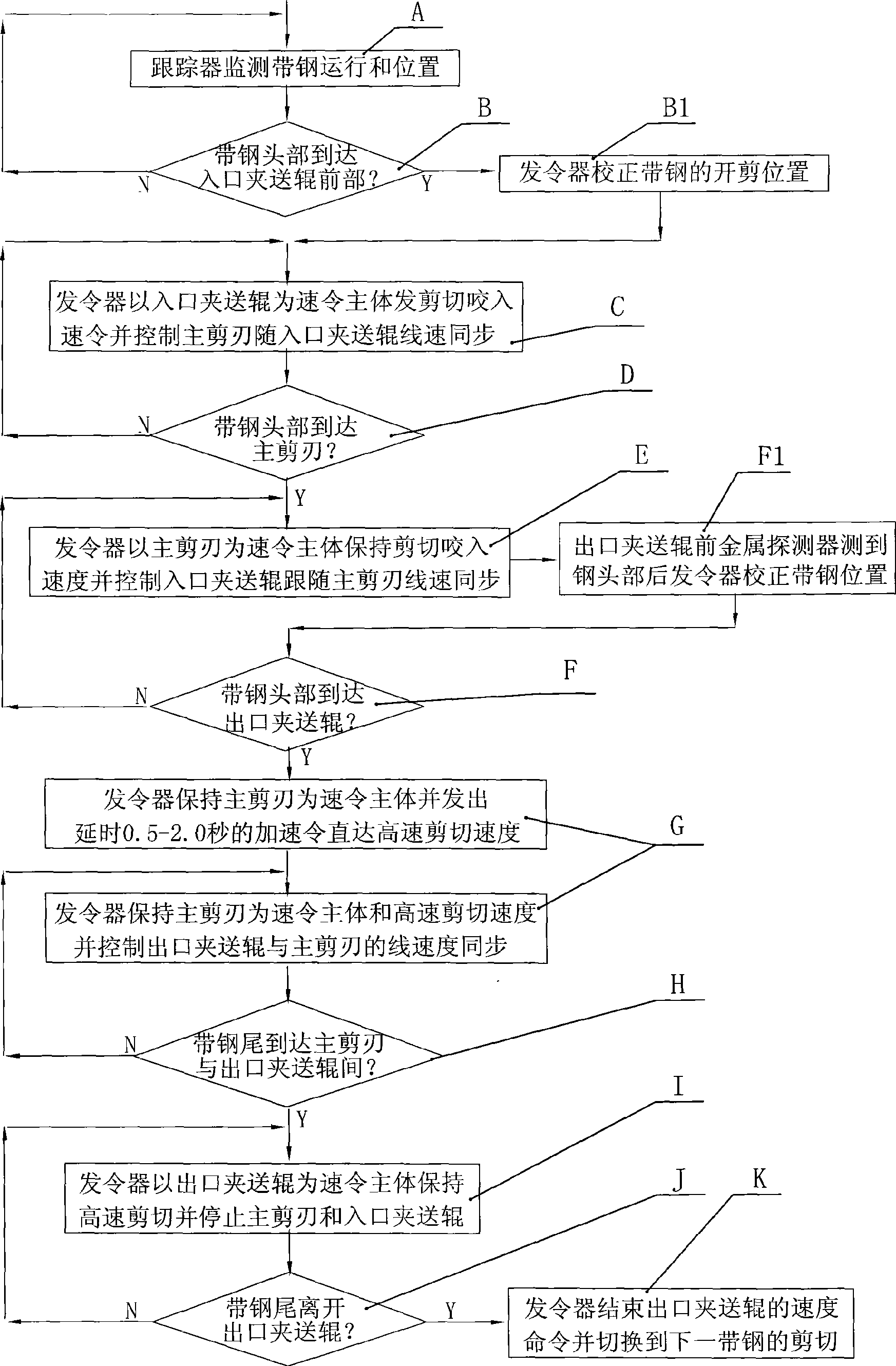

Shearing control method and control device of disc shear

ActiveCN101441462ALow failure rateStable and efficient failure rateShearing machinesNumerical controlCircular discFailure rate

The invention relates to a shearing control method and a shearing control device for circle shears. The method comprises the following steps: when the head of a steel strip reaches the front parts of entrance pinch rolls, a command sender takes the entrance pinch rolls as a speed command body to send a shearing and biting speed command; when the head of the steel strip reaches a main cutting edge, the command sender takes the main cutting edge as the speed command body, maintains the shearing and biting speed, and controls the entrance pitch rolls to follow and be synchronous with the linear speed of the main cutting edge; and when the head of the steel strip reaches exit pitch rolls, the command sender takes the main cutting edge as the speed command body to send an acceleration command, controls the main cutting edge to speed up to achieve the shearing speed required in a high-speed shearing command within 0.5 to 2 seconds, and controls the exit pinch rolls to follow and be synchronous with the linear speed of the main cutting edge. The control method and the control device effectively reduce instantaneous impact loads withstood by all mechanical parts at the time of biting, prolong the service life of shearing equipment, reduce maintenance cost, reduce the failure rate of a clamping chute at a cutting edge, and improve equipment stability and utilization rate.

Owner:SGIS SONGSHAN CO LTD +1

Pouring material for manufacturing pellet ore rotary kiln and manufacturing method thereof

The invention relates to a casting material used for producing pellet rotary kiln and a preparation method thereof, the casting material is a combination, and contained components and weight percentage occupied in the combination contain: 70 to 92 percent of casting material basal body, 3 to 8 percent of micro powder of monox or micro powder of alumina, 0.001 to 5 percent of zirconium mullite or zirconite, 1 to 12 percent of carborundum, 0.005 to 5 percent calcium aluminate cement and 0.01 to 1 percent of dispersant; the casting material basal body is the combination of one or several of corundum, bauxite and porzite. The preparation method of the casting material has the following steps: first uniformly mixing the casting material basal body, then adding other components to be uniformly mixed, and finishing goods. The casting material contains the carborundum, the carborundum has the characteristic of difficult infiltration with furnace burden containing iron, and ring formation materials are difficult to be felted on a furnace brick lining; in addition, the carborundum can increase acidic furnace burden anti-corrosion performance of the casting material, and thus the life of the rotary kiln is enhanced. The preparation method of the casting material is simple and has low cost.

Owner:武钢集团有限公司

Torpedo tank lining gunning repairing material, preparation method and applications thereof

The invention discloses a torpedo tank lining gunning repairing material, a preparation method and applications thereof, wherein the torpedo tank lining gunning repairing material comprises, by weight, 60-67 parts of a Al2O3-containing fireproof material after-using regenerating material, 3-7 parts of fireproof clay, 2-5 parts of flaky graphite, 3-7 parts of silicon carbide, 10-15 parts of an alumina homogeneous material, 3-6 parts of kyanite, 2-5 parts of alpha-Al2O3 micro-powder, 3-11 parts of a binder, and 1.2-3.4 parts of an admixture. According to the present invention, the torpedo tank lining gunning repairing material has characteristics of low raw material cost, wide regeneration material source, convenient cold-hot state gunning repairing, excellent thermal shock stability, strong repairing layer interface bonding strength, strong slag iron corrosion resistance, high torpedo tank operation rate, long service life, and the like.

Owner:武汉钢铁有限公司

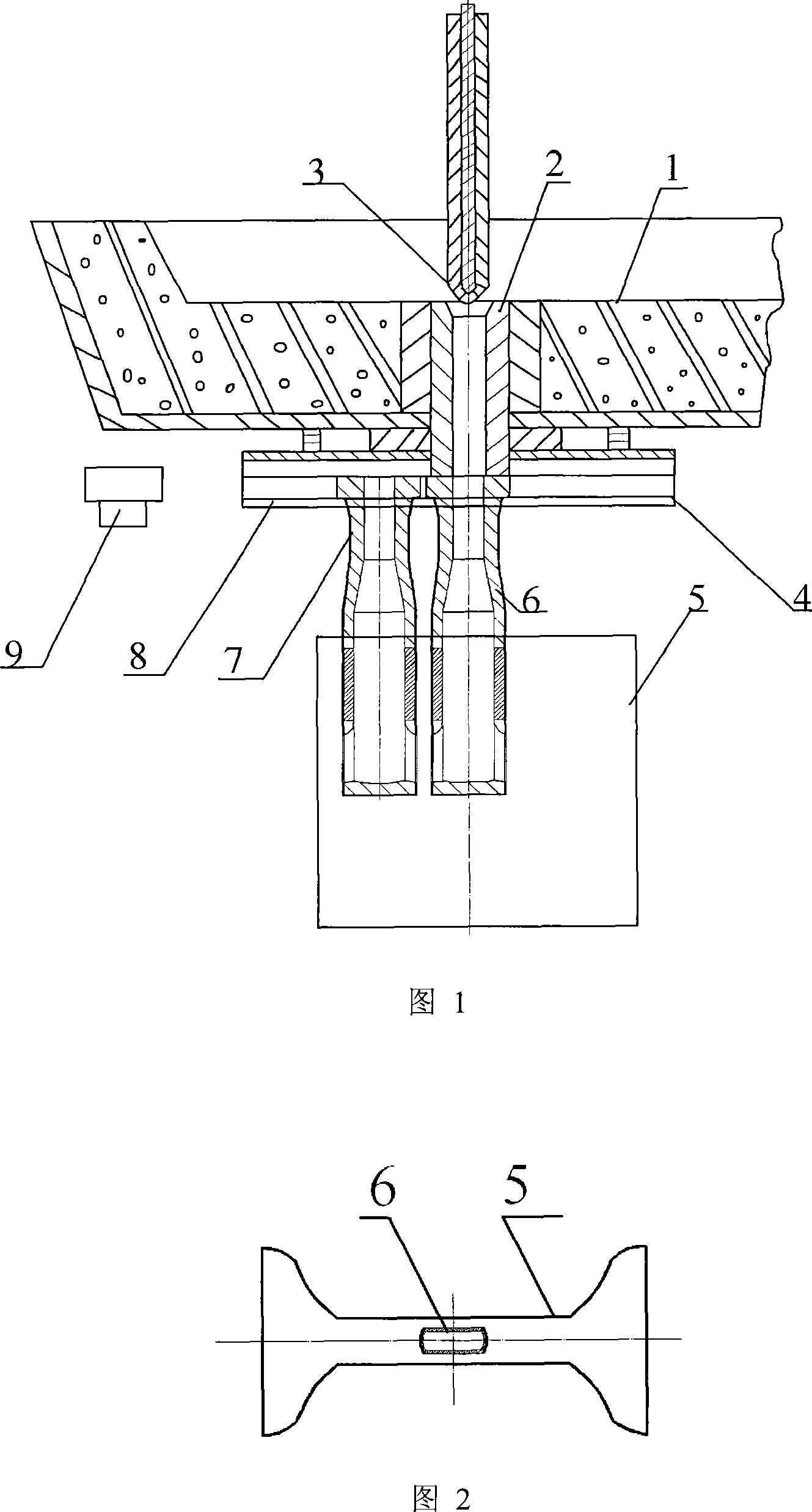

Method and device for carrying out protected casting for shaped blank continuous casting by using single immersed nozzle

InactiveCN101091982AAchieving protective castingReduce the chance of secondary oxidationWater gapTundish

The invention relates to a method and device that adopts water gap to take shaped blank continuous casting protecting casting. It inserts a dipped water gap into the center position of shaped blank crystallizer web to take casting. The upper part of dipped water gap connects to upper water gap of pouring basket. Molten steel flowing channel is formed between pouring basket and crystallizer. The stopper is used to control molten steel flow control to realize indicating control in crystallizer. The invention could realize full process protecting cast of shaped blank continuous casting to ensure cleanliness of molten steel.

