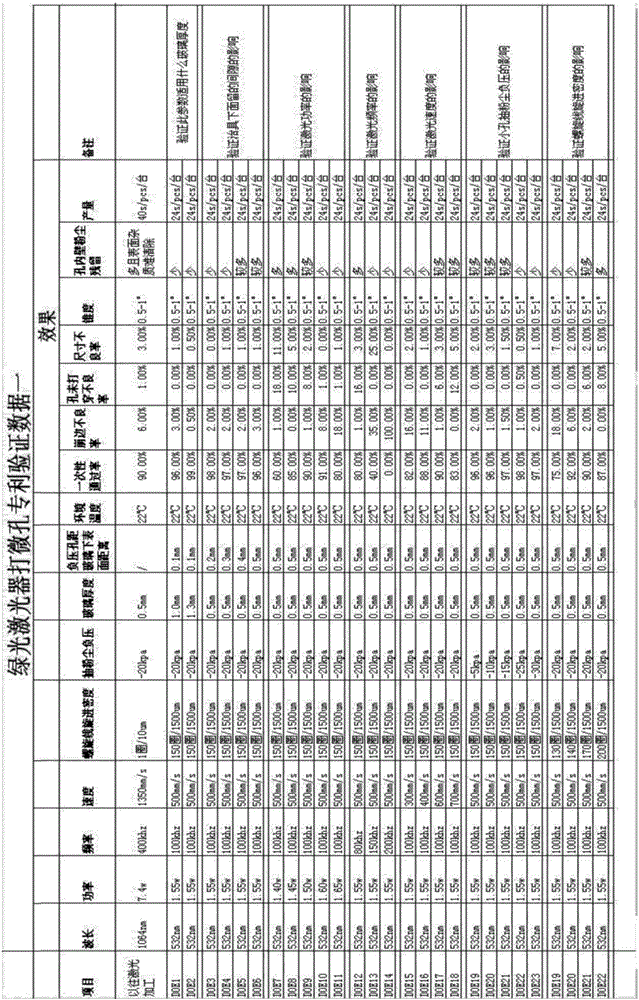

Patents

Literature

109results about How to "No chipping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

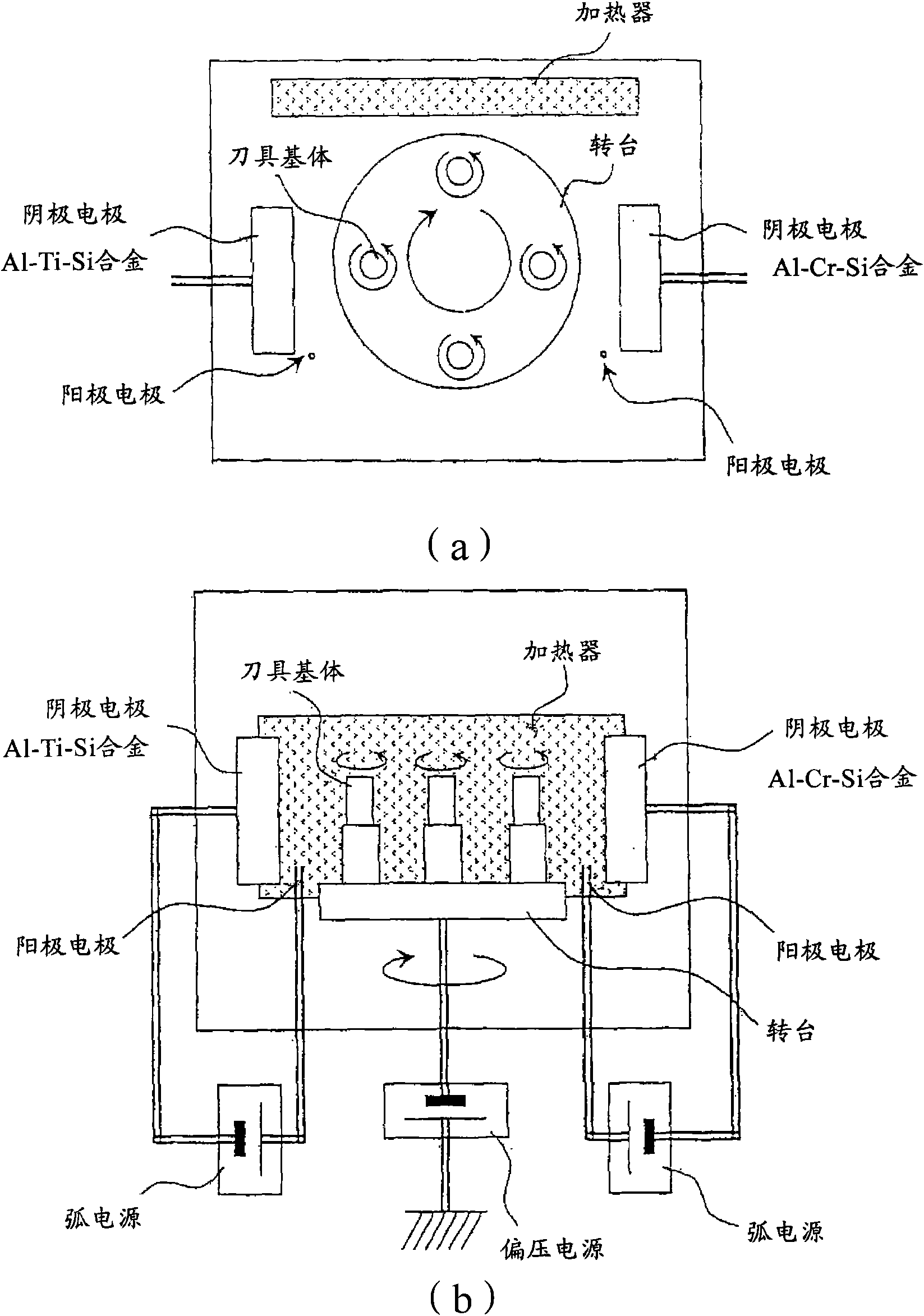

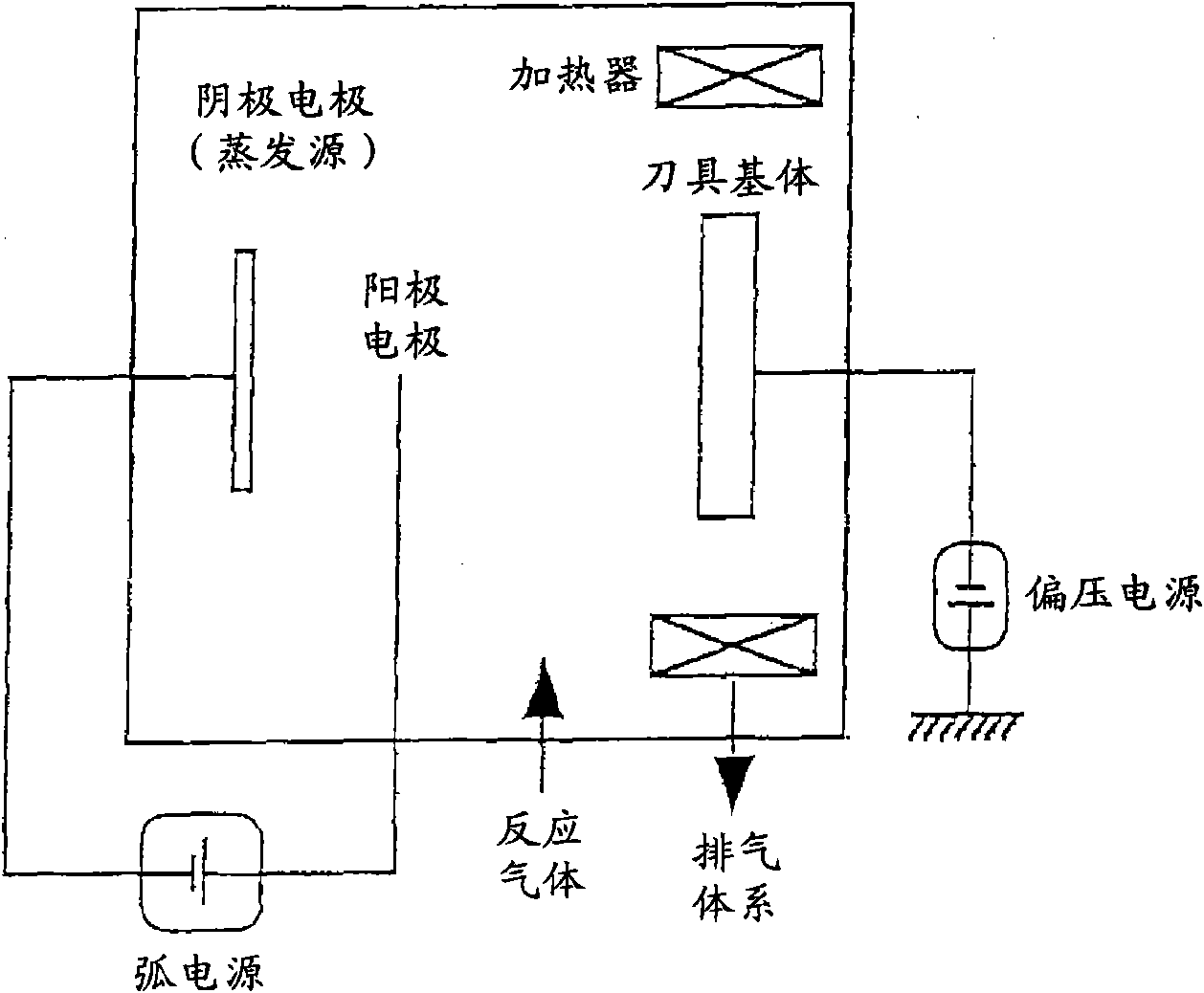

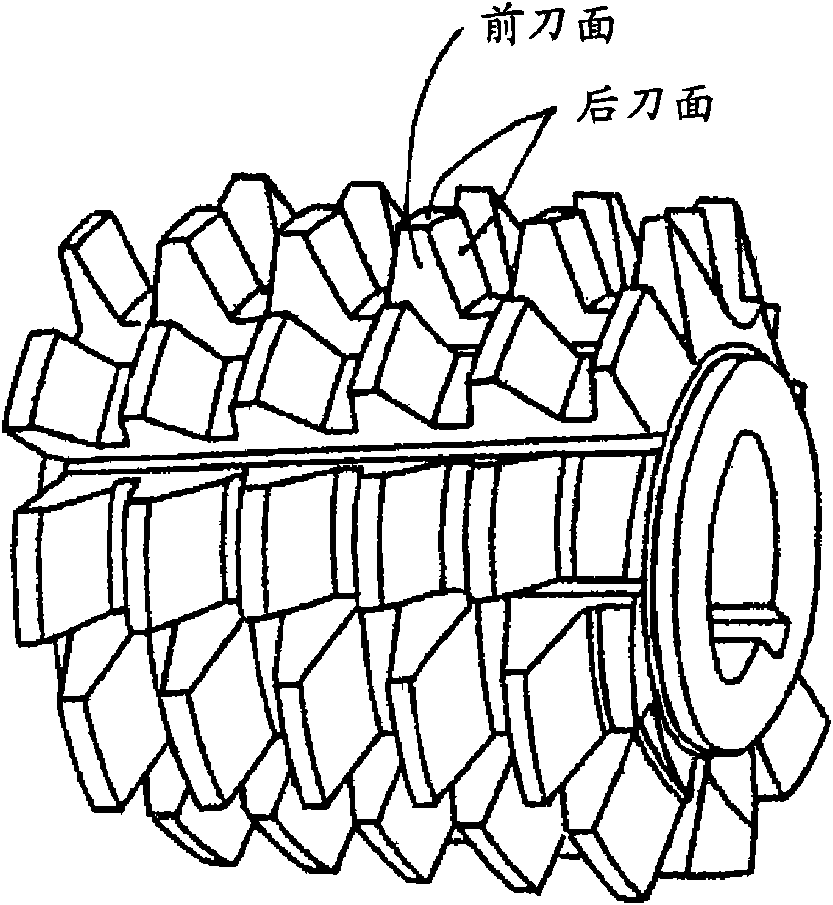

Surface-coated cutting tool

ActiveCN101678467AExcellent high temperature hardnessExcellent high temperature toughnessMilling cuttersVacuum evaporation coatingThin layerCemented carbide

A surface-coated cutting tool which has excellent chipping resistance and wearing resistance in high-speed cutting processing such as high-speed gear cutting processing, high-speed milling processing,and high-speed drilling processing. The surface-coated cutting tool comprises a tool base, e.g., a cemented carbide base, cermet base, or high-speed tool steel base, and at least a hard coating layerformed on a surface of the tool base and having a multilayer structure composed of a thin layer (A) and a thin layer (B) alternating therewith. The thin layer (A) is constituted of an (Al,Cr,Si)N layer satisfying the empirical formula ¢AlXCrYSiZ!N (wherein 0.2 <= X <= 0.45, 0.4 <= Y <= 0.75, 0.01 <=Z <= 0.2, and X+Y+Z=1 in terms of atomic ratio), and the thin layer (B) is constituted of an (Al,Ti,Si)N layer satisfying the empirical formula ¢AlUTiVSiW!N (wherein 0.05 <= U <= 0.75, 0.15 <= V <= 0.94, 0.01 <= W <= 0.1, and U+V+W=1 in terms of atomic ratio).

