Patents

Literature

45results about How to "Small thickness tolerance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

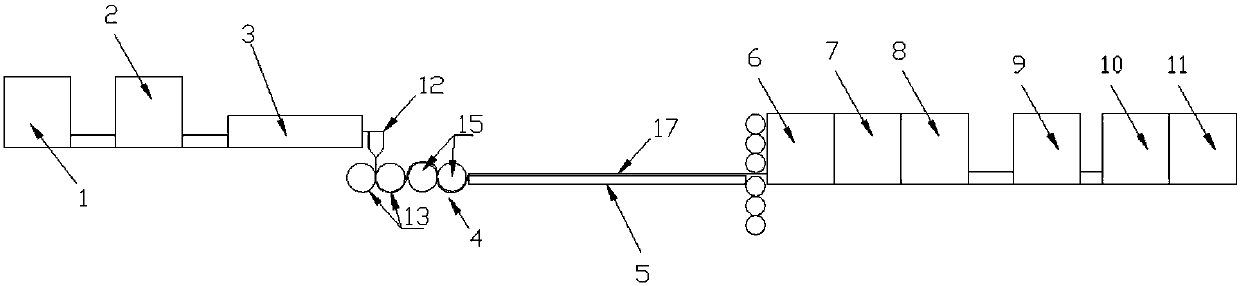

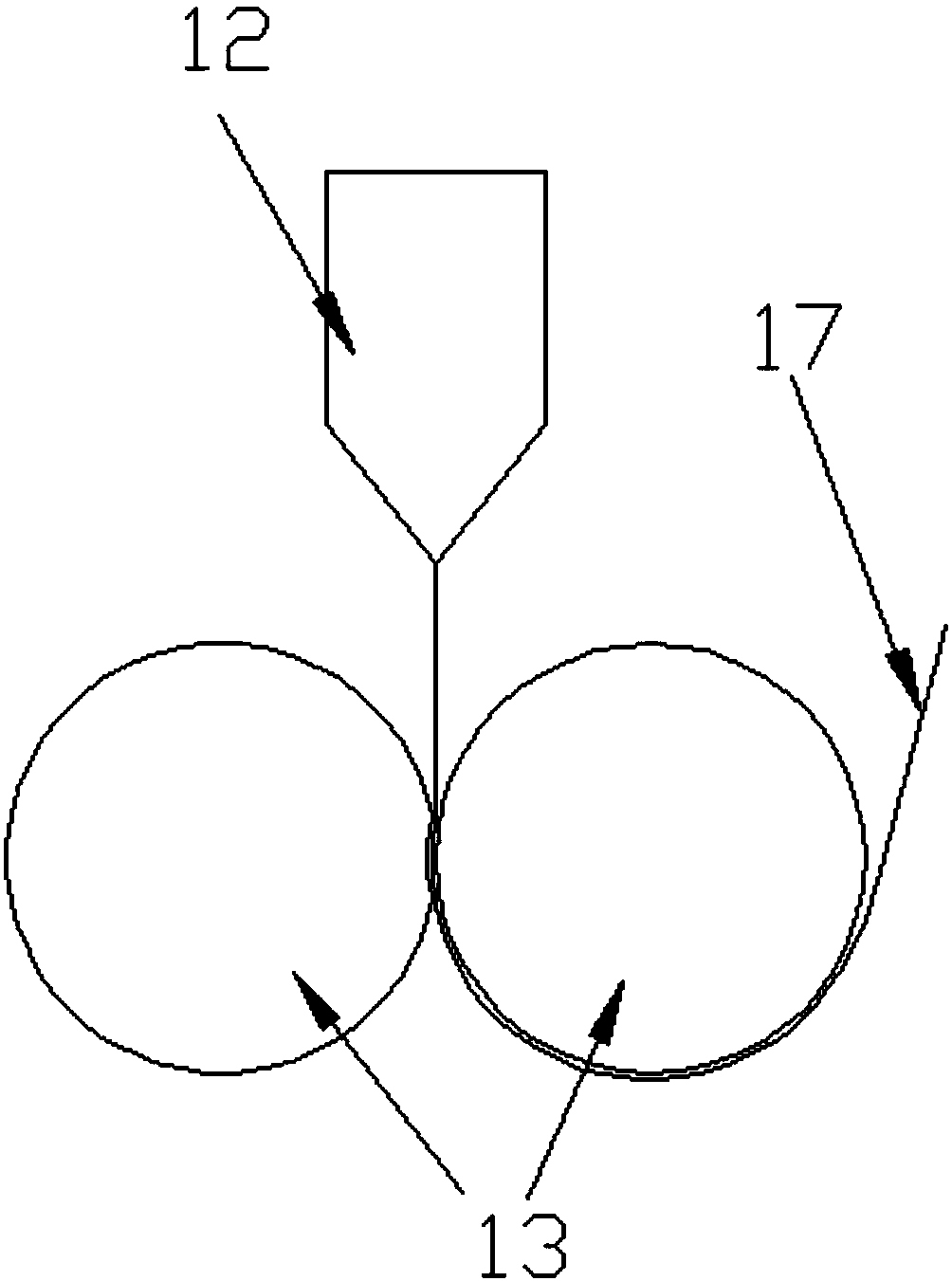

Process for manufacturing hot rolled steel strips by using compaction type continuous casting and rolling technique

InactiveCN101293257AEasy to produceIncrease production capacityFurnace typesHeat treatment process controlProduction lineStrip mill