Owner:LAIWU IRON & STEEL GRP

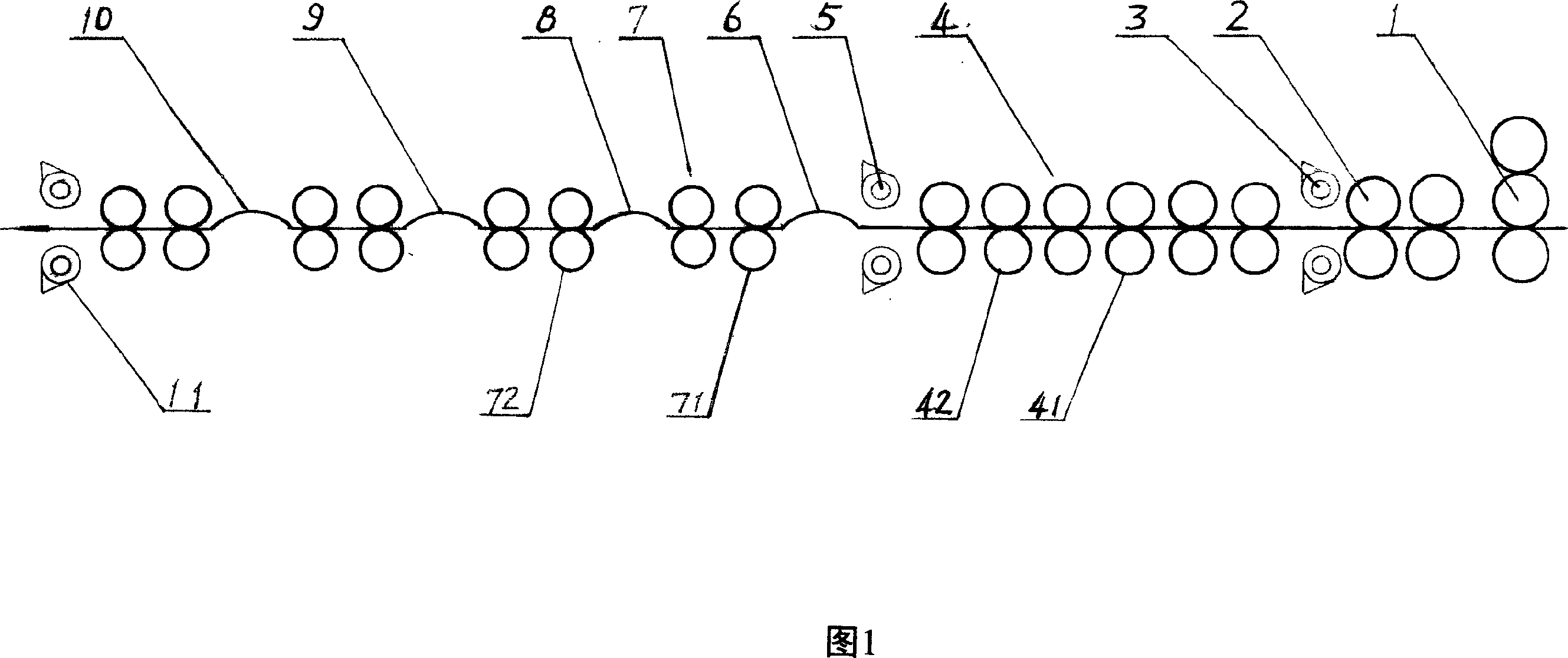

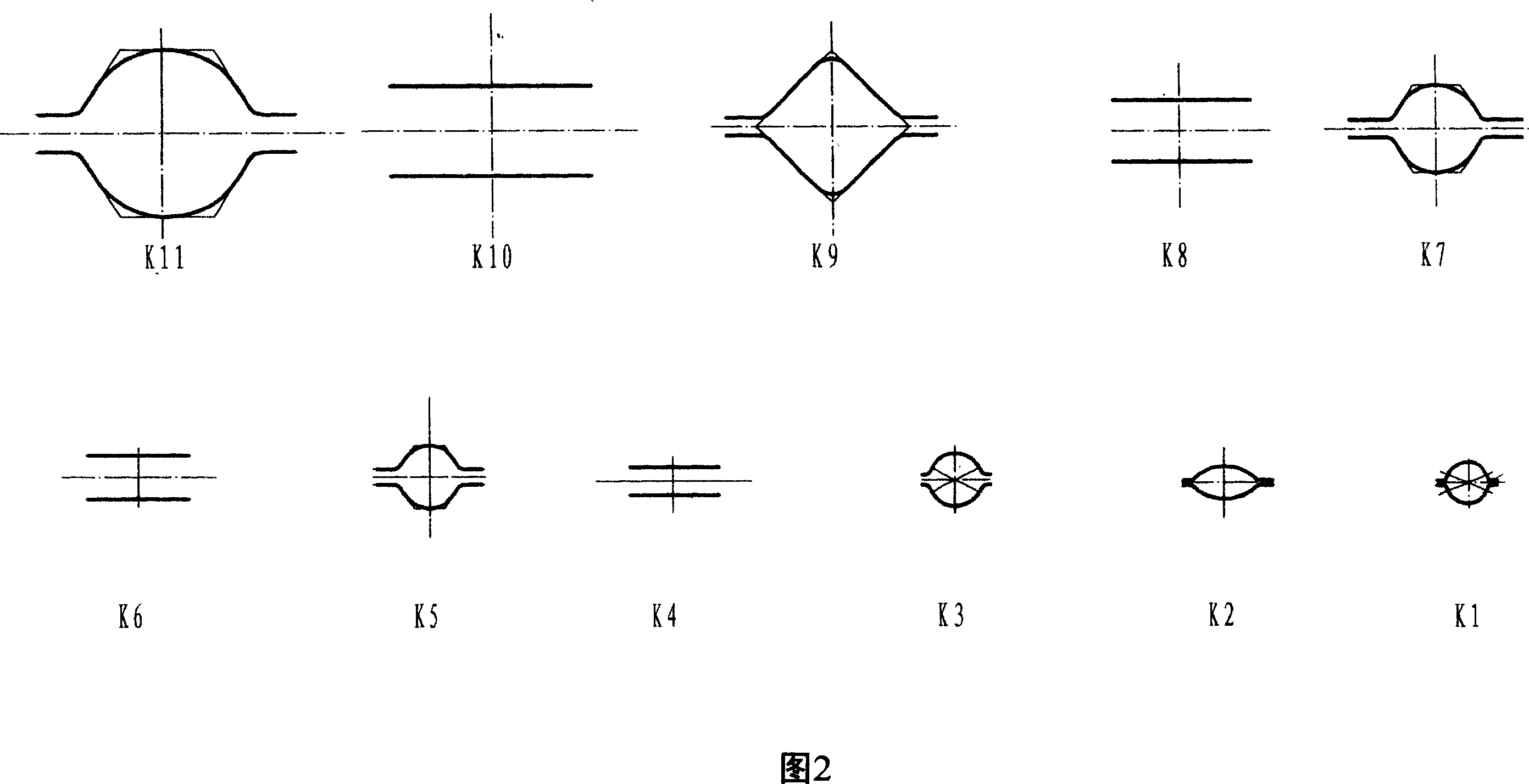

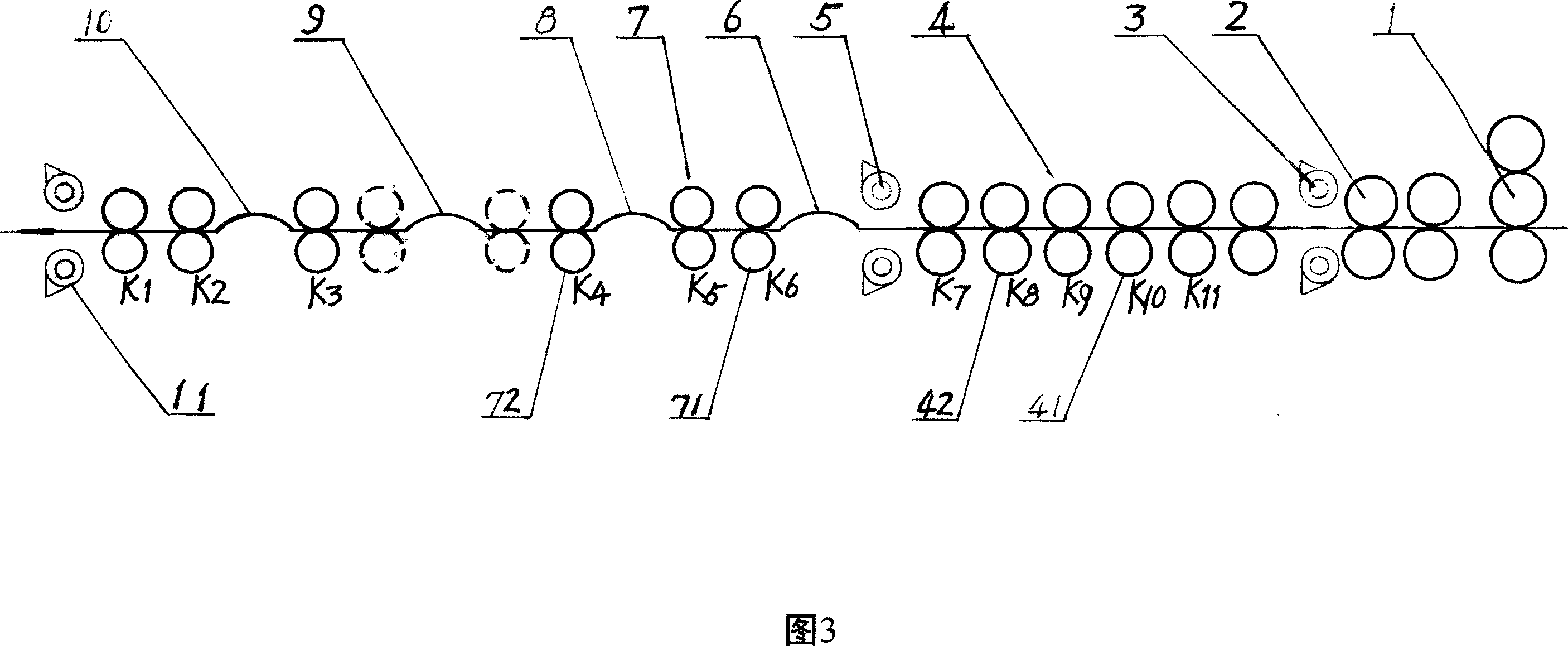

Non-groove rolling technology of horizontal mill

ActiveCN101007315AReduce rolling accidentsReduce intermediate rolling wasteRollsMetal rolling arrangementsStrip millRound bar

The invention discloses a slotless rolling art for all-horizontal rolling mill which rolls round bar and screw-thread steel on semi-continuous rolling process online. It arranges junior mill 2, crop flying shear 3, junior mills group 4, crop and crop end flying shear 5, loop 6 or 8 or 9 or 10, finishing mills group 7 and times ruler flying shear 11 after blooming mill 1 consecutively; installs plain-barreled roll 41 or 42 and 71 or 72 on the third or fifth rolling mill frames of junior mills group 4 and the first and third rolling mill frames of finishing mills group 7, the plain-barreled rolls need not be processed hole-type groove, the rolling pressure is decreased significantly. The plain-barreled rolling mills does not have wrong rollers in whole rolling process, does not generate ears, decreases central waste rollers, saves changing roller time, increases rolling mill efficiency. The plain-barreled roll slotless rolling art not only can be used in flat alternative continuous rolling process line, but has a bright prospect in development and application of all-horizontal rolling mill process line.

Owner:湖南华菱涟源钢铁有限公司

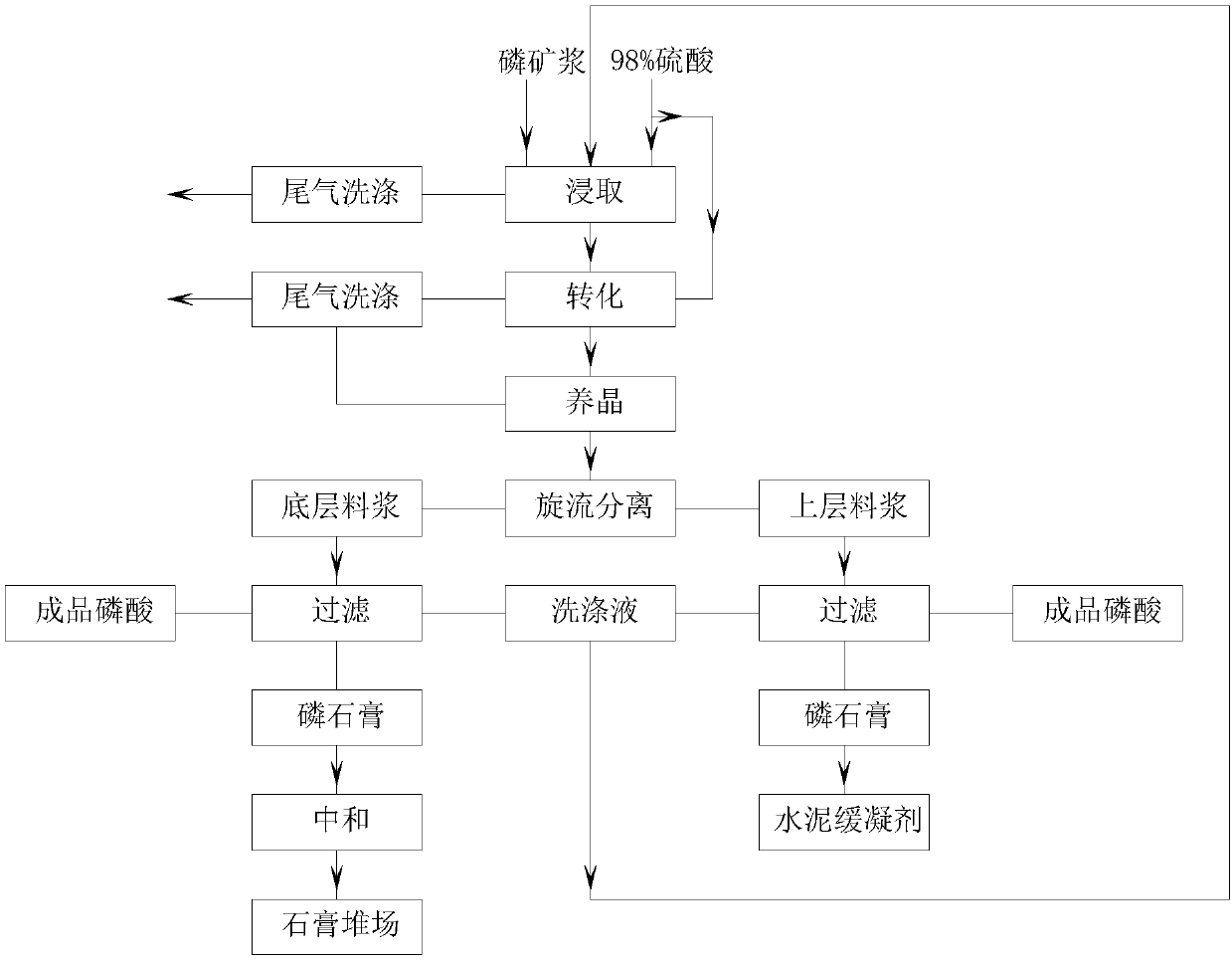

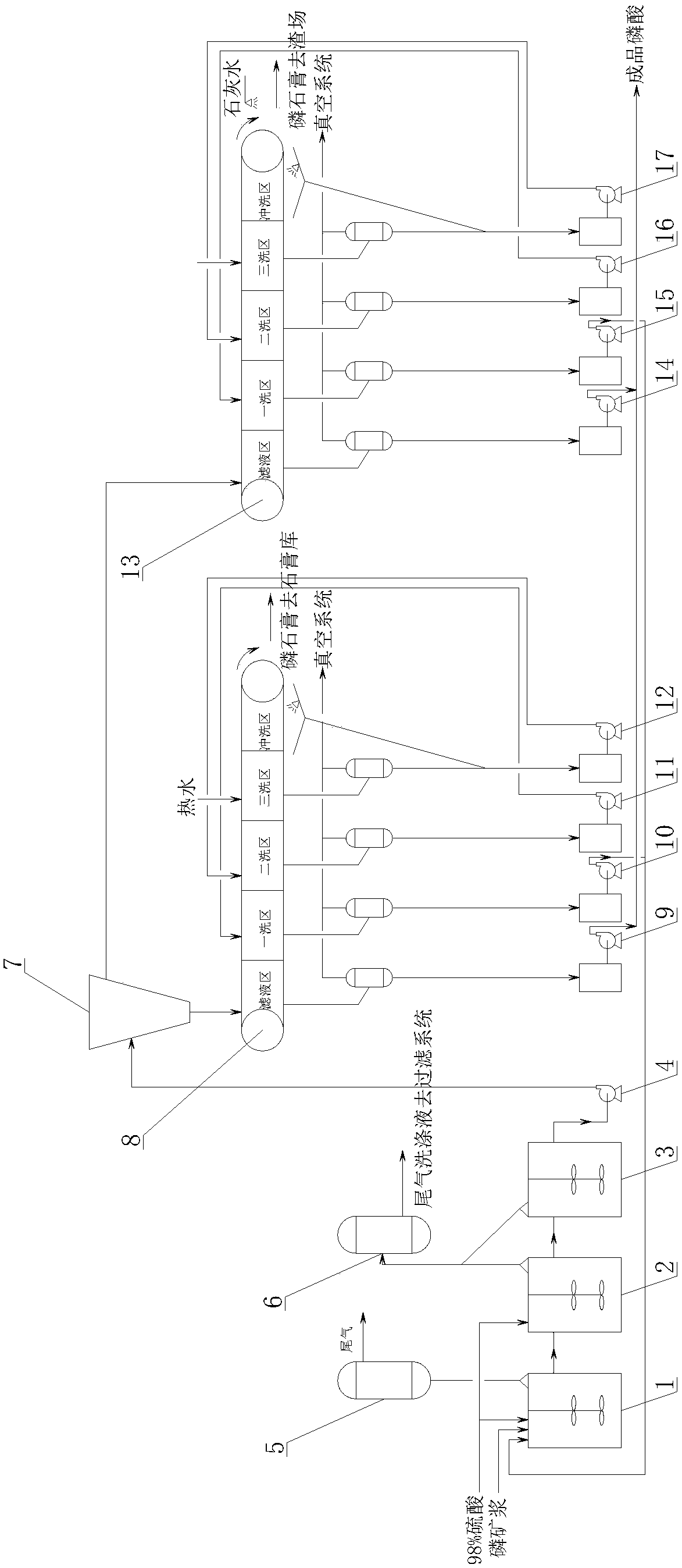

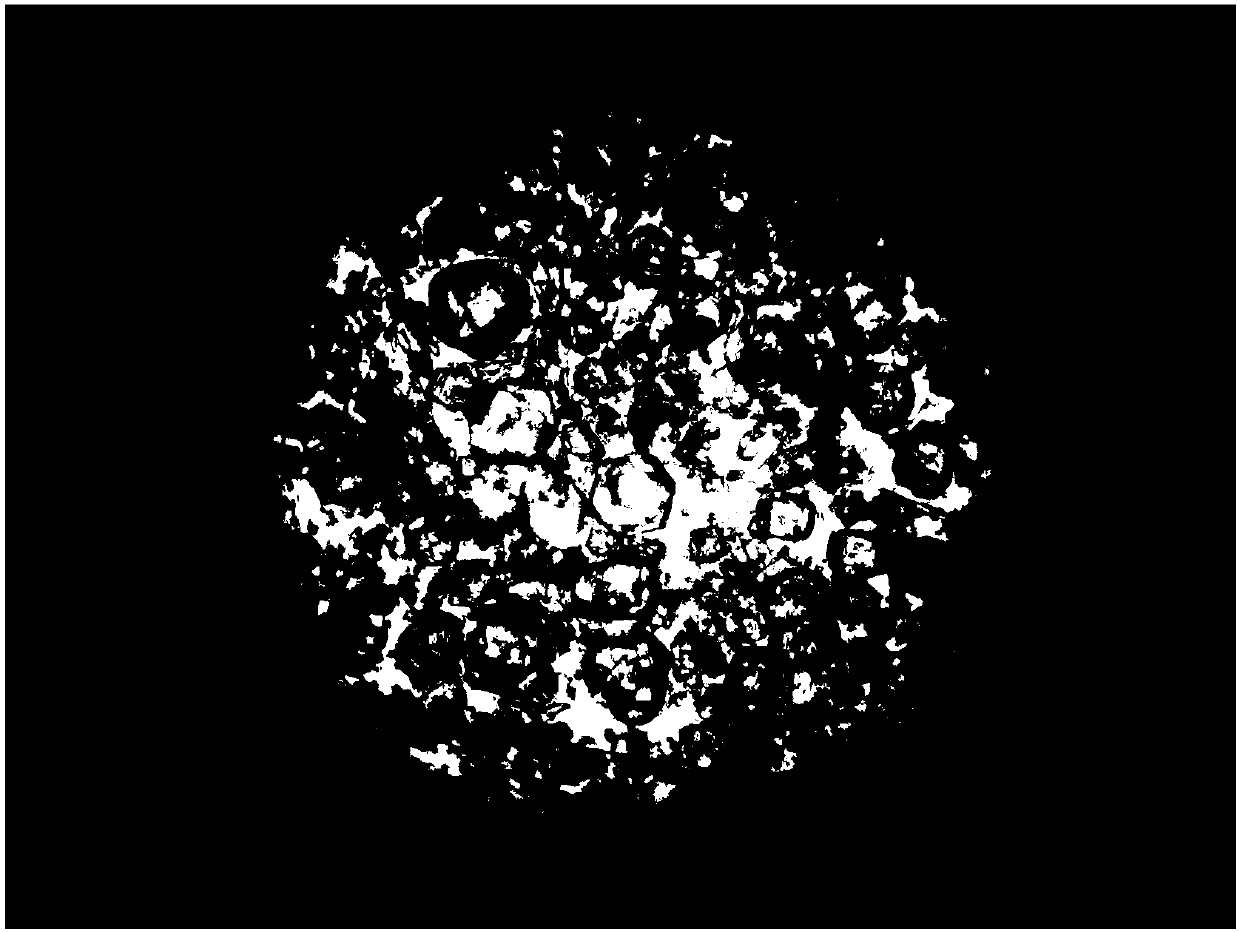

One-step method dihydrate-semi-hydrated wet production process for phosphoric acid

ActiveCN107840317AAvoid concentrated inputsGood energy saving effectPhosphorus compoundsHigh concentrationWash water

The invention relates to a one-step method dihydrate-semi-hydrated wet production process for phosphoric acid. The one-step method dihydrate-semi-hydrated wet production process comprises the following steps: carrying out leaching reaction and dehydrate-semi-hydrated conversion; growing grains; separating, filtering and washing; by controlling technological indicators of all the steps, finished product phosphoric acid filtrate with high concentration and by-product phosphogypsum with high quality are obtained. The finished product phosphoric acid filtrate obtained by production of the one-stepmethod dihydrate-semi-hydrated wet production process disclosed by the invention has the advantages that the concentration of P2O5 is about 35 percent, concentration input of the phosphoric acid canbe avoided and an energy-saving effect is good. In addition, the phosphorus conversion rate and the washing rate are high; the final by-product phosphogypsum has the characteristics that the total content of the P2O5 is smaller than or equal to 0.5 percent, the content of water-soluble P2O5 is smaller than or equal to 0.15 percent and the yield of the P2O5 reaches 98 percent. The one-step method dihydrate-semi-hydrated wet production process disclosed by the invention retains the characteristics of good energy-saving effect, high phosphorus yield and high quality of byproduct alpha-semi-hydrated gypsum of a traditional two-step method dehydrate-semi-hydrated technology; meanwhile, a dihydrate filtration procedure is omitted, the process flow is shortened and the operation rate of a deviceis improved, so that the problem that water balance of a system cannot be realized due to overhigh content of wash water for filter cloth is solved.

