Process for manufacturing hot rolled steel strips by continuous casting and rolling middle bar strip

A technology of medium-thin slab continuous casting and hot-rolled strip steel, which is applied in heat treatment furnaces, metal rolling, heat treatment equipment, etc., can solve the problems of increased production cost of electricity, increased investment, and long buffer time, and achieve stable and consistent product performance , Large production capacity of the rolling mill, small temperature difference between the head and the tail of the steel strip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

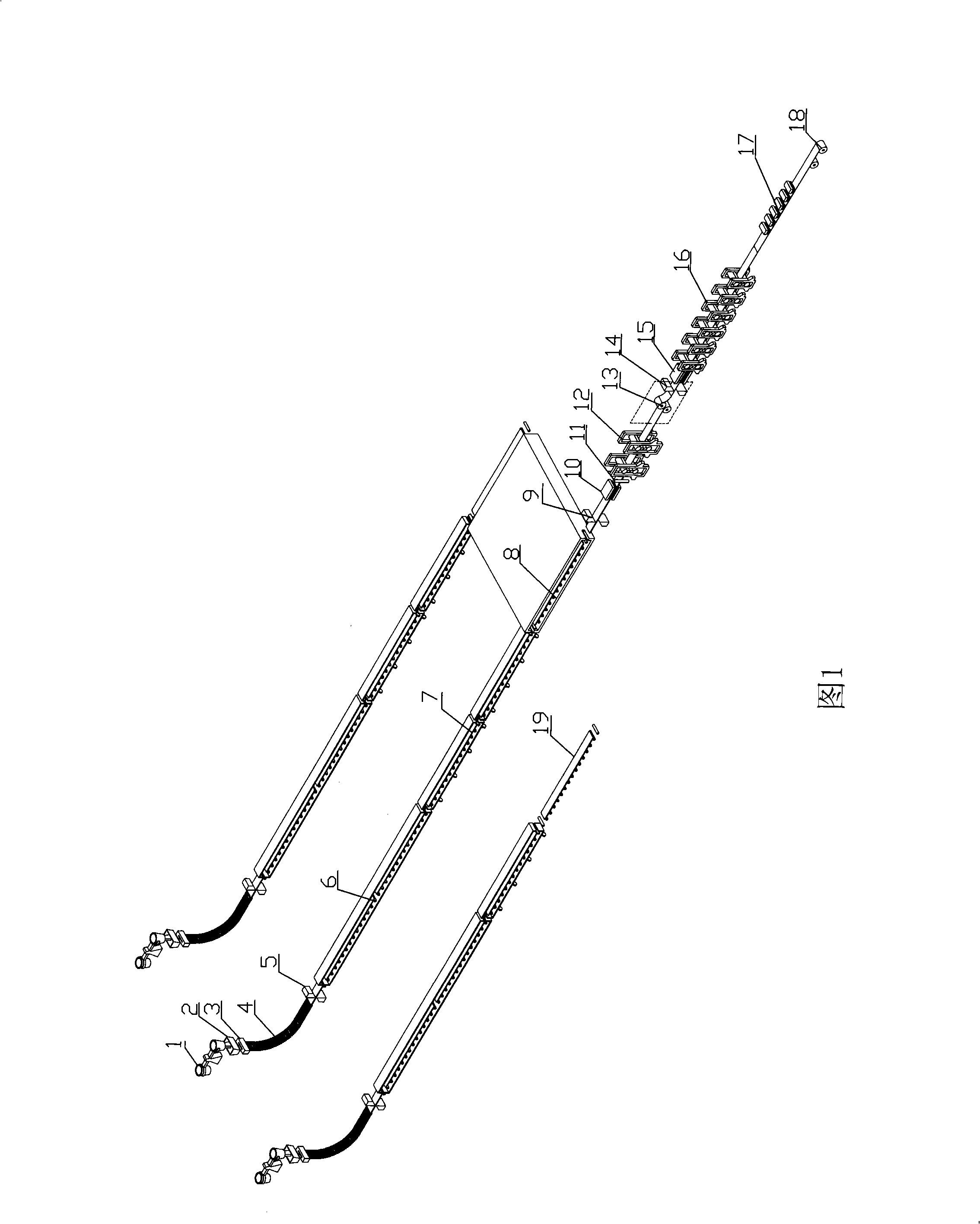

[0050] Fig. 1 shows the schematic diagram of the first preferred embodiment of the present invention, that is, the production line of hot-rolled strip produced by continuous casting and rolling of thin slabs from three-strand casting machines to a group of rolling mills at the same time. Wherein, the swinging section 7 behind the continuous casting machine 4 allows other strands and slabs to flow into the rolling line, sharing the rolling equipment in the subsequent step.

