Patents

Literature

30results about How to "Advantages of processing method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

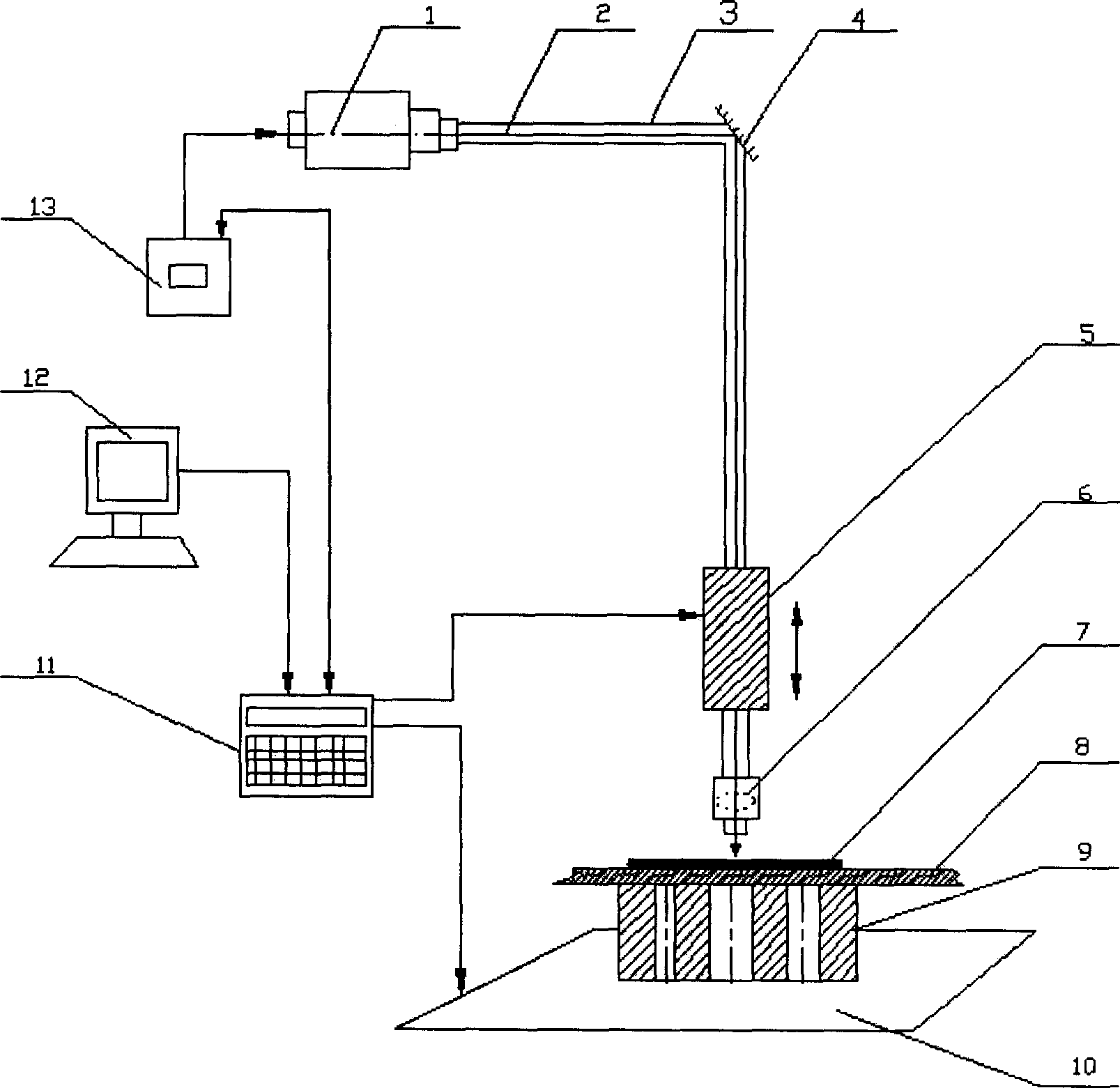

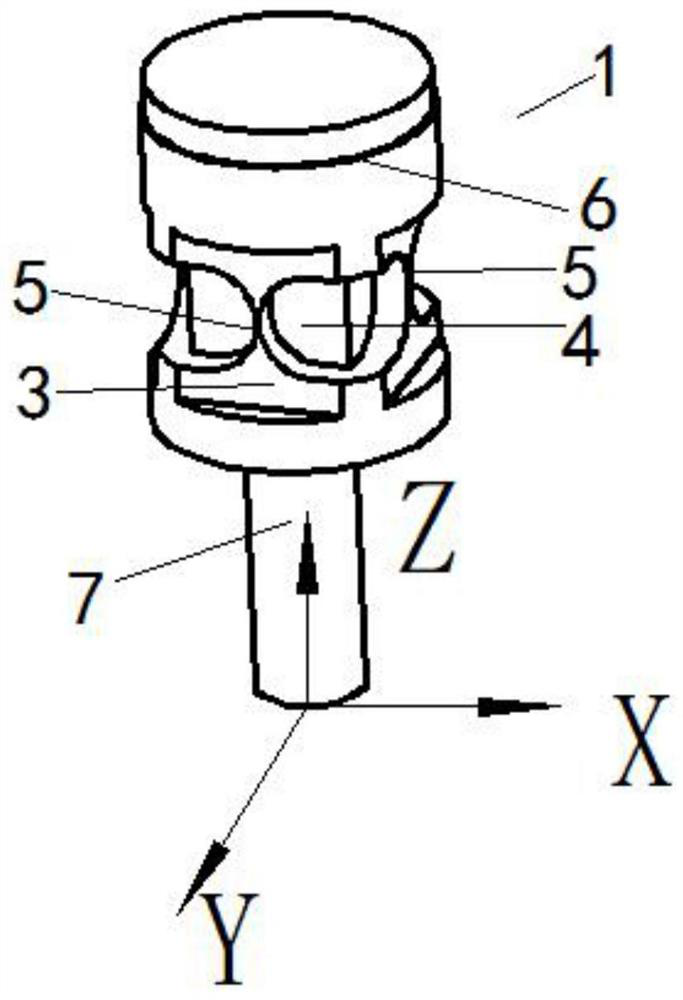

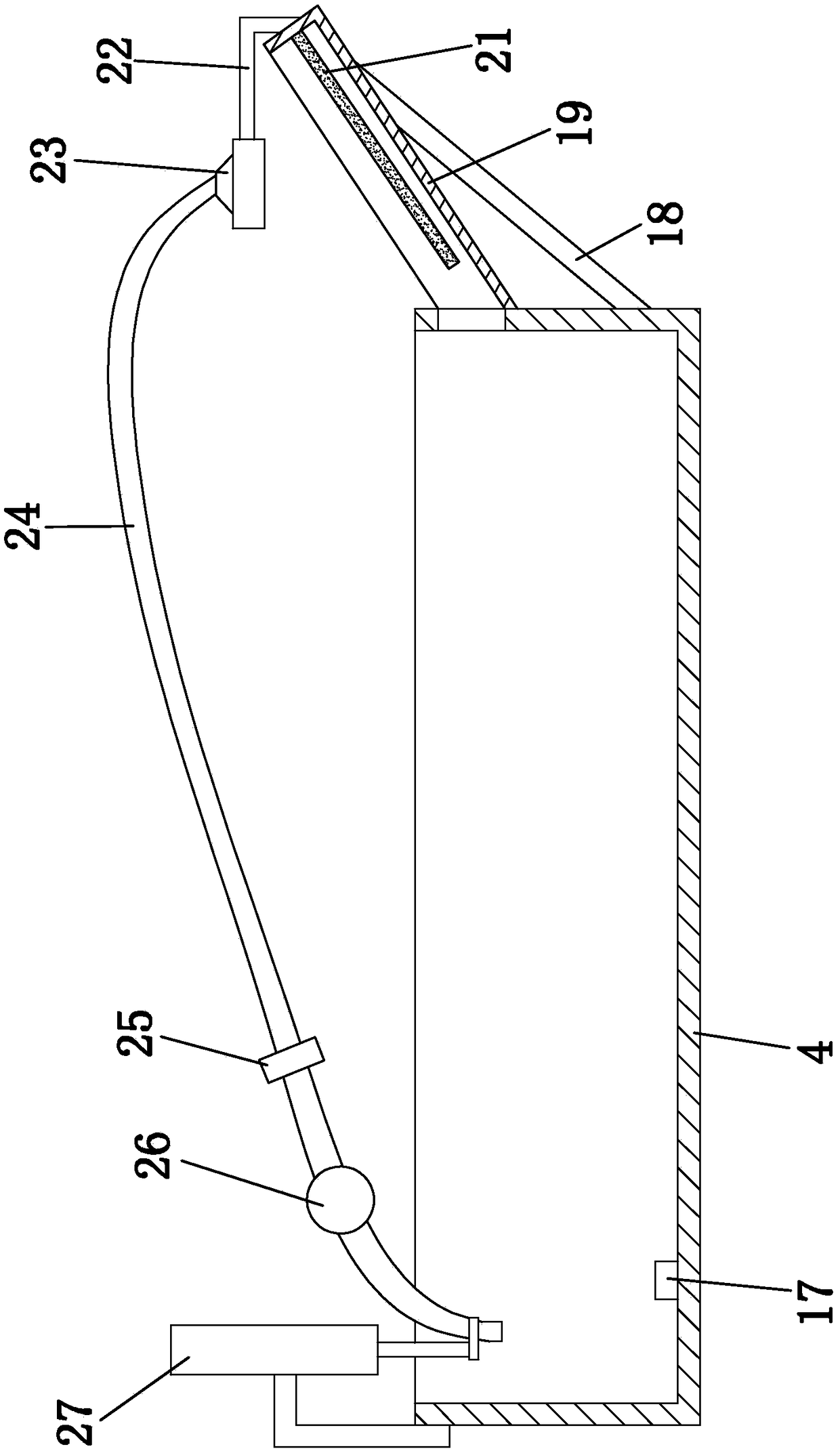

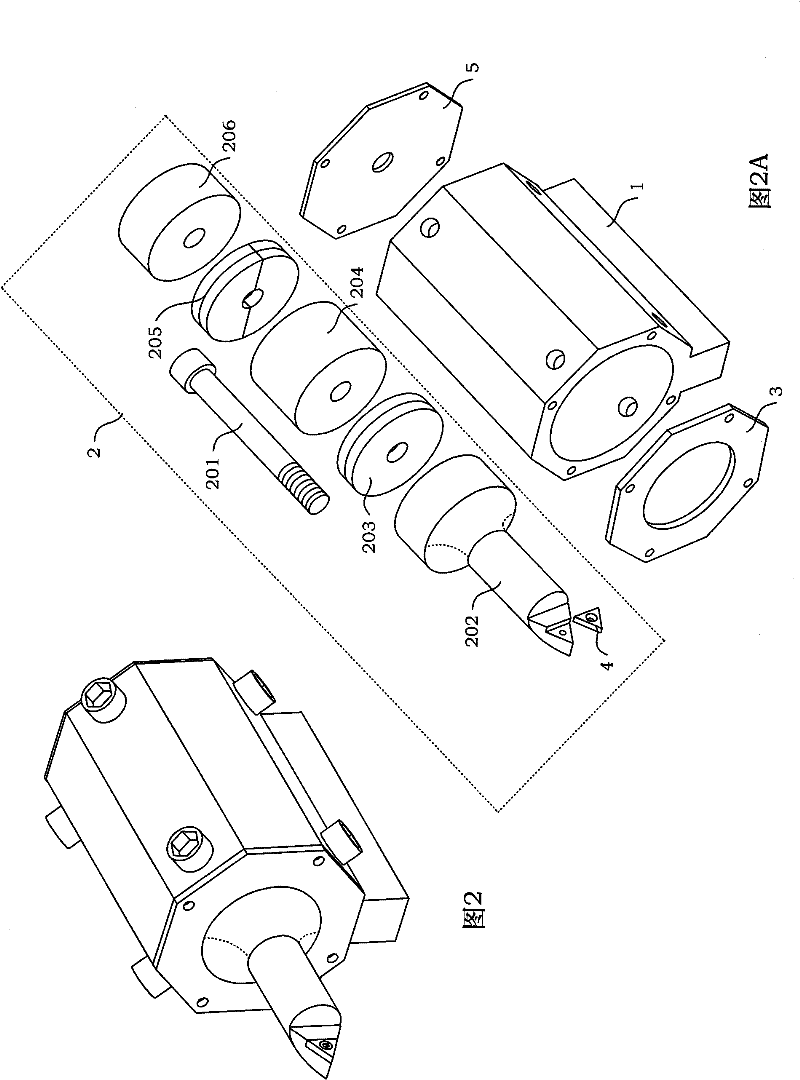

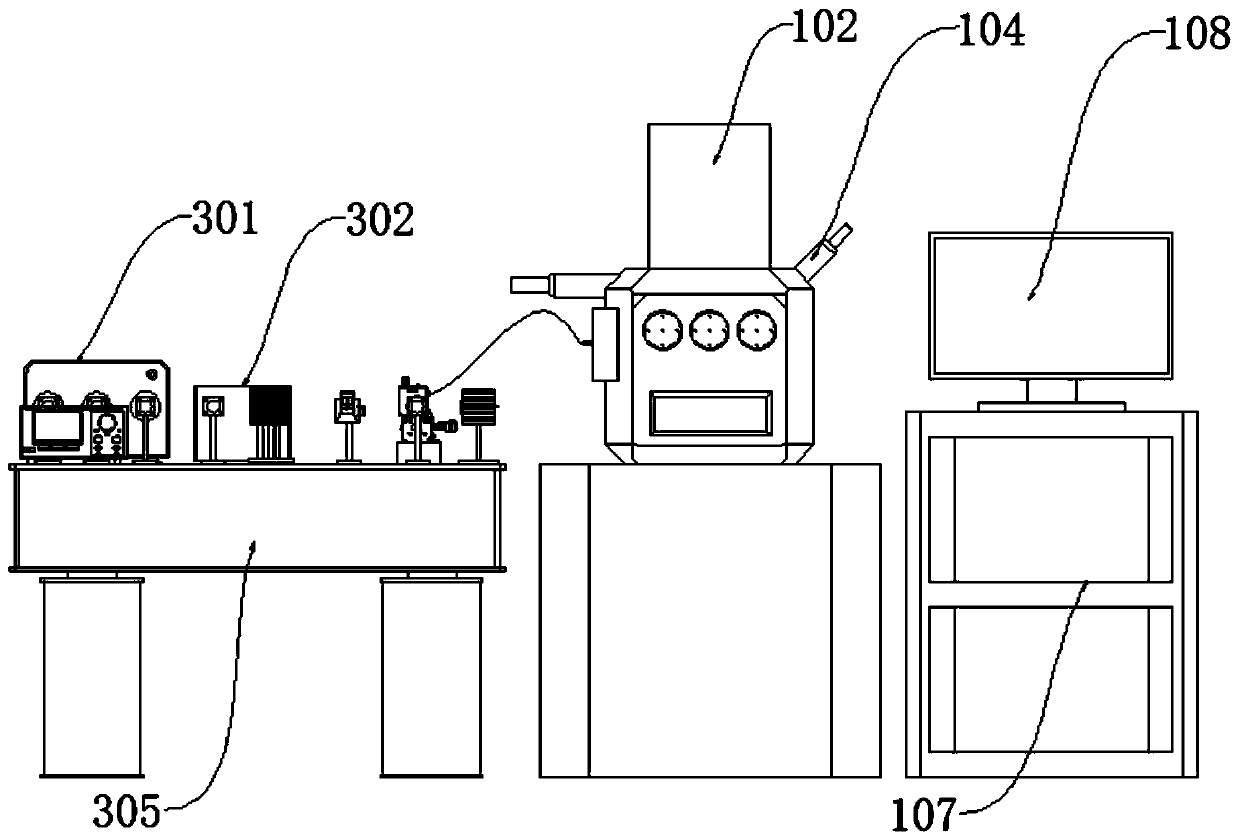

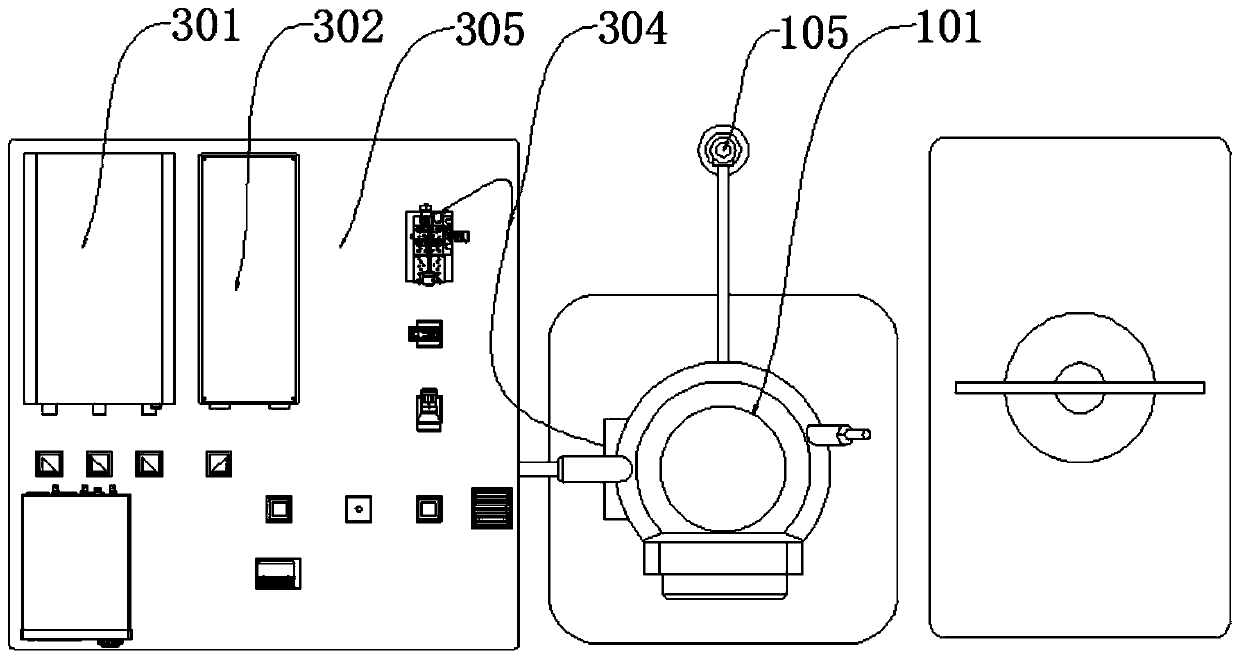

Hole-forming method and device based on laser shock wave technology

InactiveCN1827284ASmall sizeAdvantages of processing methodLaser beam welding apparatusShock waveOptoelectronics

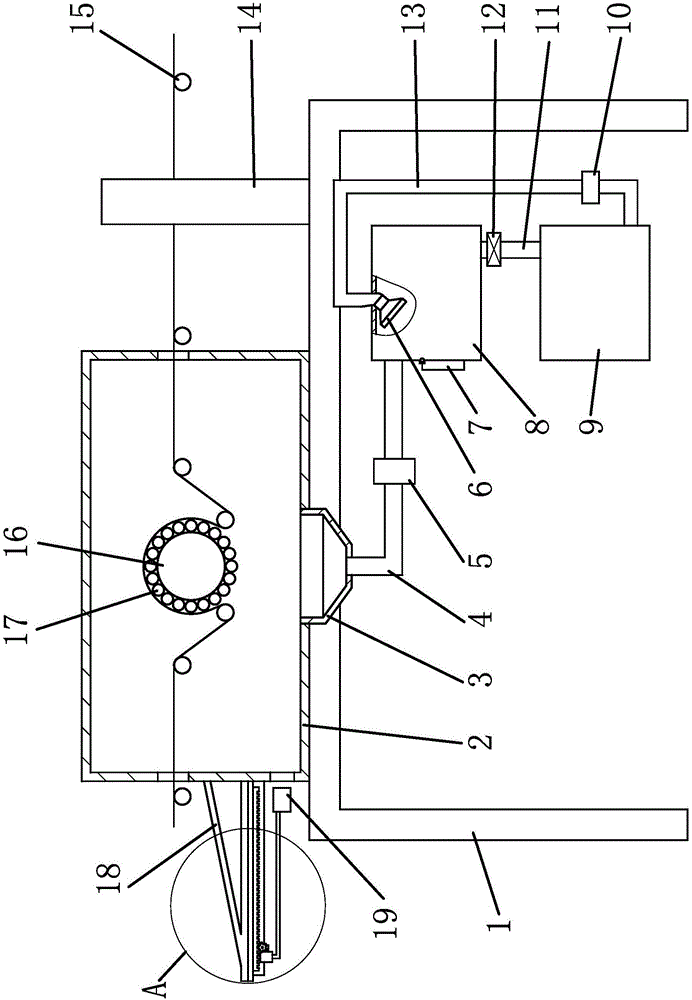

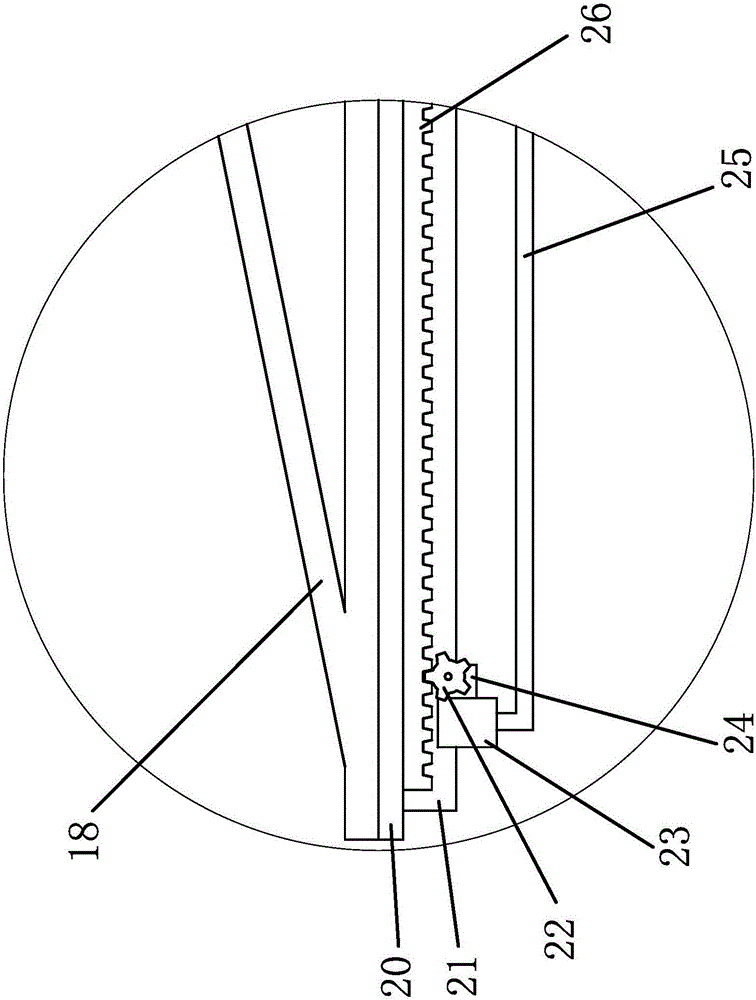

The invention relates to a hole molding method based on laser impact wave technique and relative device. Plating energy-adsorption layers and transparent restrain layers on the positions that needing holes, while the areas of them are larger than the processing hole; according to the shape and size of processing hole, preparing concave, and arranging the work-piece on the concave mold to make the centers of energy-adsorption layer, transparent restrain layer, the processed hole and concave mold matched; arranging the concave mold on the multiple-axle linkage workbench; according to the size of hole, setting the light spot size and the energy of laser impulse; the laser beam via the light guide tube, reflective glass, light spot adjuster, focusing device and transparent restrain layer is emitted on the energy-adsorption layer to induce the laser impact wave, which can compress the work-piece, to complete the punch. The invention has the advantages that: larger processing radius, and lower processing cost.