Owner:MITSUBISHI MATERIALS CORP

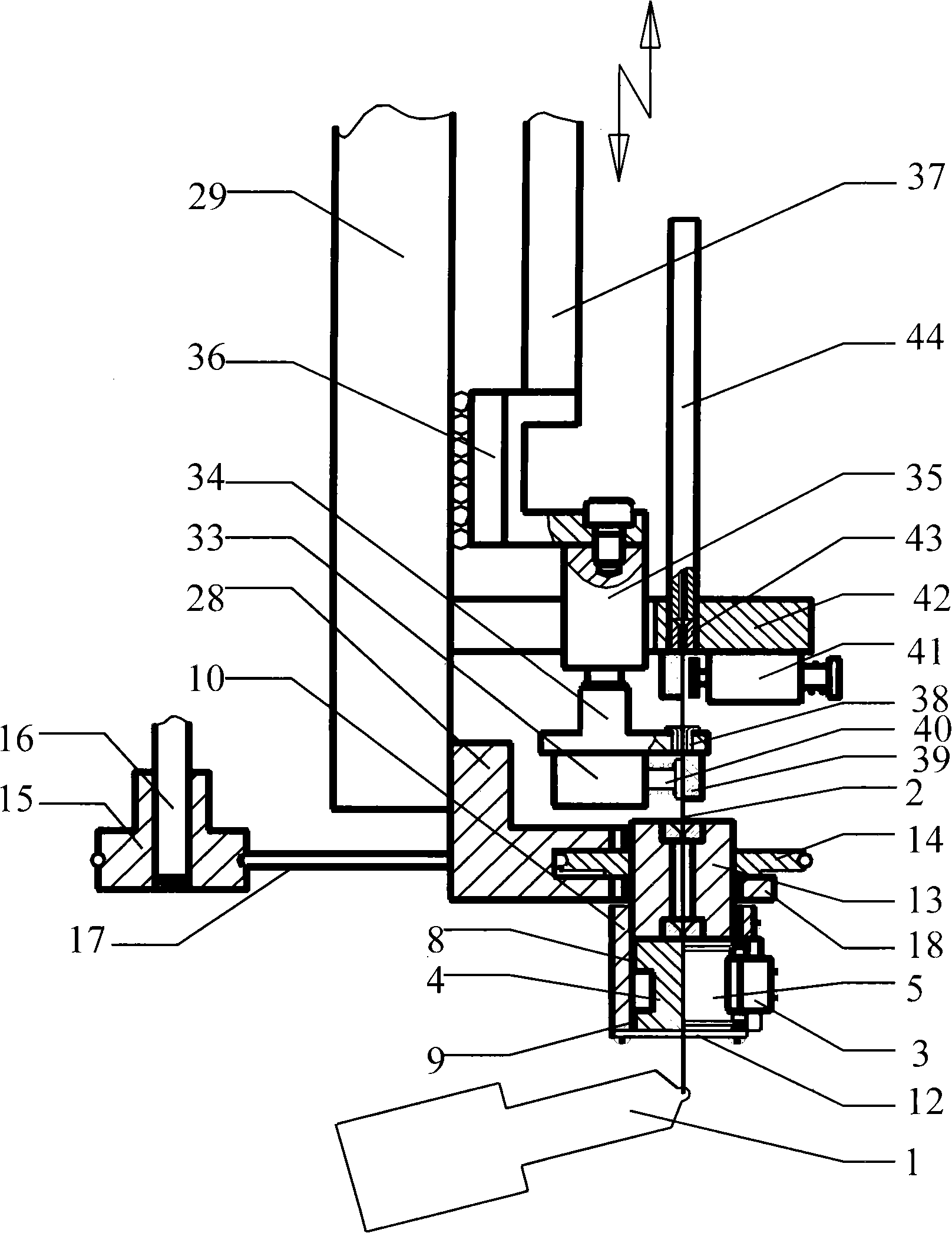

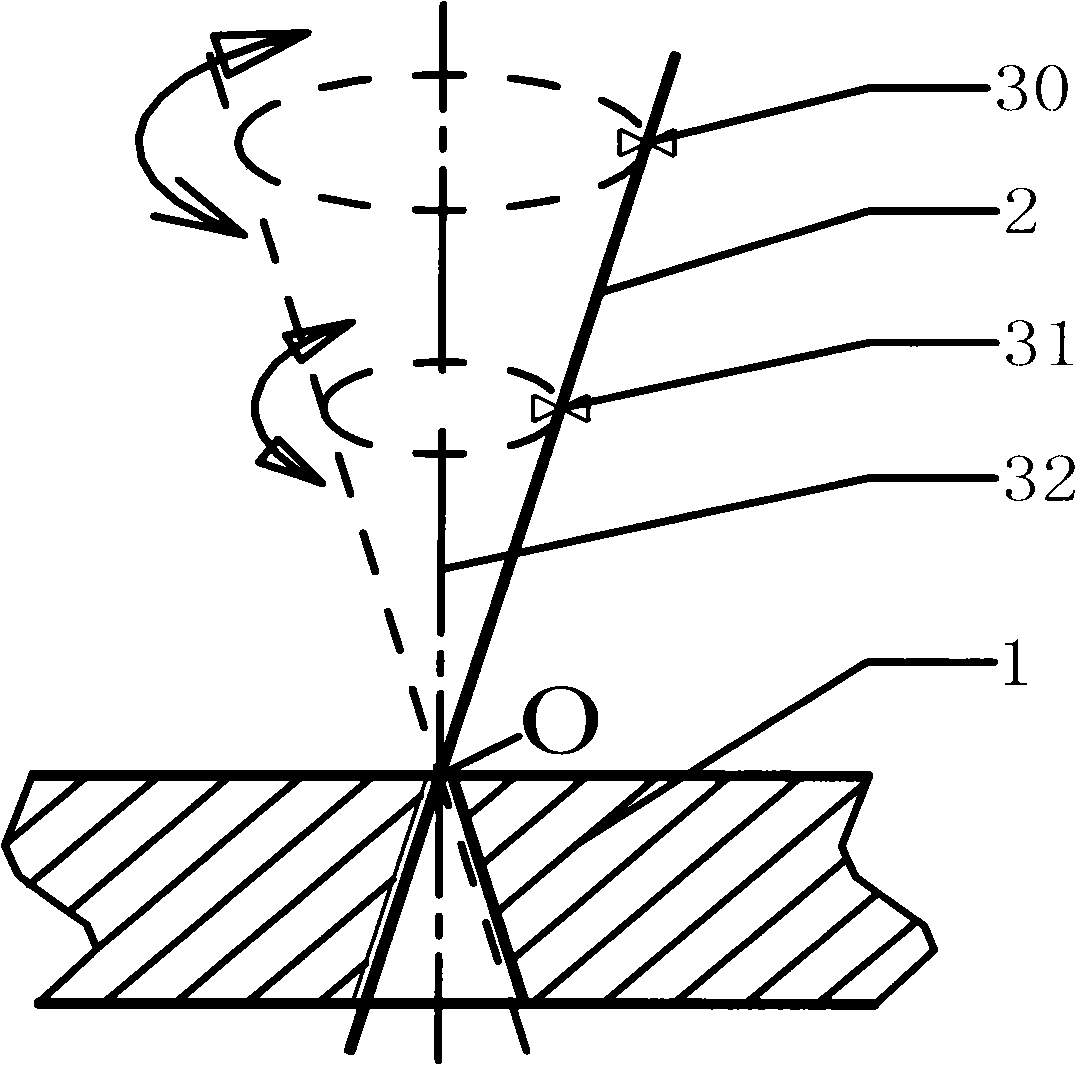

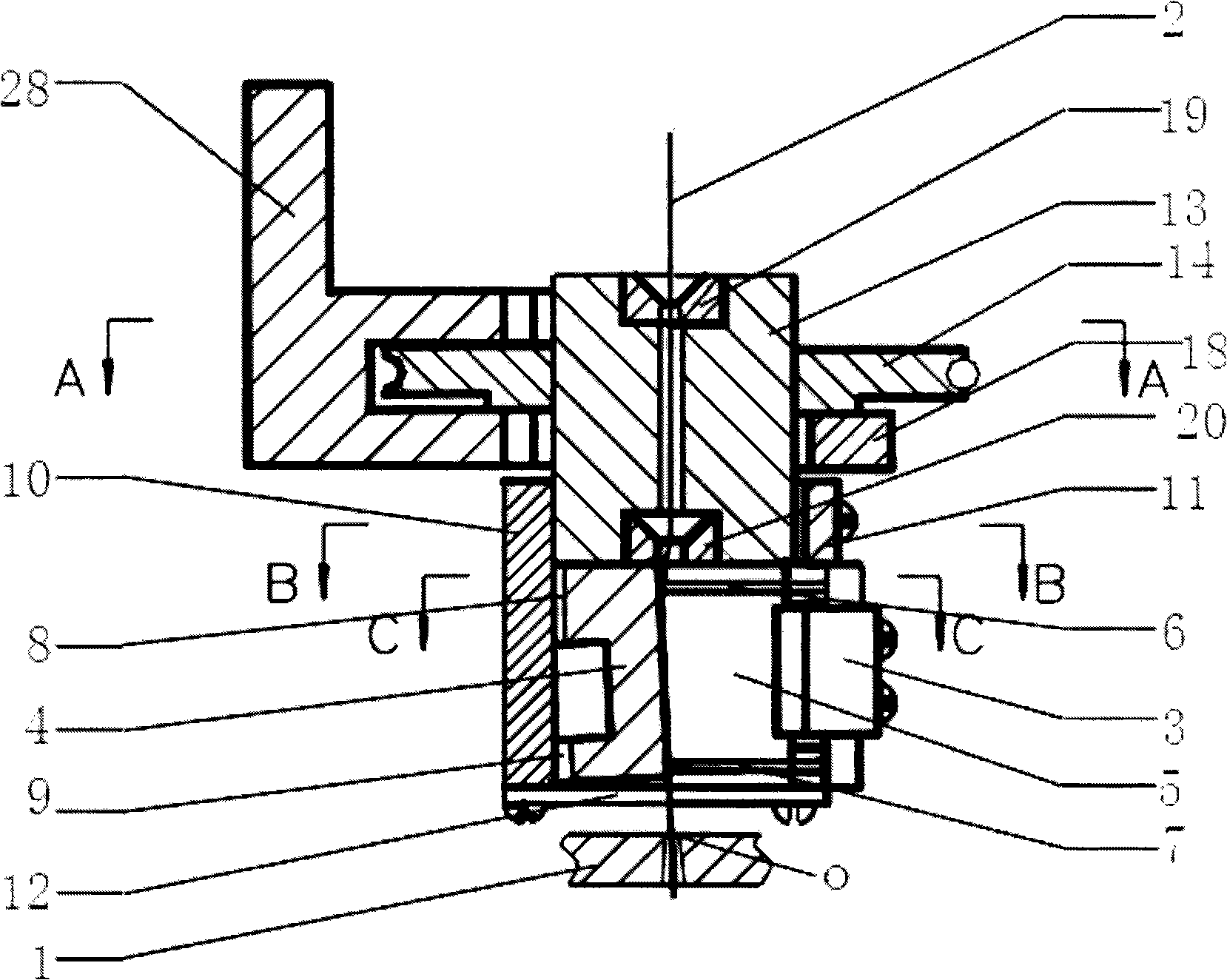

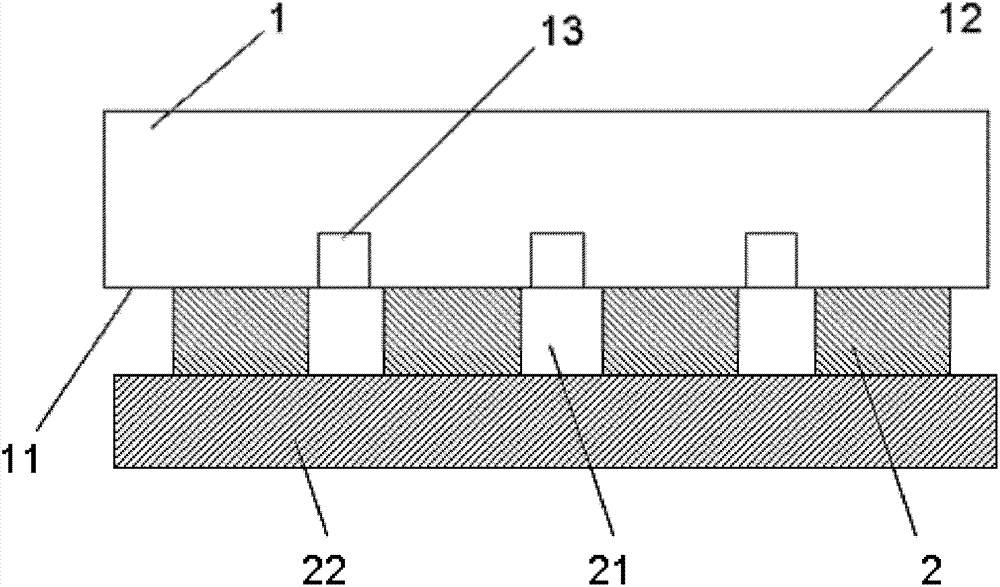

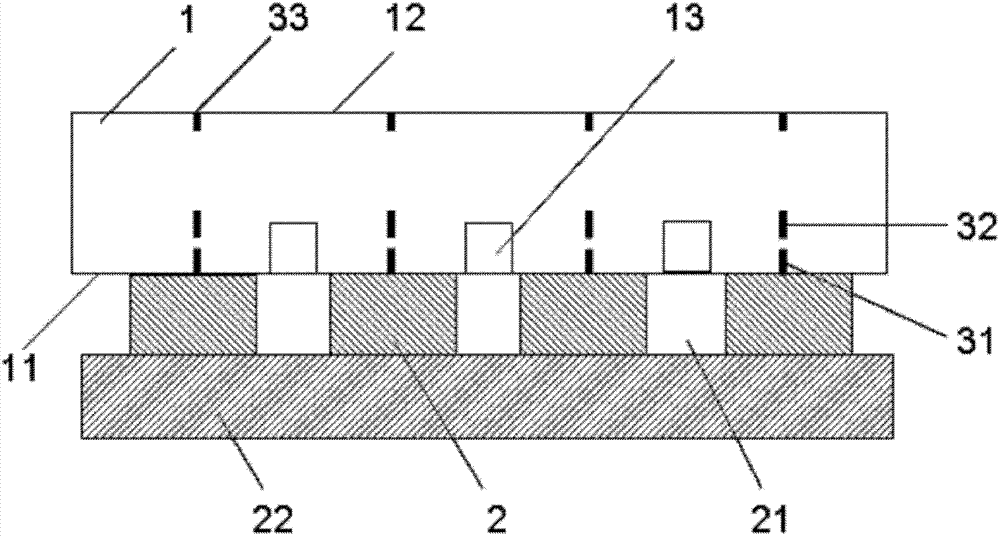

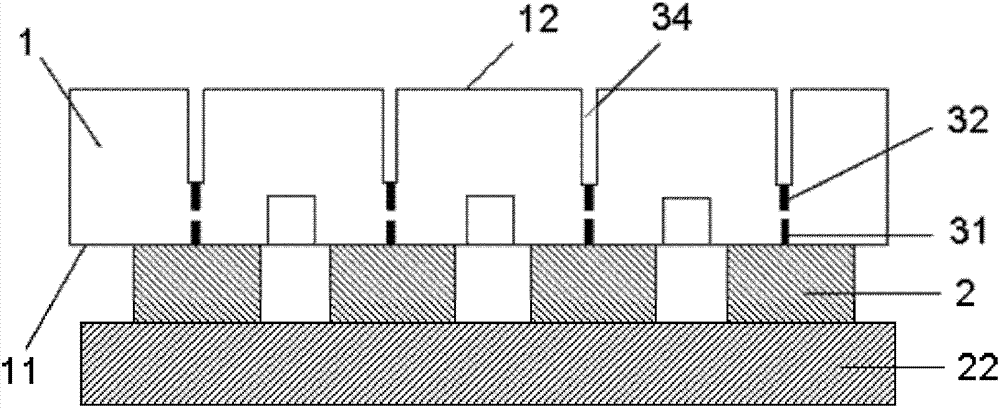

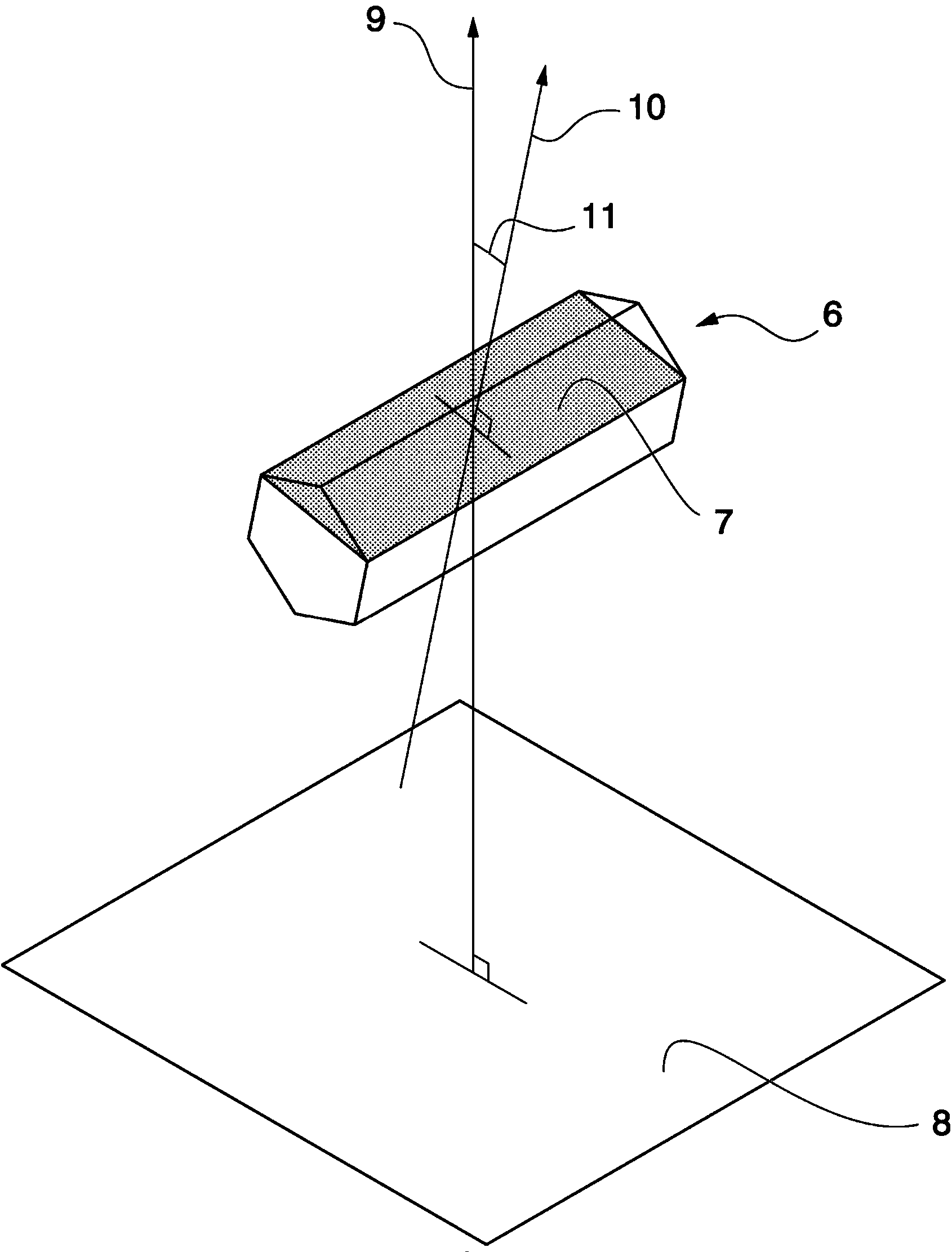

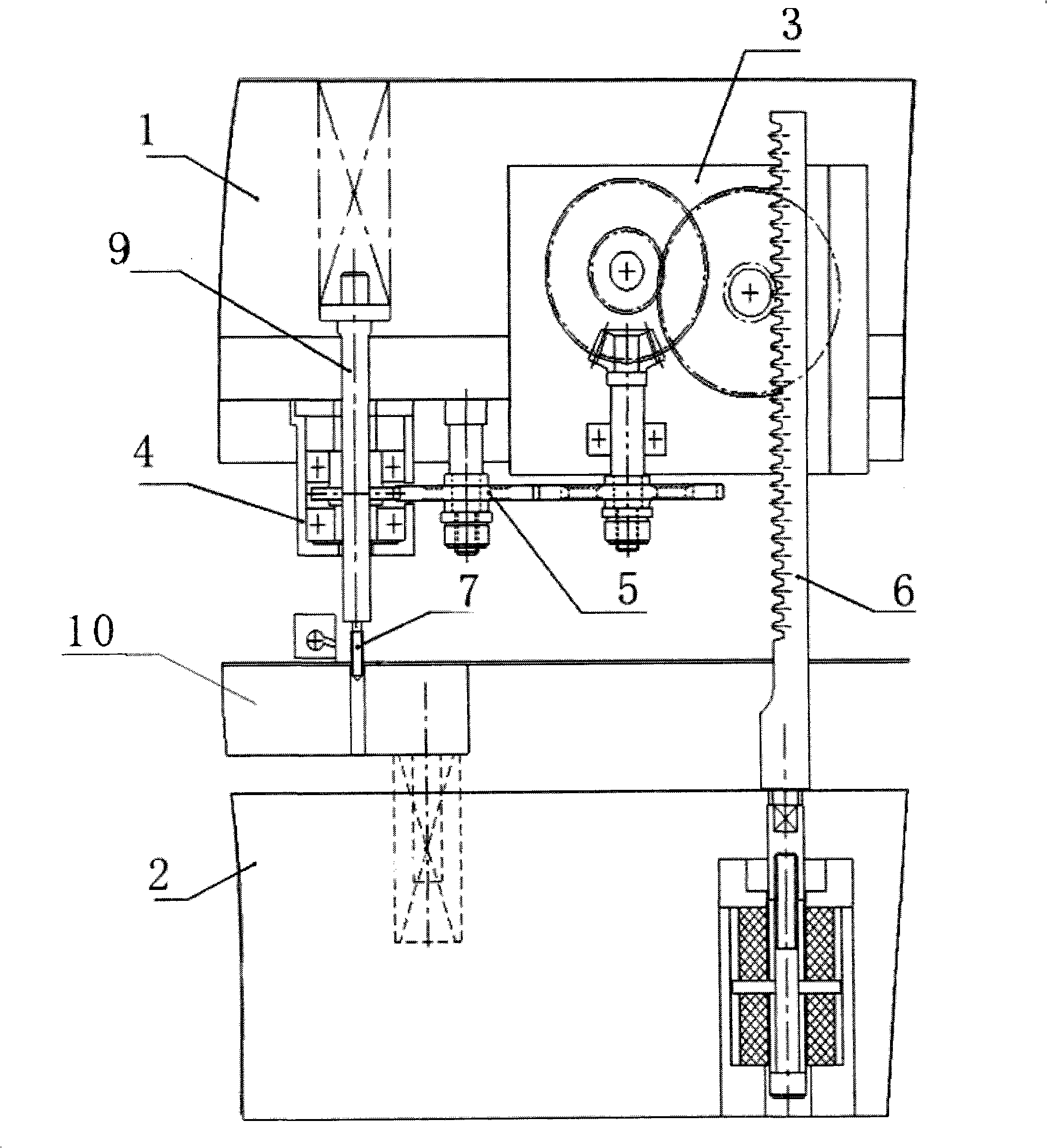

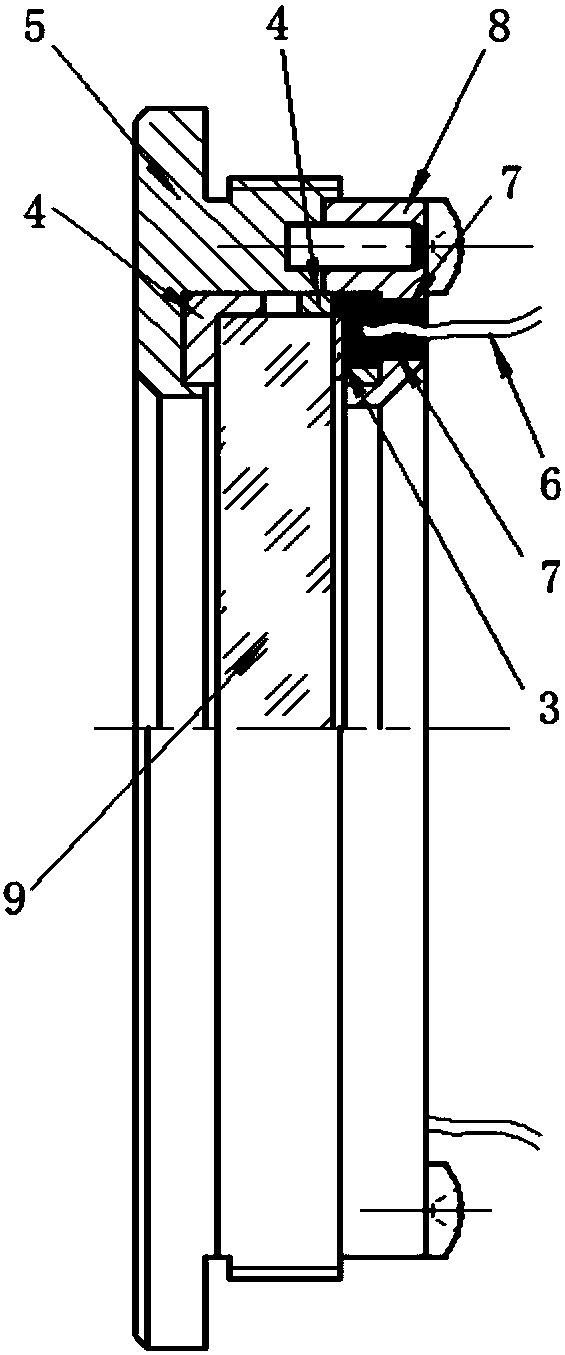

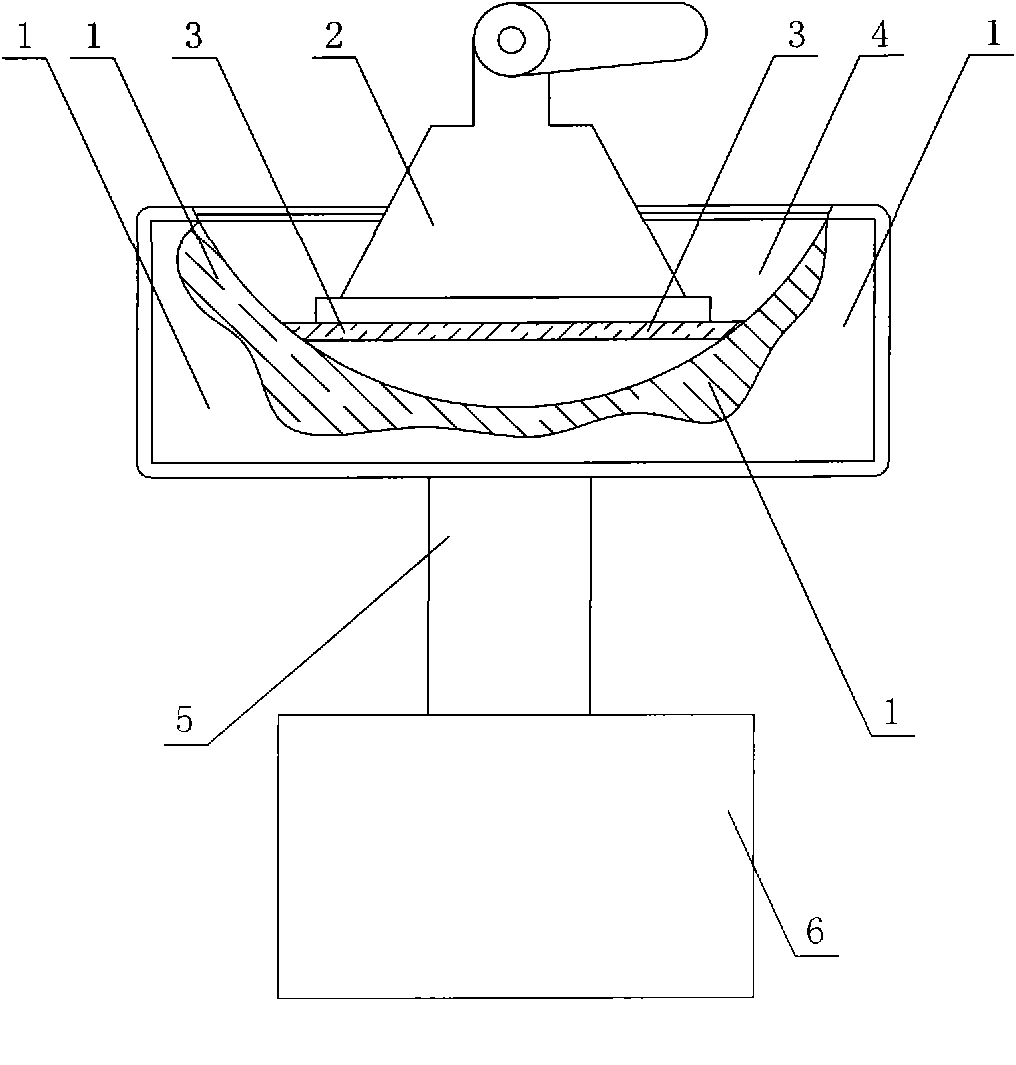

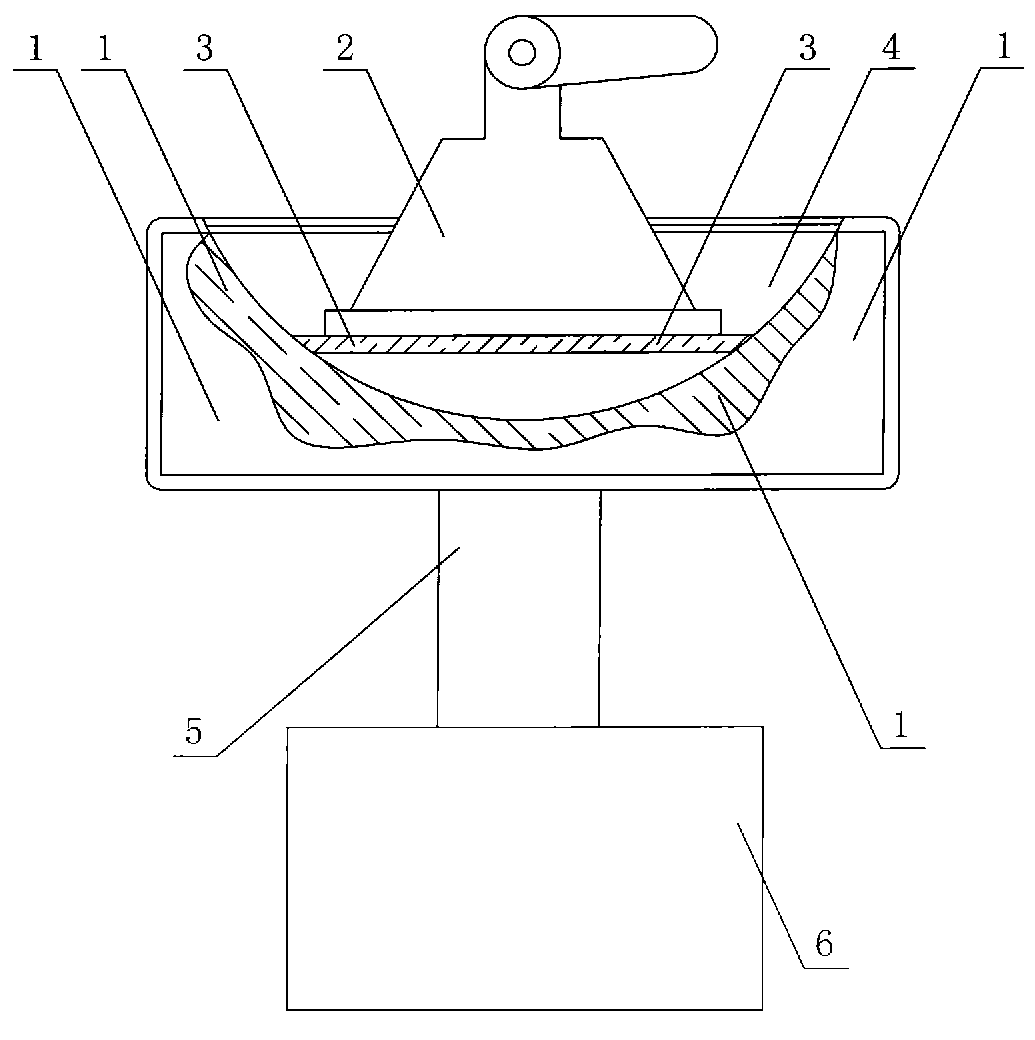

Superfine back taper hole spark-erosion machining electrode movement guide mechanism

The invention relates to an electrode movement guide mechanism for the electric spark processing of micro inverted taper holes and belongs to the technical field of the special micro machining. The mechanism adopts an external cylindrical surface of a rotating shaft to position the movement guidance of the micro electrode wires which are restricted and positioned into a rectangular guide groove which consists of a left cushion block and a right cushion block under the rotating shaft; the thickness of the cushion blocks is adjusted so as to cause the left cushion block and the rectangular guide groove to incline; the micro electrode wires incline to the axis of the rotating shaft for certain angle and the intersection point of the micro electrode wires and the axis is positioned at the upper surface of a work piece. When in processing, the micro electrode wires perform servo feed under the action of an automatic compensation mechanism for the micro electrode loss and at the same time move along a set conical surface driven by the electrode movement guide mechanism of the invention, thus processing the inverted taper holes on the work pieces. The electrode movement guide mechanism is arranged below a normal-closed screw clamping mechanism and forms an electric spark processing device for micro inverted taper holes with a micro electrode servo driving mechanism and the automatic compensation mechanism for the micro electrode loss to be used in the processing of micro inverted jet orifices of oil injection nozzles.

Owner:TSINGHUA UNIV

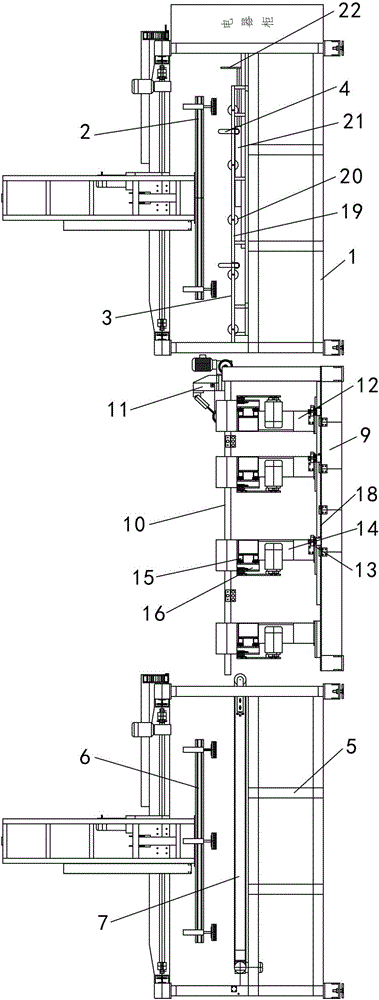

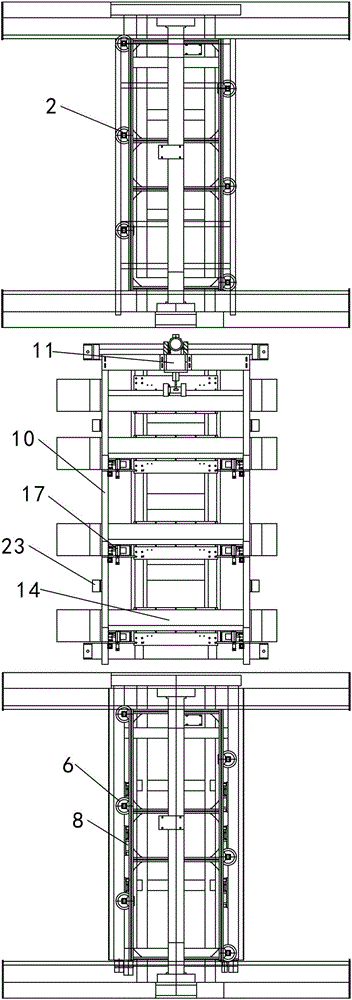

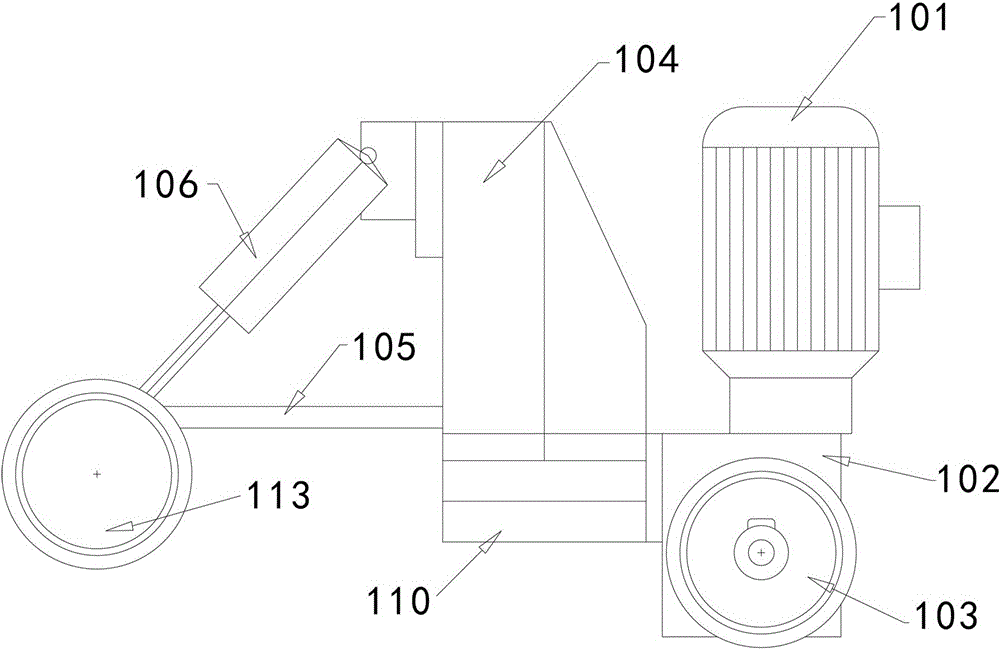

Intelligent wood floor cutting production line

ActiveCN105818217AConsistent finishNo chippingFeeding devicesCircular sawsProduction lineRejection rate

The invention relates to an intelligent wood floor cutting production line. The intelligent wood floor cutting production line comprises a feeding mechanism, a wood floor cutting machine and a discharging mechanism which are arranged in sequence. The intelligent wood floor cutting production line has the beneficial effects that the surface plate and the backing plate of a medium plate cut from a large plate are consistent in smooth finish, no cutting surface is damage, and the rejection rate is remarkably lowered; the loss is low, the outturn percentage is high, the width of a finished product is increased, and the size precision of wood floor cutting is high; the manpower is saved, the labor intensity is reduced, and the machining efficiency is improved; and the intelligent wood floor cutting production line is suitable for a wood floor cutting process, that is, the intelligent wood floor cutting production line can be used for cutting the large plate into the medium plate.