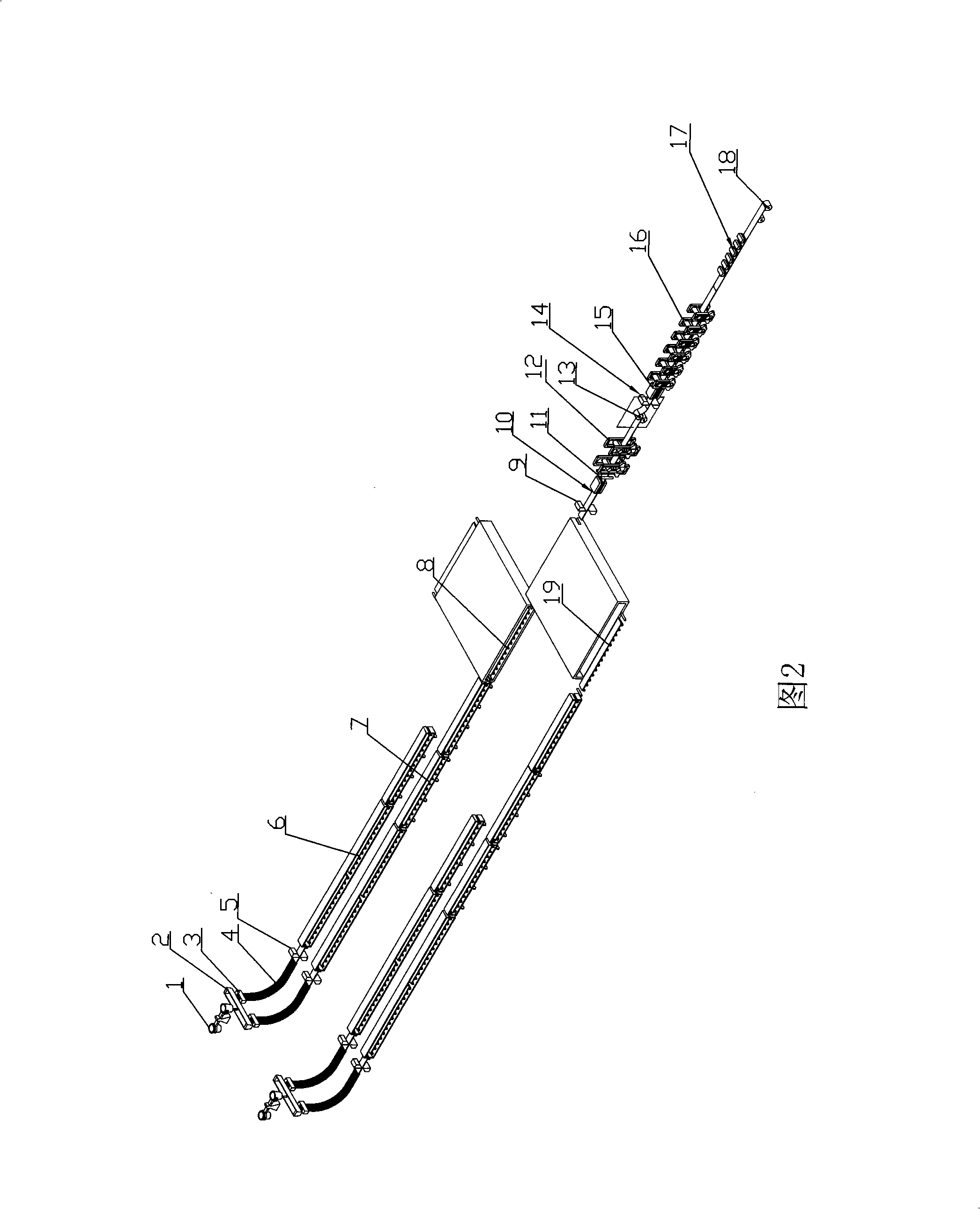

[0051] Fig. 2 shows the schematic diagram of the second preferred embodiment of the present invention, that is, the four-strand casting machine simultaneously feeds billets to a group of rolling mills to produce hot-rolled strip steel by continuous casting and rolling of thin slabs. Wherein, the two strands share one swing section 7, so that the other first strand cast slabs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com