Owner:JIANGSU UNIV

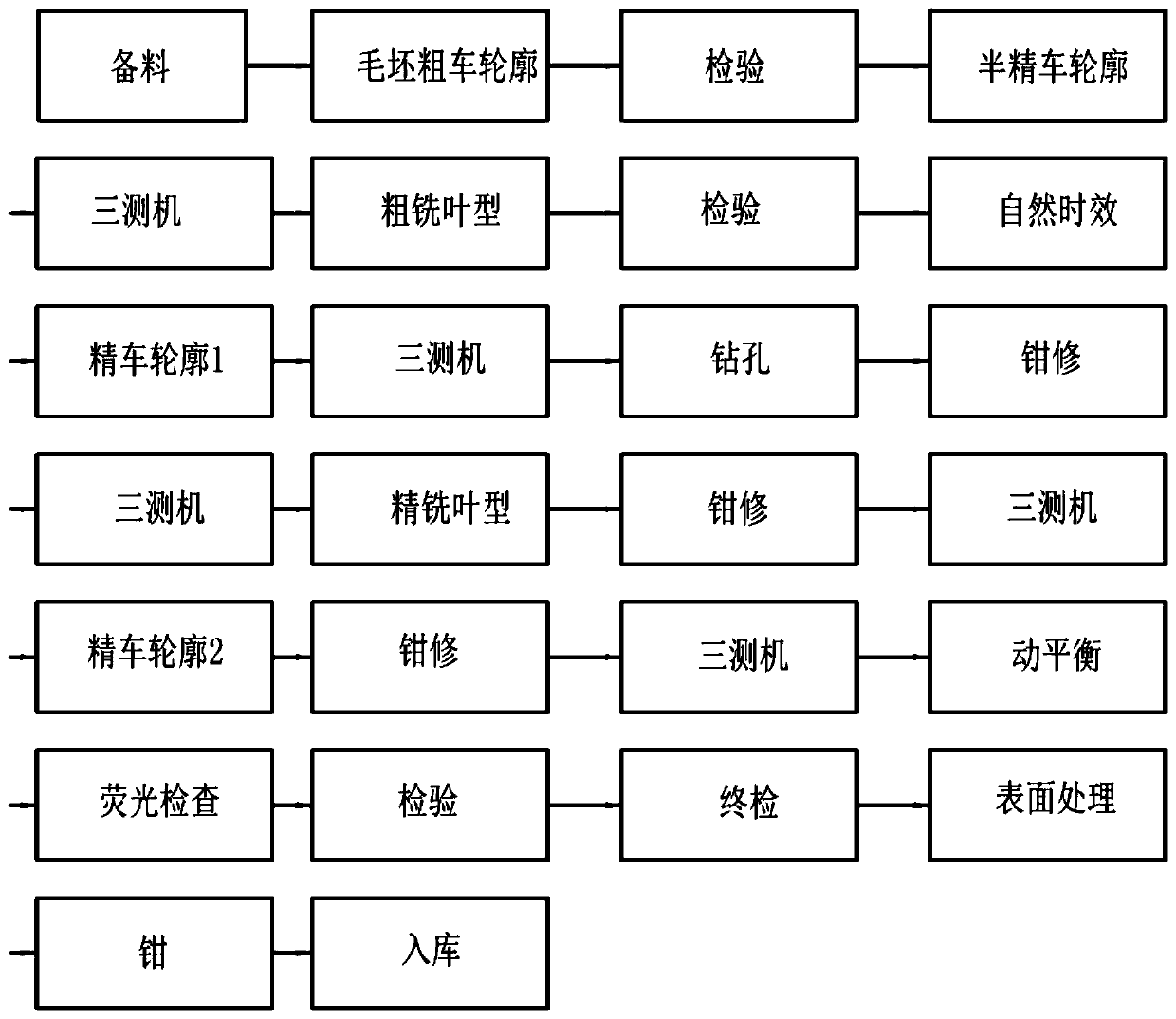

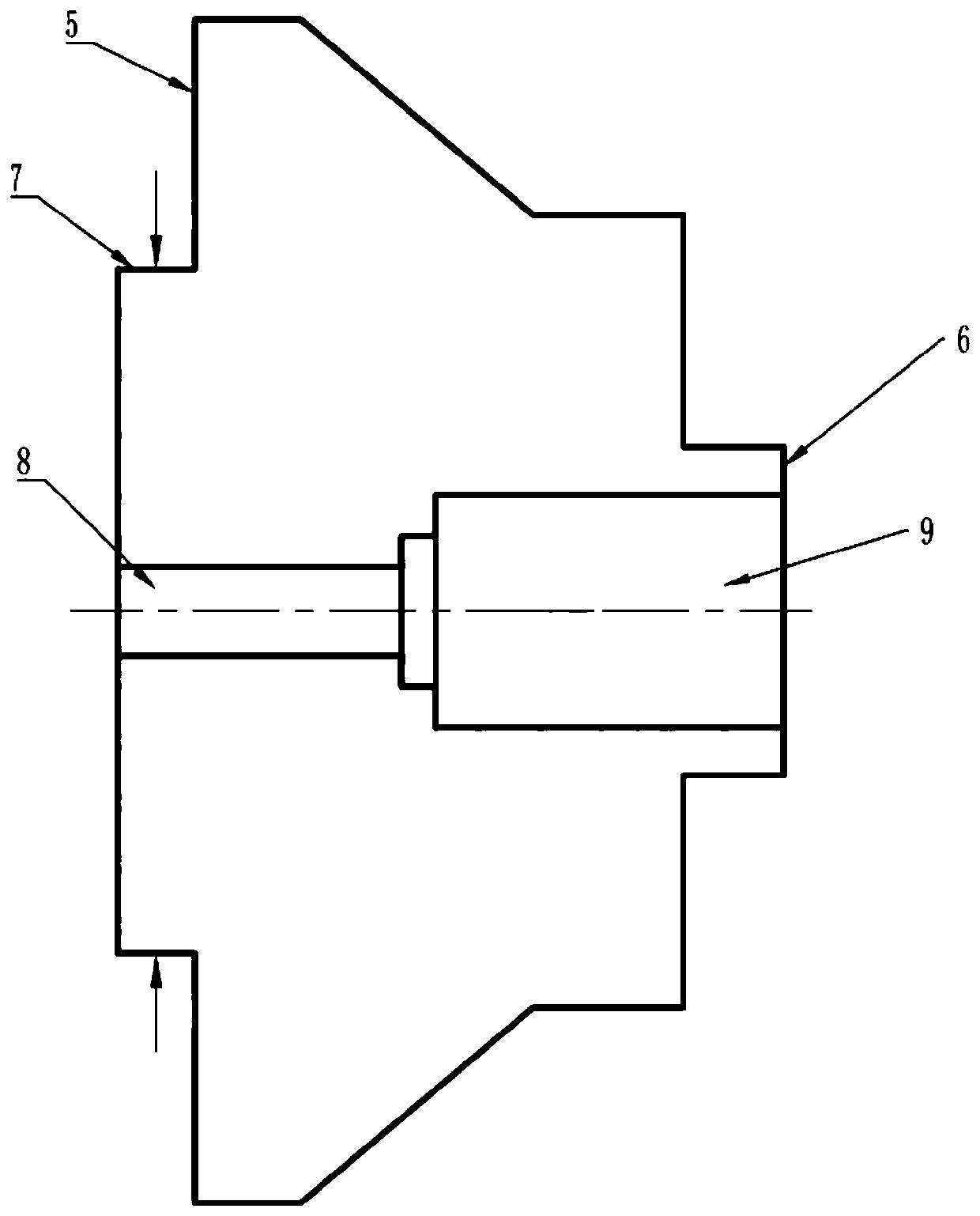

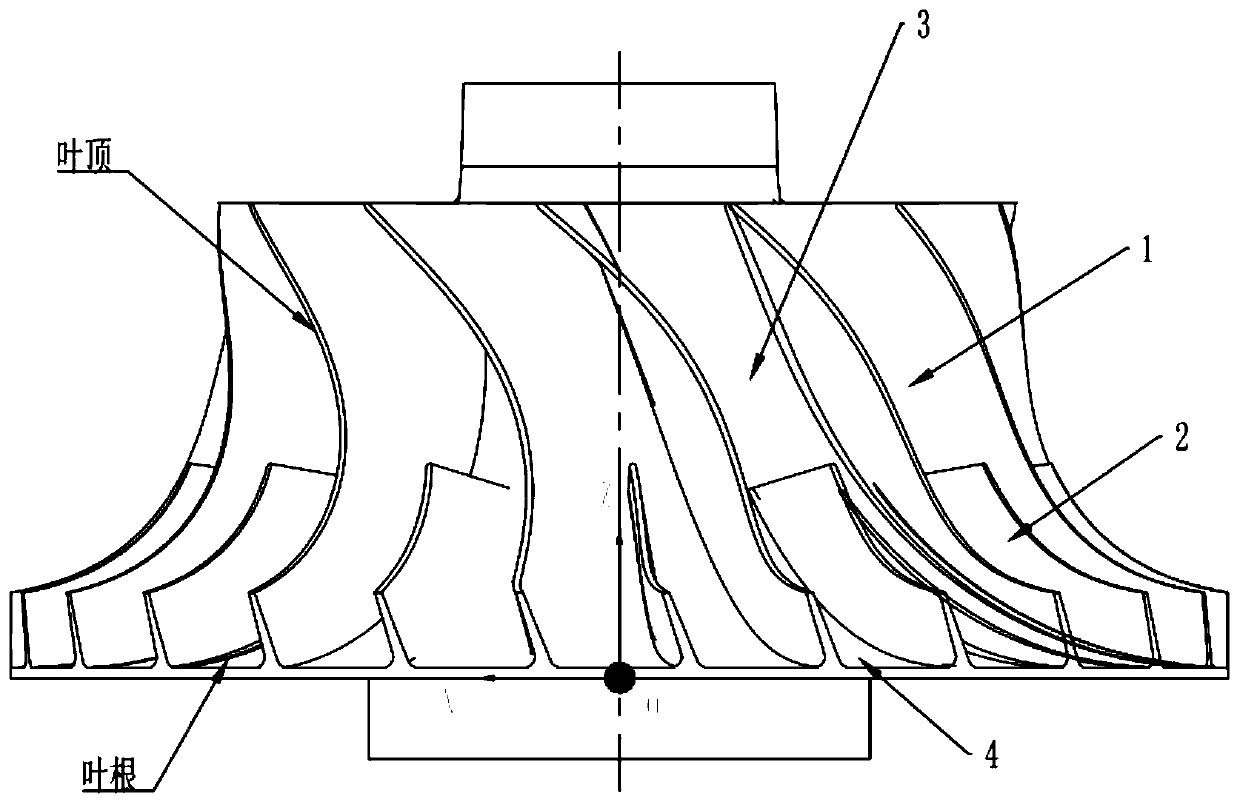

Machining method for precision inner cavity thin-wall integral centrifugal impeller of aerospace engine

The invention provides a machining method for a precision inner cavity thin-wall integral centrifugal impeller of an aerospace engine. The machine method comprises the steps of material preparation, blank rough outline turning, semi-fine profile turning, blade type rough milling, natural failure, profile 1 fine milling, drilling, blade type fine milling, blade profile 2 fine milling, clamp repair,dynamic balance, fluorescence inspection and final inspection. According to the machining method for the precision inner cavity thin-wall integral centrifugal impeller of the aerospace engine, in particular to the machining of a centrifugal impeller of a high rotation speed engine used in an aerospace vehicle, an ultra-thin multi-curved surface blade with thickness of 1.2mm can be machined, the blade does not deform during the machining process, the residual height of a hub is ensured, the knife mark in the direction of air flow is machined; meanwhile, the extremely high coaxiality of inner holes in the two end surfaces of the hub and the micron accuracy of the machining of the inner holes in the large end surface of the hub can be ensured, and the requirements of very high dynamic balance, dimensional accuracy and shape and position tolerance of parts can be met.

Owner:黑龙江省机械科学研究院

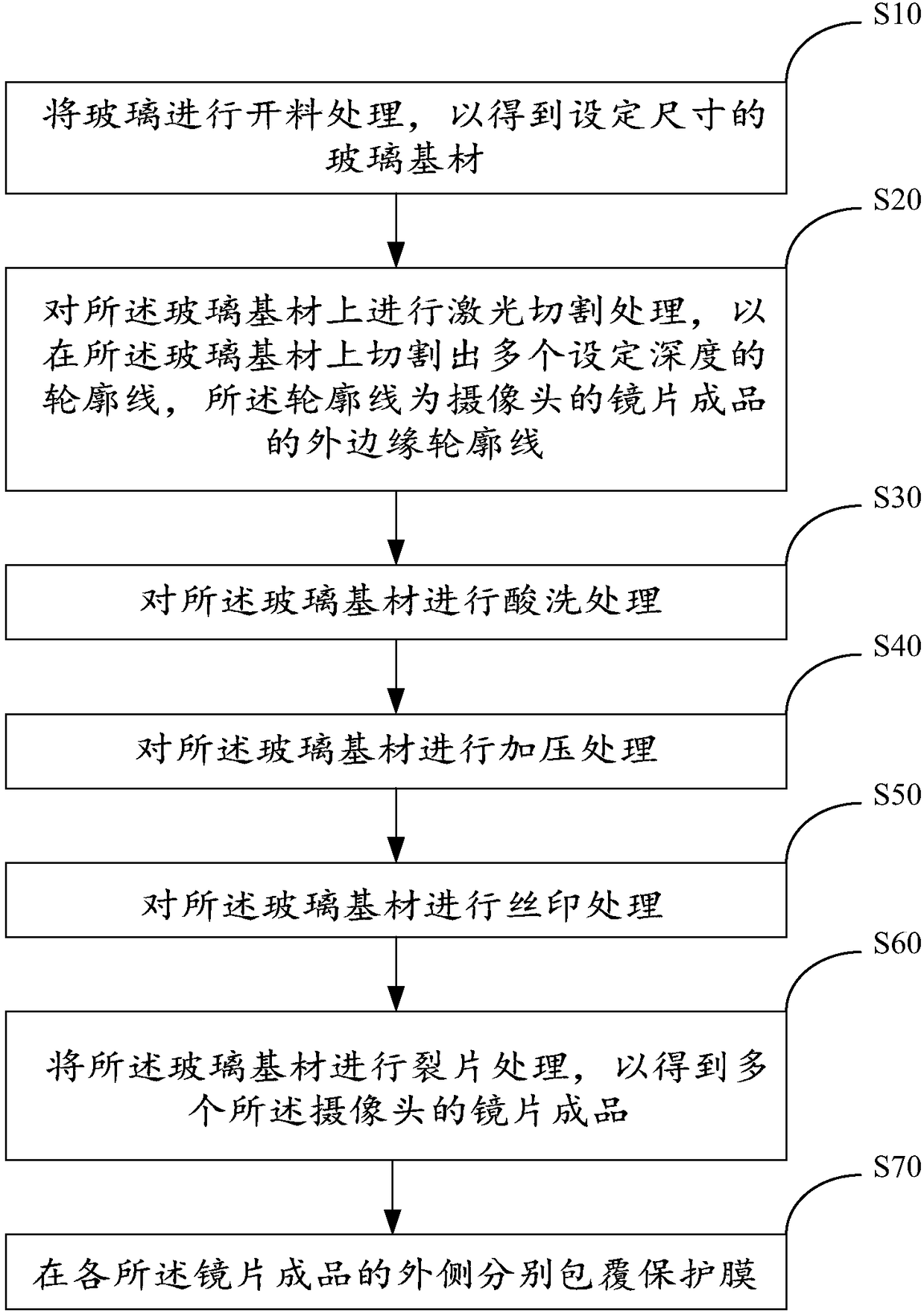

Camera processing method

ActiveCN109040531AAdvantages of processing methodEasy to handleTelevision system detailsColor television detailsScreen printingLaser cutting

The invention provides a camera processing method, which relates to the technical field of camera processing and solves the problem of low camera processing efficiency. The method comprises the followsteps: cutting the glass to obtain a glass substrate with a set size; performing laser cutting treatment on the glass substrate to cut a plurality of contour lines with a set depth on the glass substrate, wherein the contour lines are the outer edge contour lines of the finished lens of the camera; carrying out acid pickling treatment on the glass substrate; carrying out pressure treatment on theglass substrate; Performing screen printing on the glass substrate; carrying out fragmentation treatment on The glass substrate to obtain a lens finished product of a plurality of the cameras. The camera processing method is applied to process the lens of the camera, and the processing efficiency is high.