Owner:SHANDONG ZHONGXIN MACHINERY

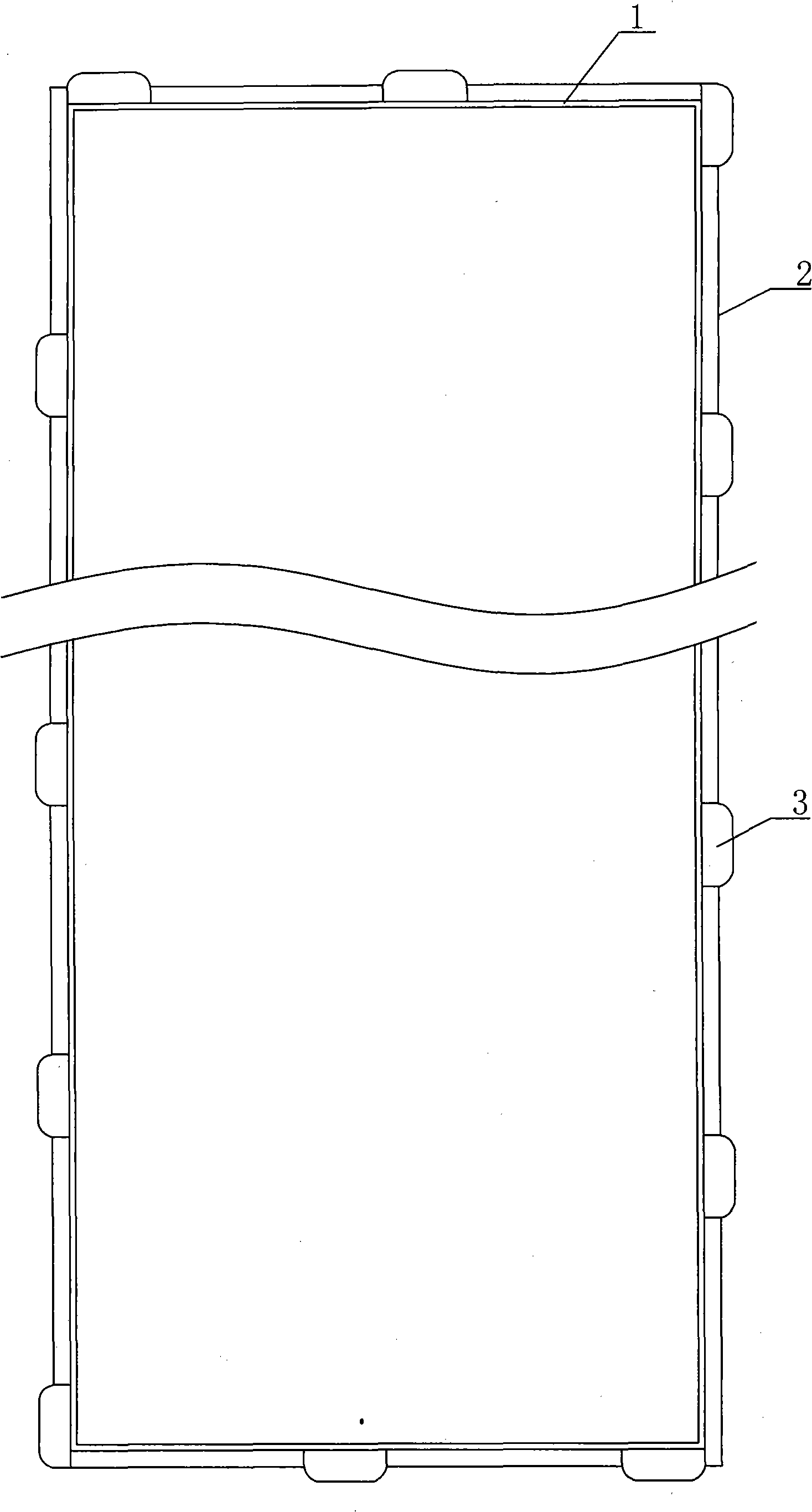

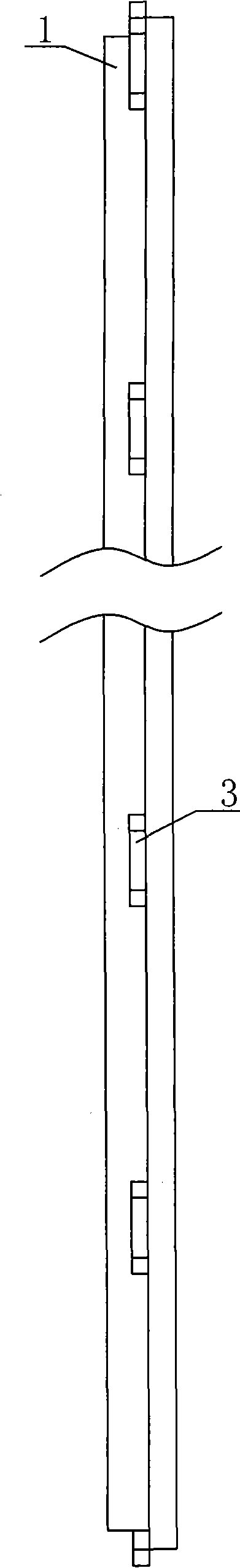

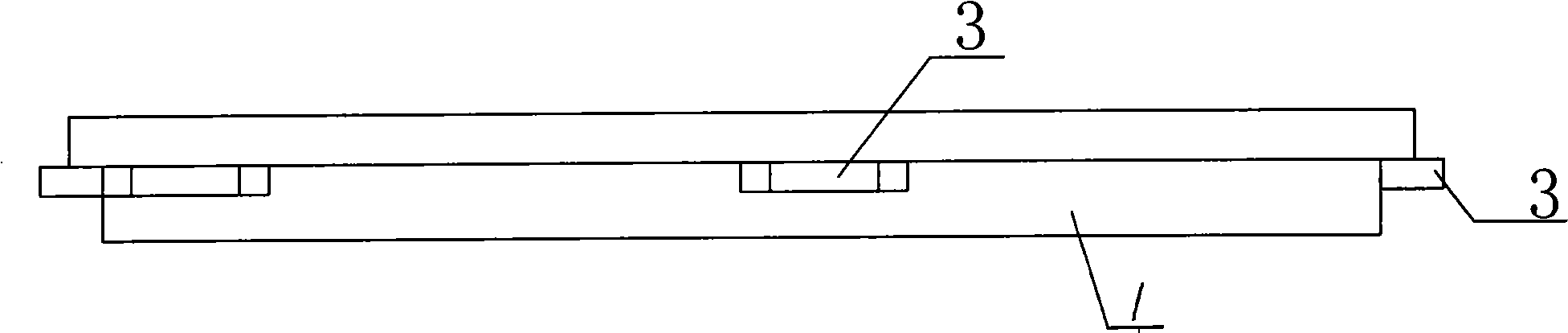

Floor plastic rubber lock catch convenient for connecting and positioning

The invention relates to the improvement of mortice structure of wood floor and fiber glued floor, and the improvement of assembly method of wood floor and fiber glued floor, in particular to floor plastic fastener which is convenient for connecting and positioning. The improvement of the invention includes that plastic frame is arranged at the periphery of wood floor or fiber glued floor; the lower part of the external side of the plastic frame is respectively provided with a step guide which is capable of drawing back; the step guides are respectively and evenly provided with a plastic slide block, the external side of which extends out of the guide surface, and the plastic slide block, the external side of which extends out of the guide surface, matches with the step guide surface corresponding to the frame of the assembly floor; while assembling, the plastic slide block sliding along guide surface causes the plastic slide block and the plastic slide block to match with each other and to be located. The mortice structure of the invention changes the fastener structure and assembly method of the existing floor, causing no squeezing of the surface decoration layer of floor edge and no edge collapsing of the decoration layer while assembling, being able to adjust the size of the clearance between floors; the fastener of the floor need not differentiate with left and right, and thus free assembly in any end can be done while disassembling, which is convenient for production and assembly; in addition, the plastic fastener has high intensity, saves material and has low cost.

Owner:罗生权

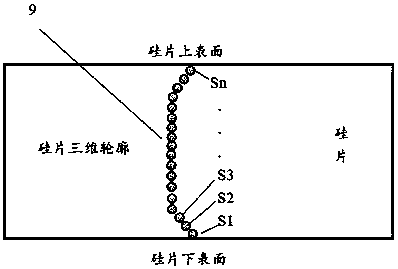

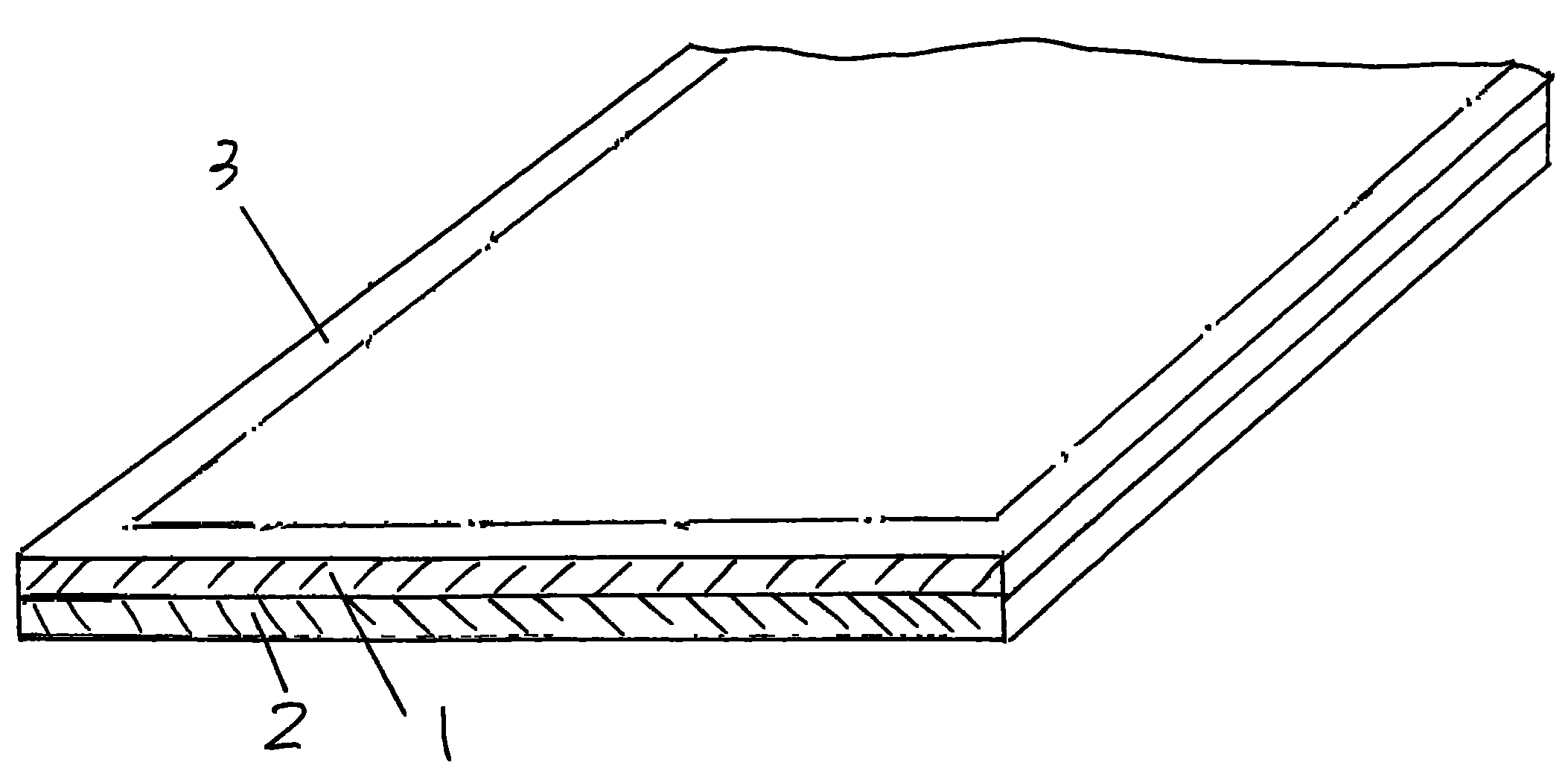

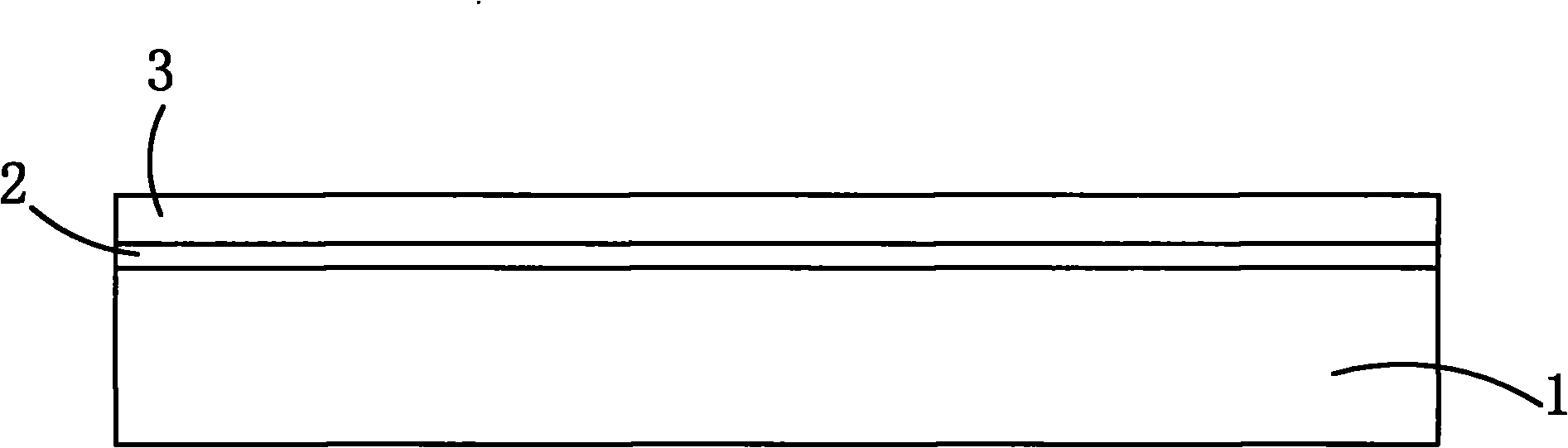

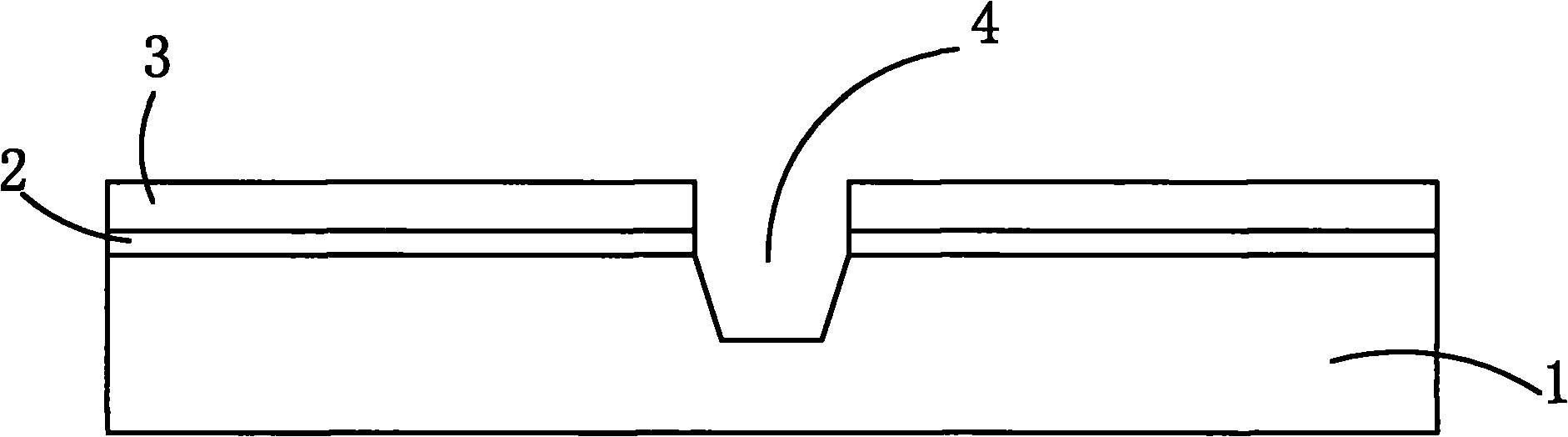

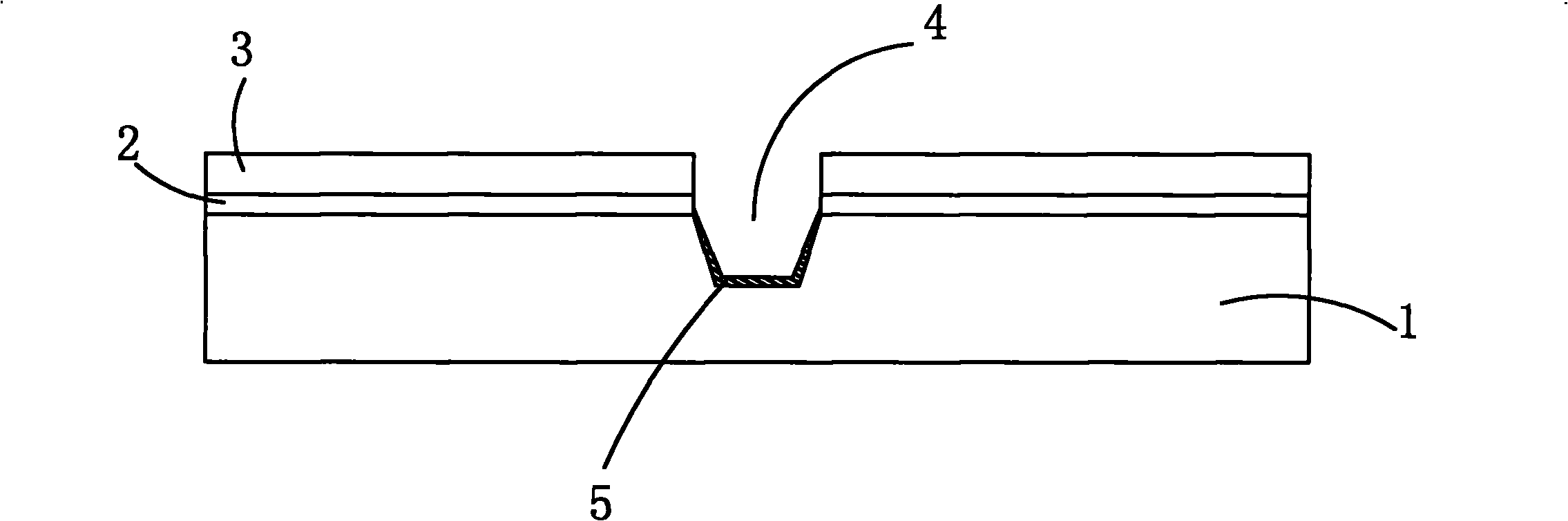

Cutting method for MEMS wafer

ActiveCN102897708ANo chippingReduce chippingDecorative surface effectsChemical vapor deposition coatingEngineeringIrradiation

The invention relates to a method for a MEMS wafer. The cutting method comprises the following steps of pasting a membrane on the front surface of the wafer to protect an MEMS structure; focusing a laser on the inner part of the wafer, irradiating to form a modified layer at a position from the front surface of the wafer to the inner part of the wafer; irradiating the laser to the back surface of the wafer at a position corresponding to that of the modified layer so as to form a mark groove on the back surface of the wafer; performing water jet cutting on the back surface of the wafer along the position of the mark groove but do not reach the bottom so as to form a water jet cutting groove from the back surface of the wafer to the inner part of the wafer, wherein one end far away from the back surface of the wafer of the water jet cutting groove is connected with the modified layer; and extending splits along the modified layer till to all the MEMS structures are separated completely from each other. The method for the MEMS wafer combines the advantages of laser irradiation and water jet cutting, and realizes the edge breakage-free and low-contamination cutting for the MEMS wafer.

Owner:MEMSIC SEMICON WUXI

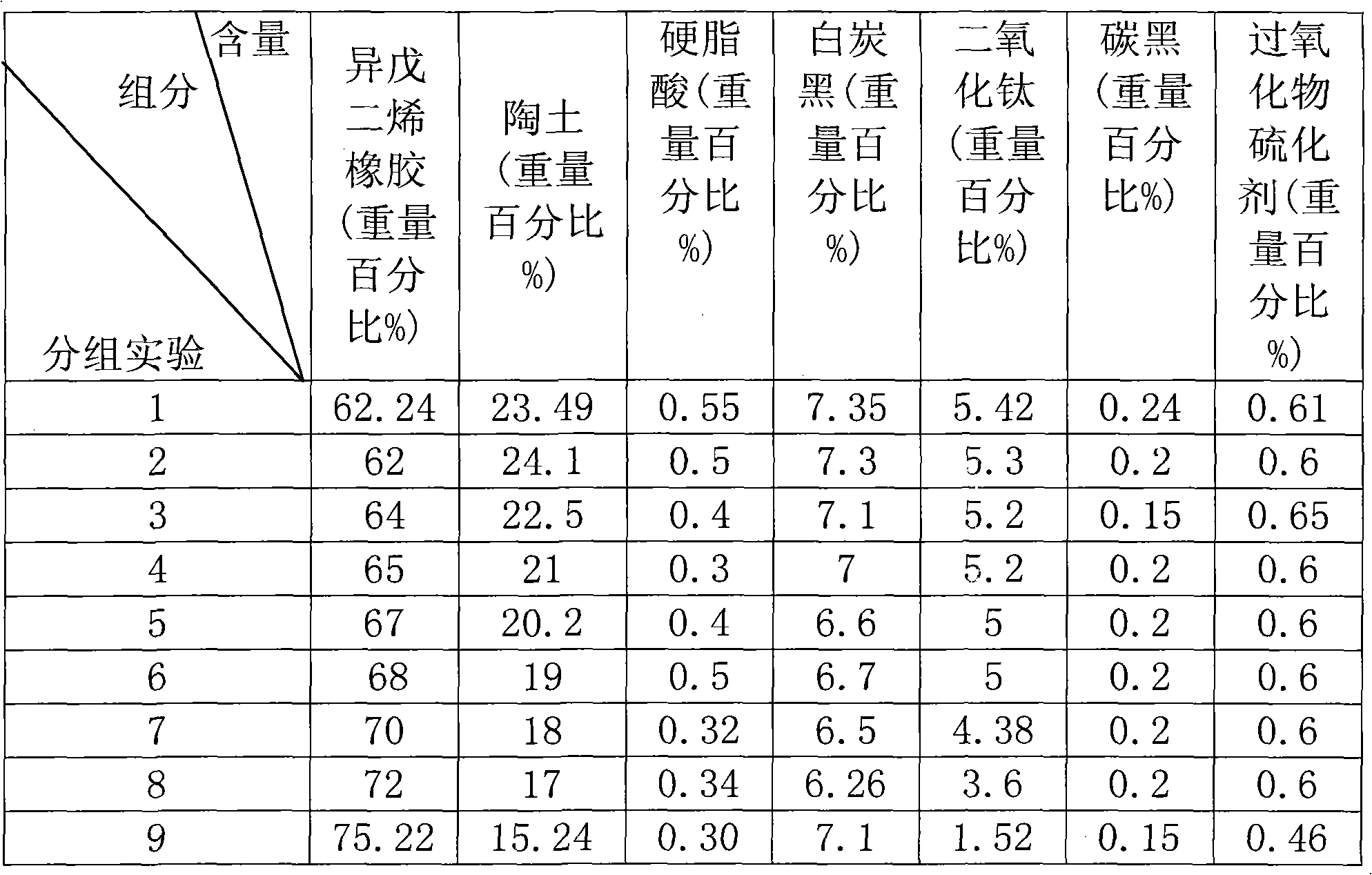

Synthetic polyisoprene rubber plug for injection and preparation method thereof

The invention relates to a synthetic polyisoprene rubber plug for an injection and a preparation method thereof. The synthetic polyisoprene rubber plug for the injection comprises the flowing components in percentage by weight: 61.24-76.22 percent of isoprene rubber, 15.24-24.49 percent of pottery clay, 0.30-0.55 percent of stearic acid, 6.1-7.35 percent of white carbon black, 1.52-5.42 percent of titanium dioxide, 0.15-0.24 percent of carbon black and 0.46-0.61 percent of peroxide vulcanizing agent. According to the synthetic polyisoprene rubber plug disclosed by the invention, due to the adoption of a peroxide vulcanizing system, an isoprene rubber product is prepared from a raw material without sulfur; the final rubber plug product cannot generate a sulfur-containing substance; and the produced isoprene rubber product can be directly contacted with medicines for use and has the advantages of stable performance, puncture resistance, no falling scraps, favorable elasticity, no needle extracting leaked liquid, favorable sealing property and the like.