Owner:ANHUI LIUGUO CHEM CO LTD

Process for manufacturing hot rolled steel strips by using compaction type continuous casting and rolling technique

InactiveCN101293257AEasy to produceIncrease production capacityFurnace typesHeat treatment process controlProduction lineStrip mill

The invention discloses a compact continuous casting and tandem rolling method for producing hot rolling strip steel, including the following steps: 1) liquid molten steel passes through a long nozzle from a ladle to be cast to a pouring box, flows through a submerged nozzle from the pouring box to be cast in a crystallizer of a continuous caster and is continuously cooled in the continuous caster to form a casting blank; 2) a shearing machine is used for cutting a flat blank into certain size; 3) the flat blank enters a tunnel roller hearth heating furnace for heating; 4) the continuous caster is provided with a plurality of casting flows, one of which is in collineation with a rolling mill, the casting blank of other flows passes through a swinging section and is converged with the casting blank of the collinear flow and then is descaled by high pressure water; 5) the casting blank carries out rough rolling into an intermediate blank by a roughing mill group; 6) the intermediate blank is coiled and decoiled by a hot coiling box; 7) the head and the tail of the decoiled intermediate blank are cut and descaling by high pressure water is carried out to the decoiled intermediate blank; 8) the intermediate blank carries out finish rolling into a steel strip with standard thickness; 9) the steel strip is coiled into a finished steel coil by laminar flow cooling. The method is characterized by stable production technique, shorter production line, low equipment investment and high utilization rate of energy in the whole production process, etc.

Owner:BAOSHAN IRON & STEEL CO LTD

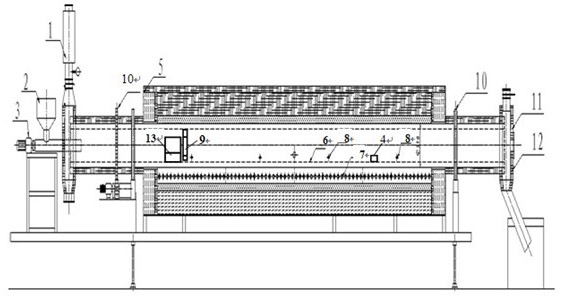

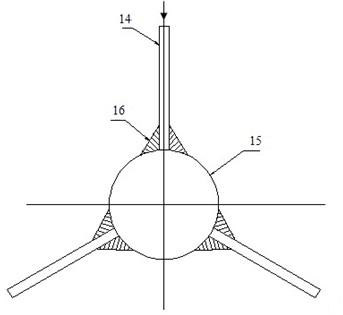

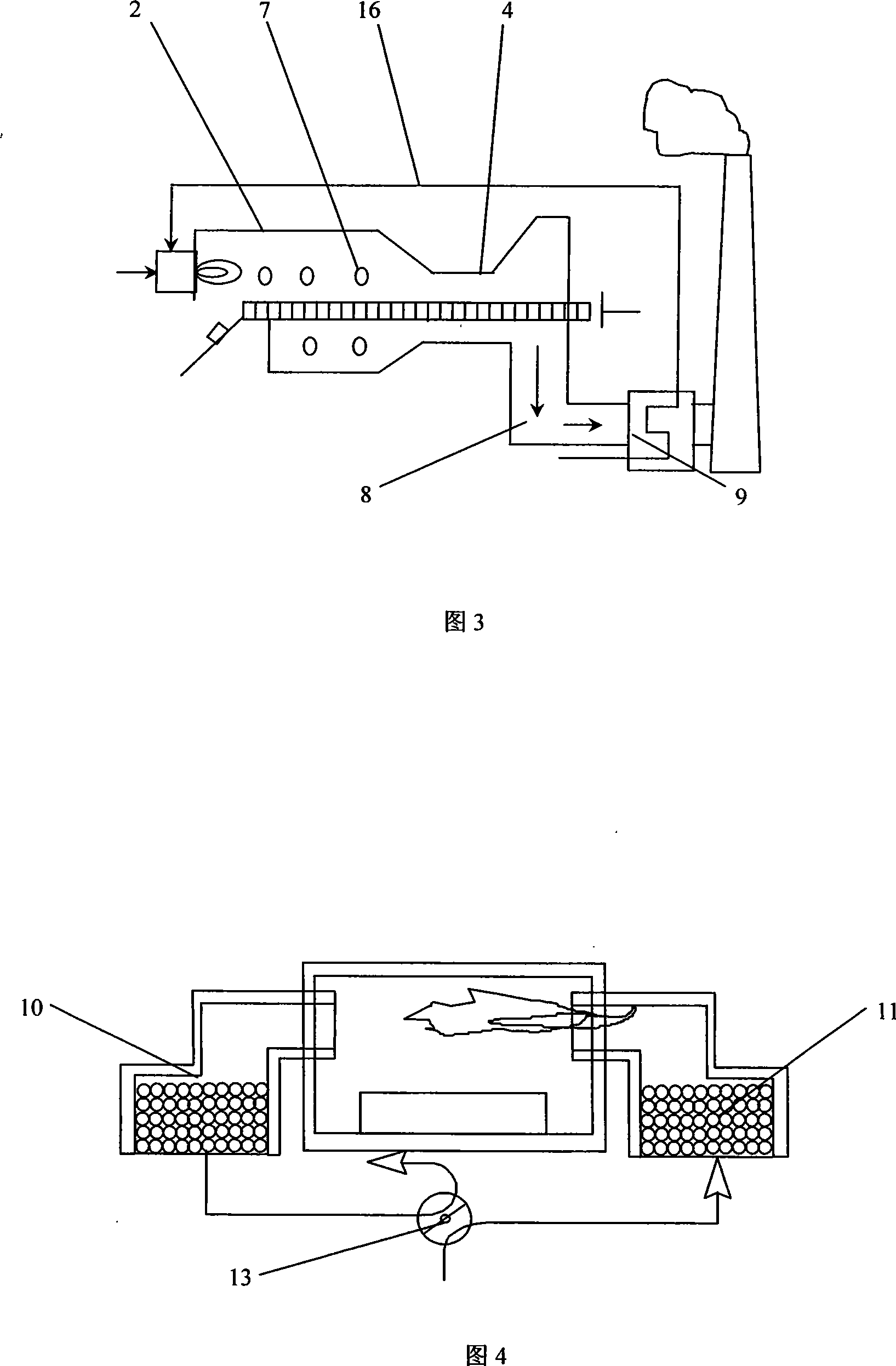

Efficient and energy-saving magnetizing roasting rotary kiln

InactiveCN102636021AAdjustable temperatureMeet the test requirementsRotary drum furnacesElectricityElectric machine

The invention discloses an efficient and energy-saving magnetizing roasting rotary kiln comprising a driving motor, a feeding device, a rotary drum (6) and a transmission supporting mechanism (10) of the rotary drum, an electric heating furnace and an electric heating element (7), a waste gas discharging device (1) and a material discharging device (12), wherein the rotary drum (6) is internally provided with a temperature monitoring device (8); the waste gas discharging device (1) is located at the upper part of one side of a kiln tail; the feeing device is located at the outer side of the kiln tail; the material discharging device (12) is located at the lateral lower part of a kiln head; and the feeding device is composed of a feeding hopper (2) and a screw feeder (3). An adjusting screw rod device is arranged at the bottom of the rotary drum (6), and a mounting inclined angle is adjustable in a range of 0-2.5 degrees. A three-blade material overturning wall scraper device (13) is arranged between a front end pre-heating section and a roasting section of the rotary drum (6); a fixed flange bracket (9) is arranged on the inner wall of a drum in front of the three-blade material overturning wall scraper device (13); an hearth outer rotary drum of the rotary drum (6) is a carbon steel compound rotary drum (5); and the carbon steel compound rotary drum (5) is filled with a heat-insulating material. The efficient and energy-saving magnetizing roasting rotary kiln is stable and reliable in operation and can effectively prevent roasted materials from being stuck on the inner wall of the rotary kiln even forming a ring; and the rotary kiln solves the key technical problem of the existing roasting rotary kiln that the ring is easily formed in the kiln and the production efficiency is influenced, and the working efficiency of the rotary kiln is high.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