Owner:LENS TECH CHANGSHA

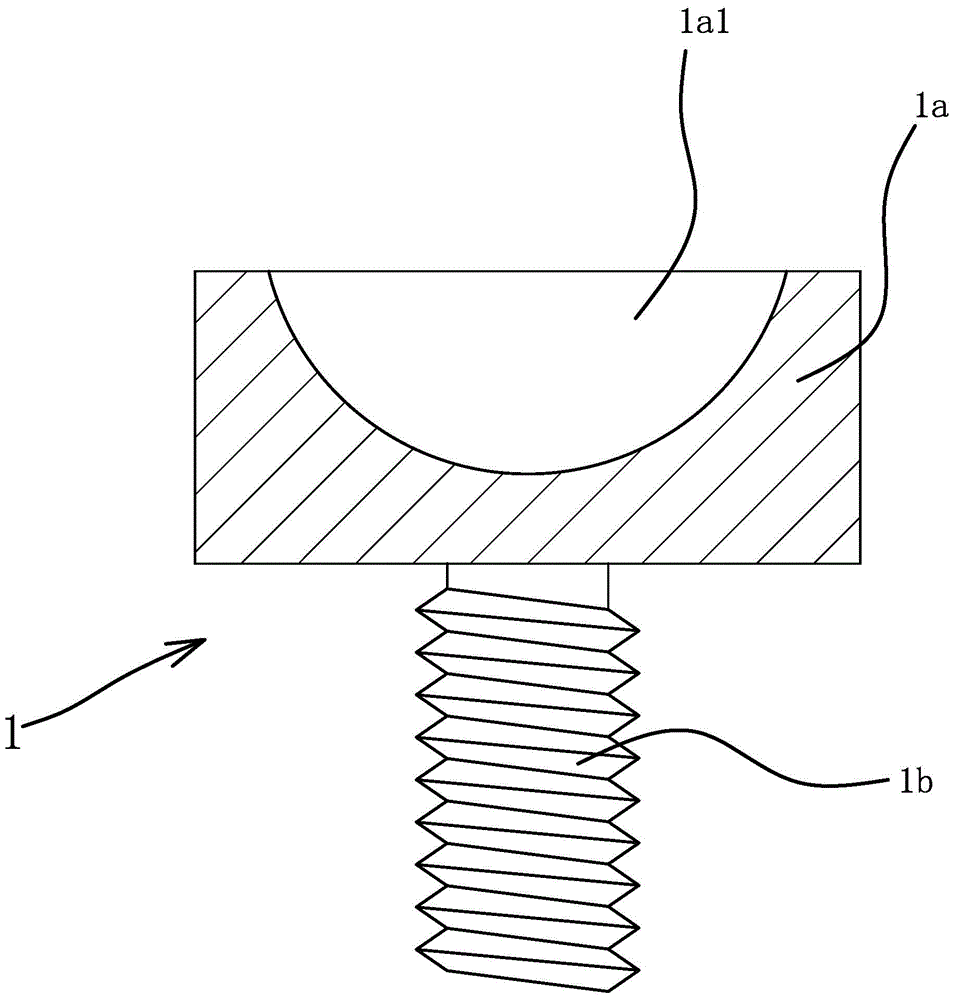

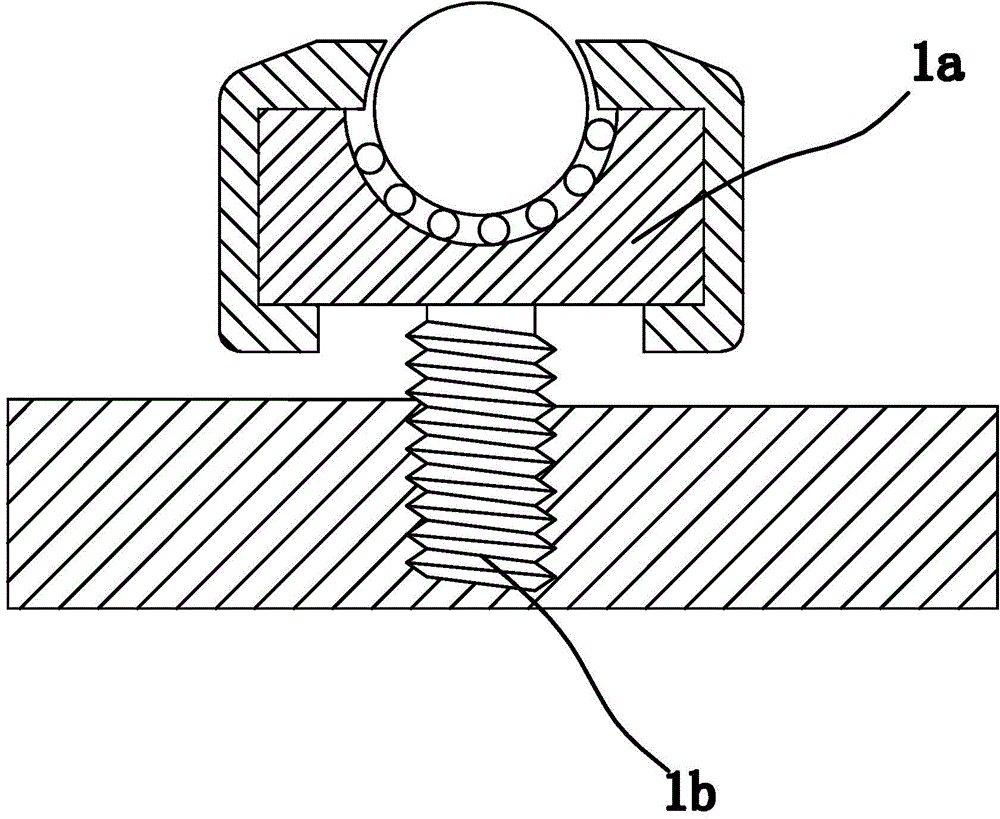

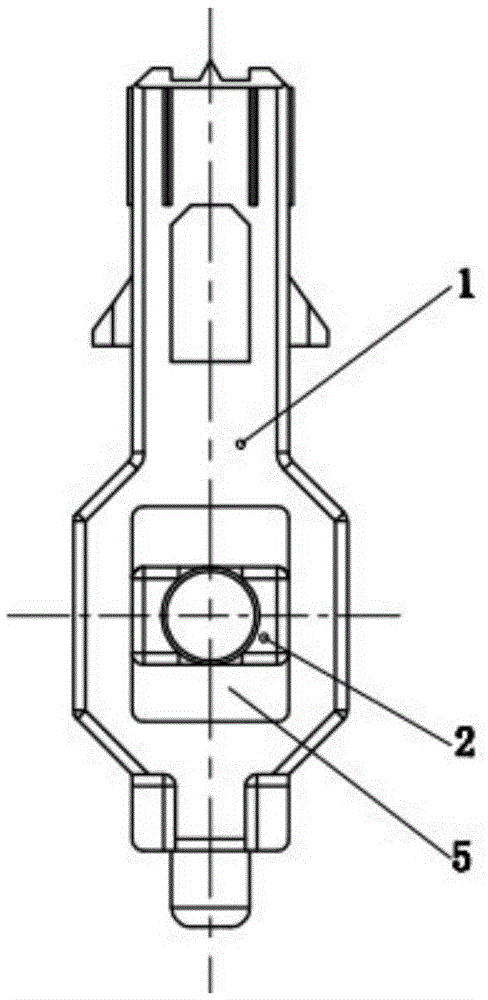

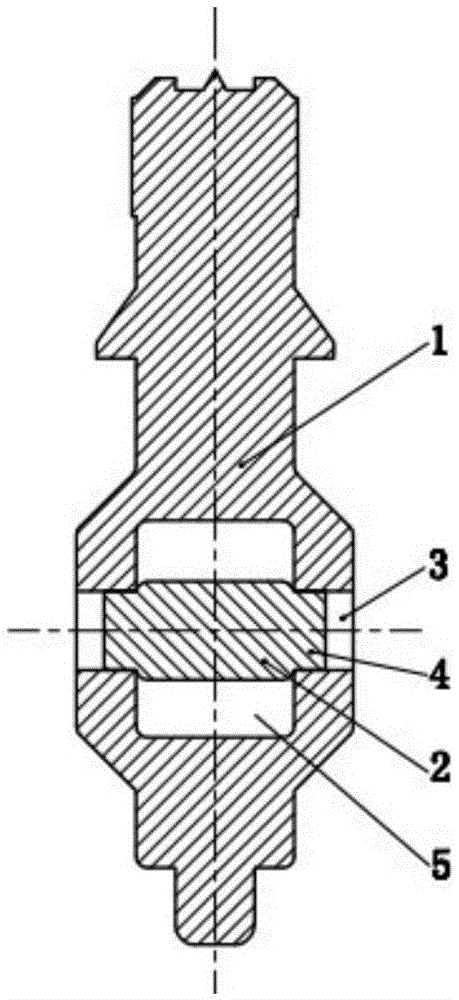

Method for machining universal ball pedestal

The invention provides a method for machining a universal ball pedestal and belongs to the technical field of machinery. The problem that the rod part of the current universal ball pedestal is easy to break is solved. The method for machining the universal ball pedestal provided by the invention comprises the following steps of A, turning a blank; B, machining a caliber groove; C, thermally treating the whole pedestal; D, performing high-frequency quenching on the head of the pedestal; E, sanding. The method for machining the universal ball pedestal provided by the invention has the advantage that the hardness of the head of the pedestal and the hardness of the rod part of the pedestal are different.

Owner:山东昆仲信息科技有限公司

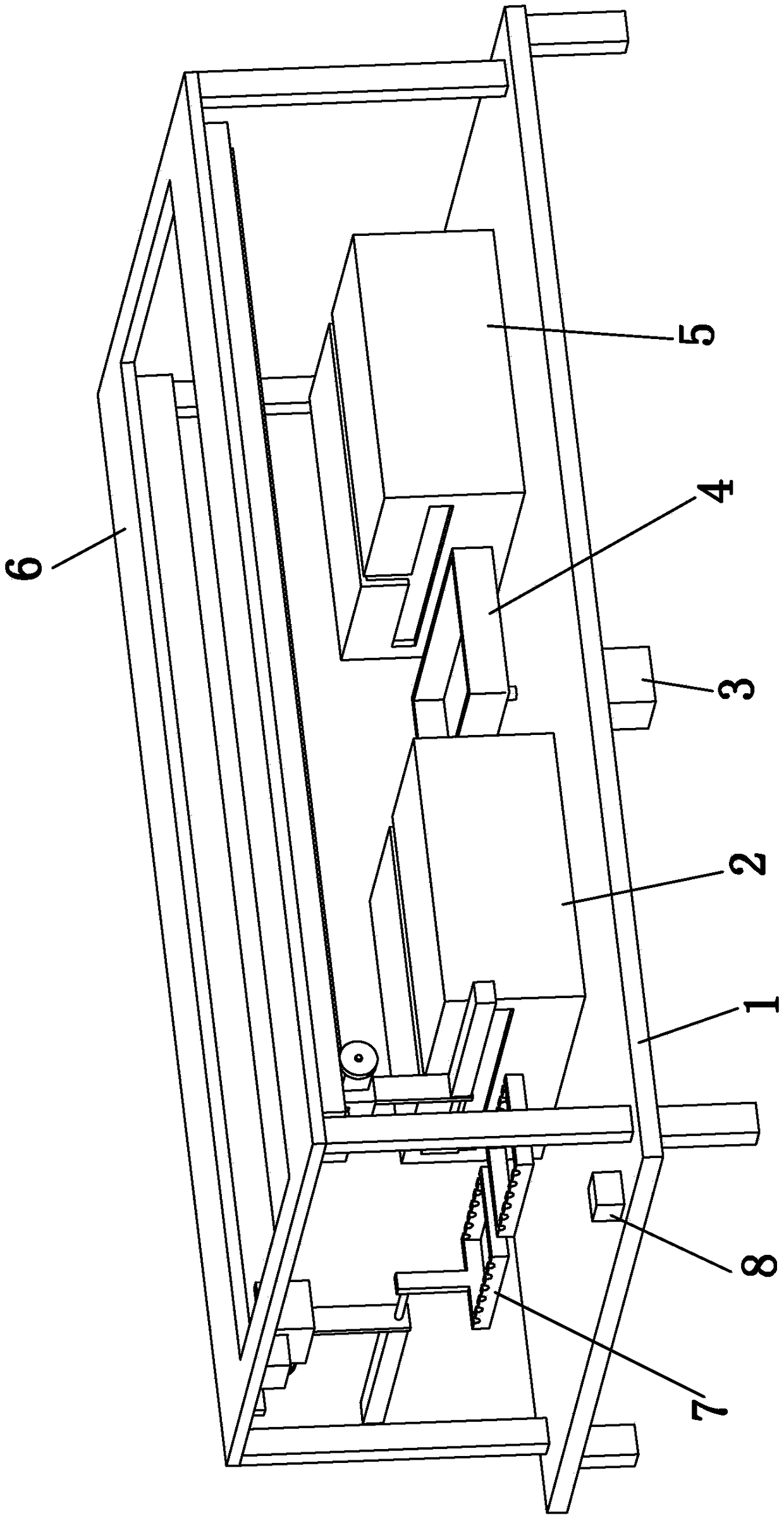

Processing method of PVC pipe joint

InactiveCN107953002AGuaranteed stabilityAdvantages of processing methodThread cutting machinesEngineeringDrive motor

The invention provides a processing method for a PVC pipe joint, which belongs to the technical field of pipe processing. The processing method of this kind of PVC pipe joint is characterized in that it comprises the following processing steps: 1) positioning and clamping: positioning and clamping the annular PVC pipe to be processed on the thread cutting device, and the thread cutting device includes a frame body and a workbench , drive motor one, drive motor two, drive motor three, push cylinder one, push cylinder two, push cylinder three, push cylinder four, push cylinder five, turning tool one, turning tool two, turning tool three and turning tool four; 2 ) internal thread processing; 3) shaft segment division; 4) undercut processing; 5) external thread processing. The invention has the advantage that the PVC pipe joint can be prepared by intensively processing the internal thread and the external thread.

Owner:QUZHOU COLLEGE OF TECH

Cornus officinalis processing method

InactiveCN101317875AAdvantages of processing methodHigh content of active ingredientsDigestive systemUrinary disorderCooking & bakingCornus officinalis

The present invention relates to a processing method for cornels. The rinsed cornels are put into a hothouse and baked at the temperature ranging from 50 to 60 DEG C with water to separate cores. The cores are mechanically removed after being cooled, and then the cornels without cores are put into the hothouse and the temperature is controlled below 70 DEG C. The finished product is obtained after the cornels are dried for 5 to 6h. The sarcocarps and cores are separated by adopting the baking technology in the processing method of cornel of the present invention. Content of active ingredient of the processed cornel can be improved by 30%; The baking dryness technology is adopted and the dried finished product is bright in color and good in taste with mild medicine incense. By adopting the processing method of the present invention, the fresh fruit collected on the day can be dried and warehoused 10 hours later. The processing method is timesaving and labor saving. Furthermore, primary taste of active ingredient of the product is guaranteed.

Owner:JINCHENG SHANZHUYU DEV

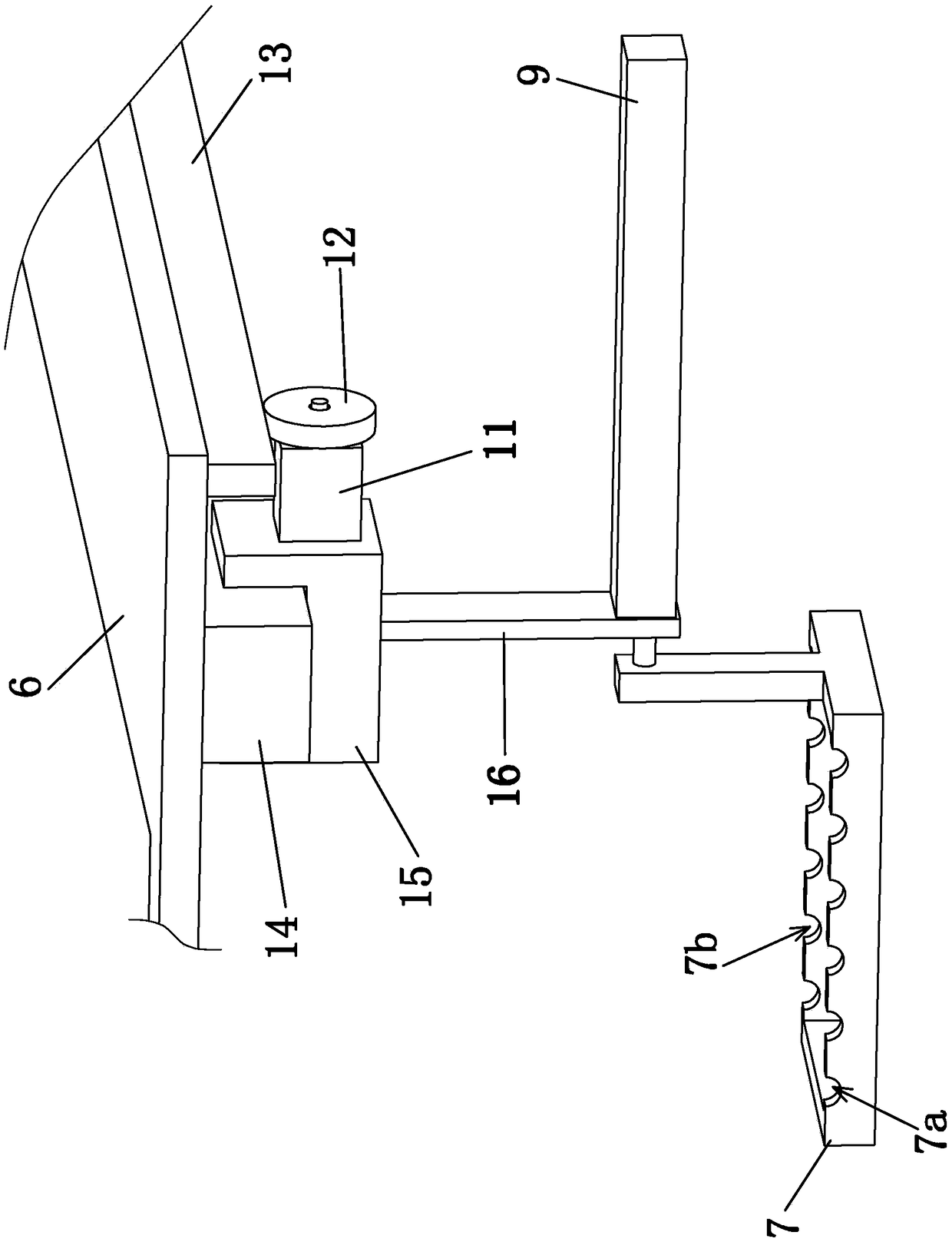

Processing method for inter-arm connection component of lifting platform

ActiveCN103100822AAdvantages of processing methodReasonable designProcessing accuracyScientific Equipment

A processing method for an inter-arm connection component of a lifting platform is characterized by mainly comprising following steps a, feeding; b, assembling; c, welding; thermally treating; e, rectifying; f, machining and g, detecting. The processing method for the inter-arm connection component of the lifting platform has the advantages of being reasonable in processing step design, simple to operate, capable of using high scientific equipment to process, high in component processing accuracy and capable of providing examples for processing components with high difficulty coefficient.

Owner:MCC5 GROUP CORP SHANGHAI

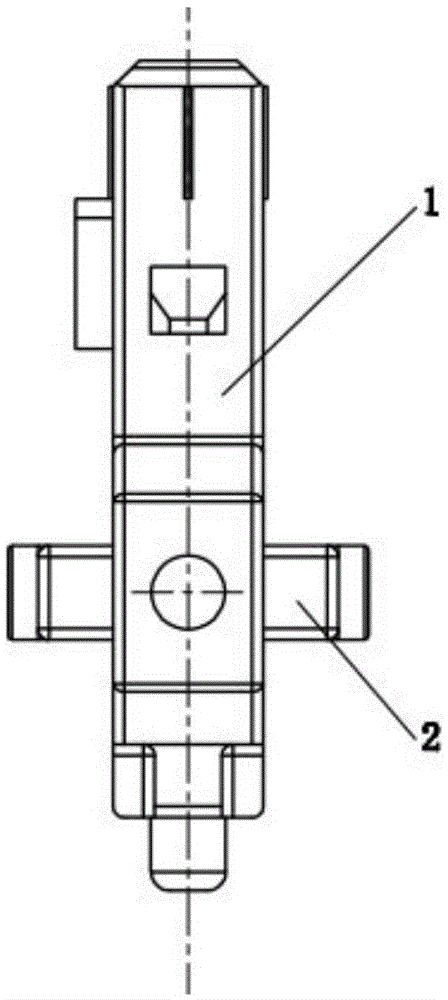

Flexible joint machining method

The invention discloses a flexible joint machining method. The flexible joint machining method comprises the following steps that a bar is mounted on a turning main shaft of a turning and milling composite machine tool, and the outer circumferential surface of the bar is turned; four planes evenly distributed in the circumferential direction of the bar are milled on the outer circumferential surface of the bar through indexing of the turning main shaft; two semicircular holes are correspondingly milled in each plane, and semicircular arc openings of the two semicircular holes in each plane are opposite; the semicircular arcs of the semicircular holes in the planes are correspondingly bored; a through hole is formed in the center of the second end of the bar; broaching is carried out at the end, corresponding to the second end of the bar, of the through hole; threads are machined on the hole wall of the broached hole; the first end of the bar is turned; and the first end of the bar is cut off. The turning and milling composite machine tool is used for machining a flexible joint, all cutting machining of the flexible joint can be completed in one-time clamping, errors caused by secondary clamping are eliminated, the machining precision of the flexible joint is improved, the grinding and adjusting procedures in the traditional technology are eliminated, the machining time is greatly shortened, and the machining efficiency is improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Method for fish flaking

A method for dissecting fish includes such steps as dissecting a fish by its vertical central line to obtain upper and lower fish sheets, and using a metal wire fixed to handle to separate the fish bones from lower fish sheet.

Owner:大连通远食品有限公司

Bolt machining method

The invention provides a bolt machining method. The bolt machining method solves the technical problems that an existing manufacturing process is too complex in steps, a lot of time is required, and the manufacture is tedious. The bolt machining method comprises the following steps of a, selecting materials; b, annealing; c, sand blasting; d, drawing; e, shearing and blanking; f, turning; g, tapping; h, heat treating; i, cleaning and drying; j, spraying; and k, drying; and l, sintering. The bolt machining method has the advantages of being convenient to machine.

Owner:浙江永欣联科信息科技股份有限公司

Machining method for plastic movable composite member

The invention discloses a machining method for a plastic movable composite member. The machining method comprises the following steps of injection molding of a first movable piece, cooling of the first movable piece, demolding of the first movable piece, injection molding of a second movable piece, cooling of the second movable piece and demolding of the second movable piece. According to the machining method for the plastic movable composite member, the connected movable pieces in the formed composite member can relatively move, movement is smooth, no clamping sense is generated, the performance is stable, and the product quality is high.