Owner:QINGDAO HUAREN MEDICAL PROD

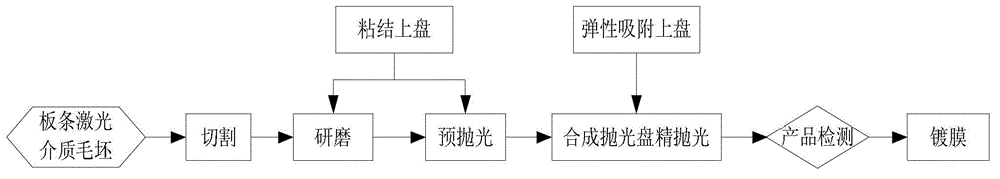

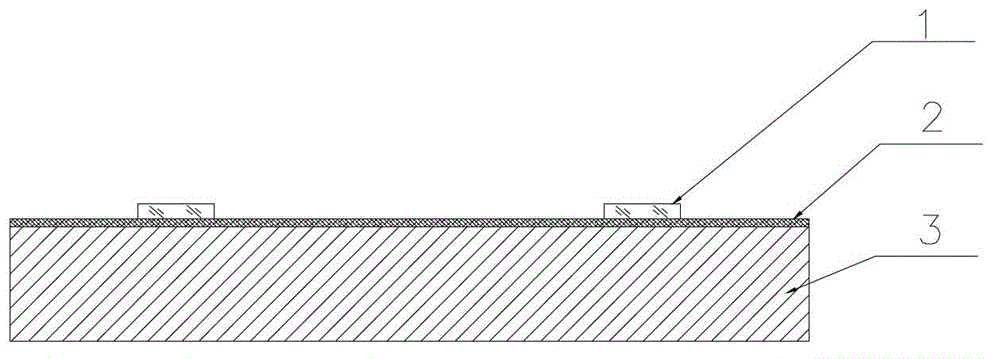

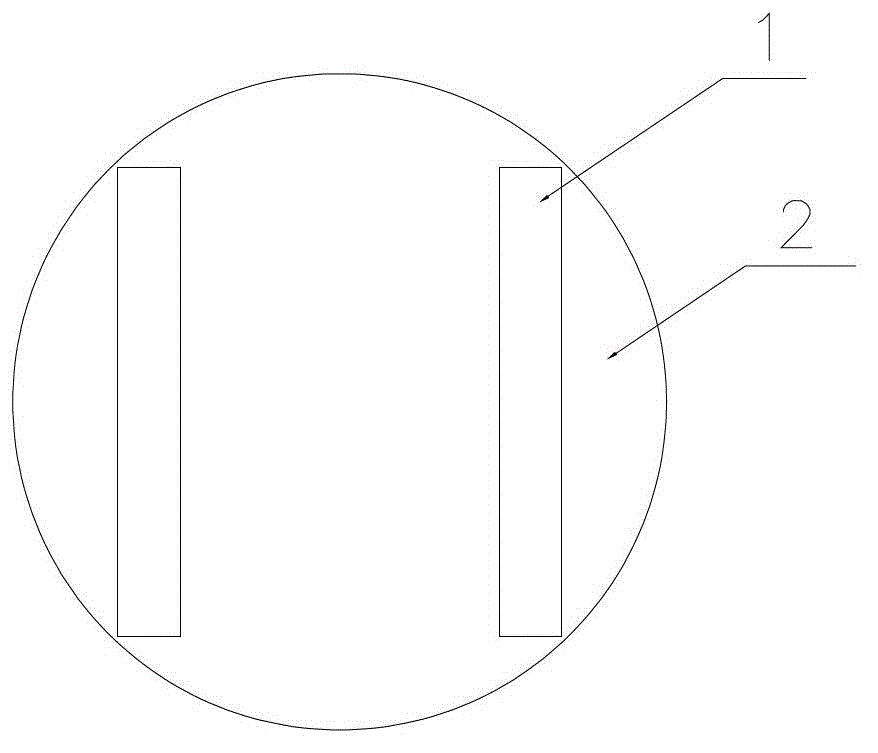

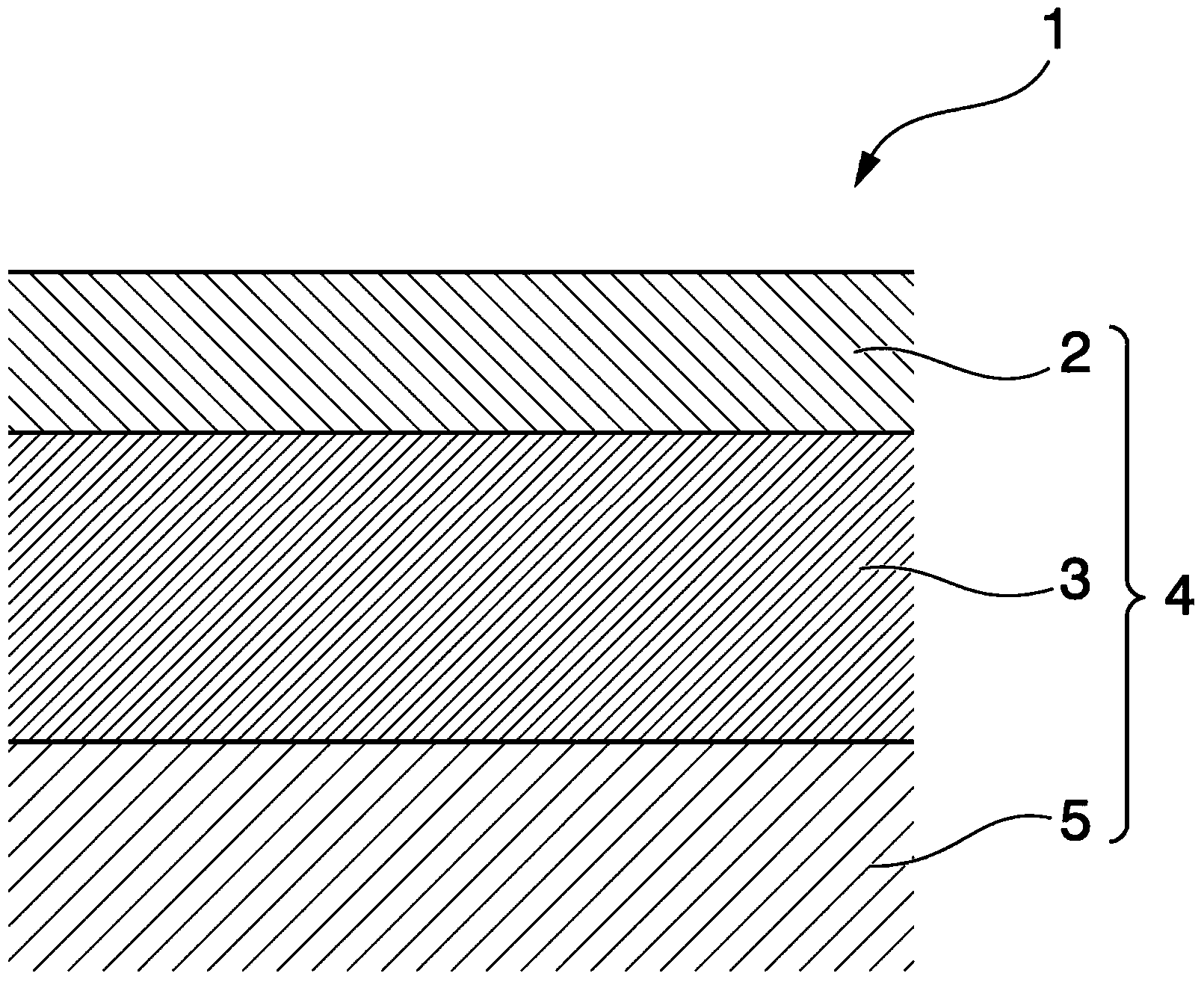

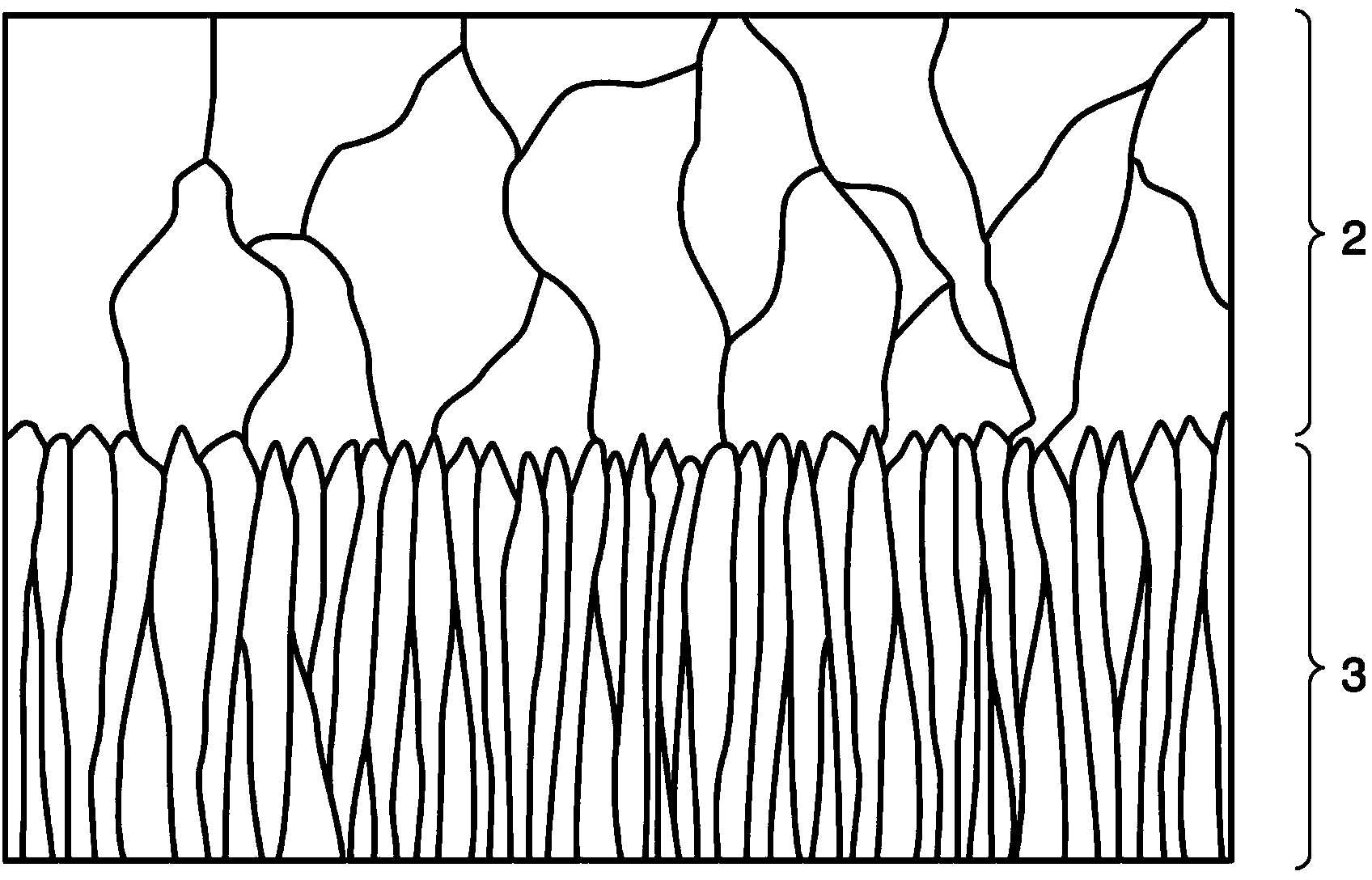

Surface processing method of strip laser medium

ActiveCN102909650AHigh precisionHigh surface finishPolishing machinesAbrasion apparatusSurface finishOptoelectronics

The invention provides a surface processing method of a strip laser medium. According to the method, high surface figure accuracy and excellent surface smoothness can be obtained by the strip laser medium at the same time. The surface processing method of the strip laser medium comprises the following steps of: bonding and hanging the cut strip laser medium by a binder; respectively grinding and pre-polishing two large surfaces on a plane grinder; hanging the pre-polished strip laser medium in an elastic adsorption manner, and precisely polishing the strip laser medium after being hung in the elastic adsorption manner on the plane grinder by a synthesis polishing plate. By adopting the surface processing method of the strip laser medium provided by the invention, hanging in the elastic adsorption manner is adopted by precisely finishing; the operation is simple and convenient; a problem of surface deformation after a element is taken off is not caused; glass or crystal for tripping does not need to be adhered around the work-piece, and a risk of edge breakage or angle breakage of the element in a processing process is avoided.

Owner:成都精密光学工程研究中心

Surface-coated cutting tool

ActiveCN103764323AImprove high temperature strengthHigh hardnessMilling cuttersTurning toolsSurface layerOptoelectronics

Owner:MITSUBISHI MATERIALS CORP

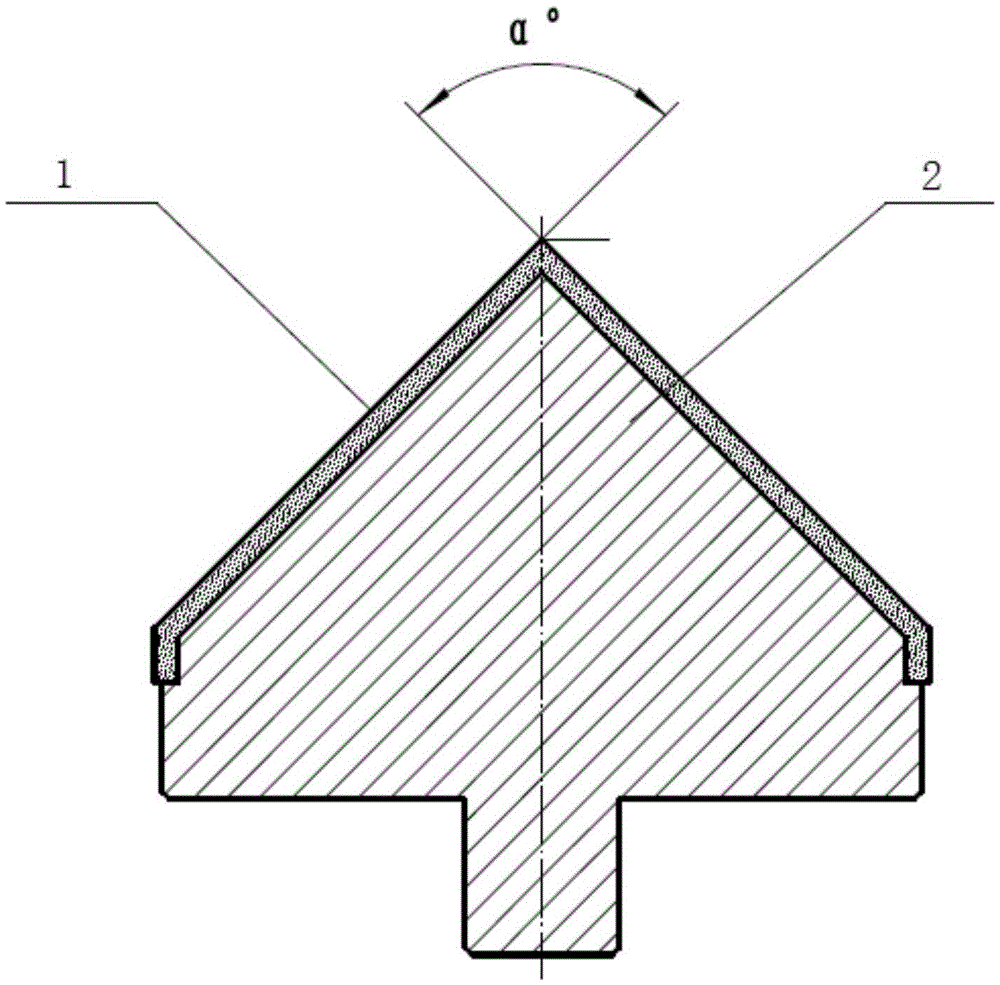

Diamond grinding wheel and manufacturing method thereof

ActiveCN105583743AHigh surface finishGood thermal conductivityBonded abrasive wheelsGrinding devicesDiamond grindingVolume percent

The invention discloses a diamond grinding wheel and a manufacturing method thereof. The diamond grinding wheel comprises a grinding wheel base body and an abrasive layer attached to the grinding wheel base body. The abrasive layer is composed of, by volume percent, 20-30% of diamond abrasive, 40-50% of phenolic resin, 5-15% of carbonyl iron, 5-15% of cryolite and 10-20% of graphite. Due to the fact that diamond, a bonding agent and functional filler are reasonably selected and all components are scientifically proportioned, a grinding wheel block conducts grinding sharply, and when the grinding wheel block is used for grinding silicon carbide ceramic materials, the high grinding efficiency is achieved; and when the grinding wheel block is applied to machining of chamfers of silicon carbide sealing rings, the surface smoothness of the chamfers can reach Ra 0.1, and the chamfers R are smaller than or equal to 0.05 mm. The grinding wheel of a specific conical structure is adopted and can be installed on a common grinding machine to directly conduct grinding and forming machining on the chamfers of the silicon carbide sealing rings, the machining efficiency is high, the angle of the grinding machine does not need to be adjusted, and consistency of the machined chamfers is good.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

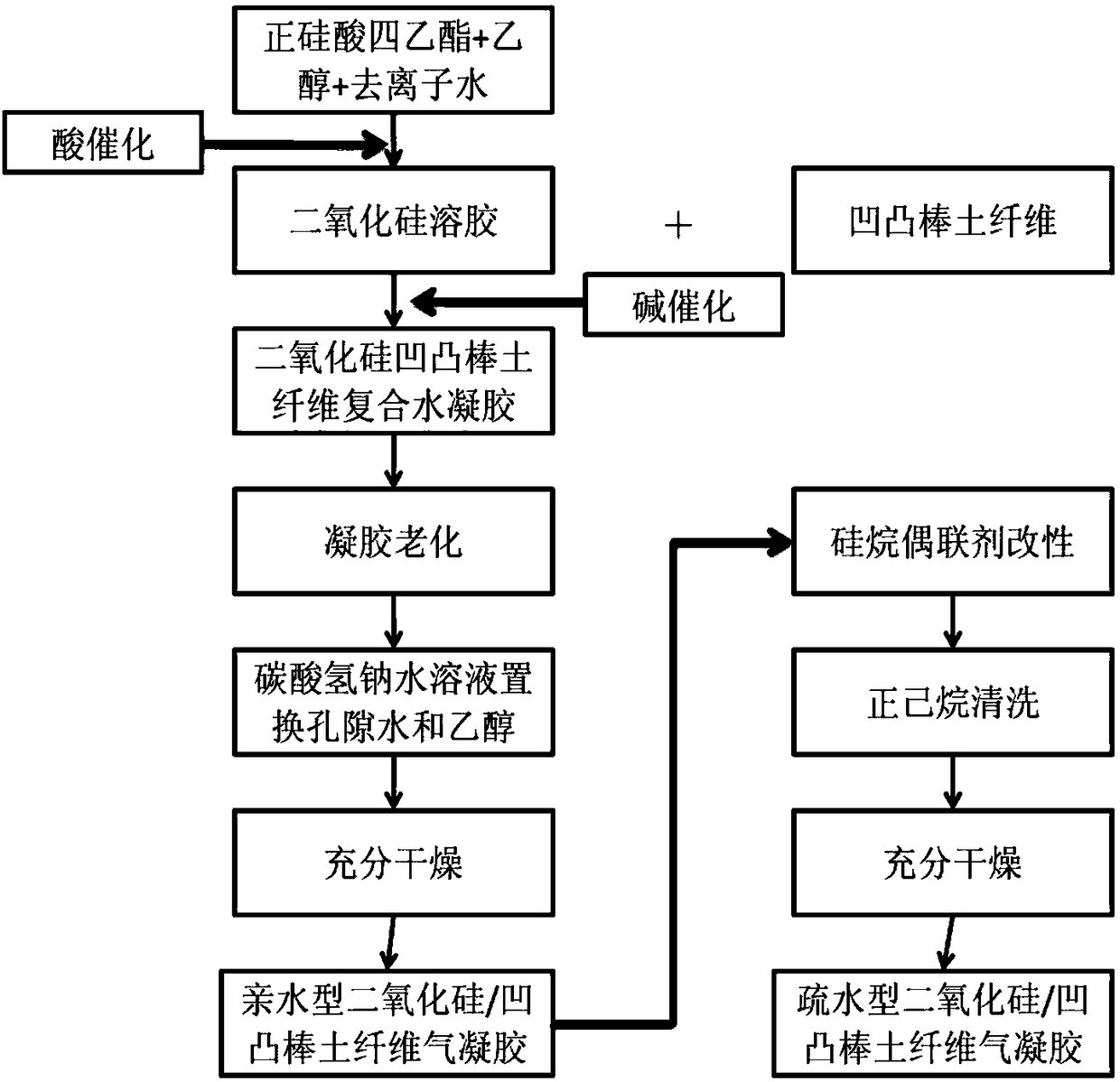

Normal pressure preparation method for silicon dioxide/attapulgite fiber compound aerogel

The invention discloses a normal pressure preparation method for silicon dioxide / attapulgite fiber compound aerogel. The preparation method comprises the following steps: uniformly mixing an organic silicon precursor, absolute ethyl alcohol and deionized water, and adding an acidic catalyst till the pH value is 2-3 to obtain silicon dioxide sol; adding attapulgite fibers and uniformly mixing the mixture to adjust the pH value to 6-8 by means of a carbonate / ammonia water mixed solution, transferring the solution to a mold to stand to obtain a silicon dioxide / attapulgite fiber compound aerogel and ageing the same; taking the silicon dioxide / attapulgite fiber compound aerogel out of the mold and impregnating the same in a sodium hydrogen carbonate aqueous solution to replace a solvent; and fully drying the same after replacement to obtain the hydrophilic silicon dioxide / attapulgite fiber compound aerogel. The method provided by the invention overcomes the problem that the aerogel has powder and small fragments by a common normal pressure drying method, so that the whole aerogel with lyophobic or hydrophilic characteristics is prepared at normal pressure.

