Sanding shoe, device for fixing same, sanding shoe bearing and method

The technology of a shoe holder and a fixing chamber is applied in grinding shoes, a device for fixing a grinding shoe, a grinding shoe holder and other fields, which can solve the problems of high consumption of pressure components or grinding shoes, and achieve quick and easy replacement Or displacement, low thermal expansion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

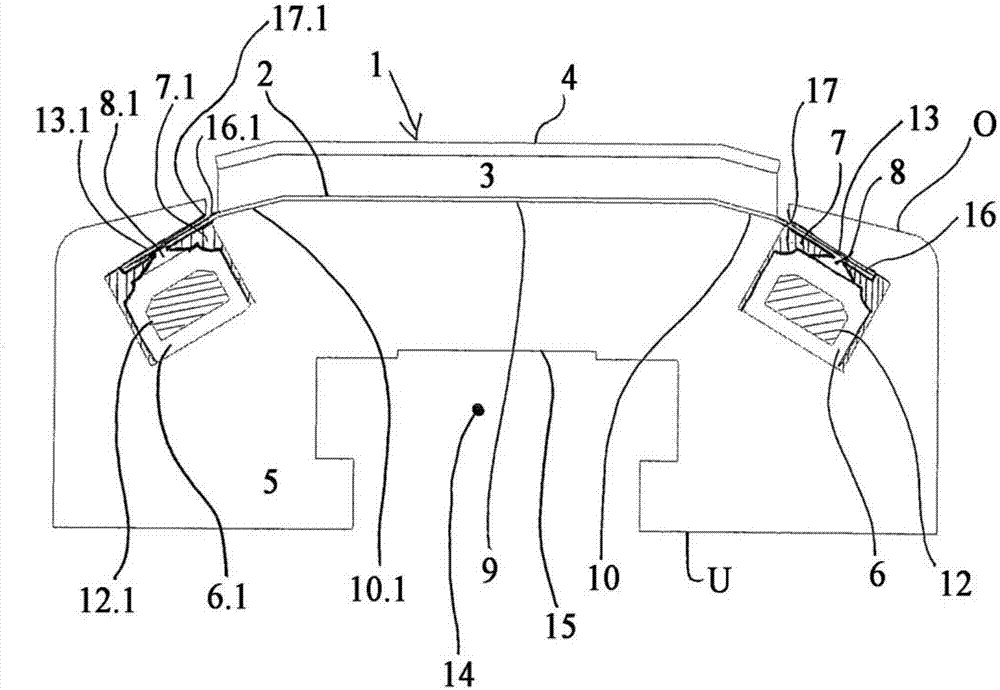

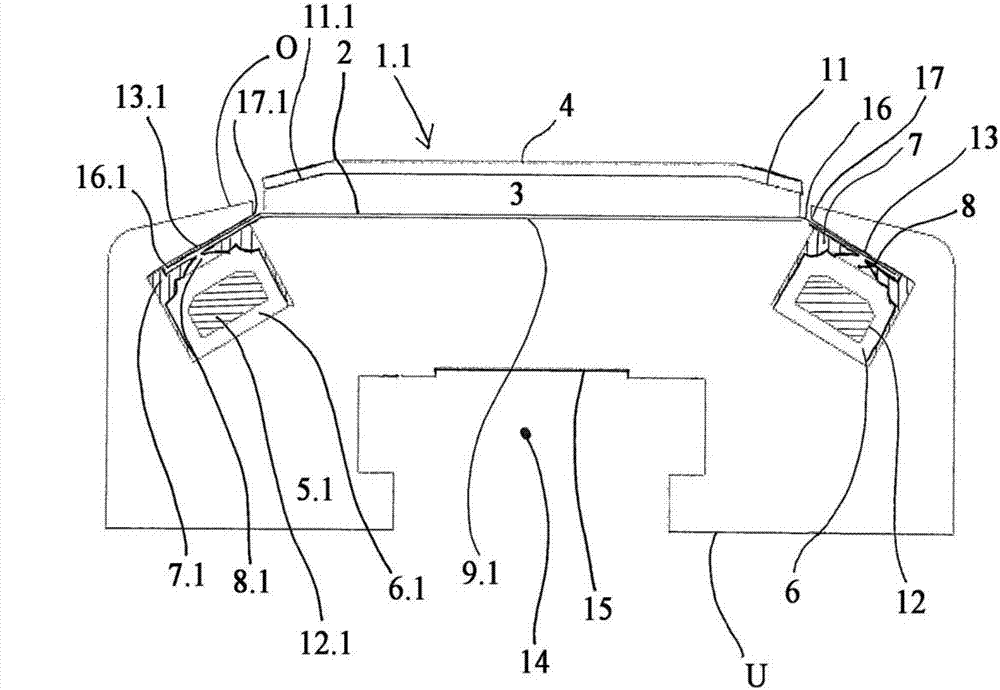

[0051] exist figure 1 A cross-sectional view of an embodiment of a grinding shoe receptacle 5 according to the invention with inserted grinding shoe 1 can be seen in .

[0052] The grinding shoe 1 consists of three layers. An intermediate material 3 is arranged in the middle. One side of the intermediate material 3 is a bracket 2 made of cardboard. The other side of the intermediate material 3 is coated with another layer, which is referred to as the belt motivator 4 . The intermediate material 3 and the belt actuator 4 do not completely cover the carrier 2, so that the first carrier strap 16 and the second carrier strap 16.1 of the carrier 2 remain uncovered.

[0053] The grinding shoe receptacle 5 has a contact surface 9 on the side O, against which the grinding shoe 1 rests. On the contact surface 9 a first bevel 10 is arranged on one side and a second bevel 10.1 is arranged on the other side. As a result, the contact surface 9 maintains the angled configuration. This...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com