Owner:GUANGZHOU KYOKUTO ELECTRONICS LTD +1

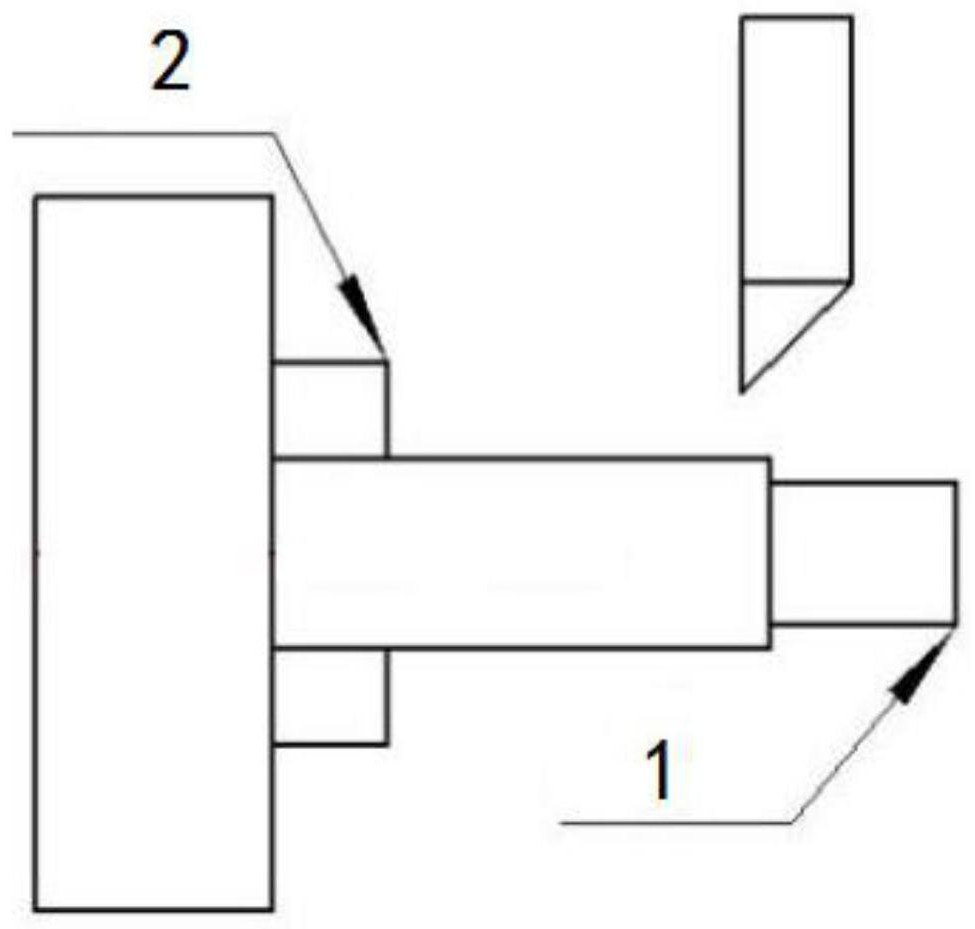

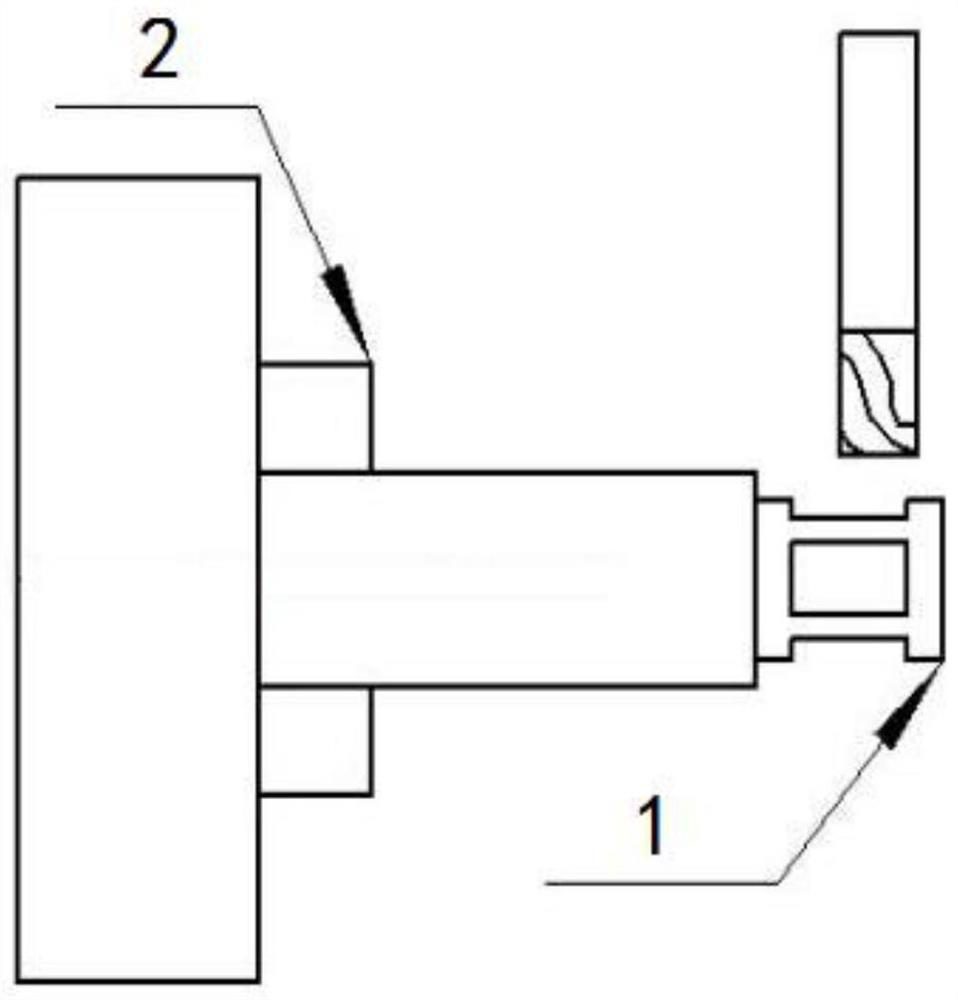

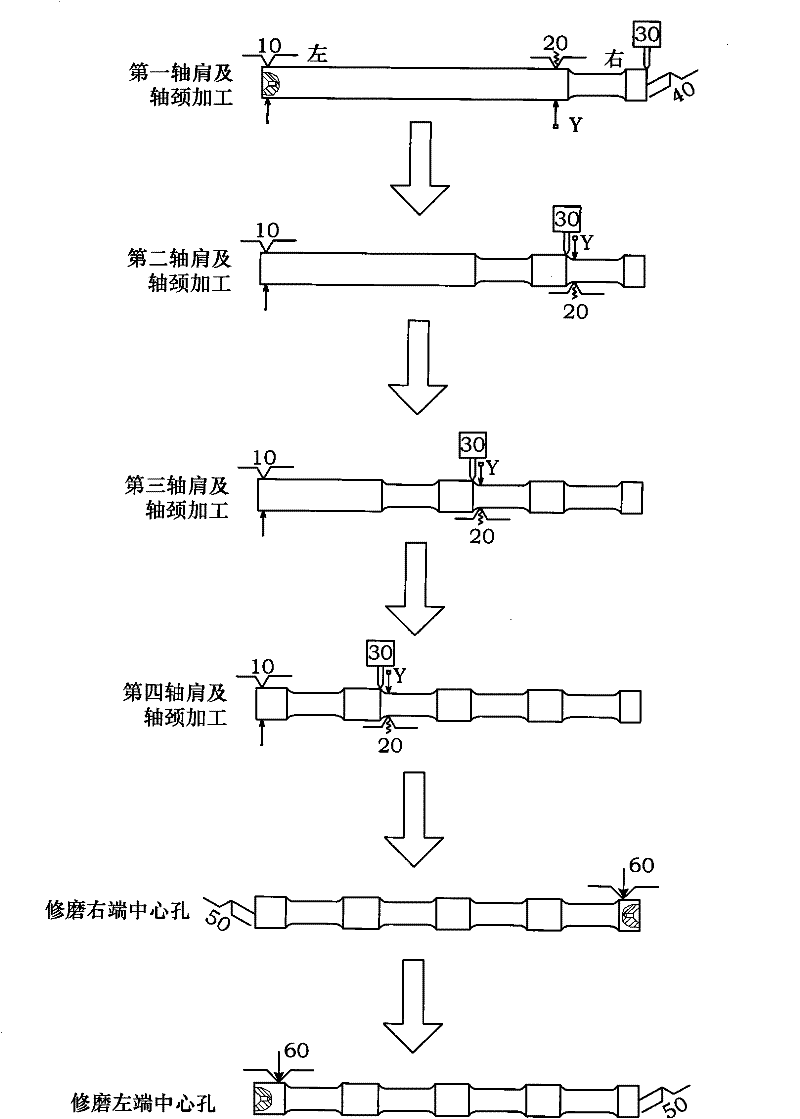

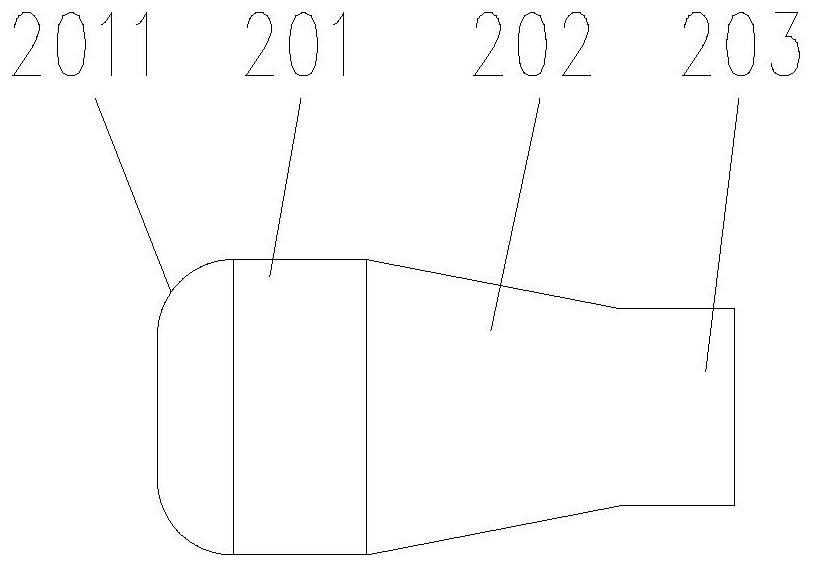

High-length-to-diameter ratio variable-section slender shaft ultrasonic elliptical vibration turning machining method

InactiveCN101966596BAdvantages of processing methodStable supportAutomatic/semiautomatic turning machinesEngineeringStructural engineering

The invention discloses a high-length-to-diameter ratio variable-section slender shaft ultrasonic ellipse vibration turning machining method, which is a new machining method for turning a high-length-to-diameter ratio variable-section slender shaft by an ultrasonic elliptical vibration turning technique. In the method, an elliptical vibration turning device as well as a sectional clamping technical means are adopted, a turning subsequent working procedure in the conventional turning-aging-milling machining process is not used, the machining time is shortened, the machining efficiency is improved greatly, the precision of a processed slender shaft with the length-to-diameter ratio being 55 is up to a level that the bounce relative to a central hole is less than 0.013 millimeters, and the dimensional precision of the slender shaft is less than a standard of + / -0.05 millimeters. The slender shaft machined by the machining method can better meet the requirements of aeromotor on used high-precision slender variable-section shafts.

Owner:BEIHANG UNIV

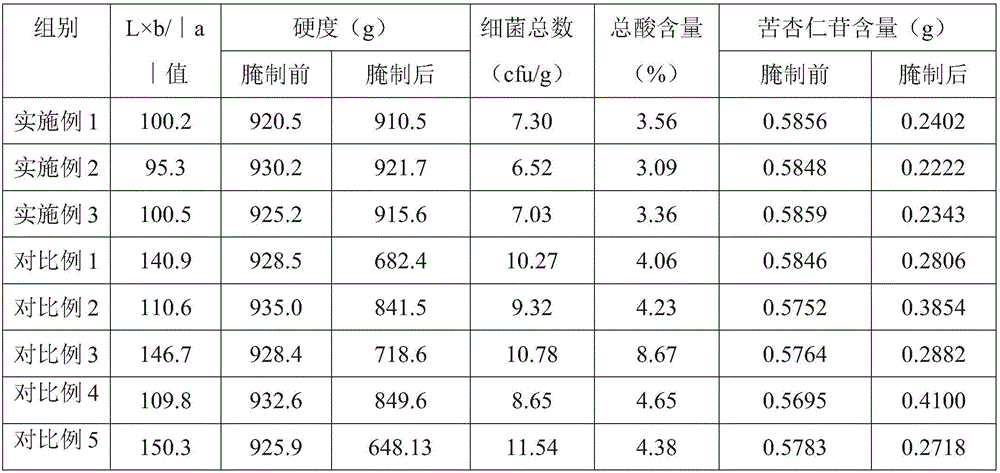

Processing method of sugar-free pickled green plum fruit products

InactiveCN106035931AReduce organic acid contentGreat tasteConfectionerySweetmeatsAlcohol sugarsSugar free

The invention belongs to the field of agricultural product processing, and especially relates to a processing method of sugar-free pickled green plum fruit products. The processing method of the sugar-free pickled green plum fruit products comprises the following steps: carrying out washing, carrying out blanching, removing bitterness, carrying out pickling by using sugar alcohol, carrying out fermentation, carrying out sterilization and carrying out packaging. The sugar-free pickled green plum fruit products prepared by the processing method disclosed by the invention very well preserve the shape, color, luster as well as refreshing and crispy taste of the green plums; moreover, the total acid contents of the pickled green plums are as low as 3.09-3.56%, and the amygdalin contents are reduced by 60-62%; thus, the taste of the pickled green plum fruit products is greatly improved.

Owner:HUIZHOU TONGFUKANG BIOTECHNOLOGY LTD

Thin-wall part machining method

The invention discloses a thin-wall part machining method. The method comprises the steps that the allowance is reserved, and specifically, an annular machining allowance edge which is coaxial with a part is reserved along the maximum outer circle position of the diameter of the part; a groove is machined, and specifically, an annular groove coaxial with the part is machined in the annular machining allowance edge; and the part is clamped, specifically, an end surface which is located at the annular machining allowance edge and is perpendicular to the axis direction of the part is used as a supporting side, an outer circumferential surface of the annular machining allowance edge is used as a positioning surface, and an annular surface, perpendicular to the axis direction of the part, in the annular groove is used as a pressing surface of a pressing hook. The thin-wall part machining method avoids that a plurality of clamps are applied to the same part during machining, and reduces the time and production cost caused by a clamp combination, a support positioning and pressing manner is adopted to prevent deformation of the part, and the pressing hook of the part is hidden inside the part and does not interference with the turning and measurement on the depth direction.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

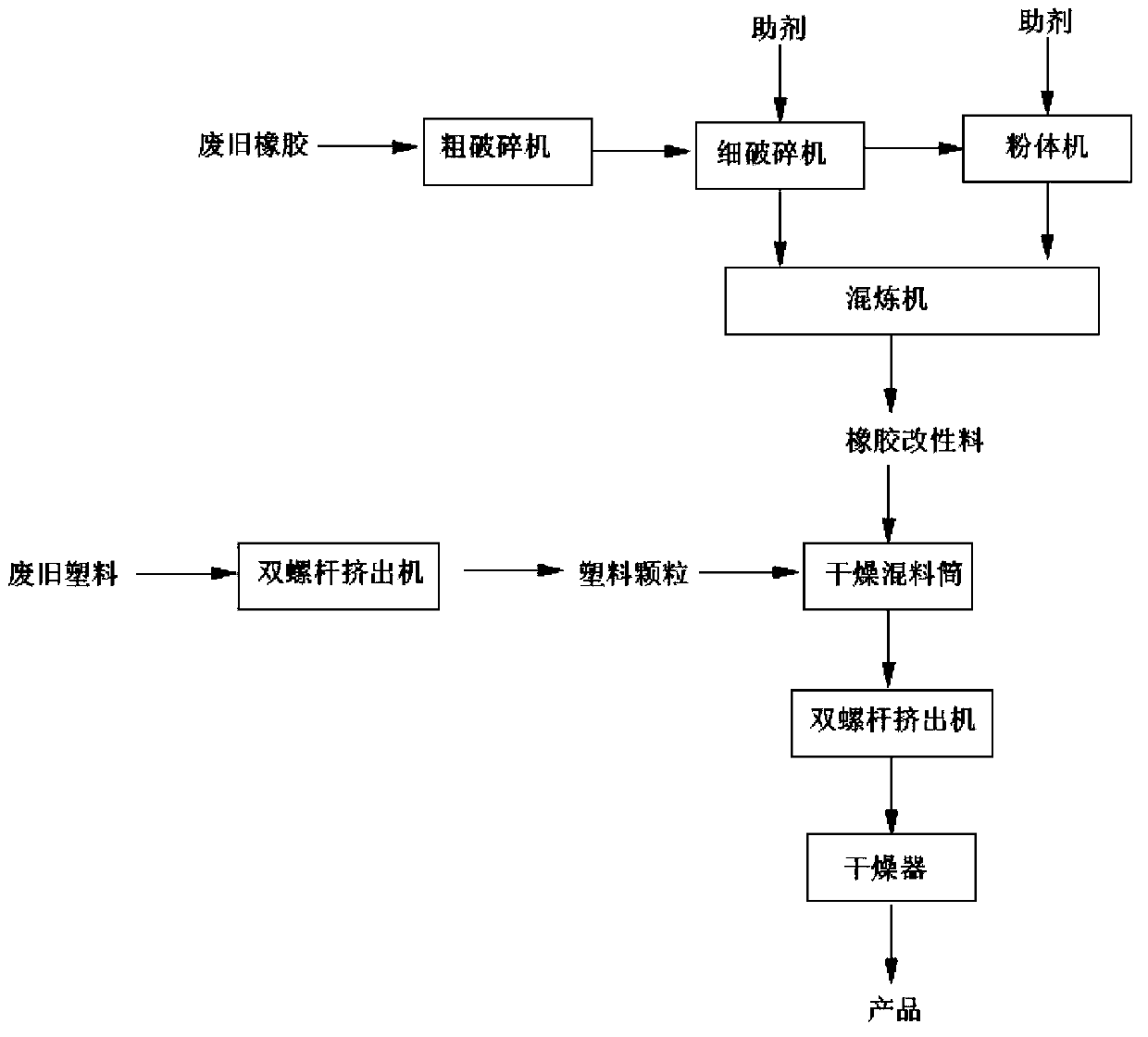

Processing method of composite plastic materials for high-toughness building templates

InactiveCN104227866AAdvantages of processing methodImprove processing fluidityPlastic materialsNetwork structure

The invention relates to a processing method of composite plastic materials for high-toughness building templates. The processing method comprises the following steps: mixing and granulating a mixture of rubber and additives to obtain a rubber-modified material, and then carrying out melt blending on the rubber-modified material and plastic particles. The processing method has the advantages that on one hand, the liquid or solid additives can be effectively mixed with rubber and enter the rubber after being mixed to enable the network structure in the rubber to be fully relaxed, so that the processing fluidity, the compatibility and the dispersing uniformity of the rubber when being subjected to melt blending with the plastic particles are improved and further the toughness of the composite plastic materials is further improved; on the other hand, the rubber-modified material is large-particle-shaped, cannot cause pollution to a production workshop for melt blending of the rubber-modified material and the plastic particles and also cannot cause hazard to related operators; in addition, since the additives are uniformly dispersed inside the rubber-modified material and the internal network structure is fully relaxed by mixing, the melt blending effects of the rubber-modified material with the plastic particles also cannot be influenced even though the rubber-modified material is the large particle material.

Owner:JIANGYIN DATIAN TECH SERVICE

Dogwood processing method

InactiveCN107115375AAdvantages of processing methodHigh content of active ingredientsDigestive systemPlant ingredientsCooking & bakingCorni Fructus

The processing method of Cornus officinalis is to rinse the fresh fruits of Cornus officinalis, put them into the barn, and bake them with water at 50-60°C to separate the cores. Below ℃, the finished product can be obtained after drying for 5-6 hours. The cornus officinalis processing method of the present invention adopts a roasting process to separate the meat nucleus, and the content of active ingredients in the processed cornus officinalis can be increased by 30%; and the cornus officinalis after drying is bright in color and emits a faint medicinal fragrance. By adopting the processing method of the present invention, the fresh fruits harvested on the same day can be dried and put into storage after 10 hours, which saves time and effort, and ensures the original flavor of the active ingredients of the product.

Owner:丁晓明

Artificial stone surface ice crack processing method

The invention provides an artificial stone surface ice crack processing method, and belongs to the technical field of ice crack manufacturing. The method solves the problems that an existing ice crackprocessing method needs the step of high temperature burning and the crack is not firm. The artificial stone ice crack processing method comprises the steps that an artificial stone product is selected, the internal surface and the external surface of the artificial stone product are shaped and polished, the external surface of the artificial stone product is coated with PU primer, the artificialstone is placed into a surface drying room to be subjected to surface drying treatment, and then the external surface of the artificial stone is evenly coated with NC finishing coat; and the artificial stone is placed into the surface drying room to be subjected to secondary surface drying treatment, the external surface of the artificial stone coated with NC finishing coat is evenly coated withPU finishing coat, after the above step is completed, the external surface of the artificial stone is placed into the surface drying room to be subjected to third surface drying treatment, meanwhile an additive and an antioxidant are added, the external surface of the artificial stone is subjected to varnish treatment, and the external surface of the artificial stone is coated with pigment. The method has the advantages that high temperature burning is not needed, and the crack is firm.

Owner:ZHEJIANG DONNA HOME FURNISHING CO LTD

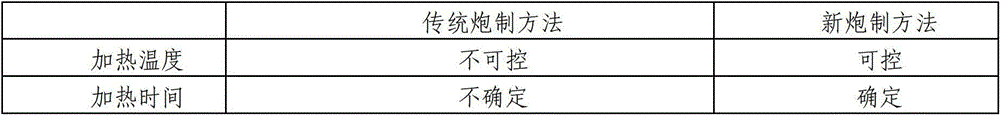

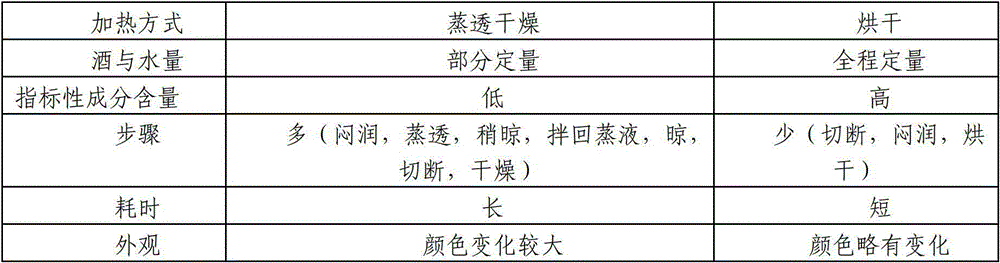

Method for processing wine stir-fried siegesbeckia pubescens

ActiveCN102973625AAdvantages of processing methodEasy to controlPlant ingredientsDrying timeSiegesbeckia pubescens

The invention relates to a method for processing wine stir-fried siegesbeckia pubescens. The method comprises the following steps of: performing covered moistening on siegesbeckia pubescens in yellow wine added with water till the yellow wine is fully absorbed by the siegesbeckia pubescens, drying, and thus obtaining the wine stir-fried siegesbeckia pubescens. According to the processing method, the technologies of wine and water proportion, covered moistening time, drying temperature, drying time and the like are specified, so that the processing process is strong in controllability.

Owner:INST OF MEDICINAL PLANT DEV CHINESE ACADEMY OF MEDICAL SCI +1

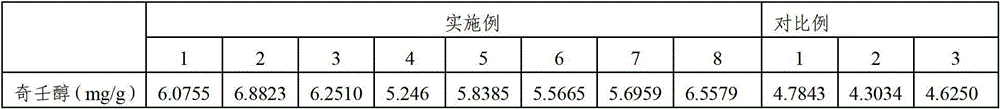

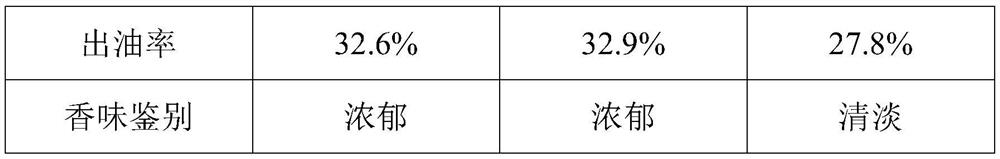

Processing method of strong-flavor peony seed oil

InactiveCN111876232AAdvantages of processing methodImprove oil yieldFatty-oils/fats refiningFatty-oils/fats productionEngineeringOrganic chemistry

The invention provides a processing method of strong-flavor peony seed oil. The method comprises the following steps: 1) pretreatment, drying and shelling; 2) stir-frying; 3) peeling; 4) crushing; 5)squeezing: putting the crushed peony seed kernels into a squeezer for squeezing oil to obtain a squeezed cake and oil residue mixed solution, then sequentially performing settling separation and filtration treatment on the oil residue mixed solution to obtain peony seed crude oil and filter residues, and then fully mixing the filter residues with the squeezed cake to obtain mixed cake residues; 6)recovery of the peony seed crude oil in the mixed cake residues: extracting the mixed cake residues by adopting supercritical CO2, and after the extraction is finished, carrying out reduced pressureseparation to obtain extracted peony seed crude oil; and 7) crude oil treatment: uniformly mixing the squeezed peony seed crude oil with the extracted peony seed crude oil, and degumming, deacidifying, decolorizing and deodorizing the mixed crude oil to obtain the peony seed oil. The peony seed oil prepared by the processing method of the strong-flavor peony seed oil is high in oil yield and stronger in fragrance.

Owner:菏泽职业学院

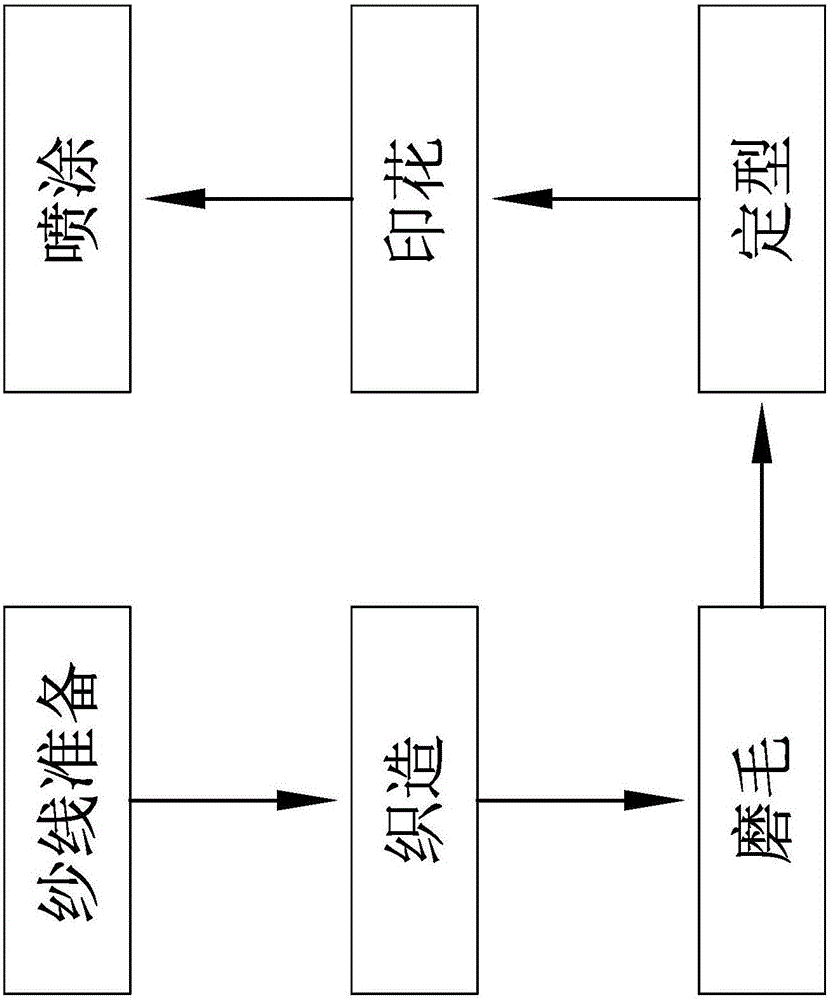

Processing method of tearing-resisting and wear-resisting suede imitated warp knitted fabric

ActiveCN105821573AIntuitive inspectionAdvantages of processing methodOrnamental textile articlesInspecting textilesDigital printingPolyester

The invention provides a processing method of a tearing-resisting and wear-resisting suede imitated warp knitted fabric, aiming at solving the technical problems that a fabric produced by an existing processing process is simple in structure, cannot meet various utilization requirements and has a single function and the like. The processing method of the tearing-resisting and wear-resisting suede imitated warp knitted fabric comprises the following steps of: a, preparing yarns, namely blending cashmere fibers and viscose fibers at the ratio of 3 to 2 to form warp yarns for later use; blending polyester fibers and acrylic fibers at the ratio of 4 to 3 to form weft yarns for later use; b, weaving, namely conveying the warp yarn and the weft yarns in the step a into a common weaving machine and weaving to form blank cloth; c, sanding, namely sanding one side face of the blank cloth through a sanding device; d, shaping, namely carrying out shaping treatment on the sanded blank cloth; and e, printing, namely printing the shaped blank cloth through a digital printing machine. The processing method of the tearing-resisting and wear-resisting suede imitated warp knitted fabric has the advantage of strong practicability.