Owner:XUYI BOTU ATTAPULGITE CLAY HIGH TECH DEV +1

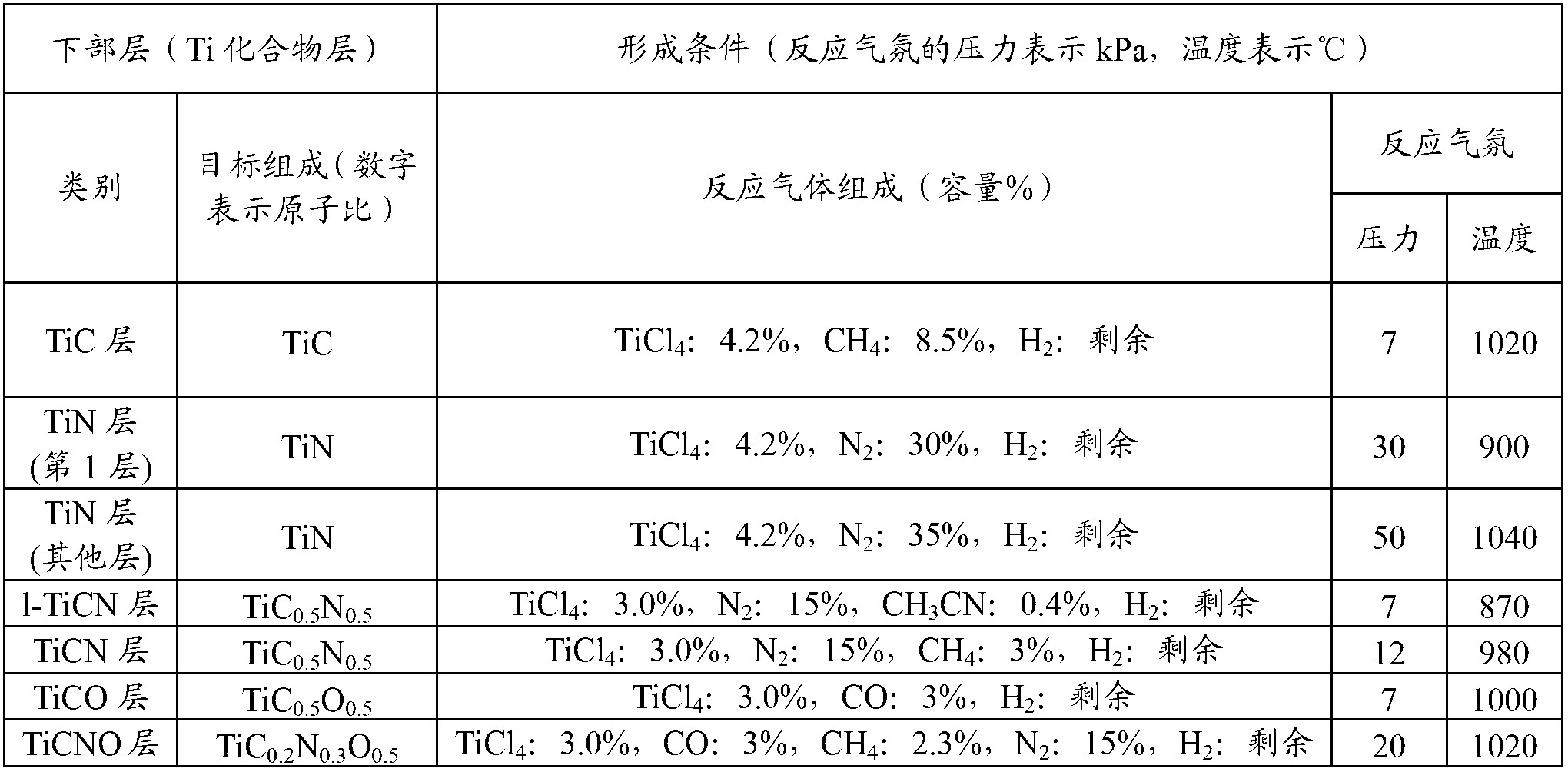

Coated surface cutting tool

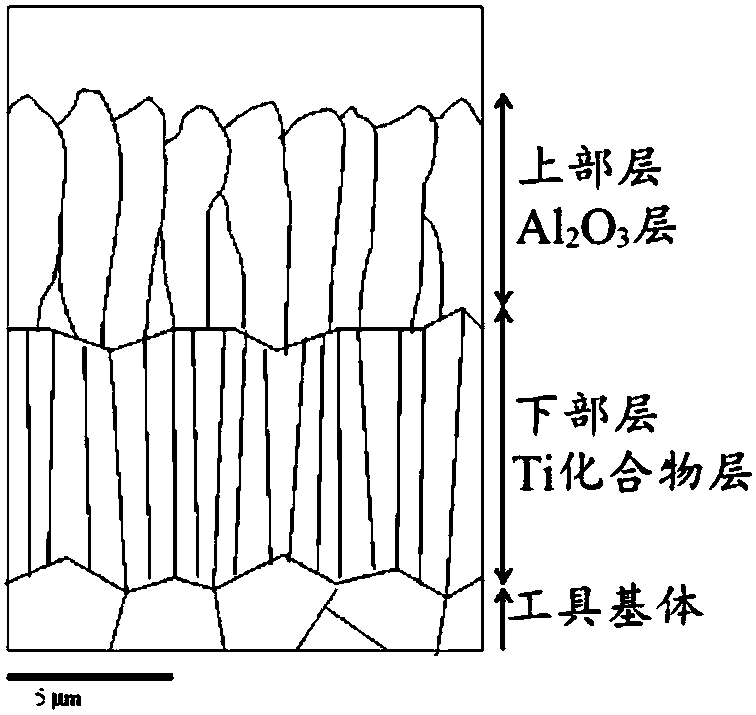

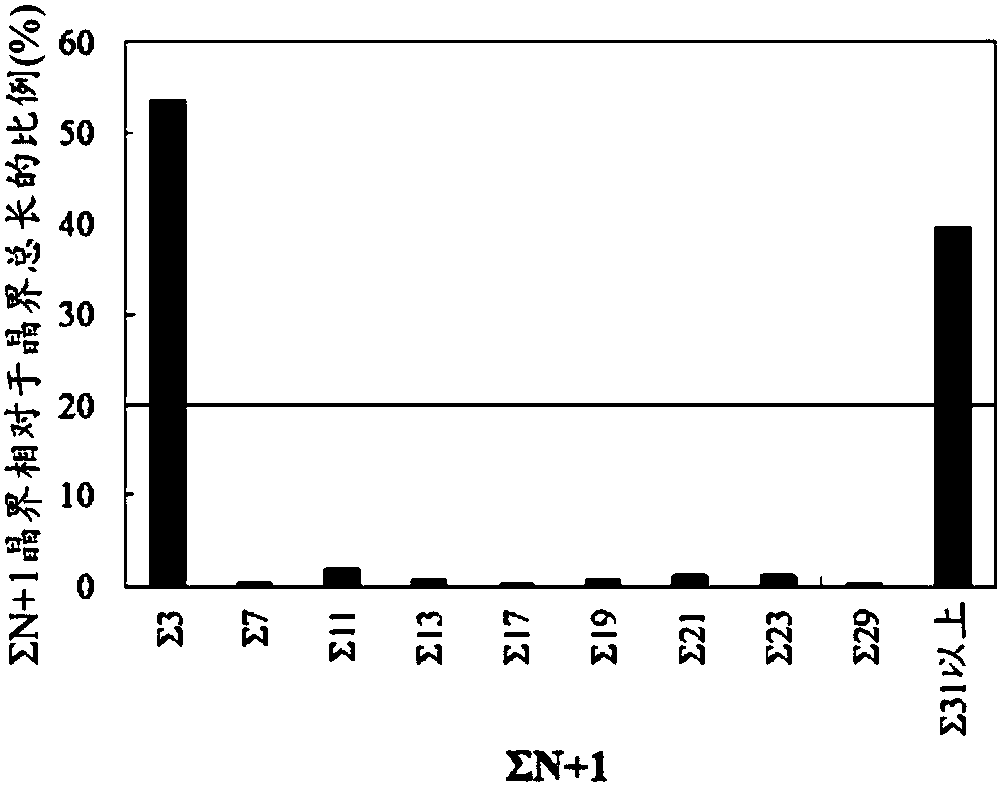

The purpose of the present invention is to provide a coated surface cutting tool that exhibits excellent peeling resistance and chipping resistance under deep cutting conditions of high speed, high cutting depth and high feed rate in which high loads act on the cutting edge. Provided is a coated surface cutting tool in which a hard coating layer obtained from an under layer and an upper layer is formed on the surface of a tool substrate configured from a tungsten carbide-based hard alloy or a titanium carbonitride-based cermet, wherein: said under layer is obtained from a Ti compound layer comprising at least a TiCN layer; and the upper layer is obtained from an Al2O3 layer with an alpha-type crystal structure and when the coincidence boundary distribution graph of the Al2O3 crystal grainsof the upper layer is measured, sulfur is segregated at grain boundaries of at least delta31, the grain boundary length thereof accounts for 20-50% of the total grain boundary length for constituentatom-sharing lattice point forms of at least delta3, and the absolute value of the residual stress of the upper layer on the flank and the cutting face comprising at least the cutting edge ridge is 100 MPa or less.

Owner:MITSUBISHI MATERIALS CORP

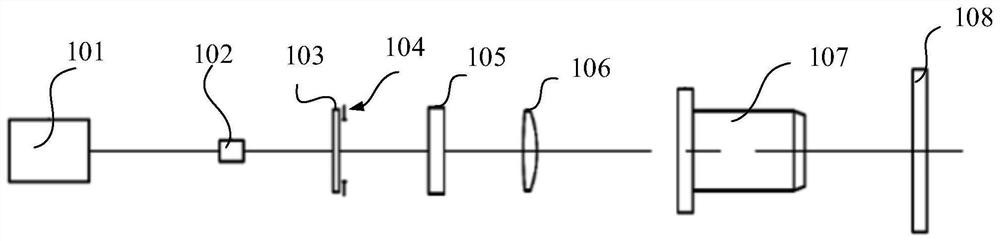

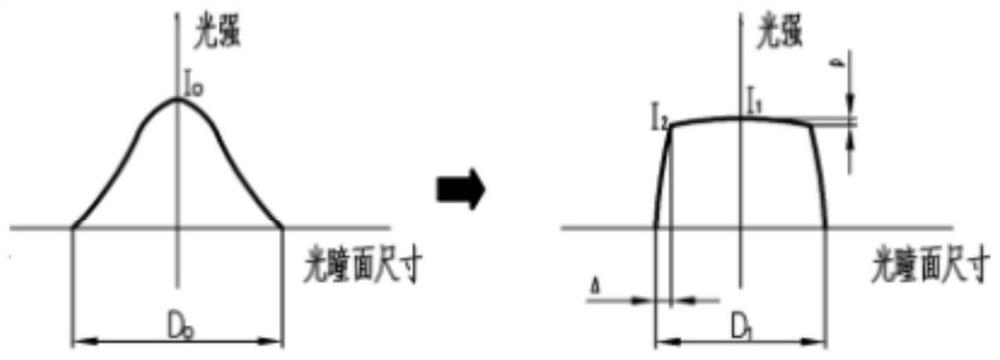

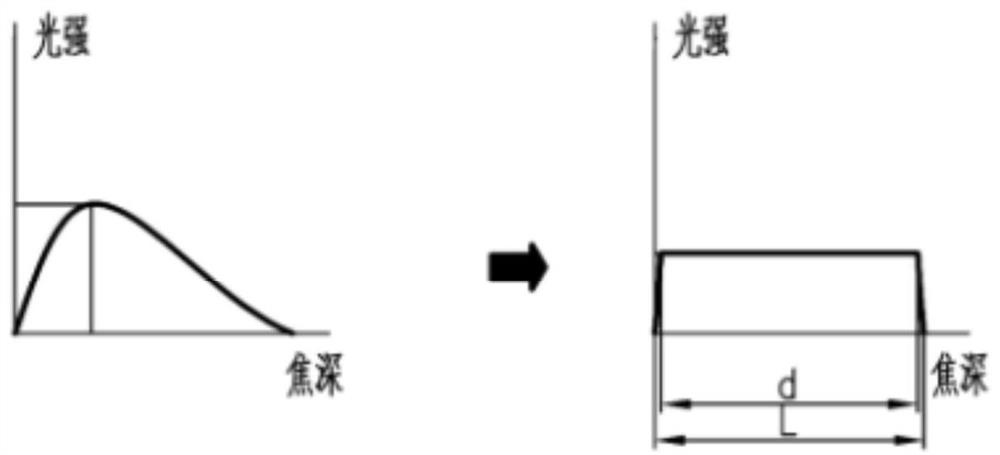

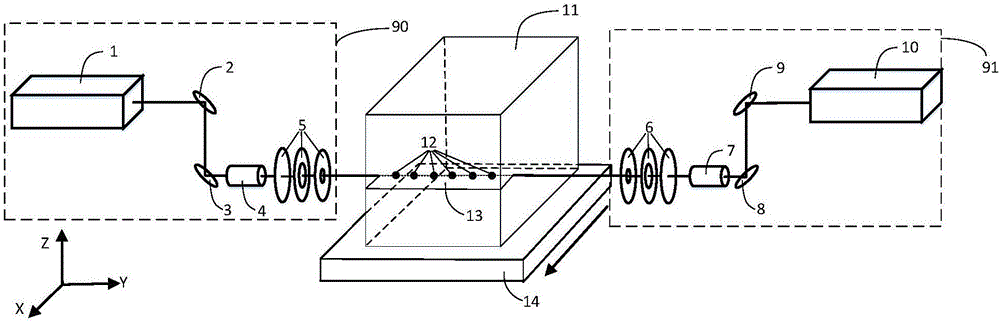

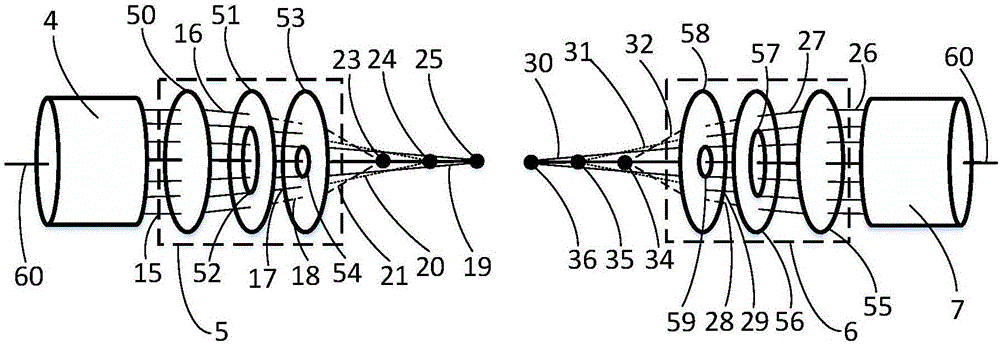

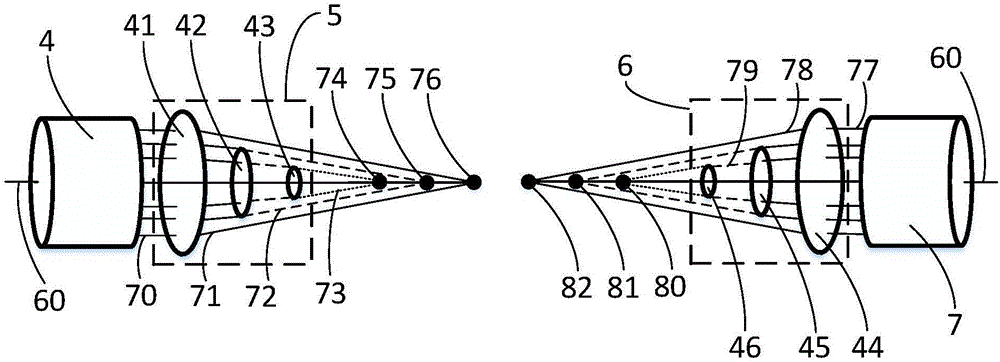

Laser cutting system

InactiveCN112496529AReduce taperImprove uniformityLaser beam welding apparatusLaser processingOptical axis

The embodiment of the invention discloses a laser cutting system. The laser cutting system sequentially comprises a laser unit, a laser receiving unit, a beam expanding unit, a dodging unit, a shielding unit, a light beam conversion unit and a collimating and focusing assembly in the light path direction, wherein the laser unit is used for providing a laser beam; the beam expanding unit is used for expanding the laser beam into an expanded laser beam; the dodging unit is used for modulating the expanded laser beam into a uniform laser beam with uniformly distributed light intensity flat top; the shielding unit is used for shielding the edge part of the uniform laser beam and stray light outside the uniform laser beam; the light beam conversion unit is used for modulating the uniform laserbeam into a hollow annular laser beam and forming a Bessel laser beam along the optical axis direction; and the collimating and focusing assembly is used for collimating and focusing the Bessel laserbeam. According to the laser cutting system, the problems of large taper, poor section uniformity and the like of the section of the cut material caused by Gaussian distribution of light intensity distribution of the existing laser processing system are solved.

Owner:SHENZHEN INTE LASER TECH

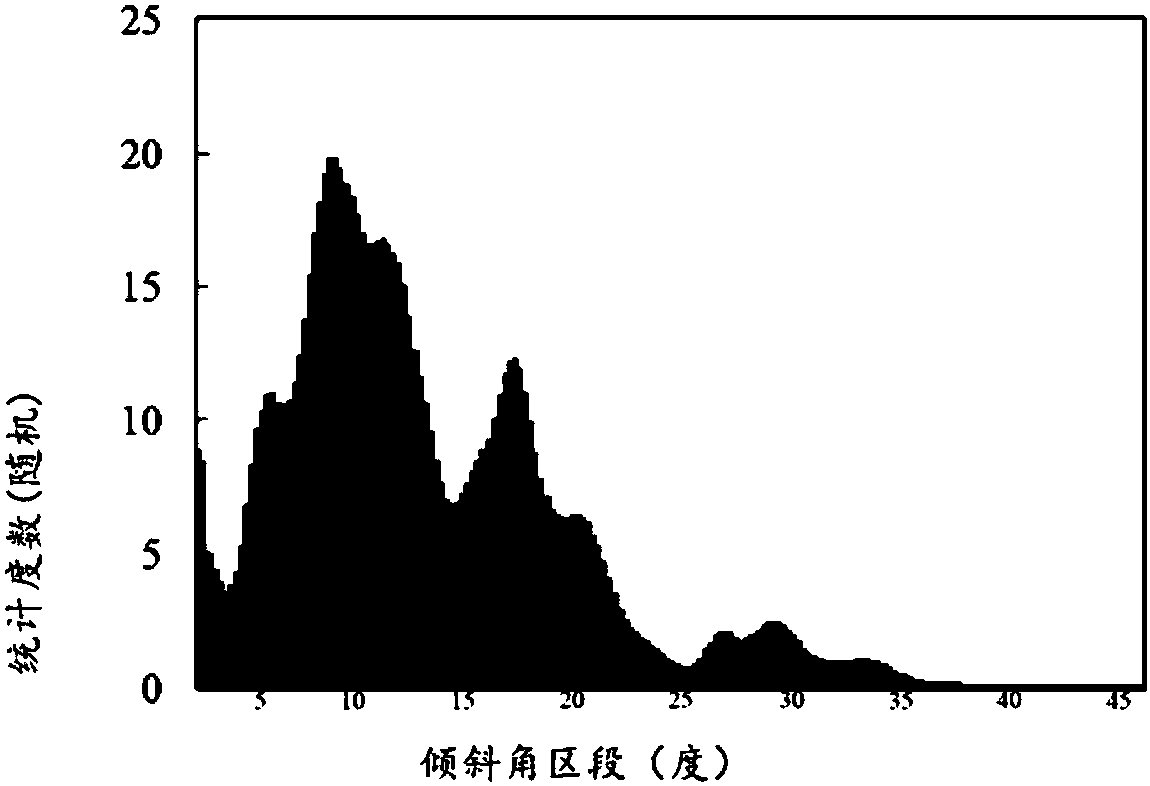

Surface-coated cutting tool in which hard coating layer demonstrates excellent chipping resistance

ActiveCN103128326ANo chippingNo peelingTransportation and packagingMilling cuttersSurface layerOxygen

The present invention provides a surface-coated cutting tool in which a hard coating layer demonstrates excellent chipping resistance in high-speed intermittent machining. The surface-coated cutting tool comprises a lower layer composed of a Ti compound layer and an upper layer composed of a columnar crystal Zr-containing alpha-Al2O3 layer which are formed by vapor deposition. A surface layer of the lower layer is composed of a TiCN layer with a layer thickness of more than 500 nm. Oxygen is only exited in a depth region up to 500 nm in a thickness direction of the TiCN layer, and has an average content of 0.5-3 atom%. The horizontal average diameter of Zr-containing alpha-Al2O3 particles right above the lower layer is 0.1-0.3 [mu]m, and the horizontal average diameter of Zr-containing alpha-Al2O3 particles right above the upper layer is 0.5-1.0 [mu]m. For Zr-containing alpha-Al2O3 particles of the whole upper layer, the Zr-containing alpha-Al2O3 particles which a tilt angle formed by the normal of a plane (0001) and a normal of the surface of a tool substrate being 0-10 degrees account for 45 area%, and in the area where the film thickness from an interface to the upper layer is less than 1 [mu]m, the orientation of the plane (0001) is less than 10%, and the orientation of (02-21) is more than 30%.

Owner:MITSUBISHI MATERIALS CORP

Upgrading mould apparatus with tapping

InactiveCN101342621AHigh strengthImprove work efficiencyShaping toolsThread cutting auxillary apparatusPunch pressDrive shaft

The invention relates to a progressive mold and tapping device which is characterized in that a gear box assembled on the upper mold is connected with a transmission box via a transmission gear. The top of the transmission shaft in the transmission box is provided with a tap. A gear rack fixed on the lower mold is coordinated with the gear in the gear box. When the upper mold moves downward, the gear box changes the straight line motion of the punch to the rotating motion, and changes the direction and velocity for enabling the tap on the transmission shaft to rotate and simultaneously move downward to tap the preserved through hole on the belt material, thus the tapping is simultaneously completed during the punching process, thereby changing the traditional production mode of firstly punching and secondly tapping, enabling the production efficiency to be greatly increased, decreasing the cost and increasing the economical effect.

Owner:CHENGDU HOMIN TECH

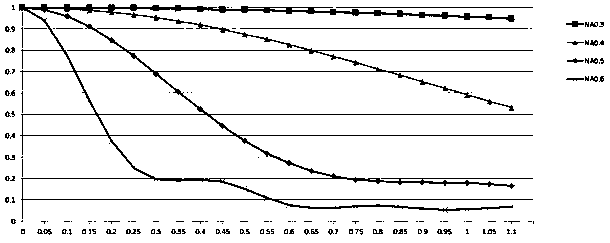

Method and device for correlative multi-focus laser separation of fragile transmission material

ActiveCN106392337AImprove the problem of uneven absorptionImprove controllabilityLaser beam welding apparatusInverse correlationLaser processing

The invention discloses a method and a device for correlative multi-focus laser separation of a fragile transmission material. The method is characterized in that the same technological parameters are adopted, and coaxial laser is utilized to penetrate multi-focus lens groups and to conduct inverse correlation on two sides in the thickness direction of the fragile transmission material to be separated, so that the number of focuses generated in the fragile transmission material is doubled to improve the laser energy absorption uniformity of the fragile transmission material in the thickness direction and to enhance the heating expansion uniformity of the fragile transmission material in the thickness direction. After a laser multi-focus beam leaves, the fragile transmission material is quickly cooled down in the thickness direction to produce tensile stress, so that separation of the thick fragile transmission material is realized by laser. The device comprises two sets of multi-focus laser processing systems and one three-dimensional working platform, wherein each set of the multi-focus laser processing system comprises a laser, light guiding mirrors, a beam expanding mirror and a multi-focus lens group. The method and the device realize high-quality, efficient and high-success-ratio separation of the thick fragile transmission material.

Owner:HUAZHONG UNIV OF SCI & TECH

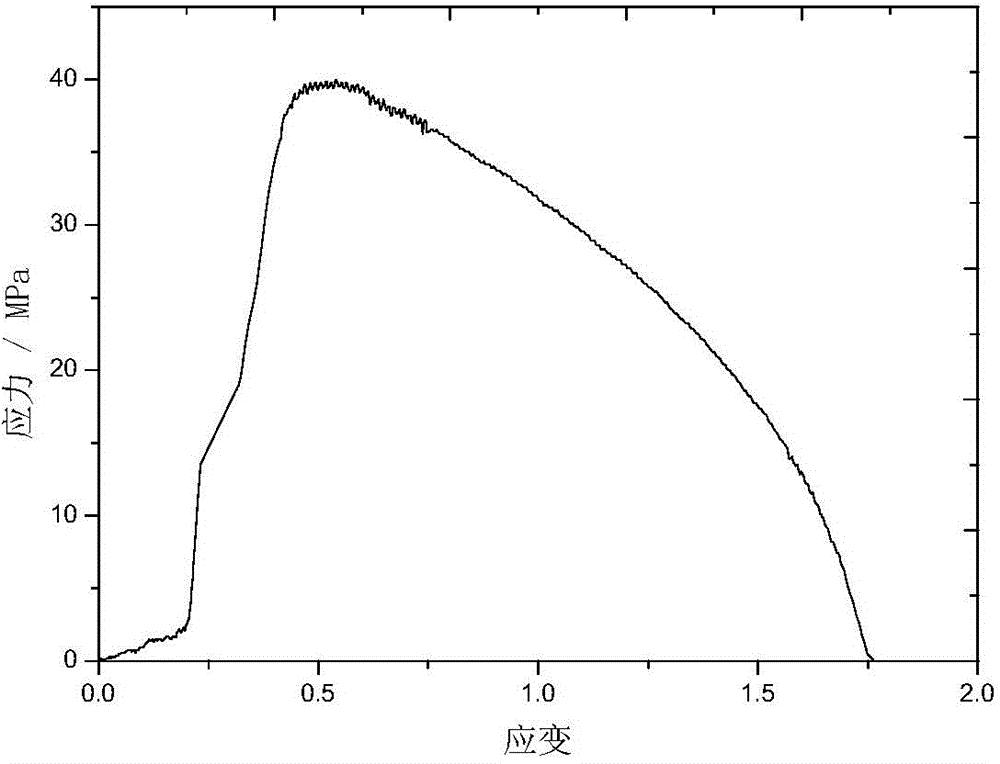

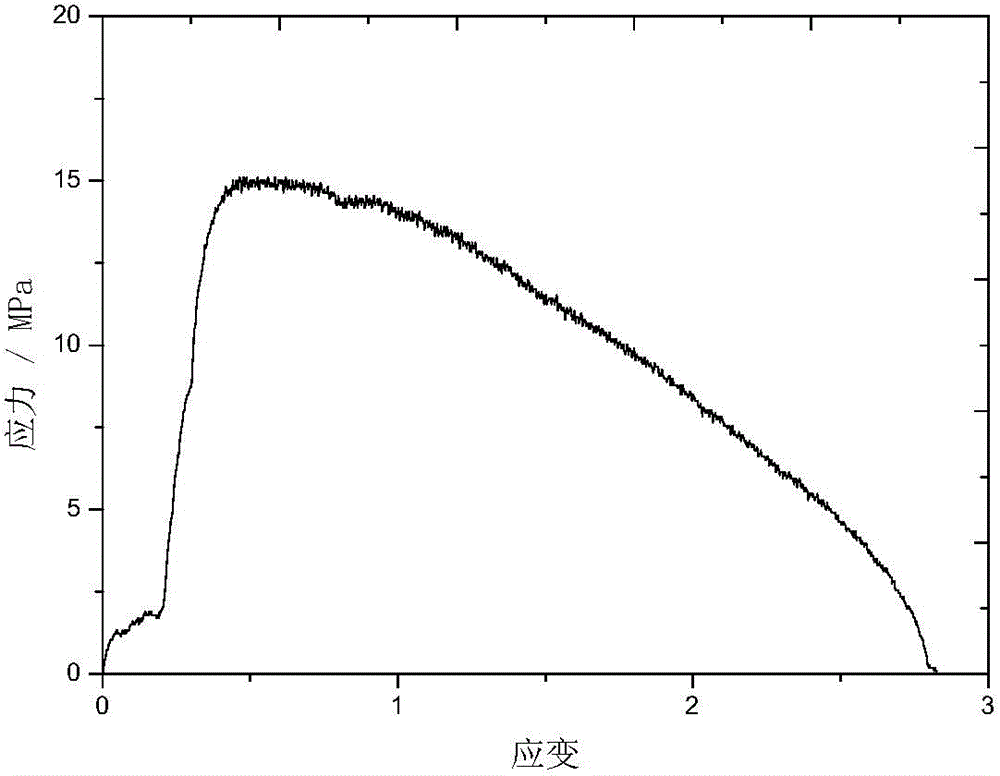

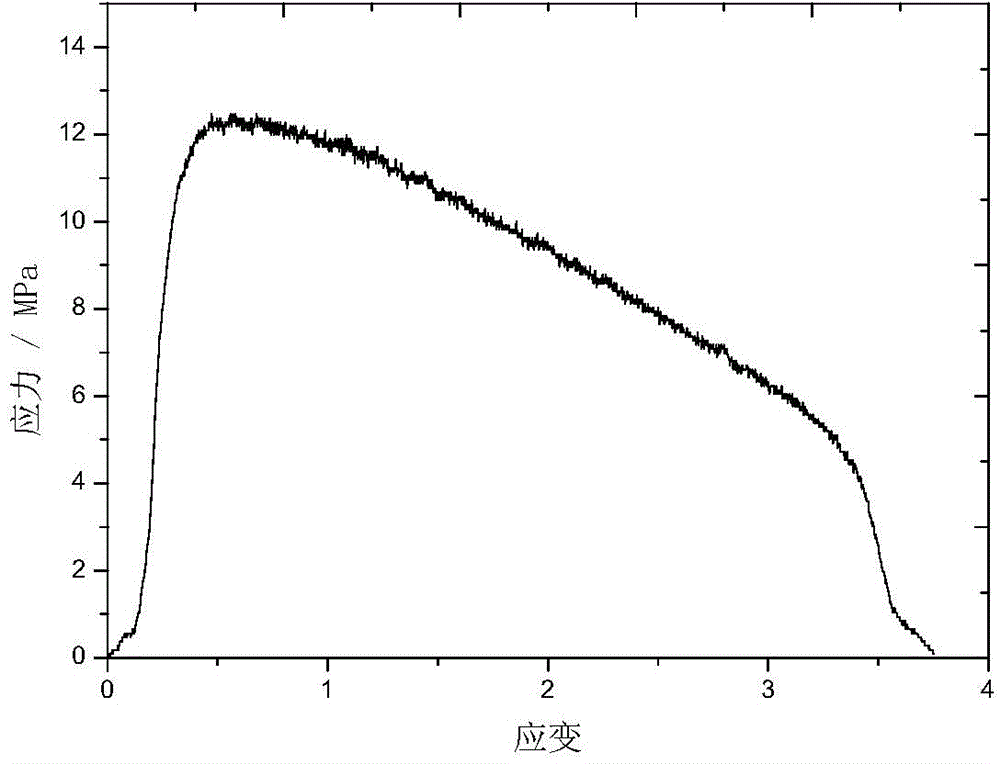

Superplastic magnesium lithium alloy material with high strain rate and preparation method thereof

The invention provides a superplastic magnesium lithium alloy material with high strain rate and a preparation method thereof. The method is as below: a) preparing the following raw materials for melting alloy according to the weight proportion: 6%-11% of Li, 0.1%-3% of Al and the balance of Mg and trace impurity elements; b) melting by using a vacuum electromagnetic induction furnace under the protection of argon; c) conducting uniformity annealing on the obtained ingot in a heat treatment furnace at 200 DEG C-350 DEG C for 6-24 h, and cooling to room temperature; and d) lathing a surface oxide layer on the ingot obtained in the step c), and then conducting a one-time extrusion with large extrusion ratio higher than 75% at 200-300 DEG C. The product of the invention is superplastic magnesium lithium alloy with low lithium content, proper amount of aluminum content and high strain rate, and the invention uses a relatively simple melting and deformation processing method for the preparation of the superplastic magnesium lithium alloy with high strain rate.