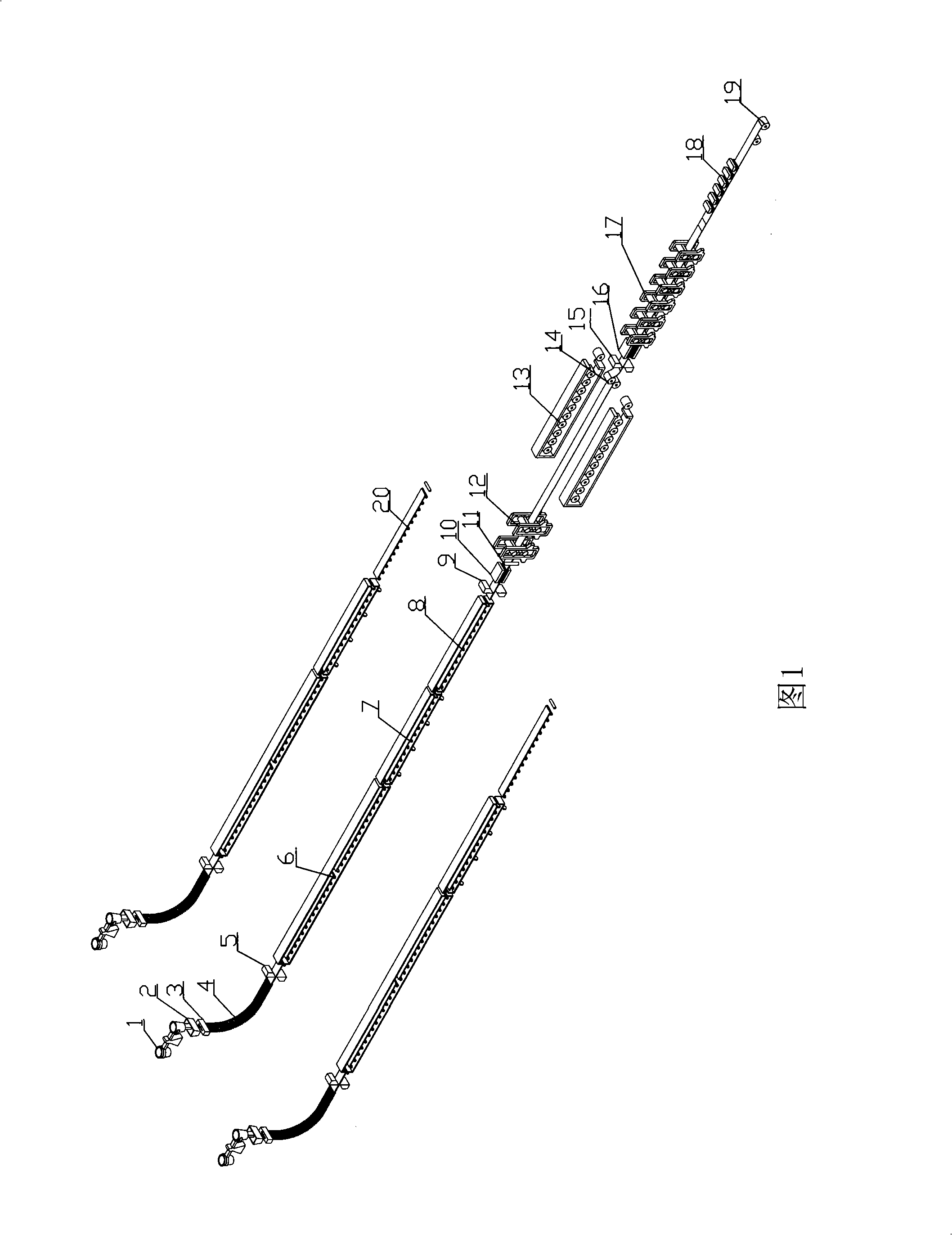

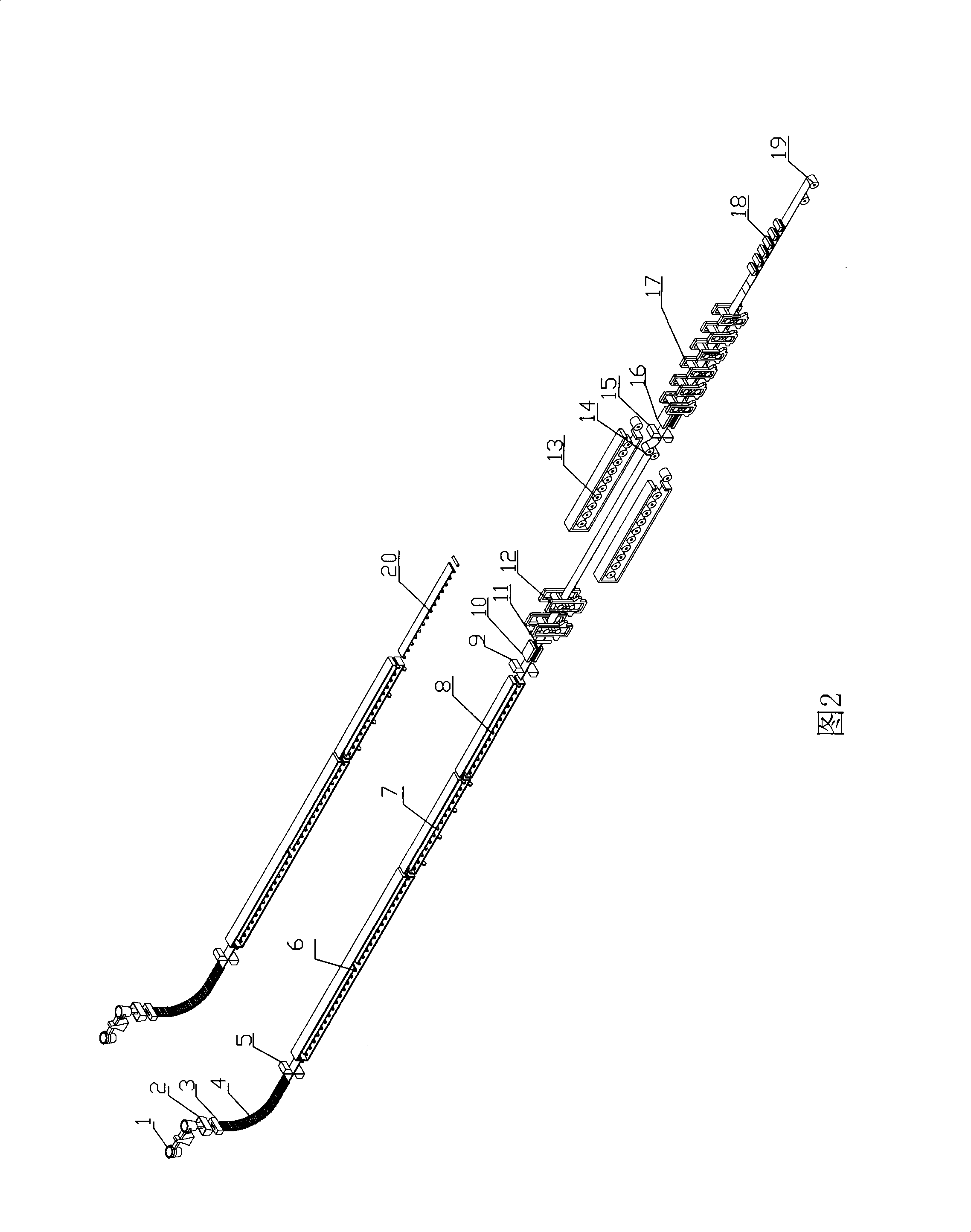

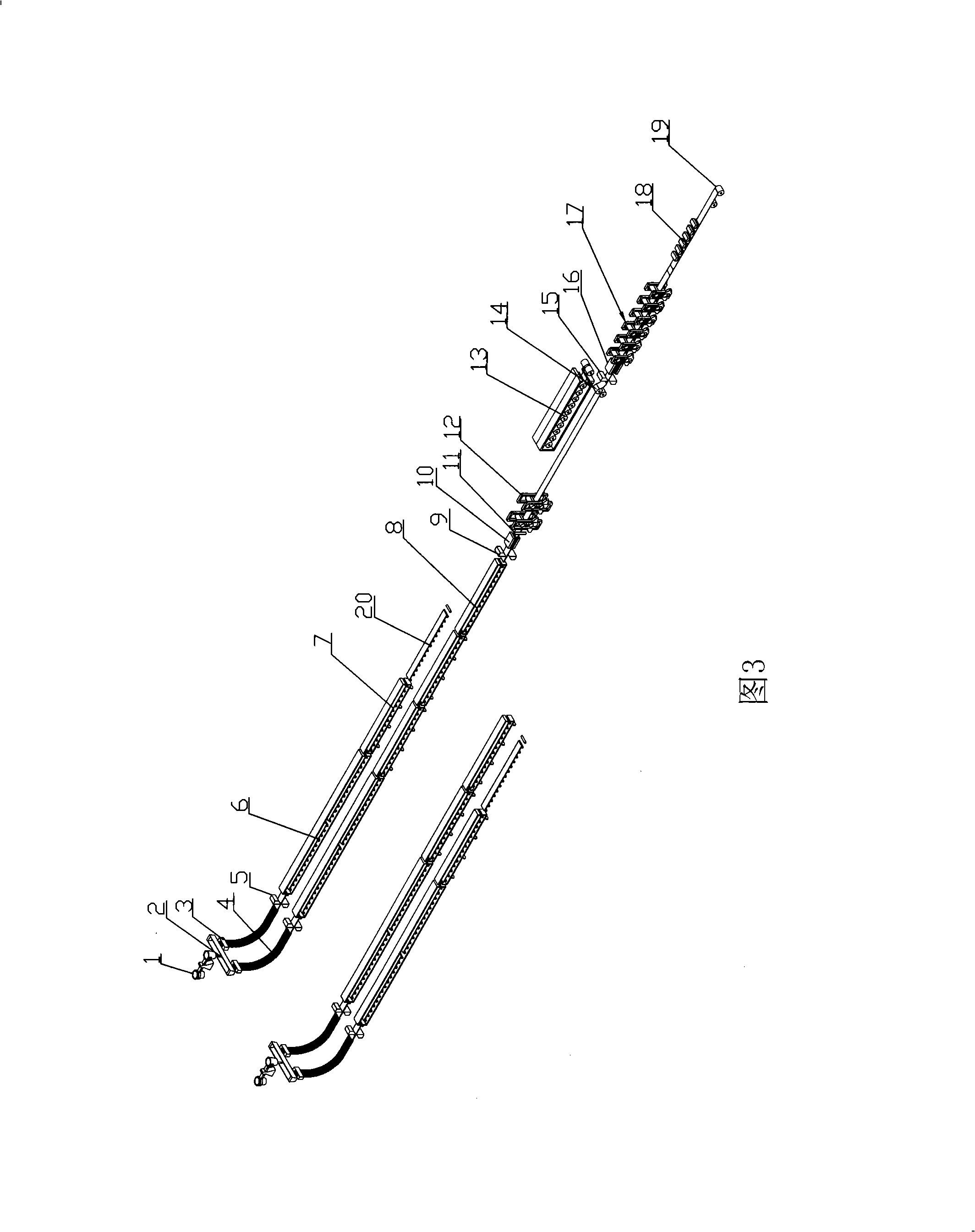

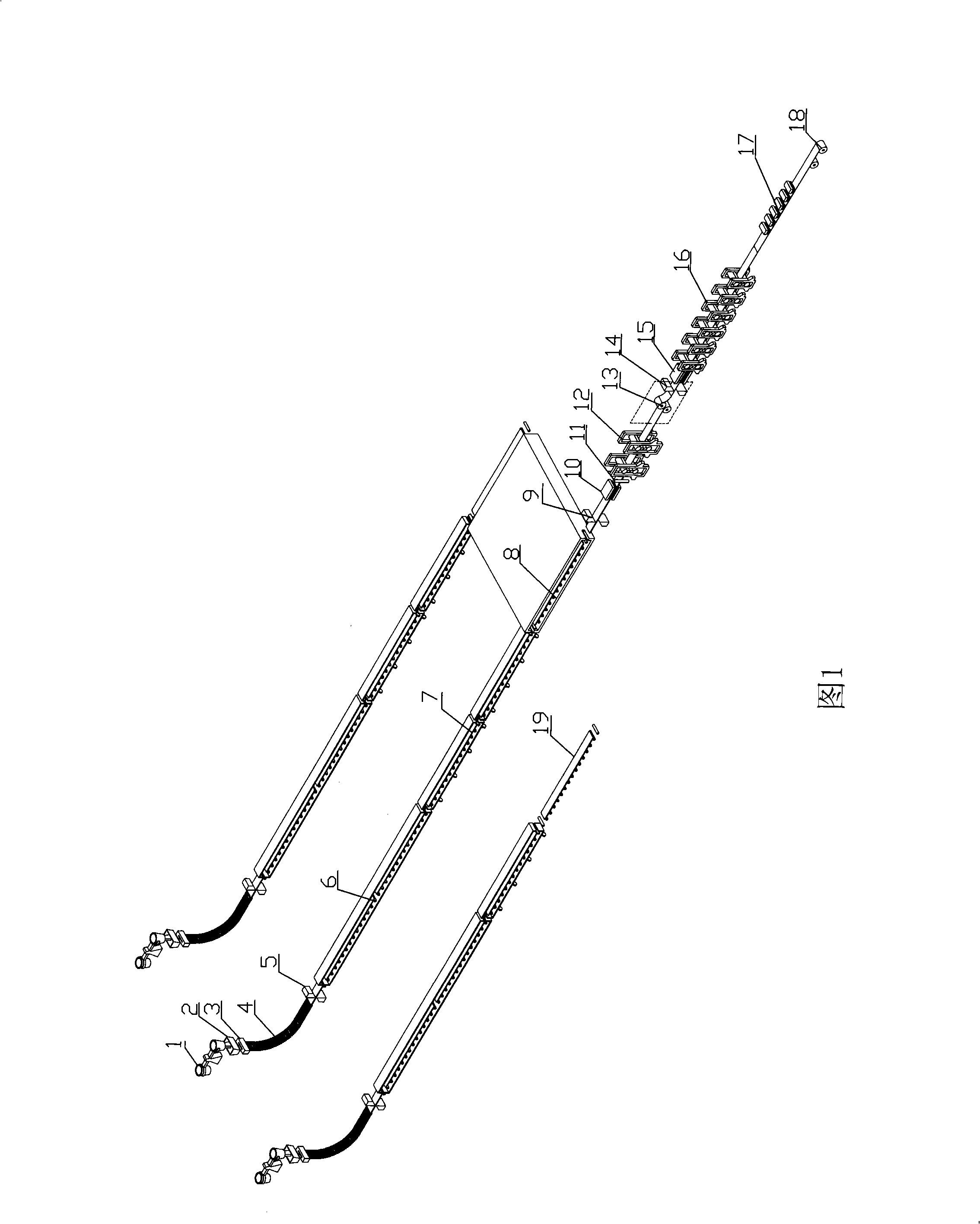

The invention discloses a compact continuous casting and tandem rolling method for producing hot rolling strip steel, including the following steps: 1) liquid molten steel passes through a long nozzle from a ladle to be cast to a pouring box, flows through a submerged nozzle from the pouring box to be cast in a crystallizer of a continuous caster and is continuously cooled in the continuous caster to form a casting blank; 2) a shearing machine is used for cutting a flat blank into certain size; 3) the flat blank enters a tunnel roller hearth heating furnace for heating; 4) the continuous caster is provided with a plurality of casting flows, one of which is in collineation with a rolling mill, the casting blank of other flows passes through a swinging section and is converged with the casting blank of the collinear flow and then is descaled by high pressure water; 5) the casting blank carries out rough rolling into an intermediate blank by a roughing mill group; 6) the intermediate blank is coiled and decoiled by a hot coiling box; 7) the head and the tail of the decoiled intermediate blank are cut and descaling by high pressure water is carried out to the decoiled intermediate blank; 8) the intermediate blank carries out finish rolling into a steel strip with standard thickness; 9) the steel strip is coiled into a finished steel coil by laminar flow cooling. The method is characterized by stable production technique, shorter production line, low equipment investment and high utilization rate of energy in the whole production process, etc.

Owner:BAOSHAN IRON & STEEL CO LTD

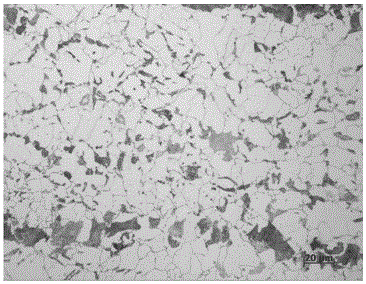

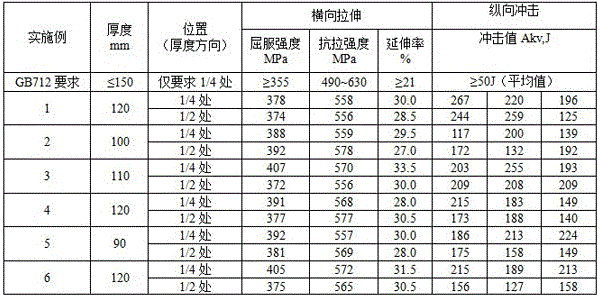

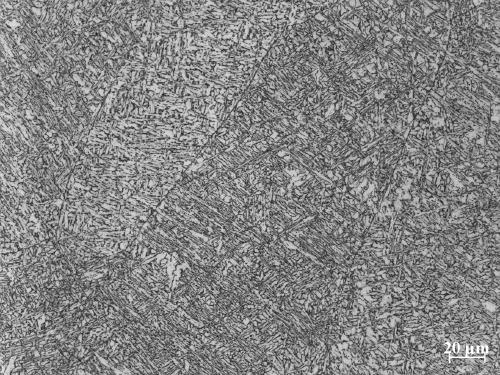

Super-thick EH36 steel for offshore wind power pipe pile and preparation method thereof

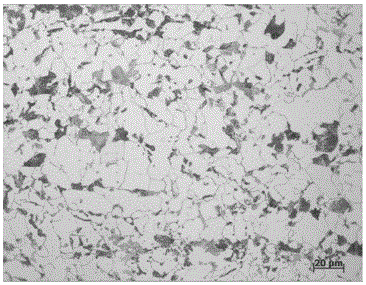

The invention relates to super-thick EH36 steel for an offshore wind power pipe pile. The super-thick EH36 steel for the offshore wind power pipe pile comprises the following chemical components in percentage by mass: .015 to 0.18 percent of C, 0.15 to 0.30 percent of Si, 1.40 to 1.60 percent of Mn, less than or equal to 0.0070 percent of P, less than or equal to 0.0030 percent of S, 0.050 to 0.070 percent of Nb, 0.015 to 0.030 percent of V, 0.08 to 0.020 percent of Ti, 0.030 to 0.050 percent of Al, 0.15 to 0.40 percent of Ni, 0.10 to 0.20 percent of Cr, and the balance of Fe. A production process flow comprises the following steps: performing converter operation, performing LF refining, performing vacuum degasifying, performing Ca treatment, performing continuous casting, dehydrogenizing, rolling, performing air cooling, performing high-temperature hot straightening, and normalizing. According to the production process flow, the super-thick EH36 steel of 90 to 120 mm for the offshore wind power pipe pile, which is high in unit weight, high in strength, high in impact toughness, small in thickness tolerance and high in straightness and does not have a surface defect is obtained.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Process for manufacturing hot rolled steel strips by continuous casting and rolling middle bar strip

ActiveCN101293258AEasy to produceSmall temperature differenceFurnace typesHeat treatment process controlHigh pressure waterHearth

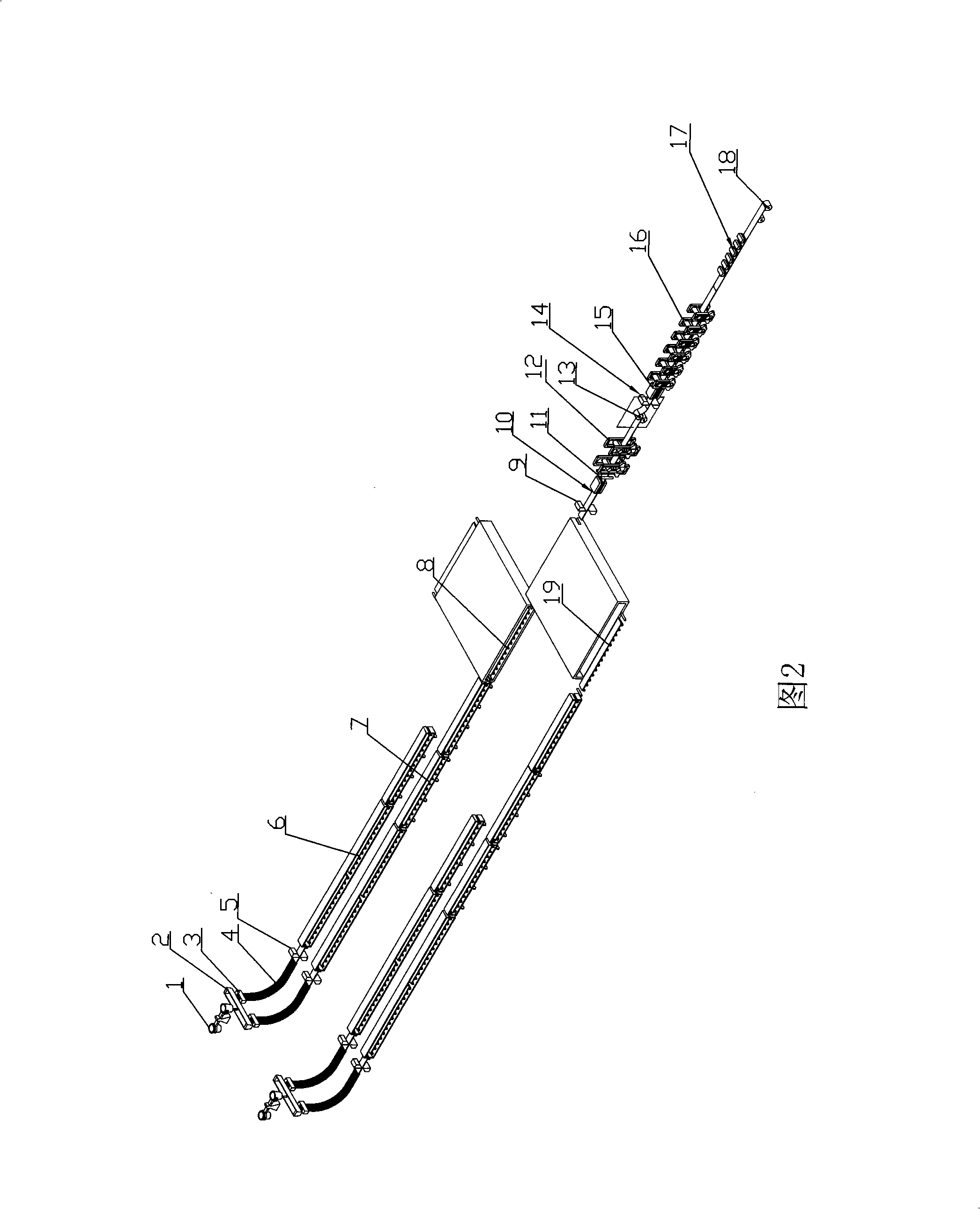

The invention discloses a continuous casting and tandem rolling method for producing hot rolling strip steel by using medium sheet billet, including the following steps: 1) liquid molten steel passes through a long nozzle from a ladle to be cast to a pouring box, flows through a submerged nozzle from the pouring box to be cast in a crystallizer of a continuous caster and is continuously cooled in the continuous caster to form a casting blank; 2) the casting blank enters a short tunnel roller hearth type heating furnace for heating; 3) a technology of converging a plurality of casting flows is adopted, one of the casting flows is in collineation with a rolling mill, the casting blank of other flows passes through a swinging section and is converged with the casting blank of the collinear flow, then passes through a walking beam and a holding zone of the roller hearth complex type heating furnace which is provided with a roller way and finally enters high pressure water for descaling; 4) the casting blank is prepared into an intermediate blank by rough rolling; 6) the intermediate blank carries out finish rolling into a steel strip with standard thickness; 7) the steel strip is cooled and coiled into the finished steel coil. The method can reduce investment, save energy resource, improve the quality of products, expand the varieties of the products and lower production cost.

Owner:BAOSHAN IRON & STEEL CO LTD

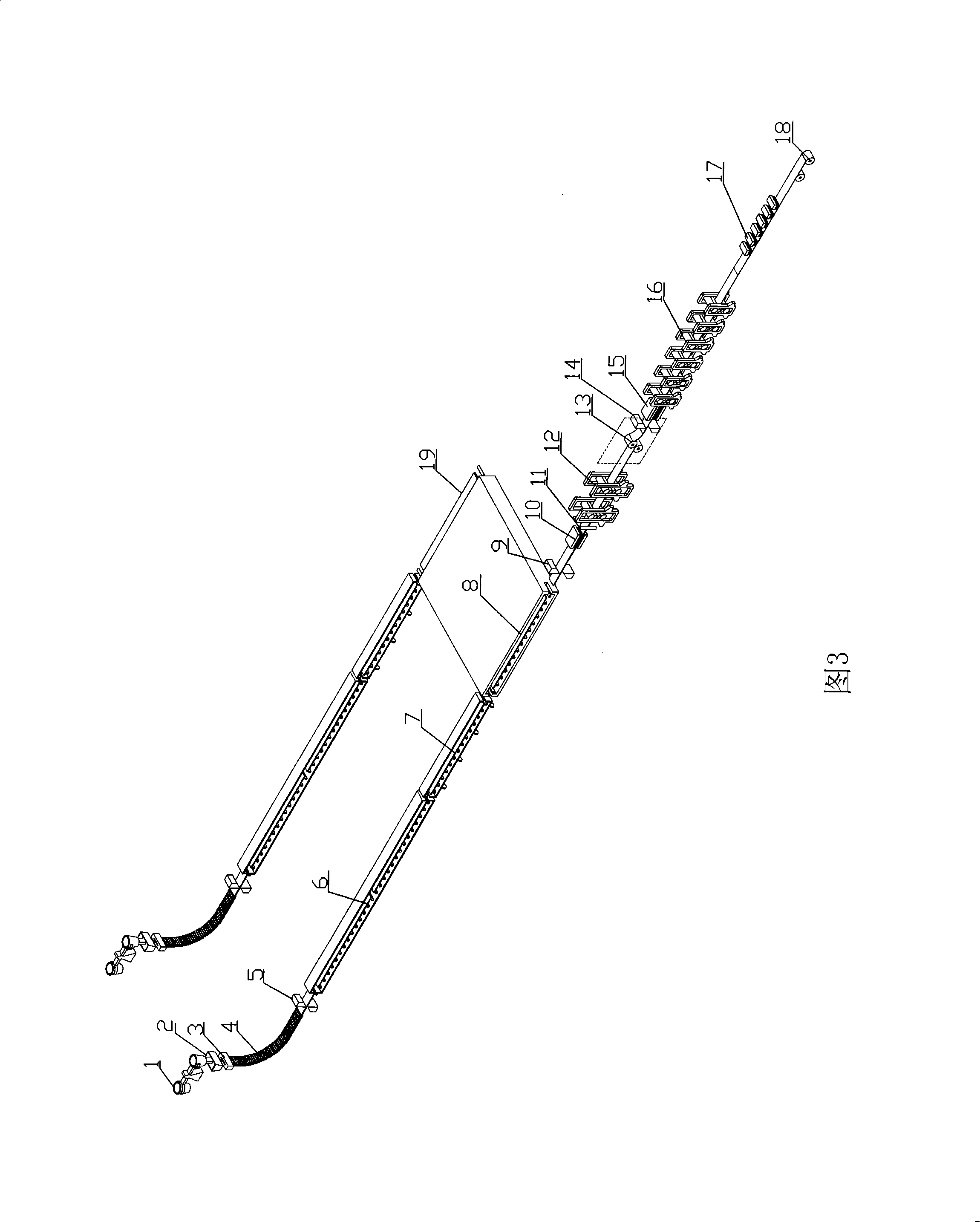

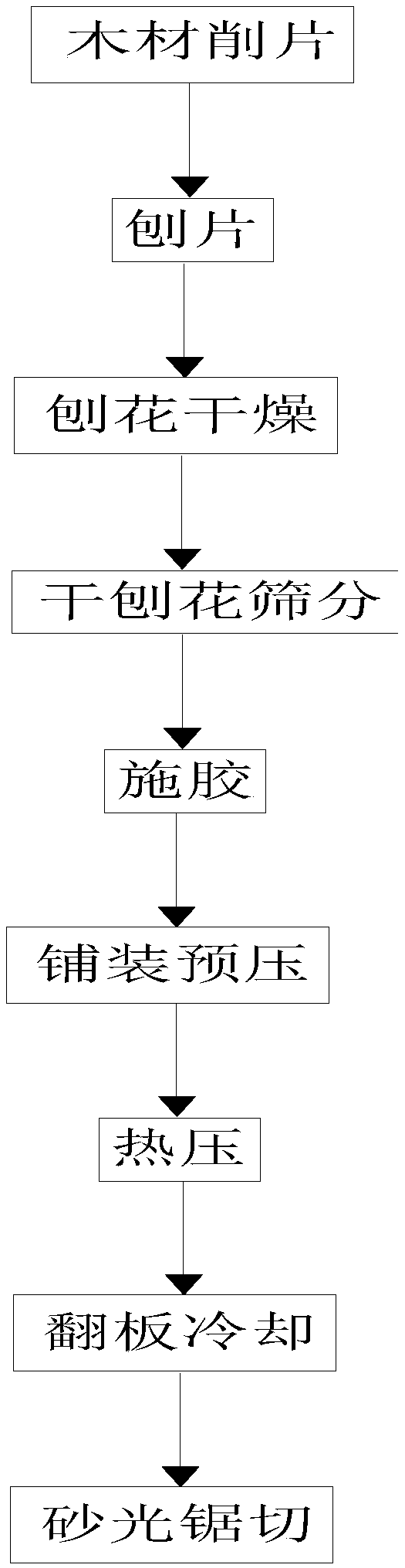

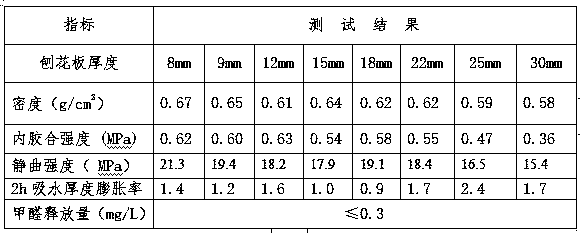

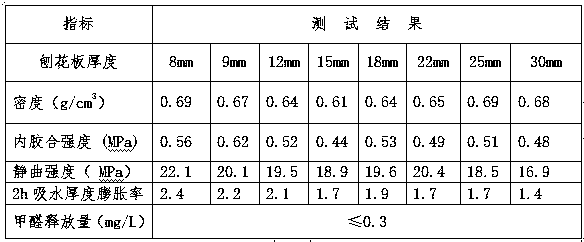

Ultra-strength shaving board manufacturing technology changing morphological structure of wood shavings

InactiveCN109624016ALess squeezeAvoid secondary damageFlat articlesDomestic articlesWood shavingsManufacturing technology

The invention relates to the technical field of artificial plate manufacturing, in particular to an ultra-strength shaving board manufacturing technology changing morphological structure of wood shavings. The ultra-strength shaving board manufacturing technology comprises the processes of wood chipping, flaking, drying, sieving, glue applying, paving and pre-pressing, hot-pressing, board reversingand cooling, sanding and saw cutting, testing and classifying, warehousing and packaging and the like. The quality performance of an ultra-strength shaving board produced and manufactured by the ultra-strength shaving board manufacturing technology is far better than the standards of an European oriented strand board in 'EN300: 2006-OSB' and 'T / CTWPDA03-2017 veneer shaving board', and the strength of the ultra-strength shaving board even reaches the strength level of a hipboard or plywood; the ultra-strength shaving board has the outstanding features of highest mechanical strength compared with a plate with the same density, lowest density compared with a plate with the same strength, and material saving, and the mechanical strength performance of the ultra-strength shaving board is improved greatly due to the fact that the product structure is uniform and compact; and the advantages of a stable size, non-deformation, small thickness tolerance and the like are realized, and the transformation and upgrading of the artificial board industry, especially shaving board industry are facilitated greatly.