Owner:深圳市影儿服饰有限公司

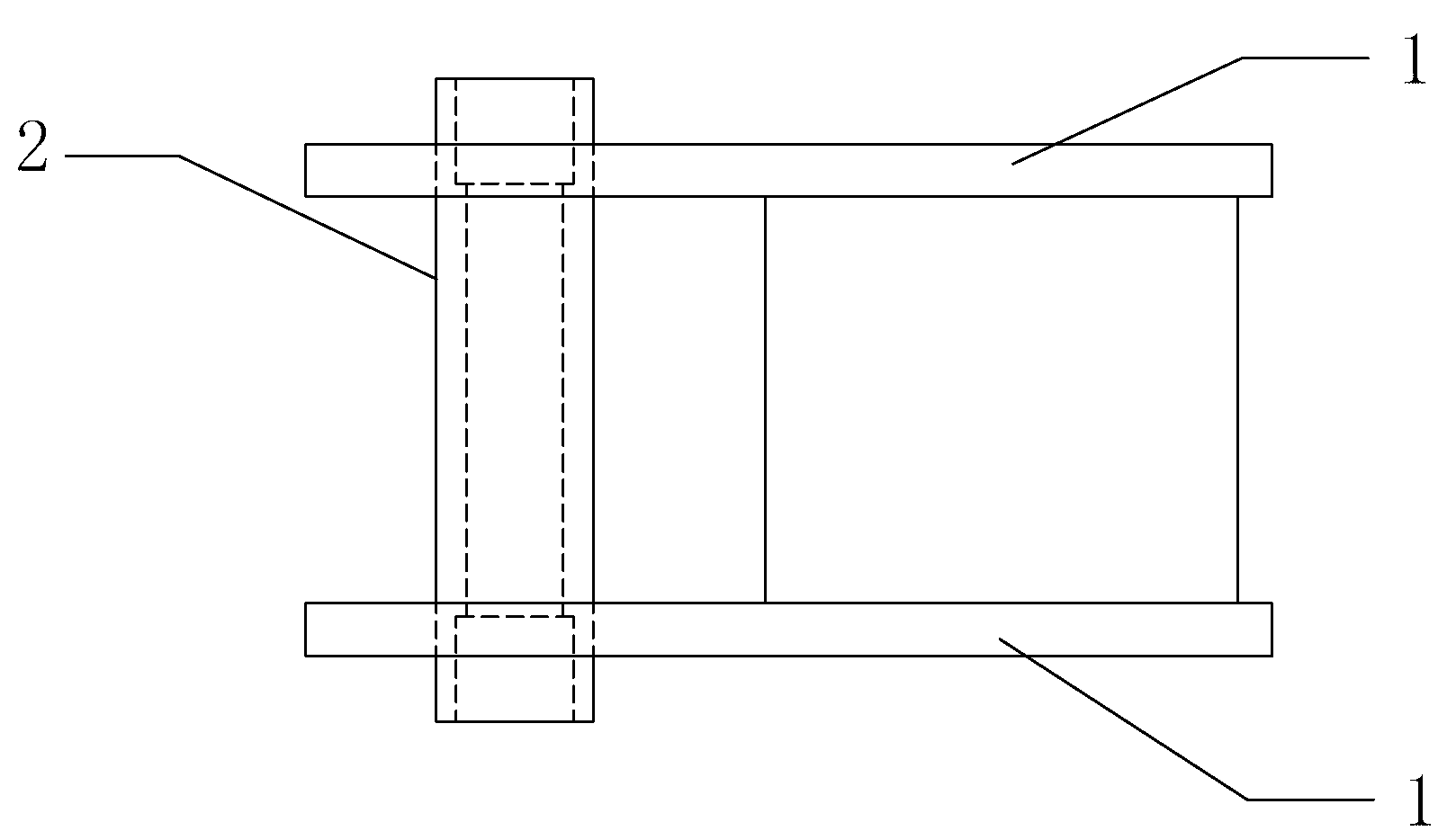

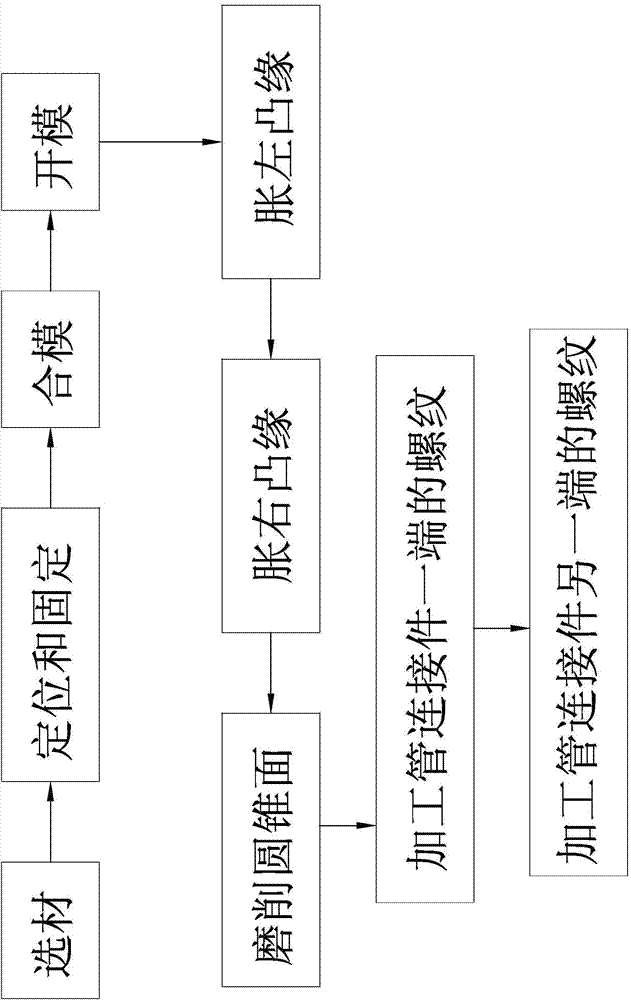

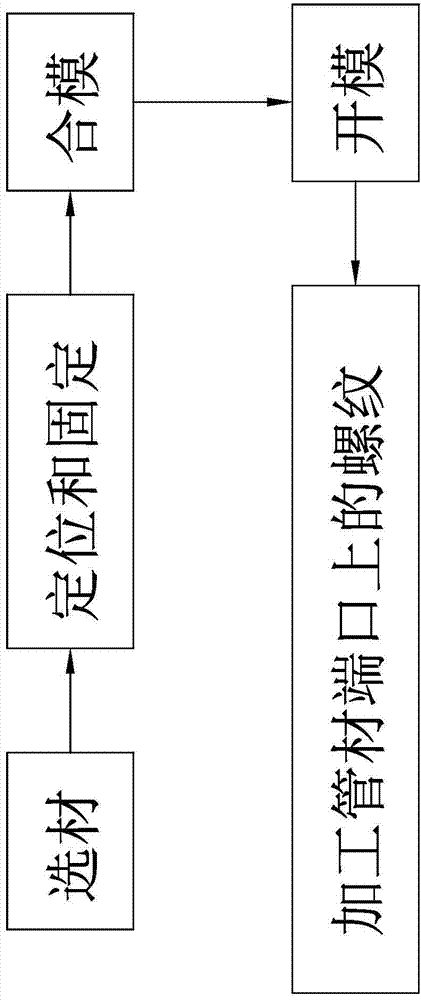

Processing method of pipe connecting part

The invention provides a processing method of a pipe connecting part and belongs to the technical field of machining. With the adoption of the processing method, the problems of the need of cutting and the like when the pipe connecting part is processed in the prior art are solved. The processing method comprises a processing method of a pipe material and a processing method of the pipe connecting part. The processing method of the pipe material comprises the following steps: (A1) selecting materials; (A2) positioning and fixing; (A3) closing a mold; (A4) opening the mold; and (A5) processing threads on the end opening of the pipe material. The processing method of the pipe connecting part comprises the following steps: (B1) selecting materials; (B2) positioning and fixing; (B3) closing a mold; (B4) opening the mold; and (B5) expanding a left flange; (B6) expanding a right flange; (B7) grinding a conical surface; (B8) processing threads at one end of the pipe connecting part; and (B9) processing threads at the other end of the pipe connecting part. The processing method provided by the invention has the advantages that cutting is not needed when the pipe connecting part is produced and processed, so that the material can be saved.

Owner:ZHEJIANG OCEAN UNIV

A kind of processing method of bolt

ActiveCN108788633BAdvantages of processing methodEasy to processScrewsManufacturing technologySand blasting

The invention provides a bolt machining method. The bolt machining method solves the technical problems that an existing manufacturing process is too complex in steps, a lot of time is required, and the manufacture is tedious. The bolt machining method comprises the following steps of a, selecting materials; b, annealing; c, sand blasting; d, drawing; e, shearing and blanking; f, turning; g, tapping; h, heat treating; i, cleaning and drying; j, spraying; and k, drying; and l, sintering. The bolt machining method has the advantages of being convenient to machine.

Owner:浙江永欣联科信息科技股份有限公司

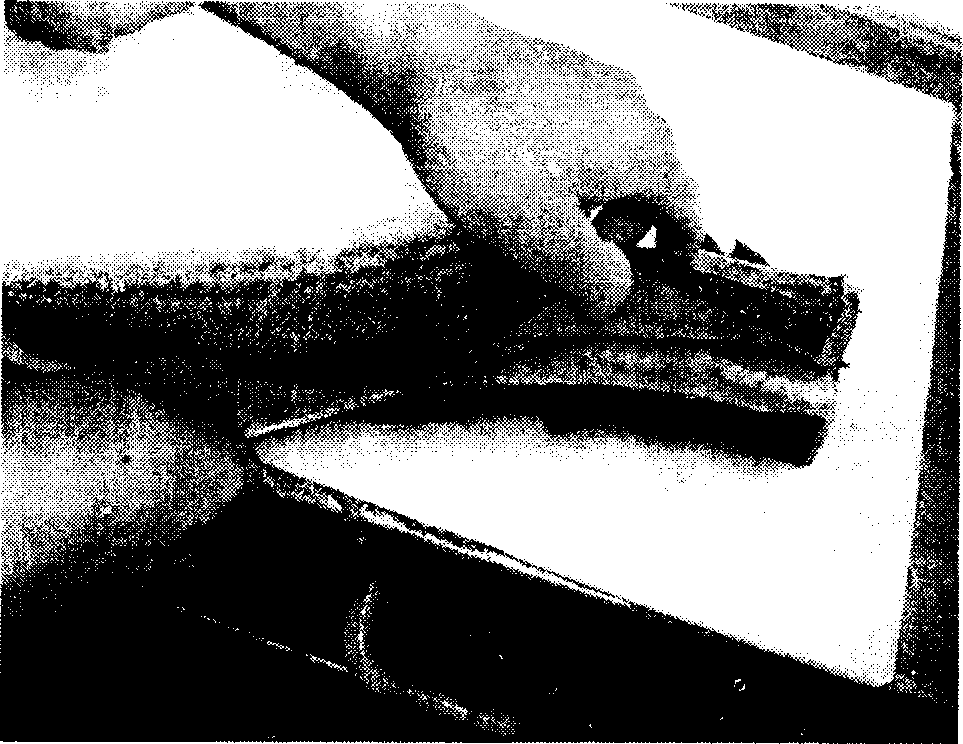

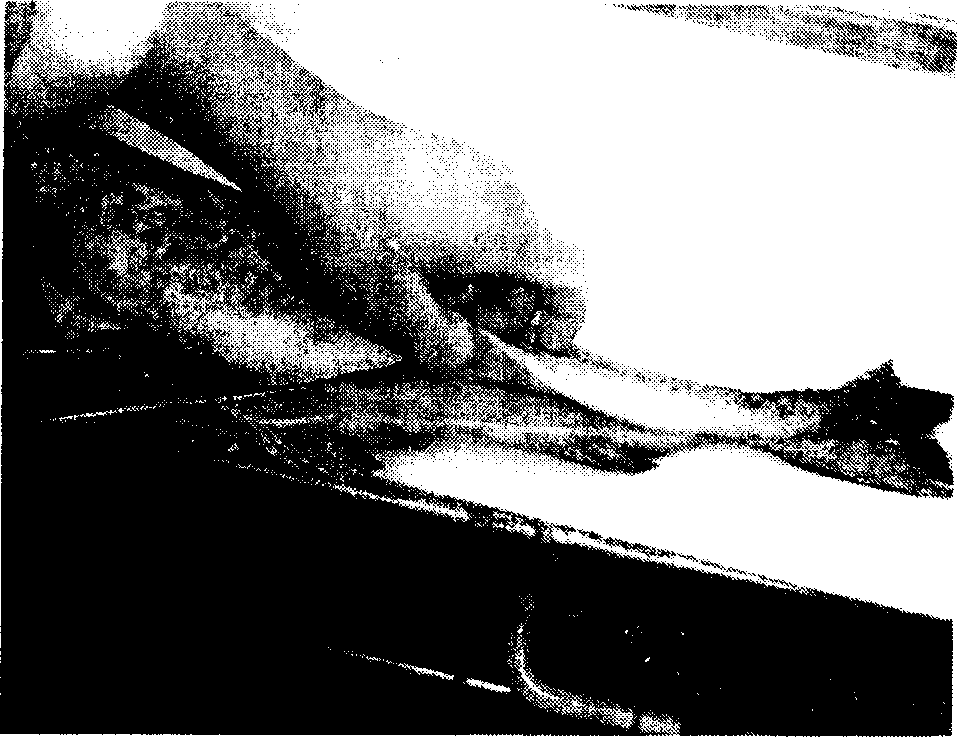

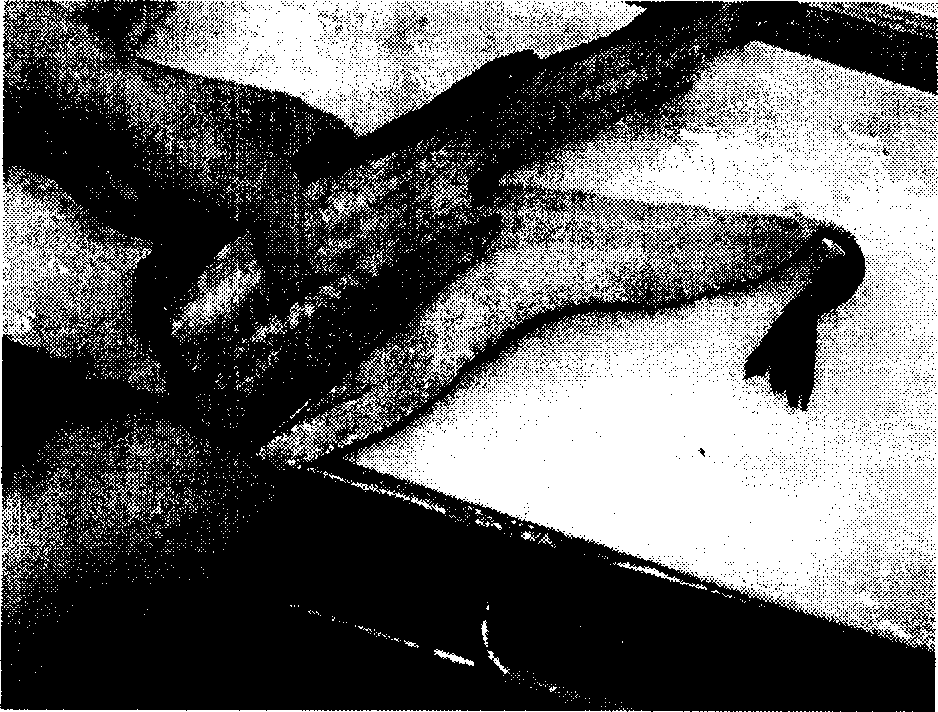

Processing method for medicinal raw material of artificially bred cobra

PendingCN112138027AAdvantages of processing methodNot easy to attackUnknown materialsBiotechnologyVenom gland

The invention discloses a processing method for a medicinal raw material of an artificially bred cobra. The processing method comprises the following steps of (1) collecting the cold-chain transportedcobra by using a thickened nylon mesh bag; (2) performing weighing in a factory, and randomly sampling and measuring medicine residues; (3) putting the cobra into a retention chamber for low-temperature retention until the cobra enters a hibernation state; (4) pouring the cobra into a normal-temperature pool, and performing immersion cleaning for 20-30 seconds; (5) putting the cobra into a cold water pool, and performing rinsing for 1-2 minutes; (6) fixing the head of the cobra without extruding the poison gland, fixing the tail of the cobra to prevent curling and struggling, obliquely putting a funnel into the mouth to receive venom, and performing electrode discharge to promote venoming; (7) after venoming is finished, cutting the head to collect the head of the cobra, and carrying outbloodletting to collect blood; (8) feeding the cobra body into a hot water pool for soaking, removing scales, and spray-washing the surface of the cobra body; (9) cutting open the abdomen of the cobrabody to strip the internal organs, and cleaning the cobra body; and (10) centrifugally spin-drying water on the surface of the cobra body, and performing disinfection, weighing and packaging in vacuum to obtain the finished fresh cobra body. The method can be suitable for processing cobras into medicinal raw materials on a large scale, and can reduce or avoid accidents that people are bitten by the cobras.