Owner:HARBIN ENG UNIV

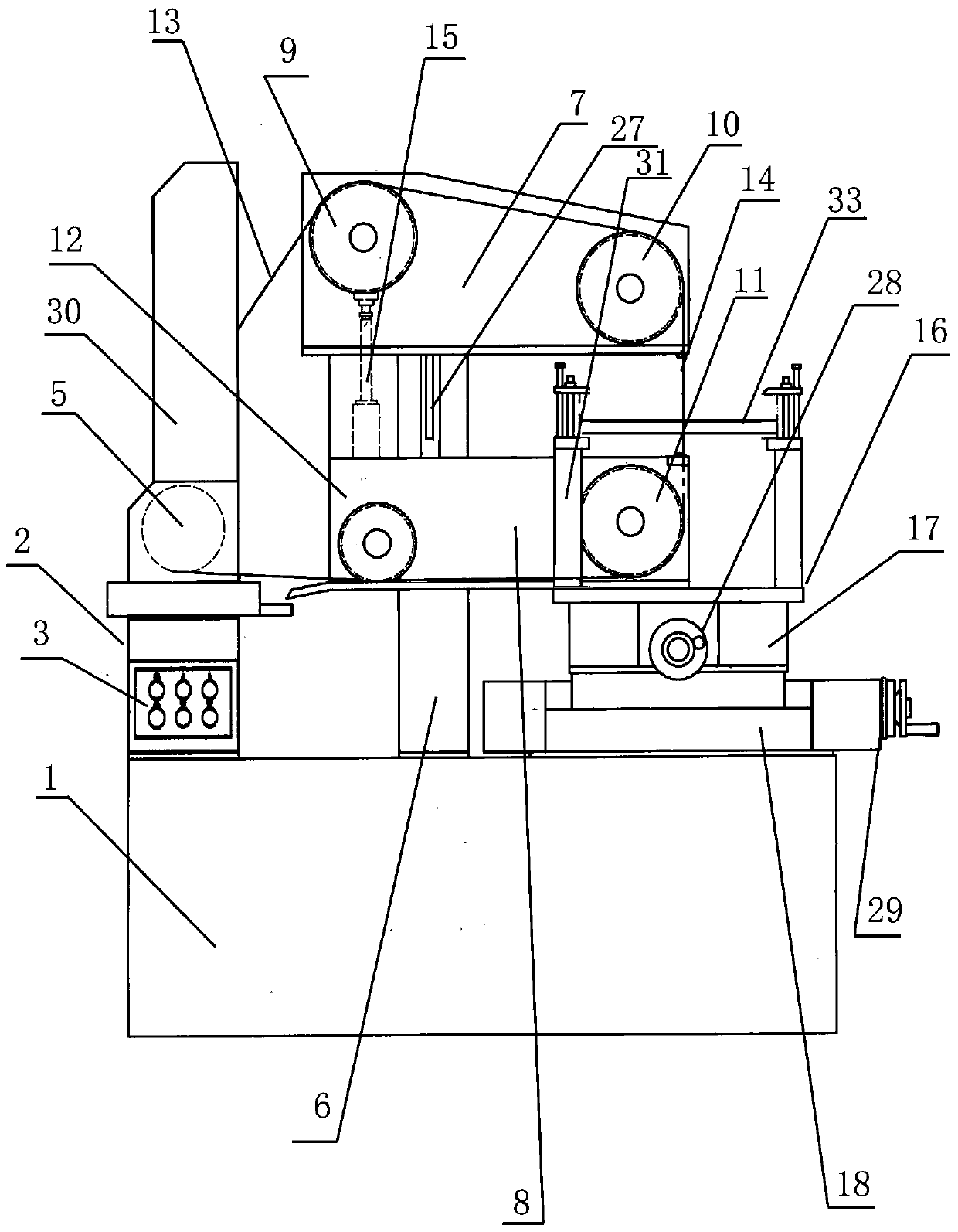

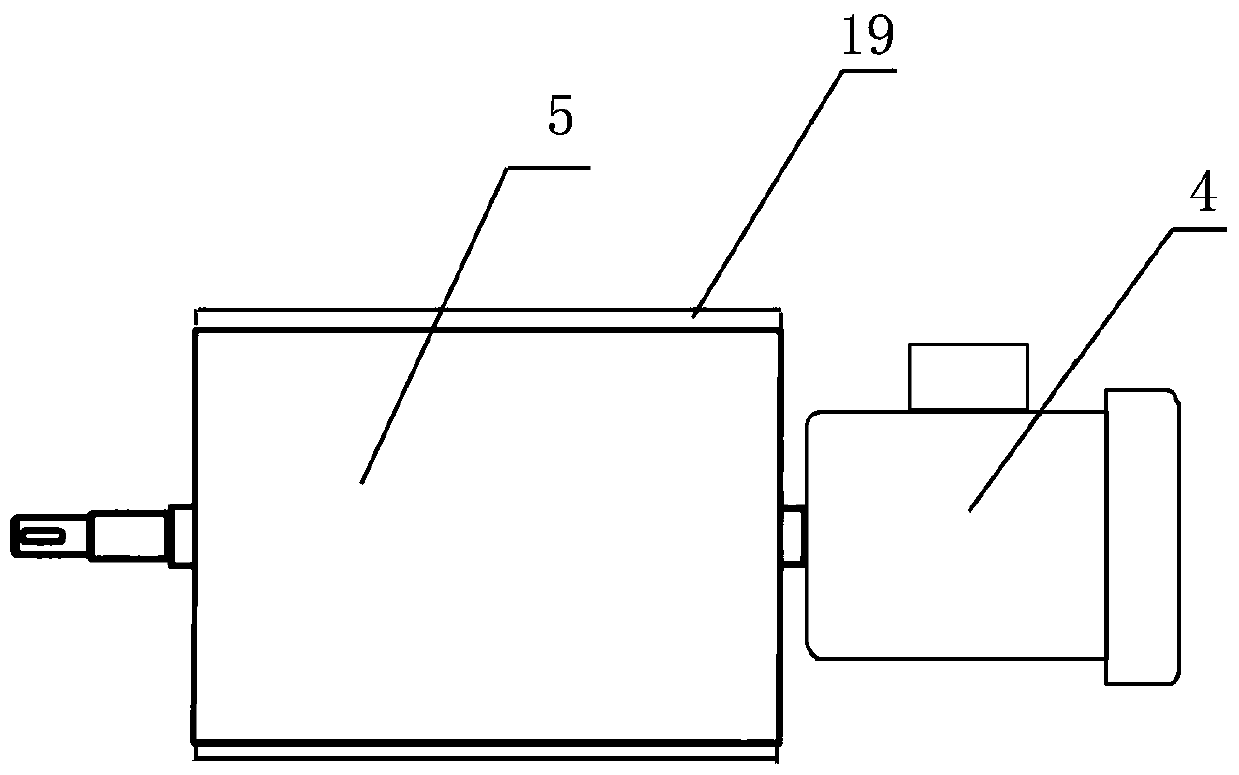

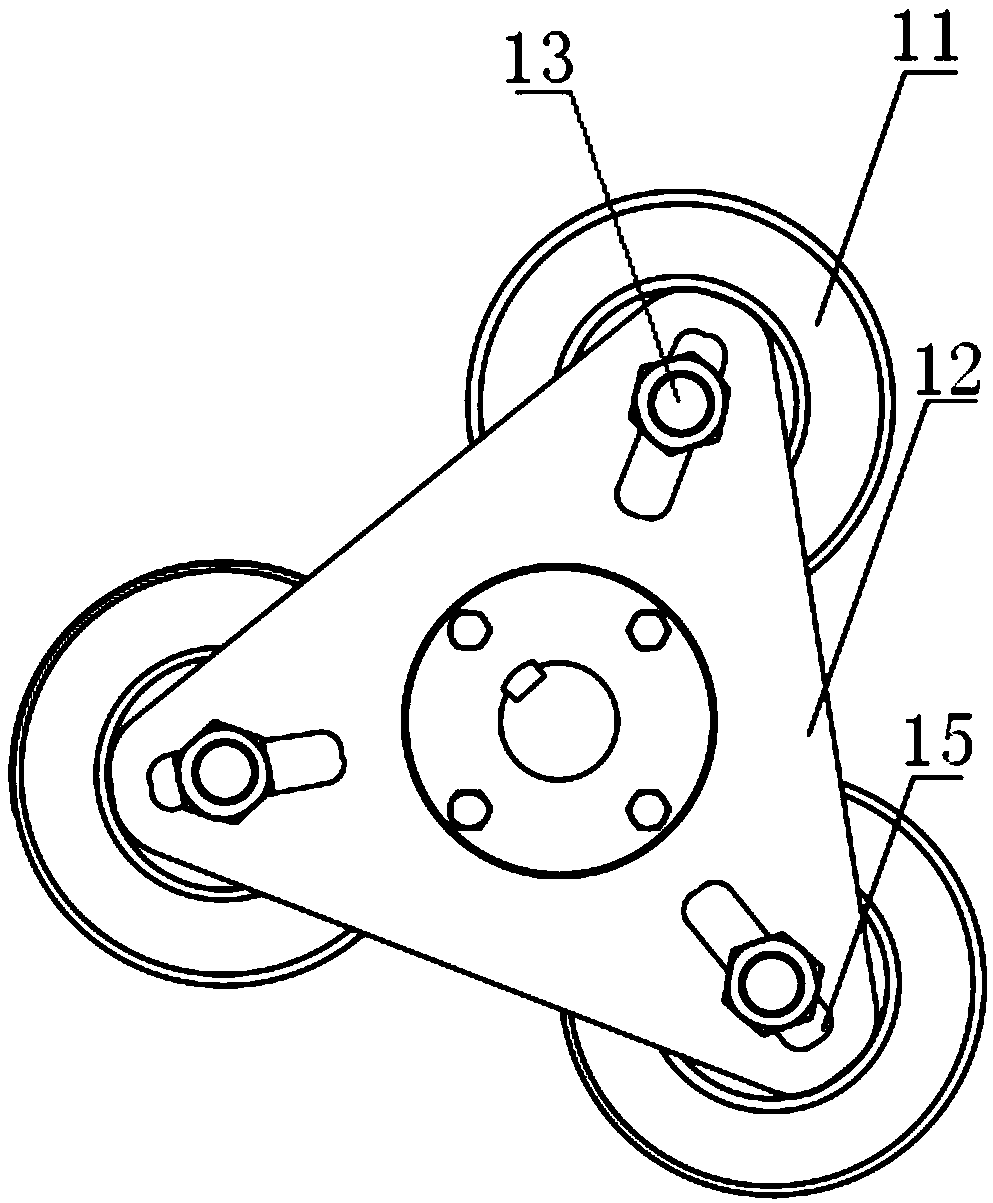

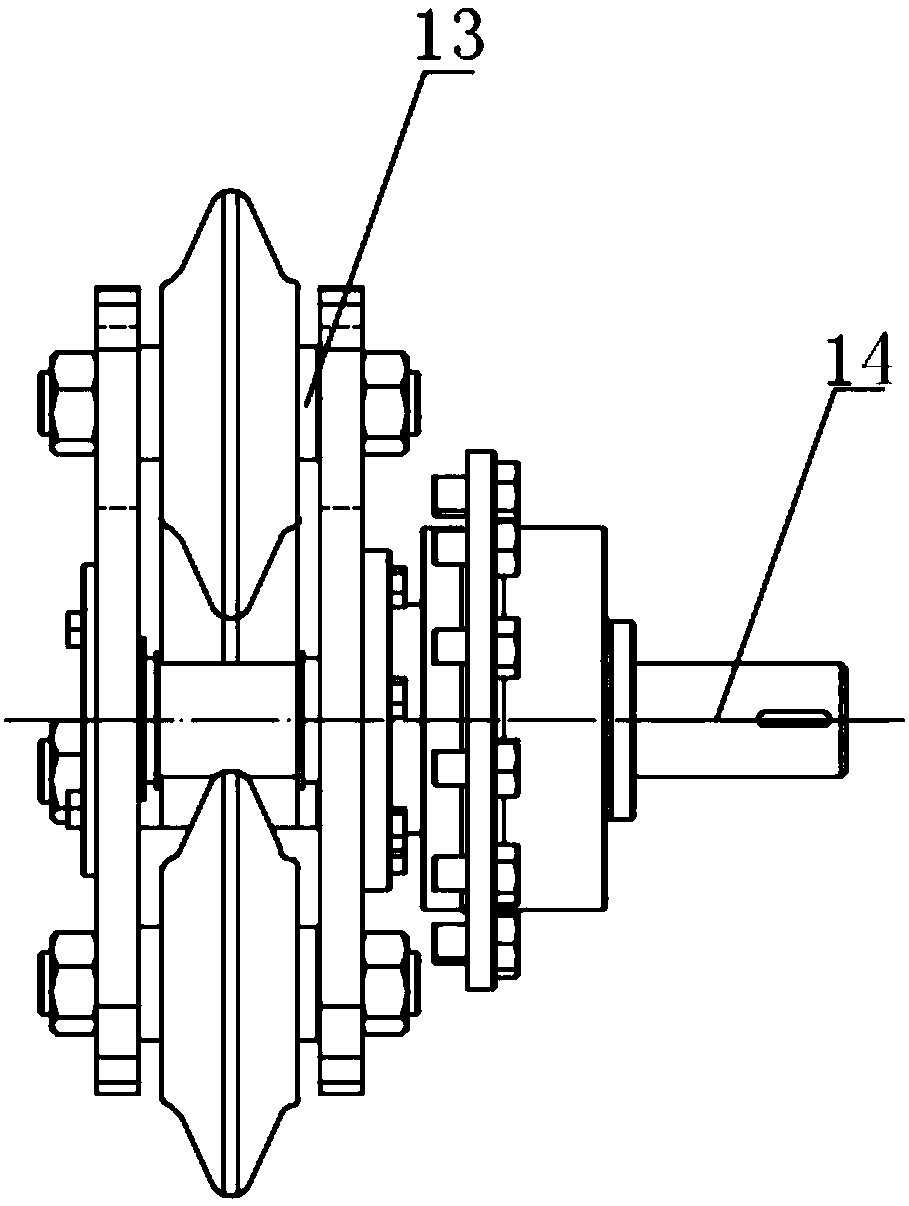

Numerical control diamond abrasive wire sawing machine

PendingCN107584396AImprove the tension effectImprove wear resistanceGrinding machinesNumerical controlDrive wheel

The invention discloses a numerical control diamond abrasive wire sawing machine. The outer surface of a wire storage barrel (5) of a wire transporting mechanism of the numerical control diamond abrasive wire sawing machine is covered with a wire barrel outer ring protecting glue layer, and an upper wire frame (7) and a lower wire frame (8) are arranged on a column (6) from top to bottom. An outerring of a tensioning wheel (9), an outer ring of a driving wheel I (10), an outer ring of a driving wheel II (11) and an outer ring of a transition wheel (12) are sleeved with protective sleeves, a diamond wire (13) is wound around the wire storage barrel (5), the driving wheel II (11) is vertically connected with a pneumatic tensioning device (15), the pneumatic tensioning device (15) pushes thetensioning wheel (9) to move up and down to adjust the position of the tensioning wheel (9) to enable the diamond wire to maintain a constant tension state, the other side of a lathe bed (1) is provided with a cutting working table (16), and the bottom of the cutting working table (16) is provided with a driving assembly. The numerical control diamond abrasive wire sawing machine not only is goodin use effect and wide in applied range, but also is resistant to abrasion and long in service life.

Owner:泰州市南光机械电子有限公司

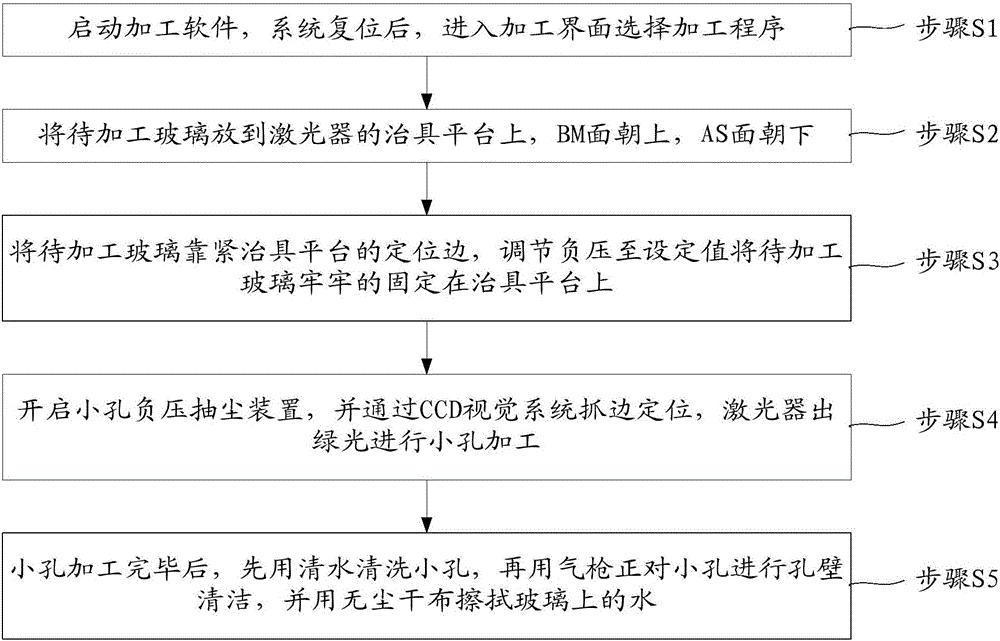

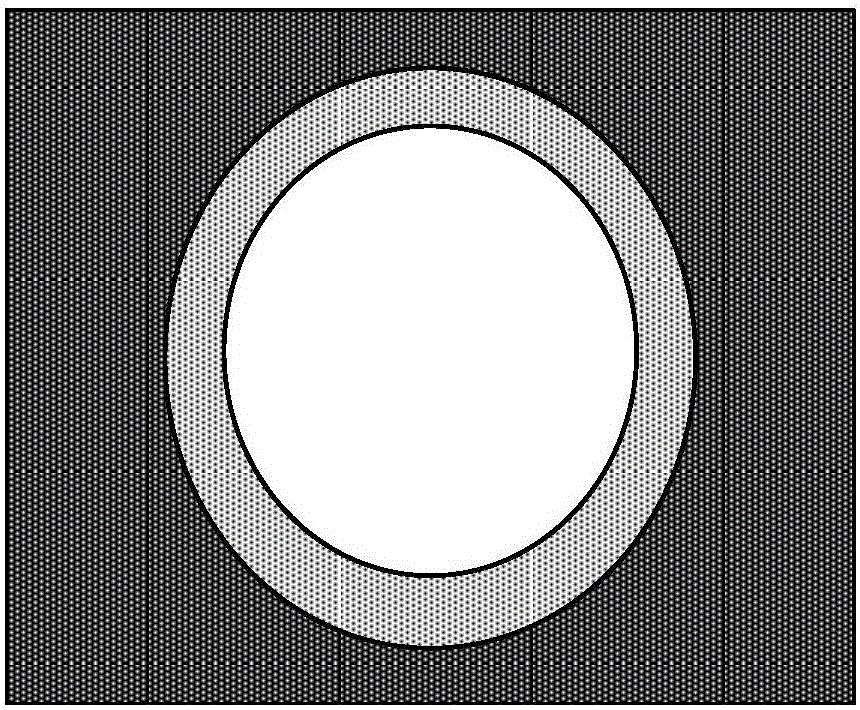

Machining method for punching small hole on glass

ActiveCN106624385AAdvantages of processing methodResidue reductionLaser beam welding apparatusPunchingEngineering

The invention discloses a machining method for punching a small hole on glass, relates to the technical field of glass punching, and aims to solve the technical problems of a current machining method that a low punching yield, a low output yield, hole caving defects and surface heterochrome defects are easily caused. The machining method for punching the small hole on glass comprises the following steps that machining software is started; after a system is reset, a machining interface is entered to select a machining process; the to-be-machined glass is placed on a jig platform of a laser, wherein a BM surface is upward, and an AS surface is downward; the to-be-machined glass clings to a positioning edge of the jig platform, and a negative pressure is adjusted to a preset value, so that the to-be-machined glass is firmly fixed on the jig platform; a small hole negative pressure dust drawing device is started, and a CCD visual system is used for edge grabbing and positioning, so that a green ray is emitted by the laser to perform small hole machining; after the small hole is machined, firstly the small hole is cleaned with clear water, and then a hole wall is cleaned by pointing an air gun at the small hole; and water on the glass is wiped with a dustless dry cloth.