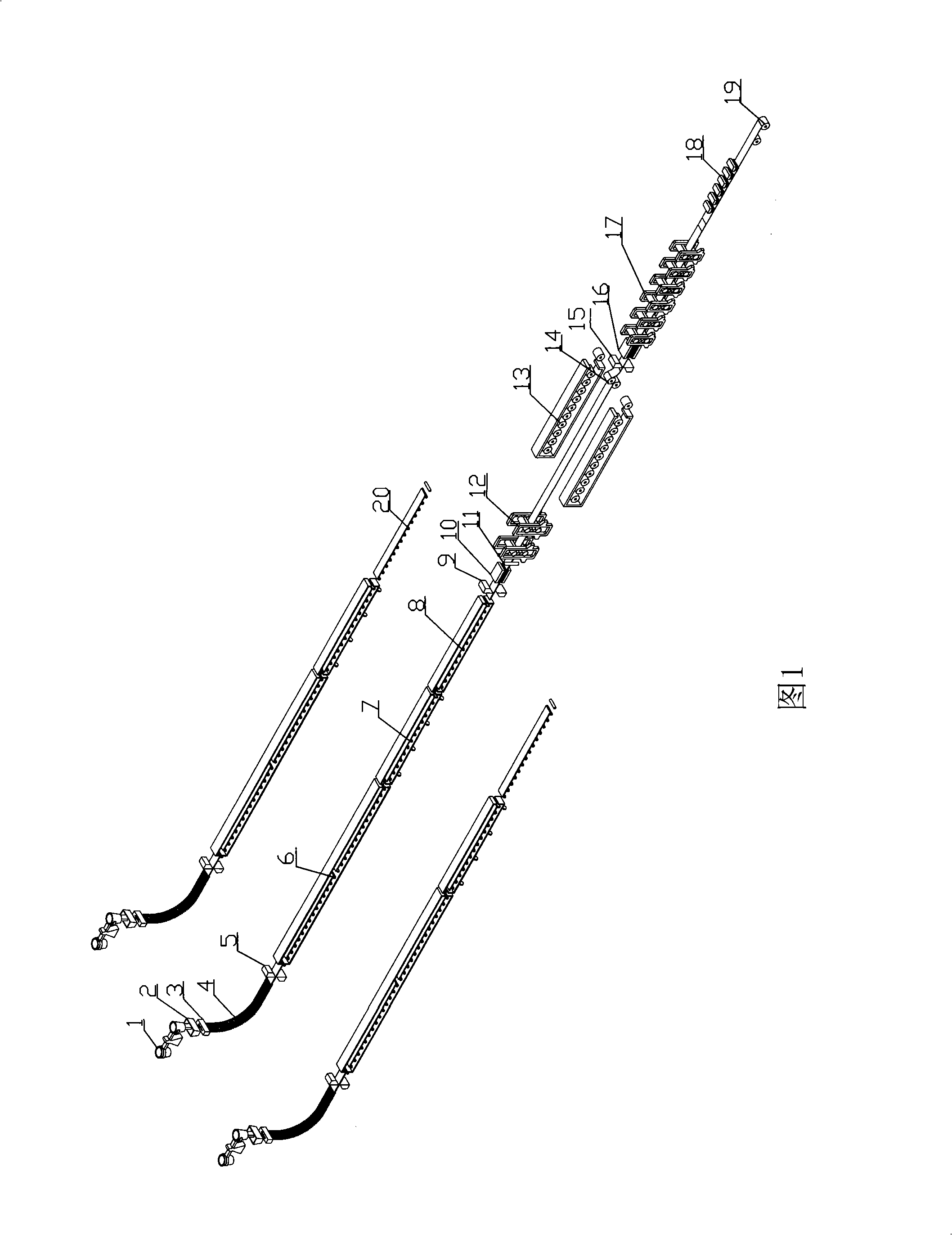

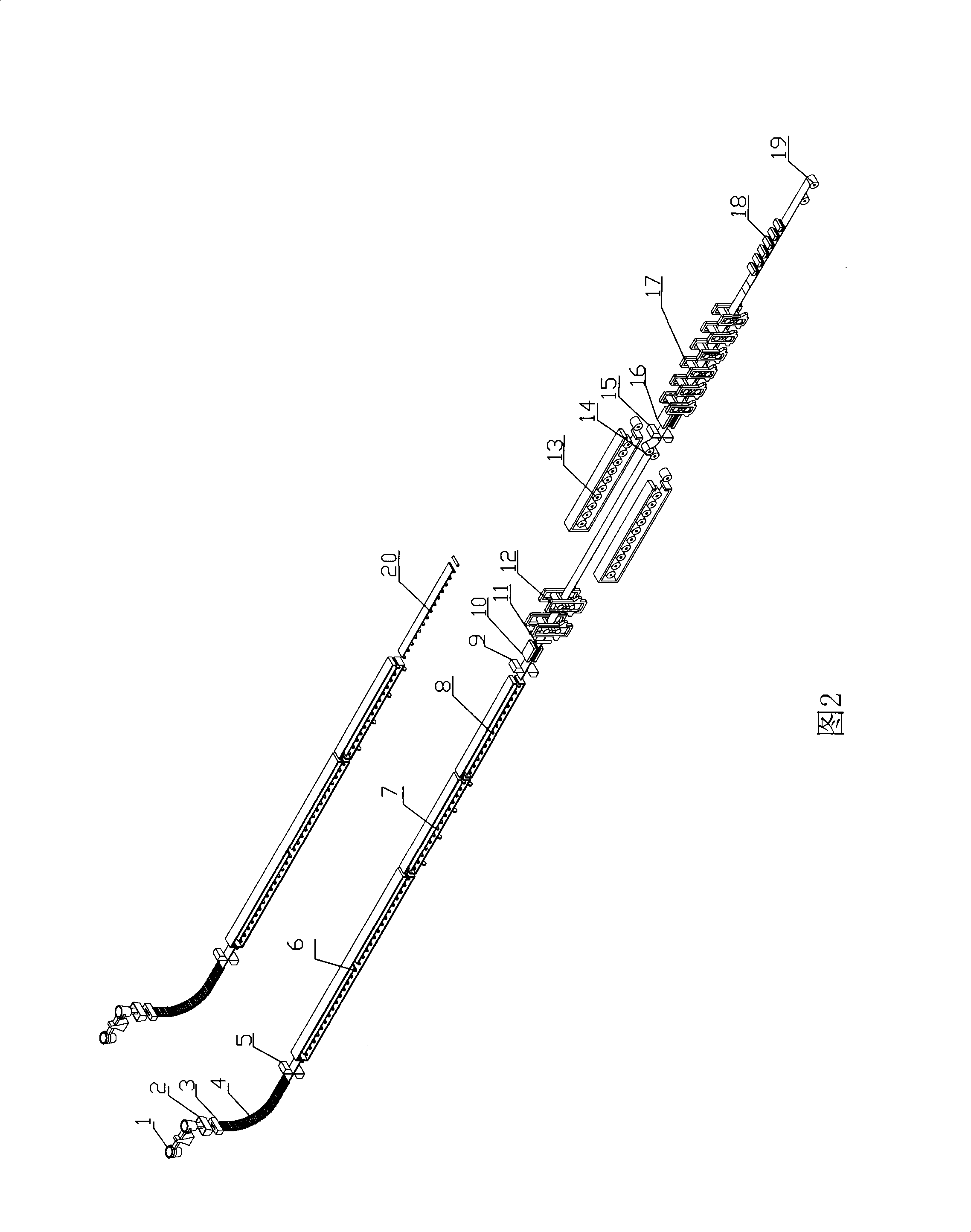

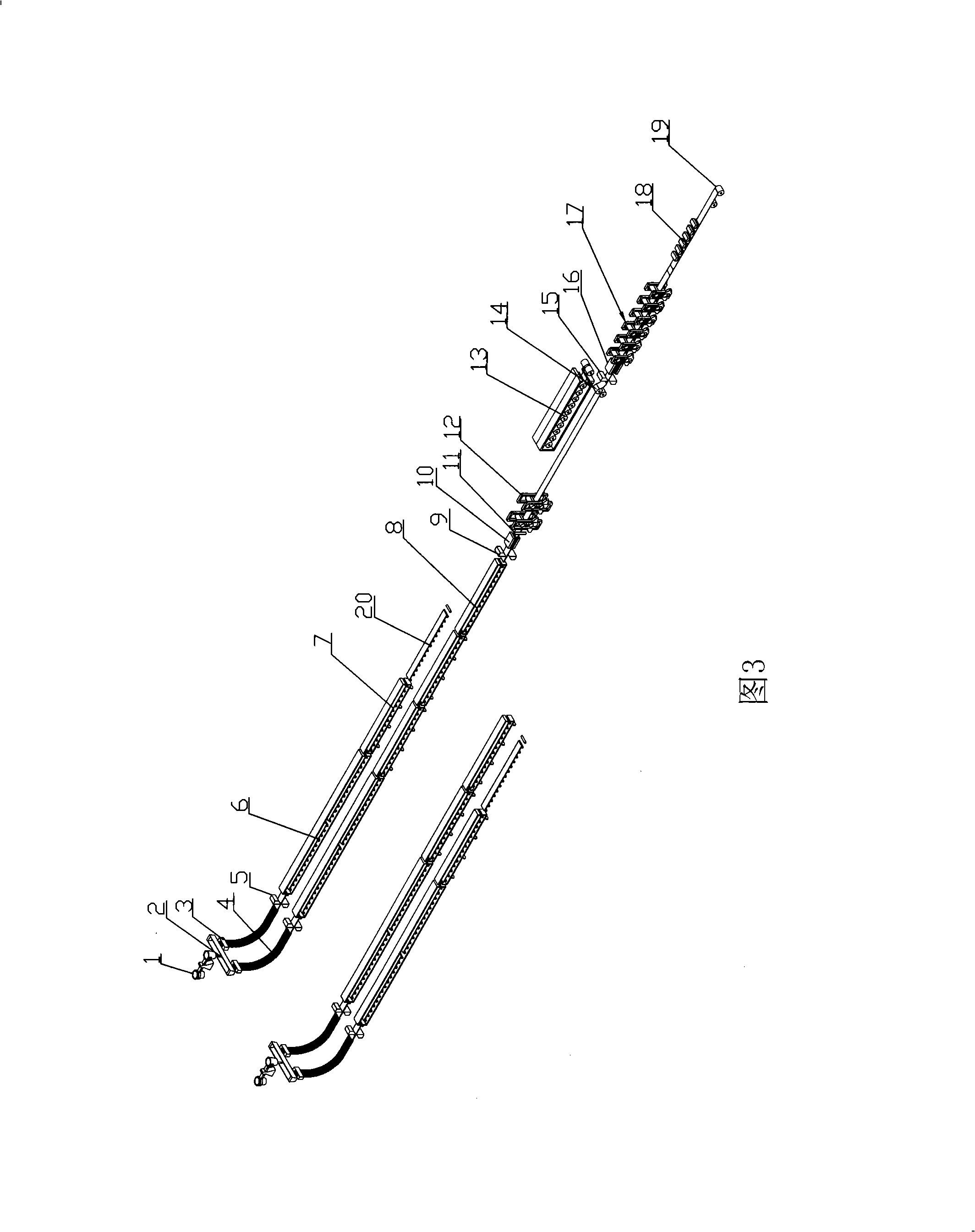

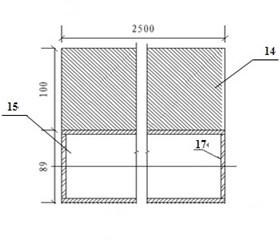

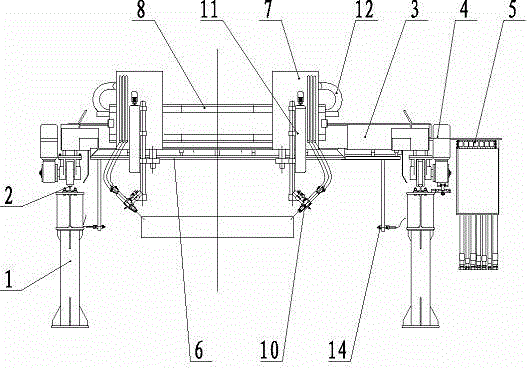

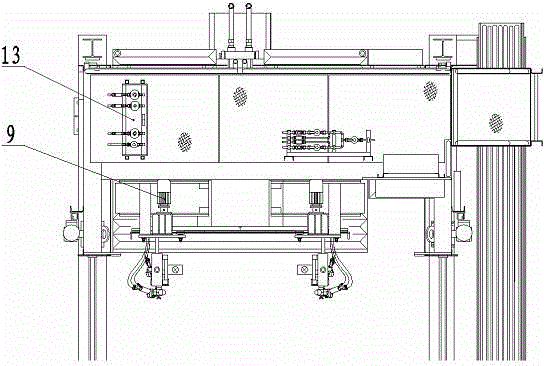

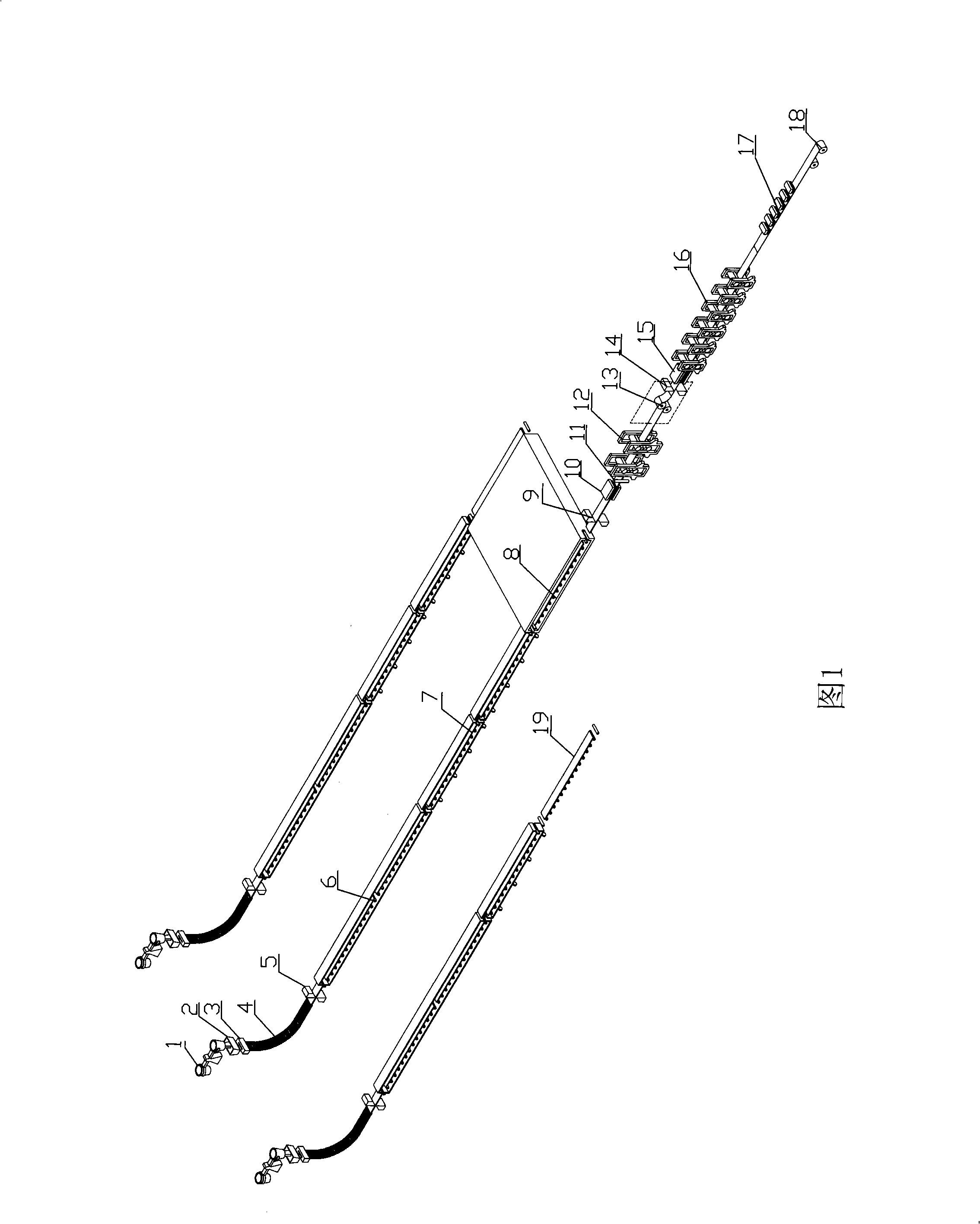

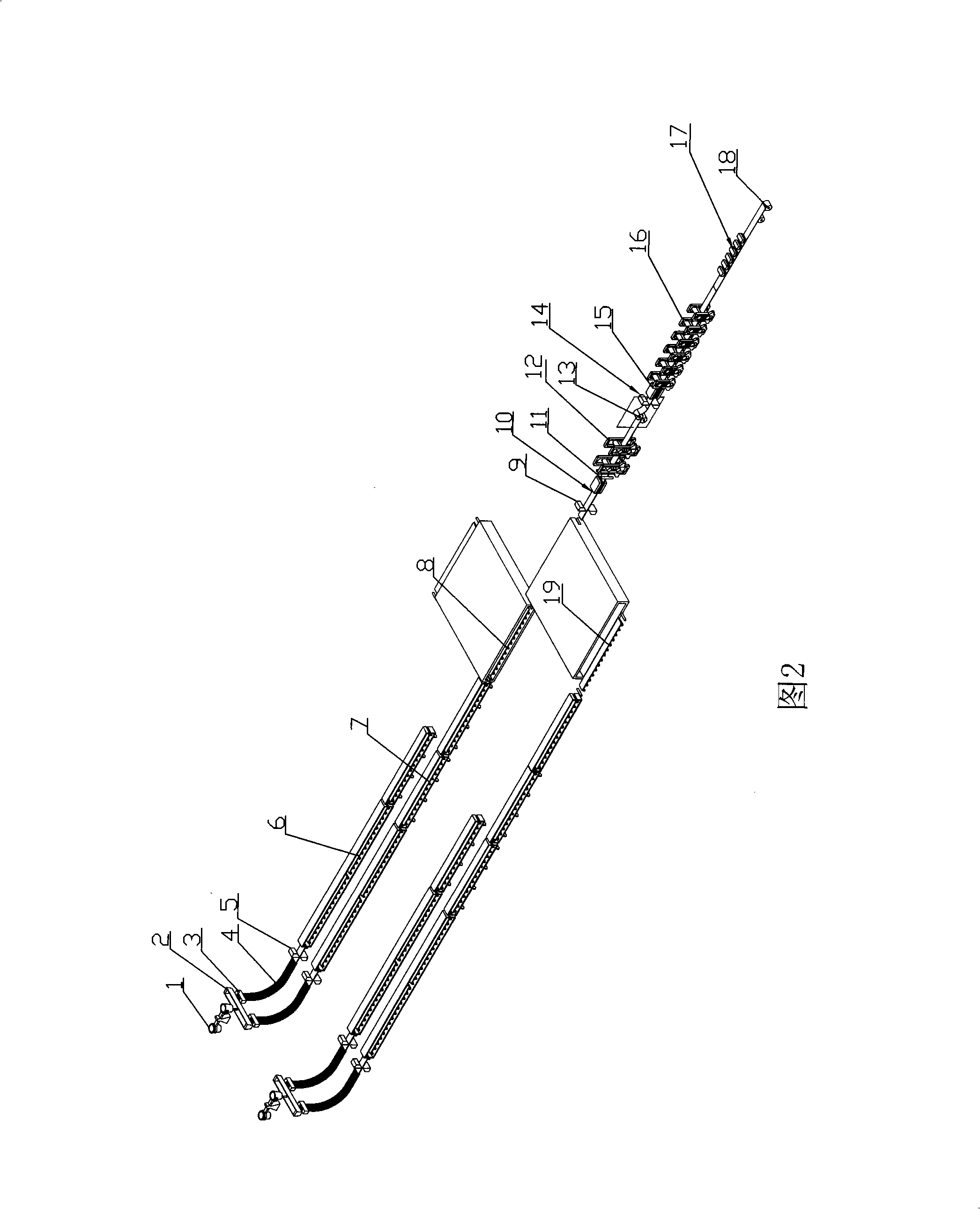

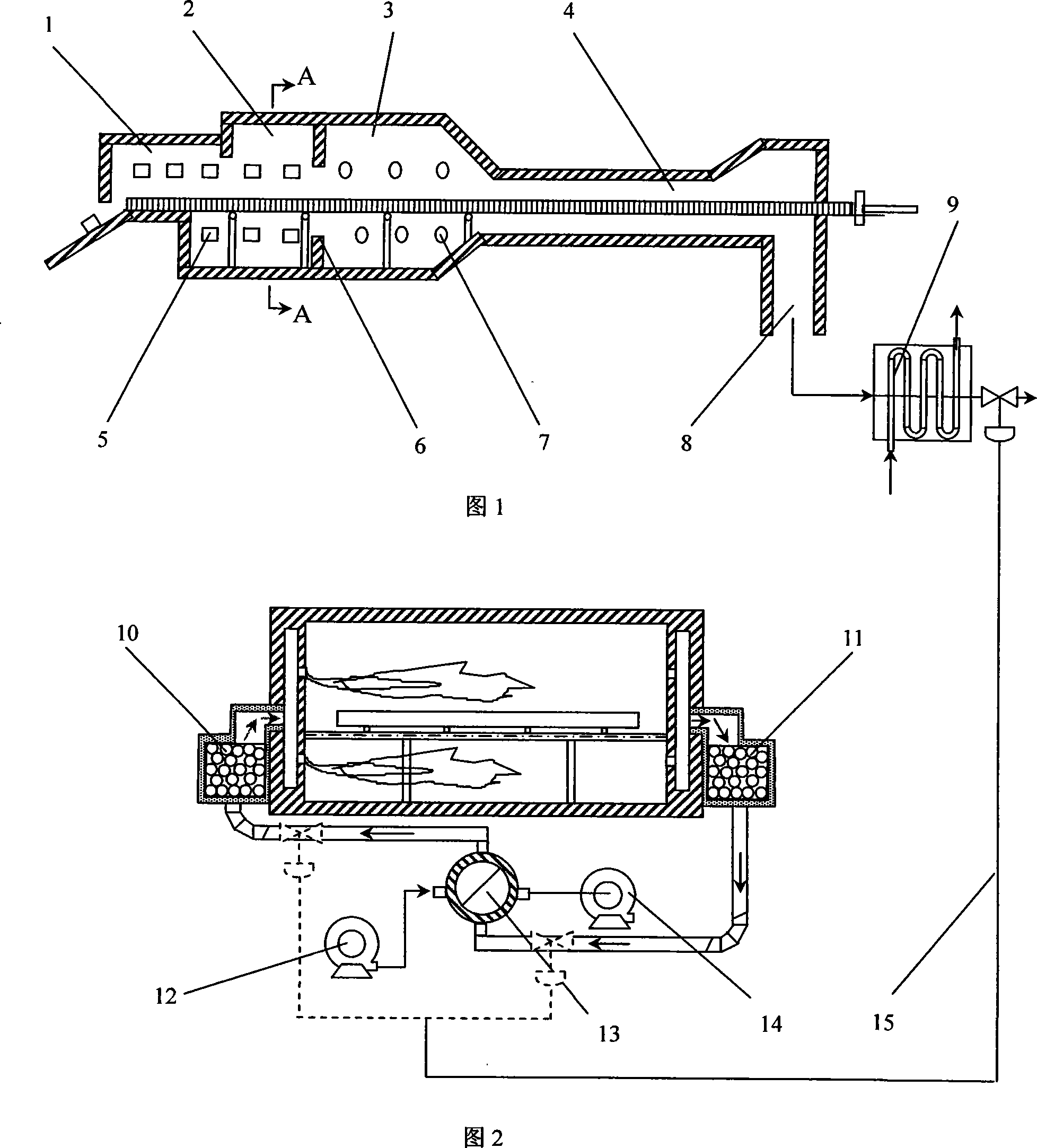

Automatic continuous casting billet flame cleaning device and operation method thereof

InactiveCN102717169AQuality improvementImprove work rateGas flame welding apparatusBogieReciprocating motion

The invention relates to an automatic continuous casting billet flame cleaning device and an operation method thereof. The automatic continuous casting billet flame cleaning device consists of a supporting rack, a cart track, a cleaning device cart, a cart driving device, a heat-insulation protective plate, cleaning bogies, a cleaning bogie track, a bogie driving device, a cleaning gun, an automatic height-regulating device, a control valve station and a billet straightening device, wherein the cleaning device cart is arranged on a cart track on the supporting rack for walking, and the heat-insulation protective plate is arranged at the lower part of the cleaning device cart. The cart driving device provides power for walking of the cleaning device cart. The cleaning bogie track is fixed on the cleaning cart, and cleaning bogies are symmetrically arranged on two ends of the cleaning bogie track. The bogie driving device drives the cleaning bogies to do reciprocating motion on the cleaning bogie track. The cleaning gun is arranged on the automatic height-regulating device. A power supply and energy pipe on the cleaning bogie is controlled by the control valve station. A set of billet straightening device is arranged on the cleaning device cart and used for straightening the cleaning locus of corners of a continuous casting billet in a cleaning process. The automatic continuous casting billet flame cleaning device and the operation method thereof are novel in conception, and simple and reliable in structure.