Owner:黄恒

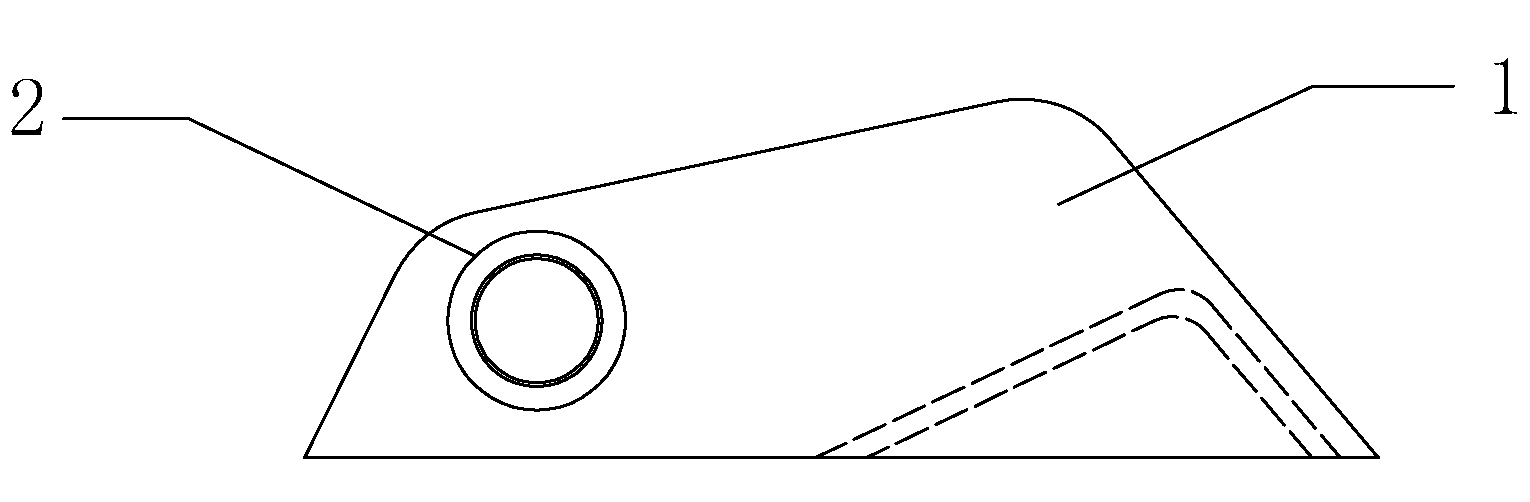

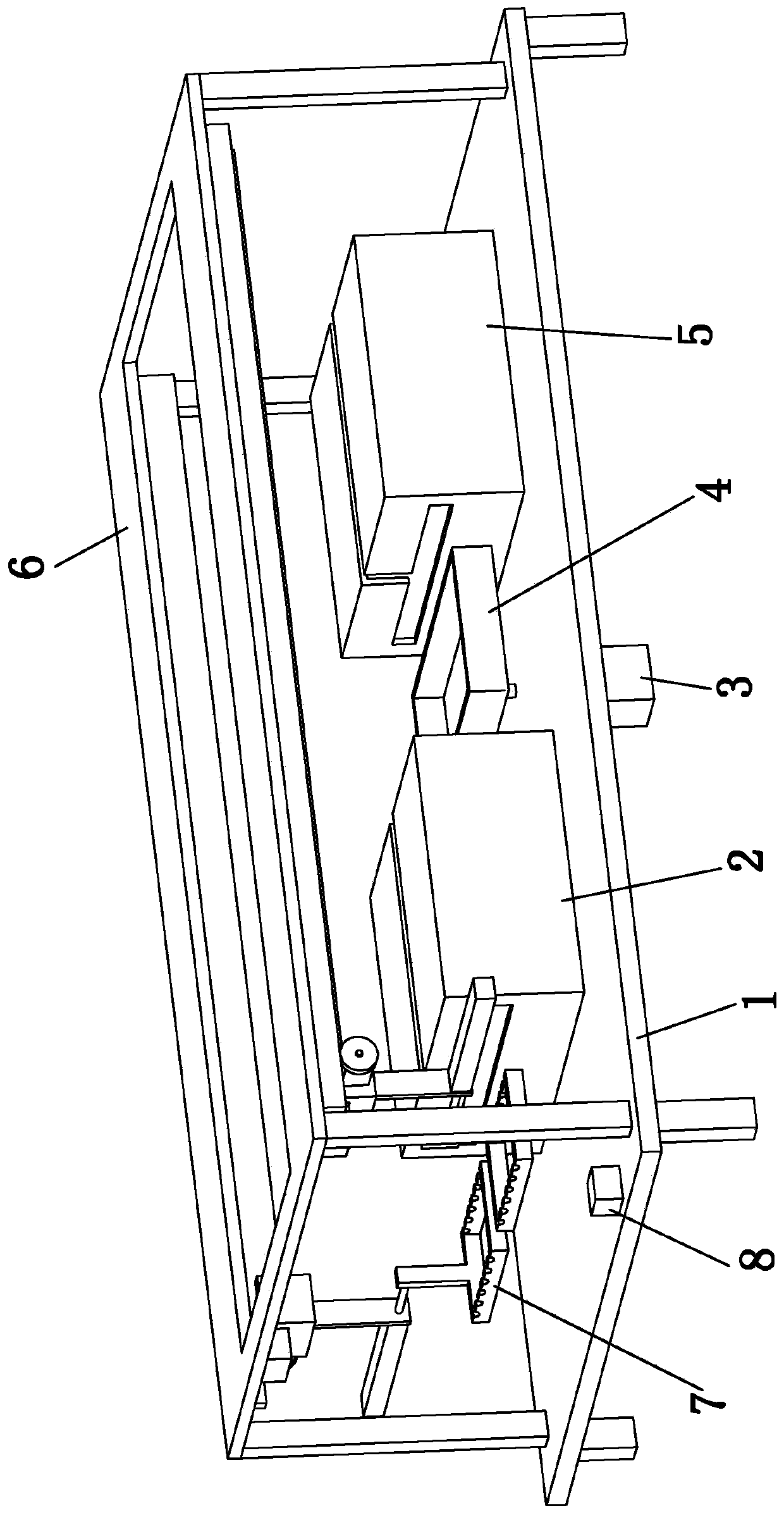

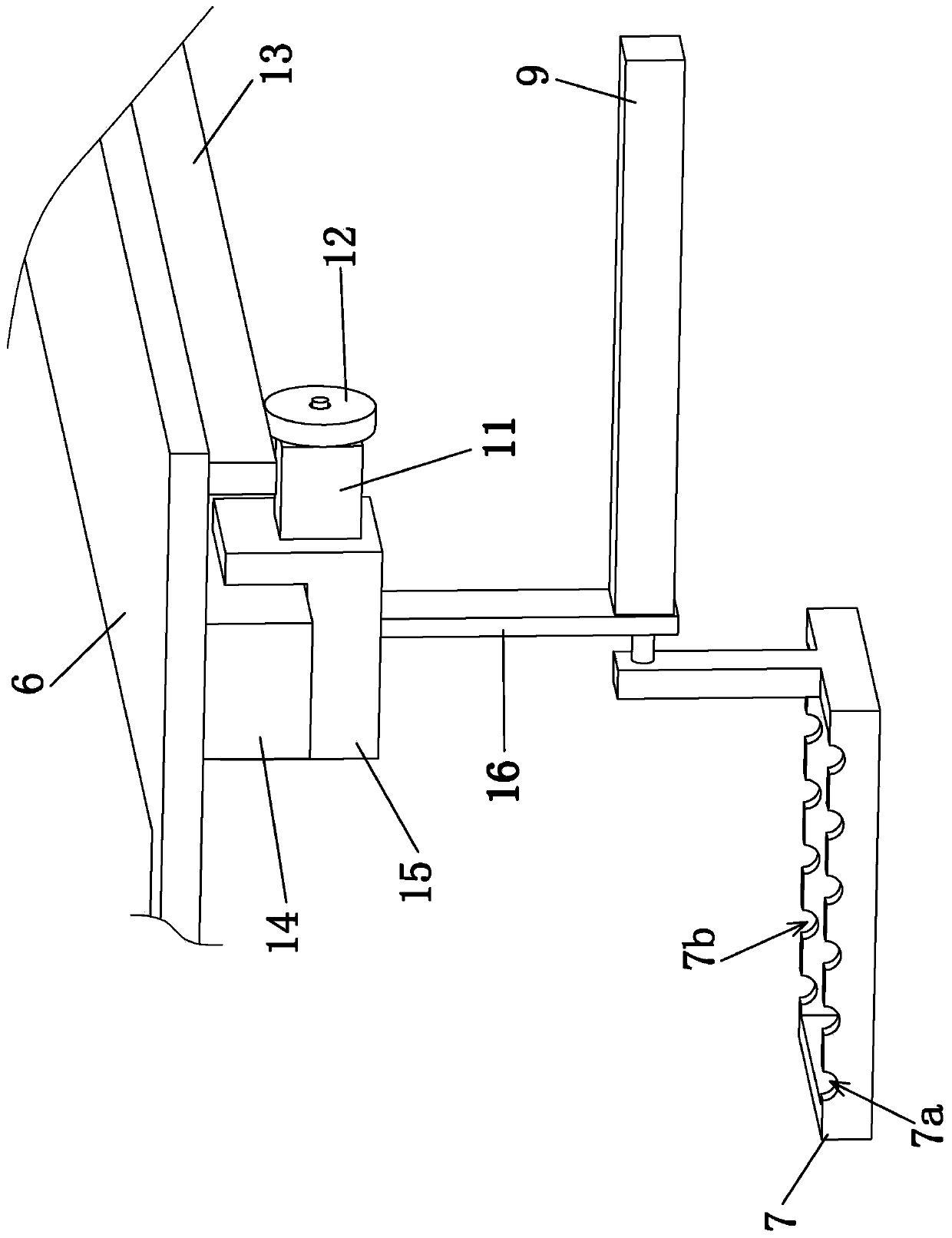

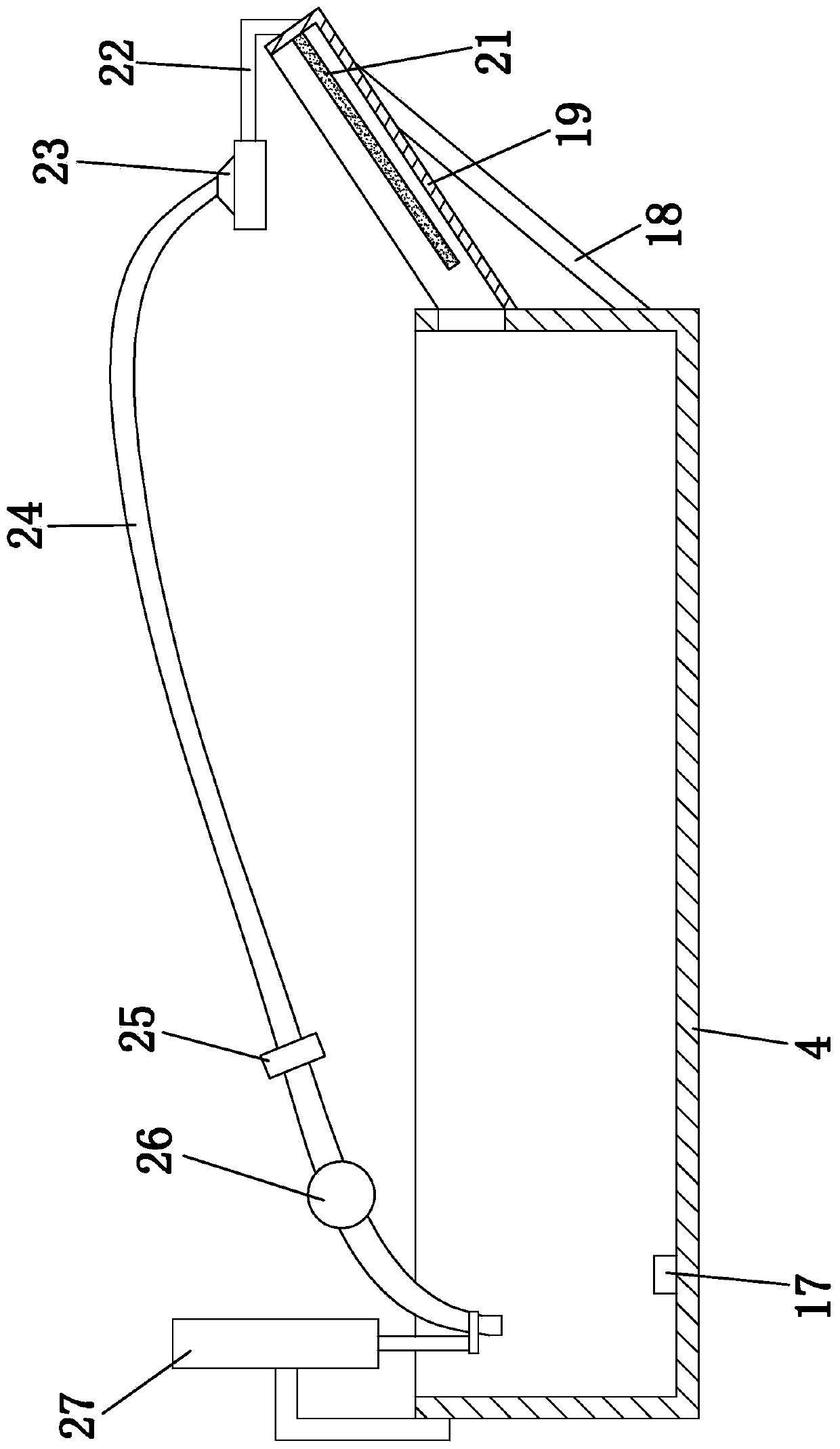

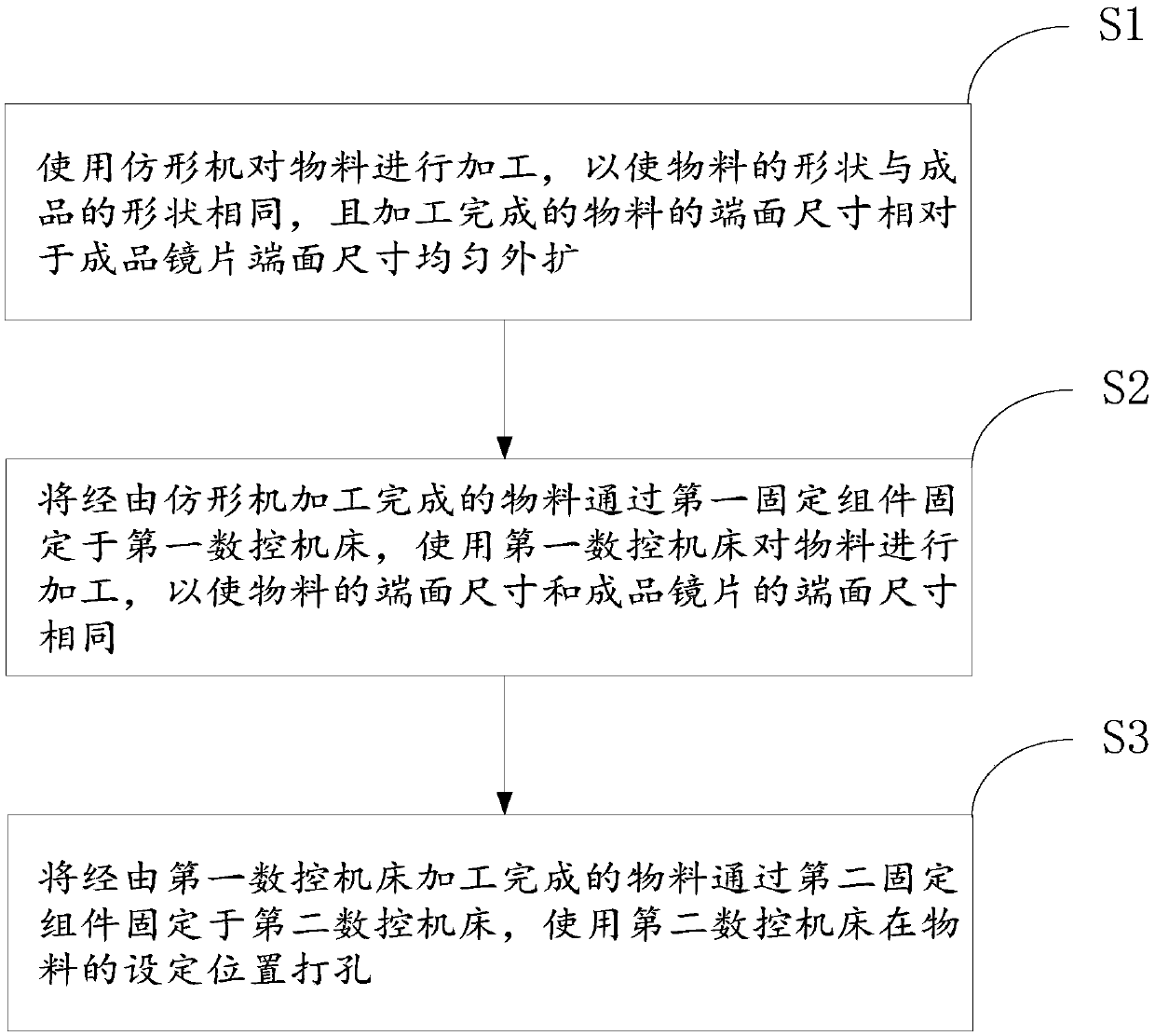

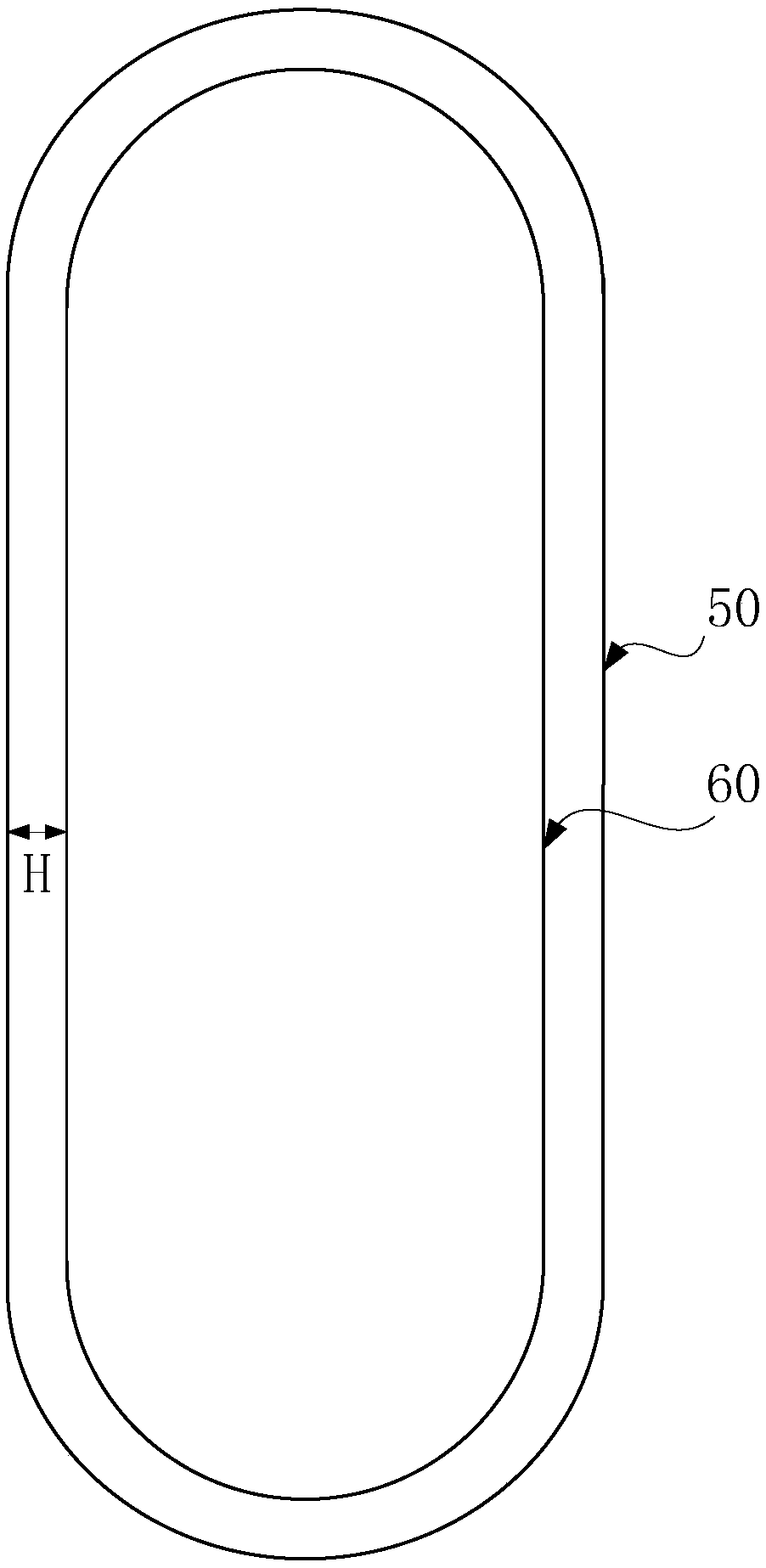

Camera lens machining method

ActiveCN110576367AAdvantages of processing methodSmall size errorEdge grinding machinesOptical surface grinding machinesNumerical controlCamera lens

The invention provides a camera lens machining method, and relates to the technical field of camera lens machining. The method aims to solve the problems that the appearance error is large and the hole opening yield is low when a camera lens is machined. The camera lens machining method comprises the following steps that a material is machined by using a copying machine, so that the shape of the material is the same as that of a finished product, and the end face size of the machined material uniformly expands with respect to the size of the end face of the finished lens; the material machinedthrough the copying machine is fixed to a first numerical control machine tool through a first positioning assembly, then the first numerical control machine tool is used for machining the material,so that the end face size of the material and the end face size of the finished lens are the same; and the material machined through the first numerical control machine tool is fixed to a second numerical control machine tool through a second positioning assembly, and the second numerical control machine tool is used for punching the material at set positions. According to the camera lens machining method, the machined camera lens is small in appearance size error and high in hole opening yield.

Owner:LENS TECH CHANGSHA

Method for processing chemical toughened glass

InactiveCN108059361AAdvantages of processing methodShorten ion exchange timeSilicon oxygenMolten salt

The invention provides a method for processing chemical toughened glass, and belongs to the field of glass manufacturing. The method comprises the steps of production of a mixed molten salt, overturning, standing, annealing, cleaning and drying. The mixed molten salt containing special components and the special overturning step improve the success rate of toughening, and destroy silicon-oxygen bonds in the surface of the glass to cause ion recombination in order to easily and quickly carry out ion exchange. The method for processing chemical toughened glass can improve the success rate of toughening and shorten the production time.

Owner:刘书刚

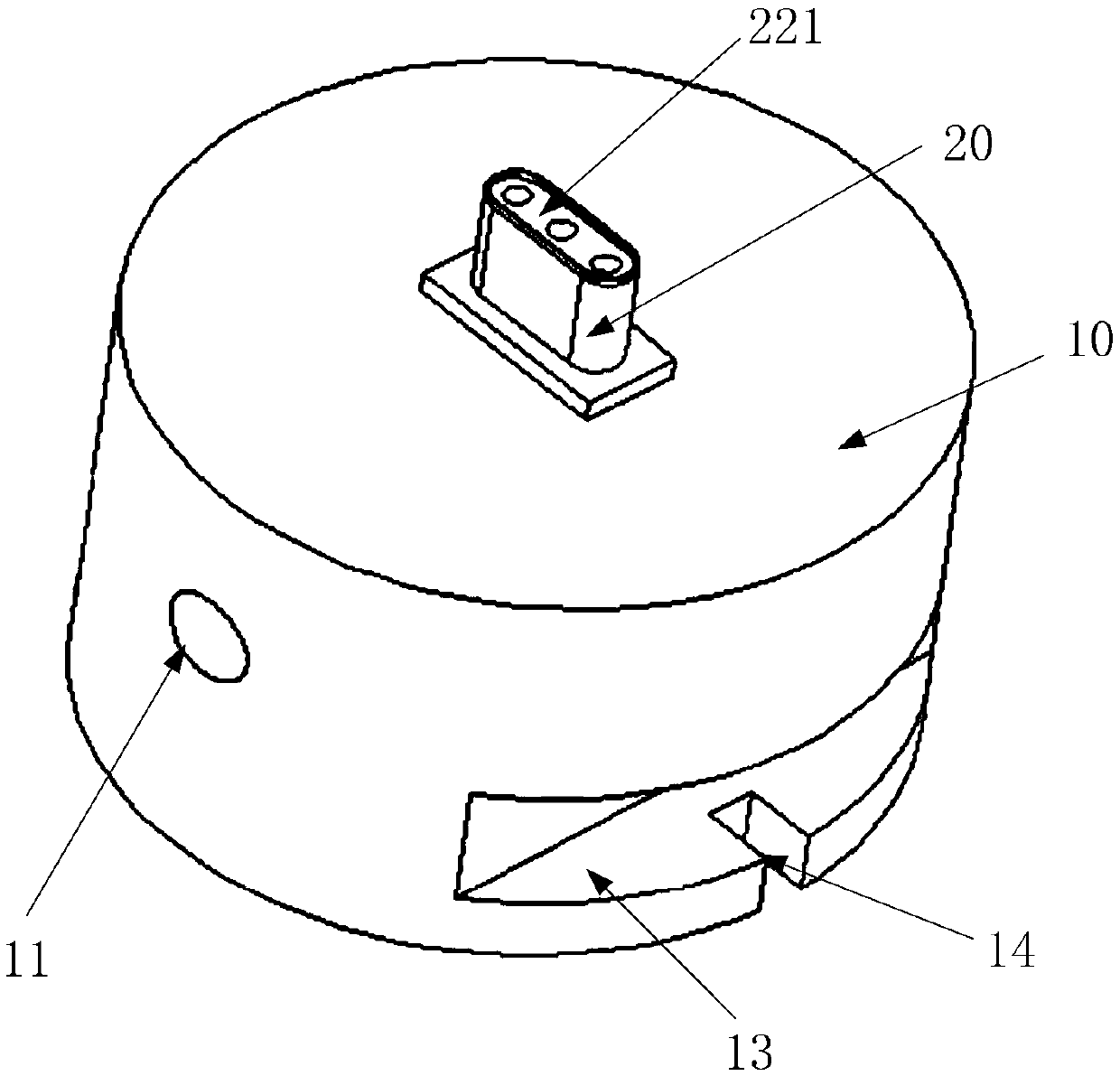

A near-infrared photoelectric device and a processing method thereof

ActiveCN109734048AIncrease photocurrentImprove response ratePrecision positioning equipmentSoldering apparatusManufacturing technologyNanowire

The invention provides a near-infrared photoelectric device and a processing method thereof, and relates to the technical field of processing and manufacturing. The near-infrared photoelectric deviceincludes a silicon substrate, a number of nano optical antennas, two electrodes and a nano wire, wherein the nano optical antennas and the two electrodes are arranged on the surface of the silicon substrate, all the nano optical antennas are located between the two electrodes, the two ends of the nano wire are connected with the two electrodes respectively, and the nano wire is in contact with atleast one nano optical antenna. The invention further provides a processing method of the near-infrared photoelectric device. When the gap between the large disc and the small disc in the same nanometer optical antenna is illuminated, plasmon can be excited, incident light can be captured and enhanced, the response wavelength range of the device is widened, the carrier concentration in the nanowire is improved, and then the optical and electrical properties of the device are improved.