Owner:GUANGXI FENGLIN WOOD IND GRP CO LTD

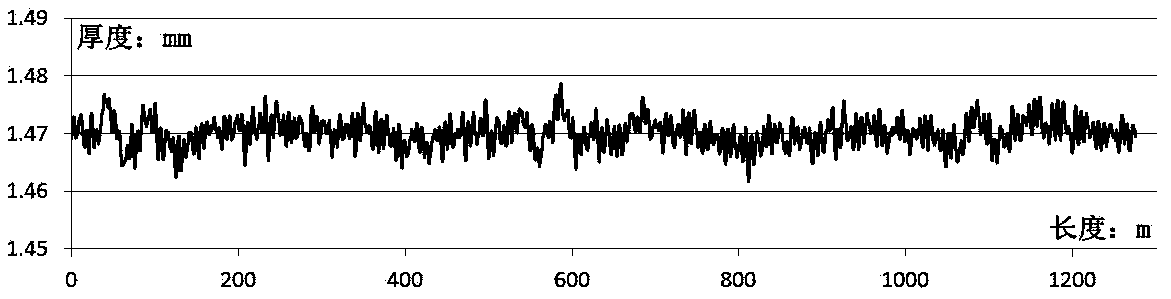

Preparation technology of PET/PETG shrink film

The invention discloses a preparation technology of a PET / PETG shrink film, comprising: 1. drying treatment: drying copolyester slices at the temperature of 65-75 DEG C; 2. melt extrusion: mixing the dried copolyester with functional master batch / functional accessory ingredient, and adding into a single screw extruder to carry out melt extrusion; 3. die head / casting strip quenching: after a melt extruded fusant enters a hanger-type die head by a fusant metering pump, a filter and a fusant pipeline, casting to a cooler drum via a die lip mouth to form the casting strip; 4. unilateral stretching: stretching the casting strip processed in the last step; and 5. rolling and slitting: measuring the thickness of the unilateral stretched film on line, dragging, and rolling; and finally, slitting, checking and packaging to obtain the film product. The product produced by the method has high transparency, good mechanical behavior, high output, high cooling speed and high production efficiency, and the tolerance of the thickness thereof is smaller than that of a blown film.

Owner:JIANGSU SHUANGXING COLOR PLASTIC NEW MATERIALS

Environment-friendly ecological board and production process thereof

InactiveCN105291207AHigh glossImprove flatnessWood veneer joiningWood layered productsWater basedEnvironmental resistance

The invention provides an environment-friendly ecological board and a production process thereof. The production process comprises: performing hot-press gluing on one side of an artificial board and impregnated bond paper into an impregnated bond paper decorative artificial board, and cooling the impregnated bond paper decorative artificial board till a room temperature for later use, wherein hot pressing is performed for 5-15 minutes at a temperature ranging from 100 to 150 DEG C and under a pressure ranging from 0.3 to 1.5MPa; coating both sides of a substrate with a cold-pressing glue and performing cold pressing on the substrate and the obtained impregnated bond paper decorative artificial board, wherein the cold-pressing glue is a water-based isocyanate adhesive; cold pressing is performed for over 30 minutes under a pressure ranging from 0.1 to 1Mpa; relieving the pressure, and aging for 5 or more hours followed by cutting edges, thereby obtaining the finished environment-friendly ecological board. The invention provides the environment-friendly ecological board that is few in production steps and high in finished product yield and grade rate, and the production process thereof.

Owner:张建明

Plastic floor and preparation method thereof

InactiveCN107722491AImprove stabilitySmall thickness toleranceSynthetic resin layered productsLaminationWaxChemistry

The invention provides a plastic floor and a preparation method thereof. The plastic floor comprises a silencing layer, a stone-plastic substrate layer, a color film layer and a wear-resistant layer from bottom to top. The stone-plastic substrate layer is prepared from the following raw materials by weight: 50-65 parts of polyvinyl chloride, 100-120 parts of calcium carbonate, 6-9 parts of a calcium-zinc compound stabilizer, 0.7-0.8 part of stearic acid, 0.5-0.8 part of polyethylene wax, 3-5 parts of an acrylic polymer and 3-5 parts of chlorinated polyethylene. The stone-plastic substrate layer, the color film layer and the wear-resistant layer are subjected to hot-press molding together, and the stone-plastic substrate layer and the silencing layer are bonded by a hot-melt adhesive. The plastic floor of the invention adopts the stone-plastic substrate layer which does not include a plasticizer, so the stability of the plastic floor can be effectively improved and the thickness of theplastic floor can be more accurately controlled; and thus, a thin plastic floor can be more easily prepared. In addition, the silencing layer is arranged and has silencing effect, and good foot feeling can be obtained through reduction in the thickness of the plastic floor.

Owner:ZHEJIANG KINGDOM NEW MATERIAL GRP CO LTD

Method for preparing titanium plate billet

The invention provides a method for preparing a titanium plate billet. The method comprises the steps of pressing titanium sponge into an electrode block, or evenly mixing the titanium sponge with an intermediate alloy and / or a metal as an alloy element and then pressing for the formation of the electrode block, welding the pressed electrode block into a cylindrical electrode and smelting the cylindrical electrode by adopting vacuum consumable electro-arc for the formation of a cylindrical cast ingot; peeling the obtained cylindrical cast ingot, then performing 90-180min heat preservation at a temperature of 800 to 850 DEG C, increasing the temperature to 950 to 1050 DEG C for 180-420min heat preservation and forging the cast ingot into a rectangular intermediate billet after the forging and drawing of one heating number; and finally performing hot-rolling and cogging on the obtained intermediate billet for the formation of the titanium plate billet. With the adoption of the method for preparing the titanium plate billet, the operation is convenient and the obtained titanium plate billet is small in thickness tolerance and good in surface quality.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

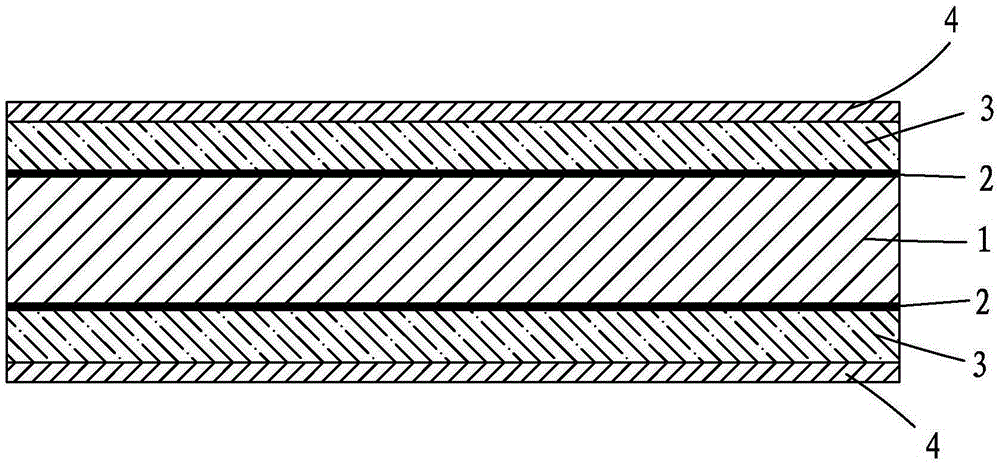

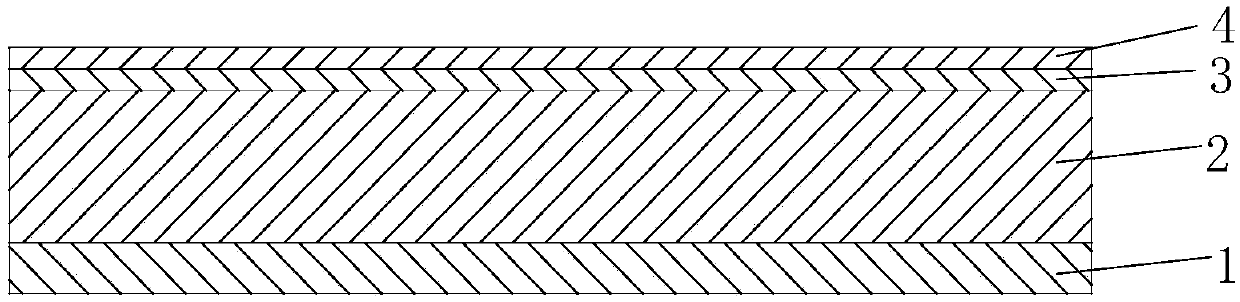

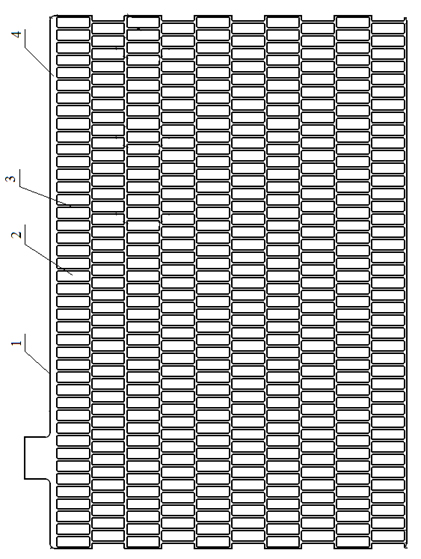

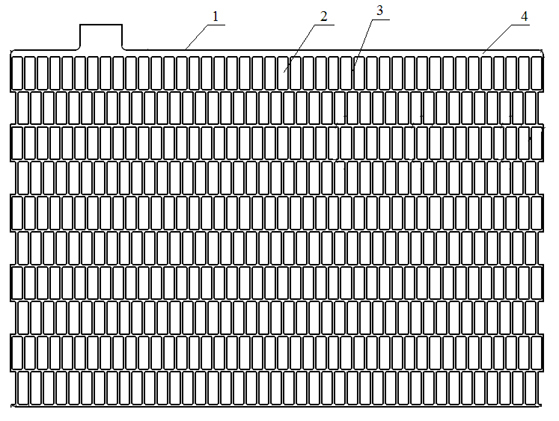

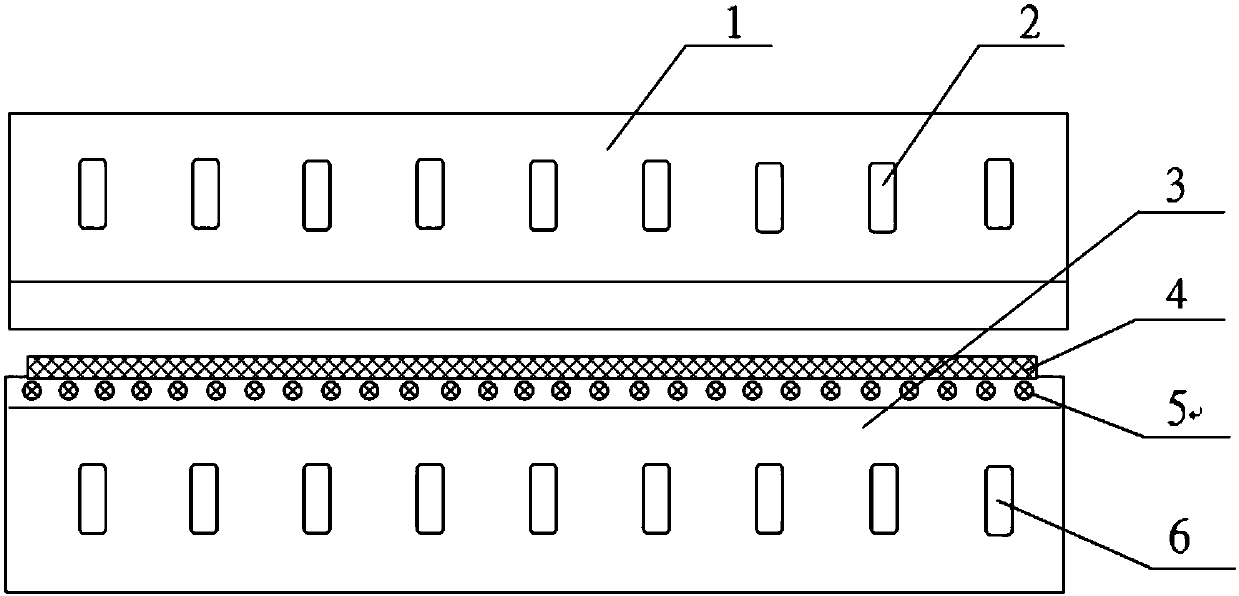

Technology for forming maintenance-free lead-acid battery pole plates

InactiveCN102034974ASmall thickness toleranceIncrease productivityLead-acid accumulator electrodesSpecific energyMaterials science

The invention discloses a technology for forming maintenance-free lead-acid battery pole plates, comprising the following steps: (1) heating to melt an alloy lead liquid in a melting furnace; (2) casting the alloy lead liquid into lead strips by using a casting machine; (3) winding the lead strips by using a winder; (4) delivering the lead strips to a stamping machine and stamping the lead strips into plate grid strips (1), wherein uniform rectangular holes (2) are formed in the middle of each plate grid strip (1), ribs (3) are arranged among the holes (2), and edge and corner lead strips (4) used for cutting plugs are arranged on two sides of each plate grid strip; (5) winding the plate grid strips by using the winder; and (6) coating the plate grid strips by using a plate coating machine and splitting the plate grid strips by using a plate splitting mold to form lead-acid battery pole plates. The technology for forming maintenance-free lead-acid battery pole plates during lead-acid battery production can improve the service life, the quality and the specific energy of a lead-acid battery.

Owner:JIANGSU LEOCH BATTERY

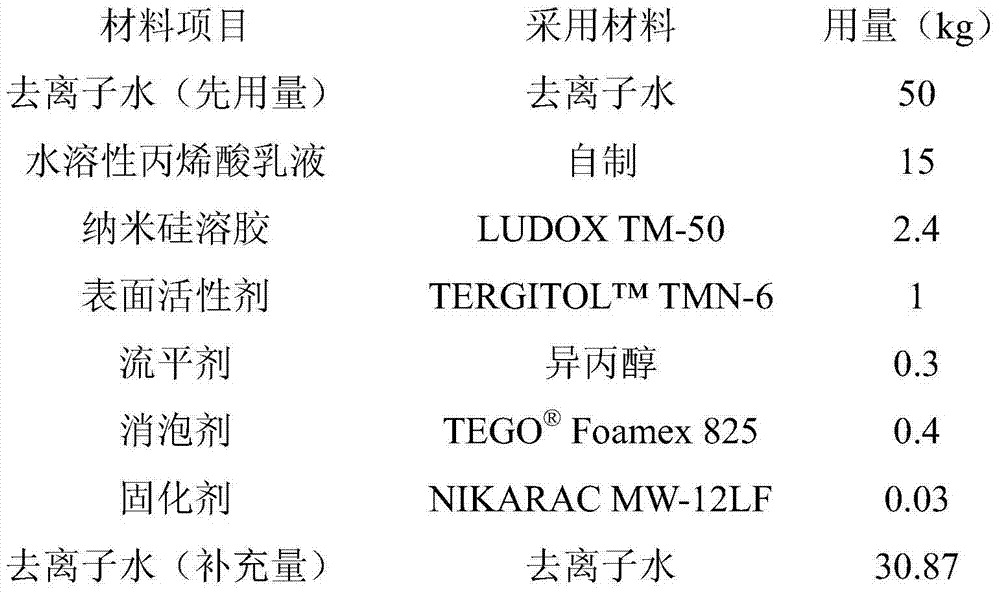

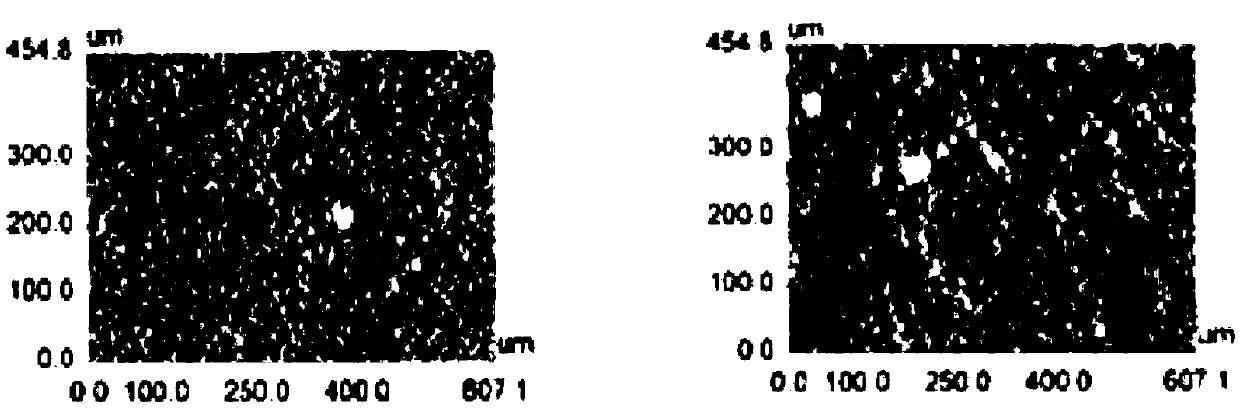

Low water vapor transmission rate type polyester film for acrylic acid type coating and preparation method of low-water vapor transmission rate type polyester film

ActiveCN103753925AHigh elongation at breakStrong water resistanceSynthetic resin layered productsCoatingsWater basedPolyester

The invention discloses a low-water vapor transmission rate type polyester film for an acrylic acid type coating. The low-water vapor transmission rate polyester film is characterized by consisting of a double-direction stretching polyester film prepared from polyethylene terephthalate or poly-2,6-ethylene naphthalate and acrylic acid type glue coatings, wherein the both sides of the film are coated with the acrylic acid type glue coatings; the thickness of the polyester film is 150-250 microns; the thickness of the acrylic acid type glue coatings is 0.08-0.32 microns; acrylic acid type glue consists of a water-based acrylic emulsion, a nanometer silicon sol, a surfactant, a flatting agent, a de-foaming agent, a curing agent and de-ionized water; after a polyester chip is cast to form a casting piece through an extruder and forms a film through vertical stretching, the both surfaces of the film are coated with the acrylic acid type glue in an online coating manner; the low-water vapor transmission rate type polyester film for the acrylic acid type coating is prepared by transverse stretching, drying, cross-linking, curing and thermal shaping. The film provided by the invention can be used for manufacturing a backboard film for a solar battery or other products in need of the low-water vapor transmission rate polyester film.