Owner:SHANGHAI DONGZHEN METALLURGY ENG TECH

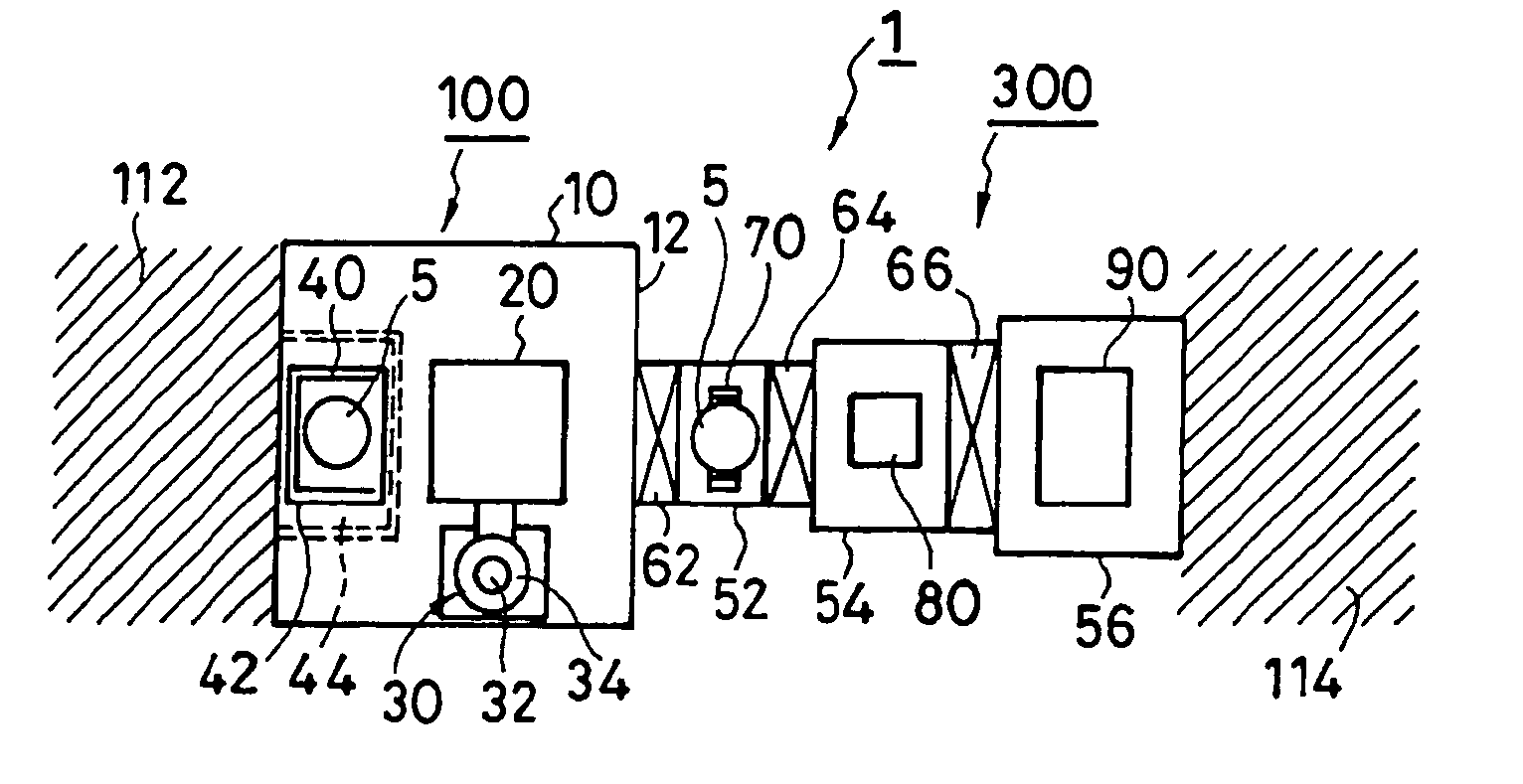

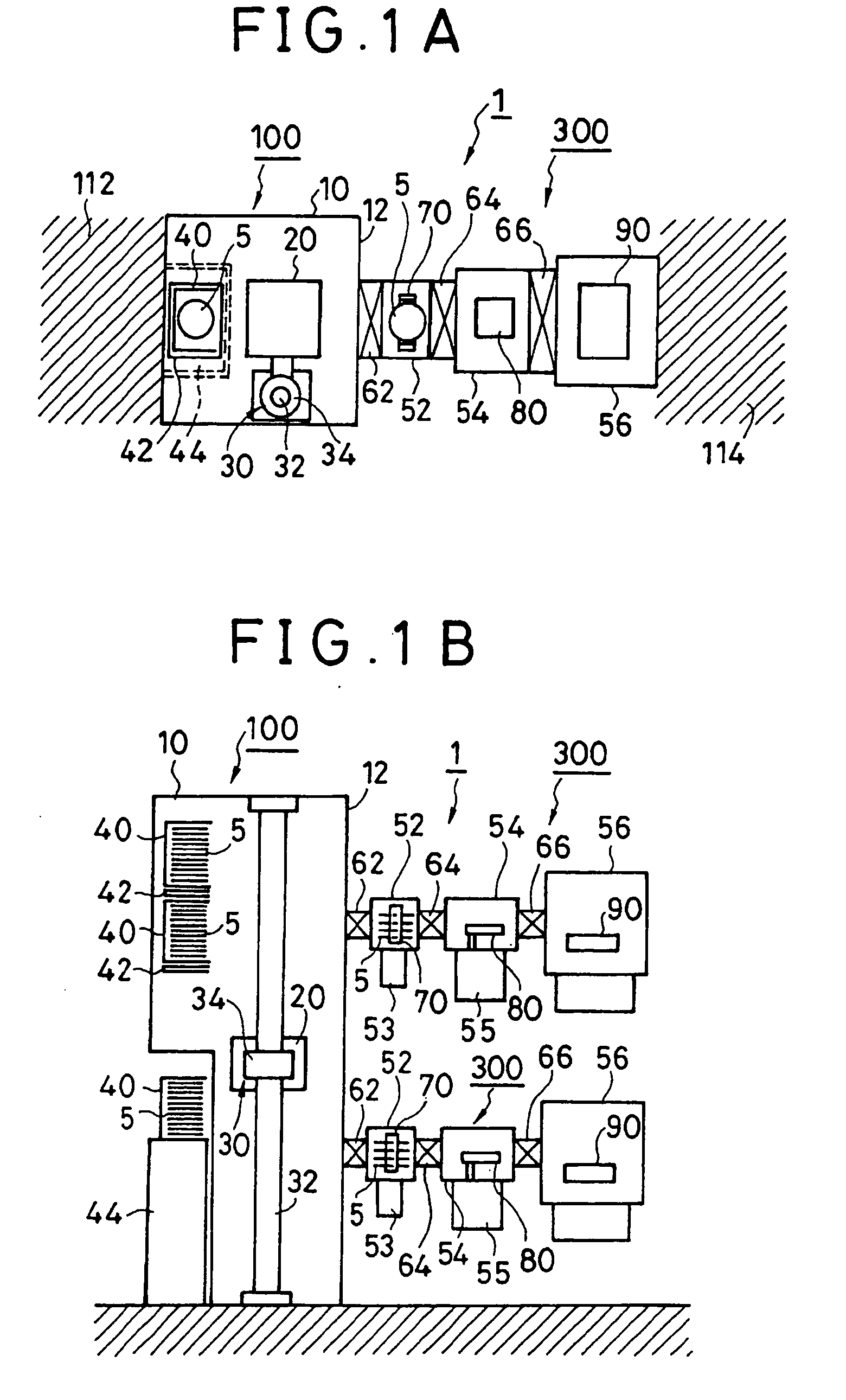

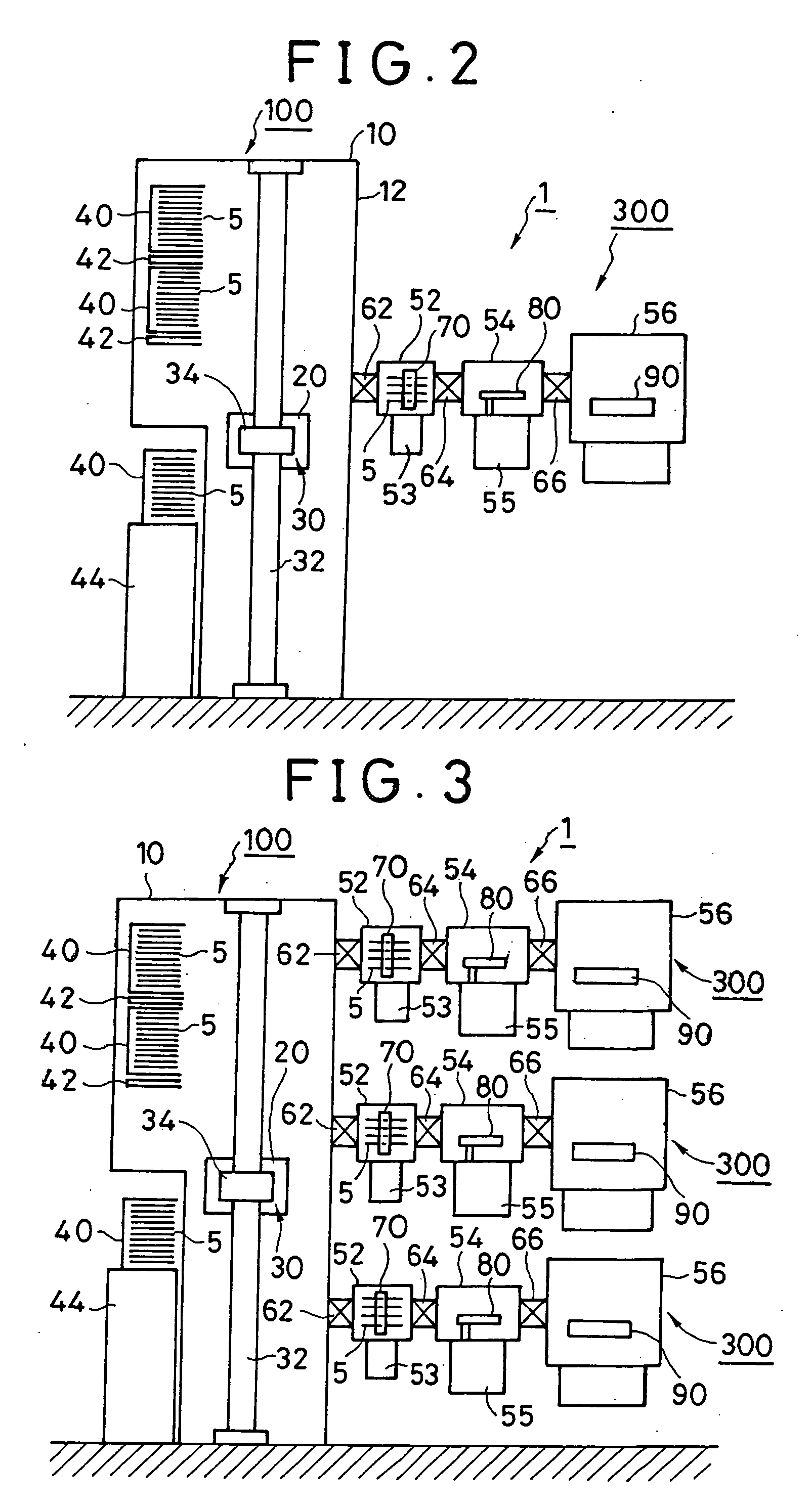

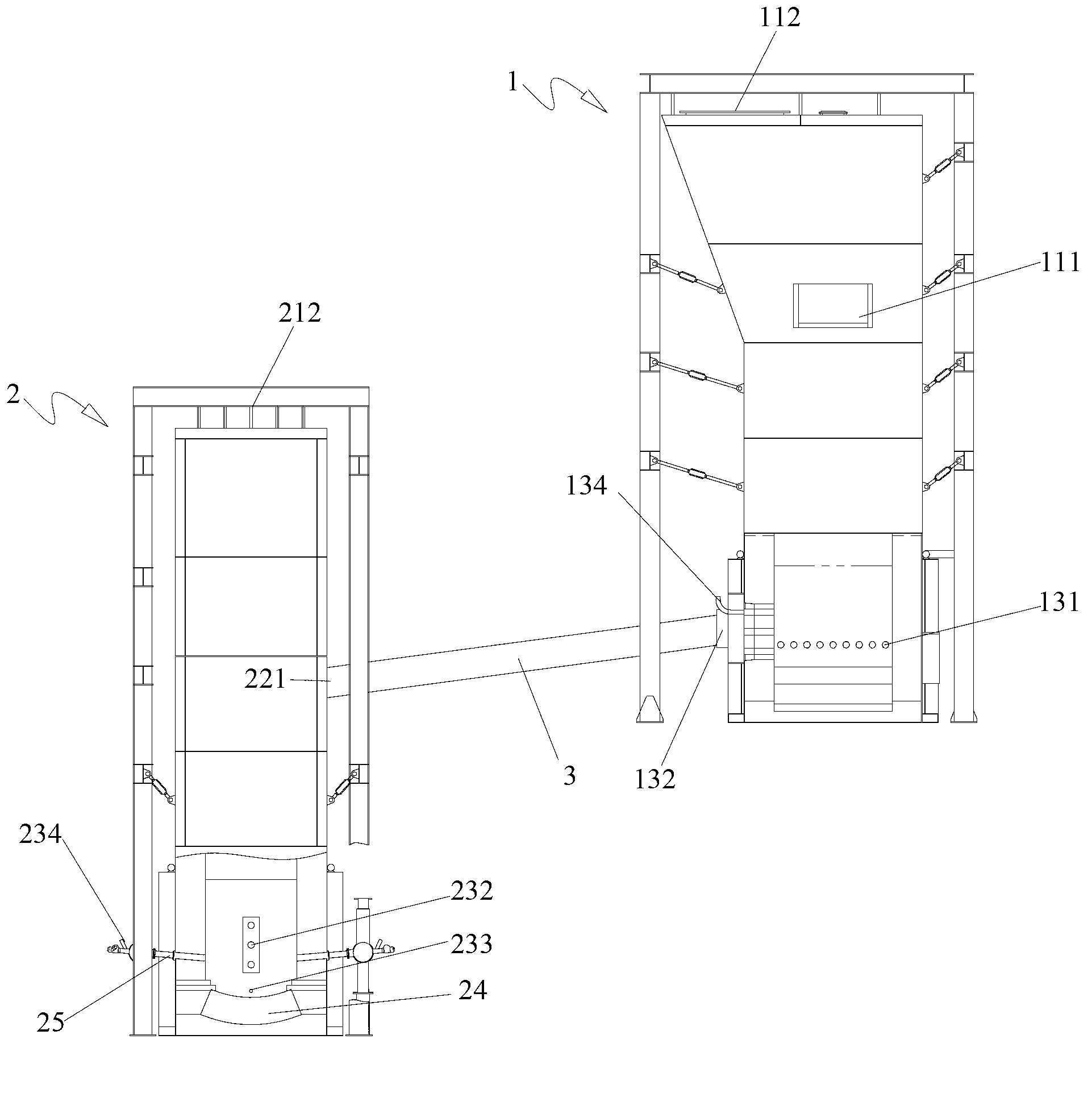

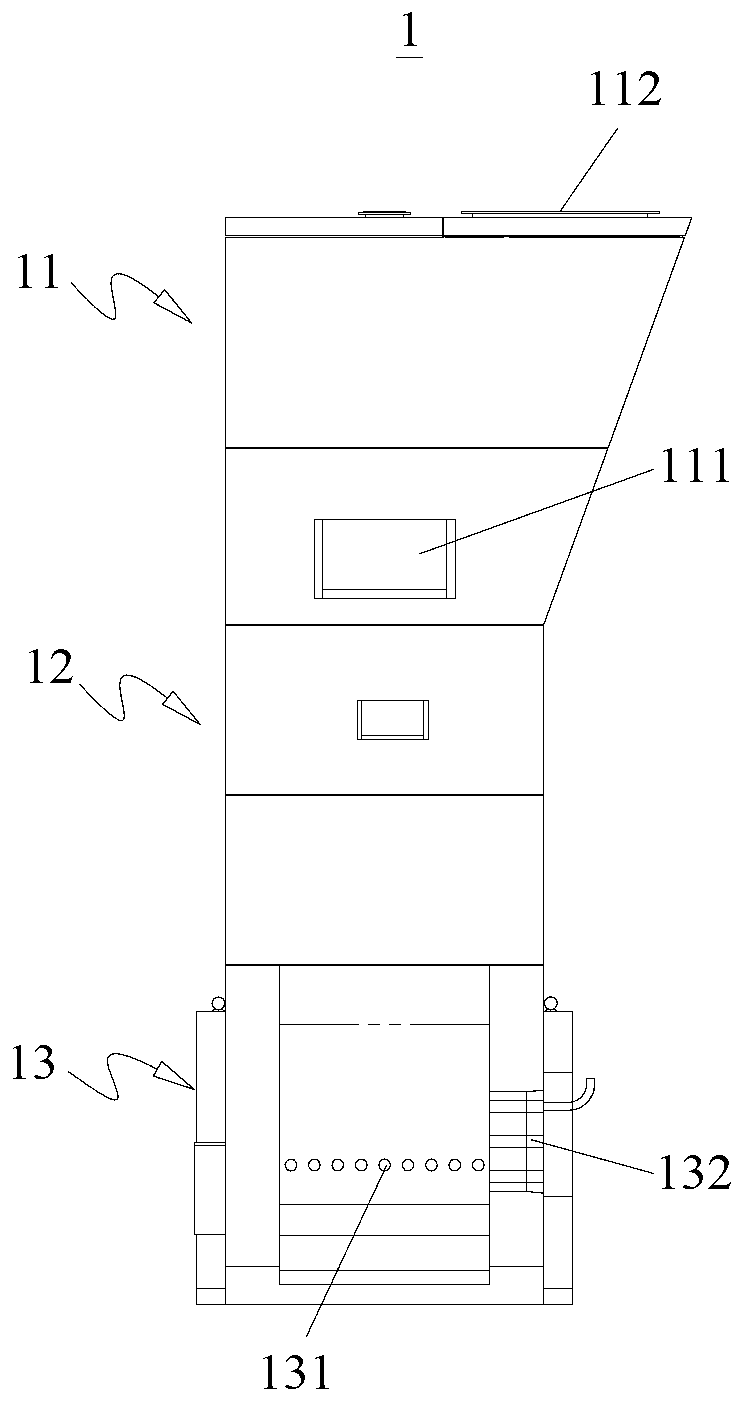

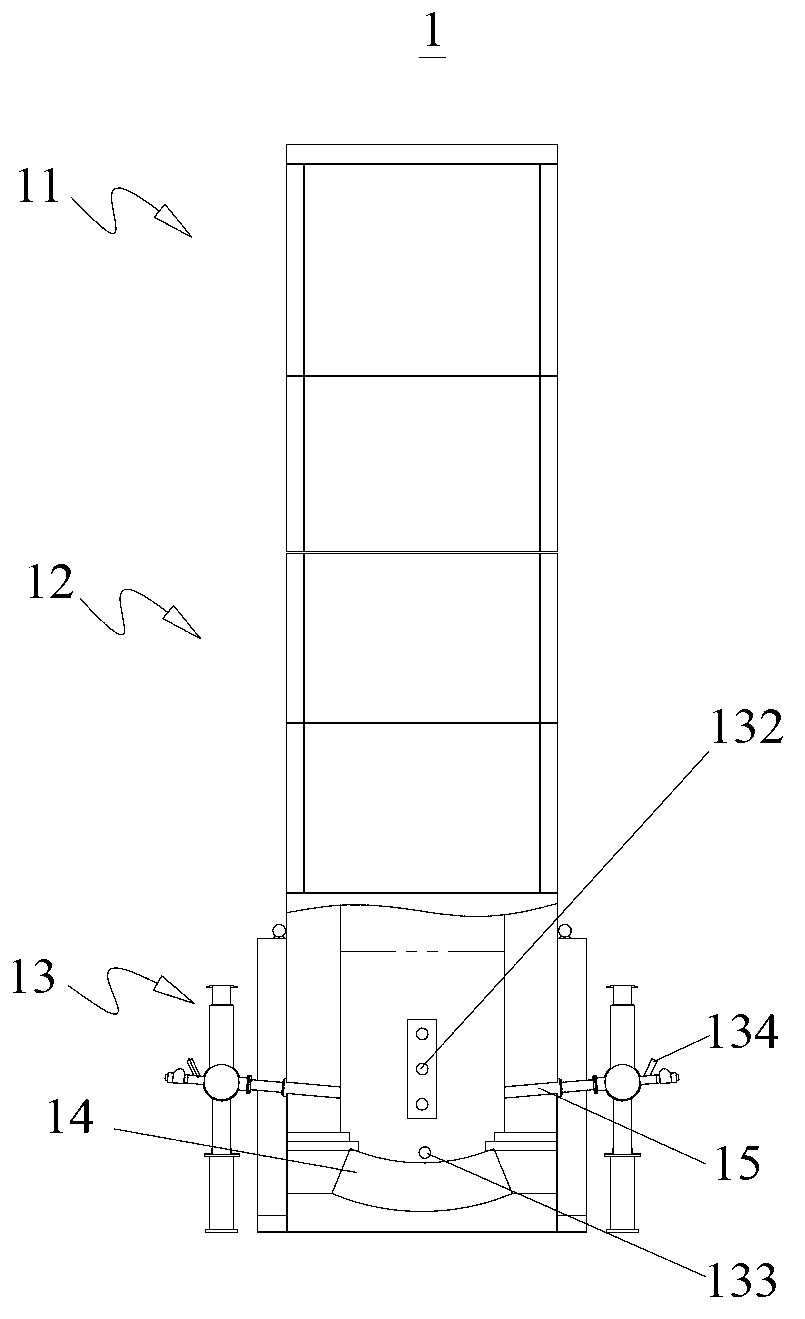

Substrate processing apparatus

InactiveUS20060090849A1Small footprintHigh net working rateSemiconductor/solid-state device manufacturingChemical vapor deposition coatingGate valveElectrical and Electronics engineering

A substrate processing apparatus comprises a substrate transfer section, a plurality of modules and a first substrate transfer robot provided in the substrate transfer section and capable of transferring substrates to the plurality of modules. The plurality of modules are piled up, separately from one another, in a vertical direction. Each of the plurality of modules are detachably mounted to the substrate transfer section and includes a substrate processing chamber, an intermediate chamber, a first gate valve disposed between the substrate processing chamber and the intermediate chamber, a second gate valve disposed between the intermediate chamber and the substrate transfer section, and a second substrate transfer robot disposed in the intermediate chamber. Preferably, the substrate processing chamber further comprises a second intermediate chamber having a substrate holder therein and disposed between the intermediate chamber and the substrate transfer section, and a third gate valve disposed between the second intermediate chamber and the substrate transfer section.