Owner:HARBIN INST OF TECH

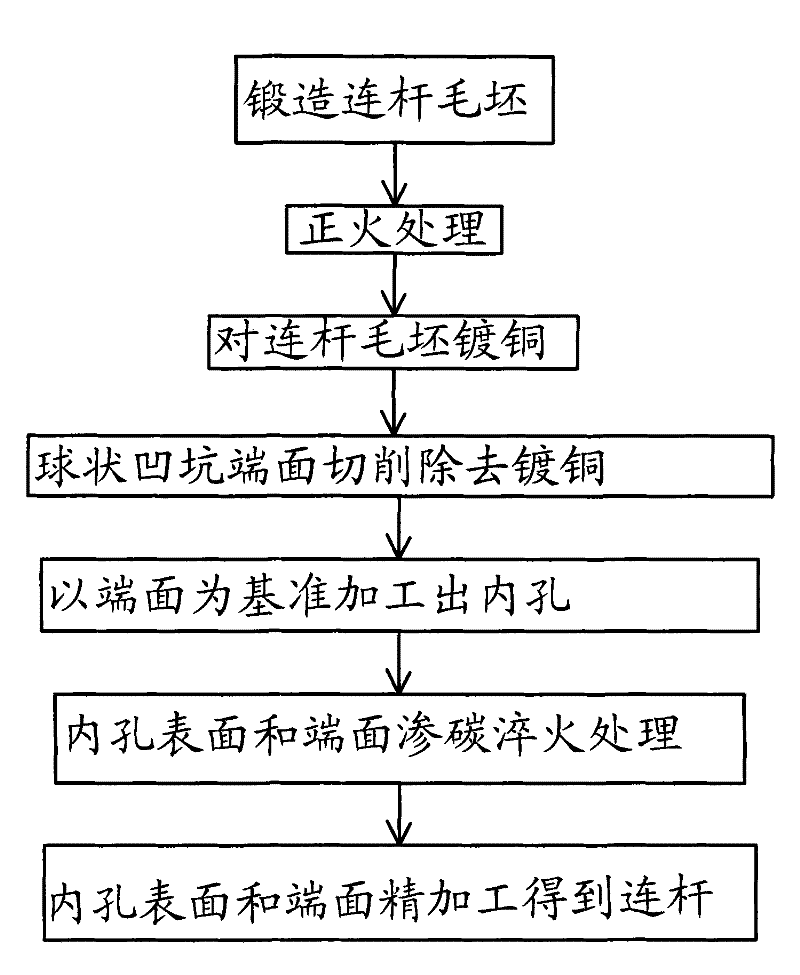

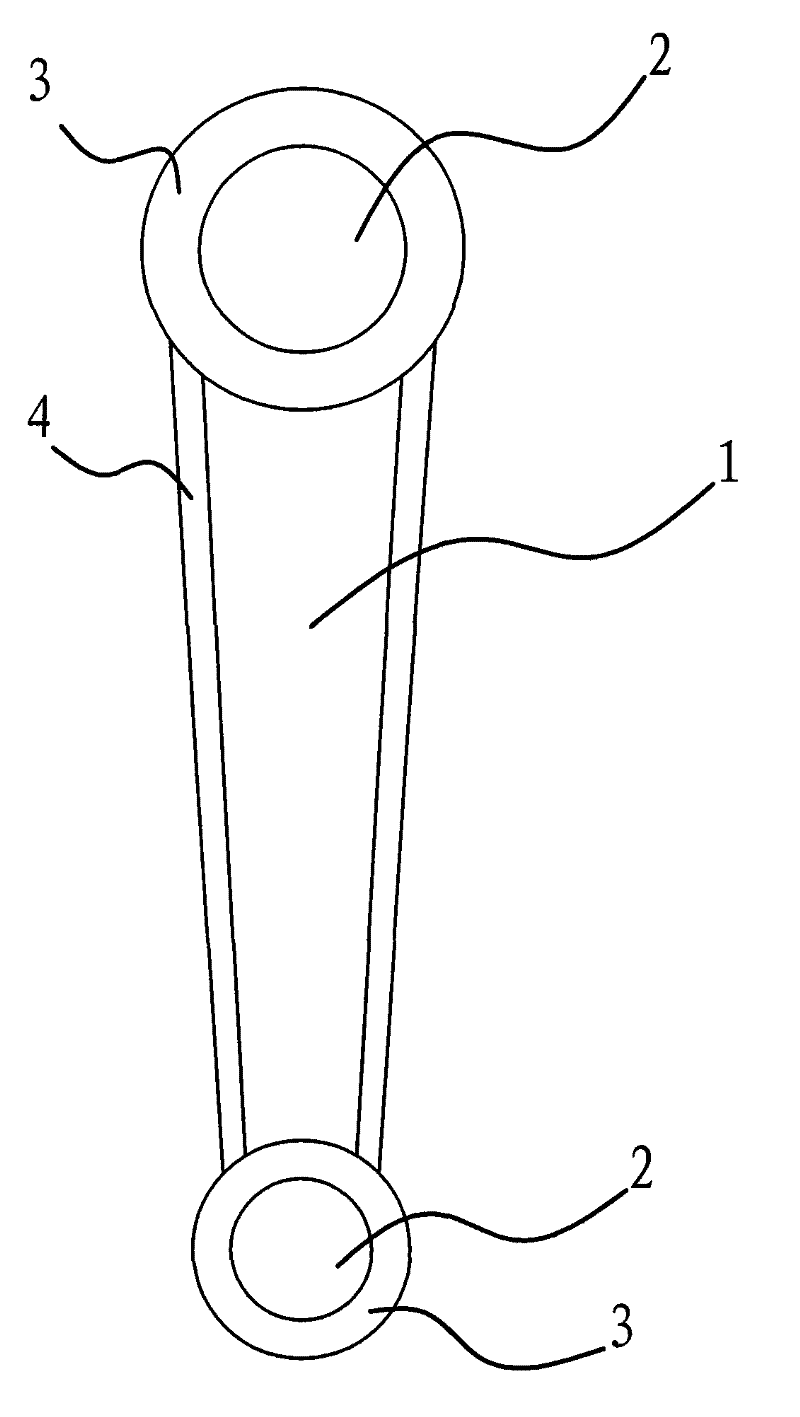

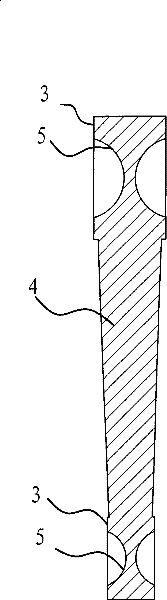

Processing method of crank connecting rod

ActiveCN101424296BAdvantages of processing methodComplies with impact toughnessConnecting rodsSolid state diffusion coatingCopper platingCrank

The invention provides a method for processing a crank connecting rod, which belongs to the technical field of mechanical processing. The invention solves the problems of poor impact toughness of the connecting rod obtained by the prior processing method of the crank connecting rod, easy fracture of the crank connecting rod, short service life and the like. The processing method of the crank connecting rod A. Making connecting rod blank; B. Normalizing and copper plating treatment; C. Carburizing and quenching treatment; D. Finished product. The processing method of the present invention is simple and easy, and realizes the effect of energy saving and emission reduction, and can improve the impact resistance toughness of the connecting rod, the inner hole and the end surface have relatively high hardness, and the service life is long.

Owner:浙江长宏科技股份有限公司

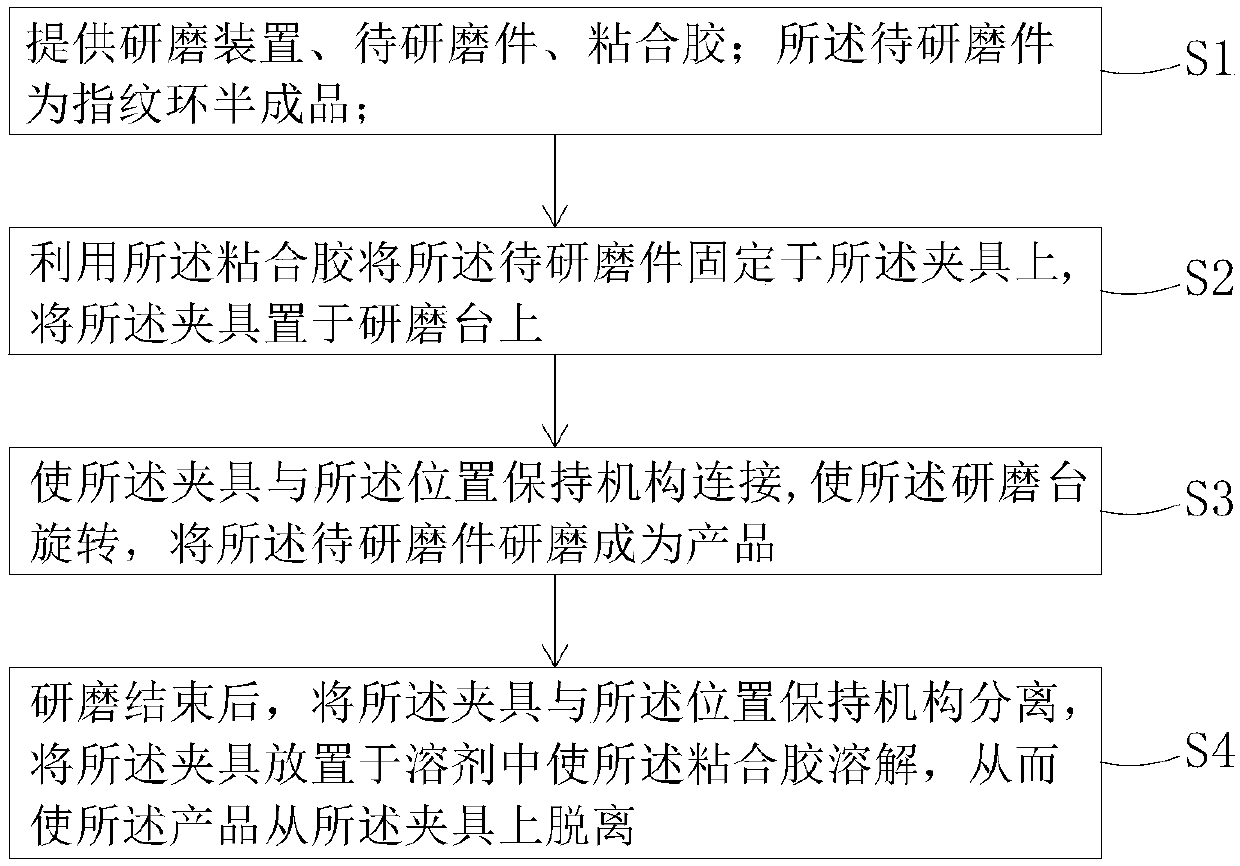

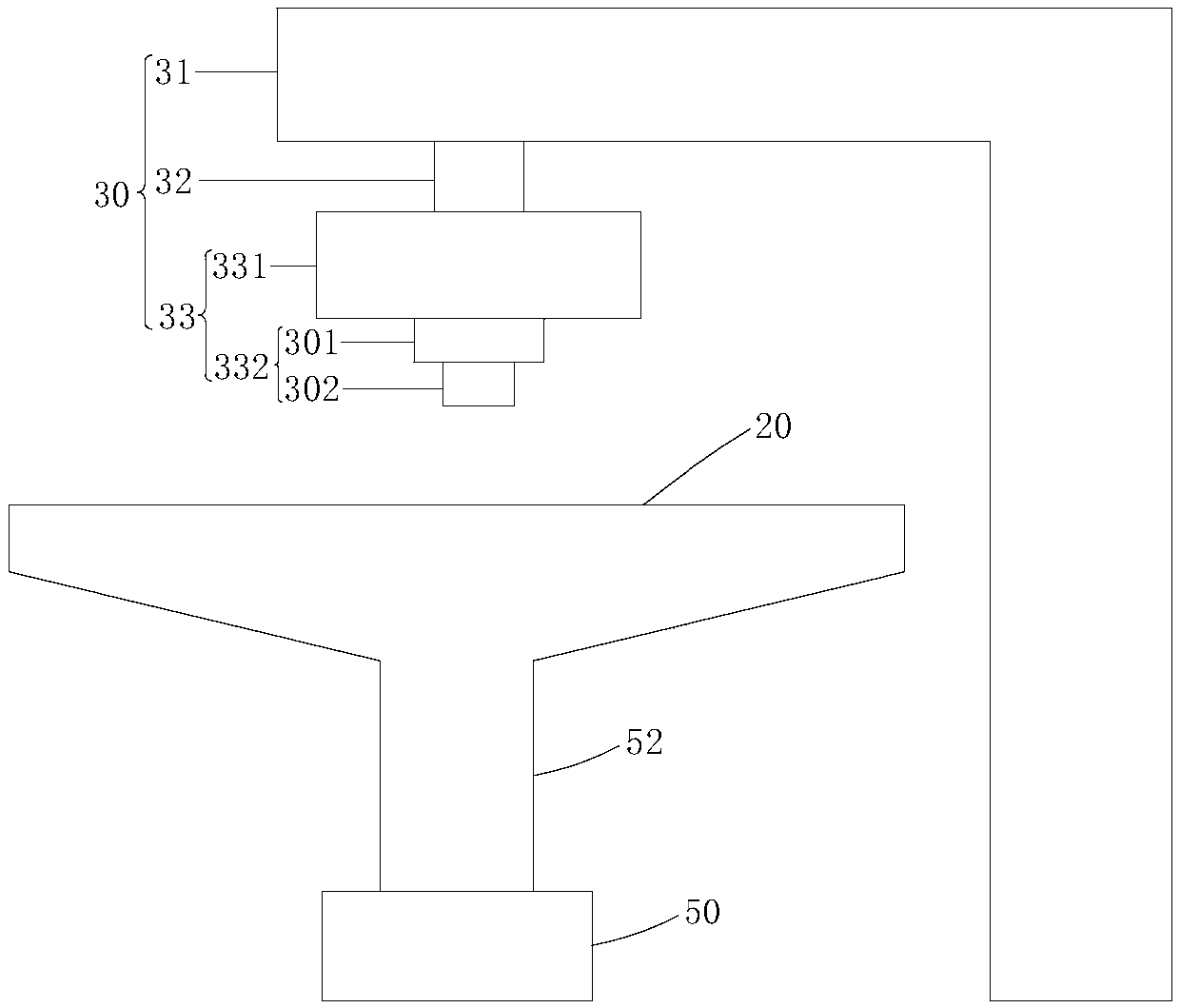

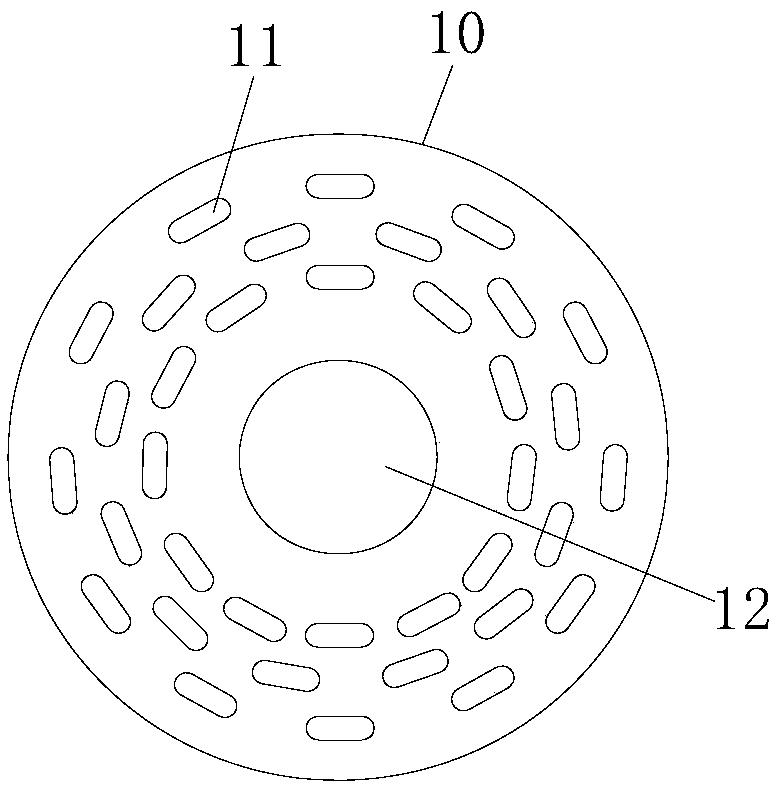

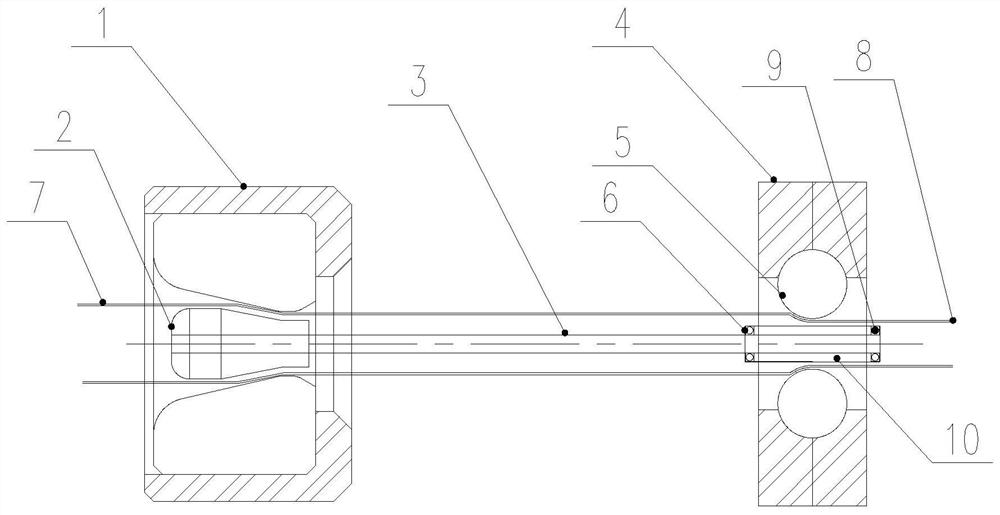

Machining method of fingerprint ring

ActiveCN110576386AAdvantages of processing methodHighly dimensionally stableLapping machinesWork carriersAdhesive glueEngineering

The invention discloses a machining method of a fingerprint ring. The method comprises the following steps of 1, a grinding device, a to-be-ground piece and an adhesive glue is provided, wherein the to-be-ground piece is a semi-finished product of the fingerprint ring, and the grinding device comprises a fixture, a grinding table and a position maintaining mechanism; 2, the to-be-polished piece isfixed on the fixture through using the adhesive glue, the fixture is placed on the grinding table, and one side of the fixture to which the grinding piece is fixed is opposite to the grinding table;3, the fixture is connected with the position maintaining mechanism, the grinding table is rotated, and the to-be-ground piece is ground into a product; and 4, after the grinding is finished, the fixture is separated from the position maintaining mechanism, and the fixture is placed in a solvent to dissolve the adhesive, so that the product is separated from the fixture. The machining method of the fingerprint ring is simple and easy to operate, low in cost, high in efficiency and good in grinding quality.

Owner:蓝思精密(东莞)有限公司

Method for machining large-helical-angle internal threaded pipe

The invention discloses a method for machining a large-helical-angle internal threaded pipe. The method specifically comprises the following steps that 1, a threaded core head is assembled, specifically, a first bearing and a second bearing are embedded into the two ends of the threaded core head correspondingly; 2, a core rod is assembled, specifically, the threaded core head and a floating corewhich are assembled in the step 1 are fixed to the two ends of the core rod correspondingly; 3, a main pipe is assembled, specifically, the core rod assembled in the step 2 is arranged in a cavity ofthe main pipe; 4, a spinning device is assembled, specifically, the spinning device is formed by combining a steel ball and a spinning ring, and the steel ball is arranged in the spinning ring; 5, themain pipe assembled in the step 3 sequentially penetrates through a reducing die and the spinning device, and the threaded core head is located at the spinning position; and 6, drawing is started, and the threaded core head freely rotates in the advancing direction of a finished pipe under the auxiliary effect of the first bearing and the second bearing. The method for machining the large-helical-angle internal threaded pipe has the advantages of being high in production speed and high in product percent of pass.