Owner:四川东方绝缘材料股份有限公司

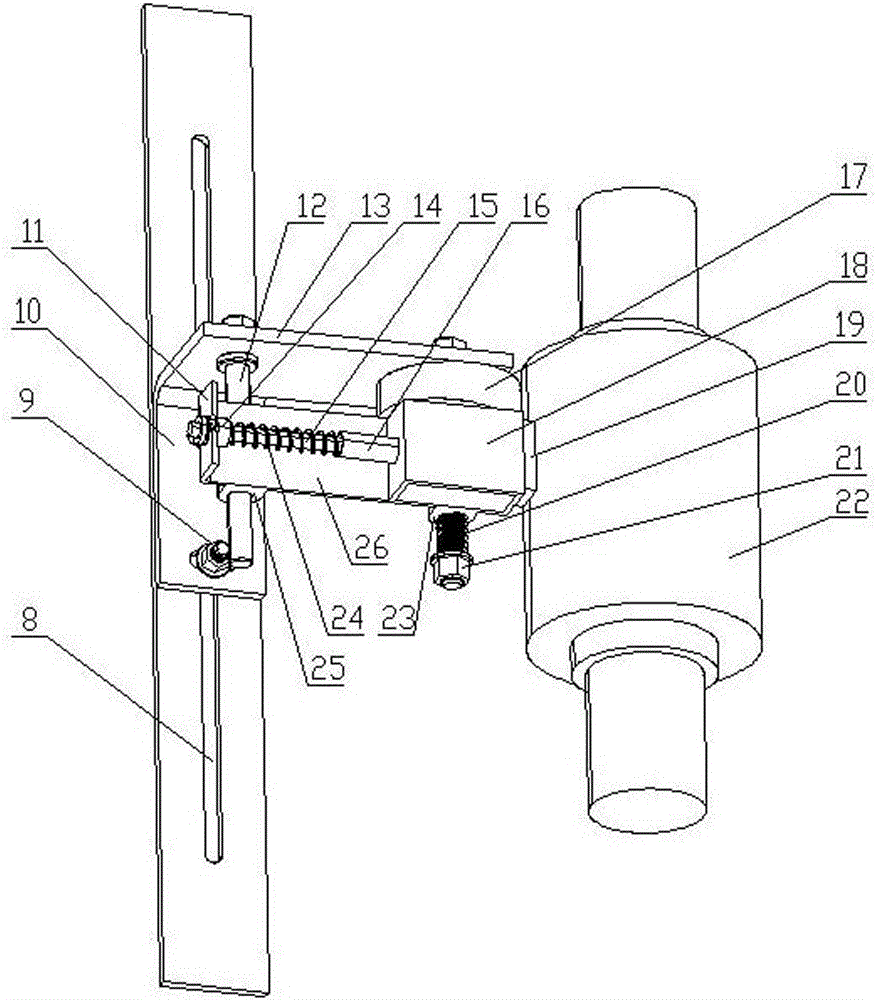

Preparing system and method of PMMA light-guide-stage transparent membranes

PendingCN107813512ALess interferenceReduce the impactOptical articlesCleaning using toolsLight guideMembrane surface

The invention discloses a preparing system of PMMA light-guide-stage transparent membranes. The preparing system comprises a washing device, a drying device, an extruding device, a polishing device, aconveying device, a relay type membrane surface dust removal device, a film pasting device, a first cutting device, a traction device, an edge cutting device, a second cutting device and a piece loading device which are sequentially arranged and further comprises negative-pressure chip sucking devices arranged on the discharging sides of the first cutting device, the edge cutting device and the second cutting device correspondingly. Squeezing rollers below a mouth die of the extruding device are a pair of flexible rollers. The relay type membrane surface dust removal device comprises an upperdust removal roller set and a lower dust removal roller set which are arranged on the two faces of the membranes. The negative-pressure chip sucking devices each comprise a plurality of negative-pressure chip sucking parts arranged on one face or two faces of a to-be-cut product. Ultra-thin and ultra-wide PMMA membranes can be produced, inner stress of prepared products is evenly distributed, andthus the products are not prone to being cracked. Meanwhile, the very small thickness tolerance (smaller than 1.5%) and extremely perfect optical quality can be obtained, and the defect that powderedscraps press the appearances of the products to be damaged is effectively overcome.

Owner:JIANGSU HANYANG NEW MATERIAL TECH

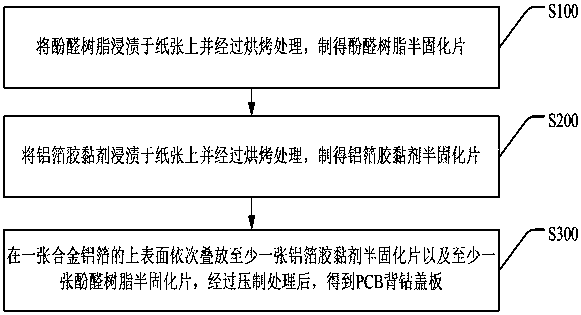

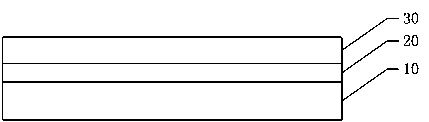

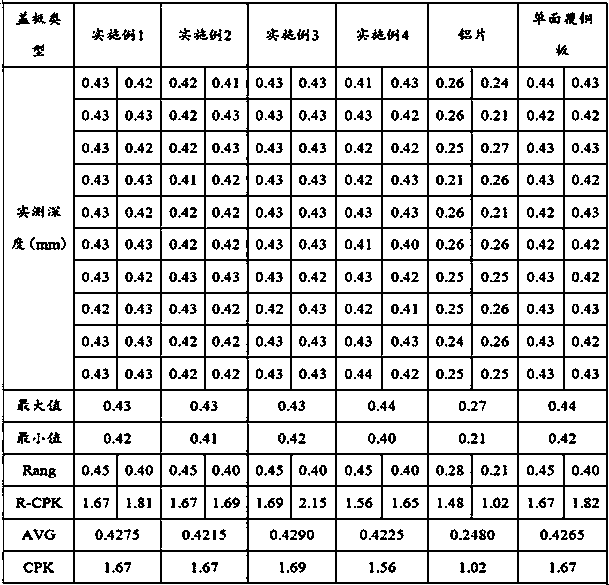

PCB back-drilling cover plate and preparation method thereof

ActiveCN107718840AEasy to drillGood positioning effectLayered product treatmentLaminationDrill holeAdhesive

The invention discloses a PCB back-drilling cover plate and a preparation method thereof. The cover plate is a single-sided aluminum-laminated foil phenolic aldehyde cover plate formed by compoundingphenolic resin, an aluminum foil adhesive, paper and alloy aluminum foil. An insulating medium layer formed by the phenolic resin, the aluminum foil adhesive and the paper is utilized for replacing ahigh-cost epoxy resin glass fiber composite insulating medium layer, and the prepared cover plate has the effects that the drilling is easy, the positioning effect is good, the abrasion of a drillingneedle is reduced; and the alloy aluminum foil is utilized for replacing a high-cost aluminum foil, so that the cost is substantially lowered, and the prepared cover plate has the characteristics thata metal conductive layer is thin, the thickness tolerance is small, the adhesion with a PCB is good, and the control depth precision of a drill hole is high. According to the PCB back-drilling coverplate, the problems of an aluminum piece that the positioning effect and the drilling precision are poor, adhesion with the PCB is poor and the control depth precision of a drill hole is poor are solved, and the problem that a single-sided copper-laminated plate is high in cost is solved, and the appearance problems of appearance corrugation and water stain in the production of single-sided aluminum-laminated foils similar to the single-sided aluminum-laminated foil phenolic aldehyde cover plate as well as and scratching in a baking process are solved.

Owner:烟台柳鑫新材料科技有限公司

Cold rolling process of precise stainless steel band for steel structure building

ActiveCN105537268AHigh strengthLight weightMetal rolling arrangementsPunchingUltimate tensile strength

Owner:ANHUI WEIHONG STEEL STRUCTURE GRP

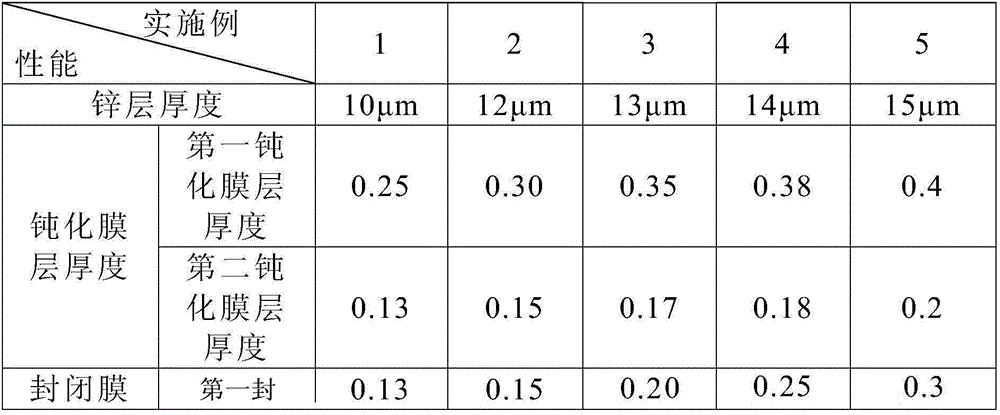

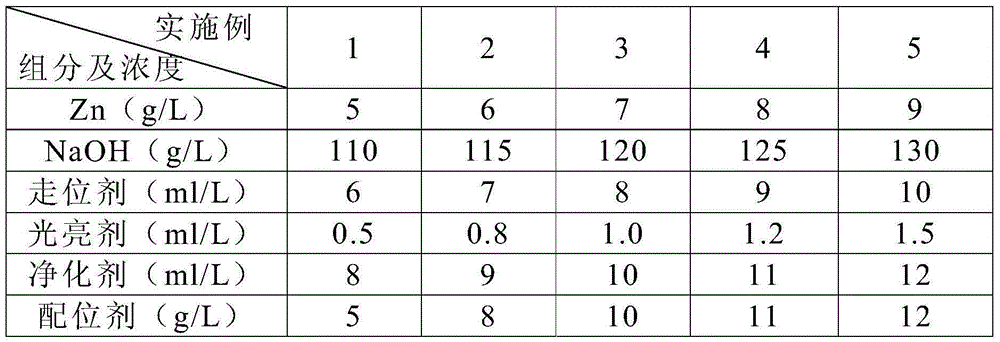

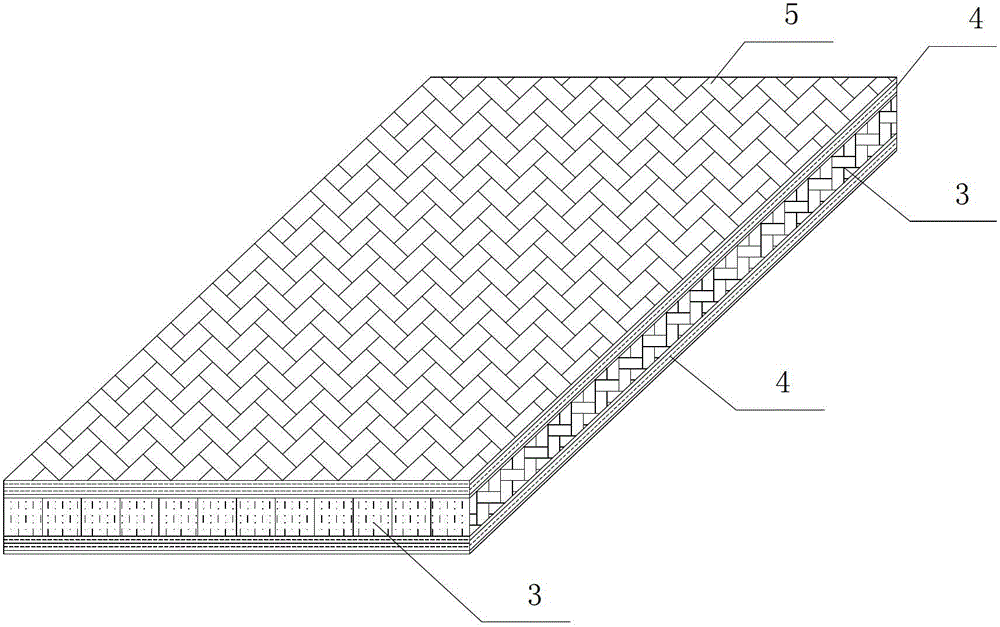

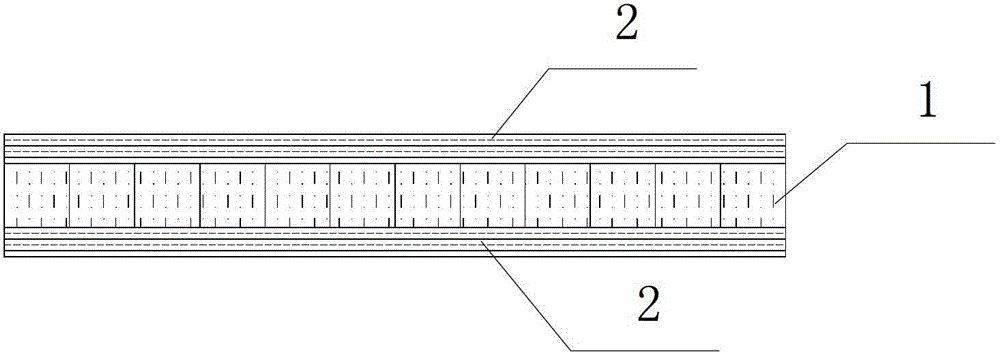

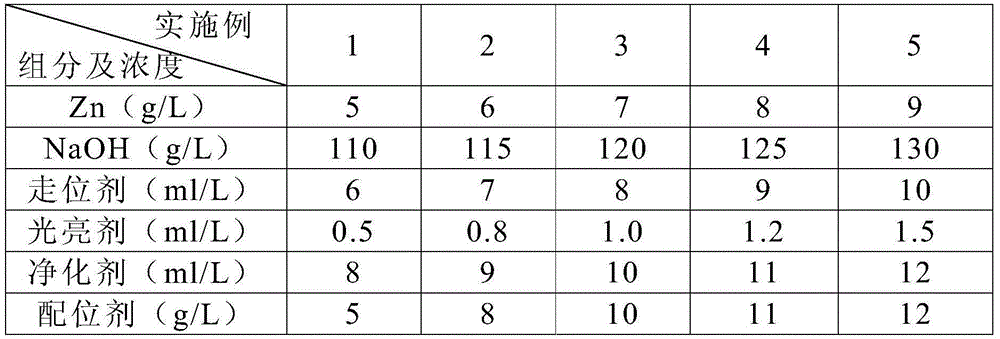

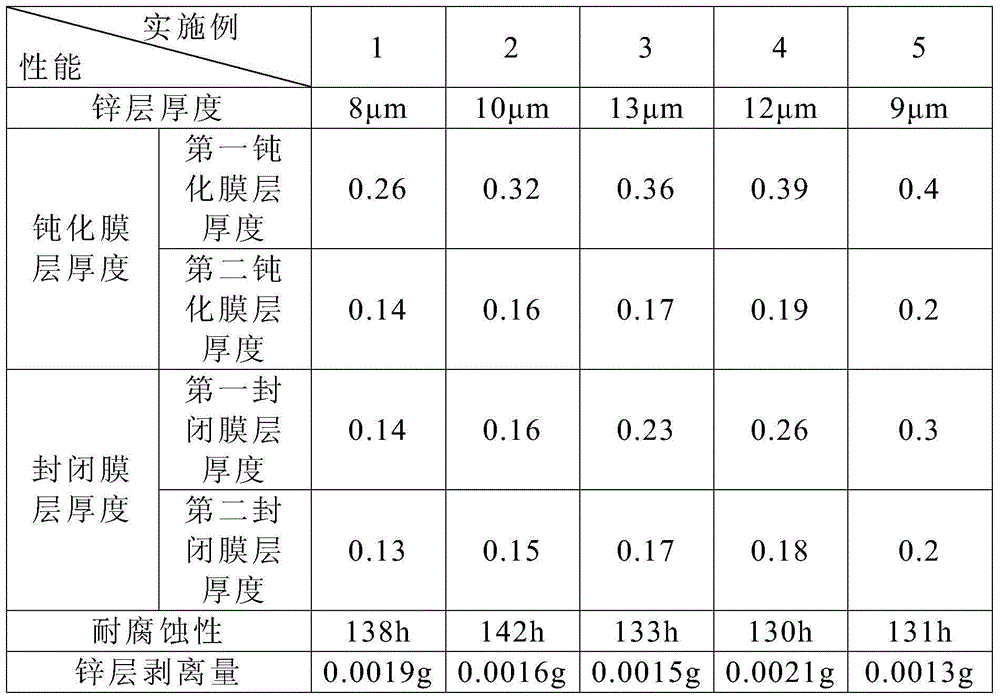

Surface treatment process for cooling water pipe joint assembly

InactiveCN105112911AImprove the protective effectImprove the decorative effectSuperimposed coating processMicrometerPre treatment

The invention relates to a surface treatment process for a cooling water pipe joint assembly. The surface treatment process comprises the steps that a base material is pretreated; a protective layer is formed on the base material and is a zinc layer, and the thickness of the protective layer is 10-15 micrometers; a passive film layer is formed on the protective layer; a closed film layer is formed on the passive film layer. After the surface of the cooling water pipe joint assembly is treated, the cooling water pipe joint assembly is more attractive, better in medium resistance, oxidation resistance, corrosion resistance and other performance, and longer in service life.