Owner:TOYODA KAZUYUKI +6

Process for manufacturing hot rolled steel strips by continuous casting and rolling middle bar strip

ActiveCN101293258AEasy to produceSmall temperature differenceFurnace typesHeat treatment process controlHigh pressure waterHearth

The invention discloses a continuous casting and tandem rolling method for producing hot rolling strip steel by using medium sheet billet, including the following steps: 1) liquid molten steel passes through a long nozzle from a ladle to be cast to a pouring box, flows through a submerged nozzle from the pouring box to be cast in a crystallizer of a continuous caster and is continuously cooled in the continuous caster to form a casting blank; 2) the casting blank enters a short tunnel roller hearth type heating furnace for heating; 3) a technology of converging a plurality of casting flows is adopted, one of the casting flows is in collineation with a rolling mill, the casting blank of other flows passes through a swinging section and is converged with the casting blank of the collinear flow, then passes through a walking beam and a holding zone of the roller hearth complex type heating furnace which is provided with a roller way and finally enters high pressure water for descaling; 4) the casting blank is prepared into an intermediate blank by rough rolling; 6) the intermediate blank carries out finish rolling into a steel strip with standard thickness; 7) the steel strip is cooled and coiled into the finished steel coil. The method can reduce investment, save energy resource, improve the quality of products, expand the varieties of the products and lower production cost.

Owner:BAOSHAN IRON & STEEL CO LTD

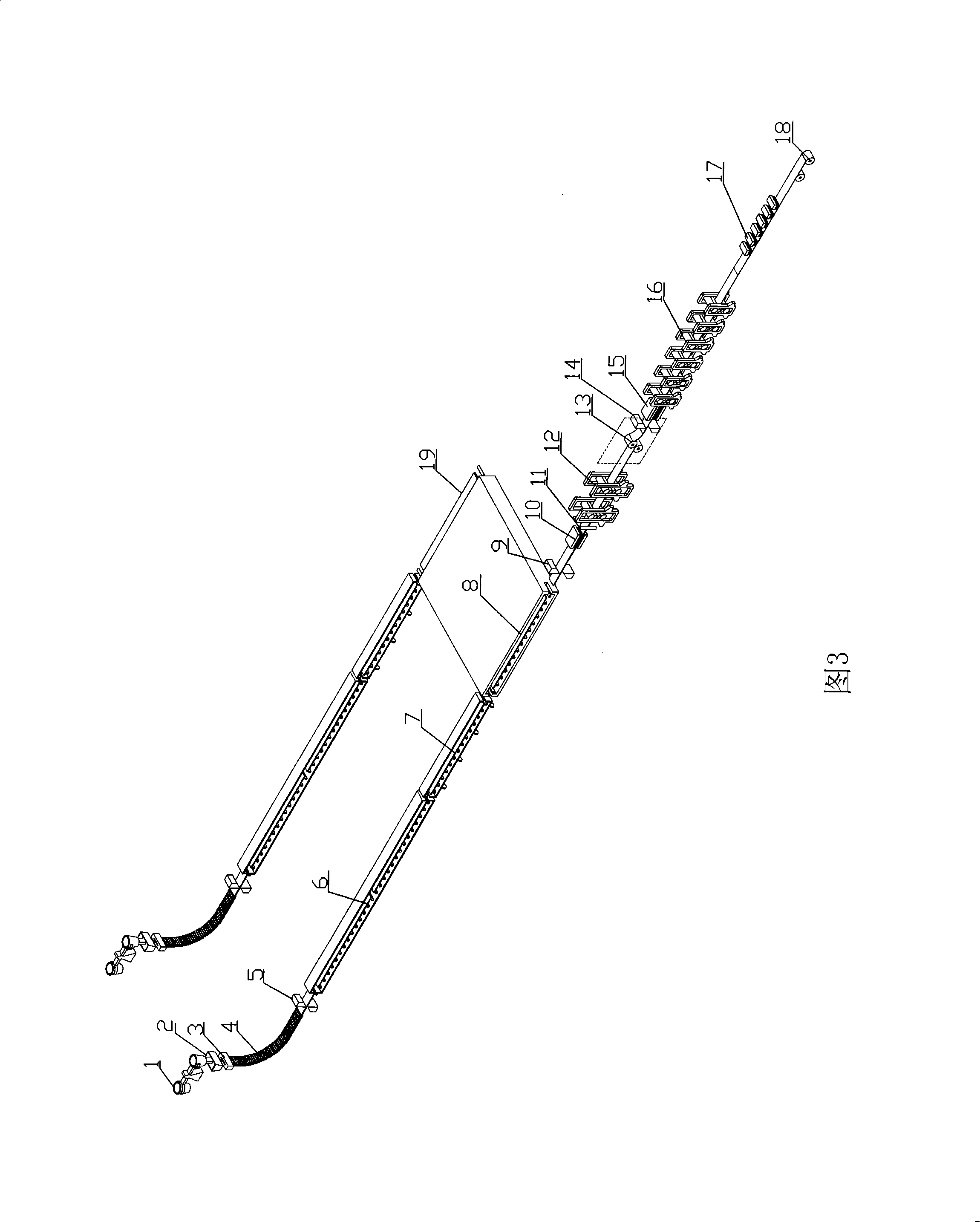

High carbon high-speed steel of containing granular carbide, and preparation method

InactiveCN1916219AImprove mechanical propertiesImprove thermal fatigue resistanceHeat treatment process controlThermal fatigueChemical composition

This invention discloses a method for preparing particular carbide-texile high-carbon high-speed steel, which is composed of: C 1.5-3.0 wt.%, V 3.0-6.0 wt.%, W 4.0-8.0 wt.%, Mo 2.0-6.0 wt.%, Cr 4.0-8.0 wt.%, Nb 0-5.0 wt.%, Co 0-5.0 wt.%, RE 0.05-0.20 wt.%, Ti 0.1-0.3 wt.%, N 0.06-0.18 wt.%, Zn 0.01-0.05 wt.%, Mg 0.02-0.12 wt.%, Ni 0-1.0 wt.%, Si 0-2.0 wt.%, Mn 0-2.0 wt.%, P 0-0.05 wt.%, S 0-0.05 wt.% and Fe, wherein the total content of Nb and Co is within 2.5-5.0 wt.%. The method comprises: casting in an electric furnace, heating at 1020-110 deg.C for 2-4 h, air-cooling, normalizing, heating at 500-580 deg.C for 4-8 h, and air-cooling or furnace-cooling to room temperature to obtain martensite-based particular carbide-texile high-carbon high-speed steel. The steel has improved mechanical properties with tensile strength of 930-980 MPa, impact toughness of 12-15 J / cm2 and fracture toughness of 48-55 MPa, improved thermal fatigue resistance and excellent wear resistance.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

High-carbon refractory and method for preparing same

The invention relates to a novel type of inorganic non-metal material, the high-alumina anthracite coal base refractory which is combined with the compound wedding agent in the continuous casting steel production. The solution loss of a refractory with the alumina anthracite coal base is decreased in the molten steel can improve the erosion resistance of the material, the high-alumina anthracite coal base refractory which still has a high intensity after the decarburization is suitable to be used to produce long nozzle and submerged nozzle. The materials of the high-alumina anthracite coal base refractory are scale graphite, silicon carbide, metallic silicon powder, fused quartz, electro-melted zirconia mullite, white alundum, liquid phenolic resin and aluminium dihydrogen phosphate powder. The preparation method of the invention is that the materials are equably mixed without liquid phenolic resin, and the mixture is added with liquid phenolic resin and granulated and parched to ensure that the volatiles satisfy the forming requirements, and the product is formed under the condition of 150-200MPa, and the formed product is fired in the furnace with the temperature between 1,500-1,600 DEG C and in the reducing atmosphere, the fired product us coated with inoxidzable coating, and the finished product is gained after the fired product with inoxidzable coating is parched. Compared with the product which is produced with the prior art, the refractory of the invention has outstanding characters and remarkable advantages that the scour resistance of molten steel is stronger, the erosion resisting is stronger, and the service life is prolonged greatly, and operation efficiency of continuous casting steel is improved, the production cost is decreased and the operating condition is improved.