Owner:广东龙丰精密铜管有限公司

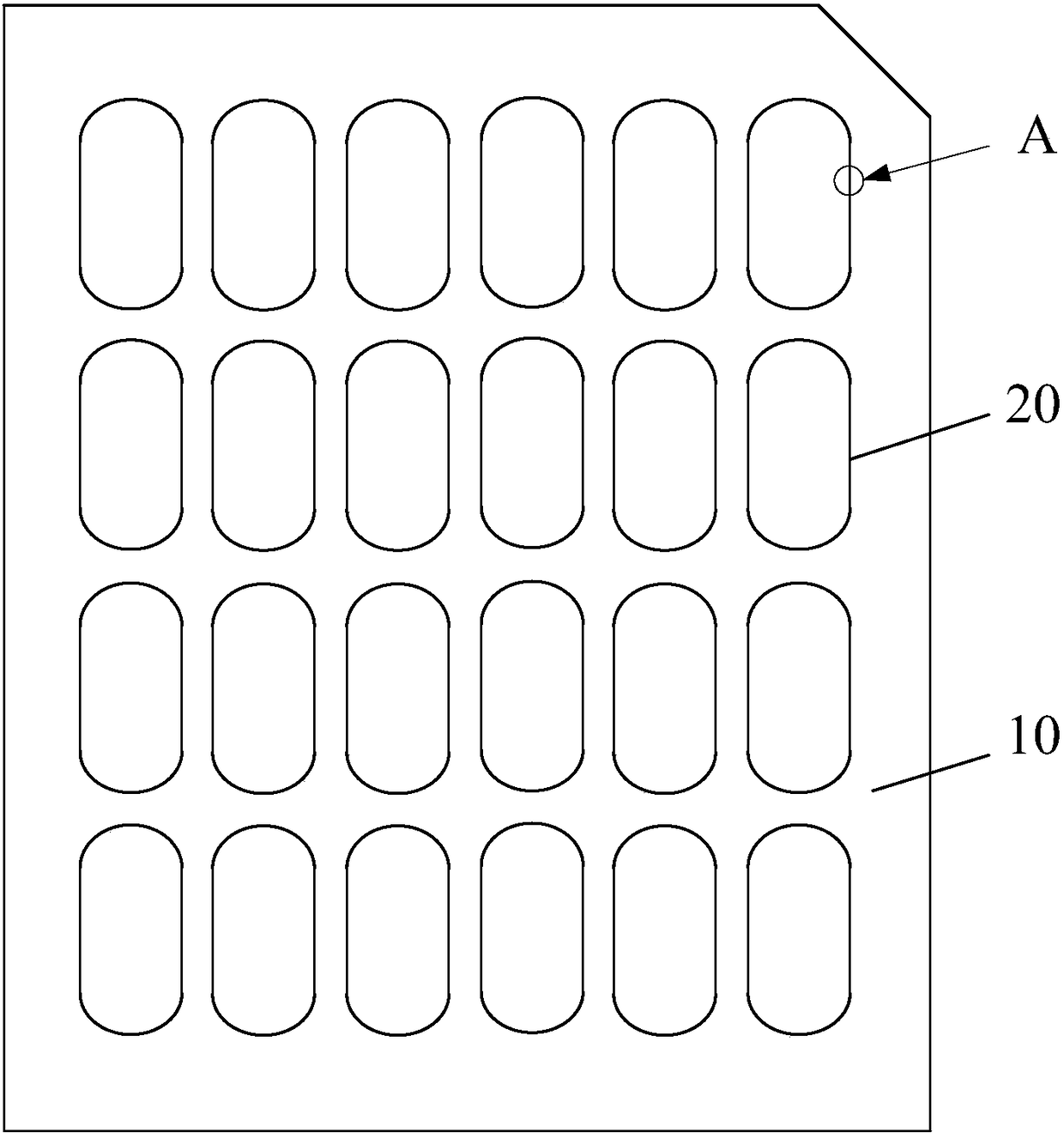

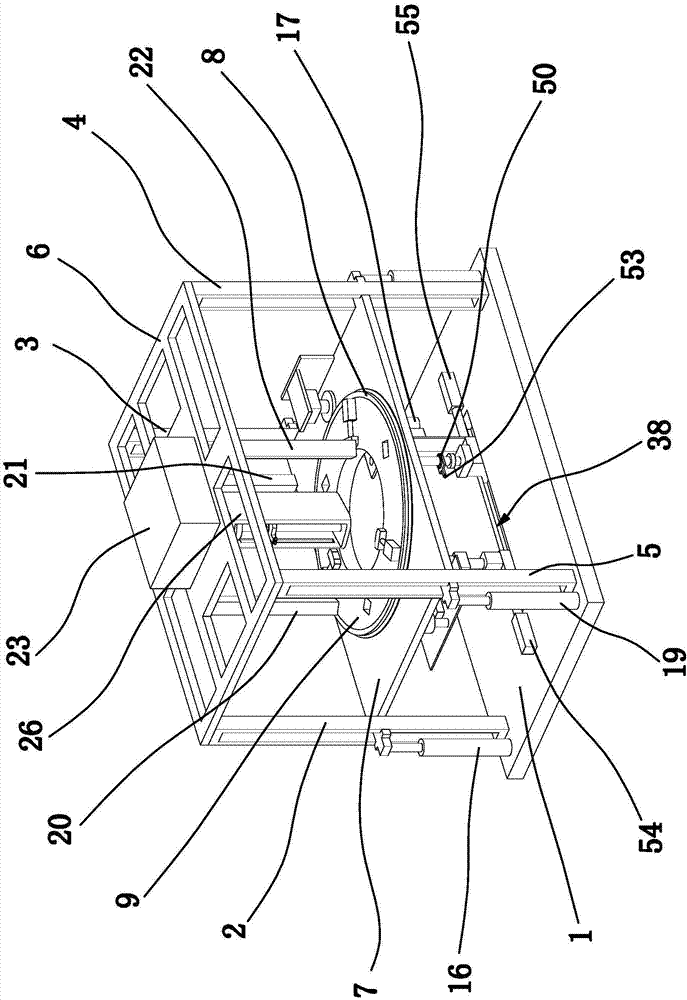

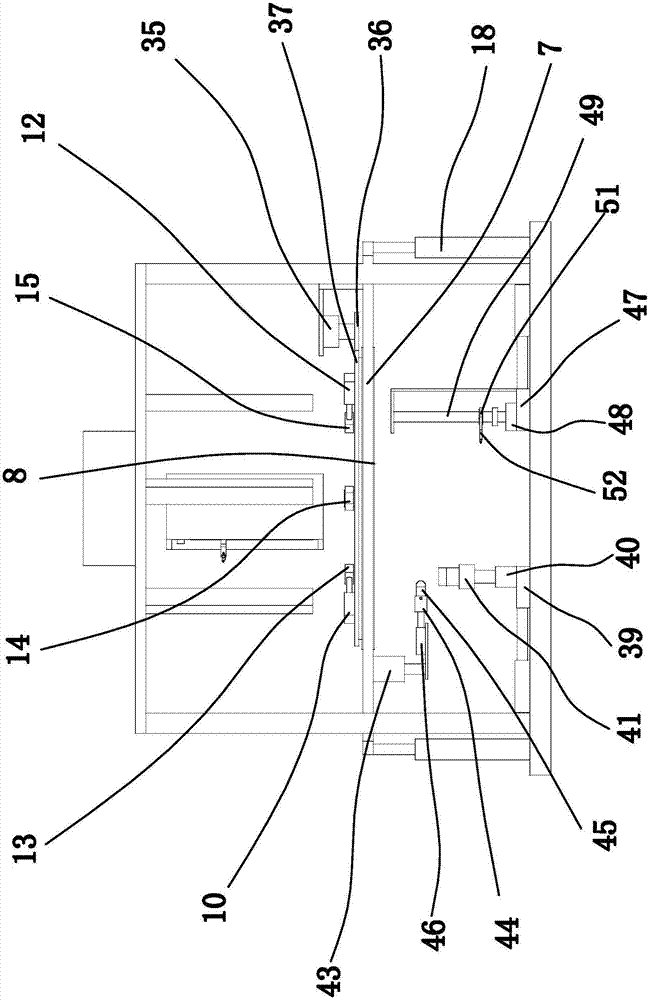

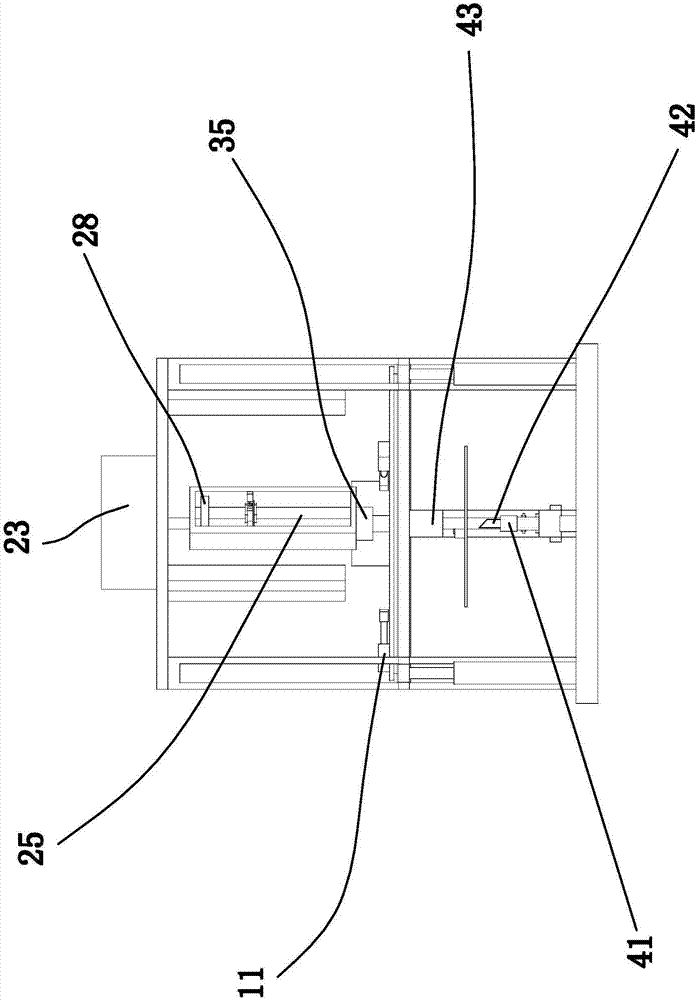

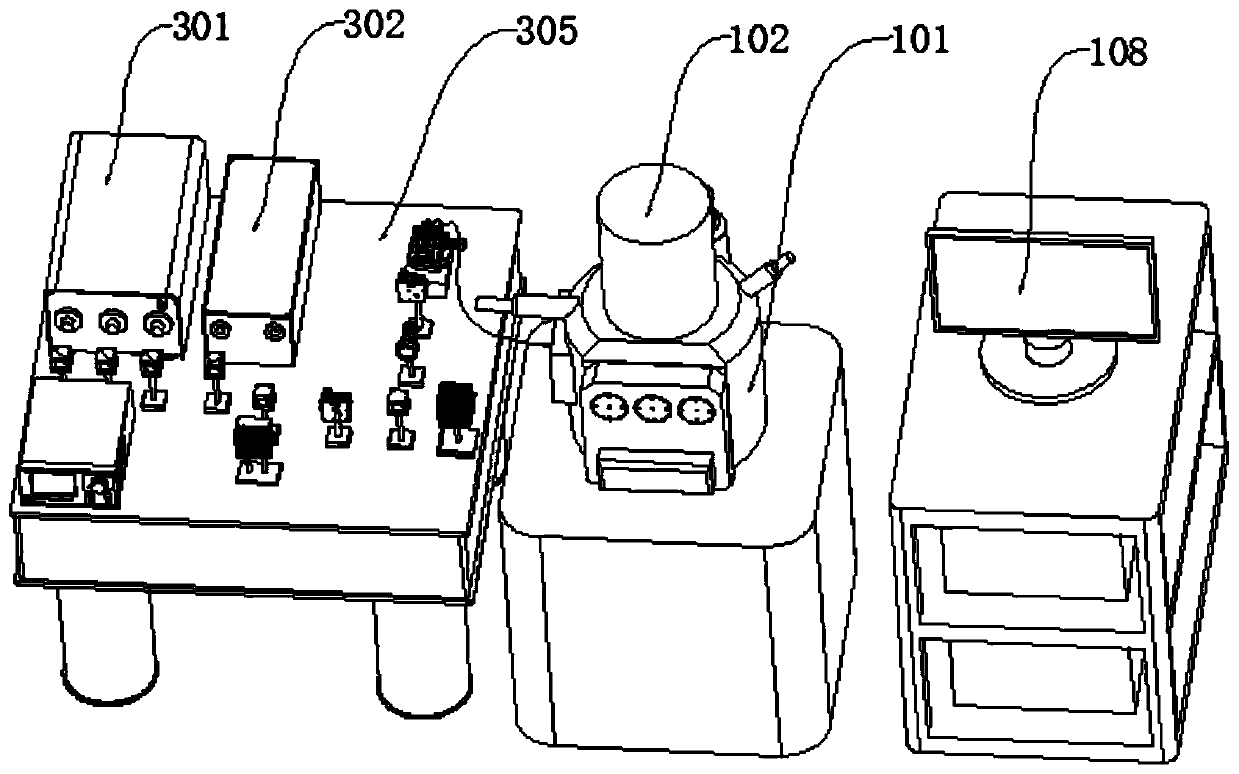

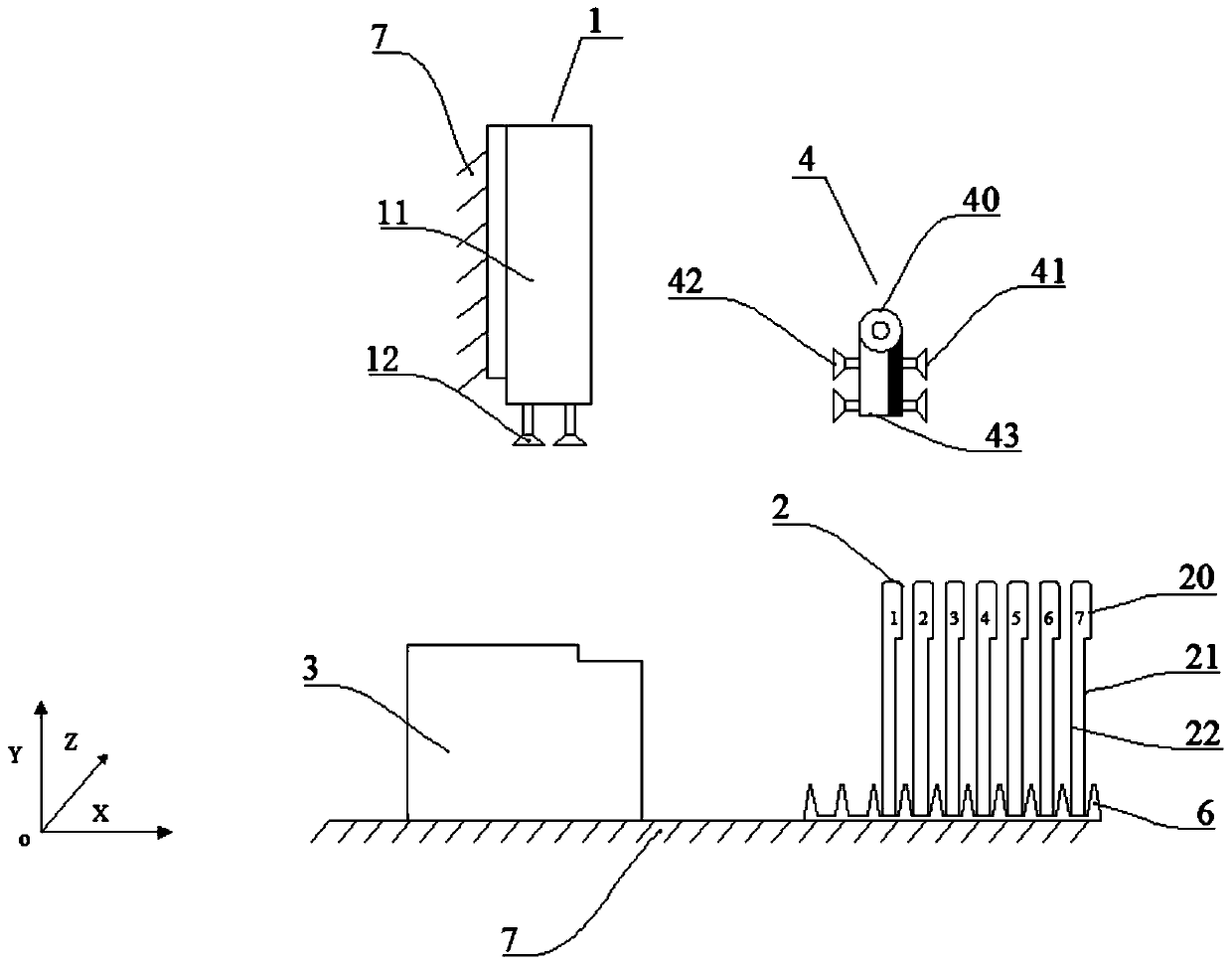

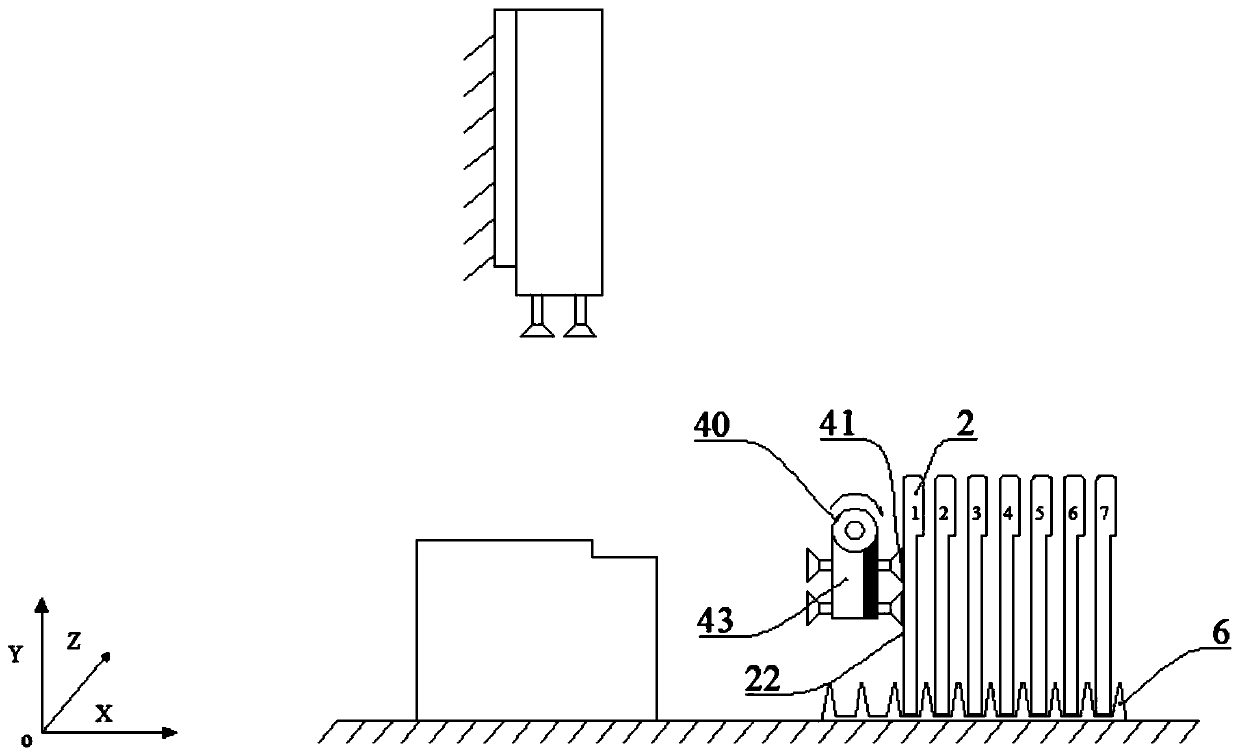

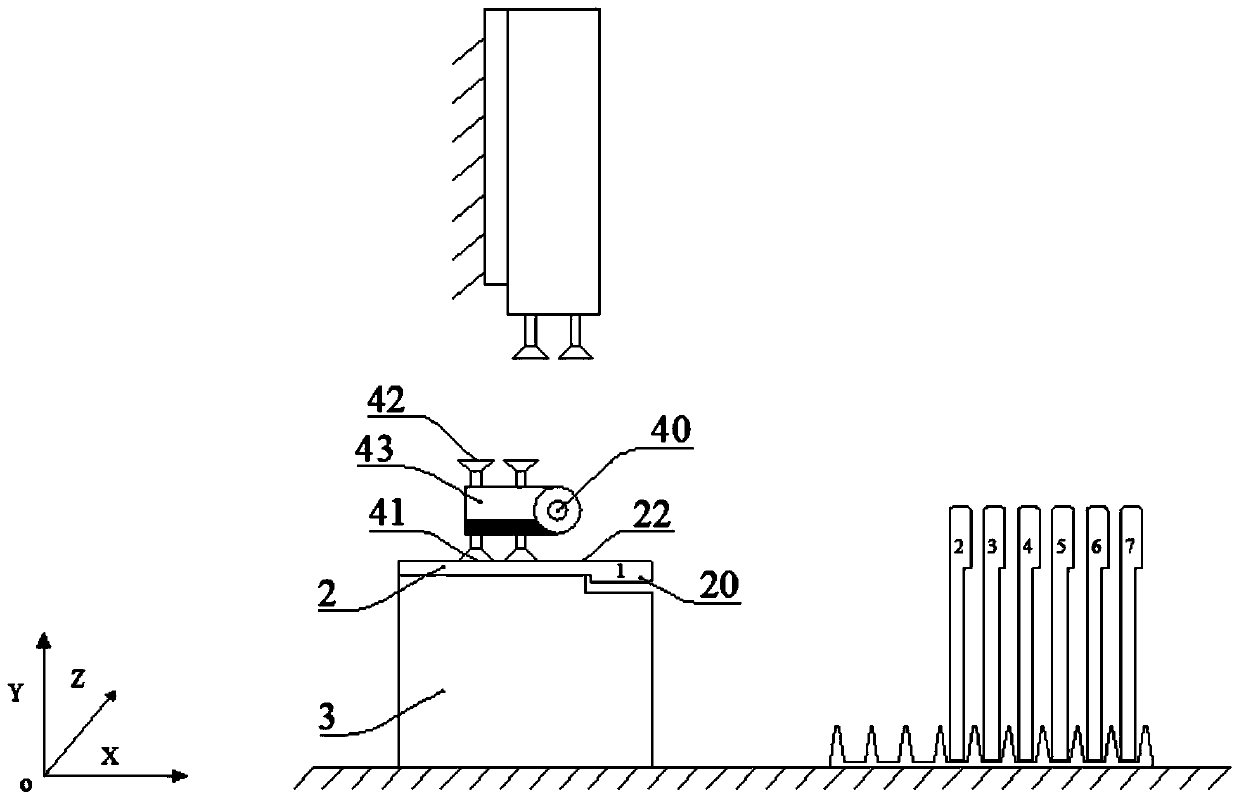

Plate turning-over machining device and method

PendingCN111086345AReduce the amount of movementFlexible loading and unloading methodsGrinding feedersOther artistic work equipmentsStructural engineeringTransfer mechanism

The invention provides a plate turning-over machining device and method. The plate turning-over machining device comprises a material box, a machining center, a feeding and discharging device and a turned-over plate transferring mechanism; the material box is used for storing plates before and after machining; the machining center is used for machining the surfaces of the plates placed on a machining table; the feeding and discharging device can rotate under driving of a rotating mechanism and is used for feeding and discharging the plates between the material box and the machining table; andthe turned-over plate transferring mechanism is arranged above the machining table and used for transferring the plates between the feeding and discharging device and the machining table so as to convert the machined faces and next to-be-machined faces of the plates. According to the plate turning-over machining device, by arranging the turned-over plate transferring mechanism to transfer the turned-over plates, the machining center can continuously machine the multiple faces of the same plates, thus the actuating quantity of the plate feeding and discharging device is decreased, the feeding and discharging time is shortened, and the machining efficiency is improved; and especially it can be guaranteed that after being machined, the special-shaped plates can be safely inserted into raw material grooves, and thus the material box cost and the storage space are saved.

Owner:江西衡源智能装备股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com