Owner:NINGBO YADA METAL SURFACE TREATMENT

Bamboo plywood for structure

InactiveCN104015231AImprove gripThe problem of realizing double-sided nailingWood veneer joiningWood layered productsEngineeringLath

The invention discloses bamboo plywood for a structure. The bamboo plywood for the structure comprises a core board layer and hot-pressed layers arranged on the two sides of the core board layer. The core board layer is made of battens through lateral cold pressing and gluing and sanding thickness determining, wherein the battens are formed by cutting bamboo plywood GluBam which is used in a structure and has the thickness of 25 mm to 30 mm. The pressed forming surfaces of all the battens in the formed core board layer are perpendicular to pressed forming surfaces of the hot-pressed layers. According to the bamboo plywood for the structure, nails can be driven into two sides of the bamboo plywood, the thickness in each bamboo plywood layer is even, and the thickness tolerance between the plywood layers is small; in addition, the hot-pressing technology efficiency is high, and the mechanical property is high. The bamboo plywood for the structure can completely overcome the inherent defects of the existing plywood GluBam and is used for production and construction of the bamboo structure.

Owner:HUNAN UNIV

Preparation method of titanium alloy plate

ActiveCN112692060ARapid productionEfficient and stable productionMetal rolling arrangementsHeat conservationContinuous rolling

The invention discloses a preparation method of a titanium alloy plate. The preparation method comprises the following steps of hot continuous rolling; annealing for the first time; board splitting; welding; hot rolling; annealing for the second time; cold rolling; and annealing for the third time. The preparation method is started from a large titanium alloy plate blank, through effective combination of roll type production and plate type production, effective coupling of the processes such as the heating temperature, the heat treatment system and the heat preservation time is comprehensively considered, the yield is increased, the production period is shortened, and the effect of rapid batch production is achieved. Meanwhile, a ply rolling process is reasonably matched with a cold rolling process, so that the dimensional precision is optimally controlled, and the thickness tolerance is small; batch, efficient and stable production of alpha + beta type titanium alloy thin-specification plates is achieved; and the method has important significance in industrial batch delivery.

Owner:湖南湘投金天钛金属股份有限公司

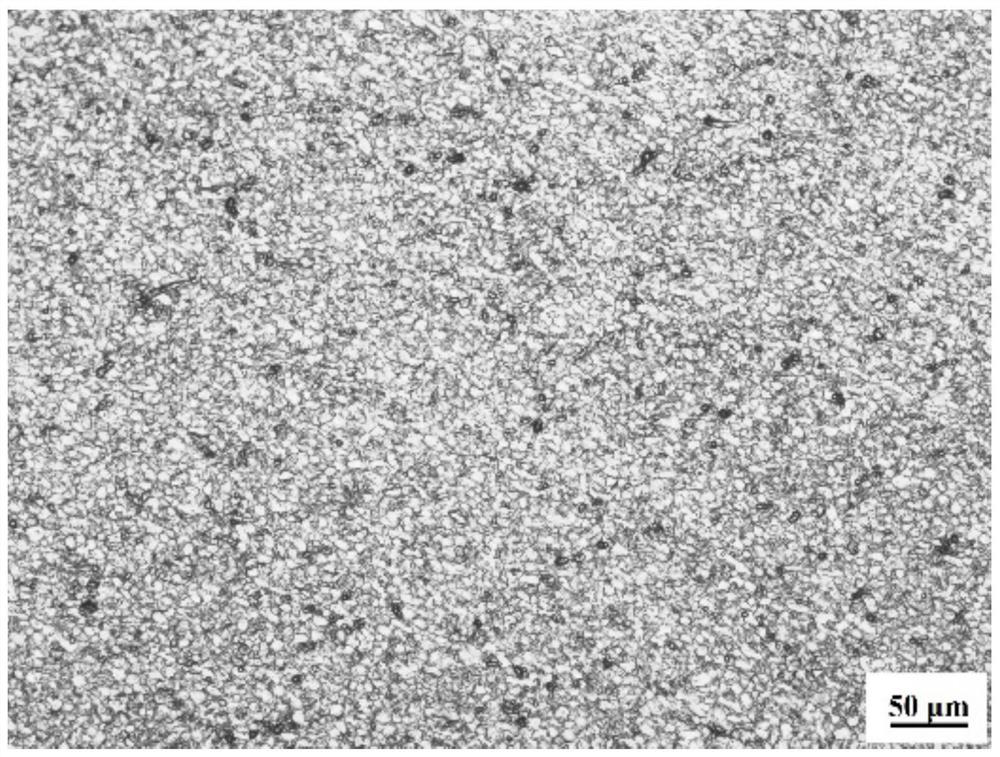

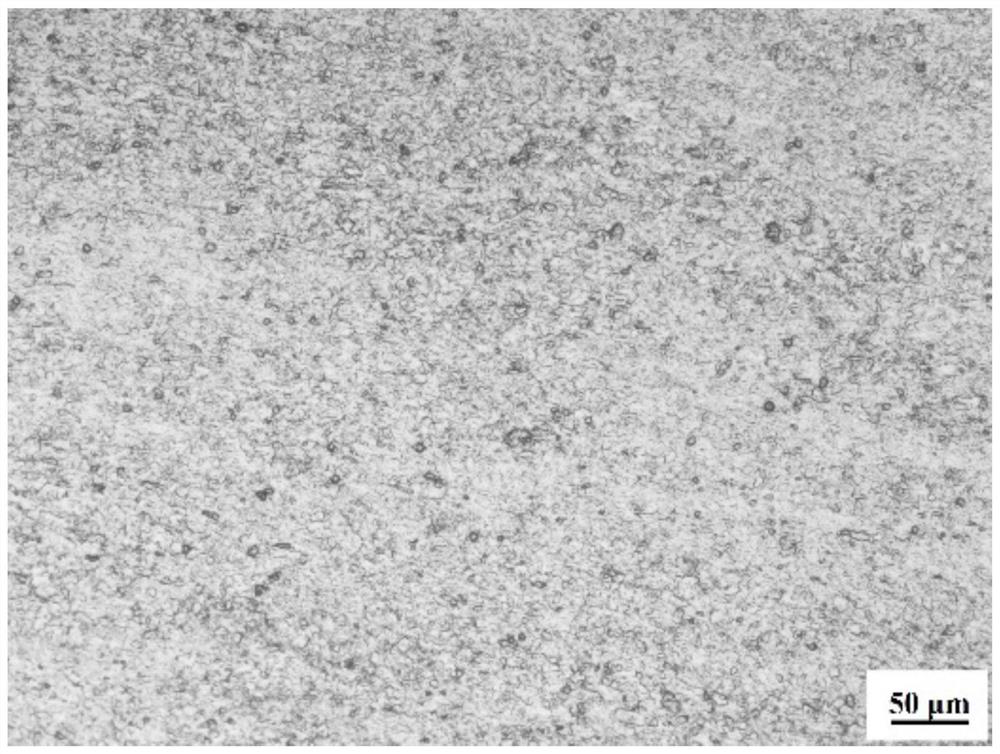

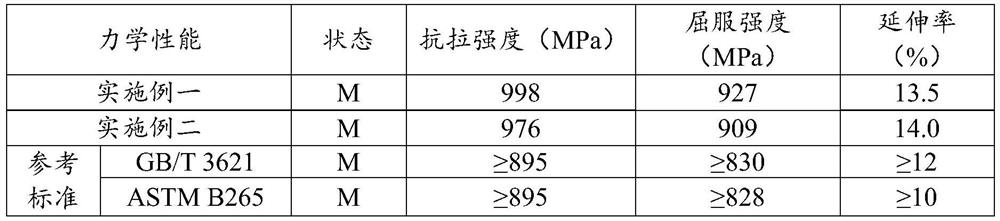

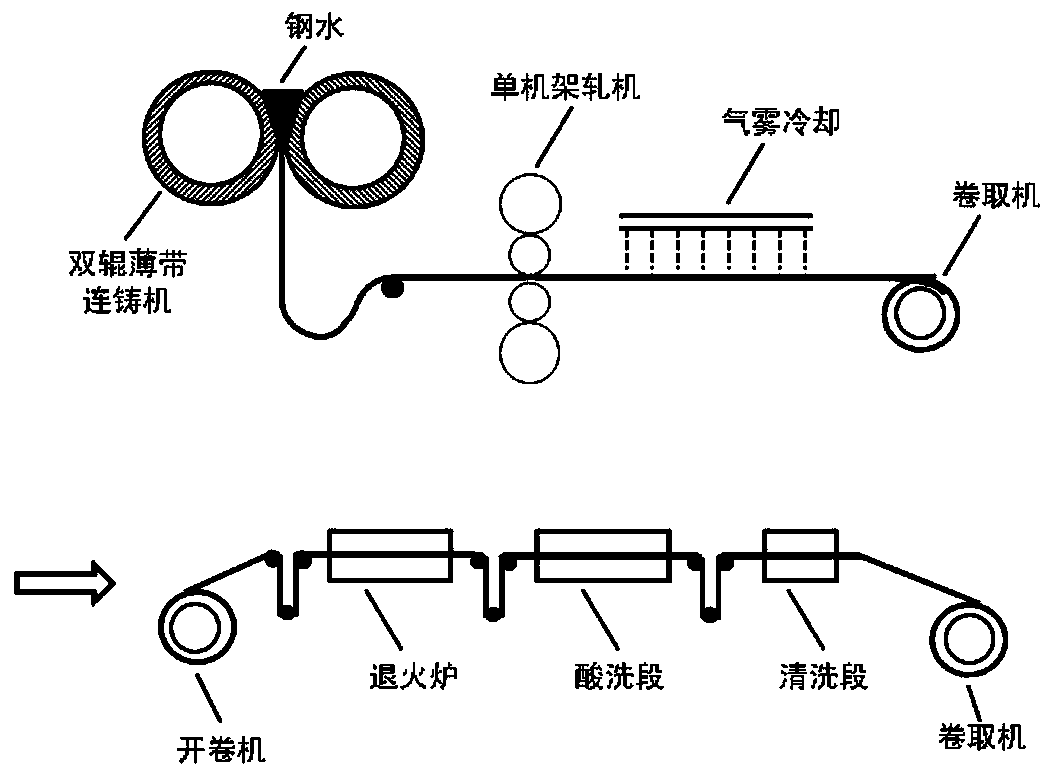

High-strength steel for seat slide rails and method for producing the same based on thin strip casting-rolling

InactiveCN111218607AReduce production processLess emissionsFurnace typesProcess efficiency improvementAerosol MistContinuous annealing

The invention belongs to the technical field of steel production, and particularly relates to high-strength steel for seat slide rails and a method for producing the same based on thin strip casting-rolling. Molten steel is subjected to thin strip continuous casting to obtain a cast strip, the cast strip is subjected to single-pass hot rolling and aerosol cooling and coiled to obtain a hot-rolledcoil, then the hot-rolled coil is opened on a continuous annealing-pickling line, and after an annealing stage and a pickling stage, cleaning, oiling and coiling are performed to obtain a high-strength pickled coil. According to the method, a thin strip casting-rolling and continuous annealing-pickling technology is adopted to produce the high-strength steel for the seat slide rails, the problem that a thin, high-strength and high-dimensional-accuracy product cannot be easily produced through a traditional hot rolling technology is solved, and the problem that a hot rolling, pickling, cold rolling and annealing technology has a long process, high energy consumption and poor product isotropy is also solved. In the product, low-temperature coiling is adopted to obtain a high-yield-ratio rodlike bainite phase, Nb, V and the like are sufficiently separated out by the subsequent annealing technology, phase transformation stress is released, the plasticity is further improved while high strength and the high yield ratio are achieved, and the steel is more suitable for manufacturing the seat slide rails.

Owner:SHAGANG GROUP +2

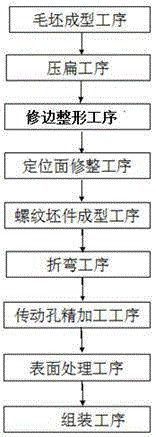

Manufacturing method of abrasion resistant transmission connecting rod assembly of automobile turbocharger

ActiveCN106553028AIncrease profitQuality improvementConnecting rodsMetal-working apparatusSurface finishHigh volume manufacturing

The invention discloses a manufacturing method of an abrasion resistant transmission connecting rod assembly of an automobile turbocharger. The manufacturing method is characterized by comprising the steps of step I, blank forming procedure; step II, flattening procedure; step III, trimming shaping procedure; step IV, locating surface finishing procedure; step V, threaded blank forming procedure; step VI, bending procedure; step VII, driving hole finish machining procedure; step VIII, surface treatment procedure; and step IX, assembly procedure. According to the manufacturing method, the material utilization rate is high, the quality is stable, the processing cost is low, the production efficiency is high, the manufacturing method is applicable to mass production, and the environmental pollution is reduced.

Owner:无锡超捷汽车连接技术有限公司

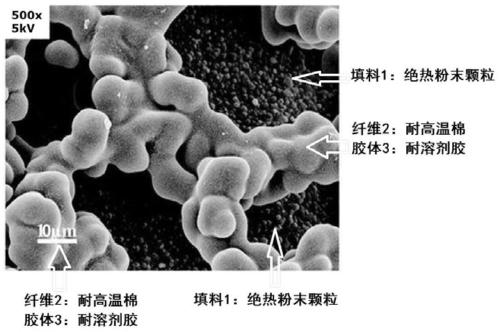

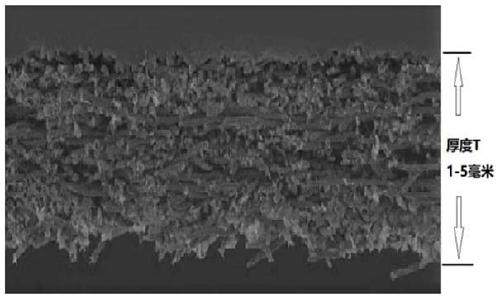

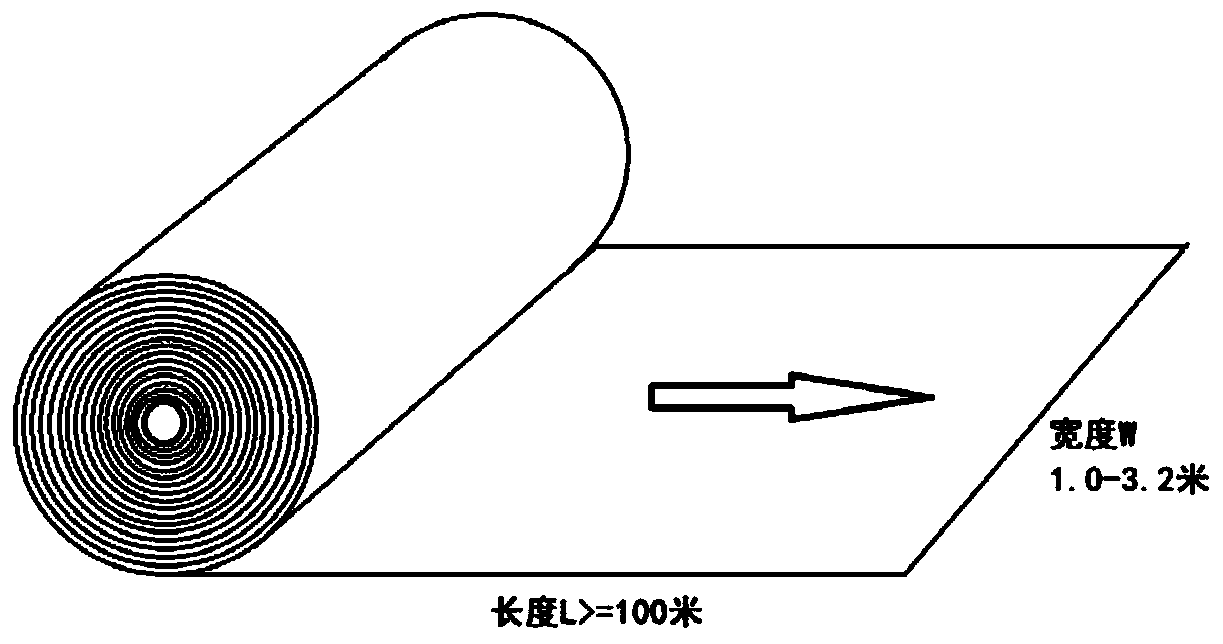

Preparation method of ultrathin adiabatic and insulated flexible non-woven fabrics resistant to 1000 degrees

ActiveCN111335024ASmall thickness toleranceContinuous productionFibre typesNon-woven fabricsPolymer scienceAdhesive glue

The invention discloses a preparation method of ultrathin adiabatic and insulated flexible non-woven fabrics resistant to 1000 degrees. The method comprises the following steps of S1) melting and purifying nonmetallic crystal mineral, and adding rare metal compounds to prepare high-temperature resistant fiber; S2) opening to card the high-temperature resistance fiber into thin webs with uniform thickness; S3) applying solvent resistance stock glue solution on the thin webs for drying and dehydration to prepare solvent resistance high-temperature resistant porous cotton, and preparing high-temperature resistance fiber non-woven rolls; S4) uniformly dispersing adiabatic powder in a 100% alcohols solvent to form a mixed solution, and soaking the high-temperature resistance fiber non-woven rolls in the mixed solution in a vacuum mixing kettle for reverse reduction reaction; and S5) recovering the residual alcohols solvent after reaction by using low-temperature vacuum centrifugation to prepare the finished non-woven fabrics. The non-woven fabrics prepared by the invention are ultrathin, ultra-light, resistant to 1000 degrees, adiabatic and resistant to alcohols solvents with 100% concentration, have excellent dry and wet strength, and are capable of maintaining complete structure, electrical insulation and explosion protection.