Owner:周成德

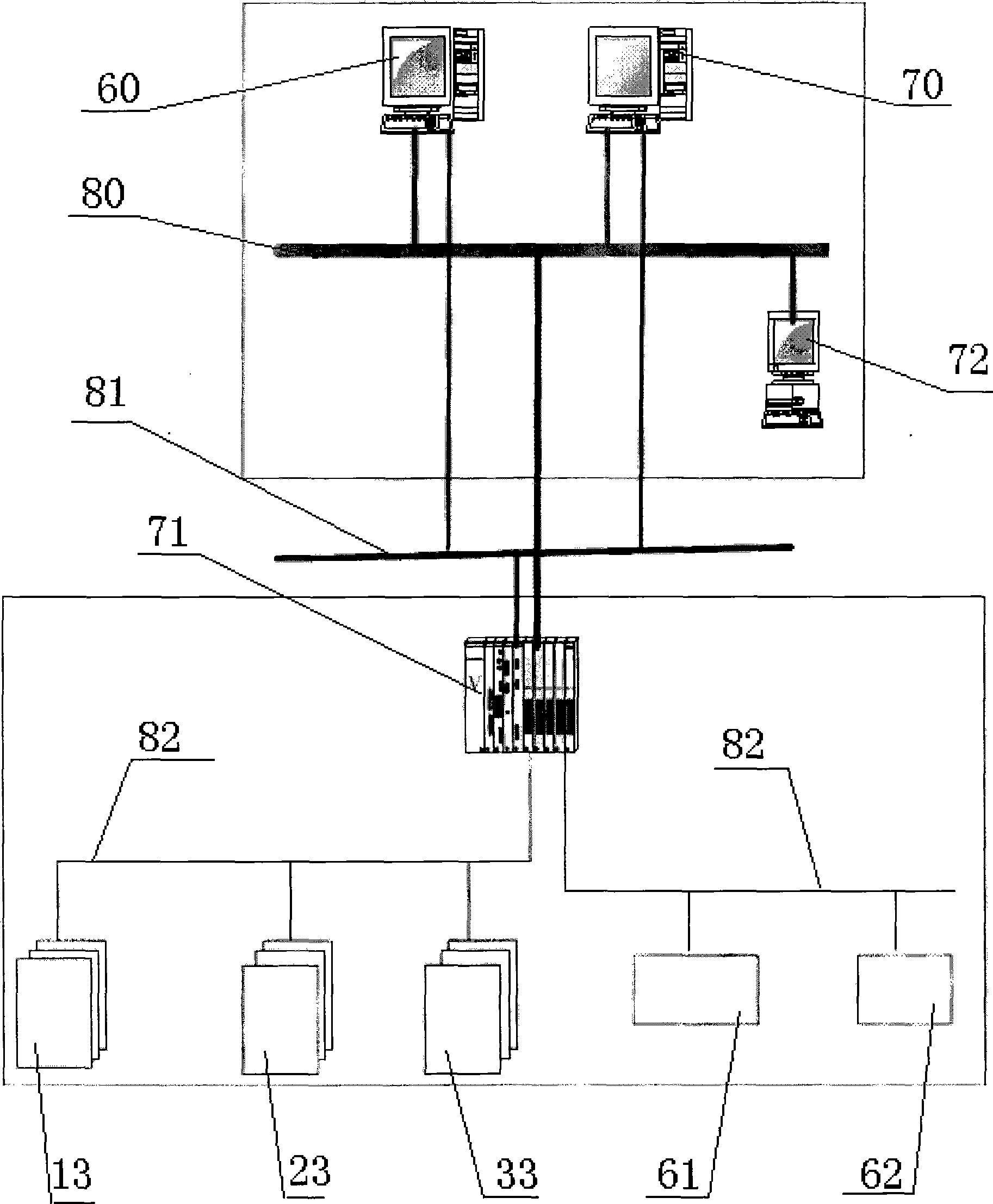

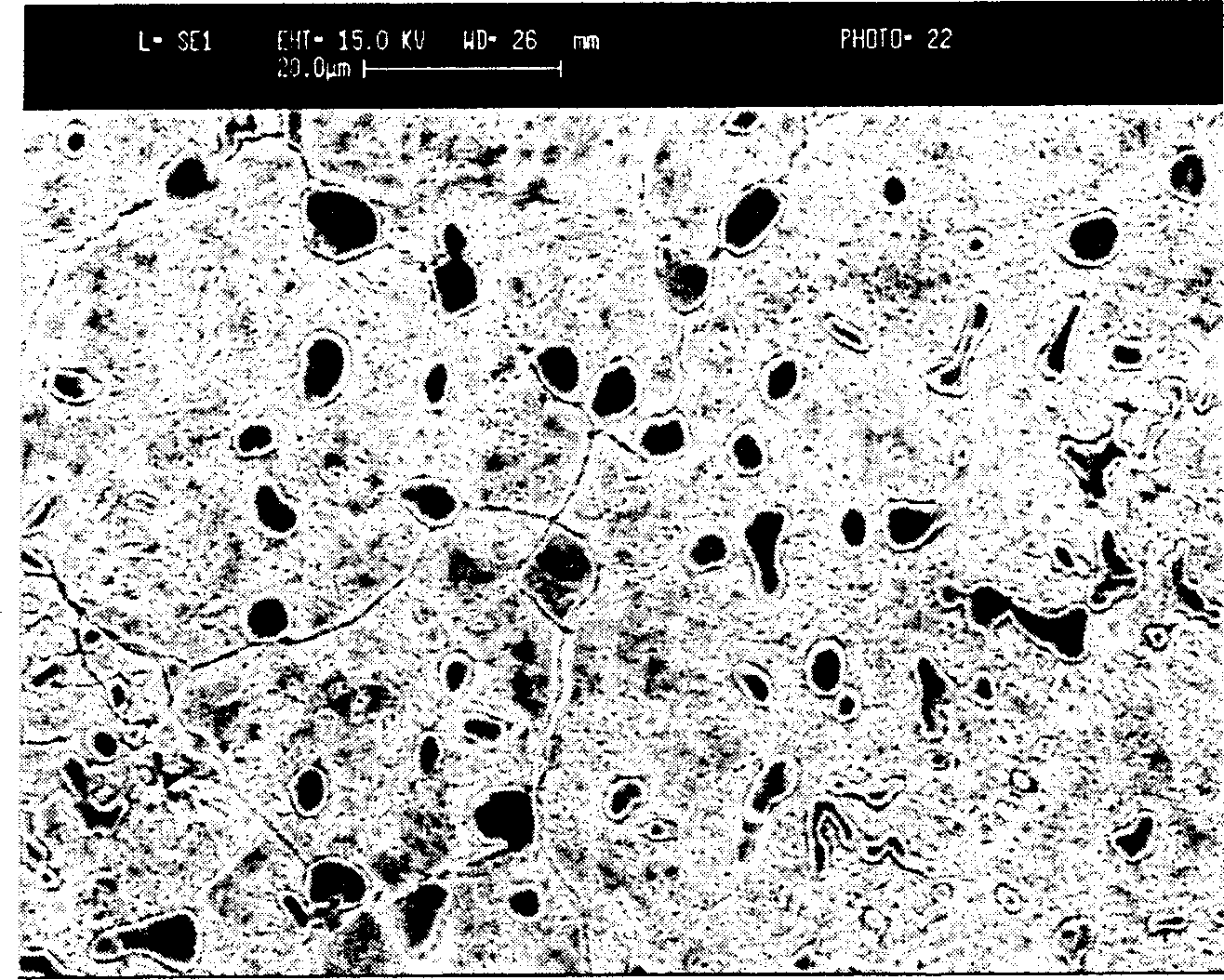

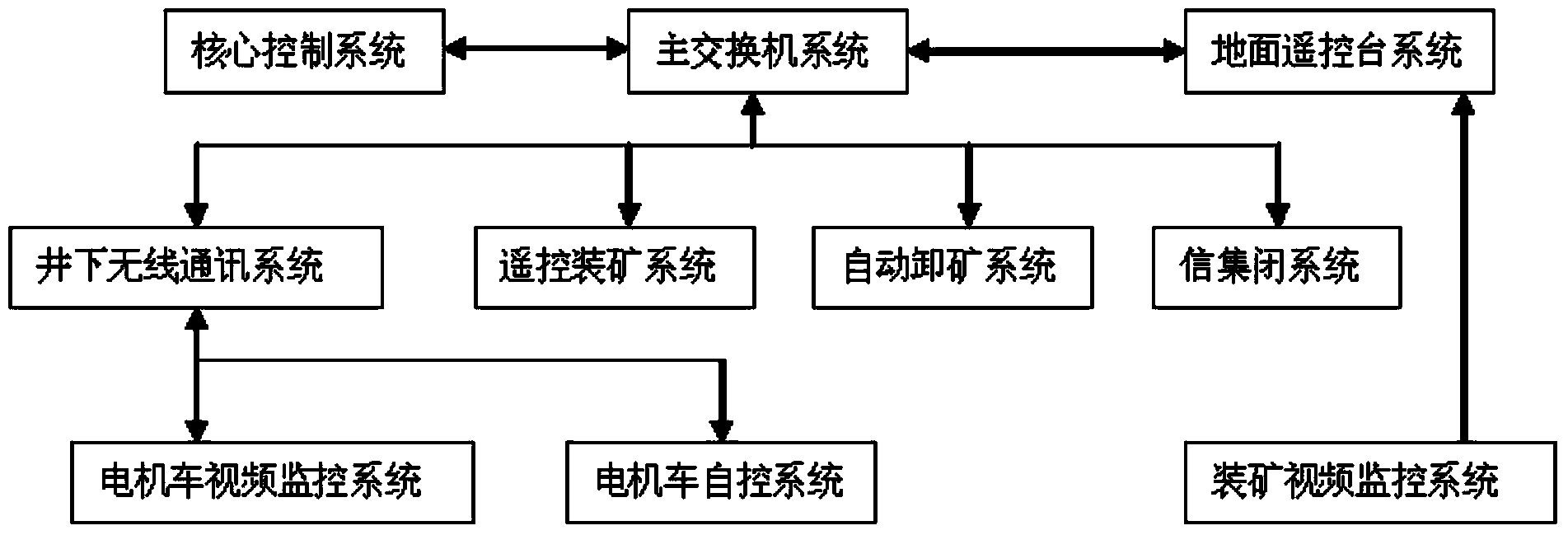

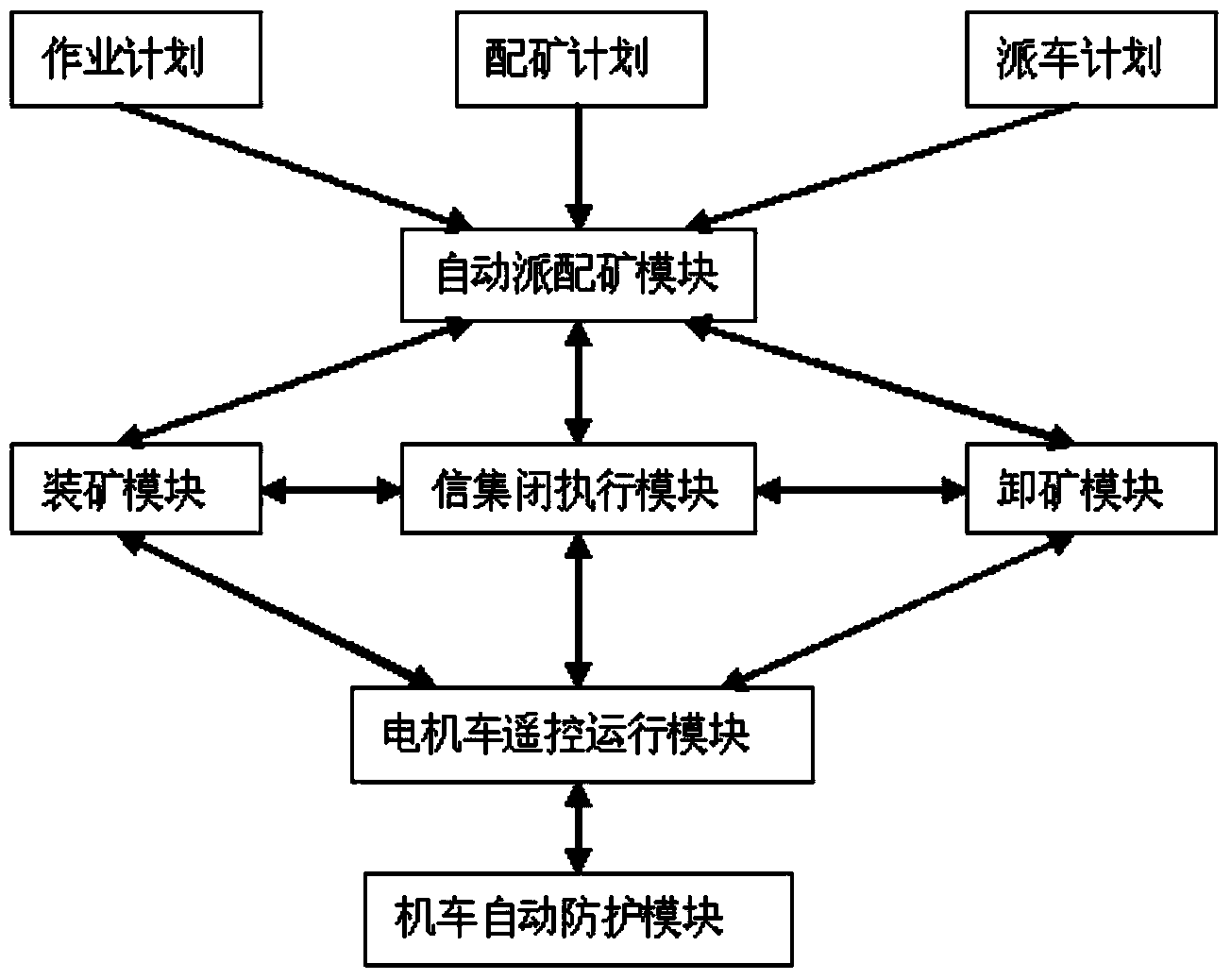

Ground remote control system for downhole electric locomotives

ActiveCN103901862AImprove work rateImprove efficiencyProgramme total factory controlElectric machineryControl system

The invention provides a ground remote control system for downhole electric locomotives, and belongs to the technical field of downhole mining. The ground remote control system for the downhole electric locomotives comprises a dispatching and ore blending unit, a locomotive unit, an operation unit, an ore loading unit and an ore unloading unit. The dispatching and ore blending unit comprises a digital ore blending system and a digital locomotive dispatching system; the locomotive unit comprises a downhole electric locomotive transport system and an electric locomotive automatic protection system; the operation unit comprises a downhole narrow gauge signal concentrating locking control system, a control console system, a wireless communication system a 100 M network communication system and an uninterrupted power system; the ore loading system comprises a draw shaft remote ore loading system and a draw shaft remote ore loading video monitoring system; the ore unloading system comprises an automatic ore unloading system and an unloaded-ore automatic sweeping system. The ground remote control system for the downhole electric locomotives has the advantages that work of a downhole electric locomotive driver and work of an ore drawing worker are integrated, the working position is moved to the ground from the downhole, the intrinsic safety level is improved, occupational diseases are avoided, safe and efficient operation of the electric locomotives is ensured, operation is simplified, the operation ratio of the electric locomotives is improved, machine-hour efficiency of the electric locomotives is improved, production and organization efficiency is improved, and stability of the output grade is improved.

Owner:BEIJING SOLY TECH

Method for preparing hot rolling strip steel capable of preventing edge crack of extremely thin rolled strip steel

InactiveCN102179407AUniform temperatureReduce temperature differenceTemperature control deviceMetal rolling arrangementsTemperature differenceAlloy

The invention relates to a method for preparing hot rolling strip steel capable of preventing edge crack of extremely thin rolled strip steel. The method comprises the following steps of: (1) smelting, namely desulfurizing molten iron, smelting by using a converter, blowing argon at an argon station, and performing continuous casting to form slabs; (2) performing hot rolling, namely heating the slabs to 1,210 to 1260 DEG C, wherein the temperature difference of the same slab is less than or equal to 30 DEG C; performing rough rolling, and finish rolling, wherein the side pressure delta B when the slab with the width B is subjected to rough rolling is controlled according to the following formula: delta B ranges from 35*B / 1,250*(B-1,050) / (1,250-1,050)+35*B / 1,050*(1,250-B) / (1,250-1,050) to 50; and finally reeling to obtain the hot rolling strip steel. The method is simple and practical, is stable in use and high in uniformity, reduces the alloy cost and shortens the production cycle; and the steel plate heat commercial (SPHC) hot rolling strip steel prepared by the method has the obvious effect of preventing the edge crack of extremely thin cold-rolled sheet.

Owner:NINGBO IRON & STEEL

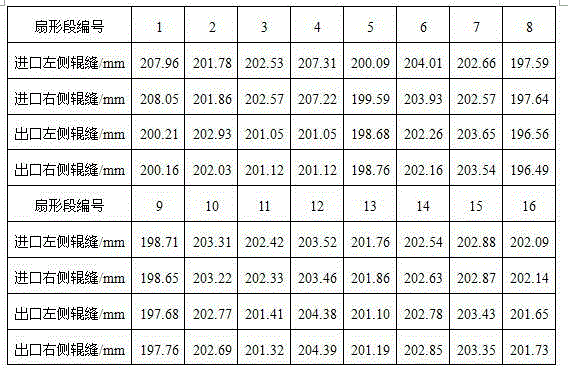

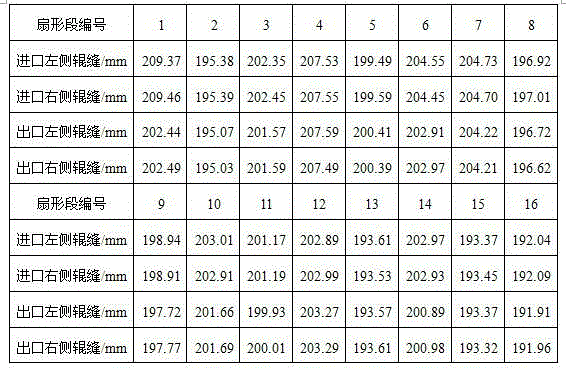

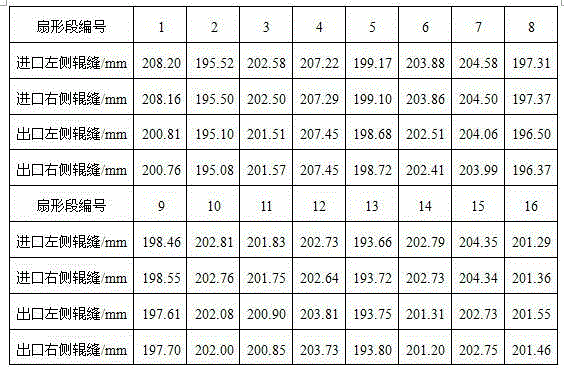

Method for calibrating sector sections of slab continuous casting machine online

The invention provides a method for calibrating sector sections of a slab continuous casting machine online, and belongs to the technical field of roll gap calibration methods of continuous casting machines. The method is used for calibrating the sector sections of the slab continuous casting machine online. According to the technical scheme, the method includes the steps that (1) two pairs of hydraulic cylinders at an inlet and an outlet of each sector section are leveled through gaskets respectively; (2) upper frames of the sector sections are pressed through pressure ranging from 800 kN to 4000 kN; (3) roll gap values of the inlets and the outlets of the sector sections are measured respectively; (4) displacement sensors in the hydraulic cylinders are calibrated according to the actually-measured roll gap values. By means of the method for calibrating the sector sections of the slab continuous casting machine online, the control precision of roll gaps of the continuous casting machine can be increased and reach 0.20 mm. The method can be used for calibrating all the sector sections at the same time, the calibrating efficiency is high, and the operating efficiency of the continuous casting machine can be improved. The hydraulic cylinders of the sector sections, calibrated through the method, of the continuous casting machine bear force uniformly, and the interior quality of casting blanks and the production stability of the continuous casting machine are improved. By means of the method, the labor intensity of workers can be greatly reduced.