Owner:LENS TECH CHANGSHA

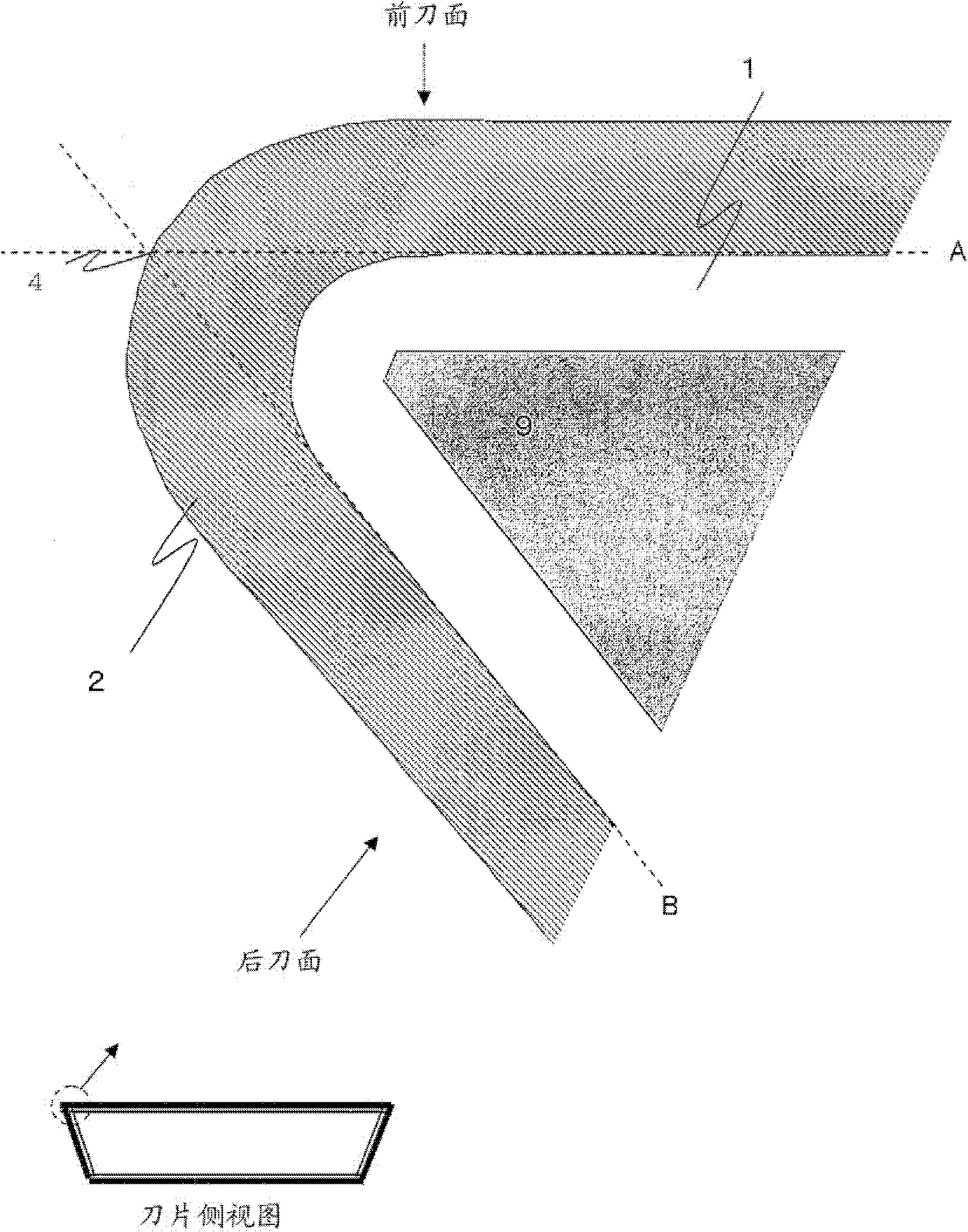

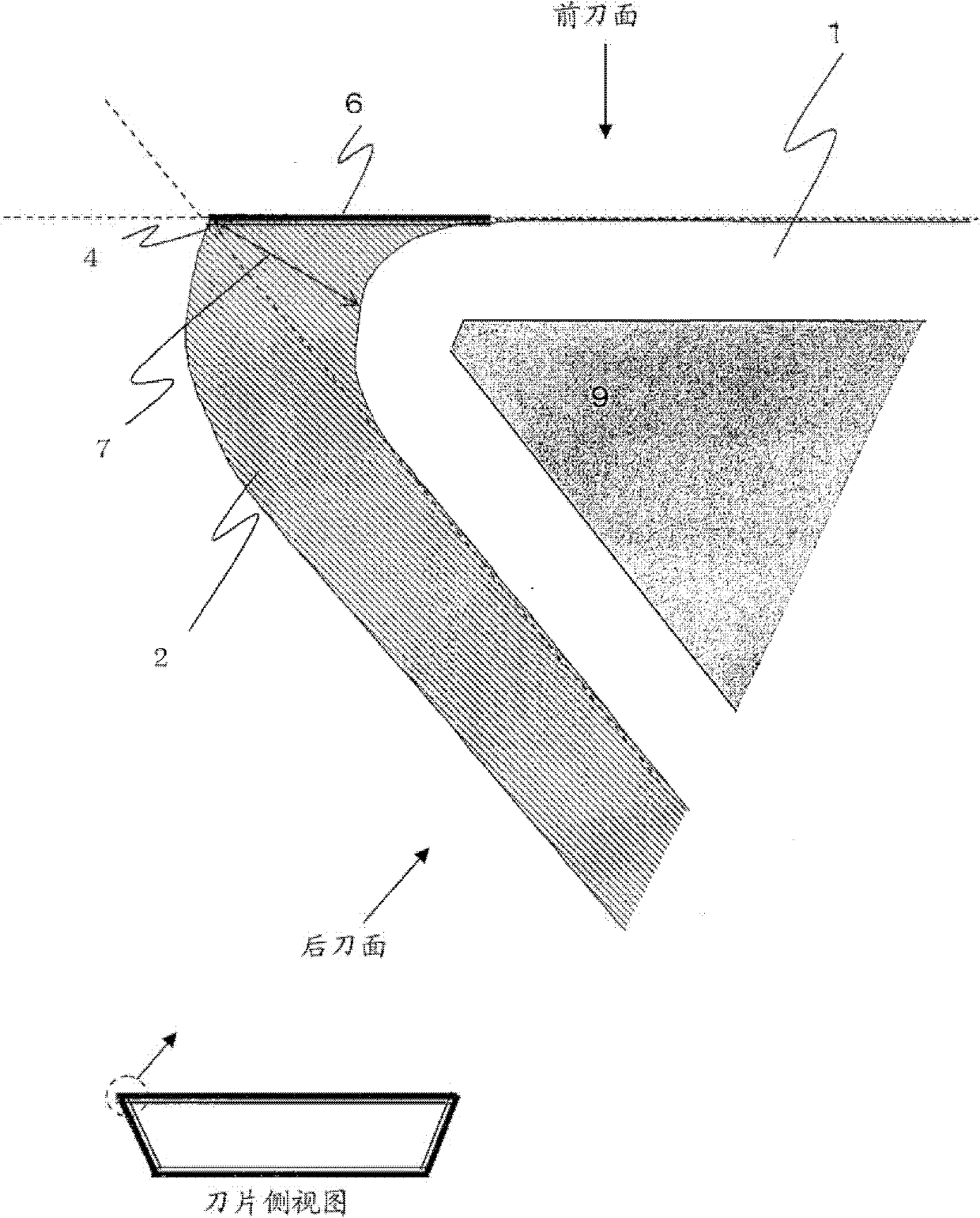

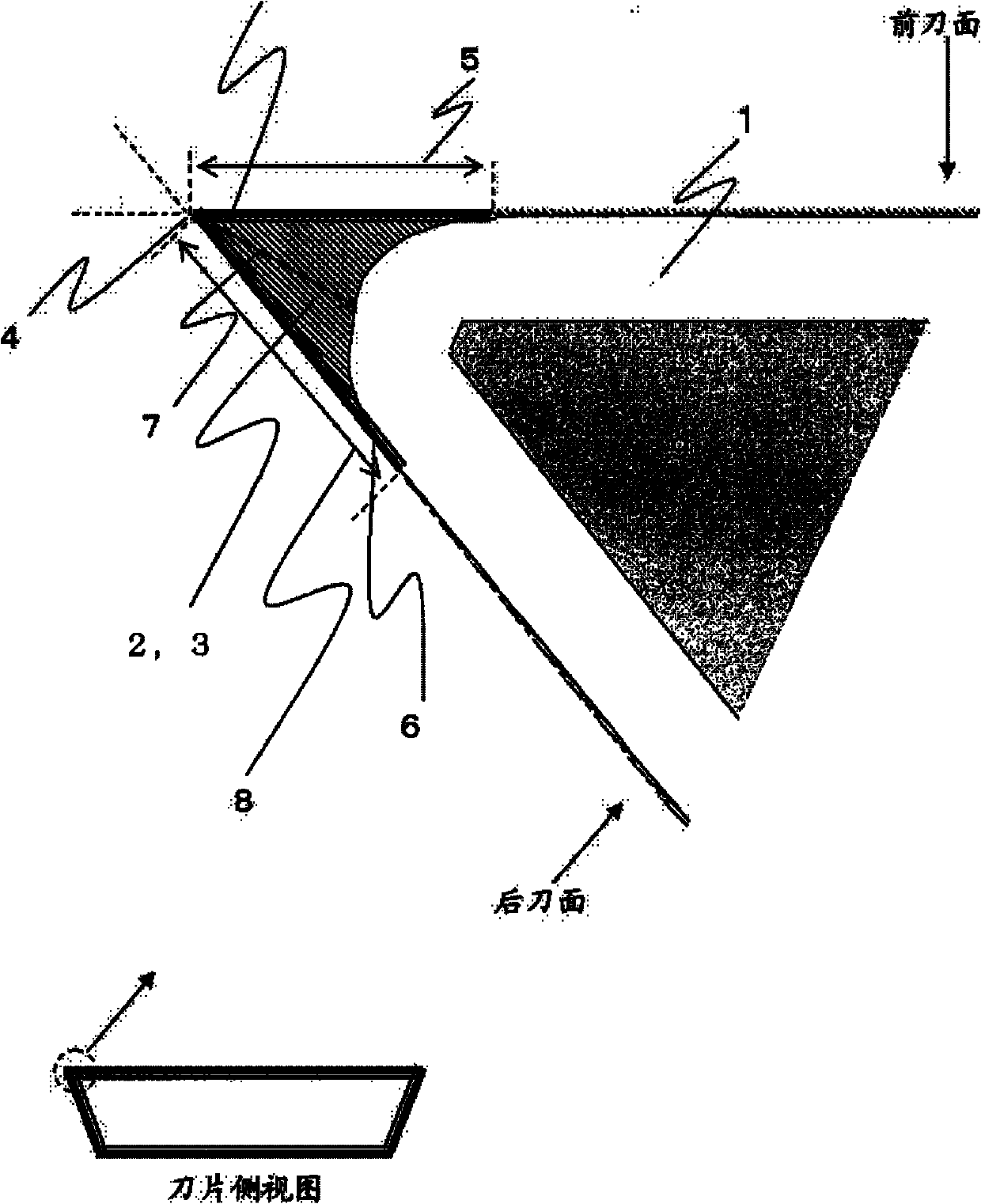

Cutting tool covered with diamond

ActiveCN102626853AImprove the lubrication effectEasy chip removalTransportation and packagingMilling cuttersCarbon filmSurface layer

The invention provides a cutting tool covered with diamond. The tool substrate composed of tungsten carbide cemented carbide or titanium carbonitride base metallic ceramics is covered with a crystal diamond layer. Nanometer diamond film having average grain diameters of 1 to 50 nm and laminated alternatively at a lamination space of 0.2 to 2.0 micrometers and alternating lamination films of crystal diamond film having average grain diameters of 0.1 to 2 micrometers cover the crystal diamond layer. The shortest distance between the front end of a cutting blade to the crystal diamond layer is determined to be 3 to 15 micrometers. And a non-crystal carbon film having surface roughness less than 0.1 micrometer and thickness of 10 to 200 micrometers is formed on the surface layer of a front blade face of the nanometer diamond layer of the cutting blade.

Owner:MITSUBISHI MATERIALS CORP

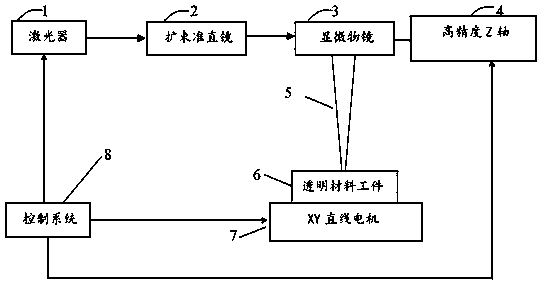

Method for processing three-dimensional contour of transparent material

ActiveCN111558785ANo crackNo damageGlass severing apparatusWelding/soldering/cutting articlesLaser processingCrack free

The invention discloses a method for processing a three-dimensional contour of a transparent material. The whole transparent material is processed according to a preset path through a laser beam, laser processing energy is continuously adjusted according to different processing depths, the Z axis height and a corresponding processing track are changed, and the three-dimensional contour of the transparent material is formed; after the three-dimensional contour of the transparent material is formed, a forming method is used for treatment, and the three-dimensional contour of the transparent material is separated from waste to be formed finally. The laser beam acts in the thickness direction of the whole transparent material, the transparent material is modified through ultra-short pulse width, the transparent material is formed and separated through a special treatment method, a crack-free damage-free workpiece is obtained, generation of small debris is avoided, and the product yield isimproved.

Owner:WUHAN HGLASER ENG CO LTD

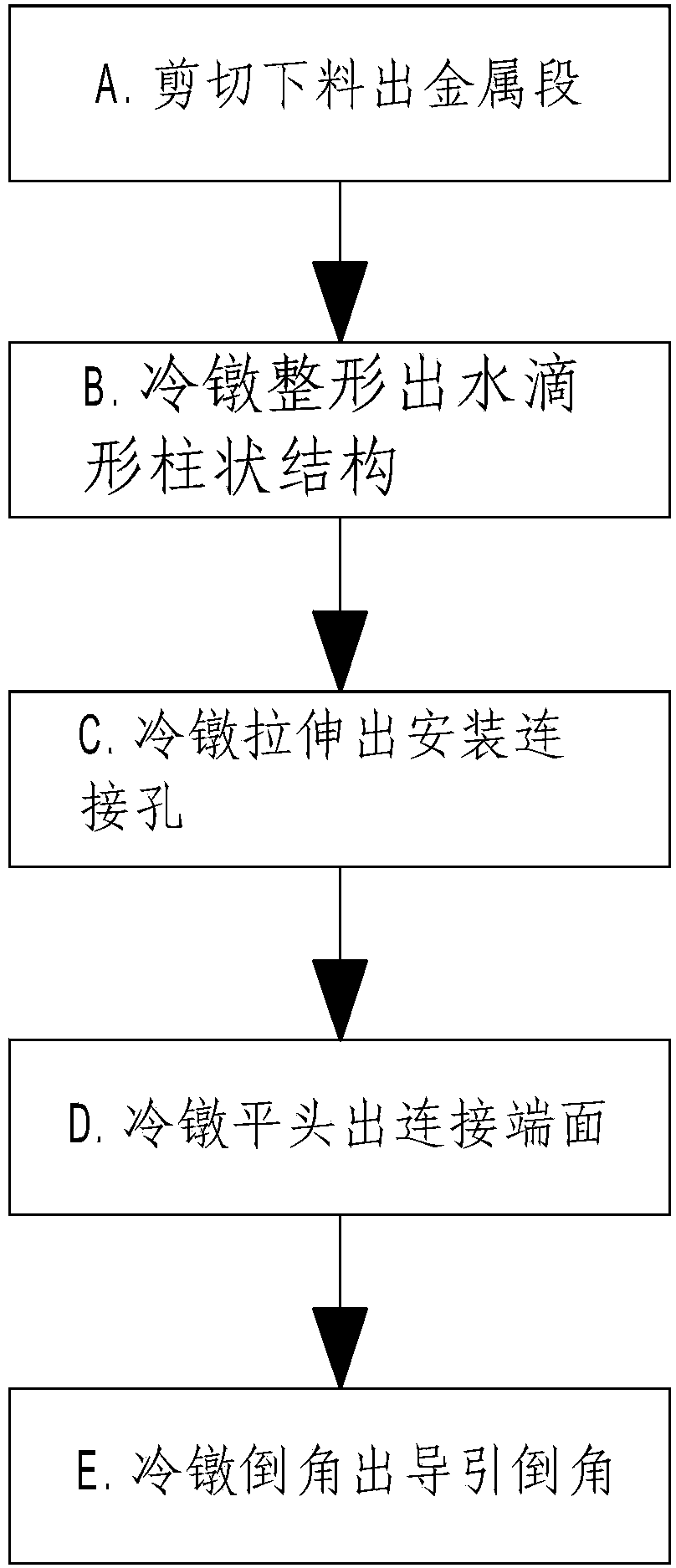

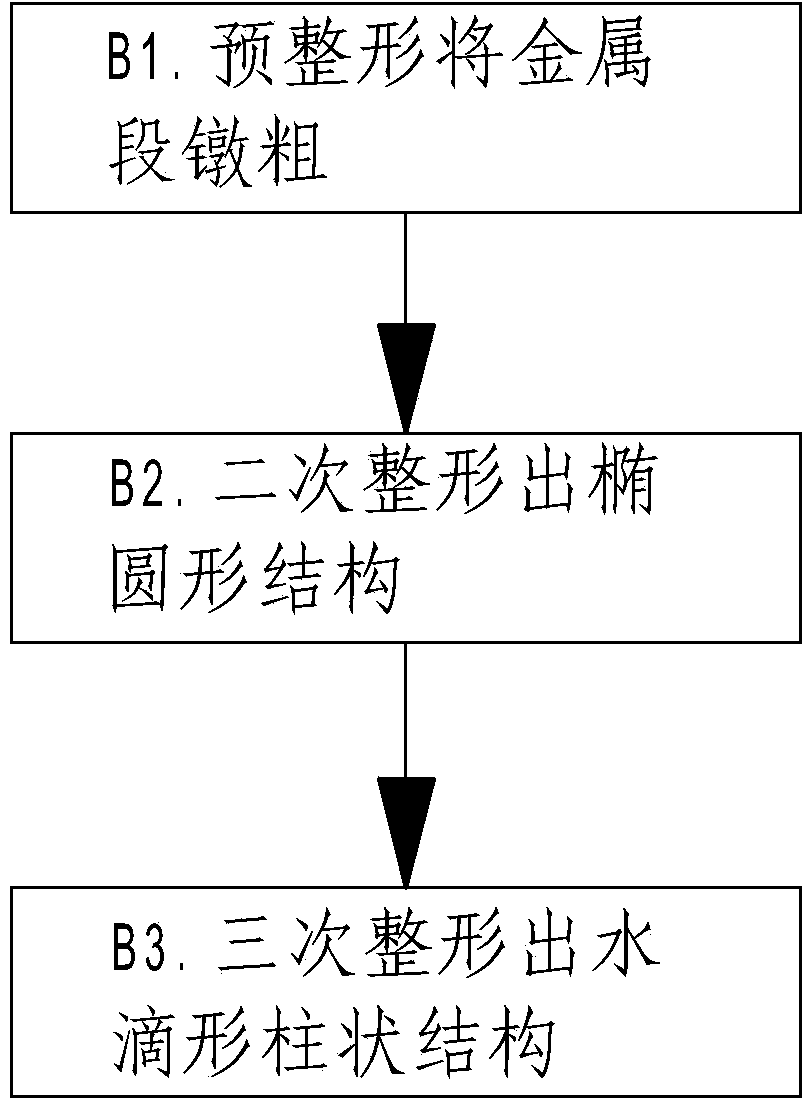

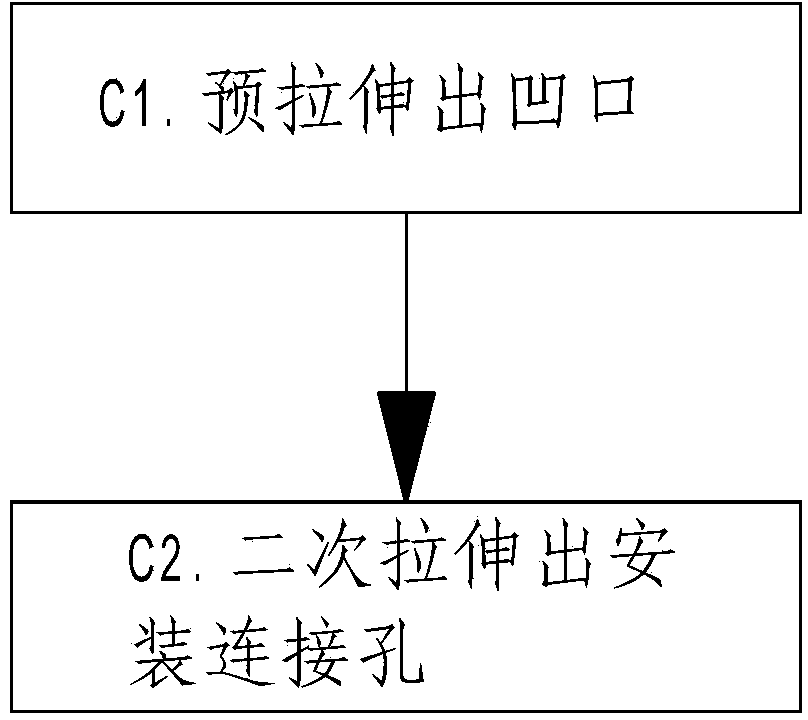

Molding and manufacturing process for hinge

ActiveCN104384429AGuaranteed structural strengthIncrease profitHingesDrop-shapedUltimate tensile strength

The invention discloses a molding and manufacturing process for a hinge, and aims at providing a molding and manufacturing process, wherein the molding and manufacturing process meets the demands of production and manufacture of a drop-shape cylindrical hinge, improves the utilization rate of raw materials, guarantees the mechanical performances of the produced hinge, and meets the requirements for high strength. The main points of the technical scheme are that the process comprises the following steps: A, cutting fed materials, i.e., employing a cutter to cut a metal rod serving as a raw material into metal segments with a specific standard; B, cold-heading shaping, i.e., employing a cold-heading machine for enabling the metal segments formed at the step Ato form drop-shape cylindrical structures in a cold-heading manner; C, cold-heading stretching, i.e., enabling the metal segments formed at the step B to form installation connecting holes in a cold-heading manner; D, cold-heading leveling, i.e., enabling the metal segments formed at the step C to form connecting end faces in a cold-heading manner; E, cold-heading chamfering, i.e., enabling the metal segments formed at the step D to form guide chamfers in a cold-heading manner. The process employs a method of cold heading to form the drop-shape cylindrical hinge, improves the production efficiency of an enterprise, and reduces the production cost.

Owner:WENZHOU YANG THAI FASTENERS

Composite spunlace fabric with wood pulp fiber layer

InactiveCN102080303AEmbody green environmental protection and safetyHigh strengthLayered productsNon-woven fabricsTextile fiberNatural fiber

The invention relates to a composite spunlace fabric with a wood pulp fiber layer, belonging to the technical field of cleaning articles. The composite spunlace fabric with the wood pulp fiber layer comprises a wood pulp fiber layer and a textile fiber layer, wherein the wood pulp fiber layer is combined with one side of the textile fiber layer which is made from chemical fiber or natural fiber or the chemical fiber and the natural fiber. According to the technical scheme, by adopting the combined structure of the wood pulp fiber layer and the textile fiber layer, the composite spunlace fabric with the wood pulp fiber layer is environmentally friendly and safe, has improved strength, is free from a rag falling phenomenon in a use process, is suitable for being used as industrial or civil wiping fabric and also has favorable water absorption.

Owner:SUZHOU MESON NONWOVEN TECH

Production process of new energy solar power generation panel

InactiveCN112349808AHigh light conversion efficiencyImprove convenienceFinal product manufacturePhotovoltaicsTest batteryElectrical battery

The invention discloses a production process of a new energy solar power generation panel. The production process comprises the steps: putting produced battery pieces into a battery testing machine for testing output parameters of the batteries and classifying the battery pieces, connecting the solar batteries in series in an infrared spot welding manner to form a solar battery string, and puttingthe batteries into the grooves in the corresponding mold plates through a mechanical arm. By adopting the process product produced and molded by the invention, the production efficiency is greatly improved by adopting a full-automatic production mode, and the positive terminal and the negative terminal can be further formed on the back surface of the base material through the electric soldering iron and the soldering tin wire, so that the convenience of the whole solar cell panel in use is greatly improved; the heat conduction coating is excellent in binding power, weather resistance meets the requirement for the service life of 25 years or longer of the solar module, the heat conduction effect is excellent, the light conversion efficiency of the solar backboard is greatly improved, and the process of the product better meets the market requirement.

Owner:曹景

Semiconductor shallow trench isolation method

ActiveCN101930940AProtect or mitigateProtectSemiconductor/solid-state device manufacturingHigh densitySilicon oxide

Owner:CSMC TECH FAB2 CO LTD

Sapphire dome grinding method

InactiveCN108818159AFlat surfaceNo fracture processing defectsGrinding machinesOptical axisSurface roughness

The invention discloses a sapphire dome grinding method. A combination of metal bond diamond grinding heads of different particle sizes and shapes are adopted for machining. The method includes adopting a cylindrical diamond grinding head to grind the end face and the outer circle of a sapphire, and adopting diamond spherical grinding heads of different particle sizes to grind the inner sphericalsurface; adopting a turning method to machine a tool with one end as the hemispherical surface concentric with the grinding inner spherical surface and the other end as an optical axis; milling 6-8 grooves in the hemispherical surface by milling; bonding the workpiece to the tool coaxially by high-strength glue, and injecting the high-strength glue from the grooves; adopting cup-shaped diamond grinding heads of different particle sizes when grinding the outer spherical surface with the coarse grinding particle size of #100-#180 and the fine grinding particle size of #240-#320. According to thesapphire dome grinding method, a ground sapphire dome is smooth in surface without chipping, crushing and fracture processing defects, and the surface roughness Ra is less than 1 Mum.