Owner:苏州格威姆新材料科技有限公司

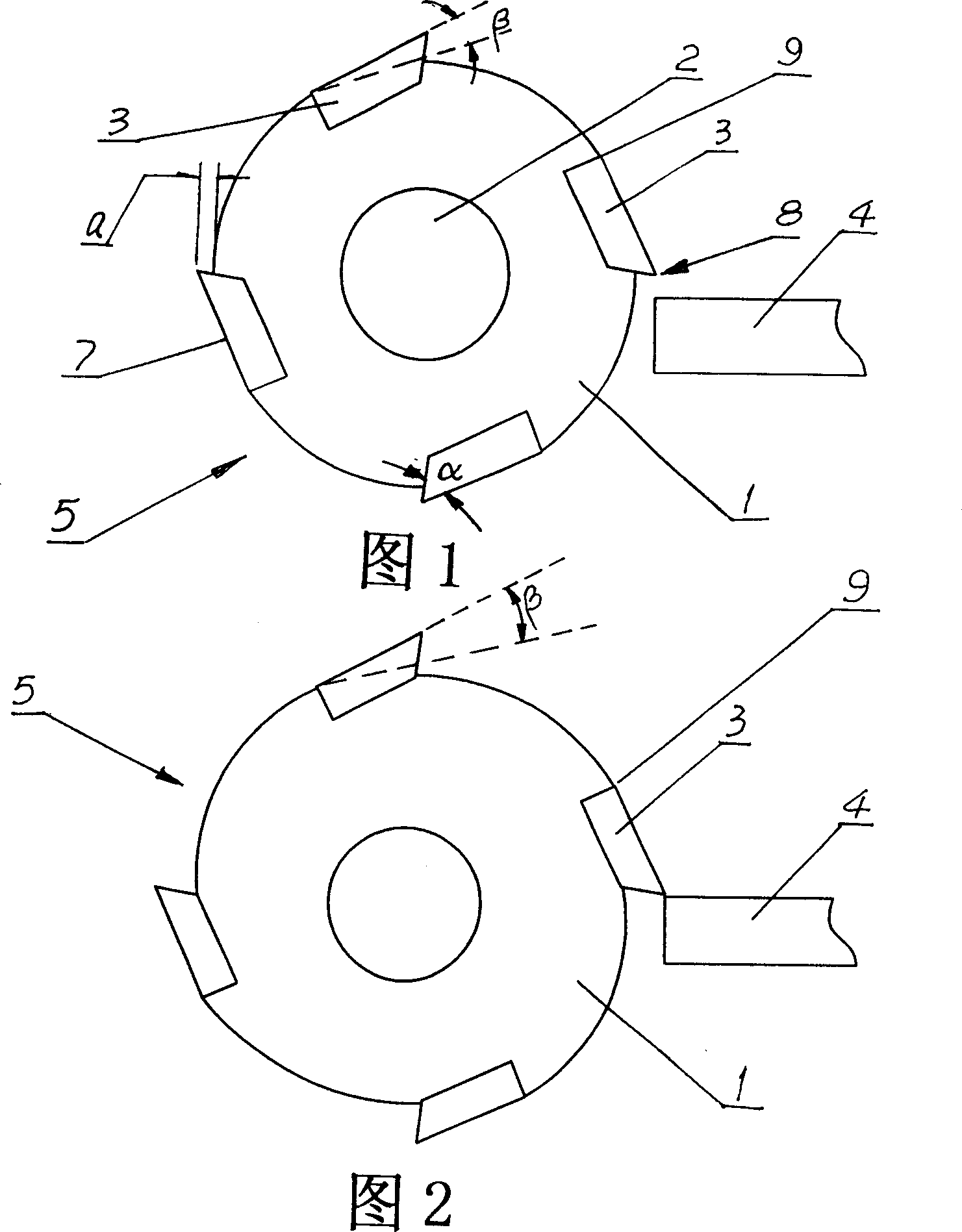

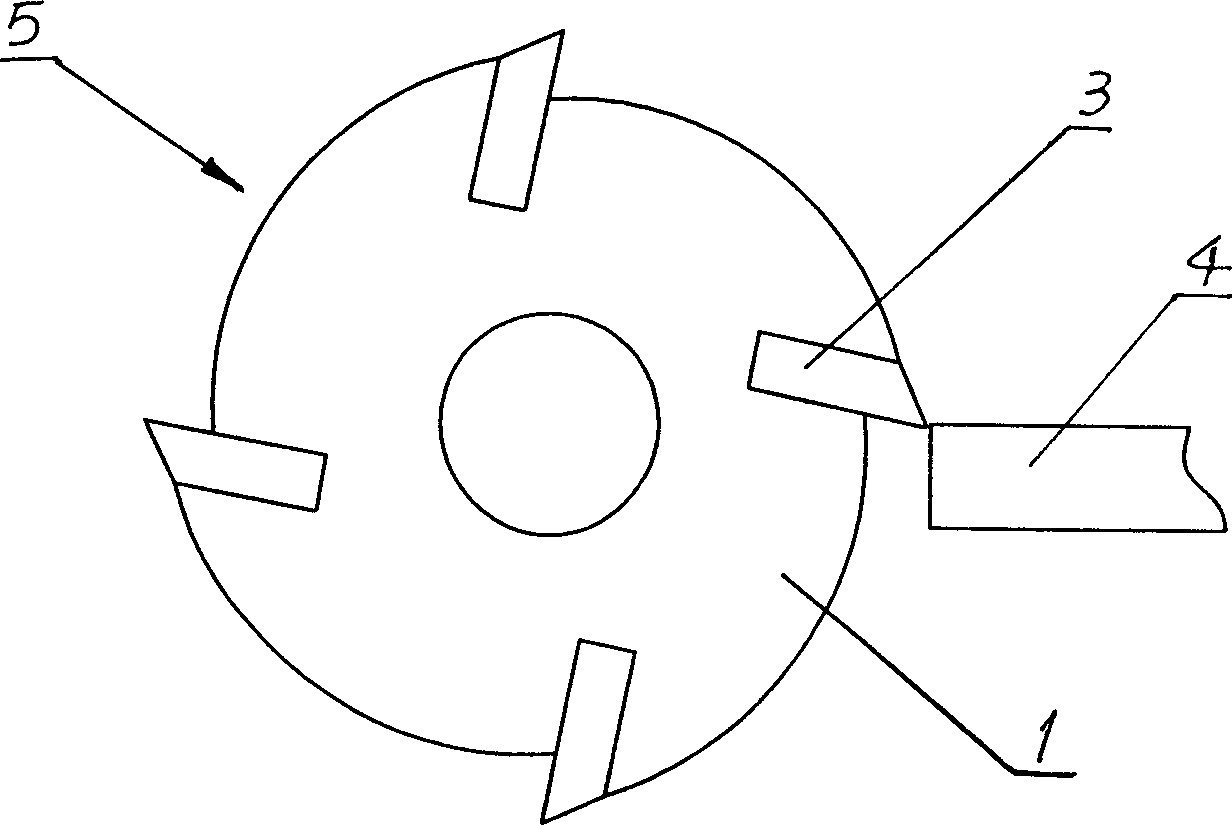

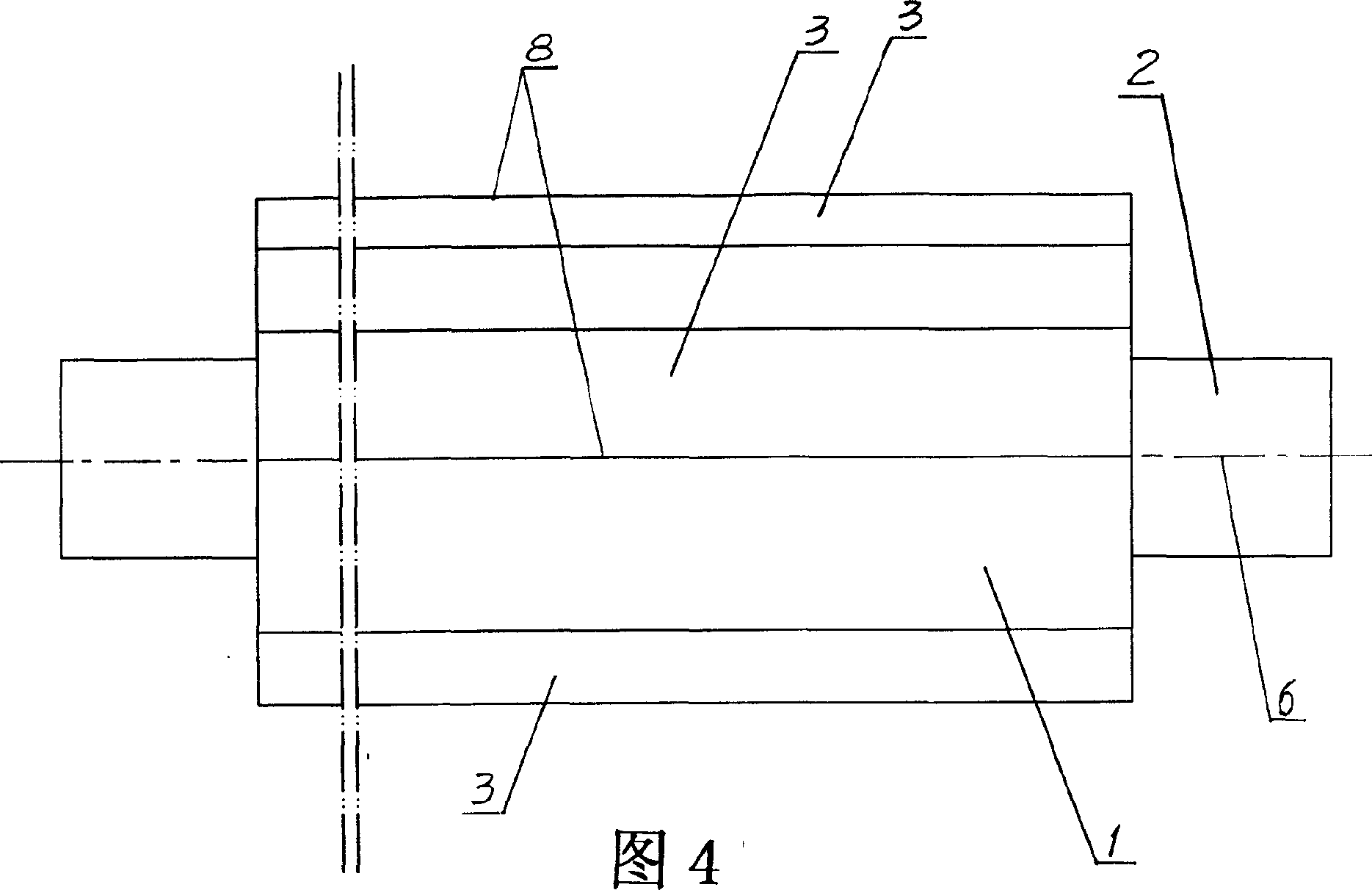

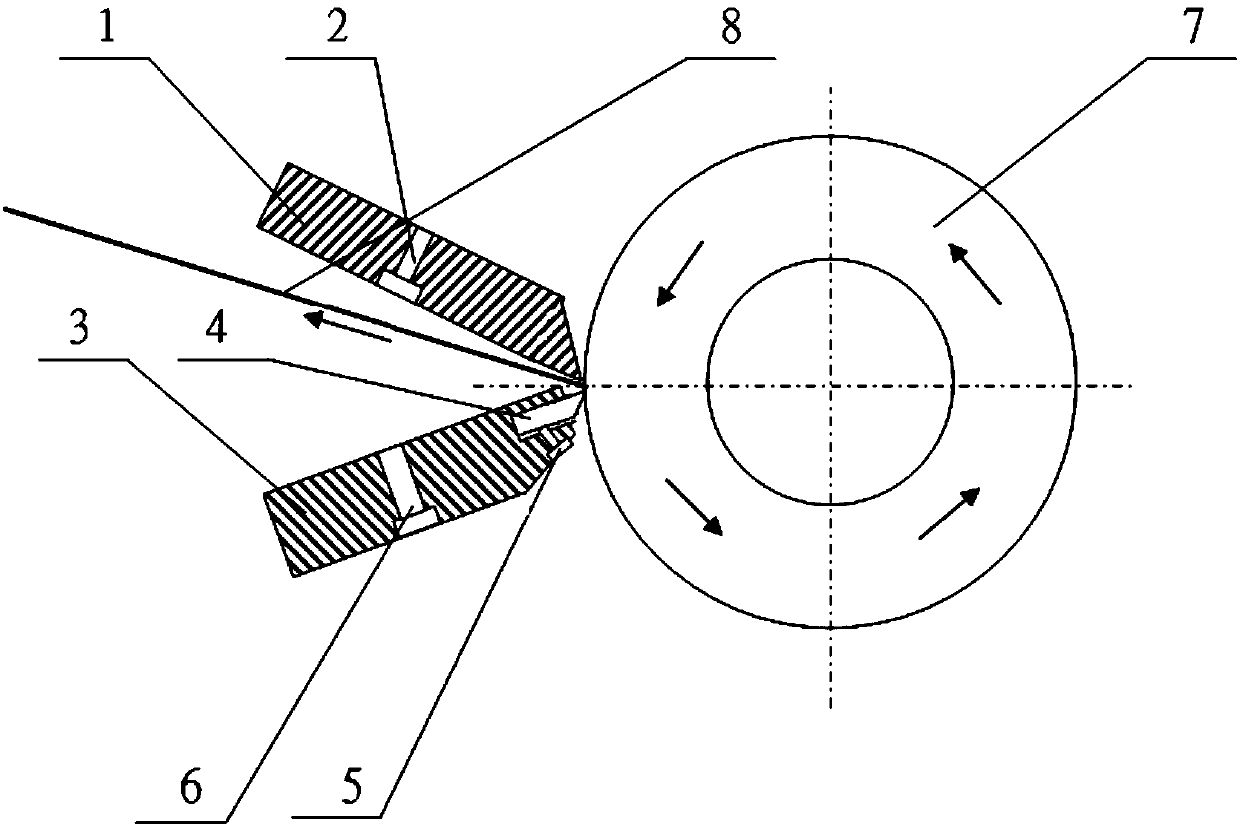

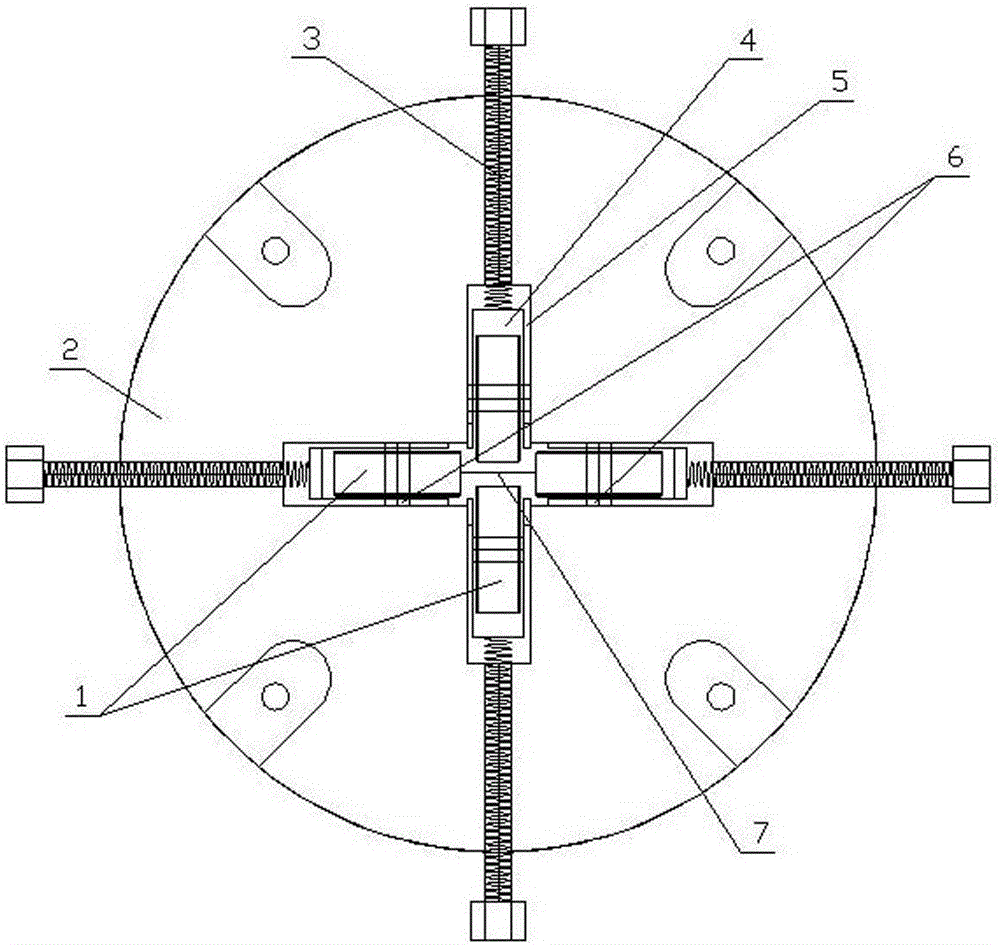

Single-roller type shearing tool

The present invention relates to a single-roller type cutting tool for processing bamboo material. It comprises a roller body equipped with a roller shaft, on the described roller body one or more than one cutting blades are mounted so as to form the moving cutting blades which can be rotated around the axis of said roller body. Besides, it also has static fixed cutting blades which are correspondent to those moving cutter blades, so that said moving cutting blades and static fixed cutting blades are formed into said invented cutting tool with high cutting efficiency and low production cost.