Owner:HEBEI IRON AND STEEL

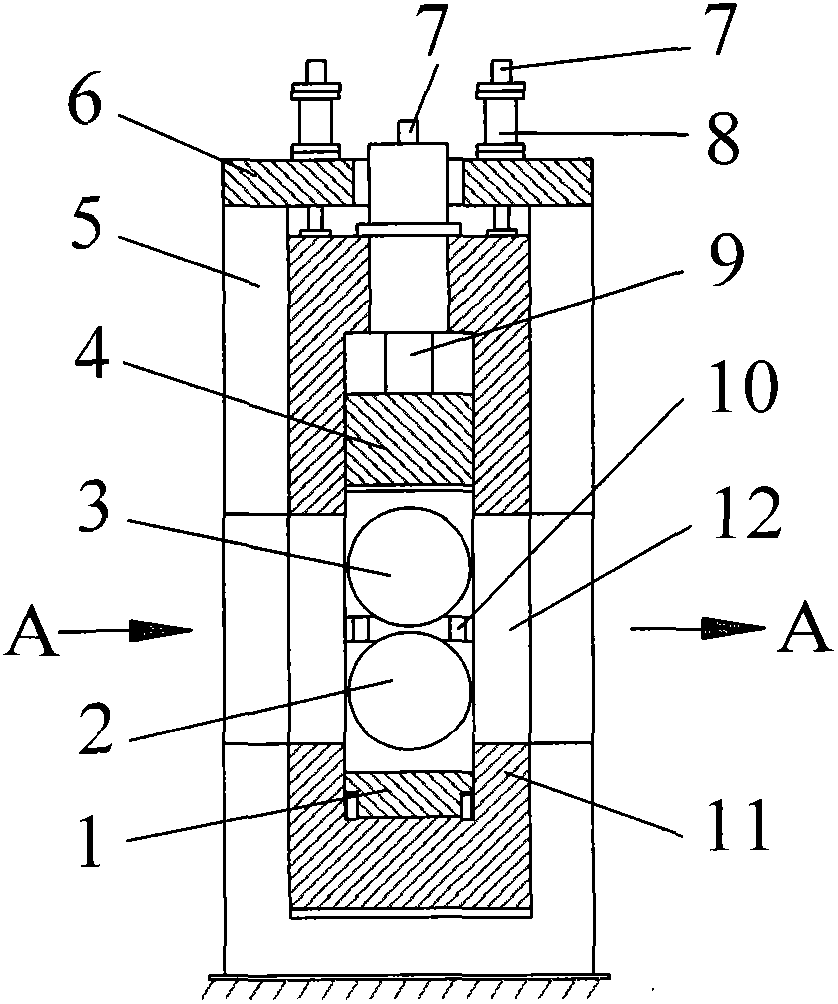

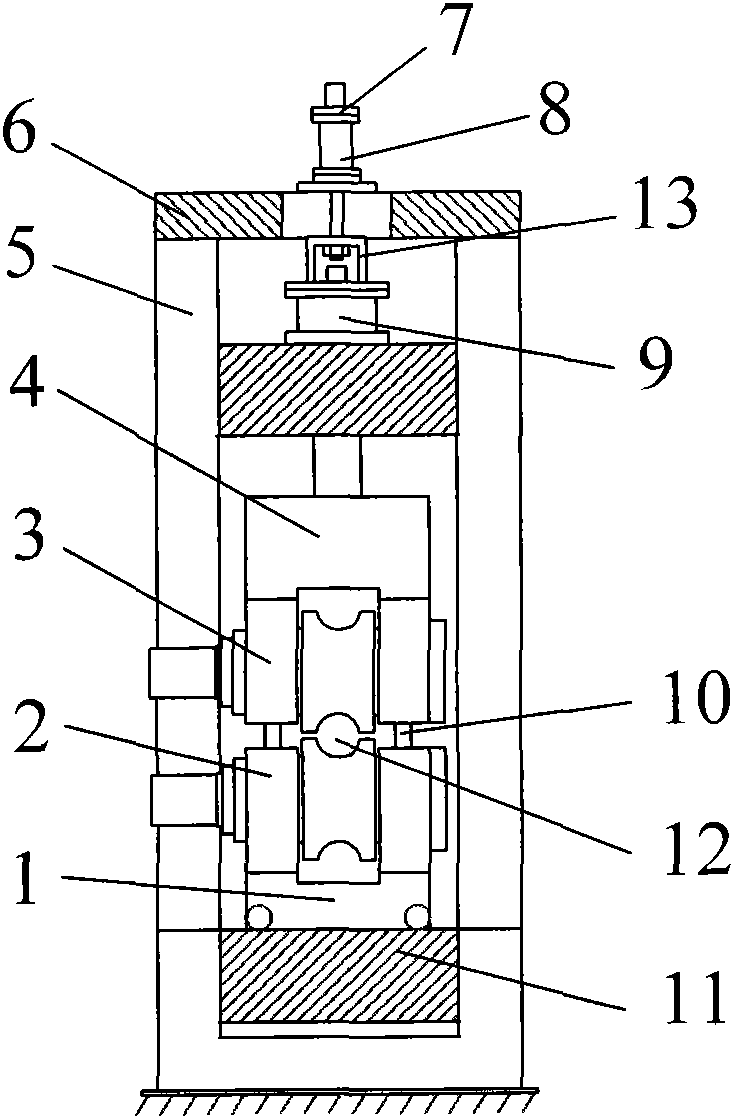

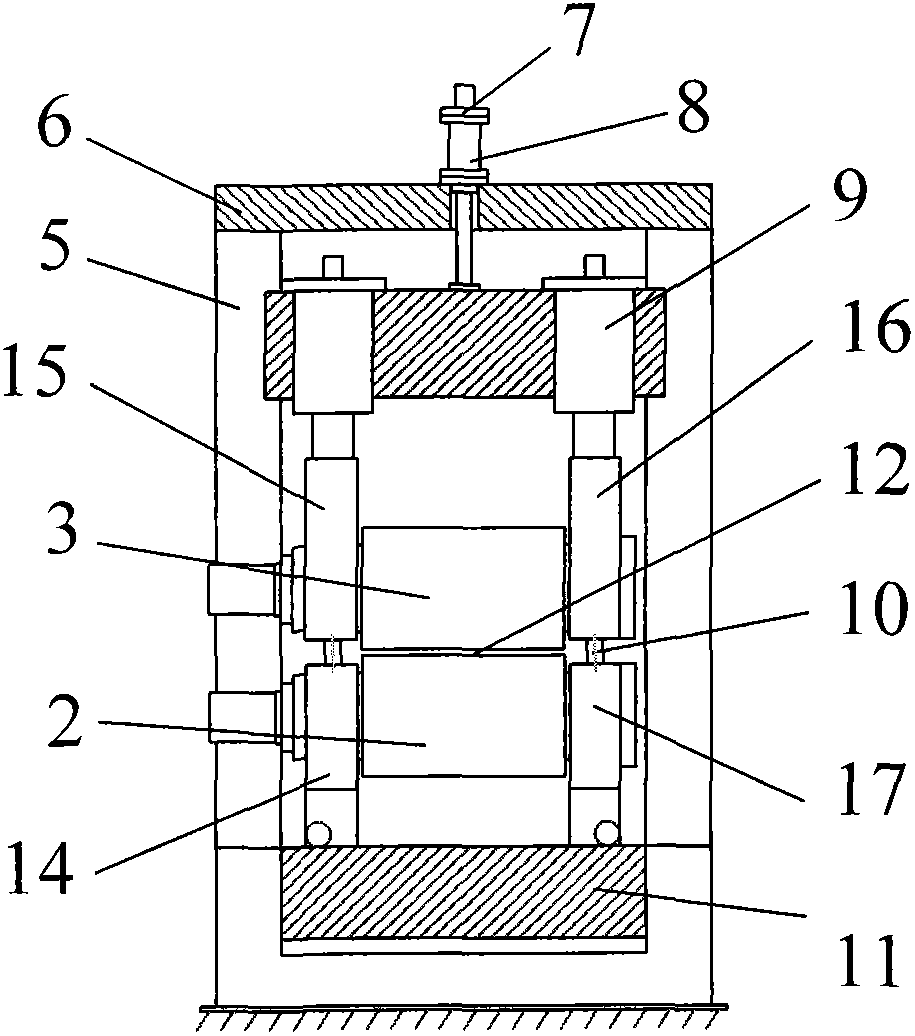

Two-roll horizontal mill

ActiveCN102581010AThe position of the center of the roll gap remains unchangedRealize gap adjustmentMetal rolling stand detailsMetal rolling arrangementsStrip millEngineering

The invention discloses a two-roll horizontal mill, which comprises a mill base, a mill frame, an upper roller and a lower roller (3, 2) and a roller gap adjusting mechanism, wherein the upper roller and the lower roller (3, 2) are arranged in the mill frame and are parallel to each other. The two-roll horizontal mill is characterized in that four angles at the upper end of the mill base are provided with an upright post respectively; the mill frame is a floating frame (11) and is positioned among the four upright posts; the upper end part of each upright post is provided with a roller gap centering mechanism for controlling the floating frame (11) to vertically move relative to the upright posts; and a lower roller bearing block (1) is arranged on a lower crossbeam of the floating frame (11). When a gap between two rollers is adjusted, the roller gap between the two rollers can be automatically centered. The equipment is simplified, low in manufacturing cost, convenient to maintain and high in operating rate and can be used for continuously rolling rectangular steel, pipes, bars and sections.

Owner:BEIJING JINGCHENG RUIXINCHANGCAI ENG TECH

Heat accumulation-exchange type heating stove and heating method thereof

InactiveCN101196369AExtend your lifeImprove work rateFurnace typesIncreasing energy efficiencyCombustionFlue gas

The invention provides a regenerative-recuperative combined heating furnace and the heating means, which relate to the technology field of industrial heating and recovery of waste heat. The invention is characterized in that: a regenerator and a heat exchanger are provided at the same time in the system; a soaking zone and a heating zone are arranged in front of the heating furnace; a preheating zone is provided on the tail of the heating furnace; multi-zone (point) heating system of the soaking zone, heating zone and preheating zone is adopted, the front of the heating furnace adopts regenerative combustion method and the back adopts recuperative combustion method; the preheating zone directly adopts flue gas waste heat to heat the materials. The objectives of the invention are to realize maximization of the heating furnace and smooth control of the furnace pressure, overcome the defects of the regenerative-recuperative heating furnaces and flue gas waste heat recovery technology and facilitate the low heat value fuels like pure blast furnace gas being applied in the heating furnace. The heating furnace has smooth pressure and long service life. The implementation of the invention realizes the maximization of the heating furnace, improves the flue gas waste heat utilization rate and reaches the aims of improving the pressure condition in the furnace, reducing air draft and sparking and energy conservation and emission reduction, etc.

Owner:蔡九菊

Zinc leaching slag treatment device and treatment process

The invention discloses a zinc leaching slag treatment device and a zinc leaching slag treatment process using the same. The zinc leaching slag treatment device comprises a primary side-blown converter and a secondary side-blown converter, wherein the primary side-blown converter is used for smelting zinc leaching slag, and provided with a first furnace body and a first side-blown spray gun for blowing oxygen-containing gas and fuel into the first furnace body; and the secondary side-blown converter is used for smelting molten slag generated by the primary side-blown converter, and provided with a second furnace body connected with the first furnace body through a hot slag chute, and a second side-blown spray gun for blowing oxygen-containing gas and fuel into the second furnace body. The zinc leaching slag treatment device and the zinc leaching slag treatment process using the same have the advantages of low energy consumption, low production cost and high recovery rate of zinc, lead, silver and dissipated metals, and can improve the operating environment.

Owner:CHINA ENFI ENGINEERING CORPORATION +1

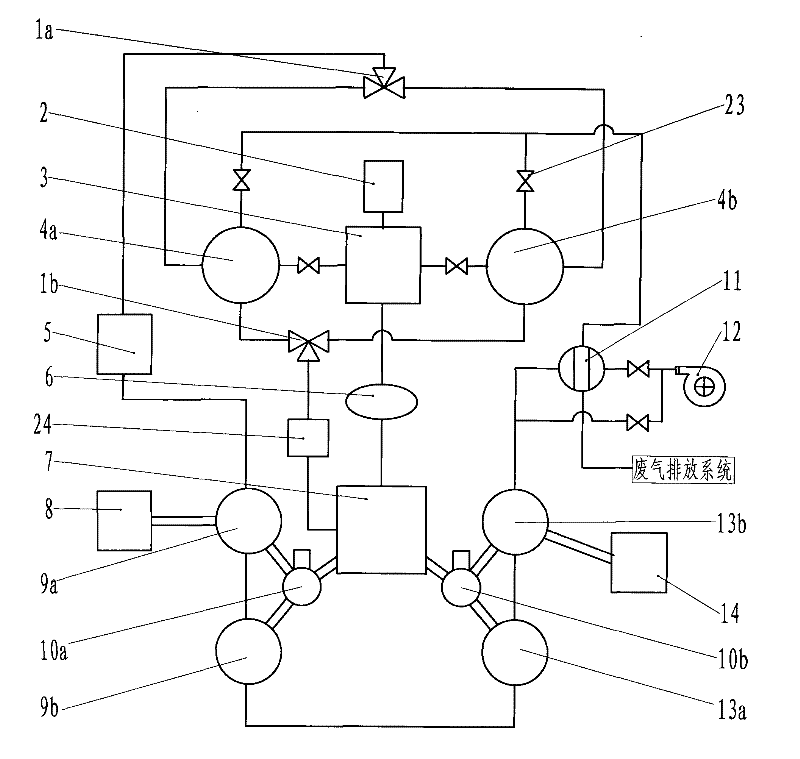

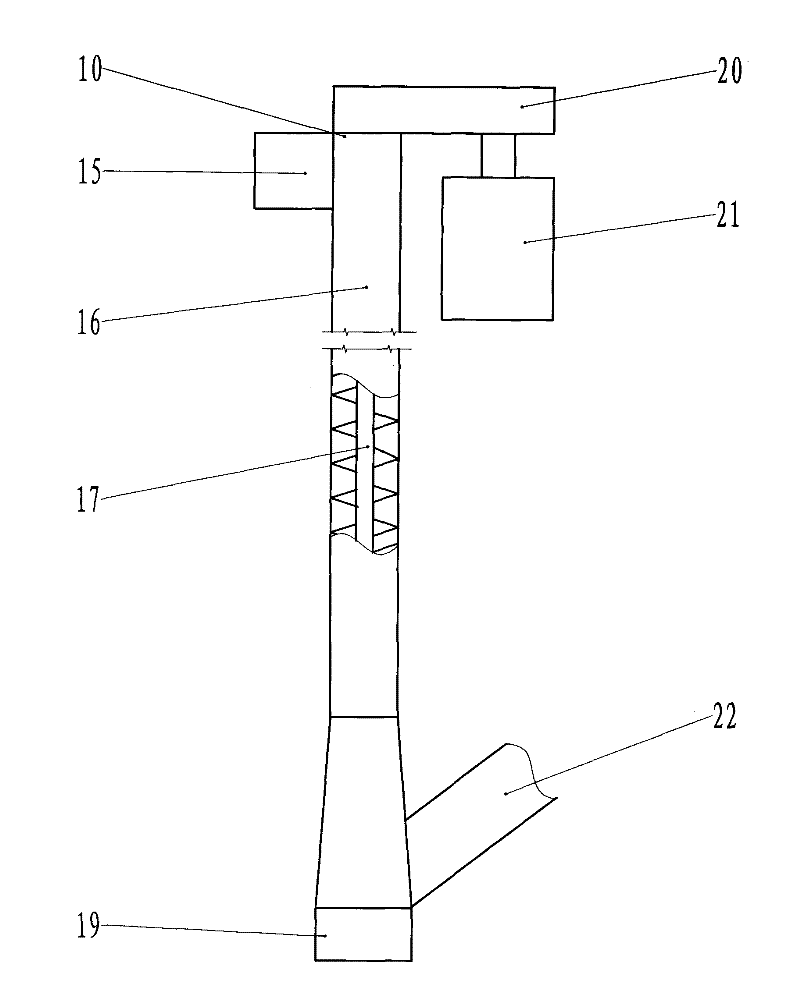

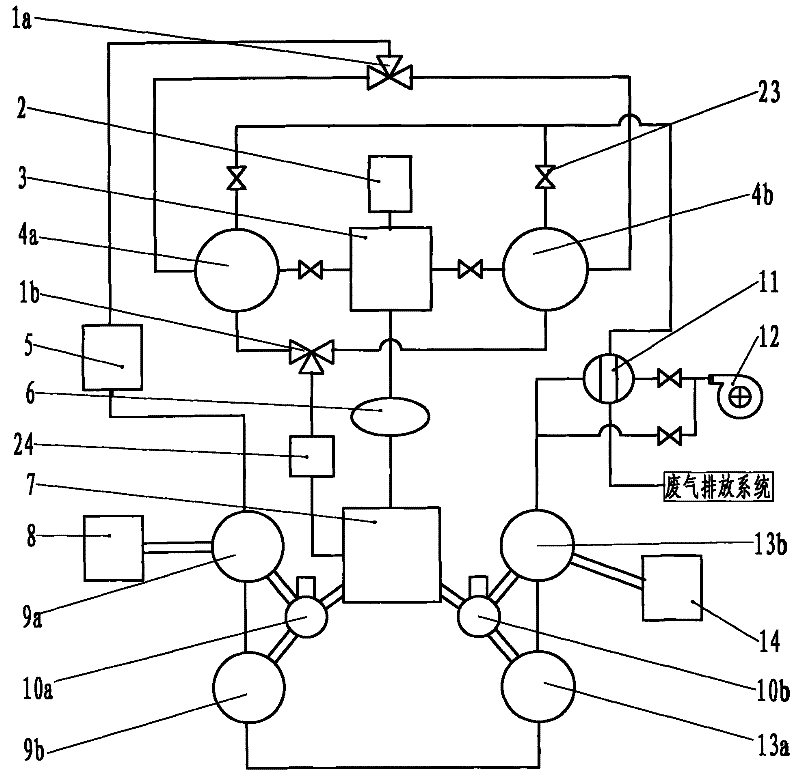

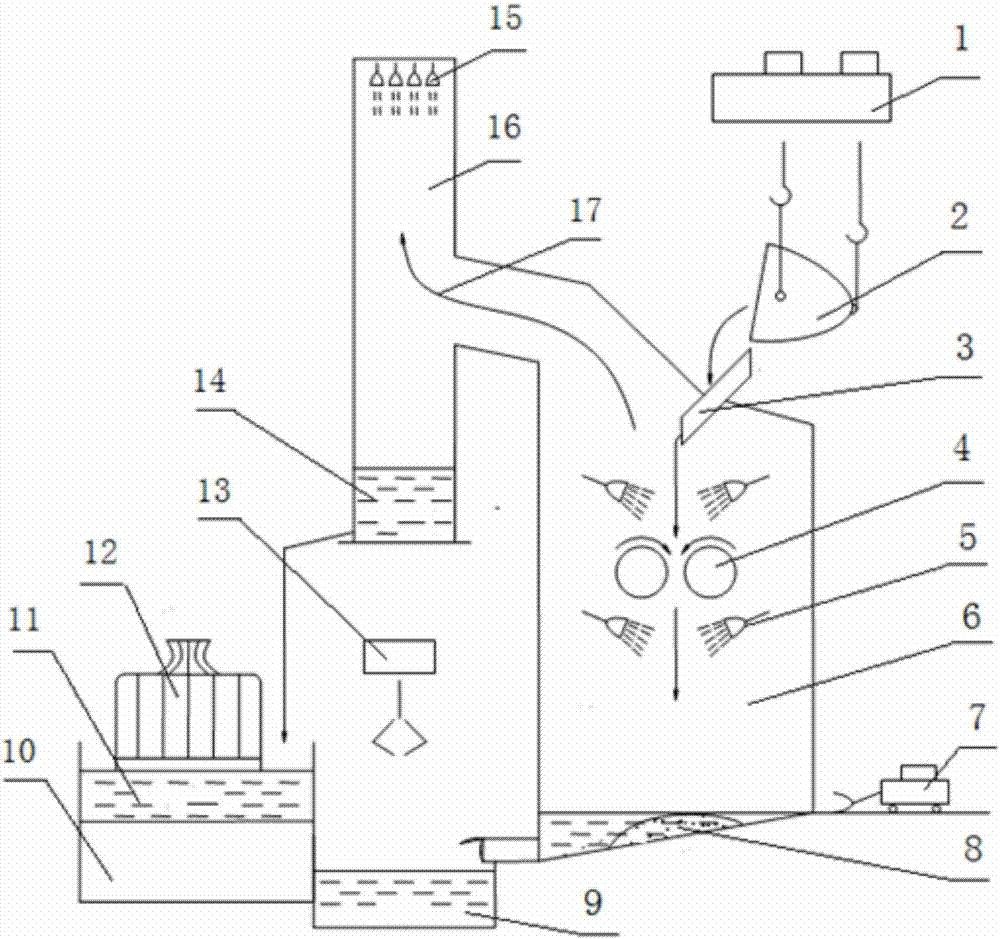

Method and device for calcining materials

The invention provides a method and a device for calcining materials. The device has a splitting type structure comprises a burning chamber, preheating chambers, a calcining chamber, cooling chambers, a heat accumulator, a gas processing unit, a material conveying machine, a feed device, a discharge device and an exhaust gas discharging system. Material to be calcined is conveyed by the material conveying machine between the preheating chambers, between the preheating chambers and the calcining chamber, between the calcining chamber and the cooling chamber and between the cooling chambers. Smoke generated by the burning in the external burning chamber is processed by the gas processing unit, and then enters the burning chamber for calcining the material. Air for cooling lime and preheating limestone material is subject to dust removing by a cyclone separator and is preheated by the heat accumulator, and then enters the burning chamber for supporting combustion. In the invention, the fuel burning and the material calcining are separated, so that the pollution of lime products caused by harmful substances can be avoided, and the quality of the lime product can be improved. The gas is subject to dust removing and then enters the heat accumulator, thus avoiding blocking a gas channel in the heat accumulator. The material conveying machine is used for conveying the material, so that the conveying efficiency is high, and the occupied space is small.

Owner:SHIJIAZHUANG XINHUA IND FURNACE CO LTD

Converter steel slag treatment device and method

ActiveCN107287368AEasy to separateReduce moisture contentRecycling and recovery technologiesCooling towerSlag

The invention relates to a converter steel slag treatment device which comprises a crown block, a slag ladle, a chute, a forklift, a steel slag pool, a bottom filtering pool, a water pump house, a water storage tank, a cooling tower, a bridge-type grab crane, a chimney, a hydraulic roller couple, nozzles, a granulating room and a condensate water tank, wherein a lifting hook of the crown block is connected with the slag ladle, the outlet of the slag ladle is connected with the inlet of the chute, and the outlet of the chute is connected with the upper part of the hydraulic roller couple; nozzles a are symmetrically arranged on the two sides of the upper part and the two sides of the lower part of the hydraulic roller couple, and the hydraulic roller couple and the nozzles a are all arranged in the granulating room; the steel slag pool is arranged at the lower part of the granulating room, and the forklift is arranged on the outer side of the lower part of the granulating room. The invention further discloses a converter steel slag treatment method. The flow of the method is as follows: steel slag dumping, steel slag crushing, steel slag granulating, slag washing water filtering and vapor condensation recovery. The converter steel slag treatment device has the advantages of high slag treatment efficiency, compact occupied area, energy conservation, environment protection and no pollution, adapts the fast-paced production mode of a converter, is good for magnetic separation extracting of grain steel and comprehensive application of grain slag, and has remarkable economical benefit.

Owner:北京中冶设备研究设计总院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com