A kind of sapphire crystal brick polishing method

A sapphire and crystal brick technology, applied in surface polishing machine tools, grinding/polishing equipment, metal processing equipment, etc., can solve the problems of high cost, chipping and cracks, easy to scratch polishing discs, etc., to save processing costs , reduce the effect of the machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Clamp and fix the sapphire crystal brick between the upper polishing disc and the lower polishing disc of the double-sided polishing machine with a jig. Both the upper polishing disc and the lower polishing disc are made of resin copper discs. The particle size of the diamond micropowder is mainly distributed in the range of 3-5 μm, the pH of the polishing solution is 9.6, and the polishing process includes three steps as described in Table 1:

[0023] Table 1

[0024] step Plate speed Bottom plate speed Polishing fluid flow Polishing disc temperature Polishing head pressure Processing time first step 15 rpm 10 rpm 18mL / min 28~33℃ 0.5N / cm2 10min second step 27 rpm 17 rpm 15mL / min 28~33℃ 0.75N / cm2 20min third step 34 rpm 24 rpm 15mL / min 28~33℃ 0.35N / cm2 10min

[0025] In the first polishing step, the second polishing step and the third polishing step of the first embodiment, the directions of the up...

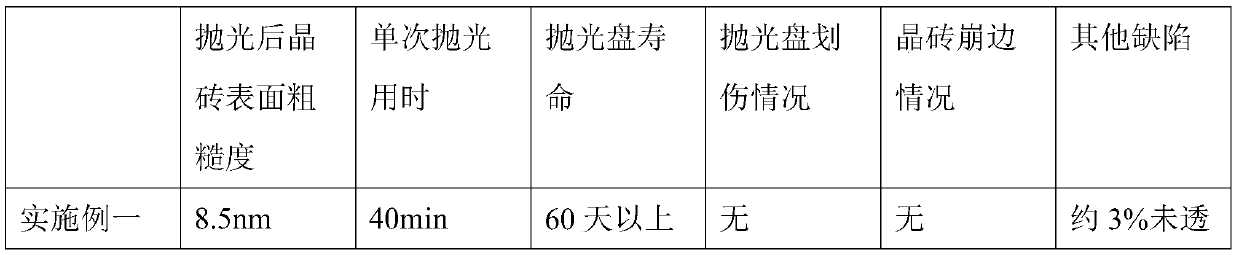

Embodiment 2

[0028] Clamp and fix the sapphire crystal brick between the upper polishing disc and the lower polishing disc of the double-sided polishing machine with a jig. Both the upper polishing disc and the lower polishing disc are made of resin copper discs. The particle size of the diamond powder is mainly distributed in the range of 5-7 μm, the pH of the polishing solution is 9.2, and the polishing process includes the three steps described in Table 2:

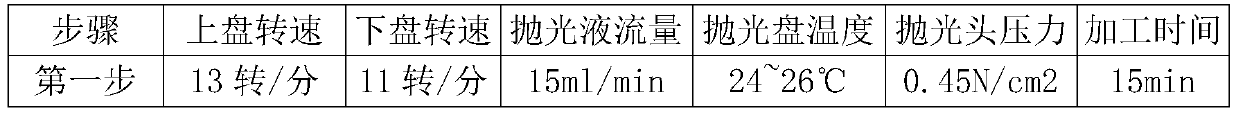

[0029] Table 2

[0030]

[0031]

[0032] In the first polishing step, the second polishing step and the third polishing step of the second embodiment, the directions of the upper polishing disk and the lower polishing disk are opposite.

[0033] The blanks polished by the sapphire crystal brick polishing method in Example 2 are several sapphire crystal bricks with a thickness of 64.5mm. The weight of the crystal brick is in the range of 1000g-3000g.

Embodiment 3

[0035] Clamp and fix the sapphire crystal brick between the upper polishing disc and the lower polishing disc of the double-sided polishing machine with a jig. Both the upper polishing disc and the lower polishing disc are made of resin copper discs. The particle size of the diamond powder is mainly distributed in the range of 2 to 5 μm, the pH of the polishing solution is = 10, and the polishing process includes the three steps described in Table 3:

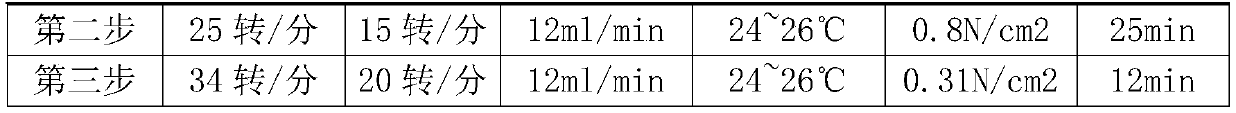

[0036] table 3

[0037] step Plate speed Bottom plate speed Polishing fluid flow Polishing disc temperature Polishing head pressure Processing time first step 18 rpm 13 rpm 20ml / min 24~26℃ 0.55N / cm2 8min second step 28 rpm 18 rpm 12ml / min 24~26℃ 0.85N / cm2 15min third step 38 rpm 24 rpm 12ml / min 24~26℃ 0.45N / cm2 10min

[0038] In the first polishing step, the second polishing step and the third polishing step of the third embodiment, the directions of the up...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com