Owner:DALIAN UNIV OF TECH

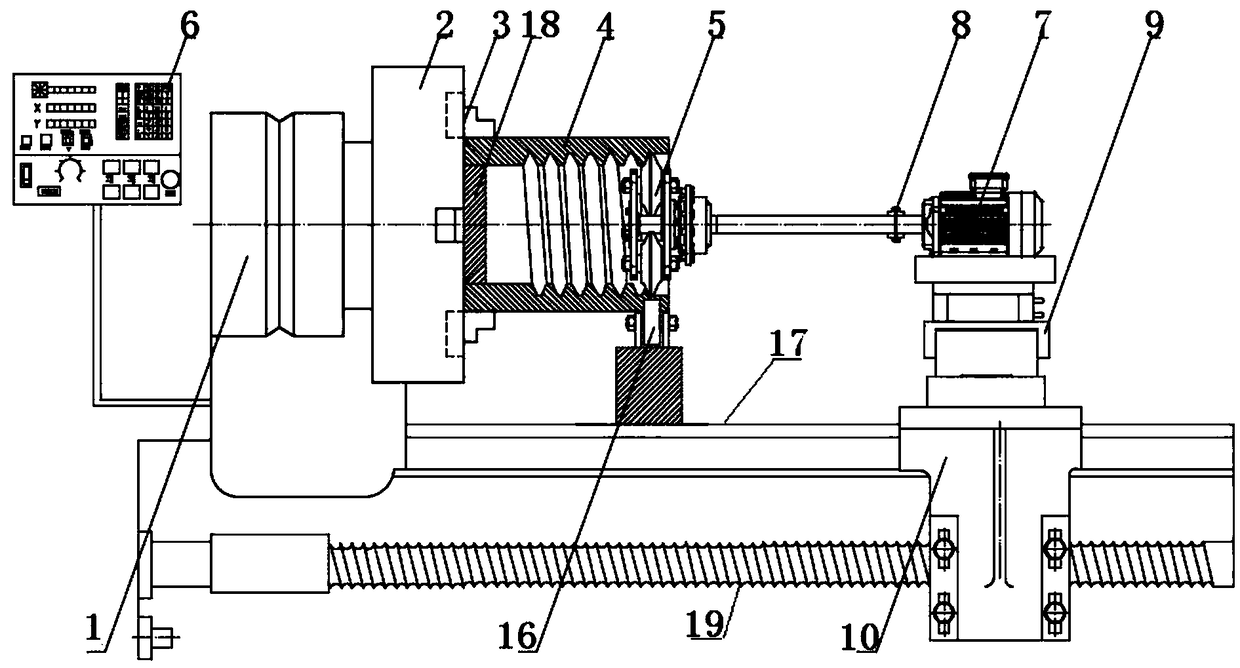

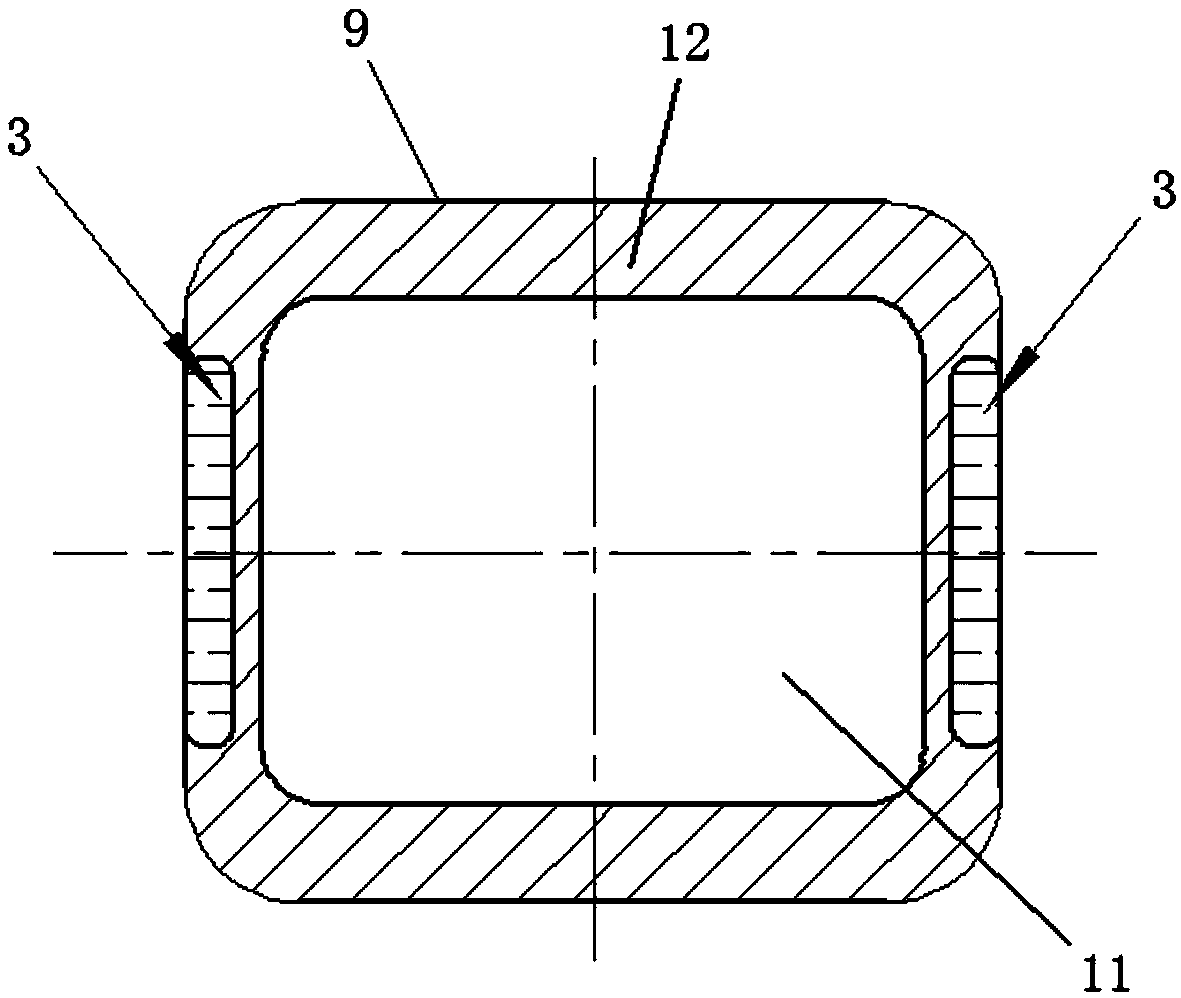

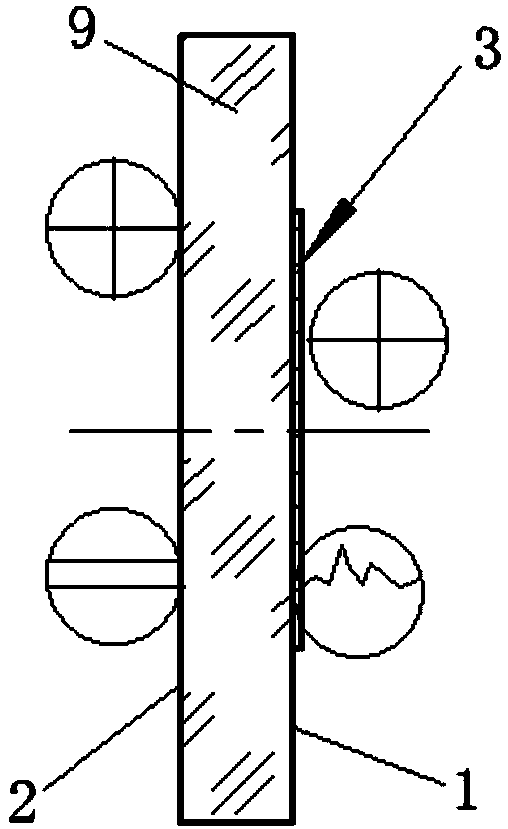

Pipe fitting internal thread incremental rolling-extruding forming device

InactiveCN108994130AImprove surface qualityImprove mechanical propertiesNumerical controlPipe fitting

The invention discloses a pipe fitting internal thread incremental rolling-extruding forming device. The pipe fitting internal thread incremental rolling-extruding forming device comprises an electricspindle box body of a numerically-controlled machine tool, a centring chuck is connected to one side of the electric spindle box body, a clamping jaw is fixed to one side of the centring chuck, a pipe fitting sample is fixed into the clamping jaw, a rolling-extruding forming tool wheel is arranged in the pipe fitting sample, a driving device is connected to one end of the rolling-extruding forming tool wheel, and a numerical control device of the numerically-controlled machine tool is connected to the electric spindle box body. The problem of low quality of an internal thread formed by current milling is solved.

Owner:XIAN UNIV OF TECH

Optical heating window of camera

The invention belongs to the technical field of optical imaging and particularly relates to an optical heating window of a camera. The optical heating window structurally comprises a window body, wherein the window body comprises a first surface and a second surface; the first surface comprises a light transmitting zone located in the center and a heating zone surrounding the light transmitting zone, and a conductive film is arranged on the heating zone and connected with a heating circuit. The technical problems that existing optical windows of cameras have poor defrosting and demisting effects and affect camera imaging easily are solved. The annular conductive film is arranged to heat the optical window of the camera, uniform and quick heating can be realized, the heating effect is good,the window transmittance is high, no effects are caused to optical system imaging, and the heating wire shielding problem is avoided. The window cannot produce stray light such as ghost images understrong light and is particularly applicable to cameras or video cameras working in humid and cold environments.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

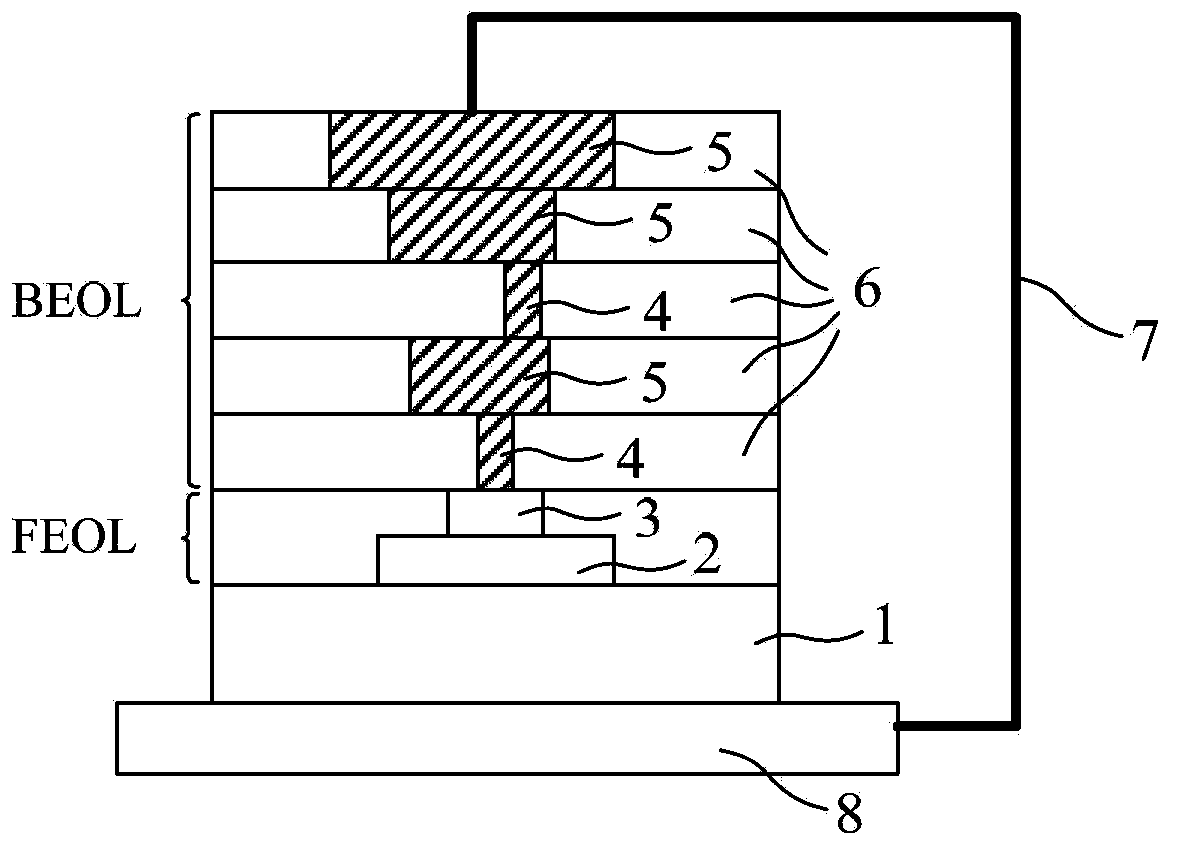

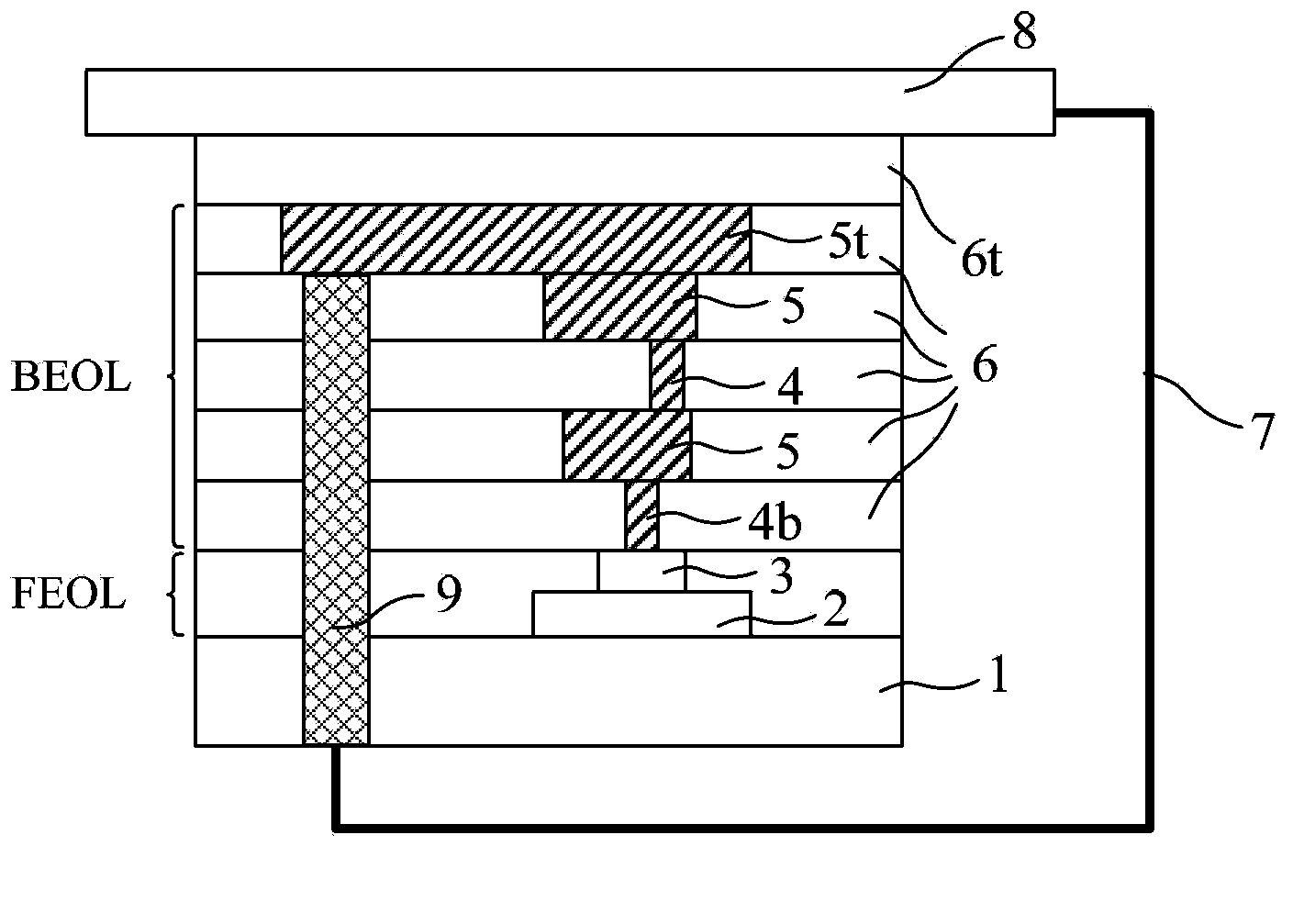

A packaging structure of a low-k chip and a manufacturing method thereof

ActiveCN103681605AWon't breakNo chippingSemiconductor/solid-state device detailsSolid-state devicesEngineeringDielectric layer

The invention discloses a packaging structure of a low-k chip. The packaging structure comprises a substrate, a metallic layer, a TSV, and a bonding pad. A chip is formed on the substrate. The metallic layer is formed on the chip and comprises multiple vias and multiple connecting lines which are mutually and electrically connected, and dielectric layers produced by material with an ultra low-k and filled around the vias and the connecting lines. A dielectric layer at the top covers a connecting line at the top in the metallic layer. The TSV is arranged from the connecting line at the top in the metallic layer to the bottom of the substrate and passes through the substrate. The bonding pad is disposed on the dielectric layer at the top of the metallic layer and is electrically connected with the one end of the TSV on the bottom of the substrate through a metallic line. In the packaging structure, the connecting line at the top is directly guided to the bottom of the substrate via the TSV and then is connected with a bonding gasket through one end of the TSV on the bottom of the substrate without material with an ultra low-k. As a result, the crack of the dielectric layer with an ultralow dielectric constant can be prevented and a CPI problem in the prior art is further improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

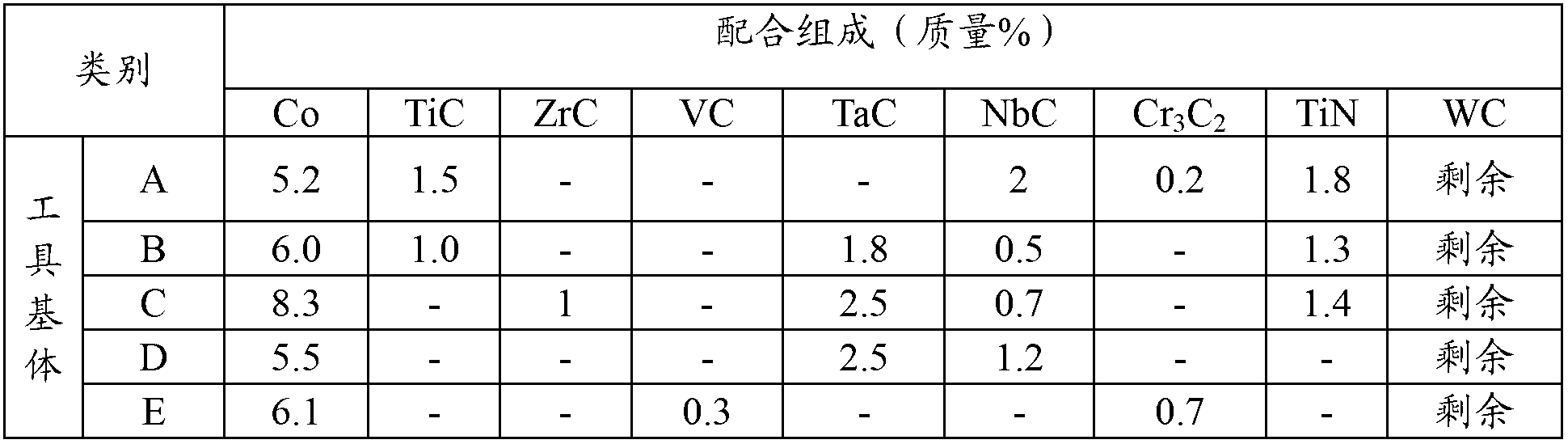

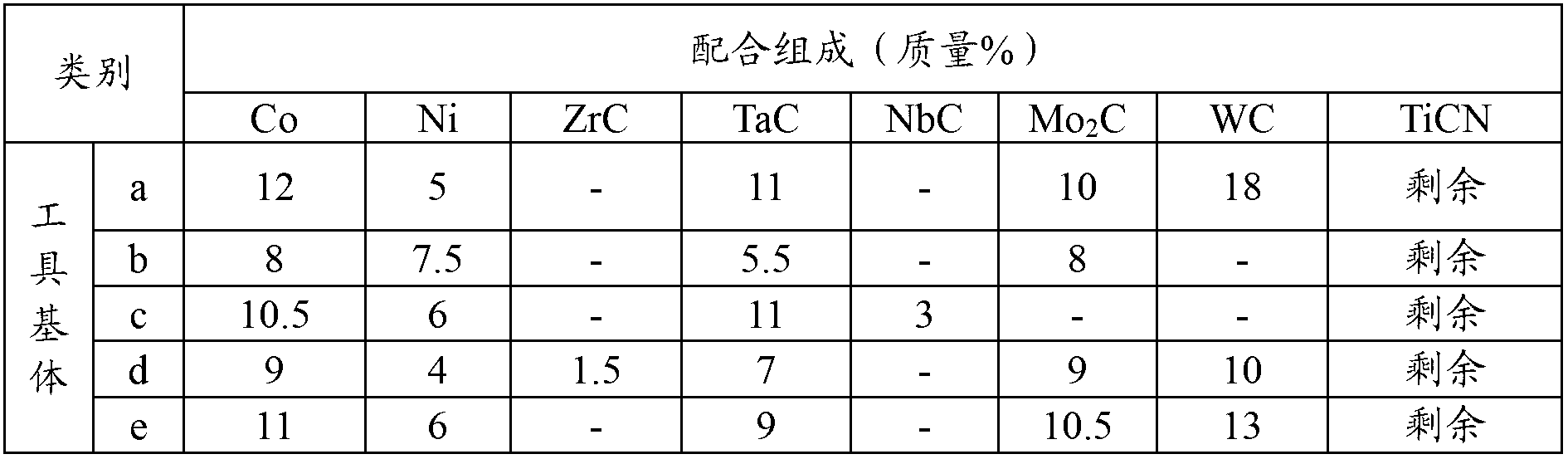

Microwave vacuum sintering method of ultra-fine grain hard alloy and hard alloy products

The invention provides a microwave vacuum sintering method of ultra-fine grain hard alloy and hard alloy products and relates to the technical field of hard alloy manufacturing. The ultra-fine grain hard alloy raw material comprises the following components in percentage by mass, including 88-92% of WC powder and 8-12% of Co powder, wherein the Fisher particle size of the WC powder is 0.3-0.6 microns, and the Fisher particle size of the Co powder is 0.6-1.0 microns; and the microwave vacuum sintering comprises four stages of inert gas positive pressure dewaxing, vacuum degassing solid phase sintering, high temperature vacuum liquid phase sintering and cooling. The hard alloy products subjected to the microwave vacuum sintering have the advantages of consistent hardness distribution, finerWC crystal grains, more uniform microstructure, good magnetic property, high density, low porosity, excellent mechanical property and chemical corrosion resistance.

Owner:河南荣泰耐火材料有限公司

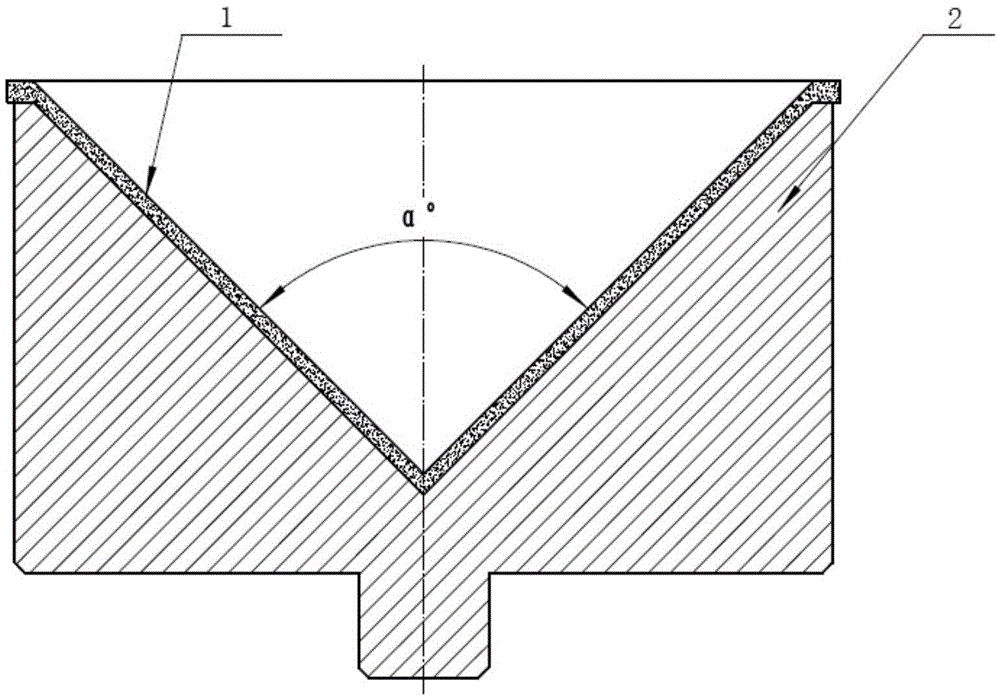

Large-diameter crystal wafer chamfering tool and chamfering method thereof

InactiveCN101972981ASolve the chamferSolve the collapseEdge grinding machinesLapping machinesDrive shaftEngineering

The invention provides a large-diameter crystal wafer chamfering tool and a chamfering method thereof. The chamfering tool comprises a four-shaft grinding machine, a bowl-shaped chamfering tool and a crystal wafer vacuum sticky hook, wherein the bowl-shaped chamfering tool comprises a bowel body with a spherical concave surface and a connector installed at the lower part of the bowl body, a grinding sand layer is arranged on the spherical concave surface of the bowel body, and the connector of the bowl-shaped chamfering tool is installed on a transmission shaft of the four-shaft grinding machine; the center of the crystal wafer vacuum sticky hook is corresponding to the center of the spherical concave surface. The chamfering method comprises the following steps of: starting the four-shaft grinding machine, and adjusting the rotating speed; absorbing the crystal wafer by using the crystal wafer vacuum sticky hook; and leading the crystal wafer to be in contact with the spherical concave surface, and chamfering the edge of the crystal wafer by rotating the spherical concave surface. The chamfering tool has the advantages of high working efficiency and low manufacturing cost and is easy to operate; the chamfering method has the advantages of simple process, ideal grinding effect, reliable chamfering quality and no broken edge.

Owner:北京石晶光电科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com