Owner:何林

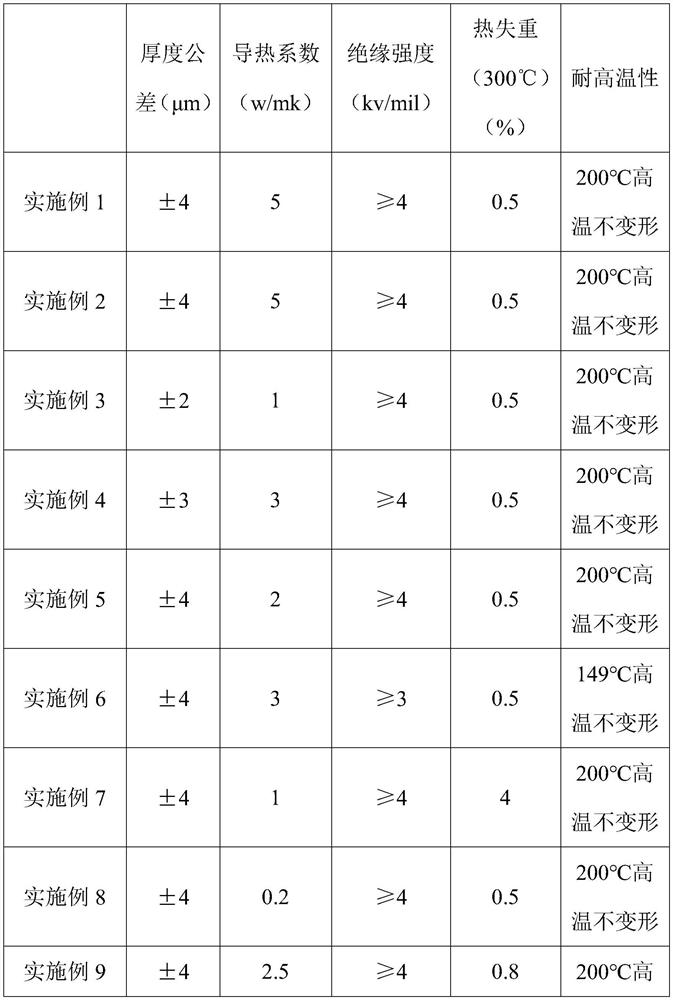

Heat-conducting insulating composite material and preparation method thereof

InactiveCN114230838AEasy to use in automated productionEasy to operateCoatingsThermal insulationUltimate tensile strength

The invention discloses a heat-conducting insulating composite material and a preparation method thereof. The preparation method of the heat-conducting insulating composite material comprises the following steps: 1) uniformly coating one side or two sides of an insulating film with heat-conducting silicone rubber; and 2) baking and rolling the insulating film coated with the heat-conducting silicone rubber in the step 1) to obtain the heat-conducting insulating composite material. According to the preparation method, the operation steps are simplified, the production efficiency is improved, unnecessary waste is reduced, the cost is reduced, and automatic production and use of customers are facilitated; the prepared heat-conducting insulating composite material is small in thickness, small in thickness tolerance, high in surface flatness and uniform in performance, does not need to be protected by a protective film, has excellent heat-conducting property, the heat conductivity coefficient is larger than 1 w / mk, the insulating strength is larger than 4 kv / mil, good heat conductivity and insulativity can still be kept in a high-temperature environment, and the product stability is good.

Owner:苏州艾乐格新材料有限公司

Method for preparing polyphenylene sulfide plate with large plane

InactiveCN100595048CImprove inner qualityReduce brittlenessFlat articlesMechanical propertyInorganic sulfide

The invention relates to a preparation method of a large planar polyphenylene sulfide board, in particular to a preparation method of a polyphenylene sulfide board, which aims at solving the problem existing in the prior art that the large planar polyphenylene sulfide board with good mechanical property is not easy to be prepared. The method comprises the following steps: a polyphenylene sulfide composite material is put into a hot-air drying oven at the temperature of 100-150 DEG C and kept for 4 to 8 hours; the polyphenylene sulfide composite material is fused at the temperature of 280-320 DEG C, mixed together and squeezed out, and the fused mass thereof is squeezed into a compacting die heated to the temperature of 280-320 DEG C; the initial states under the identical die stamping pressure and die stamping height are maintained at the temperature of 280-320 DEG C; when the temperature of the fused mass is reduced to 260-280 DEG C, pressure is applied, and pressure complementing isstopped when the temperature is reduced to 230-250 DEG C; the gradient type annealing treatment is carried out when the temperature of the fused mass is reduced between 150 and 250 DEG C; and then, natural temperature reducing and pressure maintaining are performed, stripping is carried out by pressure releasing when the ambient temperature is reached, and then the finished product is obtained. The method can be widely applied to special tool boards, working tabletops, and the like.

Owner:SICHUAN COREMER CO LTD

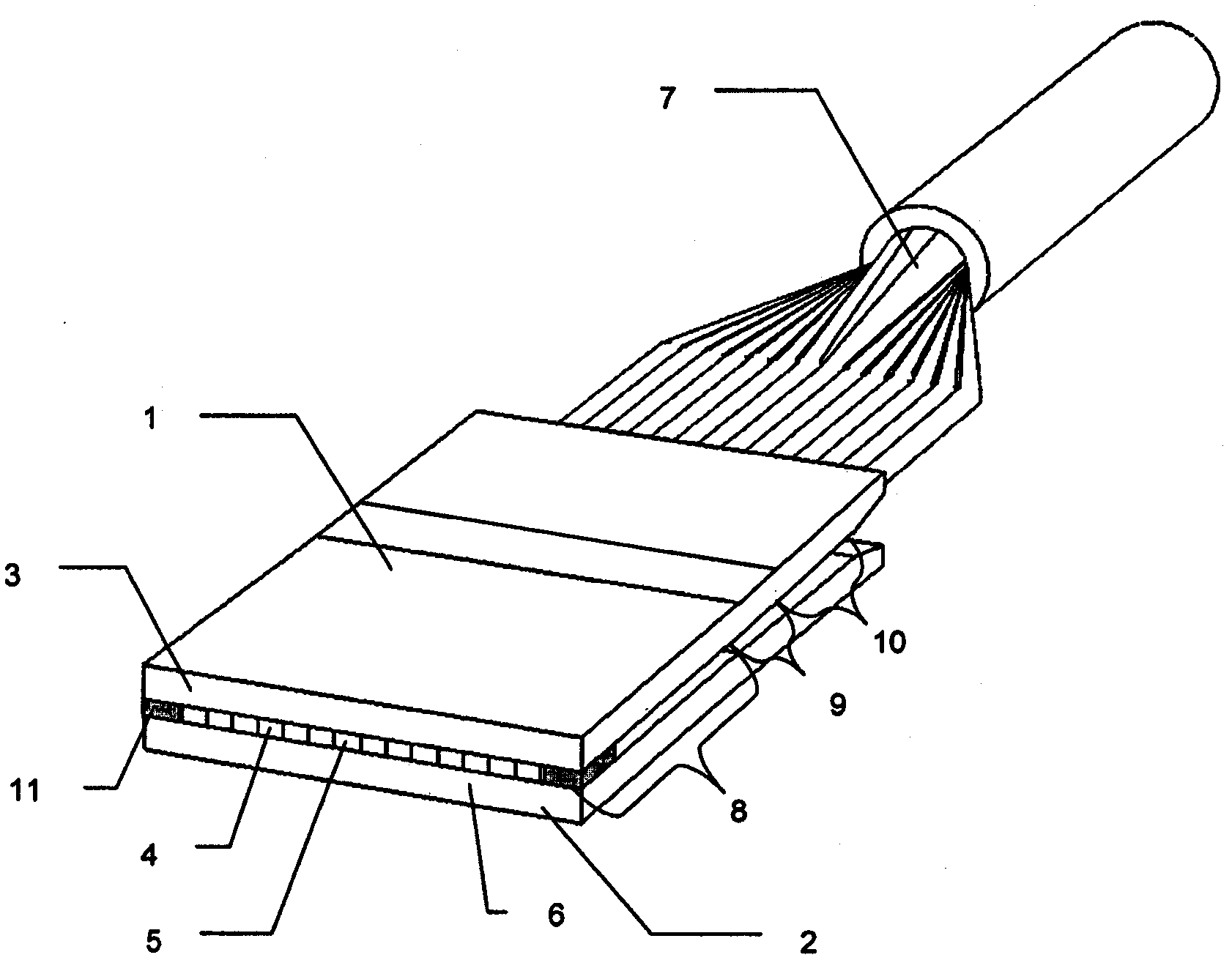

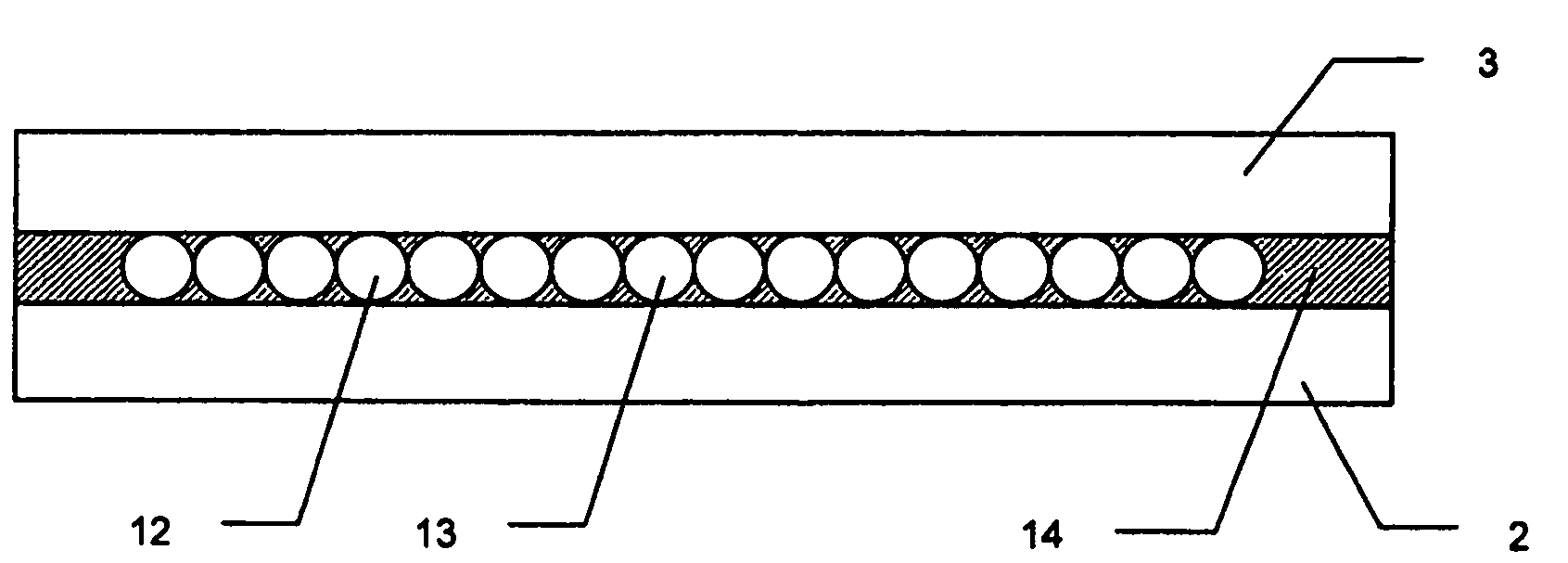

Light guide for transmitting radiation and production method

InactiveCN102326110ASmall thickness toleranceSemiconductor laser arrangementsLaser arrangementsFiberHigh power diode laser

The invention relates to a light guide for transmitting radiation, in particular the radiation from a high power diode laser, and to a method for producing the same. The light guide is characterized by a gap-shaped elongated light entry surface consisting of one or more layers of optical fibers, wherein the fibers are at least partly connected to one another and to a carrier plate in a form-fitting manner. The invention further relates to a method for producing the light guide according to the invention.

