Processing method of tearing-resisting and wear-resisting suede imitated warp knitted fabric

A processing method and suede imitation technology, applied in the field of machinery, can solve the problem of single use, etc., and achieve the effect of convenient sampling, strong practicability, and intuitive inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

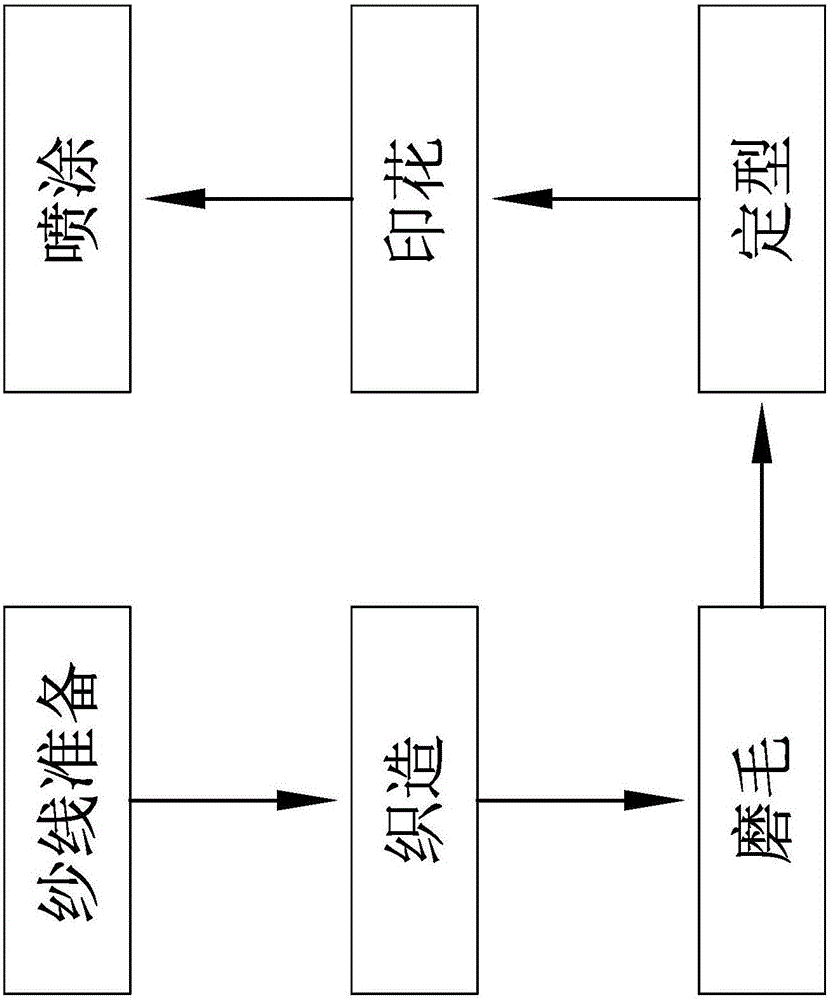

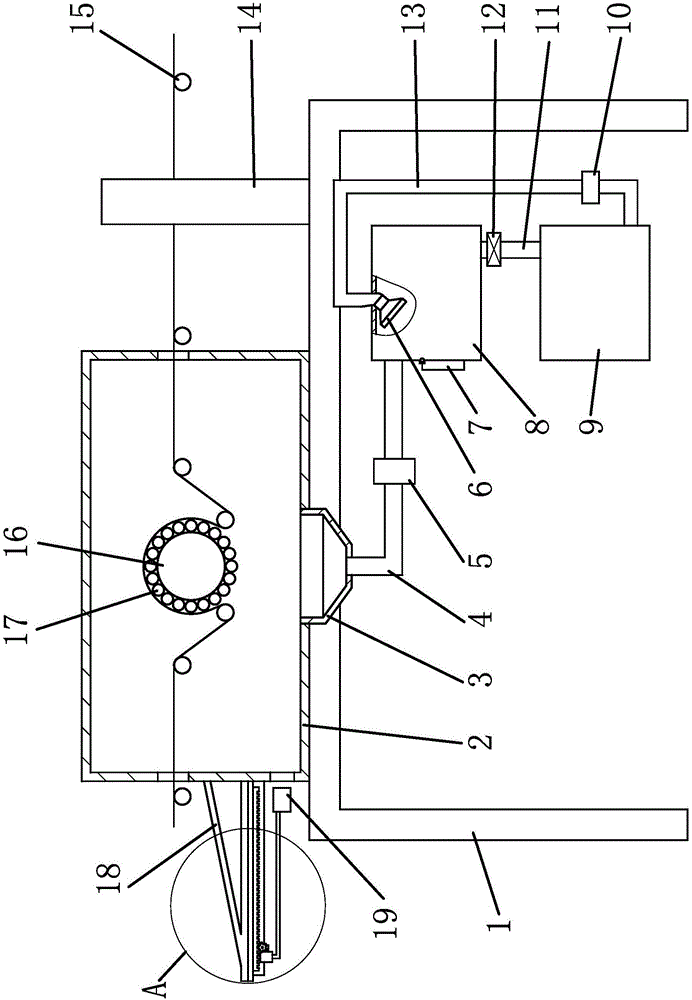

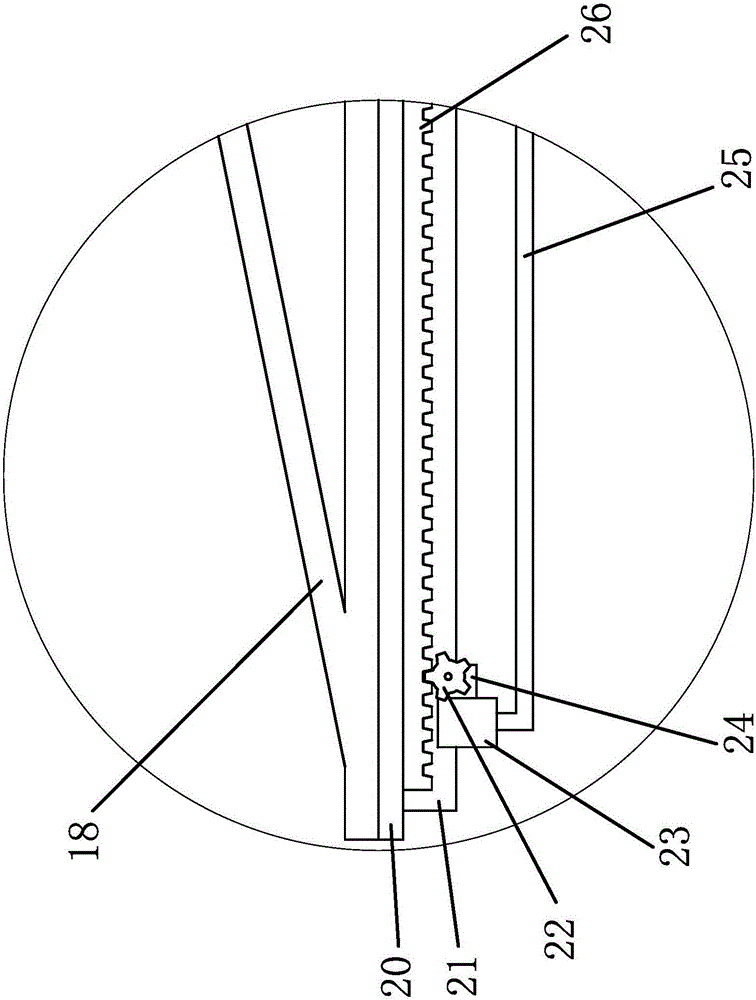

[0037] Such as figure 1As shown, the processing method of the tear-resistant and wear-resistant imitation suede warp knitted fabric includes the following steps: a, yarn preparation: blending cashmere fiber and viscose fiber in a ratio of 3:2 to form a warp thread for use, and polyester Fiber and acrylic fiber are blended in a ratio of 4:3 to form a weft for use; b, weaving: send the warp and weft in step a to a common loom for weaving to form gray cloth; c, sanding: through sanding The device sands one side of the gray cloth, so that the surface layer of the gray cloth forms plush, the sanding time is 3-12s, and the number of sanding times is 1-2 times. In this embodiment, the sanding time is 8s, and the number of sanding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com