Owner:SCHOTT AG

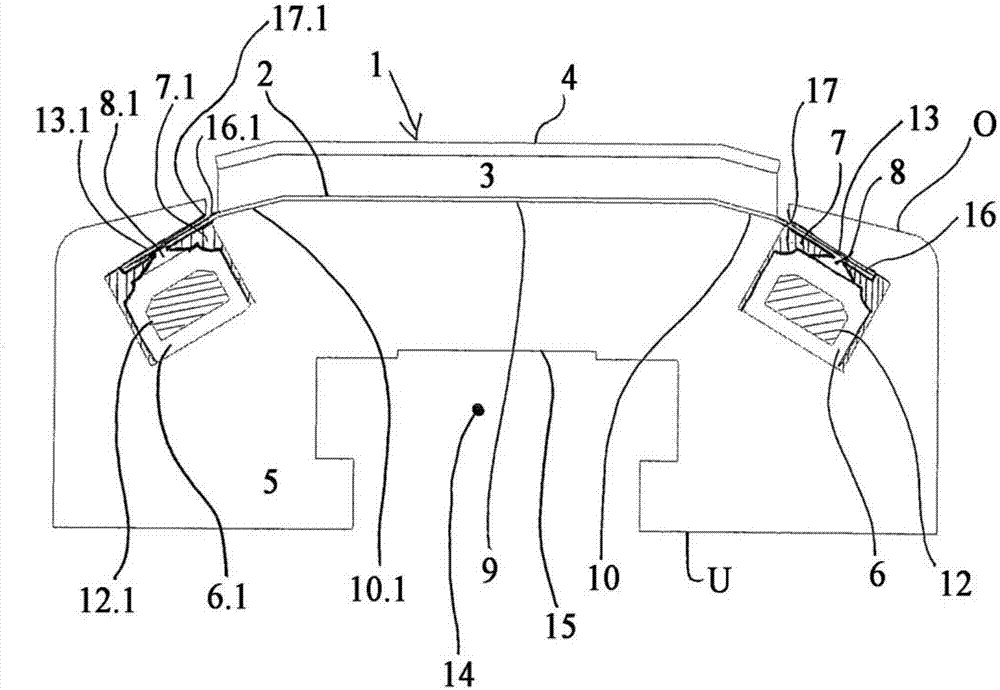

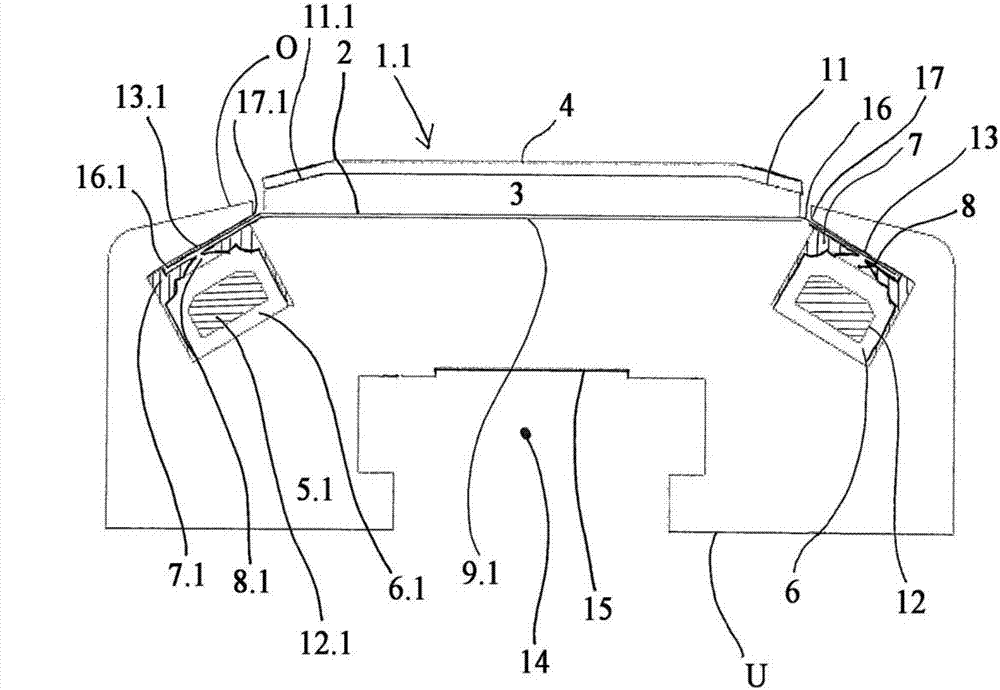

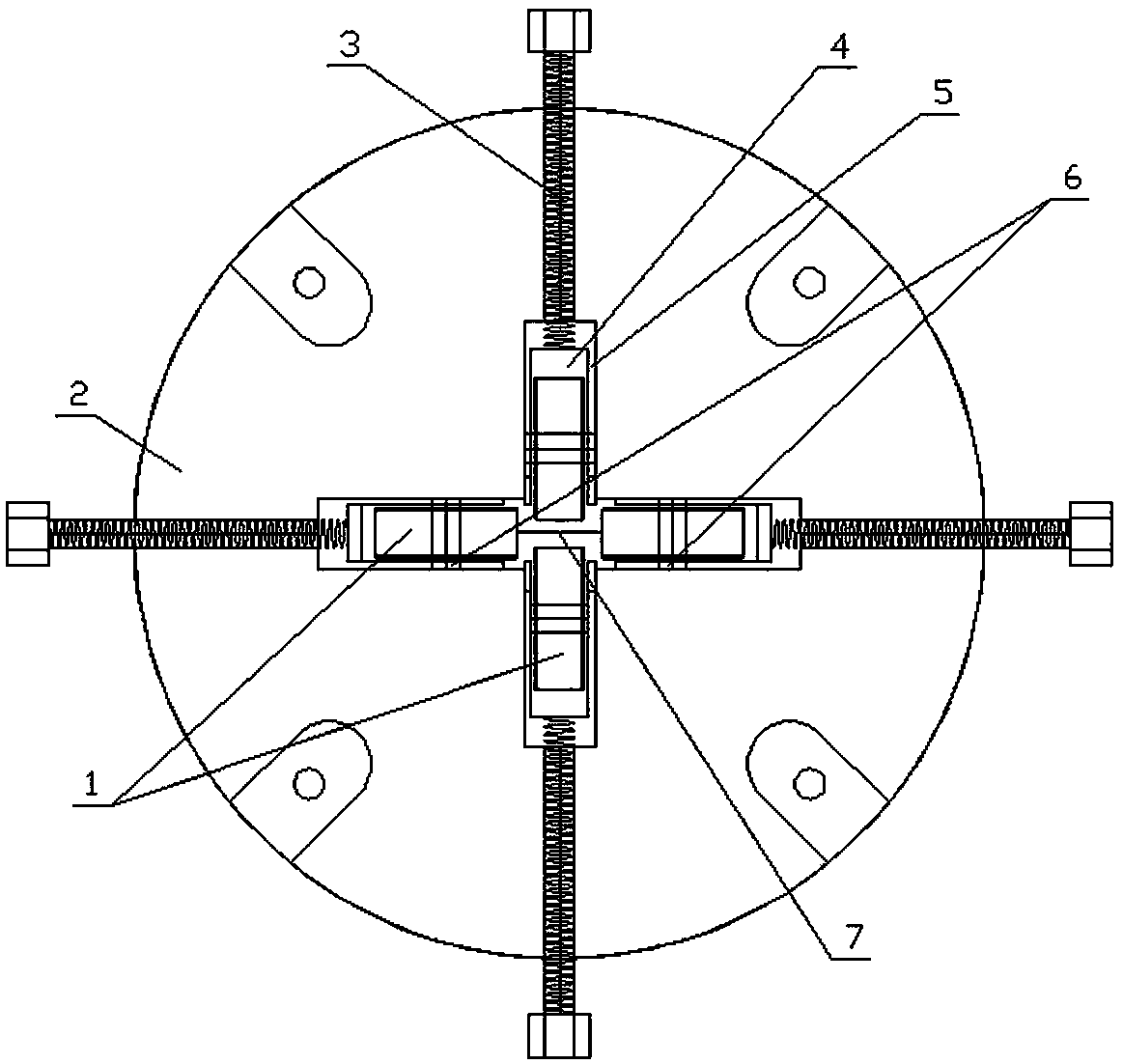

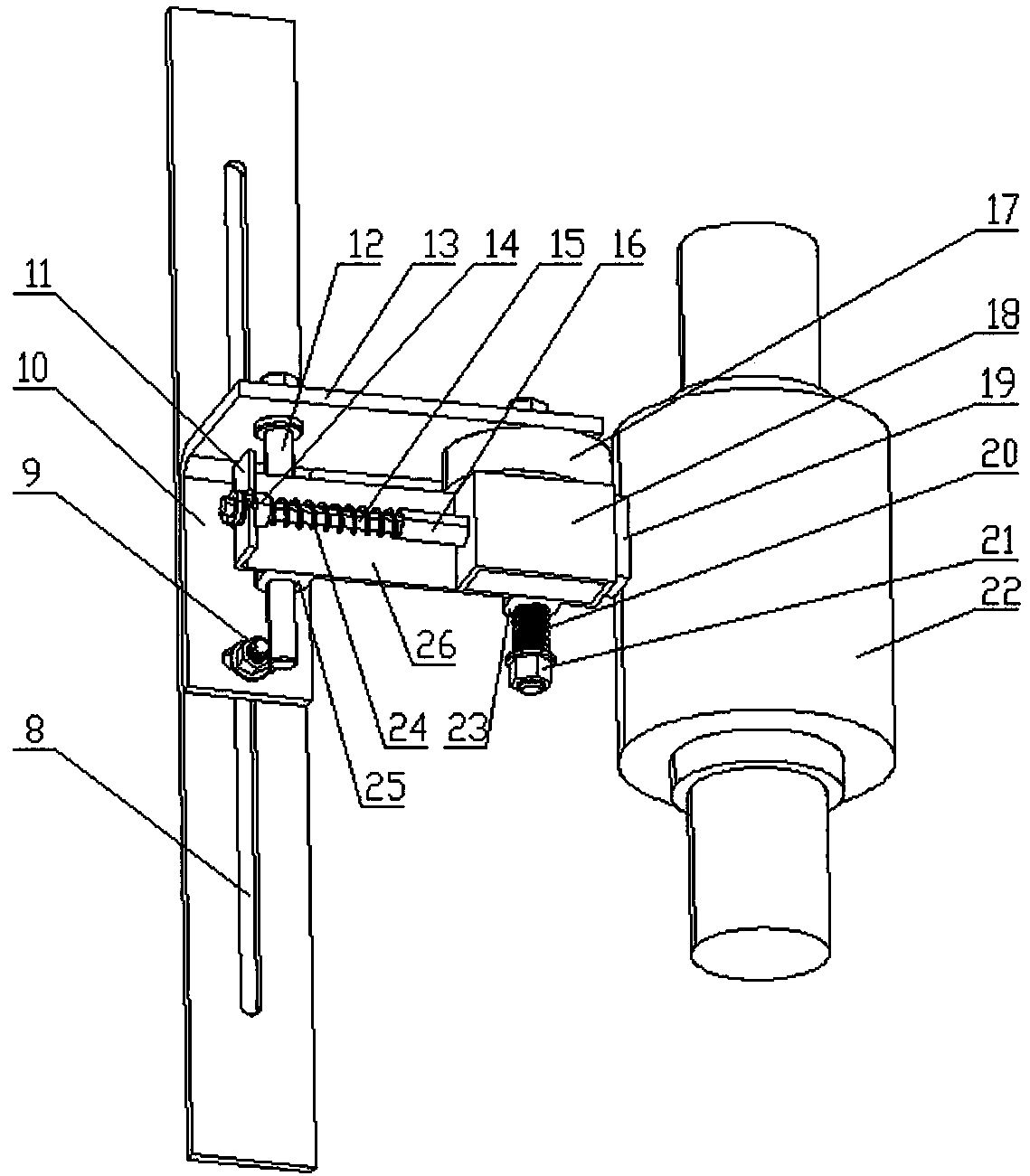

Sanding shoe, device for fixing same, sanding shoe bearing and method

PendingCN106985042ASmall thickness toleranceLow thermal expansionBelt grinding machinesEngineeringMechanical engineering

A sanding shoe (1, 1.1) for a belt grinding machine, consisting of a carrier (2), an intermediate material (3) and a sanding belt activator (4), wherein the carrier consists of a flexible material.

Owner:STEINEMANN TECH

Method of Cold Rolling into High Precision Bright Flat Steel by Wire Rod

ActiveCN106623414BReduce widthReduce thicknessMetal rolling stand detailsRolling equipment maintainenceWire rodWinding machine

The invention discloses a method of forming high-precision bright flat steel by carrying out cold rolling on a wire. The method is characterized in that the method sequentially comprises the following steps: selection of wire coiling steel is carried out; the wire coiling steel is subjected to acid cleaning with a hydrochloric acid solution; alkaline liquor is used for neutralizing; high pressure water is used for flushing, presetting and cleaning are carried out; a first five-stand tandem rolling mill, a second five-stand tandem rolling mill, a third five-stand tandem rolling mill, a fourth five-stand tandem rolling mill and a fifth five-stand tandem rolling mill are used for primary rolling; a polished rod reciprocating winding displacement and winding machine is used for winding displacement and winding; a first three-stand tandem finishing mill, a second three-stand tandem finishing mill and a third three-stand tandem finishing mill are used to roll semifinished flat steel, and the finished flat steel with the width tolerance being less than 0.08mm, the thickness tolerance being less than 0.05mm and the surface smoothness Ra being 0.08-0.13 is formed, wherein width control mechanisms are arranged at inlets of the first three-stand tandem finishing mill, the second three-stand tandem finishing mill and the third three-stand tandem finishing mill and on-line grinding roll devices are arranged on rolls of the first three-stand tandem finishing mill, the second three-stand tandem finishing mill and the third three-stand tandem finishing mill. With the adoption of the method, the width tolerance of the rolled flat steel can be reduced, the surface smoothness of the rolled flat steel can be improved, the equipment investment can be reduced and the production efficiency can be improved.

Owner:WUXI TIANCHI STEEL BAND CO LTD

A kind of acrylic coating low water vapor transmission rate polyester film and preparation method thereof

ActiveCN103753925BHigh elongation at breakStrong water resistanceSynthetic resin layered productsCoatingsPolyesterWater based

The invention discloses a low-water vapor transmission rate type polyester film for an acrylic acid type coating. The low-water vapor transmission rate polyester film is characterized by consisting of a double-direction stretching polyester film prepared from polyethylene terephthalate or poly-2,6-ethylene naphthalate and acrylic acid type glue coatings, wherein the both sides of the film are coated with the acrylic acid type glue coatings; the thickness of the polyester film is 150-250 microns; the thickness of the acrylic acid type glue coatings is 0.08-0.32 microns; acrylic acid type glue consists of a water-based acrylic emulsion, a nanometer silicon sol, a surfactant, a flatting agent, a de-foaming agent, a curing agent and de-ionized water; after a polyester chip is cast to form a casting piece through an extruder and forms a film through vertical stretching, the both surfaces of the film are coated with the acrylic acid type glue in an online coating manner; the low-water vapor transmission rate type polyester film for the acrylic acid type coating is prepared by transverse stretching, drying, cross-linking, curing and thermal shaping. The film provided by the invention can be used for manufacturing a backboard film for a solar battery or other products in need of the low-water vapor transmission rate polyester film.

Owner:四川东方绝缘材料股份有限公司

Turning tool for machining ultrathin broad-width polytetrafluoroethylene thin film

PendingCN107755722AGuaranteed service lifeLow costCutting insertsWorkpiecesStructural engineeringKnife blades

The invention discloses a turning tool for machining an ultrathin broad-width polytetrafluoroethylene thin film. The turning tool comprises a pressing knife, a blade and a lower knife body, wherein the blade is fixed on the lower knife body in a detachably movable connection manner; knife slots for mounting and fixing the blade are formed in the lower knife body; locking bolts are arranged on oneside of the knife slots of the lower knife body; and the blade is fixed on the lower knife body through the locking bolts. The pressing knife and the lower knife body are respectively connected and fixed with a lathe through fixing bolts; bolt slots convenient for adjusting fixed positions are respectively formed in the pressing knife and the lower knife body; and the blade is made of hard alloy.According to the turning tool for machining the ultrathin broad-width polytetrafluoroethylene thin film, the blade is fixedly clamped between an upper knife body and the lower knife body through bolts, so that reliable fixing of the blade can be realized, and the problem on welding of a conventional knife body and the blade is solved. The service life of the turning tool can be effectively guaranteed; and furthermore, the tool cost is reduced, and the production efficiency is improved.

Owner:JIANGSU TAIFULONG TECH

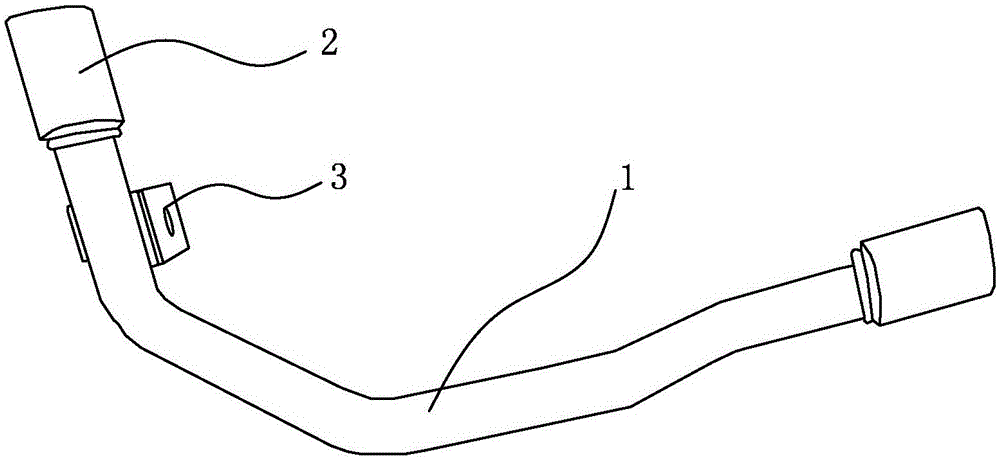

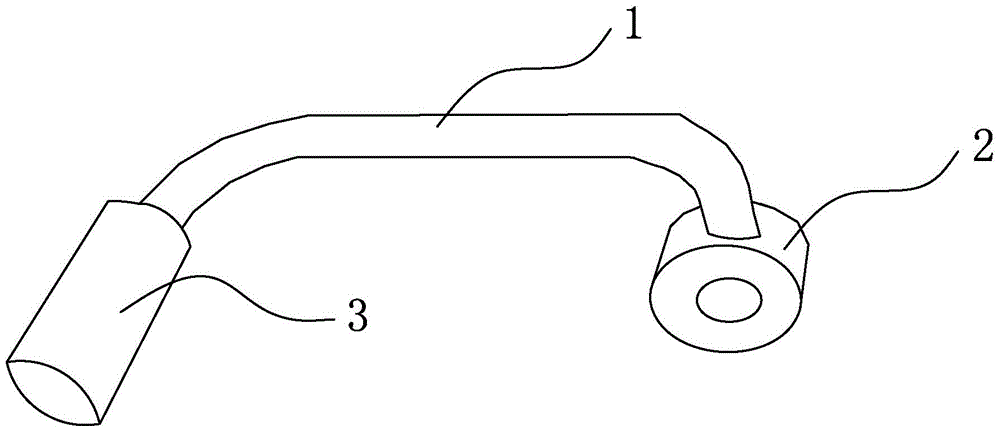

Surface treatment process for eye joint of brake pipe

InactiveCN105132907AImprove protection performanceImprove the decorative appearanceMetallic material coating processesPre treatmentMicrometer

The invention relates to a surface treatment process for an eye joint of a brake pipe. The surface treatment process comprises the steps that a base material is subjected to pretreatment; a protecting layer is formed on the base material; the protecting layer is a zinc layer, and the thickness of the zinc layer is 6-15 micrometers; a passive film layer is formed on the protecting layer; a sealing film layer is formed on the passive film layer. According to the surface treatment process, after the surface treatment is conducted on the eye joint of the brake pipe, the eye joint of the brake pipe is more attractive, the performance such as medium resistance, oxidation resistance and corrosion resistance is better, and the service life is longer.

Owner:NINGBO YADA METAL SURFACE TREATMENT

Method of forming high-precision bright flat steel by carrying out cold rolling on wire

ActiveCN106623414AReduce widthReduce thicknessMetal rolling stand detailsRolling equipment maintainenceWinding machineWork in process

The invention discloses a method of forming high-precision bright flat steel by carrying out cold rolling on a wire. The method is characterized in that the method sequentially comprises the following steps: selection of wire coiling steel is carried out; the wire coiling steel is subjected to acid cleaning with a hydrochloric acid solution; alkaline liquor is used for neutralizing; high pressure water is used for flushing, presetting and cleaning are carried out; a first five-stand tandem rolling mill, a second five-stand tandem rolling mill, a third five-stand tandem rolling mill, a fourth five-stand tandem rolling mill and a fifth five-stand tandem rolling mill are used for primary rolling; a polished rod reciprocating winding displacement and winding machine is used for winding displacement and winding; a first three-stand tandem finishing mill, a second three-stand tandem finishing mill and a third three-stand tandem finishing mill are used to roll semifinished flat steel, and the finished flat steel with the width tolerance being less than 0.08mm, the thickness tolerance being less than 0.05mm and the surface smoothness Ra being 0.08-0.13 is formed, wherein width control mechanisms are arranged at inlets of the first three-stand tandem finishing mill, the second three-stand tandem finishing mill and the third three-stand tandem finishing mill and on-line grinding roll devices are arranged on rolls of the first three-stand tandem finishing mill, the second three-stand tandem finishing mill and the third three-stand tandem finishing mill. With the adoption of the method, the width tolerance of the rolled flat steel can be reduced, the surface smoothness of the rolled flat steel can be improved, the equipment investment can be reduced and the production efficiency can be improved.

Owner:WUXI TIANCHI STEEL BAND CO LTD

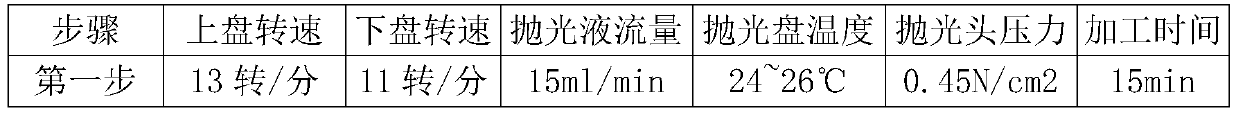

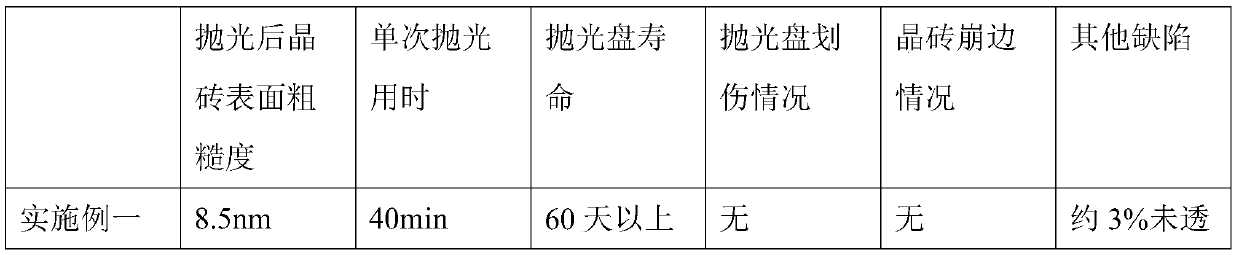

A kind of sapphire crystal brick polishing method

The invention provides a sapphire crystal brick polishing method. According to the sapphire crystal brick polishing method, firstly, polishing is conducted at a low pressure, low rotating speed and large flow in the first polishing step, so that sharp parts on the surface of a crystal brick are removed, and broken edges of the crystal brick and scratches of a polishing disc are reduced; secondly,removal polishing is conducted at a high pressure, medium rotating speed and properly-lowered flow in the second polishing step, so that the probability of incomplete polishing is lowered, and accordingly the surface of the sapphire crystal brick polished in the first step is smoother; and finally, the third polishing step is conducted at a low pressure and high rotating speed, and thus the smoothness of the polished surface of the crystal brick is ensured. Through the sapphire crystal brick polishing method, the surface of the sapphire crystal brick can be made transparent and has the effectof a mirror surface, a platform is provided for defect detection of the crystal brick, and the machining cost of the subsequent section is reduced; and defective material flow is effectively preventedcirculating to the subsequent procedure, and waste of machines, labor and auxiliary materials is reduced. In addition, in the polishing process, scratches, broken edges and cracks of the polishing disc are avoided; and the polishing method is also suitable for polishing nonmetal bricks made of aluminum oxide, zirconium oxide ceramic and the like.

Owner:LENS TECH CHANGSHA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com